In this issue:

NUTRITIONAL CHALLENGES:

Enhancing the value of flour in combating micronutrient deficiencies

- The dirty duo: Ridding the industry of Methyl Bromide and Sulfuryl Fluoride

- Combat raw material nutrient variability and boost profits with NIR

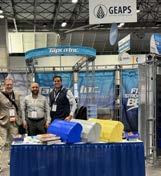

- GEAPS Exchange: 2024 event in Kansas City, Missouri breaks all records

Milling and Grain . Volume 135 . Issue 4 . April 2024 millingandgrain.com April 2024 Proud supporter of Download the Milling and Grain app to your smart phone

Volume 135 Issue 4

YOUR GLOBAL PARTNER

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Social Media Journalist’

David Harvey davidh@perendale.com

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak

8 10 24 33 36 39 80 82 86 94 100 103 104 106 Perendale Publishers Ltd 7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Roger Gilbert rogerg@perendale.co.uk

Tel:

Team

Feng

dantef@perendale.com Latin America Marketing Team

Publisher

International Marketing Team Darren Parris

+44 1242303792 darrenp@perendale.co.uk Asia Marketing

Dante

Tel: +886 227930286

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

mehmetg@perendale.com

& Events

Tan

Manager

antoinet@perendale.co.uk millingandgrain.com ISSN No: 2058-5101 ©Copyright 2024 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 MAXIMISED FLOUR MILLING 42 Nutritional Challenges: Enhancing the value of flour in combating micronutrient deficiencies 46 The dirty duo: Ridding the industry of Methyl Bromide and Sulfuryl Fluoride 50 ASYNCHRONOUS MOTORS: Drive belt versus direct drive 56 Egypt: The ancient heritage of grain processing 42 Combat raw material nutrient variability and boost profits with NIR STORAGE & HANDLING MAXIMISED 66 GEAPS Exchange: 2024 event in Kansas City, Missouri breaks all records THE PUBLISHER Milling News Gems from the Mills Archive Mill TRAINING FOCUS Product FOCUS Special CASE STUDY Commodities INDUSTRY EVENTS PEOPLE 20 Mildred Cookson, Mills Archive Trust, UK 27 Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt 10 www.millingandgrain.com Find out more at: YOUR GLOBAL PARTNER VOLUME 135 ISSUE 3 April 2024 Industry Profile CHARITIES DIRECTORY the interview Regular items Feature content

Design Manager James Taylor jamest@perendale.co.uk Circulation

Tuti

tutit@perendale.co.uk Development

Antoine Tanguy

THE PUBLISHER

World Flour Day has come and gone - in a flash.

However, the response to the recognition that one day in our annual calendar is devoted to those who work producing the flour we use to produce healthy, safe and nutritious foodstuffs, that sustains us, is having wider appeal each year. It has now become well established in just six years.

Roger Gilbert

Roger Gilbert

Milling and Grain talked about the impact of the World Flour Day and introduced a ‘Directory of Milling-related Charities’that we should all consider supporting at least once - in our March 2024 edition of the magazine.

Others took more practical measures to celebrate the day - particularly around donating - and we will be reporting on those in our May edition.

But first let me highlight what I feel is noteworthy in this edition. For instance, we report the extension of a rail transportation network in Australia; from GrainCorp’s site at Croppa Creek to the Port of Newcastle – a distance of some 560km from the north to the south-east across New South Wales.

Port Newcastle is some 160km north of Sydney.

This is a major development - in this instance for the canola crop destined for Europe - replacing some 50 B-double trucks and reducing carbon emissions associated with road transportation.

This first shipment was approximately 2600 tonnes and is the first of what will be more than a dozen similar trips to be made in the months ahead.

Called the Narrabri to North Star project, which was started back in 2021, this development involved the upgrading of lines, bridges and level crossings. A Phase II upgrade will allow for heavier freight volumes and faster speeds.

Although Phase I was completed earlier, this canola shipment is the first to take full advantage under GrainCorp.

This development signals the importance of investment in infrastructure that supports the way the world goes about feeding itself.

Ensuring our crops - and I speak from a global perspective - can make their way from cropping areas to ports and onward along international shipping lanes to markets and industries where they are needed, is vital to feeding a growing world population. And Australia is to be congratulated for making such a significant and timely investment.

Read our Case Study story on Page 84.

Talking of grain handling and transportation, we at Milling and Grain were excited to be returning to the USA in March to attend the annual GEAPS Exchange event, which focuses on grain storage and transport.

The Kansas City, Missouri location has become a more permanent home for this important event which, due to its more settled location, is attracting an increasing number of international visitors and exhibitors.

Our report this year (see Page 70 onwards), highlights individual booth holders, their companies and their key products and services being provided through a ‘picture caption’ approach.

While it may be that equipment “speaks for itself,” it’s the people and the services they provide that makes all the difference in having reliable technology to ease the task at hand and to carry out processes that do

MILLING AND GRAIN | ApRIL 2024

not damage or reduce the quality of grain – from harvest through to the mill.

In contrast over the recent Easter weekend I was fortunate enough to be taken for lunch at the cafe in the ‘Old Prison’ at Northleach, which is not far from our home town Cheltenham. Now a museum (and closed in 1857, when modern railways allowed for prisoners to be moved to more modern facilities - see https://www.theoldprison.co.uk/history). I was astonished to see in the Old Prison’s exercise yard and under cover a wide range of 18th and 19th Century horse-drawn hay and wheat wagons that had been carefully restored along with a display of a forge and the resident blacksmith’s equipment for wheel-making.

It brought home to me, in stark relief, the way we take for granted how our grains are harvested and transported today compared to the hard work and labour that was required to achieve those same tasks just 100-or-so years ago. The juxtaposition of the two visits within a month was palpable.

This collection of old wagons and farm implements, on behalf of the Cotswold District Council, was originally owned by Miss Lloyd-Baker, a landowner at Hardwick Court. She gathered the collection together in the decades following the second World War with pieces dating from the end of the 19th Century through to the first quarter of the 20th Century.

It makes me think that World Flour Day is also a time to consider just how far we have come, and in keeping with this magazine’s focus on history and the importance we place on developments over time, it is good that so many both within and from outside our industry are encouraged to take an interest in where thiese staples in our diets comes from. (If you’re interested in Miss Lloyd-Baker’s collections, please see - https://www.theoldprison.co.uk/rural-life-collection).

Progress is not always based on what comes next but is built on developments and improvements that have been hard won in the past. And with that in mind I would like to recommend the Mills Archive Trust as a starting point if you want to become more familiar with how our industry functioned prior to the development of newer technologies and since moving away from stones and onto roller mills.

Without roller mill technology it might be fair to says that we would have either missed out on a regular consumption of a sound source of protein, minerals and carbohydrates, etc – now staples in our diets - or be costing too much for the majority of us to gain access to.

As with all things we shouldn’t overlook or devalue the work that our forebears have done that allows us to enjoy the choices of foodstuffs we have today and that is why World Flour Day – March 20th – should be celebrated by everyone for the contribution millers have and are still .

Finally, I had the opportunity to interview the CEO of Bühler, Mr Stefan Scheiber, earlier this month following the announcement by the company of its financial outcome for 2022-23. A video interview with Mr Scheiber is now on MAGTv/RongoRoingo Live and he also appears as our guest interviewee on page 104. Happy reading!

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information www.millingandgrain.com http://gfmt.blogspot.co.uk Milling and Grain has a cooperative partnership with COFCOET

8 | April 2024 - Milling and Grain

Stefan Scheiber, CEO of Bühler Group in Switzerland speaks to Roger Gilbert, Publisher of Milling and Grain following the issuing of the company’s annual financial report for 2023.

Mr Scheiber talked about Bühler’s drive for innovation in alternative foodstuffs, as there is a growing acceptance of new products worldwide, and despite a recent fall back in uptake the company foresees a promising future for new protein replacement foods. Mr Scheiber anticipates higher investments over the coming years in his industry, with sustainability emerging as a crucial concern for both key players and consumers. Technological advancements are revolutionising modern mills, which in turn is emphasising the importance of training and skill accessibility to ensure sustainable food production via the milling industry meeting the needs of a growing population.

Science and technology play pivotal roles, not only in creating awareness of sustainability challenges but also in fostering transparency around CO2 footprints throughout the food-supply chain.

Mr Scheiber states, “We should not see the industry as the problem, but rather the solution.” It’s also important to recognise the importance of addressing cost concerns in a positive mindset - an investment in the future, he adds. Looking ahead, meeting basic nutritional needs amidst population growth poses significant challenges, demanding innovative solutions facilitated by science and technology. “While the journey ahead will not be easy, believing in our capacity to solve these problems is essential,” he says.

Welcome back to Milling and Grain magazine, specifically, the April edition of the Global Miller. Spring has begun so it’s the season to prep those boots and fertilise the ground as it’s time to begin planting crops. If the weather is good then we may even get to see some cherry trees and azaleas blossom.

I like to research some facts about each month and farming for some inspiration on what to write here and I found a few interesting things, my favourite that is most relevant to this magazine is that wheat is the most popular grain directly consumed by people. Both surprising and not when you truly think about it. Wheat has been in use for centuries as flour through the consumption of bread and bread-derived foods, a cheap and filling staple for most meals.

Last month we even celebrated World Flour Day. FlourWorld Museum took an initiative, as a celebration of global solidarity and charity, to make this year’s World Flour Day a “Giving Day” where the milling industry makes a difference in the lives of those in need. So far in 2024, they have delivered nearly 29 tonnes of product, benefiting more than 20,000 people. And it is a pleasure to know that they are extending World Flour Day beyond March 20.

Wheat though, is a derivative of grain, which is as we all know, incredibly important to our society. Growing annually, they play a role in feeding both people and livestock, along with being used in the manufacturing of industrial products. Talking about feeding people, India is one of the biggest producers of grains and in

Our titles are available

order to seek minimum price guarantees for their crops, thousands of Indian farmers are set to resume their march towards Delhi, the country’s capital. After a young farmer passed away during the protest, the farmers decided to call off their strike at the end of February. Delhi’s borders are closely guarded, and police have been deployed in to stop the march. As India heads to election, the government should take the demands of farmers with paramount importance as they play the main role in feeding the worlds’ most populous nation. Farmers not getting enough support from the authorities is an issue all around the world since always. It’s clear that we need to change this aspect of agriculture if we’re going to attract the next generation of farmers.

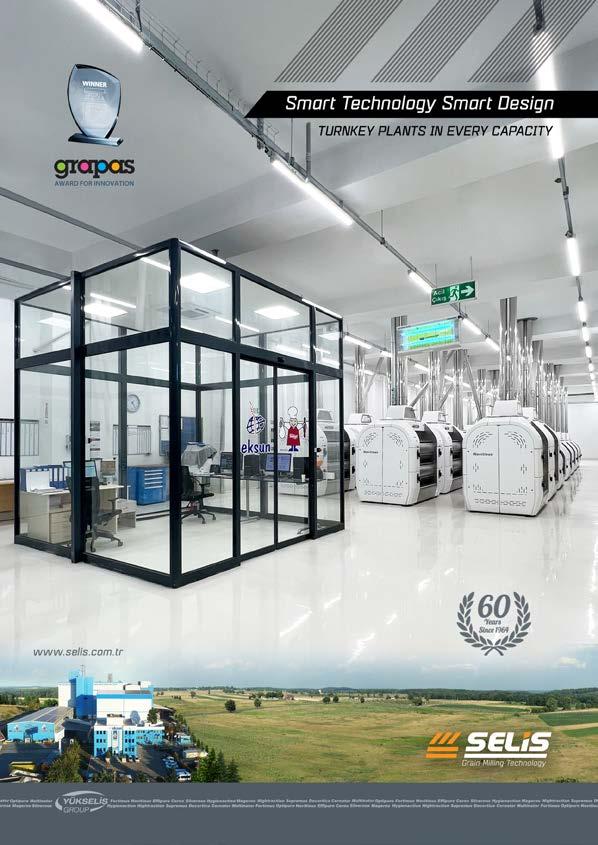

Taking a sneak peak into other news, you’ll come to find that the Turkish company, Alapala have completed 21 turnkey projects in 2023 throughout 15 different countries. What an achievement! Cimbria also dips their toes into the world of AI and takes sorting to a new level with their new AI powered software Brian. Alongside this, Yemmak is honoured with the European Product Design Award for one of their machines. Read their news to find out which.

Lot of events for the Milling and Grain team have been happening these last few months too and we’re excited to talk about them with you! Be prepared to read about all the fun everyone had at GEAPS Exchange 2024 and TUSAF in Antalya,

10 | April 2024 - Milling and Grain Milling News

IN PRINT ONLINE MOBILE

Novus acquires enzyme company BioResource International

Novus International announced that it has completed the acquisition of US-based enzyme company BioResource International (BRI). Under the terms of the agreement, Novus becomes the owner of all BRI’s products and intellectual property and takes control of the company’s facilities.

“This move will allow us to serve our customers better and expand our innovation pipeline further,” says Novus President & CEO Dan Meagher. “Enzymes are vital tools for producers to ensure animal health and well-being and help deliver on-farm profitability. We’re very excited to offer our customers more options, as well as aspire to develop new feed additives.”

The relationship between the two companies isn’t new. Novus has partnered with BRI since 2008 to manufacture its protease product, Cibenza Enzyme Feed Additive. Meagher says having full ownership and control of the product line and the option to expand Novus’ portfolio beyond protease enzymes is a natural fit in the company’s long-term strategic plans.

“As a leader in intelligent nutrition, Novus’ priorities include investing further in functional proteins and the gut health segment, growing our portfolio, and achieving stronger control of our supply chain,” he says. “Along with

supporting these goals, acquiring BRI also increases our capabilities to develop innovative solutions in the fermentation space.”

BRI’s co-founder and CEO Giles Shih says the acquisition and tapping into the knowledge of employees in both BRI and Novus allows for the continued growth of the company he helped create 25 years ago.

“We are super excited about the future where BRI’s products and people combine forces with the global reach and deep industry knowledge Novus brings to the feed additive space,” shih says. “This deal is not one of happenstance. Our two companies have worked closely together since 2008 to launch the first generation of heat-stable protease feed enzymes and shape how they are developed, marketed and optimised to add value to customers worldwide. This acquisition will enable Novus to innovate the next generation of proteases and enzymes that will do even more, from promoting gut health to promoting the bottom line.”

Along with BRI’s current product portfolio, Novus also takes over the company’s facilities in North Carolina in the US.

Meagher says continuity is key for current BRI customers and they should experience “business as usual” during the integration process.

12 | April 2024 - Milling and Grain Milling News

Yemmak wins award in global design competition

Yemmak was honoured with an award in the industrial design category of the European Product Design Award for its Fine Grinding Hammer Mill. Yemmak, a leading manufacturer of machinery and equipment in Turkey’s feed industry, aims to strengthen its success in the global arena with the design award it has received.

Halil Yırtımcı, Vice General Manager of Yemmak, said “We export a large portion of our production to 46 countries worldwide and are among the leading companies in the sector. With this success, we continue to create value for Turkey. This award we have received is the most important indicator that Yemmak combines the principle of sustainability in its equipment with design.”

Yemmak’s FGHM series Fine Grinding Hammer Mills play a critical role in the production of fish feed and petfood. Designed specifically to reduce raw materials with a diameter of 10mm to as small as 50 µm, these mills play a vital role in the production process. This machine, which attracts attention with its new design,

is made from recyclable materials and features dynamic and masculine lines. The product was elevated according to various criteria such as innovation, aesthetics, functionality and ergonomics. This design, which also boasts a modern and minimalist appearance, has been conceived in line with Yemmak’s corporate identity.

Scan the QR-Code to find your die! WWW.PCE.EU Are you in search of high-quality ring dies that perfectly fits all brands of pellet presses? Milling and Grain - April 2024 | 15 Milling News

BoMill collaborates with Baltijos Javai for upgrade of BoMill InSight

Based in Kaunas, Lithuania, UAB ‘Baltijos Javai’ provides processing and trading capabilities as well as consultancy services to the barley value chain. In September last year the company ordered BoMill InSight with two sorting units for a value of EUR 270,000 to further secure the quality and optimise supply of malting barley in the region. In partnership with Viking Malt, one of the top ten largest malt producers in the world, the equipment is installed at the malt house site in Panevėžys, Lithuania.

Following a few months of use, Baltijos Javai has decided to purchase six additional sorting units for a total value of EUR 260,000 to upgrade the existing installation and reach the maximum 15 tonnes per hour sorting capacity offered by BoMill InSight. Thanks to the modular design of the BoMill solution, these six sorting units will be easily added onto the frame already equipped with two units, from the previous order. The delivery of the additional units is scheduled for Q2 2024.

“We are excited about this agreement which is another milestone for BoMill InSight. This capacity upgrade is

a repeat order confirming our customer recognises the reliable performance and strong return on investment of our technology. We look forward to further supporting Baltijos Javai and Viking Malt in their development” stated Andreas Jeppsson, CEO of BoMill AB.

Reduce costs and prevent risks

Optimize your entire production chain

Guarantee higher quality products

BESTMIX® Feed Formulation, Quality Control, Ration Calculation and ERP solution.

Scan to learn more: www.bestmix.com

TIME FOR THE NEXT GENERATION SWISS PREMIUM MILLING TECHNOLOGY Stay tuned LinkedIn SWISCA 16 | April 2024 - Milling and Grain Milling News

The most advanced software solutions for feed production:

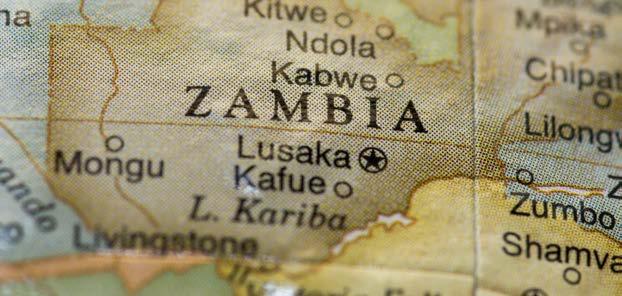

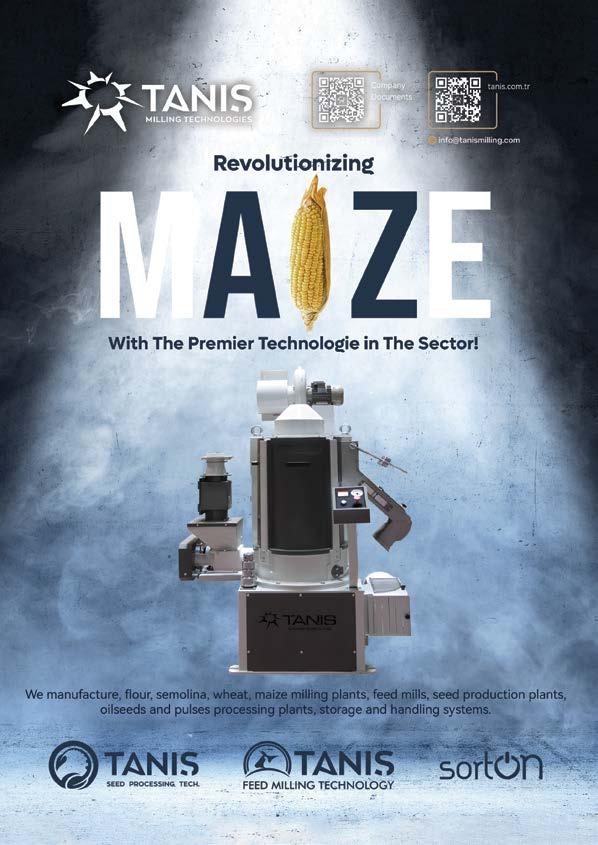

Erhan İncioğlu Highlights Grain Cleaning at IAOM

At IAOM MEA Regional Milling Forum in Lusaka, Zambia, Mr. Erhan İncioğlu, Sales and Marketing Director at Tanis Milling Technologies, took the stage to shed light on the pivotal role of grain cleaning and conditioning in agricultural processes.

The presentation, titled ‘Grain Cleaning & Conditioning: Enhancing Quality, Efficiency, and Sustainability in Agricultural Processes,’ delved into the significance of these practices within the agricultural supply chain.

Grain cleaning and conditioning were emphasised as indispensable steps in the processing of wheat, ensuring the quality and safety of the final product. The removal of impurities, such as dirt, dust, stones, and foreign materials, emerged as a critical aspect to guarantee the high quality of flour, affecting taste, texture, and overall consumer satisfaction.

higher-quality flour, free from contaminants that could compromise the end products’ taste and texture. The prevention of contamination by mycotoxins, molds, and other harmful substances was underscored as a crucial aspect of grain cleaning, directly impacting the safety of the end consumer.

Moreover, the presentation touched upon how clean and conditioned wheat optimizes the milling process, preventing equipment damage and reducing wear and tear on machinery. This, in turn, enhances operational efficiency and lowers maintenance costs. The adjustment of moisture content during conditioning was discussed as a key factor in achieving pliable wheat grains, reducing breakage during milling and resulting in higher yields and less flour waste.

In addressing insect pests, grain conditioning was presented as a method to control their growth and reproduction, preserving the quality of the grain. Additionally, the removal of impurities and controlled moisture content contribute to an extended shelf life for both the wheat and the final flour product, crucial for storage, transportation, and ensur-

Milling and Grain - April 2024 | 19 Milling News

Moinho Central, Sao Paulo, Brazil

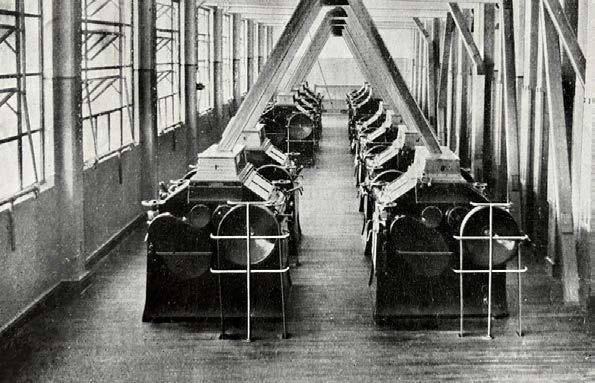

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

This important Brazilian mill was introduced in “Milling” in June 1937. In the 1930s Brazil was still suffering a great deal of political and financial instability with revolutions and coups d’état. Despite this, new industries were developing, particularly in Sao Paulo, the country’s greatest industrial centre. Standing 2,500 feet above sea level and yet only 50 miles from its port of Santos, it turned over 25 million tonnes of grain annually. The State Ministry of Agriculture controlled an Agricultural Institute in Campinas, a Biological Institute in Sao Paulo and hundreds of agricultural experimental stations.

Although South Brazil had areas that were suitable for wheat cultivation, they produced only a soft, weak type, that had been neglected in favour of more suitable crops with a better return. Up to the latter part of the nineteenth century, all flour had to be imported into Brazil, mostly from Argentina.

It was soon decided that it would be more economic to import wheat and grind it in Brazil. Several plants were quickly erected, notably ‘Simon’ plants for the late Count Matarazzo in Sao Paulo and for the Rio de Janeiro Flour Mills called ‘the English Mill’. Moinho Central, one of the Sao Paolo mills was destroyed by fire in 1934. The owners, Bunge & Born Ltd., a leading South American company for flour millers, grain exporters, decided to rebuild the mill and equip it in such a manner that it would incorporate all the recent developments in milling practice, and so become a monument to the progress of industrialism in the country. The better-known milling engineers of the time were

consulted and after a careful and detailed investigation of the various systems put forward, Henry Simon was chosen.

The site was to be between two railways, on one wheat would be received from the port of Santos, and flour could be dispatched towards the coast, on the other flour could be sent to all parts of the interior.

There were three main buildings, the silos and preliminary cleaning department which could hold 5000 tonnes of wheat, warehouses each three floors high, with facilities for loading both to railway and road. The silos and warehouses had been saved from the 1934 fire.

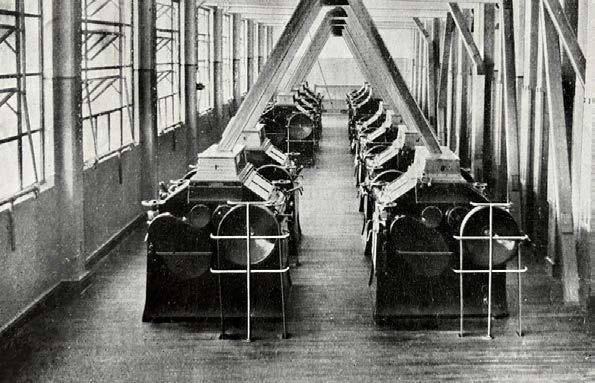

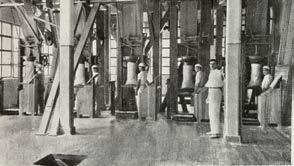

Main roller floor

20 | April 2024 - Milling and Grain

Moinho Central with the enclosed wagon way in front

Due to the high cost of steel the use of reinforced concrete was used for the building. The mill was built with seven storeys each around 12ft high with a flat roof on which a separate two storey building contained water tanks and controls. Cutting right through the building were two expansion cracks, to allow for the big variation in temperature experienced in Sao Paulo. The inside resembled more of a baronial hall than a mill with its vast expanse of polished floors.

Along one side of the building ran an enclosed wagon way. Steel fire escapes were fitted outside the building. Access to the mill, screen room and packing departments floors was through fire proof doors which would close automatically in case of fire, shutting off the stairs completely from the mill.

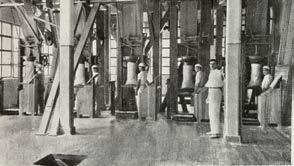

The ground floor was divided into a bag department for marking up new bags and where empty ones were cleaned and repaired. The first floor contained the elevator boots, exhaust trunks and drives to the rolls. Here also were the motor houses for the two mills, screen rooms and packing department (all had their own

separate motors). The rolls were on the second floor that also housed the main electrical control cabin. The third was the spout floor, the fourth was the purifier floor with Germinal brushes, and on the fifth flour were the plansifters, dust filters and wheat washers. On the sixth floor were the elevator heads, detachers, flour and offal weighers, fans, waterwheel dampers and the laboratory.

On arrival at the mill the trucks with the wheat were shunted under the covered wagon way, here a long grill, which covered a series of hoppers opened onto a band conveyor which ran in between the two tracks. The wagons were opened to empty by themselves, and the grain conveyed to the silo. A sample of wheat was taken from each wagon and sent straight to the laboratory for analysis.

Of the two mill plants ‘A’ was the larger and had a capacity for 30 sacks per hour, whilst the ‘B’ plant had a capacity of 15 sacks per hour. Both plants would be expanded to their full use of 45 & 30 sacks.

A line of Simon Plansifters Further Simon Plansifters showing exhaust trunking and sampling table

A line of Simon Plansifters Further Simon Plansifters showing exhaust trunking and sampling table

Milling and Grain - April 2024 | 21

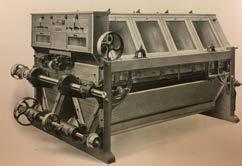

One of the roller mills

C M Y CM MY CY CMY K pubblicità italiana_MOD.pdf 1 27/01/22 10:59 22 | April 2024 - Milling and Grain

The flow of each plant was identical, the only difference being ‘A’ could deal with 200 bushels per hour and ‘B’ 100 bushels. The purification system on plant ‘A’ comprised three grades of semolina, a separate third break semolina, coarse middlings fourth coarse, fourth fine, and fifth breaks. Plant ‘B’ had only two grades of semolina, a single scratch system and less re purification. The 44 kilo bags of flour were machine sewn and sent down chutes to the warehouse.

Lighting used arc floodlights, each floor having 90 points. Lighting also illuminated four large neon signs: “MOINHO CENTRAL” along the top of each side of the mill.

The engineer in charge of the mill building and erection was Senor Belotti, engineer in chief to Messrs. Bunge. The technical manager of the mill Mr C A. Lockwood, trained in England and before going out to Brazil was milling in Kenya. He was brother to J F Lockwood of Henry Simon Ltd and author of Provender Milling (1939) and Flour Milling (1945).

Infestation control = CO2 monitoring

The iGRAIN CO2 Sniffer Cable is the most unique contribution to safe, efficient, and advanced infestation monitoring of stored crops. First introduced by

Advantages:

• Earliest possible infestation warning

• iGRAIN Risk Factor classification showing level of infestation (1-6) for each silo

• Predicts number of safe storage weeks left

• Alerts about insects and fungi in the daily report

• Effective way to avoid Aflatoxins, Mycotoxins, Ergot, and Fumonisins

• Connects with the iGRAIN Smart App

The iGRAIN CO2 Sniffer Cable alerts about any infestation (fungi and insects) weeks before temperature monitoring would.

T0: Temp. + CO2 are not increasing = NO Infestation

T1: Temp. stable, CO2 slowly rising, beginning infestation

T2: Temp. stable, CO2 rapid increase, serious infestation

T3: Temp. rising, high CO2, serious grain spoilage

This is an example from a flour mill where all grain was spoiled, 1.800 tonnes lost

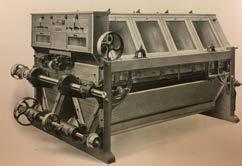

The Simon Fanless purifier

iGRAIN in 2010 and now installed in thousands of grain silos.

AIO Sniffer Cable iGRAIN - Denmark - info@i-grain.net - www.i-grain.net CO CO Hot spots 9300 8600 7900 7200 6500 5800 5100 4400 3700 3000 2300 1600 900 200 CO 2 35 30 25 20 15 10 5 0 Temperature (C) 2023 /01 /01 2023 /01 /17 2023 /02 /02 2023 /02 /18 10,000 PURPLE = CO2 concentration in the silo ORANGE = average of all sensor points RED = warmest sensor point in the silo BLUE = coldest sensor point in the silo T0 T1 T2 T3

MAG Half Page 04-2024 CO2 monitoring B.indd 1 20/02/2024 15.42.17 Milling and Grain - April 2024 | 23

Insects Fungus

Gems from the Mills Archive

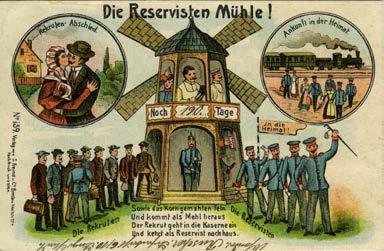

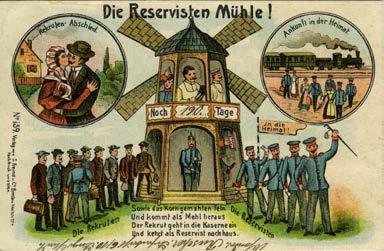

The Reservist Mill

by Nathanael Hodge, Mills Archive, UK

As well as their practical function, mills have often been used as symbols throughout history and have a variety of meanings in different cultures. The power of mills to transform wheat into flour makes them particularly suited to being used as a metaphor for other kinds of transformation.

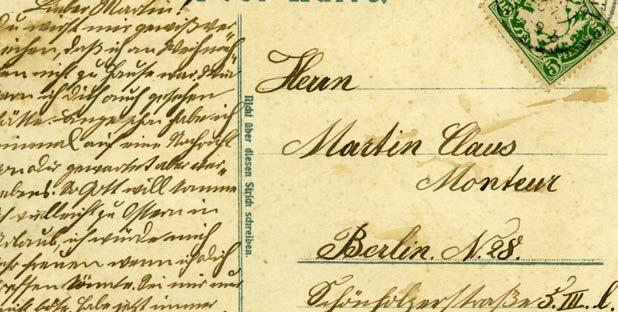

An unusual example is this postcard, dating to before the First World War, entitled ‘Die Reservisten Mühle’ – ‘the Reservist Mill’. Aimed at encouraging Germans to recruit in the armed forces, the postcard depicts civilian German men entering a windmill and exiting as reservists.

On the left we can see man embracing his beloved under the words ‘Rekruten – Abschied’ – ‘Recruits, farewell!’. In the centre is the mill, with ‘Die Rekruten’ – the recruits – entering on the left with their bags and belongings, and ‘Die Reservisten’ – the reservists – exiting triumphantly on the right in their new uniforms. A signpost points to ‘die Heimat’ – home, and above we see their arrival home by train to be reunited with their families.

The poem below the windmill sums up the metaphor:

Sowie das Korn germahlen fein

Und kommt als Mehl heraus

Der Rekrut geht in die Kaserne ein

Und kehrt als Reservist nach haus

‘Just as the corn is finely milled And comes out as flour

The recruit goes into the barracks And comes home as a reservist’

A space over the mill’s doorway allowed the recruit to write down the number of days he had left to spend in the barracks – in this case 190.

The postcard was produced at a high point of German militaristic nationalism. Following their victory in the Franco-Prussian War of 1870-1871, the Kingdom of Prussia under its chancellor Otto von Bismark had led the way in unifying the German nation. By 1914 Germany had the most efficient army in Europe and had implemented universal mass conscription. Men were recruited into compulsory military service which lasted for three years, followed by four years as a reservist.

‘Mailing cards’ such as this were introduced in Germany in 1865 by Heinrich von Stephan, the Postmaster General of the German Empire. The first legally printed postcard carried a similar Prussian militaristic theme, with a picture of a German Artillery man loading a cannon. From these origins, Germany would become the leader of the postcard printing industry, with a particular boom of ‘postcard mania’ in 1903.

www.millsarchive.org

24 | April 2024 - Milling and Grain

If you can think it, we can pack it!

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have developed machines that cover a range of weights from 50 grams to 25 kg for flour based products. In addition, we help you meet global environmental challenges without compromising on performance.

The Packaging Group GmbH · Germany · www.tpg-packaging.com

create your perfect flour packaging solution!

Let’s

Looking for a total feed mill solution? We’re listening

As industry experts, we understand the unique challenges you face in the animal feed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation. We are fully equipped to bring your vision to life!

Fane Valley, Ireland

»

Let’s talk partnership

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

Egypt raises wheat procurement price in new harvest season

Egypt’s cabinet has increased the local wheat procurement price by 25 percent from EGP 1600 to EGP 2000 per ardeb (1 ardeb = 150 kg) (One Dollar = EGP 47.25) for the forthcoming harvest season.

The decision is meant to support Egyptian farmers, stated Mohamed ElHomosany, the cabinet spokesperson, on Wednesday 13, March.

Egypt has been adopting a series of measures to encourage farmers to sell more wheat to the government. The goal is to increase local production amid the disruption in the food supply chain caused by the Russia-Ukraine war.

In November 2023, the government increased the procurement price by 6.6 percent to EGP 1600, up from EGP 1500. The step followed the rolling of a package of incentives for farmers.

Egypt’s annual wheat consumption is estimated at around 20 million tonnes, according to the Ministry of Supply and Internal Trade.

Egypt produces nine million tonnes of wheat annually.

According to the UN Food and Agriculture Organization (FAO), Egypt

imports over 12 million tonnes of wheat – a figure likely to increase to more than 15 million tonnes by 2028.

A cabinet report stated that Egypt needs 7.7 million tonnes of wheat in 2024 to make 93.5 billion bread loaves, an Egyptian staple.

Unsubsidized bakeries decided to raise the price of a loaf of bread to EGP 2, up from EGP 1, in early 2024 as a result of fluctuations in dollar exchange rates.

In January, the Ministry of Supply and Internal Trade suspended trading in wheat in the Egyptian Mercantile Exchange (EME) due to price speculation in the local market.

At the time, Abdel-Ghaffar El-Salamouni, deputy head of the Chamber of Grain Production at the Federation of Egyptian Industries, denied a shortage in the domestic wheat supply, adding that the fluctuation in the exchange rate is among the reasons behind the price speculation

In 2023, Egypt’s wheat imports amounted to around 10 million tonnes, 68 percent of which came from Russia.

Egypt has been grappling with a wheat shortage since the onset of the Russian-Ukrainian crisis in 2022. About 80 percent of Egypt’s imported wheat comes from Russia and Ukraine.

Egypt’s strategic wheat reserves are sufficient for 4.2 months, oil for 5.3 months, and sugar for 5.4 months, said Minister of Supply and Internal Trade Ali Al-Moselhi.

The remarks came after the minister inspected the West Port Said Silos project, which is located on an area of 15,000 square meters and has a storage capacity of 100,000 tonnes.

Al-Moselhi said Egypt imports six million tonnes of wheat annually through its ports, explaining that no silo has been built in the ports since 1984.

A cabinet statement said earlier this month that the country had planted 3 million fedans (3.1 million acres) worth of wheat since November 2023, an increase of almost half a million acres, Egypt Today reported.

Milling and Grain - April 2024 | 27

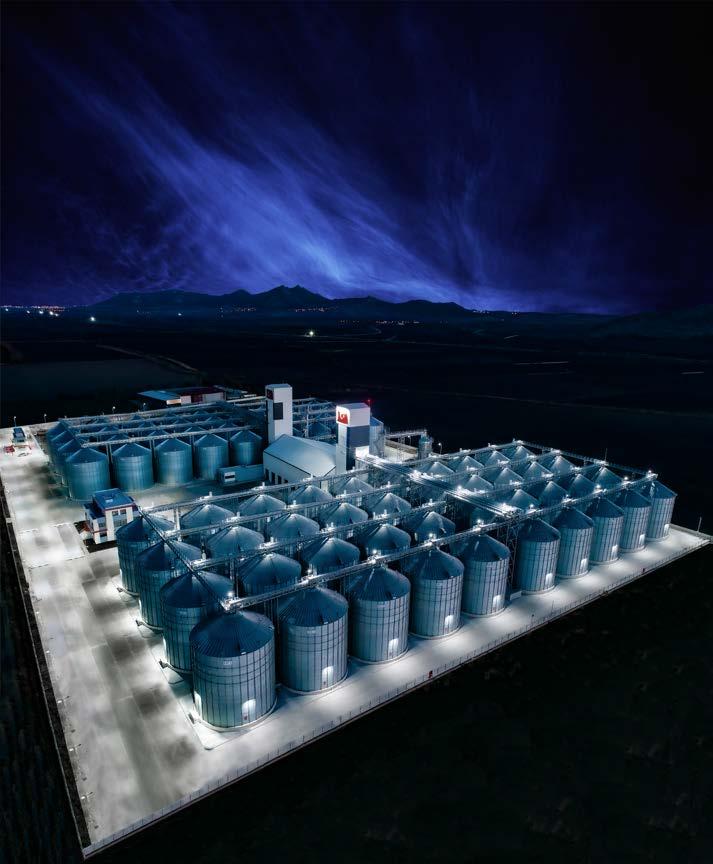

Alapros unveils flour factory project in Tajikistan

Alapros, a pioneering force in the milling machinery sector, has unveiled plans for a groundbreaking project set to revolutionise the flour industry in Tajikistan. The company has announced the construction of a state-of-the-art single-line flour factory, boasting an impressive daily capacity of 1200 tonnes. Expected to be the largest of its kind in the region, this venture signifies a significant leap forward for Tajikistan’s milling capabilities.

This innovative endeavor promises to introduce novel solu-

tions never before seen in the industry. The flour mill will feature entirely new infrastructure, including cutting-edge buildings and silos, showcasing Alapros’s commitment to pushing the boundaries of technological advancement.

Scheduled to commence operations in 2025, the project holds immense promise for both the industry and the regional economy. By leveraging advanced milling techniques and modern facilities, Alapros aims to enhance productivity, quality, and efficiency in flour production, thereby catalyzing growth and development in Tajikistan and beyond.

With anticipation building for the unveiling of this transformative venture, stakeholders eagerly await the positive impacts it will bring to the milling sector and the broader economic landscape of the region.

28 | April 2024 - Milling and Grain Milling News

FROM CONCEPTION OF THE PROJECT TO MANAGEMENT

• GRAIN STORAGE INSTALLATIONS

• GRAIN PORT TERMINALS

• GRAIN DRYING FACILITIES

• INDUSTRIAL PROCESSES

• DESIGN

Agribusiness facilities

Silos Córdoba provides engineering services for product quality control, storage and handling equipment, ensuring convenience, reliability, efficiency and profitability in plant management.

Turn-key projects

Silos Cordoba mainly operates in the post-harvest sector where it offers comprehensive solutions for your grain storage, handling and conditioning needs.

Silos Grupo S.L. Glorieta de las Tres Culturas Nr. 1, 4º A 14011 Córdoba. Spain T +34 857 835 623 info@siloscordoba.com www.siloscordoba.com

SCG

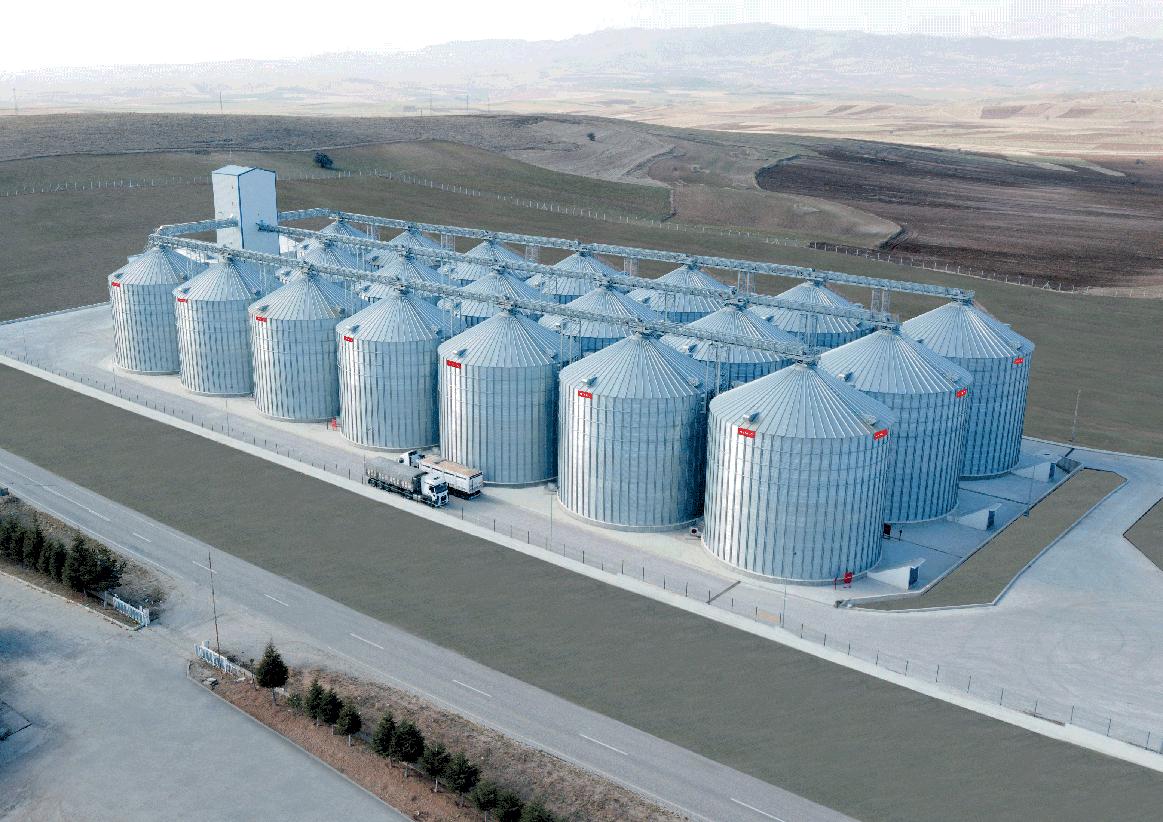

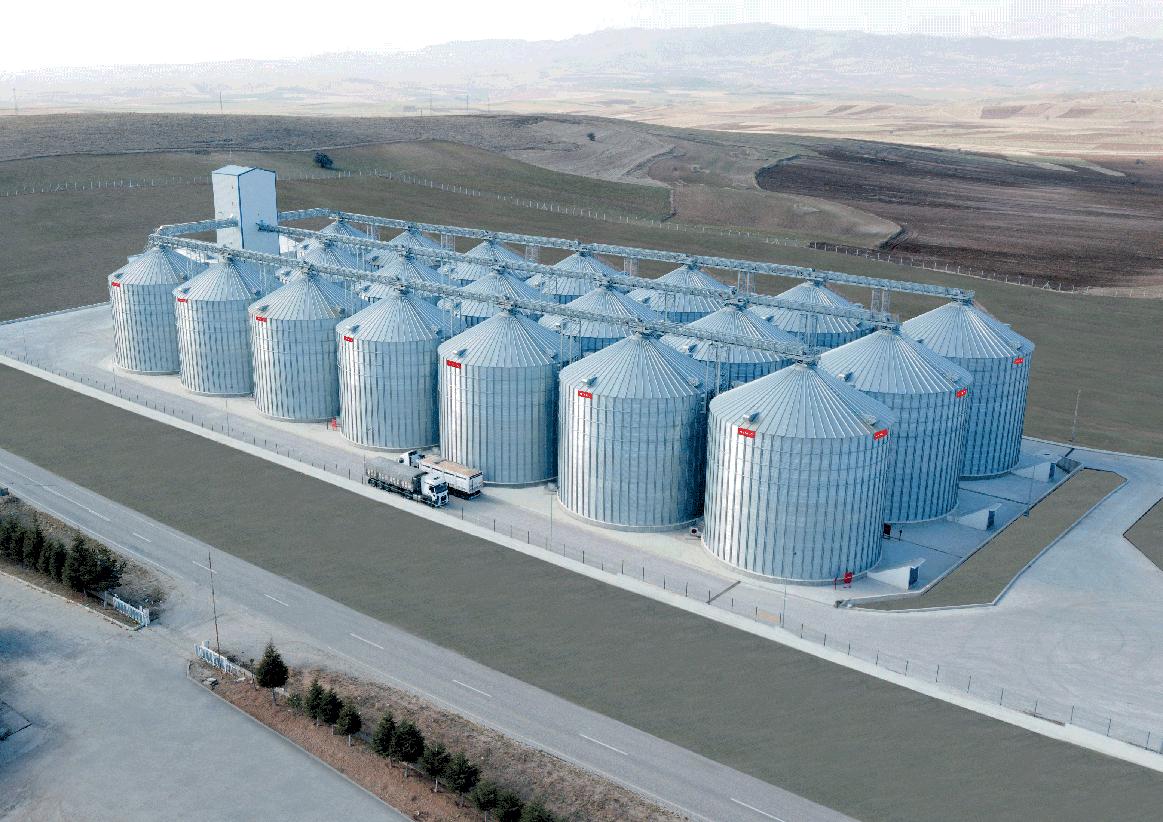

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

We will be seeking enrolments from June ...

Spread over the study year, the cost of a module is less than £12 a week

Study increases competence thereby freeing up your time

All students are allocated a tutor with a wealth of specialist knowledge

O S T E F F E C T I V E

C

T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E

learning Distance learning PROGRAMME

Distance

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

IFF Practical course: Pelleting of compound feed

In the EU, about 75 percent of the industrially manufactured compound feed is pelleted. The essential evaluation parameter for pellet quality is the abrasion resistance, which depends on many parameters. Physical and chemical properties of the feed formulations are to be considered as well as steam quality, conditioning, press parameters, cooling, and the stability of thermolabile additives.

Conditioning, pressing, and cooling consume more than half of the energy needed to produce compound feed. Rising energy costs require the use of savings potential. It’s worthwhile to expand knowledge and skills to ensure the economically successful operation of compound-feed production!

Expertise in pelleting is presented in an easy-tounderstand form in presentations by scientific and technical staff of the institute as well as with external support from the field and deepened in practical exercises in the institute’s

technical centre. Various measurement and test methods are introduced, and their handling trained.

Course participants are enabled to master the pelleting process in their daily professional practice and to control it with simple means. The target group are primarily employees who work directly with the pelleting process and are responsible for the quality of the pellets produced.

The course mainly appeals to employees who are directly involved in the pelleting process and can significantly influence the essential quality properties of the produced pellets (abrasion stability, moisture) by their technical know-how and experience.

The participation in this course is especially recommended for the training and further education of persons who have entered the compound-feed industry from other industries.

The course runs from 6-7 May 2024. The first day includes two hours of lectures and discussion, on agglomeration, milling and grinding, and material properties.

The second day runs for approximately two and a half hours, with lectures and discussions on the evaluation of the pellet quality, and influencing factors and processes around pelleting (Stem, conditioning, pelleting, and cooling).

Milling and Grain - April 2024 | 33

TRAINING

Mill

AFMA and Nef Feed Milling Short Course

The African Feed Manufacturers’ Association (AFMA) has partnered with Nef Feed Milling Consulting to offer an intensive Feed Miller Short Course. This comprehensive program is slated to run from May 6th to May 16th, 2024, at The Conclave Country Lodge, located just north of Pretoria.

Attendees can expect to gain practical knowledge in the application of machinery and process technology, ultimately enhancing feed mill efficiency. The course particularly emphasizes the practical intricacies of core processes within

compound feed production plants.

Spanning over nine days with a weekend break, the curriculum delve into various facets, including manufacturing processes, aspiration systems, batch mixing, size reduction, liquid addition, hygienizing, compacting, expansion, drying, cooling, and mechanical conveying.

Renowned industry experts will lead the course, with Ernst Nef from Nef Feed Milling Consulting at the helm. Notably, Ernst Nef brings a wealth of experience, having previously served as the Executive Director of the Swiss Institute of Feed Technology (SFT).

The course is divided into two weeks: May 6th to 10th, and May 13th to 16th, 2024. A social dinner, generously sponsored by Bühler, will be held on May 9th, fostering networking opportunities among participants.

The Conclave Country Lodge, Welgedacht, Pretoria, will serve as the venue for this learning experience.

We train the workforce of tomorrow. Expand your knowledge, exchange ideas and gain experience in our academies around the world. Let’s shape the future together

Scan the QR code for more information.

millingacademy@buhlergroup.com

.

Innovations for a better world. 34 | April 2024 - Milling and Grain Mill TRAINING

Product Spotlight - The Holmen NHP300 Fully Automatic Inline Pellet Durability Tester by Tekpro

The is a fully automatic pellet durability tester used for calculating Holmen N H P300 the Pellet Durability Index (P D I) of animal feed pellets, by simulating the transportation environment from mill to trough.

The pinnacle of pellet durability testers

The N H P300 automatically extracts and tests samples from a busy production line and displays the results in the N H P300 Windows control software, or alternatively in your existing mill management system software. After the test, samples can be returned to the production line or discharged into a waste container without operator intervention.

By testing pellets during the production process, near realtime results can be used to help maintain the quality of output, by adjusting the mills settings at a time that will save energy and minimise waste.

Fitted as standard with a 2.5mm diameter perforated hopper, the N H P300 is ideal for testing pellets with a diameter of between 3 to 12mm.

Automatic pellet sampling

OLM

Samples are extracted from the process line using an in-line Samplex IL50 sampler. The optimum extraction point is between the pellet press and the cooler Samples are taken at set intervals, and can be taken from up to four different production lines into one single N H P300 machine.

The N H P300 cools and de-dusts the pellets prior to testing, weighs the sample, tests the pellets, weighs the remaining sample and calculates the P D I, all fully automatically without user intervention.. Additionally, it has the ability to calculate the amount of Fines if required.

Results are sent to the included Windows control software or can easily be integrated into the mills current mill management software.

N H P300 proprietary control software

The software supplied with the Holmen NHP300 offers direct compatibility with any Windows X P, Windows Vista, Windows 7 and Windows 10 based operating system.

The software allows for individual pellet details, ration identity, test and delay parameters to be entered prior to process line production.

The results after each test are displayed graphically in the N H P300 Control Software, or with the addition of a printer, by hard copy The easy to understand graphical display of the results alerts the operator to any inconsistency and deviation from the preset desired durability, enabling the operator to make timely adjustments to the manufacturing process parameters to maintain and stabilise the required durability An audible alarm can also alert operators if the pellets are outside of the preset target.

Each test result is also saved into an S Q L Server Database, where the end user has the ability to interact with this information. This data can be imported and used to assist with control parameters of the mill control system, or can be used for performance analysis and production optimisation purposes.

Global demand increasing for Holmen testers

The NHP300 is perfect for larger companies who manufacture pellets in bulk, together with inline samplers to test directly after the press before too much product has been produced. This can significantly help reduce the need for rework, and optimise production efficiency. Tekpro have seen a significant increase in demand globally this year from some of the worlds leading multinational feed milling companies, as well as independent feed mills focussed on achieving consistent feed pellet durability for their end users.

To access further free information on the entire range of Holmen Pellet Durability Testers, exclusively Made in Britain by Tekpro, or to find out how you could join the growing number of feed manufacturers already using Holmen to check their PDI, scan the following QR code:

in Britain,

Worldwide.

5k Insect Detector

Made

Trusted

We are

N H ®

FOCUS Product

April 2024

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

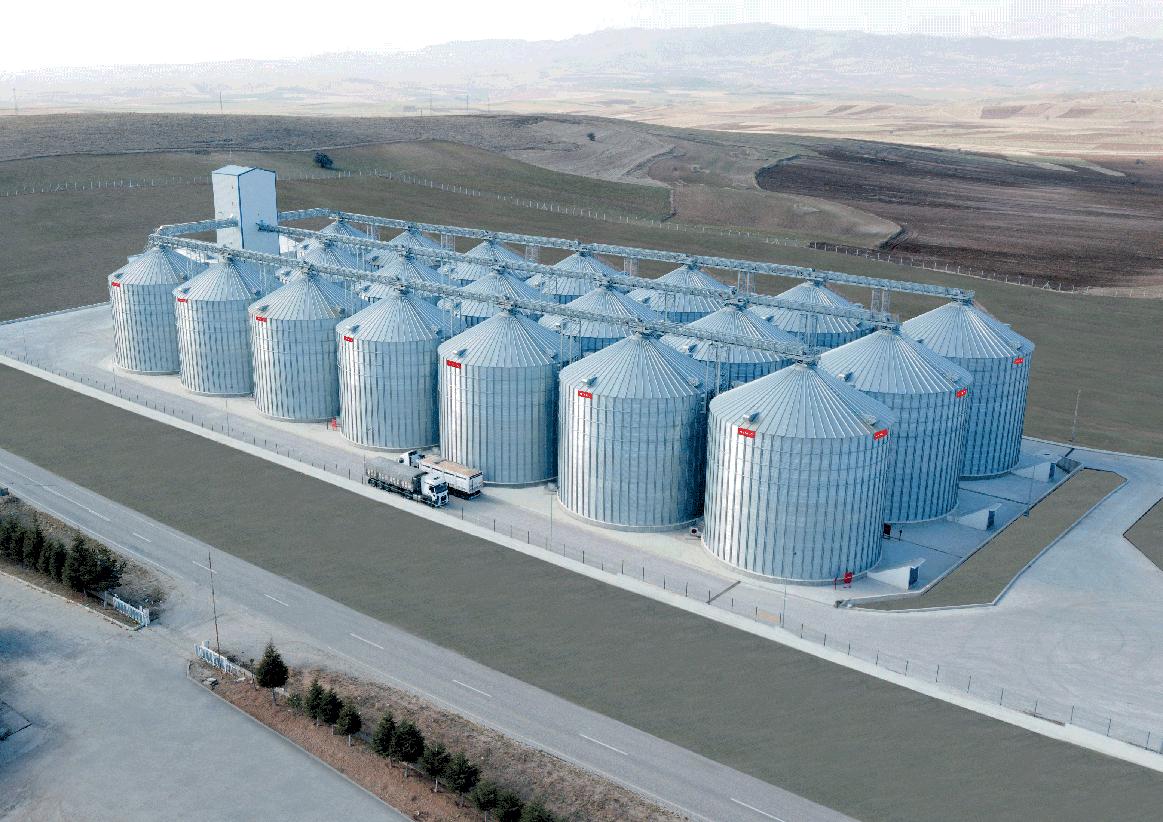

Flat Bottom Silos by Simeza

Simeza corrugated steel sheet

Flat Bottom Silos are designed for agricultural, industrial, commercial and strategic applications such as big farms, inland storage facilities, grain terminals, industrial plants fed with cereals such as flour mills, feed mills, rice mills, oil mills, and biofuel facilities. They can be used for both short -and long- term storage of cereals, maize, soya, paddy, oilseeds and any other granulated free flowing materials.

They can be designed according to either ASAE / ANSI American or Euro-Code European norms as per tender specifications or client choice and are manufactured in order to withstand the stress caused by continuous use, extreme temperatures, high winds, heavy snow and seismic loads. They also offer greater resistance to corrosion through thicker galvanisation on the steel sheets.

Simeza flat bottom silos cover a wide range of models from 4,6 meters to 30,6 meters in diameter and from 80 to 18.000 m³ individual capacity.

www.simeza.com

mymag.info/HrnK

STORM PRO by AGI

The speed, accuracy and flexibility of the STORM PRO seed treater provides the ultimate seed treating solution for your operation. Industry leading speed and capacity propels your business to the next level, allowing true just-in-time treating. The STORM PRO is a completely selfcontained, turn-key seed treater that uses an auto-calibration system and is safe enough to use on all seed types, including soybean, pulse and cereals. The STORM PRO offers the versatility of treating seed when you need it, where you need and can be controlled by the easy-touse touchscreen controls or by phone or tablet. It also meets the new industry requirements for commercial application.

Unlike other seed treaters, STORM PRO accurately measures untreated seed directly from the bin, precisely meters and applies the seed treatment, gently mixes the seed for consistent, even coverage and then transfers the treated seed into the truck, ready to be planted in the field.

Yestimun® by Leiber

Yestimun® is a natural 1,3/1,6-beta-glucan extracted from the brewers’ yeast cell wall. It is made from high-quality Brewers’ Yeasts (Saccharomyces cerevisiae) with the natural component like barley, hops and water. Yestimun® is a light beige-coloured, fine, spray-dried, powder with no taste or odour of its own. For that reason, the dispersible ingredient can easily be used in a wide range of dry or even liquid product formulations. Because of this, the dispersible ingredient can be easily used in diverse dry or even liquid product formulations. Leiber Brewers´ Yeast beta-glucan is characterised by a very high level of purity and a unique molecular structure. Its highly immune-supporting effect has been proven on the basis of human studies.

Benefits include:

Can be taken daily

Free of side effects

Efficacy proved by studies

www.aggrowth.com

mymag.info/BRey

Roller belt conveyor by CESCO

CESCO roller belt conveyors RBCM are designed with a flexible concept and modular design, for gentle horizontal or slightly inclined conveying of grain, grist, pellets, and granular products in general. They realise the completely closed conveying of the product, even in reversible mode, with zero loss during the conveying, easy cleaning, maintenance, and safety during operation thanks the fully bolted system used.

General characteristics

Drive station equipped with belt scrapers.

Tensioning station equipped with belt screw tensioner up to 60 m length and with counterweight tensioner for longer configurations.

The belt runs on 2-roller or 3 roller transoms and is permanently cleaned by internal and external belt scrapers. Trippers available for applications with multiple unloading stations running along the conveyor frame.

Watertight outer top cover made by hot dip galvanised corrugated steel sheet, suitable for outside installation and fixed by bolts.

Kosher and halal-certified, nonallergenic and GMO-free Suitable for vegetarians and vegans

Already used in hundreds of products worldwide

https://yestimun.d

mymag.info/FHPV

Crusher CR from Tietjen

The crusher CR is a versatile machine for coarse crushing of bulk materials. It is suitable for crushing agglomerates or for pre-crushing coarse material pieces for further grinding.

By homogenising the raw material in the crusher, energy is saved in the further grinding in the hammer mill, as the desired grain spectrum is achieved more quickly. At the same time, the screens of the hammer mill are protected against screen breakage. Especially in pet food and fish feed production, particularly fine screens used, here the use of the crusher is particularly worthwhile.

The crusher is designed for continuous industrial operation. It convinces with its robust design with generously dimensioned inlet, long-life rotor and hardened impact plates. The beaters are also optimised for primary crushing and are made of Hardox. A variable grain size range can also be achieved in pre-shredding by using different screen sizes.

www.grainsystems.com

www.cesco-group.com

mymag.info/LldA

www.tietjen-original.com

mymag.info/oxWT

36 | April 2024 - Milling and Grain

Vibmil Vibration Sensor

Revolutionising industrial vibration monitoring

4B Group has unveiled their latest innovation, the Vibil Vibrator Sensor (VibMil), a condition monitoring solution designed for continuous monitoring of vibration levels and temperature in industrial environments and hazardous areas up to ATEX/IECEx Zone 20 and Class II Div 1.

VibMil is a current loop-powered accelerometer, delivering precise vibration RMS velocity readings through a 4-20 mA output. Encased in a robust stainless-steel enclosure with a 3/4″ NPT thread for conduit connection, VibMil assures durability in the harshest industrial conditions. For added versatility, it can be supplied with optional inbuilt NTC or PT100 temperature sensors. Designed with ease of use in mind, the VibMil. comes equipped with a female 1/4″-28 UNF mounting thread, allowing secure attachment using screws, studs or mounting studs. Optional converts to M8 and M6 male threads provide additional flexibility. Integration into control systems is

seamless, thanks to the 2-wire, loop-powered accelerometer, providing linearised output from 4 – 20mA, proportional to the sensor’s measuring range.

“The VibMil has been designed with our core markets in mind”, explains Sam Payne, 4B Group CTO for electronics. “The mandatory requirement to have ATEX/IECEx/Class II Div 1 approved products within dust hazard location means that many similar products on the market are not suitable. The VibMil can be installed with confidence within the most demanding dust hazard areas. Also, the added temperature sensor option means the condition monitoring applications which were previously surface temperature only, can now add that extra level of analysis and visibility of the running state of a machine.”

The VibMil Vibration Sensor sets a new standard in industrial vibration monitoring, providing reliable and accurate data to optimise performance and ensure equipment longevity.

FOCUS Special

Elevator parts Conveyor chains www.vav.nl contact@vav.nl +31(0)71 40 237 01 Milling and Grain - April 2024 | 39

ai-lati.com

simaimpianti.net

BEYOND MAKES US SEE KNOWLEDGE THE HORIZON

ocrim.com

paglierani.com

Nutritional Challenges

ENHANCING THE VALUE OF FLOUR IN COMBATING MICRONUTRIENT DEFICIENCIES

Although the enrichment of foods dates back to ancient times, the principles governing this practice were established through regulations in 1987. This regulation outlines three different purposes for the addition of nutrient elements to foods. The first, known as ‘restoration’, involves replacing lost nutrients during processing, storage, and transportation. The second, termed ‘standardisation’, refers to adding missing nutrient elements to products similar to some traditional foods. The third is ‘fortification,’ involving the addition of deficient nutrient elements to foods in cases of mandatory nutrient deficiencies.

Fortification practices are regulated by the Food and Drug Administration (FDA) in the United States. The FDA’s fortification policy permits the addition of only mandatory nutrient elements. Additionally, the added nutrient quantity must not exceed the approved nutrient supplement level or exceed the Generally Recognized as Safe (GRAS) level.

Micronutrient deficiencies

Globally, over two billion people suffer from micronutrient deficiencies!

Contemporary issues related to healthy nutrition, a fundamental human right, include various problems. Among these, micronutrient deficiencies and inadequate nutrition issues such as stunting, dwarfism, and weakness are widespread worldwide. Micronutrient deficiencies represent a global public health

problem, indicating the absence of essential micronutrients in the body. The most common micronutrient deficiencies include iron, folate, vitamin A, zinc, and iodine deficiencies. These deficiencies can lead to slowed growth and cognitive development, decreased intelligence, perinatal complications, and increased morbidity and mortality. Women of reproductive age and children under five are more affected by micronutrient deficiencies due to their higher micronutrient needs.

The fact that more than two billion people globally experience micronutrient deficiencies highlights a significant and attentionworthy public health problem, and food fortification is seen as a crucial intervention.

Food fortification can be rapidly implemented, with its benefits quickly realised; it is also a safe and cost-effective method for communities at risk of micronutrient deficiencies. The fortification of staple foods can make a significant contribution to combating hidden hunger globally, addressing the issue of nutrient-poor diets.

Adding value to flour in the fight against micronutrient deficiencies

Turkey, the genetic centre of Anatolia, has been home to the world’s first settlement, Göbeklitepe, near Urfa, for 12,000 years. As the world’s largest flour exporter since 2025 with a 21.1 percent share among 150 countries, Turkey plays a significant role in the distribution of enriched flour and combating global malnutrition. Modern humans’ first source of nutrition, flour, is produced through the milling process of grains. Wheat and flour production, the most crucial activity in the country’s economy related to agriculture and food sectors, carry substantial

42 | April 2024 - Milling and Grain F MAXIMISED FLOUR MILLING

120.000 TONS G R O U P ELECTRIC MOTORS & GENERATORS

importance in terms of production, labour force, environmental impact, sustainability, and socioeconomic aspects.

Wheat and corn, in their natural state, may lose a significant portion of essential vitamins and minerals during milling processes. Therefore, adding some of these micronutrients back to the milled flour is referred to as flour fortification. The added nutrients include:

Iron: Vitamins and minerals used in fortification are vital to prevent health disorders associated with nutrient deficiency, such as anemia (iron deficiency), affecting approximately 2 billion people globally.

Zinc: Zinc is essential for supporting the immune system and cellular functions. Fortifying flour can reduce the risk of zinc deficiency. Enriching 100g of grain with 20 ppm of zinc can provide children with 20 percent of their daily zinc requirements.

Folic Acid: Particularly important during pregnancy, folic acid added through flour fortification can reduce the risk of neural tube defects.

B Vitamins (Thiamine, Riboflavin, and Niacin): B vitamins are crucial for energy metabolism and nervous system health. Fortification aims to prevent deficiencies in these vitamins. Especially, fortifying flour with B vitamins protects against neurological damage.

In some countries, flour fortification may also include other nutrients such as Vitamin A, Calcium, and B12. These additions aim to support general health and prevent nutritional deficiencies.

Bastak’s solution

Bastak Instruments, the first and only accredited laboratory in the country approved by the Ministry of Industry and Technology, serves with its 90 specialised branches and more than 265 expert

personnel in its 5-star research and innovation

centre. With our state-approved Additive Production License, Ministry of Agriculture and Forestry Operation Registration Certificate, and Ministry of Health Production Permit Certificate, we provide flour fortification solutions worldwide, adding health and flavour, and tirelessly working for the health of future generations!

SCE.BE Milling and Grain - April 2024 | 45 F

A SQUARE APPROACH FOR A WORLD WITHOUT FOOD WASTE. DISCOVER OUR TAILORED SOLUTIONS ON OUR WEBSITE

Ridding the industry of Methyl Bromide and Sulfuryl Fluoride

While often overlooked by the general public, logistics is our industry’s key operational competency, ensuring a dependable and sufficient supply of food to populations across the world. For staples such as wheat and other grains, the ability to transport and store product reliably and safely is critical to global food security and stability Geopolitical shocks, extreme weather events, and outbreaks of destructive pests can all disrupt these precious supply chains, with potentially catastrophic results on the availability of the food we need to feed an ever-growing population.

To be ready for the first two risks, farmers, growers and the supply chain often perform unsung feats of mastery to re-balance existing routes to market around a blockage or re-negotiate supply contracts to fill a specific need. However, to protect against the third risk, which can be just as complex, fumigation is an essential safeguard.

During the journey from farm to fork, across and within borders, which often sees drastic changes in the surrounding environment, fumigation takes place at multiple points to keep storage facilities free of invasive pests. However, with the most commonly used chemicals for fumigation lacking effectiveness or having a severe environmental impact, industry is now looking for new solutions to ensure that feeding a global population is not contributing to the same extreme climate change events that we have been experiencing ever more frequently over the past few years.

Fumigation – a structural part of the industry

As grain travels throughout the supply chain, it is vulnerable to pests including insects and rodents. According to the United Nations Food and Agriculture Organisation, around 40 percent of the food produced annually is lost due to pest infestations. Fumigation is essential to provide the safe storage and transportation of these commodities and takes place in grain silos as well as ship holds. On average, grain silos should be fumigated every six months to ensure a pest-free environment. As well as protecting natural flora and fauna; fumigation also plays a crucial role to promote global food security. The world is increasingly reliant on efficient, cost-effective, and uncontaminated food supply chains. Amid a more challenging

climate and exponentially rising demand for food, fumigation to guarantee safe storage for bulk commodities like grain becomes ever more crucial.

Historically, the pest control industry has relied heavily on the chemicals methyl bromide and sulfuryl fluoride for its fumigation needs, but scientific analysis of their environmental impacts is prompting industry and regulators to seek out alternatives.

The go-to fumigants have an unacceptably negative environmental footprint

Methyl bromide, once the go-to fumigant, is a toxic ozonedepleting substance. Its reactivity in ozone depletion is more than 50 times greater than bromine, and evidence suggests its use has resulted in conditions including cancer and paralysis for applicators and neighbouring communities where fumigation takes place.

In fact, estimates suggest that every kilogram of methyl bromide used destroys about 4.2 tonnes of ozone. Recognising this threat, the Montreal Protocol, an international treaty, was agreed in 1987 to protect the ozone layer by phasing out methyl bromide by 2015. Some countries, including Canada, the United Kingdom as well as the European Union’s Member States have banned its use altogether within their borders. However, many countries continue to use it under quarantine exemptions, with alarming increases in its use noted in nations including Australia, China, and India for this purpose in recent years.

Searching for an alternative to methyl bromide, industry has shifted heavily towards the use of sulfuryl fluoride as an alternative. While effective, sulfuryl fluoride presents its own risk to the climate. A synthetic greenhouse gas, sulfuryl fluoride has a Global Warming Potential 4600 times that of carbon dioxide. Approximately 1000 tonnes of sulfuryl fluoride are used annually in Europe alone, resulting in emissions equivalent to 4.5 million tons of CO2, leading to renowned climate scientist Susanne Götze to label sulfuryl fluoride a ‘climate killer’.

Despite the recognised environmental harms of both methyl bromide and sulfuryl fluoride, their use in fumigation falls outside the regulatory frameworks of major environmental agreements like the Kyoto Protocol or the Paris Agreement. Currently, there are no global targets for reducing emissions from these chemicals. As a result, around 11,000 tonnes of methyl bromide and 3000 tonnes of sulfuryl fluoride continue to be used each year, contributing to the worsening climate crisis.

While historically considered to be a preferred alternative to methyl bromide, sulfuryl fluoride is now under pressure from

46 | April 2024 - Milling and Grain F

A reliable team for a reliable project YOUR

55 million m3 built Projects in 150 countries

New pendular and rotative sensors

ATEX 20 certified, the zone with the highest risk

· SY-DP1 Pendular . Robust and simple. It does not require power and maintenance.

· SY-DR1 Rotative . Sensitive. It has 2 operating modes depending on the density of storage material.

Top Project worldwide

Flexibility and adaptability

symaga.com • +34 91 726 43 04 • symaga@symaga.com

RELIABLE PARTNER

Your Team for Great Flour

The Flourists, Part 5: Baking Technology

Protecting Baking Traditions through Innovative Ideas.

Baking industry demand for suitable ours is rising globally, and we’re supplying highly speci c answers. Developers of individual our treatment concepts: The Flourists, an interdisciplinary, worldwide networked team of experts who put their all into adapting our characteristics to the requirements of local baking ap-

plications. Thanks to our regional Technology Centers, customers get unique our additives developed locally, that are designed speci cally for local baking traditions and varying grain qualities. The result: Diversity in baking culture and consistently good baking quality in ours, for professional and home use. #the

ourists

muehlenchemie.com

regulators, especially in Europe. Last year, some EU Parliament legislators negotiating a new Fluorinated Gases Regulation called for sulfuryl fluoride to be banned. An outcome on this Regulation has still not been reached. And amid a cold snap at the turn of the year, authorities in some German states prohibited the use of sulfuryl fluoride at low temperatures due to concerns about its effectiveness, disrupting the international timber trade and causing huge backlogs at European ports.

With governments across the world imposing more stringent sustainability-related rules and obligations on business, there is now significant pressure from regulators and investors for companies to show their activities are compatible with a net zero future. There is increasing pressure on suppliers, at all levels of supply chains, to account for their carbon footprint, including their associated emissions.

Facing these challenges, the grain industry is now urgently in need of alternative options.

What are the alternatives?

While methyl bromide and sulfuryl fluoride are not the only available treatments for fumigation, there is not yet a clear alternative.

Options such as phosphine – widely used in the grain industry – as well as heat treatment, do not have the same environmental impact as methyl bromide and sulfuryl fluoride. Some countries are also actively exploring integrated pest management systems, which relies on an understanding of pest ecosystems and the changing seasons to maintain control of potential threats.

However, for all alternatives, effectiveness is king. Resistance to phosphine is being increasingly observed in some pest species. Heat treatment faces similar efficacy challenges, and in an environment of inflated energy prices, can be cost-prohibitive. Integrated pest management is 100% chemical-free, but also highly vulnerable to changes in the natural world, increasingly a problem amid a more volatile climate.

Regulators under pressure

The lack of focus from global policymakers and regulators on the environmental impact of fumigation, which is absent from any discussions in the COP process, makes life harder for an industry in need of new alternatives.

Registering a new fumigant is a challenge. Despite the known climate harm caused by traditional products, regulators often

drag their feet, resulting in a lengthy and onerous process, requiring broad and deep data sets on issues such as efficacy and environmental impact.

These same regulators more or less hold the keys to the kingdom on fumigation and so some industries are calling on them to speed up the process of registration of alternatives. As noted by The Methyl Bromide Technical Operations Committee at the UN, there is some progress on access for alternative solutions. Along with strong evidence, the backing of supply chains reliant on such products is a critical component for supporting the registration of new products.

A way forward?

Regulators in some countries, particularly those where the agricultural sector is especially important, are seeking environmentally sustainable alternatives to methyl bromide and sulfuryl fluoride. For example, in 2023, Australia registered hydrogen cyanide, a highly effective and environmentally sustainable replacement for both products for the milling and grain industry. Hydrogen cyanide is also registered in the EU, South Africa, Malaysia, and New Zealand.

In addition, and whilst not directly attributable to the milling and grain industry, both New Zealand and Uruguay’s Governments and forestry sectors aligned in opposition to methyl bromide, prompting regulators to register and approve Ethanedinitrile (EDN) as an effective, environmentally sustainable, alternative treatment for forestry products. This signals a growing industry shift towards responsible and sustainable treatment solutions.

Other countries are also exploring alternatives to the major legacy products. Yet with access to alternative products dependent on governments and regulators supporting registration and commercialisation, the voice of industry – specifically, end users – is crucial. As such, the grain storage and transportation supply chain must drive its own access to new, environmentally sustainable, alternatives by communicating the challenges and needs to decision-makers.

There is more focus than ever before on the environmental impact of supply chains and this is expected to increase. Unless new, effective and less environmentally harmful solutions are made accessible, the grain industry will continue to find itself in a difficult position. The choice, between being a laggard on sustainability, or risking the security of critical commodities, is not one our industry will want to be forced to make.

Milling and Grain - April 2024 | 49 F

ASYNCHRONOUS MOTORS: Drive belt versus direct drive

by Thomas Ziolko, Head of Product Management Wheat & Rye & Remo Friedrich, Mechanical Development Engineer, Bühler, Switzerland

In a modern flour mill, hundreds of machines are in operation, the vast majority of which are equipped with electric drives. Choosing the right type of motor and the right overdrive is vital for the efficiency, operational reliability, and maintenance requirements of the relevant application. For some years now, leading machine manufacturers have been using direct drive for some of their machines. Until now, large plansifters were an exception. They continue to be driven by an asynchronous motor with belt drive – for good reason.

Quod licet jovi non licet bovi – what is permissible for Jupiter is not permissible for cows. Even the Romans knew that it can be a good idea not to treat two things in exactly the same way. If this principle is applied to the drives of the machines and equipment in a mill, this means that what is suitable as a drive technology for a roller mill is not necessarily the best solution for a plansifter

Advantages of direct drive

The electric motor plays a central role in flour milling. Various versions of this type of motor are used with extremely diverse overdrive systems at every stage of the milling process, from the intake of raw materials through to the bagging of the end products. Over the last ten years, leading mill builders have successively replaced the classic asynchronous motor with belt drive in their machines with a direct drive or gear motor. Today, these new drive systems are mainly used to operate bran finishers, impact detachers, and modern roller mills, for example. These solutions can be divided into three categories.

Asynchronous motor with gear system

In relation to a belt drive, a mechanical gear system has a slightly higher efficiency of around 98 percent. It is also easy to maintain and comparable in price to a belt drive. However, the high efficiency of the gear system is offset by restrictions in terms of machine design. In addition, explosion protection approval causes problems for gear units with high power and low speed.

Direct drive with asynchronous motor

An asynchronous motor with direct drive has no loss of power in overdrive because the power is transmitted directly to the machine. For the most part, standard motors are used. These are available worldwide, operate efficiently, require little maintenance, have an impressively long service life, and undergo low wear.

The nominal speed of the motor must be considered in the design. If the required machine speed is outside the nominal speed, a frequency converter must be used. In addition, larger motors must be selected for lower speeds. This applies to motors used with a frequency converter as well as to motors with low nominal speeds.

Direct drive with synchronous motor

A synchronous motor with direct drive has several advantages over an asynchronous motor. It works even more efficiently and is considerably more lightweight for the same level of power. In addition, it is available in various designs, which facilitates its integration. The disadvantages are its high price and the power electronics that are vital for its use. Synchronous motors are rarely available as a standard product across multiple manufacturers. Worldwide availability is therefore not guaranteed. Finally, the required certifications (e.g. ATEX) are also difficult to obtain.

50 | April 2024 - Milling and Grain F

Behlen bins range in size from 85 to 66,000 cubic meters. These silos feature a unique trapezoidal wall panel design. COMMERCIAL GRAIN BINS Behlen hoppers are designed to ensure strength, ease of assembly, and trouble-free operation. COMMERCIAL HOPPER TANKS Behlen Steel BUILT TO LAST Behlen Grain Systems... Standing the test of time with competitive prices and Customer Service second to none. CONTACT US TODAY TO DISCUSS YOUR PROJECT! Call 1-402-564-3111 or Visit www.behlengrainsystems.com Bigger and Better than Ever!

Plansifters: the asynchronous motor in pole position

The principle of the free-swinging plansifter was developed in Germany as early as 1895. It consists of two sieve modules with a centrally placed flyweight. Thanks to this arrangement, plansifters can be suspended and allowed to swing freely. Although this option has been used for many years, after a thorough analysis of the entire system, Bühler’s engineers are convinced that for the classic plansifter, the asynchronous motor with belt overdrive is still the best choice.