www.irhace.org.nz The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries DECEMBER/JANUARY 2022 Inside this issue ➤ Where to Now for Hot Water?

The Role of Heat Pumps in Decarbonisation online conference ➤ What does good look like? ➤ HVAC Hygiene Best Practice Guideline

➤

Slim

• 0.50m2 footprint for 16HP

• 42cm deep, fits almost anywhere

Modular

• 8~16HP outdoor units

• Combine 1~4 units

• Up to 54HP Max

Ultra-Efficient

• Single cabinet COP up to 4.61

Versatile

• Up to 500m total piping

Contents Official Journal of the Institute of Refrigeration, Heating and Air Conditioning Engineers of New Zealand Inc (IRHACE), Climate Control Companies Association New Zealand (CCCANZ), and Refrigerant Licence New Zealand (RLNZ). 8 8 NEWS 21 EDUCATION & TRAINING 24 OUR PEOPLE 29 MEMBER NEWS 32 EVENTS INSIDE THIS ISSUE 12 Where to Now for Hot Water? 18 The Role of Heat Pumps in Decarbonisation online conference 20 What does good look like? 22 HVAC Hygiene Best Practice Guideline The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries 27 Where to Now for Hot Water? It’s a conundrum. A really tough question for architects and engineers. December 2021/January 2022 3 12

PUBLISHER

IRHACE/CCCANZ/RLNZ

IRHACE: www.irhace.org.nz CCCANZ: www.cccanz.org.nz RLNZ: www.rlnz.org.nz

EDITOR :

HVAC&R Centre admin@irhace.org.nz

MEMBERSHIP: admin@irhace.org.nz admin@cccanz.org.nz

REFRIGERANT LICENSING & COURSES: admin@rlnz.org.nz

ADVERTISING: admin@irhace.org.nz

DESIGN Element Design Ltd

HVAC&R CENTRE

P O Box 217184, Botany Junction 2164, Auckland, New Zealand

E: admin@irhace.org.nz

E: admin@cccanz.org.nz

E: admin@rlnz.org.nz

No part of this journal may be printed in other publications without prior written permission of the Managing Editor.

Disclaimer: Statements expressed in this publication do not necessarily reflect the policies or views of the associations, and members of IRHACE or CCCANZ. The IRHACE Journal publishes both local and international articles. Standards and or practices may differ from current New Zealand standards and or practices used. No responsibility is accepted by the associations and editor for the accuracy of information or for errors or omissions. The IRHACE Journal is distributed to all IRHACE and CCCANZ financial members.

ISSN 01148257

GINA MCMASTER

Executive Officer: IRHACE, CCCANZ, RLNZ

Another month of Covid lockdown and we are now living in an online age where most of our interaction is not face-to-face. We all are missing these interactions when getting your morning coffee, saying good morning to your colleagues these haven’t been the same; our communications need to keep strong - so stay connected with us.

If you asked people what else do you miss – yep haircuts … Those online meetings aren’t great when you are on camera and the state of people’s hair is a topic in almost all meetings. I’ve become a pseudo hairdresser in my house and I can recall my mother cutting my hair as a child and it is DeJa’Vu that I am doing the same.

Despite these interactions, it hasn’t stopped us from valuing our people and both our service awards and Apprentice of the Year have been celebrated in this issue. Thank you to everyone who was involved with these awards and making things happen – and to our great sponsors.

We wish everyone a Merry Christmas and New Year and hope that you are able to see family and friends during this holiday time.

4 www.irhace.org.nz

HVAC&R CENTRE

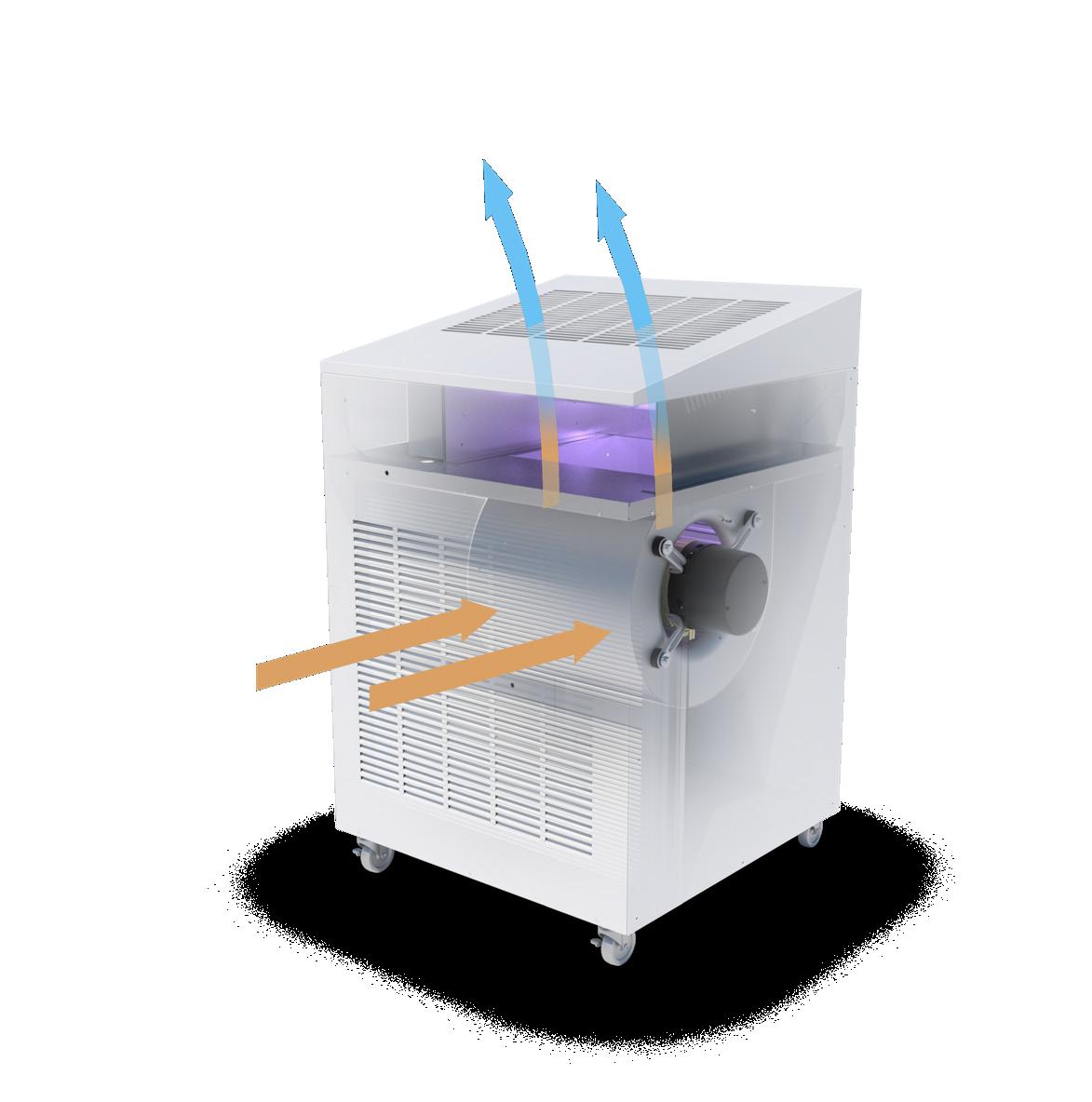

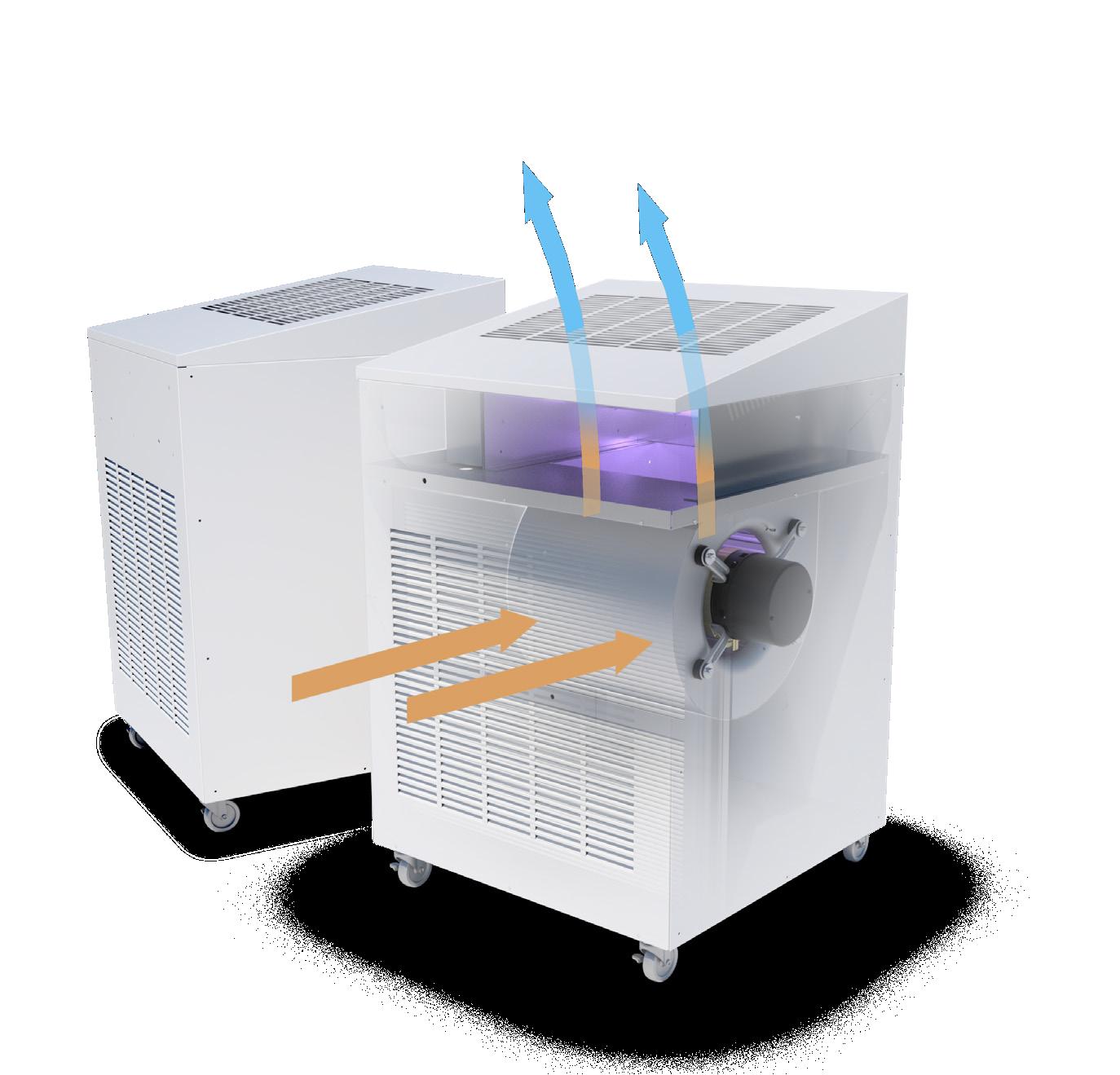

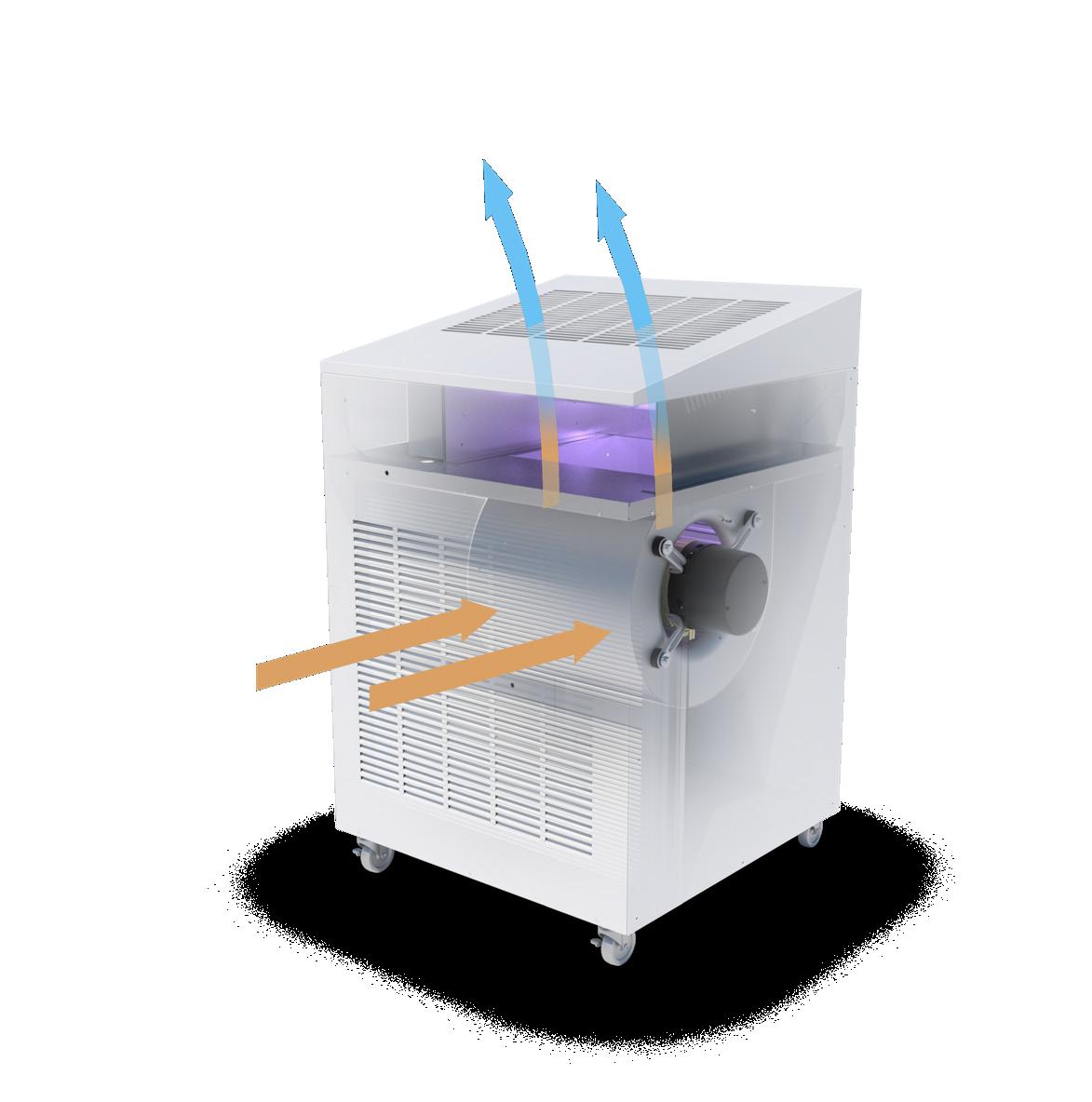

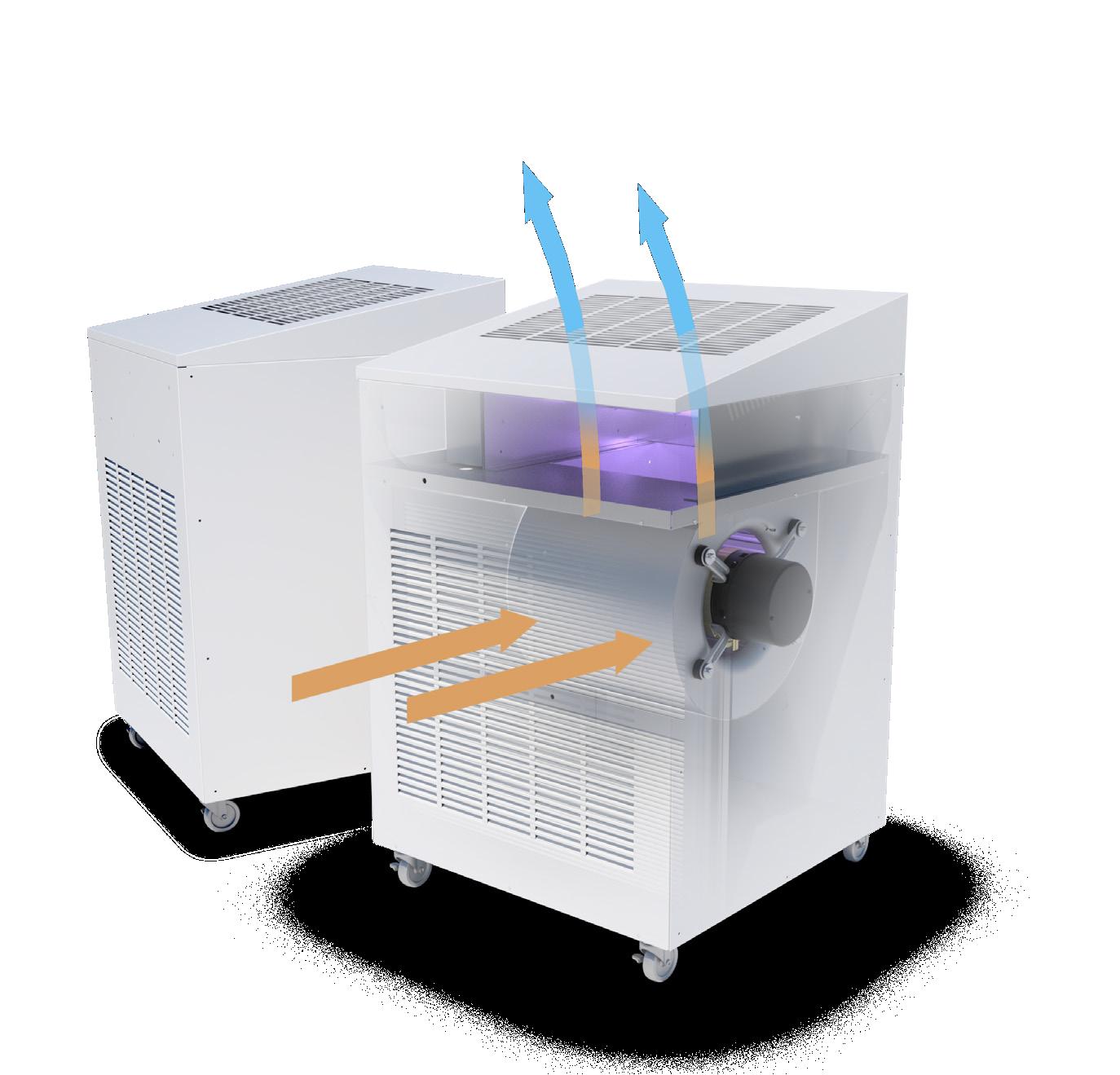

The Room Air Purifier (RAP) improves indoor air quality with air filtration by continuously circulating air through a HEPA filter, removing >99.97%

RAP FEATURES:

+ Energy efficient air purification achieved by re-filtering local air through a HEPA filter and Merv-8 pre-filter

+ Commercially constructed, heavy-duty steel casing with powder-coat finish makes this unit extremely durable.

+ Product manufactured in New Zealand.

+ Adjustable fan speed provides flexibility for bespoke application requirements.

+ Lockable casters make this unit easy to install in any room.

Everyone is eager to reopen schools and retur n to how life was before the pandemic began. We believe that the RAP is one way to immediately improve indoor air quality for students and teachers.

Contact us today! ww w.holyoakepureair.com or call: 08 0 0 114 810

Ready

reopen? Holyoake is here

help.

to

to

of particulates. Ul t r a v i o l e t g e r m i c i d a l ( U V - C ) g h t d is i n f e c t s t h e a i r- s t r e a m B i p o l a r i o n i s a t i o n p r o a c t i v e l y ne u t r a l i se s h a r m f u l p o l l u t a n t s an d m e e t s U L 2 9 9 8 f o r Z e r o O z o n e E m i s s i on s H E PA l t e r c a p t u r e s > 9 9 9 7 % o f a i r b o r n e p a r t i cl e s To d a t e , t h e o n l y a i r p u r i e r t h a t m e e t s A N S I an d A S H R A E n oi s e l e v el r e q u i r em e n t s f o r cl a s s r o o m s (a t 2 A C H f o r 9 7 m ² ) MERV 8

Ready to reopen?

Holyoake is here to help.

6 www.irhace.org.nz

A Breath o f Fresh A Even Indoor s!

W ith uncertain times ahead of us, Holyoake brings a sense of surety. We introduce to you an eco-friendly, energy-efficient product that provides clean air and is manufactured right here in New Zealand.

The Room Air Purifier (RAP) has the ability to provide clean, fresh air to immediately improve indoor air quality, particularly in high-density areas such as o ce spaces, classrooms, aged care homes, hospitals, tness centres, retail spaces, and restaurants.

The RAP is designed to continuously cycle air through a HEPA lter and MERV 8 pre- lter to eliminate >99.97% of dust particles, germs, and contaminants.

The UV light provides 360 degrees of high UV-C-intensity light and is integrated into the interior of the RAP unit. W idely used in hospitals and institutional applications, UV-C energy (254 nm) also lowers the cost of maintaining and operating HVAC equipment.

The bipolar ioniser proactively purifies indoor air by producing positive and negative oxygen ions to neutralise harmful pollutants and odours. Testing has proved the e ectiveness of Plasma Air ionisation technology in the reduction of MS2 bacteriophage, a surrogate for particulates, in indoor environments.

Other benefits of the RAP include:

+ Commercially constructed, heavy-duty steel casing with powder-coat finish, making this unit extremely durable

+ Adjustable fan speed provides exibility for bespoke application requirements

+ Easily removable and replaceable HEPA filter

+ Lockable casters, making this unit easy to install in any room

December 2021/January 2022 7

Visit us at: ww w.holyoakepureair.com or call: 080 0 114 810

R e lax , ta k e a d ee p br e at h , a n d contact u s toda y to lea r n m ore a b o u t t h e RA P

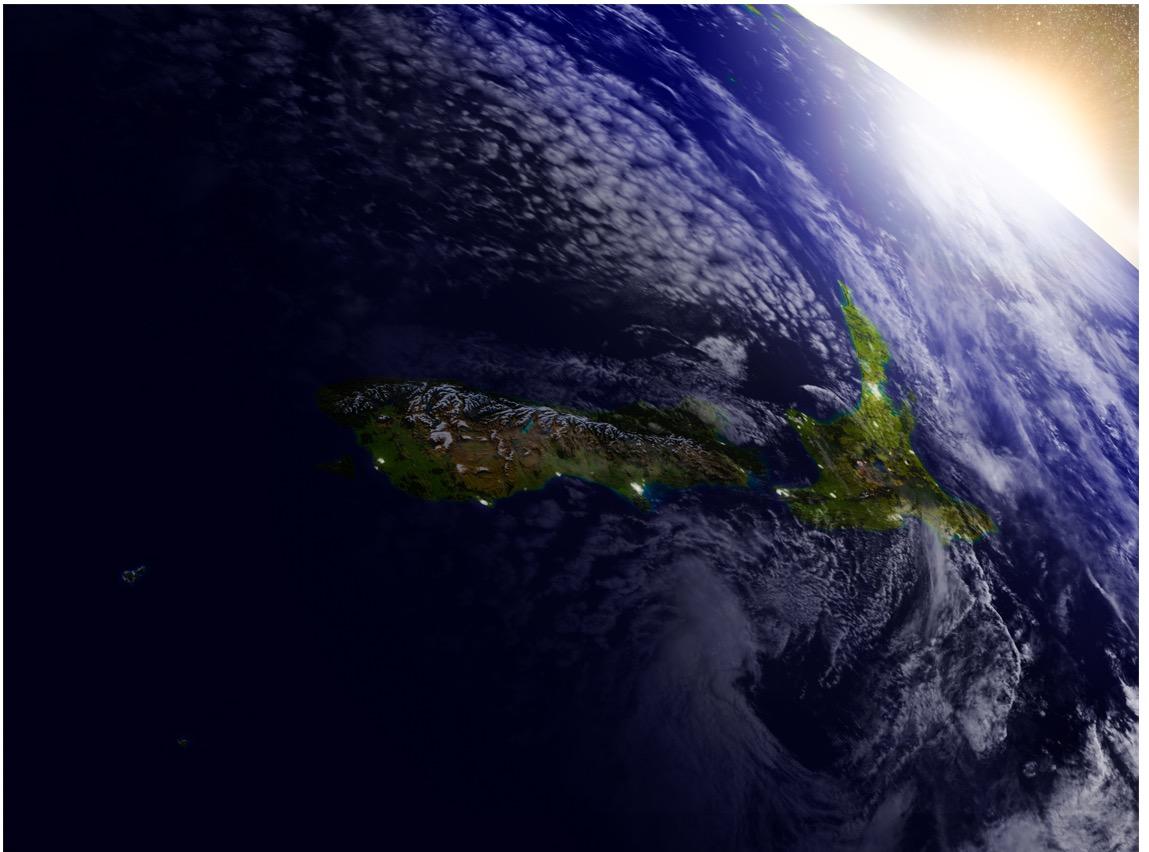

Te hau maroki ki anamata Transitioning to a low-emissions and climate-resilient future

Remove pages 8 & 9 (2 green image pages) and replace with below:

Heading would be (don’t use the image just the words) and put in the image and below link

https://environment.govt.nz/assets/publications/Emissions-reduction-plan-discussion-document.pdf

https://environment.govt.nz/assets/publications/Emissions-reduction-plan-discussion-document.pdf

Representatives from IRHACE, CCCANZ and RPGNZ established a working group for their joint submission, and they exchanged submissions for comment with the Heat Pump Suppliers Association of New Zealand (HPSANZ). Read the full submission here

Representatives from IRHACE, CCCANZ and RPGNZ established a working group for their joint submission, and they exchanged submissions for comment with the Heat Pump Suppliers Association of New Zealand (HPSANZ). Read the full submission here

Working group consisted of Mark Meyer (IRHACE), Cam Crawford (IRHACE), Pete Hutson (IRHACE), Greg Picker (Refrigerants Australia), Malcolm Miller (CCCANZ), Graham Brown (CCCANZ), Darryl Rochester (HPSA)

Working group consisted of Mark Meyer (IRHACE), Cam Crawford (IRHACE), Pete Hutson (IRHACE), Greg Picker (Refrigerants Australia), Malcolm Miller (CCCANZ), Graham Brown (CCCANZ), Darryl Rochester (HPSA), Padraic Durham (RPGNZ), Andre Van Dyk (RPGNZ)

HPSA put forward their submission to government and exchanged submissions for comment with IRHACE/CCCANZ/RPGNZ. Read full submission here

HPSA put forward their submission to government and exchanged submissions for comment with IRHACE/CCCANZ/RPGNZ. Read full submission here

Darryl Rochester (NZHPSA), Greg Picker Advisor (NZHPSA).

HPSA members include BDT, Panasonic NZ, Daikin NZ, Realcold NZ, Fujitsu General NZ and AHI Carrier.

Darryl Rochester (NZHPSA), Greg Picker Advisor (NZHPSA).

HPSA members include BDT, Panasonic NZ, Daikin NZ, Realcold NZ, Fujitsu General NZ and AHI Carrier.

8 www.irhace.org.nz

Remove pages 8 & 9 (2 green image pages) and replace with below: Heading would be (don’t use the image just the words) and put in the image and below link https://environment.govt.nz/assets/publications/Emissions-reduction-plan-discussion-document.pdf Representatives from IRHACE, CCCANZ and RPGNZ established a working group for their joint submission, and they exchanged submissions for comment with the Heat Pump Suppliers Association of New Zealand (HPSANZ). Read the full submission here Working group consisted of Mark Meyer (IRHACE), Cam Crawford (IRHACE), Pete Hutson (IRHACE), Greg Picker (Refrigerants Australia), Malcolm Miller (CCCANZ), Graham Brown (CCCANZ), Darryl Rochester (HPSA) HPSA put forward their submission to government and exchanged submissions for comment with IRHACE/CCCANZ/RPGNZ. Read full submission here Darryl Rochester (NZHPSA), Greg Picker Advisor (NZHPSA). HPSA members include BDT, Panasonic NZ, Daikin NZ, Realcold NZ, Fujitsu General NZ and AHI Carrier. NEWS

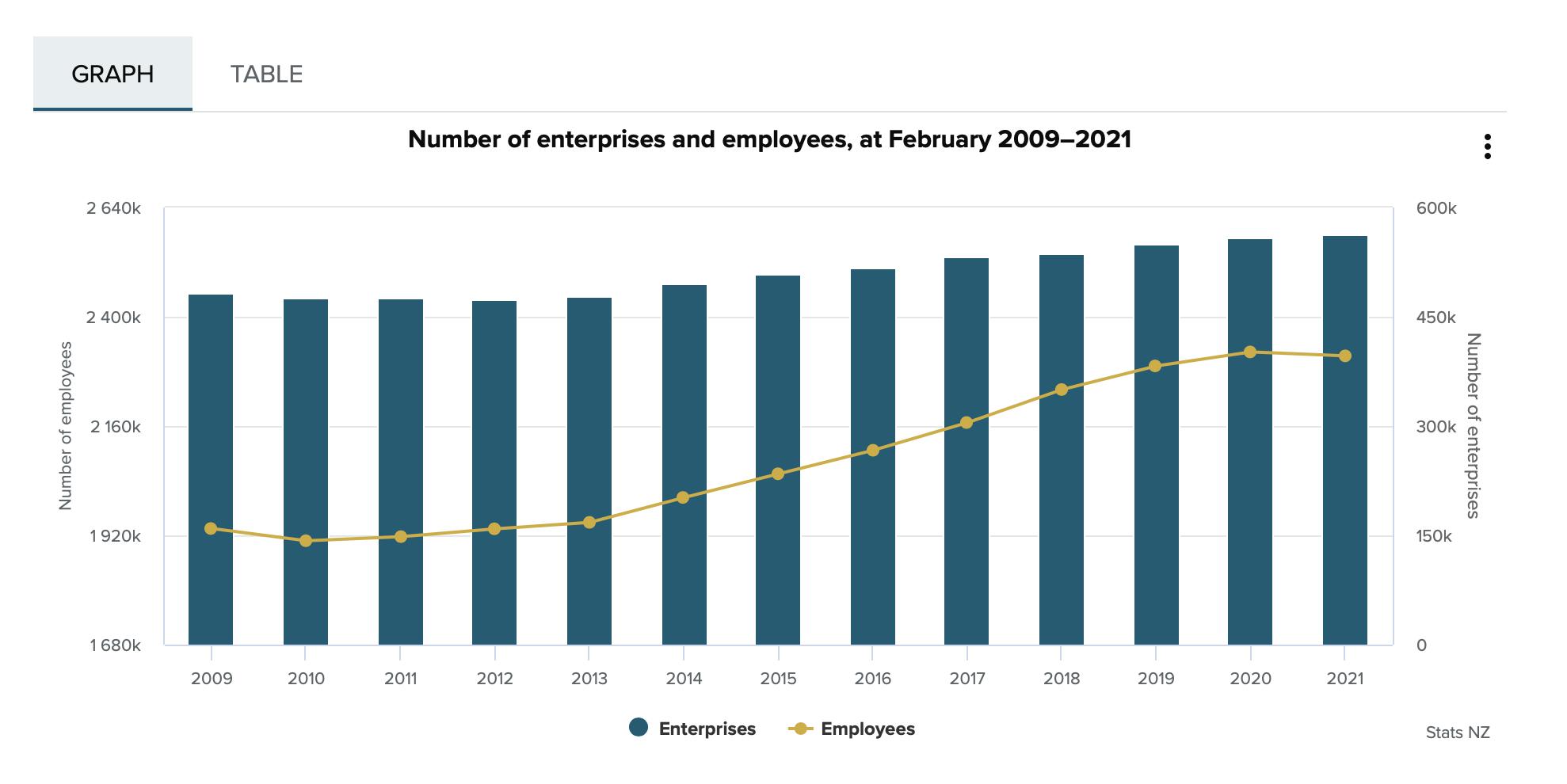

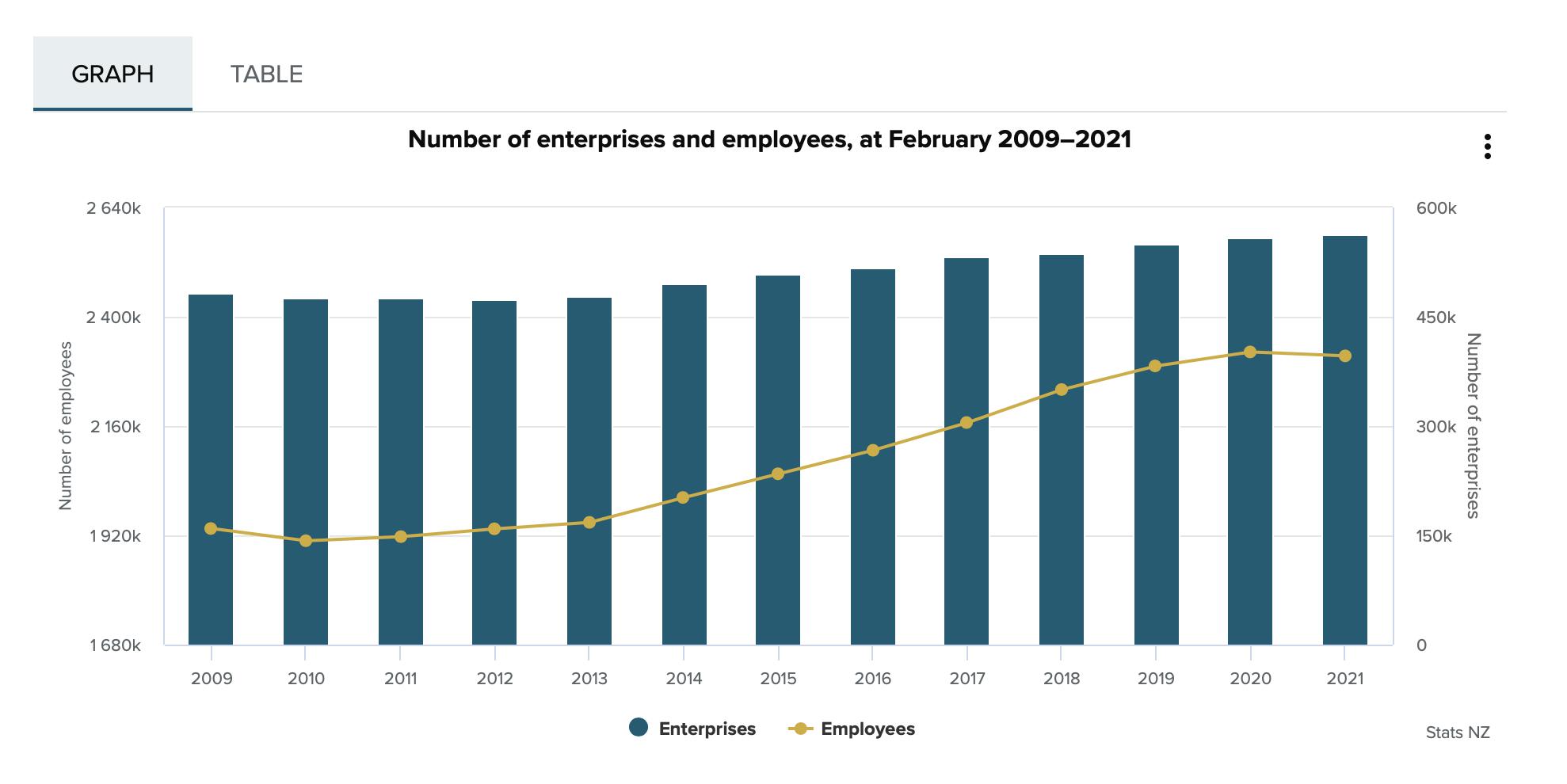

New Zealand business demography statistics: At February 2021

Business demography statistics provide an annual snapshot of the characteristics of New Zealand businesses. The statistics cover economically significant enterprises that produce goods and services in New Zealand.

Key facts

Provisional data showed that at February 2021:

New Zealand had 562,520 enterprises, an increase of 0.5 percent from February 2020.

The number of paid employees in these enterprises (not an official employment statistic) was 2.3 million, down 0.4 percent from February 2020.

• These enterprises had 598,410 business locations, an increase of 0.4 percent from February 2020.

• Of the 19 industries, 10 had more enterprises compared with February 2020, and nine had more employees.

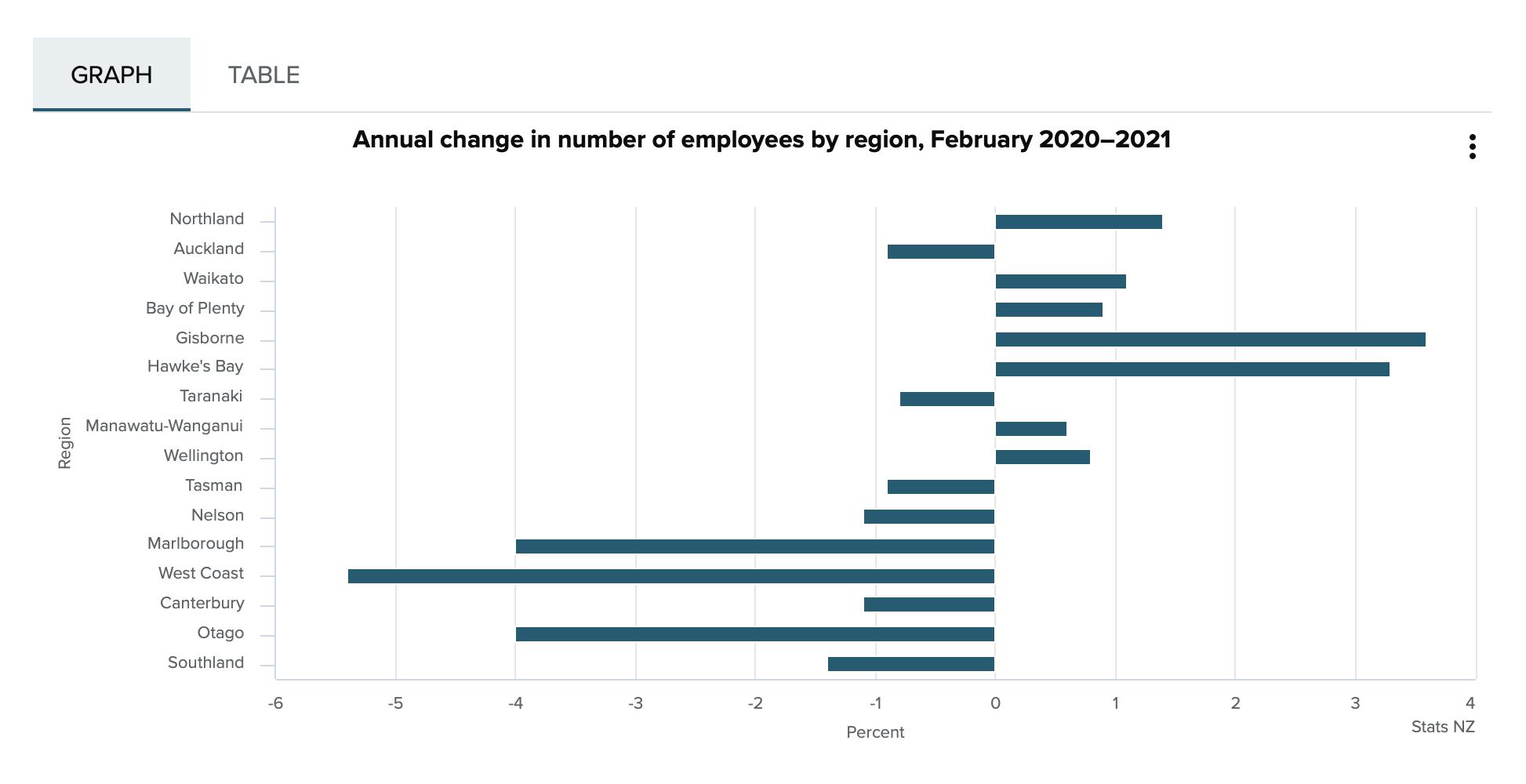

• Of the 16 regions, nine had more business locations, and seven had more employees.

• The last reference period in this release (February 2021) coincides with the first anniversary of the introduction of COVID-19 restrictions in New Zealand.

Health care and social assistance industry becomes the largest employer

• Of the 19 industries, health care and social assistance was the largest employer at February 2021, with 263,800 employees, up 4.1 percent from February 2020.

Manufacturing – historically the largest employer – had 248,400 employees at February 2021, down 1.0 percent from February 2020.

• The construction industry continued its upward trend of the past decade with 5.6 percent more employees and 4.7 percent more enterprises from February 2020.

Accommodation and food services had 160,000 employees, a 6.7 percent drop from February 2020, while enterprises dropped 0.2 percent, the first decrease in the number of employees and enterprises over the past 10 years.

• Administrative and support services had 110,200 employees, down 9.2 percent from February 2020.

• Transport, postal, and warehousing had

91,100 employees, down 9.8 percent from February 2020, while enterprises were down 5.7 percent.

• Arts and recreation services had 39,200 employees, a decrease of 3,400 (8.0 percent) from February 2020, with enterprises down 2.5 percent.

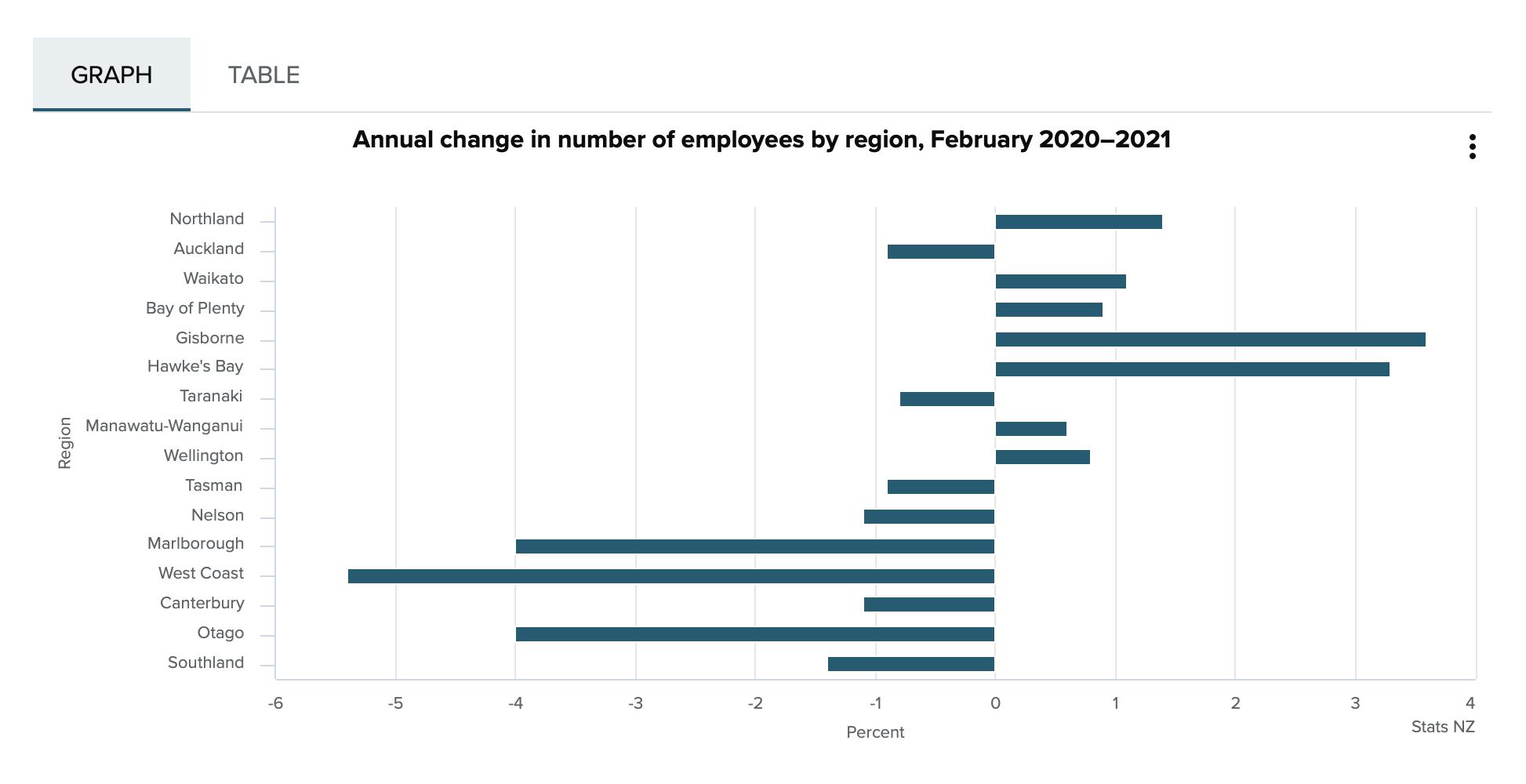

Regions at a glance

In the Auckland region there were: 208,870 business locations, up 1.0 percent from February 2020

• 801,700 employees, down 0.9 percent, the first decrease for 10 years.

The North Island regions other than Auckland had 246,100 business locations, up 0.2 percent from February 2020. The number of employees was 952,300, a 1.1 percent increase.

In the South Island there were 143,260 business locations, 60 fewer than in

February 2020. The number of employees was 558,900, a decrease of 2.0 percent.

Large enterprises decline in numbers and employment

At February 2021:

• there were 5,840 enterprises with 50 or more employees, down 2.9 percent from February 2020

• the total number of employees in this size category was down 2.8 percent.

• This was the first decline in 10 years for both the number of enterprises and employees for this size category.

For more data visit https://www.stats.govt.nz/ information-releases/new-zealand-businessdemography-statistics-at-february-2021

NEWS December 2021/January 2022 9

Non-compliant hydrocarbon-based refrigeration systems.

Over recent weeks, IRHACE have been made aware of three (3) non - compliant hydrocarbon- based refrigeration systems being installed into commercial premises. In conjunction with the relevant authorities, these sites have now been rendered safe by the safe removal of the refrigerants; but we are concerned that there could be more of them out there.

What does this mean for me?

The owner / operator (the PCBU) of plant has a right to expect that you, as a practicing refrigeration engineer, will be aware of the risks associated with using hydrocarbon- based refrigerants and will be able to provide guidance.

Even if you did not do the original installation, once you become aware of its existence, the law requires that you take all reasonably practicable steps to ensure the safety of the people working on the site, as well as that of the public at large.

What can I do?

In the first instance, look for any labels or stickers that could indicate the type of refrigerant that is actually in the system. Do not rely upon the traditional manufacturer’s labels fitted to the compressor or

expansion device – these may not reflect what is in the system.

Two of the three systems referred to in the above were, when built, R404a systems and were subsequently retrofitted to hydrocarbons.

Each of these 3 systems had been fitted with a sticker upon the compressor stating, “Hychill Minus 40. R290”

Caution, not all retrofitted systems will have these warning labels.

If you cannot be sure of the identity of the refrigerant, then the system should be treated as if it contains an A3 refrigerant. (Refer CCCANZ Fact Sheet 2; page 1 refrigerant classification and fact sheet 4; page 3, Pre-Service Safety)

Note;

• A PCBU with management or control

of a refrigeration system operating on a flammable refrigerant must ensure that the quantity and means of containing refrigerant complies with AS/NZS 5149:2016. The exceptions are domestic refrigerators, domestic heat pumps / Air conditioners.

• The retrofit of a flammable refrigerant into a system designed for a nonflammable type creates an installation that may be deemed unsafe under the Electricity (Safety) Regulations 2010. Such systems present a serious risk of explosion and/or fire if a refrigerant release occurs, and any subsequent insurance or warranty claim may be denied.

• All equipment employed in the completed installation must be certified by its manufacturer to be safe to use

10 www.irhace.org.nz NEWS

FLAMMABLE REFRIGERANTS – BE INFORMED, BE AWARE FACT SHEET 2 PAGE 1 CCCANZ – MARCH 2018

This fact sheet explores the rules for the design of A2L, A2 and A3 flammable refrigerant-based stationary air conditioning and refrigeration systems. Significant consequences may arise if you, as a designer, fail to properly address safety considerations. The content is based on the Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH) Flammable Refrigerants Safety Guide – available from www.airah.org.au. Safety group Higher flammability A3 B3 Flammable A2 B2 Lower flammability A2L B2L No flame propagation A1 B1 Lower toxicity Higher toxicity FACT SHEET 2 FLAMMABLE REFRIGERANTS – BE INFORMED, BE AWARE SYSTEM SUITABILITY If the system is not specifically designed or converted for use with flammable refrigerants, the area is not well ventilated or there are ignition sources in or close to the system, the application would be unsuitable for flammable refrigerants. For systems located below ground, additional limitations apply. The overall safety objective is for any potential release of flammable refrigerant to be contained to a safe concentration. Risks are reduced by limiting refrigerant charge. REFRIGERANT CLASSIFICATION Flammable refrigerants include A2L, A2, A3, B2L, B2 and B3 classes from AS/NZS ISO 817:2016 Refrigerants –Designation and safety classification. Flammability group classification is based on the lower flammability limit (LFL) of the refrigerant. Different design rules apply to each type of refrigerant. Unknown refrigerants should be treated as A3. FLAMMABLE REFRIGERANTS – BE INFORMED, BE AWARE FACT SHEET 4 PAGE 1 CCCANZ – MARCH 2018 Operating and maintaining flammable refrigerant-based systems This fact sheet explores the rules for the safe operation and maintenance of A2L, A2 and A3 flammable refrigerant-based stationary air conditioning and refrigeration systems. Significant consequences may arise if you, as a service provider, fail to follow appropriate maintenance or decommissioning practices. The content is based on the Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH) Flammable Refrigerants Safety Guide – available from www.airah.org.au. FACT SHEET 4 FLAMMABLE REFRIGERANTS – BE INFORMED, BE AWARE APPLICABLE STANDARDS AS/NZS 5149.4:2016 Refrigerating systems and heat pumps – Safety and environmental requirements – Part 4: Operation, maintenance and recovery AS/NZS 60079 Explosive atmospheres series MANAGING OCCUPANT RISKS The charge limits for flammable refrigerants are restricted according to the level of risk they pose to those using the equipment or occupying the surrounding area. Risks increase when occupants: are unskilled or untrained in the safety aspects of the equipment. are sleeping or are incapacitated. might introduce an ignition source (such as a room heater) into an area that potentially contains leaked flammable refrigerant. Flammable refrigerants may not have odourant added or the odourant may fade over time. If there is a leak, the flammable refrigerant may not be detected (smelt) by OPERATION people in the space. Pooled leaked refrigerant presents a flammability risk, and maximum refrigerant charge limits are applied to reduce the risks according to the application.

System design considerations

with flammable refrigerants. This includes all fan motors, compressors, thermostats, pressure switches as well as valves and interconnecting pipework.

• The system refrigerant charge must be equal to, or less than the allowable limits proscribed under AS/NZS 5149.1:2016.

The system must be in compliance with the AS/NZS 60335 series of electrical standards (of which there are many).

Apart from some domestic heat pump installations, you are not permitted to use “flare” type connections anywhere on the system including on connections to pressure switches.

• The completed system, including the interconnecting pipework, must be properly labelled with appropriate and conspicuous “flammable Gas” warning pictograms.

• All staff who will be using or operating the completed plant must be fully trained in its use. They must be made aware of the flammable nature of the refrigerant and

EVEN IF YOU DID NOT DO THE ORIGINAL INSTALLATION, ONCE YOU BECOME AWARE OF ITS EXISTENCE, THE LAW REQUIRES THAT YOU TAKE ALL REASONABLY PRACTICABLE STEPS TO ENSURE THE SAFETY OF THE PEOPLE WORKING ON THE SITE, AS WELL AS THAT OF THE PUBLIC AT LARGE.

trained in the relevant safety precautions.

If you become aware of plant out there that you suspect could be operating on hydrocarbons, and you have any concerns regarding the installation or its operation, let someone know!

Who can I contact?

Contact any of the industry bodies – IRHACE, CCCANZ, EWRB, RPGNZ, HPSA – please don’t just ignore it.

If you want to talk to someone, please reach out to us at IRHACE or CCCANZ or EWRB – our board members mobile phone numbers are on our websites, or you could email us at admin@irhace.org.nz

https://www.cccanz.org.nz/resources/ Flammable-Refrigerants-Fact-Sheets/

If you have a reason to believe there is any unsafe or dangerous refrigeration equipment in the workplace, and that people may be at risk, please notify WorkSafe on 0800 030 040.

December 2021/January 2022 11 NEWS CHILLERS & HEAT PUMPS RHOSS BOILERS & FLUES RENDAMAX, METALOTERM CALORIFIERS LAPESA FAN COIL UNITS ABILTY PROJECTS, NEW SUPER-AIRE Clima Solutions Ltd www.clima.co.nz Tel: (09) 336 1278 gordon@clima.co.nz or rob@clima.co.nz

Where to Now for Hot Water?

It’s a conundrum. A really tough question for architects and engineers. And it’s a question that is going to be asked more and more in the near future. What do we do about hot water?

12 www.irhace.org.nz ★ FEATURE

By John Greaves (NZCE- Mech) Senior Design Engineer - Black Diamond Technologies

By John Greaves (NZCE- Mech) Senior Design Engineer - Black Diamond Technologies

It’s Gas Now, But This Can’t Last

Many have already seen the writing on the wall. Despite soothing noises from several gas industry suppliers there is huge uncertainty that gas, traditionally the go-to for heating hot water, is going to play any significant part in future water heating solutions - especially in larger scale commercial buildings.

A few quick checks will tell you that NZ as a whole consumes about 2 Petajoules of gas per annum, and our current gas stocks total around 20 Petajoules.

So, unless we find new gas supplies (which is currently off limits) then NZ will run out of gas in around 10 years. What’s more topical is that burning fossil fuels for heating is an unpalatable option for many building owners and occupiers. There is now a strong groundswell for more environmentally friendly, future proofed solutions – and this particularly applies to hot water as it affects essentially every building.

So we need a new answer for hot water. There is a plethora of options, each with its own pitfalls and foibles. The key is understanding the limitations of each early in the design process to allow selection of the best solution. So what are some of the alternatives?

Historically the Alternative is Direct Electric – Do We Go Back to the Future?

Outside of gas, the hot water solution used most historically has been electric, or more precisely, electric immersion resistance heating. This solution was commonly installed in houses for many years prior to the rise and rise of instantaneous gas hot water.

While electric immersion is well proven it should really only be considered for small scale hot water, and even then there are probably better solutions available.

FEATURE ★ December 2021/January 2022 13

Outside of gas, the hot water solution used most historically has been electric

Electric immersion hot water is VERY energy hungry, and so will always require substantial electrical infrastructure to support it.

New or retrofit electric water heating will almost always require mains upgrades, which may not only involve local rewiring it may also trigger upgrades to street cables and transformers – which is expensive.

And that’s if you can get them, there are many anecdotal stories floating around of commercial sites in cities having restrictions placed on them by electricity infrastructure providers.

There simply isn’t enough power supply around to waste it like this.

From a carbon footprint point of view this option is poor. It doesn’t tick boxes for any building owner or tenant looking to do the right thing. So in the vast majority of cases this means a direct electric water heating solution is dead in the water, pardon the pun.

Solar is green – but is it New Zealand’s Alternative to Gas?

Solar hot water is a solution that’s been around for quite a while and due to current pressures is seeing a bit of resurgence. There is no doubt that this is a very green solution – what could be better than

14 www.irhace.org.nz ★ FEATURE

FEATURE ★ December 2021/January 2022 15 • Thermal • Acoustic • Preformed Tube • Sheet/ Roll Authorised distributors of ultralonfoam.com 0800 114 222 sales@ultralon.co.nz Thermobreak® is the leading and most innovative polyolefin foam thermal insulation available to the HVAC and Building industry worldwide. Thermobreak’s® performance is unsurpassed.

SOLAR SIMPLY DOESN’T STACK UP IN COMMERCIAL SETTINGS WHERE RELIABILITY IS IMPORTANT AND ROOF SPACE, RELATIVE TO GROSS FLOOR AREA, MAY BE LOW

harvesting free sunlight?

But the fact that solar has been around for a while yet has never really established itself as a mainstream solution should be a warning for you. Like direct electric, solar can throw some rather large spanners in the works.

For a start the main and obvious one is that solar really only works well with a lot of sunlight. On less sunny days, which occur mostly in winter when more hot water is needed, or with building structure or orientation not optimal, solar hot water generation is compromised.

This usually forces the need for a backup hot water system to deal with these suboptimal situations, which logically leads to the question of - why not just have a more reliable hot water solution to start with?

Additionally with solar a lot of roof real estate is needed, the aesthetics of which aren’t often palatable to the stakeholders, the capex cost is substantial in most cases and the performance of solar deteriorates very quickly if very regular maintenance and optimisation isn’t done. Solar simply doesn’t stack up in commercial settings where reliability is important and roof space, relative to gross floor area, may be low.

This means that on the surface of it solar can look pretty good, but in reality usually doesn’t live up to the hype and promises.

Hot Water Heat Pumps – On Balance a Great Option

There are plenty of other fringe solutions available for hot water production, but the only other mainstream option is hot water heat pumps.

Heat pumps for comfort, either in a residential or commercial setting, are very well accepted in NZ. But the use of hot water heat pumps here is well behind other more advanced markets such

16 www.irhace.org.nz

Hot Water Heat Pumps – On Balance a Great Option

★ FEATURE

as Europe and the UK - where their use is widespread. Based on worldwide evidence we can expect hot water heat pumps to become more in demand in our NZ future.

There is good reason for this because, like their comfort-based cousins, hot water heat pumps are extremely efficient and outperform all other hot water heating solutions.

Hot water heat pumps commonly generate hot water at over 3:1 efficiency, and will do so very reliably almost irrespective of the outdoor elements.

Excitingly from an environmental perspective, there are now some hot water heat pumps on the market that use CO2 as their refrigerant – making them super environmentally friendly. CO2 refrigerant does not harm the ozone layer and has the lowest possible index number for global warming potential of any refrigerant currently in use in any heat pump system, 1.

So both a super-efficient and super green option, which will please many building owners and tenants. In all likelihood these are the way of the future.

Ultimately Application is the Key Often overlooked but critical to success with all heat pumps is that they need to be correctly applied – and hot water heats pumps are no different. Get this wrong and it doesn’t matter how good the heat pump is it won’t be able to work well.

So the risk, if you don’t stick to a reputable heat pump brand supplied by a company who can provide good design advice and back-up support for their hot water heat pumps, is that it could all very easily end in tears.

But get it right and a hot water heat pump solution is superb, both for the stakeholders and for the environment.

Everyone wins!

Doing business with us is a breath of fresh air.

Ventilation filters for every workplace. FEATURE ★ December 2021/January 2022 17

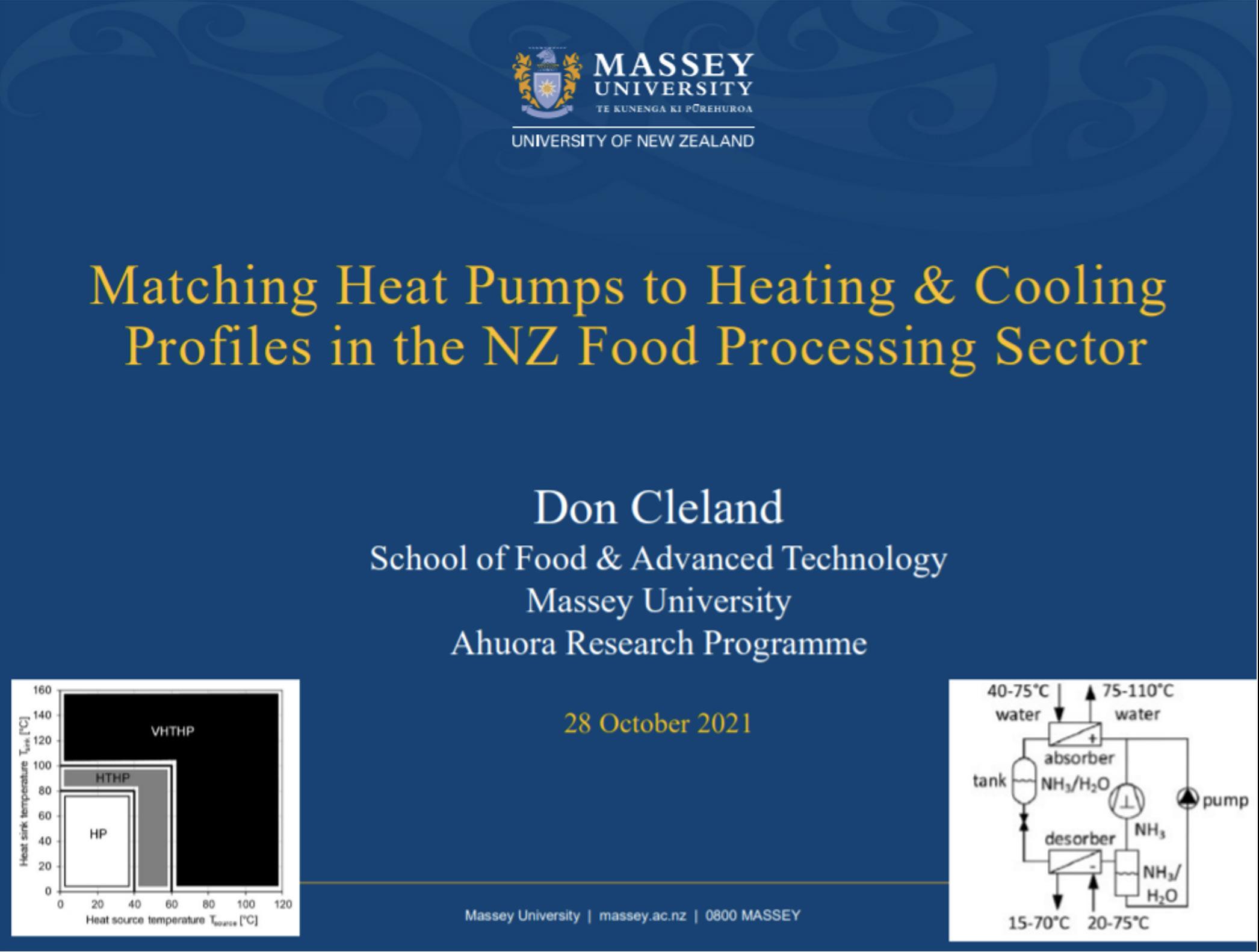

The Role of Heat Pumps in Decarbonisation online conference

The Role of Heat Pumps in Decarbonisation online conference was held on the 28th of October 2021 hosted by EECA and Massey University. It was aimed at anyone with an interest in using vapour compression technologies (such as high-temperature heat pumps) to decarbonise their process or space heating requirements. It covered both industrial and residential heat pump technologies and includes space heating and water heating applications.

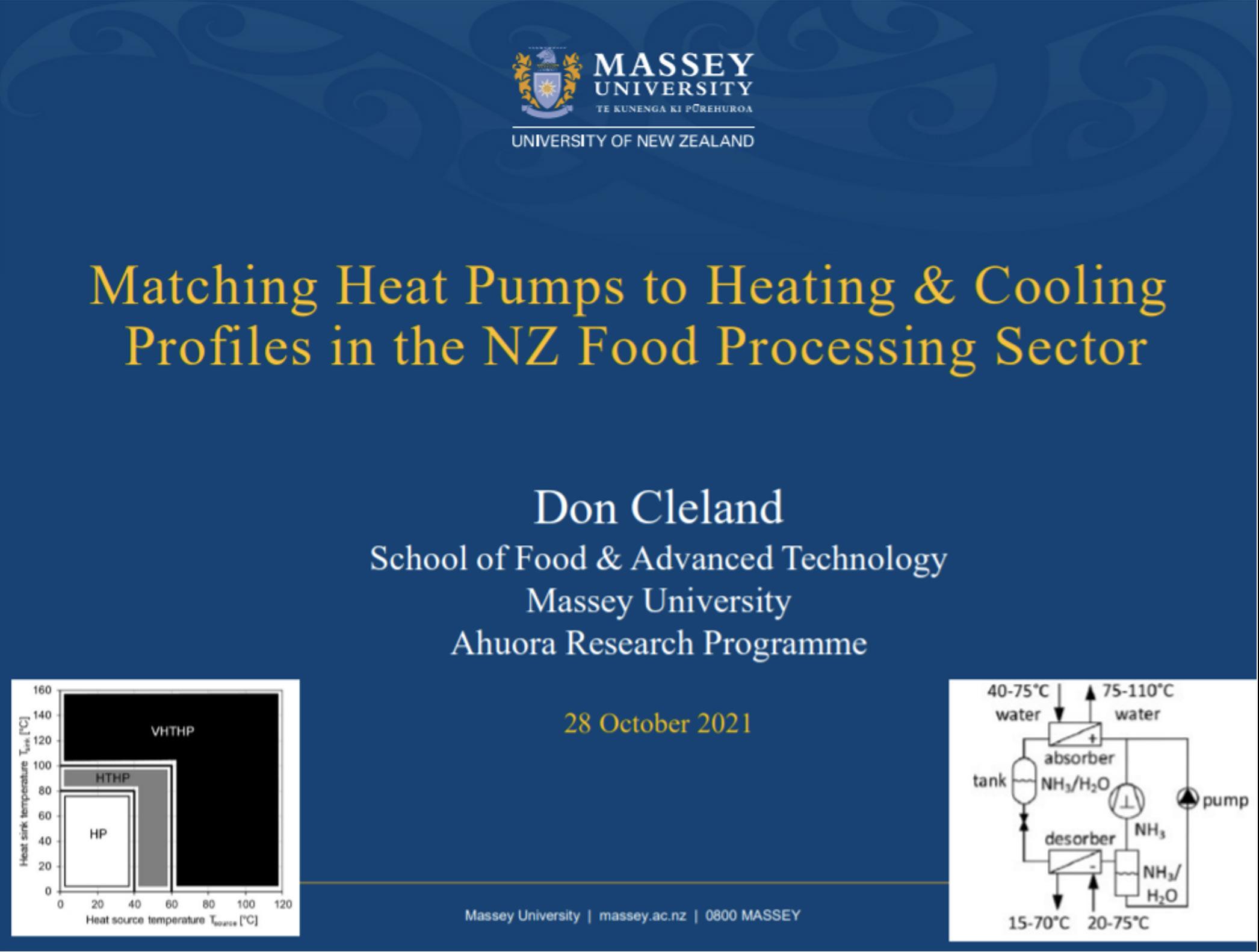

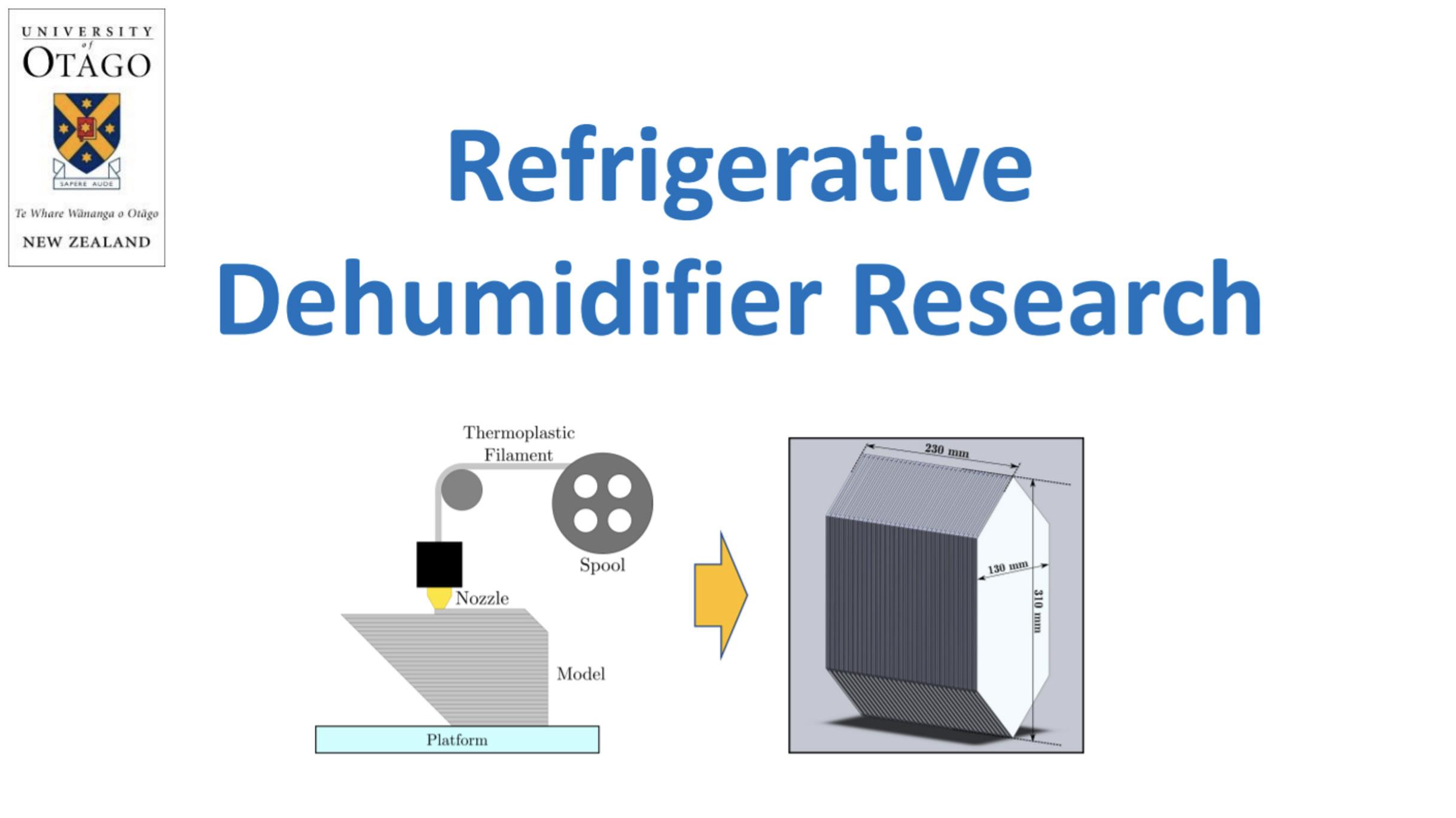

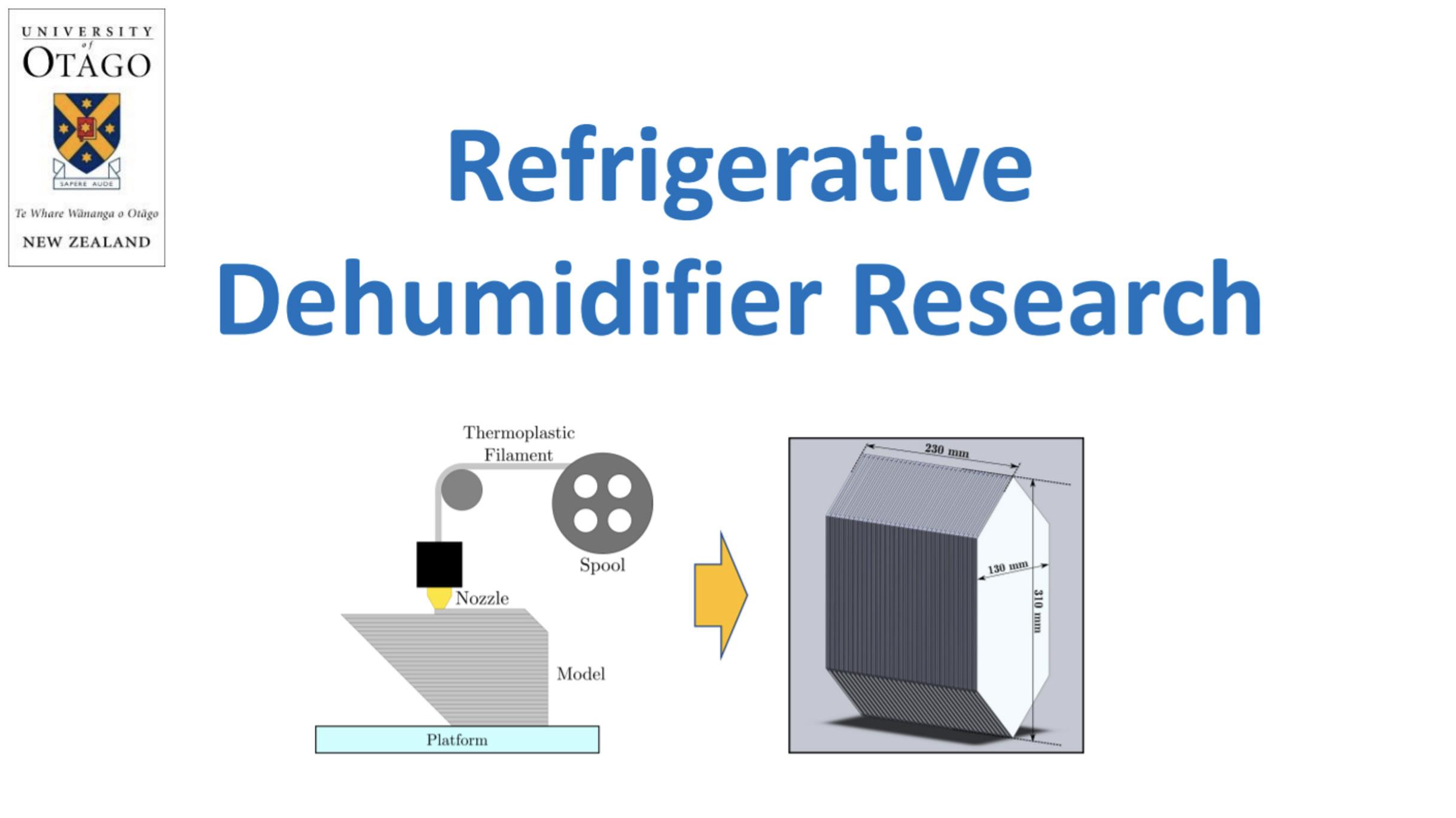

Presentations covered all elements of the decarbonisation HTHP journey from inception through to installation – what to know, what to avoid and what to expect. Click on the images below to watch the presentations on YouTube. Several IRHACE members spoke at this conference Don Cleland, Sam Lowrey and Mike Odey.

Matching Heat Pumps to Heating and Cooling Profiles in the NZ Food Processing Sector

18 www.irhace.org.nz ★ FEATURE

Don Cleland, M. IRHACE

Professor Don Cleland is a Professor of Process Engineering in the School of Engineering and Advanced Technology, Massey University.

Dr. Sam Lowrey is a Senior Lecturer in physics at Otago University and is speaking on refrigerated dehumidifiers for domestic drying.

An example processing plant hot water supply ammonia heat pump modelled for new industrial plant integration

FEATURE ★ December 2021/January 2022 19

Sam Lowrey, M.IRHACE

Mike Odey, M.IRHACE

Mike Odey is an independent refrigeration and heat pump consultant and involved in the New Zealand National Committee of the International Institute of Refrigeration.

What does good look like?

Small to medium construction businesses are currently facing a barrage of challenges, making it more crucial than ever to have a good, resilient business. But what does good look like? Grant Price spoke with Graham Burke about the 5 biggest industry issues... plus a powerful new tool to help you gauge how well your business is faring.

1. Supply chain disruptions

Supply chain issues have been top of mind with the Covid-19 lockdowns, but they don’t come out of the blue. What the lockdowns have highlighted is how fragile New Zealand’s supply chain is in many instances. We have far greater reliance than ever before on product from overseas—and increasingly from one country. This means if there are issues offshore, such as shipping problems, our supply chain is affected straight away... and so are product costs.

2. Product cost increases

Today’s businesses tend to use a ‘just in time’ model, ordering everything as we need it and holding less stock. Perhaps we need to consider more forward planning—ordering further in advance and holding more stock— to avoid project delays and resulting product cost increases. Here and overseas, product prices have been escalating at a rate we haven’t seen since the 1980s. Businesses essentially have two choices: to have contracts that pass product price increases to the client, or to purchase stock up front and lock in the contract price.

3. Labour shortages

We are experiencing a critical labour supply shortage that is likely to remain for some time, given the current high work demand. Even with the recent acceleration in apprentice numbers, we can barely keep up with the numbers retiring in our ageing population. Some businesses have looked overseas for staff, but labour shortages are an international phenomenon, and we’re all competing for the same skills. New Zealand has a housing and infrastructure deficit, and a huge forward pipeline of work. We all need to recruit people into the industry and lift productivity to stay competitive.

4. Workplace stress

Workplace stress is not a new thing. Staff shortages, long working hours and client demands can all lead to stress. Today’s workforce is more cognisant of the need for work/life balance, and good mental health

New Business Benchmarking Tool

When you’re working on your own business, it can be hard to know how well you’re doing compared with others in the industry. A powerful new online tool will change all that, by giving small to medium construction businesses the ability to measure their financial, commercial and operational performance against an industry benchmark.

and wellbeing is an absolute positive. We also live in a society that wants instant gratification, which means clients can be more demanding—perhaps because they too are under pressure to deliver. Stress goes in circles. Setting clear expectations upfront and keeping clients informed goes a long way to keeping customers happy and managing stress.

5. Cashflow concerns

Cash is king. Cashflow is the lifeblood of a business, but many don’t understand it well. This is why a similar amount of businesses fail in boom times as in lean times. They just don’t have enough working capital to maintain growth. For the average business, a lot of costs go out before you get paid— wages, petrol, rent etc—and this capital outlay can be significant if your payment terms are 30 or 40 days, or if you don’t have good debtor control. In times of growth, it may seem like you’re making a healthy profit— but if you’re spending money faster than it comes in, you might not be able to pay your bills. Just like a household budget, it’s all about understanding the demands on your cash. Putting money aside, having a good relationship with your bank, and keeping a good debtor ledger are all important factors.

Due to launch early next year, the tool will enable businesses to input their data anonymously, which will then be collated with data from other businesses to set the industry standard. Not only will the tool help businesses assess their performance against a wide range of criteria, but it will also provide practical information and resources to assist in areas where a business wants to improve.

The new tool is a collaboration between numerous specialist trade associations and is supported by the Construction Sector Accord and PwC.

It is being developed along similar lines to a successful programme already available to and in use by the vertical construction sector, through Registered Master Builders.

More information about the new online tool will be available in an upcoming edition.

Grant Price is President of the NZ Specialist Trade Contractors Federation and a past President of CCCANZ.

https://www.nzstcf.org.nz/

Acknowledgement: This piece is provided courtesy of Master Plumbers.

20 www.irhace.org.nz ★ FEATURE

:

Graham Burke is Executive Director of the Construction Industry Council and past President of the Specialist Trade Contractors Federation.

RLNZ UPDATE

Refrigerant License Trust (RLNZ)

Approved Filler training and certification

Due to an administrative oversight, over recent years candidates who had successfully completed the RLNZ fillers training and practical assessment courses have been awarded certification endorsed to allow the holder to fill not only NonHazardous refrigerant cylinders, but also to fill Class 2.1.1A and 2.1.1B Gas Refrigerant Cylinders.

This endorsement has been given, even though the RLNZ training material and its practical assessment programs contained insufficient material to properly prepare the candidates to safely fill flammable gas cylinders.

RLNZ have subsequently withdrawn its Approved Filler Training and Assessment programs whilst it re-develops its material. We unreservedly apologise for the inconvenience this is causing within our industry and are working actively to get the programs back up and running as soon as is possible.

We will notify industry as soon as the material is available for delivery, and timing of when we are able to take bookings again. At this time, this is anticipated to be early 2022.

Should you have any questions or comment regarding the Approved Filler Courses, please contact Dave Nicholls on 027 289 7389 or admin@rlnz.org.nz

Update from Competenz

We've been working hard in the background to update our Refrigeration and Air Conditioning (RAC) qualification and bring you a brand new programme in Air Conditioning Installation (ACI). This programme has been developed to support employers and learners in refrigeration, heating and ventilation, and air conditioning (RHVAC) industries.

We know you've been looking forward to using the new programmes; we ask that you hang tight for a bit longer while we make sure all aspects meet industry requirements before we make these available to you. Both qualifications are now set to launch in March 2022.

We'd like to thank everyone who's helped us so far. This includes industry, subject matter experts (SMEs) and the team at Competenz who facilitated the development of a focused and comprehensive qualification to fill training gaps.

We'll make sure to keep you in the loop as we go, so watch this space for more information early next year.

If you have any questions, please get in touch at competenz.org.nz/contact-us

December 2021/January 2022 21 EDUCATION & TRAINING

HVAC Hygiene Best Practice Guideline

Specialised HVAC cleaning services have been available in New Zealand since the early 1980s. However, it was not until the 1990s that growing public concern for better indoor air quality (IAQ), improved indoor environment quality (IEQ) and improved ventilation hygiene that the cleaning of HVAC systems became a widely adopted practice. General awareness of occupational, public health and comfort issues associated with HVAC systems continues to increase and system owners and managers have responded with better management of these systems.

More recently, building energy use and energy conservation has become increasingly important to building owners and system operators, including the need to operate HVAC systems at their maximum efficiency. Maintaining HVAC systems in a clean condition is one essential and fundamental way of achieving these objectives.

Although Australian and New Zealand Standards, such as AS1851, AS/NZS 3666.2, and industry maintenance specifications, such as AIRAH DA19, specify requirements for HVAC system and component inspection and cleaning, very little criteria for evaluating and assessing different types and levels of contamination are provided.

The Guideline establishes the criteria for evaluating the internal cleanliness of HVAC system components and clearly determines when cleaning is required, according to the building use. The Guideline describes the components of HVAC systems to be evaluated, the types of contamination likely to be encountered and includes for post fire and flood damage assessments.

Minimum inspection frequencies for various HVAC systems and components are specified for scheduled maintenance programs.

The Guideline also provides test methods that can be used to verify that a clean system hygiene level has been achieved following a system cleaning or restoration project. This document also includes recommendations for creating new access openings within HVAC systems where they are required to facilitate the inspection and cleaning of the internal surfaces of system ductwork and components.

The Guideline does not provide instructions on how to clean or restore HVAC systems but does provide some guidance on the management of cleaning and restoration projects.

This edition of the Guideline was developed by the AIRAH HVAC Hygiene Special Technical Group and modified by IRHACE for New Zealand conditions and building code requirements. This

was reviewed by Industry prior to publication.

The following is an extract from the HVAC Hygiene Best Practice Guideline.

1.10. Best Practice Hygiene Management

1.10.1. Principles

Best practice HVAC hygiene management can be achieved through the implementation of a few relatively simple management practices:

Filter Maintenance – Filters are the primary defence against dust and particulates. System filters should be regularly inspected and maintained, at least in accordance with the requirements of AS/NZS 3666.2 and AIRAH DA19 Application Manual –HVAC&R Maintenance.

The initial system assessment should include a review of the filter specifications to determine if filter application is optimal for the HVAC system, including the filter type, filter rating, system airflow and pressure, the likely contaminant profile and the general quality of installation and maintenance.

Filters shall comply with the minimum requirements of AS1668:2

Moisture Management – This is critical for minimising the potential for fungal contamination and any spills, leaks or wetting of HVAC systems or component should be dried out and inspected as soon as is practicable

Inspection and Assessment – All HVAC systems should be periodically inspected and assessed in accordance with the recommendations of this Guideline

Hygiene Level Management – Once systems or components have been identified as contaminated, cleaning and restoration work should be undertaken immediately including verifying the cleanliness of the restored system

22 www.irhace.org.nz EDUCATION & TRAINING

Good Housekeeping – HVAC hygiene also requires a common sense approach to limiting contaminant generating activities within a building and promptly responding to any unusual contamination event. Even everyday tasks such as cleaning (vacuuming, disinfecting), food preparation and document printing and copying may be inadvertently introducing unacceptable contaminants into the HVAC system.

1.10.2. Records

Best practice HVAC hygiene management requires good building and system documentation including up to date operation and maintenance manuals, accurate installed system drawings showing access points and original system commissioning data.

The building owner should maintain records of any conducted HVAC Hygiene Inspection Reports along with records of any cleaning or remedial works and any system hygiene verification carried out as a result of such inspections.

Maintaining these records builds up a hygiene profile of a building or system over time that assists in HVAC hygiene management. In addition, any reports relating to indoor air quality assessments or any energy management reports should also be retained with these records.

1.11. HVAC Standards and Regulations

The primary design standards for HVAC systems are listed in the New Zealand Building Code Section G4 which lists NZS4303 and AS 1668.2 which deals with ventilation requirements (minimum outdoor air, location of intakes and discharges, exhaust rates) and AS/NZS 3666.1 which deals with microbial control. AS/NZS 1668.1 details requirements for fire and smoke control associated with mechanical ventilation systems.

The primary standard for HVAC systems operation and maintenance is AS/NZS 3666.2. Its primary focus is the control of microbiological contaminants such as Legionella sp. In building water and air handling systems but it also focuses on general HVAC hygiene.

The standard that covers the maintenance of the fire and smoke control features of HVAC systems is AS 1851.

AS/NZS 1668.1, NZS4303, AS 1668.2 and AS/NZS 3666

Part 1 and Part 2 are called up in the New Zealand Building Code as primary referenced standards and are mandatory in New Zealand.

Apart from building legislation there may be specific occupational health and safety legislation and regulations relating to HVAC hygiene that should be complied with as they are relevant to both operation and maintenance.

The selection and application of general filters are covered by AS 1324 and minimum application requirements for the filtration of ventilation systems are specified in AS 1668.2. HEPA filters are classified in AS 4260.

It is not intended that the recommendations of this Guideline conflict with the requirements of any of these mandatory standards or with Government Regulations, Occupational Health and Safety requirements and the Workplace Exposure Standards and Biological Exposure.

Editors Michael Dane M.IRHACE and Robert Mannes M.IRHACE

IRHACE members are supplied with a copy of the HVAC Hygiene Best Practice Guide as part of their membership.

HVAC CONTROL PANEL SOLUTIONS

Car Park Ventilation Controller

The Car Park Ventilation controller enables control of car park fans (exhaust/supply/jet fans) via Modbus control signals. Multiple zones can be set up using expansion modules, for managing and monitoring car park fans and sensors.

The controller operates the car park ventilation system in accordance with AS 1668.2:2012 by checking carbon monoxide levels and regulating the ventilation system.

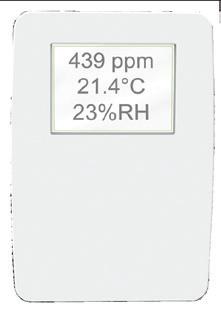

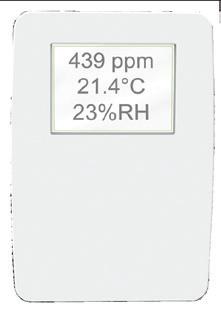

CO2 Monitoring Solutions for Schools

Indoor air quality directly impacts the usability of a space and the productivity of its occupants, so it’s particularly important to monitor the indoor environment in classrooms.

Eurotec have several solutions available for IAQ management in schools in accordance with the 2017 Ministry of Education guidelines. Once installed, teachers and students can easily monitor the CO2 and temperature levels in their respective learning space.

We have the ability to produce complete turnkey control panel solutions that are pretested and programmed for faster on-site commissioning. Contact us today!

EDUCATION & TRAINING December 2021/January 2022 23

09 579 1990 www.eurotec.co.nz

sales@eurotec.co.nz

2021 Wallie Askew Apprentice of the Year Competition

Due to the on-going issues with Covid19 within the greater Auckland / Waikato region, with great regret and frustration, it has become impossible for IRHACE to proceed with the planned finals of the 2021 Wallie Askew Apprentice of the year competition.

With heavy hearts, we will have to postpone the 2021 Wally Askew Apprentice of the Year competition indefinitely.

We still want to recognize the work that these apprentices have put into the competition thus far, and also to reward our very loyal and generous sponsors, without whom this competition could never be run.

Let’s take a look at each of our Apprentices and get to know what got them into the industry, who they work for and a little bit about their daily life in the trade.

Dylan Codlin: Air Zone - Whangarei

I got into the trade by pure chance. I had spent the past three years training as a paramedic and was looking for a change when a family friend offered me a job. The transition from the ambulance to the van was seamless and I was well equipped at dealing with emergencies like the Friday arvo callouts to get the beers cold.

I started and finished my apprenticeship with Airzone Ltd in Whangarei but moved to Wellington for a period in between where I worked at Wellington Refrigeration Ltd. I enjoy the problem-solving aspect of the trade and the evolving technology I get to work with and learn.

I’ve worked on repairing and installing commercial refrigeration

systems, building cool rooms and freezers and installing residential ducted units. Now the majority of my work is repairing and maintaining air conditioning equipment from splits and packaged units to larger chilled water systems.

I have made plenty of mistakes in the trade, one that comes to mind was setting off a smoke sensor and evacuating a seven-storey apartment building at 10pm.

My long-term plan is to move towards design, from my experience in the field, and I see the need and importance for well-designed systems and the impact this has on servicing, energy efficiency and life expectancy.

Joseph Allen: White Refrigeration - Auckland

Originally, I was working in the print design field. I decided to make a change in career, the outlook for work wasn’t good due to digital media becoming mainstream.

I started looking for a plumbing apprenticeship to begin with. After talking to one of the plumbers I approached, he suggested refrigeration as an interesting trade with lots of cool tools.

Homebrewing beer is a hobby of mine, it got me thinking refrigeration and temperature control is actually pretty interesting.

I turned up at White Refrigeration off the street and asked to

24 www.irhace.org.nz

OUR PEOPLE

Dylan Codlin

Joseph Allen

speak to the manager, Annemarie (my now boss) said “thats me!” It was not until about one year later that I had a call from Annemarie who gave me an apprenticeship. I’m very grateful they gave me that chance. This trade is rewarding, the ability to repair things, and solving real world problems makes a difference. Making beer cold is a winner!!

At White Refrigeration, the majority of my daily work is commercial refrigeration in many different environments. Every job has a different challenge which I enjoy.

Biggest stuffup and how did I fix it? Brazing in a new solenoid valve and not inspecting the internals, the spring under the plunger was damaged.

Sometimes new parts have defects. Swapping over the internals from another valve, I was able to get the system up and running.

Laurence Goodman: ATR Refrigeration Ltd.

Timaru

Hi my name is Laurence and I live in South Canterbury with my wife and son.

I started my tradie career as an electrician where I worked for 9 years. I was ready for a change and after spending some time working alongside some fridgie mates, I decided I liked the look of their job more. I approached ATR Timaru for an apprenticeship, and I have now been working with my boss, Andy, for 5 years.

We work in a mix of industrial and commercial, and I like the challenge that comes with clients and coming up with solutions that fit their needs. Having a dual-trade means I can see most jobs through from start to finish, so as well as working out the logistics of what a client needs and how to make it happen for the. I also get to do the install and commissioning too.

ATR covers most sectors of refrigeration, and I do a lot of work in the dairy industry where we work on site, as well as factories that cover everything from fish, dairy, cheese, and frozen food production, and in that area we do mostly maintenance and repairs. We also cover the

velvet industry where a lot of the work is done at the workshop building freezers which are then transported to the client.

My role is varied, and the scenery is always changing which suits me well. It’s never boring!

My biggest f**k up ......... I was blowing out a condenser in an engine room, not realising there was a smoke detector right above me. I set the fire alarm off and the whole building had to evacuate which stopped work for an hour on a Friday. I owed a couple of boxes of beers for that!

Sean Martin: Judd Refrigeration.

Palmerston North

I was working at an engineering company in sales, and I was approached by a refrigeration engineer who was working for an industrial refrigeration company at the time. I wanted a challenge to expand my skill set and I took the opportunity.

I worked in the refrigeration trade for several years before taking up an apprenticeship with Judd refrigeration.

Judd Refrigeration is a 3rd generation family business, with a team of 21 staff. Focusing on domestic & commercial HVAC and industrial and commercial refrigeration and now being a senior technician in the industry I am helping train three upcoming apprentices and technical support for installation and technical service.

I also enjoy being a part of a dynamic team and able to pass on knowledge to up and coming trainees ensuring the trade is remaining strong. Every day I work on a diverse range of equipment all the way from a spilt system to vrv, dairy vats to industrial rack systems and cascade refrigeration. Every day presents a new challenge. I find satisfaction in being able to repair and upkeep these systems and still learn something every day.

I want to thank the people around me over the years who have assisted me in the knowledge and given me the support to complete my trade.

OUR PEOPLE December 2021/January 2022 25

Laurence Goodman

Sean Martin

26 www.irhace.org.nz 2021 Wallie Askew Sponsors Premiere Sponsor OOLING EQUIPMENT LTD Engineered Refrigeration Solutions OUR PEOPLE

Congratulations to our IRHACE members

December 2021/January 2022 27

Kevin Cudmore with his Service Award.

Garrett Glynn with his Service Award.

OUR PEOPLE

Ashwin Patel with his Service Award.

Elias Mackenzie with his Service Award.

World-1st Slim & Modular VRF, SideSmart™

Hitachi Cooling & Heating – the VRF manufacturer with more than 35 years’ experience – reinforces its leadership position in air-conditioning technology, with the introduction of SideSmart™. As brand-new category of VRF which is slim and modular VRF Outdoor unit, SideSmart™ delivers ‘Living Harmony’ in middle-size commercial buildings by delivering high-performance air-conditioning with less & flexible installation space.

A first in the sector, the SideSmart™ VRF unit is an exclusive concept (for which measurements start from 1,650×1,050×420mm) and it is the ideal choice for projects of all sizes, especially those with limited space in mediumsize buildings. Its modularity means that up to 4 units can be connected, offering a maximum combined capacity of 54HP (150 kW Cooling capacity). Thanks to its slim, modular concept, larger capacity air conditioning can be achieved almost anywhere, making SideSmart™ one of the most versatile VRF units on the market.

Being a lighter unit, SideSmart™ presents fewer complications during delivery and installation. SideSmart™ can be installed on the preferred floor, either balconies or utility rooms, so you can optimize the system design. This helps reduce the length of piping between indoor and outdoor units, increasing efficiency and freeing the rooftop of air conditioning equipment.

Main features

• Single cabinet up to 16HP

With 4 modular combinations, capacity can be increased up to 54HP, which can help decrease the initial cost by shortening the installation time

• Less installation footprint with slim cabinet; installed anywhere, even limited spaces like balconies. Up to 500m piping; Adapts to your building layout, with total piping runs up to 500m and up to 120m length with indoor unit.

Available from Temperzone

28 www.irhace.org.nz

MEMBER NEWS

Why deal with a climate control companies association members (CCCA)?

Our membership encompasses companies who willingly accept the responsibility and discipline of a recognized trade association. They emphasise the professionalism we believe should identify our industry. CCCA companies have total belief and confidence in the products and services they supply – and are prepared to undergo the scrutiny of their fellow professionals should the occasion arise. CCCA professionals promote a responsibility towards their customers that goes far beyond commercial considerations.

JOIN NOW AS AN AFFILIATE MEMBER

Supporter of industry

Training organisations or providers

Societies or Government entities

Manufacturer, franchisor, consultant or partnerships

MEMBER NEWS

December 2021/January 2022 29

HVAC&R Centre – updates

NZCIIR calls for nominations for the Tony Barnard Award

The New Zealand National Committee of the International Institute of Refrigeration (NZCIIR) is calling for nominations for "The Tony Barnard Award".

The Tony Barnard Award is to a young person under 35 years judged by the prize committee to have made the most significant contribution to research and development in refrigeration within New Zealand in recent years. The NZNC IIR also wishes to thank the prize and award sponsors, Hawkes Bay Refrigeration, and Mayekawa Mycom.

Nominations to mike@mikeodey.co.nz prior to 31 March 2022, https://www.irhace.org.nz/news/164/38/ NZCIIR-calls-for-nominations-for-the-Tony-Barnard-Award/

Member invoicing –IRHACE and CCCANZ

Invoices for membership subscriptions will be sent out early January 2022 for 20th month following. Please advise us of any changes to your email address.

New members IRHACE

Kylie Guthrie - Manawatu Avinesh Lal - Auckland/ Northland

Roheel Chandra - Auckland/ Northland

30 www.irhace.org.nz

MEMBER NEWS

TOP REASONS TO JOIN IRHACE

4

Why become a member of IRHACE?

Membership is the lifeblood of our existence. The greater the representation of our industry we can gain, the stronger our Institute will be. There are several types of membership ranging from Associate member to a full member M.IRHACE either by experience or qualification. Regional branches hold committee meetings, product forums, site visits, seminars, and social events; these are organised for members within their region. Our members tell us that these are the top four reasons for joining IRHACE.

To gain access to those who influence the laws and regulations that govern our industry, such as the government.

1 2 3 4

To have a forum to up-skill knowledge in industry-related forums such as presentations, webinars, trade nights and workshops.

Want to know more? If you have questions or want to speak directly with our membership team, you can contact us at admin@irhace.org.nz or Join us today by simply clicking this page and fill out an application form.

To gain recognition in the industry to assist career fulfillment.

To gain access to others involved in the industry through networking opportunities provided in the form of conferences, committee participation, and social events.

December 2021/January 2022 31

Live Events

Coming Webinars in 2022

Dr. Alison Subiantoro is a Senior Lecturer in the Department of Mechanical and Mechatronics Engineering at the University of Auckland, New Zealand, since 2017. His research interests include refrigeration, HVAC, thermal power systems and renewable energies

Theme

Expansion work recovery in vapour compression refrigeration systems.

• Introduction to expansion work recovery (EWR) technology for refrigeration systems

• State-of-the-art research on EWR in the literature

• Research on EWR at the University of Auckland

• Challenges and potentials

Presented by Dr Alison Subiantoro, Senior Lecturer, Auckland University M.IRHACE

Date: Early 2022, https://www.rlnz.org.nz/w/rl/webinars/

Theme

Air Quality ventilation and Covid 19

Presented by Fantech

Date: Early 2022, https://www.rlnz.org.nz/w/rl/webinars/

Theme

Compliance with NZS 5419 - when using Hydrocarbon based refrigerants

Presented by Dave Nicholls, RealCold M.IRHACE

Date: Early 2022, https://www.rlnz.org.nz/w/rl/webinars/

December 2021/January 2022 33 EVENTS

Events

IRHACE TRADE NIGHT WHANGAREI

10 MARCH 20222

5.30pm - 8.30pm

Semenoff StadiumVenues and Events

Whangarei

Northland Events Centre, 51 Okara Drive 0110

Whangarei New Zealand

With Guest Speakers

Preferred Accomodation Options with Discounts. (Book Accomodation Early)

Discovery Hotel Whangarei

Distinction Whangarei Hotel & Conference Centre Code: DHotelsVIP01

Quest Whangarei Code: IRHACE

34 www.irhace.org.nz

EVENTS

Networking Events

Merry Christmas & Happy New Year

See you in 2022

By John Greaves (NZCE- Mech) Senior Design Engineer - Black Diamond Technologies

By John Greaves (NZCE- Mech) Senior Design Engineer - Black Diamond Technologies