millingandgrain.com January 2023 In this issue: Milling and Grain . Volume 134 . Issue 1 . January 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 134 Issue 1 Gluten-free flours Analytical characterisation and processing of gluten-free flours on a laboratory scale - Importance of Starch Damage in Wheat and Milling Industry - Grain cleaning and grading for tightening specifications - Doruk to aim at 200% growth in wheat production - Milling Journal Launched

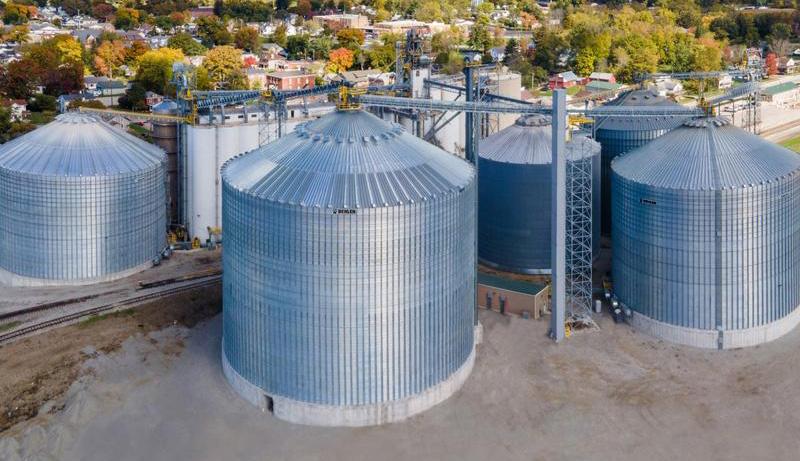

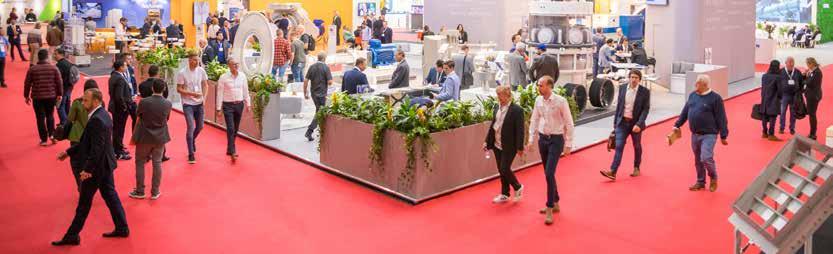

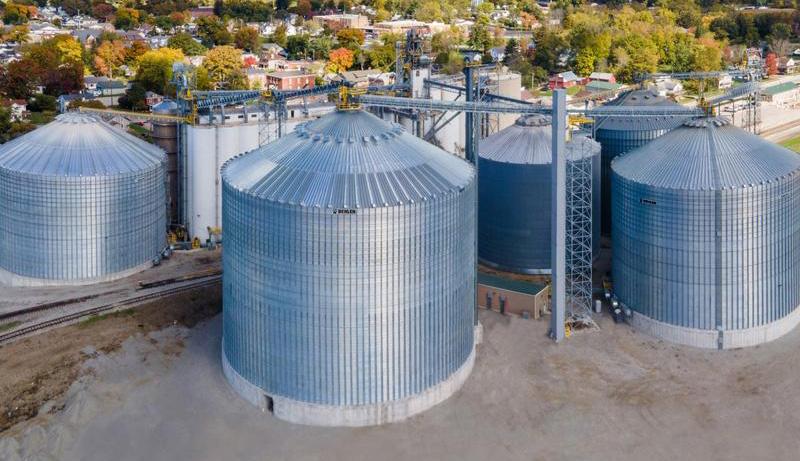

Behlen bins range

silos

wall panel design. COMMERCIAL GRAIN BINS Behlen hoppers are designed to ensure strength, ease of assembly, and trouble-free operation. COMMERCIAL HOPPER TANKS Behlen Steel BUILT TO LAST Behlen Grain Systems... Standing the test of time with competitive prices and Customer Service second to none. CONTACT US TODAY TO DISCUSS YOUR PROJECT! Call 1-402-564-3111 or Visit www.behlengrainsystems.com Bigger and Better than Ever!

in size from 85 to 66,000 cubic meters. These

feature a unique trapezoidal

Pneumatic and mechanical ship (un)loaders Up to 2500 tph for loaders and up to 1200 tph for unloaders. Low noise & no dust emission Turnkey solutions for cereals, soy flour, fertilizer, pellets and more... Handle bulk with efficiency and reliability

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher Roger Gilbert

rogerg@perendale.co.uk

International Marketing Team Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant Shannon Parsons shannonp@perendale.co.uk Niamh Cassidy niamhc@perendale.co.uk

Digital community manager Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com Professor Wenbin Wu wenbinw@perendale.com Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk 0

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager Antoine Tanguy antoinet@perendale.co.uk

FEATURES

millingandgrain.com ISSN No: 2058-5101

VOLUME 134 ISSUE 1 NEWS 10-30 42

48

52

56

64

66

STORAGE 70

8 PUBLISHER Roger Gilbert 104 INTERVIEW Freya von Czettritz and Jen Kremer

Publishers Ltd. All rights

may

reproduced

EVENTS 90 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 28 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 33 Industry training news PRODUCT FOCUS 36 CASE STUDY 84 INDUSTRY PROFILE 80 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 January 2023

Analytical characterisation and processing of gluten-free flours on a laboratory scale - see more on page 48

Opportunities and threats: In a globalised world, how does Africa become self-reliant

Gluten-free flours: Analytical characterisation and processing of gluten-free flours on a laboratory scale

Insect damage and product loss: The success story of an Australian Almond Processor in tackling the issue of ‘Pinhole’

Importance of Starch Damage in Wheat and Milling Industry

A look back at 2022 and looking forward into 2023

Can agricultural robots reverse the trends of water resource shortage and climate change?

Grain cleaning and grading for tightening specifications

©Copyright 2019 Perendale

reserved. No part of this publication

be

in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service

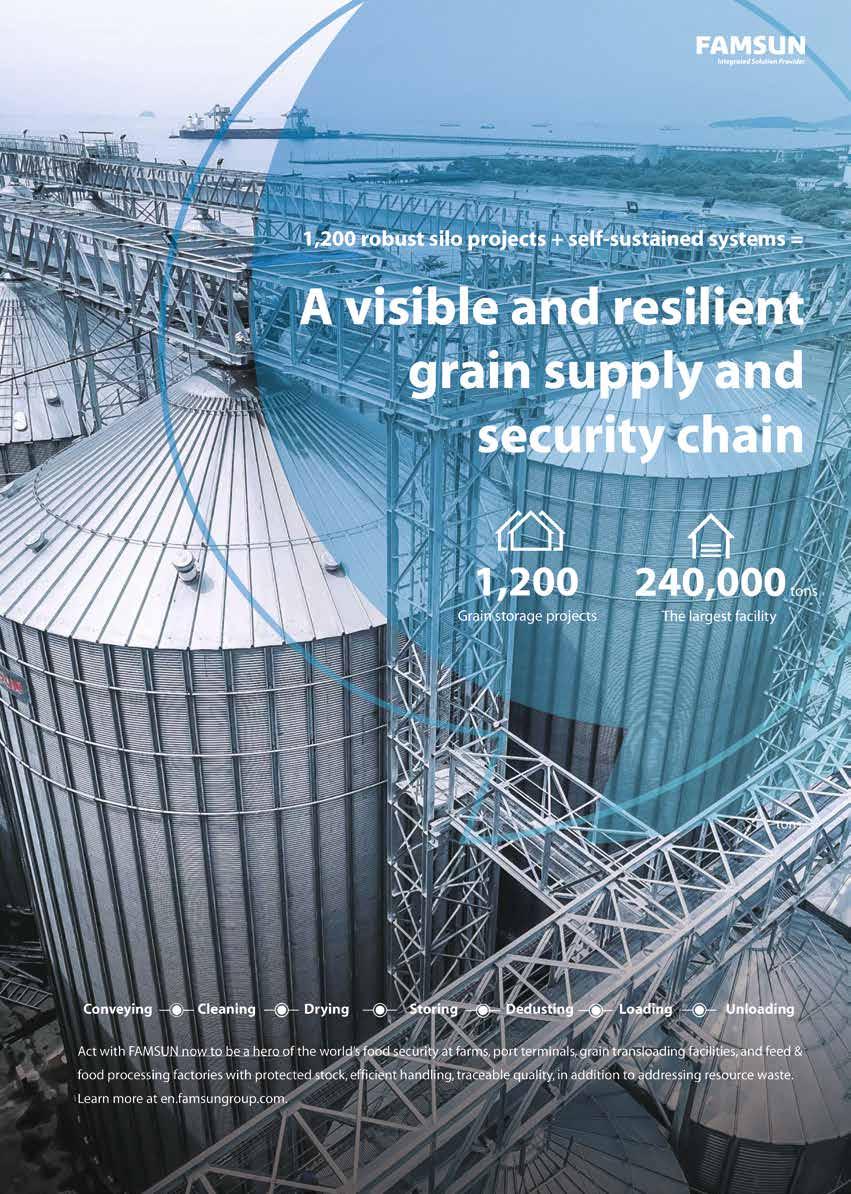

COVER IMAGE:

Opportunities and threats: In a globalised world, how does Africa become self-reliant See more on page 42

74 MARKETS

John Buckley

What’s likely to happen next?

That’s what we are all waiting for isn’t it? The next calamity that will challenge us in the way we go about feeding a growing population affordably.

It’s an expectation I have, based on the experience from the past three years of disruption – another unexpected global challenge. We weren’t prepared for any of the global events that have happened recently, yet what could we have done differently given hindsight with 20:20 vision?

I’m beginning to think that we could not have planned effectively to avoid these disasters even if we had fully appreciated them, at the time, including the impact from issues such as climatic change on food production, the pandemic and its resulting impact on global commerce and the war in the Ukraine with its international implications for energy and food production costs.

While there is much that could be debated in this statement, turning our attention to the future and planning for future global interruptions should be a priority and we should expect the role of governments everywhere to be working in greater harmony.

All three challenges of the immediate past and present show us how fragile our joined-up world has become and we haven’t even considered the likely consequences from other challenges that we face longer term, such as the causes of mass migration, the flouting of human rights, fresh water availability, human health challenges, antibiotic resistance and of course poverty and how to respond to them.

The question must be asked, “Are our governments, through bodies such as the United Nations and related NGOs, fit for purpose when it comes to dealing with these global issues mentioned above?” I would like to think so and given my lowlevel association with these groups in the past, I have to say there is very little evidence that they are managing to roll back on these matters that still threaten all our futures.

However, where do we go from here? Continue to trust exclusively in our governments and their joined-up global groups or look to alternative approaches. James Cooper, our MAG Correspondent, attempts to bring greater clarity to the possibilities of change within our food supply structure in his feature on 'Opportunities and Threats in a Globalised world - and how does Africa become self-sufficient.'

Changing attitudes

Over the past three years I have seen a significant shift in attitude towards globalisation.

There are those who think that local is best and if adopted wholeheartedly could resolve many of the above issues identified. And that approach is laudable if extreme.

However, there is clear evidence that globalisation and the sharing of the world’s resources in food production is necessary. Industry is more aware than ever of its impact on the

environment globally, its use of water resources, its dependence on energy supplies and the cost to the planet of moving raw materials and finished goods around the world.

Great advances are being made in all these areas – again, particularly in food production - in bringing about efficiencies in the manufacture of products no matter where they are produced.

It’s not just a matter of buying local and shifting our dependence from international supply to reduce food miles for example, when we all rely on products such as the mobile phone, which is made in strategic locations around the world using components that are provided via a global network of suppliers.

‘Big is not always best’ in every situation I know, and complete globalisation might not be the solution either. However, countries want and need to produce their own food for all sorts of reasons including achieving greater food security. We only have to look at the current plans Singapore is adopting to understand why.

Producing nutritious, safe and affordable protein- and energyrich foodstuffs through a combination of local and global supply is what we should be striving for and which will help us meet challenges in times of severe need.

When I pick up a 150g pack of asparagus spears in my local supermarket to see that it has come all the way from Peru, I do not think negatively of the unnecessary air miles that it took for a plane to bring them into my country - that plane was making the journey anyway - nor that asparagus are grown locally but of the farmer, the processor and the exporter in Peru who all earn valuable foreign exchange from my purchase and in turn can feed their families better, educate their children and look towards a more rewarding and prosperous future.

The Milling Journal

On occasion I have seen content from our MAG cited and/ or referred to in papers in other publications. That is very encouraging for the authors of the articles we have published, but it has not given any credit to them for providing their materials to us. That is about to change!

MAG is introducing this month its ‘Milling Journal’. We are now set up to peer-review contributions and provide an openaccess platform on our website to accommodate submissions from companies, organisations and individuals who have done considered work and wish to have their contributions properly reviewed and accredited. We will peer-review submissions across trhe board including equipment and processes.

Unlike the normal features and articles we publish, there will be a charge to cover the review process, the managing of the papers submitted, their timely publication as peer-reviewed documents and the management of the library where they reside.

It may take some time to receive regular contributions to this service. We have posted the opening page of the ‘Milling Journal’ in this edition. If you wish to contact the manager of the service please write to the journal@perendale.co.uk in the first instance.

Wishing you a Happy and Prosperous New Year ahead – without calamity!

Annual Subscription Rates

Inside UK: UK£100

Outside: US$150/€133

Milling and Grain has a cooperative partnership with COFCOET

More Information www.millingandgrain.com http://gfmt.blogspot.co.uk

Roger Gilbert

Roger Gilbert

PINGLE. PROFESSIONAL MANUFACTURER OF GRAIN MACHINERY ★ INTEGRATED MILLING SOLUTION PROVIDER ★ ISO 9001:2015 CERTIFIED Аdd: Zhengding, Shijiazhuang,Hebei,China Tel: +86-311-88268111 Fax: +86-311-88268777 E-mail:pingle@pingle.cn / www.pinglemachine.com

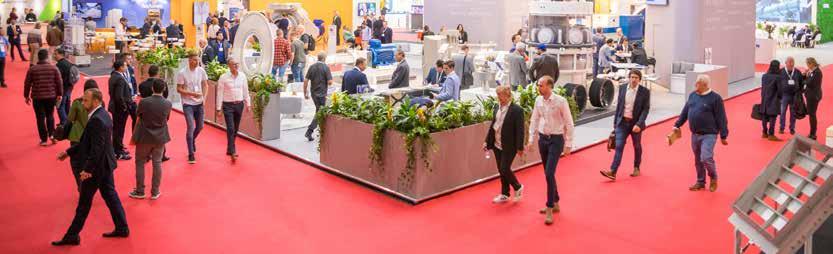

Eurotier 22 - Interview with Addcon

Christoph Hutter, the sales director for Addcon’s Business Unit for Feed talks to Roger Gilbert, the publisher of Milling and Grain and International Petfood magazines, about this long-established German family company joining with the Italian Esseco Group during the 2022 EuroTier Exhibition, which was a four-day event held in Hannover, Germany from November 15-18, 2022. Esseco, based in San Martino, Trecate near Milan in Italy is an industrial chemical group that has been creating technological innovation and improving production techniques of inorganic chemical products, such as highquality sodium, ammonium and potassium derivatives, for global supply into a broad range of industries including water treatment, the feed and food and agriculture industries for almost a century. The partnership was set up just prior to the introduction of the Covid Pandemic towards the end of 2019, and this is one of the first opportunities Addcon has had to exhibit under its new partnership arrangement. Addcon will retain and enlarge its branding and customer base under the agreement. To view the interview, visit Milling and Grain’s home page and follow the MAGTv link.

Watch the video at

Welcome to the January edition of Milling and Grain magazine, the first of the new year and the first Global Miller column along with it. I hope that the New Year has treated you all well and that everyone is prepared for 2023!

Winter is exceptionally cold here in the UK, so we’re all bundled up in puffy coats and woolly hats and scarves. And, with the echoes of the New Years’ fireworks welcoming us into the year, everyone is taking down their Christmas decorations and preparing their New Year resolutions. I’m sure no one will forget or break their resolutions, especially not me.

Unlike many getting a break over the winter holidays, farmers remain busy in this cold month following the new year. For livestock farmers, it’s time to start weaning the calves and feeding the sheep sugar beets and sheep nuts. Arable farmers though need to spread the slurry, preparing for the silage or hay that will be taken later in the year. General farm maintenance is also best to get done around now too. Things such as repairs, painting, cleaning etc.

Here in the UK though outside of the farming world, protests and strikes are happening all over the place. You could just want to catch a bus or train for a hospital appointment and find that not only are the buses and trains incredibly late or cancelled, but the nurses and doctors are walking out too, so you arrive late for your appointment, to find that it wasn’t going to happen in the first place anyway. It’s a little nuts here, I tell you.

For a sneaky peak into our news surrounding the world however, Alapala builds a sixth flour mill located in Dhaka, Bangladesh, Cargill and Owensboro Grain Company enter into a large agreement in North America and ADM and its partners win the award for Field to Market’s Collaboration of the Year. So much exciting news and more can be read in this edition and can also be found on both our website and blog.

Discussing the world further, we go into the depths of Europe with a spectacular report filled with images of Eurotier 2022 in Hanover, Germany. Members of our team went to Germany for Eurotier and we got to meet a bunch of incredible people and companies. It was a wonderful time and you can hear more about it in our events section.

Now, with the rest of the year ahead of us, new projects and plans are bound to begin or be well underway. New collaborations will start, machinery to be promoted and more. If you or your company have any exciting news to do with any of this, events, machinery, feed, please send it to us. Editorial is free and we’re happy to publish your news and stories in our magazine or website.

Please send any news that you would like featured to the email address: editorial@perendale.co.uk

News

gfmt.blogspot.com

more

all

the

at millingandgrain.com/videos

Milling

See

videos from

aspects of

industry

mymag.info/e/1717

10 | January 2023 - Milling and Grain

www.balaguer-rolls.com Facebook Youtube Linkedin

TO BOOST YOUR PROFIT

LATEST TECHNOLOGY

The Milling Journal

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream byproducts of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients.

The Journal will particularly embrace scientific and technical information on novel processes enabling the generation of ingredients for manufacture of bread, cakes, confectionary, pasta and a plethora of applications for diverse types of breakfast cereals, beverages and the infant formula markets. We also consider papers on complete animal feed manufacture as a core topic. These usually require pre-grinding and milling/flaking of grain and cereals for terrestrial animal feeds such as for poultry, swine, ruminants and equine. Animal feed production can involve drying, milling, pelleting, steam and pressure conditioning, shaping and texturisation dependent on specific machinery. Processes such as extrusion, cooking and expansion are of paramount importance with much research being undertaken on engineering, both mechanical and electrical. Effective storing and preservation methods offer opportunities for papers.

Given the diversity of different types of commercial pet diets ranging from wet, canned and extruded dry diets, treats and speciality diets, there is much scope to provide information on advances and discoveries. The rapidly growing aquaculture market is also very dependent on these technologies and scientific papers exploring such areas are also to be welcomed.

Manuscripts can consist of scientific work in the form of typical standard papers, short scientific communications or as review articles.

In essence, Milling Journal will appeal to the veterinary practitioner, scientist, technician, feed manufacturer and at various levels in academia such as undergraduate, masters, PhD students and post-doctoral researcher being an invaluable source of validated information and a potential location for their own research findings.

The manuscripts will be fully peer-reviewed by appropriate members of our editorial board and approved finally by the Editor-in Chief.

These OA papers will be available on our official website millingandgrain.co.uk and printed in the magazine as well as being downloadable. Links will be provided within our existing Milling and Grain magazine.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

Adisseo, one of the worldwide leaders in nutritional solutions and additives for animal feed, announces its participation in the new closing round of China’s first Agri-food tech VC Bits x Bites, a venture fund investing in early-stage startups with transformative technologies to address the most critical challenges in the food system in China. This investment is part of Adisseo’s strategy which focuses on activities at the forefront of the modern agricultural and livestock revolution: animal health, feed and nutrition and digital technologies serving the livestock industry.

Jean-Francois Rous, Adisseo Executive VP Research & Innovation, states, “Adisseo is a unique company committed to strategic investments in new disruptive technologies, in order to enrich our portfolio of R&D innovations while respecting a mode of sustainable growth.”

Joining this fund is also part of Adisseo’s Open Innovation initiatives to integrate Adisseo in the key innovation ecosystems in the planet, to accelerate the scouting and collaboration with startups developing disruptive technologies in the fields of Precision Livestock

Farming (PLF), alternative proteins for feed, carbon footprint reduction technologies applied to our production processes and novel feed additives and services supporting sustainable animal production.

“Adisseo has been proactively following the development of disruptive technologies in agriculture, in animal production, and has invested in startups through investment funds like in Europe and Latin America. Another example is Adisseo’s direct involvement in the Calysseo JV whose aim is to implement a novel technology (Single Cell Protein) into the Asian aquaculture market in cooperation with a Californian High-Tech company,” adds Guy Harari, Senior Global Director and one of the Adisseo’s representatives in Bits x Bites fund.

Adisseo aims to contribute to the AgTech China ecosystem and pushes for more focus in animal production disruptive technologies, providing innovative feed additives solutions for antibiotics substitution, developing smart farming to improve monitoring and performance prediction, increasing food safety, and promoting sustainable production methods.

Adisseo is the only animal nutritional expert in the new round of investors. Other investors include industry leaders such as Syngenta Group Ventures, Wilbur Ellis, ESCO, and EDBI in Singapore and ADQ in Abu Dhabi and other reputable financial institutions and family offices. Continued support comes from Temasek in Singapore.

Bits x Bites’s raised USD$100 million for its fund in an oversubscribed close.

Adisseo announces its participation in the new closing round of China’s first Agri-food tech VC Bits x Bites

Milling and Grain - January 2023 | 13 Milling News

Have A Vision For Your Business.

it

it

75

With dedicated experts

your

to finish and beyond, Cimbria will

you

confidence.

you can look

you

grain or seed processing challenge?

customized plant design to turnkey installations and expert support, Cimbria can

your

Cimbria.com A/S Cimbria Thisted, Denmark Phone +45 96 17 90 00 cimbria.holding@agcocorp.com

You

Cimbria can bring

to life. We’ve been doing

for

years.

at

side from start

help

grow with

So

forward to a prosperous future. Do

have a unique

From

help find the right solution for

success.

Ÿnsect accelerates its international development in North America

Ÿ

nsect, a certified B Corp company and world leader in the production of premium insect-based ingredients, is entering an accelerated phase of international development with the signing of a memorandum of understanding with Ardent Mills for an industrial facility in the United States and the signing of a joint development agreement with Corporativo Kosmos in Mexico.

These agreements were signed just as Ÿnsect launched the world's largest insect farm in Amiens, France, with a height of 36m and a building surface area of 40,000m2. With the arrival of the first insects on site in recent weeks, the livestock's growth phase has already started. The operation of the facility will be rolled out over the next few months, with each site's remaining workshops to be phased into operation.

With Ÿnsect having already sold more than the capacity of the Amiens site in the coming years, taking on new projects is key to matching the growing demand from its customers. This will also allow Ÿnsect to build on the momentum for its premium ingredients while fostering a positive impact on ecosystems.

The partnership announcements in the United States and Mexico reflect Ÿnsect's development ambitions, with plans to build 10 to 15 farms worldwide by 2030. Ÿnsect plans to expand its activities on all continents to help meet the challenge of feeding more than 8.5 billion people in a healthy and sustainable way by 2030.

In order to do this, Ÿnsect is focusing its developments within the heart of agricultural areas to increase easy access to raw materials used to feed the insects, such as agricultural co-products from the cereal industry. The choice of these strategic locations, with close proximity to resources needed, reflects the company's commitment to limit the impact of its activity on the environment, including CO2 emissions and water consumption. Ÿnsect has adopted a circular economy model based on its vertical farms to create value chains aligned with the Paris COP21 agreements.

An agreement with Ardent Mills to accelerate Ÿnsect's implementation in North America

Through this agreement, Ÿnsect affirms its intention to expand its insect-based ingredient production activities in the United States. As part of this expansion, Ÿnsect will explore synergies with Ardent Mills, the leading supplier of wheat flour in North America, with the aim of starting the construction of a new site in 2023. This agreement follows the acquisition of Jord Producers, the group's first farm on US soil, in Nebraska in March 2022.

"We have many synergies with Ÿnsect in the sense that both our companies are striving to help positively transform the way in which the world is fed. We are excited to explore sustainable food and ingredient production opportunities with Ÿnsect, which has unique expertise in producing insect-based ingredients," says Angie Goldberg, Director of Development at Ardent Mills.

'Ÿnsect wants to help reinvent the global food system with a focus on sustainability. That's why we are very excited about this agreement with Ardent Mills, the leading North American milling company. This marks the beginning of potential exciting collaborations between two key players in the global food industry," adds Antoine Hubert, CEO and co-founder of Ÿnsect.

This agreement comes at a symbolic time as the French President Emanuel Macron undertakes his second State visit to the US to meet with President Biden, for an encounter focused on the industry, space and climate. Antoine Hubert was part of the official delegation where he was able to highlight the benefits of Ynsect's technologies for the reindustrialization and food sovereignty of France, Europe and the United States, while respecting planetary limits.

An exclusive agreement with Corporativo Kosmos for a first location in Mexico

Ÿnsect and Corporativo Kosmos, a leading provider of food and general services in Mexico, have also just signed a joint development agreement to establish and operate a first insect farm in Mexico, with construction also aiming to start before the end of 2023. This agreement marks the culmination of a year-long collaboration between these two key players in the global food industry. Mexico is the leading country in the world in terms of human consumption of insects and insect-based proteins. In addition, this insect farm will bring Ÿnsect closer to the United States, by far the largest future market for insect proteins.

"We are particularly pleased with our continued collaboration with Ÿnsect, a company that has developed unique expertise in insect production. The future Mexican production site will allow us to combine the best of our expertise to provide a quality and sustainable product offering," says Jack Landsmanas, President of Corporativo Kosmos.

Milling and Grain - January 2023 | 15 Milling News

Wynnstay Group Plc acquires Tamar Milling Limited

Wynnstay, the agricultural supplies group, announced that it has acquired the entire share capital of Tamar Milling Limited (Tamar), a manufacturer and supplier of blended feed products, for an initial consideration of UK£1.4 million, with a deferred consideration of up to UK£0.1 million payable dependent on performance. The acquisition is expected to be immediately earning enhancing.

Established in 1994, Tamar is based in Whitstone, Cornwall, and manufactures and supplies a range of blended and coarse mix feed rations for dairy cows, cattle, and sheep to approximately 250 farmers, mainly in the south-west of England. Approximately 25,000 tonnes of feed is supplied annually. Tamar also operates a successful 'on-farm' grain milling service for farmers wanting to use home-grown or purchased grain in their livestock rations. Following its acquisition, Tamar's founder, Nick Furse, will join Wynnstay in a senior commercial feed role and continue to lead Tamar's operations.

In the year ended 30 September 2021, Tamar generated revenues of UK£6.40 million, and a profit before tax of UK£0.42 million.

The acquisition of Tamar is in line with the Group's strategy of acquiring businesses that complement its existing activities and bring further benefits. Tamar significantly strengthens the Company's presence in the south-west of England, adds a new farming customer base, additional supply chain relationships and significant cross-selling opportunities. It also establishes Wynnstay with its first feed manufacturing facility in the region, enabling it to provide its own bulk feed offering in the area.

The initial consideration of UK£1.4 million paid on completion is subject to a net asset adjustment to be calculated based on completion accounts. The deferred consideration of up to UK£0.1 million is payable dependent on product volumes transacted in the first twelve months following completion. The Group is funding the acquisition from its existing resources.

The acquisition of Tamar is the potential acquisition referred to in the Company's announcement of 17 August. The second larger potential acquisition referred to in the same announcement is no longer under consideration as commercially acceptable terms were not reached. The Company continues to review a number of acquisition opportunities that meet its strategic priorities.

Gareth Davies, Chief Executive Officer of Wynnstay Group plc, commented “Tamar is a long-established, high-quality manufacturer and supplier of blended animal feed and on-farm grain milling services to farmers in the south-west of England. Like Wynnstay, it places a strong emphasis on customer service, and has a significant customer base.”

“Tamar is highly complementary and will be immediately earnings enhancing. It fulfils multiple acquisition criteria. It increases our presence in the south-west, adds new farmer customers and provides us with our first feed manufacturing facility in the area. We look forward to working with our new colleagues and to continuing Tamar's successful growth.”

Milling and Grain - January 2023 | 17 Milling News

DSM starts construction of a new manufacturing facility to increase global production of Bovaer®

Royal DSM, a global purpose-led science-based company active in Health, Nutrition and Bioscience, has begun construction of a new manufacturing facility at its site in Dalry, Scotland. The plant will significantly increase global production of Bovaer®, DSM's unique methane-reducing feed additive for cattle. In an official groundbreaking ceremony attended by the First Minister of Scotland, Nicola Sturgeon, and Dimitri de Vreeze, Co-CEO of DSM, the company marked the next step in its plan to use Bovaer® to reduce global methane emissions and contribute to worldwide methane reduction targets.

DSM announced that planning had started during the UN Climate Change Conference last year in Glasgow. Construction officially began November 30 on a facility that will help DSM scale-up production of Bovaer® in the coming years and marks another milestone in the company's ambition to bring its methane-reducing feed additive to the market worldwide. This development of DSM's Dalry site has been supported by the Scottish Government through Scottish Enterprise, the national agency supporting economic development and innovation.

Reducing methane emissions is crucial for keeping warming below the 1.5°C target outlined in the Paris Agreement. Over 100 countries have signed a Global Methane Pledge, agreeing to reduce global methane emissions by at least 30 percent by 2030. The addition of new signatories in recent months, such as Australia in October 2022, underscores growing recognition of the need for urgent action. Ruminants (mainly cows) emit around 20 percent of all methane gases globally, so reducing emissions in ruminant herds will play a vital role in meeting global climate ambitions.

Bovaer® is a feed additive that can achieve an average enteric methane reduction of 30 percent in dairy cows, and 45 percent in beef cattle (with some tests showing reductions of up to 90%). DSM has initial product volumes available for near term market development. The product is in the early commercialisation phase in many countries around the world, including the EU/ EEA, Argentina, Australia, Brazil, Chile, Pakistan, Switzerland, Turkey, and Uruguay. Since the start of the development of Bovaer® an estimate of 15,000 tons of CO2e has been saved, and reductions will accelerate further once the Dalry plant is fully operational, expected in the course of 2025.

Rt Hon Nicola Sturgeon MSP, First Minister of Scotland, says, 'Just one year on from the announcement at COP26, I am very pleased to see the progress being made on site and the fact that spades are now in the ground.

"We are here today to celebrate a world-leading project and multi-million pound investment which will make Scotland the home of this innovative product, underlining that Scotland continues to lead the way in delivering a net zero future.'

Dimitri de Vreeze, Co-CEO of DSM, comments, 'After many years of hard work and dedication, it's a wonderful feeling to attend the groundbreaking ceremony for such a large-scale production facility. This is a historic moment for DSM: We are continuing to deliver on our 2030 methane pledge, one of our food systems commitments. I wish the construction team every success as they develop this plant in the coming years.'

Scottish Enterprise's Chief Executive, Adrian Gillespie, adds, “Today's groundbreaking ceremony is a significant milestone and the next step in delivering such an innovative project for Ayrshire and Scotland.

Royal DSM's Project Bovaer® has the potential to be a game-changer for emissions reductions from cattle. Scottish Enterprise has developed a close relationship with Royal DSM over many years and we were delighted to work with the company to secure Dalry as the home for this global manufacturing opportunity.”

Milling and Grain - January 2023 | 19 Milling News

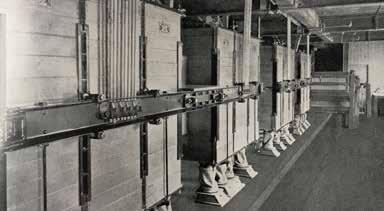

Hanover Street Mills: Re-Planning a Famous Irish Mill Another example of Plansifters Dealing with Soft Wheat Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

An article in Milling (18 June 1938) described only the second roller mill to be established in Ireland by that date. The buildings, in Hanover Street, Dublin, originally housed an oil crushing plant before being converted to a flour mill. The managing director was Mr. William Brown. His grandfather, a miller at Moniaive in Dumfries, together with his father and uncle, William and Walter came to Ireland and started the Hanover Street business.

These men were ahead of their time, installing porcelain rolls and purifiers before these machines were used to any extent in England. One of the rewards of this enterprise, and one that the article claimed casted an interesting light on their Scottish acumen, was the fact that they were able to buy Lancashire

millers’ offals to re-mill and purify, recovering a profitable percentage of good quality saleable flour. The lesson that good equipment is the finest investment was never lost sight of.

By 1885 the Hanover Street Mills were fully equipped with roller mills and a Mr Hastings Brown of Crewe had just completed three years roller mill experience in the USA. He returned home and worked out a flow chart to suit the mills. The plant required was bought from Messrs Thomas Robinson & Son Ltd of Rochdale, Lancashire, and installed by Mr. Hastings Brown, who was brother of the director of the mill at that time, William Brown.

He had joined the firm in 1888 after spending seven years gaining practical experience of roller milling and joined Robinson’s staff as their technical expert.

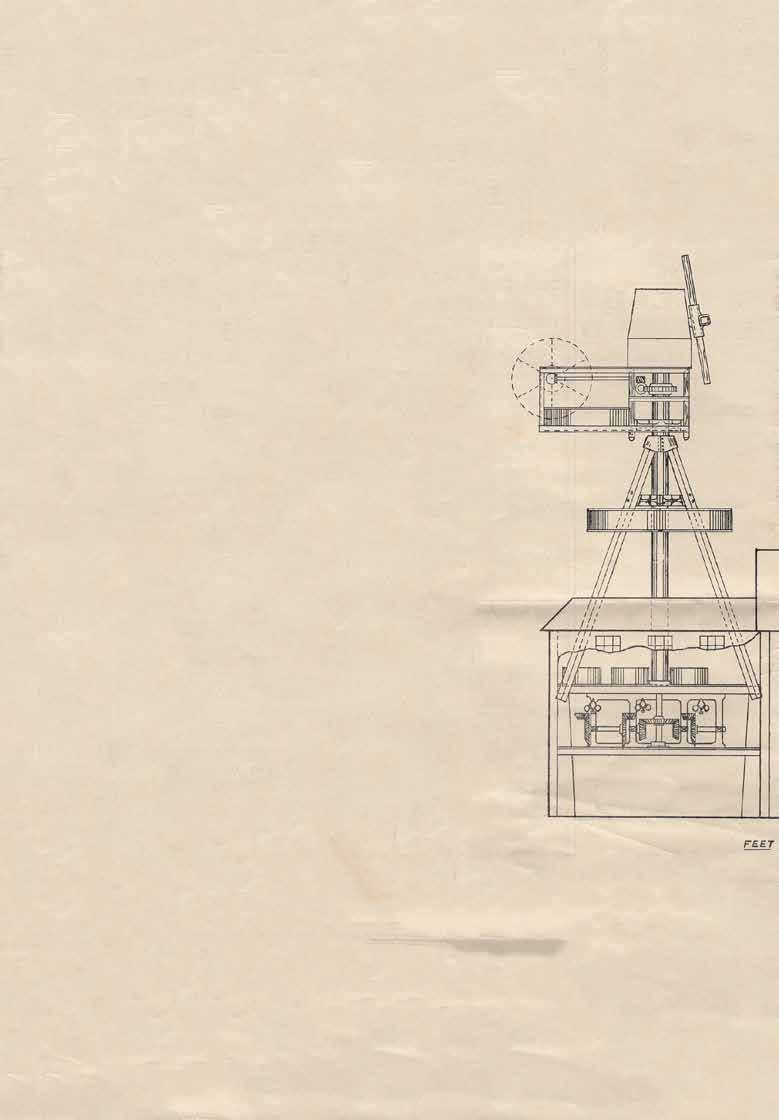

The Hanover Street mill was the first to install the Robinson patent dryer and conditioner, type JOm. Most of their wheat was brought in direct from the farms and dried on the JOm.

As the mill was not situated on the dockside the wheat was transported by bulk wagons from their storage at the docks. The screen room did not come within the recent reconstruction scheme but was very efficient and wheat reached the first break rolls in a perfect milling condition.

The object of the re-modelling of the mill was the complete revision of the purification and dressing systems. The new dressing machinery included two No 1a size sextuple JSm type plansifters with detachable clothing frames and three No 1 size LQm type purifiers. All the dressing done on the plansifters with the exception of the last break, its accompanying redresser and the three tail-end reductions.

The new system supplanted rotary graders on the break stocks and performed very fine

by Mildred Cookson, The Mills Archive, UK

The roller floor

20 | January 2023 - Milling and Grain

The mill building in 1938

work compared to the older machines which had disadvantages compared to the new plansifters. Each of the plansifters was thirteen sieves deep, and this efficiency combined with economy of space simplified the arrangement of the mill with sixteen centrifugal beings reduced to just six.

It also increased the capacity from seven sacks per hour to ten. It was noted that the two 3-inch belts driving the plansifters represented a big saving in power consumption compared to the previous arrangement which drove ten machines, each with its full complement of drives and bearings. The pleasing look of the line of purifiers, their high speed, and self-cleaning metal trunking assured the owners of a better floor layout.

Examination of the flours by means of the Pekar test showed a pleasing colour from first to last. The patent flours were of high quality, and the brands were: “Erin’s Best”, a blended baker’s flour: “Progress”, a strong baker’s flour: “Brown’s Best”, a household flour and “Dainty”, a self-rising flour. Two classes of bran were also produced, fine and broad, the latter being rolled on an existing pair of rolls.

Coming from the fourth break scalper, these products were exceptionally well finished and dusted.

The author commented that this sort of reconstruction did credit to the firm, coming from a long line of millers. It was also another example of an effective Robinson remodel. The extra production of flour in Ireland was followed by the stimulation given to the milling industry by legislation and had then reached the point where competition was increasingly intense. Only a mill efficiently equipped would hope to be successful and it appeared that Messrs. Brown had put themselves in just the right position.

The purifier floor

The plansifter floor

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets. In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more. >www.andersonfeedtech.com/healthcheck Milling and Grain - January 2023 | 21

Three members of the Brown family

Alapala completes the 6th Flour Mill in Bangladesh

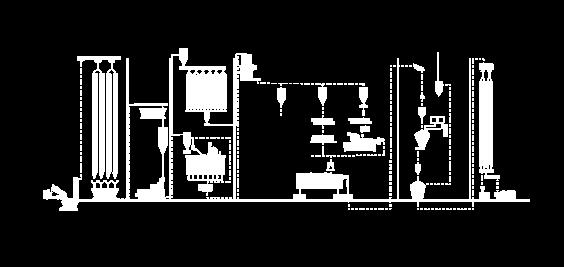

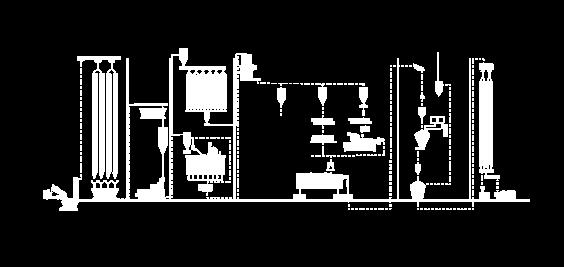

Alapala recently completed the installation of Sena Flour Mill - the new 300 TPD capacity flour production unit of SKS Holding located in Dhaka, Bangladesh.

SKS (Sena Kalyan Sangstha) is one of the largest holdings of South Asia and Bangladesh, operating as an affiliate of Bangladesh Army. The holding is active in many business fields (food, cement, textile, edible oil, real estate, construction, LPG sectors etc.), as well as having three flour

mills located at different locations in Bangladesh with a total of 430 TPD production capacity.

Being the sixth reference project of Alapala in Bangladesh, the mill is supplied and installed in turnkey basis including the process design, manufacturing, project management, installation and commissioning services.

Sena Flour Mill operates with 300 TPD production capacity, processing high quality imported wheat from different countries to produce different types of flour for domestic market.

Main types of flour production are Maida and Atta, whereas semolina –Sooji, bran, and other by-products are also produced in the plant.

The flour mill is also managed by an advanced automation system which provides a centralised monitoring ability of the entire process from the wheat intake to flour packaging, also an advanced ability for generating very detailed reports (production figures, extraction, etc.). The remote connection feature of the system enables Alapala after-sales team to access the mill whenever technical assistance is required including inspection, error diagnosis, calibration, and troubleshooting.

22 | January 2023 - Milling and Grain Milling News

MILLING MORE

COMPLETE

R O L L E R M I L L We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

YEARS IN

THAN 400

PROJECT PERFECTLY RUNNING AROUND THE WORLD

by

Egypt puts wheat for sale on the Egyptian Mercantile Exchange (EMX).

The Egyptian Supply and Internal Trade Ministry announced that “due to the repercussions of the Ukrainian crisis have surfaced and its impact on wheat supplies globally. As a result, quantities of wheat stocks will be offered for sale through the Egyptian Mercantile Exchange (EMX).”

It explained that the General Authority for Supply Commodities (GASC) would be a selling party for the available quantities.

This means that this does not affect the strategic reserve: the Egyptian Holding Company for Silos and Storage (EHCSS) will be the party obligated to deliver.

The ministry continued, “in order for milling companies to benefit from this (trading) on the platform of the EMX. This will also include participation as a buyer of wheat in these auctions, milling companies wishing to apply for these auctions must first register with the EMX.”

Egypt’s state grain buyer, General Authority for Supply Commodities (GASC) has offered quantities of wheat stocks for sale through the Egyptian Mercantile Exchange (EMX), according to the Ministry of Supply and Internal Trade’s statement.

This action will start on Sunday 27 November to represent the actual launch date for the Egyptian Commodity Exchange, the statement added.

GASC will be the selling party for the available quantities, which does not affect the strategic reserve, and the Egyptian Holding Company for Silos and Storage (EHCSS) will be the delivery party.

On November 7, the Egyptian GASC held an international tender for the purchase of wheat, for which 18 offers were submitted. Romanian and French wheat was offered at $356.45$383/t FOB, the cheapest offer for Russian wheat was $369.95/t, and the only Ukrainian wheat offer was the most expensive at $400/t C&F.

However, GASC, in view of the excessively high prices, canceled the tender, because in August and September it bought wheat at 368 and 340 $/t C&F, and now the prices for Russian wheat on a FOB basis are 310-320 $/t, and the volume of offers is increasing.

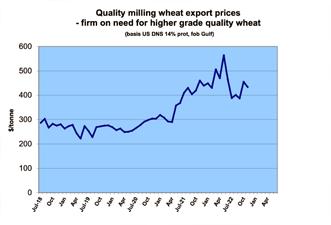

Wheat prices continue to fall in Egypt

Wheat quotations on the world exchanges continued to fall under the pressure of the resumption of the grain corridor, the

cancellation of the tender in Egypt, and pending an updated balance sheet from the USDA.

The Egyptian Minister of Supply and Domestic Trade, Ali alMoselhi, announced earlier this month. Egypt has a safe strategic reserve of various essential commodities, and that wheat reserves are sufficient for five months.

During a meeting with Prime Minister Mostafa Madbouly, Moselhi said that the reserves of wheat cover five months, subsidized sugar 4.5 months, and oil 4.8 months.

Egypt's parliament approves a $6 Six billion dollars loan agreement to help buy wheat, fuel products

Egypt's House of Representatives approved on 22 Nov 2022 a $6 billion loan agreement with the International Islamic Trade Finance Corporation to help the country meets its basic food commodity needs of imported wheat, fuel products, and petroleum derivatives.

A report by the House's Economic Affairs Committee said the loan agreement will help the Egyptian General Petroleum Organization (EGPO) and the General Authority for Supply Commodities (GASC) import the country's needs of basic food commodities, particularly wheat, and petroleum products.

The report added that the agreement, signed in January 2018, originally stated that the International Islamic Trade Finance Corporation would give EGPO and GASC $3 billion. The agreement, however, was modified in June 2022 to raise the loan to $6 billion.

"The loan was increased due to the Russia-Ukraine war, which led to a hike in the international prices of wheat, fuel products, and oil derivatives," said the report.

MP Hossam Awad, the chair of the House's Energy Committee, said the $6 billion loan comes at the right time to help Egypt contain the dramatic rise in international food commodities, particularly wheat, due to the war in Ukraine.

"The loan amount of $3 billion was just enough in 2018, but after the war erupted in Ukraine in February, the government was able to reach a new agreement to raise the loan to $6 billion to help the country absorb the shock of the global food crisis triggered by the war" said Awad.

Egypt, the world's number one importer of wheat, used to rely on Russia and Ukraine for 80 percent of its imported wheat and has recently been working on diversifying its wheat import sources and encouraging local farmers to sell their wheat to the state since the Ukraine crisis started in February.

24 | January 2023 - Milling and Grain

Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

symaga.com • +34 91 726 43 04 • symaga@symaga.com 50 million m3 built Projects in 145 countries Top Project worldwide Flexibility and adaptability A reliable team for a reliable project YOUR RELIABLE PARTNER Improve silo tightness. Double Vertical Joint.

Tightness is improved. Double sealing on both sides of the screws.

Butyl rolls are supplied with double strip to improve assembly times.

·

·

Our INTEGRA®

New digital advance to deliver expert knowledge direct to operators B

ruks Siwertell is developing an advanced digital tool, Siwertell Smartview, as part of an ongoing research and development (R&D) strategy which is designed to optimise the productivity and profitability of dry bulk handling operations and deliver a better understanding of components through enhanced data analysis. The cloud-based tool is the latest industrial Internet of things (IIoT) system planned for integration into Siwertell technology.

“Siwertell Smartview will ultimately benefit both our existing as well as new customers” explains Per Hansson, Sales Director, Bruks Siwertell. “It is planned for a phased launch, starting in 2023, and will be initially introduced on new equipment deliveries.”

The key machine for bagging food products into valve bags – clean and fast.

Contact: Phone: +49 251 9796 252 E-mail: sales@behnbates.com www.behnbates.com

Siwertell Smartview collects data during unloading and loading operations, enabling detailed analysis and follow-up of equipment performance, availability and reliability. Automated report functions ensure that operators are able to make the most of this information, including reports for each vessel handled, operational performance data and any equipment downtime.

The tool can monitor real-time operational parameters such as tons of material handled, average capacity, tons of material remaining in the vessel's holds during unloading, and the overall duration of operations. It is also able to identify areas that can be improved, enhancing efficiency and a terminal's potential profitability. Other parameters that can be analysed include equipment availability, historical performance, and component data collection.

“The cloud-based portal brings Siwertell expertise much closer to our customers,” Mr Hansson continues. “Historical data analysis enables performance studies over different vessel types and sizes or commodities. Furthermore, reviewing the performance of different shifts can identify possible training needs. All enable the continuous improvement and optimisation of our customers' terminals.

“Information can be simply accessed through a personal computer (PC), tablet or smartphone,' he adds. 'Initially, the tool was specifically designed to provide an accurate overview of unloading operations, helping customers rapidly identify any potential bottlenecks and therefore improve efficiency and availability. We soon realised that the IIoT system and its capabilities could be expanded to include much more.”

Siwertell Smartview will also be able to provide digitally enhanced maintenance management. This includes everything from monitoring service intervals and remote support with assisted fault-tracing, up to a full service update. The nextgeneration tool is suitable for all Siwertell ship unloaders, including port-mobile and road-mobile units, and ship loaders.

A HAVER & BOECKER Company

26 | January 2023 - Milling and Grain Milling News

LincolnshireWindmills

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

The county of Lincolnshire in England was renowned for its cereal cultivation. In the 18th century new developments in millwrighting, centring on the city of Hull and drawing on the expertise of Dutch millwrights, created the distinctive Lincolnshire tower mill. These were typically very tall, with a white ogee cap which became known as the “Lincolnshire cap”, first introduced by John Smeaton. He also introduced the use of a cast iron cross for mounting sails. This enabled mills to have more than the standard four sails, with some having five, six or eight.

Rex Wailes carried out his survey of the surviving Lincolnshire windmills in 1951-1952 with his friend Paul Baker (shown here holding a piece of mill machinery).

Despite bad weather a number of visits to mills were made at Whitsun 1951, by which point two of the three historic ‘parts’ of Lincolnshire, Kesteven and Holland, had been completely surveyed, with only the third ‘part’, Lindsey, remaining. Wailes and Baker found no working mills.

There were six derelict mills standing in Holland and seven in Kesteven, with 21 in Holland and 12 in Kesteven remaining only as stumps. This was a stark contrast to an earlier survey of 1923-33, which found 11 windmills still working in Holland and nine in Kesteven. Wailes’ collection of photos compiled as part of the survey included those taken during the mill visits in 1951-52 along with earlier images. They have recently been digitised by the Mills Archive and are available online at https://catalogue.millsarchive.org/lincolnshire-windmillssurvey with some of them included in the article.

The Rex Wailes Collection

28 | January 2023 - Milling and Grain

Get fast and actionable mycotoxin test results The AgraStrip® Pro WATEX® test system enables the rapid and �simple on-site quantification of mycotoxins in a variety of agricultural commodities. The streamlined workflow reduces steps to a bare minimum while independent and simultaneous testing for up to 4 samples sets new standards in accuracy and usability. Learn more at www.romerlabs.com SAMPLE ID: BR-11071 COMMODITY: CORN Aflatoxin : 3.4 ppb Deoxynivalenol : 0.8 ppm

CONTINENTS more COUNTRIES than 5 80’ APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Introduction to manual turning and milling

The Sunderland Engineering Training Association (Seta) is launching the ‘Introduction to manual turning and milling’ course in January 2023. Seta is a not-for-profit group training association that delivers apprenticeships and both standard and bespoke commercial training courses.

The Introduction to manual turning and milling is a course that will look at combination of elements from their popular manual turning and manual milling courses.

An excellent introduction to practical turning and milling, this course provides instruction in safety, use of drawings and measuring equipment, feeds and speeds, work-holding, tool setting and a range of turning and milling operations. Instruction takes place both in the classroom and in Seta’s state-

Alltech continues to support mentorship program for women in agri-food

Alltech is proud to continue to partner in the Women in Food & Agriculture (WFA) Mentorship Program. Applications are now open for new mentors of any gender and for female mentees from across the global food and agriculture sector. Now in its third year, the free-to-join program matches applicants based on their preferences, which can include gender of mentor, areas of expertise, language and industry sector, and offers opportunities for women in food and agriculture to develop meaningful industry connections.

“Over the past few years, all of us have come to more deeply value the power of human connection,” says Dr Mark Lyons, president and CEO of Alltech. “A commitment to the growth and development of another person unleashes energy, inspires ideas and empowers both individuals to have a greater impact. We view our involvement in the Women in Food & Agriculture mentorship program as an investment not only in the lives of women but in the future of agriculture as the industry most integral to the nourishment and vitality of our planet.”

Findings from the annual WFA survey and ongoing feedback from all levels of the food and agriculture sector consistently suggest that a hurdle to greater success for women in the global agri-food industry is a lack of mentorship opportunities. To tackle this issue, WFA launched its Mentorship Program. In partnership with Alltech in 2022, the initiative grew with 320 industry representatives matched across two cohorts. Now in 2023, the program will be open for applicants year-round with two matching sessions taking place to help even more women in food and agriculture progress their careers. The initiative has supported a variety of people around the world from CEOs of agribusinesses to small-scale farmers, from academics to ag-tech professionals, with sector representatives paired with

of-the-art workshop facilities.

Safety relevant to turning and milling, interpretation of engineering drawings and symbols, measuring instruments relevant to turning and milling (types, care and use), the centre lathe and its controls, the milling machine and its controls, cutting tools (terminology, selection and mounting), feeds and speeds (guidance on calculations; setting feeds and speeds), Coolants (types and uses).

Another topic covered will be Turning operations, including facing; turning diameters; centre drilling; taper turning (using compound slide method); producing threads. Other subjects approached will be milling operations, looking at milling faces; milling step faces; open and closed slots; vees and angles. Lastly the course will cover faults recognition, giving guidance on turning and milling faults and means of avoiding them.

This course is ideally suited to those with little or no previous turning or milling experience. The days start at 9:00am and end 4:00pm on January 16, and spans across five days, finishing January 19. The total cost of the course is UK£850 for attendees.

mentors that complement their professional objectives.

“We are very pleased to again have Alltech supporting the 2023 WFA Mentorship Program,” says Elisabeth Mork-Eidem, global chair of WFA. “Mentorship is vital in supporting women across food and agriculture in developing their careers, we've had very positive feedback from both mentors and mentees. Many of our mentors joined the initiative as a selfless act of support for equality in our sector, but realized they got as much out of the experience as the mentees. This is such an exciting opportunity to learn about yourself, develop your skills and support an important initiative that is working to improve diversity, equality and inclusion in the food and agriculture industry.”

For those interested in taking part in the 2023 Mentorship Program, WFA is looking for mentors of any gender who have at least one year of experience in the food and ag sector. During matching, WFA will ensure all mentors have more work experience than mentees, so this should not be a barrier to mentors applying. Potential mentees should be women working in the food and ag industry who would benefit from help, guidance and support from a senior sector representative. Alltech believes that inclusion cultivates creativity, drives innovation and is essential to the company's purpose of Working Together for a Planet of PlentyTM. In 2019, Alltech selected Gender Equality as one of the nine United Nations Sustainable Development Goals to which the company committed to advancing.

Applications are open now for the Women in Food & Agriculture (WFA) Mentorship Program, supported by Alltech.

Milling and Grain - January 2023 | 33 TRAINING Mill

A programme ‘Exploring Regenerative Agriculture’ will commence in January 2023, each a one-day virtual Course. There will be two opportunities to attend this one-day online course, one on 26 January, the other 22 February.

Sessions are split into three, session one offering an overview and welcome, session two talking about applying regenerative agriculture principles, and session three about putting monitoring into practice. All sessions intend to aid attendees with the knowledge and expertise to become a Regenerative Agriculture Practitioner in arable systems.

The course is aimed at individuals looking to explore the principles of Regenerative Agriculture and receive guidance on delivering positive outcomes from agricultural practices focused on soil health, water and air quality, carbon capture and biodiversity.

Session one will look at understanding the scope and ambition of Regenerative Agriculture and how it can help

you further deliver positive outcomes in terms of improving soil health, increasing biodiversity, improving water quality and climate resilience, capturing carbon, and restoring and regenerating the land. There will also be a practical implemtation to this, looking at case studies, and potential challenges that may be faced.

Session two will take into consideration how the region, climate and crops grown will influence the decision-making process, outlining strategies available and how the approaches interact to deliver positive outcomes in terms of improving soil health, increasing biodiversity, improving water quality and climate resilience.

Session three will establish baselines and use key performance indicators (KPIs) to monitor the impacts of regenerative agriculture and to deliver further positive outcomes.

The trainers leading these sessions are Dr Elizabeth Stockdale, Head of Farming Systems Research, NIAB, and Richard Harding. Entry requirements state attendees must be able to demonstrate practical experience. The total cost is UK£215 and will provide attendees with 5 BASIS CPD points.

The University of Missouri Extension is offering an eight-week winter webinar series on growing specialty crops in tunnels.

‘Growing Specialty Crops in Tunnels - Protected Agriculture’ runs 6:30-8pm Tuesdays, January 24-March 14, 2023.

Extension educators and researchers from the Midwest, as well as high tunnel growers, will teach the classes. Topics include an overview of structures and mulches, high tunnel fruit production, irrigation, fertility management and soil issues, insect and disease management, the economics of diversifying crop rotations, high tunnel tomato production, a grower panel on winter production, and benefits of low tunnel production.

“There has been an increased interest in the production of specialty crops in high, medium, and low tunnels over the past several decades” says MU Extension horticulture specialist Justin Keay. The USDA Natural Resources Conservation Service offers cost-share programs to support the purchase of high tunnels.

Presenters will explain how tunnels can give growers more control over temperature, light, and water, improving growing conditions for plants. Keay says extending the growing season by using tunnels lets growers’ market before and after the peak of the season when a glut of produce often leads to lower prices and smaller returns for growers.

The series will detail both the opportunities and challenges that come with growing in these systems, Mr Keay says.

Recordings of classes will be available for registrants who can't attend the live sessions.

Scholarships are available to Missouri beginning farmers and can be redeemed at registration.

Exploring Regenerative Agriculture Webinar series on specialty crops to be held from January-March, 2023 TRAINING Mill BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY 34 | January 2023 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less

£12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME We will be seeking enrolments from June ... . . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

than

FOCUS Product January 2023

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process. Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

Aspirator Channel by Bühler

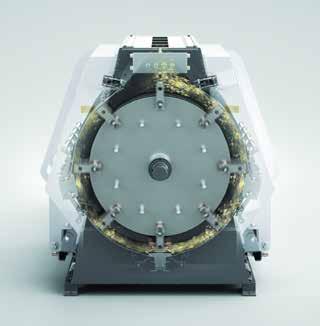

Flaking Mill FX Series by CPM Europe

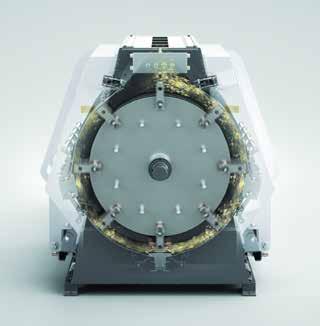

CPM Europe offers Flakers that feature quality construction and maximum materials throughout. The unique square-bearing housing design assures accurate, consistent flaking and ease of operation. Outfitted with unique features that come standard on all CPM Europe Flakers, including hopper agitators, roll end sealing devices and feeders for oilseed applications, CPM Europe Flakers represent the lowest operating-cost solution in the industry. Designed for the most challenging flaking operations, the rock-solid construction of the FX Series guarantees maximum performance around the clock. The unique bearing slides assure accurate roll positioning for consistent production. The machines utilise the most reliable and durable rolls available in the world.

Standard features include centrifugally cast, chilled iron rolls with alloy shafts, pneumatically operated gate, manual roll adjustment, and scrapers with adjustable counterweights to regulate pressure.

www.buhlergroup.com mymag.info/e/1714 www.cpmeurope.nl

Continuous Coaters by Ottevanger

The Ottevanger Continuous Coaters are perfectly suitable for adding and mixing liquids, evenly on pellets and/or extrudates. By dosing the liquids through a spray box, the product and liquids are slowly mixed together. The trough of the coater itself is executed in stainless or mild steel, with 50 mm thick insulated jacket. The heat tracing stimulates the absorption of the liquid and avoids contamination of the trough. The coater is equipped with hinged inspection hatches over the full length of the mixing trough, which allows easy access. Apart from oil and/or fat, also vitamins, enzymes etcetera can be added in small quantities. Dosing systems for these products are available upon request. It has numerous features including Low power consumption, large doors enabling easy inspection/cleaning, rigid construction and variable heating system with insulated jacket and also has a low rate of wear.

BREEDER Batching Control by BinTrac®

Designed to replace mechanical scales with an integrated solution for weigh bin filling, batching and feed monitoring. Features include its availability in single or dual operation, display monitors that show batch progress, current feed inventory, daily feed use, and fill events. Other features include scheduled or manual batching, easy to operate, accuracy & reliability, an optional relay & auto/manual override for each controlled auger system, and it comes with a patented load cell bracket.

The BinTrac Breeder Control can be connected to a single inventory bin equipped with BinTrac load cells. The BinTrac Breeder Control is programmed to unload a target amount of feed from a controlled feed delivery system.

Pellet Mill by Amandus Kahl

The KAHL pellet machines facilitate storage and transport of your bulk products and product mixtures. Particularly fine-particle or dusty products are often a challenge when it comes to storage. Both the porosity and the volume require special measures – also during transport. The KAHL pellet mills help you to save operating, transport and above all storage costs. Products with different structures, bulk densities, binding strength and particle sizes are no problem for the flat die pellet machines. It is also irrelevant whether the products are powdery, fibrous, lumpy or pasty. The following products are mainly pelleted: Compound feed, raw materials and mineral mixes as well as by-products in flour and oil mills or malthouses. Also straw, wood, biomass and dried sludge.

www.ottevanger.com www.akahl.com

36 | January 2023 - Milling and Grain

To enable full flexibility and modularity in the grain cleaning process, the final element of the Bühler Vitaris cleaning platform is now available. The new aspiration channel running with fresh air is design in two sizes. The multiple adjustment options enable a high-precision removal of light particles and impurities enhancing the end-product quality. All product contact wear parts are exchangeable to allow a fast maintenance and a long machine lifetime – resulting in low operation costs. The aspiration channel ensures a foodsafe production: closed machine design & FDA approved parts. It facilitates the individual configuration and combination of the Vitaris cleaning platform according to product and customer requirements. https://bintrac.com mymag.info/e/1715

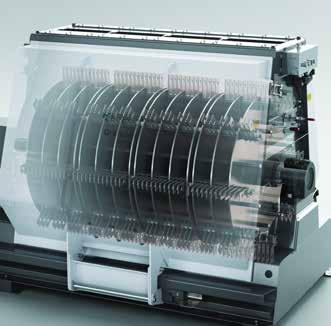

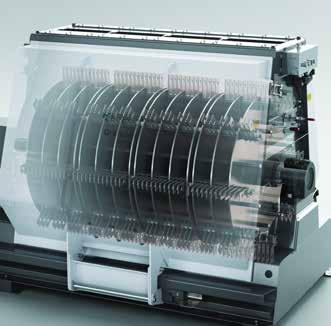

Bühler announces the launch of the Granulex® 5 series. After a decade of research, the new hammer mill series packs in many small innovations that together add up to a big boost in performance. It’s ground breaking modular system offers significant energy savings and flexibility while maintaining the highest product quality and safety standards.

Grinding is one of the most energy-intensive process steps in many food and feed plants. In today’s competitive markets, rising energy costs are a serious issue. A big challenge faced by businesses that rely on grinding is, therefore, how to make more with less. Greater energy efficiency is one of the prime benefits of the new Granulex® 5 series, with 10 percent reduction in energy consumption per ton, and in some cases the reduction can be as much as 30 percent.

The new hammer mill also has the highest throughput ranges, improved granulation profile, and an operator-friendly design. Capacity is increased by 10 percent and the time required for screen changeovers is reduced by 50 percent. The new solution can also be connected to Bühler Insights to enable 24/7/365 databased decision making.

Revolutionising the hammer mill

The hammer mill is among the most widely used grinding solution in industrial food and feed processing plants, valued for its flexibility and adaptability. “It is not easy to revolutionise an old machine category,” says Dean Ekkaia, Product Management Director Value Nutrition at Bühler Group. “But after a decade of quiet innovation, gathering the best concepts and then testing them extensively, we have created the best possible grinding system available.”

Over the past 10 years the new Granulex® 5 series team have invested thousands of hours in testing and experimenting with different designs. In addition, the development has been carried out in close collaboration with customers, including extensive lab testing in three specially set up labs in the US, China, and Switzerland.

“It is a truly global machine, tested and developed in our international labs as well as running commercially in line at customer plants. Every part has a great deal of data behind it, proving the concept and the performance of each component,” says Reto Bischof, Head of Research & Development Value Nutrition at Bühler.

360 different configurations

One of the most important characteristics of the groundbreaking concept is its modularity. The Granulex® 5 series can be configured to fit specific applications and process requirements in any country, for coarse or fine grinding, all with an optimised set-up for each customer.

The system also keeps maintenance costs low. All variants of the Granulex® 5 series operate with the same inventory of parts that can be applied in different machine settings. Overall, the setup is designed to allow for 360 different configurations and can be adapted to the most diverse products and customer targets.

Ready to connect

The Granulex® 5 series is ready to connect to Bühler digital applications, enabling customers to view grinding line data anytime, anywhere and analyse trends and track problems. But most important of all, the data transparency and preventive information provided through digital solutions provide insights that support customers in improving processes.

The Granulex® 5 series is part of Bühler’s ongoing development and restructuring of the entire portfolio. The aim is to provide a more transparent, customer-focused offering for the grinding industry.

“With 150 years of experience in grinding and other key engineering disciplines we will provide new and customised solutions for our clients operating in rapidly changing markets,” says Ian Roberts, CTO at Bühler Group. “The launch of the Granulex® 5 series is a major milestone in this development.”

Milling and Grain - January 2023 | 39 FOCUS

Special

www.buhlergroup.com

Granulex® 5 serie Bühler unveils the next generation hammer mill platform mymag.info/e/1716

www.ai-lati.com

O u r ess enc e lie s i n t h e for m s t h ro ugh wh i ch w e s how o u rsel v es. We offer j u st wha t we a r e . Al wa y s . www.paglierani.com www.ocrim.com

‘The Good Life’ is the classic situation comedy about a British middle-class couple in the 1970s who turn their suburban London home into a self-sufficient farm.

Tom Good packs in his city job and with his wife attempts to live a life completely off-grid with animals and crops. Seemingly futile and bordering on the ridiculous, it was nonetheless profoundly aspirational.

A big part of its allure was how it played on the nostalgia of the ‘Dig for Victory’ war effort to combat shortages of food imports. In wartime, Britons were persuaded to plough up every verge and playing field into allotments, from domestic gardens to public parks, even the lawns outside the Tower of London were turned into vegetable plots.

Viewed through a lens of global food insecurity, Tom Good’s project is beginning to look like a great idea. But is selfsufficiency still a fruitless pipe dream?

Certainly, after another tough year for the consumer and with food prices on an ever-increasing trajectory such pursuits today seem far from folly.

But what does self-sufficiency mean at scale? Can we produce all of it? Would we even want to? Would we be willing to give up fruits that are not only out of season but could never be commercially grown in the UK? And to be truly self-sufficient we'd also have to give up coffee, wine chocolate, sugar, soy products and many more.

I’m not sure I want to embrace this new diet.

Only possible through trade

Brexit (for better or worse, but mostly worse) has set us on a path to economic isolation from Europe, and we’re all painfully aware, especially since Covid-19 - but also other international calamities; the conflict in Ukraine, the Suez blockage, a labour crisis - that essential supplies of food, goods and energy are volatile, can be held to ransom or simply switched off.

We have all witnessed supermarket shelves stripped of basic essentials due to supply chain failures.

A trade that gives us asparagus from Mexico, snowpeas from Egypt and salad crops from Italy and Spain. To go back to precolonial food self-sufficiency would require either a massive

Opportunities

by James Cooper, Milling and Grain Contributor

drop in population or a massive increase in UK farm productivity which, while possible to some degree is unlikely.

But, rising fuel, fertiliser and feed costs are piling pressure onto farmers and, according to the NFU (National Farmers Union), the UK is “sleeping-walking” into a food supply crisis. In most respects we’re the lucky ones - other countries reached crisis point many months ago.

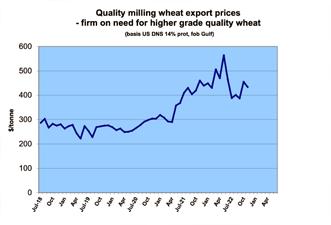

Food and energy costs are closely linked and clearly, one big factor driving up food prices has been the fallout from Russia's invasion of Ukraine and the rising cost of grain. Collectively both countries produce 30 percent of global wheat exports. And with inflation running at 23 percent, Russians too are finding out how difficult life can be, albeit for very different reasons.

National control

News agencies around the world are reporting on a call for a form of independence, for a sense of national control. It’s making us all re-think how we feed ourselves, now and in the future.

Across many nations, sub-Saharan Africa in particular, it’s a matter of survival: Of economic security and essential sustenance. Leaders are looking at their supply chain dependencies and wondering what they can do better, to become more selfsufficient. The idea of food security and self-reliance are right up there at the top of political agendas.

“The big question I always get is ‘what is a food crisis? How do we measure it? What does history say about it?’ asks economist Dan Basse, President of AgResource, a domestic and international agricultural research firm located in Chicago, talking to MAG from a ‘Farm Foundation’ meeting in Georgia, USAwhere Dan is hosting panel discussing the Black Sea situation with policymakers including USDA Secretaries and the World Food Programme.

“When I asked this question to the UN and the WTO, they said to me ‘We look back in time at the amount of grain kilos per person that are available at any particular season, and then we try to measure whether or not those kilos are enough to feed the world,” explains Basse,

“In particular, this food crisis was going to become acute for about 80 million people in sub-Saharan Africa.

and threats: In a globalised world, how does Africa become self-reliant

42 | January 2023 - Milling and Grain F

“Nations are turning inward and trying to look at themselves,” explains Dan.

“Some of this becomes evident by the competitive nature, economically and ‘business-wise’ [sic] between countries like China and the United States. The Black Sea and Russia now only enhances that view that just-in-time inventory is not the way to be looking at food security going forward.

“Over 30 countries, last spring, either taxed or restricted their exports of grain, whether they be small or large countries. And that was very concerning and showed that globalisation being flat [even] for trade is really not the case.

“We have countries like Egypt, which is seeing a tremendous appreciation of the Egyptian pound. Egypt is the world's largest wheat importer.

“Well, its cost to buy wheat from a currency perspective is skyrocketing 70 percent. So even though world wheat prices may be down for the Egyptian population, they are at record highs and the same in India.

“So, this this idea that world prices are our level and even for all was something that manifested itself for much of the last two decades. But I think it's slowly changing now.

“I think the best word we can come up with is regionalization. And those regions will look for their own food security.

“I worry that if the war continues into the spring, we will have problems with both wheat and sunflower and corn crops in the season ahead,” says Basse.

As the impacts of climate change continue to intensify and global shocks upend business as usual, sub-Saharan Africa is now feeling the brunt of what has been coined ‘the perfect storm’ – a food, fuel and fertilizer crisis exacerbated by the war in Ukraine, scarring effects from the COVID-19 pandemic, soaring inflation, rising debt and extreme weather.

“Now, becoming more self-sufficient in an uncertain world is starting to look like a very good idea indeed.”

Enhancing its own food

A big problem is lack of investment because investors don't necessarily feel comfortable their capital is safe.

“Africa needs to step forward here and enhance its own food production. Africa does not need to be an importer. It's blessed with a climate, outside of North Africa, that could be advantageous to feeding much of the of itself and even portions of the world,” Basse says. So, what is holding it back?