millingandgrain.com February 2023 In this issue: Milling and Grain . Volume 134 . Issue 2 . February 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 134 Issue 2 Wheat Tremendous potential of indoor grown wheat - The Internet of Things: Can agritech and IoT enable the agriculture sector to become more sustainable? - Grinding methods: Products with different grinding methods - Protect against feed processor recalls with the right conveyor system

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher

Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Digital community manager

Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk 0

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

VOLUME 134 ISSUE 2 NEWS 10-30 42 Global Food Security: ADM Aims to Improve Global Food Security and Mitigate Environmental Impacts 46 The Internet of Things: Can agritech and IoT enable the agriculture sector to become more sustainable? 50 Tremendous potential of indoor grown wheat 52 Grinding methods: Products with different grinding methods 56 Fibre February 2023 STORAGE 58 Protect against feed processor recalls with the right conveyor system 62 Conveyor belt cleaner tensioners: Options for safe, efficient operation 8 PUBLISHER Roger Gilbert 104 INTERVIEW Martin Kropp ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 80 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 28 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 33 Industry training news PRODUCT FOCUS 36 CASE STUDY 74 INDUSTRY PROFILE 72 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 February 2023 COVER IMAGE: Tremendous potential of indoor grown wheat - see more on page 50 FEATURES millingandgrain.com ISSN

The Internet of Things: Can agritech and IoT enable the agriculture sector to become more sustainable? See more on page 46

No: 2058-5101

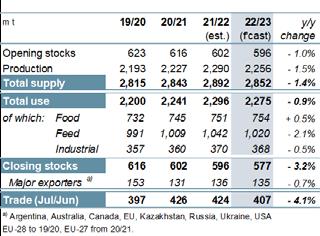

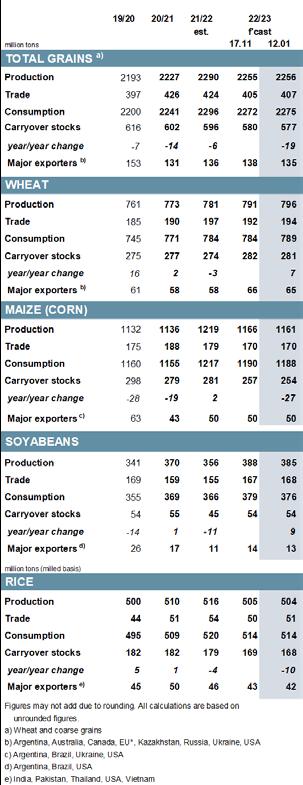

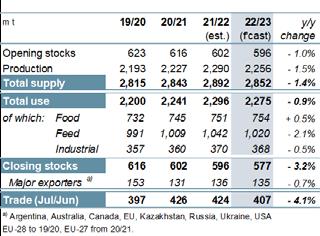

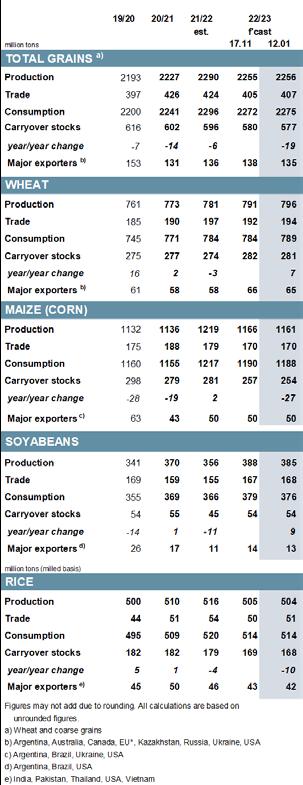

68 MARKETS Grain market report

What’s likely to happen next?

It’s a red letter day for MAG!

Yes, it’s a red letter day for Milling and Grain magazine as we go monthly with our Frenchlanguage version - which I’m please to say is being publish and distributed via our digital platforms (including our French website, our FlickRead Library and through our French App) for all those readers who have been reading our efforts on a bimonthly basis up until now.

With the help of technology, we are now able to quickly and accurately have the English edition translated into our five supporting languages - French, Spanish, Turkish, Arabic and Chinese.

We are planning to bring more of these bi-monthly editions into line with the English edition - being published monthly and within the same month as the English edition.

We believe in providing our readers with a complete monthly summary of milling topics that make for a wholistic view of what issues, technology, processes, and events are happening within our industry on a timely basis. We are a magazine that is proud to provide our content in the traditional way - on a monthly basis and in print too.

The aim of Milling and Grain is to make our content available as widely as possible and in languages that the industry can support. This is what we have set out to do and by publishing these supporting languages monthly we feel will be a major achievement within the tight budgets that we work within.

My colleague Antoine Tanguy, who has been working from our French office for many years is keen to provide access to the French FlickRead Library and to our French App free-of-charge in celebration of going monthly. Please follow this link (https:// flickread.com/edition/Milling-and-Grain-french) to view our Library and use the Coupon Code he provides below to waive subscription charges. There will be a limited number of free subscriptions associated with this code so please take advantage of his offer!

Depuis plusieurs années maintenant, nous avons traduit Milling and Grain en français tout les deux mois. Nous avons également lancé un site internet afin de partager les actualités du secteur de la meunerie et de l’alimentation animale de façon journalière. Après le bon accueil reçu et la satisfaction de nos

lecteurs français, il semblait logique de publier Milling and Grain mensuellement. Nous avons décidé de passer le cap en 2023 en étant confiant de la valeur que ce magazine apporte au secteur.

Notre but est de publier plus de contenu, plus régulièrement, afin que nos lecteurs en France et dans le Maghreb puissent continuer à s’informer sur le secteur français, ses associations et ses entreprises.

N’hésitez pas à me contacter (antoinet@perendale.co.uk) pour toute suggestion ou tout contenu que vous voulez partager à travers le réseau Milling and Grain.

PROMO CODE: MAGF2023

Online Milling School

MAG will once again be offering ‘Online Milling Courses’ this year for Feed Milling, Aquafeed Production and Petfood Production - starting in mid-April. So please check out the OMS website for precise details and how to register.

Our courses this year are based on a series of intensive one-week sessions over a six week period, culminating in a Certificate of Attainment which can be validated.

In the magazine

In this edition you will find our regular sections that should not be overlooked.

In particular, I draw your attention to the column provided by Dr Mahmoud Riyad, the Secretary General of the Egyptian Milling Association (see page 24) who outlines his milling industry’s efforts to secure greater control over raw material supplies. We are also pleased to carry a ‘Grain market report’ in our Commodities Section and Victam’s ’Showtime’ newsletter in the Events Section of the magazine.

In between our regular sections you will find some fascinating reports ranging from Global Food Security from ADM (on page 42) - please note we also feature ADM’s Dr Martin Kropp this is President Animal Nutrition EMEAI as our interviewee on page 104 this month.

We also look at the Internet of Things from the point-of-view of sustainability before we move on to ‘Indoor-grown wheat’ which we feature an image of the production process on the cover of this edition.

Finally, following Veganuary - we are now in the month of ‘Fibre February’ and as a result we publish a focus on grains and the benefits they provide through the milling process.

Enjoy the edition – and don’t forget to access our FlickRead Libraries for all language editions!

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133

Information

and Grain has a cooperative partnership with COFCOET

More

www.millingandgrain.com http://gfmt.blogspot.co.uk Milling

and use the Promo Code HNY2023 This offer entitles you to a 12 month digital subscription to Milling and Grain magazine on our app and desktop versions. This offer is on a first come first served basis and will run until 01/12/2022 Would you like a complimentary digital subscription to Milling and Grain magazine? Simply visit: https://flickread.com/edition/Milling-and-Grain

Roger Gilbert

PINGLE.

PROFESSIONAL MANUFACTURER

★ ISO 9001:2015 CERTIFIED

Аdd: Zhengding, Shijiazhuang,Hebei,China

Tel: +86-311-88268111 Fax: +86-311-88268777

E-mail:pingle@pingle.cn / www.pinglemachine.com

OF GRAIN MACHINERY

★ INTEGRATED MILLING SOLUTION PROVIDER

NewsMilling

Welcome to the February edition of Milling and Grain magazine, the fabulous month of love, and the second edition of Global Miller.

Do you have your chocolates and flowers ready for your loved ones? Valentine’s day is around the corner so if you’ve forgotten to get them, I’d better hurry if I were you. Sleeping on the couch isn’t very comfortable.

Product Manager Dr Maygane Ronsmans and Commercial Director Karel Thurman of Beneo in Belgium talk to Roger Gilbert, the publisher of Milling and Grain magazine, about the sustainability credentials of the faba bean and an investment of Euro€50 million in its processing in Germany during the 2022 EuroTier Exhibition, which was held over four-days in Hannover, Germany from November 15-18, 2022. This much underrated bean is getting a make-over by the Beneo company which focuses on improvements in animal nutrition and health.

Business Development Manager Julian Hoping of GePro, Germany, talks to Roger Gilbert, the publisher of Milling and Grain magazine, about how poultry by-products contribute to the circular economy, sustainability, and reducing the impact on the environment.

Since September 2021 the company has been authorised, via new European Regulation, to sell 100 percent of its poultry by-products into the pig nutrition sector. Poultry meal is the main product being sold but the full range of by-products are authorised, he says. To view both interviews, visit Milling and Grain’s home page and follow the MAGTv link.

mymag.info/e/1593 Watch

Valentine’s Day is a Christian holiday named after two Christian martyrs named Saint Valentine of Rome and Saint Valentine of Terni who were killed somewhere between February 13th – 15th in the third Century. There are many stories, myths and legends that descend from this martyrdom and how it evolves to what is now our current holiday of love. One such story is how Saint Valentine of Rome signed his letter to the jailer’s daughter while he was imprisoned with ‘Your Valentine’, which would explain why all the cards in shops all have the same signature inside – ‘To Your Valentine’.

It is also theorised that Valentine’s Day is the Christianised and modernised holiday of the Ancient Roman festival Lupercalia. The Roman festival was also called Februa after februum, a Latin term meaning purification or purging and was held on February 15th. The etymology for February derives from this festival, which was a day used to purify the city, promote health and fertility, and ensure safe deliveries to expectant mothers.

Lupercalia was also tied into the legend of Romulus and Remus who suckled from the she-wolf, Lupa. The name Lupercalia derives from ‘Lupus’ meaning wolf, and with its connections to the two brothers and how the festival was to boost fertility and a safe birth for expectant mothers, it’s easy for the time to alter and change the festival into what Valentine’s Day is now. Especially when one of the activities of the festival was for single people to couple together for the day and if fruitful and promising, then they would stay together.

Whilst all this history and knowledge about Valentine’s Day and the origins of the word February is fascinating, it makes you wonder why I mention all this in a magazine dedicated to milling, farming and livestock. The reason I mention this is because this Roman festival was a pastoral festival, meaning it was celebrated mainly by farmers and shepherds. This was because of the main locations of these festivals being linked to Rome’s foundation myth and that these locations were closer to the famers and shepherds than anyone else.

Our rich community of farming and livestock can be tied back to amazing historical moments like this, tying into current day festivities. History is one of my favourite subjects so I’m glad I discovered this information and got to share it with you all. Other amazing events and festivities to look forward to in the present day is IAOM MEA on Feb 6-8 and GEAPS Exchange 2023 from Feb 25-28. We plan to visit GEAPS Exchange so we are excited to see you all in Kansas City this year for the event.

If you would like to share any news with us then please email us at editorial@perendale.co.uk

gfmt.blogspot.com See more videos from all aspects of the industry at millingandgrain.com/videos

the video at

10 | February 2023 - Milling and Grain

The Milling Journal 2023

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream byproducts of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients.

The Journal will particularly embrace scientific and technical information on novel processes enabling the generation of ingredients for manufacture of bread, cakes, confectionary, pasta and a plethora of applications for diverse types of breakfast cereals, beverages and the infant formula markets. We also consider papers on complete animal feed manufacture as a core topic. These usually require pre-grinding and milling/flaking of grain and cereals for terrestrial animal feeds such as for poultry, swine, ruminants and equine. Animal feed production can involve drying, milling, pelleting, steam and pressure conditioning, shaping and texturisation dependent on specific machinery. Processes such as extrusion, cooking and expansion are of paramount importance with much research being undertaken on engineering, both mechanical and electrical. Effective storing and preservation methods offer opportunities for papers.

Given the diversity of different types of commercial pet diets ranging from wet, canned and extruded dry diets, treats and speciality diets, there is much scope to provide information on advances and discoveries. The rapidly growing aquaculture market is also very dependent on these technologies and scientific papers exploring such areas are also to be welcomed.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Milling Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral researcher being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief.

These OA papers will be available on our official website millingandgrain.co.uk and printed in the magazine as well as being downloadable. Links will be provided within our existing Milling and Grain magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

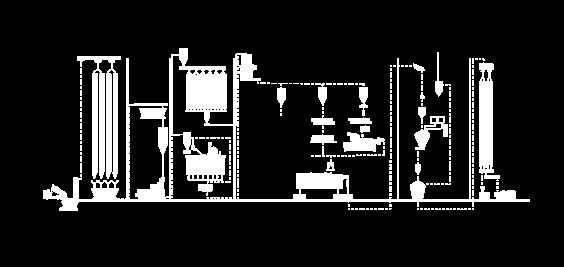

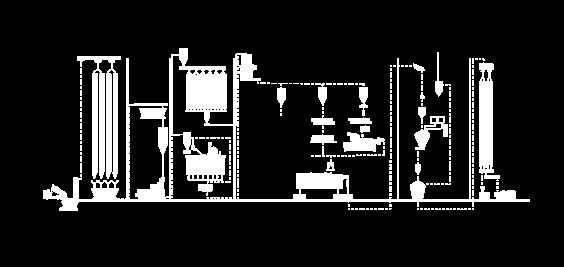

Another plant tested in Africa By Ocrim

The 350 T/24h hard soft wheat “green field” milling plant for Sanabel was tested a few months ago, with the full satisfaction of the customer and the Ocrim team.

A plant equipped with the latest generation technology, to meet the customer's needs related to food safety and energy saving. The Ocrim team took into account some specifications, requested by the customer, for a general optimization of the plant footprint. An intelligent design and cutting-edge machines, for this plant which is complete with a 420-ton flour silo and a 150-ton storage for by-products, all managed by an automation system, also branded Ocrim, designed and built to simplify the activities of the mill.

The sales director of Ocrim, Fabrizio Baccinelli, claims that "in Africa, economic development is growing and Angola is becoming an important point of reference for the entire continent, thanks to virtuous industries such as the Sanabel Group, but also many others that have the strength and foresight to invest and enhance one's business not only for self-referential issues, but also for the collective community wellbeing. We at Ocrim are happy to have become Sanabel’s partners and to contribute to this economic rise which also has a positive impact from a purely social point of view.”

Hassan Noureddine, CEO of Sanabel Group, for his part, is very satisfied to have chosen Ocrim for this project and affirmed: “it is the first time that we have entrusted ourselves to Ocrim. We have always heard of the Cremona-based company as one of the most reliable in the world and I must say that the result has exceeded our expectations. Ocrim is an attentive, innovative and punctual partner. And, to our positive surprise, the delivery times were fully respected, despite the complexities of the pandemic period. We at Sanabel have really appreciated it."

Henk van de Bunt passes away

Hendrik Jan Dirk (Henk) van de Bunt, a Board Member and General Manager of Victam International BV since 1986, passed away on Febrauary 1, 2023 at the age of 74.

He was a well-known and a valued colleague in the world of animal feed and grain processing industries with ample contacts worldwide.

Henk’s name runs throughout Victam International, the foundation of which had been set up by the international Victam milling trade fair in 1965.

During the anniversary celebrations of the then Millers' Union St Victor in 1964, Henk's predecessor Piet Schrama came up with a plan to organise a milling trade fair. It was launched in the Brabant Veemarkthallen in ’s-Hertogenbosch with 35 Dutch participants. Its success resulted in the incorporation of the Victam Foundation, under the aegis of two millers' unions St Victor and ANMB (General Union of Dutch Millers). Hence the name: VICT (for Victor) AM(for the General Union).

In 1965 the first Victam international Trade Fair was held in the Jaarbeurshallen in Utrecht, The Netherlands.

Interest was understandable, as the animal feed market

was facing considerable challenges that necessitated an increase in scale and modernisation of businesses.

At the time, there were more than 1000 businesses in The Netherlands, each with an average output of fewer than 3000 tonnes per year.

Since those early days, Victam has greatly contributed to animal feed businesses in Europe and beyond. Suppliers of machines and related products have also significantly benefited from this its events.

Intense participation

Henk became a Victam board member in 1986, its chairman in 1991 and director in 1999. He intensely participated in the further expansion of Victam. Under his guidance Victam developed into a unique global trade fair and in 1991 expanded to establish Victam Asia in Bangkok, Thailand and symposia in several other countries.

Until last year he had been a board member at IFF, the research institute in the area of compound feed technology in Braunschweig, Germany, which he served for no less than 20 years. He had also been chair of IFIF, the International Feed Industry Federation, for six years. He was the man in the right place, with a vision for the future, sharp insight and a tremendous commitment.

Milling and Grain - February 2023 | 13 Milling News

Growing Into Performance.

INNOVATIVE OPTICAL SORTING SOLUTIONS.

Better than the human eye, Cimbria sorting technology is the most advanced and reliable solution to meet the high quality standard of the grain and seed processing industry.

The all-new optical system integrates Full-Color RGB and NIR cameras, that can be combined with SWIR and UV technologies to ensure the total removal of any foreign body like stones, wood and glass, as well as the best separation of nonconforming or unwanted grains.

Great purity, optimized yield and food safety are so granted by Cimbria optical sorters.

Growing into performance is easy and effective, thanks to the extraordinary technology signed by Cimbria.

Cimbria.com Cimbria Srl Imola, Italy Tel +39 0542 361423 seainfo@agcocorp.com

Cargill announces acquisition of Owensboro Grain Company

Cargill and Owensboro Grain Company, a fifth-generation familyowned soybean processing facility and refinery located in Owensboro, Ky., has announced that they have entered into a definitive agreement where Cargill will add Owensboro Grain Company (OGC) to its North American agricultural supply chain business.

Owensboro Grain Company was founded in 1906 as a small grain merchant and today operates a fully integrated soy processing facility, producing soy products, including protein meal and hull pellets for animal feeds, crude and degummed oil, lecithin, various blends of refined vegetable oil for human consumption, biodiesel, glycerin and industrial waxes. The addition of Owensboro Grain Company enhances Cargill's efforts to modernise and increase capacity across its North American oilseeds network to support growing demand for oilseeds driven by food, feed and renewable fuel markets.

“We are pleased to welcome Owensboro Grain Company into our Cargill family,” says Leonardo Aguiar, president of Cargill's North American agricultural supply chain. “Our two companies have tremendous operational histories, similar heritages as grain merchants, and values, including an unwavering commitment to prioritising people, making this a tremendous fit. Additionally, this is a significant milestone in Cargill's journey to create a connected and modernised grain experience for our customers,” says Mr Aguiar.

“We are excited for this new chapter in the life of Owensboro Grain Company and believe an acquisition by Cargill will ensure the long-term success of the company,” says Helen Cornell, president and CEO of the fifth-generation, family-owned soy processor. “Cargill has the ability to capitalise on growing opportunities in the industry, such as renewable energy. The acquisition will ensure that Owensboro Grain Company, its employees, farmers, customers and the community are best positioned for the future. We are excited to transfer ownership to another multi-generational family held enterprise with global access to markets and capabilities to ensure the future growth of our business. Cargill has the global resources necessary to support Owensboro Grain Company's growth goals and operations.”

Terms of the deal were not disclosed. The transaction, which has been approved by the Boards of Directors of Cargill and Owensboro Grain Company, is subject to regulatory approvals and other customary closing conditions and is expected to close in early 2023.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com

Milling and Grain - February 2023 | 15 Milling News

New biosecurity strategy to protect food security, trade and plant health

Anew action plan to protect plants from pests and diseases was published today (Monday 9 January) by Defra, in partnership with the Forestry Commission and the Scottish and Welsh Governments.

The Plant Biosecurity Strategy for Great Britain sets out a five-year vision for plant health, consisting of an action plan to secure national biosecurity, protect native species and drive economic growth. It positions the UK as a global leader in plant biosecurity, setting out the vision to create a new biosecurity regime and bio-secure plant supply chain, which will safeguard food security and help mitigate the effects of climate change. It comes following updated figures which show that plants provide an annual value of UK £15.7 billion to the United Kingdom.

Specific actions include expanding the Animal and Plant Health Agency's Internet Trading Unit to step up monitoring of online retailers and social media sites for the trade of high-risk plant products, in order to stop potentially devastating pests and diseases from entering the country. Additionally, the strategy sets out how more than 30 signatories, including Defra, the Royal Horticultural Society, National Farmers Union and the Woodland Trust, will deliver an ambitious programme of behavioural change across society through the Public Engagement in Plant Health Accord. This one-of-a-kind collective commitment will kickstart a national conversation around biosecurity and promote the actions that the public can take to protect tree and plant health.

Lord Benyon, Minister for Biosecurity, says, “This landmark strategy sets out how we will protect Great Britain's plants, with the government, industry and the public working together to tackle the risks posed by plant pests and diseases. In light of climate change, tackling these varied and mounting risks will be critical to maintaining our food security, as well as facilitating safe

trade amidst a challenging economic backdrop.

“Today's announcement demonstrates this Government's ironclad commitment to protecting and restoring our natural environment for future generations, as we deliver on our tree planting targets and ambition to achieve net zero.”

Nicola Spence, UK Chief Plant Health Officer, says, “Plant pests and diseases know no borders. As the global trade in plants and plant products continues to grow, our precious ecosystems, native species and biosecurity are at risk. The resultant threats posed to our treescapes, food security and the global economy are all too real.

“Therefore, I am proud to officially launch the Plant Biosecurity Strategy for Great Britain, which will deliver a step change in our plant health protections, actions and behaviours. This will position Great Britain as a global leader in plant biosecurity and set an example for the world to follow.’’

Lesley Griffiths, the Welsh Government's Minister for Rural Affairs, says, “The Plant Biosecurity Strategy emphasises our commitment to protect the health of our plants. Plants are the foundation of our ecosystems and provide life to the whole food chain. The strategy outlines what we will do, working with others, to further protect this vital resource.”

Sara Lom, The Tree Council CEO, says, “The Tree Council was created nearly 50 years ago in response to Dutch elm disease and now leads activity into the devastating impacts of ash dieback. From first-hand experience, we know that effective biosecurity is vital in defence of Britain's trees and plants.

“We welcome the launch of the Plant Biosecurity Strategy for Great Britain and look forward to working with Defra and partners to protect our treescape.”

The Plant Biosecurity Strategy for Great Britain will also set out how enhancements to the UK Plant Health Risk

16 | February 2023 - Milling and Grain Milling News

Register, which currently lists 1,200 pests and diseases of potential threat to our biosecurity, will improve our understanding of complex and cumulative risks to plant health. As part of this, an array of new plant health IT systems will bolster our outbreak preparedness and emergency response.

Incorporated into the strategy is a commitment to work with the UK Plant Health Alliance to develop a new five-year roadmap for the Plant Healthy certification scheme, which provides biosecurity certification to nurseries, businesses and charities operating in the horticultural sector. RHS Garden Harlow Carr in Yorkshire has become the first public garden in England to be certified as Plant Healthy, in recognition of its work to prevent the introduction and spread of plant pests, diseases and invasive species and promote good plant health.

The strategy also emphasises the collective role and responsibilities we all have in upholding high standards of biosecurity — for example, the importance of not bringing home plants, trees, fruit and seeds from overseas, as doing so could inadvertently cause pests, diseases and invasive species to be introduced or to spread in new areas. This aligns with the UK Government's long-running 'Don't Risk It!' campaign, which featured on the Animal and Plant Health Agency's Gold Medal-winning stand at the RHS Chelsea Flower Show 2022.

The strategy builds on the work achieved under the previous 2014 strategy as well as the consultation launched in September 2021 by Defra, the Forestry Commission, the governments of Scotland and Wales, and our agencies and delivery partners. It follows the convening of the world's first International Plant Health Conference in London last year, which brought together 500 policymakers, academics and experts from over 74 countries to address current and future plant health challenges.

Today's announcement comes ahead of the publication of the GB Invasive Non-Native Species (INNS) Strategy in early 2023. This will set out coordinated actions across society to prevent the arrival of new INNS and tackle the impacts of those established – securing our biosecurity and minimising their environmental and economic impacts.

CESCO CEO to speak at IAOM Regional Forum 2023

KONSTANZ GERMANY – CESCO EPC will participate as invited speaker the IAOM Regional Forum 2023, an event that aims to provide a networking forum to discover the latest technologies and solutions in the grain storage and milling universe.

The conference will be held from February 6th to 8th at the Mövenpick Hotel City Star in Jeddah (Saudi Arabia) and the company will present its know-how in the field of silo and mill construction to the entire audience of this prestigious event.

Martino Celeghini, CESCO CEO and Vice President, will give a lecture entitled “Silo Design and Construction” on February 6th, starting at 10:00 am, where will first share the philosophy and guidelines for the design of the silo storage section for large one’s Industrial plants, explaining some of the possibilities in silo and conveying design. In addition, Mr. Celeghini will present the peculiarities in the design of prismatic silos and steel structures for the mill plants, also showing examples of integrated building design from past and current references.

Milling and Grain - February 2023 | 17 Milling News

Kent Nutrition Group Marshall plant wins 2022 Commercial Feed Facility of the Year

The American Feed Industry Association (AFIA) and Feedstuffs has named the Kent Nutrition Group's feed manufacturing facility of Marshall, Mo., as its 2022 Commercial Dry Feed Facility of the Year. Gary Huddleston, AFIA's director of feed manufacturing and regulatory affairs, presented plant manager Chris Igo with the award during the AFIA's Feed Education Program, happening in conjunction with the International Production & Processing Expo.

“Kent Nutrition's Marshall facility prides themselves on excellent customer service, high-quality feed and dedication, and those traits shine through,” says Mr Huddleston. “We like to honour the facilities that do the right thing every day and that is surely Kent Nutrition.”

Kent Nutrition Group (KNG) is a division of Kent Corporation, a family-owned, American company that manufactures high-quality nutrition products for everything from livestock to small animals. The KNG's Marshall animal food manufacturing facility produces approximately 52,000 tonnes of multi-species animal food annually. Originally built in 1976, the Marshall team is comprised of 14 members. In their efforts toward continuous improvement, the facility recently installed a new Repete pellet mill automation system in 2020, which has allowed the plant to streamline

its mixing process and put in place safeguards to reduce opportunities for human error, such as proceeding with a manufacturing run if the sequencing and flushing procedures are not properly followed.

The AFIA has been recognising excellent feed manufacturing facilities through the Feed Mill of the Year program since 1985. Beginning in 2016, the program was expanded to the Feed Facility of the Year and began offering awards for an overall winner and four category winners. In 2021, the FFY program separated each category into its own individual program: liquid feed, commercial dry, premix and ingredient, and integrator, with each category having its own facility of the year award.

The semi-finalists for AFIA's 2022 Commercial Feed Facility of the Year award are Kent Nutrition Group of Mason, Mich., Belstra Milling of DeMotte, Ind., and Western Milling of Goshen, Calif.

Milling and Grain - February 2023 | 19 Milling News

“We like to honour the facilities that do the right thing every day and that is surely Kent Nutrition.”

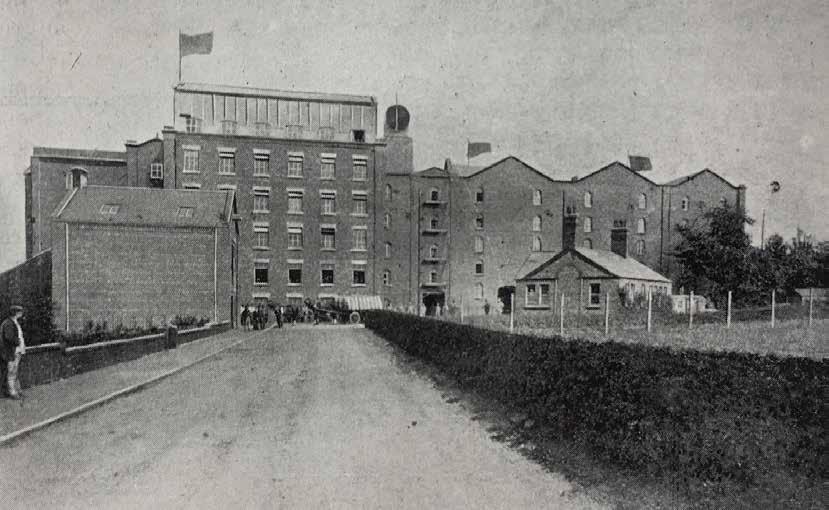

Mills recently constructed on the Simon System

by Mildred Cookson, The Mills Archive,

UK

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

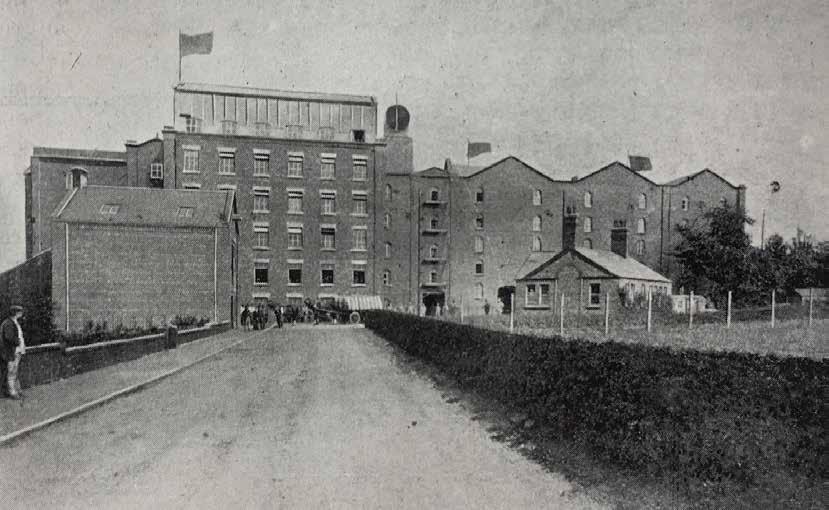

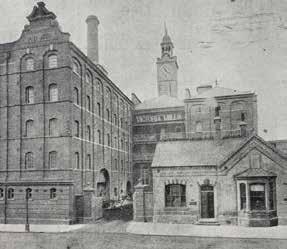

Milling in 1901 (page 409) provided a photograph and comment on seven UK flour mills that had recently been upgraded with Simon machinery and systems. Outputs ranged from 5 – 30 sacks per hour, reinforcing the general view that in 1901 British mill owners were moving to cope with the competition that existed in their several markets. All these mills originally contained complete roller mill plants or combinations of machinery on other systems.

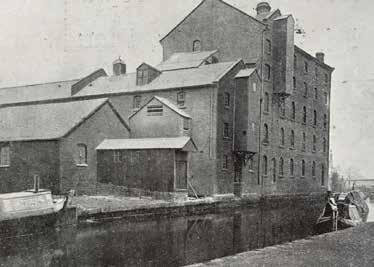

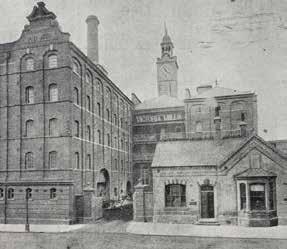

Messrs. W Marshall and Sons, Grimsby

The Victoria Mills were a fine example of a complete Simon plant to produce 25 sacks per hour. The reconstruction involved the removal of the existing machinery, including roller mills, purifiers, and a full line of plansifters. The new plant consisted of the Simon heavy pattern 4 roller mills, over 40 centrifugal scalping and dressing machines, patent “Reform” detachers, and patent dustless double purifiers. In addition the wheat preparing

plant was improved by the introduction of washing, drying and conditioning machinery. The building with its new machinery arranged was said to be one of the finest in the United Kingdom.

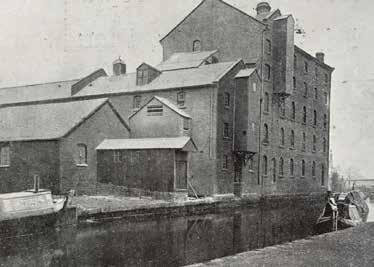

Messrs. H & R Ainscough, Burscough Bridge

This extensive property, although away from the seaboard, was well situated for canal and railway transport. It had direct water communication with the river Mersey and a fine railway siding with the Lancashire and Yorkshire Railway. The mill when completed would be driven with a new inverted cylinder, vertical engine and contain extensive silo accommodation, a complete new and fine installation of wheat cleaning, washing and drying plant, and a completely new roller mill plant for the production of 30 sacks per hour. In addition to this there was to be a comprehensive, well-arranged system to produce provender with arrangements for delivering it on to railway truck, wagon or barge. In carrying out this work the whole of the previous

The roller floor

The roller floor

20 | February 2023 - Milling and Grain

machinery installed was to be replaced.

Messrs. George Ridgway and Sons, Hanley, Staffordshire

This mill was equipped with a Simon automatic roller mill plant to produce 12 sacks of flour per hour, well arranged in a building of convenient form and dimensions. At the same time important modifications were introduced into the wheat preparing plant by improving the washing machinery and the introduction of bins and measuring machinery for the conditioning after drying of the wheat. The plant was driven by a compound horizontal engine installed during this recent reconstruction.

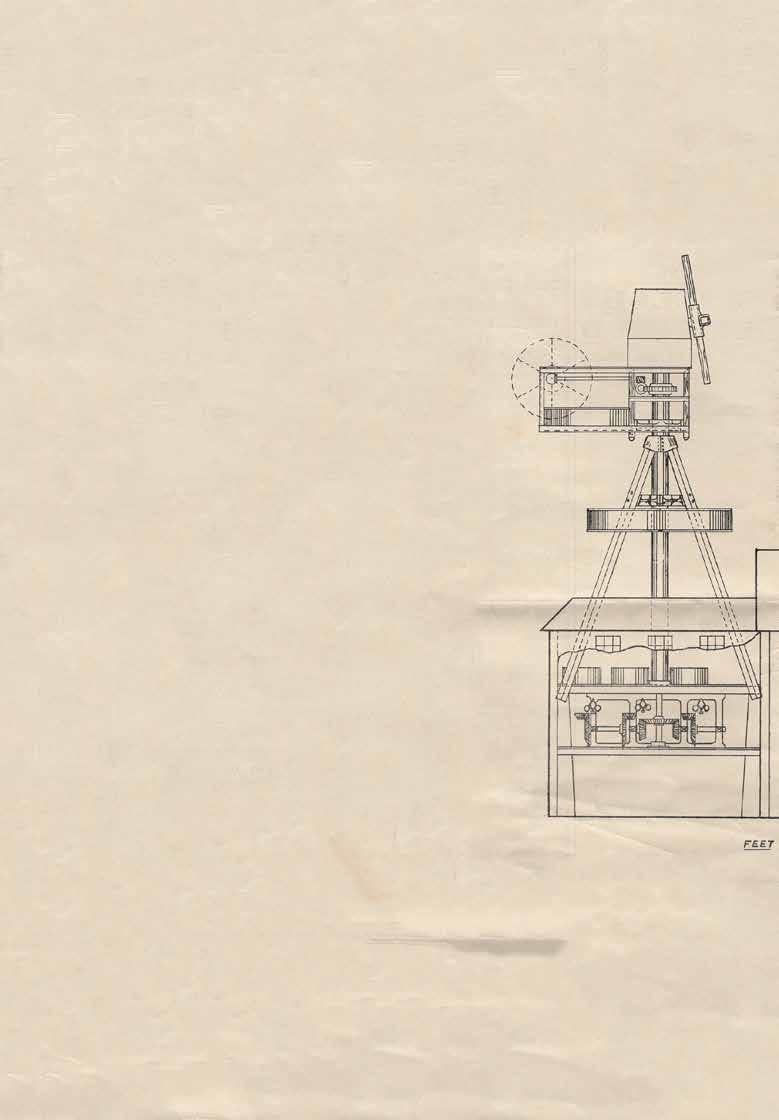

Messrs. The Scottish Co-operative Wholesale Society Ltd., Junction Mills Leith

The Scottish Co-operative Society’s Junction Mills were only purchased shortly before the new installations took place. The machinery and equipment to produce oatmeal were excellent. However, the results from the flour mill plant, when compared with those from the two roller mill plants in the Society’s Chancelot Mills, emphasised the necessity for immediate reconstruction at the Junction Mills. A new complete automatic roller mill plant for producing 10 sacks per hour was introduced, driven by a new engine supplied by Messrs. Douglas and Grant of Kirkcaldy. It was the compound tandem Corliss type, adapted to give 250 indicated horsepower, with 100 lbs. steam pressure at 500 feet piston speed. Superheated steam was used and the cylinders were 14 inches and 27 inches diameter, with a stroke of 3 feet. The highpressure cylinder had Corliss valves with Douglas and Grant’s special patent gear, with the expansion controlled by a high-speed governor. The crankshaft was 8 inches diameter by 16 inches long in bearings that ran in bronze bushes lined with white metal. The flywheel was 14ft diameter and grooved for nine ropes driving pulleys on two main lines of mill

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT

Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets.

In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more.

>www.andersonfeedtech.com/healthcheck

Milling and Grain - February 2023 | 21

YEARS IN MILLING

MORE THAN 400 COMPLETE PROJECT PERFECTLY RUNNING AROUND THE WORLD

We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

R O L L E R M I L L

shafting. The jet condenser and air pump were placed vertically below the engine frame and were driven by side rods and steel bell crank from the main crosshead. The air pump was brass lined and fitted. The boiler feed pump also worked from the bell crank.

Messrs. Marsh Mills Flour Milling Co., Plympton, Devon

This mill was for many years previous to the article in the possession of Mr. Harvey Daw but had recently come into the ownership of a new Company and was entirely reconstructed. The mill was arranged for the production of 5 sacks of flour per hour. A wheat washing, drying and conditioning plant was also introduced. In 1901 Henry Simon Ltd., were also erecting a silo granary for the storage of around 20,000 bushels of wheat. The mill had railway siding accommodation. Grain could be shot from the railway trucks or from farmers’ carts directly into the main elevator in the new silo granary.

Messrs. T.H. Smith & Sons, Harston Mills, Near Cambridge

The reconstruction of this mill had only just taken place in 1901 with, so it was said, marked success in the improvement of the milling results, the alteration consisting in the entire remodeling

of the plant on the “Simon System” for the production of 5 to 6 sacks per hour.

Messrs. John Jackson and Son, Spa Road Mills Bolton Lancashire

The mill contained a complete 15 sack roller mill plant on the Simon System. It was one of the two large mills in Bolton owned by this firm. The roller mills throughout were of the Simon heavy 4 roller mill pattern and the scalping and dressing machines were all Simon’s well-known centrifugal type. The first steps taken towards the complete overhaul of the mill were carried out earlier in 1901 when the roller mills then working were entirely replaced. Since then, the reconstruction had been carried through to completion and the mills were just back working again at the time of this article.

Milling and Grain - February 2023 | 23 Milling News

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

Egypt's efforts to secure greater supplies to the market in the face of a dollar liquidity shortage

Egypt, the world’s biggest wheat importer, has struggled to cover its essential needs for grain since imports were distributed last February 2022 by Russia’s invasion of Ukraine — the two being Egypt’s biggest suppliers — and by its indirect impact on the country’s economy.

A source from a major grain import company that last week saw a breakthrough in the release of wheat shipments from ports. This breakthrough coincided with the government announcing the release of LE5 billion worth of goods in the first three weeks of December and promising to clear the rest of the goods in short order.

December 27 witnessed the largest amount of wheat released since the crisis started early last year, the source noted. Ten importers were able to clear 19,500 tonnes of wheat. At the time, wheat prices per tonne dropped from LE13, 700 to LE12,200, while the price of consumer flour went down from LE16,500 to LE15,000 per ton.

The releases slowed down this week, however, as banks continue to struggle to provide dollar liquidity to importers, decreasing the amount of wheat offered in the market once more and bringing the prices back to previous levels, the source added.

The source estimated that there are about 600,000 tonnes of wheat procured by the private sector still stuck at ports, down from about 900,000 tonnes two months ago. “This drop indicates that private sector importers are making fewer new deals until the foreign currency is more available”, the source said.

Following a drop in the pound’s value on Wednesday, January 4, 2023, Banque Misr and the National Bank of Egypt, the two largest government banks, began providing the necessary dollars to importers, Bloomberg Asharq reported on Thursday, the first time that banks have done so in about a month, in a sign that the government will try to quicken the pace of clearances.

However, the dollar crisis is affecting another aspect of the supply chain away from the port bottleneck and thus causing prices to stay high.

Another source at a major grain importer told Mada Masr that the grain and wheat that have been released are not being put on the market right away, as traders are looking to ensure they recoup fair value for their product in the face of the central bank’s anticipated move to devalue the official exchange rate to stamp

out the parallel exchange market.

The pound’s value began dropping to unprecedented lows on Wednesday morning, reaching a selling price of LE27 and purchase price of LE26.95 at the state-owned National Bank of Egypt by Thursday afternoon.

The industry sources expect the banks to devalue the pound against the dollar twice more in the short term, dropping the value of the pound to LE28 during next week.

“We hope that the releases will continue in the coming weeks at a better pace than this week, especially since prices have rebounded and are increasing again. Price instability is harmful to all stages of production,” Walid Diab, a member of the Federation of Egyptian Industries grain industry chamber, told Mada Masr. Diab explained that the amount of wheat the Supply Ministry is offering through the recently established commodity exchange is not sufficient. The ministry puts out two bids a week of 10,000–15,000 tonnes each, but these quantities are only enough to meet the actual market needs for just one day, he noted.

An increase in the wheat offerings on the exchange, facilitated by increasing the pace of releases at ports, would bring the prices down, according to Diab, but the amounts put on the market have to be no less than 70,000 tons per day.

According to another source at the grain chamber, about 300 tons each per day is being divided among 20 to 30 mills, which has driven prices up significantly, especially since lower production capacity means lower sales.

The confusion in the markets also extended from wheat to bran. Marketing agents for bran at mills explained that the factory price of wheat bran increased this week to over LE9,000 per ton at several mills after it had fallen last week to LE7,500 per ton on average.

Soybeans, also used in feeding livestock, are similarly witnessing market confusion, one of the grain import sources said, as multiple prices per ton hit the market this week with differences of up to LE3,000 between them and the highest price reaching LE29,000.

The slowdown in the release of commodities also affected yellow maize, the price of which had dropped last week from LE16,000 to LE10,000 per ton, only to rise again this week by LE3,000 within eight hours due to the decline in supply.

24 | February 2023 - Milling and Grain

symaga.com • +34 91 726 43 04 • symaga@symaga.com 50 million m3 built Projects in 145 countries Top Project worldwide Flexibility and adaptability A reliable team for a reliable project YOUR RELIABLE PARTNER Improve silo tightness. Double Vertical Joint. · Tightness is improved. Double sealing on both sides of the screws. · Butyl rolls are supplied with double strip to improve assembly times. VISIT US VIV ASIA, Bangkok, Thailand 09 - 10 Mar, Stand 2661

OUR PNEUMATIC PACKER

With our pneumatic packer you can fill your valve bags fast and with highest weight accuracies. With our easy cleaning design the product change is as easy as it can be. Consider it bagged!

Contact:

Phone: +49 251 9796 252

E-mail: sales@behnbates.com www.behnbates.com

Dr Eckel and Evonik to cooperate on phytogenics

Dr. Eckel Animal Nutrition has entered into a partnership with Evonik, one of the world leaders in specialty chemicals, effective January 1, 2023. Evonik plans to launch a first product from the partnership – a phytogenic solution developed by Dr. Eckel – in Europe in the first quarter of 2023.

Phytogenics are plant-based feed ingredients which play an important role in sustainable solutions for livestock farming. Dr. Eckel is one of the most experienced and innovative suppliers in the field of phytogenics. The value-orientated family business is one of the world's foremost companies in the sector with a specific focus on animal welfare, developing products that make animal nutrition more resourceefficient, climate-friendly and healthy.

“As a dynamic company with a high pace in product development, we are able to create innovations in a comparatively short period of time,” says Dr. Antje Eckel, founder of Dr. Eckel Animal Nutrition. 'With a strong partner like Evonik, we can allow selected products to access a much wider market in a short time. We are therefore very happy that together with Evonik we can open up new target groups and customers.'

Evonik Gut Health Solutions focus primarily on stabilising the gut health of animals through probiotics such as Ecobiol®, Fecinor®, and GutCare®. The partnership with Dr. Eckel will allow Evonik to address further animal health issues with selected products that expand Evonik's portfolio.

"It often needs complex solutions to maintain health and productivity in the barn without antibiotics," says Gaetano Blanda, head of the Animal Nutrition business line at Evonik. “In combination with our existing Gut Health Solutions, phytogenics will help farmers achieve this goal.”

A HAVER &

BOECKER Company

26 | February 2023 - Milling and Grain Milling News

Feed Regulators Meeting

Feed regulators and industry from around the world discuss critical issues with IFIF and FAO at the 16th International

Feed Regulators Meeting

The 16th annual International Feed Regulators Meeting (IFRM) organised by the International Feed Industry Federation (IFIF) and the Food and Agriculture Organization of the United Nations (FAO) brought together feed industry representatives and government officials from around the world to discuss critical issues facing the feed sector with IFIF and the FAO.

At the meeting Ruud Tijssens, IFIF Chairman and Daniela Battaglia, FAO, welcomed IFRM delegates and reiterated their commitment to this longstanding partnership and agreed to continue to strengthen their work together to tackle the challenges facing the feed and food chains. Ms Battaglia reaffirmed the importance of "collaboration between the public and private sector to support the responsibilities of the animal production sector in a context of sustainable agriculture and food systems worldwide."

Mr Tijssens says, “I am delighted that we can meet again face-to-face at this unique event and that participants from across the world and from key regulatory bodies joined us at the 16th IFRM. This meeting, yet again, proved to be an important opportunity for the global feed industry and feed regulators to discuss key issues for the feed and food chains, including important work on nutritional innovation strategies to improve animal health and welfare, an update of Codex Alimentarius work with relevance to feed, as well as a very timely workshop on emerging feed sources and technologies in a circular bio-economy context.”

Mr Tijssens adds “This dialogue is an important example of the private sector collaborating with the FAO and

World Food Programme purchasing grain from Ukraine

Minister of Agrarian Policy and Food of Ukraine Mykola Solskyi held a meeting with Marianna Ward, Deputy Director of the World Food Programme in Ukraine.

As part of the ongoing dialogue regarding Grain from Ukraine, the parties discussed the current state and further prospects for the implementation of the humanitarian food initiative

During the meeting, Ms Ward reported that the World Food Programme purchased another 60,000 tonnes of

regulators from around the world and we believe that only by working together can we continue to ensure feed and food security and safety, while meeting the global demands for food sustainably.”

“The success of this meeting is a proof that FAO's efforts to facilitate dialogue between the public and private sector are worthwhile and given the current challenges, collaboration among all parties at international and national level to ensure among others, human and animal welfare, and feed and food safety and security is more important than ever,” says Daniela Battaglia, Animal Production Officer, Animal Production and Health Division of the FAO.

Ms Battaglia adds, “feed operators can valuably contribute to make the animal production and food sectors more responsible and sustainable and to achieve other important goals such as the containment of antimicrobial resistance and public, animal and environmental health. The IFRM is an important opportunity to exchange ideas among stakeholders from around the world and to coordinate our efforts towards common goals.”

Other topics discussed at the 16th IFRM included a panel on the successful work of the International Cooperation for Convergence of Technical Requirements for the Assessment of Feed Ingredients (ICCF), which aims towards convergence of technical requirements specific to feed additive/ingredient authorisation across regions, as well as presentations on key feed issues in Thailand and Vietnam.

Ukrainian agricultural products.

The humanitarian grain will be loaded onto two ships in the port of Chornomorsk and sent to Ethiopia. The first vessel, Amira Hana, is already awaiting a Joint Coordination Center (JCC) entry inspection.

Mr Solsky expressed his gratitude to the partners for their comprehensive support of the Ukrainian initiative. The parties agreed on further coordination of actions in matters of providing humanitarian aid to the poorest countries in Africa and Asia to prevent famine.

As a reminder, Grain from Ukraine is a food initiative aimed at providing grain to countries on the brink of starvation. It is implemented in partnership with the World Food Programme. The amount of accumulated funds provided by international partners for the Ukrainian Grain from Ukraine initiative is about 200 million dollars.

Milling and Grain - February 2023 | 27 Milling News

The collapse of Mount Ephraim Mill

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

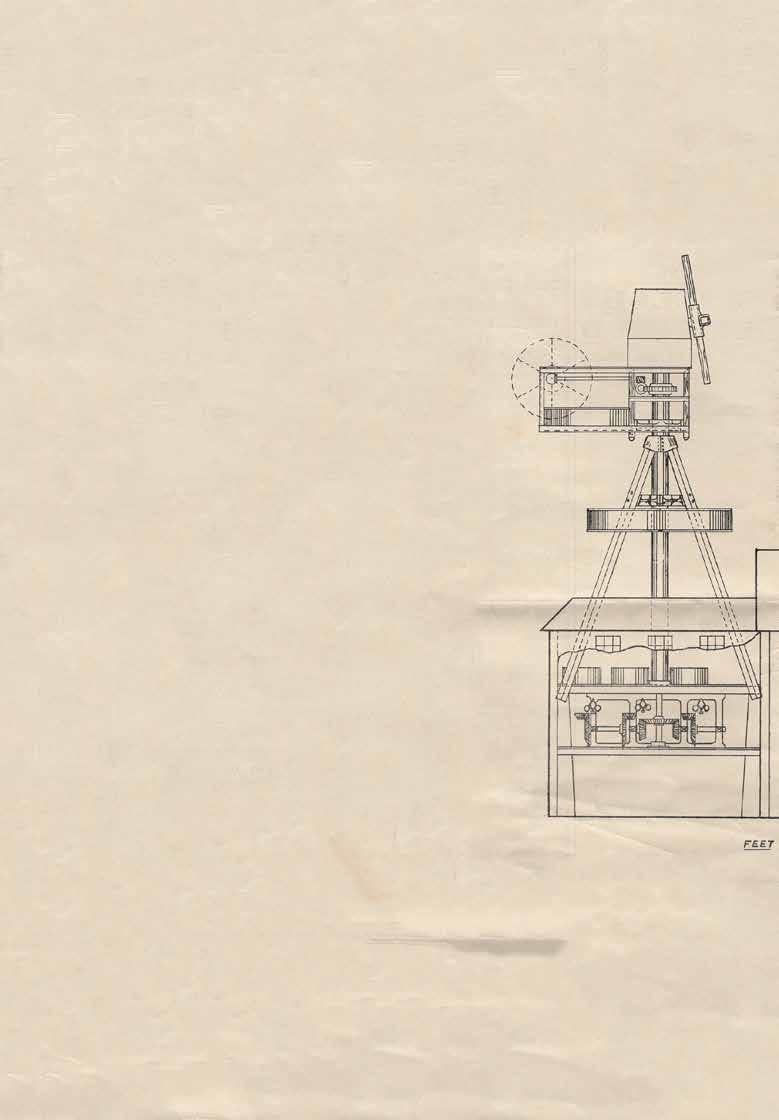

Mount Ephraim mill was a post windmill in the village of Ash, near Canterbury in Kent. Built in 1735 in Ringleton and moved to Ash in 1818, it had a single storey wooden roundhouse and a large post made of nine pieces of timber around which the upper part of the mill turned to face the wind. It was about 36 feet high, and like other mills in Kent it had two sails which were covered with canvas to catch the wind, and two which had wooden shutters. Rex Wailes first visited the mill in April 1936 when he reported that it was over 200 years old, but in fine working order. The sails were in good repair and only needed painting. Rex recommended various other repairs, which would at the time have cost about UK £35 – something like UK £2000 today. Rex visited again in June 1950, noting that the mill was one of the most interesting in Kent. Unfortunately, by this time the mill was in much worse repair, with a lot of evidence of wood worm. Rex now estimated about UK £350 would be needed for repairs – around UK £9500 today. Sadly, it seems Rex’s recommendations were still not followed – in 1952 he visited again to inspect the sails, concluding that they should be removed and examined,

as they were likely to be suffering from wet rot. Before his visit to the mill Rex had called on the nearby Holman Bros firm of millwrights in Canterbury. Unfortunately, their millwright Bob Barber was no longer carrying out this sort of work, and their only other employee with similar training was away on military service. Rex recommended that a suitable millwright should be found to remove the sails, and that he should train up the craftsmen who assisted him so that the knowledge of how to carry out this sort of work could be passed on.

The mill still continued unrepaired, however, and in 1955 the structure collapsed when it was blown down in a storm. Rex wrote to the owner, Mrs Brockland, expressing his condolences and noting that “had my advice been followed by the various bodies, she would have been repaired five years ago, and I do not think this would have occurred.”

Today there is sadly no trace remaining of this historic mill, except for the images and records contained in archival collections such as those held by the Mills Archive Trust.

The Rex Wailes Collection

28 | February 2023 - Milling and Grain

Get fast and actionable mycotoxin test results

The AgraStrip® Pro WATEX® test system enables the rapid and �simple on-site quantification of mycotoxins in a variety of agricultural commodities.

The streamlined workflow reduces steps to a bare minimum while independent and simultaneous testing for up to 4 samples sets new standards in accuracy and usability.

Learn more at www.romerlabs.com

SAMPLE ID: BR-11071

COMMODITY: CORN

Aflatoxin : 3.4 ppb

Deoxynivalenol : 0.8 ppm

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS

more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Alltech continues to support mentorship program for women in agri-food

Alltech is proud to continue to partner in the Women in Food & Agriculture (WFA) Mentorship Program. Applications are now open for new mentors of any gender and for female mentees from across the global food and agriculture sector. Now in its third year, the free-to-join program matches applicants based on their preferences, which can include gender of mentor, areas of expertise, language and industry sector, and offers opportunities for women in food and agriculture to develop meaningful industry connections.

“Over the past few years, all of us have come to more deeply value the power of human connection,” says Dr Mark Lyons, president and CEO of Alltech. “A commitment to the growth and development of another person unleashes energy, inspires ideas and empowers both individuals to have a greater impact. We view our involvement in the Women in Food & Agriculture mentorship program as an investment not only in the lives of women but in the future of agriculture as the industry most integral to the nourishment and vitality of our planet.”

Findings from the annual WFA survey and ongoing feedback from all levels of the food and agriculture sector consistently suggest that a hurdle to greater success for women in the global agri-food industry is a lack of mentorship opportunities. To tackle this issue, WFA launched its Mentorship Program. In partnership with Alltech in 2022, the initiative grew with 320 industry representatives matched across two cohorts. Now in 2023, the program will be open for applicants year-round with

CKP launches seven microlearning modules on feed safety culture

The Collective Knowledge Programme (CKP) has developed a series of seven short e-learning (microlearning) modules on feed safety culture. From January 9, you can find all the modules at the GMP+ Academy.

A microlearning module shares basic knowledge about feed safety in an accessible way. Companies can use them as a refresher course or to train new employees. Each module lasts no more than ten minutes, can be completed anywhere, at any time, and contains lots of practical examples. The modules are available in English, Dutch, Polish, Spanish and German.

Awareness

The most important goal of the series is raising awareness. Participants learn what it means to take account of feed safety.

two matching sessions taking place to help even more women in food and agriculture progress their careers. The initiative has supported a variety of people around the world from CEOs of agribusinesses to small-scale farmers, from academics to ag-tech professionals, with sector representatives paired with mentors that complement their professional objectives.

“We are very pleased to again have Alltech supporting the 2023 WFA Mentorship Program,” says Elisabeth Mork-Eidem, global chair of WFA. “Mentorship is vital in supporting women across food and agriculture in developing their careers, we've had very positive feedback from both mentors and mentees. Many of our mentors joined the initiative as a selfless act of support for equality in our sector, but realized they got as much out of the experience as the mentees. This is such an exciting opportunity to learn about yourself, develop your skills and support an important initiative that is working to improve diversity, equality and inclusion in the food and agriculture industry.”

For those interested in taking part in the 2023 Mentorship Program, WFA is looking for mentors of any gender who have at least one year of experience in the food and ag sector. During matching, WFA will ensure all mentors have more work experience than mentees, so this should not be a barrier to mentors applying. Potential mentees should be women working in the food and ag industry who would benefit from help, guidance and support from a senior sector representative.

Alltech believes that inclusion cultivates creativity, drives innovation and is essential to the company's purpose of Working Together for a Planet of PlentyTM. In 2019, Alltech selected Gender Equality as one of the nine United Nations Sustainable Development Goals to which the company committed to advancing.

Applications are open now for the Women in Food & Agriculture (WFA) Mentorship Program, supported by Alltech.

Through various exercises, cases and examples, they reflect on their actions and are inspired to consciously contribute to the feed safety culture within their organisations.

Step by step from theory to action

This series introduces participants to feed safety culture step by step.

In microlearning 1 & 2, the participant learns about the importance of food safety and about common hazards

In modules 3 to 5, the participant learns what feed safety in organisations looks like; how feed safety culture is managed and who plays which role within an organisation

Microlearning 6 is about preventing and recognising fraud

The series concludes with a module in which the participant chooses a personal goal and an action that will contribute to food safety within their organisation.

The Collective Knowledge Programme is a unique partnership

This series of microlearning modules has been developed in partnership with the GMP+ Academy's Collective Knowledge Programme (CKP). Feed experts from big names in the industry (AB Agri, De Heus, Trouw Nutrition and Veravis) pool their knowledge and experience in order to share information about feed safety culture with the world.

Milling and Grain - February 2023 | 33 TRAINING Mill

Grain Grading School programme 2023

Kansas Grain and Feed association have announced their 2023 Grain Grading School programme, with 6 available upcoming day sessions throughout February and March to provide the best training on grain standards.

The course’s will all take place across various locations in Kansas, USA. In February, the locations include Topeka (February 21), Wichita (February 23), and Parsons (February 22), and March will feature events in Garden City (March 8), Colby (March 7), and Salina (March 9).

The training is aimed at teaching elevator operators,

producers, brokers, and grain buyers about grain grades and how to use grain standards in marketing. The Kansas Grain Inspection Service will walk attendees through grading samples of corn, soybeans, wheat, and sorghum.

Participants will be trained to recognise various types of kernel damage and grade a representative sample. They will be introduced to sampling methods and techniques pertaining to grain grading and/or grain quality, with encouragement to use practical, cost-effective procedures for grain inspection.

Education materials supplied at these schools include a grain grading handbook with colour pictures depicting grain damage, samples of grain with different types of damage and grading equipment.

After attending these schools, participants will be able to assess grain quality and its market value more accurately.

All day events begin registration at 8:30 while the program starts at 9 am and runs until 4 pm. The price of attending for members of KGFA is US$85 (non-members US$110).

TRAINING Mill BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY VIV ASIA 2023 BANGKOK, THAILAND 8-10 MARCH IMPACT THE COMPLETE FEED TO FOOD GLOBAL TRADE SHOW IN ASIA Scan to register Co-located with Guided Tours onsite Shuttle Bus service to and from the venue! Register now for FREE! 34 | February 2023 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less than £12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

We will be seeking enrolments from June ...

FOCUS Product February 2023

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process. Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

Polybutadiene Rubber Ball by Rubtech Mech INDIA LLP

The company has conveniently developed Rubber Ball Sieve cleaners for edible materials which are for human consumptions; the basic Rubber compounds and specimen were duly tested by SGS & passed with distinction inconformity to all of the US FDA & EU regulations. This ball cleaners have been developed after consistent research in compound (recipe) designing with base elastomer Polybutadiene. The resilience of this rubber balls is exceptional; thus, it leads to an extra yield of the sieving process. The abrasion resistance is very high; thus, the wear rate is minimal, leading to enhanced service life. The rubber compound used for these balls is Certified Food Grade as per US FDA, EU & Japan Regulations.

NEW SIMILAGO II by Alapala

Alapala’s NEW SIMILAGO II roller mill is equipped with high technology electronic control systems for a continuous and consistent performance in the grinding of cereals, such as wheat, maize (corn), rye, spelt, barley and sorghum. The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly. Rotational speed of feed rolls is monitored against an unexpected stop due to belt problem, etc. Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls.

The main motor load is constantly measured for protection against any possible damage, and the rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

The NEW SIMILAGO II is built to comply with the high sanitation standards and ensure food safety. The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk.

“SF” Volumetric Screw Feeders by Essmueller

Volumetric Screw Feeders are used to control the flow rate of bulk material from a bin or hopper. They are designed to be flood fed, so that regardless of the amount of material in a hopper above the inlet, the outlet rate will remain consistent. Screw feeders are available to feed a wide range of materials.

Essmueller screw feeders are available in standard trough lengths, and in sizes to suit almost any need. They are available in single, double, triple and live bottom configurations. Multiple screws are used to control the flow rate of bulk material that tends to bridge a bin or hopper. Live bottom screw feeders are designed to be mounted under bins to control the flow rate of material that tend to pack or bridge. Tapered pitch or variable pitch screws are used in screw feeders to draw the bulk material evenly from all areas of inlet opening.

Vane axial fans by GSI

For applications requiring high airflow at static pressures below 6" (depending on bin diameter), GSI offers vane axial fans in 12" diameter (1 HP) through 28" diameter (15 HP). Vane axial fans 18" and smaller use cast aluminium blades. Vane axial fans 24" through 28" use durable composite airfoil blades that are lightweight for easy starting and function well in this type of environment.

The 12" through 28" (1-15 HP) units feature a 3450 RPM motor for increased fan performance and energy efficiency. Close fan blade tip clearance and straightening vanes provide maximum air flow and reduced turbulence to ensure smooth and consistent airflow. All 24" and 28" vane axial fans also include a durable plastic inlet venturi which funnels air more efficiently into the fan.

GRANIFRIGOR™

Europe by FrigorTec

The GRANIFRIGOR™ Europe range of grain cooling units are performance- and energy consumptionoptimised for the temperature and humidity of European temperate conditions. They can be used to reliably cool grain in temperate climates (rain, fog, head and cold) - assured control of air humidity due to HYGROMAT™ automatic. Complete suitability and reliable operation even at high ambient temperatures due to safe refrigerants. The units have a standard medium pressure version - ideal for tower silos too. FrigorTec grain cooling units are based on a sophisticated modular system and offer the following features:

• Fully automatic Siemens S7 controller

• Remote-controlled operation via FrigorTec app

• Rigid, welded frame construction

• Partially soundproofed housing UV-resistant external cable

• Eyelets for lashing on every housing corner

• Pressure-stable cooling air high pressure fans

• Filters for the cooling air supplied to the grain

• Compressors, for example from Bitzer/Germany

• Multi-coated steel parts

36 | February 2023 - Milling and Grain www.grainsystems.com mymag.info/e/1738 www.rubtechmech.com https://alapala.com mymag.info/e/1735 http://essmueller.com mymag.info/e/1736 www.frigortec.com mymag.info/e/1737

M18-5 GRINDING MILL by SWECO

A three-dimensional vibratory action - Vibro-Energy motion

SWECO Vibro-Energy Grinding Mills is one of the most versatile line of mills available today for fast, low-cost particle size reduction to sub-micron range. Vibro-Energy grinding action achieves higher output per input horsepower, precise control of size and distribution. Product contamination from media and lining wear is virtually eliminated. Maintenance costs are low because of few moving parts and replaceable linings made of abrasion-resistant metal, ceramic or elastomers.

The key feature of every SWECO Grinding Mill is its VibroEnergy motion. A three-dimensional vibratory action, this precise, high-frequency motion is the reason why SWECO Mills can grind a greater variety of materials to a particle size of 1/2 micron or less ... with results so consistent that batch time guesswork is virtually eliminated.

The high-frequency, low-amplitude motion, as employed in the VibroEnergy Mill is the most effective method of converting energy to accomplish particle size reduction from 100-micron to submicron range.

Contamination of materials while grinding is an important consideration in many industries. Due to the rapid wear of the grinding media in ball or pebble mills, these machines cannot be used in many applications. In contrast, VibroEnergy Mills introduce negligible media and lining contamination due to the small impact forces generated.

Pigments produced by precipitation and filtration frequently acquire electrostatic charges during the

process. These charges bond the pigment particles very tightly, slowing down conventional grinders. The high frequency impacts in a Vibro-Energy Mill quickly dissipate the small static charges originally existing in the pigment.

The movement of media in a Vibro-Energy is very small, so a high percentage of the energy is directed into the grinding effort. Once the motion generator is up to operating speed, the inertia of the rotating eccentric weights greatly reduces the power input required to maintain this speed. Consequently, very low-energy input is required per unit of ground product produced.

Unlike conventional ball and pebble mills, the Vibro-Energy Mill does not require deep, heavy concrete foundations or specially reinforced structures. The major vibrating forces are directed to the grinding chamber with a minimum of vibration transmitted to the base. This results in a substantial savings in installation costs.

The inside surfaces of the grinding vessel are constructed of abrasion-resistant polyurethane, with other linings available for special applications. This feature, combined with few moving parts in the mill, significantly reduces maintenance costs.

SWECO Grinding Mills can easily be operated in series for continuous processing. The units can be used in either open-circuit or closed-circuit grinding.

Because of the unique vibratory motion, discharge of material from the Vibro-Energy Mill is accomplished rapidly and easily while the unit is in operation. Even thixotropic materials flow readily. Samples may be taken by merely opening the valve while the mill continues to operate.

Milling and Grain - February 2023 | 39 FOCUS

Special

Welcome to the all new The website for the International Milling Directory has been totallly redeveloped for a faster and more accurate user experience, with new and improved features available for all of our members! internationalmilling.com internationalmilling.com For where ever you are! The print edition Take the International Milling Directory with you Even when you are offline! the trusted information source for the industry Our 30th edition is OUT NOW! Try the App for FREE using promo code HNY2023

http://sweco.com

www.ai-lati.com

u r ess enc e lie s i n t h e for m s t h ro ugh wh i ch w e s how o u rsel v es.

offer j u st wha t we a r e .

wa y s . www.paglierani.com

O

We

Al

www.ocrim.com

Global Food Security

ADM Aims to Improve Global Food Security and Mitigate Environmental Impacts

By Martin Kropp, President, Animal Nutrition –EMEA, ADM

limate change is of utmost priority to business and the end-consumer. Globally, consumers are demanding a higher standard from companies regarding their environmental practices and are using their purchasing power to reinforce these values and beliefs. Research finds 49 percent of global consumers claim they have made changes to their diets, and 40 percent have chosen one product over another, in order to be more environmentally responsible.

As a leader in human and animal nutrition, ADM is committed to playing our part within the global food system to serve the world’s nutritional needs while reducing environmental impacts. Extensive opportunity – and responsibility – exists within the agriculture sector to develop scalable nutrition solutions that contribute to a more sustainable food future, including efforts to improve livestock productivity, crop yields and manure management, and at the same time, reduce greenhouse gas (GHG) emissions.

Identifying Areas for Improvement

Within the livestock sector, the two main emission sources are the production and processing of feed, and enteric fermentations. Life Cycle Assessment (LCA) methodology is a tool to help quantify the environmental impact of two key phases of feed and additives: their manufacturing and their use by livestock. The results of the first part of LCA can provide brands the important supply chain data they need, from sourcing to delivery, to include critical carbon footprint information on their product labels. For a global supplier like ADM, LCA helps us identify the key areas

for operational improvement so we can implement actions that will have an effect to our downstream customers.

The second phase LCA assesses whether using the feed product can support a reduction in environmental impact across the entire value chain. This includes lowering greenhouse gas emissions through the improvement and promotion of animal health, the optimisation of animal performance, and/or the reduction of nutrient excretion in manure. The second-phase results obtained help companies demonstrate how their products and solutions can contribute to reducing the greenhouse gas emissions of their sector.

ADM recently obtained the first verified LCA results of our feed additive, XTRACT code 6930. XTRACT is registered in more than 65 countries and is an innovative combination of microencapsulated active substances found in aromatic plants and spices with demonstrated physiological effects

C

42 | February 2023 - Milling and Grain F

on livestock. Performance analyses of XTRACT for poultry broilers demonstrates its efficacy in increasing carcass yield, weight and breast weight, as well as improved feed conversion ratio3. XTRACT 6930 is one of the first products in the plant extract-based feed additives segment to have its environmental impact externally verified. Additional LCA in progress will assess ADM’s environmental impact of feed manufacturing and application on animal production.

ADM is additionally conducting extensive research to develop strategies that mitigate methane production by ruminants. Reducing the amount of methane released can lead to more energy being made available for animal performance, including higher milk production, fat and milk protein in dairy cows, or higher weight gain in beef cattle. Our preliminary phase of in vitro trials has highlighted the potential of various strategies, including the use of plant extract-based additives. Several in vivo studies are now being conducted to quantify the level of methane reduction, depending on management practices.

Fostering Sustainability and Food Security