New Products Conical-Diamond- Element Technology

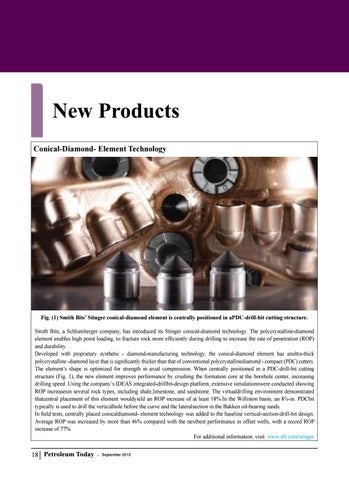

Fig. (1) Smith Bits’ Stinger conical-diamond element is centrally positioned in aPDC-drill-bit cutting structure. Smith Bits, a Schlumberger company, has introduced its Stinger conical-diamond technology. The polycrystalline-diamond element enables high point loading, to fracture rock more efficiently during drilling to increase the rate of penetration (ROP) and durability. Developed with proprietary synthetic - diamond-manufacturing technology, the conical-diamond element has anultra-thick polycrystalline -diamond layer that is significantly thicker than that of conventional polycrystallinediamond - compact (PDC) cutters. The element’s shape is optimized for strength in axial compression. When centrally positioned in a PDC-drill-bit cutting structure (Fig. 1), the new element improves performance by crushing the formation core at the borehole center, increasing drilling speed. Using the company’s IDEAS integrated-drillbit-design platform, extensive simulationswere conducted showing ROP increasesin several rock types, including shale,limestone, and sandstone. The virtualdrilling environment demonstrated thatcentral placement of this element wouldyield an ROP increase of at least 18%.In the Williston basin, an 8¾-in. PDCbit typically is used to drill the verticalhole before the curve and the lateralsection in the Bakken oil-bearing sands. In field tests, centrally placed conicaldiamond- element technology was added to the baseline vertical-section-drill-bit design. Average ROP was increased by more than 46% compared with the nextbest performance in offset wells, with a record ROP increase of 77%. For additional information, visit www.slb.com/stinger

18 Petroleum Today

- September 2013