ANNUAL REPORT 2022

Australian Research Council (ARC) Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals acknowledges the support of the Australian Research Council and the New South Wales and South Australian Governments. We also acknowledge the in-kind and financial support from all our national collaborative organisations: The University of Newcastle (administering organisation), The University of Queensland, Deakin University, The University of Melbourne, Monash University, University of South Australia, Curtin University, University of New South Wales and The University of Adelaide. We also acknowledge the support from our Industry Partners: CSIRO, FLSmidth, Jord International and Amira Global, as well as in-kind support from our international partners.

Acknowledgment of Country

The ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals acknowledges the Traditional Owners of the land where we work and live. We pay our respects to Elders past, present and emerging. We celebrate the stories, culture and traditions of Aboriginal and Torres Strait Islander Elders of all communities who also work and live on this land.

UNIVERSITY PARTNERS

INDUSTRY PARTNERS

INTERNATIONAL PARTNERS

OTHER CONTRIBUTIONS TO THE CENTRE

1 OUR INFLUENCE AND IMPACT 20 OUR CENTRE 4 About COEMinerals 6 Message from the Director 7 COEMinerals Governance Structure 9 Message from the Advisory Board 10 Message from the International Advisory Panel 11 Observations from the Research Programs Review Committee 12 Delivering on our Strategy 13 Snapshot updates from our University Nodes 15 Technology and Skill Sharing: Sink-Hole Fluidiser 21 Multi-disciplinary, Multi-node Discovery: Rare Earth Elements 23 Influencing Change in Australia & Beyond: International Reflux Flotation Cell Upscaling Symposium 25 Impacting Sector Transformation: From the Academic Mind to the Mine Site Successful Commercialisation with Jord 27 29 1 2

2 RESEARCH PROGRAMS 32 OUR PERFORMANCE 58 Program 1 Overview Project Summaries 33 35 Program 2 Overview Project Summaries 45 47 Program 3 Overview Project Summaries 51 53 2022 Highlights 59 Annual Conference 61 Gender Equity Diversity and Inclusion 65 Future Leaders in Focus 67 Training Overview 69 Outreach Overview 71 Signature Lecture and Seminar Series 73 Communications and Media 75 Publications 77 Financial Statements 79 COEMinerals 2023 Plans 81 COEMinerals: Feedback Forum 83 Glossary of Terms 85 3 4

MINERALS FOR OUR FUTURE

MISSION

To develop deep scientific knowledge that enables the establishment of new, transformational technologies in minerals beneficiation, to deliver a sustainable future for Australia’s minerals industry.

VISION

To double energy and water productivity in the mining sector by 2030, maintaining the drive towards the ‘zeroemission mine’ and reduce losses of high value metals during processing by 90%.

STRATEGY

Working in partnership with the minerals industry, Mining & Equipment Technology Services (METS), the community and other stakeholders to provide advice, thought leadership, research, education, people and transformational innovations.

3

4 OUR CENTRE About COEMinerals 6 Message from the Director 7 COEMinerals Governance Structure 9 Message from the Advisory Board 10 Message from the International Adviwsory Panel 11 Observations from the Research Programs Review Committee 12 Delivering on our Strategy 13 Snapshot updates from our University Nodes 15

Our COEMinerals Members at COEMinerals Conference, representing the following nodes: The University of Newcastle (UON), The University of Queensland (UQ), Deakin University (Deakin), The University of Melbourne (UOM), Monash University (Monash), University of South Australia (UniSA), Curtin University (Curtin), University of New South Wales (UNSW) and The University of Adelaide (UoA) and our Industry Partners Jord International (Jord) and FLSmidth

ABOUT COEMINERALS

The ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals (COEMinerals) is creating more-sustainable methods to separate and increase the availability of Minerals for our Future.

The transition to a net-zero emissions economy will be metal-intensive. Minerals are critical to delivering a greener energy path, being key components of many medical and other technology devices including solar panels and electric vehicles.

Australia is minerals-rich and minerals are likely to underpin much of Australia’s national wealth in coming years based on anticipated increasing demand, matched with the relative scarcity of some minerals or the increasing challenge of their sustainable and efficient recovery.

Despite minerals being a finite resource, many mineral separation processes are energy inefficient, and can be highly wasteful with up to 20% of minerals lost to tailings. Many processes have not advanced much in more than 50 years. It is time to change that.

COEMinerals is making mineral recovery more efficient, more effective and as a result much more sustainable.

COEMinerals was awarded $35M by the Australian Government through the Australian Research Council (ARC) Centres of Excellence funding scheme in October 2019 - and the Centre officially commenced on 29th July 2020 - to drive sciencebased and transformational sector change in

minerals processing to make it more eco-efficient (i.e., doing more with less).

The Centre harnesses the talent and skills of some of Australia’s leading scientists representing diverse scientific disciplines, from nine Australian universities. The Centre’s PhD and early career researchers (ECRs) represent the next generation of research and industry leaders. Collectively COEMinerals members are developing technologies, inventing world-first scientific techniques and enabling new capabilities for minerals recovery during minerals processing. Our ground-breaking research, discoveries and innovations strive to:

Double energy and water productivity in the mining sector by 2030, maintaining the drive towards the ‘zero-emission mine’

Reduce loss of high value metals during minerals processing by 90%, increasing the concentration of recovered products used in metals refining

Deliver exceptional educational experiences that enable, up-skill and empower a new generation of research, Science, Technology, Engineering and Mathematics (STEM) and minerals sector leaders

COEMinerals members collaborate across borders and engage with the wider Mining Equipment, Technology and Services (METS) sector to understand and align research and design sciencebased solutions to solve challenging sector problems. COEMinerals has academic institution and industry partners and works closely with sector sustainability experts and community members to

solve beneficiation (minerals processing) problems which will ultimately lead to sector change.

The Centre also engages in activities spanning academic learning, industry engagement, community outreach, site visits and skill building experiences including professional development and training programs. This ensures excellence in learning and helps build a community of researchers who are actively contributing to positive change in the minerals sector now and in the future.

The Centre’s Thematic Objectives

Objective 1 – Early gangue (waste) rejection, achieved through technology advances in coarse particle beneficiation, to minimise energy and water consumption

Objective 2 – Fast, efficient beneficiation to minimise losses of high value metals, achieved through technology advances in fine particle beneficiation, to maximise resource recovery and product grade

Objective 3 – Real time removal of solids from tailings, and rejection of water from solids, achieved through the introduction of novel hydrophobic interactions, and technology advances in dewatering (getting rid of tailings dams)

6

MESSAGE FROM THE DIRECTOR

The year 2022 saw a significant ramp up in Centre activity. With labs operational and an increase in PhD students starting, our Centre grew to more than 100 scientists comprising PhD students, ECRs and senior investigators.

COEMinerals members met face-to-face for the first time during our annual conference in Canberra in July. This was the Centre’s first in-person event and it enabled us, our industry partners (including Jord International and FLSmidth) and guests to appreciate the importance of community and personal engagement, both precursors to successful inclusivity, collaboration and innovation. Personally, I believe the main conference highlight was the emergence of enthusiasm, energy and motivation from a new generation of researchers who are forming the research community that will underpin their future careers.

We greatly appreciated the involvement of:

Ngunnawal Elder Aunty Tina Brown for her inspiring Welcome to Country

Ms Tania Constable, Chief Executive Officer (CEO) of the Minerals Council of Australia for her Opening Address

Industry representatives for their engaging panel discussions

Sector mentors (spanning departmental and industry) for their valuable advice and engagement with students, especially during the ‘Gaddie Pitches’

Centre technology advances

Jord International (Jord) secured a new installation of the Jameson Concorde Cell™ at Nickel West in Western Australia; its inventor

being Centre Chief Investigator Laureate Professor Graeme Jameson

Jord also secured funding for introducing the NovaCell™ into a site in NSW for floating coarse particles, and is working with UON on the upscaling of Centre-developed XtractORE™ agglomeration technology

FLSmidth successfully secured European funding to support Centre-developed coarseAIR™ upscaling, with involvement from our Centre

UOM node researchers secured a contract with a major multinational minerals company to evaluate the performance of the developed High-Pressure Dewatering Roll technology in improving tailings storage and water recovery

Further, West Cobar Metals (ASX: WC1) re-engaged COEMinerals to undertake beneficiation studies on the Newmont Deposit to help unlock a major rare earth mineral deposit

Ground-breaking innovation as a result of internode, cross-discipline collaboration Centre researchers began exploring and initiating collaborative research projects - sharing knowledge, skills and technical equipment - across nodes in earnest in 2022. This approach resulted in some highly productive, new and unique experimentation opportunities for members and industry. More on this in 2023!

Critical minerals, minerals processing, sustainability and ‘net-zero’ emissions targets are top of mind topics in Australia and around the globe

COEMinerals is well placed to contribute to enabling the transition to a metals-economy, making our communications and relationships with

government and industry more important than ever. Ensuring our members form close and collaborative relationships with the minerals sector is an ongoing Centre priority. Throughout 2022, Centre leaders contributed to multiple Australian government feedback forums and channels, providing strategic advice for forward planning.

The Centre extended its industry connections and influence by hosting the ‘International REFLUX™ Flotation Cell (RFC) Upscaling Symposium’ in October, involving more than 20 Centre researchers and propelling local and international awareness of our latest research and technology invention to an audience of sustainability experts representing commercial and academic interests.

We welcomed visits, engagement and planning input from numerous members of our Advisory Board, International Advisory Panel, sector specialists and renowned academics in 2022 which provided opportunities for close engagement, including 1:1 conversations with PhD students, ECRs and undergraduates, as well as Centre and university leaders. Visitors included:

Advisory Board Chair Professor Simon Biggs, Vice Chancellor (VC) of James Cook University who visited our Newcastle Administration node (November)

International Advisory Panel (IAP) Chair, Professor Cyril O’Connor (South Africa based) whom we met with in Melbourne and during a visit to our UON node (August)

IAP member Dr Martin Rudolph, from the Helmholtz Institute in Freiberg (HZDR/HIF) (Germany based), whom we met with in Melbourne (August)

7

Further, we greatly appreciated the participation of the Australian and international industry and academic leaders who spoke during our ‘Signature Lecture’ series, which we make widely available to our community via our website and social channels.

Future leaders in focus

Guided by input from the Centre’s ‘Future Leaders Committee’, we commenced the ‘Future Leaders Training Program’ this year, which incorporates technical, academic and professional training elements that build on the wide-ranging experiences PhDs and ECRs gain by being part of the Centre.

Getting off-campus, ‘out of the lab’ and into the field, many of our PhDs and ECRs visited industrial/ mine sites in Queensland, Victoria and New South Wales this year, giving them a taste of the scale and potential impact of their work to increase sustainability in minerals processing.

The Centre supported joint learning projects with international colleagues in 2022, an example being one of our Centre PhDs Siân Parkes spending two months in Germany and Switzerland to further investigate ion flotation of critical minerals using the REFLUX™ Flotation Cell (RFC), and use of Centre-developed, environmentally friendly Reversible Addition-Fragmentation Chain Transfer (RAFT) polymers at the HZDR/HIF and Technische Universität Dresden.

Navigating challenges

It was not all smooth sailing in 2022, as PhD visa delays (ongoing) and publication delays (sometimes 180 days or more) challenged the pace of research and its access. That said, we are very close to meeting our PhD targets for the year, and we plan to trial some preprint research releases in

1. https://www.industry.gov.au/publications/stem-equity-monitor

2. https://www.engineersaustralia.org.au/sites/default/files/women-in-engineering-report-june-2022.pdf

3. https://www.wgea.gov.au/sites/default/files/documents/WGEA-Gender-Equality-Scorecard-2022.pdf

the coming year to accelerate availability of our ground-breaking Centre work.

At times ore, mineral and reagent sample availability was limited, but inter-node resourcefulness literally helped deliver the goods.

Our team’s gender balance is not where we want it to be at 37% female. While in line with our planning expectations and on par with Australian academic STEM enrolment trends – where women make up 36% of course enrolments 1 - gender imbalance is a known problem for the engineering and mining industries in Australia (Engineering: 11% are women 2; Mining: 20% are female 3). As a result, we plan to double-down on our efforts to increase female researchers in the second half of 2023, against a backdrop of very active and potentially competitive industry recruitment drive for talent.

Despite some member changes as part of the Centre’s evolution, we continue to build momentum and have a solid succession plan in place.

Our flexible workplace and family-friendly culture has enabled Centre members – many of whom were finally able to visit family abroad in 2022 after an extended period of lock downs and border closures - to work from home (WFH), or indeed anywhere in support of our inclusion values.

As we enter the next exciting phase of our research program, I thank Centre members for their contribution in 2022, along with our partners, collaborators and academic mentors.

We are planning wide ranging events, industry engagement, community outreach and research collaborations to increase our knowledge and understanding through engagement and influence next year.

Our Centre’s ARC ‘mid-term review’ will occur in 2023. This is a timely reminder for us to stay focused on achievement of Centre goals through the delivery of ground-breaking research, and our progress towards achieving our ultimate aim of enabling sector transformation as a result of industry adoption of our eco-efficient and moresustainable minerals processing methods in Australia and around the world.

Professor Kevin Galvin Centre Director

Laureate

Professor Kevin Galvin Centre Director

Laureate

COEMinerals Governance Structure

Advisory Board

Centre Chief Operations Officer

Executive Committee Director

Stakeholder Committee

Australian Universities

Research Program Review Committee

Deputy Director

Centre Chief Operations Officer

Node Leaders

Research Program Committee

International Organisations

Industry Partners

CSIRO

Communications and Media Officer

Future Leaders Committee

Program 1

Program 2

Chief Investigators

Associate Investigators

International Researchers

Early & Mid Career Reseachers

PhDs

Technical Staff Professional Staff

Program 3

Executive Committee Members

L/Prof Kevin Galvin

Annemarie Fawkner

Prof San H. Thang

Prof Chun-Xia Zhao

Prof Bill Skinner

A/Prof Elham Doroodchi

Prof George Franks

A/Prof Liza Forbes

Prof David Beattie

Dr Ellen Moon

Prof Vishnu Pareek

Dr Susana Brito e Abreu

Prof Chris Aldrich

Gender Equity and Diversity Committee

A/Prof Seher Ata

Dr Eirini Goudeli

Kim Stockham

International Advisory Panel Director

9

MESSAGE FROM THE ADVISORY BOARD

The COEMinerals Advisory Board provides advice and feedback on the Centre’s Strategic Plan, and where appropriate facilitates engagement and new opportunities.

COEMinerals welcomed Advisory Board Chair, Prof Simon Biggs to UON in November 2022 for planning and engagement activities with our COEMinerals research team, colleagues and academic peers.

I was very pleased to see the bounce back in the Centre’s activities as it gathered strong momentum in 2022. I am sure this will continue through 2023 and beyond.

As momentum grows in the Centre, I am very confident that it can provide important technology advances based on high quality science and engineering research which will have global impact.

As Chair of the Advisory Board for the Centre of Excellence I am very optimistic about the next few years of its operations.

Ambitious plans globally for a new energy future will require significant amounts of precious and other metals. Given the increasingly challenging nature of the ore bodies from which these metals will have to be extracted, there is little doubt we will need innovative solutions to processing of these ores if we are to have any chance of meeting our energy system ambitions. Importantly, our processing will have to be very efficient to ensure the overall system is energy positive. We should not doubt the scale of this challenge.

Excitingly, the focus of the Centre is absolutely correct in terms of these demands.

Like so many activities in recent years, the progress of COEMinerals was significantly impacted by the COVID pandemic, especially as it was only just beginning its operations when the pandemic struck.

Professor Simon Biggs COEMinerals Advisory Board Chair Vice Chancellor and President, James Cook University, Australia

Additional Advisory Board Members

Professor Richard A. Williams, Vice Chancellor, Heriot-Watt University

Ms Denise Goldsworth AO, Chancellor, Edith Cowan University

Mr Andrew Hutchinson, General Manager, Critical Minerals Facilitation Office with the Australian Government Department of Industry, Science, Energy and Resources

Professor Jacques Eksteen, Research Director of the Future Battery Industries CRC (FBICRC)

Message from the Chair

MESSAGE FROM THE INTERNATIONAL ADVISORY PANEL

The Centre’s IAP provides strategic advice to theCentre Executive with a view to assisting in the achievement of the Centre’s goals.

The IAP reviews program reports as well as monitoring the progress and performance of projects being undertaken within the three Scientific Programs.

Panel Chair Prof Cyril O’Connor visited the UON node in person in August 2022, engaging with COEMinerals’ Director, Chief Operations Officer (COO) and Executive Committee members, as well as presenting a research update to, and taking questions from, COEMinerals research team.

Message from the Chair

COEMinerals’ IAP members are Cyril O’ Connor (Chair, University of Cape Town, South Africa), Silvia Cristina Alves Franca (CETEM, Brazil), Martin Rudolph (HZDR/HIF, Germany) and Barun Gorain (Ore2Metal, Canada). The Panel, which includes, ex officio, the Director, Deputy Director and the

COO of the Centre, is thus clearly international in its composition and all the members enjoy excellent international reputations in the domain of minerals processing and hence it is well positioned to provide an international perspective on the research activities of the Centre.

The Panel has met on four occasions since the commencement of the Centre’s activities in 2020 and these have been either fully remote or in hybrid form. The Chair and Martin Rudolph also had the opportunity of a most useful engagement with the representative of (COEMinerals partner organisation) Jord.

Notwithstanding the challenges created by the COVID pandemic, probably the most significant of which was the difficulty of recruiting new PhD students, the Centre and especially its Director, Deputy Director and COO, deserve unstinting praise for successfully ensuring that the entire program is now at a stage at which it is clearly operating as near to optimally as possible.

The Leadership, together with the impressive cohort of Program Leaders and their collaborators, are all clearly fully committed to achieving the objectives of the Centre and any COVID-related backlog in terms of outcomes has now essentially been entirely resolved.

In its relatively short existence, the Centre has already achieved major research outcomes and already established itself as a leading international research centre with an enviable global reputation.

The Panel is of the view that the Centre, through the successful implementation of its declared

strategy and through the dynamic leadership of its Director and his colleagues, is on a successful trajectory towards achieving its vision and ultimately all of its objectives.

Professor Cyril O’Connor

COEMinerals International Panel Chair

Emeritus Professor and Senior Research Scholar, Department of Chemical Engineering, Faculty of Engineering and the Built Environment, University of Cape Town, South Africa

Additional Advisory Panel Members

Dr Martin Rudolph, Head of Department of Processing of Helmholtz Institute Freiberg for Resource Technology (HZDR/HIF), Freiberg, Germany

Silvia Cristina Alves França, Director Centre for Mineral Technology (CETEM)

Dr Barun Gorain, President and CEO Ore2Metal Inc

OBSERVATIONS FROM THE RESEARCH PROGRAMS REVIEW COMMITTEE

The pace of Centre research gained considerable momentum across all three programs during 2022, with progress in multiple areas.

Centre research benefited from the participation of undergraduate and postgraduate students from different nodes in different projects. The research team grew, with more than 90% of the PhDs being recruited by the end of 2022.

Significant headway was made with progressing a suite of technologies towards eventual commercialisation, particularly in Thematic Objective 1, concerned with early gangue rejection.

A prominent and positive feature of Centre research is its interdisciplinary nature, which involves close collaboration between different nodes of the Centre and includes the exchange of research material (such as equipment, reagents and ores) as well as staff and students from several Centre nodes working on complementary aspects of various research problems.

While almost all the highest TRL technologies are from the UON, the role other nodes play in the connected path to commercialisation cannot be underestimated. This is balanced by more fundamental research in the other two Thematic Objectives, which relate to polymer science, fine particle separation and tailings disposal. As such, the Centre has innovative research and outcomes in multiple areas, spanning discovery to invention/ commercialisation.

It is worth mentioning the pre-emptive value of the Centre’s technical training in ethics as provided during the Annual Conference and attended by the researchers, and the ongoing value of increasing visits between Centre nodes, fuelling shared skill building and enabling technology access beyond any one university.

One of the benefits of the Centre’s approach is its close connectivity as a team, and with parts of the mineral sector. Building on this base, COEMinerals members could improve the extent of their industry networks, especially in the area of reagents, as well as growing their practical understanding of on-site problems faced by the industry ahead. The net result will be the better ability to understand and match contemporary industry problems to Centre solutions for greater impact, with the overall outcome being more sustainable minerals processing.

Additional Research Program Review Committee Members:

Centre Chief Investigator, Professor Peter Scales (UOM)

Centre Chief Investigator, Associate Professor Kym Runge (UQ)

Centre Associate Investigator, Dr Eirini Goudeli (UOM)

12

Professor Chris Aldrich Centre Chief Investigator (Curtin)

DELIVERING ON OUR STRATEGY

Centre activity is guided by a Strategic Plan, which is updated annually with input from Centre members, the International Advisory Panel and Advisory Board

Below are some, but not limited to, our strategic deliverables in 2022.

Strategic Objectives Strategic Initiatives

1: To develop and deliver new transformational technologies to the minerals industry

Conduct a research review and feedback, against Centre’s thematic objectives

Industry alignment and feedback into research programs

A focus on innovation and industry collaboration

IAP and Advisory Board overview and feedback on research directions

Strategic Deliverables in 2022

A TRL assessment tool was applied to a portfolio of technologies in various stages of development

Seven of these technologies have shown ≥ 1 TRL level improvement. These include NovaCellTM, Concorde and REFLUX™ Flotation Cell (RFC), and XtractORETM that have moved to TRL 5 and 6

2: To provide the minerals industry with a diverse and future-oriented technical workforce

50% gender equity targets in all activities

50% gender equity targets in all appointments

Defined leadership of equity and diversity for the Centre, including planning

Training on language, equity and racial bias

Targeted professional training for PhDs & ECRs

50/50 equity on Executive Committee

50/50 equity in Signature Lecturers

65% women speakers for Internal Seminar

Commencement of GEDI Committee

Existing GEDI Plan is morphed into GEDI Strategic Plan

3: To provide thought leadership and deep technical training to students and the industry

Monthly Signature Lectures from industry and academic thought-leaders

Technical and training seminars to all members of the Centre

Professional training for all students and industry members

Cross-university engagement of all PhD students

Continuation of monthly Signature Lectures

PhD & ECR visits between COEMinerals university nodes

Commencement of the ‘Future Leaders Program’ incorporating, technical and professional training

4: To establish strong links between the minerals industry, community and researchers

Strategic advisory board inclusive of key industry leaders

Industry involved in >50% of PhD projects

Involvement of industry in all seminars and training activities

Flexibility to produce new technical innovation delivery programs

Industry involved at COEMinerals conferences, workshops and symposiums

Industry site visits by COEMinerals members

13

14

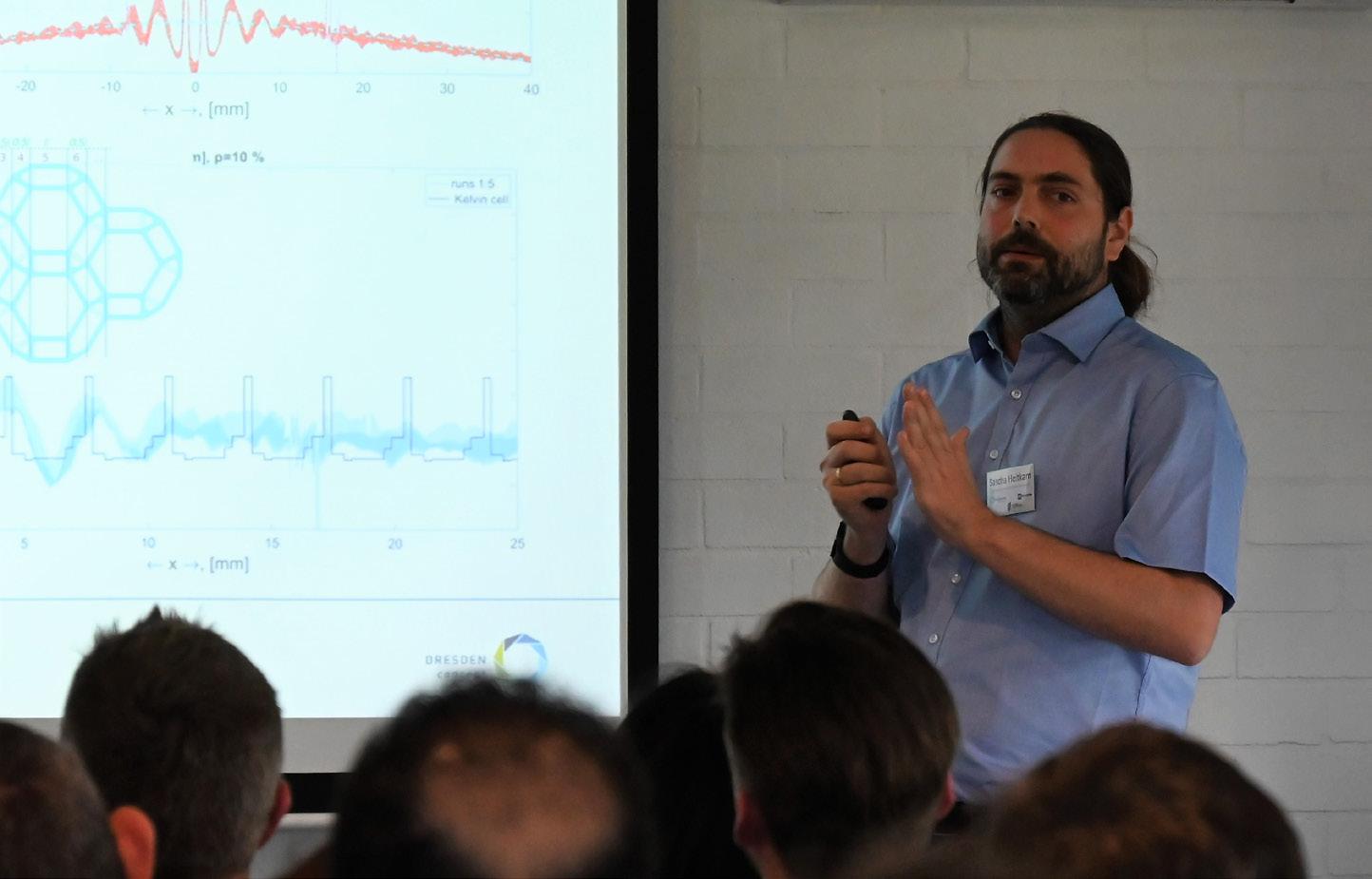

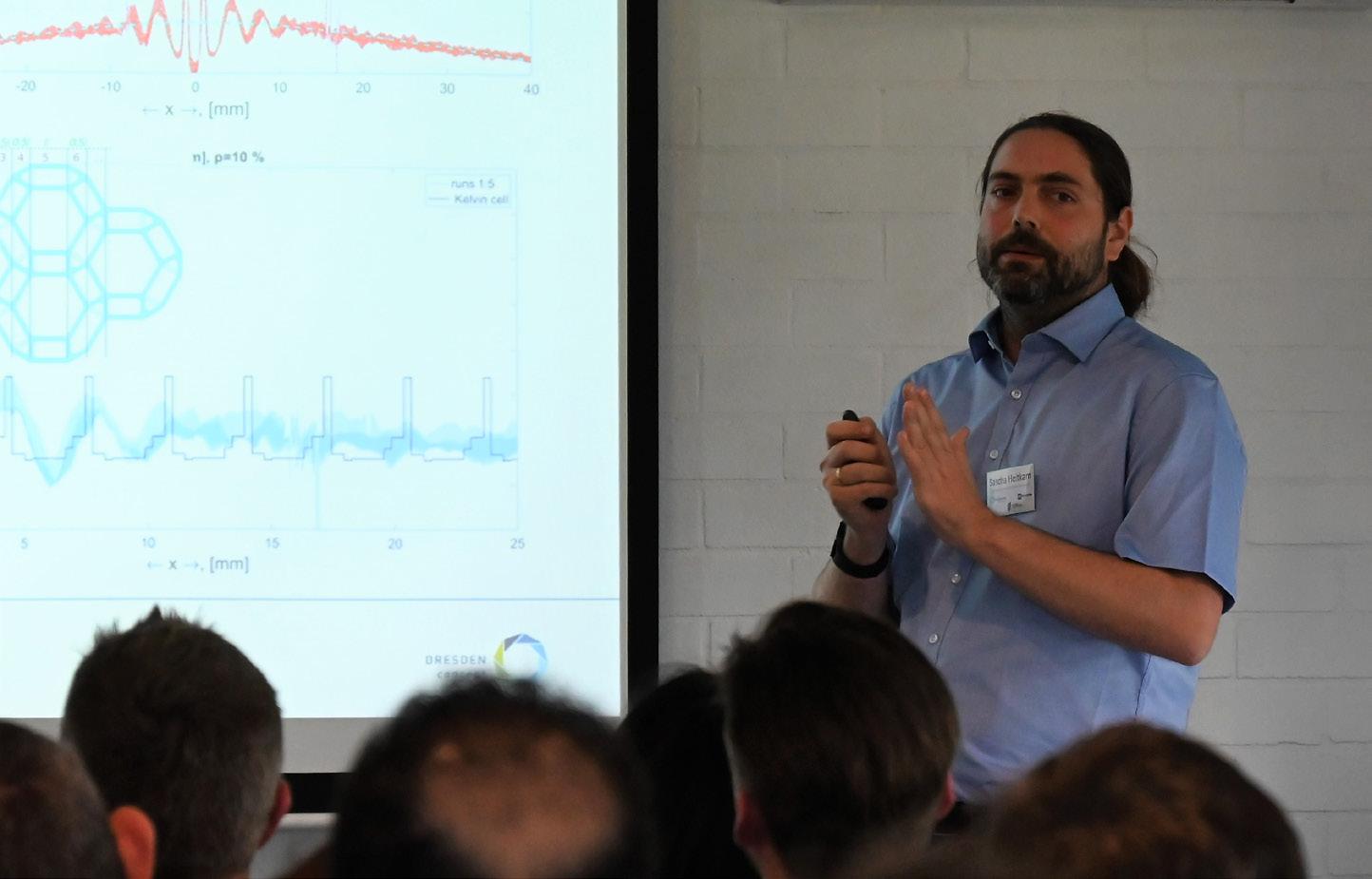

Prof Mohsen Yahyaei delivering technical training at the COEMinerals Annual Conference

Industry Involvement - Dr Verity Normington, Kevin Barber & Craig Wilson at the Annual Conference

Visiting IAP Chair Prof Cyril O’Connor with L/Prof Graeme Jameson and Director L/Prof Kevin Galvin

Industry site visits - Glencore Mt Isa Monash visit to UQ

SNAPSHOT UPDATES FROM OUR UNIVERSITY NODES

“Our approach is process application driven, and as such, we conduct problem-solving research with tangible outcomes for industry.”

Dr Erica Avelar (Curtin)

“ The UQ node has had a very productive year, particularly in the sphere of outreach, education and inter-node collaboration.”

A/Prof Liza Forbes (UQ)

“Internode collaboration brings people with different but complementary skills and talents together to reach a better end. Our research directly contributes to the recovery of minerals that will shape future technology.”

A/Prof Seher Ata (UNSW)

"A highlight was the transfer of Reflux Classifier technology to other nodes in a collaborative effort to facilitate broader deployment of this novel technology."

A/Prof Elham Doroodchi (UON)

“There have been many memorable moments and highlights at UoA in 2022, including UoA officially joining the Centre as a node.”

Prof Chun-Xia Zhao (UoA)

“2022 has been a great year for the UniSA node, particularly in the development and success of our researchers and progress toward our GEDI goals.”

Prof Bill Skinner (UniSA)

“Being part of the #COEMineralsFamily gave us some fantastic opportunities in 2022. As one of the Centre’s smallest nodes, the highlights for Deakin in 2022 centred on our collaborations and the way they have flourished this year. ”

Dr Ellen Moon (Deakin)

“This year has been fantastic and much exciting research progress has occurred in 2022 at the UOM node.”

Prof George Franks (UOM)

"A highlight of 2022 was the opportunity for our bio-inspired RAFT polymers to be tested in multiple COEMinerals nodes (UQ, UON, Deakin, UOM, UniSA) for mineral separations, as well as internationally for lithium ion flotation work at Helmholtz Institute Freiberg, Germany."

Prof San H.Thang (Monash)

15

University of Melbourne

Node’s key focus: Chemical engineering

Technology & invention

Highlights of 2022

High pressure dewatering rolls equipment underwent a major upgrade and has been used to evaluate a tailings sample of a major multinational minerals company. The result has been to produce tailings with unprecedented low water content

Team milestones

UOM had a full cohort of PhD students for the first time this year. Several have progressed past their first year confirmation

Sector engagement

Ten node members visited Fosterville gold mine in Victoria, enabling students to see how their research is applied in industrial settings

Collaboration in action

Skill sharing: The team made and welcomed several visits between nodes including UON, UOM, UQ and Monash along with frequent visits from the Deakin researchers

University of Newcastle

Node’s key focus: Chemical engineering, modelling and fluid mechanics

Technology & invention

Highlights of 2022

Technology transfer: REFLUX™ Flotation Cell (RFC) technology was disseminated to UQ and UniSA, Monash and Curtin to support research occurring as part of Projects 21 & 22 and the Sink-Hole Fluidiser was sent to Curtin (Projects 16 & 17)

Sector engagement

Hosted the 3-day ‘International RFC Upscaling Symposium’ where we welcomed industry and sustainability experts from Australia and around the world, as well as research presentations from multiple members representing different nodes

Community outreach

Conducted numerous lab tours for visiting Board & International Advisory Panel visitors, as well as wide-ranging government and industry representatives and trade delegations

Deakin University

Node’s key focus: Earth sciences and mineral surface chemistry separations using novel reagents

Collaboration in action

Highlights of 2022

Skill sharing: Deakin members have a close and collaborative working relationship with UOM. Centre members travel between nodes to make use of lab & facilities that one university has, but the other doesn’t, and to train each other in specific techniques.

Deakin welcomed teams from the UON to the Geelong campus to tour labs and utilise facilities to benefit joint projects

Community engagement

Participated in ‘Girls in Physics’ school outreach and hosted a ‘Girls in STEM’ work experience day

Provided tours and presentations to Geelong Manufacturing Council’s ‘Geelong Future Leaders of Industry’ and ‘Girls Leading Advanced Manufacturing’ (GFLOI & GLAM) programs for Y10-12 students

University of South Australia

Node’s key focus: Flotation, mineral surface chemistry, spectroscopy & physical chemistry (bubble-surface and droplet interfaces)

Highlights of 2022

Technology & invention

Technology transfer: UniSA received and installed a laboratory REFLUX™ Flotation Cell (RFC)

A new Profile Analysis Tensiometer (PAT) was acquired

Team milestones & thought leadership

Skill sharing: UQ node members visited UniSA for training on contact angle measurements, atomic force microscopy (AFM) imaging and X-ray photoemission spectroscopy (XPS)

Prof Bill Skinner participated in Commonwealth Government Critical Minerals Strategy Roundtable

Sector engagement

33rd Australian Colloid and Surface Science Student Conference was organised by UniSA node members A/Prof Marta Krasowska and Dr Amir Beheshti

Dr Asamoah (AI) leads successful Australia-India Strategic Research Fund Grant, “Advanced recovery of the battery materials and REE from ores and wastes”. UniSA node: Asamoah (AI), Abaka-Wood (ECR), Skinner (CI)

University of Queensland

Node’s key focus: Flotation & mineral surface chemistry

Highlights of 2022

Curtin University

Node’s key focus: Process Systems and Chemical Engineering

Highlights of 2022

Technology & invention

Completed a series of in-depth technology reviews, including:

- A comprehensive review of aerosol collector addition in the context of fluidised bed technology was conducted, with the findings presented to a group of industry representatives

- A comprehensive review of techniques for assessing and measuring the effect of mineral texture on random and non-random breakage

Technology & invention

Technology transfer: Sink-Hole Fluidiser received from UON

Collaboration in action

Curtin has two collaborative projects with UON associated with testing and computer modelling/data analytics informing technology development and industry application

Collaboration in action

Hosted other node members for flotation laboratory techniques training and collaboration discussions, including, UOM and Monash and Prof Chris Aldrich, Curtin node was a Visiting Prof in the second semester of 2022

Community outreach

Wide-ranging community outreach activities including:

- Science and Engineering Challenge participation

- Centre members demonstrated minerals processing laboratory experiments to a school group and followed up with presentation on overview of how metals go from being in the ground to becoming end products

University of New South Wales

Node’s key focus: Froth Flotation Systems

Highlights of 2022

University of Adelaide

Node’s key focus: Bio-inspired engineering

Highlights of 2022

Collaboration in action

UNSW hosted Monash members and provided flotation lecturing to the wider research group via Teams. Work is in progress to characterise their frother/collector samples at UNSW

Monash University

Node’s key focus: Polymer chemistry & RAFT Polymerisation

Highlights of 2022

Technology & invention

UoA has a new, fit-for-purpose laboratory for COEMinerals work. The team is currently filing patents for technology developed in the lab

Team milestones

Node leader Prof Chun-Xia Zhao started her prestigious National Health and Medical Research Council (NHMRC) Leadership Fellowship (2022-2026)

Community outreach

Wilderness high school students visited UoA as part of student work experience, where they saw the bio-engineering work we do in the lab

Technology & invention

World first, Bio-inspired RAFT polymer invention and application testing for use in minerals processing Identification and development of bio-inspired synthetic pigments as responsive froth and flotation agents

Collaboration in action

Monash team has a collaboration with UoA on bringing the best of both worlds of RAFT polymers and peptides for minerals beneficiation. We also work closely with team members in UON and UQ nodes

Design and synthesise RAFT polymers and reagents that are used collaboratively with various Projects in the Centre

Collaborative agreement implemented for access to CSIRO Rapid Automated Materials and Processing Centre (RAMP) for high throughput synthesis of bio-inspired responsive flotation agents

18

As Centre Director Kevin Galvin shares:

The Centre’s research approach and industry-ready solutions represent a step-change in academic-industry collaboration and implementation, helping to fast track the positive impact of new minerals processing innovation and technologies.

COEMinerals works hand-in-hand with industry partners and others to understand challenges, improve techniques, test solutions and drive transformation of the METS sector in Australia and around the world. The Centre leverages the knowledge, skills and knowhow of some of Australia’s – indeed the world’s – leading scientists representing diverse areas of specialisation.

Collectively, COEMinerals members work on a wide spectrum of projects from blue-sky, to proof of concept and the pathway from invention to patent and commercialisation.

This section showcases case studies and partner contributions of some of COEMinerals’ current research projects and technology evolution delivering meaningful outcomes for students and influencing sustainable change in the minerals industry.

19

“We cannot transform industry alone.”

OUR INFLUENCE

Technology and Skill Sharing: Sink-Hole Fluidiser 21 Multi-disciplinary, Multi-node Discovery: Rare Earth Elements 23 Influencing Change in Australia & Beyond: International Reflux Flotation Cell Upscaling Symposium 25 Impacting Sector Transformation: From the Academic Mind to the Mine Site Successful Commercialisation with Jord 27 29

AND IMPACT

TECHNOLOGY AND SKILL SHARING: SINK-HOLE FLUIDISER

Sharing newly invented technology and associated knowledge and skills across multiple node universities and team members has many benefits, including:

Centre members gain the ability to work on cutting edge technologies in mineral processing

Researchers build ‘hands on’ familiarity and skills with Centre-developed innovation and research infrastructure

It expands research possibilities. Different, complementary testing applications can roll out concurrently

It fuels close collaboration and delivers a more cohesive approach to research programs within the Centre overall

It raises the overall awareness of Centre innovation, as each node has unique institutional/METS networks; an important step in the technology development life cycle

Accelerating the pace of learning and novel technology development timelines may enable the Centre to address and solve problems in the mining industry faster than single-node approaches

Advancing blue-sky technology

The Sink-Hole Fluidiser is a novel dry separation technology that produces sharp separations based on mineral density, originating from the Centre’s UON node. It is being shared in the form of a physical set-up at Curtin (as part of ‘Project 16’) for further testing. Parallel workflow accelerates the pace of learning, and ideally, helps to move the invention towards the next stage of development.

The novel technology goes beyond water reduction benefits during beneficiation, as it needs no water for dense mineral separation. Using a ‘dry separation’ technique, it predominantly uses gently upward flowing air and vibrations (energy/signals) to sort and separate dense mineral particles, leveraging the principle that gangue (waste) and mineral particles have different densities.

Earlier Sink-Hole Fluidiser technology tests with sand/silica were relatively simplistic. Current multinode trials test the physical separation of actual gold ores, representing the next phase of scientific research. Simulating industry application enables better understanding about and optimisation of how the device works.

Computational modelling and simulation are also occurring at both UON and Curtin nodes, which enables better understanding of the behaviour of the physical system.

Large reductions in energy (and, it goes without saying, water) consumption can be made using the device and delivers very ‘sharp’ or ‘clean’ separations of dense mineral particles during the early stage of processing. This is very exciting from a research point of view, and very interesting to industry. Other techniques available today cannot efficiently separate dense mineral like low-grade gold ores in this way.

The combined insights of physical testing and computational modelling help discover the further potential of the technology and build a case for future industrial trials, and perhaps one day technology commercialisation and application in industry. So far proof of concept for the technology

has between established (to a TRL between 2 and 3).

According to Prof Chris Aldrich: “Having the new technology at Curtin paves the way for closer involvement of industry on the campus site, and with the WA School of Mining’s industrial partners, as we further test and refine the device to help solve industry and environmental challenges with the equipment being used today.”

Collaborative & connected ways of working

Prof Chris Aldrich says, “This project is redefining the state-of-the-art through innovative exploitation of some of the complex physical phenomena associated with granular fluid flow.”

Enabling multiple project team members access to the technology helps establish what may become a major new, Centre-developed technology.

Sharing the experimental device and related computational research across nodes provides enhanced lab test opportunities and brings the increased capacity for parallel research beyond any one campus or team. It also expands the amount of physical experimentation and data generation, fast tracking the learning through parallel experimentations and further validation of the model. It also upskills multiple Centre teams on novel minerals processing techniques.

“Working with the technology builds new skills, which are supported in-person visits where members work closely and collaboratively across nodes. Further the experience gained can be applied

21

to other Centre projects,” Prof Chris Aldrich shared.

The combination of physical experimental and computational modelling being conducted at both UON and Curtin provides insights into the fundamental mechanisms of separation, drawing on different but complementary data points from advanced sensors and application of data analytics in both systems.

The multiple diagnostic and predictive insights from the numerical modelling are shared among the group, guiding future physical experimental work, enabling the systems to be optimised while guiding equipment development. The combined and collaborative approach contributes to validating the model.

Curtin-based researchers are conducting fundamental research in modelling of granular fluid flow and gaining first-hand insights into fluid flow phenomena and vibration signals through proprietary data algorithms.

Next steps

As more data is collected - from the physical research being undertaken at UON and Curtinthere is potential for machine learning to be applied. Soon, modelling will be able to simulate and predict the results of physical experiments (in Project 16 and related Project 17) with potential application for other Centre projects over time.

The next phase of the Sink-Hole Fluidiser technology development will be validation under continuous steady-state conditions. Positive results for this phase could lead to up-scaling, ultimately with wide-reaching implications for technology application beyond gold for separation of other high-density particles, including many critical minerals.

How the Sink-Hole Fluidiser Works

The device utilises a fluidised bed with vibration applied as an additional energy source to disrupt the tendency of the excess air to pass through as ‘bubbles’, although there is no water present. It consists of a pair of fine mesh screen mounted on top of a vibrated ‘fluidised bed’. The upper mesh contains a large hole in its centre, referred to as a ‘sink-hole’

A combination of vibration and gently upward flowing air fluidises the granular media, inducing a specific state of stress. The ‘media’ consists of fine sand

Once vibrated, the fine particles expand up and through the large sink-hole spreading across the upper mesh

Some of the large particles (only those with highest density) sift back down into the lower bed

- The density of the large particles at the mouth of the sink-hole exceed the bulk density of the fluidised medium, and often also the density of the granular particles in the bed. Despite this, particles denser than the medium float, while those of even higher density sink. The fact that the separation density is higher than the density of the medium is unexpected. Our goal is to establish why such a high separation density can be achieved, and to control the separation density.

By adjusting the mix of vibration, the velocity of the upward flowing air and mass of media, it is possible to vary the separation density

22

COEMinerals

ECR Dr Tariqul Islam (UON) demonstrates the Sink-Hole Fluidiser

MULTI-DISCIPLINARY, MULTI-NODE DISCOVERY: RARE EARTH ELEMENTS

World first chemistry and biopolymer solutions are solving a Rare Earth Elements (REE) separation problem

In 2022 COEMinerals began applying research fundamentals and findings from its ‘Thermodynamic Guidance of RAFT polymerisation to control hydrophobicity at mineral surfaces’ project (Project 42) specifically to REE to solve a so-far intractable problem.

Project 42 research combines scientific discovery with industry application. The Centre works in close collaboration with industry project partner/s and involves multiple Centre nodes. It is truly multidisciplinary, tapping into the skills and experience of the Centre’s team including mineralogy, molecular dynamics, quantum chemistry, biochemistry, bio-engineering, interfacial characterisation and theoretical modelling techniques. The project team is spread across UON, UniSA, UoA and Monash nodes.

The world urgently needs a more effective and efficient way to recover REE

Rare earths predominantly comprise 15 elements of the lanthanides series 4 in the periodic table, and their efficient and effective separation during minerals processing is an unsolved global problem.

REE are fundamental to the development of ‘clean-energy’ as an essential component of the permanent magnets (as used in wind turbine

generators and in the motors that power electric vehicles 5), along with applications in medical and high-tech devices (like mobile phones). Their use offers a path to achieve a lower carbon future.

Some fast facts showcasing demand:

Global demand for REE doubled in the 15 years to 2021, reaching 125,000 tonnes per year 6 .

Global consumption reached 164,000 tonnes of total rare earth oxide (TREO) in 2022 7 .

REE demand is forecast to reach 315,000 tonnes per year by 2030 8 .

The energy sector’s overall needs for critical minerals could increase by as much as six times by 2040 9

If predictions are correct, REE supply may not meet future demand.

Solving the separation problem

The primary challenge is to recover a high proportion of the high-value minerals that comprise a relatively small portion of the total ore body. At this point in time, there is no clear way to proceed with this first and crucial stage of beneficiation. Several other groups around the world have examined the problem and not succeeded.

COEMinerals is taking an entirely new approach, firstly grinding to liberate and then hydrodynamically fractionating the ore into multiple and very clean, fractions. These will be investigated for their rare

4. https://www.ga.gov.au/scientific-topics/minerals/mineral-resources-and-advice/australian-resource-reviews/rare-earth-elements

5. https://www.irena.org/-/media/Files/IRENA/Agency/Technical-Papers/IRENA_Rare_Earth_Elements_2022.pdf

6. https://www.australianresourcesandinvestment.com.au/2022/05/03/rare-earths-australias-next-big-players/

earth mineral (REM) content.

The interaction of the mineral surfaces with the COEMinerals derived RAFT polymers and biopolymers is being investigated as a way to selectively recover REM. The goal is to identify how best to achieve the first stage extraction. These steps will be guided by thermodynamics, through Density Functional Theory simulations. The new techniques are currently being lab-tested and represent a ground-breaking approach towards unlocking new beneficiation processes for REM separation. If no solution can be found, then there will be no development of the resource.

Project 42 draws on the skills of a multi-discipline, multi-node scientific research team, leveraging experience in:

Beneficiation technology commencing with fine grinding, utilising precise desliming techniques, flotation techniques, and magnetic separation

Computational modelling

RAFT polymer and biopolymer development, and

Mineral surface characterisation techniques

The project approach is aptly described by Prof Alister Page, UON:

“We’re like The Beatles; better together” .

7. https://www.arultd.com/products/supply-and-demand.html

8. https://www.mdpi.com/2075-163X/7/11/203

9. https://www.iea.org/news/clean-energy-demand-for-critical-minerals-set-to-soar-as-the-world-pursues-net-zero-goals

23

UON

Conducts computational chemistry modelling to help determine what functional group of polymers will specifically attach/bind to the surfaces of the REM. They help predict activity and interfacial structure of new RAFT polymers and biopolymers, which will be grafted to mineral surfaces in later stages of the research

The computer simulations are constantly updated based on latest test results, helping to inform the ongoing synthetic development of new polymers and experimental investigations

Advanced methods of desliming with hydrodynamic fractionation deliver the clean components needed to firstly determine the location and concentration of the rare earth minerals. This phase is coupled with grinding to promote liberation

This preparation is essential for investigating the suite of chemicals informed by the computational chemistry

The component samples are shared across the team

Monash and UoA

The COEMinerals bio-chemistry team, working across two nodes, is informed by the computer modelling and mineral separation results to drive the molecular design of new RAFT and peptide and protein molecules.

UniSA

In parallel, these Centre members are drawing on their knowledge of physical and chemical processes of mineral surfaces and interfaces to also explore the potential for using magnetic separation to extract rare earth minerals.

Next steps

In 2023, UON and UniSA node teams will extend testing to explore the potential of using the Graviton technology to achieve desliming, agglomeration, and the REFLUX™ Flotation Cell (RFC) in combination with magnetic separation in industrial-lab test environments to maximise the recovery and grade of the rare earth minerals.

24

Photo credit: Adele Seymon, Interim CEO Copper for Tomorrow CRC bid

INFLUENCING CHANGE IN AUSTRALIA & BEYOND: INTERNATIONAL REFLUX FLOTATION CELL UPSCALING SYMPOSIUM

Centre technology is set to transform minerals processing on a global scale

COEMinerals extended its international connections and industry influence by hosting the ‘International RFC Upscaling Symposium’ at UON in October 2022. Finding ways to fast track the widespread implementation of the new minerals processing technology was a key discussion topic for the international symposium.

This event featured COEMinerals researchers presenting their latest work and demonstrating the REFLUX™ Flotation Cell (RFC) technology, along with industry speakers and the support of Centre industry partner FLSmidth.

The event attracted industrial and academic interest, with attendees representing fourteen organisations and eight countries, including

EIT RawMaterials is an Innovation Community within the EIT It provides a collaborative environment for disruptive and breakthrough innovations by connecting more than 300 partners from industry, academia, research, and investment. It is supporting the RFC project and noting “The RFC requires 30% less Capex and 20% less Opex compared to the existing flotation technologies. The new design allows higher throughputs, a broader particle size distribution and recovery of finer particles.”

Australia and Europe-based minerals sustainability experts. It was also the first in-person meeting between the European Institute of Innovation and Technology (EIT) RFC Upscaling consortium members.

Presentations, including fundamental and industrial studies, were delivered by experts from both academia and industry. Potential collaborations on the RFC development and wider areas of mineral processing technology were discussed, building worldwide awareness of the ground-breaking technologies from the Centre.

COEMinerals Director, L/Prof Kevin Galvin commented: “The international interest we are seeing from global sustainability leaders indicates the minerals sector is ready to adapt and evolve.”

Commenting on the value and impact of the event, COEMinerals ECR Dr Peipei Wang, a lead organiser of the Symposium, commented: “Organising and presenting at the event was an exciting opportunity as part of my ECR experience at the Centre. As a result, my communication, negotiation and problem-solving skills have greatly improved. The event also prompted close communications between COEMinerals’ researchers, and with EIT RFC Upscaling consortium members. Further development of Centre technologies will help transform the minerals industry to become more sustainable, saving water and energy and significantly reducing the environmental footprint of

mining. Since the event, more RFC units have been tested on mine sites, with further possibilities of collaboration and implementation being explored as a result.”

Lance Christodoulou, Global Product Line Manager for REFLUX™ Technologies at FLSmidth noted the new technology, “..not only offers faster recovery of valuable minerals, but at enhanced product grades”.

He added: “Events like this help us spread the word about the benefits for industry adoption. It was an amazing opportunity to share learnings and strengthen relationships in the Centre and industry. After our time spent together, we left with an even clearer vision of how to reach our combined goals of reducing energy and resources used in global mining .”

The RFC is a flotation technology device invented by Centre Director L/Prof Kevin Galvin in collaboration with Centre partner FLSmidth, a global leader in supplying mineral processing equipment. The RFC can extract ultrafine mineral particles previously lost as a tailings waste. Using less energy and producing less waste, it is faster at recovering more minerals than previous methods.

25

IMPACTING SECTOR TRANSFORMATION: FROM THE ACADEMIC MIND TO THE MINE SITE

Demonstrating the potential of the REFLUX™ Flotation Cell in collaboration with FLSmidth

(Centre industry partner) FLSmidth is one of the leading technology and service suppliers to the global mining and cement industries. With a history stretching back to 1882, the company has a long tradition of industry-shaping innovation. Its focus in recent years has been the development of solutions to support the shift to sustainable mining.

Under its MissionZero program, the company has set a target to make zero-emission and zero-water waste mining a reality by 2030.

Central to MissionZero is the need to do more with less: to improve mineral recovery while at the same time reducing energy, water, and other inputs. It is a mission that aligns perfectly with the research goals of COEMinerals.

Improving mineral flotation

With such similar philosophies, it is perhaps no surprise that FLSmidth – with its strong presence in the Australian mining industry – has partnered with COEMinerals to commercialise the REFLUX™ Flotation Cell (RFC) technology.

The RFC concept was developed by academics at the UON to deliver a step-change in flotation cell productivity. It is a frothless system able to operate at levels of gas, feed, and fluidisation water flux far above conventional flotation cells. It can thus

deliver fast and effective flotation performance that pushes the boundaries of concentration grade, recovery, and throughput.

The result is a seven to tenfold reduction in required flotation volumes. Ultimately, this offers flotation with significantly lower air and water consumption when compared to conventional systems; no direct power input, reducing flotation energy demand; and reduced plant footprint and capital costs.

Passing the test

However, it is not until a technology faces realworld testing that its true worth is known. Fortunately, (FLSmidth) pilot trials through 2021 and 2022 have shown that the RFC lives up to its potential. Testing took place at Australian copper and North American molybdenum applications. During these trials, the RFC pilot plants demonstrated the ability to reduce energy consumption by 60%, CO2 emissions by 60%, and plant footprint by 50% compared to traditional flotation cells. It also delivered significant process benefits that resulted in a 5-8% improvement in recovery and 10% increase in throughput.

27

COEMinerals member Dr Simon Iveson working on the RFC at site

Spreading the word in Australia and beyond

FLSmidth is actively promoting the RFC within the global mining industry with a wide range of activities across various platforms. It has also been integrated into the company’s ‘mine of the future’ flow sheet, the MissionZero Mine.

The FLSmidth team were also present at the RFC Upscaling Symposium, hosted at UON and bringing together consortium partners from COEMinerals, EIT RawMaterials, and industry. The five-day event included presentations and lab visits that ranged from basic theory to practical process assessment.

Next steps

Work on RFC upscaling is continuing. The next stage involves feasibility testing at larger-scale copper and iron ore mine sites in Poland and Sweden, along with interest from a nickel site in

Australia. Experimental and modelling work to further scale-up the design will also continue, on top of life cycle assessment, as the consortium works toward commercialisation of the technology at a global level. “FLSmidth is committed to enabling a sustainable mining future, but we also know we cannot do this alone,” said Lance Christodoulou, Global Product Line Manager, REFLUX Technologies at FLSmidth.

He added: “Collaboration with partners such as COEMinerals are vital to fasttrack technology development and see it adopted into industry. With its potential to revolutionise mineral flotation, RFC is an exciting case in point, and we look forward to continuing our strong relationship with COEMinerals to implement the technology at a commercial scale.”

28

We acknowledge FLSmidth as the author of this section-content and note that any test/ research data or information provided by FLSmidth has not been peer reviewed.

IMPACTING SECTOR TRANSFORMATION: SUCCESSFUL COMMERCIALISATION WITH JORD

The next 30 years will see massive energy investment as the world shifts from the fuels of the 20 th Century, to meet the renewable energy needs of the 21 st

(Centre industry partner) Jord International (Jord) is pioneering new technologies required for this transition and improving existing technologies to minimise their impact. The Company’s priorities include focusing on technology innovations that deliver critical minerals and power new energy

solutions in an efficient, cost-effective and sustainable manner; and ensuring brownfield solutions allow existing process plant to run more efficiently, thereby lowering emissions and extending plant life.

Jord celebrated 50 years of business in 2022 and it was successful in progressing two important new technologies towards commercialisation: NovaCell™ and XtractOre™.

Jord General Manager of Resources Kevin Barber says the company’s full-time on-campus presence at the UON has been key: “The daily interaction under an embedded partnership model with COEMinerals has allowed us to be a very hands-on partner with the ability to influence changes,” said Mr Barber.

“We also participated in the COEMinerals Annual Conference, interacting with the full team of academics and students, which provided a terrific environment for real engagement between industry partners, academics, students, government leaders and indigenous community leaders.”

In 2022, Jord (backed by funding from ACARP) collaborated closely to break ground on a full-scale XtractOre™ 500 m 3 per hour demonstration plant at a site in New South Wales (NSW), Australia.

Based largely on work led by Centre Director, L/Prof Kevin Galvin, XtractOre™ is a novel agglomeration technology that could ultimately “deliver a 10 to 100 fold increase in the speed of fine particle separation” compared to traditional flotation technology. The demonstration plant is expected to become operational in 2023.

Jord also secured an order to design and deliver a pilot-scale NovaCell™ unit for evaluations at multiple customer sites with a goal to confirm the technology benefits for a variety of high value mineral processing commodities, as well as securing government funding to deliver a fullscale NovaCell™ module at an Australian mining operation. As a winner of the NSW Critical Minerals and High-Tech Activation Fund (Stream 2), Jord received funding to deliver the first NovaCell™ demonstration plant, which will commence in 2022 and is expected to be completed in 2025. These developments represent significant progress towards the commercialisation and industrywide acceptance of the exciting new technology created by Centre Chief Investigator L/Prof Graeme Jameson.

Jord Technology Manager – Flotation, Sherwin Morgan, says receiving government funding for a demonstration plant is a significant milestone. “It’s a massive step forward in the commercialisation of the technology. It also acknowledges the NovaCell™’s potential to support the growth of the critical minerals industry and provide long-term benefits both locally and abroad,” said Mr Morgan.

29

Mr Barber says NovaCell™ stands to make huge energy and water savings for the resources industry.

“The NovaCell™ provides efficient coarse and fine particle flotation recovery in one device, which allows mine operators to reject a significant portion of feed early on, while maintaining good recoveries,” says Mr Barber.

“As a result, you can reduce energy consumption, target higher mill throughputs, and install smaller downstream equipment.”

“In addition to greatly improving recoveries, it produces a coarse tail for modern tailings management practices, such as belt filtration and dry stacking.”

Reflecting broader industry acceptance of the new technologies, Jord was announced as a winner of the ‘OZ Minerals Think and Act Differently Waste to Value Challenge’ and it developed a

new partnership with a commercial laboratory to support an increase in market interest. Jord’s team also grew with the appointment of University of Newcastle’s Lonn Cooper, bringing 16 years of NovaCell™ experience to continue supporting the product development and commercialisation.

30

We acknowledge Jord International as the author of this section-content and note that any test/research data or information provided has not been peer reviewed.

“COEMinerals is a vibrant research community determined to accelerate the realisation of the ‘zero emission mine’. We bring together expertise in the design of microbial-expressed peptide sequences, with the world’s pre-eminent polymer and physical chemists, and draw on more than 200 years of engineering capability to conceive, develop and implement ground-breaking innovation and technological solutions to impact transformative change in the global minerals industry. In doing so, we develop new scientific knowledge and empower the next generation of sector leaders.”

Chief Investigator, Prof Grant Webber

Chief Investigator, Prof Grant Webber

31

32

Program 1 Overview Project Summaries 33 35 Program 2 Overview Project Summaries 45 47 Program 3 Overview Project Summaries 51 53

RESEARCH PROGRAMS

PHYSICS OF NOVEL SYSTEM HYDRODYNAMICS

Research Program Leaders

Laureate Professor Kevin Galvin, Laureate Professor Graeme Jameson and Professor Bill Skinner

Overview

Program 1 comprises 32 projects across four subprograms, aimed at reducing energy and water consumption, while maximising the recovery of the resource to deliver high-grade product. Additionally, characterisation tools are being developed to investigate mineral properties and separation processes. Below are some key highlights.

Characterising bulk and surface properties of minerals (Projects 1-8)

High Resolution X-ray Microtomography (HRXMT) analysis methodology has succeeded in producing partition curves for describing mineral separations, in close agreement with traditional float-and-sink methods but requiring less time.

A methodology has been developed to follow the changing pulp/surface chemistry of mineral particles as a function of size and time during grinding.

Pre-concentration through coarse particle beneficiation to reduce the need for grinding (Projects 9-18)

A new algorithm has been developed to allow universal comparison of flotation separation efficiency, based on rate constants.

A Computational Fluid Dynamics (CFD) model has been developed that can accurately predict the turbulence distribution in a large laboratory flotation cell.

Novel coarse particle flotation technologies supported by industry partners are progressing to pilot scale.

Fine particle separations to achieve faster and more efficient separations (Projects 19-27)

A multiphase CFD model has been developed to study the bubble plume dispersion behaviour in the top fluidised bed section of a REFLUXTM Flotation Cell (RFC).

Theoretical work on permeable interfaces has confirmed and supported the observed high capture rates of hydrophobic, ultrafine mineral particles using the novel emulsion binder system.

The Concorde CellTM has been installed in Western Australia for full-scale application.

Pilot scale trials of the Reflux Classifier to investigate the benefits of the new channel spacing in recovering fine manganese have commenced on Groote Eylandt following industry-supported Centre research.

Solid-liquid separations to eliminate tailings dams

(Projects 28-32)

Successful demonstration of permeable oil film aggregation and densification in a helical uplift pelletiser has been achieved.

A series of dewatering reagent molecules have been successfully shown to enhance dewatering of fine mineral tailings slurries under g-forces such that their subsequent rheological properties may enable effective and safe disposal.

Some objectives for 2023:

The Centre will host an international symposium on flotation science and engineering innovation in July, attracting leading researchers from around the world.

Development of a new Graviton technology prototype with FLSmidth for the purpose of large scale and efficient desliming at 10 microns applicable to many problems in minerals processing.

Construction of a continuous flow pelletiser system for aggregation and densification, using permeable oil film emulsions.

Demonstration of recovery and mass balance of coarse magnetic-matrix synthetic composite particles from HydroFloatTM fluidised-bed flotation. Advancing the recovery and upgrading of Cassiterite (Tin) from NSW tailings dam, and in turn solving a longstanding intractable problem, paving the way to addressing many other similar challenges.

Professor Bill Skinner

33

PROGRAM 1

Personnel involved in Program

1 for 2022

Chief Investigators

Prof Chris Aldrich, Curtin

A/Prof Seher Ata, UNSW

Dr Susana Brito e Abreu, UQ

A/Prof Elham Doroodchi, UON

Prof Geoffrey Evans, UON

Dr Mahshid Firouzi, UON

A/Prof Liza Forbes, UQ

Prof George Franks, UOM

L/Prof Kevin Galvin, UON

Prof Karen Hapgood, Swin

Dr Peter Ireland, UON

L/Prof Graeme Jameson, UON

A/Prof Marta Krasowska, UniSA

Dr Angus Morrison, UQ

Prof Anh Nguyen, UQ

Prof Alister Page, UON

Prof Vishnu Pareek, Curtin

Prof Yongjun Peng, UQ

A/Prof Kym Runge, UQ

Prof Peter Scales, UOM

Prof Bill Skinner, UniSA

Dr Anthony Stickland, UOM

Prof Grant Webber, UON

Prof Ken Williams, UON

A/Prof Mohsen Yahyaei, UQ

Associate Investigators

Dr Richmond Asamoah, UniSA

Dr Ghislain Bournival, UNSW

Dr Cathy Evans, UQ

Dr Eirini Goudeli, UOM

Dr Teresa McGrath, Curtin

Dr Peter Sherell, UOM

Dr Liguang Wang, UQ

A/Prof Max Zanin, UniSA

Research Associates

Dr George Abaka-Wood, UniSA

Dr Erica Avelar, Curtin

Dr Bellson Awatey, UQ

Dr Karina Barbosa, UQ

Dr Tejas Bhatelia, Curtin

Dr Wonder Chimonyo, UQ

Dr Matt Cole, UON

Dr Farhana Diba, UQ

Dr Marko Hilden, UQ

Dr Mohammad Hoque, UON

Dr Dusan Ilic, UON

Dr Tariqul Islam, UON

Dr Simon Iveson, UON

Dr+ Saeed Kia, UQ

Dr Aleksej Lavrinec, UON

Dr Subhasish Mitra, UON

Dr Conrad Ndimande, UQ

Dr Duc Ngo-Cong, UQ

Dr Cuong Nguyen, UQ

Dr Ngoc Nguyen, UQ

Dr Tuan Nguyen, UQ

Dr Francisco Reyes, UQ

Dr Joshua Sovechles, UON

Dr Peipei Wang, UON

Dr James Zhao, UON

Research Assistants

Mr Joshua Brown, UON

Dr Shaolei Gai, UON

Dr Xiu Liu, Curtin

Dr Joshua Sutherland, UON

Ms Kitty Tang, UON

Miss Ai Wang, UON

PhD Students

Mr Bernard Selasie Agbenuvor, Curtin

Miss Margaret Amosah, UON

Mr Sayed Anzoom, UNSW

Ms Linda Ayedzi, UniSA

Mrs Carolina Macarena Carvajal, UQ

Mr Jiarui Chen, UQ

Mr Mitchell Craig, Curtin

Mr Luke Crompton, UON

Mr James Dankwah, UniSA

Mr Quang Dao, UQ

Mr Daniel Dodoo, UOM

Mr Andrew Doi, UQ

Miss Jackquline Eardley, UOM

Mr Virat Gurung, UON

Mr Sajid Hassan, UOM

Mr Minuk Jung, UNSW

Mr Syam Murali Mohan, UON

Mr Nhat Nguyen, UQ

Miss Thao Nguyen, UQ

Miss Annabelle Niu, UQ

Mr Noyan Palabiyik, UON

Mrs Siân Parkes, UON

Mr Joshua Starrett, UON

Mr Brady Wright, UON

Ms Meolla Yvon, UON

Mr Abdullaziz Zakari UON

Mr Lequan Zeng, UOM

Technical Staff

Mr Raul Cavalida, UOM

Ms Laura Jukes, UOM

Mr Antonio Moreno, UON

Undergraduate Students

Ethan Tan, Curtin

Josafat Guintu, Curtin

Emily Stiller, UON

Emma Gibbs, UON

Harrison Lack, UON

Isaac De Maria, UON

Thomas Mayer, UON

Maverick Perram, UON

William Tonniges, UON

Amanat Chaman, UON

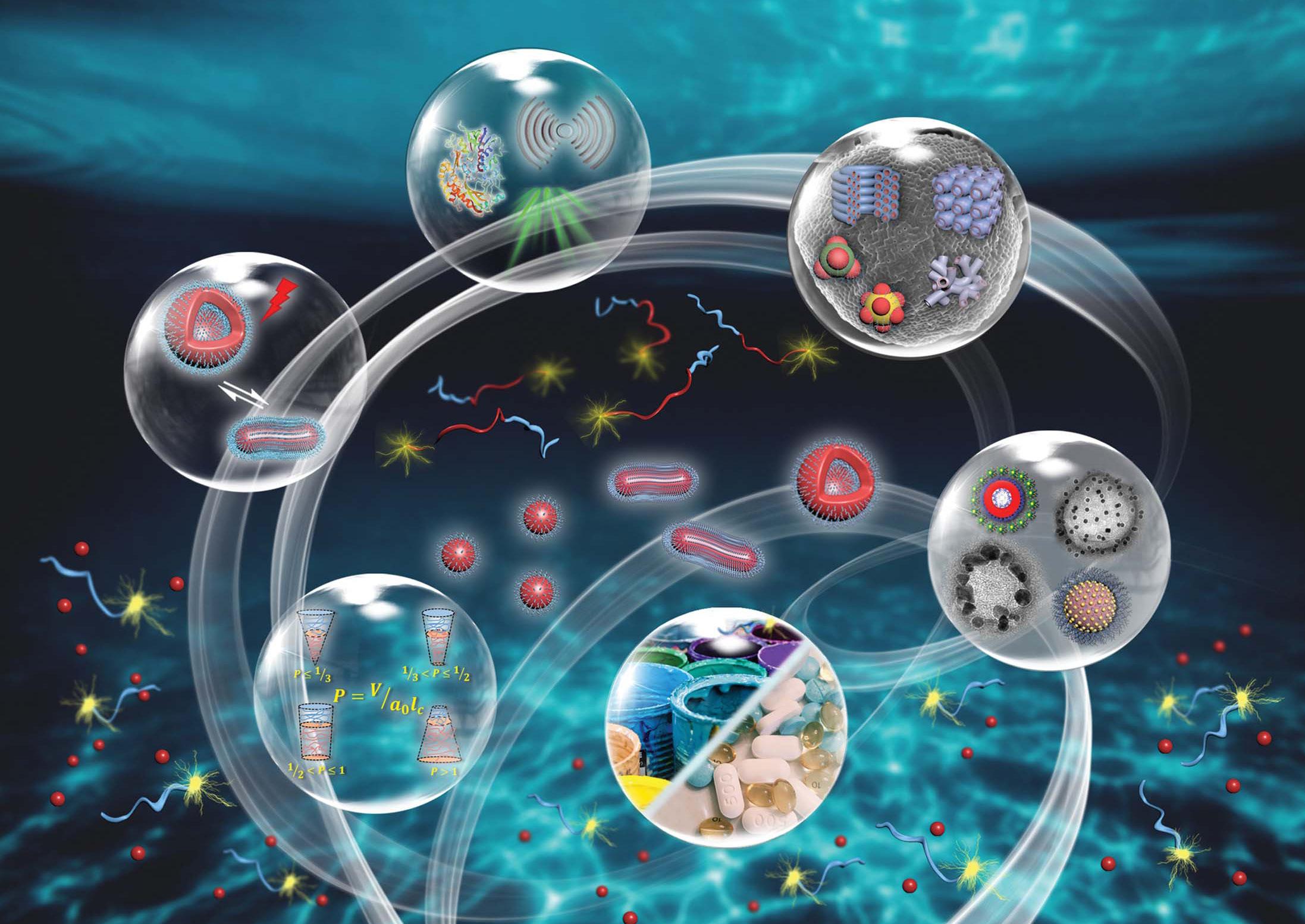

Cover Art: Interparticle Repulsion of Microparticles Delivered

a Pendent

by an Electric

34

PhD Luke Crompton (UON) (re: Project 14)

to

Drop

Field. Langmuir Benjamin T. Lobel, Erica J. Wanless et al., 2022 , 38, 670.

Physics of Novel System Hydrodynamics

NO TITLE LEADER & KEY PERSONNEL PROJECT SUMMARIES

P1.1 Quantifying Bulk and Surface Properties of Minerals

1 Application of X-ray CT scanning in describing mineral surface liberation with increasing grinding and applied breakage mechanisms

Leader: Prof Bill Skinner (UniSA)

Key Personnel:

Prof Mohsen Yahyaei (UQ)

Dr Catherine Evans, AI (UQ)

This project combines tomography and microscopy on ores to understand mineral deportment in coarse composite particles. Computed Tomography (CT) data has been collected using Xradia MicroXCT-400 sample preparation methodology developed using reference mineral materials. Parallel Quantitative Evaluation of Materials by Scanning Electron Microscopy (QEMSCAN) samples have been prepared for analysis. This will be followed by CT and QEMSCAN/optical analysis of synthetic, coarse composites. In the future, there is also an opportunity to investigate and apply a fast analysis methodology, previously developed by Associate Investigator, A/Prof Max Zanin and colleagues.

2 Application of X-ray CT scanning in describing partition curves of mineral separators

Leader: Prof Anh V Nguyen (UQ)

Key Personnel:

Dr Catherine Evans, AI (UQ)

Prof Jan Miller, AI (Uni of Utah)

PhD Student:

Quang Dao (UQ)

The project is developing an alternative to traditional Float-and-Sink (F-S) testing for the construction of methods used to generate partition curves. Samples of the feed, overflow and underflow streams of the preconcentration Pb-Zn ore circuit were scanned by X-Ray Computed Tomography (XRCT) with a new calibration and image analysis process. The samples were also analysed by F-S testing and were chemically assayed to develop a full size-by-size mass balance and reconciliation. The mass yield of the continuous separation process was determined, which is required for constructing the partition curves. Good agreement between the XRCT-based and the F-S based cumulative and partition curves was obtained, indicating the XRCT technology as a potential to replace conventional F-S analysis. The XRCT technology has potential to provide faster feedback than the F-S.

3 The manipulation and analysis of data from XRCT to quantify mineral surface liberation, with a particular focus on fine particle characterisation

Leader:

A/Prof Kym Runge (UQ)

Key Personnel:

Dr Catherine Evans, AI (UQ)

Dr Francisco Reyes, RA (UQ)

Prof Stephen Neethling, AI (Imperial College)

X-Ray Tomography (XRCT) is a non-destructive technique that has the potential to measure the composition and surface exposure of mineral particles using 3D images, overcoming stereological problems associated with 2D imaging. This project aims to test and further develop XRCT for various mineral processing applications. The project has established an engagement with an industrially funded research program to gain access to samples of different ores that have been subjected to breakage and flotation testing. Selected samples have been analysed by microscopy and the next step will be to analyse them using XRCT for comparison. The aim is to determine the mineral identification capability of XRCT and any particle size limitations.

35

PROGRAM 1: SUMMARIES

Leader: Prof Mohsen Yahyaei (UQ)

Key Personnel:

Prof Chris Aldrich (Curtin)

Dr Catherine Evans, AI (UQ)

PhD Students:

Carolina Macarena Carvajal (UQ)

Bernard Selasie Agbenuvor (Curtin)

Rock particles are usually composed of minerals in the form of grains. This project investigates fundamentals of particle breakage along the grain boundaries using novel measurement techniques. The project looks to better understand the breakage of coarse particles and the partial liberation of valuable minerals to improve the energy efficiency of mineral processing circuits. Samples from Cu-Co oxide and Cu-Au sulphide ores were selected for exploratory phase and technique validation. Mineral characterisation via scanning electron microscopy (SEM-EDS) together with nanoindentation and optical microscopy was conducted to investigate the mechanical properties such as elasticity, hardness, and fracture toughness in individual minerals to assess ore breakage for the selected samples. This phase of the project is being performed at UQ. Density separation and sample characterisation (size distribution, porosity, hardness, chemical composition, and mineralogy) have been completed at Curtin for both the high and the low gangue rejection response.

Leader: Prof Peter Scales (UOM)

Key Personnel:

A/Prof Liza Forbes (UQ)

Prof George Franks (UOM)

Dr Nathan Webster, PI (CSIRO)

PhD Student: Daniel Dodoo (UOM)

The presence of clays is ubiquitous to a range of mineral deposits. In flotation, clays cause viscosity and surface coating/selectivity issues and for hydrophobic clays, grade penalties in product streams. Fast and efficient characterisation of the amount and type(s) of clays present in a process stream and prediction of the consequences for flotation are still poor.