Highly engineered façades bring game-changing destination to life

Member’s News Tech Reviews | Project Features 2023 ISSUE 26 The official magazine of the Hong Kong Façade Association 高度工程化建築幕牆 彰顯建築物的生命力

Address: Xiao Tang Nanhai Nonferrous Metals Industrial Park, Shi Shan Town, Nanhai District, Foshan City, Guangdong Province, China

Zip: 528231 Tel: 86-757-8555 8828 Fax: 86-757-8555 0238

Website: www.jma.cn, www.jma-aluminum.com

E-mail: sales@jma.cn, jmmaster@jma.cn

MESSAGE FROM HKFA

For decades, Art has been an essential part of our culture. It allows for the exchange and expression of ideas and emotions; to connect us to our thoughts and imagination and it opens our minds to a world of creativity and imagination.

I have always found that when we connect Art with Architecture, it is possible to encounter a rise in emotions because it introduces us to new experiences and deeper emotions. The result, aka structure often provides an insight as to how one views the world. It allows you to connect to the artist's story, their perception and experiences.

The arrival of 11 SKIES is not only a major enhancement for Hong Kong but also a game-changing retail-tainment destination. Being the next big thing for retail and shopping centers, it will boost Hong Kong's position as a global shopping paradise and as Asia’s World City. 11 SKIES is Hong Kong largest hub for retail, dining and entertainment. It is first to combine wealth management as well as wellness and medical services in one complete ecosystem. The building is strategically located right next to Hong Kong International Airport which will be gi fted the power to attract locals, Greater Bay area and the rest of the world to enjoy leisure and business at one go, making this the must-visit destination in Hong Kong.

The 11 SKIES building is uniquely built with three thematically-designed business towers, offering a next generation workplace and continuing K11’s brand version of a seamless integration of art, people and nature. Upon entering 11 SKIES, the core area has committed to a promising greener and smarter future by embedding sustainable elements into the project’s life cycle from design, construction to management. Visitors can experience the bright and open architecture of the interior that also provides a natural spot light for displays and art pieces. Having to win the Gold Award of “Best Futura Mega Project” at the “Oscars of the Asian real estate world”, MIPIM Asia Awards, 11 SKIES offers world-class attractions for all ages and segments and setting new benchmark for tomorrow’s shopping malls.

Sincerely,

Mr. Richard H.C. Shek

Vice Chairman of Information & Public A ffairs Sub-Committee Director (Operations) of Hip Seng Façade Engineering Co Ltd

Vice Chairman of Information & Public A ffairs Sub-Committee Director (Operations) of Hip Seng Façade Engineering Co Ltd

About Hong Kong Façade Association

Hong Kong Façade Association (HKFA) was founded in 1998. It is a non-prof it organisation that aims to draw the industry together to serve the society, through activities organised by the association. HKFA aims to unite members on industry issues, guarantee bene f its for the industry, standardise industry norms, serve the entire membership, achieve co-operation in the competitive market and promote healthy development for the trade.

To enhance professional training in the façade industry, HKFA has successfully conducted professional courses in collaboration with universities, since 2011. Working closely with other professional institutions the Association promotes façade engineering excellence and provides support for their CPD programs by conducting periodic technical seminars covering different façade technology topics.

香港建築幕牆裝飾協會成立於1998年,是一個非牟利營運機構,旨在通過舉辦活 動,凝聚業界力量,共同服務社會。在業界問題上團結會員,保障行業權益,訂定規 範及服務全體會員,同時在競爭劇烈的市場上加強合作,一起推動行業健康發展。

為提升幕牆行業的專業培訓,自 2011 年以來,香港建築幕牆裝飾協會已成功與大 學合辦專業課程。協會並與其他專業機構密切合作,通過定期舉辦並涵蓋不同幕 牆技術的研討會,促進工程精益求精,並為他們的持續專業進修課程提供支援及 技術課題。

Hong Kong Faç ade Association

Rm 04,12/F, Kenning Industrial Building

19 Wang Hoi Road, Kowloon Bay, Hong Kong

www.hkfacade.org

Executive Secretary 行政秘書: Connie Man W.K.

香港建築幕牆裝飾協會

香港九龍灣宏開道19號

健力工業大廈 12樓04室

E: info@hkfacade.org, T: +852 2704 7597

多年來,藝術都是我們文化的重要部 分,容讓意見和情感的交流和表達, 連接思想和想像,開啟對創意和想像 的思想新領域。

我一直認為,當大家將藝術與建築聯 繫上,就能夠提升情感,因為這能為 我們帶來新體驗和更深入的情感。結 果,那就是建築本身,往往提供一個 人如何看待世界的洞察力,容讓受眾 能夠與藝術家的故事、他們的想法和 經驗連結起來。

11 SKIES 的到來不僅為香港增值, 更改變了零售娛樂目的地的生態。作 為下一個零售商店中心的大型項目, 項目將會進一步提升香港作為亞洲 國際都會中,世界性購物天堂的美 譽。11 SKIES為香港最大型零售、飲 食、娛樂的樞紐,亦是首個將財富管 理與福祉及醫療服務集結一身的完 整生態環境。建築策略性的座落於 香港國際機場附近,將會為當地居 民、大灣區及世界其他地方的人提供一份禮物,能夠在這一個地方同時享受悠閒及行商機 會,勢將成為香港必到的地方之一。

11 SKIES 大樓由三棟主題設計的商業大樓組成,除提供新一代的工作空間外,同時繼續 K11品牌,將藝術、大自然與人充分結合的願景。項目總設計、建築至管理的每個周期部 分,都有使用可持續元素在當中,一走進11 SKIES,便可見到核心部分對綠色節能未來 發展的承諾。訪客可體驗光猛開陽的室內建築外,空間也為展示和藝術作品提供自然聚 光燈。項目已獲被視為「亞太區房地產奧斯卡」MIPIM Asia Awards中的「最佳未來大型 項目」金獎,將為不同年齡及界別的人士提供一個世界性的景點,同時為未來商場奠下 新指標。

石浩才先生 資訊及公關委員會副主席 協盛幕牆工程有限公司 董事(營運)

THE FAÇ ADE ISSUE #26 2023

The FAÇ ADE is the of f icial publication of Hong Kong Faç ade Association

Publisher 出版商: Mike Staley

E: publisher@rofmedia.com, T: +852 3150 8988

Editorial Committee 編輯委員會:

Sammy Hui (Head of Editorial Committee) / Richard Shek / Elizabeth Dooley (Consulting Editor) / Mike Staley

Advertising 廣告: Bryan Chan

E: bryan@rofmedia.com, T: +852 3150 8912

Alfred Ng

E: alfred@rofmedia.com, T: +852 3150 8911

Designer 設計: Michelle Morkel

Translation 翻譯: Derek Leung / Krista Chan / Jasper Lau / Billy Leung

In-house photographer 攝影師: Walter Ding

Designed & Published by ROF Media

Printed by Elegance Printing

The FAÇADE is online at www.issuu.com/rofmedia

All rights reserved. No part of this publication may be reproduced in any manner, without the prior written consent of the publishers. All reasonable care is taken but accuracy of information rests with the clients and contributors; the publisher bares no responsibility for any factual errors that may occur.

Copyright 2022 Ring of Fire Limited

6

FOREWORD

Far East Façade’s Gao Fei discusses the race to carbon neutrality

INTERVIEW

VS-A founding partner, Robert-Jan van Santen, on Façades in China

COVER STOREY

Two highly engineered façade types bring 11 SKIES to life at HKIA

FEATURE

The intricate engineering of Galleria, Gwanggyo, South Korea

Jangho Hong Kong Holdings completes AIRSIDE for Nan Fung group

M+ building an “Icon Of Visual Culture” into Hong Kong’s skyline

ARCHITECTURAL DESIGN

The hyperbolic curtain wall of Chongqing Gaoke Group

EVENTS

The long-awaited Annual Dinner 2022

2022 iNNO FACADE - The Future of Façades

TECH TALK

Discussion on BIM Technology by Wayne Lin

NEWS

The launch of the HKGBC Retrofitting Guidebook

Certi ficate in Façade Engineering

8 前言 遠東幕牆總經理談論碳中和的重要

12 專訪 VS-A 合夥人細說中國幕牆市場

20 建築設計 11 SKIES 兩種高度工程化的外牆設計

30 專題特寫

韓國新教 Galleria 的複雜工程

江河幕牆為南豐 AIRSIDE 打造最新立面 M+ 營造香港天際線的視覺

44 建築設計

重慶 極光雙曲面幕牆大廈面世

48 活動事件

2022年度協會晚宴相片集

iNNO FACADE 介紹幕牆未來

53 技術講座

56

The FAÇADE #26 2023 | 7

淺談香港建築幕牆的BIM 技術發展

最新消息 《香港綠色建築議會建築物節能改造指南》發布 幕牆工程基礎課程 CONTENT

20 30 12 48 40

Cover story

20 44 56 8 12

Table of Content

53 30 48

New opportunities lie ahead with new challenges

The greatest challenge to the curtain wall industry in the f irst half of 2022 remained to be the pandemic as the number of cases remained high, putting a damper on work progress and supply chains. The trend only started easing back to normal gradually, in the middle of the year.

We maintained strict adherence to the requirements of the Government HKSAR during the pandemic and adopted stringent measures in both China and Hong Kong to minimise the impact to the company. In the peak of the pandemic, our factories in the mainland strived to maintain zero infections by logistics transfer hub to ensure the supply chain remained una ffected.

The reduction in ef ficiency and its associated delays were guaranteed to have an impact on the overall operating costs of the company.

New curtain wall technology

Curtain wall technology is changing with each passing day, and we should be at the forefront of the market in the application of BIM in the curtain wall industry. We can apply BIM to the entire supply chain from design, procurement, production, installation to delivery.

Our mainland factory has completed the automation and smart transformation and can connect BIM with the machining centre directly to realise 3D processing, reduce losses caused by erroneous drawing while applying RFID technology to be able to track the process in its entirety, creating a digital trace during the manufacture of curtain wall.

The unique design of the hyperboloid exterior wall of The Henderson by Henderson Land in Hong Kong, for example, is unparalleled in terms of innovation. Our factory has built the most advanced stretch bending centre in the industry, created the hyperbolic curtain wall process through the use of programmed BIM design, while equipping ourselves with the most advanced 3D scanning tools in the industry, to ensure the production accuracy of the curved unit parts of the curtain wall.

Approaching carbon neutrality

Carbon emissions are an issue on everyone’s mind of late. Di fferent curtain wall glass has di fferent energy-saving effects. We hope to design curtain walls that can not only conserve energy but also generate electricity! Building Integrated Photovoltaic (BIPV) refers to the application of solar photovoltaic materials to replace traditional building materials, making the building itself a source of energy.

Di fferent tests are being conducted with the hope to develop solarharvesting glass panels for curtain walls in the near future.

Furthermore, our factories are transforming to be powered by solar.. By June 2023, all electricity used in our factory will be powered by the sun, achieving zero carbon emissions in the processing of curtain walls. At the same time, we are encouraging manufacturers to use clean energy to create products from the upstream in order to manufacture products that are more eco friendly.

Environmental certi fication of low-carbon products is very important to the industry because products certi fied by the government will bring more opportunities. It is believed that the energy saving methods of buildings will continue to improve in order to meet the future trend as Hong Kong sets to be carbon neutral by 2050.

Challenges ahead

Hong Kong's construction industry will grow exponentially in the future with the development of the Northern Metropolis and Lantau Tomorrow. Both projects will naturally see huge demand for talent, which can be recruited from the mainland so they can contribute to the sector a fter training. The development of the Greater Bay Area has also built a bridge for the exchange of talent between the two sides.

In the next two to three years, Hong Kong's property market may take some time to recover due to the impact of the global economy and the epidemic.. It may a ffect private residences or commercial buildings in the short run and will naturally have a certain impact on the curtain wall industry, but I don't think the impact will last too long as the market is resilient.

As the epidemic eases and all industries revive, 2023 will be met with many challenges. Meanwhile, the recovery of the economy will also cause inflation. The price of raw materials will rise as the mainland, encouraged real estate development. However, I am still fully confident in the future and excited about the ongoing development of curtain walls.

Gao Fei General Manager (Presiding) Far East Façade (Hong Kong) Limited

8

The FAÇADE #26 2023 | 9 Foreward

FAÇADE DESIGN

in CHINA by VS-A

There is an outside, an inside and that which lies in between. This space might only be a few millimetres or several meters deep. The study of this space can be detailed by a few sentences, can be developed in a book, or as a full-t ime endeavour. This is how VS- A def ines their work.

VS-A Founding Partner, Robert-Jan van Santen

12

Printed with kind permission from PRC Magazine Images: ROF Media and VS-A

A fter qualifying as an architect in France in 1986 van Santen began his career in Paris with Renzo Piano. It was here that he journeyed into the world of façade technology and developed his passion for the industry. He went on to establish VS-A in Lille, France in 1989 and over the past thirty years has worked with some of the biggest names in architecture. His portfolio includes iconic buildings such as the Casa da Musica in Porto, the London Olympic Aquatic Centre, the Alcide de Gasperi tower in Luxemburg and the Casablanca Finance City Tower in Morocco.

van Santen’s interest in Asia was accelerated alongside an increasing frequency of invitations to speak at various regional conferences. During this period Suzy Huang joined the company as Partner and began to play a major role in establishing the Hong Kong of fice in 2011. He also attributes his success in Asia to Naree Kim, who has worked with VS-A since 2008 and was integral in establishing the

Seoul branch in 2014. The practice would then go on to set up an office in Shenzhen in 2018, raising the number of employees in Asia to over 22, 53 including Europe.

In 2019 the Hong Kong based team was recognised for excellence in the façade engineering category of the CTBUH Awards for their work on Vanke Binhai Cloud Center in Shenzhen.

Clearly, van Santen is a man with a great passion for design and this is reflected by his position of Technical Director over Founder or CEO.

DESIGN PHILOSOPHY

With a philosophy built upon the premise of bridging the gap between architectural design and construction, van Santen and his team are testament to the notion that the work of the façade engineer must always start from the “design vision” of the architect.

“It is important for us to understand the particular characteristics of each job,” states van Santen.

“We believe that projects are weakened as architectural vision is diluted.With so many chefs in the kitchen this is a very real problem that we are very conscious of. As such we take great care to design in a way that complements the project’s underlying logic. We very much use questioning as a design tool, and this method sees to it that the di fferent constraints of a project are gradually integrated into the design vision. In some cases this integration can even become a feature of the final design! So far architects, and even Asian developers, have responded well to our rational and neutral approach.”

At the core of VS-A’s success is not only a sensitivity towards capturing the essence of the architect’s vision, but also a team whose expertise spans all the technical facets of engineering, cost control and adherence to building regulations globally. This allows them to propose and compare multiple solutions for every part of the project.

Asked how he would define VS-A as a company, van Santen prides himself on having attracted a set of individual personalities, each of whom have a unique set of skills, but are collectively able to develop a very diverse set solutions for all types of demands.

“Globally, we consider ourselves as a well-balanced mix of technical and design-oriented consultants. Half of the team has an architectural background, and we are united by a common feeling of ful filment when we know we have provided the best solution to a client’s problem.”

The diversity of VS-A’s international team has allowed for an organic expansion into other fields. Van Santen says that the firm’s design solutions are always tailored to suit a project.

“Naturally we do this because standardized products are often unable to suit the speci fic requirements of our projects. With this approach, it becomes clear that the intricacies of façade design come

The FAÇADE #26 2023 | 13 Interview

with a considerable overlap to product design. Not only in terms of scale, but also in terms of design thinking. Thus VS-A Design and Ublo-windows are companies that were created to autonomously develop such products,” he says.

Although the profile of VS-A has provided for opportunity to collaborate with many international architectural firms now located Asia, van Santen maintains that the original reason for coming to Asia was to collaborate with local firms. This goal was quickly fulf i lled and can be illustrated by both of projects featured in this article.

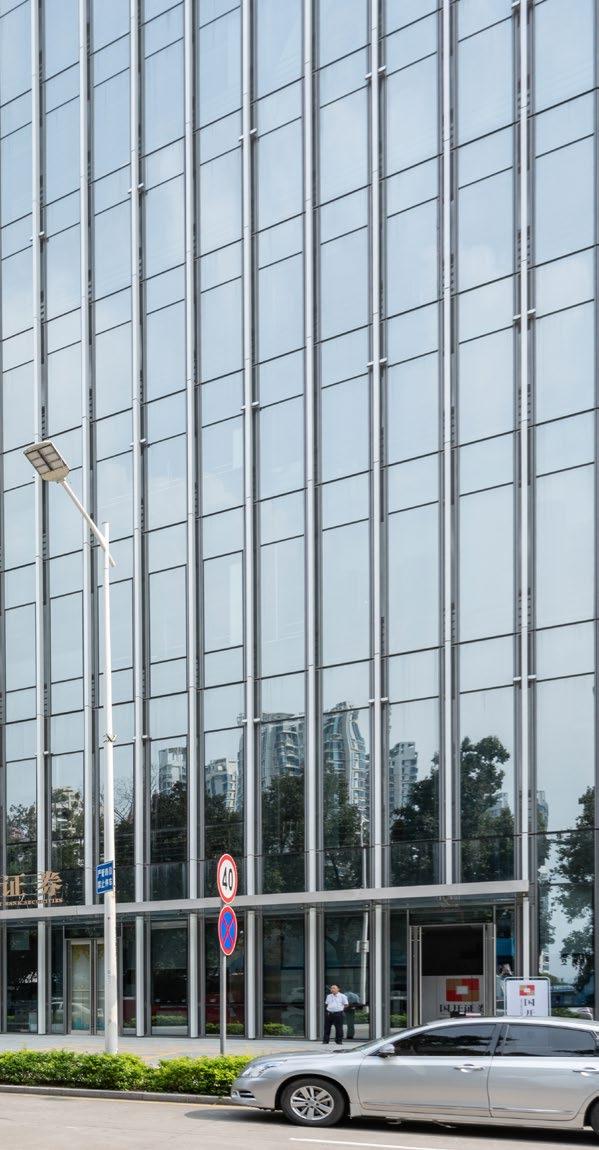

BINHAI CLOUD CITY

Firstly, the 160m tower that houses one of the headquarters of Vanke in Shenzhen. Here, VS-A was directly approached by the developer VANKE, to collaborate with 5th Architects. The buildings’ zigzag façade was driven by directing the internal view across two privileged axis of the urban environment.

Externally this concept created a building that looks totally solid and entirely glazed. Such was the logic in adopting stone panels to emphasize the stoic angle of the building. Similarly the smaller window/wall ratio required more transparent glass to achieve the required daylight factor. The glass used factors in for minimal colour distortion which allows for the creation of a pleasant and comfortable interior atmosphere.

The building’s curtain wall was designed with unique concaveconvex units. When approaching the building the façade

14

progressively reveals subtleties like the curved perforated aluminium strip that hides the operable windows (10% of the façade area). The perforation pattern itself was speci fically developed to allow the exterior lighting to be totally concealed.

“ This was one of our first projects in Shenzhen and we are proud that our façade engineering was awarded by the CTBUH,” continues van Santen. “But the award is shared by all the stakeholders of this project who positively supported the original architectural vision from the beginning to the end.”

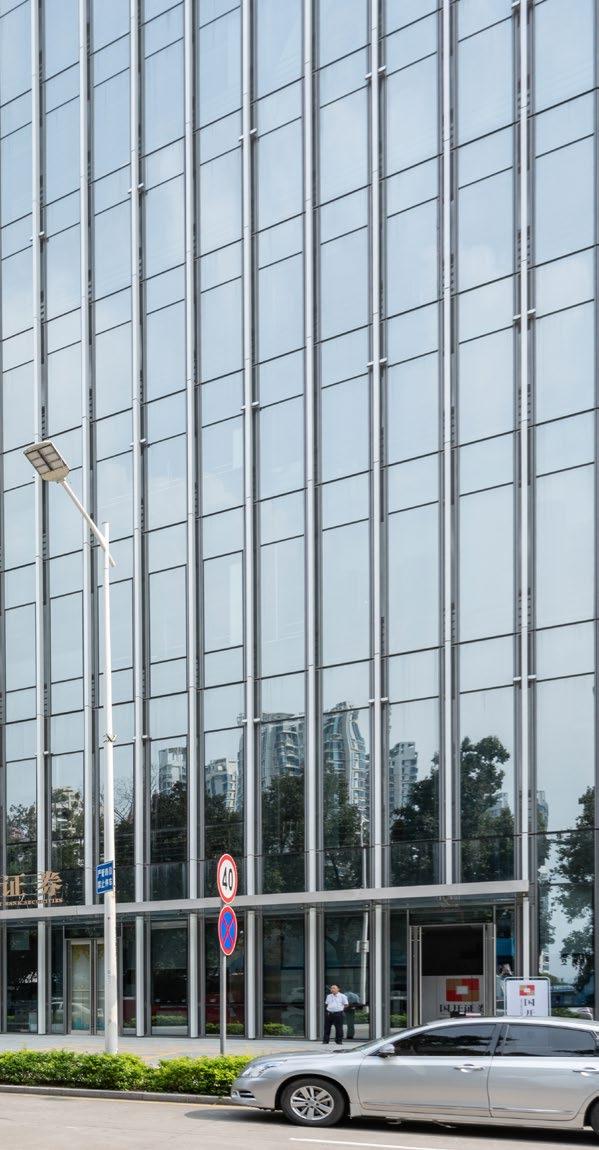

GUOYIN MINSHENG

The Second Project is the podium of the Guoyin Minsheng Financial building, designed by Zhubo Design. Here, the principal designer had sketched out a space that is open to the public and played with visceral boundaries, incorporating free flowing geometries with transparent and reflective glass panels.

The entire project is made of flat, single and double curved glasses. Such a project is strongly related and dependent on what local glass suppliers can manufacture. And what glass suppliers can do in China is totally unique.

The geometry is the first challenging topic, but the construction details had to include the architects’ request to have horizontal lines that will make it even more striking. It was immediately apparent that the glass would not be point-fixed and, to deal with the tolerances of the glass, a clamp system was developed rather than a linear frame. This would make the installation much easier.

The secondary structure is made of horizontal transoms that are offset from the main structure. This solves a 3D problem with a 2D solution. The clamps themselves were designed so that the same clamp can be used to f ix any glass, with any inclination.

VS-A HEADS INTO THE FUTURE

Van Santen says, “ The designs of office tower façades are not always inspired. Even the simpler geometries allow for a signi ficant amount of attention to architectural expression. For instance, in China glass must always be supported or secured by mechanical fixings, on at least two sides. This constraint alone provides an opportunity for a design proposal. And what about the interior perspectives? These should not be ignored; are fully glazed façades for a high-rise office building so user-friendly?”

Over time, VS-A has expanded its specialist offerings to include developing technologies. Whether a project is large or small, local or global, what is clear is that ultimately, at the heart of VS-A is a mission to merge the architectural and technical elements of a project by taking pride in the development of customized solutions that transform a creative vision into a technical reality.

Over the past year VS-A has been involved in the design and development of high-rise towers alongside a surge of projects that require the taming of complex geometries.

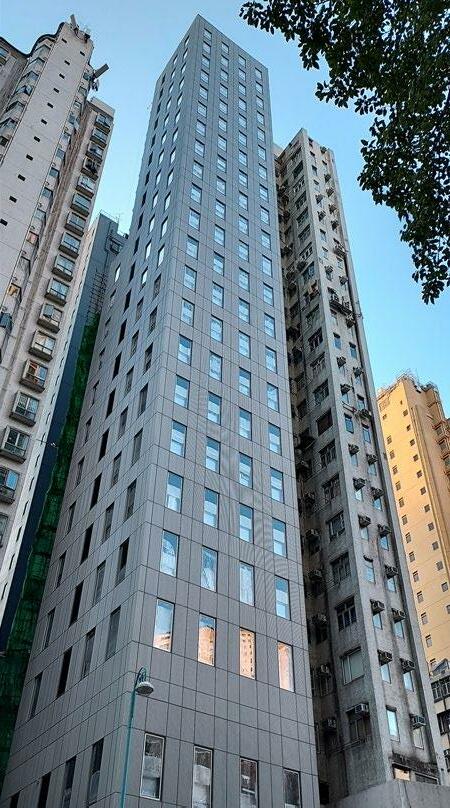

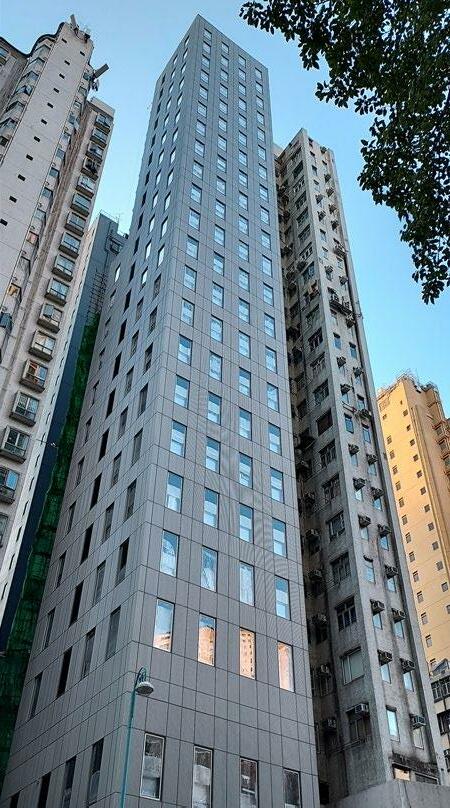

39 KING’S ROAD is a high-rise development located on a main street in North Point district of Hong Kong. VS-A.HK collaborated closely with BEAU Architect for façade design of the tower during early design stage as well as assisted on design development in later stage.

Façade design is based on a rigid grid and module which express an elegance appearance to make the tower stand out from neighboring building with minimal design feature. Façade system is a unitized curtain wall with 2 layers of wall. Inner layer is a performance layer composed of opaque panel with thermal insulation and operable window. Outer layer is a rain screen layer made out of bespoke corrugated shape aluminum extrusion. Rain screen layer and ventilated air cavity in between also functioned as solar protection for better performance of inner layer without using overhang shading or high performance material. The wall, protected by the cladding from direct solar radiation, will not heat up, which improves the comfort of the inhabitants and reduces the necessity of cooling, which is a signi ficant contribution to sustainability.

Corrugated aluminum extrusion color and finished was inspired by natural anodized aluminum. PVDF paint was applied not only to resemble the design intent but also provide better resistance to polluted environment.

The FAÇADE #26 2023 | 15

Interview

VS-A 的聯合創始人 Robert-Jan van Santen

16

The FAÇADE #26 2023 | 17 Interview

11 SKIES

Welcomes First Phase Completion

Two highly engineered façade types bring project to life

Described as a ‘game-changing retailtainment destination’, New World Development’s HK$20 billion 11 SKIES mixeduse development at SKYCITY, situated next to Hong Kong International Airport (HKIA), is set to become Hong Kong’s largest one-stop destination for retail, dining and entertainment (RDE).

Scheduled to open in phases from 2022 to 2025, the 3.8 million square feet development will consist of 2.66 million square feet of retail space, including over 800 shops and 120 dining concepts, once complete. 11 SKIES is an integral part of the government master plan for a public transit and transportation hub for the Greater Bay Area (GBA), which will also form a major part of the development of Lantau Island as a visitor entertainment hub, in association with Disneyland, Ngong Ping 360 and other existing attractions such as the Big Buddha. The 570,000 square feet of entertainment space will provide a unique customer experience destination with eight di fferent dedicated attractions designed to cater to all ages.

“ The brief for 11 SKIES in terms of the amount of dedicated entertainment area formed a key part in how the Airport Authority plans to develop the North Commercial District of Hong Kong Airport Island,” explains Claude Touikan, Co Founder & Executive

Director, of Lead8, who are the consultants responsible for the master planning, architecture and interior design of the development.

“Following the initial guidelines and research to develop a program focused on the catchment area of the airport and new airport city concept, we worked towards an ‘aero polis’ model. Our design takes advantage of the proximity of the international airport and also capitalises on the Hong Kong-Zhuhai-Macao Bridge and the GBA 1.5-hour living circle, alongside creating a neighbourhood destination in line with the Lantau Island Development plans,” he adds.

First phase complete

The first phase of development, comprising a 570,000 square feet workplace community within three grade A of fice towers and operated under K11 ATELIER, opened in July 2022. It connects to Terminal 2 of the airport, as well as providing access to the AsiaWorld Expo via an air-conditioned footbridge. The workplace offering is the first within an RDE destination to combine of fice space for GBA enterprises with a focus on wealth management, wellness and medical services.

The FAÇADE #26 2023 | 21

Cover Story

Text: Elizabeth Dooley Images: New World Development & Lead8

Positioned in the northeast corner of the site, the design of the three office towers seek to optimise the connectivity to two neighbouring hotels and the AsiaWorld Expo. The new workplace community also benefits from its integration to the wider 11 SKIES destination and transport hub featuring Airport Express and bus connectivity.

Each of the towers also serve a strategic purpose, with Tower 1 designed as a hub for GBA enterprises, Tower 2 dedicated to wellness and medical services and Tower 3 to wealth management. The concept is an attempt to redefine the traveller, consumer and business experience, whilst creating a business hub in one synergic ecosystem.

Connecting the towers is a central garden courtyard that establishes a community gathering point offering landscaped breakout space for the building’s tenants and views across the South China Sea. Furthermore, the three towers share an overall exterior design language that defines them as parts of a uni fied workplace community. And with the office towers situated on top of a green plinth, which forms one of the largest green walls in Hong Kong, the

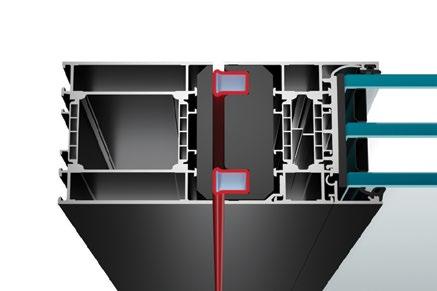

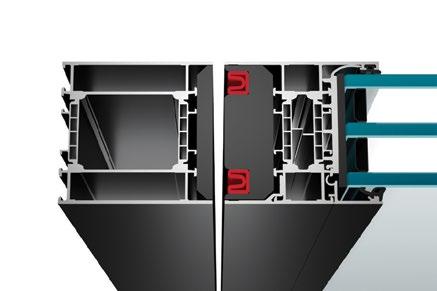

sleek, smooth, flat glass exterior (Type A) façade is part of an overall exterior design that according to Touikan is “highly engineered to allow for both technical and aesthetic purposes”.

11 SKIES façades

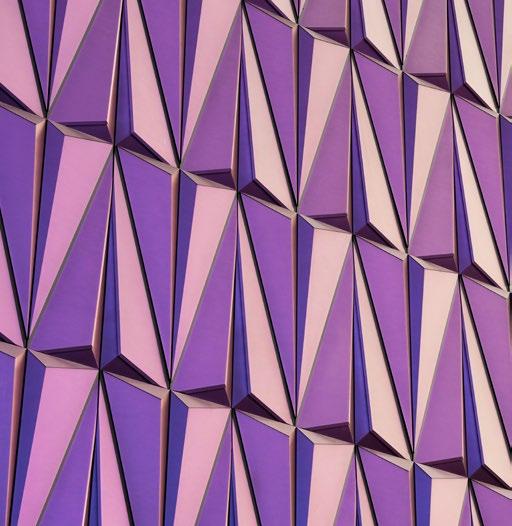

The architectural and façade design of the wider 11 SKIES development is inspired by the concept of flight. The abstracted form of a folded paper plane forms the basis of the feature façade articulation, giving the development a strong visual identity along the major viewing corridors to the development and within the surrounding ‘airport city’ context.

The design embodies the theme of 11 SKIES as a place for boundless exploration and unlimited possibilities. Home to exciting brands, vibrant experiences and groundbreaking retailtainment, the architectural concept captures the idea of soaring opportunities.

The ‘paper plane form’ has been transposed and translated to create an articulated façade for 11 SKIES. The façade language has then

been aggregated to create a pattern that embodies a holistic identity for the development. The form is further emphasised by the use of a colour-changing, high-performance coating.

Workplace architectural design

The K11 ATELIER office buildings are integrated to the wider mixed-use destination but also retain their own identity as a workplace community within 11 SKIES.

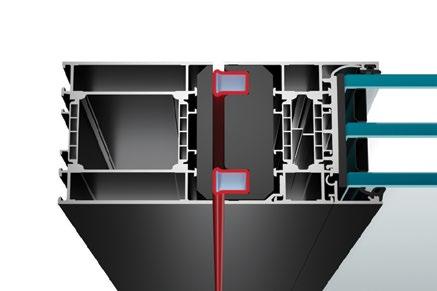

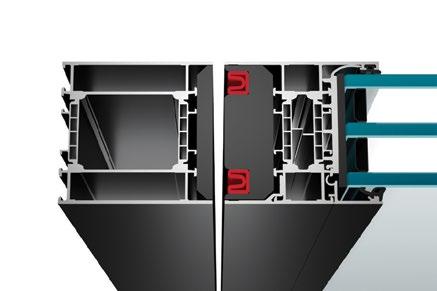

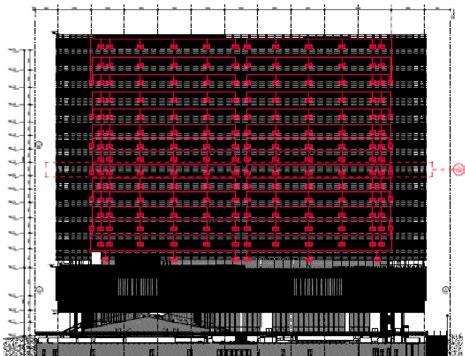

The exterior (Type A) façades of the office towers have a vertical orientation accented by a number of recessed vertical louvers that animate and break up the façade as an architectural feature with integrated lighting. The design is highly adaptable, with feature louvers increasing the future flexibility of the towers to allow tenants the opportunity to plug in additional fresh air intakes depending on their MEP needs, for example, for medical or IT services.

The exterior facing façade of the three office towers reads as a uni fied whole, the space between the towers creates a literal cut in the overall

The FAÇADE #26 2023 | 23 Cover Story

K11 ATELIER 11 SKIES Façade (Type A)

K11 ATELIER 11 SKIES Façade (Type B)

11 SKIES Glass Structure Façade

11 SKIES Feature Façade

Claude Touikan Co Founder and Execut ive Director,

massing like a slice in a cake, revealing the interior (Type B) façades, which in contrast to their exterior counterparts are very deep, highly articulated, and more human scaled. The architecture is functional, in that discrete lighting features create a smooth glossy exterior.

Meanwhile, deep angled vertical and horizontal façade features inspired by the overall geometric language of the project intentionally break down the rich interior façades facing the intensively landscaped office courtyard or secret garden. The angled vertical fins both create privacy from neighboring tenants while encouraging views to the surrounding island and sea and out through the space between the three towers.

Special attention was paid to the orientation and views of the of fice towers and future tenants. Given the tight site boundary and the need for three of fice towers, ensuring that each had a pleasant outlook to the surrounding neighborhood and also su f ficient privacy between towers was a challenge. The resulting solution was to create an intensively landscaped interior of fice courtyard or secret garden between the three towers serving to both enhance the view, incorporate nature, provide privacy, and serve as an amenity for the of fice tenants.

Commercial interior showcase

Bringing to life the 11 SKIES theme of boundless exploration, the interior design of the grade A of fice towers showcases a striking feature to welcome visitors. A dramatic double-helix staircase occupies the office lobby and forms the backdrop to the co-working space. The design concept for the staircase is inspired by an airplane engine’s wind vortex through a turbine. The form and materials capture the essence of the overall 11 SKIES concept and elevate the experience and ambience of the commercial environment.

Strategic Connectivity & Sustainability

The development is strategically positioned next to the international airport, the Hong Kong Zhuhai-Macao Bridge, and the Tuen MunChek Lap Kok Link, benefitting from a high volume of travellers, and a further 86 million people residing in the GBA. The architecture of the building facilitates connectivity across the entire destination and its neighbouring sites with a series of footbridges integrated within the design.

Sustainability has also underpinned the design and construction process. K11 ATELIER 11 SKIES has attained BEAM Plus (New Buildings) v1.2 Provisional Platinum, LEED Platinum Precerti fication and WELL Building Standard Platinum Certi fication, taking the lead in its care for the environment with best practices to promote a greener tomorrow.

“ There is always a balance between a design that has the most impact and one which we can optimise from a technical performance standpoint. We’re proud to see 11 SKIES ful fill our expectation for Hong Kong’s built environment and also the natural environment through a smart and innovative approach,” says Touikan.

The 11 SKIES mixed-used destination will continue to open in phrases until 2025, and we look forward to reporting on its progress.

24

Special attention was paid to the orientation and views of the office towers and future tenants. Given the tight site boundary and the need for three office towers, ensuring each had a pleasant view and also privacy was the challenge we needed to solve.”

Lead8

The FAÇADE #26 2023 | 25

Cover Story

K11 ATELIER 11 SKIES Façade (Type B)

26

Cover Story

28

Lead8 and New World Development on stage to collect the MIPIM Asia Gold Award for Best Futura Mega Project for 11 SKIES.

Image: Lead8 11 SKIES won Outstanding

The FAÇADE #26 2023 | 29

Cover Story

won the Greenest Overall Project, #MyFavourite Future Project (By Public Vote) and Outstanding Future Project (Silver Award) at Build4Asia Awards 2022.

Insight into the latest engineering and design marvel

Lakshmi Chirumamilla Images: WITHWORKS

Text:

Galleria in Gwanggyo & OMA

From its rustic yet modern facade to the intricately engineered elevation, Galleria in Gwanggyo is a landmark building located in the new town of Gwanggyo, South Korea.

The Galleria is notably Korea’s first and largest upscale department store franchise, founded in the 1970s, and has remained at the forefront of the luxury retail market since.

The new store in Gwanggyo is located at the center of young urban development, surrounded by tall residential buildings. The store’s stone-like appearance makes it a natural point of attraction for the public residing in the town of Gwanggyo.

The building is located between the Suwon Gwanggyo Lake Park and the tall buildings in the city. It marks an intersection between nature and the urban landscape. At first sight, the building presents a strong heaviness and massiveness that form the building's architectural language.

Lateral interventions on facade cut the building with pixelated glass volumes - serving as a public route, which are protruded from the building, to soften the heaviness of the building. The storefront features a textured mosaic stone facade that elevates the nature of the neighboring park—appearing as a sculpted stone coming from the ground, making it a visual anchor to the town of Gwanggyo.

The exterior of the building is designed as an irregular shape of curtain wall, and this was only possible because of the WITHOWRKS team’s extensive research and intricate detail of physics and modern structural engineering.

The team thoroughly understood the challenges that the existing methods could not address the requirement. The curtain wall is made with three different flat glass shapes connected via different deflection angles.

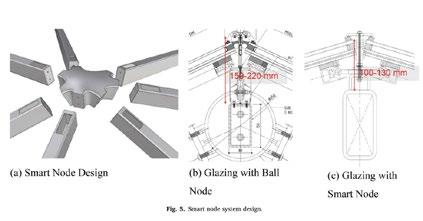

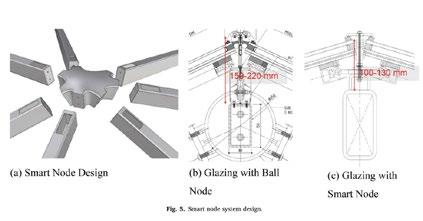

This requirement caused challenges, such as the vertex deflection phenomenon. However, with the help of the Smart Node system developed especially for the Galleria department store (GDS), the team was able to address the challenges.

In addition, additive manufacturing (AM) technology was used in production, showing an intricate method for irregular façade construction. One of the key achievements is that the developed Smart Node system performed with 99.4% construction accuracy, where only 10 out of 1652 glass sheets required reworks or corrections.

The FAÇADE #26 2023 | 31

Feature

3D Printing-applied construction: Smart node system for an irregular building façade

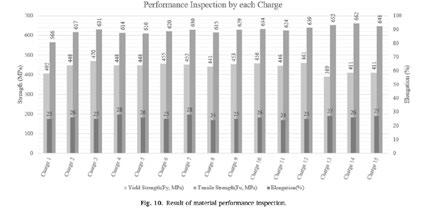

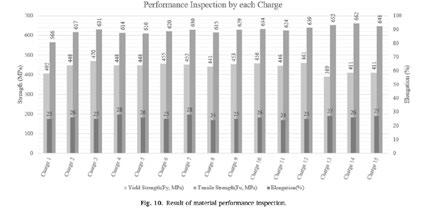

In the GDS project, 30–50 Smart Nodes were cast according to the size for each charge, and one material report was issued for each charge. 15 charges were cast, and 15 tensile test results are shown in the figure below. The yield strength was 439.6 MPa on average, performing at 123.8% compared to the standard value (355 MPa).

This made it possible for each cycle to be carried out continuously in parallel. Due to the hollow construction, the mold comprises three parts: the lower mold, core mold, and upper mold, the production process of Smart Node from the design and simulation to completion. The lower mold supports the whole mold, the core mold hollows the inside of the smart node, while the upper mold carries out casting methods, such as gate and riser.

The three parts were analyzed in advance through simulation software, such as Magma, and the mold was designed in a shape that can minimize temperature shrinkage deformation and air bubbles. After the simulation, the parts were 3D printed by a binder jetting machine. Each smart node was produced as required by the project plan, and the three parts were assembled to make a mold and cast the steel alloy. 4.2. System inspection and performance tests.

Smart Node with a hollow interior is manufactured using 3DP and weighs about 15 kg. The Smart Node system is advanced compared to the existing node systems considering production period, weight, construction error, number of arms of the node, glass angle condition, and the aesthetic function as an interior material, as verified in this paper. In addition, the Smart Node system has advantages in manufacturing irregular shapes, achieved by AM technology. One of the significant lessons from this project is how to secure the cost-effectiveness of novel technology adoption.

The development of the Smart Node & Glazing Design used in the project

To address the challenges, a hollow free-form shell node must be displayed together with glass. The below image shows the schematic design of the hollow node, named Smart Node. Smart Node provides a merged point and simplifies the glazing system. As a result, the required vertical span between the structural member and glazing part had to be shortened from 150 to 220 to 100–130 mm, to help mitigate the vertex deflection phenomenon.

Smart Node Manufacturing: 3D Printing Method

The main challenge in producing the smart nodes is finding the production method for the 647 nodes while meeting the time and cost requirements. Testing 3D sand printing confirmed several benefits. First, 3D printing laminates the sand directly with the binder without making a wax pattern, reducing the time required to make a sand mold.

Then a thermal simulation was added through the thermal analysis program, which could shorten the existing test production process from two weeks to several days. Besides the shaping accuracy of the 3DP method, the integrated thermal simulation method was available to reduce the required time for each cycle. In addition, the smart node production system simulated the mold of the next charge while 3D printing.

In the GDS project, the team tried to minimize the required number of nodes by design optimization, by which the project could achieve practically effective implementation. Compared to traditional methods, new methods have limitations, such as limited resources and a lack of practitioners’ understanding. Only three sand binderjet 3D printers were used during project manufacturing to produce the nodes.

All in all the OMA along with WITHWORKS have created a structure that is going to steal the attention of the town. The multifaceted glass facade covering the building is also a public route. Through the glass, retail and cultural activities can be witnessed by the city’s passers-by, while visitors on the interior can enjoy new vantage points to experience the beauty of Gwangyyo. In addition the public loop also offers spaces for exhibitions and performances.

32

The FAÇADE #26 2023 | 33 Cover Story Feature

34 www.withworks.kr

The FAÇADE #26 2023 | 35 Feature

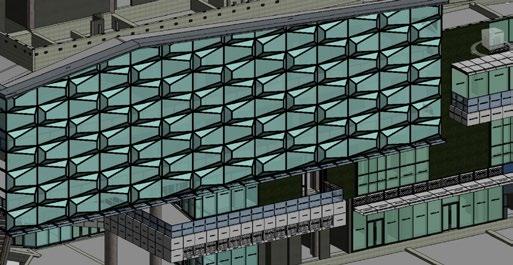

AIRSIDE Weaving A Space for Wholeness

Jangho Hong Kong Holdings Limited completes the façade for Nan Fung Group’s AIRSIDE , Kai Tak’s tallest building

At the junction of Kowloon East’s infrastructure network and sitting on a public transport interchange for CBD 2.0, AIRSIDE steps up as an all-embracing hub connecting people from all walks of life. Offering unparalleled views of Victoria Harbour and the Kai Tak Area, the 200m-high AIRSIDE embraces a new urban lifestyle concept of “Wholeness”, inviting the community to enjoy a natural space together.

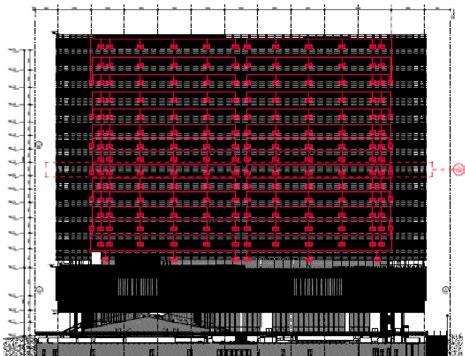

The professional team at Jangho was involved to create the project’s façade, consisting of a tower unitized curtain wall with curved & tilted glass panels, aluminium cladding and glass wall including BIM (5D). After delivering the project, Jangho was charged with the AIRSIDE office tower’s façade design and management.

From enhancing the design of the curtain walls to the performance testing, material procurement, processing and manufacturing of the

visual templates, Jangho has strengthened each aspect of the project. Its dedication and professionalism has received commendation from Nan Fung throughout the project.

A NEW GREEN LANDMARK FOR THE CITY

AIRSIDE is a 47-storey mixed-use development located at the heart of Hong Kong’s CBD 2.0., comprising a 32-floor Grade A office and multi-storey retail complex. It is also a top-rated green and smart commercial development and neighbourhood.

The project is set to achieve exemplary environmental performance through passive design, energy-efficient infrastructure, and renewable energy system. Its high-performance façade system with solar and glare responsive design will reduce thermal transfer and air conditioning use.

Text: Julienne Raboca Photos: Jangho Hong Kong Holdings & ROF Media

Composed of fluted Triple Low E IGU glass, the gently curving façade not only is evocative of Nan Fung Group's textile roots but also it was the first time being extensively used in a commercial building in Hong Kong. This heritage is present throughout the project, from the interiors, the external, inclined geometric outline, to its landscape design.

Having attained the highest sustainability ratings with BEAM Plus New Building Platinum, LEED Platinum, Building Standard™ Platinum, BEAM Plus Neighbourhood Platinum, and CGBL 3-stars, the building will be one of the most environmentally-friendly landmarks in town.

PROJECT HIGHLIGHTS: THE LANGUAGE OF ARCHITECTURAL OUTLINES

Shading fins of different sizes are the highlight of this project. The tower facade of demountable aluminium fin features forms a weaving design, incorporating various depths of dimension to form gradual transition effects. This design is attached to the concave curvatures in the facade glass modules. The colourful media wall with LED facade lighting strips is also animation-friendly and dimmable.

In addition to being a design feature, the projection shading fins are tailor-designed with various depth projections at different orientations in response to solar gain and glare reduction. A testament to resilient design, the vertical shading fin takes safety into consideration to prevent the strip from collapse during a typhoon.

Another key design element of AIRSIDE is the curtain wall system, with concave curved glass arc units in the tower. Being a top brand in the global high end curtain wall business, Jangho was more than up for the challenges brought about by different concavities on adjacent unit panels each side of the curtain wall, as well as panels on the upper and lower floors.

Located in the tower lobby, the giant glass wall system consists of triple layers of ultra-clear laminated (low iron glass) made up of a single plate measuring 14.5 by 3 metres.

The area maximises natural sunlight from outside, creating a sense of warmth, peace, comfort and harmony. Aside from this expression of sophisticated architectural design, the team also considered the wall’s detachability during the maintenance of the glass panels, reduced shaking at the end, and hid the lighting cables.

Furthermore, Jangho used computer programmes during parametric modelling to ensure flawless execution, complemented by advanced digital processing equipment and prefabrication methods.

WEAVING THE AREA’S SOCIAL AND CULTURAL FABRIC

Nan Fung Group has made sure that AIRSIDE stays grounded in Hong Kong’s rich history and Kai Tak’s cultural legacy. To illustrate the idea of the city’s wholeness in culture and heritage, the Group implemented a series of community engagement initiatives to ensure the project is well-integrated with the wider area’s development, along the Kai Tak River, and in San Po Kong and Kowloon City.

Vanessa Cheung, Group Managing Director of Nan Fung Group said, “Nan Fung has always been committed to curating unique and authentic lifestyle experiences for Hong Kong, where we weave together the social and cultural fabric of an area through fresh new approaches to urban living. AIRSIDE will foster a new cohesion between the way we live and work—people will come to expand their horizons, both personally and as part of a community; it’s also a place where professional connections can be made and businesses can prosper. We envision AIRSIDE to be a landmark destination that fully and thoroughly embodies wholeness.”

Ahead of its opening, AIRSIDE has already been reaping accolades from the real estate industry, such as the Gold Award in “Best Futura Project” Category at MIPIM Asia Awards 2020, dubbed as the “Oscars of Asia Pacific real estate world”.

Steven Au, Deputy General Manager of Nan Fung Group’s AIRSIDE project said, “With the legacy of the former Kai Tak International airport, the new developments are designed to transform Kai Tak into a vibrant hub of heritage, commercial, residential, sports and tourism destination.

AIRSIDE embraces wholeness encompassing urban lifestyle, culture, wellbeing, and connection to nature through its architecture and building fabric. Nan Fung has seized the crossover opportunities with key stakeholders in the area to lay down a good foundation in supporting the social and sustainable development of our community and city through AIRSIDE.”

Rather than being a mere escape from the city’s hustle and bustle, AIRSIDE is a place that embraces the interwoven elements of work, life, and well-being.

The FAÇADE #26 2023 | 37

Feature

38

AIRSIDE編織和而爲一的空間

The FAÇADE #26 2023 | 39 Feature

Building An Icon Of Visual Culture Into Hong Kong’s Skyline

Permasteelisa Hong Kong steps up to the challenge of creating a facade worthy of West Kowloon Cultural District’s museum for moving image works.

Every night from 6 p.m. to 11 p.m., the M+ lights up and delights viewers in Hong Kong Island with short but visually-stimulating and thought-provoking videos. Asia's first global museum of visual culture, M+ has one of the world’s largest media facfades, overlooking Victoria Harbour. Its illumination sets it apart from the gleaming display of high rise neighbors, which take the form of brand names in bright, bold lights.

The M+ Facade is a canvas for multiple commissioned works –like Nalini Malani’s In Search of Vanished Blood (2012/22) ; Ellen Pau’s The Shape of Light (2022) and studio Moniker’s Touch for Luck (2022).

The moving images and animations offer moments of play, humour, poetry, intellectual reflection, and meditative contemplation to thousands of onlookers.

But Hong Kong’s museum of visual culture is also as captivating up close and personal in the morning light.

Terracotta beauty

Green terracotta tiles similar to traditional Chinese roofing tiles clad the monolithic building. The glazed color, down to the texture and shapes of the cladding are reminiscent of the distinct Chinese architectural element found on the roofs of homes and major edifices. The hues of the tiles change, depending on the weather and color of the sky.

The Hong Kong skyline boasts of several iconic buildings, but the M+ Facade is the first of its kind in Hong Kong. Terracotta’s perceived brittle nature makes it an uncommon material for high rise buildings, according to Charles Chong of Permasteelisa, yet M+ is proof that it is possible to use a complex material like ceramics.

Text: Julienne Raboca Photos: Kitmin Lee, Courtesy of M+, Hong Kong & Permasteelisa Gartner Hong Kong

“Since Hong Kong is highly susceptible to wind-driven debris during typhoons, the risk of damage to both terracotta and pre-cast inevitably increases, which had to be overcome with replacement strategies built into the design,” said Chong, who serves as Design Director, exteriors for Asia.

The contractor has been known to install unique façades using innovative techniques around the world. It’s behind major buildings like Opus Hong Kong and the ongoing PNB 118 skyscraper in Malaysia.

So when it was time to execute the design by architecture firm Herzog & de Meuron, Permasteelisa was tapped to find solutions to turn the exterior design into reality.

Building the dream

The façade contract was awarded to Permasteelisa in 2016, with the building owner West Kowloon Cultural District Authority (WKCDA) poised to become one of the world’s largest cultural quarters, blending art, education and public space. Permasteelisa Design got the green light to supply and install a custom-made building envelope integrated with ceramic tile panels, precast concrete panels, glass panels and an LED media lighting system.

In a span of five years, the distinctive cladding was completed. But because the use of terracotta in high-rise buildings was unusual, Chong said that the work around that was presented required convincing.

“We were fortunate that the client has shown much understanding and supported us throughout the entire duration of the project, allowing Permasteelisa to deliver a unique landmark on the Victoria Harbour front,” Chong said.

Permasteelisa also worked on the two buildings next to M+ - the WKCDA Tower and Conservation and Storage Facility.

The terracotta tiles were carefully produced by Palagio Engineering, an Italy-based company that specializes in making terracotta cladding. The supplier made sure that the tiles were fired in the kiln in one go – sometimes for as long as two weeks – to make sure that the cladding would withstand external forces. This meant that the terracotta tiles for M+ Facade took a longer time to produce.

Many major elements of the building exterior were sourced from different parts of the world. The tiles were made in Chianti, Italy, where there is an abundance of special clay that were used to make the terracotta cladding. The tiles were then assembled in Shenzhen, China before it was moved to Hong Kong for the fitting.

“This is made all the more challenging given that the façade elements are particularly large, heavy, and not possible to ‘flat-pack’. Hence, any delays will incur the need for huge temporary storage space,” Chong said. He added: “The façade units, which weighed over four tonnes even for a typical panel, needed customized transportation, lifting, and installation strategies and equipment. It would not be possible to install the façade using a traditional approach.”

A visual spectacle

The M+ Facade measures 110 metres wide and 65.8 metres high. Aside from the incorporation of the complex terracotta tiles, Permasteelisa installed precast concrete as well as glass panels. More than 5,600 LED tubes were installed between the panels to allow the nightly visual spectacle of the building.

The first panel was delivered and installed in March 2018. The installation period lasted for 16 months, excluding two months of site closure. The last panel was installed in September 2019. Chong noted that this timeframe did not include the tedious and lengthy process of sourcing and shipping the terracotta tiles.

The museum’s facade was completed in 2020, and in November 2021, the repository of modern and contemporary visual culture was opened with grand exhibitions. The forward-looking museum currently hosts outstanding shows within its walls, from Yayoi Kusama’s works, to Beeple’s kinetic video sculpture, to a retrospective of the Hong Kong visual culture. From the outside, its façade amazes spectators, up close and afar, both day and night.

The FAÇADE #26 2023 | 41 Feature

42

Drone Images Courtesy of M+, Hong Kong

The FAÇADE #26 2023 | 43 Feature

44

HYPERBOLIC CURTAIN WALL

Twists in the Chongqing Light

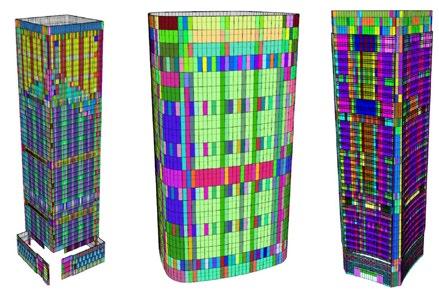

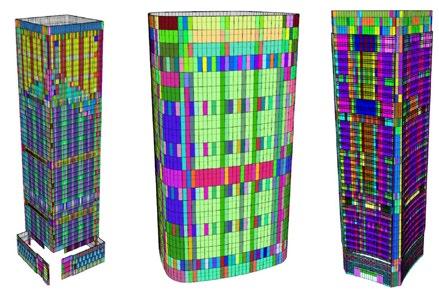

The 180m tall Chongqing Gaoke Group Ltd Office, designed by Aedas, was completed in 2022. The tower utilises a simple elegant form which creates the twisting shape of tower to form expressive double-curved surfaces on the building façades. Vertical lines accentuate the minimalistic form and through the effect of reflection and refraction from the glass create a design statement that celebrates light as the major tool to define architecture.

Information and Images: Aedas

To achieve a very smooth transition of the glass façade, the design uses double-curved cold form glass instead of the usual or more common faceted method. The maximum twisting angle is up to 8.8 degrees per floor surpassing the existing super high-rise tower in the world by nearly 1.5 times (CTBUH Journal, 2016 Issue 3).

It is expected to be one of “ The Most Twisting Towers in the world”. Innovative façade technology from façade engineer RFR empowers the precise execution of such challenging design. The area of the hyperbolic curtain wall is about 8,000 square metres, and the number of hyperbolic curtain wall panels is as many as 1,709.

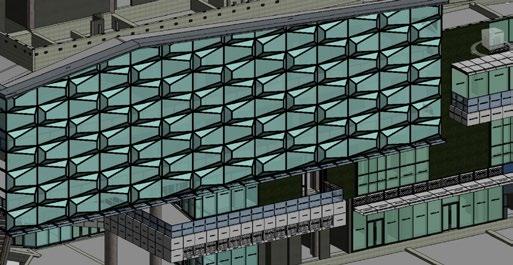

BIM

The unique twisting results in a high double-curvature ratio, which poses a major challenge for the overall façade system. Aedas and RFR joined hands to leverage the cold bend glass technique and BIM for this complex geometric façade. Such innovation was to adapt to the changing geometric parameters and dimensions while ful filling requirements on safety, waterproof and thermal performance. It also ensures a consistent façade construction in line with BIM simulations.

The system of cold bend glass on the 3D frame façade component enables a maximum of 86mm in glass deviation between floors, realising a record-breaking design in China. From overall geometric analysis, façade component modelling and clash-checking, LOD400 detail component modelling, automotive data exporting and auditing, 3D BIM has been utilised throughout the entire façade design process. Through value engineering, a portion of the hyperbolic glass with flat glass is successfully replaced, achieving savings in construction costs.

THE TWIST

The architectural form uses twisted curved glass, such that each glass panel is di fferent in size and degree of twist. With a unique twisted façade and integration with landscape, the view of the tower varies from di fferent angles.

Global Design Principal , Ken Wai, said: “ The façade is not only an outlook expression, but also a way of protection that sculpts interior spaces. The delicate design has been articulated for the top of the tower, by conveying the conceptual “Valley of Light” through the transparent glass façade and lighting, to make a coherent statement. Such a concept di fferentiates the crown of this tower from other of fice spaces. The plant room, BMU and other facilities are centralised inside the “Valley” on the top of the building, achieving functional unity without undermining the visual aesthetics.”

“As an open public space, the tower has all the credits to be a city icon, especially the signi ficant twisting of the façade, which is remarkable. As for the master layout, we have put thorough consideration to the surrounding environment and the building volume. Standing at the north of Xingfu Plaza, the 61,368 square metre project is located in Jiangbei District of Chongqing. The surrounding environment has already been developed in a spacious plot, and one big challenge for the designer was to interpret a planning concept of “solar”, into an iconic landmark well-integrated in the existing community context.”

Inspired by the dancing aurora, the design team introduced an impressive façade design through bottom-to-top connections between the northern and eastern sides. The ‘dance of light’ is characterised by the juxtaposition of rectilinear forms and tower façades with double curves

The FAÇADE #26 2023 | 45

Architectural Design

46 Architectural Design

MEMBERS REVEL IN JOYOUS ANNUAL DINNER 2022

Over 200 members and guests attended and the atmosphere in the venue was electric. The party-like atmosphere allowed attendees to catch up with friends from across the industry for a night of toasts, games, good cheer and gourmet delights ensuring that by the time the evening was over everyone left feeling happy and joyful with new memories to treasure.

HKFA President, Peter Wong delivered the welcome speech. He was followed by Ir. Dr. Cary Chan, Execuwtive Director of Hong Kong Green building Council (HKGBC), who delivered a message of future collaboration opportunities between HKGBC and HKFA.

48

Photography: Motif Production

Next, Ms. Ivy Lee Hui Ling, Senior Manager – Insustry Standards and Practices, HKGBC, addresses the audience to promote various Green Product Certi fication as initiated by HKGBC.

As one would expect from an HKFA Annual Dinner, the night was well supported by a host of sponsors, 16 in total and HKFA expresses its appreciation to all of those who supported this festive occasion. 5 signi ficant sponsors were:

• Dow Chemical Paci fic Ltd

• Hip Seng Façade Engineering Co Ltd

• Entasis Ltd

• Far East Facade (Hong Kong) Ltd

• PMB-Cyberwall Limited

ROF Media sta ff and management were delighted to attend and we thank President Peter Wong for his lovely comments about the success of The FAÇADE, the official magazine of HKFA, since the 2021 relaunch.

The FAÇADE #26 2023 | 49

Events

協會年度晚宴超過 200名會員及來 賓出席,氣氛熱烈非常,業內人士及 友好一同舉杯慶祝、參與遊戲及享用美食, 令人賓至如歸。

首先由《香港建築幕牆裝飾協會》主席黃國 強先生致歡迎辭,隨後由香港綠色建築協 會執行董事陳永康博士,向觀眾介紹綠色 建築議會與協會未來的合作機會;之後是綠 色建築議會的行業標準與實務高級經理Ivy Lee 女士,她分享了由議會倡議的各種環保 產品認證計劃的最新消息。

晚會活動獲得十六位贊助商的熱烈支持,協 會對所有贊助商深表感謝,五位主要贊助單 位分別是:陶氏化學、協盛幕牆工程、添麗 裝修設計、遠東幕牆及PMB-Cyberwall。

出版部ROF Media 員工和管理人員亦很高 興獲邀出席,感謝主席對協會自2021年改 版後的官方雜誌《 The FAÇADE 》予以認 可及讚揚。

50

2022 iNNO FACADE

The Future of Facades is in the Balance of Technological Advancement and Sustainability

2022 iNNO FACADE was held on 26 September and drew an enthusiastic crowd. HKFA would like to thank the day's Panelists, who included:

• Ms. Grace Kwok, Chairman and Executive Director of Allied Sustainability and, Environmental Consultants Group Ltd, Board of Director of HKGBC;

• Ir Dr. Dominic Yu, M.Sc., Ph.D., MHKIE, MHKISC, MHKICA, Principal of Alpha Consulting Ltd;

• Mr. Harris Sun, CEO and Founder of RaSpect Intelligence Inspection Limited;

• Ms. Florence Chan, Director of KPF (Hong Kong) Limited, President of AIA Hong Kong Chapter;

• Ir Michael Leung, MIStructE, General Manager of Hilti (HK) Limited; and

• Mr. Wayne, Lin, Co-Founder of VDC Engineering Limited, President of GHM Greater Bay Area, Institute of Urban Architecture BIM Sub-Committee.

2022 iNNO FACADE 研討會於2022年 9 月 26 日舉行,以「幕牆未 來在於技術進步與可持續性的平衡」為題,並吸引了大批參加者。 香港建築幕牆裝飾協會衷心感當天出席的嘉賓,包括:

• 郭美珩女士 - 沛然環保顧問有限公司主席兼執行董事、香港綠色建築 議會董事會成員;

• 余偉健工程師 M.Sc., Ph.D., MHKIE, MHKISC, MHKICA – Alpha顧問 公司負責人;

• Harris Sun 先生- RaSpect Intelligence Inspection Limited CEO 兼創辦人;

• Florence Chan 女士 - KPF 香港辦公室總監、美國建築師學會香港 分會會長;

• Michael Leung 工程師 MIStructE - 喜利得(香港)有限公司總經理;

• 林方偉先生 - VDC Engineering Limited聯合創始人、粵港澳大灣區 城市建築學會BIM 分會主席。

The FAÇADE #26 2023 | 51

Events

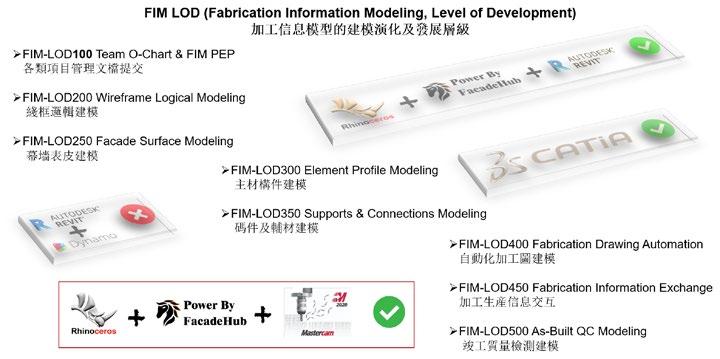

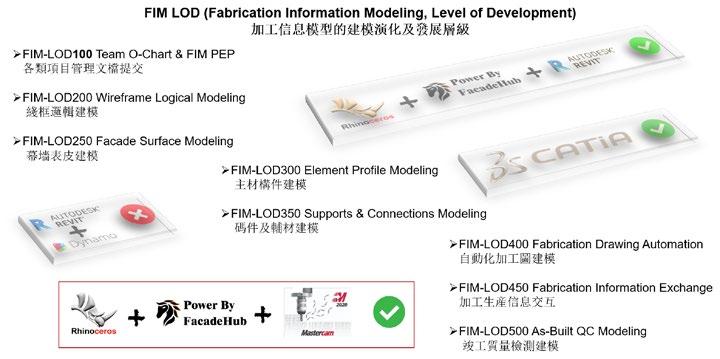

Discussion on BIM Technology Development of Building Curtain Wall Industry in Hong Kong

What is Fabrication Information Modeling (FIM)?

A perfect BIM solution without increasing the project cost; a system around the model as the carrier of geometric and non-geometric forms of fabrication and production. It generates Bill of Material (BoM) for procurement, assembly and fabrication drawings for all kinds of panels, plates, profiles, and extrusions.

Generally speaking, all the processing information and annotated drawings are generated from the model. Bill of materials is derived from the model as well with dynamic update when there are changes on the model. It reduces the error rate dramatically and optimizes its efficiency.

There are five main technical routes of FIM in the world

Autodesk AutoCAD based FIM

Permas steel has spent a fortune on the development of AutoCAD, forming its own unique PMF (permasteelisa move forward) software. As PMF does not license to the outside world and there is no BIM consulting team in Hong Kong with access to the plug-in, PMF has basically withdrawn from the stage of Hong Kong.

Autodesk Revit based FIM

The application of Revit is more suitable in concrete structure, steel bar, decorative panel and so on. In most cases, the model information can be extracted directly from the model, and the material list can be exported by using the statistical function. 2-D or 3-D drawings can be generated directly from the model as well. For complex projects, it requires mathematical model and optimized algorithm with additional based Revit foundation to achieve direct drawings

generation. Some popular plug-ins are Tool4Revit by AGACAD and Curtain Walls & Panels module. Regrettably, Revit’s limitation on level of detail making it unsuitable for fabrication use. The file size increases dramatically as the fabrication details are included, making it almost impossible to open up.

The general process is as follows:

1. Create a mass family in Revit for skin partition of curtain wall (Model can be imported from SketchUp)

2. Create a panel family generated directly from the model’s curtain wall unit and calculate material quantity through the “Schedule” function

Due to the limitation of the Revit (Up to 2020 version) software and the outdated graphics engine, it is still unable to generate the profile fabrication drawings. This method is suitable when used with CAD or other platforms for the extraction of main materials, curtain wall grid division, numbering and other information.

The FAÇADE #26 2023 | 53

Text and Images: Wayne Lin Tech Talk

FIM can be achieved for simple door and window projects, railing, ordinary rectangular glass unit.

CATIA (DP) based FIM

CATIA is a powerful tool that can directly create curtain wall skin, any free-form surface skin, or import skin from Rhino, and then generate BIM processing information model of curtain wall through derivative function.

Grasshopper allows users to generate material list and output profile processing drawing through programming. CATIA's only drawback is that the software is expensive and the learning cost is high. There are only a few face-to-face courses in Hong Kong, let alone the training for curtain wall modeling.

Industrial Software such as Solidworks or Pro-E based FIM

The advantage of this route is at the later stages of BIM for communicating with CNC programming software such as UG, Mastercam. The curtain wall model can be established by CAD drawing to generate unit curtain wall elevation, unit plate assembly, CNC machining and fabrication drawing and material list.

The disadvantages of this route are also obvious, that is, it cannot keep up with the shop drawing modi fication since the efficiency of model modi fication is slightly cumbersome.

A strategic alternative is to develop the baseline model up to LOD 300 or LOD 350 for shop drawings review using Revit or other software. A fter the shop drawing is submitted for approval (issued for construction), re-develop the model according to the final version of shop drawings since there will not be any more changes to it.

Many curtain wall companies in Hong Kong adopt this route, that is, BIM coordination for shop drawings is outsourced to local BIM consultants to coordinate and attend regular meetings. LOD 400 and LOD 500 BIM models are outsourced to fabrication bases in mainland China.

Rhino based FIM

In recent years, the whole AEC industry started to embrace parametric design. Grasshopper and Python have become the necessary examination subjects for the undergraduate degree of architects. Rhino's parametric modeling platform with grasshopper has the highest compellability, visibility and extensibility. It is widely used design tool for complex building and structural design. In particular, this combination work much better in building curtain wall model than Revit + dynamo.

Since Revit is currently dominating the realm of multi-profession BIM integration, RiR (Rhion Inside Revit) enables us to convert models into the Autodesk BIM family. All components can be directly converted to the Revit family or other formats, such as IFC, which is more applicable in the establishing CDE (Common Data Environment) online collaboration platform.

WAYNE LIN

Co-Founder of VDC Engineering Limited

Wayne has 15 years’ experience in BIM, VDC & DfMA Design and Engineering. Wayne has been in a principal manager role for the HKAA’s Mega size Project: Third Runway Concourse and Air f ield, New Traff ic Control Tower. He is also ant icipated couple of remarkable façade BIM projects in Hong Kong and Dubai. He has prof icient in combining the virtual design and construc t ion work f low with dynamic risk assessment methods in large-scale construc t ion projects.

Tech Talk

The Hong Kong Green Building Council Launches The “HKGBC Retrofitting Guidebook”

To Lead the industry in adopting the retrofitting solutions to existing buildings for the goal of achieving carbon neutrality by 2050, On 10 January 2023, The Hong Kong Green Building Council (HKGBC) launched the HKGBC Retrofitting Guidebook. The ceremony invited Ir Eric Pang Yiu-hung, JP, Director of the Electrical and Mechanical Services, Government HKSAR as the Guest of Honour, to support and encourage the industry to implement retrofitting for better operation performance in energy efficiency for their existing building stocks. Pang said, “Showcasing successful experience and case studies of retrofitting projects, the ‘HKGBC Retrofitting Guidebook’ is an invaluable reference tool for the industry.”

Representatives from the building industry including developers, property management companies, the government and representatives from various sectors also shared their successful experience in conducting retrofitting projects. To expedite lowcarbon transformation of Hong Kong and even the world, the HKGBC proactively supports the World Green Building Council (WorldGBC)’s initiatives and closely works with green building councils in other regions. At the ceremony, the HKGBC also announced that the “HKGBC Retrofitting Guidebook” would be released in over 70 regions by local green building councils. It is anticipated that retrofitting concepts can be further promoted around the globe.

Mr Donald Choi, JP, Director cum Industry Standards and Practices Committee (ISPC) Chairman of the HKGBC, remarked, “Since 2016, ISPC has been working closely with the Government on the promotion of retro-commissioning (RCx). To further our expertise on enhancing building energy efficiency, our committee has indicated the development of this Retrofitting Guidebook, which captures and provides the retrofitting solutions and case studies for readers to have a comprehensive understanding on retrofitting. Let’s construct a green society together!”

Ir Dr Cary Chan, JP, Executive Director of the HKGBC, said: “This is intended to be a living document which will be updated from time to time, with the latest best practices and technology advancements. To mainstream retrofitting in Hong Kong’s decarbonisation roadmap, the HKGBC will announce more projects and events in due course

such as webinars and conferences, competitions, pilot projects for trying out novel and smart retrofitting technologies.”

As introduced by Ir Victor Cheung, Director cum Retrofitting Expert Group Convenor of the HKGBC at the ceremony, the Guidebook has presented the retrofitting strategies in 10 key themes, including Heating, Ventilation, Air Conditioning – Water-side and Air-side, Lighting, Electricity Distribution System, Lift & Escalator, Smart Control Systems, Server Room / Data Centre, Carpark, Heating, and Building Envelope.

For more details of the HKGBC Retrofitting Guidebook, please visit https://bit.ly/3QuyQQF.

Info and Images: HKGBC

香港綠色建築議會於1月10日發布全港首份建築物節能改 造指南,並舉行啟動禮。活動邀請香港特別行政區政府機

電工程署署長彭耀雄工程師, JP 擔任主禮嘉賓,以支持及鼓勵業界

以節能改造提升既有建築的能源效益。另外亦邀請來自建築業界, 包括發展商、物業管理公司、政府及各界別的代表,分享採用節能 改造的成功經驗。

為推動香港以至全球減碳轉型,議會一直身體力行積極支持世界

綠色建築委員會的倡議,並與各地區的綠色建築議會緊密合作。在 啟動禮上,議會亦宣布《香港綠色建築議會建築物節能改造指南》 即日於全球超過70個地區由當地的綠色建築議會同步發布,期望 節能改造概念可以進一步推廣至全世界。

機電工程署署長彭耀雄工程師,JP 致辭表示:「《香港綠色建築議 會建築物節能改造指南》為業界提供絕佳的參考工具,分享節能改 造項目的成功經驗和案例。」

香港綠色建築議會董事兼業界標準及作業委員會(ISPC)主席蔡宏 興先生, JP 表示:「自2016年起,ISPC一直與政府緊密合作,向公 眾推廣重新校驗。為進一步提升建築業界對能源效益的認知,議會 運用其專業知識,推出指南介紹節能改造技術,並集結業界相關案 例,為讀者全面講解節能改造。我們相信指南有助業界提高節能改 造方面的知識,讓我們一起建設綠色社會!」

香港綠色建築議會執行董事陳永康博士工程師, JP 表示:「為促進 業界實行節能改造,議會特別推出節能改造指南,並不時更新,提 供最新的技術應用,協助業界尋找創新和技術解決方案。議會未 來將會推出更多項目及活動,例如網上研討會、會議、比賽及試點 項目等,積極推廣創新的節能改造技術,進一步推動實現低碳目標 之願景。作為世界綠色建築委員會亞太區域網絡主席,我樂見指 南同步於全球發布,可見香港在國際間推動綠色建築發展的領導 地位。」

香港綠色建築議會董事兼節能改造專家小組召集人張志剛工程師 於活動上介紹指南,指南內詳述10個主題的相關節能改造技術,包 括「輸水系統—加熱、通風、空調系統」、「配風系統—加熱、通風、 空調系統」、「電子系統—照明」、「電子系統—電力分配系統」、 「電子系統—升降機和自動電梯」、「智能控制系統」、「伺服器機 房/數據中心」、「停車場」、「供暖系統」及「建築外牆」。指南提 供的案例亦展示節能改造技術的成本及好處。

The FAÇADE #26 2023 | 57

《香港綠色建築議會建築物節能改造指南》

Related to the Building Envelope on chapter 7.2 與建築外牆結構相關資料在第 7.2 章 Scan and read the PDF version online News

正式發布

CERTIFICATE IN FAÇADE ENGINEERING

To promote the development of Façade engineering in Hong Kong, HKFA strives to nurture new talents. Since 2017 The Façade Engineering Training Course has trained up over 300 talents in the industry. The course hosted by real world practitioner successfully coached students with both theoretical and practical knowledge on façade engineering.

To accommodate talents with diverse backgrounds, two courses are introduced:

1. The Foundation Course which opens to wide candidates that are interested about the industry. It provides a basic yet comprehensive introduction to students on façade engineering, including classi fication of façade, use of material, façade design & calculation, fabrication, logistics & installation.

2. The Advanced Course which opens to professionals in the industry. It provides competent and in-depth training to students on façade engineering through variety of topics. Such as façade design in details, structural calculation, the applicable design and governing standards & codes, façade materials & selection, PMU testing, and a new chapter on fire protection in curtain wall & façade systems.

Both courses received positive feedbacks from our former students. With the coaching of our experienced lecturers, students earned deep and practical knowledge on multiple topics about façade engineering. Students are fascinated by the extensive learning experience provided by the lecturers and the course materials. The course design & materials are tailor-made by our worldclass lecturers, with deep knowledge and practical experience among the industry. The course will definitely be fruitful for students who are dedicated in a career in the façade industry.

The façade industry continues to grow globally. Rapid urbanization and increase use of façade materials promote such consistent growth among the industry. Hong Kong lies in a strategic location connecting China and other Southeast Asia market, where our leading technologies creates tremendous number of opportunities. Therefore, we must strengthen our community through educating new talents and professionals.

HKFA will continues to provide professional training courses to support the façade industry. Your active support and participation will be a great encouragement to us in developing more resourceful training and certi fications to the industry.

The 2023 Façade Engineering Foundation Course (FC1-202302) in now open for enrolment.

Seats are limited and please contact our secretariat for more details, email to info@hkfacade.org

PLEASE VISIT WEBSITE WWW.HKFACADE.ORG News

HKFA offers individual and corporate membership to those involved with façades and building envelopes, in Hong Kong, China and internationally.

CORPORATE MEMBER

Local or overseas firms, whether private or public companies authorised by government, embarking on actual façade-related work including studies, design, production, installation, commissioning and testing, or producing associated equipment, materials and promotion.

INDIVIDUAL MEMBER

Any person above 18 years old who is embarking on or involved in façade study, design, production, installation, testing, equipment, materials and relevant work.

香港建築幕牆裝飾協會為在香港、中國及國際間從 事幕牆相關行業的人士,提供個人或企業會員資格。

公司會員

凡政府認可之中外公私機構,實 際從事外牆產業相關研發、設 計、製造、安裝、測試、設備、材 料或推廣。

個人會員

任何人士年滿十八歲,從事外牆 研發、設計、製造、安裝、測試、 設備、材料及相關工作達到會員 的基本條件。

Membership

Vice Chairman of Information & Public A ffairs Sub-Committee Director (Operations) of Hip Seng Façade Engineering Co Ltd

Vice Chairman of Information & Public A ffairs Sub-Committee Director (Operations) of Hip Seng Façade Engineering Co Ltd