DESIGN + MATERIALS + TECHNOLOGY

Welcome to the October / November 2022 issue of Supplier Magazine. Inside this bumper issue you will find our Feature on Edge Banders where Philip Ashley investigates the latest in automation, gluing stations and maintenance to explain why the right edge bander certainly can provide the winning edge.

The Discovering Stone section includes our annual Sealers Guide where we look at the very latest products available in today’s marketplace and explain why achieving a perfect result when installing moisture sensitive stone does not have to be difficult.

Please feel free to contact me directly regarding any industry news, company events, training and or product information you would like us to publish at – michelle@ elitepublishing.com.au

Take a look at our new website and don’t forget to join our growing online community by visiting us on Instagram and Facebook.

Until next time,

Cammiade Editor

Over the past two years, Biesse launched a thorough process of modernisation of the group, with the aim of becoming faster and more innovative.

This path allowed them to restructure the company in line with an approach intended to positively affect the way they operate and meet customer needs. As such, the project entails the rationalisation of the company structure, as well as its reorganisation at both internal and international levels, with the ultimate purpose of transforming the group into an increasingly more streamlined and efficient entity featuring simplified processes and

Anew, big exhibition concept dedicated to manufacturing technology was launched at FieraMilano-Rho in October. A partnership between BIMU, the biennial exhibition of machine tools, robotics and automation, additive manufacturing, digital and auxiliary technologies; together with Xylexpo, the biennial exhibition of woodworking technology and furniture industry components delivered a fair where manufacturers had the opportunity to find expertise, solutions and ideas for a common goal; producing with more sustainable and efficient methods, according to Industry 4.0 principles.

According to Luigi De Vito, president of Acimall, “A more crowded exhibition calendar, now complicated by the rescheduling of many events due to the

the ability to adapt to global contexts that are in constant evolution.

They have adopted a transversal approach meant to ease the implementation processes of development projects. This path will also affect their branches abroad, with the goal of strengthening the company's international network through more efficient structures.

The new visual identity was deemed necessary to align group positioning and brands and conveys the group's new values and identity traits while also retaining the distinctive features of the various sectors in which the group operates.

“Biesse's evolution will benefit our customers, as well as allowing us to compete in an increasingly changeable market. Due to the all-encompassing nature of this transformation, we decided to explicitly express it through a new visual identity” declared Roberto Selci, CEO of Biesse. ❚

pandemic, the new technologies and stronger international competition require a deep and accurate revision of the exhibition concept, which cannot be "only" a place where demand and supply meet.” It will be interesting to see what next year’s Interzum and Ligna fairs look like. ❚

CDK Stone’s team of devoted technicians travel across Australia every day, servicing, maintaining, and repairing stone processing machines. With a growing team of 19 technicians Nationally and 24 Technicians across Australia and New Zealand, CDK Stone has become leaders in stone machinery servicing in Australia.

4 SERVICE CASE MANAGERS with coverage from 7.30am - 6.00pm EST Monday - Friday (7.00pm DST)

GOT YOU COVERED 25 technicians across Australia and New Zealand RELATIONSHIPS ACROSS THE GLOBE working with the leaders in the stone industry helping our customers achieve the best tailored solutions

Nikpol were very proud to have an appreciation night for their customers last month. More than 300 customers attended the first Nikpol Brisbane trade night at the new 10,000m2 facility in Eagle Farm. The event was long overdue, as it had been rescheduled a number of times due to COVID-19, but last month they were finally able to show their appreciation for the incredible support they had received since opening the original Brisbane facility almost two decades ago.

Directors John and Spiro Nikolakakis were in attendance helping to prepare a massive Greek feast. Mark Richards, Logistics Manager

QLD/NSW, Kenny Hurford, Sales Manager

QLD/NSW and Johnny Burr, National Hardware Category Manager, hosted the exclusive invitation-only event. No one left hungry, and drinks were available all night with an open bar until the early morning.

A feast of roast lamb, roast pork, and chicken kleftiko was made available to all guests, with an emphasis on an ‘all you can eat’ philosophy. The food was prepared in a manner using an Antikristo Cretan BBQ, giving a nod to the founder's Cretan heritage and roots.

Guests came from as far as wide as Darwin, Perth, Sydney, Alice Springs, Regional NSW/ QLD, and Melbourne to help celebrate Nikpol’s opportunity to give something back to the industry and thank its loyal customers.

One of the highlights of the night was a Dale Woods guest appearance, Dale attended the event with his Porsche GT3 cup car and thrilled those in attendance with an explosive fish tail in the car park.

Nikpol opened its newly revamped showroom on the night, displaying its incredible range of products, from the well-known international DTC hardware range of products. This includes Smooth, Dragon Pro, and Magic Move runners to complement the Pivot Star hinges which hold the coveted IF 2017 international design award and the door opening mechanisms Top Stay with single and bi-folding overhead door options.

Inspired by the Interzum 2019 showing in Cologne also on display was the amazing FLYBOX corner hardware solution, which uses the wasted space in dull and dark blind corners via an automatic pully system with a soft closing action. The swing-out and larder pantry solutions are all made in the beautiful Italian town of Trissino in the province of Vicenza.

Nikpol also launched a new sink and tapware range, along with European handles from Metakor in Belgium, which customers didn’t stop talking about.

Inspired by Milan's Eurocuccina 2022 the new showroom displayed an incredible range of exclusive decorative products. The latest European trends in decors, and inspired colour ranges. A timeless stunning range of authentic timber grains and muted organic colours were on show.

Nikpol featured both their Matt Wood and Meraki range, these proved to be the most popular and versatile colours available in decorative board. Their benchtop colours contain realistic stone designs, woodgrains, and contemporary patterns to inspire Australian designers.

The jewel in the crown is the Blaupunkt kitchen appliance range. This is distributed exclusively by Nikpol throughout Australia and New Zealand. The Blaupunkt brand itself holds a 100-year-old European heritage synonymous with quality, innovation, and value. Nikpol showcased an extensive range of stylish and modern built-in appliances including cooktops, ovens, freestanding cookers, rangehoods, dishwashers, microwaves, combi steam ovens, and warming drawers.

The trade night also provided the Nikpol team with a great opportunity to showcase their state-of-the-art facility and Homag machinery. Consisting of two automatic board and benchtop storage/picking machines, each capable of holding over 5000 sheets of product. Customers were in awe of the new Homag machinery, and the near full capacity of approx. 2000m2 of floor space using the 11m of height to store their bulk packs of product.

The one thing Nikpol do differently to stand out from the crowd, is focus on colour, on the inside. Just like the Nikpol tagline “Look Inside,” their internal cabinetry is just as important as the external cabinetry, if you want to elevate your joinery, add a colour to the inside of your cabinets. This lifts your interior cabinetry to bespoke furniture. The Essential range by Nikpol is a trendy melamine range that is ideal as carcass to match or contrast with external colours. Instead of using traditional white carcass material add a pop of colour to your internal carcass in turn, creating an element of surprise.

All Blaupunkt products enjoy a market leading six-year warranty and excellent after-sale service support. Nikpol is extremely honoured and proud to offer the quality of German engineering and design to the Australasia market and their trade night was the perfect event to showcase their elegant appliances, especially for guests who experienced the Blaupunkt lifestyle for the first time.

To support the needs of all customers their huge stock holdings of hardware and Blaupunkt appliances, were on show, with over 2200 pallet spaces of racking. ❚

As workforces return to the office, companies are demanding more sophisticated solutions to manage waste generated in staff kitchens and cafeterias. These corporate customers are often striving towards zero waste and are looking for ways to increase the amount of waste that is successfully diverted for recycling or composting.

The new Concelo 1 x 35L waste bin provides a smart solution for sorting waste and recycling in office kitchens. The single CR350-135D can be used for each type of waste stream such as using three bins for recycling, green waste and landfill. If recycling is not comingled, then additional bins can be used for paper or glass recycling for example.

Commercial environments are high use and very demanding. Bin systems in office

kitchens are used as much as 50,000 times per year, so durability and ease of servicing are an important consideration. To this end, Concelo uses premium Germanmade soft close runners that are rated to 45kg and use an innovative mounting system to make runner servicing easier. All Concelo plastic components are made using virgin polypropylene for maximum durability. While using virgin material is more expensive, it means the strength of the components are not compromised by using

fillers. At the end of life, all polypropylene parts are all fully recyclable to ensure minimal environmental impact.

Being built on the award winning Concelo platform means the CR350-135D has the all the unique features that have made Concelo so popular. The Active Lid system controls odours and is hands free. And because bins get dirty, components like the Clip’n’Clean trays and removable Active Lid make it so easy and simple to clean and keep hygienic.

The new Concelo CR350-135D comes in White and Cinder colour options and full technical information and CAD details can be downloaded from hideawaybins.com.au

Hideaway Bins are distributed throughout Australia by Hideaway’s distribution partners’ Nover, Hafele and Galvin Hardware. ❚

The Häfele Alto drawer system increases the functional use of cabinetry with perfectly straight thin 13mm drawer sides. Making the drawer capacity larger, while maintaining the stability and quality with a load capacity of 35kg.

Three side heights, 84mm, 135mm and 199mm allow for flexible and versatile use from the kitchen to the wardrobe and bathroom areas.

The option of white and black colours in matt finishes allows Häfele Alto Slim to meet everyday design requirements and complement the continuing trend of darker decorative colours.

Häfele Alto Slim has been tested and passed European DIN EN 15338 level 3 standards. This was achieved with a full 35kg weight capacity with over 60,000 opening cycles.

Comfortable height and lateral front panel adjustment from inside the drawer allows easy adjustment when installed in corners or against walls.

Complementing the range of Alto Slim drawers is a range of Häfele drawer inserts, Classico 500, Classico – multi utensil tray and Basic Cutlery Tray.

Alto Slim comes with Häfele’s renowned lifetime warranty and will last you for the life of your kitchen.

For more information scan the QR code or call your nearest, Häfele sales office or Account manager for a personal demonstration.

web www.hafele.com.au ❚

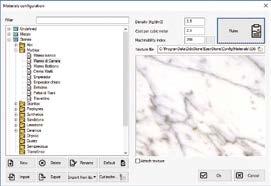

Neolith is now available direct in Australia. Having previously been available to the Australian market through a distribution partner, the premium European brand is opening their very own Melbourne- and Sydney-based logistic facilities later this year, making their products directly available to Australian clients.

Neolith has been creating state-of-the-art sintered stone surfaces for over a decade. Their revolutionary products are easily recognisable; using natural hues and raw textures, they infuse everything from kitchens and bathrooms to facades, accessories and furniture with a timeless and earthy aesthetic similar to that of a beautiful landscape.

Neolith surfaces are a practical and sustainable architectural solution, possessing all the beauty of natural stone, but none of the limitations. Sintered stone is built to last; it is backed by cutting-edge technology that can withstand water, heat, scratches, stains and UV radiation. Equal parts sturdy and luxurious, Neolith surfaces offer unmatched versatility for both indoor and outdoor applications; use it to create a stunning and hardwearing facade, to add impact to an alfresco area or outdoor kitchen, to design one-of-a-kind furniture or to add magic to a kitchen or bathroom – the options are endless.

Neolith began as a family-run business in 2009, born of extensive industry experience, a passion for artistry and design, and a deep respect for the natural environment. Today, they are the global leader in sintered stone. Made from 100 per cent natural materials, with superior colour and finish consistency, almost zero porosity and revolutionary mechanical qualities, Neolith designs and manufactures the most advanced architectural surfaces in the world.

Sustainability is a key part of Neolith’s identity. Nature serves as their aesthetic inspiration, and they are committed to conserving its beauty. From the minute Neolith first designs a product through to the moment the surface is installed, they consider how to maintain the integrity of the environment and preserve the future of our planet.

Not only are all Neolith products made from all-natural materials, they are also manufactured in carbon-neutral conditions. Neolith’s electricity usage is 100 per cent renewable, all the water they consume is recycled, and 90 per cent of the waste generated is also recycled.

These measures have been pivotal in allowing Neolith to save over 7,690 tonnes of CO2 emissions and achieve near-zero positivity. With an international carbon-

neutral certification awarded to them in 2019 for their sustainability strategy, as well as a 90R label recognising their contribution to minimising their carbon footprint, Neolith is paving the way toward a more circular economy in the architectural and design industry.

And for Neolith, this is just the beginning.

Currently, there are six collections, including Classtone, a durable and characterful surface with all the strength and lightness of natural stone; Fusion, which possesses an energetic, distinctive personality and brings an industrial element to a space; Iron, for a bold, metallic finish; Colorfeel, a versatile surface that blends with almost any architectural element; Timber, which brings the warmth, comfort and natural grains of Swedish pines and Lebanese cedar; and Steel, an urban, state-of-the-art metallic surface for an innovative and eye-catching effect. There is also a range of different finishes available for each collection, including Satin, Silk, Riverwashed, Decor Polished, Slate, Ultra Soft and Polished.

Along with the resistant properties of sintered surfaces, Neolith has also incorporated a solution called NeolEAT, which helps to preserve food hygiene by preventing bacterial growth. ❚

Having scooped up both the German Design Award and Red Dot Design Award, Kinvaro T-Slim is a movement mechanism that is a market first. Kinvaro T-Slim is the thinnest, most efficient flap lift system ever developed by GRASS. It combines purist looks with outstanding durability and the art of perfect movement in a unique way. The flap lift mechanism blends into the furniture almost invisibly, thereby unlocking completely new possibilities for overhead wall cabinets. It offers furniture designers and manufacturers maximum flexibility. Besides the aesthetic bonus, the reduction in size offers another advantage: the flap lift mechanism takes up very little room, which means that the available storage space can be used to its full potential.

Horizontal storage cabinets with lift-up flaps, that are on eye level and therefore immediately accessible, are particularly practical for many applications - directly above the worktop in the kitchen and above the sink and cooker; above the bathroom sink or next to the mirror; above a desk or the TV in the living area - in modern interior design, lift-up flap cabinets have become established as horizontal design elements. While high wall cabinets with high flap fronts used to be the norm, designers are now increasingly returning to horizontal formats. The good news is that there is a unique movement system for exactly these applications - Kinvaro T-Slim.

Transparency is one of the greatest design trends of our age. Transparency not only appears to have been established as a style factor in modern architecture but has also become a central topic in furniture making. Open shelves, glass cabinets, glass fronts – storage, has been superseded by a kind of ‘display.’ Aluminium-framed fronts with glass infills are becoming increasingly popular. This is a stroke of the new GRASS lift-up flap stay realises its full potential and demonstrates its unique features combined with aluminium-framed fronts. With Kinvaro T-Slim the open-transparent style of the front is unblemished - both when the front is open and when it is closed.

Wide fronts are as popular as ever. Their advantages are particularly obvious on wall cabinets. Wide fronts avoid irritating gaps - and when wide fronts are opened, much more storage space is revealed. This aspect could be summarised with - open once, access twice. GRASS have naturally developed an intelligent solution for such front formats. For cabinet widths of more than 1,200mm they recommend planning the installation of an additional Kinvaro T-Slim fitting. This creates a powerful trio that increases the load capacity by 50 percent. ❚

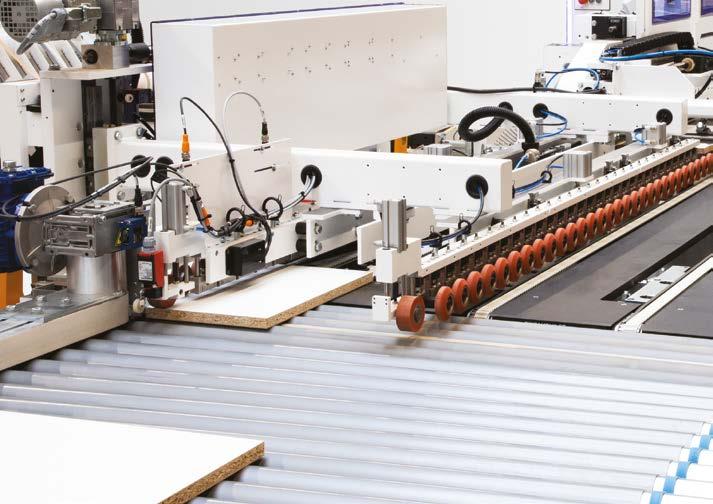

An edge bander, like a CNC processing centre, or nesting machine is a major capital investment for any company producing cabinets. While a simple machine is still available, most are now fitted with some sort of logic control that have simplified the setup of these once difficult to use machines.

The range of edge banding machines is almost as long as there are machinery suppliers; almost everyone can sell you one. And while it makes a lot of sense to get a machine by the same supplier that sold you the CNC machine, with an edge bander this is not always the most astute purchase decision. It all comes down to what you want to do with your new machine.

If long runs of whiteboard are your major requirement, then you need a reliable machine without the unnecessary option of automated changeover from one edge type to the next. If your production is typical of most Australian manufacturers and your batch sizes are between ten and fifty pieces, then some sort of programmable logic control, or even computer control is essential.

Programmable Logic Control (PLC) are used to automate industrial processes such as a manufacturing plant’s assembly line. They are used effectively on the edge banding machine. A PLC can perform discrete, repetitive functions and is suited to rough industrial environments. The CPU reads the input data from sensors, processes it, and sends the command

to controlling devices to operate saws, trimmers and buffing units. Since the PLC was invented by Dick Morley in 1964, they have revolutionized the industrial and manufacturing sectors.

Automation is Key Manual set-up machines can, in some cases, require five to fifteen minutes just to change from one edge thickness or edge detail to another. With this loss of production time every fifty pieces or so, it’s little wonder that manufacturers are turning to edge banding equipment with more and more automation. Another factor to consider is the speed at which your other equipment works, and your production not being held up by a slow, outdated edge banding machine.

In some ways, the decision on which edge bander to purchase is a far more important one than the CNC processing centre. When you discover that the controller for a new edge bander is capable of changing the program to a new one, while the previous panel is still in the machine; that’s a revelation you can see will certainly reduce your down time and increase your daily production of edge banded panels. If it costs 20% more to buy an automated machine, it’s worth every cent.

Many Australian machinery suppliers have been selling edge banders for a long time, some over 40 years so there is a lot of experience and know-how behind the product. Equipment is becoming more sophisticated as the years roll on, and manufacturers becoming more confident in the performance of the machinery. In the past the actions of an edge bander were controlled by limit switches; very unreliable and prone to inaccuracy. PLC and computer control is now the norm and is very reliable. In the case of a machine part failing, it is a simple matter to order a new part and simply plug it in.

And when it comes to maintenance, the modern edge bander can be diagnosed from the country of origin if its attached to the internet. Your problem could be diagnosed by someone in Italy, Germany or Austria, that actually had a hand in designing the machine. It’s also possible through the use of apps, to monitor your edge bander from wherever you might be, even on holiday.

The heart of any edge bander is the gluing station. Whether its state of the art laser, hot air application, near infra-red or the traditional glue pot or stick, the quality of the finished product will be determined by the glue line that is either visible but not noticeable, or nearly invisible, to the human eye at least. With an edge band product, it’s what you don’t see that matters.

When the first hot air machines came out, it was thought that an invisible glue line was only capable with a laser edge strip, but a near invisible joint is achievable with good equipment using PUR glues.

The PUR bond forms in two stages. The adhesive cools and solidifies like a hot melt, reaching its holding strength, then the moisture-curing reaction acts over the next 24 hours to reach its final structural strength. The bond is tough but flexible, has a higher heat resistance than EVA adhesive, and resists moisture. It does have some considerations such as shelf life after opening, and so, should be stored in sealed containers. Unlike the lower-cost EVA hotmelt glues, PUR cannot be stored for extended periods of time.

The heart of any edge bander is the gluing station. Whether its state of the art laser, hot air application, near infra-red or the traditional glue pot or stick, the quality of the finished product will be determined by the glue line...

You can get expert advice about using PUR glues from adhesive suppliers. Most of this product comes from Europe where it is heavily researched and provides a level of confidence every manufacturer needs. There’s a lot of Chinese-made edge bander adhesive on the market but as the glue is literally the bond between the board and the edge, is it worth the small cost savings to risk your company’s reputation?

Whatever edge bander or type of glue you use, keeping it clean “Puts you 70% ahead of everyone else” according to one expert at SCM. Another expert at HOLZ-HER says dust can be an issue. An expert with the Homag brand speaks highly of allotting five minutes to blow the machine free of debris every day. Other leading people say dust collection is one of the main issues leading to poor edge

bander performance and yet another speaks about the perils of using low-cost glues.

Advances in edge banding technology are now mostly in software that reduces setup times and provide more production flexibility. Return systems are also gaining momentum, not only to provide a oneperson operation, but to load from a part library or to rout the part to other machinery. Almost every supplier can provide a hot air or similar solution, and true laser edging is almost never heard of, except in the largest producers so there is very little interest here in Australia. The ability to automatically apply different radii on the edges is something relatively new and is a joint initiative with some of the tooling manufacturers. No doubt about it, the right edge bander can certainly provide the winning edge. ❚

Advances in edge banding technology are now mostly in software that reduces setup times and provide more production flexibility. Return systems are also gaining momentum, not only to provide a oneperson operation, but to load from a part library or to rout the part to other machinery.

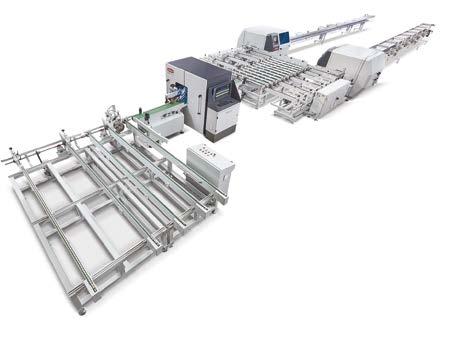

Biesse Group are proficient in working stone, glass, advanced composite materials, wood and manufactured board. This wide diversity of operations stands Biesse Group apart from their competitors. From the top down, every machine is built to the same high quality standard, including their wide range of edge banding machines, tailored for every sector of the cabinet industry

Biesse Group was founded in 1969 by Giancarlo Selci and in 1983 delivered their first Rover CNC machine. Rover is now as synonymous to the working of wood as Hoover is to the vacuum cleaner. The Rover was enthusiastically accepted by the manufactured board sector of the industry, particularly here in Australia, and in the United States of America. Following this success, Biesse Group quickly followed with the development of the Selco Beam Saw, and in the 1990’s, their extensive range of edge banders.

Biesse edge banders benefit from the group’s high-end technologies in other vital areas of furniture production such as CNC processing and panel cutting. This co-operation means Biesse edge banders are produced with proven, reliable technological components and features that guarantee long, troublefree work with a consistent quality outcome. At all times, the top end of the industry is the initial target, with every other machine down to Biesse’s smallest models, benefitting from modern technologies and developments.

Biesse Group continually develops more efficient machines to meet the changing demands of various industries. You get a lot more for your money with Biesse Group. Their extensive range of edge banding machines means that there is one suited to every need, be it a small, one or two person shop, through to the biggest enterprises with highly efficient, automated production lines. Your Biesse edge bander has been manufactured with the knowledge used in their most advanced machines, with components and operating efficiencies designed for the most demanding user.

Roberto Selci, CEO of Biesse Group said, “We innovate to bring new standards of technology to the market and to provide solutions that make work simpler for our customers.”

In this way, Biesse Group customers are guaranteed equipment that meets the demands of the most challenging applications. From the very beginning, Biesse Group edge banding machines were developed with a focus on innovation and a continuous search for excellence to ensure their customers remain competitive.

The technology utilized in Biesse Group’s most advanced, million-dollar edge banding solutions comes from thirty years of experience. Biesse Group build all their own strategic and critical components to ensure long-lasting reliability. The techniques, skills, methods, and processes used is evident in every machine in the range. The only visible difference is the speed of the machine and panels produced per shift. Innovation is applied to every machine in the full range of edge banders Biesse Group produce.

Biesse Group are now amongst the top three edge bander suppliers worldwide and have left other producers with fifty years’ experience in their wake. Pierluigi Tacchi is

Sales Director for Biesse Group edge banding machines and said, “When you start out with a formidable challenge, you must never stop believing.” The belief is real, and a new factory has just been completed in Italy to accommodate the additional demand. Here in Australia, more parts are available 24/7 with Sophia Parts to ensure downtime, should it ever occur, is kept to an absolute minimum. Lee Crow of LCR Shopfitters in Clyde, NSW is one user who loves the connection to the machine through the Sophia IOT software.

Biesse Group offer a full range of edge banding solutions, from the single and double-sided Stream for high-end production, through to the Akron for small to medium-duty use, to the entry-level Jade for flexible production in limited space. Edge banders are complex machines and need to be easy to set up, operate and maintain. A dedicated program has been developed in the last 5 years, aiming at making the technology more user-friendly and, as consequence, the machines cleaner and more dependable. Some users have used their Biesse Group edge bander for over fifteen amazing years and only replaced the machine for modern technology!

Biesse Group offers the innovative AirForce System for laser edge strips. The technology is one of Biesse Group’s foremost innovations

in the world of edge banding. This technology melts the laser edge banding strip with high temperature air that when applied to the board, penetrates the wood fibres so as not to have any joint between the strip and the panel surface. This avoids the need to use glue as a joint and as a result, does away with the glue line. AirForce produces a perfect visual result that's particularly suitable for highly visible parts of the furniture item.

There is a Biesse Group edge banding solution for all applications. Biesse Group has World-wide experience with installations of edge banders in almost every country on Earth, operating under the most diverse conditions imaginable. Every year Biesse Group invest 4% of yearly revenue on research and development. Customers can be sure that whatever they ask of their edge banding machine, Biesse Group has seen it before; has built it before and has the practical experience and expertise to meet any challenge, from the top down.

Pierluigi says, “The advantages of AirForce lies in the simplicity of a machine that doesn't require glue. While gluing systems have evolved in recent years, the use of a hot melt bonding agent involves a series of precautions and maintenance that has a definite impact on the use of the machine. In addition, there's no longer the problem of finding a glue of the right colour for the specific edge banding strip: changing from a white-on-white finish to a dark colour finish requires no particular set-up time and glue change because it's the polymer on the edge tape that melts and doesn't need a bonding agent of the same shade.”

Giuseppe Serpentino is Biesse Group’s Australian edge banding sales manager and brand specialist. He said, “Biesse Group’s largest edge banders are designed to work multiple shifts. The technology applied to those machines has been naturally applied to our future machines developed over the years. It’s top-down technology and represents an original and intelligent way of developing new product. Biesse Group innovation is targeted at reliability; less operator input; more automation inclusive of maintenance, especially at the gluing station, all critical issues for today’s high-demand cabinet manufacturing.” Biesse Group edge banding, be a part of it!

The sealed system prevents the glue from burning, ensuring that it maintains its original colour and does not emit any unpleasent adhesive vapors. Complicated, labour-intensive cleaning work on the adhesive basin and glue rollers is eliminated.

100 % ADHESIVE FORCEMelting the glue as needed, ensures that the glue always maintains its full adhesive strength without losses resulting from repeated heat-up.

The Glu Jet thin film technology means the glue penetrates deep into the panel structure. You get a highstrength joint and an invisible look at the same time.

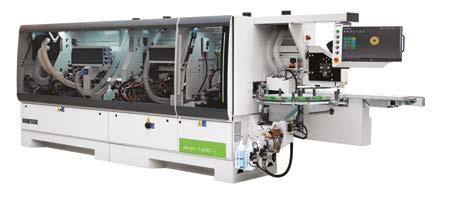

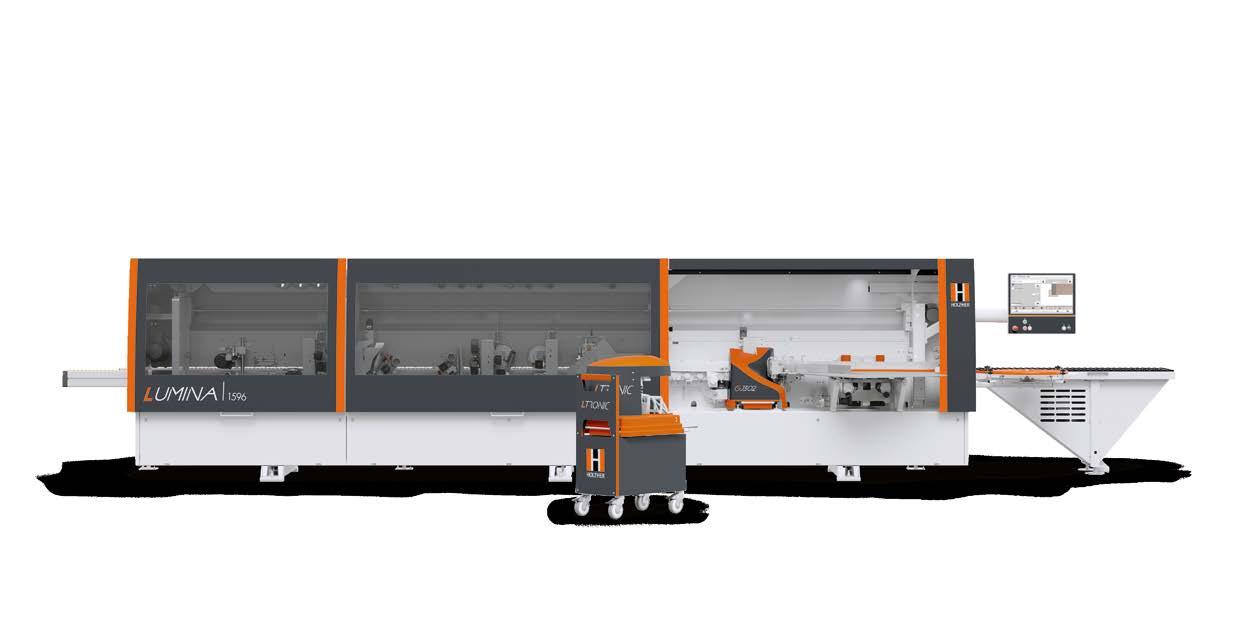

From zero to operating temperature in only 3 minutes and back to zero just as quickly. The HOLZ-HER edgebanders operate with Glu Jet – not with traditional glue pots and application rollers.

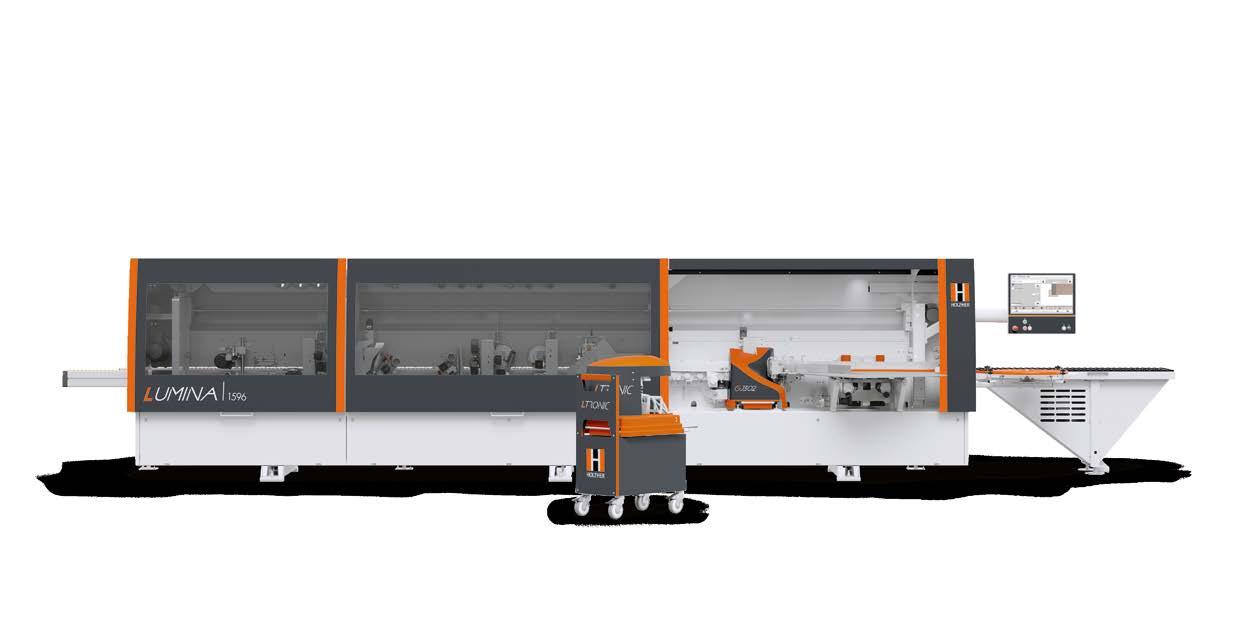

With the LTRONIC, you can process state-ofthe-art laser edging silently, without heat-up time, excessive loud generation of expensive compressed air that requires large panel spacing at the detriment of your productivity and time consuming, unnecessary cleaning work for results with a perfect appearance.

To facilitate your decision in favour of Glu Jet, we are pleased to offer a three year warranty on the complete Glu Jet system.

Ensures that operators can always identify which corrections are being made in which direction on a graphical display. The values entered for tool feed are converted to the actual axis values fully automatically in the background. This makes sample workpieces a thing of the past.

ITRONIC – YOUR INTELLIGENT EDGEBANDING ASSISTANT!

This multi-version is based on the axis-controlled standard version, however offers up to four different profile variants in addition to 8 mm flush cutters. These profiles can be selected on the control with a touch of the button, offering an uncompromising finish on the workpiece.

NO NON-PRODUCTIVE WAITING TIMES!

fa.s.t (set-up in the gap) enables you to run different machining processes at the same time on the edgebander. This process is extremely efficient in combination with the high speed NC servo-axes.

Just push a button to clean the gluing station perfectly. The monitor for the remaining glue quantity ensures that you always know how much more work you can complete. Whether thin edging or thick veneer edging – always the right power at the guillotine. Real wood coils or thin edging – the pressure combination at the pressure unit is always perfect.

HOLZ-HER has been part of the Weinig Group since 2010 but still operates as a uniquely identifiable brand. Founded in 1914 and approaching 110 years of service to the woodworking industries, HOLZ-HER has become one of the leading suppliers of technologically advanced equipment for the solid wood and flat panel furniture industries.

HOLZ-HER manufactures machines that cover a wide range of products. Whatever you produce, HOLZ-HER will have a machine suited to your needs, including CNC processing centres and edge banders, the two major pieces of equipment necessary for any leading manufacturer of wood products. In both these areas, HOLZ-HER excels with class-leading machines built not only to outperform their competitors, but strong enough to provide many years of trouble-free service.

HOLZ-HER CNC machines are particularly suited to heavy work on solid wood, built with strong frames and equipped with powerful motors. And their edge banders are amongst the most popular brands on the market; and have been for decades. With over 150,000 machines operating around the globe, Weinig Group, incorporating HOLZ-HER, has the credentials to stand as one of the world’s leading brands.

For 45 years HOLZ-HER has produced edge banding machines from entry-level machines to highly-flexible equipment suitable for large-scale production. HOLZ-HER is without a doubt, one of the World’s best-known and respected edge bander brands. The reason HOLZ-HER edge banders are highly regarded is the heart of the machine; the gluing station. HOLZ-HER uses their own, widely accepted system known as Glu Jet, a closed system where only the amount of glue needed is melted, burning of expensive glue is not possible and cleaning takes only a matter of minutes.

Further advantages of this technology are that there is no waste that you normally get with glue in a heated pot, and there is also no loss of adhesive strength you get when glue is reheated. With its unique hybrid technology, this unit ensures perfect interaction between glue, edging and panel material. With Glu Jet and PUR glue it is also possible to achieve the holy grail of edge banding; the ‘zero’ join without the need for hot air or prohibitively expensive laser equipment. Glu Jet will deliver ultra-thin glue joints, easily equivalent to industrial laser edges.

HOLZ-HER’s SPRINT range of edge banders are designed to meet the highest

requirements of quality and flexibility. Various compact models are available for complete processing of state-of-theart edging and panel material. Program selection allows the machine to be set up without even opening the hood, so that it is ready for production immediately. With the SPRINT, you can have invisible Joints with Glu Jet thin film technology. The machine also comes standard with the advanced iTronic system that includes an adaptive trimming blade and pressure unit; automatic glue quantity control; an automatic cleaning routine and remaining glue quantity indicator.

Motor-driven adjustable axes are used for the entire machine. This enables you to precisely reproduce any setting at the touch of a button. The SPRINT uses Holz-Her’s new high-speed servo-axes where the rapid in-feed capability allows what Holz-Her refer to as “set-up in the gap”, which makes it possible to run various applications in the machine simultaneously. You now have the ability to execute a programme while the first panel is in the machine and thanks to process control, the machine won’t move into position until it’s safe to do so. Production speed is increased by up to 50%.

The SPRINT edge bander provides multifunction technology at the highest level. SPRINT comes with a PC control with touch screen; variable feed rate up to 18 m/

Above: SPRINT 1329

min; and will handle workpiece thickness up to 60 mm and edge thickness up to 15 mm. Markus Ostermaier is Managing Director of Weinig Australia. He said, “We understand what our industry needs, and we create solutions for the changing market. With our patented Glu-Jet system the Sprint range has a collection of highly dynamic machines which were first launched in 1999 and are still our best-sellers today.”

Enter the next generation of CNC woodworking with HOLZ-HER’s EPICON Series. The optimized design of the EPICON CNC machining centres offers the ideal basis to ensure absolute precision and perfectly machined workpieces while simultaneously allowing extremely high acceleration and cutting rates. To this HOLZ-HER have added a high precision direct servo-drive, wear-free couplings and covered, precision linear guides, all covered by HOLZ-HER’s 10-year guarantee. A comprehensive range of optional equipment is offered to satisfy all production requirements, allowing the EPICON to be configured optimally for furniture production, staircase construction, window and door joinery, and machining solid wood or manufactured board.

EPICON comes standard with a fully interpolating 13 kW, 5-axis spindle with ceramic bearings, and optimally equipped drilling assemblies of 14, 21 or 31 spindles.

For more grunt, opt for the optional PRO torque spindle. With an output of 18 kW and mechanical brakes on the A and C axes, this machine provides for extreme rigidity and perfect results at high feed rates with maximum chip removal. The machine table can be set using the practical dot laser, the visual support offered by the unique HOLZ-HER VISE LED table or the complete automatic Synchro-Drive Table.

On September 14th this year, Holz-Her announced a two-stage investment program with a total investment of 15 million euros. Stage one will be a new machine production facility with floor space of 1,700 square metres to cater for the increased worldwide demand for HOLZ-HER machines, including right here in Australia and New Zealand. The new facility should start producing machines as early as the beginning of December this year. Stage two, a new, highly automated

storage hall, will be started in 2023 and will ensure effective, real-time supply of spare parts that for the customer, is more important than ever. The new automated storage facilities save space and provide for an additional 3,000 square metres of floor space.

HOLZ-HER is a name trusted worldwide, not only for their excellent edge banders but more recently, their range of heavy-duty CNC processing centres that continue to break new ground. An investment in a HOLZ-HER CNC machine adds value to your product in terms of accuracy and quality. Ease of setup adds to improved time saving and more flexible production on your shop floor. For heavy work on solid timbers, there is no substitute for a HOLZ-HER CNC machine. And for the cabinet industry, HOLZ-HER SPRINT edge banders offer a compact solution for the production of quality edged panels using their patented Glu Jet system and PUR glue that delivers high strength and an ‘invisible’ glue joint, even on black panels with black edging. With HOLZ-HER, there are no compromises.

HOLZ-HER have state of the art showrooms in Sydney and Melbourne and welcome you to arrange a demonstration day to experience their exciting range of woodworking machinery. Please contact HOLZ-HER on 1800 736 460 or sales@holzher.com.au with any inquiries or booking requests.

web www.holzher.com.au ❚

Above: EPICON 7135

SCM's new industrial edge banding machine has been designed to offer top- quality machining on any kind of panel and material, to fully meet the needs of a connected and integrated digital factory.

Yet another high-tech entry from SCM to satisfy the latest trends in furniture and design in terms of flexible and 4.0 production. The new Stefani X industrial edge banding machine has everything it takes to win over the market. Each detail has been designed to offer an innovative solution and in line with the industry's more complex demands: from the machine's structure to the digital and electronic control systems; from the machining units with power assisted movement to the latest gluing devices, for an even faster, more efficient glue change.

The result is a highly configurable, customised edge banding machine, designed to reliably work several shifts and capable of providing top-quality machining, both in the stand-alone version and in integrated cells or lines.

Another important advantage is its ability to achieve maximum quality standards easily without interruption, even on the most delicate, state-of-the-art materials, thanks to SCM's new electronic touch systems.

Furthermore, in an attempt to meet the increasingly widespread demands for flexible, connected and integrated production, Stefani X offers and exclusive digital control system that means it can operate in perfect synergy with other technologies and IT systems as well as MES management used in the factory.

The end of compromise in productivity

SCM's new industrial edge banding machine can machine panels at a speed of up to 30 m/min during several shifts per day. All this, thanks to top-of-the-range units and a new, highly rigid mechanical structure. It also has new dynamic units, custom-designed to further increase performance and to include additional high-end functions if requested.

Highly flexible even when changing the glue

Another significant feature of Stefani X is the gluing unit which, thanks to the unique glue switch solution, allows for a just in time change of colour and glue type, thus achieving even more flexible, efficient production.

The secret lies in the fact that there are simultaneously two glue tanks which, during machining, can be interchanged using the type and colour of glue requested by the work program. The glue tank can also be replaced, or maintenance work carried out on it without having to stop the edge banding machine.

The new Stefani X offers top-quality gluing no matter what type of edge there is. The intensity of the first pressure roller can be automatically adjusted by the edge banding machine's control system. Furthermore, the edge can be replaced without any distance limit between the panels thanks to the new automatic edge change device with 2 and 6 rolls and with a roller change system that allows for a reduced interspacing of 350 mm.

The new Stefani X electronic units are designed to meet two objectives that are key to the market: ease of use even for more complex machining on delicate, trending materials, thanks to an automatic, flexible set-up, as well as repeatability, quality and accurate production processes, due to the electronic touch.

Y-SE 1000 Servo and Y-SE 1200 Servo

For constant precision when cutting, irrespective of the amount and kind of panels machined, to optimise machining work even on the most delicate panels, automatically control adjustments and correct any machining errors on the spot.

RC-E Multileaf glue scraping unit

Ideal for machining panels with film, thanks to the automatic tool adjustment for any film thicknesses.

To ensure top quality machining on any profile and optimise the processes even on three different edge thicknesses.

"This new edge banding machine is a further advancement to accompany and support designer furniture businesses in optimising their production processes together with the technological innovation and know-how acquired by SCM in the edge banding sector over a period of seventy years - highlights SCM's Edge banding Business Manager, Fabio Cernoia. The new Stefani X is proof that an edge banding machine needs to be much more than a machine. In fact, it needs to be an all-round technological project that is highly configurable and versatile, where it is the quantitative and qualitative composition of the units that make a difference to the panel machining process".

web www.scmgroup.com ❚

Spirit Sealers and Cleaners have been particularly busy of late. Even with the many day-to-day challenges of running a business over the last 2 years, the company has not lost its focus on the continual research and development of their product line. It has been, and still is all systems go for the team, with the introduction of a stone consolidator, as well as further development of their existing sealer range.

Spirit’s Premium Consolidator, which hit the market at the beginning of 2022 introduces a completely new product to the range for the company.

So, why the need for a consolidating sealer?

Spirit’s Premium Consolidator is designed to protect friable natural stones in harsh salt water and extremely cold freeze-thaw environments by filling the pores of the stone with a silica-gel like binder (SiO2) that increases the substrate strength. The silica-gel migrates through the treated stone over a period of 2-4 weeks filling the pores, occupying the space where salts or ice could potentially form and

cause spalling. Breathability of the treated surface is maintained, allowing water vapour transmission which prevents moisture building within the substrate. Premium Consolidator is boosted with a high-performance water-repelling sealer that protects the stone during the curing and laying process. However, if oil staining resistance is desired, a final seal should be done with Spirit Premium Seal on completion of the project. The formula has been independently laboratory tested in Australian sandstone against known competitor products in the market. It came out on top in all four categories, a notable one being ‘Resistance to Salt Attack’ where it achieved an AA rating. Compare that to the untreated sample that achieved a D rating, suffering from severe crumbling, and it more than validates its efficacy.

Spirit’s Premium Seal has seen a significant change to the old formula. The current sealer now boasts a unique combination of three resins. Silane and siloxane resins have been added to complement the existing fluoropolymer resin, adding greater stain resistance, and better depth of penetration.

The resins are carried into the stone by a new dual component carrier that has been carefully blended with the new resins to create a high-performance sealer that is also easy to use. Over the years, when talking to professional applicators, it had become clear to Spirit that there was a demand for a versatile sealer that provided the high performance while also being user friendly at the same time. After creating literally dozens of different formulas and painstakingly testing them over multiple varying substrates, Spirit recently settled on the one that they felt ticked all the necessary boxes.

Spirit Sealers and Cleaners, a 100% Australian owned and operated company have been at the forefront of the manufacture of sealing and cleaning products for the stone and tile industry Australia wide, since 1991. Spirit believes that their great products and industry knowledge when combined with a strong emphasis on excellent customer service is their formula for success.

web www.spiritsealers.com ❚

Achieving a perfect result when installing moisture sensitive stone does not have to be difficult. There are two important points, that are certain to make a big difference. In this section, we discuss the benefits of pre-sealing stone and the benefits on advancement in technology of water based penetrating sealers.

When installing moisture sensitive natural stone such as limestone (and even some granite varieties), it is important to remember, that moisture damage is easy to prevent, but very hard to remedy after installation, if preventative measures have not been taken. When using a pre-seal to protect natural stone, be sure to check that the pre-seal contains adhesive pairing technology. Adhesive pairing technology is designed to not only work seamlessly with the polymer fortified adhesives, but actually enhances their performance.

Pre-seal is designed to inhibit the ingress of moisture particularly during the installation process. A quality pre-seal will prevent picture framing, tile warp and moisture bruising.

The other function that a quality pre-seal provides, is to ensure easy grout smear clean up. Pre-seals are cost effective and easy to apply.

Penetrating sealer technology has come a long way in the past 10 to15 years. As the construction industry continues to work toward more responsible choices in general. Specialists the world over, have been putting greater efforts into producing equal or better performance, from water-based technology products. The market took a significant hit when the fluoropolymer regulations banned the use of longchain technology. Since then, attention has turned to alternatives that have lower VOC content and meet criteria for green building, while still providing premium water repellent and stain repellent performance.

Modern technology, water-based, penetrating sealers are quickly showing themselves to be catching up to their solvent-based cousins. Solvent based penetrating sealers have for a long time, held the mantle of being far superior in stain prevention than water-based alternatives. However, now we see products like Actichem Stone Sealer Gold producing results on surfaces like Limestone, that are equally as impressive as the solvent based options.

When installing moisture sensitive natural stone such as limestone (and even some granite varieties), it is important to remember, that moisture damage is easy to prevent, but very hard to remedy after installation, if preventative measures have not been taken.

The question then comes, when should I steer hard toward using a solvent based penetrating sealer and when should I use a water-based penetrating sealer? While the answer isn’t exactly a hard and fast rule, we can follow some basic principals in our selection process.

A solvent based penetrating sealer is typically going to have slightly better penetration into dense stone than a water based penetrating sealer. This is important when we are trying to protect dense, polished surfaces such a benchtop or vanity. A premium solvent-based product will also typically provide longer lasting protection in harsh environments such as a pool surround or a kitchen floor. Waterbased penetrating sealers are ideal for areas where there are Green Star requirements and product being applied in enclosed environments.

It is important to remember that the application at time of laying may be very different to the application at the time of conducting a scheduled top-up seal after the floor has been down for 5 years. Water-based penetrating sealers are also excellent for moisture sensitive stone such as Limestone and Granite.

When using penetrating sealers, it is helpful to give consideration to what you are trying to protect the surface from. When sealing an external stone wall or façade, we are typically only trying to protect the surface from water ingress and pollution. Remember, that all common issues with walls externally like this, are caused by moisture ingress. This being the case, you will get better protection from a quality water repellent like Defender SV, than

from a stain repellent. Alternatively, if you are sealing a stone surface in a shower or bathroom, we are trying to protect the stone from oils, soaps, shampoo and water damage. In an environment like this, a stain repellent sealer like Solv Sealer Gold or Stone Sealer Gold will give the best overall protection for the long term.

web www.actichem.com.au ❚

Lithofin was first developed by Stingel Chemie in Stuttgart, Germany in 1953. Today, Lithofin is expertly guided by grandson Garvin Stingel. Built on the two pillars - quality and service, the brand operates in more than 25 countries worldwide. Designed for both professional and end users, Lithofin has an extensive range of cleaning, protecting, maintenance, and professional problem-solving products. Together, these products form an effective three-step stone care system.

Cleaning, Sealing, and Maintaining is an essential process to help uphold the beauty of stone and tile surfaces. Lithofin’s premium cleaning, sealing and maintenance products are carefully crafted to the individual properties of ceramic and porcelain tiles, external pavers, natural stone, concrete, terrazzo, and engineered stone. Using Lithofin products with the correct application method for each surface type is vital to achieving the finest results.

Cleaning newly installed surfaces removes all kinds of grime and dirt including grout residues, builder’s dirt, and production dirt.

Cleaning returns the material to its desired finish in preparation for use or sealing.

Existing surfaces are also cleaned to remove accumulated care product residues, heavy dirt residues, grease and oil films, food matter and a variety of dirt found on internal and external surfaces. This process restores the material to its original finish or is done in preparation for re-sealing.

Sealing polished porcelain tiles, natural stone, concrete and terrazzo materials or external pavers with an impregnating sealer enhances the materials' properties, and prevents moisture penetration from water, oil, grease, and general dirt. It does not alter the slip resistance or appearance, it allows water permeability, and facilitates ongoing maintenance.

The sealing stage of the process includes all products that work to protect the surface including impregnating sealers and topical sealants. An impregnating sealer penetrates the materials surface developing a repellence to water and oil, it works by forming a reduction to capillary absorbency in the material. Colour enhancing impregnating sealers also develop a repellence to water and oil and improve the appearance of the surface by deepening the materials natural colour using solvent-based products that mimic the active ingredients in the materials natural structure. Topical sealants work by developing a surface layer closing the materials capillaries and eliminating the original water vapor permeability. Lithofin

impregnating sealers are available with a 20-Year Written Warranty when applied by a Certified Lithofin Applicator.

Regular maintenance is a cleaning process to remove general dust and dirt residues while conditioning the material. Lithofin’s maintenance products are designed to work for individual properties on a range of surfaces. Maintenance slightly improves the appearance of the material and prevents surface films while maintaining the benefit of the applied impregnating sealers with continued use.

Lithofin stone care system sets the standard in product quality, meeting the professionals' expectation of effectiveness as well as the end consumers’ need for ease of use. To see the full range of Stone and Tile Care Products visit - www.lithofin.com.au

Certified Lithofin Applicators are trained industry professionals providing optimum stone and tile care services. If you have comprehensive experience with stone and tile sealing and are interested in becoming a Lithofin Certified Applicator you can learn more here: https://www.cdkstone.com.au/cla web wwww.cdkstone.com.au/cla ❚

The latest care technology for sealing precious surfaces

To view the full Lithofin range visit: www.lithofin.com.au

When sintered stone first entered the market, architects, designers, and stonemasons excitedly rushed to explore its potential. At last, they had a material that was hard, heat-proof, stain and UV-resistant - and available in a wide range of colours. The only problem? Sintered stone is not easy to cut.

Saw blades, tools and techniques that worked so well on natural and engineered stone cause porcelain slabs, Dekton, and other ultra-compact surfaces to crack and break. As a result, many fabricators have banished it from their workshops, ridding themselves of a headache - and a potentially lucrative new market. Others, like European Ceramics, planted the seeds for a fruitful future; expecting greater growth in years to come.

“Porcelain slabs are growing in every market worldwide. Today, we see many companies bringing out their own range of porcelain slabs. When we first started with porcelain slabs, we only had one factory and supply chain, and it was certainly a bold move to invest in the industry,” says David Serra, second-generation Director of the Perthbased firm.

Everywhere you look, porcelain, Dekton and sintered stone is on the rise. Architects love it for its looks, versatility, and consistency; allowing them to create trendy kitchens and outdoor spaces. The only trouble is finding a fabricator who is willing to carry out their projects.

For many manufacturers, cutting sintered material causes such a headache that they will do everything they can to get out of it.

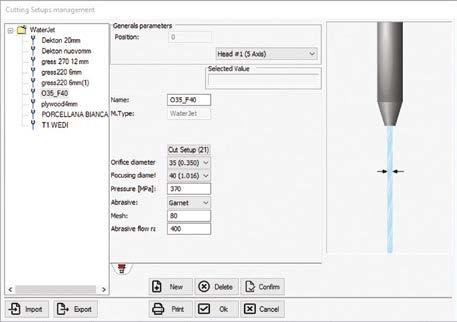

Above: CMS Smartline waterjet

One single crack and a whole slab could be ruined, costing the business dearly. That thought alone has fabricators nervous about taking on Dekton and porcelain jobs - especially if they don’t have the equipment or labour to ensure that quality products are consistently produced.

“Using traditional methods like a bridge saw even with a special blade requires an experienced and skilled sawyer. We find that many manufacturers either reject jobs because they can’t handle it, or price themselves out of it; pricing for four or five slabs, instead of two as they assume that

Above: CMS active main interface

breakages will happen - which is unheard of,” says Dominik Holfter, Stone and Glass sales rep at Innovync.

The answer lies in having the right technology on board. Depending on the kind of jobs coming through, specialised machining centres could be used - especially if straight lines are being cut. But there is a much safer, more versatile alternative that is perfectly suited to cutting brittle materials - and its value is becoming more and more apparent in the industry.

“Only recently did the Stone industry decide to pick up on water jets and incorporate them into the machinery toolkit. The way the waterjet cuts, it’s a gentler process on the stone, because the pressure is so concentrated on the cut - rather than having downwards and sideways pressure as from a bridge saw,” explains Dominik.

Models from world-renowned Italian brand CMS, which Innovync carries, are especially easy to work with. Equipped with a highly detailed materials database that allows for plug-and-play setup, plus fine-tuned controls, quality results consistently emerge.

“Once you program the job and tell the machine what to do, you can cut - there are no physical parameters required. It’s all on the machine, taking responsibility from the operator. You can probably cut faster on a bridge saw, and it’s a little cheaper to run it, but you need to have a skilled operator to run it. But, unless you have an operator that knows how to listen to a saw and knows when to speed it down or up, you will run into problems,” Dominik remarks.

With massive skilled labour shortages across the industry, it is becoming even more difficult to find an operator who can reliably run Dekton and other sintered stone through a bridge saw. David and his team are leaders in the space, and run workshops all over the world, teaching operators how to work with such materials using CNC machines. Despite decades of expertise, they too, know how difficult it is to find a suitable operator.

"Finding the right operator is very difficult as the new stonemason needs a high level of both physical and digital expertise. From our past experience, it could take several months or even years to fully train a person to work with porcelain slabs,” says the Director.

Above: Easyjet materials database

Those who dare to work with sintered stone tend to prefer the safety and security of waterjets - of which CMS has become leaders in. Coming out with their first Stone models in the 1980s, the equipment manufacturer has earned a reputation for reliability, efficiency, and quality. These traits don’t go unnoticed by innovators in the industry.

"We have used CMS machines from the beginning. Being of Italian origins, construction, design and manufacturing have always been my passion.

CMS – ‘Made in Italy’ is a no brainer and the fact that, in the 1980s, they were the first manufacturer of a Stone machining centre was a simple reason to invest and purchase CMS Stone machines. Today in our factory, we operate the CMS Idroline waterjet and Maxima CNC. Both machines serve us very well in the manufacturing of large porcelain slabs," says David.

The beauty of waterjet machines is that they are versatile. Whether or not you decide to cut porcelain on them or prefer to stick with natural and engineered stone, they won’t sit unused in your factory. Just imagine what that means for a rapidly changing market, where demand for new materials is rising. Dekton is only the beginning.

web wwww.innovync.com.au ❚

Above: Easyjet cutting setup

Stirling Group brings together three specialist brands: Stirling Global (Machinery), Accurate Australia and New Zealand (solid timber tooling and consumables), and Panel Tools (tooling for CNC machinery).

Since 2001, Stirling Group has grown to become an industry leader, dedicated to delivering high-quality, cost-effective solutions and service to growing companies in Australia and New Zealand.

Stirling Group was founded by Craig Honeyman, a qualified wood machinist with over thirty years of experience in the timber industry, including an extensive sales record over seventeen years with one of the most innovative European suppliers of high-output woodworking equipment. When it comes to solid timber, Craig has a depth of knowledge and a passion for the industry that is not easily matched. Focused on quality machinery and service, Craig recently said, “It’s either right or it’s not right.”

Stirling Group started as Accurate Timber Products in 2001 as a tooling supply and service company committed to building genuine partnerships with their customers.

In 2015 Stirling Machinery was established at the request of many of Craig’s tooling customers who knew they had to start moving into new products. They needed the right machinery to manufacture either complex components or to produce at competitive prices. Stirling’s range includes docking saws and multi-rips, wide belt sanders, moulding machines, tool grinders,

mechanical handling equipment and finger joint machines for the solid timber industry, just to name a few.

In 2018, the Panel Tools division was started to supply specialist CNC Machinery and tooling for 3- and 5-axis machines covering solid timber and flat panel industries. Craig says, “Our aim is to connect our customers with process solutions that will upgrade their operations, introduce new revenue stream possibilities and deliver a significant competitive edge while streamlining the connection between machinery, tooling and the finished product. We don’t see ourselves as a machinery and tooling supply company, we see ourselves as a process solutions company encompassing all areas of Tooling, Machinery, Servicing and Training.”

“Our handshake is our bond”

Stirling Group works in partnership with customers to create the perfect result between machinery, tooling and the finished product, providing the right solution for the right application. Their team has a high level of technical expertise and is equipped with hands-on operational skills.

They work with their partners to meet their business challenges and priorities, recommending the right machinery and tooling solutions for their specific and often demanding operations.

In everything they do, integrity is paramount. Craig says, “To look someone in the eye, to be able to deliver on your promise, to take responsibility, to be the best at what we do, not just in machine or tooling knowledge, but in how you treat others, that’s what is important to us at Stirling Group. Every day, we challenge ourselves to be better than we were yesterday, to bring our passion, skill and care to the industry’s front line, and find ways to deliver greater value to our partners.”

Over the years, the company has committed to delivering high-quality solutions. Stirling Group products are sourced from an array of world-class suppliers from all around the world, predominantly from Europe, but also the US and Taiwan. One example is the Bacci brand, an extremely progressive company supplying multi-axis CNC equipment for the most demanding solid timber manufacturing sector, including gun stocks and stair components. If you are looking for a solution for a new product, it is highly likely it has already been mastered by a European company. The technology is there and, thanks to Stirling, ready for you to implement.

Stirling Group products are not limited to machines and tools. Craig sees their service to the industry as a product that adds value to their customers’ manufacturing capabilities. “The sale of a machine is the easy part,” Craig says. Our customers already know what they want. What we at Stirling deliver are choices, alternatives that add to our customers’ bottom line. We provide solutions to manufacturing issues that develop our customers and improve their performance and profits.”.

“From next year, we will add our Stirling Training Academy to our list of services,: Craig says “We’re moving to bigger premises to provide this customer benefit and Kate Honeyman will be visiting the worldrenowned Rosenheim Wood University in Germany to make this happen.” Such is his

“What we at Stirling deliver are choices, alternatives that add to our customers’ bottom line. We provide solutions to manufacturing issues that develop our customers and improve their performance and profits.”

passion for the trade, Craig still believes a woodworker needs to feel the wood being machined, to appreciate the sound blunt cutters make and to appreciate the effects of vibration on the finished component. Of this exciting initiative, Kate said, “I’m looking forward to this next stage for Stirling Group. Getting to work on a project that is going to have such far reaching positive impacts for the industry is exciting, to say the least.”

Stirling Machinery offers a service agreement with their machinery. A qualified engineer completes the installation, commissioning and training on every installation and will go above and beyond to work with customers to tailor their plant and have it running at optimum performance. Stirling’s service team is ready and can be onsite within 24 hours around Australia should any major issue arise. For all other servicing, they can arrange site visits and maintenance to accommodate customers’ operational schedule. All Stirling equipment is compliant with CE standards and with AS/NZS3000 electrical standards. “We’ve put the four parts of the compass together; machines, tools, training and service,” says Craig.

Craig’s growing team include Operations Manager, Leon Botes, and Service Manager, Craig Halfpapp, who is one of the most experienced people in the industry. “We have an extremely experienced team and factories behind us to improve production efficiencies within the Australia and New Zealand timber industry,” Leon says. When it comes to installing and commissioning new equipment, Process Engineer Hayden Aymes will ensure everything works as promised. While some suppliers never want to make a competitor’s machine better by enhancing its performance with automation, Craig is

non-aligned to any brand; his company’s only focus is on the process for the customer and their satisfaction.

“We’re passionate about contributing to the evolution of manufacturing in the timber industry through technologies that are more efficient, reduce waste, and are data-driven,” Craig says. “Dad might have made furniture the same way as Granddad, but now, newer, more modern and higher-performing equipment gives the grandson greater options. Raw materials are also changing; the forest industry is no longer cutting the same sizes so laminated products are more the norm. Understanding the equipment, glue technology and tooling required to produce these new products is something we understand, something we can pass on to our customers.”

Stirling Group work closely with their international suppliers to bring new processes and products to the Australian and New Zealand markets, always looking for new ways to bring value to their customers, working closely with them to provide tailored solutions to maximise the potential of their operation. “Our team has a high level of technical expertise,” Craig says, “and they all happily share their knowledge to support customers in developing their

people and growing their business. Our goal is to find ways to deliver greater value to our customers.”

Craig adds, “Something we take great pride in is our ability to truly understand the process of machining. We work closely with our manufacturers and customers to understand the uniqueness of these processes, including CNC machining, moulding, docking, shaping, finger jointing, sanding, polishing, and so much more. This understanding means we can provide accurate solutions and the best service.”

Craig acknowledges the solid timber sector has fewer players, and that resources are an issue, but he also believes the players in this market are stronger, more focused on manufacturing for expanding markets, and that timber is still a fashion item, sought after by top restaurants, hotels and the corporate sector. Volumes may be smaller, but the profits are much higher. Stirling Machinery is performing strongly and making a positive impact on the timber processing industry. “We don’t just sell machines. We offer a comprehensive and tailored consultancy service that works with you to identify your business’s needs and find the best possible machinery solution. We are in your corner,” Craig promises. ❚

Training.com.au website states, “TAFE is one of the best training options you can make. You can get qualified in no time and enter the job market with skills and confidence. Ninety percent of the highest growing jobs in the next five years only require a VET qualification.”

Sounds fantastic doesn’t it? Do a little bit of training, get the skills you need, and you are set for 90% of the growing job market. But is it that simple and is that good for the industry? What happened to 5-year apprenticeships, then 3-year apprenticeships, and now you can get the skills you need ‘In no time.’ In the 1980’s, before CNC manufacturing became a big thing in Australia, apprentices underwent a comprehensive skills program that enabled them to find a job in any company. But after 40-years the trades have been watered down so much, when you put an ad in the paper for a ‘tradesperson’ you have no idea what you’re getting.

Sure, who needs a tradesperson who can make a cane rocking chair or a fine dining table? Maybe you just need someone to put sheets onto a CNC machine and press the go-button. The reality is, if you think your cabinetmaking tradesperson, fresh out of trade school can give you the skills you need for CNC manufacturing above loading and unloading the machine, think again. They’re not likely to have much CNC or CAD experience at all and might be simply good enough to spend their time screwing cabinet carcases together. This isn’t a trade, it’s a job.

A trade certificate is a form of documentation issued by a government or industry regulatory board or entity that demonstrates the owner’s knowledge, expertise, and compliance with the training standards of that industry. Most certificates require the holder to pass an exam, take a course or complete other activities to obtain the document. The certificate tells the employer that the holder of the document has passed all of the tests and meets the requirements of that particular trade. It could be cabinet making, wood machining, furniture polishing or upholstery, glass and glazing, stonemasonry, or any of the hundreds of trade courses available.

It's what is in the document that matters to an employer. Given the document was generated with industry input, it seems logical to suggest that the training delivered is what the industry needs and wants.

However, most industry training boards are filled with employers who have a vested interest in what’s in the training, meaning their version of what a tradesperson is will be what their specific manufacturing needs are. If the industry training board is filled with kitchen manufacturers, the course will likely be most suited for someone making kitchens. As over 90% of cabinetmaking businesses in Australia make kitchens or bathroom, this is naturally what the trade has become.

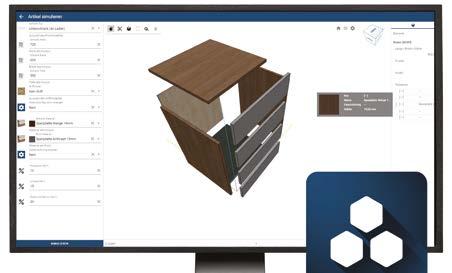

CABINET VISION 2022 is poised to accelerate feature and functionality development to deliver next generation capabilities. CV 2022 has been boosted to 64bit, delivering a larger memory footprint.

Following this train of thought, what a kitchen manufacturer needs in a worker is someone who can run a CNC machine, assemble cabinets, instal hardware and fit cabinets onsite. What they don’t need is someone who can join solid timber or use a planer or spindle moulder. Those skills come in electives that the kitchen manufacturer will not select in the training plan. Fair enough, they are getting what they need, but again, is this good for the industry as a whole? With so many electives and so few core units of study, an employer looking to hire a ‘skilled’ tradesperson can only be assured his potential employee can read a plan, measure the material, use hand and power tools, communicate, and exercise environmentally sustainable work practices.

All the rest of the training comes in either a furniture or kitchen and bathroom pathway where 16 units must be selected. Obviously, these units will be selected by the student in consultation with the employer. You can

see that the employer making kitchens will choose the kitchen pathway, and 16 units that are most closely aligned to his/ her business. What this means is that the traditional notion of what a cabinet maker is has changed. On one hand, it could be a person making particleboard boxes for mass kitchen manufacture; or it could mean a person making fine cabinets from a mixture of materials, using more traditional joinery methods. It is unlikely that the same person could do both jobs effectively, and it’s even less likely that the kitchen person could produce an acceptable job in solid timber.

Cabinet Makers are currently on the Medium and Long-Term Strategic Skills List, and is a course available for international students. First, let us remind ourselves that an Australian citizen doing this course will need to be indentured for four years. At 38 hours a week by 48 weeks a year by four years equals

7,296 hours of work the employer will get over the training period. Even taking away the one-day a week the trainee spends at college for 3 years, this still comes out at 6,976 hours. During the first three years the apprentice will study between 800 and 960 hours, depending on the course.

Compare that to an international student who, according to the ‘Pathway to Aus’ website, is required to complete between 12 and 24 months of training at 20 hours a week, equalling 800 hours. The difference comes with the on-site work experience (vocational placement) which for an international student will be only 360 hours! That’s a huge difference of 6,616 hours for the potential employer to consider. Sure, the international student has to cough up $30,000 compared to $2,000 for a local student, but we’re looking at the value to the employer here; the cost for an international student includes the chance to live and work in Australia.

Many years ago, you used to know exactly what a tradesperson’s skills were, but not anymore. Apart from the basic units (the core) your new employee could have a range of skills defined by the company that indentured him/her. This is designed to offer the employer flexibility to get his apprentice trained in exactly the skills needed for that job. The apprentice moving to another employer was expected to pick up other units to suit the new employer, but that almost never happens in real life. In over 30 years of training, I only ever heard of a handful of people going back to school to pick up a new unit of study.