Inside this issue

➤ Case Study

PAK’nSAVE Wairau Road

➤ NZS5149 – The HVAC standard you probably don’t know about, but should.

➤ The Future of Work: In-Demand tech skills everyone should learn

➤ Case Study

Getting worker buy-in on Health & Safety –ACC subsidy for health and safety advice

www.irhace.org.nz

Journal for

New Zealand Refrigeration, Heating, Ventilation

Conditioning Industries

The Industry

the

& Air

AUGUST/SEPTEMBER 2021

SHOWGROUNDS:

ASB

16 - 17 SEPT

High Performance Central Plant Equipment

Temperzone NZ has a full range of high-performance, high-quality central plant equipment for your building heating & cooling needs. Visit temperzone.com for more information.

August/September 2021 3 Contents Official Journal of the Institute of Refrigeration, Heating and Air Conditioning Engineers of New Zealand Inc (IRHACE), Climate Control Companies Association New Zealand (CCCANZ), and Refrigerant Licence New Zealand (RLNZ). 12 5 NEWS 17 EDUCATION & TRAINING 20 HVAC&R EXPO & CONFERENCE 22 OUR PEOPLE 30 MEMBER NEWS 31 PRODUCT FOCUS 34 EVENTS INSIDE THIS ISSUE 9 Case Study PAK’nSAVE Wairau Road 10 NZS5149 – The HVAC standard you probably don’t know about, but should. 14 The Future of Work: In-Demand tech skills everyone should learn 16 Case Study Getting worker buy-in on Health & Safety –ACC subsidy for health and safety advice The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries 14 10 You need to know about NZS5149. The consequences of getting it wrong are huge – maximum penalties of $500,000 and 2 years’ jail are possible.

PUBLISHER

IRHACE/CCCANZ/RLNZ

IRHACE: www.irhace.org.nz CCCANZ: www.cccanz.org.nz RLNZ: www.rlnz.org.nz

EDITOR :

HVAC Centre admin@irhace.org.nz

MEMBERSHIP: admin@irhace.org.nz admin@cccanz.org.nz

REFRIGERANT LICENSING & COURSES: admin@rlnz.org.nz

ADVERTISING: admin@irhace.org.nz

DESIGN Element Design Ltd

HVAC&R CENTRE

P O Box 217184, Botany Junction 2164, Auckland, New Zealand

E: admin@irhace.org.nz

E: admin@cccanz.org.nz

E: admin@rlnz.org.nz

No part of this journal may be printed in other publications without prior written permission of the Managing Editor.

Disclaimer: Statements expressed in this publication do not necessarily reflect the policies or views of the associations, and members of IRHACE or CCCANZ. The IRHACE Journal publishes both local and international articles. Standards and or practices may differ from current New Zealand standards and or practices used. No responsibility is accepted by the associations and editor for the accuracy of information or for errors or omissions. The IRHACE Journal is distributed to all IRHACE and CCCANZ financial members.

ISSN 01148257

Mark Meyer President

Welcome to our first edition of the IRHACE Journal in digital format. If you are reading this for the first time, there are six editions annually and it is the industry journal for the New Zealand Refrigeration, Heating, Ventilation and Air Conditioning Industries. Going digital has already increased the Journal’s circulation to 7,000+ and this is expected to continue to grow with the new platform.

The HVAC&R Technology EXPO and Conference is back on at the ASB Showgrounds with new dates of Thursday 16th and Friday 17th September 2021. Come along for two FREE days of technical education, visit exhibitors stands and see the HVAC&R Apprentice of the Year competition.

The EXPO in the “AirTouch Pavilion 3” incorporates the Thursday conference programme and Friday supplier product presentations and construction and building

control technology updates will share with exhibitors. Please register at: HVACREXPO2021.EVENTBRITE.CO.NZ

In July 2021, IRHACE welcomed new Council members Matt Birch, Pat Kilduff and Vikrant Bhatt; and our continuing Councilors Ashwin Patel and Paul Shaw; and Mark Meyer (President). There have been many changes that IRHACE has had to make in recent times, but we are emerging to be in a strong position to continue our role which is to be the voice of our industry and to influence key decision makers. Our role now is even more important than ever, as the role out of low GWP refrigerants, training and licencing has and will impact everyone in our industry.

A change of Board for CCCANZ sees new Board members Phil Mohan, Brendan Clarkson and Gary Reily join Garry Ko (Treasurer), Greg McCarthy (Deputy Chair) and Malcolm Miller (Chair). The RLTB Board comprises of Dave Nicholls (Chair) and Pat Kilduff (Deputy Chair).

Congratulations to our IRHACE Members who have reached milestones of 10 years+.

Join us on Facebook or LinkedIn to keep up to date with information from the HVAC&R industry.

4 www.irhace.org.nz

HVAC&R CENTRE

The COVID-19 vaccination and the workplace

The COVID-19 vaccination will not be needed for most work

Businesses should support workers to access vaccinations

If there are practical barriers to accessing vaccination (eg travel or time off work is needed), businesses should help address these. Some workers will have individual health concerns or other reasons for needing support. Businesses should ensure they do not directly or indirectly discriminate against workers on the basis of their vaccination status.

Health and safety reasons for requiring work to be done by vaccinated workers Businesses cannot require any individual to be vaccinated. However, businesses can require that certain work must only be done by vaccinated workers, where there is high risk of contracting and transmitting COVID-19 to others. This will be a minority of all work in New Zealand. This could change if there is a significant shift in the COVID-19 situation domestically.

To decide that work is high risk and therefore needs vaccination for health and safety reasons, businesses must first assess their COVID-19 exposure risk. This applies to work done by all workers, whether employees or independent contractors. Businesses must involve workers, unions and other representatives in the risk assessment process, and when deciding how to eliminate/minimise risks. Businesses should consider whether other public health measures (eg physical distancing, PPE usage) can minimise the risk of exposure and transmission of COVID-19.

Assess whether a specific role needs to be performed by a vaccinated worker Businesses and services can also require a specific role be performed by a vaccinated person - if you have done a health and safety risk assessment to support this.

You must focus on the role and not the worker performing it because you can’t require an individual to be vaccinated. If you think a role in your business or service needs to be performed by a worker vaccinated against COVID-19, you need to assess the role’s exposure risk to the virus.

You must assess the risk in collaboration

with your workers and their representatives. The WorkSafe website has general guidance about carrying out health and safety risk assessments. An assessment usually includes two factors: the likelihood of being exposed to a risk while performing a role, and the potential consequences of that risk.

To carry out a risk assessment for exposure to COVID-19 you need to consider two main things about the role:

• the likelihood of a workers being exposed to COVID-19 while performing the role, and

• the potential consequences of that exposure on others (e.g. community spread).

Identifying the likelihood of COVID-19 exposure

The first thing you need to consider in your risk assessment is the likelihood that a worker performing the role will be exposed to COVID-19.

If regular testing isn’t mandatory for the role, but you still think there may be a high likelihood of exposure, the Ministry of Health has information about the transmission of COVID-19 that may help you decide this. This includes information about exposure duration and where and how the exposure occurs.

Identifying the potential of that exposure on others

To help you work out potential consequences,

you need to consider whether the role involves regular contact with vulnerable people (e.g. those with health conditions) and older people.

The Ministry of Health has information about people who are at high risk of severe illness if they contract COVID-19.

Completing the risk assessment

If there’s a high likelihood that the person performing the role may be exposed to COVID-19 and the consequences would be significant for other people, it’s likely the role needs to be performed by a vaccinated person.

If you decide the role needs to be performed by a vaccinated person you’ll need to work through the employment implications. Employment New Zealand has guidance on this

Public health guidelines for businesses and services – Ministry of Health

Reasons for requiring vaccination other than health and safety are unlikely to be sufficient, for example, requiring vaccination to promote your workplace as being fully vaccinated.

This would amount to requiring workers to undergo a form of medical treatment solely for a marketing benefit.

If certain work can only be done by vaccinated workers, businesses should set a reasonable time-frame for workers to decide if they will be vaccinated.

If an employee cannot work during this time, special paid leave should be considered, especially in the short term while employers and employees discuss what happens next.

A person’s vaccination status is personal information

Collecting, storing and sharing information about people’s vaccination status must be done in accordance with the Privacy Act.

For more information visit

https://www.employment.govt.nz/leave-andholidays/other-types-of-leave/coronavirusworkplace/covid-19-vaccination-andemployment/

NEWS August/September 2021 5

Calling Registered Electrical Workers

Book your seat for the next one-day electrical safety competence course. To attend this course, you must already be a Registered Electrical Worker. On completion of this course, you will be eligible to renew your Electrical Workers Registration Board (EWRB) practising license and First Aid/CPR.

The Registered Electrical Workers course is for registered residential and commercial Electrical Workers, including those who are selfemployed (this course is not applicable for Line Mechanics or Cable Jointers).

With the Registered Electrical Workers course, you will:

• Renew your practising license and your Site Safety Card at the same time, saving money, time and travelling costs.

• Gain practical testing skills in line with AS/NZS 3000:2007 Section 8 and AS/NZS 3760:2010

• Gain competence in First Aid/CPR

• Earn 4 credits towards your Health and Safety in Construction Programme.

Please note: While completion of this course will renew your EWRB practicing license, you must still pay a license renewal fee to the EWRB to complete your renewal.

Important Pre-Course Action

As required by the EWRB, please complete two brief online modules before attending this course and bring your certificate to the course.

• Bring your own test equipment – Multi-meter, Insulation Resistance Tester and RCD Tester.

• Review and bring a copy of AS/NZS 3000:2007 Section 8 to the course.

Additionally, please open and read the attachment to ensure this is the right course for you before booking.

• Covered shoes MUST be worn on the course.

What the course covers

Electrical Safety

• Revise electrical supervision

• Testing appliances AS/NZS 3760:2010

Revise Residual Current Devices (RCD)

• Revise Multiple Earthed Neutral (MEN) Systems

• Understand AS/NZS 3000:2007

• Revise Code of Compliance and Certificate of Verification

• Theoretical and practical competence testing

Health and Safety

• Shape health and safety culture through positive conversations

• Take action to improve health and safety on site

First Aid/CPR

• Covers specific requirements in legislation and codes of practice for the electrical industry.

• Run by a qualified First Aid/CPR trainer.

Site Safe regularly reviews and updates course content in partnership with the construction industry to ensure alignment to best practice industry standards. Our latest version of the Site Safe Passport takes an interactive format, including group workshops and videos to ensure an engaging and enjoyable learning experience.

What You Will get at the End of the Course:

• A Site Safety Card/Passport (valid two years)

• A course workbook detailing the electrical competence training 8 Licensed Building Practitioner points

• Earn 4 credits towards your Health and Safety in Construction Programme

Next learning steps

Completing a Site Safe Passport means you'll gain site access for the next two years.

Next time you want to renew your site access, you can expand your health and safety knowledge with a new course that's relevant to you. We now offer a suite of cost-effective four-hour Passport Plus courses on specific subjects, as well as a variety of one and two-day courses, all of which will renew your Site Safety Card/Passport.

Book your next course at www.sitesafe.org.nz

6 www.irhace.org.nz NEWS

Also available:

DuctBelt and Anchors

on

available as an upgrade)

Also available:

Sedona-Xm and TufTex or available as an upgrade)

available

may

require a premium charge

Cover-Up Sleeve Concealing DuctBelt and Anchors

Blue

Fabric Colors for Sedona-Xm, TufTex, and Verona. DuraTex is also available in these colors

on some fabrics, but may require a premium charge

White Tan Blue

Fabric Colors

“It goes beyond just making a conclusion based on the data presented, and gives real-world considerations and insights to support high-quality work,” he says.

The Handbook summarises the key components of AIRAH’s Design Application (DA) manuals. The new edition is the result of a comprehensive review in 2020.

Stat-X, Light Blue

and patterns.

(Standard on Sedona-Xm and TufTex or available as an upgrade) specific color types

lot. TufTex, and

and Patterns are available on some fabrics, but may require a premium charge

texture

of

According to the editor of the Technical Handbook, Vince Aherne, F.AIRAH, every edition of the Handbook builds on the previous one.

Smooth-Air will provide itemised quotes for your AirTouch zone controlled ducted systems.

Stat-X, Light Blue

Please note that the appendices for the Handbook are now only available for AIRAH members digitally via the AIRAH members portal.

IRHACE members are able to purchase the hard copy of the AIRAH Technical Handbook for $149. Please contact the AIRAH office on airah@

We can also make professional colour coded, ducted design presentations superimposed over your customers’ house plans.

With optional Individual Temperature Control Technology, AirTouch monitors temperatures and smartly adjusts airflow as needed around your home. some rooms get too hot or cold, AirTouch will adjust their airflow to maintain temperature, without wasting energy on rooms already comfortable. With ITC, you get wireless On/Off zone in your home doubles as a smart temperature sensor. 75% 100% OFF

Zone Control

Also available:

White Tan Blue

Rx, White

fabric or

dye lot.

Christchurch 264 Annex Rd, Riccarton Ph 03 343 6184 Wellington 15 Te Puni St, Petone Ph 04 566 7969 Auckland 6 Stanway Pl, Ellerslie Ph 09 579 3257 0800 SMOOTH (0800 766 684) sales@smooth-air.co.nz www.smooth-air.co.nz

also available in these colors

Cover-Up Sleeve Concealing DuctBelt and Anchors patterns.

(Standard

Smooth-Air August/September 2021 7

Rx, White

Verona. DuraTex is also available in these colors

Doing business with us is a breath of fresh air.

8 www.irhace.org.nz

filters for every workplace.

Ventilation

PAK’nSAVE Wairau Road

Temperzone Humidity Intelligence R32 Rooftop Packaged System Installed by Fonko NZ.

PAK’nSAVE Wairau Road in Glenfield was opened on 3rd May 2009. In 2019 the store was looking to undertake the replacement of their existing air conditioning system, two Temperzone R410a refrigerant rooftop package units. As part of Foodstuffs North Island Ltd, they adhere with a wider initiative to reduce their carbon footprint while installing more energy efficient systems.

Along with HVAC system upgrade, PAK’nSAVE Wairau Road was also looking to upgrade to Trans-critical CO2 refrigeration systems and energy efficient lighting solutions to reduce overall energy consumption and reduce carbon emissions.

The HVAC solution needed to maintain consistent humidity levels, typically around 50% RH, 22 DB, to keep glass cases clear and to avoid using excess energy by adding load to the refrigeration cases. Older refrigeration cabinets can require extra defrost which results in reduced cooling, has the potential to spoil product and produce condensate which could result in floor slippage. Effectively maintaining consistent humidity levels can avoid these issues.

Fonko NZ, HVAC Mechanical and Trans-critical CO2 Commercial Refrigeration specialists, wanted to use Temperzone’s new OPA2100 humidity intelligence systems to meet the humidity control and energy efficiency requirements of this project. However, at the time the unit was only available in R410A refrigerant. To meet the low GWP requirement for this project Fonko engaged Temperzone to develop an R32 refrigerant OPA2100 system, Temperzone had designed smaller R32 systems but nothing this large.

Following further research and development the first OPA2100 R32 unit was successfully built for this project. R32 has a GWP (675) which is less than a third of the currently used refrigerant R410A (GWP of 2,088). The R32 unit also required less refrigerant charge than the R410a version which resulted in an overall reduction of GWP of around 75% per kW of cooling.

Two OPA2100 units were commissioned in late 2019, these were among the very first commercial R32 products installed in the NZ market. Each with a capacity

range of 15 ~ 200kW, equipped with 4 independent refrigeration systems featuring inverter compressors and EC fans, they are specifically designed to target dew point temperature. Dew point is the temperature to which air must be cooled in order to produce condensation (dew). It represents

how much moisture is in the air: the higher the dew point temperature, the greater the atmospheric moisture content. Traditionally air conditioning is controlled solely on temperature however the OPA 2100 is unique as it also focuses on moisture content in air leading to precise cooling applications. The OPA2100 has been designed to control the room conditions with an innovative focus on humidity. By considering the humidity levels, the space temperature can be maintained in the most efficient way.

Utilising four independent systems allows precise control over the temperature as well as moisture levels of the air being supplied. The unit controller compares the customer setpoint for heating and cooling as well as the required RH% with the current room conditions which in turn automatically activates the specific control mode. The on-board controller calculates the dew point and then ramps the inverter compressor to control the indoor coil temperature in order to remove moisture only when required.

The OPA2100 uses precise evaporator control, when latent removal is required, each individual inverter is controlled so that the evaporating temperature is below the dew point. During cooling if the space doesn’t call for moisture removal compressor speeds are reduced which results in reduced power input to cool the space.

The control offers a unique approach based on an intuitive algorithm that adjusts compressor speeds as the room load changes. This approach plays perfectly to part load efficiencies by drastically reducing the energy demand on the building and improving comfort conditions due to curbing out extreme high and low temperature fluctuations when a unit is running to meet the target setpoint.

The units feature heat reclaim water coils to be connected to the refrigeration chillers. With the upgrade to new Trans-critical CO2 refrigeration systems, the heat reclaim coils will utilise the reject heat for the first stage of heating.

Economisers were installed for ventilation and economy cycle to reduce power input when outdoor conditions are favourable.

CASE STUDY ★ August/September 2021 9

NZS5149 – The HVAC Standard you

probably don’t know about, but should.

By John Greaves (NZCE – mech), Senior Design Engineer, Black Diamond Technologies Ltd

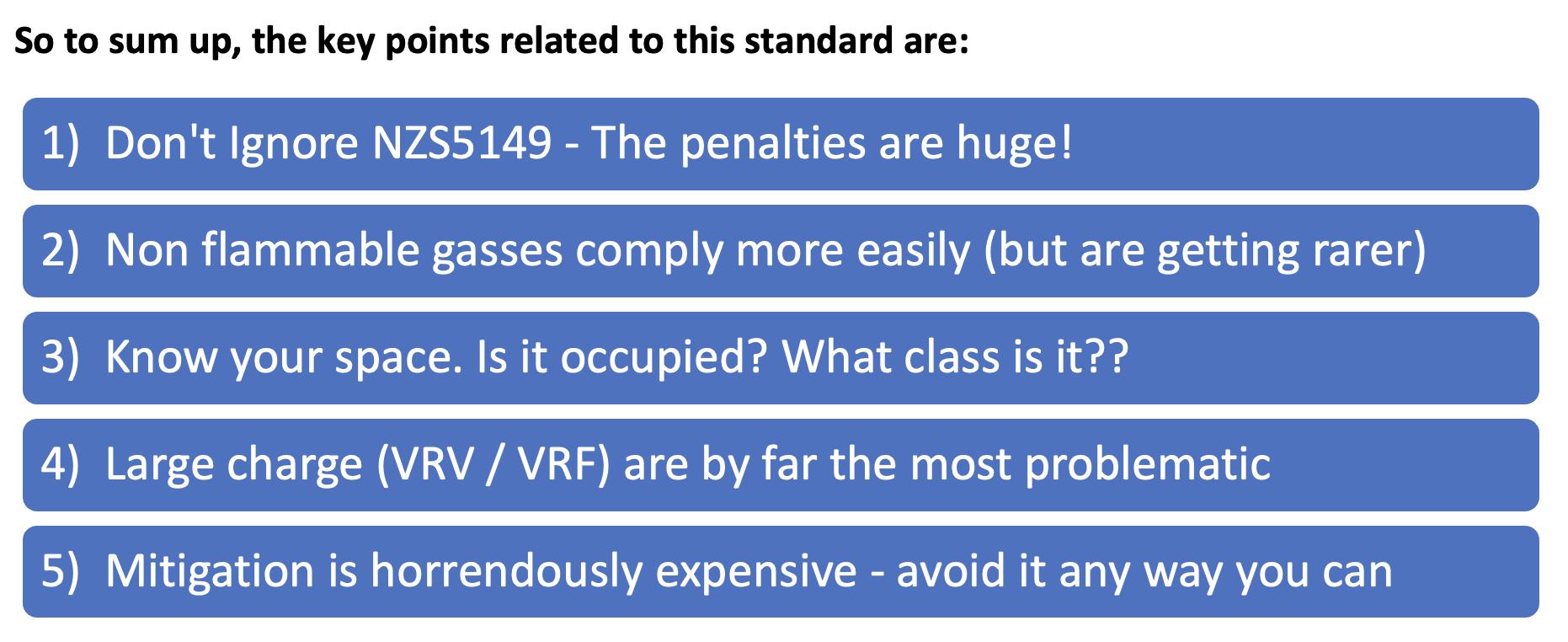

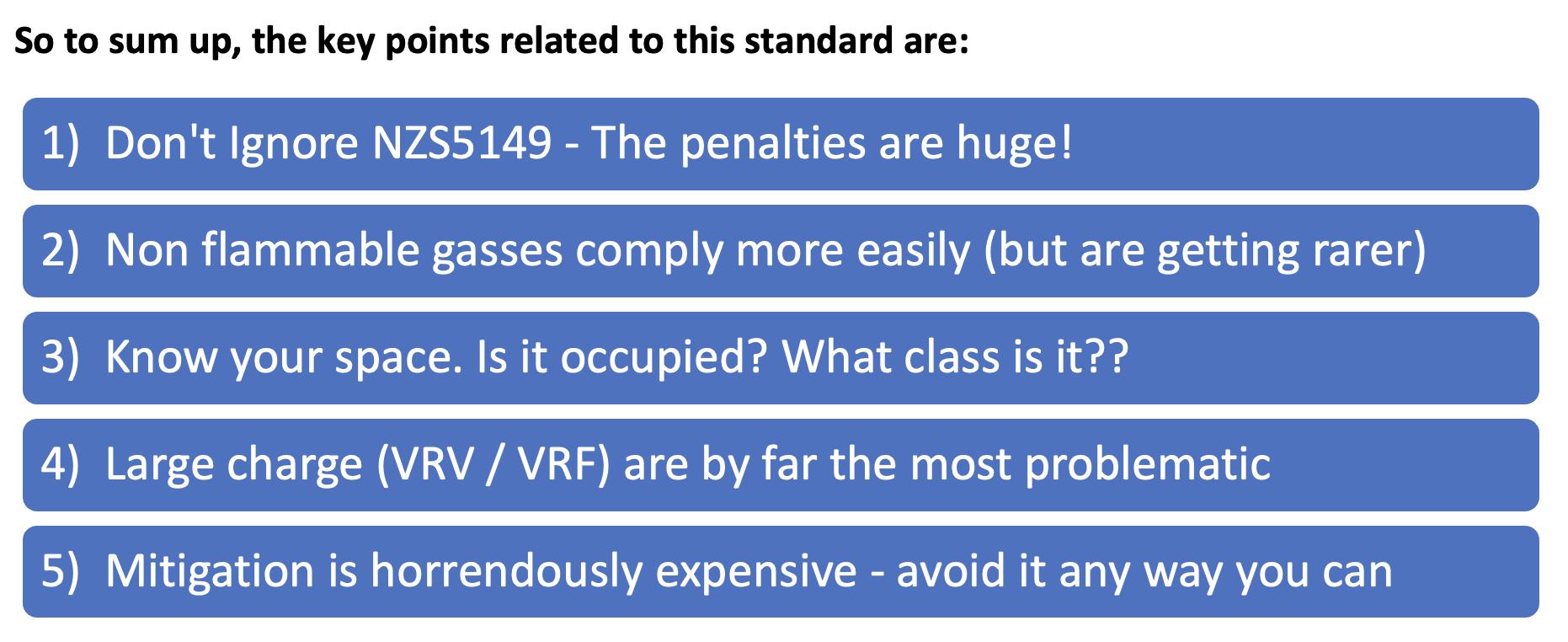

The NZS5149 standard, dealing with refrigerant concentration in confined spaces, has been around since 2016. It’s important as it affects every new or altered DX system installed in NZ –but it is largely overlooked. If you are designing or installing DX HVAC systems YOU NEED TO KNOW ABOUT NZS5149. The consequences of getting it wrong are huge – maximum penalties of $500,000 and 2 years’ jail are possible.

10 www.irhace.org.nz ★ FEATURE

Let’s start off by demystifying the standard a bit..........

NZS5149 is a safety and environmental standard that primarily deals with refrigerant leakage – and more precisely the risk of asphyxiation or fire that can result from any leak. The standard itself is around 200 pages long set out in four sections covering:

1. Definitions – describing terms, identifying refrigerants, classifying applications, explaining limits and describing mitigation. This is probably where you will spend most of your time trying to understand what is or isn’t required for any project.

2. Design & construction – requirements for piping, components and assemblye.g. pressure testing, tightening torques, inspections methods etc. Needed after you have decided what is required to meet the standard in section 1.

3. Installation site – specific requirements for applications such as machinery rooms and requirements for mitigation methods such as alarms or ventilation. Hopefully not too much time spent in here as this section as it means expense.

4. Operation maintenance & repairs – covers ongoing use of HVAC and mitigation systems to ensure correct performance. Also covers reclaim, disposal handling & storage of various refrigerants.

NZS5149 definitely is a tricky standard, but anyone working with DX air con or DX industrial plant should be using it regularly – I know I am.

Obviously wading through 200 pages of standards to work out what you need isn’t fun so I’ve distilled it down it to a few tips and

tricks that should help you at least get going in the right direction or know what other questions to ask. These are:

• What types of refrigerants to look out for

• What types of systems and applications to look out for

• Some quick guides to help determine if there is a problem or not

• What you can do if there is a problem So let’s get on and clear up some of these points.

What types of refrigerants should I look out for?

Many of the old school refrigerants we have been using (like R410a) are class A1 refrigerants. These are non-flammable but somewhat toxic. So they under NZS5149 have a toxicity limit only. However many of the newer refrigerants (think R32, R1234ze, etc) are A2 class, which means they are both mildly toxic and mildly flammable. These have the double whammy of both a toxicity and a flammability limit – with the stricter of the two being your overall limit. So any flammable refrigerant will likely be harder to make comply to the standard.

However as we’re all aware many “old” gasses like R410a have high Global Warming Potential, so are in a heavy phase out period. Therefore going forward you’re much more likely to have to deal with a “new” gas that has more stringent requirements.

Annexes B1, B2 & B3 in section one of NZS5149 will tell you all the details for the gas you have. These can be applied in to tables A1 & A2 in the same section – which is where you start to see what you are up for and how big the mountain is that you have to climb.

FEATURE ★ August/September 2021 11

What types of systems and applications should I look out for?

Let’s start with the systems. From a comfort cooling perspective obviously hydronic systems generally have the chiller sited outside in the open air – so even though the volume of refrigerant in them could be large, 99% of the time they won’t be a problem for safety under NZS5149.

Most 1:1 split systems usually won’t be too much of an issue either, as often the refrigerant charge volumes they have are pretty small. So unless you have a high capacity split serving a small volume space these are unlikely to cause you any issues under NZS5149 either.

The real problem child is VRV / VRF systems as these often have a large gas charge with the refrigerant going right into occupied spaces – which can be small. So potentially a major headache for compliance with NZS5149. Add to this the heavy phase down of R410a gas that all large VRV / VRF systems use and you can see why designers are moving away from these types of systems. NZS5149 is also why you won’t find any large VRV / VRF DX systems

being offered in R32. There is simply no way they could comply with the more stringent flammability requirements of R32 – they have enough trouble complying with the lesser toxicity levels of R410a.

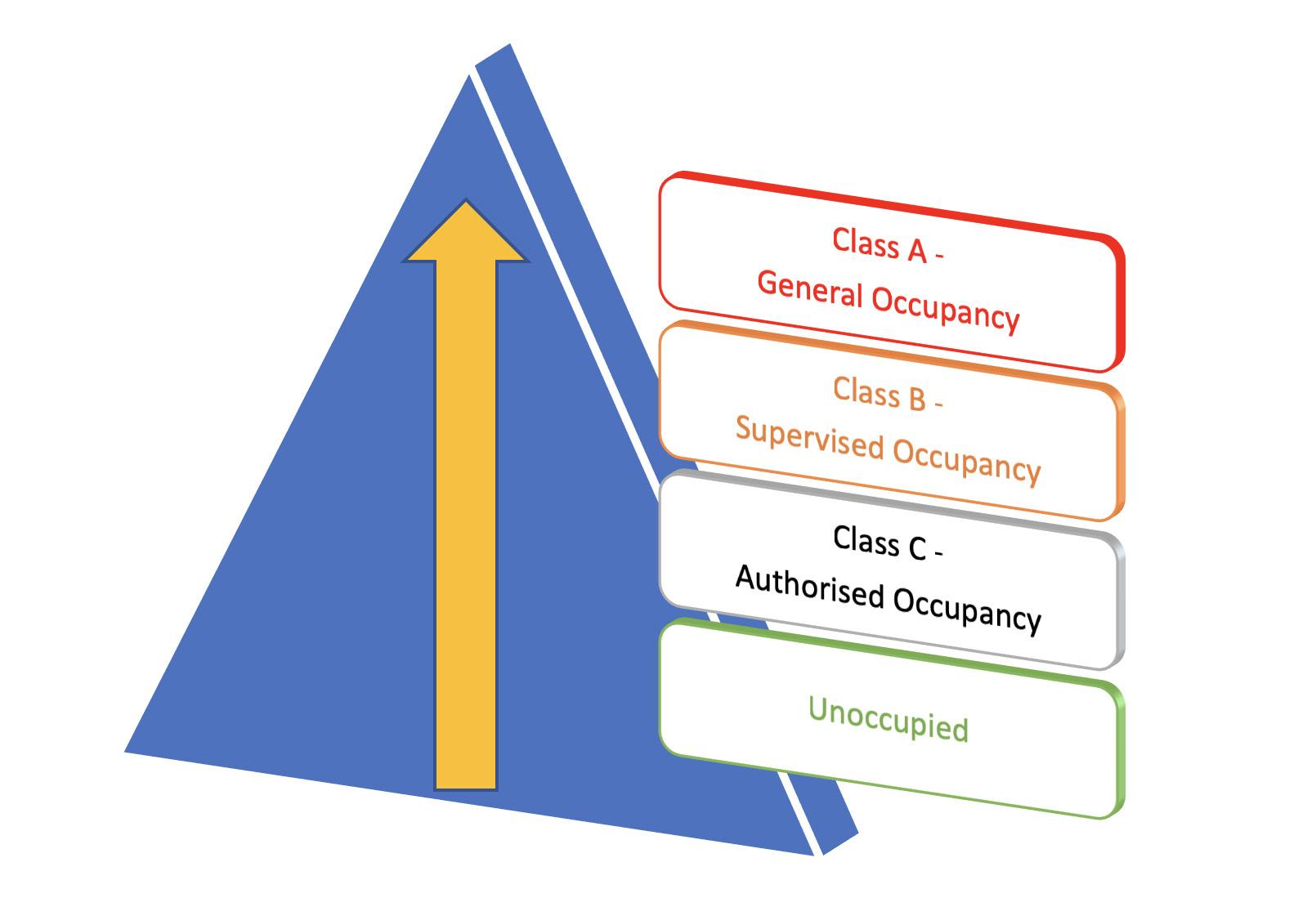

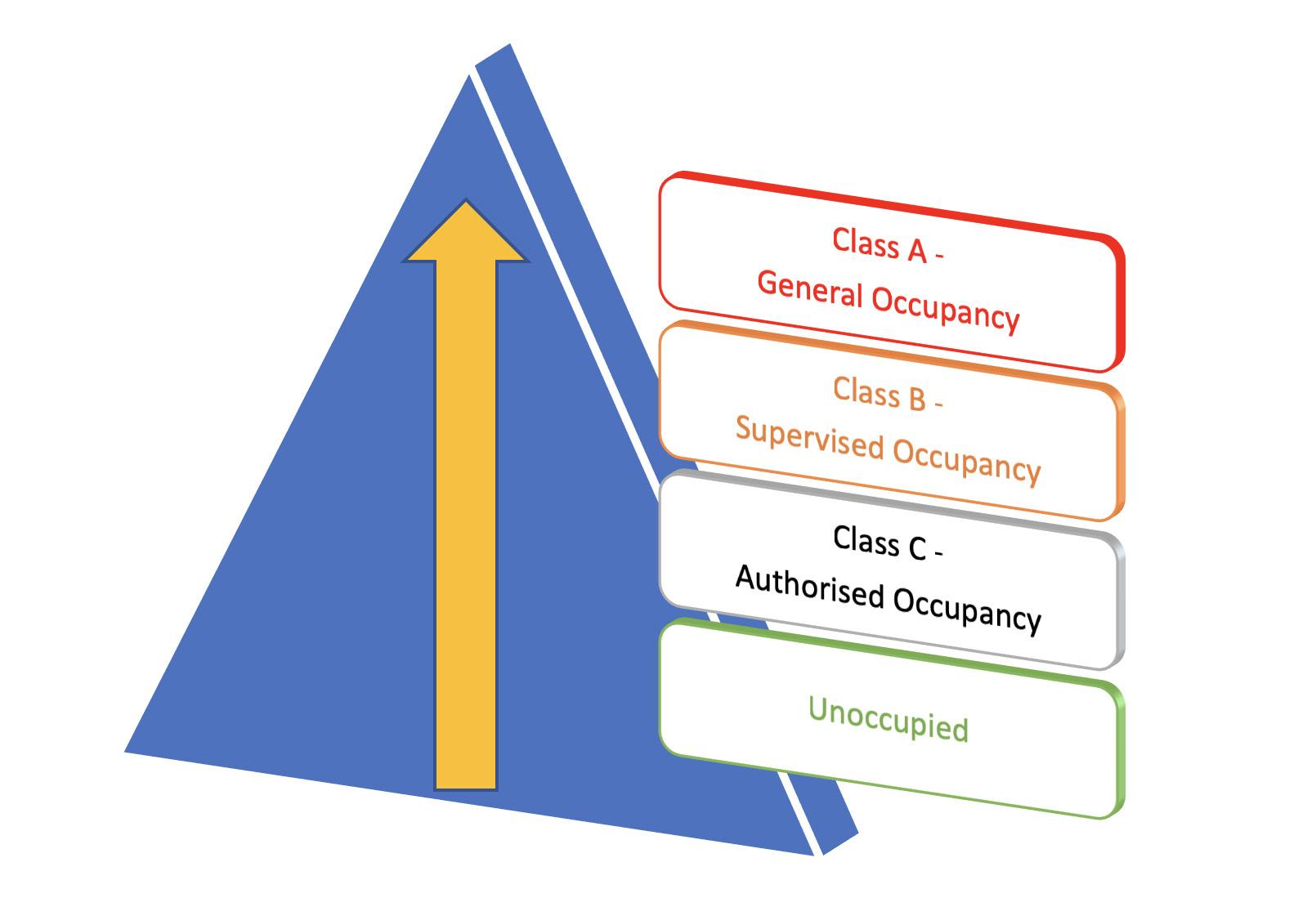

Now looking at applications, the standard sets out a sliding scale for requirements based on room occupancy. As you go up the scale the requirements to comply become more and more onerous (see chart page 10).

Class A – General Occupancy

Public access spaces such as schools, restaurants, theatres or supermarkets. Additionally, any place with sleeping facilities such as hotels, houses or retirement facilities.

• Absolute maximum charge kg for a system applies

• If exceeding the limit generally 2x forms of mitigation are required.

Class B – Supervised Occupancy

• Access somewhat limited, with regular repeat occupants. Most offices and professional spaces will fall in to this category.

No max charge kg for a system

• However if concentration limit is exceeded (same as class A) sensors & alarms are required.

Class C – Authorised Occupancy

Restricted access to only a selected few people. Often a locked space such as a store room or restricted area in manufacturing

• No max charge kg for a system

• However if concentration limit is exceeded (same as class A) sensors & alarms are required.

Unoccupied

• Any space which is not occupied for significant periods by a person.

• No max charge kg for a system

• No treatment required

Now that you know what to look out for, let’s take a look at some quick rough guides to determine if there is likely to be a problem or not.

In comfort cooling the potentially problematic DX systems are currently all

12 www.irhace.org.nz ★ FEATURE

• Thermal • Acoustic • Preformed Tube • Sheet/ Roll Authorised distributors of ultralonfoam.com 0800 114 222 sales@ultralon.co.nz Thermobreak® is the leading and most innovative polyolefin foam thermal insulation available to the HVAC and Building industry worldwide. Thermobreak’s® performance is unsurpassed.

either R410a or R32. So for a standard room the maximum concentration levels are:

R410a = approx. 1kg per 1m2 of any room served

R32 = approx. 1kg per 6m2 of any room served

(*note assumes 2.4m floor to ceiling height. Ceiling void cannot be included in room volume).

Alright, so you now know what to look out for, and can identify the problem areas, what can you do about them. Well my best advice here is:

AVOID MITIGATION ANY WAY YOU CAN!

In my experience mitigation for excessive refrigerant concentration will be expensive, or difficult or both. So the first approach you should look at is changing the design to avoid exceeding the maximum concentration levels by:

Breaking up larger DX systems in to several smaller ones (although take care as this can add significant costs).

Changing to a different type of system. Splits, Hybrid VRF or hydronic systems could all get you out of jail, but of course may require re-work of the design. If doing this be mindful of solving one problem but creating another – for example splits generally have shorter pipe run maximums which can cause problems for proposed or existing outdoor unit locations.

Not directly treating some spaces with A/C. A no-brainer but if the spaces don’t have A/C in them then they can’t be a problem.

Changing the size of the problem spaces. This sounds strange, but if you can increase the size of a space you could solve the problem. Removing a physical barrier like a door, or providing a decent door undercut so that the problem space sums with an adjacent larger one could do the job.

If you can’t do any of the above then you are up for mitigation. I’m not going to get into chapter and verse on mitigation, this can be found in section 3 of NZS5149, but some of the possible methods are:

• Natural Ventilation – both high and low level openings in each room that exceeds the limit are required.

• Mechanical Ventilation – Both supply and extract vents in each room that exceeds the limit are required. The vents must be positioned “as low as is practicable”, so read this as vents in the ceiling aren’t acceptable.

IN MY EXPERIENCE MITIGATION FOR EXCESSIVE REFRIGERANT CONCENTRATION WILL BE EXPENSIVE, OR DIFFICULT OR BOTH. SO THE FIRST APPROACH YOU SHOULD

LOOK AT IS CHANGING THE DESIGN

• Safety Shut Off Valves – Operated by sensor and positioned close to the space in question to prevent the maximum concentration level being exceeded in the event of a leak.

• Sensors & Alarm System – Must provide an audible and visual warning, and if the application is class A also report to a supervised remote location. Any sensor

must be re-calibrated at least annually (some are more frequently). Note all sensors have a limited service life of between 2 ~ 5 years and so must be regularly replaced.

Now lets take a look at some mitigation costs in a relatively common application. For example, a floor in a commercial building that has been separated in to 40x small offices and VRV system has been proposed to condition them. Clearly an office is a class B application, so there is no limit on the system charge and no problem right?

No, wrong!

In class B any space that exceeds the maximum concentration limit still needs to have sensors and an alarm system. So if all 40x offices exceed the maximum limit we are up for approximate costs as follows:

As you can see from Table 1 (above) the hidden cost is horrendous, and will often be a lot more than changing to a different system type or another design related change.

BDT is a heat pump supplier not a refrigeration supplier, so all comments are given from this perspective. Everything discussed is BDT’s opinion or interpretation. Other opinions may differ. It is recommended you check any designs you do against the NZS5149 standard for yourself or engage a professional to verify your interpretation.

Table 1

FEATURE ★ August/September 2021 13

The Future of Work: In-Demand Tech Skills Everyone Should Learn

The digital transition has caused a massive job disruption and now workers are wondering if they have what it takes to face future challenges. Digital technologies have reinvented how we work. For that reason, learning tech skills has become essential. With several programming tools available in the market, it can be challenging to decide which one you should learn. However, you’ll have nothing to worry about if you read this article. It provides you with a list of some in-demand tech skills everyone should learn in 2020.

Python

Python is a versatile programming tool that enables tech professionals to deal with data more easily. It’s fantastic for interpreting and visualizing information. These days, most companies lean on data to make better business decisions. Otherwise, they may be left behind. Learning Python is a great way to be ready for the future of work because data will become more valuable in the following years.

Learning Python is easy because of its simple syntax. It’s a great alternative for beginners; even if you’re a tech expert, you need to have it on your skills-set. Nowadays, many coding bootcamps offer Python courses. However, if you want to learn from experts in the field, you should consider enrolling in Thinkful’s online coding bootcamp. At Thinkful, you’ll learn not only Python but other in-demand data science skills that will help you stand out from the crowd.

Thinkful is a good option for those who seek to learn from home. The company offers full-time and part-time courses to fit students’ needs. Nonetheless, if you prefer to see other

available options, you can visit Bootcamp Rankings. On their site, you’ll find a list of the best online coding bootcamps in the US.

Cybersecurity

The Internet might seem like a safe place for many people. But, since data is the new gold, the demand for professionals with cyber-security skills has increased. Cybersecurity experts are responsible for keeping businesses’ information safe. They must monitor software and hardware to identify vulnerabilities. Also, they have to learn new

techniques to improve companies’ security strategies.

Becoming a cyber-security engineer can be challenging. Fortunately, Flatiron School makes it easy for you. The company has designed its cyber-security program to help students develop their potential through hands-on projects. At Flatiron School, you’ll also learn analytical skills that are key to provide the best results. After graduation, you’ll know how to deal with rapidlyadvancing threats and set traps to catch hackers. In other words, keeping companies’

14 www.irhace.org.nz ★ FEATURE

data safe will no longer be a barrier for you.

WordPress

In 2020, WordPress is a very popular CMS that powers over 30% of the web. It allows developers to create fantastic websites in only a few minutes. By using templates, developers can design very dynamic sites without coding. Also, WordPress offers a wide range of plugins that developers can use to improve websites’ functionality. WordPress is a great alternative for those who seek to build websites without coding.

But, if you want to show off, you better learn HTML and CSS skills. Likewise, whether you are looking for a new job or becoming a freelancer, learning WordPress will help you achieve your goal. In 2020, a WordPress developer makes, on average, $76,000 per year according to Glassdoor. There are many options to learn WordPress skills, but you should not forget that education is becoming the new currency—getting a degree is vital.

Java

If you want to be ready for future challenges,

THE TECH INDUSTRY IS GROWING FAST AND YOU’LL NEED TO KEEP YOUR SKILLS UP-TO-DATE. FAMILIARIZING YOURSELF WITH NEW TECHNOLOGIES WILL ALSO HELP YOU TO STAND OUT FROM THE COMPETITION

you can’t stop learning Java. Java is a great programming tool for building not only Android apps but also IoT solutions. Therefore, whether you want to become a software engineer or an Android developer, you’ll have the right tools to meet employers’ needs.

Java is the best tool for building crossplatform apps. It has a great collection of libraries that makes the development process much easier.

Additionally, there’s a huge community of Java developers that can give you an extra hand when necessary. In that case, no matter how big the challenge may be, you’ll receive the right support to face it. To learn Java coding skills, you can take free online courses or enroll in General Assembly’s coding bootcamp. General Assembly, offers an excellent Android development program that allows you to learn from great tutors.

Conclusion

In general, these skills are all you need to be ready for the future of work. However, you shouldn’t forget that the tech industry is growing fast and you’ll need to keep your skills up-to-date.

Familiarizing yourself with new technologies will also help you to stand out from the competition. After all, in the next decade, companies will invest even more money in new tech inventions.

Anthony Scott Senior Editor at BootcampRankings www.bootcamprankings.org

FEATURE ★

August/September 2021 15

Getting worker buy-in on Health & Safety –ACC subsidy for health and safety advice

Involving staff in selecting their own personal protective equipment (PPE) has paid off for the Christchurch-based maker of the Woodsman brand of log fires, W.H Harris. In the past, the company sometimes had issues getting staff to wear the correct PPE, says W.H Harris Operations Manager Mark Streeter. “But rather than go down the track of forcing people to wear equipment they didn’t like, we decided to involve them in choosing new PPE themselves,” Mark says. To do this, the company engaged Sue MacEwan, a HASANZ-registered H&S Professional with consultancy Safe & Sound Solutions.

Sue worked with a group of W.H Harris staff to find new eye protection to replace the existing equipment that fogged up and wasn’t comfortable to wear. She got the workers to test a selection of new safety glasses and visors for two weeks, then to recommend which ones the company should buy. Since the new eye protection arrived there have been no further eye injuries at the company’s Christchurch factory, Sue says. “It doesn’t fog up and it’s comfortable, so people wear it and their eyes are protected.”

Joseph Mercado, one of W.H Harris’ assemblers, says he and his workmates appreciated the opportunity to be involved in selecting the new eye-wear. “It was great that we were involved because it meant that the glasses and visors we got really suited our needs.”

Mark says involving staff in health and

safety decisions has helped the company improve compliance and improve safety. He’d recommend getting help from a health and safety professional like Sue. “We’ve found that four to six hours a week of focused attention from a consultant has achieved more than we could've ever dreamed. It's been very, very cost effective.”

There is an ACC subsidy to help SMEs in construction and manufacturing gain access to qualified health and safety professionals through the HASANZ register. See more: https://www.hasanz.org.nz/acc-subsidiesfor-businesses/

Background info regarding the “Build a Better Business Campaign”

This is a six video series designed to make businesses aware of the tangible benefits

real NZ businesses have gained from implementing good health and safety. They’ve got there with the help of the ACC Health and Safety Subsidy, and by working with someone from the HASANZ Register, (NZ’s free to search Register of verified health and safety people.)

The case studies have visited six typical SME’s across New Zealand, predominantly in the Manufacturing sector, who have had wide ranging Health and Safety problems.

Hearing directly from the businesses themselves both leaders and their workers, it shows how they solved their problems and how this has improved their business overall.

For some it has been peace of mind, for others a competitive advantage to win work, or increased productivity due to less down time from employees, increased morale. The case studies touch on the multitude of benefits.

By launching this campaign we hope to encourage more SME’s to take that next important step on their health and safety journey. When they do, by taking advantage of the subsidy, not only will it lead to better health and safety outcomes for their business, an introduction to a trusted health and safety adviser but they can save money whilst doing so, and we think this knowledge can help them now or in the future.

For more information visit www.hasanz.org.nz/ acc-subsidies-for-businesses

16 www.irhace.org.nz ★ CASE STUDY

Update from Competenz

Here’s the latest update on the changes happening to vocational education and training in New Zealand, including the role Competenz will continue to play in supporting your apprenticeship training.

While there are indeed significant changes to vocational education coming in the latter half of this year, you can rest assured you and your learners will continue to receive the same great level of support and care from Competenz throughout this transformational period and beyond.

From 02 August 2021, Competenz is a business unit within the Te Pūkenga Work-based Learning (WBL) subsidiary. Our

organisation is evolving but we continue to be your industry training partner.

A quick RoVE recap

Prior to 02 August, Competenz was one of 11 transitional industry training organisations (TITOs), supporting our industries, employers and learners. Now our functions that arrange, support and assess work-based training (apprenticeships) have transitioned to become the Competenz business unit within the work-based learning subsidiary of Te Pūkenga - The New Zealand Institute of Skills and Technology. Te Pūkenga is the new entity that will incorporate all 16 New Zealand institutes of technology and polytechnics (ITPs) and 11 industry training organisations (ITOs) when the transformation is complete.

From 04 October 2021, our qualification standards-setting functions will be transferred to new entities, called Workforce Development Councils (WDCs). Our RHVAC qualifications and standards will

go to the Hanga-Aro-Rau Manufacturing, Engineering and Logistics WDC.

What does this mean for you as an employer?

Despite these organisational changes, we remain here for you, just as we always have been. While under the reforms, our training advisors’ work now fall under the remit of Te Pūkenga. However, you will connect with Competenz in the same way, your training advisors will not change, and we will continue to support our learners and employers to the same high standard we always have. We are committed to making the transition as seamless as possible for everyone. If you have any RoVE-related questions, please don’t hesitate to contact us for advice or support.

www.competenz.org.nz

EDUCATION & TRAINING

August/September 2021 17

New qualification supporting air conditioning installation set to launch in late-2021

To meet industry demand, Competenz will be launching the New Zealand Certificate in Air Conditioning Installation (Level 4) later this year. This qualification has been developed to support employers and learners in the heating, ventilating, air conditioning and refrigeration (HVACR) industry.

During a review of the available industry qualifications back in 2019, a gap was found around the installation of commercial and

residential air conditioning systems. Since then, Competenz has worked alongside the industry to develop a focused and comprehensive qualification to fill this training gap.

The qualification has been created to facilitate the growth of skilled people within the HVACR industry who can install air conditioning systems up to 50kW nominal cooling independently and work with synthetic refrigerants, including HFO’s, following manufacturer’s specifications and industry best practice. It also covers several specialist compliance areas such as passive fire sealing, seismic fixing, and bracing to ensure the graduates will have a broad skill set relevant to the New Zealand construction industry.

This qualification has been designed

for both new entrants to the industry and competent people who may not have a qualification and want to gain a credential, enhancing their employment opportunities. It will also be useful for people in allied trades such as electrical or plumbing who are involved in installing air conditioning and wish to enter the HVACR industry.

Graduates will operate independently, safely installing air conditioning systems using relevant tools, knowledge, and techniques to ensure they meet all applicable environmental and industrial legislative requirements.

Find out more about what pathways and qualifications are available in the refrigeration and air conditioning industry at: competenz.org.nz/aci

18 www.irhace.org.nz EDUCATION & TRAINING

RLNZ to cease taking enrolments while re-structuring

The Refrigerant License Trust Board (RLTB) was established by CCCANZ and IRHACE, with funding provided by refrigerant levy collection, initially to develop and provide refrigerant filler and handler training and certification for HVAC&R practitioners. Subsequently RLNZ has expanded its activities to provide a wider range of training and professional development for people in the HVAC&R industry.

With the impact of COVID-19, RLNZ is conducting a review of the delivery model and course content of all training courses. As at 1st August 2021, the Trust Board of RLNZ are ceasing taking enrolments for training courses including filler, filler renewals and online courses whilst we re-structure the operating model.

RLNZ is the only training provider in New Zealand that offers a NZQA training course for Refrigerant Filler and handler training. It is important that course content is regularly reviewed against current legislation so that it fits best industry standards.

We sincerely regret having to take this decision and RLNZ believe we can restructure the operating model to offer courses again in the future. Keep checking the RLNZ website for further updates.

EDUCATION & TRAINING CHILLERS & HEAT PUMPS RHOSS BOILERS & FLUES RENDAMAX, METALOTERM CALORIFIERS LAPESA FAN COIL UNITS ABILITY PROJECTS, NEW SUPER-AIRE Clima Solutions Ltd www.clima.co.nz Tel: (09) 336 1278 gordon@clima.co.nz or rob@clima.co.nz

August/September 2021 19

hvacrexpo2021.eventbrite.co.nz 16-17 SEPT Please register at POSTPONED

Two FREE days of Education

The Expo in the "AirTouch Pavilion 3" will incorporate the Thursday conference programme and finals of The Apprentice of the Year competition, where the best of the apprentices for 2021 will complete the practical section to win the title. On Friday, supplier product presentations Industry Updates and Building Control Technology updates will share the "AirTouch Pavilion 3" with exhibitors.

http://www.tonyalexander.nz

Speakers

Ciaran

www.massey.ac.nz

https://employsure.co.nz/contact/

HVAC&R EXPO & CONFERENCE

SEP

se register at

17

hvacrexpo2021.eventbrite.co.nz

Richard Love Massey University

Tony Alexander Economics Speaker and Writer

Liz Tibutt Employsure

Louise Rutter Competenz www.competenz.org.nz

Slade McFarland Mates in Construction www.mates.net.nz

Kelly

Norman Disney & Young www.ndy.com

August/September 2021 21

POSTPONED

Wellington branch Fishing Trip

This year’s Wellington branch fishing trip in April I have to say was one of the best trips we have had with good weather and a full crew on board the Cook Strait fishing Charter. Johnathan Delish putting us onto to some of the best stops in Wellington and we all had full bags of fish for all to go home with. It was a great day and what could be called one of our most successful trips.

Thanks to Andy Henderson of Pattons for organising the day. Special thanks also goes to Mark Cottis of Aquaheat who put on the beverages (the beers) and to Fale FaleFatu for going out of his way in finding a KFC open to have pre-start refreshments.

See you all for the next one and may all of your lines, be Tight ones.

22 www.irhace.org.nz OUR PEOPLE

Photo centre: Craig Levien of Temperzone (left) hands over the IHRACE trophy to Mike Odey (right) for the biggest fish and well done, Andy Henderson (at the back) is sad to see his trophy go.

Canterbury Westland Branch Annual Meeting

Then it was pizza and the meeting for those who wanted to stay. Canterbury is proud to announce their new Branch Chair Matthew Hunter and for those who were present you will vouch he has some great ideas to carry us forward. Many thanks to Mike Pero, our wonderful hosts / volunteers Mark and John, and all who attended.

Canterbury/Westland branch held their Branch Annual Meeting on 2nd June 2021. This was held at Mike Pero Motorcycle Museum and we had a great night poring over all the beautiful bikes. All the smells and memories and comments of "I used to have this one" or "I had a poster of this one on my bedroom wall". They even started some of them up for us.

Canterbury/Westland branch held their Branch Annual Meeting on 2nd June 2021. This was held at Mike Pero Motorcycle Museum and we had a great night poring over all the beautiful bikes. All the smells and memories and comments of "I used to have this one" or "I had a poster of this one on my bedroom wall". They even started some of them up for us.

OUR PEOPLE August/September 2021 23

Auckland branch hold first trade night at Manukau Institute of Technology Tech Park

By Matt Birch

By Matt Birch

On the 22 April the Auckland branch of IRHACE held their first trade night of the year, gathering at Manukau Institute of technology’s new Tech park. The trade night was an overwhelming success with over 100 attendees including 14 trade table holders displaying their offerings to our trade.

The evening was hosted by Matt Birch, Auckland IRHACE branch chair and Pip Schollum-Manase, Campus General Manager (Acting) Tech Park at Manukau Institute of Technology.

The event was held at MIT’s new 9,000 square metre, state-of-the-art facility, the evening before our Prime Minister officially opened the site.

All attendees were offered a guided tour of the HVAC+R training workshops, which generated huge interest and provoked a number of interesting questions. The tour was very well received by all.

The evening provided a great chance to catch up with friends and suppliers with each supplier offering a door prize which were gratefully accepted by the lucky attendees.

24 www.irhace.org.nz

OUR PEOPLE

The speakers on the night were:

Garrett Glynn (senior lecturer) MIT, presenting a training map of trade education, now and in the future.

John Grieves (senior engineer) BDT, presented on standard AS/NZS 5149, Refrigerating systems and heat pumpsSafety and environmental requirements.

John offered a general understanding and interpretation of this misunderstood and largely unknown standard. Interestingly only 10% of attendeees raised their hands when asked if they were aware of this standard and implications towards their businesses.

The adoption of this standard is

vital amongst our members and their companies.

Thanks to all who those who worked behind the scene, suppliers and attendees.

Thank you to Matt for a very successful evening from Irhace

OUR PEOPLE August/September 2021 25

IRHACE AUCKLAND A GREAT

TRADE NIGHT 2021 SUCCESS

Tony King Biography

I’ve been asked to write a biography for myself and although I’ve been accused a number of times of talking about myself too much in conversation, putting something down on paper is a different ballgame. Careful what you ask for I say! Anyway here goes.

I was born in Edgware (North London) in 1949 and lived in the Harrow area until I emigrated to New Zealand in 1970 one of the last of the 10 Pound Poms! I never aspired to much at school, managed to achieve three GCE ‘O’ Levels which was a shame as with four I could have had free flying lessons with the Air Training Corps, instead took a gliding course and got to fly solo at Hendon Aerodrome a few times.

I took on an apprenticeship at Frigidaire/General Motors in Hendon in 1965 (not there anymore it’s an ASDA supermarket and housing estate!) in Toolmaking/Draughting - someone thought I was good at Technical Drawing! Frigidaire used to run Service training courses for refrigeration installers and service personnel around the country and they would put a couple of apprentices on these courses to teach us a bit about refrigeration systems. Just out of interest it was the last time I ever brazed a copper pipe joint!

When I came out on top at the final test they asked me how come I did so well and I said that I had finally found something that really interested me (apart from music which is another story I’ll get to later!). So they tweaked my apprenticeship such that the last half was more involved with refrigerated display cases and condensing units and I ended up in the Commercial Refrigeration Sales Engineering Department.

One of the other apprentices who joined at the same time as me was a drummer and as I had started playing guitar we set about forming a band that ended up playing pubs and working men’s clubs. I started song-writing and then used to go up to London’s Denmark Street with my guitar on my back hawking my songs. Met up with Albert Hammond and recorded some stuff with him and then got a contract with Shapiro Bernstein for two songs. The latter rang me up saying that Manfred Mann were interested in recording one of them, I dithered a bit and by the time I went back and said yes they had gone on to something else. My Dad was furious with me!

In 1970 I emigrated to New Zealand contracted for two years to McAlpine Refrigeration initially in the drawing office and then working with Tony Edley and John Bowen in the Industrial Division including working on some ammonia jobs.

In 1972 I formed a band called Tramp with another songwriter to work on some of our songs. We got on TV’s Studio One New Faces with one of my songs but we were rubbished by Phil Warren for having too many guitars in the band! We had a band reunion in 2018 which is another story I will get to later.

I was offered a job at Temperzone late in 1972 specialising in heat transfer coil selections and engineering for manufacture along with fan coil units, air handlers, evaporative condensers and cooling towers. Working in this arena was what made me very knowledgeable about psychrometrics and this became my forte.

Towards the end of the 1970’s I was encouraged, probably by the late Jim DeCourcey, to join the NZIHVE (Heating and Ventilating Engineers) which I did and gradually became more and more involved eventually joining the Auckland Region Council, becoming Chairman in 1983 for four years.

I had a brilliant council team (Mike Dane, Malcolm McGill, Garry Wright, Dave Wornell and Reg Earl amongst others) and it was a great period. We had been experiencing meetings at the CT club with just 10 -11 attendees but at the end of the four years we were getting up to 100 attendees at the meetings. This was by holding meetings about challenging and controversial topics. We pushed the boundaries.

In 1979 and 1980 I went in to the recording studio to record a dozen of my own compositions and from those songs had some musical highlights, first with “Song for the Pacific – NZ’s entry to Pacific Song Contest” where I had one of my songs “Foolish Heart ” in the final selection of seven songs performed on a TV special. Unfortunately my song came 6th but I have to say the orchestration and the singer they picked to perform it did an atrocious job of it. The female singer I had record the original was far better but unfortunately the TV people make the decisions. Secondly one of my songs “Looking For Trouble Tonight ” was picked for the 1980 Hauraki Homegrown album (last track side 2!) and there are still a few of these vinyl LPs found in bargain bins! Lastly I appeared on TV in Threshold Promotions singing one of my own songs – video of this is unfortunately on Youtube which is a bit embarrassing as I had an afro at the time! The Topp Twins were discovered on this program – I wasn’t!

Somewhere around 1983 I went on to the National Executive Council of NZIHVE and it was there that I raised the subject of too many institutes and why couldn’t the BSG (Building Services Group), NZIHVE and NZIRACE merge together. After much negativity and comments like “it’s been tried before” I was elected to go down to Christchurch to speak at the IRACE AGM on the subject.

From there an ‘initial’ amalgamation Committee of six consisting of three from each organization (I remember Keith Stewart and Bob Sturrock were on the NZIRACE side) to investigate whether it was feasible to both organizations to do so. Keith Stewart and I chaired the

www.irhace.org.nz 28

OUR PEOPLE

meeting and jointly produced a detailed report.

The committee came out on the side of amalgamation but after a massive argument I had with the President of NZIHVE over the negativity towards it I walked out and cancelled my membership. In due course BSG joined NZIHVE and the decision was made to merge NZIHVE with NZIRACE where another amalgamation committee sorted out the finite details which thence became NZIRHACE. For a while I remained on the sidelines until later being asked to represent Temperzone on the Heating Ventilation and Air Conditioning Contractors Association (HEVAC – yet another separate group!).

Meanwhile at Temperzone I gradually moved on to split systems and reverse cycle packaged units (didn’t call them heat pumps much back in the seventies!). Probably the most interesting jobs I worked on were Heat Pump timber driers that took the temperature from as low as -5° to 74°C. Most of the time, about 10 days or so, spent at 50°C where most of the moisture seemed to be drawn out. We had to use imperial psychrometric charts for the higher and lower temperature and moisture content ranges as none were available in SI units at the time. The systems were so successful that we flooded the floor after which we recommended drains be put in the floors of the kilns to save re-evaporating the moisture a second time and wasting energy. Had an interesting experience in Rotorua once, working inside a kiln at 50°C changing over a wet bulb sensor that had failed. Stripped down to my underpants because of the heat and moisture when the door flew open and a tour party stepped in.

In 1987 I was made Specialised Air Conditioning Products Manager of a division to look after a range of products that no one else was really looking after including a new range of Modular Chillers, Computer Room units, Humidifiers and Controls. Over time this was tweaked and I was looking after pretty well all special applications such as Full/ High Proportion Fresh Air, Dehumidification, Heat Recovery and Close Temperature/Humidity Control.

Eventually HEVAC merged and became what is now CCCANZ. I stayed with CCCANZ representing Temperzone until 2017 when I could no longer do so as I had retired from the company! I was asked to sit on the IRHACE board so I was then required to officially join as a retired member.

So yes I retired from Temperzone in 2017 after 45 years having held several positions in the last few years including Engineering Manager, Business Manager and finally as Temperzone Product Manager.

In 2008 I started doing some volunteering work as an announcer on our local community radio station originally called Howick Village Radio but now known as East FM. I do three programs a week including the Saturday morning Budget Breakfast. I gave up performing in bands and duos a few years ago, using my musical knowledge instead on my radio shows. I also do some extra work for TV and Film; Programs years ago like Xena, Hercules and Street Legal (as a body in the bath – not a pretty sight!), but, more recently I have been regularly seen on the insurance ads prior to and after “Seven Days” and a handful of times on Shortland Street but many others as well. So I am keeping myself relatively occupied in my retirement.

One last thing I referred to earlier the band Tramp had a reunion. In 2018 we were asked through the talent agency if anyone had a photo from years ago that they wanted to recreate. I initially discarded this but then thought of the band photo we had taken at Auckland Airport in 1972 on our way to Wellington for Studio One/New Faces, so I sent this in. A week later I had a video crew around for an interview where I was asked to make contact with one of the members living in Australia to see if he would be keen on a reunion. With him on board they contacted the rest of the band (who all thought they were being scammed!) and to cut a long story short we were flown to Wellington from various parts of the country had a couple of days jamming in the studio and

videoed playing the fool around Wellington streets. The 2 minute video is still on Jetstar NZ’s Facebook page parts of which were used as adverts for Jetstar on TV. https://www.facebook.com/JetstarNZ/ videos/10216481226891068

I was asked to make comments about a few personal favourites;

• Favourite car (I am not really a car person just need it to get from A to B) Mazda CX-5 probably the most comfortable I have ever had; Movie would be Once Upon A Time In America or Dr. Zhivago;

• I’m a Bourbon drinker and rather partial to Honey Bourbon and Red Stag – my sweet tooth!;

Love Asian food, particularly Chinese and Japanese;

• When it comes to music the list is long - I like a lot from Classical to Progressive Rock, not keen on Jazz though, favourites would be Beatles, Genesis, Dire Straits, Queen, The Who to name just a few;

• I love cricket, I was never any good at it especially bowling which Malcolm McGill could attest to when I was playing indoor cricket for a Temperzone team I was captain of (that’s a laugh), we even won a tournament one year and got a trophy we never worked out how we did that. I watch a fair bit of cricket, favourite game I went to would be the 2015 One Day World Cup semi-final at Eden Park, that was so emotional when we won in the last over with a six. Went to the final at the MCG but didn’t enjoy that quite as much!

I’m guessing the industry will be going through a lot of changes, I remember designing a lot of units for Sylvia Park shopping centre, our first forte in to R410A and we had little information to work with for units up to 200 kW, it was a massive challenge. I think refrigerants will come and go regularly now until they find one that satisfies all the requirements for climate change, low GWP as well as friendly to the atmosphere, I am just glad I am not involved going through another change, it’s hard work.

The industry has been good to me, it has been thrilling at times and certainly challenging so I would certainly recommend it as a trade but not just putting in domestic heat pumps the excitement is in the special applications, well it was for me. Learn psychrometrics in detail

Well that pretty much wraps it up. My tenure with the IRHACE council is up at this year’s AGM and as I am now getting too far removed from the AC business and have other fish to fry. I sit on the board of the Radio Station Charitable Trust and also of PTUA (Public Transport Users Association) trying to fight the idiocy of light rail to the airport, but then, that’s another completely different kettle of fish!

Enough to say I am relatively busy.

On behalf of IRHACE and our Industry I would like to thank Tony King for his years of service across our industry, both in a volunteer and work capacity.

I was lucky enough to have access to Tony as my technical phone support for Temperzone TTO Packaged Units that were in Telecom Exchanges throughout the South Island (and North I suspect). He was always cheerful, helpful and super knowledgeable. And usually knew what the problem was (code word for What the Technician had Mucked With) before I did. It was great to work with someone so passionate, who understood their product so thoroughly, but could also provide practical support to technicians in the field. He provided a great interface between designers and tradespeople and he could translate the most confusing manuals into useful, practical terms for us on the tools.

I also had the pleasure of sitting on the IRHACE Council with him, where again his wealth of experience in the industry and commercially was a great asset. His wise counsel, sense of humour and good taste in music were always to be counted on.

I wish Tony well with his “retirement” And hope he finds enough spare time to still pop into IRHACE events for a catch up.

Deirdre Johns

OUR PEOPLE August/September 2021 29

IRHACE MEMBERSHIP MILESTONES

WELCOME NEW MEMBERS:

Desmond Moore Cant/Westland

Jishnu Bala Wellington

Moon Soo Lee Auckland/ Northland

Christopher Eckhoff Cant/Westland

Haochang (Steve) Xie Auckland/ Northland

Charles Bernard Pardo Waikato/ Bay Of Plenty

Gavin Brown Waikato/BOP

10 YEARS

Christopher

20 YEARS

60 YEARS

Daniel McIntyre Hawkes Bay/ Poverty Bay

Mike Dubey Auckland/ Northland

Cameron Matheson Otago/Southland

Mike Tantrum Manawatu

Neil Adkins Manawatu

Patrick Brydon Auckland/ Northland

Brendon Whitcombe Auckland/ Northland

Ian Merrylees Auckland/ Northland

Steph Martella Nelson/Marlbough

Nicholas Mogford Hawkes Bay/ Poverty Bay

Nathaniel Berry Nelson/Marlbough

Binoy Goundar Auckland/ Northland

Krishneel Ram Auckland/ Northland

Paul McIntyre Hawkes Bay/ Poverty Bay

Paul Johnston Cant/Westland

Anthony Brown Waikato/BOP

Peter Mason Otago/Southland

MEMBER NEWS 30

Paul Phillips

Raymond Landon

Clarke

Winter Craig

10 20 60

www.irhace.org.nz 30

Anthony Edley

Modular Sigma 05 Sensor Platform with Interchangeable Sensing Probes

The Sigma 05 accommodates up to three Modbus probes. A total of five physical quantities can be monitored using the display and two analogue outputs.

(Engerwitzdorf, 18.03.2021) The Sigma 05 acts as a sensor hub for E+E Elektronik’s intelligent Modbus probes. It makes it easy to set up a modular sensor platform with up to three probes and five measurands.

The Sigma 05 supports E+E sensing probes for CO2, humidity, temperature, ambient pressure and air velocity, making it suitable for a wide range of applications.

Plug-and-Play Sensor Platform with Automatic Probe Discovery

The Sigma 05 can centrally manage up to three sensing probes with an RS485 interface and the Modbus RTU protocol. Compatible E+E sensing probes are automatically

identified by the sensor hub and are immediately ready for use. Of the total of five supported physical quantities, three can be assigned to the graphic display and two to the freely configurable analogue outputs.

The sensing probes can be connected to the Sigma 05 either directly or via an M12 cable. Connecting and replacing the intelligent probes is quick and easy thanks to the plug-and-play functionality.

Easy Software-Based Configuration and Adjustment

The new PCS10 configuration software gives the user full access to the sensor platform. This allows for convenient PCbased assignment of physical quantities, scaling of analogue outputs, adaptation of the display layout, setting of threshold values and adjustment of the connected sensing probes. The software is available free of charge on the E+E Elektronik website.

Reference Probe and Loop Calibration

A special reference probe is available for

a functional and accuracy check of the Sigma 05 or the entire measurement chain. The probe supplies fixed values for various physical quantities, is configurable using the PCS10 software and is automatically detected by the sensor hub.

The Sigma 05 supports easy, FDAcompliant loop calibration in the field. The cables facilitate on-site calibration of the connected probes in a portable calibrator.

High Quality and Flexibility

The Sigma 05 features a rugged IP65/NEMA 4 enclosure and is available with or without a display. With the various, high-quality E+E sensing probes, it can be used in HVAC, clean room or agricultural applications, for example.

Thanks to its modular plug-and-play design, the sensor platform offers a high degree of flexibility.

For more information contact Eurotec Ltd. Email: sales@eurotec.co.nz Website: www.eurotec.co.nz

PRODUCT FOCUS August/September 2021 31

Sigma 05: The modular sensor platform by E+E Elektronik

Photos: E+E Elektronik Ges.m.b.H

The new Climaveneta NX2 Air Cooled Chiller Range extends capacities up to 921kW

Mitsubishi Electric Climaveneta (MEHIT) has extended the successful NX2 Air Cooled Chiller Range. The new NX2-G02 and NX2-G06 models now range from 40kW to 921kW and are available in R410A or low GWP refrigerant R454B.

With electronic expansion valves and variable speed condenser fans included as standard, the NX2 Air Cooled Chillers are designed to deliver high operating efficiencies with low noise, making them ideal for comfort applications. All the main hydraulic and mechanical components are integrated inside the unit, providing the ideal plug and play solution for HVAC plants.

Evaporator types

The NX2 Range of air cooled chillers is available with either brazed plate or DX shell and tube evaporators depending on size. Single circuit chillers available only with brazed plate evaporators (P) from 40kW to 226kW

• Multiple circuit chillers available with brazed plate evaporators (P) from 167kW to 367kW

• Multiple circuit chillers available with DX shell and tube evaporators (T) from 167 to 921kW

Eurovent certification

The complete NX2 Range is Eurovent certified and all sizes are completely ErP2021 compliant.

Low noise operation for optimum quiet comfort

The NX2 Range has been designed with low operational sound levels in mind. Thanks to a specific design, the new series models are quieter when compared to the previous versions.

The optional Noise Reduction Kit (NR Kit) achieves best-in-class sound power levels while maintaining the same performance and footprint as the standard noise version. The NX2 with NR Kit is even quieter than the previous low noise versions.

High seasonal efficiencies for increased energy savings and minimised environmental impact

The new NX2 Chiller Range has been engineered for optimal seasonal

efficiencies, achieving improved SEER values that are over 15% higher on some models compared to the previous range. These values could be further increased by selecting options such as the ultra-performance kit in the single circuit NX2 machines and EC fans throughout the entire range.

The NX2-G06 version uses environmentally-friendly R454B refrigerant as standard

In line with the F-gas and the Kigali Amendment objectives, the NX2-G06 features R454B refrigerant – the lowest GWP alternative to R410A.

Key features of R454B refrigerant:

• Lowest GWP in the market for scroll units at only 467 (-76% vs R410A, -31% vs R32)

• Reduced refrigerant charge (-10% vs R410A)

• Higher efficiency (+3,5% vs R410A) with little capacity reduction

• Compatible with the same materials and components as R410A

• Same operating map as R410A in cooling

32 www.irhace.org.nz PRODUCT FOCUS

Mildly flammable A2L, PED fluid group 1

• Composition: 69% R32 + 31% R1234yf

Ideal for both new building and replacement applications with easy installation

The NX2 Range has been designed to achieve higher efficiencies at both full and part load, lower sound power levels, larger operating limits and a smaller footprint compared to previous models. As a result the NX2 Range of air cooled chillers is not only ideal for new projects but also the perfect replacement of old units in existing plants.

Furthermore the integrated hydronic modules (with optional buffer tank available) guarantee simplified installation and time-saving commissioning. The result is a ready-to-be-installed solution.

The new ranges are equipped with state-of-the-art options, such as:

• Multi Manager with embedded LAN logics for an easy connection between a group of chillers

• EC Fans with available static pressure up to 150Pa

• Variable-speed hydronic modules

• Optional Energy meter BMS or W3000 connection

• Leak detector

Optional control technology is available for enhanced functionality:

• Optional smart control functions such as night mode, user limit control and activation from a remote temperature probe

Optional KIPlink and new communication protocols (Konnex, Modbus TCP/IP, SNMP, M-net)

NX2 Range – summary of key features:

• R454B refrigerant used in the G06 Series with a GWP of 467 - the lowest-GWP alternative to R410A in this product category

• High-end standard configuration with electronic expansion valve, variable speed fan control and condenser coil end covers

• Very high efficiencies at both full and partial loads – Fully ErP2021 SEER compliant

• Large operating envelope from -20°C to +52°C of outdoor air temperature, from -10°C to +20°C of evaporator leaving water temperature

• Quiet operation in standard configuration

• Standard plus NR Kit option is ideal for specifications offering the best-in-class sound power levels and excellent operating efficiencies

• Range of optional accessories available including hydronic kits with pumps and buffer tanks, EC fans as well as high static option, VFD pumps, multi-manager

IMPORTANT

Due to the mild flammability of the refrigerant R454B, some restrictions must be observed during transport, storage, installation, and service activities.

To learn more visit www.mitsubishi-electric.co.nz

PRODUCT FOCUS

Ltd

Dylan Codlin AirZone

Whangarei

Refrigeration Auckland

Joseph Allen White

Refrigeration

North

Sean Martin Judd

Palmerston

Timaru Wallie Askew Memorial Workskills Competition (HVAC&R Industry Apprentice of the Year Competition) CONGRATULATIONS to the following apprentices for making it through to the finals of Come along and support them competing in the finals at the HVAC&R Conference on 16 & 17 September 2021 at the ASB Showgrounds Auckland. Principal Sponsor August/September 2021 33

Laurence Goodman

ATR

Events

Thursday, 26th August 2021 5.30pm - 8.30pm

IRHACE TRADE NIGHT WHANGAREI

National Events 2021

Semenoff Stadium - Venues and Events Whangarei

Northland Events Centre, 51 Okara Drive 0110

Whangarei New Zealand

With Guest Speakers

Preferred Accomodation Options with Discounts. (Book Accomodation Early)

Discovery Hotel Whangarei

Disctinction Whangarei Hotel & Conference Centre Code: DHotelsVIP01

Quest Whangarei Code: IRHACE

AUGUST Brazing Training at Refspecs

OCTOBER Site Visit Supermarket Plant tour

NOVEMBER Networking Evening

Email: whvacrnz@outlook.com

Facebook: " Women in HVAC-R New Zealand "

LinkedIn: "Women in HVAC+R NZ"

International Events

34 www.irhace.org.nz

Date Location Event 15-17 August Wellington Intercontinental Conference Centre, Wellington. 88th Cold Storage Association Annual Conference

Date Location Virtual Link Event

August Toronto, Canada www.ashrae.org./ conferences/topicalConferences/ventilation-2021

International Industrial Ventilation Conference for Contaminant Control 29 Sept2 October Istanbul, Turkey www.sodex.com.tr ISK Sodex 2021 POSTPONED

15-18

13th

35 August/September 2021 Advertise in the IRHACE Industry Journal Bi-monthly publication dedicated to the HVAC&R Sector The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries Inside this issue: REHVA COVID-19 guidance www.irhace.org.nz Inside this issue: heritage buildings: review night Hotel The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation Air Conditioning Industries –www.irhace.org.nz Calculating Combustion Air the refrigeration industry Post... ‘World Refrigeration Contact: HVAC Centre - admin@irhace.org.nz www.irhace.org.nz The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries Check out our Facebook group at www.facebook.com/groups/1158608134338628

NOW OFFERING Therma-Fuser™ Systems - Independent Zone VAV Control - Thermal or Electric Power Options - Zero Maintenance SOLD EXCLUSIVELY BY Visit our website to learn more www.holyoake.com

Canterbury/Westland branch held their Branch Annual Meeting on 2nd June 2021. This was held at Mike Pero Motorcycle Museum and we had a great night poring over all the beautiful bikes. All the smells and memories and comments of "I used to have this one" or "I had a poster of this one on my bedroom wall". They even started some of them up for us.

Canterbury/Westland branch held their Branch Annual Meeting on 2nd June 2021. This was held at Mike Pero Motorcycle Museum and we had a great night poring over all the beautiful bikes. All the smells and memories and comments of "I used to have this one" or "I had a poster of this one on my bedroom wall". They even started some of them up for us.

By Matt Birch

By Matt Birch