A MATERIAL WORLD•SCIENCE MAGAZINE•MAY 2019

Letter from the editors

M

aterial breakthroughs have brought us where we are today. Without a pioneering use of Silicon, we would never have had the computer chips that are the namesake for the valley we call home. This is simply one example of a material we take for granted. Every day, we use glass cups, run in sneakers and work in libraries. Seldom do we stop to consider the unique materials that enable these commonplace activities. Glass has a unique structure enabling it to be sturdy yet malleable when heated (pg. 16). We almost never research what keeps our running shoes springy yet light (pg. 8). And we’d guess you don’t wander around the Mitchell Park Library marvelling at its environmentally friendly paint (pg. 14). This hits the heart of our mission at Veritas: Answering questions students never knew they had. We focus on a different science topic every issue. Recently, we’ve focused on big-picture topics like space and the oceans. This issue, we encourage you to join us as we zoom in on modern life on a miniature scale. – Kaitlyn and Nicole

Volume 2, Issue 3 / May 2019 Editors-in-Chief

Staff Writers

Nicole Adamson

Estelle Martin

Kaitlyn Khoe

Allison Mou

Digital Editor

Antonia Zhou

Calvin Yan

Adviser Paul Kandell

@palyveritas /palyveritas palyveritas.com

Write for us! Email palyveritas@gmail.com to be a guest writer or staff member.

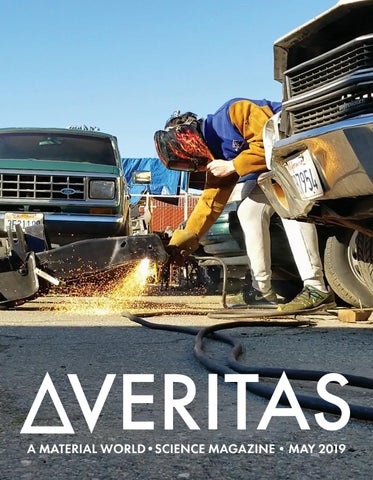

On the Cover Senior Christopher Clark uses a plasma cutter to cleanly cut metal during Auto class. High-pressured air forces electricity through a nozzle to melt the metal, according to Automotive Tech teacher Doyle Knight. Although the electric arc that is produced by this process can reach up to 40,000 degrees Fahrenheit, according to Lincoln Electric, Clark understands the necessary precautions. “Because of Auto, we are taught how to handle the equipment properly,” Clark said. “No limbs lost so far.” Photo by Kaitlyn Khoe

Letters to the Editors The staff welcomes letters to the editors but reserves the right to edit all submissions for length, grammar, potential libel, invasion of privacy and obscenity. Send all letters to palyveritas@gmail.com or to 50 Embarcadero Road Palo Alto, CA 94301. All Veritas stories are posted online and available for commenting at palyveritas.com.

Advertising The staff publishes advertisements with signed contracts providing they are not deemed by the staff inappropriate for the magazine’s audience. For more information about advertising with Veritas, please contact the Veritas business manager Allison Mou through our adviser at 650-329-3837 for more information.

Publication Policy Veritas, a science magazine published by the students in Palo Alto High School’s Magazine Journalism Incubator class, is a designated open forum for student expression and discussion of issues of concern to its readership. Veritas is distributed to its readers and the student body at no cost.

Printing & Distribution Veritas is prints three times a year in October, February and May by aPrintis in Pleasanton, California. All Veritas work is available online at palyveritas.com.

2

MAY 2019

EDITOR’S CHOICE SNEAK PEEK: In this feature by staff writer Estelle Martin, learn about the breakthroughs in the field of prosthetics. From computerized knees preventing buckling to S-glass, a newer relative of fiber glass, prosthetists at the VA hospital in Palo Alto are part of the effort to advance replacement limbs. Photo by Estelle Martin

Thank you to our generous sponsor: The office of Jeffrey Sasaki, D.D.S.

TABLE OF CONTENTS 4 6 7

Beginnings Gallery 1700s Student Innovators

8 9 10 12 14 16

Findings Shoes Architect Alumnus Prosthetics 3D Printing LEED Libraries Glass Blowing

19 20

Opinion Ballet Physics Last Thoughts

Computerized composers, 4D printing and metal art

Printed plastic and one senior’s business success

The chemistry behind a common Paly elective

BEHIND THE SCENES:

ON THE COVER T he auto shop not only holds the plasma cutting machine featured on the cover, but it is also home to an oxyactylene welding apparatus. The machine utilizes the combustion reaction between oxygen and the hydrocarbon acetylene to produce a flame that reaches about 3,200 degrees Celsius, according to TWI Global, which is hot enough for senior Sam Moore to melt bolts and separate portions of a car frame. “It’s something we don’t get to often do, so it’s an amazing experience,” said senior Claire Qiao, another Auto student who has used the technology. Photo by Kaitlyn Khoe

PALYVERITAS.COM

3

GALLERY The beauty of science in images Email palyveritas@gmail.com to have your science photos featured. Text by NICOLE ADAMSON

GREEN SEA TURTLES rarely come ashore, except to lay 75-200 eggs on the same beach where they hatched, according to the National Wildlife Federation. After baby turtles hatch, they follow moonlight towards the ocean; however, light pollution can misdirect them, leading to increased mortality. Estimates show that the population has decreased by 90 percent in the past 50 years, and Green Sea Turtles are now considered an endangered species. Photo by Kamala Varadarajan in Punalu’u State Beach, Hawai’i BADGERS dig as many as one 10-foot-deep burrow per day during the summer, according to Animal Diversity Web. Marked by a mound of dirt, burrows allow badgers to sneak up on prey. Photo by Kamala Varadarajan in Yellowstone National Park SILKMOTH wings are covered in hairlike scales in colorful patterns meant to distract predators, according to the Butterfly Conservatory. Photo by Zoe Wong-VanHaren in Little Basin State Park, California.

4

MAY 2019

FLAMES are simply extremely hot gas produced by a combustion reaction, according to Chemistry LibreTexts. When the gas atom is heated, electrons jump to higher energy levels. Then, the electrons fall back to a lower energy level, releasing energy as light. Photo by Maia Lagna in Moss Beach, California

BULBS allow plants to rapidly produce flowers early in spring. When conditions are unfavorable in winter, the plant lies dormant until temperature rises, according to Washington State University. Colorful flowers are meant to attract pollinators like bees and birds. Photo by Nicole Adamson in Palo Alto, California

PALYVERITAS.COM

5

THE SCIENCE DEPARTMENT SCOOP

FACULTY UPDATES Text by NICOLE ADAMSON

T

•STAFF CHANGES•

he administration is hiring three science teachers next year to replace two teachers who are leaving, according to Science Instructional Lead Erik Olah. Because Olah and science teacher Alicia Szebert will have reduced schedules next year due to increasing Teacher Advisor schedules, additional faculty are needed.

New Teachers • Chemistry: Michael Mishali • Biology: undisclosed • Physics: undisclosed

Leaving Teachers • Chemistry and Physics: Dunant Hin • Additional undisclosed teacher

6

MAY 2019

GLOBAL ADVENTURES Among the places future chemistry teacher Michael Mishali traveled the past two years is Timna Park in Southern Israel. “I’ve been to lots of wonderful places but my top spots aren’t really determined by the place so much as the people,” wrote Mishali. Photo by Eliza Uster, Mishali’s friend and travel companion

Teacher returns to chemistry after travels

F

ormer teacher at Jordan Middle School (currently known as Greene Middle School), Michael Mishali, will teach Chemistry at Palo Alto High School next year. From 2013 to 2017, Mishali taught eighth grade physical science. For the past two years, Mishali has taken a break from teaching to travel and visit family. “Because my job at Jordan was my first job out of grad school, I wanted to take some time to see the world and have some adventures before settling down,” Mishali wrote in an email from Bali. He says his experience abroad has enabled personal development that he hopes will make him a better teacher.

“I’m more certain of myself, my goals, my skills, my strengths and weaknesses,” Mishali wrote. “I’ve become more empathetic, open minded and flexible. ... I’m certain that all these things will help me create better learning experiences for my students.” Over the past two years, Mishali hasworked at the Ronald McDonald House in Palo Alto and visited Spain, Israel and Long Island, where he grew up. Now in Bali, his adventures continue. “This week we hiked up a volcano to see a sunrise, took motorbikes to see some rice terraces and went to a sound meditation class,” wrote Mishali. Check palyveritas.com for more on Mishali and the latest teacher updates.

STUDENT INNOVATORS

Text/Photos by CALVIN YAN

GENERATIVE MACHINE LEARNING Franklin Wang, Class of 2022, has spent the past couple years exploring generative machine learning models, which attempt to generate their own spin on products of human creativity like speech and music. His work includes synthesizing song lyrics, reconstructing three-dimensional models out of two-dimensional images and superimposing art styles on top of other pictures. Wang is quick to emphasize that much of his work is in an incomplete state. For example, despite spending two years on a program to automatically compose music, “I never really got it to fully work,” Wang says. He claims that hilarity sometimes ensues, especially with his lyrics generator’s tendency to converge to a specific phrase. “’I’m never gonna give you up; I’m never gonna let you down,” Wang reads from one of the program’s outputs, but eight lines later has it “just repeating ‘I want to be a little girl.’”

4D PRINTING While 3D printing has become a household phrase, the bleeding edge of additive manufacturing is one step — or rather, one dimension — ahead. According to senior Kaushik Seshadri, not only does 4D printing seek to produce an object with any desired three-dimensional shape, but one which, when exposed to an external stimulus, achieves a different shape at a different point in time. A combination of the right material and the right stimulus is required for such an effect. Seshadri, who is studying the newly developed process for his Advanced Authentic Research project, is working to find existing combinations. “I have one model that uses an alloy of nickel and titanium, which bends when you heat it,” Seshadri says. Because the cost of 4D printing technology limits more intensive exploration, Seshadri has reached out to industry leaders at the National Aeronautics and Space Administration and Massachusetts Institute of Technology to understand the technique.

CALCULATED ART Senior Dion Li holds an anodized metal knife. Although it may look painted, the coloration is in fact part of the surface of the metal, which was made from the process of anodizing. Typically, aluminum is anodized by placing it in an aqueous solution with another piece of metal and connecting the two solid metal pieces with a wire outside of the solution. When a current passes through this new circuit, electrons are forced off of the electrode, and they are deposited on the aluminum surface. This gives the metal surface its endearing appearance.

PALYVERITAS.COM

7

Findings Text by ALLISON MOU Art by MAYA ANDERSON

Flyknit upper

First layer of ZoomX foam Carbon fiber plate

Second layer of ZoomX foam

CROSSING THE LINE

A

Nike Vaporfly 4% energy return claims

MID THE DUST being kicked up by the runners, John Tayeri, senior captain of the cross-country team, emerges over the crest of the hill, triumphant, wearing a pink headband and neon orange running shoes, the Nike Vaporfly 4%. When these $250 shoes were unveiled in 2017, they were released with a Nike-sponsored peer-reviewed journal article claiming that the shoes gave runners a 4% increase in running economy compared to an Adidas marathon shoe. Wouter Hoogkamer, a postdoctoral researcher at University of Colorado, Boulder, and one of the researchers involved in the original Nike sponsored study, makes an important distinction on what exactly the 4% refers to. The “4%” in the name refers to a reduced energetic cost of running, rather than a 4% increase in speed, according to Hoogkamer. Researchers measured oxygen consumption while running, allowing them to calculate burned carbohydrates and fatty acids.

8

MAY 2019

Using this information, they were able to calculate the amount of energy the runners were using when running in different shoes. The researchers concluded that the Nike Vaporflys reduced the runner’s energetic cost by 4% as compared to other shoes. The “4%” claim has been verified by both an independent New York Times analysis and an independently funded study by Grand Valley State University, which also included women, unlike the original Nike funded study. Notably, studies show that energy economy affects race speed proportionally, although they are not interchangeable. After initial skepticism regarding the claim, attention in the running world shifted to how the shoes increased performance. According to the Nike website, the shoe boasts a “full-length carbon fiber plate [that] feels like it’s propelling you forward.” Due to Nike’s marketing, most thought this carbon plate was thought to act somewhat like a spring, skirting the line between a shoe and a propulsion device, and drawing calls to ban the shoe in competition.

A little more than a year after their mass-market release, Hoogkamer released a follow-up study examining the cause of the metabolic savings of the shoe. There is not one specific technology the shoe uses to whcih the increase in economy is attributed. Differences in ankle movement, partially due to the carbon fiber plate, seem to partially contribute to the 4%, while the bouncier foam delivers slightly more energy return. Though neither carbon fiber plate nor the foam are individually responsible for the significant energy return. “It’s not just one plus one is two,” Hoogkamer says. “They seem to work together very nicely where it’s more like one plus one might be three.” Tayeri wore the shoes in two races this season and enjoyed the experience. However, because he works at Fleet Feet, a running store in Menlo Park, he bought the shoes at a discounted price. “Usually, one of the trade offs of a cushion shoe is it’s much heavier, but [when wearing the Vaporfly 4%] I only felt like I was being sprung off the ground,” he says.

Findings Text by CALVIN YAN

Art by JENNIFER XU

BEYOND THE BLUEPRINT Architecture major and Paly alumnus talks shop

A

“It [architecture] is all LASER CUTTER. 3D printers. Foam board for about working within parameprototyping. A computer numerical control maters, whether that’s like a budchine for fabricating metal. To many, the imagery get or tectonics [earthquake is evocative of a factory or machine shop. To Ehepreparedness], et cetera,” Ricatl Rivera, Palo Alto High School Class of 2018, it is more vera says. “The question beevocative of his homework. comes ‘How do you take these As a freshman major in architecture, Rivera pursues a field [traditional] materials and rework them so of study more in line with the high-rises of New York than the that they last longer and are stronger and have high-tech of the Bay Area. It is for this reason that these qualities that are Rivera studies at the Pratt Institute tectonically necessary?’ in Brooklyn. There, he found his exand I think that’s where pectations of architectural study chalthe innovation really lies.” lenged and eventually reformed. The cutting edge of the “You come into Pratt with these architecture industry, where preconceived notions that you’re going additive manufacturing has to be building these giant projects and increasingly made inroads, houses,” Rivera says, “but once you actakes a more experimental tually arrive here, it becomes about the approach. Leading the effort, use of space.” and capturing headlines in the His entry level courses, for example, process, is the West Coast archimade frequent use of architectural drawtecture firm Emerging Objects. ings without expecting them to be realized in The Cabin of 3D Printed Curiosities, the third dimension. considered their flagship work, is built “The idea is that they’re really trying to from printed ceramic tiles—which are break down the way you think spatially,” Rivera combined with materials as diverse as grape says. skins and sawdus—and specially designed to alAs freshman year progresses, Rivera says that the funlow the cultivation of plants on the room’s exterior. damentals give way to a wider selection of courses. The company’s founders, architecture profes“For example, there’s this set of classes called Morphology, sors Ronald Rael and Virginia San Fratello, don’t limit which is all about the study of form,” Rivera says. “Within that, themselves to exercises in innovative housing.They’ve printthere’s a huge variety of materials people are using, like balloons. ed coffee cups from coffee grounds and study You wouldn’t think that would be something to models from salt. be considered in architecture at all.” Back in the halls of the Pratt Institute, RiTechnics courses, by contrast, bring a math“It [architecture] is all vera says that older students are given room to ematical perspective to architecture by exploring about working within paexperiment in the same vein as Emerging Obthe tectonics or earthquake resistance, of material jects. systems. rameters, whether that’s “As you transition to second year and on“There’s a lot of experimentation, so we were like a budget or tectonics.” wards towards your thesis [at Pratt], pretty constantly building models and breaking them,” much you’re strictly only using 3D printers,” — EHECATL RIVERA, Paly alumus Rivera says. Rivera says. However, he emphasizes that such experiSo much so, he adds, that a team of thirdmentation is the exception, not the rule. Much of years has devised a method of printing concrete in a 10-by-10-foot his work remains grounded, using a set of mundane and well-estabspace. lished materials. “The direction I would really look towards would be … how you take old and commonly used materials such as wood or concrete and SCINTILLATING SCIN, an architectural materials consulting firm, asked a small group of designers to showcase their design thinking though the rework those towards making them more efficient.” As an example, Rivera cites experiments with materials from production of a small cube. Emerging Objects recreated one submission, ilcarbon nanotubes to carrot extract, which, like rebar, can be used to lustrated above, using layers of a 3D-printed cement polymer that increase in thickness as they reach the edge of the cube. improve concrete’s resistance to damage.

PALYVERITAS.COM

9

Findings

SOCKET Polypropylene Stress and crack resistant

PROSTHETIC PROGRESS Material developments in artificial limbs

KNEE Contains Computer Chip

Text by ESTELLE MARTIN

T PYLON Aluminum or Titanium Lightweight metals

FOOT Polyurethene Foam Absorbs energy Art by HANNAH LI NOTE: The materials shown here are only examples of various materials found in prosthetics. Each prosthetic is custom made based on an individuals needs and preferences.

10

MAY 2019

HE PROSTHETICS LAB at the Palo Alto Veterans Affairs Hospital is a stark contrast to the surrounding building. Outside the doors of the lab, ordinary, sterile waiting rooms bustle with patients and family members. Inside the Prosthetics Lab, however, many of the rooms resemble a machine shop, including one caked with cream white plaster from floor to ceiling. It seems that everywhere, spare plastic limbs are tucked into shelves. Showing me around is Chris Chandler, a certified prosthetist and orthotist at the VA Hospital. He is quick to show me various artificial limbs and devices perched on window sills and leaning against walls as we walk towards the main room of the lab. In my hand is a black upper portion of a prosthetic leg — the socket. The outside shell is hard and seems unbreakable, but my fingertips sink into the soft silicone lining on the inside, a testament to the diverse types of materials in a single prosthetic. Career of service Chandler began working for his uncle’s prosthetics business at age 15, motivated by the prospects of buying video games with the money he earned, he says. Quickly, Chandler realized his natural skill in the field and continued to study prosthetics, artificial devices that replace missing limbs, and orthotics, artificial devices to help structure or support the body, in school. Chandler says many amputations are a result of diabetes. The disease often causes the constriction of blood vessels in the lower extremities, according to Mayo Clinic. This effect, in combination with reduced nerve sensation, can lead to infections of wounds that go unnoticed. Since blood cannot reach the wound, it is unable to heal and, in some cases, the affected

Findings

limb must be amputated to avoid risk of spreading infection. More than 23 million adults in the United States suffer from diabetes, according to a 2017 report by the Center for Disease Control and Prevention. With increasing prevalence of diabetes, there are increasing efforts to advance the field.

of magnetic fluid in the knee,” states the website of Össur, a prominent prosthetics manufacturer. “Thus, RHEO KNEE 3 is capable of shifting almost instantaneously from the high resistance required for stability in stance phase to the low resistance needed for a dynamic, free-swing phase.”

Advances in materials Computerization After 28 years of work experience, Chandler has witChandler says an increase in prosthetic computerization nessed a rapid evolution in prosthetics and orthotics; the field has transformed the field and will continue doing so. is often years ahead of other industries when it comes to the Before integrating electronics into artificial limbs, Chanuse of new materials. dler says that the industry had been unable to make much sub“We were one of the first industries to adopt carbon fiber stantial progress, since mechanical methods are limited. when it was still pretty much an aerospace-only technology,” “We were kind of hitting that point in prosthetics where Chandler says. “When the rest of the country had only just we needed more of a computer-controlled system that could heard of carbon fiber, the prosthetics field was already using do more functions,” Chandler says. “Prior to that, we hit pretty it regularly.” much every body function you could do Increasingly, the field has [without it].” “When the rest of the country had been using S-Glass, a fiberglass Now, with computerized limbs, a found in helicopter blades. Fionly just heard of carbon fiber, the person can walk backwards without the berglass is a type of plastic that prosthetics field was already using fear of their knees buckling — a common utilizes glass fiber for reinforceconcern with mechanical limbs. Rathit regularly.” ment. This material is known for er than using methods such as loaded its strength and ability to with— CHRIS CHANDLER, Certified Prosthetist springs, these limbs contain sensors and stand breaking under high tenpersonalized motors. These devices can sion while being more flexible then process incoming external stimuli compared to carbon fiber, according to Chandler. and adapt its response movement. Chandler emphasizes that the materials of different parts Upper limb extremities are also experiencing new breakof an artificial limb are dependent on the point it touches on throughs: better grasping patterns and individual finger mothe body. There are pressure-sensitive areas that require soft- tors. Previously, artificial hands could only slightly open and er materials, like silicone, while pressure-tolerant areas can close, which limits task performance. As a result, those who withstand firmer plastics. required a prosthetic hand often chose to use hooks instead. An even newer material used in prosthetics and orthotics is magnetic fluid, which can only be currently found in two Looking ahead Chandler says the field has yet to fully incorporate prosthetic products, according to Chandler. “It [magnetic fluid] is a hydraulic fluid [liquid that op- everything that computerization has to offer. Studies are erates machinery through movement], filled with a bunch of currently being conducted on neural surgical implants that metal shavings inside of it. When you apply a magnet to the process impulses from the brain and then transfer that influid, it becomes hard as a rock. When you take the magnet formation to an artificial limb. This could potentially allow many paraplegics and quadriplegics regaining their ability away, it turns into a fluid again,” Chandler says. The fluid is used globally, from shock absorbers in tall to walk, or those with lost limbs being able to have robotic skyscrapers to the suspension in high end sports cars, accord- limbs that match the full function of their original appending to Chandler. The advantage to the material is that it can be age. While the industry is taking great strides with the use fine tuned instantaneously with a magnetic field. Magnetic fluid is now used in electronic knees, which fea- of computerization and complex materials like S-Glass tures a cylinder containing many disks with the fluid floating and Magnetic Fluid, Chandler emphasizes the importance of continuing research in the field. For now, you can find in between. “This proven MR [Magnetorheological Fluid] technolo- Chandler working away every day in his workshop at the gy utilizes electromagnetic force to rapidly alter the viscosity VA, helping people get back on their feet.

PALYVERITAS.COM

11

Findings

Text by NICOLE ADAMSON and KAITLYN KHOE Photos by KAITLYN KHOE

FINE PRINTS

Plastic properties and innovations PRINTS ON PRINTS Founder of Vora’s Hub, Ria Vora has printed a myriad of projects for herself, including puzzle prisms as part of a promotional tactic, a mini model of The Gherkin skyscraper in London, England and her business cards. “I ended up learning that in order to sell yourself to customers, you need to be sure about yourself and present the product in a [certain] way,” Vora says. FILAMENT FLOSS Vora holds up excess filament produced when a 3D printer transitions betwen different colors of printing material. “I got the printer because I wanted to print things around the house [and] make things by myself,” Vora says.

12

MAY 2019

A

SMALL BLACK BOX ZOOMS AROUND, depositing thin strings of molten plastic on a growing structure, layer-by-layer. Like a regular printer, a 3D printer can fit on a desk, hums as it prints and is susceptible to clogs. Palo Alto High School senior Ria Vora founded Vora’s Hub, a 3D printing company based on this technology, in 2016. Clients send in their 3D-printable files, and Vora uses her 3D printer to construct the desired object. Some clients use the service to make prototypes for their start-ups, and others get customized Settlers of Catan pieces for game night. Unlike other production methods, 3D printing allows for plastic to be made into shapes with intricate systems of holes, as well as highly detailed surfaces. Vora considers the unique properties of each type of plastic such as flexibility, durability and transparency for her prints. She

Findings uses two main types of filaments: polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). “PLA is this type of plastic that is a little bit more brittle and thin, but it is food safe and does not smell when it prints,” Vora says. Since PLA filament is made from organic resources such as corn starch or sugarcane, it is commonly used for bioplastics like biodegradable cups, according to 3D Hubs. It prints at a lower temperature than ABS, the material used for LEGOs, which makes PLA a popular printing material. However, ABS has a higher ductility, or ability to stretch under stress. Although ABS has a higher heat resistance, it can emit harmful fumes, so it is often used industrially for prints where strength is crucial, according to Vora. Recently, Vora has experimented with PolyWood, a type of plastic designed to appear like wood and with a similar density. She has also tried to use a water-soluble plastic known as polyvinyl alcohol (PVA) in her 3D prints. Often, when hot plastic is printed on its own, it will slump over if it is unsupported. This is where water-soluble materials come in. The water-soluble material is printed from one of the two nozzles on the printer to make supports, and the main plastic is printed from the other. The finished product can then simply be rinsed under a faucet to dissolve the supports. As a member of the 3D printing industry, she often attends conventions to learn more about these innovations. Vora says that there, she acquires sample plastics and meets others with similar interests.

Business Forward

Originally, Vora purchased the printer for personal projects and to make gifts, and she founded the printing business to recoup the cost of the printer. She works with other seniors including Zage Strassberg-Philips and Acacia Lung, who helped build her website and manage the company, respectively. Vora’s Hub is part of a network of 3D printers called 3D Hub. People looking to print a 3D file can search for a company on 3D Hub that fits their needs. Users then rate the companies, so customer satisfaction is key. “It’s [Vora’s Hub is] helpful for start-ups because prototyping is super expensive when they have to create a mold for every single [part],” Vora says. “Having an accessible 3D printer … makes it more affordable.” At its peak, Vora’s Hub received up to four orders per week, but because of her increasingly hectic schedule, Vora has temporarily stopped printing. Although Vora does not plan to continue to run her business from college, she hopes to use the skills she has learned. She plans to pursue computer science in college, and this business has helped her become comfortable with 3D printing — an important application of programming — as well as entrepreneurship skills. “Now I know how to take any idea that I have and plug it into any 3D printer — whether it’s the one at home or one at a college campus,” Vora says. The chance to run a business has also instilled Vora with confidence, and she has observed how the 3D printing world has grown. “I started four years ago when there was barely any information out there about commercial 3D printing” Vora says. “The 3D printing handbook was not out, [so] I would look up how to fix clogging problems for this specific printer ... and I wouldn’t find [answers]. It was so much trial and error. Now if you were to look it up, you would find a million results, and that is insane.”

•3D PRINTING BASICS• 1. The nozzle heats up in preparation to melt PLA, which requires a temperature around 200 degrees Celsius, according to Vora.

2. Customers send files to her that are often designed in tinkerCAD, an intuitive, cloud-based software.

3. Spools of different plastics attached to the back of the printer feed into the printer’s extruder.

4. The printer works layer-by-layer to squeeze out plastic, which could take hours to complete.

PALYVERITAS.COM

13

Findings Text/Photo by CALVIN YAN

LEED-ING THE EFFORT

Local libraries set the standard for environmental sustainability

A

COLD BLAST OF AIR and muted, sterile odor mean little more than a welcome respite for library-goers on an unseasonably hot Friday afternoon. Yet to Valerie Tam, a 28-year-old engineer with the City of Palo Alto Public Works Department, they represent countless hours of planning and construction, the products of which she points out like exhibits at a museum, such as the windows with environmentally friendly sealant and external water-based cooling system. These features were part of a coordinated attempt to maximize the Mitchell Park Library's sustainability. For its careful employment of green materials, ranging from stone recycled from quarries to wood sourced from sustainably managed forests, the facility received a Platinum certification in Leadership in Energy and Environmental Design. Such a distinction requires construction managers like Tam to leave no stone unturned, with seemingly mundane choices in carpeting, temperature regulation and lighting yielding opportunities for environmental optimization.

Volatile compounds

SEAL OF APPROVAL A pillar outside the entrance to the Mitchell Park Community Center enshrines the building’s LEED Platinum status. It earned more than 80 points out of 110 on the certification scorecard for its various sustainability features. “LEED platinum is actually the highest honor you can get … then it goes down to Gold, Silver and Certified,” Tam says.

U.S. G RE

CIL

LEED

UN

MAY 2019

O

14

C

The new car smell is a commonly dis- thing that’s present in your building. LEED cussed phenomenon, but its potential health focuses on trying to lower that emission.” risks garner less acknowledgment. SustainFinding non-emitting alternatives to ability architects, Tam says, must deal with common building components is key. Tam something similar — a new building smell, finds one such example in a mounting board so to speak. on the wall of an indoor reception area. The underlying principle is the release “You want to have no urea formaldeof volatile organic compounds. The Environ- hyde — that’s a resin used to bind particle mental Protection Agency classifies these board,” Tam says, gripping the board with compounds, abbreviated as VOCs, as her fingers. any carbon-based substance that is L D I IN BU Fly ash concrete chemically volatile, meaning it G N E Concrete's earliest use vaporizes below 250 degrees dates back to the Egyptian Celsius. According to Tam, empire, according to the RoyVOCs are most commonal Society of Chemistry. Yet ly emitted from things like the grey façade that greets paints and adhesives, meanpatrons of the recently rening that everything from novated Rinconada Library diffresh carpets to countertops fers from the concrete of old. can hamper indoor air quality. This difference lies in the use “VOCs are actual particles in of fly ash, a waste product from coal-fired the product that become emissions,” Tam says. “It’ll fade over time, but it is a constant powerplants. Fly ash is cementitious, mean-

ing that it possesses cement’s ability to hold rocks together. “When you’re using cement, you can use a percentage of fly ash as recycled material,” Tam says. The Portland Cement Association lists fly ash as a pozzolanic material, meaning that its binding properties are activitated by products of aging concrete and allows concrete’s binding to effectively replenish itself. Despite the exhaustive measures the library has taken to merit certification, the LEED standard marches on. Mitchell Park obeys version three of the standard. A fourth version was released before construction could finish. “LEED challenged the status quo with the concept that buildings actually function as living, breathing organisms,” a spokeswoman explains in a video revealing LEED version four.” It intends to continue this trend well into the future, and civil engineers like Tam are taking notes.

Go to college for free!

Learn how at foothill.edu/promise • Free tuition • Up to $1000 for books • Unlimited rides on VTA public transit

SUMMER C AMP 2019

CAMPAMENTO DE VERANO 2019

MIDDLE AND HIGH SCHOOL

SECUNDARIA Y PREPARATORIA

Join us at Foothill for a summer of science fun and hands-on learning.

Acompáñanos en Foothill para un verano de diversión con la ciencia y aprendizaje práctico.

• Chemistry of Cooking • ECOAdventures • Animation • Robotics, and more!

• La química de la cocina • Adventuras de ECO • Animación • Robótica, ¡y más!

June 17 - July 19

17 Junio -- 19 Julio

Registration now now o open! pen!

¡Las inscripciones están abiertas!

Check out all the classes at

foothill.edu/sli/stemcamp.html

Hay becas disponibles

foothill.edu/sli/stemcamp.html

Scholarships available

PALYVERITAS.COM

15

Findings

ALL ABOUT THAT GLASS

The material behind the class

S

HAPING SCALDING HOT glass with confidence, Palo Alto High School sophomore glassblower Eli Crystal begins the steps for his twisty canes. These twisty canes start with four short purple rods, lined up on a ceramic plate and slid into the gloryhole, a small reheating furnace. The rods are then painstakingly melded into a plate. When the colored center is deemed hot enough, Crystal pulls clear glass out of the furnace, where it is kept at 2300 degrees Fahrenheit. In its molten state, the glass glows a bright orange and is stringy. Maintaining consistent temperature is critical in glassblowing because of its poor heat conductivity. If the outside of the glass touches something cold, it shrinks slightly. However, the inside is still warm, generating stress in the glass that can cause cracking. The metal poles used to gather glass are kept over open flame, so both the metal and the glass aren’t shocked with a dramatically different temperature. Alternating rolling with heating, Crystal forms a base and attaches the plate. The glass cools from a hot orange to a duller red. What follows is a process of gathering, molding and reheating until the glass forms a symmetrical cylinder. Crystal and his partner sophomore Tucker McBride pull the cane apart with a twisting motion, careful not to let the rapidly cooling glass touch the cold cement.

16

MAY 2019

The pulled cane is laid over a flat wooden ladder, the top charred black from previous projects. In 50 minutes, Crystal and McBride have turned viscous glass into a six-footlong clear pole. In the center, the former purple rods have twisted into long strips spiraling up and down the entire length; the helix inside looks vaguely like DNA. “I feel glassblowing is more technical and physical than traditional art, and that’s why I like it,” Crystal says. Glass is a highly versatile medium. Its trademark properties come from its random molecular, or amorphous, structure. Because of this, the definition of glass is much broader than its classic use. In fact, even some hard candies are considered glass. “Every specific kind of glass discipline has a specific recipe,” says ceramics teacher Steven Ferrera, who has more than 22 years of glassblowing experience under his belt. “The formula for soft glass and glass blowing is a little bit different [than other glass].” Typically, the glass used in glassblowing is a “soft glass” or silica glass. It retains its malleability much longer than industrial glasses like borosilicate, which makes up the beakers and flasks used in laboratories because of its extreme durability. This property comes from the addition of boron. The manufacturing of glass is a complex process of balancing materials and trying to retain glass’ essential properties.

Text by ANTONIA ZHOU Photos by KAITLYN KHOE Silica, which composes 70 percent of glass, goes by several names. Technically, it’s silicon dioxide. In layman’s terms, it’s quartz, silica and sometimes just glass. Silica contributes to the stability of glass and increases glass’ melting temperature. To reduce its melting temperature, manufacturers add sodium carbonate. However, adding sodium carbonate causes the resulting product to be water soluble, which is less than ideal in a building material. To counteract this property, manufacturers also add lime, or calcium oxide. Although the skill of glassblowing will remain relevant, the future of glass art might drift in the same direction as many other industries — towards 3D printing. In 2015, Massachusetts Institute of Technology’s Mediated Matter group introduced its take on 3D printed glass. Instead of printing with a glass powder like previous experiments, the Mediated Matter group used molten glass, enabling a greater control over shape and color. MIT’s scientists envision their printer, called G3DP after “Glass 3D Printing,” as a bright future for optical lenses. Their glass carries the durability and transparency of industrial silica glass, without the brittle, crumbling properties of earlier attempts. “I’ve seen people — normal people, not scientists — 3D print glass,” Ferrera says. “The technology is there. If somebody wanted to and was proactive enough to figure it out, then it’s totally possible.”

Findings LEFT PAGE The gathered, clear glass wrapped around the purple center is lifted into the gloryhole. The glass taken out of the main furnace must be kept hot in order to retain its malleability. BOTTOM A shelf in the ceramics classroom displays older cane projects, both twisty and solid color. LEFT Sophomore Eli Crystal molds what will become a six-foot-long glass cane. The center looks red hot, but it will cool to a dark purple. BELOW Canes like this one can later be incorporated into other projects.

PALYVERITAS.COM

17

Opinion Text by NICOLE ADAMSON

MORE TO THE POINTE

Ballet through the lens of rotational physics

P

RACTICING TURNS EVERY DAY during ballet class, I never really considered the physics behind the technique of turning en pointe. That changed last semester when we learned about angular momentum in physics. In the demonstration, a student sat on a spinning stool with outstretched arms and spun even faster when he brought his arms closer to his chest. Our teacher explained why: Momentum is the product of mass and velocity and represents how difficult it is to stop an object from moving. Similarly, angular momentum is the difficulty associated with stopping a spinning object.

moment of inertia

angular velocity

Angular momentum is unchanged unless an external torque acts on the spinning object. In the case of ballet, the only external torques come from air resistance against the spinning dancer and the friction between the floor and two square inches of satin on the tip of the shoe. In both of these cases, this force is negligible, so for practical purposes, angular momentum is conserved after the dancer has pushed off of the ground and is spinning. Initially, the turn starts with arms outstretched, and then the dancer pulls them in. Bringing the arms closer to the axis of rotation decreases the moment of inertia (rotational equivalent of mass). As a result, angular velocity (speed of turning) must increase to keep the angular momentum constant. After years of ballet training, I understood what made me turn faster or slower. Now, I have a scientific explanation for why I am able to turn around multiple times without landing on the ground. CALCULATED SPINS Menlo Atherton senior Tara Elingson practices pirouettes. The bent leg is used to push off of the ground to generate torque. Photos by Kelly Lim, photo illustration by Nicole Adamson and Hannah Li

18

MAY 2019

LAST THOUGHTS Science comics

WHERE THE WILD THINGS GO

Text/Art by KAITLYN KHOE

WHILE ON THE WAY TO SCHOOL...

WHO TO CALL?

Y

ou veer into the bike lane, and as you frantically pedal your legs in that familiar circular motion, a lump appears in the way. You swerve around it, casually looking back, only to find the pelt of a squirrel, softly resting on the ground. You would remove it from the road, but you don’t know who to ask or where it’s supposed to go. Most Palo Alto residents — especially the students biking to school daily — see dead squirrels a couple of times each year, smushed into the pavement. Although the next time they folllow the same route, they may come across the same spot expecting a body but find only a cleared road. Where do these squirrels magically vanish off to, you ask? The responsibility rests upon Palo Alto residents to call and notify the Animal Services Division of the Palo Alto Police Department, which removes the many remains from the road. In 2017, they took in 642 wild animals that were either dead or required a humane euthanization, according to Officer Cody Macartney. “If someone is driving by it [animal remains] and thinking ‘Oh, somebody else will call, somebody else,’ it could stay there until that somebody else calls,” said William Warrior, Senior Animal Control Officer. Once Animal Services is notified, an officer will pick up the carcass and bring it back to the shelter. While beloved pets may be cremated, unclaimed wild or domestic animals, like squirrels, get stored in a refrigerator located on the outskirts of the building. Two metal barrels on the left of the fridge hold the remains of some animals while others are spread across a cart, prepared for cremation. The barrels get emptied by a dump-truck-like vehicle from the San Jose Tallow Company that whisks away the animals to a rendering plant. “They’re [the animals] essentially recycled,“ Warrior said. “[The plants are] essentially facilities that are boiling any unclaimed dead bodies down into bone meal, blood meal [a type of fertilizer] and high protein chicken feed.” If you find a lingering body on the way to school or you have any other concerns about animals, call (650) 329-2413, even it it is a presumed mountain lion that turns out to be an orange tabby cat.

HOW YOU FOUND IT...

THE NEXT DAY

BEHIND THE DISAPPEARING ACT

THE WHO THAT CLEANS UP OUR MESSES...

THE MESSES THAT ARE PICKED UP

DROPPED OFF AT A RENDERING PLANT AND RETURNED TO EARTH’S RESOURCE CYCLE

FERTIL

IZER

FOR THE UNCLAIMED

PALYVERITAS.COM

19

EDUCATION IS for LIFE register now! PAAdultschool.org (650) 329-3752

PALO ALTO ADULT SCHOOL

Comprehensive College Advising and Personal Statement Consultations Contact Beth: beth@peninsulacollegeadvising.com

Raftrey College Advising Supports Student Journalism

— Summer quarter begins June 10th — Art / Crafts / Career Gardening / Health & Fitness / Music Upholstery / World Languages www.johnraftrey.com

NEUROSCIENCE SUMMER CAMPS

• At Stanford University • For middle school & high school students • July 8 to July 26

Learn about: • Cells & Molecules • Cognition & Behavior • Brain Scans & Technology

CHECK US OUT/ ENROLL: ApogeeEdu.com EMAIL: inquiries@ApogeeEdu.com