Women in Milling

This month contains an annual event close to my heart: International Women’s Day. And so it feels timely to celebrate the contributions of women to milling, past and present.

- ‘Beans in toast’ - Can Britain raise the pulse?

- Determination of rheological properties of dough

- Automatic drum emptier: A unique technology for toxic/explosive powdery products

millingandgrain.com March 2023 In this issue: Milling and Grain . Volume 134 . Issue 3 . March 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL

Volume 134 Issue 3

PARTNER

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher

Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Digital community manager

Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

VOLUME 134 ISSUE 3 NEWS 10-28 42 Women in Milling 46 ‘Beans in toast’ - Can Britain raise the pulse? 52 Determination of rheological properties of dough 56 Grain quality assessment in the new age: GRAMS-M10 mobile app for accurate grain analysis 60 Four good reasons to include soy in diet formulation for young animals STORAGE 58 Automatic drum emptier: A unique technology for toxic/ explosive powdery products 8 PUBLISHER Roger Gilbert 104 INTERVIEW Thomas Kaesar ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 80 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 28 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 33 Industry training news PRODUCT FOCUS 36 CASE STUDY 78 INDUSTRY PROFILE 76 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 March 2023 COVER IMAGE: Women in Milling - see more on page 42 FEATURES millingandgrain.com ISSN No: 2058-5101 ‘Beans in toast’ - Can Britain raise the pulse? See more on page 46

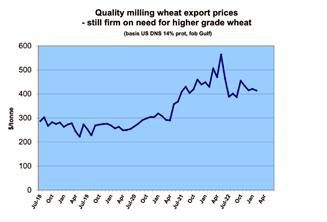

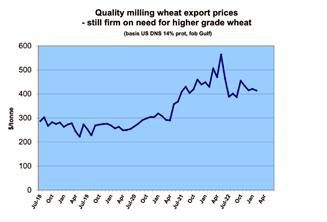

MARKETS

70

John Buckley

I heard it on the radio ...

From the BBC evening news, as I start to write my editorial, I’m informed that tomatoes and other early summer fruits and vegetables might have to be ‘rationed’ by some UK supermarkets due to poor spring growing conditions in southern of Spain and North Africa.

What are we to do?

Roger Gilbert

Go without? Now there’s a thought to be considered. Would we be prepared to go without to help reduce the transportation associated with growing crops, vegetables and even animal products long distances from where we consume them? I’m not so sure we would do that voluntarily.

Food rationing was the order of the day here in the UK following the Second World War but at a point in time when the whole population was pulling together to make the best of a bad situation left after four or so years of intensive fighting across Europe, the Middle East and Asia.

There was camaraderie in facing a difficult situation together - and that coupled with stoic good humour of British people helped to pull the country through.

That might not be the case in a situation almost 100 years on when the cause we are asked to address is not universally agreed upon. Rationing on a national scale and involving all aspects of imported foodstuffs might not work as well and while there was an end sight to rationing following WWII there would be no possibility of future relief from rationing in response to managing climate change.

There is a place for globalisation in our world - and we all know it.

James Cooper writes in this edition about alternative, locally produced protein sources to supplement a basic food staple, bread. He looks at the possible inclusion of locally grown faber beans to add to bread’s nutritional value and at using a crop that can be grown readily in the UK - a win-win he calls it. There is a significant three-year project underway to evaluate such a change might have on an essential food source.

We in the milling industry rely on global supplies of wheat varieties that make up the wide range of flours that bakers in particular, and consumers in turn, have come to expect from us on a daily basis. Tampering with the supply chain can only cause anxiety at one extreme to human health implications at the other. However, we cannot sit by and feel comfortable what we are doing without explanation. Transparency is everything. We have to make our case for the continuing global trade in grain crops so that millers can continue to deliver the best and most relied upon staple at prices consumers can afford everywhere.

Reducing food miles is not the answer. Producing locally grown grains to compliment imported basics is very much a way forward and millers must be open to engaging in that development.

By that I mean we have to show a willingness to moderate

our production processes to handle smaller intakes of grains from local farmers and produce flours that retailers and bakeries would like to use. In the eyes of consumers ‘local is good’ and we are in a position to provide an integrated approach bringing together local-and-global supply chains to benefit consumers and assist towards greater self-sufficiency. This does not just apply to flour millers but to animal feed millers as well.

We should also have higher expectations of ourselves in explaining what we do and why. We should look into the true cost in terms of the carbon footprint associated with growing, harvesting and moving significant volumes of grain and how that compares to the cost of locally produced milling raw materials. I would not be surprised that the cost in terms of price and carbon per kg at the mill intake favours that coming farthest.

We live in a world where self-sufficiency for many nations is not possible or realistic; where populations have fare outpaced their country’s ability to provide sufficient food from local sources, year-round.

Worldwide we have a strong and sound milling industry for flour and feed that uses the same equipment, processing the same types and varieties of grain and raw materials to produce a vast array of end products for bakeries and farmers that meet local and cultural needs.

It’s up to us to champion the success of our globally, joined-up milling industry in terms of safety, nutrition, economies of scale and affordability by identifying and justifying our impact on the planet.

World Flour Day - March 20th

There is every good reason for you to remember when World Flour Day is - that’s because we have carried the date on the cover of each edition for the past year, and prior to that.

World Flour Day is the day in which we should celebrate those who are involved in the production of flour right from the development of the wheat and grain varieties we use. There is a website for World Flour Day (https://worldflourday.com/) where I’m requesting all of you to visit and leave your thoughts and your plans for World Flour Day in your communities. Let’s show and tell the world who we are and why what we do is so essential!

I hope you enjoy this edition of Milling and Grain … after all, you won’t hear this content on your radio.

Milling and Grain has a cooperative partnership with COFCOET

Annual Subscription Rates

Inside UK: UK£100

Outside: US$150/€133

More Information

www.millingandgrain.com

http://gfmt.blogspot.co.uk

PINGLE.

PROFESSIONAL MANUFACTURER

★ ISO 9001:2015 CERTIFIED

Аdd: Zhengding, Shijiazhuang,Hebei,China

Tel: +86-311-88268111 Fax: +86-311-88268777

E-mail:pingle@pingle.cn / www.pinglemachine.com

OF GRAIN MACHINERY

★ INTEGRATED MILLING SOLUTION PROVIDER

NewsMilling

Welcome to the third edition of this year’s Milling and Grain magazine, let me begin by offering my sincere condolences and sympathy to Turkey and Syria for their devastating loss in the powerful earthquake. We urge our readers to consider donating to support these two countries’ recovery effort in any possible way.

IPPE 2023 - Interview with Giuseppe Bigliani and Noam Silberstein, AGI

Giuseppe Bigliani, International Account Executive also at AGI talks to Roger about opportunities at the Online Milling School.

Giuseppe tells Milling and Grain magazine about his experience stating that if you’re in the petfood, aquafeed, or milling business, attending these courses is a must! The knowledge and experience gained from direct contact with experts in the field gives attendees a first-hand learning experience and invaluable knowledge of every step of the production process.

To find out more about the OMS, go to: www.onlinemillingschool.com

Noam Silberstein, Senior Vice President of Global Feed at AGI, talks to Roger Gilbert, the publisher of Milling and Grain magazine, during the 2023 IPPE Exhibition, which was held over threedays in Atlanta, Georgia, USA from January 24-26, 2023.

Noam tells us about the companies’ development in the feed sector, their initial focus being North America, Brazil, and LATAM. Now, AGI is launching into feed milling proper with its Flexmill Solution which involves its new Flexmill feed system.

To view both interviews, visit Milling and Grain’s home page and follow the MAGTv link.

mymag.info/e/1593

To start off this edition, I would like to emphasise the importance of the month March to you all- in the Northern hemisphere, spring begins and so does the time for planting. In the Southern hemisphere, autumn draws in so the harvest season must start. Not only does March signify the beginning and ending of harvests, but there is a very significant date that should be in every miller’s calendar- March 20th, World Flour Day.

Here in UK, we narrowly escaped a recession but we are stuck in the stage of ‘stagflation’ - weak growth and elevated inflation mimicking the economic turmoil of the 1970s. Experts are giving out varied opinions on how the economy can survive, but the fact that unemployment has started to rise suggests one thing: this is going to hurt. For a little look into our news surrounding the world, in Germany Evonik has invested €25 million into a new production plant and multiplies production capacity for probiotics.

ADM opens a US$30 million+ state-of-the-art production facility in Spain and AB Vista broadens their portfolio on gut-health with a product acquisition. You can gain some more insight into these interesting things in our news section of the magazine or on our website.

Mentioning the world further, we offer some inside information on IPPE 2023 with lots of pictures from Atlanta, USA. Members of our team visited the event and got to reconnect and meet with many people from around the world. We also have an amazing report on IAOM MEA in Jeddah, Saudi Arabia where they tell us all the fun facts about the stuff that happened at the event.

Finally, we have a little reminder about VIV Asia as well. Milling and Grain are not only attending this event in Bangkok, but we’re also helping host three separate conferences too. If you didn’t get a chance to attend then you’ve truly missed out on some amazing talks that happened.

If you or your company would like to share your own experiences at these global events or would like to showcase any new products in either our magazine or website, then shoot us an email here:

editorial@perendale.co.uk

gfmt.blogspot.com See more videos from all aspects of the industry at millingandgrain.com/videos

10 | March 2023 - Milling and Grain

The Milling Journal 2023

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream byproducts of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients.

The Journal will particularly embrace scientific and technical information on novel processes enabling the generation of ingredients for manufacture of bread, cakes, confectionary, pasta and a plethora of applications for diverse types of breakfast cereals, beverages and the infant formula markets. We also consider papers on complete animal feed manufacture as a core topic. These usually require pre-grinding and milling/flaking of grain and cereals for terrestrial animal feeds such as for poultry, swine, ruminants and equine. Animal feed production can involve drying, milling, pelleting, steam and pressure conditioning, shaping and texturisation dependent on specific machinery. Processes such as extrusion, cooking and expansion are of paramount importance with much research being undertaken on engineering, both mechanical and electrical. Effective storing and preservation methods offer opportunities for papers.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Milling Journal will appeal to the scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral researcher being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief.

These OA papers will be available on our official website millingandgrain.co.uk and printed in the magazine as well as being downloadable. Links will be provided within our existing Milling and Grain magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

ADM opens $30 million production facility in Spain

ADM, one of the world's leaders in science-backed nutrition solutions, has announced that it has opened a new production facility in Valencia, Spain to help meet rising global demand for probiotics, postbiotics and other products that support health and well-being.

The production facility represents an investment north of $30 million and a more than five-fold increase in ADM's production capacity, increasing it to 50 metric tons per year. The facility will allow ADM to supply growing markets for probiotics and postbiotics in the U.S., Asia-Pacific and Europe. ADM expects its customer base will more than triple over the next five

the company fulfil its expansion strategy in the health and well-being sector. ADM is on its way to realising its ambition to increase health and wellness revenue from over US$500 million in 2022 to $2 billion within 10 years.

“Health and well-being is one of the three enduring trends powering ADM's growth strategy: Consumers are increasingly aware of the role their gut microbiome can play in their everyday lives, and they're seeking nutrition solutions that are backed up by science-based research,” says Mark Lotsch, president, Global Health & Wellness. 'ADM is a leader in meeting this growing global demand, and we're continuing to invest in the cutting

Kult brand of products.

The new facility is located close to ADM's pioneering research and development center in the University of Valencia Scientific Park, where ADM scientists undertake activity including next-generation genome sequencing and early-stage testing of new bacterial strains.

Market research estimates that the probiotic supplements retail market could surge to $10.4 billion by 2027

Milling and Grain - March 2023 | 13 Milling News

You Have A Vision For Your Business.

Cimbria can bring it to life.

We’ve been doing it for over 75 years. With dedicated experts at your side from start to finish and beyond, Cimbria will help you grow with confidence. So you can look forward to a prosperous future.

Do you have a unique grain or seed processing challenge? From customized plant design to turnkey installations and expert support, Cimbria can help find the right solution for your success.

Cimbria.com A/S Cimbria Thisted, Denmark Phone +45 96 17 90 00 cimbria.holding@agcocorp.com

World Flour Day 2023

Focus on the Future of World Nutrition! On March 20th, the global milling community will come together to honour the significance of flour, a staple food for mankind with the theme "The Future of Flour”.

The FlourWorld Museum in Wittenburg launched this initiative for the global celebration of the “white gold of life” once a year on 20th March – from New York to Sydney, from Buenos Aires to Mexico City, Lisbon to Moscow. This date, halfway between the two solstices, was deliberately chosen for “World Flour Day.” In the Northern hemisphere the spring marks the start of the planting season, whereas in the southern hemisphere it is autumn and harvest time. Therefore the period around 20th March is a special time of hope and gratitude.

In 2023, the entire flour processing industry celebrates diversity and belonging on this day. To this end, the museum has invited all farmers, producers, processors, retailers or shippers of flour to submit stories on what your vision for the future of flour is. You can speak for yourself or your mill, your institution, your company, your bakery, your family, your team by Submitting your photos, videos, and stories on www.worldflourday.com. Flour knows no limits. The stories will be featured in World Flour Day Website, FlourWorld Museum Social Media sites and Mühlenchemie Social Media sites.

It’s the third time this day is celebrated, and together with the global community of dedicated flour professionals, with the focus for this third World Flour Day being the significance of flour for each individual. The FlourWorld Museum in Wittenburg near Hamburg, Germany, holds the world’s largest collection of flour sacks, with over 3700 sacks from 140 countries.

The chief aim of this project is to give a varied picture of the important role flour plays around the globe and how it affects, shapes and enriches all of our

The future of flour.

What is your vision?

Share your thoughts: contact@worldflourday.com

Milling and Grain - March 2023 | 15 Milling News

The Chilean Ministry of Agriculture and INDAP delivers aid to 6,500 farmers

The Chilean ministry of agriculture and INDAP will allocate close to $1,500 million pesos, in the first instance, to ensure fodder and food for animals in the regions declared in emergency. Meanwhile, the Biobío region began the delivery process in the commune of Santa Juana. To date, 291,574.24 hectares have been consumed by fire.

“We are starting to deliver aid to farmers who are having a hard time in this emergency.” said the Minister of Agriculture, Esteban Valenzuela when he began the process of delivering aid to the regions affected by the forest fires. “With an immediate focus, as requested by the President of the Republic Gabriel Boric, INDAP and the SEREMI -through the Undersecretary of Agriculture- begin to count the distribution of $1.5 billion in aid to the 3 most affected regions –Ñuble, Biobío and La Araucanía-in addition to partially Maule and Los Ríos. The aid consists of bales with animal feed that allows for 15 days to feed a heifer and its calf or its equivalent in five smaller animals such as lambs and goats or 100 chickens, depending on the reality of each producer," says Minister Valenzuela.

In detail, about 26,000 bundles will be allocated to the Ñuble region; 40,000 for the Biobío region and 40,000 for the La Araucanía region, both for INDAP user farmers and non-INDAP user farmers. Additionally, it is planned to distribute 14,000 bundles in the Maule region and 10,000 in the Los Ríos region.

“This contribution will help more than 10,000 animals, and if they are chickens it will multiply much more, and it will continue to grow progressively; it is a shock aid, which is very important for small farmers,” Minister Valenzuela says.

Delivery in Biobío

In parallel, in the Biobío region, the delivery of multispecies concentrate began to support affected farmers in Santa Juana. This consists of 30,000 kilos of food, which was distributed by the Minister of Public Works, Juan Carlos García, and the national director of the Institute for Agricultural Development (INDAP), Santiago Rojas.

As Minister García explains, “this fire affected places where the rural population is very important and what we are doing is not only making it visible, but we are acting quickly to protect something as valuable as their animals. We made a commitment to the mayoress of Santa Juana that we were going to leave here, due to the magnitude of this emergency and here we are in great coordination with INDAP and the Ministry of Agriculture so that as a Government we arrive in a timely manner.”

Along these lines, the director of INDAP explains that “we have provided more than US$1.200 million to support this emergency as a first measure for, in this case, animal feeding (…) These peasant families cannot wait; This is their sustenance, their way of life, their chickens produce their eggs for their own food, and what we do today is support 120 peasant families here (Santa Juana).

Subsequently, we go to Nacimiento, and 10 bags of animal feed with 25 kg each will be delivered, which allows a feeding of 7 to 14 days depending on the livestock mass. This is just a first step.”

For her part, the mayoress of Santa Juana, Ana Albornoz, thanked the help and emphasised that 'the President has listened to us. He is doing miracles, something that has never been seen in this country, because good things must be said. It is the fifth or sixth day since the emergency began and we are already arriving with help for the animals, which are the most important thing left to the peasants'.

Sanitary measures

During the day, Minister Valenzuela, together with the Undersecretary of Public Health, Cristóbal Cuadrado; the presidential delegate, Gabriel Pradenas, and the national director (s) of the Agricultural and Livestock Service (SAG), Andrea Collao, delivered a series of measures to care for the animals affected by the fires, this within the framework of the Management Board of Animal Dimension Disasters. This instance aims to ensure animal safety considering the complexities of the current emergency situation, addressing aspects such as food, veterinary and health medical treatments and hospital care for animals, among others.

It is that as explained by Undersecretary Cuadrado, regarding animal welfare, an articulated action has been arranged together with the SAG to be able to respond to the need for human and animal health. “All of our shelters are seeking coordination to be able to provide an answer to those people who transport or have been evacuated with their animals and give them peace of mind that their animals will also have an answer and for that we are working with the SAG, and the Veterinary Medical College, among other actors. Additionally, reiterate that when we have an animal that has died, that animal must be buried avoiding transfers and handling, they must be buried away from water sources, at least one meter deep," says the authority.

For her part, the national director(s) of the SAG, emphasised that “what we mainly seek is to emphasise animal welfare and the rescue of wildlife, given that wildlife has a fundamental role in reforestation because each animal, pudu, monito del monte, will contribute to the fertilisation of the soil and the dispersal of seeds; Therefore, we have to be clear that each animal is an ecosystem,” Ms Collao points out.

Finally, the presidential delegate, Gabriel Pradenas, revealed that “as a presidential delegation, community and region we feel very accompanied by the central government and the territorial and institutional articulation that has been deployed throughout the region (…) We have deployed a series of devices that respond to both farm animals and those of small farmers, livestock and responsible pet ownership, that is all the deployment of the Ministries of Agriculture and Health in the Ñuble Region.”

16 | March 2023 - Milling and Grain Milling News

Evonik invests €25 million in production plant upgrade

Evonik has invested €25 million developing and expanding its methylmercapto-propionaldehyde (MMP) production plant in Wesseling, Germany, in the latest move to strengthen its world-scale global methionine production network.

MMP is integral in the production of MetAMINO® (DL-methionine) which is used in animal feed to improve the performance of livestock farming. The precursors of this essential amino acid have been produced in Wesseling for more than 50 years.

Dr Gaetano Blanda, head of Animal Nutrition business line, says, "With this investment, Evonik is strengthening the European methionine network to safeguard the long-term supply of MMP to our MetAMINO® production hub in Antwerp, Belgium. The move underscores our commitment to serving and expanding the global DL-methionine market and secures the best possible supply security for our customers.”

The conversion and expansion of the plant in Wesseling has been made possible by the development of a new production process, that will allow to avoid the storage of chemical intermediates, such as acrolein, at the site.

Commenting on the plant upgrade, Dr. Jan-Olaf Barth, head of the Essential Nutrition product line, says, 'Evonik is known for its innovative approach and world-class technology, and in Wesseling we have now developed a process that increases efficiency and, with Responsible Care in mind, further enhances safety at the site."

He adds “This investment is a building block of our global methionine asset strategy with the clear goal of being the cost and technology leader in all regions, and the reliable partner for our customers.”

At the heart of Evonik's methionine asset strategy are three worldclass global production hubs covering Europe (Antwerp, Belgium), Asia (Singapore) and the Americas (Mobile, Alabama).

Consolidating production at these hubs ensures a reliable product supply as well as offering opportunities for cost-efficient debottlenecking and future expansion.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com Milling and Grain - March 2023 | 17 Milling News

Genome boost for nature-friendly pest control

Anew database of 19 insect genomes encompassing some of the most damaging pests of crops worldwide has been made publicly available. It includes some of the most common pest threats faced by UK farmers including wireworm, cabbage stem flea beetle and pollen beetle, as well as other globally important species.

It is hoped that the new database will help speed up the development of novel pest control approaches that can overcome resistance and create more nature friendly solutions to crop protection.

The four-year Pest Genome Initiative, a consortium of Rothamsted Research and the agriscience companies Syngenta and Bayer, firstly sequenced the genomes, and then assembled them into their constituent chromosomes before adding information about what individual genes code for.

The team say their efforts will help in the development of crop protection products that are more species-specific and overcome the problem of resistance. They will also help develop non-chemical pest control methods, such as manipulating insect behaviour; focusing on the genes that control how insects find mates and host plants and hence shepherd them away from crops.

Before the research team set to work, detailed genomes had been assembled for only a handful of the planets one million plus insect species – and even fewer of these were crop pests.

The team say their efforts will also help in the development of pesticides that are less likely to incite resistance evolving in their target species – a huge problem for farmers and often the reason for excessive pesticide use.

Rothamsted's Professor Linda Field, one of the research leaders, says the future of farming would be 'smarter' and involve less pesticide use: dovetailing the electronic surveillance of insect movements and measures that encourage natural pest control, with these newer, more targeted pesticides.

She says, “Currently as much as a fifth of all crops are lost globally to pests, and this is predicted to increase to 25 percent under climate change. Whilst non-chemical control methods can have some success in reducing crop losses, pesticides remain a necessary weapon in our fight against devastating crop losses and will so for the foreseeable future.”

Pesticides have long been implicated in wider biodiversity declines, most notably with the impact some neonicotinoids

have on bee populations, leading to the subsequent banning of these pesticides in Europe.

By assembling these detailed genome 'maps' of annotated sequences, researchers can start to develop the next generation of pesticides – ones that very specifically target the pest whilst leaving other species unharmed, says Professor Field.

All the pests included in the Pest Genomics Initiative are well known for attacking vitally important crops worldwide, including oilseeds, vegetables, cereals, fruits, beans, sugar and cotton.

The hope is that by having these higher quality genomes available, researchers will be able to better understand how resistance to pesticides evolves – and it will also improve their understanding of insect chemical communication channels, opening up the possibility of non-lethal control methods that 'hijack' insect behaviour.

“Understanding the pests' genes means we can understand the specific proteins they make. By comparing these proteins to the proteins made by non-target species, we can tailor control methods that only work on pests. Examples include those proteins that allow pests to de-toxify pesticides, the basis of much evolved resistance.”

Another exciting area for research will be into the genes involved in insect behaviour, the so-called odorant binding proteins and receptors, which allow insects to find mates or host plants. she adds.

“If we can produce products that target those, we can potentially manipulate pest behaviour and shepherd them away from the crops.”

A further use for these genome sequences is in identifying insect species that have the potential to switch diets to feed on other crops – something that may become an issue in certain countries as pests migrate or new crops are grown as the climate changes.

The genomes will also be an important resource for the wider entomological community studying insect evolution, physiology, biochemistry and ecology.

In recognition of the fact that the future of pest management will involve both better targeted chemicals and other techniques, the project also assembled the genomes of three beneficial insects, the European hoverfly, and the pirate bug, both of which predate crop pest species, as well as a species of parasitoid wasp that lays its eggs inside the crop pest, the cabbage stem flea beetle.

Milling and Grain - March 2023 | 19 Milling News

Flour mills in Delhi and Bombay in 1902

by Mildred Cookson, The Mills Archive, UK

by Mildred Cookson, The Mills Archive, UK

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

At the start of the 20th century there was much interest in the Indian milling trade as flour mills were being erected in various parts of the country. Calcutta, Delhi, and Bombay hosted some of the most important mills in India. At the time some ten flour mills were under European administration and there were several small, independently owned mills as well as competition with rice mills. In 1902 the journal Milling, the ancestor of Milling & Grain, published two well illustrated articles on two of the successful firms and I have summarised the reports here.

The roller mill of A John & Co, D

This mill had just been erected in July 1902 when the short

article about it was written. Mr John’s mill was built under the direction of Mr E Roberts, who had the mill completed and running within 3 ½ months, including building the mill up from the third floor and putting in all the floors. The mill was officially opened by Sir Edwin John on March 31st.

The John family were the exclusive owners of three spinning mills and one roller flour mill, all situated at Agra, and popularly known as the “John Mills of Agra”. Sir Edwin and his younger brother Sir George were the grandsons of Antonius Joanides, a Greek merchant, better known by his Anglicised name Anthony John. Sir Edwin built spinning and weaving mills at Delhi, Meerut, Agra and Lucknow. The mills were established in the late 1880s and had been languishing when the brothers became to revive them.

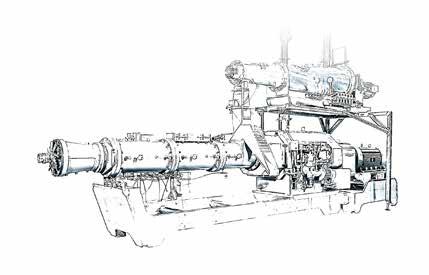

The new mill, equipped entirely by ER Turner Ltd of Ipswich and Mark Lane had a plant installed capable of producing 9 sacks per hour. They were 5 breaks done on 3 four roller mills with rolls 40 inches long and 10 inches diameter. The ten reductions were done on four 25 x 9 mills and one 30 x 9. The 5 purifiers were Turner’s “Dustless” type, all single machines. The scalping was done on patent ‘Vibrometer’ rotary machines, and the

Bombay Co's A and B Mills

The Turner Dustless Patent Purifier

20 | March 2023 - Milling and Grain

Messrs A John's Delhi Mill

dressing on two inter elevator reels and ten centrifugals. Later in 1902 the company decided to more than double the output of the mill and another order was placed with Mr. Turner for all the new machinery.

The Bombay Flour Mills Ltd

The Bombay Flour Mill Company Limited owned three mills, designated A, B and C. The first two adjoined the nearby C mill. Together they had a capacity of around 1,800 bags of 196 lbs in 24 hours. All the mills were equipped with the ‘Simon’ system and kept constantly up to date.

The A mill was re-modelled by Henry Simon in 1899 and was on

the five-break system. The brake rolls were 5 four roller mills, 40in x 40in and the smooth rolls eight four roller mills, 32in by 10in., along with one four roller mill for the scratch system. The scalping was done on Simon double horizontal scalpers, and the purification done on six No. 1 double ‘Reform purifiers. This was the smallest plant. B mill was remodelled a year later in 1900 and was on the four-break system. The break rolls were also 5 four roller mills 40in x 10in., with half a mill for the first scratch, and the smooth rolls 11 and a half four roller mills, 32in 10in., with half a mill for the second scratch. The scalping was done on double horizontal scalpers and purification on eight of the latest type of double Reform purifiers.

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT

Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets.

In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more.

>www.andersonfeedtech.com/healthcheck

The Delhi mill roller floor

Milling and Grain - March 2023 | 21

YEARS IN MILLING

MORE THAN 400 COMPLETE PROJECT PERFECTLY RUNNING AROUND THE WORLD

We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

R O L L E R M I L L

C mill was entirely remodelled from another system by Henry Simon when bought by the Bombay Company and had started milling in 1895. The plant was on a six-break system. Break rolls were six four roller mills, 40in x 10in., and the smooth rolls ten four roller mills, 32in. x 10in. for the scratch system. The scalping was done on double horizontal scalpers and purification on eight double Reform purifiers.

All the mills had Simon “Manchester” washers and the latest vertical whizzers, as well as a drying installation by Simon. The same firm’s machines were also in the wheat cleaning departments. They were also fitted with electric light, and “Grinnell” sprinklers.

Only Indian wheat varieties were used, principally Kurrachees and Delhis. However, in the early 1900s Australian wheat was

imported because of local bad harvests. Part of the output was consumed in Bombay, the remainder was shipped to Jeddah, Aden, Zanzibar, Mauritius, Madras and Colombo.

Conveying the flour to the docks and railway stations was difficult as there were no wharfs or sidings connected with the mills. Consequently, the flour had to be initially carried on bullock carts. This created additional problems as a bullock cart could only hold 9 bags and each load cost between 4 to 7 pence for hire of the cart.

The hot weather affected the woodwork in the mills and during monsoon the stout teak suffered from damp and had to be entirely renewed. This was regarded as part of the ongoing maintenance and despite these climate difficulties the mills were kept in splendid condition.

The Delhi mill scalping and dressing floor

Milling and Grain - March 2023 | 23 Milling News

Bombay Co's C Mill

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

The Future of the Bread Subsidy in Egypt

It is difficult to imagine a future scenario in which Egypt runs out of wheat. Bread is just too important. But what will be the costs of meeting Egyptians’ high demand for this staple food?

One option the government is exploring for reducing reliance on wheat is the addition of other things, like sweet potatoes, to the bread. Past efforts to add maize and rice flour to wheat bread, however, faced technical challenges and generated complaints about the taste, calling into question the feasibility of such initiatives.

The government has also changed its specifications for the subsidized loaves, shifting to less refined, slightly darker flour by raising the extraction rate. The extraction rate refers to the amount of flour extracted from the grain; it is an indicator of how much bran and germ are removed during the milling process. Whole wheat flour, for instance, has an extraction rate of 100 percent, whereas highly refined white flour has an extraction rate of around 72 percent. The higher the extraction rate, the more flour can be produced from a given quantity of grain. By raising the requirement for subsidized bread from 82 percent flour to 87.5 percent flour, the government reduced imported wheat requirements by about 10 percent (500,000 tons) in the coming year. Implemented in July 2022, this change has not received prominent coverage in the media, suggesting that the impact on the color and taste of the bread has been sufficiently subtle so as to not have sparked outrage.

In addition, the government has taken provisional steps to reduce demand, using the electronic ration card system that it introduced in 2015. Under this system, only those with ration cards can get bread at a subsidized price. In an incentive to limit their consumption below the allotted five loaves per day, they are able to exchange unused bread points for other subsidized goods, such as tea, cooking oil, and sugar. In 2019, the government tightened the eligibility criteria for obtaining a ration card, removing great numbers of people from the program. But the vast majority of Egyptians—about 70 percent of the population— remain eligible and further efforts to reduce access would be controversial. Even among middle-class Egyptians, who may be living above the poverty line but are far from affluent, bread is highly valued as a form of sustenance that is reliably inexpensive, whatever the fluctuations in other market prices. It is a food that can be turned to when times are tough.

As the conflict in Ukraine becomes protracted, a key question is how the government copes with the cost of purchasing grain either from farther away, with larger freight costs, or at higher prices due to an uptick in global grain markets. In June 2022, the Egyptian government signed a $500 million loan agreement with the World Bank to help finance its grain imports. This

project—specifically designed to support the subsidy and ensure the uninterrupted supply of subsidized bread—represents a notable turnaround from bank officials’ previous critiques of the subsidy for being overly costly, inefficiently operated, and poorly targeted. The bank’s openness to supporting the program suggests that the recent reforms have addressed at least some of the officials’ concerns about the subsidy getting to those who need it the most.

That the government chose to reduce expenditures on fuel subsidies while the poor benefit from cheap bread, they also bear the brunt of the other cuts required to maintain its ongoing supply.

Even given this assistance, the government may still have to cut other costs to help pay for grain. Notably, in July 2022 when the prime minister announced an increase in diesel prices, he justified this decision by saying the government needed to save resources to cover costs associated with the war in Ukraine.

A critical concern among the poor is that the budgetary pressure could lead the government to raise the price of bread, which has been 5 piasters since 1989. Although the government has reduced the size of the loaves over the years, the five-piaster price has become the marker of an affordable staple and a valuable symbol, one wielded by the government to proclaim its support for the people. Under pressure from international financial institutions to reduce expenditures and reform the economy, the government has shown its willingness to whittle away other forms of social support, but it has, thus far, refused to raise the price of bread, fearful of the instability such a move might produce.

Recent indications suggest, though, that political leaders contemplating a change. Since then, officials have stated that they are looking into different options, though they have yet to announce any further steps. With high rates of inflation and the spiraling of other costs of living generating considerable hardship and discontent, the government is no doubt wary of what an increase in bread prices might mean for internal stability. Indeed, despite reports that IMF officials pressed for a complete lifting of the bread subsidy during recent loan negotiations, when the $3 billion loan agreement was signed in December 2022 it contained no stipulation for a change in the bread program (fuel subsidies, on the other hand, were targeted for further cuts).

As policymakers and international experts continue to consider various options for reforming the bread subsidy and conflict in a major area of wheat production and exports continues, it is important to appreciate what is at stake. Subsidized bread is not just an object of policy. It is something that enters into the homes and bodies of tens of millions of Egyptians, which satiates their hunger and makes their meals whole. It is part of their lived experience of security.

24 | March 2023 - Milling and Grain

symaga.com • +34 91 726 43 04 • symaga@symaga.com 50 million m3 built Projects in 145 countries Top Project worldwide Flexibility and adaptability A reliable team for a reliable project YOUR RELIABLE PARTNER Improve silo tightness. Double Vertical Joint. · Tightness is improved. Double sealing on both sides of the screws. · Butyl rolls are supplied with double strip to improve assembly times. VISIT US VIV ASIA, Bangkok, Thailand 09 - 10 Mar, Stand 2661

The Israeli Ministry of Agriculture approves import quotas for duty-free eggs

The Israeli Ministry of Agriculture is opening quotas for the import of eggs with exemption from customs duty to authorised marketers from countries

from which the Ministry has approved imports, in order to increase the supply of eggs, and to meet the growing demand prior to Passover. The opening of imports at this time will allow

OUR ROTO-PACKER®

Contact:

Phone: +49 251 9796

E-mail: sales@behnbates.com

www.behnbates.com

importers to organise themselves, so that they can import eggs in preparation for the increase in demand for the festival, as is the case every year. In general, the State of Israel produces the vast majority of eggs consumed in Israel, amounting to approximately 2.2 billion eggs per year. However, as is the case every year in the run up to Passover, as well as the Tishrei [September / October] festivals, the demand for eggs increases. Therefore, again this year the Ministry approved import quotas of an amount of 40 million eggs, with exemption from customs duty, which will supplement the local production. Currently, egg imports are approved from five countries: Spain, Italy, Ukraine, Poland and Argentina. According to the estimates of professionals, the importers will only import eggs in accordance with the local demand, as is the case every year, certainly in light of the global price of eggs, which has risen significantly over recent months.

Professional echelon officials at the Ministry of Agriculture continue to monitor, and as necessary, will act to increase egg import quotas in accordance with supply and demand in the local market.

4 TO 10 MAY 23 DÜSSELDORF WE LOOK FORWARD TO MEETING YOU IN HALL 12/A27

Precise weighing and clean filling of valve bags - up to 2000 bags/h each 25 kg.

252

26 | March 2023 - Milling and Grain Milling News

BROCK® Mid-Roof Walkarounds

BROCK® Mid-Roof Walkarounds give workers safe, 360-degree access for equipment inspection and maintenance. They are pre-engineered to integrate seamlessly with Brock’s EVEREST® bins, stairways and ladders.

solid.brockgrain.com/walkarounds-int

Scan code to watch video E ciency Maintenance Confidence Safety Storage | Handling | Drying & Conditioning | Structures +1 866.658.4191 brockgrain.com

The life of Rex Wailes

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

Rex Wailes was born in 1901 in Hadley Wood, Middlesex, to a family of engineers. After school he became an apprentice engineer to the firm Robey and Company in Lincoln, before joining the family firm George Wailes and Company in 1924. The firm had been started by Rex’s grandfather in 1855 and manufactured a variety of machinery. Rex would remain there for the rest of his working life. But his interest in engineering was more than a job – it was his life’s passion. So outside of working hours he devoted himself to researching and preserving the history of industry in the United Kingdom and worldwide – and central to that history is the story of milling. In 1929 Rex discovered that his pet hobby, windmills, had been making national news with an article in the Daily Mail in which the Society for the Protection of Ancient Buildings requested the public’s help in saving mills. Rex was quick to respond. He was soon taking on the role of Technical Advisor to the SPAB, overseeing the repair of Arkley Mill in Hertfordshire and Stansted mill in Essex. In 1932 he became a founder member of the Windmill Section. Rex met Enid Berridge through their common love of music – she was a professional violinist. They married in April 1930 and had two daughters, living in a flat in Hampstead in London until the Second World War, when Enid and the girls were evacuated to Argylshire. Rex remained in London, living in the basement of George Wailes and Co and taking his place on fire watching duty at the weekends. The house they had lived in was destroyed, and after the war they moved out of London to a cottage at the bottom of the garden of Rex’s parent’s house. As soon as Rex’s daughters were old enough he often took them on his mill hunting trips, usually over the weekend. They helped him measure the mills and count the cogs on the gear wheels, as well as sketching and taking photographs. The results of many years of studying and surveying windmills were published in Windmills in England, 1948, and the longer work The English Windmill, 1954. Rex didn’t limit his work to the UK, but carried out surveys of mills in Spain, France, Barbados, Sweden and Finland.

After his retirement when the family firm closed in 1960, Rex was made consultant to the Industrial Monuments Survey for the Ministry of Public Building and Works. He continued in this role until 1971, carrying out surveys of Britain’s industrial heritage. He was also Honorary Consultant to the National Trust and the Royal Commission on Historic Monuments. He was chairman of the SPAB Mills Section from 1971 to 1974 and was made its first president in 1978. He received an OBE in 1973.

Rex Wailes died at his home, Davidge Cottage, Knotty Green, Beaconsfield on 7 January 1986, aged 84.

The Rex Wailes Collection

28 | March 2023 - Milling and Grain

Differentiating poultry products as safe, high quality, and sustainable protein sources is the focus of every producer. By helping to reduce waste and to improve food security sustainably, we at DSM support you to deliver premium poultry products to build your reputation in the market with confidence.

If not us, who? If not now, when? WE MAKE IT POSSIBLE

Follow us on: www.dsm.com/anh

Promote your product with confidence

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS

more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Sandvik Coromant – ‘Milling I Knowhow’ training

Part of Sandvik, a global industrial engineering group, Sandvik Coromant, a manufacturing and machinery solutions company are holding a ‘Milling I know-how’ training session, which is taking place in Renningen, Germany.

The objective of these training sessions includes expanding attendees’ knowledge on face-, corner-, end-, disc-, solid carbide-, hard-, thread-, and high feed milling. The first training opportunities are taking place in March 8-10, 2023. The sessions are 1 hour long and run from 12:00pm to 1pm. There will also be another opportunity later on in the year, with sessions taking place September 11-13, 2023.

The training will cover developing successful milling concepts, including component costs, tool selection, and metal removal rates are important factors for an optimal milling concept. It will also look at smooth commissioning and minimized production interruptions thanks to intensive advance planning, as well as important aspects for safe milling processes such as approach paths, ramp angles and chip space.

Other topics include digital solutions and online services for efficient milling. The training emphasizes the opportunity for practical exercises on the machines in small groups.

Attendees that would particularly benefit from this training includes; Engineers, Foremen, Machine operators, Production managers, Programmers, Technology Purchasers, Tool technologists, and Students.

The participation fee for the practical knowledge trainings is EU€500, the number of places is limited. This includes the costs of the booked event, all documents and catering. Sandvik Coromat also offer attendees help to book a partner hotel nearby.

Because it’s all about life.

The greatest global challenge is to ensure food security. Eight billion human lives depend on it. However, it matters how we source animal protein. Because it has consequences that affect animals, humans – and ultimately the entire planet. There is only one way to do it right: using science. Only well thought through, evidence-based solutions can establish a truly sustainable and secure food supply.

Sciencing the global food challenge. | evonik.com/animal-nutrition

9577_AZ_Sciencing_190x132_EN_230213-1.indd 1 13.02.23 10:56 Milling and Grain - March 2023 | 33 TRAINING Mill

IAOM PCQI Training

The IAOM Preventive Controls Qualified Individuals (PCQI) Training will be offered on May 9-11 in Kansas City, Missouri. The Current Good Manufacturing Practice, Hazard Analysis, and Risk based Preventive Controls for Human Food regulation (referred to as the Preventive Controls for Human Food regulation) is intended to ensure safe manufacturing/processing, packing and holding of food products for human consumption in the United States.

The regulation requires that certain activities must be completed by a “preventive controls qualified individual.” This course, developed by the Food Safety Preventive Controls Alliance (FSPCA), is the “standardized curriculum” recognized

by FDA; successfully completing this course is one way to meet the requirements for a “preventive controls qualified individual.”

Dr. Jeff Gwirtz, JAG Services, will be the lead instructor for the course, which offers a focus on food safety programs in a milling environment.

The event is taking place in the Embassy Suites by Hilton Kansas City Internatinoal Airport, USA, running from May 9 –May 11, 2023.

Fee’s for IAOM members are US$1075, and US$1150 for non-members. These feeds include tuition, materials, and lunches. Shuttle services are available from the airport to the hotel. To receive the certificate of completion, attendance is required for the entirety of the course, which adjourns at 3pm, Thursday May 11.

To enrol on this course, visit: https://www.iaom.org/online-course-enrollment-form/

TRAINING Mill Get weekly updates from the feed and flour milling industries with our email newsletter! Want more industry news? myMAG.info/e/289 YOUR GLOBAL PARTNER BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY 34 | March 2023 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less than £12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

We will be seeking enrolments from June ...

FOCUS Product March 2023

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

Hot Start Steam mixer by Van Aarsen

The Hot Start Steam Mixer helps to optimise the feed conditioning process and feed safety while minimising spoilage.

With the Hot Start Steam Mixer a guaranteed and accurate heat treatment is ensured. All the product exiting the hot-start steam mixer has reached the set temperature within ± 3°C tolerance. The Van Aarsen hot start steam mixer comes with a uniquely short start-up time. Some of the ingredients in feed pellets are also suitable as ingredients for food for human consumption. Therefore also from a sustainable perspective it has become ever more important to make sure spoilage of raw materials is minimised.

The hot start steam mixer helps feed millers to ensure the desired feed quality while maximising capacity as a result of the uniquely short batch start-up time, thus keeping feed costs low.

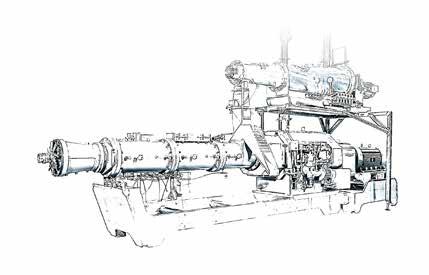

Extruder Barrels by Extru-tech

Extru-tech extruder barrels are already designed for broad production capabilities with maximum efficiency and minimal metal-to-metal wear. However, to further eliminate pathogens in the extruder barrel, extrutech advanced feature extruders utilize a modified barrel profile and increased steam injection into the barrel. Each extruder model can be equipped with multiple barrel length packages, each designed for the production of specific product types. Naturally, all extruder screws and liners continue to be constructed of high quality, wear-resistant stainless steel alloys that are subsequently polished, heattreated to required hardness specifications and then parallel ground to ensure proper fit between barrel components.

From unprecedented production capacities to exacting finished product quality, Extru-Tech Extrusion Cooking Systems have established the industry standards for performance and value. Extru-Tech’s Advanced Feature Extrusion systems were designed with two important criteria. The unit needed to be quick and easy to clean, and it needed to allow customers to control, reduce or eliminate contaminants in the system.

Rice Whitener unit NCP by Satake

This unit uses a proprietary rice milling system based on a combination of abrasion and two types of friction. Milling degrees can be changed to deliver optimum rice milling performance across many varieties and applications. High milling yield and low temperature rice milling are key features of this rice milling system.

Rice remaining inside the machine can be discharged at the push of a button, without disassembling the machine. The fully automatic model automatically discharges any rice remaining inside the machine or bucket elevator when rice milling finishes. This feature also prevents contamination when changing materials.

The machine can operate unattended by measuring whiteness after milling and controlling load with automatic weights. A constant on-site monitor is not necessary.

Adding mist to the final rice milling process removes isolated bran from the rice surface to create good taste and appearance. Wastewater treatment is not necessary because only a small quantity of water is used.

High Speed Dough Mixer by Baker Perkins

HS (High Speed) multi-purpose batch mixers feature heavy-duty construction and components, essential for mixing of pet food doughs. They offer high levels of automation, ease of use and cleaning, and outstanding reliability. A unique blade design ensures good dispersion and rapid dough development.

A stainless steel mixing blade which does not require coating can be specified for abrasive doughs containing bone meal. Variable frequency drive capability provides the ability to select mixing speed at will. It means that a mixing profile can be developed to match the characteristics of each type of dough. This is particularly effective with the heavy doughs used for pet food.

PLC control with full-colour touch screen makes this an easy machine to operate. A stay clean / easy clean design, shaftless blade, negligible dough retention in the mixing bowl, and easy access minimise cleaning requirements.

PEGASUS® 5-IN-1 MIXER by Dinnissen

The Pegasus® 5-in-1 Mixer is a true multiprocessing machine. It allows you to mix, vacuum coat, dry, germinate and acidify your product. The mixer produces flavored products with a high hygiene requirement and a fresh-sour taste sensation, such as tea, cereals, (crispy) sweets, and snacks. In sectors such as the food industry, there is an increasing need for multiprocessing machines. Production must become ever faster and more efficient, to produce the best possible product using the least number of materials and resources possible.

By combining several process steps in one machine, the Pegasus® 5-in1 mixer saves on both cost and energy. The dual axis mixing mechanism airily tosses powders, pellets and granules during mixing. Then the finely atomized liquid particles mix homogeneously with the dry raw materials. The 5-in-1 mixer can also dry, germinate and acidify the product. No transport is needed between the different process steps, saving time and manpower.

36 | March 2023 - Milling and Grain https://satake-group.com

http://extru-techinc.com www.bakerperkins.com www.dinnissen.com mymag.info/e/1741

www.rubtechmech.com

Varion G from Buhler

Loss-in-weight scale Varion G

The Varion G provides a way to control and define process streams. Weighing and dosing applications are extremely important in all the food and feed processing lines. Scales and dosers are technically taking over these functions and are installed during process steps which are critical for process and quality. The Varion G perfectly copes with these requirements and provides operation modes for weighing and dosing

Dosing

Defines product streams for downstream processes by running them under the most effective conditions as well as blending requirements, thereby achieving the desired product composition.

Weighing

Provides transparency on the most relevant process streams, ensuring maximum yield on raw materials and controlling incoming and outgoing product flows.

Sustainability

Proven energy cost reduction of up to 92 percent thanks to the designed-for-purpose DriveX module with an integrated power management system

Quality

Uniquely high and repeatable accuracy down to ±0.2 percent thanks to a perfect combination of process logic, a super-efficient differential pressure compensation and high-precision load cells.

Availability

Maximized up-time thanks to the powerful and extremely easy to operate bUnify control system, with a modern and intuitive user interface.

Safety and ease of use

Easy and safe to operate and maintain thanks to its uniquely ergonomic, robust and hygienic design.

Digitalization

Unlimited connectivity with Bühler Insights and any plant control system ensures full transparency and utilization of the Scales Monitoring System.

Commodities the Varion G is used for includes:

– Maize, oat flakes, barely, wheat, pulses, brown rice, rye, seeds, and other granular products.

– Best accuracy of down to ± 0.2 percent

Self-learning process algorithm continuously optimizes the weighing process

– Smart differential pressure measurement system actively compensates and monitors external influences

Separately connected high-precision load cells allow individual analysis of the measuring signals

– DriveX saves energy of up to 92 percent

– Designed-to-purpose servo drive and gearbox ensure not only significantly reduced energy requirements but also increased life-time of the drive system

– Power management system buffer restores energy and ensures safety of the machine in case of power cuts

– Maximized up-time thanks to bUnify control system

– Intuitive and modern user interface enables fast and high-quality interaction when required

– Full transparency on process and machine parameters thanks to trending charts and event management

– Guiding wizards ensure the most effective root cause analysis and user guidance e.g., calibrations

– Highly flexible integration into the processing line thanks to various interface options

– Unmatched safety thanks to outstanding design

– Operational – no product build-ups in the process zone thanks to the avoidance of complex and inaccessible areas

– Maintenance – sufficient openings for cleaning and maintenance to comfortably reach all relevant parts and sections

– Equipment – product zone free of screws and bolts protects downstream equipment

– Food – minimal accumulations of product and dust thanks to first-class hygienic design

– Scales Monitoring System provides solid ground for various improvements

– Improved performance and process stability thanks to full transparency on critical machine and process parameters

– Long-term monitoring of the incoming product flow leads to maximized and uniform overall processing line efficiency

– Smart Bühler Insights dashboards ensure transparency across all organizational levels

Continuous weighing is provided by two sub-process steps: weighing and refilling. The product level in the weighing hopper is always between high and refill level.

In the operation mode FlowMeter, the Varion G measures the mass flow of a process stream with a given throughput. Key performance parameters such as high weight accuracy with maximal consistencies in the weight measurement process are given throughout the operation. The actual mass flow rate is calculated and provided at any time.

FOCUS Special

–

–

www.buhlergroup.com

www.ai-lati.com

u r ess enc e lie s i n t h e for m s t h ro ugh wh i ch w e s how o u rsel v es.

offer j u st wha t we a r e .

wa y s . www.paglierani.com

O

We

Al

www.ocrim.com

Women in Milling

This month contains an annual event close to my heart: International Women’s Day. And so it feels timely to celebrate the contributions of women to milling, past and present.

by Elizabeth Bartram, Director of The Mills Archive Trust, UK

The history of women in milling has in some ways been a hidden one. And yet women have played important and interesting roles in the processing of grain and the production of flour over the course of history.

At the Mills Archive Trust, we care for 3 million photographs, drawings, letters, reports, books, journals and small artefacts revealing global stories of milling and the people who have been responsible for feeding the world. Our records include snapshots and memoirs of some of the women who have been millers or have been connected to milling in some way. It is not usually easy to find this information, since the recorders of

‘The maid-servant that is behind the mill’. Grinding grain on a saddle quern, after an ancient Egyptian statuette (drawing by Martin Watts).

42 | March 2023 - Milling and Grain F

history have not always captured the full accounts of women. However, the threads are there, and I am grateful to have this opportunity to share some of their stories with you.

Milling grain and creating flour is not a new process. Archaeological evidence for milling of some form goes back millennia. As the centuries passed, women around the world have continued to support the feeding of their household and their local community.

Some stories of specific women can be found going back hundreds of years, such as to the medieval mystic Margery Kempe, who lived in England during the 1300s. She sought a variety of business ventures, including running a donkey powered mill, though it doesn’t sound like it was a very successful project! She is reputedly the first woman to write her autobiography (with the help of a literate monk who wrote down her words), which is still in print today. She became renowned for her religious experiences and she travelled around the world on pilgrimages.

Moving forward to more recent times, I am a fan of Canadian agronomist and journalist, Dr Cora Hind who made a name for herself during the first half of the 20th century due to her uncanny ability to accurately predict future grain harvests. She also received funding to travel to 29 countries to explore how Canada might market its grain to other countries. Cora must have been a very

C M Y CM MY CY CMY K pubblicità italiana_MOD.pdf 1 27/01/22 10:59 Milling and Grain - March 2023 | 43 F

Some of the watermills in the Ounien Valley and a woman milling at Tamsoult n'Ougard (Michael Harverson Collection)

unusual woman in those days, some grain merchants were not keen on her crop forecasts, which could affect pricing, and gave her the nickname ‘Calamity Cora!’

Morocco’s women millers

There is a group of women about whom I would like to know more. In one of our collections are photographs and written notes about women living in Morocco’s Atlas Mountains during the 1980s.

Visiting Morocco in 1985, Michael Harverson wrote that the women were responsible for grinding the corn for their bread, couscous and soup. They would ‘adjust their routine to take account of each day’s priorities so far as the outflow from the pond is concerned. They grind for a very few day’s needs at a time; each mill serves only a handful of families and, if a small queue forms, one is chatting to one’s neighbours in the shade of the walnut trees which seem to flourish beside Atlas watermills: a restful contrast to the hard work of harvest or weeding or household chores like fetching fodder, fuel and water. Incidentally, a more usual figure quoted for grinding barley was about seven kilos per hour; a typical family will consume about thirty kilos of flour per week’.

Much closer to home is our founding Trustee, Mildred Cookson, who also has a regular column in ‘Milling & Grain.’ Mildred was a miller at an historic watermill in South-east England for 30 years, so she knows a thing or two! I’m particularly fascinated by her expertise in the traditional craft skill of millstone dressing, which historically required a skilled craftsperson to cut grooves

into millstones by hand. A painstaking process, this skill is at risk of dying out. Mildred’s own extensive and important archive is one of our foundation collections.

We are keen to find expand our knowledge of women’s roles in milling, around the world, in times past and nowadays. If you are such a woman, or you know of a woman or group of women who you feel should be recorded in our archive for future generations, please email me at director@millsarchive.org

some of the watermills in the Ounien Valley and a woman milling at Tamsoult n'Ougard (Michael Harverson Collection)

Dr E. Cora Hind, a picture from her obituary in a 1942 issue of the US Northwestern Miller magazine

44 | March 2023 - Milling and Grain F

Miller Mildred Cookson working in Mapledurham Watermill during the 1980s (Mildred Cookson Collection)

in X

Can Britain raise the pulse? ‘Beans on toast’

by James Cooper, Milling and Grain contributor, UK

Everyone knows that Beans-on-Toast are nothing short of culinary perfection, but beans in toast.

As a child I absolutely loathed them. Not the sugary ones in tomato sauce, but the bitter green type that came in fury pods; the dreaded … broad beans. My mum’s vegetable plot yielded buckets of the things and they were frequently presented to me as essential fodder: they were ‘good for me.’

The baby ones drenched in butter were manageable but the large mature ones - complete with their arid, bitter mouthfeel - for a child they are practically inedible. An acquired taste though, and one I acquired in later life, in fact now I love them. But the reality is most people in the UK at least, don’t eat or even particularly like them.

Yet here we have a crop perfect for our UK temperate climate, packed with nutrition (it counts as one of our 5-a-day) and as a bonus, organically fixes nitrogen in the soil for free. It’s a winwin crop, yet one that at present we mainly export or feed to animals. What a waste!

If only we could adjust our taste buds to like them, or perhaps more to the point, learn how to cook and eat them.

“The fava beans had a bit of an identity crisis,” says James Maguire, President of Pulses UK, the trade body which seeks to communicate the value of pulses in crop rotation, while helping its members cash-in on a steadily increasing demand for

domestically produced protein.

“What is a legume? How do you grow them? How do you use them at home and cook with them?

“I think there's a huge education piece that needs to be done at the consumer level,” he says, identifying this as the real issue.

World Pulses Day - February 10th - has just passed, but there’s a lot more work to be done in getting the consumer to understand the value of this remarkable bean.

“Global supply and trade flows are well established; pulses are there in the market. And, what’s lacking now is education of the consumer, they’re just not in most diets.

“Whether they are beans, chickpeas, or lentils, there's an education piece needed. Most people don’t know how to use them, or probably even the health benefits.”

It wasn’t always the way - we used to eat lots of them – but the haricot bean took over with the popularity of baked beans, and today most fava beans are exported to North Africa.

And apparently, it’s not only humans who don’t like the bitter taste.

“There’s also an emerging market in aquaculture where they are de-skinned for fish feed,” James Maguire proffers.

Health by stealth

However, things are changing. Plant protein is seen by younger generations as an important component of their diet.

Recent Mintel research shows that Generation Z, those under 25 who probably cannot remember the stigmatisation of beans as ‘food for the poor’, consume far more plant-based protein for

46 | March 2023 - Milling and Grain F

environmental and health reasons.

And with over 50 percent of global consumers now identifying as flexitarian, there is a clear shift towards alternative protein sources.

Governments are also becoming more acutely aware, for food security reasons, that homegrown crops are a safer bet. There is a big push towards incorporating more plant-based protein into our diets across all age ranges and in particular how to get older generations and those of disadvantaged demographic, or living in ‘food deserts,’ to eat more protein crops.

Therefore, sneaking pulses into bread where the taste can be designed and disguised is, perhaps, quite a good way of getting consumers to eat more.

Finding the pulse

Researchers in the UK are now working with the British Nutrition Foundation (BNF) to shift people’s negative perception of beans and pulses.

The research project aims to encourage British consumers to eat more broad beans and is backed by UK£2m of government funding as part of a wider programme, the UK£47.5m Strategic Priorities Fund (SPF), to make UK food systems healthier and more sustainable.

The programme aims to fundamentally transform the UK food system, addressing questions around what we should eat, produce, and manufacture, and crucially - the Achilles heel of any food system - what we should or shouldn’t import.

Professor Julie Lovegrove is Head of the Hugh Sinclair Unit of

Human Nutrition at the University of Reading and sits on several government advisory committees including the UK’s Scientific Advisory Committee for Nutrition.

Leading the BNF research, Professor Lovegrove said fava beans could appeal to UK consumers as “Beans in Toast”, improving the nutritional quality of bread while making it less damaging to the environment.

“We had to think laterally: what do most people eat and how can we improve their nutrition without them having to change their diets? The obvious answer is bread,” she said.

But the idea of putting broad beans, or fava beans as they are more commonly known, in bread to complement wheat might not have appeal when you consider the old saying: ‘If it ain’t broke don’t fix it.’

The main aim of the project is to increase the consumption of pulses within the UK population’s diet. Pulses are important components of our diet; they’re classed as fruit and vegetables. They have high nutrient composition, including high fibre and micronutrients such as iron, which are often low in the population’s diet. They also have high protein faculty.