INSIDE THIS ISSUE

FROM THE CCCANZ CHAIR FROM THE IRHACE PRESIDENT COMMERIAL KITCHEN EXHAUST EFFLUENT PART 2

RLNZ UPDATE IOR RESOURCES

WALLIE ASKEW MEMORIAL WORKSKILLS COMPETITION

SEPTEMBER 2022 irhace.org.nz

Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries

The

WALLIE ASKEW

Wallie Askew served as President of NZIRACE from 1974 -1982 and was awarded Life Membership for his achievements during this service. The Wallie Askew Memorial Workskills Competition was established by IRHACE in 1999 on the tenth anniversary of the tragic deaths of Wallie and his wife Betty in a traffic accident. Wallie was a strong supporter of the HVAC&R industry, the Institute, and apprentice training.

WALLIE ASKEW

MEMORIAL WORKSKILLS COMPETITION

FINAL COMPETITION

26th - 28th October

Steelfort

500 Rangitikei Street

Milson

Palmerston North

Special thanks to MIT, SIT, Active Refrigeration, McAlpine Hussman for hosting the regional events.

6 COMPETITORS FROM ACROSS NEW ZEALAND

SEE REGIONAL WINNERS ON PAGE 19

irhace.org.nz SEPTEMBER 2022

Enjoying dinner at a restaurant with friends and family may seem like a very normal experience but behind delivering the meal to your table is the generation of airborne effluents resulting from the cooking process.

1 ISSUE: SEPTEMBER 2022 INSIDE THIS ISSUE From the CCCANZ Chair From the IRHACE President Commerial Kitchen Exhaust Effluent Part 2 RLNZ Update IOR Resources Wallie Askew Regional Competitions 8

8 19 6 7 8 16 18 19 Official Journal of the Institute of Refrigeration, Heating and Air Conditioning Engineers of New Zealand Inc (IRHACE), Climate Control Companies Association New Zealand (CCCANZ), and Refrigerant Licence New Zealand (RLNZ) The Industry Journal for the New Zealand Refrigeration, Heating, Ventilation & Air Conditioning Industries

PUBLISHER

IRHACE/CCCANZ/RLNZ IRHACE: www.irhace.org.nz CCCANZ: www.cccanz.org.nz RLNZ: www.rlnz.org.nz

EDITOR

HVAC&R Centre admin@irhace.org.nz

MEMBERSHIP admin@irhace.org.nz admin@cccanz.org.nz

REFRIGERANT LICENSING & COURSES admin@rlnz.org.nz

ADVERTISING admin@irhace.org.nz

DESIGN

Bellacreative Ltd

HVAC&R CENTRE

PO Box 217184 Botany Junction 2164 Auckland, New Zealand

e: admin@irhace.org.nz e: admin@cccanz.org.nz e: admin@rlnz.org.nz

No part of this journal may be printed in other publications without prior written permission of the Managing Editor.

Disclaimer: Statements expressed in this publication do not necessarily reflect the policies or views of the associations, and members of IRHACE or CCCANZ. The IRHACE Journal publishes both local and international articles. Standards and or practices may differ from current New Zealand standards and or practices used. No responsibility is accepted by the associations and editor for the accuracy of information or for errors or omissions. The IRHACE Journal is distributed to all the IRHACE and CCCANZ financial members.

ISSN 01148257

GINA MCMASTER

IRHACE Executive Officer

Our business is the HVAC&R industry and our strength is in our people. There have been a few people changes in both the IRHACE and CCCANZ Boards which will only strengthen our organisations.

It was a pleasure to attend ARBS2022 in Melbourne and to see and talk with so many kiwis who made the trip across the Tasman. A three-day packed event with 220 feature packed stands, which included a number of CCCANZ member companies, and total visitor numbers in excess of 7,000.

This was also a great opportunity to meet with our fellow industry associations AMCA and AIRAH and to discuss our common issues and build on new and existing relationships.

We congratulate Temperzone on being awarded the Product Excellence Award Winner and to AMCA Australia for the Outstanding Industry Education/Training Award for their event Building Ventilation Summit.

Within New Zealand we saw the 2022 Wallie Askew Memorial Workskills Competition – Regionals which took place in Auckland, Hamilton, Palmerston North and Christchurch. The value each of the 25 apprentices obtained whilst competing against their peers is what makes this such a great competition. Special thanks to MIT in Auckland, SIT in Christchurch, Active Refrigeration in Palmerston North and McAlpine in Hamilton for providing the venues for these competitions.

irhace.org.nz SEPTEMBER 2022

3 Ceiling Air Purifier (CAP) Visit us at: www.holyoakepureair.com or Call: 0800 114 810 FEATURES: - Easily removable and replaceable HEPA filter with MERV-8 pre-filter - Square plaque or louvred diffuser - 3-speed high-efficiency motor - Motion sensor - Smart filter replacement indicator - UV light treatment - Bipolar ioniser

irhace.org.nz SEPTEMBER 2022

Mitsubishi Electric (BDT)

Daikin

Fujitsu

Fantech

SmartTrade

Chilled Water Fan Coil Units

IMD/L-Y

Std

� Energy Efficient EC Fans

� Flexible handing configurations

� Multiple coil configurations

� Wide water temperature range

� BMS Integration

� Long life durable design

� Up to 5 independent EC Fans

� Controls 1-5 individual zones

� Variable temperature zone control

� Flexible handing configurations

� BMS integration

� Long life durable design

5

&

Low Profile EC Fan Coils

Coils Chilled Water Fan Coils Units 5.0kW - 215.6kW

IXDL-Y Multi-zone EC Fan

IMDL-Y

IMD-Y

Contact us at nzsales@temperzone.com Product information visit www.temperzone.com

High Rise Offices � Hospitals

Convention Centres

Shopping Centres

Airports & Train Stations

Education Centres

Financial Institutions

Public Buildings

IXDL-Y

�

�

�

�

�

�

�

Temperzone has an extensive and flexible range of fan coil units. Whether you require individual zone control, low profile or high static, temperzone can provide the unit to meet your project needs.

FROM THE CHAIR

CCCANZ Board have held their first meeting after the AGM back in June 2022. As per our constitution we have voted in our officers for the 2022/2023 financial year. We continue with our project work and good governance whilst we work towards a better and bigger organisation going forward.

Chair

Malcolm Miller

CCCANZ Member

Absolute Airconditioning & Refrigeration Ltd

Board Director

Brendan Clarkson

Deputy Chair RLNZ

CCCANZ Member

Clarksons Air Conditioning Ltd

Deputy Chair Gary Reily

IRHACE/CCCANZ Delegate

CCCANZ Member

Degree Air Conditioning & Electrical

Board Director

Mark Hoskin

CCCANZ Member

AMT Maintenance Services Ltd

Treasurer Garry Ko

CCCANZ Member RCR Infrastructure

Board Director Phil Mohan

IRHACE Councillor

CCCANZ Member Air Con Services Ltd

To further our relationship with IRHACE, two of the CCCANZ Board members have been appointed to the IRHACE Council.

Phil Mohan and Gary Reily have agreed to take on dual roles to better our working relationships.

Brendan Clarkson continues his additional role as the Deputy Chair of RLNZ.

irhace.org.nz SEPTEMBER 2022

From the left – Malcolm Miller, Mark Hoskin, Gary Reily, Brendan Clarkson, Phil Mohan and Garry Ko.

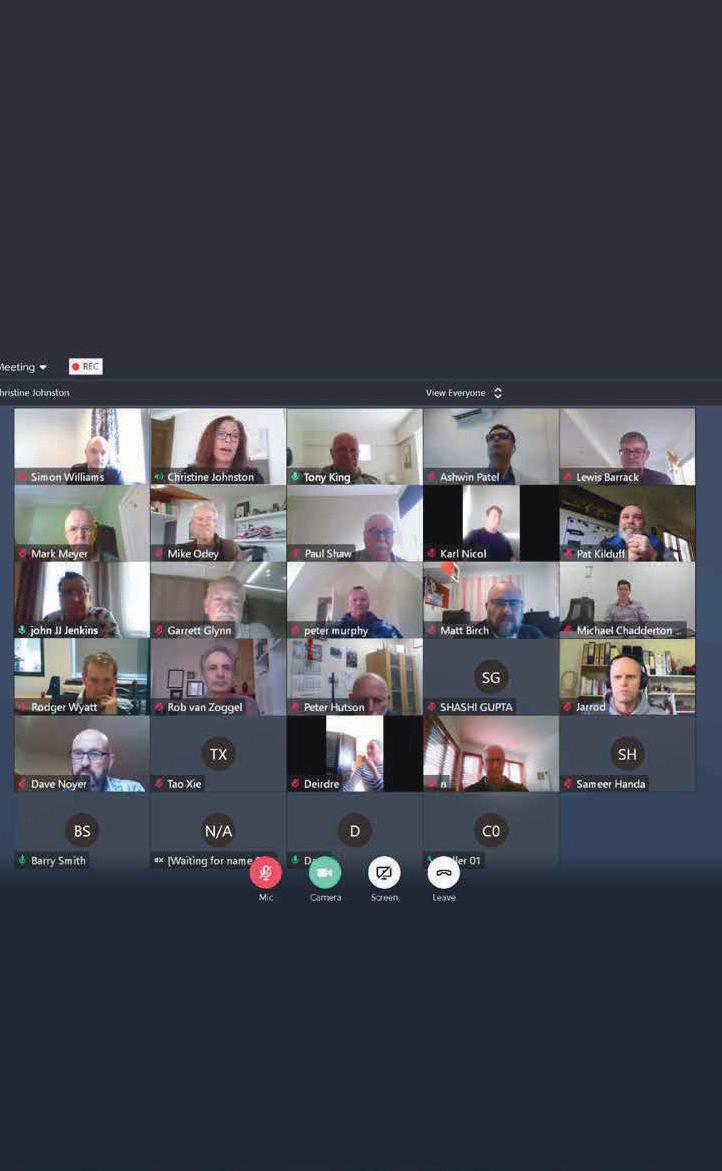

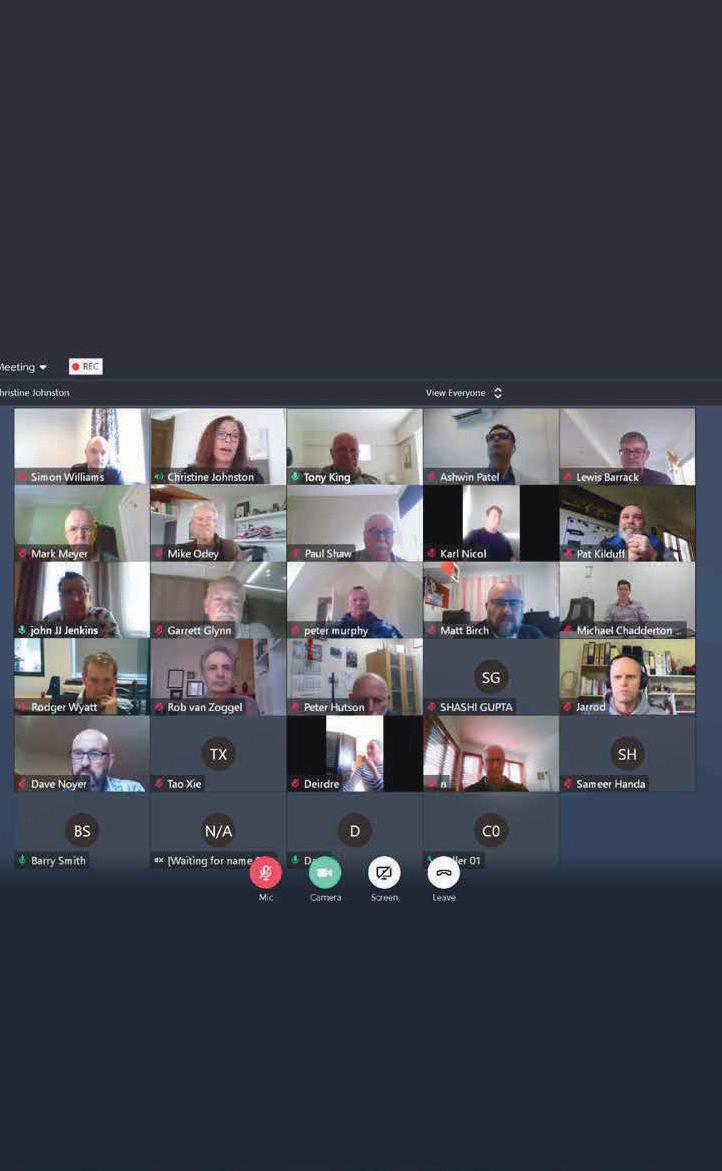

FROM THE PRESIDENT

It has been a busy time for IRHACE since the AGM in June. IRHACE advertised recently for volunteers to join the Council, and we are pleased to announce that Trent McDonald and David Everett have joined the IRHACE Council as co-opt members.

Trent is a Project Manager with Ideal Air and has recently joined as a M.IRHACE and was previously an apprentice in the 2011 Wallie Askew Memorial Workskills Competition.

David is the Director of Everett Consulting Ltd, M.IRHACE and provides Refrigeration Consultancy, Design, Tender and Project Management Services.

Two AGM appointed Councillors have chosen to step down and focus their efforts elsewhere.

• Matt Birch continues his role as Chair of RLNZ.

• Pat Kilduff has chosen to step down from the IRHACE Council.

• Gary Reily, Deputy Chair of CCCANZ joins as the IRHACE/CCCANZ delegate.

• Phil Mohan, M.IRHACE, IQP joins the IRHACE Council and has been appointed President Elect.

We welcome all our new appointments and thank Matt Birch for his continual support and expertise in his role as RLNZ Chair and Pat Kilduff for his efforts particularly in membership.

IRHACE/CCCANZ DELEGATE

Gary Reily

7

President Mark Meyer M.IRHACE

Immediate Past President Ashwin Patel M.IRHACE

Councillor Paul Shaw M.IRHACE

Councillor Vikrant Bhatt M.IRHACE

Co-opt David Everett M.IRHACE

Co-opt Trent McDonald M.IRHACE

President Elect Phil Mohan M.IRHACE

COMMERCIAL KITCHEN EXHAUST EFFLUENT & TREATMENT OPTIONS PART 2

Enjoying dinner at a restaurant with friends and family may seem like a very normal experience but behind delivering the meal to your table is the generation of airborne effluents resulting from the cooking process. This effluent is discharged to the exterior contributing to environmental pollution with detrimental effect on human health. This article examines the size of the New Zealand hospitality industry, the various cooking processes, the composition of airborne effluent and available control technologies.

Management of Airborne Effluents

The cooking process generates airborne particles of various sizes and composition which have been demonstrated to be detrimental to the environment and to human health. AS1668-2-2012 sets out the requirements in dealing with cooking effluents. Section 3.3.1 categorises cooking effluents as type B which are required to be removed by local exhaust (5) using a hood or similar means. The most common approach in dealing with this has been the installation of an extract system comprising of a metal hood fitted with filters installed above the cooking appliance, ducting and an extract fan discharging to the atmosphere. Although this represents the most basic and commonly applied solution, it has limitations in dealing with smaller particles and odours.

Hoods

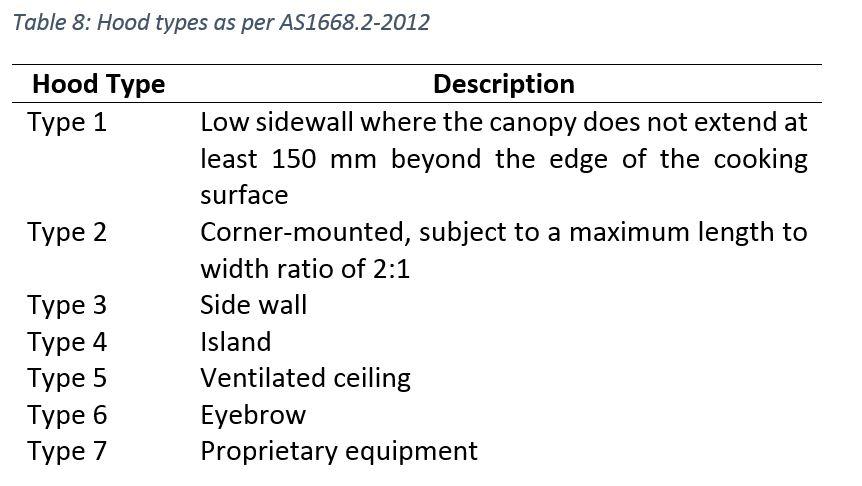

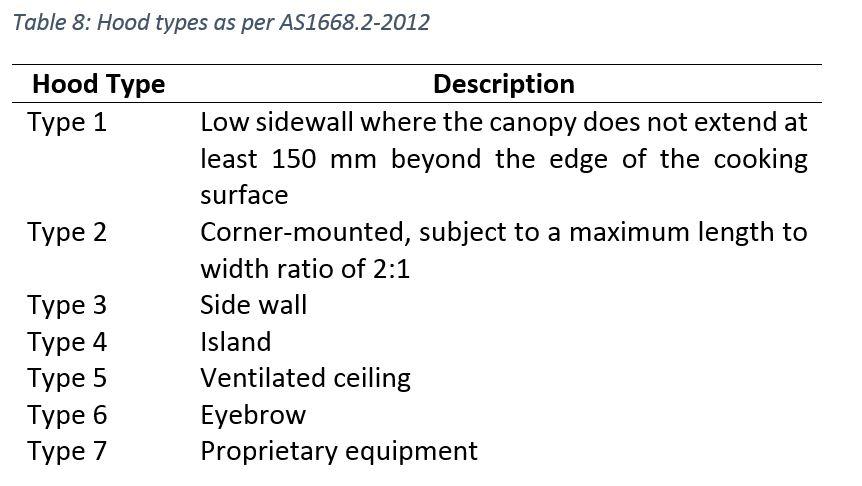

Under AS1668.2-2012, hoods are required to be manufactured of materials deemed noncombustible in accordance with AS1530.1, such as steel or stainless steel sufficiently rigid and with smooth surfaces. Hoods are classified in seven types as shown in Table 8.

Section 3.5 of the standard provides a prescriptive method -excluding hoods type 5 and 7- to determine airflows for different types of cooking processes and hood types. Where several cooking appliances are being used, the equation relevant to the worst case is to be used for calculating airflows. In any case the airflow shall not be less than 250 l/s/ m2. Hoods type 5 and 7 are designed for lower airflows and consequently lower energy consumption, therefore, requiring more empirical calculations. Airflows for proprietary hoods type 7 designed to standards such as German VDI 2050 or DIN 18869 are acceptable.

irhace.org.nz SEPTEMBER 2022

READ PART 1 OF THIS ARTICLE IN OUR AUGUST ISSUE

Filtration

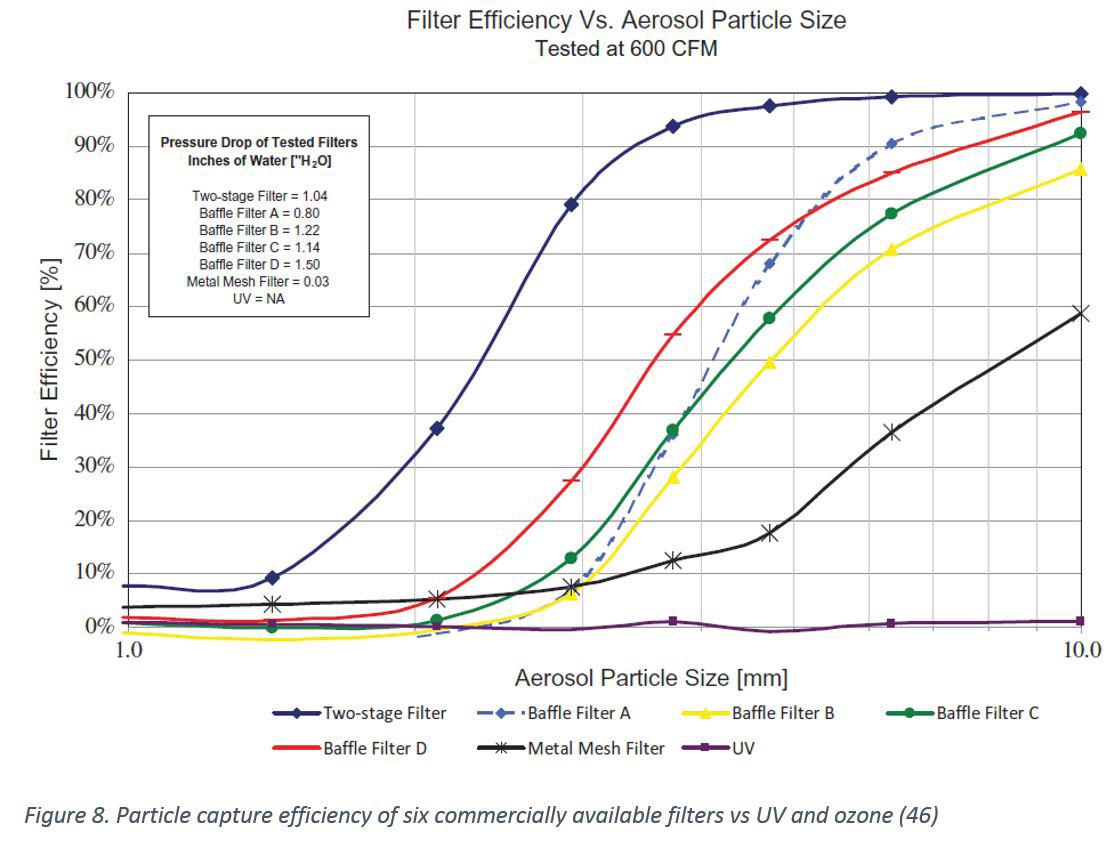

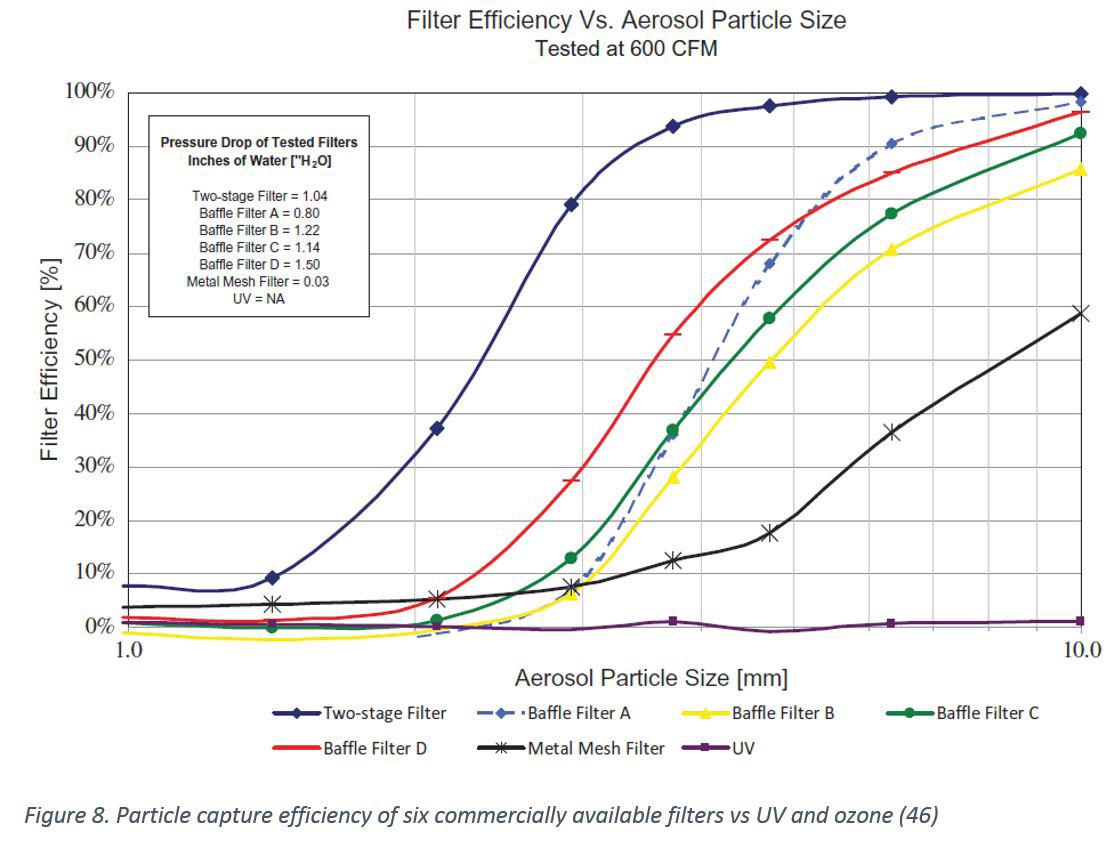

Baffle and the mesh type are commonly used as primary filters.

The commonly known grease filter comprises of an interwoven mesh held within a metal frame or arranged in a honeycomb pattern. Particulate matter is captured within the mesh. Common materials are aluminium and stainless steel. Baffle filters comprise of plates folded in U shape and interlocked in such a way as to impart a change of direction to the airflow. As a result of this, the larger particles impact on its walls and slide down and drain away. Baffle and mesh type filters have little effect on capturing grease vapour, gas or odours. The efficiency of these two types of grease filters is low for fine particulates. They are limited to capturing 18% to 20% of particles going through it (6). Both types rely on impact for particulate collection (44). However, these types of filters are relatively cheap and easier to clean. Comparatively, baffle type filters exhibit higher pressure drop than mesh type (19) (45).

Electrostatic Precipitator (ESP)

These devices are effective in the capturing of smaller particulate ranging from 0.1 µm to 10 µm (43). This is achieved in a two-stage electrostatic process. As particles enter the device, they go through an initial stage where particles of smoke, grease and other effluent components are electrically charged or ionised. As these par ticles travel along into the second stage, they encounter another electric field comprising of parallel plates where the particles are collected. Maintaining the collection efficiency of these devices depends on regular cleaning with its frequency being governed by the cooking load. Excessive build up on the plates would reduce performance and could lead to the unit ceasing to work. There are ESP units available in the market which incorporate automatic washing functionality. The alternative to this is regular manual washing by qualified personnel. These devices operate under high voltage, typically between 12-14K volts. Depending on the effluent discharge requirement limits, ESP units can be placed in series configuration to further reduce emission levels. Prefilters should be used upstream the ESP unit to collect larger particles. ESP technology although higher capital cost with respect to traditional grease filters, when installed downstream, close to the hood or within the hood, will result in cleaner ductwork and reduced fire risk. This, in conjunction with other filtering technologies, would be an acceptable solution where vertical discharge is not possible or is impractical. Where further odour mitigation is required, consideration should be given to use ESPs in conjunction with other treatments such as ozone or activated carbon.

It is recommended filter efficiency be evaluated at 0.3 mµ (47). This is because this particle size is considered the most penetrating particle size (MPPS) and because it forms part of smoke.

9

Ozone

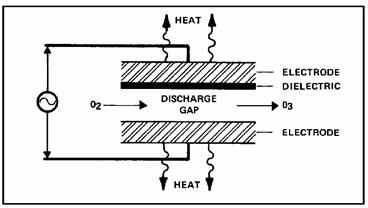

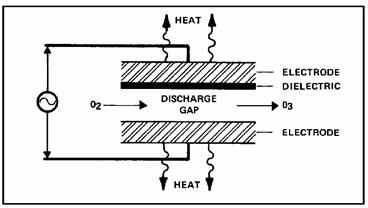

Ozone is a highly oxidative unstable molecule comprising of three oxygen atoms and its chemical formula is O3. In the field of commercial kitchens, it is used to mitigate odour through the oxidisation of smaller particles and vapour. The result of that chemical reaction is a sooty powder (18). Although there are several processes to generate ozone, in kitchen’s applications the common generation methods are the corona discharge and ultraviolet light. In the former, air is passed through a gap between electrodes subject to a strong electric field which split the O2 molecule into individual oxygen atoms as it passes through. The free oxygen atoms then adhere to other O2 molecules to form ozone. Figure 9 shows the corona discharge effect and how this generates ozone.

A common installation configuration is to have the ozone generator located in the proximity of the ductwork and injecting ozone into it via a connecting pipe. The generator should be interlocked with the operation of the extract fan. An important consideration is the exposure time within the duct required for ozone to react with the effluents such that there is no residual ozone left in the system at the point of discharge to the exterior. A residence time in the duct between 2 to 5 seconds is considered necessary for the chemical reaction to take place (6). Lower duct velocities would give greater exposure. Where residual ozone may exist, activated carbon filters can be used in conjunction with ozone generators.

Ozone is also produced by ultraviolet light and this is covered in the next section.

Ultraviolet Light (UV)

In the context of kitchen effluent control, lamps emitting UV light are used as a means of breaking down smaller grease particles and reducing odours. Lamps emit ultraviolet light in a wave length range of 280 nm to 100 nm (UVC) and also produce ozone. This dual action process breaks down the long molecules of carbon and hydrogen in a process called photolysis with ozone contributing to the oxidation of the particulate yielding smaller harmless substances (6). The chemical reactions in the breaking down of the effluent result in carbon dioxide and water vapour (46) (49) (50). UV treatment is used to breakdown smaller particulate and therefore is important to have efficient filtration prior to the UV device. Given that these lamps also produce ozone, consideration has to be given to allowing sufficient residential time for oxidation to take place within the ductwork. Exposure to UV radiation in these applications would be harmful therefore appropriate system design and personnel awareness would be essential.

irhace.org.nz SEPTEMBER 2022

Figure 9: Corona discharge effect and ozone generation (48)

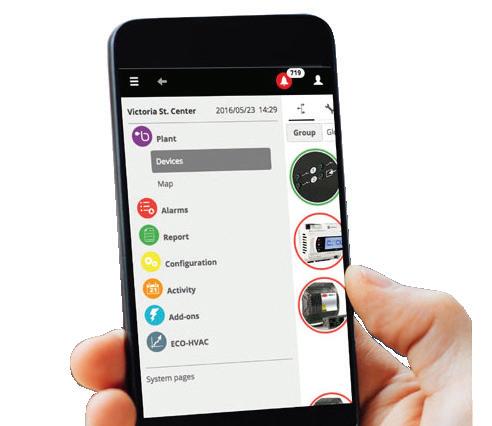

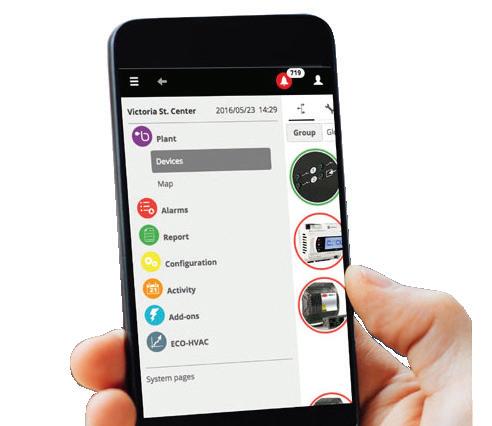

CAREL SUPERVISORY SOLUTIONS

The CAREL bOSS mobile-ready supervisors offer a complete and reliable solution for management, monitoring and optimisation of refrigeration and air conditioning systems.

• Integrated WiFi & access from all mobile devices.

• Modbus, Bacnet TCP/IP, Bacnet MS/TP built in

• Ideal for cold stores, supermarkets and convenience store applications

• Combine bOSS with CAREL RED optimise to guarantee secure & profiled remote connections to allow access to information on energy consumption, units performances and alarm management.

High end supervision in a new compact format

boss micro is the latest addition to the boss family. Designed to cover applications like c-stores, petrol stations and quick service restaurants, where a limited number of units is present but advanced system management functions are required as in the larger sizes.

Carel boss can also be integrated into a total control panel solution for your refrigeration supervisory needs. Contact us today!

11

579 1990

09

www.eurotec.co.nz sales@eurotec.co.nz

Ltd. | www.clima.co.nz | 0274 593 363 | rob@clima.co.nz

& Heat Pumps

Clima

Solutions

Chillers

& Flues

Boilers

Coil Units Doing business with us is a breath of fresh air. Ventilation filters for every workplace.

Calorifiers Fan

Activated Carbon

Filters utilising activated carbon have extensively been used to deal with airborne pollutants and odours such as volatile organic compounds (VOCs) generated by the cooking process. Carbon is also referred to interchangeably as charcoal. It seems that historically carbon had been used as a purifier by earlier cultures such as the Egyptians (51). Carbon is the result of incomplete combustion. Industrially, where wood is used, this is subject to heating at high temperatures in the absence of oxygen or under vacuum (51). For carbon to become “active” further processing is carried out, consisting of the injection of hot air, CO2 or steam resulting in the creation of tiny surface pores which result in increased surface area (43). The capturing of effluent is by a process called adsorption where particulate fill the pores on the carbon surface (19) (43). Adsorption is due to molecular forces or chemical bonding (6). Activated carbon filters work as long as there is sufficient surface to fill. Once all pores have been filled the filter has reached its saturation point and requires to be replaced. Odour removal efficiencies between 80% to 99% is achievable (19). However, its effectiveness is vey dependant on the residence time, therefore lower airflow velocities would be beneficial (6). It is considered that carbon filters have a short service life and they are not effective on effluents not attracted to carbon (6). Figure 10 shows the adsorption process.

CONCLUSIONS

Emissions generated by a cooking process produce a variety of substances with particulate size ranging from 0.01 µm to 100 µm. The amount and composition vary and is dependent on the actual cooking process being used. There are studies that strongly suggest that cooking emissions are detrimental to the human health especially for particulate smaller than 10 mµ. Standard grease filters are effective in capturing larger particles but are not as effective on smaller ones, gases and odours. However, there are several technologies available in the market that would mitigate the impact to humans and the environment. Apart from the commonly used baffle, mesh and honeycomb filters, these include electrostatic precipitators, ozone generators, UV lamps and activated carbon filters. Economic factors seem to be the predominant factor in the selection criteria, unless there are compelling reasons for reducing the level of pollutants being discharged. Regular maintenance and cleaning would be a prerequisite in order to achieve optimal equipment performance and reduction in fire risk.

As air pollution and its effect on human health becomes a central topic, much effort is needed in mitigating the impact of cooking processes effluent discharge.

Author: Jorge Villazon-Leon, AOM New Zealand, General Manager, Mob: 027 6433750 Jorge has been involved in the HVAC industry for over 30 years in various roles from design, project and general management. He has been a member of IRHACE for just over 30 years

Technical Review: Sven Bolomey, AOM Australia, General Manager

irhace.org.nz SEPTEMBER 2022

Figure 10: Activated carbon filter process (52)

References

1. 2020 Hospitality Report- Restaurant Association of New Zealand.

2. 2018 Hospitality Report- Restaurant Association of New Zealand.

3. Shead, R. Cafe, Restaurant & Catering Industry Snapshot. 2017.

4. Symons, M. Meals Matter. [Online] 2015. https://mealsmatter.co/2015/11/06/how-many-kitchen-in-the-world/.

5. Australia, S. The use of ventilation and airconditioning in buildings Part 2: Mechanical ventilation in buildings. AS 1668.2: 2012.

6. Ling, A., Zhong, R. and Shi, J. Commercial Kitchen Hood Exhaust System and Standard Development. School of Chemical and Biomolecular Engineering, University of Sydney. 2018. Review.

7. McDonald, J.D. Emissions from Charbroiling and Grilling of Chicken and Beef. Journal of the Air & Waste Management Association. 2003, pp. 185-194.

8. Watson, J. Northern Front Range Air Quality Study Final Report. Colorado : Colorado State University, 1998.

9. N/A, 2011 ASHRAE Handbook - Heating, Ventilating, and Air-Conditioning Applications (SI Edition). American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

10. Tiwari, S. Aerosol optical properties and their relationship with meteorological parameters during wintertime in Delhi, India. Atmospheric Research. 2015, pp. 465-479.

11. Pipal, A.S. and Satsangi, P. Gursumeeran. Study of carbonaceous species, morphology and sources of fine (PM2.5) and coarse (PM10) particles along with their climatic nature in India. Atmospheric Research. 2015, pp. 103-115.

12. Gong, W. An Investigation of Aerosol Scattering and Absorption Properties in Wuhan, Central China. Atmosphere. 2015.

13. Oberdörster, G., Oberdörster, E. and Oberdörster, J. Nanotoxicology: An emerging discipline evolving from studies of ultrafine particles. Environmental Health Perspectives. 2005, pp. 823-39.

14. Bai, Y. Carbon loading in airway macrophages as a biomarker for individual exposure to particulate matter air pollution — A critical review. Environment International (Supplement C). 2015, pp. 32-41.

15. Franklin, B.A.;Brook R.; Arden Pope C. Air Pollution and Cardiovascular Disease. Current Problems in Cardiology. 2015, pp. 207-238.

16. Aziz, T.N. Analysis of grease abatement devices and the measurement of fat, oil, and grease in food service establishment waste streams. Civil Engineering. ProQuest Dissertations & Theses Global., 2010.

17. Ho, S.S.H. Carbonyl Emissions from Commercial Cooking Sources in Hong Kong. Journal of the Air & Waste Management Association. 2006, pp. 10911098.

18. The Australian Institute of Refrigeration, A.C.a.H., Fire safety - Kitchen hood exhaust systems Understanding and addressing the special fire risks inherent in commercial kitchen ventilation systems in Technical Bulletin 2016, AIRAH.

19. Netcen. Guidance on the Control of Odour and Noise from Commercial Kitchen Exhaust Systems. 2005.

20. Editors, The. Broiling. Encyclopidia Britanica. [Online] September 10, 2019. [Cited: September 10, 2019.] https://www.britannica.com/topic/broiling.

21. Identification and Characterization of Effluents from Various Cooking Appliances and Processes as Related to Optimum Design of Kitchen Ventilation Systems in ASHRAE Reserach Project Report RP-745 1998, ASHRAE. Gerstler, W.D. s.l. : ASHRAE, 1998.

22. A New Standard Method of Test for Determining the Grease Particulate Removal Efficiency of Filter Systems for Kitchen Ventilation. Schrock, D. 2006, ASHRAE Transactions.

23. Buonanno, G., Morawska L., Stabile, L. Particle emission factors during cooking activities. Atmos Environ. 2009.

24. Comparison of emissions from selected commercial kitchen appliances and food products. . Kuehn, T.H. 1999, ASHRAE Transactions.

25. Zhong, X. , Ling, H. , Van, J., Bolomey, S. , Shi, J. Commercial kitchen exhaust contaminants removal using combined treatment techniques and filtration efficiency assessment with developed standardised alternative test protocol.

26. Pope, C.A., et al. Cardiovascular Mortality and Long-Term Exposure to Particulate Air Pollution. Epidemiological Evidence of General Pathophysiological Pathways of Disease. 2004, Vol. 101, pp. 71-77.

27. Arden Pope Iii, C. and D.W. Dockery, 31. Epidemiology of Particle Effects A2 - Holgate, Stephen T, in Air Pollution and Health, J.M. Samet, H.S. Koren, and R.L. Maynard. London : Academic Press, 1999. pp. 673-705.

28. Verrier, R.L., Mittleman M.A., Stone P.H. Air Pollution. An Insidious and Pervasive Component of Cardiac Risk. 2002. pp. 890-892.

29. Dockery, D.W., et al. An Association between Air Pollution and Mortality in Six U.S. Cities. 1993, pp. 1753-1759.

30. Pope, I.C., et al. Lung cancer, cardiopulmonary mortality, and long-term exposure to fine particulate air pollution. JAMA. 2002, 287(9), pp. 1132-1141.

31. Uzoigwe, J., et al.,. The emerging role of outdoor and indoor air pollution in cardiovascular disease. North American Journal of Medical Sciences. August 2013, pp. 445-453.

32. Torkmahalleh, M.A., et al.,. PM2.5 and ultrafine particles emitted during heating of commercial cooking oils. Indoor Air. 2012, pp. 483-491.

33. Olson, D.A.,Burke J. M. Distributions of PM2.5 Source Strengths for Cooking from the Research Triangle Park Particulate Matter Panel Study. Environmental Science & Technology, 2006. 2006, pp. 163-169.

34. Lee, S.C., W.-M. Li, and L. Yin Chan. Indoor air quality at restaurants with different styles of cooking in metropolitan Hong Kong. Science of The Total Environment. 2001, pp. 181-193.

35. See, S.W., Balasubramanian R. Risk assessment of exposure to indoor aerosols associated with Chinese cooking. Environmental Research. 2006, pp. 197204.

36. ASTM-E176. Standard Terminology of Fire Standard.

37. Air filtration. Modern Casting, 2011. 101(2): p. 62.

38. Australia, S., The use of ventilation and air conditioning in buildings Part 1: Fire and smoke control in buildings in AS/NZS 1668.1: 2015. 2015, Standards Australia.

39. Schoenberg, J.B., et al., Case-Control Study of Bladder Cancer in New Jersey. I. Occupational Exposures in White Males23. JNCI: Journal of the National Cancer Institute, 1984. 72(5): p. 973-981.

40. ASTM-D121. Standard Terminology of Coal and Coke.

41. Page, T. What is The Process of Olfaction – Odor Perception ? Odotech. [Online] December 12, 2010. [Cited: September 18, 2019.] http://www.odotech. com/en/process-olfaction-odor-perception/.

42. Zhu, L. and J. Wang, Sources and patterns of polycyclic aromatic hydrocarbons pollution in kitchen air, China. Chemosphere, 2003. 50(5): p. 611-618.

43. Brattoli, M., et al., Gas Chromatography Analysis with Olfactometric Detection (GC-O) as a Useful Methodology for Chemical Characterization of Odorous Compounds. Sensors (Basel, Switzerland), 2013. 13(12): p. 16759-16800.

44. Kuehn, T.H., et al., Grease particle emission characterization from seven commercial kitchen cooking appliances and representative food products. ASHRAE Transactions, 2009. 115: p. 126-137.

45. Analysis of Chemical and Physical Effects of Ultraviolet Bulbs on Cooking Emissions, Journal of the Air & Waste Management Association. Farrell, F.M., Fitch, T.M., Bicking, M.K.L. 2011.

46. Farrell, F.M., T.M. Fitch, and M.K.L. Bicking, Analysis of Chemical and Physical Effects of Ultraviolet Bulbs on Cooking Emissions. Journal of the Air & Waste Management Association, 2011. 61(10): p. 1005-1014.

47. Kitchen Exhaust Filtration Design. Bunge, J. 2018, Ecolibrium, pp. 28-33.

48. Smith, W. Principles of Ozone Generation.

49. D’Antonio, P., C. , Grease removal and kitchen exhaust systems. Heating/Piping/Air Conditioning Engineering : HPAC, 2004. 76(5).

50. Livchak, A., et al., The facts about mechanical grease filters. ASHRAE Journal, 2003. 45: p. 4.

51. Myers, P. Activated Carbon Air Filters: Everything You Need to Know. [Online] January 31, 2018. [Cited: September 29, 2019.] https://molekule.science/ activated-carbon-air-filter/.

52. BeyonddCompare. Activated Carbon Filter- Air Purifiers. 2017 Available from: http://www.beyonddcompare.com/activated-carbon-filter/. [Online]

13

NEW RAC ACI PROGRAMMES

We are pleased to announce the launch of new qualifications in Refrigeration and Air Conditioning (RAC) and Air Conditioning Installation (ACI).

As a result of the NZQA-mandated five-yearly qualification review, we have updated our RAC apprenticeship programme and developed a new ACI certificate programme, both of which opened to new enrolments on 15 August 2022.

The updated level 4 New Zealand Apprenticeship in Refrigeration and Air Conditioning (Trade) remains a comprehensive 4-year apprenticeship programme designed to equip learners already in the Heating, Ventilating, Air Conditioning & Refrigeration (HVAC&R) industry with the knowledge and experience to independently install, maintain, service, and commission plant and equipment to industry standards.

The new level 4 New Zealand Certificate in Air Conditioning Installation is a 2-year certificate programme designed for people looking to improve their employment prospects who are already working in the HVAC&R industry, or for those in allied trades who wish to enter the industry. Graduates will be able to independently install air conditioning systems up to 50Kw nominal cooling, and work safely with synthetic refrigerants, including Hydrofluoro-olefins (HFOs), in accordance with manufacturer’s specifications and industry best practice.

These new work-based programmes have been developed in collaboration with the HVAC&R industry, to provide skilled tradespeople working at industry standard. Both programmes have been developed with the future in mind, to ensure graduates are equipped with the skills needed to respond and adapt to continuing advancements in technology and environmental requirements.

As always, the qualifications are open to anyone employed in the industry.

Competenz would like to thank all the industry professionals who gave their time to progress these reviews. This includes employers, workers, operators, and assessors. Their involvement acting as subject matter experts in technical advisory groups has been crucial to ensuring these qualifications are fit for purpose and provide an accurate representation of what is needed in the sector.

All Competenz resources, learning support materials, and assessment guides have been updated to facilitate a seamless rollout, and ensure learners and employers get the most out of these refreshed qualifications.

Both programmes are fully funded under the Targeted Training and Apprenticeships Fund (TTAF) until 31 December 2022.

If you would like to learn more about the qualifications our programmes cover, you can do so on the links below:

Air Conditioning Installation

Refrigeration and Air Conditioning

To contact us, please visit: https://www.competenz.org.nz/contact-us/get-in-touch

irhace.org.nz SEPTEMBER 2022

INDUSTRY AWARDS

For over two decades the ARBS Industry Awards has recognised and honoured the outstanding contributions made by individuals and organisations within the Australian HVAC&R and building services profession. The unparalleled ARBS Industry Awards program bestows the highest accolade to those that have demonstrated professional excellence and a significant commitment to innovation within the industry.

CCCANZ congratulates all winners at the ARBS Industry Awards in particular Temperzone (CCCANZ member company) who won the Product Excellence Award.

PRODUCT EXCELLENCE AWARD WINNER: Temperzone

Econex R32 Inverter Air Cooled Package Units

This award highlights commercially viable HVAC or refrigeration products that demonstrate sustainable practices and innovation.

The Econex air-cooled R32 Inverter package unit range is a new mid-range product family consisting of four models with nominal cooling capacities of 25.4, 35.9, 44.9 and 55.6kW. The product is the first R32 inverter package unit range in the ANZ market. Compared to the Eco R410a range the Econex range has a 71–79% reduction in refrigerant related global warming potential (GWP) per kilowatt of cooling or heating capacity.

As higher GWP refrigerants face increasing cost due to emissions tax levies, using R32 systems represents a significant reduction in the costs of maintaining these systems, combined with a reduced global warming impact.

Read more on the awards, https://www.arbs.com.au/arbs-2022-awards-finalists/

RLNZ UPDATE

RLNZ’s new Approved Filler courses are an assessment of your abilities similar to a car drivers licence test and not a training course.

Prior to starting the course, you should have a working knowledge of the collection of refrigerants and have practical experience in performing an actual recovery and have your own gear and equipment.

ONLINE THEORY COURSE

Image courtesy of Air Mc Ltd

Each topic in the online theory course has a course presentation under the learning material heading. You simply select the presentation and then work through it. Your progress is saved as you work through the presentations. When you leave a presentation, and then come back later you’ll start at the point you left off. The course is also self-guided, and you are free to move forward.

Once you’re happy that you understand the content of each topic you can try the assessment. Learners need to get 80% of the questions correct to complete the assessment and are provided with 3 attempts. If you don’t achieve, you can pay again to re-sit the online theory – but be aware that some of the questions might change!

We recommend reading the following documents and familiarising yourself prior to starting the online A1 or A2/A2L theory courses:

• AS/NZS 5149.4: 2016

• Health and Safety at Work (Hazardous Substances) Regulations 2017

irhace.org.nz SEPTEMBER 2022

REGISTER HERE

PREPARING FOR THE PRACTICAL ASSESSMENT

You are required to demonstrate knowledge, skills and experience of the refrigerant recovery procedures presented to you on the day of the practical assessment. This will include the following:

1. Completing pre-recovery risk assessment.

2. Completing a successful A1 recovery, ready for safe line and equipment opening within the time allowed.

3. Completing post-filling tasks to industry best practice.

4. Applying safe work practices throughout assessment.

Special note:

1. No formula are provided – you are expected to completely understand the calculation methods.

2. Learners are responsible to provide all equipment (see below table). All equipment must meet NZ legal obligations i.e. must be tested and tagged.

Time allowed

Minimum PPE

Materials and equipment

Health and Safety

Number of attempts

Assessment Criteria

60 minutes maximum

Overalls or full-length cotton clothing, Hi-Viz, protective eyewear, protective footwear, hearing protection and gloves.

Gauge manifold and hoses, thermometer, P/T chart or application, recovery plant, refrigerant scales, recovery cylinder, LOTO resources, Big-blue.

Health & Safety requirements are paramount prior to commencing the practical assessment, you must follow instructions given by the assessor during the practical demonstration.

You will receive only one attempt for this assessment. Should your attempt be not satisfactory, the verifier/assessor will discuss the deficiencies with you. You will have to schedule and pay for a second attempt through the verifier.

Should your second attempt be unsuccessful, or you have made critical failures, you will be required to re-enrol in the theory A1 course module.

The verifier/assessor will be observing your ability to demonstrate the key skills and knowledge detailed in the observation checklist that is based on the RLNZ Safe Work Procedure and the knowledge gained in the online course module.

Critical point failure

The assessment includes “critical point” failures which indicate that you are yet competent for practical assessment. Your verifier or assessor will discuss these with you during the assessment if they arise. In this case you will be asked to cease the assessment.

17

Air-Cooled Condensers (GPG 112)

Domestic Air to Water Heat Pump Recommendations (GPG 113)

These bulletins, which are only available to IOR members, Not a member yet? Visit their membership page to find out more.

Have You Tuned in to the IOR Podcast?

Our Beyond Refrigeration Net Zero podcast channel brings you episodes on the critical issues facing the refrigeration, air conditioning and heat pump sector in the move towards net zero and engineering experts driving the change in our sector.

Listen to the episodes available at https://tipoftheiceberg.podbean.com/

IOR Fantastic Fridges

Find out about how the science of refrigeration is used in practice in the world today

http://www.fantasticfridges.com/

irhace.org.nz SEPTEMBER 2022

Guides

IOR RESOURCES IOR publishes new Good Practice

Top Tips for Installation

WALLIE ASKEW MEMORIAL WORKSKILLS COMPETITION

REGIONAL

COMPETITIONS

Four regional competitions were run across the 8 branches of IRHACE located at Auckland, Hamilton, Palmerston North and Christchurch. All competitions are run on the same day to ensure consistency and integrity of criteria. Competitors must be 3rd or 4th year apprentices who have successfully completed their third-year block course or former apprentices who have completed their training within the past twelve months.

In 2022, there were 25 contestants from across New Zealand who competed in the regional competitions and represented the following companies:

Active Refrigeration, AB Teat, Aquaheat, ATNZ, Beattie Air Conditioning, Ecochill, Excel, Johnson Controls, McAlpine Hussman, Shannon Refrigeration, Piersons Refrigeration & Air Conditioning, Temperature Control Solutions Ltd, Wellington Refrigeration and Perfect Air.

Regional winners were:

LOCATION

Auckland

Manukau Institute of Technology (MIT)

Hamilton

McAlpine Hussman

Palmerston North Active Refrigeration

Christchurch

Southern Institute of Technology (SIT)

BRANCH

REGIONAL WINNER

Auckland/Northland Jacob Newton Aquaheat

Waikato/Bay of Plenty

Manawatu Hawkes Bay/Poverty Bay

Wellington

Nelson/Marlborough

Canterbury/Westland Otago/Southland

Blake Wilkins Perfect Air

Cameron Wilson-Meek McAlpine Hussman

Wessel Bakker Piersons Refrigeration & Air Conditioning

Donated prizes for the regional competitions came from: Actrol, Cooling Equipment Ltd, Cooling Supplies, Daiken, Eurotec, Fujitsu, Lims, Monkeytoe, RealCold, Refspecs, Patton.

Special thanks to SIT, Active Refrigeration, McAlpine Hussman and MIT for hosting the event, and to the army of people who made it all happen on the night.

FINAL COMPETITION

On behalf of the organising group, we extend our congratulations to all of the 2022 contestants and thank you for supporting the regional events.

The final competition will be held at Steelfort, 500 Rangitikei Street, Palmerston North from Wednesday 26th through to Friday 28th October 2022.

Should your company wish to be involved in this event please contact Dave Nicholls, dave.nicholls@realcold.co.nz or admin@irhace.org.nz

19

TAP A TRADIE ON THE SHOULDER

2012

Ivan

Ben Barney

Ron Coenders

irhace.org.nz SEPTEMBER 2022

MILESTONES

IRHACE MEMBERSHIP

10 YEARS

(Ivica) Sever

Martin Tucker

1992 30 YEARS

Brendan Davidson 1982 40 YEARS

Kevin MacBeth

If you can talk to your colleague or friend and get them to join IRHACE, and if they do, we will reward you with a $20 discount off your next membership subscription. Help us strengthen our membership by attracting your peers!

MEMBER COMPANIES

Competenz

www.competenz.org.nz

0800-5261800

Auckland

Cool Air (2005) Ltd

https://www.coolair.nz

03-6848034

Timaru

Crawford Refrigeration 2020

Ltd

https://www.crawfordrefrigeration.co.nz

03-7684140

Greymouth

Daikin New Zealand

https://www.daikin.co.nz

09-5711101

Auckland

Degree Air Conditioning & Electrical

https://www.degreeac.co.nz

09-8270697

Auckland

Comprex industries Limited

www.comprex.co.nz 06-3239834

Palmerston North

Cooling Equipment Ltd

https://www.coolingequipment.co.nz 06-3554066

Palmerston North

Cuddon Ltd

https://www.cuddonfreexedry.com 03-5784299

Blenheim

DCP Air Conditioning

https://www.dcpair.co.nz 09-2130803

Auckland

Dobsons Refrigeration and Electrical Ltd

https://www.dobsons.net.nz 07-5730065

Te Puke

21

A-Z listing of CCCANZ companies, full listing is available from www.cccanz.org.nz

CCCANZ INDUSTRY MEETING WITH AMCA AUSTRALIA

A valued face-to-face industry meeting took place between CCCANZ and AMCA during ARBS in Melbourne. This followed an industry networking dinner on the Tuesday evening in which our Chair Malcolm Miller attended representing CCCANZ.

CCCANZ has had an MOU with AMCA Australia in the past and we are keen to work closer together as like industry associations. It was great having further discussions with Amanda Searle, National Events and Partnerships Manager and Mark Johnstone, Database and Systems Administrator.

We congratulate AMCA Australia on winning the 2022 Outstanding Industry Education/Training Award for their event Building Ventilation Summit.

irhace.org.nz SEPTEMBER 2022

Photo left: Phil Mohan, Brendan Clarkson, Gina McMaster (EO, CCCANZ), Malcolm Miller, Scott Williams (CEO, AMCA), Mark Hoskin, Garry Ko.

From left: Scott Williams (CEO-AMCA Australia), Malcolm Miller (Chair CCCANZ), Garry Ko (Treasurer-CCCANZ)

IRHACE INDUSTRY MEETING WITH AIRAH

At ARBS IRHACE met with AIRAH to strengthen ties across Australasia in the HVAC&R space.

The meeting was held at the AIRAH offices in South Melbourne and included: Paul Jackson AIRAH President, Tony Gleeson CEO- AIRAH, Brendan Pejkovic Education and Technical Services Manager-AIRAH and Matt Dillon Communications Manager-AIRAH, Mark Meyer IRHACE President, Gina McMaster EO-IRHACE, Phil Mohan IRHACE and Gary Reily IRHACE.

It was great to finally meet face-to-face after two years of Covid and to understand what issues our industry faces Australasia. We discussed key areas of our MOU with Education and Training and information exchange and publications.

We look forward to a closer working relationship with AIRAH going forward.

23

ARBS22 AIRAH STAND

IRHACE TECHNICAL EDUCATION 2022

Brought to by IRHACE our Webinar series for the HVAC&R industry. IRHACE members* receive access to webinar library as part of their membership.

*exclusions apply.

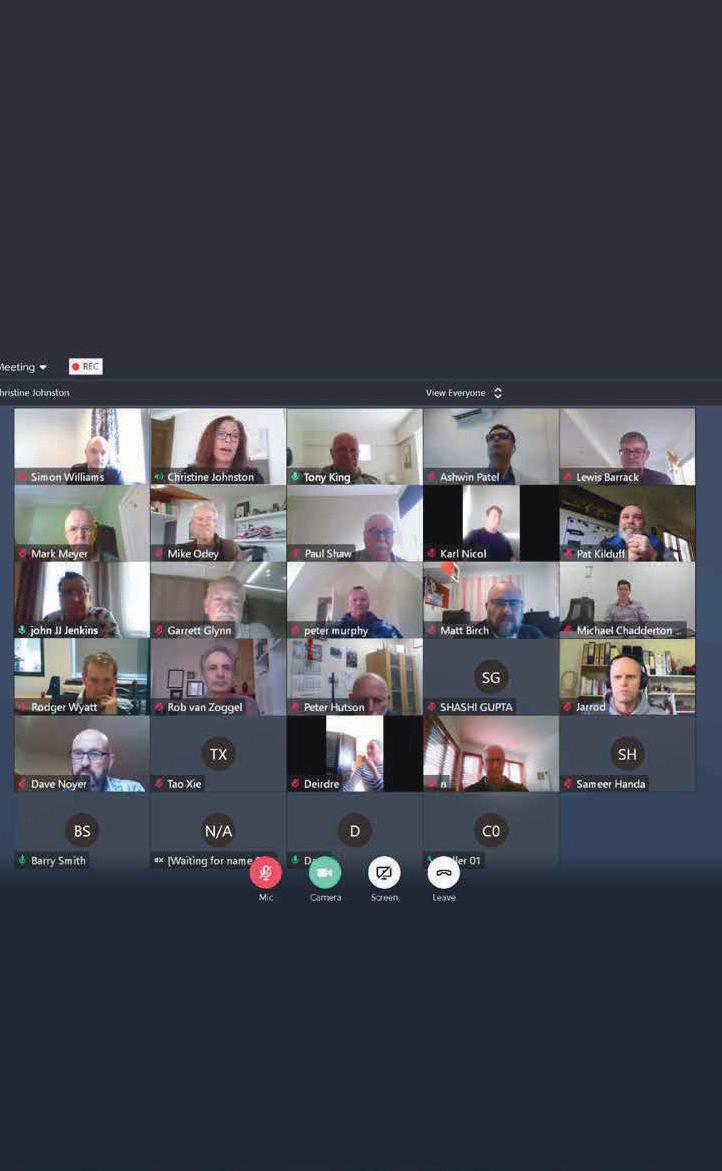

Pete Hutson from BDT speaking on Air Conditioning Refrigerants Past-Present-Future at his recent webinar in July 2022.

Only available from the Online Library

IRHACE ONLINE LIBRARY

LOGIN

Recorded webinars are available to IRHACE Members as part of their membership. If you have missed a previous Live webinar, go to the library to view.

TOPICS AVAILABLE IN ONLINE LIBRARY

· Designing with Ventilation Louvres

· Expansion work recovery (EWR)

· Air Quality ventilation and Covid 19

· The application of reinforcement for vapour compression cycle control

· Flammable refrigerants in an airconditioning application

SPEAKER SERIES 2022

NEW

Commercial Kitchen Exhaust Systems

The Rise of the Performance Solution

Presented by Sven Boloney from Air and Odour Management

Australia

Webinar follows feature article on Commercial Kitchen Exhaust

Effluent and Treatment Options

Date: T hu r sday 22nd September, 2022, 12:30 -1.30 pm

25

Novotel Hotel

Christchurch International Airport

Included in presentations material from NZ EPA giving insight on what they are thinking with respect to our carbon emission reduction plan, as well as and presenting an overview of global trends / low GWP refrigerants taking us through to Carbon Zero 2050.

irhace.org.nz SEPTEMBER 2022 REGISTER NOW

PRESENTED BY

NICHOLLS

methodology

DOOR PRIZES TRADE TABLES SPEAKERS

IRHACE Manawatu

TRADE

Thursday 27th October 5.30pm - 8.30pm Food & Refreshments available Marist Clubrooms, Arena Manawatu, 19 Pascal Street, Palmerston North admin@irhace.org.nz

DAVE

F.IRHACE Refrigeration

of Standard NZ 5149

Hosted by

Branch MANAWATU

NIGHT

CONNECT WITH US

27

HVAC&R INDUSTRY NEWS ALL IN ONE PLACE