Ernesto Maurer

Alessandro Zucchi

Franco Oliaro

Marco Salvadè

Massimo Becheri

FAIR ITMA, a history of more than 70 years INTERVIEWS

CITY Milan at the center of the world SHOWCASE

Interviews / Interviste

08 ERNESTO MAURER

Burdens and honours

Presidente di Cematex in un periodo difficile

14

ALESSANDRO ZUCCHI

The master of the house

Il numero uno di Acimit presenta il salone

22 FRANCO OLIARO

Biella puts itself in the spotlight

La vetrina di Biella

28 MARCO SALVADE'

The trade show as seen from the Lake Le aspettative di Como

Prato is looking for confirmation

Prato, il 2023 sulla scia del 2022

48

City / Città

At the center of the world

Milano al centro del mondo

Redazionali / Focus

56

58

61

Believing in innovation

Il distretto pratese tesse con Itema

Future sinergies

La collaborazione tre Gruppo Colle e Schneider

Ensuring sustainability

L'impegno di Girani nella produzione sostenibile

62 Meet the technology

Shima Seiki presenta i nuovi prototipi

65 Innovations takes time

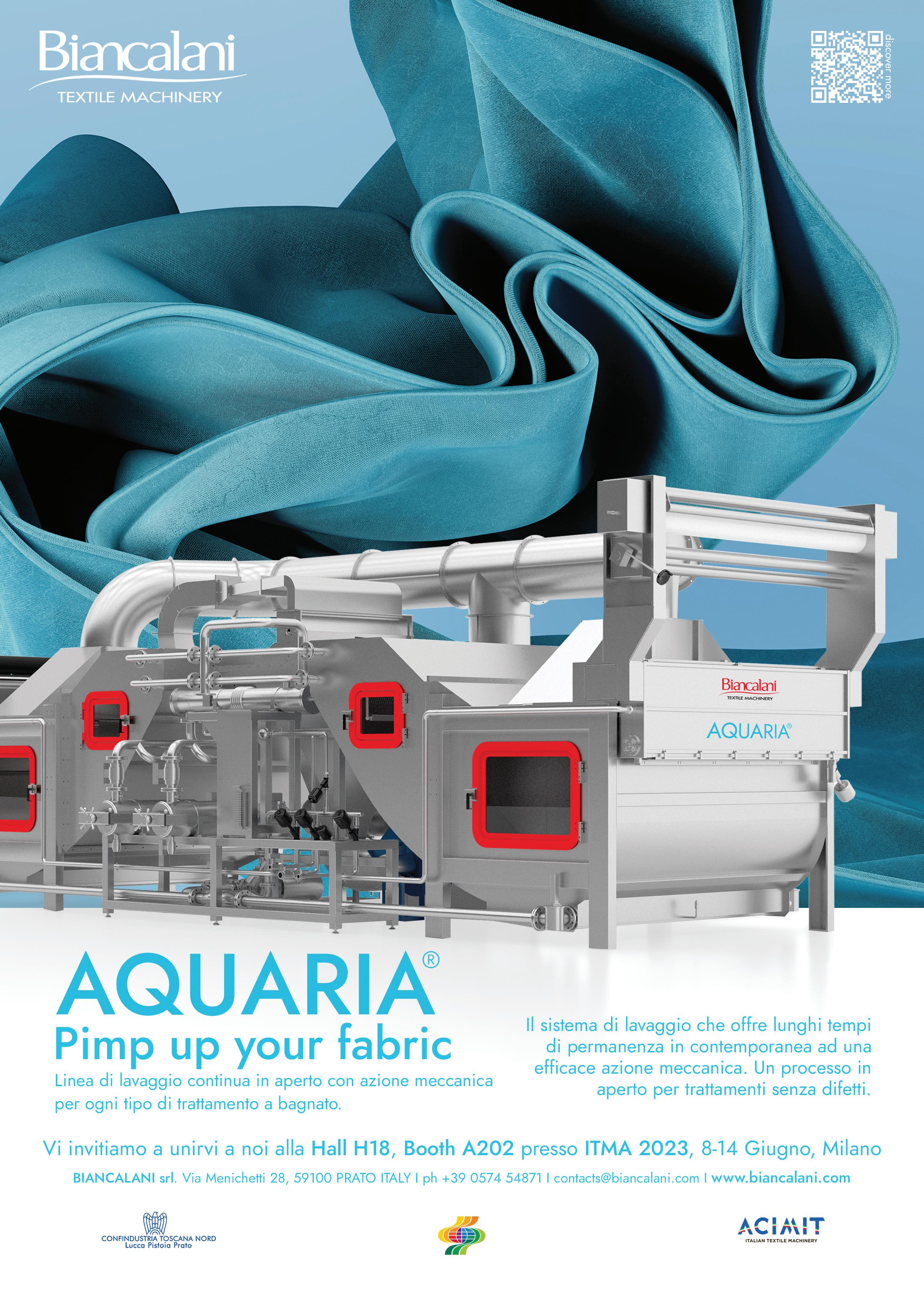

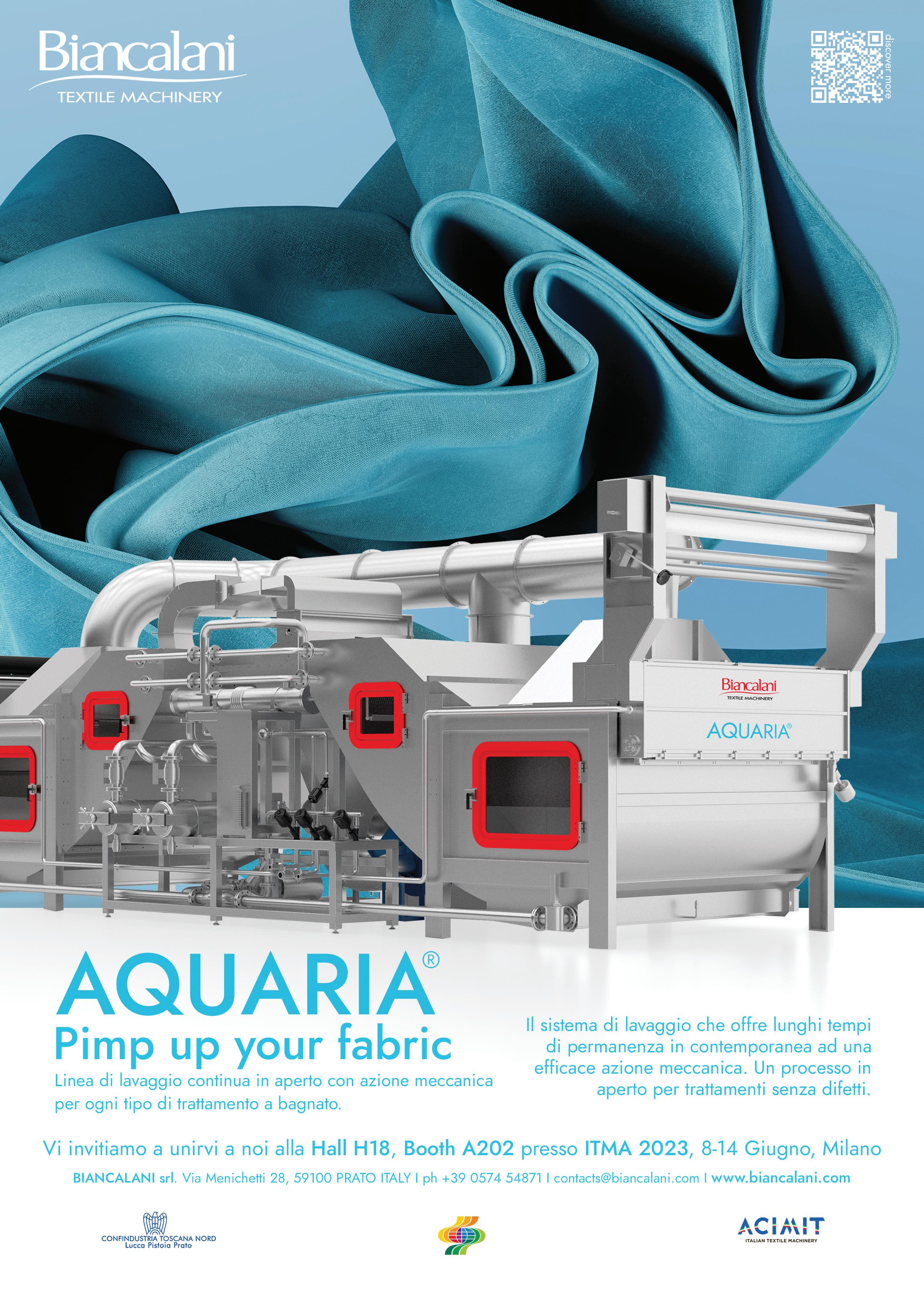

Da Aquaria alle novità top secret di Biancalani

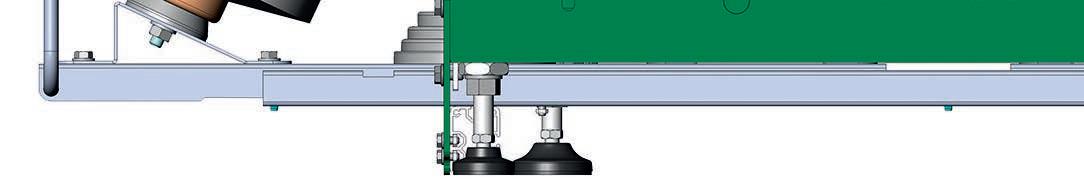

66 On the customer's side

Officine Gorgeri, dalla parte del cliente

registrati al portale per ricevere ogni giorno le notizie dal mondo del tessile abbigliamento

Editor in Chief Matteo Parigi Bini | Fashion EditorTeresa Favi, Marta Innocenti Ciulli | Economic Editor Matteo Grazzini

Editorial Staff Francesca Lombardi, Virginia Mammoli, Elisa Signorini | Layout Martina Alessi, Melania Branca

Translation Tessa Conticelli | Commercial Director Alex Vittorio Lana | Advertising Gianni Consorti

Publisher Alex Vittorio Lana, Matteo Parigi Bini | via Cristoforo Landino, 2 - 50129 Firenze - Italy

redazione@laspola.com

Baroni&GoriPrinting(Italy)

Questo periodico è associato alla Unione Stampa Periodica Italiana

34 MASSIMO BECHERI

Fair / Fiera 40 A history of more than 70 years Una storia lunga più di 70 anni

SHOWCASE

14 8 40 48

Foto: Deepak Rautela (Unspalsh)

The fruit of innovation

Fibre Blending Plants

Sixty years of experience, business and technology have allowed us to make innovative machinery and systems, working closely together with the textile and other industries.

Our goal is to respond to the demands of new products (especially nonwoven fabric) with focused and innovative projects and using high technology.

VIA PROVINCIALE PRATESE, 11 51037 MONTALE (PT) ITALY TEL. +39 0574 718222 FAX +39 0574 710006 info@officinegorgeri.it www.officinegorgeri.it

Welcome back ITMA

BENTORNATA ITMA

by Matteo Grazzini

Four years seem to have gone by in a flash. The four years that separate ITMA 2019 in Barcelona from the show that’s about to open in Milan. Four years marked, unfortunately, by a pandemic that has compromised, ruined and upset the plans, business, sales and hopes of the international textile machinery industry, as well as of all the other textile chain sectors.

The day after the ITMA show in Barcelona, the textile machinery industry seemed headed toward a period of growth after a slight slowdown in 2018 and the boom of orders and deliveries following ITMA 2015 in Milan, probably one of the most successful shows in ITMA’s over seventy-year history. The week in Catalonia left very good feelings which were, however, swept away only one year later, with companies forced in lockdown, technicians having to design machinery on their computers at home and entrepreneurs monitoring closed borders and blocked markets.

Now that it is clearing up again after the storm, thousands of textile industry insiders gathering in Milan will have the chance to set the wheels in motion again ( this is really the case) and reestablish a connection with the rest of the world. China has completely reopened its borders to travelers, the trade show schedule of the industry’s “downstream” sectors is at its busiest and so all the pre-Barcelona conditions have been re-established.

The sustainability theme has been gaining ground since 2019 and the ITMA show’s success will depend on it: research and innovation have been pushing in this direction and markets are increasingly demanding environmental protection and recycling, even from the textile machinery industry.

Seven days of business, in-depth talk, debate, shared experience and cultural exchange: the best of the textile machinery industry is on show and it will prove itself.

Have a nice ITMA everyone!

Quattro anni passati in un lampo. Sono quelli che separano ITMA 2019 a Barcellona dall’edizione che si apre a Milano. Quattro anni caratterizzati purtroppo da una pandemia che ha pregiudicato, rovinato e scombussolato affari, programmazione, vendite e speranze del meccanotessile internazionale, così come di tutti gli altri settori della filiera.

All’indomani di ITMA a Barcellona il settore sembrava avviato ad un periodo di crescita dopo un leggero rallentamento nel 2018 ed il boom di ordini e consegne seguite a ITMA 2015 a Milano, probabilmente una delle edizione più fortunate nella storia ultra settantennale della manifestazione. La settimana in Catalogna aveva lasciato sensazioni ottime spazzate però via meno di un anno dopo, con le aziende costrette al lockdown, con i tecnici a progettare macchinari sui computer in casa e con gli imprenditori a monitorare frontiere chiuse e mercati bloccati.

Adesso che è tornato il sereno, o che almeno è passato il tremendo temporale, le migliaia di addetti ai lavori che si ritroveranno a Milano hanno la possibilità di rimettere in moto gli ingranaggi (è proprio il caso di dirlo) e di ritrovare la connessione col resto del mondo. La Cina ha ormai riaperto completamente le frontiere, il calendario fieristico dei settori “a valle” della filiera è quasi congestionato e quindi si sono ricreate tutte le premesse del pre Barcellona.

Dal 2019 ad oggi però ha preso ancora più corpo il tema della sostenibilità e sarà su questo piano che si misurerà il successo di ITMA: la ricerca e l’innovazione hanno spinto in questa direzione ed i mercati chiedono tutela dell’ambiente e riciclo, anche al meccanotessile.

Saranno sette giorni di affari, approfondimenti, dibattiti, scambi di esperienze e cultura: il meglio del meccanotessile è in mostra e saprà farsi valere.

Buona ITMA a tutti.

EDITORIAL 7 La Spola

Burdens and honours

by Matteo Grazzini

by Matteo Grazzini

ERNESTO MAURER GUIDA CEMATEX IN UNO DEI PERIODI STORICI PIÙ COMPLESSI

Swiss, president of his country's textile machinery association, president of the SFB centre, board member of the International textile Manufactures Association and finally board member of SSM, a company specialising in yarn processing machinery: Ernesto Maurer is at the helm of Cematex, the European Committee of Textile Machinery Manufacturers that organises ITMA. An experienced manager sitting in the command post of a machine that is based on the union of many national realities: a prestige to lead it but also a great responsibility.

You became president of Cematex at a very difficult time for the world economy. Three years on, how do you view the general economic situation and the mechanical textile industry in particular?

I was elected to be the president of Cematex in June 2020 for a four-year term. The coronavirus pandemic started that year, which adversely affected the global economy, and face-to-face exhibitions around the world were cancelled or postponed. This impacted our combined show in Shanghai. ITMA Asia + CITME in Shanghai in 2020 and 2022 had to be postponed. The pandemic has highlighted the importance of local sourcing and manufacturing. This has led to an increase in domestic demand for textile machinery, in emerging and established markets alike. We expect this trend to continue in the coming years. Overall, as much as the global economic situation remains challenging, the textile industry is well-experienced and well-positioned to weather the storm and emerge stronger than ever. The industry is adapting to the “new normal” by embracing digitalisation and sustainability, and we see a bright future ahead.

How much has the pandemic affected the results ITMA 2019 in Barcelona?

We are pleased to note that ITMA 2023 will gross 200,000 square metres with a showcase of cutting-edge technologies from about 1,700 exhibitors. This is a very strong demonstration of the capability and performance after the pandemic, considering that we had 1,717 exhibitors in 2019, and 1,691 exhibitors in 2915. Europe now seems to be 100% back on track, in the East however, where are we in terms of trade fairs and business?

The situation regarding trade fairs and business in the East varies depending on the country and industry. Many countries have resumed in-person events. Our ITMA ASIA + CITME exhibition in Shanghai has received remarkably good response after China abandoned its strict Covid controls late in 2022.

What do you expect from ITMA 2023 and what should visitors expect?

ITMA 2023 will be the first mega textile machinery exhibition in the post-pandemic aera. The exhibition theme is Transforming

Svizzero, presidente dell’associazione dei meccanotessili del suo Paese, presidente del centro di formazione SFB, membro del board della direttivo dell’azienda SSM, specializzata in macchine per la lavorazione

un aumento della domanda interna di macchine

una buona posizione per superare la tempesta adattando alla "nuova normalità" abbracciando

INTERVIEW 10 La Spola

Lei è diventato presidente di Cematex in un momento

"L'industria si adatta alla nuova normalità abbracciando la digitalizzazione e vediamo un futuro brillante davanti a noi"

INTERVIEW 11 La

Spola

Ernesto Maurer

the World of Textiles. It is underscored by four trending topics: automation and digital future, advanced materials, sustainability and circularity, and innovative technologies. It will be an exciting demonstration of the best-in-class solutions as many exhibitors will be showcasing their latest innovations from across the entire manufacturing value chain. These innovations will help textile and garment manufacturers to become more competitive, as well as to demonstrate their ability to produce more sustainably. ITMA is not only a launchpad for innovative technology, it has always been an important event for networking and collaboration within the textile industry. With greater emphasis on collaboration among various stakeholders, ITMA 2023 will present great opportunities for dialogues and sharing of knowledge among industry groups. Cematex brings together manufacturers' associations from many nations. How do you maintain the balance between entities that are competitors in the market?

Cematex is a conglomerate of nine national textile machinery associations within Europe. The organisation of such exhibitions is the core business of Cematex. As owner of ITMA and ITMA ASIA exhibitions, we help to ensure that our members will be able to promote their machinery at high-quality, cost-effective exhibitions for the textile machinery industry. Organised by the industry, for the industry, ITMA remains a relevant platform to drive the development of this business sector. While our members may be competitors, through ITMA, Cematex is able to offer a level playing field for European textile machinery manufacturers.

Cematex members can leverage ITMA to showcase their latest technologies and innovations, and to network and collaborate with other industry stakeholders. By fostering an environment of open dialogue and cooperation, ITMA helps to drive the development of the textile industry as a whole, while also supporting the business interests of individual manufacturers.

INTERVIEW 12 La Spola

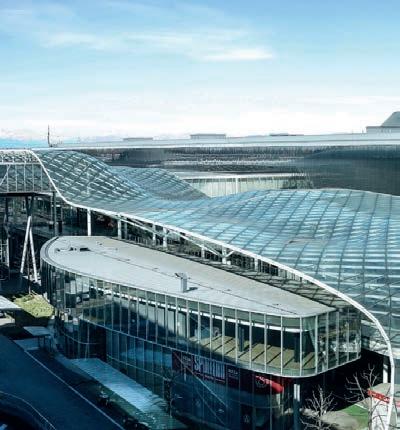

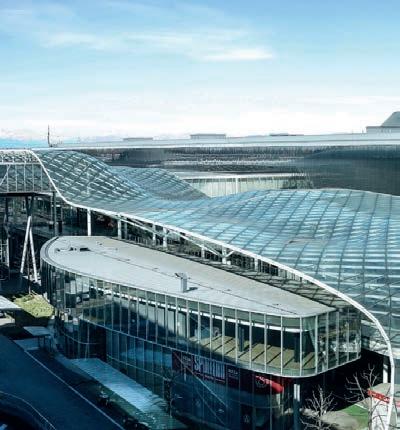

Fiera Milano a Rho

ITMA 2019 a Barcellona

ITMA 2019 a Barcellona

ph.

Dario Garofalo

ph.

Dario Garofalo

The master of the house

IL PRESIDENTE DI ACIMIT ALESSANDRO ZUCCHI PRESENTA IL SALONE

by redazione La Spola

In his sixth year as President of Acimit, the Italian association of textile machinery builders, Alessandro Zucchi enjoys his first experience at the ITMA show as the “boss”: born in Bergamo, MD and partner of Ferraro, he coordinated and supervised the preliminary work for the event of all the Italian textile machinery companies, going from the difficulties caused by the pandemic to a more prosperous period with an upturn in orders and production.

In what condition does the Italian textile machinery industry attend ITMA?

Contrary to what is commonly believed, the past few years have not been so difficult. 2020 was, of course, the year of the pandemic, but 2021 was a year of recovery and 2022 was an extraordinary year. We should not feel too sorry for ourselves, although the signs that we have been looking at since early 2023 are disturbing, because what we need to take in account now is not the current order book, which is substantial, as much as the considerable slowdown in collecting orders. That is why the ITMA show comes at a good time for us and makes us hope for a revival of the market.

So this ITMA show does not count for two, considering a few positive effects from Barcelona 2019 that may have been lost due to Covid?

No. We’re starting all over again from Milan, because in the past few years, there have been so many new developments, such as Industry 4.0, and then the European Union introduced the 5.0 with artificial intelligence and putting workers back at the center of the business. All these factors encouraged our companies to work on new projects. Industry 4.0, however, is not over yet and we have still a lot of things to learn about sustainability and green economy. Being the “master of the house” is an honor but also a responsibility. What has Acimit done from the logistic point of view to contribute to organizing the show?

We worked on a project for two years, investing with ICE about € two million to support our companies and carry on all the activities that the association is required to engage in, first of all, education, in order to create a culture for the future generations that says clearly that working for our companies is not demeaning and is not about tightening screws. The textile machinery industry is abreast with the times and has the best technology that is currently available on the market. We carried on the Green Label project and created the recyclability index. You have an absolute record event in terms of exhibition space. But what if the large attendance is matched with a boom in orders? Are the companies ready to handle it?

We need to take a step back and reckon with the pandemic, transport

Al sesto anno da presidente di Acimit, l’associazione italiana dei costruttori di macchinari per l’industria tessile, Alessandro Zucchi “vive” la sua prima ITMA da padrone di casa: bergamasco, AD e socio di Ferraro, ha

Come arriva il meccanotessile italiano a ITMA?

Contrariamente a quanto si pensa gli ultimi anni non sono stati del tutto

Quindi non è un’ITMA che vale per tivo di Barcellona andato perso per il Covid?

ci sono stati tanti sviluppi, come ad esempio quelli

tantissimo le nostre aziende ad elaborare nuovi progetti che includano questa nuova visione, dove l’operatore diventa la parte preponderante dell’atci sono ancora tante cose da scoprire riguardo alla

Essere padroni di casa è un onore e un onere. Cosa ha Abbiamo elaborato un progetto su cui abbiamo lavorato due anni, investen-

associativo, a iniziare dall’education, col quale vogliamo creare una cultura

passo coi tempi e chi ci lavora può trovare il meglio della tecnologia che oggi

I numeri vi hanno premiato, con un’edizione record in

16 La Spola INTERVIEWS

"Abbiamo elaborato un progetto su cui abbiamo lavorato due anni, investendo con ICE Agenzia circa due milioni di euro"

Alessandro Zucchi

Alessandro Zucchi

costs, raw materials out of control, difficulty in finding electronics components, the war in Ukraine, energy costs and inflation; the next thing is a meteor shower and then we’ve seen it all. But we have the advantage of having medium to small-sized companies, thus, flexible enough to respond to any market change almost immediately. A boom in orders is more than welcome, we will be able to meet the requests, although we do have a problem with the shortage of qualified staff. It’s a problem that has its roots in the past and in poor professional training. The latest agreements with technical high schools may allow us to recruit a few people, but the demand is one hundred times greater than the supply, considering that the big industry is looking for young people just out of secondary school too.

With all your engagements as Acimit’s president, how do you find the time to run your company?

It is hard to do both jobs, but I have a couple of aides within the association who helped me a lot with the event planning. But I’m kind of addicted to ITMA, I began attending it in the 1980s and I haven’t missed a single show since then, so it’s rewarding to be part of the organizing team.

Thousands of people will be experiencing Milan for a week. What advice would you give to those who wish to combine business and leisure?

Milan has a lot to offer in every way, from ITMA’s side events to culture, including art exhibitions, and food, one of the city’s strengths. There are also those travelling from non-European countries with the family to enjoy the city as tourists, including shopping for Italian fashion. For those who would like to travel outside of the city, I recommend Bergamo, which is just a half-an-hour drive from Milan. It’s Italy’s Capital of Culture, along with Brescia, and the upper part of the city is beautiful beyond words, something so unique and rare in cultural and historical terms that it’s definitely worth the trip.

prire la richiesta?

ponentistica elettronica, che ora sembra superata, quindi ben vengano gli

Con tutti gli impegni da presidente di Acimit dove trova il tempo di fare anche l’imprenditore?

collaboratori che mi hanno dato una grande mano seguendo tutta l’organiz-

Migliaia a Milano per una settimana. Che consigli dà a chi vuol abbinare lavoro e momenti più mondani?

parte alta lascia senza parole, abbiamo un qualcosa di unico e di rarissimo

18 La Spola INTERVIEWS

Acimit a Techtextil

Fiera Milano Rho

Fiera Milano Rho

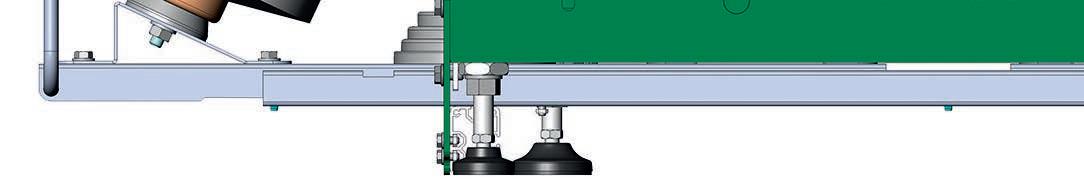

Sector Plan

Chapter 1

Spinning

Chapter 2

Winding

Chapter 19

Research & Innovation

Chapter 5

Knitting

Chapter 12

Testing

Chapter 20

Fibres, Yarns & Fabrics

Chapter 9

Printing & Inks

Chapter 16

Colourants & Chemicals

Chapter 4

Weaving

Chapter 7

Braiding

Chapter 3

Nonwovens

Chapter 8

Finishing

Sector & Facility

Chapter 6

Embroidery

Chapter 10

Garment Making

Chapter 11

Composites

Chapter 13

Logistics

Chapter 14

Recycling

Chapter 15

Software & Automation

Chapter 17

Plant Ops Equipment

Chapter 18 Services

South

Congress & Service Centre (Ground

West

H24 H22 H18 H14 H11 H15 H13 H9

Corso Italia (Ground Floor)

Floor)

Gate

C ATM ATM V V Congress & Service Centre (Mezzanine Floor) A M L C

South Gate / Ponte Dei Mari (1st Floor) Congress Service Centre (Ground Floor) East Gate H4 H2 H6 H10 H3 H1 H7 H5 Facility

Legend CEMATEX & Rest of the World Association Offices A Media Centre M ITMA Club & Group Hospitality Lounge L Mezzanine Floor Visitor Registration V Conference Rooms C Exhibitor Liaison Office E ATM / Bank ATM Left Luggage Information Counter / ITMAconnect Help Desk / Lost & Found Ground Floor First Aid Automated External Defibrillator (AED) Prayer Room Rho Fiera Station E S ATM ATM V V V V S Start-Up Valley

Plan

ph. Expi

Biella puts itself in the spotlight

ITMA COME VETRINA PER IL TERRITORIO

by Matteo Grazzini

Biella’s textile machinery industry lands at ITMA with a brilliant idea in mind: using the trade show’s visibility to promote and make the district better known in all its expressions of excellence.

The idea was concretized by organizing “Biella Wonderland. Where creativity and technology meet beauty”, the event promoted by Biella’s Industrialists’ Union, as ITMA 2023’s Official Supporting Organization, and by Regione Piemonte through the textile integrated supply chain project carried out by Centro Estero per l’Internazionalizzazione – Ceipiemonte.

On June 10, at Palazzo Gromo Losa, Biella will put itself in the spotlight to an audience of select guests during an event which aims to highlight not only the area’s textile machinery industry, but also its culinary culture and artistic heritage, as described by Franco Oliaro, President of the Mechanics’ Section of Biella’s Industrialists’ Union and CEO of Roj: “It is a great example of joining forces, of collaboration for years within the local Industrialists’ Union in which, as the Mechanics’ Section, we have been working towards a joint vision. It’s a good sign for the textile machinery industry, but also for the textile supply chain and the area as a whole, probably a unique case in Italy. ITMA offered to collaborate with other textile and textile machinery districts in Italy without, however, finding the answer that we were able to give. We see ourselves as a united district providing training with ITS TAM, subcontracting, technology, textile machinery, fabric, yarn and knitwear producers, finishing and also fashion brands. Our wool industry is a niche sector of the highest quality”.

What does the textile machinery industry mean to the district?

Over the years, we have diversified our production, our mechanics has been applied to other sectors as well, such as logistics, electronics, the food industry and we want to tell this story to the public, like we will be doing to ITMA’s 150 visitors for Wonderland.

What are the district’s figures at the ITMA show?

37 companies from Biella will be attending the show, that is, 9% of the exhibitors and 7% of the Italian exhibition area.

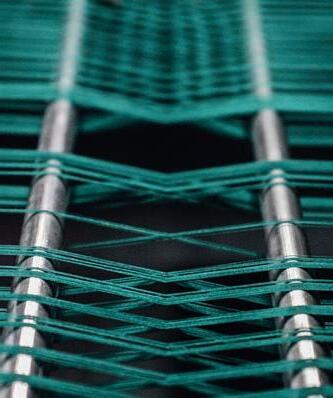

We are a large group: 22 companies that generate a turnover of € 130 million and employ about 800 people, 12% of the companies which have joined Acimit. We showcase machinery for specific sectors, such as nonwoven fabrics, finishing, spinning

Il meccanotessile biellese arriva a ITMA con un’idea brillante in testa: usare la visibilità offerta dal salone per far conoscere, scoprire o apprezzare maggiormente il distretto, in tutte le sue eccellenze.

Un’idea che si è concretizzata con l’organizzazione di “Biella Wonderland. Where creativity and technology meet beauty”, l’iniziativa promossa da Unione Industriale Biellese, in qualità di Official Supporting Organisation di Itma 2023, e dalla Regione Piemonte attraverso il progetto integrato di filiera dedicato al tessile e realizzato da Centro Estero per l’Internazionalizzazione – Ceipiemonte

Il 10 giugno, a Palazzo Gromo Losa, Biella si mostrerà a ospiti selezionati con una serata che esalterà non solo il valore del meccanotessile ma anche quello di territorio, gastronomia e arte, come racconta Franco Oliaro, presidente della Sezione Meccanici dell’Unione Industriale Biellese e ceo di Roj: “E’ un bell’esempio di coesione, di un lavoro iniziato da anni all’interno dell’Unione Industriale dove come Gruppo Meccanici cerchiamo di trainare questa visione unitaria; è un bel segno non solo per il meccanotessile ma per tutta la filiera tessile e per il territorio, forse un caso unico in Italia. ITMA si è proposta di collaborare con altri distretti tessili e meccanotessili in Italia senza trovare la stessa risposta che siamo riusciti a dare qua. Ci piace vederci come un distretto raccolto, dove c’è formazione con l’ITS TAM, subforniture, tecnologie, macchine tessili, produttori di tessuti, filati, maglieria, nobilitazione ed anche i marchi della moda. Il settore laniero è una nicchia di eccellenza”. Cosa significa il meccanotessile per il distretto?

Negli anni ci siamo anche diversificati, la nostra meccanica ha trovato impiego anche in altri settori, come la la logistica, l’elettronica, l’alimentare e questa storia la vogliamo raccontare al pubblico, come faremo con 150 visitatori di ITMA per Wonderland.

Quali i numeri del distretto a ITMA?

Saranno 37 le aziende biellesi a Rho, ovvero il 9% degli espositori e il 7% dell’area espositiva made in Italy. Siamo una compagine importante, ci sono 22 aziende per un fatturato di 130 milioni e circa 800 dipendenti, siamo il 12% delle aziende associate ad Acimit. Presentiamo macchinari specifici per determinati settori, come il tessuto non tessuto, il finissaggio e la specializzazione in filatura e negli accessori, come è tipico per le aziende mediopiccole.

INTERVIEWS 24 La Spola

Il distretto si presenta a 360 gradi con la serata "Biella Wonderland. Where creativity and technology meet beauty"

Franco Oliaro

Franco Oliaro

and accessories, which medium to small-sized companies usually specialize in.

How does Biella deal with the shortage of professional figures?

It’s a problem that adds to the rise in energy and raw material costs. It’s a problem that affects the workers of the manufacturing industry in general and is not easily solved because it will last for years. The Confindustria association is working hard to make the manufacturing industry more attractive, there is not a clear perception of what factories are: everyone, especially young people, want to work in the service industry, in big cities such as Milan. So we have to make factories and the areas where they are based more attractive through improved infrastructure and better services.

Can ITMA be the turning point to go back to the 2019?

The trade show has a trend reversal effect and there are definitely great expectations after the forced break and the pandemic. We’ve seen a few shows already, but not very successful, while ITMA is a major event, no doubt. The show is not going to solve the financial problems of emerging countries such as Pakistan and Bangladesh, which have no money. There is usually a pause in investments before the show, everyone wants to take a look at the latest developments. We’ll see whether there’s going to be the expected speeding up.

Who are Biella’s main competitors?

Ours are medium to small-sized companies and, thus, they cannot compete with the international colossuses. Our products are used in the wool industry, for niche, highly-specialized production and each can find its own space within it. Our competitors are in Italy and in Europe, but we need to watch out for China, which is growing. In the finishing and nonwovens field, we have competitors also in Italy, in Tuscany, as well as in Germany.

Come vive Biella la questione della carenza delle figure professionali?

E’ un problema che si aggiunge all’aumento del costo dell’energia e delle materie prime. E’ un problema che riguarda i lavoratori nel manifatturiero in generale e che non è di facile soluzione perché dura e durerà per anni. Come Confindustria ci stiamo dando da fare per rendere la manifattura più attrattiva, non c’è la percezione corretta su quelle che sono le fabbriche; tutti, soprattutto i giovani, si sono buttati nel terziario, verso le grandi città come Milano. Quindi dobbiamo rendere attrattive le fabbriche ed i territori che le ospitano con infrastrutture e servizi migliori.

ITMA può essere la svolta per tornare ai mercati del 2019?

La fiera ha un effetto di inversione delle tendenze e sicuramente c’è molta attesa dopo la pausa forzata e la pandemia. Qualche fiera c’è già stata ma non con grande successo, mentre ITMA è decisamente importante. Non sarà il salone a risolvere i problemi finanziari dei paesi emergenti, come il Pakistan ed il Bangladesh che non hanno soldi; prima della fiera c’è sempre una pausa degli investimenti in attesa delle novità, vediamo se ci saranno le accelerazioni sperate.

Per Biella da dove arriva la concorrenza?

Le nostre sono piccole e medie aziende e come tali non si possono permettere di andare a scontrarsi coi colossi internazionali. I nostri prodotti trovano applicazione nel laniero, magari in lavorazioni di nicchia, molto specializzate e in questa specializzazione ognuno trova il suo spazio. I concorrenti sono in Italia ed in Europa ma bisogna stare attenti alla Cina, che cresce in qualità ed ha una potenza di fuoco notevole. Sul finissaggio e sul tessuto non tessuto la concorrenza è anche in Italia, in Toscana, come in Germania.

INTERVIEWS 26 La Spola

The trade show as seen from the Lake

ASPETTATIVE E SPERANZE DEL DISTRETTO DI COMO

by Matteo Grazzini

by Matteo Grazzini

Una vista

Lago

del

di Como

The Como district is not traditionally one of the areas devoted to the production of textile machinery, but it is home to companies which have made the history of this industry: companies that specialize in printing, but work with the rest of the textile chain suppliers as well.

The local Confindustria association does not have a section devoted to textile machinery builders, but they are somehow represented at the national management level by Marco Salvadè, the president of the family-run company and member of Acimit’s board. He takes us inside the Como district and through the ITMA show as seen from the Lake’s shores. What does this trade show mean to Como?

I don’t know exactly how many companies will be attending the show, but I’m sure that no one will want to miss this event, which promises to be memorable because of the record attendance at the Rho center. Our textile machinery industry will be represented just like the Italian one.

What are the Como producers’ main markets and, in particular, Salvadé’s?

We deal with finishing and the geographical spectrum is wideranging. We have recently discovered the Uzbekistan market, which has always grown cotton, but now they decided also to process it before selling. We were not involved in the beginning, because it was only a matter of spinning and weaving, but now that the finishing phase has begun, the country has opened up as a new market for us and the business is quite good. In Asia, we have China -although it has its problems now- Thailand, Indonesia, Vietnam, Korea, India, which is giving us the most positive feedback at the moment, Bangladesh and Pakistan which is, however, politically at a standstill, for the use of letters of credit and the free flow of capital towards foreign countries are not allowed. Companies would like to buy, but the government does not allow them to. As for the domestic market, up to 2022, the 4.0 Industry Plan and the state aid have been very helpful. Now that we have reached 20% and the crisis has hit the printing sector, there has been a slowdown, although there are companies that keep buying. Anyway, our sales in Italy range from 10 to 20% and, since we have customers based close to our headquarters, we are able to better develop the products, for they can see first-hand how the machinery works at the plant. 2019 to 2023, a difficult time for everyone. How did you manage the situation?

Those have been four very strange years. Paradoxically, the Covid pandemic allowed us to deliver all the machines previously sold and, in 2020, we had a 10% decrease in sales which, however, was ascribed to 2019, the company’s record year of all times. Instead, 2021 was unimaginable, with a 40% increase as compared to the previous year. In 2022, we had a 10% decrease again because of the war in Ukraine and the rise in energy costs, which forced us to postpone the delivery of 9 machines to 2023. I’m more worried about the future, considering the

Il distretto di Como, per numeri, tradizione e tipologia di lavorazioni non è tra quelli più dediti al meccanotessile ma ospita sul territorio eccellenze che hanno fatto la storia di questo settore: aziende che guardano alla stampa come ambito primario ma

espressamente ai costruttori di macchinari per il tessile ma è in qualche modo rappresentata ai vertici nazionali da Marco Salvadè, presidente della azienda di famiglia e membro del con-

Cosa rappresenta per Como questo salone?

Non ho un conteggio preciso di quante saranno le aziende ma tempo si preannuncia come quella del record per gli spazi occu-

Quali sono i mercati di riferimento per i produttori di Como e per la Salvadè in particolare?

solo coltivato il cotone adesso ha deciso anche di lavorarlo prima

alla nostra sede abbiamo la possibilità di sviluppare meglio il

Come lo avete gestito?

Sono stati quattro anni molto strani, paradossalmente il Covid ci ha permesso di portare a consegna tutte le macchine vendute

INTERVIEWS 30 La Spola

Marco Salvadè

Marco Salvadè

elections in Turkey, which represents 30-40% of our sales and is at a standstill right now. We have already seen a drop in sales, but it has been amortized in other countries. Instead China has disappeared: we have sold and installed a few machines by doing video-conferences, but we are far from reaching the sales numbers we expect from that country. In November, ITMA Asia will be held in Shanghai and we will be going back there after four years, but they have the same energy cost problems we have right now.

Is Como suffering from a shortage of qualified staff too?

We have an even greater problem, that is, Como is located at just 15 kilometers from the Swiss border and is, thus, less attractive for the local young people who prefer to be cross-border commuters by working in Switzerland, where the salaries are lower, and living in Italy where life is cheaper. It’s a problem of taxation: Lombardy did a good job with fuel cards and discounts, but I don’t know if they can also do something about taxes in the manufacturing industry. It’s hard to find drivers, mechanics and electricians, not to mention more qualified staff. We have trouble even finding something willing to sit down to a job interview; young people go to university, but not everyone can be a lawyer or do an office job. We have moved some employees, who have working experience in the machine shop, to the technicians’ department, but now we are understaffed in the machine shop.

What are expectations and hopes for this ITMA show?

I hope everyone will have a positive attitude. The new developments we are going to introduce in Milan are big and I’m very optimistic about them, so let’s not be held back by the customers’ low attendance which, however, seems impossible considering the initial response in terms of pre-registration and booking. Therefore, we can be certain that there are going to be a lot of people at the show, whether they are willing to spend money I’m not so sure.

previste in Turchia, che al momento è ferma e che rappresenta il montato qualche macchina grazie alla possibilità di fare videoconferenze ma siamo lontano dalle percentuali di mercato che Shanghai, dove torneremo dopo quattro anni e dove al momento Anche a Como c’è un problema di carenza di

go, che preferiscono vivere da frontalieri andando a lavorare là, dove gli stipendi sono più bassi, tornare la sera in Italia, dove aveva fatto un buon lavoro con la carta-benzina e gli sconti,

Quali sono le aspettative e i desideri per questa ITMA?

remo a Milano sono importanti ed io ci credo moltissimo, quindi non dobbiamo essere frenati da una partecipazione bassa di

INTERVIEWS 32 La Spola ITMA Asia + Citme

per BINARE ROCCARE INCANNARE IN AUTONOMIA E CON QUALITA’ H.24 FADIS S.p.A. - ITALY - Via Colombera 70, 21048, Solbiate Arno (VA), Italy - tel: +39 0331 989533 - fax: +39 0331 989532 - email: sales@fadis.it - website: www.fadis.it il cobot al tuo servizio 8-14 GIUGNO MILANO ITALY H3 - B106 LEO NOVITA’ MONDIALE

Prato is looking for confirmation

by Matteo Grazzini

by Matteo Grazzini

2023 VIAGGIA SULLA SCIA DEI DUE ANNI PRECEDENTI

IL

The Becheri family, that is, Laip, remains at the helm of Confindustria Toscana Nord’s textile machinery builders’ section, going from ITMA 2019 to ITMA 2023. Marco, the production manager, gave up his seat to Massimo, the Prato-based company’s general manager and head of the association on Via Valentini. In the past few difficult years, the textile machinery industry has embodied the Tuscan district’s hopes and sales, since the local textile manufacturing companies paid a high price to the pandemic and lockdown restrictions. The city reacted by appealing to all its best resources, including textile machinery producers: a microcosm made up of small and medium-sized companies with a range of production that covers all processing stages.

How many Pratese companies will be attending the ITMA?

30 Prato-based companies which, according to the latest 2021 data, employ 500 people and generate a turnover of € 145 million. In addition to the producers, there are 60 workshops, mostly artisan workshops, which employ 230 people. Almost all the Pratese textile machinery companies will be attending the ITMA show.

What has changed compared with the Barcelona show?

The textile machinery industry enjoyed a recovery in the past few years, in both the domestic and foreign markets. In Italy, the Industry 4.0 facilitations brought excellent results and we need more of them if we want to continue down the path of modernizing the industrial system, which translates into benefits to the GDP too, even compared with our competitors.

What does Prato’s textile machinery industry offer?

Our companies produce machinery that ranges from textile fiber recycling to finishing, carded yarn spinning and dyeing. In these fields, competition has no boundaries, both in Italy and abroad. Our main markets are definitely Southeast Asia - Bangladesh, Pakistan and India- while China is back too. Then Turkey and South-America with its ups and downs. In Europe, Italy enjoys a significant increase in textile machinery sales, along with Portugal.

What will Prato be showing at ITMA?

We come as a united front by sharing the same communication resources, but this is a trade show in which every company represents itself and at its best, in terms of both product innovation and image. Everything will be revolving around sustainability and digitization with efficient and reliable machinery.

How did you spend the two years of pandemic?

With the exception of 2020 and the forced break, we were able to contain the effects owing to a good order portfolio that we had already built up. 2021 and 2022 were definitely years of growth in terms of sales, revenue and exports.

Is the shortage of qualified staff a problem that affects you as well?

It’s a problem that affects everyone, and not only as far as

Resta in casa Becheri, e di conseguenza Laip, la guida della sezione riferimento per le speranze e il fatturato del distretto toscano, con il

comparto dei produttori di macchinari per il tessile: un microcosmo fatto di piccole e medie aziende con una produzione che abbraccia

Quale sarà la rappresentanza pratese a ITMA?

Cosa è cambiato rispetto a Barcellona?

guire sulla strada dell’ammodernamento del sistema industriale che

cui ogni azienda rappresenta se stessa e cerca di farlo nel migliore dei modi possibile, sia sotto l’aspetto dell’innovazione del prodotto che

INTERVIEWS 36 La Spola

“qualified” staff is concerned. Let’s move from the assumption that we apply the national collective agreement for metalworkers, which provides labour protection, job security and wages agreed through collective bargaining. So we’re talking good jobs. Nonetheless, we have trouble recruiting staff, for both the machine shop and office. In Prato, we signed a convention with the Marconi Institute in order to facilitate the transition of its students to the labour market, and also the Buzzi school trains students to work in the textile machinery industry, but many of them end up going to university and very few become mechanical engineers. The point is that there is a lot of demand and very little supply and things have changed because apprenticeship and in-company training are no longer available, very few young people are attracted to manual or manufacturing work and would rather find a digital or office job. And all this despite the fact that our industry allows its employees to learn languages, travel abroad and build a product with their own hands. And the mechanical industry is one of Italy’s most strategic sectors.

What expectations do you have from ITMA as a company and as Prato’s textile industry?

It’s not an easy time, because international markets are suffering from the central banks’ restrictive measures on currency, with high rates and very little money circulating across the world, even in emerging countries. And on top of that, high inflation which reduces the purchasing power of consumers in the developed countries and results in less investments. There is a stagnation of requests from the markets, but we are confident in the driving force of the trade show, which is held in one of Europe’s most beautiful exhibition spaces.

formazione interna, pochi vogliono imparare un lavoro manuale e manifatturiero rispetto a settori italiani che ha una vera importanza

Laip che come settore meccanotessile pratese?

frendo le misure restrittive sulle valute da parte delle banche centrali, con tassi alti e pochi soldi veri in giro per il mondo, anche nei paesi

INTERVIEWS 38 La Spola

"Sul mercato c’è stagnazione di richieste ma confidiamo nell’effetto traino della fiera"

A history of more than 70 years

by redazione La Spola

by redazione La Spola

ITMA, UNA STORIA LUNGA PIÙ DI 70 ANNI

ITMA, which stands for Internationale Textil-Maschinen Ausstellung, has its roots in the years after the Second World War, a time when Europe was recovering from the devastation of conflict and the textile machinery industry was benefiting from the economic boom that was about to sweep the continent.

On Friday, April 20, 1951, in a small town to the north of France, Lille, on the border with Belgium, in the heart of a well-known textile manufacturing area, the first textile machinery trade show opened its doors. The show was first organized- and still is- by Cematex, Comité Européen des Constructeurs de Machines Textiles, an organization specially established for the purpose of planning trade shows, which gathers the textile machinery associations of nine European countries: France, Italy, Belgium, Germany, Austria, The Netherlands, the UK, Spain and Sweden. It was then decided that the show would be held every four years, in different locations, and that exhibitors were forbidden to introduce over twoyear-old technological developments (but this rule no longer stands).

Over the years, the trade show has grown in size and stature, reaching staggering figures, such as 18,000 tons of machinery showcased at ITMA Paris in 1999, with an insurance value of over 600 billion.

The decision of holding the ITMA show every four years was taken literally and, since that early spring Friday in France, the cities hosting the show have been: Brussels, Milan, Hannover, Basel, Paris, Milan again, Hannover, Milan, Paris, Hannover, Milan, Paris, Birmingham (the first of the new century), Munich, Barcelona and Milan in 2015, one of the most successful shows in the history of ITMA, judging by the orders in the months and years that followed. The evolution of the show is well-described by the machinery showcased over the years by European firstly and then Asian companies too (ITMA+CITME is the trade show that alternates with ITMA every two years).

In Lille, the most impressive tech developments were the mechanical weaving and dyeing operations, which had been performed by hand until then. Then came the first high-speed looms and double twist machines in Brussels in 1955; the high-pressure dyeing machines in 1959; non-woven fabrics in 1963; the advent of electronic knit-

ITMA, ovvero Internationale Textil-Maschinen Ausstellung, affonda le sue radici nel secondo dopoguerra. In un’Europa che si stava rialzando dopo le ferite quasi mortali del conflitto mondiale il settore del meccanotessile traeva grande spinta proprio dal boom economico che si stava affacciando all’orizzonte. Venerdì 20 aprile 1951 è il giorno del debutto della fiera, a Lille, una città del nord della Francia, ai confini con il Belgio, nel cuore di un’importante area tessile. Ad organizzarla, ieri come oggi, Cematex, Comité Européen des Constructeurs de Machines Textiles, un organismo appositamente costituito per l’organizzazione di manifestazioni fieristiche a cui aderiscono le associazioni meccanotessili di nove paesi europei: Francia, Italia, Belgio, Germania, Austria, Olanda, Gran Bretagna, Spagna e Svezia. La decisione è di farne una ogni quattro anni, in sedi diverse e con il divieto, adesso abolito, di presentate innovazioni tecniche proposte o pubblicizzate più vecchie di due anni. Negli anni la fiera si è ingrandita in numeri e prestigio fino ad arrivare a saloni dai dati impressionanti, come le 18.000 tonnellate di macchinari esposte a Itma Parigi nel 1999, con un valore assicurato di oltre 600 miliardi.

L’impegno di organizzare ITMA ogni quattro anni è stato preso alla lettera e da quel venerdì di inizio primavera in Francia sono state le sedi che hanno ospitato la fiera: Bruxelles, Milano, Hannover, Basilea, Parigi, ancora Milano, Hannover, Milano, Parigi, Hannover, Milano, Parigi, Birmingham (la prima nel nuovo secolo), Monaco di Baviera, Barcellona e infine Milano nel 2015, un’edizione baciata da un grande successo organizzativo e commerciale, stando agli ordini arrivati nei mesi e negli anni seguenti.

A raccontare l’evoluzione della fiera sono anche i macchinari, che via via sono state presentate dalle aziende, sia europee che, in seguito orientali (ITMA+CITME è il salone che si alterna con ITMA ogni due anni).

A Lille fecero scalpore e suscitarono ammirazione gli svolgimenti in modo meccanico di operazioni di filatura e tintoria fino a quel punto fatte a mano. Poi arrivarono i primi telai veloci e le ritorcitrici doppia torsione a Bruxelles nel 1955; le macchine da tintoria ad alta pressione nel 1959; i tessuti non tessuti nel 1963;

HISTORY 42 La Spola

La prima edizione risale al 1951, a Lille.

Negli ultimi anni spazio all'alternanza tra Milano e Barcellona

HISTORY 43 La Spola ITMA

2003 - Birmingham

HISTORY 44 La Spola ITMA 2015 - Milano

ITMA

2011 - Barcellona

ting machinery in 1967, the first great stride toward the use of electronics in the textile industry. The introduction of jet dyeing machines in Paris in 1971 paved the way for the uniform dyeing of fibers. The open-end spinning method, still at the experimental stage, was introduced in Milan in 1975: the result of 13 years of research in Czechoslovakia and then officially introduced in Hannover four years later.

The eighties led to the first automated machines, with winding machines shown in Milan in 1983 and computerized textile machinery in Paris in 1987. From 1991 on, it’s modern-day history, with automation and computers playing an increasingly important role and being applied to other sectors, such as the leather industry, energy conservation and fast production processes. Since the arrival of the new century, technological development and sustainability have been inextricably linked, and this is really the “here and now”.

ITMA 2023 is taking over from Barcelona, with a common thread that connects Lombardy and Catalonia. The last four shows, in fact, have been held in these two regions: 2011 and 2019 in Barcelona, 2015 and 2023 in Milan. The weight of ITMA Barcelona’s legacy is heavy to bear, considering that the past show at the Fira Gran Via saw great attendance of visitors and brought a lot of business and opportunities which were, however, almost immediately swept away by the pandemic. So what we are all expecting from the Rho show is the addition of a new and solid puzzle piece to the future of ITMA.

l’avvento dell’elettronica nelle macchine da maglieria nel 1967, primo storico passo dell’elettronica nel tessile. La Tintoria jet a Parigi 1971 ha spalancato le porte alla tintura uniforme delle fibre, mentre a Milano 1975 fu presentato in anteprima e in via sperimentale il metodo di filatura Open-end, già studiato da 12 anni in Cecoslovacchia e confermato quattro anni dopo ad Hannover. Gli anni ’80 (Milano 1983) portarono le prime fasi d’automazione, in questo caso con le filoroccatrici e già nell’87 a Parigi vengono installati nelle macchine tessile i computer. Dal 1991 in poi è praticamente storia dei nostri giorni, con automazione e computer sempre più importanti e “esportati” anche al settore pelletteria, prima di essere applicati al risparmio energetico e alle lavorazioni in tempi brevi. Nel nuovo secolo e sempre più con insistenza alla ricerca tecnologica è stata abbinata quella per la sostenibilità e qui, davvero, è storia di oggi.

ITMA 2023 raccoglie il testimone da Barcellona, con un filo continuo che lega la Lombardia alla Catalogna. Le ultime quattro edizioni della fiera infatti non sono uscite da questi due territori: 2011 e 2019 a Barcellona, 2015 e 2023 a Milano.

Ed il testimone è di quelli pesanti, visto che l’ultima edizione alla Fira Gran Via aveva fatto segnare un ottimo successo di visitatori e soprattutto aveva dato il là ad un giro di accordi e affari stroncato quasi sul nascere dalla pandemia.

Quindi da Rho ci si attende un nuovo tassello saldo per il mosaico, anche futuro, della storia di ITMA.

HISTORY 46 La Spola

ITMA 1951 - Lille

ITMA 1999 - Parigi

ITMA 2007 - Monaco di Baviera

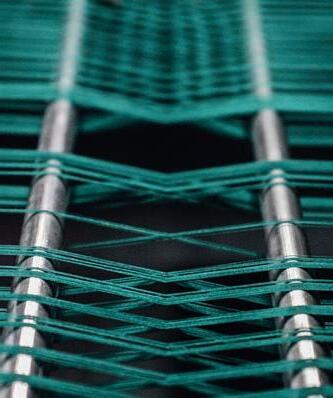

FEEL of ITEMA

THE ADDED VALUE

TECHNOLOGY

Scopri il valore aggiunto della tecnologia Itema

È la tecnologia che ha prodotto il tuo tessuto che rende il tuo prodotto così speciale.

Le macchine per la tessitura Itema garantiscono ai tessitori di tutto il mondo la tecnologia più innovativa in linea con i più recenti trend di mercato: prestazioni superiori, eco-efficienza e maestria tessile sono i valori aggiunti che puoi toccare con mano quando scegli Itema.

Vieni a trovarci

Milano 8-14 Giugno 2023

H6 - B105

47 La Spola

Textile Machinery itemagroup.com Industrial Innovation and Solutions

SCOPRI DI PIÙ

Milan at the center of the world

AL CENTRO DEL MONDO

by Gruppo Editoriale

Since always a modern, active, productive and dynamic city, but also in constant growth and, following the 2015 Expo, attractive in every way. Milan hosts the ITMA show again after eight years since the last time thanks to the services and spaces offered by Milano Fiera Rho, but the one-week show extends well beyond the spaces of the city’s north-western outskirts, with events and parties held downtown, where also the hotels chosen by tens of thousands of visitors are located. And Milan is ready, as always, to manage the crowds of people eager to access the ITMA show. La Spola magazine periodically brings the best of Milan to its readers and, on the occasion of the textile machinery fair, it extracts its top articles from the latest issues.

For those of you who have the time and energy to enjoy Milan beyond the show hours, art and food are the two things you should focus on.

Art. The tour of Milan’s must-sees begins with Pinacoteca di Brera and its permanent collection of hundreds of works of art, from the Madonna with Child by Ambrogio Lorenzetti to the San Luca Altarpiece by Mantegna. The second stop is at the Modern Art Gallery (GAM) which showcases six main collections: the Stories- Women, GAM Milano’s Faces, Childhood- and Tales- from Myth to History, Sculpture and Masterpieces.

Located beside the Duomo is Palazzo Reale which, over the days of the show, houses two exhibitions devoted to two masters of image. The first one is on the work of Bill Viola, the great video art artist from the 1970s to the present day. The second exhibition illustrates Helmut Newton’s legacy with the scientific collaboration of the Helmut Newton Foundation, to celebrate the 100th anniversary of the birth of the great photographer through 300 photos, in addition to magazines, documents and videos.

Food. Obviously the offerings are endless and, when it comes to taste, there are no rules, which is why we “jump” from one tip to another among the many we have given our readers in the past few years.

History is exactly the theme of the first restaurant on our list: Beda House, more of a pub than a restaurant, located at 2 Via Murat at the corner with Viale Marche. The food is not what you would describe as gourmet, but there is a wide choice of beers. At LùBar ( 16 Via Palestro), the feeling is that of dining in an art gallery, housed in the southern wing

Città da sempre moderna, attiva, produttiva e dinamica, ma anche in pieno sviluppo e, dopo l’Expo del 2015, anche attrattiva a 360 gradi. Milano ospita ancora ITMA a distanza di otto anni dall’ultima volta grazie

settimana di salone non si limita agli spazi alla periferia

dove si trovano anche gli alberghi scelti dalla decine di migliaia di visitatori.

E Milano è pronta, come sempre, a gestire la marea di ospiti legati ad ITMA. La Spola, con il suo magazine, presenta periodicamente le eccellenze di Milano e per il salone del meccanotessile estrapola il meglio delle ultime uscite.

Per chi ha tempo e modo di vivere Milano fuori dagli orari del salone arte e gastronomia sono i due settori sui quali concentrarsi.

Arte. Per scoprire i must milanesi si può iniziare dalla Pinacoteca di Brera, con centinaia di opere in esposizione permanente, dalla Madonna col Bambino di Ambrogio Lorenzetti al Polittico di San Luca del Mantegna. Seconda tappa alla Galleria d’Arte Moderna (la GAM): nelle sue sale si possono ammirare sei principali collezioni, le Storie: Donne, I volti di GAM Milano, storia, Scultura e Masterpieces.

Palazzo

Reale mostre dedicate a maestri dell’immagine. La prima è su Bill Viola, il grande artista della videoarte dagli anni Settanta a oggi; la seconda invece racconta L’eredità di Helmut Newton con una esposizione realizzata con Foundation, concepita per il centesimo anniversario della a riviste, documenti e video.

Cibo

comanda, per questo facciamo un percorso “a salti” tra i vari consigli dati ai lettori negli ultimi anni. La prima proposta è la Beda House, più pub che ristorante, in via Murat 2 angolo viale Marche: una volta varcata la soglia si torna indietro nel tempo, tra una chiesa gotica e una Milano anni ’70 nel giardino interno. La scelta di birre è ampia. Al LùBar (via Palestro 16) la sensazione

CITY 50 La Spola

Bill Viola e Helmut Newton sono protagonisti di due mostre a Palazzo Reale, tra videoarte, documenti e fotografie

CITY 51 La Spola

I Navigli (ph. Giulio Boem)

of Villa Reale, in a porticoed space that was once the carriage house. An eighteenth-century atmosphere, Sicilian cuisine and, weather permitting, a park where you can listen to jazz music and relax. A must-see for design lovers is bar Luce, at 2 Largo Isarco: we recommend to go there even if only for the experience of taking a look at the venue’s interiors and design. The menu is more café-like than restaurant-style, so with limited options. In order to recreate the atmosphere of old Milano, the Prada Foundation recruited film director Wes Anderson to design the interiors and he gave free play to his imagination: hypnotic wallpaper, round chandeliers, pastel tones, Formica tables and wonderful, at least sixty-year-old pinballs machines make the place and experience unique. Milan is the Italian city where Hawaiian food first arrived, because of its innate ability in sensing and seizing trends and because of its being at the crossroads of different cultures. I Love Poke Milano has five branches in various areas of the city (Piazza dei Mercanti, 20 Via Tortona,4 Via Fabio Filzi, 7 Via Filippo Turati and 23 Via Sebastiano del Piombo) and it has been serving healthy Hawaiian-style food for years: the poke bowls come in two formats, the toppings include algae, cucumbers and pineapple, among the proteins are salmon, chicken and octopus. Two locations for Poke Away (5 Via Santa Tecla and 1 Corso di Porta Ticinese) and, again, a mix of Hawaiian and Peruvian cuisine, including a bowl with an unmistakable name, Machu Picchu, made with perch, shrimps, avocado mousse, sweet potato mousse, coriander, cherry tomatoes and leche de tigre. Maui Poke (Via San Vittore al Teatro 3) features colorful exotic-style interiors and, with a bit of imagination, Milan’s scorching-hot July sun may

è invece quella di mangiare in una galleria d'arte, ricavata volta ospitava le carrozze. Ambiente da pieno 1700, cibo siciliano e, tempo permettendo, un parco all’aperto per ascoltare jazz e rilassarsi.

Tappa obbligatoria per chi ama il design ma non solo è il bar Luce, in Largo Isarco 2: ci si può andare anche solo per guardare gli interni e apprezzarne lo stile, anche perché il menù è da bar e non da ristorante, quindi con una scelta non troppo ampia.

Per ricreare le atmosfere della vecchia Milano in questo

Wes Anderson, che non ha posto limiti alla fantasia. Carta da parati ipnotica, lampadari rotondi, colori

di almeno 60 anni rendono unici il luogo e l’esperienza. Per restare in sintonia con le mode del momento c’è il poke e Milano è la città dove il cibo hawaiano è arrivato prima. I Love Poke Milano ha cinque punti in varie zone (piazza dei Mercanti, via Tortona 20, via Fabio Filzi 4, via Filippo Turati 7 e via Sebastiano del Piombo 23) e da anni serve il cibo salutare di ispirazione hawaiana: le poke bowl sono in due formati, tra i condimenti ci sono alghe, cetrioli e ananas, tra le proteine il salmone, il pollo e il polpo. Due locali per Poke Away (via Santa Tecla 5 e Corso di Porta Ticinese 1) ed anche in questo caso c’è un mix con la cucina peruviana, tanto è vero che tra le varie bowl ce n’è una dal nome inconfondibile, Machu Picchu, che ha come ingredienti il pesce persico, i gamberi, la mousse di avocado, quella di patata dolce, il

CITY 54 La Spola

The Raft - Bill Viola

project customers in the middle of the Pacific Ocean. A journey of the mind before dishes of fish tacos, fresh centrifuged juices and bowls with salmon, shrimps or vegan ingredients. The range of grilled meat that you can find in Milan is much more international than in Florence, in particular, it features a strong South-American influence. So the city offers a variety of different solutions in terms of types of meat and spices used.

La Griglia di Varrone (7 Via Alessio de Tocqueville, in the Porta Garibaldi area) is a restaurant but also a brand with three branches (Lucca and Pietrasanta in addition to Milan) whose strength lies in an oak wood-burning grill and meat cuts which are the best in the world, from Cinta Senese to the Japanese Kobe, in addition to the uncommon Rubia Gallega. Also El Carnicero has three branches, at 108 Corso Garibaldi and 31 Via Spartaco, and a summer location in Ibiza: it uses the so-called Parrilla, the traditional Argentinian method for grilling food: cheese and vegetables as much as meat, from veal ribs to 1,3 kg-fillet steak. There is quite a different atmosphere at Taverna degli amici (4 Via Spartaco), with lots of informal seating at long wooden tables, perfect for sharing convivial meals, and a grill that can be seen by the diners. The fixed-price menu includes Angus steak with side dish and dessert. The wine list, including about 500 labels, will delight connoisseurs.

coriandolo, i pomodorini e il leche de tigre. Maui Poke (via San Vittore al Teatro 3) ha l’esotismo di palme e colori nelle decorazioni e con un po’ di fantasia il sole torrido del luglio milanese potrebbe proiettare i clienti in

fare con davanti tacos di pesce, fresche centrifughe e bowls con salmone, gamberi o con ingredienti vegani.

carne alla brace, con una contaminazione di culture marcata e con una forte La Griglia di Varrone (via Alessio de Tocqueville 7, zona Porta Garibaldi) basa la propria forza su una griglia alimentata a legno di quercia e sui tagli di carne che rappresentano il meglio al mondo, dalla Cinta Senese alla giapponese

Per El Carnicero, che si divide tra Corso Garibaldi 108 e via Spartaco 31, il riferimento è la Parrilla, il metodo tradizionale della griglia argentina. E sulla griglia

Alla Taverna degli amici (via Spartaco 4) si mangia con brace a vista su tavoloni di legno, adatti ad una cena conviviale di molte persone. Nel menù a prezzo può rientrare anche una tagliata di Angus con contorno e dessert. Per gli appassionati di vino ampia scelta tra circa 500 etichette.

CITY 55 La Spola

Pinacoteca di Brera

El Patio

I love Poke

L'offerta gastronomica spazia a 360 gradi, dalla tradizione alla griglia, passando dalle Hawaii

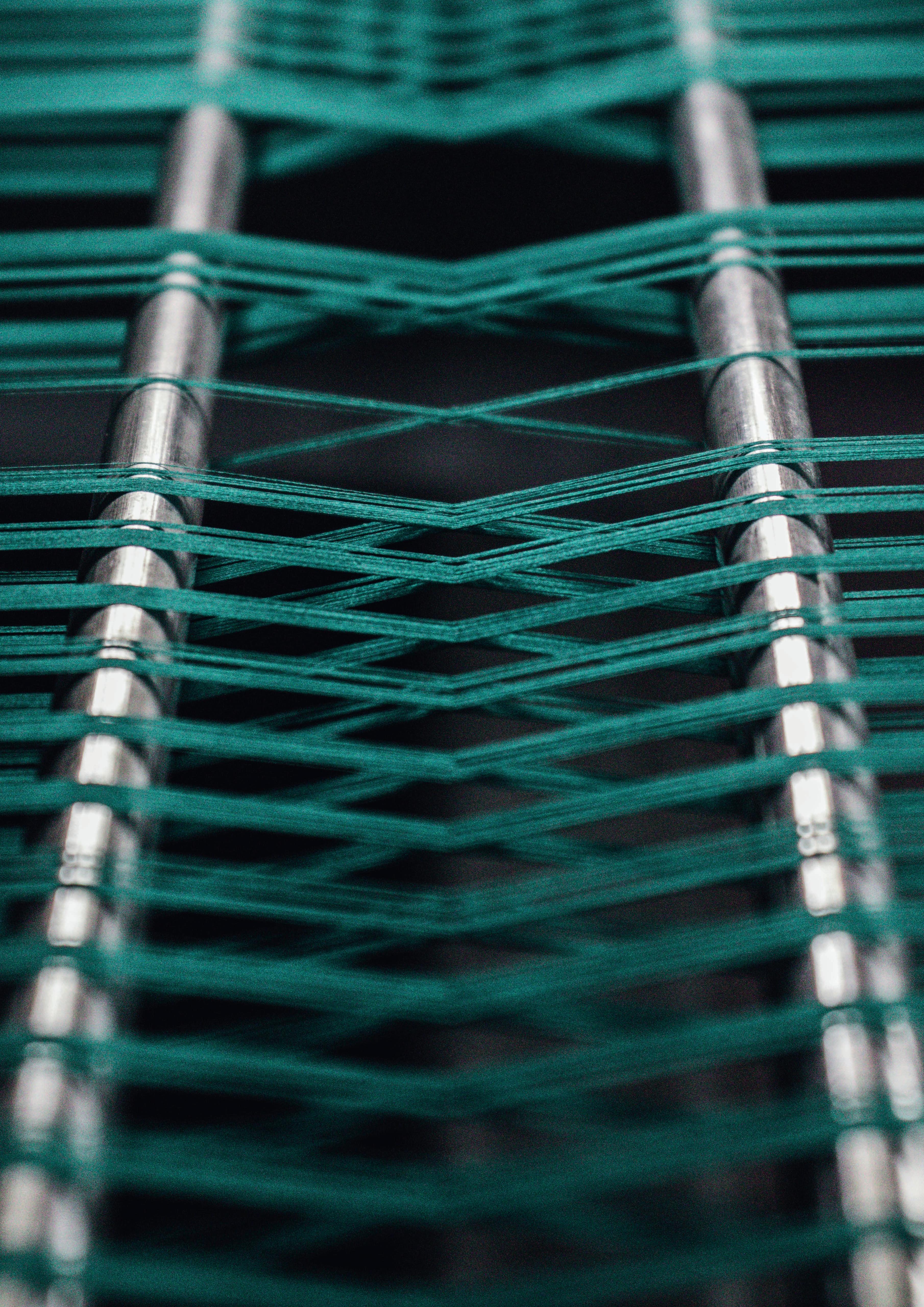

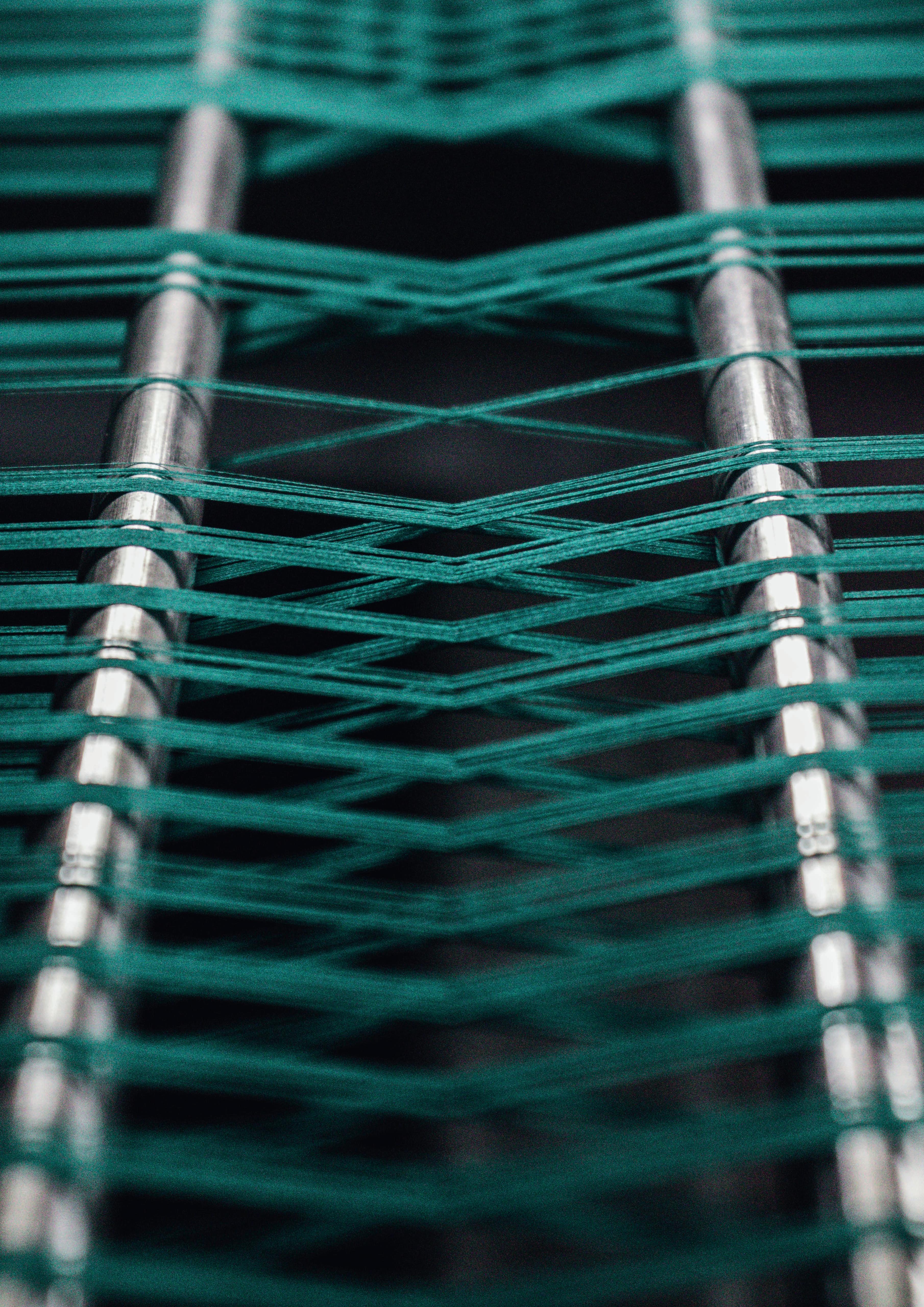

inBelievinginnovation

IL DISTRETTO PRATESE TESSE CON ITEMA

by redazione La Spola

“Man’s love of innovation will never die. This I believe and I believe it passionately”. Karl Friedrich Benz was definitely not a weaver, but the words of the engineer who is considered to be the inventor of the first modern automobile apply perfectly, one century later, to the textile world, where tradition always goes hand in hand with innovation and with the upgrading of machinery.

The Prato district in Tuscany is an emblematic case of the supply chain remaining intact, despite the current difficulties, and keeping abreast with the times by investing in textile machinery. And this is possible only by relying on long-standing companies which the district has always been able to count on to increase its production. Such is the case of Itema which, in Prato, supplies a great number of weaving mills that have purchased new looms in the past two years at a time when, following the Covid pandemic and the increase in prices of all kinds of goods, everyone was expecting a slowdown.

We are talking about big-sized companies, such as Nova Fides, with its weaving mill Paola Textile,and Beste with Tessitura Serena, but also medium-sized and family-run businesses, like Nesi & Nesi and Innocenti e Nesi.

“After the pandemic, the market responded surprisingly wellClaudio Calabresi, the director of Nova Fides, says- and our weaving mill did not even have enough looms to complete the orders. Public incentives definitely encouraged us to invest in Itema’s new R9500 looms for our Paola Textile mill, where we will keep some of the old machinery, we will be nearly doubling the productivity by going from 36 to 70 machines. We chose Itema because it provides the best service and very careful assistance, not only during the sales process, but throughout the machinery’s life cycle”.

Outsourcing is one of the Prato district’s cornerstones and even for Nesi & Nesi the post-Covid period brought growth: “The articles keep changing and we need state-of-the-art technology to meet the market’s requests - Fausto Nesi explains - which is why we are always ready to embrace innovation. We purchased Itema’s R9500 looms and we go on working with this company because we are optimistic at a time when many others are not. We believe in a wide-ranging district in which the future is rosy for companies like ours”.

“L'amore dell'uomo per l'innovazione non morirà mai. Ne sono convinto e ci credo appassionatamente”.

Karl Friedrich Benz non era certo un tessitore ma le parole dell’ingegnere al quale è attribuita l’invenzione dell’autovettura moderna trovano conferme, a distanza di un secolo, anche nel mondo del tessile, dove la tradizione va da sempre a braccetto con l’innovazione e l’aggiornamento dei macchinari. Un caso emblematico arriva dalla Toscana, dal distretto di Prato,

al passo coi tempi investendo in macchinari tessili. E lo fanno

contato per far crescere la produzione. E’ il caso di Itema, che a Prato ha un bacino di tessiture notevole, molte delle quali hanno acquistato nuovi telai negli ultimi due anni quando, dopo Covid e rincari di tutti i tipi, ci si poteva attendere una frenata.

Si va da aziende grandi, per dimensioni e numeri, come Nova Fides con la sua tessitura Paola Textile e Beste con la Tessitura Serena, ad altre di medie dimensioni, come Nesi & Nesi e Innocenti e Nesi.

“Dopo la pandemia il mercato ha risposto in modo sorprendente – racconta Claudio Calabresi, direttore di Nova Fides – ed in tessitura sono addirittura mancati i telai per completare gli ordini. Gli incentivi statali sono stati sicuramente un incentivo ad investire in nuovi telai R9500 di Itema per Paola Textile, dove terremo parte di quelli vecchi ma andiamo quasi a raddoppiare la produttività passando da 36 a 70

ed un’assistenza capillare, non solo nella fase di vendita ma anche durante tutto il ciclo di vita delle macchine”.

La lavorazione conto terzi è uno dei capisaldi del distretto pratese

“Gli articoli cambiano, ci vuole una tecnologia perfetta per rispondere alle richieste del mercato – spiega Fausto Nesi – quindi siamo sempre pronti all’innovazione. Abbiamo aggiunto telai R9500 di Itema proseguendo nella collaborazione con questa azienda, anche perché siamo ottimisti in un momento in cui altri non lo sono. Pensiamo ad un distretto ampio dove per le aziende come la nostra c’è un futuro roseo”.

Una parte dei 13 milioni investiti nel distretto pratese nella

FOCUS 56 La Spola

A part of the € 13 million invested in Prato’s weaving industry comes from Innocenti & Nesi, fifty years of business and profits always reinvested in innovation, including a photovoltaic system. “We work a lot with the Biella district - Roberto Fossi says - and we are probably the only weaving company that has joined the Confindustria association in Prato. We have always had a direct relationship with Itema, they have always supplied us with very versatile looms for the production of the most varied fabrics, such the nine ones we have recently installed”.

“Taking over Tessitura Serena, as well as Texco - Giovanni Santi says from his Beste Hub office in Prato - is a step forward in terms of performance and we have also invested in new Itema machinery, which we had already purchased for the Serena mill. Among the many reasons for working with Itema is a visit to Kilometro Rosso and the Itemalab, where I experienced first-hand how this company operates. We bought ten looms which allow us to meet the market’s demand for modern and reliable suppliers”.

tessitura arriva anche da Innocenti & Nesi, cinquanta anni di attività e di utili sempre reinvestiti in innovazione, fotovoltaico compreso.

“Lavoriamo tanto con il distretto di Biella – racconta Roberto Fossi

Prato. Con Itema abbiamo da sempre un rapporto diretto, ci ha

la produzione dei tessuti più svariati, come i nove che abbiamo installato ultimamente”.

“L’acquisizione della Tessitura Serena, così come di Texco – dice Giovanni

Beste Hub – è un passo in avanti dal punto di vista prestazionale e l’abbiamo accompagnata in investimenti su nuovi macchinari Itema, già presenti alla Serena. Tra le tante motivazioni che ci spingono a collaborare con Itema c’è anche una mia visita al Kilometro Rosso e all’Itemalab, dove ho potuto vedere il modo di pensare e progettare di quest’azienda. Abbiamo acquistato dieci telai che ci consentono di rispondere ad un mercato che

57 La Spola

Innocenti & Nesi Nesi & Nesi

13 i milioni investiti sul territorio per innovazione e macchinari per la tessitura

Claudio e Paolo Calabresi

Tessitura Serena

Future synergies

GRUPPO COLLE E SCHNEIDER RAFFORZANO LA COLLABORAZIONE

In the manufacturing industry world, where terms such as “ not unfamiliar anymore, there are people who are looking to the future by strengthening already established collaborations. Such is the case of Gruppo Colle and Schneider Electric, who are now weighing the impact of CO2 emissions generated by the

the relationship between the two companies and the sharing

growing awareness. Many of them, in fact, are much more likely to reward the brands that lead the way in this respect. The

toxic and harmful chemicals from its manufacturing processes, to safe production and to optimizing the consumption of resources required in the dyeing department for a long time.

“Schneider Electric – the President of Gruppo Colle Matteo Gualtieri explains- supported us in the modernizing of the preexisting plants and in the design and extension of the monitoring built a partnership with Schneider to reduce our CO2 emissions and digital solutions. They collaborate with us on a transformation that has important organizational and managerial implications. We need to work on the company’s performances and, at the same time, promote social and labour sustainability. The textile consumption and using energy from clean sources are fundamental

FOCUS 58 La Spola

E -HWA/ PLASCO/ DONG HONG/ DIING KUEN

ACME MACHINERY/ AKM/ LOGIC ART/ LK/ OSHIMA/ TONG GENG

ASI

CHARMING STAR/ DONG HONG/ EN-HWA/ PLASCO/ E-HWA

DAHU/ E-HWA/ KYANG YHE

DAHU/ E-HWA/ GIN HONG YU/ PAI LUNG/ TAI HO SHING/ T.C.H. TAIWAN/ C.C.I./ GIN HONG YU/ PAI LUNG/ WELLKNIT

ACME INTERGROUP/ PCCL

E-HWA

E-HWA/ HSIANG CHUAN

OSHIMA

ACELON/ CHAIN YARN

https://reurl.cc/Rvp8Vx

AD by BOFT

( )

Organized by Implemented by

Via Martiri di Cefalonia, 6 | 20054 - Segrate (MI) Tel (+39) 02-216621 | Fax (+39) 02-2139410 info@shimaseiki.eu

Ensuring sustainability

L’IMPEGNO DI GIRANI NELLA PRODUZIONE RESPONSABILE

Girani is engaged in various projects to create a more sustainable and responsible product. Particular attention is paid to the development of “green” ecological fabrics and to the water consumption.

planet and its resources.

We were the forerunners of the development of viscose

from sustainable managed forests. We use “Cotton Linters” viscose where the cellulose comes from the waste of cotton processing.

attests the origin pf organic agricultural raw materials traceable in compliance with social and environmental criteria and the use of chemical products with low

pulp and low environmental impact processing. Our hope is to make our contribution to creating greater “green” awareness.

Girani è impegnata in diversi progetti per realizzare un prodotto più sostenibile e responsabile. Una particolare attenzione è rivolta allo sviluppo di tessuti ecologici “green” e al consumo dell’acqua. Il nostro modello di sviluppo delle collezioni soddisfa le più ricercate esigenze stilistiche con la massima attenzione al pianeta e alle sue risorse.

FSC ®, viscosa prodotta con polpa di legno tracciabile proveniente da foreste gestite in modo sostenibile. Utilizziamo la viscosa “Cotton Linters” dove la cellulosa si ricava dagli scarti della lavorazione del cotone.

attesta la provenienza delle materie prime da agricolture biologiche tracciabili nel rispetto dei criteri sociali e ambientali e l’utilizzo di prodotti chimici con bassi valori tossicologici.

FSC® e processi di lavorazione a basso impatto ambientale. La nostra speranza è di dare il nostro contributo alla creazione di una maggior consapevolezza “green”.

61 La Spola

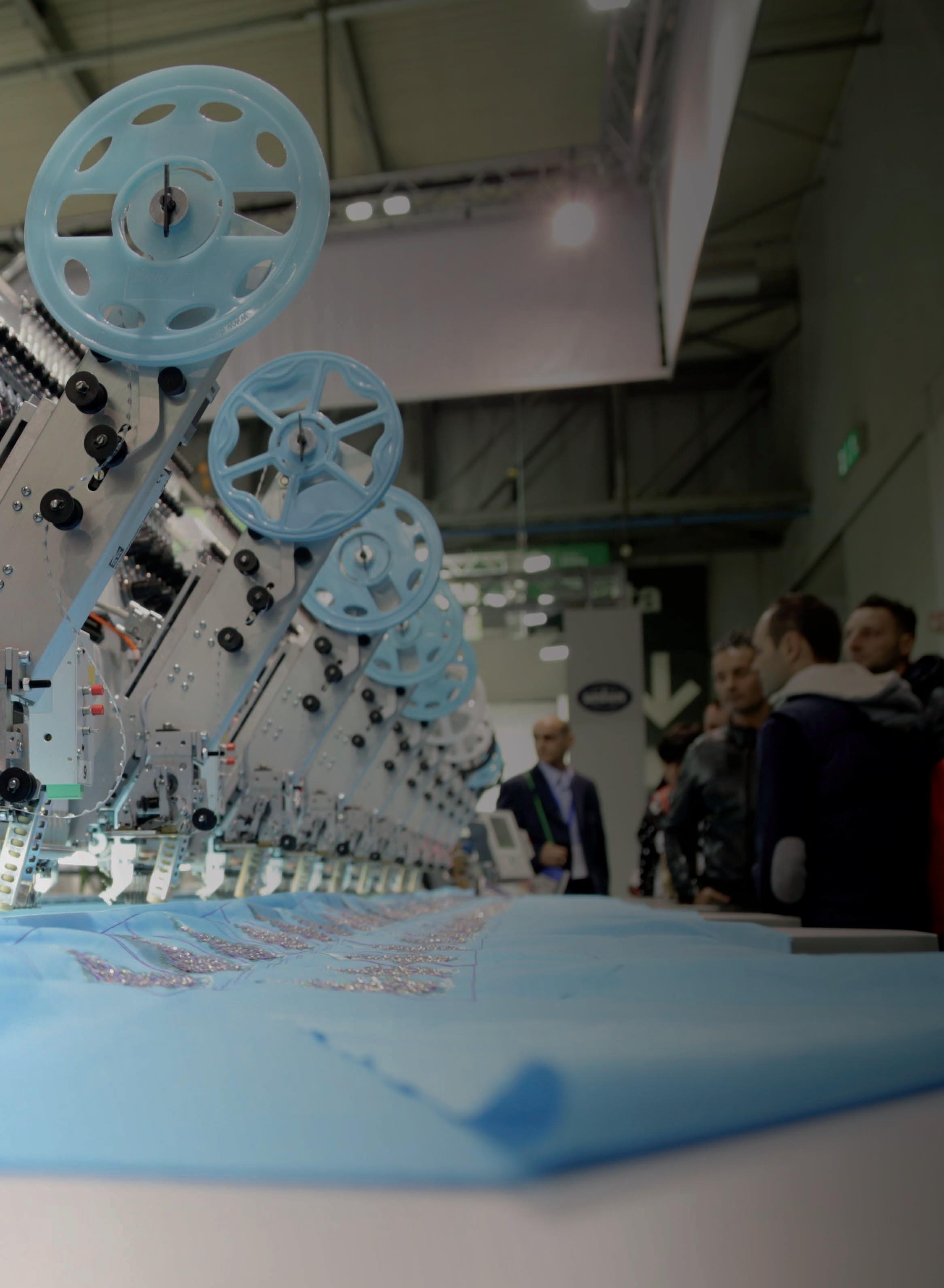

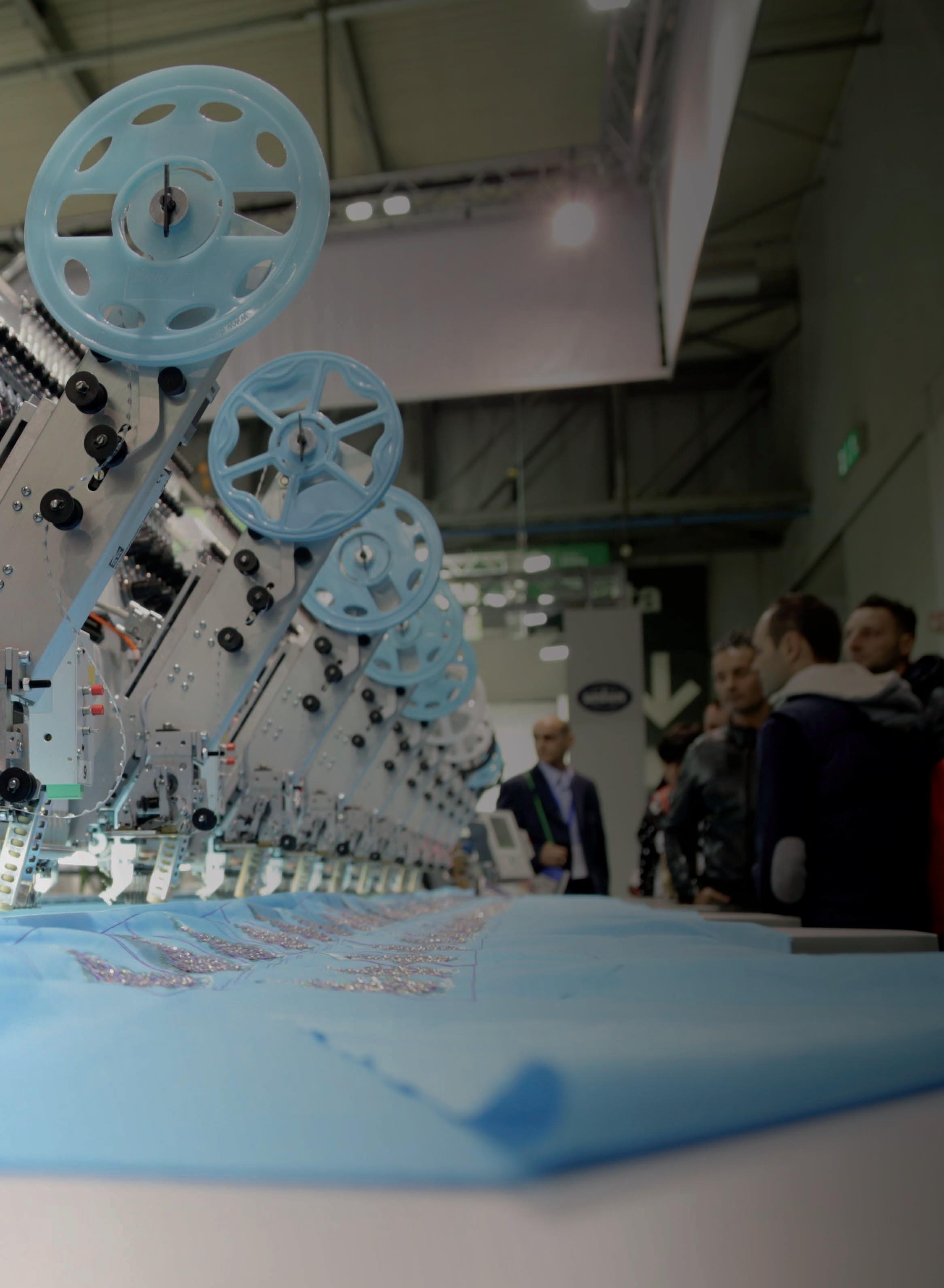

Meet the technology

SHIMA SEIKI PRESENTA I NUOVI PROTOTIPI

Shima Seiki Italia is coming to the ITMA show with a lot of news to share about technology, sustainability and plans for the future. A very important event for the company, as CEO Davide Barbieri explains.

ITMA is an important event because it is the place where companies can introduce their latest developments and products. It is an opportunity to meet new customers and suppliers, to establish business relationships and learn about the market’s latest news. At this show, Shima Seiki Mfg. Ltd introduces its new machinery prototypes. We are interested in getting feedback from the market to understand its needs and produce or modify technologies for all types of customers. What can visitors expect from Shima Seiki?

Shima Seiki is a benchmark in the field, the precursor and leading company in the production of the WholeGarment, seamless knitwear, and is very attentive to sustainability issues. Shima Seiki is increasingly committed to reducing environmental impact and to improving social conditions during production. WholeGarment allows us to reduce textile and yarn waste by producing with a lower consumption of energy and water as compared to the traditional methods. Shima Seiki Mfg. Ltd.’s local machinery production at Wakayama , Japan, and the distribution across the world helps us reduce the CO2 emissions generated by transportation and support the local economy. Furthermore, the garments produced with WholeGarment technology are easily recyclable. All these factors contribute to making it a sustainable and eco-friendly choice. Shima Seiki’s visitors can expect to find state-of-the-art technology and the development of innovative products, in terms of new sample collection. All this at a 600-squaremeter stand, including 9 machines, 7 design and software systems and about 300 samples.

And your post -ITMA plans…

Shima Seiki’s motto is “Ever Onward”. The next Pitti event for Shima Seiki Italia will be at Pitti Immagine Filati which is a very important event for the Italian market. We are also committed to the training of programming technicians and to collaborating with spinning mills, schools and brands in order to achieve the best results in terms of technological innovation and product development.

Shima Seiki Italia arriva all’appuntamento con ITMA con tante novità su tecnologia, sostenibilità e progetti. Un appuntamento importante che l’azienda si prepara a vivere a 360 gradi, come spiega il CEO Davide Barbieri.

ITMA rappresenta un evento importante, perché è il luogo in cui le aziende possono presentare innovazioni e prodotti. E’ un'opportunità per trovare nuovi clienti e fornitori, per stringere relazioni commerciali e conoscere le ultime novità di mercato. In questa edizione Shima Seiki Mfg. Ltd mostra nuovi prototipi di macchinari. Interessante è poter raccogliere feedback dal per ogni tipologia di clientela.

Shima Seiki è un punto di riferimento per il settore, precursore e leader del WholeGarment, capo completo senza cuciture, ed ha un’attenzione particolare sulla sostenibilità. Shima Seiki si impegna sempre di più a ridurre l'impatto ambientale e a migliorare le condizioni sociali durante la producon una produzione a basso consumo di energia e acqua rispetto ai metodi tradizionali. La produzione locale in Shima Seiki Mfg. Ltd., a Wakayama , in Giappone, dei macchinari e la distribuzione in tutto il mondo consentono di ridurre le emissioni di carbonio legate al trasporto e di sostenere l'economia locale. Inoltre, i capi prodotti con tecnologia WholeGarment sono facilmente riciclabili. Tutti questi elementi lo rendono una scelta sostenibile e rispettosa dell'ambiente. I visitatori di Shima Seiki possono aspettarsi di vedere tecnologie all'avanguardia e lo sviluppo di prodotti innovativi, in termini di campionario nuovo. Tutto questo in 600 mq di stand, con 9 macchine, 7 sistemi di disegno e software e circa 300 campioni.

Shima Seiki è rappresentata dal motto “Ever Onward” – Sempre Avanti. Il prossimo appuntamento per Shima Seiki Italia sarà Pitti Immagine Filati, punto di riferimento e di discussione per il mercato italiano. Si impescuole e brand per raggiungere i migliori risultati in termini di innovazione tecnologica e di sviluppo prodotti.

FOCUS 62 La Spola

with

In

Innovation takes time

DA AQUARIA® ALLE NOVITÀ TOP SECRET DI BIANCALANI

ITMA 2023 will be centered on innovation, and so far, there’s nothing new. ITMA has always been a reservoir of innovation. Biancalani Textile Machinery will introduce two textile machines at the show– one top secret project and AQUARIA® – proving that making the most of time is crucial to innovation.

The AQUARIA® project is now a complete finishing line covering a wide range of processing operations which are usually considered to be very expensive, mostly in terms of water and energy use. AQUARIA® is a revolutionary finishing process designed to reduce the consumption of water and energy at an initial lower cost.

AQUARIA® is the line’s innovative heart, but it can be paired up with more traditional products, such as pre and post-rinsing tanks. Again, everything is based on making the most of time. The pandemic period, widely seen as a stalemate, was actually precious for ongoing adjustments and, owing to tests performed at Biancalani’s headquarters and very positive feedbacks from customers, AQUARIA® has become a completely new textile finishing machine.

The development of new methods was also very important and proved that AQUARIA® can convert traditional finishing processes into an eco-sustainable approach to fabrics. Eco-bleaching, organic scouring and washing after printing are only three examples of how biodegradable substances can be used in place of polluting products thanks to AQUARIA®, by ensuring energy and water conservation and, thus, cost-effective solutions.

And now let’s get to the top secret machinery: a dryer for continuous and open-width tumble-drying in step with the Biancalani philosophy. A textile finishing machine that allows to dry and soften fabrics while reducing the consumption of energy and increasing productivity and efficiency. But you’ll get to know more about it at the show in Milano Rho.

qui, niente di nuovo. ITMA è sempre stata un bacino di innovazione. Biancalani Textile Machinery presenterà due macchinari tessili – un progetto top secret e AQUARIA® – dimostrando quanto sfruttare il tempo al meglio sia fondamentale per l’innovazione.

pronta per essere usata in processi molto diversi e solitamente considerati molto costosi, soprattutto in termini di consumi

acqua ed energia a un costo iniziale inferiore.