DESIGN + MATERIALS + TECHNOLOGY

The mobile showroom is packed full of Grass products, including the TECMATOR drawer assembly machine that can assemble a drawer in under 25 seconds.

Also on display are the Nova Pro Scala product range of drawers, Tiomos hidden hinges, Kinvaro T-Slim Flap fittings and so much more.

Talk to your Häfele Account Manager today to ensure you don’t miss out on seeing the Grass Mobile showroom and TECMATOR assembly machine in action.

Häfele mobile showroom is now on the road and making its way around Australia.

Welcome to the August / September 2023 issue of Supplier Magazine. Inside this issue you will find our annual Eco and Sustainability Feature where the experts at Good Environmental Choice Australia (GECA), discuss the circular economy. Explaining that it is a transformational framework forcing organisations and individuals to rethink how they live and work in this global community.

Philip Ashley attended both interzum and Ligna for us earlier this year and in this edition, he has written a full report on both shows. Supporting our environmental focus Ashley explains there is much green potential to be found in the furniture industry, whether it’s the smart conservation of resources, renewable energy, or with the use of new materials. It seems the supplier sector proved to be innovative and progressive, with a particular focus this year on sustainability.

Please feel free to contact me directly regarding any industry news, company events, training and or product information you would like us to publish at – michelle@elitepublishing. com.au

Have a look at our new website and don’t forget to join our growing online community by visiting us on Instagram and Facebook.

Until next time, enjoy your read.

Michelle Cammiade Editor

Anew entity has emerged in the timber processing industry, but its name will probably be familiar to most. The Stirling Group has been named as the main brand under which its subsidiaries, Panel Tools, Accurate Australia New Zealand, and Stirling Machinery already co-exist. According to Managing Director, Craig Honeyman, it was important to represent all arms of the business as one for a very important reason.

“Some of our customers deal with one of our businesses, some deal with two or all of them,” he says. “Bringing all three together under one unifying brand streamlines everything and means we can service our customers all along the processing cycle with clarity and cohesion.”

It was identified that by bringing together the combined team’s experience and expertise over all three entities, this would supersize the group’s position as a powerful

resource for information, training, and tangible products.

“Combining so much incredible experience into one overarching group,” Craig says, “has strengthened our ability to provide ways for process gains, waste reduction, improved safety, greater productivity and profitability, structured training programs, and more.”

The cohesion is a factor that extends beyond the sales team. Craig says that by communicating via a single brand, the company’s marketing team is better able to deliver Stirling Group’s message.

“To us, knowledge and experience are golden assets and genuinely something that sets us apart from other players in the industry,” he says. “It’s important that we show others what we’re made of, and that we do have answers, sometimes to questions our customers didn’t even know they had.”

On the factory floor, the same unification applies.

“Our factory team are dedicated, passionate, and driven. The precision and attention to detail they apply are incredible and they have such great depth of skill that there’s never a question that can’t be answered or solved.”

Craig names Service Manager and living legend, Pappy Halfpapp and Wood Machining Engineer, Kane Obst, as just two members of the team who are dedicated to ensuring Stirling Group customers benefit from top-level service.

“Pappy and Kane exemplify what Stirling Group is about. We operate with respect and integrity, always making sure things are better today than they were yesterday,” Craig explains.

Craig says the sales team’s appointment book is steadily filling with customers keen to learn more about automation and explore ways to implement it in their business.

To learn more, visit thestirlinggroup.com.au or call the team on 1800 077 862. z

“Our factory team are dedicated, passionate, and driven. The precision and attention to detail they apply are incredible...”

Being able to change the aesthetic perception of a drawer when it is installed –that would be innovative, we thought. And with the supplementary designer panels from Nova Pro Scala, this idea has become a reality. Thanks to the right-angled shape of the Scala drawer side, the L profiles are not only easy to apply, they also offer a whole cornucopia of new design options. Nova Pro Scala. The drawer.

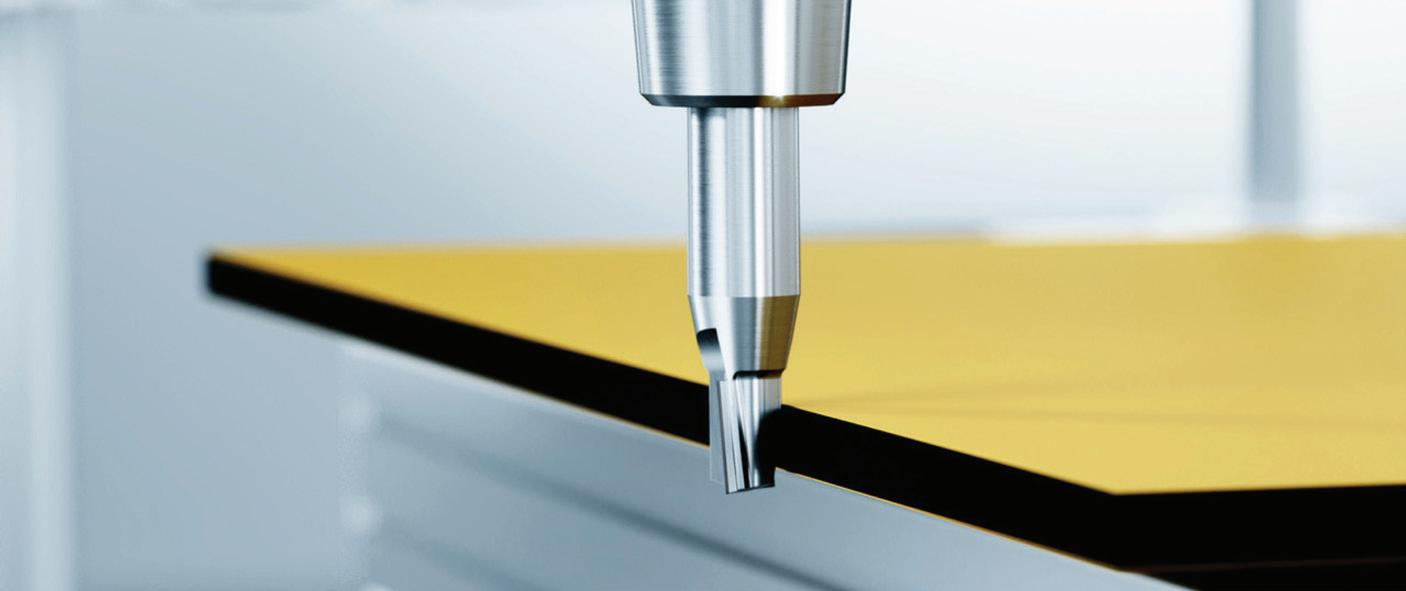

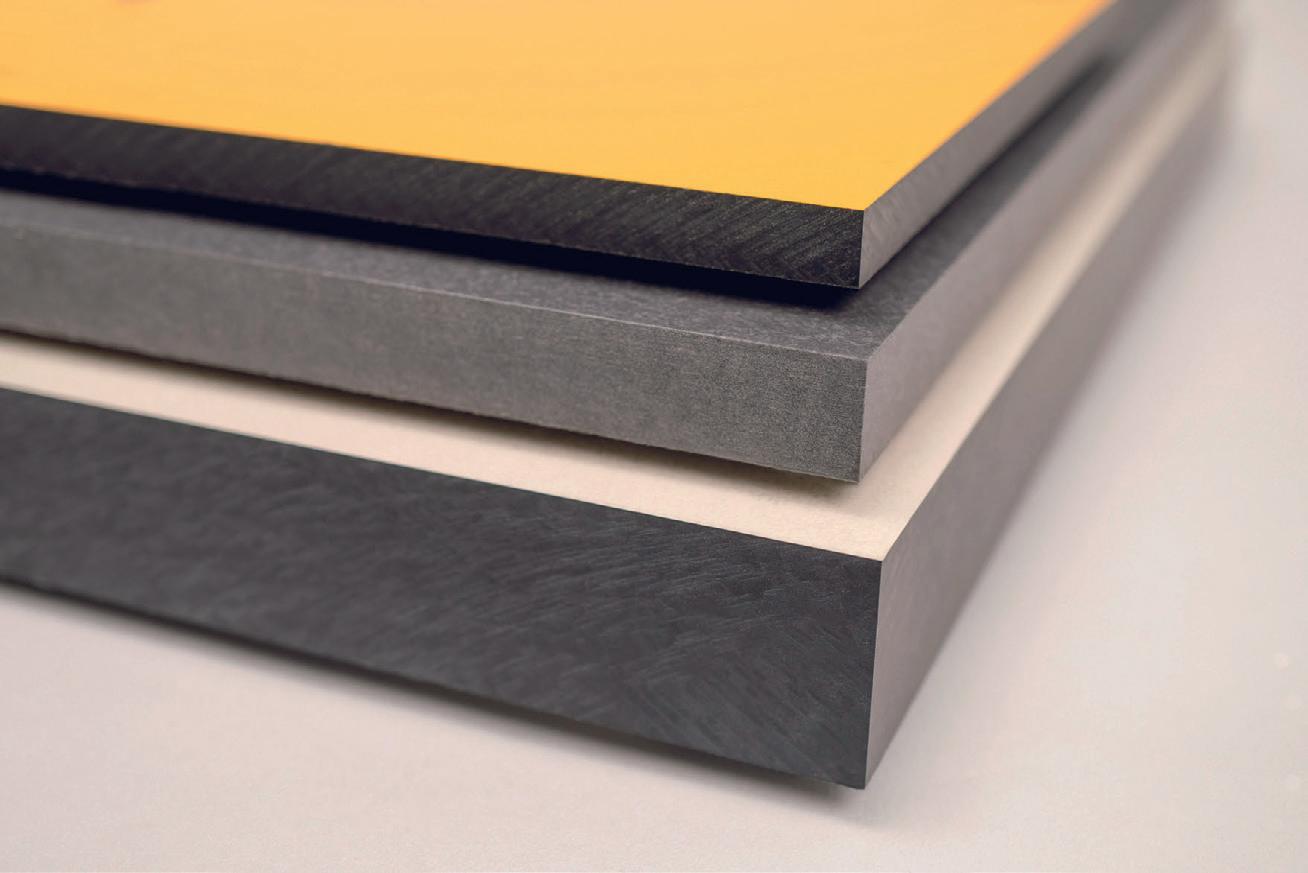

Compact laminates such as HPL, hard paper or hard fabric find a wide range of applications due to their design possibilities and robust properties. These materials are especially popular in kitchen and cabinetry construction and the sanitary sector.

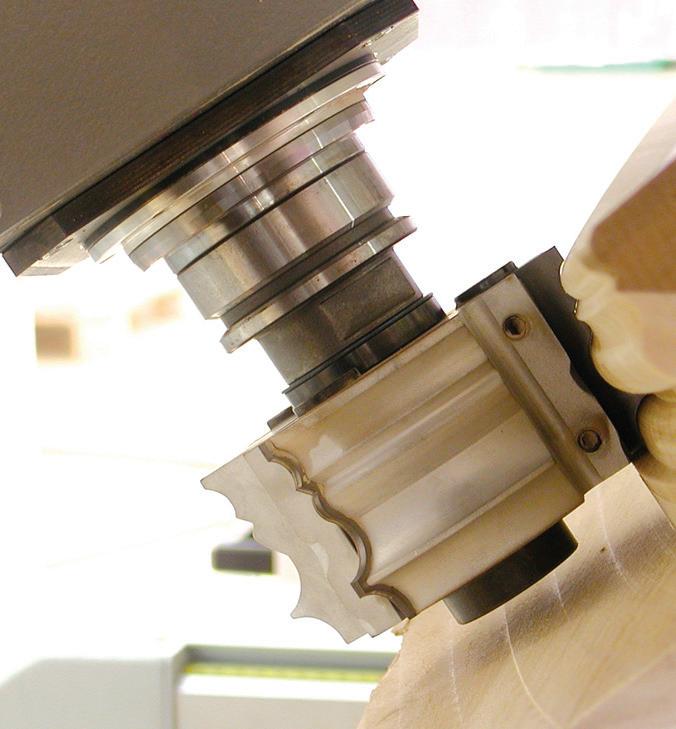

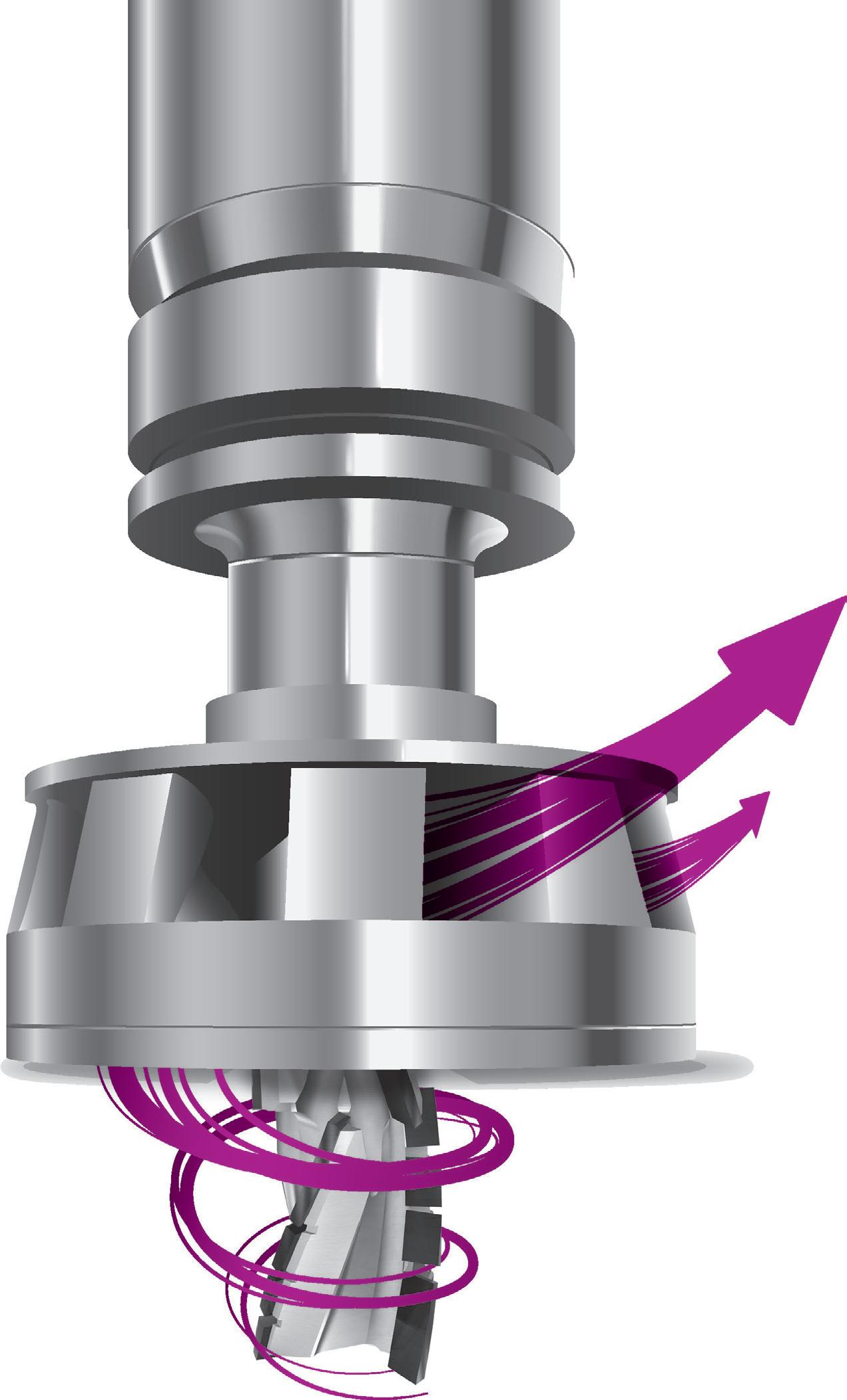

However, the hardness attributed to these materials causes tooling stress during machining. Processing requires tools with carbide or diamond-tipped cutting edges to achieve good cutting results while reducing tool wear. Diamond-tipped tool cutting edges are the best option, especially for large machining quantities, as they are significantly more economical due to the longer tool life.

The Leitz tool range has the right tool for every type of machining and achieves outstanding results in terms of quality, productivity and efficiency.

When it comes to perfect cutting results in grooving and sizing, the diamond-tipped router Diamaster PRO Z 1and Z 2 is the right tool. Featuring a slightly positive cutting angle it ensures that the chips are ejected from the groove and the cutting surfaces are clean and free of chips. This increases efficiency, as time-consuming cleaning work is no longer necessary. The diamond basic cutting edge is particularly suitable for flying plunging.

Leitz has developed the Diamaster PLUS Z 2 router especially for grooving and sizing, with neutral cutting characteristics and high feed rates. The special feature of this router is the alternating cutting angle, which produces good edges at the top and bottom as well as a perfect cutting surface when sizing. The high feed rates are made possible by the stable design of the tool. There is also a version of the Diamaster PLUS Z 2 router which is perfect for grooving in the nesting process. Thanks to the negative cutting angle, this tool ensures tear-free edges during grooving and eliminates the need for troublesome reworking of the edge. In addition, this tool design supports workpiece clamping for small workpieces in the nesting process.

The router cutters of this series are available from stock for all conventional machines in various diameters. Compared to other conventional routers, they impress with their long lifetime and multiple resharpen ability.

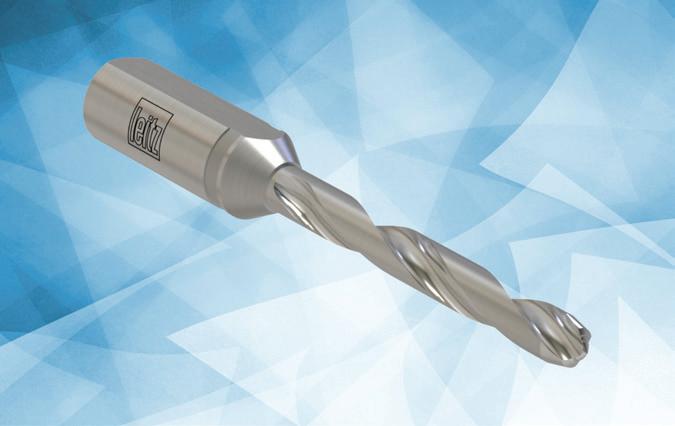

With the drill HW solid Z 2, which is specially adapted to the material requirements of HPL, break-out-free boreholes are achieved, which significantly increases the quality of the final product. This is ensured by the special cutting-edge arrangement. The HW-solid Z 2 drill stands for increased tool life and high

stability. In addition, the polished gullet area ensures good chip removal.

Leitz panel sizing circular sawblades and scoring circular sawblades ensure perfect cutting when processing panels. The combination of with-feed pre-scoring and against-feed cutting-off achieves break-outfree edges both above and below and thus a correspondingly high quality. They can also be resharpened several times and are significantly more long-lasting. They also feature an innovative tooth geometry as well as filled-in laser ornaments, producing significantly less noise. In carbide or diamond-tipped versions, these circular sawblades are available from stock and are suitable for all conventional panel-sizing and sizing saws.

With this coordinated tool range for compact laminates, Leitz has developed the key to the perfect final product and has the ideal solution ready for every requirement. With its promise of quality in for tools and processing results, Leitz creates sustainable solutions in new dimensions that save time and money through greater efficiency and productivity.

www.leitz.org/en-au/highlights/tools-forcompact-laminate z

We

The finance company will then arrange a combined finance package for the software and hardware, if needed.

We will liaise with the machine company

We can consult with

Hafele lifestyle appliances celebrate the iconic Australian lifestyle and bring European design together with their renowned commitment to quality. For more than 100 years Hafele has led the way for innovative kitchen solutions and their appliance range continues their mission to foster connections to family life in every Australian home.

Hafele’s comprehensive range of ovens cooktops, range hoods, microwaves, dishwashers, refrigeration, and laundry appliances, ensures they have products to suit the needs of every decerning cook and lifestyle.

Accompanying Hafele’s lifestyle appliances, is their extensive range of sinks and taps. The current range includes stainless steel tap wear and sinks in a variety of colour options that are on trend in today's market. With over 60 models plus additional accessories to choose from, this makes Hafele’s range a versatile compliment to your kitchen design.

With Hafele’s Assisted Living range of extensive hardware options they also have a range of sinks and taps to suit the SDA standards. For more information or a product demonstration don't hesitate to contact your nearest Hafele representative.

web www.hafele.com.au z

Hafele’s comprehensive range ensures they have products to suit the needs of every decerning cook and lifestyle.

We are passionate about cooking, and we are inspired by you. Your needs, desires and experiences have shaped the functionality and design of our products to make every day cooking a pleasure and entertaining a breeze.

Häfele Lifestyle Appliances, Sinks & Taps celebrate the iconic Australian lifestyle and bring European design together with our renowned commitment to quality. For over 100 years Häfele has led the way for innovative kitchen solutions and our range continues our mission to foster connections to family life in every Australian home.

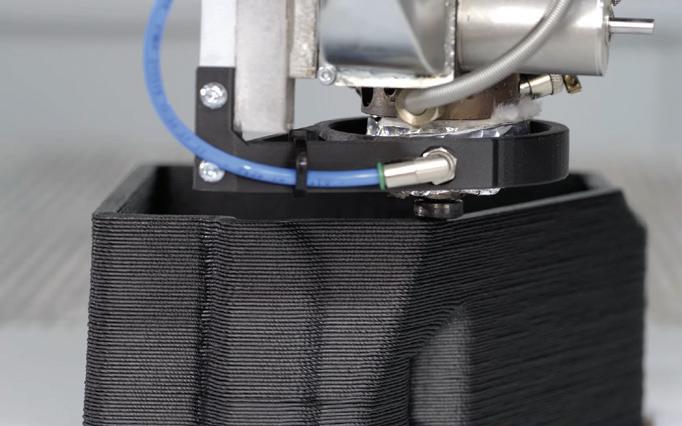

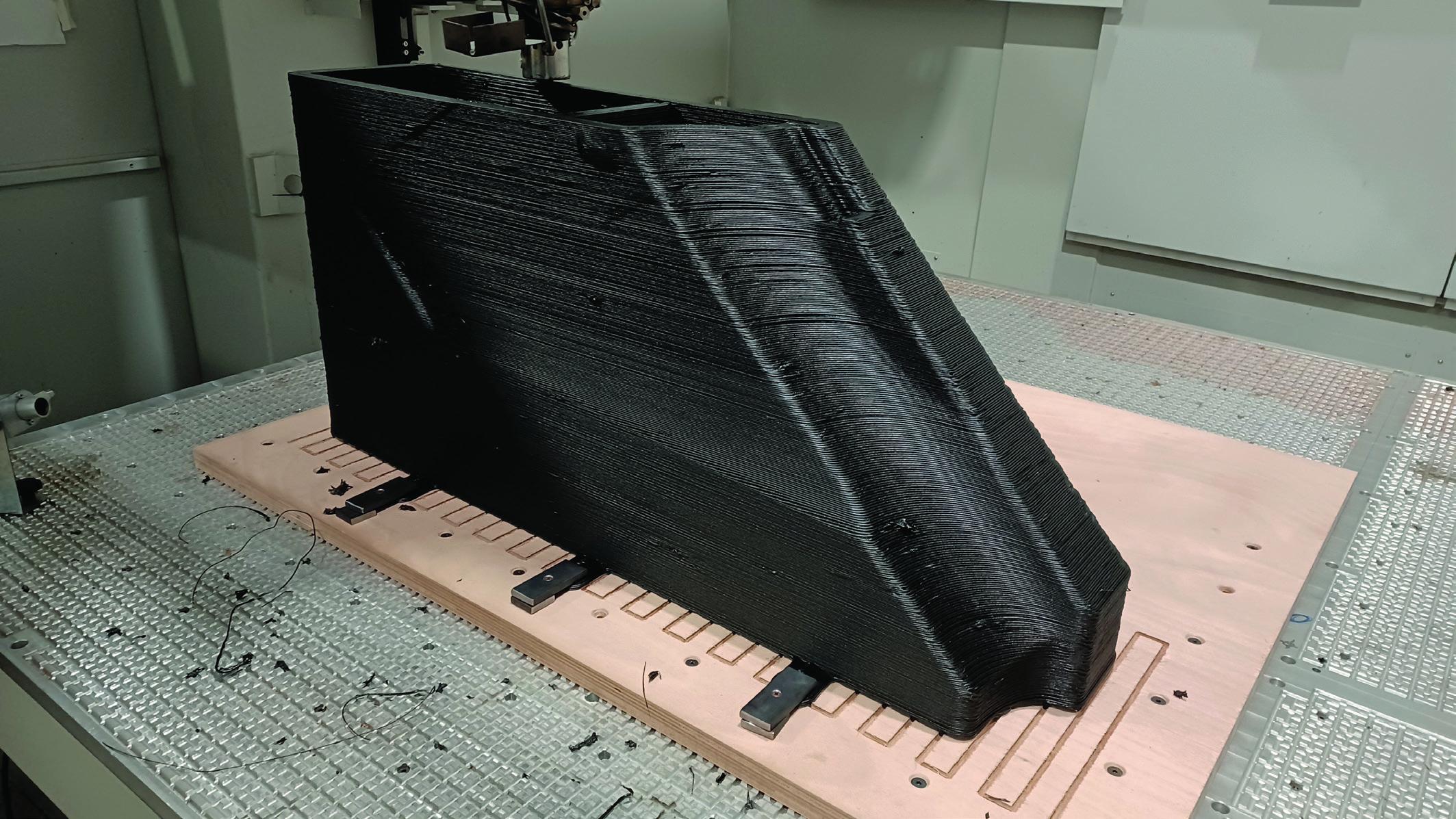

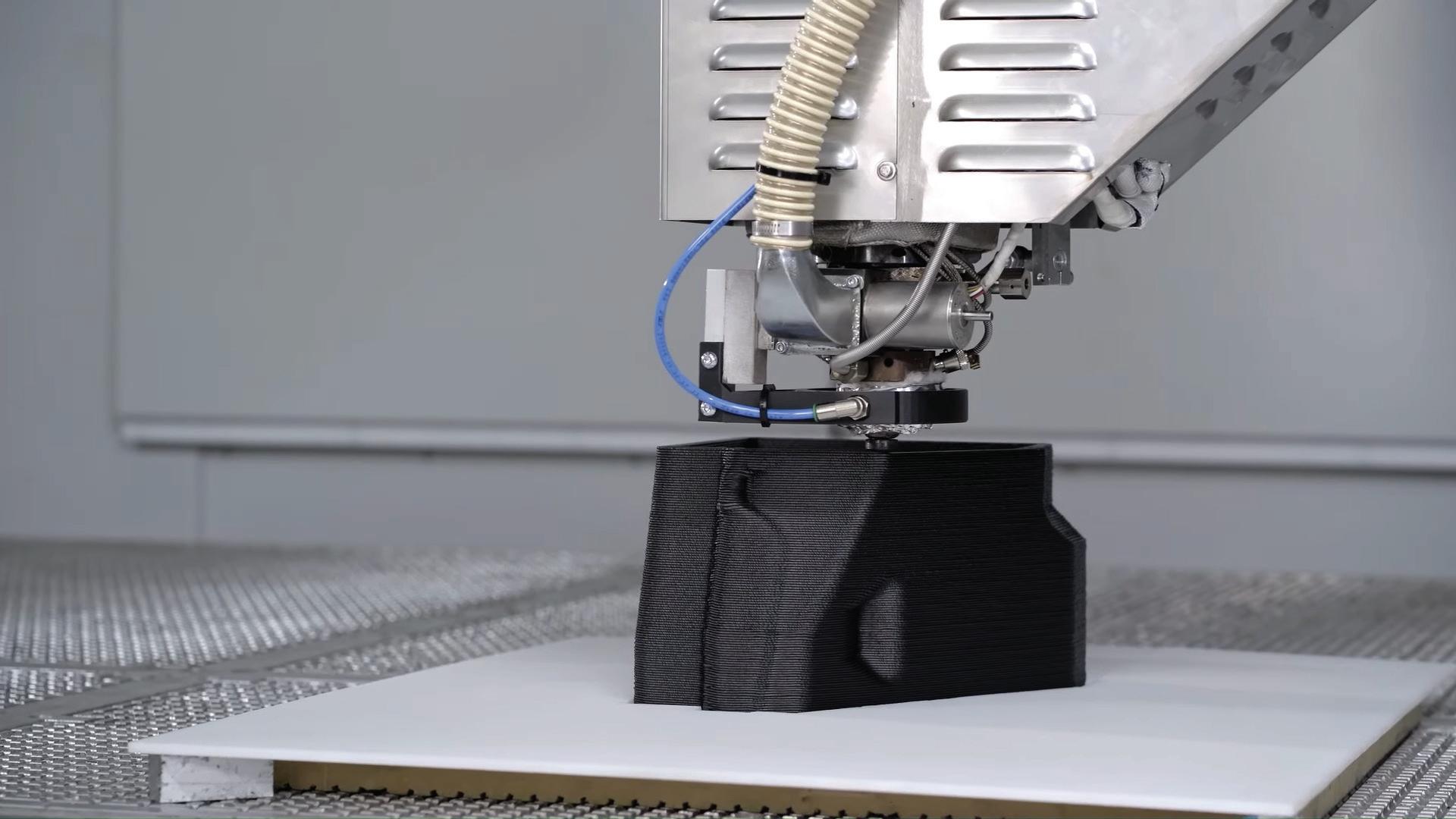

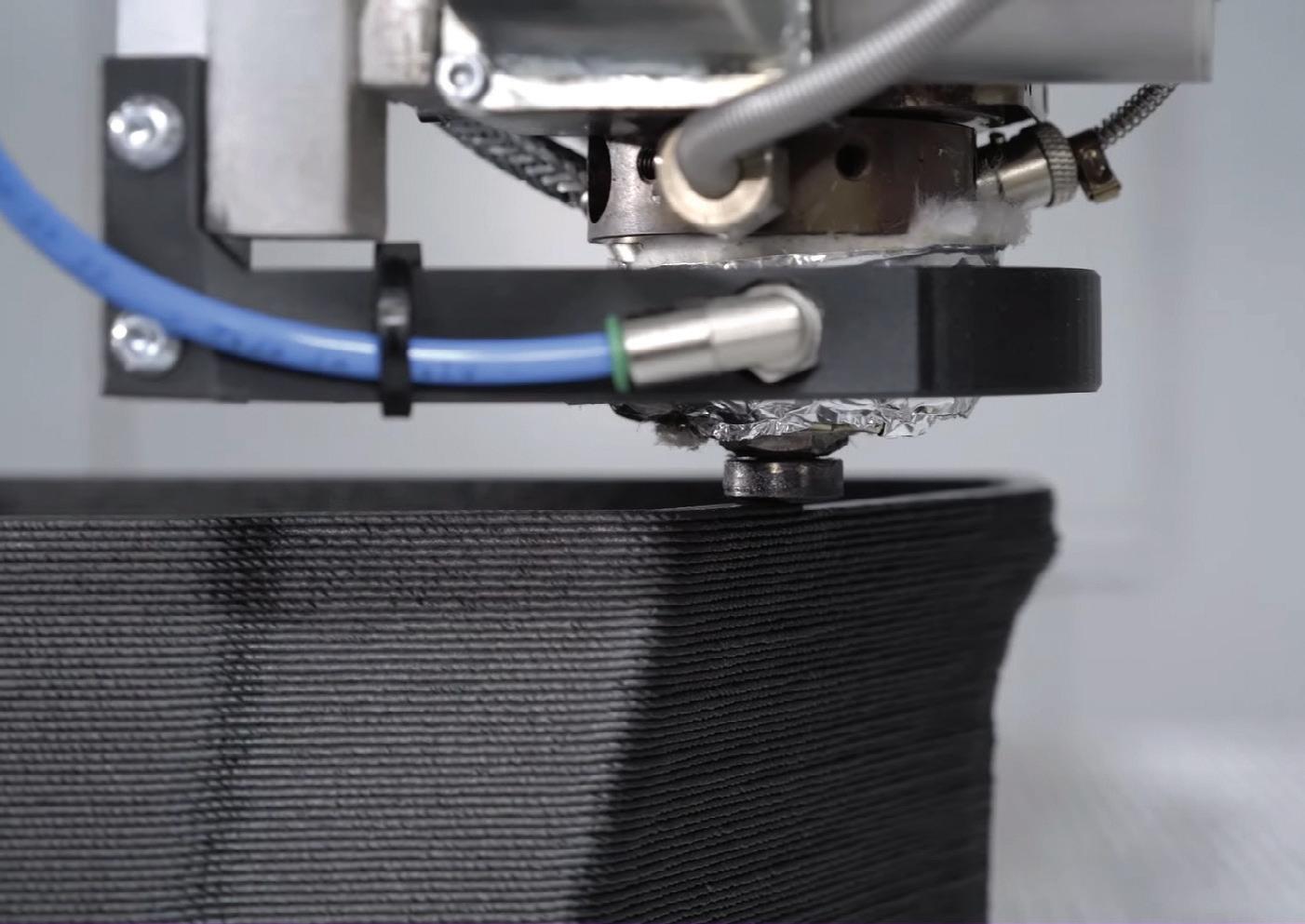

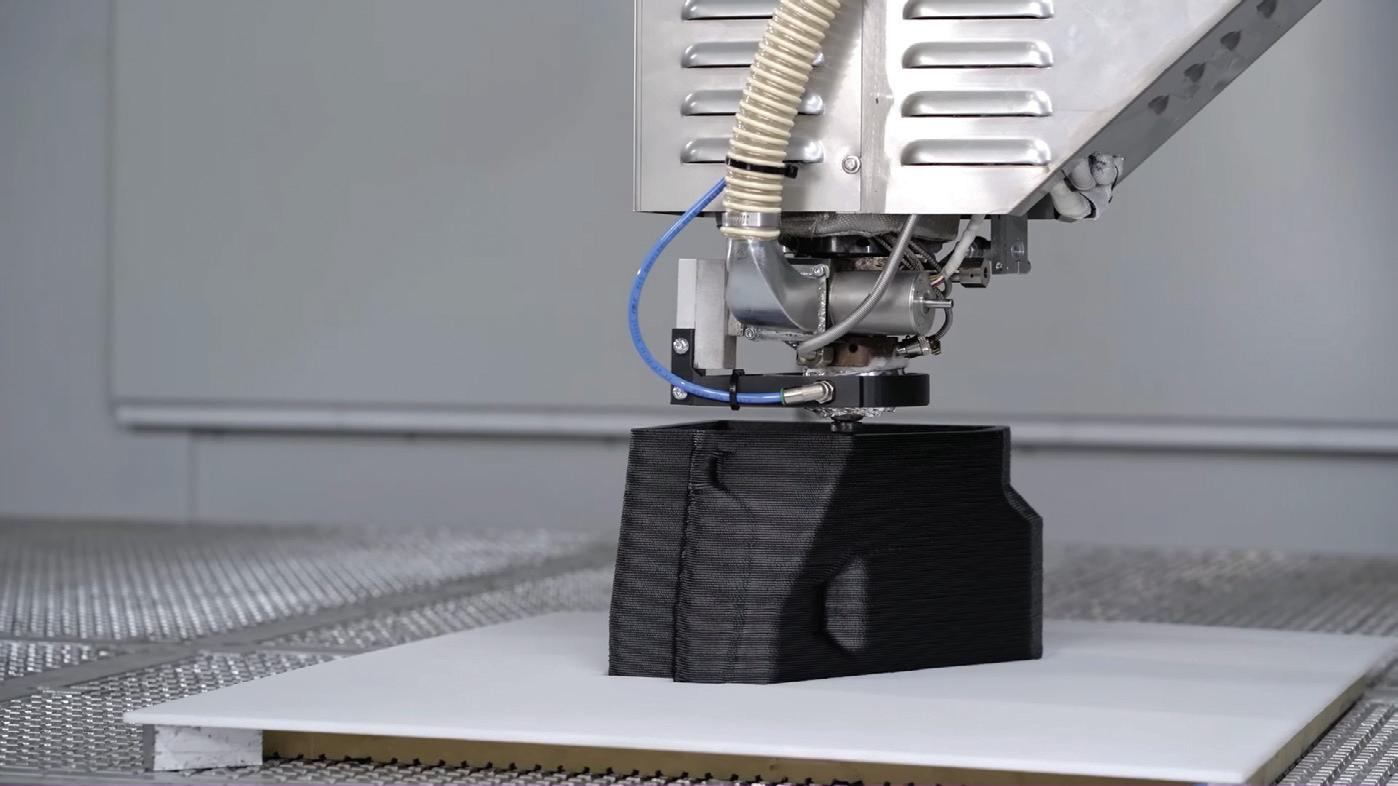

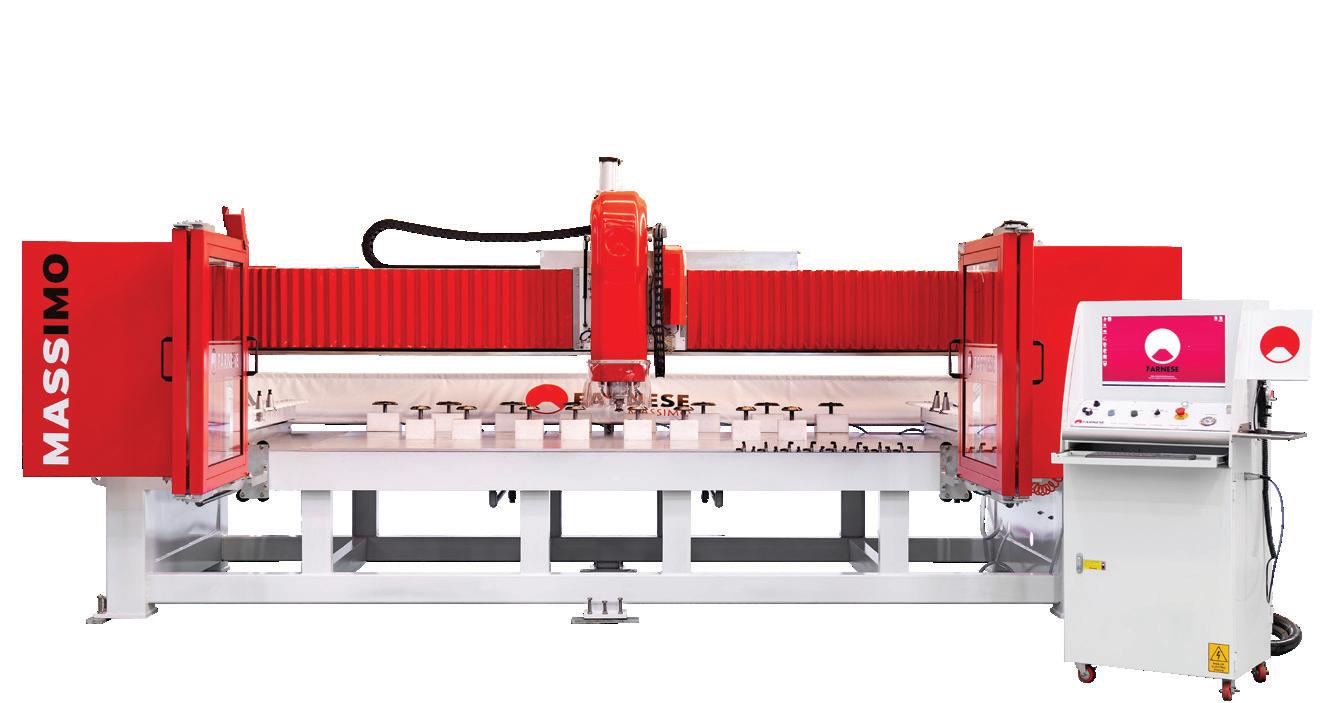

Few technological advancements truly deserve to be called innovations. The CMS Kreator is one of the lucky ones.

This state-of-the-art hybrid manufacturing system fuses 5-Axis milling with Screw Extrusion Additive Manufacturing (SEAM) to deliver unparalleled efficiency, flexibility and quality. Put simply, the system is designed to quickly build composite jigs, fixtures and tools that are lighter in weight than aluminium counterparts.

“The Kreator has quickly become a favourite machine in the range. Basically, it’s a classic 5-axis large-format CNC machining centre, integrated with large-format additive manufacturing. In this day and age, sourcing reliable suppliers of composite parts or tools proves to be a challenge, this is incredibly useful and a game-changer. Just imagine printing your part and achieve a high-quality

finish within the same machine frame. It’s a major selling point for the Kreator,” says Anthony Cruz, Advanced Materials and Plastics expert for Innovync.

The concept is to empower manufacturers to produce at premium quality in the leanest possible way, streamlining the manufacturing process while boosting material and weight savings. The result is quicker and easier material supply, leading to more sustainable production.

Developed by the Italian firm CMS, in partnership with Germany’s prestigious Fraunhofer Institute, The Kreator expands the possibilities for Advanced Materials and Plastics manufacturing. With the fusion of CMS’ already excellent milling capabilities, plus the ability to 3D print large-format parts, tooling and moulds become far more economical to produce.

That positions it perfectly for rapid prototyping in the automotive, marine, and aerospace sectors. These industries use highperformance materials and require precision for optimal results. Usually, the high cost of these requirements would drive firms to seek offshore production. Not anymore.

The CMS Kreator’s hybrid technology is designed to cater to a wide range of applications and industries. Its versatile build volume, ranging from 3x2x1m to a massive 10x4x2m, allows you to create parts in various shapes and sizes. What's

14

more, the system enables vertical 0°, 45°, and 90° 3D printing, making it an all-round manufacturing solution for your business.

Capable of processing an array of thermoplastic fibre-reinforced polymers including PLA, PP, PET, PA, ABS, PC, PEI, PESU, and many others, the Kreator ensures compatibility with a diverse range of materials. An extrusion flow rate from 10 up to 100 kg/h facilitates optimal efficiency, pairing speed with precision.

CMS' patented milling-to-printing automatic head change system eliminates the need for manual operation, streamlining production processes. Specialised slicing software has also been developed to manage print temperatures, minimise print time, and simplify the production process. The results speak for themselves. Material and weight savings of up to 80% are possible - a number that is far from insignificant. Especially in the current economic and logistics climate.

How much time and material would you save using this process? What would that mean for the oh-so-costly craft of mould production? Now you see how powerful this milling-printing fusion is.

The very first Kreator is set to hit Australian shores next year, thanks to CMS' local dealer, Innovync. The Sydney-based firm landed an exclusive distribution contract with CMS for Advanced Materials and Plastics back in 2020, adding to their Stone and Glass

coverage. None of the machines in their range or any in Australia, for that matter - are quite like this one, especially on the printing front.

"The advantage of the Kreator, apart from its capabilities, is that it’s a high-quality equipment in itself. Additionally, there are not a lot of large-format hybrid machines that are on offer out there, leaving little competition to contend with. The primary stand-out feature is its ability to print and mill high-quality parts, especially for tools, patterns and mould-making", says Anthony.

This is great news for composite manufacturers, more broadly: anyone who makes trimming and assembly jigs, machining fixtures, lamination masters and direct lamination moulds. The unique printing-milling pairing is so disruptive that it may even cultivate a new kind of manufacturing culture. Could we even go as far as to say that it has the potential to spur innovation and protect intellectual property?

Only time will tell. The real effects will only become evident once this new breed of machine flares into life. Until then, direct your questions to Anthony and the Innovync team - or follow the Kreator's progress on their newsletter and socials. z

“The primary stand-out feature is its ability to print and mill high-quality parts, especially for tools, patterns and mouldmaking."

Häfele was founded in 1923 and for 100 years adopted a policy of personal contact with its customers to better understand their needs. Häfele has become synonymous with pioneering ideas for living, working and leisure. Today, Häfele offers a complete one-stop service, comprehensive advice, sound development competence, and sophisticated logistics.

Innovative strength, courage and optimism: these are qualities which have accompanied Häfele from the very beginning. The Häfele Group has developed into the leading expert for hardware and fitting systems,

electronic access control systems and LED lighting. This year Häfele celebrates 100 years internationally and over 40 years in Australia.

It was 1923 and inflation reached its highpoint in Germany. Taking their destiny into their own hands, Adolf Häfele and Hermann Funk started a new company, ‘Products for the hardware and tool industry’ in Aulendorf in Württemberg. Within a few years the fledgling company specialised in joinery and carpentry supplies and moved to Nagold, the former centre of the furniture production in Württemberg, near the Black Forest region. It was here that Adolf established the principle of personal

contact, industry and product knowledge, reliability and fast delivery; principles that still exist today.

Coming through the second world war largely intact, Häfele became actively involved in the reconstruction of the country with the supply of fittings and joinery products. Company founder Adolf Häfele passed away in 1949, in the midst of the rebuilding and his 26 year old nephew Walter Thierer assumed the management of the company with the support of the Häfele and Thierer family shareholders. Häfele is now a global company with subsidiaries in 38 countries and an export share of 81%. In the 2022 financial year, the Häfele Group achieved sales of 1.87 billion Euros.

Since 1923, Häfele has been an innovative family business, initially serving the local market through the economic miracle years following World War II; supplying premium products made by other companies. The foundation for today's headquarters in Nagold was laid in 1950 after a fire destroyed the company building during the night of New Year's Eve. Häfele, under the management of Walter Thierer turned the disaster into a positive outcome and in 1954, Häfele started their own production of special fittings for furniture ornaments and brass grills. Demand for the products grew quickly and the production area was expanded several times.

Over the following years, Häfele established their third subsidiary in the United Kingdom in 1980, followed by subsidiaries in Australia, Canada, France, Italy, Ireland, the Netherlands, Singapore, New Zealand, Malaysia, and Japan. Today, architects, joiners, cabinet makers and dealers from more than 150 countries rely on the expertise of the innovative family business that has developed into the leading expert for hardware and fitting systems, electronic access control systems and LED lighting. In January this year Häfele took another step into the future with the appointment of Gregor Riekena as Managing Director.

Häfele offices were successively opened in Western Australia, Queensland, and Melbourne. Peter spent a few years in Melbourne before moving to New Zealand to establish Häfele there. Peter returned to Australia after ten years when in 1998 Konrad Hengstler handed over the management of Häfele Australia. Coincidentally. Konrad moved to New Zealand to open a winery where he established a winery producing Sauvignon Blanc. During most of this time, Häfele Australia maintained the founder’s principle of personal contact to the most remote areas of Australia with their 'Travelling Showroom' fitted with the latest hardware technology.

In the 1960’s a worldwide spirit of optimism existed and Häfele took advantage of this in 1964 and founded the first foreign subsidiary in Switzerland. In 1973, Häfele America was founded. The following year saw the start of Häfele’s in-house development with the company producing innovative hardware that over the years has had a lasting influence on furniture construction worldwide. A classic example of this influence was during the CNC revolution of the 1980’s; Häfele’s minifix and rafix ‘knock-down’ furniture connectors allowed manufacturers to make huge savings by assembling on-site.

1982 Häfele Australia Pty. Ltd. is founded with its headquarters in Mordialloc, Victoria. Prior to this, Konrad Hengstler was Häfele Australia’s Sales Representative. Working from home, Konrad stocked a small amount of the most popular items in his garage. All other orders were shipped and delivered direct from Germany. In 1985 Häfele celebrated the opening of the first South Australia office in Underdale, SA. In the same year, Häfele opened its first New South Wales office in Lidcombe, NSW and it was here that Häfele Australia’s current Managing Director, Peter Farrugia (pictured) started with the company.

Häfele maintains an extensive number of offices and design centres throughout Australia and New Zealand to support their customers. 'The Complete Häfele’ is a comprehensive product library builders, cabinet makers and architects turn to for up to date product. At AWISA 2012 Häfele Australia launched the Häfele catalogue app, the first of its kind in the industry.

Gary Cahoon, Head of Marketing for Häfele Australia said, “We work hard all the time to re-invent ourselves allowing us to remain at the forefront of the hardware industry.”

Häfele supplies products from leading manufacturers, co-operating with them on new product innovations. Kesseböhmer, Grass, HAWA and Salice are only a few of the companies Häfele work with. In addition, Häfele produce products such as connectors, flap fittings, bedding hardware and lighting and acoustic systems as well as electronic locking systems, in-house in several locations around Germany. Häfele’s ‘Service Plus’ value-adds by supplying complete preassembled systems.

Gary has been with Häfele Australia for 34 years. He says, “I’ve seen a company that is extremely progressive. Häfele has a fantastic culture based on family values, we invest in people, in training and in new ideas. I’ve never looked at something we did and ask why we did that. We change things for the greater good.” Konrad once said, “Change the small things, then big things will happen.” Gary agrees and says, “The little things we do build loyalty and a sense of worth.”

The international Häfele company group is preparing for the next century on the occasion of its 100th birthday with a groundbreaking change of personnel. After 20 years at the helm of the innovative specialist for furniture fittings and architectural hardware, electronic access control systems and LED lighting, Sibylle Thierer (CEO) is handing over the chair of the company management to 45 year old managing director Gregor Riekena. The Häfele Group is using its 100th birthday to look back on previous achievements, and also for restructuring under the motto of “Ready for the Future.”

“With this change at the top, we are confidently underlining our launch into the next Häfele century,” says the outgoing CEO, remaining true to her motto of: “Standing still is a step backwards” with the statement, “It’s not about doing everything like we did before, it’s about the further development of the industry.”

The trend of small spaces continues under Häfele’s slogan, “More life per square metre” but heading into the future, digitalisation will take centre stage with increasing levels of connectivity in which Häfele is positioned to take a leading role.

Sibylle Thierer will remain the chairperson of the Board of Directors, continuing the company’s family-oriented, customerfocussed culture. Sibylle said in 2007, “Without fittings, furniture is nothing more than a pile of boards.” It’s this simple and obvious observation that highlights the importance of fittings, and the company that invests in the ongoing development of product, that after 100 years, makes Häfele what it is today. z

www.leitz.com.au

Save with our special limited time offers on Leitz Compact Laminate Routers and Leitz nesting Router Cutter Diamaster PLUS

Compact Laminates have a wide range of applications due to their design and strong physical properties Since Compact Laminates usually consist of melamine, or phenolic resin impregnated papers or wood fibres, their machining is always associated with high tool wear The use of diamond and carbide cutters from Leitz is the solution for your success

Our nesting Diamaster Plus routers will cut up to 20m/min feed rates with a purposefully engineered diamond arrangement, designed to maximise tool life while maintaining perfect cut quality. These routers feature a straight cutting edge arrangement with sheer angle, Z2 for better finish quality at higher feed rates and DP cutting tablets for superior edge life. They can be sharpened up to 3 times with normal wear.

Special offers available until 30th September 2023, unless sold out Contact us now to discuss options tailored to you

Article by GECA

Article by GECA

Acommon misconception is that the circular economy is a synonym for a waste reduction strategy. However, it is far more radical than that. Talking about the circular economy only through a lens of waste reduction is like discussing the complexity of ecosystems exclusively in terms of decomposition. A truly circular economy impacts the entire structure we operate in, from design, manufacturing and consumer demand to broader social and environmental issues such as greenhouse gas emission reduction.

The circular economy is a transformational framework that forces organisations and individuals to rethink how they work and live in this global community and on this planet. A crucial part of moving away from the traditional linear approach of extract, manufacture, use and discard is keeping products and materials in use for as long as possible. A circular economy adopts a regenerative system that embraces maintaining, repairing, reusing, refurbishing, and recycling.

When we design products, services or buildings using regenerative principles, we aim to move beyond 'sustainability' and contribute a net positive impact on our natural systems. Arup describes this as designing "to improve societal resilience, restore planetary health and regenerate ecological systems."

According to the World Business Council for Sustainable Development: "The goal is to retain the value of the circulating resources, products, parts and materials by creating a system with innovative business models

that allow for renewability, long life, optimal (re)use, refurbishment, remanufacturing, recycling and biodegradation. By applying these principles, organisations can collaborate to design out waste, increase resource productivity and maintain resource use within planetary boundaries."

According to the Ellen MacArthur Foundation's glossary created in collaboration with IKEA, a circular economy is: "A systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. It is underpinned by a transition to renewable energy and materials. Transitioning to a circular economy entails decoupling economic activity from the consumption of finite resources. This represents a systemic shift that builds long-term resilience, generates business and economic opportunities, and provides environmental and societal benefits."

Thankfully, things are starting to shift. Australia's National Waste Policy, released in 2018, specifically calls for a shift from governments, industries, businesses and the public away from 'take, make, use and dispose' to a more circular approach where we maintain the value of resources for as long as possible.

In 2019, CSIRO developed a Circular Economy Roadmap, which focuses on four materials that are common waste streams in Australia, plastics, tyres (automotive and mining), glass and paper. The roadmap identifies circular opportunities across supply chains focusing on innovation and industry collaboration.

And in 2020, the Australian Government committed $190 million to a new Recycling Modernisation Fund (RMF) that will

generate $600 million of recycling investment and drive a billion-dollar transformation of Australia's waste and recycling capacity. State governments have also clarified that business as usual is no longer an option by publishing circular economy policies, statements and resource recovery strategies.

These policy examples reflect a global movement toward circular economy thinking. Individuals are increasingly becoming aware of the social and environmental impact products and services have. From where the materials come from, how we use them, to where they end up.

According to the Institute for Sustainable Futures at the University of Technology in Sydney, "By adopting the 'take-makerecreate' approach of the circular economy, Australia can go from being a global leader in primary resource production to being a leader in generating value through resource productivity.

At GECA, we know that embracing the transition to a circular economy is a significant step toward achieving our vision of a better future for all. Whether through creating or purchasing products or services, joining the circular economy is crucial to show authentic leadership in sustainability.

Trust and transparency are integral factors in creating lasting behaviour change. The best marketing an organisation can do is to prove its commitment to positive social and environmental impacts. Unfortunately, some businesses continue to make self-declared incorrect, misleading, and sometimes entirely false claims, which is a breach under Australian Consumer Law.

Often known as 'greenwashing', this practice makes it difficult for consumers to choose genuinely sustainable products and

services. Greenwashing has led to increased consumer scepticism and doubt whenever an organisation makes sustainability claims about their company, products or services, including those related to a circular economy.

This can lead to a loss of legitimacy and reputation in the marketplace. The Australian Securities and Investments Commission (ASIC) and the Australian Competition & Consumer Commission (ACCC) have prioritised greenwashing as a significant compliance priority.

"As consumers become more environmentally conscious, businesses need to be honest and transparent when making environmental or sustainability claims so consumers are not being misled," ACCC Chair Gina Cass-Gottlieb said.

The term 'environmental labelling' refers to a voluntary method of environmental performance certification that provides information about a product or service's overall sustainability benefits. The purpose of voluntary labelling is the communication of verifiable and accurate information.

The International Organization for Standardization (ISO) has created global principles and procedures for environmental labelling. ISO is an independent, nongovernmental international organisation with a membership of 165 national standards bodies. They recognise three different types of environmental labelling:

1. Type 1 - Lifecycle Ecolabels (ISO 14024)

2. Type 2 - Environmental Claims (ISO 14021)

3. Type 3 - Environmental Product Declarations (ISO 14025)

By providing all three types of environmental labelling, GECA gives consumers, suppliers and procurement teams confidence and transparency when choosing products and services.

At GECA, we've developed our rigorous lifecycle ecolabel standards, following ISO 14024 principles, which our Assurance Providers independently assess. Lifecycle ecolabels are globally recognised as the most robust and credible form of environmental labelling by the United Nations. They look at multiple impacts across a product or service's entire lifecycle, from the extraction of raw materials to the end of its life. GECA is the only Australian member of the Global Ecolabelling Network (GEN), the leading network of the world's most credible and robust ecolabels.

We currently have 27 standards based on lifecycle thinking ranging from furniture and paint to steel and cement, personal care and cleaning products, waste collection services and much more. Our lifecycle ecolabel standards are recognised by the

Infrastructure Sustainability Council's (ISC) IS Ratings Scheme, with many also contributing to the International WELL Building Institute's (IWBI) WELL Building Standard and NABERS. Over half of our standards contribute towards buildings and fitouts achieving Green Building Council of Australia's (GBCA) Green Star credits.

Contact GECA to discover how to integrate trust and transparency into your organisation, products and services.

web www.geca.eco z

DECO Australia (DECO), a leading manufacturer of aluminium buildings products, has partnered with Capral Aluminium (Capral) to supply LocAl Green lower-carbon aluminium. DECO is leading the way by being the first to commit to switching all their Capral aluminium extrusions to LocAl Green.

Announced with the Prime Minister in attendance, the agreement to switch 100 per cent of DECO’s aluminium supply from Capral to lower-carbon aluminium is an important step in DECO’s commitment to reducing carbon emissions.

“Capral Aluminium is Australia’s largest aluminium extruder, and we are pleased to announce today that DECO Australia and Capral have reached agreement for Capral to supply DECO with lower- carbon aluminium to assist in producing more environmentally friendly building products.” said Ross Doonan, founder and director of DECO Australia.

DECO’s commitment to LocAl Green aluminium is part of the company’s Sustainable Framework, which has a core environmental commitment to reducing emissions across the business, including their product offerings.

“We are continuously looking to improve our responsible material sourcing and this agreement with Capral Aluminium will assist in reducing the emissions intensity

of one of our major material inputs.” said Richard Hamber, General Manager DECO Australia.

“The switch to LocAl Green aluminium will also directly support our customers across the architectural and building industries by supplying aluminium building products made from responsibly sourced, lower-carbon aluminium, helping them to achieve their own sustainable initiatives and outcomes. “

The LocAl Green aluminium has the same technical properties as primary aluminium, however, is produced using lower emission energy sources and therefore reduces the embedded carbon of the aluminium by 50 per cent (when compared to the global

average for primary aluminium).

“We have worked together to ensure we can support DECO on their sustainability journey.” said Luke Hawkins, Capral’s General Manager of Industrial and Procurement.

“This is what it’s all about, making it possible for Australian manufacturers to make responsible and sustainable procurement decisions around Aluminium.”

DECO Australia has long been dedicated to investing in innovative and sustainable outcomes for the Australian building industry. The partnership between DECO and Capral, and both organisation’s commitment to lower-carbon aluminium, are set to pave the way for a cleaner and greener building industry.

DECO began receiving the supply of LocAl Green lower-carbon aluminium in June this year. For more information on LocAl Green visit lowcarbonaluminium.com.au.

web www. deco.net.au z

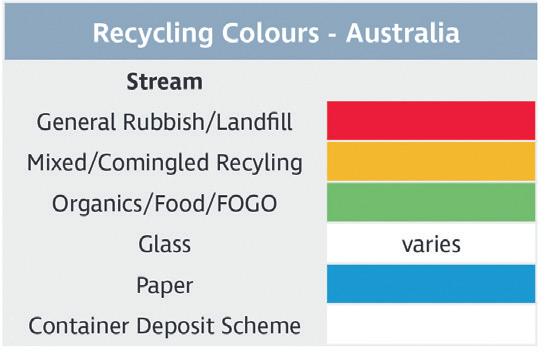

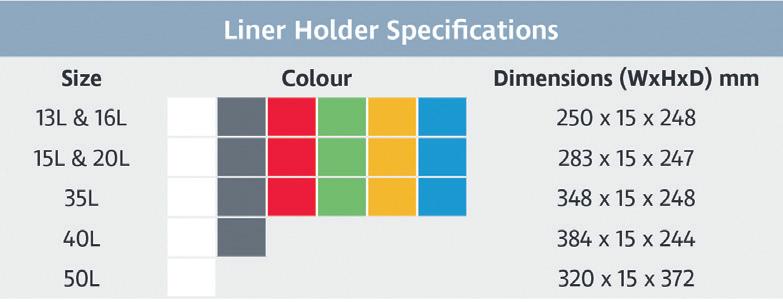

With most city councils around Australia collecting 3 or 4 types of waste and recycling, there is an increasing demand for easier ways to separate waste and recycling. Hideaway Bins are please to introduce colour coded liner holders, a simple yet effective upgrade which can have a bigger impact than you thinkread on to see the benefits of colour coding your waste bin.

Recycling can be confusing, especially if you are unsure which bin to put your rubbish or recycling into. Colour-coded bins offer a visual cue that simplifies the process of waste separation. By assigning different colours to each type of waste or recycling, such as paper, glass, and food, you can easily identify the right bin for each item.

Whether in the home or the office environment, colour-coded recycling bins serve as educational tools that promote awareness about the importance of recycling and waste reduction. The visible differentiation of bins helps everyone, even children, understand the significance of separating waste and the positive impact it can have on the environment. This increased awareness leads to improved participation and commitment to sustainable practices.

One of the most significant advantages of colour-coded bins is the reduction of contamination in recyclable materials. When materials are placed in the wrong bin, like food going into a paper recycling bin, then the material becomes contaminated. This adds more work downstream in sorting or may mean that those materials cannot be recycled at all. Colour coded bins help by separating waste at the source and reducing contamination. This in turn leads to improved recycling rates and a more efficient use of resources.

With the Hideaway Colour Coded Liner Holders, you can pick and choose which ones match your local requirements best. Not all city councils have the same colour wheelie bins for their rubbish and recycling collection, but the general colours used in Australia are:

These are available in four new colours – Red, Green, Yellow and Blue – and are available to suit all Concelo bins and most of the Hideaway Compact range.

Hideaway Coloured liner holders can be purchased separately, either to be installed with new bin units or as an upgrade to existing Hideaway Bins. The full range of Hideaway Liner Holders are:

To learn more, visit the website or contact one of Hideaway’s distribution partnersHafele, Nover or Galvin Hardware.

web www. hideawaybins.com.au z

Create a simple, sustainable waste management system at home or in the office with the new colour coded Hideaway liner holders.

These liner holders are compatible with Hideaway 13L, 15L, 16L, 20L and 35L buckets. Mix and match the colours to suit your local collection services.

Available to purchase as a separate accessory from Nover, Häfele and Galvin Hardware.

hideawaybins.com.au/linerholders

The Woodpanel Centre have partnered with American company, ModernMill, to bring their innovative ACRE material to the Australian market.

Modern Mill is leading the way toward a more sustainable future, one tree-free board at a time. Their award-winning building material, ACRE, is the ideal alternative to wood for countless exterior and interior applications. It’s beautiful, easy to work with, easy to care for and better for the environment. ACRE is a sustainable choice that doesn’t sacrifice performance.

ACRE is produced in a zero-waste manufacturing facility - using rice hulls that would have otherwise been sent to landfill - to create a panel product that has the look and feel of real timber without felling a single tree. The majority of ingredients required for ACRE’s production are sourced from within the USA, minimising emissions from logistics and creating resilient supply lines.

ACRE products are free of phenolic plasticisers such as bisphenol A, formaldehyde, and adhesives, to maximise installation potential in sensitive environments. ACRE has also received a Clean Air Gold certification.

Not just sustainable, ACRE is durable. It is water and weather resistant and will not rot, even when installed on the ground or in contact with water. Nor will ACRE splinter, as can be the case with natural timber products. Containing no timber content, ACRE is not a target of pests such as termites.

The environmental credentials of ACRE have been recognised in America, with the product being awarded as Green Builder Magazine’s 2022 sustainable product of the year. ACRE can also make a positive contribution to new construction or major renovations with points assigned to it in the Leadership in Energy and Environmental Design scheme.

Modern-Mill are not only focused on the environmental credentials of ACRE. ModernMill is re-invigorating manufacturing in the gulf coast of the USA. Their manufacturing facility has been established in a part of the country where manufacturing has waned. Their efforts include ensuring staff receive a ‘living wage’ and receive training for career progression. By sourcing their rice hulls from local farmers, they are ensuring that the benefits of ACRE are experienced by those in the local community.

Suited for a wide range of applications, ACRE sheet goods are the perfect medium for executing your ideas. This revolutionary material can be cut, curved, shaped and

moulded to fit countless applications, both exterior and interior. ACRE is also thermoformable, creating opportunities for creative design.

ACRE requires no special tooling and can be machined similar to particleboard or MDF. When being machined, ACRE does not produce any potentially harmful dust or residues.

ACRE has been installed across America in conditions that closely mirror those experienced throughout Australia. Installations of ACRE in America have reached from coastal conditions to arid desert areas and extended to snow covered areas.

The Woodpanel Centre has ACRE available in two finish options – sanded two sides, which has a timber grain look similar to quartercut veneer, or embossed on one side, which accentuates the sanded grain appearance with a crown cut pattern embossed into the face of the sheet.

Find out more at www.twpc.com.au or by visiting https://modern-mill.com/resources/ why-acre/.

web www. twpc.com.au z

Decking

Sheets

ACRE elevates building materials to a whole new level.

ACRE isn’t wood. It isn’t a traditional composite. It’s a brand-new material engineered from rice hulls that combines convenience, durability, beauty, and sustainability.

With less static or dust than PVC, ACRE is easy to stain or paint, has smooth edges and a limited-lifetime guarantee, ACRE raises trim, decking, millwork and siding to a whole new level.

interzum 2023 was a resounding success, despite the pandemic’s pause on people’s willingness to travel. The supplier sector proved to be innovative and progressive, with a particular focus this year on sustainability. Environmentally conscious and space-saving solutions should not mean sacrifices, interzum showed us they inspire creative and extraordinary new products.

interzum in Cologne, Germany, ended successfully on Friday, 12th May. With approximately 62,000 trade visitors from some 150 countries, the leading international trade fair for suppliers to the furniture and interior design industry exceeded all expectations and inspired everyone at the stands and numerous special event areas over the course of four days. “The trade fair could barely have showcased its importance for the industry any better. First-rate flagship events such as interzum are more vital than ever,” said Oliver Frese, Chief Operating Officer of Koelnmesse, the event host.

The importance of interzum for the industry was underlined by the high number of international trade visitors. Predictably, the countries with the largest number of visitors were Germany, Italy, Spain, and Poland but hundreds of Australian and New Zealand visitors were also present. Hettich’s Australian representative Martin Gane said that 60 Australian businesses were attending this time. Given the travel restrictions for China, visitors from that country were also encouraging. Foreign trade visitors accounted for approximately 76 per cent of all attendees to the fair.

The supplier sector, inspired by the neoecology megatrend is becoming greener with every passing year. Neo-ecology could best be interpreted as environmental awareness, making the most of what the planet has to offer. In a gross exhibition area of around 163,000 m², trade fair visitors were offered a broad field of creative and environmentally friendly innovations. There is much green potential to be found in the furniture industry, whether it’s the smart conservation of resources, renewable energy, or with the use of new materials.

However, not only pioneering new products provided a look into a more sustainable future for the furniture industry. Several companies also used their trade fair stand to make a very conscious statement. Subsequent to the trade fair, Vauth Sagel will plant a tree for every visitor and will reuse most of its trade fair stand. Even the fair’s organizer accepts responsibility. In the run-up to the event, interzum launched an initiative to make the world’s biggest industry event for furniture production and interior construction more sustainable in the future. Drawing on the experiences gathered

this year; the trade fair will explore how it can further integrate sustainability into future events.

Blum is a family company located in Austria, they are not in the stock market so their green focus is voluntary. All their new products must pass a sustainability test. Their main circular design interzum displayed their products in living spaces from bachelor pad through to a home for the aged. Their ‘green’ credentials were seen in their research that suggests that less food waste saves 122.9 kilograms of carbon compared to 10.41 kilograms saved by using CO2 reduced steel in their products.

Because a large percentage of the ecological impact of a piece of furniture is determined by its components, there lies an enormous potential for transformation towards a circular economy. For example, Egger sources 71 per cent of the wood used in its TM9 PerfectSense Smoothtouch Matt lacquered boards from the circular economy. This new product is 100% recyclable at the end of its life cycle and can be used to produce new boards.

Häfele showed what can be achieved, not what they supply, it was a more conceptual stand in nature. One product that did stand out was the new ‘Free Slim’ family of flap fittings, available in Australia some time next year, speak to your Häfele representative. Free Slim is unique in terms of both design and functionality. Free slim is a hardware system with a minimalist design. Thanks to its extremely slim design and the possibility of integrating it directly into the cabinet wall, it maximizes the storage space volume of furniture, therefore putting furniture design and the impression of movement in the foreground.

forms of movement: swivel action as well as rotation through 180 degrees. FurnSpin from Hettich fascinates in all types of furniture.

The Salice Folder is a system developed to allow complete access to the internal space of both conventional and corner cabinets and, at the same time, to minimize the space taken up by the cabinet doors when they are fully open. Folder is a combination of hinged doors with a sliding system. When opened, the two doors fold and overlap each other until they automatically reach the point of maximum opening. This frees the cabinet interior from any obstruction and allows the unencumbered opening of full-width internal drawers without the use of spacers. The closing action is extremely smooth and controlled with a gently decelerated movement.

Visitors to the Titus stand were able to experience the Titus flagship T-type hinge family, designed for quick assembly and consistent lifetime performance. Now with a tool-free hinge cup fixing system for fast and easy mounting along with the exceptional stability of the recent T-type-i 170-degree hinge with integrated damper effective for tall doors. In the area of custom damping solutions, the highlight was the new damper for cold environments.

Hettich’s award-winning FurnSpin is inspiringly different. The innovative fitting for the high-end segment does away with old style formats and puts a creative new spin on furniture design. Open doors or flaps no longer get in the way – most of the cabinet body can now be moved with effortless ease. A stylish turn leaves furniture to reveal what's inside. Hiding everything from view again, a further spin returns furniture to its closed state. FurnSpin synchronizes two different

Also from Titus, the new Tekform Slimline+ drawer, the latest addition to the Titus drawer range. One of the standout features of the drawer is the three-dimensional adjustment mechanism and front panel connection making engagement and disengagement reliable and easy. z

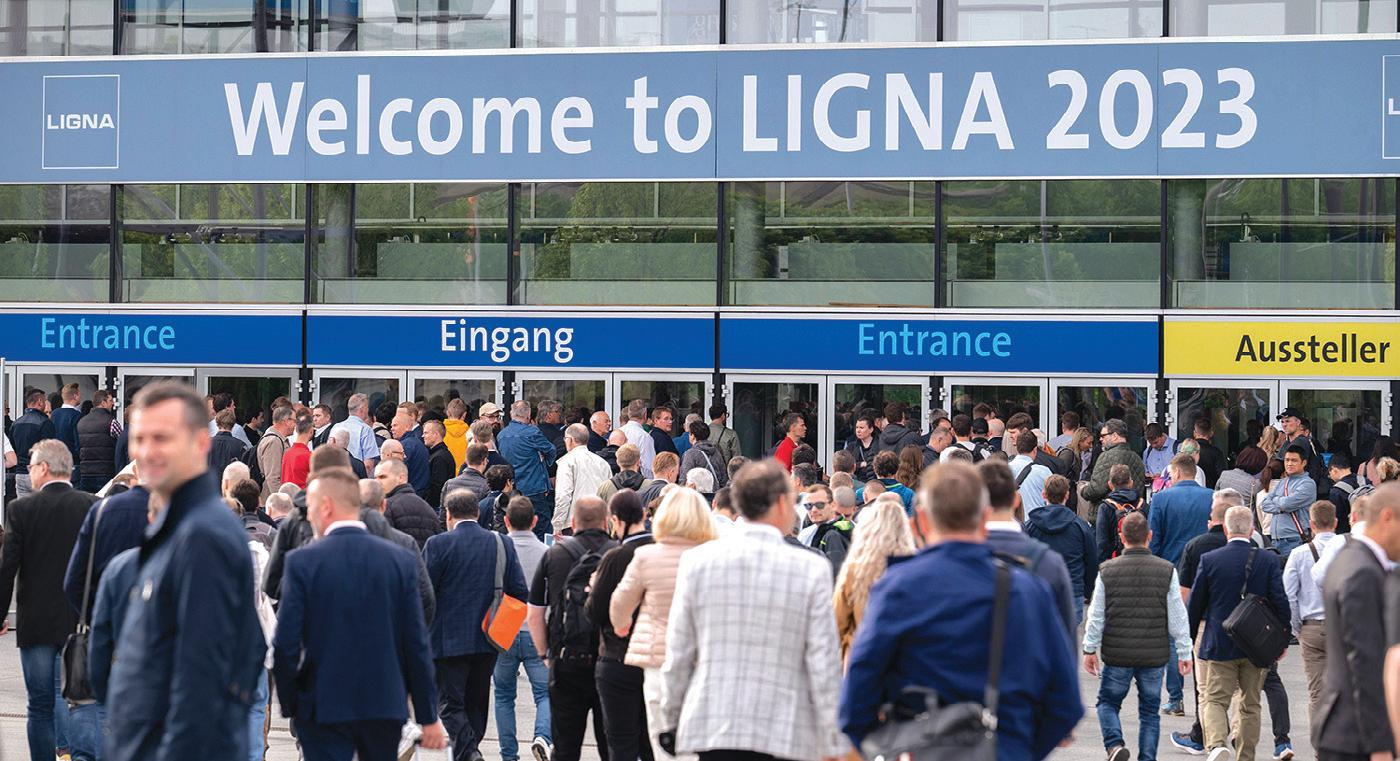

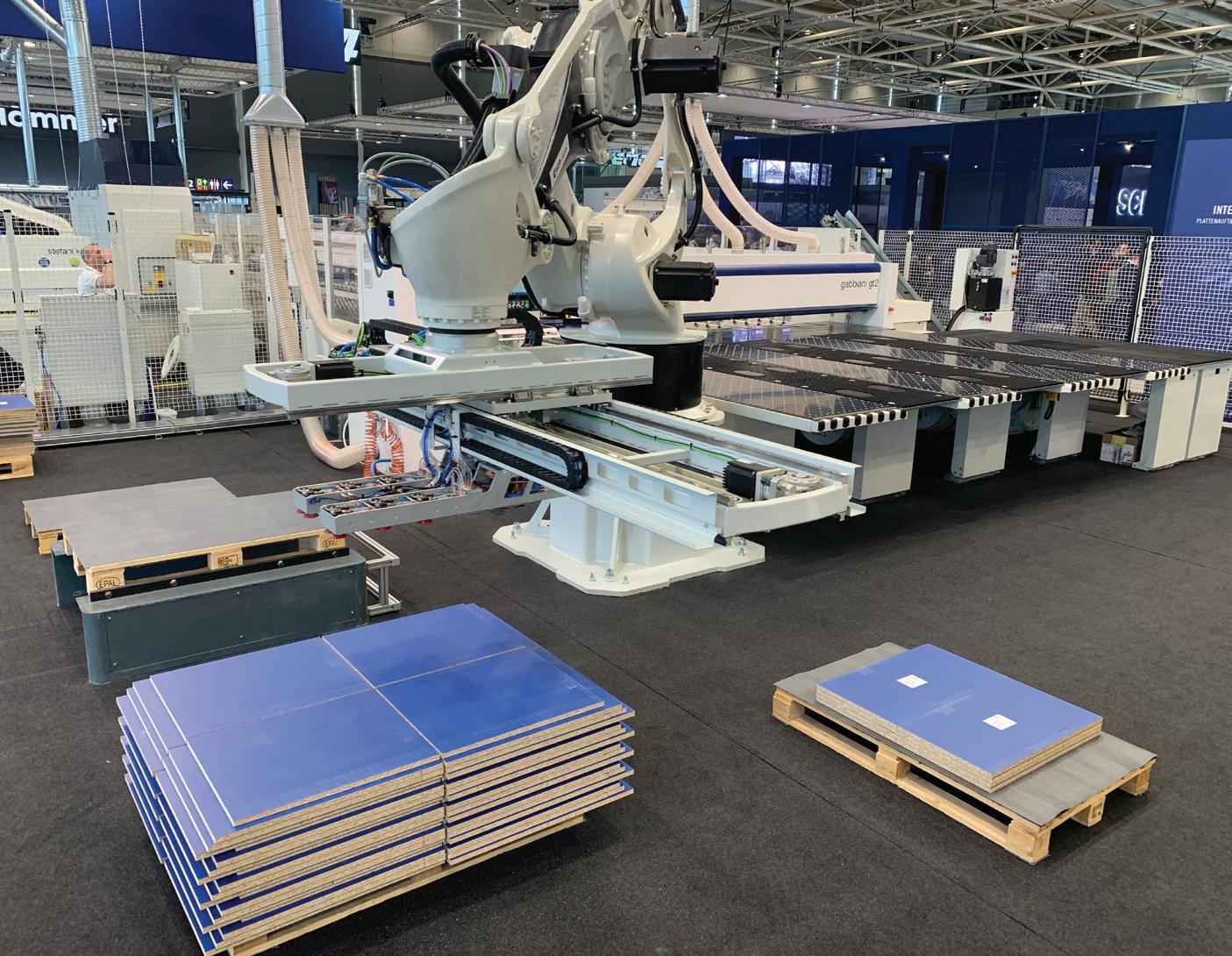

Exhibitors and visitors to Ligna 2023 were thrilled to finally meet again in person after a four-year interruption and witness firsthand the concentrated innovative power of the woodworking and wood processing industry. Not only is Ligna a driver for the industry in good times, but it also delivers solutions for the challenges ahead.

Over its five-day run, from 15 to 19 May, LIGNA 2023, the world’s leading trade fair for woodworking and wood processing featured a flood of innovations, inspiration, and networking. 1,300 companies from 50 different countries presented their solutions for the wood industry, the furniture and cabinet-making industry, the woodworking trades, and the primary sector. The focus was on the ‘megatrends’ of sustainability and digitization. 80,000 visitors from 160 countries took advantage of the opportunity to inform themselves about smart machines and resource-saving production processes.

“LIGNA 2023 was not only a platform for presenting new technologies, but also a venue for knowledge transfer and networking,” said Dr. Bernhard Dirr, Managing Director of VDMA Woodworking Machinery. “The show demonstrated that the woodworking and wood processing industry offers its customers the necessary technologies for competitive, and sustainable production. Smart, connected machines, systems and processes make costs and production more efficient. There was also strong demand for automation and process-optimizing solutions to cushion the impact of the shortage of skilled workers.

The entire range of the value chain was on display, from woodworking machinery and equipment to tools and work processes, industrial robots and even exoskeletons from Festool to support experts from the skilled trades and forestry. The machines on display are often no longer exclusively limited to processing wood, but are also usable for glass, plastics, and composite materials. Furniture or even construction elements are made from a wide variety of materials. It’s logical that LIGNA exhibitors are expanding their product portfolios and offering their customers a wide range of processing options.

Vit Kafka, CSO of the Altendorf Group said, “A lot of great achievements have happened at Altendorf Group to make the work of our partners and customers even more efficient and successful.” At this event Altendorf Group showed HAND GUARD, the world’s ‘first and only’ AI- and camera-based safety assistance system for sliding table saws; the new,“next” series of Hebrock edge-banders; the wellknown F 45 sliding table saws in a multitude of configurations; the new, F 35 sliding table saw, and the myALTENDORFGROUP Service App.

Raphaël Prati, Biesse Group Marketing & Communications Director said, “We're here with a new visual identity, presenting ourselves as a multi material company providing solutions under one brand for wood, of course, but also glass, stone and the Advanced Materials Sector.” Biesse showed an integrated system with panelsizing and nesting solutions connected with SmartConnection, its internal order management software. The focus was also on a new edge-banding machine with batch size 1 and robotic automatic loading and unloading, with which Biesse aims to take an important step towards sustainability. Also on display, a showstopper, was-a prototype edgebanding machine using hydrogen power to apply laser edge-bandings.

PCS in cooperation with the Vienna University of Technology. Specifically, the worldwide patented safety system detects human tissue in the danger zone and by the Electromagnetic repulsion principle, makes the saw blade disappear under the table in a few milliseconds as if by magic.

Achim Homeier, HOMAG GmbH, Senior Director, Global Marketing & Product Management said, “Digitization along the entire process chain of our customers offers considerable resource savings potential. As a production partner, we offer digital solutions to permanently increase efficiency, for example value stream mapping and various service assistants to increase machine availability.” Revealed at the Homag stand was an algorithm to check cut quality of the sawblade, high speed edge-banders now use mechanical ‘dogs’ spaced evenly to maintain flow of material through machine: no overhead belts. Homag showed how you can print colors or designs on neutral edge banding to reduce inventory of edge bands.

tool changer. The horizontal machining of the workpieces in conjunction with two automatically controlled clamping tongs enables a very high machining speed. It is possible to machine several workpieces on top of each other.

process costs from rising unnecessarily. Socially, a clear sign and visible statement of the high level of responsibility that prevails within Leitz is that over the last year, more than 1,600 employees in 31 countries on four continents spent around 3,200 hours cleaning waterways, maintaining landscapes, assembling school supplies, donating blood, or getting involved in other social or environmental projects.

Colin Clisby, Andrew Masters, and Peter Schilling were at the KDT stand and revealed that KDT is now the biggest beam saw manufacturer in the world; the biggest CNC drilling machine manufacturer in China, with 3,000 machines per year; and produce 10,000 edge-banders a year. A new factory later this year will double production. Now with real laser edge banding and speeds of up to 40 metres a minute means you will need a feed system. KDT released their new TF 600 KT 6-sided machining center with 5-station

The aim of sizing with jointing cutters is tear-free edges on both surfaces, best achieved with diamond-tipped tools that have alternating shear angles. Studies over many years by Leitz Group have shown that the best processing results in terms of tear-free edges are best achieved with tools that have a shear angle of 50 degrees, for example, with the EdgeExpert cutting tools from Leitz. This is the only way to produce a perfect cutting result during jointing and prevent

LEUCO uses the Fibonacci system from nature in the design of its products to further improve their performance and has applied for a patent on the design principle. Thus, with the spiral-like arrangement, LEUCO is able to fit the highest possible number of cutting edges into the limited space of the body of a tool, like a sunflower is able to accommodate the maximum number of seeds in its flower.

Arranged at a golden angle of 137.5 degrees, the cutting edges are also in an optimal position in relation to each other. The advantages of the new design range from better cutting quality to smoother operation, a finer cutting pattern, higher feed rates, longer tool life, and can reduce the power requirement of the machine by up to 20 percent.

SCM Group Smart&Human Factory is an integrated system of machines, software, and services. The process starts in the office where orders are imported from management software (ERP) or order-entry systems and other SCM office software is used at the design, optimization, and simulation stages, before production. The orders to be produced are then planned using MES software that allows the work to be distributed across the machines, optimizing productivity. The cells are automated using articulated robots to ensure quality, repeatability, and guaranteed process times. They are also connected by unmanned AMR shuttles, an evolution of the traditional AGVs because they can move safely in the areas and around people thanks to 3D cameras.

Oliver Kunzweiler, Director Central Marketing Weinig Group said, “It was absolutely crazy to be here at LIGNA 2023. The place was crowded! We measure ourselves in constructive competition in order to convey the best possible solutions to customers.” On 5000 m² Weinig Holz-Her showed innovative large-scale plants for industrial companies up to stand-alone machines for the craft.

Customers can take advantage of the Digital Transformation with completely engineered Weinig plants including allround worry-free packages for profitable production and to successfully counteract the shortage of skilled workers. At Ligna, Weinig announced a partnership with Essetre, a family-owned Italian company. Essetre design and produce exclusive and customized NC woodworking machines with patented technologies.

Biesse, Burkle, Homag, Ima Schelling, SCM, Weber and Weinig have worked together as a team in defining a standardized interface to connect all their woodworking machines, machine to machine, and machines to the customers’ Manufacturing Execution Systems. It’s a common machine link called IZY. This means no individual interfaces need to be programmed and overall control of the production process is readily put in place. In future, the same way as you connect your printer in the office world, just as easily you will connect a WEINIG automatic profiling machine to an SCM CNC machining center. The next LIGNA runs from 26 to 30 May 2025. z

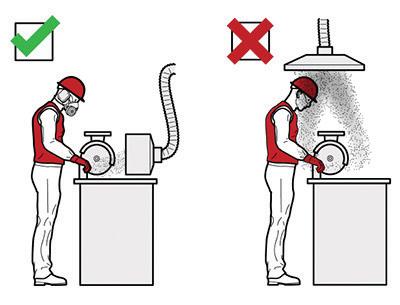

The control measures that are the most effective for your workplace will depend on your industry, work processes and the risk of exposure.

It is most likely you will need to use a range of control measures to protect your workers from exposure to silica dust. You will also likely need air monitoring and health monitoring programs to confirm your control measures are working and your workers are protected.

When managing workplace risks, WHS Regulations require duty holders to work through hazard identification and Hierarchy of Control. There are four steps involved in managing workplace health and safety risks according to a Safe Work Australia fact sheet, beginning with hazard and risk assessments followed by implementing and reviewing control measures.

While the best way to control a risk is to eliminate the hazard altogether this may not always be ‘reasonably practicable’, in which case risks should be minimised as much as possible using the following steps.

Identify what could cause harm.

Understand what harm could be caused, the likelihood and how serious it could be and whether any existing control measures are effective.

Implement the most effective control measures that are reasonably practicable in the circumstances using the Hierarchy of Risk Control.

To ensure they are working effectively.

In light of this, a Safe Work Australia Model Code of Practice mandates Hierarchy of Control measures. Hence, the Workplace Health and Safety (WHS) Regulations require duty holders to work through the hierarchy when managing risks.

Ultimately, the Hierarchy of Control ranks risk control measures from the highest level of protection and reliability to the lowest level of protection and reliability.

Eliminating the hazard creating the risk is the most effective. Then, substituting the hazard with something safer follows. Lastly, isolating the hazard from people or reducing risk using engineering controls.

Personal Protective Equipment (PPE) and administrative actions sit as the last line of defence. It should only be used after all other control measures have been assessed or a supplementary control measure.

Whenever a single control measure is not sufficient, use a combination of controls.

Level 1)

Eliminate the hazard altogether

Get rid of the dangerous machine.

Level 2)

Substitute the hazard

Use a safer alternative by replacing the machine with a safer version.

Isolate the Hazard

Keep the machine in a closed room and operate it remotely.

An example of this would be to attach a guard to the machine to protect users.

Practice administrative controls

Train workers how to use the machine safely.

Personal protective equipment (PPE) is anything a worker uses or wears to keep them healthy and safe.

Engineering controls use physical methods to change the characteristics of a task. The best engineering controls for your workplace will depend on the tasks your workers carry out.

Engineering controls to control silica dust include:

• Automation when cutting, grinding or drilling

• Using wet cutting methods

• Local exhaust ventilation

• Drills, routers, saws and other equipment designed to be fitted with H-class local exhaust ventilation and a water attachment to suppress dust

• Using sacrificial backer-boards or spoil boards

Above: Examples of local exhaust ventilation use

• Fitting large machinery such as excavators and bulldozers with positive pressure enclosed cabs, and

• Cleaning up dust with a M or H-class industrial vacuum cleaner

Research has found that even when wet methods are used on products that contain high levels of silica that silica dust is not adequately controlled. Applying water to

rotating tools can also generate silica contaminated mist that must also be controlled.

For this reason, properly designed water suppression and local exhaust ventilation should be used in combination when working with these products. It is important to only use tools and machinery that have been specifically designed for

use with water attachments with the appropriate ingress protection.

For more information visit Safe Work Australia - www.safeworkaustralia.gov.au z

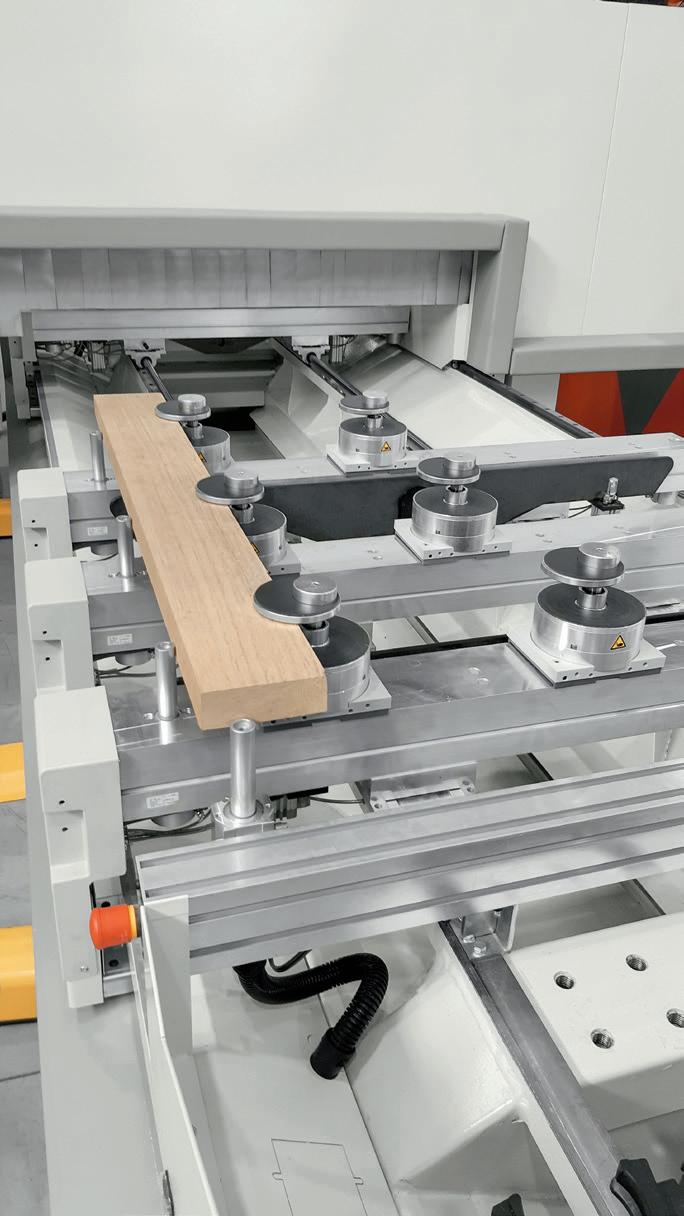

Pfitzner Furniture produce quality bespoke furniture from mainly solid timbers, using traditional methods of furniture construction. To meet the demands of small batch production while maintaining consistent high quality, Pfitzner turned to Biesse Group for their latest technological advantage, a high end ‘Rover A’ 5-axis CNC machine.

For over fifty years, Pfitzner Furniture have designed and created high-quality bespoke furniture from solid timbers. Starting out in a farm shed in 1972, John Pfitzner began making furniture using traditional methods such as mortise and tenon joints for leg and rail construction, and dovetail joints in his drawers. Pfitzner Furniture continue to design their furniture with these traditional construction methods at the core, while adopting modern technology with a recently installed five-axis Rover A CNC machine from Biesse Group.

The company is now operated by John’s sons, Andrew and David, but the passion for product quality and customer satisfaction was instilled by their father, who over many years was totally devoted to his customers. John said, “It’s really important to work with our customers, to understand what they are expecting us to make for them. We try and involve them as much as possible.” Pfitzner have an extensive range of furniture products, but each piece is crafted individually, and custom made to customer requirements.

The traditional ways of individually ‘benchmaking’ furniture remains at the core of the business but with the investment in 5-axis Biesse technology, parts with consistent and repeatable quality can quickly be produced in small batches to meet Pfitzner’s current business model of individuality. In fact, on the Biesse Rover A, every part for an entire piece of furniture could be machined in the one setup, a feat that meets the highest and purest level of the meaning of ‘batch size one.’

Initially, Pfitzner rented time on CNC machinery owned by other companies in their network. David spent some time working these machines and writing programs. With this background knowledge John, David; a qualified wood machinist, and Andrew made an astute investment in what they believed to be the best, most cost-effective CNC machine available at the time; a 3-axis Biesse Rover 30. This machine was installed in 1999 and provided over 20 years of service, a fantastic return on investment.

John saw CNC processing as the future of the industry and recognised the ability of computer numerical controlled equipment to provide a means of adapting to their customer’s needs, of being an integral element in the ability to bring a new design to market. At the time, the Rover 30 was an important factor in the production of a range of furniture Pfitzner was exporting to Japan. Fast forward to June 2022 they installed their new 5-axis Biesse Rover A after a similar thorough investigation of all the available 5-axis CNC machines on the market.

With the new CNC machine Pfitzner invested in Biesse Group’s electronic positioning system (EPS) machine table that automating the movement of the pods and rails, eliminates the risk of collisions and drastically reduces the set up time. A second significantly productive investment was made in Biesse Group’s innovative -pneumatic locking devices ‘Uniclamps’ that allow more extensive machine movements and the ability to hold narrow and -small components and together with auxiliary vacuum system for customer jigs make it possible to lock and process any shape. David said, “These

innovations are awesome. With the EPS table and Uniclamps, we can cut a panel in half to maintain the grain matching, automatically separate the pieces with the EPS table and machine the hinges in both parts for a butterfly extension.”

It has been said of furniture making that ‘If you can make a chair, you can make anything.’ Pfitzner Furniture crafts a huge range of dining chairs. The chair is an evolving demonstration of design and represents the highest level of applied materials and technology. Acclaimed for its reliable functionality; it is the most used piece of furniture. Andrew said, “It’s one of the unique things we make. In the early days of our company, we made a lot of traditional Victorian furniture and that’s where our fine furniture mindset has come from.”

Pfitzner’s extensive range includes solid timber dining tables and chairs; cabinets and sideboards; hall, coffee and lamp tables; TV entertainment cabinets; bedroom and lounge furniture; sofa’s and recliners; executive commercial and boardroom furniture, home office and bookshelves; bespoke wall units and custom made furniture. Each of Pfitzner’s craftspeople works on just one 38

piece of furniture at a time, using parts that invariably come straight off the Rover A.

Today, Pfitzner furniture is sold exclusively from their Adelaide Hills factory showroom and Norwood Parade store in Adelaide. Pfitzner furniture is tested to the highest standards of durability by Furntech-AFRDI in Tasmania. They are so confident with the construction and quality produced by their skilled cabinet makers and Biesse equipment that Pfitzner provide a 10-year structural guarantee. On any piece of Pfitzner Furniture you will find their original logo. Pfitzner like to think their customers will enjoy their furniture for decades, possibly for centuries.

A Cliché,

Nonetheless,

Often overused, the cliché that your machinery supplier is also your business partner, is for Pfitzner Furniture, accurate. David says, “We have a really good relationship with Biesse Group, they are very supportive. They spent a lot of time with us to make sure we got the machine we needed, that it would do everything we wanted from it. The training provided by Biesse’s Australian-based 5-axis technician was quicker than we expected, and we were able to start using the machine confidently by ourselves in only a few weeks. It was actually a lot of fun.”

David adds, “Two of the reasons we stayed with Biesse the second time was because of their technological advantage and their software, which we believe is superior to any other we looked at. Sophia IoT adds value to our machine and our company by providing information about the performance of the machine and any maintenance we need. Sophia Parts also allows us to order any parts we need and will certainly reduce our downtime.” Andrew adds, “Our Biesse Rover A will enable us to compete with high-end European-made imports. There is more of this coming into Australia than you would think.”

Pfitzner’s maintains a commitment to sustainable business practices. They take pride in being very active on minimising their imprint on the environment. All timbers are sourced from Environmentally sustainable mills in Australia and USA and are FSC and PEFC compliant. Andrew recalls a recent request by a customer building a new home on his farm. “He asked us to make his furniture from the roof beams of his demolished house, we always enjoy a challenge and while working with recycled timber isn’t always easy, we were up to the task.”

Pfitzner Furniture is a true family business, and this culture extends to the people who work with Andrew and David. As David said, “We are nothing without our people, they are involved in every part of our business, in all of our decisions.”

Pfitzner have always apprenticed people and many of the 15 or so people in the factory started out as a Pfitzner apprentice, some of these people being employed for 30 years! This long term commitment is matched by their partnership with Biesse Group. As Andrew said, “We are very excited about the possibilities.” z

In another exciting development for The Stirling Group, they have now become the authorised Australia and New Zealand distributors of Casadei Busellato woodworking machinery. The Italian manufacturer’s product line includes 5-axis CNCs, wide belt sanders, spindle moulders, thicknessers, surfacers and sliding table saws, and more.

The Stirling Group’s Craig Honeyman says the distributorship represents yet another way the Group can service customers’ needs with high-quality machinery.

“We’re making a strong foray into the furniture and joinery industry,” he says. “We originally brought on Bacci, another incredible Italian machinery manufacturer, as a starting point, and we’ve had our eyes on a couple of other suppliers. Casadei Busellato fulfils the complete range for us.”

Aside from the company’s longstanding reputation for excellence, another compelling feature of Casadei Busellato is that it offers versatility along the spectrum of business size and output. As such, The Stirling Group can support customers utilising very simple manual operations through to industryleading technology-driven machines.

“With Casadei Busellato on board, we can service businesses from sole traders through to high-volume manufacturers,” Craig explains. “We can cater for anyone going into CNC for the first time, right up to quite intricate 5-axis CNC work. And we can supply traditional machinery as well as the high-end automated equipment.”

Leon Botes, Group Product development Manager for The Stirling Group says the Casadei Busellato offering opens up a wide array of options for customers.

Wide belt sanders

Six models of wide belt sanders are on offer, starting with the Libra 10, catering for small artisan shops right up to the Libra 65X for large factories requiring high production rates.

The Libra 45 model will be an excellent addition to most factories, equipped with technologies that are usually only available on larger machines, which makes it a very versatile machine for small to medium size factories.

“A unique feature we are really excited about,” Leon says, “is their Sanding Belt/Feed Mat Optimising System. This feature shows the operator the optimal position to place the workpiece to optimise the sanding belt and feed mat wear by means of coloured LEDs.”

Casadei Busellato offers three ranges, starting with the basic range with manual adjusting through to the top range offering NC adjusting and electronic programming, ensuring quick and precise setups.

The F235 Spindle Moulder will be a welcome option for small to large factories, equipped with NC adjustment for the spindle and fence positioning and the option to add an HSK spindle for quick tool changes.

“We’re particularly thrilled with the heavyduty independent tenon table for the spindle moulder. It provides the ability to process large tenons with a cutter diameter of up to 300mm.”

There are two models in pod and rail CNCs, starting with the Jet Elite, available in 3- or 4-axis, with a set working area of 3115mm x 1320mm. The Jet Master T is available in 3-, 4-, and 5-axis, with a maximum working area of up to 5515mm x 1620mm.

Leon says the Jet Master T–XL will be a particularly attractive solution for door and staircase manufacturers, offering a 5515mm long X-axis, ideal for machining long frames and stringers.

“We know our customers will be excited by the IMCs (Interchangeable Modular Cups), supporting the whole range of vacuum pods and clamps and offering the flexibility to use the best-suited support for any application.”

On the CNC side, Panel Tools (The Stirling Group’s CNC tooling business) will be supplying the tooling package to go with the Casadei Busellato machines. Panel Tools specialises in supplying CNC tools and producing custom tools for the flat panel and solid timber manufacturing industries. Its co-founder and co-director, Fraser Killen, says there is an obvious synergy in the partnership.

“We see Panel Tools as being another jewel in the crown for The Stirling Group’s Casadei Busellato distributorship,” he says. “Even the most elite machinery in the world can only be as good as the tooling used with it. We are already known by our customers to go the extra mile to help. Not only is our tooling of the highest quality, but we also provide custom tooling options to suit specific purposes.”

Leon says that bringing together The Stirling Group, Casadei Busellato, and Panel Tools creates a powerful supply line for customers in the furniture and joinery industry.

“Having them all under the one umbrella is fantastic,” he says. “When we talk about supplying multiple machines to the same customer, all from the same brand, it makes it easier to interlink the equipment. Also, when customers set up a brand new factory, if we can accommodate that with the same brand of machinery throughout, it streamlines everything.”

Craig is keen to point out that the Casadei Busellato distributorship means The Stirling Group can also look after the manufacturer’s existing customers in Australia and New Zealand.

“Honestly, Casadei Busellato machines are built to last and offer many years of reliable service,” he says. “In terms of support, maintenance, and servicing, we’re here for all Australian and New Zealand Casadei Busellato users. If they have questions, we’ll have answers. If they need special tooling, we’ll have that too. I can’t emphasise enough how powerful this relationship is. We look forward to introducing the Casadei Busellato excellence to customers all over the two countries.” z

AI (Artificial Intelligence) is used worldwide to improve production times and safety in manufacturing, including woodworking industries. For a decade, we’ve known it as Industry 4.0 or the ‘fourth industrial revolution’ and the ‘internet of things’. But what is AI and how will it affect manufacturing industries?

Turing. Turing was a leading cryptanalyst (code breaker) at the Government Code and Cypher School in Bletchley Park, Buckinghamshire, England during World War II. Turing’s research in the early 1950s laid the foundation for modern computer science. In 1947 Turing said, “What we want is a machine that can learn from experience,” and that the “Possibility of letting the machine alter its own instructions provides the mechanism for this.”

software; condition-based monitoring that optimizes the performance of equipment by continually assessing its condition in real time. AI software collects data from sensors and applies diagnostic tools and processes including machine learning that can identify, detect and address issues as they occur, and predict the likely future state of your machine, all good news.

Not so long ago Artificial intelligence was a thing of science fiction. Think Terminator; the Matrix; 2001 A Space Odyssey, and the brilliant but chilling Ex Machina. AI hit the news in March of this year when Elon Musk, CEO of SpaceX, Tesla & Twitter co-signed an open letter calling for a pause of at least six months in the training of AI systems. Musk was a partner in OpenAI, an artificial intelligence research and deployment company that launched ChatGPT in November 2022. In July, the Telegraph (UK) reported that Musk actually warned of a ‘Terminator’ future right about the time he launched his own AI venture, xAI.

The first person pushing the AI initiative was British computer pioneer, Alan

The practical test for computer intelligence is known as the Turing Test. If questioners are unable to distinguish the computer from a human being, asked the same questions, then the computer is considered an intelligent, thinking entity. Interestingly, the computer is permitted to lie and deceive. In late 2022 the advent of the large language model ChatGPT reignited conversation about the likelihood that the components of the Turing test had been met. Data scientist Max Woolf said that ChatGPT had passed the Turing test in December 2022, although this is contested.

Of interest to the woodworking industry is that Computer Numerical Control was developed in 1952 at MIT (Massachusetts Institute of Technology), that was at the same time conducting research into AI. Recently, suppliers of CNC equipment have introduced predictive maintenance

Industrial AI is the application of AI to industrial use like the movement and storage of goods, supply chain management, advanced analytics, and automation and robotics. In 2022, North

In 2022, North American companies ordered over 44,000 robots; 11% more than in 2021, costing US$2.4 billion.

American companies ordered over 44,000 robots; 11% more than in 2021, costing US$2.4 billion. DHL uses Boston Dynamic’s ‘Stretch Robot’ that can grab packages from all corners of a shipping container without knowing how it was loaded or having information about the individual packages themselves. Industrial AI is distinguished from other types of AI because it’s more focused on the application of AI technologies than in the development of human-like systems.

Manufacturers use AI-powered solutions to optimize operational efficiency, drive innovation, and improve profitability. industrial AI in manufacturing includes predictive analytics that helps identify early signs of anomalies anywhere in the factory, reduce unplanned downtime, and fine-tune maintenance scheduling. Self-

aware smart equipment can independently measure performance to generate alerts when quality or performance is reduced for any reason. Robotics and automation can replace human involvement, increasing efficiency and boosting production while improving safety for human workers.