millingandgrain.com April 2023 In this issue: Milling and Grain . Volume 134 . Issue 4 . April 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 134 Issue 4 “A great number of usefull books” From a small library to a worldleading collection - Pulse rising: Technology adaptations in the pulses in the industry - Importance of Humidity Factor for Food Safety in Raw Materials - World Earth Day - Silo design and construction

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

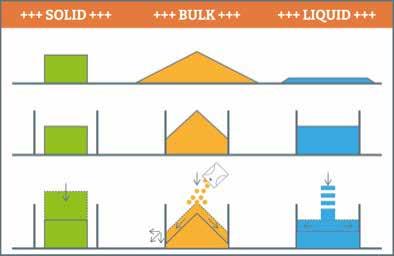

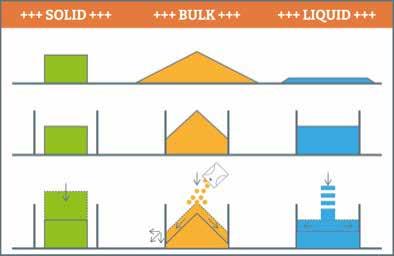

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

2023

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Digital community manager

Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

ISSN No: 2058-5101

VOLUME 134 ISSUE 4 NEWS 10-28 42 Pulse rising: Technology adaptations in the pulses in the industry 46 “A great number of usefull books”From a small library to a world-leading collection 52 How millers & bakers can use technology to speak a common language of quality 56 Importance of Humidity Factor for Food Safety in Raw Materials 58 World Earth Day 62 A healthy gut feeling: Why the gut is the key for animal welfare and performance STORAGE 66 Silo design and construction 8 PUBLISHER Roger Gilbert 104 INTERVIEW Arnaud Dubat ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 84 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 28 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 33 Industry training news PRODUCT FOCUS 36 CASE STUDY 80 INDUSTRY PROFILE 78 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 April

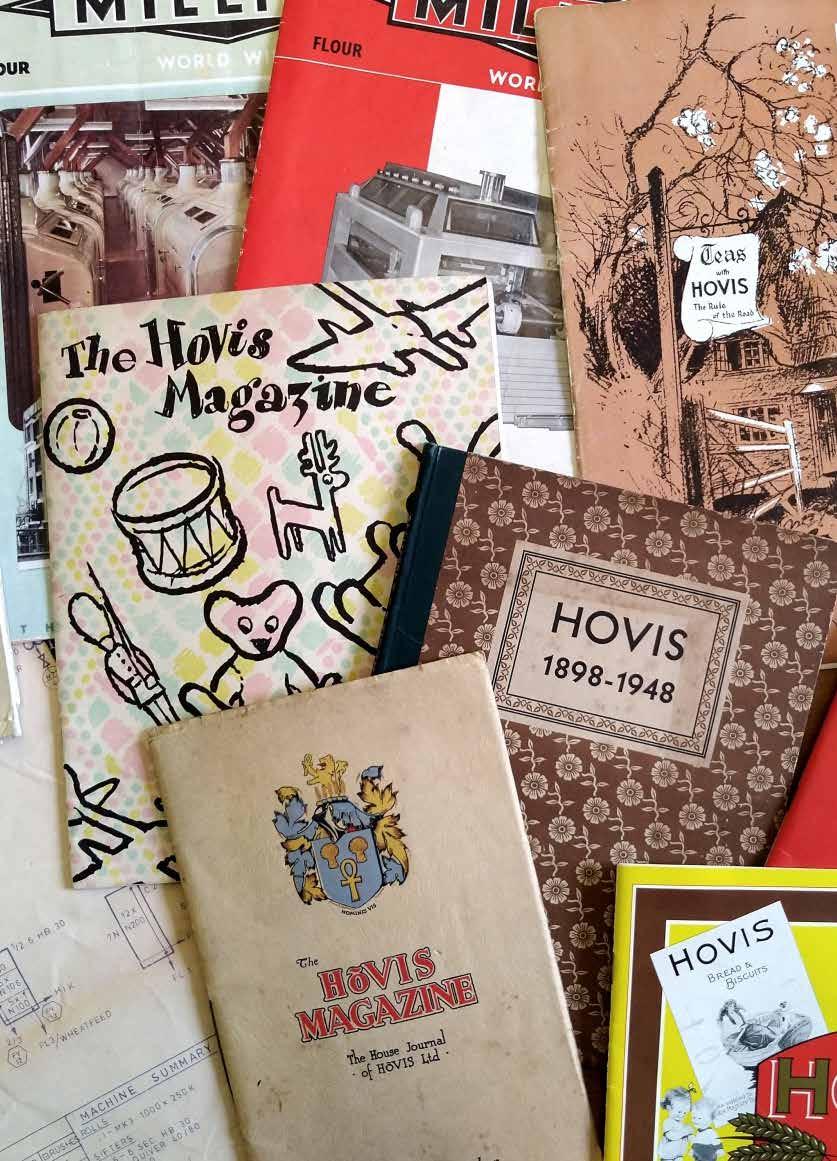

COVER IMAGE: “A great number of usefull books” - From a small library to a world-leading collection - see more on page 46 FEATURES millingandgrain.com

Pulse rising: Technology adaptations in the pulses in the industry See more on page 42

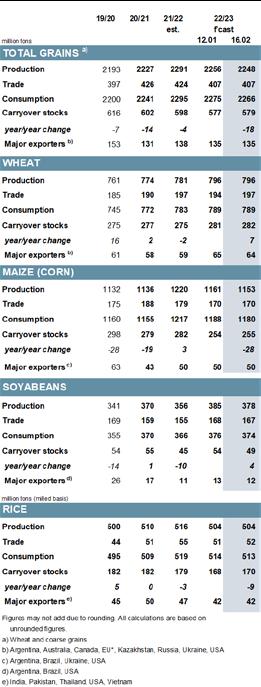

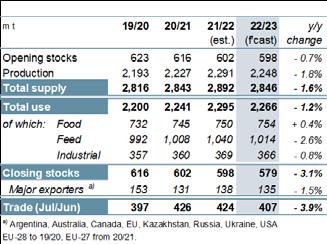

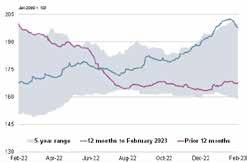

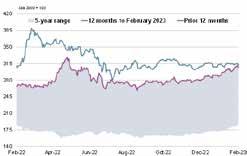

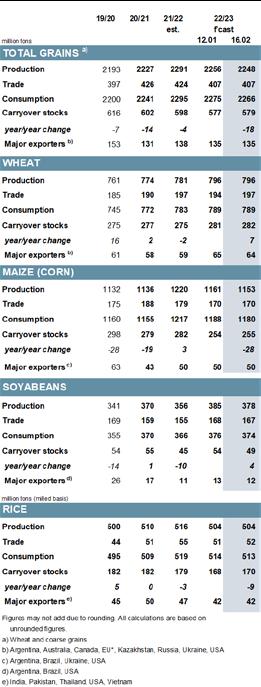

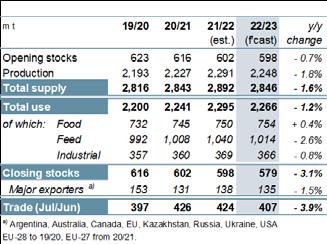

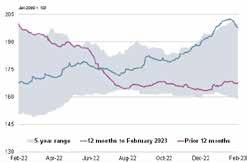

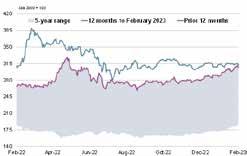

72 MARKETS

Sunshine after the storm ...

That’s the headline I’ve chosen for one of the events I attended at the end of February in India. While the event - a company’s 50th Golden Jubilee - was not directly connected to our milling industries, it demonstrates how we are all inter-connected in the work we do.

If true and BSE was thought to have reached India in such quantities then testing, surveillance and culling would have been the order of the day and public concern about the well-being of its most prized animal - the cow - would have been devastating.

Earlier, as a young man in my 20s, in 1971, and on my own, I had spent four months travelling the length and breadth of India enjoying its cultural differences along with the hospitality and warmth of its people.

Roger Gilbert

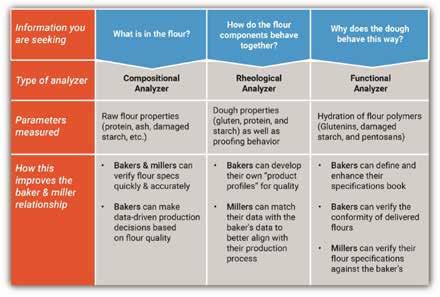

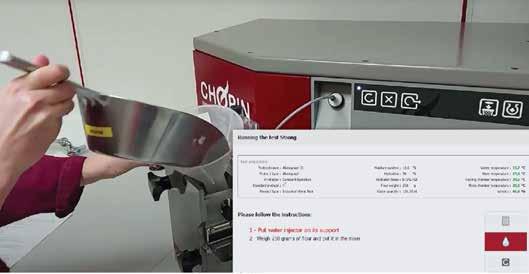

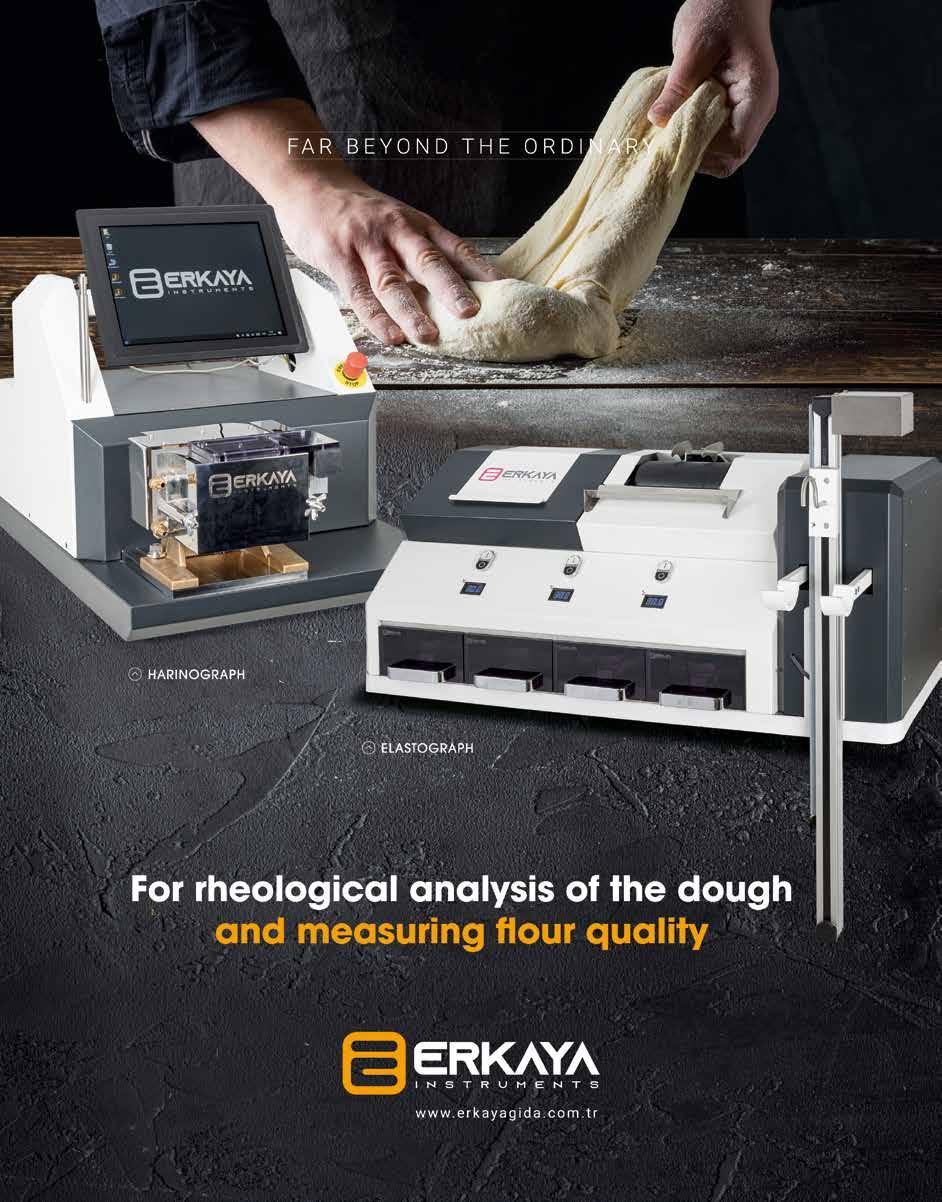

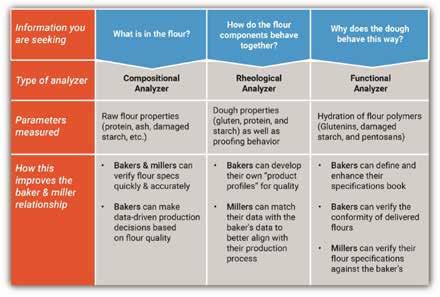

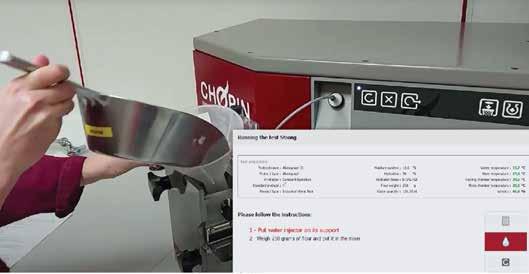

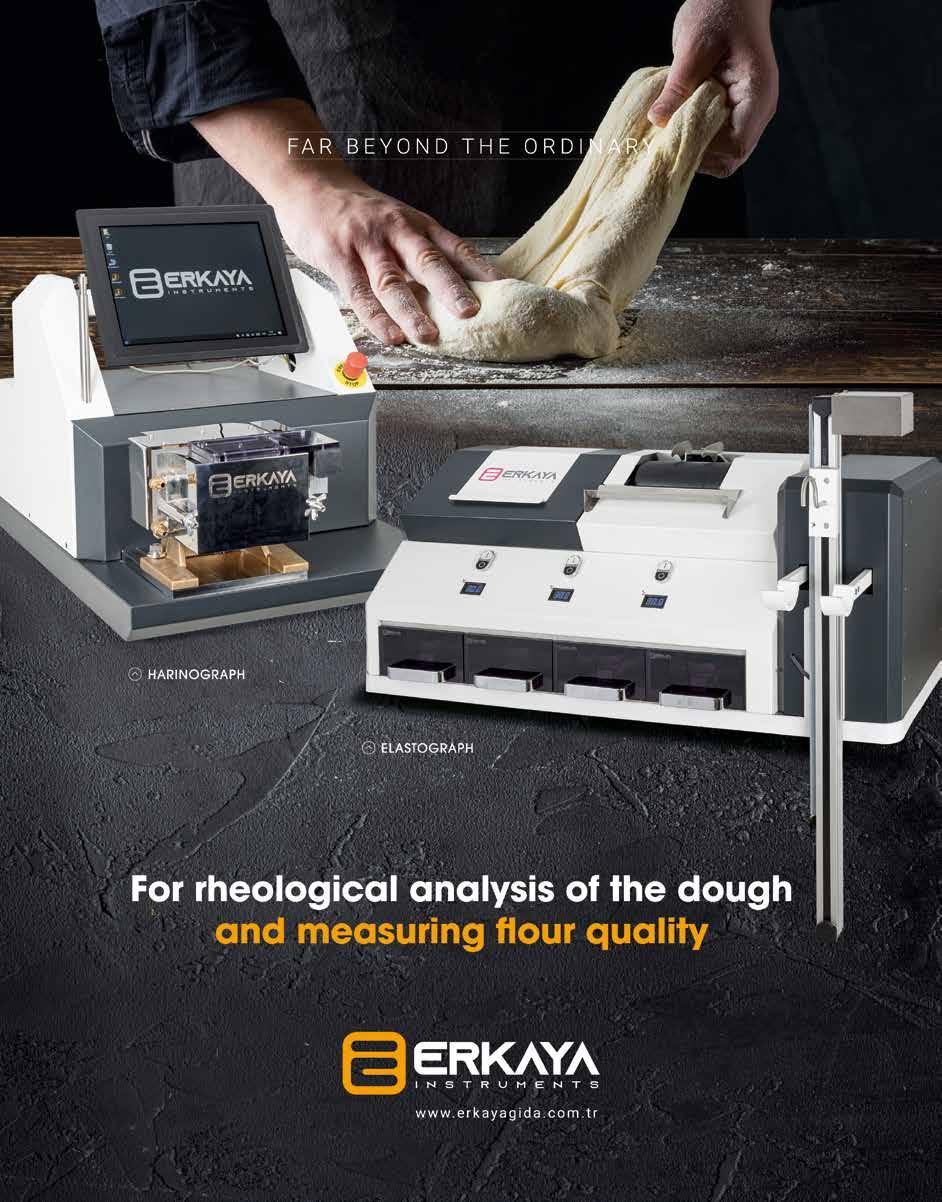

All milling sectors, while unlike eachother, are all about providing the essential components used in our food supply chain.

Not only that but they are inter-dependent and when something goes wrong in one area of food production it has an impact on other parts of the food chain.

My visit to India was not an essential one, but it was one that I felt represented the outcome of work I had done some 20 years ago and how that had impacted not only this one company, but a country’s livestock industry and possibly the supply chains in a number of trading partner countries.

Can you imagine India without its beloved cows roaming the streets freely and being treated as the Gods they are believed to be? I can and I did in 2004 when I was confronted when attending a feed conference in Pune by the then Executive Director of the India Gelatine and Chemicals Limited company who was distraught to say the least. He explained to me that India was believed to have imported large quantities of BSEcontaminated meat and bone meal throughout the BSE crisis. The implication was obvious.

World Flour Day - World Earth Day

In Pune in 2004 I could not turn away from the vision I had and the finality that might occur in the livestock sector without doing my best to help.

To cut a long story short, on my return to the UK I was able to track down the records of meat and bonemeal exports and began the arduous task of questioning them. It turned out they were incorrect and did not involve any exports to India whatsoever.

Today the Indian gelatine industry is in good health. It’s a global supplier of products that make up many of our essential health, food and now feed additive products based on dairy industry by-products.

My trip this February was more of a pilgrimage for me; to bring back not only good memories but to demonstrate that there are challenges in life we must take up and try to conquer no matter how bleak the prospect appears.

Today, the India Gelatine and Chemicals Limited company is in good health and so too is its industry. The sunny day on which we celebrated its 50th anniversary together is I believe a precursor of even better times ahead for India and its livestock industries.

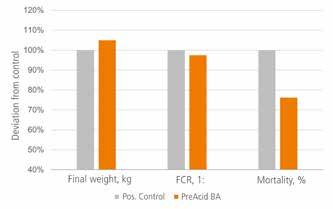

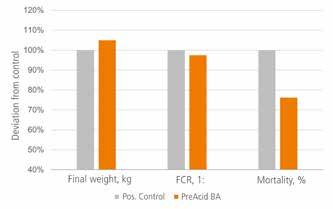

Our congratulations to Mr Viren Mirani and all his staff at IGCL in Vapi.

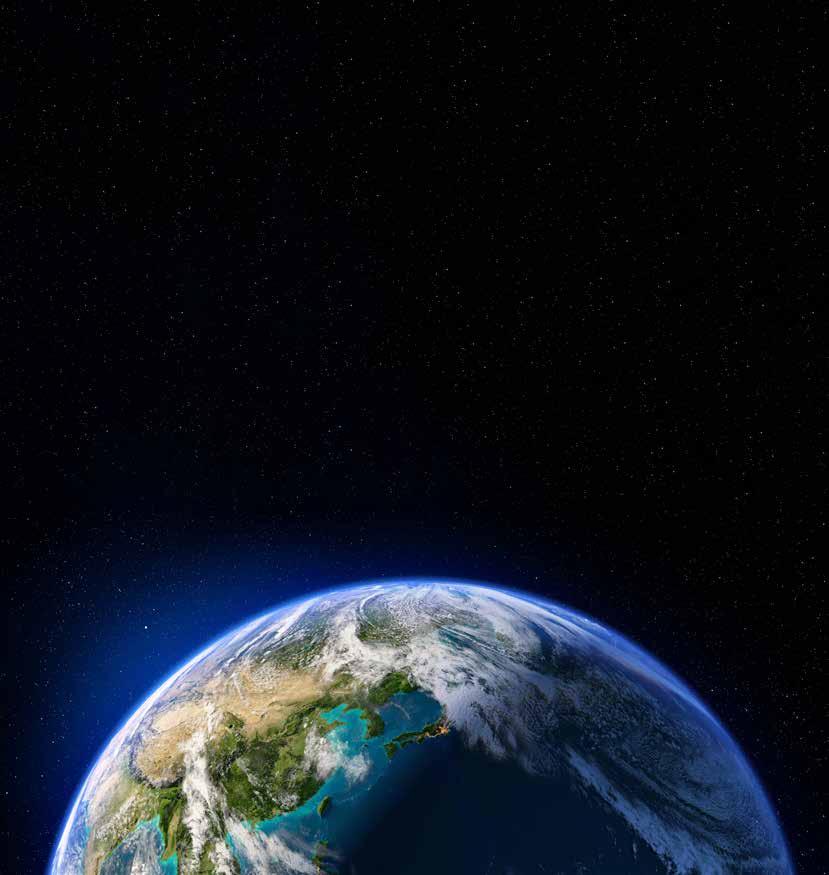

Within a four-week period we will have celebrated World Flour Day (on March 20), World Water Day (on March 22) and World Earth Day (on April 22).

In my view these three dedicated name days are significant to our global food production systems and to all those involved - but in particular to those who work in the milling industries - in bringing foodstuffs to a world of 8.2 billion inhabitants.

And right before World Earth Day this month, which we celebrate in this edition by asking a selection of milling industry leaders to comment on the meaning it has for them, we have the International Association of Operative Millers (IAOM) hosting its 127th Annual Conference in Minneapolis, United States (from April 17-21, 2023).

This is proving to be a very important time in the annual calendar for our food producing industries and an ideal time when we can focus public and government attention on what really matters to a world desperate to protect itself from climate change, overcome wars and disputes and develop economies that allow all of us the ability to purchases sufficient food at prices we can afford. That delivers the nutrition we and our children need and which ensures not only good health but proper physical and mental development.

Let’s celebrate these three name days by reminding those around us that we must protect these resources if we are to support a growing the world’s population beyond the projected 9.5 billion people who will be on the planet in 2050.

It is too early to carry a report on the outcome of activities around World Flour Day 2023 in this edition, as we were preparing for publication before activities had completed and outcomes announced. We will review the results of these activities in our next edition.

That brings me to the final point I wish to make this time. To celebrate World Flour Day in a small yet meaningful way we have gone monthly - publishing within each month of publication - our Milling and Grain magazine in Turkish, Spanish and French. Each of these magazines has a website, social media support, e-Newsletters, a library, an app and of course printed editions. We also publish bi-monthly in Arabic and Chinese.

On World Flour Day we launched our ‘Useful Language Links at Perendale.’ A brochure which identifies all the links associated with our various magazines. You can download a copy from this link: http://flk.bz/xxsY or by searching on Google.

Annual Subscription Rates

Inside UK: UK£100

Outside: US$150/€133

More Information

Milling and Grain has a cooperative partnership with COFCOET

www.millingandgrain.com

http://gfmt.blogspot.co.uk

PINGLE.

PROFESSIONAL MANUFACTURER

★ INTEGRATED MILLING SOLUTION PROVIDER

★ ISO 9001:2015 CERTIFIED

Аdd: Zhengding, Shijiazhuang,Hebei,China

Tel: +86-311-88268111 Fax: +86-311-88268777

E-mail:pingle@pingle.cn / www.pinglemachine.com

OF GRAIN MACHINERY

NewsMilling

Welcome to the fourth edition of Milling and Grain magazine and a big hello from the Global Miller column. You best stick around because we have a lot to cover in this edition with lots of interesting information and news. Spring should be well on its way now in the Northern hemisphere and something I found interesting about this month is the etymology of April. It derives from the Latin word aperio, which means ‘to open [bud]’, as its when plants begin to grow and bloom.

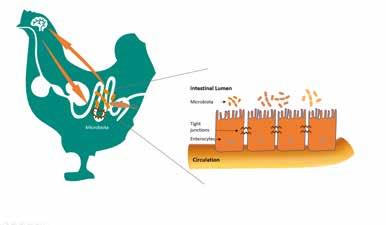

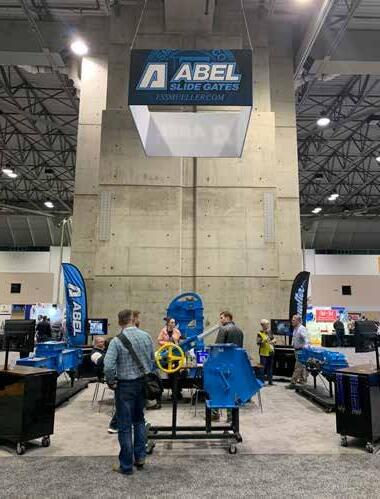

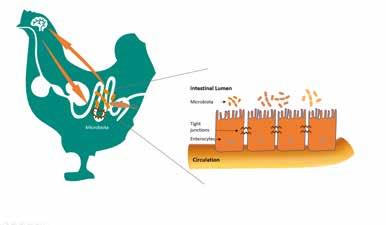

Interview with Emilie Fontaine, Jefo

Vice President of Brand & Products at JEFO, Emilie Fontaine, speaks to Milling and Grain magazine about the company's new, development at this year's 2023 IPPE Exhibition, which was held over three-days in Atlanta, Georgia, USA from January 24-26, 2023.

Emilie tells us Jefo is currently celebrating 40 years in business, and have invested US$40 million in their new Jefo Matrix Technology Production plant, which will finish construction in April 2023, and is expected to begin full commercial operation by the end of 2023/beginning of 2024. To view the interview, visit Milling and Grain’s home page and follow the MAGTv link.

IPPE 2023 - Interview with Glycon Santos, ICC

CEO of ICC, Glycol Santos, talks to Roger Gilbert, publisher of Milling and Grain magazine, about the many benefits of their yeast products, whilst at this year’s 2023 IPPE Exhibition which was held over three-days in Atlanta, Georgia, USA from January 24-26, 2023. ICC are a Brazilian company, who last year celebrated 30 years in business. It specialises in the production of yeast additives that come from the sugar cane ethanol fermentation industry. ICC regards this type of yeast additive as the best in the world, and for good reasons, not least their included nutritional benefits but also their disease resistance and control, gut health, and immunity. He says the knowledge and interest in the benefits of yeast additives is growing worldwide. The company is currently exporting to 70 countries. To view the interview, visit Milling and Grain’s home page and follow the MAGTv link.

It’s also Earth Day on April 22, a perfect month to celebrate this event. The theme this year for Earth Day is Invest in Our Planet featuring five programs: The Great Global Cleanup, Sustainable Fashion, Climate and Environmental Literacy, Canopy Project, Food and Environment, and the Global Earth Challenge. These programs help to ensure the planet continues to thrive and that people in developing countries receive the rights they deserve and aren’t taken advantage of by countries in power dumping their waste irresponsibly. Within our industry, we can help and show our support for Earth Day by sharing all the way that we act sustainably and ethically. Show the improvements we’ve made over the past year and continue to make improvements in the coming years.

Focusing a little on the UK, the taxes are still rising, and people are still struggling. The world is an economically difficult place to live in, no matter where you are. It’s only easy financially if you’re Jeff Bezos or Mark Zuckerberg. Despite the rise in taxes, the Government thinks that economy will grow by 2.5 percent and the inflation will fall 2.9 percent in the next two years. I can almost hear the crowds cheering. (Please note my sarcasm here, I don’t want anyone taking me too seriously now.)

For some interesting international news, BENEO provides the local rice farmers in Laos with farm machinery and Adisseo announces the completion of the acquisition of NorFeed. AFIA also awards Animix as the Premix and Ingredient Feed Facility of the Year while IFF introduces a new animal nutrition solution for piglets. It all sounds so exciting this month!

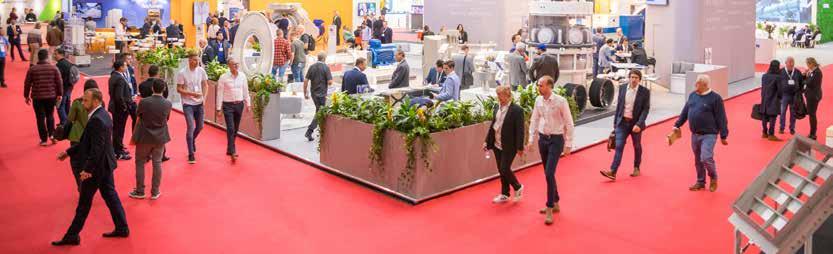

As for events around the globe, our team has been incredibly busy travelling to various places around the world to give you the latest pieces of information we can about some of the biggest event’s goings. We first stopped off in Kansas, USA for GEAPS 2023, meeting many lovely people there and then took off to Bangkok, Thailand for VIV Asia 2023. It was a very lucky time for our team there and we held some amazing conferences too at the event. Be sure to read our report for more information.

If you or your company would like to share your own experiences at these global events or would like to showcase any new products or news in either our magazine or website, then send us an email here: editorial@perendale.co.uk

gfmt.blogspot.com

mymag.info/e/1593 10 | April 2023 - Milling and Grain

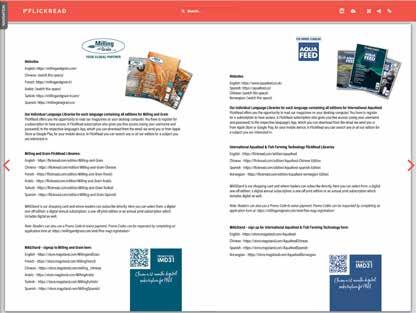

Looking for Milling and Grain in your language? Find links to all of our editions in one place

See more at:

http://flk.bz/xxsY

The Milling Journal

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream by-products of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients. The Journal will particularly embrace scientific and technical

information on novel processes enabling the generation of ingredients for manufacture of bread, cakes, confectionary, pasta and a plethora of applications for diverse types of breakfast cereals, beverages and the infant formula markets. We also consider papers on complete animal feed manufacture as a core topic. These usually require pre-grinding and milling/flaking of grain and cereals for terrestrial animal feeds such as for poultry, swine, ruminants and equine. Animal feed production can involve drying, milling, pelleting, steam and pressure conditioning, shaping and texturisation dependent on specific machinery. Processes such as extrusion, cooking and expansion are of paramount importance with much research being undertaken on engineering, both mechanical and electrical. Effective storing and preservation methods offer opportunities for papers.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

Useful links

Axor launches new logo, taking the next step for the brand

AXOR Srl, an Italian company one of the leading in pasta manufacturing technologies, has announced the launch of its new logo, representing the next step for the brand. The new logo has been created to adapt the brand while rooted in its heritage, featuring a modern, elegant font and lines that reflect the company's next level of evolution.

In 2021, ALAPALA, one of the leaders in grain processing technologies became a majority shareholder of AXOR Srl. This acquisition has enabled AXOR to expand its capabilities, to have the opportunity to grow in global markets, as well as to provide integrated innovative solutions for the needs of its customers in the food processing industry. "We are thrilled to introduce our new logo, which represents the next level of our brand," says Görkem Alapala, CEO of ALAPALA Group. "With this new brand identity, we aim to showcase our evolution, modernity, and ambitious plans for the future. This is the next step in our journey and we're excited to share it with our customers and stakeholders."

The new logo is a modern and elegant representation of AXOR's transition towards a future-oriented approach. The minimalist design embodies the company's new ambition and its commitment to continue growing in

the market. Featuring the Italian flag with an aesthetic appearance emphasises that AXOR is an Italian company with the highest level of production quality, technology, know-how, and engineering. "At AXOR, we believe that it's important to stay ahead of the curve and embrace change," says Marco Mistroni, CEO of AXOR: "The new logo represents our propensity to change and our willingness to take bold steps to achieve our goals. We're ambitious for the future and this new brand identity reflects that."

Milling and Grain - April 2023 | 13 Milling News

You Have A Vision For Your Business.

Cimbria can bring it to life.

We’ve been doing it for over 75 years. With dedicated experts at your side from start to finish and beyond, Cimbria will help you grow with confidence. So you can look forward to a prosperous future.

Do you have a unique grain or seed processing challenge? From customized plant design to turnkey installations and expert support, Cimbria can help find the right solution for your success.

Cimbria.com A/S Cimbria Thisted, Denmark Phone +45 96 17 90 00 cimbria.holding@agcocorp.com

BENEO provides local rice farmers in Laos with farm machinery

BENEO's rice ingredients production site in Wijgmaal, Belgium, has changed the long-term working life of more than a hundred smallscale farmers in Laos, thanks to the provision of harvesting and threshing machinery. This investment reflects BENEO's commitment to its stakeholders throughout the entire supply chain and has enabled the business to strengthen its farm level partnerships even further.

As the primary economic activity in Laos, small-scale rice farming accounts for 70 percent of the total cultivated area and one-fifth of the total GDP. BENEO liaised with its longstanding partner IDP, the leading producer and supplier of rice in Laos, to find out how working conditions for local farmers could be improved. As a result, eight harvesting machines and four threshers were purchased to help ease workloads and improve field yields.

Whilst BENEO retains full ownership of the equipment, the farmers have been trained on how to use and maintain it to ensure the long-standing success of the project. The machines support 10 groups of 10 small-scale farmers. They help lighten the workload and speed up the harvesting process for them and their families by eradicating the need for hand cutting and manual threshing. With threshing now taking place directly on the field, this lowers the risk of loss caused by rainfall, as well as mould formation. As a result, the farmers can expect higher yields and better income. They can also earn additional money by renting out the machines to other farmers in the region, enabling many more families to benefit from BENEO's investment.

Roland Vanhoegaerden, Operations Managing Director for BENEO's rice ingredients comments, 'We value our long-term relationship with our farming and logistical partners in Laos. By liaising with IDP, we could quickly see where our investment would make the most impact. As a result of supporting our farmers with new equipment, more than 100 farming families have their everyday workloads eased. Also, by offering these economic resources to rice farmers we are helping to further work towards the UN's 17 Sustainable Development Goals (SDGs). Given the success of this initiative, we intend to launch another project of this type in the coming year to support more rice farmers.'

Frédéric Jullien, CEO at IDP comments, “We are honoured that BENEO chose IDP to work with on this project. As a company, we are focused on assisting farmers to improve their work conditions, whilst maintaining rice quality. BENEO's contribution has shown its commitment to the sustainable development of the rice value chain here in Laos.”

Milling and Grain - April 2023 | 15 Milling News

Marel announces partnership with ADM to accelerate alternative protein innovation

The innovation partnership will enable the opening of a collaborative space to innovate plant-based and alternative protein products from concept to commercialisation, meeting the growing demand in the region and globally.

Marel, a leading global provider of advanced food processing solutions, announces a partnership with ADM, a global leader in human and animal nutrition, to open a state-of-the-art taste and texture innovation centre. The anticipated opening is scheduled to occur in the second half of 2024.

The new facility, located in the heart of the Wageningen Campus in the Netherlands, will offer a unique space, including a pilot plant and laboratory, to further boost plant-based innovation, from concept to commercialisation. As one of the most reputable life sciences university’s worldwide and located at the heart of the Dutch food technology valley, Wageningen Campus provides the ideal location to foster future-forward food innovation.

With collaboration intended to be at the core of the customer centre, the joint venture partnership will invite food manufacturers to work alongside food scientists and extrusion and prepared foods experts to prototype, manufacture and market new plant-based and alternative protein products, as well as leverage pilot plant production with novel processing techniques.

'The taste and texture innovation centre will further strengthen our customer centricity in new, emerging market segments,' says Jesper Hjortshoj, President of Wenger (a subsidiary of Marel) and VP Business Development at Marel. 'The long-standing relationship between our companies is the foundation of this partnership and with our downstream processing capabilities, the centre will offer unique capabilities from raw ingredients to the final products.'

With applications ranging from meat alternatives and extensions, specialised nutrition, ready meals and snacks, the centre will offer a wide range of opportunities, including training and workshops, to deliver next generation solutions. Innovation and sustainability will be at the forefront throughout the collaborative conceptualisation and commercialisation processes, helping drive consumer adoption of new protein sources through exemplary sensory experiences and meet tomorrow's nutritional challenges, today.

'The creation of this innovation centre is another example of our continued investment in expanding our alternative protein innovation and investments in the talent and technologies that will help us meet the needs of our growing population,' says Allyson Fish, president of global plant and alternative proteins for ADM. 'Partnering with Marel is another important step as we advance protein innovation for the EMEA region and beyond. We're committed to meeting customer needs and powering continued profitable growth as we live our purpose by supporting a secure and sustainable global food system,' continued Fish.

Increased investment in alternative protein capabilities

This strategic partnership and intended taste and texture innovation centre follows Marel's increased investment in alternative protein capabilities. In 2022, Marel successfully acquired Wenger, the global leader in extrusion cooking solutions for plant-based protein food, pet food and aquatic feed. This platform investment provided Marel the opportunity to expand into new markets, where Wenger's industry-leading technologies and process expertise have created a strong business foundation for nearly 90 years. The addition of Wenger created a new segment in Marel's business model entitled Plant, Pet, and Feed.

To support the rapidly growing plant-based food market, Marel and Wenger together offer complementary technologies and product portfolios that strengthen the value proposition with line solutions for processors of plant-based protein. Wenger's industry-leading extrusion and dryer technologies are a strong anchor point in the value chain that creates proper texture, moisture content, and mouth feel that closely resembles whole muscle structure from plant proteins. Marel's extensive product portfolio, such as weighing, sorting, inspection, lowpressure forming, and thermal treatment, can be added upstream and downstream of the Wenger extruder to establish a complete end-to-end processing solution, ensuring that tasty, high-nutrition products are processed in a safe and sustainable way.

At the new taste and texture centre, Wenger extrusion and drying systems will form the core of the research and development chain, with complimentary Marel equipment employed to allow food manufacturers to develop and test new and enhanced food ideas through the complete process of raw ingredients to final product.

16 | April 2023 - Milling and Grain Milling News

IFF introduces new animal nutrition solution for piglets

Danisco Animal Nutrition & Health, a business unit of IFF, has announced the launch of Axtra PRIME, an optimised enzyme blend designed to address key challenges in piglet production. Now available in the U.S., this highly effective feed solution improves nutrient digestion, enhances gut health, and delivers measurable performance results.

Targeted nutrition from an early age is essential for successful swine production, but several issues can disrupt feed strategies and adversely affect performance during this critical time. Stress during weaning can reduce feed intake and increase susceptibility to diarrhoea. At the same time, diet changes and use of cheaper ingredients often introduce more variability and higher fibre into the diet. This can negatively impact nutrient digestibility and animal performance.

'Axtra PRIME is specifically formulated to mitigate these risks by targeting key digestibility challenges,' says Madhukar Kulkarni, global segment manager, swine, Danisco Animal Nutrition & Health, IFF. 'By improving nutrient digestion and feed utilisation, it helps to create a favourable nutribiotic state in the gut of the piglet, thereby minimising susceptibility to disturbances in

the gut and maximising overall performance.'

Axtra PRIME - a combination of xylanase, beta-glucanase, alphaamylase and protease enzymes - has been shown to consistently support healthier and faster piglet growth across different diet types. A growing number of studies [1], [2] highlight the significant potential benefits of supplementing various feed formulations with this optimised enzyme blend – both in terms of piglet growth performance and producers' profitability.

[1] Ester Vinyeta and others (2023). The effect of a multi-enzyme containing xylanase, β-glucanase, protease and amylase added to a high-fibre corn-based complex diet containing by-products, in comparison to a conventional commercial diet, on the growth performance of weaned pigs.

[2] Ester Vinyeta and others (2023). The effect of a multi-enzyme containing xylanase, β-glucanase, protease and amylase added to a high-fibre wheat-barley-rye based diet containing by-products, on the growth performance of weaned pigs.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com

Milling and Grain - April 2023 | 17 Milling News

Evonik expands production capacity for DL-methionine in Singapore

Evonik is expanding its capacity to produce MetAMINO® (DLmethionine) on Jurong Island, Singapore, by 40,000 metric tons to around 340,000 metric tons per year. The high double-digit million euro investment in this further technological development is to reach target capacity by the third quarter of 2024. The planned process optimisation measures will improve the carbon footprint of MetAMINO® produced in Singapore by six percent.

"Increasing capacity for MetAMINO® production in Singapore is another important step in the consistent implementation of our global methionine asset strategy, further improving supply security for our customers in Asia," says Dr Gaetano Blanda, head of Animal Nutrition business line. "In the face of fragile supply chains, our strategy of producing MetAMINO® in three different regions of the world has proven its value to our customers."

At the core of the methionine strategy are the three production hubs in Singapore, Mobile (Alabama, USA) and Antwerp (Belgium).

All three of Evonik's world-scale plants are based on best-in-class technologies and are designed to grow with the expanding global market through modular expansions.

Evonik's methionine plants in Singapore, which came on stream in 2014 and 2019, were already the largest production complex for DLmethionine in the world, with an annual capacity of around 300,000 metric tons of MetAMINO®.

"The additional capacity of 40,000 metric tons is primarily intended to accompany the growth of our customers in Asia and continue to offer the highest product quality and security of supply – now even more sustainably," says Noel Kim, head of Region Asia for Evonik Animal Nutrition.

The company has succeeded in maintaining its technology and cost leadership in DL-methionine for decades by continuously optimising its processes and equipment. "We are

particularly proud of the highly innovative new processes that are now being implemented in Singapore", says Dr Jan-Olaf Barth, head of Evonik's Essential Nutrition product line. "For example, we are taking another major step toward process efficiency and reducing our carbon footprint by implementing an electrolysis unit for green hydrogen supply and various energy integration measures."

These technological adjustments are an important building block in the sustainability strategy of the Nutrition & Care division. The carbon footprint of the additional volume will be reduced by 50 percent thanks to process improvement measures. This reduces the carbon footprint of the entire MetAMINO® production in Singapore by six percent.

In the United States, a new plant for methyl mercaptan production is currently being built at the methionine hub in Mobile, further strengthening Evonik's ability to offer reliable and cost-optimised supply and reducing the carbon footprint of DL-methionine from this site by about seven percent. Having a fully integrated 'Verbund' means Evonik will be able to produce all the necessary precursors for DL-methionine on site in 2024, as it already does at its other hubs. Additionally, in 2022, Evonik further developed and expanded the production facility for MMP (methylmercapto-propionaldehyde) in Wesseling (Germany), reinforcing the European methionine hub in Antwerp (Belgium).

Methionine is used in livestock production to feed animals healthily, efficiently, and sustainably. With its science-based approach, the Animal Nutrition business line develops products, services and system solutions that help supply a growing world population with healthy, highquality and affordable animal protein. Animal Nutrition is part of Evonik's Nutrition & Care Division and makes a major contribution to the profitable growth of Nutrition & Care through its self-financing power.

Milling and Grain - April 2023 | 19 Milling News

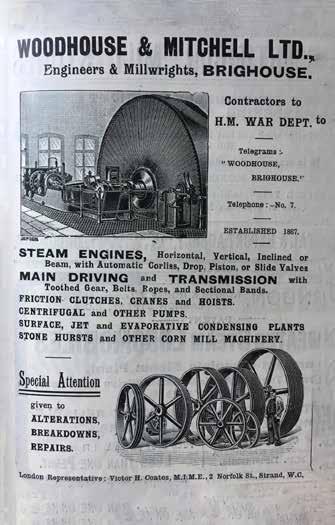

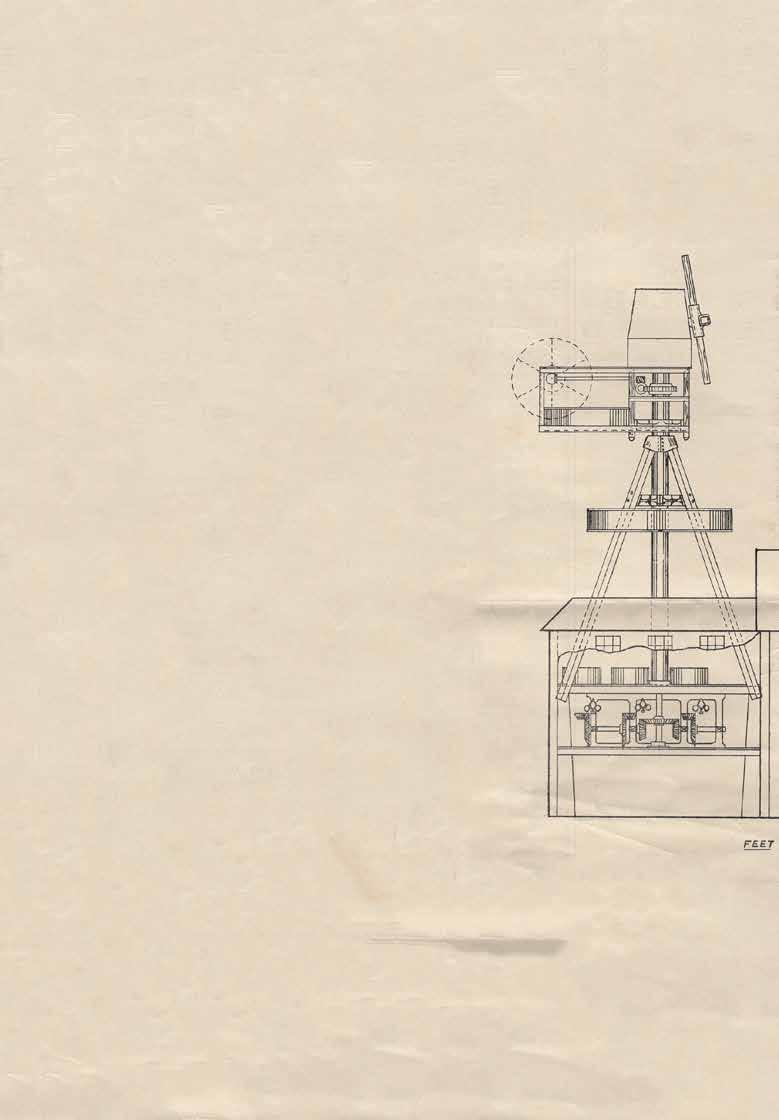

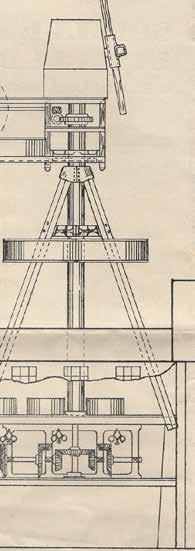

Messrs. Woodhouse & Mitchell Ltd. Engineers and Millwrights of Brighouse

by Mildred Cookson, The Mills Archive, UK

by Mildred Cookson, The Mills Archive, UK

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

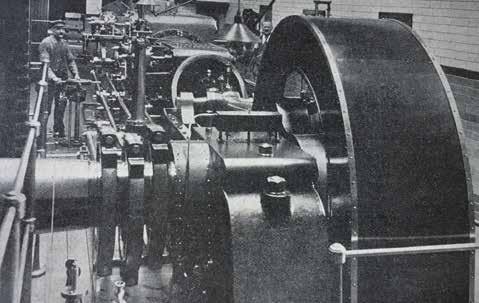

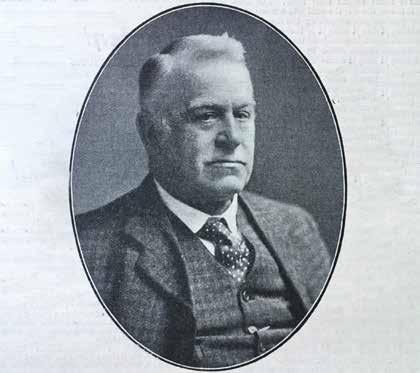

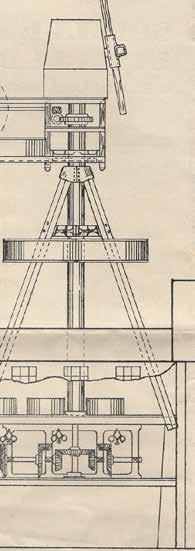

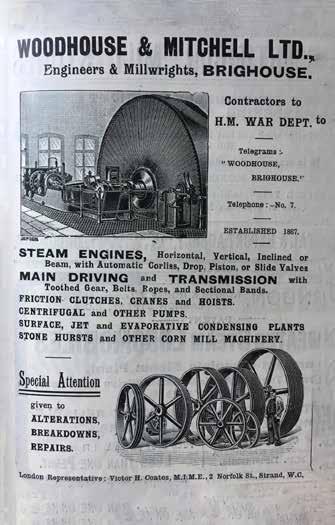

any of the articles on roller mills I have written over the past years have included layouts of the mill, sometimes with a brief mention of their motive power. An article in The Miller of 6 December 1909 provided some interesting background to one of the companies that built some of the engines that drove mills of that time. Representatives of that journal enjoyed a trip across the Pennines to Brighouse near Halifax in Yorkshire. They visited the works of Woodhouse and Mitchell and published their impressions. The firm started out in 1867 when four clever and enterprising employees of an engine building company decided to set up on their own account. Their names were: Joseph Wood, John Baldwin, Samuel Mitchell, and Richard Woodhouse. They secured a small workshop at Brighouse, hiring

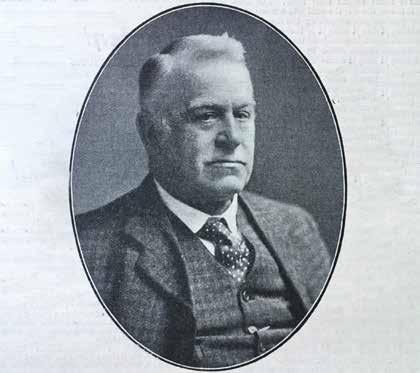

power from their next-door neighbours, and started out on what was going to prove to be a successful career as engine builders. Richard Woodhouse was the owner of the firm at the time of the article in 1909. He was a member of the Institute of Mechanical Engineers, and of the society of Arts as well as a Justice of the Peace for Brighouse and Churchwarden of St. James’ Church. He

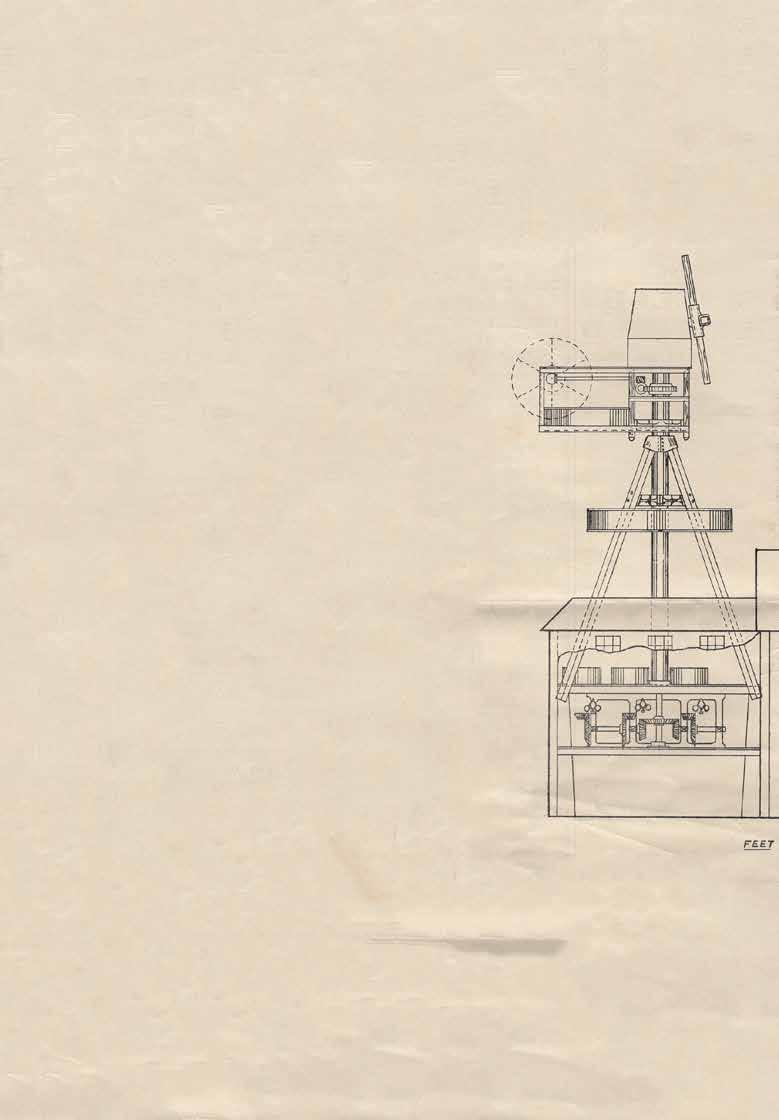

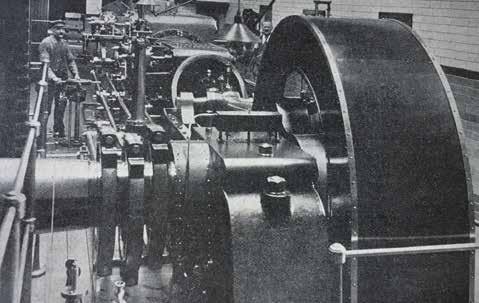

MA Woodhouse and Mitchell horizontal engine

20 | April 2023 - Milling and Grain

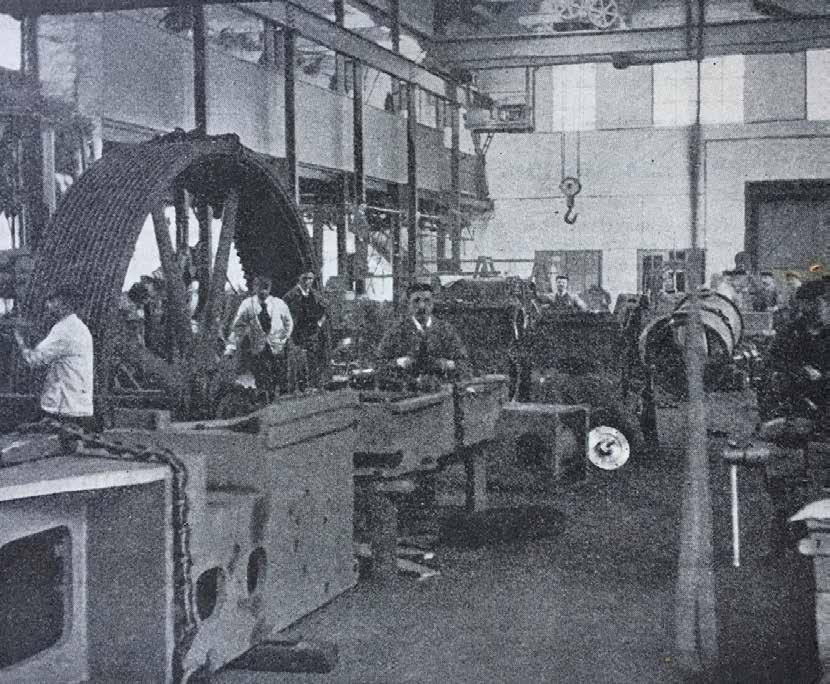

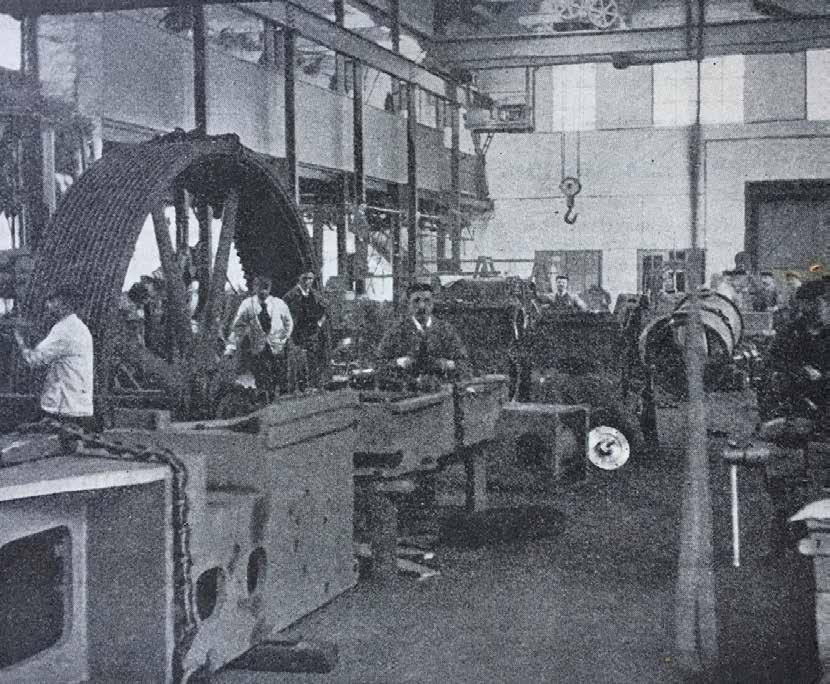

A corner of the erecting shop at the Clifton Bridge Works

had served 5 years in the office of Wm. McNaught, a wellknown Manchester consulting engineer, where he learned much by working in several departments of this large and busy engine building & millwrighting works.

In contrast Joseph Wood was an old-fashioned millwright and took charge of this aspect of their work until his death in 1881. John Baldwin (nicknamed’ The Doctor’) superintended the erection and starting of engines. He retired in 1883 leaving Messrs. Woodhouse and Mitchell to continue the business. On the death of Samuel Mitchell in 1902 the firm became a limited company with Richard Woodhouse as governing director.

On the ground floor of the works, immediately behind the general offices, the erecting shops featured a 15-ton travelling electric crane to lift parts into place. The machine shop, running parallel to the erecting shops, was where the parts of the engines were turned, bored, fitted to gauge, and polished ready to assemble into the complete engine.

At the time of the visit, one engine under construction was a high and low-pressure tandem engine with surface condenser being prepared for a Scottish flour mill. Mr. Woodhouse believed in some cases it was possible, by compounding existing engines and fitting them with proper valves, to reduce coal consumption by more than half.

One of the products of the firm was their special air pump, noted both for good vacuum and for noiseless working. The firm also made gearing and pulleys of all sizes, including grooved fly wheels and pulleys for rope drives. They also built wheels of all sizes; those over 18ft diameter or 20 tons in weight were built up in sections for convenience of carriage and erection. Friction clutches were also another specialty.

EXTRUSION AND EXPANSION TECHNOLOGY YOU CAN TRUST

Scan the QR-Code for more information www.almex.nl

A 1909 advertisment for the firm

www.almex.nl

The Almex AXT 220 Single screw extruder consists of a robust base frame that supports the main motor, gearbox, and extruder barrel. This frame can be executed in mild steel or stainless steel for extended lifetime. The direct coupled inline geared motor ensures the optimal energy efficiency.

Capacity: 10,0 - 12,0 t/h (indication only)

Milling and Grain - April 2023 | 21

with the Extruder AXT 220

YEARS IN MILLING

MORE THAN 400 COMPLETE PROJECT PERFECTLY RUNNING AROUND THE WORLD

We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

R O L L E R M I L L

Next to the machine shop was the pattern makers department, which was fitted out with small band and circular saws, wood planning and other machines. The patterns themselves were stored in some of the upper rooms and were grouped and numbered systematically, so that any required pattern could be found at a moment’s notice.

Next to the pattern shop were the smithies, fitted out with forges of various sizes and a massive steam hammer of the firm’s own make. It was supplied with steam from a new boiler, the power in some cases carried by cables from a dynamo to various electrical motors in different parts of the works.

Across the street was the foundry, housed in what was once a cotton mill with the floors taken out to make a roomy foundry. Iron castings up to 12 tons each could be made and handled there. It was also equipped with two blast furnaces for iron, besides four smaller furnaces in the brass foundry, together with various drying ovens for dry sand moulds and cores. The firm also had their own stables accommodating horses over 17 hands.

To view the machines in action, the group also visited a large cotton mill nearby which had just installed a high- and lowpressure tandem cylinder with condenser and Corliss valves. Next-door was another factory with a pair of engines of the same pattern which the owners said had reduced the coal bill by £1,000 a year. A third factory was quite different; this had a pair

of ‘inverted’ vertical engines of the marine pattern. Various cotton mills were visited, as well as a silk mill.

The company was well known to flour millers all over the country and abroad, having built many engines, which were shipped, to Chile, the Cape, Durban, South America and India as well as other parts of the world. The journalists finished with a plea for mill owners of that day to let them know if they had a Woodhouse & Mitchell engine in their mill.

Milling and Grain - April 2023 | 23 Milling News

Mr Richard Woodhouse JP

The Future of the Bread Subsidy in Egypt

Egypt, one of the world's largest importers of wheat, announced that it will withdraw from a decades-old United Nations (UN) grain agreement by the end of June, Reuters reported on March 9th.

The country's given notice for withdrawal from the multinational Grains Trade Convention (GTC), which is concerned with enhancing market transparency to increase trade cooperation, comes amid disturbance in the grain market due to the negative repercussions of the Russian-Ukrainian war.

"This came without prior information. Several delegations within the IGC are surprised and sad about the decision," Arnaud Petit, executive director of the International Grains Council, which administers the treaty, told Reuters. He added that many of the treaty members would call on Egypt to reconsider its decision.

Egypt is to withdraw from the UN’s Grains Trade Convention after more than a year in arrears over the International Grains Council’s membership fee. For Egypt, that cost was GBP48,000 ($57,806) in the most recent fiscal year, said Arnaud Petit, executive director of the London-based council that administers the treaty, of which Egypt has been a member for nearly 30 years. The fee is calculated as a percentage of the country’s share of the global grain trade.

“We can understand that, for the time being, the [foreign currency crunch] has had a huge impact,” Mr. Petit told The National. “The cost of the exchange rate has really been a double burden for importing countries.”

Egypt's pound under renewed pressure as the dollar shortage persists

Egypt, one of the world’s largest wheat importers, has been deeply affected by the economic fallout of the Russia-Ukraine war. The Egyptian pound has been devalued three times over the past year and has lost nearly 50 percent of its value against the US dollar. Inflation is up nearly 32 percent year on year, primarily on soaring food prices.

Although Egypt was in arrears, it still had access to this information and faced no financial penalties, Mr. Petit said. Its vote was suspended on very limited decisions, such as the council's chairmanship.

Mr. Petit urged Egypt to look beyond the “short-term problem” of its foreign currency shortage “because market transparency is really the only way to avoid speculation and volatility in the global market”. The former advisor to the Minister of Supply and Internal Trade Nader Nour-Eddin said that Egypt’s withdrawal from the United Nations Grains Trade Convention (GTC) agreement came as a result of the agreement’s inability to control the grain market.

Egypt had given notice that it would withdraw from GTC by the end of June, causing concern among some of the other signatories to the agreement.

Egypt signed the agreement, which represents the only international treaty covering the grain trade, since its inception in

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

1995, and has been a member of the council that governs it since 1949. This February, it submitted a request to withdraw from the deal effective June 30.

Nour-Eddin explained that Egypt signed the convention in 1995 with the confidence of this agreement to control the grain market, as Egypt is one of the most important importers of grains in the world – especially wheat and corn.

In the past year, he noted that Egypt has suffered from the RussianUkrainian crisis, which brought on a significant rise in grain prices –the global price of wheat doubled to record currently about US$520 per tonne.

He said that the treaty was not able to intervene with the producing countries to control the rise in prices or stand by the importing countries, especially poor African countries which depend on grain imports to a large extent.

Egypt’s withdrawal from the agreement was a result of the agreement's failure to achieve the interests of both grain producers and importers at the same time.

“What we witnessed recently is that it is achieving the interest of producers only,” he lamented.

Nour-Eddin added that the US has tended to increase the price of wheat to unprecedented levels, taking advantage of the global war crisis, without any significant interference from the agreement to address the harm of this move on importing countries.

Egypt bore the cost of paying for the subscription to this UN agreement worth several million dollars annually without benefiting from obtaining grain at reasonable prices, he said.

Nour-Eddin added that the agreement was also absent in previous crises, including in 2010 when grain was used in the production of biofuels, which led to an increase in global prices and greatly impacted importing countries such as including Egypt – and in 2008, when world prices increased without any effective input from the GTC.

The Egyptian Foreign Ministry confirmed that the decision was taken after an evaluation carried out by the Ministry of Supply and Internal Trade, which concluded that Egypt’s membership in GTC does not have any value.

No final decision made on grain treaty exit, says El Moselhy.

To leave or not to leave?

Egypt could rethink its decision to exit from the UN grain treaty after receiving several letters from the Grain Trade Convention calling on the government to remain a member, Supply Minister Ali El Moselhy said. Officials said earlier this month that Egypt plans to withdraw from the treaty at the end of June because the government doesn’t see any benefits of paying almost USD 58k in annual membership fees.

It’s not looking too good: “We think that our membership of such organizations is of no use as new technology made it much easier for us to get all the information we need about grain and wheat

24 | April 2023 - Milling and Grain

markets,” El Moselhy said, pointing to the convention’s failure to provide aid during the spike in food prices last year triggered by the war in Ukraine.

Egypt wants to open the door to more USD-less trade: As Egypt prepares to swap the greenback for the RUB to trade with Russia; it is now looking at making similar arrangements with China and India. “Egypt is currently studying exchanging trade with China and India in local currencies in the same way we are working to adopt the RUB and the EGP,” Supply Minister Ali El Moselhy said over the weekend.

Move to the RUB “moving well”: “Cooperation between Egypt and Russia in local currencies is now open and receives support from all, but it needs a link between the Central Bank of Egypt and the Russian Federal Bank, and it is technically moving well,” the minister said. The Russian central bank earlier this year approved the EGP as a trade currency, opening the door to the two countries cutting out the USD in bilateral trade. The countries are also exploring swapping goods, allowing Egypt to import Russian wheat in return for exporting oranges, he said.

Adisseo announces the completion of the acquisition of Nor-Feed

The Adisseo Group announces that it has completed the acquisition of Nor-Feed, a French group that designs, produces and markets plant-based specialty ingredients and plant extracts for animal nutrition.

This acquisition is part of the Adisseo Group's strategy to become one of the world leaders in specialty ingredients for animal nutrition.

Jean-Marc Dublanc, CEO of Adisseo, "We are pleased to have completed the acquisition of the Nor-Feed Group, and on behalf of Adisseo, we warmly welcome all its employees.

“This investment is a key step in our strategy to develop specialty ingredients, in particular through unique and differentiating technologies and natural and sustainable solutions for our customers. Adisseo is positioned in an emerging market, growing at nearly 10 percent per year."

Olivier Clech, co-CEO of Nor-feed, "The botanical additives for animal

nutrition that Nor-Feed has developed are safe, effective and manufactured in France in a structured CSR framework. The demand is strong, and our average annual growth of more than 20 percent since the creation of the company is an illustration of this.”

The entire Nor-Feed team is very committed to continuing this development.

The Nor-Feed project, created 20 years ago by Cécile and Pierre Chicoteau, is focused on the preventive role of nutritional strategies, using botanical extracts from agricultural co-products in animal nutrition and hygiene to limit the use of antibiotics, coccidiostats and pesticides.

Nor-Feed maintains its organisation and will continue to serve its customers directly, while benefiting from the services, support and expertise of the Adisseo Group to help achieve its objectives and implement the synergies identified.

Milling and Grain - April 2023 | 25 Milling News

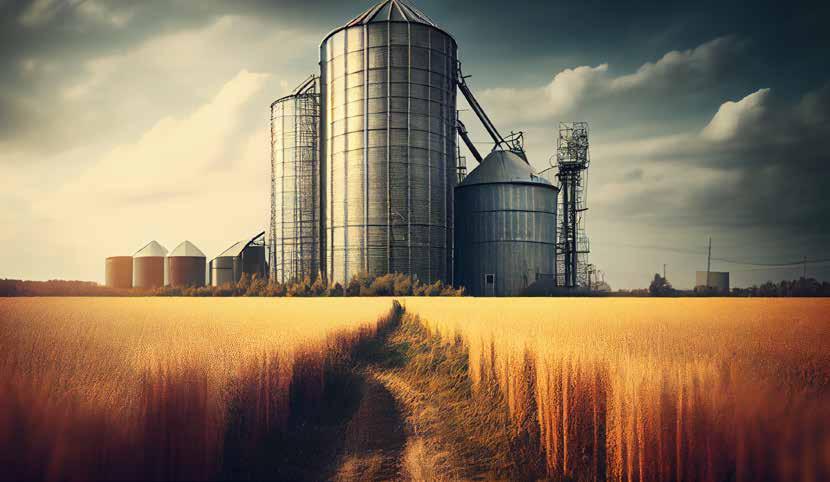

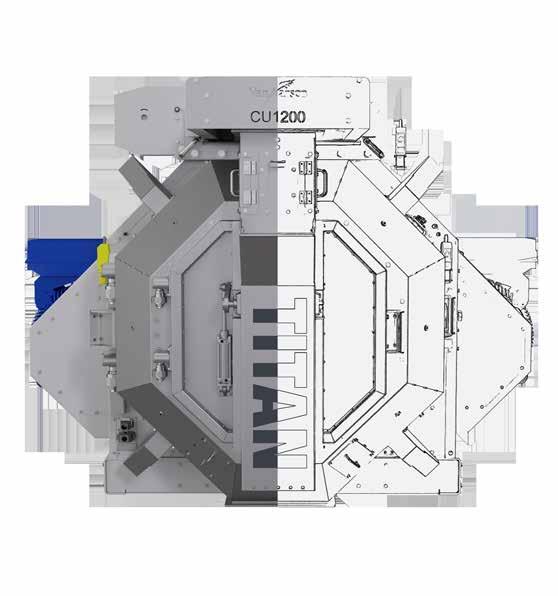

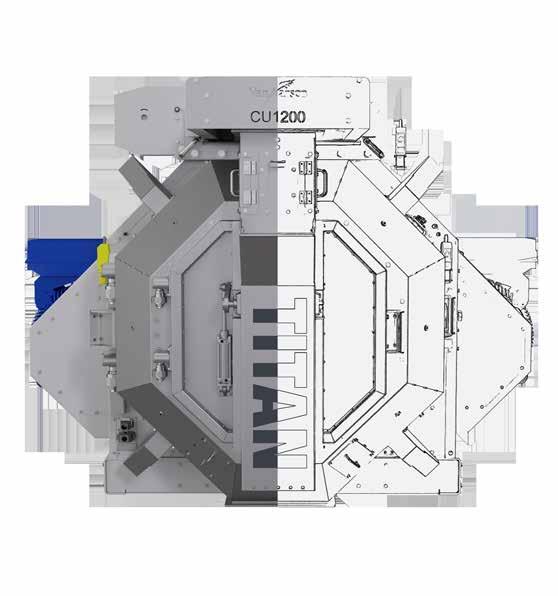

Grain unloading technology selected for new West African hub port

Bruks Siwertell has secured an order from Senegal Minergy Port SA (SMP) for a high-capacity grain handling Siwertell ship unloader for a new port development, Bargny-Sendou, located near Dakar, Senegal, West Africa.

SMP has been established to undertake the development of the bulk facility, which will be the largest and most sophisticated of its kind in West Africa. The contractor made its analysis for selecting which dry bulk handling system to invest in based on three factors: unloading capacity; unloading efficiency; and environmental impact.

'SMP is a new customer but was aware of Bruks Siwertell's reputation for delivering world-class dry bulk material handling assets, which are efficient, cost-effective and environmentally friendly,' notes Bertil Andersson, Sales Manager, Bruks Siwertell.

'Grain is the third largest cargo that our machines handle, amounting to around 600 million metric tons every year, so we understand what it takes to ensure the quality of grain shipments and meet high-demand, high-capacity import requirements,' continues Mr Andersson.

'So far, we have been very impressed with Bruks Siwertell's work,' says Alexander Zalocosta, CFO, SMP. 'As well as being technical leaders in the dry bulk handling industry, the project team has been extremely personable throughout the process, showing keen attention to detail and professional rigour, which is second to none.

'Understanding that the success of any ship unloader will depend on the overall efficiency of the port's dry bulk material handling system, Bruks Siwertell's team has taken a hands-on approach to all

elements, not just the unloader. This has been extremely useful to us, particularly given how important the successful integration of all elements of the port's material handling system is,' adds Mr Zalocosta.

In addition to minimising any material degradation in grain handling, the low weight of Siwertell technology also ensures specific advantages to this new port development.

The Siwertell 640 M-type ship unloader will be installed on a jetty 1,500m from the shore, and so minimising infrastructure weight, reduces the cost of jetty construction.

Around ninety percent of Senegal's trade comes through its current Atlantic Ocean port, the Autonomous Port of Dakar. Growing import and export demands has outstripped the port's capacity and Senegal urgently needs to address this issue.

SMP are looking for the new port to improve environmental protection and act as a major hub for global trade, not only as a gateway to Senegal and its neighbouring countries, but as a hub for the wider West African region as well. Bargny-Sendou will have an initial capacity of 20 million metric tons and will handle 15 million metric tons of commodities in its first year of operation.

The totally enclosed unloader will have a continuous rated grain handling capacity of 1,200t/h, and ensure spillage-free operations with minimal dust emissions. It will be assembled on site under Bruks Siwertell supervision and is planned to commence operations in mid-2024.

The unloader is being financed by the Swedish Export Credit Agency (EKN) and the Swedish Export Credit Corporation (SEK), which only invests in environmentally sustainable enterprises.

OBSERVE YOUR PACKING MACHINE IN REAL-TIME

Contact:

Phone: +49 251 9796 252

E-mail: sales@behnbates.com

www.behnbates.com

Optimize your processes and reduce your downtimes and costs – with QUAT²RO® Monitoring!

4 TO 10 MAY 23 DÜSSELDORF

LOOK FORWARD TO MEETING YOU IN HALL 12/A27 26 | April 2023 - Milling and Grain Milling News

WE

Milling and Grain - April 2023 | 27 Milling News

Saving the Rex Wailes Collection

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

When Rex Wailes died in 1986, he left behind him a lifetime’s worth of diaries, notebooks, correspondence files, boxes of photographs and rolls of architectural drawings, crammed full of information about mills and other engineering topics. He had stated in his will that the collection should all be passed to the National Monuments Record and the Science Museum, but in the event only a small amount of material was transferred. The rest seemed doomed to be consumed by mould and damp in the sheds at the bottom of Rex and Enid’s Garden. After some years, Enid began to throw the material away in preparation for the sale of the property. We owe the rescue of the collection to Alan Stoyel, who took it upon himself to salvage what he could – in his words: “I acted as an unofficial executor, and worked my way through all the sheds, salvaging whatever relevant material I could find. Unfortunately, much of the material was damp, quite a lot was actually sopping wet and full of mould and small animal life, and some had been attacked by mice. I took a series of car-loads of material to my home in Oxfordshire, cleaned what I could, and laid everything out to dry. Unfortunately, some relevant material I found in the sheds was too far gone even to be salvageable.”

Alan spent many hours drying, separating, cleaning and sorting the material, some of which then made its way to the Science Museum. When the Mills Archive was formed in 2002, Alan agreed with Rex’s family that this was the place Rex would have wanted his collection to go. Then in 2019, the Science Museum offered to pass those items it had been caring for over to the Mills Archive. At last the collection was together again. We now had over a hundred boxes of files, photos and crumpled papers, much of it shoved together in no discernible order, all in need of listing, sorting, cleaning, conserving, repackaging, cataloguing and digitising - separating the wheat from the chaff and make the gems of the collection easily accessible

A lot of the initial work was done by volunteer Guy Boocock, who made a painstakingly detailed spreadsheet listing of the entire collection, with details of contents, dates and related subjects and mill sites. Once this was compiled the themes covered by the collection could be discerned and the files assigned to categories. Now the items and folders themselves had to be rearranged into these categories and repackaged in archival boxes, as well all being numbered in pencil with reference codes to enable finding. Finally, the data from the spreadsheet was uploaded into our online catalogue. The lockdowns of 2020 delayed the process, but at last by the start of 2021 the catalogue was complete. Meanwhile volunteers had been going through and digitising individual photographs and uploading them. This work is still ongoing, but there are now around 6100 items that can be viewed on our website, https://catalogue.millsarchive.org

The Rex Wailes Collection

28 | April 2023 - Milling and Grain

in

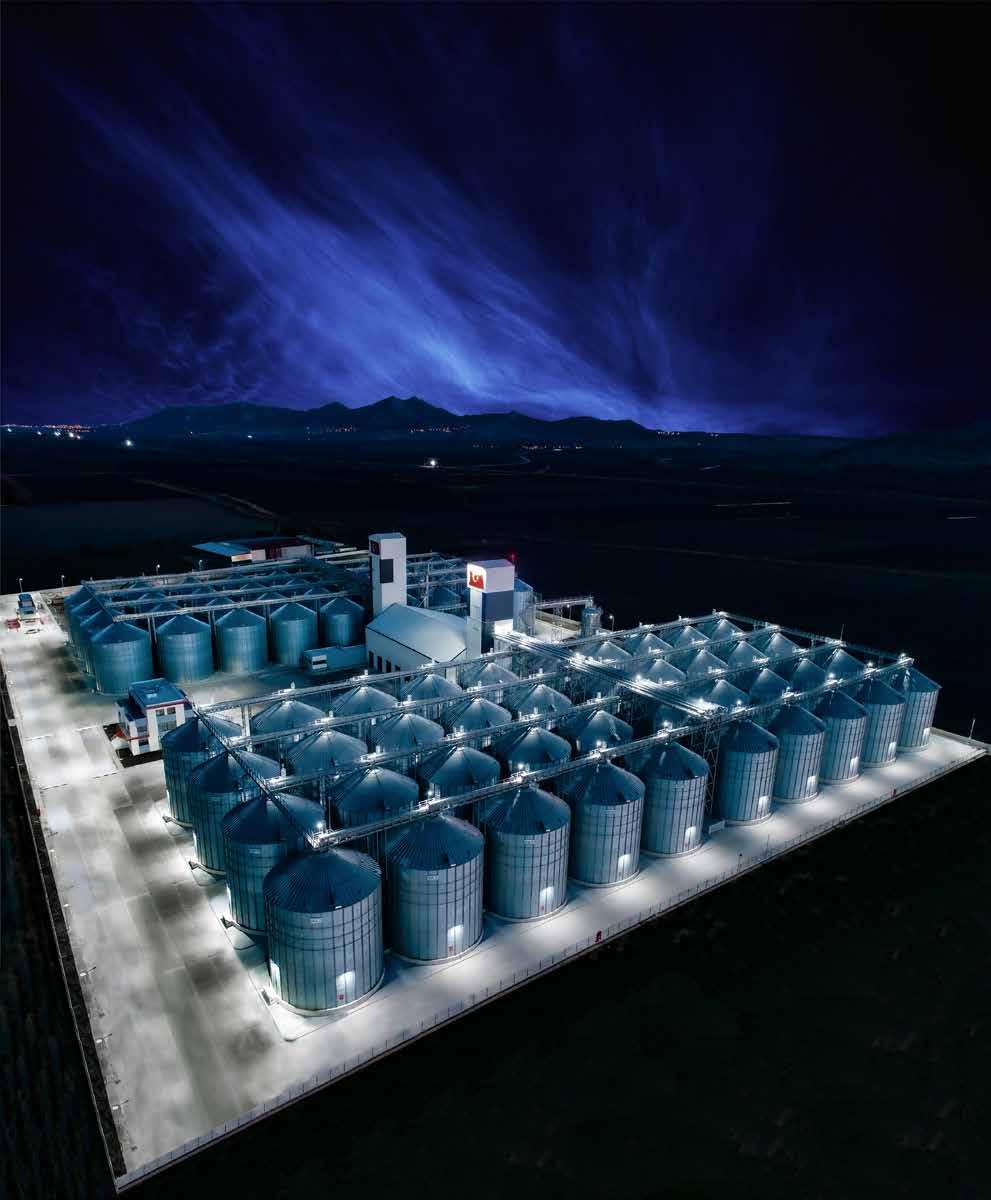

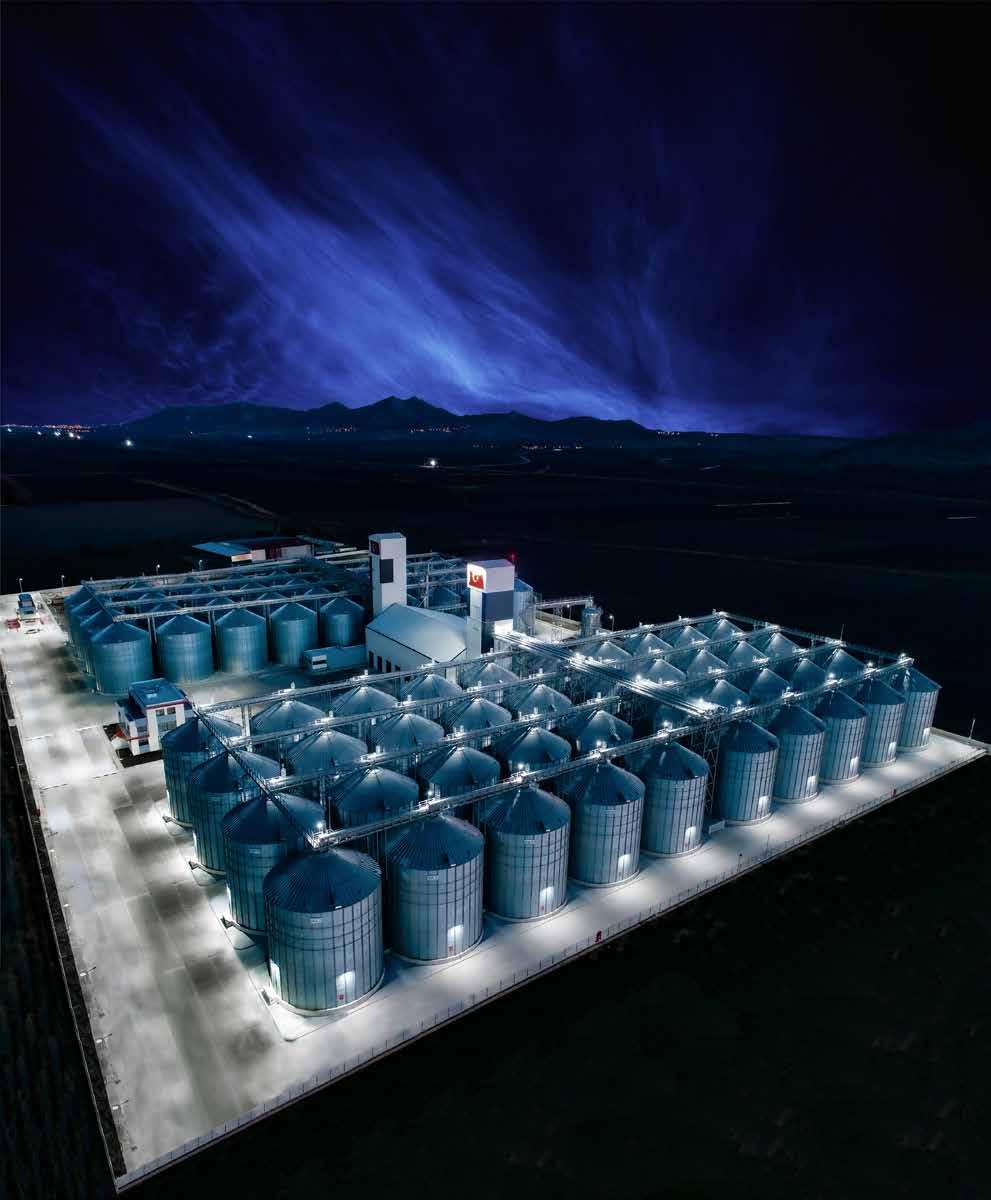

Improve silo tightness. Double Vertical Joint.

· Tightness is improved. Double sealing on both sides of the screws.

A reliable team for a reliable project

Flexibility

VISIT US RICE MARKET & TEC CONVENTION, Cancun, Mexico 30 May - 1 Jun, Stand 13

symaga.com • +34 91 726 43 04 • symaga@symaga.com

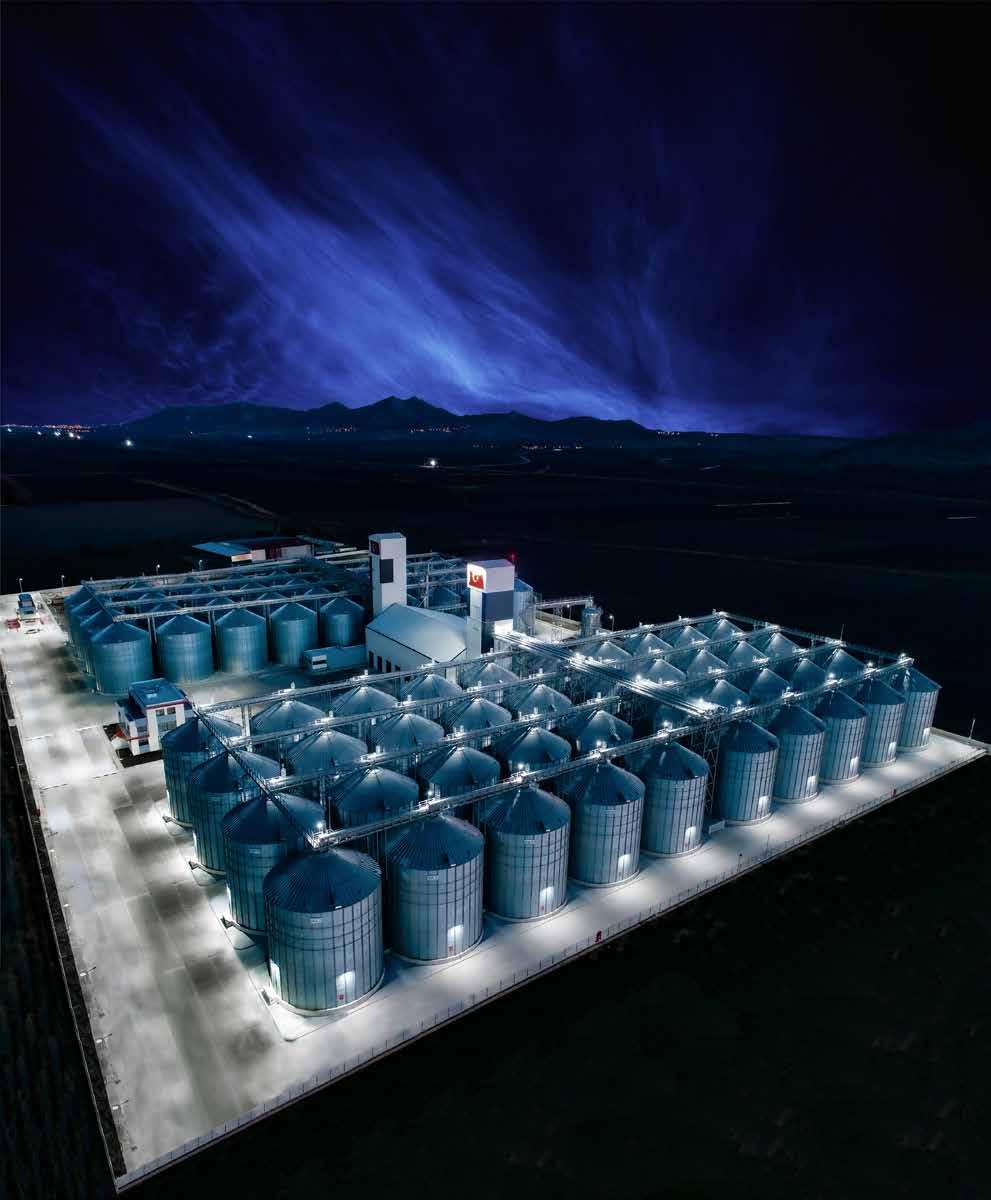

50 million m3 built Projects YOUR RELIABLE PARTNER

145 countries Top Project worldwide

and adaptability

· Butyl rolls are supplied with double strip to improve assembly times.

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS

more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

IAOM PCQI Training

The IAOM Preventive Controls Qualified Individuals (PCQI) Training will be offered on May 9-11 in Kansas City, Missouri. The Current Good Manufacturing Practice, Hazard Analysis, and Risk-based Preventive Controls for Human Food regulation (referred to as the Preventive Controls for Human Food regulation) is intended to ensure safe manufacturing/processing, packing and holding of food products for human consumption in the United States.

The regulation requires that certain activities must be completed by a “preventive controls qualified individual.” This course, developed by the Food Safety Preventive Controls Alliance (FSPCA), is the “standardised curriculum” recognised by FDA; successfully completing this course is one way to meet the requirements for a “preventive controls qualified individual.”

Dr Jeff Gwirtz, JAG Services, will be the lead instructor for the course, which offers a focus on food safety programs in a milling environment.

Your company has made a significant investment in your food safety programs. Enhance your programs with this new IAOM PCQI training, offered for the first time in 2023.

To register for this training, go to the IAOM Online Store and select the PCQI Training item.

You may also apply for a course using the online form. Be sure to select the PCQI Training under the heading, IAOM Mill Training Courses.

Class sizes are limited and will be filled on a first-come, first-served basis. Applications received without payment will be placed on a waiting list. Confirmation as a participant in each course will be sent upon receipt of payment. Please do not make travel plans that cannot be easily cancelled until you receive notice of confirmation or cancellation, which you will receive no later than four weeks prior to the course start date.

Because it’s all about life.

The greatest global challenge is to ensure food security. Eight billion human lives depend on it. However, it matters how we source animal protein. Because it has consequences that affect animals, humans – and ultimately the entire planet. There is only one way to do it right: using science. Only well thought through, evidence-based solutions can establish a truly sustainable and secure food supply.

Sciencing the global food challenge. | evonik.com/animal-nutrition

9577_AZ_Sciencing_190x132_EN_230213-1.indd 1 13.02.23 10:56 Milling and Grain - April 2023 | 33 TRAINING Mill

Distance learning programme by UK Flour Millers

Each year UK Flour Millers – the trade association for the UK flour milling industry, runs seven modular courses to provide millers with an essential understanding and underpinning knowledge of the milling industry. The courses are studied by hundreds of students around the world and lead to the Advanced Certificate in Flour Milling.

The modules cover every aspect of flour milling: from wheat to flour; from milling to management. Each module is split up into ‘bite-size’ chunks, to help students learn.

The modules may be studied in any order and in any combination; students are not required to have any previous qualifications. Students are encouraged to study between 1 and 3 modules in their first year (approx. 12 hours minimum study time per module).

For each module, students receive the benefits a course textbook each written by trained millers; and will be allocated a tutor,

who will comment on their work during the year. The tutors are all experienced in the operation and management of flour mills, providing students with expert assistance in their training. The student’s workplace will need to appoint a mill mentor to support their learning which should help maximise the rewards of their study.

The 2023 exams begin on Tuesday 2 May at 09.30 am local times. The flour milling industry is a highly skilled and challenging industry, with training and education playing a vital role for employee development. It has recently developed a virtual flour mill which is now the hub of all its training resources.

For over 100 years UK Flour Millers has been responsible for industry training. Its world-renowned flour milling correspondence courses form a Distance Learning Programme structured into seven modules. This programme provides an overview of the industry and process and prepares students for examinations that lead to the Advanced and Intermediate certificates in Flour Milling.

Much work has also been done over the years on promoting practical milling skills, including a Craft Skills Certificate, Occupational Standards and Proficiency Qualifications. Recently, the focus has been more on the identification of suitable apprenticeship routes.

TRAINING Mill Get weekly updates from the feed and flour milling industries with our email newsletter! Want more industry news? myMAG.info/e/289 YOUR GLOBAL PARTNER BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY 34 | April 2023 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less than £12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

We will be seeking enrolments from June ...

FOCUS Product April 2023

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process. Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

Extruder Barrels by Extru-tech Extru-tech extruder barrels are already designed for broad production capabilities with maximum efficiency and minimal metal-to-metal wear. However, to further eliminate pathogens in the extruder barrel, extrutech advanced feature extruders utilize a modified barrel profile and increased steam injection into the barrel. Each extruder model can be equipped with multiple barrel length packages, each designed for the production of specific product types. Naturally, all extruder screws and liners continue to be constructed of high quality, wear-resistant stainless steel alloys that are subsequently polished, heattreated to required hardness specifications and then parallel ground to ensure proper fit between barrel components.

From unprecedented production capacities to exacting finished product quality, Extru-Tech Extrusion Cooking Systems have established the industry standards for performance and value. Extru-Tech’s Advanced Feature Extrusion systems were designed with two important criteria. The unit needed to be quick and easy to clean, and it needed to allow customers to control, reduce or eliminate contaminants in the system.

AIRFLOW II conveyor dryer by Wenger

The AIRFLOW II conveyor dryer has a controlled, balanced airflow for Uniform Product Drying, with horizontal and vertical dryers and 1-3 passes available. It comes with customisable controls, configuration, material and size, and technical assistance available 24 hours a day. The dryer is designed to scale for increased production needs, with heated airflow from both sides of the dryer, and minimises uneven drying across the bed, eliminating the need for air diverters.

PRINCIPAC by Statec Binder

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world.

The PRINCIPAC is characterised by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products. Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

Maize Grinder by Pingle

The maize grinder is developed on the basis of a hammer mill. For the integral maize kernels that have been moisture conditioned, this machine is able to finish dehulling, degerming and grinding operations in one step, and the processing efficiency is improved. Technically speaking, the power consumption for producing one tonnage of maize grit is reduced by 20-30 percent when compared with traditional machines, thereby significantly enhancing the economic returns.

With the help of this machine, a complete granule of maize is shattered into 4-6 fragments with a tidy appearance. The embryo breakage rate is less than 10 percent, and the hull is kept whole. This brings great convenience for the following separation of embryo, hull and grit. So, this maize grinder is highly recommended.

Oryem Coating System

The coating system in feed mills is an equipment that provides the desired coating with oil (fat), an enzyme or liquid methionine for granulated products that undergo pre-cooling and sieving. Feeding and dosing of oils, enzymes, etc is carried out in automatic mode.

With regard to capacity, it is designed with a single-shaft or two-shaft mixing screw, which undergoes special heat treatment and is covered with a special insulation material. This process of coating gives a noticeable result of adding oil, enzymes, etc., makes the granules harder, and smoothes the shell. It features automatic weighing, spray nozzles, a mixing screw from chrome material, and is covered with a special insulation material with easy maintenance and cleaning.

36 | April 2023 - Milling and Grain www.statec-binder.com www.wenger.com www.plflourmill.com www.oryem.com.tr mymag.info/e/1748 http://extru-techinc.com

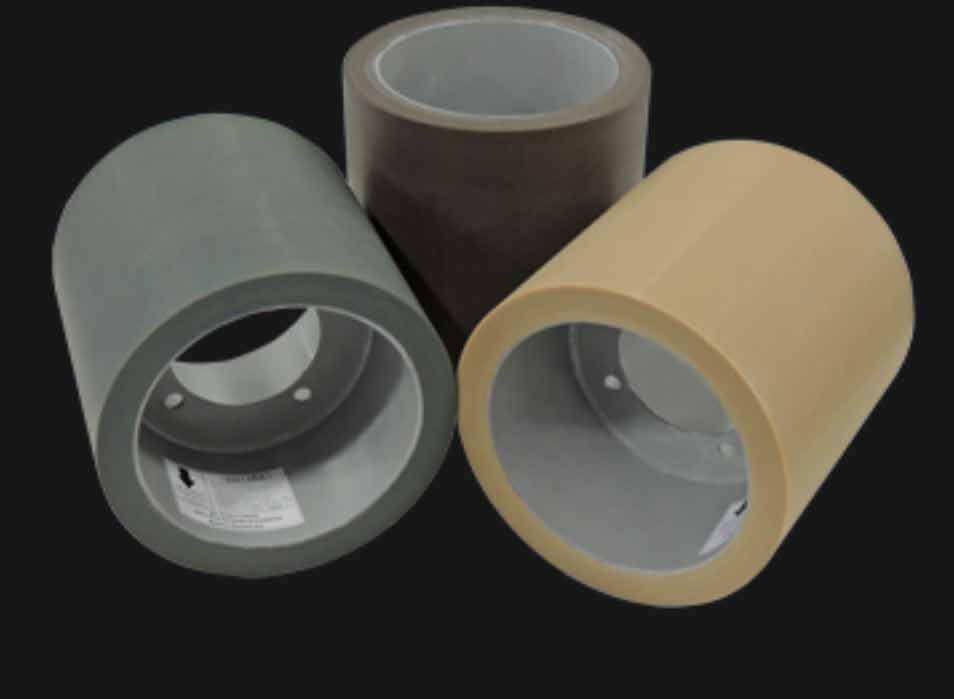

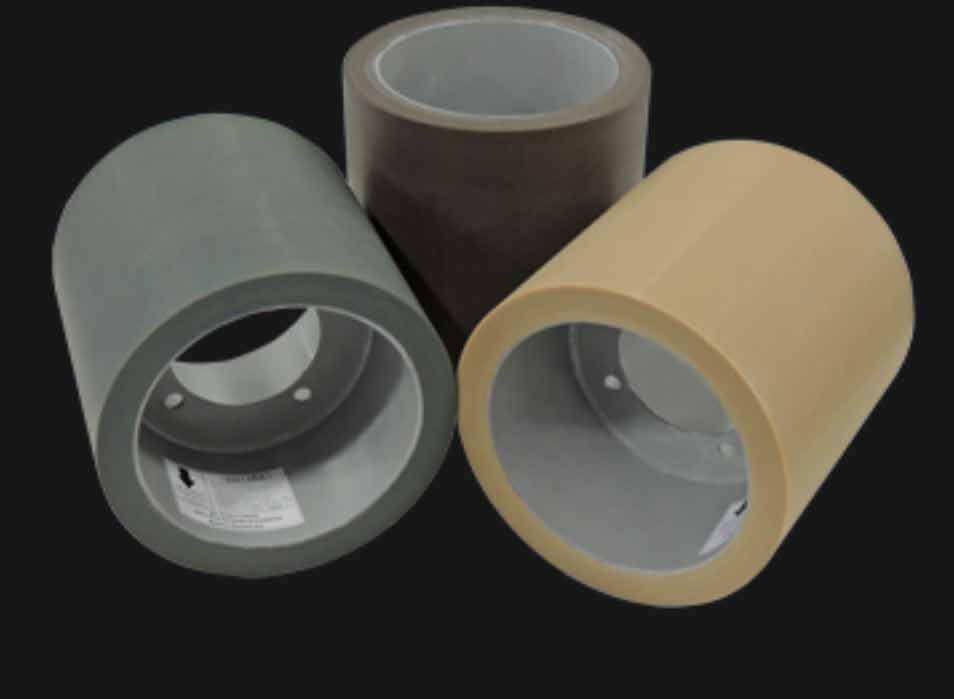

Rubber rolls

Zaccaria - Equilibrium, Performance, And Extreme

Improvement! This word has always been part of Zaccaria’s history on the manufacturing of rice milling equipment. In the last two years Zaccaria put a higher focus into its rubber factory, investing in equipment modernization, manufacturing process improvement and development of new rubber formulations, using special chemical compounds developed with an European multinational consultancy specialized in chemical and rubber products.

From the old rubber rolls, Zaccaria just kept the rubber colors to make reference on our consolidated markets. As these improvements reflect in a new era for the Zaccaria rubber rolls 10”x10” and 12”x10”, we’re stopping to commercialize the old ones named by the respective colors, and we’re starting to sell three new models: Rubber rolls Zaccaria Equilibrium, Rubber Rolls Zaccaria Performance, Rubber Rolls Zaccaria Extreme.

Rubber rolls Zaccaria Equilibrium

The rubber roll Zaccaria Equilibrium uses the same brown colour because it’s the substitute of the consecrated brown rubber rolls. The rubber roll Zaccaria Equilibrium has inside its composition more natural rubber so, it’s softer than the others which helps to preserve the rice integrity avoiding broken

grains and also, preserves one characteristic important for some rice millers, that is the reduced price with an equilibrated performance from beginning until the end of the husking rubber. Its production per pair is suitable for low capacity paddy huskers.

Rubber Rolls Zaccaria Performance

The rubber roll Zaccaria Performance is a new product developed to be an alternative for the customers who needs high production with reduced prices, giving the best cost-benefit ratio. This rubber roll has a good adaptability to different working conditions, so, it can be used on high capacity paddy huskers, and in low capacity paddy huskers. Its durability is around 40%-45% over the rubber roll Zaccaria Equilibrium. Compared to a car tire, it’s a “sport tire”!

Rubber Rolls Zaccaria Extreme

The rubber rolls Zaccaria Extreme uses only the color of our old beige rubber rolls. The formulation of the rubber roll Zaccaria Extreme is totally new, developed to attend the needs of the most rigorous customers. Due its longer durability, this rubber roll is indicated for high capacity paddy huskers, where its chemical characteristics are favored by the elevated working temperatures. Compared to a car tire, it’s a “race tire”!

Milling and Grain - April 2023 | 39 FOCUS Special

www.ai-lati.com

u r ess enc e lie s i n t h e for m s t h ro ugh wh i ch w e s how o u rsel v es.

offer j u st wha t we a r e .

wa y s . www.paglierani.com

O

We

Al

www.ocrim.com

Pulse rising Technology adaptations in the pulses in the industry

by Tinu Titus, Senior Product Manager for Pulses, Bühler Group

by Tinu Titus, Senior Product Manager for Pulses, Bühler Group

The demand for pulse-based products is rising all over the world. With a growth forecast of more than 21 percent for alternative proteins, it is one of the fastest growing markets in the food industry. As promising next-generation ingredients, pulses have great potential for responding to these trends. Beans, peas, lentils, and chickpeas are very healthy and environmentally friendly. With more than 80 million tonnes produced globally every year, pulses are readily available and therefore are destined to play an even more prominent role in future food formulations. With the changing times and advancements in the development of pulses market, it is imperative that further research be carried out to discover more novel ways of utilising this highly versatile food ingredient.

Pulses are edible seeds from the legume family that are high in fiber and protein. The many varieties differ in size, shape, and composition. Traditionally pulses have been consumed whole, split or baked in nourishing dishes. Innovations in healthy

alternative foods have paved the way for more usage of pulses as an ingredient in many consumer foods. The most popular ones are ingredient products such as pulse flour and pulses protein concentrates/isolates, which are all increasing the popularity and demand for pulses. The newest trend is the use of pulse protein to produce meat and dairy alternatives. Pulses are now thought to be a superfood that can help to meet the challenge of feeding the world’s population in a sustainable way by 2050. In order to meet global food requirements, the processing of pulses is evolving and traditional cleaning and dehulling facilities are being modernised like never before. Let’s delve into the details of the technology adaptations and changes happening in the pulses industry.

The first step: Getting the pulses cleaned

Harvested pulses are generally cleaned by mechanical machines. Added value for end products has forced the industry to make its cleaning facilities more efficient, with minimum good product wastage and maximum impurity separation becoming the norm. Fabricated cleaning units with round screeners are

42 | April 2023 - Milling and Grain F

constantly being upgraded with multiple-stage specific cleaning facilities comprising pre- and fine cleaning along with destoner and gravity separator machines. We are also seeing consolidation in the industry towards higher capacities, mainly with the objective of optimised production costs and commercial viability.

Dehulling of pulses: a critical process step that defines the yield

Dehulling of pulses is also on the path to modernisation, with dust-free and well-designed processing facilities. Dehulling is at the very heart of milling and defines its yield. Conventional pulse dehulling systems, where the plant and machinery are fabricated on site or built with less precision, prove to be highly labor-intensive, with inefficient plant utilisation, unacceptable quality, and poor hygiene. All these contribute to low productivity and low profitability. Pulse dehulling facilities that offer more options for adjustments based on different raw materials and intelligent tracking of process are fast replacing the conventional process. The new developments ensure that the highest yield is maintained in the process and product information is tracked and monitored to allow the operator to make quick adjustments.

Taking color sorting to the next level

Everyone deserves access to safe food. Sorting technologies have evolved to suit ever-growing market challenges. Smart sorting maximises the transparency of the sorting process with data capture and visualisation

PulsRoll Roll Dehuller from Bühler

PulsRoll Roll Dehuller from Bühler

C M Y CM MY CY CMY K pubblicità italiana_MOD.pdf 1 27/01/22 10:59 Milling and Grain - April 2023 | 43 F

Plant-based burger, only one of the many varieties

and helps to transform the plant digitally. It also helps in maintaining the highest food safety standards.

New features, software solutions, and frequent upgrades help the SORTEX machine become a state-of-the-art piece of equipment in every plant. A new suite of algorithms and advanced learning techniques has been developed to take the ability to remove foreign matter and subtle defects to the next level while increasing the product yield. The all-new calibration and product tracking algorithms ensure that machine performance is consistently high.

Smart milling is the future

In line with Industry 4.0 standards, pulses mill can also control and observe machine performance from anywhere. Automation and intelligent features allow data capture and online monitoring of the process. These features help to make manpower-dependent processes like pulse dehulling much simpler and easier to carry out. Automation is critical when there is a need for higher capacity in processing facilities.

Top ingredients

The use of all types of pulse-based ingredients in food and feed offers great potential. Whether such ingredients are used solely or mixed with other cereal ingredients, the key will be to find the right proportions to satisfy local consumer preferences, especially in terms of taste. Healthy, sustainable, versatile, and convenient, pulses are the perfect answer to every food trend. When processed into functional ingredients, they can enrich the nutritional value of common foods like bread, pasta and snacks with fiber, protein, and several micronutrients. As there is always room for innovation and product development, the processing of pulses into ingredients will continue to prove highly important and is set to maintain the dynamism, variety, and excitement of the shopping experience for decades to come.

Alternative protein: the highest value driver

It is estimated that by 2050 an extra 265 million tonnes of protein will be needed to meet the demands of the world’s population. As such, finding new protein sources is essential. From pulses, soy and oilseed, to upcycling side-streams or newer ingredients like microalgae or insects, the market is exploring new ways to develop sustainable alternatives. More and more consumers are now demanding environmentally friendly products

such as meat and fish substitutes. With over 80 million tons produced globally, pulses are essential in ensuring sustainable protein security. Pioneering processing technology makes it possible to examine the potential of pulses as a sustainable protein source. Integrated processing solutions such as protein separation, extrusion, or texturing of protein-rich pulse flours into textured vegetable protein (TVP) products are making the pulse value chain even more lucrative. From bean to burger, the pulse journey is more exciting now than ever.

Bühler in the pulses industry

There are more than 20 varieties of pulses, and the processing requirements for all of them are diverse and complex. Bühler has been able to close the gap in the value chain by helping processors around the world to adopt hygienic, sustainable, and profitable methods of processing pulses. With an increasing number of consumers seeking more choices in healthy, convenient, and tasty food products, the future of pulses looks very promising. Bühler recognises the enormous value of pulses and has developed a broad portfolio of complete solutions in this segment, from processes such as cleaning, splitting, dehulling, and grinding to protein extraction and value-added finished products such as meat and dairy alternatives, snacks and pasta. Bühler now has more than 100 pulse processing facilities spread across the globe, where a variety of pulses is processed using the most advanced solutions.

With its three Food Application Centres in India, Switzerland, and North America specialising in pulses, Bühler supports its customers in developing the most suitable process for the profitable utilisation of pulses. In response to the growing demand for pulse protein extraction, our facilities in Switzerland will be expanded later this year to include a Protein Application Centre equipped with the latest technologies from us and our partners, enabling us to conduct customer trials for protein concentrates and protein isolates. This makes Bühler the go-to partner for catering to the demands of a rapidly growing food market. With the advent of these novel solutions, billions of people now rely on Bühler technologies to cover their basic needs for food and mobility every day. Basking in this global relevance, we are in a unique position to turn one of our global challenges into a sustainable and expanding business.

www.buhlergroup.com/pulses

44 | April 2023 - Milling and Grain F

Mercury MES plant control system for mill performance data capture

OVER 20,000 CONVEYORS SOLD AROUND THE WORLD

OPEN BELT | ENCLOSED BELT | CHAIN BUCKET ELEVATORS

aggrowth.com

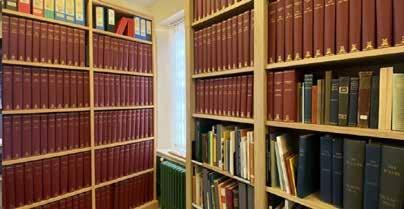

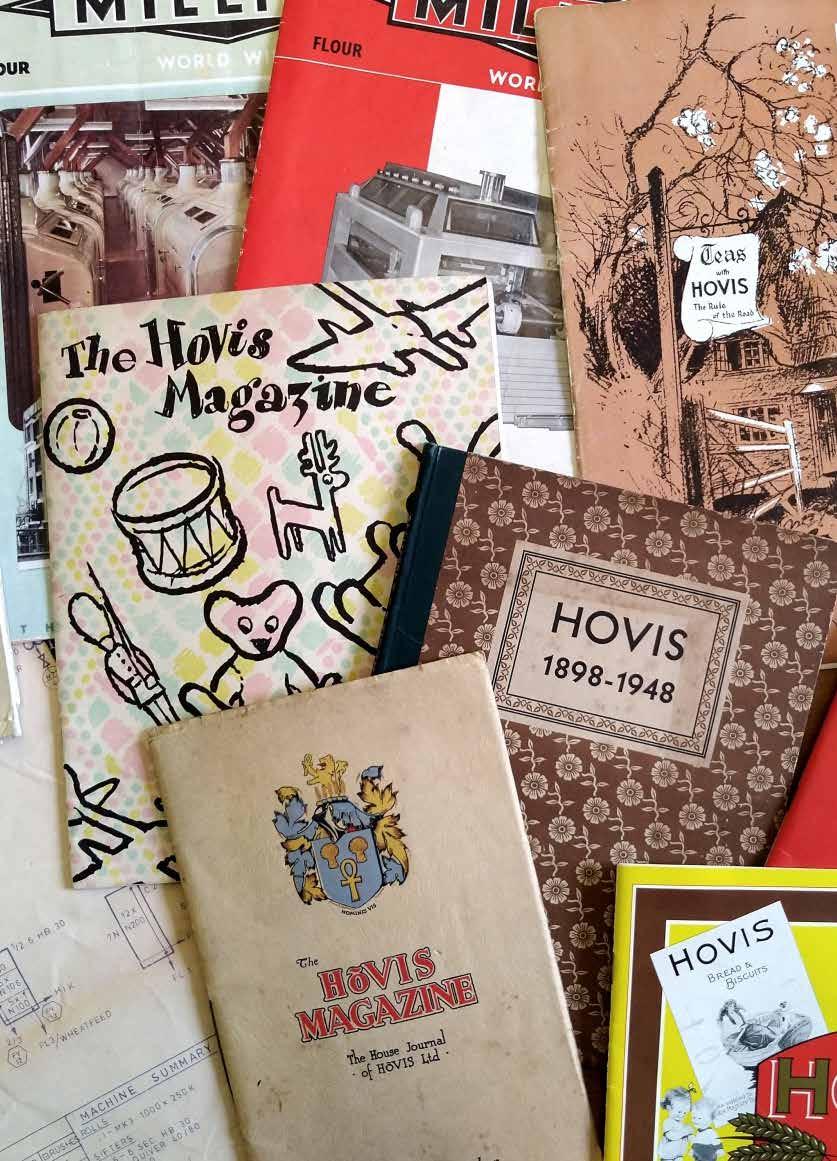

“A great number of usefull books”

From a small library to a world-leading collection

by Ron Cookson, The

by Ron Cookson, The