Contact Dyna Rack for your customer’s storage needs. 800/939-3962 • sales@dyna-rack.com • www.dyna-rack.com The Dealers’ Source For Portable RacksTM Customized designs are considered! Pallet Frames Stack Racks Nestable Racks Stock Available on some sizes & designs Made in the USA SEPTEMBER 2023 Call or email Kip Krady 563 557-4493 kip.krady@MHNetwork.com to be in our next issue! Deadline: September 15th

Amazing performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range make the CB15-5E the most powerful, compact multidirectional forklift yet.

The new COMBi-CB15-5E electric forklift is the most compact 15500 lbs counterbalance truck on the market. It is loaded with a host of features that greatly enhance operator comfort, including excellent all-round visibility, a spacious gas-strut suspension cab, independent electric traction and our newly developed Auto Swivel Seat which intelligently swivels 15 O in the direction of travel.

To find out how Combilift can help you unlock every inch of your storage space.

A2

1

Introducing

25

Material Handling Network Colin 7.375 x 9.625 euro rev 1.1 Timber.indd 1 19/07/2023 16:07:44

Contact Us Today

combilift.com

www.MHNetwork.com Material Handling Network September 2023 3 https://shop.fsip.biz/en/content/remanufacturing?utm_source=MHN&utm_medium=dig-mag&utm_campaign=05-RM-PA&utm_content=Full_0923 Flight Systems Industrial Products • 800-333-1194 Check out this “NEW” part alternative at shop.fsip.biz. We don’t just repair electronics, we ufacture them, returning them to a “better-than-new” condition. In addition to replacing broken components, Replace compromised stressed components Components upgraded to the latest specification (with enhancements available) FSIP ensures you receive top quality remanufactured parts and products at prices far less than new! REMAN the difference

4 September 2023 Material Handling Network www.MHNetwork.com SEPTEMBER 2023 VOL. 42 NO. 9 6 Cover Story By: Eileen Mozinski Schmidt Meeting the need: A look at trends in warehousing, along with a few logistical and new tech solutions in the industry 10 Safety First By: indeed Warehouse safety tips to keep your employees safe 14 Chain Reaction By: Bill Denbigh Unlocking Warehouse Potential: Exploring AMRs in Automated Material Handling 16 Business Management By: Invar Group Warehouse automation: Five key points on securing operational resilience 20 Industry News 24 People News 26 SalesLeads 32 Product Showcase 34 Marketplace 36 Advertiser Index Don't miss our next issue: Staffing Your Warehouse All warehouse operations are different. We will take a look at some warehouse operations and how they balance warehouse personnel with automation technology. Deadline: September 15th CONTACT INFORMATION Kip Krady Account Executive 563 557-4493 kip.krady@MHNetwork.com. Nikole Hoffman Production Lead, Graphic Design Eric Faramus Graphic Design Have some news to share with Network readers? Email a word doc and JPG photo when available networkeditorial@MHNetwork.com TO SUBSCRIBE TO MATERIAL HANDLING NETWORK VISIT US AT www. MHN etwork.com Material Handling Network (ISSN #21551685) is published monthly serving the material handling industry. Editorial opinion expressed herein are the authors and do not necessarily reflect the opinion of Material Handling Network. Material Handling Network assumes no responsibility for inaccuracies, errors or advertising content and reserves the right to reject or cancel any advertising for any reason, at any time.

LITHIUM SAFEFLEX BATTERIES AND CHARGERS

Maintenance free Li-ion batteries increase safety and efficiency with a lower total cost than lead acid.

High-frequency chargers with CAN communication, voltage detection and multiple outputs enable fast charging with lower utility costs.

www.MHNetwork.com Material Handling Network September 2023 5

LEARN MORE AT GREENCUBES.COM

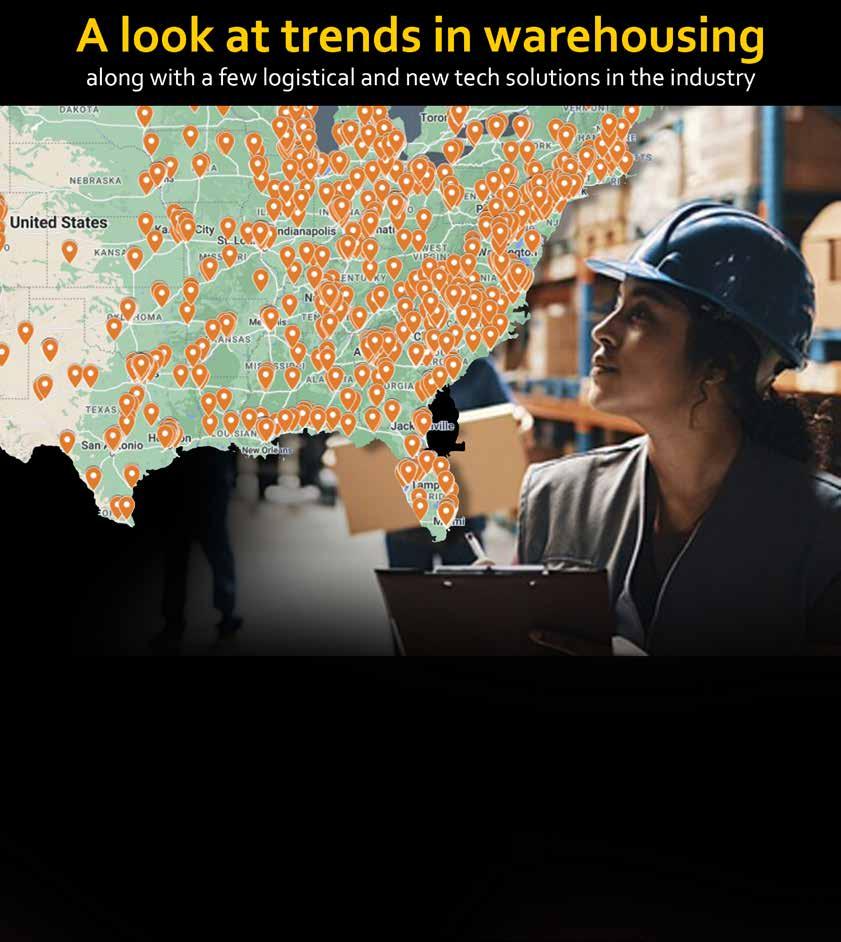

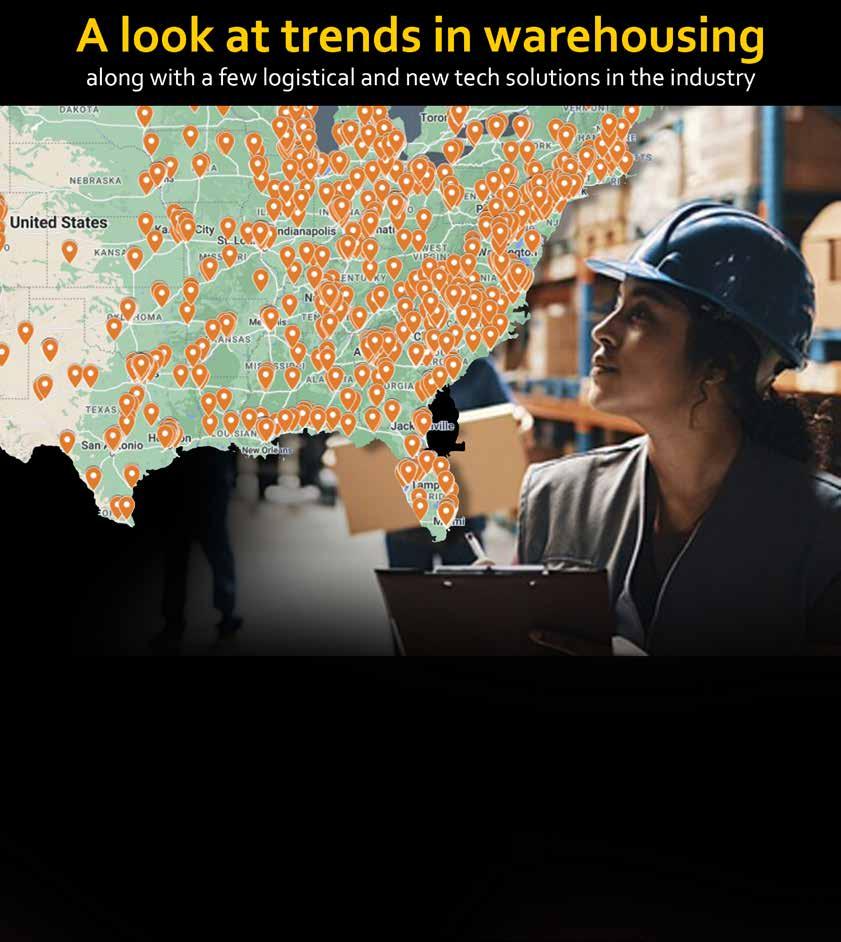

Cover Story

Meeting the need: A look at trends in warehousing, along with a few logistical and new tech solutions in the industry

Industry impacts

And within warehouses, Schramm said racking is a top priority for many businesses. “The influx of racking is probably the biggest part of the interior of the warehouse. Everyone is looking at the most efficient ways to optimize internally,” Schramm said. Labor, meanwhile, remains a concern.

As 2023 races to the finish, warehousing is in demand throughout the material handling industry. “We’re seeing an increase in a need for warehouses across the board, across the country,” said Chris Schramm, director of sales and accounts for Nexterus, a full-service supply chain and logistics partner offering customized solutions. Schramm said available warehousing space was close to capacity in 2020 and 2021 and that has loosened up somewhat recently.

Nexterus offers the ability to research “bestin-class supply chain strategies employed by the largest companies in the world,” the website said. “We bring them to you in scalable, affordable applications,” the site said, noting the company uses a unique approach of modeling and optimizing supply chain needs. Schramm said the company studies network opportunities, current and expanding client bases and more, to help determine where a warehouse should be placed. He said many companies are looking for opportunities for expanded capacity wherever possible.

“The equipment side has definitely started looking at that. Everyone is fighting for the same people. You can saturate a market quickly with four to five warehouses” in one area, he said, noting that automated trucks are helping fill the labor gap in some places. “The Targets, Walmart’s, the bigger players have putting those into facilities. Now we’re starting to see some of those smaller players take advantage of automated trucks,” Schramm said.

The supply chain will undoubtably be impacted in the coming months by the bankruptcy of Yellow Corp., he added. “The financial collapse of Yellow will have the biggest effect across the board for supply chain. Yellow is the number three truck load carrier in the country,” said Schramm, who said other shippers were already operating at 90 percent or more of capacity, so the transportation needs won’t necessarily be immediately absorbed.

As a result, he said shippers may look at changing the dynamics of what they’re shipping and how warehouses are structured. “Shippers are going to be looking at operating their freight and using tools like what Nexterus provides,” said Schramm, who said the company’s Warehowz tool helps find warehousing solutions to meet changing needs.

6 September 2023 Material Handling Network www.MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 7 RAVAS forklift scales provide users with critical material flow data in a single efficient operation so you can optimize your process and increase revenue. More than just a scale, RAVAS mobile weighing systems are an intelligent solution. iCP Weigh Materials On the Go with Turn your forklift scale into a profit generator with a mobile weighing system. iForks-32 For forklift and reach trucks iJack RAVAS-520 Complete range RAVAS USA 1500 Enterprise Parkway Twinsburg, Ohio 44087 330.425.3092 www.ravas.com Visit ravas.com/MHsolutions to learn more + Forklift Scales + Electric Pallet Jack Scales + Hand Pallet Jack Scales NTEP Certified Legal for Trade Options Available Proudly made in Ohio, USA

For the average shipper, drawing up solutions takes around four weeks, according to Schramm, who said Nexterus will incorporate data and costs to create simulations and optimizations. “We can model pretty much anything,” he said. Schramm said many economic analysts feel consumer spending will be solid through the rest of 2023 and will likely not drop off to start in 2024.

Power possibilities

At Flux Power, lithium batteries provide warehouse solutions for its large-sized customers through use in forklifts and material handling equipment. “As a general statement, there’s a strong surge to find anything that will provide higher productivity,” said Ron Dutt, CEO, of material handling warehouse operations.

CAPACITY

• 77,000 lbs. at a 33” load center up to137.7” with ground jacks

• 59,520 lbs. at a 33” load center up to 137.7” without ground jacks

MAST

• Collapsed Height: 156”

• Max. Fork Height: 137.7”

SPECIAL ATTACHMENT

• Carriage is hydraulically extendable to 67’

• Outer forks have independent hydraulic vertical adjustment

8 September 2023 Material Handling Network www.MHNetwork.com

Cover Story continued

TEREX MODEL SF350

TON CAPACITY SIDELOADER

Condition. Very Low

Ideal for Heavy Fabrication.

2011

35

Excellent

Hours.

CONTACT: Rob Alling rob@sideloaders.com 540-359-0350

“One big area is if they can move more pallets during the shift,” he said, noting Flux Power’s customers typically achieve this by switching from lead acid, while smaller operations are often using propane power. “Our target is people that want more productivity at lower cost. That value proposition is becoming very well accepted in the marketplace,” Dutt said.

Another factor for some warehouse operations is cutting down on carbon emissions. “All of these larger companies have sustainability goals. This resonates,” he said.

Dutt said Flux Power is growing fast, at over 50 percent per year. “One of the features that comes with lithium that does not come with lead acid is a computer in the pack that transmits to the cloud (computing.) It gives the battery’s state of health and allows the warehouse people to switch the batteries and extend the useful life of the batteries,” Dutt said.

“It’s so great for asset management. It allows remote monitoring for the customer. It provides for early detection of problems.” Equipment malfunctions with forklifts and batteries are one of the biggest pain points in warehousing, according to Dutt, who said mitigating and reducing down time of equipment is key for warehouses. “Having a computer in the battery for the piece of material handling equipment really enables great productivity in many ways,” he said.

Tech and industry partnerships

And Flux Power is developing artificial intelligence capabilities into its computers to provide oversight monitoring. “All equipment at some point needs to be serviced or replaced and there needs to be planning for that. We are developing AI into our computers and the equipment to provide oversight monitoring. We can have somebody monitoring all of our batteries around the country and advising actions they need to take,” Dutt said.

Other companies in the industry are working on similar technological offerings, according to Dutt. He said the advantage of lithium is offering an 80 percent cost savings for three-shift operations. “One lithium pack could operate for all three shifts and wouldn’t have to be changed out,” he said. “Product, life cycle, cost. That’s been the template for us.”

For warehouse managers, another current consideration is coordinating with suppliers, according to Dutt. “Most of the suppliers are not big. The question is, can a smaller supplier keep up with these big Fortune 500 companies? Can you really deliver on time to all their locations around the country? Can you provide the service?” Dutt said.

For Flux Power, Dutt said relationships are key. “We have relationships with forklift OEM’s, Crown Equipment, Toyota. We can approve our packs to go in their equipment. Batteries are typically not provided by forklift manufacturers, so relationships are crucial,” he said, especially since lithium batteries are not used throughout the industry at the same level as lead acid.

Still, Dutt said Flux Power has almost 20,000 battery packs currently in the market. And he said as labor remains “a big deal,” lithium does provide the relief of not having to change the packs as often. And Dutt believes warehouse robotics will continue to increase in use. “A lot of our customers have automated guided vehicles. We’re seeing a lot of robotics,” he said.

Eileen Mozinski Schmidt is a freelance writer and journalist based in the Greater Milwaukee area. Email Networkeditorial@MHNetwork. com or visit eileenmozinskischmidt.wordpress.com to contact Eileen. If your company would like to be featured, email Networkeditorial@ MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 9 Cover Story continued For more Cover Stories visit www.MHNetwork.com

Warehouse safety tips to keep your employees safe

you might rearrange equipment to eliminate a cord that’s a tripping hazard. Looking at employee grievances about the work environment can also reveal risks you haven’t considered.

3. Create a safe layout

In the transportation and warehousing industries in 2020, there were almost 207,000 reported nonfatal occupational injuries and illnesses, according to the Bureau of Labor Statistics. The nature of the work makes warehouse employees vulnerable to injuries. Implementing the following warehouse safety tips can help reduce the number of injuries among your employees, so you don’t contribute to those injury statistics.

1. Establish safe procedures

Establishing clear company policies and procedures for various activities in the warehouse helps reduce unsafe behaviors that can lead to injuries. This may include things like using protective equipment, never working alone, wearing the right clothing, inspecting equipment regularly, leaving phones in the locker room and following specific procedures when retrieving something from the warehouse. Evaluate every step of your work processes and create corresponding safety warehouse procedures.

2. Identify risks

Warehouses have many common risks, including heavy machinery, items that can fall, tripping dangers and hazardous materials. Identify specific risks related to those and other categories in your warehouse. Verify that you’re handling those risks properly based on OSHA standards. Determine if you can reduce the risks even more. For example,

Evaluate your current warehouse layout to determine if it’s as safe as possible. Look for wide, clear passageways that allow equipment and people to move through them safely. Create a separate walkway for people and another for machinery. The setup should be logical and allow employees to complete their tasks easily without getting in the way of each other. Ensure you have secure shelving and equipment that allows inventory to remain safe.

4. Mark hazards clearly

Clear signage and markings alert employees about potential hazards in the warehouse. All hazardous items or storage areas where hazardous items are kept should have easily identifiable warning signs per OSHA requirements. Mark safety equipment like fire extinguishers and automated external defibrillators to make them easy to access in an emergency. Use colorful, reflective tape or paint to mark forklift lanes, steps, drop-offs and other dangerous areas.

5. Provide safety gear

Issue personal protective equipment for your warehouse employees based on the hazards they encounter daily. Examples include hard hats, steeltoe boots, safety goggles, harnesses, gloves and high-visibility vests or jackets. Your employees may not need all of this equipment, so tailor the list to your environment. Establish a dress code policy to ensure your employees wear clothing that reduces their injury risk, such as closed-toe shoes with good traction or no loose-fitting items.

6. Train employees on safety topics

Regular warehouse training keeps safety at the forefront. It’s easy for warehouse employees to take shortcuts or fall into old habits if you train

10 September 2023 Material Handling Network www.MHNetwork.com

Safety First

www.MHNetwork.com Material Handling Network September 2023 11 The Trusted Name in Remanufactured Industrial Engines • Quality engine packaging for safe and efficient transporation • 1 year unlimited hour warranty • Core credits are processed in a timely manner • Available from the world’s leading supplier of industrial equipment parts and accessories Make it easy to order, anytime and anywhere. Shop Now ww w. tvh .com ALL INDUSTRIAL ENGINE SERVICE

them once and forget about it. Don’t wait until an accident reminds you to schedule warehouse training. Establish new-hire and additional safety training to occur throughout the year for all employees.

7. Hold safety meetings

Touching base with daily meetings gives you a chance to review warehouse safety rules with employees. It’s also a good time to discuss things you’ve noticed people doing that aren’t safe. Address the issues generally instead of calling out individuals in these meetings. You can also share new warehouse safety tips as needed and allow employees to ask questions or share their concerns.

8. Require certifications and training for equipment use

If your warehouse uses heavy equipment, establish certification and training requirements for people who operate those machines. All forklift operators should have a forklift certification, for example. It might be tempting to have someone jump in to do a quick task, but this puts everyone at risk. To avoid this problem, you could have everyone certified on the equipment and hold regular refresher courses on how to use it safely.

9. Do drills regularly

Warehouses can be dangerous in emergencies, such as fires or severe weather events. Finding your way out of the warehouse can be tricky, and shelves full of inventory can present a danger in those situations. Test fire and smoke alarms regularly as well as emergency lighting that will help employees get out in case of an emergency. Do practice drills at least once every three months or more often based on the local fire code. If your warehouse has hazardous materials in it, having more frequent drills is important, since the risks are higher.

10. Establish reporting procedures

Create procedures for reporting accidents in the warehouse. These reports help you follow up on incidents to ensure your employees received proper care and an adequate response. Review the reports regularly to look for patterns and determine ways to improve warehouse safety.

11. Emphasize cleanliness

Many warehouse accidents can be prevented by keeping the workplace clean and organized. Wet spots, cords and obstructions in walkways can lead to injuries. Train employees to clean up wet spots immediately and use wet floor signs when necessary during cleaning. Loading docks can become wet easily in bad weather, so emphasize this risk to employees. Train workers to clean as they go instead of letting clutter build up throughout the day.

12. Inspect things regularly

Everything in the warehouse needs to be inspected regularly to ensure it’s in good condition. Create inspection checklists for each shift to look at forklifts, personal protective equipment, machinery and other gear that employees use regularly. Have a reporting process for issues discovered during these inspections.

13. Practice communication

Clear and timely communication can help prevent injuries and accidents. Establish expectations and processes for communicating things like safety hazards. For example, all employees should know about a dangerous spill in a main pathway or a forklift that isn’t working properly. Employees communicating with supervisors also ensure they learn about accidents and hazards, so they can better control the situation.

14. Encourage employee care

Don’t push employees too hard in the name of increased productivity. Ensure your workers get proper breaks and stay hydrated to keep them alert and focused. Employees who try to meet unrealistic quotas are more likely to rush, make mistakes or lose focus, which can lead to injuries and accidents. Remind employees to stay focused on the job by not using their phones or getting distracted by chatting with coworkers while they’re working in the warehouse.

Indeed is the #1 job site in the world1 with over 300M unique visitors every month2. Indeed strives to put job seekers first, giving them free access to search for jobs, post resumes, and research companies. Every day, we connect millions of people to new opportunities. www.indeed. com

12 September 2023 Material Handling Network www.MHNetwork.com

Safety First continued

www.MHNetwork.com Material Handling Network September 2023 13 LET PFLOW DO THE HEAVY LIFTING! MATERIAL HANDLING SOLUTIONS PFlow vertical reciprocating conveyors are the ideal solution for safely moving materials of any size, shape, or weight to two or more floor levels. Ready to let PFlow do the heavy lifting? 100% employee-owned and proudly made in the U.S.A. 414-352-9000 www.pflow.com CONTACT US TODAY!

Chain Reaction

Unlocking Warehouse Potential: Exploring AMRs in Automated Material Handling

dynamic environments using advanced mapping and localization technologies. AMRs across vendors cater to diverse warehouse environments, ensuring that the right solution is available for specific operational needs.

In the realm of warehouse automation, Autonomous Mobile Robots (AMRs) have emerged as a revolutionary solution for streamlining material handling operations. AMRs offer a myriad of benefits, but it is essential to understand their pros, cons, and alternative technologies to make informed decisions. This article delves into the world of AMRs, their advantages and limitations, and explores alternative technologies worth considering.

AMRs offer numerous advantages that contribute to improved warehouse efficiency. Providers like Fetch Robotics have developed advanced AMRs equipped with cutting-edge perception and navigation capabilities. These robots can autonomously navigate complex warehouse environments, collaborate with human workers, and perform tasks such as picking, sorting, and item transportation. Locus Robotics, another prominent player, specializes in AMRs tailored for e-commerce fulfillment operations. Their robots work collaboratively with human pickers, increasing productivity and reducing order fulfillment time. MiR (Mobile Industrial Robots) offers a diverse lineup of flexible and collaborative AMRs for material transportation and logistics within warehouses. MiR's robots autonomously transport pallets, carts, and bins, adapting to

Operating tirelessly, 24/7, AMRs ensure optimal performance and accelerate operational throughput. The versatility of AMRs allows them to adapt to changing warehouse layouts and operational requirements, making them highly flexible and scalable. Integrated with warehouse management systems, AMRs enable real-time monitoring and optimization, contributing to continuous improvement and streamlined operations.

Safety is a paramount consideration in warehouse environments, and AMRs excel in this aspect. Equipped with advanced sensors and intelligent navigation systems, AMRs from providers like Fetch Robotics, Locus Robotics, and MiR can detect obstacles, avoid collisions, and ensure safe movement within the warehouse. This eliminates the risk of accidents caused by human error, enhancing overall workplace safety.

While AMRs offer substantial benefits, they are not without limitations. Initial investment costs, including the procurement of AMRs, necessary infrastructure modifications, and system integration, can be significant. However, the longterm gains in efficiency and productivity often outweigh these costs. Warehouse layouts with high complexity or dynamic elements may pose challenges for AMR navigation and operational efficiency. In such cases, alternative technologies or hybrid solutions that combine AMRs with other automation systems may be more suitable. Furthermore, regular maintenance and repair requirements should be considered to minimize downtime and ensure smooth operations.

14 September 2023 Material Handling Network www.MHNetwork.com

Determining the ideal scenarios for AMR implementation requires careful assessment. AMRs are particularly well-suited for repetitive material handling tasks, stable environments with clearly defined paths, and high-volume operations that demand efficient and agile movement.

AMRs offered by notable providers like Fetch Robotics, Locus Robotics, MiR and others provide significant advantages for warehouse automation, including enhanced efficiency, safety, and scalability. However, a thorough evaluation of specific warehouse requirements is crucial to determine their suitability. By considering factors such as complexity, flexibility, and budget constraints, warehouse operators can make informed decisions regarding AMRs or alternative technologies. Embracing the right mix of automation solutions, including those offered by leading providers, ensures optimized operations, and unlocks the true potential of your warehouse. Remember, the journey to warehouse excellence encompasses a diverse range of technologies, and AMRs are just one exciting piece of the puzzle.

Bill Denbigh serves as the vice president of product marketing at Tecsys. Bill started working in supply chain software some 30 years ago; his entire career has been laser-focused on designing and building pragmatic supply chain solutions that address the real problems that customers are facing in their supply chain operations. Bill has worked on virtually every aspect of the software in the supply chain, gaining insight into the inner workings of some of the industry’s most complex challenges; Bill, however, tackles those challenges with a no-nonsense levelheadedness that has earned him great repute both internally and among customers.

Blocks the Spread of FireActivates the Sprinkler System

Today’s warehouse fire protection systems include more than just pipes and sprinklers. When the products being stored include highly flammable items such as plastics, aerosols, liquors or oils, fire barriers may be required inside the racking structure.

Solid steel rack decking and flat sheet accessories from DACS make effective fire or heat barriers in warehouse environments.

They can be used on storage racks horizontally or vertically to block the spread of fire, or to capture heat for in-rack sprinkler activation.

www.MHNetwork.com Material Handling Network September 2023 15

Chain Reaction continued For more Chain Reaction visit www.MHNetwork.com

DACS inc. Proven Solutions - One Source / dswanson@dacsinc.com 800-909-4937 dacsinc.com Also from DACS:FlueKeeper® Scan to watch our video now! s

Business Management

Warehouse automation: Five key points on securing operational resilience

1. Vendors and OEMs

For those with the luxury of a new build facility, it may seem that the original equipment manufacturers (OEMs) or vendors can be relied upon, there will be warranties and guarantees and some sort of service contract. But it is rare for all the automation to derive from a single OEM or vendor, there is much scope for dispute as to who is responsible. And if individual items of kit have had to be modified to integrate with other machines, the OEM may reject all responsibility.

Automation in its varied forms is increasingly ‘mission critical’ to warehouse operations. But with such high reliance on sophisticated systems, how do you ensure reliable performance and a risk-free peak? Dan Migliozzi, Head of Sales at independent systems integrator, Invar Group, looks at the options available for maintenance and support.

Advanced automation is transforming the efficiency, accuracy, and throughput of warehouses and distribution centers. But increasing dependency on technology brings risks. Unplanned downtime can no longer be covered by taking on more casual labor, even if this is available, or physically possible in a warehouse laid out for automated systems.

The cost of downtime, in a high-volume 24/7 operation or at the top of a vital seasonal peak, may be existential. Sadly, too many businesses only realize this when the worst has already happened.

So, for any warehouse operation with significant levels of automation, a robust strategy for maintenance, repair and support to minimize downtime is essential. But how can this be achieved? Here are five key points to consider:

As equipment ages, OEMs or their vendors may cease to offer support, or recommend that you update to the latest model. They may even leave the geographic or technical market entirely.

Further considerations, especially with overseas suppliers, are that support may already be outsourced, and of course that support in terms of both response times and pricing, are aligned with the vendor’s business model, not yours. A service contract with an OEM or vendor does not necessarily represent value for money.

2. The in-house option

Not so long ago it was commonplace to have an in-house maintenance team. That was fine when systems were less sophisticated, and most problems could be sorted out by a dual trained mechanical/ electrical fitter and a store of spare parts. However today, the required skill base is much richer, above and beyond the traditional mechanical and electrical skills that have always been essential. There are now further, elevated levels of expertise required, with deep knowledge on pneumatics, hydraulics and the many generations of electronics/ control systems ranging from ‘simple’ PLCs to the software that informs autonomous vehicles and the like. Finding or training such individuals is not easy.

16 September 2023 Material Handling Network www.MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 17 Heavy Machinery Movers Cart 200 Ton Capacity • 20’L x 10’W x 2’H Dual Steering Direct lift, no chains Low profile 8’ - 10” high x 16’ - 7” long x 8’ - 0” wide Optional telescoping rigging boom solo matic tires REMANUFACTURED RIGGER SPECIALS 80,000 lb. to 120,000 lb. at 24” L.C. Direct lift, no chains FOLLOW THE REST, OWN THE BEST Bristol Manufacturing 4416 N. State Rd. (M-15) Davison, MI 48423 Phone: 810.658.9510 Fax: 810.653.5749 Contact Rachelle or Ray www.bristolmanufacturing.com

Even if you can staff that maintenance function, you then have the task of determining an appropriate monitoring and maintenance regime that keeps equipment operating at capacity while meeting manufacturing or other operational requirements. And, of course, there will be staffing issues around holidays or absence to contend with; not many in-house teams have sufficient contingency to cover such eventualities.

In addition, it will be necessary to acquire and maintain an appropriate stock of spares, duly prioritized, knowing exactly where to source the less commonly required parts at short notice. Interestingly, maintenance, repair and operations (MRO) sourcing and inventory control can often be more complex, and administratively more costly, than the procurement of production parts. No surprise, then, that many businesses tend to downplay the risks they are running through inadequate support for warehouse automation.

3. Third parties and service strategies

A third-party maintenance and support specialist may be a favorable alternative to managing the whole process yourself, but this does require some serious thought. So, what should a warehouse operator be looking for?

Firstly, what level of service, in the broadest sense, is actually needed? This is a question that is inevitably coupled with risk. Ideally, this should be considered when the automation is acquired, but often that boat has sailed. Would a packing line breakdown, for example, stop the entire operation? Or are there workarounds that will keep things going, albeit less efficiently, for a few days? It’s a question of redundancy – and the answer may be far from uniform across the warehouse.

As an independent systems integrator, our approach with a potential client is to analyze every aspect of warehouse automation: possible failure modes, their frequencies, their criticality. What

skills, and parts, do we need ever-present on site; what can we risk needing to bring in, and how confident are we of the sourcing? What are the appropriate levels and techniques for machine and condition monitoring, and what are the red lines for intervention? How does downtime for repair or maintenance fit with production or distribution targets?

Broadly, this analysis prescribes one of three approaches. There is a model where the maintenance contractor’s staff are fully embedded in the warehouse. And let us be honest. We are big advocates of planned and predictive maintenance, of serious condition and performance monitoring and so on, but we can’t always predict one-time failures. If such a failure poses an existential threat, an embedded maintenance and support operation becomes a compelling option.

This approach offers a comprehensive, highservice level solution, and therefore is a premium service.

Similar analysis may suggest that, if risk is lower and unplanned downtime won’t, if swiftly addressed, impact the business, a ‘scheduled’ solution may be preferred. Here, the maintenance team turns up to a schedule, which may differ according to the nature of the equipment and agreed maintenance schedules – some might need weekly inspection or even complete strip-down and rebuild, other elements may be on much longer timelines. And, of course, the team is on call for unplanned emergencies.

Or for lower risk and relatively uncomplicated automation, a remote service may suffice for advice, instruction, sourcing parts and so on. That is also the approach advocated for control/software issues – you can’t feasibly trial patches when the system is up and running.

It is also important that there should be a wellestablished escalation system, so that a problem

18 September 2023 Material Handling Network www.MHNetwork.com

Business Management continued

which cannot easily be resolved by the person in direct contact can be raised to someone who can fix it.

Whichever approach is chosen, it is important that it arises from a comprehensive assessment of risk, which can vary, especially across multiple facilities.

4. Technical capabilities

Few maintenance and support service suppliers can guarantee to have all the technical capabilities on tap – especially when it comes to software and the rapidly-developing field of robotics. However, an independent integrator with a team of in-house software developers, such as Invar Group, offers significant capabilities. In particular, we have over 100 staff worldwide working on the development, implementation and support of industry leading technology and we can offer a range of support services from a complete residential service, through to comprehensive remote helpdesk services, available 24/7.

Other factors to look out for when considering a service supplier are staff qualifications / certification, understanding of and adherence to Health & Safety and other principles, along with proof of experience with similar businesses. However, some third parties rely very largely on hiring skills as needed, which isn’t a responsible approach – indeed we reckon to serve around 85% of customer needs from our own resources. It’s worth noting that sourcing and procurement capabilities will be necessary too.

5. Continuous improvement and partnership

An important point to consider is that many third parties can, to a greater or lesser extent, be ‘tied’ to particular OEMs, vendors, or in some cases parts suppliers. This could lead to conflicts of interest or ‘unconscious bias’. Therefore, a level of independence allows for a ‘best practice’ solution to solving problems and sourcing the most appropriate / best value components.

It really isn’t enough just to address failures, and potential failure, as they arise. A competent third party will be continuously gathering and analyzing data on failures, failure modes, and performance. And this shouldn’t be passive: it should be

firmly linked to job tickets, costs of spare parts, downtime, whether there are repeating issues, and other KPIs, so that informed decisions can be made to enhance performance and improve up-time.

Warehouse automation is a significant, often critical investment in the future of the business, and therefore must function reliably day-in, dayout – particularly at peak. Your maintenance and support supplier needs to recognize and respect your business commitments, and work with you to ensure that up-time is maximized, and the best possible performance of the system is maintained throughout. They also need to be prepared to do this across all your technologies and legacy systems, suggesting enhancements that deliver value.

As an independent, full-spectrum automated warehouse solutions provider, Invar Group is cognizant of the broad array of technologies used to support warehouse operations, and being a multifaceted organization that brings together skilled individuals with competencies across warehouse management software, systems integration and controls, we have all that’s needed to de-risk warehouse performance.

Invar Group, headquartered in Cranfield UK, is focused on delivering complete turnkey warehouse automation solutions using advanced technologies such as industrial robotics, AMR goods-to-person solutions, pick-to-light technology, sortation systems, as well as conventional warehouse automation. The Group comprises: Invar Systems, a developer of warehouse control and management systems; Invar Integration (Greenstone Systems), a front runner in solutions design, hardware integration and project management; and Invar Controls, specialists in the design, implementation and maintenance of PLC software and hardware. Further independent advice on transforming operational performance in the warehouse can be found at: www. Invargroup.com

www.MHNetwork.com Material Handling Network September 2023 19

For more Business Management visit www.MHNetwork.com

Business Management continued

American Logistics Aid Network (ALAN) mobilizes for Hawai'i fires

The American Logistics Aid Network (ALAN) is calling on members of the material handling community to be on long-term alert for opportunities to assist the recovery efforts. The Disaster Micro-Site (www. alanaid.org/operations/) includes key details about the fires and their related material handling needs. ALAN Executive Director Kathy Fulton encourages you to consider making a pre-offer of any space, services and equipment you would like to donate to assist with the fire relief efforts.

www.alanaid.org/offerinkind

Intella Parts Company searches for the oldest Hyster forklift

Intella Parts Company, LLC recently conducted a contest on finding the oldest Hyster Forklift that included their customers. They were encouraged to submit their entry if they felt they had the oldest Hyster. The rules were that they must actually own the forklift. The winner of the oldest Hyster forklift was Public Steel, Inc. based in Amarillo, TX with a 1945 Hyster KD Krane. Public Steel has been in business since 1948 and believe it or not has three of this model in their possession. Phillip reports that it still runs, and the machine is still used once in a while, they also have a few more modern forklifts they use on a regular basis. They won a $100 gift certificate from Intella, a Carhart sweatshirt and a $100 VISA gift certificate.

www.intellaparts.com

Crowley and the Port of San Diego celebrate groundbreaking for AllElectric Tugboat Charging Station

Crowley and the Port of San Diego broke ground for the shoreside charging station designed to provide clean energy for the company’s forth-coming zero-emissions tugboat, eWolf. Joined by key partners and community stakeholders, the ceremony marked a significant step forward in the industry’s journey to decarbonization and reduce emissions in the San Diego community. The eWolf, under continuing construction, is a crucial component of the shared commitment between Crowley and its federal and local partners to invest and develop emissions-free technology.

www.crowley.com www.portofsandiego.org

ARA’s quarterly economic forecast updates CIE rental revenues

The American Rental Association (ARA) has released an updated forecast for the construction and industrial equipment rental industry. In the quarterly update, the ARA presented significant changes in the economic forecast, particularly for construction and industrial equipment (CIE) rental revenues. In the previous forecast, CIE rental revenue was expected to reach $45.5 billion in 2023 and $46.7 billion in 2024. With new considerations, the CIE rental revenue is expected to total $56 billion this year and $59 billion in 2024.

www.ARArental.org

20 September 2023 Material Handling Network www.MHNetwork.com

Industry News

www.MHNetwork.com Material Handling Network September 2023 21 Largest online market for used forklifts, attachments and work platforms. DEALERS DID YOU KNOW YOU CAN GET YOUR EQUIPMENT ONLINE FOR JUST $99 A MONTH? PLUS, WE HAVE AN EQUIPMENT QUOTING TOOL INCLUDED AT NO ADDITIONAL CHARGE. CALL KIP 563 557-4493 | KIP.KRADY@MHNETWORK.COM OR MONTY 563 588-3855 | MONTY@FORKLIFT-INT.COM TO BE PART OF THE FORKLIFT FAMILY OF DEALERS. WWW.FORKLIFT-INTERNATIONAL.COM 2000 CAT Lift Trucks PD50 American Equipment Sales, Inc. Lawrence | 785-843-4500 1 2012 Hyster H90FT ATP Equipment Exchange Rockdale | 815 744-1683 13 2018 Hyster E65XN MH Equipment Company Des Moines, IA | 515 288-0123 5 2023 Aisle Master 44SE Easy Street JD&S, LLC Carol Stream, IL | 630 682-0021 2 2017 Clark CTX40 Russell Equipment Twinsburg, OH | 330 405-8300 7 2015 Hyster E65XN MH Equipment Company Des Moines, IA | 515 288-0123 5 2022 Doosan G25E-7 DF Industrial Lift Truck Service Chattanooga | 423 332-5533 1 2013 CAT Lift Trucks PD6000-D Wolter Inc. Brookfield, WI | 888 272-0601 1 2009 CAT Lift Trucks E6500AC Wolter Inc. Brookfield, WI | 888 272-0601 1 2016 Combilift C8000 Easy Street JD&S, LLC Carol Stream, IL | 630 682-0021 5 Raymond 71SL60TN Somerset Equipment Sales Batavia | 708 921-0751 6 2018 Hyster H135FT Chicago Industrial Equipment Rockdale | 815 569 6499 17 2004 Yale GP330-EC Forklifts of St. Louis St. Louis | 573-335-2244 1 2017 Hyster S120FTPRS A Lift Above Inc Aurora, IL | 630 758-1023 4 2023 Doosan BC25S-7 36V Industrial Lift Truck Service Chattanooga | 423 332-5533 2 Crown SC4520-35 Somerset Equipment Sales Batavia | 708 921-0751 6

Industry News

Green Cubes announces Preferred Supplier Agreement with Doosan

Green Cubes Technology (Green Cubes) has announced that Doosan Industrial Vehicle America Corporation (DIVAC) named Green Cubes as preferred power systems vendor to support its electric forklift product line. The DIVAC group supplies quality material handling equipment for the North American network of 105 independent authorized and trained dealers. The Industrial Vehicle product line includes 133 separate models of 82 various engine/ battery configurations of Internal Combustion and Electric-powered vehicles. Under the agreement, Green Cubes will provide its Lithium SAFEFlex batteries and chargers for these electric industrial trucks.

www.greencubes.com www.doosanlift.com

A Light of Hope, Felling Trailers announces 2023 Trailer for a Cause Auction dates

Felling Trailers, Inc. is conducting its eleventh annual online auction of an FT-3 drop deck utility trailer to benefit a nonprofit organization. Pockets of Hope is the 2023 recipient. Every day, children are rescued from abuse, neglect, and abandonment. The Trailer for a Cause auction will start on Monday, September 11th at noon, running for five days, ending Friday, September 15th at noon. The online auction can be viewed at https://www.felling.com/ourcompany/trailer-for-a-cause.

www.felling.com

Rack Manufacturers Institute (RMI) embraces a new look for 65th anniversary

RMI has unveiled a new logo and fresh branding to coincide with its 65th year of promoting rack safety. Founded in 1958, RMI is an MHI Industry Group and the leading racking industry association. It currently boasts 38 members, who are identified as leaders in the rack manufacturing and material handling industry space. Some of the new elements of the RMI site include the newly minted logo, a refreshed infographic design, and a fresh look for its free informational blog site, www.rmiracksafey.org.

www.mhi.org/rmi

Chang Industrial and Hai Robotics combine to launch Advanced Manufacturing Initiative

Chang

Industrial and Hai Robotics announced the formation of a strategic partnership targeting North American manufacturers. Chang Industrial has built a consortium of engineering and supply chain partners and features Hai Robotics, a global provider of intelligent automated storage and retrieval systems (ASRS). This collaboration aims to improve flexibility and sustainability in manufacturing offerings. In forming the advanced manufacturing consortium, the teams of Chang Industrial and Hai Robotics plan on delivering innovative turnkey solutions for their customers worldwide and developing new business together.

www.changindustrial.com

www.hairobotics.com

22 September 2023 Material Handling Network www.MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 23 The Superior Turret Advantage Why the Superior Turret ? • Save Money by Increased Storage Capacity • Not Difficult to Use like the Others • Work Both Sides of the Aisle • Versatility - Rack to Truck • Limit the Learning Curve • Simplicity in Design • Low Maintenance • Multiple Options • Electric or LP www.superioreng.com 800-359-3052 AmericanMade

TVH announces changes in Customer Service and Sales Teams in the U.S.

TVH Americas just announced changes to the Customer Service and Sales teams in the USA.

Effective July 2023, Ryan Walker was promoted to Director of Sales and Services for the USA. Cathy Diaz will remain in her current role, as Sales Director USA, until December 2023 when she will retire. Diaz began her career with System Material Handling Inc. (SMH) in 1984. Her wealth of experience and knowledge proved vital during the acquisition of SMH by TVH in 2003. In 2006, Cathy Diaz played an integral role in the IMC Holdings (Intrupa and LPM) acquisition.

www.tvh.com

Equipment Depot appoints Anthony Garcia as President to succeed David O Turner

Equipment Depot announced that Anthony Garcia has been appointed president by the company’s Board of Directors with the transition date of September 11, 2023. Garcia succeeds president and CEO, David O. Turner, who has announced his departure after 12-years at the helm. Turner exits after successfully integrating five new companies into the Equipment Depot fold, reaching over 50 nationwide locations. Garcia joined Equipment Depot in 2022 as the Regional Vice President of the South Region.

www.eqdepot.com

Toyota Material Handling promotes Jimenez to Vice President

Toyota Material Handling (TMH) has recently announced the promotion of Cesar Jimenez to Vice President of Regulatory Affairs, Product Planning, and Product Assurance. In this new role, he is responsible for Toyota’s industry-leading product line throughout its life cycle, including pre-development, launch, warranty and ongoing resolution of any technical problems. Jimenez began his career at Toyota as a college intern in the summer of 1996. Over the last 27 years, he has worked in various capacities, including product planning engineer, product marketing manager, and joined the Toyota executive team in 2015.

www.toyotaforklift.com

Skyjack announces retirement of President Ken McDougall and appoints Charlie Patterson

Skyjack division announce the retirement of Skyjack President Ken McDougall, and subsequent appointment of Charlie Patterson as President, effective January 1, 2024. The two will be working together over the next several months to ensure a seamless transition for the organization. Patterson’s title as Skyjack President will be effective January 1, 2024, as he and McDougall work together for the remainder of 2023 to facilitate a smooth transition.

www.skyjack.com

24 September 2023 Material Handling Network www.MHNetwork.com People

News

Ryan Walker - Cathy Diaz

L to R Ken McDougall and Charlie Patterson

www.MHNetwork.com Material Handling Network September 2023 25 Give Them AIT’S QUALITY & YOUR SERVICE. American Industrial Transmission Inc. 20395 Hannan Pkwy. Walton Hills, OH Fx 440-232-8142 sales@aittransmission.com www.aittransmission.com 800-588-7515 Give YOUR Customers MORE Than They EXPECT. Reman Transmissions Reman Torque Converters Transmission Rebuild Kits Reman Drive Axles Reman Steer Axles Let us be an EXTENSION to your COMPANY!

Distribution and Supply Chain Project Report

Data provided by SalesLeads

196 New Distribution and Supply Chain Planned Industrial Project in July 2023 – A Third Straight Month Increase

SalesLeads announced the July 2023 results for the new planned capital project spending report for the Distribution and Supply Chain industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 196 new projects in the Distribution and Supply Chain sector compared to 180 in June and 158 in May 2023.

ILLINOIS: Food and beverage company is planning to invest $400 million for the construction of a 775,000 SF distribution center in DEKALB, IL. They are currently seeking approval for the project. Completion is slated for 2025.

SOUTH DAKOTA: Industrial supplies mfr. is planning to invest $158 million for a 200,000 SF expansion of their manufacturing and warehouse facility in BROOKINGS, SD. They are currently seeking approval for the project.

The following are selected highlights on new Distribution Center and Warehouse construction news.

Distribution and Supply Chain - By Project Type

• Distribution/Fulfillment Centers - 26 New Projects

• Industrial Warehouse - 172 New Projects

Distribution and Supply Chain - By Project Scope/Activity

• New Construction - 110 New Projects

• Expansion - 44 New Projects

• Renovations/Equipment Upgrades - 39 New Projects

• Closings - 6 New Projects

Distribution and Supply Chain - By Project Location (Top 5 States)

• Florida - 19

• Georgia - 9

• Illinois - 8

Largest Planned Project

• Texas - 17

• New York - 9

During the month of June, our research team identified 5 new Distribution and Supply Chain facility construction projects with an estimated value of $100 million or more.

The largest project is owned by Walmart, who is planning to invest $350 million for the renovation and equipment upgrades on their distribution center at 2200 7th Ave SW. in CULLMAN, AL. They are currently seeking approval for the project.

Top 10 Tracked Distribution and Supply Chain Project Opportunities

TEXAS: Tissue paper MFR. is planning to invest $400 million for the construction of a manufacturing and warehouse facility on Gene Campbell Rd. in NEW CANEY, TX. They are currently seeking approval for the project. They will relocate their operations upon completion.

KENTUCKY: Startup distillery is planning to invest $144 million for the construction of a production and warehouse facility in MOREHEAD, KY. They are currently seeking approval for the project.

FLORIDA: Global online retailer is planning to invest $120 million for the construction of a 100,000 SF warehouse and satellite processing facility at Kennedy Space Center in MERRITT ISLAND, FL. Completion is slated for late 2024.

MISSOURI: Food service distributor is planning to invest $117 million for the construction of a 350,000 SF distribution facility at 5321 Hern Ave. in ST. LOUIS, MO. They are currently seeking approval for the project. They will relocate their operations upon completion.

INDIANA: Global retail chain is planning to invest $108 million for the expansion and equipment upgrades on their distribution center in SEYMOUR, IN. Construction is expected to start in late 2023, with completion slated for 2024.

OHIO: Beverage company is planning to invest $100 million for the construction of a 400,000 SF distribution center at 1489 Rohr Rd. in COLUMBUS, OH. They are currently seeking approval for the project. They will relocate regional operations upon completion in Spring 2025.

GEORGIA: Cold storage service provider is planning to invest $66 million for the construction of a 268,000 SF warehouse and office facility at 3875 Cornelia Hwy. in LULA, GA. They are currently seeking approval for the project.

FLORIDA: Electric power equipment mfr. is planning to invest $50 million for the construction of a 302,000 SF manufacturing and warehouse facility on Jericho Road in CRESTVIEW, FL. They are currently seeking approval for the project. Construction is expected to start in late 2023, with completion slated for 2027.

Since 1959, SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline.

26 September 2023 Material Handling Network www.MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 27 Label Holders for Pallet Racking with Wire Decking 800.242.3919 | www.aignerlabelholder.com Slip•Strip™ Black Hang•Vu™ Deck•ID™ Slip•N•Stik™ Magnetic 6 – 140,000 lb. Rigger Booms Bristol RS80 $169,500 USD Call Toll Free (877) 621-5438 www.whiteblazeinc.com WHITE BLAZE EQUIPMENT 12 – 15,500 lb. Class IV Booms in Stock Optional Swivel Clevis Stingers

Industrial Manufacturing planned Project Report

Data provided by SalesLeads

June 2023 Shows 141 New Industrial Manufacturing Planned Project with Renovations & Equipment Upgrades Remaining Constant

SalesLeads announced the July 2023 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 140 new projects in July as compared to 141 in June, unchanged for the Industrial Sector.

TENNESSEE: Automotive component mfr. is planning to invest $790 million for the construction of two manufacturing and warehouse facilities totaling 940,000 SF in STANTON, TN. The project includes the construction of a 400,000 SF manufacturing facility in LAWRENCEBURG, TN. Completion is slated for 2025.

The following are selected highlights on new Industrial Manufacturing industry construction news.

Industrial Manufacturing - By Project Type

• Manufacturing/Production Facilities - 129 New Projects

• Distribution and Industrial Warehouse - 82 New Projects

Industrial Manufacturing - By Project Scope/Activity

• New Construction - 44 New Projects

• Expansion - 48 New Projects

• Renovations/Equipment Upgrades - 57 New Projects

• Plant Closings - 13 New Projects

Industrial Manufacturing - By Project Location (Top 10 States)

• California - 10

• Texas - 9

• Ohio - 8

• Georgia - 6

• Tennessee - 6

Largest Planned Project

• New York - 9

• Indiana - 8

• Michigan - 7

• Minnesota - 6

• South Carolina - 5

During the month of July, our research team identified 16 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more.

The largest project is owned by Formosa Plastics Corporation, who is planning to invest $12 billion for the construction of a processing facility in ST. JAMES, LA. They are currently seeking approval for the project. Construction is expected to start in Summer 2024.

Top 10 Tracked Industrial Manufacturing Projects

CALIFORNIA: Semiconductor MFR. is planning to invest $2 billion for the expansion, renovation, and equipment upgrades on their manufacturing facility at 7501 Foothills Blvd. in ROSEVILLE, CA. They are currently seeking approval for the project. Completion is slated for 2026.

TEXAS: Tissue paper MFR. is planning to invest $400 million for the construction of a manufacturing and warehouse facility on Gene Campbell Rd. in NEW CANEY, TX. They are currently seeking approval for the project. They will relocate their operations upon completion.

INDIANA: Plumbing equipment MFR. is expanding and planning to invest $300 million for the construction of a 300,000 SF manufacturing facility adjacent to their existing plant in WABASH, IN. Construction is expected to start in early Fall 2023.

ARIZONA: Semiconductor equipment MFR. is planning to invest $270 million for the construction of a laboratory and manufacturing facility on the Arizona State University campus in TEMPE, AZ. They are currently seeking approval for the project.

FLORIDA: Building materials MFR. is planning to invest $235 million for the expansion and equipment upgrades on their manufacturing facility in PALATKA, FL. They are currently seeking approval for the project.

GEORGIA: Automobile MFR. is planning to invest $200 million for the renovation and equipment upgrades on their manufacturing facility in WEST POINT, GA. Completion is slated for Spring 2024.

OHIO: Tissue paper MFR. is planning to invest $185 million for a 500,000 SF expansion of their manufacturing facility in CIRCLEVILLE, OH. They are currently seeking approval for the project. Completion is slated for 2025.

SOUTH DAKOTA: Industrial supplies MFR. is planning to invest $158 million for a 200,000 SF expansion of their manufacturing and warehouse facility in BROOKINGS, SD. They are currently seeking approval for the project.

KENTUCKY: Automotive components mfr. is planning to invest $153 million for a 752,000 SF expansion and equipment upgrades on their manufacturing facility in BEREA, KY. They are currently seeking approval for the project.

Since 1959, SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline.

28 September 2023 Material Handling Network www.MHNetwork.com

www.MHNetwork.com Material Handling Network September 2023 29 Quality Hydraulic Components Cylinders Power Steering Pumps Valves Quality & Value for Over 50 years New & Remanufactured Exchange HADER Incorporated P.O. Box 510260 • New Berlin, WI 53151-0260 Shipping: 15600 W. Lincoln Ave. • New Berlin, WI 53151 Toll Free: 877.388.2102 • Phone: 262.641.8000 • www.haderind.com Toll Free Fax: 877.384.1654 • Fax: 262.641.8010 • Email: hadersales@haderind.com H a der INCORPORATED

Industrial Food and Beverage Report

Data provided by SalesLeads

78 New Food and Beverage Industry Planned Projects Remain Unchanged for July 2023

SalesLeads announced the July 2023 results for the new planned capital project spending report for the Food and Beverage industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction and significant equipment modernization projects. Research confirms 78 new projects in the Food and Beverage sector as compared to 79 in June.

facility at 4832 Camp Rd., HAMBURG, NY. They are currently seeking approval for the project. Construction is expected to start in Spring 2024 and they will relocate their operations upon completion.

WASHINGTON: Grocery retailer is planning for the construction of a 1-million sf distribution center on Anderson Rd. in ELLENSBURG, WA. They are currently seeking approval for the project.

The following are selected highlights on new industrial construction news and project opportunities throughout North America.

Food and Beverage Project Type

• Processing Facilities - 45 New Projects

• Distribution and Industrial Warehouse - 35 New Projects

Food and Beverage Project Scope/Activity

• New Construction - 34 New Projects

• Expansion - 21 New Projects

• Renovations/Equipment Upgrades - 19 New Projects

• Plant Closing - 5 New Projects

Food and Beverage Project Location (Top 10 States)

• California - 7

• New York - 6

• Indiana - 4

• Ohio - 3

• Florida - 2

Largest Planned Project

• Minnesota - 6

• Alabama - 4

• Michigan - 3

• Pennsylvania - 3

• Georgia - 2

During the month of June, our research team identified 5 new Food and Beverage facility construction projects with an estimated value of $100 million or more.

The largest project is owned by Walmart, which is planning to invest $350 million for the renovation and equipment upgrades on their distribution center at 2200 7th Ave SW., CULLMAN, AL. They are currently seeking approval for the project.

Top 10 Tracked Food and Beverage Projects

KANSAS: Global retail chain is planning to invest $257 million for the construction of a 320,000 SF processing facility in OLATHE, KS. They are currently seeking approval for the project. Construction is expected to start in late 2023, with completion slated for 2025.

NEW YORK: Food bank is planning to invest $99 million for the construction of a 200,000 SFwarehouse, food prep, and office

ALABAMA: Frozen food MFR. is planning to invest $28 million for an expansion of its processing facility in MOBILE, AL. They have recently received approval for the project.

TEXAS: Food products MFR. is planning for the renovation and equipment upgrades on a 540,000 sf processing and distribution facility in NORTHLAKE, TX. They are currently seeking approval for the project

GEORGIA: Specialty ingredient MFR. is planning for the construction of a 160,000 sf processing facility at 5901 Technology Pkwy, COLUMBUS, GA. They are currently seeking approval for the project.

KENTUCKY: Hydroponic farming company is planning to invest $25 million for the renovation and equipment upgrades on their processing facility in FLORENCE, KY. They have recently received approval for the project.

NEW YORK: Specialty food products MFR. is planning to invest $16 million for a 12,000 SF expansion and equipment upgrades on their processing facility at 75 Empire Dr. in WEST SENECA, NY. They are currently seeking approval for the project.

MINNESOTA: Fresh produce grower is planning to invest $15 million for the renovation and equipment upgrades on their processing facility in MORRIS, MN. They have recently received approval for the project.

INDIANA: Ice Cream MFR. is planning to invest $13 million for the expansion of its processing and warehouse facility at 3426 N Wells St., FORT WAYNE, IN by 58,000 SF. They are currently seeking approval for the project.

Since 1959, IMI SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services for sales and marketing teams to ensure a predictable and scalable pipeline. The Outsourced Prospecting Services, an extension to your sales team, is designed to drive growth with qualified meetings and appointments for your internal sales team. Visit us at salesleadsinc.com.

30 September 2023 Material Handling Network www.MHNetwork.com

• Manage Economic Uncertainty

• Train and Engage Employees

• Access Industry Resources

• Create and Maintain Business Connections

• Save on Everyday Expenses

• Recruit and Retain New Hires

• Stand Out from the Competition

• Understand and Act On Shifting Industry Trends

www.MHNetwork.com Material Handling Network September 2023 31

you facing business challenges that you need help with?

today and we will do our best to help you find resources. Call 847-680-3500 or email connect@mheda.org or visit us online at www.mheda.org

YOUR NETWORK. EDUCATE YOUR ASSOCIATES.

YOUR BOTTOM LINE.

is the Material

Distributors Association.

600 companies worldwide

MHEDA’s

to

are

Are

Contact MHEDA

EXPAND

ELEVATE

MHEDA

Handling Equipment

Over

utilize

resources

stay competitive and connected. We

committed to serving this essential business community.

FACING CHALLENGES?

IF YOU ARE LOOKING FOR A RELIABLE NETWORK OF PEERS AND INFORMATION…MHEDA CAN HELP:

Product Showcase

TGW presents new generation of shuttles

The Stingray shuttle is the efficient all-rounder for transporting totes, cartons, trays, and hanging goods. More than 20,000 shuttles are in use worldwide and prove their reliability day after day. With this advanced shuttle generation, robustness and sustainability are the focus. Covers are now made of wood, a renewable raw material from local production sites, saving 25 tons of plastic per year. As part of the FlashPick® goods-to-person system, shuttles play a central role in automated warehouses, along with other TGW solutions. www.tgw-group.com

Connect tubes securely and without visual clutter

Cabka has announced its participation in the upcoming Pack Expo Las Vegas (September 11-13, 2023), where it will showcase its innovative products designed for the circular economy at booth N-9403. With a focus on tailormade solutions and sustainability, Cabka aims to transform storage and transport processes while benefiting customers and the environment. Cabka will present its diverse portfolio of large load carriers and pallets, highlighting its commitment to the circular economy. www.cabka.com

HC Forklift America introduces the new

XE Series Electric Lithium-Ion Pneumatic Forklift

HC Forklift America Corporation (HCFA) has announced the new XE Series Electric Lithium-Ion Pneumatic Forklift with a 4,000-7,600lb capacity. The new XE Series of lithium-ion pneumatic forklifts were designed from the ground up to provide operators with a true lithium-ion alternative to I.C. pneumatic forklifts. Because of this, the integrated 80V lithium-ion forklift features lift speeds, travel speeds, gradeability, ground clearance, and a competitive price point that rivals comparable I.C. pneumatic forklifts. www.hcforkliftamerica.com

Matrix demonstrating its excellence with

Flexible Packaging Machines at PACK EXPO 2023

Matrix will be demonstrating its portfolio of VFFS, pre-made pouch, and sachet solutions, including its MVC-300 continuous boxmotion bagger, in booth C-2825 at PACK EXPO 2023, September 11-13. Matrix is a provider in VFFS packaging equipment producing a variety of flexible bag styles, including pillow, gusseted, flat bottom, and modified doy.

www.matrixpm.com

www.packexpolasvegas.com

Yale launches new Power Key option to help warehouses change among lift truck motive power technologies

Yale Lift Truck Technologies announces Power Key™, a one-of-a-kind solution engineered to provide flexibility in a world of increasing electric power options. Expanding on the previous offering, lithium-ion-ready lift trucks, Power Key allows operations to easily switch among not only leadacid and lithium-ion, but now also thin plate pure lead (TPPL) battery modes, without external accessories. Like lithium-ion, TPPL produces zero emissions and enables opportunity charging but offers a lower acquisition cost, attributes that make it a strong consideration as a lift truck power option for some warehouses. www.yale.com

32 September 2023 Material Handling Network www.MHNetwork.com

Product Showcase

KEEN Utility footwear unveils Arvada for the fall

New for Fall ‘23, KEEN Utility’s Arvada is designed for jobs requiring constant movement and long hours on your feet. A perfect blend of athletic-level cushioning and style, this safety-toe work sneaker series features the lightweight, compression-resisting KEEN. ReGEN midsole that returns 50% more energy than standard EVA foam and a sneaker-like ultrabreathable mesh upper. Offering energy-returning jobsite performance with all-day style, the Arvada will be available for both men and women in several colorways. www.keenfootwear.com

EnerSys® expands NexSys® iON battery offering with addition of 80 volt model

EnerSys® has expanded its line of virtually maintenance-free, high-performance NexSys® iON Lithium-ion batteries with the addition of its 80 Volt model. Engineered for fast recharge, long run times and to deliver high energy capacity in a smaller footprint, the latest NexSys® iON battery model provides customers with a premium power solution catered to meet the energy demands of a variety of heavy-duty applications, including those converting from LPand diesel-fueled equipment to fulfill sustainability requirements. www.enersys.com

Continental introduces NightViu LED Driving Lights

Continental has introduced 10 new, professional-quality driving lights as part of the company’s NightViu® Lighting Solutions line. These new lights have been designed to help improve operational safety by dramatically increasing nighttime visibility. They feature rugged aluminum die-cast housings with cataphoretic coating, and resilient shatterproof polycarbonate lenses. Depending on the model, they are rated IP69K or IP67K for Ingress Protection (IP) from dust and water.

www.continental-aftermarket.com

WillScot Mobile Mini unveils innovation in space management - PRORACK™

WillScot Mobile Mini Holdings Corp. has announced PRORACK, a proprietary space management solution aimed at delivering unparalleled organization, productivity, and efficiency in storage containers used on job sites and projects across a variety of industries. PRORACK is a new solution of adjustable surfaces that can be configured as a workstation, pipe rack, tool organization, or general material storage – or a combination of these formations, all at once.

www.willscotmobilemini.com

Signode to showcase suite of automated turnkey solutions at Pack EXPO

Signode will present an array of automation advancements and support solutions in booths C-4814 and C-5017 at PACK EXPO Las Vegas 2023. Held at the Las Vegas Convention Center September 1113. This year at PACK EXPO Las Vegas, Signode highlights the benefits of automation for manufacturing and distribution operations through its advanced line of Simplimatic® robotics, palletizers and conveyors, Little David® case packing equipment, Lachenmeier® stretch hooding equipment and others.

www.signode.com

www.MHNetwork.com Material Handling Network September 2023 33

34 September 2023 Material Handling Network www.MHNetwork.com ASSOCIATIONS Your direct connection to the Material Handling Industry’s hottest trends, newest products, best management training workshops & represents a wealth of resources for all material handling businesses. www.mheda.org — 847.680.3500 For more articles, news, products and more visit www.MHNetwork.com ERGONOMIC HOLSTERS ENGINES Toll Free 877-303-LIFT • 440-943-9546 • FAX 440-943-9547 www.all-industrial.com ✓ Remanufactured engines ✓ Engines in-stock for same day shipment ✓ Quality assured workmanship from people who know the business! Marketplace DECKING PROVEN SOLUTIONS ONE SOURCE DACS inc. 800-909-4937 dswanson@dacsinc.com Punch Deck ® & Punch Deck Plus® Open Area Rack Deck FlueKeeper ® Keeps Flue Spaces Open Fire and Heat Barriers Racking / Shelving Mezzanine Decking Solid Rack Deck BATTERIES FIND IT. SELL IT. ENJOY IT. forklift-international.com

www.MHNetwork.com Material Handling Network September 2023 35 Interested in this space? Next Deadline: September 15th www.MHNetwork.com TRANSMISSION REBUILD NEED A TRANSMISSION REBUILD KIT? ◆ OUR KITS ARE DESIGNED FOR TECHS, BY TECHS! ◆ AIT CARRIES KITS FOR MOST TRANSMISSION STYLES. 800.588.7515 www.aittransmission.com AMERICAN INDUSTRIAL TRANSMISSION, INC. TIRES At Tires International Corp., we offer a variety of solid tires for forklifts, telehandlers, skid steer loaders as well as larger loaders and other construction equipment. If you don’t see the tire you need on our website or need help in making your selection, call us. We’re always ready to help! “We ship our solid tires nationwide!” (800) 818-1139 WWW.TIRESINTERNATIONAL.NET FORKLIFTS PA Industrial Equipment, Inc. Delivering Quality Since 1977 PA CONTACT: ROY BRAMM 610/369-9778 www.PAIndustrial.com 215 S. Washington St. Boyertown, PA 19512 USED FORKLIFTS & INDUSTRIAL EQUIPMENT FORKLIFT PARTS RENTALS FIND IT. SELL IT. ENJOY IT. forklift-international.com FORKLIFTS Marketplace

36 September 2023 Material Handling Network www.MHNetwork.com The advertisers’ index is an extra service to the advertisers. The publisher does not assume liability for errors. Aigner Label Holder Corp. .............................. 27 www.aignerlabelholder.com All Industrial Engine Service 11 www.all-industrial.com American Industrial Transmission, Inc..... 25, 36 www.aittransmission.com Bishamon Industries WS18 www.bishamon.com Bristol Manufacturing .................................... 17 www.bristolsteel.com Cavaion Baumann USA 8 www.cavaionbaumannusa.com CombiLift USA ............................................... A2 www.combilift.com Custom Industrial Products, Inc. / CIP ....... WS5 www.customindprod.com DACS, Inc. ...................................................... 15 www.dacsinc.com Dyna Rack ......................................... A1, WS2-3 www.dyna-rack.com Enersys A4 www.enersysinc.com Flight Systems Industrial Products (FSIP) ...... 3 www.fsip.biz Forklift-international.com .............................. 21 www.Forklift-international.com Generix Group .................................. WS7, WS19 www.generixgroup.com Green Cubes Technology ................................. 5 www.greencubestech.com Hader Industries Inc ...................................... 29 www.haderind.com Industrial Forklifts ........................................ A3 www.IndustrialForklifts.com Joseph Industries, Inc.................................... 36 www.joseph.com LD Systems ............................................... WS11 www.LDSLC.com MHEDA .............................................................. 31 www.mheda.org Nucor Warehouse Systems .................... WS14-15 www.nucor.com PFlow Industries, Inc. 13, WS13 www.pflow.com RAVAS USA, LLC .............................................. 7 www.ravas.com Superior Engineering ..................................... 23 www.superioreng.com Vestil Mfg. Corp. .................................. WS20-21 www.vestil.com West Point Rack, Inc. ................................ WS22 www.westpointrack.com White Blaze Equipment .................................. 27 www.whiteblazeinc.com Wy'East Products .................................... WS8-9 www.clearcap.com ADVERTISER INDEX • TRANSMISSIONS • REBUILD KITS • DIFFERENTIALS • DRIVE AXLES • STEER AXLES • TORQUE CONVERTERS TRANSMISSIONS WE KNOW American Industrial Transmission Inc. 800-588-7515 sales@aittransmission.com www.aittransmission.com Remanufactured Transmissions, Engines, Torque Converters, Steer Axles, Overhaul Kits and Aftermarket Parts for: • Material Handling • Construction • Agricultural Equipment 800-321-9983 www.joseph.com sales@joseph.com Authorized Distributor Authorized Distributor Authorized Distributor Authorized Distributor Authorized Distributor

A3 *Plus local delivery, applicable taxes, maintenance and insurance. Restricted to normal clean application. Plus applicable sales taxes. While supplies last. FOB: Industrial Forklifts. Call for more details. CALL FOR MORE INFORMATION 230 N 48th Ave. Phoenix, AZ 85043 303-887-3953 www.IndustrialForklifts.com NOW IN STOCK CALL TODAY

A4 Find out more: www.enersys.com/throughput © 2023 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E. Sold my customer cheap batteries. They failed. Like our relationship.

of customers likely switch providers after a negative experience.* Bundling new equipment with bargain batteries jeopardizes customer operations and your relationships. Is it worth the risk? When it comes to power, EnerSys® can help you choose wisely.

89%

Warehouse Solutions Supplement insert for Material Handling Network September 2023

utilize

Dyna Pallet stacking frames turn your warehouse pallet into a stackable rack within seconds.

Infinite sizes available with custom made racks. Custom engineered per application.

WS2 September 2023 Warehouse Solutions www.MHNetwork.com Contact Dyna Rack for your customer’s storage needs. 800.939.3962 | sales@dyna-rack.com | www.dyna-rack.com THE DEALERS' SOURCE FOR PORTABLE RACKSTM CUSTOMIZED DESIGNS ARE CONSIDERED STOCK AVAILABLE on some sizes & designs

Add casters to your stack rack cart base to increase mobility and versatility.

Stack racks

vertical storage by safely stacking racks up to 5 high.

PORTABLE STACK RACKS STACK RACK CARTS DYNA PALLET STACKING FRAMES CUSTOM RACKS Made in the USA

www.MHNetwork.com Material Handling Network September 2023 WS3 • Store product up and off the floor preventing product damage. • Racks store easily with little storage space required when not in use. • Standard rack designs/sizes can be changed to meet your specific needs. Portable Stacking Racks • For storing or transport, these long-wearing racks save space & time. • Utilize vertical storage space by safely stacking these racks up to 5-high. • Forklift portable for easy handling of loads up to 4000 lbs & more. • Rugged construction features stand up to heavy industrial requirements. • Save time by moving more material with fewer moves. “Ideal for your customer’s material handling needs.” STOCK PROGRAM AVAILABLE Call for assistance. 800-939-3962 www.dyna-rack.com sales@dyna-rack.com Made in the USA Customized designs are considered!

Warehouse Management

Will warehouse automation replace humans?

Read any article on automated warehouse vehicles, and it’s pretty easy to see there is a lot of hype. Although automation in automated guided vehicles (AGVs) and autonomous mobile robots (AMRs)—my specialty—have come a long way, they are not replacing all warehouse workers.

There is a fair amount of automation hype but automation and various technologies like AGVs impact workers. Companies that manufacture this increasingly sophisticated equipment must consider the social impacts.

AGVs are getting smarter