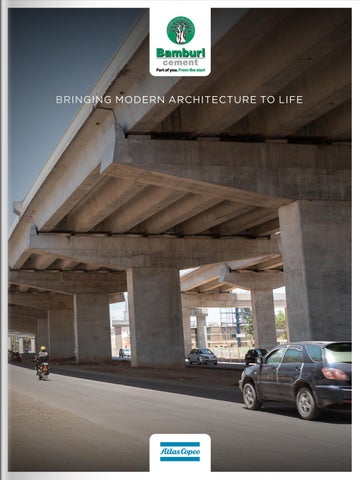

BRINGING MODERN ARCHITECTURE TO LIFE

As Kenya’s most trusted cement and concrete partner with over 70 years of expertise, Martin Kariuki, Commercial Director at Bamburi Cement PLC, speaks to us about putting innovation and customised solutions to work to build a nation Writer: Lauren Kania | Project Manager: Kierron Rose

It is impossible to tell the story of East African cement manufacturing without starting with Bamburi Cement PLC (Bamburi).

When Croatian construction magnate, Felix Mandl, arrived in Kenya in 1951 whilst on an exploration mission, he promptly decided to make the country his home, beginning a cement company in the coastal town of Mombasa and thus invigorating the now colossal industry.

Having been synonymous with cement manufacturing and marketing in the region for decades, Bamburi is at the forefront of innovation in construction, driven by high performance, new technologies, and sustainable building and construction products and solutions.

Martin Kariuki, Commercial Director of Bamburi, has nearly two decades of experience in auditing, assurance, and finance, along with a

BAMBURI READYMIX CONCRETE:

Provides convenience, coupled with guaranteed quality for any construction process. The concrete mix is weight-batched using a highly controlled and computerised process which is then delivered via transit mixers, ready for use without additional labour costs, material wastage, or pollution.

BAMBURIBLOX:

High-quality precast concrete paving blocks that offer superior paving solutions. Manufactured by the Bamburi Special Products subsidiary, these come in a variety of designs, colours, and other aesthetics for every preference, offering an affordable, easy, and durable option for exterior pavement applications.

BAMBURI PRECAST MOULD:

A variety of precast mould concrete products for different applications and specifications ranging from black drainage, hollow blocks, road kerbs, and edge restraints to fencing products.

diversified financial services career. These abilities and attention to detail have proven to be crucial in project management and cost analysis within the ever-growing building sector.

“My career in financial auditing exposed me to a variety of industries.

I viewed the possibilities of the construction sector as a substantial transition that could provide a new

perspective to the organisation,” he opens.

With products and solutions that have helped build the nation, the company’s history speaks for itself –shaping a world that works for both people and the planet.

“Since our inception, Bamburi’s cement and concrete products have been used in the construction of many

“SOCIAL INITIATIVES ARE A PART OF OUR BUSINESS MODEL THAT HELPS US REMAIN ACCOUNTABLE TO STAKEHOLDERS AND MAXIMISES OUR POSITIVE IMPACT WITHIN THE COMMUNITIES IN WHICH WE OPERATE”

– MARTIN KARIUKI, COMMERCIAL DIRECTOR, BAMBURI CEMENT PLC

homes, community infrastructure, and building projects every day across Kenya and the wider region. We take great pride in the trust our customers and partners place in us to bring their dreams to life,” enthuses Kariuki.

“We are proud to have built most of the country’s road infrastructure, facilities, monumental buildings, and iconic structures in partnership with contractors and the government.”

Leading the industry in technical expertise, Bamburi continually expands its solutions to find the best ways to build sustainably.

Cement is a key ingredient in construction, and no business understands cement in the East African region like Bamburi does. The company has three subsidiaries in Kenya - Bamburi Special Products Limited, the major provider of readymix concrete and precast blocks; Lafarge Eco Systems Limited, an environmental arm whose operations include sustainable land use and quarry rehabilitation; and Diani Estates Limited, whose primary

activity is the management of land reserves.

With these three extensions encompassing everything from commercial operations to social impact, there is much excitement and growth to be found within the current market, especially with the profound dynamics of urbanisation.

According to statistics, Africa’s population will reach one billion by 2050, with cities absorbing two-thirds of that total. With more than half of the predicted population being of a young age, the potential for

sustainable building and affordable housing is enormous.

Equally significant is the expansion of matching infrastructure connecting major cities, as well as the continent’s rising need to close the infrastructure gap found in other emerging markets.

“With over 50 years of experience in the building sector, we see this as a two-pronged opportunity. First, we must position ourselves to facilitate this growth, and second,

“SINCE OUR INCEPTION, BAMBURI’S CEMENT AND CONCRETE PRODUCTS HAVE BEEN USED IN THE CONSTRUCTION OF MANY HOMES, COMMUNITY INFRASTRUCTURE, AND BUILDING PROJECTS EVERY DAY ACROSS KENYA AND THE WIDER REGION. WE TAKE GREAT PRIDE IN THE TRUST OUR CUSTOMERS AND PARTNERS PLACE IN US TO BRING THEIR DREAMS TO LIFE”

– MARTIN KARIUKI, COMMERCIAL DIRECTOR, BAMBURI CEMENT PLC

we must ensure that the next phase of infrastructure development is constructed in a sustainable manner,” expands Kariuki.

“This entails reducing the impact of construction on our environment in all activities undertaken and using ecofriendly materials in the process.”

This sustainable mindset is linked to Bamburi’s efforts to implement green methods of construction material production and contribute to

its decarbonisation goal to attain net zero by 2050.

Such environmentally-friendly efforts can be directly observed in some of the company’s recent projects, including the nowcompleted Nairobi Expressway Project, the Kenya Standard Gauge Railway, the Dongo Kundu Bypass Highway, the Makupa Bridge, and the Thwake Dam Project. Specifically, the latter is expected

In the dynamic realm of the cement industry, where precision and reliability are paramount, one name stands out as a gamechanger—Atlas Copco. In a cement factory, compressed air is an integral part of the operation. The company offers a complete range blowers and compressors that fit all cement industry applications, making sure you have the optimal solution for both your production process and business.

Our expertise in the sector, focus on service, and our global presence has resulted in a range of reliable compressed air solutions with a low total cost of ownership in the cement industry.

Your Benefits-

Atlas Copco offers a wide range of generators that deliver unrivalled versatility, optimised performance, and excellent fuel economy in many applications, including the demanding modular power plants (MPP). It offers a quiet operation, small footprint, low emissions, enhanced fuel economy, high resale values and the lowest total cost of ownership perclass. The perfect solution to your prime and critical standby power needs to suit a range of applications, including utilities, events, rental, construction, quarrying, mining and oil and gas.

Helping you optimise your process and achieve the lowest possible total cost of ownership by offering you the right solution.

- Choosing the right technology

Each technology Atlas Copco offers you is designed to optimise your process. Choosing an installation that fits the exact demands of your process will help you save money on the biggest component of a blower’s or compressor’s total lifecycle cost: energy consumption.

- Sizing your pneumatic conveying installation

So how exactly do you know which size compressor is right for your pneumatic conveying process?

A correctly sized installation will help you maximise your energy savings. But don’t worry, we’ve got you covered! Our experts can help youdo this as well as define the correct size of your compressed air installation by calculating the exact flow and pressure required for your pneumatic conveying process.

- Saving energy with a Variable Speed Drive (VSD) Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35 percent. In addition, lowered system pressure with VSD minimises energy use across your production dramatically.

- Service

We offer you different service plans to fit your needs. Our dedicated service experts are available to assist you in keeping your business up and running in the most efficient way. Tel:

to have a reservoir capacity of approximately 688 million cubic metres with the potential to serve 100,000 hectares of irrigated land, as well as generate and inject 20 megawatts of electricity into the national grid.

This project is particularly special as it utilises one of the company’s green cements, Duracem, which reduces carbon emissions while still being durable and versatile in aggressive environments, highlighting Bamburi’s dedication toward a greener future.

Managing its industrial impact on the environment is a deliberate agenda for Bamburi. This is in line with the UN Sustainable Development Goal (SDG) 9 on building resilient infrastructure, sustainable industrialisation, promoting inclusivity, and fostering innovation.

As a green company, it takes emission control seriously and is leading the industry in its steadfast belief that adopting sustainable initiatives in day-to-day operations should be the standard.

“Through Holcim Group, we are part of the global solution when it comes to sustainable development for people and the planet, and we, therefore, go beyond holding a locallevel social license to operate. Over the past five years, we have invested over CHF200 million in facilitating a positive social impact, benefitting millions,” insights Kariuki.

“In our region, we have positively and socially impacted approximately 130,000 individuals this year through infrastructure programmes, as well as community initiatives on education, water and sanitation, health, and the environment.”

For Bamburi, it’s not just about meeting environmental management regulations but having the best sustainability practices across every area of its operations and committing to the progression of the community and the environment.

Alongside its sustainability endeavours, the company works to ensure its 370 employees are recognised and empowered for their continuous dedication.

With a talent, growth, and management agenda focused on all

aspects of employee engagement and development, lateral and vertical mobility from inside teams to senior and managerial positions are being highlighted to encourage employee growth and retainment.

“There is also a strong commitment in prioritising diversity and inclusion, with efforts underway to improve diversity at all levels of leadership. It’s the reason females comprise 40 percent of our board, 20 percent of senior management, 40 percent of professional and line management, and 17 percent of operations,” expands Kariuki.

Bamburi has been setting itself apart from the competition since its inception.

With comprehensive health and safety, cutting-edge innovation, a high-quality portfolio, value-added products, and a rich history of sustainability, Bamburi is proud of the trust its customers and partners have in the company to bring their dreams to life.

Having built some of Kenya’s most formidable construction projects,

From the beginning, the company has engaged in the rehabilitation of its quarries, such that after it extracts minerals from the ground the exhausted quarries are turned into thriving ecosystems. Bamburi Haller Park and Bamburi Forest Trails are two examples of these barren quarries being transformed into lush flora and fauna.

Industrial and municipal waste and biomass are used to power the cement plants, allowing for a safe and environmentally-friendly way to recover waste and reduce the company’s carbon footprint.

Completed via Bamburi Fundi (masonry and plaster work), Bamburi Tembo (all-purpose applications), Bamburi Nguvu (structural applications and precast concrete), and Bamburi Duracem (sulphate resistance and low-heat cement), all of which reduce carbon emissions by 54 percent, 41 percent, 41 percent, and 64 percent, respectively.

The company strives to make a positive, tangible, and sustainable difference among the communities in which it operates and serves. This sustainable development agenda is organised around a social, economic, and environmental pillar.

Bamburi recognises the importance that supplier relationships have within the industry.

“Supply chain operations are the glue that holds all of our operations together, both internally from demand creation to supply execution, and externally from customers, suppliers, and regulatory agencies,” explains Kariuki.

Looking to proactively procure through supply chain partnerships, the company has made it a mission to increasingly include minority-owned businesses in its supply base, with a goal of channelling 30 percent of its total addressable spend by 2025 into underrepresented groups.

“We are committed to continuously making a positive impact towards this goal. Our suppliers and partners are critical allies in this journey,” he continues.

Additionally, Bamburi is looking ahead as it continues to grow on a feasible, sustainable path to a net zero future.

One of the most fascinating initiatives it is involved in is 3D printing technology in building. This innovation seeks to provide greater operating efficiency along with quick, scalable, and affordable

housing, saving close to 20 percent on construction expenses and lowering carbon dioxide emissions by up to 80 percent.

Over the years, the company has embarked on a mission to build the nation through investment in innovation, high-quality cement, solutions that meet the specific needs of the industry, and most importantly, a sustainable approach.

Today, Bamburi proudly stands as the leading cement manufacturing and marketing company in the East Africa region.

“We simply transform customer dreams into reality by exceeding their expectations,” concludes Kariuki.

Bamburi Cement PLC

Tel: 254 20 2101000

corp.info@lafarge.com

lafarge.co.ke