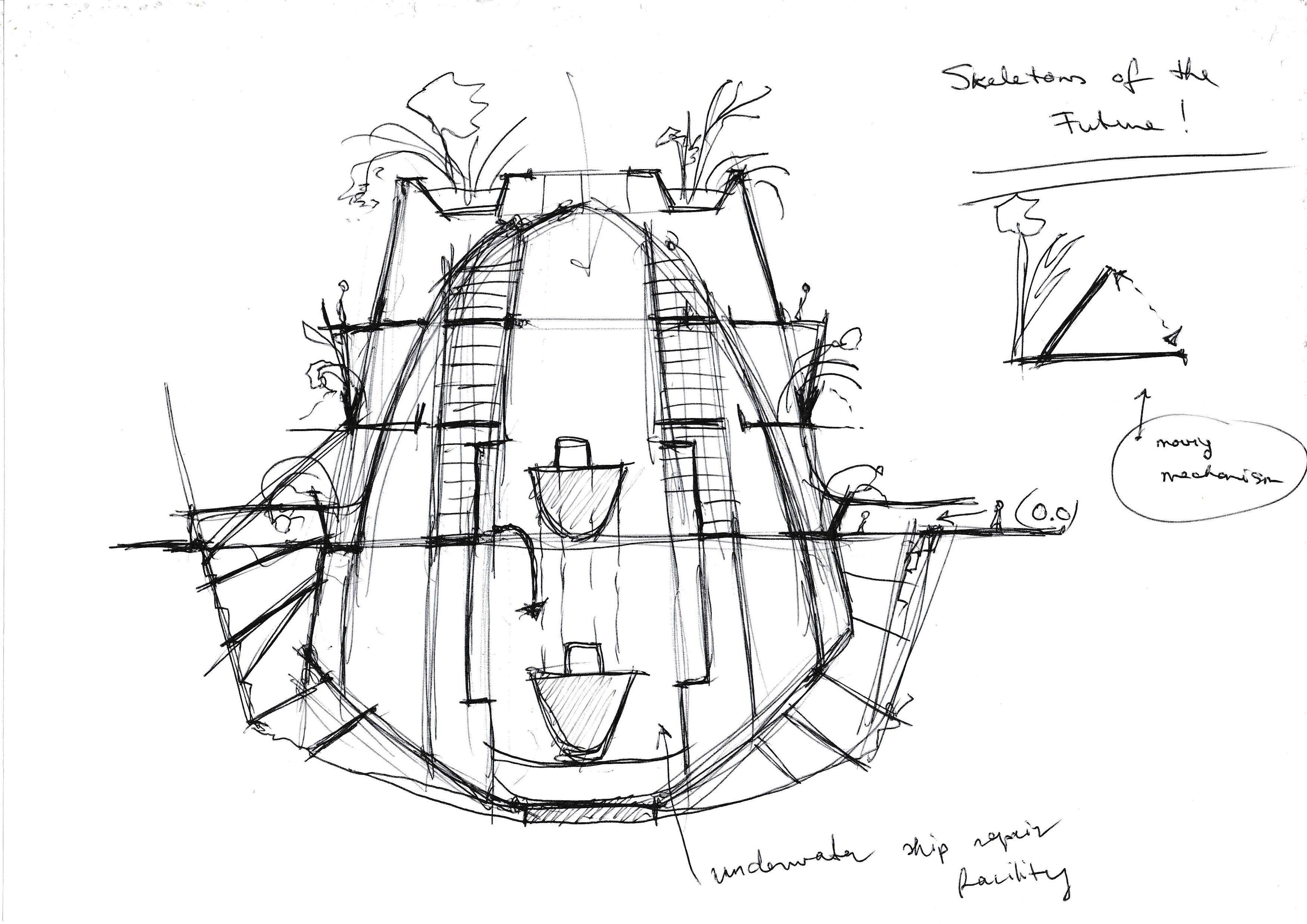

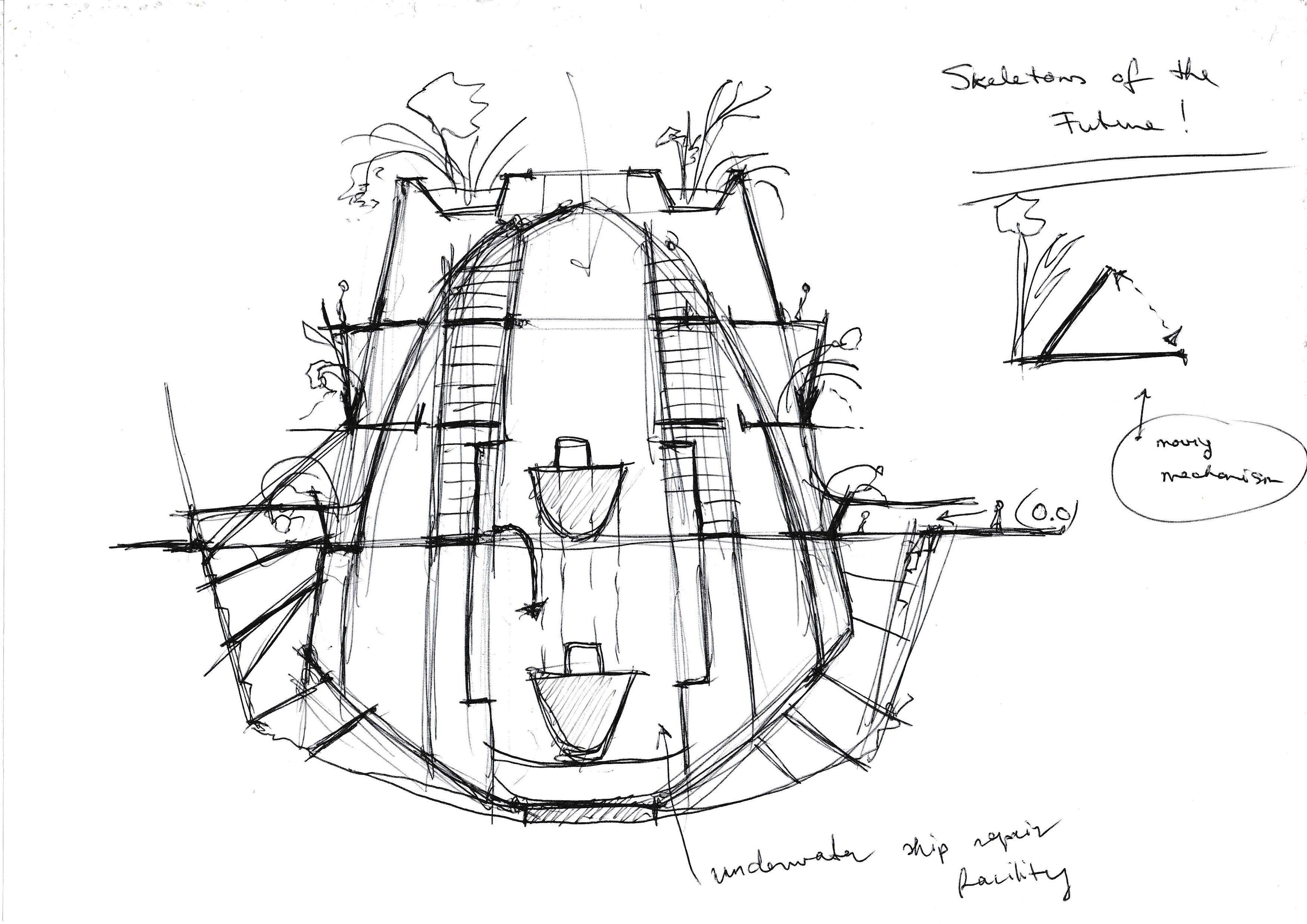

Skeletons of the Future

The future of ship manufacturing

by Paula Bloma 2022/2023

by Paula Bloma 2022/2023

Mentor

Jan Richard Kikkert (Architect and professor, mentor at AHK)

Commission member

Ben Milbourne (Architect AIA, ARBV, Senior Lecturer, Architecture at RMIT)

Jason Hilgefort (Architect, urban theorist, and curator, professor at the HKU)

External advisors

Jeremy McLeod (Architectural / Design Support, Breath Architecture)

Joseph Carrozzi (Chair, Harbour Trust)

Mike Horne (Principal consultant, Turf Designs)

Yatu Widders Hunt (Senior Consultant, Cox Inall Ridgeway)

A meeting place of many stories

Bring people back to the island to learn about those stories

Gadigal

PARRAMATTA River

WAREAMAH

Cammeraygal

Wallemudegal

Wangal

GONG-UL

AR-RA-RE-AGON

MOCOBOULA

OCEAN

TIDE

MEL-ME

GOOGLE EARTH

Gadigal

PARRAMATTA River

WAREAMAH

Cammeraygal

Wallemudegal

Wangal

GONG-UL

AR-RA-RE-AGON

MOCOBOULA

OCEAN

TIDE

MEL-ME

GOOGLE EARTH

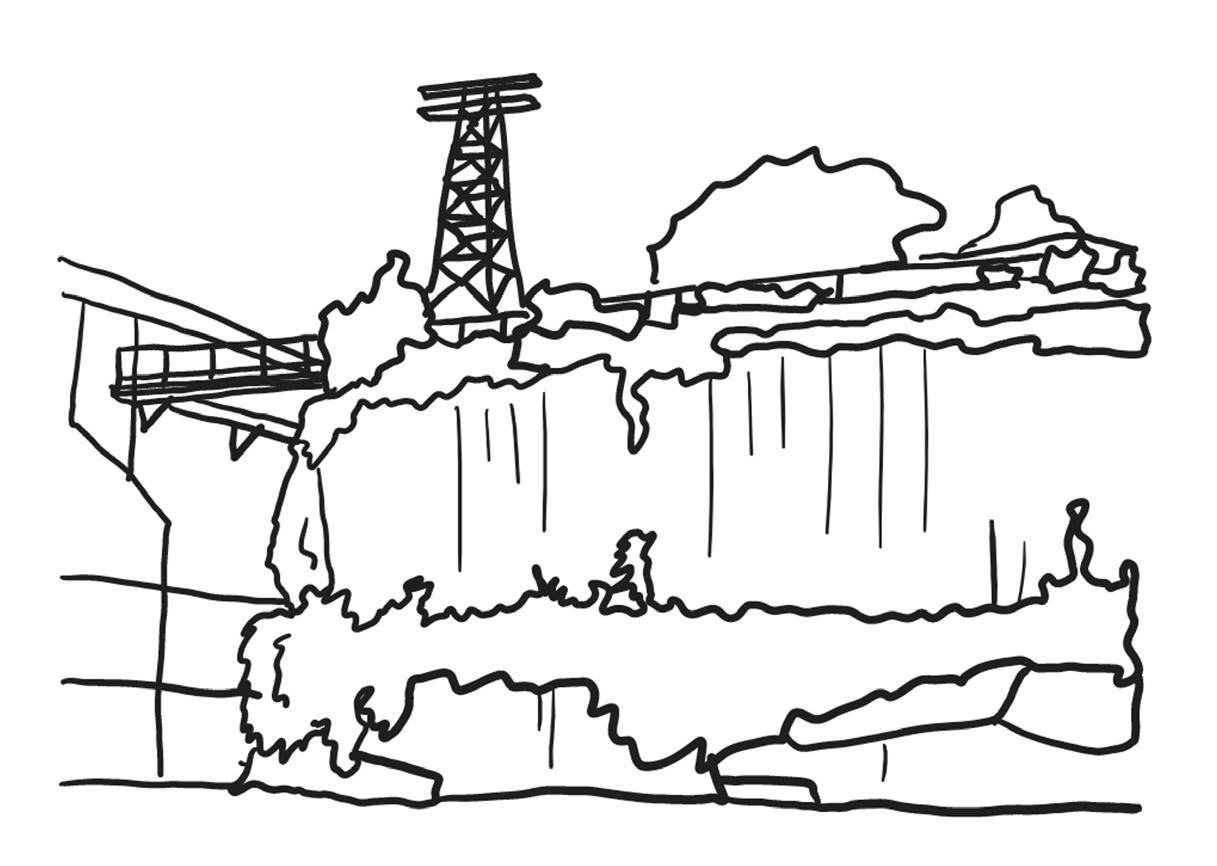

Cockatoo Island before and after

Cockatoo Island before and after

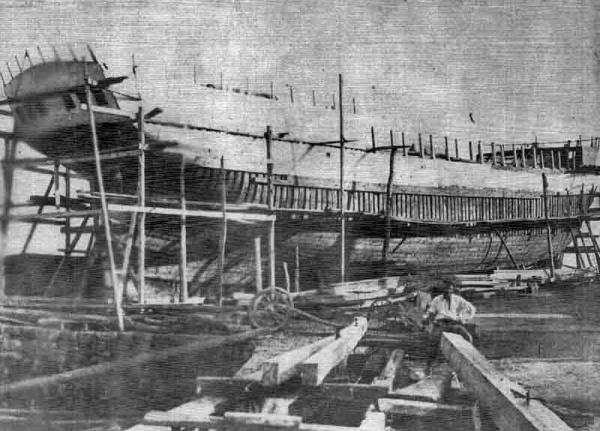

Pre 1788:

Frequented by sulphur-crested cockatoos, the island’s first visitors were most likely the Eora people, the Aboriginal people of Sydney’s coastal region. They called the island Waremah. It would have been a great base to fish from for them, in their bark canoes made from the red gum forests that once covered the island hill.

New penal establishment

The Fitzroy Dock and a workshop Industrial School for Girls and a reformatory.

The island reverts back to a gaol

1839-1850:

In 1839 the Governor of the colony of New South Wales, Sir George Gipps, chose Cockatoo Island as the site of a new penal establishment to alleviate overcrowding on Norfolk Island. Convicts were put to work building prison barracks, a military guardhouse and official residences.

1850-1870:

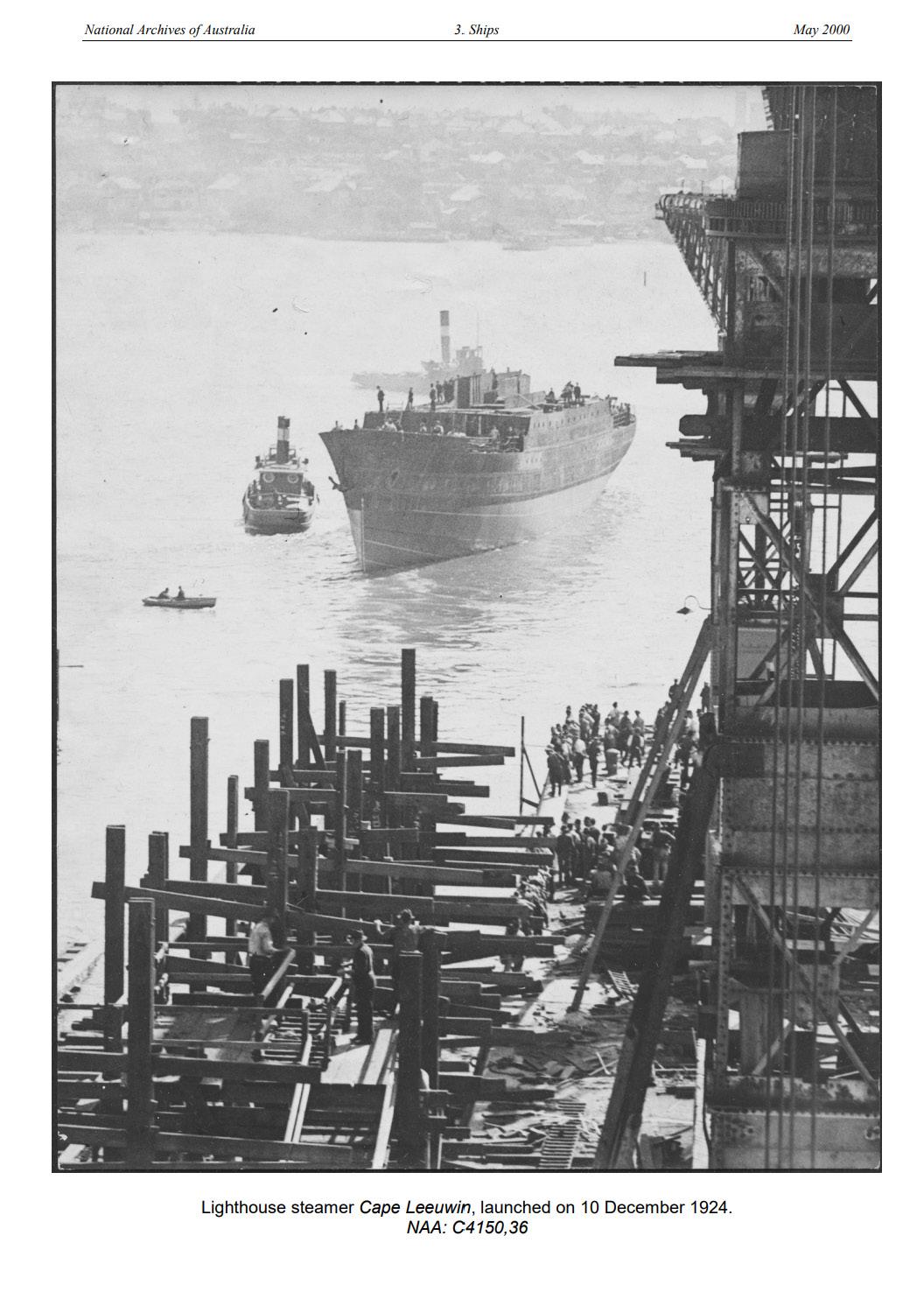

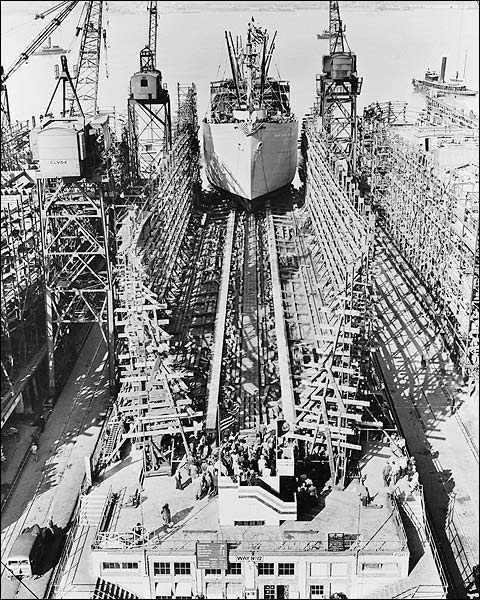

The Fitzroy Dock and a workshop are built by prisoners to service Royal Navy and other ships.

1870-1880:

Prisoners relocate to Darlinghurst Gaol and the island is used for an Industrial School for Girls and a reformatory. The ship, Vernon, is anchored nearby to train wayward and orphaned boys.

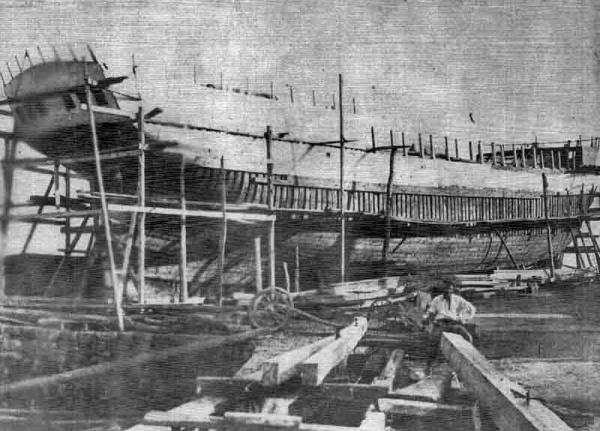

1880-1900: Shipbuilding and repair activities expand steadily and Sutherland Dock is completed. The island reverts back to a gaol from 1888-1908 due to overcrowding elsewhere.

Commonwealth Naval Dockyard

Becomes the major shipbuilding and dockyard facility for the South West Pacific in WWII

Additional buildings are constructed for shipbuilding and repair.

1900-1930:

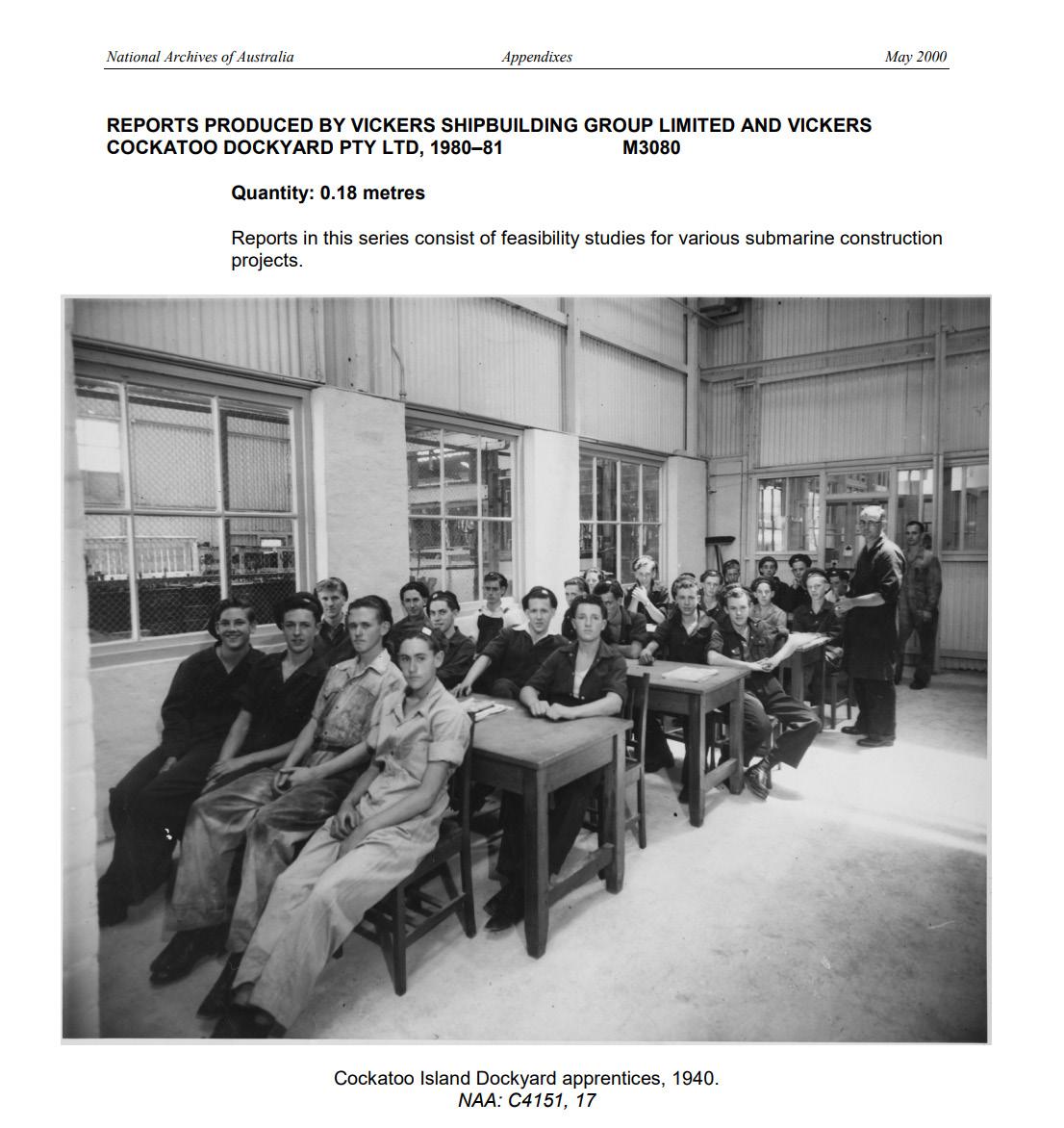

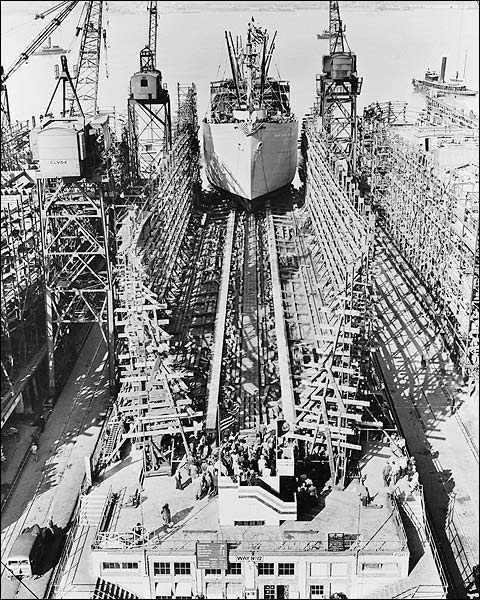

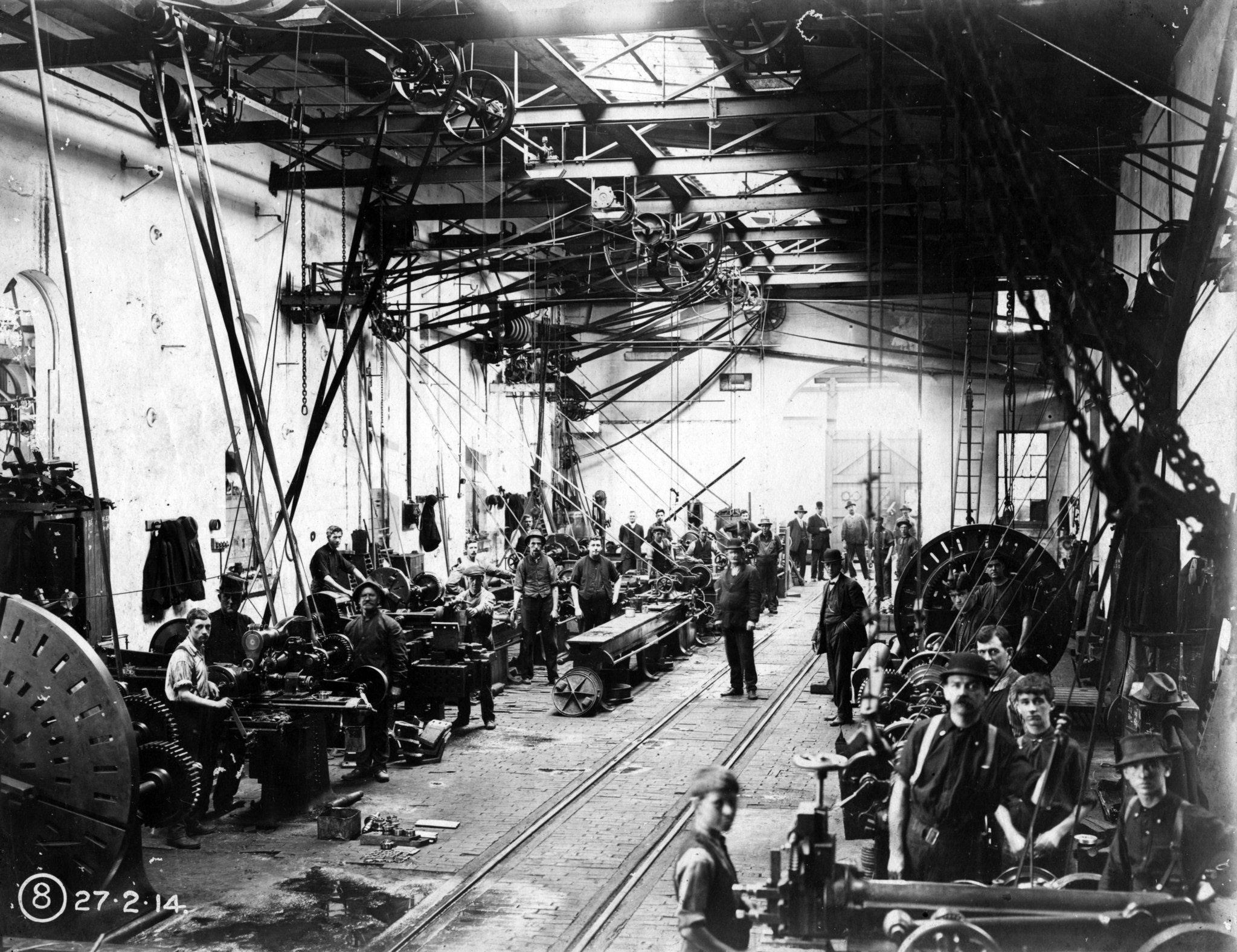

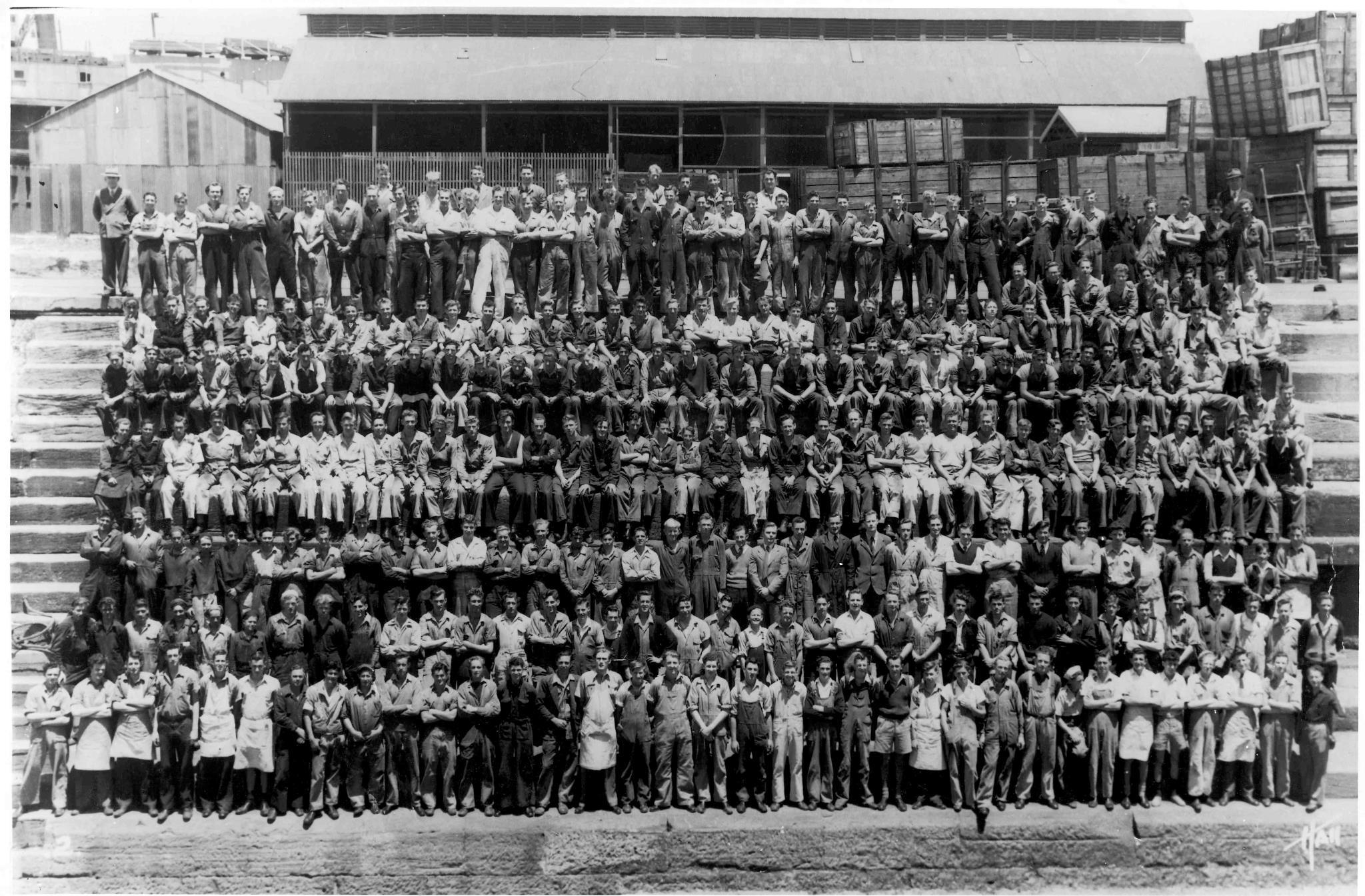

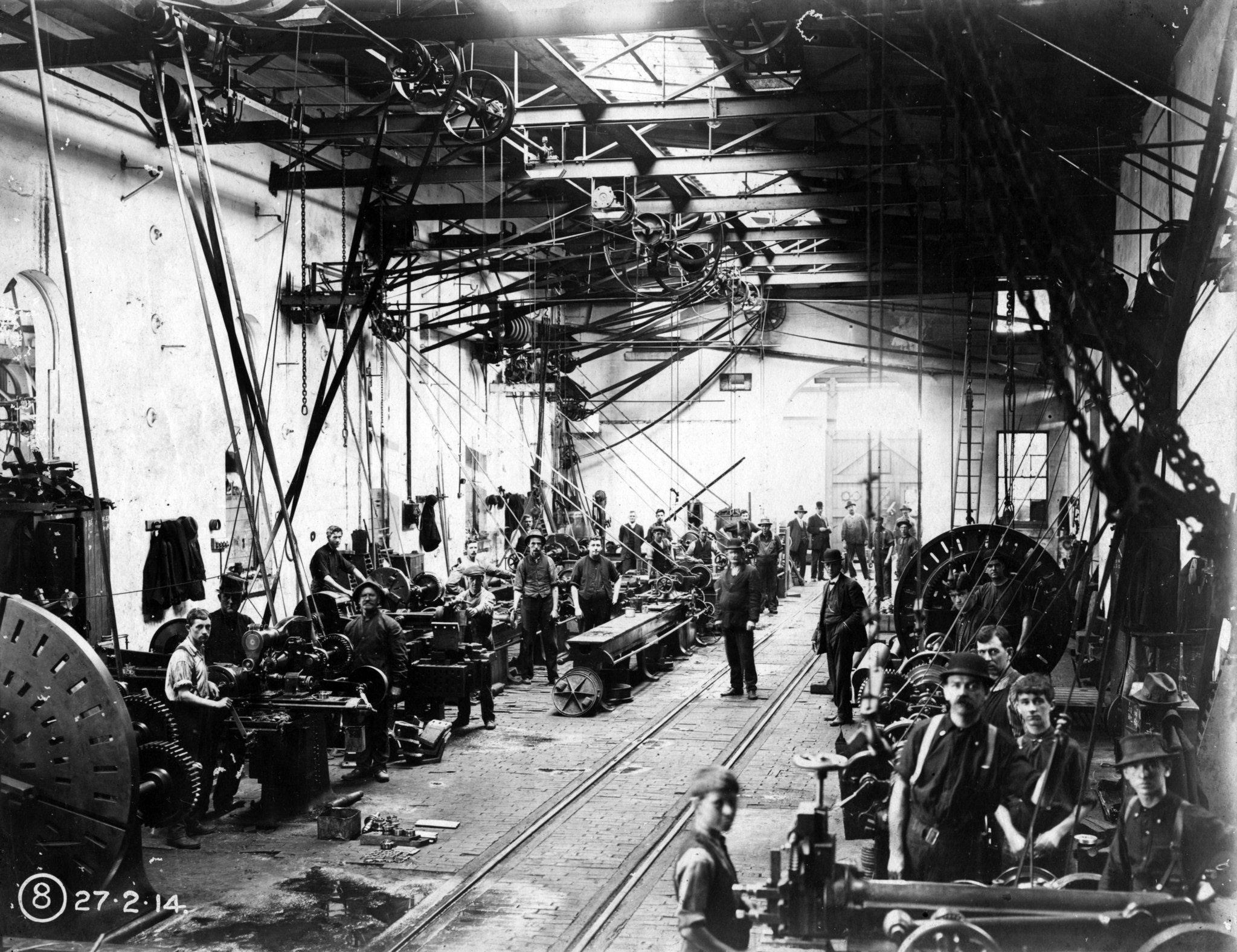

Cockatoo Island becomes the Commonwealth Naval Dockyard in 1913 and Australia builds its first steel warship on the island.

1930-1945:

The island becomes the major shipbuilding and dockyard facility for the South West Pacific in WWII following the fall of Singapore.

1945-1965:

Additional buildings are constructed for shipbuilding and repair. The refit of T-Class submarines occurs and the Navy destroyers, HMAS Voyager and HMAS Vampire, are built.

The dockyard closes in 1992 Harbour Federation Trust assumes control of the island. Cockatoo Island was opened to the public in 2007.

1965-1992:

The island’s work includes service and refit of Oberon Class submarines and construction ofHMAS Success. The dockyard closes in 1992, machinery is sold off, and about 40 buildings and several wharves are demolished.

2001-present:

Cockatoo Island lays dormant for a decade until the Sydney Harbour Federation Trust assumes control of the island and embarks on major restoration works. After extensive remediation works, Cockatoo Island was opened to the public in 2007. The Harbour Trust continues to actively rehabilitate the island.

UNESCO World Heritage List. Unknown future of the island

2010: Cockatoo Island, together with 10 other historic convict sites in Australia, is inscribed on the UNESCO World Heritage List.

2050:

?

Fishing base for Aboriginal people

My vision

RE - connect RE - pair

• Connecting sea, land & sky

• A harbour that connects the people and layered history of 60000 years

• Country as meeting place

• Spreading city from East to West (extending city )

RE - purpouse RE - nature

• Renovation & restauration of existing builts and structures

• Repair existing fabric to contemporary use by using local materials & historical ways of building

• Maintain heritage & its role in the city and the whole country

• Improved cartilages

• Repurpouse & utilise ≠ ruin

• Existing spaces unocupied - how to achieve an outgoing program?

• Maintain heritage & its role in the city and the whole country

• Repurpouse & utilise ≠ ruin

• Existing spaces unocupied - how to achieve an outgoing program?

• Maintain heritage & its role in the city and the whole country

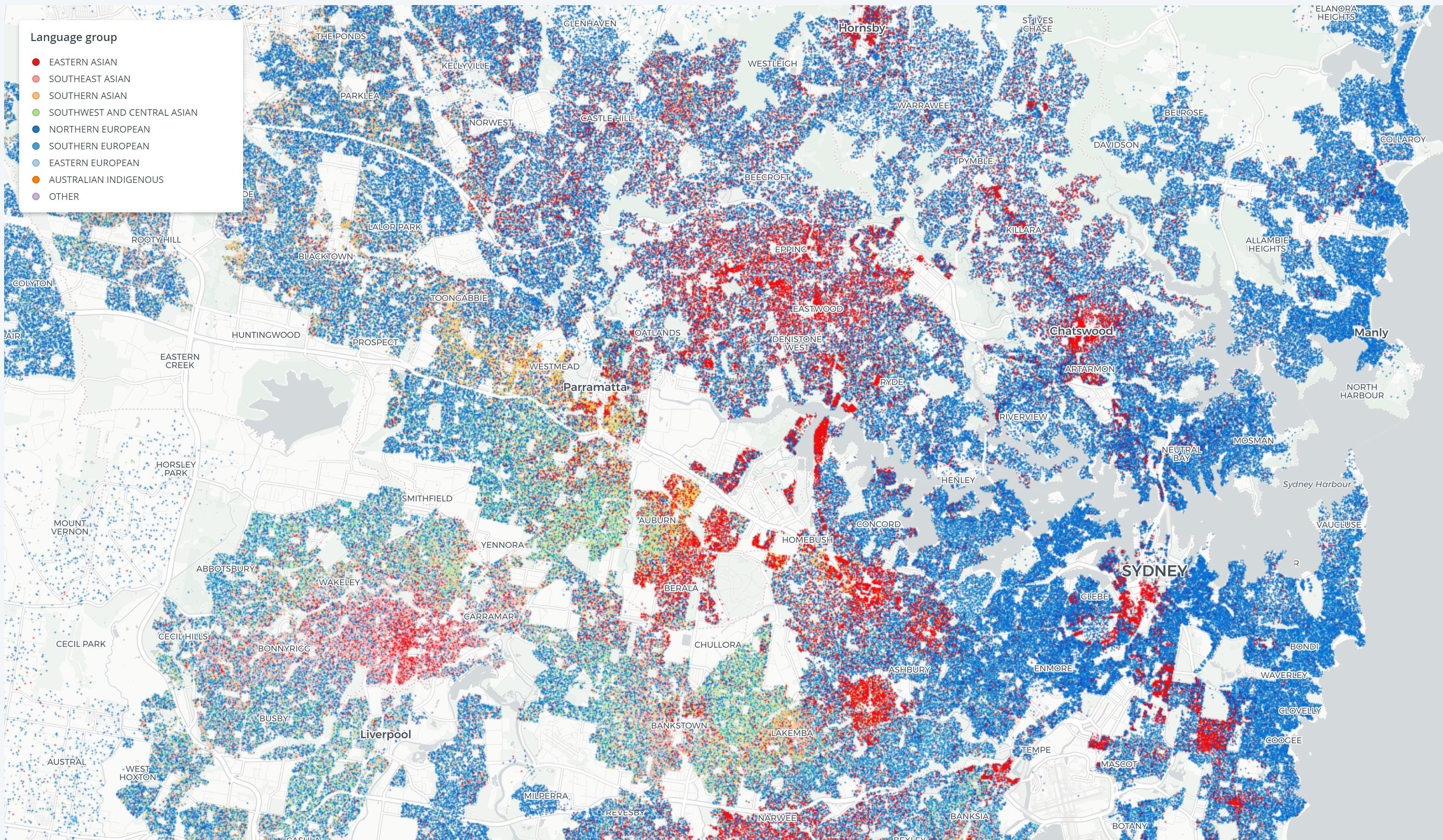

A City of Villages

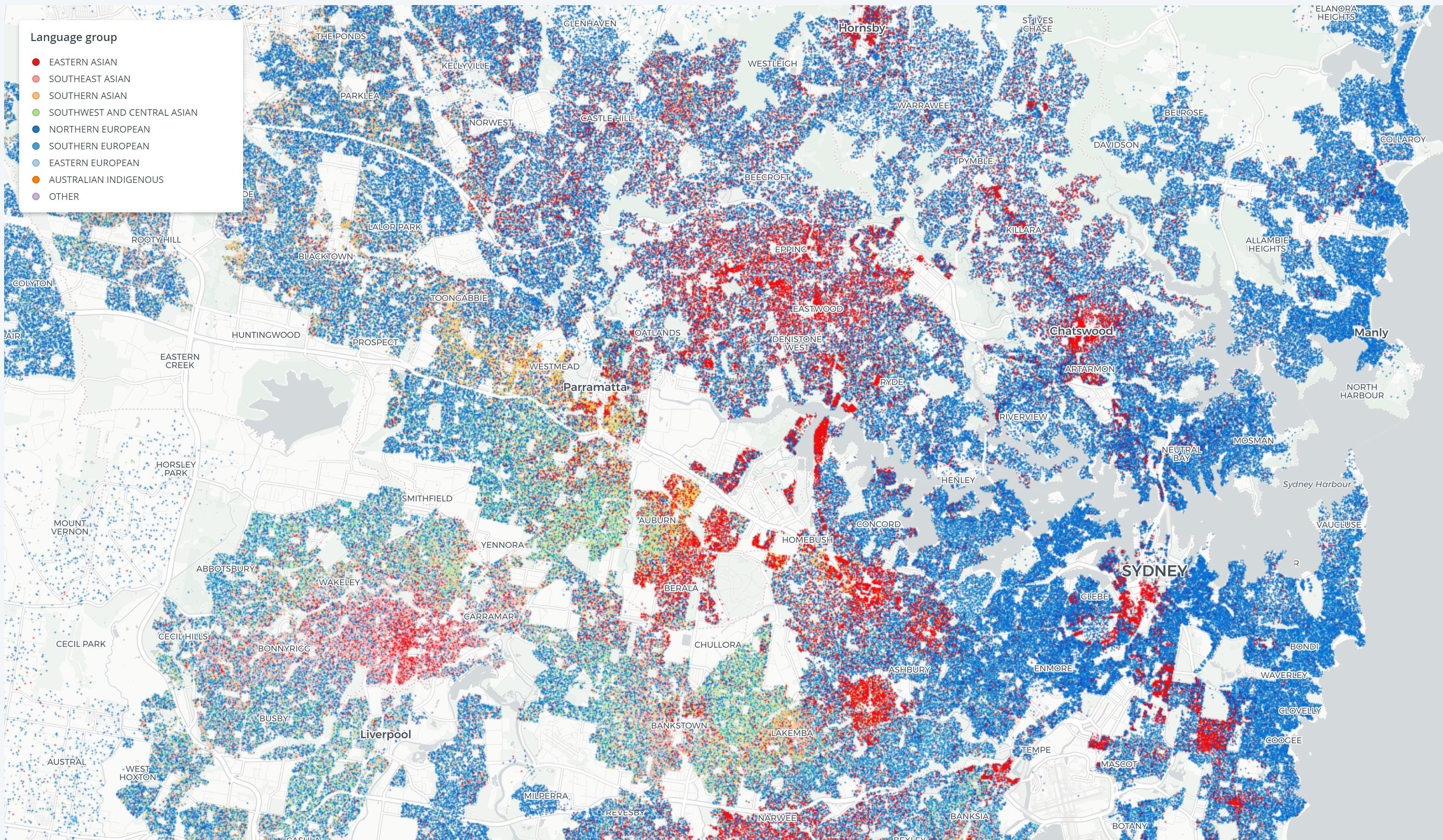

Sydney is one of the most multicultural cities in the world. Of the total population of Greater Sydney, 39.2% of people were born overseas. This is even higher in the City of Sydney, with 47.7% of people born overseas. Travel to Western Sydney, and it increases to 53.8%.

The most common languages in Sydney other than English are Mandarin, Arabic, Cantonese, Vietnamese and Greek. Cultural and linguistic diversity has always been a feature of the Aboriginal groups who have lived in the Sydney region for at least 70,000 years. In the over 230 years since colonization, cultural diversity has continued to be a feature of the Sydney population and has shaped the city and its suburbs.

Sydney is known as a city of villages, made up of many different neighborhoods, each with their own character. Sydney’s neighborhoods celebrate the city’s cultural diversity and rich immigrant histories. Many localities are excellent examples of ‘everyday multiculturalism’, places where you can experience the lived reality of cultural diversity in Australia. Some areas of the city have become associated with the cultures and nationalities that predominate there. Enjoying yum cha (dim sum) in Chinatown, eating gelato in Leichhardt or pho in Cabramatta is a must during any visit to Sydney.

THE STORY OF CULTURAL DIVERSITY

- Dr. Justine Greenwood, instructor for The Australian Experience.

www.smallmultiples.carto.com/builder

www.smallmultiples.carto.com/builder

COMING TOGETHER TO CELEBRATE DIVERSITY IN COMMUNITY

SITE VISIT

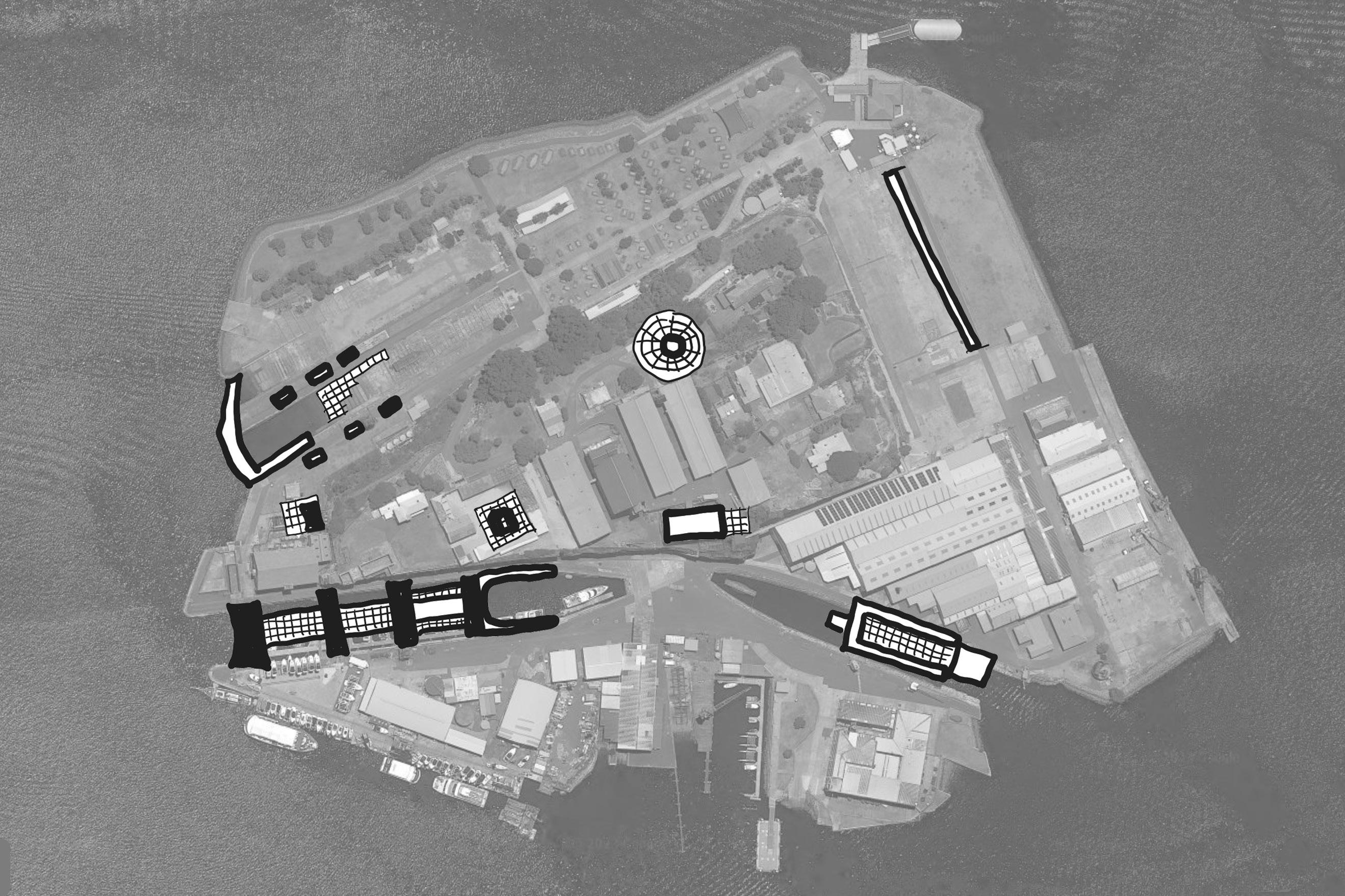

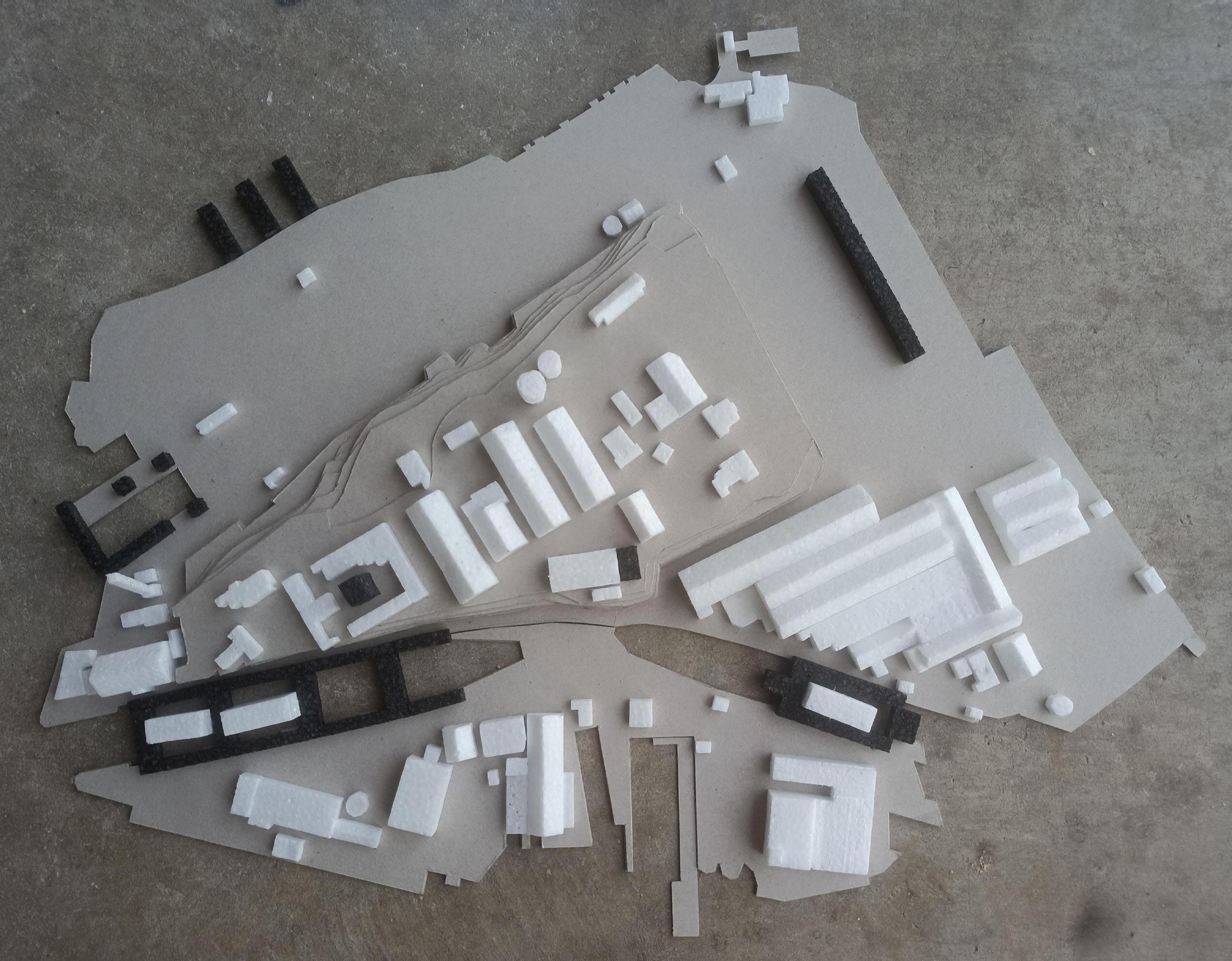

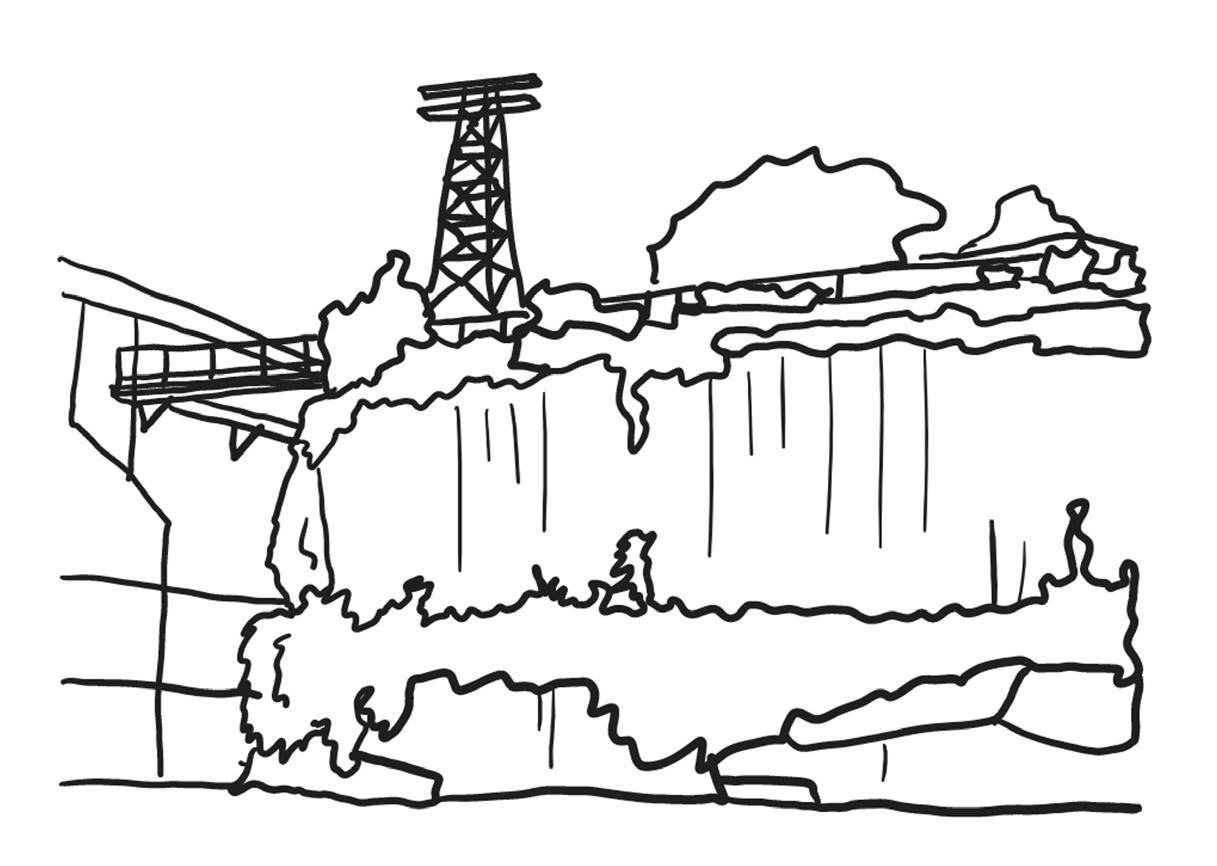

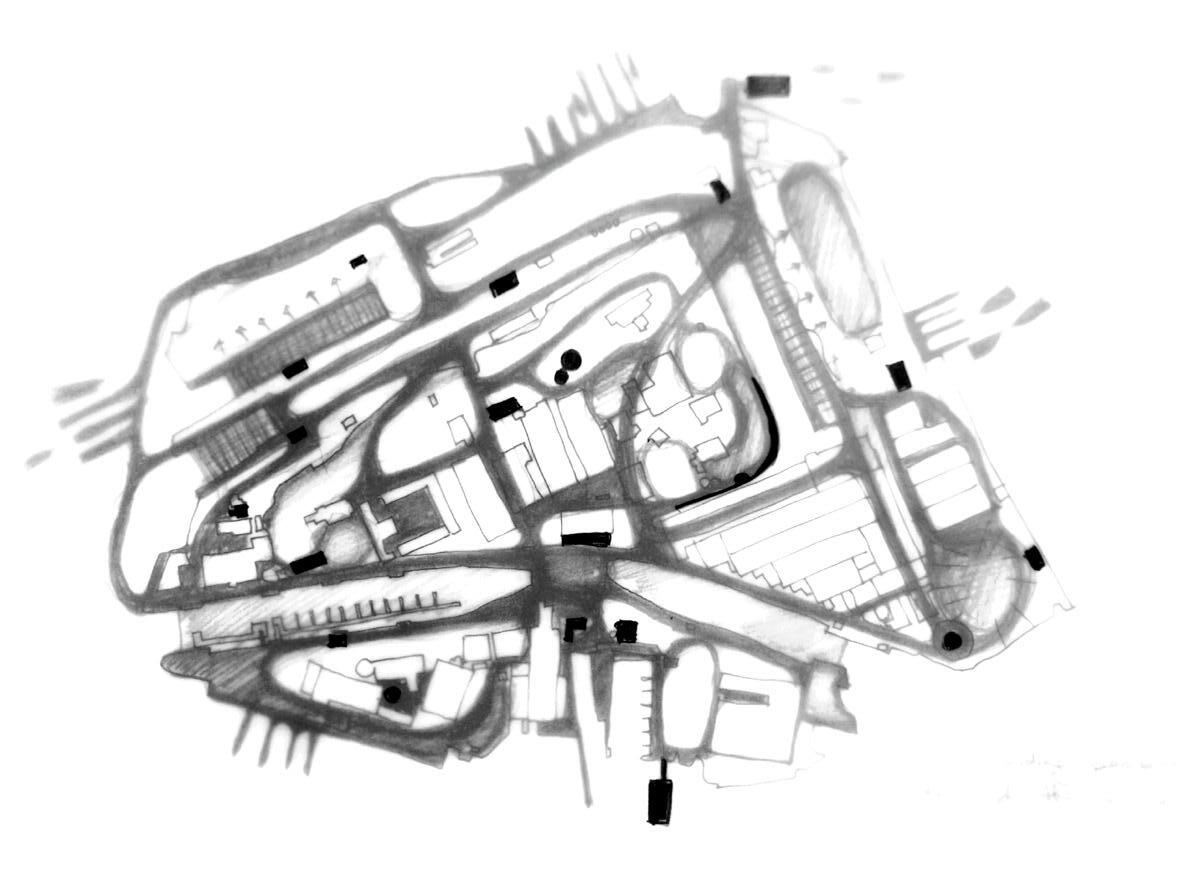

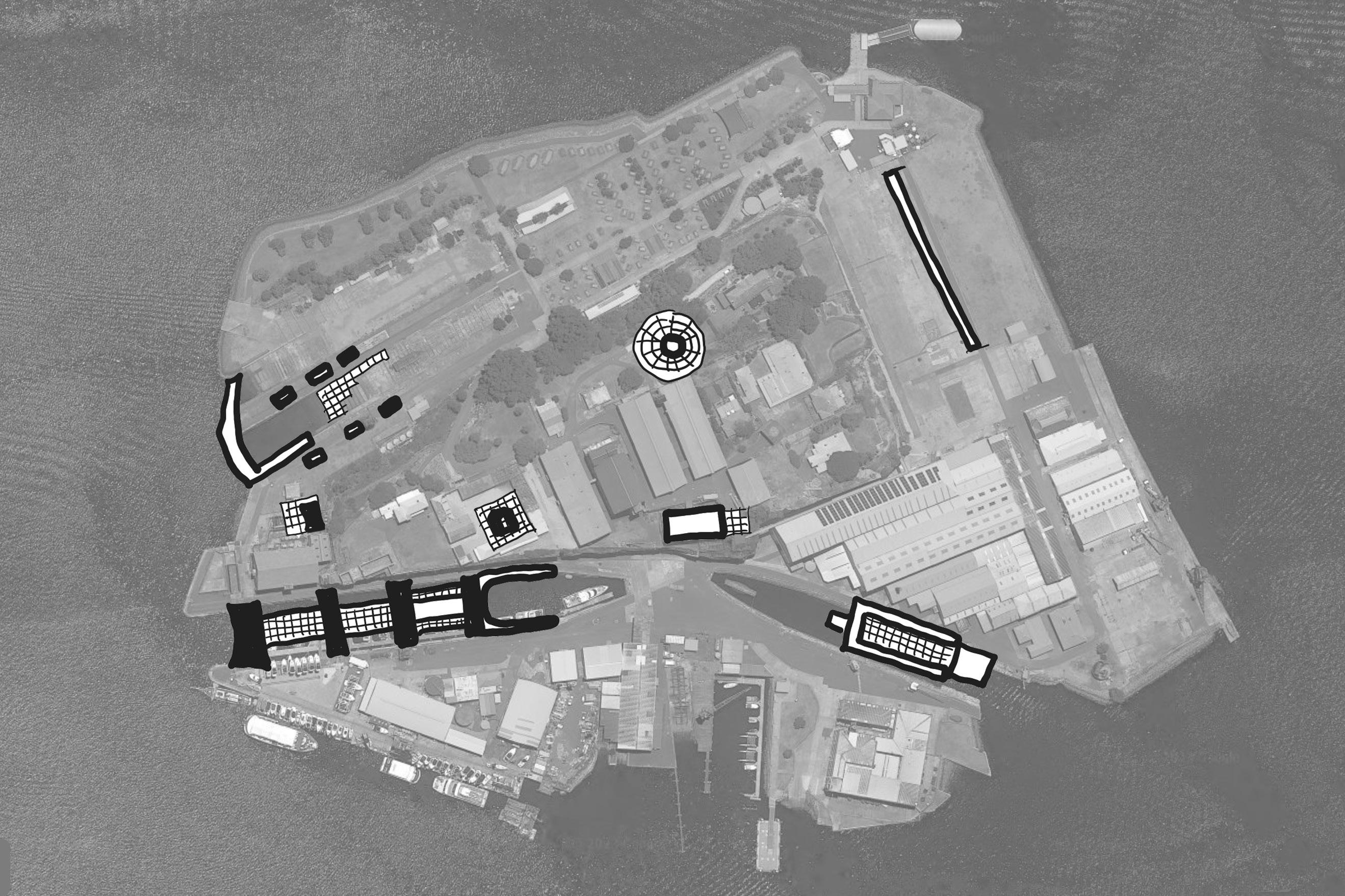

EXISTING STRUCTURES. COCKATOO ISLAND

loud bird sounds

windy, urban sounds a lot of empty space feels more free

industrial sounds

11.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

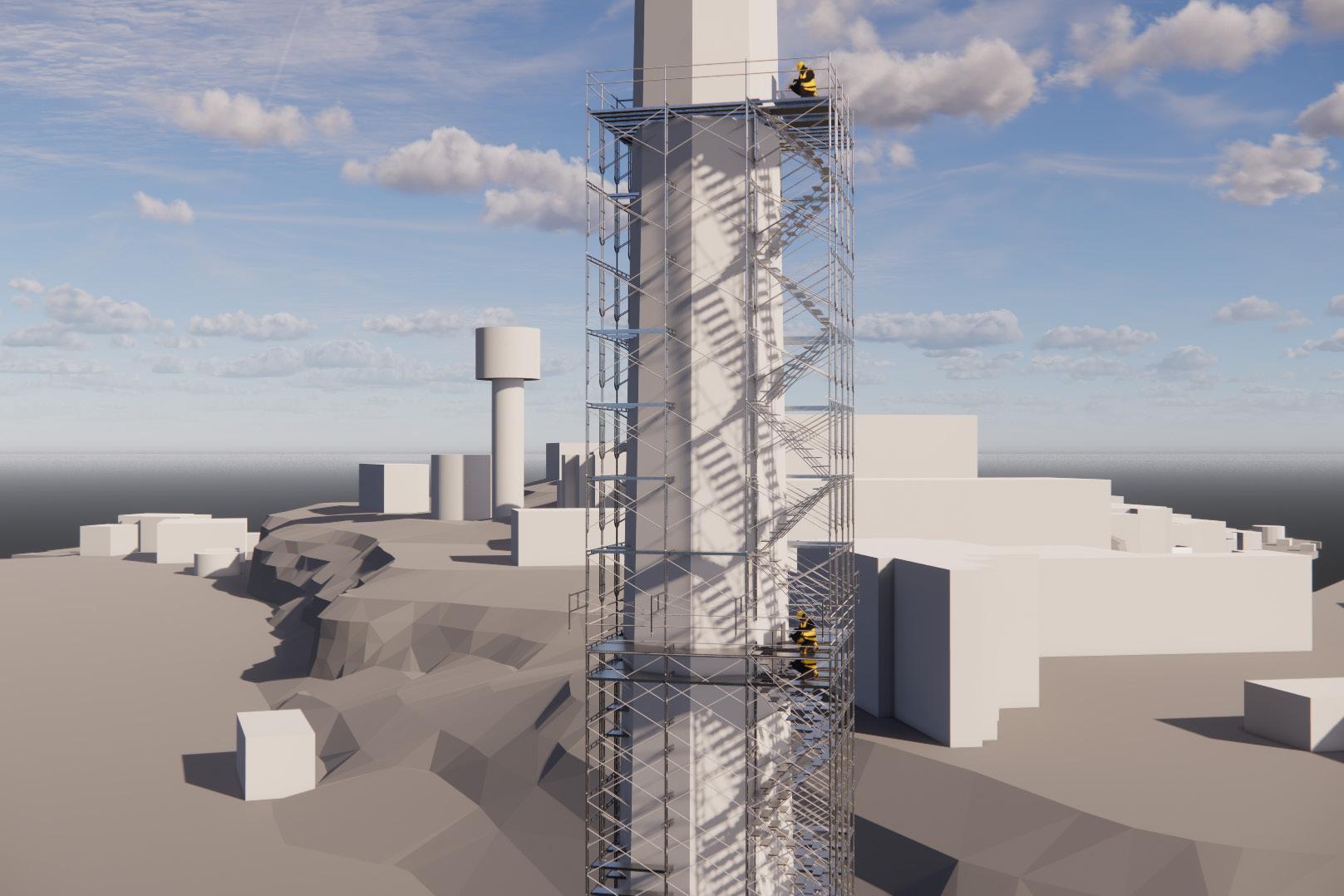

1. A clibing tower

2. Education facility

3. Accomodation facility

4. Craft workshops

5. Sports facility/stadium

6. Watch tower

7. Store and cafe

8. Accomodation facility

9. Communal kitchen

10. Art gallery & center

11. A new school for woman

11.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1. A clibing tower

2. Education facility

3. Accomodation facility

4. Craft workshops

5. Sports facility/stadium

6. Watch tower

7. Store and cafe

8. Accomodation facility

9. Communal kitchen

10. Art gallery & center

11. A new school for woman

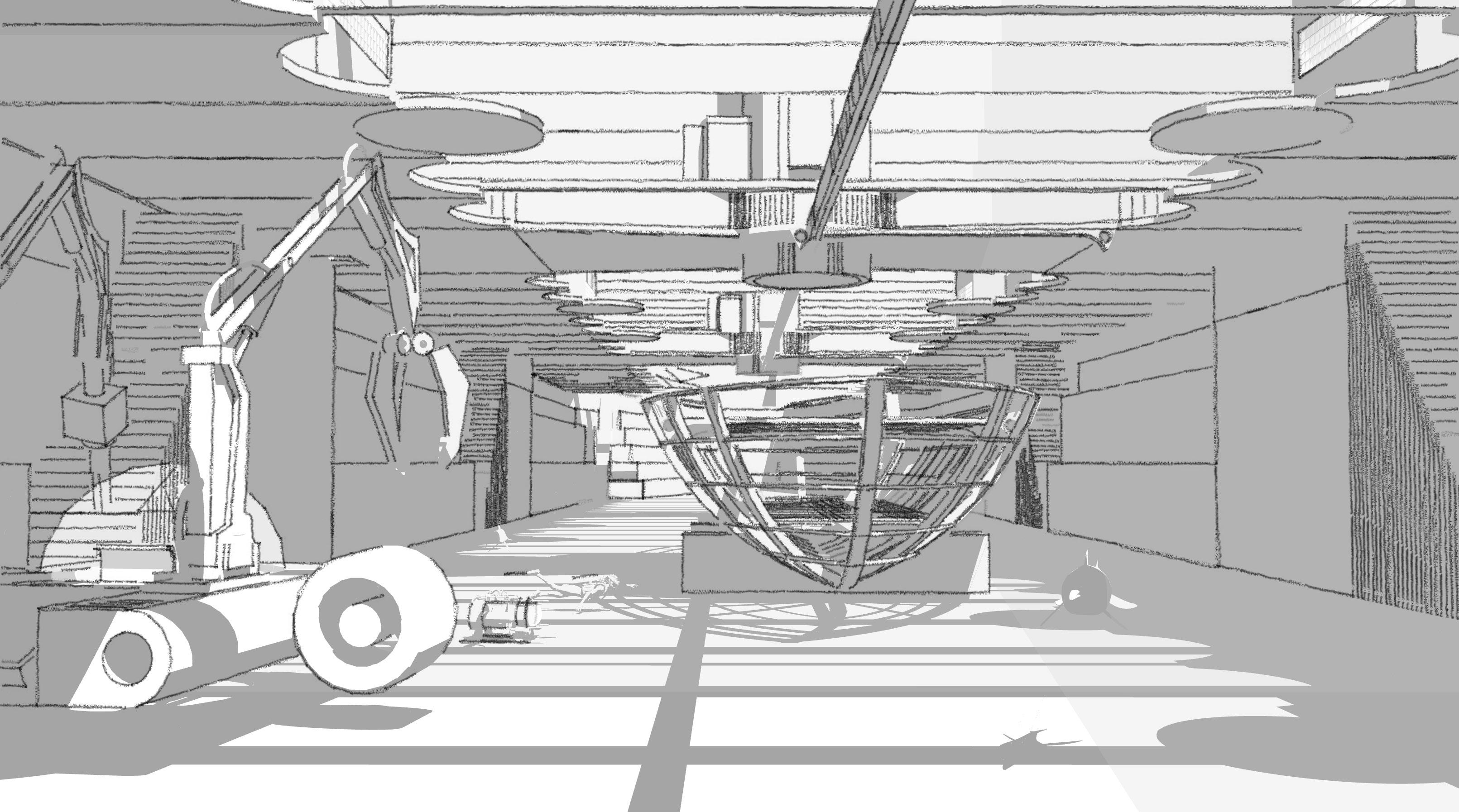

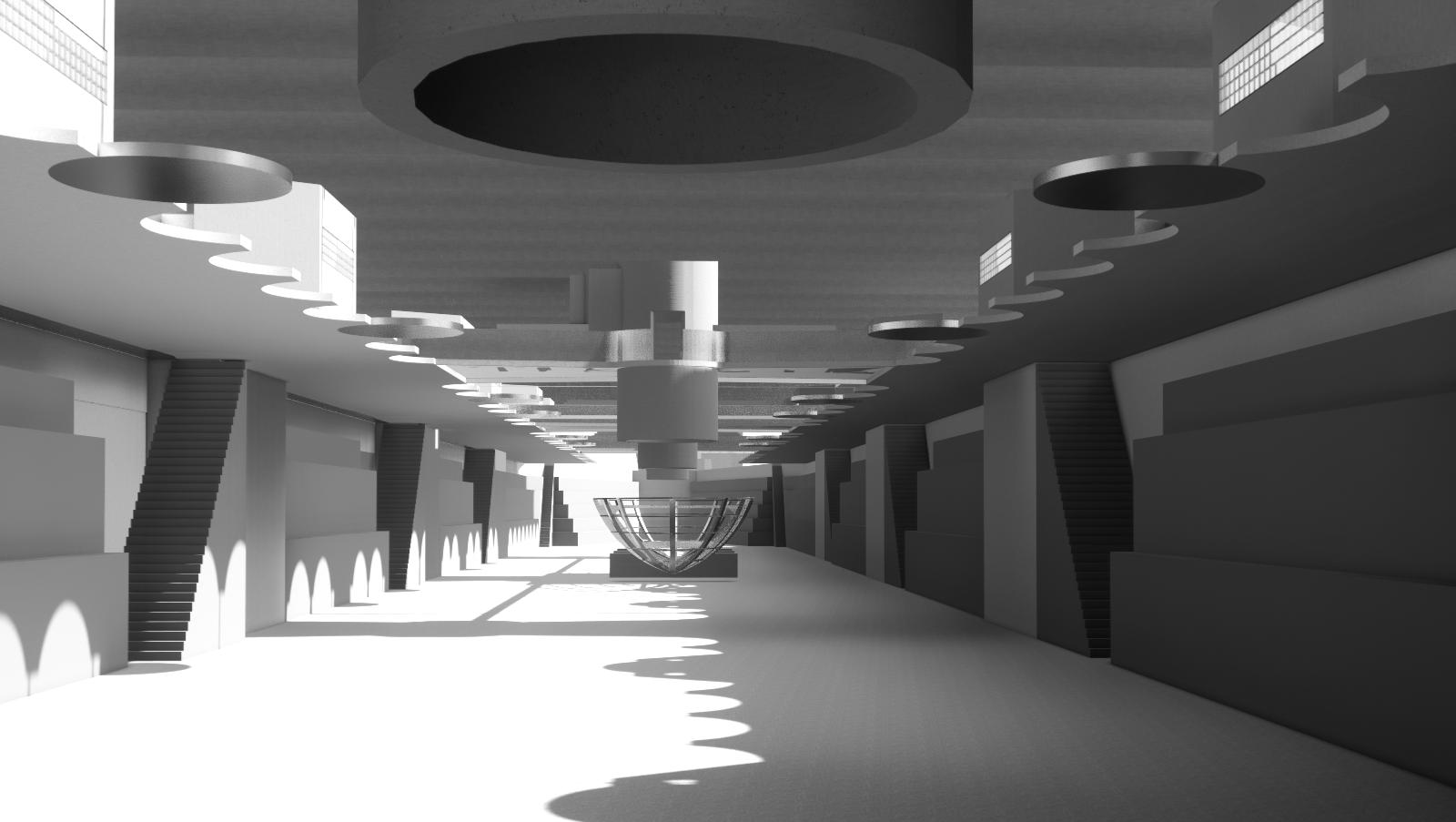

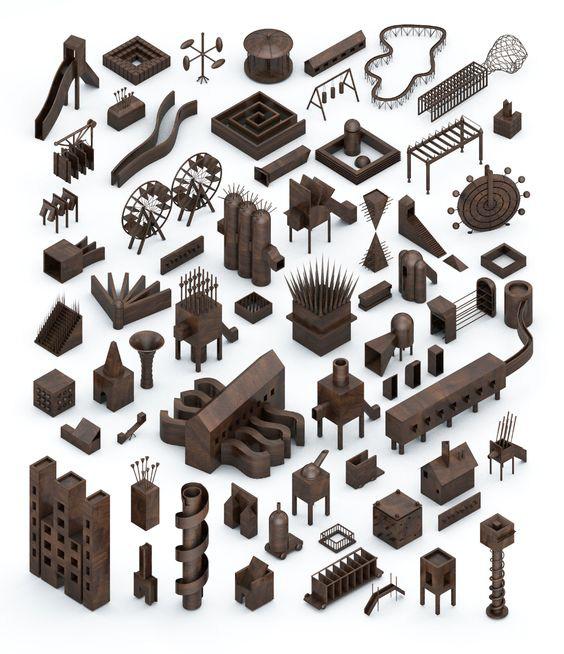

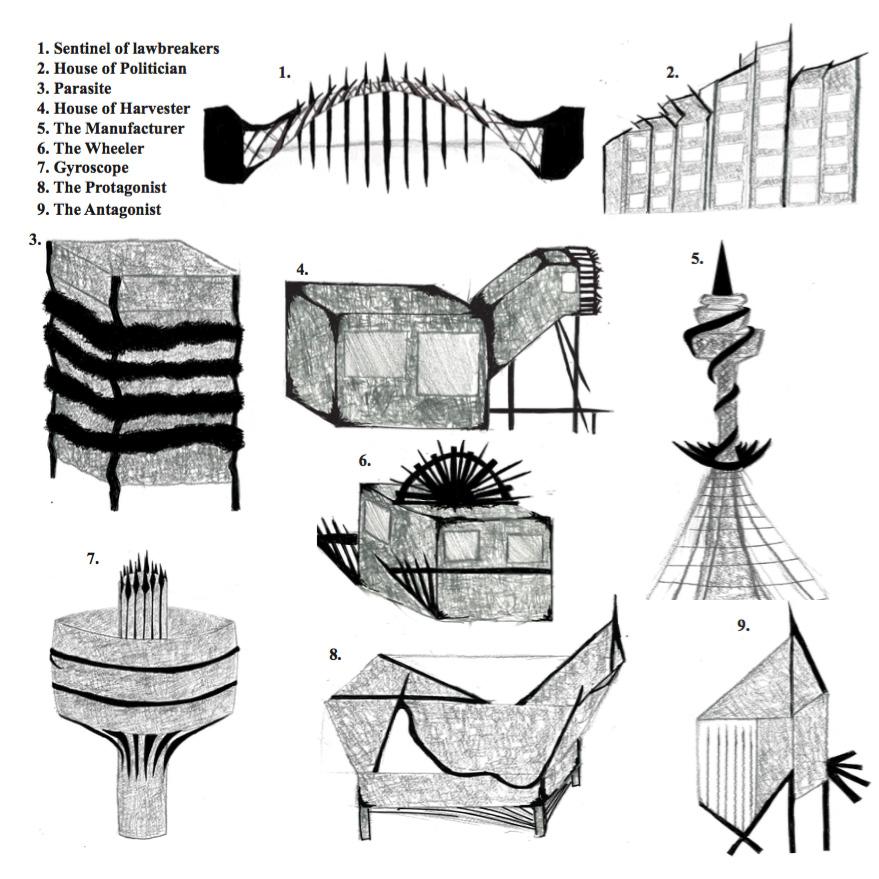

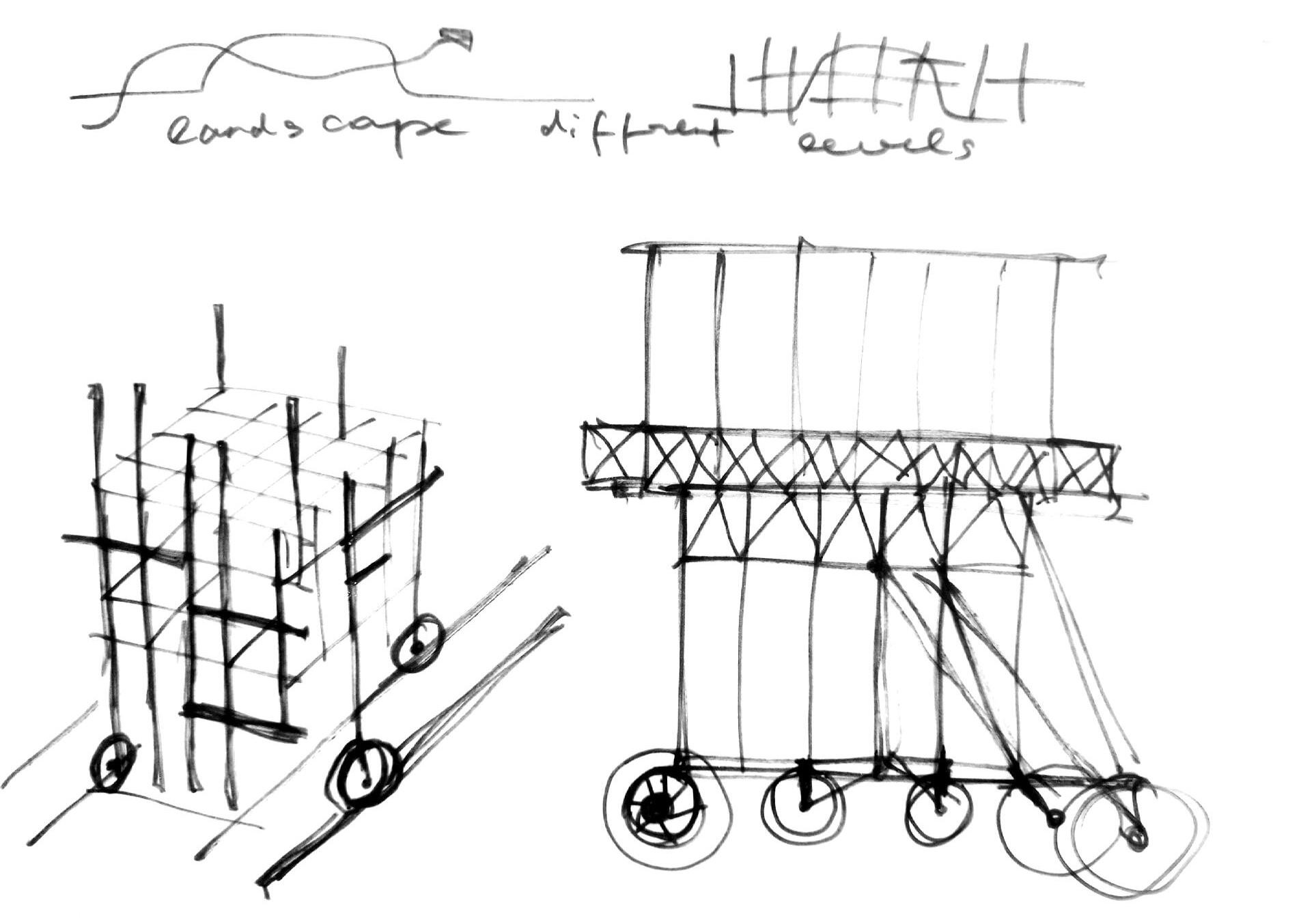

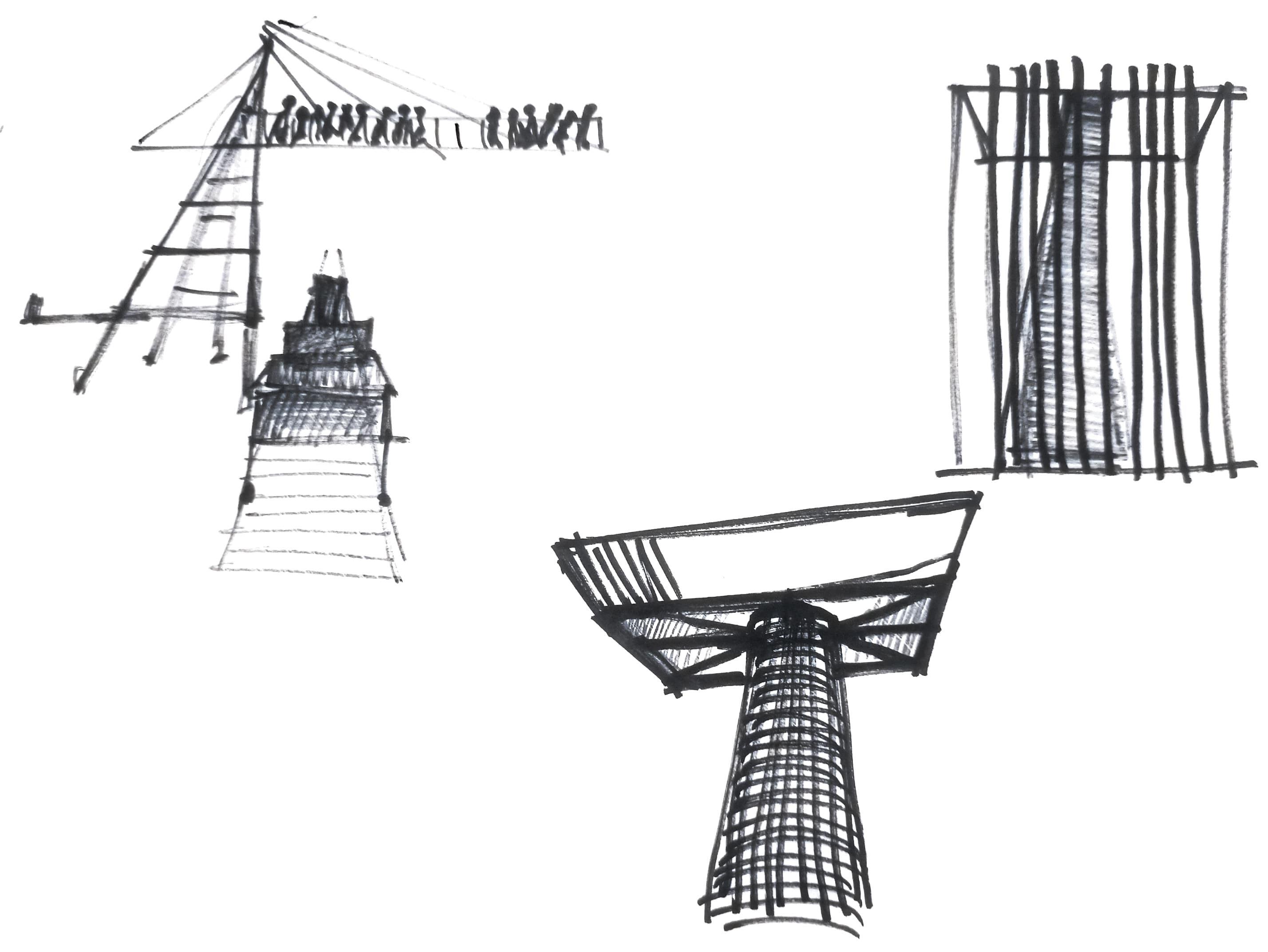

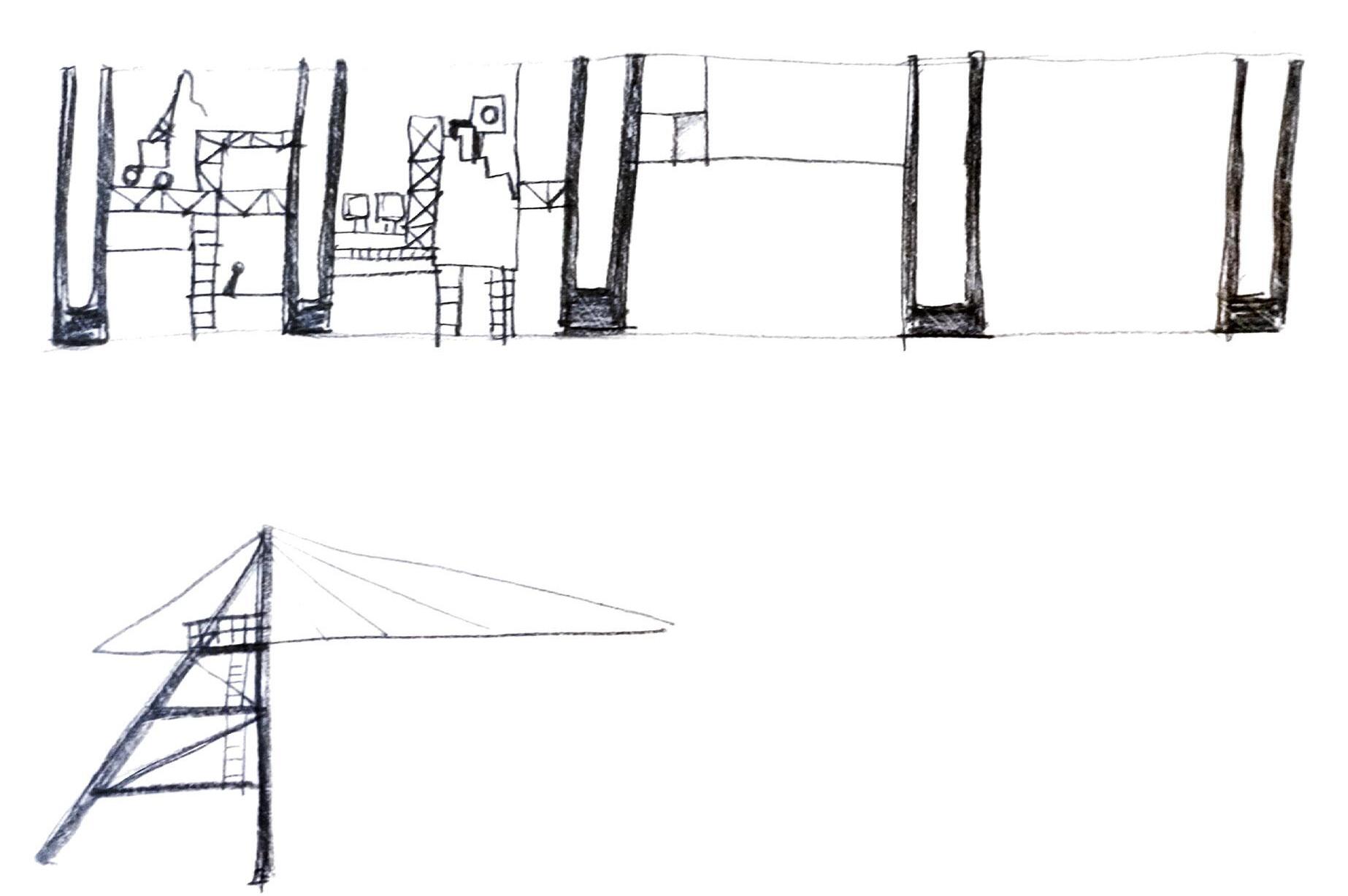

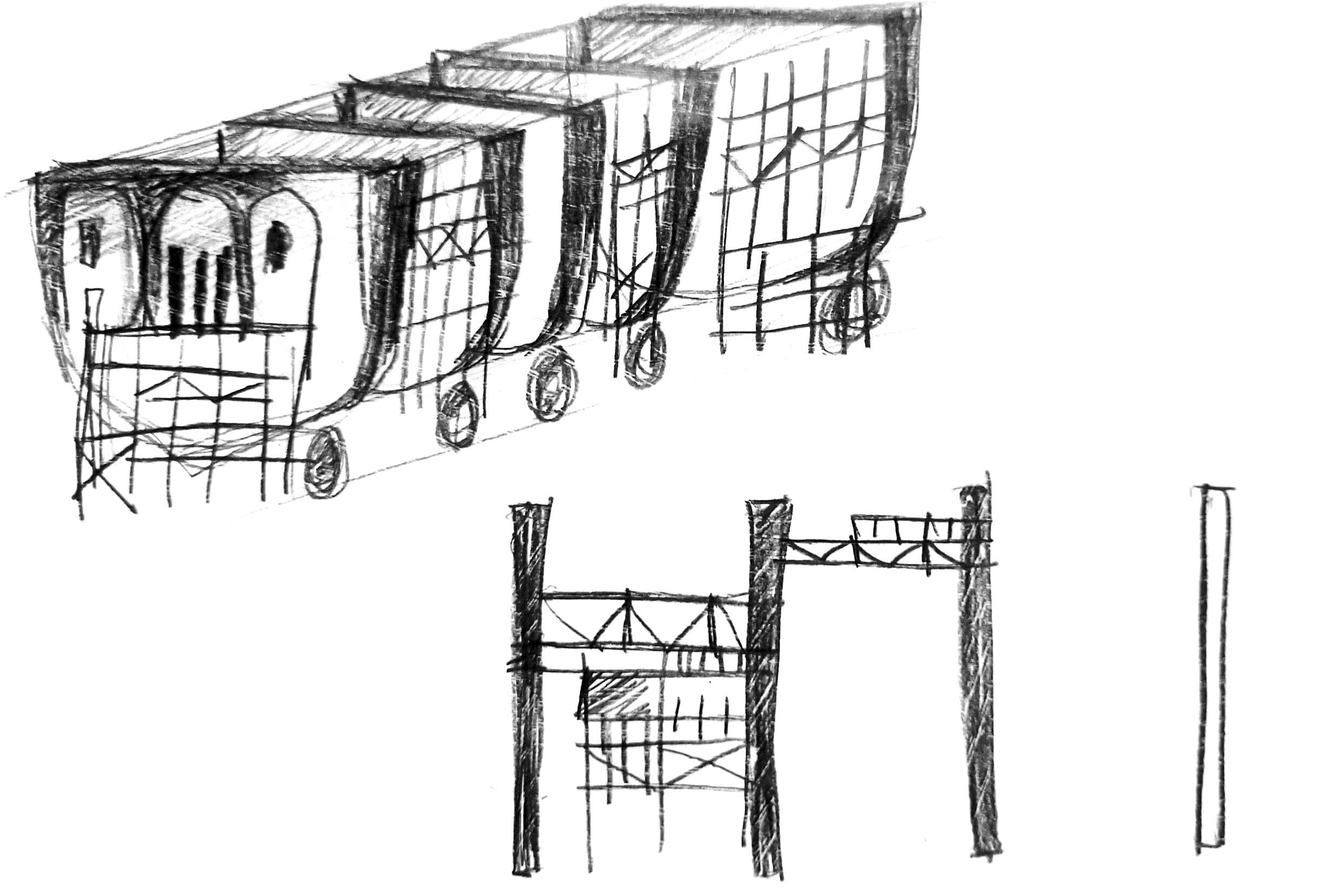

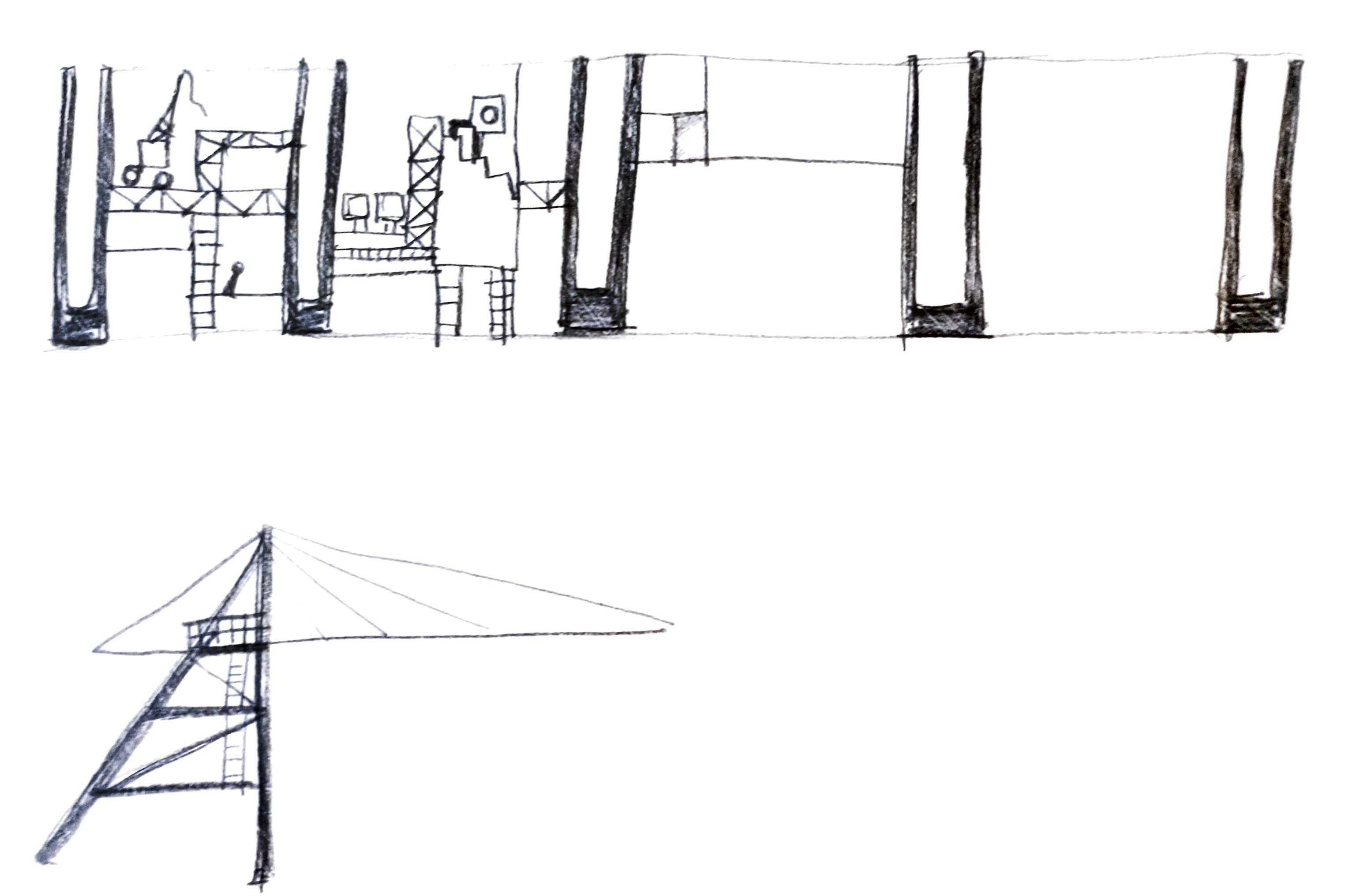

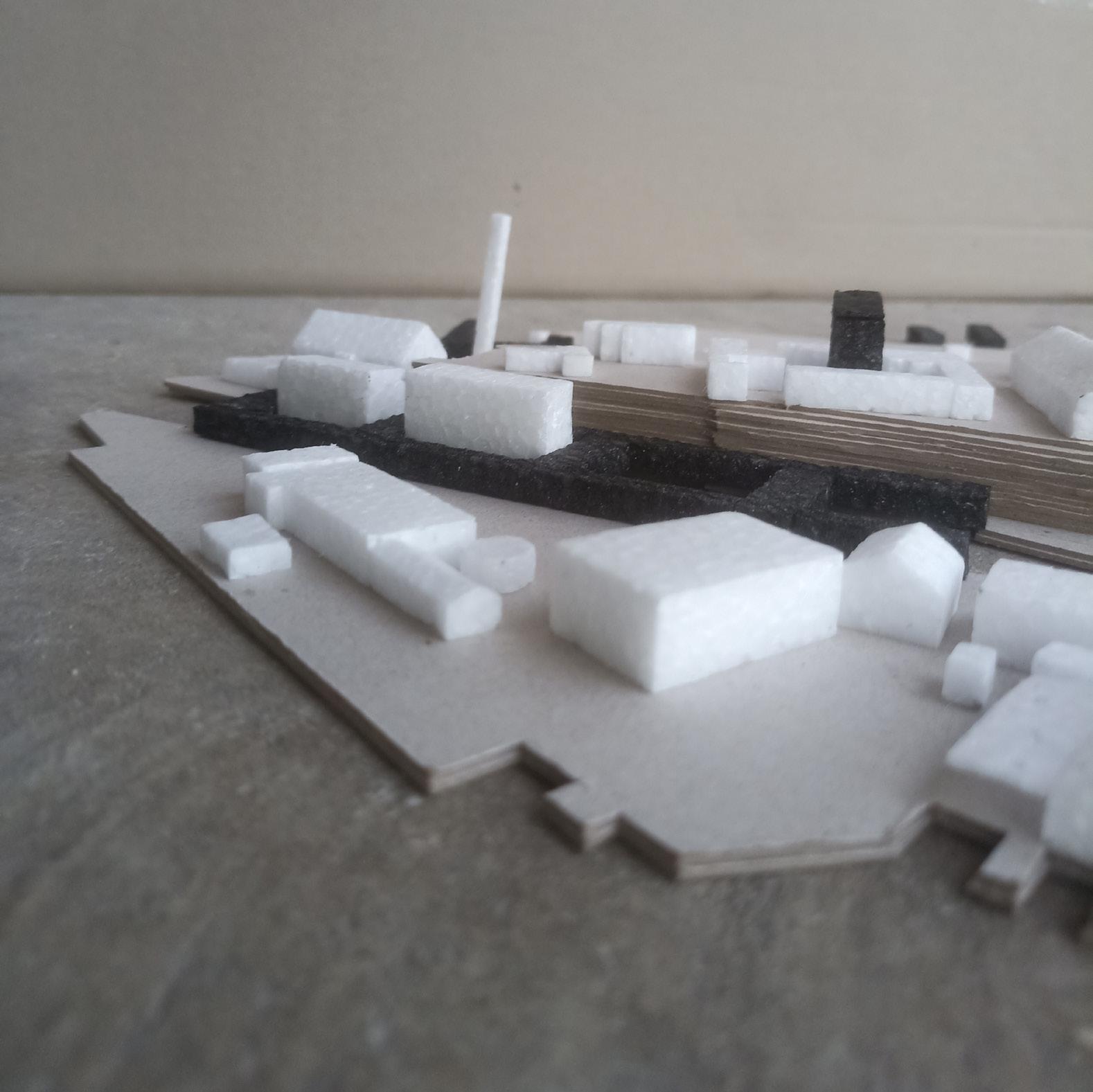

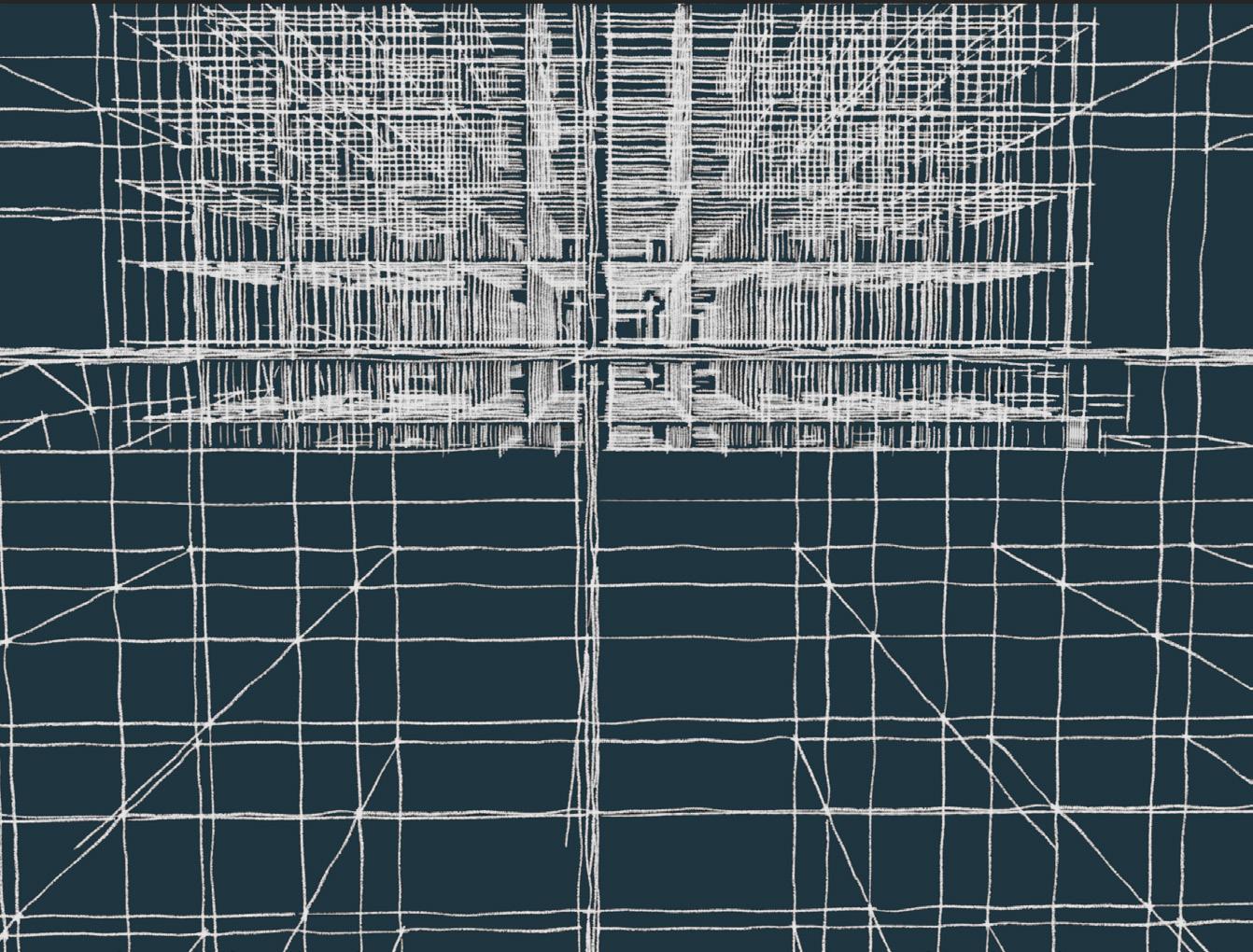

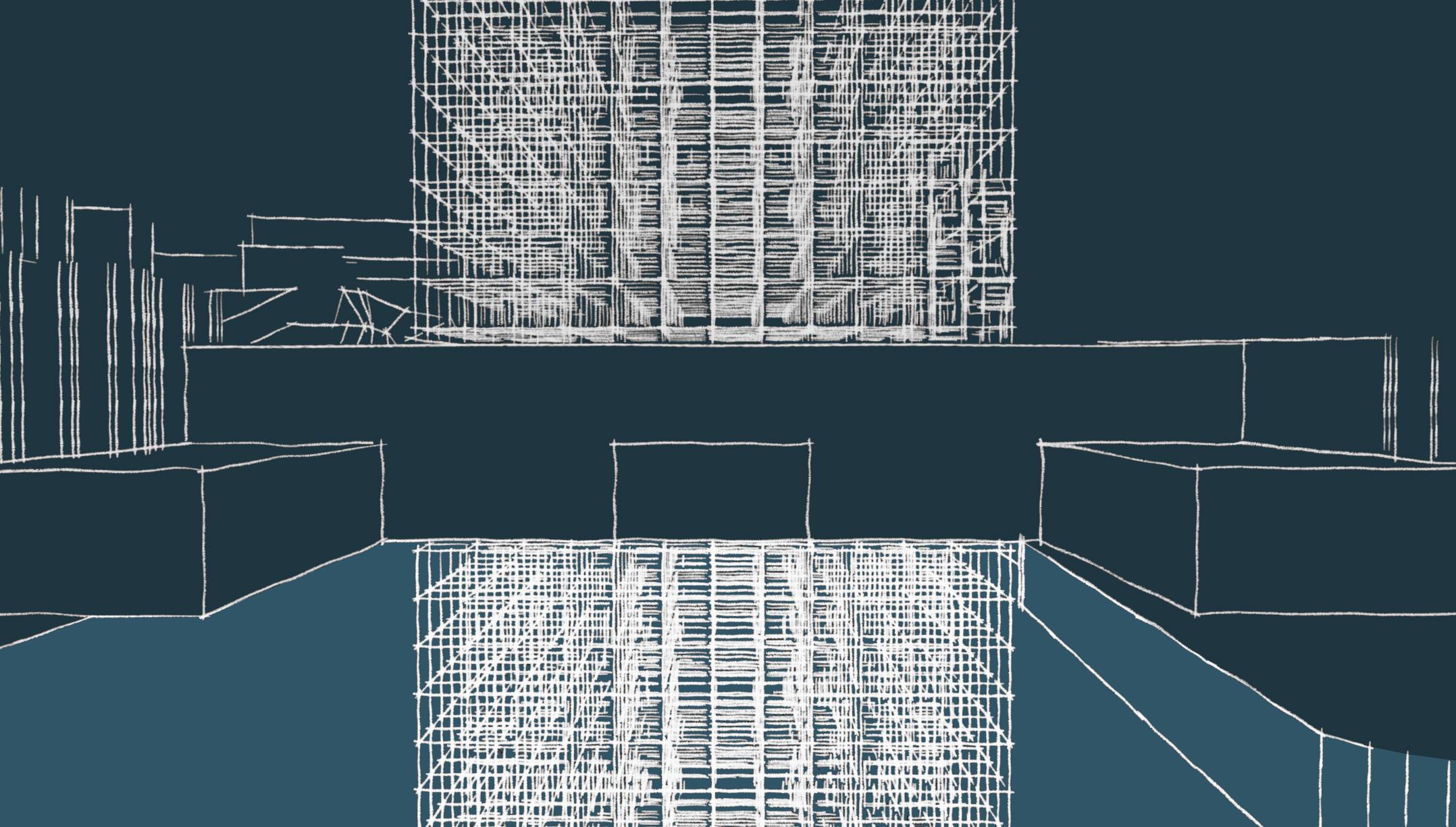

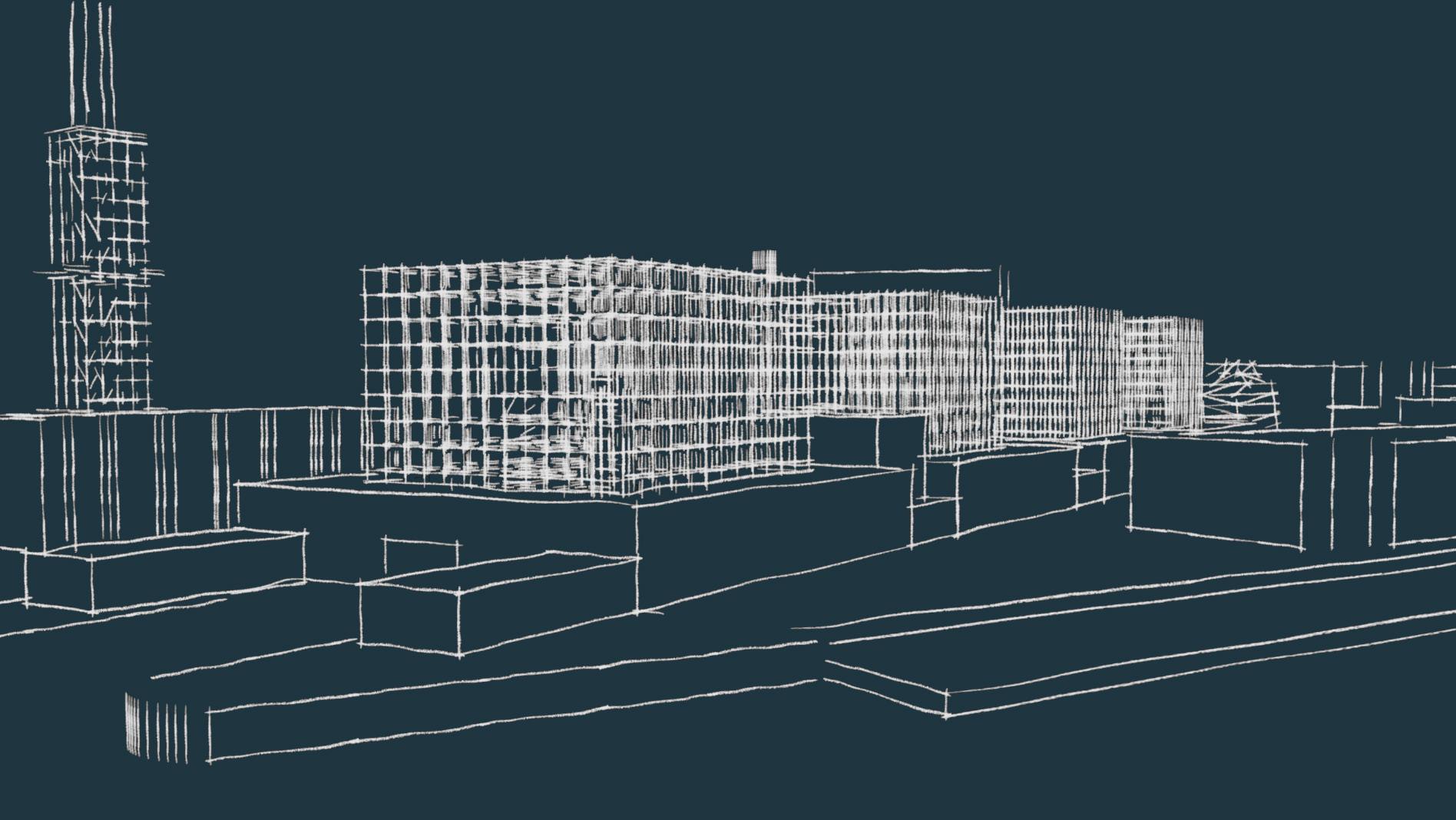

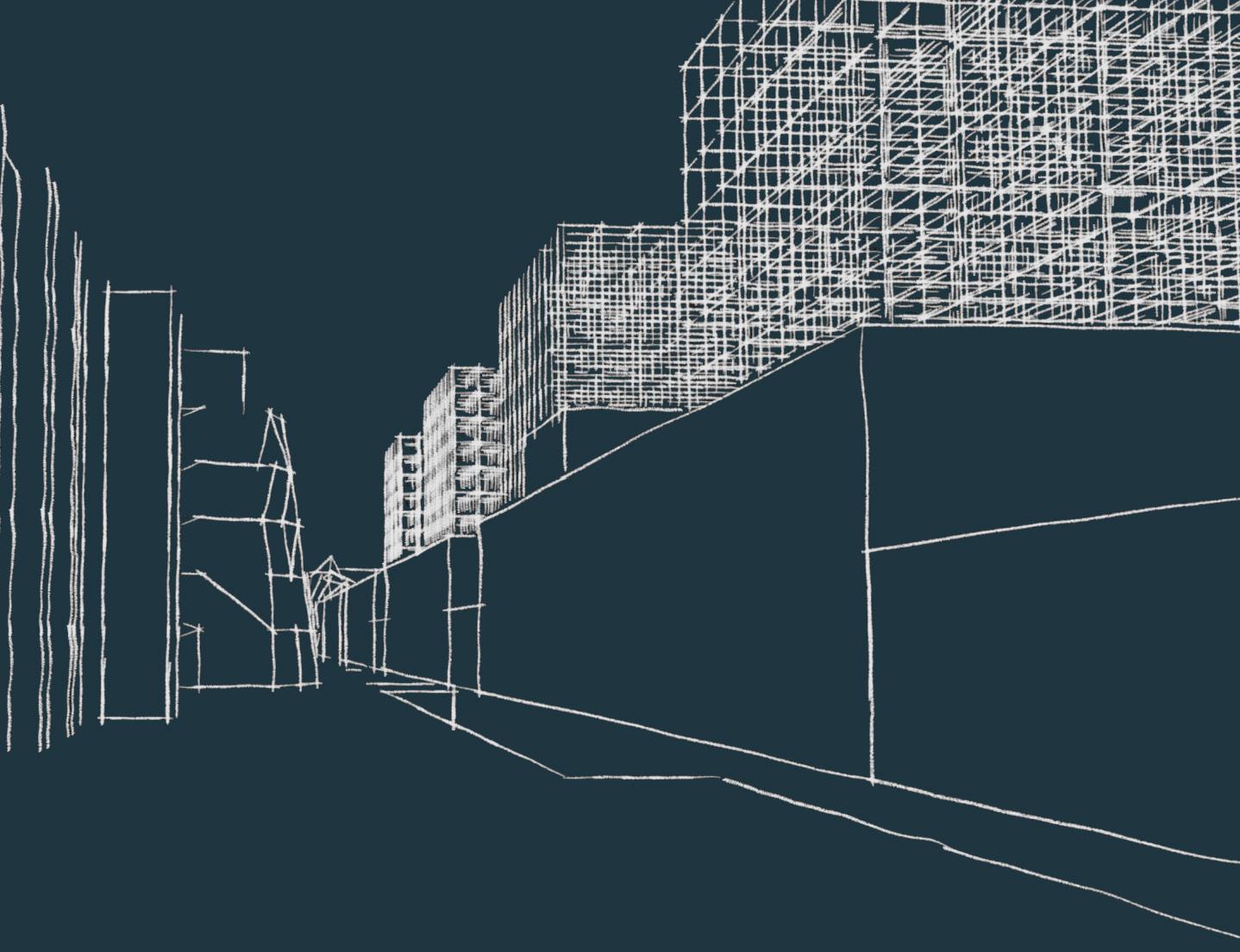

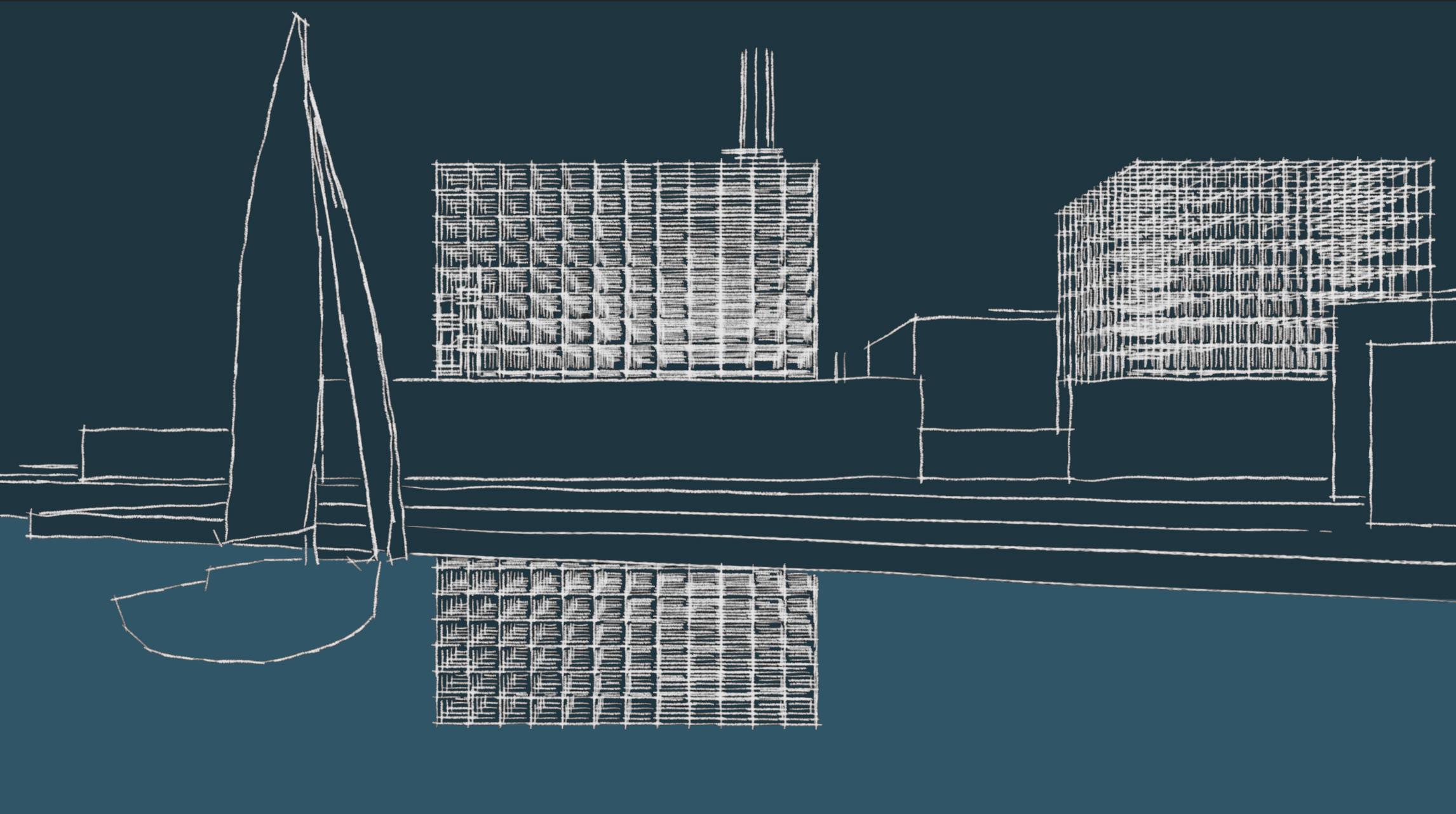

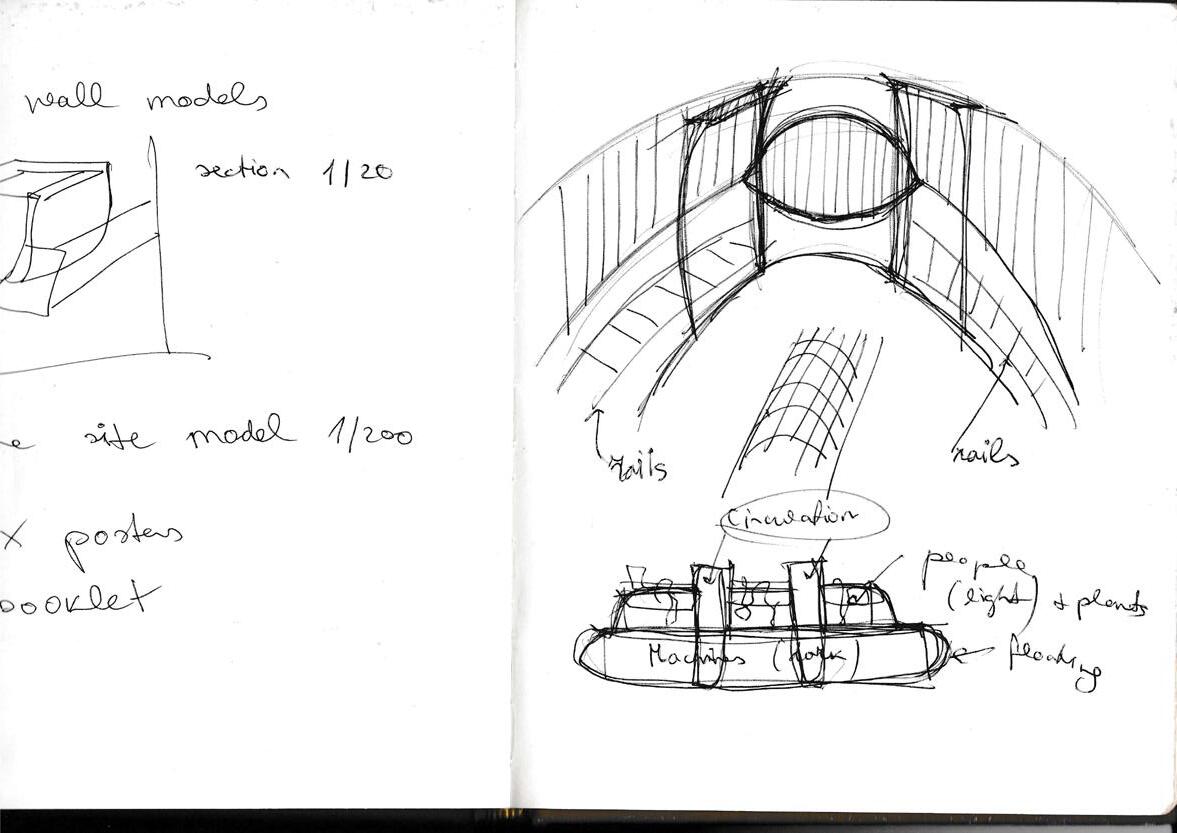

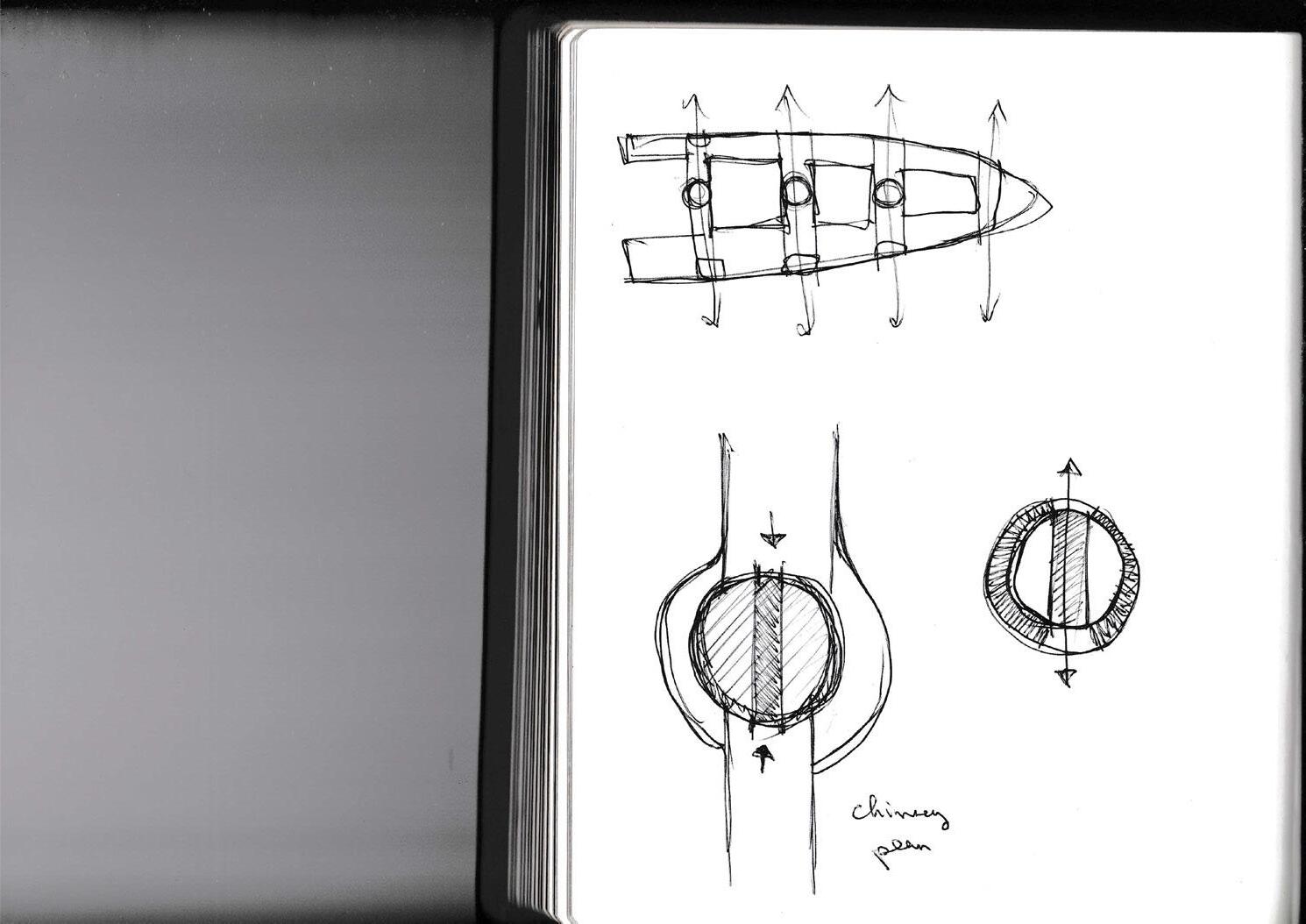

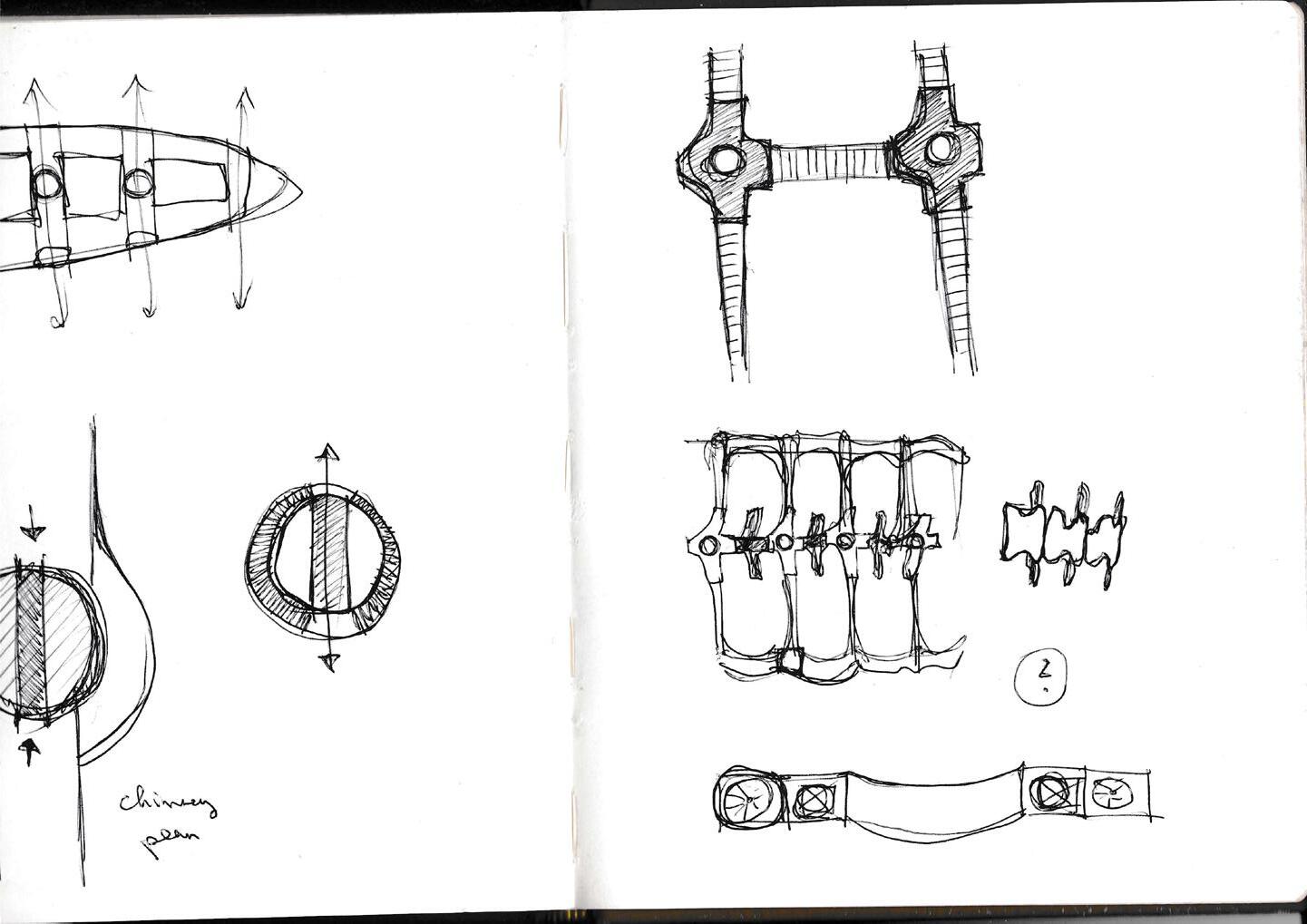

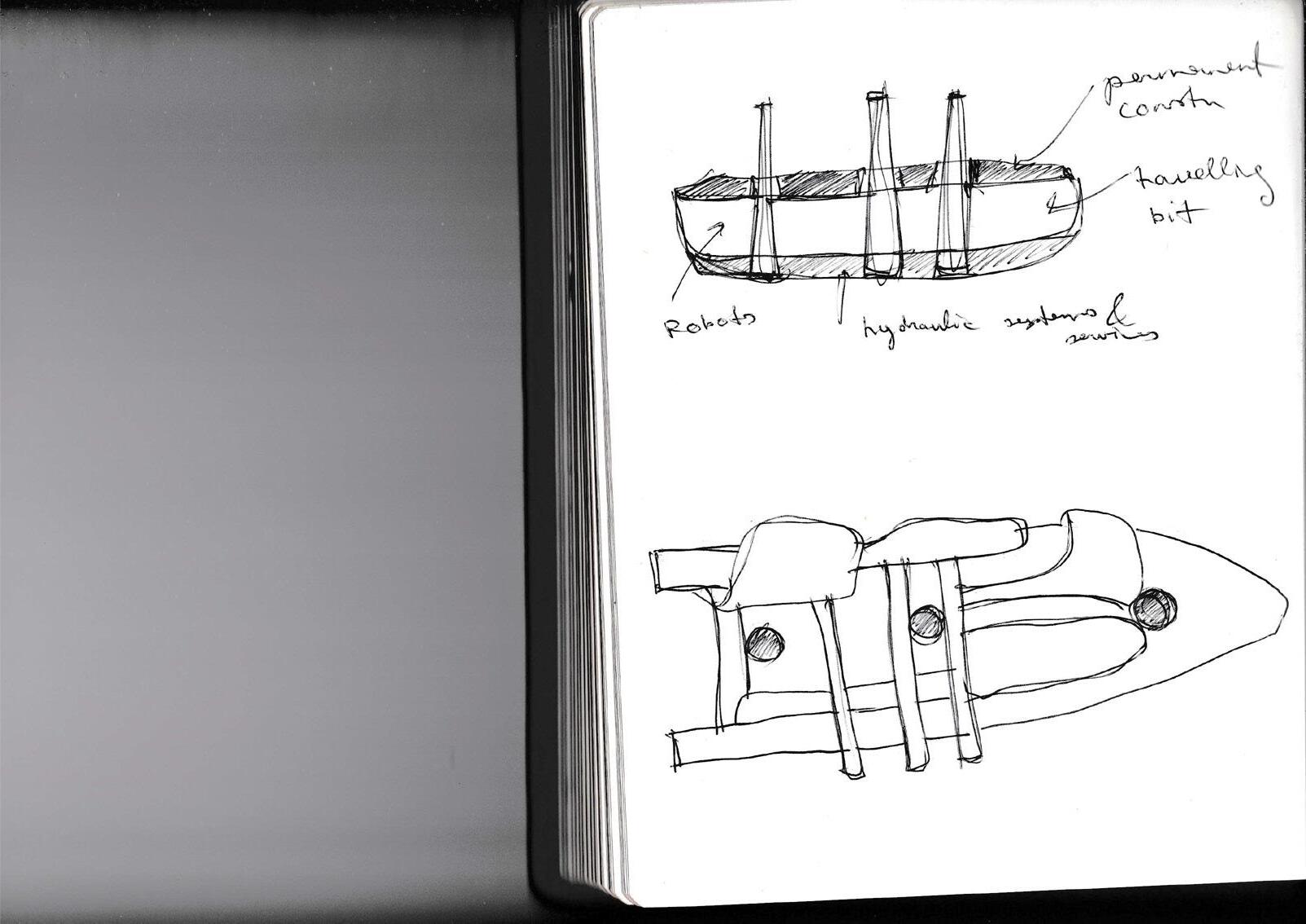

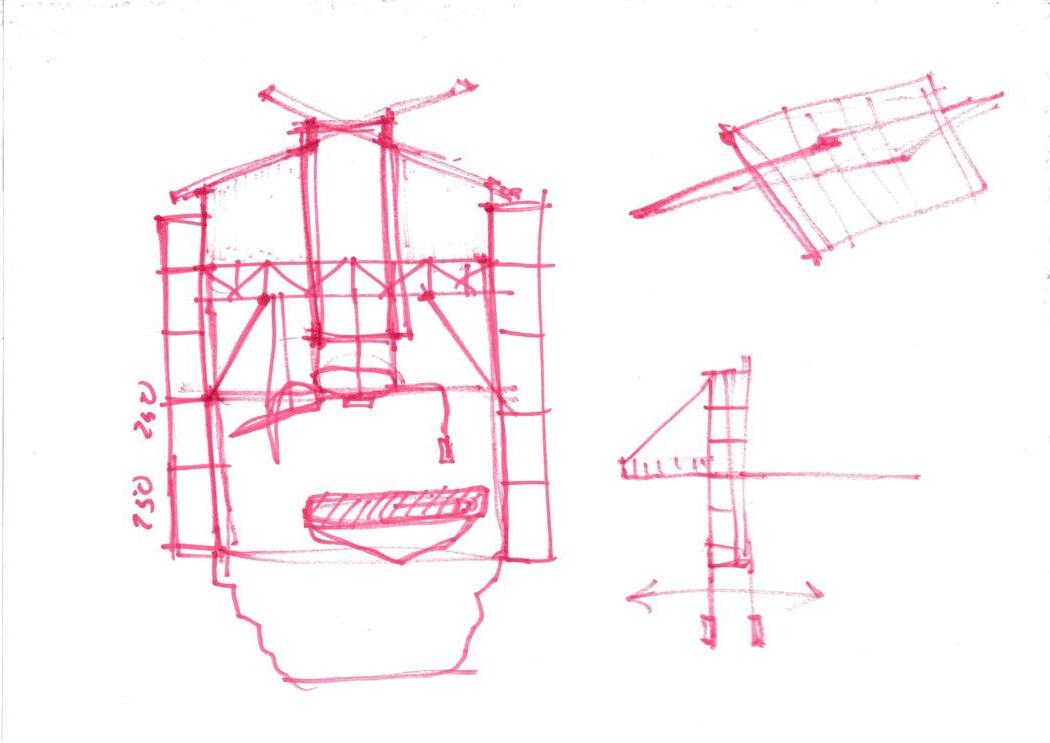

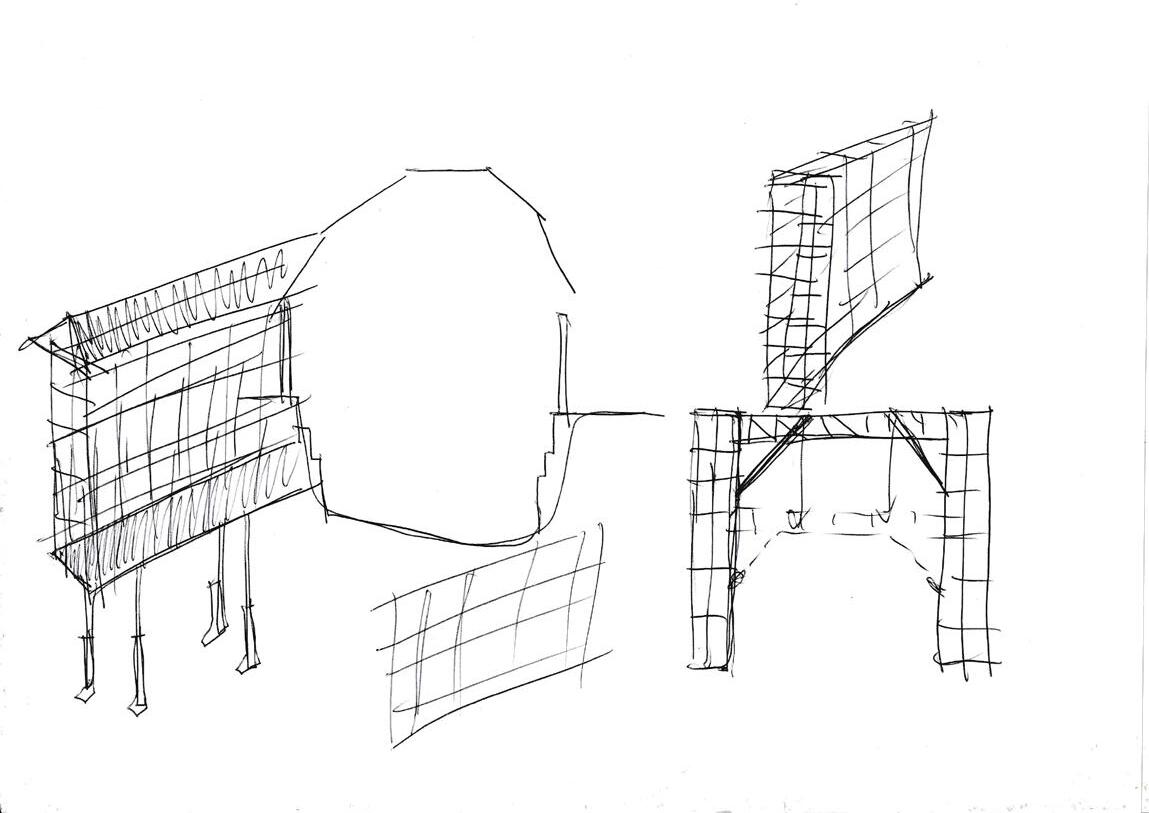

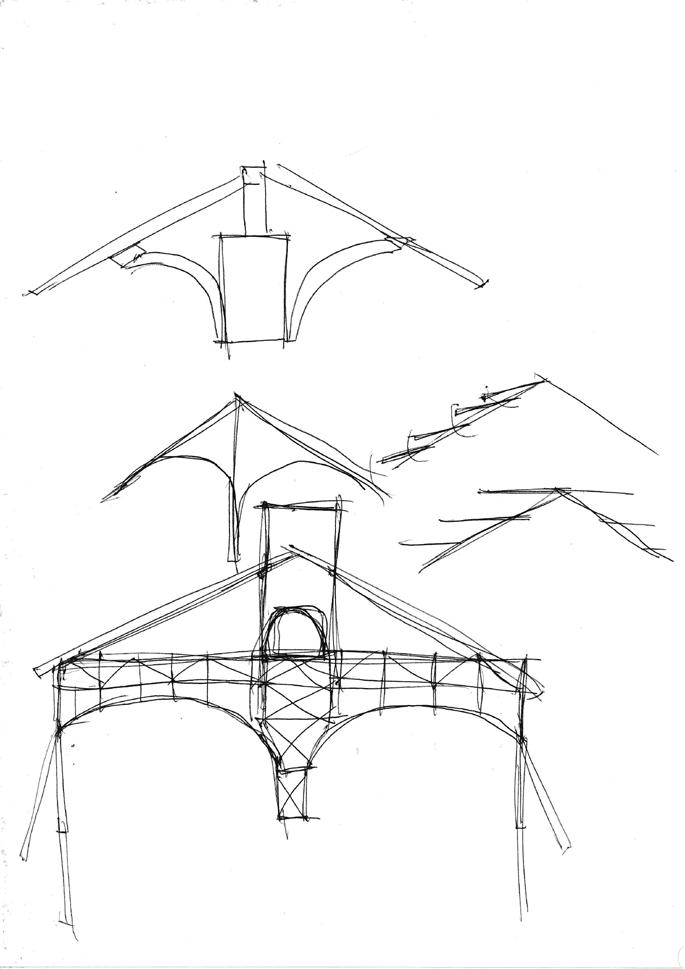

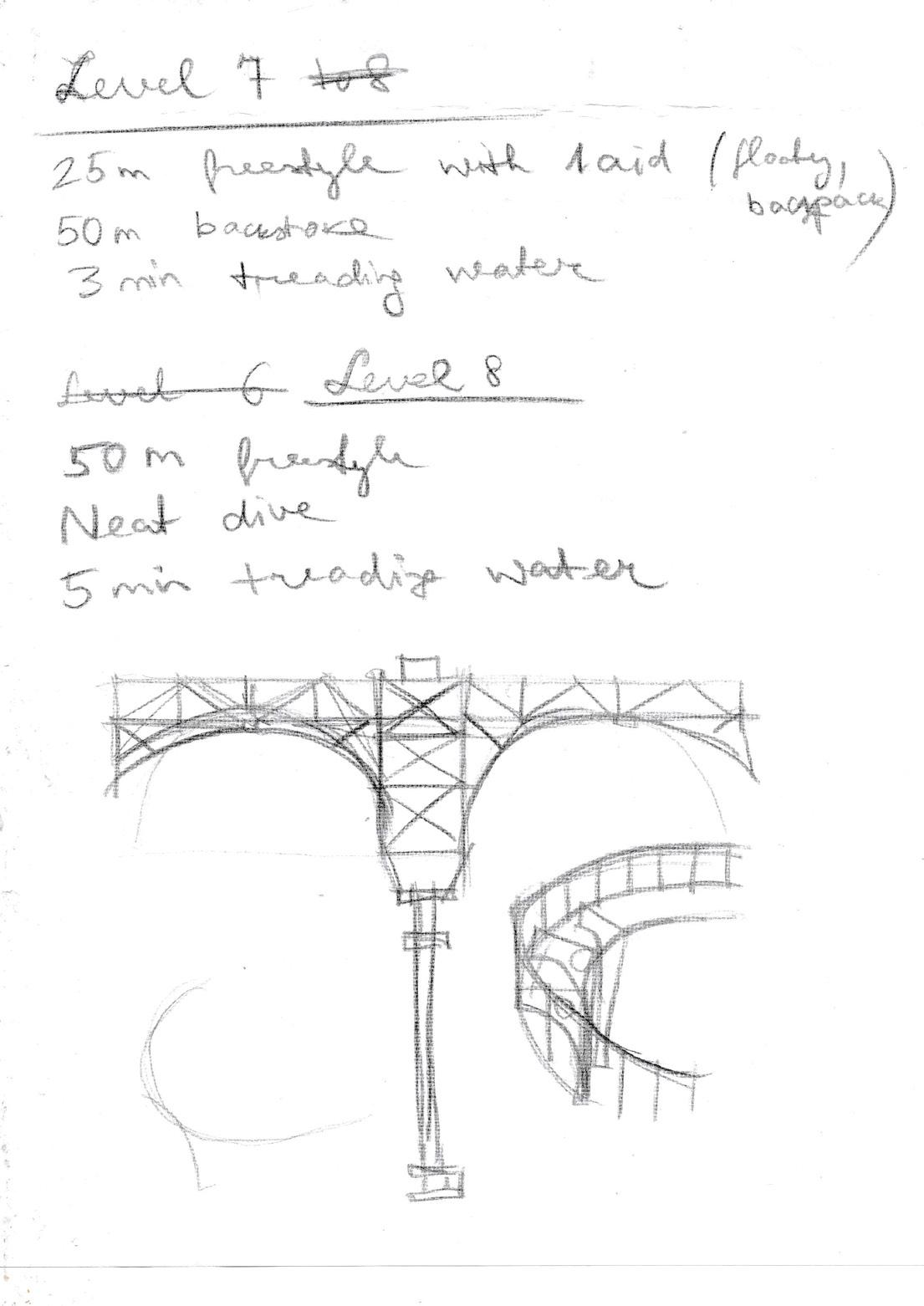

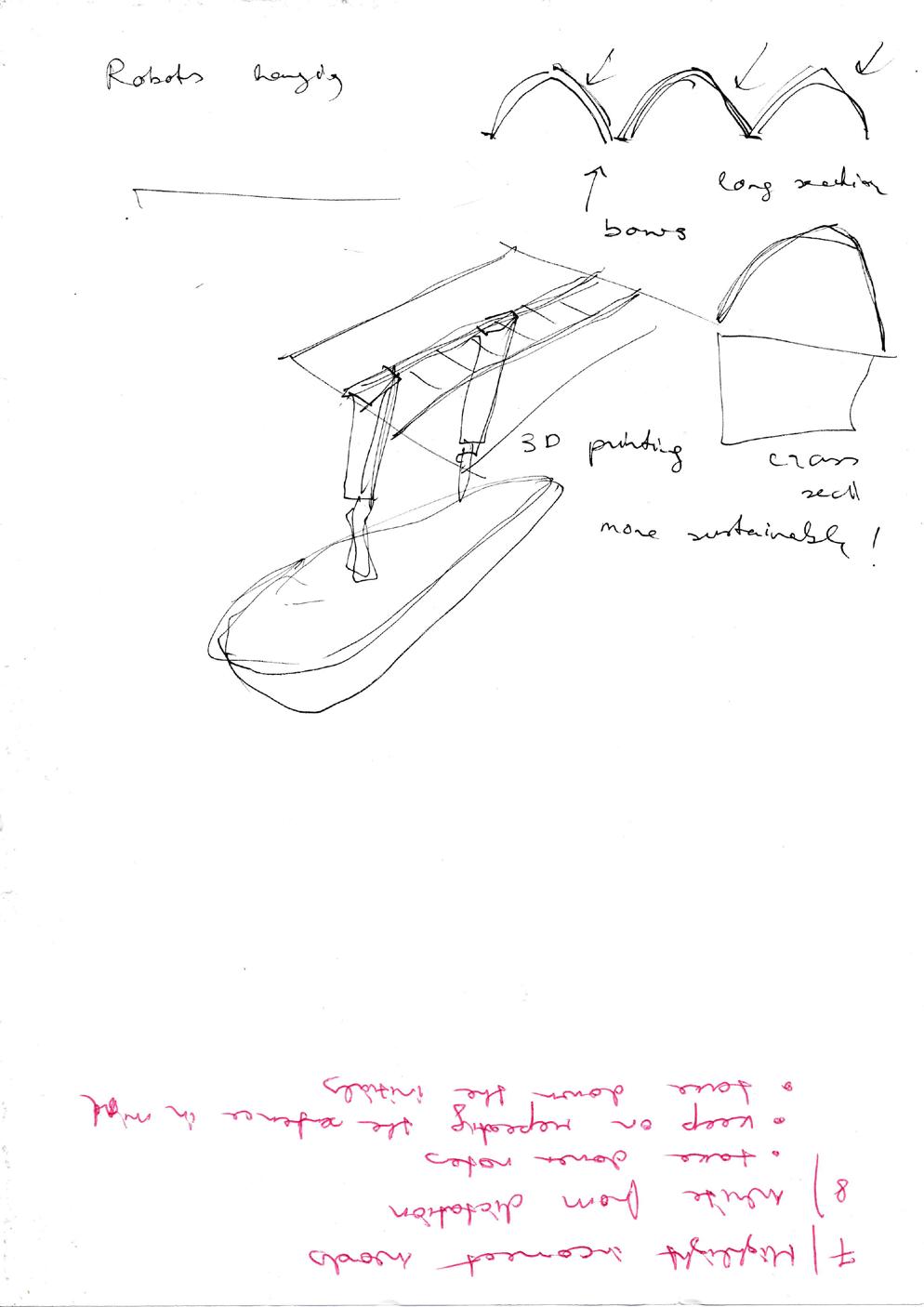

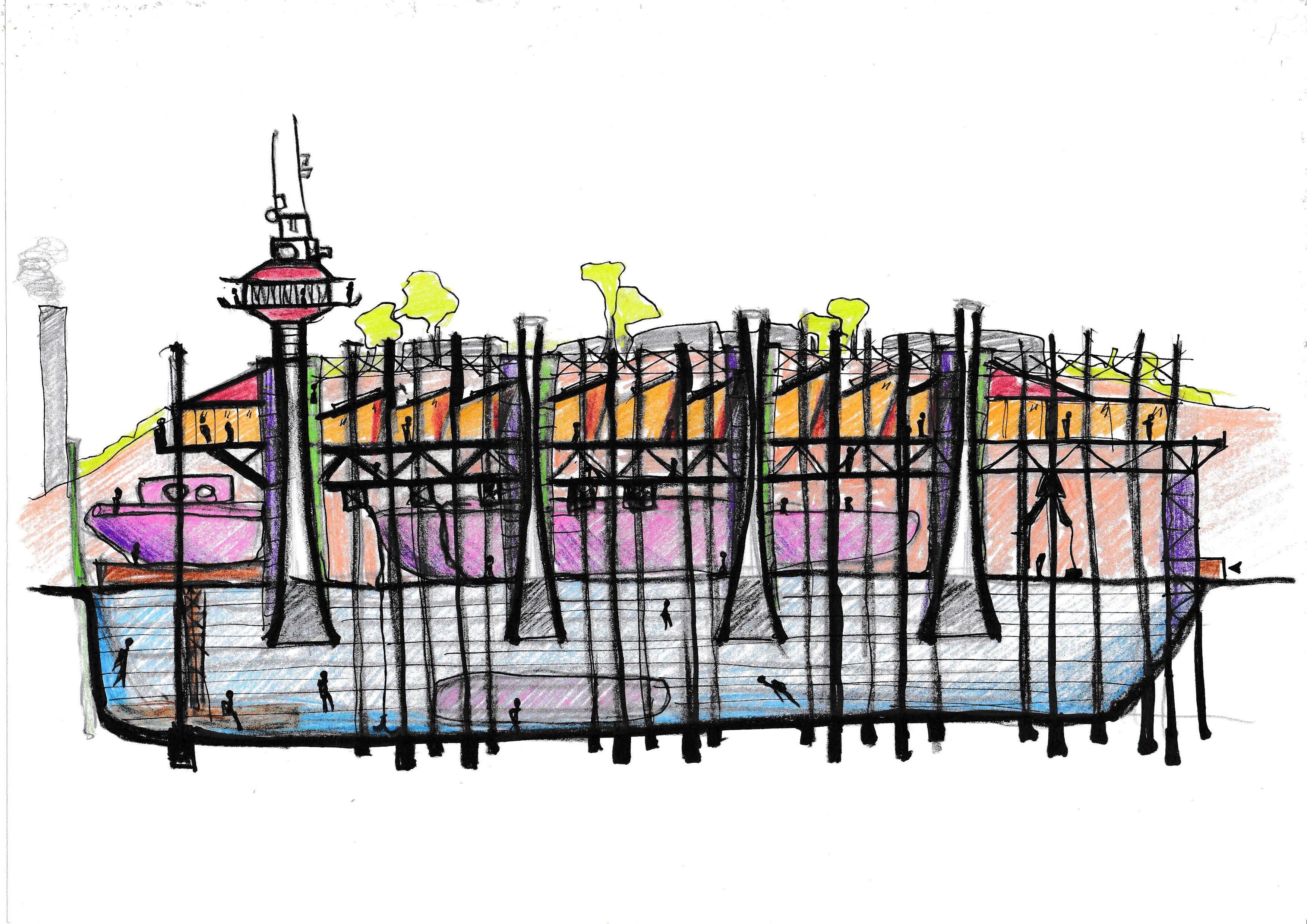

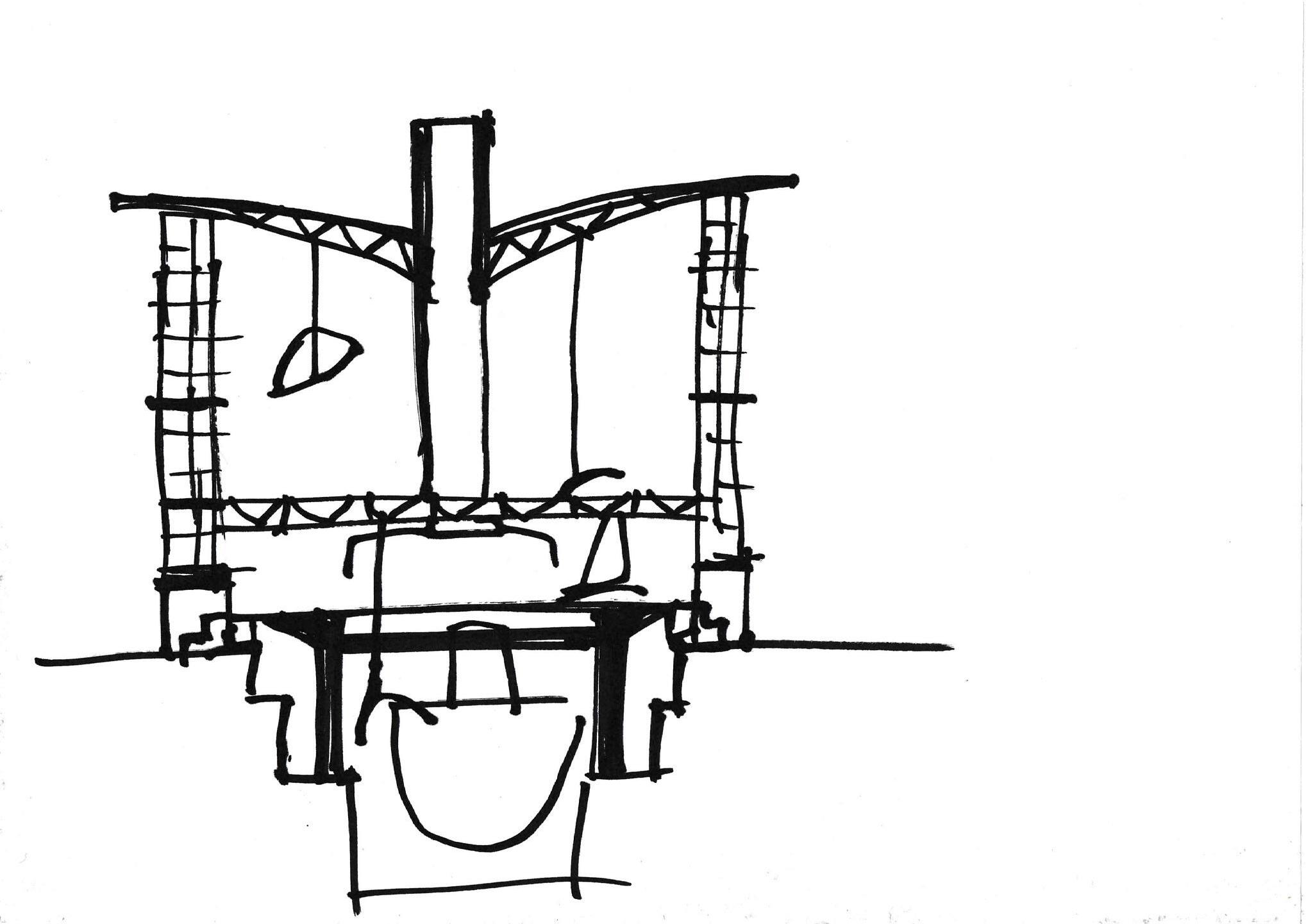

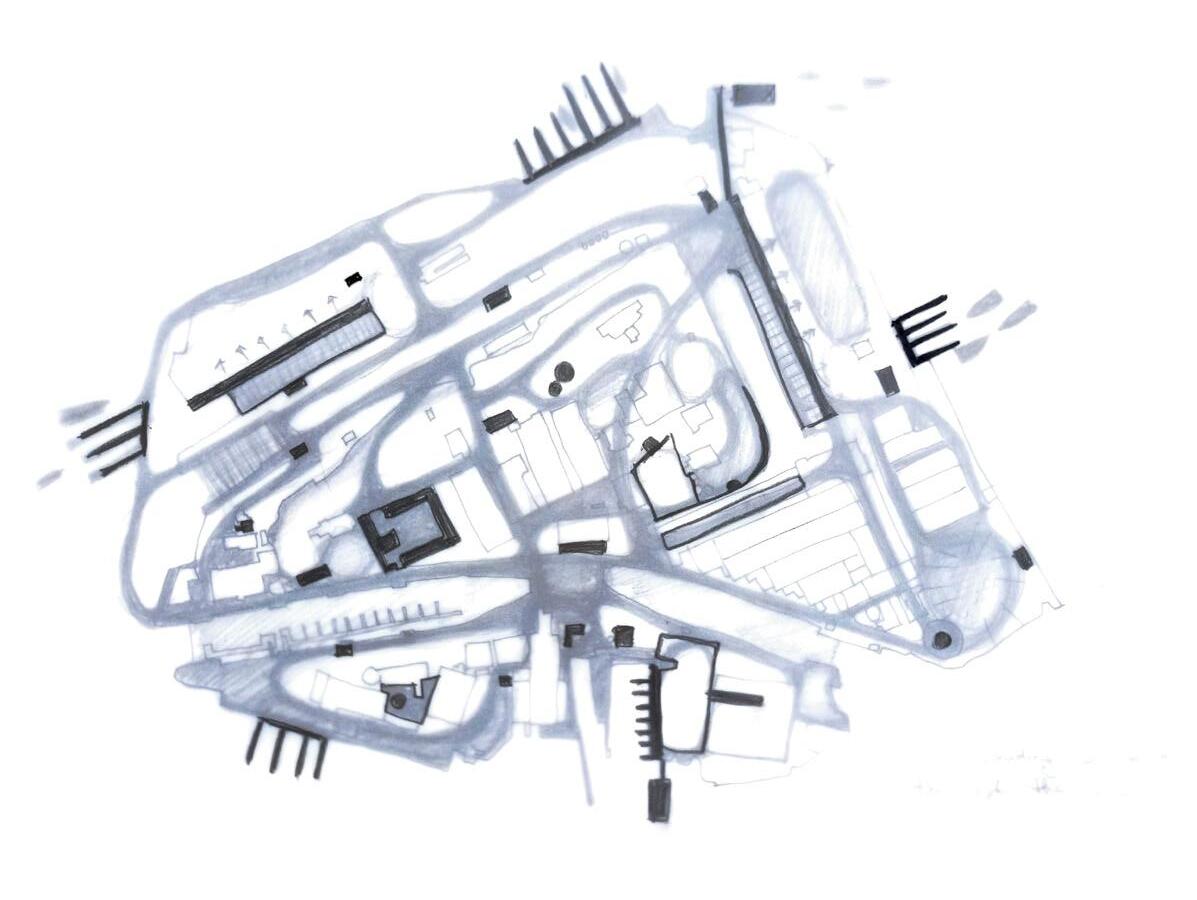

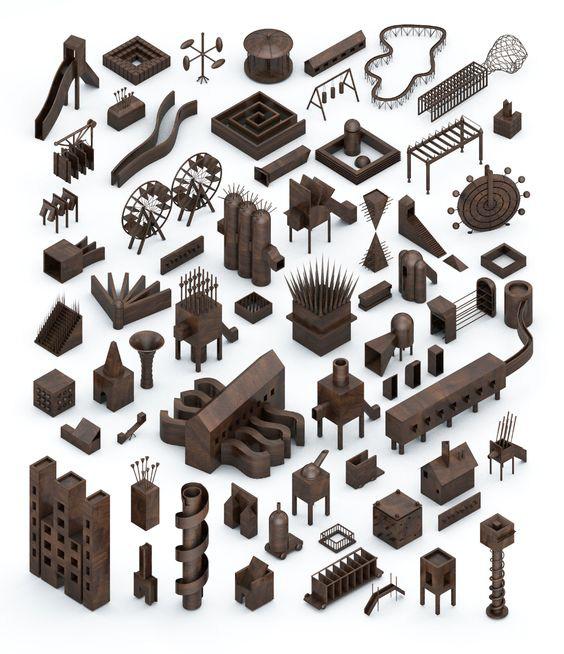

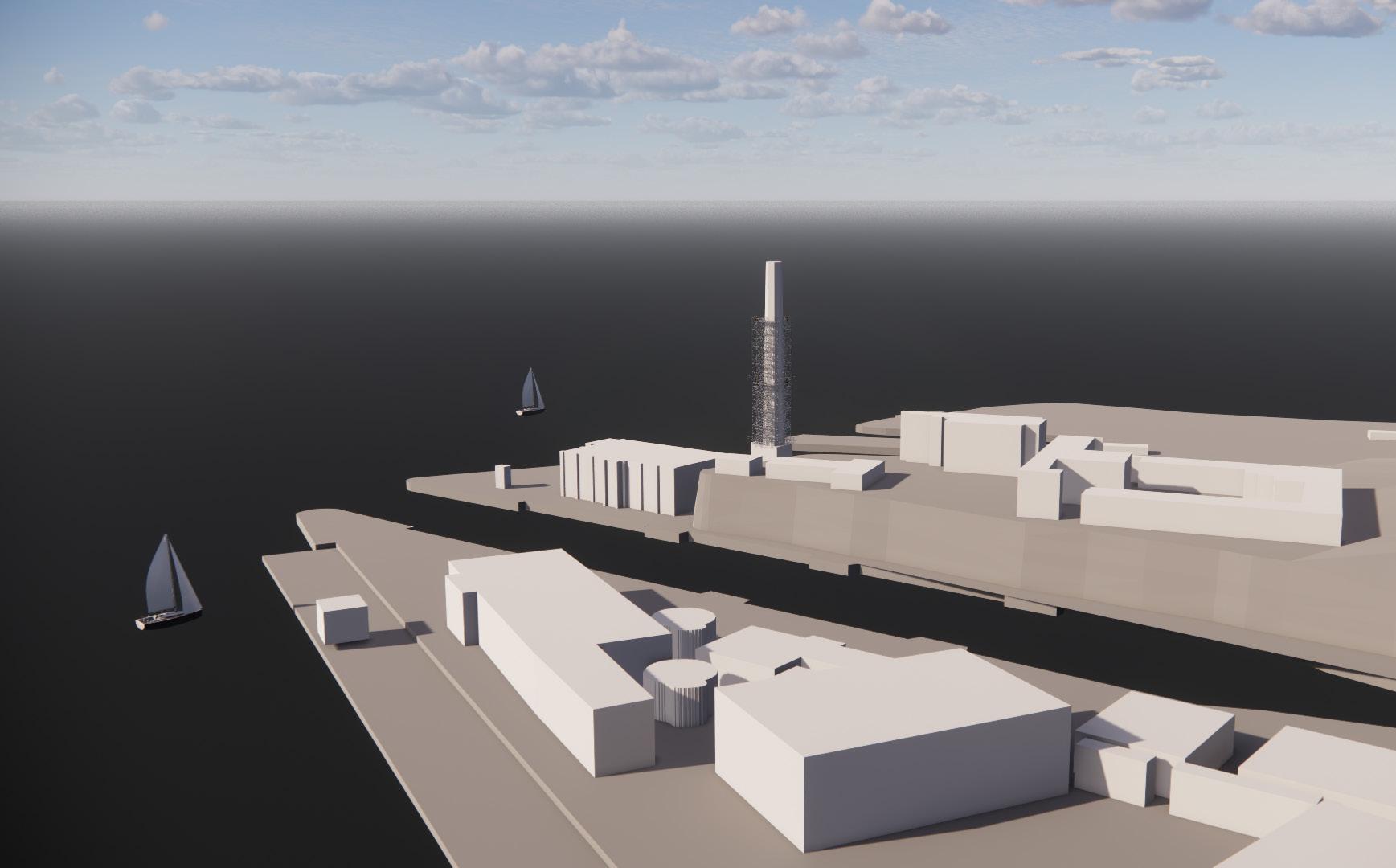

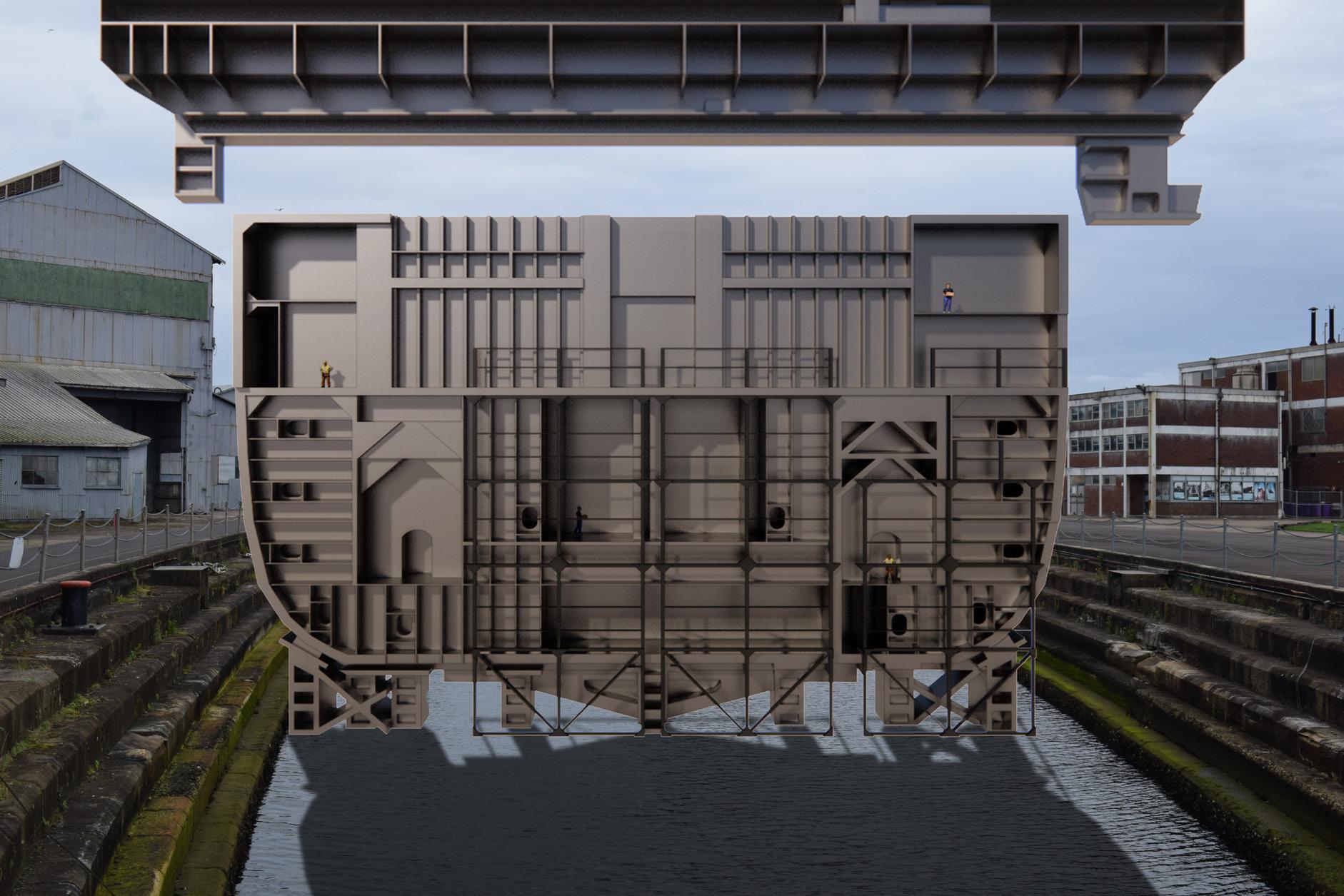

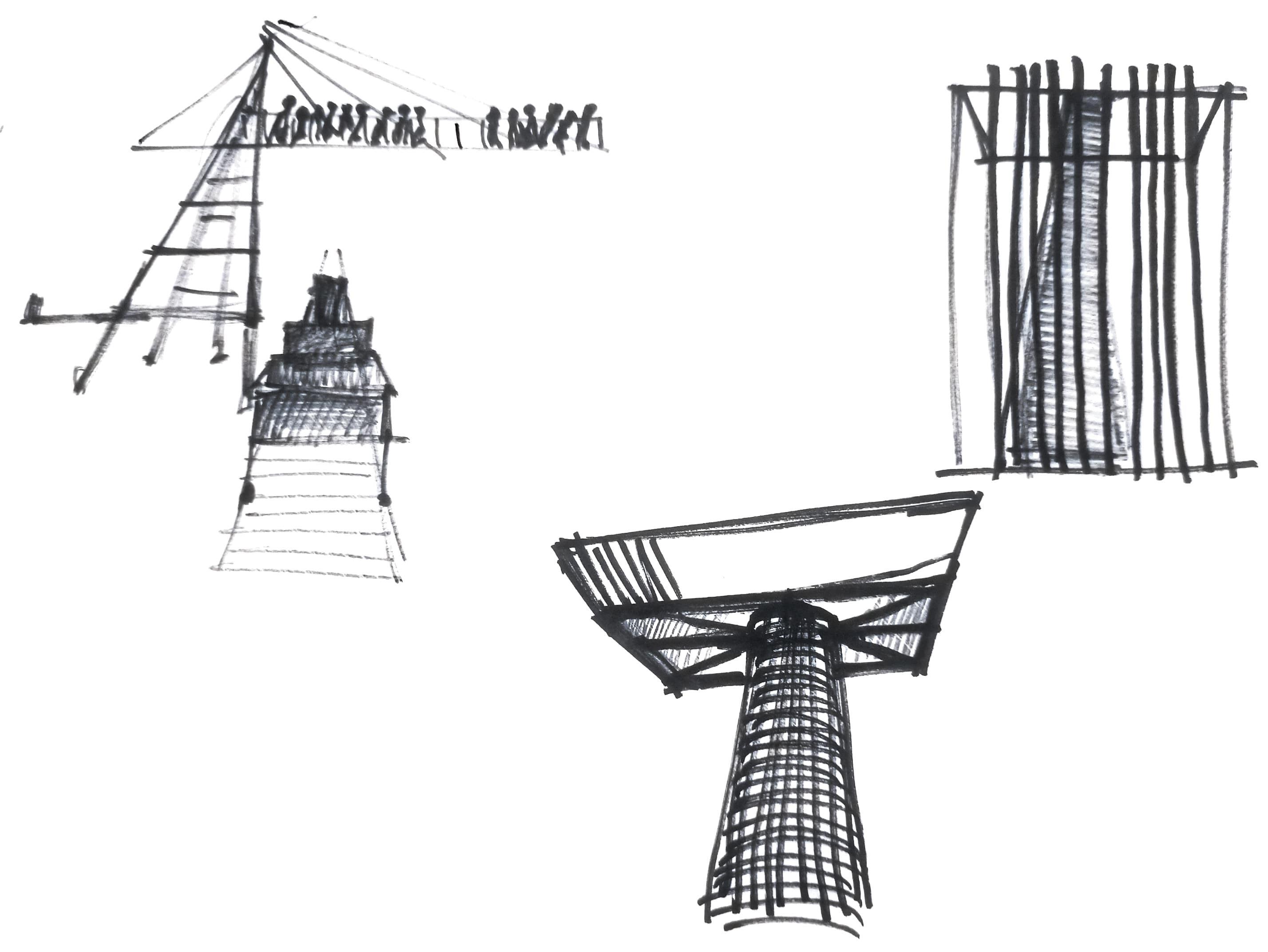

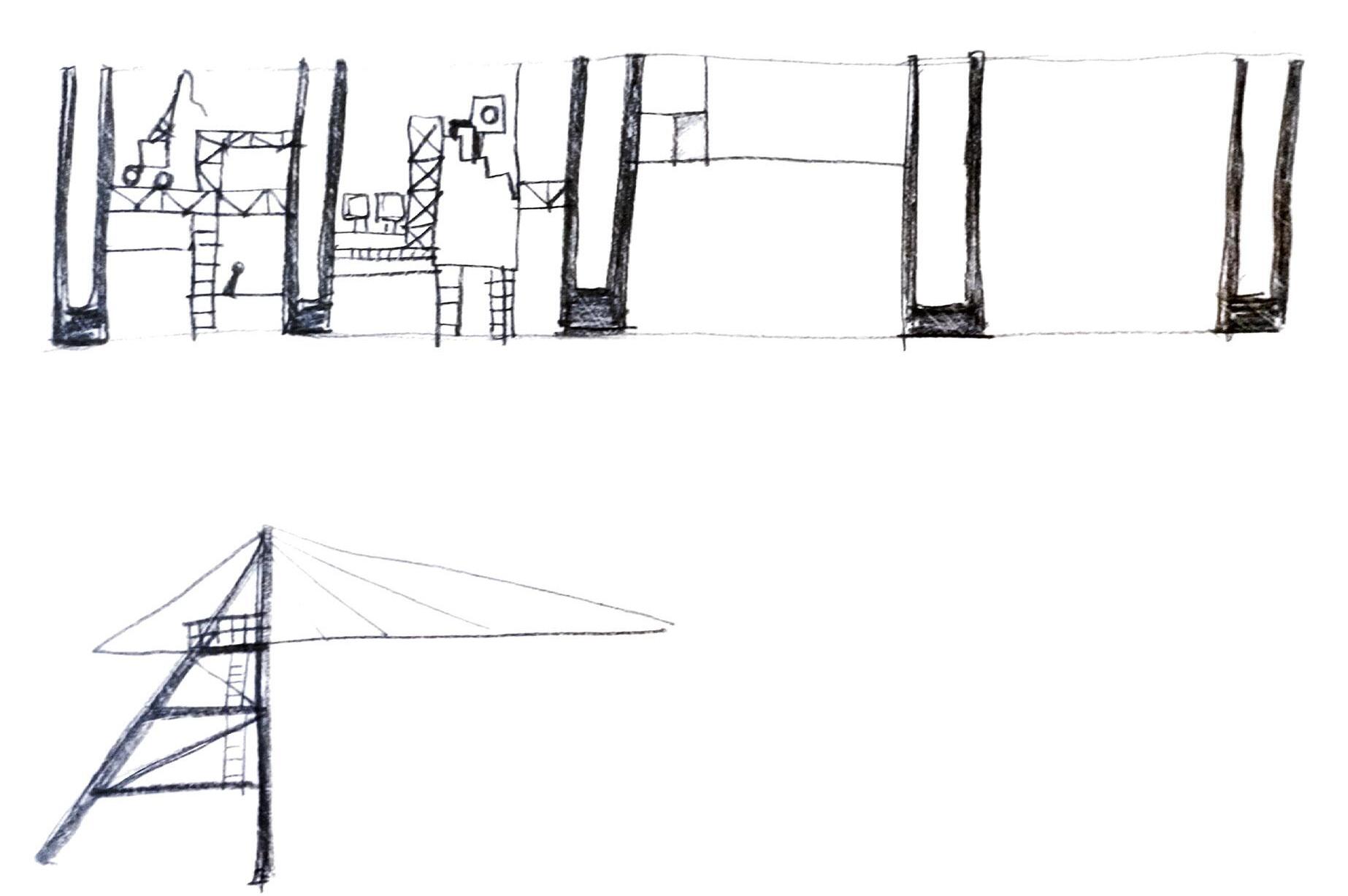

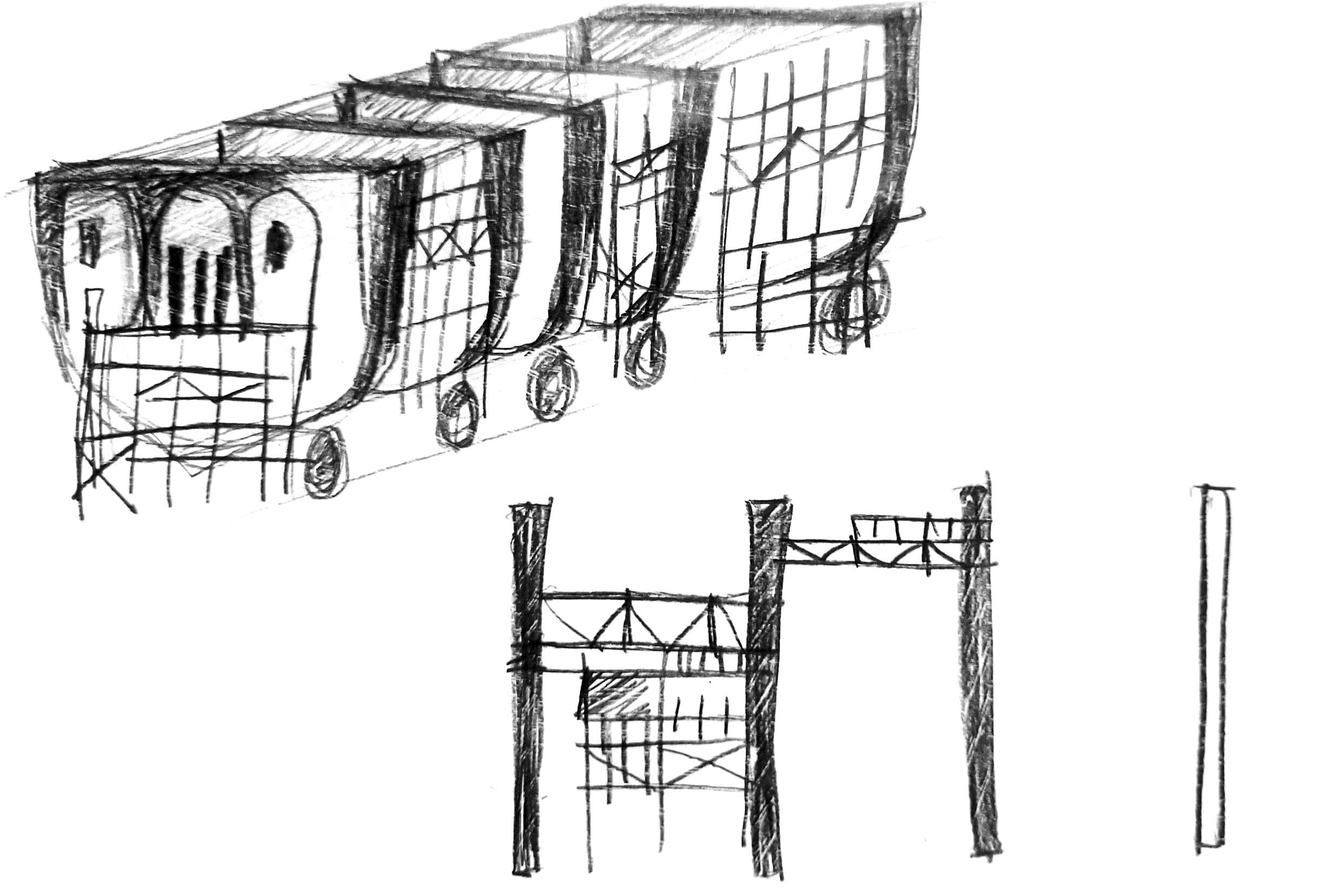

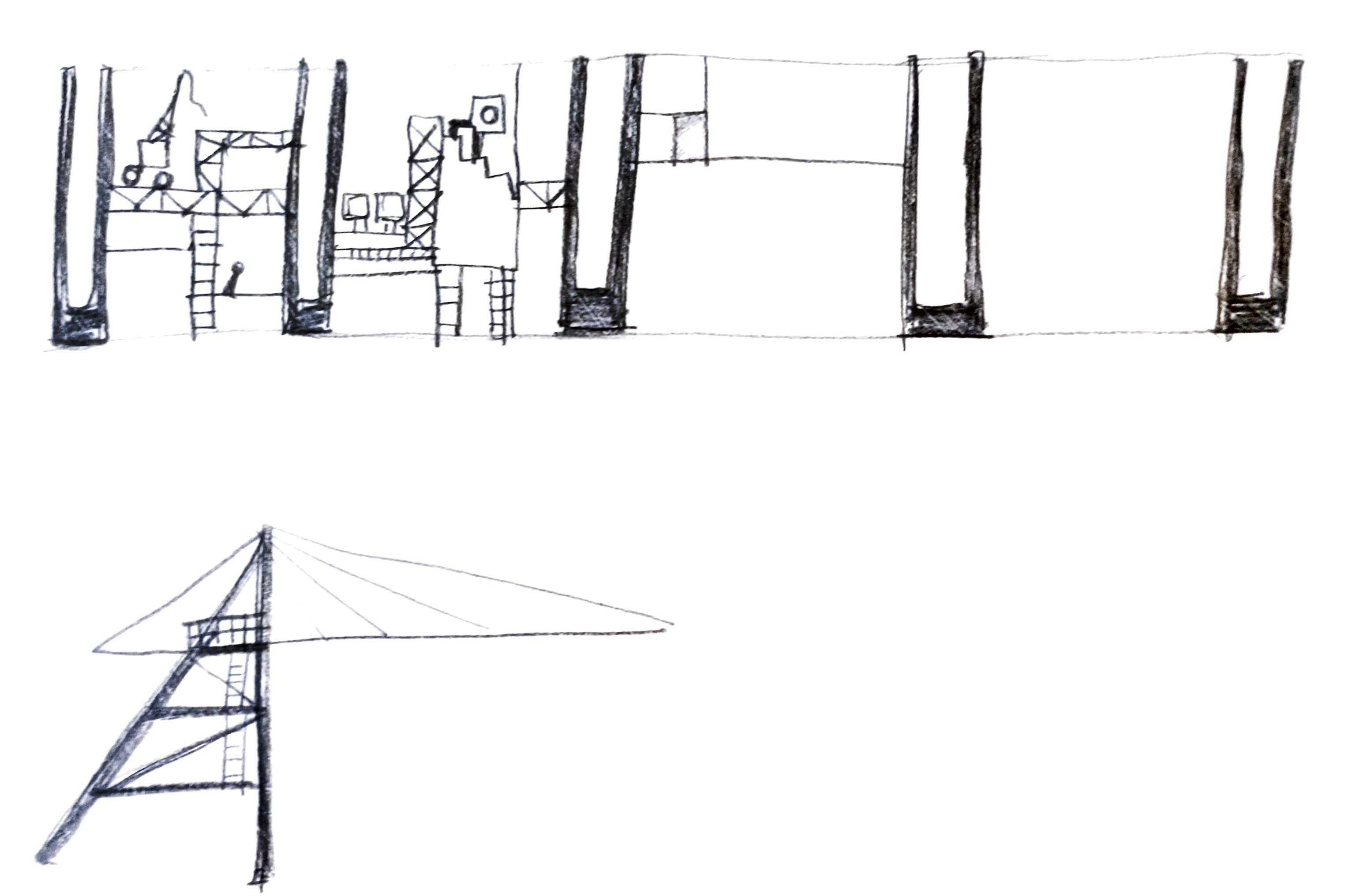

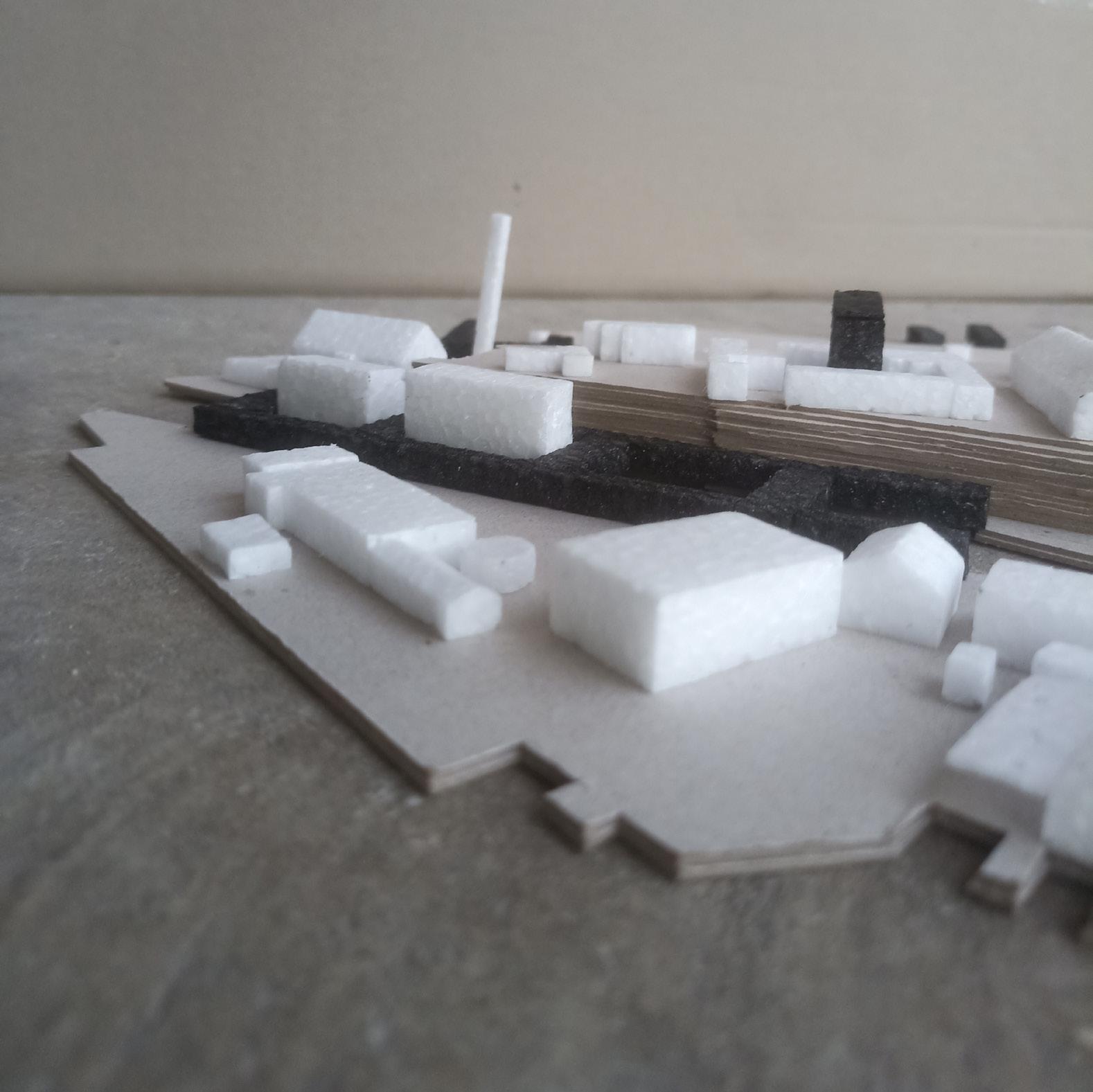

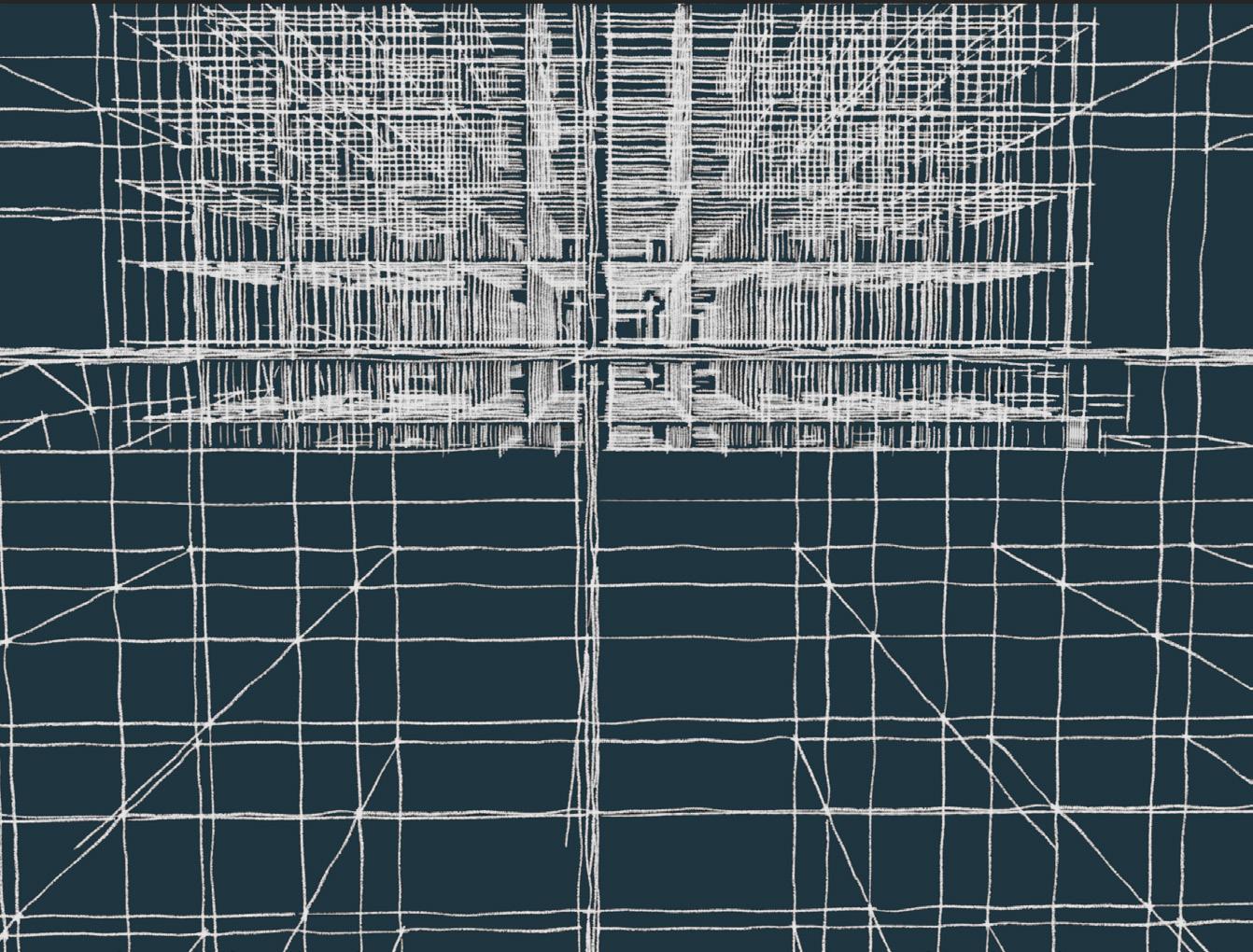

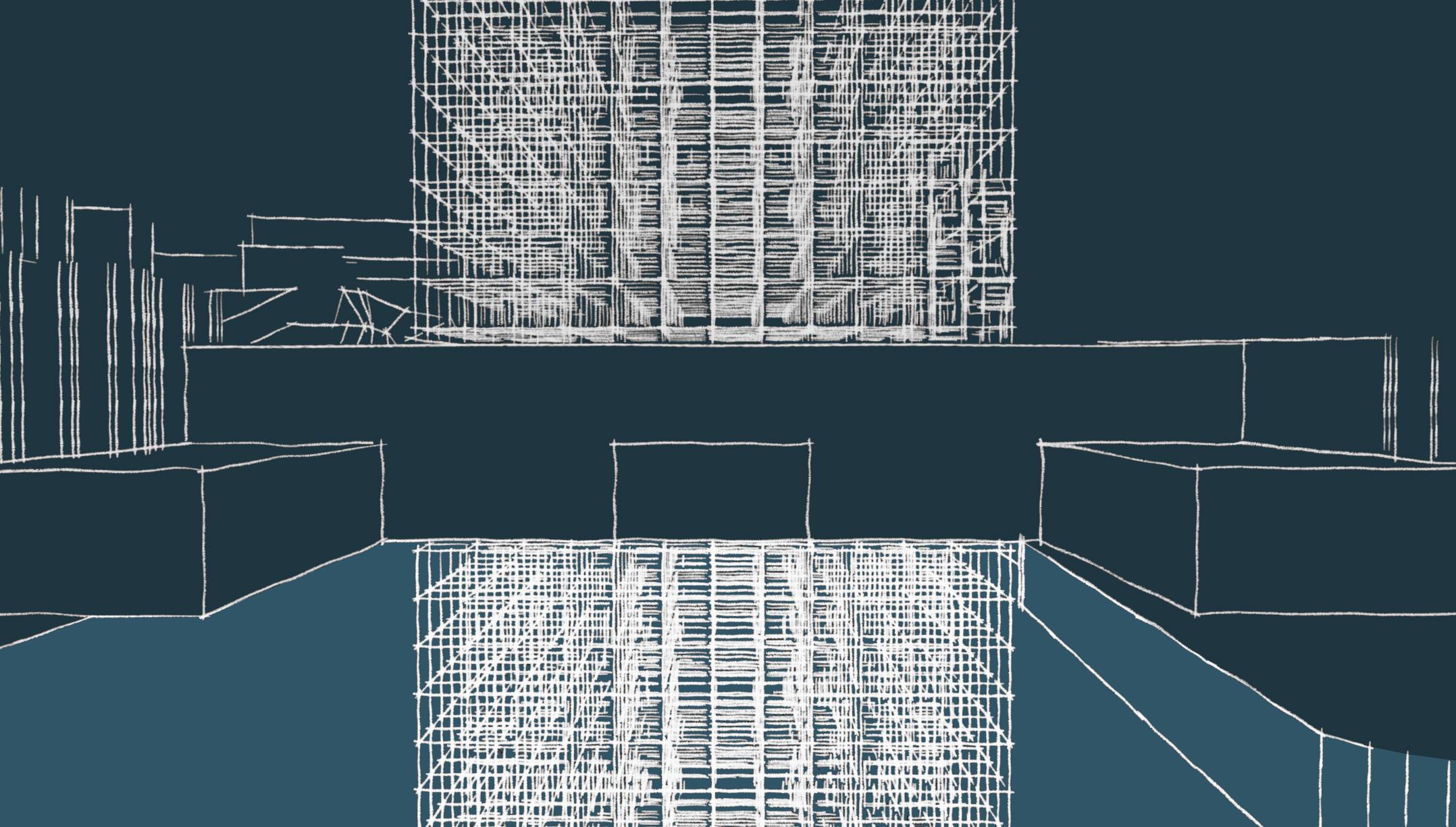

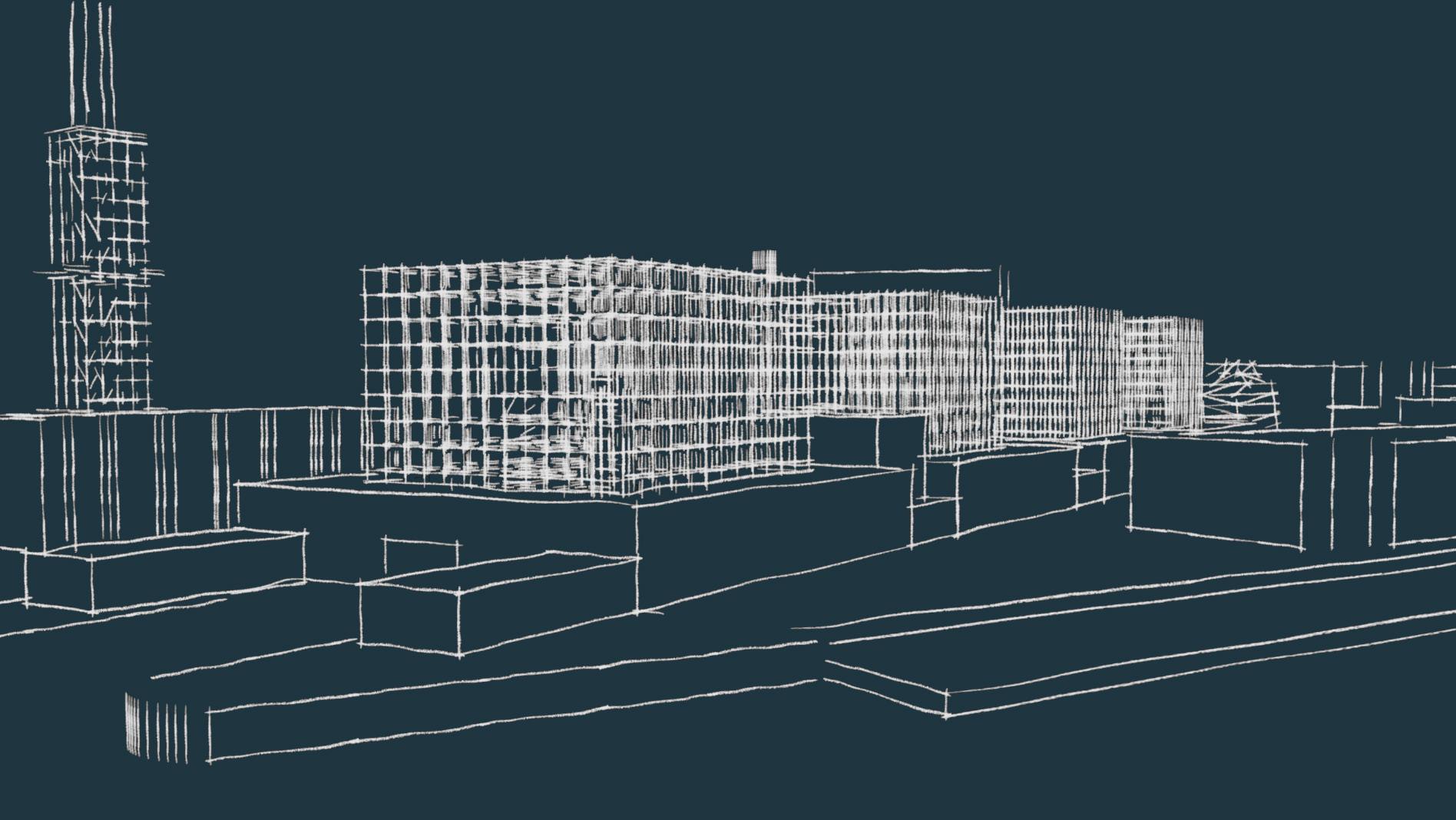

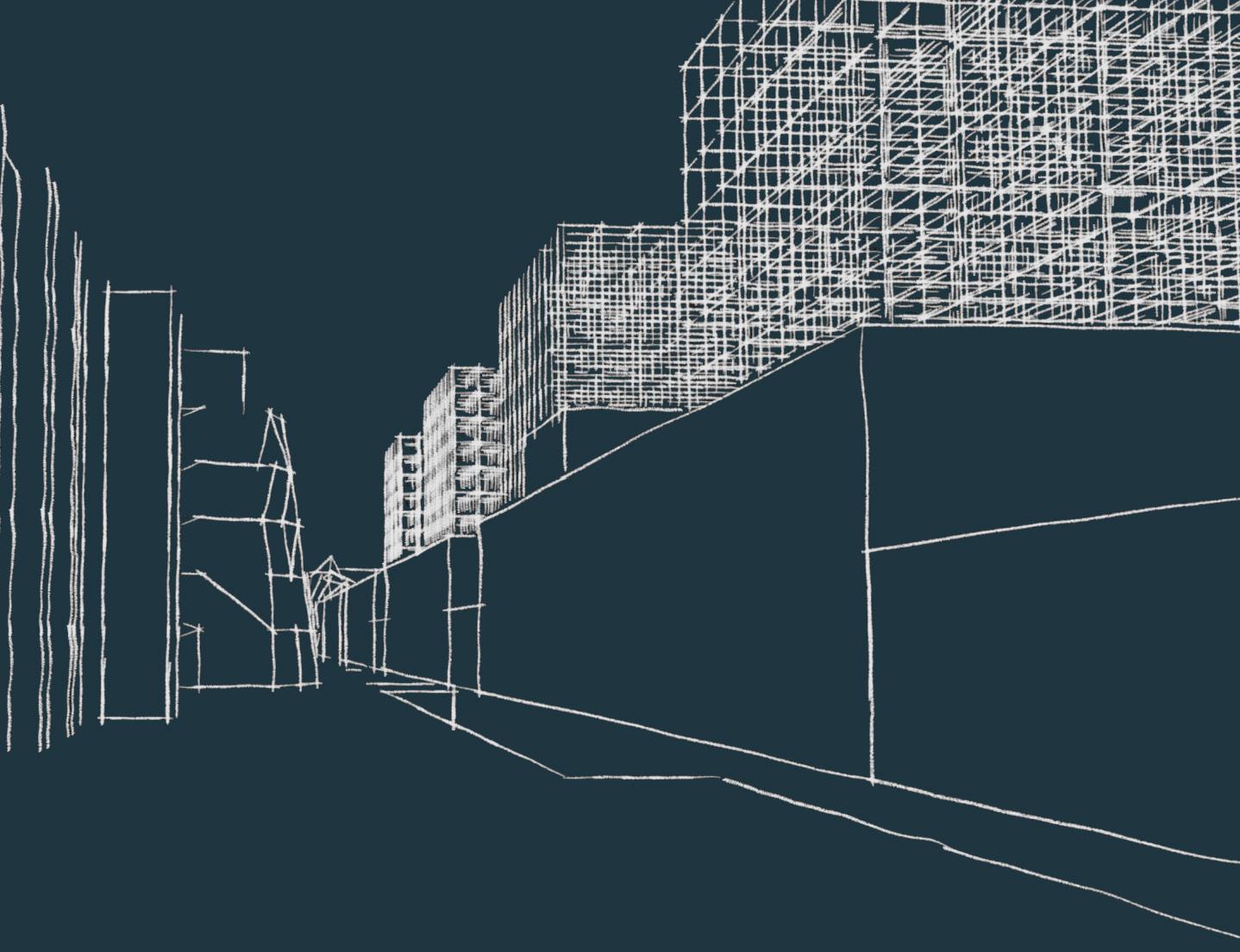

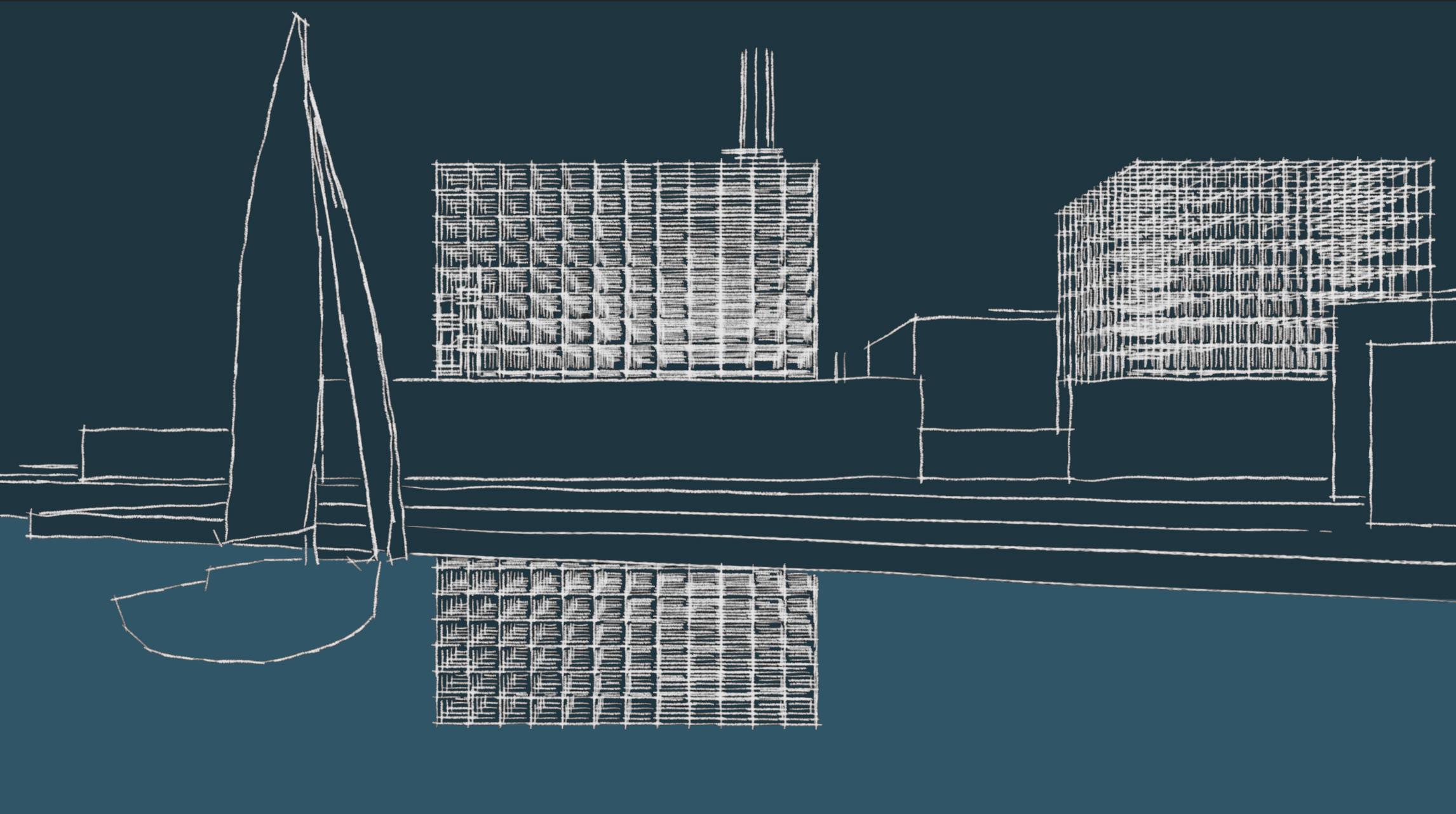

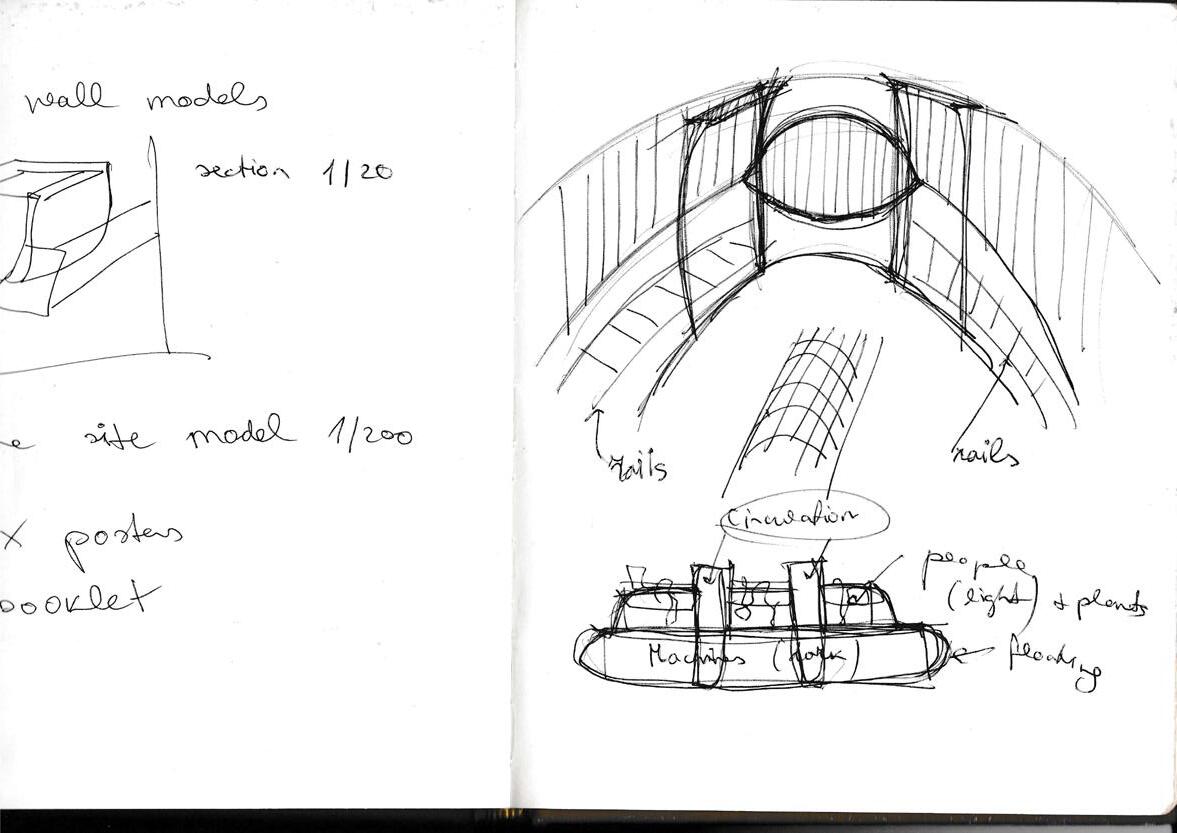

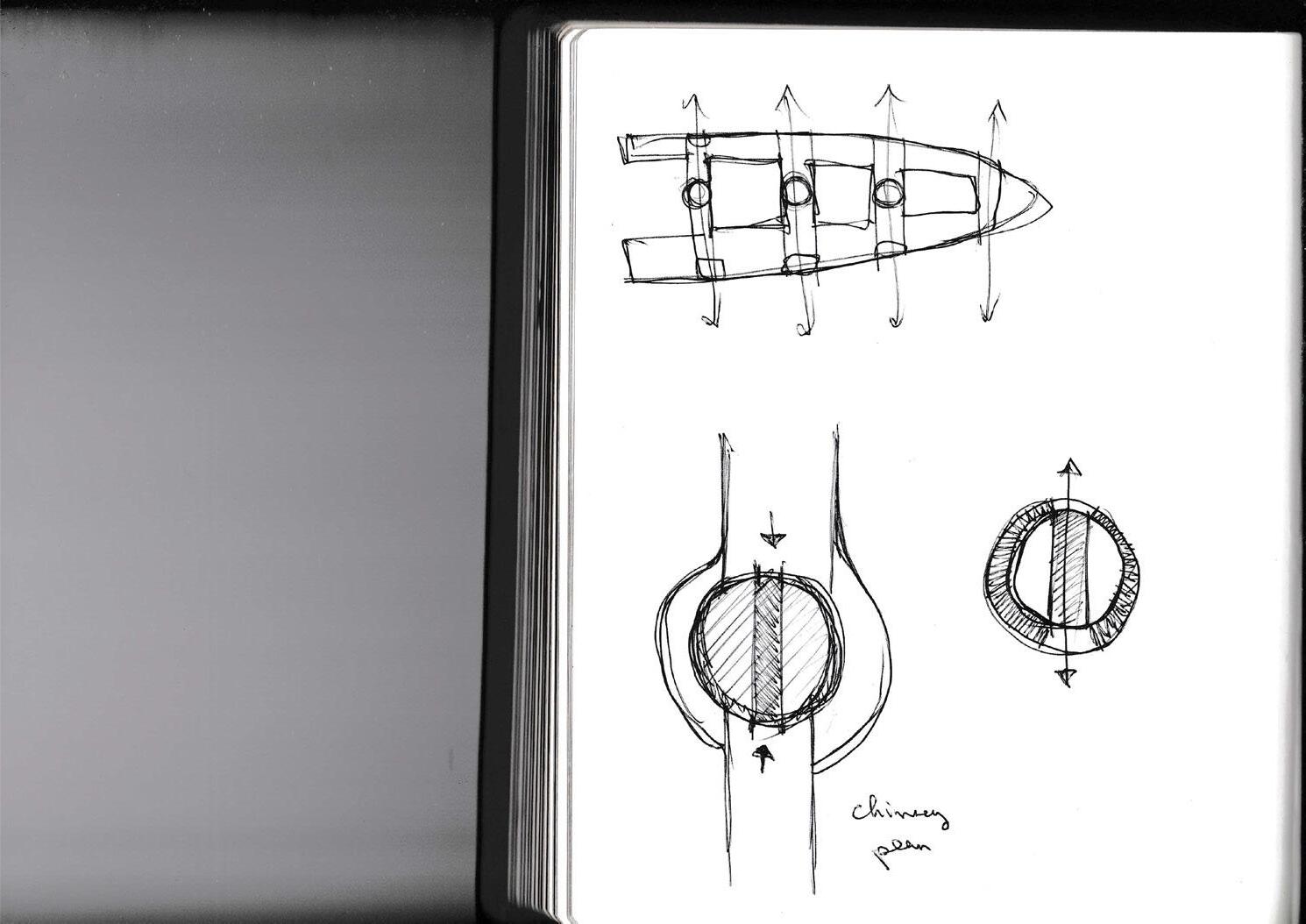

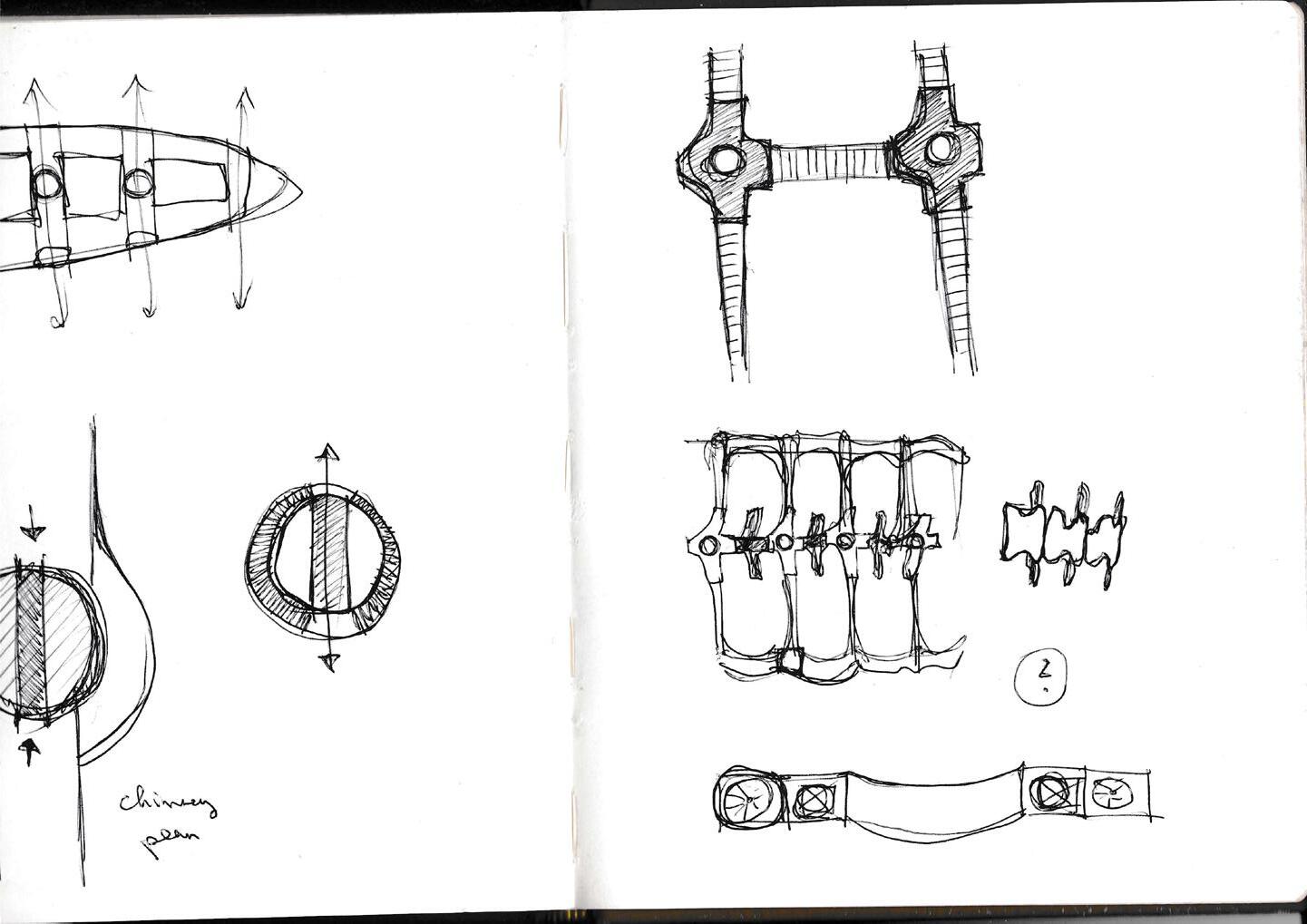

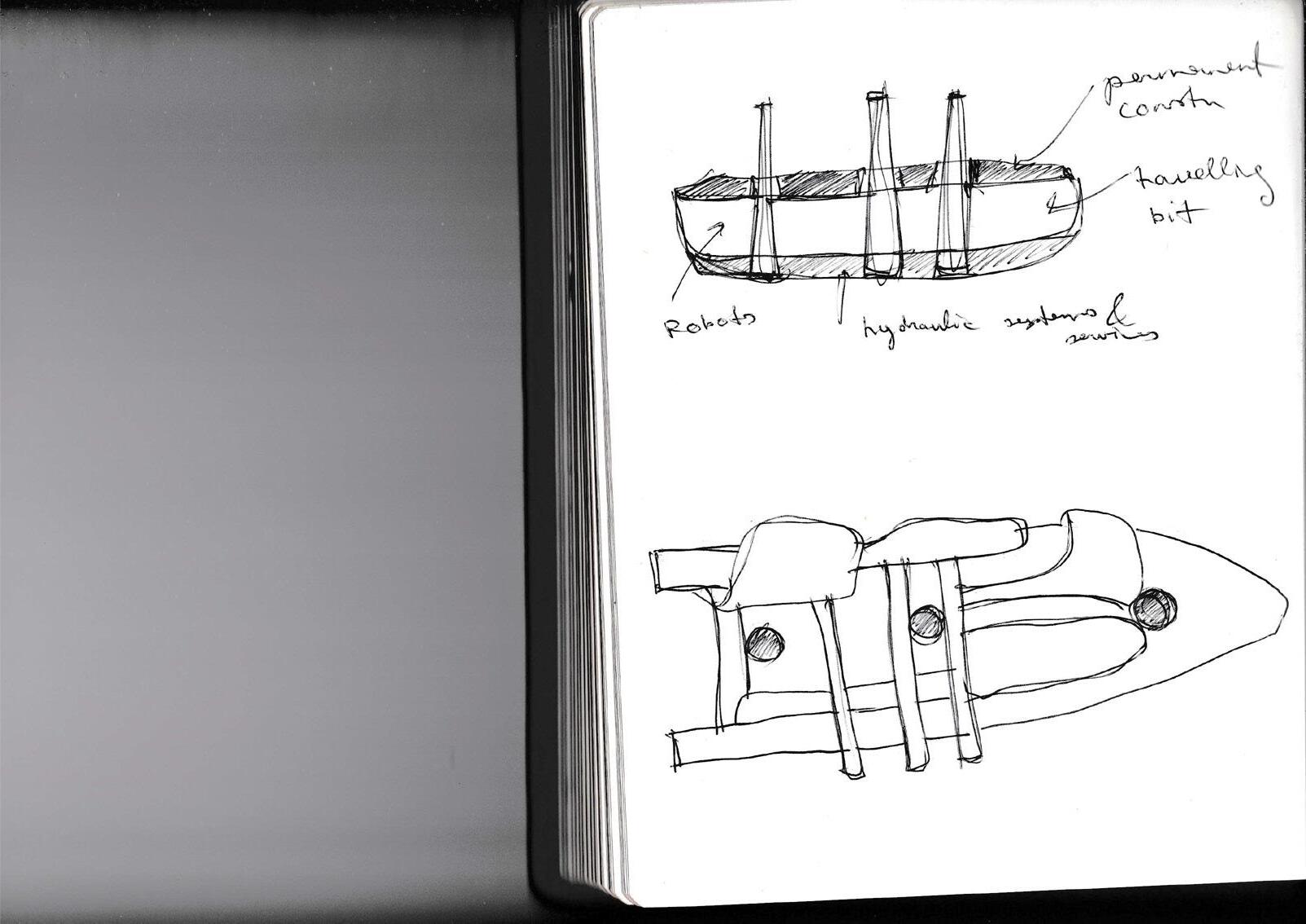

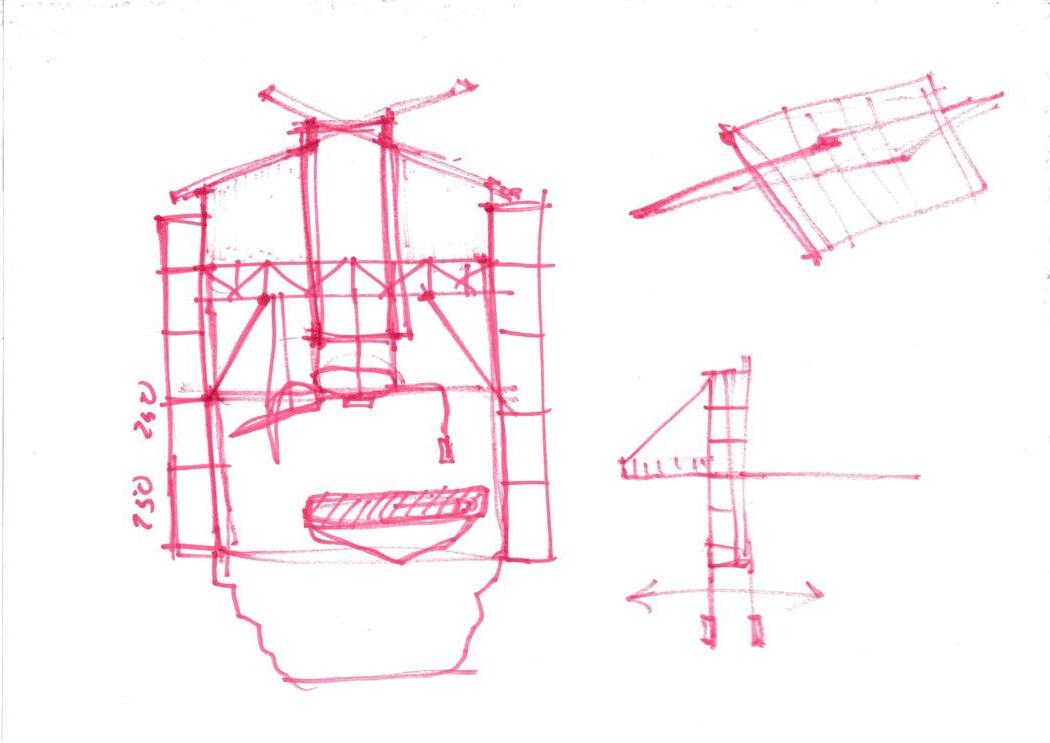

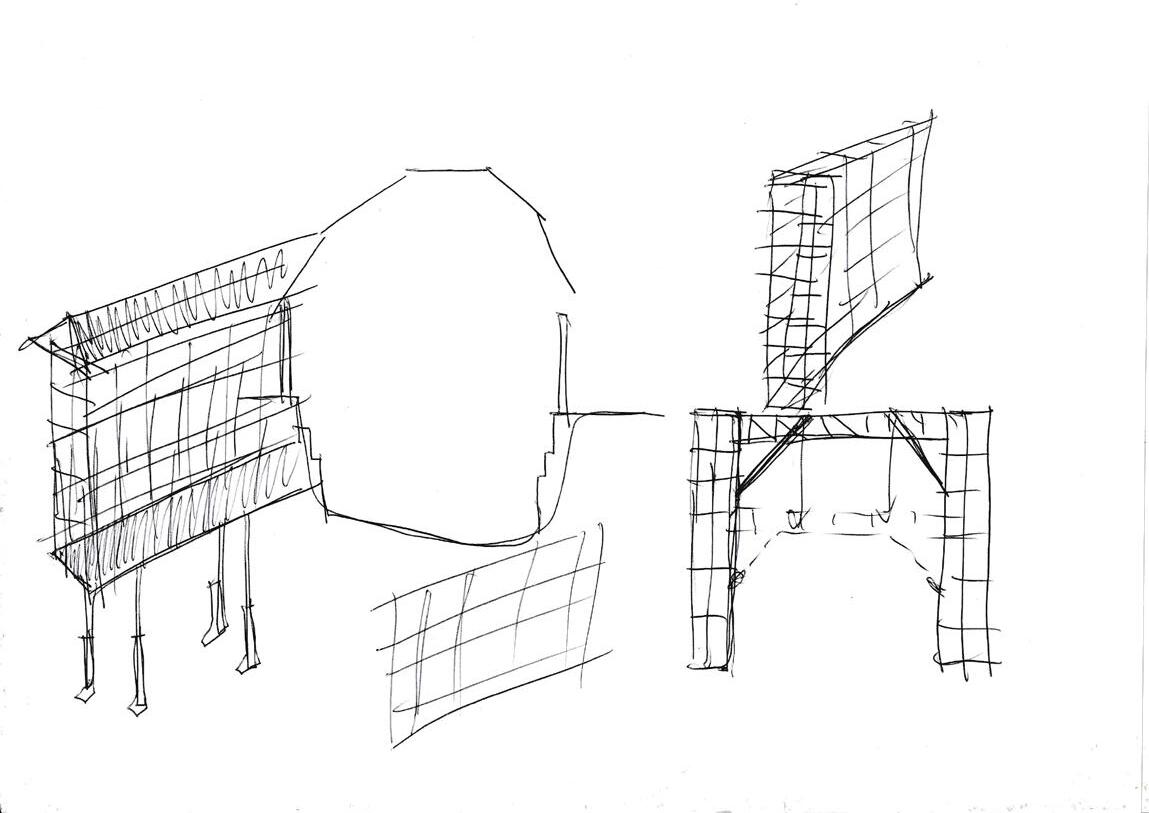

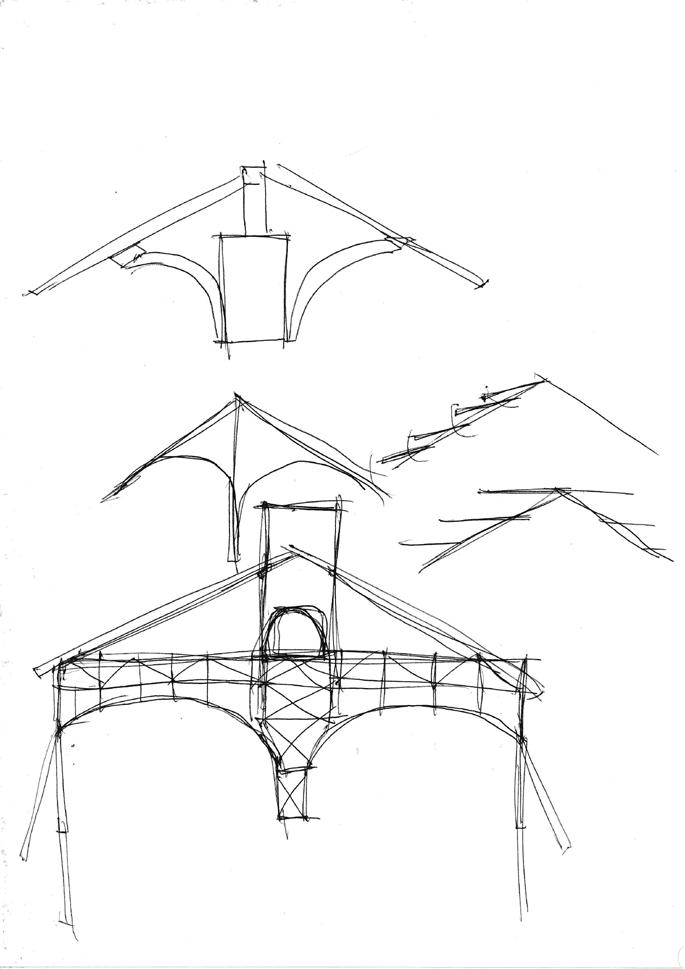

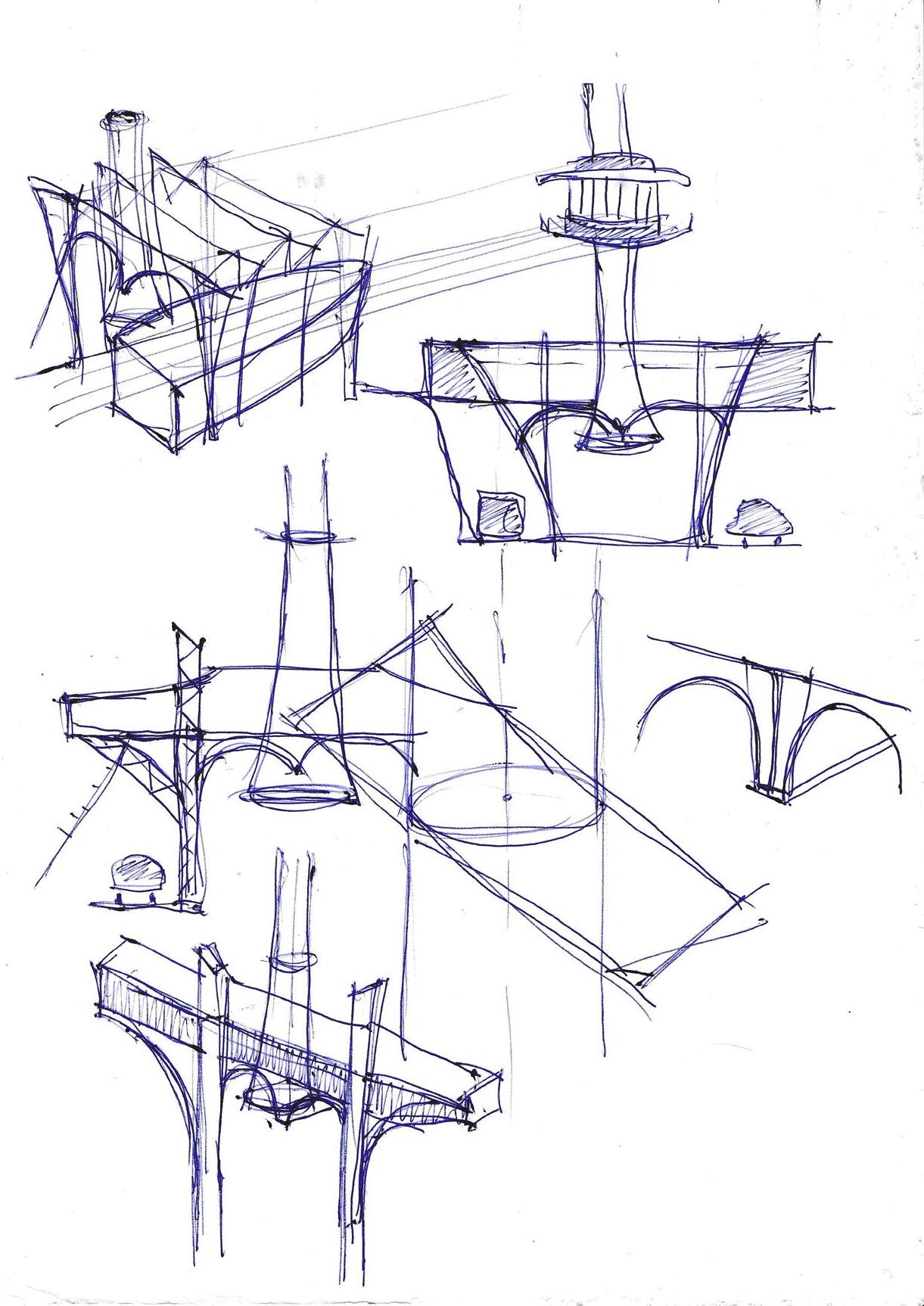

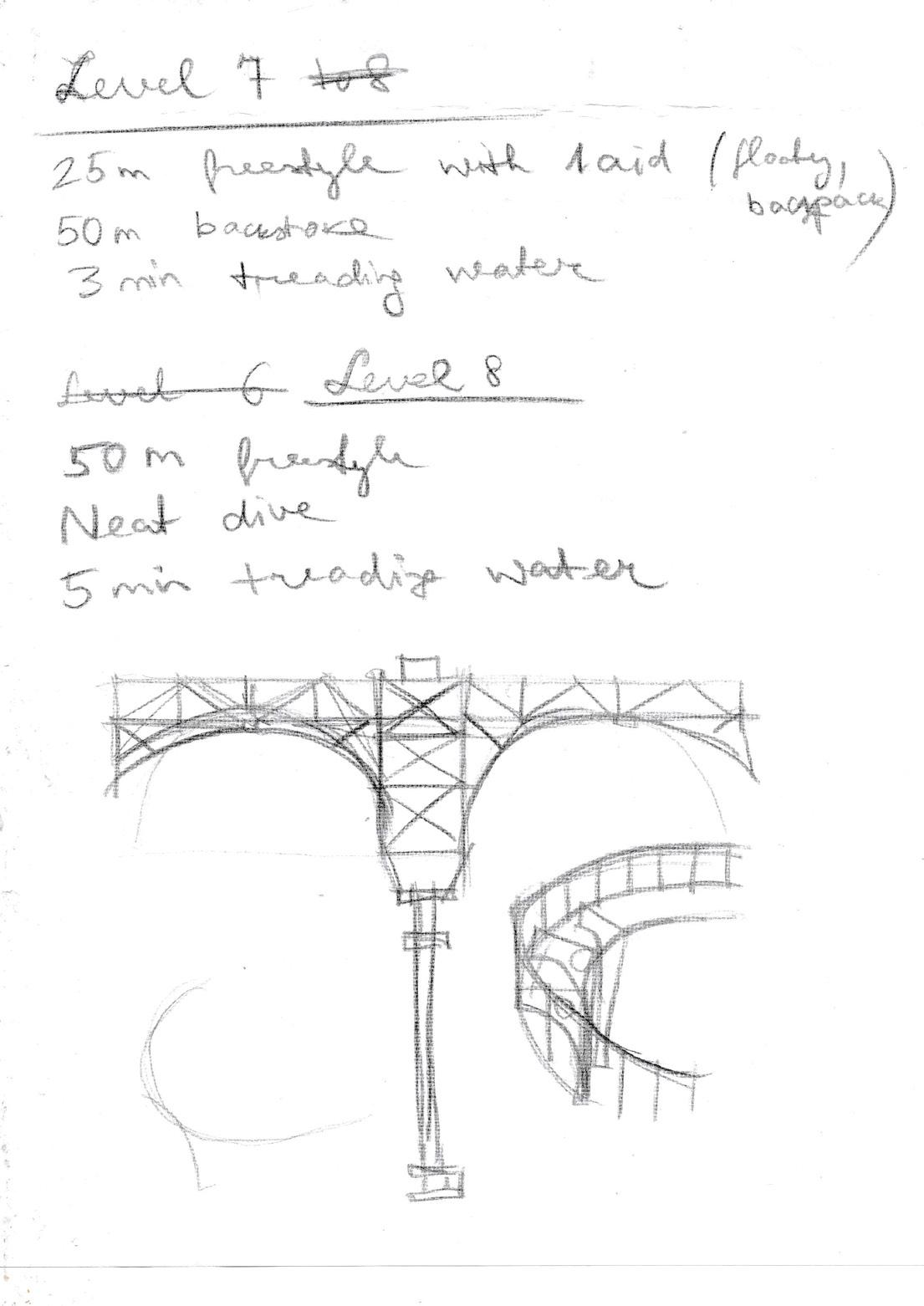

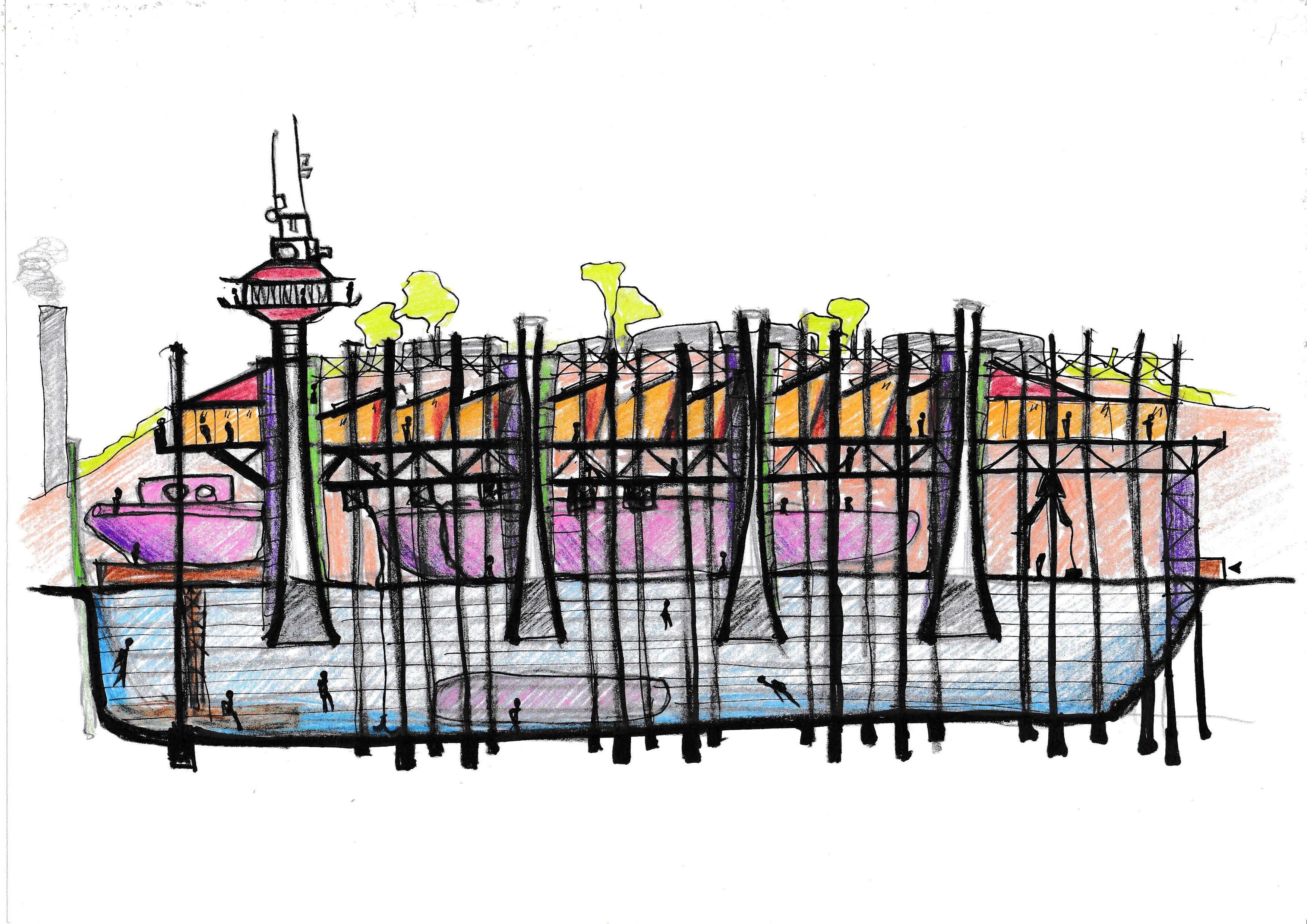

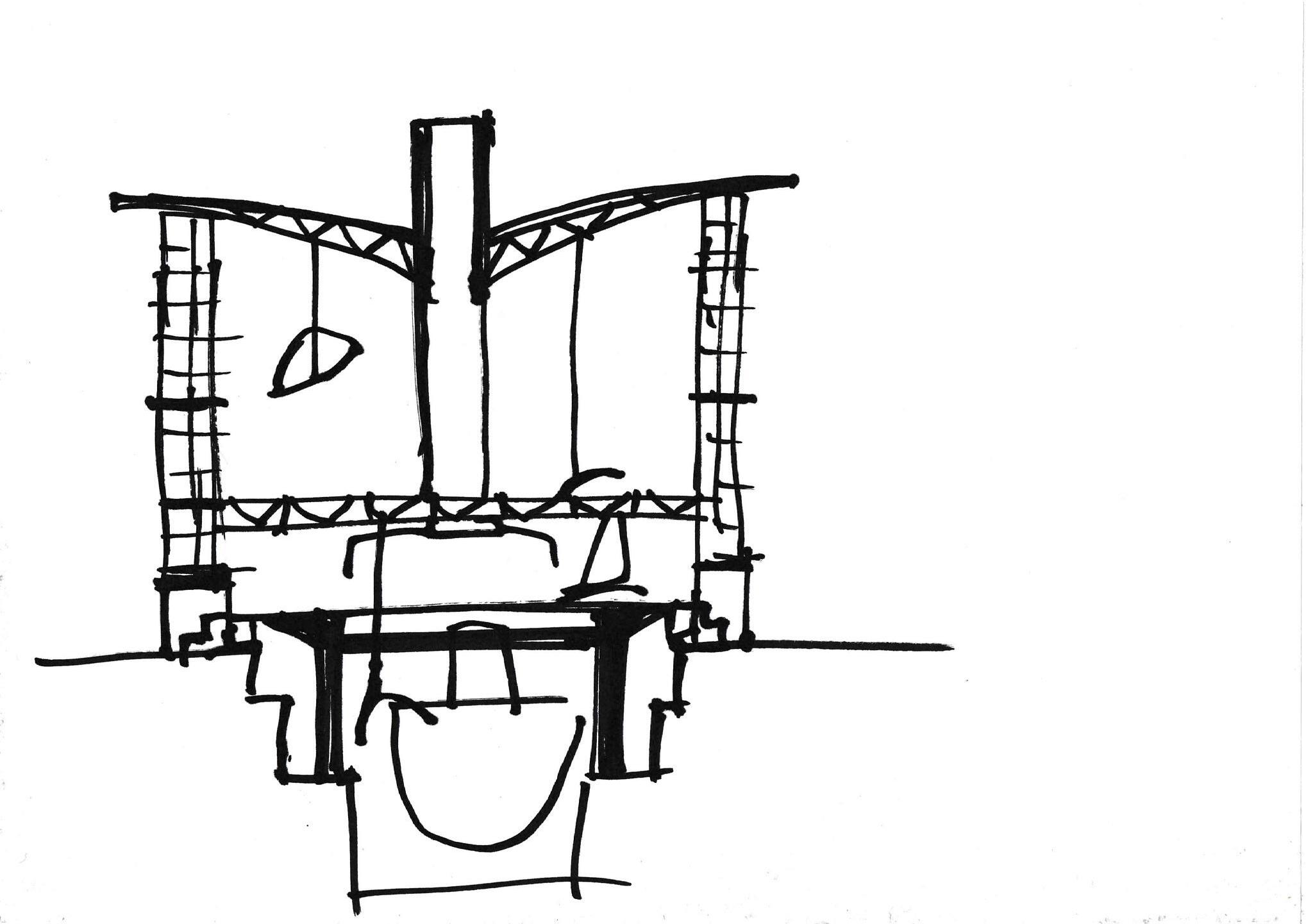

3D REPRESENTATION AND SKETCHES BY JOHN HEJDUK

3D REPRESENTATION AND SKETCHES BY JOHN HEJDUK

Importance:

Sydney’s Multicultural school

• To provide future generations a hands on experience

• A place for innovation and experimentation

• Not many places with hands-on facilities and freedom to learn, express yourself through movement and play

• High advanced technological resources

My concept

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

MFO Park by Raderschall in Zürich

MFO Park by Raderschall in Zürich

RETHINKING

ARCHITECTURAL CONSERVATION: HILL HOUSE BOX BY CARMODY GROARKE

ARCHITECTURAL CONSERVATION: HILL HOUSE BOX BY CARMODY GROARKE

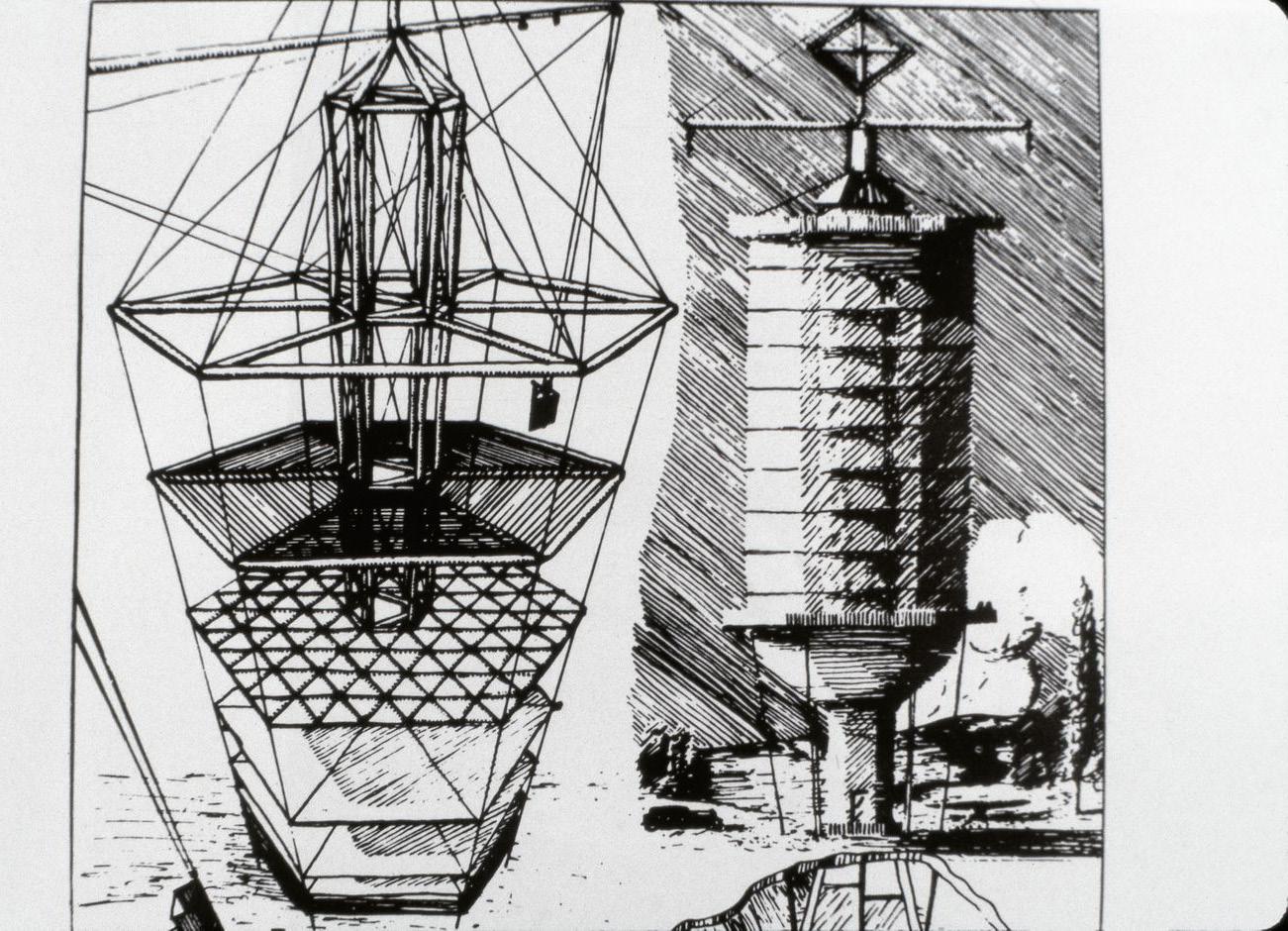

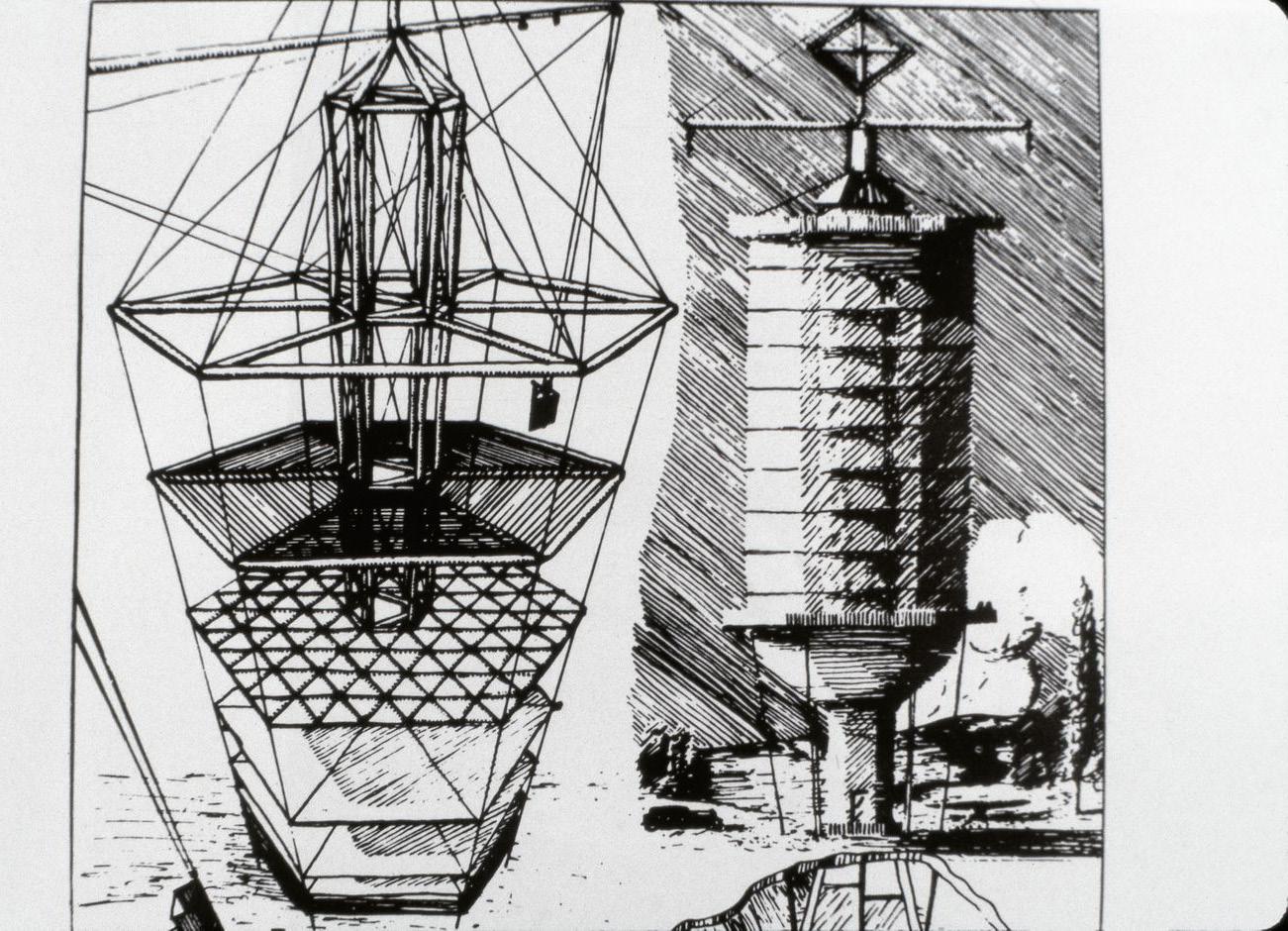

JOHN HEJDUK TOWERS. CITY OF THE CULTURE OF GALICIA. SANTIAGO DE COMPOSTELA.

JOHN HEJDUK TOWERS. CITY OF THE CULTURE OF GALICIA. SANTIAGO DE COMPOSTELA.

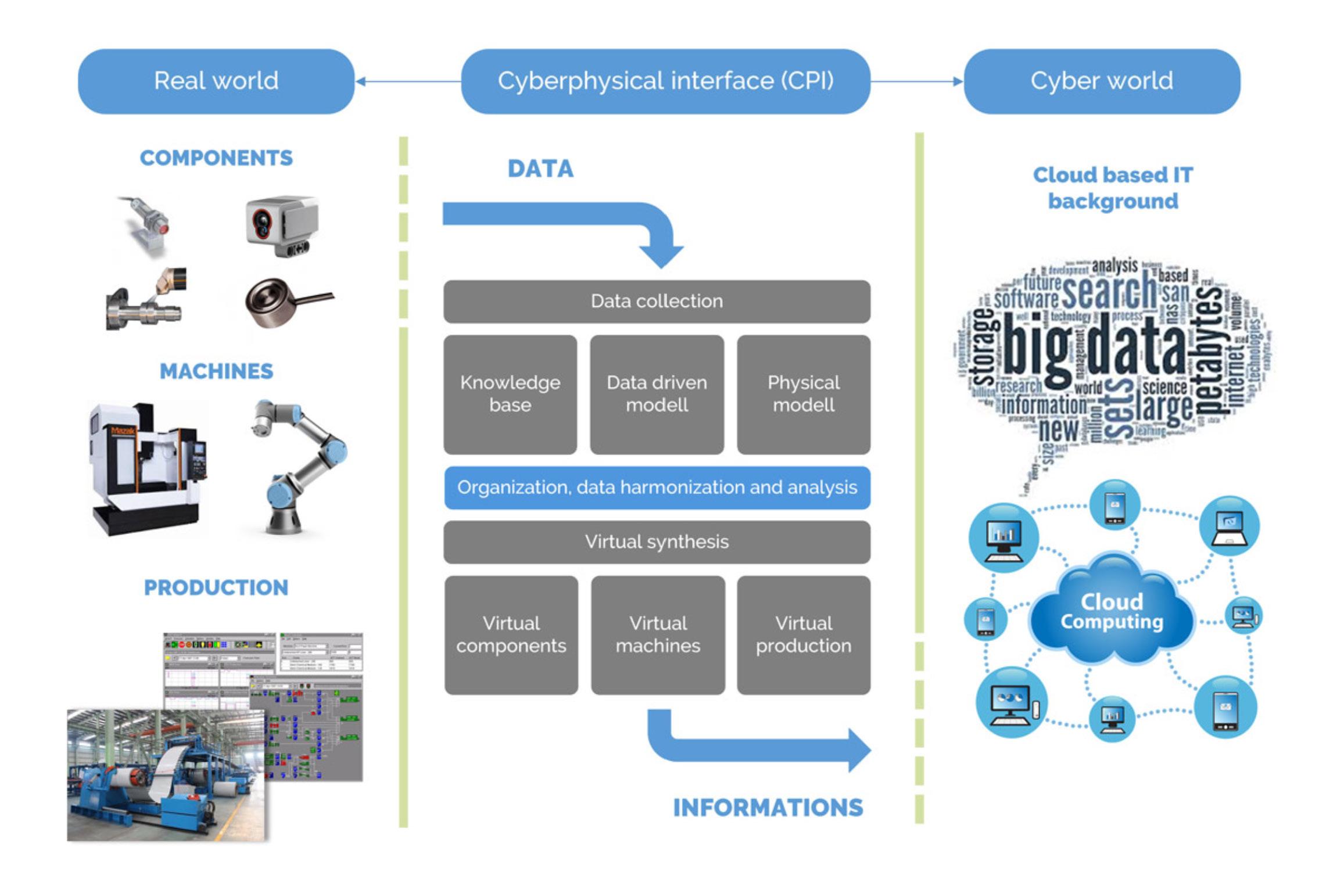

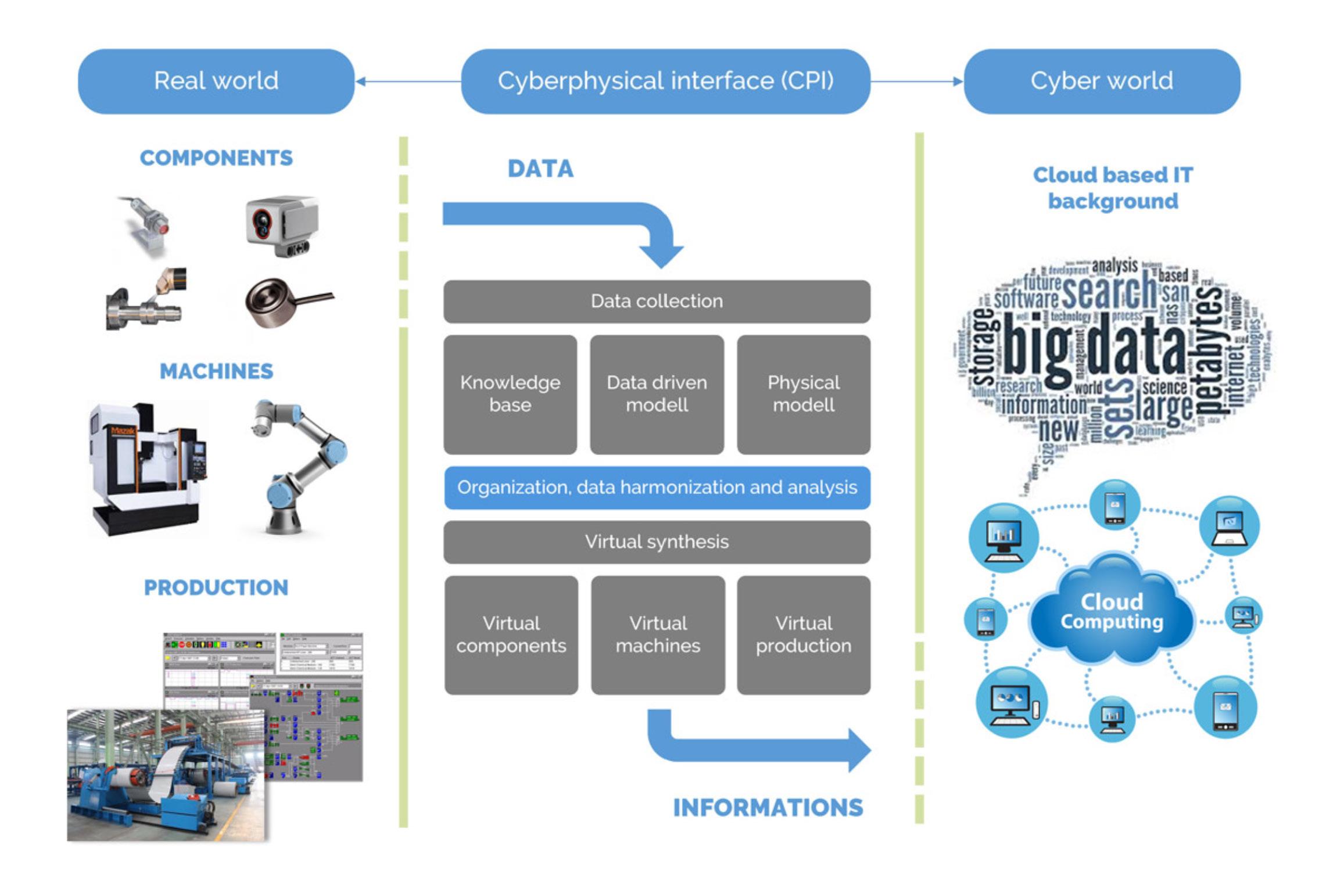

The Fourth Industrial Revolution

I will tell you a bit about something that will probably affect you for the rest of your life. It is the fourth Industrial Revolution.

Just a very quick lesson on industrial revolutions. We’ve had three large industrial revolutions in the world:

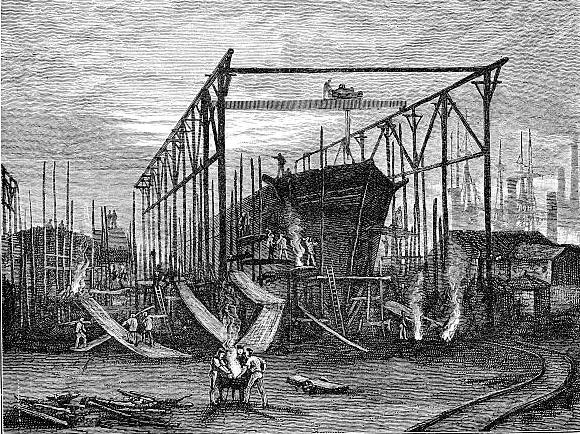

The First Industrial Revolution happened when the steam engine was invented. So that was a big thing. All of a sudden manual processes were out of the way. The steam engine powered industry automobiles, locomotives and what had you at that time. It was a huge step for Humanity to be able to do things faster.

The Second Industrial Revolution was when electricity was invented and that took things a little bit farther away. Now the technology of the times Suddenly you were able to power factories, street lamps and transport that electricity out way out using cables and so on.

The Third Industrial Revolution happened around the 1940s, 50s, and 60s. And this is when automation took over. Now you were able to produce goods faster and faster and more rapidly and then transport those goods further out wherever you wanted to sell them.

At this moment in time, we are at the cusp of what is called as the fourth Industrial Revolution. What is different with this revolution is that it has started and kicked off because of technology. Specifically internet-related technologies are going to propel us much further, than we would anticipate. The key part about this revolution is that it is the time when men and machines come together. It is a time when artificial intelligence will work to create different outcomes as we have never seen before and is going to go forward no matter what you do. Technology is going to be a huge part of our lives. So it’s time that we start adopting ourselves more to technology and start learning how it can help us, and how we can use it to create change in the world.

The 4th industrial revolution is characterized by the integration of advanced technologies such as artificial intelligence, the internet of things, and robotics into the manufacturing process.

Industrial revolution will lead to a significant increase in productivity and economic growth.

1. One of the key advantages of the 4th industrial revolution is that it enables greater customization and flexibility in the manufacturing process. With the use of advanced technologies, manufacturers can produce highly customized products at a lower cost, leading to a more efficient and competitive manufacturing industry in Australia.

2. In addition, the 4th industrial revolution is expected to lead to significant advancements in automation, robotics, and artificial intelligence, which will have a profound impact on the workforce. While there will likely be some displacement of workers in certain industries, it is also expected that new jobs will be created in areas such as software engineering, data analysis, and robotics.

3. Finally, the 4th industrial revolution is expected to have a significant impact on the environment by reducing waste, energy consumption, and carbon emissions. By using advanced technologies to optimize the manufacturing process, manufacturers can significantly reduce their environmental footprint and contribute to a more sustainable future.

The 4th industrial revolution is believed to lead to a more productive, efficient, and sustainable manufacturing industry, with significant economic and environmental benefits.

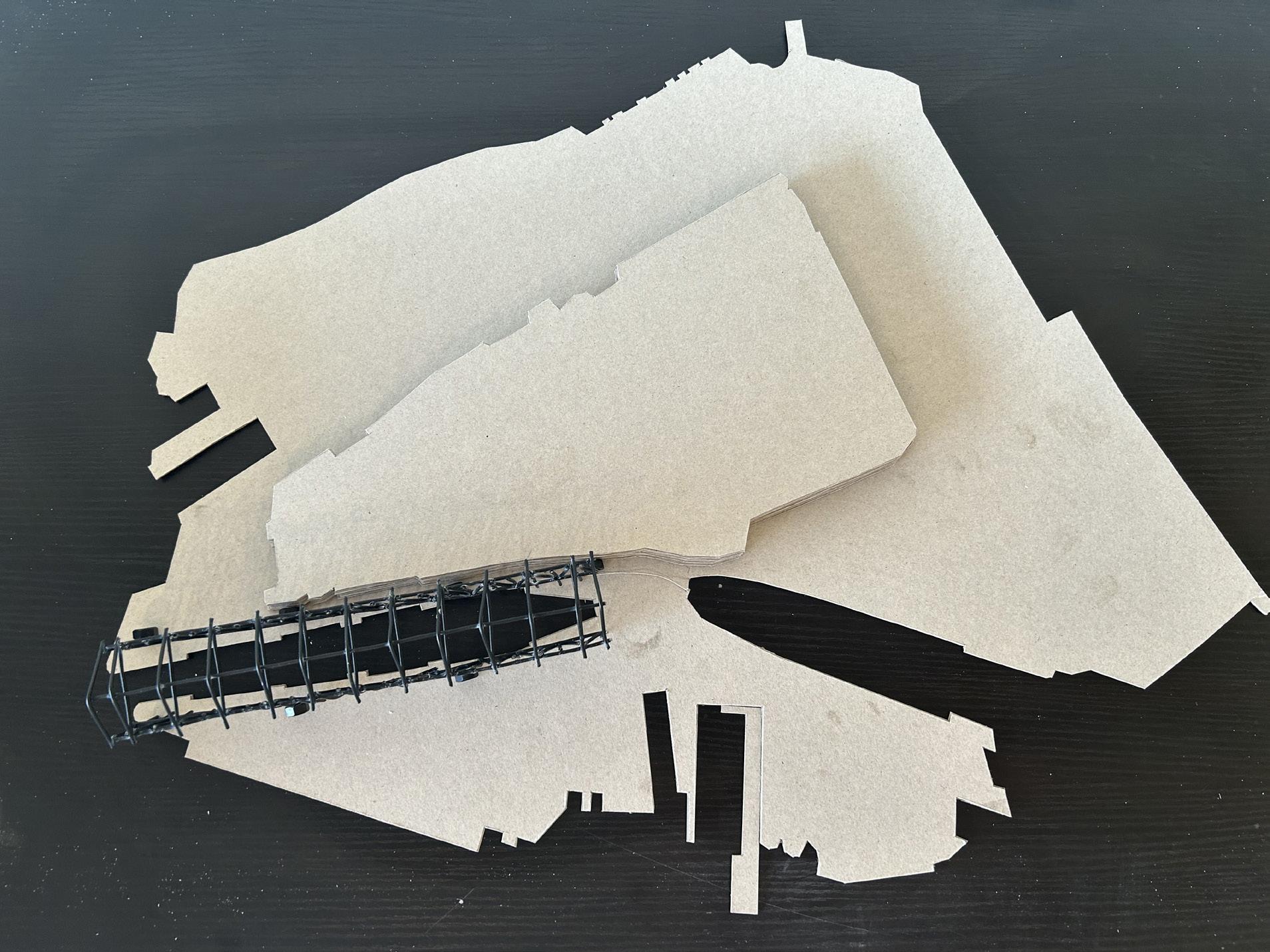

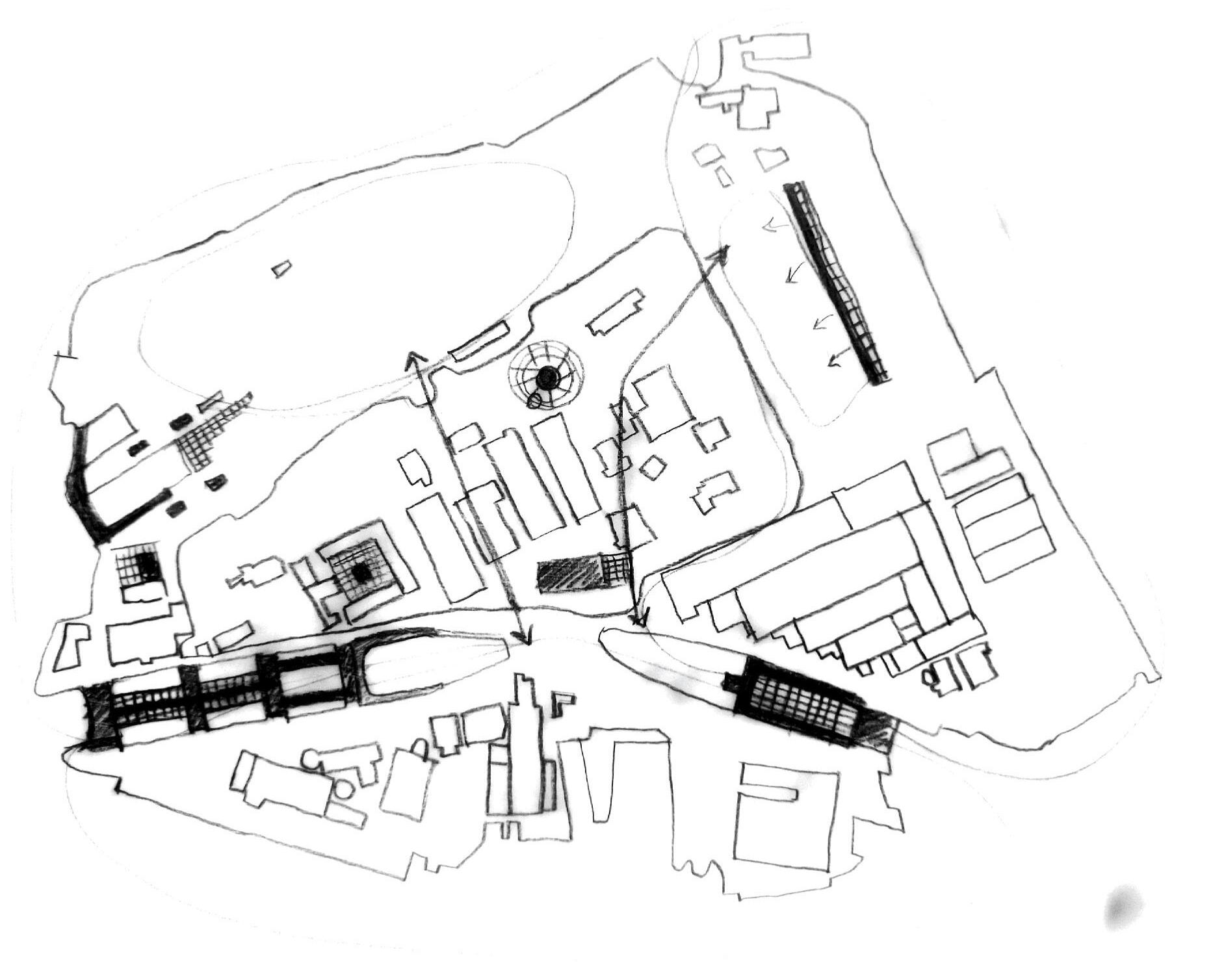

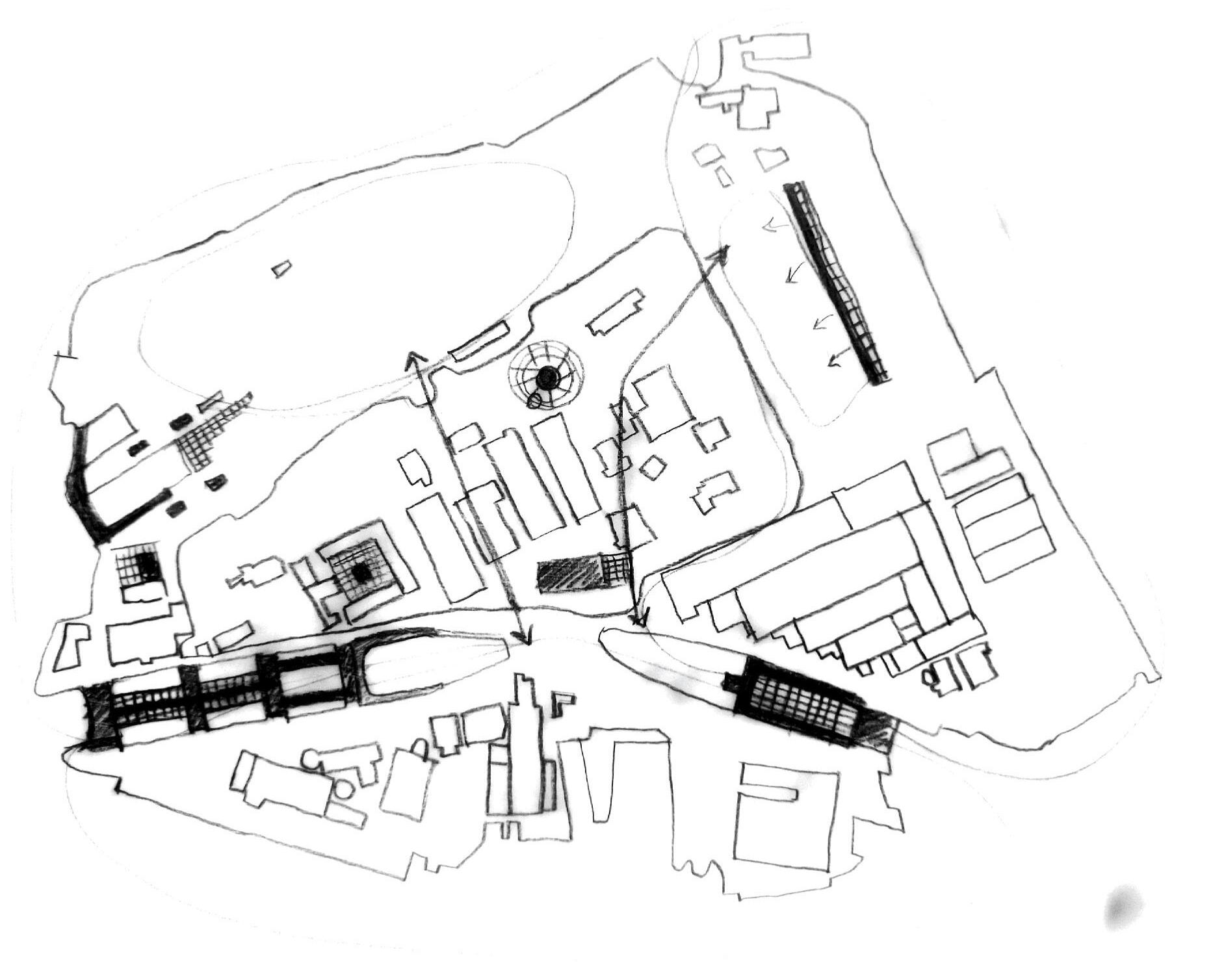

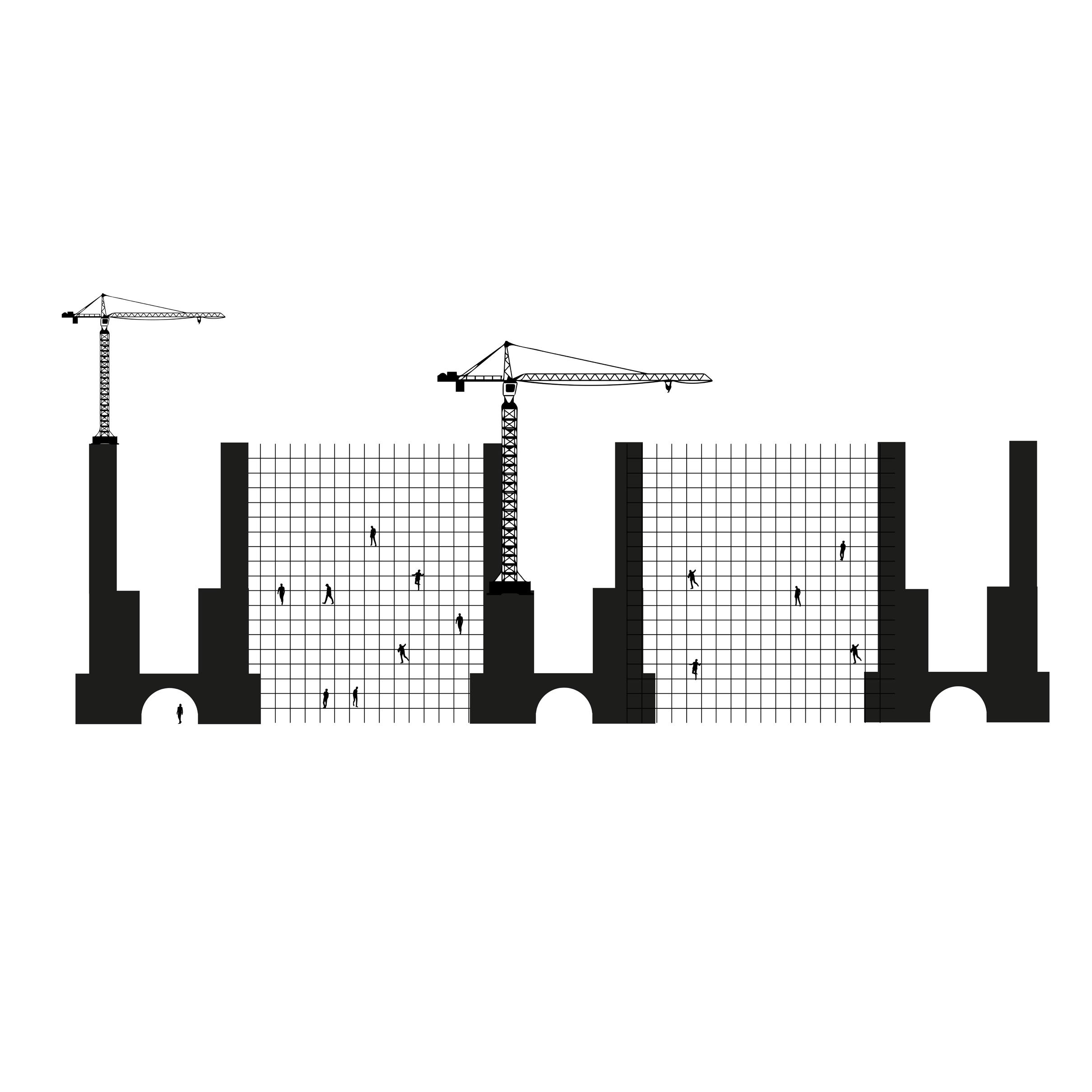

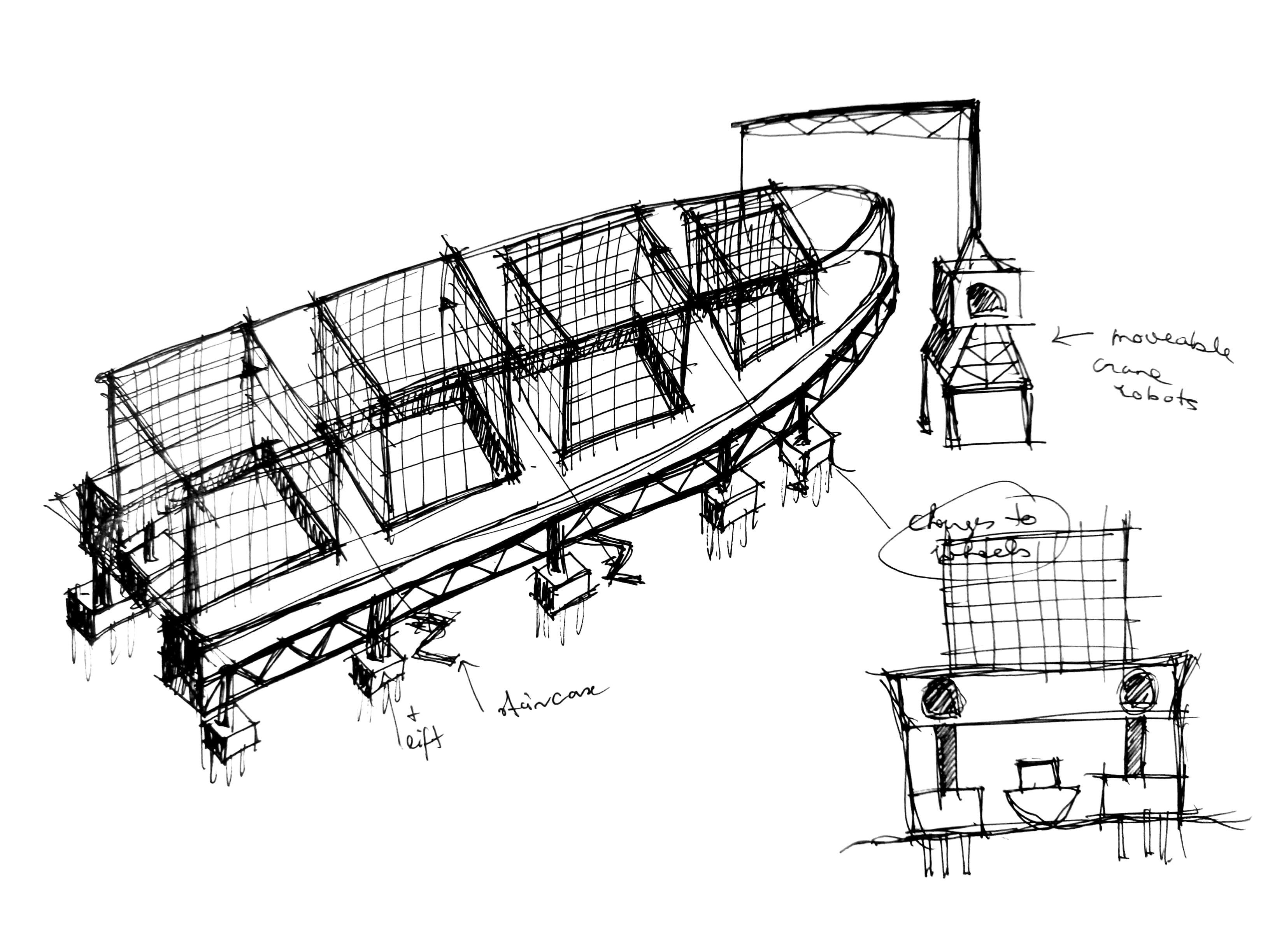

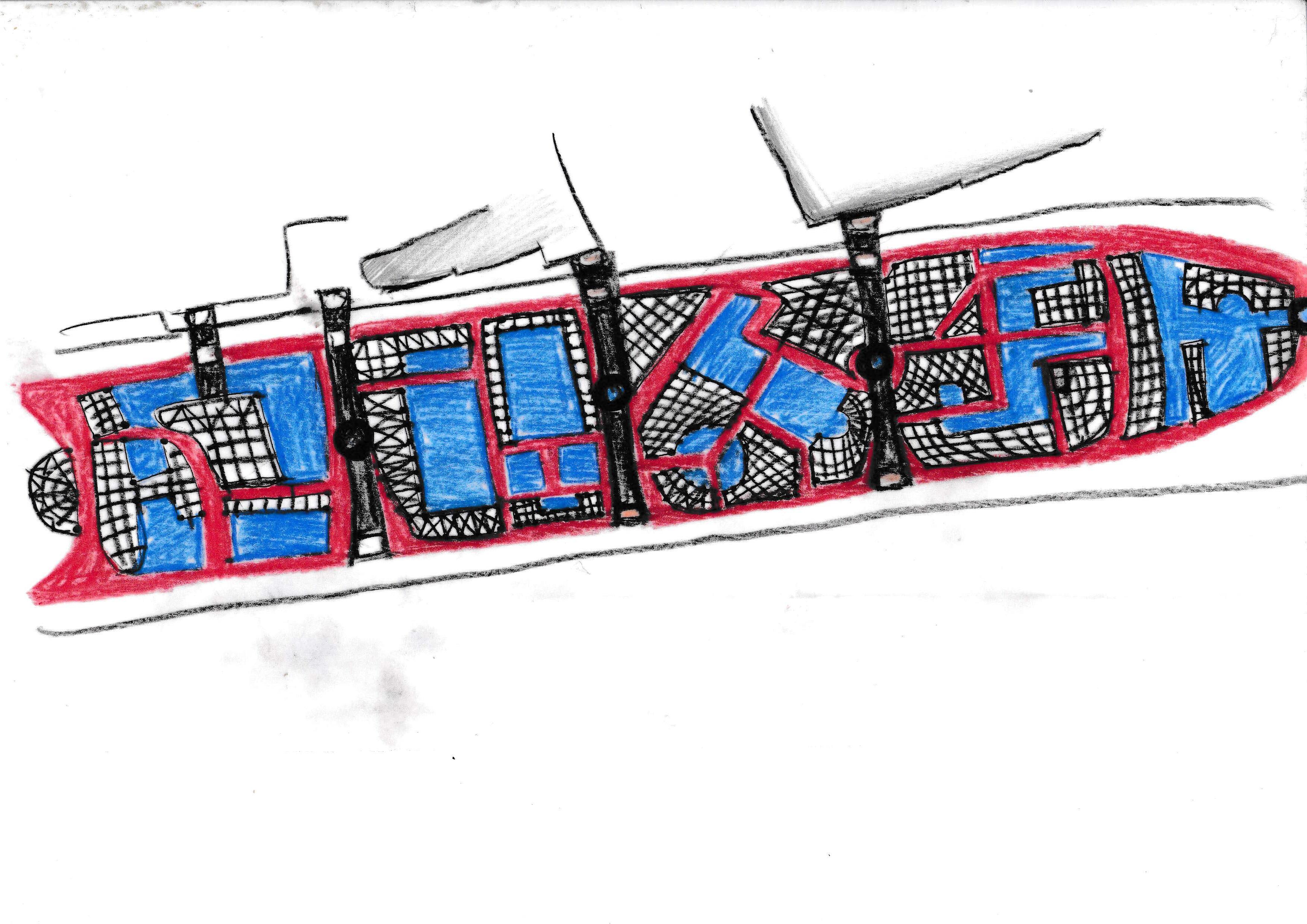

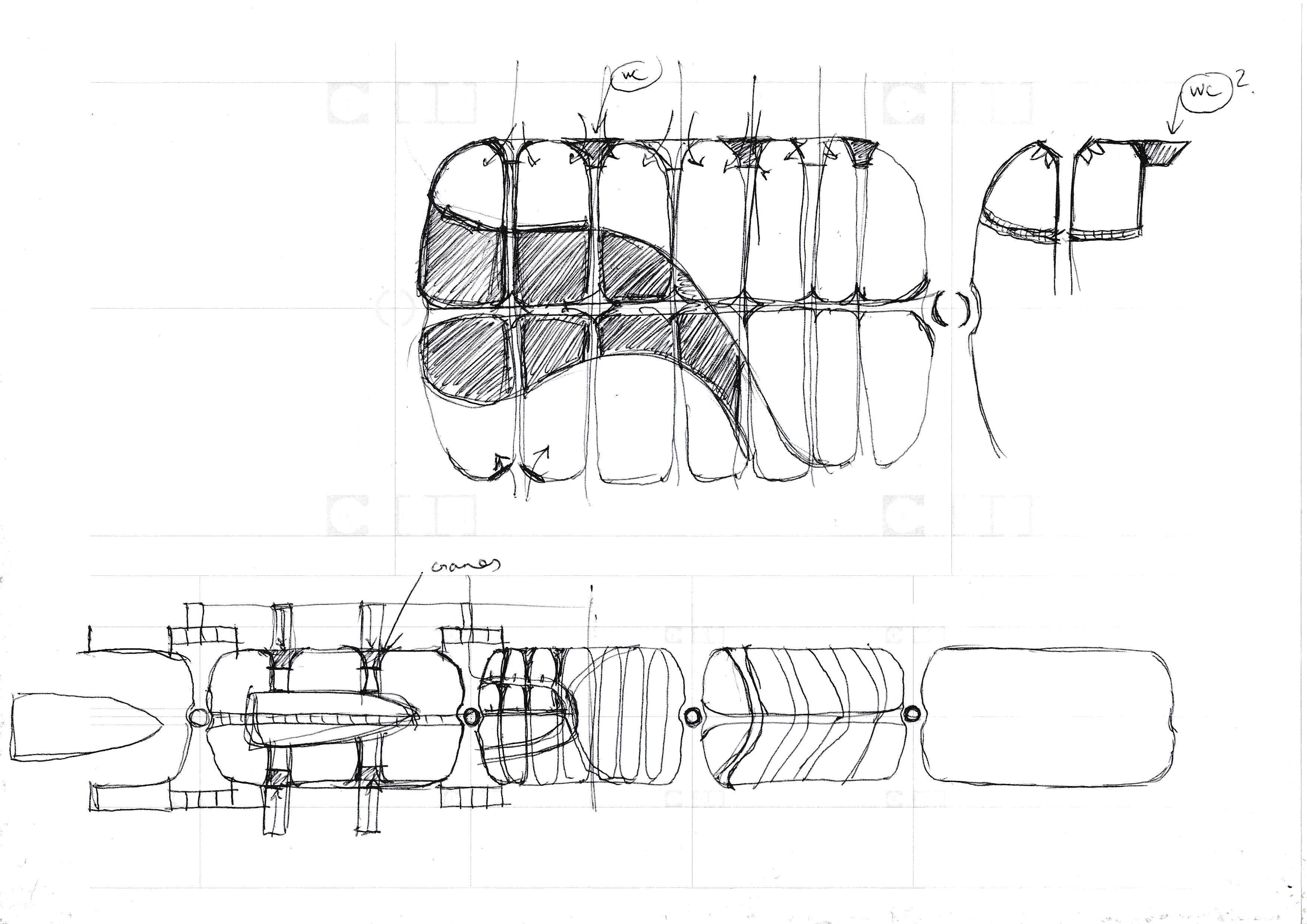

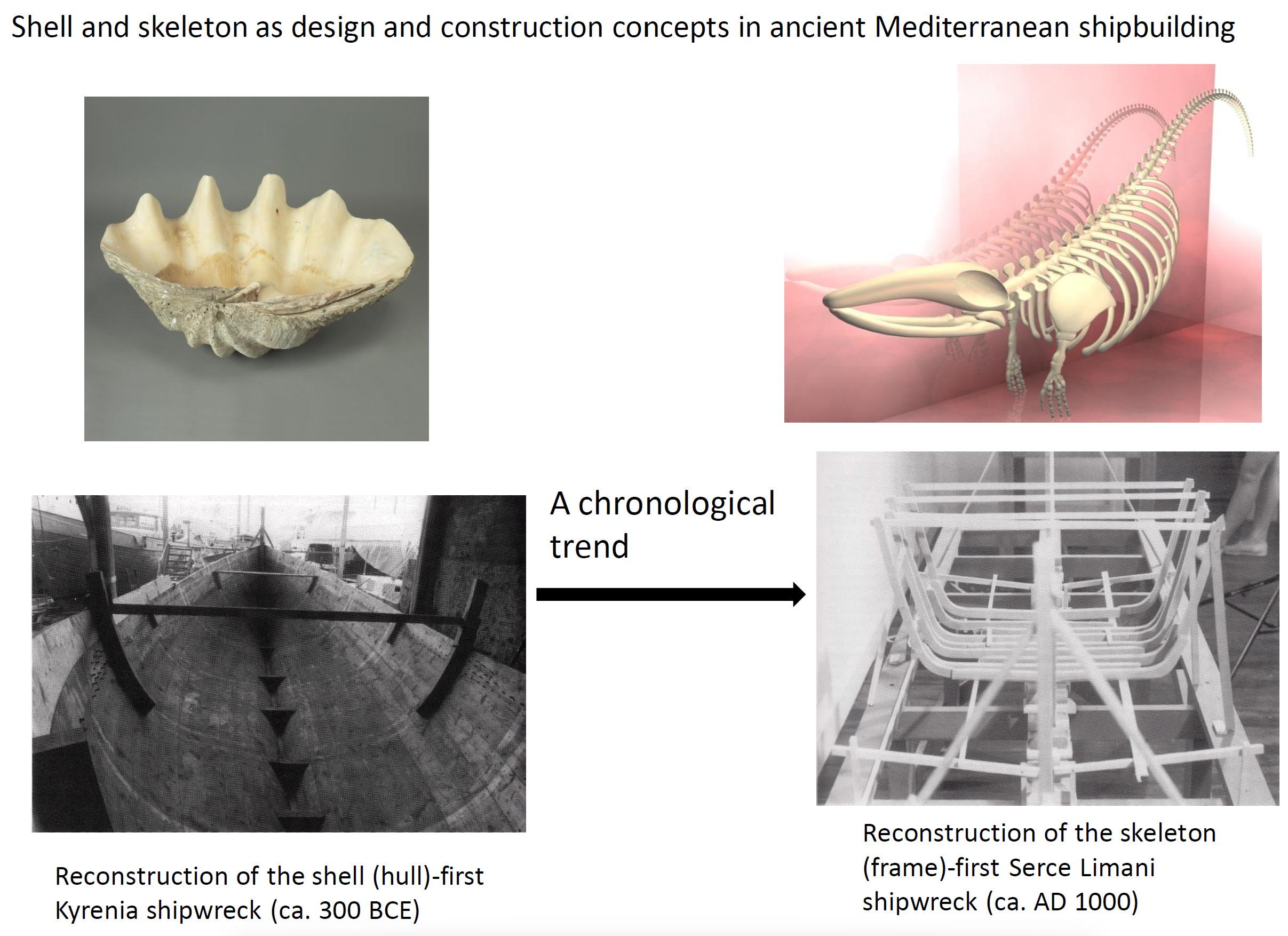

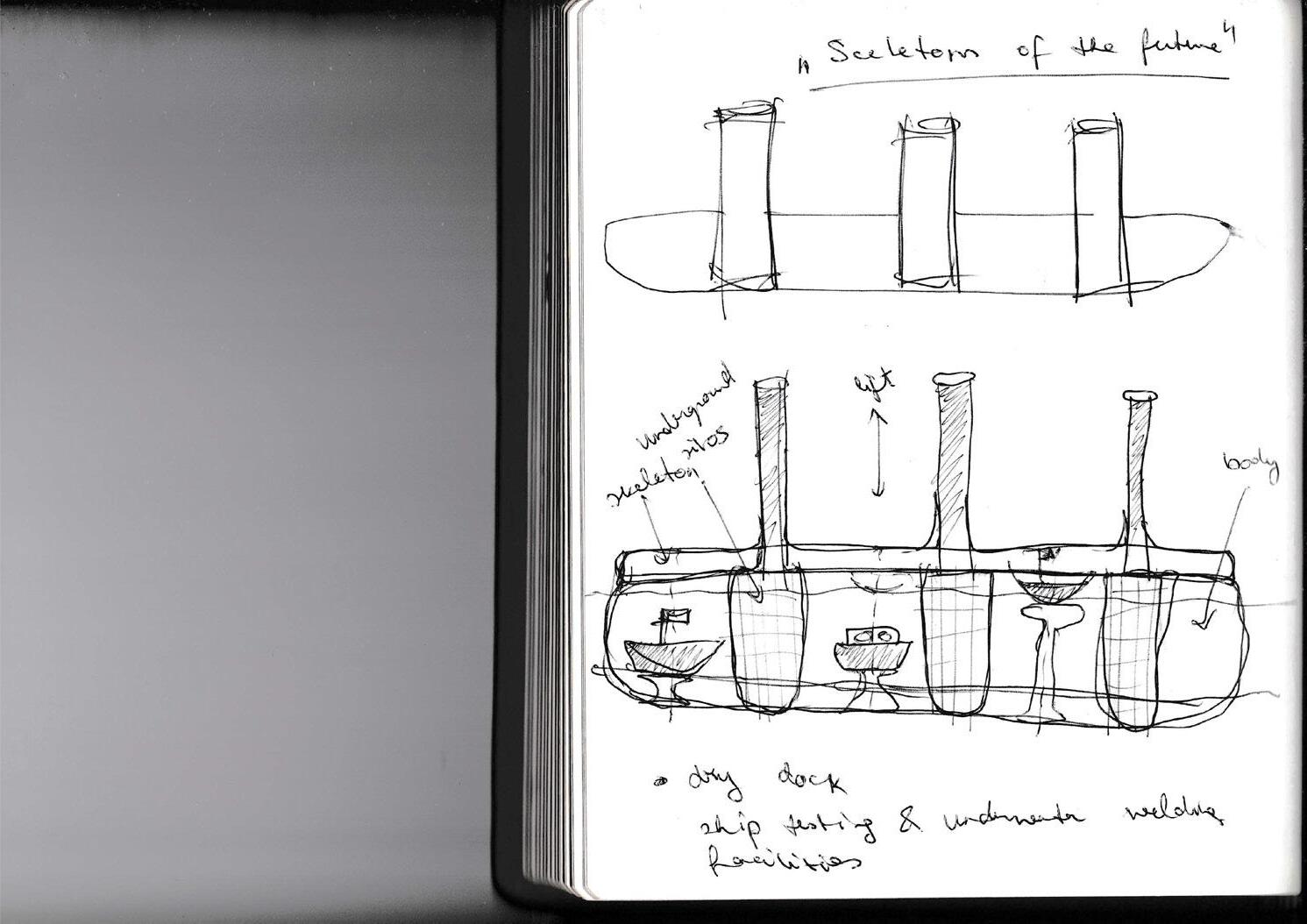

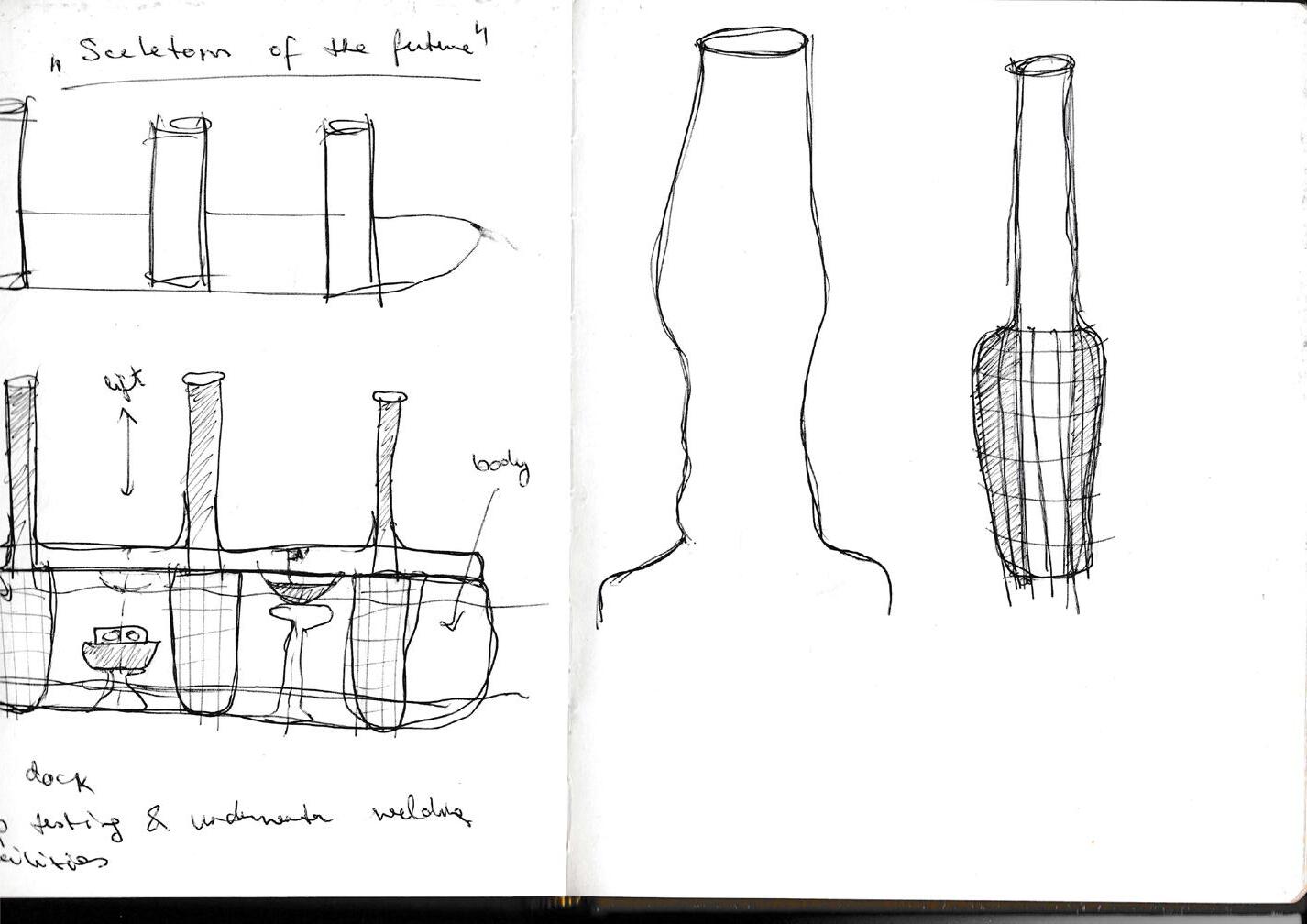

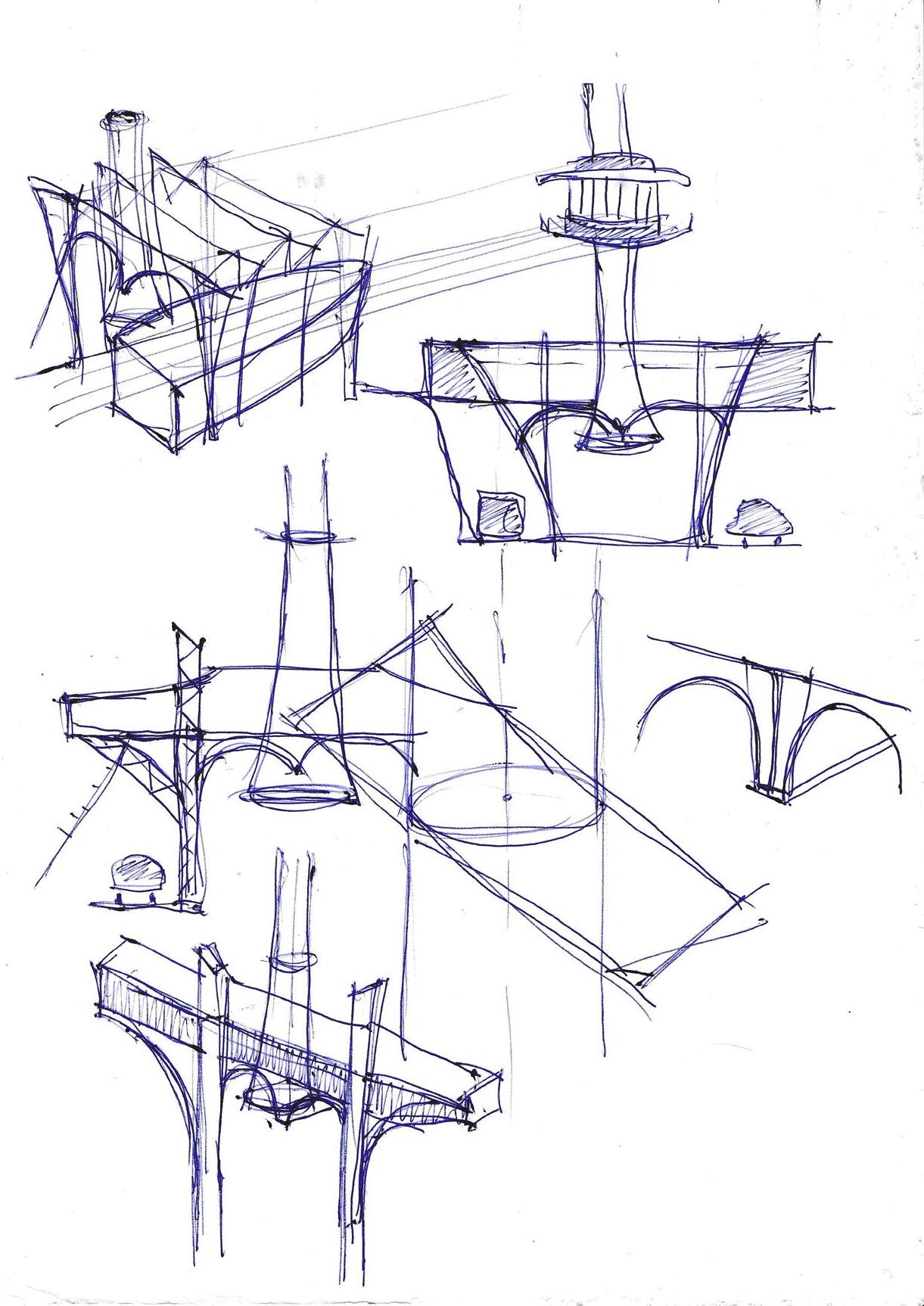

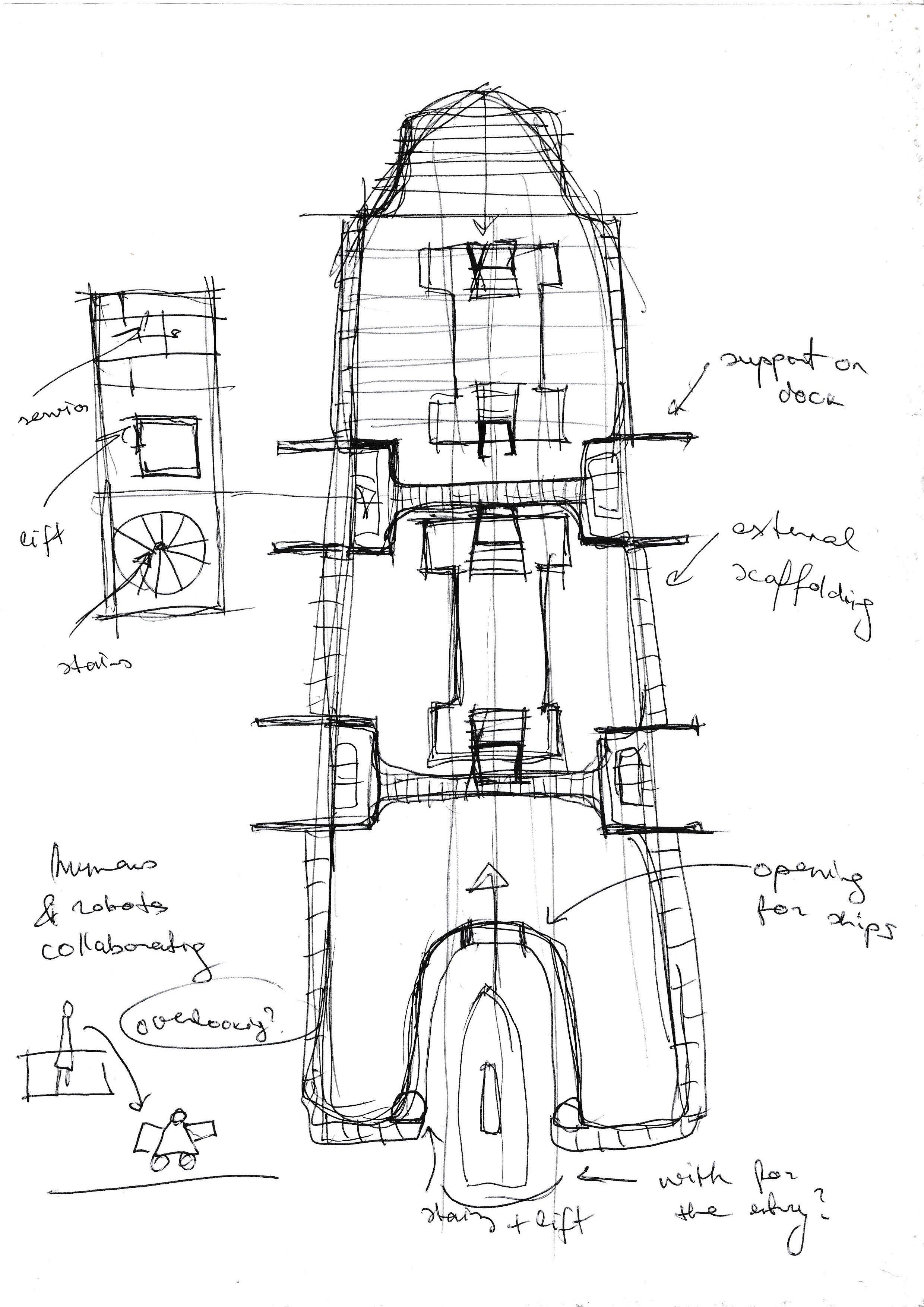

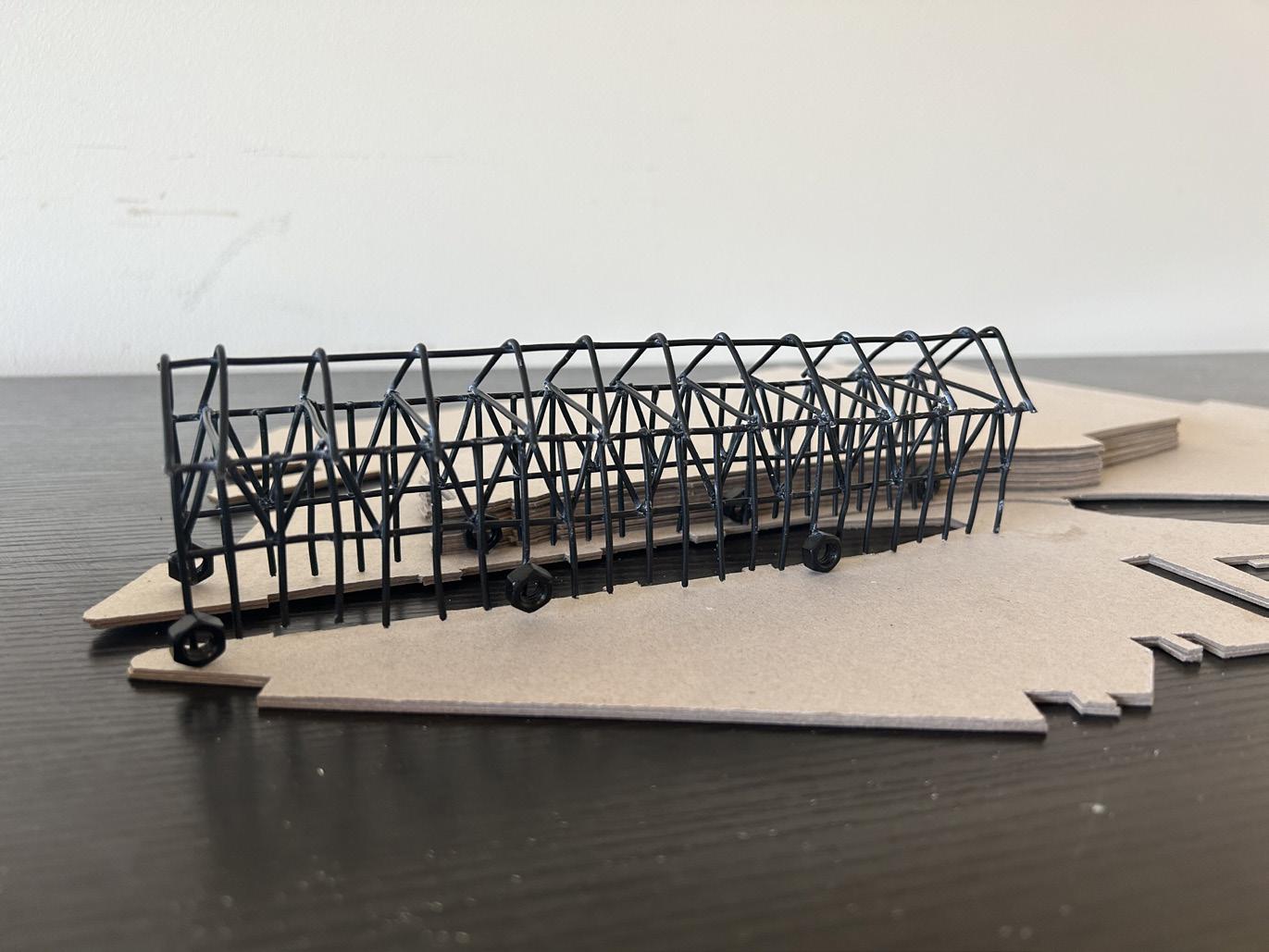

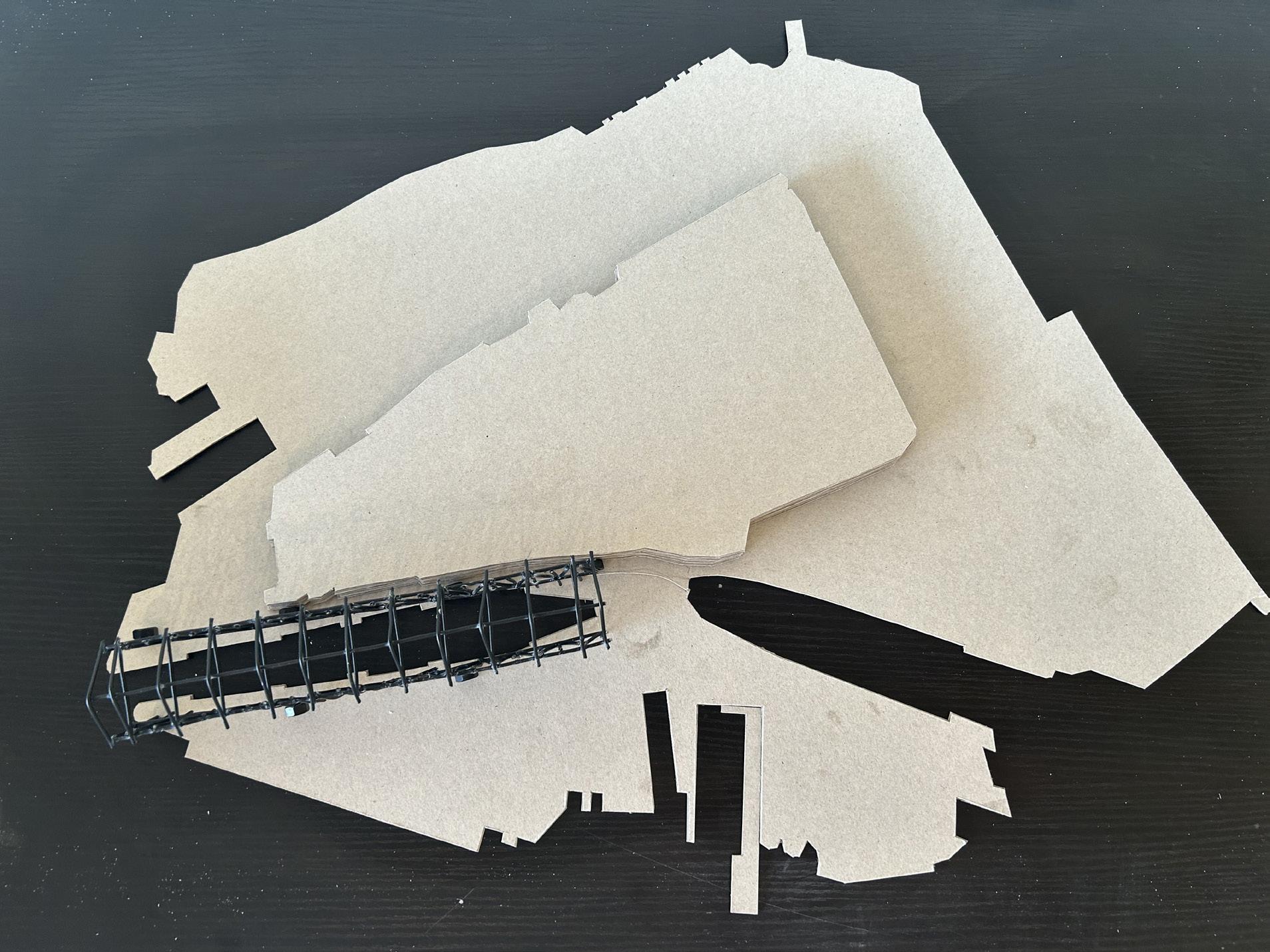

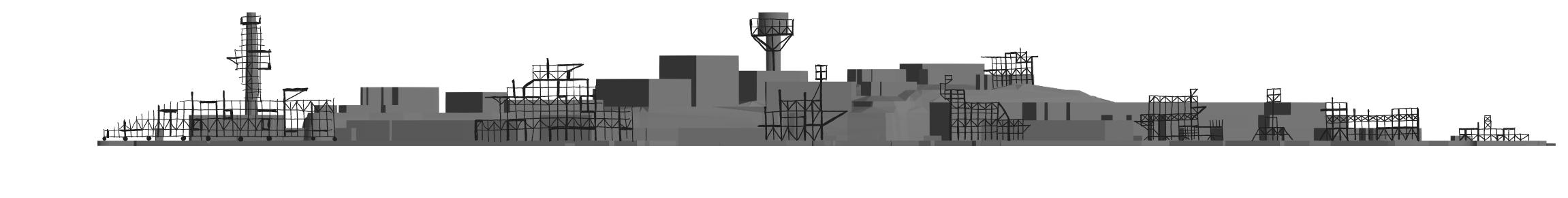

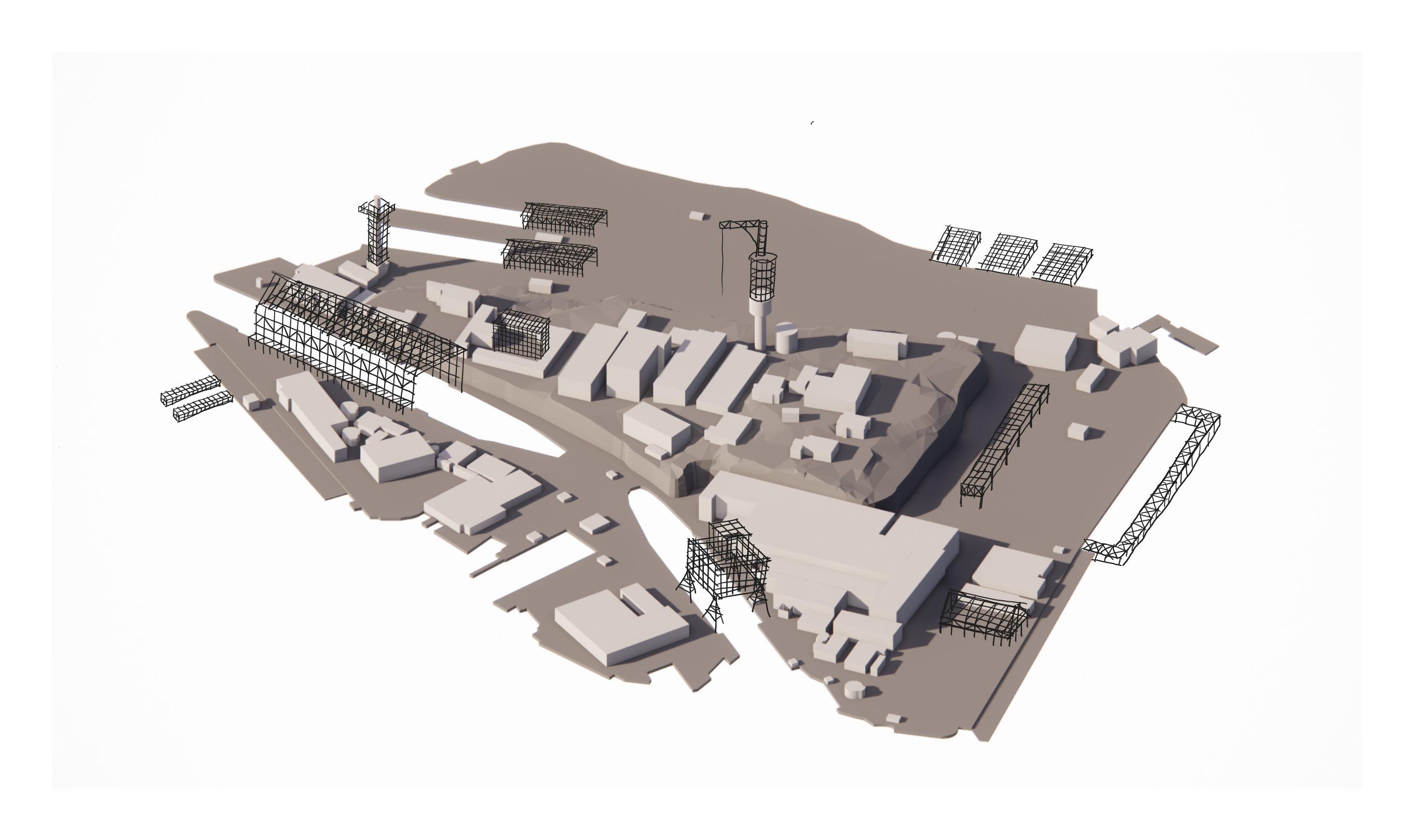

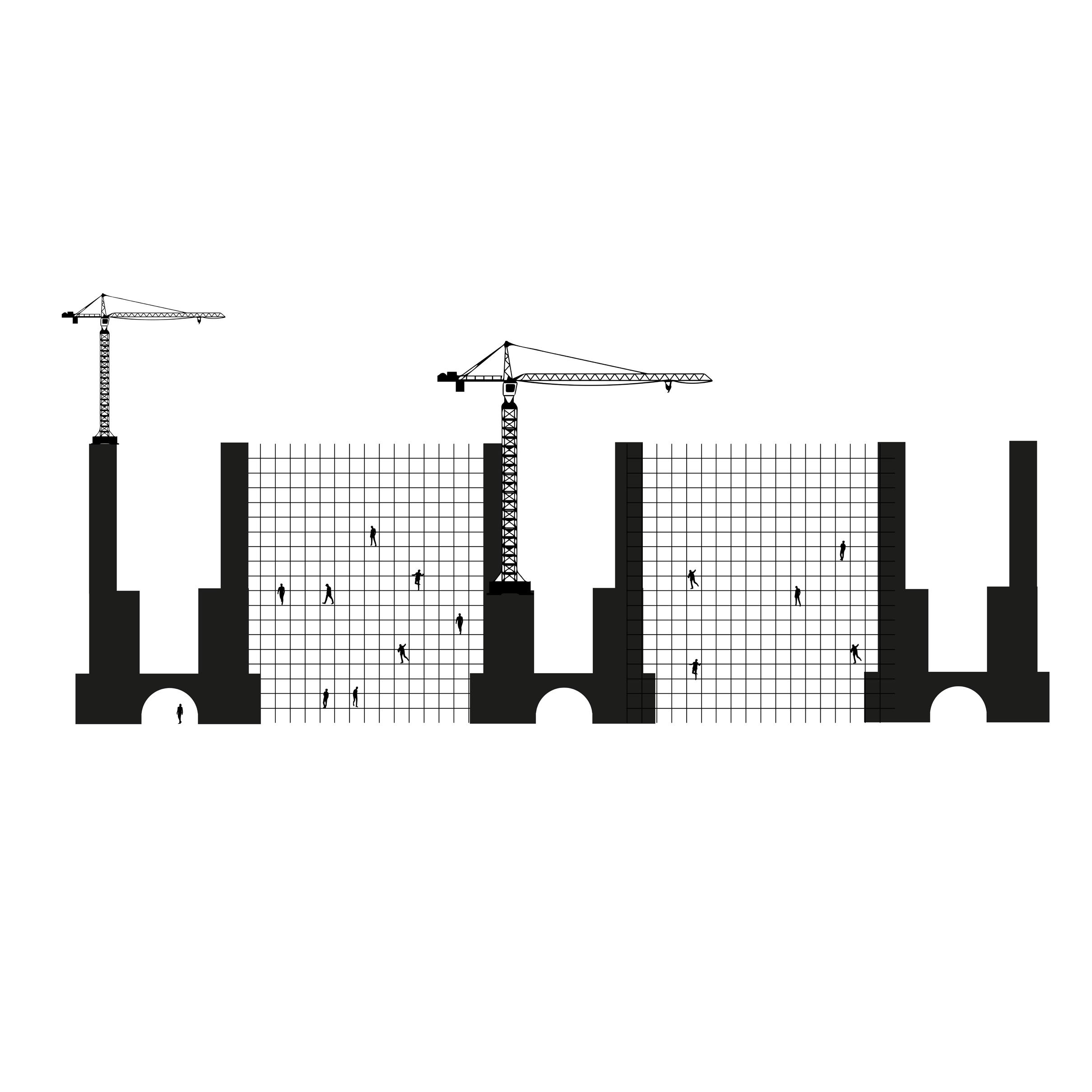

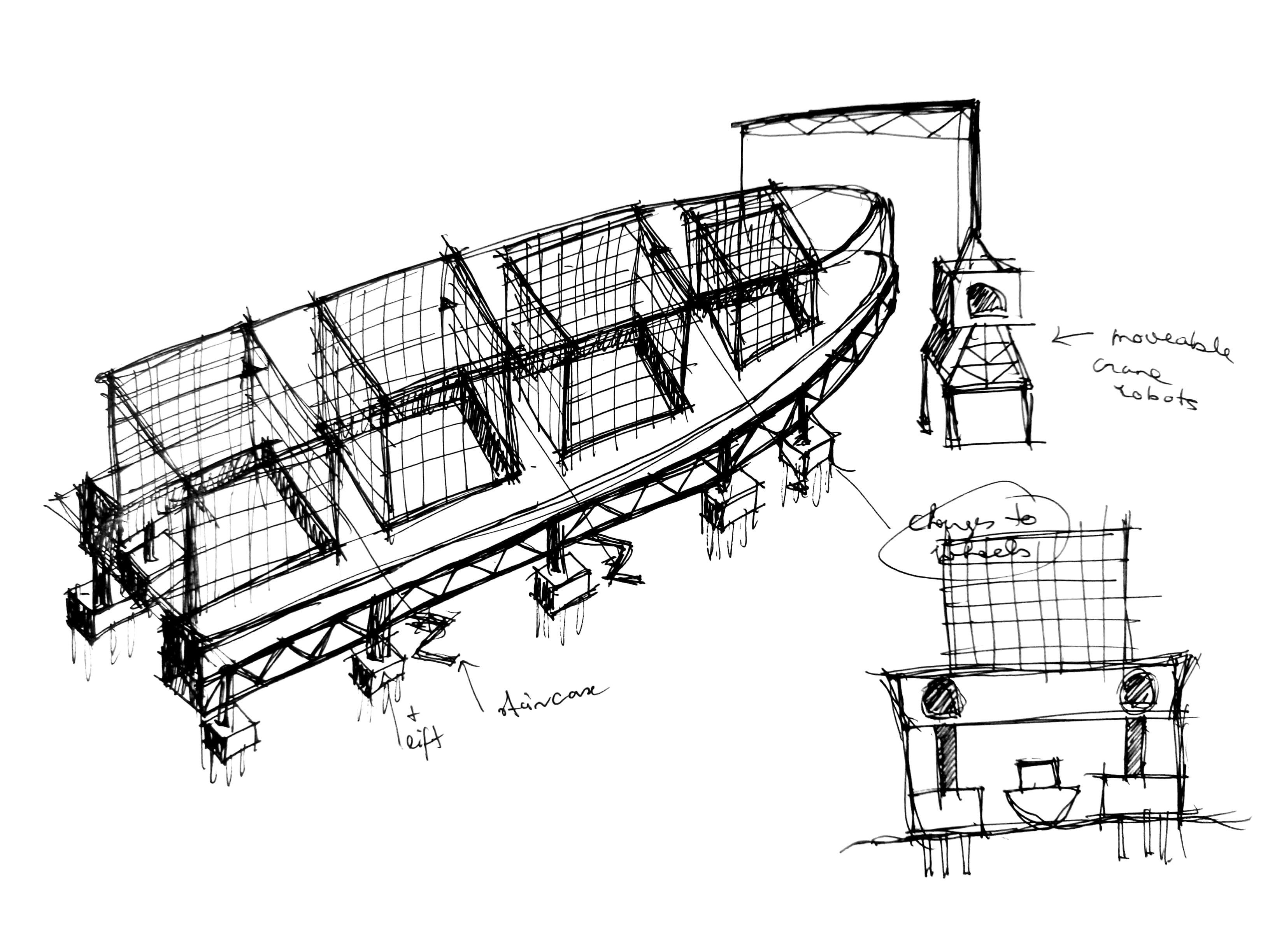

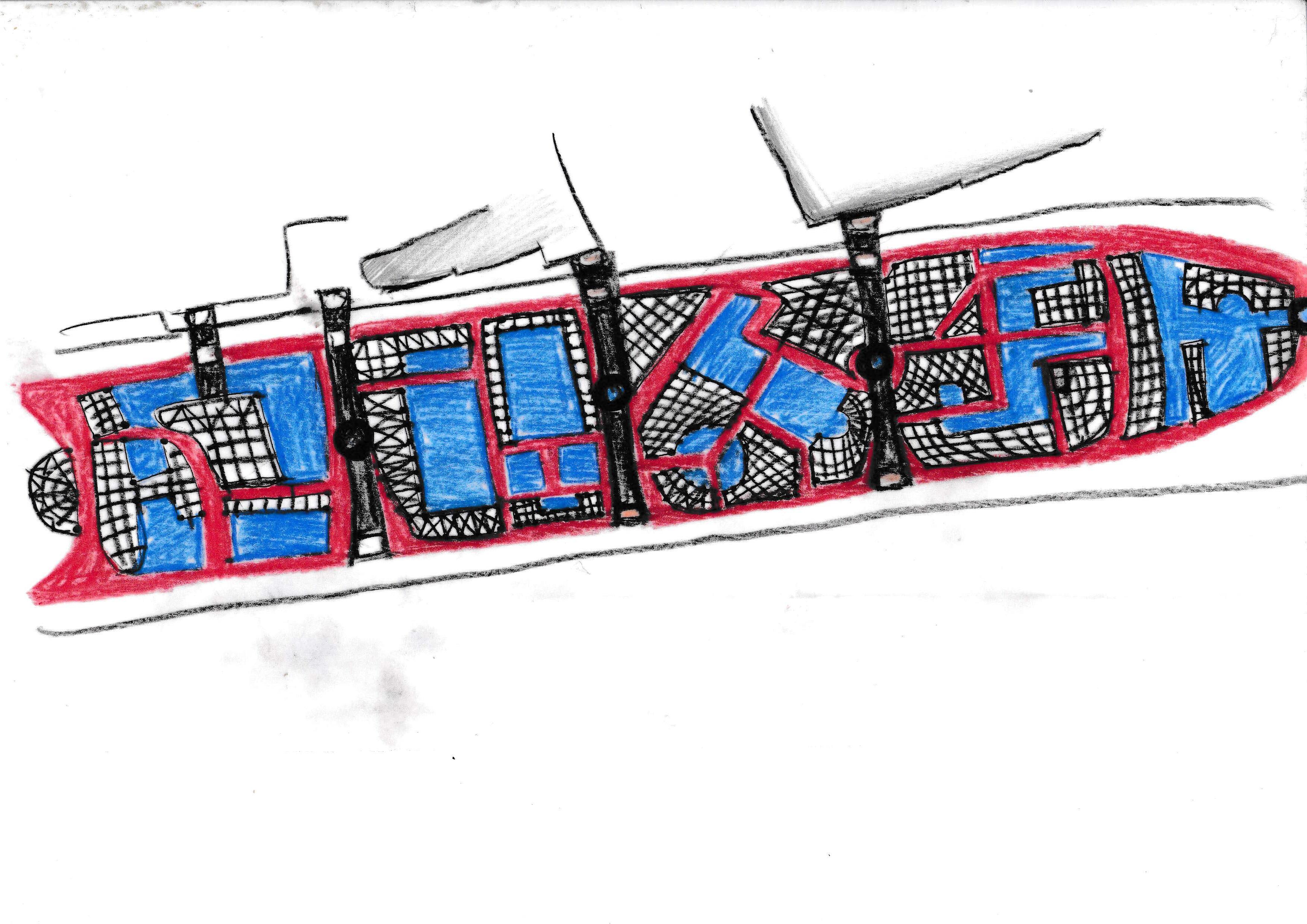

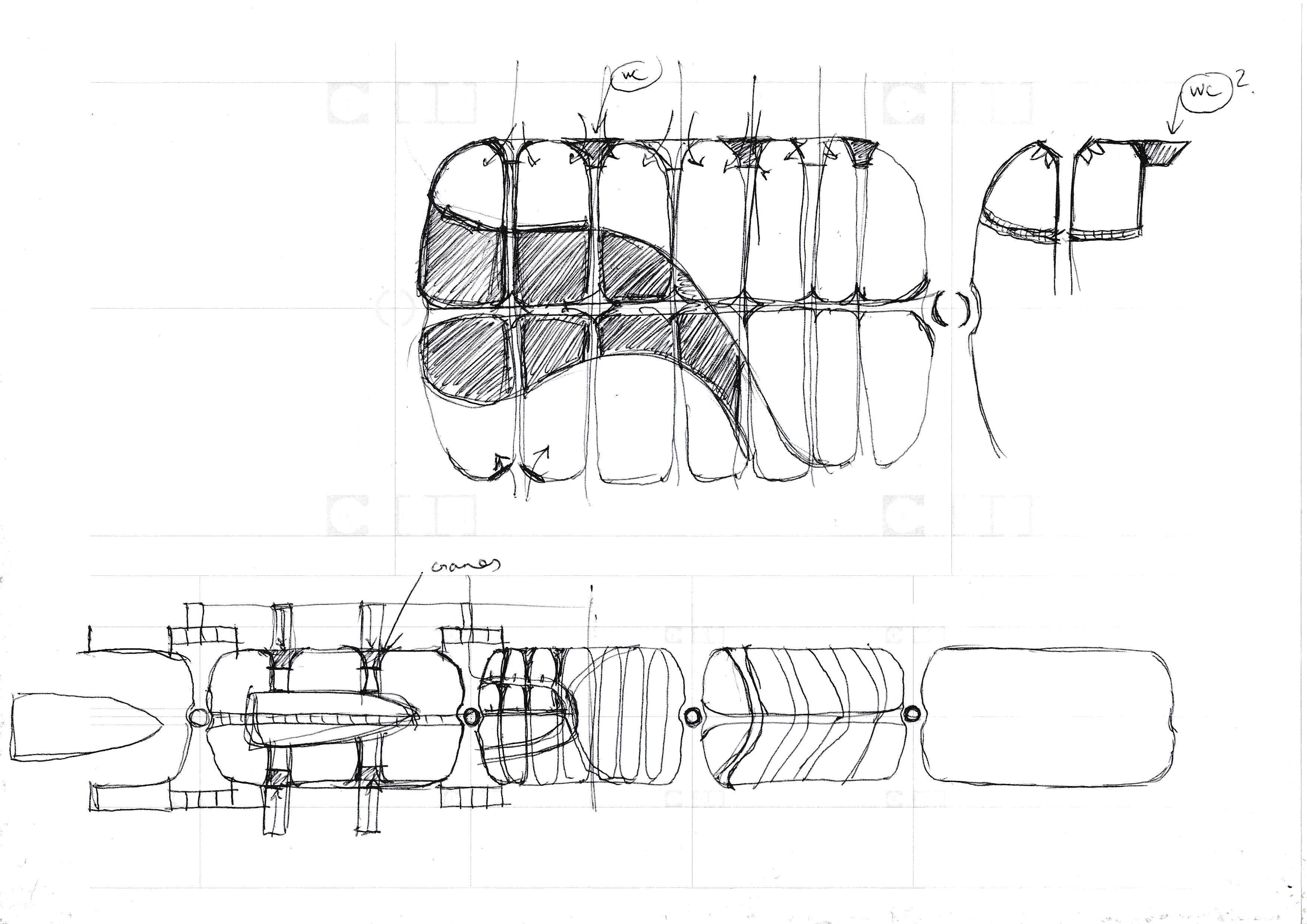

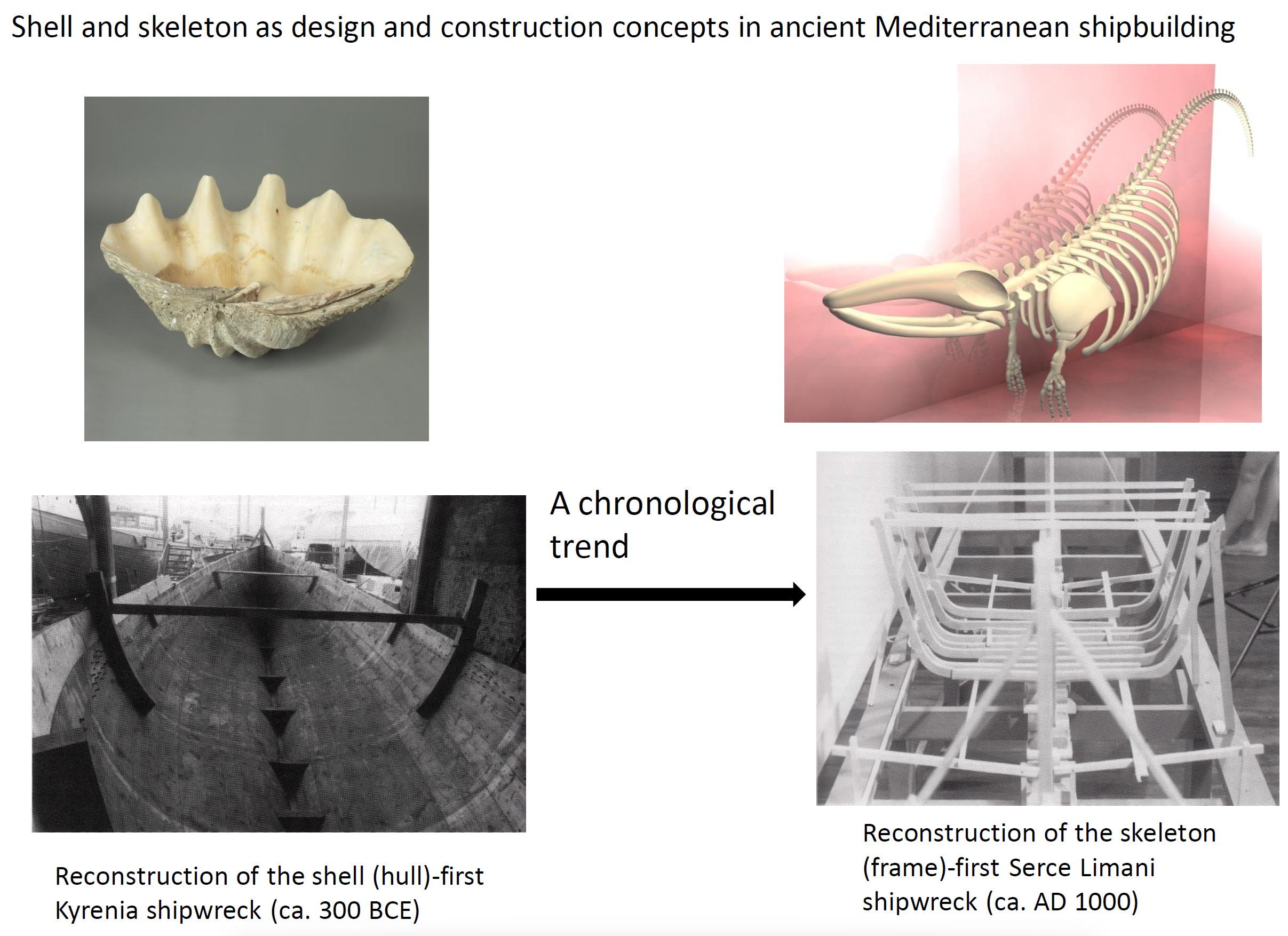

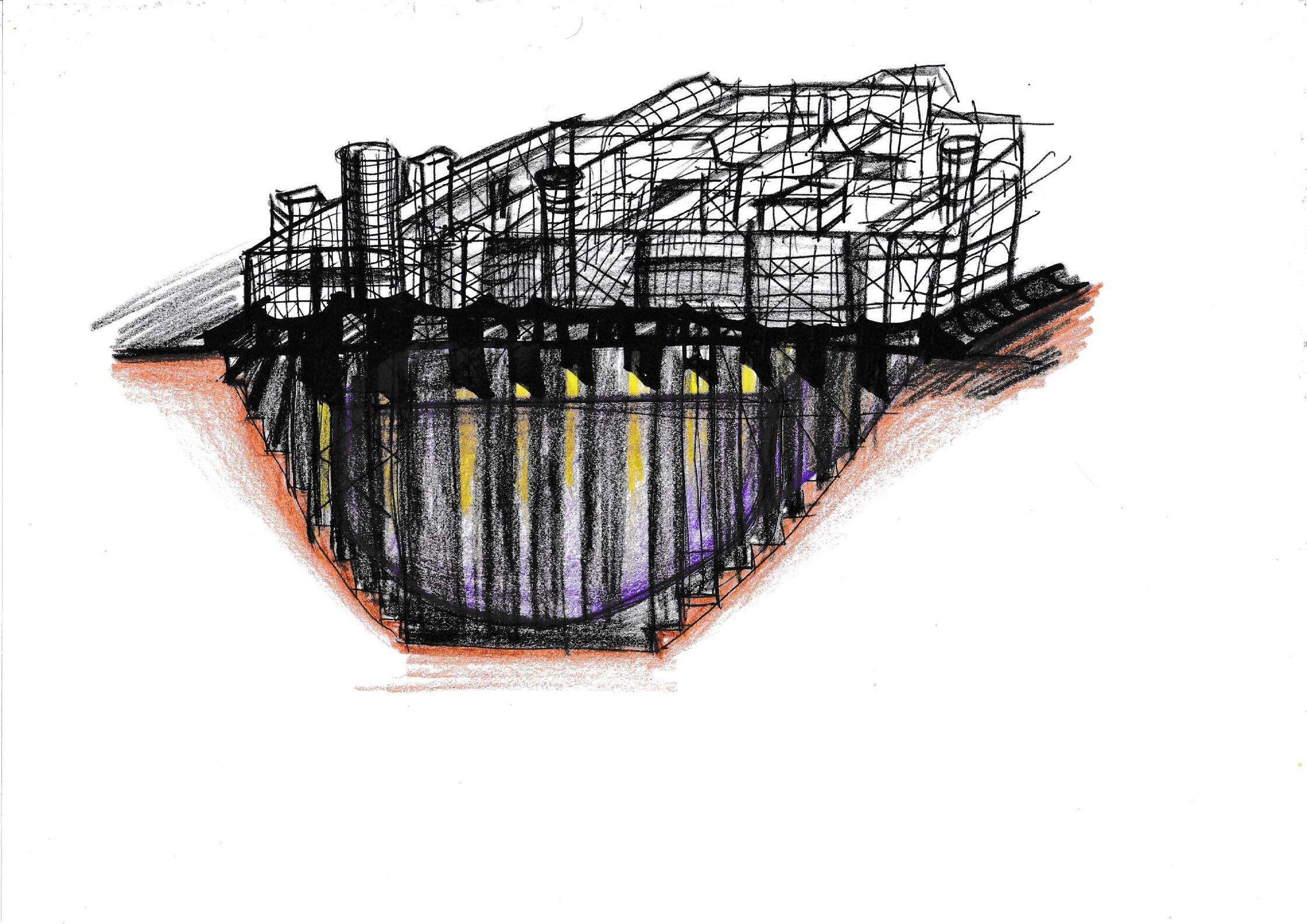

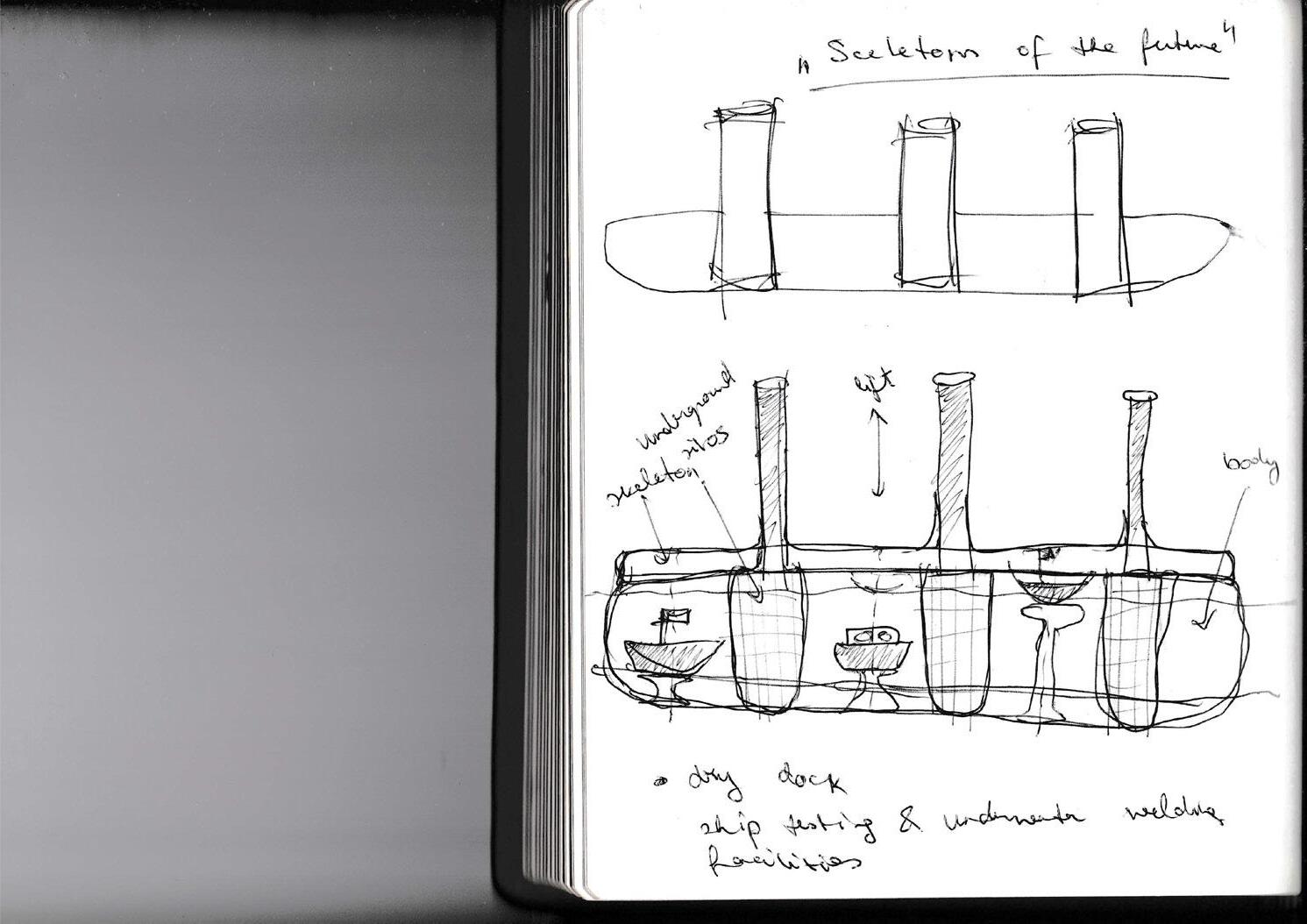

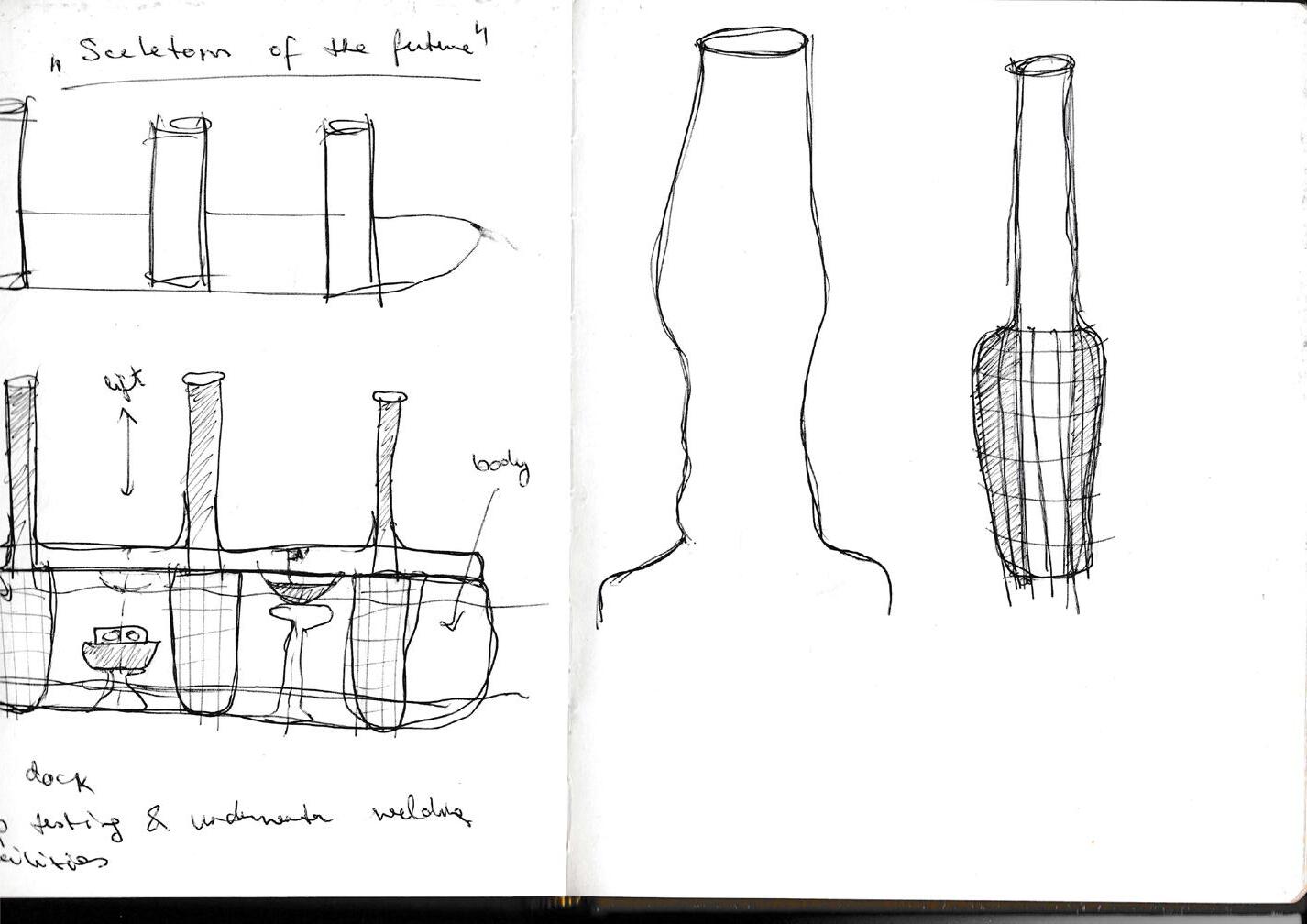

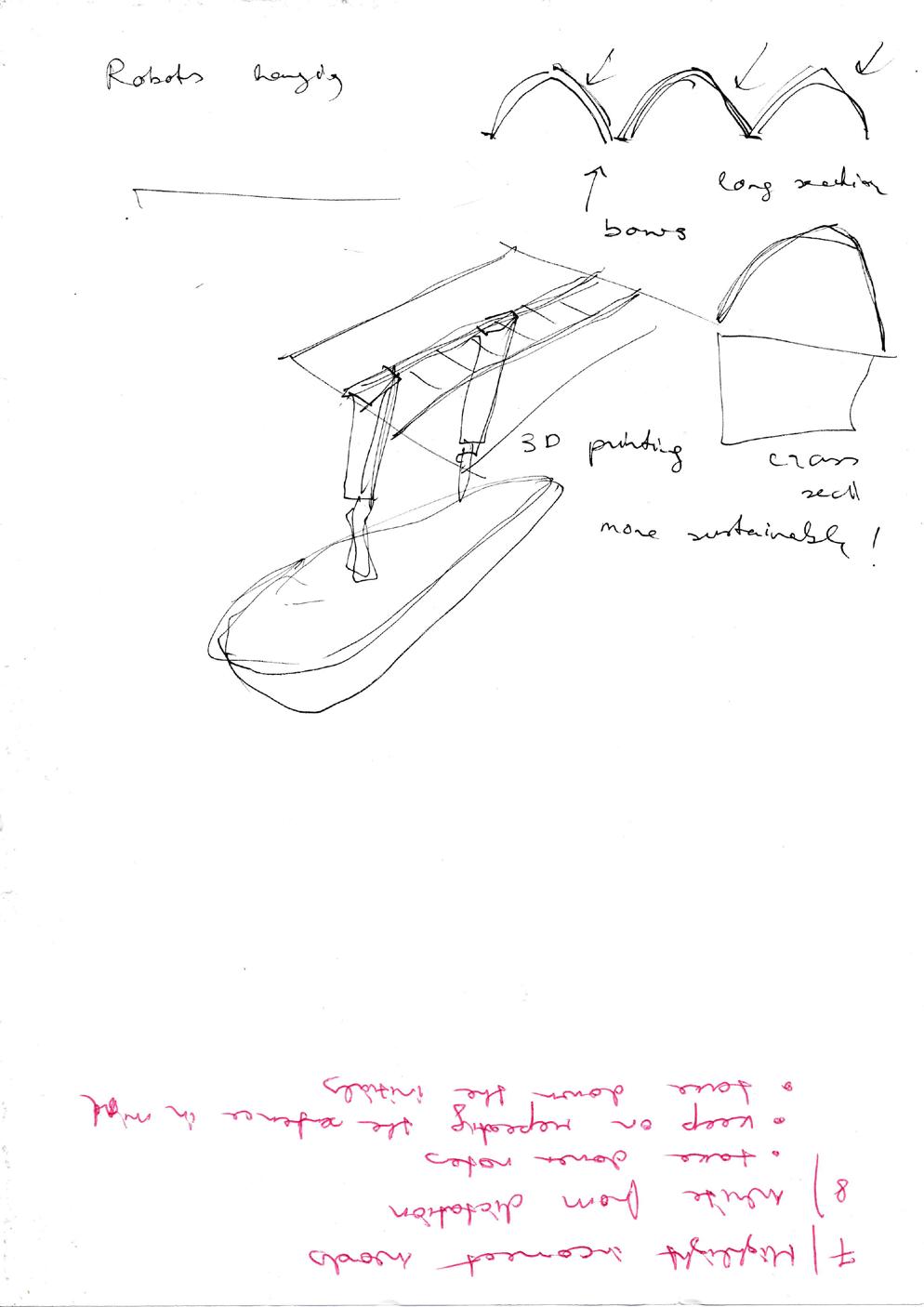

SKELETONS OF THE FUTURE

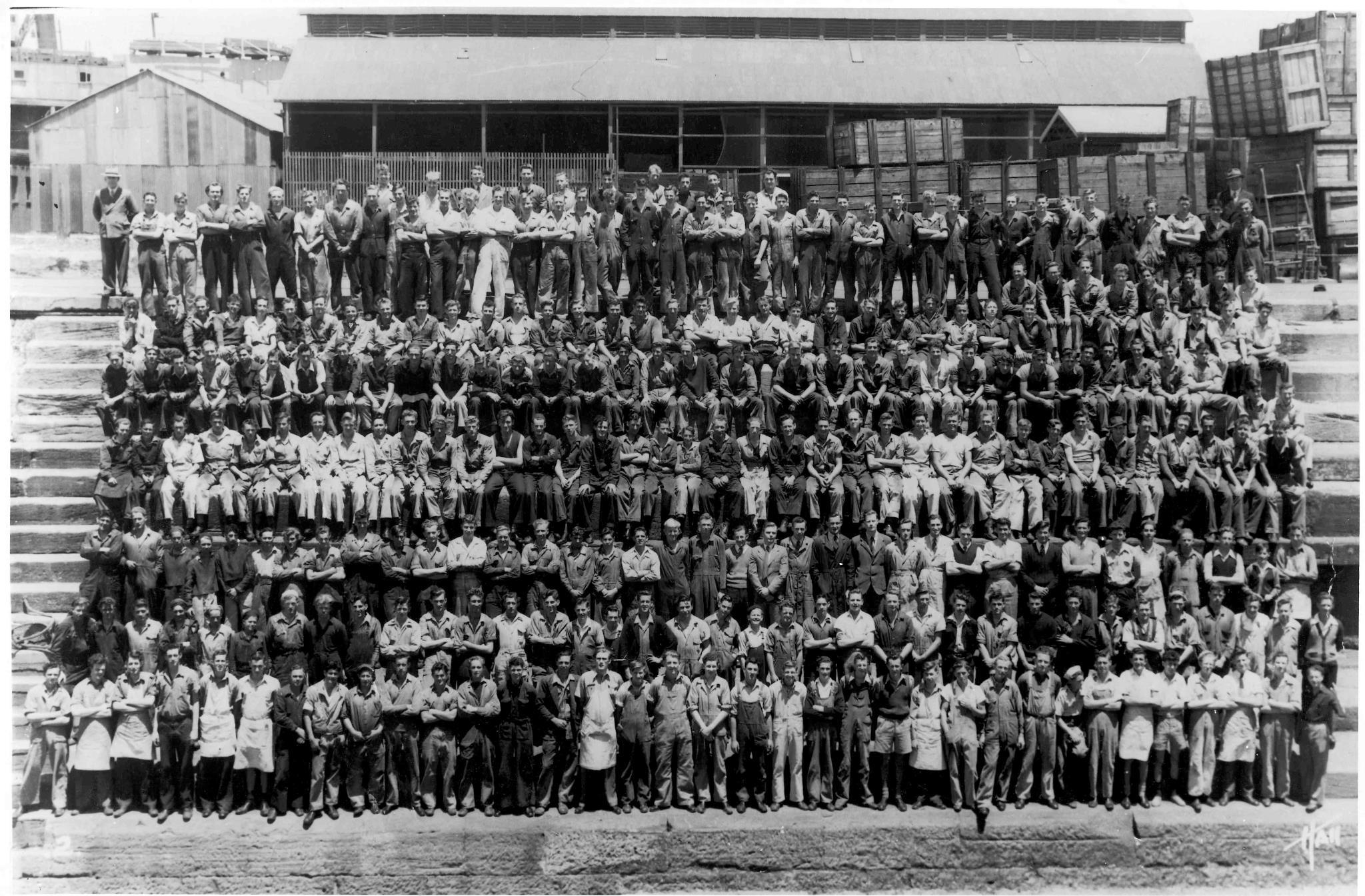

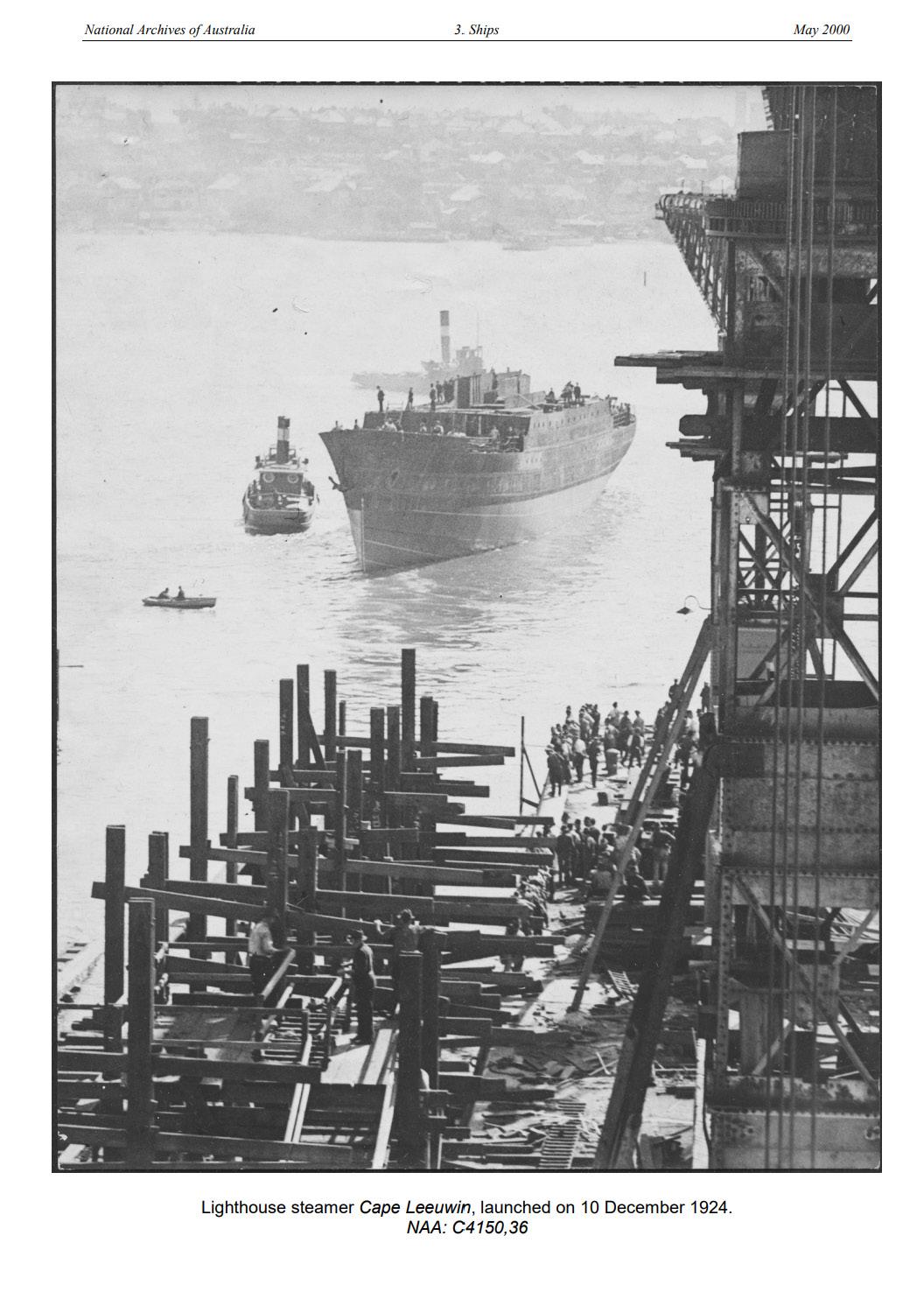

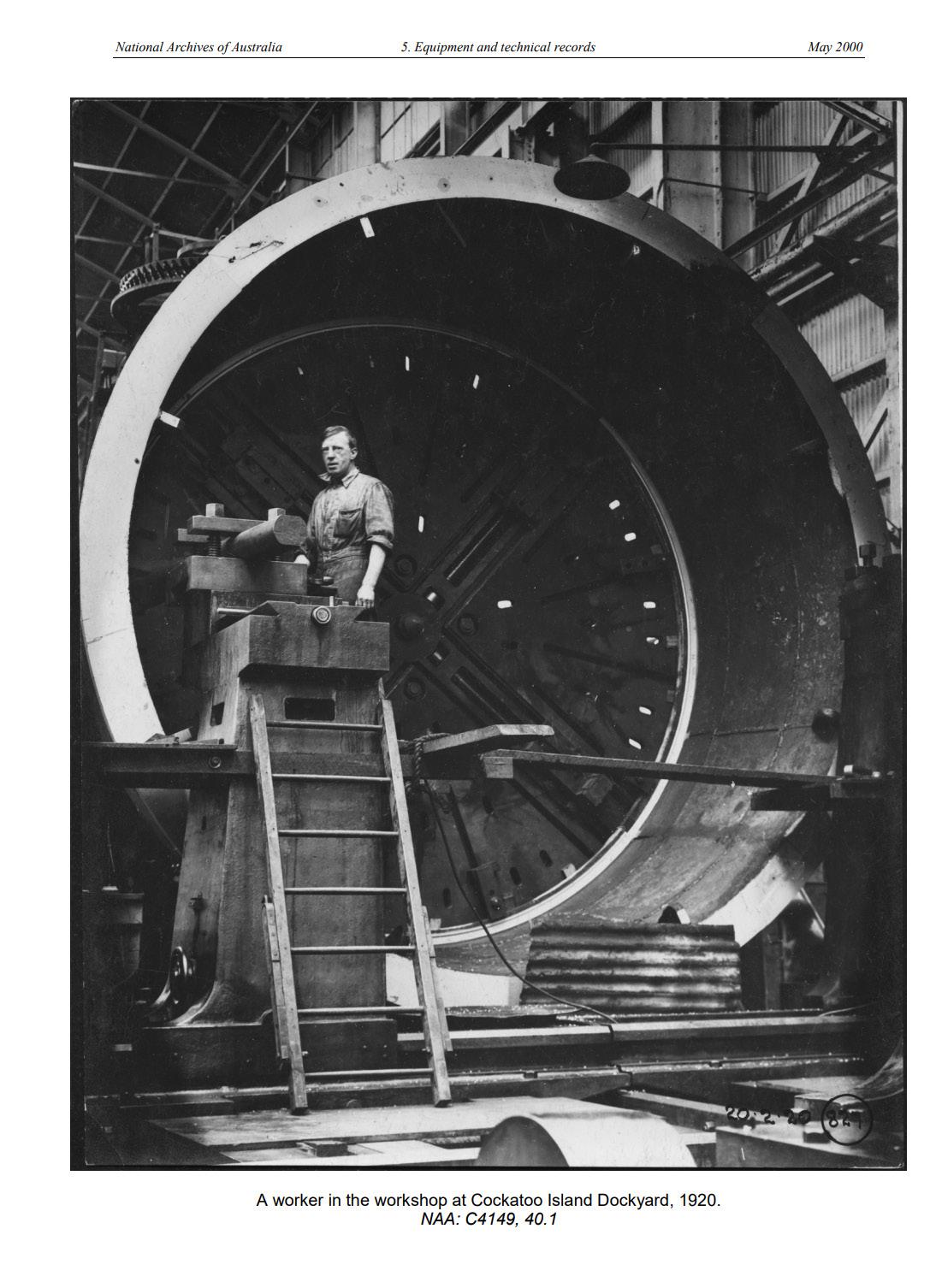

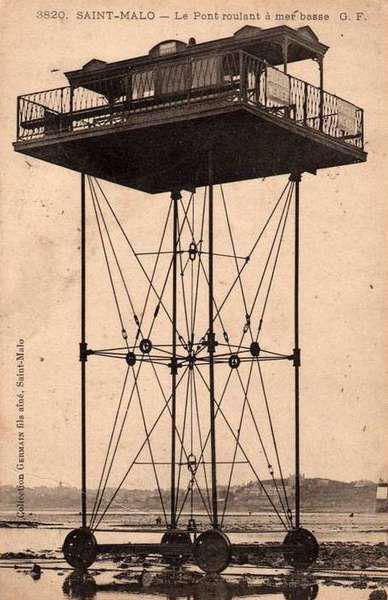

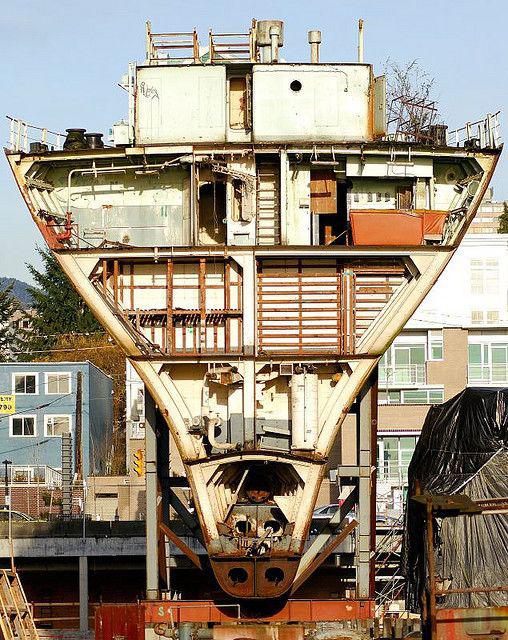

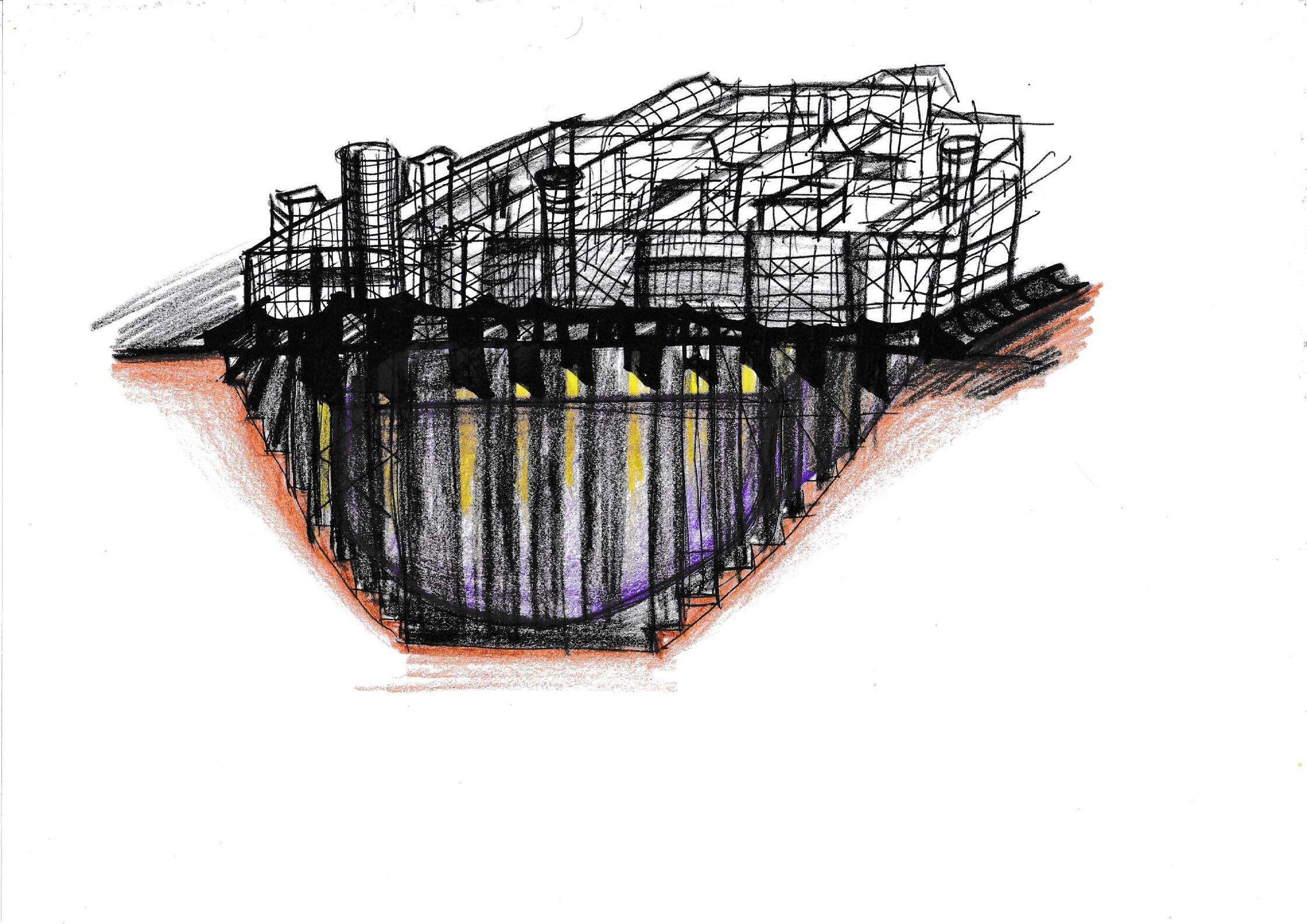

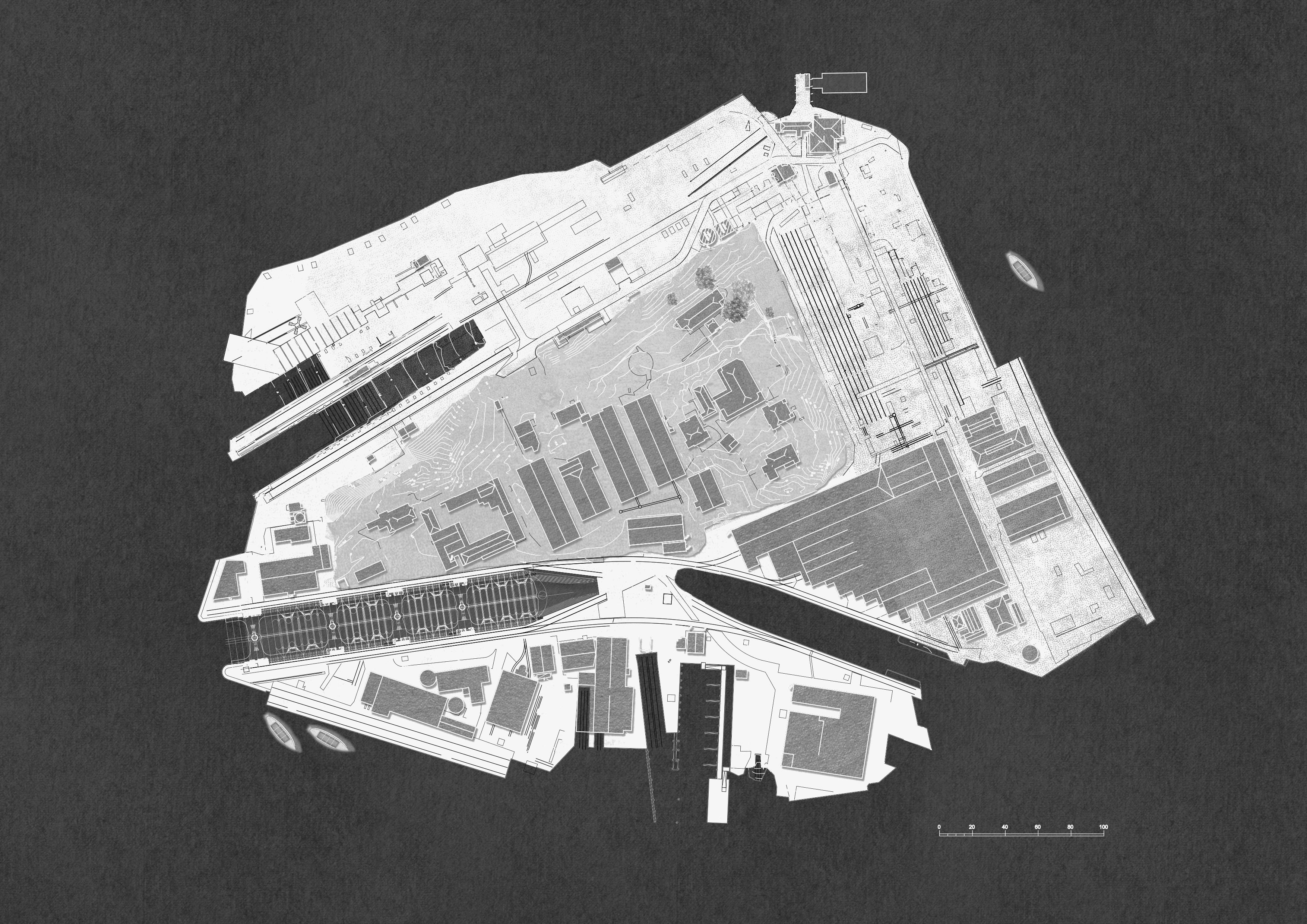

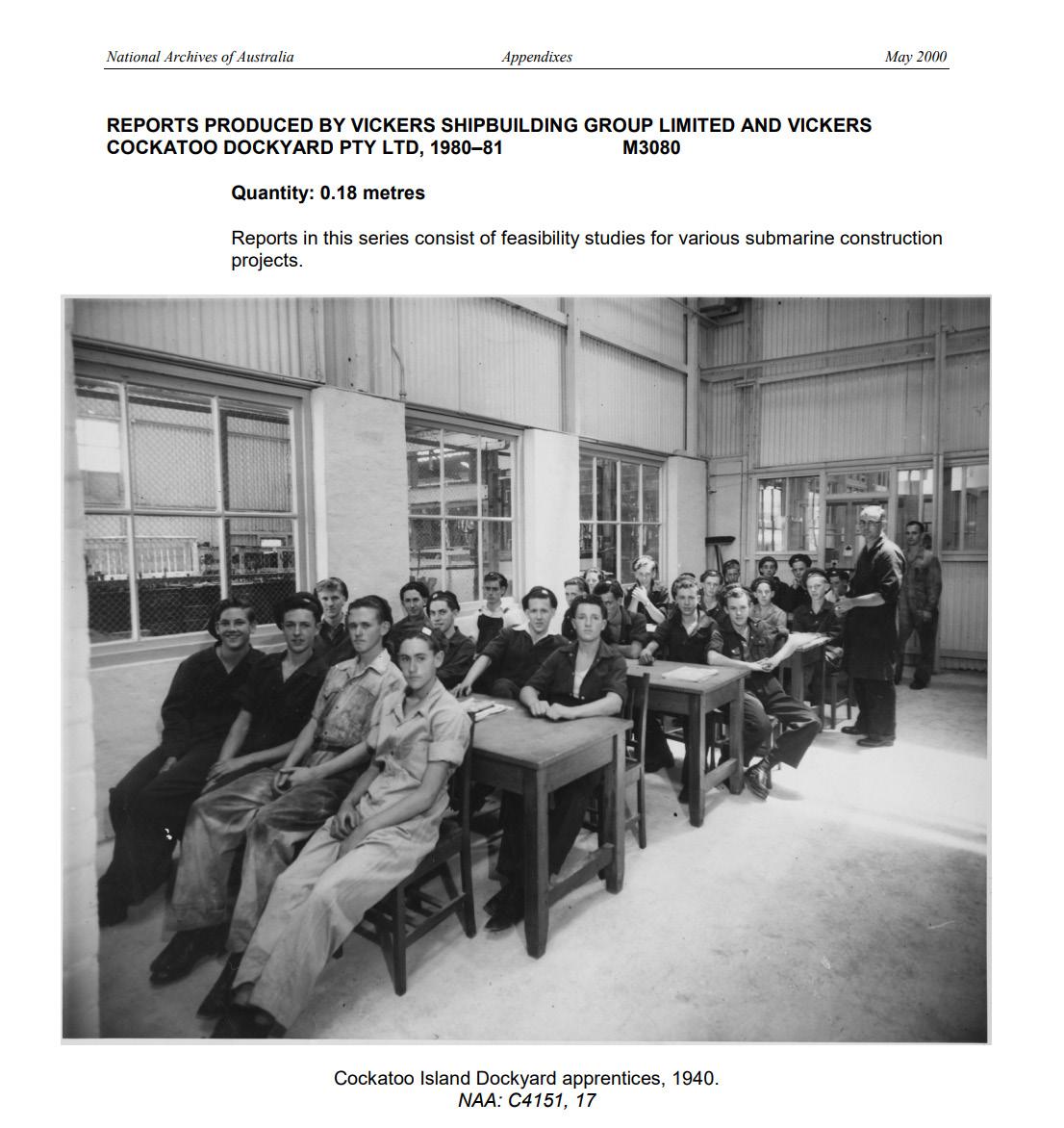

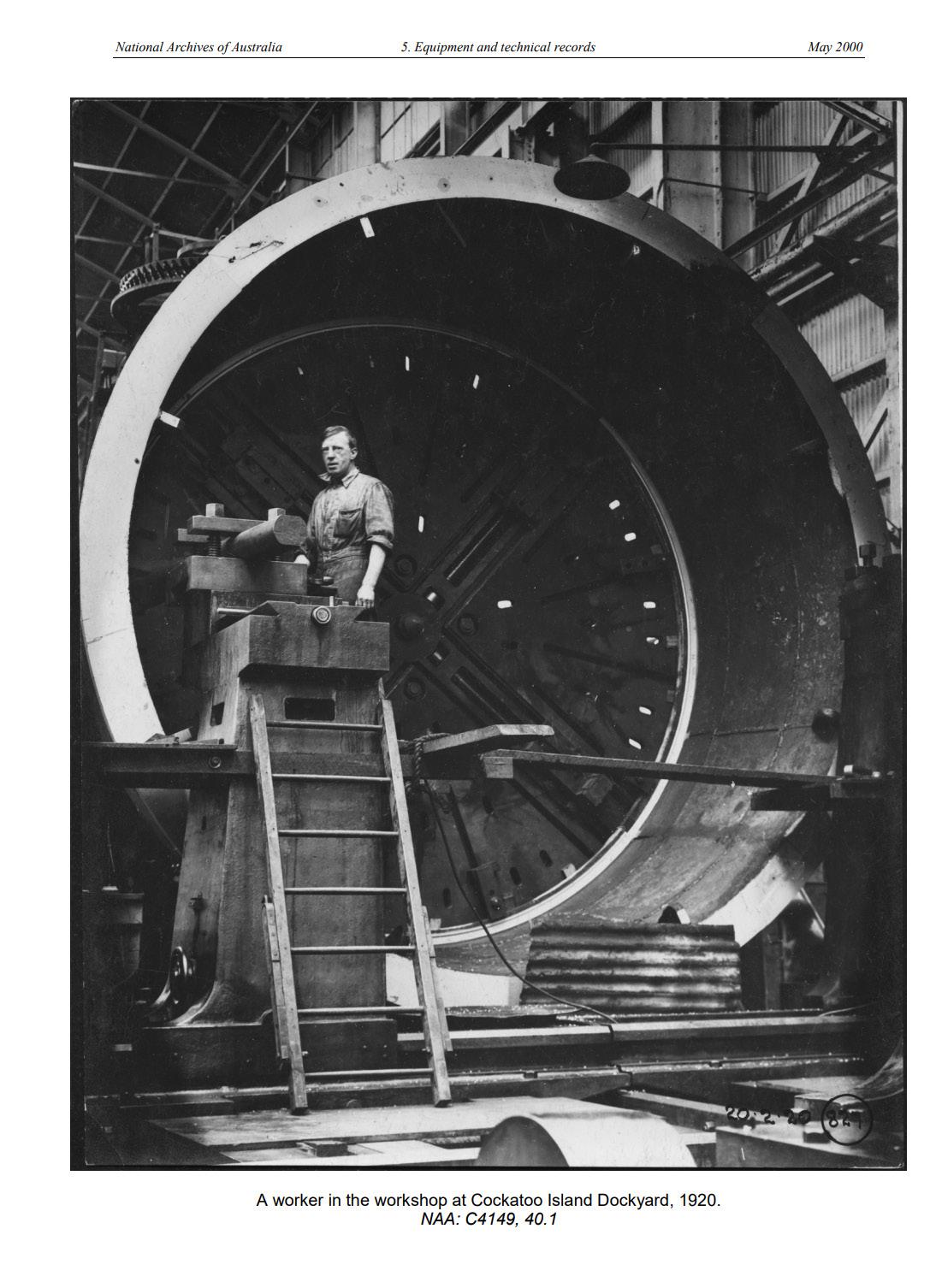

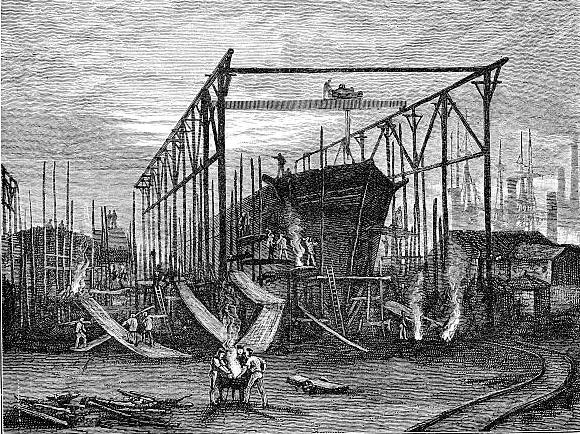

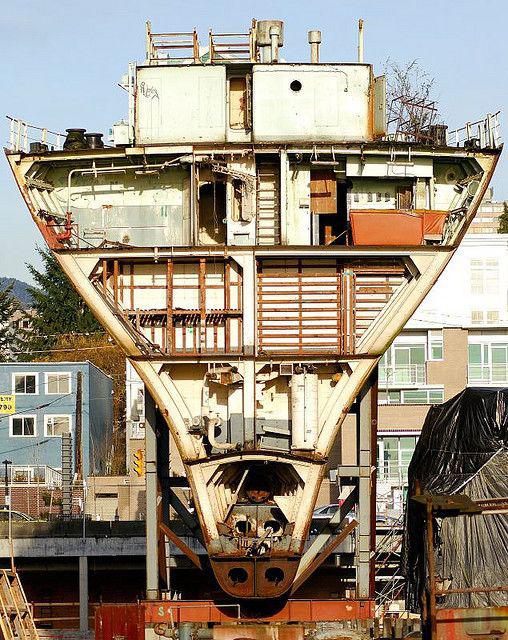

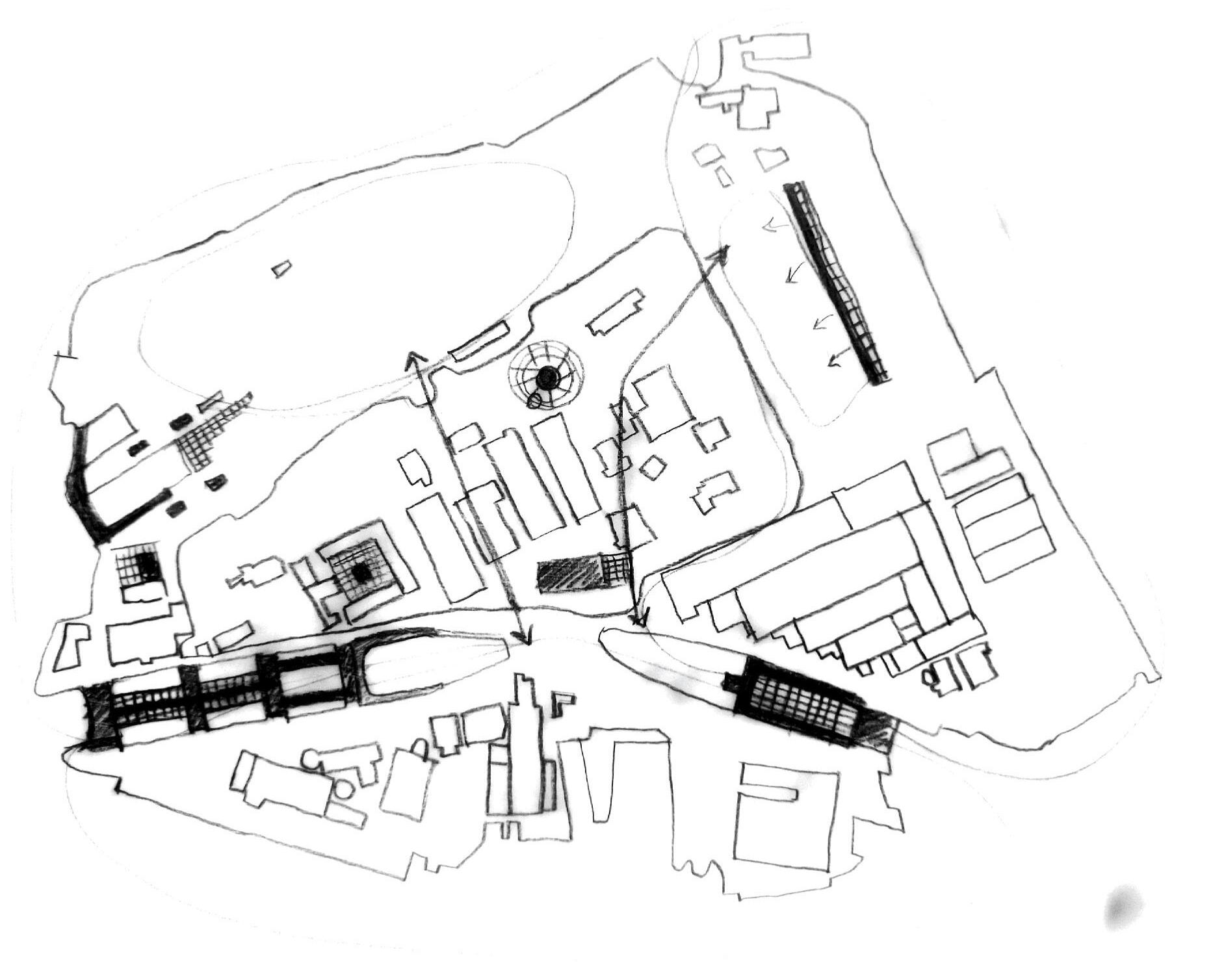

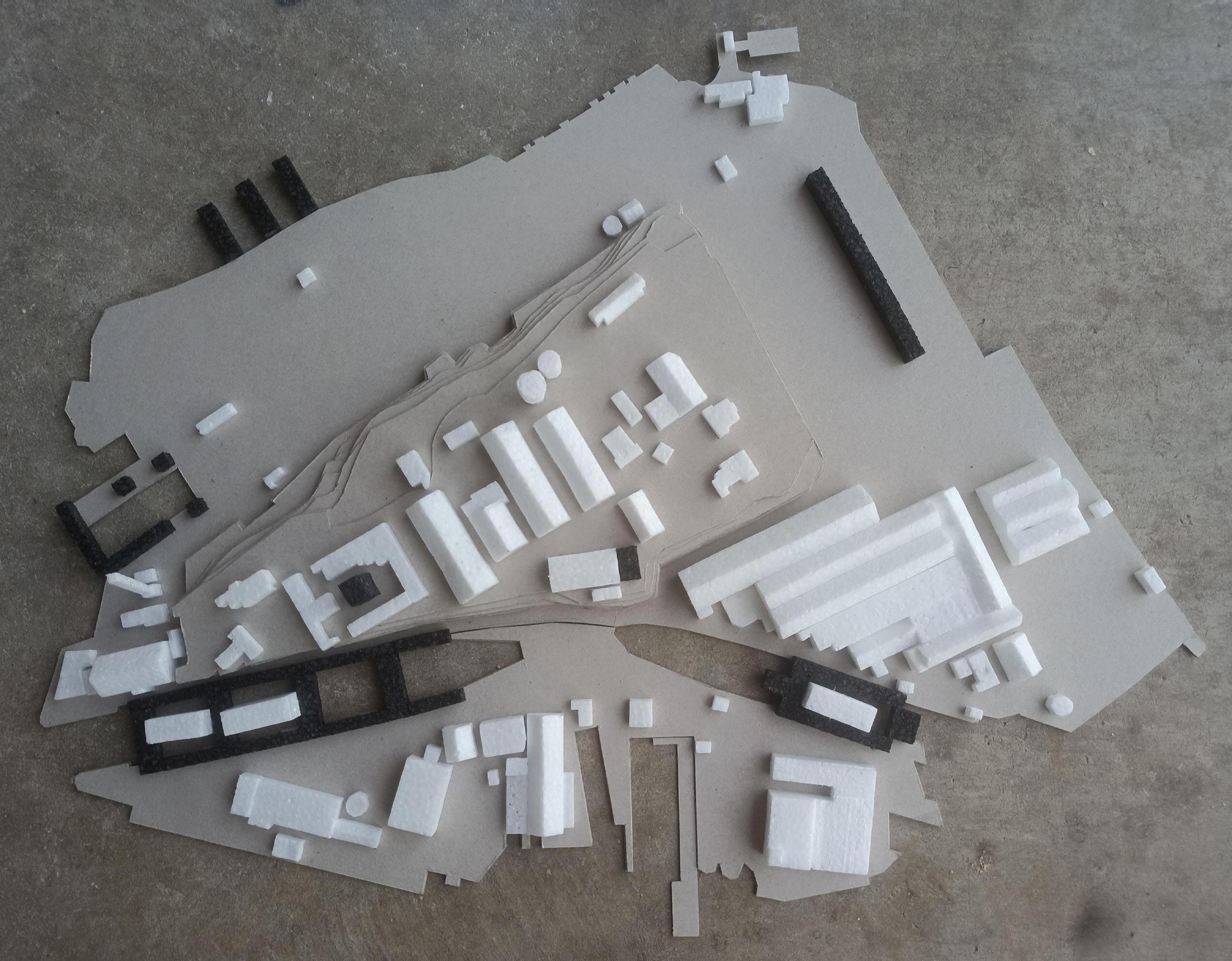

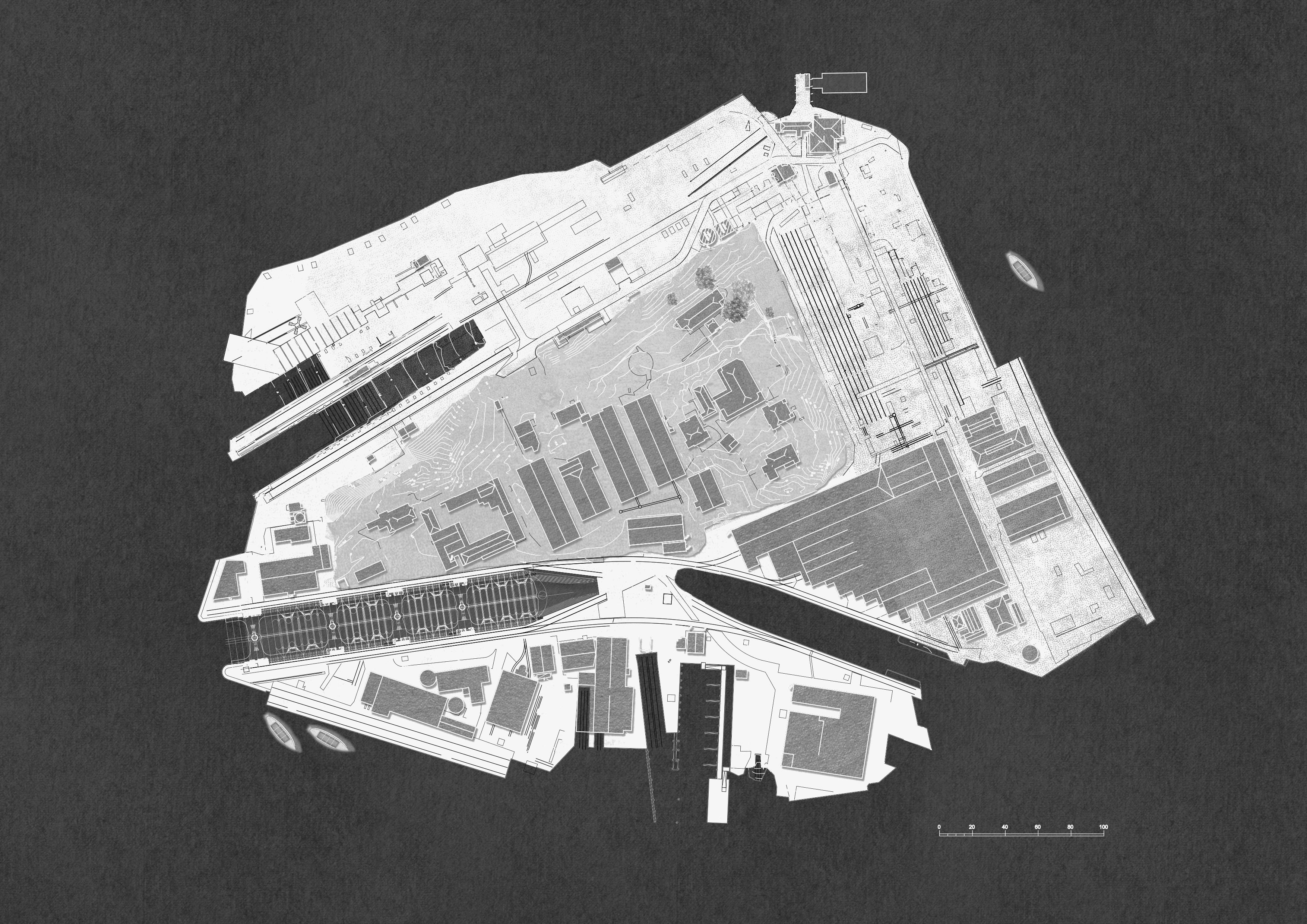

Construction of the Cockatoo Island

Construction of the Cockatoo Island

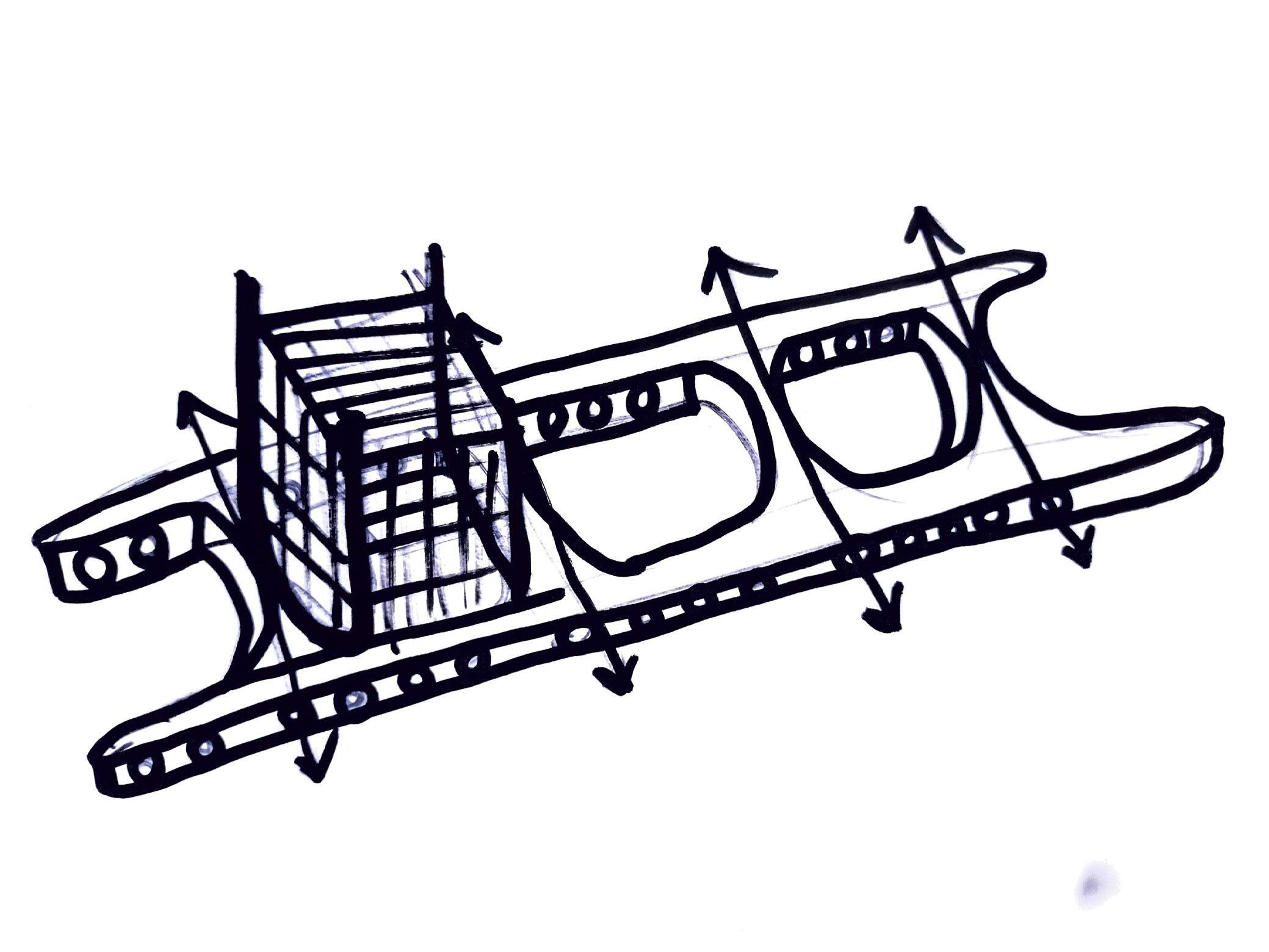

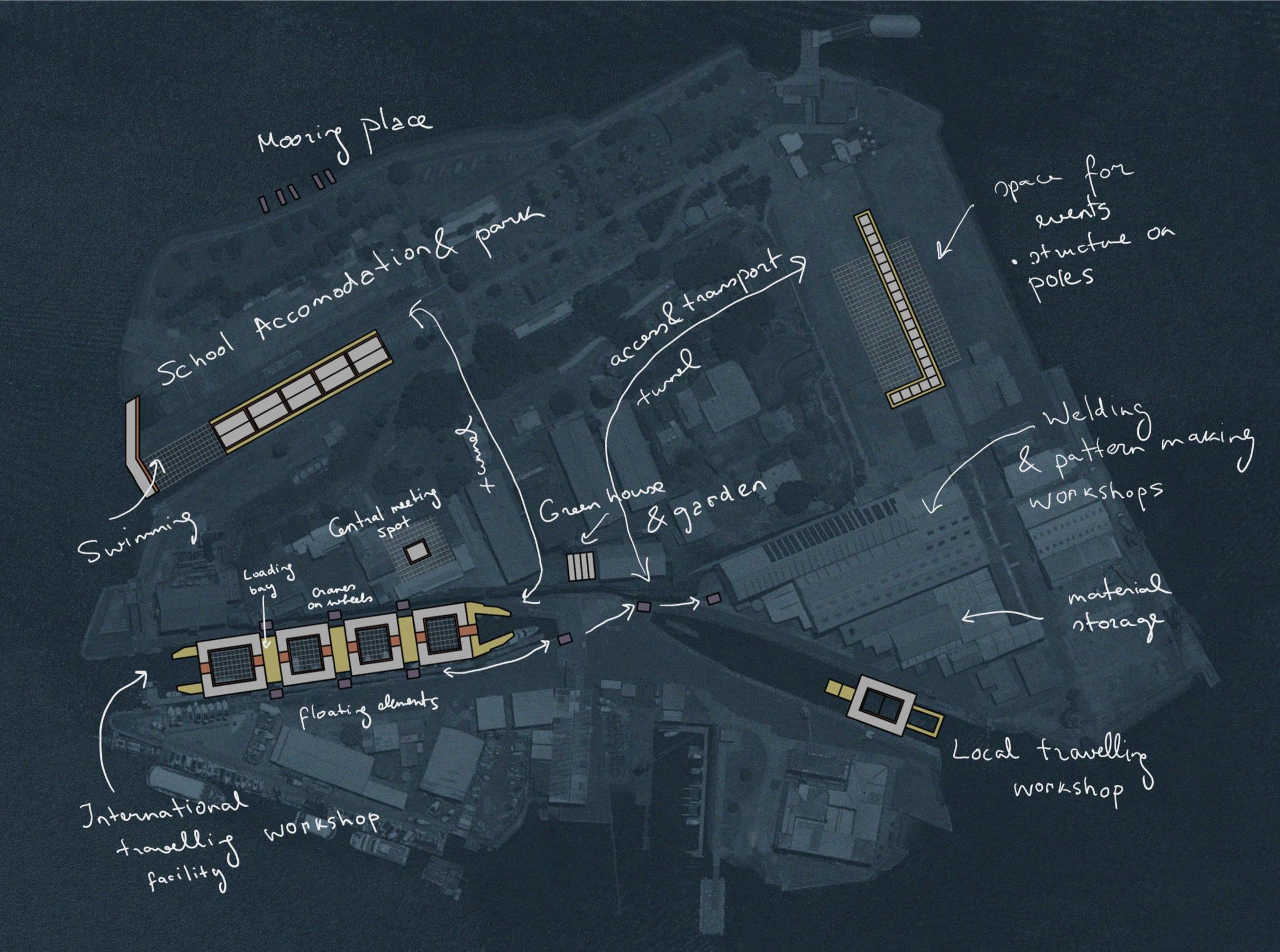

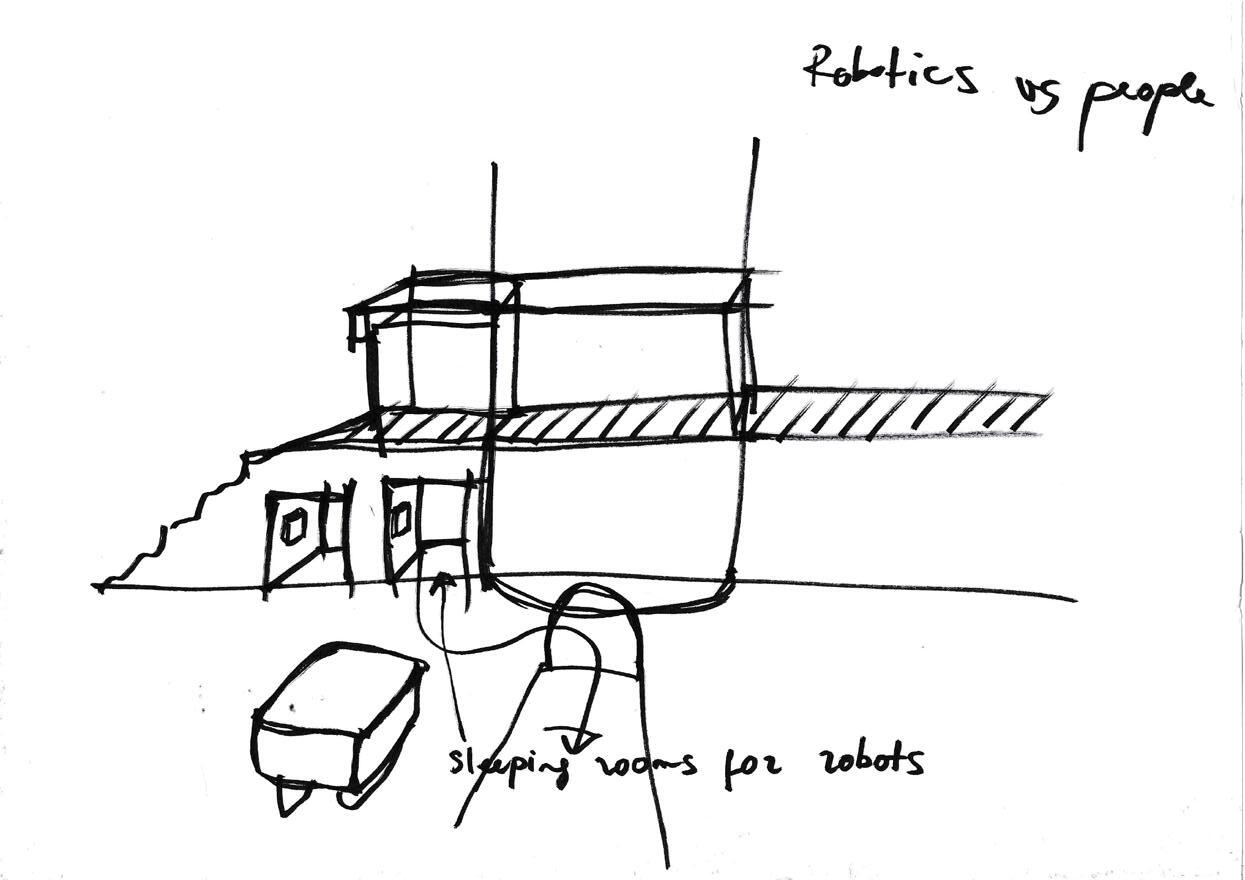

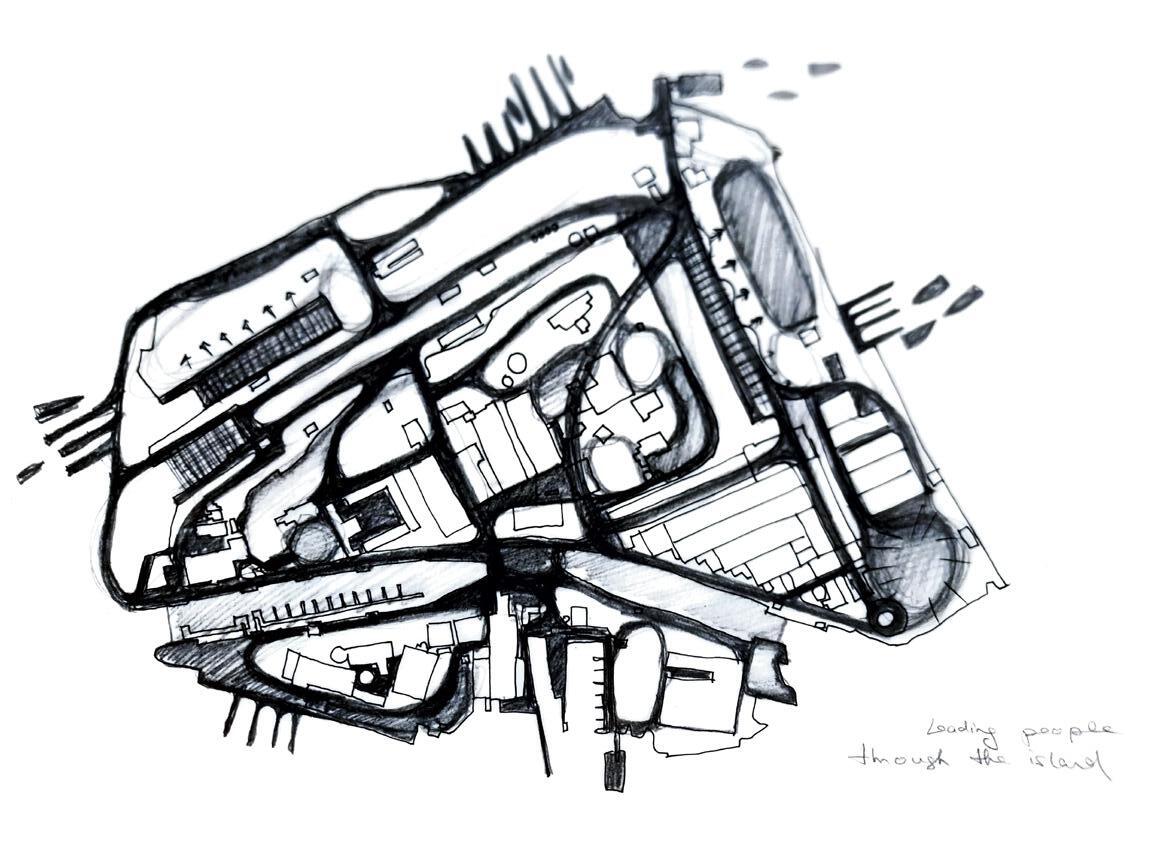

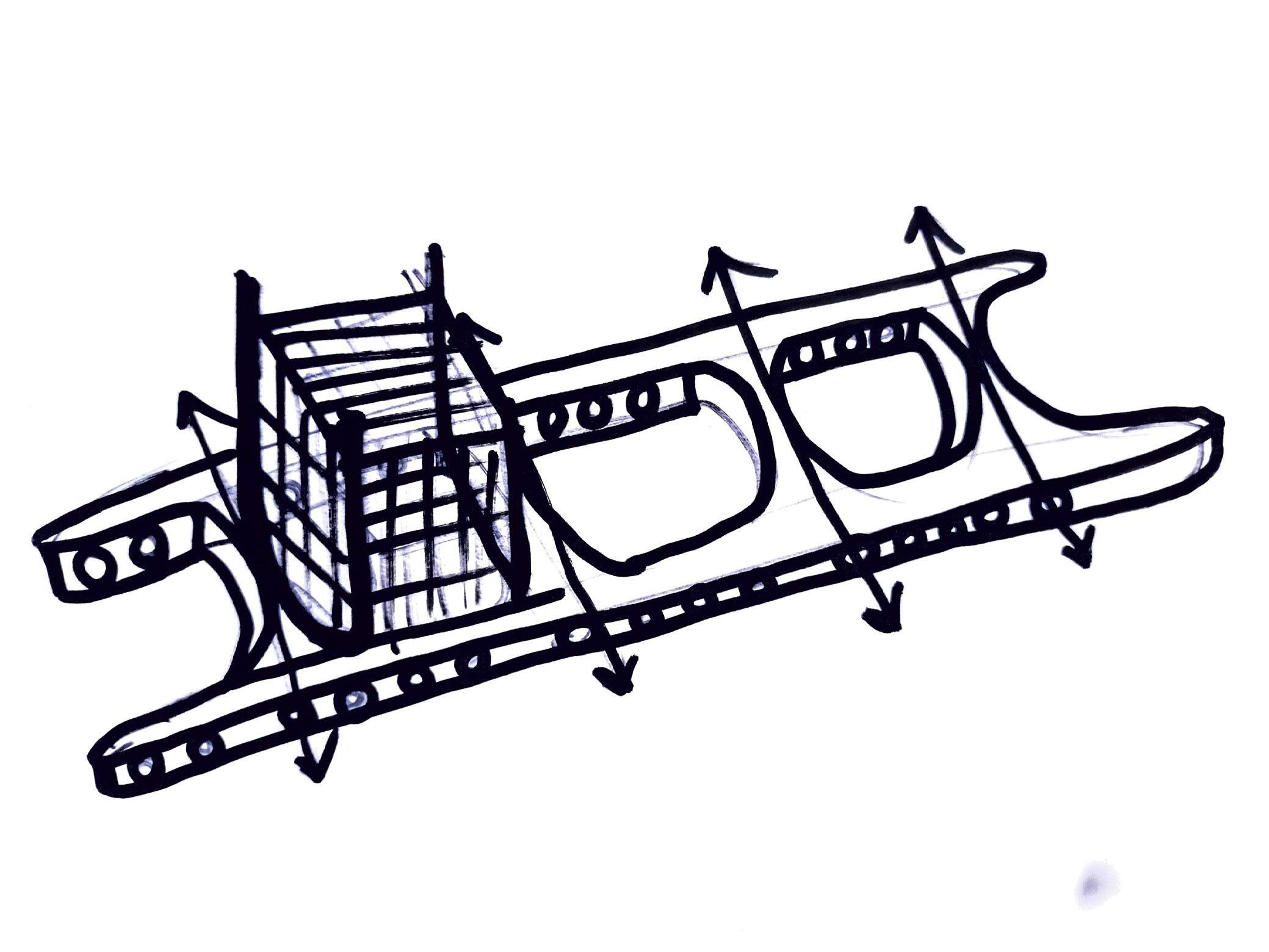

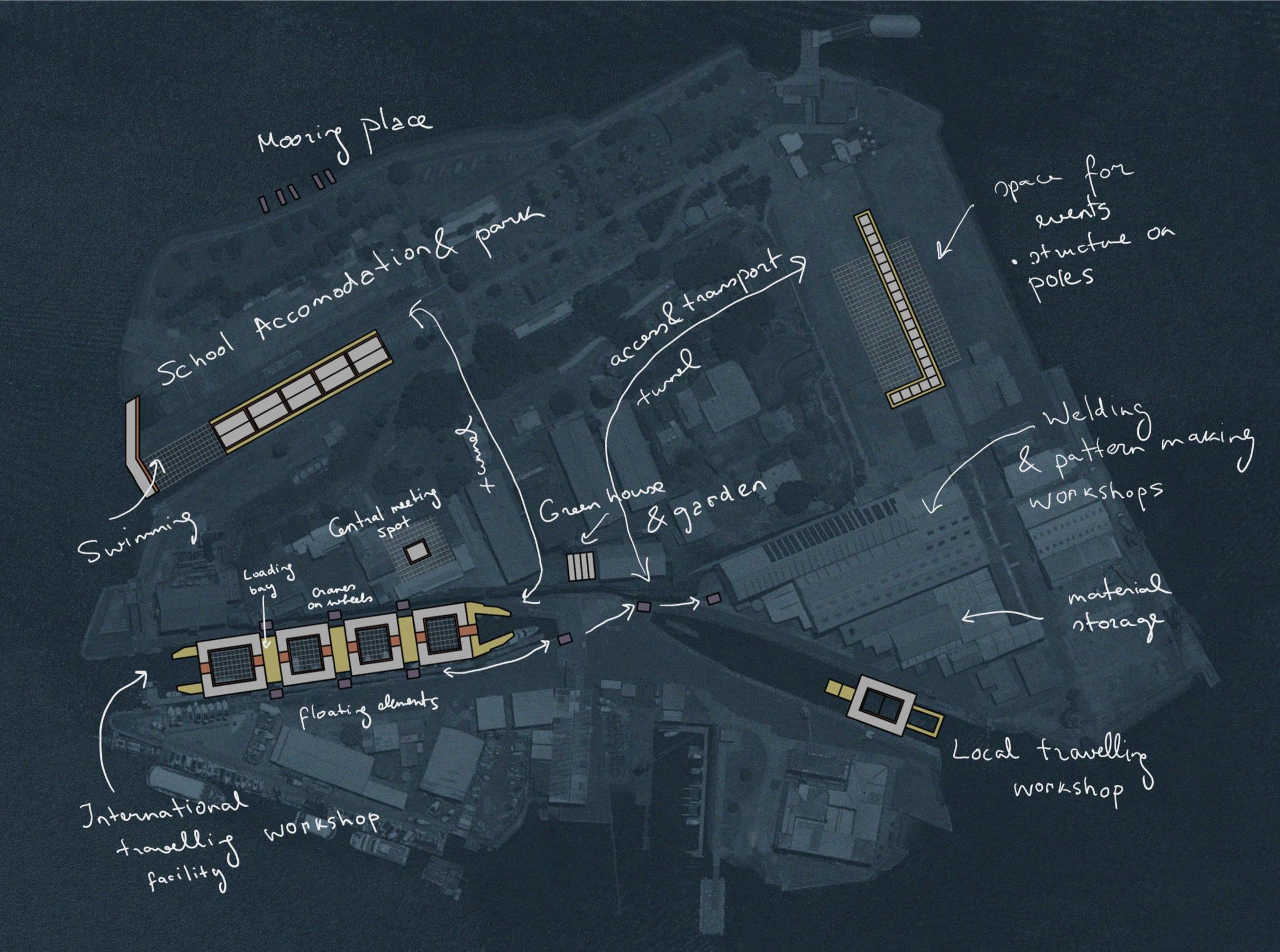

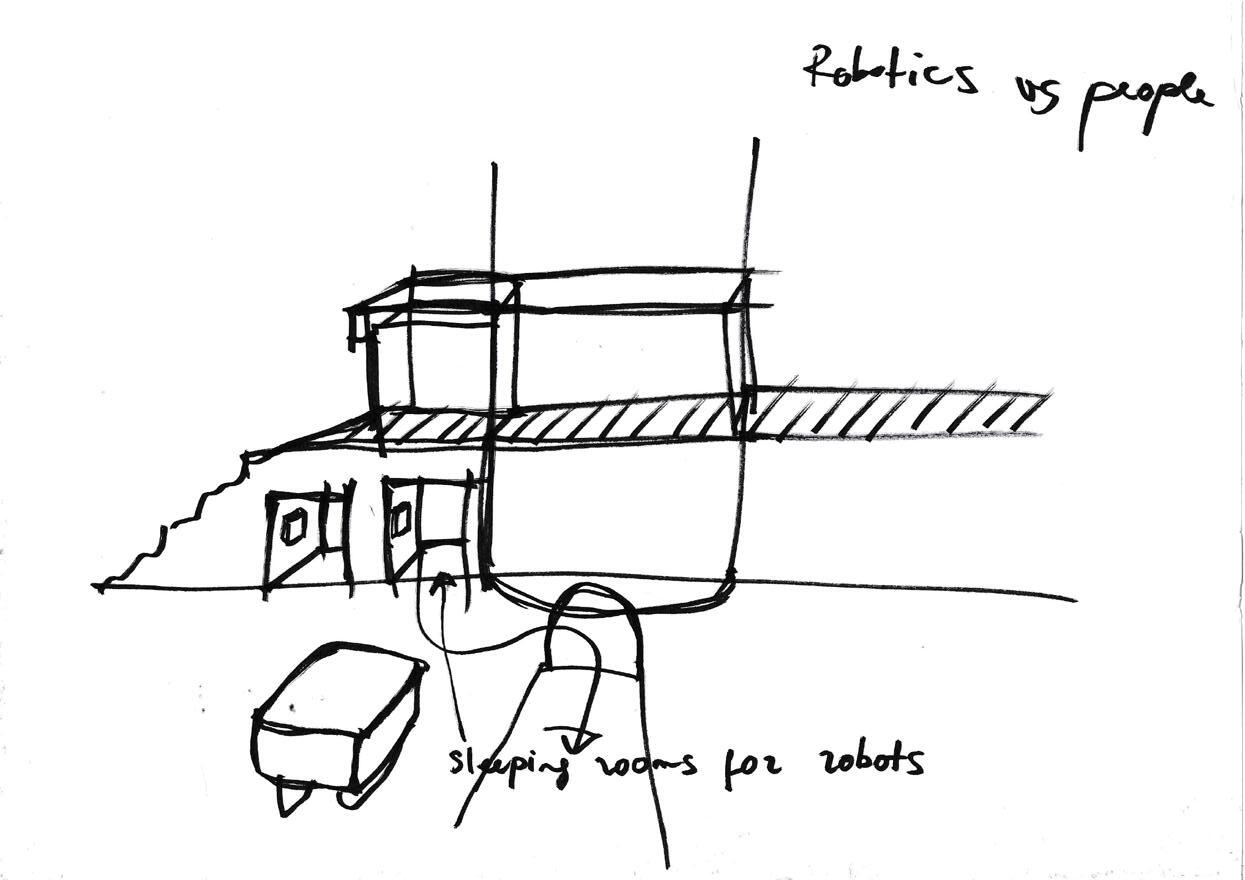

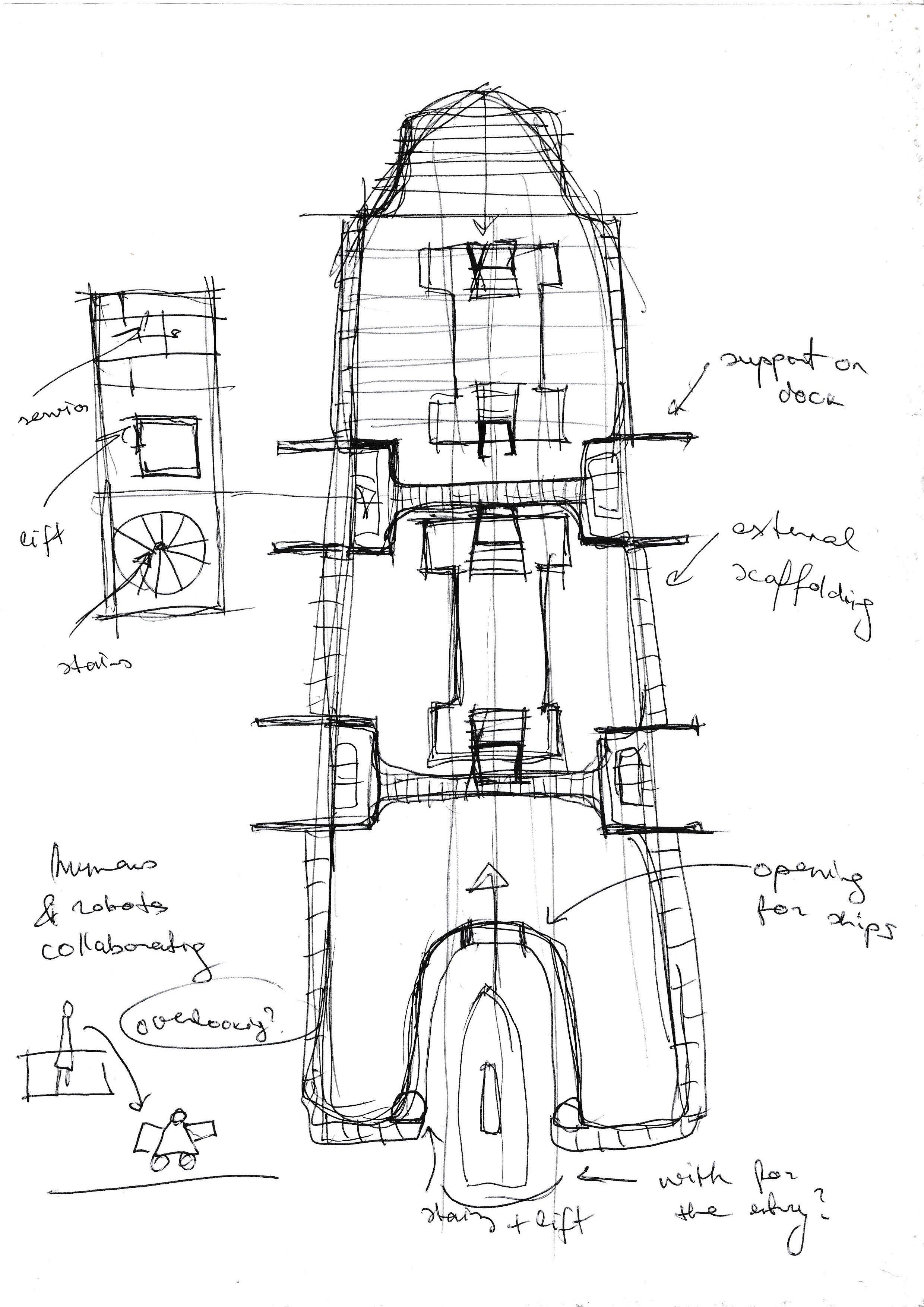

I imagine the future of the world to be a place - a living habitat for humans and machines. A space for creation and collaboration.

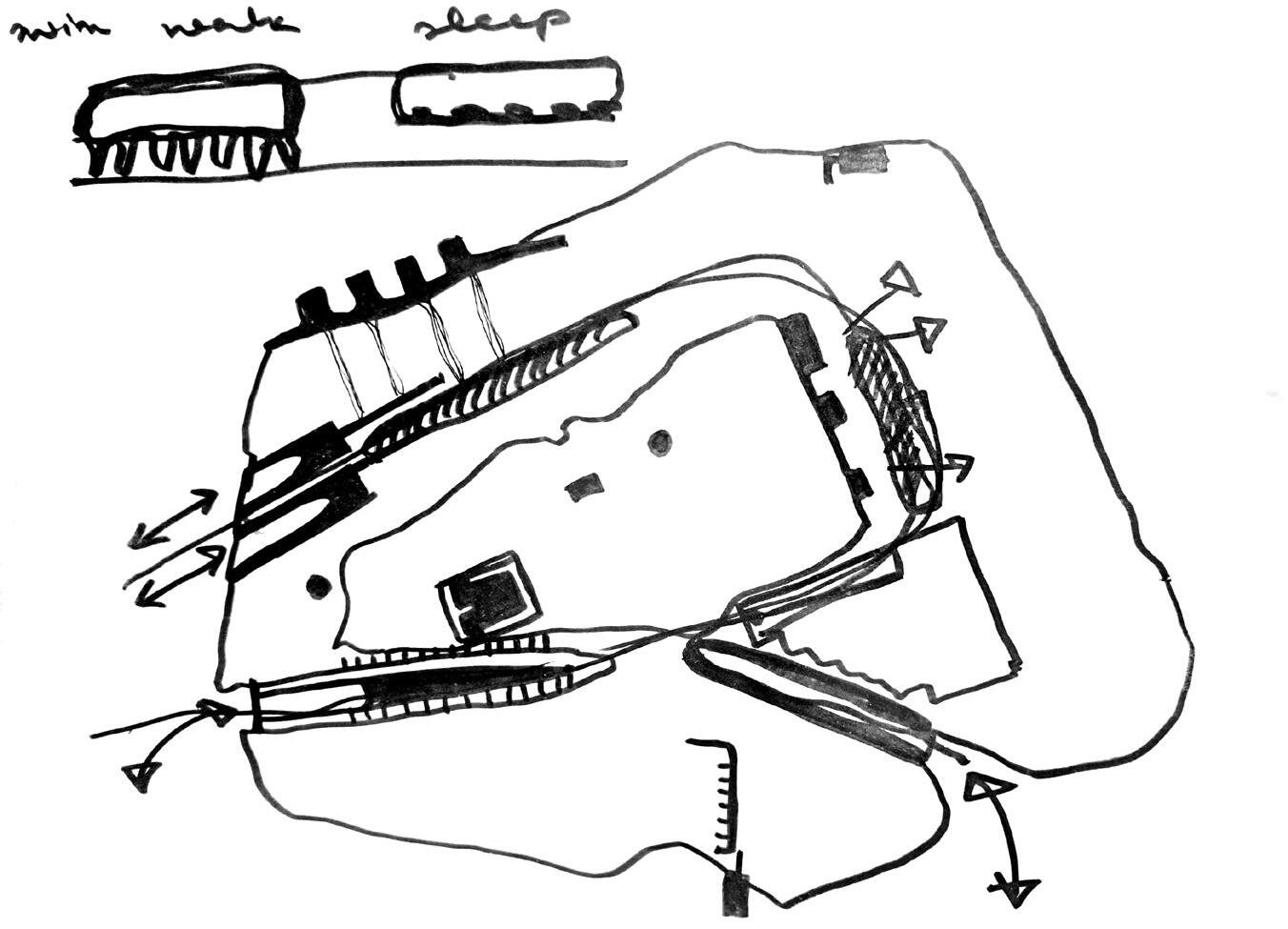

Workshops for a range of potential uses such as education/training facilities and short-term accommodation.

accomodation & enjoyment

viewpoint & cafe

greenery&technology

central meeting space

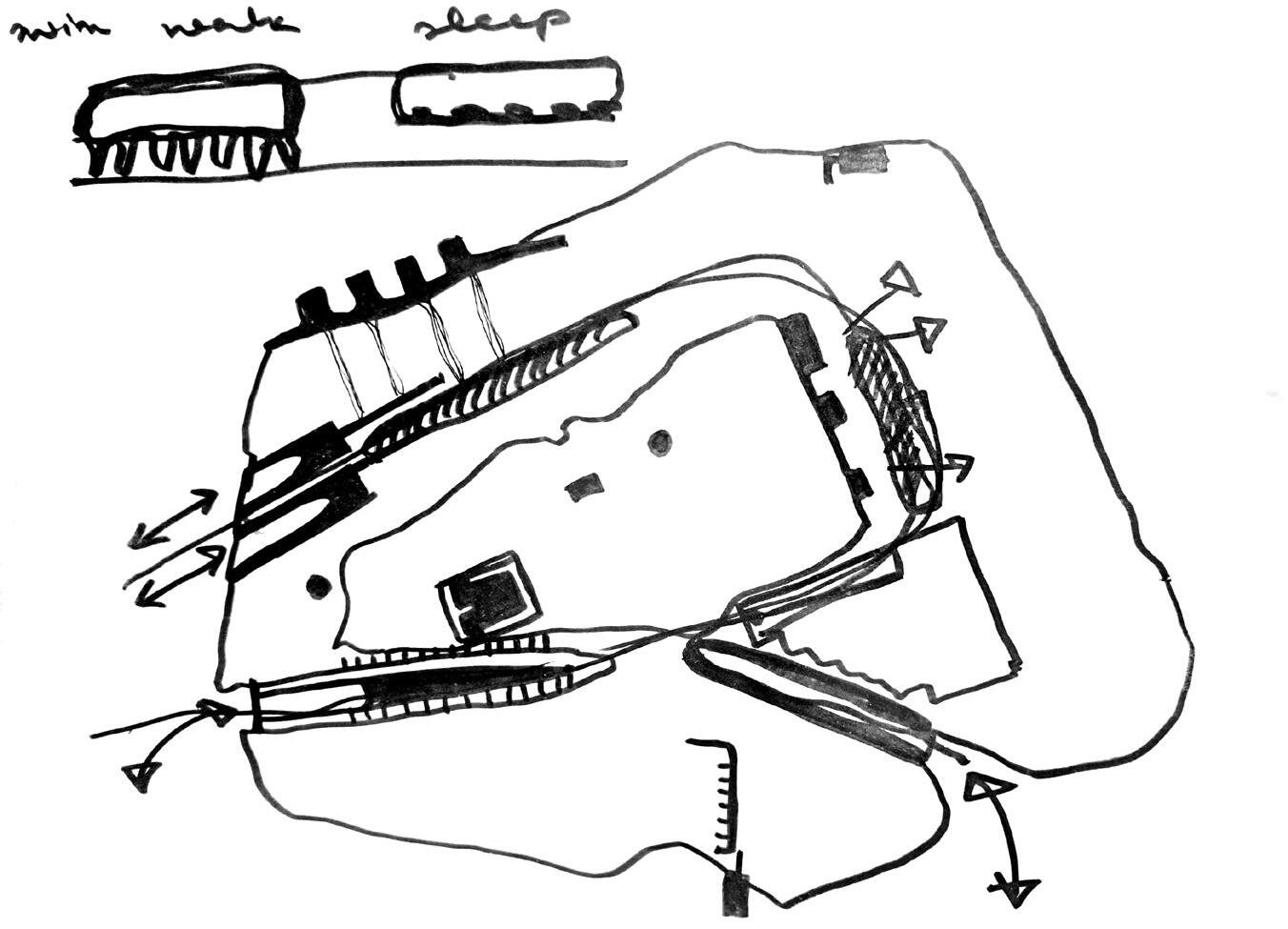

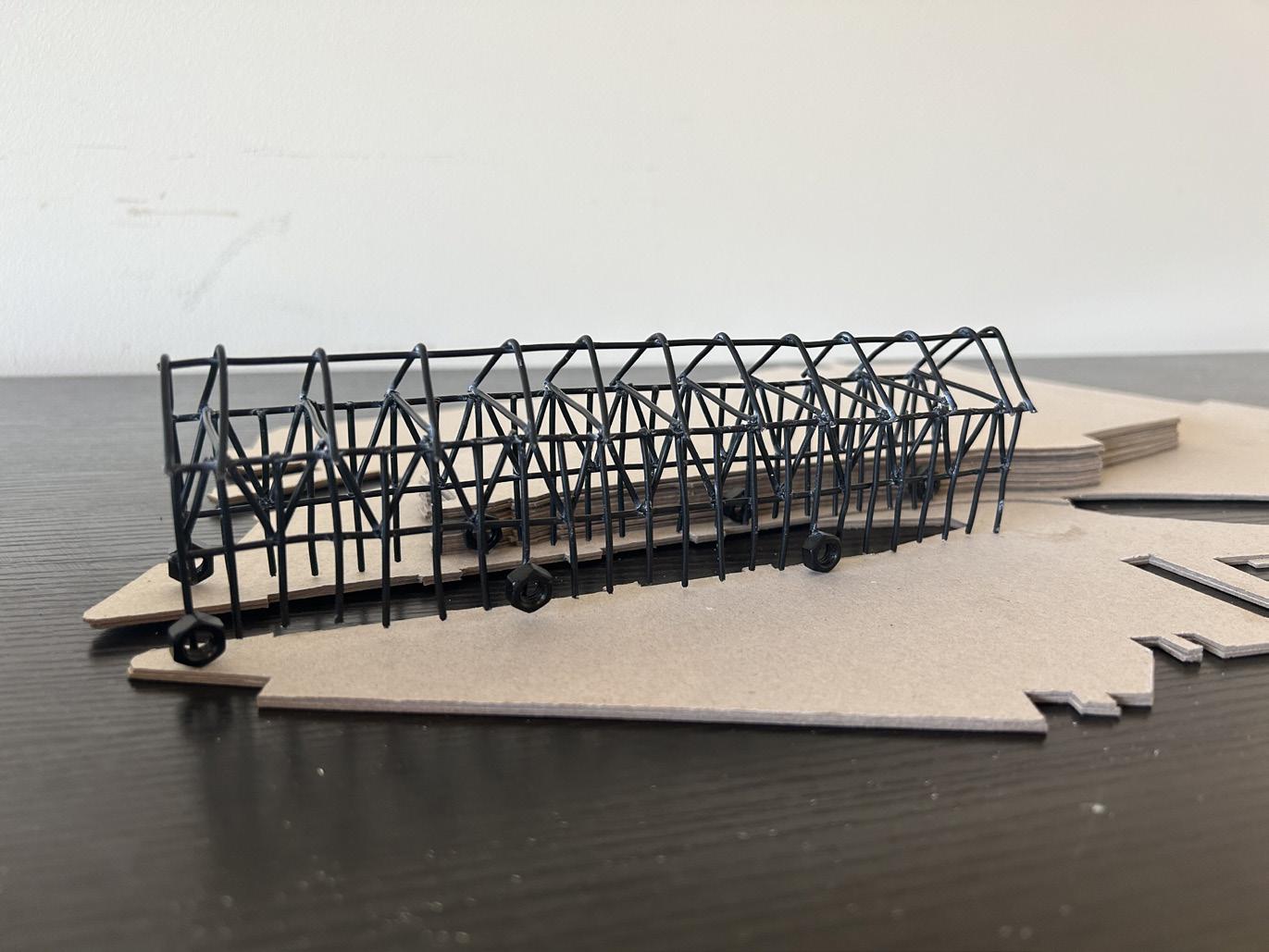

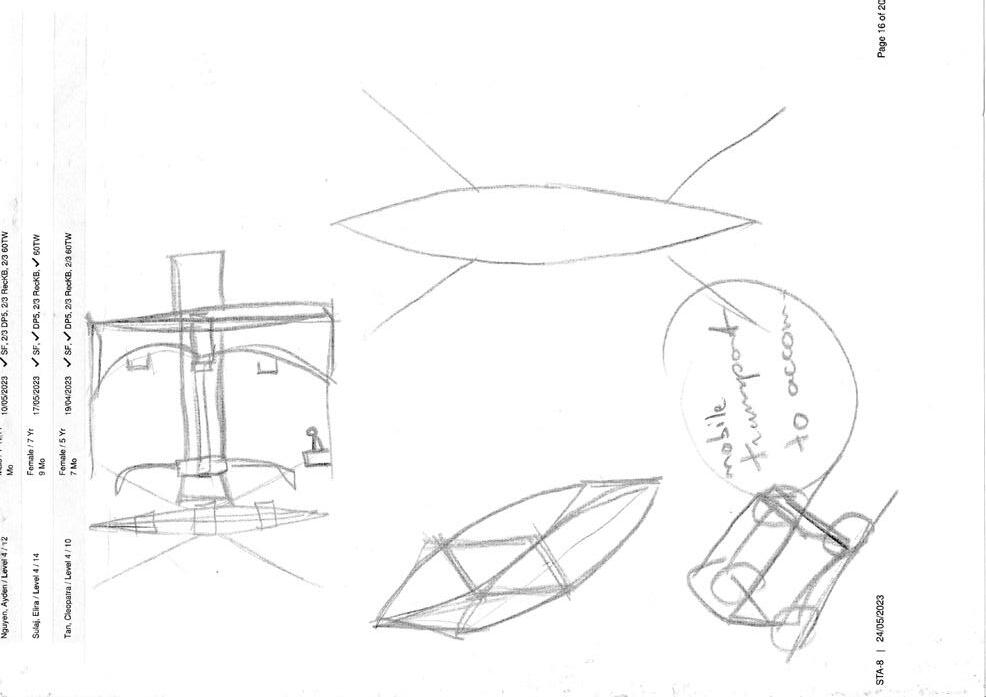

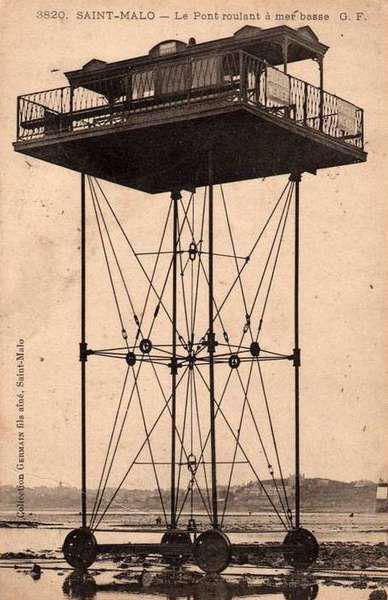

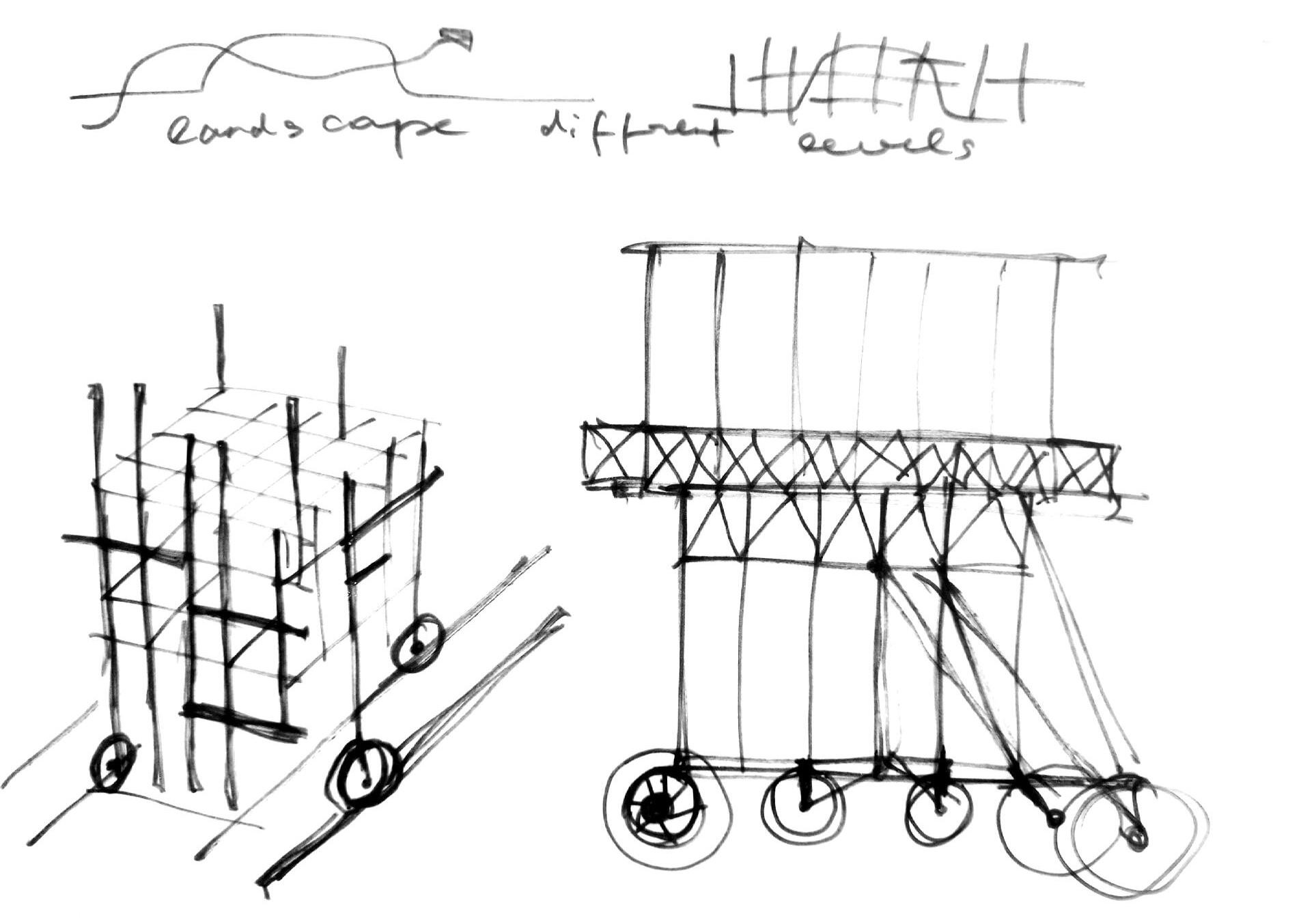

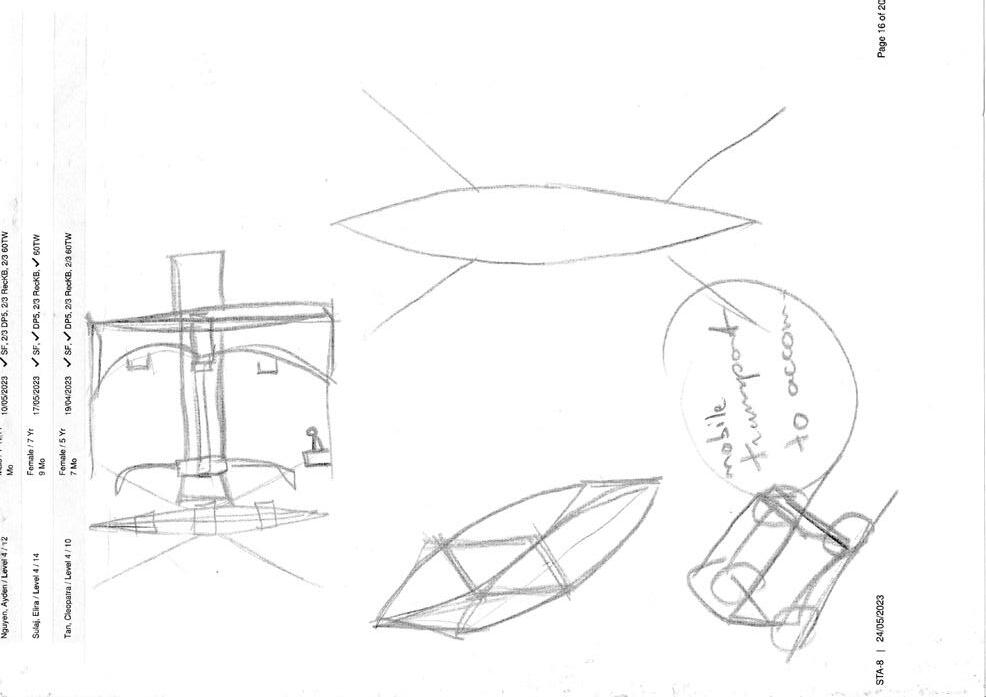

travelling workshop facilities

a vehicle / local transport, that moves through the tunnel

sports & events structure on poles

urban greenhouse

welding, patternmaking workshops

travelling workshop facilities

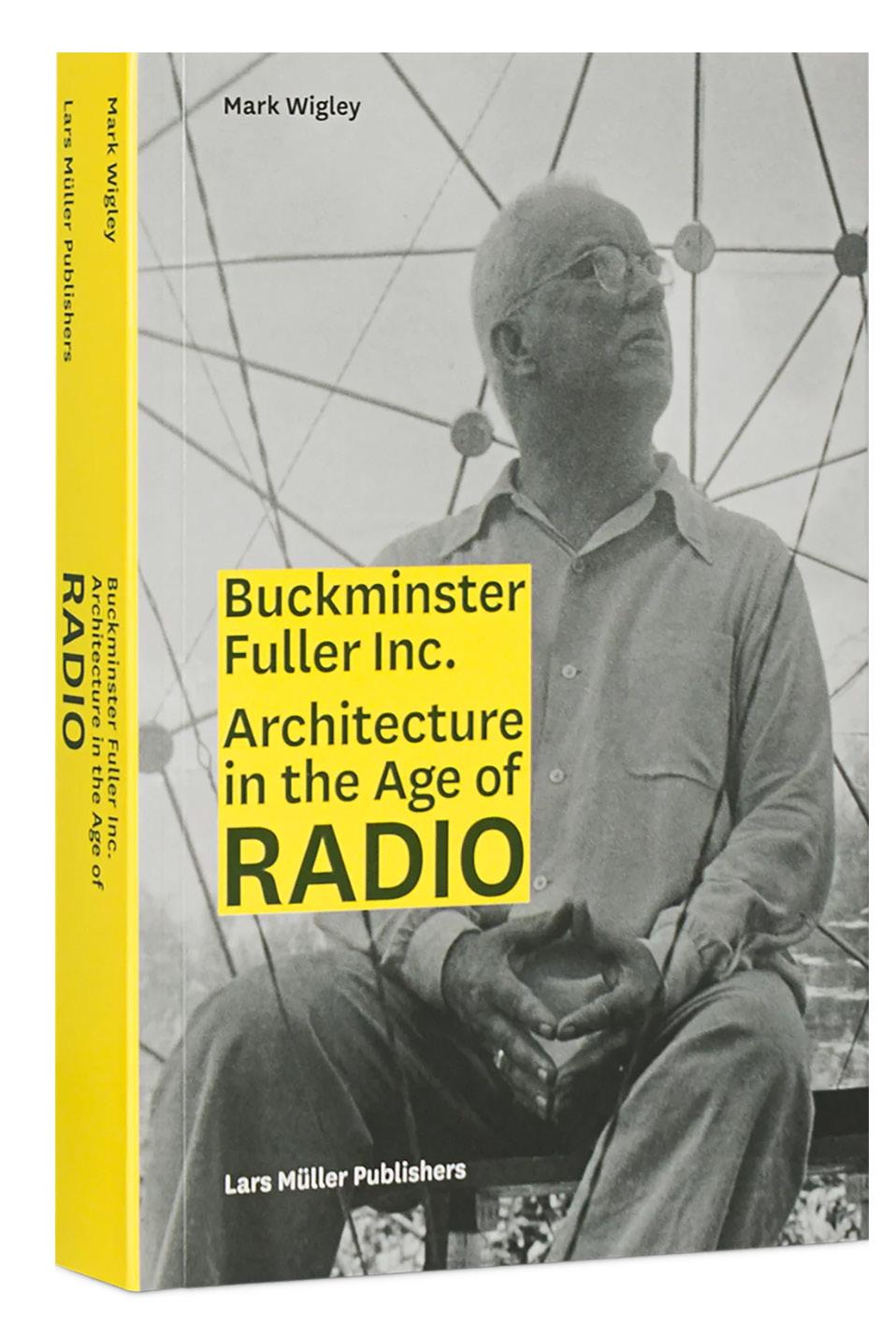

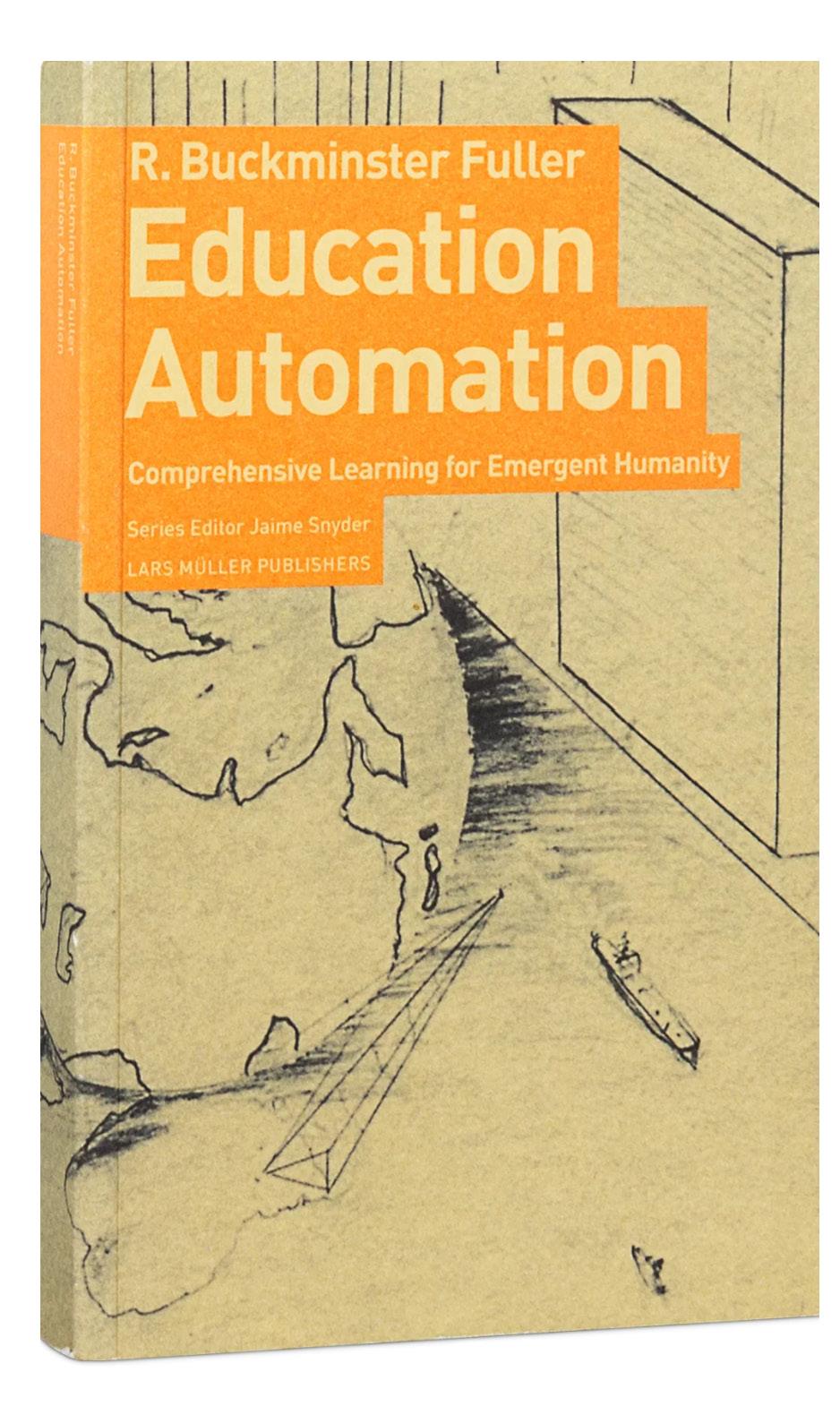

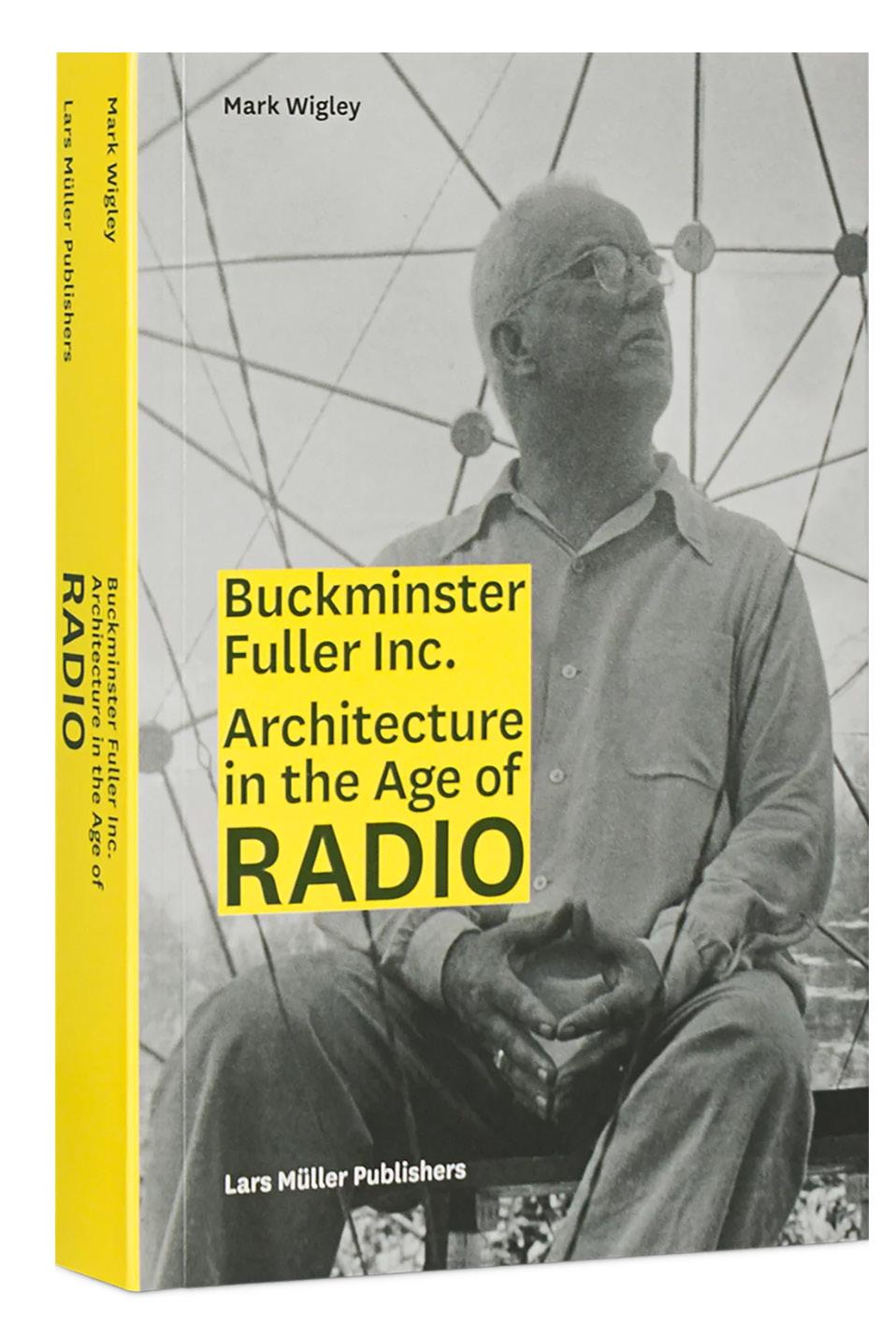

Buckminster Fuller’s prophetic 1962 book “Education Automation” brilliantly anticipated the need to rethink learning in light of a dawning revolution in informational technology – “upcoming major world industry.”

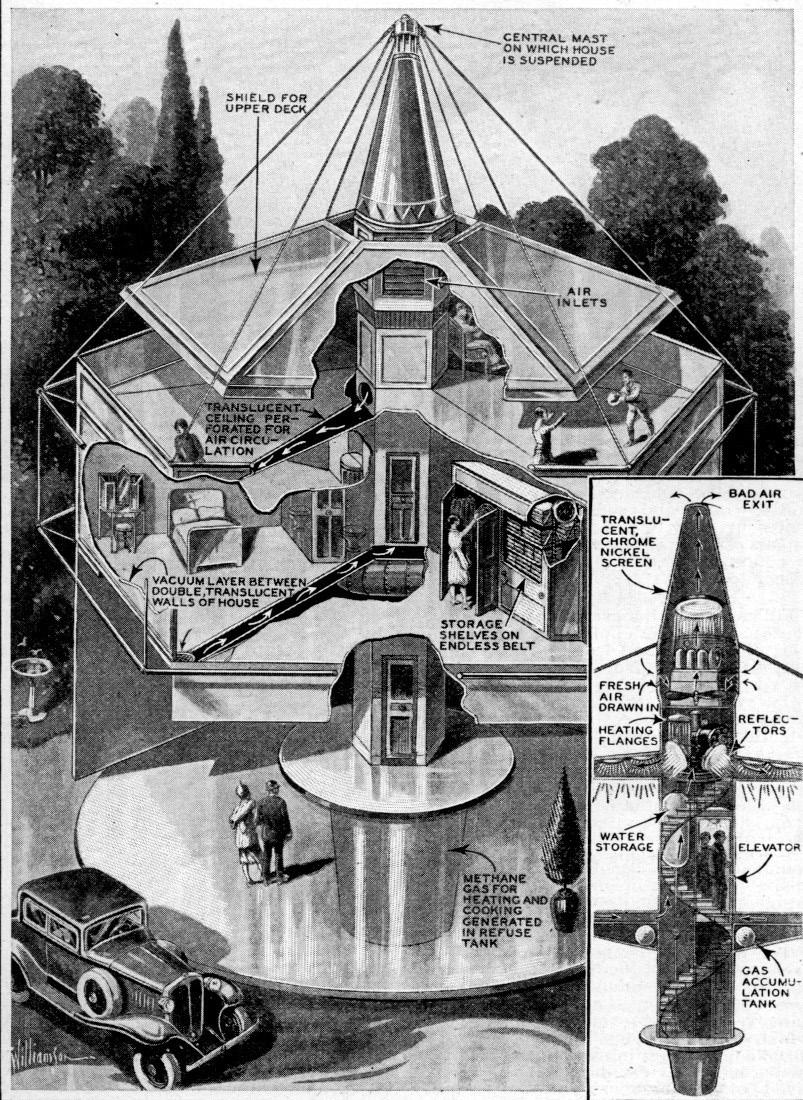

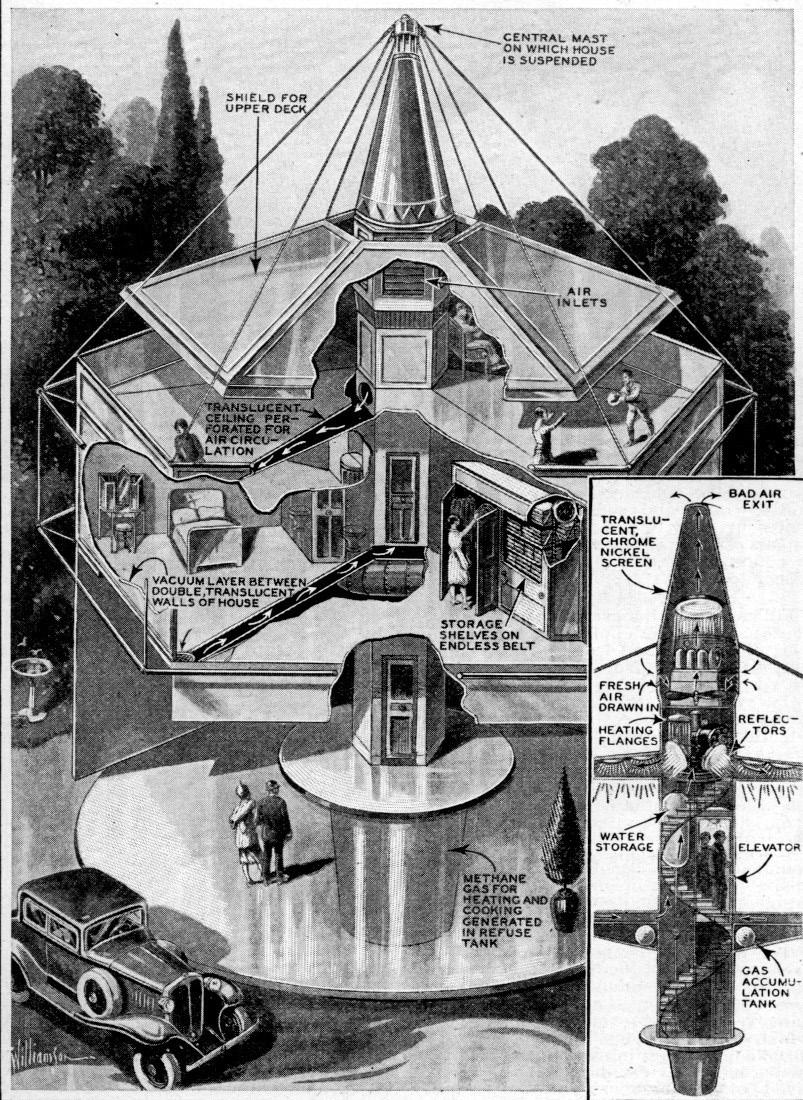

Manufactured house prototypes by Buckminster Fuller

Manufactured house prototypes by Buckminster Fuller

Galerie des machines

Galerie des machines

Cristal Palace, London

Cristal Palace, London

“In a time of economic, climatic and security disruptions, it’s more important than ever to foster diverse ways of moving goods around Australia. Enhanced sovereign coastal trading would reduce the nation’s dependence on road and rail infrastructure, which is regularly affected by major flooding as we’ve seen across large parts of eastern Australia this year.”

Savage, G. (2022) The Strategist.

Hypothesis

Problem:

Lack of local skills and equipment mean many industry sectors require substantial investment before they can even think about bringing manufacturing back onshore.

The many attempts to tackle the issues facing sovereign coastal trading highlight that this is a complex and challenging problem. However, the push to establish a strategic fleet is yet another example of focusing on a symptom rather than solving the core problem.

Solution

Australia needs more than a domestic strategic fleet; we need a framework that encourages a mix of coastal and international trading ships. Solutions solely for a small coastal strategic fleet don’t address the real strategic problems Australia has created for itself in this sector.

Result

Boost Australia’s Economy

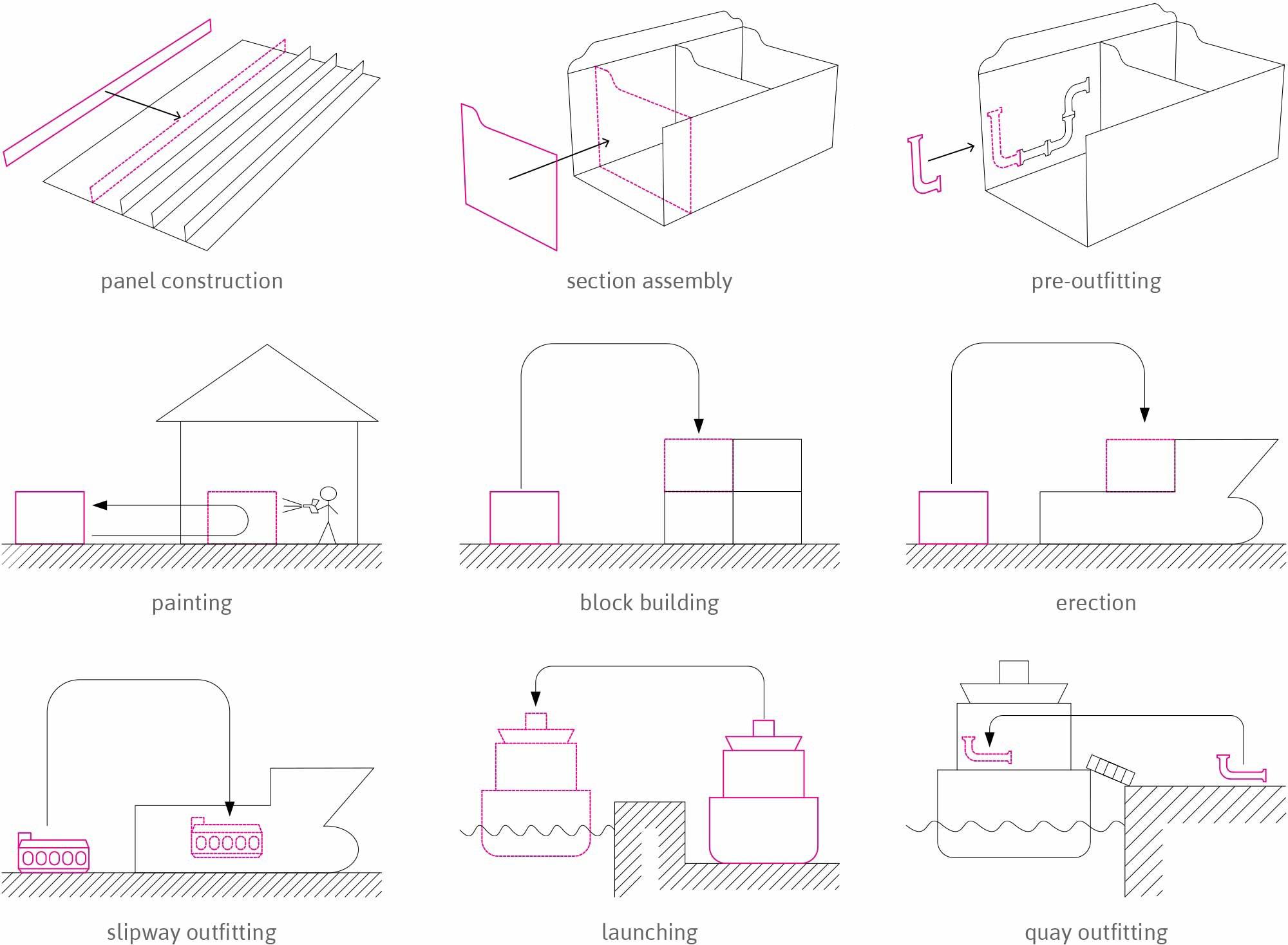

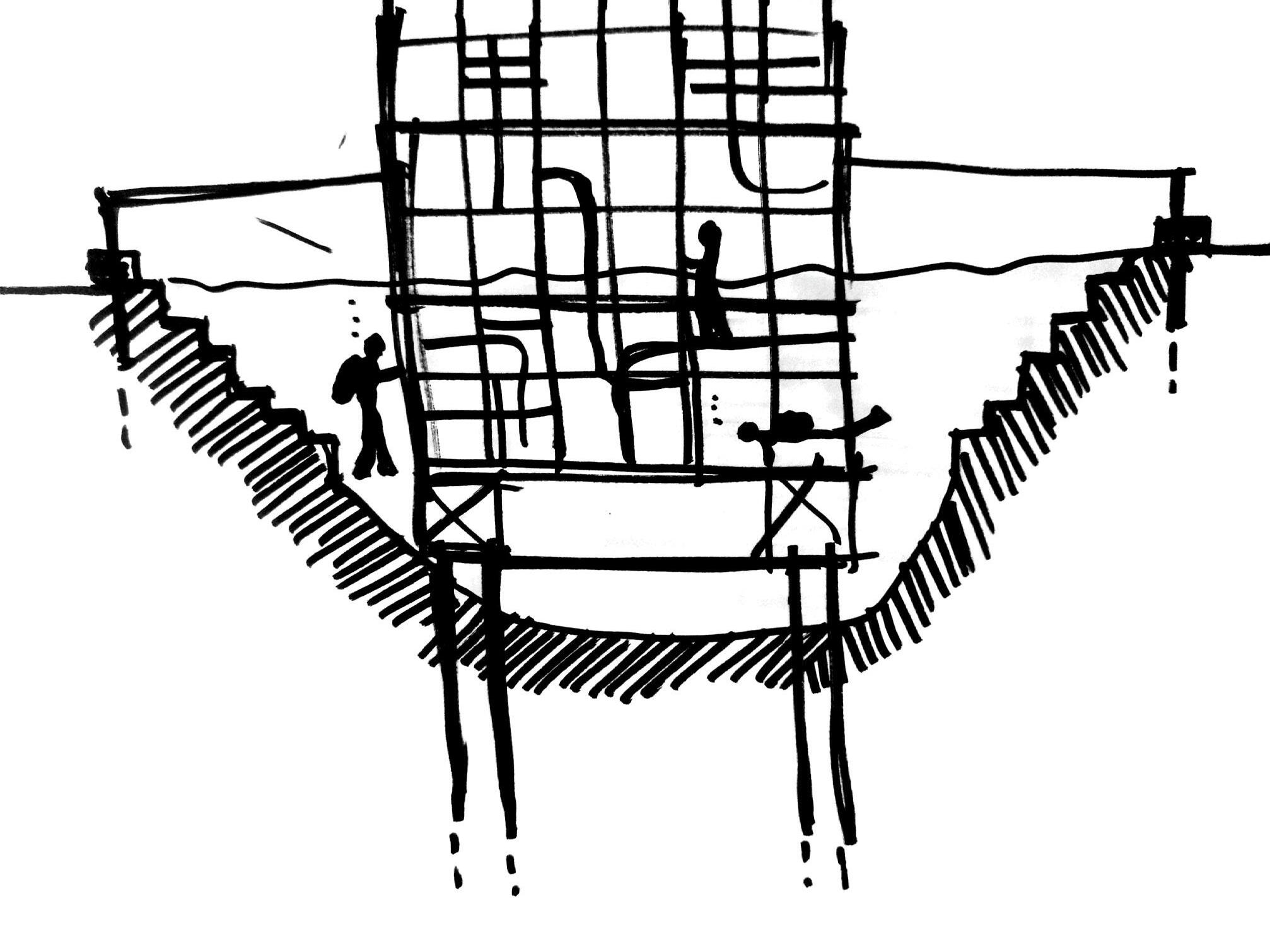

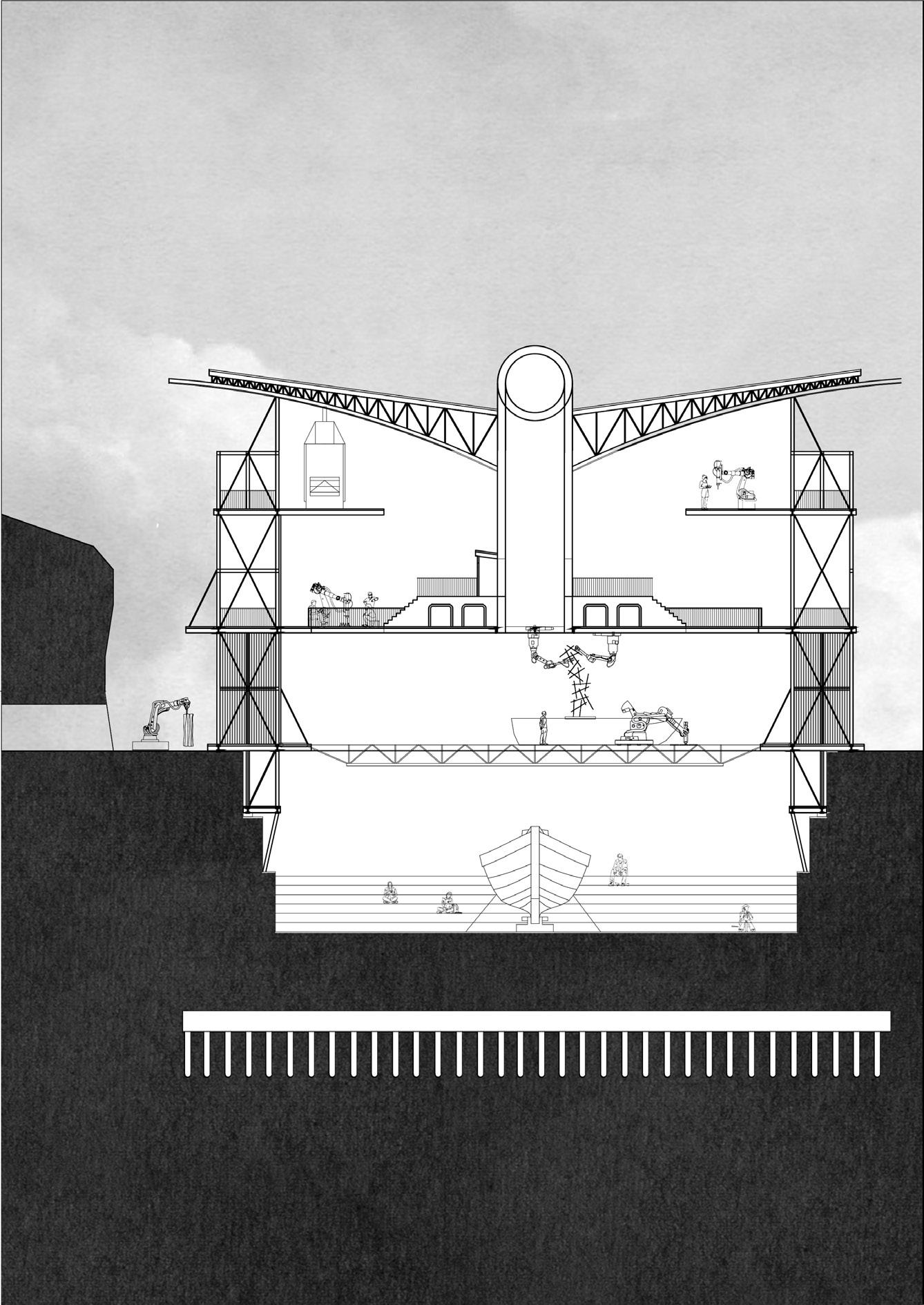

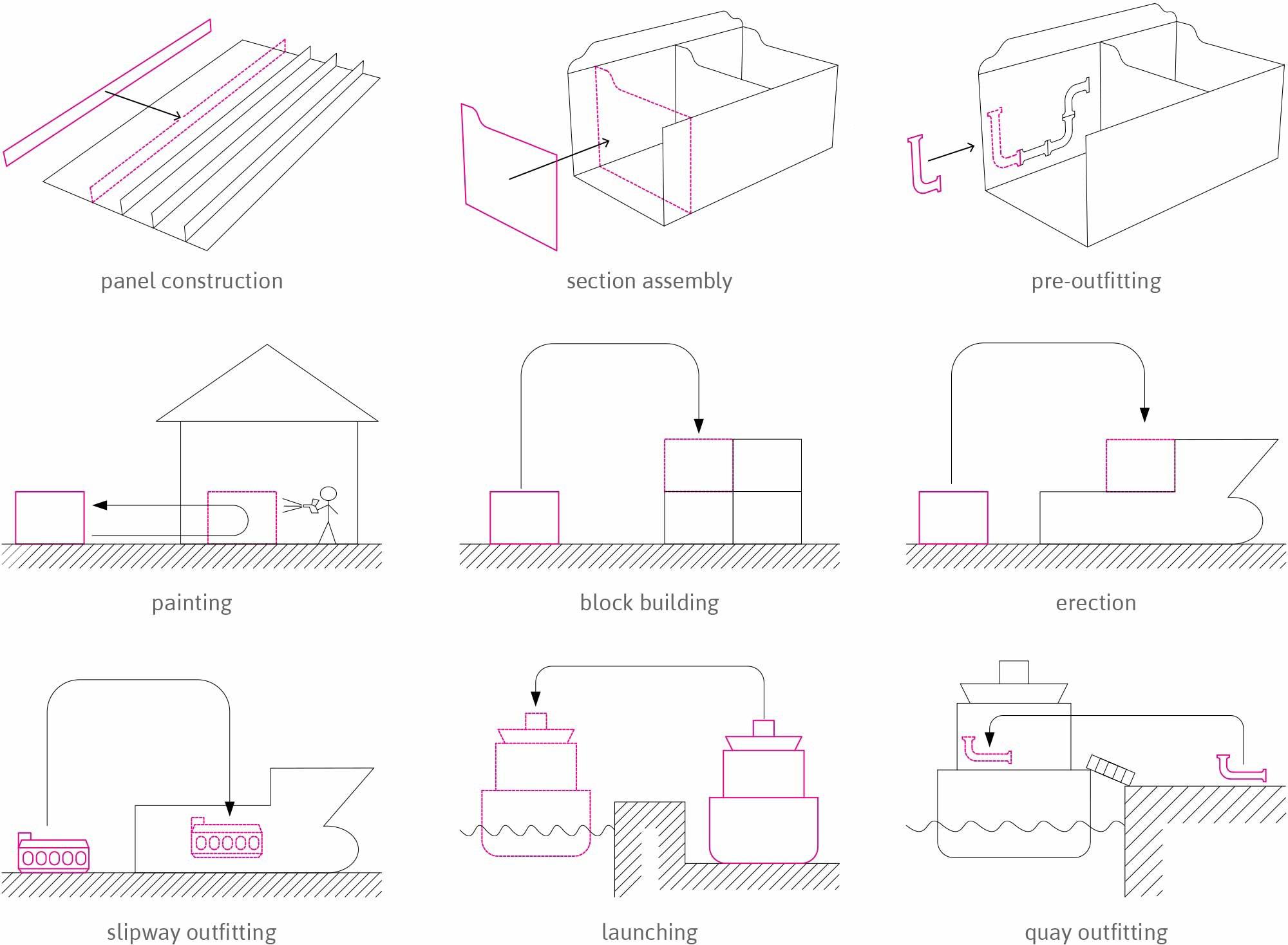

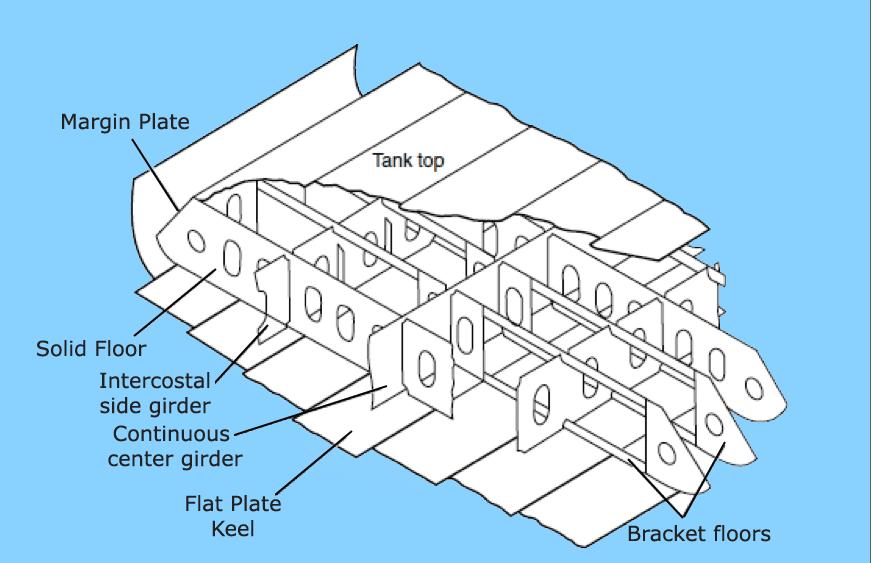

Modern shipyards are large, complex facilities that are designed to efficiently and effectively build, repair, and maintain a wide range of vessels. A typical modern shipyard layout is composed of several key areas, each of which serves a specific purpose in the shipbuilding process.

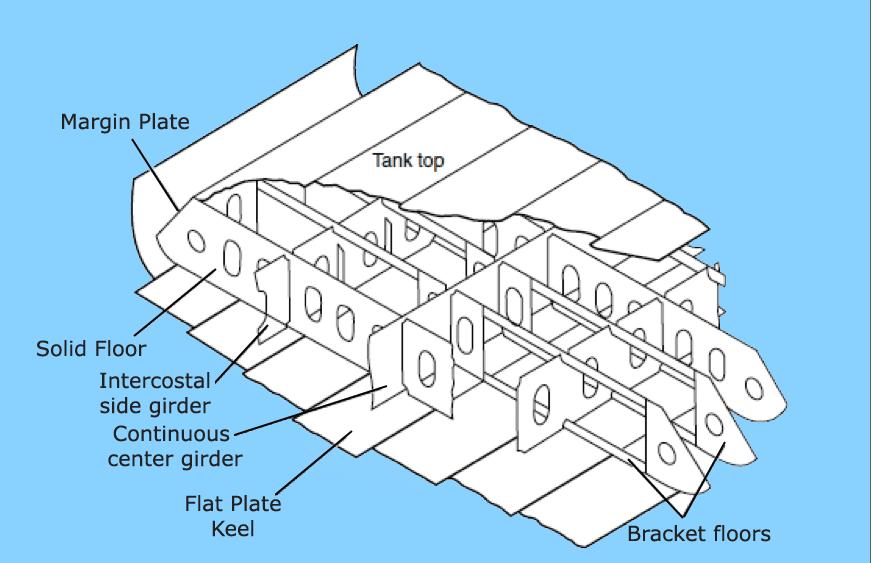

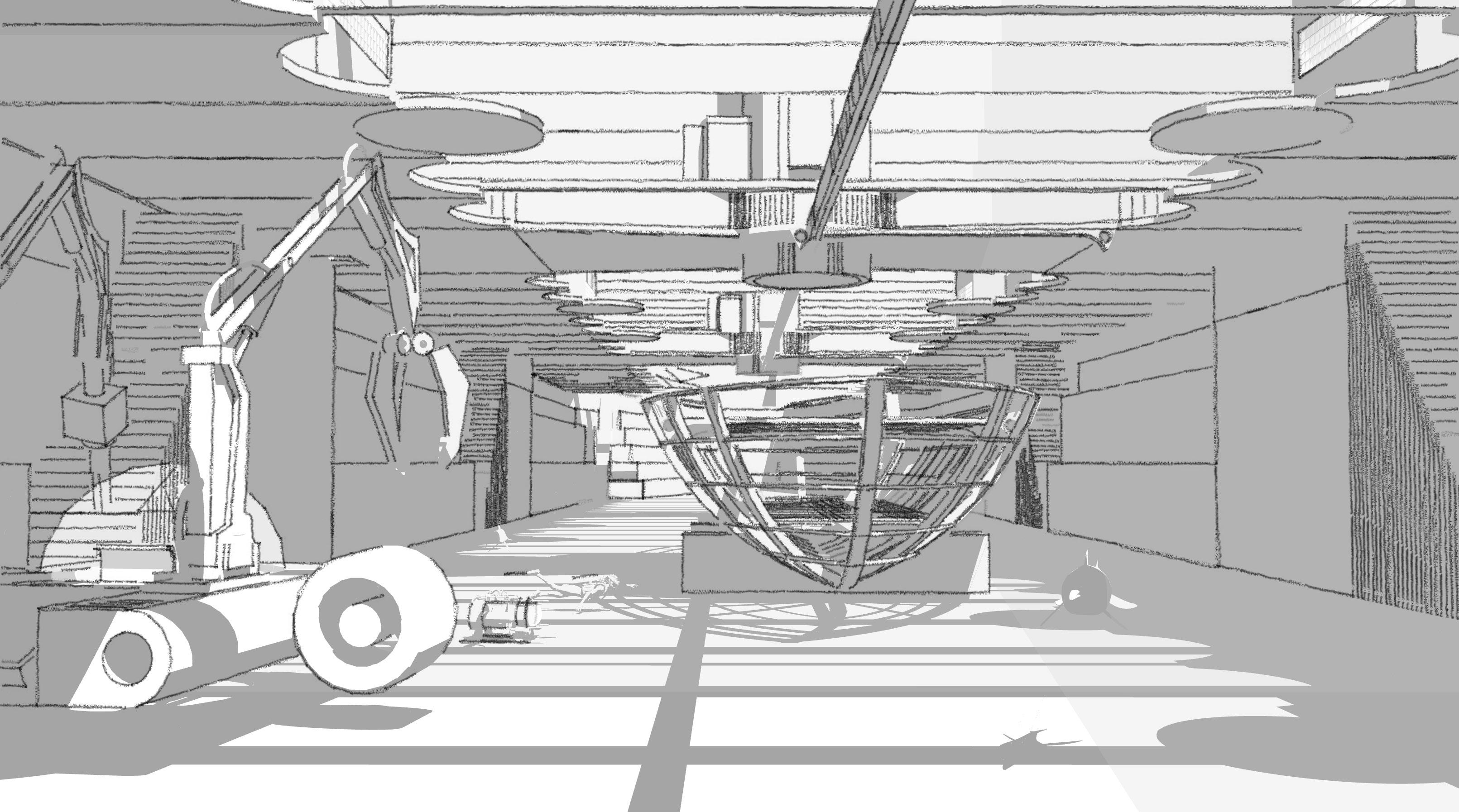

Fabrication Shop: The fabrication shop is where steel and other materials are cut, shaped, and welded into various components and sections of the vessel. This area may include computer-controlled cutting machines, automated welding robots, and other high-tech equipment.

Assembly Shop: The assembly shop is where the various components and sections of the vessel are brought together to form the complete structure. This area may include large cranes and lifting equipment to move heavy parts and assemblies.

Outfitting Shop: The outfitting shop is where the vessel's systems and equipment are installed, including engines, electrical systems, plumbing, and other essential components.

Painting and Finishing Shop: The painting and finishing shop is where the vessel is painted and coated to protect it from corrosion and other environmental hazards. This area may include specialized paint booths and other equipment for applying protective coatings.

Launching and Testing Area: Once the vessel is completed, it is launched into the water for testing and sea trials. This area may include a large dry dock, launch ramps, and other facilities for moving the vessel into the water.

Maintenance and Repair Area: The maintenance and repair area is where vessels are brought for routine maintenance and repairs. This area may include dry docks, cranes, and other equipment for lifting and moving vessels.

Overall, a modern shipyard layout is designed to maximize efficiency and productivity while providing a safe and controlled environment for building, repairing, and maintaining vessels of all types and sizes.

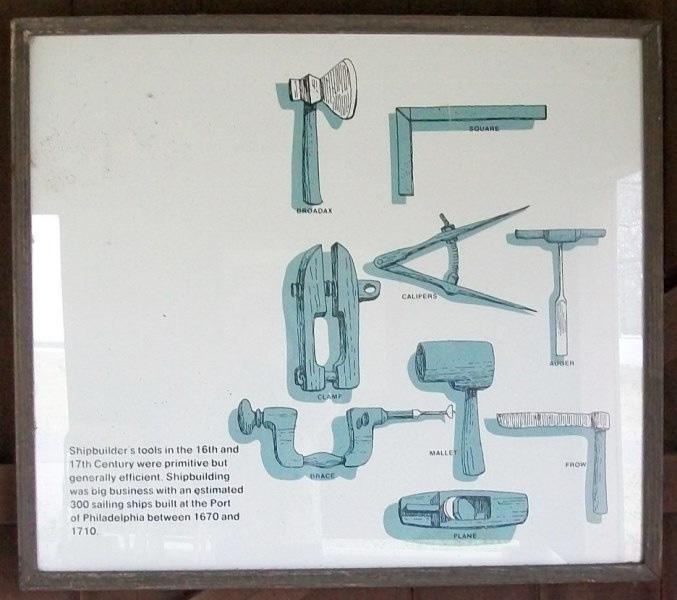

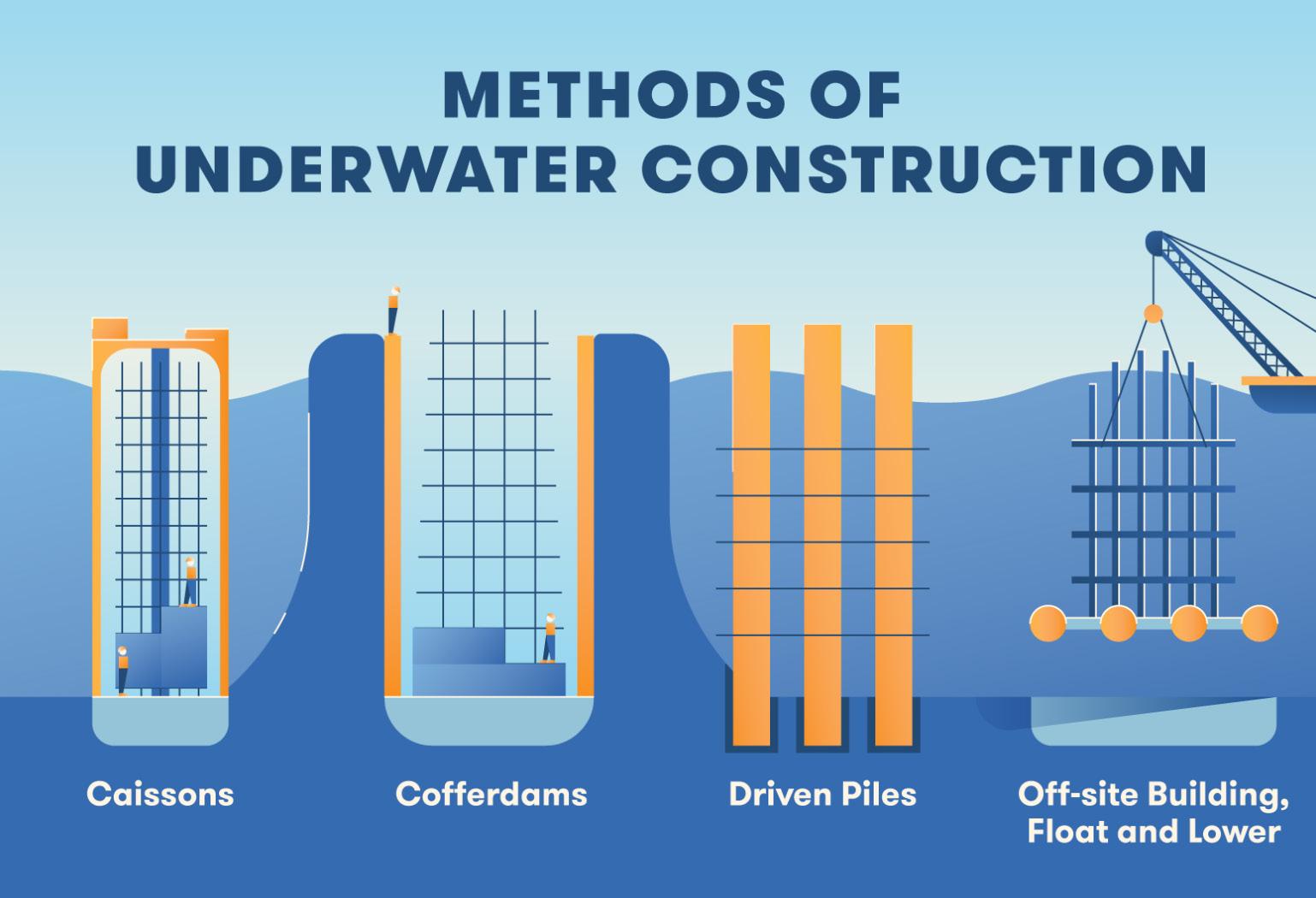

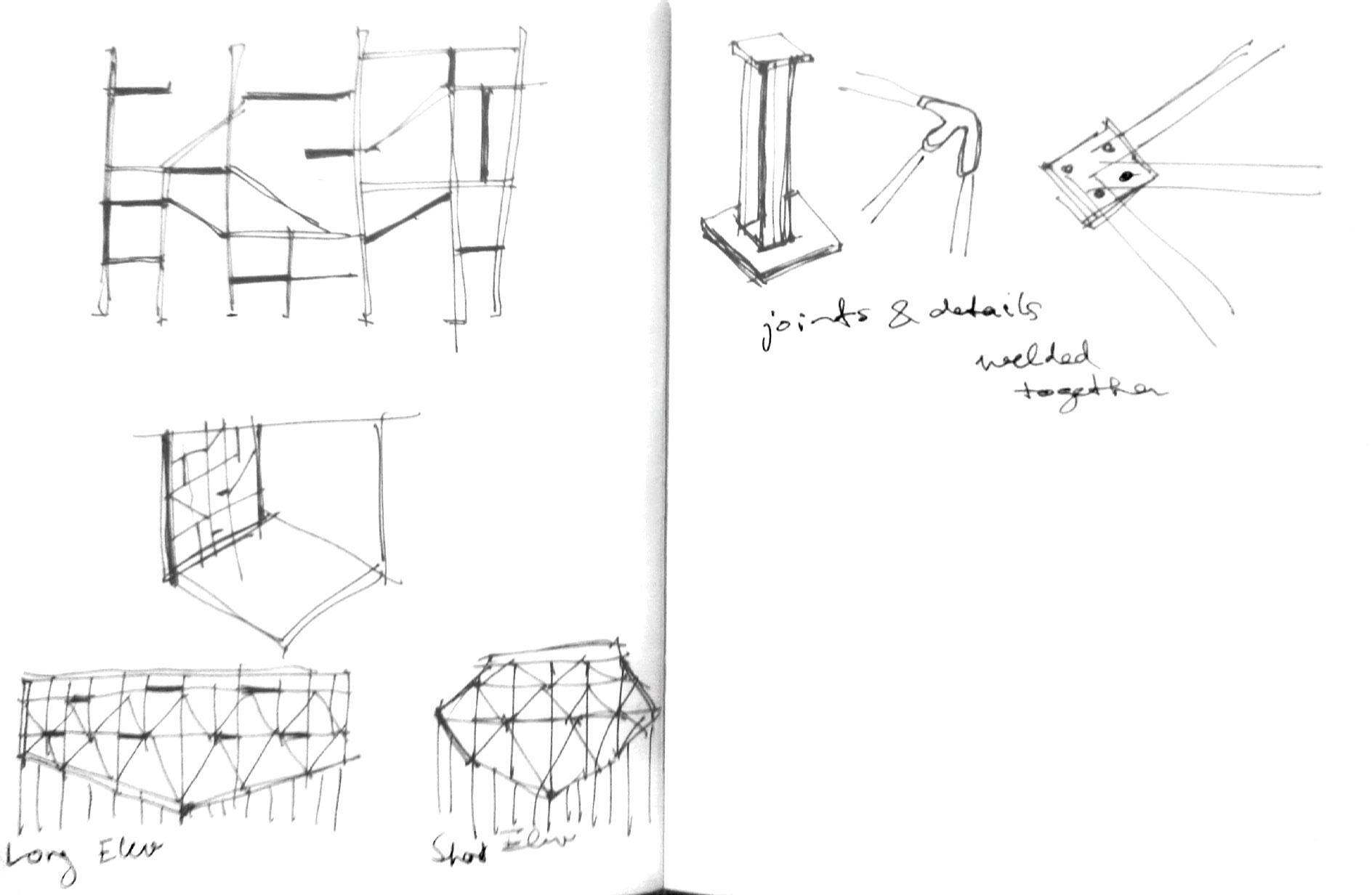

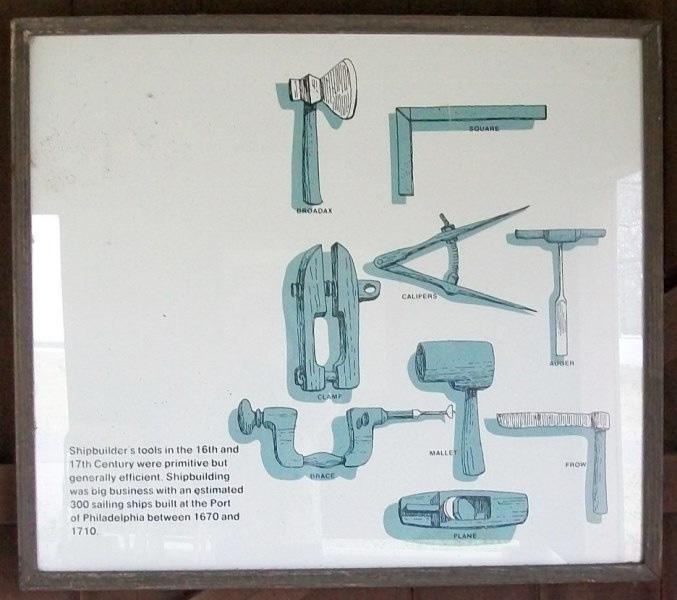

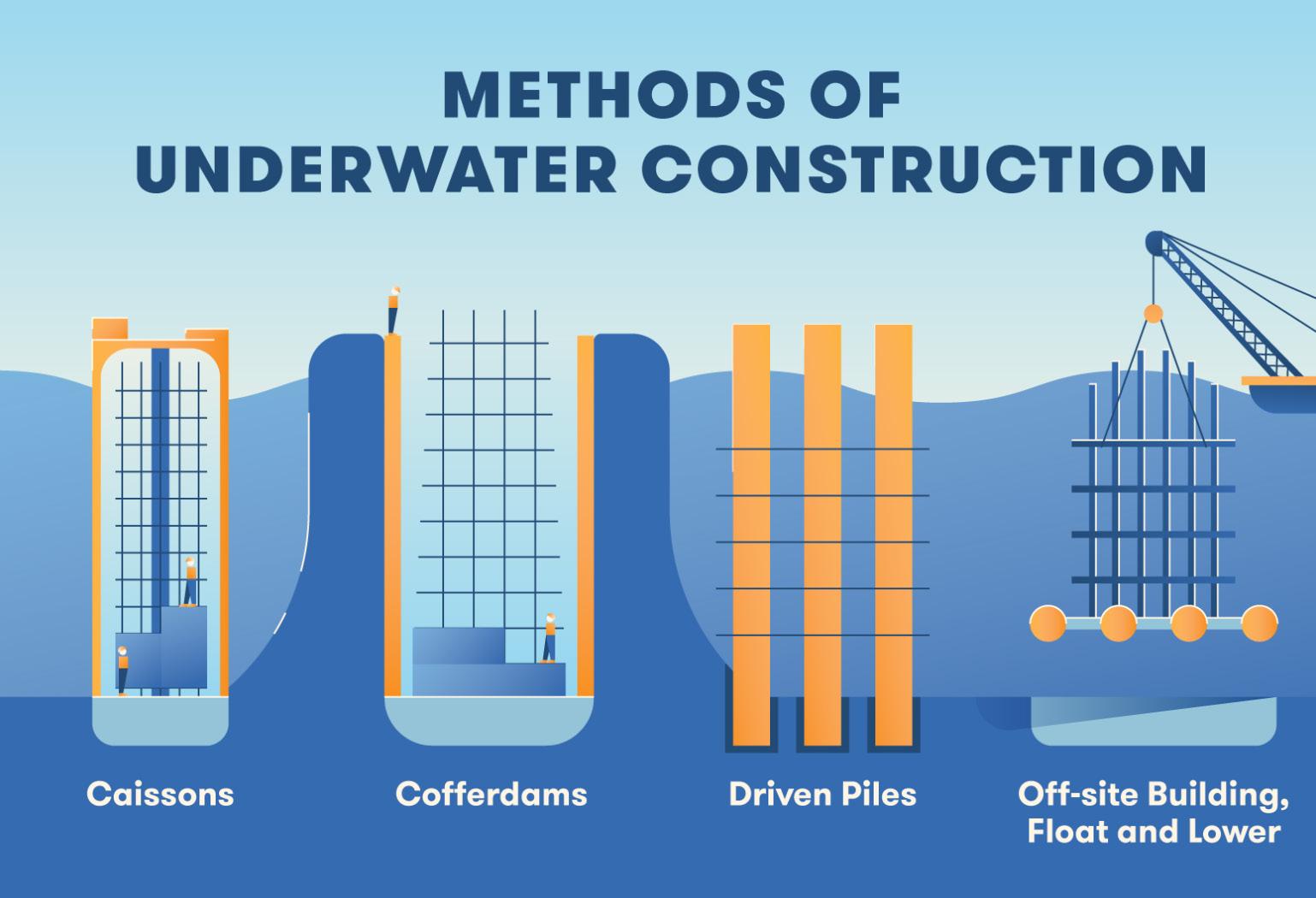

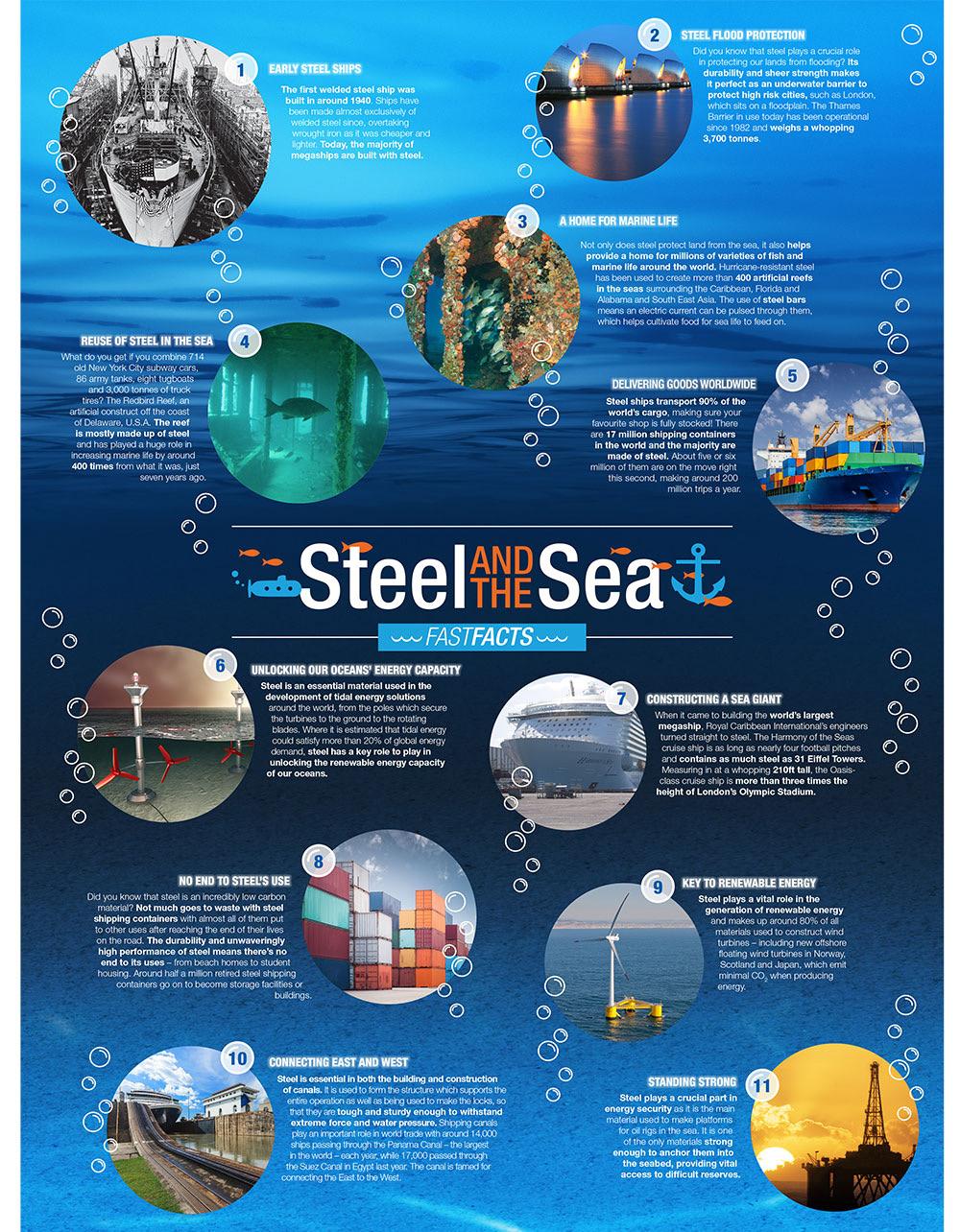

Materials and construction methods

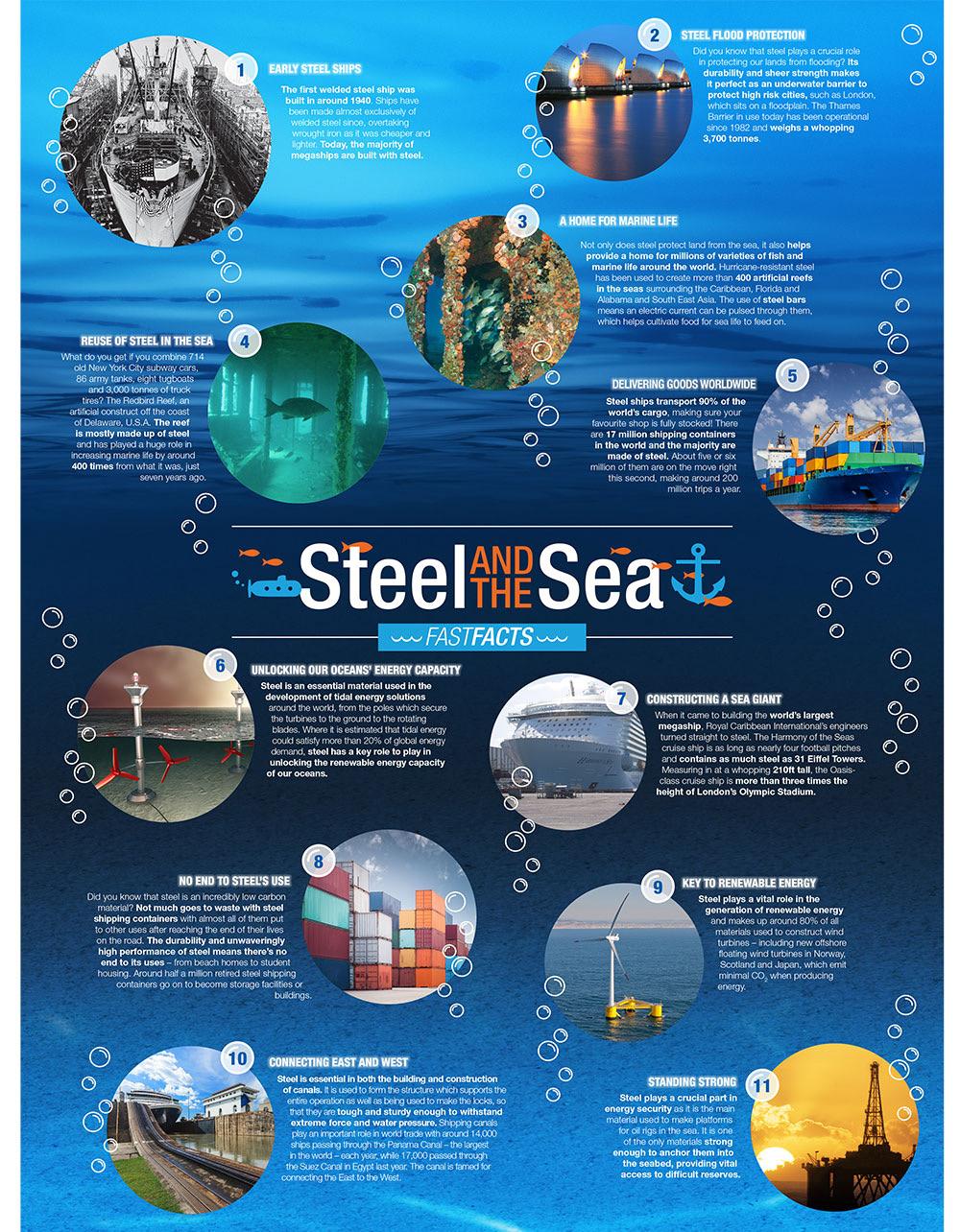

Marine metal: the partnership between steel and the sea

Travelling underwater welding workshops

Introduction:

Begin by introducing the project and its location on Cockatoo Island. Mention that the project aims to establish an innovative ship-making facility that emphasizes sustainability and local sourcing.

Sustainability:

Emphasize the commitment to sustainability in the project. Discuss how the facility will incorporate eco-friendly practices such as:

Energy-efficient infrastructure: Highlight the use of renewable energy sources like solar panels or wind turbines to power the facility.

Waste management: Describe plans for implementing proper waste disposal systems, recycling initiatives, and minimizing waste generation during the ship-building process.

Water conservation: Discuss strategies for water conservation and sustainable water usage, such as rainwater harvesting and efficient water treatment systems.

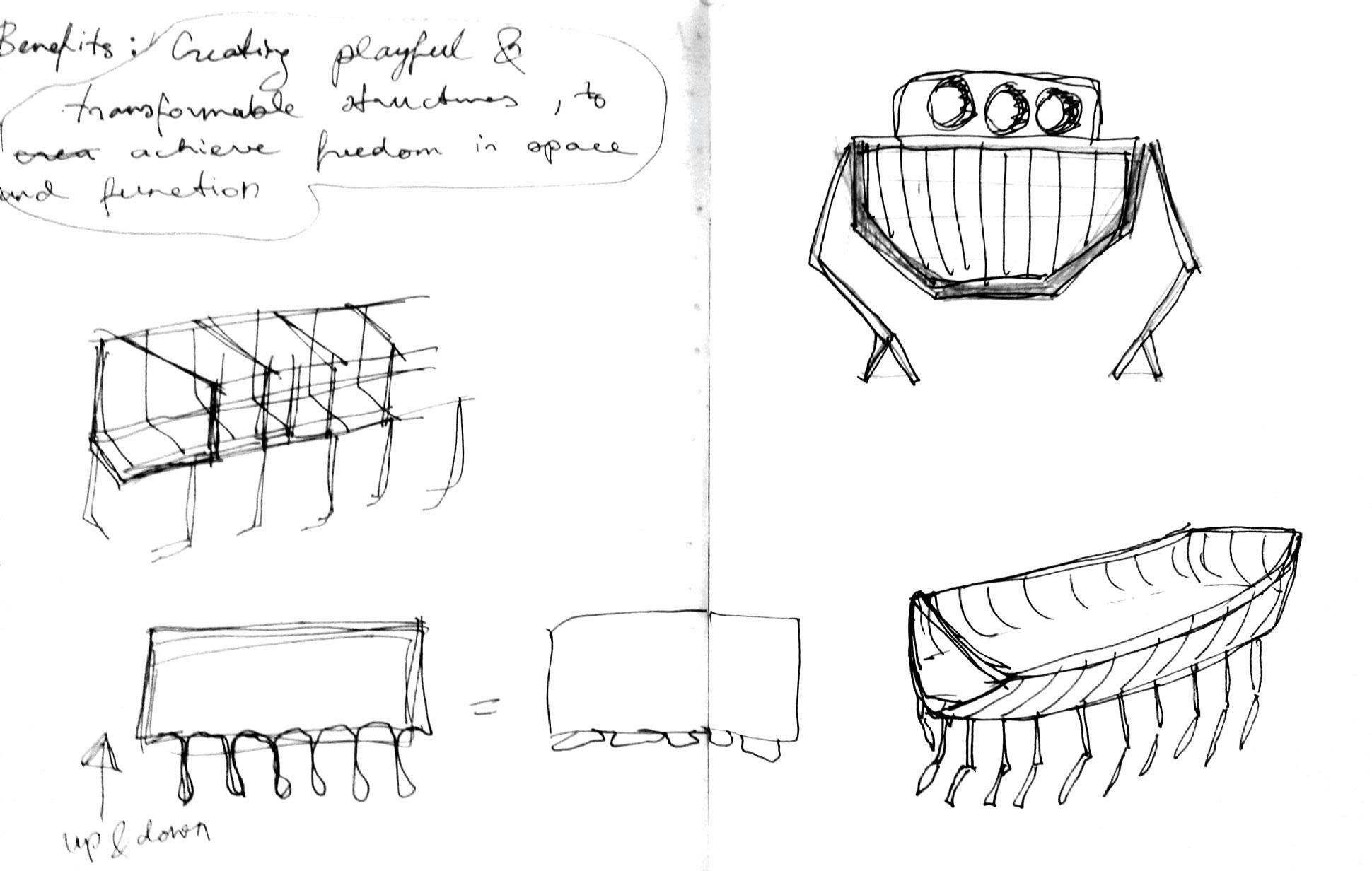

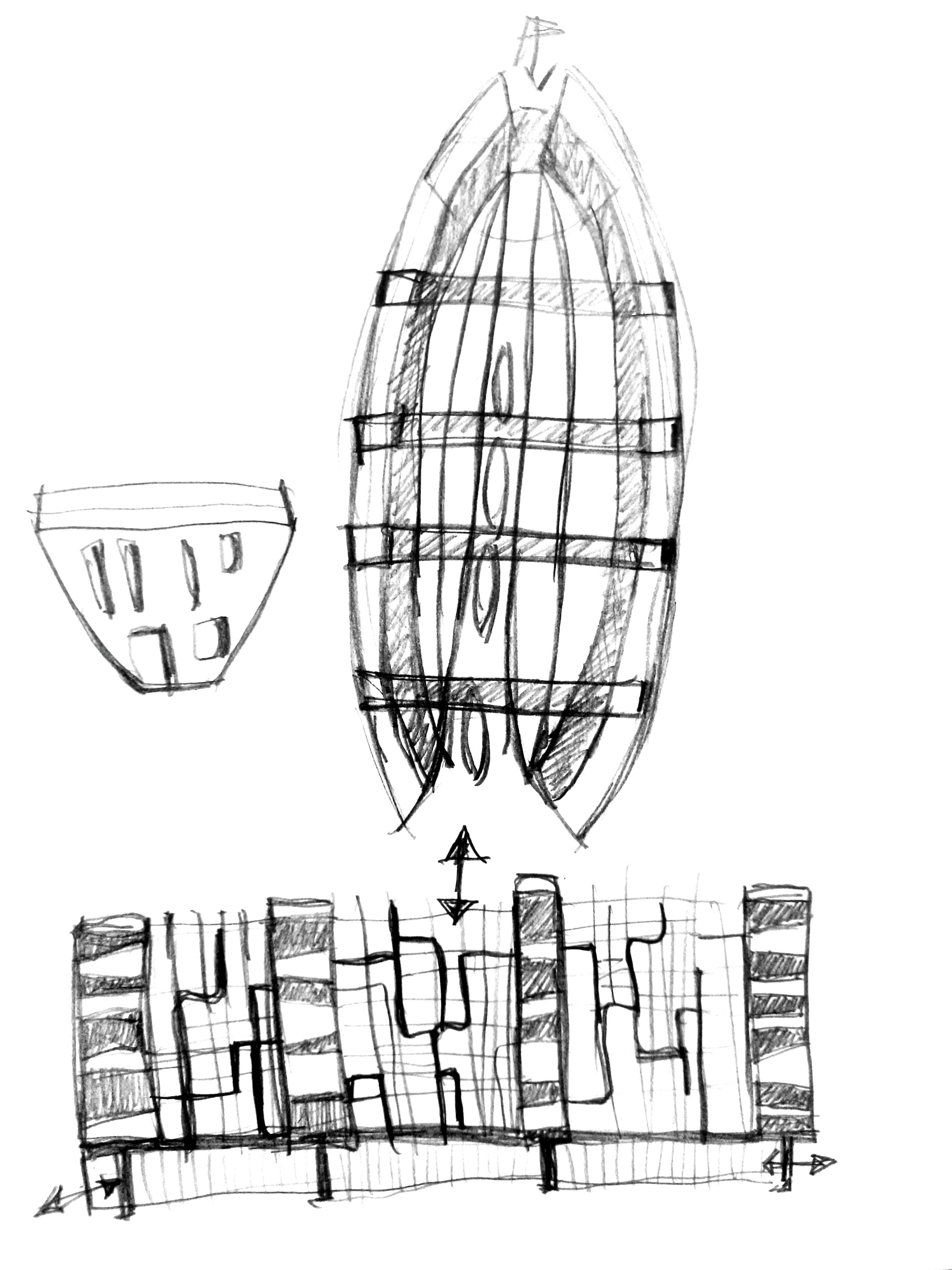

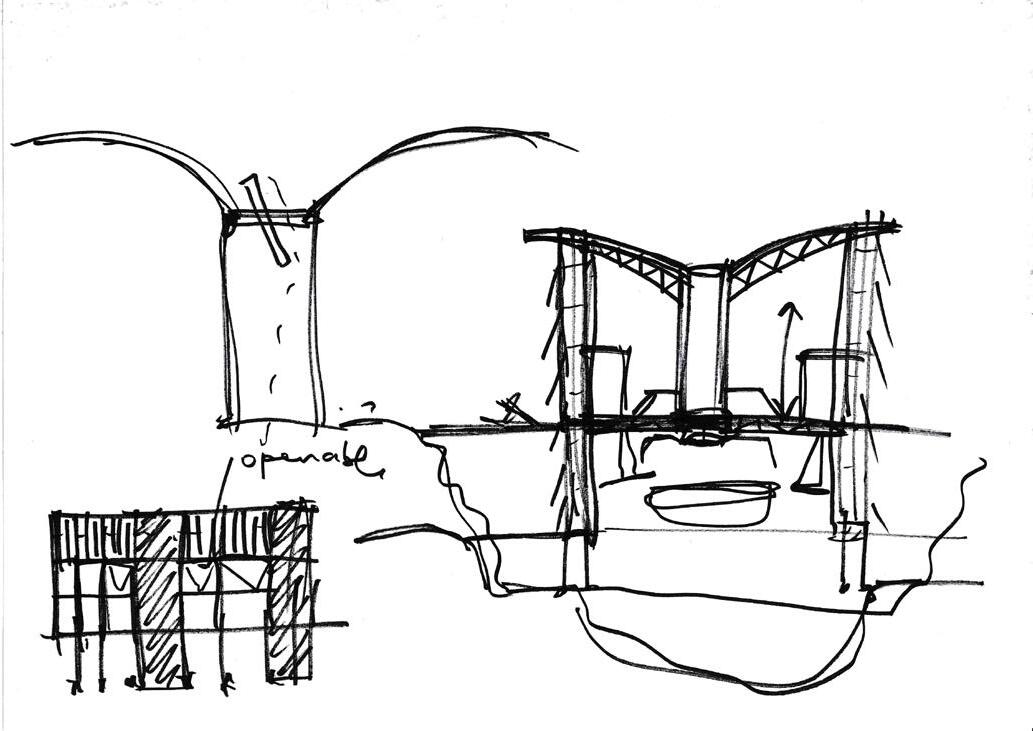

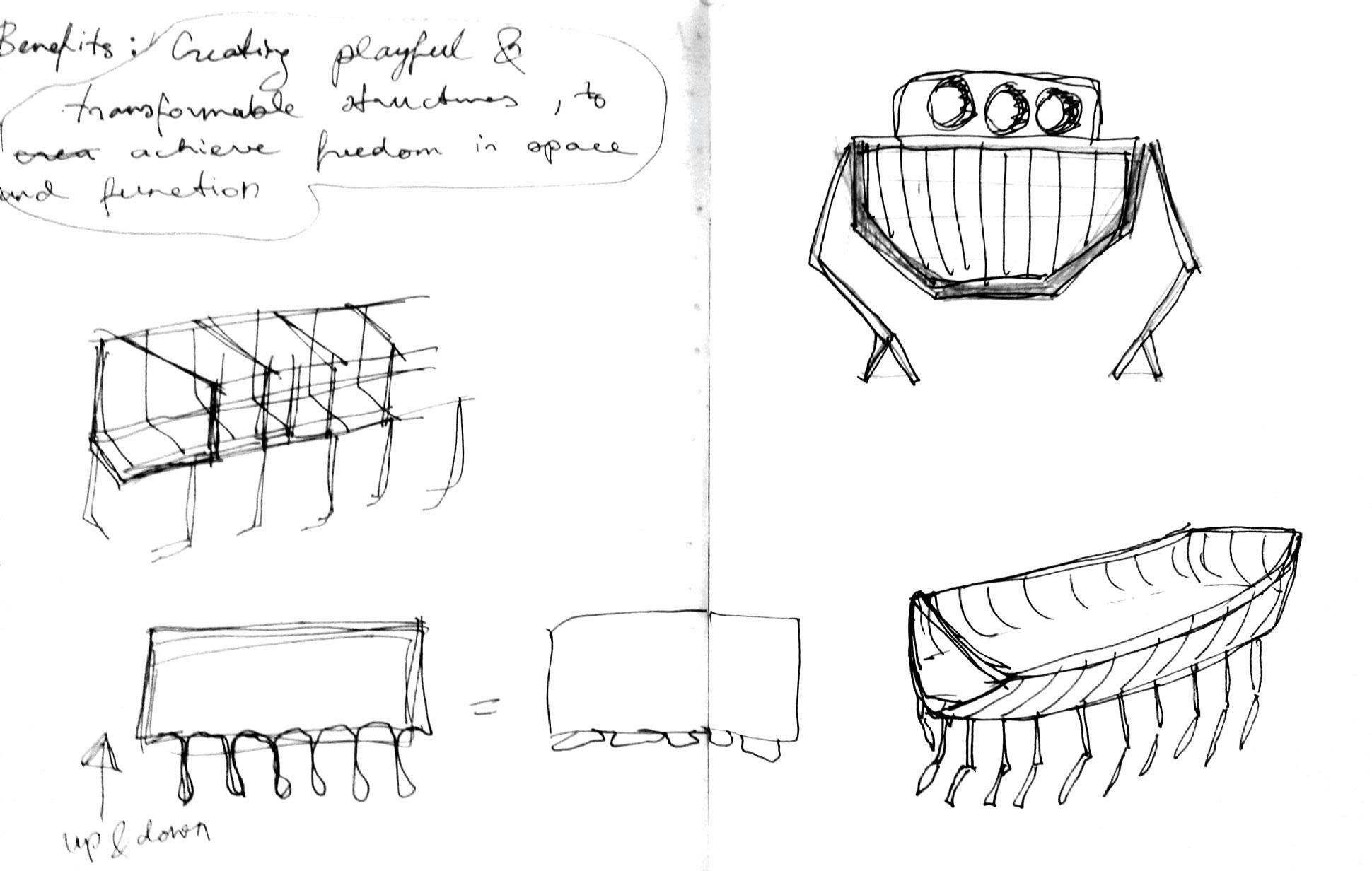

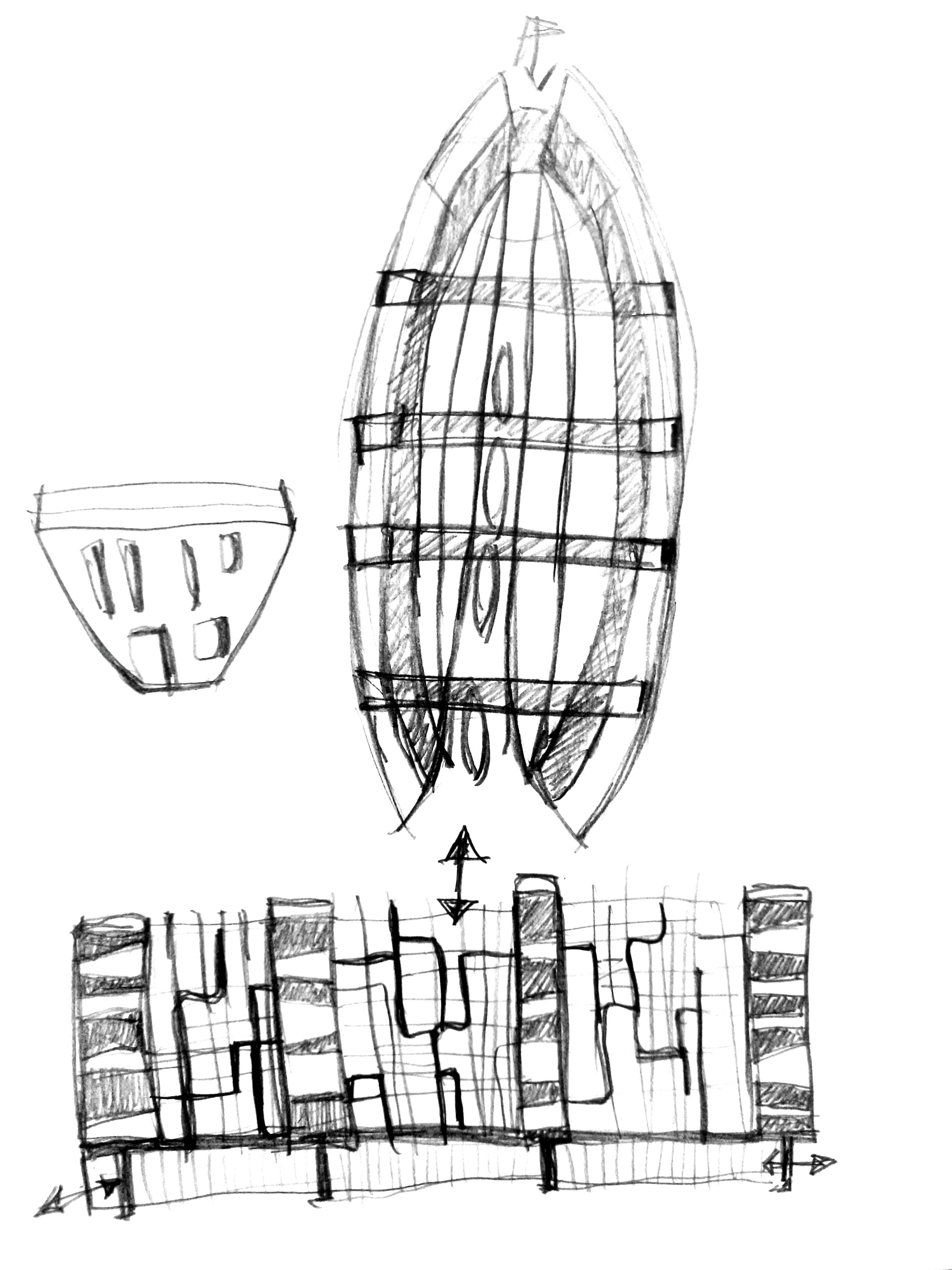

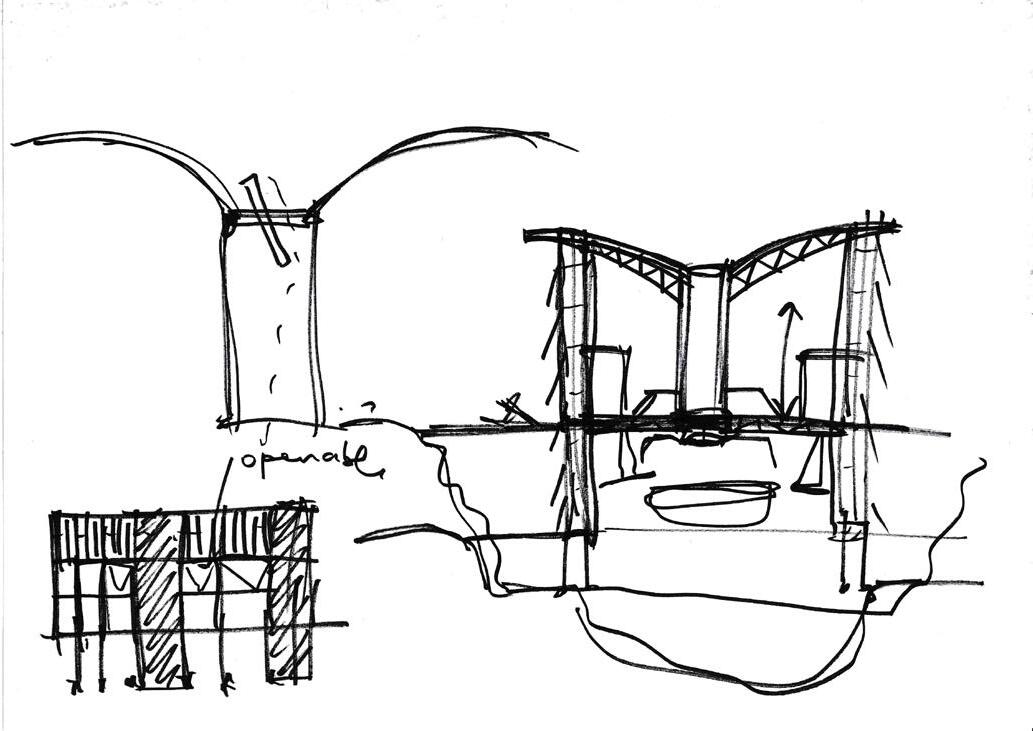

Transformability:

Explain how the ship-making facility will be designed for transformability, allowing for adaptability and future growth. Highlight the following aspects:

Modular construction: Describe how the facility will be built using modular components that can be easily reconfigured or expanded as needed, enabling flexible and scalable production capabilities.

Technological integration: Highlight the incorporation of advanced technologies and automation systems that can be upgraded or modified over time to keep up with industry advancements.

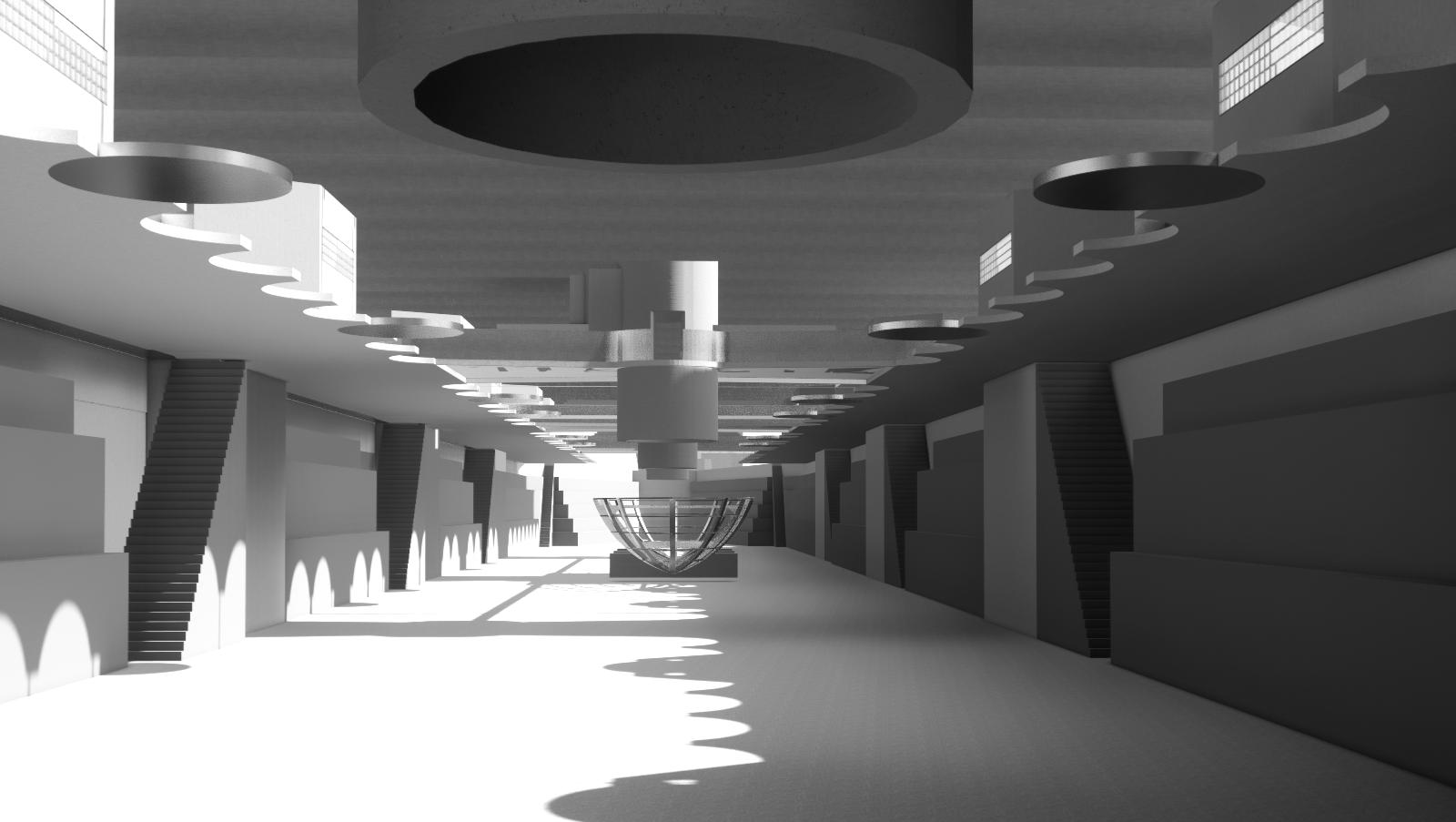

Multi-purpose spaces: Explain the design of adaptable spaces within the facility that can serve different purposes, such as research and development areas, training centers, or collaborative workspaces.

Locally Sourced Produce: Highlight the project's commitment to supporting local businesses and utilizing locally sourced materials. Discuss the following:

Supply chain partnerships: Explain how the project aims to collaborate with local suppliers, fostering economic growth and reducing the environmental impact of transportation.

Sustainable materials: Emphasize the use of sustainable and locally sourced materials in the ship-building process, such as responsibly harvested timber or recycled materials.

Job creation: Mention how the project will contribute to job creation in the local community, providing employment opportunities and supporting the local economy.

Conclusion:

Summarize the key points of your project, emphasizing its innovative approach to ship-making while prioritizing sustainability, transformability, and local sourcing. Highlight the potential positive impacts on the environment, the community, and the ship-building industry as a whole.

manual to fully automated processes

From

PROJECT DESCRIPTION

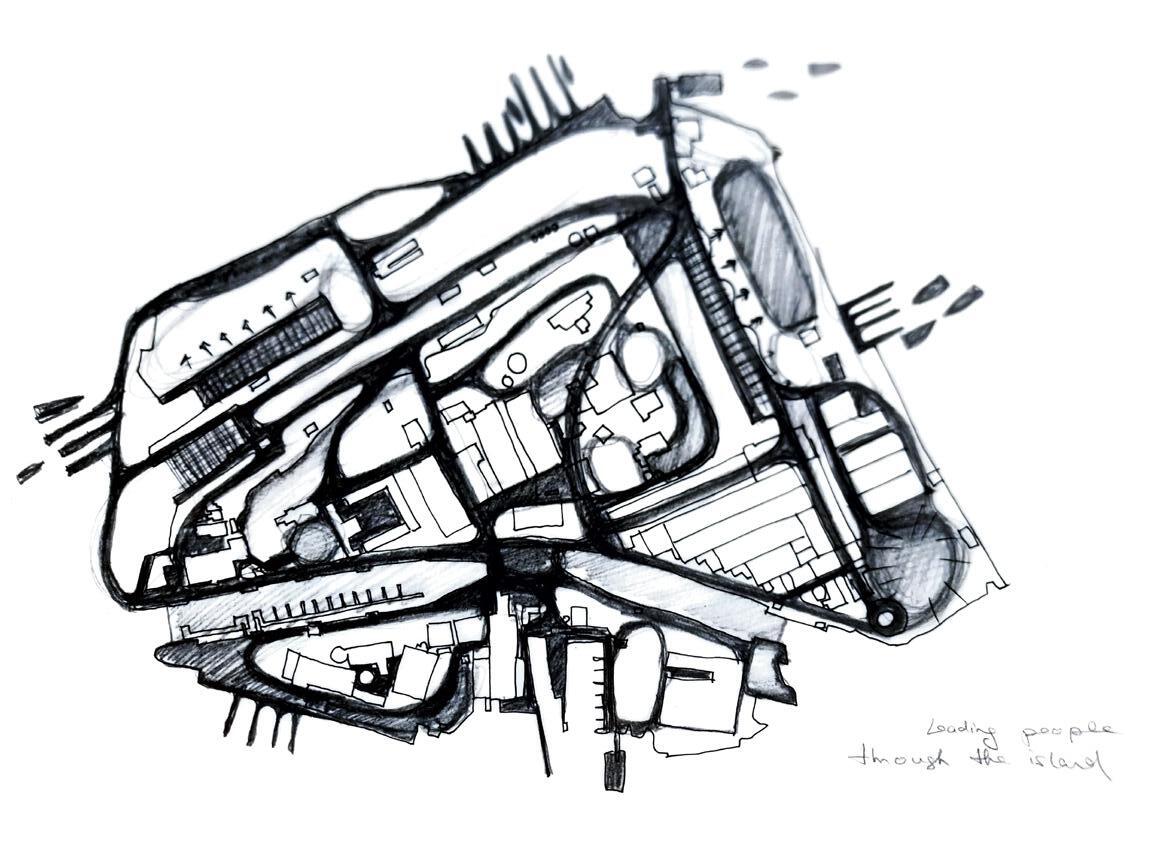

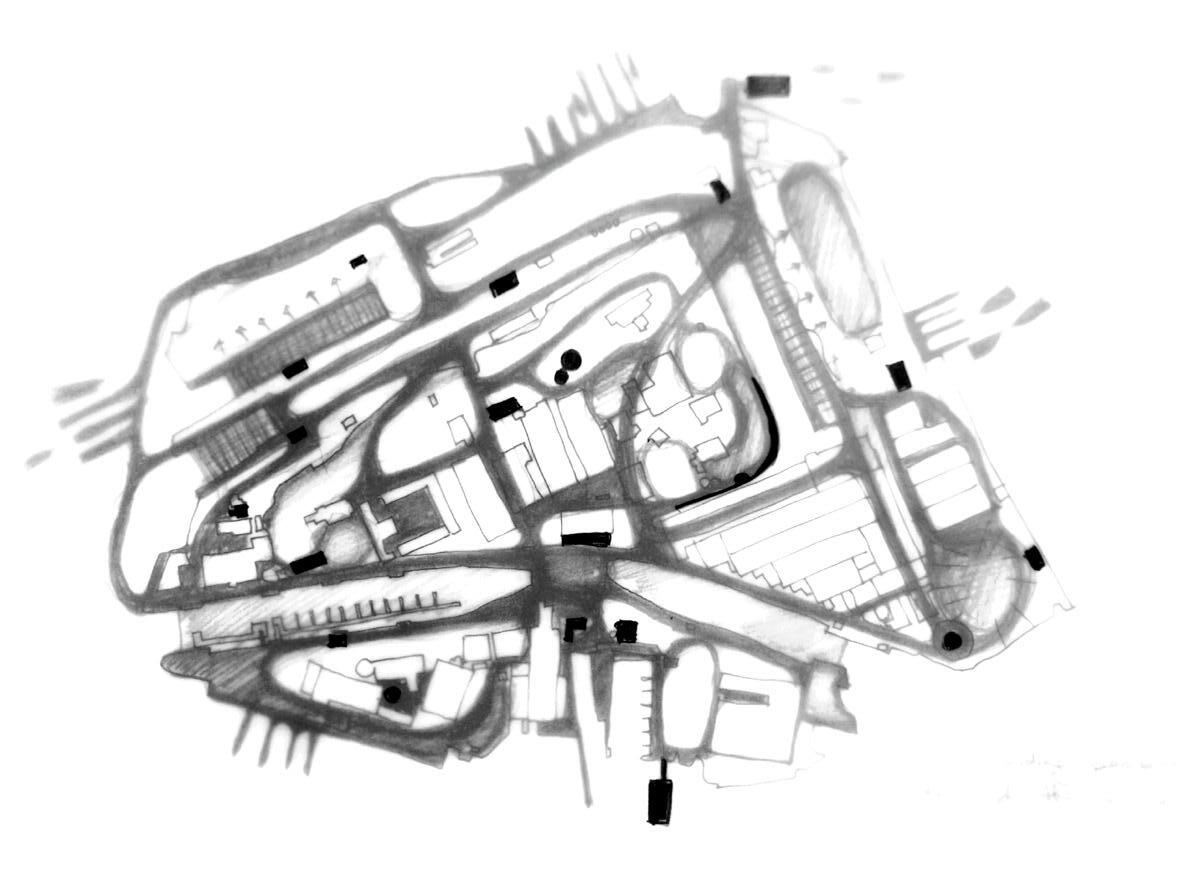

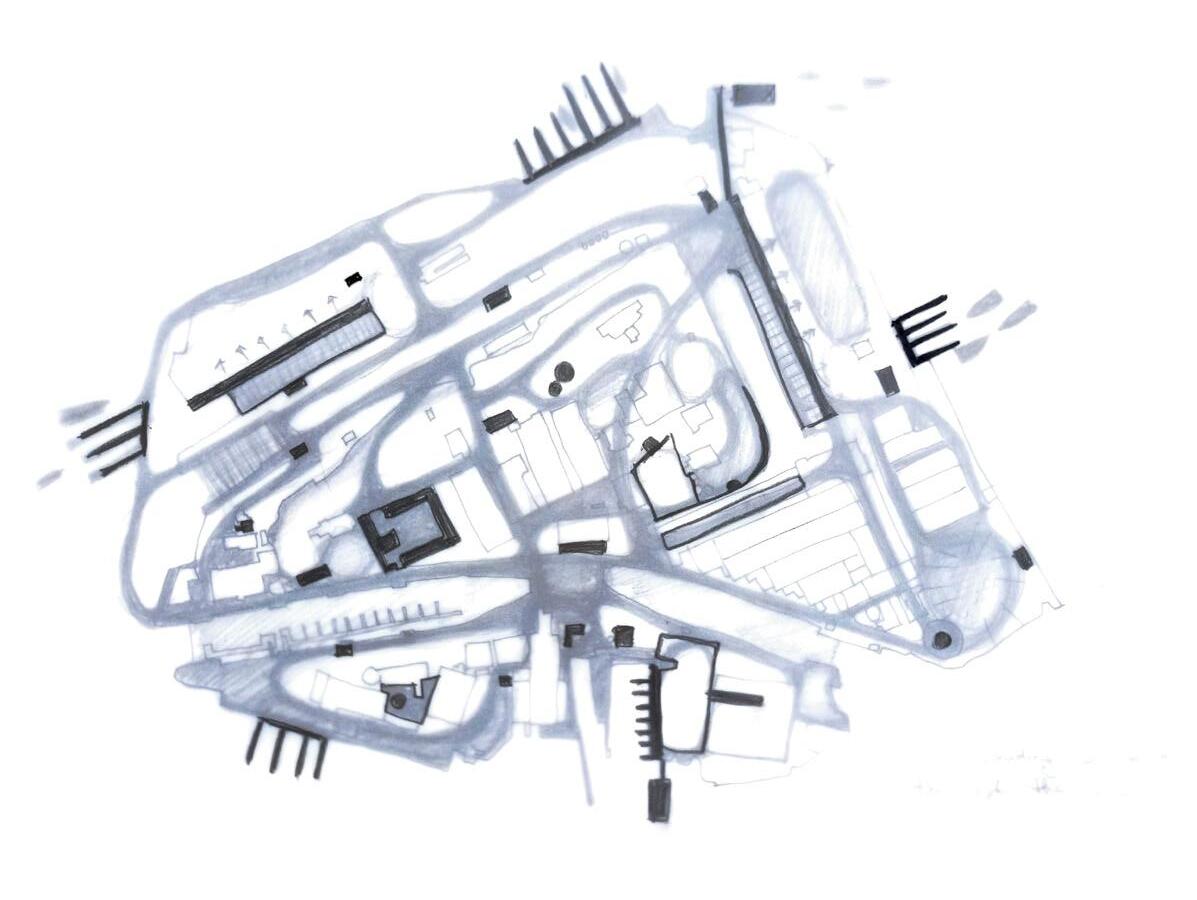

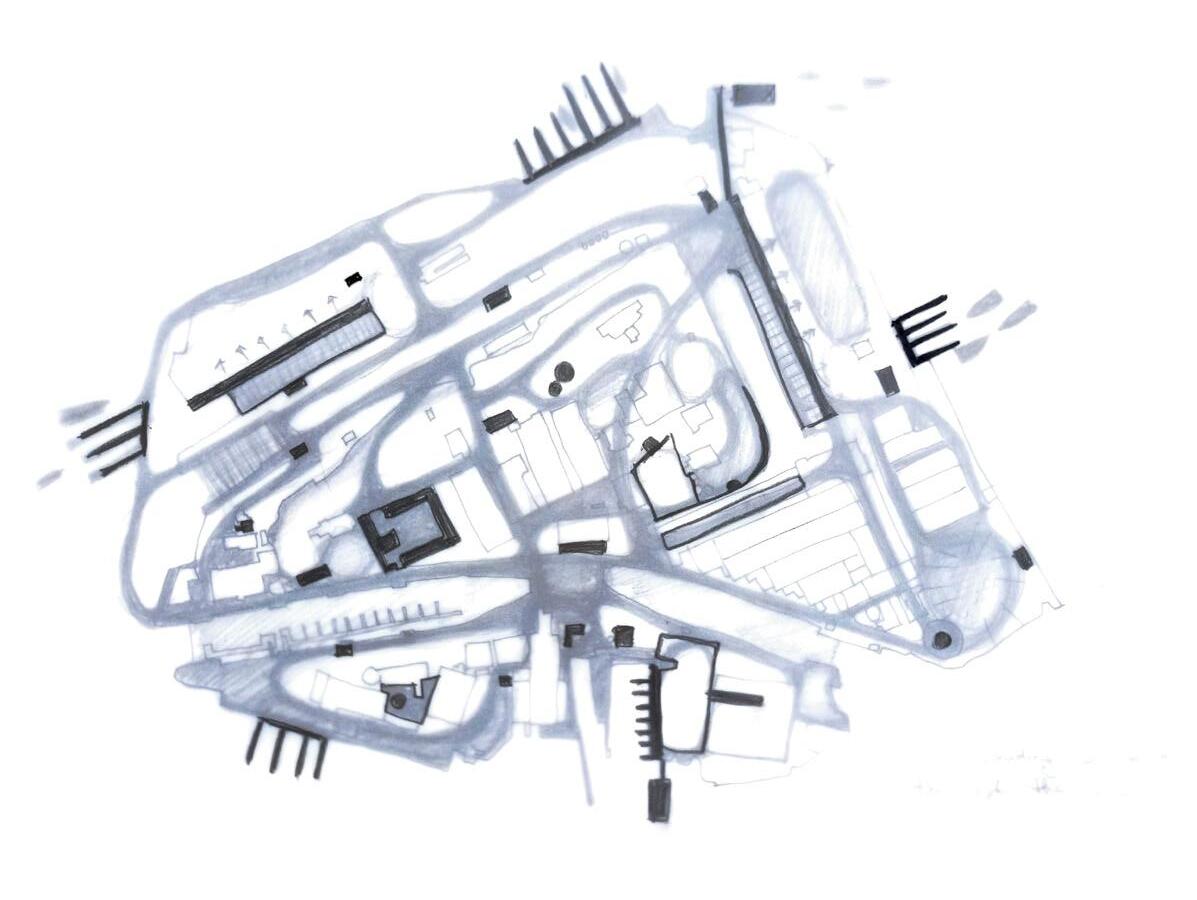

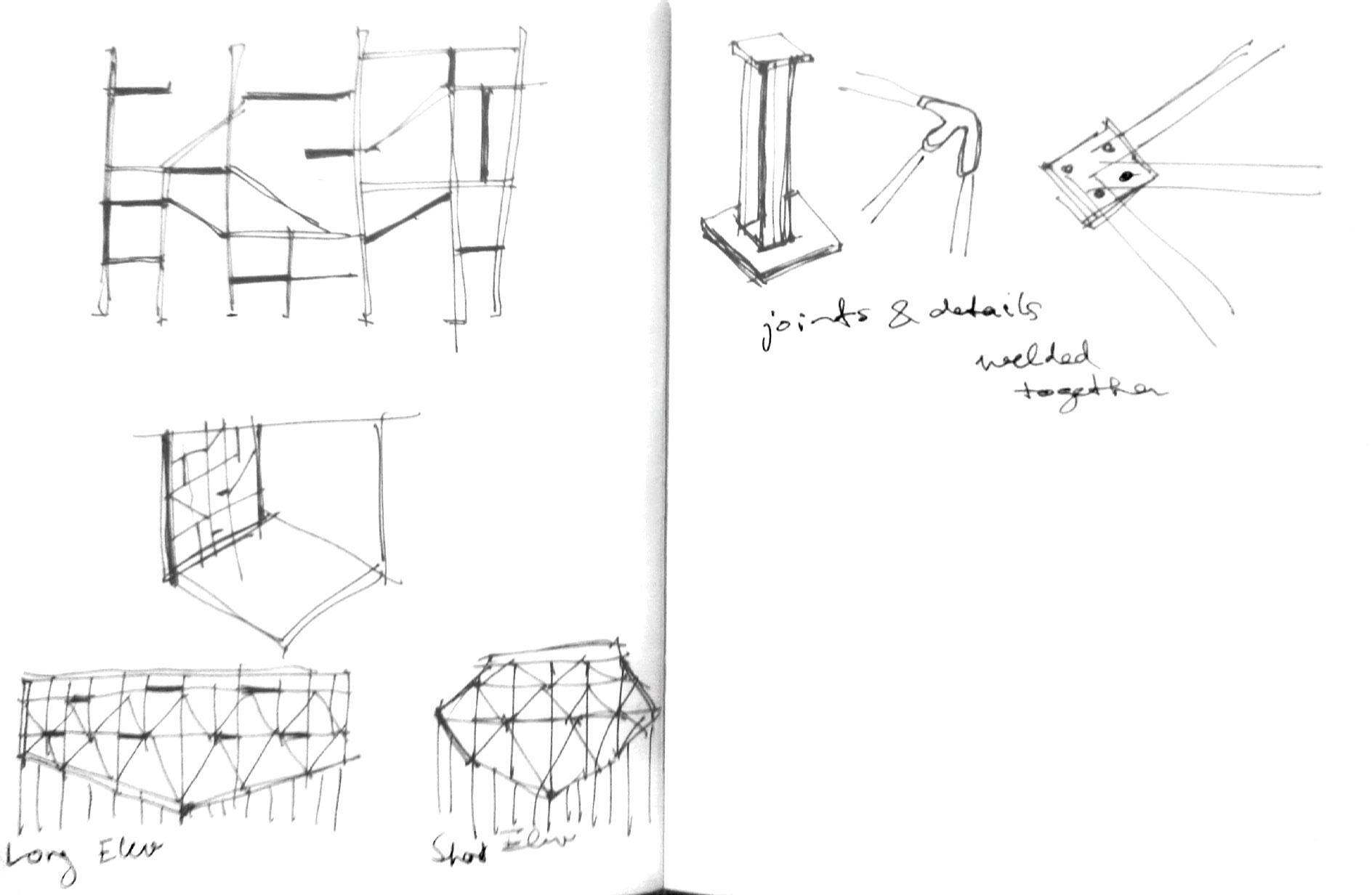

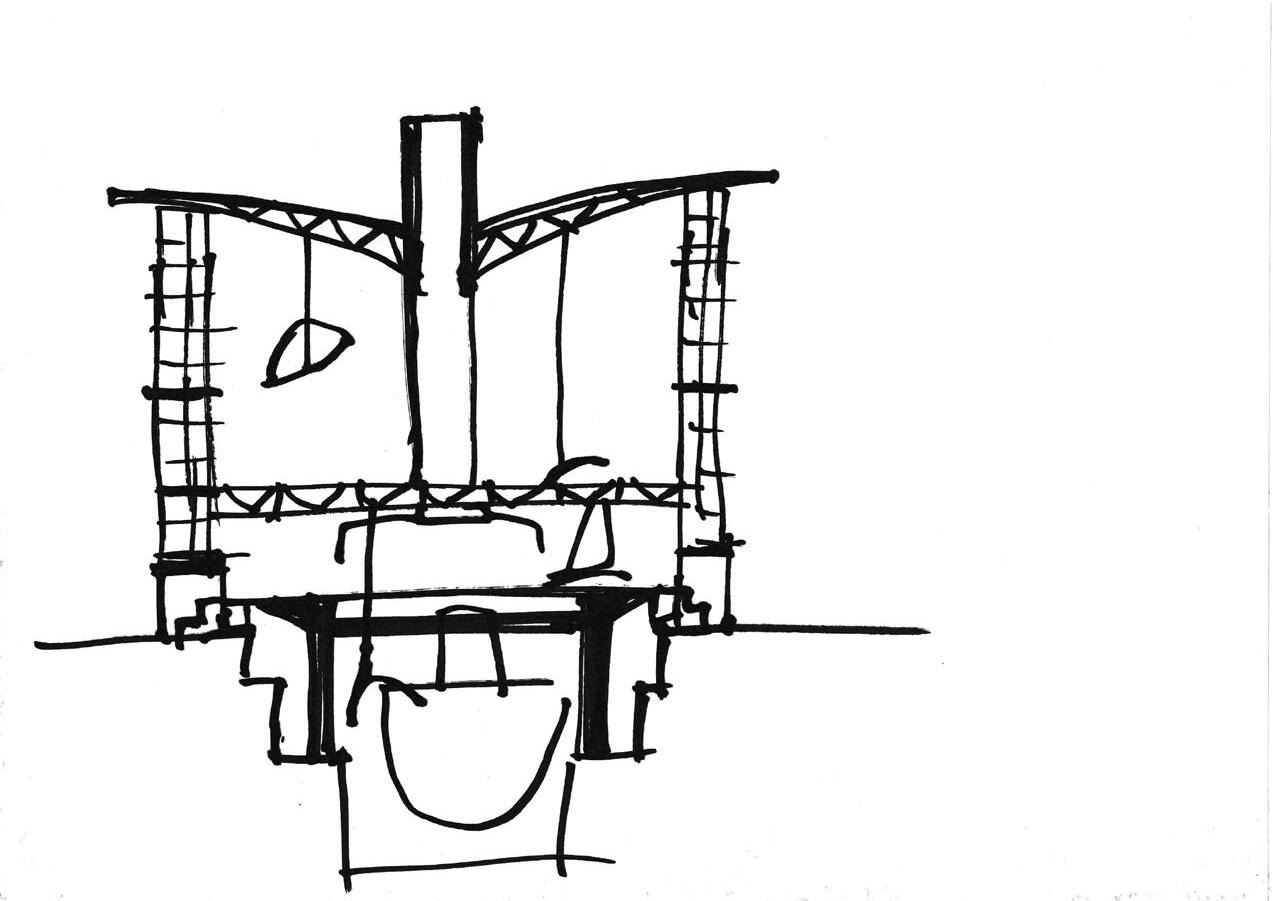

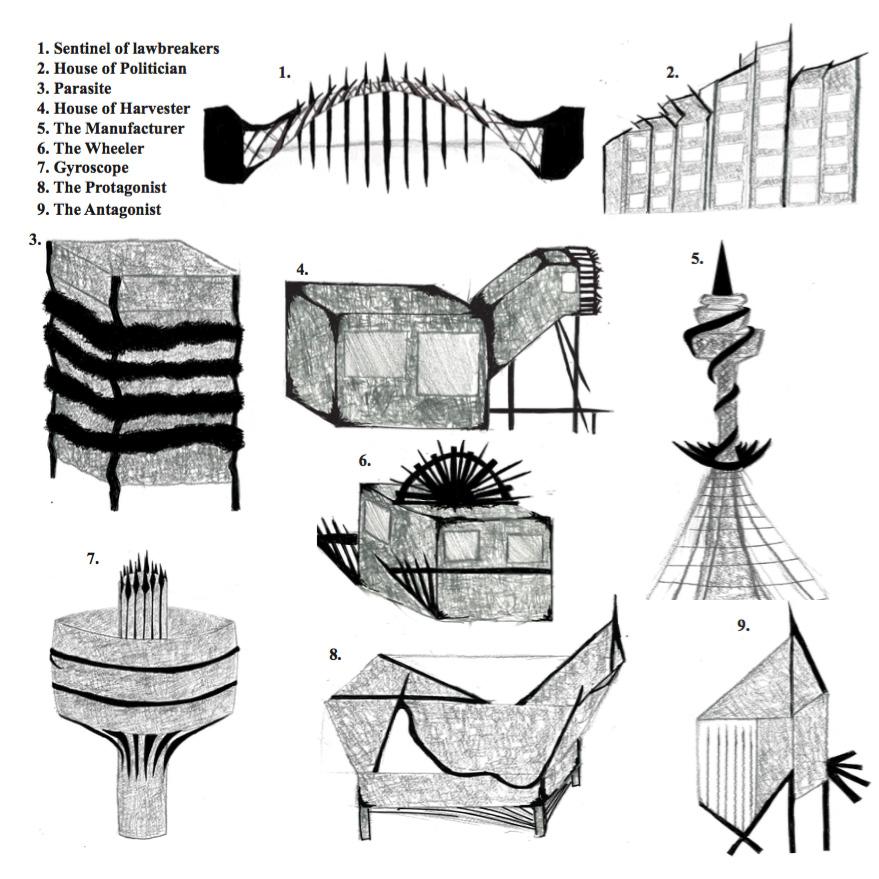

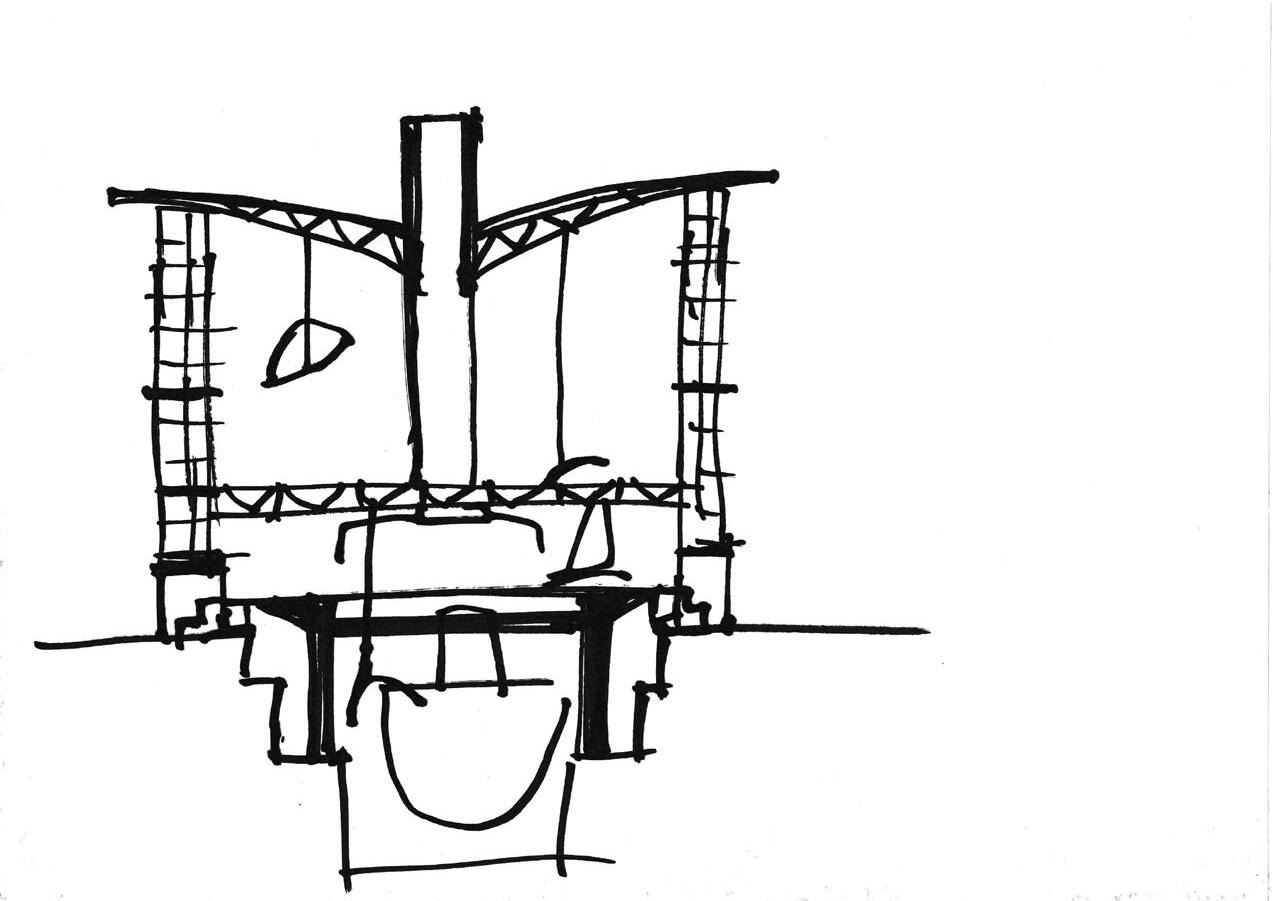

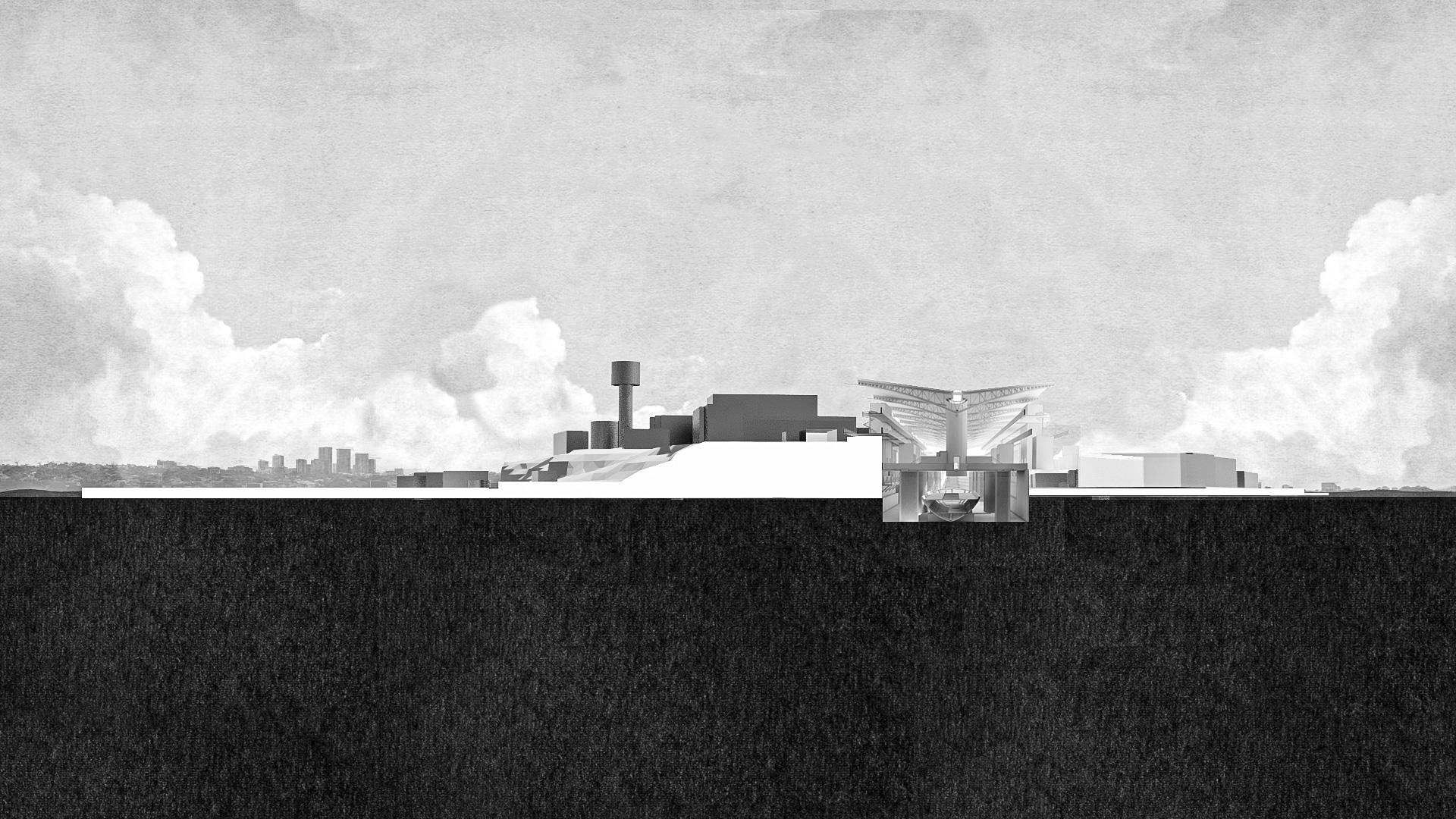

This is a proposal for a network of buildings that resemble shipbuilder's tools. The buildings are intended to function as a cohesive unit, transforming the layout of the island and maintaining its existing industrial character.

Although each building possesses its own unique characteristics, they are all interdependent and cannot function without one another. The network of buildings is versatile and can accommodate various activities and functions. Additionally, the design is flexible enough to accommodate future changes and foster relationships between public and private sectors.

The buildings are composed of a skeleton, connections, a network, and an exterior shell or skin, forming a comprehensive system. The ultimate goal is to incorporate Industry 4.0 as a new industrial paradigm.

1. Program - manufacturing facility for ships

2. Culture

3. Material Benefits:

Boost Australia’s Economy

Bring back overseas manufacturing jobs

Fostering job growth and cultivating a more skilled local labor pool

Why Cockatoo Island?

Cockatoo Island has a remarkable history as a shipbuilding and ship repair facility, contributing significantly to Australia’s maritime affairs between 1857 and 1991.

Re-inventing the shipbuilding facilities

I have chosen the Cockatoo Island as a strategic location for a shipbuilding infrastructure

That’s despite being an island continent where 99% of imports and exports are transported by sea, with thousands of large commercial ships operating in Australian waters.

The 4th industrial revolution is expected to have a significant impact on the environment by reducing waste, energy consumption, and carbon emissions. By using advanced technologies to optimize the manufacturing process, manufacturers can significantly reduce their environmental footprint and contribute to a more sustainable future.

URGENCY:

Ongoing market instabilities will drive more than half of Australian businesses to bring back overseas manufacturing jobs to Australia in high volumes, as discovered in a new industry survey, as Covid-19 interruptions have pushed business leaders to reconsider the resilience of their companies with off-shore manufacture.

Despite the obvious emotional appeal, Australian companies manufacturing offshore can face very real challenges in bringing production back onshore.

Lack of local skills and equipment mean many industry sectors require substantial investment before they can even think about bringing manufacturing back onshore.

Skeletons of the future is sequence of interventions - a community on Cockatoo island, which is self-sustained, providing the innovative ship making, manufacturing facilities, as well as intorducing new ways of ship construction methods. It has ship making facilities, indoor, outdoor and underwater classrooms and facilities, accomodation.

Humans and robots can coexist together, creating more effective ways of working and living together.

Problem: CO 2 emissions from most of the transportation techniques

Ship building facilities that manufacture fully autonomous vessels with no pilot, no captain and no crew on board, where robotic technology in shipping takes new turns. Recreating new modern ships from old ones, repurpousing and recycling steel elements, which can later be used in construction of new ships, boats or simply construction elements for buildings.

Classrooms and learning units

Accomodation

Manufacturing and assembly

Steel production

2.26 2.21 1.91 1.99 2.00 1.92 1.91 2.01 1.98 2.07 2.10 2.07 2.05 2.23 2.25 15.53 14.32 2.67 4.36 11.66 8.67 2.87 2.74 5.41 8/.7/4 8/.4/8 20/2.3/15 10/.5/8 10/.7/15 30/2/30 20/1/15 18/.8/15 8/.8/7 6/.5/6 12/.6/12 23.37 21.32 23.43 23.73 21.84 22.30 22.06 21.79 21.70 21.61 21.54 21.55 23.78 23.66 22.92 21.98 22.62 23.21 18.58 16.58 15.93 14.41 15.60 15.44 12.55 14.85 15.10 14.03 15.68 17.24 17.13 17.20 17.36 18.52 18.60 21.10 20.73 18.16 18.09 13.14 16.45 16.57 10/.6/8 7/.4/5 4/.4/10 12/.9/7 3/.4/9 5/.3/8 5/.3/8 8/.4/8 4/.4/7 8/.5/6 8/.3/7 5/.5/9 8/.5/8 8/.4/9 12/.8/10 12/1/10 7/.4/8 8/.4/6 8/.4/8 8/.4/8 8/1.1/6 8/.8/8 12/.8/10 12/1/10 12/1/10 5/.4/4 8/.5/6 8/.5/6 8/.4/5 8/.4/5 6/.6/5 5/.5/6 17/1/15 6/.3/5 15/.9/17 15/.7/1715/.7/17 15/.9/17 6/.3/6 6/.3/6 20/1.1/15 17/1.2/15 12/.6/20 8/.3/12 15/2/9 8/.4/5 6/.4/6 8/.4/5 7/.4/5 .5 .5 1 1.5 1.5 2 2 2 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 3 3.5 3.5 3.5 3.5 4 4.5 4.5 5 5 5.5 5.5 6 6.5 6.5 7.5 7.588.5 9.510 10.5 11 11 11.5 11.5 12 12 12.5 12.5 12.5 12.5 13 13 13 13.5 13.5 13.5 14 14 14 14 14 14.5 14.5 14.5 14.5 14.5 14.5 15 15 15 15.5 15.5 15.5 16 16 16.5 16.5 16.5 16.5 16.5 17 17 17.5 17.5 18 18.5 18.5 18.5 19 19 19.5 19.5 19.5 20 20 20.5 20.5 21 21.5 21.5 21.5 22 22 22.5 23 2.60 2.2 2.2 2.4 100 80 60 40 20 0 69 19 EDGE CONCRETE 2.54 2.60 15.31 14.93 15.13 2.31 2.34 2.45 2.38 2.39 2.44 BUILDINGBRICK BUILDINGCONC

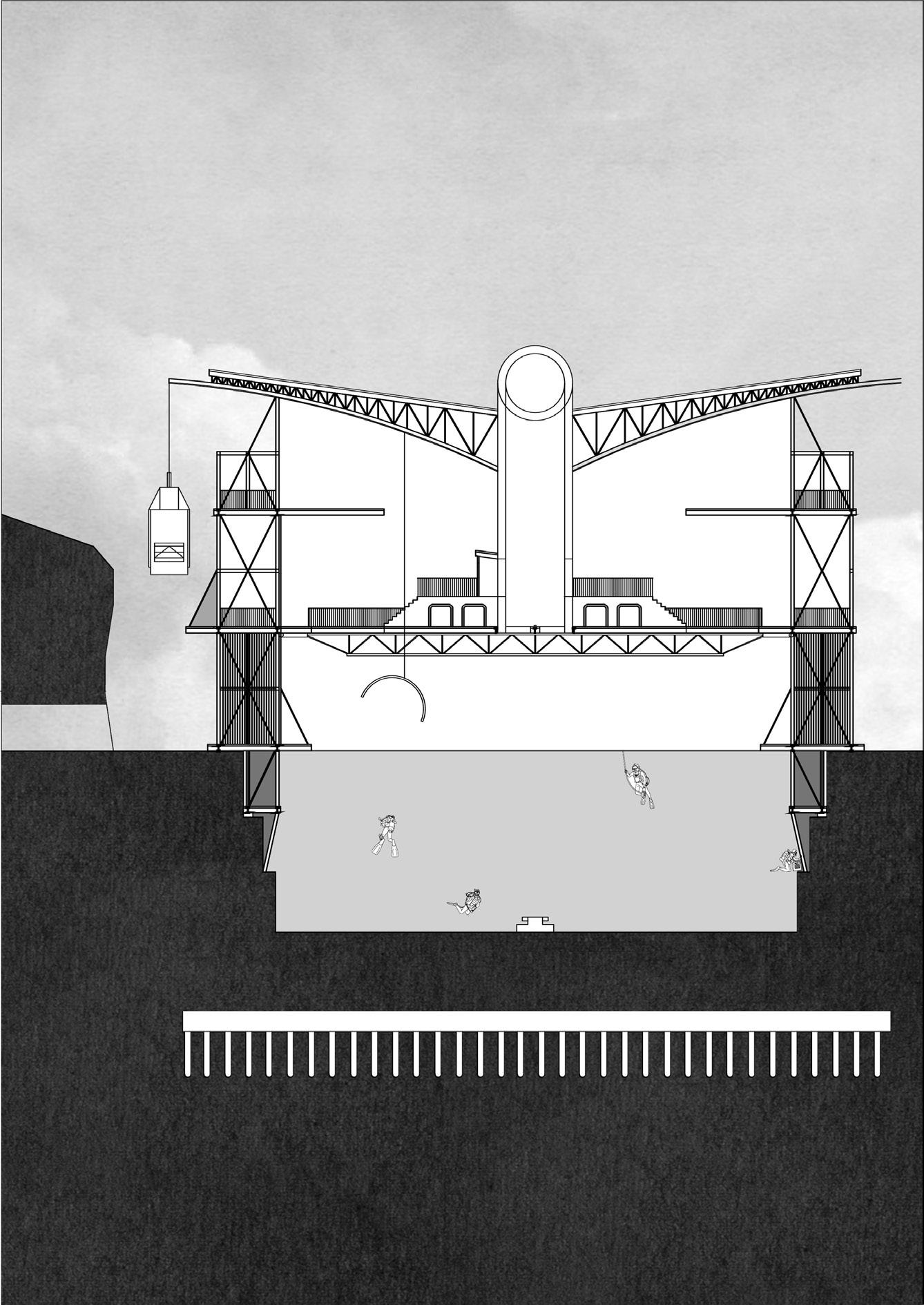

Manufacturing space

Access points

Material loading and services

Solar chimneys

Public corridors

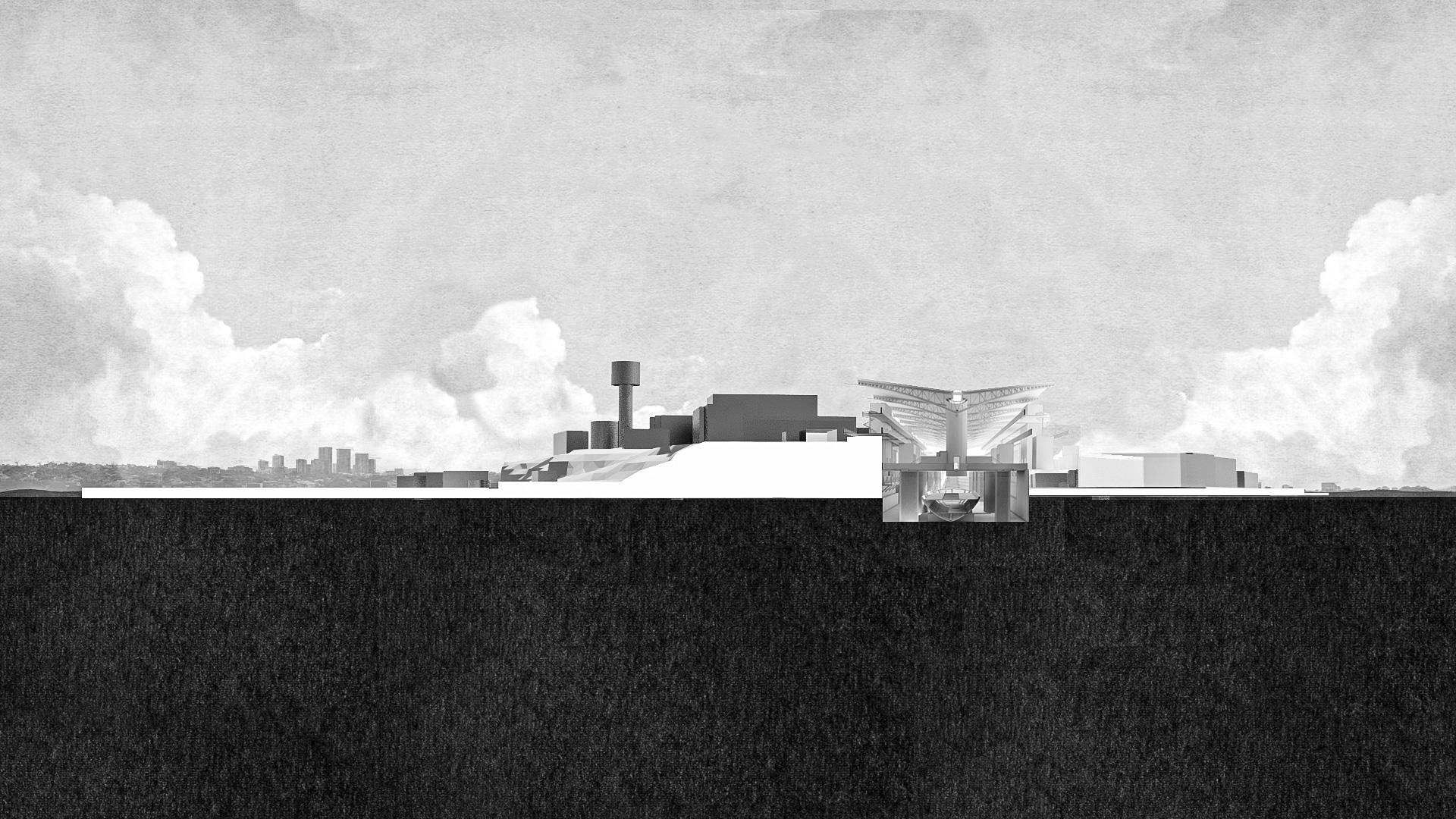

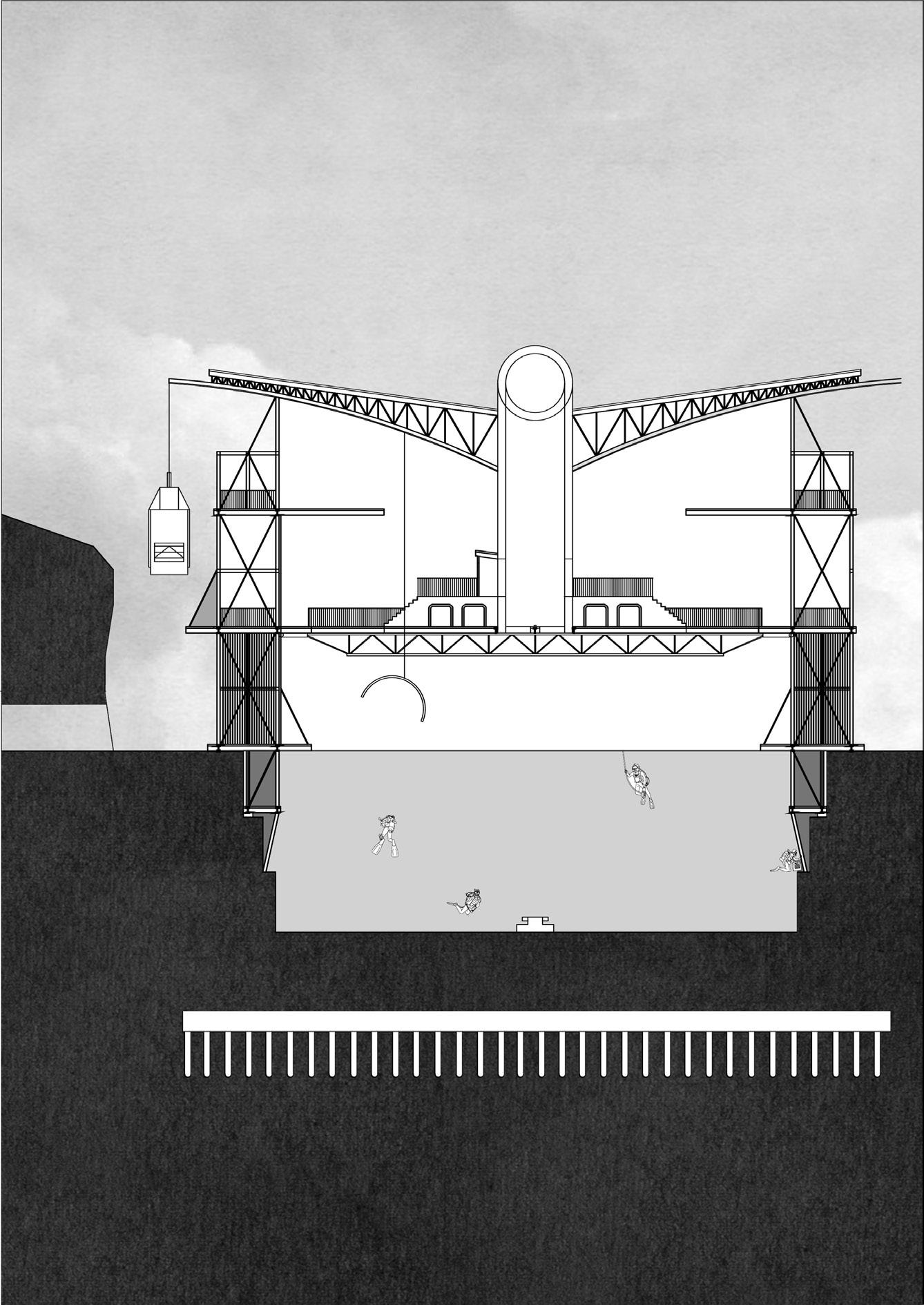

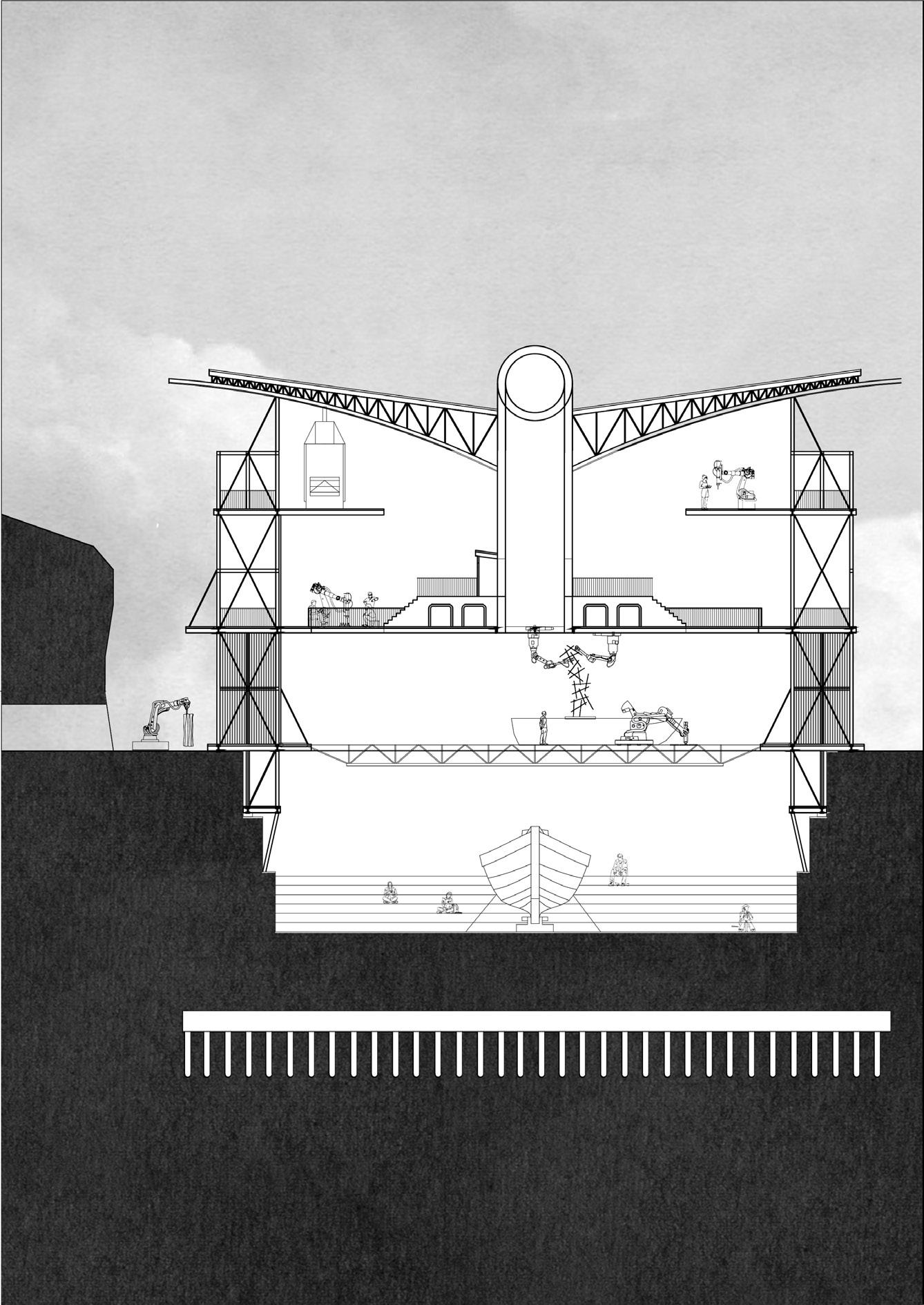

Long section

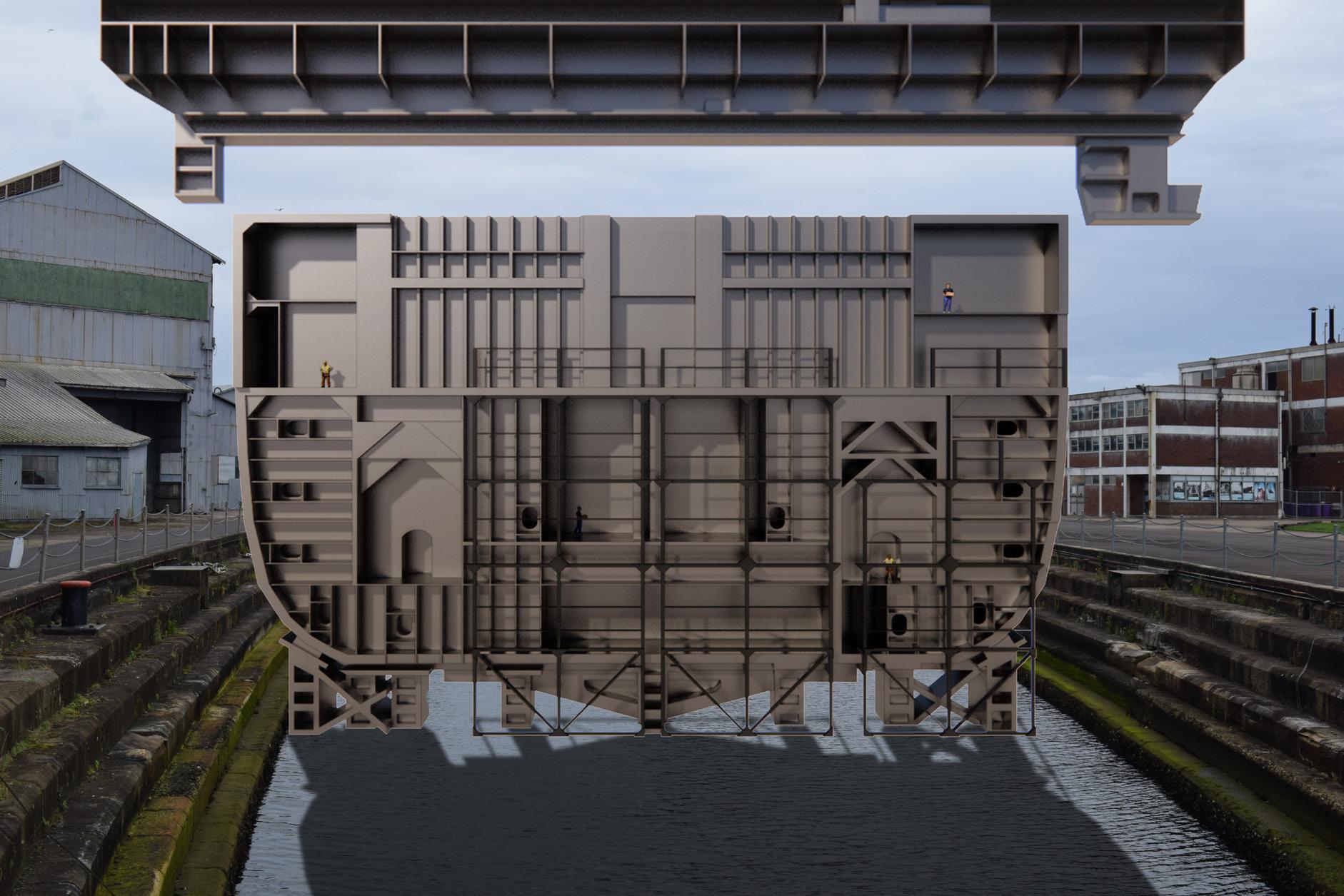

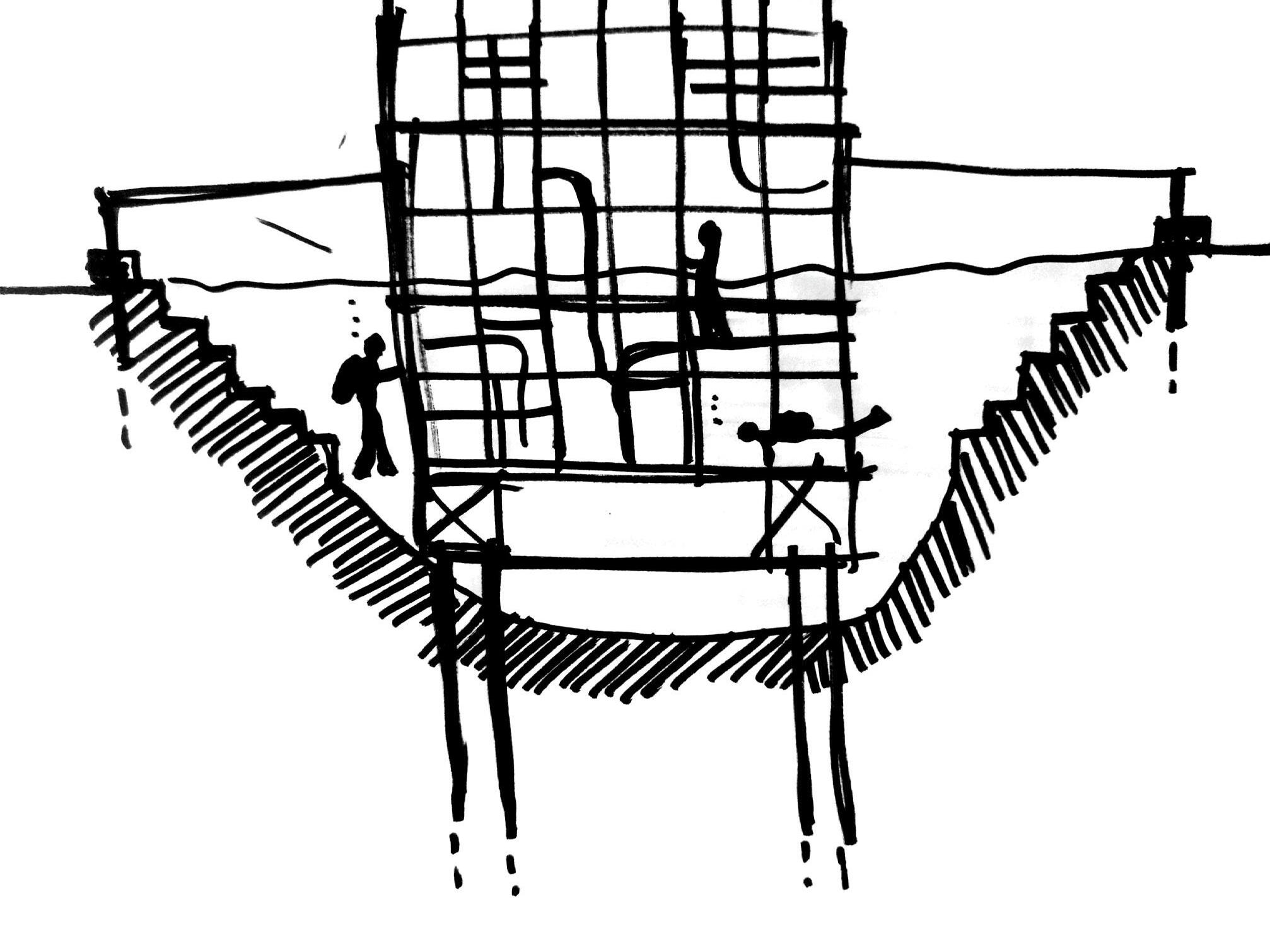

Dry dock workshop facilities

Dry dock workshop facilities

Dry dock workshop facilities

Underwater

Dry dock workshop facilities

Dry dock workshop facilities

Underwater

Dry dock workshop facilities

by Paula Bloma 2022/2023

by Paula Bloma 2022/2023

Gadigal

PARRAMATTA River

WAREAMAH

Cammeraygal

Wallemudegal

Wangal

GONG-UL

AR-RA-RE-AGON

MOCOBOULA

OCEAN

TIDE

MEL-ME

GOOGLE EARTH

Gadigal

PARRAMATTA River

WAREAMAH

Cammeraygal

Wallemudegal

Wangal

GONG-UL

AR-RA-RE-AGON

MOCOBOULA

OCEAN

TIDE

MEL-ME

GOOGLE EARTH

Cockatoo Island before and after

Cockatoo Island before and after

11.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1. A clibing tower

2. Education facility

3. Accomodation facility

4. Craft workshops

5. Sports facility/stadium

6. Watch tower

7. Store and cafe

8. Accomodation facility

9. Communal kitchen

10. Art gallery & center

11. A new school for woman

11.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1. A clibing tower

2. Education facility

3. Accomodation facility

4. Craft workshops

5. Sports facility/stadium

6. Watch tower

7. Store and cafe

8. Accomodation facility

9. Communal kitchen

10. Art gallery & center

11. A new school for woman

3D REPRESENTATION AND SKETCHES BY JOHN HEJDUK

3D REPRESENTATION AND SKETCHES BY JOHN HEJDUK

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

TYPICAL STEEL FRAME BUILDING CONSTRUCTION EXAMPLES IN AUSTRALIA

MFO Park by Raderschall in Zürich

MFO Park by Raderschall in Zürich

ARCHITECTURAL CONSERVATION: HILL HOUSE BOX BY CARMODY GROARKE

ARCHITECTURAL CONSERVATION: HILL HOUSE BOX BY CARMODY GROARKE

JOHN HEJDUK TOWERS. CITY OF THE CULTURE OF GALICIA. SANTIAGO DE COMPOSTELA.

JOHN HEJDUK TOWERS. CITY OF THE CULTURE OF GALICIA. SANTIAGO DE COMPOSTELA.

Construction of the Cockatoo Island

Construction of the Cockatoo Island

Manufactured house prototypes by Buckminster Fuller

Manufactured house prototypes by Buckminster Fuller

Galerie des machines

Galerie des machines

Cristal Palace, London

Cristal Palace, London

Dry dock workshop facilities

Dry dock workshop facilities

Dry dock workshop facilities

Underwater

Dry dock workshop facilities

Dry dock workshop facilities

Underwater

Dry dock workshop facilities