KAZAKH INNOVATION, EXPLORATION, AND EXCAVATION

RG Gold’s primary target in terms of procurement is to create a stable and timely supply of goods, works, and services with the highest possible economic efficiency. We discover how the gold mining company is achieving and surpassing these ambitious goals with CEO, Lawrence Rossouw

Writer: Ed Budds | Project Manager: Eddie ClintonKazakhstan has worked meticulously to position itself as a global leader in the mining and processing of gold; the country produces around 70 to 80 tonnes (t) of refined product each year.

The success of its domestic refined gold industry, along with the investment characteristics that gold has demonstrated throughout the last decade, have positioned the precious metal as fundamental to the reserves of the Central Bank of Kazakhstan.

Within this monumental industry, a crucial national resource is the impressive Raygorodok gold mine.

The history of Kazakhstan’s Raygorodok gold deposit dates back to 1996; it was in this year that the first geological exploration work was carried out at the Novodneprovskoye contract area, which consists of two quarries – Northern and Southern Raygorodok, forming the overall gold deposit located in Burabay District

in the Akmola Region, combining to create one of the nation’s largest and most profitable sites.

RG Gold is a gold mining company that develops the Raygorodok deposit field, where, according to Joint Ore Reserve Committee (JORC) classification, gold reserves total 100 t, which also makes it one of the largest mono-gold fields in the country. In future, the company’s plan is to potentially develop Novodneprovskoye and the Sharyk deposits.

The Australasian Code for Reporting of Exploration Results, Mineral Resources, and Ore Reserves, produced by JORC, provides a mandatory system for the classification of exploration results, mineral resources, and ore reserves according to the levels of confidence in geological knowledge and technical and economic considerations in public reports.

APAC

COULD YOU DESCRIBE TO US HOW YOU FIRST BECAME INTERESTED IN THE MINING INDUSTRY?

LAWRENCE ROSSOUW, CEO: “I grew up in the 1970s and 80s in South Africa. During this time, there was a massive boom in the mining industry across the country, and gold mining specifically.

“South Africa was the biggest gold producer in the world up until the late 90s, when gold mining companies were aggressively promoting the mining industry. Platinum group metals (PGM) miners soon followed suit. They used to come into schools and offer bursaries to top performers in mathematics and science; this is where the prospect of a very bright and exciting future in mining and engineering lured me to the industry.”

Lawrence Rossouw, CEO of RG Gold, believes it is a very exciting time within the industry in Kazakhstan, as the country is busy attracting foreign investment which will undoubtedly prove critical for the development of the mining landscape.

“I think Kazakhstan is still fairly new in terms of being a mining investment hub for large international corporations. However, more and more of the bigger mining companies are looking for opportunities here, alongside a boom of junior businesses that are searching and doing extensive exploration,” he introduces.

“At present, there also seems to be a drive from the Kazakh government to support foreign investment into this space and remove obstacles that traditionally made it challenging for foreign investors to bring their money to the nation.”

Since its foundation, RG Gold has invested over USD$20 million in exploration at Raygorodok.

Just a decade after operations began, 18,000 kilogrammes (kg) of gold reserves from the Northern Raygorodok site, as well as 19,000kg from the Southern Raygorodok facility, were successfully verified by RG Gold, and incremental mining was then initiated at both pits. Interestingly, the deposit was once considered small, with a development period of only five years.

In 2014, Verny Capital received the rights to develop the contract area. From this moment on, a new stage began in the history of the field with the purchase of modern equipment,

expansion of the crushing and screening complex capacity, development of a professional team, investment in geological exploration, and increase in the resource potential of the field.

A new core storage facility was built to store ore samples obtained during exploration drilling, while active development of the South Raygorodok deposit had simultaneously begun. By heap leaching oxidised ores, more than 1 t of gold in the Doré alloy was produced immediately in 2015, which increased production volume by 75 percent.

In addition to new production processes, the lives of workers and engineers gradually improved with the introduction of a new rotation camp complete with dormitories, a canteen, and a sports ground. Alongside this, active social work began to improve the villages adjacent to the deposit.

Next, airborne geophysical, groundbased areal, and geophysical profile work was carried out. More than 3,000 exploratory and specialised wells with a total length of 350 kilometres (km) were drilled to study the geological conditions of the field, and 232,000 samples were taken for detailed assay analysis. In addition, the technological properties of gold ore were studied and, through metallurgical tests, regulations were drawn up on the most effective processing method.

Based on RG Gold’s exploration results, ore reserves in Raygorodok increased threefold according to the standards of the State Reserves Commission, from 34 t in 2014 to 108 t in 2018.

“AT RG GOLD, WE AIM TO PROVIDE NOT JUST A JOB, BUT A PLACE THAT PEOPLE FEEL PROUD TO BE ASSOCIATED WITH”

– LAWRENCE ROSSOUW, CEO, RG GOLD

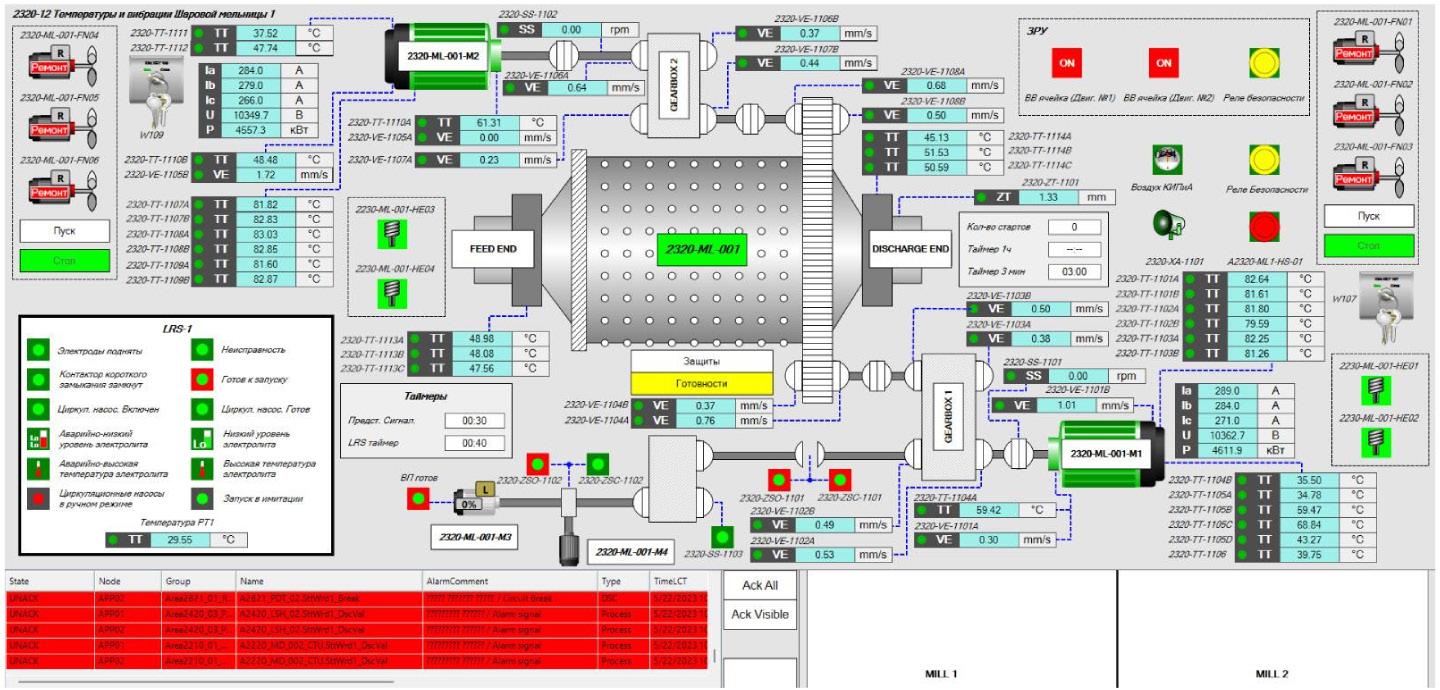

RG GOLD, a gold mining company, has implemented an ambitious project in Kazakhstan having applied the complex solutions of engineering company, Silumin-Vostok, in power supply and process automation of the plants.

The history of the deposit dates back to 1996, when the first geological exploration work was carried out at the Novodneprovskoye contract area consisting of the two open pits –Northern and Southern Raygorodok. However, the gold reserves were confirmed only 10 years later. At that time, the potential of Raygorodok was not completely studied.

The Raygorodok deposit is located in the Burabay district of Kazakhstan’s Akmola region and is considered one of the biggest deposits in the republic. The gold resources were assessed according to the international JORK classification as 100 tonnes, which makes it one of the largest gold monodeposits in the country, and the third largest gold deposit in Kazakhstan. The confirmed resources extended the term of the deposit mining from five to 20 years.

In 2014, the Verny Capital group of companies received the right to develop the contract area, and the company RG Gold was founded.

In March 2021, construction of a large mining and metallurgical complex for primary gold ore processing commenced. In a year and a half, the plant carried out smelting, and the first gold bar was produced. By the end of 2022, the full output capacity was reached which amounted to five million tonnes of ore per year.

The mining and metallurgical complex of RG Gold at the Raygorodok deposit was constructed in a record 18 months. For implementation, the RG Processing project team was created and succeeded in reaching incredible results in the short term.

It became a great challenge for RG Gold to find contractors in Kazakhstan capable of implementing such a largescale project in reduced terms.

The design and construction firm, ААЕngineering Group, undertook preparedness to fulfil all the tasks within the established deadline having become the general contractor.

Silumin-Vostok, who came forward as one of the main contractors, implemented its engineering solutions in turnkey electric power supply and

process automation of the plant using the equipment of its own production, assembled with the components of world leading manufacturers. The advantage of Silumin-Vostok became its solid experience in mining projects for the large subsurface users on the territory of Kazakhstan and Central Asia. From 2010 to 2022, the company successfully delivered 14 projects in power supply and the automation of gold recovery plants under construction.

The initial stage of the project implementation was the design engineering, comprising development of the design documentation for the plant power supply and process automation. The design-engineers of the design and engineering department developed a customised solution according to the technical specification, selected the necessary equipment with consideration of the characteristics, loads, and operating conditions, and performed calculations and drawings.

The next stage consisted of the production and supply of electrotechnical equipment for the complete electric power supply of the plant. The following equipment was installed: transformer substations КТПБ – 2 pcs, and КТПН – 2 pcs, switchgears НКУ-SVМСС – 17 pcs, containing 640 draw-out modules, complete switchgear 10 kV of 14 cells, switching cabinets ЩРВ, power take-off cabinets, contactor cabinets, mills blocking cabinets, and push-button control stations. For automated monitoring and control of the production cycles, Schneider Electric Modicon 580 redundant controllers and Schneider Electric

Modicon 340 local controllers were installed. Raygorodok is a digital mine where the control and analysis of the exploration and the further ore processing are highly automated. This reduces the risk of making a mistake and excludes the human factor. The equipment of Endress+Hauser, a constant partner of Silumin-Vostok, provided the basis for the field instruments. The following equipment was installed: 50 flowmetres, 41 level metres, 111 pressure measuring devices, and about 20 devices for density, pH, ORP metering, and gas analysers. Since it was a new-built plant, it was necessary to create a process automation system greenfield, using up-to-date corporate practices and standards. New ore monitoring technologies have been introduced with the application of

leading developments in the field of software. During open-pit mining, a threefold control is performed by means of the automation systems. A special mention was made to the data collection from the electric power distribution systems. The total number of the process flow parameters and data from the switchgears was about 11,000! The availability of such an extensive data assets allows the process engineers to make reasoned decisions.

To ensure control, Danfoss MD-202 and MD-302 frequency converters in the amount of 106 pcs, and MСD-600 soft starters in the amount of 11 pcs, have been installed.

To increase the production capability in all process areas, the AVEVA System Platform 2020 R2 software

has been introduced. The software is a flexible scalable solution for dispatch control applications, which integrates the production and the plant management. It provides the basis for a multi-user operation based on standards, and integrates people, processes, and assets on all sites for continuous operation, improving and supporting decision making on a realtime basis.

Installation and commissioning work included setting up the electrical equipment, instruments, and all process machines with minimum overloads and the possibility of regulating the production capacity of the plant process equipment. For ease of operation, the process equipment was selected in such a way to ensure further fault-free operation of the plant, and resist intensive overloads and severe operating conditions.

The difficulty of the project itself was in the very limited delivery terms, and the restrictions imposed during the СOVID-19 pandemic conditions made the work more complicated since they were affecting the material logistics and the work of the personnel.

Being a part of the RG GOLD project, the specialists of Silumin-Vostok successfully performed all the work on supply, installation, set-up, and programming, having proved their expertise once again. The project of the Raygorodok GRP became one of the key projects in the portfolio of Silumin-Vostok.

The company was founded in 1996 and is located in the city of Ust-Kamenogorsk in the east of Kazakhstan.

It is a leader in the market of the country in process automation and power supply, complex development of projects, and supply of high-quality equipment for various industries including mining, metallurgical, petrochemical, electric power engineering, construction, and heat power engineering.

The personnel of the company totals more than 400 specialists. There is a 12,000 square metre (sqm) production complex housing complete cycle production, and a 3,000 sqm warehouse.

The design and engineering department performs the development of customised engineering solutions for each specific project. The logistics department and the truck fleet, comprising about 40 vehicle units, deliver products to the customer’s site.

Throughout its existence, SiluminVostok has proven itself as a reliable partner, responsible contractor, and qualitative producer.

Having extensive experience in implementing the projects of subsurface users, and participating in large construction projects of new ore processing plants and mining

complexes, Silumin-Vostok is able to offer solutions in the following areas:

COMPLEX DESIGN ENGINEERING of the electrotechnical and automation parts of a project adapted for a specific customer:

• Low-voltage (0,4kV) and high-voltage (6-220kV) electrical switchgears, transformer substations

• Process automation systems

• Software development for automation and dispatch control systems

ELECTRIC POWER SUPPLY AND DISTRIBUTION

of low and medium voltage, which is customised and able to fully correspond to the design concept:

• Switchgear units of normal miningtype execution КРУ-РН-SV (6 kV)

• Switchgear units with a middle draw-out circuit breaker КРУ-Уба SV (6,10 kV)

• Substation relay protection cabinets

• Low-voltage switchgears НКУИртыш (0,4-0,69 kV)

• Operating current control cabinets ШУОТ-SV

• Complete transformer substations КТП-SV

• Substations in packaged modular buildings

INDUSTRIAL PROCESS AUTOMATION in production process automation, direct digital control systems, data collection, control and monitoring:

• Process automation systems

• MES-system

• Software and hardware suites

• Automatic control systems

• Power distribution monitoring and control systems

Silumin-Vostok is a leading Kazakh industrial equipment manufacturer, complex engineering solutions developer, and software system integrator. +7

ELECTRONIC AND MECHANICAL SYSTEMS OF DRIVE EQUIPMENT according to the customer requirements, technical specifications, and operating conditions:

• Variable frequency drives and soft starters of low (0,4-0,69kVВ) and medium voltage (6-10kV)

• Asynchronous and synchronous electric motors

• High-voltage power factor compensation systems and harmonic filtering systems

• Control cabinets for process installations with frequency converters or soft starters

• Liquid resistance starters up to 3000А

• Uninterruptible power supply systems of frequency converters

INDUSTRIAL COOLING SYSTEMS for the industrial cooling of production facilities in order to ensure the necessary indoor temperature conditions:

• Industrial chillers (64 kW - 860 kW)

PUMP EQUIPMENT

for pump stations in packaged modular buildings

• Borehole pump units

• Horizontal centrifugal pumps

• Double-ended suction pumps

• Vertical multistage pumps

• Slurry pump units for abrasive media

• Sewage and drainage pumps

• Container-type complex pump stations

VALVES

ball valves of stainless steel with diameter range up to 1,000mm

COMPRESSOR EQUIPMENT AND AIR SUPPLY SYSTEMS

for providing compressed air of any grade of treatment and of any capacity:

CONSTRUCTION, INSTALLATION, START-UP AND COMMISSIONING SERVICE MAINTENANCE

For the first time in the history of the field, an assessment was carried out according to the international JORC classification. The total resources were estimated at 185 t, of which economically viable reserves for processing amounted to 100 t. Subsequently, confirmed reserves then extended the development period of the field from five years to two decades.

When studying the mineral composition of ore samples, it was established by the company that gold in oxidised and primary ores is found mainly in free form and large intergrowths with pyrite, galena, and quartz, or in microcracks of pyrite and quartz. 1 t of ore from Southern Raygorodok contains about 1.3 grams (g) of gold on average, compared to 1g from Northern Raygorodok. Furthermore, continued geological exploration confirmed that

RG Gold’s mission is to efficiently extract and process gold from its lowgrade, open-pit mines, continually expand its reserves through geological exploration, and provide a safe and inspiring workplace for its people. The company remains committed to responsible mining practices that benefit shareholders, employees, and the environment.

To be recognised globally as a leader in sustainable and responsible gold mining, delivering prosperity to shareholders, employees, and the communities in which it operates, while setting the standard for excellence and environmental stewardship in the industry.

Raygorodok is a large gold ore object of the zonal stockwork type.

Responsibility is a crucial principle of RG Gold.

This foundational value means being responsible towards not only the company’s own resources and employees, but also the people who live near the Raygorodok mine.

“Our company implements social projects worth about KZT100 million every year, and we regularly meet with local residents and representatives where we discuss potential directions for future investments that would help improve the socioeconomic quality of life in the area,” Rossouw affirms.

“Meanwhile, our sponsorship portfolio is continuously growing; new projects arise based on residents’ requests as well as the projects initiated by RG Gold. Infrastructure in the nearby villages is being improved, and schools are being repaired and fitted

out systematically with materials and equipment,” he continues.

To supplement this, local residents are prioritised for employment, regional small businesses receive support, the best regional graduates are given educational grants to go to colleges or universities, and cultural, sports, and entertainment events are organised for the community by the company.

In this way, RG Gold adheres to its own carefully established principles of sustainable development and aspires to implement social projects locally.

In September 2022, a brand new five million tonnes per annum (Mtpa) primary gold ore processing plant was brought into operation by RG Gold, capable of reaching greatly enhanced production levels.

The new carbon-in-pulp (CIP) plant’s design is unique as it allows ore processing with the lowest operating costs and presents an opportunity

to implement global environment protection standards.

“Our new CIP plant was designed by international engineering companies with a focus on automated production and the implementation of advanced metallurgy technologies. Incredibly, the plant was erected in an astonishing 18 months,” details Rossouw.

A jewel in the RG Gold crown, the game-changing plant features state-of-the-art equipment made by leading manufacturers, such as Metso Outotec, ThyssenKrupp, FLSmidth, Weir Minerals, Roytec, and Kemix. This high-tech equipment not only ensures the safety of staff, but has notably increased the efficiency of production and led to lower operating costs across the board.

“The launch of the new processing plant was a key milestone for RG Gold. It is underpinned by the highest global industry standards using the latest innovation and technical expertise from Resource Capital Funds, our strategic partner,” he adds.

AK-NIET BURGA is a drilling company that focuses on the production of geological prospecting and drilling of wells, as well as the trenchless laying of oil and gas pipelines, urban utility service communications, and much more.

These areas are focused on by AK-NIET BURGA both within Kazakhstan and further afield in Russia and Uzbekistan.

A powerful production base, along with a talented team of highly qualified professionals, allows the company to successfully solve tasks of any complexity and ensure the high-quality performance of operations for its customers.

AK-NIET BURGA was founded in February 2005, and during those 19 years, it has become a leader in the field of reverse circulation (RC) drilling, and has drilled more than 3,000,000 meters. This is one of three services provided by the company along with diamond drilling and horizontal directional drilling (HDD).

The RC drilling offered by AK-NIET BURGA is similar to air core drilling, in that the drill cuttings are returned to surface inside the rods.

The drilling mechanism is a pneumatic reciprocating piston, which drives a tungsten steel drill bit. By utilising much larger rigs and machinery, RC drilling routinely achieves depths of up to 500 metres.

RC drilling ideally produces dry rock chips, as large air compressors dry the rock out ahead of the advancing drill bit.

As it is cheaper than diamond coring, RC drilling is therefore preferred for most mineral exploration work.

In the diamond drilling services offered by AK-NIET BURGA, a diamond encrusted drill bit is used to penetrate the rock. The bit is mounted onto a drill stem, which is connected to a rotary drill.

The drill produces a core, which is split longitudinally. Half of the split core is assayed, while the other half is permanently stored for future use and re-assaying if necessary.

AK-NIET BURGA uses HDD in the construction of water and wastewater mains, cables and casing, and gas and oil pipeline areas.

Before commencement of operations, the properties and composition of the soil, and the dislocation of existing underground utilities, are carefully studied. Appropriate permits and approvals for the performance of underground work are executed.

Selective penetration tests are also carried out, along with probing of the most complex intersections of the drilling route with existing utilities if required.

Long-term partnerships with leading subsoil users in Kazakhstan’s mining industry testify to the high professionalism of AK-NIET BURGA’s team. KazMinerals, Polymetal, RG Gold, AltynAlmas, Caravan Resources Group are the main companies we work with. Honesty, integrity, and dedication serve as key values in the company’s internal corporate culture, whilst competitive salaries, opportunities for career growth, and regular training are evidence of AK-NIET BURGA’s high standards.

What services does AK-NIET BURGA provide?

The main focus is RC drilling, followed by core drilling and horizontal directional drilling.

What makes AK-NIET BURGA a leader in the field of RC drilling?

In 2005, we saw the great potential of RC drilling in the Kazakhstan market and were one of the first to launch this type of drilling. 19 years of practical experience, high quality of work, annual performance records and successful implementation of more than 40 projects for the leading subsoil users of Kazakhstan have consolidated our position as a leader in RC drilling.

How do your powerful production base and team of highly qualified professionals allow you to successfully solve tasks of any complexity and ensure high-quality operational performance for customers?

Our priority is to ensure quality work performed in accordance with the client’s deadlines. Our team of 200 qualified specialists, drilling equipment park of 10 drilling rigs and 10 compressors for RC drilling, four drilling rigs for core drilling and one drilling rig for horizontal directional drilling, production base in Almaty, warehouse, repair box, and about 50 pieces of auxiliary equipment allow us to successfully realise tasks of any complexity.

How much experience does AK-NIET BURGA have in implementing complex projects in various fields?

Prolonged cold winters with a lot of precipitation and very hot summers create additional difficulties in drilling operations. In our experience we have realised projects where drilling was carried out in mountainous terrain, as well as drilling works carried out on dumps using drilling technology with simultaneous casing (symmetrix). Exploration drilling works were carried out for gold, copper, tin, molybdenum, zinc, vanadium, etc.

In designing and erecting the CIP plant, RG Gold pursued a zeroemission environment policy, and the site’s cyanide will continue to be neutralised in line with international standards. Furthermore, after preliminary treatment and destruction, all waste is pumped into a vast storage facility constructed for this specific purpose and supervised by international experts.

The launch of this groundbreaking new production hub promises to have a beneficial and multifaceted effect on regional development; new jobs will be created, and small businesses will grow through supplying services and goods to this major industrial plant.

Additionally, as part of the project, RG Gold has built a brand new accommodation camp where over 300 additional people have been employed, mostly made up of local residents.

“At RG Gold, we aim to provide not just a job, but a place that people feel proud to be associated with.”

Expanding on this bold statement from Rossouw, the company maintains a keen focus on employee development and implements international best practices in the technologies it deploys, as well as the systems and business processes it uses.

“Our international shareholder owns multiple projects across the world, and we tap into this opportunity to ensure we stay ahead. The implementation of modern engineering and digital tools provides our people with skills and qualifications that give us an edge over other mines. We also strive to be the safest mine not just in Kazakhstan, but the whole region,” he voices.

Elsewhere, RG Gold systematically contributes to the development of the region.

When hiring new personnel, the company gives preference to local specialists, allocates educational grants for local youth, purchases

EXCELLENCE IN WORK:

EFFICIENT MINING – Implement the latest technology and advanced mining methods.

CONTINUOUS PROCESS IMPROVEMENT – Focus on mill efficiency and throughput.

COST MANAGEMENT – Streamline operations, reduce waste, and negotiate favourable contracts.

GEOLOGICAL EXPLORATION:

EXPLORATION INVESTMENT – Allocate resources to explore the company’s identified properties.

RESOURCE EXPANSION – Evaluate and expand gold reserves using advanced exploration techniques.

INTELLIGENCE INNOVATION – Use technology and data analytics to improve accuracy and efficiency.

SAFETY AND WELL-BEING:

SAFETY AS A PRIORITY – Focus on zero injuries and regular safety training.

EMPLOYEE WELLNESS – Create a work environment that prioritises physical and mental well-being.

ENVIRONMENTAL RESPONSIBILITY:

ENVIRONMENTAL COMPLIANCE – Adhere to the highest environmental standards and regulations.

SUSTAINABILITY INITIATIVES – Adopt sustainable mining practices and energy efficient technologies.

INTERACTION WITH STAKEHOLDERS:

COMMUNITY PARTNERSHIPS – Strengthen positive relationships with local communities.

SHAREHOLDER VALUE – Deliver continued returns while maintaining responsible practices.

TALENTS AND ATTRACTIVENESS:

INVESTING IN THE WORKFORCE – Develop and empower employees.

EMPLOYER OF CHOICE – Offer competitive compensation, work-life balance, and career growth opportunities.

INNOVATION AND TECHNOLOGY:

TECHNOLOGICAL ADVANCEMENT – Improve operations, reduce environmental impact, and increase exploration efficiency.

DATA-DRIVEN DECISION MAKING – Use data analytics to make informed decisions.

CORPORATE GOVERNANCE:

TRANSPARENCY AND ETHICAL BEHAVIOUR – Maintain high standards of corporate governance, ethics, and compliance.

SGS, the paragon of excellence in testing, inspection, and certification, stands as a luminary across the globe. In any domain, within any industry, our distinguished experts offer bespoke solutions, enhancing your enterprise’s speed, simplicity, and efficiency.

Our seasoned connoisseurs deliver services of unparalleled international stature, embodying both strategic partnership and sage advisory roles. Our vast network unfurls a tapestry of independent, quality, and quantity services, including meticulous inspection, revered laboratory testing, sovereign laboratory management, and esteemed quality certifications by neutral arbiters.

In the intricate web of natural resources - vital to economic vibrancy and daily life - the sectors of agriculture, mining, and energy are in flux, driven by global trade, market dynamics, and a deepened commitment to environmental and social governance. SGS stands at the forefront, offering an unrivalled spectrum of services powered by cutting-edge technology. Our global experts assist with laboratory outsourcing, commodities logistics, geochemistry, metallurgy, and sustainability, enabling risk reduction, informed decision-making, and integrity maintenance. Our services are designed to foster sustainable practices and compliance, boosting productivity, quality, and consumer confidence.

A landmark collaboration with RG Gold led to the inauguration of a major SGS laboratory in the Caspian region in May 2023, part of RG Gold’s ambitious project at Kazakhstan’s Raygorodok deposit. Staffed by highly qualified

Phone: +7 (727) 2 58 82 50/51

Email: kz.enquires@sgs.com

https://www.sgs.com/ru-kz

Kazakhstani nationals, the team benefits from continuous development through our SGS Caspian University programme

Equipped with top-tier international instruments, the laboratory epitomises reliability and precision. We champion sustainable development and a green global economy, with our labs utilising energy-efficient lighting and advanced air purification systems.

SGS’s commitment to accuracy, reliability, transparency, and professional growth cements our status as a global leader in laboratory management. The opening of this complex underscores our dedication to quality and our capability to offer superior services. We remain steadfast in providing toptier analytical services to our clients.

Facebook: SGSCaspian

LinkedIn: SGS

Instagram: sgs caspian

household goods and services from local entrepreneurs, and invests in the improvement of villages near the deposit.

Today, alongside its monumental growth, 1,100 people are employed by RG Gold to work at the Raygorodok mine and the company headquarters.

“Employees play a key role in any production, and despite the importance of material and technical resources, the human factor remains a priority and is the main asset which requires attention and support, as well as safe labour conditions,” Rossouw acclaims.

RG Gold has an effective staff incentive system in place in addition to an advantageous employee rewards programme. Staff salaries are revised annually and depend on the planned production targets achieved, as well as key performance indicators (KPIs).

“Our main priority in terms of

“THE LAUNCH OF THE NEW PROCESSING PLANT WAS A KEY MILESTONE FOR RG GOLD. IT IS UNDERPINNED BY THE HIGHEST GLOBAL INDUSTRY STANDARDS USING THE LATEST INNOVATION AND TECHNICAL EXPERTISE”

– LAWRENCE ROSSOUW, CEO, RG GOLD

employees is to enhance labour conditions with a resolute focus on safety. We strive for a zero-harm culture where every employee is responsible not just for their own safety, but also the safety of their fellow colleagues,” he insights.

Protecting personnel and ensuring safe work is one of the company’s fundamental values.

RG Gold invests heavily in

improving its safety culture and maintains the highest standards of management control in the field of occupational health and safety.

Additionally, RG Gold pays special attention to sustainability issues and environmental protection. The principle that the company follows is ‘zero emissions released into the environment’; all processes are therefore carried out in accordance with the requirements of local and international standards.

Accounting for public opinion,

Eurasian Machinery is the official distributor in Kazakhstan and Central Asia of Hitachi Construction Machinery Co.Ltd, a leading global Japanese manufacturer of mining equipment, employing more than 1,000 people, and having 20 branches in Central Asia. Eurasian Machinery is renowned for providing high quality technical services to its customers through 10 centres, including a high-tech component repair centre in Karaganda City, Kazakhstan.

“To date, three units of Hitachi EH11005 dump trucks, one unit of a Hitachi ZX470LC-5G hydraulic excavator, and one unit of a Manitou MT-X 1440 telehandler are in operation at RG Gold’s mine site. We believe that our cooperation with RG Gold will become even stronger in the future,” says Sergey GREKHOV, Managing Director of the Mining Division at Eurasian Machinery.

“There is no doubt that the mining sector in the region continues to grow. Having an OEM partner such as Hitachi Construction Machinery Co.Ltd, a leading manufacturer of high-performance, high-quality mining equipment for a wide range of applications, will enable us to remain strong in this growing market.”

+7 (727) 344 33 66

+7 701 110 21 12 info@eurasiancm.com eurasianmachinery.kz

RG Gold creates conditions for open cooperation in the field of environmental protection with government agencies, interested organisations, and the public.

It does this through an open demonstration of environmental responsibility, fulfilment of target indicators of information, and communication technologies in the field of environmental protection.

As such, public hearings on planning issues for the construction of new facilities are periodically held in the form of open meetings.

Equally concerned with the protection of its people, RG Gold also rewards exceptional attitudes towards safety and has created a fund to reward employees who prevent serious production and safety incidents.

Elsewhere, the company offers support for employees affected by natural disasters or emergencies resulting in

considerable financial damage or a threat to either health or life.

As well as improved labour conditions provided by the company, RG Gold’s employees are entitled to a special social support package which includes medical insurance for staff and their family members, mobile communication services, languages training, transportation, and discounts as part of partner programmes.

Additionally, the company hosts various corporate events, including training, sporting events, and festivals, and provides opportunities for further education and training.

When employees face major events in their lives, RG Gold also offers bonus social leave. For example, in case of the birth of a child or a wedding ceremony, an additional holiday is given; employees are likewise given free time to attend important family and school-related events.

On top of this, the company provides financial aid to employees who retire, give birth to a child, or get married. Staff who have three or more school-aged children are also given financial support to prepare for the new academic year.

No doubt, it is the company’s unmatched dedication to social development, alongside the technical enhancement of its mines, that will continue to distinguish RG Gold within such a competitive and constantly expanding field.

Tel:

+7 (7172) 739-780

info@rggold.kz

www.rggold.kz