DESIGN + MATERIALS + TECHNOLOGY

FEB/MAR 2023

30

Editor’s Note

Welcome to the February / March 2023 issue of Supplier Magazine. As we kick off the year with our annual CNC Machinery Feature it is hard to imagine a manufacturing situation where technology, both in machinery and tooling, and now software; does not play a major part. In this issue Biesse, CDK Stone, Stirling Machinery and Yeti Tool showcase their CNC machines as well as explain why there are few companies that will not benefit from the inclusion of some CNC equipment or automated processes into their manufacturing system.

Also in this issue you will find our Q & A with long time collaborators, 3d Kitchen. Now in their 30th year in business the 3d Kitchen software brand is going strong and still supporting cabinetmakers with solid solutions to complement their businesses. Chris Adams, the mastermind behind 3d Kitchen and creator of 3d Kitchen software sat down with Supplier Magazine to discuss all things business.

Take a look at our new website and don’t forget to join our growing online community by visiting us on Instagram and Facebook.

Please feel free to contact me directly regarding any industry news, company events, training and or product information you would like us to publish at – michelle@elitepublishing.com.au

Until next time, enjoy your read.

Michelle Cammiade Editor

3 Supplier February/March 2023 www.suppliermagazine.com.au Contents

Front Cover Multicam www.multicam.com.au Find Supplier Magazine on: @suppliermagazine @suppliermagazine News 4 Trade shows, the interruption is over Feature 16 CNC Machinery Talking Business 27 Planit Australia tailoring unique solutions for their customers Software 32 3d Kitchen Software celebrating 30 years Discovering Stone 40 Slab falls take lives Fitouts and Trends 42 Tiny houses Overseas News 48 Wood Taiwan 2023 highlights sustainability Issue #217 Volume 39 No 1

Trade Shows, the interruption is over

During the recent pandemic all of the World’s industry trade shows were suspended as any form of travel ground to a halt. In their place, suppliers turned to ‘virtual’ shows and networked events that arguably, few buyers took advantage of. International shows generally missed one event but in Australia, our own AWISA show missed 2020 and 2022, due to the timing of the pandemic.

For the furniture and allied industries trade show junkie there is a lot to choose from with dozens of shows, mostly across Asia, Europe and North America. This year, all being well, expect to see trade shows in Cologne (Interzum 9th to 12th May); Hannover (Ligna 15th to 19th May)

and Toronto, Canada (WMS 2nd to 4th November). Next year we look forward to our own AWISA show in Sydney (3rd to 6th July), Milan (Xylexpo, date to be announced but likely to be late in the year), and Atlanta, USA (20th to 23rd August).

Looking forward to the big Interzum and Ligna shows this year, both show organisers are (of course) reporting high exhibitor bookings following on from the 2019 event where exhibitor records were broken. However, Supplier magazine is aware some of the major players have booked only 75% of the floor space they occupied last show. This is to be expected as many show goers are likely to be hesitant getting on an aircraft, what with the changed travel

conditions and still, to some, a small risk of infection. If you can visit though, it is realistic to expect a firework of innovations.

Dr. Bernhard Dirr, Managing Director of the VDMA Woodworking Machinery Association, referring to the high level of Ligna registrations said, “After four years, the industry needs this opportunity for face-to-face contact in Hannover. It is all the more gratifying that all market leaders have already made their decision to exhibit at LIGNA 2023 and will be unveiling innovations at the event. This and next year, LIGNA’s appeal will be enhanced by digital elements designed to increase the event’s reach before, during and after the show. ❚

4 Supplier February/March 2023 www.suppliermagazine.com.au News

Base Mount Slides

GO THE EXTRA DISTANCE

OFFERING UP TO 33% FRONT OVERLAY

BASE MOUNT SLIDES MAKE EVERYTHING ACHIEVABLE

Nova Pro Drawer System grass.eu NP

more WOW.

novapro

Feel

GRASS Australia / New Zealand to book an onsite product presentation Info-australia@grass.eu 03 9421 3048

Nova Pro Base Mount slides can be used in combination with standard side mounted slides, are push to open compatible and are rated to a weight capacity of 70kg

Contact

In house industry expo a huge success

Multicam Systems, suppliers of the fully Australian made range of Multicam CNC Routing machines, recently held a series of in-house trade expos. The events were held at their offices in Brisbane, Melbourne, and Newcastle in March.

The expos attracted visitors and companies from a wide range of industries, including kitchen manufacturers, cabinetmakers, shopfitters, point-of-sale display companies, engineering and fabrication companies, sign and display companies and composite cladding companies.

The purpose of the expos was to present to the visitors the wide range of CNC routing machines and accessories available from Multicam Systems. New and existing owners of Multicam CNC machinery were shown the latest products and developments in CNC machinery and productivity attachments. These included special automated clamping systems, CNC rotary axis attachments, automated location and positioning systems, vacuum pods and cutter cooling and lubrication systems.

Multicam invited other great Australian companies, StripLox, CarbiTool, Sutton Tools and NC Tools (suppliers of SolidWorks CAM and CAMWorks) to be part of the events and show how their products can enable CNC

machine owners to get the best from their machines. Multicam also demonstrated their unique KitchenCAD Pro, Door Manufacturer, Ezi-Panel Pro and Ezi-Duct Pro software products, which are designed to offer cost effective and versatile software solutions for various industries.

of manufacturing industries. Many visitors were pleased to learn that these accessories and attachments can be retro fitted to existing machines, allowing owners to expand their capabilities with minimal outlay.

Being an Australian supplier and manufacturer allows Multicam to develop and provide solutions specific to Australian conditions and needs. Their ability to design, manufacture and implement bespoke solutions based on an individual company’s needs, is just one of the benefits of buying from, and supporting Australian manufacturers.

There were a variety of machines on display and in action, including a complete nesting cell with a 3600mmx1800mm nesting machine, automatic material loading and unloading for cabinetmakers and kitchen manufacturers. A 2400x1200 CNC machine demonstrated cutting of ACM and other products, while a high-speed triple head cutting machine showed how CNC machinery can be utilised in the sign and display industries. Each of the machines had various accessories fitted, such as air assisted constant depth attachments, camera recognition systems, mist cutting systems and loading and positioning systems. This highlighted the flexibility of Multicam CNC routing machines and their appeal to a diverse range

Stephen Heusz, organiser of the events said that Multicam were very excited by the response and attendances that they had at the expos.

“Visitors were eager and willing to attend and interact with us at these expos. The lack of trade shows in the past may have had something to do with this, however we also feel that many companies are looking to build on their capabilities and enhance their appeal and the services that they can offer.” said Stephen. “Being able to see a variety of machines in action, and talk with our representatives and technicians, also presented a unique opportunity.” he added.

Stephen said that “The support we received from StripLox, who made generous contributions of their patented jointing system, Carbi-Tool and Sutton Tools, who offered very generous discounts and incentives on their range of tooling, and NC Tools, aided in making the events extremely successful. We also provided incentives on our range of machinery and then sweetened the deal by presenting visiting companies with a carton of their favourite beer.” ❚

6 Supplier February/March 2023 www.suppliermagazine.com.au News

ALTO SLIM DRAWER SYSTEM BY HÄFELE

The Häfele Alto Slim drawer system increases the functional use of cabinets with perfectly straight and thin 13mm drawer sides.

• 35kg load capacity.

• 3 side heights allow for flexible and versatile use.

• Black and white options.

• Comfortable height and lateral front panel adjustment from inside the drawer.

• Independently tested to 60,000 opening & closing cycles.

• Supported by Häfele’s lifetime warranty.

info@hafele.com.au 1300 659 728 www.hafele.com.au

National Building and Construction award winners

Tools were down to celebrate the building and construction industry’s best and brightest at the recent National Excellence in Building and Construction Awards.

Master Builders Australia CEO Denita Wawn congratulated the winners of the 51 award categories and finalists for reaching this highly competitive stage.

“The pre-eminent national awards for the industry was the first time it returned to its normal face-to-face format following disruptions from the pandemic.

“The annual three-day event culminates in the announcement of the country’s best builders in residential, commercial and civil construction and recognises the projects that have won them acclaim.

“To be in the running for a National Excellence Award, entrants must have progressed from winning awards in their State or Territory and must be nominated by their local Master Builders Association to being judged for a national award.

Multiplex Constructions took out the top spot winning the National Construction Master Builder of the Year Award for their work on the world’s first upcycled skyscraper.

“The 50-storey Quay Quarter Tower is the catalyst for the transformation of Sydney's iconic Circular Quay, supporting Sydney's future as green, global and connected city. Multiplex was required to overcome key construction challenges of building movement, complex demolition and strengthening works, large cantilevered elements, and concurrent construction across multiple fronts,” said Ms Wawn.

National Residential Master Builder of the Year Spadaccini Homes won the accolade for their Hirniak residence project in Western Australia.

“This resort-style home makes the most of its surroundings to take the ocean vista, with every aspect of the build reflecting the highest quality workmanship.

“The judges were impressed with the exemplary finishes and the attention to detail by the builder and all trades,” said Ms Wawn.

Vos Construction & Joinery took out the 2022 National President’s Award for their work on the My State Bank Arena in Tasmania.

“The My State Bank Arena project encompassing civil, renovation, newbuild and fit out, was a complex project delivered in a very short time frame.

“Vos Construction & Joinery employed a unique management structure and provided a masterclass of technical skill to overcome construction obstacles,” said Ms Wawn.

In addition to celebrating successful businesses, the awards recognises the hard work of up and comers in the industry. Tassie local Zac Smith was award National

Apprentice of the Year for his high degree of intelligence, a positive attitude and outlook, and a keen passion for work.

“Zac’s outstanding efforts on site were also reflected by his TAFE results. His understanding of the importance of WHS and respecting others on a work site saw him become a sought-after team member and offered additional project responsibilities,” said Ms Wawn.

Andrew Kerr from the Northern Territory won Toyota National Young Builder of the Year for his managerial skills in delivering quality projects on time and within budget.

“Andrew is the founder of AusCon NT, a commercial and residential building company and has over 14 years of experience within the industry.

“Born and raised in Alice Springs, Andrew is passionate about the local community of Alice Springs and aims to build a lasting reputation through supporting local businesses and working on construction projects for the betterment of the local community and its people.

The building and construction industry has demonstrated that in the face of adversity, it continues to provide the highest quality outcomes for clients around the country. ❚

8 Supplier February/March 2023 www.suppliermagazine.com.au News

forget this:

enjoy this:

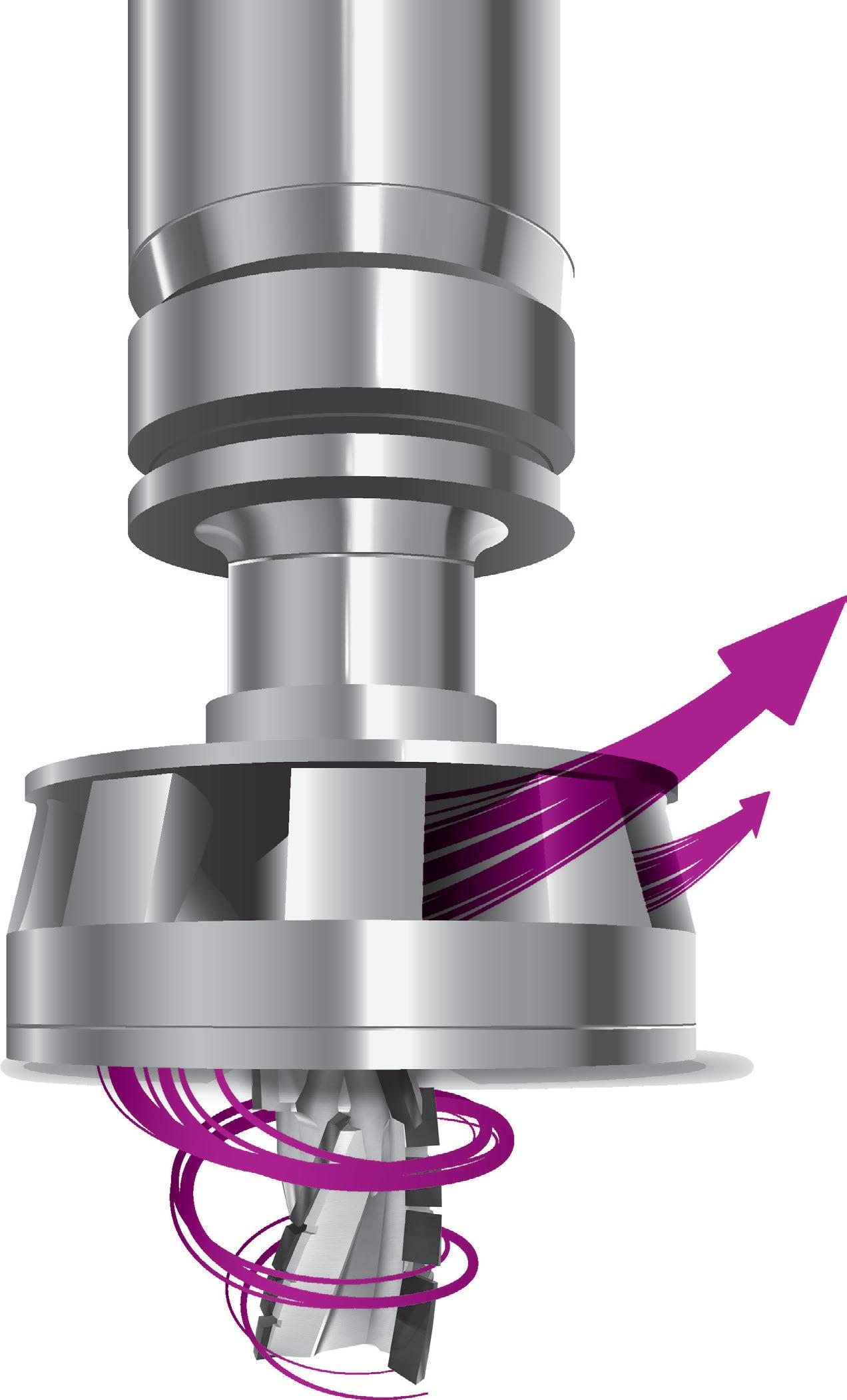

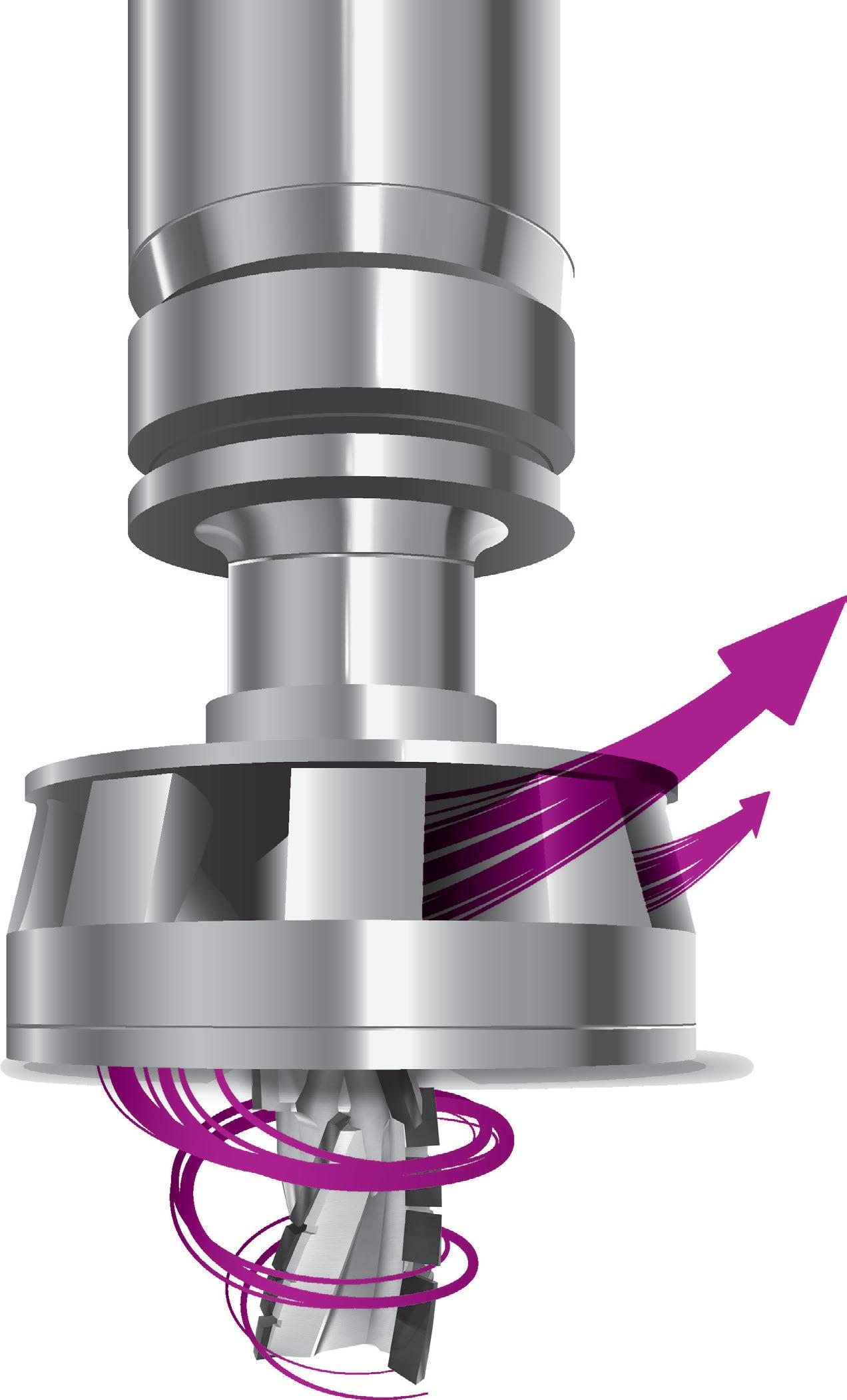

DUST-FREE WORK ON THE CNC WITH LEUCO

LEUCO „AEROTECH System“

1 SYSTEM – 2 FUNCTIONS: Clamping device and extraction turbine at the same time

Dust-free nesting and routing with all the benefits for

Tool

Production

Energy efficiency

Health!

| different designs depending on your application and material (MDF, Fibre )

| machine manufacturer approved versions available

CONTACT US

DIRECTLY

Your LEUCO technical advisers

T (61)-02-8708-4900

ONLINE PRODUCTS

LEUCO tools online catalog www.leuco.com/products

ONLINE NEWS www.leuco.com

Scan and watch the video on YouTube!

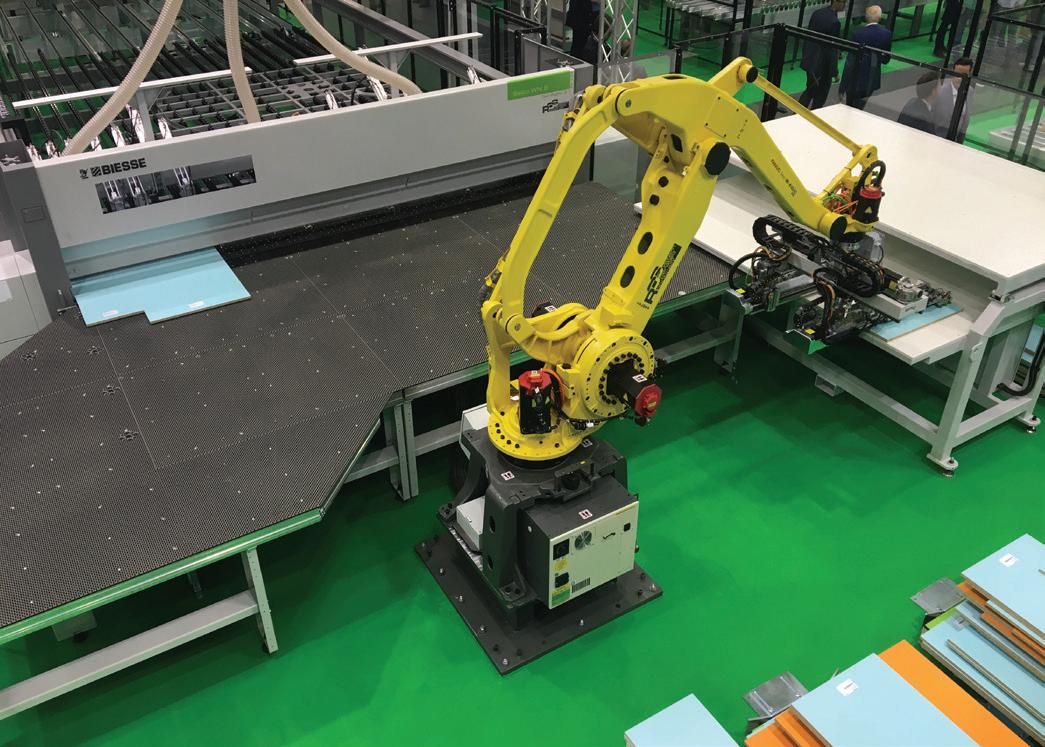

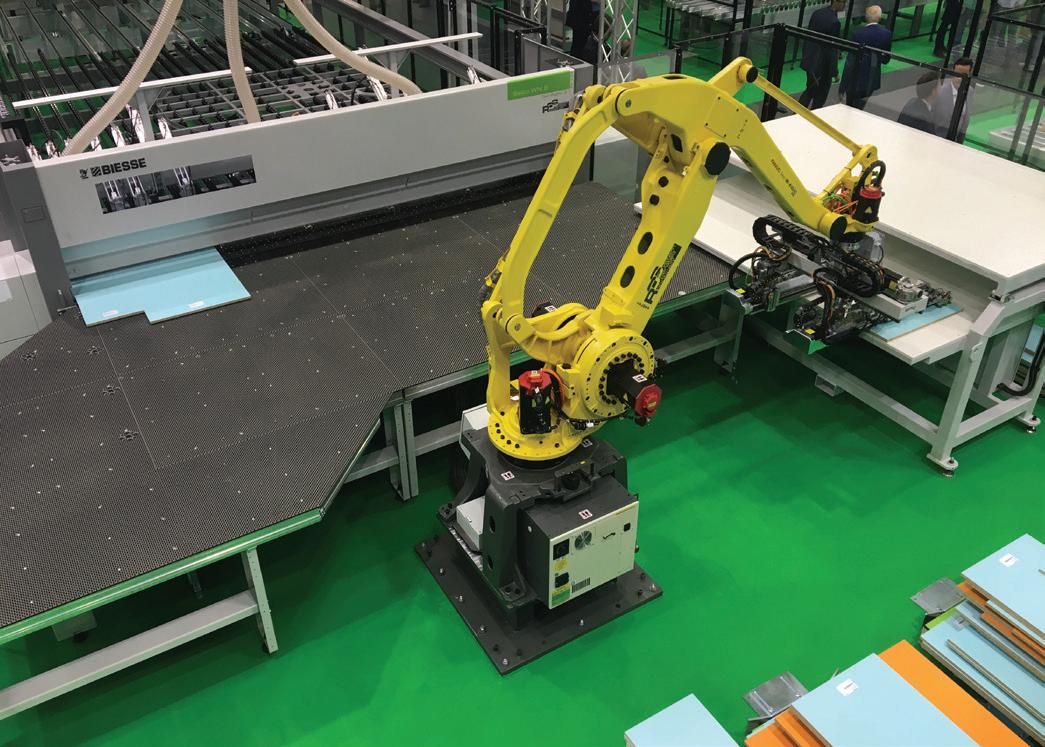

LIGNA 2023: the perfect stage for Biesse

Biesse returns to LIGNA, the world event for woodworking technology, scheduled from the 15th to the 19th of May 2023.

At LIGNA, Biesse will showcase a new visual identity that represents the corporate renewal process and actively expresses the group’s values and identity – centred on multi-materiality and being inherently international – while preserving the features that distinguish the various sectors in which it operates. It’s an evolution that will enable the company to compete in ever-changing international markets and bring tangible benefits to customers.

Hall 11 - Technology in action

“We look forward to meeting all who visit Hall 11 to discover the group's evolutionary journey and its emphasis on multi-materiality, which distinguishes Biesse from its competitors,” says Ettore Vichi, Chief Regional Officer EMEA and APAC.“High-tech solutions, integrated systems and lines designed to accommodate the needs of manufacturing companies wishing to strengthen and increase production performance will be in action,” Vichi concludes.

A great emphasis will be placed on automated solutions, which ensure a decisive

increase in production and the complete reliability of both the production process and the loading and unloading operations. Visitors will get a first-hand look at an integrated plant consisting of panel sizing and nesting solutions, with automatic loading and unloading linked together thanks to SmartConnection, a software program for in-house order management.

of the new product marks the beginning of a path towards sustainability which, thanks to the skills and assets available, will enable the group to recognise and assess its environmental and social impact and integrate innovation into product development processes. It is in this context that Biesse presents its new product, introducing technological innovation while also improving environmental performance.

The focus will be on the new batch one edge banding line with robotic loading and unloading. The dual characterisation

Hall 12 – LIGNA stage

In Hall 12, trade fair visitors will be able to participate in a rich program of panel discussions (streamed to the LIGNA website with simultaneous translation into English) covering the most relevant, trending topics in the woodworking industry. Biesse will contribute to the program with three panel discussions on the following topics:

• Smartconnection - Production planning and control software for factory/ production management

• Woodworking made Izy – A common language connecting machines

• Technologies and Sustainability

Hall 11 - Biesse stand tours

Biesse invites visitors to take part in the Guided Tours organised by the trade fair, during which innovative products and optimal solutions for every process will be demonstrated alongside top product specialists. ❚

10 Supplier February/March 2023 www.suppliermagazine.com.au News

Product Update

Introducing the Alto Slim drawer system by Häfele

The Häfele Alto drawer system increases the functional use of cabinetry with perfectly straight thin 13mm drawer sides. Making the drawer capacity larger, while maintaining the stability and quality with a load capacity of 35kg.

Three side heights, 84mm, 135mm and 199mm allow for flexible and versatile use from the kitchen to the wardrobe and bathroom areas.

The option of white and black colours in matt finishes allows Häfele Alto Slim to meet everyday design requirements and complement the continuing trend of darker decorative colours.

Häfele Alto Slim has been tested and passed European DIN EN 15338 level 3 standards. This was achieved with a full 35kg weight capacity with over 60,000 opening cycles.

Comfortable height and lateral front panel adjustment from inside the drawer allows easy adjustment when installed in corners or against walls.

The App-Plus Package by Homag

Lightning-fast service, transparent machine status updates and a complete tool overview are always at hand on your tablet, smartphone or PC with the new App-Plus package, free of charge with every new HOMAG machine.

With the Homag App-Plus Package, you can test the full version of various HOMAG apps free of charge throughout the warranty period of your new HOMAG machine. This means that nothing stands in the way of your entry into the digital world of woodworking. Enjoy the advantages contained in these HOMAG apps without obligation.

As part of the App-Plus Package, you will receive five selected apps for each new machine: ServiceBoard, MachineBoard,

serviceAssist and twinio are completely free of charge for you until the end of the machine's warranty. In addition, MMR Mobile, the smartphone app for easy analysis of your machinery, is always free of charge.

The team at Homag will also take over the full activation of your user account with tapio. This includes registering, connecting your machines and setting up the apps. Tapio is Homag‘s partner for secure access to their apps and other apps in the tapio store. Tapio takes care of user administration and ensures certified, secure data exchange. If you like, they will prepare everything for your account, then all you have to do is activate it. You will receive the necessary activation link from the Homag team when the new machine is delivered.

Complementing the range of Alto Slim drawers is a range of Häfele drawer inserts, Classico 500, Classico – multi utensil tray and Basic Cutlery Tray.

Alto Slim comes with Häfele’s renowned lifetime warranty and will last you for the life of your kitchen.

For more information scan the QR code or call your nearest, Häfele sales office or Account manager for a personal demonstration.

www.hafele.com.au

Why do they do this? Homag want to make it as easy as possible for you to try out the digital assistants. Get started with the App Plus pack from HOMAG today. ❚

11 Supplier February/March 2023 www.suppliermagazine.com.au

❚

Product Update

New Nova Pro base mount runners

For some time now, a key consideration for interior designers has been efficient use of space. In particular, there is one space in the residential construction that is underutilised: the cabinet under the sink. Trends in Europe are shifting towards drawers being used in this space; unlike the hinged doors we still typically use in Australia today.

It has also become very common to include other systems within this space; pull-out bins and under-counter appliances such as water filtration systems or in sink food waste disposers. When you include one of these elements and consider the traditional plumbing approach – one is left with a cabinet space that is significantly underutilised.

Thinking towards commercial fit out spaces, the challenge faced could originate from the

need to have a computer server beneath a serving counter, or varied storage spaces.

Traditionally, these applications have been limited to hinged doors. This has all changed with the launch of the new Nova Pro base mount runners.

Base mount runners offer the designer considerable flexibility. Once the requirement for side mounting runners is removed, the possibilities become endless. This means that we can easily design the utilisation of the space depending on the item that is included in the design requirement.

Your Nova Pro Scala drawer can be installed anywhere within the cabinet space, and the drawer front overlay is processed relative to this position. A total overlay of one-third cabinet width is possible. Typically, 300mm is required for many of the under-counter

appliances, which means we can have a 900mm wide cabinet and utilise 600mm for drawer space.

Combining this with high drawer fronts and elegant internal drawers leads to beautiful design aesthetics and highly functional spaces. When using base mount runners in combination with a Nova Pro Scala H186 or H250 drawer side, it is possible to use drawer fronts up to 780mm in height.

Base mount runners retain the market leading pull out force of 20N, which is the market leading standard for all Nova Pro runners. As such, Nova Pro Base Mount runners can be specified for projects that are focussing on Assisted Living.

You can also use the existing Nova Pro pushto-open mechanisms for handless drawer fronts. ❚

12 Supplier February/March 2023 www.suppliermagazine.com.au

Product Update

Avoid rust issues with Concelo

Kitchen bins are one of the most used appliances in the kitchen, and subject to a lot of dirt and moisture over their lifetime. A dirty bin can soon go from being a minor annoyance to a real issue if it is left unresolved. Dirt traps, typically between the door front and the bin, can hold moisture and this can cause the metal structure of the bin to rust. This is a common complaint from homeowners, with rust sometimes appearing within just a few years of installation. This often leads to service calls and warranty claims.

That is why Concelo waste bins are fundamentally different to almost all other bins on the market and have been specifically designed to minimise the risk of rust and

corrosion. Firstly, key components of Concelo waste bins are constructed using materials that simply will not rust. The Clip’n’Clean trays that support the buckets are made from Polypropylene, a durable plastic that will not rust. The trays are then supported by drawer sides made from powder coated aluminium extrusions which, again, will not rust.

The second strategy to prevent rust is minimising dirt traps that can hold moisture. The removeable Clip’n’clean trays make it quick and easy to remove dirt and grime, especially between the door front and the bin. The door bracket mechanisms on Concelo are protected by plastic covers to reduce dirt and moisture reaching key components.

MAXIMISE DURABILITY, MINIMISE RUST.

Concelo and its unique Clip’n’Clean system are made from durable materials that simply do not rust, including polypropylene plastic and powder coated aluminium. The ease in which the Clip’n’Clean trays can be removed and cleaned eliminates dirt traps that can lead to rust. Concelo’s award winning design makes it the obvious choice for anyone wanting a bin that stands the test of time.

Cleaning with warm soapy water is all that is required to keep Concelo in showroom condition. Removing dirt, grease and grime from the Clip’n’Clean trays and other components is especially easy as the polypropylene they are made of does not allow substances to adhere to their surfaces.

Hideaway Bins are 100% designed and made in New Zealand and have been engineered to endure. Concelo bins will stand the test of time, and that is why they are confidently backed up by a 10-year warranty for the homeowner.

To learn more, visit hideawaybins.com.au or contact one of Hideaway’s distribution partners – Hafele, Nover or Galvin Hardware. ❚

hideawaybins.com.au/concelo Available

13

CLIP ‘N’ CLEAN SYSTEM

UNIQUE

now from Nover, Häfele and Galvin Hardware.

Product Update

New interactive showroom by Hettich

Hettich has unveiled its all-new showroom in the heart of South Melbourne – a harmonious mix of world-class brands coming together in a space that brings Hettich products to life.

Designed by Zephyr + Stone, and located at 220 Coventry Street, South Melbourne, the new space showcases the latest innovations from Hettich, for architects, designers, industry professionals, residential home buyers and renovators. Each display demonstrates a curated collection of Hettich’s finest Germanmanufactured cabinetry hardware fittings.

As you move through the showroom, you are immersed in the world of Hettich, from the kitchen to the bathroom, wardrobe, laundry and office. These spaces are blended together to visually represent the role that quality fittings can play in a working home-like environment.

“Melbourne is renowned for its thriving architecture and design community and Hettich was inspired to create an inviting showroom experience that would meet the needs of our customers and provide the ultimate platform to showcase what is possible with our products,” says Martin Gane, Managing Director of Hettich

Australia. "The new location makes it easier for industry and design professionals to access quality cabinetry hardware solutions for their next residential or commercial project."

The showroom creates a sense of interaction with customers, so they can understand the physicality of Hettich products and experience their movement firsthand. Upon opening the WingLine L bi-folding doors, for example, which emulate the ideal kitchen cabinet, you’ll find AvanTech YOU internal drawers, illuminated by LED lighting and complemented by glass inlays that showcase kitchenware beautifully. The WingLine L’s massive doors are supported by Hettich’s

award-winning Sensys hinge, which offer a silent soft-closing system and are resistant to temperature changes, making them reliable in a range of applications.

Elsewhere, the Cadro frame system seamlessly integrates with SlideLine M sliding doors to create a functional wall cabinet best suited for home offices or kitchens.

To bring the showroom to life, Hettich has proudly partnered with a collection of leading brands – Zephyr + Stone, Forest One, Cosentino, ADP Australia, Fisher & Paykel, Wattyl and Yale Home. It helps tell a story of how the Hettich range fits perfectly into kitchens, bathrooms, laundries and home offices for consumers.

The showroom is open by appointment, Monday to Friday between 8.30am and 4pm. ❚

14 Supplier February/March 2023 www.suppliermagazine.com.au

Product Update

Series Six Washplanes by Corian

Corian are pleased to be extending their washplane range with the new six series washplanes. Pre-designed in two and three person options, these new sleek lineal Corian washplanes have been designed with compatibility and convenience in mind. They can be used with a multitude of tapware.

Corian washplanes for public bathrooms are popular for good reason. By including Corian in your design, not only are you selecting a product that is fit for purpose, but you are also providing your client with an investment for the long run. Corian is backed by a 10 year installed warranty, is hard wearing and low maintenance. Corian can also be designed in such a way that it will fit within any budget and will look good for many years to come.

Why Corian for Public Bathrooms?

Hygienic and easy to clean

Corian is non-porous which means no bacteria, mould, germs or viruses can harbour in the material. Stains are never permanent with Corian. Being a non-porous material, it is easily cleaned with soapy water and a damp cloth. For a more vigorous clean, a mild abrasive cleanser such as Gumption and a soft cloth or blue scotchbrite pad can be used.

Repairable and renewable

Should accidental damage occur to a Corian surface, all but the most severe damage can be repaired on site. Corian can also be renewed at any time, bringing the surface back to its original finish.

Adaptable to any design

Corian can be cut, joined and thermoformed in to most any shape or design. The only limit is your imagination.

Wide range of colour options to suit your scheme

Boasting a colour palette of over 80 finishes, you are sure to find a colour to suit your design scheme.

Zero Silica

Corian is made from a unique blend of natural minerals and acrylic binder. This formulation contains zero silica and as such provides no risk of silica exposure when working at the fabrication level or during installation on building sites. ❚

15 Supplier February/March 2023 www.suppliermagazine.com.au

To Need a Machine

Article by Philip Ashley

Article by Philip Ashley

Feature

Henry Ford once said, “To need a machine and not buy it, one will ultimately discover, that you have paid for the machine and don’t own it.” We should take note of Ford because in 19 years almost seventeen million Model T Fords were built, half the world’s automobile production.

In the wood or stone trades, machinery is vital, especially in a mass production environment. Some highly skilled woodworkers may be able to command huge sums for bespoke work, let us say for Parliament House or some 5-star hotels, but for most, competition means lowering costs with the use of technology that like in the days of Henry Ford, led to his company offering double the wages of his competitors and Ford himself amassing what today would be a 200 billion dollar fortune. Ford had his issues and in later life made a few mistakes, but his manufacturing prowess arguably changed the lives of everyone.

16 Supplier February/March 2023 www.suppliermagazine.com.au

Above: Henry Ford

Above: (From Top) Robotic handling; Automated production; Advanced tooling.

The astonishing manufacture rate of Model T’s was made possible by the most advanced production technology conceived at the time. Ford and his engineers put into place a system that by 1914 was able to deliver parts, subassemblies, and assemblies with precise timing to a constantly moving main assembly line, where a complete chassis was finished every 93 minutes compared to the 728 minutes formerly needed. The subdivision of labour and coordination of a large amount of operations produced huge gains in productivity. Integral to this was Ford’s use of technology that greatly increased the rate at which quality parts could be produced on a repetitive basis.

The Case for Technology

A static woodworking or stone machine still relies on a human to operate it, and

in today’s climate of skills shortages, their output in terms of volume and quality depends mostly on the operator. On the other hand, CNC machines will perform repetitive operations all day long with the same guaranteed quality standard. There are situations where a CNC machine can operate unattended throughout the night, in the dark with not a single person looking after it, except maybe the security guard and his dog. Cutting tool wear is measured and tools changed when required. A robot feeds the machine and stacks the finished parts and if you think this is only possible with panel materials, consider that a children’s furniture manufacturer in Switzerland achieved this twenty years ago. And if something goes wrong the machine stops and the manager gets a text message.

Here in Australia our isolation has allowed us to maintain our small industries until now. While our larger manufacturing industries such as automotive are going offshore, the furniture, and particularly the cabinet making industry that includes stone bench tops, is surviving with the only competition coming from fellow Australian companies. Overall the balance of trade between Australia and our biggest trading partner China doesn’t look too bad with China exporting $7.36B and importing $11.1B from Australia in December 2022.

However, around 60% of our exports come from the mining industry and that figure is falling. Furniture imports from China amount to $157 million and almost no measurable amount of furniture leaves Australia for China.

17 Supplier February/March 2023 www.suppliermagazine.com.au Feature

Above: Phil Ashley discusses CNC machining at Biesse in Germany

There is no doubt that the competition for furniture and cabinet sales will come from within Australia from domestic competitors, and this is where your technology could play a pivotal role in establishing your position within the industry. If you are able to produce a quality product with minimal human input; with flexible delivery and desirable product options such as customer focused design and colour for a competitive price, you will win more sales than you lose. CNC machines, robotics and modern materials handling equipment

can achieve these outcomes and there is an increasing number of Australian companies that are fast approaching the automation of European cabinet making companies, maybe not on sheer scale but certainly on technological innovation.

A Sound Investment

Like the automotive industry, the more advanced players will usually survive at the expense of those that, like in the days of Henry Ford, took eight times as long to produce a similar product. There are

few companies that will not benefit from the infusion of some CNC equipment or automated processes into their manufacturing system. It will take some effort, investment and maybe some sleepless nights but is worth the initial pain. Your preferred supplier is ready and able to assist you in getting the right equipment for your specific manufacturing requirements, and providing the backup support, parts and training you need to make it all work.

The CNC machine was invented in 1952 to support the aircraft industries, especially those producing military aircraft where exacting tolerances (quality) was vital. That was seventy years ago last year and we have come a long way since then. One cannot imagine a manufacturing situation where technology, both in machinery and tooling, and now software; does not play a major part. Over a hundred years ago Henry Ford used technology to change the way people lived, in 2023 and beyond the possibility for success based on technology is no less a reality. ❚

18 Supplier February/March 2023 www.suppliermagazine.com.au Feature

Above: Furniture imports

Above: Technology at Nikpol

SmartBench CNC - Small footprint, endless capabilities

It is truly amazing the scale of projects that can be undertaken with the Yeti Tool SmartBench.

Mark Miller, Director of Forme Design was recently commissioned to design and produce all loose furniture for Eclat, based in Camberwell, Victoria. Eclat presents a unique, members only workspace that provides not only a higher quality of work life balance; but a new level of hospitality integrated into every facet of the experience.

The Yeti Tool SmartBench CNC was used to prototype furniture from materials such as 30mm veneer ply, structural ply and composites. As the project grew,

Forme Design was tasked to design and manufacture architectural and built in furniture. Two stand out examples are the ceiling arches and banquet seats.

The ceiling arches are presented throughout the hallways and open spaces in the working areas, and the banquet seating throughout the events and hospitality spaces. Cut from structural ply, the production of nearly 100 ceiling arch units and over 150 banquet seat sections, comprised over 200 sheets of 15mm ply cut on the SmartBench CNC.

Mark saved time and money with the ability to rapidly prototype in-house. Without SmartBench, CNC fabrication would have

been outsourced, where you have little control over iteration and time. At a little over $15k investment, SmartBench was quickly amortised and saw Mark get an almost instant return on investment through this project.

“Put simply, the SmartBench is a work horse, it allows me to design in a way that frees my workers from unnecessary labour so they can concentrate on the fine finishing details that our business is known for. It quickly became an essential part of our manufacturing process. At that price point, it was an easy choice to invest.” - Mark Miller, Director of Forme Design.

web www. yetitool.com.au ❚

19 Supplier Feature

CDK Stone launches GMM’s latest bridge saw

CDK Stone, which has represented the top Italian bridge saw manufacturer GMM for 30 years, launches the new Extra 480 CNC bridge saw in Australia in March. This model supersedes the Extra 400, which proved to be one of the best-selling machines globally for the kitchen countertop sector.

GMM is the leading manufacturer of bridge saws in the world, and is known for very high-quality machines, ease of use and reliability, says James Clark, CDK Stone’s General Manager, Business Development –Tooling and Equipment.

The company will launch the new model at their Fabrication Innovation Day in Sydney on March 16, and the machine will be then available in all states.

“The 480 is a monobloc machine and is the latest incarnation of the range, and the build quality has been upgraded,” Mr Clark says. “It’s one tonne heavier than the 400 model, so it’s a very solid machine with a larger table and a more rigid bridge and Z-axis.”

“This assists with greater accuracy, especially at the high cutting speeds now possible with new diamond blade technology.”

Improved user interface

The user interface has also been upgraded, from a 15-inch touchscreen on the 400 model to a 21-inch full colour touchscreen. This uses similar technology to mobile phone screens, with the ability to pinch and zoom into workpieces.

Extensive information is available at a glance on the home screen, meaning operations are far more efficient than switching between the previous subfolders.

The Extra 480 standard software called Combined Cuts from CAD now includes contouring software and drilling as standard, with additional software options available such as profiles and shapes, coring, basreliefs, lettering, and offline programming.

The EXTRA 480 features an optional lateral spindle separate from the blade's main spindle motor. Operators can use a blade to do the majority of a cut, then route out the corners and tap holes, allowing more complete jobs to come off the machine.

Previously, the machine operator needed to manually load a router or drill bit, or optionally have a two or four position automatic tool changer. Having two separate spindles on the bridge means no tool change is required. As well as the saw blade and separate Lateral spindle the EXTRA 480 can still optionally be fitted with an additional four position tool changer with additional tools for drilling and milling.

While the machine is equipped with all required software for programming jobs, it can also be operated with the SeKON modular CAD/CAM software available through CDK Stone. SeKON has been developing software for the production of slab materials, particularly stone, for more than 20 years. It offers an outstanding production management system for stone installers, with all programs for automatic manufacturing contained in a modular software solution.

The GMM Extra 480 has remote TeleService that can be accessed by CDK Stone’s technicians around Australia, as well as GMM Italy. The company now has 19 technicians, supported by service managers, service case managers, three software experts and a machinery parts department.

“We invite those in the kitchen manufacturing industry to inspect the new Extra 480 in any state or territory,” Mr Clark says. “It’s a significant step up from the 400 model, and we expect it will become another best seller for GMM.”

web www. cdkstone.com.au ❚

20 Supplier February/March 2023 www.suppliermagazine.com.au Feature

DEDICATED SERVICE ON ALL YOUR MACHINES

THE ONE PARTNER YOU NEED FOR STONE

CDK Stone’s team of devoted technicians travel across Australia every day, servicing, maintaining, and repairing stone processing machines. With a growing team of 19 technicians Nationally and 25 Technicians across Australia and New Zealand, CDK Stone has become leaders in stone machinery servicing in Australia.

TECH SUPPORT DESK manned from 7.30am – 4.00pm EST

4 SERVICE CASE MANAGERS with coverage from 7.30am - 6.00pm EST

Monday - Friday (7.00pm DST)

RELATIONSHIPS ACROSS THE GLOBE working with the leaders in the stone industry helping our customers achieve the best tailored solutions

WE’VE GOT YOU COVERED 25 technicians across Australia and New Zealand

Discover more at cdkstone.com.au/SUPPLIER MACHINERY | SOFTWARE | TOOLS + EQUIPMENT | SERVICE | FINANCE

Striving to create the perfect result between machinery and tooling.

The Stirling Group is creating synergy between machinery and tooling, with two specialised companies, Panel Tools and Stirling, working together to provide customers with a complete solution specific to their needs.

According to Managing Director of Stirling Group, Craig Honeyman, who recently introduced Italian made Bacci to the groups CNC line-up, these two divisions are revolutionising CNC for their customers.

The Stirling Difference

Stirling Group’s clientele list is not just a who’s who of the biggest names in furniture and joinery. Increasingly, smaller factories are exploring the new CNC machines for their automation capabilities, resulting in the need for a smaller workforce.

“ROI is really quickly realised on the staffing factor alone,” Brad explains, “without even looking at the incredible volume output that can be achieved.”

He explains that there are three main factors to consider when improving efficiencies.

“First, there’s the working parameters. Is the customer running their existing tooling and machine the way they should be to get the best output, reduce running costs, get the best quality cut, the best longevity, least wear and tear?”

“Our customers aren’t just facing an increasingly competitive market, they’re also dealing with other major challenges like an ageing and shrinking workforce,” he says. “It’s time we put technology to work in the most advantageous ways to give them back their competitive edge, reduce manufacturing costs, and ease these burdens.”

Brad Anderson, CNC Product Manager for the Group, works closely with customers to optimise their operations through CNC machinery and tooling.

“CNCs can pretty much fit in any type of production scenario,” Brad says. “Anything that was a traditionally very labour-intensive process can be completely automated with our machinery solutions. The machines bring huge accuracy and repeatability into these businesses, working to within 0.1mm accuracy and eliminating human error.”

Versatility is another great attraction in this latest generation of machinery and tooling innovations. “Ten years ago, a CNC machine was for sizing and hardware fitting,” Brad tells. “Now they can do every task in a production line, from profiling and joint cutting through to bead recovery, detailed 3D machining of complex parts and units, and fully complete assemblies.”

He says that with the human factor removed, waste is dramatically reduced, if not eliminated, saving money and increasing profits.

Tooling expert and Panel Tools Area Manager, Fraser Killen is extremely passionate about the tooling aspect.

“Aside from collaborating with Stirling for new machines, Panel Tools can also assist with existing machinery. There are a few approaches we can take to sweat the equity of existing infrastructure prior to making a capital equipment purchase. There are so many ways we can help you get the most out of your equipment it before you invest in a higher performance machine.”

“Then we look at whether they can combine processes on their existing machine. We could create a tool for them that’s customised to the component they’re making.”

“And finally, how can we improve the performance of their operations? We look at tool sizing, different coatings, geometries, and clamping systems. We replace the tool they were using with something completely different and achieve far superior results for them.”

Ultimately, Stirling Group is determined to be the catalyst for change, elevating customers’ capabilities while saving them time, money, and waste.

“CNC is the way forward,” Craig explains. “And with this latest generation of machines – combined with our expertise and tooling capabilities – anyone who doesn’t see the light is in real danger of getting left behind.”

Contact the team at Stirling Group today to discover how they can revolutionise your business’s CNC operations. 1800 077 862

web www. stirlingmachinery.com.au ❚

22 Supplier February/March 2023 www.suppliermagazine.com.au Feature

Art of Kitchen

David Bartlett has a unique insight into kitchen design and an intimate understanding of the kitchen as a space in the home. This perspective comes from getting to know every customer, understanding how their family lives, cooks, entertains and relaxes. To create the perfect space, David relies on Biesse Group as his technology partner.

After his apprenticeship David was managing building sites for a company specialising in high-end architectural work. He was also building kitchens for himself. A friend recommended him for a contract to supply kitchens to a Sydney builder and David saw an opportunity to specialise in kitchen design and manufacture. And so, in 1988 Art of Kitchen was established. David said, “I went into kitchens for the work and found my passion for design and manufacturing. Even after all these years I still feel just as strongly about the process today.”

Art of Kitchens was still a young company when David and his partner Ingrid set up a small factory in Thornleigh, Northwest of Sydney. David thrived on the challenge of kitchen design and soon found himself employing a dozen cabinetmakers. With an expanding list of happy customers, the factory moved to a larger factory in the same suburb, slowly taking over all the complex to eventually occupy 1500sqm. During this time David purchased two CNC machines and a Beam saw from Biesse Group.

In 2002, when this space became too small for their operations, David moved the company into a purpose-built factory space in Mt Kuring-gai where they installed their first Biesse flatbed machine, and then in 2018 to a new, purpose-built site in the same street. Art of Kitchens now employ 34 people who provide the highest levels of quality in their products and service to their clients. This commitment has always been nonnegotiable and it’s one of the business areas David feels deeply about.

A Brand We Know

To manufacture his design-focused kitchens, David recently returned to Biesse. The company had a long association with Biesse Group over the years, upgrading their Biesse CNC machines several times. However, some years ago David was lured away and purchased another brand. He said, “The CNC machine we bought was a solid machine but we were running it 60 hours a week and still not meeting our production targets. Just over a year ago we decided to come back to Biesse, a brand we’ve known for decades.”

David continues, “We thought we might need two machines to do the work of

24 Supplier February/March 2023 www.suppliermagazine.com.au Feature

26

NEXT LEVEL NESTING

DYNAMISM, TOP RESULTS, PRODUCTIVITY: THE NEW AGE OF NESTING

Top speed accelerations and interpolation are what characterise the Rover B FT HD, the nesting machining centre designed to guarantee outstanding results and unprecedented productivity levels.

IT’S NEW...

IT’S FAST, DYNAMIC AND UNLIKE ANYTHING YOU HAVE SEEN BEFORE.

Now at the Sydney showroom

1300 Biesse (243 773)

the one we were replacing. We purchased one Rover A FT, and quickly found it did all our CNC machining in only three days. The Rover runs rings around the machine we replaced, it eats up the board.” And a few months ago, David and his team installed a Biesse Stream A edge bander. He says, “We’re committed to Biesse as a machine partner, we won’t be making the mistake of trying out another brand again. It’s a good feeling knowing we can depend on our Biesse Group equipment to produce what we need quickly and efficiently.”

Giving Back to Industry

Like Biesse Group, Art of Kitchen’s machinery partner, David and his team give back to industry. David spent many years on the Housing Industry Association (HIA) Kitchen & Bathroom Committee. In addition, Art of Kitchens has employed 40 apprentices over the years. A qualified carpenter and joiner himself, David is committed to maintaining basic industry skills whilst at the same time, embracing the skills to adopt new technologies incorporated in their Biesse equipment.

Many of David and his partner, Ingrid’s apprentices have gone on to stay with the company. Both the current Operations Manager and Check Measurer started as apprentices and now assist David in training and mentoring the next generation of cabinet makers. Ongoing training and professional development are the backbone of the Art of Kitchens philosophy. Every opportunity is explored to ensure the team skills are at the highest level.

Seamless Support

Art of Kitchens relies on their Biesse Group equipment to cost-effectively produce designer kitchens that cater for

the individual needs of their clients. Of the Biesse Group service David recalls, “I remember even in the early days someone from the Biesse Team would come out, often in the evening to sort out any issues we might have had. Now, Biesse monitor our machines remotely and a technician could be here even before we know we need one. The service we get from Biesse has always been very good, we are very happy.”

For David and Ingrid, Art of Kitchens is more than just a business; it’s a passion. As an Australian manufacturer they have a commitment to excellence in design and manufacturing resulting in numerous industry awards. David said, “If I can ‘see’ it, I know that with my team and our Biesse technology, we can make it. Understanding how to design a space and how to build it, and having the Biesse technology to manufacture it means we always know our kitchens, vanities, offices, home theatres and outdoor alfresco kitchens will operate in exactly the way they are meant to”.

web www. biesse.com ❚

26 Supplier February/March 2023 www.suppliermagazine.com.au Feature

Planit Australia tailoring unique solutions for their customers

Since its foundation in 2008, SMW Kitchens in Tamworth has grown into a thriving business that has been providing quality kitchen design and renovation services to the local community and broader East Coast markets for many years. With a focus on customer satisfaction and attention to detail, SMW Kitchens has become a trusted name in the industry.

One of the key factors that has contributed to the success of SMW Kitchens is the support provided by the Planit Australia service team. As a leading provider of software solutions for the kitchen, cabinet, and furniture industries, Planit Australia’s

services team has played a vital role in helping SMW Kitchens grow and evolve over the years.

According to SMW Kitchens' owner, Simon Wiley, "Our experience with the guys at Planit has been awesome.” Having grown from three guys in a small shed with a panel saw to now, 35 staff across three companies in a large purpose-built factory with three CNC machines, Simon has always known that “if we need a helping hand, the Planit service team has been really helpful. They fix any problem we have, are all very helpful and all very much up to speed. Over time, we have changed the way we produce our

kitchens, incorporating a stone shop and paint shop to work alongside our kitchen shop. We have always made sure we still have the same quality, and Planit has been key in helping us greatly in performing the integration of our new machines, integrating as many new features and capabilities into our day-to-day workings as possible, which has essentially made our lives much easier as cabinetmakers and drafters."

One of the key benefits of working with Planit Australia has been the ability to create 3D designs that allow customers to visualize their new kitchen before it is built. "When

27 Supplier February/March 2023 www.suppliermagazine.com.au Talking Business

Talking Business

we moved into the new factory, we saw an opening that needed to be rectified - our presentation skills to clients with our design and sales teams," says Simon. "We are very much looking forward to seeing where Vortek Spaces takes us with our journey with Planit.” Vortek Spaces allows SMW to show customers exactly what their new kitchen will look like, and make changes before any construction work begins, thereby increasing customer satisfaction and reduce the risk of errors or misunderstandings during the installation process.

In addition to the software customisation and training provided by Planit Australia, Simon also notes the excellent support provided by the company's service team and technical support. "The Helpdesk has always been great – happy days, they just sort it out for us." The face of the Planit Australia service team, customer concierge, Noel Sayer, explains that “working as a facilitator and

ensuring that our customers have the best possible service experience” is the keystone to “providing fast, efficient, and effective service on time, every time, something we pride ourselves on. Our technical support

consists of a combination of deliverables beyond the technical aspects - the best possible communication, response time and operating effectively to provide customers with the right solutions to their problems, so customers can obtain the most benefit while minimising downtime.

As Planit Australia National Service Manager, Gordon Guppy, observes, “The most important thing in providing good service to a customer is a strong foundation to the relationship - you really need to know who the customer is and how they're operating, both internally with their own team, as well as externally with their own customers. Seeing the excitement on our customers' faces when they incorporate new technologies and capabilities into their operations is always a really proud moment, knowing that we have been a part of, and have been able to contribute to, their growth and journey. Having met Simon and his team

28 Supplier February/March 2023 www.suppliermagazine.com.au

Seeing the excitement on our customers' faces when they incorporate new technologies and capabilities into their operations is always a really proud moment, knowing that we have been a part of, and have been able to contribute to, their growth and journey.

Talking Business

over six years ago, it's been really rewarding to see the changes in SMW Kitchens, using Planit's products and service offerings.”

Through the entire Planit Australia service team, there is a focus on “facilitating improvement of business practices utilising Cabinet Vision and Vortek Spaces,” according to senior product solutions expert, George Farrell. “The most important thing, when providing customisation, training or education for a customer, is to understand the needs of their business. With this understanding, we are able to tailor appropriate and unique solutions to address each individual customer’s circumstances. Customers recognise that being up to date with Cabinet Vision through regular customisation, training and education is always of great benefit, through improving staff skills and utilising the latest features.”

As SMW Kitchens continues to grow and expand its services, the partnership with Planit Australia remains a critical part of the business's success. With access to the latest technology and ongoing support from a trusted provider, SMW Kitchens is well-positioned to continue providing exceptional service to its customers for many years to come. ❚

R I N T E R S

Supplier February/March 2023

R E M O V A B L E Direct Thermal Labels specifically made for: Printers, CNC Application, Panel Saws etc Many more sizes available Also available in Permanent adhesive 80mm x 80mm 100mm x 73mm 102mm x 48mm 102mm x 63mm 102mm x 74mm Pricesfrom $18per1000 R E M O V A B L E Compatible Brother Labels available in continuous & die cut suitable for QL Series Brother label printers Genuine Brother & Dymo labels available FREE with every purchase R E M O V A B L E Paper Laser Sheet Labels Many other size sheets available Also available in Permanent adhesive Prices from $15 per pack 1300 762 603 allaboutlabels.com.au cabinetrylabels@allaboutlabels.com.au 2/22 Collinsvale Street, Rocklea, Queensland 4106 BUY DIRECT FROM THE MANUFACTURER Ask about our printer and label packages which can be tailored to suit your specific business requirements members Suppliers of Premium Quality Labels for the Cabinet Making Industry Download Cabinetry Labelling Guide for more info ZEBRA CITIZEN BIXOLON DATAMAX TSC Removable, No Residue, Best Price Guaranteed* Request a FREE Sample to try for yourself All prices ex GST Dedicated label printers P

3d Kitchen Software celebrating 30 years

Chris and Rose Adams began business in 1993 providing software solutions to the joinery industry. Now in their 30th year in business the 3D Kitchen software brand is going strong and still supporting cabinetmakers with solid solutions to complement their businesses.

Chris Adams, the mastermind behind 3d Kitchen and creator of 3d Kitchen software sat down with Supplier Magazine to discuss all things business.

1. 3d Kitchen is celebrating 30 years in business. What is the 3d Kitchen story?

In 1993 we saw an opportunity in the market to supply software to the joinery industry. It was a big step in those days as this type of software was in its infancy and also at a time when cabinetmakers were very sceptical about computers and software in general. Our business has no employees. Instead we made the decision to allow sales agents to be completely independent. This

business model has worked extremely well. It means that all of our sales agents own and control their sales territories. We, (Chris and Rose), have recently pulled out of the daily running of the business and have passed the control to our two eldest sons, Harley in New Zealand and Clutha in Melbourne.

2. Walk us through some of the 3d Kitchen milestone moments achieved over 30 years in business. Of course the major milestone right now is actually hitting the 30 year mark in this business. It's something that I definitely did not expect at the start.

Selling quietly in New Zealand at the beginning then branching out to Australia. Australia quite quickly became our most productive market and so sales agents were sought. We have been very fortunate to secure fantastic sales representatives who are loyal and dedicated to extending our business. They are the reason for our success operating with integrity and consistency.

Branching out further with agents in India, South Africa, Ireland and the UK, with other minor sales happening through our online presence.

3. 3d Kitchen has a variety of software solutions to suit all cabinet making and design applications in their collection, can you take us through your product offering?

Yes we have three categories of software to offer:

• Firstly, Pro Design. This produces floor plans, elevations, 3D images with textures, colours, lighting and shading, and design documentation. It includes

32 Supplier February/March 2023 www.suppliermagazine.com.au Software

Software

a custom built cabinet library to suit each client (so it is not a one size fits all product).

• Secondly Pro Custom. This everything that the Pro Design version does but also produces full job costing, cutting lists, hardware lists, labour calculations, edging details and material optimisation (printouts showing how to cut cabinet components for processing on a panel saw).

• Thirdly Pro Toolpath. This does everything the other two versions do but also produces output to directly process to CNC machines. This takes data from the 3D design. So whatever is added or modified in design passes accurately to CNC.

4. What sort of training and technical support is made available to customers when purchasing your software for the first time?

Training and technical support is provided for all versions and is included in the cost of the software. This is absolutely key to having clients who are competent and confident in running our software to their best advantage.

5. Looking ahead, what plans have you got for the future of 3d Kitchen?

We never stop developing and moving our software ahead. So, development is a constant process.

We are in the process of shifting to a true CAD system. This is a significant shift from the current version and will apply a much higher level of design and design modification. This is the most exciting development we have undertaken and will provide some great advantages for our clients. It is due for release later this year.

And finally, a message from Chris.

This is an appropriate time to thank our many loyal customers. We have got to know most of you very well over the years and have really appreciated your support. Although I am retiring from day to day business affairs I will make myself available for clients who would still like to contact me for assistance, so I am not abandoning the business completely. ❚

33 Supplier February/March 2023 www.suppliermagazine.com.au

Keep track with CAD+T

Think an automated parts tracking system is only suitable for largescale manufacturers? Think again. Austrian software specialist, CAD+T has launched a fully customisable RFID parts tracking software solution that can be tailored to your company’s production needs, whatever its size.

With contactless parts tracking, you can quite simply have the answers at your fingertips. CAD+T’s digital network offers consistent and precise parts tracking for your production cycle which lets you keep a track of every part going in and out of your factory at any one time. What’s more, the whole process is live, allowing you to see the exact status of each part from your computer, laptop or mobile device.

Regardless of your production output, the ability to manage and optimise your production processes in this way offers significant time and cost savings. Plus, the software’s ability to offer real-time insight into your company’s workflow and resources lends itself to improving efficiencies across the board. From human operation and machinery running times to material usage,

it includes simple, measurable processes that highlight efficiencies within any manufacturing facility.

So how does it work? The scale of your production will determine the level of automation required. Strategically placed gateways work with RFID tags or labels that are attached to individual parts during the manufacturing process. When scanned, either by a mobile scanner or automated reading device, part numbers will allow you to identify where the item is.

34 Supplier February/March 2023 www.suppliermagazine.com.au Software

Depending on the structure of your business, this could start with the raw materials being delivered to your factory, followed by stepby-step tracking that shows you what stage of the cycle a specific part is currently in, if it has been assembled or packaged and if the order has left the warehouse.

Martina Schwarz, CEO of CAD+T says: “There are huge cost savings to be had when using a RFID system and it is proven to reduce losses, limit human error and improve customer service. Whether you want an all-encompassing tracking system that tracks parts throughout your entire production cycle or want to track specific areas within the business, CAD+T works

with you to create the most effective solution. For smaller businesses, parts can be manually scanned but still offer live data feedback at any time and highlight delays in production. Alternatively, larger manufacturing facilities could benefit from automatic reading devices that follow the parts from the warehouse all the way though to shipping. The level of tracking is unique to you and CAD+T’s specialists are here to help you create a digital network that is specific to your production facility. To make it even more simple for you - we supply you the softand hardware.”

For further information please visit www.cadt-solutions.com ❚

Software for Interior Design and Production Complete software solutions for interior design and manufacturing CAD+T Australasia PTY/LTD +61 2 800 620 67 NSW, 2000 Sydney, Australia office@cadt-solutions.com www.cadt-solutions.com We offer + Specialised for bespoke furniture + CNC connection in less than a week + Cloud Solutions & Online-Shops

Software Supplier February/March 2023

Innovync: The tale of a trailblazer

In February 2020, a new kind of machinery distributor and supply service opened up. Rebranded from Unimac Machinery, Innovync set out to make a difference in the Stone, Glass, and later Advanced Materials and Plastic sectors. Three years later, they continue to make leaps and bounds in the Australian manufacturing world.

“When I came here, it was just a room with a table by itself. Just a room and a toilet. Pierre, our Managing Director, asked: are you ok to work in this? It will improve but will take some time. I could see in the first financial year how successful the company was. It was good sales, regardless of having only one sales rep - he did so so so well.

Then COVID came, and it didn’t affect us at all. I am excited about what the future will bring to Innovync, and feel proud to be part of this amazing team!”, says Diana Avila, the company’s Financial Engineer.

The firm’s impressive growth comes as a direct result of helping those around them. Driven by a passion to serve, Innovync’s employees do what it takes to boost customers’ businesses and solve important production problems.

Their efforts have not gone unrecognised. Last year, the young business won its first local council award for “Outstanding Specialist Business”. Voted into the finals by grateful customers, all aspects of Innovync’s operations were assessed - from community

involvement to services - and the prize was awarded. This year, the company is set to bring its award-winning operations beyond NSW borders, where more customers can benefit from excellent technical expertise and dedicated service.

Renovations for the new Queensland facilities are currently underway; setting up an environment where spare parts can be collected and dispatched, technicians sent out locally, and Friday night drinks enjoyed. Like the Sydney hub, this location will also boast a range of popular stock machinery models that are ready for immediate installation, giving customers a distinctive competitive edge. Especially if they are in the Stone industry.

Supplier February/March 2023 www.suppliermagazine.com.au Discovering Stone

36

With the recent push to take engineered stone out of the workshop, Innovync’s technology and fast service hold the key for silicosis-free production. As exclusive distributors of CMS Brembana, the machinery supplier is seeing increased demand for automated solutions, which range from waterjets and CNCs to customised equipment. Factories like Pacific Stone, North Coast Stone and Ideal Stone already have several of CMS’ products installed, some of which are set up as cutting cells. The user-friendly interface makes it easy for operators to manage multiple machines - and for new employees to quickly pick up on the ins and outs of the software.

Specially designed production lines take the benefits of CMS’ machinery even further. Innovync’s experts have ordered a range of complete processing lines for the Stone and Glass spaces, as well as cutting cells and large-format machines for clients in the Advanced Materials and Plastics sectors. Due for installation later this year, these

solutions drastically increase automation in the workshop - and raise Australia’s capacity for local production.

Last year, Innovync introduced a unique service that allows manufacturers to maximise machinery use from day one. By giving businesses the opportunity to send operators in for training on stock machines, the learning curve is significantly shorter -

meaning that machines are ready to be used from the get-go.

This kind of thoughtfulness and ingenuity has fuelled Innovync far, in very little time. Even despite obstacles brought on by events in 2020 and 2021, a clear upwards trajectory is evident. Watch from the sidelines and see where their path leads - or join forces and travel alongside a trailblazer. ❚

Supplier February/March 2023 www.suppliermagazine.com.au Discovering Stone

37

Slab Falls Take Lives

Every year workers are injured and often killed in accidents involving stone slabs falling. In addition to the suffering of workers and their families, employers are often left with poor morale and reduced productivity from other employees in the company. These injuries are preventable.

A storeman was crushed under 22 sheets of porcelain, leaving him a quadriplegic. A female employee died while unloading stone slabs from a shipping container. Two workers suffered serious lower limb injures when unsecured engineered stone slabs fell from a trolley; and a warehouse worker sustained fatal injuries when he was crushed beneath two stone slabs. These are just four of the more widely-known incidents involving slab falls.

Theo Kanellos is a risk management consultant (Kanellos Consulting Pty Ltd). He says,“Moving stone slabs can be a dangerous task if it’s not done properly by trained people, using the correct equipment and process. Workers may have a lack of awareness of the unpredictability of natural stone slabs that often have imperfections and micro cracks you cannot see. These make the slab weak and could break without warning when handled.”

Many breakages occur where the lifting clamp attaches to the slab, creating a stress point. Theo said, “A slab falling from two metres could see pieces landing as far as ten metres away.” Unrestrained slabs can also fall from an A-frame. Slabs fall into what is known as a ‘fall-shadow’ (see diagram). It is critically important to stay out of the fall shadow. Sheets can typically weigh 80 kilograms or 250 kg for slabs and can be fatal. In one case, 22 sheets fell on a worker.

A slab fall is a notifiable incident to the state safety regulator, even if no one is injured. The area must be isolated, the state regulator advised, and work cannot continue until approval is given. Because of a lack of awareness, Theo suspects that slab falls are under reported. The actual number of slab falls is higher because data available is based on incidents where someone was seriously injured or killed, which cannot be hidden.

Supplier February/March 2023 www.suppliermagazine.com.au Discovering Stone

40

Some of the causes of slab falls are poorly designed or maintained racks and A-frames used to store and transport slabs. These could degrade or suffer structural damage over time. Poor slab handling and storage safety procedures and systems can also result in a slab fall. A risk assessment should identify the potential hazards and what control should be implemented, including safe work practice documents.

State regulators safety measures for the storage and handling of slabs should include ensuring support frames are

provided and maintained; ensuring loads and support frames are inspected for movement or damage prior to removing restraints; ensuring workers never stand in the drop zone/fall shadow of an unsecured or suspended load; developing safe work practices (SWPs) which are then implemented, monitored and enforced.

Cranes, slings and any other equipment should be checked during a pre-start check. Cranes and lifting gear should be regularly inspected and maintained by a qualified person and lifting gear tagged accordingly. Records must be kept detailing the maintenance done, and by whom. Operators should be trained in the use of the equipment and the lifting process. While a licence for high risk work may not be necessary for some cranes, a licence for high risk work is required to sling loads or to operate a forklift.

The same care and attention should be given every time a stone slab is lifted. Many businesses have documented SWPs for slab handling. If a slab looks a bit of a ‘worry’ the slab could be labelled so future crane operators can take additional precautions. It’s this attention to detail that could make the difference between a good day, and a very bad day for both the workers and the company alike because when a slab falls, everyone is affected.

If your business operates in Victoria, you may be eligible for free advice from an OHS consultant through the WorkSafe OHS Essentials program. See details at www.worksafe.vic.gov.au/ohs-essentialsprogram.

web www. cdkstone.com.au ❚

Supplier February/March 2023 www.suppliermagazine.com.au Discovering Stone TRANSPORTING STONE SAFELY Discover more at cdkstone.com.au/SUPPLIER MACHINERY | SOFTWARE | TOOLS + EQUIPMENT | SERVICE | FINANCE

2000MM / 3000MM WORKSHOP TABLE

BUGGY TRANSPORT TROLLEY

STRONG SLAB RACKING SELF UNLOADING CONTAINER

41

Fitouts and Trends - Tiny Houses

Tiny homes in Australia are a reality. A quick internet search reveals dozens of builders spread throughout the country. And while the concept requires a compromise for space, there is no compromise in the quality of the living space, or the overall standard of living.

A tiny house could be temporary housing, relief accommodation or an additional dwelling; a granny flat; rental accommodation; an office, studio or pool room. It could also be a holiday home, either permanent or mobile; a mobile retail business or rural accommodation. They aren’t cheap, costing between 45 and

150-odd thousand dollars, around the same range as a caravan. With a caravan all the fittings and furniture are usually included. Depending on the design, a tiny home may include everything, or could be a shell that is furnished by the occupier.

With a tiny home the owner gets whatever is included in any full-size dwelling but designed to optimise the available space. Häfele is one furniture hardware company that has been working for many years with tiny house designers to realise effective living spaces. Hafele have not taken up designing multi-functional furniture or cabinetry, they’ve provided the backdrop and support for designers to achieve their goals and some of these are stunning.

What is it?

A tiny home has been defined as a space of 37 square metres or less. For context, a 20-foot long caravan occupies 15.25 square metres of space. The tiny house movement has taken off in Europe where land is at a premium, and also in the United States after the 2008 financial crisis when thousands of people lost their homes. Another group of people who see the tiny home as an attractive alternative are those people who are becoming more aware of their ‘footprint’ on the Earth. It is their desire to occupy less of the land, consume less raw materials and energy and often, to live a simpler lifestyle.

Where can you park it?

There’s not a simple answer to this question.

42 Supplier February/March 2023 www.suppliermagazine.com.au

& Trends

Fitouts

Owners will need space on private property, but the location and setup will determine how long people can stay there and this could be different in every state. The tiny home may qualify for a building permit, or like the majority of tiny houses in Australia it could remain mobile in which case it will need to meet vehicle standards limiting its size, and weight to no more than 4.5 tonnes. If it will be permanent, it will need connections to sewer, water and power, or alternately, solar panels that are becoming very popular. People who plan to live in a tiny space need to do a lot of homework before they begin.

Living in it

A tiny home may be considered a caravan in some states, and this will restrict the number of nights or the length of stay people can live there, although some councils are providing a permit to live there full time. Given this, a tiny

43

Fitouts & Trends

Fitouts & Trends

home can be suitable for families, but more likely used by couples or young people such as students. A tiny home is generally built more stronger than a caravan and include fittings such as those found in a regular sized dwelling. A tiny home mirrors the materials and aesthetics of a conventional home, making it more suitable for permanent living. Our images show a tiny home produced by Hangan Tiny Homes and located in the Yarra Valley, East of Melbourne.

A Challenge for Suppliers

Hardware and other cabinet surface and edge treatments provided by Rehau, Nikpol and Elton Group are widely used in Tiny Homes. Smart components like hideaway bins from Hettich, Häfele, Kitchen King; Nover and Galvin Hardware are in great demand. Flexible fittings and furniture providing more than one function are highly desirable, especially

those fittings that can be hidden when not in use. As far back as 2012 Häfele revealed their Functionality Cube, with its 40 sqm of living space. And in 2017 Häfele followed this up with a demonstration of the tiny spaces ‘megatrend’ at Interzum in Cologne with the motto ‘More life per square metre.’