MAGAZINE MAGAZINE

ERIEZ FORGES THE FUTURE OF SEPARATION TECHNOLOGY

SPOTLIGHT

SPANG

SPECIAL

BUSINESS

Q&A:

MARKS

YEARS AS DIVERSIFIED MANUFACTURER IN WESTERN PA

& COMPANY

130

2024 SHOWCASE OF MANUFACTURERS VOL. XXXVII NO. 5 | MAY 2024 MADE15thAnnual INPA

SECTION:

DEPARTMENTS EVENTS

BUSINESS BUZZ

WHAT’S NEW

PEOPLE BUZZ

AWARDS AND PROMOTIONS

HR CONNECTION WORKPLACE TRENDS

HR Q&A GET ANSWERS

Executive Editor

Karen Torres ktorres@mbausa.org

Contributing Writers

Eileen Anderson

Rose Bruno

Rachel Loper

Lisa McKinney

Donald Racey

Dan Zugell

FEATURES

WHAT’S INSIDE | FEATURED STORY

3 MAKE THE MFG CONNECTION

Save the date and be a part of Manufacturing Day (MFG Day) 2024 in Erie.

COVER STORY | LOCAL PROFILE

5 ERIEZ

Eriez, which is firmly rooted in Erie, Pennsylvania, is a global manufacturing leader forging the future of separation technology

SPOTLIGHT Q&A | MANUFACTURING

7 Lynne Ellis, executive vice president of diversified manufacturer Spang & Company, headquartered in Pittsburgh, Pennsylvania, shares the importance of manufacturing as it marks 130 years of operation in 2024.

EDITORIAL

LEGAL BRIEF | TECHNOLOGY

29 NETWORKING AND MORE

See the latest photos from Butler MFG Day on April 18!

READ ON THE GO!

For the most current Business Magazine updates, visit mbabizmag.com

Feature Photography Eriez Additional Photography iStockPhoto.com

Matt Zimmerman Wabtec Design, Production & Printing Printing Concepts Inc. info@printingconceptsonline.com

Advertising Sales

Shawn Netkowicz snetkowicz@mbausa.org

Frank Mehler fmehler@mbausa.org

Judy Rosatti jrosatti@mbausa.org

Patty Welther pwelther@mbausa.org

On the Cover: Eriez is a global leader in separation technologies serving the mining, food, recycling, packaging, aggregate and other processing industries. Shown here is new Eriez CEO Jaisen Kohmuench with one of the company’s iconic orange suspended electromagnets in Erie, Pennsylvania. See full story, page 5.

Mission Statement:

– Board of Governors

| mbausa.org

9 Artificial intelligence in PA: Navigating the legal landscape.

Rachel Loper

BUSINESS ADVISOR | PLANNING

13 Employee stock ownership plans offer powerful benefits for everyone.

Dan Zugell

COMPANY PROFILE | INDUSTRY

14 Industrial Sales & Mfg.: Three-generation leader in contract manufacturing for 57 years ON THE HILL | TOUR

15 A magical moment at Abram’s Nation. Eileen Anderson

MANUFACTURING TRENDS | SUSTAINABILITY

21 Embracing sustainability: The rise of green manufacturing.

Donald Racey

HEALTH & BENEFITS | HIGHMARK

24 Prioritizing mental health coverage: A key to a healthy and productive workforce

SHOWCASE OF MANUFACTURERS | RECOGNITION

26 See our list highlighting some of the most innovative manufacturing firms in the Keystone State.

1 mbabizmag.com MAY 2024 © Copyright 2024 by the Manufacturer & Business Association. All rights reserved. Reproduction or use of editorial, pictorial or advertisements created for use in the Business Magazine, in any manner, without written permission from the publisher, is prohibited. Unsolicited manuscripts cannot be returned unless accompanied by a properly addressed envelope bearing sufficient postage. The magazine accepts no responsibility for unsolicited manuscripts or artwork. The Business Magazine and Manufacturer & Business Association do not specifically endorse any of the products or practices described in the magazine. The Business Magazine is published monthly by the Manufacturer & Business Association, 2171 West 38th Street, Erie, Pa. 16508. Phone: 814/833-3200 or 800/815-2660.

“We are dedicated to creating and delivering services and expertise that help businesses solve problems and succeed.”

Manufacturer & Business Association Headquarters: 2171 West 38th Street, Erie, PA 16508 Pittsburgh: 850 Cranberry Woods Drive, Suite 2224 Cranberry Township, PA 16066 814/833-3200 | 800/815-2660

10 11 18 23

SAVE THE DATE!

Please save the date for our 11th Annual Manufacturing Day celebration from 8 a.m. to 1 p.m. Wednesday, October 9, at Erie’s Bayfront Convention Center.

The event will showcase more than 60 exhibits, programs and demonstrations, designed for participants to experience innovative manufacturing technology in a hands-on, interactive environment plus educational breakout sessions throughout the morning. More than 2,000 educators, students and community leaders are expected to attend.

Visit mbausa.org/mfg-day for the latest updates.

PRESENTED BY:

ALONG WITH OUR PARTNERS:

MANUFACTURE

FUTURE!

YOUR

11th

ANNUAL

Make the MFG Connection

Save the Date, Be a Part of Manufacturing Day 2024 in Erie

Manufacturing jobs are critical to Pennsylvania's economy as they provide stable employment opportunities, contribute significantly to the state's GDP and support related industries. Additionally, manufacturing fosters innovation and drives regional development, enhancing Pennsylvania's overall competitiveness and economic resilience.

At the Manufacturer & Business Association (MBA), we understand the importance of manufacturing and the urgency to equip individuals with the skills needed to meet industry demands, foster innovation and sustain economic growth. We are consistently advocating for our manufacturing members and changing the perception of modern manufacturing careers, as demonstrated by our second annual Butler MFG Day held on April 18 and one of our most highly anticipated events yet to come — the 11th annual Manufacturing Day (MFG Day) celebration on October 9 in Erie.

Our #MFGDay2024 event, set for 8 a.m. to 1 p.m. at the Bayfront Convention Center, promises to be bigger and better than ever, with more than 2,000 students, teachers, school administrators, business leaders and community members expected to attend.

MFG Day, which has been rebranded with our new, more modern logo, showcases the cutting-edge technologies and high-paying career opportunities available in modern manufacturing. As Pennsylvania boasts an economic impact of more than $113.2 billion from manufacturing, representing nearly 10 percent of all jobs in the state, it ’s clear that manufacturing is deeply ingrained in the fabric of our communities. Moreover, throughout history, Pennsylvania has been at the forefront of manufacturing innovation, and MFG Day continues this tradition by inspiring the next generation of creators.

One of the key highlights of MFG Day is the hands-on experiences for students. From

interactive demonstrations in 3D printing and robotics to exploring the intricacies of CNC machining and drone technology, participants are immersed in the dynamic world of modern manufacturing. Additionally, the event offers informative breakout sessions led by industry experts, shedding light on the diverse array of high-paying careers available in manufacturing.

Looking ahead, the importance of MFG Day becomes even more pronounced as the United States faces the challenge of filling 4 million manufacturing jobs over the next decade. By engaging students, educators, parents and community leaders, MFG Day plays a crucial role in bridging the skills gap and inspiring the future workforce. It empowers manufacturers to collaborate in building excitement around modern manufacturing careers, thereby ensuring the prosperity of our communities and future generations.

MFG Day serves as a catalyst for changing perceptions about manufacturing. It underscores the reality that modern manufacturing careers are not only well-paying and highly skilled but also diverse and inclusive. From science and research to marketing and sales, there truly is a place for everyone in manufacturing. By embracing creativity, problem-solving, teamwork and technology, individuals can make a positive impact on their communities and the world at large.

MFG Day is more than just a celebration of innovation; it ’s a testament to the boundless opportunities that manufacturing offers. As we come together to emphasize the importance of

modern manufacturing jobs and technologies, we also highlight the invaluable contributions that manufacturing makes to our region.

It’s also one of the many reasons I’m so thrilled to share this month’s 15th annual Made in PA issue of the Business Magazine with all of you. In this special edition, the MBA is proud to highlight the many engines that drive our economy, such as Eriez, a global authority on separation technologies founded and headquartered in Erie, as well as Spang & Company, a diversified manufacturer based in Pittsburgh with global operations as well.

In addition to the many manufacturers featured throughout the pages, I also hope you’ll check out our Showcase of Manufacturers, which lists many of the innovative companies operating here in the Keystone State — some right in our own backyard.

As we prepare for #MFGDay2024, I hope you will be a part of shaping the future and save the date for October 9! To learn more about how to get involved, visit mbausa.org. We hope to see you there!

Lori Joint is the president and chief executive officer of the Manufacturer & Business Association. Contact her at 814/833-3200, 800/8152660 or ljoint@mbausa.org.

3 mbabizmag.com MAY 2024 #MFGDAY2024 WHAT’S INSIDE | FEATURED STORY

EE

EE

4 MAY 2024 • mbabizmag.com Healthcare • Education • Institutional • Retail • Hospitality • Industrial • Concrete FIRST CHOICE

offers a dynamic management team committed to providing construction excellence. Austin is the leading regional general contractor and construction management firm...and has

delivering for its clients since 1906.

Austin & Son

been

Son remains steadfast in its century old promise to... “Do the right thing...all the time.” It’s the Austin Difference. in Regional Healthcare Construction...EE Austin & Son Contractors & Construction Managers Since 1906 814.454.7147 | www.eeaustin.com

Austin &

PA

AHN Saint Vincent Emergency Department, Erie,

NY

UPMC Chautauqua, Jamestown,

UPMC Hamot Patient Tower, Erie, PA

PA

AHN Saint Vincent Hardner Building, Erie,

The rich history of Eriez traces back to 1942, when Orange Fowler “O.F.” Merwin, an enterprising traveling salesperson specializing in grain milling equipment, observed a pervasive problem among his clientele: ferrous contamination disrupting their milling operations. From small metal fragments such as wire and nails to larger items like horseshoes and hammers, these stray materials would inadvertently find their way into the process, causing significant damage and, in extreme cases, sparking fires.

With an eye for innovation and a commitment to problem-solving, O.F. embarked on a mission to remedy this issue. Working in the basement of his home in Erie, Pennsylvania, he poured his efforts into developing what would ultimately become the world ’s first permanent magnetic plate separator. This groundbreaking invention provided a transformative solution to ferrous contamination and set the company on its path to success.

From Basement Prototype to Global Leader

From humble beginnings to a worldwide powerhouse, Eriez’ journey has spanned more than 80 years, shaping the profound legacy that defines Eriez today.

Under the leadership of the Merwin family, Eriez has emerged as a global leader in separation technologies, boasting more than 900 employees around the world, an extensive sales representative network, and more than 500,000 square feet of manufacturing space. The company’s comprehensive range of state-of-the-art magnetic separation, metal detection, and material handling equipment is now manufactured through 12 wholly

Eriez Forges the Future of Separation Technology

owned international subsidiaries. Eriez’ headquarters remains firmly rooted in Erie, with 350 employees locally in its two Erie facilities.

Eriez’ unwavering dedication to research and development has helped solidify its position as a pioneering force across many industries including food, packaging, plastics, recycling, mining, aggregates and various other processing sectors.

Embracing Change is the Name of the Game

Guiding the ongoing growth of the organization is Jaisen Kohmuench, who assumed the role of president and CEO of Eriez on January 1, 2024. The leadership shift was meticulously planned, with Kohmuench collaborating closely with former president and CEO Lukas Guenthardt and the company’s board of directors to ensure a seamless transition.

Kohmuench’s education, extensive experience and strategic vision uniquely prepared him to navigate Eriez into the future, capitalizing on the substantial foundation established by his predecessor. His leadership promises to chart a path for sustained success and continuous innovation in the dynamic field of separation technologies.

The year is already off to a strong start, with significant strides in product innovation, highlighted by the introduction

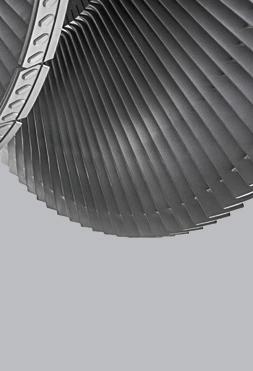

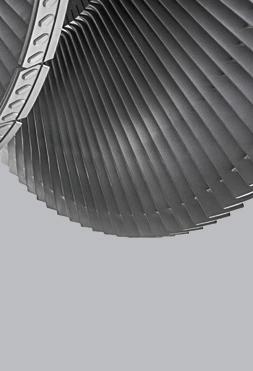

Eriez suspended electromagnets are used to automatically remove damaging tramp iron from products such as coal, aggregates, wood and other conveyed materials. This especially large unit is destined for a mine in Arizona.

of Eriez’ revolutionary PrecisionGuard X8 metal detectors. These cutting-edge metal detectors feature advancements in signal processing and electronic design. With robust construction and an intuitive touchscreen interface, these units excel at identifying small ferrous, nonferrous, and stainless-steel contaminants in food applications and other processing industries. Consumers and brands alike are protected against unwanted metal particles thanks to technologies from Eriez.

Paving the Pathway to Tomorrow

With its comprehensive range of innovative solutions, Eriez stands ready to address the ever-changing demands of the global market. By cultivating a culture of creativity and collaboration, Eriez fosters an environment conducive to continuous improvement and revolutionary advancements. In this era of rapid change and disruption, Eriez serves as a beacon of stability and progress, paving a path forward while remaining steadfastly anchored, to Erie, by its fundamental principles.

For more information about Eriez, visit eriez.com.

5 mbabizmag.com MAY 2024 COVER STORY | LOCAL PROFILE

Eriez is a global company that is firmly rooted in Erie, Pennsylvania. Shown here are the company’s two Erie locations – its corporate headquarters at 2200 Asbury Road (right) and manufacturing facility at 1901 Wager Road (left).

Jaisen Kohmuench, President and CEO

MILLIONS of Springs

IN STOCK AND READY TO SHIP!

Spang & Company Marks 130 Years as Diversified Manufacturer in Western PA

Manufacturing has a proud history in Pennsylvania. Today, the Keystone State boasts a robust and varied industrial economy as home to key players in defense, pharmaceuticals, electronics, steel industries and much more. Here, Lynne Ellis, executive vice president of diversified manufacturer Spang & Company, headquartered in Pittsburgh, Pennsylvania, shares the importance of manufacturing as it marks 130 years of operation in 2024.

Spang & Company was founded as an oil repair shop by George Spang in Butler, Pennsylvania in 1894. Tell us how the business came about.

From 1894 through the 1980s, Spang became the world’s leading manufacturer of cable system drilling tools, when the country was drilling for oil all through the Eastern and Midwest states. Spang manufactured a large variety of drilling tools, drill pipe, and other equipment to serve the oil, gas, blast hole and water well drilling industries. Through the years, the company expanded into providing high-temperature refractory specialties and slag processing to the steel industry. There was an additional division that fabricated steel structures for highway and railroad bridges. At one point, the company also owned a toy factory that it had acquired from a Pittsburgh family, which was later moved to Arkansas in 1970, and also had a retail division, comprised of 56 drug stores and pharmacies throughout Western PA.

Longtime Pittsburghers may also remember the Eiben & Irr department stores in Pittsburgh and Butler, another arm of the company. Most of these companies were either divested or closed in the 1980s as the world’s economy changed.

Spang & Company has owned a variety of corporations and has continued to evolve in electrical and electronic manufacturing. Please describe the company’s operations and workforce today.

Spang & Company is made up of three operating lines. Magnetics began in Butler in 1949 and was acquired in 1970 by Spang. Although we did have manufacturing in the United States, in 2004 we moved the electronic components manufacturing plant to Xiamen China, where we employ about 220 people. Many of our customers and competitors are and have been in Asia Pacific for many years. The electronic components we manufacture are made from various magnetic property

materials and are used on circuit boards or in the power systems of products in the alternative energy, uninterruptible power supplies, telecommunications, aerospace and medical systems. There are another 30 employees of the Magnetics Division in Pennsylvania and Arizona, supporting the sales, research and design, and distribution warehouse operations for this global company. There are also 11 employees of Magnetics in a Hong Kong sales office.

Spang Engineered Solutions builds on the Magnetics core business, by utilizing this base component to design high frequency inductors, transformers and power supplies that support medical, defense, aerospace, rail systems and other users with special power needs. The division began in 2012, staffed initially by Magnetics employee’s intent on growing this new arm of design business. Services include design, re-design, prototyping, and final production assembly of over a hundred designs for power. Through three acquisitions in the last five years, this division has grown to include operations in Phoenix, Arizona; Dallas, Texas; and Pittsburgh, Pennsylvania, with about 80 employees.

Spang Power Electronics, formerly Kemco Corporation, was acquired in 1966, and has since grown to employ about 70 people in Sandy Lake, Pennsylvania, and Mentor, Ohio, and another 23 employees at a plant in Xiamen, China. Spang Power Electronics produces a full line of AC and DC power control products, at mid- to highvoltage ranges, supporting industries in the glass, hydrogen, fiberglass, polysilicon and industrial heating industries.

All of our product lines are capable of design, engineering, rapid prototyping, manufacturing, and extensive testing for quality and performance. Many of our products and operations have extensive compliance requirements for both quality and manufacturing facility controls,

including ISO 9001, ISO 14001, and country of manufacture standards.

Describe your customer base and worldwide reach.

All three operating lines have worldwide customers. Most automakers throughout the world have industrial lines in their plants that include a Spang Power Electronics system.

New interest in green energy has spurred sales across all our product lines, as well as investment in new manufacturing plants worldwide. Other customers may not be well-known names in the world, but in the niche industries that serve automotive, glass, fiberglass and other manufacturing, they are well known.

Our products may be in anything from the pagers used in hospitals to medical equipment such as AEDs to locomotive engines and helicopters.

Although Spang & Company is a global operation, it is still headquartered in Pittsburgh. What does it mean to you to still retain Spang’s PA roots?

This local family had deep connections throughout the Western PA area, along with impressive growth plans in the 1960s and on through the 2000s. The operating locations we have in Pennsylvania and Ohio have a long history of employing many people who stayed with the company throughout their careers. Our relationship with local businesses, customers and employees has been a strong point for keeping our base of operations local.

To learn more, visit spang.com.

7 mbabizmag.com MAY 2024

SPOTLIGHT Q&A| MANUFACTURING

Decisions you trust from bankers you know.

Automated Industrial Systems (AIS), a locally owned business known globally for its high-quality O-ring installation machines, has been thriving since 1977.

Continuously optimizing the custom design to improve installation and speed since their first O-ring system in 1978, the company now proudly distributes assembly machines to nine countries.

When Frank Victor and his wife Dr. Melissa Brasco acquired the business in 2021, they chose Marquette, a locally headquartered bank, as their financial partner.

“I trust Marquette with our business because I know the people making decisions. I know they understand our company, what we do and what we need to succeed. And I know I can trust them to make informed decisions,” says Victor.

Brasco, vice president of AIS, also appreciates the bank’s personal approach. “Marquette is big enough to handle our growing business, but small enough to care — not just about AIS, but about us personally.”

Marquette is proud to support local businesses like AIS as they find success on a global scale.

Frank Victor, owner Automated Industrial Systems

Talk with us at 814-455-4481. Or to learn more visit MarquetteSavings.bank/Business.

Artificial Intelligence in PA: Navigating the Legal Landscape

Rachel Loper is an associate at MacDonald Illig Attorneys and her practice focuses on Banking & Finance, Real Estate, and Business Transactions.

Stanford Professor John McCarthy first introduced the term “artificial intelligence” (AI) in 1955, which he defined as “the science and engineering of making intelligent machines.” Since then, the use of AI has developed into technologies that enable computers to perform a variety of advanced functions, including the ability to analyze data, make recommendations, understand and translate languages, and even defeat world-class chess champions and dethrone trivia game-show stars. AI has also become an integral part of modern manufacturing and business operations, offering tremendous opportunities for innovation and efficiency.

The rapid adoption of AI-powered systems and robotics raises complex legal considerations and challenges that have yet to be fully explored under current Pennsylvania laws surrounding data privacy, data security, and product safety laws. The void in state guidance has outpaced existing regulatory frameworks, creating uncertainties, compliance challenges, and potential liability pitfalls for the unwary. However, AI implementation

in manufacturing is subject to various existing regulations that apply to the broader use of technology and industrial processes.

Data Privacy and Security

AI relies on a vast amount of data, which can include sensitive information about business operations, employees, and even customers. As such, businesses must comply with Pennsylvania laws and regulations aimed at protecting the privacy rights of its residents.

Under the Commonwealth ’s Data Breach Notification Law, businesses are required to provide prompt notification to all parties whose data is compromised during a security/ data breach. Additionally, businesses in certain industries, such as financial and health care, must also comply with federal data breach notification laws (for example, HIPPA Breach Notification Requirements). While Pennsylvania does not have a comprehensive privacy law akin to the European Union ’s General Data Protection Regulation or the California Consumer Privacy Act, it is important to stay up to speed with any proposed data privacy legislation that may require stricter data privacy protocols for Pennsylvania businesses.

Additionally, it is paramount that the manufacturing and business industries utilizing AI-powered systems implement strong data security measures to safeguard personal information from unauthorized access or disclosure (for example, use encryption software to secure sensitive data, implement access controls, and regularly audit and monitor AI algorithms). Finally,

contractual agreements with AI vendors should include provisions addressing data security obligations, confidentiality requirements, and incident response protocols in the event of a data breach.

Product Liability and Safety

Manufacturers must ensure that any systems, AI-powered systems, and robotics used within the business comply with product safety regulations, which can include the standards and policies set forth by federal regulatory bodies such as the Occupational Safety and Health Administration (OSHA).

To prevent injuries caused by mechanical equipment, OSHA sets forth standards and guidelines for machine safety. These standards and guidelines includes conducting a thorough risk assessment, adding additional safety training, maintaining equipment maintenance, such as following manufacturer recommendations for maintenance schedules, perform routine inspections and promptly address any issues or defects to prevent accidents and malfunctions. Also included in these guidelines, continuing clear communication of hazards associated with AI-powered systems and robotics to workers. Further, OSHA recommends assessing the reliability of AI algorithms, the safety of robotic components, the potential impact of malfunctioning or errors on workers safety before implementing AI-powered technologies and robotics.

It is crucial for manufacturers to prioritize worker safety and comply with product liability regulations when utilizing AI-powered systems and robotics. This will ensure a safe and productive work environment and mitigate the risk of accidents or injuries.

Conclusion

Navigating AI regulatory compliance in Pennsylvania presents unique challenges for businesses utilizing AI technologies. Business owners must balance continued innovation and efficiency while upholding legal standards and protecting consumer interests. By staying informed, proactively addressing compliance challenges, and adopting best practices, manufacturers and businesses can navigate the evolving regulatory landscape surrounding AI-powered systems and robotics in Pennsylvania.

For more information, contact MacDonald Illig Attorneys at 814/870-7600 or visit macdonaldillig.com.

9 mbabizmag.com MAY 2024 LEGAL BRIEF | TECHNOLOGY

NEW NAME, NEW LOGO UNVEILED FOR PITT-TITUSVILLE’S EDUCATION AND TRAINING HUB

Officials from three of the University of Pittsburgh’s campuses, partner representatives and community members recently celebrated the launch of a new name, logo and messaging for what was PittTitusville’s Education and Training Hub.

Those attending the brand launch on March 11 saw the grand unveiling of the new logo and name — the Education and Training Center at Pitt-Titusville. In addition, new campus signs were uncovered.

“This is a very exciting day,” said Dr. Stephanie Fiely, executive director of the ETC. “Our new name, logo and messages will help us enhance the way we talk about all of the exciting things that have been happening and will continue to happen here.”

Some of those exciting initiatives include renovations, according to Pitt-Titusville President Rick Esch, with new spaces where students can learn, create and collaborate. Renovations to the J. Curtis McKinney II Student Union are under way and will include adding an art gallery, a new machine workshop, a makerspace, an industrial maintenance and workforce development lab, and a digital arts lab and studio.

Also offering remarks was Dr. Joseph McCarthy, interim provost and senior vice chancellor for the University of Pittsburgh who has been named Pitt’s new provost and senior vice chancellor pending official approval by Pitt’s Board of Trustees. “The rebranding here at the Pitt-Titusville campus is really indicative of what we have done with all of our regional campuses. The regional campuses are aimed at serving the Commonwealth and helping to supply the workforce needs for the Commonwealth. The rebranding is really leaning into that fact. We really want to emphasize our partners and our collective value.”

The Education & Training Center has a new website that will soon be live and that can be found at ETCGoSucceed.org. ETC will continue to inform the community and region of the new name, logo, and student offerings starting with a six-countywide billboard display campaign, digital marketing tactics, radio spots and social media.

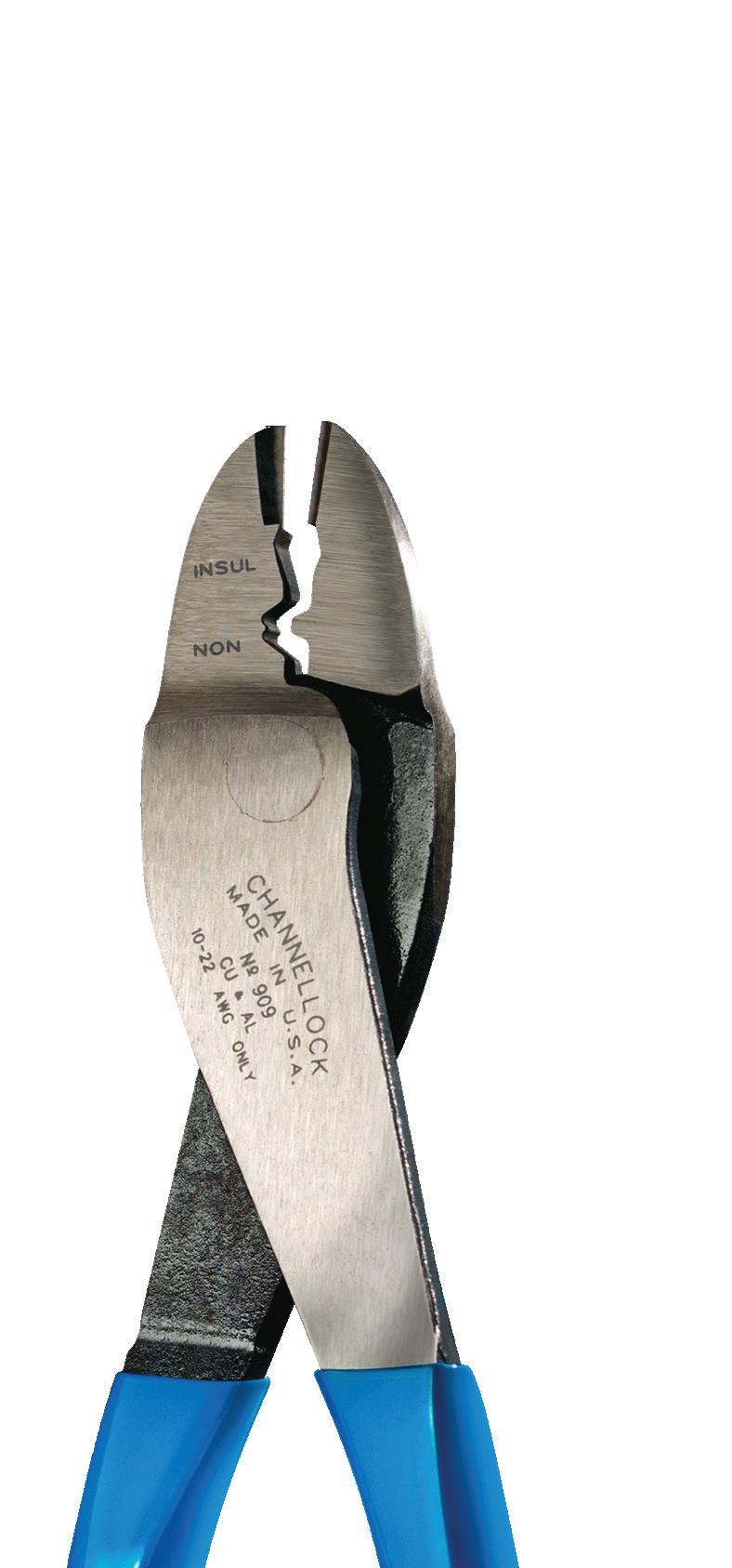

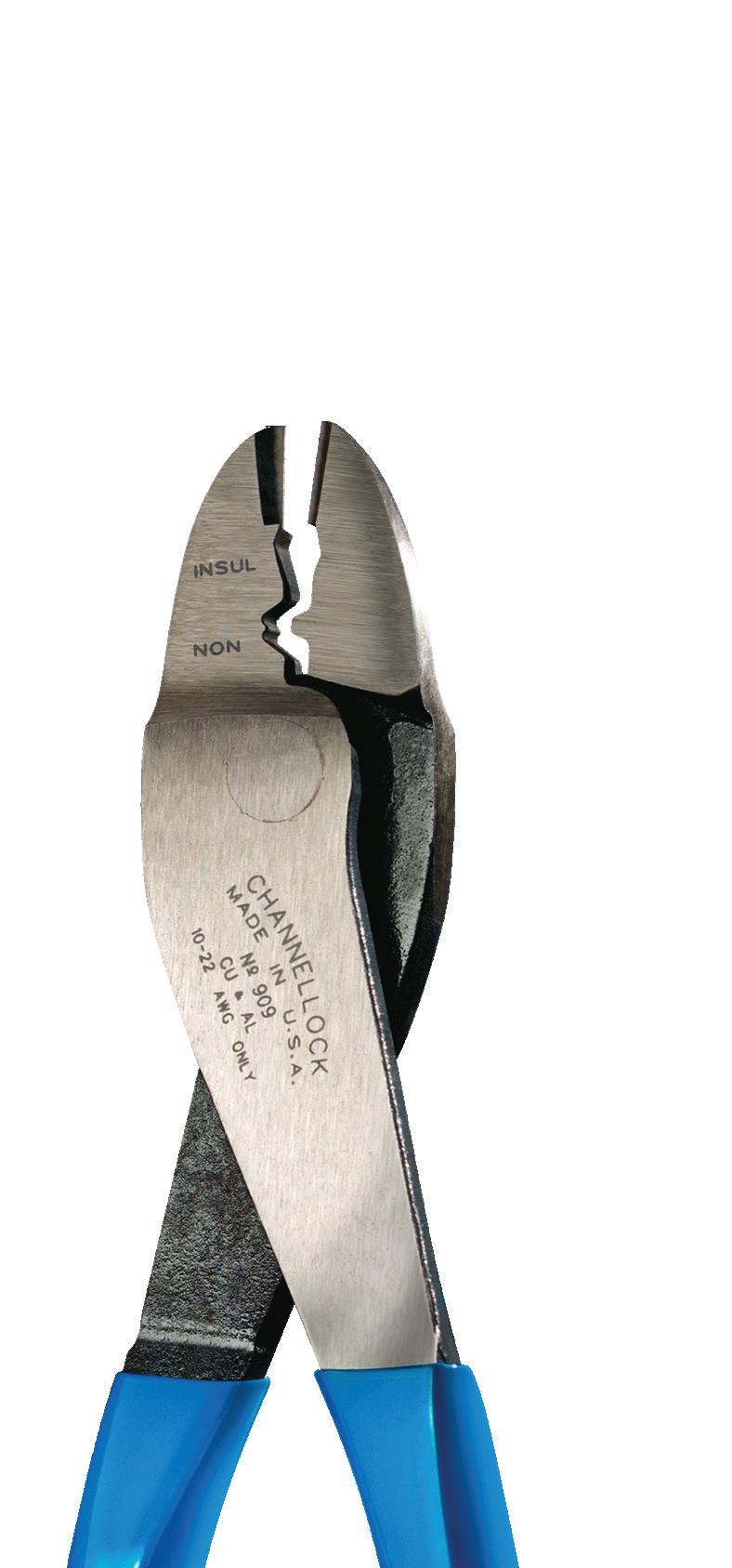

CHANNELLOCK RECEIVES 2023 RISK MANAGEMENT COMMENDATION

In recognition of its unwavering dedication to employee safety, Channellock, Inc. was presented with the annual Risk Management Commendation Award.

PMA Companies, Channellock, Inc.’s workers’ compensation insurer, grants this award to a very small percentage of PMA clients who demonstrate a strong commitment to employee safety, effective risk mitigation strategies, and contingency planning. Channellock, Inc.’s ongoing safety initiatives and strong employee engagement have contributed to a significant reduction in workplace injuries resulting in lost work claims over the last three years.

“Our ultimate goal is to ensure our associates return home safely to their families,” said Jon DeArment, president and chief operating officer at Channellock, Inc., in a recent press release. “That’s why we’ve made it a priority to implement proactive safety measures and foster open communication channels.”

With more than 350 full-time associates at its two facilities in Meadville, Pennsylvania, Channellock, Inc. is among the largest employers in Crawford County and remains dedicated to the safety of its workers as the company continues to grow.

“We are proud to maintain an excellent safety record even as we continue to hire and train new employees,” said Marc Johnston, vice president of Operations at Channellock, Inc. “This award speaks to the processes we have set in place and the dedication of both new and longtime associates to create a safe work environment for all.”

PMA Companies presented Channellock, Inc. with the 2023 Risk Management Commendation Award during the CHANNELLOCK® monthly safety committee meeting at its headquarters in Meadville on November 22.

Channellock, Inc. is a worldwide leader in the manufacturing of high-quality pliers

and assorted hand tools, including its iconic, American-made CHANNELLOCK® Tongue & Groove Pliers.

Founded by George B. DeArment in 1886, the Meadville-based company is now in its sixth generation of family ownership and operation.

For more information, visit channellock.com.

WABTEC UNVEILS FIRST PRODUCTION FLXDRIVE BATTERY HEAVY-HAUL LOCOMOTIVE

Wabtec and Australian mining firm Roy Hill unveiled the world’s first 100-percent battery-powered, heavyhaul locomotive for mainline service in ceremonies this past fall at Wabtec’s Erie, Pennsylvania manufacturing facility.

The FLXdrive locomotive contains 72 lithium-ion modular battery packs with a total of 36,288 cells, giving the locomotive an energy capacity of 7 megawatt-hours. This is about three times the power of a 2.4-megawatt-hour FLXdrive prototype that operated 13,000 miles on BNSF Railway in California with zero failures in 2021.

“This FLXdrive locomotive represents a major step in the journey to a low-tozero-emission future in the rail industry,” said Rafael Santana, president and CEO of Wabtec, in a news release.

“The FLXdrive is driven from within by our battery technology and the innovative spirit of our employees. Roy Hill is an ideal customer to partner with given their leadership and excellent operational record.”

The new locomotive will operate in some of the most challenging conditions on the planet, with temperatures reaching 130 degrees, and will provide a double-digit percentage reduction in fuel costs and emissions per train.

For more information, visit wabteccorp.com.

10 MAY 2024 • mbabizmag.com

BUSINESS BUZZ | WHAT’S NEW

The new name — the Education and Training Center at Pitt-Titusville — was recently unveiled at the campus, along with a new website and logo.

ERIEZ PROMOTES KLINGE TO DIRECTOR-EMEA OPERATIONS & STRATEGY

Eric Nelson, Eriez vice president of Global Operations, has announced the promotion of John Klinge to director – EMEA Operations & Strategy, effective February 1, 2024. In this pivotal role, Klinge will spearhead the company’s strategic management initiatives in the Europe, Middle East and Africa (EMEA) region.

Klinge will manage and collaborate extensively with Eriez’ EMEA leadership teams to drive profitable growth and implement enhancements in products, systems, and capacity. His overarching goal is to further elevate Eriez’ presence in the diverse EMEA markets, solidifying the company’s position as an industry leader in the region.

Nelson expressed his confidence in Klinge’s capabilities, stating, “John’s exceptional management acumen, deep industry expertise, and strategic sales skills uniquely prepare him for this leadership role. Under his guidance, Eriez will accelerate its commitment to providing innovative solutions that exceed customer expectations in the EMEA region.”

After serving as a captain in the U.S. Army, Klinge earned bachelor’s degrees in political science, business and military science from the University of Pittsburgh and a master’s degree in business administration from Pennsylvania State University at Erie. He joined Eriez in 2008, earning numerous promotions during his tenure. Klinge’s previous experience with the company includes roles in regional market and product management, aftermarket department leadership and, most recently, he served as Global Product manager for Metal Detection. Established in 1942, Eriez is a global leader in separation technologies.

EVIDENT FINANCIAL WELCOMES

KNOX AS FINANCIAL ADVISOR

Evident Financial recently announced that Joseph Knox has been appointed financial advisor. In his role, Knox will help clients develop strategies for investing and achieving their financial goals. In addition, he will contribute to the expansion of the company’s retirement plan services.

“We are excited to welcome Joe to our team. Joe brings a strong work ethic and a passion to help others achieve their full potential, as evidenced by having served as the captain of Gannon University men’s soccer team,” said David Cullen, president of Evident Financial.

Knox earned his bachelor’s degree in finance and international management and an MBA from Gannon University. Originally from Gold Coast, Australia, he came to Gannon on an academic and soccer scholarship. Knox will soon take the Series 65 exam to become a licensed financial advisor.

Headquartered in Erie, Evident Financial is a fiduciary investment advisory firm serving individuals and their families and 401(k) plan sponsors.

CHANNELLOCK, INC. PROMOTES

DEARMENT TO PRODUCT MANAGER

Channellock, Inc., a leading manufacturer of high quality pliers and assorted hand tools, recently announced the promotion of Will DeArment to product manager.

In this role, DeArment is responsible for the “life cycle” and organization of the company’s products from concept to launch as well as collaborate with end users, distribution partners, and vendors to identify new opportunities and further enhance product offerings.

In addition to overseeing the company’s product portfolio, DeArment manages special-order products and Channellock, Inc.’s private-label customer base.

With the launch of over 80 new products, DeArment’s promotion comes at a pivotal moment in the company’s history. Now responsible for managing the entirety of Channellock, Inc.’s product offerings, DeArment will help develop innovative strategies to expand them — ensuring the company’s continued growth.

Previously, DeArment spent several years in production, maintenance, and shipping at Channellock, Inc. while completing his bachelor’s degree in supply chain management at Duquesne University in Pittsburgh, P.A. Most recently, DeArment served as the company ’s Production Materials coordinator, where he assisted with inventory management and production planning.

Will DeArment is a sixth-generation member of the DeArment family, which has owned and operated Channellock, Inc. for over 135 years. “Having your kids join a family business and help carry out a legacy that was built by the hard work of those who came before us is something that every parent hopes for,” said Jon DeArment, president and COO at Channellock, Inc. “Will’s role comes with a great deal of responsibility, but I am confident in his ability to drive new product growth for CHANNELLOCK®.”

WABTEC APPOINTS YATES TO VP OF INVESTOR RELATIONS

Wabtec Corporation recently announced the appointment of Kyra Yates as vice president of Investor Relations. In this role, Yates will be responsible for communicating Wabtec’s vision, strategy, financial performance, and future expectations to shareholders and the financial community. She succeeds Kristine Kubacki, who has held the role since 2019.

“Kyra is a well-respected leader with a deep understanding of the company’s financials, operations and growth strategy,” said John Olin, executive vice president and CFO of Wabtec. “Having held diverse leadership roles in our Finance organization over the years, Kyra’s in-depth experience in transportation, manufacturing, supply chain, and commercial sales will be valuable in communicating how Wabtec is bringing value to our shareholders by delivering innovative products and services to the industries we serve.”

Yates has been with Wabtec since 2008. Throughout her tenure, she has held several leadership positions within the finance team supporting various parts of the business.

Most recently, Yates served as the vice president and chief financial officer for the company’s Global Operations, where she managed the financial performance for the company’s manufacturing, sourcing, and logistics operations. Yates earned her BA in accounting from Bellarmine University. Yates will report to John Olin, Wabtec CFO.

Headquartered in Pittsburgh, Wabtec Corporation is a leading global provider of equipment, systems, digital solutions and value-added services for the freight and transit rail industries, as well as the mining, marine and industrial markets.

11 mbabizmag.com MAY 2024

PEOPLE BUZZ | AWARDS AND PROMOTIONS

12 MAY 2024 • mbabizmag.com BUSINESS MAGAZINE Got great news? Share it! The Business Magazine publishes MBA member news on major appointments, mergers, grants and/or awards, as space permits. To submit your company news, email ktorres@mbausa.org!

Employee Stock Ownership Plans Offer Powerful Benefits for Everyone

In contrast, a 2015 study by the National Center for Employee Ownership found that 93 percent of sellers to an ESOP are either “Very Satisfied” or “Satisfied” with the sale, with only 7 percent expressing “Neutral” or “Dissatisfied” sentiments. These findings suggest that selling a business to an ESOP can lead to a more positive and fulfilling outcome for business owners.

Dan Zugell (Dan The ESOP Man) is the executive vice president of Business Transition Advisors, Inc., a 100-percent employee-owned consulting firm specializing in the implementation of employee stock ownership plans.

Employee stock ownership plans (ESOPs) have gained popularity in recent years as a unique way for business owners to sell some or all of their business and facilitate employees becoming beneficial owners of the company where they work.

ESOPs offer powerful benefits for business owners, employees and the community. Owners can enjoy immediate liquidity from a ready buyer at full fair market value, deferring and eliminating capital gains normally due on a business sale and indefinitely maintaining corporate control while preserving their company, employees and family legacy. ESOP companies are also afforded significant tax and other benefits. Remarkably, profits of a 100-percent ESOPowned company are income tax exempt since an ESOP is a tax-exempt retirement

plan. The tax savings are redirected to pay off the debt incurred to buy the business from the seller. ESOP companies statistically outperform their peers with increased productivity, greater return on assets, increased sales and other metrics.

Employees of ESOP companies benefit greatly. The employees are given shares of the company over time at no cost to them and are “cashed out” when their employment ends. If fact, an ESOP participant averages 2.5 times greater total retirement plan account balance than a similar employee at a company with a 401(k) only. Employees also gain enhanced job security and are four times less likely to be laid off during economic downturns.

Communities are strengthened by ESOPs as well. ESOPs keep local jobs and help defend against the potentially devastating consequences of a sale to some outside buyers who have little regard for local jobs or the community. ESOPs create independent wealth for employees fostering positive economic activity and less people relying on social safety nets.

MORE POSITIVE OUTCOMES

According to a study by PwC, more than 75 percent of business owners who have sold their business experience “profound regret” within a year after the sale. This statistic underscores the emotional significance of letting go of a business.

Elizabeth Smith, president of Acutec Precision Aerospace, Inc. in Meadville, Pennsylvania, said, “I have a long career ahead of me, but I want the employees to be on the journey with me. Why not give a stake to the person who’s working their butt off?” This sentiment captures the essence of what ESOPs aim to achieve — aligning the interests of employees with the success of the business.

Ashleigh Walters, former owner and former president of 100-percent employeeowned Onex, Inc. in Erie, PA, stated, “It rewards all the people who have worked with us. The business will go on. It stays in Erie and will never move.” This quote emphasizes the sense of continuity and loyalty that ESOPs can foster within a company, ensuring that the business remains rooted in its community and that employees are motivated to contribute to its long-term success.

IN CONCLUSION

ESOPs represent a powerful and innovative way to create a win-win situation for business owners and employees alike. By embracing the principles of shared ownership, collaboration, and long-term thinking, companies can cultivate a culture of engagement, empowerment and sustainability that benefits everyone involved. As more businesses explore the potential of ESOPs as a succession planning and employee engagement strategy, we can expect to see a continued rise in the adoption of this unique ownership model across a variety of industries and sectors.

For more information about ESOPs, contact Dan Zugell at Business Transition Advisors at dzugell@bta.us.com or visit businesstransitionadvisors.com.

13 mbabizmag.com MAY 2024 BUSINESS ADVISOR | PLANNING

Three-Generation Leader in Contract Manufacturing for 57 Years

In 1967, James Rutkowski Sr. and Joan Rutkowski founded Industrial Sales & Mfg. Company in their family garage on Connecticut Drive with a Fosdick drill press and some parts to be machined for Copes Vulcan. Fast forward to today, Industrial Sales & Mfg. Inc. (ISM) is a contract manufacturer that employs over 150 hard-working Pennsylvanians in six facilities in Millcreek Township in Erie County, Pennsylvania. In that time, ISM has produced over 25,000 distinct parts numbers lifetime sales of over half a billion dollars in revenue. In 2024, ISM has added additional laser welding capabilities, a new hi-definition plasma burner, laser marking and a Trumpf TruBend Brake Press – 36 Ton x 41” Length Capability to our manufacturing buffet of services. Furthermore, we have upgraded our offices to the latest in workspace and technology.

ISM is a premier contract manufacturer and supplier of quality machined, fabricated and assembled components for over 800 original equipment manufacturers (OEMs). With advanced technology and highly skilled employees, ISM can produce a range of components and assemblies ranging from a single prototype to millions, exactly as ordered, on time, every time. “ISM’s commitment to quality and performance has allowed us to achieve the growth that benefits our company, our employees, and the community in which we live,” says Founder and CEO Jim Rutkowski Sr.

4982 Pacific Avenue, Erie, PA 16506

P: 814-833-8080

146 S Broad Street, Grove City, PA 16127

P: 724-458-7889

16226 Conneaut Lake Rd., Meadville, PA 16335

P: 814-813-5030

14 MAY 2024 • mbabizmag.com

SERVING THE TRI-STATE REGION SINCE 1969 printingconceptsonline.com O FFS E T & D IG I TA L PR I N T I N G PRE PR E S S & D E S I G N B I N D E RY & M AI LI N G S E RVI C E S

COMPANY PROFILE 2609 West 12th Street Erie, PA 16505 Phone: 814/833-9876 www.ismerie.com

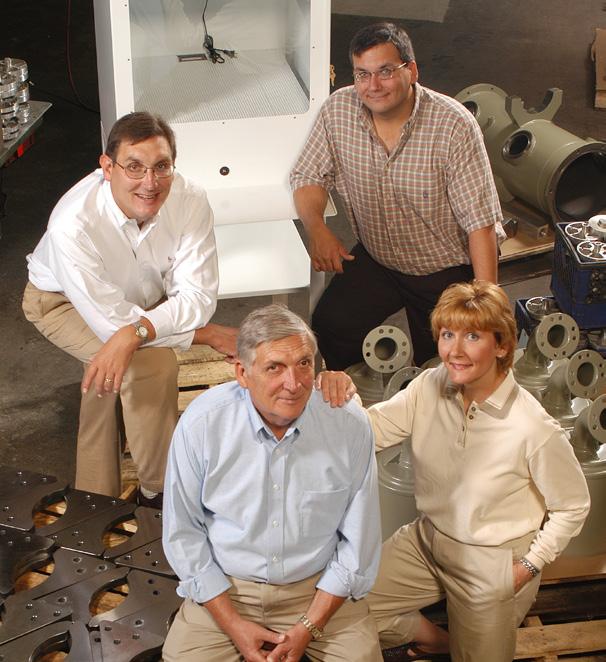

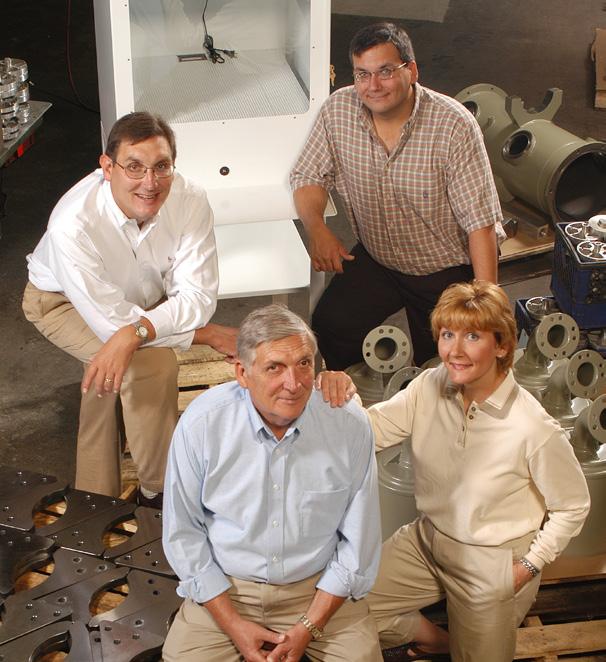

Front

row, from left: ISM Founder and CEO Jim Rutkowski Sr. and Secretary and Business Manager Ann E. RutkowskiMarx, along with (back row, from left): General Manager and Treasurer Jim Rutkowski Jr. and Vice President of Manufacturing Charlie Rutkowski.

A Magical Moment at Abram’s Nation

Eileen Anderson is the director of Government Relations at the Manufacturer & Business Association. Contact her at 412/805-5707 or eileenanderson@ mbausa.org.

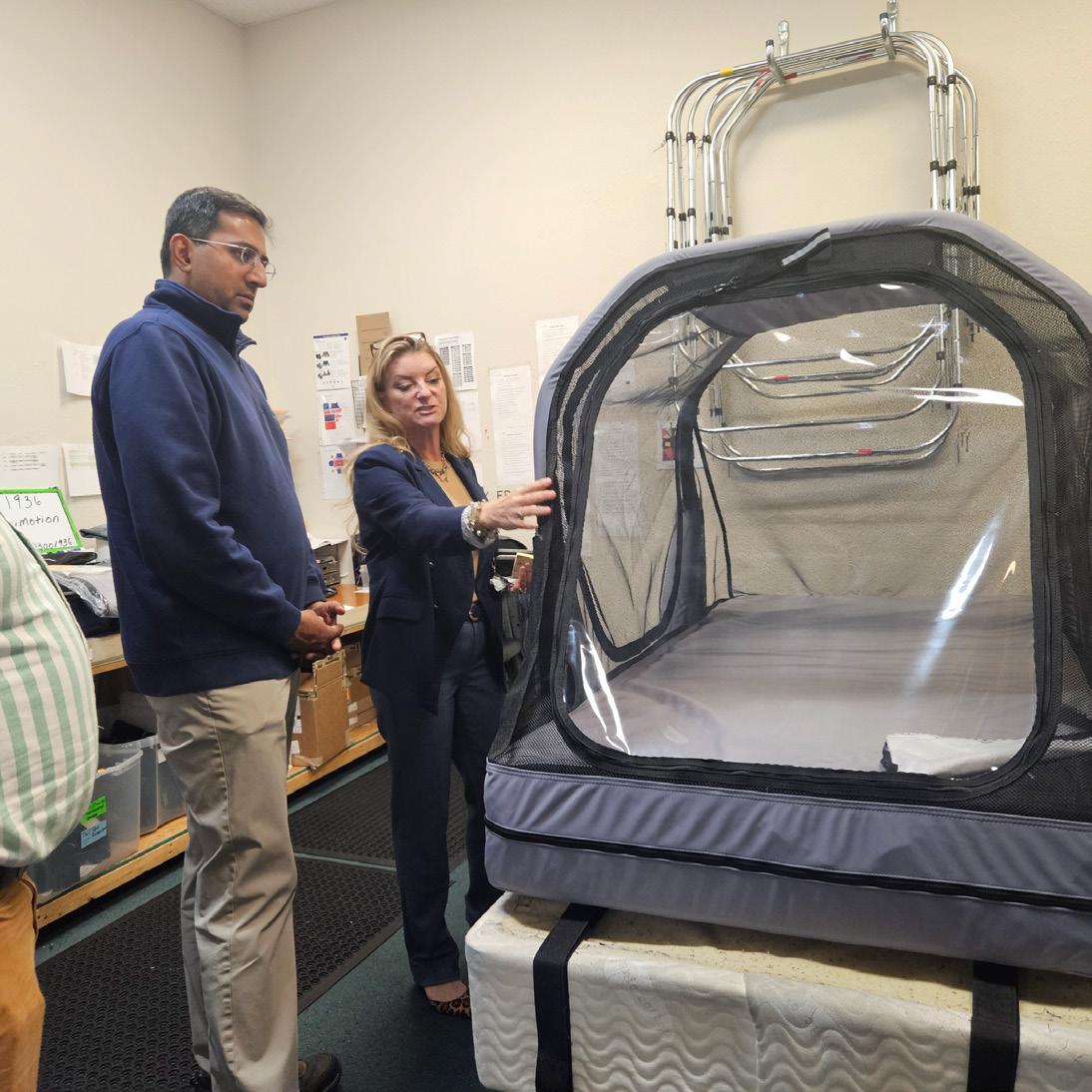

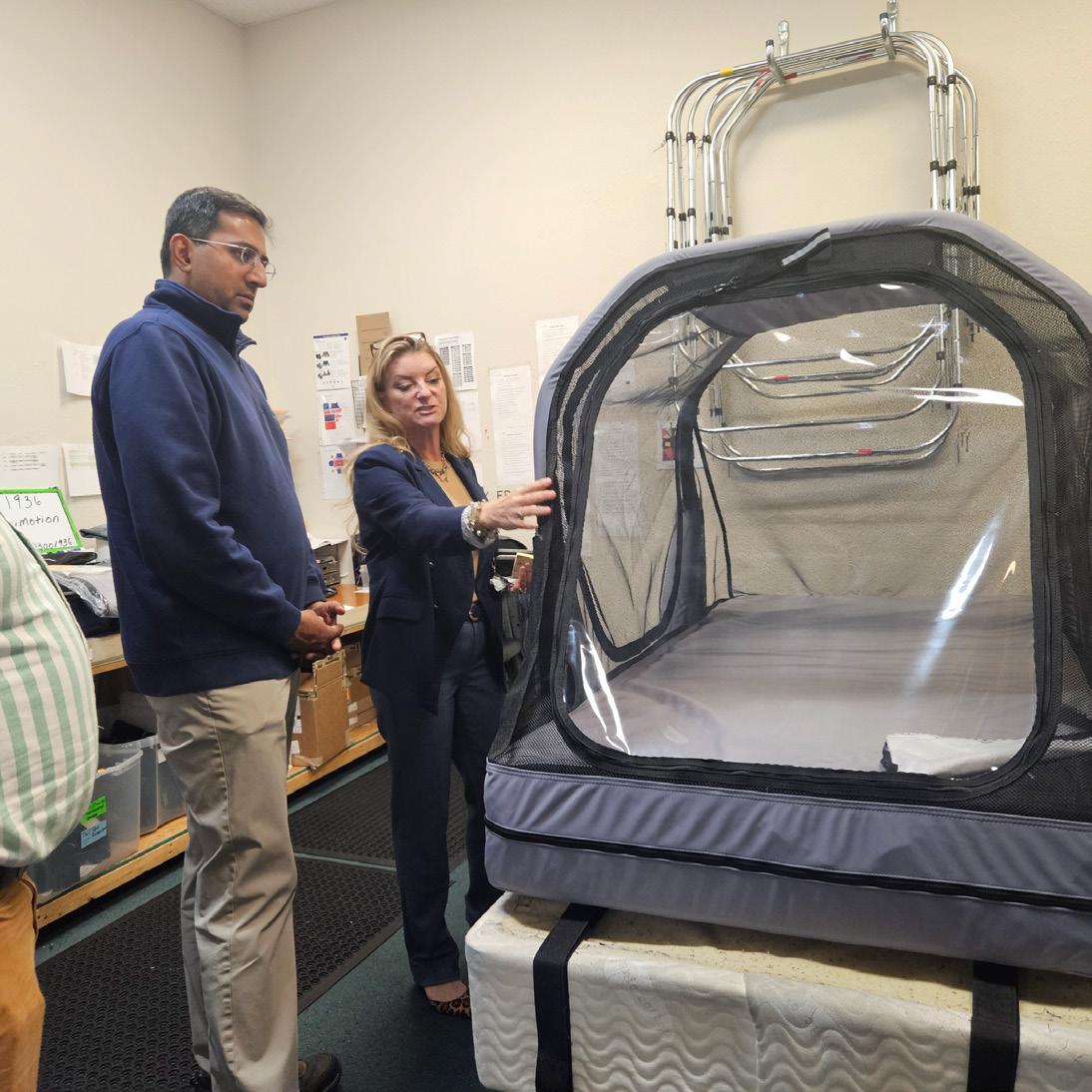

Every once in a while, there is a magical moment that washes away the grinding reality of partisan bickering, a divided legislature, and a gridlocked Congress. For me, that moment was March 8 at MBA member Abram’s Nation facility tour.

Rose Morris, Abram’s president and founder, agreed to host the Allegheny County House Democratic Delegation. The purpose was to increase their understanding of how small manufacturers operate and their challenges.

Abram’s Nation is an exceptional small business. It produces “Unique Solutions for the Special Needs Community.” It sells the Safety Sleeper and other products domestically and all over the world, and was named the Small Business Administration’s 2017 National Exporter of the Year.

Morris and her husband, Jeff, invented the Safety Sleeper out of necessity for their disabled toddler son, now a teen, who would often hop out of bed and wander at night, courting danger. The mesh sleeping tent kept him contained, secure and safe.

Representative Arvind Venkat, District 30 (Allegheny), is Morris’s PA representative. It was their first time meeting. The representative is an exceptional lawmaker. He is Harvard educated and a graduate of Yale Medical School. He previously worked in the Emergency Room at Allegheny General Hospital and continues to work some weekends. Venkat serves on every committee in the PA House that is related to health care.

I’ve met him in his district office twice and am always impressed by his knowledge of government and legislation even though he is a newcomer and now running for his second two-year term in office. He told me the number of people who make minimum wage — 66,000 in PA — and on another occasion answered some detailed questions on PA’s complex benefit system. He describes himself as a Democrat who resides in the middle.

The “magical moment” for me was seeing and hearing Morris and Representative Venkat talk to each other. For over an hour, they walked around the facility, stopping at each station. Morris explained and Venkat listened, responded and questioned. As a medical doctor, he has some knowledge of those disabled by autism, and was absorbed and fascinated by Rose, Abram’s Nation and its staff.

Rose Morris is like a fountain; stories and technical equipment specs pour out. She and her staff have been producing the Safety Sleeper and other products for the disabled for 15 years. She has dealt firsthand with many families whose

enthusiasm for her business and “families” are heartfelt and contagious, illustrated by the photos of children and families lining the foyer.

Part of any facility tour is always dedicated to a policy discussion to uncover barriers to growth.

Morris needs more space and will solve that by adding alternative shifts of workers. That means she will have the additional expense of increased wages to attract workers to a later shift. She has never paid minimum wage.

She and client families struggle with Medicaid and insurance companies for coverage and payment for the tents. It is always a fight. Medicaid does not always consider the tents a necessity and prioritizes other items.

Workforce is a problem. The production bottleneck is the sewing of the tents. She at times uses Indeed, Craig’s List and referrals and claims she can teach anyone to sew.

Transportation is an occasional problem. The MBA provided a contact for the Southwestern Planning Commission’s CommuteInfo program.

Regarding regulations, Morris must comply with the FDA’s seven zones of entrapment which is based off hospital beds.

If you would like to host a facility tour or have a private discussion of your business issues and innovations, email me at eileenanderson@mbausa.org

15 mbabizmag.com MAY 2024

❯ Turbine Component Manufacturing

❯ Precision grinding (up to 136” in length)

❯ Mul�-Axis Milling, Machining, & Turning

❯ Saw Cu�ng (straight, angle, radius, angle + radius)

❯ Wire EDM

❯ Trepanning, Boring & Honing

403, 405, 410, 415, & 422 *EFFICIENT RESPONSE TIMES

STEEL ALLOYS

9001:2015 CERTIFIED

2019 SECTION 889

READY

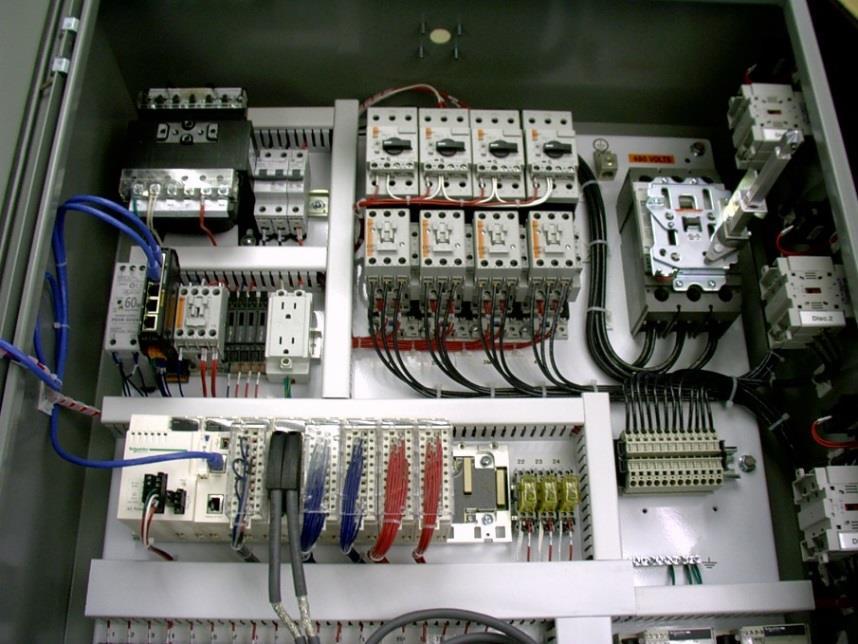

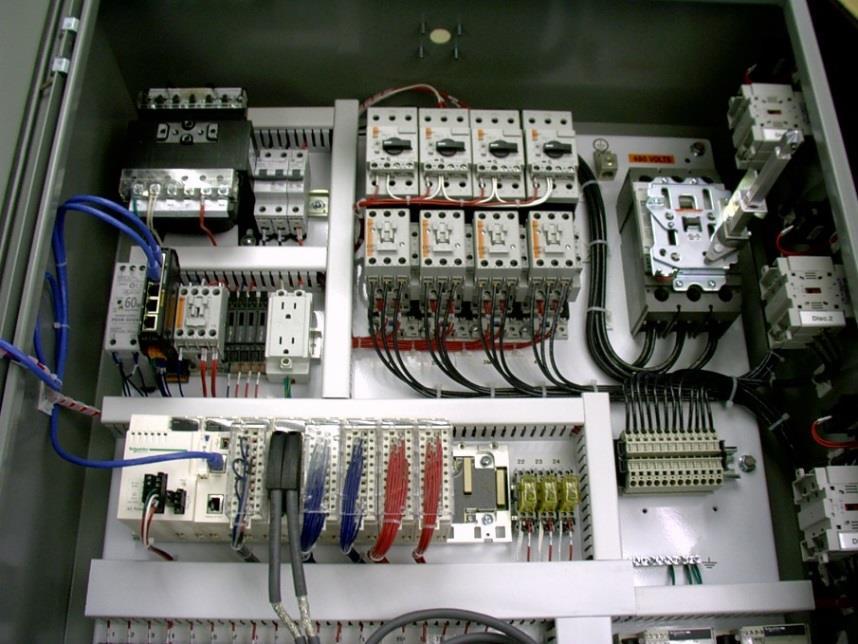

16 MAY 2024 • mbabizmag.com Wettekin Electronics Automation for Industry Design and Assembly of Industrial Control Panels Motor Controls, Programmable Logic Controls, Operator Consoles Distributor of Industrial Electrical Components Parts and Service Center for Van Air Systems 4506 West 12th Street Erie, PA 16505 sales@wettekinelectronics.com www.wettekinelectronics.com Ph: 814-838-9184 Fax: 814-838-6060 WE

SUCH AS:

REGULARLY STOCK STAINLESS

1 1663 MCKINNEY ROAD , TITUSVILLE, PA 16354 ❯ 814-827-9887 ❯ precisionprofilesllc.com QUALITY ❯ INTEGRITY ❯ ON TIME DELIVERY CORE CAPABILITIES PRECISION MACHINING SINCE 1994 ISO

ITAR

US/CA

(CAGE

DFARS

NDAA

NIST

CMMC

SAM

SIX

EXPERTISE SMALL BUSINESS (<25 Employees)

REGISTERED

JCP CERTIFIED

CODE Available Upon Request)

COMPLIANT

COMPLIANT

800�171 COMPLIANT

REGISTERED

SIGMA

MADE RIGHT. RIGHT HERE.

SINCE 1886

For five generations, we’ve been making high-quality pliers and assorted hand tools the right way, right here on American soil. Today, we proudly employ over 350 hardworking Pennsylvanians who manufacture more than 75 different sizes and types of pliers in our two Meadville plants.

Legendary strength. Uncompromising quality. That’s the CHANNELLOCK® Way.

©2023 CHANNELLOCK, Inc. Meadville, PA, U.S.A.

MORE HANDS-ON EXPERIENCES COULD HELP SPUR INTEREST IN STEM CAREERS, EXPERT SAY

Less than one-third of teens and young adults listed a role in science, technology, engineering, or mathematics fields as their first-choice career, even though a sizable majority of them are interested in STEM occupations, according to a recent survey from Gallup and the Walton Family Foundation.

Lack of exposure to STEM concepts may be contributing to the disconnect between students’ interests and the career they say they most hope to pursue, according to the report based on a nationally representative survey of 2,006 12- to 26-year-olds conducted in September 2023.

“The findings point to the fact that despite students’ interest in STEM, they’re not finding viable pathways to those careers, or something prevents them from pursuing those careers, and we need to understand what those barriers are and address them,” said Maud Abeel, a director for Jobs for the Future, a national nonprofit that develops programs and public policies focused on boosting students’ college and career readiness.

Jobs in STEM pay substantially more than those in other fields and are growing at a faster rate than all other occupations, according to the U.S. Department of Labor. Recent technological advances — especially in the field of artificial intelligence — mean more organizations are in search of STEM-savvy employees.

As a result, educators and policymakers should bolster the pipeline of future STEM workers, according to a recent report.

“By creating programs that allow students the opportunity to explore, understand, and apply core STEM concepts and to participate in hands-on learning, we can set youth up for successful careers in an industry that desperately needs them,” Stephanie Marken, a Gallup senior partner and executive director for education research at the polling firm, said in a press release about the report.

To learn more about the MBA’s 2024 MFG Day event on October 9 at the Bayfront Convention Center, visit mbausa.org.

PCORI Fee Amount Adjusted for 2024

The Internal Revenue Service (IRS) has issued Notice 2023-70 to increase the PatientCentered Outcomes Research Institute (PCORI) fee amount for plan years ending on or after October 1, 2023, and before October 1, 2024. The updated PCORI fee amount is $3.22 multiplied by the average number of lives covered under the plan.

For plan years that ended on or after October 1, 2022, and before October 1, 2023, the PCORI fee amount is $3.00 multiplied by the average number of lives covered under the plan.

Applicability of PCORI Fee

The PCORI fee was created by the Affordable Care Act (ACA) and first applied for plan or policy years ending on or after Oct. 1, 2012. The fee is imposed on health insurance issuers and self-insured plan sponsors to fund comparative effectiveness research. The PCORI fee was originally scheduled to expire in 2019. However, a federal spending bill extended the PCORI fee for an additional 10 years. As a result, the PCORI fee will apply through the plan or policy year ending before October 1, 2029.

Payment Deadline

PCORI fees are reported and paid annually on IRS Form 720 (Quarterly Federal Excise Tax Return). These fees are due each year by July 31 of the year following the last day of the plan year. For plan years ending in 2023, the PCORI fee is due by July 31, 2024. Employers with selfinsured health plans should have reported and paid PCORI fees for 2022 by July 31, 2023.

Calculating the PCORI Fee

The PCORI fees are calculated based on the average number of covered lives under the plan or policy. This generally includes employees and their enrolled spouses and dependents, unless the plan is an HRA or FSA.

For more information, contact me at 814/833-3200, 800/815-2660 or lmckinney@mbausa.org.

Lisa McKinney is an insurance agent for the Manufacturer & Business Association Insurance Agency. Contact her at 814/8333200, 800/815-2660 or lmckinney@mbausa.org.

18 MAY 2024 • mbabizmag.com

HR CONNECTION | WORKPLACE TRENDS

At Workpartners®, we call our unique approach to human capital management People Activation. We believe it’s the key to ensuring that your company and employees flourish. As part of our efforts to support employees, we offer resources to improve their quality of life during trying times and everyday life. One such resource is the LifeSolutions® employee assistance program (EAP). LifeSolutions offers mental well-being services in person, by phone, online, or by text, and has tools and programs that are designed to promote better mental health and improved productivity. Support your employees by offering a mental well-being solution.

Members of MBA save 10 percent on our mental health services. To learn more, visit work.partners/mba.

Furnished Private Bedrooms and Bath

Parking

Kitchen, Living and Laundry Outdoor Recreational Area Many Units Available 2834 Banksville Rd., Pittsburgh, PA 15216

19 mbabizmag.com MAY 2024 Heating Oil - Propane - Commercial Fuels Servicing Western PA For Over 50 Years! www.colivingpittsburgh.com

RENTALS

MID-TERM

Indoor/Outdoor

Shared

People. Activated. analytics | advocacy | absence | technology

WELL-BEING

SUPPORTING MENTAL

IN MAY—AND ALL YEAR.

YOUR ONE STOP STEEL SERVICE CENTER

LOCAL WAREHOUSES FULL OF QUALITY STOCK WITH QUICK DELIVERY

We carry thousands of stock metal products. Choose from carbon, alloy, aluminum, stainless steel, brass, copper, and more. Call ahead, and we’ll deliver within 100 miles the next day. Pick from stock or have us cut it to length. We have more than 155,000 sq. ft. of storage, and a fleet of our own delivery trucks.

STOCK MATERIAL AVAILABLE

SERVICES YOU CAN COUNT ON

Our metal cutting and fabrication services cannot be beat. Select your metal, shoot us your specs, and name your deadline. We’ll grind it, bend it, saw it, shear it, weld it, and punch it. We also specialize in taking large-scale projects from concept through delivery. Whatever you need, we’ve got you covered.

2201 Loveland Avenue Erie, PA 16506

2020 West 1st Street Oil City, PA 16301 1806 East Main Street

NY 14733

TheWarrenCompany.com

»

» Plate » Bar /

» Structural

» Expanded

» Tread

» Tube / Pipe » Flat / Strip » Floor

THE WARREN COMPANY

Sheet

Rounds

/ Shapes

Metal

Plate

Grating

Falconer,

(814) 838-8681 • 1 (800) 562-0357

Embracing Sustainability: The Rise of Green Manufacturing

Donald Racey is the chief executive officer of Enage Energy & Industrial Consulting, Inc. and Engage Sustainability Solutions. Contact him at 412/848-3773, dracey@engageeic.com or visit engageeic.com.

Manufacturers worldwide are leading the way towards a more sustainable future. Corporate Social Responsibility, Sustainability, and Environmental, Social and Governance (ESG) reporting is changing our economy and will change your business. This is driving manufacturers to reevaluate their practices to make a positive impact on the environment while mitigating risk and reducing costs.

The concept of “green manufacturing” is not just an environmental initiative but an intelligent business strategy. It aims to reduce waste, conserve resources, and minimize pollution throughout the production process. At its core, green manufacturing is about marrying economic prosperity with environmental stewardship. By acknowledging that traditional manufacturing practices, often characterized by high energy consumption and waste generation, are unsustainable long-term, manufacturers can pave the way for a more profitable and sustainable future.

By adopting greener and leaner approaches, manufacturers cannot only reduce their costs and environmental impact but also gain a competitive edge. They position themselves as leaders in sustainability, attracting new consumers and investors who are increasingly conscious of the environmental impact of the products they use, as well as the companies they invest in. In this way, sustainability becomes a key differentiator in the market.

KEY PRINCIPLES OF GREEN MANUFACTURING INCLUDE: Resource Efficiency: Green manufacturers prioritize using raw materials, energy and water efficiently. This involves implementing technologies and processes that minimize waste and optimize resource utilization. For example, advanced manufacturing techniques such as additive manufacturing (3D printing) can significantly reduce material waste compared to traditional subtractive methods.

Renewable Energy Adoption: Transitioning to renewable energy sources like solar, wind and hydropower is a cornerstone of green manufacturing. By powering operations with clean energy, manufacturers can drastically reduce their carbon emissions and dependence on fossil fuels. Additionally, integrating on-site renewable energy systems can reduce costs and enhance resilience to energy price fluctuations and supply chain disruptions.

Waste Minimization and Recycling: Green manufacturers are committed to

reducing waste generation through the implementation of lean manufacturing and closed-loop production systems. This involves designing products that are easy to disassemble and recycle, as well as reusing or repurposing waste materials within the production process. By adopting the principles of the circular economy, manufacturers can derive maximum value from resources while minimizing their environmental impact.

Eco-Friendly Materials: Another crucial aspect of green manufacturing is choosing sustainable and non-toxic materials.

This includes opting for recycled or biobased materials whenever possible and avoiding hazardous substances that can harm human health and the environment. Manufacturers can create products with a lower environmental footprint from cradle to grave by prioritizing eco-friendly materials.

Supply Chain Transparency and Collaboration: Green manufacturing extends beyond the factory walls to encompass the entire supply chain. Manufacturers are increasingly scrutinizing their suppliers' environmental practices and seeking partnerships with like-minded organizations committed to sustainability. By fostering transparency and collaboration across the supply chain, manufacturers can address ecological challenges holistically and drive collective progress toward sustainability and cost reduction.

Moreover, by aligning with evolving regulatory requirements and consumer preferences, green manufacturers can future-proof their businesses and gain a competitive edge in the market.

Transitioning to green manufacturing is not without challenges. It often requires upfront investment in new technologies, workforce retraining, and potentially reengineering processes. Additionally, navigating the complex landscape of environmental regulations and standards can be daunting for manufacturers, particularly those operating across borders.

Fortunately for small and mid-sized manufacturers in our region, there are several grants and funding resources available to support this journey. By embracing green manufacturing principles, manufacturers can not only mitigate their environmental impact but also contribute to building a more resilient, sustainable and profitable future for generations to come.

21 mbabizmag.com MAY 2024 MANUFACTURING TRENDS | SUSTAINABILITY

Over the past 100 years our sponge candy has been called newfangled, the bees knees, aces, dreamy, cool daddy-o, real gone, neato, groovy, fab, righteous, awesome, far out, off the hook and fire. But we’ll let you decide.

22 MAY 2024 • mbabizmag.com

1525 West 8 Street in Erie • 814.452.1933 • RomoloChocolates.com C H O C O L A T E S R O M O L O ®

May is Mental Health Month: Take Care of Yourself, Your Team

Mental health disorders, which include depression, anxiety, stress and other psychological disorders, affect over a quarter of all American adults, according to the National Institute of Mental Health Disorders. Employees afflicted with poor mental health could potentially experience symptoms, such as reduced focus, low productivity, reduced cognitive abilities and poor physical well-being.

The monetary repercussions of poor employee mental health are tangible — costing the U.S. economy nearly $48 billion each year in lost revenue. Fortunately, your business can implement programs to help your employees cope with and manage their mental health.

Activities and Programs

Despite its intangibility, mental health can be managed through programs, activities and treatment. For that reason, you may want to consider these suggestions to assist your employees and minimize the effects of poor mental health on your business:

• Develop an employee assistance program (EAP) that offers screening, counseling and referral services for mental health and other issues. Ideally, the EAP would offer customized services based on the needs of your employees by being responsive to acute and emerging stressors in the workplace. Reassure your employees that all health information is confidential and sharing this information will not affect their jobs.

• Provide mental health screenings and educate your employees on the symptoms of mental health illnesses and the methods of treatment. Encourage employees to be screened, either through their primary doctors or through your EAP, if they have symptoms. Encourage employees to engage in physical activity, both during the workday and at home. Mild exercise can decrease some mental health disorder symptoms, and, in some cases, even prevent mild depressive episodes.

• Conduct employee surveys and ask about work stressors (such as conflicts with co-workers or managers), job demands (such as time pressure or physical demands), the level of support provided by supervisors, etc. All of these issues can affect the mental health of employees and can give you a baseline for implementing further training or workplace changes.

Remember to Breathe

How a workplace is structured can either help or exacerbate an employee’s mental health. By developing helpful programs and communicating with your employees, your business should be able to minimize the impact of poor mental health.

Rose Bruno, PHR, SHRM-CP, is an HR consultant for the Manufacturer & Business Association. Contact her at 814/833-3200, 800/815-2660 or rbruno@mbausa.org.

WHAT ARE SOME PHYSICAL ACTIVITIES EMPLOYERS CAN OFFER THEIR EMPLOYEES?

Consider the following:

• Organizing a company sports team

• Scheduling walking meetings

• Offering gym memberships at a reduced cost.

WHAT OTHER WAYS CAN EMPLOYERS SHOW THEIR SUPPORT FOR EMPLOYEES WITH MENTAL HEALTH ISSUES?

Here are a few other examples:

• Provide training on problem solving, effective communication and conflict resolution to support the mental health of employees.

• Create policies citing appropriate standards of conduct. Include conflict resolution and other training initiatives.

HOW CAN EMPLOYERS ESTABLISH A WORKPLACE ENVIRONMENT THAT IS SUPPORTIVE OF EMPLOYEES WHO HAVE MENTAL HEALTH DISORDERS?

Here a few things employers can do: Encourage social support among employees, such as an organized support group that meets regularly.

• Educate all employees about mental health to reduce stigmas and confusion.

• Treat people who have mental health problems with respect and dignity. Never label people by their conditions.

23 mbabizmag.com MAY 2024

HR Q&A | GET ANSWERS

A Key to a Healthy and Productive Workforce PRIORITIZING MENTAL HEALTH COVERAGE:

The COVID-19 pandemic thrust mental health into the spotlight of employee well-being discussions. While isolation and pandemic-related stress undoubtedly contributed to the surge in depression and anxiety, experts suggest that mental and behavioral health challenges were already prevalent before the pandemic. This “quiet crisis” has significant implications for businesses, as workers with fair or poor mental health are estimated to have nearly 12 days of unplanned absences annually compared with 2.5 days for other workers. This missed work is estimated to cost the national economy nearly $48 billion annually in lost productivity.

Mental health issues not only affect employees ’ productivity and job performance but also have a ripple effect on their personal lives, families, and communities. Untreated mental health conditions can lead to increased healthcare costs, relationship problems, substance abuse, and even suicide. By providing comprehensive mental health coverage, employers can help their employees address these challenges and lead healthier, more fulfilling lives.

In addition to the moral imperative to support employee well-being, there is a strong business case for offering mental health coverage. Studies have shown that companies with robust mental health programs experience reduced absenteeism, increased productivity, and improved employee morale. Furthermore, offering mental health benefits can help attract and retain top talent, giving businesses a competitive edge in the job market.

Highmark’s Commitment to Mental Well-Being

Recognizing the critical need for mental health support, Highmark Blue Cross Blue Shield has taken significant steps to enhance its mental health benefits. The introduction of Mental Well-Being, a comprehensive digitally based resource, provides members with access to 6,000 additional mental health professionals. This multi-faceted program offers various levels of support, including wellness tools,

24 MAY 2024 • mbabizmag.com

one-on-one care navigation, in-person or virtual therapy, medication management, and 24/7 crisis support. Certified coaches are available to help members build better habits, navigate life transitions, and set and achieve personal goals. Members can expect to see an in-network therapy or psychiatry provider within three days or less, ensuring timely access to care.

... companies with robust mental health programs experience reduced absenteeism, increased productivity, and improved employee morale.

In addition to Mental Well-Being, Highmark offers a range of programs tailored to specific mental and behavioral health needs. For individuals with obsessivecompulsive disorder (OCD), Highmark collaborates with NOCD to provide virtual face-to-face therapy with specialized therapists. Members struggling with eating disorders, substance use disorder, alcohol

use disorder, or opioid use disorder can access Bright Heart Health for online support. Ria Health, a technology-enabled telehealth practice, offers medically assisted treatment combined with digital tools to help track progress for those with alcohol use disorder

Delivering on the Promise of Living Health

Highmark’s Mental Well-Being solution is just another example of how the company is bringing to life its strategy to reinvent health care and coverage, which it calls Living Health. Highmark is creating better insurance products that support a person’s whole-body health — physical, mental, and social — and reduce fragmentation and frustration for both members and health care providers. The result is a simpler, more personalized, and proactive health experience for individuals and clinicians that promotes better engagement and empowers everyday health rather than just treating illness.

In today’s challenging times, prioritizing mental health coverage is essential for businesses seeking a healthy and productive workforce. By offering comprehensive mental health benefits, such as those provided by Highmark, employers can support their employees’ well-being, reduce absenteeism, and ultimately drive business success. Investing in mental health is not only the right thing to do but also a smart business decision.

One of America's leading health insurance organizations, Highmark Inc. and its Blue-branded affiliates proudly cover the insurance needs of approximately 7 million members in Pennsylvania, Delaware, New York and West Virginia. For more information about Highmark and its many health benefit solutions, visit www.highmarkemployer.com

Make every

health

Your employees want mental health solutions that are always available. And you want coverage that will save you money. That’s why Highmark’s added more than 6,000 therapists for everyday support. With healthy employees, you’ll have a healthier bottom line — 365 days a year.

and watch business thrive.

25 mbabizmag.com MAY 2024

day

mental

a

day.

Create a culture of caring with Highmark

Benefits and/or benefit administration may be provided by or through the following entities, which are independent licensees of the Blue Cross Blue Shield Association: Highmark Inc. d/b/a Highmark Blue Cross Blue Shield, Highmark Choice Company, Highmark Health Insurance Company, Highmark Coverage Advantage Inc., Highmark Benefits Group Inc., First Priority Health, or First Priority Life. Your plan may not cover all your health care expenses. Read your plan materials carefully to determine which health care services are covered. For more information, call the number on the back of your member ID card or, if not a member, call 866-459-4418.

CHANNELLOCK

1306 S. Main Street, Meadville, PA 16335

Phone: 800/724-3018

Website: channellock.com

Founded in 1886, Channellock, Inc. is a worldwide leader in the manufacture of high-quality pliers and assorted hand tools. Family owned and operated, Channellock, Inc. has more than 4,000 U.S. wholesale and retail customers and ships to customers in 45 countries.

ERIE STRAYER COMPANY

1851 Rudolph Avenue, Erie, PA 16502

Phone: 814/456-7001

Website: eriestrayer.com

Erie Strayer Company, family owned since 1912, is a fourth generation industry leader in the designing, engineering and manufacturing of concrete batch plants. From custom ready-mix plants to highly mobile paving plants, ERIE’s rugged quality and timely after-sale support remain key to its success. ERIE also manufactures its own heavy-duty Tilt Drum Mixer, Liberty Computer Control Batching System and state of the art PLC-Based Automatic Material Handling Controls. The company remains under the direction of the Strayer family as it has for the last century. Kyle F. Strayer, great-grandson of the founder, is the president/CEO.

2024 SHOWCASE

F3 METALWORX, INC.

2731 West 11th Street, Erie, PA 16505

Phone: 814/838-9444

Website: F3metalworx.com

Comprised of precision & heavy sheet metal manufacturing, powder coating and Wire Weld store fixtures, F3 Metalworx is a one-stop resource for a wide range of fabricating, finishing and custom fixture solutions. F3 guarantees to meet your lead time and quality needs.

MATRIC GROUP

2099 Hill City Road, Seneca, PA 16346

Phone: 814/677-0716

Website: matric.com

INDUSTRIAL SALES & MANUFACTURING

2609 West 12th Street Erie, PA 16505

Phone: 814/833-9876

Website: ismerie.com

Quality contract machining, fabrication and assembly for OEMS since 1967.

Founded in 1971, Matric has provided worldclass Electronics Manufacturing Services (EMS) for 50 years. The company specializes in high mix/low to high volume contract assembly. Services include Surface Mount & Through-Hole Technology Assembly, Cable & Harness Assembly, Electromechanical Assembly, Aftermarket Services, and Obsolescence Management. Certifications include AS 9100, ISO 9001, ISO 13485, ISO 14001, NADCAP Accredited in Electronics, ITAR, RoHS, and ATEX/Ex Qan compliant, and a HUBZone business. From design to production, throughout a product’s lifecycle, Matric partners with customers to achieve their products’ highest potential.

JOSEPH MCCORMICK CONSTRUCTION

CO., INC.

3340 Pearl Avenue Erie, PA 16510

Phone: 814/899-3111

Website: jmccormickconstruction.com

Family owned heavy highway construction company specializing in asphalt paving, excavation, site development, demolition and sanitary/storm sewer installation work for various state, county, city municipalities, commercial developments and local companies throughout Erie County.

26 MAY 2024 • mbabizmag.com

SHOWCASE OF MANUFACTURERS

MICRO MOLD CO., INC.

4820 Pittsburgh Avenue, Erie, PA 16509

Phone: 814/838-3404

Website: plastikoserie.com

Provides custom mold design & fabrication services along with plastics engineering support services to the medical device and electronics industries.

PARKER LORD

2455 Robison Rd W Erie, PA 16509

Phone: 814/868-0924

Website: parker.com/Lord

Since 1924, Parker Lord team members have been creating innovative solutions globally to the automotive, aerospace, industrial and oil and gas markets. We continue to invest in new solutions that support us in Enabling Engineering Breakthroughs that Lead to a Better Tomorrow®.

PLASTIKOS MEDICAL

8121 Hawthorne Drive, Erie, PA 16509

Phone: 814/868-1656

Website: plastikoserie.com

Plastikos Medical is a state-of-the-art, medical injection molding company with a certified ISO-7 (Class 10,000) cleanroom molding floor, and which is strategically located just down the street from Plastikos.

PRECISION PROFILES

11663 McKinney Road, P.O. Box 324 Titusville, PA 16354-5835

Phone: 814/827-9887

Website: precisionprofilesllc.com

URBAN ENGINEERS

152 West 12th Erie, PA 16501

Phone: 814/453-5702

Website: urbanengineers.com

A multidisciplinary planning, design, environmental and construction support services consulting firm with 15 locations across the United States.

THE WARREN COMPANY

2201 Loveland Avenue, Erie, PA 16506

Phone: 814/838-8681

Website: thewarrencompany.com

“We put the ‘service’ in Service Center”

PLASTIKOS, INC.

8165 Hawthorne Drive, Erie, PA 16509

Phone: 814/868-1656

Website: plastikoserie.com

Plastikos provides custom injection molding along with plastics engineering support services to the medical device and electronics industries.

Since 1994, Precision Profiles has specialized in producing tight-tolerance turbine components for defense and industrial applications. In addition, the company offers a full suite of machining services, including: multi-axis milling & machining, turning, and Wire EDM services. Precision Profiles’ Hollow Machining Division specializes in trepanning, boring and honing services for various metals and alloys, including tool steel, Inconel, Titanium, and Aluminum. The company processes OD’s up to 32" and lengths up to 300". Precision Profiles is committed to delivering these products and services on time and free of defects.

A leader in materials supply and custom fabrication. Providing value added services of laser cutting, plasma cutting, torch cutting, rolling, shearing, forming and precision fabrication.

27 mbabizmag.com MAY 2024