Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher

Roger Gilbert

rogerg@perendale.co.uk

International Marketing Team

Darren Parris

darrenp@perendale.co.uk

Fred Norwood

Tel: +1 405 834 2043 fredn@perendale.com

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

Mehmet Ugur Gürkaynak

Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Sub-editor

Andrew Wilkinson andreww@perendale.co.uk

Levana Hall

levanah@perendale.co.uk

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

James Taylor jamest@perendale.co.uk 0

Circulation & Events

Tuti Tan

tutit@perendale.co.uk

Antoine Tanguy antoinet@perendale.co.uk

millingandgrain.com

Over the past year the UK£ has lost 16 percent of its value against the US$; although the UK£ is bouncing back after the initial impact - of a mid-September mini budget from a changed Conservative leadership - had been digested.

They will continue to need government support. We are already being told in the UK that while 50 percent of our electricity is generated by gas driven turbines, we are even less self-sufficient when it comes to food. I’m sure this situation is reflected in many other countries and demonstrates the dependence we all have on imported raw materials along with food and feed ingredients to sustain our populations. Global transportation that is timely and economic has never been more important.

Roger Gilbert

While currencies try to realign themselves during this current period of global instability, it is clear that the US$ stands strong among all major currencies.

Overlooking the currency market’s impact on the global price of food is tempting, given the obvious repercussions of the war between Russia and the Ukraine and the resulting energy crisis stimulated by the dependence we now have - particularly in Europe - on gas.

We should not overlook the fact that over the past decade most leading currencies have lost between 20 and 30 percent of their value against the US$.

To counter food price increases, the food industry has been modernising, adopting new technologies, innovating, improving additives and producing at scale to absorb costs that would otherwise have been transferred to consumers in higher food prices.

Our current situation cannot disguise the fact that we will have to be prepared to pay more for our foodstuffs in future as energy, fertiliser and transportations costs to name a few – remain outside the control of producers – and have to be passed on.

However, higher food prices might not mean our farmers will

Into this complex global food supply structure we now have to consider climate change, resulting from carbon and other greenhouse gasses being emitted from human activities into the atmosphere, along with the need to reduce waste, to focus on more circular economies, reduce our water usage and cut our energy consumption with the goal of becoming more sustainable as a planet which supports the human condition within our solar systems.

These are all good reason why all of us need to work together.

Food production and food costs are of critical importance and the milling industry is at the very heart of the transformation of globally-produced raw materials and commodities into high value foods and feedstuffs that are affordable to both farmers and consumers alike no matter where any of them live.

We have to learn more about global economics, more about how and where our raw materials come from, the true impact our companies make on the environment and what our carbon footprint is. Without this knowledge we cannot participate in the debate that will determine food supply and food costs for the future.

It is the milling industry - in all its rolls – after all that should be leading this debate with facts that support the production of the safest, most nutritious and affordable food for all.

September was a busy month for events and among them the hosting of the 2022 SPACE Expo in Rennes in France did not dissapoint. Milling and Grain attended this year’s offering which experienced an almost capacity crowd os farmers and the agriculture supply industry came together for its annual gathering. The weather held and food accompanied by good dining supported the display of all things available to farmers and the industry’s service providers. This year saw the event host the feed industry in Hall 7 - there is a focus on feed manufacturing every second year at SPACE - which had found a more convenient place to exhibit.

Milling and Grain’s publisher Roger Gilbert took the opportunity to interview the organiser of SPACE, Ms Anne Marie Quemener, who explained why the international attendance was up compared to immediate past years with a focus on Middle East and Eastern Europe. She explains that SPACE is becoming a meeting point for agriculture from a wider European and North American regions. The event also focused on aquaculture. This edition of Milling and Grain carries a report on SPACE in the Events Section and International Aquafeed will carry an additional report in its edition later this month. To view the interview with Ms Anne Marie Quemener please use the link below.

Welcome to this, the tenth edition of your Global Miller column that I have had the pleasure and you have (hopefully) had the pleasure of reading in 2022.

As the winter begins to tighten its grip on the northern hemisphere, we begin to look tentatively at our heating system’s thermostat control, wondering if the kids will be content with a little bit less for Christmas this year, should we decide to give in and bump the temperature up a degree or two.

Not that I’m complaining about our lot here in the UK. Truth be told we have it very good when compared to our friends in Ukraine - not forgetting the many Russian families who are sending their sons over to fight in a war that appears to be moving away from rather than towards a meaningful and long-lasting peace.

Once again, we are all also having to navigate the increasingly hawkish news coverage that comes with the unravelling situation. A situation that is especially tragic as it’s at times like this when the world needs to be working together much more closely to produce more food and energy.

But the east and west now find themselves on either side of an ‘us and them’ type of binary global politik that we all hoped we’d long seen the back of. And you seldom see politicians and journalists suffer much during these hot and cold wars either.

Back here in the UK, October is one of the busiest months in the agricultural year. Should the weather be dry, autumn cultivation should be perfected early in the month. Then as soon as the leyground is wet enough, the ploughs should be set to work, with the furrow slice immediately consolidated by a heavy roll or press.

On some light land early planting wheat is necessary, but the turn of the month is a good time to begin to drill wheat, and it is best to be all over by the first week in November. The quantity of seed should vary from seven to ten peeks per acre, the former quantity being as early as possible in the month as the heavy seeding of the latter will be in the middle of November.

In threshing wheat for seed, care should be taken that the machine is well cleansed of the grain it has previously threshed. Unless this is attended to, these combined threshing and dressing machines may spoil the purity of any sample intended for seed.

As the malting season commences earlier than it did some years ago, it often happens that barley threshed in October sells for a higher price than it does in any other month. With this in mind, if resources can be spared to thresh and deliver the grain, it may also be advantageous to thresh some barley in October.

This month sees a delegation from Milling and Grain magazine attending JTIC en France. Now in its 72nd edition, the event will take place in the famous French city of Dijon, the capital of the country’s famous Burgundy region, we hope to see you there to raise a glass together this year!

Watch the video at

The American Feed Industry Association (AFIA) and Feedstuffs named Quality Liquid Feeds' (QLF) Comstock Park, Michigan, liquid feed manufacturing facility as the 2022 Liquid Feed Facility of the Year (FFY) award winner.

Gary Huddleston, AFIA's director of feed manufacturing and regulatory affairs, presented a plaque to plant manager David Schnicke at AFIA's Liquid Feed Symposium (LFS), being held in New Orleans, this week.

“QLF's Comstock Park liquid feed facility is best in class for the industry, with well-documented standard operating procedures and training programs that should be revered,” Mr Huddleston says.

“Their work has led to experienced and engaged employees who play a critical role in ensuring the safe manufacture of quality liquid feed for beef and dairy producers.”

Constructed in 2014, the Michigan liquid feed facility produces approximately 75,000 tons of feed annually, specialising in suspensions for beef and dairy cattle. The facility boasts three mixers for increased efficiency and abundant finished feed storage, allowing for continued growth in the future. This is the third time a

QLF facility has won the Liquid Feed Facility of the Year award.

“QLF Comstock Park is honoured to be recognised as the 2022 Liquid Feed Facility of the Year,” Mr Schnicke says. “The team at Comstock Park strives to manufacture the highest quality products for our customers and the livestock they feed.”

The AFIA also recognised several semi-finalists, including QLF's Wellsville, Ohio; Clovis, NM; and LaSalle Illinois, as liquid feed manufacturing facilities.

US feed and pet food manufacturers continuously strive for excellence in their operations, which includes everything from optimising animal food nutrition to improving the safety of their products and workplaces to complying with government regulations.

In 1985, the AFIA sought to recognise top facilities as part of its voluntary FFY program, which assesses manufacturers' overall operations against their peers using key industry metrics.

As the industry has evolved, the FFY program has evolved with it, now recognising award winners throughout the year in four categories – liquid feed, commercial dry, premix and ingredient and integrator. To date, 40 facilities have earned FFY awards.

… because that’s what we do, too. On every single FILIP cleaner, we monitor every detail throughout the entire manufacturing process. We know that our proven quality will guarantee effective sieve cleaning within your plansifters. And that, in turn, will ensure a high yield from your passages.

The Institute for Feed Education and Research (IFEEDER) released new research today which shows that if more US food companies are to require feed for their livestock and poultry be free from genetically modified (GM) ingredients.

This could cause greenhouse gas emissions on farms to rise, grain elevator and feed mill product handling and production requirements would be greater, meaning that the price of meat, milk and eggs for consumers could increase.

The study, ‘Impact of Non-GM Livestock and Poultry Feed on the US Feed Industry,’ conducted by Iowa State University and Decision Innovation Solutions, examined the environmental and economic implications should U.S. animal food manufacturers need to boost the production of non-GM feed.

Partnering with Dairy Management Inc, MFA, the National Corn Growers Association, the US Poultry and Egg Association and others, IFEEDER initiated the research to inform companies throughout the food value chain of the complexities involved with producing GM and non-GM feed lines from the farm to grain elevator to feed mill.

“Like many industries involved in the production of America’s food supply, the U.S. animal feed industry is diligently working to be more sustainable and efficient, using all available tools at its disposal, as part of our commitment to consumers to be good environmental stewards,” says Lara Moody, IFEEDER executive director.

“The research released today shows that when you limit the use of safe, proven technologies, like GM crops, the costs for both the environment and consumers can increase. As food retailers and manufacturers pursue ambitious sustainability goals in the future, we hope this research will inform their decision making on the value that GM feed provides.”

From a monetary viewpoint, GM seeds cost corn and soy farmers more initially, but are typically offset by lower costs for herbicides, insecticides and field operations when compared to

non-GM production. For a farmer to consider switching to non-GM farming from GM, the research showed that a significant premium on non-GM would be needed to offset the production cost difference.

A shift away from non-GM seeds creates land sparing benefits; for example, the use of GM seed traits produced between 6.8 to 15.9 million acres of land sparing and 35 to 65 percent less land conversion from grassy habitats to crop production, which would have occurred otherwise for the period from 2007-16.

The researchers evaluated the impact of on-farm fuel reductions to lower carbon dioxide (CO2) emissions to the environment by using GM crops and found that the GM corn no-till system emits the least CO2 for diesel combusted in field operations at 0.0258 metric tons per acre, based on 2020 corn production budget data.

Nitrogen efficiency has improved with the expansion of GM seed use and other technologies. Examining corn alone, the research shows that if it takes 4.9 percent more corn acres to yield the same level of production with non-GM corn as would be expected with GM corn, then total nitrogen volatilisation and leaching losses under all non-GM corn production would be expected to be 2.7 and 4.3 percent higher than with all GM corn production.

The study found that all participants in the non-GM feed production supply chain would be subject to additional costs related to segregation and isolation of GM and non-GM ingredients.

For example, the grain elevator could potentially spend an additional US$0.05 to US$0.07 per bushel to handle and segregate non-GM soybeans, compared with regular soybeans, and US$0.07 to US$0.09 per bushel more for non-GM corn.

The feed mill, at the end of the feed production chain, would be subject to the largest increase in the price of the final product, which would directly impact consumer prices for meat, milk and eggs derived from animals fed non-GM feed.

The overall consumer retail price of meat, milk or eggs from animals fed non-GM feed is expected to increase over animals fed GM feed.

Muller Beltex BV, VAV Aandrijvingen BV and Germany based

Bechtel GmbH have announced their strategic alliance. By a transfer of shares, the owners Lars Muller and Emiel Schoutsen have established this cooperation.

The know-how and expertise in components for bulk handling equipment is not limited to the Netherlands and Germany, where the three companies are located. They operate worldwide and the close cooperation between the three companies will therefore provide major benefits for their entire, geographically widespread, customer base.

Both owners emphasise that this alliance is not a merger and that the companies will retain their own identities. Company locations and contact points will remain unchanged.

VAV Aandrijvingen is globally known for their chain applications in the feed and grain handling industry. They are able to deliver immediately from stock, or within days, all components for chains as well as elevator components and parts for various screw conveyors.

Muller Beltex provides solutions for the bulk handling and process industry and specialises in bucket elevator troubleshooting. Further to this their components, Polysur® elevator belts, Kryptane abrasion resistant polyurethane liners, and the Atex approved monitoring systems are known worldwide.

Bechtel GmbH is a strong ‘service related’ supplier of components for bucket elevators and chain conveyors. Their knowledge of chain conveyors and problem-solving capacity enables them to build, for the entire German industry, all types of chain conveyors even for the most complex applications.

The advantages arising from the collaboration are, in particular, the bundling of their expertise and the use of each other’s network, especially abroad. In certain markets or geographic regions, the one partner is better represented than the other.

“This collaboration will enable all three of our companies to better position themselves in the market and to provide our customers with materials, knowledge and service in an even better and more efficient way,” states Messieurs Muller and Schoutsen.

VAV Aandrijvingen is globally known for their chain applications in the feed and grain handling industry. They are able to deliver immediately from stock, or within days, all components for chains as well as elevator components and parts for various screw conveyors.

Muller Beltex provides solutions for the bulk handling and process industry and specialises in bucket elevator troubleshooting. Further to this their components, Polysur® elevator belts, Kryptane abrasion resistant polyurethane liners, and the Atex approved monitoring systems are known worldwide.

Bechtel GmbH is a strong ‘service related’ supplier of components for bucket elevators and chain conveyors. Their knowledge of chain conveyors and problem-solving capacity enables them to build, for the entire German industry, all types of chain conveyors even for the most complex applications.

The alliance of the three companies wishes to further improve their already very high service level to the bulk handling industry, and thus securing quality and continuity of their efficient supply chain.

TheInternational Seed Federation (ISF) gave its support to the World Trade Organization (WTO)'s calls for securing seed trade and highlighted its role in protecting the food supply chain in the long-term through:

Increased access by growers to seed as the essential first input in farming

Higher yield and greater food diversification via improved crop varieties adapted to local conditions

Mitigating climate change impacts through the development of climate resilient and resourceefficient crops

Representatives of the private seed sector will join the WTO Trade Dialogue on Food on Thursday September 22, led by UN Food and Agriculture Organization (FAO) chief economist Maximo Torero. This dialogue comes on the heels of the WTO's 12th Ministerial Conference where commitments were made to facilitate trade and improve the functioning and resilience of global markets.

“We know the devastating impacts of trade disruptions to agriculture and food supply,' says Michael Keller, ISF Secretary General. 'ISF, which represents the private seed sector at the international level and whose members account for 96 percent of global seed trade, calls for a concerted emergency response to the unfolding global food crisis. We seek urgent and

critical discussions with our partners in the food supply chain to achieve Zero Hunger targets outlined in the 2030 Agenda.”

Food prices have been escalating worldwide, with some 25 countries reacting to higher food prices by adopting export restrictions affecting over eight percent of global food trade. Complicating the food supply response is the doubling of fertiliser prices over the last 12 months due to record-high costs of inputs like natural gas.

The World Food Programme reports that the number of acute food insecure people has increased to 345 million in 82 countries. Beyond the short term, climate change is structurally affecting agriculture productivity and threatening food supply.

On a global level, approximately seven million metric tons of seed are imported every year. ISF notes that the price of seed has remained rather stable compared to other agricultural inputs.

Innovation within the sector is a consistent priority: seed companies invest as much as 30 percent of profits in R&D to develop resource-efficient and low-input new varieties that require less water, tolerate drought and extreme weather, improve soil health by boosting natural nutrients, capture carbon through enhanced root systems, and others.

These crop varieties provide significant yield increases for farmers, helping improve farm productivity and food supply without increasing land use and other inputs.

German manufacturer of feed additives Dr Eckel Animal Nutrition launches a worldwide series of events on the use of phytogenics in animal nutrition.

The Dr Eckel World Tour 2022 kicked off with a wellattended event in Hua Hin, Thailand. The series focuses on the use of phytogenic additives for profitable and sustainable animal production.

Following a visit to VICTAM Asia, the participants travelled to the conference venue. Dr Andreas Lewke, Managing Director of Dr Eckel Animal Nutrition (Thailand), welcomed around 50 participants from all over Asia to the InterContinental Hua Hin Resort.

Over three days, academic and industry experts shared and discussed the most promising innovations and solutions for effective ruminant feeding, poultry production and aquaculture.

Rarely has the industry faced such challenges: lockdowns, sanctions and political instability are putting markets, supply chains and pricing under enormous pressure, while the impacts of climate change are becoming increasingly manifest.

Producers worldwide need to find solutions to utilise resources that are becoming increasingly scarce and expensive as efficiently as possible, in order to meet the demand for animal protein and still remain profitable. And these are the solutions the first World Tour conference in 2022 addressed.

In his keynote address, Vice President Dr Bernhard Eckel posed the central question of how we can secure a global food supply for a growing population in the face of current challenges. He clearly demonstrated how phytogenic additives can be used to attain the United Nations' sustainability goals and even increase production.

Professor Carsten Malisch from Aarhus University in Denmark outlines the various potential uses of plant secondary compounds and provided exciting insight into his current research on tannins and their benefits to animal nutrition, particularly that of reducing emissions in ruminant feeding.

The potential of plant-based additives in aquaculture has

so far been hardly exploited. Dr Tirawat Rairat from the Department of Fishery Biology at Kasetsart University in Thailand clearly stated why it is urgent to reduce the use of antibiotics in aquaculture and why phytogenic additives are the better choice.

And finally, Dr Eckel's Muhammad Umar introduced Anta®Phyt, a phytogenic champion from the Dr Eckel product portfolio, and its possible applications. He also presented compelling trial results demonstrating its effectiveness.

Veterinarian and entrepreneur Dr Forouzandeh Boroujerdi from Mavicarno Co. Ltd in Iran corroborated this with evidence of her own, acquired from her experience of using Dr. Eckel's product Anta®Phyt in poultry.

Dr Viktor Eckel concludes the series of talks with a presentation on the company's product portfolio, present and future, in terms of phytogenic additives.

The well-debated concluding discussion reaffirmed the topicality of phytogenics. Both the participants and the speakers examined the most promising solutions and exchanged practical experiences.

They agreed that, in addition to the technical information, the exchange between the various countries and regions was particularly valuable. All at the World Tour conference came to the unanimous conclusion that it is only through production methods that make the most efficient use of resources and promote healthy animal production that we will manage to produce sufficient healthy food in the future.

Indeed, the path to successful, profitable and sustainable production is through the efficient use of resources, while that to optimal performance is through a focus on animal welfare and healthy animals with a strong immune system, combined with a holistic approach to management. This is the only way to secure the future of animal nutrition. And phytogenic additives are the key to this.

Conference host Andreas Lewke thanked all the participants and speakers for their valuable contributions and the overall success of the event. The World Tour 2022 will proceed to Surabaya in Indonesia, São Paulo in Brazil and, just before EuroTier, Braunschweig in Germany.

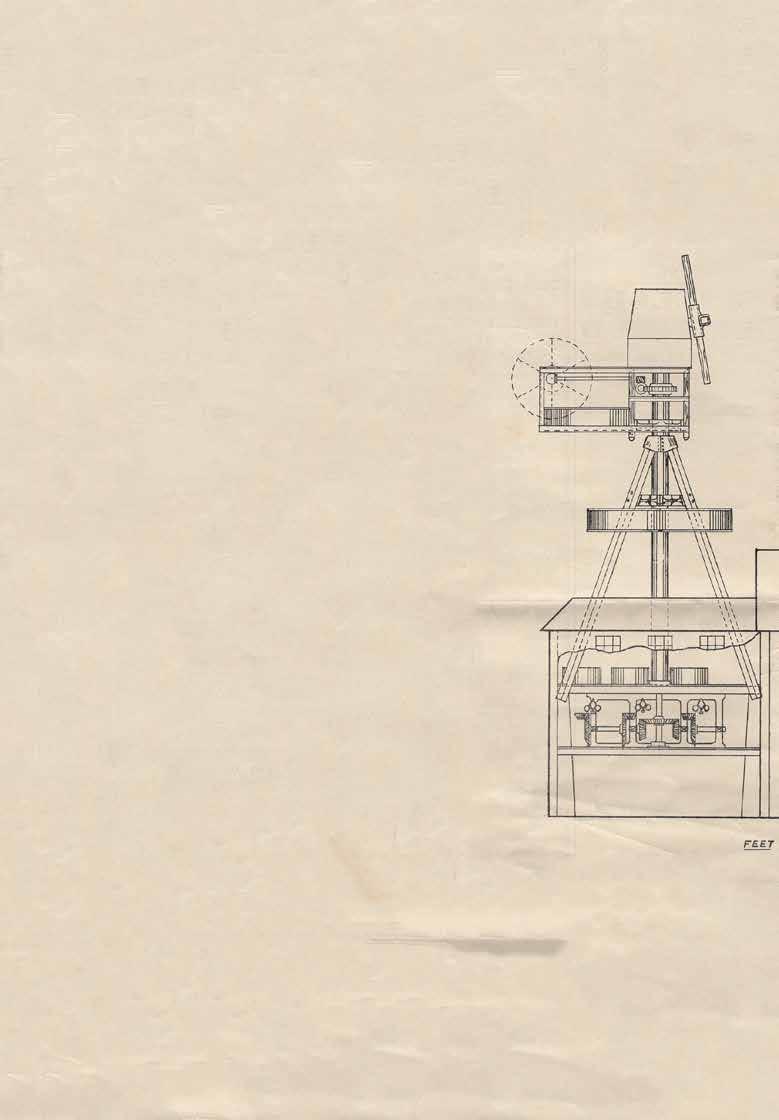

The Royal Burgh of Stranraer, Wigtownshire in Scotland is situated at the head of Loch Ryan, where it has a safe and spacious harbour. At the time of this article (MILLING magazine, June 18, 1938) the writer commented on the strategic importance of it as a seaplane base on seeing a squadron of giant, triple engine bombers riding at anchor next to the more peaceful traffic of the daily service of passenger steamers to their destination of Larne in Northern Ireland.

On the western shore of the Loch stood the white walled mill of Messrs R&A Hannay Ltd, which blended in with its

surroundings. The Hannays were famous in Scottish milling history, and although the Stranraer mill had been in their hands since 1845, it was by no means their oldest property.

The oatmeal mill at Corswall, five or six miles from Stranraer, was acquired by the family in 1820 and even at that time the Hannays had a record of several centuries as millers behind them.

The commercial firm of AH Hannay was founded in 1870 by the brothers Robert and Alexander and in 1911 became a limited liability company. The firm did not have all smooth sailing as in 1899 the mill was burnt down and had to be built almost completely.

Originally the oatmeal mill traded in feeding stuffs and

gradually increased this from year to year until in 1937 it was decided to extend this side of the business. In that year a new provender section was built, equipped with the most modern lines.

At the same time, it was decided to provide new motive power, as the steam engine provided insufficient horsepower to drive both the existing oatmeal mill and the proposed provender plant.

George Porteus & Sons of Leeds were asked to submit their ideas. Steam, electricity and crude oil were all considered; calculations as to working cost and efficiency were given and, in the end, electricity took preference for economy and cleanliness of operation.

This, along with the erection of the new mill was entrusted to Mr Porteus. The new provender mill was brought into operation in August 1937.

The district surrounding Stranraer was ideal for provender milling. It had a famous dairying centre and almost adjoining the mill was a modern creamery. The mill was ideally situated for receiving grain supplies, as oats could be obtained from local farmers, while barley, maize, peas etc, could be brought easily from Glasgow or Belfast.

The new extension to the mill consisted of four well-lit and spacious floors, the outer walls were painted white to conform with the older building. Entering the mill via the loading bay one encountered an intake elevator capable of dealing with seven and a half tons per hour, and adjacent to this was a five-tonne mixer and molassing plant for the manufacture of balanced rations.

In a special fireproof bay stood the ‘Porteus No 4’ grinder, a massive machine that would deal with two tonnes of maize per

hour, driven by a 65hp engine. The product of the grinder was blown up to a cyclone extending from the fourth to the third floor and was bagged off on the first floor.

On the first floor was the Porteus patent feeder for the grinder,

Mirrored in Loch Ryan

which together with the measurers below the four bins, worm etc, was driven by a 3hp motor. The whole layout appeared ingenious as well as space saving.

Near the feed was the oat and pea roll fed from its own bin, and not far away was the ‘Porteus No 2’ cereal cutter, which had a capacity of 30cwts per hour and driven by a 20hp motor on the floor above.

Sacking was carried out near the machine itself. Standing apart from the other machines on the first floor was the Porteus cubing machine, having a capacity of two tonnes of cubes or one ton of poultry pellets per hour. Cubes and pellets came out of the machine with a polished appearance that impressed customers.

On the second floor was the cooler and service bin as well as the meal mixer with all the cubing accessories driven by one motor. The cooler extended to this floor from the one above.

As every provender miller knew, cooling was one of the most difficult problems of the cubing process, but Mr Porteus solved it. When the cubes left the machine, they were cool, and no bags were to be seen steaming, as was the case in some plants.

The fourth floor was laid out neatly with the tops of the meal mixer, service bin and cooler with the appropriate elevators, also the fan for the cooler and the sieve for the dressing of the final cubes. Near the stair head was the top of the grinder cyclone, with its calico sleeve etc.

The main portion of the floor was occupied by the upper portion of the storage bins which were neatly varnished. There were five

bins each capable of storing 20 tonnes of grain and in addition there was a smaller service bin feeding the oat and pea roll. It was said that what struck the visitor most was the absence from every floor of unnecessary spouting and conveyors, and the compactness of each unit saving considerable space.

Mr Porteus had provided a provender plant that would compare favourably with anything similar in the kingdom. Beside the original produce of oatmeal and flaked oats they produced and sent out, they could now add to their already wide range of cereal meals and balanced rations a complete range of cubes and pellets to their large circle of customers, which extended throughout the southwest of Scotland.

These new products were regarded as adding a fresh lustre to the house of Hannay, already an honoured name.

www.millsarchive.org

Egyptian wheat growers have this year supplied the government with an unprecedented 4.2 million tonnes of wheat, amounting to half of Egypt’s wheat production this year.

Minister of Supply and Internal Trade Ali Moselhi said that the quantity of wheat sold by the farmers to the government this year reflected the growers’ positive response to the better price offered by the government this year for wheat.

It is the first time that Egypt has collected more than four million tonnes of local wheat, said Chairman of the State-run General Company for Silos and Storage Kamal Hashim.

The local wheat supply has increased from 3.5 million tonnes in 2021 to 4.2 million tonnes this year, boosting the strategic wheat reserves to cover local consumption until January 2023 according to official statements. The increase, according to the Ministry of Agriculture, is a result of increasing the amount of land devoted to wheat cultivation by more than 400,000 feddans.

Mr Moselhi had told the Senate last May that Egypt is doing its best to achieve greater self-sufficiency in wheat production, aiming, “to meet 65 percent of domestic needs by 2024.”

The Supply Minister said that Egypt needs to import five million tonnes of wheat for the fiscal year 2022/23. The country had imported 5.5 million tonnes of wheat in 2021, he said, a huge drop from 12.8 million tonnes of wheat imported in 2020.

Egypt is working to diversify its wheat imports which had primarily come from Ukraine and Russia before the current war.

Egypt is in its latest round of talks to buy wheat by direct purchase, traders said, a system the government has said can provide more attractive prices since the Ukraine war disrupted grain markets.

Egypt’s state grains buyer, the General Authority for Supply Commodities (GASC), held private talks with at least three suppliers, the traders said.

They said Egypt was believed to have bought 120,000 tonnes of Russian wheat via direct talks.

Egypt, one of the world’s biggest wheat importers, has not

issued international purchasing tenders since it canceled one in mid-July.

The country has opted instead to buy around 1.5 million tonnes of wheat through private direct talks with global companies.

Egypt’s government has sought to diversify both origins for wheat supplies and purchasing options following Russia’s invasion of Ukraine in February, which disrupted grain markets and cast uncertainty over exports via the Black Sea.

In May, the cabinet approved purchases of global wheat supplies through direct offers from companies or governments sent to its state grains buyer GASC, in an effort to boost its wheat reserves.

Those include an outstanding agreement to purchase wheat from India.

Egypt’s current wheat reserves stand at around seven months, according to the supply ministry.

In times of uncertainty, “we can obtain better prices and conditions compared to when there are global tenders,” Supply Minister Ali Moselhy told Reuters at a news conference.

Private talks allow for price negotiations to go on for days instead of hours, he said. “When the markets are stable, there’s no difference,” adding that price trends would not determine whether the government used tenders or direct talks.

Direct deals also allow the government more flexibility to buy in smaller quantities, said Mohammed El Gammal, a Cairo-based grains consultant for the U.N. Food and Agriculture Organisation.

The shift to direct purchases has unsettled some traders. Unlike a tender where bids are submitted and announced on the same day, the supply ministry can request or accept bids at any point, and it does not reveal offer details such as prices and suppliers.

“Any time prices are falling suppliers can offer that lower price to GASC, without having to wait for the tender day,” one trader said.

A second trader said direct talks might give the government more leverage in negotiations, and that it might be trying to gauge market prices or get lower prices by not showing its hand as a buyer.

“They’re still in crisis mode despite having secured a significant amount of forwarding and spot purchases,” said a third trader.

BEHN+ BATES

Two companies, Evonik and BASF, have entered into an agreement, which will grant Evonik certain non-exclusive licensing rights to Opteinics™ - BASF’s digital solution to increase understanding and reduce the environmental footprint of the feed and animal protein industries.

Evonik integrates the digital ready-to-use sustainability platform Opteinics into its global feed consultancy services. Combining Evonik’s innovative farm management tools and sustainability services with BASF's digital sustainability solution Opteinics will help customers to produce more sustainable feed and animal protein.

Launched by BASF in 2021 to measure, analyse and minimise the environmental impact of animal protein, with an emphasis on animal feed production, Opteinics is a software solution. Currently the software offers modules for pig and poultry production and can be integrated with feed formulation software.

Opteinics for pork has recently been fully verified to conform with the ISO 14040 and 14044 LCA standards as well as with the UN Food & Agriculture Organization Livestock Environmental Assessment & Performance (LEAP) partnership guidelines. Applications for the dairy value chain and for the optimisation of compound feed mixtures will follow soon.

With the use of BASF’s software package, Evonik can even better support the livestock industry to make significant progress in fighting climate change, safeguarding ecosystems, and ensuring health and wellbeing as it works to achieve sustainable food production.

“BASF has over 25 years of expertise in life cycle assessment,” says Manuel Rez, Director Global Product Management Performance Ingredients & Solutions and Marketing BASF Animal Nutrition.

“Based on our profound knowledge in sustainability improvement, we have independently developed Opteinics. With Evonik, we have a strong partner to make it a preferred and leading solution as a digital sustainability platform for the global feed industry,” he adds.

“We are incorporating BASF’s ready-to-use software Opteinics into our comprehensive sustainability solutions for customers,” explains Dr Stefan Mack, head of Service Marketing at Evonik's Animal Nutrition business line. “Along with Evonik’s global sustainability feed consulting services, it will help to deliver expert knowledge, built on decades of expertise, research, and extensive data.”

BASF and Evonik are already targeting further developments in digital sustainability offerings as they both aim to help the animal production sector become more sustainable.

by Amanda Knight, Volunteer, Rex Wailes Collection, Mills Archive, UK

by Amanda Knight, Volunteer, Rex Wailes Collection, Mills Archive, UK

A quest to begin a new career as an Archivist led me to seek some hands-on experience at an accredited archive before embarking on the recommended qualifications; and who better to ask than the Mills Archive?

Happily, running true to form as a recipient of the prestigious Queens Award for Voluntary Service, the team at the Mills Archive kindly welcomed me aboard as a volunteer in September 2021 and since then I have spent much of my time in digitising and cataloguing images from the Rex Wailes Collection.

Rex Wailes’ extensive collection of images of French windmills arrived on my desk in a small, unassuming but weighty, cardboard box. Inside were 52 neatly labelled envelopes containing a vast array of prints, negatives, drawings and postcards of more than 50 French windmills.

Most of these seem to have been taken by Wailes himself on trips to France in 1928, 1938 and 1950. The principal regions covered are in Northern France (Finistère, Pas-deCalais, Nord), the southern-most windmill featured being the Moulin de Rochoux at Bouée, Loire-Atlantique.

The Collection features many superb images of both the exteriors and interiors of post mills, tower mills, drainage and smock mills and it is difficult for me to pick out one particularly beautiful mill or interesting approach to their construction or operation over any other.

However, certain details seemed to stand out to Mr Wailes; the Archimedian screws deployed in the area’s drainage mills feature heavily as do the cap and sails of the small tower mills in the Finistère region.

Another striking aspect of the Collection stems from Rex Wailes’ trip to France in August 1950 where firm friendships were struck between Mr Wailes and his wife, Enid, and two French-Flanders milling families - the Vercruyce family at Moulin du Nord post mill at Hondschoote, Nord, and the family of Abel and Lucie Deschodt whose post mill was at Wormhout, Nord.

Warm-hearted Christmas cards from the Deschodt family continued to be sent to Rex and Enid Wailes throughout the 1950s. The last featured in the Collection remarked, “the sails still turn.” This was in December 1959 but sadly, the mill ceased the production of flour just four years later, with Mr Deschodt gifting the mill to the municipality of Wormhout just one year before his death in 1967.

The mill has since been restored and is open to visitors.

There seems to be a tendency in these parts of Northern France to name the mill after the resident miller. For example, Moulin Deschodt was formerly known as Moulin Briarde.

This nomenclature may make locating them for the purposes of indexing slightly challenging, particularly where the mills in question have since been demolished. But surely the most intriguingly named must be the Moulin De l’Ingratitude, a seemingly innocuous looking post mill at Boeschepe, Nord but with a tale perhaps worth investigating!

Designed to give you an in-depth review of the process of making petfoods, a brand new course from the team at Progressus Agrischools is set to take place between October 27 and December 22, 2022.

Created in association with Milling and Grain magazine, the course’s rigorous and in-depth program provides a simplified guide to the complex world of petfood and treat production.

This includes discussions relating to overall plant design, equipment used in production and advancements of designs, as well as seminars that describe what the most used ingredients are and how they are changing.

This information is to be presented alongside discussions on quality testing, storage, preparation for use and traceability, as well as batching, mixing, weighing both the dry and possibly wet ingredients used in modern day petfoods.

There are many different ways of petfood production but the major method, extrusion cooking, is discussed comprehensively – with preconditioning and extruder barrel design discussions.

The discharge end of the extruder yields the shape and has an influence on the product itself is reviewed with discussion on possible situations that develop and how to correct these.

Dryers, both vertical and horizontal are also reviewed with explanation of the value of accurate drying and how these devices are becoming more energy aware including possible solutions to drying issues.

The various coating methods reviewed will also include accuracy discussions and the importance of cooling before packing, as well as final product review, packaging and storage round out this comprehensive course on petfood production.

If you have an interest in petfood production from the point of view of owning a company, working in a production facility, or a supplier to the industry who wishes to know more about the process, then this course will get you started in the right direction.

This program is also designed as a review for those in the industry who wish to learn what is new and the direction that future developments in petfood production are headed.

To find out more, be sure to visit the Petfood Schools’ website at: https://mymag.info/e/1664

The American Feed Industry Association (AFIA), in coordination with Feedstuffs, has opened the application phase for its Premix/ Ingredient Feed Facility of the Year (FFY) program. The program is open to all AFIA member premix/ingredient feed manufacturing facilities.

“Participating in the FFY program can be incredibly valuable for facilities," says Gary Huddleston, AFIA's director of feed manufacturing and regulatory affairs. "Participating facilities receive an individual report on how their facility measures against other facilities within the category. In addition, it gives members an opportunity to show off their dedication to safety and efficiency."

The AFIA has been recognising excellent feed manufacturing facilities since 1985. In 2016, the AFIA created four distinct manufacturing categories to be more inclusive of the various industry facilities.

In 2021, the FFY program separated each category into its own individual program: liquid feed, commercial dry, premix/ ingredient, and integrator, with each category having its own facility of the year award.

The application phase for the Premix/Ingredient Feed Facility of the Year is now open and submissions, with the US$100 application fee, are due by November 11, 2022. The winning facility will be recognised on March 8, 2023, at the AFIA's 2023 Purchasing and Ingredient Suppliers Conference in Orlando, Florida.

The winning plant manager will receive overnight accommodations and a free registration to the conference.

By utilising parallel-shaft twin screws, the Magnum ST Series extruders by Wenger are ideal for unique processes that require extreme operating parameters including higher torque at lower speeds for extreme processes.

In every edition of Milling and Grain magazine,

to taking a look at the products

save you

time and money in the food and feed milling process.

you have a new product or service

feature on this page

to contact

a

The horizontal ribbon mixers are highly efficient batch mixers which can mix with accuracy in a very short period. The mixer consists of a ‘tulip’-shaped mixing and a shaft with mixing spirals. The ribbons move the materials in opposite direction. The geometric design guarantees an intensive mixing process with a low rotation speed. This results in an accuracy of 1:100.000 in a mixing time cap of three-to-four minutes.

Special attention has been paid to hygienic aspects. Connections inside the machine are smooth to prevent pollution and cross contamination. The construction of the shaft with the bars that hold the spirals is done with an absolute minimum of welding, avoiding clamps with external bolts for hygiene reasons.

Ribbon mixers has safety lockers and a pneumatic outlet side for dosed output. It has an average mixing time of 180-240 seconds and is consumes low energy.

The palletizer - Series 500 / 1000 GRIP palletises bags that need to be overlapped on the layer. Therefore, it is especially suitable for palletising difficult-tohandle bags that are not very full or contain extremely fluid products. The filled bags are handled one-by-one by a robotic gripping arm and deposited on a double false pallet. The completed layer is squared before being placed onto the pallet. Each layer is then pressed individually. The position of the bags is determined automatically depending on the pallet size, the bag dimensions and the chosen palletising pattern. This series offers two models for working rates of 300 to 1200 bags/h.

Its user-friendly machine operation with integrated touch screen and the software with automatic pallet calculation. It is also equipped with a reliable full bag take-over by the full bag gripper equipped with special aligning plates.

The Magnum ST Series is especially suited for applications with extreme product viscosities, processes requiring high SME inputs, continuous physical and chemical reactions dispersive mixing applications.

The Magnum ST Series is ideal for applications requiring high torque at low extruder shaft speeds and for jobs that require increased rate potential, where rate is dependent on SME and shaft speed. Unique to Wenger extruders, the overhead rail system permits operators to conveniently add process tools or remove extruder barrel components without heavy lifting or the need for additional equipment. The rail system also supports the hood, knife and additional options for cleaner floor space and greater durability.

The Holmen NHP300 is a fully automatic pellet durability test used for calculating the pellet durability index (PDI) of animal feed pellets, by simulating the transportation environment from mill to trough.

The NHP300 automatically extracts and tests samples from a busy production line and displays the results in the NHP300 Windows control software, or alternatively in your existing mill management system. After the test, samples can be returned to the production line or discharged into a waste container without operator intervention.

By testing pellets during the production process, near real time results can be used to help maintain the quality of output, by adjusting the mills settings at a time that will save energy and minimise waste.

Fitted as standard with a 2.5mm diameter perforated hopper, the NHP300 is ideal for testing pellets with a diameter of between 3 and 12mm.

Satake’s latest high specification Optical Sorter “Nirami” is designed to efficiently sort a wide range of products.

Newly designed optics detect and distinguish subtle colour differences utilising RGB full colour cameras and with the addition of optional infrared (IR) cameras, inorganic foreign material is also rejected. It also incorporates shape recognition technology to sort the material by shape, such as broken or adhered, which conventional colour sorters could not achieve. Its new responsive reject ejection system and Satake's latest image processing technology guarantees the maximum product purity with minimum loss of good material.

NIRAMI has been designed with an open frame which allows for easy cleaning to prevent cross contamination and convenient access for maintenance, whilst Satake’s unique 3S software allows for simple intuitive set up and adjustment to maximise performance, profitability and fast return on investment.

Industrial vibration pioneer’s breast cancer campaign expands to its Cougar DC Truck Vibrator or Cougar THD Hydraulic Vibrator conveyor products

One of the pioneers in industrial vibration and bulk material handling technologies is announcing this year's annual program to support breast cancer education, screening, treatment and research around the world.

Continuing its commitment during National Breast Cancer Awareness Month in the US, Martin Engineering invites customers to 'Go Pink!' For the month of October, along with replacing the traditional Martin orange paint scheme on truck vibrators, the company will add the option of conveyor guarding, Twist Tensioners and inspection doors to Go Pink as well. This is to honour all those affected by the deadly disease which has touched so many Martin employees and their families. By merely saying, 'Make mine pink' when purchasing the company's popular Cougar DC Truck Vibrator or Cougar THD Hydraulic Vibrator, Martin Engineering will donate a portion of its sales revenue to support the Susan G Komen® Foundation.

Along with the colour change, the equipment retains the same high-quality standards. Discharging heavy and often compacted material from dump trucks, hopper rail cars, and other vehicles can require a lot of vibration power in a punishing environment putting high demands on equipment. Operators choose Cougar DC Truck Vibrators and Cougar THD Hydraulic Vibrators to replace OEM vibrators that tend to have a limited service life.

Reliable and durable truck vibrators like the DC and THD reduce manual labour and downtime while ensuring the safe evacuation of cargo. Faster unloading increases the number of trips by operators, improves efficiency and reduces the cost of operation.

To further boost awareness, all the Cougar DC Truck Vibrators or Cougar THD Hydraulic Vibrators ordered in October will be painted pink unless orange is requested. In addition, conveyor guarding, twist tensioners and inspection doors will also be included as items customers can choose to order in the pink colour scheme.

The conveyor guards protect workers from the hazards of a working conveyor. Twist Tensioners ensure that conveyor cleaner blades stay in proper contact with the belt to adequately discharge and clean adhered material from the surface.

Inspection doors are attached to sealed chutes

and enclosures that contain dust and spillage, allowing workers to safely view bulk handling operations. These items are prominent exterior components that, when made pink, commemorate lost loved ones and remind people of the ongoing battle against breast cancer.

With more than 70 years of experience, when they talk about the fact that the company commands a global presence in 19 countries on six continents, with customers in dozens of industries at Martin Engineering, these are more than just numbers.

These figures mean that, no matter what your particular challenge is, Martin Engineering has probably seen it many, many times and already know how to fix it.

So, whether it’s material clogging the discharge port of a container or railcar, or a fugitive dust issue you can’t seem to get under control, its experts will be able to provide a solution.

If you’re shutting down way too often because material is sticking to the belt past the head pulley, they know exactly what to do. In fact, no company has seen and solved more problems in this industry than Martin Engineering has.

To find out more about what Martin Engineering can do for you, visit the company’s website at: https://mymag.info/e/1663

A group of milling professionals tour a Premier Tech manufacturing facility in Belgium: Here’s what they saw

by Roger Gilbert, Publisher, Milling and Grain, UK

by Roger Gilbert, Publisher, Milling and Grain, UK

In late June 2022, Premier Tech of The Netherlands extended an invitation to UK flour millers, and members of the London and Southeast Milling Society, to visit its manufacturing facilities near Eindhoven for a two-day tour along with a visit to the installation of a packaging unit at a flour mill in Belgium.

Mr Stefan Schut, the Managing Director of Client Solutions for Premier Tech Systems and Automation’s operation for Europe, Middle East and Africa, hosted the visit along with his Management and Sales Assistant Brigit Baudoin and Sales Manager Luke Thomas.

Milling and Grain was privileged to be invited, and to learn not only about the most recent developments in packaging, but also about the history of Premier Tech, its equipment and the future of packaging and palletising.

As Mr Schut pointed out to attendees, 2022 is the penultimate year in Premier Tech’s soon-to-be-celebrated 100 years of business in 2023. Worldwide, the company is going from strength to strength and achieved an 11.5 percent growth in turnover to break the CAD $1 billion mark in 2022 over 2021.

Supporting the company’s global achievements are the different brands that now form the backbone of Premier Tech and have served the milling industry over many decades.

Mr Schut also highlighted Premier Tech’s vision to “Feed, Protect and Improve our World.”

That being said, packaging for the flour and feed

Premier Tech’s headquarters at Eersel near Eindhoven in The Netherlands Bringing the work of the two factories together, plus locally-produced components, impressed the group of UK millers Enjoying the visit: From top (L-R) Tuti Tan, Brigit Boudoin and Nick Lucken; Claire Williams, Gerry Falvey and Alex Vaks; Tim Hall, Nick Hinton, Ian Christie; Diana Ferns, Andrew Bourne, Daren Wade and Roger Gilbert; Paul Messenger, Dave Ferns and Alex Williams; Richard Lunzer and Luke Thomasmilling industries is only one area of focus within the Premier Tech Systems and Automations business group. Further, Systems and Automation is one of five other business groups that make up the company, a Canadian-based business that includes Growers and Consumers, Water and Environment, Digital, and Life Sciences.

Within Premier Tech Systems and Automation, Mr Schut specified that Premier Tech provides net weigh scales, baggers, palletisers and stretch wrappers for automated packaging lines that can handle a whole range of seeds and crops. Premier Tech also provides packaging solutions for flour, feed, meats, dairy foods, fruits and vegetables and other products including spices, barley malt, rice, pastas, cookies, and bakery mixes, to names a few. They also direct some of their company focus to organics, chemicals and minerals. Their expertise seems endless.

Naturally, the 25-strong group was interested to gain insight into the manufacturing of bagging equipment for the flour milling industry, and how the equipment they may use in the future is designed and assembled. They were also eager to

Premier Tech’s engineering plant at Hapert, also located near Eindhoven in The Netherlands

Mr Stefan Schut, Managing Director of Client Solutions for Premier Tech Systems and Automation outlines the history of the company

UK flour millers from the London and Southeast Milling Society pass a word of thanks to Premier Tech and the team, which hosted a farewell lunch

The group of UK flour millers enjoy the atmosphere and banter during the introductory talk at Premier Tech’s headquarters in The Netherlands

Premier Tech’s engineering plant at Hapert, also located near Eindhoven in The Netherlands

Mr Stefan Schut, Managing Director of Client Solutions for Premier Tech Systems and Automation outlines the history of the company

UK flour millers from the London and Southeast Milling Society pass a word of thanks to Premier Tech and the team, which hosted a farewell lunch

The group of UK flour millers enjoy the atmosphere and banter during the introductory talk at Premier Tech’s headquarters in The Netherlands

see for themselves the kinds of innovation offered through digital solutions that will make packaging more reliable and efficient in future mills.

A walk through the assembly facility at the Eersel headquarters near Eindhoven allowed the group to see the best in production line operations and provided an opportunity to explore each area of the assembly process. The following day, the group visited the company’s second factory at Hapert, where much of the engineering work is carried out.

Alongside the latest in packaging equipment and technology, the group also had a chance to witness how Premier Tech actively refurbishes older machines, including a 30-year-old Chronos Richardson machine which will be returned to service in a flour mill and hopefully continue operating for another 30 years.

A brief discussion emerged around the sustainability of refurbishing older equipment that cannot support newer “smart” technologies versus modern “smart” machines that are potentially more productive and energy efficient in the long run.

It must be said that the flour milling industry has a reputation of maintaining equipment well so that it can provide reliable service, often 24/7, without requiring replacement. However, the industry will eventually have to address questions of new technology as the pressure on production prices increases and competition encourages the uptake of newer, smarter and more efficient machinery.

On the second day, the group was also invited to visit the flour milling company of Paniflower, Brabomills at Westkaai near Antwerp, Belgium and on the river Merksemburg, to view the installation of Premier Tech’s latest packaging machine, a project which involved retrofitting into an older mill building.

This project showcased a twin-bagging unit that can process a range of bag sizes and has the unique function of filling bags from the bottom up, eliminating dust and ensuring smooth and fast filling.

Seeing the automated bagging equipment in operation was mesmerizing, as a special feature of this system is the bottom filling of bags to avoid dust emission and improve throughput. The complete system is automated all the way through to palletising and shrink wrapping at the Paniflower Mill, Brabomills at Westkaai, Antwerp in Belgium

Deliveries of wheat and dispatches of flour are a continuous routine in this traditional mill in the Paniflower Mill, Brabomills at Westkaai, Antwerp in Belgium

Seeing the automated bagging equipment in operation was mesmerizing, as a special feature of this system is the bottom filling of bags to avoid dust emission and improve throughput. The complete system is automated all the way through to palletising and shrink wrapping at the Paniflower Mill, Brabomills at Westkaai, Antwerp in Belgium

Deliveries of wheat and dispatches of flour are a continuous routine in this traditional mill in the Paniflower Mill, Brabomills at Westkaai, Antwerp in Belgium

The animal feed production industry’s top priority is to produce healthy, highquality and ethical products to ensure that poultry, fish and other livestock are well-nurtured. However, it is also under increased pressure to improve the cost-efficiency, safety, sustainability and overall productivity of its processes.

This concern has been heightened by an ongoing supply chain crisis which has resulted in a global shortage of grains and oilseeds. It has added even greater urgency to make existing animal feed production processes as efficient as possible, with minimum wastage. The rise in oil and gas prices, along with labour shortages, has also produced an additional squeeze on costs for businesses.

Furthermore, the actual production process for animal feed – whether that’s chicken feed for poultry farms or fish feed for aquaculture – typically involves the use of various industrial machines required to run optimally at all times. These could include hammer mills, extruders, mixers, and conveyors, depending on the specific type of feed.

These applications are primarily controlled by motors, drives, and programmable logic controllers (PLCs), the selection of which is critical for several reasons.

Motors often have unique and demanding requirements in segments such as animal feed production. Reliability and 24/7 operation are critical to ensure a steady production environment in all conditions while responsibly using raw materials and energy.

Crucially, animal feed production must be a carefully controlled, precise process to provide the right quality and mix of food for animals and avoid unnecessary wastage.

Whether or not these production processes can be performed optimally depends on how well the motors and drives control the machines. With growing pressure on farms and the wider food

supply chain, these motors and drives must also be as robust and reliable as possible, avoiding unnecessary downtime that could disrupt operations.

Digitised methods such as remote condition monitoring – the practice of using sensors and software to monitor equipment performance – are also business-critical. Disrupting machines for maintenance is troublesome when considering the cost implications of asset downtime, labour, and spare parts, not to mention the contamination risks when opening up a machine for repairs mid-cycle.

By providing real-time data that shows fluctuating asset behavior, condition monitoring tools make it possible to perform predictive maintenance. Once the erratic behavior exceeds the accepted, user-defined norms for the asset, the plant leaders and maintenance personnel receive an alert through the monitoring platform, which allows them to act before a problem becomes acute.

This approach eliminates the waste typically associated with unnecessary routine maintenance checks.

Animal feed production can be very energy-intensive and expensive, especially with the increasing costs of energy. It is, therefore, in the best interest of production companies to fully optimise the energy usage of their heavy machine applications.

Deploying a condition monitoring solution can also provide real-time data on energy usage. This allows an operator to make manual adjustments or add a PLC (such as ABB’s AC500) to make automatic adjustments to reduce energy consumption and cut costs.

Further, electric motors will typically run at full speed all the time, regardless of the particular demands of the process, which wastes energy. Pairing motors with variable speed drives (VSDs) can automatically adjust the motor’s speed and torque to match demand.

Swiss-based UFA’s Sursee poultry feed mill is one of only a few unmanned feed mills in the world, running from 9pm until 5am

every day without any operating personnel. The plant’s production is overseen by only one mechanical engineer.

Until 2015, the mill used an aspiration ventilator with a conventional 75-kilowatt (kW) induction motor directly coupled to the power grid and operating at a fixed speed. While the ventilation system was considered advanced when it was installed in the 1980s, it was time for a replacement.

Having read about a hospital ventilation system that uses synchronous reluctance motor (SynRM) technology, the engineer was impressed with the high energy efficiency of these motors. On his advice, UFA decided to invest in the same motors for the feed mill’s new ventilation plant.

ABB installed a 37 kW SynRM motor to power the new aspiration ventilator, controlled by an ACS880 variable speed drive. Combining the latest ventilation and motor-drive technology resulted in a 50 percent drop in power consumption and a considerable reduction in CO2 emissions. As a result, the drive package paid for itself quickly.

Animal feed production is critical for all animals in the food supply chain, as livestock safety is paramount. Animal feed must be nutritious and free of contaminants so that food products are safe for human consumption.

The quality of animal feed is also highly regulated. It’s possible to address all these safety concerns by ensuring that different animal feed applications run as safely and efficiently as possible, using the right drives, motors and services. Moreover, when these applications work correctly, it also minimizes the chance of accidents that endanger people working at production facilities or on farms.

Balancing the need for hygiene with the need for productivity and reliability is a challenge. However, new developments in electric motor technology are helping animal feed production facilities to meet hygiene standards while still achieving maximum uptime.

Yet drives, motors, PLCs, and service all play a vital part. Therefore, specifying the best equipment for each environment is essential in ensuring optimised, reliable, and efficient production.

is one of the most used grains around the world following corn and soybeans. It is a critical plant as it is the oldest, cheapest and multipurpose crop which is mostly used to make flour. To get wheat flour, the wheat grain needs to be grinding up in flour. Then it comes three main parts – endosperm, germ and bran parts that contain protein, vitamin and fibre parts, respectively, with endosperm used to make white flour.

On the other hand, brown flour is made from germ and bran

Wheatparts. The last one is the whole grain flour that includes all three parts together: endosperm, germ and bran parts and is considered to be the healthiest version of the wheat flour. Wheat is mostly separated into different types by seasons.

Moreover, it can be hard or soft depending on how much protein it contains. You can notice easily from its colours as light golden colour is soft and has less gluten but wheat in bronze colour is the hard type of wheat and contains more gluten.

Wheat flour is widely used as an ingredient to make bread, pasta, baked goods, pancakes, thicken sauces, coating foods and many others. It is the main type of food that feeds people all over the world but now we are facing a shortage of it from the pandemic, war and climate change.

In this article, we gather information about reasons behind the

shortage of wheat, learn more about the brown rice flour and the comparison between wheat flour and brown rice flour.

More than 80 percent of exporters of wheat around the world, Russia and Ukraine are in the top five. In 2020, the world's largest wheat exporters are Russia, USA, Canada, France, Ukraine, Australia, Argentina and Germany. Russia ranked in the first with 37.3 million tonnes while Ukraine made 18.1 million tonnes of wheat exporting. In fact, only seven countries get a fair share of 86 percent of wheat exporting.

As the conflict between them is still going on, it affects the shortage of wheat especially for countries in North Africa, the Middle East, and Asia such as Egypt, Indonesia, Bangladesh, Turkey, and Yemen. Producing wheat flour is even more challenging as sanctions on Russia are affected by inflated energy prices and fertilisers are even more pricey. Apart from the war since February 2022, this wheat shortage is also the result of climate change due to heatwaves and dryness and the pandemic as well.

As a result, exporting is disrupted, food prices are rising, and poverty is increasing all over the world. Because of this, people are worried about the security of food and start to think about what we can use as a substitute for wheat? Thereafter rice is coming on the way as another option.

Wheat flour is used widely in the bakery and food industries. The process to make wheat flour uses a dry milling method. So, wheat grain does not require to be cleaned in the first stage. Moreover, the dry milling system has no control with the high temperature at the

end of the line. Thus, this type of process can cause impurities mixed up in the product or even include toxins along the process.

Brown rice grains are in the transforming process by soaking in pure water as good as the quality of drinking water. This process is to separate impurities through the drainage system before feeding to the milling process.

The key factor for the drying process of brown rice flour is to bake it at the suitable high temperature to kill the bacteria and disinfect. At the end of the line production will be the finest brown rice grain as a premium wellness product.

Brown rice can be used as a substitute for wheat among many other types of crops. It is a type of grain that contains lots of fibre and is also gluten free. It can be processed as brown rice flour and used to bake as well.

It also has fibre, calcium and protein that benefit your health. People can just use brown rice flour to bake both cake and other types of baked food. Brown rice flour works best in bread, muffins and cookies.

This is also a type of flour that is derived from brown rice can help to reduce the risk of some diseases. It has phenolic acids that have the potential to reduce obesity and cancer in some cases as such acids contain chemo-preventative properties for breast and colon cancers.

Another pro is that brown rice flour through a wet milling method contains no unhealthy fats. whole grains reduce the risk of coronary heart disease and cardiovascular disease as its ability to lower cholesterol. It will also make your digestive process better as it contains high fibre. With all of this coming together, this type of grain can also assist with weight dieting in some cases.

In summary, the key difference between wheat flour and brown rice flour is that brown rice flour is gluten-free while wheat flour contains it. Many people have problems with gluten, with gluten being a wheat protein that can cause an allergic reaction as it irritates the digestive system.

Brown rice flour can definitely be a good substitute as it can be used as the main type of ingredients for westerners and Asians which are bread, pasta, rice and noodle. If wheat shortage really becomes a problem in the future, at least we have an alternative for it there.

In today’s world, nutritionists and developers in food technology are researching and developing brown rice flour by wet milling method in terms of rheology by deforming of the viscosity, starching the stabilisation and improving the variety of recipes for using brown rice flour as a substitution of wheat flour in bakery and food industries. On top of that, the consumers can get the benefits from this kind of premium wellness product as well.

- It is a premium wellness product.

- Brown rice flour from the whole brown rice grain contains lots of properties and nutritious ingredients including bran, fibre, fat, carbs, protein, sugar, high calories but low sodium.

- Brown rice flour in the wet milling method makes the finest size of brown rice flour in 150 microns which has soft and high-quality texture.

Feed is constantly being researched, improved and changed. Supplements are being added and removed. Choosing the right feed and supplements for your animals can be difficult when there are various factors to consider and multiple options to choose from.

Algae, along with macroalgae and microalgae, are some of the many types of feed supplements available that farmers are turning towards as it holds numerous positive benefits.

Researchers are still looking into the many properties that algae offer in terms of feed, and with the thousands of strands of algae and microalgae that we already know of, different types of algae provide differing benefits from each other.

Farmers have choices in which strand of algae they prefer, depending on the costs, sustainability, and health benefits they provide to poultry, livestock, and aquaculture.

With various types of algae to trial and experiment, research has shown the benefits that algae provide and that individual strands can provide more properties in specific areas that others can’t or are easier to obtain through financial or sustainable means.

With over 36million tonnes produced and farmed in 2020, 30 percent of microalgal biomass is presently sold for animal feed. Farmers and researchers want to find the best algae to use as feed along with as many benefits it can provide, all while trying to be as sustainable and cost-efficient as possible.

With over 30,000 types of algae, including both microalgae and macroalgae, research has found that different strands can provide targeted benefits as supplements. Macroalgae is one of two types of algae, visible to the naked eye, it is a large and multicellular marine organism that resembles plants in the sea. They are commonly referred to as seaweed. Microalgae are microscopic organisms that are mainly unicellular and cannot be seen with the naked eye. Chlorella and phytoplankton are the

most well-known microalgae and are among the most used. The most known and used types of algae in feed are seaweed, spirulina, and chlorella. Spirulina is known for its ability to boost the immune system and chlorella for its ability to purify and detox the body. More research for both algae is required still to determine their full effectiveness but these are the most popularly used in feed.

Seaweed has three general classifications; brown, red and green seaweed, and each has thousands of their own species within each classification and their own specialities. Brown seaweed is generally the largest seaweed and is usually identified by the population as kelp and found along beach coasts. Red seaweed is found deeper in the ocean and green in marine or fresh waters.

Also, unlike most land-based fibres, seaweeds ferment more readily as they have negligible lignin which enhances the probiotics in the gut.

There is an increasing need for protein to be added to feed and the costs are rising. Algae is one of the growing solutions for this problem, due to it being a less costly source of protein than others. Growing in popularity, many farmers are turning to algae as a supplementary feed source due to its high quantities of vitamins, minerals, proteins and carotenoids. It is also a source of antioxidants, fibre, lipids, carbs and more.

Algae is a natural alternative free from metals, contaminants, pesticides and microbes, making it an increasing interest for the farmers who are interested in an uncontaminated and chemicalfree diet.

Additionally, algae contain an immense amount of other key nutrients such as omega-3 fatty acids (docosahexaenoic [DHA] and eicosapentaenoic [EPA]) or also known as polyunsaturated fatty acids or PUFAs), lutein, zeaxanthin, protein and more.

PUFAs, or polyunsaturated fatty acids, are essential in an animals feed as they are what helps with ensuring the growth and

proper brain development needed in livestock and poultry.

Key PUFAs are omega-3, omega-6, linoleic and linolenic. The fatty acid in the feed can affect the fatty acid composition of the tissues of animals fed the feed. This can positively affect the meat and eggs in poultry and tissues, milk and embryo development in pigs. Furthermore, PUFAs can increase reproductive performance in livestock and poultry.

Unfortunately, the accumulation of PUFAs inside meat and milk means that they can affect the flavour and quality along with an increased risk of oxidation. The increase in oxidation can affect the routine processing procedures of meat. This can, however, be slowed down using antioxidants, tocopherols and carotenoids. This can fortify the meat and minimise the lipid oxidation, enhance PUFA absorption while maintaining its concentration during storage, and preserving the colour of the meat.

All the nutrients that the various types of algae provide encourage a variety of physical benefits in the livestock, swine and poultry. Some may be more obvious than others, but they all help to provide a better profit-to-cost ratio. The benefits can also vary with it being the produce from the animals to the animals themselves that glean the nutrients that the algae supplements offer.

For the produce, things such as flavour, quality and amount increase regarding the milk, eggs and meat. For the animals themselves, the effects are both internal and external. Some of these external effects are the improvements of the skin, coat, oral hygiene, and weight of the animals. The skin, coat and oral hygiene all become healthier while the weight increases.

For the internal benefits, there are many. From reduced

cholesterol levels, to improved gut and intestinal health and functioning. The nutrients provided by the algae also help to activate probiotics in the gut and boost the immune system, helping the livestock and poultry create a stronger resistance to disease through antiviral and antibacterial action.

by Precious Adedayo Adesina, International Management Office, Satake, Japan.

by Precious Adedayo Adesina, International Management Office, Satake, Japan.

‘Measure twice, cut once’ is an old adage that encourages a manufacturer to take great care in order to avoid wastage of material or time.

This approach can be applied to food manufacturing because taking measurements, such as weight, volume, flow rate etc, is crucial to monitoring the production process, ensuring quality management and preventing losses due to defectives, over processing or under processing.