millingandgrain.com November 2022 In this issue: Milling and Grain . Volume 133 . Issue 11 . November 2022 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 133 Issue 11 TUBULAR DRAG CONVEYORS Debunking six common misconceptions relating to their use in feed processing - Wheat, Flour and … Ocrims open day 2022 - Respecting the formula: How to manage the dosing of liquid & powder additives effectively - Commodity handling equipment

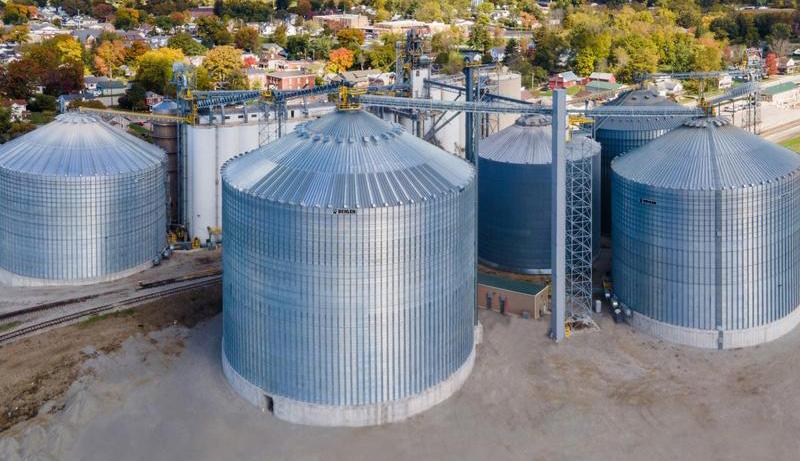

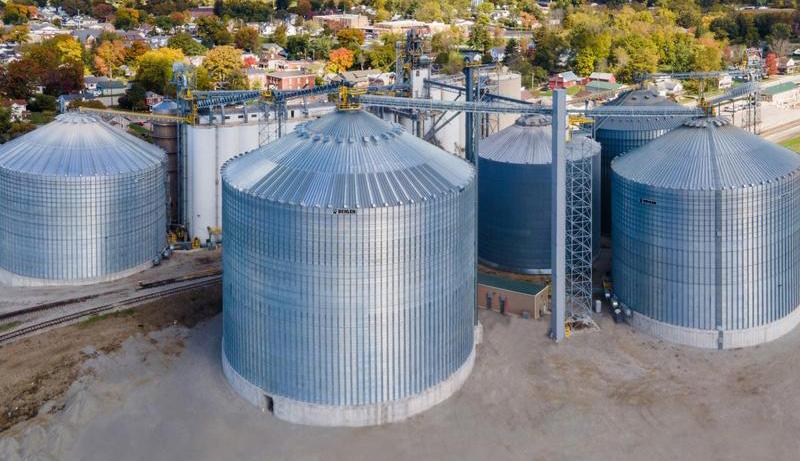

Behlen bins range

silos

wall panel design. COMMERCIAL GRAIN BINS Behlen hoppers are designed to ensure strength, ease of assembly, and trouble-free operation. COMMERCIAL HOPPER TANKS Behlen Steel BUILT TO LAST Behlen Grain Systems... Standing the test of time with competitive prices and Customer Service second to none. CONTACT US TODAY TO DISCUSS YOUR PROJECT! Call 1-402-564-3111 or Visit www.behlengrainsystems.com Bigger and Better than Ever!

in size from 85 to 66,000 cubic meters. These

feature a unique trapezoidal

Pneumatic and mechanical ship (un)loaders Up to 2500 tph for loaders and up to 1200 tph for unloaders. Low noise & no dust emission Turnkey solutions for cereals, soy flour, fertilizer, pellets and more... Handle bulk with efficiency and reliability

PINGLE. PROFESSIONAL MANUFACTURER OF GRAIN MACHINERY ★ INTEGRATED MILLING SOLUTION PROVIDER ★ ISO 9001:2015 CERTIFIED Аdd: Zhengding, Shijiazhuang,Hebei,China Tel: +86-311-88268111 Fax: +86-311-88268777 E-mail:pingle@pingle.cn / www.pinglemachine.com

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom Tel: +44 1242 267700

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East

Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Sub-editor Andrew Wilkinson andreww@perendale.co.uk

Editorial Assistant Shannon Parsons shannonp@perendale.co.uk Niamh Cassidy niamhc@perendale.co.uk

Digital community manager Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com Professor Wenbin Wu wenbinw@perendale.com Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk 0

Circulation & Events Tuti Tan tutit@perendale.co.uk

Development Manager Antoine Tanguy antoinet@perendale.co.uk

VOLUME 133 ISSUE 11 NEWS 10-30 44 Wheat, Flour and … The Ocrim open day 2022 52 Whole vs refined grains:

of recent study indicates a link between grain choice & heart health 56 Respecting the formula: How to manage the dosing of liquid & powder additives effectively 56

STORAGE 66 Commodity handling

the

for your operation is key 72 Tubular drag conveyors:

use in feed processing 8 PUBLISHER Roger Gilbert 104 INTERVIEW Gunnar Hallmann ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish

International

Directory’ and

Global Miller’ news service EVENTS 88 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 22 Mildred Cookson 26 Dr Mahmoud Riyad 30 The Rex Wailes collection FACES 106 People news from the global milling industry TRAINING 35 Industry training news PRODUCT FOCUS 38 CASE STUDY 84 INDUSTRY PROFILE 82 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 November 2022 COVER IMAGE: Cablevey, Tubular drag conveyors - see more on page 72 FEATURES

Respecting the formula: How to manage the dosing of liquid & powder additives effectively See more on page 56

Findings

Argonauta - Act IV (Part two)

equipment: Why understanding what

right configuration

Debunking six common misconceptions relating to their

‘The

Milling

‘The

millingandgrain.com ISSN No: 2058-5101

76 MARKETS

John Buckley

All

That’s what I thought when the events of September gave way to a less demanding October in terms of travel and reporting.

Not so, as the International Association of Operative Millers (IAOM) stepped into the breach with its 12th Southeast Asia Region Conference and Expo in Penang, Malaysia in the first week of the month.

They followed that with their 32nd IAOM Middle East and Africa Conference and Expo from October 25-28 in Zanzibar, Tanzania.

It is heartening to see the IAOM move south into Africa to host this important event in less prestigious venues. In my view its valuable for all concerned to engage with industry in countries that need assistance in meeting their growing population’s need for nutritious wheat-based products, such as bread which is the obvious staple no matter where you are.

In between the above two events which help to achieve greater inclusiveness, the industry’s attention was drawn to the celebrations on October 20th of one company achievement in particular - the North Dakota Mill and Elevator Company (which is one of the few remaining stateowned flour mills left in the United States) celebrating its 100th anniversary.

This company has been generating a reliable income and profit for the state of Minnesota while supporting its farming communities and providing its nation-wide customer base with quality flours needed in a modern era of consumer demands and cultural needs.

And talking of celebrations, a second occurred just a few days later on October 24th when the Food Fortification Initiative marked its 20th anniversary by identifying 20 countries it

considers ‘Fortification Champions.’

I was moved when I was approached by a street seller in Zanzibar on my first day out walking. He was trying to interest me in a simple wrist bracelet made of seashells when he told me he was 47, had six children and one wife and had to share out limited bread to his family each morning.

All the above events mark the progress our industry is making in ensuring that the world’s population has the food it desires at the prices that meet the needs of all.

We still have a lot to achieve, and our industry is the only one with the means to make a significant and lasting difference in the state of human health. Long may these events continue to reach out to millers everywhere and help us identify the challenges we need to overcome.

On a lighter note

In this issue we also report on our September visit to Ocrim’s Open Days under the overall theme of ‘Grain, Flour and …’ This was a stand-out event that had a flavour and atmosphere of traditional yet modern and artistic Italy. It had something of everything - a conference, a debate, socialising, al fresco dining, a violin concert in a purpose-built conservatory, a new mill and much more - and all located in the town of Cremona on the Po River in Italy.

This edition of Milling and Grain publishes the last chapter in the serialisation of the book Agronauta, written by Sergio Antolini of Ocrim, in this edition. Our thanks go to him for his insightful writings about the production of wheat and flour in Europe down the ages.

Finally, we conclude this issue with a great interview with Gunnar Hallmann of Andritz – this interview is well worth the read!

We at MAG will continue to bring you insights into both companies and individuals who shape and drive our industry forward.

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information www.millingandgrain.com http://gfmt.blogspot.co.uk Milling and Grain has a cooperative partnership with COFCOET

good

end

things come to an

and use the Promo Code ZANZIBAR22 This offer entitles you to a 12 month digital subscription to Milling and Grain magazine on our app and desktop versions. This offer is on a first come first served basis and will run until 01/09/2022 Would you like a complimentary digital subscription to Milling and Grain magazine? Simply visit: https://store.magstand.com/millingandgrain

Roger Gilbert

The 32nd IAOM MEA 2022 was concluding in Zanzibar, Tanzania as we went to press. The annual event gathers delegates from 50 countries and around 100 exhibiting companies for a 3-day conference. The program looks at topics such as management, milling technology and trends, as well as trading sessions presented by international speakers.

Our full report will follow in our December 2022 edition on this important industry gathering which attracted traders, buyers, and millers from across the continent to discuss the implications of the war, inflation and the environment are having and likely to have on the milling of grains in Africa and the Middle East.

Here, Roger Gilbert, publisher of MAG, took the opportunity following the closing ceremony to interview Melinda Farris, the CEO of the international Association of Operative Millers, about the event, its outcome and where it goes next.

The full interview can be viewed on our homepage or MAGTV. To see more of our video content visit: www.millingandgrain.com/videos/

Welcome to the November edition of Milling and Grain magazine and this, the very latest addition to the Global Miller column archives. I hope that wherever in the world you happen to be, that you are happy, comfortable and setting down for the temperature fluctuations that the changes of season bring at this time of year

As readers in the southern hemisphere are soaking in the warmth of summer, winter is well and truly starting to unfold here in its northern counterpart. This change will see farmers starting to feed their livestock with processed feed more.

This is because, owing to the reductions in sunlight and excessive rain that comes with the colder months, the grass in the fields will stop growing and will deteriorate in quality. The incoming colder temperatures will also mean that the livestock will usually be kept indoors by November, if not before.

Arable farmers will be continuing to drill wheat, but the process will start to come to an end by mid-month. Liquid fertiliser will be applied to sugar beet fields, and the countryside in November sees a lot of ploughing going on, in preparation for next year’s harvest.

Here in the UK, as the government’s continued dalliances with disorder continue to destabilise the country’s economy, the optimists amongst us are left to try and make the most of a bad situation.

With the passage of time, remaining stoic is increasingly becoming less identifiable as a British trait, that’s for sure.

I am under no illusion though readers, we don’t really have much choice when it comes to party politics here in the UK. Choosing between the Conservatives, Labour and Liberal Democrats is very much like choosing between being run over by a bus, a car or a motorcycle - I’ll leave it up to you to decide which is which!

In the world of events, Milling and Grain magazine continue to strive to maintain the global aspect of this closely associated title by trying to be everywhere on the planet at once.

November sees the leading innovation platform of the global animal production industry, Eurotier return again to Hanover, Germany. Offering an overview of innovations and established standards, the German giant provides answers and solutions for current and future challenges.

We will also have a presence at the AFIA Equipment Manufacturers Conference in St Petersburg, Florida and at Ildex in Indonesia.

With locations all over the world covered by our intrepid team of representatives, no other publication has a global presence quite like ours.

If you want to take full advantage of this and have your company’s name and products shared all over the planet, then there is no better solution than speaking to us about one of our many flexible and great value advertising packages.

If you are at all interested, be sure to get in touch with tutit@ perendale.co.uk

See more videos from all aspects of the industry at millingandgrain.com/videos

News

gfmt.blogspot.com

Milling

myMAG.info/e/1593 Watch the video at

10 | November 2022 - Milling and Grain

www.balaguer-rolls.com Facebook Youtube Linkedin

TO BOOST YOUR PROFIT

LATEST TECHNOLOGY

Celebrating 100 years

The largest single-site production facility, possibly anywhere in the western hemisphere, celebrated its 100th year anniversary on October 20, 2022 while at the same time announcing the recent commissioning of its new ‘H’ and ‘I’ milling units and the conversion of the ‘D’ milling unit, which provides a 22 percent increase in milling capacity.

North Dakota Mill and Elevator, in Grand Forks, North Dakota, USA, welcomed visitors to its facilities for tours and an explanation of the advancement this mill has made over the past 100 years and its plans for the future.

“Since the North Dakota Mill opened its doors at the Grand Forks facility in 1922, it has been fulfilling its mission to promote agriculture, commerce and industry,” comments the Commission in a recent North Dakota Industrial Commission news release.

“What began with an initial capacity of 588,000 pounds of flour per day (266 tonnes) has grown by more than tenfold to over six million pounds per day (2721 tonnes), making it the largest standalone flour mill in the nation and the eighth-largest milling company in the United States.”

The State Mill adds value to 40 million bushels of spring wheat and durum per year (1.09 million tonnes), providing a reliable market and enhancing profitability for our state’s farmers.

Since the year 2000, the Mill has transferred over US$100 million in profits to the state’s general fund or Ag Products Utilisation Fund, supporting services to North Dakota citizens and projects that keep our agricultural industry on the cutting edge, according to the statement.

“We are deeply grateful for the North Dakota Mill team that works hard every day to

provide a superior product and great customer service.”

Mr Vance Taylor, President and CEO of the North Dakota Mill says that, “Along with our 100th anniversary celebration, we are also pleased to announce the completion of the ‘H’ and ‘I’ mills and the ‘D’ mill conversion which increased the milling capacity by 1.1 million pounds of flour per day.”

That’s just under an additional 500 tonnes per day.

“This expansion was done to meet increasing demand from our customers for the quality product we produce here in North Dakota.”

The North Dakota Mill and Elevator Association – the only state-owned mill in the country – was created in 1919 by House Bill 20 and began its operations in Grand Forks on October 30, 1922.

The cost of the State Mill at that time was just over US$3 million. The North Dakota Mill has become the largest single-site flour mill in the United States and has 10 milling units within the mill complex.

“Partnering with the farmers in the surrounding area and across the state, we are committed to drive growth by leveraging our consistent superior quality, great customer service and our dedicated hard-working employees to fulfil our mission,” Mr Taylor says.

Mill tours were led by Kevin Ayotte and Travis Devlin, grain terminal supervisor and director of milling respectively. Mr Ayotte says the mill has grown steadily in the 28 years he has been employed there.

“The facility is three times larger than it was when I started,” he was quoted as saying in the local Grand Forks Herald newspaper.

However, more improvements are underway.

A major project under development is a wheat middlings handling facility which is on schedule to be completed by February 2024. This facility will allow the company to process its by-products more efficiently.

“By improving our efficiency, we will be able to free up capacity to capitalise on emerging trends in the wheat market. We’ll be able to offer our customers

This North Dakota flour mill grows larger by the day

12 | November 2022 - Milling and Grain Milling News

more of what they want and increase profitability,” says the newspaper, quoting Mr Devlin.

US Senator John Hoeven, in a media statement released to coincide with the celebrations at the mill, adds, “Throughout its history, the North Dakota Mill has helped provide a dependable market for our farmers, and we appreciate the hard work of the Mill’s employees in supporting our state as a global ag leader.”

“Through the dedication of our farmers and ranchers, every American benefits every day from the lowest cost, highest quality food supply in the world. Their continued success is central to our quality of life, and that’s why in the Senate, we are working to provide strong farm policy that empowers our producers to manage their risk and grow their operations.”

Tours of the mill were made the following afternoon, followed by a gala dinner held at the Cloud 9 Event Center in downtown Grand Forks. Approximately 400 people attended, including ND Mill employees, its customers, the ND Governor, several local legislators and key vendors/ suppliers.

Mr Taylor praised the organisation’s culture and vision

and talked about the importance of relationships – with customers, suppliers and local government officials.

One of its long-time customers, Steve Tardella, President and CEO at Tardella Foods Inc - a food distribution company specialising in grain commodities - commented on how important his company’s relationship with the mill has been. When COVID-19 hit and their orders dropped dramatically in the first month, they received calls from North Dakota Mill that were inquiries about how they were doing, and if there was anything that the Mill could do to help. Many of Tardella’s restaurant customers, etc closed their doors and the demand for Tardella’s products evaporated.

Mr Tardella backed up his comment on how reliable a partner ND Mill is by adding that he knew of several companies that consistently had supply chain issues and problems with their suppliers. He said that Tardella never once had a supply issue with ND Mill.

Once the formalities were over, the group was entertained by Deuces Wild, a local dueling piano group. The dinner rolls and desserts were prepared by customers of the mill.

Milling and Grain - November 2022 | 13 Milling News

Farm tool expanded to optimise nitrogen use & water quality

With pressure mounting on farmers to measure and reduce their impact on water quality, Trinity AgTech has launched an enhanced module within their natural capital navigation tool, Sandy, to specifically support farmers to optimise nitrogen use and reduce nitrate leaching in realtime.

Utilising more than 300 data points, the module has the potential to protect water through a substantial reduction in nitrate leaching and reduce costs by analysing each farm and field's nitrogen uptake efficiency on a daily basis.

“Sandy's dynamic water protection module will help all farmers to manage and reduce their impact on water

quality, while also saving money through a reduction in nitrate wastage,” explains Dr Milad Toolabi, director of artificial intelligence-machine learning (AI-ML) advanced analytics at Trinity AgTech.

“Sandy's forecasting and scenario analysis capabilities can alert farmers to the optimum time and quantity of nitrogen to apply. This allows a precision approach to applications, contributing towards a cost saving and a reduction in water pollution risk.”

Having already been adopted by farms across Europe, UK farm trials have indicated improvements not only in terms of financial savings and efficiency but also for farm sustainability.

“Reducing nitrogen usage also reduces carbon dioxide equivalent emissions from fertiliser applications, which significantly improves a farm's sustainability or carbon score,” says Dr Toolabi.

He adds that Sandy connects information already gathered from the farm, such as soil data, regionality, crop information, application and management practices, alongside external metrics including weather data, to enable farmers to make realtime, evidence-based decisions.

“Integrating with farm management software such as Gatekeeper and Muddyboots, farmers can use Sandy to map out the financial and environmental impact of immediate and future farm decisions,” he says.

“Whether farmers are in the business of growing grass or arable crops, the tool can provide them with the right insights to support environmental and financial gains. Ultimately, it will help farmers profit from their decision making, which is key for a sustainable, resilient farm business.

… because that’s what we do, too. On every single FILIP cleaner, we monitor every detail throughout the entire manufacturing process. We know that our proven quality will guarantee effective sieve cleaning within your plansifters. And that, in turn, will ensure a high yield from your passages.

Efficient. Quality. Cleaning.

“Despite the model being based on complex science, artificial intelligence and machine learning engineering, it's very easy to use. It's a useful tool for farmers in NVZs, and for those who are looking to improve the efficiency of farm inputs and save money, while also capitalising on the environmental gains of improved water quality,” he concludes. FILIP GmbH

Müllereibürsten

Anemonenweg 4 • D-33335 Gütersloh Telephone: +49 (0)5241 29330 • Telefax: +49 (0)5241 20321 E-mail: info@filip-gmbh.com • www.filip-gmbh.com

Subscribe with our all new app!

mymag.info/e/1456 YOUR GLOBAL PARTNER

Get notified when new issues are available as well as access to our back catalouge of issues.

SIEVE CLEANERS

•

•

14 | November 2022 - Milling and Grain Milling News

Have A Vision For Your Business.

it

it

75

With dedicated experts

your

to finish and beyond, Cimbria will

you

confidence.

you can look

you

grain or seed processing challenge?

customized plant design to turnkey installations and expert support, Cimbria can

your

Cimbria.com A/S Cimbria Thisted, Denmark Phone +45 96 17 90 00 cimbria.holding@agcocorp.com

You

Cimbria can bring

to life. We’ve been doing

for

years.

at

side from start

help

grow with

So

forward to a prosperous future. Do

have a unique

From

help find the right solution for

success.

Leiber constructs new sustainable biomass power plant

In the future, Leiber will use waste wood to generate a large proportion of the heat energy and about one third of the electricity required for its production operations in Engter, Lower Saxony, Germany. To this end, the brewers' yeast specialist is investing around 14 million euros in a new biomass power plant.

Regarding the start of construction in October 2022, Bernd SchmidtAnkum, Managing Director of Leiber GmbH, says,“With the biomass power plant in Engter, we want to use waste wood to replace around 70 percent of the gas previously required for our production. Here, we are pursuing the goal of manufacturing our products not only in a sustainable way, but also in a climate-neutral way in the future.”

Leiber needs heat for the production process: for drying the brewers' yeast in spray towers and for extracting high-quality, health-promoting ingredients. At Engter, this thermal energy has been generated from gas, until now. To replace this fossil fuel with a renewable raw material, Leiber is building a biomass power plant that will be fuelled by waste wood.

“By the end of 2023, the new biomass power plant should be supplying

around half of the gas and electrical energy. This will allow us to save up to 10,000 tonnes of CO2 per year,” says Oliver Beckmann, Director Technology & Production. “This will bring us closer to our goal of using energy even more efficiently and manufacturing Leiber's products as sustainably and climate-neutrally as possible.”

The boiler plant of the new biomass power plant will be constructed on a footprint of 760 square metres. The wood storage facility covers an area of 570 square metres and can store up to 2500 cubic metres of waste wood.

A maximum of three tonnes of wood will be burnt per hour, equating to around 15,000 tonnes per year. The waste wood used to fuel the plant is waste from wood processing facilities or pruned material from landscape conservation.

Leiber will have the effects of this energy generation checked annually and recorded in a transparent manner as part of the company's sustainability strategy. Leiber is certified on a regular basis according to the ZNU Quality Seal for Sustainable Management, which is awarded by the Center for Sustainable Leadership at the University of Witten Herdecke.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic

millingandgrain.com Visit:

Milling and Grain - November 2022 | 17 Milling News

Turkish company targets 400% growth with US$59.5 million investment

Doruk Un (Doruk Wheat), one of Turkey's biggest wheat flour producers and exporters, is aiming to grow by more than 200 percent in wheat and bakery products and 400 percent in its other investment and business branches.

The company aims to achieve this with its investment of US$59.5 million (Turkish Liras 1.1 billion) that it plans to realise mainly in retail sales and agriculture and seed growing, noodle and pasta, feed and feed raw materials in its five-year projection.

Additionally, Doruk Un is planning to make RES and GES investments for needing its own energy and is getting ready to dominate the retail wheat market with Panpan brand, in addition to its export to 41 countries.

The brand, with its advance in the retail market, will develop special products for needs and uses in a wide range from domestic use to bakeries and restaurants, from hotels to baklava and dough shops.

Doruk Un, one of the three biggest brands of Turkey in wheat and wheat-based products, holds a strong place in the Turkish economy with its wheat breaking capacity of 438,000 tonnes annually, annual 350,000 tonnes wheat production, 60,000 tonnes wheat capacity, its 20,000m2 advance technology facility and its sales & distribution network getting wider every year.

Gürsel Erbap, who is CEO and Chairman of the Board of Directors of Doruk Un, indicated that they started from the point where energy is a big expense item after the situation in the world in terms of energy prices, and they plan to meet their own consumption with a solar energy facility that they will establish and that they will minimise their costs.

2022 has been a productive year

Mr Erbap stated that 19 million tonnes of wheat harvest was realized approximately in 2022, adding that, “Turkey is a country sufficient for itself in wheat production. If it is moved with correct agriculture policies in Turkey and if TMO continues its agriculture supports as it did in this year especially, there will be a significant increase in wheat production.

“Current production can be increased in 60 percent rate by combining agriculture lands and bringing land that are not planted into agriculture through making land consolidation and by making investments for productivity and by integrating it to technology. It means that it is possible to create a value-added economy by reaching to export capacity without making import.”

While it is estimated that there will be 19.8 million tonnes of wheat production in Turkey in 2022, it is expected that this figure will exceed 22 million tonnes in 2025.

Bringing Turkey forward

Erbap, who attracted attention to the importance of the Marmara Region and Thrace lands for wheat harvest for Turkey, highlighted that approximately 3.12 million tonnes of wheat harvest in Turkey (which was 19.8 million tonnes in 2022 wheat harvest) was obtained from the Marmara Region.

Marmara Region, and especially Tekirdağ province as one of the important locations for wheat in terms of productivity and with its planting area size, ensure a logistic advantage for use, as a result of their proximity to ports, and also stated Marmara Region as the second region after Central Anatolia Region to meet the wheat harvest of Turkey.

The 'Grain Corridor'

Turkey is one of the 10 biggest wheat exporters in the world, with its wheat export of approximately seven million tonnes, according to United States Department of Agriculture (USDA) data. “Its proximity to the Black Sea basin and being a critical interim point in wheat production, especially after the RussiaUkraine war, bring Turkey forward in terms of export, adds Mr Erbap.

“We, as Doruk Un, realise 13 percent of total wheat export of realised from Turkey, except Iraq and Syria. Making only border export carries a serious risk for Turkey in further period, therefore we moved to different markets.“They also state that Turkish wheat will increase its existence in export markets with the 'Grain Corridor Agreement.”

Since the agreement will ensure secure dispatch of grain and foods from Ukraine, with hosting provided by Turkey, it will ensure balancing food prices on a global scale, which will be followed with attention by the whole world.

Milling and Grain - November 2022 | 19 Milling News

Turkish milling machine service provider and Italian packaging company sign agreement

Acompany that exports spare parts for milling machines and provides after-sales services to more than 80 countries all over the world, signs a collaboration agreement with Italy's leading packaging company, Duetti Packaging.

Alapala Holding's group company Depart; entered a new business area after mill machinery spare parts and after-sales services. After signing the cooperation agreement, the company officials of Depart and Duetti, stated that their targets are high and announced that they will start the operation straight away Already working with Duetti in Turkey, Zambia, Uzbekistan and Angola; Depart will continue its sales operation in other countries too.

“As Depart; we have signed a collaboration agreement with Duetti Packaging, the leading Italian company that has been producing packaging systems for more than 40 years,” comments Depart's General Manager Cengiz Tiryakioğlu in a statement regarding the agreement.

"Duetti designs and manufactures endof-line packaging systems offering the best possibile solutions for all industries. So, their product range is quite wide. Some of its products are palletisers, case formers, conventional or robotic box packers, case closers, palletisers, pallet wrapping systems, industrial conveyors, case check-weighers and safety containment systems.

"I believe that we will announce our name Depart in the packaging industry, just like the great breakthroughs we make in the milling machines spare parts sector all around the world in a short time.

"I wish the sales and marketing cooperation that we have started under the roof of Depart will be beneficial to all of us,” he also adds.

Ukraine and Canada strengthening cooperation

The Minister of Agrarian Policy and Food of Ukraine Mykola Solskyi held a meeting with the Minister of International Development of Canada and the Minister responsible for the Pacific Economic Development Agency of Canada Harjit Sajan.

During the negotiations, the parties discussed the state, problems, the most relevant areas of cooperation and the possibilities of support from Canada to the agricultural sector of Ukraine.

The subject of the discussions were the issues of grain storage and export, supply of alternative energy sources and providing the country with fertilisers.

“First of all, I want to thank the government of Canada for supporting Ukraine, in particular, in solving the problem of shortage of grain storages. It was Canada that was one of the first to provide financial assistance for the purchase of means for temporary storage of the crop,” says the Minister of Agrarian Policy and Food of Ukraine.

He emphasises that the issue of grain storage became relevant after the aggressor invaded Ukraine and blocked the export of Ukrainian products. Despite the partial unblocking of sales and transportation, the perspective of the grain corridor remains uncertain, so the issue of warehouses does not lose its relevance, as it ensures proper storage of the harvest – a vital product.

Mykola Solskyi also talked about the problems that farmers had to face. Unfavorable weather conditions and the

consequences of the military invasion, which led to a lack of profit for this year's produced products, jeopardised the financial ability of farmers to sow fields with winter wheat or barley. According to the minister, the supply of any other grain crop that can be sown in the spring will be a necessary support for farmers.

The Minister of Agricultural Policy and Food of Ukraine emphasised the need to supply additional sources of energy for farmers and agricultural producers.

“Systematic and targeted shelling of infrastructure facilities is aimed at depriving Ukraine of energy resources, does not allow to ensure continuity of processes and preserve the existing capacities of the agricultural sector.

“Without adequate electricity supply, farmers, agricultural producers and, in fact, the entire chain of the agricultural complex will suffer. The supply of diesel generators will be a real way out of the energy collapse caused by the enemy,' Mykola Solsky emphasised during the meeting.

In addition, the parties discussed the possibility of providing Ukraine with various types of fertilisers. In particular, regarding the supply of nitrogen, phosphorus and potassium.

During the meeting, the parties also outlined further concrete steps that will allow Ukraine to receive the necessary assistance and agreed to work together on a number of discussed topics. Both leaders are determined to further close cooperation in solving bilateral agro-political issues.

Milling and Grain - November 2022 | 21 Milling News

Messrs Le Tall install new machines at Crown Mills

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

Lincoln cathedral, high on a hill above the river Witham dominates the city and at the time of this article in Milling (18 June 1938) it had its modern residential districts, mills and factories. One business that combined aspects of the city’s life was that of Messrs. Henry Le Tall Ltd, owner of the Crown Mills. They had a fine 10-sack set up with an up to the minute roller mill plant, a large proportion of which was housed in the tower of what was claimed to be the tallest windmill in the country.

Mr Henry Le Tall was born near Sheffield in 1824 where he ran a milling business for many years. However, the steam mill that he had erected in Chapel Street burnt down in 1871 and he decided at that point to move to fresh fields. On his move to Lincoln, he acquired a large six sailed windmill in Princess Street and at once he proceeded to improve this by installing a steam engine.

In 1882 he put in the first roller mills to supplement the French Burr millstones and in

1886 instructed Messrs. Thornton of Retford to install a complete roller system. This would include rotary scalpers, dressing machines etc., and bring the capacity of the mill up to eight sacks per hour.

Many improvements

At the same time, extensive warehouses and a silo of 2000 quarters capacity were added to supplement the already 5000 quarters of grain stored. The business was formed into a limited company in 1893 and in 1895 the capacity of the plant was increased to 10 sacks per hour.

In 1920 the mill was remodeled by Messrs ER & F Turner of Ipswich, and among their improvements was a line of diagonal four roller mills and three free swinging plansifters.

by Mildred Cookson, The Mills Archive, UK

Modernisation at Lincoln

by Mildred Cookson, The Mills Archive, UK

Modernisation at Lincoln

The plansifter floor The new purifiers The roller floor 22 | November 2022 - Milling and Grain

The directorate of the company at this time consisted of Mr. Sydney Le Tall who had joined the firm in 1894 and after serving in all the milling departments for 12 years was appointed Secretary in 1906.

Mr Harry Birks Le Tall who joined the firm in 1898 took on the job of looking after the practical work in the mill and Mr Percy H Le Tall was the firm’s engineering expert and millwright. Early in 1937 it was decided to bring the screen room up to date and at the same time, improve the purification section of the mill. Turners were called in again as consultants, work commenced in the September and was finished in the following February.

Room for improvement

The firm’s supply of foreign wheat was brought from Hull in 100-ton lighters along the River Trent and the Fossdyke Canal via the Torksey Lock. This was then delivered at the mill by motor wagons.

On arrival, the wheat was shot into an intake hopper that delivered it to an elevator of 500 bushels per hour capacity; the wheat travelled over a moving reel and a receiving separator to the dirty wheat bins.

In the screen room the wheat received a thorough washing, cleaning, and conditioning, but it was in this department that Mr Turner found room for improvement. Up to then the mill had been using the old-fashioned cylinders for the separation of barley, oats and cockle, and they were not really satisfactory to

get the best results. Turners suggested installing their well-known high-capacity cylinders. A No 5 model incorporating re- treatment cylinders in the frame, and a capacity of 80.9 bushels of wheat an hour, was chosen for the job.

The wheat, once through the screen room, was sent to the grinding bins on the upper floors of the windmill, directly above the break rolls, which were housed on the first floor.

The wheat fell by gravity from grinding to first break. There were four breaks, the second, third and fourth being graded into coarse and fine. The break scalping was done on the freeswinging quadruple plansifter on the fourth floor of the windmill.

The mill in 1992 (Frank Gregory Collection, Mills Archive)

The mill in 1992 (Frank Gregory Collection, Mills Archive)

IF YOU THINK YOUR FEEDMILL COULD RUN FASTER... >YOU’RE PROBABLY RIGHT Here at Anderson Feed Technology, we believe that building a successful feed milling operation is about more than just a building. With a combined 200 years-plus milling experience, we help you build efficiency into your entire process – unlocking more from your existing assets. In fact, our popular Feed Milling Health Check is proven to realize improvements of 10-20% for customers. So why not contact us to arrange one or visit our website to learn more. >www.andersonfeedtech.com/healthcheck Milling and Grain - November 2022 | 23

The tallest windmill in the country

SEFAR NYTAL ® . The name you can trust. Since 1830, Sefar is the single-source supplier to millers for all products for sieving, grading, and dust filtration as well as connector sleeves, sieve cleaners and tensioning equipment. FOOD SAFETY FDA COMPLIANT Headquarters Sefar AG Hinterbissaustrasse 12 9410 Heiden – Switzerland Phone +41 898 57 00 filtration@sefar.com www.sefar.com As your trusted supplier of precision woven fabrics, Sefar is proud to introduce our newest complimentary innovation: SEFAR NYTAL® Sieve Cleaners

Advantageous for mills

The grading of semolina and middlings were carried out on plansifters on the top floor of the mill. The reduction rolls were Turner’s diagonal four roller mills, installed in 1920 and which in 1938 still looked as good as new. The purifier floor had four of the double fanless purifiers in line. Each side of the double purifiers had double worms as a standard fitment. This had proved advantageous for mills with low floors, and saved worms and band conveyors on the roller floor.

Holding his own

Although Mr Le Tall’s mill was small compared to some mills, he could hold his own and his trade extended throughout Lincolnshire and into the Midlands as far as Nottingham. The new adjustments to their plant had made it possible for them to face the future boldly and with ever-increasing business.

The windmill with nine floors was built by a Mr Seely and it still stands today. It was converted into apartments in 1994, but still presents an imposing sight. It stands 77 feet and 6 inches to the curb and originally had five sails.

In 1863 a hurricane caused severe damage to the mill and the sails were taken down. The mill was repaired but with six sails. Unfortunately to date no images have come to light showing the mill with sails. By 1871 it was powered by steam and it remains Grade II listed to this da.

The Mills Archive has a press cutting showing the mill without sails and the photographer is asking the public for any image showing the mill with sails. We also have other images of the mill, showing it before and during conversion to apartments.

www.millsarchive.org

Milling and Grain - November 2022 | 25

1932 sketch by Karl Wood (Mills Archive)

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

Egypt’s private-sector wheat importers suffer an urgent crisis

The price of wheat and flour used to make unsubsidised bread has spiked in Egypt as importers struggle to pay for wheat stuck at ports amid a US ‘dollar shortage’, traders and the country’s chamber of cereals told Reuters in the first week of October.

Around 700,000 tonnes of wheat haven’t been released from customs, causing around 80 percent of mills producing commercially sold bread, pasta and other goods to “cease activity completely,” according to a September 26 letter from the Federation of Egyptian Industries’ Chamber of Cereals to the minister of supply.

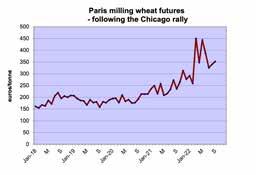

While global wheat prices have fallen to their levels before the Russia-Ukraine war, prices in Egypt have risen due to depleting stocks, said Hussein Boudy, the Chamber’s deputy head.

Egypt’s importers can no longer replenish their wheat stocks amid a US dollar shortage caused by a rising import bill and decreasing tourism revenues from two of its largest markets — Ukraine and Russia.

Wheat prices rose by around 10 percent to 9000 Egyptian pounds (US$458.02) per tonne in the last two weeks, Mr Boudy said, while some traders reported steeper rises of up to 15 percent. Flour also rose by 18 percent to 11,500 Egyptian pounds (US$585.24) per tonne.

“Bigger mills … used to store for a month and a half or two, but today some mills have stocks for seven to five days,” said Walid Diab, managing director of the Egyptian Millers Company. “We are in the red zone.”

The government “will work on the issue” of declining private sector wheat stocks, Egypt’s Supply Minister told Reuters on the sidelines of a conference.

Supply crunch

As foreign currency reserves dwindled, authorities introduced rules in March that restricted access to dollars for imports.

Although wheat and other strategic goods were exempted, private-sector traders say wheat import payments have nearly stopped since September and no new contracts have been signed.

Imports of corn, poultry, and soybeans have also been affected, traders say.

“Suppliers understand that there’s an issue with Egypt but now they don’t want to do new business until the old stocks are released,” said one local trader.

Since early September, only 2000-3000 tonnes of wheat got through customs, the Chamber’s letter said. Monthly private sector needs are estimated at around 450,000 tonnes, and according to the Chamber, mills need the immediate release of around 300,000 tonnes.

The supply crunch has caused a spike in the price of bread in some bakeries, said Hesham Soliman, a Cairo-based private sector trader.

There were no signs of shortages at bakeries, said Attia Hammad of the Cairo Chamber of Commerce, though he said some bakeries could hike prices or decrease the weight of loaves because of rising costs.

Egypt, with a population of 104 million, is typically the world’s biggest wheat importer. Private sector imports recently overtook those by the state buyer, which purchases wheat for a large, subsidised bread program.

The war in Ukraine has exacerbated the shortage of foreign currency. Capital inflows have dried up, particularly to the local debt market. Net foreign reserves decreased to around US$33 billion at the end of August, dropping from around US$41 billion in January 2022.

According to an article that appears in print in the October 6, 2022 edition of Al-Ahram Weekly, which declared that grain mills are also affected. The Cereals Chamber of the Federation of Egyptian Industries wrote a memo to the Ministry of Industry complaining that mills were coming to a standstill because of a lack of wheat to grind.

Speaking on television Karim Abu Ghali, a member of the chamber, said 700,000 tonnes of wheat imported by the private sector are sitting at ports because they cannot access the hard currency to release it.

He said if the CBE made US$50-US$60 million available enough wheat would be released to cover the needs of the market for 10-15 days. At a time when the price of wheat has fallen to pre-Ukraine War levels the scarcity of hard currency has caused its local price to jump to LE11,500 per tonne whereas a more realistic level would be around LE9500.

Abu Ghali estimated that at the moment 60-70 percent of mills cannot find the wheat to grind, and for three to four weeks no new wheat has entered the market. He added that suppliers are reluctant to conclude new contracts until goods already held in ports are released.

In repose to the scarcity of flour, private bakeries are selling smaller loaves rather than raising the unit price. Poultry producers also complain that feed is selling for triple its real value.

Matta Bishai, head of the Internal Trade Committee in the Importers’ Division of the Federation of Egyptian Chambers of Commerce said, “Traders are hiking prices, but who can blame them if the bulk of their capital is frozen in the form of goods stuck in ports?

“They need to increase the price of the stocks they have in order to cover their expenses.”

26 | November 2022 - Milling and Grain

IN MILLING MORE THAN 400 COMPLATE PROJECT PERFECTLY RUNNING

R O L L E R M I L L We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

YEARS

AROUND THE WORLD

First half of autumn sees 10.4 million tonnes shipped from Ukraine

In one and a half months of autumn, Ukraine shipped 10.4 million tonnes of grain, legumes, oil crops and their processing products. This is one million tonnes more than for the entire summer of 2022. In particular, in 16 days of October, 3.6 million tonnes of grain left Ukraine. In just 7.5 months, 23 million tonnes of agricultural products crossed the Ukrainian border.

This month, for the first time since the beginning of the war, wheat took the lead in terms of supplies, while corn, which had been the leading export in recent months, took second place. Thus, the volume of shipped wheat as of October 16 is 1149 million tonnes, which is 100,000 tonnes more than in mid-September. 1089 million tonnes of corn were also shipped, which is 300,000 tonnes less than in the previous half of the month.

In total, since the beginning of the war, 4.6 million tonnes of wheat and corn have been shipped from Ukraine, almost twice as much.

Rapeseed supplies decreased by 237,000 tonnes compared to the first half of September. As of mid-October, 341,000 tonnes of this crop were exported. The same downward trend is observed in sunflower oil: 365 thousand tonnes in mid-September against 265 thousand tonnes in midOctober.

The amount of meal deliveries remains almost unchanged – 257 thousand tonnes, which is 14 thousand tonnes less than in mid-September. Barley and sunflower seeds also have similar volumes in terms of shipments. 165,000 tonnes of barley and 152,000 tonnes of sunflower went, which is 44,000 tonnes more than in the first half of September.

118,000 tonnes of soybeans were shipped, which is 7,000 tonnes less than in the first half of September. Minor changes in the supply of soybean oil: as of mid-October, 13,400 tonnes were shipped, which is 3000 tonnes less than in the middle of September.

The general picture of the quantities of agricultural products that actually crossed the border of Ukraine in percentage for the first half of October is as follows: 30.70% is planted with corn, 32.37% with wheat, 9.61% with rapeseed, 7.47% with sunflower oil, 7. 23% – meal, 4.28% – sunflower seeds, barley – 4.64%, soybeans –3.33%, soybean oil – 0.38%.

The export of agricultural products in terms of their transportation in the first two weeks of October is as follows: 2.8 million tonnes were sent through ports (sea and river), 436 thousand tonnes by rail, 318 thousand tonnes by car, and 22.3 thousand tonnes by ferry.

Information on the volume of shipments by individual types of goods and modes of transport in accordance with EAIS 'Delivery Control'.

Get weekly updates from the feed and flour milling industries with our email newsletter! Want more industry news? myMAG.info/e/289 YOUR GLOBAL PARTNER A HAVER & BOECKER Company Optimize your processes and reduce your downtimes and costs – with QUAT²RO® Monitoring! Contact: Phone: +49 251 9796 252 E-mail: sales@behnbates.com www.behnbates.com OBSERVE YOUR PACKING MACHINE IN REAL-TIME

28 | November 2022 - Milling and Grain Milling News

• continuously rotating carousel for a well filled bag

• highest precision in packaging and palletizing

• our bagging & palletizing specialists are dedicated to find the perfect solution for your requirements

STATEC BINDER stands as a strong and reliable partner for the packaging of your products

STATEC BINDER GmbH

Industriestrasse 32, 8200 Gleisdorf, Austria Tel.: +43 3112 38580-0, office@statec-binder.com

World Leaders in Microwave Moisture Measurement Oil Animal Feed Coffee Rice Grain Hydro-Probe XT Hoppers, chutes, belt conveyors Hydro-Mix XT Mixers, conveyors, Ducting System Hydro-Mix XT-EX Certified for use in ATEX, IECEx and NEC/CSA Hazardous Locations (Dust) Hydro-Mix HT Mixers, conveyors, Ducting System, High Temperature enquiries@hydronix.com www.hydronix.com Contact us for more details Hydronix-Milling and Grain-Advert Jan 2022 215x140mm.indd 1 15/12/2021 12:53 Your specialist for BAGGING & PALLETIZING Solutions for the efficient packaging and palletizing

Milling and Grain - November 2022 | 29 Milling News

CAROUSEL

Stansted Windmill, Essex

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

Stansted windmill stands in the village of Stansted Mountfitchet in Essex, England, not far from London

Stansted airport. It was first erected in 1787 by Joseph Linsell and his wife, along with the adjacent house, granary, bakehouse and malthouse (later destroyed in 1877). At the time the mill was mortgaged for UK£500 to Mrs Cressell of Little Sampford, Essex.

The mill was sold by auction in 1807 to Henry Chaplin, who mortgaged it to Robert Sworder. As Chaplin’s heir was unable to pay the interest on the mortgage the mill passed to Robert’s son Thomas Sworder in 1854.

Although the Sworder family owned the mill, the millers were Edward and Charles Hicks and their descendants. The unreliable nature of the wind and competition from newer forms of milling technology meant that it was hard to make a profit from running a windmill.

There were frequent disputes between landlord and tenant over the funding of repairs and improvements, with Hicks requesting the addition of steam power, which was never carried out. In 1867 the mill was sold to William White and in 1887 to James Blyth, later Baron Blyth of Stansted Mountfitchet. In the same year it was dressed from top to bottom with bunting for Queen Victoria’s Golden Jubilee.

The Hicks family continued to mill until 1910 when the mill finally ceased work after 123 years. In the 1930s the second Lord Blyth had the mill repaired and made over by deed of gift to the Stansted Parish Council, with Rex Wailes as a co-trustee.

The mill was a Scout hut from the 1940s to 1963 and became a Scheduled Ancient Monument in 1952. In 1964 it was opened to the public, and restoration work was carried out in 1966 and again in 1984-5 and in 2010. It remains open to visitors today.

The Rex Wailes Collection

30 | November 2022 - Milling and Grain

CONTINENTS more COUNTRIES than 5 80’ APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

With a recent article in the New York Times stating that “many employers say college graduates often do not have the skills required for a job,” the impetus to bridge this apparent skills gap is with the candidate themselves now more so than ever.

With the more widespread introduction of automation, the milling industry job market is now much more competitive than in previous years too, so with this information in mind, it is very timely that the Online Milling School and Credo are conducting a 12-week training course.

Beginning on October 26 and concluding on December 14, the course involves a weekly two-hour live webinar, which consists of a comprehensive presentation with Q&A sessions, and an Online Milling School certificate of attendance will be received at the end.

Accessible to Europe, Asia, US & Latin America, the program gives the opportunity for participants to register individually or as a group (to watch and participate in the webinars together). The schedule has been especially suited to accommodate busy work timetables and can be completed at the workplace.

The course will inform participants on the latest technologies and machinery for feed plants, to help those who want to fully understand the feed milling process and what

it takes to produce sustainable feeds - giving those attending the opportunity to review key milling operations, gain ideas and acquire knowledge that will help further improve the feed production process.

Broaden your milling knowledge

The course webinars will benefit a wide range of people, such as feed mill plant owners, managers and operators, quality assurance and maintenance staff, nutritionists and feed formulators, feed additive and animal health suppliers, in addition to industry advisors and technical consultants.

The speakers will consist of industry experts, and the sessions allow for audience participation at the end with a Q&A with the program facilitators. The topics range from raw material receiving and storage (effective warehouse inventory), grinding & Batching operations, mixing operations, and the principles of conditioning.

The following sessions will refer to the pelleting process, cooling, crumbling, and packing, considerations of associated process equipment, feed mill management, quality assurance, and quality control.

The training course is a great learning platform or a refresher for those involved in feed production of livestock and aquaculture feeds at their place of work.

The event is organised and delivered by Milling and Grain, and Progressus Agrischools, and is sponsored by Agentis Innovations and The International Milling and Grain Directory.

To find out more, visit the online Milling School website by going to: https://mymag.info/e/1666

Online

Livestock

edition begins - enrol now! Elevator parts Conveyor chains www.vav.nl contact@vav.nl +31(0)71 40 237 01 Milling and Grain - November 2022 | 35 TRAINING Mill

Milling School:

Feed Progressus AgriSchools Autumn 2022

Nutrition Congress by College of Animal Welfare

A one day virtual training event with a focus on animal nutrition, diets, strategies and nutritional requirements will take place on 1 December, 2022. The full price of the course is £175, and aims to increase your knowledge and confidence on nutritional topics. The day will feature a range of expert speakers ,delivering lectures on senior feline nutrition, cardiac diets, pet obesity, communicating with owners, raw feeding, and nutrition for exotic pets.

Aimed at veterinary nurses, the course will develop your animal nutrition knowledge, subsequently improving the nutritional advice given to pet owners. It provides attendees with the ability to specialise and progress within their role, as well as a way to keep up-to-date with everything happening in the industry.The course provides a wide range of lectures and speakers, who will share their experiences and knowledge. There will also be Q & A sessions with the speakers, who will give you practical takeaways to implement in your practice. The virtual exhibitors will equip you with information, product knowledge, and offers. The event also gives you the opportunity to gain online access to recordings of all the lectures, including previous lecture events.

The first Lecture will be on nutrition for super senior felines, delivered by Alexandra Taylor, who runs the company ‘The Cat Nurse’. This talk looks at the physical and mental changes in older cats, and how it affects their appetite, digestion, body

condition and changing nutritional requirements compared to younger felines.

The next speaker is Dr Marge Chandler from Vets Now, talking about ‘The overweight Pet and His Owner’, discussing the consequences of canine and feline obesity, giving a better understanding into the aetiology and difficulties in weight loss and weight management.

The day will also feature a talk on ‘The Raw Truth’ by Katie McCaul, from The Pet Diet and Raw Feeding Veterinary society. This lecture will address nutritional adequacy and safety concerns in regards to raw food, and provide resources and answers to common myths. It will ultimately impart knowledge on minimising the risks of raw feeding, based on unbiased and evidence based information.

Next will be an exhibition on ‘Advances in Cardiac Nutrition’ by Nicola Lakeman, from Plymouth Veterinary Group. This talk will touch upon how diets and nutrients affect cardiac health and issues, by discussing new findings and what it means for veterinary practices.

Lastly, Matthew Rendle, from The Association of Zoo and Exotic Veterinary Nurses (AZEVN), will give a talk on ‘ExoticsNutritional advice for common exotics seen within practice’. This will look at commonly kept species, how to prevent nutritional problems as well as what to do when those problems occur.

Your industry training platform

and aqua feed products.

The Pet Food and Aquafeed Workshop took place recently, running from September 20 to September 23 at Bühler headquarters in Uzwil, Switzerland. This extensive 4-day training event gave participants the opportunity to continue their education in extrusion production, whilst observing practical demonstrations with Bühler’s cutting edge technology.

The workshop provided those attending with an introduction to the basics of extrusion technology, focusing on preconditioning, energy, moisture and mass flow balance. The training is in the style of a hands-on workshop, and will discuss topics such as Single v/s twin screw extrusion technology, screw configuration, die and knife technology, SME control, product density control and its significance in vacuum coating. Additional topics covered in the workshop are micro-feed for aqua as well as fresh meat addition and filled pillow treats for pet food.

There were practical demonstrations to help attendees apply everything they learnt in Bühlers modern pilot plant. The demonstration featured Bühler's Twin-screw extruder. The equipment is a multifunctional PolyTwin, EcoTwin and CompacTwin twin-screw extruders that offers flexible, reliable 24/7 processing for breakfast cereals, food ingredients, pet food

The sessions were administered in English, and took place at their Extrusion Application Centre, which is a multi-purpose lab where tests are conducted on food and animal feed, for example, checking new recipes, product shapes or textures. The food trials that take place in this lab include cereals, extruded breadcrumbs, reconstituted rice, flavouring, modified starch and modified flour, soybeans, sunflower seeds, peas and new proteins. They use their latest technology to run regular tests on pet food, animal feed and aqua food for freshwater and marine species.

Understanding how to apply the opportunity of extrusion technology for various products is the goal of this training event. The subjects targeted to demonstrate this concept are cereals, pulses, bypass proteins, fish feeds, pet food treats, texturization of proteins, and any other specific topics of interest from participants.

The workshop was designed for individuals who are actively involved in the technological aspects and feasibility of extrusion production for aqua/pet food, such as operation supervisors, engineering or R&D personnel. The sessions were run by experienced extrusion experts and included hands-on training for theoretical aspects. Once attendees completed the 4-day course, they were awarded a certificate of participation.

Bühler Petfood and Aquafeed Workshop TRAINING Mill

www.onlinemillingschool.com Learn more – Learn onsite Enroll in the 12-week Course 36 | November 2022 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less

£12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME We will be seeking enrolments from June ... . . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

than

FOCUS Product November 2022

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

The Pegasus mixer by Dinnissen

Increasingly efficient and faster production has led to a need for more and more multiprocessing machines in the food industry. That is why an increasing number of producers see the Pegasus mixer as a good addition to their production line.

The core of this double-axis Pegasus paddle mixer comprises two opposingly-rotating shafts, making it ideally suited for ultra-fast mixing of powders, pellets grain and granular materials. The shape of the paddles and the mixing chamber ensure optimum mixing with the least possible product damage.

Fragile products can also be mixed, heated and cooled with the Pegasus mixer. And the Pegasus mixer has the added advantage of large wing-doors to allow easy access for inspection, maintenance and cleaning.

If desired, you can also opt for mobile bunkers and two large floor hatches for complete emptying of the mixing chamber.

www.dinnissen.eu

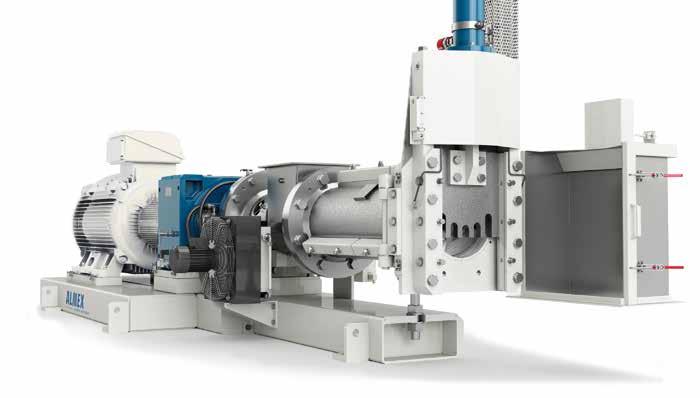

BOA compactor by Anderson Feed Technology

The BOA compactor is a unique alternative for double pelleting or expanding. It has a double-walled mixing chamber in which steam and liquids are introduced and the mixture is compacted using a hydraulically operated compacting chamber.

Generously sized paddles, adjustable in both height and pitch, guarantee a homogeneous mixture and a hygienic process. The mixture is introduced into the compacting chamber where a rotating three-roller head presses the material through two conical friction rings.

Three hydraulic cylinders accurately assess the adjustable distance (0.125 – 2.0) between the friction rings which, along with the motor power of the main motor, determine the compaction level. The unique combination of mixing chamber and compacting chamber ensures an optimum absorption of steam and liquids, a more homogeneous distribution of the raw materials, a higher pelleting capacity and excellent pellet quality.

Debugger DB09 by Frigortec

The Debugger DB09 ensures guaranteed killing of insects at all stages of development and is specially designed for heat treatment in smaller rooms. The Debugger method (heat treatment) from FrigorTec increases the air temperatures to minimum 45°C without exceeding the upper limit of 60°C.

In this temperature range insects, larvae and eggs die by protein coagulation without the additional use of chemical substances. Ideal for targeted applications in rooms and smaller areas and frequently used for mattress and upholstery debugging in hotels, trains, etc.

Its main benefit is easy handling and quick assembly and disassembly along with low-noise operation. For many years, Frigortec have been producing Debugger devices for effective heat treatment. This has given them extensive expertise in all aspects of pest control.

FrigorTec also provides worldwide solutions for grain cooling, room air conditioning, hay drying, insect heat treatment, heat pumps and special cooling solutions.

www.andersonfeedtech.com

RG Series Rotary Paddle Level Indicators by 4B

The RG Series Level Sensors have been designed to indicate the presence or absence of bulk materials such as grains, pellets, chemicals, wood chips and other powders. The detection of material is achieved by a rotating paddle.

The RG Series has a variety of compatible paddles which offer the ability to detect a wide range of products. The paddles are interchangeable, making the RG Sensors adaptable to different densities of measured materials.

An easy to install instrument, the RG Series sensors do not require any calibration, maintenance or specific tool for their installation. The sensors are customisable, not only with paddles, but also with extensions and voltages.

Working with ambient temperatures from -20° to +70°C, he sensors are extremely versatile, and can be installed on tanks, hoppers, on walls or roofs of silos, in a vertical, horizontal or oblique position.

www.frigortec.com

Horizontal dryers by Extru-tech

Extru-Tech horizontal dryers are the leading industry tool for the production of a diverse range of food and feed products, including pet and aquatic foods and foods for human consumption.

The company has taken dryer technology to the next level with the new Advanced Feature Dryer, which features improved performance and new sanitary dryer features. Its tool-free door assemblies and increased dryer bed floor clearance for easier access and inspection allowing overall cleanout in 15 minutes.

The dryer includes filtered make up air and burner air to reduce cross-contamination or re-contamination and redesigned chute with span and speed controls for ‘in-process’ adjustments, reduced horizontal ledges allow for ease of cleaning.

Stainless steel solid construction hinged interior doors permit easy access to product conveyors. Fines removal augers and air supply plenum discharge gates provide simple, quick clean-out at one common collection point.

http://extru-techinc.com

https://go4b.co.uk 38 | November 2022 - Milling and Grain

Grain Improvers

Higher milling efficiency & flour quality

Crisis situations often force manufacturers to seek hidden reserves for self-preservation, and to look for new ways of survival and development.

2020 became a stark example of the global crisis, which affected even the basic industries - baking and grain processing.

Now all those who know that the crisis is the time for new opportunities, are the companies that will succeed.

In relation to a global decrease in purchasing power, maximising production efficiency with minimal costs and an emphasis on environmental friendliness became more in everyone’s best interests than ever before.

The coronavirus pandemic has also focused global attention on health and good nutrition, not just for each person, but across entire countries. Now it has become more important to evaluate food products in terms of nutritional and biological value. And production is moving to a new level, in which the main task is to get a product under the ‘Clean label.’

Looking for new opportunities

The grain crisis of 2022 has further forced millers to look for new opportunities that will help them get more and better from their grain reserves than in previous years, when standard flour milling methods were practiced.

With this in mind, the company would like to present a line of innovative products that fully comply with all modern global trends. Examples of this include the range from Grain Improvers – a patented 100 percent natural enzymatic composition, with the sole purpose of facilitating grain grinding and improving flour quality.

Cellulose of grain shells is the substrate for Enzymes’ action. Grain improvers are applied in dry form by a simple in-line dispenser on wet grain at the stage of Tempering. The product also softens and disintegrates grain shells, making them much more flexible than with standard way of grain preparation for grinding with only water.

Grain Improvers is an environmentally friendly solution that allows you to process plant cereals (wheat, rice, corn and oats) as efficiently as possible at lower costs, while increasing the nutritional and biological value of finished products.

A unique composition of enzymes

Since 2011, the company’s team has begun the R&D for a unique composition of enzymes - Grain Improvers and since then excellent results were achieved, which we would be glad to share with you.

In 2015, world priority was received for Grain Improvers and at the moment there are patents in Europe, Australia, Russia and patenting in USA, India and other countries is ongoing.

The Grain Improvers range is designed to meet requirements of a specific mill. The main advantage is that better results can be achieved without additional CAPEX and by increasing the yield of flour which is also important for overcoming the extended economic crisis.

The use of Grain Improvers gives millers high-quality-value flours’ yield increase, prolongs milling equipment life, extends service intervals and reduces energy costs thus allowing a mill to operate economically more efficient and complying with the modern industry and market trends and requirements.

Milling and Grain - November 2022 | 41 FOCUS

https://bdcsystems.com Special

www.ai-lati.eu

Let

www.paglierani.com www.ocrim.com

’ s w a l k t o g e th e r i nto a n e w E r a

Wheat, Flour and …

Where honour is a burden to be carried for life

(A slightly abridged version)

by Sergio Antolini when opening Ocrim Open Days ‘Wheat, flour and … 2022,’ Cremona, Italy

Along with my brother Alberto, I have the honour of opening this wonderful appointment, an event awaited by all of use for more than two years.

I leave it to the talented Ocrim engineers who are going to inform you about technical development, milling techniques and technologies. They are going to tell you something exciting, something that makes Ocrim special, something that is not written on contracts or technical records, but which nevertheless represents enormous value of our large family.

I would like to tell you about the Ocrim world, an out of the ordinary world. This is a world where dreams are not left behind but held in hand, a world where every new day is a new challenge, a world where you never live the same day twice. The energy and talent of those who live there is vital lymph.

It won’t be a perfect world and certainly not an easy one, but, for sure, those who will experience it will have great opportunities because they will be motivated by the passion to give the essence of their work and their lives.

In the ancient Roman language, there was an ‘adagio’ that sounded like this:

“Honor is a burden, a weight to be carried on your shoulders every day of your life.”

Although the word honour seems to be disappearing in the working world, honourability is a central characteristic feature buried in Ocrim’s DNA.

Ocrim takes care of its duty because it’s the main pinnacle; a romantic vision that takes me back to my childhood, where there is a much more intense reward, where each of us finds himself, finds his identity again and finds his independence. The reward today is the working industry. Learning to love your work and make your work loved is utmost important as the basis of every democracy.

Ocrim is a company similar to all successful companies, with extraordinary entrepreneurial stories which have decided that the world is an arena in which it wants to compete and get on the podium, linking industrial capabilities to product and brand.

Here is the commitment and duty to guarantee, with my brother Alberto, to my niece and nephew Annalisa and Andrea and to my sons Luca and Matteo. A business progress that is not limited to expanding markets but extends to research and development, safety at work and to everything that will be applicable to preserve our beautiful planet. Thanks to all the work force. Thanks to Alberto.

Ocrims Open Days in Cremona, Italy

Working with millers to reduce their operational costs

by Roger Gilbert and Niamh Cassidy, Milling and Grain

Away from its town-centre head office, Ocrim hosted it’s much postponed ‘Wheat, Flour and …’ Open Days 2022 at its factory complex, its Farmhouse and its new Milling Hub, all located between Italy’s River Po and the Milano-Cremona-Po Canal on the outskirts of Cremona

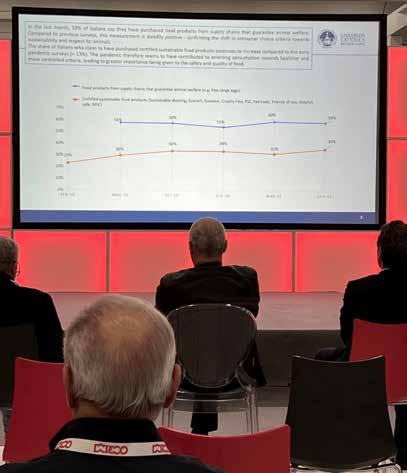

t was mid-September when milling industry events were getting into full swing, that Ocrim hosted its long-awaited Open Day 2022 in Cremona, Italy for 170 customers coming from over 20 countries.

The two-day event started on the afternoon of the first day with a welcome cocktail and a three-part conference session focused on energy usage in the flour mill and a technical explanation of how energy using could be minimised.

GRAIN, FLOUR AND … I

But first brothers Alberto and Sergio Antolini received visitors by both providing individual welcomes (see side bar) before getting down to the task in hand in the unusually warm weather conditions for the region, despite the open and airy space of the conference setting.

Maximising productivity while closely controlling energy consumption is still a focus of our industry globally and Ocrim’s decision to lead off with a session involving three presenters on this important subject was valued by the audience.

Energy in three parts

Simone Pedrini, Ocrim’s manager of its Mechanical Department provided an analysis of mechanical power transmission. He was followed by Ocrim’s manager of its Automation and Electrical Department, Paolo Molinari, who reviewed how millers might use automation to achieve energy saving in their mills.

Mr Pedrini along with his colleague Mr Molinari undertook the task of the equipment designer and manufacturer in helping millers reduce their energy usage. The detail was technical but not lost on this audience.

At one point Mr Pedrini turned his attention to the torque motor benefits and says that the lower the rpm the lower the efficiency a motor delivers, and possible below 90 percent. And not one torque motor fits all sizes.

“Torque motors must be electronically controlled, and their position and velocity monitored,” he added.

Bringing the discussion together was Mr Marco Galli, Ocrim’s director of its Technological Department who looked at power consumption and detailed operations

44 | November 2022 - Milling and Grain F

1: Professor Lorenzo Morelli - Food Science and Technology Department

Università Cattolica del Sacro in Cremona, Italy

2: Marco Galli, Ocrim’s director - Technological Department

3: Simone Pedrini, Ocrim’s manager - Mechanical Department

4: Paolo Molinari, Ocrim’s manager - Automation and Electrical Department

Right

5: Professor Stefano Boccaletti - Agro-food Economics Department, Università Cattolica del Sacro in Cremona, Italy spoke on ‘Nutrition and its complex path’

6: Mr Marco Galli presented twice during the event, once on energy savings and once on biodiversity and technology

that make a difference.

Mr Galli asked where a miller should start to look to reduce power consumption in the mill as today’s energy costs are the second highest cost, besides raw materials, in a flour mill.

The activities that impact power consumption include automation, equipment, technologies adopted and the plant layout.

“Layout and flows must be considered in power consumption evaluations.”

It’s monitoring these details that makes the difference in energy bills, he adds.

He offered a range of solutions including how to save on pneumatic lines that could return over €120,000 per year over traditional set ups. Pneumatic systems are the second highest energy consumer in the mill behind the rollermills.