Volume 38 October 2019

Petroleum Today Not For Sale

Technology Applications

DESERVEDLY SUPPORT

Industry At A Glance

Talent & Technology

MEDITERRANEAN LNG MARKET EVOLUTION

OFFICIAL MEDIA PARTNER

MEDIA PARTNER

Integrating Big Data: Simulation, Predictive Analytics, Real Time Monitoring, and Data Warehousing in a Single Cloud Application

Climate Change Policies & Regulations

HSE Laws & Policies

Green Finance

Oil & Gas Concession

Oil & Gas Logistics

Procurment Contracts

OUR LEGAL SERVICES :

MYDESIGN

COMMITTED TO SUPPORT , OUR CLIENTS SUCCESS

5th Settlement, Financial Center, Red-Con Building, (140), Zone 1, Banking Road, From 90th Street, New Cairo, Egypt. PO. (11835) M : (+20) 1000064769 T : (+20) 2 - 26141617 E : info@linksandgains.com w : www.linksandgains.com

- Arbitration (ICC/AAA, CRICICA)

- Labor Laws & Employment.

- Banking & Project Finance.

- Litigation & Dispute Resolutions.

- Contract Laws & Consultancy.

- Intellectual Property Rights.

- Companies & Corporate Services and Restructure.

- Sustainable Development Policies & Regulations.

- Government Issues & Compliance.

- Tax Laws & Custom Regulations.

COOPERATION PARTNERS

Alex Office: Address: P.O.Box 114 Elsaray 242 Abdel Salam Aref st., Loran, APT. 103, Alexandria, 21411, Egypt Phone: +20 (3) 5833301 - 5833294 Fax: +20 (3) 5823514 Email: catec@catecegypt.com

W W W. C AT E C E G Y P T. C O M

Cairo Office: Address: 2B Nozha st., Heliopolis, APT. 7, Cairo, 11341, Egypt Phone: +20 (2) 24145127 / +20 (2) 24145128 Fax: +20 (2) 24145129 Email: catec.cairo@catecegypt.com

Alex Office: Address: P.O.Box 114 Elsaray 242 Abdel Salam Aref st., Loran, APT. 103, Alexandria, 21411, Egypt Phone: +20 (3) 5833301 - 5833294 Fax: +20 (3) 5823514 Email: catec@catecegypt.com

W W W. C AT E C E G Y P T. C O M

Cairo Office: Address: 2B Nozha st., Heliopolis, APT. 7, Cairo, 11341, Egypt Phone: +20 (2) 24145127 / +20 (2) 24145128 Fax: +20 (2) 24145129 Email: catec.cairo@catecegypt.com

M I C O P E R I

Above, the main vessel DLV SEMINOLE assisted by cargo barge and tugs is in operation at El-Hamra Field to install a 36�x8.5 km subsea pipeline at El-Alamein, Egypt, in the Med Sea. The pipeline shall import and export crude oil between El-Hamra facility and tankers through a new offshore SBM system, including a new CALM buoy single point mooring, anchor legs, mooring hawser, floating hoses assembly and manifold (PLEM), for the tie-in to the onshore existing plant. Main Contractor: Petroleum Marine Services (PMS), Egypt Client: Western Desert Operating Petroleum Company (WEPCO), Egypt

1 Ahmed Kamel Street Off Lasilky (CIB Building) New Maadi-Cairo, Egypt T : +202 25166064 F : +202 25166046 M : +201000360107 E : sgiddio@eos-eg.com w : www.micoperi.com

Petroleum Today Contents

11 12 22 34 45 50

http://www.facebook.com/PetroleumTodayMagazine

60 74 96

Back to the Pearl of the Mediterranean News Talent & Technology A Business Case for Environmental Solutions Well control Safety and Regulations on Deep Water and Onshore wells Electrical Submsersible Pump Powered Injection ESPPI Systems Enable the Development of West of the Nile Egypt Assets Integrating Big Data: Simulation, Predictive Analytics, Real Time Monitoring, and Data Warehousing in a Single Cloud Application Environmental Mainstreaming for SelfRegulation EMSR Industry At A Glance

28

MEDITERRANEAN LNG MARKET EVOLUTION

اتفاقيات تعاون مع ش���ركات البترول4 البت���رول توق���ع العالمية العاملة فى مصر الف برميل700 مص���ر تخطط لرفع انتاج الزيت الخام الى يوميًا شل ما زالت تملك الشهية لالستثمار:الرئيس التنفيذي في الشرق األوسط حوار بترولي���م توادى مع المحاس���ب محمد مصطفى رئيس شركة إبسكو

2 3 4 8

Petroleum Today Chairman Mohamed Bendary

Back to the Pearl of the Mediterranean

T

he Government of Egypt continues to demonstrate a very strong commitment to embrace new and emerging analytical fields providing the Oil and Gas industry with groundbreaking methods evolving in this way, the needs of future generations.

The recent gas discoveries have contributed to repositioning Egypt in the oil and gas industry both on the regional and international levels. And while such big discoveries represent an economic blessing, they still carry with them a lot of hard work and necessary collaborative efforts for the best monetization of the region’s natural resources. All these factors along with Egypt’s strategic location and well-established infrastructure have greatly contributed to making Egypt a regional energy hub, which has in turn made the establishment of the East Mediterranean Gas Forum (EMGF) inevitable. I take great pride in welcoming all participants to the legendary city of Alexandria to attend the 10th Edition of the Mediterranean Offshore Conference (MOC). This beautiful city known as “The Pearl of the Mediterranean” simply resonates with the richness of its history and culture, maintaining and atmospheric juxtaposition between old and new. The Conference is held this year under the theme “EGYPT: Connecting the two shores of the Mediterranean”, promoting regional coordination of efforts and cooperation. You will enjoy the readership of MOC show daily news through the coverage of petroleum today editors updating your insight with minute on minute events in the conference, exhibition and gas club in cooperation with Shell E&P. We would like invite all visitors, exhibitors, company leaders and professionals who have the vision, the knowledge and experience to visit our booth at the MOC venue getting the unrivalled publications from Petroleum Today. In the end, greetings to you, Egypt has pride and dignity

Petroleum Today

Vice-Chairman Ali Ibrahim Executive Editor-in-Chief Magdy Bendary Scientific Secretary Ali Afifi Marketing Mahmoud Mabrouk Medhat Negm Magdy Ahmed Athar Yousry Senior Editor Osama Radwan Editing Staff Mohamed Ahmed Magdy Rashid Financial Management Wael Khalid Art Director Walid Fathy Office Manager Marwa Negm Photography Mohamed Fathy Scientific Staff Dr. Attia M. Attia Dr. Adel Salem Dr. Ahmed Z. Nouh Dr. Ismail Aiad Dr. Gamal Gouda Eng. Mahmoud A. Gobran Eng. Mohamed nada Eng. Taher Abd El Rahim Eng. Mohamed Bydoun Eng.Samir Abady Dr. Lubna Abbas Saleh Special thanks to all the Society of Petroleum Engineers (SPE) Mr. Hany Hafez All opinions expressed through the magazine is pertaining to their authors & don,t express the magazine,s point of view Publisher & Distribution The Egyptian Company For Marketing 29th Abd El - Aziz Gawesh st. Lebaonon Sq., Mohandeseen Giza - Egypt Tel. : +202 33050884 Mob.: 01006596350 Mob.: 01000533201 E-mail: petroleum.mag@gmail.com E-mail: mohamed@ petroleum-today.com www.petroleum-today.com Copyright Reserved Design and Print by:

MYDESIGN

info@mydesign.com.eg www.mydesign.com.eg

egypt news Talks with German Ambassador on the Partnership Developments between Both Countries

E

ng. Tarek El Molla, Minister of Petroleum and Mineral Resources, received Dr. Cyril van Nun, German Ambassador to Cairo, in his first meeting after taking over his responsibilities in Egypt. They discussed cooperation domains concerning oil and gas industry, in light of the strong bonds and extended economic partnership relations between both countries, as well as the successful projects for oil and gas development and production. During the meeting, they reviewed the current status of the German companies operating in Egypt; and their activities in the exploration and production domains, in addition to pointing out the project of transforming Egypt into a regional hub for oil and gas trade. Moreover, El Molla highlighted the EU’s support to Egypt in implementing its project as a regional hub for oil and gas trade, which was clearly reflected by the European Commissioner for Energy and Climate’s visit to Egypt last year, as it witnessed signing a number of MoUs in this regard. He also affirmed the EU,s financial and technical support for the project. The meeting, as well, discussed the role of the East Mediterranean Gas Forum and its objectives, represented in fostering cooperation, partnership and coordination among member countries for achieving best economic exploitation of the gas resources in the region, as well as achieving integration between these countries in exploiting the available infrastructure and natural gas resources.

Egyptian LNG to return to full operation

E

gyptian LNG (ELNG) facility will return to 100pc of nameplate capacity, the firm’s senior optimization manager Tamer Abdelsalam told the Gastech conference in Houston. It is currently operating at 90pc capacity. Full output is a far cry from the dark days of mid-2013 to mid-2019, when the volume of feed gas reaching the plant

hovered at 1315-pc of design capacity. During that period, ELNG produced just 31mn m³ of LNG and exported 21 cargoes, bring in only $354mn in revenues, says Abdelsalam. The return of ELNG, located at Idku, to full capacity may not, though, be followed swiftly by a full restart of Egypt’s other export terminal at Damietta. “That is for the government,” says Adelsalam. “They are taking the lead in negotiations around Damietta.” The vast majority of feed gas into ELNG is coming from the offshore Simian and Sapphire fields, with just a very small proportion supplied by the national grid, say Abdelsalam. That obviously raises questions around Egypt’s existing LNG infrastructure’s capacity to export gas not just from Egypt but also from East Med neighbors Cyprus and Israel.

12 Petroleum Today - October 2019

Eni Starts Production of Baltim South West Field

E

ni announces the successful commissioning and start-up of production of the offshore Baltim South West gas field in Egypt. Discovered by Eni in June 2016, the field goes on-stream in a record time, just 19 months after the final investment decision (FID) was approved in January 2018. This result further confirms the success of the strategy adopted by Eni and the company capability in pursuing a fast track approach to development projects. The field is located in shallow waters 12 kilometers off the Mediterranean coast of Egypt in the Baltim South development lease. It lies 10km from the Nooros field, but still within the Great Nooros area. This is an area in which Eni first recognized great gas production potential and where it is conducting other new exploration projects. With the

Abu Sennan Transaction Update

start-up of the first well, BSW1, the field is now producing with an initial rate of 100 million standard cubic feet per day (scf/d) from a new offshore platform connected to the existing onshore Abu Madi Gas Plant through a new 44 km long, 26 inch diameter pipeline.

R

ockhopper Exploration plc (RKH), the oil and gas exploration and production company with key interests in the North Falkland Basin, is pleased to provide the following progress update in relation to its previously announced disposal of Rockhopper Egypt Pty Limited to United Oil & Gas Plc (United). At close of business on 3 October 2019, all the existing joint venture partners in the Abu Sennan concession had irrevocably and unconditionality waived their pre-emption rights under the Joint Operating Agreement. The process to satisfy the remaining conditions precedent, including United shareholder approval, completion of the readmission of United to trading on AIM and receipt of Egyptian government approvals, are progressing well. The transaction remains on track to complete by the end of Q4 2019.

Egypt Seeks More Investments in Mining Sector

E

gypt and two world companies discussed boosting cooperation in the mining domain.

This came in a meeting between Minister of Petroleum and Mineral Resources Tareq el Molla with Jeremy Crozier, President of Principle Verve International and Brian Rudd, CEO of Capital Drilling. The meeting tackled investment opportunities after the amendments of the new mineral wealth law, especially since the two companies have a long history of nearly 30 years in the field of mineral exploration and mining industry in Europe, North America, Africa and Australia. Molla reviewed Egypt›s geological advantages and its open mines, which can be operated throughout the year due to the existence of an infrastructure that helps and encourages mining work. The heads of the two companies expressed their willingness to invest in the field of gold exploration in Egypt in light of the political and economic stability and future plans of the Ministry of Petroleum to develop the mining sector in Egypt. The meeting was attended by Fekry Youssef, Petroleum Undersecretary for Mining and Geological Affairs and Osama Farouk, Chairman of the Mineral Resources Authority.

Petroleum Today - October 2019 13

Arab & International News

Britain set to receive two LNG tankers

Cyprus, Greece, Egypt call on Turkey to end ‹provocative› actions

C

yprus, Greece and Egypt called on Turkey to “end its provocative actions” in the Eastern Mediterranean Sea, including exploring for oil in Cyprus’ territorial waters, which they called “a breach of international law”. Turkey said it had sent a drilling ship to the area where Greek Cypriot authorities have already awarded hydrocarbon exploration rights to Italian and French companies. “The Heads of State and Government expressed their grave concern over the current escalation within the maritime areas of the eastern part of the Mediterranean, condemning the continuing Turkish actions in the exclusive economic zone of Cyprus and its territorial waters, in violation of international law,” Cyprus, Greece and Egypt said.

A Saudi Aramco chief: attacks may continue without international response

14 Petroleum Today - October 2019

B

ritain is set to receive liquefied natural gas (LNG) tanker Gaslog Savannah, with a capacity of 153,000 cubic metres, from the U.S. Cove Point facility on November 5. LNG tanker Lijmiliya, with a capacity of 258,000 cubic metres, is due to arrive in Britain in October and is likely to load as it appears to be empty, Refinitive shiptracking data showed.

ttacks such as the one on Saudi oil facilities which sent oil prices up by as much 20% may continue if there is no concerted international response, Saudi Aramco’s Chief Executive Amin Nasser said “An absence of international resolve to take concrete action may embolden the attackers and indeed put the world’s energy security at greater risk,” he told the Oil & Money conference in London in rare political comments. He added Aramco was on track to regain its maximum oil production capacity of 12 million barrels per day by the end of November.

www.geoeagles.net info@geoeagles.net

GeoEagles is official distributor for Faro technologies , Hi target , Seafloor and Tcarta

1-Hydrographic Survey 2- Topographic Survey 3-Dredging Support Survey 4-Mining Survey 5- 3D Laser Scanner Survey 6-Oil and Gas Geospatial Survey 7-Technical Manpower Support

MYDESIGN

OPERATION:

Almahdy Tower - Elbitash - Alexandria - Egypt Egypt 00201553470906 Saudi Arabia 00966536360576 Kuwait 0096556623608

Thai energy ministry sets March target to resolve Chevron dispute

T

hailand’s energy ministry said it had set a March target to resolve a $2 billion dispute with U.S. oil and gas major Chevron Corp and would make the “utmost effort” to reach a deal after the company halted arbitration. The dispute resulted from a retroactive Thai law in 2016 requiring gas field operators to pay the costs of decommissioning assets they have installed even if they no longer operate them. “This negotiation will require our utmost effort because it concerns national interests,” permanent-secretary Kulit Sombatsiri said. “We have up to 180 days to work it out,” Kulit said, adding that the time frame was stipulated by law.

E

Exxon to make $500 mln initial investment in Mozambique LNG project

xxon Mobil plans to invest more than $500 million in the initial construction phase of its liquefied natural gas (LNG) project in Mozambique. The U.S. oil company’s $30 billion Rovuma LNG project, jointly operated with Italy’s Eni, has a capacity of more than 15 million tonnes a year (mtpa) and is set pump much-needed cash into the southern African nation’s ailing economy. “The Area 4 partners will advance midstream and upstream area project activities of more than $500 million as initial investments,” Exxon head of power and gas marketing Peter Clarke said. Construction of onshore facilities has been awarded to a consortium led by Japan’s JGC, U.K firm TechnipFMC and U.S. company Fluor Corp. “These EPC (engineering, procurement and construction) contracts cover the construction of two natural gas production trains with a total capacity of 15.2 million tons per annum, as well as associated onshore facilities,” Clarke said. Final investment decisions, a term used by the oil industry to mean the commercial and regulatory aspects of a project are finalized, would be made in 2020, Clarke said.

Petrobras removes 133 tonnes of oil from Brazil,s beaches, CEO says

S

tate-run oil company Petroleo Brasileiro has collected 133 tonnes of oil along Brazil’s northeastern shoreline, Chief Executive Roberto Castello Branco said, in an unexplained mystery he said was worrying. Speaking with lawmakers, he said the company had not identified any of its own oil in its analyses. He also said that, in order to maintain stable production, Petrobras, as the company is known, needed new reserves of 1 billion barrels per year, at a cost of $3 billion.

16 Petroleum Today - October 2019

Corporate News

Rockwell Automation and Schlumberger Announce Closing of Sensia Joint Venture

S

ensia, the oil and gas industry’s first digitally enabled, integrated automation solutions provider, will drive efficiency, optimize performance and reduce risk Rockwell Automation (NYSE: ROK) and Schlumberger (NYSE: SLB) announced the closing of their previouslyannounced joint venture, Sensia, the oil and gas industry’s first digitally enabled, integrated automation solutions provider. The joint venture leverages Schlumberger’s deep oil and

gas domain knowledge and Rockwell Automation’s rich automation and information expertise to address this fastgrowing market. “Sensia will make industrial-scale digitalization and seamless automation available to every oil and gas company so their assets can operate more productively and profitably,” said Allan Rentcome, Chief Executive Officer of Sensia. “It will make oil and gas production, transportation and processing simpler, safer, and more secure.”

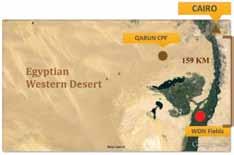

Eni Announces New Production from the Western Desert Eni announces that production from South West Meleiha Development Lease, located in the Egyptian Western Desert, some 130 Km North of the oasis of Siwa, has started. The current production, delivered through two oil producer wells, is around 5.000 barrel of oil per day (BOPD) and is expected to reach 7.000 BOPD within September 2019. The oil is transported and treated at the Meleiha Plant facilities operated by AGIBA, a company equally held by IEOC and

the Egyptian General Petroleum Corporation (EGPC). South West Meleiha oil discoveries have been made in 2018, while other exploration wells are now planned to be drilled on the nearby prospects within the exploration area. Eni, through its subsidiary IEOC, holds a 50% interest in South West Meleiha while EGPC holds the remaining 50%. AGIBA is the operator.

Successful MSD-19 Well at West Gharib Concession in Egypt

S

DX Energy plc (SDX) is pleased to announce that the MSD-19 development well in the West Gharib Concession in Egypt (SDX 50% Working Interest & Joint Operator) has encountered a commercial oil accumulation. The well was drilled to a total depth of 4,665 feet and

18 Petroleum Today - October 2019

encountered approximately 135 feet of net heavy oil pay across the Asl Formation, with an average porosity of 24%. The well was completed as a producer, connected to the central processing facilities at Meseda and brought online at an average stabilised rate over five days of approximately 315 bbl/d (gross).

Wintershall Dea Committed to Egypt

I

n early 2018, Wintershall Dea announced the start of an extensive work program in all own-operated Egyptian assets. The company is currently investing more than 500 Million US-Dollars over three years (20182020-), aiming to significantly boost its gas and oil production in the country. “We look back on very active 18 months in Egypt”, says Mario Mehren, CEO of Wintershall Dea. «We have already realized a good part of the upside potential in our ownoperated assets Disouq and in the Gulf of Suez. Furthermore, the West Nile Delta project is progressing towards completing the development of the five fields by end of this year. These achievements are indicative of our lasting and sustainable commitment to Egypt», he adds. «We look forward to making further contributions to the development

of the Egyptian energy sector, supporting the country on its way to become an energy hub for the region.»

BP announces industry-first, continuous methane measurement programme

D

rones equipped with space-age sensors are part of a wave of advanced technology zooming into operation at BP’s new major oil and gas processing projects as part of a programme to continuously measure methane emissions. The high-tech kit is part of an industry-leading BP programme to continuously detect, measure and enable the reduction of methane emissions at new and existing BP-operated Upstream assets. This crackdown on emissions has been made possible by a raft of new and complementary technologies.

Hady Meiser Egypt

H

ady Meiser Egypt for producing steel gratings is specialized in fabricating steel gratings (blackgalvanized) as well as steel stair steps which is also made with gratings by press welding according to DIN 24537 & 24531 and ISO 1461 & ASTM A 123 . All specification is according to the shown onto our catalogue and dimensions are according to client›s inquiries.

Mr. Eslam Abdel-Hady CEO

Address :ElShrouk Industrial Zone – Khanka – Kaiobia Contacts : 01001726068 -01144877633 - 0127 679 8800 – 01001726135 Fax : +2 02 44698047 – 44698212- 44604123 E-mail :trabia.meiser@gmail.com trabia_meiser@hadymeiser.com

20 Petroleum Today - October 2019

Mr. Taha Abo Rabia General Manager

Talent & Technology

Electro-mechanical downhole cutting technology

[ Fig-1 Halliburton Electro-mechanical downhole cutting tools ]

H

alliburton Company has announced an asset acquisition of a new portfolio of electro-mechanical downhole cutting tools and tubing punches from Westerton (UK) Ltd. These services provide operators with a safe and reliable alternative to traditional pipe recovery and intervention across the well lifecycle from exploration to abandonment. The electro-mechanical downhole cutting portfolio includes single and rotating blade configurations that perform precision cuts on oilfield tubulars. Operators can achieve single blade cuts in less than two minutes with real time downhole data that reduces uncertainty. This new technology eliminates the need for traditional explosive charges and chemicals, resulting in improved safety and easier transportation. Each cutting operation requires minimal surface equipment to enable faster deployment from any wireline unit. “The ability to deploy cutting services rapidly and efficiently is important for pipe recovery,” said Trey Clark, vice president of Wireline and Perforating. “This new technology complements Halliburton’s extensive well intervention portfolio, helping operators reduce the cost to construct new wells and extend the life of old wells.” On a recent campaign in the North Sea, an operator utilised the electro-mechanical downhole cutting service for a well abandonment program. The technology successfully saved one and half days of rig time per well – a substantial reduction from the initial plan.

Monitoring Pressure in Applications with Vibration and Pulsation

L

iquid-filled gauges have several drawbacks that can introduce unnecessary elements of risk into a work environment. The issues associated with liquid-filled gauges can now be overcome with a new product solution that can be applied in all applications with vibration and pulsation, without the restrictions associated with liquid filling. One of the initial challenges that arose in monitoring pressure with dry gauges was caused by applications with vibration and pulsation. It was difficult to measure pressure in these types of applications as the pressure gauge pointer would shake making it impossible to get an accurate reading. Liquid-filling pressure gauges became the common method for steadying the pointer of a gauge in vibrating and pulsating applications. By filling the gauge case with a liquid, the movement of the gauge was dampened preventing the pointer

22 Petroleum Today - October 2019

from shaking. Liquid-filling has been the primary way of dealing with vibration up until today. While adding liquid to a gauge allows operators to accurately monitor the pressure of a process, it has limitations on where it can be installed compared to a dry gauge. In addition, liquid-filed gauges have several drawbacks that can introduce unnecessary elements of risk to a work environment. The challenges associated with liquid-filled gauges can now be overcome with a new product solution that can be applied in applications with vibration and pulsation without the limitations. Winters’ StabiliZR™ pressure gauges are dry gauges that can be installed in applications where liquidfilled gauges have traditionally been installed. The reason for StabiliZR’s effectiveness where other dry gauges fail is the StabiliZR™ movement which provides pointer dampening without requiring the entire case to be filled with liquid.

Connector Subsea Solutions acquires Hydratight’s MORGRIP business

P

[ Fig- 5 MORGRIP subsea pipeline repair connector ]

ipeline repair connectors are critical components in the repair of oil and gas pipelines. The operator’s requirements for this type of equipment are extremely high as the consequences of failure are dramatic with regards to potential environmental and commercial impacts and even to a region’s overall energy supply. MORGRIP Connectors boast a 100% leak free in-service track record of over 30 years. Hydratight’s MORGRIP business has a reference list second to none with more than 3,000 connectors delivered to the global oil and gas industry. MORGRIP’s offer a unique, robust, field proven, durable design that meets all of the industry’s strictest qualifications. This makes MORGRIP the primary choice of connector for the repair of critical pipelines and is in use by most of the major operators. The MORGRIP connector has also proven to be the connector of choice for emergency pipeline repair systems (EPRS) worldwide and through the acquisition; CSS takes a lead position providing emergency pipeline repair for more than 300 high value pipelines. The acquisition of the MORGRIP business completes CSS’ products and service offering enabling CSS to take a lead role in providing complete subsea and deepwater pipeline repair solutions, delivering it’s services on a sale or rental basis worldwide. “This has been a strategic move to build a foothold in a market that we believe will grow significantly the next few years. With the MORGRIP Connector and the MORGRIP team onboard we have taken a position to meet client’s requirements for the effective execution of demanding deepwater pipeline repair projects,” said Pål Magne Hisdal, chairman of CSS.

Petroleum Today - October 2019 23

Chevron Technology Ventures pitches in on Well Conveyor development The Conveyor has been optimized for running on batteries, with an efficient electro-mechanical design, allowing for extended tractoring distances of more than 15,000 feet. Not being dependent on power and communication from the surface allows operators greater flexibility and lower priced conveyance alternatives. The Conveyor has been designed for simplified operations and reduced maintenance, enabling the service to be provided by the regular wireline / conveyance providers. This translates into less interfacing and manpower being needed for operations. Well Conveyor was founded in 2015 by Kenneth Fuglestad to pursue the development of a novel downhole tractor that would be more cost-effective, slimmer, simpler to operate and more power efficient than existing offerings, allowing for the utilization of downhole battery power. Early support came from angel investors, the Research Council of Norway and Innovation

Norway, which took the company through the concept, feasibility and early development phases for the Conveyor. ProVenture and Investinor invested in the company early 2018, and Chevron Technology Ventures (CTV) invited Well Conveyor to participate in its Catalyst Program. CTV’s Catalyst Program was created to support early-stage companies advancing cutting-edge technologies that can directly benefit the oil and gas industry. These relationships provided the means to advance the development and qualification phases and to expand the organization. Well Conveyor has carried out extensive in-house qualification testing of the technology and is now preparing for first field trials in the US. The patented Slim Batterypowered Conveyor will serve as a platform for additional innovative and cost-effective conveyance solutions to be developed by the company.

Probe releases new calliper for geothermal well operations

P

robe has launched its UHT Dimension XY Caliper, the first XY Caliper Tool specifically designed to operate in ultra-high temperature environments. This new development expands upon the renowned Kuster® geothermal logging tool portfolio, used extensively in the global geothermal industry for its performance and reliability. Developed to operate in hostile environments up to 325°C (617°F), the UHT Dimension tool provides two continuous independent perpendicular measurements (X and Y) of the internal diameter of the casing. The tool also produces a highresolution temperature profile of the well via an external fastresponse resistance temperature detector (RTD). There is no other caliper tool that offers this versatility for ultra-high temperature and geothermal well operations. “The introduction of ultra-high temperature XY Caliper technology for the geothermal industry is a major breakthrough. A critical factor is that mineral deposition regularly affects geothermal well conditions. Until now, gauging the internal diameter of these wells was ineffective. The ability to generate a continuous log and accurately calculate flowrates is huge differentiating advantage,” said Steve Beattie, Sales Manager for Well Monitoring for Probe.

24 Petroleum Today - October 2019

“By gathering accurate, reliable on-depth casing dimensions, geothermal companies can quantify scale build-up and any other restrictions due to [ Fig-3 UHT first XY Caliper Tool ] the reduction in casing diameter. The tool also identifies downhole components and other anomalies. By detecting such issues early on, the operator engaging in such proactive maintenance can maintain a critical flowrate by removing the restriction; which will aid in reducing the operational downtime and treatment cost.” The UHT Dimension tool is very versatile. It can be run stand-alone or combined with other Kuster geothermal PT and PTS tools. Its robust mechanical design features single roller arms that conform easily to most wellbore conditions. However, if there is a need to run over slotted sleeves or sandscreens, an optional triple roller arm is available for increased run efficiency.

we make doing your job where you want possible because we create systems that let you monitor nearly anything, anywhere. At Rockwell Automation, we’re expanding

human possibility

Add.: (42R) El-Safa Tower Bisector 6 Zahra El-Maadi - Cairo Tel: +202 27320174 / 5 / 8 Fax: +202 27320260 Mob.: +2 010 28464665 www.kmt4is-eg.com

sales@kmt4is-eg.com

About the Course: This course is of interest to Engineers - both Operating and Service Companies personnel – who are familiar with basic completion processes and willing to extend their understanding to cover more advanced aspects. The course also suits Production personnel, Engineers from disciplines other than Production Technology

About the Material: Each participant will be given a copy of the original textbook WELL COMPLETION DESIGN March 2009, 700+ pages Elsevier Publication.

Book your Place: Mobile: +2 (010) 05618777 Line : +20 (2) 25194800 Fax : +20 (2) 25194900 Email : asalah@sapesco.com

MEDITERRANEAN LNG MARKET EVOLUTION

The transformation of global and regional LNG trade over the last twenty years has been a story of rapid growth, change and increased flexibility in LNG cargo movements. Asia continues to predominate global LNG trade, but the European LNG market has promoted significantly in the past decade and seems destined for sustained growth and change over the next decade or so. Despite the LNG import market in North America being overwhelmed by unconventional gas developments in the last few years, future sustained development of LNG demand in Asia and Europe are enhanced by firm new project commitments.

28 Petroleum Today - October 2019

cord, reaching 316.5 million tonnes (MT). This marks an increase of 28.2 MT from 2017, equating to 9.8% yearon-year (YOY) growth. The continued growth in trade was supported by increases in LNG output from liquefaction plants ramping-up and coming online, more than offsetting lower production from several legacy projects. Australia led all exporters in gradual growth (+12.2 MT), supported by the Wheatstone LNG and Ichthys LNG projects. The United States was again the second-biggest driver of LNG supply growth, adding 8.2 MT as trains at Sabine Pass LNG operated for the full year and Cove Point LNG came online. Asia continued to be the driver of international LNG demand growth, as China broke its own record for gradual LNG by importing an additional 15.8 MT in 2018. This was driven by the powerful enforcement of environmental policies prepared for promoting coal-to-gas switching as well as continuing economic growth. Other key markets that lead global LNG growth included India, South Korea, and Pakistan, which took in a combined 12.8 MT of incremental imports. The Pacific Basin continues being the key driver of trade growth, with intra-Pacific trade flows reaching a record 134.2 MT, confirmed by Australian production and Chinese demand.

A number of North American LNG export projects are progressing to supply this growing market demand in Europe and Asia. Unprecedented gas discoveries in deep-water offshore Eastern Mediterranean and East Africa are also likely to compete for LNG market share in growing Asian and European gas markets. The regional statistics reveal the complexity of commercial, political and technical drivers at play, particularly in the case of Europe, and how these drivers are collaborating to boost future demand for LNG. State of the LNG Industry and Global Trade For the fifth successive year, global LNG trade set a re-

East Med Gas Potentials Massive gas reserves are considered the game changers in the East Med. The three big finds of that period – Egypt’s offshore Zohr field, with reserves of 21.5trn cu feet of gas; the Israeli offshore Tamar and Leviathan fields, with 11trn cu feet and 22trn cu feet of reserves, respectively; and the 8trn-cu-feet Aphrodite find off the coast of Cyprus – have the prospect to transform the .region’s energy landscape In Egypt, the Zohr Progress by ENI, among others, has led to a revival in gas production: output grew from a low of 3.9bn cu feet per day in 2016 to 6.65bn in February 2019. For Israel and Cyprus, the gas discoveries assure greater energy security and new export revenues. A group of other fields have also been and are starting .to be developed, notably in Cyprus more recently Mediterranean Gas Infrastructure and Liquefaction Plants On 16thApril 2019, on the occasion of the Mediterranean Gas Infrastructure Operator (MedGio), organized by the Egyptian Natural Gas Company, Eng. Tarek El Molla, Minister of Petroleum and Mineral Resources,

Petroleum Today - October 2019 29

delivered a speech, in which he assured that the Mediterranean region holds a significant importance in the world order politically, economically and geographically. It is gaining major significance over the coming years, in the light of the existence of abundant gas resources, due to the big discoveries especially in the Eastern Mediterranean Region. El Molla assured that cooperation among the Mediterranean countries, members of MedGio, will consolidate the available infrastructure, in the light of the growing strategic importance, for the security of energy supply, in which the gas represents a fundamental role towards cleaner energy system. Compared to other countries on the Mediterranean, Egypt’s gas infrastructure is more developed. It has a relatively large natural gas export infrastructure, but is underutilized. With a total length of 7,485 km of transmission grid and 38,000 km of distribution grid, Egypt has the biggest infrastructure in the East Mediterranean area. Connecting the Mediterranean discoveries to Egyptian infrastructure necessitate ultimately lower in-

30 Petroleum Today - October 2019

vestment than the construction of Greenfield LNG facilities in Cyprus or Israel. The Egyptian option is beneficial to all parties involved and enhances the role of Egypt in the region and its ability to secure revenue from being a transit route and re-operating the two LNG plants. Global liquefaction capacity still in the widespread phase of build-out that began in 2016, driven largely by capacity additions in Australia, the United States, and Russia. Between January 2018 and February 2019, 36.2 million tonnes per annum (MTPA) of liquefaction capacity was added. In September 2018, Egypt signed an agreement with Cyprus to connect Aphrodite gas field to its liquefaction plants in Idku and Damietta, whereby Cypriot gas would reach Egypt via a marine pipeline to be liquefied and re-exported. Also, $15 billion worth of gas from Israel’s Tamar and Leviathan fields will be processed in Egypt as part of a 10-year deal between the Israeli Delek Drilling Company and the Egyptian Dolphinus holding company. Existing LNG terminals on the two branches

of Nile Delta provide Egypt with an edge as a transit point for gas coming from Cyprus and Israel. The two plants are capable of exporting 1.8 BCFD, providing a platform to handle the combined production of both Leviathan and Aphrodite gas fields. Egypt’s strategic location and an infrastructure including refineries, liquefaction plants and petrochemical factories, poises it to become an important trading and distribution center for natural gas. This is a boost to Egypt’s international standing to grow reliance on natural gas, especially from Europe. EU gas demand is rated to range at around 400 billion cubic meters per year. Currently, Russia and Norway are considered the leading suppliers to the EU. Regional Integration between East Med Countries A series of major natural gas discoveries made in recent years and the prospect of substantial hydrocarbons resources waiting to be tapped beneath the Eastern Mediterranean waters have sparked major international interest. If developed in a successful way, they may significantly alter the energy picture in the Mediterranean region. They may also be a force that enhances energy security, economic evolution and regional cooperation. If not, they might become a major component of the geopolitical struggle, fuel existing disputes and add to the various anxieties in the region and beyond. Egypt’s Steps towards Regional Integration Egypt is in a strategic location and proximate to the gas

resources-rich countries, which helps it to take steps towards regional integration. Egypt Initiated a strategic dialogue with the EU on energy and Signed a Memorandum of Understanding on an Egypt-EU Strategic Energy Partnership (April 2018). It signed an agreement with Cyprus to establish a natural gas subsea pipeline between the two countries, in order to facilitate natural gas delivery from Cyprus to Egypt’s liquefaction plants in Idku and Damietta. (September 2018). With Jordan, both countries signed MoUs between natural gas companies to regulate the sale and purchase of natural gas (January 2019). Also, it signed an MoU with Iraq and Jordan to transport Iraqi natural gas and crude oil to Egypt via Jordan. The discovery of hydrocarbon resources presents an exceptional window of opportunity for regional cooperation, and long term energy security. Exploitation and transportation of these resources in a timely and effective way could pave the way for minimizing the time-tomarket and boost the access to more valuable markets. Influential cooperation between the different countries and the energy companies active in the area could result in “optimal” investment decisions, such as the development of joint export infrastructure for fields located in various countries. As mentioned by Amos J Hochstein, US former Special Envoy for International Energy Affairs, countries will save billions if they share infrastructure and market access. If they don’t share those resources, most of the gas will have to stay in the ground.

Petroleum Today - October 2019 31

Jotun A/S P.O. Box 2021 N-3202 Sandefjord, Norway Tel:+47 33 45 70 00 jotun.com

The first mesh-free epoxy fire protection solution for all hydrocarbon and jet fires. No additional mesh reinforcement. Just significantly reduced installation time and substantial material and labour savings. When exposed to fire, Jotachar JF750 produces a robust and temperature stable insulating char whilst risks associated with incorrect mesh installation are completely eradicated.

Jotachar 1709 combines passive fire protection and corrosion protection with low lifecycle costs to asset owners. Jotachar 1709 is a highly durable solution with extended life to first maintenance, tested to rigorous industry fire & durability standards.

THE MOST SIGNIFICANT HAZARDS FOR FACILITIES IN THE OIL, GAS & PETROCHEMICAL INDUSTRIES ARE EXPLOSION AND HYDROCARBON FIRES. WITHOUT PASSIVE FIRE PROTECTION (PFP) MEASURES, INCIDENTS CAN ESCALATE RAPIDLY, LEADING TO CATASTROPHIC LOSS OF LIFE, ASSETS AND INVENTORY.

As steel temperature increases during exposure to fire, strength dramatically reduces. PFP measures prevent or delay collapse of steel structures by significantly reducing the rate of temperature increase. Until now, the industry has depended upon epoxy PFP coating systems that require additional mesh reinforcement to deliver the required performance. Mesh can be difficult and complex to install correctly. Incorrectly installed mesh can lead to uncertified installation and system failure when exposed to fire. With Jotachar, there is no requirement for any additional mesh, meaning significantly reduced risks associated with incorrectly installed PFP. Jotachar incorporates an advanced fibre matrix, eliminating the need for complex mesh reinforcement.

No additional mesh reinforcement. Just significantly reduced installation time and substantial material and labour savings.

Jotachar benefits: • Mesh-free time-saving solution • Up to 50% increase in installation efficiency • No compromise in fire and corrosion protection • Zero cost for mesh reinforcement materials. No pins, no additional metal or fabric mesh. • Substantial time savings on installation • Lower lifetime maintenance costs compared with all other systems

Find out more at www.jotun.com/jotachar

Technology Applications

Performance and Cost Benefits of Environmental Drilling Technologies:

A Business Case for Environmental Solutions By: Lydia Brantley, Jennifer Kent, Natalie Wagner, SPE, National Oilwell Varco

A

bstract

Environmental impact has become business critical as we have been unable to crack certain issues to the degree expected for our industry. It is the central challenge for the continued development of shale markets, as it has been offshore. In a customer survey completed in the first quarter of 2012, a diverse group of operators, drilling contractors, and service companies identified their top three challenges for shale development: pricing, inexperienced personnel, and—of paramount importance—environmental impact. The industry recognizes the need for reduced environmental impact, but what do we need to achieve it? In the aforementioned survey, many operators and drilling contractors expressed looking to oilfield service and supply companies for continued innovation with the expectation that they continue to be to be forward-thinking and present ideas that provide value. The industry has two primary means for reducing environmental impact of its operations: processes (operator and contractor-driven) and equipment (service and supply-driven). This paper proposes that the two must work hand-in-hand. It explores the opportunity to take this further: identifying critical steps such as process design for reduced environmental impact with lower-impact technology and industrial engineering. The dual approach is needed to affect large-scale change. This paper will examine the positive impact of the implementation of select environmental technology can have on oilfield economics from the perspective of an oilfield equipment, technology, and services provider. It aims to: Ó Demonstrate a case for environmental solutions

Ó Establish the importance of improved environmental

34 Petroleum Today - October 2019

performance for market access Ó Identify areas in which operators evaluate environmental impact Ó Discuss the technology opportunities available to operators Ó Recognize and quantify the performance and cost benefits of aforementioned technologies.

The Positive Impact of Environmental Technologies on Oilfield Economics

Easy oil is gone. The aging of the conventional reservoir base, evident in the dearth of conventional green fields, acceleration of production decline rates, and limitations on spare capacity, combined with increasingly restricted reserve access following the wide reassertion of state control over national petroleum resources worldwide has driven operators to pursue higher-risk/higher-cost projects in order to replace reserves and maintain attractive assets. Along with the technical and economic challenges of these projects, operators now have to manage new challenges associated with drilling in areas that are more socially sensitive areas (e.g. northeast US, continental Europe, and Australia) and environmentally sensitive (e.g. the Arctic). Mitigating environmental impact has become business critical—both on land and offshore—as we have yet to effectively address certain issues to the degree expected for our industry. It would be naïve to think that regulations will drive improvement in our industry. Economics drive technology, and technology drives change. The oil and gas industry constantly seeks new ways to drill better, faster, and safer. Like any industry, oil and gas strives to do so while

increasing performance and reducing direct and associated costs; yet unlike many others, oil and gas faces the additional challenge of managing and mitigating the environmental impact of its operations. Our actions are magnified in part due to the areas in which we operate, and our missteps can have a significant impact on local communities and the environment. Engineering and industrial controls should be used together to achieve parallel goals of increased performance and reduced environmental impact. By aligning the right people, processes, equipment, and technology, we can do more. Increasing operational performance and reducing environmental impact do not have to be mutually exclusive (Harvard Business Review 2006). Admittedly, there are reasons why this perception exists. In some instances, environmental regulations have contributed to lower rates of return for oilfield players. For example, emission control regulations for new non-road diesel engines (i.e. the US and Europe’s respective Tier 4 Interim/Stage IIIB and Tier 4 Final/Stage IV) have forced oilfield equipment manufacturers and technology providers to pursue costintensive technology development and engineering. While some companies have taken advantage of the opportunity to establish a competitive advantage in these fields, the transition has been demanding in terms of resources, both financial and otherwise. This paper examines the positive impact that the implementation of select environmental technology can have on the economics of the oilfield. Across the industry, the main focus areas for improved environmental performance involve: energy efficiency and emissions, water use and recycling, leak prevention and spill containment, and drilling waste management. Acknowledging that the implementation of processes and technologies needed to mitigate the environmental impact of oil and gas drilling will be a longterm process achieved through incremental goals, this paper will concentrate primarily on the possibilities for improved environmental performance matched with operational and efficiency gains in one area: drilling waste management.

Drill Cuttings: An Introductory Definition

The largest source of drilling waste, drill cuttings present a significant challenge both on land and offshore as their presence, treatment, and disposal can inhibit the operational and economic efficiency of a drilling program. Drill cuttings refer to the materials (mainly solids plus some residual fluids) removed from the wellbore during drilling operations. Drilling fluid circulated through the wellbore and annular space during drilling carries the cuttings out of the wellbore and out to the surface. There the cuttings are separated and disposed: either discharged, re-injected, or (in the case of

offshore wells) shipped to land-based treatment facilities (Oil & Gas UK 2012). While cost plays a role in determining the disposal option, environmental laws and regulation limit options based on the drilling location as well as the type of drilling fluid used. Cuttings generated from wells drilled with oil-based mud, for example, must be treated extensively prior to disposal (as compared to those generated from wells drilled with water-based mud). Treatment vis-à -vis technologies like centrifugal dryers and thermal desorption units can limit the environmental risks associated with disposal both on land and offshore. Processes and technologies that reduce the amount of drill cuttings and/or treatment required before disposal can deliver operational and economic benefits while mitigating environmental impact, proving: what’s good for business can also be good for the environment.

Waste Management Helps Enable Market Access

With the increase of drilling in more technically challenging operating environments, environmental performance has become business critical as we have been unable to resolve certain issues to the degree expected for our industry. Improved waste management enables market access, particularly in environmentally and socially sensitive areas. Compliance with environmental laws and preservation of positive public opinion play a role in market access. While the conversation below focuses on waste management, the same general ideas are transferrable to the other major focus areas for improving environmental performance in the oil and gas industry.

Compliance with Environmental Laws and Regulations

The way in which environmental risks are perceived and regulated can impact the support for and development of drilling in certain areas. Regulations have barred drilling in areas rich in resource potential at various times due to political and public concerns of environmental impact. For example, various countries controlling Arctic access declared a temporary moratorium on drilling following 2010s Gulf of Mexico oil spill due to concerns that current infrastructure for spill cleanup was inadequate (Bolstad 2010). Similarly, multiple countries with technically recoverable shale gas resources (e.g. France and Bulgaria) have placed a temporary moratorium on the hydraulic fracturing necessary for shale gas development pending further environmental investigation (Jacobs 2012). Certain areas of the US are banning the practice following recently passed ballot amendments (Associated Press 2012). The aforementioned may be extreme examples, but they demonstrate the business

Petroleum Today - October 2019 35

importance of managing environmental performance throughout the entire drilling and completions process. Reducing the presence and/or environmental impact of drill cuttings may be essential for obtaining market access, complying with regulations, and avoiding possible remediation costs. Complying with environmental laws and regulations is business critical as non-compliance may result in either the inability to drill or substantial fines. Regulatory controls minimize the impact of permitted discharge of cuttings based primarily on toxicity. Laws and regulations vary by location. On US land, for example, waste requirements typically originate at the state level for oil and gas exploration and production while the Environmental Protection Agency is the primary regulatory agency for environmental concerns (API 2011). In addition, many of the local watersheds and ground water protection agencies are either at a multi-state level or a river basin level (EPA 2012). Offshore, national government agencies regulate the permitted discharge of cuttings to prevent unreasonable degradation of the marine environment. Depending on the drilling location, the target level of non-aqueous fluids on cuttings typically ranges from 0% to 8%. In recent years, regulations governing the treatment and disposal of drill cuttings have become more stringent with multiple areas moving towards complete zero discharge (Figure 1).

Maintaining Social License to Drill

The rising power of local community stakeholders— particularly in US land, where individual landowners maintain subsoil ownership rights—may have greater impact on our industry today than ever before. Now, the ability to conduct oil and gas drilling is subject to opinions of outside parties in addition to environmental laws and regulation. In today’s technology-driven world, everyone has access to information. Traditional news outlets are no longer the sole opinion leaders. Everyone has the ability to create and disseminate information, fact-based or not. In some cases, this can contribute to more entrenched environmental opposition, especially in ecologically and socially sensitive areas like those described above. How environmental risks are perceived and regulated has impacted access to oil and gas reserves worldwide. Today, public opinion helps determine the ability to obtain and maintain drilling permits. A company that is not conscientious of its environmental impact and/or working to mitigate may be subject to losing its social license to drill (Kitasei 2011).

Technologies Delivering Operational and Cost Benefits Along with Improved Environmental Performance A central challenge surrounding the implementation of select

36 Petroleum Today - October 2019

environmental technologies is ensuring efforts to reduce the environmental impact intrinsic in oil and gas development do not negatively impact operational and cost performance. For waste management, technologies that reduce the amount of drill cuttings and/or treatment required before disposal achieve this balance. The technologies discussed below demonstrate how business and environmental goals can be achieved in parallel, proving that technology decisions made on the basis of performance and bottom-line dollars can also deliver legitimate environmental gains.

Drilling Tools for Wellbore Stabilization Reduce Amount of Cuttings Generated While Drilling

When a drill bit deviates from the desired well path, drillers must reduce the pressure applied to the drill bit and make frequent adjustments to the bottom hole assembly (BHA) to steer the bit back to the desired course. These corrective actions consume valuable drilling time and result in crooked oversized wellbores for drilling efficiency losses estimated as high as 200%. Through the use of rotary steerable systems and similar low-cost alternatives, drillers can maintain verticality in the wellbore and recover the lost time and cost. They can also reduce the amount of environmental waste by an estimated 30% through decreased cuttings and fuel consumption. Therefore, along with well-accepted efficiency gains, drilling straighter wells delivers positive environmental impact by reducing drilling waste from the source.

Centrifuges and Dryers Reduce Presence of Non-Aqueous Fluids on Cuttings

Drilling fluid type and local discharge requirements (in terms of the permitted level of non-aqueous fluids on cuttings) help determine the method for cuttings disposal offshore. For cuttings with non-aqueous fluids, the main options include: Ó Cuttings re-injection into existing or new wells Ó Shipping cuttings onshore for treatment and disposal Ó Offshore discharge following treatment (Tullow Oil 2009). While cuttings re-injection and shipment are the preferred methods for zero discharge environments, in environments where offshore discharge is allowed centrifuges and dryers offer operational and cost efficiencies along with environmental performance. Centrifuges separate fine drilled solids from the drilling fluid. Doing so prevents drilled solids volume from exceeding a threshold level in the drilling fluid that could inhibit the drilling process and/ or damage additional rig equipment. When drilled solids increase above the acceptable threshold level, the only way to reduce the solids to fluid ratio to acceptable levels involves dumping and diluting the fluid.

Generally, the desired ratio between drilling fluids and drilled solids is 95:5. Therefore, for every barrel of drilled solids a centrifuge removes, it eliminates the need for ~19 supplemental barrels of drilling fluid. Using a centrifuge eliminates the costs associated with adding extra base fluid (estimated at USD 2500 for 19 barrels) as well as treating the increased volume of produced waste. The use of dryers further eliminates cost by returning base fluid back into the mud system for re-use. Centrifuges can be considered an environmental tool, as demonstrated by the above example. Proper waste management begins with shale shakers. Improved and automated shakers increase the efficiency with which solids are removed from the drilling fluid, leading to better reuse and fewer requirements for additions for time and cost savings (El Dorry 2012). However, one operator explained that, on average, centrifugal dryers offered a 65% reduction in the amount of barrels of cuttings discharged over shale shakers alone (Figure 2).

Enhanced Water-Based Mud Delivers More than Environmental Benefits

Drilling with water-based mud eliminates the more environmentally damaging side effects of oil-based mud: no hydrocarbons and no chlorides that require treatment prior to proper disposal. Oil-based mud remains popular for land applications because of its consistent performance. New drilling fluid technologies offering improved environmental performance as a primary benefit must also deliver bottomline operational and cost gains. An oil and gas equipment manufacturer developed an enhanced water-based mud that does just that: matching oil-based mud’s performance in days versus measured depth and cost. Proven on land and inland waters, the enhanced water-based mud has proven to be as fast as oil-based mud. For a sample of wells with a total vertical depth of 12,500 feet to 14,000 feet, drilling with oil-based mud took an average of 15.9 days to complete while enhanced water-based mud took 15.8 days. It has also matched performance in ways other than days versus measured depth. One operator in the Eagle Ford Shale in south Texas, US has used the enhanced waterbased mud on 43 wells. Each was drilled with no stuck pipe and casing reached bottom. Enhanced water-based mud also offers an improved lubricity coefficient over traditional water-based mud. Whereas water-based mud has a lubricity coefficient of 0.28, the enhanced water-based mud has 0.14 which results in improved penetration rates, consistent reduction of lost circulation and delivery of stable wellbore. Enhanced water-based mud matches oil-based mud performance without the increased disposal cost typically associated with non-aqueous fluids. Upfront costs for

38 Petroleum Today - October 2019

enhanced water based mud is higher, with an operator in the Eagle Ford reporting a cost of USD 150,000 compared to an USD 85,000 cost for oil-based mud. However, associated costs for oil-based mud add up quickly, notably the cost for the required base oil (Figure 3). Operators may spend nearly as much on diesel as they are on oil-based mud, ranging from USD 50,000 to USD 70,000 according to one operator. Additional savings associated with disposal costs include additional equipment rental, rig cleaning, oil-based mud and base oil trucking, and cement slurry to surface for oil-based mud recovery. In the Eagle Ford, an operator saved USD 300,000 per well using enhanced water-based mud. The operator reported a total savings of USD 12.9 million over 43 wells. In areas where leasing requirements forbid landforming cuttings and/or require cuttings to be disposed offsite the savings are less substantial. Nonetheless, the cost of enhanced waterbased mud is comparable to the combined cost of oil-based mud and necessary diesel.

Market Acceptance of Environmental Technology Related to Operation’s Economics

The market acceptance of technologies that improve environmental performance is directly tied to the operational and/or cost efficiency gains they also deliver. Consideration of environmental impact, while important for market access in terms of compliance with laws and regulatory and maintaining social license to drill, will only become commonplace should the technologies offered meet the operational and/or cost demands of standard drilling operations. One of the challenges oilfield service and supply companies face is addressing the environmental gains offered by some of their more traditional products. The root cause of this challenge is the lack of common metrics for evaluating environmental performance. Nonetheless, across the industry operators, drilling contractors, and service and supply companies have identified the main focus areas for improvement: energy efficiency and emissions, water use and recycling, leak prevention and spill containment, and drilling waste management. Considering these areas, oilfield service and supply companies can begin preliminary evaluations of their existing product portfolio and market added benefits. Taking the next step of creating and incorporating a standard method for assessing environmental performance of technologies requires industry-wide support. The challenge of demonstrating the positive economic impact of the implementation of select environmental technologies cannot be resolved by one company alone; it will require the collective commitment and collaboration of all industry players.

Acknowledgements

The authors would like to thank David Reid, Tom Yost, Federico Mezzatesta, Khaled El Dorry, Garry McCraw, Mike Usher, Scott Jackson, Carl Tolbert, and Joe Blanc of National Oilwell Varco for their contribution of expertise and support. REFERENCES API. 2011. Environmental Regulation of the Exploration and Production Industry. Associated Press. 2012. Vt. Becomes first state to ban hydraulic fracturing. Bolstad, Erika. 2010. McClatchy Newspapers. Arctic drilling still a no-go, despite judge’s moratorium ruling. El Dorry, Khaled and Bill Dufilho. 2012. Automation Improves Shaker Performance. SPE 151180-MS. Environmental Protection Agency. 2012. Ocean Discharge Criteria Evaluation.

ExxonMobil.2012. Environmental Drilling Initiatives. Harvard Business Review. 2006. Strategy and Society: The Link Between Competitive Advantage and Corporate Social Responsibility. Jacobs, Justin. 2012. Petroleum Economist. Bulgaria joins France in fracking ban. Kitasei, Saya. 2011. World Watch Institute: Vision for a Sustainable World. License to Drill? Revised Study from New York Department of Environmental Conservation Outlines Conditions for Permitting Shale Drilling- but Not in Unfiltered City Watersheds. Neff, Jerry. 2010. Neff & Associates. Fate and Effects of Water Based Drilling Muds and Cuttings in Cold Water Environments. Oil & Gas UK. Knowledge Centre: Drill Cuttings. Railroad Commission of Texas. Surface Waste Management Manual. Reddoch, Jeff. 2008. World Oil. Why cuttings reinjection doesn’t work everywhere—Or does it? Tullow Oil. 2009. Summary of Development Drilling Impacts and Assessment of Drill Cuttings Disposal Options.

Fig. 1—Environmental discharge requirements

Petroleum Today - October 2019 39

Fig. 2—Relative drill cuttings discharge by equipment type

Fig. 3—Cost savings offered by enhanced water-based mud

40 Petroleum Today - October 2019

H350 a multipurpose masterpiece for all business needs in Egyptian market

WHATEVER YOU WANT. EQUIPPED WITH WHATEVER YOU NEED Egyptian international motors (EIM) the sole agent for Hyundai commercial vehicles in Egypt. Introduces newest member of Korean giant family Hyundai H 350 in Egyptian market, a multipurpose vehicle that suits all business and commercial needs.

H350 The H350 is a reliable and efficient partner that gives your business a real advantage. It’s impressively well equipped with features that are designed to save you time and money. Active ECO drive mode, for example, improves fuel efficiency and is now standard across the entire range. Clever interior layout and packaging creates a ‘Mobile office’, designed to ease the driver’s daily task. For maximum practicality, there are up to 25 storage compartments around the cab. H350 is classified into two applications: Bus and van. Moreover, it can be customized such as overall lengths, overall heights, and door locations. H350’s infinite transformation still continues. H350 Bus application EIM & Hyundai offer a business class comfort on the road, with various seating layout starting from 14+1 seats up to 29+1 seats in addition to luxurious limousine application. The refined interior design reflects the latest design trends achieving elegant and classy interior space for passengers. LED overhead lighting is precise without being harsh, a sliding door or the front passenger door with inbuilt step makes entry easy and the hand rails are in the right place.

42 Petroleum Today - October 2019

There is even a sophisticated 8 speaker sound system that brings clear sound to every seat. Flush fitted side windows and specially developed air conditioning help ensure the perfect interior climate.

H350 Van application Whatever you need to move, wherever you need to take it, H350 delivers. The design philosophy for H350 van application makes it durable and operational efficient as the loading or unloading of H350 is easy work thanks to the short distance from the ground to the cargo deck. Load space between the rear wheel arches has not compromised thus maximizing cargo hauling capacity and convenience. H 350 can be in different applications as, -Ambulance -Cargo van -Maintenance vehicle -Refrigerated -Mobile office -Double cab -Prisoner transportation

H350 Ambulance application In cooperation with one of the biggest companies in petroleum sector, EIM succeeded in 2019 to supply Gulf of Suez petroleum Co. (GUPCO) with two H350 ambulance application vehicles equipped with all needed equipment that serves the hard and dangerous business locations the company operates in.

EIM Group EIM group was established in 1979 as one of ALKAN holding companies. Its remarkable growth over years has positioned it as a market leader in various business fields. EIM became sole agent for Hyundai commercial vehicles since 2010. EIM exclusively has been distributing and serving more than 28 world reowned brands in more than 9 business sectors in the region operated through 2000 EIM business experts .Group activities include; multinational enterprise representation, after sales activities and free zone storage and clearance.

Technology Applications Well control Safety and Regulations on Deep Water and Onshore wells

By: Prof. Dr. Ahmed. Nooh - Eng. Mohamed Safan

W

ell control has always been

process.

a very important issue in the

We have many important points which can be very improved

oil and gas industry because it involves enormous amount of money, people’s safety, and

environmental issues. Well- control fundamentals have been understood and taught for almost half a century, but still well control problems and blowouts occur in the industry. Substantially, all blowouts are related to human failure and error relative to well operations. Early acknowledgment of a kick and fast close in are the keys to successful well control. Well control consider as a very sensitive and a systematic process. It is a team work and it requires a complete dedication to the job from each member of the team. A large portion of the blowouts are caused by either human error or equipment failure. Human mistakes are generally a result of the lack of regard, ignorance and miscommunication between the workers. Equipment

to make sure a safe drilling process. Human mistakes and equipment failures are the primary driver of the blowouts in an oil and gas well drilling process, as exhibited in the BP, 2010 and a well in Western Desert, Egypt. This contemplate infers that drilling mud is the essential obstruction to prevent hydrocarbons from going into the wellbore thus a cautious checking of the well is critical. It is the first obligation of the apparatus group to ensure that the thickness of the drilling fluid is more than the thickness of the reservoir fluid. Ó This study about accentuate that the rig crew should ensure that there are sufficient barriers in the wellbore to control oil from going into the wellbore. For instance separated from the drilling mud there ought to be blowout avoidance equipment introduced at the wellhead to seal the well if kick happens.

failure can likewise be a piece of human ignorance. On the

Ó Blowout prevention (BOP) equipment at the wellhead go

off chance that the objective is a protected and effective

about as an optional obstruction amid kick circumstances

drilling procedure then each and every detail ought to be

via fixing admirably from the wellhead. A watchful

considered and ought to be sufficiently given consideration

checking and testing of the Bow out preventer equipment

from the administration. An entire coordination between

previously and amid drilling process is vital. As showed in

the workers is obligatory and a far reaching and dependable

the BP contextual analysis that Macondo BOP system was

communication system is a fundamental piece of drilling

not tried and checked for extensive stretch of time.

Petroleum Today - October 2019 45

Ó If possible companies ought to introduce two blind shear

continuing the drilling. The choices how to stop the lost

rams (BSR) in BOP system on the off chance that on the

circulations destinations ought not be deferred as occurred

off chance that one neglects to seal the well amid crisis

in the Egyptian well blowout, it enabled hydrocarbons to

The accident of the April 20, 2010 involved a well integrity

movement a significant separation up to the wellbore. Ó Driller,s and Engineering method are generally utilized

failure, followed by a loss of hydrostatic control of the well.

as a part of the business to circle out the influx of

This was followed by a failure to control the flow from the

hydrocarbons from the wellbore after a fruitful well closed

well with the BOP equipment. The following are few main

«shut in» in case of kick circumstances.

circulation there is another accessible as a backup.

key findings relating to the casual chain of events, a better performance in the respective areas could have saved this

Ó The comparison between these two wells shows that: Engineering method is more efficient than Driller method

catastrophic incident from happening.

as its kill the well in less time but its need more drilling

1. The negative pressure test results were accepted

training for the rig: crew.

although the well integrity was not established. 2. The annulus cement failed to isolate the hydrocarbon zone and allowed hydrocarbons to flow from the formation into the wellbore.

Ó By Studying the Macondo well case study , it was found that: Ó Cementing of a well ought to be done carefully and companies ought to never move to the following stage

3. Hydrocarbons entered the wellbore undetected; the rig

unless the well respectability is set up. Once establishing

crew ignored the abrupt pressure changing readings

is done companies should run well integrity tests to ensure

from the Macondo Well monitoring system.

a successful cement activity. As BP sent Schlumberger

4. The shoe track cement could not provide a strong barrier to the hydrocarbons and allowed them to enter into the production casing. 5. Float valves were not converted, which allowed hydrocarbons to rise up in the production casing. 6. BOP system completely failed to seal the wellbore. 7. Delay in the recognition of the hydrocarbons influx. The crew could not realize the influx until it entered into the riser. 8. Well control actions after explosions failed to regain the control on the well. 9. Diversion of the flow towards MGS resulted in gas venting to the surface of the rig. 10. Lack of real leadership and unprofessionalism was another big contributor to this incident.

group home without performing cement integrity tests which turned out to be a wrong choice. Ó Cement slurry design ought to accord to the wellbore conditions and its strength and uprightness ought to be tried before sending it into the wellbore. As BP did not have any desire to sit tight for the bond slurry integrity results about rather they raced to cement the Macondo Well. Therefore they wound up with an extremely poor cement job. Ó After completion of a cement job the positive and negative pressure tests to set up the well integrity ought to be done and perused deliberately. Confusion of their outcomes can prompt a blowout as occurred at the BP Macondo well. Ó There ought to never be an absence of real leadership at the rig because drilling a well is a consider team work and a team cannot succeed without a great leader.

Onshore well was taken as an example for Egyptian blow out well was at The Western Desert.

Comparing between the two cases (Macondo of Gulf of Mixico and the well of Egypt) it was found that:

Ó During lost circulation, drilling process ought to be ceased

1. The pressure of Macondo was higher as its deep water

and lost circulation sites ought to be stopped before

horizon and the depth of the waster was extra weight and

46 Petroleum Today - October 2019

extra pressure affect on the overburden pressure which in

and the leak in pipe rams, while the Egyptian well the

turn affect on the total pore pressure of the well.

loss of circulation affect on Hydrostatic head.

2. The two killing methods was different as in Macondow they tried with Kill mud then with relief well and finally the top hat. In case of Egyptian well we tried to kill the well with kill mud and Engineering method was the best 3. Macondo was off shore while the Egyptian well

is

onshore.

5. The depth of Macondo was too high while the Egyptian well was 4600 m as TD. 6. The total cost of killing for Makondo was too high (over 20 billion dollar) while the Egyptian well was low killing cost ($ 50.000). From all the above discussion, we can find that, well control

4. The 2 cases was completely different in the reason of bow

is a vital process as it may cost the life of the rig crew and

out: The Macondo because the cement job was not good

must be early detected to avoid disaster as Macondo well.

The main categories of oil well control

Offshore Blowout preventer.

Petroleum Today - October 2019 47

Moniring Drilling parameters for early kick detection

Drilling Simulator to simulate killing process

UNDERGROUND BLOWOUT at ONSHORE RIG

Use remote chock to control the blow out well

48 Petroleum Today - October 2019

UNDERGROUND BLOWOUT at OFFSHORE RIG

TransGlobe Energy Corporation, in an interview with Petroleum Today Magazine highlights the remarkable strides Egypt has taken to modernize its petroleum sector and the opportunities for further investment, TransGlobe ,s steering strategy towards stable production along with the company ,s aim to expand it ,s operations in Egypt through synergistic acquisitions

Can we update our readers insight on the TransGlobe strategy in light of the current oil market? Given the ongoing oil price volatility, TransGlobe is continually focused on strict capital discipline through operational cost controls andminimizing our exposure to financial leverage by remaining debtaverse. Despite fluctuations in the markets, we position ourselves as a nimble company with the ability to create value through a balanced portfolio of exploitation, development and exploration opportunities across our diversified onshore assets in Egypt and Canada. This approach has enabled us to build our production base and generate strong cash flows, as demonstrated by recently declaring and payingour first dividend (US$0.035 in August 2018) since 2015.

AN INTERVIEW WITH

Mr. RANDALL C. NEELY, C.A., CFA President and CEO, Director TransGlobe Energy Corporation