In this fifth edition of the Trouw Pet Nutrition Outlook, experts Scott Buchwalter, Senior Quality Assurance and Laboratory Manager; Ryan Hicks, previous Director of Quality and Food Safety; and Tom Best, who returned to his role as the Director of Quality and Food Safety for Trouw Nutrition; explain the complicated processes, analyses and technology that comprise a sophisticated quality control program that includes an average of 101 checks for every pet premix.

With over 25 years’ experience managing ingredients, Buchwalter directs Trouw Nutrition’s laboratories and oversees the company’s extensive Item Supplier Assessment & Management (ISAM) program, thoroughly validating every new supplier, reviewing all incoming ingredients, and supervising customer audits.

Buchwalter holds a Bachelor of Science in Analytical Chemistry, an associate’s in Pharmacy Technology, and an associate’s in Education and Training Management. He attained certifications in Advanced Hazard Analysis and Critical Control Points (HACCP) and Current Good Manufacturing Practice and Regulatory Compliance (cGMP & RC), as well as training in internal auditing.

At the start of his career, Buchwalter oversaw Trouw Nutrition’s quality and regulatory program for the U.S., developed

standard operating procedures (SOPs) for the plants and labs, and initiated the development of a laboratory information management system (LIMS) and nearinfrared (NIR) spectroscopy testing.

Hicks then joined the team and brought these programs through to fruition by providing the unique programming of the LIMS, named Lab RetrieverTM, and by introducing the fingerprinting and discriminant analysis technique that serve as the backbone of Trouw Nutrition’s NIR spectroscopy testing program. Drawing on more than 10 years’ experience in quality, he also initiated and built the company’s energy dispersive X-ray fluorescence (EDXRF) testing program.

Through Hicks’ leadership of the quality program for Trouw Nutrition’s U.S. operations, both the Highland, IL and Neosho, MO premix plants achieved Safe Quality Food (SQF) certification. In addition to a Bachelor of Science in Chemistry and a Master of Science in Analytical Chemistry, Hicks earned certifications as a Preventative Controls Qualified Individual (PCQI), HACCP coordinator, and National Animal Supplement Council (NASC) cGMP training, among others. Hicks recently took over as the Director of Sales to bring his knowledge and expertise deeper at the customer level.

Best brings over 38 years of experience in the pet food and animal feed industry, drawn from roles in many different areas. He started his career in the silage bagging industry, revolutionizing how to manage silage quality. Transitioning to liquid feeds exposed him to many aspects of how ingredients interact when blended and how important sequencing of ingredients can be. In the mid ’90s, he started working with dry feeds, concentrates and premixes, including dispersible premixes.

Best started his Trouw career managing all aspects of Trouw’s chelated trace minerals: operations, quality, regulatory, and international and domestic sales and marketing. He mentored with the founder of Optimin® Organic Trace Minerals, Dr. Fred Madsen, and the two revitalized the Optimin product line. In his 16-year tenure with Trouw Nutrition, Best has been the Optimin Product Manager, Manager of Regulatory Affairs, Director of Health Safety, Environment and Quality (HSEQ), Commercial Livestock National Sales Manager, and Director of Quality and Food Safety. He has served on the global Quality Platform for Nutreco, as well as the global HSE team.

Now let’s explore the intricacies of pet premix quality control with Buchwalter, Hicks and Best.

Most pet food manufacturers and premix suppliers only use wet chemistry to analyze product consistency and uniformity, but near-infrared (NIR) spectroscopy analysis provides a quicker, non-destructive method without producing hazardous waste or requiring chemicals or consumables.

Historically, quality teams often utilized manual sieve testing to measure particle size. This process typically includes passing a sample through a series of sieves, shaking the sieves with a machine for 5-10 minutes, weighing each sieve and computing the percentage passed through each sieve. The process can take quite some time, especially if performed on every incoming raw material.

Thankfully, research shows that NIR analysis, a much quicker form of analysis, is an effective alternative for manual sieve testing. Studies consistently find particle size expressed throughout the whole spectrum with combined color/NIR regions yield the best predictability of particle size.

Conducted with a rapid content analyzer, NIR spectroscopy analysis measures the

absorption of light, or lack thereof, of organic bonds, making it an excellent quality assurance method for analyzing organic compound-containing vitamins, proteins, liquids, fat, starch, cellulose, carbohydrates and glucose. However, inorganic material, such as minerals, are not as easily identified with NIR analysis.

Many chemometric techniques, such as multiple linear regression (MLR), principal component analysis (PCA), and partial least squares (PLS), successfully extract the correct information from NIR spectra.

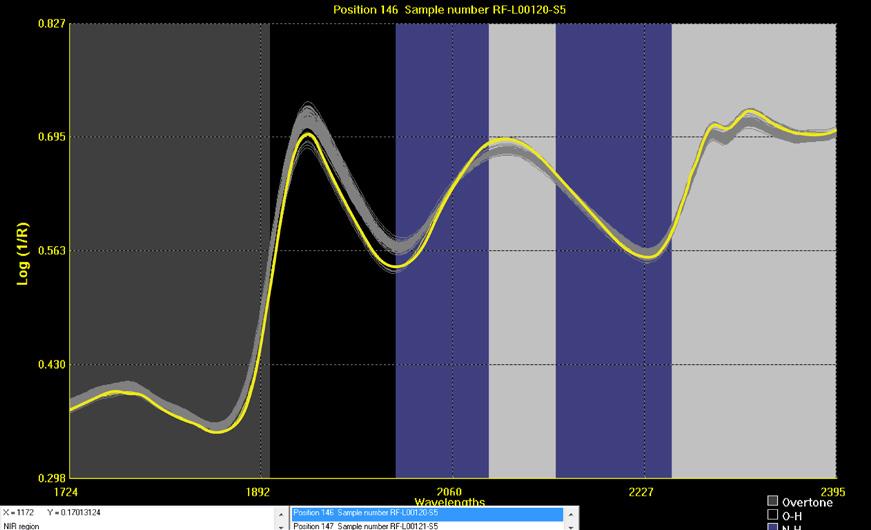

Another such method, discriminant analysis, takes the NIR spectra results of a single sample and compares it to the comprehensive collection of historical data. Through this comparison, lab technicians can discern if and where the

sample deviates from the accepted “norm” established by the data.

In order to account for all expected variations, such as sample consistency, seasonal changes, and multiple suppliers, the historical data set needs to include a library of spectra collected over at least a few years to produce a successful calibration. Trouw Nutrition’s database, for example, is built on 10 years of data collected across multiple locations. With a robust library, a calibration model optimizes specific settings for wavelength region, scatter correction, math treatment and regression for optimal results.

Variations in the data could be a sign of potency abnormality, particle size inconsistency, color variation, contamination or raw material sourcing differences. NIR testing can also serve as a method for vetting a new supplier by comparing different samples

The NIR spectra to the left shows how a single sample, represented by the yellow line, compares to the collection of historical sample data, represented by the gray line.

Written by Scott Buchwalter, Ryan Hicks and Tom Best

Written by Scott Buchwalter, Ryan Hicks and Tom Best

The Association of American Feed Control Officials (AAFCO) holds the industry to strict tolerances of raw materials in effort to ensure the safety of our four-legged family members. To meet these high standards, quality departments employ a variety of methods to test the physical and chemical properties of all raw materials.

from the supplier to the historical data of other suppliers. This analytical tool helps technicians know and identify in a matter of minutes when an outlier exists. The data reveals inconsistencies not visible to the human eye.

Whereas NIR analysis best applies to vitamins, energy dispersive X-ray fluorescence (EDXRF) effectively tests for minerals. EDXRF also provides qualitative and quantitative analyses of material composition and checks for potential contaminants in trace mineral premixes.

The EDXRF spectrometer analyzes specific elements present in a sample to determine the concentration of trace minerals, verifying that they were not over- or under-formulated. As a non-destructive analytical technique, EDXRF provides a sustainable method of analyzing bulk and trace analyses of inorganic substances, minerals and trace elements.

When outsourced, inorganic test results could take anywhere from 2-3 weeks to process. After Trouw Nutrition invested in an analyzer and obtained certification for its staff expert to perform the tests, EDXRF results take only a few days. Specification,

“EDXRF will be integral to Trouw’s future,” said Kelly Chism, Quality Assurance Lead and EDXRF operator. “This technology will enhance Trouw’s quality programs to add value and efficiency for our customers.”

The EDXRF machine is another level of protection to discover any inconsistencies before product leaves the facility.

Vitamin A aids vision, growth, cellular differentiation and immune response. Vitamin D3 helps regulate serum calcium levels. However, pets will not receive the multitude of benefits provided by vitamins if those vitamins are not supplied in the right amounts, which vary by species.

In fact, certain vitamins in excess, such as Vitamin A or Vitamin D3, can actually cause harm to the pet, including vomiting, dizziness, loss of muscular coordination, birth defects, and liver problems. Therefore, vitamin testing is crucial to not only ensure that our beloved pets receive the vital nutrients they need, but also to protect them from the harmful effects of high levels of vitamins or even too low of levels in the premix.

With our pets’ lives literally on the line, the International Organization for Standardization (ISO) establishes standards

for the industry and requires proficiency testing by an ISO certified vendor for the facility to maintain its ISO certification. The Association of American Feed Control Officials (AAFCO) and Bureau of Interprofessional d’Etudes Analytiques (BIPEA), both ISO-certified vendors, test the proficiency of Trouw Nutrition’s vitamin chemistry lab, for example.

Both organizations periodically conduct a ring test in which multiple labs, across different companies, receive the same sample with unidentified nutritional components, and the testing organization reviews the lab results of all the laboratories to compare and check for accuracy. Recognizing the importance and value of its vitamin testing, Trouw Nutrition has been conducting its own ring tests on its premixes since 2011 to ensure the safety and accuracy of its labs. Most recently, 81 participants from 30 countries participated in Trouw Nutrition’s ISO/IEC 17043-accredited ring test.

As with Trouw Nutrition’s ISO/IEC 17025:2017 certification, the ISO determines which tests and methods the lab is certified to perform and what vitamins can be tested under the scope of that certification. See the table for specifics.

Premixes and Feeds

Premixes and Feeds

Premixes

Premixes and Feeds

Trouw Nutrition’s chemistry lab in Wyandotte, MI uses high-performance liquid chromatography, an analytical chemistry technique for separating, identifying and quantifying the various components in a mixture. The team employs a unique cleanup method between every sample vitamin test to prevent cross-contamination and ensure

ISO/IEC

This ISO certification applies specifically to vitamin premixes, a specialization rarely given in the pet food industry but signifies that the facility has achieved a higher level of quality assurance and certification. The ISO certification also applies to straight vitamins.

accuracy. Such Waters-specific equipment and software must be serviced at least annually for preventative maintenance.

Trouw Nutrition developed its ISO-certified methods decades ago and modifies them to improve efficiency when possible. Thanks to these efficiency improvements, the lab can obtain most vitamin test results in just two days, compared to the 7-14 days customary to the industry. The lab frequently conducts as many as 40 different Vitamin A sample analyses in a single day, in addition to conducting many other vitamin tests.

“What makes the Trouw Wyandotte Analytical Laboratory unique? Three words: People, experience and culture,” said DeAnn Lazere, Laboratory Analyst at Trouw Nutrition’s vitamin analytical laboratory. “Trouw Nutrition values the people in this company, which in turn, gives the company a lot of knowledge and experience. Most of the experience is labrelated, but we also have backgrounds in R&D, quality, stability, production and premixing. This comprehension gives us the edge because we understand what goes into the products we are testing daily.”

Whereas some labs may not consistently run certain vitamin tests, Trouw Nutrition’s vitamin chemistry lab tests for A, D3 and Thiamine daily. The team of experts then inputs the results into Lab Retriever, the company’s laboratory information management system (LIMS), so the data can be centrally accessed and stored.

To properly manufacture a homogenous pet food premix, it must flow freely between bins, hoppers, mixers and into the final bag. If the mixture blocks the flow between any of these vessels, production time and expenses could both be impacted. To optimize handling characteristics, quality teams measure a premix’s flowability, or ability of feed ingredients or premixes to flow during handling. Flowability also impacts how ingredients or premixes are stored and transported.

A free-flowing premix demonstrates one of two primary flow patterns: core-flow or mass-flow. Core-flow, considered the default flow pattern, is signified by a firstin, last-out release order with the premix toward the bottom of the receptacle remaining static until the contents of the upper part of the container are first released. By contrast, mass-flow, considered the optimal flow pattern for poor-flowing premixes, follows a first-in,

first-out release order with all of the premix freely flowing downward.

Flowability is primarily measured by powder flow function, which provides a measure of the strength level that the ingredient or premix retains after experiencing a given stress level.

A powder flow tester (PFT) measures:

• Flowability

• Bulk density (a measurement of the weight of a given volume)

• Wall friction (amount of friction between a powder and a given wall surface)

• Compressibility (a measure of the change in volume resulting from the application of external pressure)

• Normal stress (stress applied perpendicularly [i.e., normally] to the sample)

• Shear stress (stress between parallel layers of ingredients or between a layer of ingredient and the PFT sample lid)

The PFT drives a compression lid vertically down onto an ingredient or premix sample stored in a ring-shaped container. As the stress is methodically applied, the sample is rotated at a defined speed, and the level of resistance is measured.

Formulators can use this information to adjust composition and prevent both of the two primary types of flowability issues: rat-holing, in which the premix forms a hole or narrow channel directly above the discharge point, rendering the remaining premix stationery against the mixer walls; or arching, in which the premix forms an arch over the exit point, preventing emission.

PFT measurements can also be used for benchmarking, in which a single sample result is compared to the historical data set of all ingredients and premixes to identify significant differences. Similarly, new ingredients or blends can be compared to the historical data set to gauge how it will handle based on previous measurements.

“

Quality is a science and an art. You must understand the rules to implement programs that serve and protect your customer, company and environment, but you must also be able to fit the rules into the nuances of the processes of your manufacturing facility.

Scott Buchwalter, Senior Quality Assurance and Laboratory Manager

Mixer studies are designed to ensure that a vitamin, trace mineral, premix or blend is being mixed as intended, and if the test should fail, the results can be used to identify the cause of the unevenly dispersed components. Mixer studies are typically performed for the first production of a new product and randomly thereafter for essential nutritional parameters.

The specific execution of a mixer study depends on the quantity of product being tested. Taking into account how many bags or totes are to be tested, the quality lab technician will strategically

divide the total amount to be included in the study into 20 equal samples. The various components, such as copper and zinc, for example, are tested for each of the 20 samples and compared.

For each component, the average analysis; standard deviation, a measure of the amount of variation between samples; and coefficient of variation (CV), a statistical measure of the dispersion of data points around the mean; are computed. These measurements are compared to the expected average and the percent guarantee. A CV of five or less must be achieved for the test to pass.

As the tests are performed, the following factors are taken into consideration:

• Substituting hand-add ingredients for ingredients added via a bin

• Altering when in the process an ingredient is added

• Adjusting the amount of mineral oil

• Modifying the ratio of carrier to active ingredients

• Changing the batch size

• Poor Flowability

These variables, and possibly others, are adjusted one at a time to improve the premix. After corrections are made, the mixer study is repeated until acceptable consistency is achieved. Mixer studies are an important quality tool for identifying and correcting issues.

For every pet food premix, multiple lab tests provide an abundance of data, which adds up fast. To manage and organize this data, many pet food manufacturers use a laboratory information management system (LIMS). A LIMS provides a central location for all applicable data.

LIMS enables sophisticated data analysis to:

• Ensure analysis consistency

• Share data across locations

• Identify methods for improving lab efficiencies, such as integrating LIMS with other digital systems

• Increase automation of processes, thereby reducing the risk of human error

• Run trend analysis of ingredients, such as reviewing analysis results for Out of Specifications (OOSs), statistical prediction of normal variances (upper and lower limits) and consistency of variant ranges

In collaboration with his Trouw Nutrition colleagues, Hicks developed the company’s LIMS, called Lab RetrieverTM. Unlike other quality control systems that are typically managed by just the Quality Control team, Trouw Nutrition’s digital systems, connected with Lab Retriever, go beyond simple data management and involve the production team as well. Trouw Nutrition’s warehouse team, for example, can enter ingredient Certificate of Analysis information into the system.

In the rare event of a recall or if an analyte is out of specification, a LIMS can provide analysis results, showing what parameter of the product varied, by how much and the specification. With an integrated inventory system, the out-of-specification ingredient will not be released for use and will automatically and immediately be marked as quarantined. Such audit information and immediate actions are vital for proper recall response and for protecting our beloved pets.

Ryan Hicks, Director of Sales“Our job is to protect the integrity of our customers’ brands. Food safety is our top priority at Trouw Nutrition. It takes a team of experts and the best support staff to provide that safety and protection. Trouw’s quality people make the difference in pets’ lives every day!

Unlike other quality control systems that are typically managed by just the Quality Control team, Trouw Nutrition’s digital systems, connected with Lab Retriever, go beyond simple data management and involve the production team as well.

Trouw Nutrition is developing a one-page product physical analysis (PPA) to succinctly report the key findings, including:

• Particle size distribution

• Sieve analysis

• Dust measurements

• Homogeneity

• Hygroscopicity

• Flowability

• pH

• Density

With this information, nutritionists can make more informed decisions about improving a premix. The comprehensive report helps show how ingredient interactions affect the finished premix and how adjusting one or more ingredients could impact the overall product.

Guided by the data supplied in a PPA, premixes can be modified for optimal functional performance, while controlling for factors that could impact employee safety, such as dustiness.

But technology is only as effective as the people operating it, making employee selection and training as critical as the equipment. Only with the right combination of experts, training, technology, standard operating procedures, safety regulations and high standards can a quality assurance program be effective. The effectiveness of a quality assurance program is crucial not only for the success of a company, but for that of its customers and the safety of its employees, and of course the reason we’re in the industry – our incredible four-legged family members.

Quality assurance is a serious topic. Companies should challenge their teams in ways to make their program better and continually invest in processes and people. The right leadership is important to guide the team. Combining science and expertise with quality brings the entire program together.

Certificate of Analysis (CoA)

Written documentation and results of specific laboratory tests that have been performed on a specific lot of manufactured product or ingredient. Each CoA will vary in the tests performed by manufacturer/ supplier and ingredient or product.

The standard deviation divided by the mean and multiplied by 100, a measure of uniformity.

Flow properties of feed ingredients or premixes during handling

The level of similarity or consistency of premix

The level of absorption or attraction of a substance to water

Particle size distribution is expressed as a range to capture the amount of each size particle in the sample.

With quality assurance technology constantly evolving, the challenge becomes effectively and efficiently communicating the extensive results to customers.

“

Quality is our culture! Everyone who touches the raw materials augments the process leading to the final product. All parties understand the responsibility of their role in upholding our fiduciary obligations to deliver excellent quality and protect our customers’ brands!

Tom Best, Director of Quality and Food Safety

Association of American Feed Control Officials (AAFCO), 2019. Proficiency Testing Program: Participant Guidebook, Association of American Feed Control Officials (AAFCO), Champaign, Illinois.

Best, T. Premixing Complexity. Petfood & Animal Nutrition. 2(2015) 12-14.

Best, T.; Project Discovery presentation. August 2011.

Blanco, M., Peguero A.; An expeditious method for determining particle size distribution by near infrared spectroscopy: Comparison of PLS2 and ANN models. Talanta. 77(2008) 647-651.

Coelho, M.B., 2018, Vitamins in Animal Nutrition and Premixing, A BASF Practical Field Manual, Florham Park, New Jersey.

Gell, A.; Foss ISIScan and WinISI Software Certification Training presentation. Observed June 2010.

Harris, D. C., 1995. Quantitative Chemical Analysis, W. H. Freeman and Company, U.S.

Khemiri, C. 2019. Detailed Scope of Accreditation, BIPEA, Paris, France.

Otsuka, M.; Chemoinformetrical evaluation of granule and tablet properties of pharmaceutical preparations by near-infrared spectroscopy. Chemometric and Intelligent Laboratory Systems, 82 (2006) 109-114.

Starkey, D., Hicks, R. Particle Size Determination Using Near Infra-Red Spectroscopy.

Pasikatan, M.C., Steele, J.L., Spillman, C.K., Haque, E.; Review of Near infrared reflectance spectroscopy for online particle size analysis of powders and ground materials. J. Near Infrared Spectrosc. 9 (2001) 153-164.

Pasikatan, M.C., Steele, J.L., Spillman, C.K., Haque, E.; G. A. Milliken Evaluation of a Near-Infrared Reflectance Spectrometer as a Sensor for First-Break Ground Wheat: Studies with Hard Red Winter Wheats. Cereal Chemistry. 79 (2002) 92-97.

Phibro Animal Health Corporation, 2001. Trace Mineral Overview, Handout Information and Backgrounder, Phibro Animal Health Corporation, Inc. Quincy, Illinois.

Skoog, D. A., Leary, J. J., 1992. Principles of Instrumental Analysis, Saunders College Publishing, Orlando, Florida.

Zumdahl, S. S., Zumdahl, S. A., 2007. Chemistry: Instructor’s Annotated Edition, Houghton Mifflin Company, Boston, New York.

With an average of 101 quality checks on every pet premix, Trouw Nutrition’s rigorous quality program protects your brand, and especially, the health of our four-legged family members. Quality isn’t expensive; it’s priceless.