YOUR GUIDE TO THE LATEST PRESS BRAKE TECHNOLOGY

MAY 2023

ISSUE 14

LAMIERA SPECIAL EDITION

Represented by Via Artigianato, 2 | I – 25011 Calcinato (BS) T: +39 030 2061781 | E: info@alpemac.it www.alpemac.it www.adira.pt adira@adira.pt +351 226 192 700 Rua das Lages 67 , 4410-272 Vila Nova de Gaia Portugal Visit us at Hall 15P - Stand D28 Higher levels of performance and reliability Increased profitability and greater safety Doubling production capacity Simplification and automation of the industrial production process PH TANDEM AN AUTOMATIC SOLUTION FOR 24/7 PRODUCTION Scan me to know more VISIT US AT www.adira.pt Represented by Via Artigianato, 2 | I – 25011 Calcinato (BS) T: +39 030 2061781 | E: info@alpemac.it www.alpemac.it www.adira.pt adira@adira.pt +351 226 192 700 Rua das Lages 67 , 4410-272 Vila Nova de Gaia Portugal Visit us at Hall 15P - Stand D28

Articles

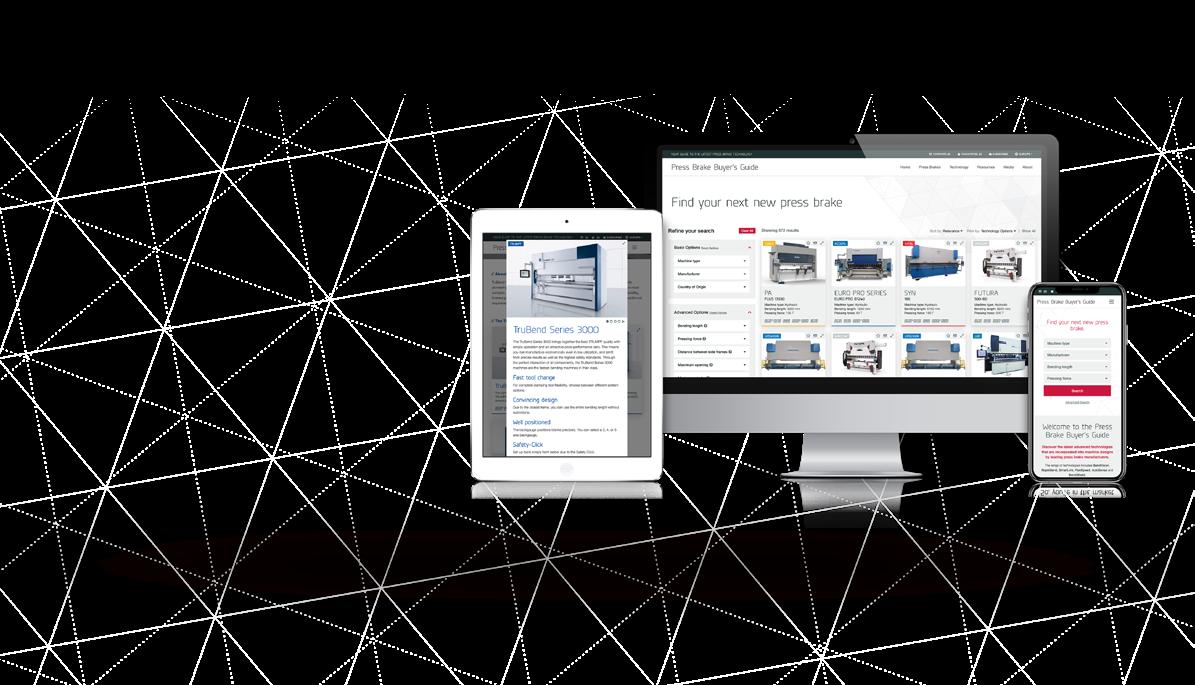

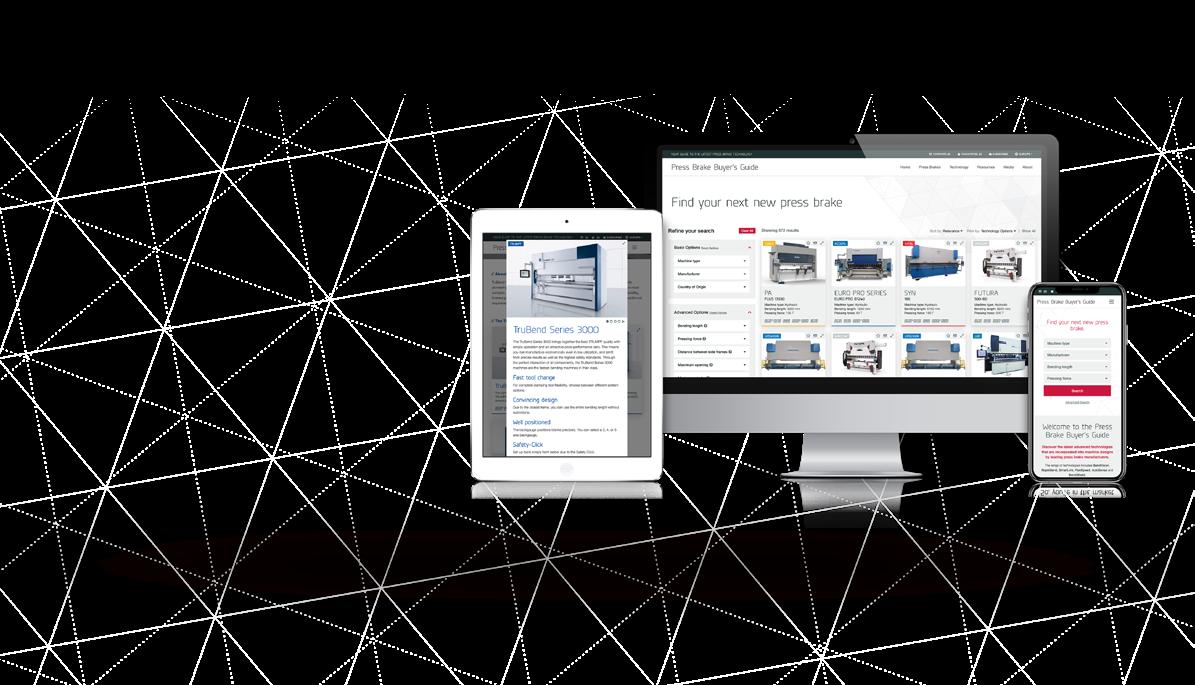

16 Press Brake Buyer’s Guide Website Update

The Press Brake Buyer’s Guide website has been expanded, and now presents 26 leading press brake manufacturers, more buying resources, and features more than 700 machine models for you to search and compare.

26 Prima Power solutions protagonists at the LAMIERA exhibition

For Prima Power this event will be an opportunity to present the most recent solutions and to discuss the latest trends in the sector with Italian and international visitors in a large stand designed, also from the point of view of hospitality, to make networking even more enjoyable and effective.

28 LVD is ‘Shaping Flows’ with Bending & Laser Cutting Technology

LVD spotlights the theme of “Shaping Flows” with its latest model of Dyna-Press electric-drive press brake, an ultra-practical laser cutting machine and CADMAN® software suite for optimized fabrication on display at Lamiera.

30 Vimercati: The solidity in bending for 50 years Italian press brake manufacturer Vimercati has been guaranteeing ongoing and prompt supply of machinery and technical assistance to customers since 1973.

32 Autonomous Guarding: Press brake automation takes another step forward.

Level 3 Autonomous Guarding technology is set to change the way in which machine operators interact with press brakes.

36 Aspir Mecc invests in Salvagnini Hybrid Press Brake Technology

Terni-based company Aspir Mecc invests in a Salvagnini B3: a hybrid press brake, designed by combining the characteristics and benefits of the most common electrical and hydraulic solutions on the market.

40 Powerful, automated, and sustainable: TRUMPF launches new bending machine for XXL parts TruBend Series 8000 machines from TRUMPF bend oversize parts faster and more efficiently.

42 ACCURL Launches New 100% Electric Press Brake eB Ultra Series

ACCURL, a leading manufacturer of sheet metal machinery, has recently announced the launch of its newest product, the eB Ultra 100% Electric Press Brake. This machine is the latest addition to the company’s product line and is set to revolutionize the sheet metal bending industry with its cutting-edge technology and impressive energy efficiency.

44 TRUMPF laser-blanking system cuts costs and saves 4000 metric tons of CO2 a year

The new TruLaser 8000 Coil Edition is suitable for any industry that requires flexible, high-volume cutting solutions.

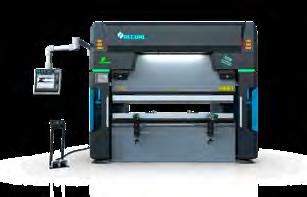

pressbrakebuyersguide.com Contents Follow us online or subscribe at www.pressbrakebuyersguide.com Technology 4 RapidBend 6 BendVision 8 BendShield 10 SmartLink 12 AutoSense 14 FlexSpeed Lamiera Preview 19 Lamiera Hall Map 20 Salvagini, 21 Vimercati, LVD 23 ADIRA, G.A.D.E, 24 ACCURL 1 Cover image courtesy of Vimercati. Press Brake Catalogue 48 Drive System Overview 50 Hydraulic Press Brakes 62 Hybrid Press Brakes 68 Electric Press Brakes

None of the above listed manufacturers pay to have their information included in this publication. The Press Brake Buyer’s guide is published to showcase leading press brake manufacturers that offer machines with the embedded technologies that are presented in this publication and on the Press Brake Buyer’s Guide website. Only manufacturers with machine models that offer the embedded technologies including BendVision, RapidBend, SmartLink, AutoSense, BendShield and FlexSpeed are represented. The Press Brake Buyer’s Guide is produced and published by Lazer Safe Pty Ltd.

2

Press Brake Buyer’s Guide presents you with information on the latest advanced technologies that are incorporated into machine designs by leading press brake manufacturers. The range of technologies includes BendVision, RapidBend, SmartLink, FlexSpeed, AutoSense and BendShield.

Learn how these technologies can benefit your bottom line through maximised productivity and performance, streamlined operation plus enhanced functionality and safety. All of which are important factors to consider when purchasing your next new machine.

In each issue we also bring you information on the latest machine models from our press brake manufacturing partners, exhibition previews, our press brake catalogue section and industry news from around the world.

3 pressbrakebuyersguide.com

So, you’re in the market for a new press brake.

Technology

RapidBend

Turbo charge your press brake.

Flexible part profiles

RapidBend technology adapts to work with a wide range of part profiles including box bending with side flanges.

Save up to 3 seconds per cycle

RapidBend technology can reduce the cycle time by as much as 3 seconds to significantly enhance your productivity.

Ultra-low speed change

RapidBend technology can reduce the minimum speed change point to 0mm above the sheet, eliminating unnecessary slow speed travel to minimise the machine cycle time.

PRESS

4

BRAKE BUYER’S GUIDE

While ensuring user safety is critical for both press brake manufacturers and operators, it is equally important to maintain machine performance. In general, traditional safety and optical protection methods can restrict machine performance and interfere with part production that can result in significantly reduced productivity.

Press Brakes with embedded RapidBend technology utilise high speed progressive muting that enables the tools to close safely at high speed until the punch is only millimetres above the material. This reduces the slow speed travel distance on every cycle for both flat profile parts and box profile parts with side flanges.

RapidBend technology is available in two performance levels - RapidBend and RapidBend Ultimate - to boost machine performance and significantly enhance your productivity.

RapidBend

The entry level RapidBend option enables the press brake to close safely at high speed until the punch is just 4mm above the material. During approach to the pinch point, the machine travels at maximum closing speed with dynamic sensing enabled for various part profiles for uninterrupted closing and shorter deceleration to forming speed minimising the slow speed travel distance to the final 4mm above the pinch point.

RapidBend Ultimate

RapidBend Ultimate technology changes the game by enabling press brakes to operate without restriction to achieve maximum safety and performance. Through a high-speed dynamic muting process and in conjunction with BendShield technology, the tools can close safely at maximum speed, then transition to bending speed right at the material pinch point. This effectively reduces the minimum speed change point to 0mm, eliminating unnecessary slow speed travel to minimise the machine cycle time. RapidBend Ultimate works with a wide range of part profiles including box bending with side flanges.

With time savings of as much as 3 seconds per cycle, RapidBend Ultimate boosts machine performance to significantly enhance your productivity.

Press Brakes equipped with RapidBend technology provide users with higher levels of safety and performance that consistently outperform any other machines on the market. Only press brakes with embedded RapidBend technology can guarantee higher levels of performance, so consider RapidBend or RapidBend Ultimate when purchasing your next machine.

RapidBend technology is available on selected models from these manufacturers:

5 pressbrakebuyersguide.com

Technology

BendVision

Real-time bending analysis - unlimited possibilities.

What is BendVision?

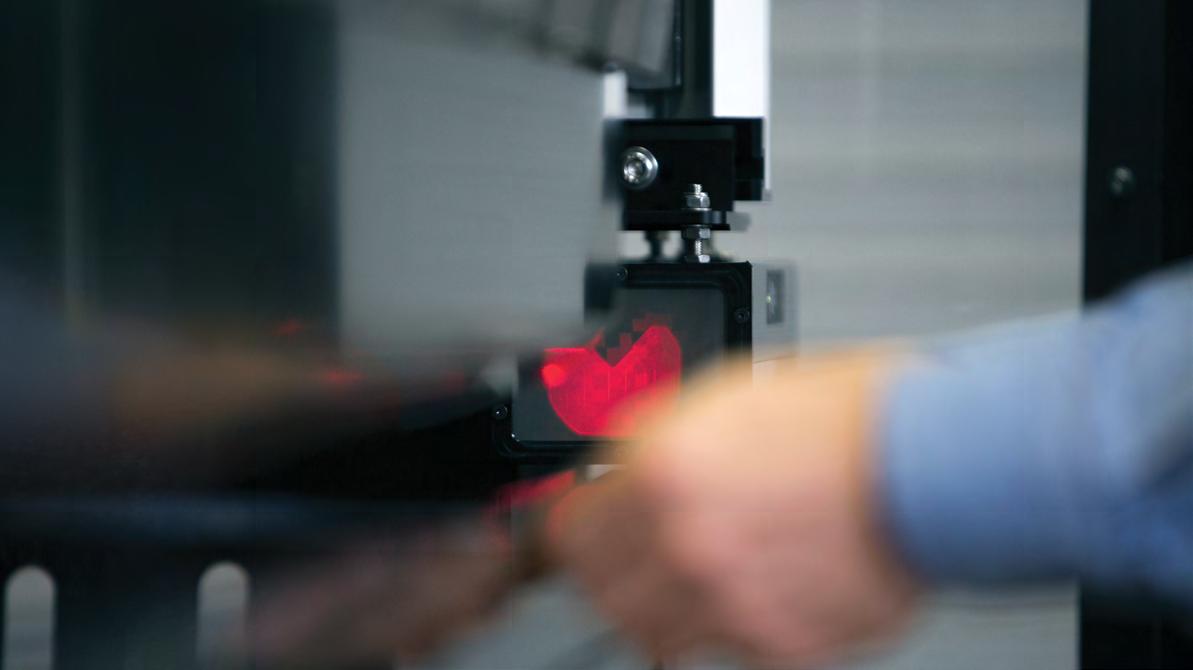

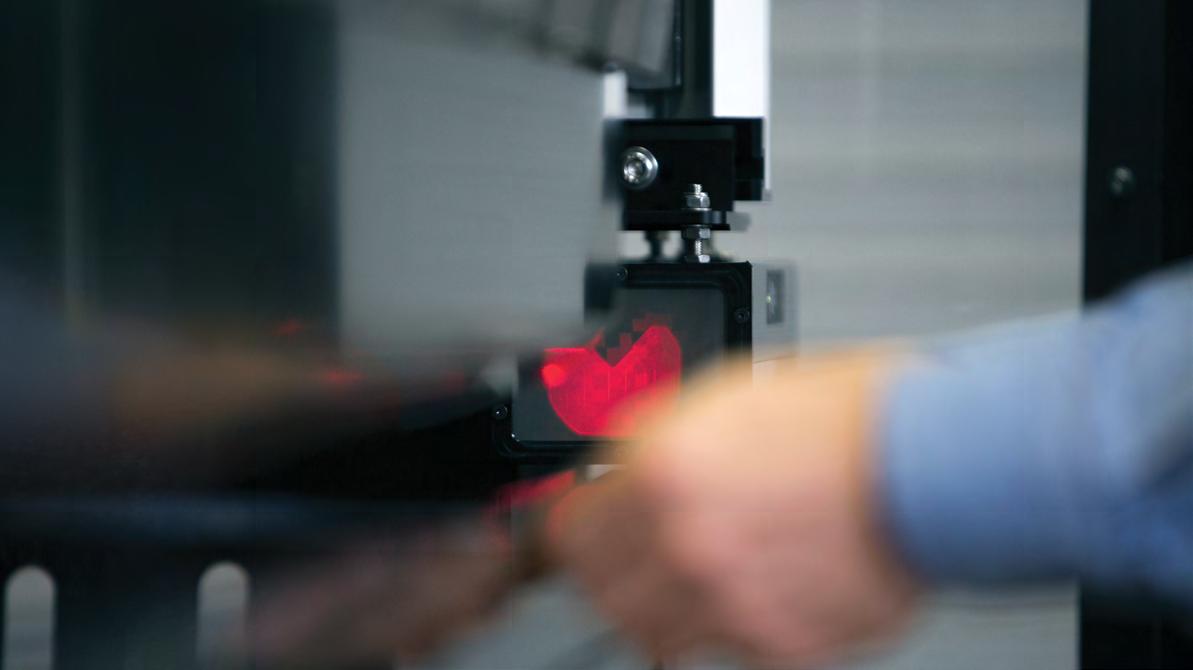

BendVision is an advanced high-speed image processing technology that provides real-time analysis of the bending process. The technology is incorporated into the existing hardware of the press brake optical guarding system so no extra components are required, resulting in an efficient and cost effective solution.

What does BendVision do?

BendVision processes images of the press brake tools and material during the bending process and transfers a range of information to the CNC via SmartLink, including raw and processed images, material bend velocity and live angle data. Press brakes equipped with BendVision can make use of this real-time data to provide users with a wide range of customised functions.

BendVision for angle measurement

BendVision technology provides a range of angle measurement data that includes the inside and outside angles of the material, average angle, material warp angle from machine deflection, material spring back angles for various material types, thickness and grain direction, plus end of relaxation angle once the bend has been completed.

BendVision for angle control

The ability for the CNC to receive BendVision angle data opens up a wide range of possibilities for real-time angle control. Instead of just confirming angles are within tolerance, the CNC can use the live angle plus a measured spring back angle to control the bending depth for flexible active and dynamic angle control solutions.

Find out more

The features and functions that are available with BendVision equipped press brakes will differ and are unique to each press brake make and model. Contact our Partners for more information and to learn how BendVision technology can improve your production efficiency, speed and accuracy.

BendVision technology is available on selected models from these manufacturers:

PRESS BRAKE BUYER’S GUIDE 6

Live angle bending

The CNC can display the live angle to the machine operator as well as the final angle after decompression.

Angle control

Instead of just confirming angles are within tolerance, the CNC can use the live angle plus a pre-measured spring back angle to control the bending depth for flexible active and dynamic angle control solutions.

Angle measuring

BendVision technology provides a range of angle measurement data including the inside and outside angles, material warp, spring back and end of relaxation angle.

7

Technology

BendShield

Protecting your productivity, not just your operators.

Advanced tool collision protection

If operators accidentally install or program an incorrect tool, BendShield protects your tooling investment by avoiding high-speed collisions that could lead to tool damage.

Special tools detection

BendShield adapts for upper tool profiles from V shaped punches to radius and flattening tools.

Automatic tool scan and alignment of the protective zone

BendShield automatically scans the upper tool to determine the tool profile then dynamically adjusts the protective zone relative to the tool tip.

Dynamic sensing technology

BendShield adapts to accommodate various part profiles from flat parts to box shaped parts with single and double sides flanges as well as back-gauge fingers.

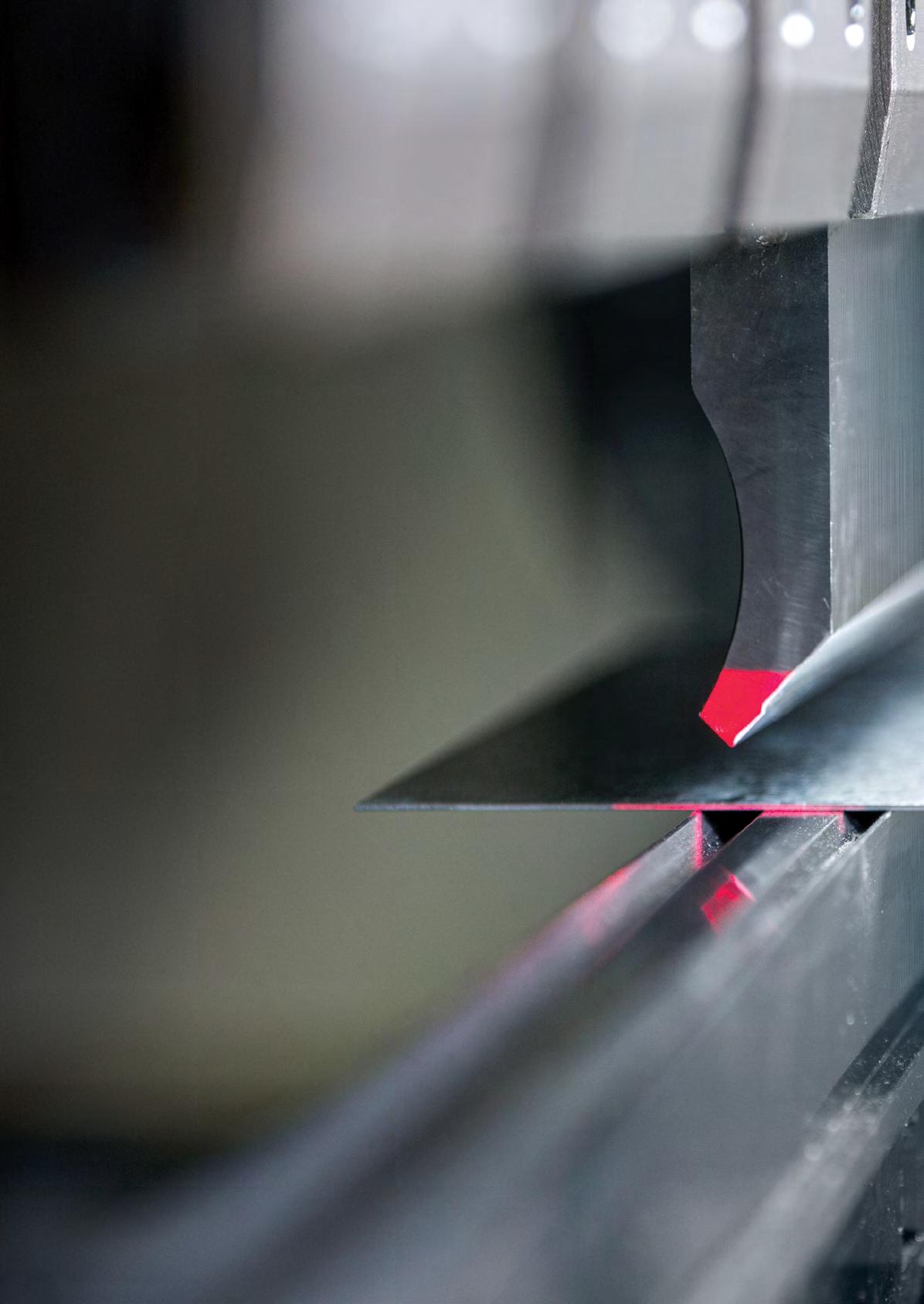

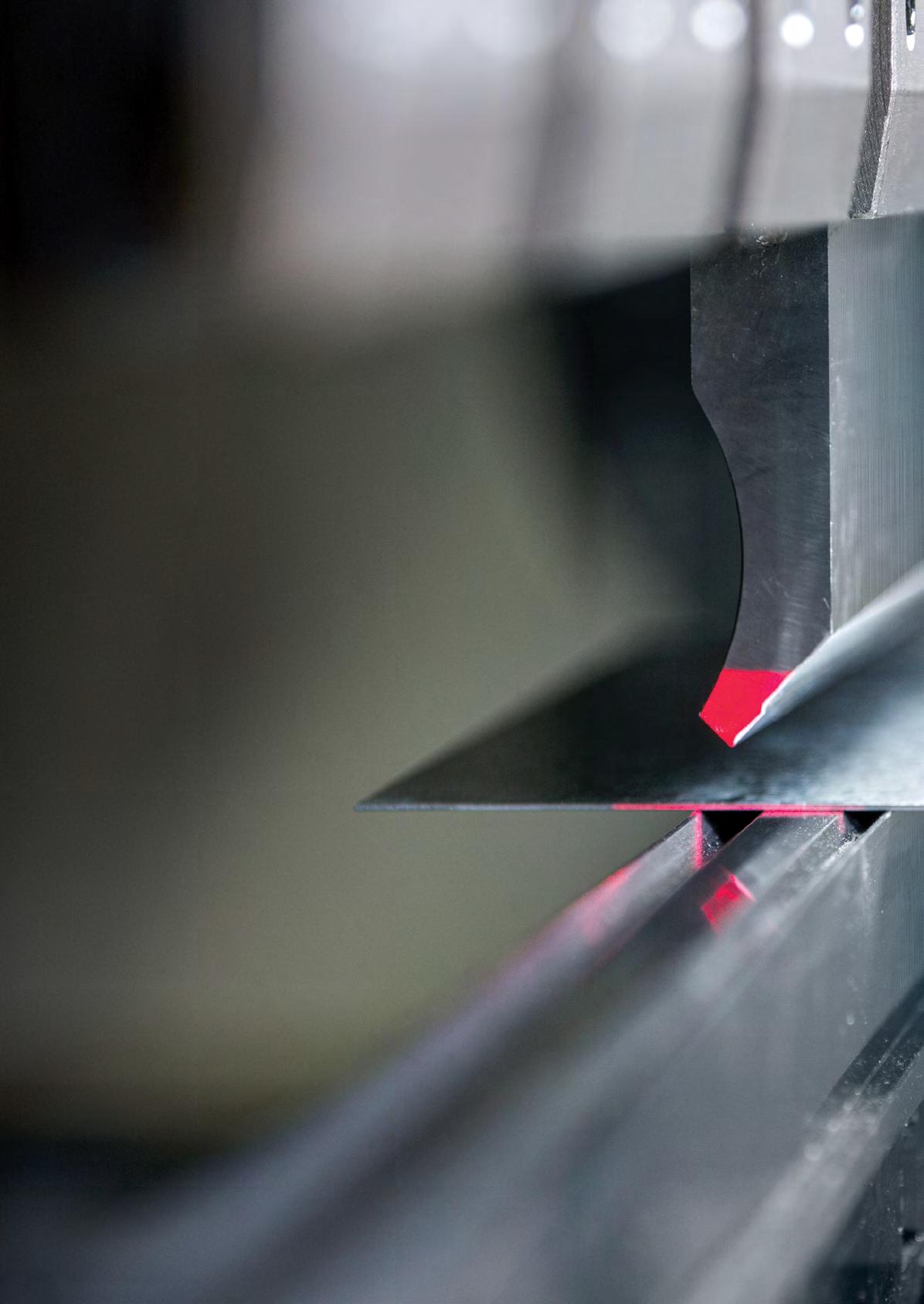

BendShield is a dynamic sensing technology that provides an advanced level of optical tool protection for press brake operators by enveloping the punch tip with a protective field that has no gaps while maintaining high speed operation. With an object detection resolution of 2mm, BendShield detects even the smallest obstruction from any angle. Press brakes with BendShield technology are not only the safest but also the most productive with guaranteed levels of safety and high-speed performance.

Automatic Tool Alignment

BendShield automatically scans the upper tool to determine the tool profile then dynamically adjusts the protective zone relative to the tool tip.

Special Tools Detection

BendShield also works with a variety of upper tool profiles from V shaped punches to radius and flattening tools. The optical technology adapts to the tool profile to provide an optimal level of protection for machine operators.

Dynamic Sensing Technology

BendShield adapts to accommodate various part profiles from flat parts to box shaped parts with single and double sides flanges as well as back-gauge fingers for short bend cycles. Multiple segments within the protective zone are automatically and dynamically blanked on each bending cycle to maintain high-speed machine operation with optimal protection and minimal interruptions.

Advanced tool collision protection

BendShield not only protects machine operators, but protects against high-speed tool collisions. If operators accidentally install or program an incorrect tool, BendShield protects your tooling investment by avoiding high-speed collisions that could lead to tool damage.

BendShield technology is available on selected models from these manufacturers:

9 pressbrakebuyersguide.com

SmartLink

Enhancing the operation, functionality, performance and efficiency or your press brake.

What is SmartLink?

SmartLink technology provides a seamless integration between key machine elements including the machine drive system, safety control, optical protection, optical imaging and the CNC system. This enables an intelligent flow of information that significantly enhances the operation, functionality, performance and efficiency of the press brake.

Press brakes with SmartLink technology offer users a wide array of functions that can include;

Safety and control

SmartLink manages synchronised control of the machine drive system, safety control, operator controls and the CNC system for more efficient and streamlined operation. Overall machine system status can be displayed on the CNC in realtime for an improved user experience.

Functionality and productivity

SmartLink enables optical protection modes to be selected and customised in the CNC bend program. A different mode or combination of modes can be selected for each bend, allowing for streamlined bend programs that match the profile of the work piece.

SmartLink automatically switches modes on each step of the bend program with intelligent blanking of individual sensors to eliminate unnecessary stops and pedal presses for reduced cycle time and the fastest possible part production.

Automated adjustment

SmartLink enables fully automated adjustment of the integrated protection system in conjunction with BendShield technology. The protection system can be automatically raised and lowered according to the tools selected in the bend program without the need for any operator intervention. Advanced optical verification of the installed tools confirms that the machine is correctly configured, ensuring safe and error free operation.

Advanced functions

When paired with BendVision technology, SmartLink manages the flow of image data to the CNC to enable advanced bending functions such as angle measurement, real-time angle control, active tool recognition and much more. Press brakes with SmartLink technology produce parts with greater flexibility, speed and efficiency.

SmartLink technology is available on selected models from these manufacturers:

PRESS BRAKE BUYER’S GUIDE 10

Technology

Automated adjustment

SmartLink enables fully automated adjustment of the integrated protection system in conjunction with BendShield technology.

Safety and control

SmartLink manages synchronised control of the machine drive system, safety control, operator controls and the CNC system for more efficient and streamlined operation.

Functionality and productivity

SmartLink enables optical protection modes to be selected and customised in the CNC bend program. A different mode or combination of modes can be selected for each bend, allowing for streamlined bend programs that match the profile of the work piece.

Automated guarding

SmartLink automatically switches modes on each step of the bend program with intelligent blanking of individual sensors to eliminate unnecessary stops and pedal presses for reduced cycle time and the fastest possible part production.

Tool and material verification

SmartLink facilitates optical confirmation of the tool and material data in the CNC bend program.

Advanced functions

When paired with BendVision technology, SmartLink manages the flow of image data to the CNC to enable advanced bending functions such as angle measurement, real-time angle control, active tool recognition and much more.

11 pressbrakebuyersguide.com

Technology

AutoSense

Automatic monitoring technology that tracks machine operation and performance in real-time.

Automatic monitoring

AutoSense automatically monitors control commands, motion, direction, speed and stopping performance to maintain a high level of machine and operator protection.

Dynamic Valve Monitoring

Dynamic Valve Monitoring technology automatically monitors hydraulic valves, associated control commands and machine actions independent of traditional valve sensors.

CNC messaging

AutoSense Plus provides additional monitoring to detect and diagnose specific machine electrical and hydraulic faults with visual alerts displayed on the CNC.

PRESS BRAKE

12

BUYER’S GUIDE

AutoSense

AutoSense automatic monitoring technology tracks machine operation and performance in real time. AutoSense automatically monitors control commands, motion, direction, speed and stopping performance to maintain a high level of machine and operator protection. Press brakes with AutoSense technology guarantee compliance with international safety standards that mandate automatic monitoring of machine overrun and safe speed.

AutoSense Plus

AutoSense Plus provides additional monitoring to detect and diagnose specific machine electrical and hydraulic faults with visual alerts displayed on the CNC. Machine problems are quickly and easily identified to help get your machine back into production with minimal downtime.

AutoSense Ultimate

AutoSense Ultimate adds advanced Dynamic Valve Monitoring technology to automatically monitor hydraulic valves, associated control commands and machine actions independent of traditional valve sensors. Press Brakes with embedded AutoSense technology give you peace of mind so you can focus on getting the job done.

AutoSense technology is available on selected models from these manufacturers:

13 pressbrakebuyersguide.com

Technology

FlexSpeed

Streamlined, responsive and efficient machine control.

FlexSpeed

FlexSpeed safety control with high speed processing technology provides the platform for more efficient machine operation and superior performance.

Traditional press brake designs employ a combination of hardware and software safety processing. This inefficient process slows down overall response and reaction times and when coupled with optical protection systems leads to a reduction in machine performance by forcing the machine to operate at reduced closing speed in order to improve stopping performance and increasing slow speed travel prior to bending.

Machines with FlexSpeed technology operate with maximum efficiency and productivity with no restriction on operating speed or performance.

FlexSpeed technology are available on selected models from these manufacturers:

PRESS BRAKE BUYER’S GUIDE 14

Efficient machine control

FlexSpeed safety control with high speed processing technology provides the platform for more efficient machine operation and superior performance.

15 pressbrakebuyersguide.com

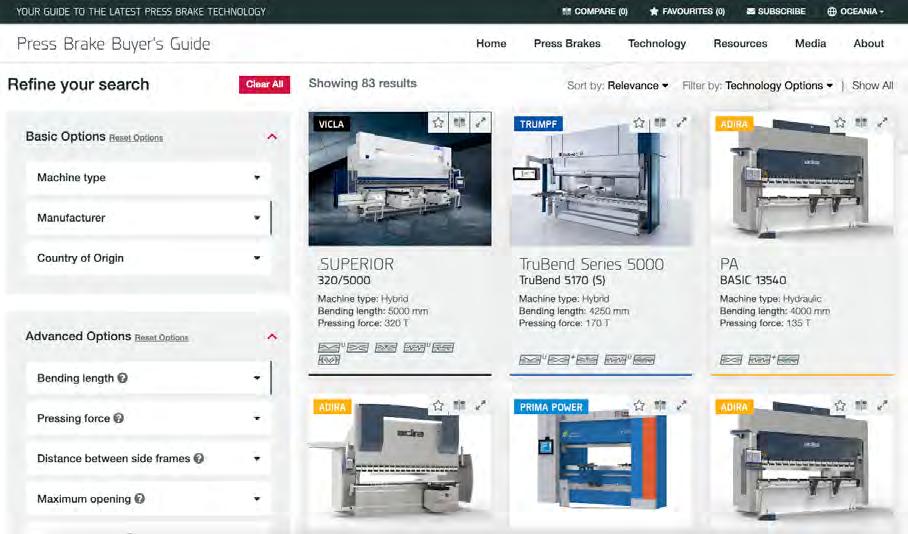

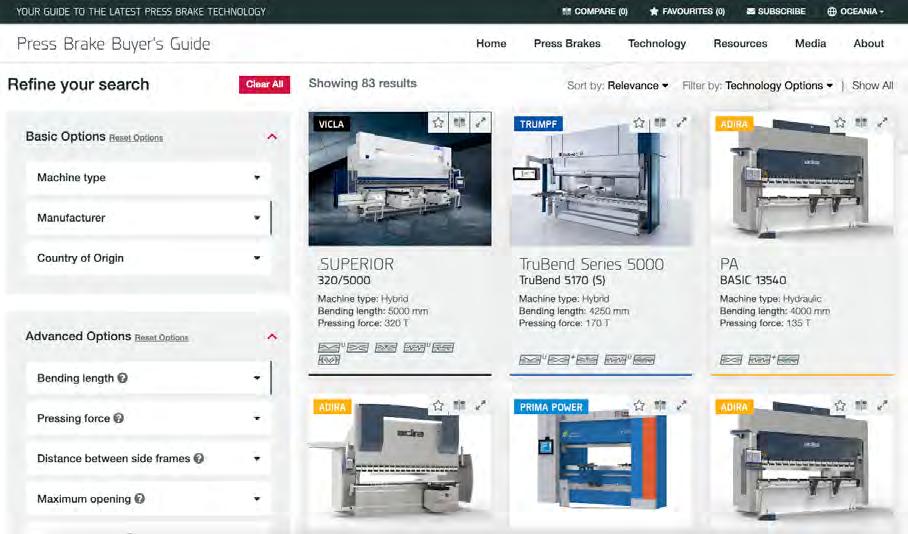

Press Brake Buyer’s Guide website updated with more buying information and resources

The Press Brake Buyer’s Guide website has been expanded, and now presents 26 leading press brake manufacturers, more buying resources, and features more than 700 machine models for you to search and compare.

PRESS BRAKE FINDER

The updated Press Brake Finder is a handy tool that you can use to search and compare hundreds of new press brake models. Currently there are over 700 models listed from market leading press brake manufacturers. Start with a simple search by selecting a drive type from hydraulic, hybrid, or electric, plus machine bending length and pressing force. Using the advanced search option, you can define additional specifications including distance between the side frames, maximum opening and stroke, frame type, throat depth, plus the fast closing and bending speeds. Select models to compare, then once you find a model that matches your requirements, simply fill in the enquiry form, and your message will be sent directly to the press brake manufacturer.

PRESS BRAKE DRIVE SYSTEMS

When deciding to purchase a new press brake, there are many factors to consider. One important factor is selecting the type of machine drive system that will best suit your production requirements, purchasing budget and running costs. Learn more about various press brake drive systems, and discover the range of hydraulic, hybrid and electric machines.

AUTOMATIC TOOL CHANGERS

Automatic Tool Changer (or ATC) press brakes make machine setup and tool changeover faster, more reliable and a lot more efficient compared to a manual tool change process. The new section provides an overview of ATC machines, plus detailed information and videos of ATC solutions including the LVD ToolCell, TRUMPF ToolMaster, Prima Power eP Genius, Salvagnini B3.AU-TO, the BEND-MASTER from Warcom, VICLA ATC, ADIRA BB + ATC, and the Vimercati VSB.

BENDING CALCULATORS

Explore and download a range of press brake bending aids and calculators including the Euromac App, Salvagnini Formula, LVD Bend Advisor, Cincinnati Load Calc App and the TRUMPF BendGuide. All apps are available for download from Google Play and the App Store.

NEW MEDIA SECTION

Explore the new video gallery and view content covering a wide range of press brake types and technologies including hybrid, hydraulic and electric machines, tandem machines, automatic tool changers, wireless foot pedals, BendVision image processing for angle measurement, robotic bending, and automated bending cells.

PRESS BRAKE BUYER’S GUIDE 16

In addition to the Press Brake Buyer’s Guide magazine, you can also read the latest issues of LVD Discovery, Prima Power: Power Line and TRUe magazine by TRUMPF. Keep up to date with the latest industry news and upcoming events including international exhibitions, open house events and virtual events such as PRIMA@HOME and LVD Virtual Tech Sessions.

MORE RESOURCES COMING SOON

Over the coming months, additional resource pages are being added to include more information, videos and the latest manufacturer solutions in tandem press brakes, press brake tooling, robotic bending, and automated bending cells.

17 pressbrakebuyersguide.com

Visit pressbrakebuyersguide.com and subscribe to receive news and updates.

Shaping flows.

Getting your bend angle right the first time is a challenge, we know!

Constantly making machine adjustments, testing, trial-and-error bending; all costs a lot of time and material.

But it doesn’t have to be that way. Our adaptive bending technologies ensure uninterrupted process flows. They continuously check and correct the angle of the sheet as it is being bent. The result?

A correct angle each and every time, whether you are processing small batches, complex parts or XXL profiles.

Shape your flows with LVD.

Learn more about our Dyna-Press, Easy-Form and Synchro-Form press brakes.

C15

adaptive Hall 13 Stand

19 pressbrakebuyersguide.com Lamiera Preview May 10 – 13, 2023 • Milan, Italy Discover all our partners and press brakes offering the latest embedded technologies at Lamiera 2023. 8. Hall 15 Stand D28 7. Hall 15 Stand D24 11. Hall 15 Stand E12 12. Hall 15 Stand E16 13. Hall 15 Stand E26 14. Hall 15 Stand E33 9. Hall 15 Stand D30 10. Hall 15 Stand G01 3. Hall 13 Stand C25 2 Hall 13 Stand C15 6. Hall 15 Stand D18/20/22 1. Hall 13 Stand C13 5. Hall 15 Stand D14 4. Hall 13 Stand C37 Entrance 8 13 12 2 6 5 1 9 7 3 4 10 11 14 Press Brake Buyer’s Guide Hall 13 Hall 15

Lamiera Preview

Hall 15 - D14

In the era of digital transformation and the current volatile market scenario, the sheet metal working industry is focusing more and more on key issues such as automation and sustainable production. This is a perfect backdrop for Salvagnini, which is presenting in the Lamiera trade exhibition, presenting a brand new P2 panel bender, an L3 laser and a B3 press brake, in addition to a wide portfolio of services and software solutions.

The first new innovation concerns the P2 panel bender, one of the most successful models in the Salvagnini range, with the new 2225 model being unveiled for the very first time worldwide. This new size confirms the characteristics of productivity, flexibility, precision, high technological content, reduced energy consumption and compact layout that have always made P2 particularly attractive to the market, and also reaches a maximum bending height of 254 mm. P2, with its universal bending tools and automatic bending and handling cycles, natively combines productivity and flexibility, completing an average of 17 bends per minute. No re-tooling is required because the upper and lower blades, counterblade and blankholder are universal tools that are able to process the whole range of thicknesses and machinable materials. The automatic blankholder adapts the tool length according to the size of the part being produced in-cycle, without machine down times or manual re-tooling. A wide range of options extends its application horizons. P2 is really the perfect solution for batch-one and kit production. Its advanced sensor technology measures the actual thickness and effective size of the blank, detecting any deformations caused by variations in temperature, while MAC3.0 allows the P2 to adapt to the material being machined by measuring the tensile strength in real time and automatically compensating for any variations in the range ±25% of the reference value. MAC3.0 greatly reduces the risk of obtaining faulty parts, and eliminates reworking and material waste - increasing the financial sustainability.

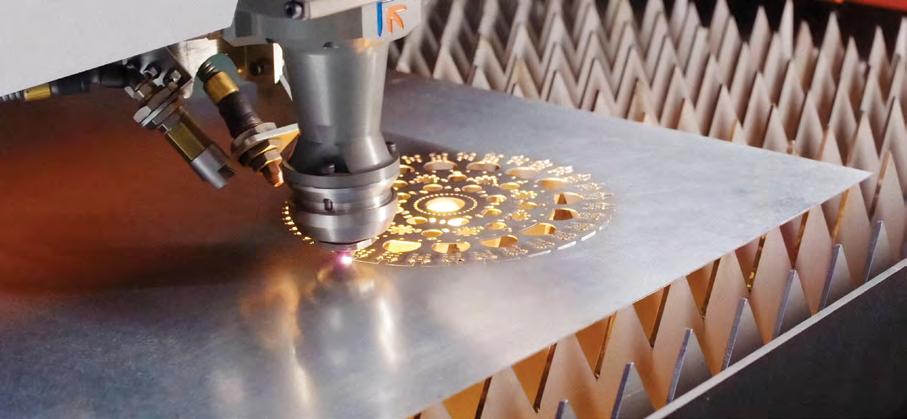

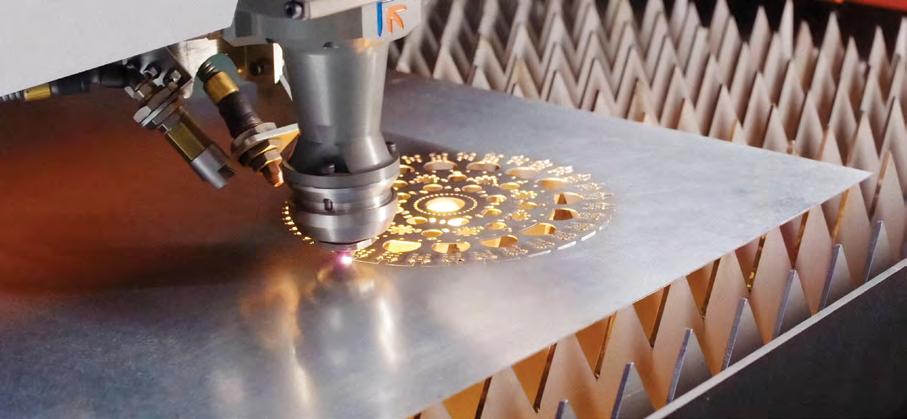

At the Lamiera trade exhibition, Salvagnini is also presenting its L3 fiber laser, with reduced consumption and competitive operating costs, designed for transversal use regardless of application, material and thickness, as it is equipped with a single laser head which allows all workable thicknesses and materials to be cut. Equipped with a 10 kW power source, L3 is an agile laser with numerous proprietary functions that allow the operator to effortlessly solve any problems in their day-to-day work. L3 is fed by ADC, a compact automation for sheet metal loading and unloading. Its strengths are its compact footprint, rapid cycle times and fast installation. the L3 is equipped with the ACUT option, which allows to cut thicknesses up to 20mm with compressed air, while ADC’s gripping devices are equipped with the new AVC technology, adaptive vacuum control,resulting in a reduction in compressed air consumption of around 90%.

PRESS BRAKE BUYER’S GUIDE 20

Hall 13 - C15 Hall 13 - C13

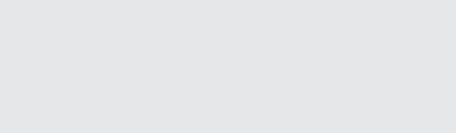

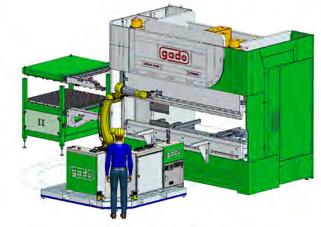

AkuBend represents the most suitable solution to make the bending operations dynamic and flexible. An efficient, precise robotized bending cell with maximum automation optimization in terms of production batches and kind of product. Optimal for small batches and high variability, it is in fact possible to conciliate/gain with maximum simplicity an unattended automatic production with a production in manual mode of the press brake, through the automatic sliding of the press brake on the lateral rail system. In addition, the offline programming of the robot and press brake software eliminates the operator’s checking and reprogramming times, that will only take care of the loading and unloading operations.

At Lamiera, LVD showcases its latest Dyna-Press 60/20 Pro electric-drive press brake.It provides 60-tons of pressing force, two meters of working length and a fiveaxis backgauge to handle a wide range of applications at bending speeds up to 25 mm per second. The press brake will be exhibited with the Easy-Form® Laser system adaptive bending system to ensure accurate and efficient bending. The Pro model offers an optional crowning system.

Also on display is the YSD LaserONE fiber laser cutting machine. It addresses the market need for a low cost, ultra-practical fiber laser cutting machine. Designed, manufactured, sold and serviced by LVD, it offers reliable operation backed by a leading OEM. LaserONE cuts a variety of materials and thicknesses, has low operating and maintenance costs, and provides a quick return on investment. The machine is equipped with an automatic pallet changer for fast interchanging of the shuttle tables in a cycle time of approximately 30 seconds. An optional Load-Assist automation system offers easy sheet transfer. The LaserONE 3015 at Lamiera will feature a 6kW laser. Finally, LVD will demonstrate the complete suite of CADMAN products, with the latest software enhancements, all designed to improve process flow. As manufacturers increasingly turn to digitalization and smart manufacturing, LVD continues to drive the factory of the future with its integration philosophy, also reflected in the theme of “Shaping flows”

21 pressbrakebuyersguide.com

Bending is an

B3

The scalable automation including ATA (the automatic tool length adjuster) and AU-TO (the automatic tool changer) allows to configure the machine according to the real manufacturing needs, whether it is batch one or kit production. The B3 was designed by combining the features and benefi ts of electric and hydraulic press brakes with Salvagnini’s in-depth knowledge of automation, software, mechanics and electronics.

For sixty years Salvagnini has been designing, producing and selling fl exible systems for sheet metal processing. Our panel benders, punching machines, press-brakes, fiber laser cutting machines, FMS lines, automatic storetowers, and software have found application in a wide range of industries.

PRESS

BRAKE BUYER’S GUIDE

13

Hall 15 - D28

At ADIRA, we make innovations in all the equipment to meet all our customer’s needs, from the simplest request to integration with complex production processes (software and hardware). We design customised solutions that adapt to the needs of your business and that optimise your production system. Represented by our partners Alpemac in this event, we will be showcasing a full electric press brake with 35 tons of bending force, a 1.5 metre bending length, and equipped with a Hexa-C frame, that ensures precision in guiding the movable ram. This fully electric machine, powered by the Blue-Drive system, is capable of faster bending and, at the same time, allows energy savings thanks to its economical operation. We also by presenting the capabilities of our most-known PA, a versatile hydraulic press brake, also equipped with the Hexa-C frame, that brings flexibility and precision, an ideal solution for a wide range of industries, offering a large number of accessories and optional equipment. With increased return speed and the Greendrive system that makes the motor turns very slowly, thereby reducing consumption when the operator is not pressing the pedal or using the machine.

Hall 15 - E26

G.A.D.E., will present in Hall 15 – Booth E26, of the Milanese edition of Lamiera 2023, a cutting-edge technological solution resulting from the synergy and research between the PINETTE PEI group and the Ferrarabased company. In detail, it is a high-performance G.A.D.E. HYBRID series model SPC-H 3180 which is associated with a fast and precise mobile robotic work station developed by PINETTE PEI.

This solution was designed to meet the growing precision and speed production requirements required by the market. It is a flexible and versatile plant oriented both to the production of small batches and to those of large quantities of products. Simple to equip and configure, the “technological island” that G.A.D.E. presents therefore allows extraordinary flexibility and adaptability to the production needs required by modern industrial companies. The setup is completed by the NEW GADE TOOLBOX, an effective, safe and fast system that allows you to change the tool, increasing productivity and preserving tools and the operator from any damage and accidents. As regards the beating heart of the solution proposed in Hall 15 – Booth E26, the HYBRID series bending machine model SPC-H 3180 includes among its characteristics a useful working length of 3060 mm., free passage between uprights 2600, a maximum work of 1800 kN, a stroke of the upper blade holder of 350 mm., a distance between the table and the blade holder of 585 mm., a speed of 300 mm/ sec in descent and fast ascent. The controlled axes of the machine are 7 (Y1–Y2–X1–X5–R–Z1–Z2). The SPC-H 3180 is equipped with a double monitor S675 W – MULTI TOUCH 21” graphic video numerical control with touchscreen 3D image management, WILA table and upper equipment with hydraulic locking.

23 pressbrakebuyersguide.com

Lamiera Preview

This bending machine is also equipped with an Iris-type LAZERSAFE laser beam front protection system, motorized laser support brackets for front protection of the work area, active crowning system, LED string on the upper blade holder and wireless control panel.

The rich range of accessories supplied as standard on all our bending machines can be further customized through a wide range of options, to further facilitate and speed up the operator’s work. Finally, all the machines of G.A.D.E. they can be set up in an INDUSTRY 4.0 perspective, and benefit from a declaration of conformity issued by a primary certification body to protect and guarantee its customers for the purpose of satisfying the legal requirements.

The ESA NEW S875 2D graphical Control Unit is the most advanced control system in the market. This system provides a user-friendly interface and advanced functionalities to the machine operator.

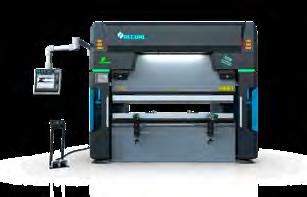

The HAWE ePrAX GREEN Hydrid Servo System, which is the most advanced hybrid power system, is also included in the machine. It can reduce energy consumption by up to 65%, making it an ideal solution for those looking to reduce their energy costs. The ePrAX hybrid system features a lowered sound pressure level of 45 dB, which makes it quieter than other machines in the market. This feature is critical for those who work in noise-sensitive environments. Additionally, the machine is equipped with ACCURL “WILA WAVE” WEDGE ULTRA CNC Corwning, which guarantees bending accuracy and consistency. Safety is a top priority in the ePrAX hybrid system, and it features the world’s most advanced Lazer Safe IRIS system.

Hall 15 - E33

At Lamiera, ACCURL is exhibiting multiple press brakes, including the new eB Ultra electric model and the energy efficient EuroMaster hybrid.

The ACCURL 100% Electrical Press Brake, also known as eB Ultra, is a fully electric machine that utilizes servo electric technology to improve energy efficiency and productivity. With up to 80% energy savings and 100% electrical power drive, the eB Ultra offers maximum return on investment while reducing CO2 emissions. The transmission components are of high quality and capable of withstanding high loads, ensuring high reliability and maximum productivity.

The EuroMaster hybrid press brake features high-speed ram and backgauge that enhance the machine’s performance. The ram speed can reach up to 220 mm/s, while the Z-axis speed can reach up to 1000 mm/s. These features enable the machine to create complex parts with precision and consistency.

This system provides excellent protection to the operator and ensures that the machine operates safely and efficiently. Finally, the ESA S875 is compatible with SMART INNOVATION Industry 4.0, which enables the machine to connect to your ERP system. This feature allows you to monitor and control the machine remotely, improving your overall efficiency and productivity. In conclusion, the ePrAX hybrid system is an innovative and advanced solution for those looking to improve their energy efficiency, productivity, and safety in sheet metal bending machines.

With its advanced features and functionalities, the system is a game-changer in the market and can significantly improve your bottom line.

PRESS BRAKE BUYER’S GUIDE 24

POWERING YOUR BUSINESS

INCREASE THE POWER OF YOUR PRODUCTION. CHOOSE PRIMA POWER

Choose a single partner able to provide you with all the technologies for sheet metal working: the best in terms of integration, scalability, flexibility and efficiency.

1. Ecosystem of automations and software for the native integration of all solutions.

2. Modular and scalable solutions to adapt to any production and support growth over time.

3. From kits to mass production, no compromise between flexibility and efficiency

2D & 3D LASER CUTTING | BENDING | PUNCHING & SHEARING | AUTOMATION | SOFTWARE | FMS

Prima Power solutions protagonists at the LAMIERA exhibition in Milan.

Prima Power will be the protagonist at the LAMIERA exhibition in Milan, the reference event for the sheet metal working machine tool industry, which will take place from 10 to 13 May.

For Prima Power this event will be an opportunity to present the most recent solutions and to discuss the latest trends in the sector with Italian and international visitors in a large stand designed, also from the point of view of hospitality, to make networking even more enjoyable and effective.

Under the spotlights of the Milan fair, Prima Power will exhibit two entirely Made in Italy products: a laser cutting solution and a bending one, produced respectively in the Collegno (TO) and Cologna Veneta (VR) plants. As always, the software will play a key role and it will be possible to request demonstrations and simulations of the digital ecosystem at the service of intelligent production at any time. The public at the fair will be able to discover, also through multimedia presentations, the entire range of technologies and automation solutions offered by the Prima Power brand to give more strength to the business of its customers.

At LAMIERA it will be possible to get to know the Laser Genius+ machine with 15kW fiber laser, compact and efficient automatic material handling system Compact Server and Gas Mixer function, which enhances the versatility and effectiveness of the system. Laser Genius+, which stands out for its high productivity, application and configuration flexibility, and the complete range of automation and software functions, will be exhibited with a 15kW laser power, which allows a productivity increase of up to 53% compared to the 10kW source.

The machine will also be equipped with Gas Mixer, the assist gas management system which allows for an improvement in cutting speed up to 15%, a reduction of residual burr by 50% on medium and high thicknesses and a reduction in operating costs.

For bending technology, visitors will be able to see the Bending Center BCe 2720 semi-automatic panel bender at work. It is a servo-electric solution designed to achieve high productivity also thanks to the LUT loading and unloading table, which allows the operator to load a single sheet to be folded in masked time while the machine processes the previously loaded piece. Two safety laser scanners mounted on the LUT table, if interrupted, block the work cycle, protecting the user during all production phases. The BCe is the ideal solution for small to medium batches, including kits and fully perforated material. The machine can bend materials up to 2750 mm in length, with a bend height of 204 mm and can be equipped with options such as API angle correction which, combined with servo-electric technology, guarantees excellent bending quality, and the BCP device which allows the cutting and unloading of the bent profiles from the LUT table. The BCP option allows to bend profiles with the only panel bender that would otherwise require the use of a press brake, with an increase in productivity of over 15%.

PRESS BRAKE BUYER’S GUIDE 26

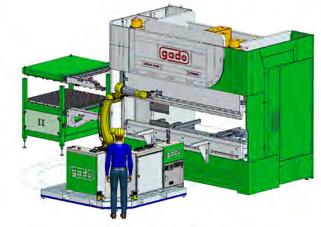

The software plays a strategic role in making production more efficient and in implementing digital and sustainable manufacturing, to create future-proof competitive advantages. The Prima Power software ecosystem offers solutions for each stage of production and Prima Power experts will be available to the LAMIERA public to illustrate the features and benefits of the various suites. Among these, Tulus Office, for production planning using a calendar that reduces the time it takes to put the piece into production; Remote Care, which accelerates diagnostic times and

resolution of any machine alarms; NCExpress Parametric Programming, which maximizes speed and accuracy in the production of parts with slightly different dimensions or characteristics, allowing a single program to be used for several parts.

Prima Power’s presence at Lamiera confirms its commitment to being close to customers with its experience and with efficient, smart, and flexible technological solutions, capable of responding to the needs of a constantly evolving market.

www.primapower.com

27 pressbrakebuyersguide.com

1. Prima Power’s Laser Genius+ machine will be exhibited with the 15 kW fiber laser source, which increases the cutting speed and versatility of the machine.

2. The BCe 2720 servo-electric panel bender with LUT table for loading in masked time that increases productivity.

3. Among the suites presented by Prima Power at LAMIERA, Tulus Office reduces the time to put the piece into production.

learn more, visit Prima Power at Lamiera 2023: Hall 15 - Stands C18, 20 & 22

To

LVD is ‘Shaping Flows’ with Bending & Laser Cutting Technology

LVD spotlights the theme of

Flows” with its latest model of Dyna-Press electric-drive press brake, an ultra-practical laser cutting machine and CADMAN® software suite for optimized fabrication on display at Lamiera, 2023 Hall 13 – Stand C15.

NEW 60-TON ELECTRIC PRESS BRAKE

The Dyna-Press 60/20 is the latest addition to LVD’s line of high-speed electric-drive press brakes. It provides 60-tons of pressing force, two meters of working length and a five-axis backgauge to handle a wide range of applications at bending speeds up to 25 mm per second. Exhibited will be the Dyna-Press 60/20 Pro equipped with LVD’s Easy-Form® Laser system for greater control of the bending process to achieve high output at a high level of quality. The Pro model offers an optional custom-made crowning system.

MORE OUTPUT AT LOWER COST

Dyna-Press press brakes consume low electricity and deliver fast cycle times to bend more parts per minute more efficiently at a lower cost per part.

The coupling between ram and servomotors is accomplished using two heavy-duty ball screws to distribute force and tonnage evenly across the working length for a streamlined design that requires low maintenance. Dyna-Press is built to ensure accuracy across a broad range of small-to-medium-sized bending jobs.

ULTRA-PRACTICAL LASER

YSD LaserONE addresses the market need for a low cost, ultra-practical fiber laser cutting machine. Designed, manufactured, sold and serviced by LVD, it offers reliable operation backed by a leading OEM. LaserONE cuts a variety of materials and thicknesses, has low operating and maintenance costs, and provides a quick return on investment.

The machine is equipped with an automatic pallet changer for fast interchanging of the shuttle tables in a cycle time of approximately 30 seconds.

An optional Load-Assist automation system offers easy sheet transfer. The LaserONE 3015 at Lamiera will feature a 6kW laser.

CADMAN® ADVANCES PROCESS FLOW

As manufacturers increasingly turn to digitalization and smart manufacturing, LVD continues to drive the factory of the future with its integration philosophy and CADMAN® software suite. The complete suite of CADMAN software products will be demonstrated, showcasing the latest software enhancements – all designed to improve process flow.

ABOUT LVD

LVD is a leading manufacturer of sheet metalworking equipment, including laser cutting systems, punch presses, press brakes, guillotine shears and automation systems, integrated to and supported by its CADMAN® software suite. LVD Industry 4.0-ready products and technology make smart manufacturing possible.

www.lvdgroup.com

PRESS BRAKE BUYER’S GUIDE 28

“Shaping

pressbrakebuyersguide.com 29

Vimercati, the solidity in bending for 50 years

Vimercati was established in 1973: ever since it has been guaranteeing ongoing and prompt supply of machinery and technical assistance to its customers. Specialized in the production of press brakes, guillotine shears and sheet metal processing systems. With its decade-long experience on Italian and international markets, Vimercati offers reliable and top-quality products entirely made in its plants. Its highly specialized staff takes care of the whole production process, from the purchase of raw materials to all the manufacturing phases combining the new opportunities offered by modern electronics and computing to create strong, hightech, reliable, accurate and extremely flexible machines.

Vimercati offers a wide range of hydraulic and hybrid press brakes, starting from the smallest 30 tonnes x 1250 mm up to the 600 tonnes x 8050 mm, without stroke and opening limits along with a varied series of optional accessories. Tandem press brakes with various setups: with two or more press brakes with the same length and the same nominal bending forces; with two or more press brakes with different lengths and different bending forces. Along with the vast offer already available, we can design customized and specific solutions based on the production needs of individual customers.

Press brakes are equipped with: ACTIVE - HCL crowning system. One or more sensors, detects in real time the flexion, and instantaneously adjusts the deformations of the bench, allowing a perfect bending linearity. The cylinders of this crowning system are located in spherical housings that grant an excellent grip of the mechanical parts, avoiding at the same time any kind of wear and jamming during the working phase. Special mechanical solutions isolate the supports of the optical lines to check the linearity of the table and allow for perfect functionality of the Active HCL crowning system. The whole system is fully automatic and controlled from the CNC through dedicated software.

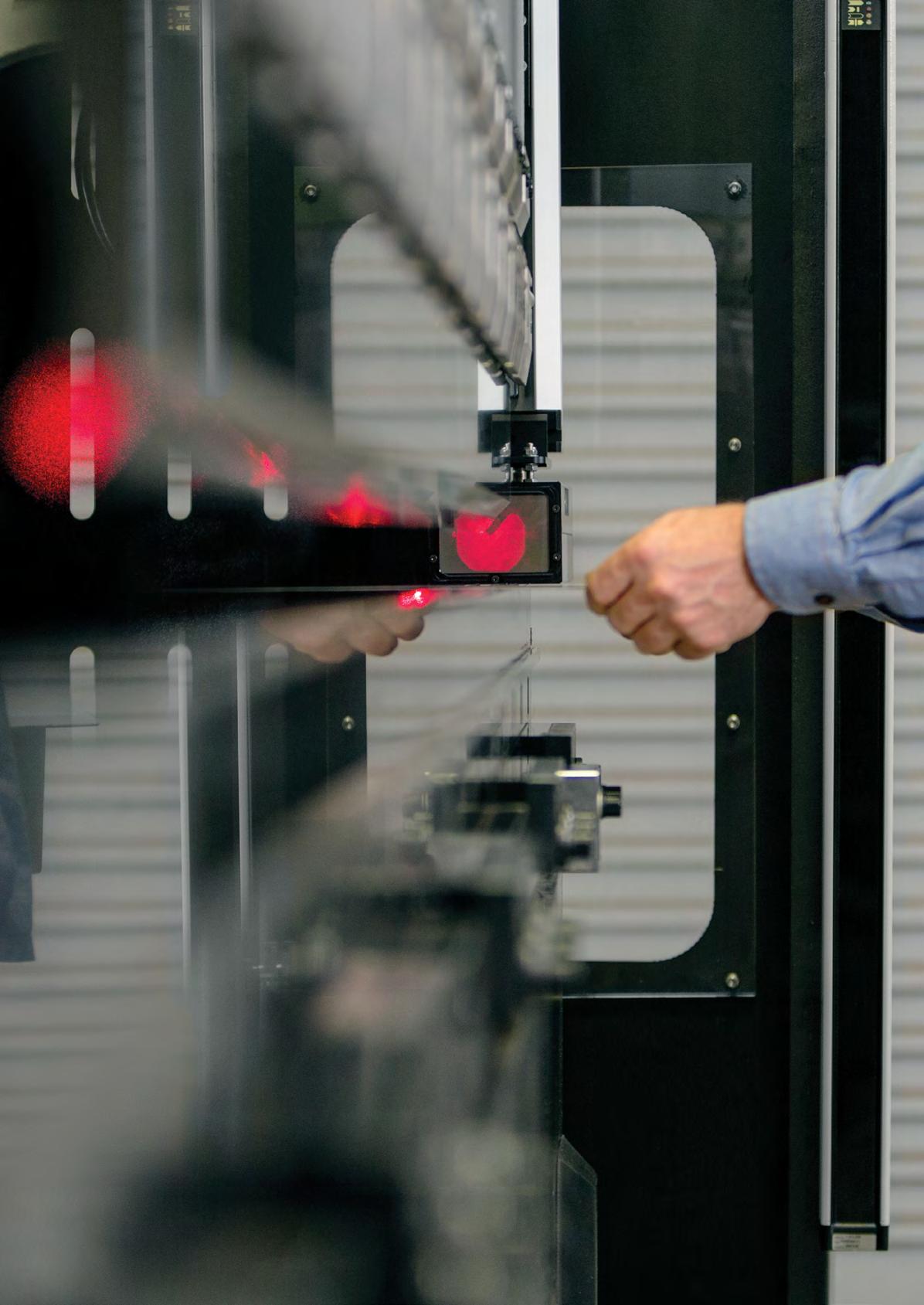

LAZER SAFE IRIS safety devices that manage, through a dedicated PLC and under top safe conditions, the speed change (fast approach – bending speed) at contact with the sheet metal. The LAZER SAFE safety devices are also available in a motorized version with automatic positioning managed by CNC control.

LAZER SAFE IRIS PLUS devices can be installed on press brakes up to maximum two metres in length. In addition to the above features, they can measure, check, and correct the bending angle to obtain, right from the first piece, minimum precision tolerances regardless of any changes in thickness, strength and rolling direction. The system can be used in real-time mode with elastic return measurement for each single bend or in database mode, with elastic return value detected and saved in a customizable database. Optional: system to measure, check and correct the bending angle, the Laser Check Data M is set to obtain, right from the first piece, minimum precision tolerances regardless of any changes in thickness, strength and rolling direction of the material. The measuring sensors are located in metal casings for protection against any possible damage. They are motorized, have a side parking area, and entirely managed from the CNC. As soon as the bending sequence starts, the measurement sensors automatically align themselves with the piece to be bent to measure the angle, which can also be carried out in several points and wireless pedalboard: extremely user-friendly for operators, as there are no connecting cables.

Vimercati also offers robotized systems solutions such as the one presented at the fair at its stand. AkuBend robotic cell represents the most suitable solution to make the bending operations dynamic and flexible. An efficient, precise robotized bending cell with maximum automation optimization in terms of production batches and kind of product.

PRESS BRAKE BUYER’S GUIDE 30

Optimal for small batches and high variability, it is in fact possible to conciliate/gain with maximum simplicity an unattended automatic production with a production in manual mode of the press brake, through the automatic sliding of the press brake on the lateral rail system. In addition, the offline programming of the robot and press brake software eliminates the operator’s checking and reprogramming times, that will only take care of the loading and unloading operations.

Still on the subject of automation, Vimercati also offers the VSBVimercati Storage Bend solution which consists in the integration of the press brake with an automatic tool changer warehouse. The VSB solution makes bending process more versatile, faster, and more reliable. It eliminates the manual configuration of the machine and allows the operator to dedicate their own time and skills in preparing the bending batches. It is ideal for small, complex, and uneven batches where setup times impact the productivity of the press brake and the production cost.

www.vimercati.eu

31 pressbrakebuyersguide.com

To learn more, visit Vimercati at Lamiera 2023: Hall 13 - C13

Autonomous Guarding: Press brake automation takes another step forward.

Press brakes have seen significant advancements in automation as technologies such as automatic tool changing cells, automated material handling and robotic bending have becoming increasingly common over the last decade.

However, for the most part, press brakes are still manually operated machines that require trained and skilled operators to achieve safe, efficient, and productive bending. Aside from bending parts, press brake operators are required to manage the setup and configuration of the machine safety and guarding devices and systems. An incorrect, or poor setup can not only result in a potential reduction in safety function but can also lead to a significant reduction in machine efficiency that results to lower productivity.

A press brake with an automated safety and guarding solution eliminates the need for manual adjustments to be performed by the operator by automatically driving the optical

OF AUTONOMOUS GUARDING

components to the correct position, then automatically making any necessary adjustments based on the tooling that had been installed. In addition, secondary processes automatically check and confirm the positioning and setup, thereby ensuring that the machine is always safe to operate.

The team at Lazer Safe, who are the industry leading specialists in the field of press brake safety and guarding solutions, are improving the way in which machine operators interact with the press brake through more advanced levels of Autonomous Guarding technology. Lazer Safe is leading the industry in Autonomous Guarding and have defined five levels of automation ranging from Level 0 through to Level 4.

Press brakes designed to Level 0 essentially offer no automation, and therefore completely lack any automatic functions. The safety and guarding system and processes

that are integrated with the machine are purely manual and rely solely on the machine operator for any adjustment, setup, and alignment of the guarding system, plus safety performance testing and mode selection. This generally applies to press brakes that are designed and manufactured to achieve a lower cost or supplied into economy markets.

Level 1 progresses to low automation, where we start to see the introduction of press brakes with automatic functions such as automatic verification of the optical sensor position to the upper tool, verification of the tool height and material thickness, plus automatic guarding mode selection for each step in the bend program. This typically requires the press

brake manufacturer to adopt integrated functions where processes are embedded in the CNC system software to facilitate more streamlined and user-friendly operation.

Press brakes designed with Level 2 Autonomous Guarding take a larger step forward to where all the of the safety and guarding setup, adjustment and operating functions are now automated. This presents the ideal solution where the operator turns on the machine, installs the tooling and starts bending parts – all without have to setup, adjust, or check any of the safety and guarding functions, and provided that the bend program has been optimised, there is very little to no interference when forming parts.

PRESS BRAKE BUYER’S GUIDE 32 FEATURE ARTICLE -

Level 0 No Automation All functions require manual operator intervention. Level 1 Partial Automation A combination of automated and manual functions. Level 2 High Automation All setup and operating functions are automated. Level 3 High Automation Optimisation of the bend program is automated (requires user verification) Level 4 Full Automation Optimisation of the bend program is fully automated and requires no user verification.

LEVELS

Streamlined configuration and optimisation of the bend program can eliminate or drastically minimise interference with the sensing zone, which results in fewer pedal presses, no unnecessary stops in the bending cycle and significantly more time in high-speed, resulting in faster and more efficient production. The only part of this process that is not automated (at Level 2), is optimisation of the bend program, which requires a higher level of automation.

Press brake manufacturers are already offering machines designed with Level 2 Autonomous Guarding, which has been widely available for around the past 5 years, and this has already driven positive results for the sheet metal industry.

Optimisation of the safety and guarding functions within the bend program is a significant factor that determines the true productivity output of the machine. If the bend program is not optimised, or is poorly configured, then this can result in an increase in cycle times and therefore a reduction in the number of parts produced per hour.

Without optimisation, we see several factors that impact productivity since there is no synchronisation between the guarding system’s optical sensing zone and the part profile. The effects of this are amplified when bending more complex parts that comprise multiple steps with side flanges.

33 pressbrakebuyersguide.com

FEATURE ARTICLEAutonomouns Guarding

The lack of optimisation results in interference between the optical sensing zone and the work piece, that requires the operator to make additional pedal presses either before or during each cycle. In addition, there is often an increase in the slow speed travel distance before the upper tool reaches the material.

If the bend program is optimised, then the optical sensing zones are dynamically and automatically managed according to the part profile. Not only that, but the configuration of the bend program is optically verified against the physical part profile to ensure a higher level of safety. When starting a new job, the machine operator only needs to change the tools, start the bend program, then begin bending parts immediately. The addition of an Automatic Tool Changer in combination with Autonomous Guarding (Level 2 or above) eliminates another manual process and improves efficiency even further.

Currently with Level 2 automation, press brake operators and CNC programmers, are required to manually configure and optimise the safety and guarding functions in the bend program.

This process involves analysing the part profile as is changes from one program step to the next, then selecting the most efficient guarding mode, or combination of modes, as well as inputting the parts dimensions such as the height of side flanges. Provided that the bend program is optimised correctly, then maximum efficiency and production output can be achieved.

Feedback from the sheet metal industry consistently identifies a common issue with this optimisation process, is that press brake operators may not always receive the necessary information or training. This is compounded due to frequent turnover of machine operators, or when experienced operators leave, taking valuable knowledge and skills with them. Another issue is the general shortage of skilled sheet metal workers which continues to present a challenge for employers.

To address these issues, Lazer Safe has identified the next stage of automation, with a transition to Level 3 Autonomous Guarding. This represents a significant development in press brake efficiency and productivity that was previously not possible.

PRESS BRAKE BUYER’S GUIDE 34

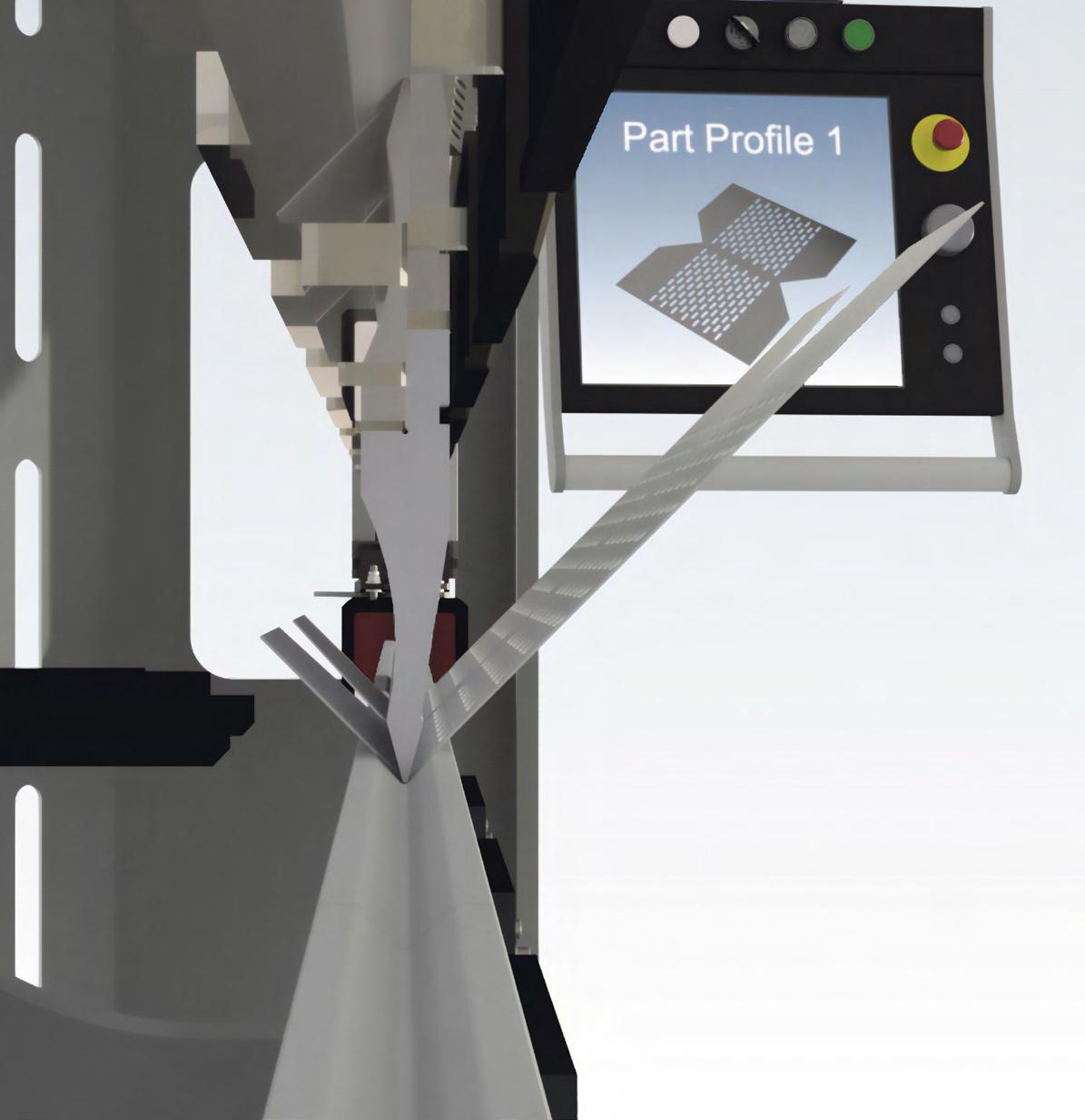

Level 3 automation introduces a new process where the safety and guarding system in collaboration with the CNC system, share information to automatically learn the part profile and determine the optimal modes and settings for each step of the bend program. This takes the manual process and decision making out of the operator’s hands, saving time, and ensuring that bend programs are always optimised for maximum bending efficiency.

The learning process is automatically activated when a new bend program is run for the first time, and active only when the first part is formed. As each bend is processed, part profiles are optically detected, and the CNC displays a message to the operator confirming the optimal mode and parameter settings that will be automatically applied to each step of the bend program. Once the first part is completed, the bend program is now optimised, and the settings are automatically saved in the CNC. All subsequent parts can then be formed with maximum efficiency. Since the bend program is now optimised and settings automatically saved, the learning process does not need to be repeated the next time the operator runs the same program.

Level 4 Autonomous Guarding takes optimisation a step further, where software analyses the bend program and part profile in 3D, then automatically determines and applies mode and parameter settings without the need for a learning cycle. Level 4 is a more advanced process that will evolve over time, as Lazer Safe continues to drive innovation for the press brake industry.

Users that currently own and operate press brakes with Level 2 Autonomous Guarding are already realising the benefits of reduced setup times, less reliance on machine operators, and improved machine efficiency. The transition to Level 3 Autonomous Guarding will offer users even greater levels of productivity.

Many of the industry’s leading press brake manufacturers are already in the process of implementing Level 3 Autonomous Guarding and Lazer Safe anticipates rapid market adoption of this technology over the coming months.

www.lazersafe.com

35 pressbrakebuyersguide.com

Lazer Safe at Lamiera 2023:

13 Stand C37

To learn more, visit

Hall

Aspir Mecc invests in Salvagnini Hybrid Press Brake Technology

Since 1985, Aspir Mecc has been designing, producing, and installing extraction systems for treating and purifying air of fumes, dust, solvents, vapors, odors, exhaust gases and bacteria – pretty much everything that harms the environment and human health. While keeping a craftsmanship’s imprint, the company from Castel Viscardo (Terni) has in any case become the benchmark for the wood and ceramics industries in Umbria, Tuscany, and Lazio, manufacturing tailor-made systems. We met with the owner Carlo Graziani and his son Marco to talk about their production cycle.

All the advantages of a simple press brake

With a staff of 9, including the owner, and a turnover that has grown over the years, Aspir Mecc works with small and medium businesses by supplying them with HVAC systems and a complete, customized service from design to installation and assistance. The company was founded in 1985 from an idea of Carlo Graziani, who having gained extensive experience in the plant engineering industry, decided to start his own entrepreneurial journey.

“When I met my wife, her parents were partners in a company that produced extraction systems,” Graziani explains. “Although I was from Orvieto, I worked in Bologna: I quit my job and returned to Orvieto to work with them, mainly in the sales department. After about a year and a half, the company closed, but I can’t deny that by then the sheet metal industry had won me over, and I developed the idea of setting up my own business. With a partner, we decided to invest in some machinery and rent an industrial building: and that’s how Aspir Mecc was born, in 1985.”

These were the years of the second Italian economic miracle, the era of success for small businesses that led the economic recovery.

“We invested immediately in customization, designing tailor-made systems,” the owner continues. “We built our niche in the world of wood processing machinery, for historical reasons more than anything: the company I used to work for built extraction systems for carpentry shops. We produced the components with a manual press brake, which we still have today, a welding machine and a secondhand shear. We invested firstly in a second-hand press brake, a tube bending machine, a clinching machine and then, in 1993, the industrial building.”

Without its own sales network, Aspir Mecc focuses essentially on the central Italian market, building strong relations with some technology retailers who work with the company to produce their extraction systems. But this doesn’t mean giving up completely on foreign markets.

“We have a major venture with a Swedish company that produces packaging machinery, which supplies its customers with bundles, including filters. We have installed a lot of systems for them, in Europe and beyond. But our market remains very much a local one: 80% of our systems are produced without a quote, as over time we have built loyal relations with our customers, they trust us.

PRESS BRAKE BUYER’S GUIDE 36

This result probably depends on our approach too because we only accept orders if we are sure that we can guarantee the result,” Graziani adds.

Close attention is paid in particular to the design of each plant: Aspir Mecc receives the machine specifications and a draft system layout, and then calculates load losses, the required surface area, and the motor required. With Industry 4.0, technological requirements are increasing: some elements – an electrical control cabinet with certain characteristics, a fire door, a spark detector – have become decisive in guaranteeing safety. Dust is potentially explosive, and the level of system complexity and the required certifications inevitably depend on the final application. The level of customization also affects the batch sizes and the production strategy: 4/6 panels per filter, plus the top and bottom, produced in kits and often in batch ones. The item turnover rate is quite high, and consequently so is the machine re-tooling frequency.

Precisely to manage this variability in production, in 2020

Aspir Mecc had to invest again in technology, in order to replace a press brake. After a careful assessment, the Terni-based company chose a Salvagnini B3: a hybrid press brake, designed by combining the characteristics and benefits of the most common electrical and hydraulic solutions on the market. It has a maximum bending force of 135 tons and maximum bending length of 4250 mm, with 7 axes and 4 backgauges to ensure maximum flexibility in production. It is equipped with FACE, Salvagnini’s simple and intuitive new human-machine interface, which minimizes the operational complexity of the press brake. To meet the industry 4.0 paradigm, the B3 also has OPS, the modular software that optimizes the whole production process and monitors it by interacting with the company’s management software and ERP/MRPs.

37 pressbrakebuyersguide.com

“Salvagnini was quite a revelation for me,” Graziani tells. “We had an old press brake, with 4 axes and hydraulic crowning, made by a company that doesn’t exist anymore. Of course, we had heard of Salvagnini, but it was a brand we had never considered: we thought it was a premium manufacturer, and too expensive for our needs. We had already begun talks with several Italian firms, then Renato Segoloni – the Salvagnini sales agent in our area - came to visit us. A little against our will, we accepted an invitation to visit the Salvagnini Campus: it was a real turning point, and a visit I would recommend to anyone. They told us about the machinery and the software and were extremely competent. We were quickly convinced by the technical features of the B3 press brake. But we also visited the Salvagnini Robotica production site, and we spoke to the people working in the service department - that’s always been a bit of a fixation for me, something fundamental when choosing a machine tool. And Salvagnini also has the advantage of producing technology for practically all the sheet metal forming cycle: if we need a laser or a panel bender tomorrow, we know we can rely on them again. And this is also a huge advantage, because the technologies of the same manufacturer dialog better with each other, and the technicians find it easier to use the software and the HMI interfaces are very similar.”

For Aspir Mecc, choosing the B3 also meant opting for STREAMFORMER, Salvagnini’s proprietary CAM. STREAMFORMER is part of STREAM, the programming suite for managing all activities in the office and on the factory floor, a single point of access for all technologies, from cutting to bending, meeting all planning, programming, production, management, control, and optimization needs throughout the production process.

“Today we program everything in the office,” says Marco Graziani, Carlo’s son and the second generation in the company. “Our process starts with a 2D drawing. Having analyzed it, STREAMFORMER automatically proposes the ideal bending sequence. It’s a really useful support, especially for more complex parts, and of course in any case I can change the sequence if I need to. A side effect of programming in office is that it also helps to reduce the tool set-up time: we already know which punch we need, where it has to be positioned, we have no doubts over the process and so we avoid mistakes and wasted time. This approach certainly helps operators with less experience. But generally, it’s really simple to switch from the office to the workshop: the press brake is really precise, intuitive and high-performing. With the HMI interface, all the commands are available in just a few clicks.”

PRESS BRAKE BUYER’S GUIDE 38

“At first, we imagined that we would have some waste, but we’ve never thrown even one piece away. This means that the software is intuitive, and those who use it can easily see how to use it in the best way. Every afternoon we also program the work for the next morning; the operators find the cut materials and the bending program in the machine. And we have an archive of completed programs, which is really useful if we need to repeat the production in future. At Salvagnini, I saw something that helps our evolution, our future. I was really impressed with the reliability of the company, it’s something I recognize in us. And the installation confirmed this impression: it was completely managed by in-house staff, which is a further guarantee. And the sales philosophy is very similar to mine: it was a transparent, honest process focusing on my needs and not on the desire to maximize profits. This is the same approach I use with our customers. I didn’t just buy a product, I bought a relationship with a reliable supplier,” Graziani concludes.

www.salvagninigroup.com

39 pressbrakebuyersguide.com

To learn more, visit Salvagnini at Lamiera 2023: Hall 15 - D14

Powerful, automated, and sustainable: TRUMPF launches new bending machine for XXL parts

With an 880-millimeter open height and a stroke of 700 millimetres, the TruBend 8000 bending machine offers a superbly efficient way to bend very large parts, allowing workers to easily bend and remove workpieces that require a large box height. It also provides numerous optional extras designed to facilitate the bending of heavy parts. These include a bending aid that makes operators’ lives easier by automatically positioning the workpiece for bending. This series of machines can also be equipped with a special tool clamp for XXL parts. “The new TruBend Series 8000 is the perfect addition to our portfolio of bending solutions. Whatever their bending application, companies can rely on TRUMPF to have the technology they need – from entrylevel machines to fully automated solutions for oversize formats,” says product manager Deborah Lidauer.

THE BEST WAY TO BEND HIGH-TENSILE STEELS

With a press force of 400 metric tons, the first in this new generation of machines is an efficient powerhouse that has no trouble processing short, thick pieces of sheet metal. But thanks to its generous 4.40-meter bending length, it is equally at home with longer, thinner parts. The machine is also suitable for bending high- tensile materials such as Hardox or Weldox engineering steels. Station bending is another option available with the TruBend 8000. By moving workpieces from one station to the next, each equipped with different upper and lower tools, workers can tackle a range of parts and bending operations without having to change the machine setup for each operation.

This makes the TruBend 8000 particularly suitable for companies that bend large parts in small batches, including fabricators in the vehicle manufacturing, mechanical engineering, and building-services sectors. This model is also a great choice for general-purpose work in job shops.

AUTOMATION AND SUSTAINABILITY

Its numerous automation functions make the TruBend 8000 a suitable candidate for use in a smart factory. The most advanced version includes features for fully automated operation provided by TRUMPF partner Starmatik. These include a six-axis industrial robot that handles loading and unloading. Moreover, the use of a robot allows downstream processing steps to be integrated in the automation system, such as forming, joining, and welding. The TruBend Series 8000 also comes with TRUMPF’s triedand-tested Boost and TecZone Bend bending software for offline programming. The machine operator simply uploads a 2D or 3D model of their part into the program. The software then independently creates a 3D simulation including collision monitoring, which the operator can then adopt for the bending process, either in its entirety or with minor manual changes. TruBend 8000 machines are also designed to facilitate the trend toward greater sustainability in manufacturing. Users can choose to equip their machine with an on-demand drive, which automatically adjusts the motor’s revolution speed to the movement of the press beam. As well as limiting noise generation, this feature can also reduce energy consumption by up to 26 percent.

www.trumpf.com

PRESS BRAKE BUYER’S GUIDE 40

High-tech company TRUMPF used the recent INTECH in-house trade show as an opportunity to showcase the latest generation of its TruBend Series 8000

41 pressbrakebuyersguide.com

With a press force of 400 tons, the TruBend 8000 from TRUMPF bends high-strength steels with ease.

The new TruBend 8000 generation of machines from TRUMPF is particularly suitable for bending large components or high sheet thicknesses.

ACCURL Launches New 100% Electric Press Brake eB Ultra Series

The eB Ultra is a fully electric machine that is integrated with the highest technology, making it one of the most advanced press brakes on the market. The machine uses Servo Electric Technology, which allows it to achieve up to 80% energy savings, making it both environmentally friendly and cost-effective.

One of the main benefits of the eB Ultra is its high reliability and maximum productivity. The machine is designed to guarantee better performance and durability, reducing unwanted effects caused by inertia. This top-of-the-line machine also ensures high precision and competitiveness, making it an ideal investment for any sheet metal bending business.

The eB Ultra’s heavy-duty ball screw drives with circulation design have a high DN value, which ensures high-quality stop accuracy by AC servo motor and ball screw for unequalled ram positioning of up to ±0.001mm.

This means that the machine can achieve unmatched accuracy in bending, allowing businesses to produce complex parts with ease and consistency.

Another notable feature of the eB Ultra is its user-friendly design. The machine is equipped with the ESA NEW S875 2D graphical control unit from Italy, which is one of the most advanced control systems on the market. The control system also supports Industry 4.0, allowing businesses to connect the machine to their ERP systems and streamline their production processes.

In addition to its advanced control system, the eB Ultra is also equipped with Wilson Pneumatic Upper Clamping, which allows for faster tool changes and improved efficiency. The machine is also equipped with the most advanced and strict safety system, the Lazer Safe IRIS, which includes BSM bend speed management function that can improve bending efficiency by up to 55%.

One of the key advantages of the eB Ultra is its ecofriendliness. The machine uses 100% electrical power, reducing CO2 emissions and making it an environmentally sustainable choice for businesses looking to reduce their carbon footprint. This feature also makes the eB Ultra eligible for government grants and incentives that reward businesses for investing in sustainable technology.

In conclusion, the ACCURL eB Ultra 100% Electric Press Brake is a game-changing machine that is set to revolutionize the sheet metal bending industry. With its advanced technology, impressive energy efficiency, high productivity, and user-friendly design, the eB Ultra is a musthave investment for any business looking to increase its competitiveness and reduce its environmental impact. www.accurl.com

43 pressbrakebuyersguide.com

To learn more visit, ACCURL at Lamiera 2023 at Hall 15 - E33

TRUMPF laser-blanking system cuts costs and saves 4000 metric tons of CO2 a year

It is an attractive option for any company interested in flexible, high-volume solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers and HVAC manufacturers. “The TruLaser 8000 Coil Edition is another example of TRUMPF helping its customers to join the drive toward greater sustainability in the manufacturing industry while simultaneously boosting efficiency. Compared to conventional laser-cutting machines, the solution allows companies to save almost 1,700 metric tons of steel a year, which equates to a saving of some 4,000 metric tons of CO2 and a reduction in material costs of 1.6 million euros,” says Richard Bannmüller, CEO at TRUMPF Laser Technology Germany.

IMPRESSIVE FLEXIBILITY EXTENDS TO VOLUME PRODUCTION

Thanks to TRUMPF’s new laser-blanking system, companies can enjoy the benefits of laser processing even in high-volume production environments. “Volume manufacturers often use presses for blanking operations. But that means they need to adjust or even replace the tool whenever they make the slightest modification to their components, which ultimately costs time and money. Many industrial sectors are seeing significant reductions in the scale of individual production runs, which makes these modifications even more costly and time intensive.

PRESS BRAKE BUYER’S GUIDE 44

The TruLaser 8000 Coil Edition can process up to 25 metric tons of coiled sheet metal from start to finish without any human intervention.

The laser allows users to carry out these modifications without requiring a new tool, so it’s much, easier, faster, cheaper, and more flexible,” says project manager Oliver Müllerschön, who is responsible for the new system at TRUMPF. The high-tech company developed the new system in cooperation with SIEMENS and mechanical engineering company ARKU. Together with TRUMPF, Siemens is responsible for the control system and ARKU for the coil system. The fischer group in Achern is one of the first companies to put the new solution into practice. “Deploying a laser-blanking line is a new approach for us. It offers huge benefits to our production process, partly due to its high flexibility and quality, but also thanks to the fact that we require hardly any tools compared to conventional blanking presses,” says Hans-Peter Fischer, CEO and owner of the fischer group.

The company is an early adopter of TRUMPF’s laser-blanking system, which it uses to produce high-strength aluminium structural components for vehicle-body manufacturing.

MATERIAL SAVINGS FOR SUSTAINABLE PRODUCTION

Coil production enables users to achieve more efficient nesting of parts. Conventional sheets are limited by their four outer edges, which often make it difficult for production workers to make full use of the entire sheet. Unused sections of the sheet either have to be discarded as scrap or melted down. A coil, which can be up to 1.5 kilometres long, solves this problem by allowing users to nest an almost endless number of parts on the sheet. This reduces material consumption by around 15 percent. Compared to conventional blanking presses, the new system also heralds a significant reduction in construction and logistics costs.

45 pressbrakebuyersguide.com