14 A Sneak Peek at the 245th Meeting

26 Heavy-Duty Transportation in 10 Charts

49 Electrolysis in Chloride Molten Salts for Sustainable Critical Metals Production and Recovery

55 Electrochemical Gas Separation for Green Energy Integration

14 A Sneak Peek at the 245th Meeting

26 Heavy-Duty Transportation in 10 Charts

49 Electrolysis in Chloride Molten Salts for Sustainable Critical Metals Production and Recovery

55 Electrochemical Gas Separation for Green Energy Integration

ECS, a prestigious nonprofit professional society, has led the world in electrochemistry, solid state science and technology and allied subjects since 1902, providing a rigorous and high-quality home for the whole community.

ECS is dedicated to moving science forward by empowering researchers globally to leave their mark on science. The Society connects a diverse and representative constituency of members and nonmembers to accelerate scientific discovery, facilitate the engagement of an inclusive network, and champion the dissemination of research to support a sustainable future.

For more information on becoming a member, or publishing in ECS publications, visit electrochem.org

We’ll see you at the 245th ECS Meeting May 26th through May 30th and ECS PRiME October 6th through October 11th.

LEADING ENERGY CONVERSION AND STORAGE TECHNOLOGIES SINCE 1980

Fuel Cell Test | Electrolyzer Test | Membrane Conductivity Test | Redox Flow Cell Test

Continuity is a goal for all organizations. Successful organizations are built in such a way that their excellence is maintained over the long term, from generation to generation. ECS is a great example; its divisional and editorial board structures have provided robust mechanisms for continuity for over 120 years. A succession plan (or lack thereof) is so key that TV series have been made about it (one with the ingenious title Succession). Organizations that are successful over multiple generations are those that can handle such planning well, whether by luck or by science. Organizations that do not handle this aspect well may be spectacular while their founder/star is involved, but the Grim Reaper remains undefeated. At that point, the organization drifts and eventually fades away. I am sure you can think of a couple that fit the latter description.

In academia, there is another layer of intrigue which is the requirement that a department’s faculty and dean of the school agree on how to “replace” someone who is retiring. In the US, there is no mandatory retirement age, so succession planning can be a little uncomfortable for all involved. Seniority carries a lot of weight, whether it should or not, and department chairs generally avoid conversations like, “So, Mike, we have been colleagues for 25 years. Not to seem like we are putting you out to pasture, but if we did, what kind of pasture would be your favorite? And when can you pack up your office?” Faculty themselves can be grumpy about the topic as well (grumpy faculty, shocking, I know). We are in the enviable position of being paid to do something we love (generally). Why should we leave? In most cases, faculty want the department to continue to have active research in their area as it is the most important topic anyone could work on (obviously). But faculty positions are like gold. As I have noted in previous columns, in the research arena, departments are like groups of independent small businesses. Thus, when a faculty position opens there is often intense jockeying to either maintain an area of research, strengthen a different area, move the department into a new research direction, or to move the position to another department at the dean’s fancy.

My department has been thinking about this topic a lot because we have faculty who make up our Silver Seven, as I lovingly call my six colleagues and me. We are faculty that (trying to be polite here) are a lot closer to the end than the beginning of our careers to put it mildly. Our corrosion/electrochemistry group is well represented in that seven. The ongoing importance of our fields, the established infrastructure, and the health of the research enterprise here were compelling arguments for hiring replacements in the same general area, although the $50 bribes paid to some faculty probably helped. Glenn Stoner established our group 50 years ago, and he implemented a succession plan, one that would have been successful if only it hadn’t included John Scully and me. Part of that plan was to expand the research focus from only applied electrochemistry to corrosion. Now, 30 years later, we need to consider what’s next, although we have the help of Beth Opila and her outstanding high-temperature oxidation work and reputation. It is a daunting task, but an exciting one as well. The position is using a broad definition of “harsh environments” which will complicate the selection, but also provide the most opportunities for the next generation of research in our group.

By the time you read this missive, we should be well into the process, I expect/hope. One tenet of any hiring is that one should “hire better than you are.” The cruel among you (looking at you, E. J. Taylor) are already thinking how easy that would be in my case. We also believe that some overlap between when the new faculty member starts and when the mature faculty exits has tremendous benefits to the new faculty member’s academic career. Overlap requires good luck and a supportive department chair, faculty, and dean. Those seem to be in place here. That said, we are keeping our fingers crossed (which makes typing a lot harder), because as the great philosopher and heavyweight boxer Mike Tyson said, “Everybody has a plan until you get punched in the face.” Wish us luck.

Until next time, be safe and happy.

Rob Kelly Editor

Rob Kelly Editor

Published by:

The Electrochemical Society (ECS) 65 South Main Street Pennington, NJ 08534-2839, USA Tel 609.737.1902, Fax 609.737.2743 www.electrochem.org

Editor: Rob Kelly

Guest Editors: Christopher G. Arges and Hui Xu

Contributing Editors: Christopher L. Alexander, Christopher G. Arges, Scott Cushing, Ahmet Kusolgu, Donald Pile, Alice Suroviec

Director of Publications: Adrian Plummer

Director of Community Engagement: Shannon Reed

Production Editor: Kara McArthur

Graphic Design & Print Production Manager: Dinia Agrawala

Staff Contributors: Frances Chaves, Genevieve Goldy, Mary Hojlo, Christopher J. Jannuzzi, John Lewis, Anna Olsen, Jennifer Ortiz, Francesca Di Palo, Jennifer Tarantino, JaneAnn Wormann, Fern Oram

Advisory Board: Brett Lucht (Battery Division)

Dev Chidambaram (Corrosion Division) Uroš Cvelbar (Dielectric Science and Technology Division)

Luca Magagnin (Electrodeposition Division)

Qiliang Li (Electronics and Photonics Division) Katherine Ayers (Energy Technology Division)

Cortney Kreller (High-Temperature Energy, Materials, & Processes Division)

Maria Inman (Industrial Electrochemistry and Electrochemical Engineering Division)

Eugeniusz Zych (Luminescence and Display Materials Division)

Jeff Blackburn (Nanocarbons Division)

Shelley Minteer (Organic and Biological Electrochemistry Division)

Stephen Paddison (Physical and Analytical Electrochemistry Division)

Larry Nagahara (Sensor Division)

Publications Subcommittee Chair: James Fenton

Society Officers: Gerardine Botte, President; Colm O’Dwyer, Senior Vice President; James (Jim) Fenton, 2nd Vice President; Francis D’Souza, 3rd Vice President; Marca Doeff, Secretary; Elizabeth J. Podlaha-Murphy, Treasurer; Christopher J. Jannuzzi, Executive Director & CEO

Statements and opinions given in The Electrochemical Society Interface are those of the contributors, and ECS assumes no responsibility for them.

Authorization to photocopy any article for internal or personal use beyond the fair use provisions of the Copyright Act of 1976 is granted by The Electrochemical Society to libraries and other users registered with the Copyright Clearance Center (CCC). Copying for other than internal or personal use without express permission of ECS is prohibited. The CCC Code for The Electrochemical Society Interface is 1064-8208/92.

ISSN : Print: 1064-8208 Online: 1944-8783

The Electrochemical Society Interface is published quarterly by The Electrochemical Society (ECS), at 65 South Main Street, Pennington, NJ 08534-2839 USA. Subscription to members is part of membership service. © Copyright 2024 by The Electrochemical Society. *“Save as otherwise expressly stated.”

The Electrochemical Society is an educational, nonprofit 501(c)(3) organization with more than 8,500 scientists and engineers in over 75 countries worldwide who hold individual membership. Founded in 1902, the Society has a long tradition in advancing the theory and practice of electrochemical and solid state science by dissemination of information through its publications and international meetings.

https://orcid.org/0000-0002-7354-0978

41 26

by Ahmet Kusoglu42

by Christopher G. Arges and Hui Xu

The

Christopher49

G. Arges Electrolysis

55

by Ben Holcombe, Nicholas Sinclair, Alexander Baker, Eunjeong Kim, Scott K. McCall, and Rohan Akolkar

Electrochemical

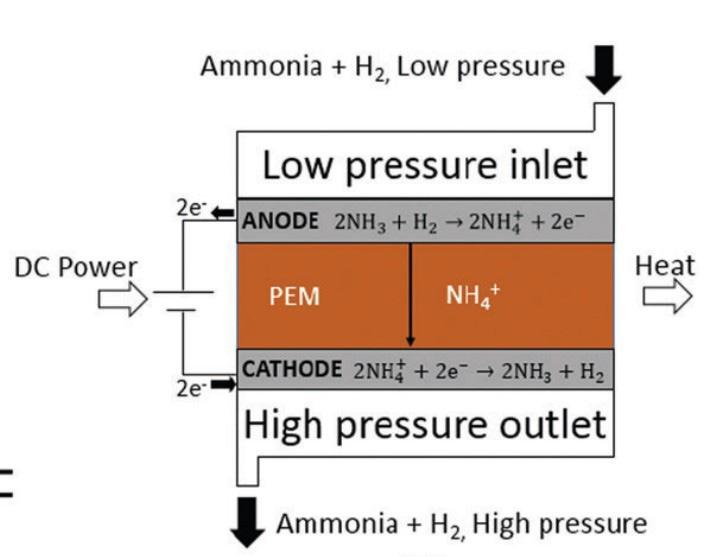

byThomas Stracensky and Hui Xu

3

7

10

14

17

33

ello friends! Welcome to the first Interface edition of the new year.

As I write, we have just finished reviewing the initial round of 245th ECS Meeting abstract submissions. As we have seen with every meeting since the COVID “blip,” the ECS community continues to grow, attracting new and more diverse members, reaching new constituents, and expanding the products, programs, and services we offer in support of ECS’s mission. With more than 3,000 manuscripts accepted already (even before accepting late submissions!), the 245th ECS Meeting from May 26th to 30th in San Francisco will be our largest spring meeting, breaking the record set in Boston last spring.

This is an incredibly encouraging and inspiring indication of the value the larger technical community places on engaging with ECS, especially considering the tumultuous times and myriad disruptions we navigated in recent years. It is wonderful to see that ECS is stronger for what we have endured together.

We have great momentum behind us, and I would like to discuss efforts we have launched to build on that momentum and advance two initiatives ECS President Gerardine Botte outlined in the previous edition of Interface—Sustainability and Diversity.

On the Sustainability front, we are helping advance green transportation technologies and address a critical labor shortage in the battery industry. To that end, I am excited to announce that later this year we will launch our new distance learning platform and release our first suite of long-form online courses to provide workforce development training for the battery industry. The courses are:

• Components for Lithium Ion Batteries: Electrolytes, Anodes, and Cathodes: Participants develop a general understanding of the properties and challenges associated with different commercial electrode materials and electrolytes and learn about materials characterization techniques for electrode materials and electrolytes.

• Electrochemical Techniques and Diagnostics for Batteries: Basic electrochemical testing techniques and diagnostic methods for commercial lithium ion batteries are covered.

• Fabrication of Batteries and Pack Design: General methods for the preparation of laminate electrodes, electrode stacking/winding, and pack construction are reviewed. Participants also develop a general understanding of commercial laminate electrode preparation and the challenges associated with electrode stacking and winding processes.

Each course is a self-directed, online learning experience, featuring 20–25 hours of instruction, with various levels of assessment given throughout the course. The initial set of courses is geared to those with existing technical expertise in an adjacent technology (materials science, physics, chemistry,… etc.) who want to re-skill for work in the burgeoning battery industry.

The teams developing these courses have worked hard since early last summer to create the content and assessments. Concurrently, ECS staff partnered with instructional design experts to launch ECS’s first-ever Learning Management System (LMS), which will integrate seamlessly with the ECS website and the accounts of ECS members and constituents enrolled in these courses. Stay on the lookout for more information on the platform’s beta launch later this spring.

To help meet our Diversity goals, the “Redefining ECS Membership” project was launched last year. The ECS Board of Directors is working with the Individual Membership Committee chaired by E. J. Taylor to develop new, lowercost options for joining the ECS community. The team’s final recommendations will be submitted for review by the Board in advance of the May meeting. In the meantime, some great news: ECS membership has now grown beyond pre-pandemic levels! “Redefining ECS Membership” will extend that growth trajectory, finding new audiences by lowering barriers to engagement with the Society.

An important aspect of our Diversity effort is establishing new ECS Student Chapters to help develop and nurture the new generation of scientists and researchers in our field. We have already experienced phenomenal results through this effort. A new chapter recently launched at the Universidad Autónoma de Nuevo León in Mexico, joining new chapters at universities in India, Singapore, Thailand, and the Republic of Korea. With these new additions, ECS has more than 130 student chapters around the globe!

And of course, we look forward to seeing you at our meetings in 2024. The spring meeting in San Francisco is already shaping up to be an amazing event. In October, we convene PRiME 2024 with our partners, The Electrochemical Society of Japan (ECSJ) and The Korean Electrochemical Society (KECS), in person in Hawaii for the first time in eight years! Since we last met there in person in 2016, our field and respective societies have experienced incredible growth. The 2024 conference promises to be the largest single gathering in our 122-year history. Don’t miss being part of this historic event! Click here to learn more and submit your work before the April 12th PRiME 2024 abstract submission deadline.

Last, I want to extend my thanks and gratitude to the entire ECS community. The ECS HQ team and I are incredibly honored to serve this organization. We look forward to joining with you in 2024 and beyond to advance the ECS mission around the world!

See you soon!

Christopher J. Jannuzzi ECS Executive Director/Chief Executive Officer https://orcid.org/0000-0002-7293-7404

Christopher J. Jannuzzi ECS Executive Director/Chief Executive Officer https://orcid.org/0000-0002-7293-7404

For data-driven decisions you can trust

OBSERVATION EXPLANATION SOLUTION

The system is not linear

Decrease the perturbation amplitude of the input signal

The system is not stationary

Increase the rest period before the EIS measurement

The output signal is too small

Increase the perturbation amplitude of the input signal

Electrochemical Impedance Spectroscopy provides valuable data on redox processes, which can lead to significant advances in science and industry.

However, acquiring this data can be complex, even for seasoned experts. EIS QI helps you to find the delicate balance between linearity (THD) and noise (NSR) and ensures you know exactly how long to wait for a stable system (NSD).

Biologic’s quality indicators streamline and validate impedance experiments, ensuring you get the data you need.

Only BioLogic allows you to get quantitative feedback for your Electrochemical Impedance Spectroscopy data. QI

Our members’ crucial role in addressing global challenges such as climate change, renewable energy, connectivity, and pandemics became increasingly clear in 2023. As the leading society in solid state and electrochemical science, we take pride in fulfilling our urgent mission and in empowering members at the forefront of discovery amid ongoing global uncertainties. Key 2023 achievements include:

• Convening scientists at all career stages— from academia, industry, and governmental organizations—at ECS meetings designed to drive research, discovery, and collaboration;

• Promoting global awareness of our science and technology;

• Supporting and nurturing future leaders and recognizing rising stars in electrochemical and solid state science via ECS Student Chapters and awards;

• Expanding ECS’s global membership;

• Expanding traditional journal offerings and fostering open access for faster scientific progress;

• Strengthening diversity and inclusion through the ECS Presidential Ad Hoc Committee on Diversity, Equity, Inclusion, and Engagement;

• Increasing our international presence post-pandemic with meetings in Europe and leadership visits to Asia and Mexico; and

• Achieving strong financial results to sustain these initiatives.

We invite you to join us in 2024 for the 245th ECS Meeting in San Francisco (May 26–30), and PRiME 2024 in Honolulu (October 6–11), and submit your work to the ECS Family of Journals, which have been delivering peer-reviewed excellence since 1902.

• More than 8,000 members strong and a return to pre-pandemic membership levels.

• The 2,690 student members is the largest number of student members ever!

• Representing 13 new Student Chapters in India, Mexico, Republic of Korea, Singapore, Thailand, and the United States, these students now bring their passion for the Society and electrochemistry and solid state science to their local student bodies.

+12.2%

• The 2023 ECS Class of Fellows welcomed 15 new members: Martin Bazant, Jeffrey Blackburn, Teruhisa Horita, Ajit Khosla, Po-Tsun Liu, Robert Mantz, Nazario Martín, John Muldoon, Mikael Östling, Bryan Pivovar, Minhua Shao, Peter Strasser, Alice Suroviec, Chunsheng Wang, and Bilge Yildiz

• With the addition of two 2023–2024 ECS Toyota Young Investigator Fellows, the Society’s partnership with the Toyota Research Institute of North America has, since its inception, provided more than $1.5M in research funding to 30 young investigators.

• The ECS Mid-America Section reestablished the Ernest B. Yeager Electrochemistry Award (previously offered by the ECS Cleveland Section), recognizing significant contributions to fundamental electrochemical science and engineering and distinguished careers as educators/researchers in Indiana, Illinois, Ohio, and Kentucky. 2023 2023 2023 2023

• Linda L. Horton, Associate Director of Science for Basic Energy Sciences (BES), US Department of Energy (DOE) Office of Science (SC), delivered the ECS Lecture at the meeting’s plenary session.

• For the first time since 2011, the 243rd ECS Meeting was co-located with SOFC-XVIII. Their day-long plenary session featured talks by David Tew, ARPA-E; William Gibbons, DOE EERE; Shailesh Vora, DOE; Mirela Atanasiu, Clean Hydrogen Partnership; Yosuke Fujii, NEDO; and Rak-Hyun Song, KIER.

• Zhenan Bao, K. K. Lee Professor of Chemical Engineering, Stanford University, delivered the ECS Lecture at the meeting’s plenary session.

• A special seminar, Young Researchers in Europe, highlighted the work of up-and-coming scientists, provided funding information, and fostered crossborder collaboration.

• Meeting attendees showed off their poetry, singing, and performance chops at a new and unique event, It Could be Verse: An Evening of Poetry and More

• Eliminated barriers to scientific progress by doubling transformative and read-and-publish agreements globally, enabling authors to access content behind paywalls and publish open-access without fees.

• Expanded our pool of qualified peer reviewers through training and education opportunities and designed new ways to encourage authors to choose ECS as their publication home.

• Attracted new reviewers dedicated to the ECS mission, equipped with ECS and IOP Peer Review Excellence training and certification.

• Maintained a digital library with record-breaking download and readership metrics.

The ECS Continuing Education program continues to grow to meet and support the needs of the community, offering webinars, short courses, and professional development opportunities. ECS also announced efforts to launch battery workforce development coursework, focused on three initial courses set to launch in 2024:

• Components for Lithium Ion Batteries

• Electrochemical Techniques and Diagnostics for Batteries

• Fabrication of Batteries and Pack Design

Articles and abstracts downloaded from the ECS Digital Library: 9,015,249

Journal articles published in the 2023 volume year: 1,763

Total Short Course registrants: 79

Percentage of articles published open access in 2023: 35%

# of open access papers published: 614

Webinars: 10

Participants: 5,274

Speakers: 10

Short Courses: 4

Professional development workshops: 7

Professional development workshop registrants: 325

oin your peers at this international conference where scientists, engineers, and researchers from academia, industry, and government laboratories gather at this unique interdisciplinary forum to share electrochemical and solid state science and technology research and issues. Absorb and exchange information on the latest scientific developments and related topics through oral presentations, poster sessions, panel discussions, tutorial sessions, short courses, professional development workshops, exhibits, and more!

Start planning now for these technical and networking opportunities:

• Five days of technical programming across 48 symposia;

• More than 3,000 abstracts;

• More than 2,250 oral presentations, including 575 invited talks by the world’s leading experts;

• More than 700 posters over three evening poster sessions;

• 14 hours of exhibit hall time over three days;

• Daily morning and afternoon coffee breaks;

• Complimentary WiFi in meeting rooms;

• Special program for nontechnical registrants.

San Francisco captivates visitors with its unique blend of iconic landmarks, cultural richness, and natural beauty. This vibrant and diverse city is renowned for its distinct neighborhoods, each with its own charm and character. From Chinatown’s historic streets to Union Square’s trendy boutiques, the city provides a wide range of experiences. Visitors can wander through Golden Gate Park’s scenic landscapes or explore notorious Alcatraz Island. San Fran’s culinary scene is also a major draw, with a plethora of world-class restaurants showcasing a variety of cuisines. Whether it’s the iconic cable cars, vibrant arts scene, or welcoming atmosphere, San Francisco promises travelers memorable and enriching experiences.

Monday, May 27

“What MXenes Can Do for Efficient Generation, Storage, and Conversion of Electrical Energy”

Yury Gogotsi, A. J. Drexel Nanomaterials Institute and Department of Materials Science and Engineering, Drexel University

Yury Gogotsi is Distinguished University Professor and Charles T. and Ruth M. Bach Endowed Chair in the Department of Materials Science and Engineering at Drexel University. Together with his students and colleagues, he has made principal contributions to the development of materials for electrochemical capacitors and other energy storage devices, discovered MXenes and polygonal nanotubes (graphite polyhedral crystals), demonstrated the tuning of structure and porosity of carbide-derived carbons, and developed new processes for the synthesis, surface modification, and purification of nanotubes and nanodiamonds. He also serves as Director of the A. J. Drexel Nanomaterials Institute. He received his MS (1984) and PhD (1986) from Kyiv Polytechnic and a DSc degree from the National Academy of Sciences of Ukraine in 1995. Prof. Gogotsi is a Fellow of the Electrochemical Society. With an h-index of over 200, he has been recognized as a Highly Cited Researcher in Materials Science and Chemistry, and a Citations Laureate in Physics by Clarivate Analytics (Web of Science). His lecture will describe the synthesis, structure, and chemistry of 2D carbides and nitrides known as MXenes, as well as their electrochemical applications, with a focus on the generation, storage, and conversion of electrical energy.

(Consult the meeting app for times.)

Society Award-Winning Speakers

Uziel Landau, Case Western Reserve University

Henry B. Linford Award for Distinguished Teaching

Daniel Lincot, Centre national de la recherche scientifique (CNRS)

Vittorio de Nora Award

Division Award-Winning Speakers

Xiang Gao, University of North Carolina at Charlotte Battery Division Postdoctoral Associate Research Award sponsored by MTI Corporation and the Jiang Family Foundation

Peter Mascher, McMaster University Dielectric Science & Technology Thomas Callinan Award

Travis Anderson, US Naval Research Laboratory Electronics and Photonics Division Award

Noor Ul Hassan, National Renewable Energy Laboratory

Energy Technology Division Graduate Student Award sponsored by BioLogic

Maha Yusuf, Princeton University

Energy Technology Division Graduate Student Award sponsored by BioLogic

William Mustain, University of South Carolina Energy Technology Division Research Award

Nikolay Kornienko, Institut für Anorganische Chemie, Universität Bonn Energy Technology Division Supramaniam Srinivasan Young Investigator Award

Yirui Zhang, Stanford University

Industrial Electrochemistry and Electrochemical Engineering

Division H. H. Dow Memorial Student Achievement Award

Deepra Bhattacharya, GE Vernova

Industrial Electrochemistry and Electrochemical Engineering

Division Student Achievement Award

R. Bruce Weisman, Rice University

Nanocarbons Division Richard E. Smalley Research Award

Delphine Bouilly, Université de Montréal Nanocarbons Division SES Research Young Investigator Award

Stefano Cinti, Università degli Studi di Napoli Federico II Sensor Division Early Career Award

Yaoli Zhao, University at Buffalo Sensor Division Student Research Award

Sunday, May 26

ECS Short Courses are all-day classes designed to provide students and seasoned professionals with in-depth education on a wide range of topics. These small classes taught by academic and industry experts offer personalized instruction and help novices and experts advance their technical expertise and knowledge.

An Integrated Approach to Chemical Mechanical Planarization Technology Advances

Basim Bahar and Jason Keleher, Instructors

Basic Impedance Spectroscopy

Mark Orazem, Instructor

Fundamental and Modern Technological Aspects of Electrodeposition for Material Processing Sudipta Roy, Instructor

Introduction to Lithium Ion Batteries

David Hall and Chock Karuppaiah, Instructors

(Check the meeting app for times.)

ECS provides professional development opportunities at its biannual meetings—including workshops and professional panels as well as career resources. They are targeted to students, early career researchers, and experienced professionals.

Mentoring Session

Facilitator: Alice Suroviec, Berry College

Peer Reviewer Excellence Certification Workshop

Instructors: Paul Cooper, The Electrochemical Society, and Jessica MacDonald, IOP Publishing

Essential Elements for Employment Success

Instructor: Michel Fouré, Berkeley Grant Writing, LLC

Resume Review

Instructor: Michel Fouré, Berkeley Grant Writing, LLC

Strategic Tools for a Successful Career

Instructor: Michel Fouré, Berkeley Grant Writing, LLC

Win Funding: How to Write a Competitive Proposal

Instructor: Michel Fouré, Berkeley Grant Writing, LLC

(Consult the meeting app for times.)

Opening Reception

Get a taste of San Francisco and kick off an exciting week! All attendees are welcome to enjoy light snacks, open bar, ample networking time, and a chance to meet with ECS division members.

ECS members are invited to join us for food, drinks, giveaways, and light entertainment. Jump-start the meeting with ECS community members before the Opening Reception. Register now, as only 400 tickets are available!

Wrap up the meeting’s first full day with friends and peers. Students and early-career professionals mingle in a relaxed setting and enjoy light hors d’oeuvres and refreshments.

Annual Society Business Meeting and Luncheon*

Join us as to celebrate 2023’s many successes and look ahead to an even brighter future!

With hundreds of posters to explore, don’t miss a minute of these sessions. Grab a snack, wander the aisles, review presentations, talk to authors, and get to know our exhibitors. These sessions are a great way to end the day!

Take time to explore electrochemistry and solid science’s leading vendors’ exhibits. Then stop by the exhibit hall for Poster Sessions, Networking Breaks, complimentary Professional Portraits, and the ECS Booth.

Many ECS divisions and meeting symposia host social events (receptions, banquets, luncheons, and more!) throughout the week. Be sure to check the online program for these opportunities to socialize and network with your peers!

*These events require pre-registration or purchase of a separate ticket.

A Batteries and Energy Storage

A01 New Approaches and Advances in Electrochemical Energy Systems: In Memory of Sri Narayan

Ayyakkannu Manivannan, Brett L. Lucht, Loraine Torres Castro, Chockkalingam Karuppaiah, Ratnakumar V. Bugga Energy Technology Division; Battery Division; Industrial Electrochemistry and Electrochemical Engineering Division

A02 Lithium Ion Batteries

Kang Xu, Jie Xiao, Shirley Meng

Battery Division

A03 Large Scale Energy Storage 15

Daniel Steingart, Joshua Gallaway, Nian Liu, Jacob Spendelow, Ertan Agar

Battery Division; Energy Technology Division

A04 Battery Material Scale-up and Manufacturing

Dongping Lu, Neil Dasgupta, Jagjit Nanda, Fang Dai Battery Division

A05 Battery Student Slam 8

Feng Lin, Chixia Tian Battery Division

B Carbon Nanostructures and Devices

B01 Carbon Nanostructures for Energy Conversion and Storage

Andrew Ferguson, Kyu-Young Park, Uroš Cvelbar, Jeff L. Blackburn, Avetik Harutyunyan, Chunsheng Wang

Nanocarbons Division; Battery Division; Dielectric Science and Technology Division

B02 Carbon Nanostructures in Medicine and Biology

Delphine Bouilly, Ardemis Boghossian, Tatiana Da Ros, Markita Landry, Jeffrey Halpern, Mekki Bayachou, Jessica Koehne, Anton Naumov, Nicole Iverson, Noe Alvarez, Daniel Heller

Nanocarbons Division; Organic and Biological Electrochemistry Division

B03 Carbon Nanotubes - From Fundamentals to Devices

Ming Zheng, R. Bruce Weisman, Slava Rotkin, Shigeo Maruyama, Yan Li, Benjamin Scott Flavel, Yutaka Ohno, Emilio Perez, YuHuang Wang

Nanocarbons Division

B04 NANO in India

Slava Rotkin, Francis D’Souza, Anunay Samanta, K. George Thomas, Angshuman Nag

Nanocarbons Division

B05 Fullerenes - Endohedral Fullerenes and Molecular Carbon, in Memory of Bob Curl

Yoko Yamakoshi, Alan Balch, Francis D’Souza, Luis Echegoyen, Dirk Guldi, Nazario Martín, Steven Stevenson, Shangfeng Yang, Akimitsu Narita, Uroš Cvelbar

Nanocarbons Division

B06 2D Layered Materials from Fundamental Science to Applications

Michael Scott Arnold, Uroš Cvelbar, Slava Rotkin, Yaw Obeng, Stefan De Gendt, Zia Karim, Stephen E. Creager, Elisa Miller-Link, Richard Martel

Nanocarbons Division; Dielectric Science and Technology Division

B07 Light Energy Conversion with Metal Halide Perovskites, Inorganic/Organic Hybrid Materials, and Dynamic Exciton

Hiroshi Imahori, Kei Murakoshi, Tsukasa Torimoto, Mahesh

Hariharan, Zhiqun Lin, Prashant Kamat

Nanocarbons Division

B08 Porphyrins, Phthalocyanines, and Supramolecular Assemblies

Nathalie Solladie, Karl Kadish, Tomas Torres, Roberto Paolesse, Norbert Jux, Ãngela Sastre-Santos

Nanocarbons Division

B09 Nano for Industry

R. Bruce Weisman, Dan Wang, Thorsten Lill, Oana Leonte, David Estrada, Mark Hersam, Slava Rotkin

Nanocarbons Division; Dielectric Science and Technology Division; Industrial Electrochemistry and Electrochemical Engineering Division

B10 On-Surface Synthesis of Carbon Nanomaterials

Nazario Martín, Hiroshi Imahori, David Ecija, Wilhelm Auwarter

Nanocarbons Division

C Corrosion Science and Technology

C01 Corrosion General Session

Dev Chidambaram, Eiji Tada

Corrosion Division

D Dielectric Science and Materials

D01 Chemical Mechanical Polishing 17

Bahar Basim, Yaw Obeng, Vimal Chaitanya, Robert Rhoades, Gautam Banerjee, Jason Keleher

Dielectric Science and Technology Division

D02 Dielectrics for Nanosystems 10: Materials Science, Processing, Reliability, and Manufacturing

Durgamadhab Misra, Toyohiro Chikyow, Dong-Kyun Ko, Yaw Obeng, Zhi Chen, Daniel Bauza, Kay Song

Dielectric Science and Technology Division

D03 Nanoscale Luminescent Materials 8

Peter Mascher, Dong-Kyun Ko, David Lockwood, Federico Rosei

Dielectric Science and Technology Division; Electronics and Photonics Division

D04 Quantum Dot Science and Technology 3

Dong-Kyun Ko, Vladimir Svrcek, Soong Ju Oh, Preston Todd Snee, Ivan Marri, Qiliang Li, Danielle Reifsnyder Hickey, Andrew Greytak

Dielectric Science and Technology Division; Electronics and Photonics Division; Nanocarbons Division

D05 Plasma Electrochemistry and Catalysis 3

Davide Mariotti, Uroš Cvelbar, Mohan Sankaran, Mahendra

Sunkara

Dielectric Science and Technology Division; Energy Technology Division

E Electrochemical/Electroless Deposition

E01 Magnetic Materials Processes and Devices 16

Stanko Brankovic, Adriana Ispas, Luca Magagnin Electrodeposition Division

F Electrochemical Engineering

F01 Advances in Industrial Electrochemistry and Electrochemical Engineering

Maria Inman, Elizabeth Biddinger, Paul Kenis

Industrial Electrochemistry and Electrochemical Engineering Division; Electrodeposition Division

F02 Highlighting Startups Pursuing Electrochemical Manufacturing

William Tarpeh, Juan Lopez-Ruiz

Industrial Electrochemistry and Electrochemical Engineering Division; Electrodeposition Division

G Electronic Materials and Processing

G01 G01—Silicon Compatible Emerging Materials, Processes, and Technologies for Advanced CMOS and Post-CMOS Applications

14

Hemanth Jagannathan, Zia Karim, Kuniyuki Kakushima, Paul J. Timans, Evgeni Gousev, Stefan De Gendt, Durgamadhab Misra, Yaw Obeng, Fred Roozeboom

Electronics and Photonics Division; Dielectric Science and Technology Division

G02 Organic Semiconductor Materials, Devices, and Processing 9

Benjamin Iniguez, Jamal Deen, Hagen Klauk, David Gundlach, Zhi Chen, Sunghwan Lee Electronics and Photonics Division

H Electronic and Photonic Devices and Systems

H01 Wide-Bandgap Semiconductor Materials and Devices 25

Qiliang Li, Steve Kilgore, Jennifer Hite, Vidhya Chakrapani, Travis Anderson, Marko Tadjer

Electronics and Photonics Division; Dielectric Science and Technology Division

H02 Solid State Electronics and Photonics in Biology and Medicine 10

Zong-Hong Lin, Yu-Lin Wang, Wenzhuo Wu, Chih-Ting Lin, Toshiya Sakata, Mark Ming-Cheng Cheng, Lluís Marsal, Revathy Padmanabhan

Electronics and Photonics Division

I Fuel Cells, Electrolyzers, and Energy Conversion

I01 Low Temperature Water Electrolysis (LT-WE) for H2

Production 2

Hui Xu, Karen Swider-Lyons, William Mustain, Marcelo Carmo, Svitlana Pylypenko, Shaun Alia, Peter Strasser, Sara Cavaliere, Shigenori Mitsushima, Karel Bouzek, Fan Yang

Energy Technology Division; Industrial Electrochemistry and Electrochemical Engineering Division; Physical and Analytical Electrochemistry Division

I02 Renewable Fuels via Artificial Photosynthesis or Heterocatalysis

10

Nianqiang Nick Wu, Vaidyanathan Subramanian, Ayyakkannu Manivannan, Pawel Kulesza, Frank Osterloh, Bunsho Ohtani, Eric Miller, Gary Wiederrecht, Tianquan Lian, Heli Wang Energy Technology Division; Physical and Analytical Electrochemistry Division; Sensor Division

I03 Materials for Low Temperature Electrochemical Systems 10

Minhua Shao, Gang Wu, Enyuan Hu Energy Technology Division; Battery Division; Physical and Analytical Electrochemistry Division

I04 Electrosynthesis of Fuels 8

Xiao-Dong Zhou, Hui Xu, Huyen Dinh, Gessie Brisard, Dong Ding, Jianhua Tong, Damilola Daramola

High-Temperature Energy, Materials, & Processes Division; Energy Technology Division; Industrial Electrochemistry and Electrochemical Engineering Division

I05 Mechano-Electro-Chemical Coupling in Energy Related Materials and Devices 5

Jason Nicholas, Nicola Perry, Chengcheng Fang

High-Temperature Energy, Materials, & Processes Division; Battery Division

I06 Energy Conversion Based on N, P, and Other Nutrients 3 Lea Winter, Marta Hatzell, William Tarpeh, Gang Wu, Julie Renner, Pawel Kulesza, Damilola Daramola Energy Technology Division; Industrial Electrochemistry and Electrochemical Engineering Division; Physical and Analytical Electrochemistry Division

K Organic and Bioelectrochemistry

K01 Advances in Organic and Biological Electrochemistry: In Memory of Diane Smith

Kevin Moeller, Dan Little, Shelley Minteer, Mekki Bayachou

Organic and Biological Electrochemistry Division

K02 Bioelectrochemistry – From Ions to Proteins to Living Organisms

Sabine Kuss, Lior Sepunaru, Sanela Martic, Sadagopan Krishnan, Alice Suroviec

Organic and Biological Electrochemistry Division; Physical and Analytical Electrochemistry Division

L Physical and Analytical Electrochemistry, Electrocatalysis, and Photoelectrochemistry

L01 Physical and Analytical Electrochemistry, Electrocatalysis, and Photoelectrochemistry General Session

Anne Co, Stephen Paddison

Physical and Analytical Electrochemistry Division

L02 Computational Electrochemistry 9

Stephen Paddison, Yue Qi, Scott Calabrese Barton, Steven DeCaluwe

Physical and Analytical Electrochemistry Division; Energy Technology Division

L03 Electrochemical Studies by Synchrotron Techniques 3

Svitlana Pylypenko, Anne Co, Iryna Zenyuk, Kelsey Stoerzinger

Physical and Analytical Electrochemistry Division; Battery Division; Electrodeposition Division; Energy Technology Division

L05 L05—Electrochemistry at the Nanoscale 2

Plamen Atanassov, Vito Di Noto

Physical and Analytical Electrochemistry Division; Electrodeposition Division; Energy Technology Division

M Sensors

M01 Recent Advances in Sensors Systems 5

Praveen Kumar Sekhar, Jessica Koehne, Aida Ebrahimi, Dongmei Dong, Thiagarajan Soundappan, Larry Nagahara Sensor Division

M02 Printed and Wearable Sensors and Systems

Jessica Koehne, Milton Cordeiro, Lok-kun Tsui, Leyla Soleymani, Milad Navaei, Aida Ebrahimi, Yaw Obeng, Uroš Cvelbar Sensor Division; Dielectric Science and Technology Division; Nanocarbons Division

M03 Sensors for Energy Production, Conversion, and Storage

Dongmei Dong, Rangachary Mukundan, Gary W. Hunter, Praveen Kumar Sekhar, A. Robert Hillman, Kannan Ramaiyan, Milad Navaei Sensor Division; High-Temperature Energy, Materials, & Processes Division

Z General

Z01 General Student Poster Session Alice Suroviec All Divisions

Z02 Education in Electrochemistry 4

Alice Suroviec, Plamen Atanassov, Thomas Fuller, Christopher Arges, Praveen Kumar Sekhar

Physical and Analytical Electrochemistry Division; Battery Division; Corrosion Division; Energy Technology Division; Industrial Electrochemistry and Electrochemical Engineering Division; Sensor Division

Z03 Electrochemical Recovery, Recycling, and Sustainability of Critical and Value Added Materials 2

Chockkalingam Karuppaiah, Natasa Vasiljevic, Zheng Chen, Luca Magagnin, Xiao Su, Santosh Vijapur, Shiqiang Zou, Luis Diaz Aldana, Shuang Andersen, Hojong Kim

Industrial Electrochemistry and Electrochemical Engineering Division; Battery Division; Electrodeposition Division; Energy Technology Division; High-Temperature Energy, Materials, & Processes Division; Interdisciplinary Science and Technology Subcommittee

Z04 Electrochemistry for Chemical Manufacturing 2

Elizabeth Biddinger, Chockkalingam Karuppaiah, Wenzhen Li, René Böttcher, Paul Kenis, Scott Calabrese Barton, Martin Leimbach Industrial Electrochemistry and Electrochemical Engineering Division; Battery Division; Corrosion Division; Electrodeposition Division; Energy Technology Division; Organic and Biological Electrochemistry Division; Interdisciplinary Science and Technology Subcommittee

Z05 Materials, Devices, and Systems for Neuromorphic Computing and Artificial Intelligence Hardware

Durgamadhab Misra, Kuniyuki Kakushima, Revathy Padmanabhan, Vidhya Chakrapani, Jeff L. Blackburn, Gitanjali Kolhatkar, Bilge Yildiz

Dielectric Science and Technology Division; Electronics and Photonics Division; High-Temperature Energy, Materials, & Processes Division; Nanocarbons Division; Interdisciplinary Science and Technology Subcommittee

2023 was another amazing year for ECS Publications—another year of accelerating scientific discovery, championing the dissemination of research, and supporting authors in their goal to leave their mark on the scholarly record.

Readers of the highly cited content published by The Electrochemical Society are located in every continent of the globe, with downloads of our content already exceeding nine million, from Australia, China, the USA, Canada, New Zealand, and countless other nations; connecting their research with authors from 65 nations, including but not limited to Indonesia, Ukraine, Sweden, Germany, Mexico, France, and Canada. We saw growth in the number of citations of this impactful research and are proud to say that the content of our digital library is more than 50% open access!

To our Peer Reviewers: Thank you for taking time out of your busy schedules and lives to share your expertise and feedback

with the prospective authors of our published content. Without our reviewers’ contributions, our editors would not be equipped with the vital feedback necessary for the peer review process. We hope that you will continue to serve ECS and the scientific community in 2024 and, we hope, be among the first to be recognized in our NEW! Peer Review Excellence Recognition Program

To our Editors: Thank you not only for your commitment to the quality and integrity of the ECS publications portfolio but also to the Society’s overall mission. Through your dedicated efforts, ECS is able to further our vision to be the recognized steward of electrochemical and solid-state science and technology by advancing theory and practice. We have reappointed many of our editors in 2024 and have added new esteemed members to our editorial boards to continue to maintain our standard of excellence!

To our Authors: We know that you have options for where you publish your precious work. We are grateful that you chose the ECS family of publications as your publications home. For over 120 years, ECS publications have contributed to the scholarly record as a community publisher and a place where authors—whether they are early career or highly experienced senior scientists—come together to advance scientific research into the future.

Thanks to all of your efforts, ECS continues to be a community publisher of quality content for the members of the electrochemical and solid-state science communities.

Gang Wu

Initial Appointment as Associate Editor for the Journal of The Electrochemical Society Fuel Cells, Electrolyzers, and Energy Conversion topical interest area (TIA) for the term December 1, 2023 –November 30, 2025

Wataru Sugimoto

Initial Appointment as Associate Editor for the Journal of The Electrochemical Society Battery and Energy Storage TIA for the term January 1, 2024 –December 31, 2025

Scott Donne Associate Editor for the Journal of The Electrochemical Society January 1, 2019 –December 31, 2023

Meng Tao Associate Editor for the ECS Journal of Solid State Science and Technology May 1, 2019 – December 31, 2023

The summer issue of Interface is scheduled to hit your mailbox on June 28. It will be guest edited by the Electrodeposition Division's Natasa Vasiljevic and Rohan Akolkar. The summer issue will also feature the new

2024 ECS officers; a chance to meet the new ECS Advances editor-in-chief; and of course Society, division, student, and people news; Looking at Patent Law; and Tech Highlights.

Battery

Brett Lucht, Chair

University of Rhode Island

Jie Xiao, Vice Chair

Jagjit Nanda, Secretary

Xiaolin Li, Treasurer

Doron Aurbach, Journals Editorial Board Representative

Corrosion

Dev Chidambaram, Chair

University of Nevada Reno

Eiji Tada, Vice Chair

Rebecca Schaller, Secretary/Treasurer

Sannakaisa Virtanen, Journals Editorial Board Representative

Dielectric Science and Technology

Uroš Cvelbar, Chair

Jožef Stefan Institute

Sreeram Vaddiraju, Vice Chair

Zhi David Chen, Secretary

Thorsten Lill, Treasurer

Peter Mascher, Journals Editorial Board Representative

Electrodeposition

Luca Magagnin, Chair

Politecnico di Milano

Andreas Bund, Vice Chair

Rohan Akolkar, Secretary

Adriana Ispas, Treasurer

Takayuki Homma, Journals Editorial Board Representative

Electronics and Photonics

Qiliang Li, Chair

George Mason University

Vidhya Chakrapani, Vice Chair

Zia Karim, 2nd Vice Chair

Helmut Baumgart, Secretary

Travis Anderson, Treasurer

Khanna Aniruddh Jagdish, Journals Editorial Board Representative

Fan Ren, Journals Editorial Board Representative

Energy Technology

Katherine Ayers, Chair

Nel Hydrogen

Minhua Shao, Vice Chair

Hui Xu, Secretary

Iryna Zenyuk, Treasurer

Minhua Shao, Journals Editorial Board Representative

High-Temperature Energy, Materials, and Processes

Cortney Kreller, Chair

Los Alamos National Laboratory

Xingbo Liu, Senior Vice Chair

Teruhisa Horita, Junior Vice Chair

Dong Ding, Secretary/Treasurer

Minhua Shao, Journals Editorial Board Representative

Industrial Electrochemistry and Electrochemical Engineering

Maria Inman, Chair

Faraday Technology, Inc.

Paul Kenis, Vice Chair

Elizabeth Biddinger, Secretary/Treasurer

Paul Kenis, Journals Editorial Board Representative

Luminescence and Display Materials

Eugeniusz Zych, Chair

Uniwersytet Wrocławski

Chong-Geng Ma, Vice Chair

Marco Bettinelli, Secretary/Treasurer

Im Won Bin, Journals Editorial Board Representative

Nanocarbons

Jeff L. Blackburn, Chair

National Renewable Energy Laboratory

Ardemis Boghossian, Vice Chair

Yan Li, Secretary

Hiroshi Imahori, Treasurer

Dirk M. Guldi, Journals Editorial Board Representative

Organic and Biological Electrochemistry

Shelley Minteer, Chair

University of Utah

Jeffrey Halpern, Vice Chair

Sabine Kuss, 2nd Vice Chair

Ariel Furst, Secretary/Treasurer

Janine Mauzeroll, Journals Editorial Board Representative

Physical and Analytical Electrochemistry

Stephen Paddison, Chair

University of Tennessee, Knoxville

Anne Co, Vice Chair

Svitlana Pylypenko, Secretary

Iwona Rutkowska, Treasurer

David Cliffel, Journals Editorial Board Representative

Sensor

Larry Nagahara, Chair

Johns Hopkins University

Praveen Kumar Sekhar, Vice Chair

Dong-Joo Kim, Secretary

Leyla Soleymani, Treasurer

Netz Arroyo, Journals Editorial Board Representative

Stefano Cinti, Journals Editorial Board Representative

These divisions have nominated new officers for the spring 2024 to spring 2026 term. Elections take place from April 1 through April 30, 2024. The results are reported in the summer 2024 issue of Interface.

Chair

Sreeram Vaddiraju, Texas A&M University

Vice Chair

Eva Kovacevic, GREMI/Université d’Orléans

Secretary

Zhi David Chen, University of Kentucky

Treasurer

Thorsten Lill, Lam Research Corporation

Member at Large

Gautam Banerjee, Micron Technology Inc.

Vimal H. Chaitanya, New Mexico State University

Stefan De Gendt, IMEC

Dennis Hess, Georgia Institute of Technology

Hemanth Jagannathan, IBM Corporation Research Center

Zia Karim, Yield Engineering Systems

Steve Kilgore, NXP Semiconductor

Dong-Kyun Ko, New Jersey Institute of Technology

Paul Kohl, Georgia Institute of Technology

Hiroki Kondo, Nagoya University

Sunghwan Lee, Purdue University

Oana Leonte, Berkeley Polymer Technologies, Inc.

Durga Misra, New Jersey Institute of Technology

Yaw Obeng, National Institute of Standards and Technology

Neelakandan Santhosh Marath, Jožef Stefan Institute

Kay Song, Yield Engineering Systems

Kalpathy Sundaram, University of Central Florida

Mahendra Sunkara, University of Louisville

Chair

Paul Kenis, University of Illinois at Urbana-Champaign

Vice Chair

Elizabeth Biddinger, City College of New York

Division Secretary/Treasurer

Chockalingam Karuppaiah, Vetri Labs

Member at Large

Christopher Arges, Argonne National Laboratory

Saket Bhargava, Dow Chemical Company

Gerardine Botte, Texas Tech University

Fikile Brushett, Massachusetts Institute of Technology

Damilola Daramola, Northeastern University

Luis Diaz Aldana, Idaho National Laboratory

James Fenton, University of Central Florida

Taylor Garrick, General Motors Holdings, LLC

Matthew Graaf, Corteva Agriscience

John Harb, Brigham Young University

Marta Hatzell, Georgia Institute of Technology

Shrisudersan Jayaraman, Corning, Inc.

Wenzhen Li, Iowa State University

Juan Lopez-Ruiz, Pacific Northwest National Laboratory

Trung Van Nguyen, University of Kansas

Mark E. Orazem, University of Florida

Tyler Petek, Lubrizol Corporation

Doug Riemer, TDK Ventures

Shrihari Sankarasubramanian, University of Texas at San Antonio

Robert Savinell, Case Western Reserve University

John Staser, Ohio University

Xiao Su, University of Illinois at Urbana-Champaign

Venkat Subramanian, University of Texas at Austin

William Tarpeh, Stanford University

Santosh Vijapur, Faraday Technology, Inc.

John Weidner, University of Cincinnati

Chair

TBD

Nanocarbons

Vice Chair

Ardemis Boghossian, École Polytechnique Fédérale de Lausanne

Secretary

Yan Li, Peking University

Treasurer

Hiroshi Imahori, Kyoto University

Member at Large

Noe Alvarez, University of Cincinnati

Mike Arnold, University of Wisconsin–Madison

Delphine Bouilly, Université de Montréal

Tatiana Da Ros, Università degli Studi di Trieste

Francis D’Souza, University of North Texas

Andrew Ferguson, National Renewable Energy Laboratory

Daniel Heller, Memorial Sloan Kettering Cancer Center

Mark Hersam, Northwestern University

Nicole Iverson, University of Nebraska–Lincoln

Markita Landry, University of California, Berkeley

Fernando Langa, Universidad de Castilla–La Mancha

Richard Martel, Université de Montréal

Nazario Martín, Universidad Complutense de Madrid

Shigeo Maruyama, University of Tokyo

Elisa Miller-Link, National Renewable Energy Laboratory

Anton Naumov, Texas Christian University

Roberto Paolesse, Università di Roma Tor Vergata

Slava V. Rotkin, The Pennsylvania State University

Ángela Sastre-Santos, Universidad Miguel Hernández de Elche

Steve Stevenson, Purdue University

Tomás Torres, Universidad Autónoma de Madrid

R. Bruce Weisman, Rice University

Yoko Yamakoshi, Laboratorium für Organische Chemie –ETH Zürich

Shangfeng Yang, University of Science and Technology of China

Ming Zheng, National Institute of Standards and Technology

It is with great pleasure that we recognize the following ECS members who have reached their 30, 40, 50, and 60-year anniversaries with the Society in 2024. Congratulations to you all!

Arthur H. Graham

Donald L. Maricle

Robert A. Rapp

Brooke Schumm

Rajaram Bhat

Uri Cohen

Robert B. Comizzoli

Gary M. Crosbie

Harry O. Finklea

Dennis W. Hess

Thomas D. Kaun

Kyong-Min Kim

John A. Kosek

Samuel C. Levy

J. Ross MacDonald

James A. McIntyre

Kashmiri L. Mittal

Shohei Nakahara

Richard E. Novak

Bruce A. Parkinson

Wayne H. Smith

Ralph E. White

Gilbert M. Brown

Pietro Cavallotti

Thomas W. Chapman

Fausto Croce

Lili Deligianni

Gerald R. Dietze

Ross E. Dueber

Robert Paul Flicker

Stephen J. Fonash

Jorge G. Ibañez

Robert G. Kelly

Wayne I. Kinney

Wilbur C. Krusell

Andrzej Lasia

Jean Lessard

Stuart Licht

Jacek Lipkowski

Marcin Majda

Richard L. McCreery

Trung Van Nguyen

Mikael Östling

Miguel Mateo Paz Soldán

Ralph A. Petersen

Mark D. Pritzker

Daniel A. Scherson

César Augusto C. Sequeira

Michael Paul Setter

James J. Steppan

Jean St-Pierre

John R. Susko

Robin A. Susko

Jun-ichi Yamaki

Cammy R. Abernathy

Stuart B. Adler

Pankaj Arora

David Reed Atherton

Supriyo Bandyopadhyay

Christina Bock

Felix N. Büchi

Nieves Casañ-Pastor

Yufei Chen

Stuart M. Davis

Emory Sayre De Castro

Felice DiMascio

Huyen Ngoc Dinh

Scott W. Donne

Yasuhiro Fukunaka

Diana Golodnitsky

Srikanth Gopalan

Arthur M. Greenberg

Hiroki Habazaki

Michael T. Hicks

Bing-Joe Hwang

Tatsumi Ishihara

Radha S. Jalan

Patrick I. James

John R. Johnson

Jerry J. Kaczur

Oana M. Leonte

David J. Lockwood

Dennie T. Mah

Mani Manivannan

Robert A. Mantz

Jeremy P. Meyers

Minoru Mizuhata

Krystof J. Mocala

Masatsugu Morimitsu

Rangachary Mukundan

Evert Nagel Soepenberg

Hameed A. Naseem

Ikuzo Nishiguchi

Kazuyoshi Okuno

Jinshan Pan

Stefano Passerini

Fan Ren

Mamoru Saito

Yoji Sakurai

Kazunari Sasaki

Patrik Schmuki

Akshey Sehgal

Peter Miles Anson Sherwood

Drew Sinha

Giovanni Sotgiu

Kalpathy B. Sundaram

Yung-Eun Sung

Waltraud Taucher-Mautner

Thomas N. Tucker

Atsushi Ueda

Steven Joseph Visco

R. Bruce Weisman

MasahiroYanagida

April

Selected for you by

Alice H. SuroviecThe Journal of the Electrochemical Society is the flagship journal of the Society. With an impact factor of 3.9 and a SCOPUS score of 7.2, this journal should be everyone’s first landing spot when looking for current research in the solid state and electrochemical sciences.

While there are several focus issues every year, the focus issue on Electrochemical Separations and Sustainability is well suited to match the content of this Interface issue.

https://iopscience.iop.org/journal/1945-7111/page/focusissue-on-electrochemical-separations-and-sustainability

These open access databases contain Gibbs energy models and values for molten salt components. There is also a comprehensive list of MSTDB reference documents and publications.

https://mstdb.ornl.gov

The explainer articles are a series of informative articles that cover a wide variety of topics. The articles are written for the novice scientist looking to learn more about a topic. The articles all link to current research at PNNL as well as current literature on the topic. An example is linked below to an article on Renewable Integration.

https://www.pnnl.gov/explainer-articles/renewableintegration

Alice Suroviec is a Professor of Bioanalytical Chemistry and Dean of the School of Mathematical and Natural Sciences at Berry College. She earned a BS in Chemistry from Allegheny College in 2000. She received her PhD from Virginia Tech in 2005 under the direction of Dr. Mark R. Anderson. Her research focuses on enzymatically modified electrodes for use as biosensors. She is a Fellow of the Electrochemical Society and Associate Editor of the PAE topical interest area for the Journal of the Electrochemical Society. She welcomes feedback from the ECS community.

https://orcid.org/0000-0002-9252-2468

JES is the flagship journal of The Electrochemical Society. Published continuously from 1902 to the present, JES remains one of the most highly cited journals in electrochemistry and solid state science and technology.

JSS is a peer-reviewed journal covering fundamental and applied areas of solid state science and technology, including experimental and theoretical aspects of the chemistry and physics of materials and devices.

ECS Sensors Plus is a one-stop shop journal for sensors. This multidisciplinary, Gold Open Access journal provides an international platform for publishing high-quality impactful articles and promoting scholarly communication and interactions among scientists, engineers, and technologists whose primary interests focus on materials, structures, properties, performance, and characterization of sensing and detection devices and systems, including sensor arrays and networks.

ECS Advances is a multidisciplinary, Gold Open Access forum of peer-reviewed, high-quality content covering all technical areas supported by the Society. ECS Advances publishes full-length original work, brief communicationstyle papers, perspectives, review articles, and special issues.

SUBMIT TODAY! SUBMIT

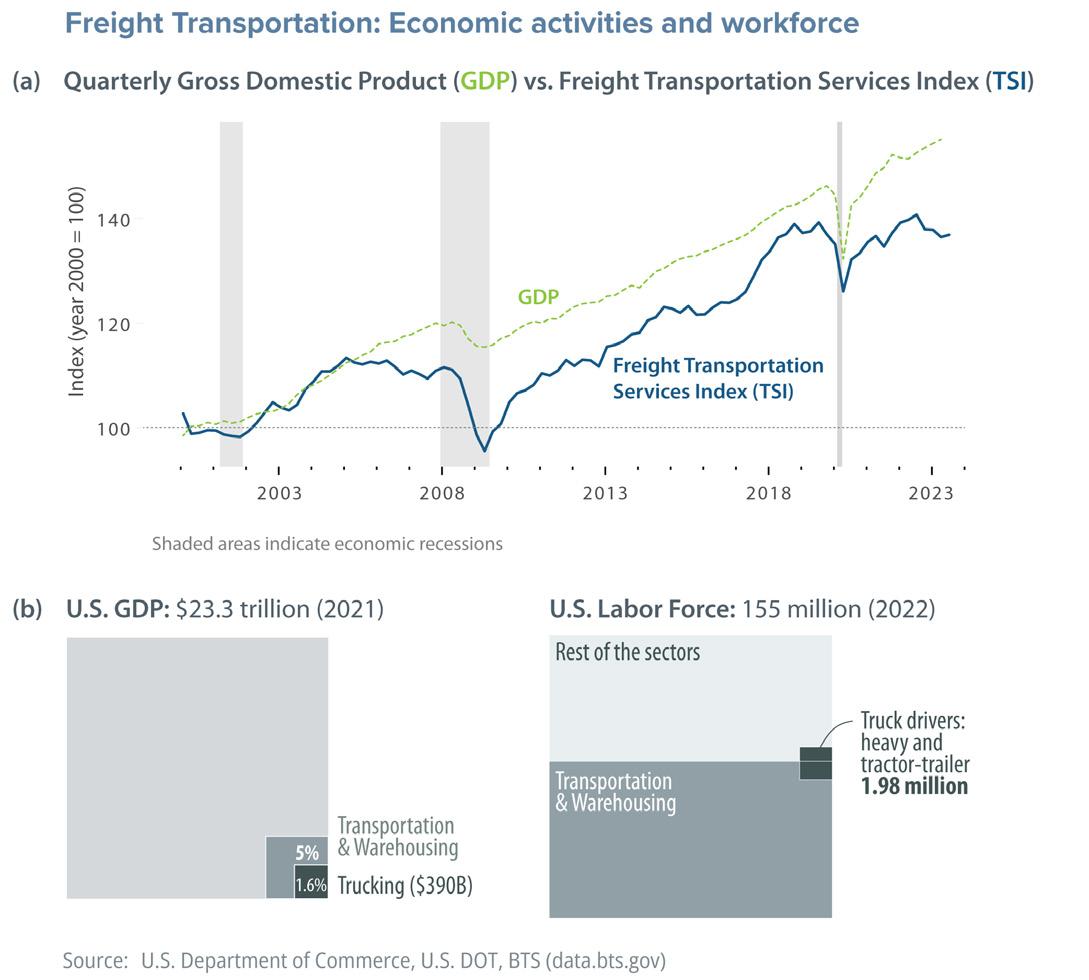

Transportation is one of the most important and visible indicators of the mobility of people and goods, both globally and locally. A rather less visible aspect of the transportation sector is freight movement, which is considered the backbone of many sectors and of the economy overall. In the United States, for example, the freight transportation services index very closely follows the gross domestic product (GDP), which illustrates how a nation’s economic activity and output is tied to freight transportation (Fig. 1a).

While freight movement occurs in many modes—from on-road transportation to rail, aviation, and shipping—heavy-duty truckinga is responsible for most of the cargo movement in the nation. In 2021, trucks carried 72% of US freight in terms of value and almost twothirds of freight in terms of tonnage (Fig. 2).1,2 In addition, the US Department of Transportation (DOT) projects an almost 50% increase in the nation’s freight capacity by 2050, the majority of which is still expected to be handled by trucks.2 With their dominant role in freight movement, trucks contribute over $390 billion to the US economy as part of the transportation and warehouse sector, with a 5% share of the GDP.1,2 Trucking also has the most employees in transportationrelated occupations, with almost 2 million drivers for heavy-duty and tractor-trailer trucks, which includes drivers working within the transportation and warehousing sector and in non-transportation sectors (e.g., truck drivers employed by the wholesale and retail trade industry), see Fig. 1b.

Moving the majority of the nation’s cargo requires a lot of energy. Energy demand by trucks reached 5.55 quads in 2022, constituting 20% of the transportation energy use in highways.4 This is the result of a combination of longer annual miles traveled by trucks and their much higher fossil fuel consumption per mile compared to light duty vehicles (LDVs) like passenger cars. In fact, the gap between the annual fuel consumption and miles traveled per truck versus LDV has been increasing over the decades (Fig. 3). A direct consequence of this activity is the higher greenhouse gas emissions by the internal combustion engines of trucks. The transportation sector is currently the major source of carbon emissions in the United States, with

a In this article, trucks are used to describe heavy-duty trucks including, but not limited to, Class 8 and combination trucks. Due to the differences in classifications of vehicles, or their grouping, between reports cited in this article, values and facts shown in each figure reflect the designations used in the original datasets. Interested readers are encouraged to check the referenced online databases for details on reporting structures and methodologies.

energy use and resulting emissions despite constituting only 5% of the entire vehicle inventory.

While these annual emissions provide a picture painted by broad brushes, the real impact of the transportation emissions is the air pollutants associated with the combustion of the gasoline and diesel fuel, including carbon monoxide (CO), hydrocarbon (HC) and nitrogen oxide (NOₓ), and particulate matter (PM). Transportationrelated GHG emissions primarily originate from burning gasoline and diesel fuel for light and heavy-duty vehicles, with additional emissions coming from jet fuel in aviation and other fuels (Fig. 6). The share of gasoline fuel consumption by light-duty trucks is the

a share of 29% in 2021 according to the EPA (Fig. 4). Within the transportation sector, heavy-duty trucks are responsible for almost a quarter of these emissions. In fact, trucks are responsible for 7% of annual greenhouse gas (GHG) emissions, which puts the HDV sector on par with the residential and commercial sectors in terms of share of carbon emissions.

The share of the trucking sector in carbon emissions, however, can be understood much better if the vehicle inventory is considered. Of the entire US vehicle fleet (282 million as of 2021), only 5% are heavy-duty trucks, including single-unit and combination trucks (10.7 and 3.1 million, respectively).1,2 Despite their small fraction of the vehicle fleet, trucks cover ~10% of the total annual miles traveled on the highways, consume 29% of the transportation fuels annually, and contribute 28% of annual transportation emissions (Fig. 5). These numbers illustrate the disproportionally high impact of trucks on

highest, and MDV/HDV trucks and buses consume 90% of diesel fuel.2,5 A better way to assess and compare these emissions from different classes is the emissions per mile of vehicle travel (Fig. 7). HDVs emit significantly more NOx and HC per mile traveled compared to light-duty passenger cars and trucks.1-3

A major environmental and health concern is PM2.5 emissions, especially from diesel engines. PM2.5 stands for particulate matter with a diameter of less than 2.5 micrometers. While particulate matter in general refers to a mixture of solid particles and liquid droplets in the air, PM2.5 poses the greatest risk to health. PM2.5 emissions are

transportation sector are strongly intertwined. One way to accomplish this is to reduce vehicle mileage; yet, given the increasing global economic activity, there is increased freight movement projected in the United States, and heavy-duty truck mileage in the world toward 2050 (Fig. 10). IEA Net-zero scenariob projections for economic indicators show increases in the energy demand and total mileage for trucks compared to passenger cars.9,10

As is the case in the United States, on a global scale, heavy trucks also release more CO2 per distance traveled than passenger cars (Fig. 10).9 Yet, achieving net-zero emissions globally by 2050 requires decarbonization of transportation sector. Therefore, this dichotomy between the increasing freight tonnage and truck mileage vs. higher per-vehicle emissions from trucks calls for a significantly higher reduction in emissions in HDVs compared to LDVs, as illustrated in the IEA analysis (Fig. 10). The disparities in per-vehicle mileage and fuel consumption metrics for HDVs (in contrast to LDVs) results in a disproportionally higher impact of trucks on emissions

linked to many adverse health effects, such as lung and heart diseases and increased respiratory symptoms.6 HDV trucks release up to 50 PM2.5 emissions/mile more than do LDV cars. Converting these values to the total annual emission per vehicle reveals a striking difference between light and heavy-duty vehicles: a diesel truck emits over 100 times more PM2.5 than does a gasoline passenger car (Fig. 8).

In other words, in terms of eliminating total PM2.5 emissions and mitigating their adverse health impacts, decarbonizing one diesel truck would be equivalent to decarbonizing ~100 passenger cars 1,3 Such an action would not only reduce transportation-caused GHG emissions and their influence on climate change, it will also negate the harmful pollutants and their impact on communities. In fact, the effects of PM2.5 emissions on communities also change with geography and demographics.7,8 A recent study reported disproportional impact of PM2.5 emissions on underserved populations, which was found to be the case also for transportation-related emissions, including heavyduty trucks (Fig. 9a). On a global scale, a recent update by IEA on NZE7 also noted the disparities in overall PM2.5 concentration among the advanced and emerging market economies (Fig. 9b). In addition to the critical role of heavy-duty diesel trucks in contributing to PM2.5 emissions, the adverse health effects of these emissions also vary by region, economy, income, and demographics, making this an energy equity issue and environmental justice problem.

Thus, eliminating harmful pollutants from combustion of fuels in vehicles, especially heavy-duty trucks, and decarbonizing the

b The Net Zero Emissions by 2050 Scenario (NZE) is a normative IEA scenario that shows a pathway for the global energy sector to achieve net zero CO2 emissions by 2050, consistent with limiting the global temperature rise to 1.5 °C with no or limited temperature overshoot (with a 50% probability), in line with reductions assessed by the Intergovernmental Panel on Climate Change (IPCC) in its Sixth Assessment Report.

and air pollution, which makes the decarbonization of the trucking sector a distinct challenge. As such, overcoming this challenge with zero-emission truck technologies will also lead to a significantly more positive change for demographics and communities impacted most adversely by the emissions and air pollutants from the freight movement and truck activity on highways, warehouses, and ports, as well as off-road activity such as construction and mining. This impact of decarbonization, aided by the increasing share of zero-emission vehicles, on emission reduction is captured in the IEA NZE analysis which projects a global decrease in PM2.5 concentrations from current levels if the targets are achieved by 2050 (Fig. 9b).7

This article brings together disparate datasets on heavy-duty transportation to establish a visual story of key facts and figures on heavy-duty trucks and freight transportation, as well as their role in greenhouse gas emissions and associated impact on people. In light of increased emphasis on decarbonization of the transportation sector given its major share in emissions, emergence of zero-emission truck regulations to aid decarbonization efforts, and development of roadmaps and analysis on electrification of the trucking sector (with batteries and hydrogen fuel cells), this article aims to provide a brief yet coherent story on the facts and challenges regarding freight movement and the trucking sector, with a focus on numbers in the United States from various government databases (EPA, BTS, EIA) along with global projections by the IEA and US AEO As decarbonization efforts continue, there will be a growing need to analyze the transportation sector by accounting for the unique characteristics of each mode, including and especially, heavy-duty trucks and freight movement.

The views and opinions of the author expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights.

© The Electrochemical Society. DOI: 10.1149/2.F04241IF

Ahmet Kusoglu, Staff Scientist, Lawrence Berkeley National Laboratory

Education: PhD (University of Delaware), Post-doctoral Fellow at Berkeley Lab. Research Interests: Ionomers, Polymer electrolytes, Mechanochemistry, Structureproperty relationships, Hydrogen technologies, Fuel cells and electrolyzers.

Pubs + Patents: >80 peer-reviewed journal papers, 2 book chapters, >50 invited talks and tutorials at international meetings, academia, and industry forums.

Work Experience: Scientist at Berkeley Lab working on functional polymers and interfaces for clean energy systems, Communications Director of the MillionMile Fuel Cell Truck (M2FCT) Consortium, and data visualization and data-driven stories on energy and environmental topics, including hydrogen, transportation, and electrochemical clean energy technologies.

Awards: Srinivasan Young Investigator Award and ECS Toyota Young Investigator Fellowship.

Work with ECS: Contributing Editor, ECS Interface; ECS member for 10+ years; Member-at-large, Energy Technologies Division (ETD), Symposium co-organizer for Polymer Electrolyte Fuel Cells and Electrolyzers.

Website: https://kusoglulab.lbl.gov

https://orcid.org/0000-0002-2761-1050

1. P. Hu, R. R. Schmitt, R. Robinson, et al. Transportation Statistics Annual Report 2022 (2022).

2. US Department of Transportation, Bureau of Transportation Statistics, Freight Facts and Figures.

3. US Department of Transportation, Bureau of Transportation Statistics (BTS), Freight Facts and Figures.

4. US Energy Information Agency, Monthly Energy Review.

5. Transportation Energy Data Book (ORNL), Ed 40.

6. Particulate Matter (PM) Pollution, EPA.

7. International Energy Agency (IEA). Net Zero by 2050: A Global Pathway to keep the 1.5 °C Goal in Reach (2023).

8. C. W. Tessum, D. A. Paolella, S. E. Chambliss, J. S. Apte, J. D. Hill, J. D. Marshall, Sci Adv, 7(18), eabf4491 (2021).

9. International Energy Agency (IEA), Net Zero by 2050: A Roadmap for the Global Energy Sector (2021).

10. International Energy Agency (IEA), World Energy Outlook (2020).

The European Federation of Corrosion (EFC) has awarded Michael Rohwerder the European Corrosion Medal, honoring his 25 years of significant contributions to the field of corrosion science. The prize consists of a bronze medal and a certificate.

The author of more than 200 publications on corrosion science, Rohwerder leads the corrosion group at the Max-Planck Institut für Eisenforschung (MPIE). His research includes metallic, organic, and self-healing coatings; hydrogen in materials; and corrosion. Rohwerder also has a strong interest in how metallic materials and coatings can be tailored for future sustainable energy applications: “To reduce carbon emissions and achieve a climate neutral industry, resilient infrastructures are required. Green energy often relies on the use of hydrogen as a renewable energy source. Meanwhile, hydrogen often leads to materials failure due to a phenomenon called hydrogen embrittlement. Also, other severe corrosion problems are seen in the green energy sector, for example in electrolyzers. Thus, solving corrosion problems is crucial for the transition to a sustainable future. This challenge drives my passion for corrosion science. Receiving the European Corrosion Medal has been a great honor and strengthens my motivation further,” says Rohwerder.

Joan B. Berkowitz, ECS President 1979–1980, passed away on January 22, 2020, at the age of 88. A distinguished chemist, her areas of research included materials for the space program, reusable molds for spacecraft construction built from molybdenum disilicides and tungsten disilicides, and the disposal and treatment of hazardous wastes. Dr. Berkowitz was the first woman to serve as president of The Electrochemical Society. She was born in Brooklyn, New York on March 13, 1931. She received her BA in chemistry from Swarthmore in 1952. She wished to follow her high school boyfriend (and fellow Swarthmore graduate) to Princeton University, but at the time Princeton did not accept women for graduate study in chemistry. Instead, she attended the University of Illinois Urbana-Champaign, graduating with a PhD in physical chemistry in 1955. From 1955 to 1957 Dr. Berkowitz was a National Science Foundation postdoctoral fellow at Yale University studying polymeric electrolytes.

Dr. Berkowitz joined Arthur D. Little, Inc. in 1957, where she was responsible for basic and applied research programs in high temperature chemistry and environmental science. She worked on the kinetics of oxidation of molybdenum, graphite, and the refractory borides and silicides. She investigated the effect of applied electrochemical potentials on reactions associated with hot corrosion of chromium-based alloys. She explored the thermodynamics of vaporization of high temperature materials in both vacuum and reactive atmospheres. Dr. Berkowitz also synthesized single crystals of high melting point materials and directed work on the growth of gallium arsenide for solar cell applications.

For the lunar space program, Dr. Berkowitz designed experiments in metals melting and eutectic solidification in space. She also assessed the possibility of photochemical reactions among the LEM exhaust products. She co-authored a monograph on industrial utilization of NASA developments in electroplating.

Rohwerder received the medal and presented his research at the European Corrosion Congress (EUROCORR) in August 2023. The EFC brings together 45 research organizations from 25 European countries to advance corrosion science through cooperation and networking.

In her pioneering environmental work, she headed a team that wrote the two-volume handbook, Physical, Chemical and Biological Treatment Techniques for Industrial Wastes (1976), a survey of manufactured goods and their potential for causing pollution. She examined limestone scrubbers that removed sulfur dioxide, demonstrated how to reduce hard deposits which hindered their effectiveness, and improved their design. She also studied the disposal of hazardous wastes in landfills and produced the first handbook on alternative disposal methods. By the 1980s she was a vice president and later head of the Environmental Business Worldwide section at A.D. Little.

In 1986 she left A.D. Little to become CEO of Risk Science International. In 1989 she co-founded the consulting firm Farkas Berkowitz & Company. In addition, she was an adjunct professor at the University of Maryland University College.

Dr. Berkowitz joined the Society in 1961. She was active in the Electrothermics and Metallurgy Division and served as Member-atLarge, Vice-Chair, and Chair (1971–1973). She became a Division Editor of JES in 1966. She served on many Society committees: Membership, Nominating, New Technology, and Ways and Means. She organized Society symposia on high temperature oxidation, oceanography, and energy storage. She authored over 35 technical papers and review papers in the fields of high temperature chemistry and oxidation of refractory hard materials and held 2 patents.

Dr. Berkowitz was also affiliated with the American Chemical Society, American Physical Society, Sigma Xi, Phi Beta Kappa, and the National Association of Corrosion Engineers. In 1970 she was a member of the National Academy of Science/National Academy of Engineering task group on high temperature oxidation-resistant coatings. She also chaired the chemistry panel for review of NAS/NRC fellowship applications. Her many awards include the Stanley J. Drazek award for excellence in teaching, the Sylvia M. Stoesser Lecturer in Chemistry, and the Achievement Award from the Society of Women Engineers.

Dr. Berkowitz is survived by her daughter, Rosemary, who is also a chemist.

Yasuhiko Ito, emeritus ECS member, passed away on October 17, 2023 at the age of 82. He joined The Electrochemical Society in 1985. He received the Physical and Analytical Electrochemistry Division Max Bredig Award in Molten Salt and Ionic Liquid Chemistry in 1999. He awarded Fellow of The Electrochemical Society in 2000. Professor Ito was born on March 14, 1941. He entered the Department of Industrial Chemistry, Faculty of Engineering, Kyoto University in 1959, and graduated from the same department in 1963. He completed a master’s course in the Department of Industrial Chemistry at the Graduate School of Engineering, Kyoto University in 1965, and received his PhD degree in 1969. In 1968, he was employed as an assistant professor in the Faculty of Engineering, Kyoto University, and in 1971, he was promoted to an associate professor at the Faculty of Liberal Arts, Kyoto University. In 1981, he was reassigned to the Department of Nuclear Engineering, Faculty of Engineering, Kyoto University, and in 1989, he was promoted to a professor at the same department. In May 1996, with the establishment of the Graduate School of Energy Science, Prof Ito was reassigned to the Department of Fundamental Energy Science at the same graduate school. He served as Dean of the Graduate School of Energy Science of Kyoto University for two terms from May 1998 to May 2002. During his many years of teaching students and supervising researchers at Kyoto University, he fostered many talented scientists.