THE PREMIER SUPPLIER OF DEFENCE PRODUCTS AND SYSTEMS

Following a period of stagnation in the Australian automotive manufacturing sector, caused by the removal of operations to offshore capabilities, the Australian government is focused on reinvigorating the country’s domestic manufacturing capabilities to become more self-reliant and resilient.

The Australian government has a strong focus on

Manufacturing world-leading technology Kongsberg Defence Australia is working suppliers to deliver proven and effective systems Royal Australian Navy.

John Fry,

shipbuilding, particularly in the development of nuclear submarines, which places the country on a similar trajectory to that of the US and the UK.

There is also a growing priority by the Australian government on the domestic production of guided weapons and explosive ordnance, potentially offering exciting opportunities for the country’s defence industry.

Writer: Lucy Pilgrim | Projecttechnology for the Australian Defence Force, together with industry partners and key systems to both the Australian Army and General Manager, enlightens us

The combination of significant international growth and good product alignment with Australian capability investment priorities means that Kongsberg Defence Australia is well placed to take advantage of the recent drive for increased domestic capability, especially noting its distant geographical location from its parent company in Norway.

“It has been exciting for us because we have transitioned from a marketing presence to an established production presence in Australia. This has resulted in an increased workforce, growth in the domestic manufacture of critical capability solutions, and development of a national supply chain across our key programmes,” introduces John Fry, General Manager.

Project Manager: Thomas ArnoldKongsberg Defence Australia is the Australian subsidiary of Norwegian parent company, Kongsberg Defence and Aerospace (KDA), a rapidly growing business unit within the KONGSBERG Group (KONGSBERG).

A global technology company, KONGSBERG delivers critical capability solutions to customers operating in extremely challenging environments.

Established in 1814, the group has a proud 200-year history of providing innovative solutions to meet the needs of customers, partners, and society.

As a subsect of KONGSBERG, KDA has nurtured best-in-class capabilities, with a highly successful export business, possessing strengths in particular global market segments.

Examples include the National Advanced Surface to Air Missile System (NASAMS), an integrated air and missile defence capability, as well as the Naval Strike Missile (NSM) and Joint Strike Missile (JSM), both precision strike weapons. Arguably, they are the most known of the PROTECTOR family of remote weapons systems, with over 20,000 units sold across more than 25 nations.

KDA, meanwhile, is growing significantly as a consequence of increasing global instability that has caused many nations to increase spending to acquire defence capabilities quickly.

The US is a key customer, as the company stands out as one of the few non-US organisations that has been successful in delivering capability to North America. Therefore, the Australian Defence Force’s (ADF) alignment with the US places Kongsberg Defence Australia in an even greater position for growth.

KONGSBERG is deeply proud of its partnership with the ADF, which has a history of more than 30 years.

Together with Prime Contractor, Raytheon Australia, Kongsberg Defence Australia is currently delivering NASAMS, a short/medium range ground-based air defence system, to the Australian Army.

The company established manufacturing and production activities in Adelaide to support the NASAMS programme. A significant amount of the scope was the local production of the NASAMS Fire Distribution Centres that integrate

and control all system elements. To successfully achieve this, the company established partnerships with Australian suppliers such as Adelaide-based REDARC Electronics, Daronmont Technologies, Zenith Custom Creations, Defence Coating Systems (DCS), Albury-based Milspec Manufacturing, and Sydney-based Eylex.

The NASAMS programme has significantly benefitted these companies, allowing them to grow their local business, increase their Australian workforce, and enhance their manufacturing processes to make them globally competitive. It has also provided businesses exposure and qualification into KONGSBERG’s global supply chain, facilitating opportunities for future exports in other international programmes.

“The Australian NASAMS configuration is unique in the sense that it has an indigenous radar in its system. KONGSBERG worked as part of the programme to integrate the new sensor technology into the capability,” explains Fry.

NASAMS has now been delivered to over 13 nations, including Ukraine, where it is combat-proven following

“WE ENGAGE CLOSELY WITH OUR SUPPLIERS BECAUSE WE UNDERSTAND THAT THEY ARE CRITICAL TO OUR SUCCESS, AS WE RELY ON THEM TO DELIVER TO THE REQUIRED STANDARD ON TIME, SO THAT WE CAN DO THE SAME AT A CAPABILITY LEVEL”

– JOHN FRY, GENERAL MANAGER, KONGSBERG DEFENCE AUSTRALIA

protracted operations, which saved countless lives and exemplified the system’s reliability and effectiveness.

Another key programme for Kongsberg Defence Australia is the support of prime contractor Hanwha Defense Australia (Hanwha), as part of the Protected Mobile Fires capability - the acquisition of the AS9 self-propelled Howitzers and AS10 Armoured Ammunition Resupply Vehicles.

KONGSBERG is Hanwha’s C4 systems and integration partner, incorporating the Protected Mobile Fires capability into the Army’s C4 Force Structure. This involves the integration of tactical communication systems and Battle Management Systems into the KONGSBERG CORTEX C4 solution.

In doing so, the organisation is transferring hardware and software technology and expertise to Kongsberg Defence Australia to execute and support the Australian programme.

“It’s a Korean gun with a Norwegian brain. We’re leveraging the work that was done for the Norwegian Army and taking it to the next level by adapting it to the ADF force structure and introducing new interfaces and capabilities for our specific needs.”

Most recently, Australia announced the selection of KONGSBERG’s NSM to replace the Harpoon AntiShip Missile capability on the Royal Australian Navy’s (RAN) ANZAC Class Frigates and Hobart class destroyers,

significantly enhancing the ADF’s ability to strike targets at extended range.

With a range of 250 kilometres, the NSM is a fifth-generation precision strike missile that can be used for both maritime strike and land attack. Offering operational flexibility and survivability with proven precision and lethality, NSMs can be launched via ship, vehicle, and helicopter, providing flexibility for multi-domain employment.

NSM is in service and has been selected by 12 countries, including the US, UK, Canada, Germany, and Norway.

As part of delivering this capability to the RAN, Kongsberg Defence Australia is focused on expanding its local manufacturing base and partnering with key suppliers to provide a significant amount of locally manufactured content.

Since the NSM acquisition announcement in 2022, the company has established small to mediumenterprise (SME) partnerships with Melbourne-based companies Marand, Australian Precision Technologies (APT) Advanced Manufacturing, and Stahl Metall.

The company has also worked with Adelaide-based companies Aerobond Defence, QPE Advanced Machining, and Axiom Precision Manufacturing, as well as Newcastlebased Nupress Group to deliver a range of complex assemblies and components.

With the extended stagnation of Australian manufacturing capabilities in previous years, the government is encouraging organisations to conduct as much business on home soil as possible.

Kongsberg Defence Australia’s suppliers are important to the ADF, as its strong network will support and maintain the defence force’s systems for decades to come.

JOHN FRY, GENERAL MANAGER: “As a growing organisation, we have become increasingly active in the communities in which we operate.

“Significantly, veterans comprise over half of our workforce, so supporting the veteran community is important to us. Therefore, we partner with several veteran organisations such as Legacy Australia as well as Soldier On Australia, where we are currently a Platinum Pledge Partner.

“We recently joined in the Gift of Life Walk to raise awareness of national tissue and organ donation. We have also partnered with Australian Red Cross Lifeblood (Lifeblood) and formed a Kongsberg Defence Australia team that regularly gives blood. This is an important cause as one in three Australians are going to need a blood donation at some point in their lives, and that’s something we are all embracing.”

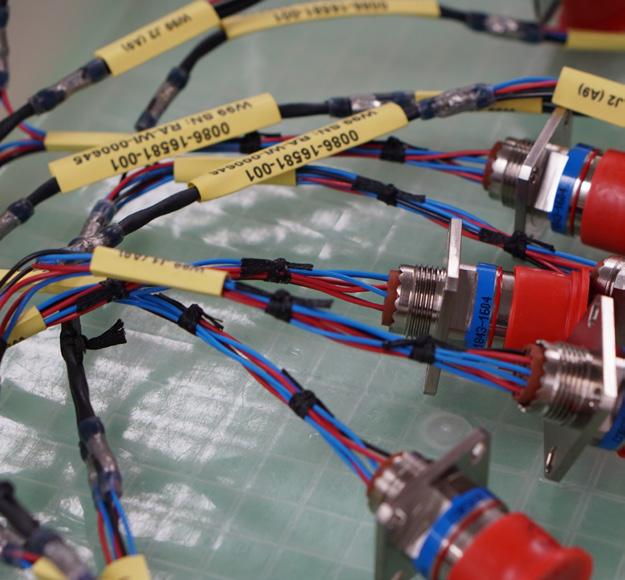

Eylex specialises in the supply of world class communications, power, and cable system solutions to the Australian and New Zealand Defence Forces and key primes within the defence industry.

In early 2020, Eylex was selected by Kongsberg Defence Australia (KONGSBERG) as the cable system provider for their key subsystems of the National Advanced Surface to Air Missile System (NASAMS) with being delivered to the Australian Army under Project LAND 19 Phase 7B. In June 2021, it was announced that Eylex was selected by KONGSBERG to provide cable systems for an International NASAMS programme.

This critical business enabled Eylex to further invest in its production capability and capacity, doubling its usable cable assembly space and sparking the company’s move to our new premises in Norwest. At 2,150 square metres, the facility is 210 percent larger than the previous building. The climate-controlled ground floor space is more than double the area at Castle Hill

and combines service and cable production technicians into one area. The additional space and latest modular workspace arrangements will allow the team to adapt the operation to manage a wide range of cable / electronic assembly and kitting activities.

Warehousing has also increased by more than 200 percent allowing for future expansion in logistics and storage. The first-floor open plan office incorporates an expansive training room and rapid prototyping lab to provide the engineering team with a dedicated area for the test and development of new concepts and designs.

Eylex is a quality driven and customer service focused company who pride themselves on the local manufacture of complex and military grade cable systems.

We are focused on creating long-term relationships with our customers that are built on transparency, customer satisfaction, and supply chain performance. Our aim is to continuously build our value proposition for our defence customers and to contribute to the development of Australia’s sovereign defence capability.

Eylex is certified to ISO 9001:2015, IPC-620 and IPC-J-STD.

Our dedicated team are vital to our success, and we are committed to the continuous development of their skills and knowledge with structured learning plans and progression through tiered technical levels. The Cable Systems team are experts in the design and manufacture of cable assemblies to the highest quality and Mil-Spec standards. Our team of engineers is ready to support with a range of services that include customised cable design, computeraided design (CAD) 3D and 2D design, application engineering, production and process engineering, electrical and mechanical expertise, project management and planning, and configuration management of our customers’ specific requirements.

“This involves being able to sustain and maintain military equipment from local industry to the greatest extent possible, and this has been a core element in the transfer of technology whilst encouraging Australian suppliers into the global supply chain,” Fry details.

“We engage closely with our suppliers because we understand that they are critical to our success, as we rely on them to deliver to the required standard on time so that we can do the same at a capability level.

“We also want to ensure that these Australian companies have the best chance of being competitive in other global programmes, which benefits both parties.”

Kongsberg Defence Australia has also been working with other Australian companies, such as Thales

KONSBERG is committed to achieving sustainable development through the global delivery of innovative and reliable products and services.

The group recognises that some of its operations may have a negative effect on the planet and society, and is therefore dedicated to mitigating these impacts through responsible and environmental practices.

For example, its new South Australian facility is being constructed with a focus on sustainability.

“We are striving to earn a Leadership in Energy and Environmental Design (LEED) Platinum certification for the facility; if we achieve it, we will be the first building in Australia to reach that level of sustainability,” Fry discloses.

“WE HAVE TRANSITIONED FROM A MARKETING PRESENCE TO AN ESTABLISHED PRODUCTION PRESENCE IN AUSTRALIA. THIS HAS RESULTED IN AN INCREASED WORKFORCE, A GROWTH IN THE DOMESTIC MANUFACTURE OF CRITICAL CAPABILITY SOLUTIONS, AND DEVELOPMENT OF A NATIONAL SUPPLY CHAIN ACROSS OUR KEY PROGRAMMES”

– JOHN FRY, GENERAL MANAGER, KONGSBERG DEFENCE AUSTRALIA

AEROBOND DEFENCE IS AN ADVANCED SUSTAINMENT and manufacturing company working globally in the aviation, defence and space sectors.

The company employs state-of-the-art design methodologies and strategic problem-solving to deliver enhanced products for its customers. This dedication to excellence and innovation has earned it accolades and recognition both in Australia and around the world.

AEROBOND Defence is partnering with KONGSBERG Defence Australia to produce launcher-canisters for the KONGSBERG Naval Strike Missile (NSM).

Our contract with KONGSBERG is a recognition of the deep skills, experience and expertise that we have cultivated within AEROBOND and across our workforce. It is an important milestone in our pathway to becoming a leading supplier in the Defence industry supply chain.

Justin Struik AEROBOND Founder and Managing Director

Australia, to position it for possible future opportunities by tailoring its products to best align with the force structure of the ADF.

One example is the StrikeMaster launcher configuration for the proven and fielded NSM Coastal Defence System (CDS). StrikeMaster comprises the Thales Australia Bushmaster utility vehicle carrying a twin-pack NSM launcher.

“Mating the Thales Australia Bushmaster vehicle with the NSM provides a rapidly deliverable, land based maritime strike capability, which can leverage the support infrastructure already being delivered by other programmes.

“From a capability perspective, it also aligns with what the United States Marine Corps is doing, albeit on a different platform. Hopefully, the ADF will look to pursue a land-based maritime strike capability in the future,” says Fry.

With the advancement in Kongsberg Defence Australia’s

contracts and customer base, the company has expanded its operations in the form of a new facility in Adelaide, South Australia (SA), set to be fully occupied and operational by June 2024. The purpose-built facility comprises a 2,500 square metre integrated production capability, alongside office accommodation to complement its existing headquarters in Canberra.

This is a landmark investment by Kongsberg Defence Australia, with the facility being the first defence business building in the region. The AUD$25 million investment in SA demonstrates the company’s commitment to supporting local production and sustainment activities for current and planned defence programmes.

To deliver the project successfully, Kongsberg Defence Australia has partnered with local SA companies, Tandem Building Group, Norman Disney Young, and Section Six Architects.

“This is exciting for us as it demonstrates to the Australian government that the company is committed to the long-term support of the ADF.

“It also shows our suppliers and the Australian market that we are here for the long term and want to maintain our relationships with our supply chain,” concludes Fry.

Tel: +61 2 6174 2269

kdaustralia@kongsberg.com

www.kongsberg.com

Senop ensures operability in all conditions through high-performance military optronics and fire distribution center integration projects.

Our experience in demanding system integration services makes us an excellent partner for producing reliable systems for harsh environments. Senop has been Kongsberg’s trusted supplier since 2009, and our partnership covers various systems and parts for NASAMS and NSM systems.

Senop’s ARCTIC FOX Shelter System adapts easily to customer-specific needs while offering excellent agility as well as protection for mobile operations.

Senop is an experienced developer of enhanced night vision devices and target acquisition systems. Our new Senop AFCD TI smart sight is designed for use with the Carl-Gustaf M4/M3 Multi-Role Weapon System.

Senop is a part of PATRIA Group | Senop Oy, Lentolantie 7, FI-36220 Kangasala, Finland