Editor’s Office and Advertiser Information: Florida Water Resources Journal 1402 Emerald Lakes Drive Clermont, FL 34711 Phone: 352-241-6006 Email: Editorial, editor@fwrj.com Display and Classified Advertising, ads@fwrj.com

Business Office:

1402 Emerald Lakes Drive, Clermont, FL 34711 Web: http://www.fwrj.com General Manager: Editor: Graphic Design Manager: Mailing Coordinator:

Michael Delaney Rick Harmon Patrick Delaney Buena Vista Publishing

Published by BUENA VISTA PUBLISHING for Florida Water Resources Journal, Inc. President: Richard Anderson (FSAWWA) Peace River/Manasota Regional Water Supply Authority Vice President: Jamey Wallace (FWEA) Jacobs Treasurer: Rim Bishop (FWPCOA) Seacoast Utility Authority Secretary: Mish Clark

Mish Agency

Moving? The Post Office will not forward your magazine. Do not count on getting the Journal unless you notify us directly of address changes by the 15th of the month preceding the month of issue. Please do not telephone address changes. Email changes to changes@fwrj.com or mail to Florida Water Resources Journal, 1402 Emerald Lakes Drive, Clermont, FL 34711

Membership Questions FSAWWA: Casey Cumiskey – 407-979-4806 or fsawwa.casey@gmail.com FWEA: Karen Wallace, Executive Manager – 407-574-3318 FWPCOA: Darin Bishop – 561-840-0340

Training Questions FSAWWA: Donna Metherall – 407-979-4805 or fsawwa.donna@gmail.com FWPCOA: Shirley Reaves – 321-383-9690

For Other Information DEP Operator Certification: Ron McCulley – 850-245-7500 FSAWWA: Peggy Guingona – 407-979-4820 Florida Water Resources Conference: 407-363-7751 FWPCOA Operators Helping Operators: John Lang – 772-559-0722, e-mail – oho@fwpcoa.org FWEA: Karen Wallace, Executive Manager – 407-574-3318

Websites Florida Water Resources Journal: www.fwrj.com FWPCOA: www.fwpcoa.org FSAWWA: www.fsawwa.org FWEA: www.fwea.org and www.fweauc.org Florida Water Resources Conference: www.fwrc.org Throughout this issue trademark names are used. Rather than place a trademark symbol in every occurrence of a trademarked name, we state we are using the names only in an editorial fashion, and to the benefit of the trademark owner, with no intention of infringement of the trademark. None of the material in this publication necessarily reflects the opinions of the sponsoring organizations. All correspondence received is the property of the Florida Water Resources Journal and is subject to editing. Names are withheld in published letters only for extraordinary reasons. Authors agree to indemnify, defend and hold harmless the Florida Water Resources Journal Inc. (FWRJ), its officers, affiliates, directors, advisors, members, representatives, and agents from any and all losses, expenses, third-party claims, liability, damages and costs (including, but not limited to, attorneys’ fees) arising from authors’ infringement of any intellectual property, copyright or trademark, or other right of any person, as applicable under the laws of the State of Florida.

News and Features 4 First Florida, Then Nationals: Winners of FWEA High School Video Contest Triumph at WEF Competition—Shea Dunifon 6 Florida Water Resources Conference Welcomes New Executive Manager 32 Contractors Roundup: A Contractor’s Perspective on Florida’s Shift to Increase Beneficial Reuse—Michael Rood and Courtney Dantone

33 Leadership Awards Nominations Being Accepted 48 Meet Morgan Barnes, Florida’s 2021 Stockholm Junior Water Prize Winner— Shea Dunifon

52 APWA Selects New Members for Board of Directors 58 News Beat

Technical Articles

21 FSAWWA Water Conservation Awards for Excellence 47 TREEO Center Training 51 FWPCOA Online Training

Columns 22 FSAWWA Speaking Out—Fred Bloetscher 26 Let’s Talk Safety: Climb Into ConfinedSpace Safety 28 Committee Profile: FSAWWA Contaminants Committee—Rae Hafer 30 FWEA Focus—Ronald R. Cavalieri 34 Test Yourself—Donna Kaluzniak 35 C Factor—Kenneth Enlow 54 Reader Profile—Bartt Booz

Departments 59 Classifieds 62 Display Advertiser Index

8 Guidelines for Use of Mini-Horizontal Directional Drilling for Placement of High-Density Polyethylene Pipe for Water Applications—Lawrence M. Slavin 40 Developing Effective Funding Strategies for Compliance With the Lead and Copper Rule Revisions—Christopher Hill, Quirien Muylwyk, and John Konkus

55 Realizing the Benefits of Process Advisory Digital Twins for Water, Wastewater, and Reuse—Benjamin D.

Stanford, Ryan Nagel, and James MacDonald

Education and Training 14 2022 Florida Water Resources Conference Call for Papers 15 CEU Challenge 16 FSAWWA Fall Conference Calendar of Events 17 FSAWWA Fall Conference Overview 18 FSAWWA Fall Conference Students and Young Professionals Activities 19 FSAWWA Fall Conference Water Distribution System Awards 20 FSAWWA Fall Conference Competitions

Volume 72

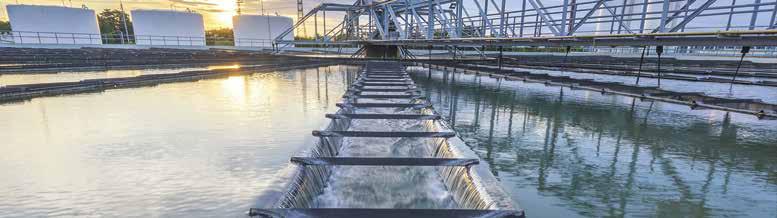

ON THE COVER: If you know the name of the facility pictured on the cover, email it (along with your name and email) to the FWRJ editor at ricklharmon@comcast.net by October 31, 2021, and your name will be entered in a drawing for a complimentary registration to the 2022 Florida Water Resources Conference being held April 24-27 in Daytona Beach!

October 2021

Number 10

Florida Water Resources Journal, USPS 069-770, ISSN 0896-1794, is published monthly by Florida Water Resources Journal, Inc., 1402 Emerald Lakes Drive, Clermont, FL 34711, on behalf of the Florida Water & Pollution Control Operator’s Association, Inc.; Florida Section, American Water Works Association; and the Florida Water Environment Association. Members of all three associations receive the publication as a service of their association; $6 of membership dues support the Journal. Subscriptions are otherwise available within the U.S. for $24 per year. Periodicals postage paid at Clermont, FL and additional offices.

POSTMASTER: send address changes to Florida Water Resources Journal, 1402 Emerald Lakes Drive, Clermont, FL 34711

Florida Water Resources Journal • October 2021

3

First Florida, Then Nationals: Winners of FWEA High School Video Contest Triumph at WEF Competition This past summer, the inaugural 2021 Water Environment Federation (WEF) Water Palooza video contest was hosted by the WEF Students and Young Professionals Committee (SYPC). Student entries, open to all ages, were received from the Illinois Water Environment Association (IWEA) and Florida Water Environment Association (FWEA), WEF member associations that each host their own respective video contests. With an entry “so far above the rest” the grand prize went to none other than FWEA’s own 2021 first-place high school video contest winners!

caught! For winning first place, Leo and Hubert were awarded a $700 cash prize. As winners of the WEF Water Palooza video contest, Leo and Hubert will also receive gift cards from United By Blue, a company that promotes sustainable materials and ethical manufacturing to lead the charge toward better business practices. The company pledges that, for every product purchased, one pound of trash is removed from the ocean or waterways. To learn more about the company and shop its products, visit www.unitedbyblue.com.

Winning Entry

Water Palooza

The FWEA Public Communications and Outreach Committee (PCOC) hosts an annual high school video contest and this past spring awarded first place to Leo Meng and Hubert Pilichowski of Strawberry Crest High School in Hillsborough County for their mock news skit titled, “Toilets Tonight.” The 45-second video features host, Lav A. Tory, and lead reporter, Latrine Larry, in a breaking-news segment: the culprits of clogged toilets and sewers have been

For those curious about WEF’s Water Palooza, it’s an annual daylong educational event that’s organized by SYPC with support from WEF PCOC. Water Palooza takes place the Friday before the Water Environment Federation Technical Exhibition and Conference (WEFTEC) at a local elementary school where students visit multiple stations to learn about the value of water and initiatives in their community, and how to conserve water

Water Palooza logo.

while protecting the environment at home. To learn more about Water Palooza, visit https:// www.wef.org/membership/students-andyoung-professionals2/waterpalooza/. While the WEF Water Palooza video contest was a first this year, WEF and its SYPC hope to sponsor the contest again in the future and get more member associations involved.

Thanks to Staff and Members A special thanks goes to all the WEF members and staff who helped make this inaugural contest possible: S Brandon Friedland, InnovaTreat S Stephanie Schramm, Jacobs S Allison Fore, Metropolitan Water Reclamation District S Natalie Cook, Donahue and Associates S Tim Moran, Rogue Water S Megan Livak, WEF Don’t forget to check out the WEF YouTube channel this fall to see all the video entries. To view the winning Florida (and now national) video on the FWEA YouTube channel, click on the “High School Video Contest 2021” playlist and then select the video titled, “Toilets Tonight.”

WEF’s mascot, Niles the Crocodile,interacting with students at a Water Palooza event.

4 October 2021 • Florida Water Resources Journal

Shea Dunifon is the education coordinator at Pinellas County Utilities South Cross Bayou Advanced Water Reclamation Facility in St. Petersburg. She is chair of the FWEA Public Communications and Outreach Committee (PCOC) and co-vice chair of the WEF PCOC. S

Settled Solids Management

WWTP Tank Cleaning Florida’s Original On-Line Tank Cleaning Service Since 1982

Inventors of Sand Dragon Technology

State Funding Available to Pay for Cleaning - Contact us for Details!

WE REMOVE GRIT WHILE YOUR PLANT REMAINS IN SERVICE & FULL OF WATER Eliminate Your Grit: visit SSM.Hydro-int.com or call 407.322.0330 or email SSM@Hydro-int.com

Florida Water Resources Conference Welcomes New Executive Manager Michelle (Mish) Clark, president and founder of The Mish Agency LLC, has been hired as the executive manager for the Florida Water Resources Conference (FWRC), overseeing and managing all details to ensure a successful yearly event. She will also provide general administrative and executive services, and conference-related content, to the Florida Water Resources Journal. Mish has had a successful career of more than 27 years in the theme park/hospitality industry. She has been credited with the ability to analyze numerous components of a project and communicating them to others in a very simple, relevant manner. She has found great reward in developing initiatives to strengthen an organization’s strategic plans, then executing them efficiently and flawlessly. Mish is a skilled business leader and has built relationships with such dynamic clients as SeaWorld Entertainment, Cirrus Aviation, J.M. Smucker, Baha Mar Resort, and Advent Health. She graduated from the University of Central Florida with two bachelor’s degrees, in advertising/public relations and business/ marketing, and received a master’s degree in human resource management from Troy State University. Mish is currently a member of the University of Central Florida Alumni Board and is on the board of advisors for Nona Volleyball Academy. “Within the first couple of weeks on the job, I was incredibly impressed by the hospitality, teamwork, and sense of family within the various water organizations and the FWRC board,” says Mish. She has four teenagers and they love boating the Florida lakes and hiking the Georgia S mountains together.

6 October 2021 • Florida Water Resources Journal

SIMPLE. EFFI C I E NT. I NT E LLI GE NT. Generate Revenue with Raptor ® Septage Acceptance Plants

Cleaner Water for a Brighter Future® and Raptor® are registered trademarks owned by Lakeside Equipment Corporation. All other trademarks are property of their respective owners. © 2021 Lakeside Equipment Corporation.

Grow your septage, FOG, and sludge receiving business with a Raptor Septage Acceptance or Complete Plant. REPRESENTED LOCALLY BY: Trippensee Shaw, Inc. Eustis and Sebring, FL www.TrippenseeShaw.com T. 863.382.2101 Florida Panhandle Only T: 205.424.7570 www.eshelmancompany.com

NOT YOUR ORDINARY RECEIVING SYSTEM R a p t o r S e p t a g e A c ce p t a n ce P l a n t Removes debris and inorganic solids from municipal and industrial septage, FOG, and sludge. This heavy-duty machine incorporates the Raptor Fine Screen for screening, dewatering and compaction. Accessories include security access and automated accounting systems. Raptor Septage Complete Plant With the addition of aerated grit removal, the Septage Acceptance Plant is offered as the Raptor Septage Complete Plant.

Cleaner Water for a Brighter Future® Speak to an expert at 630.837.5640 or visit www.lakeside-equipment.com for more information.

Visit us at BOOTH #1826 October 18 - 20, 2021 Chicago, IL

F W R J

Guidelines for Use of Mini-Horizontal Directional Drilling for Placement of High-Density Polyethylene Pipe for Water Applications Lawrence M. Slavin

U

ser-friendly guidelines for the placement of high-density polyethylene (HDPE) pipe with mini-horizontal directional drilling (HDD) equipment have been developed by the Municipal Advisory Board (MAB) of the Plastics Pipe Institute (PPI). Previously available as Technical Report TR-46 and published in 2009, “MAB Guidelines for Use of Mini-Horizontal Directional Drilling for Placement of HDPE (PE4710) Pipe in Municipal Applications” emphasizes the applications for potable water and sewer projects and provides detailed information for both iron pipe size (IPS) and ductile iron pipe size (DIPS) constructed of the latest PE4710 material. The MAB-7 provides information analogous to that provided in the American Society for Testing and Materials (ASTM) F1962, “Standard Guide for Use of MaxiHorizontal Directional Drilling for Placement of Polyethylene Pipe or Conduit Under Obstacles, Including River Crossings,” but at a level appropriate for the less-complex mini-HDD technology and typical project characteristics.

The MAB-7 includes the following 10 main sections, as well as six supporting appendices: S Scope S Referenced Standards and Specifications S Terminology S Preliminary Site Investigation S Safety and Environmental Considerations S Regulations and Damage Prevention S Pipe Design and Selection Considerations S Bore Path Planning and Drill Rig Setup S Implementation S Completion The document is readily available to the public via the website of PPI at http://plasticpipe. org/pdf/mab-7-mini-hdd-guide.pdf.

Background Figures 1 and 2 illustrate typical mini-HDD equipment, and pilot boring and back-reaming operations, including placement (pullback) of the product pipe, such as for water distribution applications. Mini-HDD is typically employed for

Figure 1. Typical Mini-Horizontal Directional Drilling Equipment and Pilot Boring Process

8 October 2021 • Florida Water Resources Journal

Lawrence M. Slavin, Ph.D., is principal of Outside Plant Consulting Services Inc. in Rockaway, N..J.

boring segments less than 600 ft in length, at depths up to 15 ft, and placing pipes up to 12 in. in diameter. In contrast, maxi-HDD technology is capable of accurately boring holes thousands of ft in length, and placing pipes of 48 in. or greater at depths up to 200 ft. Maxi-HDD machines may weigh as much as 30 tons (or greater) and are appropriate for placing pipes under large rivers or other major obstacles. The ASTM F1962 provides recommended procedures for the placement of HDPE pipe using maxi-HDD. The ASTM document provides overall guidelines, addressing preliminary site investigation, safety and environmental considerations, regulations and damage prevention, bore path layout and design, implementation, and inspection and site cleanup. One of the significant contributions of ASTM F1962 is the provision of a rational, analytical method for selecting the polyethylene pipe strength based on the estimated installation and postinstallation (operational) loads on the polyethylene pipe. The ASTM F1962 therefore provides a means of determining project feasibility, as well as initial design information. While the ASTM F1962 guidelines are convenient and practical to apply by experienced engineers for a maxi-HDD operation, the corresponding equations and procedures represent relatively complicated formulas (and an extensive tedious methodology) when considering smaller, lower-cost operations associated with typical mini-HDD applications, including placing a new water or sewer distribution line. Some mini-HDD installations may be considered to be relatively critical or approach Continued on page 10

® PATENTED

US 10,478,755 B2 US 10,688,454 B2

Gri

t∙S

cum ∙ Cl /C ar i en t fied rifu Un Lim ge der F eS ee d flo lur w ∙W ry ∙ A Lim S∙ R eS AS lu d ge

BF P

0 0

ZERO RELATIVE VELOCITY AT BOUNDARY LAYER

0 0

DISCFLO Pumps with their unique principle of Boundary Layer & Viscous Drag keeps all your processes up and running.

UpTime Service

As opposed to downtime which costs time and money for our end users

Extremely Long Life Expectancy

Typically 20 years in the municipal market, as opposed to 6-36 months between rebuilds with the competitive pumps

The P6 Difference:

Zero Maintenance 10-Year Wear Warranty Reduce Polymer Consumption

Non-Clogging

Eliminates downtime for cleaning out (unplugging) the competitive pumps that plug up.

Life Cycle Costs (LCC)

Are the lowest for the abrasive and abrasive/viscous pumping application typical of water and wastewater pumping applications.

Increase Cake Solids Gentle Mixing Optimize System

sales@gerberpumps.com

sales@gerberpumps.com

407.937.8689

407.937.8689

Florida Water Resources Journal • October 2021

9

Continued from page 8 limits with respect to the capability of the available drill rig and/or the strength of the product pipe being installed, and for which a relatively convenient, although possibly less precise, design procedure would be desirable. Any construction procedure must address basic safety rules, avoid damage to existing facilities, adhere to applicable government regulations, and consider environmental issues. The MAB-7 was therefore developed to serve as an inclusive document, providing practices for placement of HDPE (PE4710) pipe for municipal applications using mini-HDD. In particular, MAB-7 includes easy-tounderstand guidelines for proper drill rig positioning, consistent with meeting required placement depths and drill rod capabilities, as well as for estimating the relevant forces and effects present during installation, allowing proper selection of the pipe strength.

Description The MAB-7 contains 10 main chapters, or sections, as briefly described, supplemented by several appendices. Scope, Related Industry Standards, and Terminology (Sections 1, 2, and 3) The MAB-7 addresses planning, design, drill rig setup, and installation practices for the placement of polyethylene pipe using miniHDD equipment. The primary focus is on commonly used HDPE pipe with a material designation code of PE4710. Depending on the diameter, polyethylene pipe may be supplied in continuous lengths on reel or discrete segments,

which would typically be fused together in the field. Preliminary Site Investigation (Section 4) The general feasibility of utilizing miniHDD technology for placing the proposed pipeline(s) must be determined prior to any proposed construction activities. Such a preliminary investigation is required to gain an understanding of the local characteristics in order to help ensure a cost-effective, efficient, and above all, safe operation. Of particular importance, and as addressed in other sections of the guidelines, is the awareness of existing utilities in the vicinity of the proposed pipeline and the need to maintain minimum specified clearances during the construction process. Safety and Environmental Considerations (Section 5) Safety is a primary concern during any activity, including construction utilizing mini-HDD equipment and procedures. Potential safety issues fall into two general categories: those directly related to the setup and operation of the mini-HDD equipment; and those associated with the proper location, identification, and marking procedures intended to avoid contacting and damaging existing utilities. Section 5 of MAB-7 addresses the first category, providing practices to avoid or minimize equipment-related risks during miniHDD operations. Employees must be trained to prevent injuries to themselves and others during the operation of the equipment and be prepared to mitigate the effects of accidents. Electric power

and gas-line strikes are specifically addressed. Although not considered to be hazardous materials, the proper handling and disposal of drilling fluid is also discussed to avoid possible environmental issues. Regulations and Damage Prevention (Section 6) Section 6 of MAB-7 addresses the second category of potential safety issues, focusing on procedures to eliminate or reduce hazards associated with damaging existing utilities, including during the initial boring or backreaming operations. Recommended practices include: S “Call before you dig” (811). S Properly locating and marking existing utilities, as well as exposing such utilities at anticipated crossings with the bore path. S Avoiding mechanized digging within the required tolerance zone. S Use of subsurface utility engineering, as described in the Construction Institute/ American Society of Civil Engineers (CI/ ASCE) 38, “Standard Guidelines for the Collection and Depiction of Existing Subsurface Utility Data.” Pipe Design and Selection Considerations (Section 7) and Bore Path Planning and Drill Rig Setup (Section 8) Sections 7 and 8 contain particularly useful information, provided in a convenient format, as discussed in greater detail. Implementation (Section 9) It’s beyond the scope of the MAB-7 guidelines to provide detailed operational procedures for the various mini-HDD and auxiliary equipment, which are generally available from the manufacturers or other sources. Proper procedures, however, are described for pilot boring, tracking, steering, reaming, and pullback operations, as well as pipe handling/connection and recordkeeping. Completion (Section 10) Following installation of the pipe, it’s necessary to confirm the viability of the new facility, provide a permanent record of the actual placement location, and ensure final site cleanup. The integrity of the pipes should be appropriately verified, depending on the application and the owner’s specifications. Any mud or debris that may have entered the pipe must be expelled and the pipeline flushed, and the system then pressurized and checked for leakage.

Figure 2. Typical Mini-Horizontal Directional Drilling Back-Reaming and Pipe Pullback Process

10 October 2021 • Florida Water Resources Journal

Continued on page 12

3017M

DPD Chlorine Analyzer

Simple. Accurate. Reliable. © 2021 Xylem, Inc.

Accurate & Reliable Uses EPA- approved DPD methodology

Compliance Monitoring Suitable for drinking water reporting in the U.S.

Easy to Operate Factory-calibrated with low maintenance requirements

Onboard Display See your data anytime without extra equipment or data subscriptions

• +1.937.767.7241 • 800.765.4974 (US) • info@ysi.com

YSI.com/3017M

Table 1. Safe Pull Tension (lb), High-Density Polyethylene (PE4710) Pipe, 1-Hour Iron Pipe Size

Pipe Diameter-to-Thickness Ratio (DR)

Nominal Size

7

9

11

13.5

2-in.

3,038

2,450

---

3-in.

6,597

5,321

4-in.

10,906

6-in.

Table 2. Safe Pull Tension (lb), High-Density Polyethylene (PE4710) Pipe, 1-Hour Ductile Iron Pipe Size

Pipe Diameter-to-Thickness Ratio (DR)

17

Nominal Size

7

9

11

13.5

---

---

3-in.

8,445

6,812

---

---

---

---

---

4-in.

12,408

10,008

8,375

6,950

5,610

8,796

7,361

6,109

4,931

6-in.

25,641

20,681

17,306

14,362

11,593

23,638

19,066

15,954

13,240

10,687

8-in.

44,109

35,578

29,771

24,707

19,943

8-in.

40,064

32,315

27,040

22,441

18,114

10-in.

66,356

53,522

44,786

37,168

30,002

10-in.

62,237

50,200

42,006

34,861

28,140

12-in.

93,838

75,689

63,335

52,562

42,428

12-in.

87,549

70,616

59,090

49,039

39,584

Continued from page 10 Appendices (A - F) The 10 main sections outlined are intended to provide user-friendly guidelines for the installation of HDPE (PE4710) pipe in municipal applications using mini-HDD. These sections are supported by six appendices that provide examples of the application of the information described in Sections 7 and 8, as well as the theoretical basis for their development.

Pipe Design and Selection Considerations (Section 7) The MAB-7 contains a convenient calculation method for the selection of the HDPE (PE4710) pipe strength. The procedure is presented in an easy-to-understand format,

appropriate for users with various backgrounds. The procedure provides a means of selecting the pipe strength to avoid collapse due to hydrostatic pressure at the desired placement depth, as well as to withstand the required pulling loads during installation. Minimum Wall Thickness Based on Depth The pipe strength is directly related to the wall thickness, as specified by its dimension ratio (DR), which is defined as the pipe outer diameter by the wall thickness. The MAB-7 guidelines indicate that essentially all the commonly used wall thicknesses for PE4710 pipe, with the possible exception of DR 17 pipe, would be sufficiently strong for depths to approximately 15 ft, the typical limit for mini-HDD installations. A DR 17 pipe should generally be limited to

Figure 3. Unplanned Curvature (n2)

12 October 2021 • Florida Water Resources Journal

17 ---

less than a 10-ft depth, although 15 ft may also be acceptable in some cases. For depths greater than 15 ft, thin-walled pipe, or special situations, the adequacy of the product for the application should be verified using the supplementary information provided in the document. In some cases, such as thinwalled pipe and/or relatively large depths, special practices or precautions not typically employed during mini-HDD installations may be required. For example, filling the pipe with water during pullback simultaneously reduces the net external hydrostatic pressure during (and following) installation and the buoyant weight of the pipe, resulting in reduced pull loads. Minimum Wall Thickness Based on Pulling Load Table 1 provides the “safe pull tension” for HDPE (PE4710) pipe as a function of pipe (nominal) diameter and wall thickness (DR value) for IPS pipe sizes, while Table 2 provides the strengths for DIPS pipe sizes. These values are intended to account for the cumulative load duration on the pipe, and avoid nonrecoverable viscoelastic deformation. The indicated strengths are based on the minimal required wall thickness, as opposed to that of the actual manufactured product, and therefore underestimate the average safe pull tension by approximately 6 percent. The following simplified equation has been developed for the purpose of estimating the pull load during mini-HDD installations of polyethylene pipe: Tension (lb) = [Bore Length (ft) x Buoyant Weight (lb/ft) x (1/3)] x (1.6)n

The buoyant weight may be conveniently determined as follows: Buoyant Weight (lb/ft) = ½ [Pipe Outer Diameter (in.)]2 – Pipe Weight (lb/ft) The term “n” is equal to the number (including fractions) of effective 90-degree bends due to cumulative route curvature where n = n1 + n2. The quantity n1 is the number of planned (deliberate) 90-degree route bends, and n2 is the number of effective route bends resulting from typical path corrections and route curvature during the pilot boring operation for which the following guideline is suggested: n2 = [Bore Length (ft)/500 ft] x [2-in./ Rod Diameter (in.)] The quantity n2 is shown in Figure 3 for various rod diameters. For a specified pipe diameter, the procedure for selecting an appropriate pipe strength (DR value) consists of comparing the estimated pull load to the strengths in Table 1 or 2. This procedure is similar to, but much less complicated than, that incorporated in ASTM F1962 for the more-sophisticated maxi-HDD installations. The present miniHDD calculations will generally result in considerably shorter placement distances than those corresponding to the design methodology provided in ASTM F1962, which may result in possible pullback distances of several thousands of ft. Mini-HDD installations suffer relative to those performed using typical maxi-HDD technology due to the lesser degree of control (e.g., greater cumulative route curvature) and the desire to forego the use of antibuoyancy techniques, such as inserting water into the pipe during pullback to reduce buoyant weight and significantly reduce required pull loads. In general, the preceding formulas and methodology are recommended for estimating pull loads for mini-HDD installations. Other methods for determining pulling loads are typically based on well-controlled maxi-HDD installations and are not representative of actual mini-HDD applications with respect to anticipated pull loads.

Bore Path Planning and Drill Rig Setup (Section 8) In comparison to maxi-HDD installations, for which the design of the bore path is typically performed by experienced engineers or organizations, the mini-HDD contractor

Figure 4. Drill Rig Setup and Related Distances

Figure 5. Drill Rig Minimum Setback Distance Drill Rods: 10 Ft Long, 100-Ft Radius of Curvature

is generally responsible for cost-effectively accomplishing this task. Thus, MAB-7 provides user-friendly drill rig setup and bore path planning information that is consistent with meeting the requirements of the project owner, including geographic constraints and placement depth. The ability to satisfy the overall requirements depends on the bending characteristics of the steel drill rods and the drill rig setup parameters. Figure 4 illustrates a typical mini-HDD bore vertical profile trajectory, including occasional pits along the route. These pits may be required for pipe splicing, completing lateral connections, or to expose existing utilities. The pits may also be useful for collecting drilling fluid from the boring or reaming operations. The bending capability and length of the drill

rods, and their entry angle to ground surface, will determine the minimum depth achievable at the beginning of the bore path. In order to achieve a specified depth at a particular point toward the beginning of a pilot bore operation, the front of the drill rig must be located at an appropriate distance rearward from the point of interest. Knowledge of such minimum setback requirements is important with respect to verifying that there is sufficient space available to properly perform the miniHDD operation. For example, point 1 (Figure 4) is located directly along the entry path of the drill rod, where the resulting bore path is inclined at the entry angle and for which the setback distance corresponding to reaching the depth (d1) is designated as S1. The S1 Continued on page 14

Florida Water Resources Journal • October 2021

13

Continued from page 13 represents the minimal setback distance for achieving a specified depth, independent of the orientation of the bore path, which is not level at that point. Beyond point 1, the drill rods are steered, such that the bore path trajectory becomes level at point 2, corresponding to a depth (d2) and S2. For the same depth of interest, S2 is significantly greater than S1. The greater distance is required to allow

the drill rods to establish an upward curvature consistent with achieving a horizontal orientation. The S2 depends on both the entry angle and rod characteristics. Due to the limited bending capability of the rods, as well as the recommendation that the first drill rod be placed in the ground without any curvature or steering (see Figure 1), there is a minimum depth, designated as (d2)min, at which the trajectory is able to become level.

The S1 and S2 are a function of the depth (d1 or d2), respectively (Figure 5), for a representative 10-ft-long drill rod, with a minimum bend radius of curvature of 100 ft. (d2)min identified by the minimum depth plotted for the S2 curves. As an example, for an entry angle of 15 degrees, a depth (d1) of 72 in. will be achieved at a setback distance S1 of approximately 22 ft. In comparison, an S2 of at least 35 ft is required to reach the same depth (d2) at a level trajectory. Figure 5 also indicates that this entry angle and drill rod combination is not consistent with achieving a level trajectory at depths shallower than approximately 72 in. If it’s necessary to become level at a shallower depth, a lower-entry angle and/or drill rod with a smaller allowable bend radius would be required. Information regarding other significant dimensions, including the required horizontal distance to rise to the surface and for drill rods for different characteristics, is also provided in a similar format.

Summary The MAB-7, “MAB Guidelines for Use of Mini-Horizontal Directional Drilling for Placement of HDPE (PE4710) Pipe in Municipal Applications,” has recently been published by the MAB of PPI, representing a comprehensive set of information supporting the placement of HDPE (PE4710) pipe by mini-HDD equipment for potable water and sewer applications. The new document, previously available as Technical Report TR-46, is intended to provide information analogous to that provided in ASTM F1962 for maxi-HDD projects, but at a level appropriate for the less complex mini-HDD technology and typical project characteristics. Although the MAB-7 guidelines are primarily described with respect to mini-HDD operations, guidelines for the use of midi-HDD machines and associated practices may be obtained from the present MAB-7 document, and/or ASTM F1962, depending on the particular application and the judgment of the contractor or engineer.

References • A STM F1962, “Standard Guide for Use of Maxi-Horizontal Directional Drilling for Placement of Polyethylene Pipe or Conduit Under Obstacles, Including River Crossings.” American Society for Testing and Materials. • CI/ASCE 38, “Standard Guidelines for the Collection and Depiction of Existing Subsurface Utility Data.” American Society of Civil Engineers. S

14 October 2021 • Florida Water Resources Journal

Operators: Take the CEU Challenge! Members of the Florida Water and Pollution Control Operators Association (FWPCOA) may earn continuing education units through the CEU Challenge! Answer the questions published on this page, based on the technical articles in this month’s issue. Circle the letter of each correct answer. There is only one correct answer to each question! Answer 80 percent of the questions on any article correctly to earn 0.1 CEU for your license. Retests are available. This month’s editorial theme is New Facilities, Expansions, and Upgrades. Look above each set of questions to see if it is for water operators (DW), distribution system operators (DS), or wastewater operators (WW). Mail the completed page (or a photocopy) to: Florida Environmental Professionals Training, P.O. Box 33119, Palm Beach Gardens, Fla. 33420-3119. Enclose $15 for each set of questions you choose to answer (make checks payable to FWPCOA). You MUST be an FWPCOA member before you can submit your answers!

___________________________________ SUBSCRIBER NAME (please print)

Article 1 ____________________________________ LICENSE NUMBER for Which CEUs Should Be Awarded

If paying by credit card, fax to (561) 625-4858 providing the following information:

___________________________________ (Credit Card Number)

___________________________________ (Expiration Date)

Developing Effective Funding Strategies for Compliance With the Lead and Copper Rule Revisions Christopher Hill, Quirien Muylwyk, and John Konkus (Article 1: CEU = 0.1 DW/DS02015391) 1. W hich of the following is not one of the five ways listed by which service lines are replaced? a. I ndividual replacements by third parties b. E mergency replacement due to water main or service line repairs c. C ustomer request d. R eplacement as part of planned water main rehabilitation or replacement project 2. Th e revised rule requires water systems to conduct a materials inventory of all service lines by a. O ct. 16, 2024. b. D ec. 31, 2023. c. A ug. 15, 2022. d. J une 30, 2023.

3. Th e revised rule establishes 10 µg/l as a. t he action level concentration for copper. b. t he action level concentration for lead. c. t he trigger level concentration for copper. d. t he trigger level concentration for lead.

4. I f a sufficient number of qualifying sites exist, the revised rule requires that ____ percent of lead and copper sample sites be taken from single-family sites with lead service lines. a. 2 0 b. 2 5 c. 5 0 d. 1 00 5. W ater systems must conduct sampling upon request at ______________ for the first five years following the revised rule’s effective date. a. h ospitals b. s econdary schools c. e lementary schools d. c hildcare facilities

EARN CEUS BY ANSWERING QUESTIONS FROM PREVIOUS JOURNAL ISSUES! Contact FWPCOA at membership@fwpcoa.org or at 561-840-0340. Articles from past issues can be viewed on the Journal website, www.fwrj.com.

Florida Water Resources Journal • October 2021

15

PRELIMINARY CALENDAR OF EVENTS

November 28 to December 2, 2021 Hyatt Regency Grand Cypress

Sunday, November 28, 2021 10:00 AM - 12:00 PM 12:00 PM - 5:00 PM 1:00 PM - 5:00 PM

Executive Committee Meeting Registration Board of Governors Meeting

Windsong 1-3 Grand Cypress Foyer Windsong 1-3

Monday, November 29, 2021 7:00 AM 8:30 AM 8:30 AM 8:30 AM 8:00 AM 9:00 AM 9:00 AM 9:30 AM 10:00 AM 10:00 AM 11:00 AM 12:00 PM 12:00 PM 12:00 PM 12:00 PM 11:30 AM 2:30 PM 4:00 PM 6:00 PM 9:00 PM

- 6:00 PM - 11:00 AM - 11:00 AM - 11:00 AM - 5:00 PM - 10:00 AM - 11:00 AM - 10:30 AM - 11:00 AM - 11:00 AM - 12:00 PM - 2:30 PM - 2:30 PM - 2:30 PM - 2:30 PM - 1:00 PM - 4:00 PM - 6:00 PM - 9:00 PM - 12:30 AM

Registration Workshop 1A: Looking Down the Road- What to Expect in the Regulatory Future Workshop 1B: Automation and SCADA Technology Workshop Workshop 1C: Cybersecurity 2021 Workshop 1D: Utility Systems Symposium Top Ops & Operators / Maintenance Council Meeting Member Engagement & Development Council Meeting Finance and Rates Committee Meeting Distribution Division Meeting Public Affairs Council Meeting Water Equation Committee Meeting Workshop 2A: Get Your Research On Workshop 2B: From High School to Hired Workshop 2C: Financing the Utility Workshop 2D: Water Conservation Symposium Regions / Council Chairs Lunch Meeting Opening General Session Exhibit Hall Meet & Greet BBQ Challenge & Incoming Chair's Reception Poker Tournament

Grand Cypress Foyer

Grand Cypress Portico Patio La Coquina & Alcove

Tuesday, November 30, 2021 7:00 AM 8:15 AM 8:30 AM 8:30 AM 8:30 AM 8:30 AM 9:00 AM 9:00 AM 10:00 AM 10:00 AM 9:30 AM 11:00 AM 11:30 AM 11:30 AM 1:00 PM 1:00 PM 1:00 PM 1:30 PM 1:30 PM 1:30 PM 1:30 PM 2:00 PM 2:00 PM 2:00 PM 3:00 PM 4:00 PM 4:00 PM 4:00 PM 4:00 PM

- 6:00 PM - 9:15 AM - 11:30 AM - 11:30 AM - 11:30 AM - 11:30 AM - 11:00 AM - 4:00 PM - 11:00 AM - 11:00 AM - 10:30 AM - 12:00 PM - 1:00 PM - 1:00 PM - 2:00 PM - 2:00 PM - 2:30 PM - 4:30 PM - 4:30 PM - 4:30 PM - 4:30 PM - 3:00 PM - 4:00 PM - 4:00 PM - 6:00 PM - 5:00 PM - 5:00 PM - 5:00 PM - 6:00 PM

Registration Continental Breakfast Session 1A: Potable Reuse Session 1B: SEDA/Membranes Session 1C: Navigating the New Normal Session 1D: Lead & Copper FWRC/FWRJ Board Meeting Full STEAM Ahead Youth Program Young Professionals Meeting Backhoe Rodeo Water Equation Committee Meeting Ductile Iron Tap Competition High School Academy Students Session Students / Young Professionals Lunch Contaminants Committee Meeting Technical & Educational Council Meeting Fun Tap Competition Session 2A: Asset Management Session 2B: Addressing Water Treatment Process Improvements Session 2C: Collaboration, Communication, and Protecting Critical Knowledge Session 2D: PFAS/PFOS Young Professionals Water Bowl Automation Committee Meeting Water Utility Council Meeting Young Professionals Poster Session FL2040 Committee Meeting Meter Madness Water Quality & Resources Division Meeting Meet & Greet

Grand Cypress Foyer Grand Cypress

7:00 AM 8:00 AM 8:15 AM 8:30 AM 8:30 AM 8:30 AM 8:30 AM 9:00 AM 12:00 PM 12:00 PM 2:00 PM

- 12:00 PM - 12:00 PM - 9:15 AM - 11:30 AM - 11:30 AM - 11:30 AM - 11:30 AM - 11:00 AM - 2:00 PM - 8:00 PM - 4:00 P M

Registration Exhibits Continental Breakfast Session 3A: GIS, SCADA, and Asset Management Session 3B: Alternative Water Supplies Session 3C: Water Treatment – Disinfection By-products Session 3D: Water Treatment - Disinfection By-Products Hydrant Hysteria Competition Annual Business Lunch & Awards Ceremony Tear Down / Move Out Water Use Efficiency Division Meeting

Grand Cypress Foyer Grand Cypress Grand Cypress

Wednesday, December 1, 2021

Self-Parking Lot Self-Parking Lot

Self-Parking Lot

Grand Cypress Grand Cypress Foyer Grand Cypress Grand Cypress

Grand Cypress Windsong 1-6 Grand Cypress *Other Rooms TBA

The FSAWWA Fall Conference brings together utilities, consultants, manufacturers, regulators, and students. Register and learn from the industry’s best through technical session, workshops, and exhibits. Network with water industry professionals. Over 160 exhibitors will give you first-hand information on the latest developments to help your utility take actions to implement Florida’s future.

Exhibitor Registration: Booths SOLD OUT! Attendee Registration:

fsawwa.org/2021fallconference

Technical Sessions

• Potable Reuse • Alternative Water Supply Options • Utility Finances in Challenging Times • Strategies to Communicate Your Message in the Changed World

• Increasing Optimization of Utility

For more information: fsawwa.org/2021fallconference

• •

Hotel Accommodations: fsawwa.org/2021hotel

•

Host hotel is Hyatt Regency Grand Cypress CHEER for Meter Madness!

Prep for HYDRANT Hysteria!

•

Let loose at the RODEO!

Join the Tapping FUN!

•

Systems (Pipes, SCADA, Sewer Systems) Asset Management PFAS, PFOS, Lead and Copper, and Other Regulatory Strategies What’s New with Covid-19? And How Does it Affect our Workplace? The New Workplace Normal – Zoom, Remote, Home and Office Challenges for Utilities Water Conservation

Conference Highlights

• BBQ Challenge &

Incoming Chair’s Reception

• Operator Events:

N

E W O RM

Meter Madness Backhoe Rodeo Hydrant Hysteria Tapping Competition

A L

• Young Professionals Events:

Luncheon Water Bowl Fresh Ideas Poster Session

• Water for People’s Fundraising Events: Exhibitor’s Raffle Fundraiser

Events

Looking forward to seeing you at the Hyatt Regency Grand Cypress on November 28 to December 2, 2021.

Poker Tournament Monday, November 29, 2021 Starts at 9:00 pm Golf Tournament Thursday, December 2, 2021 8:00 am Shotgun start

Event Highlights

Students & Young Professionals Conference Activities Tuesday, November 30, 2021

YP Committee Meeting

10:00 - 11:00am | Locations: TBA

Students/YP Lunch

11:30am - 1:00pm | Location: TBA

Please submit Water Bowl Registration form to Michael Stanley by e-mail at Michael.Stanley@kimley-horn.com by November 8, 2021.

Water Bowl Competition

FREE Student Registration | Lunch is $25

Fresh Ideas Poster Session

Must register for a badge >> fsawwa.org/2021fallregistration

2:00 - 3:00pm | Location: Exhibit Hall

3:00 - 6:00pm | Location: TBA

Water Bowl Team Registration Water Bowl is a jeopardy-like competition for students from Florida universities. Teams compete against each other to see who can answer the most questions correctly in the least amount of time. All questions are related to the drinking water industry. Universities can have more than one team.

Sign up your team today! Team University | College ____________________________________________ Team Member #1 ____________________________________________________ Team Member #2 ____________________________________________________ Team Member #3 ____________________________________________________

Fresh Ideas Poster Competition The “Fresh Ideas” Poster Session is an effort of the Young Professionals Committee to encourage YP participation in the technical program at the conference through presentation of a poster. Posters will be judged and the winner will receive airfare, hotel, and conference registration to attend the AWWA Annual Conference & Exposition ( ACE22 ) in June 2022, in San Antonio, TX to compete against other “Fresh Ideas” AWWA Section winners. Competition is open to any student or YP with less than three years of work experience. Any poster topic related to the water industry is encouraged. Poster Presenter: _________________________________________ Poster Title: _________________________________________ _________________________________________ _________________________________________

Looking forward to seeing you at the Hyatt Regency Grand Cypress on November 28 to December 2, 2021.

Thank you for your interest in the FSAWWA.

Divisions based on the Number of Water Services

2021 Water Distribution System Awards

Division 1 = 1 - 5,999 Division 2 = 6,000 - 12,999 Division 3 = 13,000 - 19,999

The FSAWWA Water Distribution System Awards are presented to utilities whose outstanding performance during the preceding year deserves special recognition by the section.

Division 4 = 20,000 - 29,999

The Award Criteria is based upon the following:

Division 7 = 70,000 - 129,999

Water Quality Operational Records Maintenance Professionalism Safety Emergency Prepardness Cross Connection Control Program Must be an AWWA member (Organizational or Individual) Actively supports the activities of the FSAWWA Demonstrates high standards and integrity The selection committee is under the Manufacturers/Associates Council.

Division 8 = 130,000+

• • •

Division 6 = 46,000 - 69,999

Send applications to: Mike George 10482 Dunkirk Road Spring Hill, FL 34608 tapitflorida@att.net

Deadline

2020 Winners: Division 1: Division 2: Division 3: Division 4: Division 5: Division 6: Division 7: Division 8:

Division 5 = 30,000 - 45,999

Ozello Water Association, Inc. Destin Water Users, Inc. City of Tamarac Village of Wellington Not Awarded Charlotte County Utilities Not Awarded Hillsborough County Public Utilities Department

Friday, October 22, 2021 Download the application form:

www.fsawwa.org/ distributionawards

E W Looking forward to seeing you at the Hyatt Regency Grand Cypress on November 28 to December 2, 2021.

Thank you for your interest in the FSAWWA.

Join the Competition

2021 Competitions

Tuesday & Wednesday November 30 - December 1, 2021

Let loose at the RODEO!

fsawwa.org/2021fallconference FSAWWA hosts fun and lively competitions between municipalities to find the most skilled person or team in the Meter Madness, Tapping, and Back Hoe Rodeo contests. Please join us as a spectator or visit our website to download the application to complete. Join the Tapping FUN!

Back Hoe Rodeo: Tuesday | 10:00 am - 12:00 pm

Backhoe operators show off their expertise by executing several challenging lifts and drops of various objects in the fastest time.

Tapping Contests: Tuesday | 11:00 am - 2:30 pm

In a contest of skill and dexterity as well as speed, teams of four compete for the fastest time while they perform a quality drill and tap of pipe under available pressure. Penalties are assessed in seconds for infractions of rules such as leaking connections or safety violations. Only two taps are allowed per team.

CHEER for Meter Madness!

Ductile Iron Tap: 11:00 am - 12:00 pm Fun Tap: 1:00 - 2:30 pm

Meter Madness: Tuesday | 4:00 - 5:00 pm

Contestants are challenged to put together a completely disassembled meter against the clock. To make the contest more interesting, three to six miscellaneous parts are included in the bucket of meter components. Once the meter is assembled, it must operate correctly and not leak.

Prep for HYDRANT Hysteria!

Hydrant Hysteria: Wednesday | 9:00 - 11:00 am

Hydrant Hysteria is a fast paced two person competition as to who can assembly a fire hydrant quickly, totally, and accurately. Two or more teams go head to head while assembling the hydrant. All parts will be assembled in proper manner and reassembled hydrant shall be tested by the judges for ability to operate correctly.

Sponsorship Opportunities Please Contact: Mike George tapitflorida@att.net (352) 200-9631

Looking forward to seeing you at the Hyatt Regency Grand Cypress on 2021 November 28 to December 2, 2021.

Thank you for your interest in the FSAWWA.

FSAWWA Water Use Efficiency Division

2021 Water Conservation Awards for Excellence This annual awards program of the FSAWWA Water Use Efficiency Division (WUED) recognizes innovative and outstanding achievements in water efficiency throughout Florida.

Award Categories:

• Comprehensive Water Conservation Programming • Program Element- Single Program Highlight Agencies will be awarded one of the following awards: Best in Class or Show of Excellence.

To Apply: fsawwa.org/2021wcawards Entries must be submitted by: Friday, October 15, 2021

.

For additional information, please contact: Keeli Carlton Water Use Efficiency Division (WUED) Chair kcarlton@mywinterhaven.com

Looking forward seeing you at November 29 totoDecember 3,the 2020 Hyatt Regency Cypress on Omni OrlandoGrand Resort at ChampionsGate November 28 to December 2, 2021.

Thank you for your interest in the FSAWWA.

FSAWWA SPEAKING OUT

Everyone Has Challenges With Water

Photo 1. Kawuneeche Valley in 2005 when the trees were green.

Fred Bloetscher, P.E., Ph.D. Chair, FSAWWA

T

he utility industry is one industry—we are all bound together by water. As an old friend Tom Lane once said, “There is only one water.” The problem is that we tend to see only our own issues, as opposed to the bigger picture that may affect others and that hurts all

of us. We need to see that bigger picture and the interrelated concepts among utilities. For example, we are in the midst of hurricane season here in Florida. We know what challenges weather can bring and we know many of the impacts—just look at Louisiana and the Northeast. Florida’s utilities have worked together to create the Florida Water/Wastewater Agency Response Network (FlaWARN) and are willing to help with materials, equipment, and people when problems occur. Our goal is to keep everyone—and everything—operating. Because Florida gets the majority of its water from groundwater, we think little of the

Photo 2. Kawuneeche Valley in 2018, with lots of beetle-killed trees.

22 October 2021 • Florida Water Resources Journal

many utilities that rely on surface water for their supply. Nationally, over half of the 91 percent of people served by a water utility are served by a surface water system, which has a host of potential impacts that are generally different, but no less consequential, than ours. Let’s take a look at an example.

A Changing Landscape Many of you know that over the past 15 years or so I have spent time in Colorado and other places in the West. My goal is to hike over 100 miles at elevations over 8,000 feet. Many

Photo 3. Kawuneeche Valley in 2021 after the East Troublesome Fire.

Photo 4. Another view after the fire.

years I have gotten into the middle to upper 90s. I have over 100 miles in many years if the bar is 6,500 feet—144 in 2017 when I went to Yellowstone National Park. With the exception of a few desert locations, the vast majority of places I hike are forested. Forested land makes up 766 million acres, or 33 percent, of the total land in the United States. Over 53 percent of U.S. surface water supplies have their beginnings in these forested areas. Rocky Mountain National Park is my most-frequent visit, and it’s heavily forested between 7,500 and 10,500 feet. When I went out in 2007 with my wife (her first trip to the Rockies), the mountains were generally covered with green lodgepole pines (see photos 1 and 5). Two years later, it was the mountain pine beetle that killed millions of acres of pine trees because the temperatures never got low enough to kill them (see photos 2 and 6). Millions of acres in the West, from Canada to Mexico, have been hit hard by beetle infestations that occur because the trees are old and the temperatures do not get cold enough in the winter. I recall telling my wife that all the dead trees were a huge fire hazard. Then 2020 happened. A lack of precipitation (increasing fire risk), low humidity, wind, higher temperatures, and human activity caused the East Troublesome Fire in Grand County, Colo., which grew by 100,000 acres in 24 hours, barely skirting Grand Lake by virtue of heroic efforts by firefighters, and nearly reaching Estes Park on the other side of the park to the east. Two people died, hundreds of structures were lost, and well, there was a lot of burned forest. The next set of photos (3, 4, 7, and 8) tells you much of what you want to know (or not). Temperatures were reported as high as 3800 degrees via satellite. I cannot fathom that kind of heat.

Photo 5. Hills adjacent to the Kawuneeche Valley in 2005 when the trees were green.

Grand Lake got lucky, as did Estes Park, but today, there are millions of acres at risk, and the fires have created a serious threat to many rural communities. We lost Paradise, Calif., (not a small town by the way) a couple years back when high temperatures caused power lines to sag, and the failure of people and power companies to clear debris below the power lines ignited a fire. We also lost historic Greenville, Calif., in 2021.

Solutions Won’t Be Easy A published study by the Ecological Society of America found that “protected forests—those that had not been thinned—had lower levels of burn severity despite having higher amounts of biomass and fuels” (Bradley

et al., 2016). So, thinning and clear-cutting are not solutions. Clearing under power lines helps, but we will need more power lines to deal with increased population dispersion and power demands. Across the U.S., the average number of wildfires has been 64,000 per year (fewer than in 1990), but the average acreage burned has increased (CRS, 2021). Summer heat, less rainfall, less snow, and impacted trees create the risk. Of more concern, however, is that most of the fires have been caused by people as opposed to nature (Where is Smokey the Bear when we need him?). The situation has not been helped by the millions of acres of trees killed by pine bark beetles, which has increased the potential for Continued on page 24

Photo 6. Hills adjacent to the Kawuneeche Valley in 2018 with tree damage.

Florida Water Resources Journal • October 2021

23

Photo 7. Hills adjacent to the Kawuneeche Valley in 2021.

Continued from page 23 fires (see the comparative photos from 2007 to 2021). The beetle damage is something that anyone who has hiked the Rockies has noted, with miles of dead trees. The beetles thrive when temperatures are not really cold, in drought conditions, and when trees are stressed. Sounds like the West today. Cutting all these trees quickly has been impossible to manage without severe damage to the land, although the Grand County (Colo.) newspaper notes that much of the accessible beetle trees have been harvested and the lumber industry is looking in a new direction. Aside from the remaining trees, changes in summer heat intensity and less rainfall in the summer and early fall increase the risk of fires. Clearly, this is a long-term climatic issue that has changed the forest paradigm. Loss of forest increases runoff, creating flooding and water quality concerns. The loss of trees and habitat is only the obvious impacts. From a water supply perspective (Ball et al., 2016) it’s been found that “wildfire activity is one of the largest drivers of aquatic impairment, though it is not routinely reported by regulatory agencies.” The obvious water quality impacts relate to ash, which can pass into the lungs, exacerbating asthma and a host of other health impacts. After a rain occurs, the ash runs into the rivers and downstream to water intakes— and fish gills. Downstream, the damage to ecosystems due to ash and silt runoff and the impacts to fish and water supplies will continue for years. The lack of tree cover increases water temperatures, which endangers native fish that adapt to cold waters. Temperatures in the Rocky Mountain waters climb into the high 70s in the summer in Fraser, Colo., which is

Photo 8. Hills adjacent to the Kawuneeche Valley in 2021.

way too warm for stressed mountain cutthroat trout (so daytime fishing is suspended regularly). Warm water is prone to algae and is more difficult to treat. The National Climate Assessment indicates a substantial increase in temperatures by 2070, and California, Nevada, and Arizona are all areas that will be challenged. Fire in the mountains will increase and we have all seen the crisis that unfolded with fires this summer.

Water Supply Challenges Ash is a huge issue for water purveyors. The fire-retardant materials that firefighters wear may be toxic and they can leach into water supplies. Firefighters require protective equipment that creates toxic compounds that may endanger their lives. Some question if aerial firefighting has value, given the number of times the target may be missed (reportedly up to 80 percent of runs are misses). The fire danger to water systems also includes volatile organic contaminants (VOCs) and semi-VOCs that occur as a result of the heat and the attraction of plastics for organic compounds. Precursors for disinfection byproducts are a major issue for water suppliers. The fire in Paradise two years ago, which burned over 18,000 structures and killed 85 people, also revealed the ugly truth that the intense heat may impact high-density polyethylene and polyvinyl chloride plastic pipes. The plastic pipe melts under intense heat, and benzene, toluene, styrene, and dichloromethane are among the compounds detected above the drinking water standards. Testing after a fire is critical, and the burial depth of pipe may be an issue as well.

24 October 2021 • Florida Water Resources Journal

We’re All in This Together So we all agree that fires are bad, but what is my point here in Florida? Summer and fall are the height of hurricanes in Florida and it’s also the height of fire season in the Rockies. Much of our focus here is protecting our water systems and keeping the water flowing to our customers; that is the goal of utilities in the mountains as well. Why should people in Florida care about fires in the West? Because we all have challenges, albeit they may be different. One-size-fits-all solutions never work—there is always nuance. We focus our attention on our own issues, but many others have different challenges that they face. We need to listen to each other, even within Florida, where the length of the state makes a huge difference in some of the issues we face. We are not alone, and in many cases, we can learn from each other. Just because the situation seems different does not mean we should not pay attention.

References • G . Ball, Peter Regier, Ricardo GonzálezPinzón, Justin Reale, and David Van Horn, 221. “Wildfires Increasingly Impact Western U.S. Fluvial Networks.” Nature Communications | (2021) 12:2484 | https://doi.org/10.1038/ s41467-021-22747-3. • Bradley, C.M.; Hanson, C.T.; and DellaSala, D.A. 2016. “Does Increased Forest Protection Correspond to Higher Fire Severity in Frequent Fire Forests in the Western United States?” Ecosphere 7(10); e01492. 101002/ ecs2.1492. • Congressional Research Services, 2021. Wildfire Statistics, CRS, Washington, D.C. https://fas.org/sgp/crs/misc/IF10244.pdf. S

Get a New Unit for the Cost of a Repair Facing an expensive repair or replacement bill on your current grinder? We’ll match that quote and give you a brand new XRipper grinder that plugs into your existing panel. > Contact PSI for details.

ROBUST SOLIDS REDUCTION. EASY, LOW-COST MAINTENANCE.

Vogelsang XRipper® Twin-Shaft Grinder •

Monolithic Ripper Rotors

• • •

Wider High-Torque Cutting System Easy Onsite Maintenance Drop-In Replacement Design

• •

Optimized for Wipes & Rags 2-Year Warranty, Parts & Labor, Including Wear Parts

Vogelsang Distribution, Sales & Support

Riviera Beach, FL (305) 998-1371 eric@psi-techinc.com www.psi-techinc.com

sales@vogelsangusa.com (330) 296-3820 vogelsangusa.com

L ET’ S TA LK S A FE TY This column addresses safety issues of interest to water and wastewater personnel, and will appear monthly in the magazine. The Journal is also interested in receiving any articles on the subject of safety that it can share with readers in the “Spotlight on Safety” column.

A

Climb Into Confined-Space Safety

confined space is any area with limited entry and exit that contains known or potential hazards and is not intended for continuous human occupancy. In the water industry, these spaces include manholes, trenches, storage tanks, wells, vaults, and tunnels. Hazards within a confined space include: S Oxygen deficiency by displacement with other gases and the introduction of nitrogen from cable pressurization S Toxic gases from decomposing soil, chemical spills, and engine combustion exhaust (from vehicles and equipment) S Combustible or flammable vapors and gases from underground storage or piping facilities S Moving equipment parts, structural hazards, entanglement, slips, and falls

S T emperature extremes, including atmospheric and surface S Shifting or collapse of bulk material S Barrier failure resulting in a flood or release of free-flowing solids S Uncontrolled energy, including electrical shock or water pressure S Visibility S Biological hazards The buildup of gases, including carbon monoxide and radon, poses one of the mostcommon and lethal dangers in confined spaces. If an oxygen deficiency or hazardous atmosphere may exist in the work area, the air must be tested before employees enter and also while the work is being conducted. If necessary, ventilation must be provided and continued as long as the manhole or vault is open. If the confined space is vacated for any

period of time, such as a lunch break, the atmosphere should be retested before re-entry is allowed.

Safety Equipment Several pieces of equipment are required for safe entry into a confined space: S Work-area protection devices, such as traffic (reflective) vests, traffic cones, manhole guards, work-area protection signs S Manhole cover lifter and manhole hook S Atmospheric tester for combustible gas, oxygen deficiency, and other toxics S Power ventilator (blower) S Pump to remove water S First aid kit S Portable fire extinguisher (dry chemical)

The 2020 Let’s Talk Safety is available from AWWA; visit www.awwa.org or call 800.926.7337. Get 40 percent off the list price or 10 percent off the member price by using promo code SAFETY20. The code is good for the 2020 Let’s Talk Safety book, dual disc set, and book + CD set.

26 October 2021 • Florida Water Resources Journal

Atmospheric Conditions The air within the confined space must be tested prior to entry into the space. Atmospheric conditions are considered unacceptable if oxygen levels are less than 19.5 percent or greater than 22 percent. The following levels of other hazards are unacceptable: S A flammable gas, vapor, or mist greater than 10 percent of its lower flammable limit (LFL). The LFL means the minimum concentration of the flammable material that will ignite if an ignition source is present. S A irborne combustible dust at a concentration that obscures vision at a distance of 5 feet or less. S A n atmospheric concentration of a substance greater than the allowed limit in the Safety Data Sheet (SDS) for that substance.

Testing Procedures After all work-area protection devices are in place and the atmospheric test equipment has been tested as operational, you can do the following: S L ower the sampling hose approximately 6 inches through the hold in the manhole cover to make the first pre-entry test. If no combustible gas is found, remove the cover and proceed. If the flammable gas concentration is above 60 percent of the lower explosive limit (LEL), suspend operations and follow company procedures. S After the manhole cover is removed, continue to test for combustible gas by lowering the sampling tube within 12 inches of the manhole or vault floor. If no flammable gas is found, purge the manhole with the power blower for the period of time based on the blower capacity and manhole configuration, following company procedures.

Ventilation If flammable gas is detected and above 10 percent (but below 60 percent) LEL, purge and ventilate the manhole for a minimum of 10 minutes, depending on the manhole or vault size. If combustible gas was detected, but subsequently cleared, continue to monitor and ventilate to maintain the flammable gas level below 10 percent LEL. When ventilating a manhole, insert the blower hose in the manhole opening, positioning the blower hose to direct the flow of air horizontally, midway between the

manhole’s floor and roof toward an end wall and away from the work area, if possible. To minimize the intake of exhaust fumes from passing vehicles, the blower intake should be positioned away from the flow of traffic. Wind direction must also be considered. Ventilation of the manhole must continue as long as the manhole is open to avoid the possible development of a hazardous atmosphere. If the confined space is vacated for any

period of time, the atmosphere of the confined space should be retested before re-entry is permitted. Further testing should be conducted with ventilation systems turned on to ensure that contaminants are removed and the ventilation system is not causing a hazardous condition. For more information go to the Occupational Safety and Health Administration (OSHA) website at www.osha.gov/SLTC/ S confinedspaces.

Florida Water Resources Journal • October 2021

27

FWRJ COMMITTEE PROFILE This column highlights a committee, division, council, or other volunteer group of FSAWWA, FWEA, and FWPCOA.

Contaminants Committee Affiliation: FSAWWA Current chair: Rae Hafer, utility engineer, Gainesville Regional Utilities Year group was formed: Early 2000s

Scope of work: The committee provides information for water professionals on water quality. The original scope was on biological contaminants, but it has expanded to include biological, chemical, and best practices on

multiple aspects of water quality. Topics include opportunities and challenges with drinking water, wastewater, and reclaimed water treatment and distribution. I love what I do as chair because of the connections I make with the dedicated and talented professionals in our industry. These individuals make me feel like I am part of an extended water industry family. It’s a small world after all. Recent accomplishments: We provided webinars throughout the pandemic with no interruptions! We also created a dedicated website for our archived webinars and offered timely topics to viewers, including cybersecurity, flushing buildings after lockdown, monitoring SARS-CoV-2 in wastewater, impacts of flushable wipes, and microbial-induced corrosion. The committee members also organized and successfully delivered virtual conference sessions on wastewater virus monitoring and per- and polyfluoroalkyl substances (PFAS). Current projects: We continue to seek topics of interest to our audience for webinars and conferences. Future work: Provide additional information on our website to enhance interactive features in our webinars and continue hosting two PFASrelated webinars per year. Group members: S Rae Hafer, P.E., Gainesville Regional Utilities (chair) S Amber Kiger, Hach S Iulia Siemen, P.E., Orange County Utilities S Ashlee Hollifield, P.E., Southwest Florida Water Management District S Melanie Lasch, Veolia Water S Bina Nayak, Ph.D., (past chair, Technical and Education Council chair), Pinellas S County Utilities

FloridaSection 28 October 2021 • Florida Water Resources Journal

SINCE

Maintenance & Repair Service Available

Water & Wastewater Process Treatment & Pumping Equipment RELIASOURCE® AUTO-START LIFT STATIONS

Made in USA

Delivers Affordable Protection from Power Failures Standard and Custom Designs Available for New and Existing Installations

3524 Craftsman Blvd. Lakeland, FL 33803

www.hudsonpump.com

Copyright ©2021 Tencarva Machinery Company. All Rights Reserved.

100% Guaranteed Warranty

Ph: (863) 665-7867 Fax: (863) 667-2951 TM.FL.FWRA.MU.5.12.2021

Florida Water Resources Journal • October 2021

29

FWEA FOCUS

All Water is One Water Ronald R. Cavalieri, P.E., BCEE President, FWEA

B

y the year 2040, Florida will need an additional 1 billion gallons per day of potable water supply to meet the projected demands. The rich quality of life that we enjoy here, and across the United States, is dependent on ensuring that sufficient clean water is available for all reasonable and beneficial uses within our community, while protecting natural systems and the environment. Water is the life of a community. The development of an integrated (One Water) management approach is critical to meet projected water needs, as well as to support Florida’s future economic success.

Florida’s Population Growth According to the University of Florida’s Bureau of Economic and Business Research (BEBR), Florida’s population is expected to grow from its current 21.6 million (Bulletin 190, June 2021) to 26.4 million by 2040. Florida represents about 6.5 percent of the U.S. population (estimated at 331.4 million in 2020) and is ranked third behind California and Texas. According to the U.S. Census, Florida’s population grew by 14.9 percent from 18.8 million in 2010 to its current population.

What Florida’s Population Increase Means Florida’s increasing population has important implications for planning and public policy.

The population growth affects the demands for education, healthcare, housing, recreation, and transportation, with impacts to the environment and potable water supply. The Florida Office of Economic and Demographic Research (EDR) projects that the state’s potable water demand will increase by more than 15 percent between 2020 and 2040, reaching 7.4 billion gallons daily. The increased demand is having a significant impact on the state’s water utilities to supply the projected demands and has brought about both new legislation and innovative water supply approaches. According to the regional water supply plans and water supply assessments developed by Florida’s water management districts (WMDs), the water needs of the state can be met through the 2040 planning horizon by a combination of traditional and alternative water sources. This, however, assumes that appropriate management, continuing conservation efforts, and necessary investments are made. These efforts are related to alternative water supply projects identified in the regional water supply plans. Because none of the WMDs can meet future demands solely with existing source capacity, these extra efforts are critical, beginning now and continuing through 2040.

Focus on Water Quality and Protecting the Environment Water quality has continued to be considered a high-profile issue in Florida by the governor, the Legislature, news media, and the public at large. Several environmental bills have been passed by the Legislature, including the Clean Waterways Act (SB 712) in 2020 and the Reclaimed Water Bill (SB 64) in 2021. The Clean Waterways Act addresses several environmental issues, including provisions specifically related to water quality improvement. Provisions related to wastewater are as follows: S R equires local governments to create wastewater treatment plans for certain best management action plans (BMAPs), but authorizes different cost options for projects that meet pollution reduction requirements. S P rohibits, beginning July 1, 2025, wastewater treatment facilities from discharging into the Indian River Lagoon without providing advanced waste treatment. The bill imposes new requirements on wastewater facilities and the Florida Department of Environmental Protection (FDEP) to prevent sanitary sewer overflows and underground pipe leaks.

30 October 2021 • Florida Water Resources Journal

S Directs FDEP to develop requirements for the establishment of asset management programs and associated reporting for domestic wastewater collection systems. The emphasis of the reclaimed water bill is on elimination of wastewater treatment effluent surface discharges and incentivizes the beneficial reuse of reclaimed water. The bill requires domestic wastewater utilities that dispose of effluent, reclaimed water, or reuse water by surface water discharge to: S Submit a plan to FDEP to eliminate nonbeneficial surface water discharges by Nov. 1, 2021. S Fully implement the plan to eliminate discharges by Jan. 1, 2032. S If no plan is submitted or approved, it must eliminate discharges by Jan. 1, 2028. The reclaimed water bill also: S Specifies that potable reuse is an alternative water supply for purposes of making reuse projects eligible for alternative water supply funding. S Incentivizes the development of potable reuse projects. S Incentivizes residential developments that use graywater technologies. S Specifies the total dissolved solids allowable in aquifer storage and recovery in certain circumstances.

One Water Approach The concept of One Water (integrated water management) has been around in Florida for many years. The state is a recognized nationwide leader in reclaimed water/reuse and currently reuses approximately 884 million gallons per day (nearly 50 percent) of its reclaimed water for various beneficial uses. Water recycling is an integral part of Florida’s wastewater, water resource, and ecosystem management. The FDEP is currently engaged in rulemaking for implementation of potable reuse programs; however, the stress of increased population demands and an emphasis on protecting the environment has brought about a heightened awareness on the value of water and the need for a One Water approach. According to the Water Research Foundation, One Water is defined as: “An integrated planning and implementation approach to managing

finite water resources for long-term resilience and reliability, meeting both community and ecosystem needs.” The term One Water describes a comprehensive and long-term approach to community-based water management. The One Water approach considers “the urban water cycle as a single integrated system” and recognizes all urban water supplies as resources, including surface water, groundwater (fresh and brackish), seawater, stormwater, wastewater/reclaimed water, and improved storage opportunities. These interconnected resources are managed for their combined impacts on water supply, water quality, and the environment. This integrated management of all water supplies, considering multiple end uses, improves the overall quality of life in a community by benefitting both the environment and the economy.

References 1. F lorida Population Studies, Bulletin 190. University of Florida, College of Liberal Arts and Sciences, Bureau of Economic and Business Research. June 2021. 2. Office of Economic and Demographic Research, Annual Assessment of Florida’s Water Resources and Conservation Lands. 2021 Edition.

3. F lorida Water Environment Association Utility Council, 2021 Annual Report. 4. U.S. Water Alliance, “One Water Roadmap: The Sustainable Management of Life’s Most Essential Resource.” 5. “Framework for the Implementation of Potable Reuse in Florida.” Potable Reuse Commission. January 2020. 6. One Water LA 2040 Plan, Volume 1 Summary S Report. Final Draft, April 2018.

ARE YOU READY?

One Water – Water Cycle The One Water approach also considers the needs of multiple stakeholders and addresses climate change and long-term resilience and reliability to meet both community and ecosystem needs. One Water emphasizes that all water has value, encouraging those in the water industry to work together to solve Florida’s complex water supply challenges.

WE CAN HELP YOU PREPARE FOR NOVEMBER 1ST.

Conclusion Water is vital to our health, environment, prosperity, and future. Florida’s needs have grown, and due to the conservation of limited resources, there has been as increased awareness for the need of a One Water approach to water supply planning. This water evolution has resulted in recognition that water should not be labeled by its source—stormwater, groundwater, reclaimed water, etc.—but should be managed as simply One Water.

- Port Orange - Tampa - Tallahassee

EXPERIENCE EXCEPTIONAL

meadhunt.com

Florida Water Resources Journal • October 2021

31

CONTRACTORS ROUNDUP

A Contractor’s Perspective on Florida’s Shift to Increase Beneficial Reuse

Michael Rood and Courtney Dantone

A

ll water is recycled—there is no new supply of water. With enough time and space, nature can and will clean even the dirtiest water to acceptable drinking standards. Of course, it has been quite a while since nature had the time to run its course. In fact, it’s becoming more and more apparent across the United States that there is a need to further accelerate the transformation of wastewater to potable water.

Many Methods of Reuse The term potable reuse (PR) is the process of taking highly treated wastewater and processing it into drinking water. A system that uses indirect potable reuse (IPR) takes the highly treated wastewater to an aquifer, well, or other environmental barrier for storage prior to