Vol. 14 1technation.com ADVANCING THE BIOMEDICAL / HTM PROFESSIONAL MAY 2023 NEW HIRE PLAYBOOK 12 Professional of the Month Taylor Dunbar 40 Guide to the AAMI eXchange The Ultimate Guide to AAMI 2023 60 Corporate Profile Renovo Solutions 93 Biomed Brainbuster Sponsored by PM Biomedical PAGE 64

ALL OLYMPUS EVIS 100, 140, 160, 180 SERIES

LIMITED REPAIRS ON 190 SERIES SCOPES

BF - BRONCHOSCOPES

CF – COLONOSCOPES

PCF – PEDIATRIC COLONOSCOPE

TJF - DUODENOSCOPES

WE ALSO REPAIR 100, 140, 180 SERIES VIDEO PROCESSORS AND LIGHT SOURCE

SERVICE OR REPAIR WE OLYMPUS SCOPE MODELS 333 NORTHPARK CENTRAL DR SUITE Z HOUSTON, TEXAS 77073 CALL: 1.855.888.8762 VISIT: USOCMEDICAL.COM

ISO 9001:2015 and 13485:2016 Certified

THE WORLD MOVES FAST. WE MOVE FASTER.™ vFSE is a unique technology provided by 626 with full-service agreements. It is both a unique and powerful technology. It is OEM and modality agnostic. It is as if we have a highly talented FSE on site 24/7/365. CALL FOR A DEMO SOLUTIONS BEYOND BREAK-FIX Introducing... (800) 516-0990 | weare626.com

I look pretty but I’m useless without a brain. Connect me to a PCU with the wrong software and listen to me scream! I’m sturdy for the most part, but if anything is slightly loose, scratched, or cracked, I probably won’t start. Hi! I’m an Alaris 8100! �� Not to worry! Send me to Adepto and they’ll surely x me! Drop me on the ground, shattered screen is all you’ll see. Hello I’m an X3! �� Put me with an MX or MP that’s where I want to be. No comparison when it comes to me! I got NBP, SP02, and ECG! Check alarm? ��… sounds like a problem to me! Send me to Pioneer, that's where I want to be! Speaking of humor... have you seen our latest YouTube videos? *These are NOT real actors... A special THANK YOU to all the HTM Professionals! We appreciate everything you do! Support@piobio.com Piobio.com 888-644-3274 833-423-3786 Adeptomed.com Sales@adeptomed.com Infusion Pumps Patient Monitors HTM WEEK? We think you guys deserve the whole month! But, we don’t make the rules, so please enjoy some shop humor!

VERIFY THE INTEGRITY OF EQUIPMENT

The Insulation tester, Leak Tester Tester and Cable Continuity Tester are easy-to-use devices for verifying the functionality of equipment for safety

McGan Insulation Tester

Detect & locate defects such as pinholes, cracks and bare spots in the jacket or coating of laparoscopic and bi-polar electrosurgical instruments

Cable Continuity Tester

Leak Tester Tester

Test the functionality of automated & handheld endoscope leakage testers with healthmark’s new Leak Tester Tester.

Test the quality of monopolar and bipolar cords with this user-friendly, durable device. A green light notifies the user that the cable passed testing.

For more of Healthmark’s intelligent solutions for instrument care and infection control, visit HMARK.COM

INTELLIGENT SOLUTIONS FOR INSTRUMENT CARE & INFECTION CONTROL

HMARK.COM | 800.521.6224

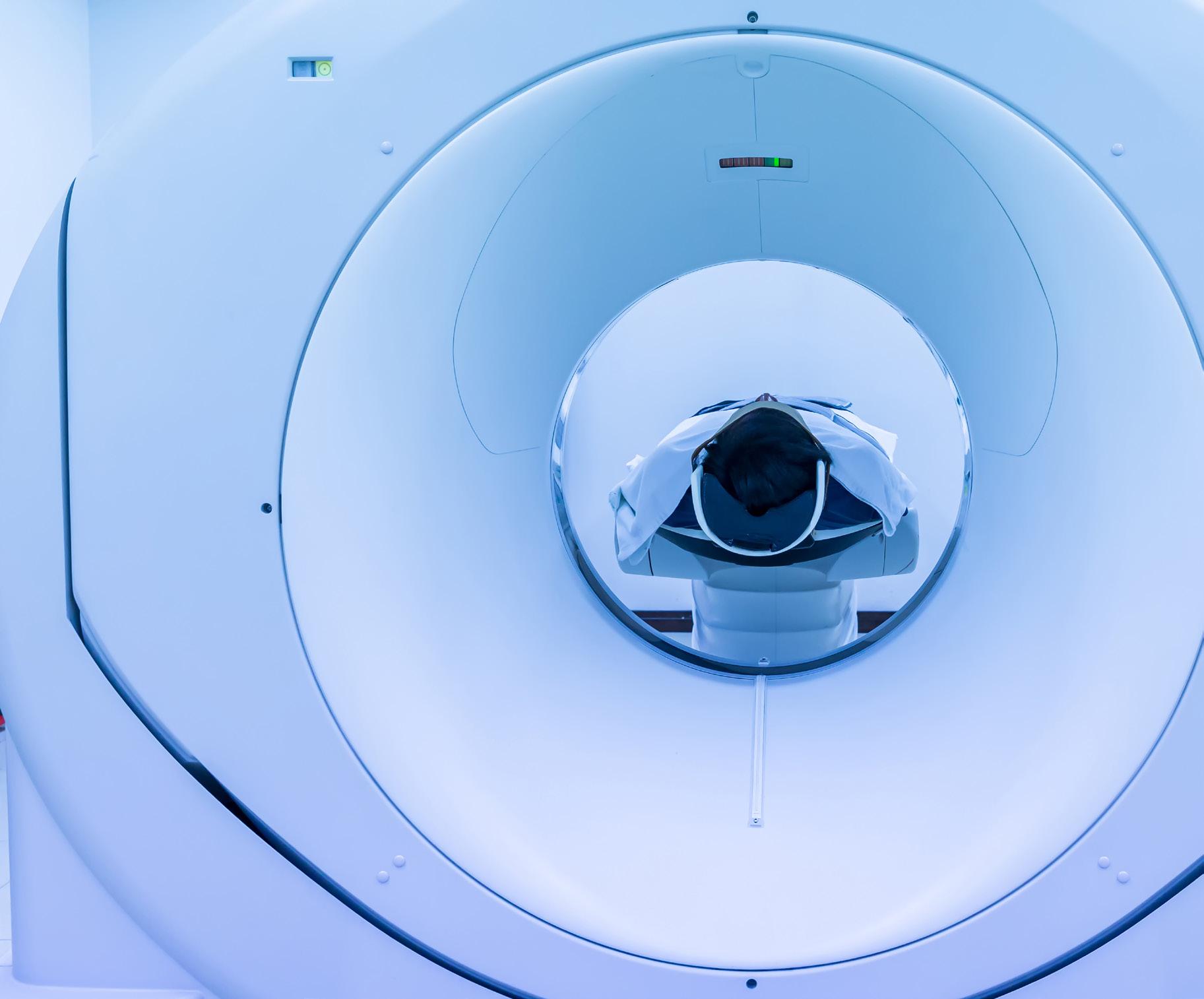

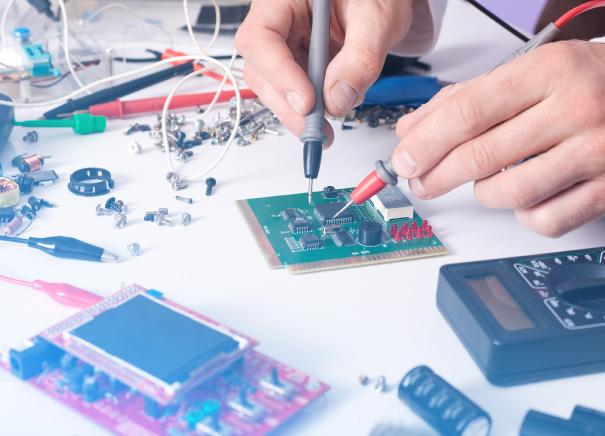

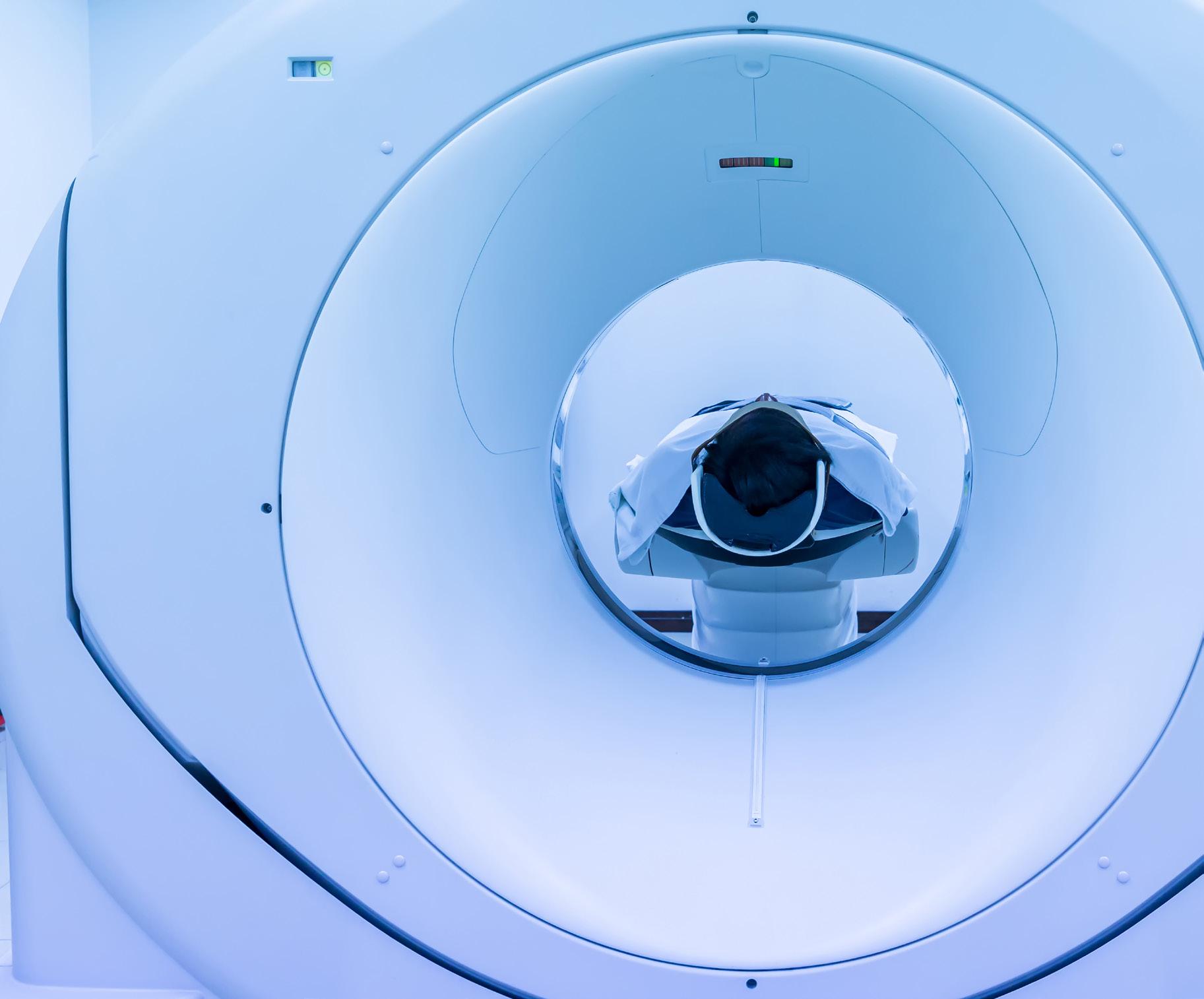

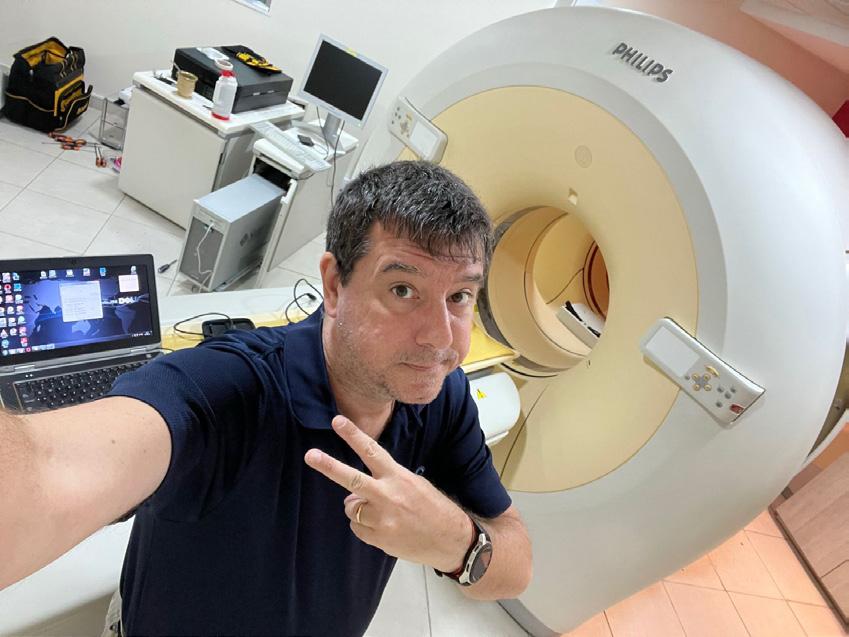

At RSTI, we teach application of technical knowledge, not just concepts, using a combination of classroom and lab instruction. By allowing students to get vital hands-on experience while learning the theory behind the application, the skills we teach can be applied to a variety of equipment. All basic theory and lab exercises are based on a multivendor approach consistent with today’s technology. RSTI students complete lab assignments on our install base of over 70 diagnostic imaging systems representing all major equipment manufacturers. More in-depth service capability can be obtained through RSTI’s product-specific classes.

RSTI COURSE OFFERINGS:

• eLearning Training Options (On-line with a Live Instructor)

• X-Ray Certificate Series, Phases 1-4 (approved for veterans training)

• Management, Networking and Digital Information

• Product-Specific (Rad/Fluoro, Portables, C-Arms, Cath Lab, Mammography)

• Modality-Specific (CT, MRI, Nuclear Medicine, Ultrasound)

ISO 9001:2015 CERTIFIED (IQC CERTIFICATE NO. Q-1158) STATE OF OHIO REG. NO. 93-09-1377T

(440) 349-4700 parts@rsti-exchange.com registration@rsti-training.com CALL US TODAY! ENGINEERED FOR LEARNING ™ TRAINING THE INDUSTRY SINCE 1985 – ALMOST 40 YEARS! Visit us at HTMA-SC: May 3 and HTM Mixer Baltimore: May 11-12

FULLY ENGAGED HANDS-ON TRAINING

Regardless of the make, model or field strength, we have the team and infrastructure to get almost any MRI coil back up and running. Quickly With over 35 years of experience and more than 40,000 successful repairs, you can trust your devices to be repaired to their original design. Yes! We can repair your Philips dStream™, GE Air™ coils, and Invivo coils, and we can fully restore your coil’s system cable. All covered by a 6-month warranty. Setup a repair or arrange for a loaner, today 844-687-5100 customercare@innovatusimaging.com Centers of Excellence for Ultrasound Probe and MRI Coil Repair, and Design & Manufacturing When You Are Down... We Can Help You Get Back Up Visit us at the AAMI Exchange at booth 1129

TechNation (Vol. 14, Issue #5) May 2023 is published monthly by MD Publishing, 1015 Tyrone Rd., Ste. 120, Tyrone, GA 30290. TechNation magazine is dedicated to providing medical equipment service professionals with comprehensive, reliable, information concerning medical equipment, parts, service and supplies. It is published monthly by MD Publishing, Inc. Subscriptions are available free of charge to qualified individuals within the United States. Publisher reserves the right to determine qualification for a free subscriptions. Every precaution is taken to ensure accuracy of content; however, the information, opinions, and statements expressed in the articles and advertisements herein are those of the writer and/or advertiser, and not necessarily those of the publisher. ©2023 CONTENTS P.12 SPOTLIGHT p.12 Professional of the Month: Taylor Dunbar p.14 Company Showcase: USOC p.18 Department of the Month: UConn Health Clinical Engineering Department

Shifting Gears: The NextJenn TechMom: Delivering STEAM Knowledge

Company Showcase: Tenacore p.26 Next Gen: Codi Nelson P.29 INDUSTRY UPDATES p.29 News & Notes p.35 ECRI p.36 Welcome to TechNation p.38 AAMI p.40 Guide to AAMI P.47 THE BENCH p.47 Tools of the Trade p.51 Biomed 101 P.54 FEATURE ARTICLES p.54 Roundtable: Patient Montiors p.60 Corporate Profile: Renovo Solutions p.64 Cover Story: New Hire Playbook P.71 EXPERT ADVICE p.71 Career Center p.72 [Sponsored Content] Innovatus Imaging p.74 Right to Repair p.77 [Sponsored Content] BC Group p.78 The Future P.80 CONNECTED p.80 Cybersecurity p.84 Health-ISAC p.86 Networking Notes p.88 HIMSS p.89 Get Connected Company Directory 64 54 May 2023 | TechNation 9

p.20

p.24

PUBLISHER John M. Krieg

VICE PRESIDENT

Kristin Leavoy

Jayme McKelvey OF SALES

VICE PRESIDENT

EDITORIAL

CONTRIBUTORS

John Wallace

Roger Bowles

K. Richard Douglas

Jim Fedele

Joie Marhefka

Manny Roman

Connor Walsh

David Witt

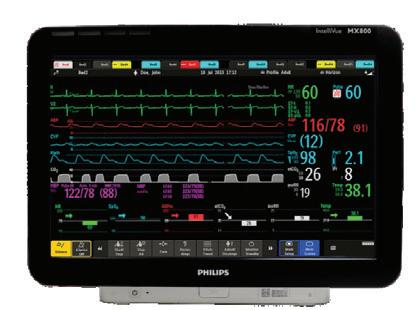

Steven J. Yelton

ACCOUNT

EXECUTIVES

ART DEPARTMENT

Megan Cabot

Emily Hise

Karlee Gower

Taylor Hayes

Kameryn Johnson

DIGITAL SERVICES

Cindy Galindo

Kennedy Krieg

Haley Wells

EVENTS

WEBINARS

HTMJOBS.COM

ACCOUNTING

CIRCULATION

Kristin Leavoy

Linda Hasluem

Kristen Register

Sydney Krieg

Diane Costea

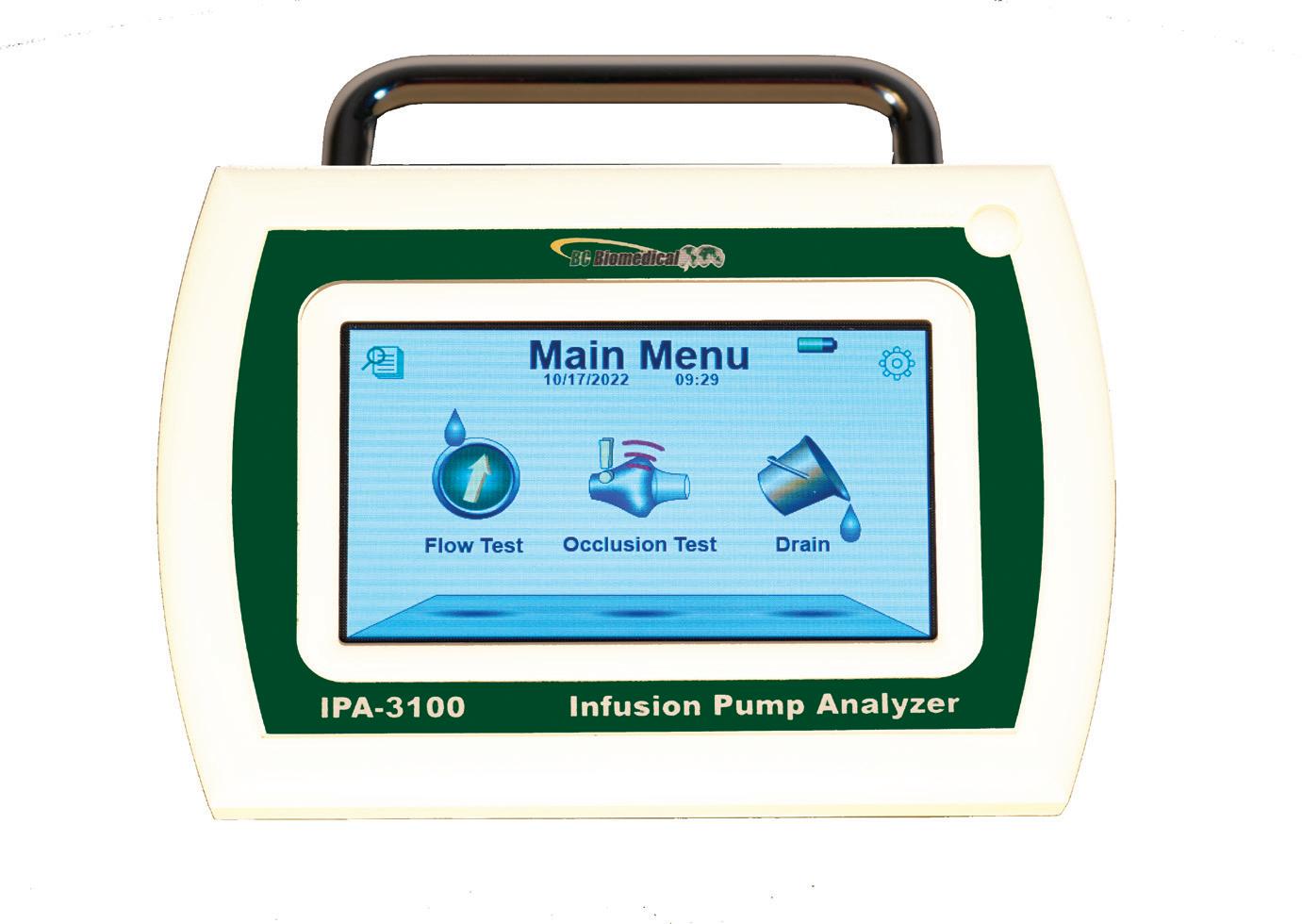

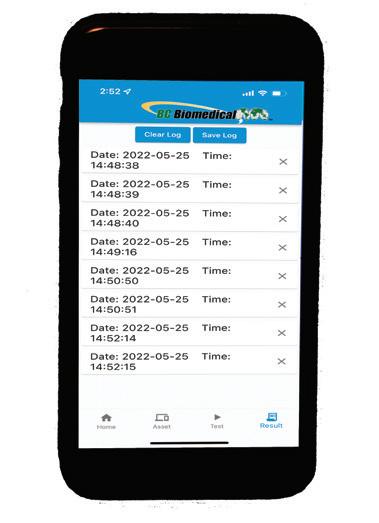

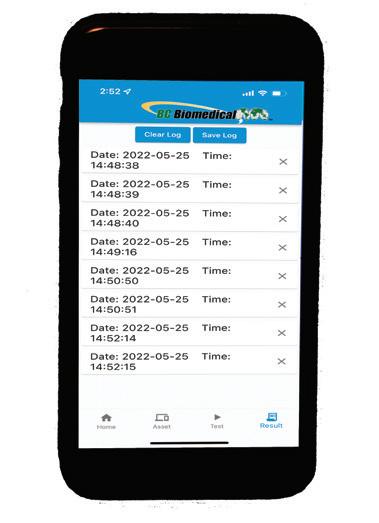

Joanna Manjarrez

EDITORIAL BOARD

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Jim Fedele, CBET, Senior Director of Clinical Engineering, UPMC

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Benjamin Scoggin, MBA, MMCi, Director, Clinical Engineering | Biomedical Operations, Equipment Distribution, Clinical IT, DHTS, Duke Health Technology Solutions

Allison Woollford, Biomedical Equipment Specialist at Duke University Health System

MD Publishing / TechNation Magazine 1015 Tyrone Rd., Ste. 120, Tyrone, GA 30290 800.906.3373 • Fax: 770.632.9090 Email: info@mdpublishing.com www.mdpublishing.com Proud supporters of

Like us on Facebook, facebook.com/TechNationMag Follow us on LinkedIn, linkedin.com/company/iamtechnation 98 P.90 BREAKROOM p.90 MedWrench Bulletin Board p.91 TechNation Poll/What’s On Your Bench? p.92 HTMA-OH Scrapbook p.93 Biomed Brainbuster p.98 #IAmTechNation p.99 HTM Week p.94 Service Index p.97 Alphabetical Index

10 TechNation | May 2023

COLLEGE OF BIOMEDICAL EQUIPMENT TECHNOLOGY

Accredited College Programs

The College of Biomedical Equipment Technology is accredited by the Accrediting Council for Countinuing Education & Training (ACCET), an accrediting agency continuously recognized by the U.S. Department of Education as a reliable authority on educational quality since 1978.

Strategic Partnerships

We actively cultivate strategic partnerships with healthcare organizations, service providers, and biomedical equipment manufacturers to provide externships, hands-on training and career services to our students. Our nationwide network of partners makes it possible to create real-world training and employment opportunities for students.

High Placement Rates

We assist students in finding employment after training. We help students secure jobs through various means including job searches, career fairs, direct communication with employees to identify upcoming requisites, resume writing assistance, and interview coaching. Graduates are eligible to access the College’s placement assistence program at no additional cost.

Biomedical Imaging Information Systems Principles of Injector Service Fundamentals of Computed Tomography May 8-June 18 May 8-June 9 May 8-June 18 100% Online May 8-19 May 15-June 2 Imaging Courses Beginning May: 844.879.9043 admissiondept@cbet.edu

EARN

YOUR AAS IN 15 MONTHS, ONLINE!

PROFESSIONAL OF THE MONTH Taylor Dunbar

BY K. RICHARD DOUGLAS

ometimes the influence of family members and a general sense for what you want to do with your life is just enough to get pointed in a general direction. That was the case for Taylor Dunbar, a clinical engineering specialist at the Ohio State University Wexner Medical Center in Columbus, Ohio.

“My major when I first started undergrad was ‘Engineering-Undecided.’ I knew that I wanted to do some kind of engineering, but I wasn’t sure which one. I was always interested in math and science, and I was very crafty, and I enjoyed tinkering with things – understanding why and how things worked (or didn’t work) – so deciding on pursuing an engineering degree was the easy part,” Dunbar says.

She says that both of her grandparents – Alice and Derwood – worked in health care for many years.

“I remember hearing so many stories from them –their favorite memories, their hardest days, coworkers and patients that left an everlasting impact on them. I always thought it would be cool to work in health care, but I just wasn’t sure how. I could tell from their stories that they were making a difference every day throughout their careers, and they inspired me to want to do the same. I wanted to find a way to use my skills to create a positive impact like they did,” Dunbar says.

She says that when she learned about Ohio State’s biomedical engineering program, it felt like the perfect blend of engineering and health care.

“I didn’t learn about clinical engineering specifical -

ly until I was about halfway through undergrad. I was browsing the student positions available at the Wexner Medical Center and just so happened to stumble upon a posting for a clinical engineering student assistant,” Dunbar says.

“The description was a little vague and it was a department I had never heard of before, but I took a chance and applied. During my interview, the biomed director at the time, Tony McCabe, took me on a little tour around the hospital. I honestly don’t remember much of the interview, because I was mesmerized by the size and complexity of the building we were walking through. After working for clinical engineering for two years as a student assistant, I was very excited when I was offered a full-time position to join the team after graduation,” Dunbar adds.

After the work as a student assistant, and then joining the CE team full time after graduating in the spring of 2018, Dunbar was promoted to clinical engineering specialist in January of 2021, and is now a specialist 2. Beyond her formal training, Dunbar has also attended several OEM training classes. Some of that training has allowed her to specialize in apheresis equipment.

MANAGING PROJECTS

Dunbar’s interest in project management has been an academic pursuit and she also has an interest in women’s opportunities in engineering fields.

Challenges are a part of the HTM profession and instilling confidence in clinical colleagues may be one of them. Yet, overcoming some of those challenges results from proving capability. Dunbar has taken on the challenge.

“One challenge I have encountered is being a young woman in a field that is male dominated. I

S 12 TechNation | May 2023

SPOTLIGHT

would receive tickets for broken equipment from our dispatcher, and when I would show up on the floor, the users would be shocked that a young woman was there to fix their equipment. I think there were even some people that doubted me because of my age, or gender or both. I had to work extra hard to gain their respect and trust,” she says.

Dunbar says that she has a strong interest in project management. She recently went back to school part time for her MBA and her management has granted her many opportunities to be part of various projects throughout the medical center.

“One of my favorite projects, that I am currently a part of, is a Go-Live Initiative for 12-lead at the bedside. I am super excited about this project because I can see how it will improve patient care,” she says.

“Another project I have really enjoyed being a part of, was an inventory audit in preparation for our new hospital building, which is in the construction phase. As part of the audit, we created a scorecard which would allow us to determine what equipment can and should be moved to the new tower and which equipment would need to be replaced,” Dunbar says.

“I have also recently become more involved with the DOI (diversity, outreach and inclusion) office at Ohio State, specifically with Women in Engineering. I sat on my first engineering alumnae panel during National Engineers Week for an event called ‘EmpowHERing the Future,’” Dunbar adds.

Asked about what people should know about her, Dunbar says that she strongly believes in the work biomeds are doing.

“It is certainly behind the scenes work – and many times thankless – but I don’t let that discourage me. My mom is a two-time cancer survivor, so the fact that I work in the James Cancer Hospital makes my job that much more meaningful,” she says.

On the home front, family is important.

“I have the most supportive family – they push me every day to challenge myself and to be the best version of myself possible. I would not be where I am today without my parents, Brian and Jane, grandparents, Derwood and Alice, and my sister, Sydney,” Dunbar says.

In her free time, she enjoys trail running and hiking, teaching herself DIY home projects, gardening and snuggling with her fur-babies (Hallie Rae and Harold Brown).

For patients and clinicians in Columbus, Ohio, they can be grateful that they have a project-management-minded clinical engineer watching out for them.

BIOMETRICS

FAVORITE BOOKS:

“Everybody Always” and “Love Does” by Bob Goff

FAVORITE MOVIE:

“How to Lose a Guy in 10 Days”

FAVORITE FOOD:

Watermelon and McIntosh Apples

WHAT’S ON MY BENCH?

Pictures of my family, friends, and fur-babies, giant whiteboard and a collection of very colorful dry-erase markers to help me stay organized, my electric screwdriver and multi-bit sets, unisolve wipes (because no one likes sticker goop), and my (emotional support) water bottle – can’t go anywhere without my water bottle

FAVORITE PART OF BEING A BIOMED?

Knowing I am doing my part to create an environment that is safe, so that patients can receive the best care possible.

May 2023 | TechNation 13

COMPANY SHOWCASE

USOC Adds Texas Location to Better Serve Clients

SOC Bio-Medical Services is a leader in the medical device industry determined to know its customers, provide high-quality services, build solid relationships and maintain vendor neutrality. As stated in its mission statement, the company’s core values are quality, integrity, innovation, accountability, collaboration and leadership.

USOC employs more than 100 people who provide biomedical equipment repair solutions to health care facilities, clinics and medical companies of all types and sizes. The company’s commitment to providing high-quality, cost-effective equipment and services is reflected in its ISO 9001:2008 and 13485:2016 certifications.

Initially located in Irvine, California, and now offering a second location in Houston, Texas, USOC has a proven approach designed to keep medical equipment running in peak condition at a guaranteed cost savings. The company is used as a reference by the market for patient monitoring equipment repair and for refurbished devices. Additionally, the USOC team strives to help biomeds who may not specialize in specific types of equipment when faced with the daunting task of maintaining patient monitoring devices and every type of hospital equipment. The company partners with the BMET community and is present at biomed tradeshows throughout the United States. For more about USOC, we asked them to share their insider knowledge about the company’s recent acquisition by CSAT Holdings LLC as well as its services, goals and customer service.

Q: CAN YOU SHARE A LITTLE BIT ABOUT YOUR COMPANY’S HISTORY AND HOW YOU ACHIEVED SUCCESS?

USOC: USOC was founded in 2010 and provides patient monitoring device repair services, equipment and parts sales, onsite technician services, and rental solutions for hospitals, clinics and medical equipment management companies. USOC

specializes in patient monitors, modules, telemetry, CO2 modules, infusion pumps and an array of other modalities.

One of the keys to USOC’s success lies in our commitment to understanding not just the equipment, but each customer’s unique situation, level of expertise and needs. The company has achieved success by understanding the pressures that today’s health care professionals face. Our innovative practices and expert engineers have allowed us to reduce the price of patient monitoring services without sacrificing quality.

Q: WHAT ARE SOME ADVANTAGES THAT YOUR COMPANY HAS OVER THE COMPETITION?

USOC: Our edge is our value proposition, especially when compared to the competition. We are more than a repair facility for our biomeds. We are a trusted partner to our biomeds. We create bonds with the biomeds and support them. We are a biomed shop as well as 24/7 technical support. Most importantly, we understand more than anyone else the biomed’s needs. We have leveraged our experiences to create a unique repair facility that meets the quality standards and turn times of each valued customer. Our quality is why we have the confidence to offer a 12-month end-to-end warranty for most repairs. We facilitate our biomeds’ daily tasks through our updated customer portal (USOC e-link) that is used not only for repairs but also provides support and guidance. We also have an emergency kit for our biomeds. The emergency kit consists of the most popular items that break down. It can be used as an exchange program when devices break down.

Q: CAN YOU EXPLAIN YOUR COMPANY’S CORE COMPETENCIES AND UNIQUE SELLING POINTS?

USOC: USOC provides biomedical equipment repair solutions to health care facilities, clinics and medical companies in the USA, Canada and beyond.

Here is how it works: The hospital calls for troubleshooting and, if necessary, sends equipment to us. We test, diagnose and repair it at our facility and then send it back to them. We offer a warranty that allows the biomed shop to send the equipment back free of charge if there is ever a problem. We also offer troubleshooting over the phone. If the equipment needs to be sent in for repair, USOC Bio-Medical Services will

COMPANY SHOWCASE

U 14 TechNation | May 2023

program a loaner based on the hospital’s data and expedite shipping to the facility.

Q: CAN YOU SHARE INFORMATION ABOUT THE REASON FOR THE RECENT ACQUISITION BY CSAT HOLDINGS LLC AND WHAT IT MEANS FOR USOC BIOMEDICAL?

USOC: USOC is always looking to expand across equipment types and geographies in order to serve our customers better. CSAT has core expertise in engineering and logistics and will greatly enhance our value proposition. We are extremely excited for this new chapter of USOC.

Q: WHAT CAN USOC CUSTOMERS EXPECT FOLLOWING THE ACQUISITION?

USOC: Our customers can expect the same customer service and quality equipment repair solutions that we have always provided. Overall, this partnership will benefit our customers’ needs. With the addition of CSAT on our side, USOC has opened its second repair facility location in Houston, Texas. In the near future, we will be able to offer a wider array of services and faster shipping services to help customers have less downtime in their facilities.

Q: CAN YOU TELL US ABOUT YOUR EMPLOYEES AND WHAT THEY MEAN TO THE COMPANY?

USOC: Our employees are what make USOC great. Their dedication, determination and passion for each of their jobs is unmatched. Everyone at USOC works as a team for one

common goal – the customer. They understand that each person’s job is unique and doesn’t work without each other. We are a team that respects each other.

Q: WHAT IS YOUR COMPANY’S MISSION STATEMENT?

USOC: Our vision is empowering better patient health with technical insights. Our three goals are to promote a healthier world, build value and create an inspiring workplace. Our five-point strategy to achieve our goals is to grow through innovation, drive operational excellence, simplify the organization, focus on technical information services, and deliver great products and services. An important part of the USOC Bio-Medical Services environment is our behaviors, which are customer-focused, performance-oriented, united as one team, transparent and agile. The core values at USOC Bio-Medical Services are quality, integrity, innovation, accountability, collaboration and leadership.

Q: IS THERE ANYTHING ELSE YOU WANT READERS TO KNOW ABOUT YOUR COMPANY?

USOC: USOC has always been and will continue to be customer driven. We are always looking for their feedback, as it’s their suggestions that we take to heart for our continued improvement. We are definitely looking forward to what the future holds and the new exciting opportunities we have created.

For more information, visit usocmedical.com.

SPONSORED CONTENT May 2023 | TechNation 15

PROBO MEDICAL

Your Ultrasound Partner

Your Ultrasound Partner

FREE TECH SUPPORT

FREE TECH SUPPORT

QUALITY, TESTED PARTS

QUALITY, TESTED PARTS

ULTRASOUND SERVICE TRAINING

ULTRASOUND SERVICE TRAINING

PROBE REPAIR WITH FREE LOANERS

PROBE REPAIR WITH FREE LOANERS

NEXT DAY RENTALS

NEXT DAY RENTALS

SERVICE ACROSS THE US

SERVICE ACROSS THE US

Mention this ad for 10% OFF your next part or repair.

Mention this ad for 10% OFF your next part or repair.

HAVING PROBLEMS WITH YOUR ULTRASOUND PROBE?

HAVING PROBLEMS WITH YOUR ULTRASOUND PROBE?

Scan the QR code and get an instant quote by using our free ultrasound probe evaluation tool.

Scan the QR code and get an instant quote by using our free ultrasound probe evaluation tool.

WWW.PROBOMEDICAL.COM

WWW.PROBOMEDICAL.COM

PROBO MEDICAL

SOLUTIONS Become an Imaging Engineer ISO 13485:2016 certified Join our Apprentice Program. Start an exciting career as a Medical Imaging Service Engineer with the Apprentice Program at Tri-Imaging! We have a world-class hands on training facility at our facility in Madison, TN. 2 WEEKS BMET to Imaging 1 training 2 WEEKS BMET to Imaging 2 training 8 WEEKS Technical Services 12 WEEK APPRENTICE PROGRAM Visit triimaging.com/training/training-program.html to see our 2023 Training Calendar! 855.401.4888 Located in Nashville, TN Maximize your learning in small classes, allowing more time with your expert instructors and personalizing your experience.

DEPARTMENT OF THE MONTH

UConn Health Clinical Engineering Department

BY K. RICHARD DOUGLAS

Whether talking about college sports or the institution’s storied history, the University of Connecticut (UConn) is a stand-out among institutions of higher learning. With its roots going back to the late 1800s, the university is a leader in research and boasts a student population of 32,000.

The affiliated UConn Health includes schools of medicine and dentistry, graduate programs, clinics and hospitals.

“UConn Health’s Clinical Engineering Department is composed of 18 employees. This does not include third-party full-time engineering and service support techs,” says Ken Blier, director of clinical engineering at UConn Health’s Clinical Engineering Department.

Other members of CE leadership include Vice President Eric A. Kruger and Chief Clinical Engineer Sam Elsemany. Located in Farmington, Connecticut, UConn Health’s campus comprises two towers – the University Tower and the Connecticut Tower – which collectively offer over 400,000 square feet of clinical space and 224 beds.

“As a teaching academic health center, UConn Health is home to students from the UConn School of Medicine, UConn School of Dental Medicine and affiliations with UConn School of Nursing and Allied Health Services. Moreover, the hospital houses a full research facility that collaborates with the Jackson Laboratory for Genomic Medicine, located on campus,” Blier says.

There are also several offsite clinics across the Hartford, Connecticut area.

“To provide support to these locations, the clinical engineering department operates an equipped hospital vehicle to service medical devices. This innovative approach

ensures that UConn Health can provide efficient and comprehensive care to patients, regardless of their location. With this extensive network of facilities and resources, UConn Health is well-positioned to deliver cutting-edge medical care and research that advances the field of medicine,” Blier says.

The CE department also includes a procurement specialist, a medical device cybersecurity engineer, two imaging specialists, six BMET IIs and two BMET Is, as well as interns and student workers.

The group provides myriad services including capital purchase reviews, managing vendor medical device repairs, contract management and renewals and PMs, participation on committees such as EOC and medical device incident investigations.

There is a close collaboration with IT.

“Our clinical engineers and BMETs work very closely with IT to work on all medical technology-related projects. All medical device capital purchases must be reviewed and approved by both IT and CE, and integration assignments are given to teams within both departments to complete,” Blier says.

The group has been innovative with how it manages service contracts.

“We implemented a major project linking all medical device contracts to our CMMS system. Our contracts team in the finance department now has access to this tool, allowing them to streamline the repair process and set reminders to get quotes and reinitiate contracts. This innovative solution helps identify any devices that slip through the cracks without a service contract while other models have contracts,” Blier says.

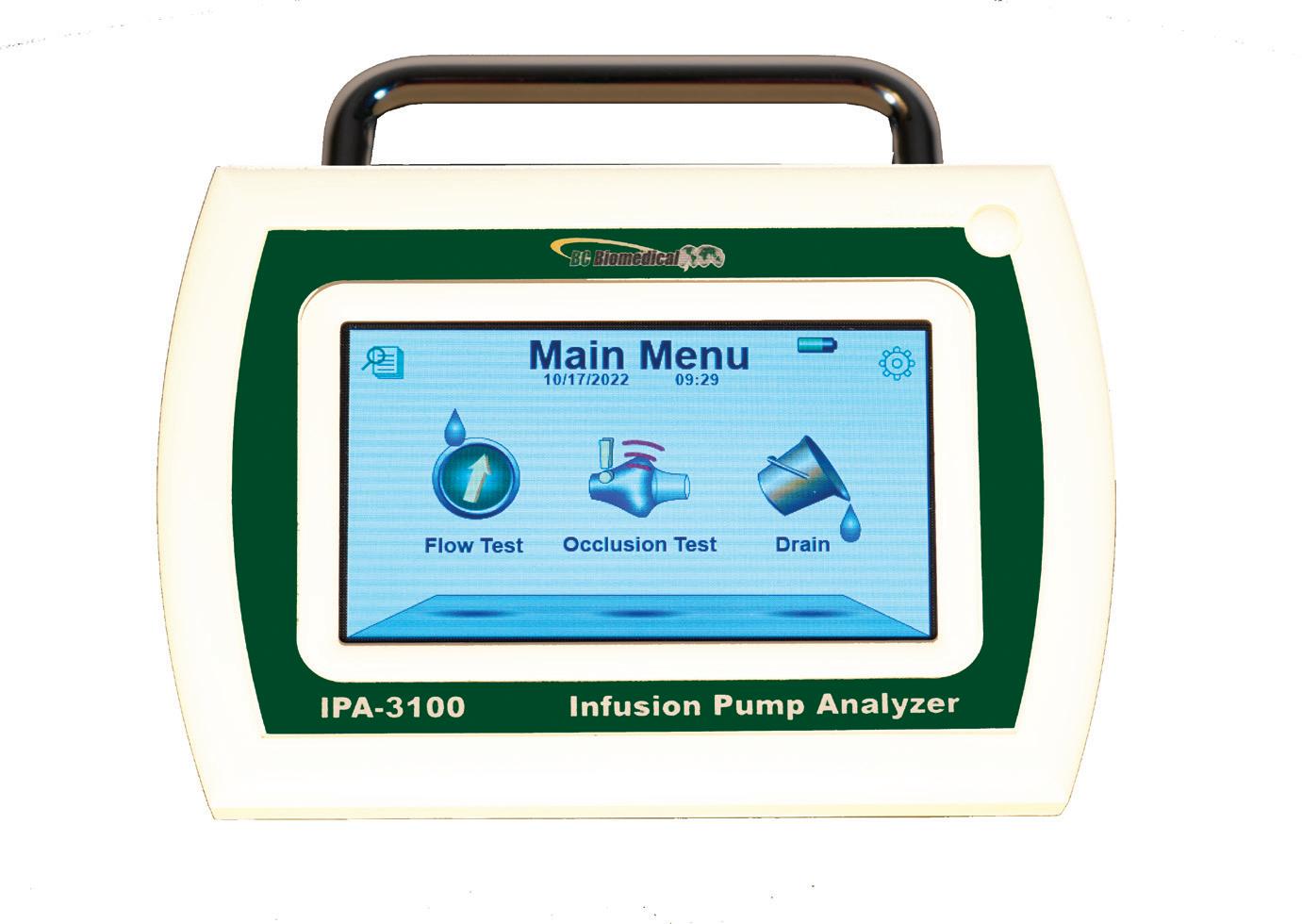

STREAMLINING INFUSION PUMP AVAILABILITY

The team has been involved in special projects, including a thorough review of inventory and its accurate inclusion in CMMS.

“In 2021, the UConn Health CE management team

SPOTLIGHT

18 TechNation | May 2023

conducted a gap analysis against regulatory requirements and identified several opportunities. One major opportunity was to review the CMMS device inventory and ensure all in-use medical devices are captured in our database and has the correct device information such as serial number, model, manufacturer, PM frequency and maintenance checklists,” Blier says.

He says that although this challenge exists to some degree in almost all HTM departments, the UConn Health CE team decided to address the issue and create a process to maintain inventory accuracy going forward to ensure patient safety and department regulatory compliance.

“The first phase of project was to touch every in-service medical device and ensure it was included in the CMMS inventory, and the second phase was to complete an in-depth device review of each device’s OEM maintenance requirements, and the accuracy of all device-related data in CMMS. The project will not only help us ensure the accuracy of the medical device inventory, but it will also help in other regulatory and compliance-related tasks such as device recalls and capital purchases planning,” Blier says.

Problems that come up in the health care setting often call upon the skill sets of HTM professionals. The department’s resources and problem-solving skills were tested during the COVID-19 pandemic.

“The COVID-19 pandemic has caused unprecedented pressure on health care systems worldwide, with hospitals facing surging patient numbers. At UConn Health, this surge also created an increased demand for infusion pumps, resulting in a shortage on clinical floors. To address this challenge, the clinical engineering department collaborated with the third-party company responsible for managing the IV pumps disinfection and

distribution,” Blier says.

Together, they identified some opportunities to optimize the pumps’ cleaning and distribution process.

“As part of the project, clinical engineering developed a new distribution process assigning a specific number of IV pumps to each clinical department. After undergoing the cleaning process, the pumps were then returned to the same department to ensure efficient use. The team also purchased additional pumps that could be provided to different clinical departments if needed, serving as ‘floater pumps.’ The clinical engineering team thoroughly tested and reviewed the condition of every pump during the project, ensuring proper operation and accurate information in the CMMS,” Blier adds.

He says that the project’s success was evident as it eliminated a major daily issue that the clinical team had been struggling with.

“By optimizing the distribution of infusion pumps, the clinical engineering department was able to provide critical support to their colleagues on the clinical floors during the COVID-19 surge. The solution helped ensure that patients received the necessary care and resources, even during the most challenging of times,” Blier says.

Beyond showing its value with important projects like this, that meet a critical need, the UConn Health Clinical Engineering Department provides specialized equipment repair and maintenance throughout the year and throughout each device’s life cycle.

Through innovation, they reflect the reputation of a university that has made medicine a central focus.

May 2023 | TechNation 19

“As part of the project, clinical engineering developed a new distribution process assigning a specific number of IV pumps to each clinical department.”

SHIFTING GEARS

The NextJenn TechMom: Delivering STEAM Knowledge

BY K. RICHARD DOUGLAS

hile there may be a laundry list of reasons why the Internet has been bad for children, there is one very real benefit that often goes unnoticed. The ability to teach, train and inform brings valuable content to kids that can benefit them in many ways.

One platform for this content is the video-sharing service YouTube. While thousands of these videos are only created for entertainment, others fulfill the promise of providing educational and informative content that points to the more atypical value that is possible.

One of those value-added YouTube channels is the NextJenn TechMom Inc. channel. It has been providing content for five years and is tied to actual in-person training sessions, teaching kids about science, technology, engineering, arts and mathematics (STEAM).

“The purpose of NextJenn TechMom Inc. is to provide an opportunity for all kids and parents to develop a beginner-level knowledge of STEAM in a safe environment. We give students and parents the tools to build, test, and play, applying engineering concepts through projects and activities. All kids deserve a safe place to discover the world around them,” says Jennifer Chester, a BMET II in Houston, Texas.

She says that this is her fifth year as the NextJenn TechMom.

Children are more likely to pay attention to STEAM if a parent works in a related field. This means that a lot of kids don’t fully appreciate the opportunities that could lie ahead if they get on this path. Chester says that children learn not only what they are taught in a classroom but what they are surrounded by daily.

Chester’s own love of electronics and engineering led to

a lightbulb moment and the realization that kids could enjoy these topics as well.

“My love for the craft prompted me to do electronics kits and build robots on YouTube. I realized that my children began to show an interest in what I was doing and that they were learning so much by doing my projects with me soon after; it blossomed into outreach to all kids that might like learning about electronics and engineering too. I sincerely enjoy seeing the lightbulb come on in a child that has learned and applied that knowledge to make something remarkable,” she says.

MUCH MORE THAN VIDEOS

The NextJenn TechMom STEAM education experience morphed into an in-person experience.

“It started as just videos I did with my kids, and I was in a meeting where someone said the chances are more significant when a parent is in the field of science or technology, so I thought, why not try to bring this into other households and to other families. I currently create videos for YouTube and host in-person classes on the second Saturday of every month at the recreation center at Bear Branch Park for the Woodlands Parks and Recreation,” Chester says. “Each class covers engineering principles, and in the last month, we have a Young Inventors Workshop Event showcasing everything the kids have learned, and they get to apply the knowledge by building a large project.”

The hands-on experience gives kids exposure to engineering concepts and the world of STEAM that they might otherwise not notice.

“We give students and parents the tools to build, test and play, applying engineering concepts through projects and activities,” Chester says.

As an example, she says that a recent class was about DC motors.

“In this class, the children got the opportunity to not only learn how a DC motor works but they build their own DC motors. With the DC motor they made, they could see how

SPOTLIGHT

W 20 TechNation | May 2023

the electricity reacted when it entered a magnetic field, they discovered how to change the direction the motor would turn, etc. Next week we are learning about sound, sensors and microphones, and I can’t wait to see what they discover,” she says.

During the last month of classes, there is something called the “Young Inventors Workshop Event.”

“The Young Inventors Workshop is an event where we take the culmination of all of our knowledge throughout the year and build a large project. In the future, I would like to get companies involved and have them send mentors to see what the students have learned and give mentors an opportunity to teach. This will help bridge the gap between education and career,” Chester says. “In my classes, I try to get the parents involved along with their children because I am a believer that parent involvement is pivotal in a child’s learning. If the parent is engaged in what we are doing, so are the children.”

Chester ought to know how science and math-minded parents can influence their children.

“My father, Jesse L. Chester Jr. – my business partner – was a chief master sergeant bomb technician in the United States Air Force. He also majored in engineering technology, and my mother was a math teacher. They both were inspirations for what I do now as a career and for what I do as NextJenn TechMom,” she says.

As a biomed, Chester summarizes what she does on the job succinctly.

“I take care of people by taking care of the medical equipment around them,” she explains. “As a biomed, I get the unique opportunity to repair, maintain and install machines and care for people simultaneously.”

It is clear, she also cares about the future of kids.

What advice would she give to other HTM professionals or anyone else thinking of starting their own YouTube channel or teaching courses?

“The advice I would give to other HTM professionals is: 1. Don’t wait for the perfect time! Get started, 2. If it’s something you love, plant seeds, be a mentor and grow more of it! 3. Call me and we can do it together! 4. Refer to number 1,” she says.

Since most of the kids in Chester’s classes are still young, none have had the chance to declare a STEAM-related area as a focus of college studies yet. Chester doesn’t push them, but just allows them to enjoy what they learn.

“I like to think what I do is a gentle nudge for young minds to think big and never stop learning about the world around them. Good knowledge is power, no matter where it comes from, whether it be a college professor, a day at the park, a good book or the lady across the street who taught me all about earthworms. My purpose is to show the next generation of learners what I know and introduce them to a world they may have never considered because nobody showed them,” she says.

Find the NextJenn TechMom Inc. videos at youtube.com/@nextjenntechmominc/videos.

May 2023 | TechNation 21

The complete defibrillator analyzer

Features include:

• Light handheld, battery operation

• Pacer functionality

• Compatible with monophasic, biphasic and pulsed waveforms

• Reliable and non-inductive test load of 50Ω

• Patient simulator with ECG hi output

Scan the QR code to find out more or visit rigelmedical.com/TN3

Reduce Acquisition Costs for Medical Equipment

Tenacore provides immediate access to highquality, pre-owned medical equipment at a greatly reduced price. Typically, you can realize a savings of over 50% compared to new!

T.CERTIFICATION

• Ten-step process ensures that all equipment is tested and cosmetically like new

• Six to twelve-month warranty on all equipment provides peace of mind with your purchase

• Ongoing inventory allows immediate shipment on most orders

tenacore.com 800-297-2241

COMPANY SHOWCASE

Tenacore

Tenacore has made quality and patient safety the primary focus in all that we do. “In the many years that we have been in business there have been changes in the industry that have caused ripple effects,” Tenacore LLC President Riley Van Hofwegen explains. “The drive toward lowering cost has been a significant contributor in the deterioration of many third parties’ quality. It is a precarious game that all of us in the HTM community must cautiously play. Can price be driven down year over year and quality and patient safety remain high? There is definitely not a simple answer to this question and oftentimes the solution could easily go in either direction but, in general, this is the main question we all face in how we service and purchase medical equipment.”

“Tenacore’s success in recent years can be directly related to our commitment to continuous improvement in all that we do. From customer service, to sourcing of parts and products, to our technical expertise and emphasis on quality and excellence,” Van Hofwegen adds.

TechNation magazine found out more about Tenacore in a question-and-answer session with Van Hofwegen.

Q: WHAT ARE SOME ADVANTAGES THAT YOUR COMPANY HAS OVER THE COMPETITION?

A: Simply put, Tenacore’s people are what give us our advantage over our competitors! We are a confluence of industry veterans as well as outside professionals who all possess a similar mindset and ambition to being the best. The senior leadership team at Tenacore is built of people who are passionate about patient safety and understand that everything we do relates back to this simple premise. It is never to be sacrificed. This is then driven into all of our teams and no questions are left to be answered. With over 20 years of industry momentum, Tenacore has the staying power that

many companies cannot comprehend. We have proven that we are not a “fly by night” operation and that we will stand proud behind all that we do. When we offer extended warranties, our customer can rest assured that we will be here to honor them.

Q: WHAT ARE SOME CHALLENGES THAT YOUR COMPANY FACED LAST YEAR?

A: The COVID-19 pandemic has thrown a major curveball into how the market flows. For instance, when the virus first hit there was a quick frenzy of purchases occurring. Short-term acute care facilities were gearing up for war and preparing for the influx of patients that were already overwhelming them and parking lot treatment tents became the standard. Demand was huge and supply was limited making it very difficult for all. In the recent timeframe there has been a reset of this buying behavior as many facilities are overstocked with product and have no more government subsidies to assist with the cost. This really affected the servicing side of our business where HTM professionals have an overabundance of products they can exchange out to their clinical teams to keep them up and running. We were also hit with a few rounds of COVID infection amongst our staff which caused great difficulty in operating the business and further exacerbated our supply/ demand challenges.

Q: CAN YOU EXPLAIN YOUR COMPANY’S CORE COMPETENCIES AND UNIQUE SELLING POINTS?

A: Tenacore is an expert at depot and onsite service and sale of medical equipment. Our focus is on moveable medical equipment that can easily be shipped to our facility for service and then quickly returned to the customer. We operate in seven primary market segments: patient monitoring, air/ oxygen mixers, suction, fluid delivery, portable ventilation, defibrillation, and electrosurgical units (ESU). Our staff is highly trained with many years of experience working with health care professionals and understanding the needs of the environment.

COMPANY SHOWCASE

24 TechNation | May 2023

Our team members are solutions-minded and know what it takes to service the health care industry. If commitments are made, then they are kept. We will not make promises just to win a deal knowing full well that delivering will be impossible. We really think of ourselves as extensions of the health care facility. When a product needs to be sent out for service, we understand that there are clinicians in need of getting the device returned quickly and in working order so that they can do what they do best and treat their patients.

Q: WHAT PRODUCT OR SERVICE THAT YOUR COMPANY OFFERS ARE YOU MOST EXCITED ABOUT RIGHT NOW?

A: Tenacore is really excited about our onsite service programs for air-oxygen mixers (oxygen blenders) and infusion pumps. There is a two-year overhaul procedure recommended by original equipment manufacturers, including Tenacore’s air-oxygen mixer. We are also very excited about our Tenacore OEM product lines of suction regulators, air-oxygen mixers, fetal transducers and compatible patient cables.

Q: WHAT IS ON THE HORIZON FOR YOUR COMPANY?

A: We will remain true to our core business model with an emphasis on continuous improvement and being known as the best name in the game. We will be diligent in listening to our customers’ feedback about products or services that they find valuable. Rather than chasing down the next new product category, we aim to perfect what we currently do. There seem to be many companies chasing down the “next great thing” to support and sell and they fail to perfect their current business. They remain inconsistent and mediocre. Tenacore is a company that has been steady through the years in the third-party service and sales industry. We listened to customers talk about the need for a quality supplier of suction regulators and air-oxygen mixers which triggered us to start the journey of becoming a manufacturer and offering these products directly which we still do today.

Q: CAN YOU SHARE SOME COMPANY SUCCESS STORIES WITH OUR READERS?

A: Tenacore has a program for onsite service within health care facilities called T.Care. We will physically come onsite and service, perform preventative maintenance (PM), or calibrate medical equipment for our customer. We recently had a very large hospital customer reach out to us about our T.Care service offerings. They were up against a tight schedule, needing to overhaul more than 500 air-oxygen mixers before a Joint Commissions audit of their facility in the coming weeks. Our sales team was able to gather all the necessary requirements and quote the project in a matter of hours. We were onsite the following week to start the project with a team of highly skilled, T.Care professionals, who finished the job in a matter of days and put the hospital back on track with their PM cycles. The audit went smoothly, and the customer is now in a great position with their equipment maintenance cycles. They are now signed up for our T.Care program to keep them in long-term compliance.

Q: IS THERE ANYTHING ELSE YOU WANT READERS TO KNOW ABOUT YOUR COMPANY?

A: Tenacore has been a name in the biomedical industry for many years! This leadership team is solely concentrated on creating value and supplementing health care providers with a partner they can consistently count on! My resolute focus is to take on an upgraded approach to innovation, customer service and relationships, and solutions-based approaches. We have a leadership team comprised of individuals with a long-standing history within the HTM environment who understand the needs of clinical staff within health care facilities and organizations. Tenacore owes everything to our customers, they are the heroes supporting the health care community and servicing the products that allow clinicians to treat patients and save lives. There is nothing more motivating and gratifying than to be engaged in support of such a great cause.

For more information, visit tenacore.com.

SPONSORED CONTENT

May 2023 | TechNation 25

NEXT GEN POWERED BY Codi

Nelson

rothall Healthcare Technology Solutions (HTS) Program Director Codi Nelson, CBET, CHTM, holds a Bachelor of Science in Business Management and an Associate of Applied Science in Biomedical Equipment Technology.

TechNation recently learned more about this up-and-coming HTM professional.

Q: WHERE DID YOU GROW UP?

A: The Foothills of the Appalachian Mountains in North Carolina.

Q: WHERE DID YOU RECEIVE YOUR HTM TRAINING/ EDUCATION?

A: Caldwell Community College & Technical Institute (CCC&TI) in Hudson, N.C.

Q: HOW DID YOU FIRST DISCOVER HTM?

A: I heard about HTM in a high school masonry class. Our instructor’s son was a biomed, and he spoke to the class about how he worked on anesthesia equipment. Helping maintain life support equipment sounded cool to a 16-year-old!

Q: HOW DID YOU CHOOSE TO GET INTO THIS FIELD?

A: Honestly, after first hearing of HTM, I didn’t give it a second thought until it was time to start my college classes and I had to pick a degree. I looked for something that suited me in the program directory and remembered hearing of HTM in high school. Our economy was also nearing a recession in 2005 when I entered college, so I figured I needed to do something in a stable industry like health care, but without entering direct patient care.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: Like any of us, I’m sure … helping others. That’s why we do what we do!

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: Forging the pathway for the next generation through AAMI’s BMET Apprenticeship Program.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: Implementing AAMI’s BMET Apprenticeship Program at Crothall HTS. So far, we have hired seven apprentices in various accounts nationwide. We plan to hire 10 more this year. Our team of BMET apprentices is progressing rapidly and has already been able to help support and make an impact in many of our HTS departments!

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: To grow in my leadership abilities to remotely manage and provide BMET apprenticeship instruction to my team. This allows us to hire team members based on their attitude and drive to succeed. No matter their backgrounds or whether they were afforded the opportunity for higher education, Crothall provides the necessary training to grow as a BMET and develop a long, successful career.

FUN FACTS

FAVORITE HOBBY:

While stationary, studying God’s word and growing in faith. Otherwise, I truly enjoy hard, productive and helpful manual labor.

FAVORITE SHOW OR MOVIE:

It’s actually a YouTube channel. Just search for Wranglerstar.

FAVORITE MEAL:

My wife’s Saturday breakfast; she’s an excellent cook!

WHAT WOULD YOUR SUPERPOWER BE?

An endless amount of time and resources so I can always provide meaningful help to others.

1 THING ON YOUR BUCKET LIST:

To make the best of every moment I have with my children.

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU:

I’m an open book with my co-workers; what you see is what you get. For the TechNation audience, I like to play guitar and bass.

SPOTLIGHT

C 26 TechNation | May 2023

LET OUR CMMS STREAMLINE YOUR WORK

What you need is always at your fingertips - using a CMMS designed specifically for hospitals: “HEMS One” by EQ2.

• Manage Equipment/Loaner

Pool and Supply Processing Distribution Equipment

• Dashboard: essential metrics for work orders and inventory plus hyperlinks to drill-down further

• Convenient quick links to reports

• Search using auto-complete

• Advanced search

“HEMS One” empowers HTM/Biomed teams to do their best work! Schedule your demo of HEMS today: 888-312-4367 or EQ2LLC.com

AAMI: Booth 1050

May 2023 | TechNation 27

OF INNOVATIO N

Years

At Elite, we take pride in our U.S. manufactured parts. As a company we have made a promise and commitment to high quality products. By allowing this production in the states we create jobs, security, and lower risk of issues. Visit Our Website To Learn More www.elitebiomedicalsolutions.com Manufactured in the U.S.

NEWS & NOTES

Updates from the HTM Industry

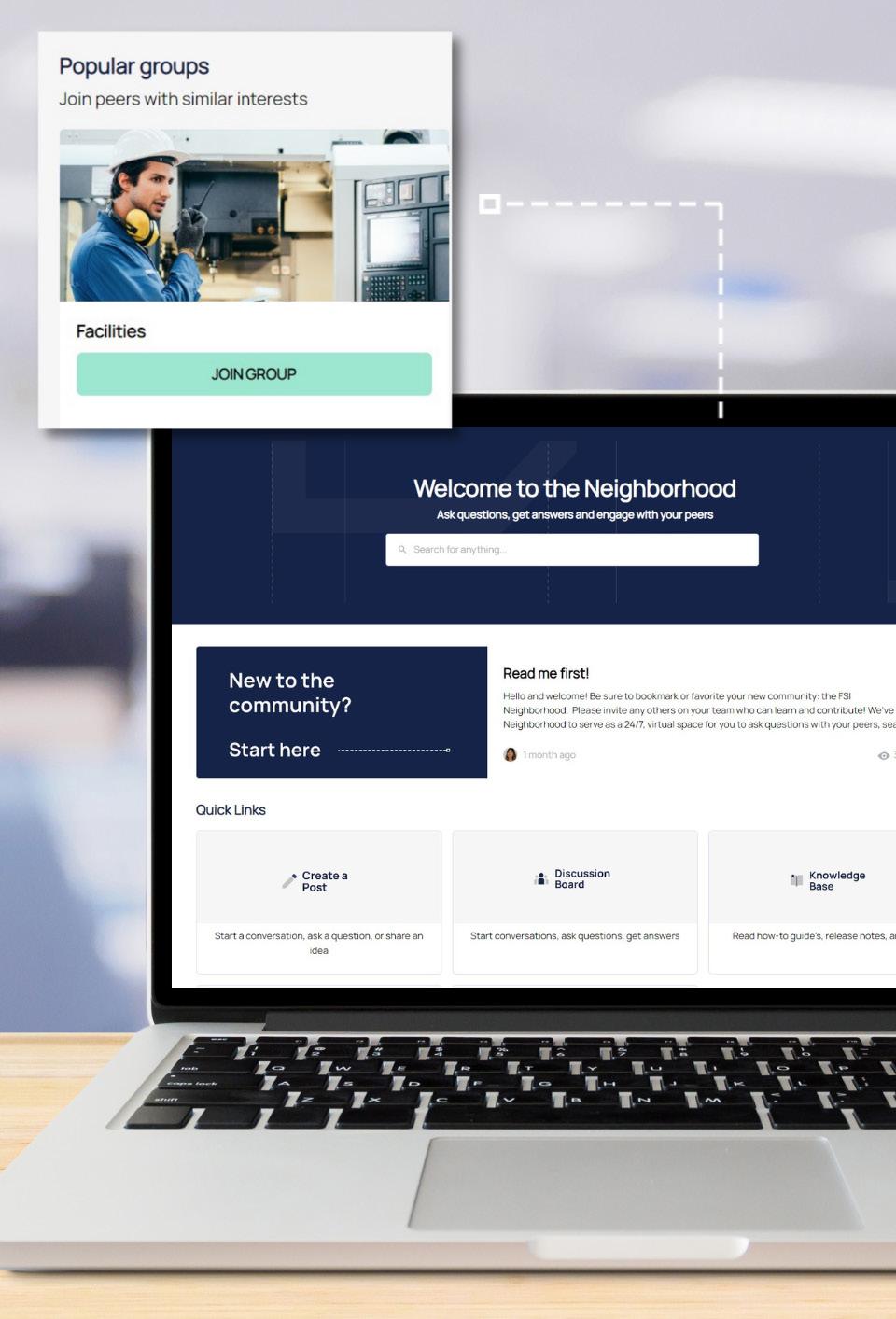

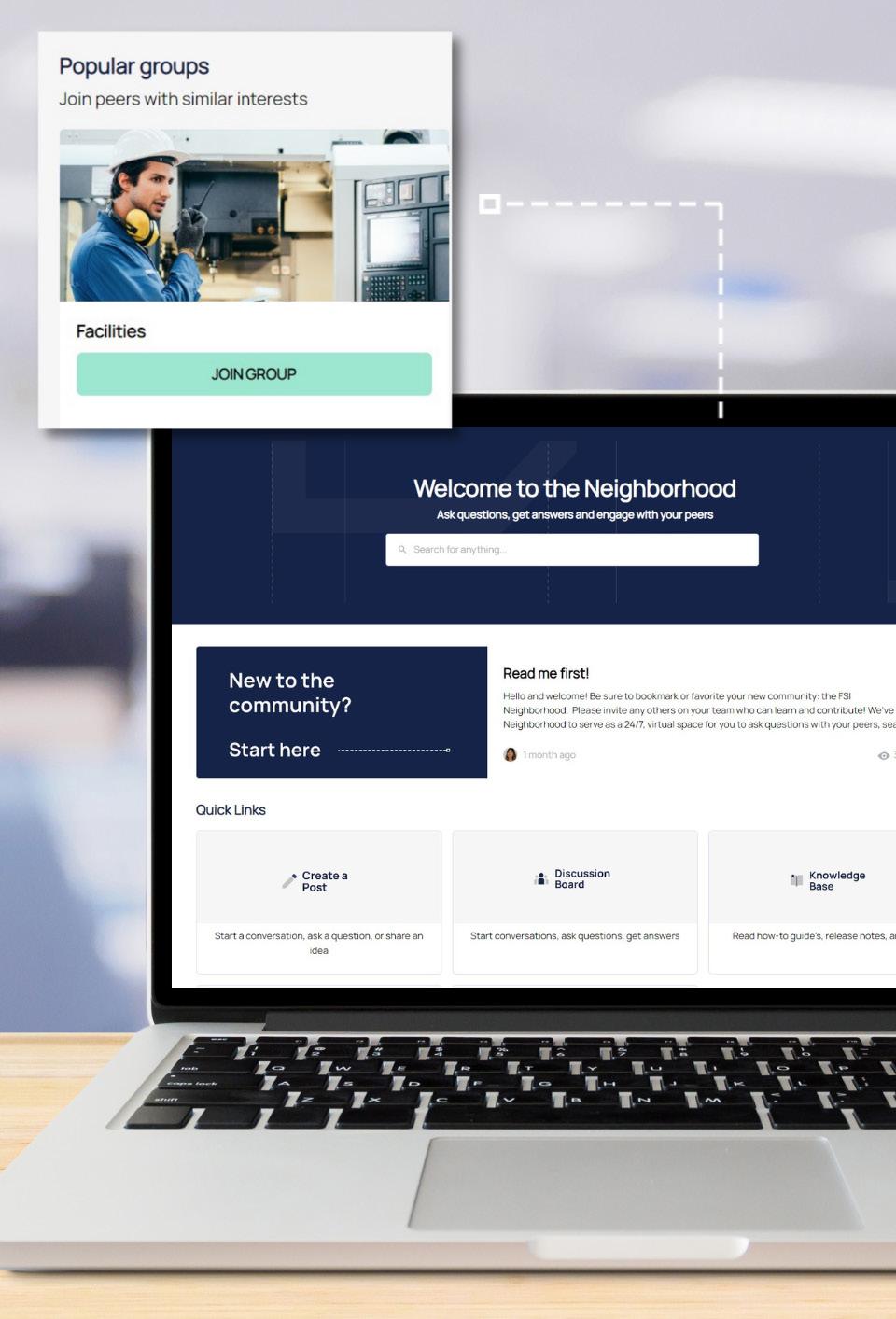

FSI LAUNCHES ONLINE COMMUNITY PLATFORM FOR HTM PROFESSIONALS

FSI Services, a health care CMMS provider, has launched an online community, The Neighborhood, designed for health care system professionals. The Neighborhood invites collaboration between users to share how they use FSI’s CMMS solution, CMS.

Managed by FSI’s Customer Success team that is responsible for ensuring facilities and HTM teams are continuously supported and educated, The Neighborhood has seen tremendous interest from users across the country.

“There’s almost no end to the number of ways our customers can use CMS to strengthen efficiency, cut time and costs, and maintain compliance,” said Zachary Seely, CEO of FSI. “We’re proud to offer a platform for our customers to ensure they’re getting the most out of CMS by discovering new ways to use it to improve their systems every day.”

Users can utilize The Neighborhood to:

• Join groups for focused discussions with customers who work in similar segments of the industry, including higher education, facilities and biomed/HTM.

• Participate in discussion boards by asking and answering important questions.

• Seek out best practices, how-to guides, videos and release notes

• Share ideas for product features and enhancements

“We’ve heard time and again that our customers love having the opportunity to hear from other customers,” explained Claire Salinas, associate director of customer success at FSI. “The Neighborhood is born out of FSI seeking to give our customers a platform to learn from each other, as well as creating a centralized location for FAQs, release notes, videos and more.”

Customer response has been positive and hospital administrators have been promoting the Neighborhood to members of their teams, which speaks to the nature of FSI customers wanting to engage with other professionals in their field, share their successes and gather ideas for new ways to utilize the software.

“The Neighborhood has been a good way for us to bounce ideas off other customers, FSI employees or anyone who has a little bit more knowledge than we do currently,” Samuel McFarlane, database admin manager at the University of Utah recently shared. “My favorite part of the Neighborhood so far has been the collaboration, and joining groups related to

things I’m directly working with.”

The Neighborhood is supported by Insided, a customer community platform based in Amsterdam that works with leading B2B SaaS companies, like FSI, to offer customers an online community component to share knowledge and gather new ideas.

Launched in 2002, FSI was created by and for health care service professionals and engineers, offering a purpose-built CMMS specifically for healthcare-managed operations. FSI’s 1,000 plus hospital segments rely on a full suite of services and software that empowers their teams to use data to make smart decisions: including on-site data collection, barcoding, and CAD services.

INDUSTRY UPDATES

May 2023 | TechNation 29

HTM WEEK CONTEST ANNOUNCED

TechNation celebrates healthcare technology management (HTM) professionals everywhere each and every day and especially during the upcoming HTM Week (May 14–20). TechNation joins health care facilities and organizations to promote awareness of – and appreciation for – the critical work of professionals who manage and maintain the vast assortment of health technology found in healthcare delivery organizations.

HTM professionals are encouraged to participate in the Rock Your Socks! Contest for a chance to win a daily prize and an entry in the grand prize drawing! It’s easy to enter. Snap a photo of yourself wearing your most fun, craziest socks. It can be crew socks, dress socks, knee socks, fuzzy socks, any pair of socks. Then, visit 1technation.com/htm-week-contest to submit your entry form.

Contest begins May 1, and you can submit your entry anytime through May 18. A daily $25 Amazon gift card will be awarded

HTM WEEK

ROCK YOUR SOCKS

Monday through Friday of HTM Week. One lucky person will win the grand prize package that includes flight, hotel and admission to the MD Expo set for Orlando in late October!

Recognized Component Approved for Use in Patient Care Areas

HOW TO ENTER: HTM WEEK MAY 14–20

5 daily prizes of $25 Amazon gift card.

1 grand prize winner receives flight, hotel, and admission to MD

Locking Bolt with Nut 785A HAPPY MAY 14-20, 2023

& UL1363A

INDUSTRY UPDATES *With

UL60601-1

A NEW WINNER EVERY DAY!

1. Snap a photo of you wearing your most fun, craziest socks. Crew socks, knee socks, fuzzy socks, any pair of socks. 2. Visit 1technation.com/htm-week-contest/ to fill out contest submission form.

ORLANDO.

EXPO

SPONSORED BY 30 TechNation | May 2023

REPORT PREDICTS VITAL SIGNS MONITORING DEVICES MARKET GROWTH

The “U.S. Vital Signs Monitoring Devices Market - Industry Outlook & Forecast 2023-2028” report has been added to ResearchAndMarkets.com’s offering.

The U.S. vital signs monitoring devices market is projected to be valued at $11.21 billion by 2028 from $7.21 billion in 2022, growing at a CAGR of 7.62% from 2022 to 2028.

The COVID-19 pandemic has brought significant challenges to the entire health care industry and impacted the growth of the U.S. vital signs monitoring devices market. This has accelerated the adoption of vital signs monitoring devices in the patient population and end-user.

Similarly, most people are opting for home precautions with the help of temperature monitoring devices to measure their body temperature amid the pandemic. Also, amid COVID-19, vital signs monitoring devices, such as standalone or wearable devices, have gained significant traction in clinical trial studies over patients and support providers with systematic, real-time information.

Vital signs patient monitors are used to monitor patients’ vital signs in emergency care settings and for continuous management of chronic diseases. There is rising demand for various vital signs monitoring devices to treat this increasing patient population.

As the demand for these devices has increased, vendors are constantly focusing on increasing their production capacity to meet the increasing demand and provide quality care to patients in the U.S. vital signs monitoring devices market. Further, patients’ vital signs monitors are the most required products, along with portable ventilators and medical consumables for non-invasive and invasive ventilation to treat a broad range of respiratory conditions.

Also, the increased awareness of telemedicine is anticipated to drive the U.S. vital signs monitoring devices market during the forecast period. Further, the increase in demand for technologically advanced products due to benefits over traditional ones is anticipated to fuel the growth of the U.S. vital signs monitoring devices market. Companies are investing in the development of advanced products to improve treatment.

The trend toward using a wireless patient monitoring system to monitor vital signs continues to grow. Among the many benefits being brought to the health care service by wireless patient monitoring is the facility to escalate home care for both chronic and acute conditions. Various pandemic-related factors have created an opportunity to integrate care at home. The emergence of new technologies and capabilities makes taking care of one at home possible.

PUMP YOU UP! Does pump month make you feel weak? We are here to 1 (888)-492-3400 multimedicalsystems.com If you mention you saw us in TechNation we have a team perk for your shop! We manage it all from locating the pumps, cleaning, PMs, minor repairs, batteries and returning to your patient care areas. We provide daily and end of project reporting. If you don’t have the need for support on all your pump PM’s then we also have hourly infusion pump specialists available to assist during pump month. May 2023 | TechNation 31

ADVANTUS HEALTH PARTNERS, GE HEALTHCARE AGREEMENT EXPANDS HTM SERVICES

Advantus Health Partners, a health care solutions company delivering more effective, efficient supply chain models to health care organizations, and GE HealthCare, one of the largest providers of medical equipment maintenance services in the world, have announced an agreement of up to $760 million over 10-years to provide GE HealthCare’s Healthcare Technology Management (HTM) services to Advantus Health Partners’ clients.

“Advantus was founded following our team’s success designing a better supply chain model for a large health system with 48 hospitals. We understand the growing challenges that health care providers – large and small – face in today’s environment,” said Dan Hurry, president of Advantus Health Partners. “We are constantly working to bring next-generation supply chain management models to our customers, and this relationship with GE HealthCare underscores our commitment to delivering benefits to health systems, suppliers and the overall health care supply chain.”

The comprehensive HTM program can provide complete management of medical equipment in a health care facility – including ongoing maintenance, monitoring for and addressing recalls, disinfection and distribution, and more for Advantus Health Partners’ clients.

The program also can help reduce costs and improve

productivity for clients through standardization of processes to manage equipment across health care systems and proactive monitoring of data safety. Further, their clients will have access to Encompass, GE HealthCare’s real-time location system technology that tracks and locates a provider’s equipment so caregivers can spend less time searching for equipment and more time with patients. Other services include advanced asset management and an advanced scopes program with proactive service strategy for endoscopes.

“We are excited to build a healthier future by managing the comprehensive service needs of health care providers and helping ensure they have the latest technology available to provide quality care to their patients,” said Mohamed El-Demerdash, GE HealthCare U.S. and Canada Services President. “Together with Advantus Health Partners, we will support health care organizations as they continue to evolve and adapt to meet their ever-changing needs and those of the communities they serve.”

Through this expanded relationship between Advantus Health Partners and GE HealthCare, health care providers will have access to a scalable, end-to-end solution for managing medical equipment performance and risk.

HTM MIXER OFFERS TOP-NOTCH EDUCATION

MD Publishing, the parent company of TechNation and MD Expo, is bringing back HTM Mixers! Biomeds should mark their calendars for May 11-12, 2023, to attend the next HTM Mixer at the Turf Valley Resort in Baltimore, Maryland. It is supported by the Baltimore Medical Engineers and Technicians Society (BMETS).

What are HTM Mixers?

Think of them as MD Expo 2.0 – a slightly modified, smaller, shorter-duration and less-crowded event that still provides valuable continuing education, networking and vendor engagement opportunities.

The mixers serve as a regional conference for HTM professionals eager to earn continuing education credits, explore solutions in an exhibit hall and network with peers.

The educational lineup for the HTM Mixer features 9 one-hour sessions designed to cover hot topics and great insights for attendees. Career development, leadership, certifications, electrosurgery, contrast injectors, health technology hazards, art of contract negotiations, cardiology for biomeds and ultrasound will be covered.

More than 40 of the leading HTM companies have already secured space in the exhibit hall to share solutions with attendees.

A welcome reception, coffee breaks and a happy hour will each provide additional networking opportunities for everyone in attendance.

For more information about the Baltimore HTM Mixer, visit htmmixer.com.

INDUSTRY UPDATES 32 TechNation | May 2023

Contrast Injector Training • 100s of Error Codes not found in OEM Lit • Online and Onsite Training Available • Training BMETs since 2008 • Up to $5,500 in FREE Parts, PM Kits and Service • Massive Troubleshooting Library WWW.MAULLBIOMEDICAL.COM | 440-724-7511 | STEVE@MAULLBIOMEDICAL.COM ON-SITE AVAILABLE 34 TechNation | May 2023

ECRI UPDATE

Supply Chain Resilience: 3 Ways to Save Despite Rising Costs, Frozen Spend

BY EDWARD NUBER, DIRECTOR OF MARKETING, ECRI

hanges in the supply chain, or supply chain disruptions, can happen at any time, but the COVID-19 pandemic set off a domino-effect series of shortages and delays that impacted financial, reputation and clinical outcomes.

ECRI included supply chain disruptions in its annual list of Top Patient Safety Concerns in 2021, and again in 2022. And while 2023 may bring some improvements, challenges remain.

Health care leaders will continue to grapple with supply chain challenges that effect patient safety, health care quality, financial standing and emergency preparedness. In fact, supply chain problems may be compounded by additional medical issues such as RSV and a rampant flu, as well as geopolitical and economic factors, such as war, inflation, spend limits and staff shortages.

Together these factors slow the supply chain, delaying needed goods, services and transportation.

Additionally, spend budgets have remained stagnant, and vendors are not likely to offer discounts like they once did. Without price reductions, providers must find new ways to save.

But the good news is that you can now better prepare for and get ahead of supply chain disruptions.

In ECRI’s newest whitepaper, “Healthcare Supply Chain Resilience: 3 Ways Providers Can Save Amid Rising Costs and Frozen Spend Allocations,” Timothy Browne, vice president, supply chain solutions, outlines how to be proactive, strategic and agile to meet your supply clinical needs while controlling spend.

Whether you are a procurement manager, supply

chain director, administrator, budget analysist or clinical staff member, you’ll find useful information that helps you engage in the procurement/supply chain process in a more deliberate and strategic way.

The white paper provides more detail about three key strategies:

• Identify Product Substitutes: The pandemic forced many organizations to seek out substitute products simply because they could not procure their preferred or current products. The substitute products needed to be clinically effective, obtainable within budget and available when needed. Your organization is no longer searching for functionally equivalent PPE, such as masks or gowns, but there still may be savings to be had. Confer with your clinical and procurement staff for ideas about where savings might be identified.

• Access Utilization: Does your right hand know what your left hand is doing? Does one group use the same needles as a second group within your one-location hospital? Within your larger network organization, does your emergency department at location “A” use the same sanitizer as your emergency department at location “B” that happens to be in another state? Standardizing purchases can save money and increase patient and staff safety.

• Implement an Evidence-based Assessment Process: If you do not already have one, create a rigorous value analysis process. Such a process can prevent and reduce waste and bring in only products that have been carefully vetted. Want to learn more, including how ECRI identified potential savings of $700,000-plus for one organization? Download ECRI’s free white paper at www.ecri.org/ healthcare-supply-chain-resilience-white-paper/ and reach out to an ECRI expert for further assistance.

C INDUSTRY UPDATES May 2023 | TechNation 35

WELCOME TO THE TECHNATION COMMUNITY!

Q: WHAT PRODUCT, SERVICE, OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Tenacore offers clinical equipment life cycle solutions to the global healthcare technology community through quality service delivery and dedication to continuous improvement. Tenacore has comprehensive service and repair capabilities for the following medical equipment modalities: infusion pumps, gas analyzers, modules, patient monitors, oxygen blenders, surgical light sources, telemetry, ultrasound probes ventilators and wall suction regulators.

Q: WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

Professionals who choose Tenacore can rest assured they’re partnering with a healthcare technology management company whose clinical equipment life cycle solutions meet ISO 13485:2016 quality and safety standards. With over 20 years of specialization in depot-based service and repair of a broad range of medical equipment, Tenacore offers a quality, costeffective alternative to hospitals, clinics and health care facilities.

For more information, visit tenacore.com.

INDUSTRY UPDATES

SEE OUR AD ON PAGE 23

Riley Van Hofwegen, President

36 TechNation | May 2023

SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSA

KOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMED

SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSA

KOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMED

SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSA

KOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMED

SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSA

KOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMED

SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDS

AKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

MEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSA KOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMED SAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKOMEDSAKO

27751 LA PAZ RD. STE A LAGUNA NIGUEL, CA • 92677 (844) 433-SAKO • INFO@SAKOMED.COM Anesthesia Machines Respiratory Ventilators Electro Surgical Units • Patient Monitors & Telemetries • Defibrillators and AEDs • Parts and Accessories Equipment Repair, Spare Parts & Accessories www.sakomed.com 27751 LA PAZ RD. STE A LAGUNA NIGUEL, CA • 92677 (844) 433-SAKO • INFO@SAKOMED.COM REFURBISHED MEDICAL EQUIPMENT SALES AND SERVICES JOIN US AT SakoMed is here to help, offering 2-3 days turn around time on all repairs. Anesthesia Machines Respiratory Ventilators Electro Surgical Units Patient Monitors & Telemetries Defibrillators and AEDs Parts and Accessories Need a FREE loaner and FREE evaluation?

AAMI UPDATE

AAMI Releases Special Report on Artificial Intelligence

If you’re wondering how artificial intelligence (AI) will affect your health care institution, company, or career, the Association for the Advancement of Medical Instrumentation (AAMI) has you covered.

AAMI has recently released an in-depth report, “Artificial Intelligence, the Trust Issue,” that provides expert insights for product developers, regulators, standards developers, hospital systems, healthcare technology management (HTM) professionals, risk managers, and clinicians. The report is the first of an ambitious new AAMI series of Medical Device Safety in Focus reports that will explore hot topics in healthcare technology.

According to AAMI’s Joe Lewelling, vice president of industry, the digital report, which consists of an estimated 40 pages of content including informative videos, figures and expert insights, will serve as “an introduction for people in health care who need to know more about AI but are not necessarily specialists in AI.”

“Artificial intelligence is something that the health care industry is going to be focusing on, and working with, and struggling with for the next decade or longer,” said Lewelling “This document is not going to make an expert in artificial intelligence, but it is going to prepare you to make important decisions.”

“Artificial Intelligence, the Trust Issue,” tells a compelling story about the opportunities and risks of AI in health care –and provides wide-ranging perspectives on efforts to balance risks and opportunities. The report is presented in three sections:

1. The first section, Rehumanizing Healthcare with AI, sets the stage with a look at the potential of AI to remake health care – and what’s driving high hopes now. Many experts believe that AI could revolutionize health care delivery in terms of access, quality, and outcomes, including health equity. AI also could rehumanize health care by freeing up clinicians to focus on patient care and driving efficiencies that improve patient experiences.

If you’re still trying to wrap your head around what AI can do, this section is a good primer. There are many examples of the benefits that AI-enabled health technologies are already delivering. But the AI era is still in its infancy. Market indicators and physician adoption rates suggest the potential for exponential growth in coming years.

“When done right, AI has enormous potential,” noted report contributor Jesse Ehrenfeld, president-elect of the American Medical Association, professor of anesthesiology at the Medical College of Wisconsin, and co-chair of AAMI’s Artificial Intelligence Committee. “Digital medicine has enormous opportunity to improve health outcomes. There is tremendous enthusiasm about disruptive innovation as long as it’s clinically validated. Where we hear concerns, and I hear this all the time as around lack of transparency that will interfere with that trust, with understanding how these tools were designed and validated.”

2. Inside AI’s ‘Black Box’ focuses on the myriad ways that AI-enabled health technologies could jeopardize patient health and safety, increase inequalities and inefficiencies, undermine trust in health care, and adversely impact the management of health care.

There are concerns about the Big Data that makes AI possible, including data quality, access, bias, selection, and control, as well as change management of AI systems and the safety and security of cloud services. The Black Box conundrum makes it hard to understand what happens in very complex, multilayered systems that are capable of learning from large data sets, which engenders distrust. AI also can fail in “weird ways” and make mistakes that no human would make. Cybersecurity is a massive – and massively increasing – concern.

Finally, the potential of AI in health care is also luring algorithm engineers to product development, but their inexperience with medical device development, standards, and regulations can pose risks. AI health technology also raises basic questions about financial risk to health care systems and providers.

INDUSTRY UPDATES

38 TechNation | May 2023

“The proliferation of developers who are good at developing artificial intelligence systems, but who’ve never done it in a life-sciences setting, can cause problems in terms of safety, efficacy, and unintended consequences,” said contributor Scott Thiel, global head of regulatory policy and intelligence, Hologic, Inc. “Frankly it can also cause compliance issues out of ignorance of the regulatory requirements for these systems.”

3. Balancing Opportunities and Risks. Given the lofty expectations for AI to transform health care and the broad scope of vulnerabilities and risks, it will take broad collaboration among a wider variety of stakeholders to ensure the quality, safety, and effectiveness of AI-enabled healthcare technology.

Managing risks encompasses standards and guidance for risk management, regulatory clarity, and resources for risk management and governance in health care facilities. The report includes practice guidance and an AI vendor checklist for HTM professionals. It also addresses an irony in the growth of AI health technology and the complex challenges associated with it: Everyone involved in developing, managing, and using it needs to bolster their knowledge and competencies.

“Communication buys grace,” added Mike Powers, system director of healthcare technology management, Intermountain Healthcare, and a member of AAMI’s Artificial Intelligence Committee. “The more manufacturers, AI developers, and organizations that have experience with AI products communicate the risks and benefits of AI technology, the more informed additional parties can be to make informed decisions.”

At the root of the report is the insights of professionals who are invested in a future where AI is used to enrich, not burden, the health care space.

“We know that artificial intelligence is going to change the world. Those working with healthcare technology may be wondering where they fit in or what they can do about it. The best action you can take – right now – is to get informed,” said Gavin Stern, MPH, MS, editor in chief at AAMI and the association’s director of publications. “That’s why we developed Medical Device Safety in Focus, a new kind of publication that provides an in-depth look at a specific healthcare technology topic. The first edition of MDSIF puts you in the room with the foremost experts working at the confluence of artificial intelligence and health care, from multiple fields and viewpoints. This is the AI primer you’ve been waiting for.”

The report is free for AAMI Members and available for purchase. Interested parties may read the executive summary for free at array.aami.org.

For more information, visit aami.org.

May 2023 | TechNation 39

AAMI EXCHANGE 2023 Your Guide to Prepare

The annual health technology conference of the Association for the Advancement of Medical Instrumentation — known as the AMMI eXchange — is back, this time under the sunny skies of Long Beach, California! Professionals from the healthcare technology management (HTM) fields will bump elbows with innovators, regulators, and industry thought leaders on June 16 through 19.

“This June will bring together the entire healthcare technology management fields for what is sure to be another empowering, rejuvenating and inspiring AAMI eXchange,” Pamela Arora, president and CEO of AAMI, said in anticipation of the event. “We look forward to seeing everyone together in-person as we share our knowledge, learn new approaches to today’s challenges, and unite together to move the health technology industry forward.”

The 2022 eXchange in San Antonio, Texas, hosted nearly 2,000 professionals. This year, AAMI intends to keep even larger crowds engaged with 160 exhibitors, 10+ hours of total exhibit time, more than 80 concurrent breakout sessions and workshops, and — for the first time ever — an à la carte technical training schedule for BMETs looking to sharpen their skills on a wide array of hands-on courses.

PEER-TO-PEER LEARNING