“All dairy, all the time”™

Dairy industry continues to grow in SD

Recent data shows large increase

By Jan Lefebvre jan.l@star-pub.com

PIERRE, S.D. — The dairy industry’s growth trend in South Dakota rolls on, according to a press release Feb. 13 from the South Dakota State News.

As of January, the total number of dairy cows in the state equaled 208,000, the press re-lease said. This represents a 70.5% increase since 2019 and a population that more than doubles that of 12 years ago when it stood at 90,000.

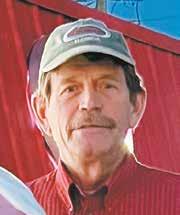

Tom Peterson is executive director for South Dakota Dairy Producers. He summed up the reason his state has seen success in growing its dairy industry when many other states have not.

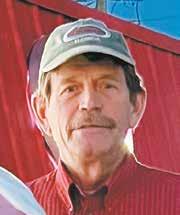

Tom Peterson Executive Director, South Dakota Dairy Producers

Tom Peterson Executive Director, South Dakota Dairy Producers

“In a nutshell, the growth was the result of commitment from the dairy industry and dairy community, including processor investment to create plant capacity, dairy farmer investment to ll the capacity, and the entire dairy industry creating infrastructure and support for the growth in cow numbers,” Peterson said. Creative planning, he said, helped to foster the upward trend.

“If we go back around 20 years in the early 2000s, South Dakota’s dairy cow numbers hit an all-time low at just under 80,000 milking cows and a trend that put dairy (in the state) in real peril,” Peterson said. “A future-thinking group of stakeholders came together with a vision to turn the dairy industry around and not just survive but create a path to grow South Dakota into a recognized dairy state.”

Finding common ground

Iowa dairy farmers to lead National Young Cooperators Program

By Abby Wiedmeyer abby.w@dairystar.com

CLINTON, Iowa — Matthew and Hannah Lansing are combining their experiences of growing up on dairy farms to grow their network and be a voice for fellow producers. The pair was elected to serve as chairperson for the National Young Cooperators Program as representatives of Prairie Farms Dairy Inc.

The Lansings want consumers to know that just because farms look different from the road, they often face similar challenges and work toward similar goals.

“We’re excited to have this platform to share our story as well as gain leadership to help us along the way,” Hannah said. “(We’re also excited to) meet other producers that share the same struggles we do.”

A new chapter

Schefers brothers decide time is right to sell herd

By Jan Lefebvre jan.l@star-pub.com

LAKE HENRY, Minn. — When Schefers Brothers LLC sells its 55 dairy cows later this month, it will be the rst time that cows have not been milked on the farm since 1943.

It will be a big change for brothers Ralph and Ken Schefers as well as for Ken’s wife and son, Julie and Jason, who own and operate the dairy farm near Lake Henry. However, they said the time has come for the next chapter.

March 9, 2024 Volume 26, No. 2

PHOTO SUBMITTED

Turn to LANSING | Page 2

Ma hew and Hannah Lansing a end the cheese contest held during the Naonal Milk Producers Federa on na onal mee ng. The Lansings were selected to serve as chairperson for the Na onal Young Cooperators Program. The Lansings work with Hannah’s family on the farm, where they milk 1,200 cows and farm over 5,000 acres.

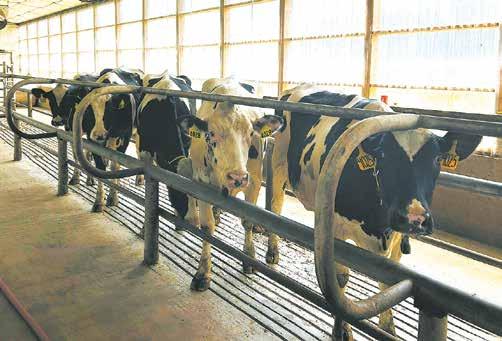

MARK KLAPHAKE/DAIRY STAR

Turn to SCHEFERS | Page 6

Ralph, Jason and Ken Schefers stand in their estall barn Feb. 27 near Lake Henry, Minnesota. Ralph and Ken have been milking cows together since 1979 and recently decided to sell their herd. Jason is a partner on the farm.

Turn to SD GROWTH | Page 9

LOOK INSIDE FOR OUR CENTRAL PL AINS DAIRY PLAINS EXPO PREVIEW EDITION!

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com 320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer

608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303

Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN)

507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota)

605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN)

320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin)

608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA)

507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

The Lansings work with Hannah’s family near Clinton. Matthew works on the dairy full time while Hannah works for a feed nutrition company. Blue Hyll Dairy is home to 1,200 milk cows and over 5,000 acres of crops. The Lansings work in partnership with Hannah’s dad, Marty, and uncle, Mike.

Marty runs the day-to-day operations for the cows and employees while Mike handles the business and cropping portion of the operation. Hannah said it is a family-run operation with her grandpa’s siblings and cousins helping along with Matthew.

Matthew and Hannah joined the operation one year ago. Before that, Matthew worked in genetic sales for four years with a focus on managing heifer inventories, reproductive performance and synchronization programs. He also served as team and budget manager.

Hannah travels to various farms around the Midwest focusing on the nutrition.

“That also provides a unique perspective coming into this as a chairperson as well,” Hannah said. “We can see different stories from these farms that we interact with. We had an opportunity to come home, which was always our dream, to be involved in the farm.”

The Lansings plan to take on an ownership role in the farm eventually. Leaning into the topic of transition has been eye-opening for the couple as they realize how much there is to learn. They

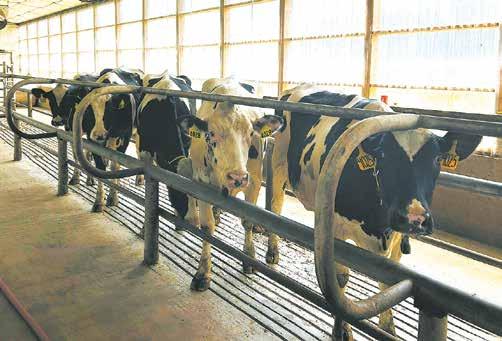

Cows are sorted to the

rail

Blue Hyll Dairy near Clinton, Iowa. Ma hew and Hannah Lansing were

to serve as chairperson for the Na onal Young Cooperators Program. are working with consultants in the industry to explore early steps they can take to make as smooth a transition as possible since the older generation could be a decade from retirement.

Figuring out the next steps for the farm’s future is a topic that a lot of farmers struggle with, the Lansings discovered.

“We felt we were alone and the

only farm experiencing this,” Hannah said. “As we talked to different people, we found that they are all experiencing the same things, just in different capacities. So, connecting with these people to see how they’re dealing with their transition can give us insight into our future as well.”

Turn to LANSING | Page 5

Page 2 • Dairy Star • Saturday, March 9, 2024 North America dealers. DAIRY ST R ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com Deadlines The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication. Subscriptions One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order. Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. © 2023 Star Publications LLC

Isaacson Sales & Service Lafayette, MN Dave's Repair Farm Equipment Hills, MN Northland Farm Systems Owatonna, MN Bodsensteiner Implement Company Elkader, IA Burco Sales Independence, IA Dee Implement Of Waukon Waukon, IA Kunau Implement Company Dewitt, IA Rexco Equipment Farley, IA Greiner Implement Company Ottumwa, IA Helmuth Repair Kalona, IA Beck Implement Elgin, MN Woller Equipment Swanville, MN Miller Sellner Slayton Slayton, MN Invest in Quality ® www.kuhn.com Visit your local KUHN Hay & Forage dealer today! GMD PREMIUM & SELECT SERIES | Mounted Disc Mowers 5'3" – 10'2" working widths CLEAN , EVEN CUTTING • • ® • •

Con nued from LANSING | Page 1

PHOTO SUBMITTED

palpa on

for breeding or health assessment on

selected

Why did you decide to serve as a board member, and how has that involvement beneted you? First Section: Pages 15 -16, 18 FROM OUR SIDE OF THE FENCE: For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, March 9, 2024 • Page 3 Staricka loses skid loader in re Second Section: Page 36 Swanville, MN Zone 2 Zone 1 Udermanns awarded as First District Association’s Young Cooperator of the Year Third Section: Pages 2, 4 Sartell, MN FFA: Inside the Emblem Third Section: Pages 10 - 11 Dyersville, IA Hoeers upgrade to robotic milking system Second Section: Pages 3 - 4 New Vienna, IA Deters takes part in shows, makes goat dairy products Second Section: Pages 32 - 33 Spring Grove, MN Wolf shares information about trends in the dairy community Third Section: Page 3 Norwood Young America, MN Columnists Ag Insider Page 10 First Section F Dear County Agent Guy Page 36 First Section Dea Ag P Firs The “Mielke” Market Weekly Pages 10 - 11 Second Section Veterinary Wisdom Page 37 First Section Vet V W Pa P Fir F s From the Zweber Farm Page 38 First Section n F Zwe P Firs Country Cooking Page 38 Second Section C C P The NexGen Page 39 First Section Bluff View Elementary welcomes farm procession for ‘I love to read’ month First Section: Pages 32 - 33 Lake City, MN Carrington, ND Cows and Co. Creamery now bottles milk First Section: Pages 8, 12 Leidings are added to list of Gopher Dairy Club Distinguished Service Award winners First Section: Page 26 Roseville, MN

Page 4 • Dairy Star • Saturday, March 9, 2024 LET OUR TEAM DO A COMPLETE WASH ANALYSIS • Reduces equipment wear & replacement costs. • Reduces water, energy and chemical use. • Decreases cleaning time. •Increases production capability. BENEFITS $ Compare and Save! High Performance Single-Cycle CIP Acid Detergent FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 THE NEXT GENERATION IN ON-FARM WATER TREATMENT Chlorine Dioxide Technology Dirty Water? • Respiratory Issues • Scours • Crypto • Salmonella • E-coli GREATLY REDUCED: Pure 3000 CLEAN IT UP WITH Removes IRON, MANGANESE and SULFUR in water! HEALTHIER CALVES HEALTHIER COWS S. S. ONE SHOT HIGHLY EFFECTIVE AGAINST: Prototheca • Staph Aureus Mycoplasma • Pseudomonas Improve Footbath Accuracy and Reduce Costs! The AgroChem Footbath Dosing System delivers the results you’relooking for in a high-quality footbath program. • SIMPLY SET IT AND FORGET IT! AUTO-PROGRAM FEATURE SIMPLIFIES FOOTBATH PROCEDURE. • REPLENISH SYSTEM FEATURE AUTOMATICALLY ADDS WATER AND CONCENTRATE AS NEEDED. • SAVES MONEY BY REDUCING LABOR THROUGH AUTOMATION, MAINTAINING PROPER FOOTBATH CHEMISTRY AND ONLY ADDING FOOTBATH SOLUTION WHEN NEEDED. • SAFE - REDUCES EMPLOYEE INTERACTION WITH CHEMICALS • BEST WHEN USED WITH HEALMAX®, DURAHOOF, OR ULTRA 2N1 423 US Hwy 61 N Lancaster, WI 53813 900 US Hwy 14 W Richland Center, WI 53581 (800) 887-4634 | Dairy Supply Online: www.dairysupplyonline.com Visit StearnsBank.com/DairyStar or call (800) 247-1922 Member FDIC | Equal Housing Lender You’re working hard today for a better tomorrow. We’re here to lend a hand. With over a century of personal service, we’re ready to help you and all you are working toward. Equipment finance Farm & land lending Full-service banking options

Matthew agreed.

“A lot of it right now is up in the air,” Matthew said. “Right now, we’re trying to absorb and learn as much as we can while they’re still here working alongside us. We’re just taking it day by day and learning as we go.”

Duties as chairperson for the Lansings will include attending the National Milk Producers Federation board meetings and speaking on behalf of farmers as well as attending other dairy events like World Dairy Expo. There will also be a meeting in June in Washington, D.C., which will focus on dairy legislation.

“That will be cool for us because that’s something that neither of us is very familiar with,” Hannah said. “When you’re a farmer, you focus on the day to day of the farm and not necessarily everything that’s going on around you.”

Matthew said he is also looking forward to learning more about the Federal Milk Marketing Order, how to increase labor options for the industry and product expansion.

“What are some things that we could do in the future to keep dairy a place that people want to come work and they want to be a part of this industry?” Matthew said. “And, how do we innovate to get more products to these millennials and (members of Generation Z) and into their life as something that they need to have to continue sales and protability within the dairy industry?”

Hannah said it was important to her and Matthew that they run for the role of chairperson as a couple so they could effectively bring both their perspectives

to the table.

“There’s power in numbers,” Hannah said. “We complement each other well and provide unique perspectives that we each have. (By) growing up in the dairy industry, but on different farms and different sales routes, we’ve gotten to experience a lot of different things.”

Matthew agreed.

“It’s learning as we go and nding a plan and a path along the way,” Matthew said.

Dairy Star • Saturday, March 9, 2024 • Page 5 320-836-2145 or 800-450-2145 www.famofeeds.com Check out our newly redesigned website to nd a Famo Feeds dealer near you! At Famo Feeds, we strive to provide the best support for your operation and work to accommodate your specific needs. From calf to cow and everything in between! TRUST THE EXPERTS • Milk Replacers • Starter Feeds • Protein Concentrates • Premixes • Minerals • Animal Health Products • Lick Tubs FEED THEM FAMO!

Con nued from LANSING | Page 2

PHOTO SUBMITTED

A calf is born at Blue Hyll Dairy near Clinton, Iowa. Ma hew and Hannah Lansing work with her family on the farm, where they milk 1,200 cows and farm over 5,000 acres.

“I consider ourselves fortunate we were able to go that long and have had family working together and good quality employees,” Ken Schefers said. “It was hard work, but it was fun.”

terest in the different breeds and even the color.”

Ralph agreed and said registered cattle t their operation better.

The Schefers brothers have dairy farmed together since 1979 when they combined their herds, and they will continue their other operations on the farm after the cows are sold.

“We are going to do some cropping and raise some steers,” Ken said. “Jason wants to remain part of the operation as well.”

As the brothers wrap up their dairy farming careers, they can look back to successes they have had, and they have a number of awards as well as recognitions from their co-op to show for it.

“I’m most proud of that one, when we got platinum,” Ken said, referring to an award they received for low somatic cell counts.

Ken said they have worked hard to reach and maintain low SCCs and credited his dad, Leander Schefers, with always focusing on clean cows even though he did not have any way to measure SCCs when he owned the farm.

“Dad always had one of the cleaner (barns),” Ken said. “Our parents were always a little bit fussy about being clean, and there was always an interest in quality.”

When the brothers took over, they began to focus on genetics and started building a registered herd, using the prex RaKen.

“I liked the registered end of it,” Ken said. “I always had more of an in-

Today, their herd’s average SCC is 89,000, production is at 27,630 pounds, butterfat 1,210 pounds and protein 932 pounds.

“When we started here, our cows averaged 600 pounds of fat,” Ken said.

Ralph said they also have bred for characteristics that helped make their cows better for milking.

“We used to use a lot of udder supports at one point — we had about a third of the herd that had them on — and now we haven’t had one in 10 years,” Ralph said. “We have always done the corrective breeding, more now than in the past, but we sit down after chores at night and look through the bull book and look at the cow’s weak points and try to nd a bull that nicely ts her.”

Ralph handles reproduction, and another of Ken’s sons, Jonathan, does the sire selection and the registrations.

The Schefers family has also incorporated conservation methods. In 2014, their dairy became one of the rst certied farms in the Minnesota Agriculture Water Quality Certication Program. Ken serves on the Stearns County Soil and Water Conservation District board, being elected in 2020.

“We always wanted to do as good of a job as we could, and that goes for everything,” Ken said. Turn

Page 6 • Dairy Star • Saturday, March 9, 2024 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! Call Us At (715) 223-3361 Or visit us on-line at www.cloverdaleequip.com N13835 County Rd. E - Curtiss, WI 54422 HOME OF THE CLOVERDALE MIXER Artex S200 CALL FOR PRICING New Hoosierland 1450 Spreader - CALL FOR PRICING Hoosierland 1300 spreaders $44,500 Artex SB600 CALL FOR PRICING New JBM Mfg T-1200DB Dirt Boss Dumper 12 ton dump wagon CALL FOR PRICE Electronic Dairy Board Repair Service Specializing in: WestfaliaSurge, BouMatic, & DeLaval pulsators & Takeoffs, circuit boards, Mueller milk tank circuit boards. Call: (c) 406-590-7764 www.circuit xer.wixsite.com/ boumaticboardrepair Repair vs. Replace BULK OR BAG Wood Shavings S&S Wood Products 35335 Green Street | Independence, WI 54747 800-234-5893 | 715-985-3122 320-836-2284 • 1-888-276-1751 29033 Co. Rd. 17, Freeport, MN In St. Rosa www.arnzenconstructioninc.com Your One-Stop Shop • Agricultural Building • Welding • Barn Parts • Equipment

nued from SCHEFERS | Page 1

Con

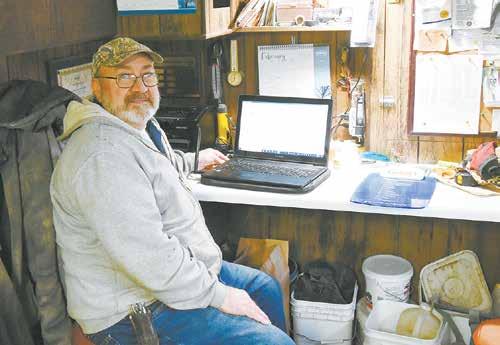

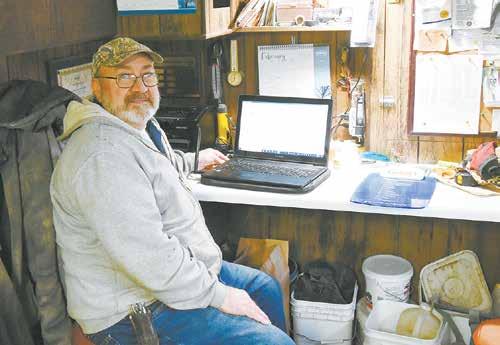

MARK KLAPHAKE/DAIRY STAR

Ken Schefers does computer work Feb. 27 on the dairy he operates with his brother, Ralph, and his son, Jason, near Lake Henry, Minnesota. Ken and his wife, Julie, started milking in 1975.

SCHEFERS

7

to

| Page

The farm came into the Schefers family when Leander bought the site in 1943 and began milking six cows by hand. Ralph and Ken remember helping their dad and their mom, Rosa, milk 21 cows, using milking stools in the tiestall barn that was expanded and upgraded in later years and is still used today. The original part of the barn has half-logs for its beams.

Ralph graduated in 1975, bought the cows from his dad and began his career on the home site. He said he always knew he wanted to be a dairy farmer.

“I had a passion for it always,” Ralph said. “I remember my dad used to sing in German while we milked, and I always liked at the end of the day when you thought you did things right and everything was taken care of. I liked doing the best we could.”

The same year that Ralph took over the herd at home, Ken and Julie started acquiring and milking cows in a rented barn at a different site.

In 1979, Ralph formed a partnership with Ken and Julie. They expanded the barn on the home farm to allow for a bigger operation, adding 48 cows. They also built two silos. With Ken and Julie living in the farmhouse and Ralph living across the road, they handled the work together.

As Ken and Julie’s family grew, the barn became a hub of activity with their four sons and one daughter each taking turns with chores.

“Some preferred feeding more,” Ken said. “Everyone had a milking at night.”

Julie, Ken and Ralph handled the morning milking. Julie did the record keeping. Leander and Rosa continued to help at the farm after they moved to town.

“Dad came out a lot and did most of the eldwork for many years,” Ken said.

The farm’s success was a true family effort and became a third-generation farm in 2013 when Ken and Julie’s son, Jason, joined the partnership after several years working in construction.

With Ken and Julie’s kids now grown, Ralph and Jason milk cows with the help of one employee. Ken mixes feed and washes buckets. A high school student works two hours at night. Julie helps where needed and still handles the books.

However, Ken is now 72 and Ralph 66, and the physical toll of dairy farming is a challenge. The time has come to sell the cows.

“It’s got to the point where it’s hard for us older people to get the work done,” Ken said. “It’s also getting more difcult to nd people to work in stall barns who have the skills to

run the equipment.”

Ken has a plate in his back and has had two knees replaced. Ralph has arthritis. Running the dairy operation would be too much work for Jason to do alone.

So, the farm will go on without the dairy cows. The decision is difcult, the brothers said, because they have loved dairy farming.

“It’s been a great pleasure, and it’s going to be hard,” Ken said.

Schedule-wise alone, the change will be big for Ken and Ralph, considering they can remember only one day when they both missed milking. That was in August 2021 when they went to a Willie Nelson concert.

Looking back, the brothers said they appreciate the people they have worked with in the industry.

“You’re not alone,” Ken said. “It’s a community. You need all of them to make the farm work.”

Mostly, the Schefers brothers said they feel gratitude for their long career.

“It’s a gift,” Ralph said. “It’s a job you can do for 50 years and still learn things. Farming keeps you humble. … I like that.”

Mark Klaphake contributed to this article.

Dairy Star • Saturday, March 9, 2024 • Page 7

nued from SCHEFERS | Page 6

Con

MARK KLAPHAKE/DAIRY STAR

Ralph Schefers preps a cow during night milking Feb. 27 on Schefers Brothers LLC near Lake Henry, Minnesota. The Schefers brothers are selling their herd in March.

Moo-ving forward with A2A2

Cows and Co. Creamery now bottles milk

By Jan Lefebvre jan.l@star-pub.com

CARRINGTON, N.D. — In recent years, research has shown that some people previously identied as lactose intolerant are, in fact, not so. They simply have trouble digesting the A1 protein that is in much of the milk we consume, which is often the A1A1 or A1A2 variant for beta casein.

This has opened an opportunity for a niche market within the dairy industry for milk without the A1 protein — A2A2 milk.

With this in mind, Cows and Co. Creamery, a gelato and cheese processing business in North Dakota, began bottling and marketing A2A2 milk on a small scale last month with plans to grow the venture.

Casey and Maartje Murphy own Cows and Co. Creamery, which is located on their farmstead near Carrington.

The Murphys, along with Maartje’s mother, Conny Van Bedaf, as well as two other full-time workers, run the creamery with assistance from up to 20 part-time employees.

Milk for the enterprise comes from Van Bedaf Dairy, which is about 3 miles away. Here, Maartje’s brother, Piet Van Bedaf, her father, Corne, and 23 employees milk 1,500 cows and grow feed on 1,200 acres. Another brother, Dries, helps there as well. The cows are milked in a double-24 parallel parlor.

The bottling venture at Cows and Co. Creamery could not have happened without a supply of A2A2 milk. That is where Piet Van Bedaf comes in. For about ve years, he has been breeding his farm’s herd using only A2A2 bull semen to convert the herd to producing only A2A2 milk.

“At the same time, we started testing our heifers being born to conrm whether they were A2A2 or not,” Van Bedaf said. “There was potentially a market in the future (for A2A2 milk), and genetics-wise, it was not holding us back in any way — A2A2 bulls are just as good as non-A2A2 bulls — so we didn’t think we were giving anything up in that aspect.”

Today, about 75% of all rst- and second-lactation heifers at Van Bedaf Dairy have been tested and proven to

be producing A2A2 milk. The farm is getting close to its goal of being 100% A2A2.

“People have the thought, and there is some data to suggest, that Jerseys and Brown Swiss have a higher tendency to be A2A2, but that doesn’t always seem to be the case,” Van Bedaf said. “We have some Brown Swiss in our herd, and

some of them are A1A2. Our herd is 99% Holstein, and we are using only Holstein bulls.”

The Van Bedafs are careful to pen off cows that have been tested and proven to produce A2A2 milk to ensure the 1% of the farm’s milk that is used at Cows and Co. Creamery is A2A2. The rest of the farm’s milk goes to Cass Clay Cream-

ery in Fargo.

“We have two pens, each consisting of 170 cows, that are 100% A2A2,” Van Bedaf said. “If the creamery needs milk on a certain day, we milk those cows into a clean tank, and then, they load milk out of that tank.”

Page 8 • Dairy Star • Saturday, March 9, 2024

Turn to COWS & CO. | Page 12

PHOTO SUBMITTED Casey (le ) and Maartje Murphy stand in the café at Cows and Co. Creamery, which is located on their farmstead near Carrington, North Dakota. The café is open two Saturdays per month and draws 500-600 customers each me.

The stakeholders came from many sectors of the dairy industry.

“This group (included) … dairy farmers, state ofcials, South Dakota State University leaders — especially the department of dairy science — processors, dairy supply companies, nancial institutions and SDDP,” Peterson said. “Due to the efforts of all involved, processing capacity expanded to create an estimated need of 85,000 additional cows to ll the newly created capacity. While a lofty goal, the cows came more quickly than many could have realized, surpassing the original goal (and) leading to just over 200,000 in total today.”

“Even with time to plan, growth always has some challenges which arise. Examples of that continue to this day in terms of higher construction costs, ination and occasional supply chain issues with materials and components needed for construction, be it on-farm or with processors expanding.”

Marv Post Board Chair, South Dakota Dairy Producers

Marv Post Board Chair, South Dakota Dairy Producers

Most of the increase has been in the size of herds as opposed to the number of herds.

“South Dakota, like most states, has seen an overall decline in number of farms over the years; the state has leveled off at around 145 permitted dairy farms for several years,” Peterson said. “The growth in cow numbers has been a mix of new-to-South Dakota farmers as well as existing farms willing to expand to grow into the capacity available.”

Peterson said there are reasons for the increases coming in that form.

“Like most segments of agriculture, dairy farming is very capital intensive, limiting the ability to just jump into rst-time farming,” he said. “That said, a number of existing farms have expanded to create opportunities for nextgeneration family to be involved with the farm.”

Marv Post is board chair for SDDP and has been involved in the association’s efforts to pro-mote dairy. He said the long-term plan for increasing dairy in South Dakota included infrastructure and other support systems.

“Processing and an available market are generally the limiting factor when it comes to growth in dairy,” Post said.

“When the South Dakota Dairy Drive vision created by key stakeholders in the dairy industry took shape (in 2012), the balance of new processing capacity being added, along with cow numbers growing to ll that new capacity, sparked the growth curve upward. In addition to the efforts of the entire dairy industry, readily available forage and feeds and an overall business-friendly environment in South Dakota create a great place to dairy with a reasonable cost of production.”

Post said stakeholders not only needed to create and execute a plan, but they also had to accept that it would take time to see effects.

“Plant expansions are at least a twoto three-year process at a minimum, which also gives a window for other related work to take place, including new farms being constructed,” Post said.

Dana Munyon is the public affairs specialist for the South Dakota Department of Agriculture and Natural Resources. She said the state’s government has striven to make South Dakota a dairyfriendly state.

“Our taxes are low; our regulations are common sense and provide certainty,” Munyon said. “Both of these are key components of successful industry development.”

Munyon said clarity in regulations helps dairy producers and others navigate through those regulations.

“South Dakota works hard to provide a consistent and straightforward regulatory framework encouraging compliance and protecting our natural resources for our kids and grandkids,” Munyon said. “Our producers know if they come to South Dakota and follow the rules they will be able to build and grow their businesses.”

Looking to the future, Peterson said he expects continued growth.

“There is a current plant expansion of approximately 3 million pounds (of milk) per day slated to be completed in early 2025, which equates to somewhere around 30,000 cows, so growth will continue into the immediate future simply based on that,” he said. “The mindset remains the same for South Dakota in that balanced growth is still the goal as long as it makes sense.”

That will include adjustments as unpredictable things happen.

“High building costs, interest and ination have created a cautionary look forward along with periods of lethargic demand,” Peterson said. “However, the dairy industry has a history of being optimistic, and there is a sense that these challenges will be addressed, creating future opportunities.”

Munyon said the state’s government also remains positive about dairy’s future in South Dakota.

“The Governor’s Ofce of Economic Development made a concerted effort to grow the dairy industry,” Munyon said. “In addition, expansions in processing capacity and the availability of feed and water have helped the dairy industry thrive in South Dakota. Since 2010, we have seen consistent growth in our dairy cow herds and, based on our strategic location in the center of the country, DANR believes the industry will continue to grow.”

Dairy Star • Saturday, March 9, 2024 • Page 9 Footbath DOSING SYSTEM 423 US Hwy 61 N Lancaster, WI 53813 900 US Hwy 14 W Richland Center, WI 53581 (800) 887-4634 | Dairy Supply Online: www.dairysupplyonline.com “We looked at installing an automatic footbath to eliminate employees having to handle and mix the chemicals like they would with a traditional footbath. We are happy with the system, as it has proven to be easy and efficient to use. It has also helped us to save on chemical costs.” Daniel Kieler, Kieler Farms Inc. - 1,800 cows - Automatic Footbath installed January 2018 Stall Bedder Specialists with bidirectional belt fills all stalls on dead-end alleys! FRONT UNLOAD OR REAR UNLOAD “Custom Built Equipment, Built to Last” 360.354.3094 405 Birch Bay-Lynden Road, Lynden, WA 98264 info@whatcommfg.com www.whatcommfg.com Truck-mounted units available Straw Bedders Rear Discharge Stall Bedders Rear Unload Sand Bedders And much more! Visit our website for more pictures, options and specifications. Models up to 30 yard capacity

Con nued from SD GROWTH | Page 1

Authorized Bobcat Dealer K & L Bobcat, Inc. Darlington,WI 13866 HIGHWAY F | DARLINGTON, WI | 608.776.4556 | www.klbobcat.com Bobcat® and the Bobcat logo are trademarks of Bobcat Company K & L Bobcat, Inc. Darlington,WI Customer Appreciation Day March 27, 2024 Special on Bobcat Parts Only 10% Discount on Cash Purchases 8% Discount on Credit Card Purchases

Buffer bill signicantly increases penalty

A bill moving through the Minnesota House would dramatically increase the penalties for violation of the state buffer law. Failing to plant vegetation on land bordering water would rocket from $500 to $10,000. The Environment and Natural Resources Finance and Policy Committee approved this bill on a party-line vote, and it will now move to the Judiciary Finance and Civil Law Committee. South St. Paul Rep. Rick Hansen is the bill’s sponsor.

Marginal drop in milk production

Ag Insider

Ag Insider

Arab Emirates, to monitor and advise U.S. trade negotiators. “NMPF supports a holistic work plan on agriculture that includes an equal commitment to increasing market access and limiting domestic support,” said Gregg Doud, president/CEO, NMPF. Doud previously served as the chief agricultural trade negotiator during the Trump administration.

NASDA considers trade opportunities in Cuba

Milk production in the 24 major states totaled 18.3 billion pounds in January. That’s down less than 1% from one year ago. South Dakota milk production rose nearly 11%. Over the past year, South Dakota farmers added 21,000 cows to the state dairy herd. Minnesota milk output declined 0.8%. Minnesota cow numbers dropped 5,000 head.

By Don Wick Columnist

A trade delegation from the National Association of State Departments of Agriculture traveled to Cuba this past month. There were seven state ag leaders on the trip, including Minnesota Agriculture Commissioner Thom Petersen. This delegation met with government ofcials and private industry representatives to discuss opportunities for collaboration between the U.S. and Cuba.

‘21 Rhino 3150-15’Batwing Mower

‘00 MF 6270, MFWD, loader ‘21 MF 2850, CAH, hydro, loader, ONLY 139 HOURS! IH 966, NICE!

MF GC2400, 60” deck, 500 hrs.

MF GC2400, 60” deck, 600 hrs.

‘21 MF GC1723, ldr., mower, 180 hrs.

CIH Farmall 45A, 649 hrs ‘09 MF 573, MFWD, Loader, 2200 hrs ‘07 JD 790 w/loader, 600 hrs.

‘19 Bobcat T770, SJC, 500 hrs.

‘20 Bobcat T770, CAH, highflow, SJC, 765 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘17 Bobcat T770, foot, 1,000 hrs.

‘14 Bobcat S770, 3,200 hrs.

‘18 Bobcat T770, A91, highflow, SJC, 2,000 hrs. ‘12 Bobcat S650, 9,000 hrs. ‘18 Bobcat S650, SJC, 9,000 hrs.

‘16 Bobcat S590, 3,900 hrs. ‘20 Bobcat S570

‘18 Bobcat 3400 SideXSide, C/H, 6,700 hrs.

‘16 Bobcat E50, long arm, thumb, 1,510 hrs.

‘20 Bobcat V923 Telehandler, 1,100 hrs.

‘18 Bobcat E50 long arm, 700 hrs.

‘11 MF 8947 Telehandler, 3,000 hrs

Consolidation trend continues in Minnesota

The average Minnesota farmer in 2022 was 57.1 years old, up from 56.5 years old when the last Census of Agriculture was done in 2017. Farm numbers statewide declined from 68,000 to 65,531. In 2022, Minnesota farms reported an average net income of $141,869, more than twice the $65,753 in the last report.

DMC enrollment begins

Enrollment is underway for the Dairy Margin Coverage safety net program. This U.S. Department of Agriculture program compensates dairy farmers to offset milk and feed price differences. Rules have been changed to allow eligible dairy farms to make a one-time adjustment to their established production history. Sign up continues through April 29.

It’s not business as usual

Farmers are facing a very different economic landscape today. Commodity prices are lower and interest rates are higher. “It’s not business as usual,” said Tony Jesina, senior vice president of crop insurance, Farm Credit Services of America. “Farmers need to take a look at some different options than may have considered in the past.” Firstly, it is important to know the cost of production. Secondly, Jesina concentrates on the cost of production relative to the market. That data may require adjustments in the farming operation. “Maybe it’s how your debt is structured; maybe there’s a way to restructure or rebalance your debt so that the cash ow is more in line with where your revenue’s going to be going forward,” Jesina said. Ultimately, a risk management plan is needed to protect the bottom line.

Ag census continues trend to larger farms

The Census of Agriculture reafrmed the trend toward larger farms. Farmers National Company Senior Vice President Matt Gunderson said the census is generating a lot of discussion. “It’s creating a conversation within production agriculture and internally in terms of what does that look like for the next generation, how does that look from a generational planning perspective and brings to the forefront the importance of estate planning,” Gunderson said.

World Trade Organization ministerial ends without ag agreement

World Trade Organization negotiations went into overtime at its ministerial meeting in Dubai but failed to reach consensus on agriculture or any other major trade initiatives. In an apparent reference to the Hamas-Israel war and the Russia-Ukraine war, WTO Director-General Ngozi Okonjo-Iweala said the summit occurred “against an international backdrop marked by greater uncertainty than at any time I can remember.” India pushed for an expansion of its public stockholding program, a policy used to purchase, stockpile and distribute food to needy people. This program is promoted as a food security measure, but the United States describes the public stockholding plan as an expansion of trade-distorting policy. The U.S. Dairy Export Council and National Milk Producers Federation were represented in Abu Dhabi, United

A volatile time for exports

The latest agribusiness review from Rabobank cites the ongoing conict on the Red Sea as causing global shipping capacity to tighten. Most shippers are avoiding that region and adding emergency risk surcharges. The report said this will be another year of volatility for anyone managing logistics. Uncertainties over the U.S. election and potential labor disruptions on both coasts are expected.

Winterkill possible this month

A lack of winter snowpack shouldn’t be a huge issue for alfalfa stands in the Northern Plains yet. University of Minnesota Extension forage agronomist Craig Sheaffer foresees bigger problems if drastic temperature uctuations continue. “Watch out for March; March is a killing month,” Sheaffer said. “If alfalfa breaks dormancy, starts to grow, and we encounter low temperatures, there is a very good chance that we’re going to have some killing of those new shoots that are formed in the spring.”

Bongards receives $20M in nancing

Bongards has been awarded $20 million in New Markets Tax Credit nancing to expand its cheese and whey processing facility in Perham, Minnesota. The funding is from Rural Development Partners, which receives the allocation from the U.S. Treasury Department.

Yogurt gains qualied health claim

The Food and Drug Administration has approved the rst-ever qualied health claim for yogurt. It recognizes the potential connection between the regular consumption of yogurt and a reduced risk of type-2 diabetes. International Dairy Foods Association Senior Vice President of Regulatory and Scientic Affairs Roberta Wagner reacted by saying, “Dairy products continue to demonstrate they are central to healthy, balanced diets for all people of all ages.”

Sjostrom receives University of Minnesota honor

Lucas Sjostrom has been awarded the Golden Graduate Award by the Gopher Dairy Club. Sjostrom serves as managing director and executive director for Edge Dairy Farmer Cooperative and Minnesota Milk Producers Association. Sjostrom is also a co-founder of Redhead Creamery, which is known for its artisan cheese.

Trivia challenge

The average American consumes 180 slices of pizza per year. That answers our last trivia question. For this week’s trivia, how many gallons of milk does the average American consume every year? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Page 10 • Dairy Star • Saturday, March 9, 2024 REISERIMPLEMENT Waukon,IA 563-568-4526 AfterHours: Ken563-380-3137•Dave563-380-8680 www.reiserimpl.com CHECKOUTTHE 7700SERIES Used Equipment PLANT/TILLAGE MISCELLANEOUS TRACTORS ‘20 Kinze 3660, 16R30, bulk fill ‘12 CIH 1250, 16R30, bulk fill ‘97 Kinze 2600, 31R15” DMI 530B Disc Ripper JD 712 9 shank disc chisel CIH MRX690, 5 shank disc ripper disc JD 980 Field Cult., 44’ w/harrow CIH 4800 30’ Field Cult, w/3 bar coil tine harrow BUILT TO KEEP GOING. BECAUSE A FARM NEVER SLEEPS. Kory 185 Gravity Box, 250 bu w/gear Brent 640 Gravity Box Loftness 20’ Stalk Shredder, NICE!! ‘08 AGCO 3000 corn head, 8R30, poly ‘19 Bobcat 3400 SideXSide, C/H, 9000 miles JD 146 loader w/bucket Skid Loaders HAY & FORAGE ‘16 Anderson Hybrid X, Custom Operator Pkg ‘14 MF 9770 SP, w/9196 double conditioning rolls, 1,200 hrs Hesston 565A Round Baler CHI 8465 Round Baler, w/mesh ‘20 MF 3983 Hicap Rake, 12 wheel ‘19 Kuhn GA7501 Rotary Rake ‘22 MF 1393, 13’ Disc/Mow Cond. ‘16 Pottinger NovaCat Triple Mower w/rolls ‘17 JD 835 9’ MoCo, center pivot JD 946, hyd. swing, rubber rolls ‘14 CIH DC112 Disc Mow/Cond. Gehl 2450, 15’ hydro swing JD MX7 3PT Brush Mower Patz Bale Chopper

hrs. ‘19 Bobcat

CAH, SJC,

hrs. ‘14 Bobcat S570, ACS, CAH, 4,800 hrs. ‘13 Bobcat S570, CAH, 3,400 hrs. ‘15 Bobcat T550, ACS, Open Station, 1,855 hrs. ‘23 Bobcat NW56 Toolcat, 225 hrs. ‘02 Bobcat S300 ‘15 Gehl R190, 1,900 hrs. ‘20 Gehl R220, 1,000 hrs. ‘13 Mustang RT2100 track 3000 hrs ‘23 NH L318, C&H, 1400 hrs. ‘21 Bobcat S76, SJC, 1,500 hrs. ‘22 Bobcat S76, 95 hrs. ‘20 Bobcat S76, 233 hrs. ‘22 Bobcat S64, 4,100 hrs. ‘21 Bobcat S76, CAH, SJC, 600 hrs. ‘21 Bobcat T76, SJC, 600 hrs. ‘21 Bobcat S76, CAH, SJC, 1,800 hrs. Bobcat T76 ‘21 Bobcat S64, SJC, 2,700 hrs. ‘22 Bobcat TL619, 1,000 hrs. ‘20 Bobcat T870, A91, 600 hrs. ‘22 Bobcat T770, 200 hrs. ‘20 Bobcat T770, 240 hrs. tfn Les Kuehl Repair Service 30+ Years Experience No Emergency Charges--Ever! • Sealed silo parts & service • Best chains on the market • Used and rebuilt unloaders • Stainless steel roofs • Stainless steel conveyor chains 320-760-2909 Eve. 320-762-1827 YOUR CENTRAL MINNESOTA GOLIATH REPAIR SERVICE! • All parts needed to service your Goliath Unloaders Not af liated with the Harvestore brand Call for early maintenance specials Tell the advertisers you saw their ad in the Dairy Star!

, CAH, 2900

S570,

2100

Dairy Margin Coverage enrollment is open

The enrollment period for the 2024 Dairy Margin Coverage program began Feb. 28 and ends April 29.

DMC is a safety net program offered through the U.S. Department of Agriculture. For those who sign up for 2024 coverage, payments may begin as soon as March 4 for any payments that triggered in January.

The Farm Service Agency has revised the regulations for DMC to allow eligible dairy operations to make a one-time adjustment to established production history. This adjustment will combine previously established supplemental production history with DMC production history for those dairy operations that participated in Supplemental Dairy Margin Coverage during a prior coverage year.

DMC is a voluntary risk management program that offers protection to dairy producers when the difference between the all-milk price and the average feed price (the margin) falls below a certain dollar amount selected by the producer. In 2023, DMC payments triggered in 11 months including two months, June and July, where the margin fell below the catastrophic level of $4 per hundredweight, a rst for DMC or its predecessor Margin Protection Program.

FSA has revised DMC regulations to extend coverage for calendar year 2024, which is retroactive to Jan. 1, and to provide an adjustment to the production history for dairy operations with less than 5 million pounds of production. Dairy producers can establish one adjusted base production history through DMC for each participating dairy operation to better reect the operation’s current production.

Dairy operations that established supplemental production history through Supplemental Dairy Margin Coverage for coverage years 2021-23 will combine the supplemental production history with established production history for one adjusted base production history.

For dairy operations enrolled in 2023 DMC under a multi-year lock-in contract, lock-in eligibility will be extended until Dec. 31. In addition, dairy operations enrolled in multi-year lock-in contracts are eligible for the discounted DMC premium rate during the 2024 coverage year. To conrm DMC lock-in coverage or opt out in favor of an annual contract, dairy operations having lock-in contracts must enroll during the enrollment period.

DMC offers levels of coverage, even an option that is free to producers, minus a $100 administrative fee. The administrative fee is waived for dairy producers who are considered limited resource, beginning, socially disadvantaged or a military veteran. To determine the appropriate level of DMC coverage for a specic dairy operation, producers can use the online dairy decision tool.

Payments are calculated using updated feed and premium hay costs, making the program more reective of actual dairy producer expenses. These updated feed calculations use 100% premium alfalfa hay.

For more information, visit the DMC webpage or contact your local USDA Service Center.

“Accurate results, it’s safer and less stressful on the cow.”

What do you like about the DHIA Pregnancy Tests?

We like the milk pregnancy test because it has accurate results, it’s safer and less stressful on the cow, it’s safer for us, and we have less vet bills.

How long have you been using the DHIA pregnancy test? Since it came out, maybe around 2013. We switched 100 percent to it and haven’t looked back.

Why did you choose to use it? We chose to use it because we didn’t like separating cows every month for pregnancy checks.

What are some other tests you use through DHIA? We do the normal monthly testing, and manure sampling yearly.

Why is testing with DHIA valuable to your dairy?

The value we get out of it is seeing the performance on a cow level, making culling decisions based on SCC, fat, protein etc. Also, the record keeping of cow and heifer events has helped better our management.

Charlie Dicke

Dicke Century Farm • Goodhue, MN • 200 cows

Tell us about your farm. I farm with my dad, Lyle, and mom, Shannon, on about 800 acres. We like trying new rotations of crops and utilize no-till practices. I have a sister in Buffalo, New York and a brother in Idaho dairy farming. We milk in a double-9 parallel parlor, with sandbedded free stalls. We raise our own replacements, utilize Cowmanager on all animals, and sell our milk to First District Association.

763.682.1091 www.mndhia.org

Dairy Star • Saturday, March 9, 2024 • Page 11 Who do you call? The Best Service Crews, The Best Replacement Parts, The Best Service... That’s The Osakis Silo Advantage To You!!! 320-808-3936 300 E Main St., Osakis, MN • 320-859-5340 Visit us online at www.osakissilo.com IF YOU HAVE A PROBLEM CALL US TODAY! It’s 30 below zero and you break an auger. Who do you call? You’re lling your silo and you blow up your distributor or ll pipe. Who do you call? You’re running feed out and your gear box fails. Are you going to fork the feed out? It’s chore time, you throw the power switch and nothing happens. Who do you call? An electrician will not climb up there or be out in a timely manner. Osakis Silo will answer the call and handle these problems year round! We will get you up and running anytime and under any conditions. 24 Hours 7 Days A Week Call Anytime l WE FIX ALL SILOS! Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere Guess where your feed dollars are going? Our soybeans have the energy, protein, amino acids and bypass protein for your cows! Incorrectly roasted soybeans?

Sauk Centre, MN Buffalo, MN

DHIA: Now MORE

ever

than

Maartje Murphy said the A2A2 milk used at Cows and Co. Creamery is processed in a particular way.

“Using a licensed milk transfer truck, we go to the dairy, ll it up and bring it to the creamery,” Murphy said. “Our milk is vat pasteurized, kind of the old-fashioned way of low temperature for 30 minutes, and we don’t homogenize our milk, so it has that cream line at the top.”

Their bottled milk, Murphy said, has already received positive feedback from customers.

“Vat pasteurized is a nice, happy medium, knowing that it’s safe and everyone can enjoy it, from young to old, and still have that fresh avor and cream on the top,” Murphy said. “We’ve had a lot of people say they have been able to drink our milk (who previously could not drink milk). There isn’t too much research on it yet, but it seems to be a good thing and is getting people back to milk.”

Cows and Co. Creamery was born from a part-time business Murphy, then a college student, launched with her mother ve years ago at Van Bedaf Dairy.

“Throughout my childhood, we traveled back to the Netherlands to visit family, and lots of gelato shops and on-farm cheesemakers were there,” Murphy said. “It was inspiring, and I thought that would be fun to do in Carrington, especially because we had so much milk.”

After taking a weeklong course in gelato making, daughter and mother began making the product in 2018.

“We renovated my mom’s side of the garage to be a little dairy processing facility, and that’s where we started making gelato,” Murphy said.

They purchased a gelato cart from

Wheels of Gouda cheese wait for customers in the cooler at Cows and Co. Creamery near Carrington, North Dakota. Maartje Murphy and her mother, Conny Van Bedaf, began making the cheese in 2022 as a nod to their Dutch heritage.

Italy, and Murphy began selling their product, Duchessa Gelato, at events.

Sales of Duchessa Gelato led to the purchase of their farmstead in 2021

where they renovated a shed to launch Cows and Co. Creamery and their new full-time occupation. Murphy’s career in nursing and her husband’s career as

a physical therapist were put on hold.

“Now, we’re both medical professionals turned cheese and gelato makers,” Murphy said. “We always say we’ll keep our licenses up just in case people stop eating cheese and gelato. You never know.”

The creamery’s cheese, which Murphy said they began producing in 2022, was also inspired by the Netherlands.

“Gouda cheese is a Dutch cheese, and my mom has a little history of making it when she was younger and worked at a creamery in the Netherlands. And in her college years, she went to New Zealand and worked with Dutch dairy farmers who made Gouda cheese,” Murphy said. “I went to the Netherlands in February 2021 to a dairy farm run by family friends who made Gouda cheese, and they showed me how they made it.”

Murphy bought the necessary equipment from the Netherlands, and then she and her mom practiced.

“From there, it was trial and error,” Murphy said. “I always tell people … our cows produce good quality milk, so when you have a really good-tasting base product, it’s not that hard to make something taste good.”

Today, Cows and Co. Creamery also makes fresh cheddar curds. The on-site store is open every day and operates on the honor system. There, customers can purchase gelato, cheese and bottled milk. The site also has a commercial kitchen and cafe with a coffee bar that is open two Saturdays per month and draws 500-600 customers. In March 2023, the creamery opened a shop at Brewhalla in Fargo where customers can buy scoops of gelato in 12 avors or purchase pints of gelato along with the creamery’s other products.

Turn to COWS & CO. | Page 13

Page 12 • Dairy Star • Saturday, March 9, 2024 Come in and Save! www.modernfarmequipment.com ∙ SAVE 10% ON PARTS ∙ SAVE 10% ON FILTERS ∙ SAVE 10% ON BATTERIES ∙ SAVE 10% ON TILLAGE WEAR PARTS ∙ SAVE $10 PER ROLL OF NET-WRAP ∙ SAVE $2 PER BALL OF TWINE PLEASE JOIN US FOR OUR OPEN HOUSE MARCH 18-23, 2024 SPECIAL FINANCING AVAILABLE! Ask us about shipping options GET 10% OFF LABOR ON SERVICE AND REPAIRS, ALONG WITH 50% OFF TRUCKING Schedule your spring maintenance inspections before March 31 and you may also be eligible for 6 extra months of parts warranty on repairs we complete! NO INTEREST FOR 120 DAYS* ON QUALIFYING PURCHASES OF $750 OR MORE** Interest will be charged to your account from the end of the 120 day promotional period if the promotional balance is not paid in full within the promotional period. Offer valid on new genuine New Holland or remanufactured parts and related services. Purchases must be made on the CNH Industrial Capital Productivity Plus® Account within 14 days of the Event at a participating New Holland dealership located in the United States. * Subject to credit approval. Terms and conditions apply. Ask an associate for details. With credit approval. After the promotional period, the standard variable information and additional details. Offer valid for Accounts in good standing; see dealership for details. Minimum payments required. May not be combined with any other credit promotional offer. ** Purchase requirement before taxes, fees and other discounts and must be made in a single transaction. At the Pierz and Sauk Centre locations!

Con nued from COWS & CO. | Page 8

PHOTO SUBMITTED

Piet Van Bedaf pushes up feed in the summer of 2023 at Van Bedaf Dairy near Carrington, North Dakota. For ve years, Van Bedaf has been conver ng the milking herd of 1,500 to producing A2A2 milk, some of which is now bo led and sold at Cows and Co. Creamery.

“We’re trying to bring some of the European, Dutch products here, and drinkable yogurt is a thing there that I miss,” Murphy said. “We are testing strawberry and mixed berry drinkable yogurt, and hopefully, we will be coming out with that soon.”

This summer, a building project will begin at Cows and Co. Creamery to expand its café and processing room and add refrigerator and freezer capacity. The expansion will also give more space for customers to see the processing and aging rooms to better understand what goes into making the products they are purchasing.

To further connect people to dairy, the Van Bedafs began offering tours of their dairy farm. This led to Van Bedaf starting a YouTube channel, North Dakota Farmer, which posts videos mostly about the dairy farm but also the cream-

ery. Murphy said dairy outreach and support of their community are important to her family.

“It’s been an honor to have people travel from all over to not only visit the creamery but to also support other businesses in town … and then connecting the consumer to my family and our cows has been really nice,” Murphy said. “They can tour the farm and see how we milk cows nowadays, because it’s very different from what it used to be, and a lot of people don’t get the chance to see that anymore.”

Murphy said she is happy they made the choice to raise their family in Carrington and build a business that melds so well with her family’s dairy farm.

“We love what we do,” she said. “It’s a pretty fun gig.”

Dairy Star • Saturday, March 9, 2024 • Page 13 Calf Zone Melrose, MN Brock Zierden bzierden@Leedstone.com 320.293.6192 Glencoe, MN Paul Becker pbecker@Leedstone.com 320.510.0200 Plainview, MN Keith Fuerstneau kfuerstneau@Leedstone.com 507.273.3367 Menomonie, WI Darren Pieper dpieper@Leedstone.com 715.307.5750 CONTACT YOUR LEEDSTONE REP TODAY! Leedstone.com/equipment-team • • Family & veterinarian owned since 1994 for the latest barn equipment news from Leedstone! GET THE BEST IN CALF FEEDING & HOUSING • Data analysis app for management support • Scales for weight measurement • Automatic animal monitoring & alerts • Individualized feed programs • Removable sidewalls provide pen-to-pen isolation & disease prevention • Fully customizable; various wall lengths back wall options, & bucket & bottle holder options • Easy to clean Talk to us about all your calf feeding needs! Raised Calf Zone pens are also available! Automatic Calf Feeder Freestanding Pens CalfExpert

Con nued from COWS & CO. | Page 12

SUBMITTED

PHOTO

CURTISS 715-613-7308 EDGAR 715-352-2011 BOSCOBEL 715-937-5190 Edgar Curtiss Boscobel Valmetal 400 2 speed, RH discharge Valmetal 280 side discharge Valmetal 280 end discharge EQUIPMENT IN STOCK Valmetal 5600 bale chopper, 1,000 RPM Valmetal 5600 Auto-Trac In-tank agitation, AR steel Valmetal Forage Blower 1,000 RPM Valmetal 630 1,000 RPM, front RH conveyor, rear door, 2 speed Valmetal 700 right and left discharge Ask about Valmetal’s NEW Financing program! Valmetal 530 Super Cart 542 Supercart Choose 3.99% for 24 or 36 months / Zero Down / Zero residual or 3.99% for 48 or 60 months / 25% down payment or trade / Zero residual

Page 14 • Dairy Star • Saturday, March 9, 2024 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com Holy Used Slinger Spreaders! KUHN KNIGHT 8141 # 22124 - $38,500 2009 HOULE EL84-5000 # 2342- $39,500 KUHN KNIGHT SLC150 # 2364 - $79,900 2009 HOULE EL48-6D6100 #2285 - $38,500 KUHN KNIGHT 8124 # 23112- $24,500 H & S 3143 #2379 - $19,900 KUHN KNIGHT PS160 #2403- Call KUHN KNIGHT 8141 # 22132 - $41,500 MEYER 9530 #2351- $95,900 NEW HOLLAND 195 #2359- $18,900 2018 ARTEX SB600 # 23121- $49,000 KUHN KNIGHT SLC126 #2291 - $42,900 2020 HAGEDORN HYDRA-SPREAD SERIES II 2277 #2382 - $38,900 H & S HP550VB # 2393- $31,500 NEW HOLLAND 195 #23110 - $18,900 2015 ARTEX SB600 #2402- $49,000 KUHN KNIGHT 8150 #2284 - $59,500 The most versatile spreader on the market! More Used Spreaders

from our side our side OF THE FENCE THE

Why did you decide to serve as a board member, and how has that involvement benefited you?

Ken Herbranson

Battle Lake, Minnesota

Otter Tail County 500 cows

What board do you serve on, and how long have you served? I have been on the Lakes Community Cooperative board for over 20 years.

Why did you decide to serve on this board?

We need farmer voices represented at each of the various local, regional and state boards. One of the mainstays of a co-op are the equities earned by the members. As member-owners, we should be involved in the decision-making process.

How do you nd time for meetings and duties amid dairy farming? Busy people always seem to make the time. It is a matter of priorities; somebody needs to step up and serve on these boards. It’s not always easy nding time, with the schedule of dairy farming, but we make time because it’s important to have dairy farmers on our dairy cooperatives.

Tell us the best experience you’ve had since being appointed to this board. I used to be on the Midwest Dairy board for many years, and one year, they sent me to China. That was when Tim Pawlenty was governor, and he went on a trade mission to China and brought industry representatives with. We promoted exporting dairy products to China. There are a lot of people in China to feed. That was denitely a high-water mark for sure.

How has being involved within this organization beneted you? I get to meet other dairy farmers. I have learned a lot from other farmers. We would do the same thing day in and day out if we didn’t get out in the industry and see what other farmers are doing and learn why they are doing it that way. I have also met higher-ups in the industry and across the state. I have met Gov. Pawlenty and Gov. Dayton. It widens your horizons. I have gained a lot by getting involved. That betters our farm and general knowledge about the industry. It takes a lot of time to attend meetings and gather information for the board, but it’s worth it.

What do you enjoy most about this role? It’s nice to be a part of the decision-making process. Any business needs to stay relevant in the industry, and it’s important to know what they are doing. The networking with others in the industry is a plus. Being involved is not always easy, but it needs to be taken seriously. We need good people to step forward and take on these roles.

Tell us about your farm and your plans for your dairy this year. My brother and I and our wonderful team of about a dozen employees milk 500 cows in a double-20 parlor. Our employees are key to our success. We have good leadership within our employees so that we are able to do what we do each day. About 15 years ago, we worked with Dr. Les Hansen with the University of Minnesota and did a study with crossbreeding Holsteins, Montbeliarde and VikingRed cattle. We found success with it and have continued the ProCROSS program ever since. We grow our feed, growing corn, soybeans and alfalfa. We ship our milk to Bongards.

Mark Bechtold Rockville, Minnesota Stearns County 300 cows

Which board do you serve on, and how long have you served? I have served on the Minnesota Dairy Herd Improvement Association board for around eight years.

Why did you decide to serve on this board? They were looking for members, and my cousin told me I should take my turn. I want to have DHIA around, so I need to put in my time. If everybody contributes a little, things are a lot easier.

How do you nd time for meetings and duties amid dairy farming? Everybody at the farm has to pick up the slack for me. Sometimes it’s a struggle. We meet around six times a year. The meeting dates vary quite a bit. They send out an email to see which dates t best for everyone. Our meetings start at 10:30 a.m. and are done by 4 p.m. We usually go over the nancials at the end of the year and the budget at the start of the year.

Tell us the best experience you’ve had since being appointed to this board. We just hope we are helping the general manager and can make somethings easier for him. We continually get people out to test cows. It’s great knowing the cows are being tested every month.

How has being involved within this organization beneted you? It’s nice to talk to farmers, especially as we seem to be further and further apart. You get to hear a lot of different ideas. I learn how different farmers solve their problems.

What do you enjoy most about this role? I have really enjoyed meeting the different testers. I’ve met eld reps, and they are interesting to talk to about their experiences. They have a lot of enthusiasm that is so important to the livelihood of dairy producers.

Tell us about your farm and your plans for your dairy this year. I have been working here since I got out of high school. We milk 300 cows in a double-10 herringbone parlor. We have one-third of our cows in a freestall barn and two-thirds of our cows on a bedding pack. There are six full-time people. We farm around 500 acres and raise corn and alfalfa. We ship our milk to Land O’Lakes. My mom, LeMay, and my sister, Mary Ruth, live on the farm as well.

Keith Welgraven

Ruthton, Minnesota Pipestone County 100 cows

Which boards do you serve on, and how long have you served? I have been the treasurer of Aetna Township for 30 years. I have been on the Pipestone County American Dairy Association board for about ve years, a trustee on our church board for two years and a FarmFirst Dairy Cooperative delegate for several years.

Why did you decide to serve on these boards? I like to be involved. I enjoy visiting with and meeting people.

How do you nd time for meetings and duties amid dairy farming? Getting time to serve can be challenging as my cows take most of my time. I do enjoy getting things accomplished and meeting new people.

Tell us the best experience you’ve had since being appointed to these boards. I would say that my best experience is serving on our county ADA board, because we try to be active with our community to tell the dairy story. I’ve been blessed to meet and work with many nice people and gained many good friends.

How has being involved within these organizations beneted you? The main benet has been seeing old friends and making new ones. It’s fun to have an inside look at how things are run. I have an excuse to get away from the farm for a little while when the board meeting is located far away.

What do you enjoy most about these roles? I enjoy being involved with our local community. I help the ADA serve ice cream at the Pipestone County Fair. It’s great to see the smiles on kids’ faces when you serve them ice cream. We had 13 avors last year, and some people came back several times in a day so that they could try them all. I guess we are all kids when it comes to ice cream.

Tell us about your farm and your plans for your dairy this year. Our farm has Milking Shorthorn and Holstein cattle. We farm about 450 acres and raise corn, alfalfa, soybeans, oats and rye. We have a parlor and freestall setup. The farm was started by my dad and mom, Bert and Alvina, in 1968. My wife, Jeanna, and I operate it now. Our daughter, Katelyn, is a freshman at the University of South Dakota in Vermillion, South Dakota.

Dairy Star • Saturday, March 9, 2024 • Page 15 Turn to OUR SIDE | Page 16

www.norbco.com 67962 State Hwy 55, Watkins, MN 55389 • 320-764-5000 MA KING COW COMFORT OUR PRIORITY Curtain SystemsVentilation SystemsFreestall SystemsHeadlocks

Jeff Hammerand

Bankston, Iowa

Dubuque County

170 cows

Which boards do you serve on, and how long have you served? I am on the District 8 Iowa Holstein Association Board and Iowa Holstein Association board of directors. I have served for 20-25 years. For the local board, duties include planning and scheduling meetings, making agendas for meetings, partaking in execute meetings, and hosting and planning state conventions, picnics and state shows. State board duties include carrying out state business, and helping plan and host two national Holstein conventions. I also co-chaired the Dairy Bar for the 2014 National Holstein Convention. My wife, Tammy, and I have also been chairs of the Iowa Junior Holstein Association for 15 years. Duties there include running food stands, meetings and state junior conventions as well as coaching juniors for national convention contests. For the Iowa State Dairy Association Princess Board, I just completed a six-year term. Duties there include organizing and improving princess contest and trying to make each princess appearance more impactful, informative and educational for consumers.

Why did you decide to serve on these boards? As a family, we believe it is important to give back and encourage the youth of our industry. If you are going to give back, you might as well do something you are passionate about. I am passionate about teaching young people, so they have a more informed future and will pay the passion forward.

Leah Kurth

Cosmos, Minnesota Renville County

150 cows

Which boards do you serve on, and how long have you served? I have been involved with the McLeod County American Dairy Association for about eight years. I’m the sitting secretary but have also been the president and vice president. I have been involved for two years on the McLeod/Renville/Sibley Dairy Herd Improvement Association board. I am the secretary/treasurer/vice president. I have been involved in the Region 7 Dairy Show Committee for ve years. I have been a McLeod County 4-H dairy supervisor for one year. I am also the association manager for the Hutchinson Area Bowling Association where I oversee all leagues and association operations. Previously, I have been a part of the First District Association Young Cooperatives Board as well as co-chair for the 2023 Minnesota State Holstein Show.

Why did you decide to serve on these boards? Serving on these boards and being involved in these activities allows me to get off the farm and make a difference within my community. It allows me to network and meet people in the dairy community who share the same passion and drive that I do.

How do you nd time for meetings and duties amid dairy farming? Luckily, most of the organizations I am involved with hold their meetings during the day. For most of the responsibilities I have for these organizations, I am able to do them during the day between chore times. On the rare occasion that an event runs during chore time, my husband and kids are usually able to pick up some of my slack, which I appreciate.

How do you nd time for meetings and duties amid dairy farming? It is a family affair. My wife does a lot of chores. Also, I have my daughter and son-in-law’s help. We get stuff done as a family. You have to be willing to make the extra effort.

Tell us the best experience you’ve had since being appointed to these boards. Watching our juniors as their friendships and passion grow throughout the years. Also, seeing them earn national championships in dairy bowl and jeopardy isn't too bad either. Being co-chair of the Dairy Bar for the National Holstein Convention was a challenging yet worthwhile experience, which we are receiving compliments on 10 years later.

How has being involved within these organizations beneted you? It has given us a chance to serve and meet many incredible people as well as help grow the youth of our industry and ignite their spark. The chance to network and learn from others has been quite valuable. We use some of the pieces of information learned along the way from other directors on a daily basis. There is a sense of satisfaction in being able to serve others.

What do you enjoy most about these roles? Relationships. The opportunity to meet people with our same passion and build upon that is priceless. Watching the juniors join at 9 years old, a little apprehensive, and then not only grow up but also grow in condence. Along the way, watching them become lifelong friends gives me great pleasure. Working side by side with the District 8 Holstein group; they have become some of our very best friends.

Tell us about your farm and your plans for your dairy this year. We milk 170 cows with my brother and niece in his swing-11 parlor. We concentrate on breeding good registered Holstein and Brown Swiss. Our milk is shipped to Scenic Central Milk Producers. We have recently started using some of our heifers for embryo recipients to improve and diversify our genetics even further. Tammy is employed by the neighbors as a calf care giver. We also own 110 acres in Bankston, our home location, that serves as the feed for our dry cows and youngstock.

Tell us the best experience you’ve had since being appointed to these boards. Our ADA board has been motivated the last few years to try new things and improve our association and royalty program. In February, we hosted almost 50 people in our rst Dairy Royalty Workshop. We invited our local and surrounding county royalty to join us for a workshop that was educational and engaging. It was a huge success, and we are looking forward to hosting this annual event. A close second for me, and worth mentioning, was co-chairing the 2023 Minnesota State Holstein Show with my friend, Alison Rickeman. If you haven't planned and hosted a state show before, the amount of work and planning that goes into a successful state show on a county level is no joke. Luckily, we have a passionate and driven local association, so the show went off without a hitch.

How has being involved within these organizations beneted you? The people and connections that I have made during my years within these organizations have paved the way for the future. The ability to get in the community and promote the dairy industry helps mold the way consumers portray our industry.

What do you enjoy most about these roles? I am a pretty social person and love planning and organizing events. I enjoy all the people who are involved in these organizations and the passion we all share. When you get enough people together with the same passion and drive, it's amazing the things you can accomplish.

Tell us about your farm and your plans for your dairy this year. Myself, as well as my husband, Bill, own and operate KurthKine Holsteins near Hutchinson, Minnesota. Our kids, Larkun, Livia, Briecyn and Taelyn, make up the bulk of the workforce. We have occasional part-time help. We milk around 150 cows in a double-8 herringbone parlor. The cows and breeding/pregnant heifers are housed in a sand-bedded freestall barn about 1 mile south of our home farm. All calves and young heifers are housed at the home farm. We ship our milk to First District Association. We farm around 175 acres of crops, typically corn silage and alfalfa, that is all used for feed purposes. Our main goal for 2024 includes building a heifer facility for our milk and weaned calves.

Page 16 • Dairy Star • Saturday, March 9, 2024 Con nued from OUR SIDE | Page 15 CALL FOR A QUOTE TODAY 605.368.5221 OR VISIT US AT equipmentblades.com Loader Edges Grader Blades Snow Plow Blades Custom Edges Skid Steer Blades Box Scraper Dozer Blades Wear Steel N6503 Pit Road Mount Calvary, WI, 53057 920-922-9966 americanimplement920@gmail.com IMPLEMENT INC White 2-135, duals, front weight - Call for Pricing WE BUY SCRAP METAL! Oliver Super 77 3,372 hours - $4,000 USED PARTS AVAILABLE! Glenco soil finisher Call for price Turn to OUR SIDE | Page 18

Dairy Star • Saturday, March 9, 2024 • Page 17 JOIN OUR TEAM Now Hiring Service Technician Intern Apply Now! SCAN ME bit.ly/3fwYBl6 Paid Internship +1-800-636-5581 | Proudly serving you from Brookings, SD; St. Peter, MN; and Melrose, MN! DEALER Cutting-Edge Milking Equipment | Supply Delivery | Preventive Maintenance Herd Advisory & Software Support | Manure Management Services | Feed Management farm-systems.com © 2022 Farm Syststeems. All rig ts hts rese e rved. A-3386648395 Need Service? Keep your operation up and running with Farm Systems Your Local Milking, Manure and Feed Management Solutions & Service Provider

Page 18 • Dairy Star • Saturday, March 9, 2024

Andrew Gathje, pictured with Emily Gerber

Pleasant Grove, Minnesota Olmsted County

60 cows

Which boards do you serve on, and how long have you served? Since graduating from college in 2019, I have decided to serve on the Olmsted County American Dairy Association, Olmsted County Dairy Herd Improvement Association, the Board of Elders at St. Paul Evangelical Lutheran Church in Chateld and the Chateld FFA alumni. The Olmsted County ADA has been a part of my life since 2021. The board of elders at church became a part of my life in late 2020 as well as the Chateld FFA alumni. I was elected to the county DHIA board in 2023.

I am on the board for the Miracle of Birth Center at the Olmsted County Fair. I started doing overnights at the Miracle of Birth Center in 2021. My role on the county ADA board has resulted in the promotion to the chair position which had not changed hands in Olmsted County for over two decades. Last year, I served as the vice chair. Since I joined the board of elders at church, I have served as the parliamentarian.