FUTURE CONSTRUCTOR & ARCHITECT SEPTEMBER 2022 ISSUE 151

FC&A – SEPTEMBER – 2022 2 Now you see it Now you don’t! Take control with SwitchableTM www.esg.glass t: 01376 520 061 e: sales@esg.glass

Only last month, I was talking of the unbearable heat we were experiencing here in the UK. Following several additional weeks of sweltering temperatures and a recently-actioned hosepipe ban, our call for a much-needed downpour was finally answered. Whilst the rainfall's cooling effects were most certainly welcomed, some parts of the south of England, unfortunately, suffered from extreme showers. This, of course, resulted in flash floods in areas such as Central London, Kent, Devon and Cornwall. In fact, in mid-August, the Met Office issued 17 flood alerts and predicted up to 100mm of rainfall in some locations.

As we've been advised by environmental professionals over the years, such drastic and prompt changes to the weather is unquestionably a cause for concern, and these meteorological shifts are beginning to palpably take shape. As such, we must adapt current practices to protect ourselves from swiftly-moving, potentially perilous weather conditions.

For example, in this month's issue, Ian King, COO at Zeroignition, talks to us about the 'invisible dangers of timber construction'. Here, he not only discusses the vital use of fire retardants in the wake of record temperatures and destructive wildfires, but he also explains how architects and specifiers must consider the risk of toxic pollution caused by harmful chemicals found in fire retardants. Turn to page 20 to read the full article.

Elsewhere, James Walsh, CEO of Studio Anyo, fills us in on what inspires him and how young architecture students can get ahead, Allen Coldrake from Carlisle Construction Materials discusses the Ecodorp project and we profile Konstantin Arkitekter's Qaammat Pavilion in west Greenland.

I hope you enjoy this issue. Don’t forget, you can also access all of the magazine’s features, product news and supplier information on FC&A’s user-friendly and engaging website. Fully responsive, the website allows you to read all the latest stories on-thego either on

phone or tablet. Simply search www.fca-magazine.com.

Rebecca

REBECCA KEMP

Editor, Future Constructor & Architect

ON THE COVER:

The CASAMIRADOR Savassi

residential building is located in Brazil and features boldly-designed architecture that stands out in the local landscape.

SEE PAGE 14.

Threshold

FC&A – SEPTEMBER – 20223

WELCOME TO EDITOR’S NOTE

your

Red Hut Media Ltd 5 Mansion Row, Brompton, Kent, ME7 5SE Tel: 01622 946150

FUTURE CONSTRUCTOR & ARCHITECT MAGAZINE EDITOR IAL Rebecca Kemp rebecca@redhutmedia.com Hannah Woodger hannah@redhutmedia.com PRINT & DIGITAL ADVERTISING Sam Ball sam@redhutmedia.com Jim Moore jim@redhutmedia.com PRINT DESIGN MANAGER Jack Witcomb jack@redhutmedia.com DIGITAL DESIGN MANAGER Matt Morse matt@redhutmedia.com ACCOUNTS/CREDIT CONTROL Rachel Pike accounts@redhutmedia.com SALES SUPPORT & STATISTICS Klare Ball klare@redhutmedia.com PUBLISHER Sam Ball sam@redhutmedia.com Terms and Conditions: Contributions are invited and when not accepted will be returned only if accompanied by a fully stamped and return addressed envelope. No responsibility will be taken for drawings, photographs or literary contributions during transmission or in the editor’s hands. In the absence of an agreement the copyright of all contributions, literary, photographics or artistic belongs to Red Hut Media Ltd. The publisher accepts no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the view of the publisher. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. SEPTEMBER 2022 RED HUT MEDIA fcamagazine fcamagazine fcamagazine FC&A Magazine CAVITY TRAYS specialism • experience • service01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • England • UK

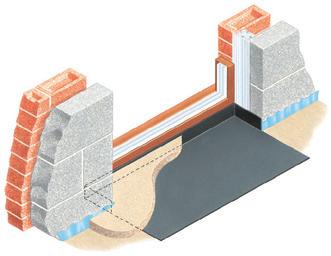

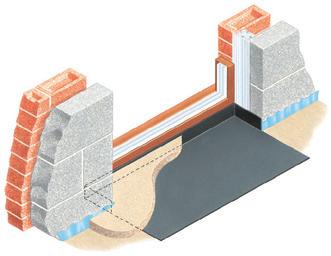

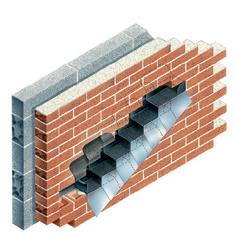

Protection Optimised Alleviates damp protection shortfall where horizontal and vertical DPC’s merge ● Three-sided Type TST Threshold and Sill Overlay Tray addresses localised DPC and membrane misplacement and damage. ● Protection introduced where foot traffic is heavy during construction ● Overlay isolation where vertical closing interfaces ● Protection extends vertically against sill. Email enquiries@cavitytrays.co.uk and request our guide delivered to your door

FC&A – SEPTEMBER – 2022 4 Firman offer a wide range of fire resistant glass options with varying levels of protection as required by your project. Contact our sales office for further information. www.firmanglass.com Fire Rated Sealed Units 01708 374534 sales@firmanglass.com www.firmanglass.com • Attestation 1 Certified • Rated 30/0 to 60/60 • Certifire compliance • Impact resistance • Sound insulation • Thermal insulation • Integrity only – in stock • Internal / External use • Fire Doors • Partitions

18 20

LEGAL & BUSINESS:

Do Design Codes represent housing development by consensus, or will they result in consultation fatigue? And, will they fast track ‘beauty’ or will the layman’s greater involvement in design result in a dumbing down? Niamh Burke, Associate at Carter Jonas (London), investigates.

VOICE OF THE INDUSTRY:

Ian King from Zeroignition explains why innovation has led to a generation of low-toxicity fire retardants and outlines how this significant leap forward will lead to an uptick in using renewable building materials; from timber to engineered bamboo.

FEATURES

22 24 26 28 30 32

DOORS, WINDOWS & BALUSTRADES:

In this article, Paul Smith, Head of Marketing at F.H. Brundle, explores the rise of balustrades.

RCI:

Allen Coldrake from Carlisle Construction Materials discusses Ecodorp, a sustainable community in The Netherlands where Hertalan EPDM membrane has been specified as part of a cradle-to-cradle approach to circular sustainability.

HVAC:

Jack Smith, Product Manager at AET Flexible Space, explores the world of underfloor air conditioning (UfAC) and its role in driving carbon reduction and health and wellbeing.

FLOORS, WALLS & CEILINGS:

Neil Sanders, Technical Director at F. Ball and Co., advises on cutting the time it takes to install floorcoverings without compromising on finished results.

TECHNICAL FOCUS:

There are many reasons why clay brick remains the building material of choice for architects, developers, builders and planners across the UK, and why it will continue to be so as we move to ever more sustainable methods of construction. Here, Forterra explains further.

BUILD FOCUS: Workplace :

British Architect Guy Hollaway forecasts the future of the office and explains how his practice's latest HQ scheme, for bike manufacturer, Brompton, demonstrates the workplace design of tomorrow.

14

QAAMMAT PAVILION, KONSTANTIN ARKITEKTER:

The Qaammat Pavilion, designed and built by Architect Konstantin Ikonomidis, has won an A+Award.

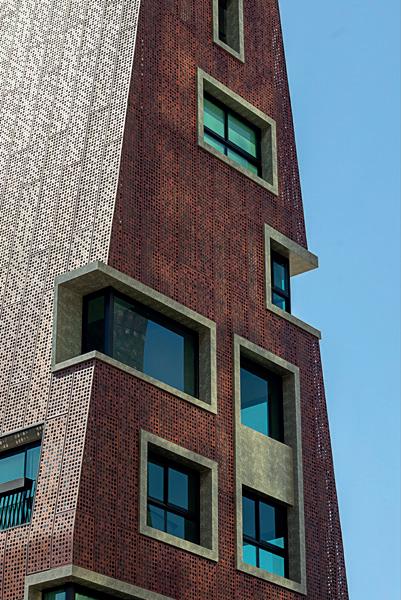

CASAMIRADOR SAVASSI , GISELE BORGES ARQUITETURA:

The CASAMIRADOR Savassi residential building is located in Belo Horizonte, Minas Gerais, Brazil, and features boldly-designed architecture that stands out in the local landscape.

FC&A – SEPTEMBER – 20225

NEWS

10

PORTFOLIOS

SEPTEMBER CONTENTS CAVITY TRAYS specialism • experience • service01935 474769 enquiries@cavitytrays.co.uk www.cavitytrays.co.uk Yeovil • Somerset • England • UK Sloping Abutments in Brick, Block or Stone Combined ready-moulded DPC cavity wall protection with attached roof flashing ● Adjustable Type X Cavitray to suit all cavity widths ● Ready to use – eliminate cutting, fabrication and variances on site ● Control cost and stock + packaged per dwelling ● Look for the name and logo to secure approved ETA solution with accompanying warranty from the longest-established specialist Email enquiries@cavitytrays.co.uk and request our guide delivered to your door Cavitray Compliancy & Consistency

NEWS IN BRIEF:

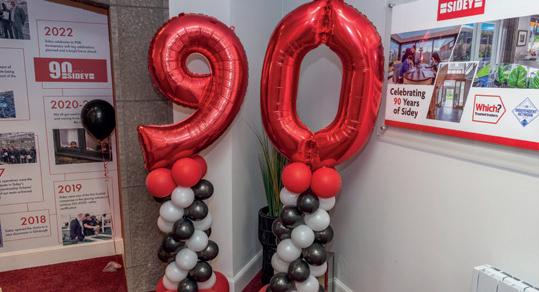

WARRINGTONFIRE MARKS 50 YEARS OF ‘MAKING TOMORROW SAFER THAN TODAY’

Warringtonfire is marking the 50th anniversary of its first commercial fire test, which took place at a newly-completed fire testing laboratory in High Wycombe, Buckinghamshire, in 1972. 50 years later, what is believed to be the UK’s oldest-existing fire-resistance testing laboratory continues to operate. Today, it is one of Warringtonfire’s main sites and is a centre of excellence for the testing of timber fire doors. In addition to being an early pioneer in fire testing, Warringtonfire has remained at the forefront of the industry. Through its collaboration with associations and standards committees, Warringtonfire’s team of technical experts continue to play a pivotal role in raising standards in the fire protection industry.

DHF CONTINUES ITS ‘SUMMER OF INFORMATION’ WITH SERIES OF WEBINARS

Door & Hardware Federation (DHF) is hosting a series of webinars that are proving popular with its membership. The webinars provide clarity and guidance on a range of subjects that affect the door and gate industries and have been launched to enable member companies who manufacture or work with industrial doors, garage doors, fire doors, automated gates and traffic barriers to enhance their knowledge. Three webinars were held on 14th July, 27th July and 4th August and covered such subjects as CPR Tests and certification, fall-back protection, force limitation, compliance assessments of vertical doors and horizontal doors and gates, UKCA Marking and System 3 type testing. A further four webinars are scheduled.

INDUSTRY UPDATES

FC&A ROUNDS UP THE LATEST INDUSTRY NEWS AND UPDATES.

SGP DESIGNS OFFICE IN GRADE II LISTED EX-BANK

Stephen George + Partners LLP (SGP) is delighted to be working with The 55 Group, a leading team of companies comprising Pagabo, Sypro, Social Profit Calculator and Tequ, on its new office premises in Hull.

STEPHEN GEORGE + PARTNERS LLP (SGP)

The 1878 building on Whitefriargate in the centre of Hull contains a remarkable amount of original, in-situ decorative details, from stunning ceilings and a glazed dome lantern to rich woodwork, stonework and window details. E xplains Alan Soper, Studio Director at SGP: “We worked directly with The 55 Group to fit a flexible, vibrant office space within this remarkable heritage asset. Spread across a basement and five floors, the space had to provide workspace and breakout areas for the group’s staff across its various brands, plus a members’ bar, private rooftop terrace and three floors of offices that could be let out.”

SGP’s design embraces Victorian boldness with colour, mixing pure white with deep, rich blues and fresh green highlights. A stunning decorative ceiling, picked out in white and dark blue, arcs over a mix of informal and formal workstations, complete with a circular juice bar. A cantilevered mezzanine floor, which leaves the original decorative features and columns untouched, is flooded with light from the dome lantern and generous windows across the main office space.

The ground floor includes SGP’s designs for a separate private members’ bar area, to be run by Hotham’s Gin School, one of the new tenants. SGP’s design works with the relatively low ceiling height to create a 1920s speakeasy feel, with dark-painted retained brick, chevron wood flooring and low-level lighting. The beautiful timber from the old cashiers’ stations and clerks’ cubicles has been re-used as feature panelling on the walls and also as partitions, with the bar back being built from old bookcases found elsewhere in the bank.

FC&A – SEPTEMBER – 2022 6

INDUSTRY UPDATES

SGP’s new office premises in Hull

www.stephengeorge.co.uk

SGP’s new office premises in Hull

PERSONNEL

The latest appointments from the construction and architectural industries.

NEW HEAD OF MEMBERSHIP AT FIS

The Finishes and Interior Sector (FIS) is delighted to announce the appointment of Michelle Armstrong as the Head of Membership. The role has been newly created in support of the company’s growth strategy, achieved by the development of a programme of member engagement and recruitment activities. Michelle has over two decades of experience in the construction industry, having worked for the Construction Industry Training Board (CITB) since 2000. She is a skilled and practised Company Development Advisor, making her FIS’ clear choice to fulfil the new position of Head of Membership. In her new role, Michelle will continue to develop the company’s growth strategy by developing and leading a programme of member engagement and recruitment activities.

SURVEY HUB REVEALS NEW DYNAMIC DUO

Survey Hub has boosted its team with the appointment of two new trainees. Arun Hari and Bohdan Buleha – who has recently left Ukraine – have both joined Survey Hub’s Nottingham office as Trainee Land and Building Surveyors and will be learning the ropes of specialist services such as measured building and topographical surveys, EPCs, asbestos surveys and more. Bohdan, who recently completed his masters –specialising in geodesy as well as computer engineering – joined the firm not only to start his career but also gain knowledge and pass his experience back to his fellow Ukrainians. Arun recently completed his post-graduate education in MSc Civil Engineering at Nottingham Trent University and decided to join Survey Hub to develop his skills and knowledge with a company that has a good reputation in the sector.

SENIOR PROMOTION AT DMWR ARCHITECTS

DMWR Architects has promoted Mariya Krasteva to Associate Director. Mariya joined DMWR in 2014 as an Architectural Assistant before progressing to an Architect in 2016 and subsequently Associate in 2017.

Barry Harper-Smith, Managing Director of DMWR Architects, comments: “Mariya is an extremely valuable member of our team, and it is wonderful to see her progression over the years in the practice. Her new role is thoroughly deserved, and I look forward to seeing the next chapter in her career at DMWR.” Mariya has worked on a number of high-profile projects within the practice, including Greetham Street in Portsmouth, 25-storey student accommodation project and £42m student accommodation in Oxford both for Unite Students and more recently, an interior design project for a 15-storey, mixeduse building in Varna, Bulgaria and Bristol Royal Infirmary for Unite Students.

IN BRIEF:

E7 BUILDING SERVICES AWARDED WORKS AT ASTON

MARTIN F1 HQ

Mclaren Construction has awarded E7 Building Services – part of The Michael Lonsdale Group –the MEP design and build works for Aston Martin Cognizant Formula One Teams’ new headquarters. E7 Building Services will be handling the full MEP design and build for the brandnew facility at Silverstone as part of its expanding activity in the Midlands area. Works will incorporate state-of-the-art MEP design alongside specialist research and development installation, including BMS and EMS systems, specialist gases, local extract ventilation systems and photovoltaic systems. The scheme will span 15000ft 2 of facilities, including external specialist plant areas. E7 will work alongside Mclaren and Aston Martin F1 to deliver the first Smart Factory in Formula One.

RIBA REPORT SHOWS JCT IS DOMINANT CONTRACT PROVIDER

The RIBA Construction Contracts and Law Report 2022 has been published, with the results showing that JCT continues to be the most widely-used standard form contract provider in the UK construction industry. 59% of respondents indicated that JCT contracts were the forms that their organisation used most often, whilst 71% said that they had used a JCT contract over the last 12 months. When asked to give reasons for their choice, respondents said of JCT: “Industry standard and tested in the courts”, “fair, equitable and well understood”, “standard lump sum contract understood by the industry” and “simple and familiar”. JCT contracts were dominant in project value between £250,000 and £5m.

FC&A – SEPTEMBER – 20227 INDUSTRY UPDATES NEWS

SGP’s new office premises in Hull

ARCHITECT IN PROFILE

In this month’s Q&A, James Walsh, CEO of Studio Anyo, fills us in on what inspires him and how young architecture students can get ahead.

Please tell us a bit about your career background.

After graduating from Hull School of Architecture, I worked for several London practices, including Swanke Hayden Connell Architects, Sheppard Robson and Hamiltons Architects, cutting my teeth on various projects before setting up Studio Anyo in 2010. I learnt an awful lot, and for a young architect, it all provided great exposure to the work of renowned architects, such as Foster and Rogers, on some of London’s biggest regeneration projects, including Oxford Street’s Armadillo Connect.

Have you always wanted to pursue a career in architecture?

Yes, I’ve always wanted to be an architect for as long as I can remember. No one else in my family had worked in architecture, but I found myself drawn to it early on. I was also stronger in technical drawing, graphics and design than in other subjects at school, so it was perhaps a natural career for me to pursue.

Who has been your greatest influence and source of inspiration?

The modern geometric work of the great Polish-American Architect Daniel Libeskind has always inspired me, particularly his design of the Jewish Museum Berlin, Germany. I’m also intrigued by buildings with stories to tell. This includes churches and cathedrals, whose design and architectural narratives have transcended the generations to remain as influential and inspiring as ever.

What has been your most notable project to date?

The citizenM Tower of London hotel, completed in 2012, has to be one of my most important pieces of work and the one I’m particularly proud of. This complex building sits within a UNESCO World Heritage site and above the nearby London Underground station. The development saw a lot of technical and design challenges to overcome to deliver a flagship luxury hotel where concrete, glass and high-tech works across architecture, interiors, urban development and brand significance.

How do you approach your projects?

It begins by working closely with the client to identify a storyboard for the project, whether it’s a new or refurbished hotel, office block or leisure facility. From this, the first concept flows, feeding the design narrative and, ultimately, a distinct meaning and purpose for the building.

What do you think is the greatest challenge for designing in sustainability?

Designing in sustainability is one of the key requirements for almost all new buildings, regardless of whether they are commercial or residential developments. For architects, this presents a tough ask – the great challenge is to create functional, inhabitable buildings that aren’t compromised by sustainability requirements and the need to use energyefficient technologies and materials.

FC&A – SEPTEMBER – 2022 8

INDUSTRY UPDATES

citizenM Tower of London hotel

www.studioanyo.com STUDIO ANYO

JAMES WALSH IS THE CEO OF STUDIO ANYO

What is your favourite building?

Daniel Libeskind’s Jewish Museum Berlin. It’s a testament to the value and power of narrative within design and architecture, conveying the social, political and cultural history of the Jews in Germany from the fourth century to the tragedy of the Holocaust in an achingly-powerful, evocative and acute style. The light and darkness of the subject matter are captured by a unique building that’s both brutal and compelling by turns, relating a story for the ages and reminding people of what happened during one of the darkest chapters of our time.

What do you think is the greatest challenge for architects today?

Striking a balance between delivering beautiful, energy-efficient buildings that we would all want to live and work in with budget constraints can be highly challenging for architects. We are seeing good design and architecture being stripped away because of the rising cost of sustainable technologies and the products used in construction. Energy efficiency and net-zero carbon emissions always come with a price.

What do you think is the greatest challenge for architecture students?

Understanding that academic courses bear little relevance to the actual job of being an architect is a massive challenge for

A new range of lodges

students. Those students who come to a commercial practice must then attain two to three years of learning and experience before they can be considered ready and equipped with the skills to work in the real world. This can be a costly process, placing considerable strain on practices’ budgets.

What advice would you give to newly-qualified architects?

Try to get as much real-world experience as quickly as possible. Get yourself involved with live projects via work experience and, crucially, understand how builders work and interpret architectural drawings. Possessing the skills that

enable you to communicate designs succinctly and unambiguously to builders is paramount to being a successful architect and delivering projects.

What can we expect to see from you over the next year?

We are growing our work in residential and high-end sectors through creating and delivering new products incorporating the latest developments in MMC and offsite, modular construction. For example, our new range of sustainable prefab houses for consumers will offer more choice and variation than ever before.

FC&A – SEPTEMBER – 20229 INDUSTRY UPDATES

citizenM Tower of London hotel

MMC example

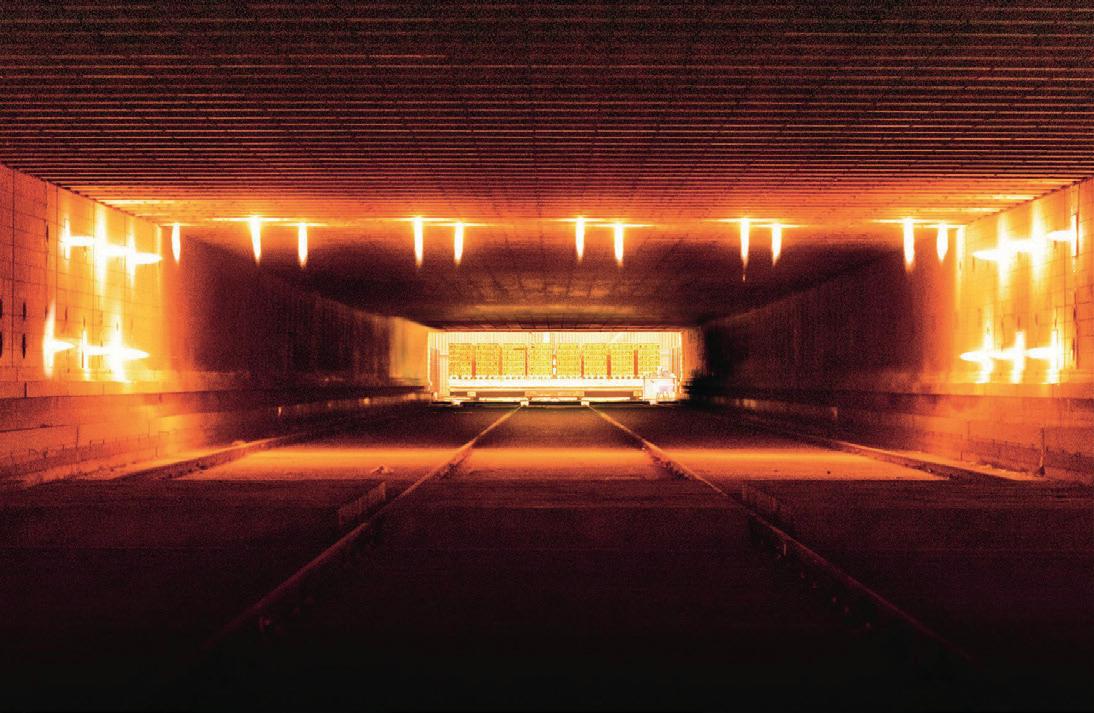

QAAMMAT PAVILION WINS A+AWARDS

The Qaammat Pavilion, designed and built by Architect Konstantin Ikonomidis in cooperation with UNESCO and the Qeqqata Municipality, located in Sarfannguit, Greenland, has been crowned Popular Choice Winner of the Cultural (Pavilions) category in the A+Awards.

KONSTANTIN ARKITEKTER

Lo cated in Sarfannguit, a cultural landscape in west Greenland and a UNESCO World Heritage site since 2018, the Qaammat Pavilion by Konstantin Ikonomidis is designed to celebrate and promote the Inuit intangible cultural heritage and traditional knowledge of the environment.

Characterised by the two fjords that meet on Sarfannguit’s eastern tip on the hills, the pavilion’s location has been carefully chosen by the local community, Site Manager, Paninnguaq Fleischer-Lyberth, and Architect, Konstantin Ikonomidis, for its impressive view over the municipality.

S et on the planned trail between Sarfannguit and Nipisat, this sitespecific installation will serve as a landmark and a gathering point and dissemination site, where the World Heritage Site’s beautiful surroundings can be experienced by locals and visitors to the village. The Qaammat Pavilion is designed as a poetic and aesthetic object, but, most importantly, as a symbolic gesture acknowledging the natural site and rich history, the distinctiveness of the Greenlandic culture and the spiritual sensibilities rooted in Sarfannguit.

The pavilion is anchored in the rocky terrain. Drilled into the ground with 40mm holes, the foundation is constructed with rock anchors exactly like every typical house in the settlement. Attached to the upper part of the metal poles is a custom-made, stainless-steel bracket with a circular geometry. The metal bar is fully horizontal, and the poles vary in length according to the terrain. The curving walls, constructed in glass blocks, form a linear pathway open at both ends, which serves as an entrance to the pavilion. One of the more distinctive features of the structure is its glass ‘shell’, its play of transparencies, scale and weight, resulting in a feeling of surreality. The Qaammat Pavilion can simultaneously alter the viewer’s perspective, merge and even vanish into the surrounding topography.

The design draws inspiration from the moon and the Arctic light in combination with the snow’s reflections. An essential part of the design phase was site-specific research by Konstantin. Following his earlier work and analysis on the subject of home, Konstantin focused on his interest in integrating landscape, culture and human stories into the design. Marked by encounters, conversations and interviews with the locals, the architect’s intention is to reflect these experiences, stories and myths poetically in the design of the pavilion.

FC&A – SEPTEMBER – 2022 10 QAAMMAT PAVILION, KONSTANTIN ARKITEKTER

www.konstantin-ik.com

FC&A – SEPTEMBER – 202211 QAAMMAT PAVILION, KONSTANTIN ARKITEKTER

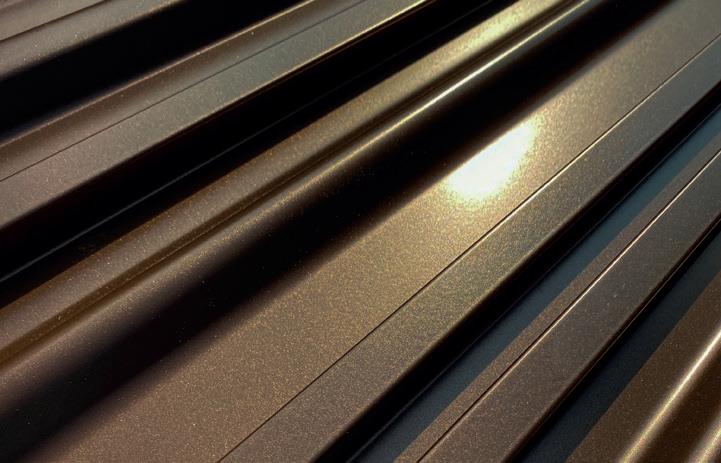

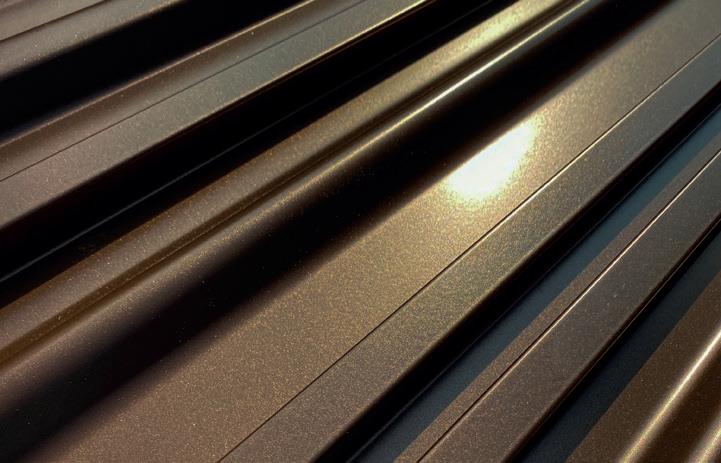

‘SATELLITE’ – POWDERTECH’S UNIQUE LUSTROUS FINISH WITH AN IRIDESCENT GLEAM

A beautiful brand-new collection of powder-coated finishes has arrived on the scene. Called ‘Satellite’, these are unique finishes developed by the innovative powder coating company, Powdertech Corby. The range is made exclusively for Powdertech to the company’s visual and technical requirements and conforms to BS EN 12206-1 standards and Qualicoat specifications.

POWDERTECH CORBY

Sa tellite finishes have a distinctive iridescent gleam with layered metallic and pearlescent effects and a depth of colour unrivalled in a one-coat application. As Richard Besant, Director at Powdertech, explains: “The name ‘Satellite’ came once we saw the initial samples. The mid-sheen finish with vibrant flashes of light, set in a rich colour, is so intense that it looked like a million satellites in the sky. The range name was obvious once we saw it. The individual names are taken from the hundreds of man-made satellites that orbit the earth, so we have plenty of options as the range expands.”

D evelopment of the range arose from a casual conversation between Powdertech and Amron Architectural, one of the leading players in metal mesh for architecture and interior design. Amron mentioned the frustrations of anodic coatings and the difficulty in finding a powder coating that offers a similar depth of colour and layered iridescent effect to anodising. That set the Powdertech team thinking, and the result was the Satellite range, launched in July. Amron is delighted with the range and used it, prelaunch, on the profiled sheet walls of the company’s stand at the Surface Design Show in February 2022. Using ‘Callisto’ from the Satellite range, the undulating surface of the profiled sheet was wonderfully enhanced as light bounced off the glittering finish.

S atellite finishes are suitable for internal and external applications and can be applied to most metallic substrates. It is a range that stands alongside anodising, bronzes and golds as a high-quality, flexible, unique and economic finish with excellent durability and colour stability.

P owdertech has launched several other new collections over the last 12 months. By listening to customers, forecasting and following trends in the architectural and interior design markets, Powdertech develops shades, effects and textures that stay ahead of the curve.

R ecent new collections include Zest, a range of mouth-wateringly energetic shades bringing added pizzazz to any project. Zest offers the same highperformance protection and colour retention as the company’s other finishes. Freeform is another new collection, launched at the end of 2021. This range is unique in that it is actually designed by each individual customer. If you have a design or text, or even an image in mind, then Freeform can bring it to life.

S atellite itself has already attracted so much interest that in November 2022, Powdertech will be launching even more Satellite finishes with great depth of colour and sparkle.

FC&A – SEPTEMBER – 2022 12 www.powdertechcorby.co.uk 01536 400890 pcl@powdertech.co.uk

COATINGS & FINISHES

Satellite ‘Ariane’

Satellite ‘Callisto’ on Amron wellTec

FC&A – SEPTEMBER – 202213 Structural Glazing Specialists 01708 374534 contracts@firmanglassprojects.com www.firmanglassprojects.com GLASS PROJECTS

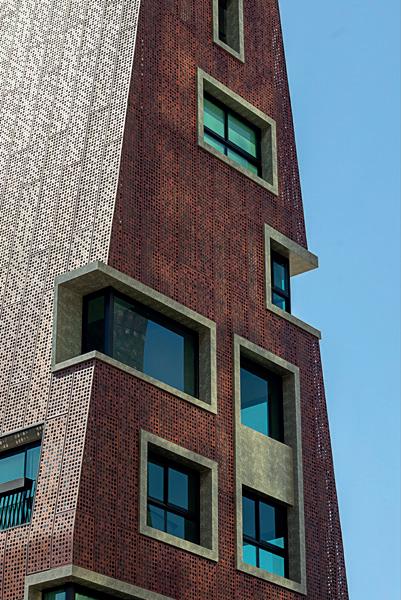

A RESIDENTIAL BUILDING WITH A BOLD DESIGN AND ITS OWN IDENTITY

The CASAMIRADOR Savassi residential building is located in Belo Horizonte, Minas Gerais, Brazil, and features boldly-designed architecture that stands out in the local landscape.

Th e building has 14 lofts and 24 studios and is spread over nine floors in a construction located on a narrow lot, with a width of 12.7m. The challenge of its volumetric mathematics, to respect distances, was one of the factors that influenced non-obvious decisions resulting in architecture being created with its own identity.

The interdependence between the building’s structure and the architectural project enabled great creative freedom, culminating in the most prominent element; a second skin that ‘wears’ the building like a garment, giving it unique characteristics. The material used was aluminium, painted in an earthy, reddish sepia tone that alludes to the abundance in Minas Gerais of raw ore.

GISELE BORGES ARQUITETURA

In order to obtain lightness and transparency, the aluminium sheets received perforations in different sizes and were made in an asymmetrical yet harmonic way. That process makes it possible to see through them from the inside out, where city views are exposed through the skin. However, from the outside looking in, it isn’t possible to see the interior, guaranteeing privacy to the resident. This element also made it possible to explore a rich range of effects, from hiding smaller, functional windows, to tearing the skin to expose the large spans. Conceived as generous openings, these windows allow the city to become an extension of the house, with abundant light and ventilation. The concrete frames of the openings contrast with the predominant oxidised colour.

FC&A – SEPTEMBER – 2022 14

CASAMIRADOR SAVASSI, GISELE BORGES ARQUITETURA

T +44 0161 804 9500 | F +44 0161 804 9505 sales@onlevel-uk.com | www.onlevel.com TL 6020 1.5 kN TOP MOUNT | Fully adjustable from one side. | Only system in the UK which will meet 1.5 kN with 21.52 mm PVB Glass | Tested to 0.74 kN with fixings at 600 mm centres (all competitors are generally 200/250 mm) meaning you only need a third of the fixings saving you a lot of time and money | Tested to 1.5kN with fixings at 400mm centres (all competitors are generally 200/250 mm) so again you need half as many fixings saving you time and money | Tested to 1800 mm high with 21.52 mm Sentry and only deflects 18 mm at the top making it an ideal solution for privacy screens when you want the channel detail to remain the same CHESHIRE PLAINS, ENGLAND TRANS LEVEL FRAMELESS GLASS BALUSTRADE

T he skin covering the building also provides thermal comfort to the units. Away from the masonry, it provides shading for the fences and good ventilation through a mattress of renewable air. From that perspective, sustainability guided many of the project’s choices. Due to the reduced dimensions of the land, and minimal rooftop space for installing equipment or photovoltaic panels, it was necessary to find a solution that would avoid the entry of heat, to the detriment of an air conditioning project.

T he building’s pyramidal shape, which is the result of staggering, also made it possible to allocate technical areas on the outer face of the masonry, as well as on the internal face of the skin, ensuring a clean and unadorned plastic.

Another project highlight concerns the challenge of placing the pyramid on the ground, touching the land lightly at a single point. Under the influence of Brazilian Architect Oscar Niemeyer, a V-shaped pillar was created, which is widely used in his works.

F inally, to ensure flatness on the facades, the sheets were bent on all four sides, thus increasing their rigidity. Although the sheets were randomly perforated, the joints were aligned, and the volume was harmonious, several studies were carried out until the final fixing model produced an alignment of the slabs and the midpoint of each floor. The study ensured optimisation in the secondary structure for fixing the plates. There are only three horizontal profiles per floor, and the upper and lower profiles were also combined to fix the plates of the adjacent floors.

T he final plastic is the result of a marriage between covering sheets, frames and structure. There are three elements that alternate on the facades with greater or lesser relevance to the skin, ensuring a clean and unadorned plastic.

FC&A – SEPTEMBER – 2022 16

www.giseleborges.arq.br CASAMIRADOR SAVASSI, GISELE BORGES ARQUITETURA

Technical characteristics

Raw material: Aluminium EN 5005

Picture

L’École Internationale Edward Steichen is a high school in Clervaux, Luxembourg, with room for 650 students. Jonas Architectes Associés won the assignment for construction and devised not only a plan for the buildings, but also an idea for decorative facades and sun protection. RMIG ImagePerf made it possible to realise their vision.

L’École Internationale Edward Steichen is a high school in Clervaux, Luxembourg, with room for 650 students. Jonas Architectes Associés won the assignment for construction and devised not only a plan for the buildings, but also an idea for decorative facades and sun protection. RMIG ImagePerf made it possible to realise their vision.

L’École Internationale Edward Steichen is a high school in Clervaux, Luxembourg, with room for 650 students. Jonas Architectes Associés won the assignment for construction and devised not only a plan for the buildings, but also an idea for decorative facades and sun protection. RMIG ImagePerf made it possible to realise their vision.

L’École Internationale Edward Steichen is a high school in Clervaux, Luxembourg, with room for 650 students. Jonas Architectes Associés won the assignment for construction and devised not only a plan for the buildings, but also an idea for decorative facades and sun protection. RMIG ImagePerf made it possible to realise their vision.

facade

Pattern: RMIG ImagePerf

Technical characteristics

Raw material:

Anodising Finishing operation: Bending

Thickness:

mm

Surface treatment: Anodising

Pattern: RMIG ImagePerf

operation:

Thickness:

mm

Surface treatment: Anodising

operation:

As the school is more or less surrounded by woodland on all sides, a striking photo of a spring forest from a nature park in the Ardennes was chosen as the template for the facade image.

Using perforation in various hole sizes, the beautiful image of the forest was transferred on to metal sheets.

As the school is more or less surrounded by woodland on all sides, a striking photo of a spring forest from a nature park in the Ardennes was chosen as the template for the facade image.

As the school is more or less surrounded by woodland on all sides, a striking photo of a spring forest from a nature park in the Ardennes was chosen as the template for the facade image. Using perforation in various hole sizes, the beautiful image of the forest was transferred on to metal sheets.

Using perforation in various hole sizes, the beautiful image of the forest was transferred on to metal sheets.

As the school is more or less surrounded by woodland on all sides, a striking photo of a spring forest from a nature park in the Ardennes was chosen as the template for the facade image. Using perforation in various hole sizes, the beautiful image of the forest was transferred on to metal sheets.

FC&A – SEPTEMBER – 202217 Picture perforation used for a facade depicting a forest RMIG Ltd | 1-7 Adlington Court | Risley Road | Birchwood Warrington | WA3 6PL Chesire | Tel: + 44 1925 839610 | info.uk@rmig.com | www.city-emotion.com

RMIG City Emotion we

make ideas come to life

Picture perforation used for a facade depicting a

forest

RMIG Ltd | 1-7 Adlington Court | Risley Road | Birchwood Warrington | WA3 6PL Chesire | Tel: + 44 1925 839610 | info.uk@rmig.com | www.city-emotion.com

Technical characteristics Raw material: Aluminium EN 5005 Pattern: RMIG ImagePerf Thickness: 3.0 mm Surface treatment:

RMIG City Emotion

we make ideas

come to life HIGH SCHOOL, CLERVAUX, LUXEMBOURG

perforation

used for a facade depicting a forest

RMIG Ltd | 1-7 Adlington Court | Risley Road | Birchwood Warrington | WA3 6PL Chesire | Tel: + 44 1925 839610 | info.uk@rmig.com | www.city-emotion.com

3.0

Finishing

Bending RMIG City Emotion we make ideas come to life HIGH SCHOOL, CLERVAUX, LUXEMBOURG Picture perforation used for a

depicting a forest RMIG Ltd | 1-7 Adlington Court | Risley Road | Birchwood Warrington | WA3 6PL Chesire | Tel: + 44 1925 839610 | info.uk@rmig.com | www.city-emotion.com

Aluminium EN 5005

3.0

Finishing

Bending RMIG City Emotion

we make ideas come

to life HIGH SCHOOL, CLERVAUX, LUXEMBOURG

NIAMH BURKE

IS AN ASSOCIATE IN THE CARTER JONAS (LONDON) PLANNING AND DEVELOPMENT TEAM AND WORKS ON A RANGE OF RESIDENTIAL, COMMERCIAL AND MIXED-USE PROJECTS FOR HOUSEBUILDERS, LAND OWNERS, GOVERNMENT AGENCIES AND LOCAL AUTHORITIES

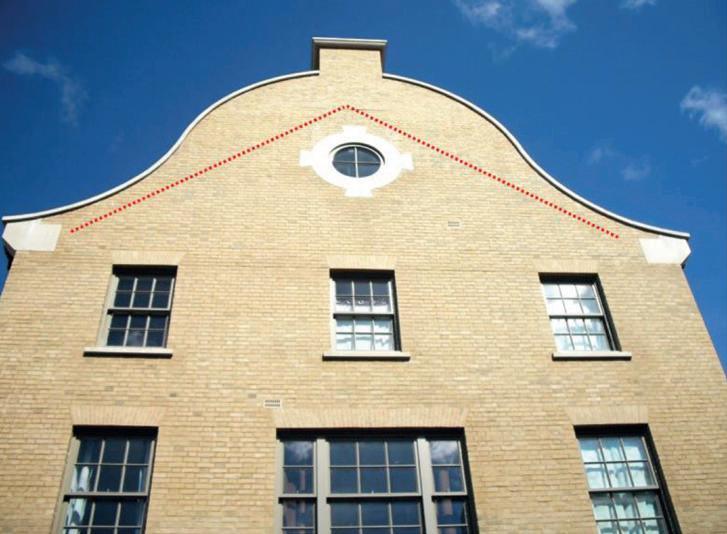

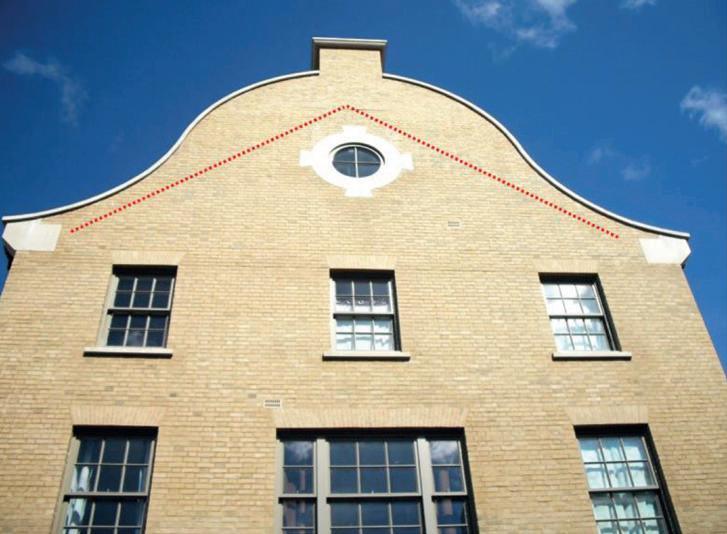

PUBLIC ENGAGEMENT WITH DESIGN CODES

Will this additional tier of engagement succeed in accelerating development or result in further delays? Do Design Codes represent housing development by consensus, or will they result in consultation fatigue? And, will they fast-track ‘beauty’ or will the layman’s greater involvement in design result in a dumbing down? Niamh Burke, Associate at Carter Jonas (London), investigates.

CARTER JONAS (LONDON)

An emerging theme in planning policy is that of ‘beauty’. While ostensibly raising the standards of design, the underlying aim of the beauty agenda is to increase the delivery of more homes. As the then Secretary of State indicated in a webinar on ‘Building Beautiful Places’ in July last year, very few people actively support planning applications for new homes, but this could be addressed by, “putting beauty back at the heart of how we build”.

I t follows, therefore, that if public support for the design of new communities is achieved at an early stage, planning consent is more likely to be forthcoming. This is what Design Codes are intended to achieve: as a template by which local residents, via their local planning authority (LPA), can create their own aesthetic wish list, they allow communities to exercise more control over the built environment.

I n July 2021, the National Planning Policy Framework (NPPF) was amended to urge all councils to develop a local Design Code, and the National Model Design Code (NMDC) provides advice on both the process and the content, along with methods to capture and embody the views of the local community.

T he first consideration is how Design Codes will fit into our current system. Public consultation is required on the formation of a Local Plan, the drafting of a Design Code and at both the masterplanning and detailed planning stages of a development proposal. Never before has consultation been required to such an extent.

Furthermore, Design Codes can be applied at county, local authority, neighbourhood or site level. And, the NMDC requires consultation at no fewer than three points: on the analysis, the vision and the formation of the code. This runs the risk of creating consultation fatigue and an imbalance in local engagement. It is widely understood that objections to planning applications are often brought about by a vocal minority of ‘NIMBYs’. A potential problem of increased consultation is that NIMBYs presented with more opportunities to object increasingly outweigh the voices of those who do not.

Furthermore, research demonstrates that increased engagement is likely to favour a conservative approach to design. The Government’s own polling has demonstrated that support for traditional design is preferred over contemporary architecture: 85% of respondents surveyed said that new homes should either fit in with their more traditional surroundings or be identical to homes already there.

S o, will Design Codes result in a dumbing down in housing design? While consultation can open minds to new ideas, this takes considerable time and skill. A much-repeated comment from the pilot NMDCs was that local authorities lacked the resources to consult fully. This would suggest that without a significant investment in public consultation, the design of new homes will favour pastiche over progression.

W hile many questions remain about how consultation is conducted and with whom, the success of NMDCs also depends on how this additional requirement fits into the broader planning process. For Design Codes to have a role in the planning system, they must be fully integrated – rather than existing as a relic of the 2020 Planning White Paper – planning policy that never was.

FC&A – SEPTEMBER – 2022 18

LEGAL & BUSINESS

www.carterjonas.co.uk

Park View by Blenheim Estate Homes used a Design Code in its pursuit of ‘beauty’

FC&A – SEPTEMBER – 202219 Traditional Timber Window and Door Specialists 01344 868 668 www.sashwindow.com Beautiful timber windows and doors, designed to improve energy efficiency. Tailor made solutions for your project. Supply only, supply and install, secondary glazing and draught proofing. BRUNDLE F.H.BRUNDLE SERVING THE TRADE SINCE 1889 For more information 01708 39 80 22 sales@brundle.com www.fhbrundle.co.uk FREE DELIVERY ON ORDERS OVER £150 NO TRADE ACCOUNT REQUIRED COMPETITIVE PRICES DELIVERED FROM STOCK ORDER ONLINE 24/7 Stand-Offs Stainless Handrail Frameless Glass Spigots Glass Clamps Wire Rope PRO-RAILING® BALUSTRADE SPECIALISTS The stainless steel handrail & component system. The widest range of innovative and stylish handrail & balustrade from a single supplier. Whatever the project, we have a cost effective solution.

IAN KING

IS THE CHIEF OPERATING OFFICER AT ZEROIGNITION. WITH OVER 30 YEARS OF GENERAL MANAGEMENT EXPERIENCE IN VARIOUS GLOBALSCALE, BRAND-DRIVEN BUSINESSES IN TECHNOLOGICALLY-FOCUSED INDUSTRIES, IAN HAS HELD SALES, MARKETING, GM, VP AND CEO POSITIONS IN GLOBAL BRANDS.

TOXIC FIRE RETARDANTS: THE INVISIBLE DANGER OF TIMBER CONSTRUCTION

Timber as a building material has come a long way in recent times. The completion of the world’s tallest timber building in Milwaukee is a shining example of what’s possible. Closer to home, Central London’s new Black and White building is the tallest mass timber office building. As technology and construction methods have evolved, architects now have greater flexibility when designing buildings with wood – an attractive and increasingly-sustainable material, writes Ian King, COO at Zeroignition.

However, despite timber’s potential as a building material, architects must be aware of the risk of toxic pollution caused by harmful chemicals found in fire retardants. Awareness around the topic is lacking, presenting health risks when specifying materials. Following the recent legislative changes and the increasing number of heatwaves across the UK, fire safety is top of the agenda. With record temperatures and an unprecedented number of wildfires, fire chiefs are warning that we must be aware of the dangers posed by this extreme weather and the risk of fires breaking out.

T his means that the use of fire retardants is vital – and for a good reason. However, specifying retardants that pose a health risk is not the solution either.

Fortunately, toxic pollution is being addressed by ongoing R&D and new technologies. Yet, a great deal of progress is still needed to develop a deeper understanding of building materials and the risks associated with timber construction to inform the use of safer fire retardants.

Building more sustainably with timber Timber is an incredibly versatile material with solid green credentials due to its lower embodied carbon and reduced emissions from manufacturing processes compared to that of steel and concrete. Yet, we can’t ignore the increased fire risks, including when wood burns. When this occurs, volatile organic compounds (VOCs) are released, and this danger is exacerbated by deadly fumes released from some fire retardants. These harmful chemicals can also seep into water sources through drainage and rain. Toxic ingredients in fire retardants, such as halogenated chemicals, can negatively affect human health through neurological damage, hormone disruption and even cancer.

To secure a greener future for construction and improve our use of timber, it’s essential that we completely phase out dangerous chemicals in fire retardants. Brominated fire retardants have already been restricted in the EU, and I expect there will be more to come for other harmful products that are currently still on the market. For architects, staying one step ahead of the game and broadening their understanding of the dangers associated with fire retardants is one way we can reduce the risk to health.

FC&A – SEPTEMBER – 2022 20

ZEROIGNITION

VOICE OF THE INDUSTRY

Is building with timber risky?

T he legislation associated with the Fire Safety Act has seen tighter restrictions on building materials. Timber use is seen as high risk, given that unprotected wood easily burns. While there are risks, it’s encouraging that developers are still using timber thanks to the availability of fire retardants which can protect building materials. What’s more, through extensive R&D, innovations of low-toxicity fire retardants are being developed that are much safer, and those containing toxic chemicals no longer need to be a choice.

T his progress means a range of new products are coming to market, providing more options for suppliers and increasing design agility for architects. If using fire-

safe, non-toxic, treated timber, professionals across construction can rest easy knowing that buildings are safe and sustainable. To ensure this is the case, improved levels of knowledge, education and awareness must first be prioritised.

A more holistic understanding of fire safety

To fully understand the benefits of fire protection methods, it helps to look at how different elements work as part of a system in a building. This means assessing all the parts and observing how they interact with one another in the event of a fire. It can be easy to rely on methods like sprinklers which are hailed as a one-size-fits-all solution, but other solutions, including fire retardants, should not be overlooked.

T his holistic outlook on fire safety is essential in the planning stage of construction, meaning architects can understand the use of non-toxic fire retardants, creating a greener and cleaner industry. We need to be sensible about the materials we are putting into homes and commercial buildings and ensure the latest methods to treat wood are the correct choice, beyond the risks associated with fire.

What’s next for timber construction?

T ime is of the essence, and everyone across the construction industry must do their part to ensure toxic materials are removed from supply chains. A greater degree of education from suppliers and architects on the underlying dangers associated with some fire retardants will help to drive this change.

T here is no denying that timber is a viable solution to many of the challenges the construction industry currently faces, particularly in terms of sustainability. It’s now vital we don’t overlook the bigger picture and create other health risks in our rush to use timber as the next major building material. Safety must be a priority above all else, so let’s make sure we’re considering all angles and create the sustainable future we’re all aiming for.

FC&A – SEPTEMBER – 202221

www.zeroignition.com VOICE OF THE INDUSTRY

BALUSTRADES: WHAT YOU NEED TO KNOW

In this article, Paul Smith, Head of Marketing at F.H. Brundle, explores the rise of balustrades.

To day, we think of balustrades as the epitome of modern design. When we hear the word, we picture futuristic new builds – flat roofs, floor-toceiling windows, sliding doors with frames that are almost invisible. But the ancient structures that the earliestsurviving balustrades are found on couldn’t be more different. A s strongly as we associate them with the glass-and-steel age we’re living in now; they date back to a time when wood, stone and marble were the dominant materials used in construction. There are murals from the ancient kingdom of Assyria – encompassing parts of Iraq, Turkey and Syria as we know them today – that depict buildings with balustrades from over 3000 years ago.

F.H. BRUNDLE

There’s also evidence of their use in India and China in ancient times – although, interestingly, none whatsoever that they were ever used in Greece and Rome, despite their reputation for impressive architecture. However, they didn’t come into their own until over 2000 years later in Renaissance Italy, where their use became widespread. In the 1500s, they featured on landmark buildings like the Villa Medici and in designs by Michaelangelo – and it was also in Italy that they first got their name.

A s everyone reading this will know, a balustrade essentially consists of a horizontal ‘rail’ section, which is held up by many vertical balusters. In the architecture of the day, these balusters

were often a bulb-like shape, which locals thought looked like pomegranate flowers – ‘balaustra’, in Italian. Unsurprisingly, it’s from here that the name ‘balustrade’ was derived.

What’s not changed, however, is the fundamental purpose that balustrades serve. They’re an elegant, visually-pleasing solution to an age-old problem – providing safety at height. Instead of ugly, oppressive structures that block out natural light and spoil scenic views, balustrades offer a much more seamless alternative.

Today’s sleek and stylish glass balustrades might not look all that much like something you’d find on the Villa Medici, but they fundamentally serve the same two key purposes. They exist to keep people safe –allowing them to admire the view in high-up places and prevent accidents. And they exist to look good.

H owever, one thing Michaelangelo – and the architects of Ancient Assyria –

didn’t have to contend with is the large and often complex amount of regulation governing balustrade use that we do in 2022. In residential settings in the UK, Building Regulations require that balustrades, or similar barriers, be used in spaces with a height difference of more than 600mm. In nonresidential applications, they have to be used on staircases with more than two risers and spaces where the height difference is over 380mm.

There are also strict regulations governing the height of glass used, which varies depending on the setting. According to Approved Document K in the Building Regulations, when used in conjunction with stairs, landings, ramps and edges of internal floors, the balustrade must be 900mm in height. For external balconies and the edges of roofs, they have to be 1100mm. In public sector buildings, offices and retail settings, similar rules apply – balustrades must be 900mm for flights of stairs and 1100mm for all other settings.

FC&A – SEPTEMBER – 2022 22 DOORS, WINDOWS & BALUSTRADES

I n addition, there are several key performance markers balustrade products have to meet to ensure they’re offering optimum safety performance. The first concerns ‘line load’ – the amount of horizontal force a balustrade can withstand on the top as if someone was leaning against it. Another is ‘uniformly-distributed load’, or the amount of force a product can withstand being applied to its midsection. The third concerns ‘concentrated load’, or the sudden impact that occurs if someone falls against a product or some other accident occurs.

I n all three cases, products have to demonstrate a certain level of performance, laid out in Part B of Building Regulations and BS EN 1991-1. Particular attention has to be paid to the type of building, as different structures with different uses and occupancy levels have different requirements.

FC&A – SEPTEMBER – 202223 DOORS, WINDOWS & BALUSTRADES

www.fhbrundle.co.uk

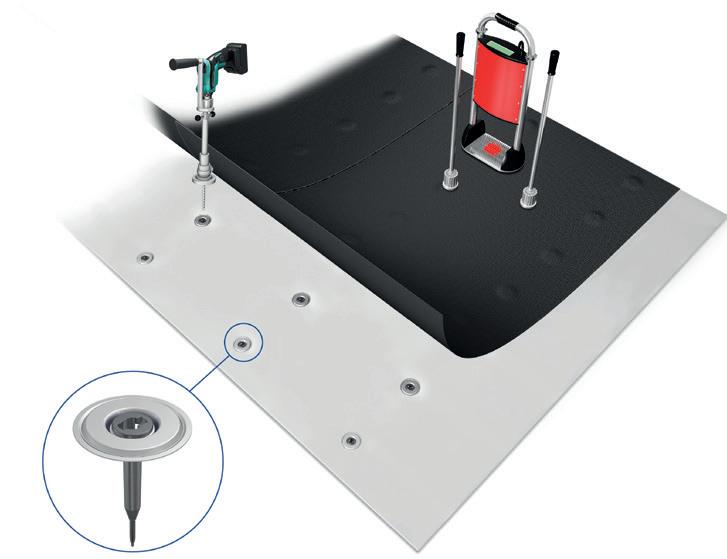

ECODORP: A STUDY IN CIRCULARITY

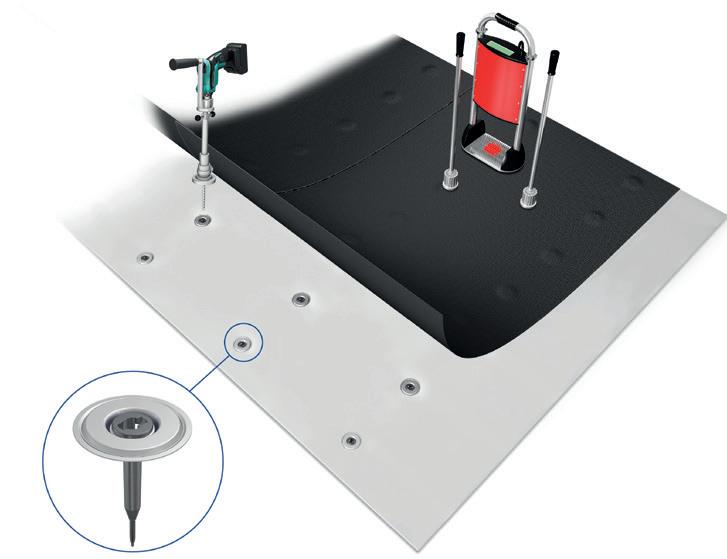

Allen Coldrake from Carlisle Construction Materials discusses the Ecodorp project; a sustainable community in The Netherlands where Hertalan EPDM membrane, installed using induction technology, has been specified as part of a cradle-to-cradle approach to circular sustainability.

CARLISLE

Th

ere have been several showpiece sustainable social housing developments in the UK, combining environmental and social value within a single project. The concept of a project that is sustainable in terms of both materials and community is gaining traction across Europe, and one project in The Netherlands is providing a benchmark for how this idea can be advanced still further.

T he Ecodorp development in Boekel, southern Holland, is a neighbourhood of 30 climate-adaptive and climatepositive rental homes, along with six informal care homes, a community centre, a knowledge and education centre, a workshop and offices, located in three circular buildings, constructed from renewable timber. The community is not only being built using natural, sustainable and recyclable materials, but it has also been designed to enable residents to grow their own food supplies, generate their own energy and purify their own water supply.

I t is a project that chimes with the environmental aims of Carlisle Construction Materials and was an ideal development for the use of the Hertalan Induction System. This combination of EPDM, which is considered the greenest roofing membrane technology, and the mechanically-fixed induction installation method, which enables the membrane to be removed for re-use or recycling at the end of its service life, aligns with the development’s focus on circularity,

articulated in both its specification and the design of the round buildings.

Specification

D esigned by Van Laarhoven Architects and built by ecological contractor Eco+Bouw, Ecodorp is an ERDF, Dutch Government and regional Government-funded project that has circular sustainability at the heart of its design strategy. Alongside natural and renewable materials, the buildings have been specified with a ‘fabricfirst’ approach that considers the environmental credentials, performance, lifecycle and end-of-life potential of each material. This philosophy not only aligns with the environmental and social goals of the project but also enables the project to benefit from a Dutch Government initiative, which enables developers and building owners to claim back up to 12% of both material and installation costs if the products can be returned to the manufacturer for recycling or repurposing at the end of their service life.

C arlisle has made this commitment to taking back the Hertalan EPDM membrane installed on the buildings as part of the Ecodorp project. Using net environmental benefit analysis (NEBA) data and evidencing the ability to remove and recycle the membrane cleanly at the end of its service life was central to both achieving the specification and demonstrating that the project can qualify for the fiscal arrangement.

I n reality, Hertalan EPDM membranes are BBA certified and have an anticipated service life of 50+ years, so it will be some time before the principle is tested. However, this longevity is an integral part of the environmental goals of the development. When the membrane does reach the end of its service life, the same induction process used to fix the Hertalan EPDM to the roof can be used to cleanly lift it from the substrate with no residue from primers or adhesives. Only ‘clean’ EPDM membranes can be fixed and detached in this way. Once the membrane is returned to Carlisle, it will be possible to reverse the process used to manufacture the material, returning the EPDM to its component compounds for re-use.

Installation

T he 36 homes constructed as part of the Ecodorp development are made from waste or organic materials, including lime, hemp and cross-laminated timber, to drive the goal of 100% circularity. The project has been designed to ‘lock up’ more CO 2 than was required in its construction, with 808 tons of CO 2 stored in the homes, versus approximately 600 tons of CO 2 emitted during construction. The project also used geopolymer concrete, which is made from recycled sand and gravel, and Hertalan EPDM on the roof, which can be lifted cleanly from the substrate at the end of its service life, with no residue from primers or adhesives. Only ‘clean’

FC&A – SEPTEMBER – 2022 24 RCI

CONSTRUCTION MATERIALS

EPDM membranes can be fixed and detached in this way because the chalk used to separate the material before vulcanisation in other types of EPDM prevents the technology from sealing the membrane to the metal fixing. Once the membrane is returned to Carlisle, it will be possible to reverse the process used to manufacture the material so that the component compounds of the EPDM can be re-used.

T he roof build-up on each building comprises recyclable PIR insulation board on the timber roof substrate, followed by the Hertalan EPDM membrane. The 2mm-thick membrane requires no primer or adhesive for mechanical fixing using the Hertalan Induction system, and Carlisle’s team worked with the delivery partners to provide a technical specification, which included wind uplift calculations, the layout of the membrane to optimise the use of materials and positioning of the fixing plates, most of which were used to fix both the EPDM membrane and the insulation with a single plate.

T he layout for the fixing plates was specified as a grid on a technical drawing as part of the technical specification. While standard fixing plates can be used for any insulation-only fixing locations, the plates used to install the EPDM roofing membrane with the Hertalan Induction system have a special coating. This becomes tacky when the plate is heated by magnetic radiation and solidifies again when it cools, achieving a secure bond. If the membrane needs to be removed, for modifications to the building, for example, or at the end of the building’s service life, the same induction process can be used to release the plates and remove the membrane. This allows installation with neither adhesives nor penetrations.

A ll the metal plate fasteners were installed on each building prior to the installation of the EPDM membrane, which was pulled across the roof, making it watertight very quickly. The bonding process was equally fast, with the contractor’s team utilising the lightweight Hertalan Induction device at each location to create the firm bond. In a single pass of each fixing plate, the equipment heats the plate, which adheres to the underside of the EPDM, and a magnet then cools and applies pressure to the point of adhesion, enabling a fast and secure bond in a matter of seconds. Because the induction equipment heats the plate using magnetic radiation, no hot works were required, and it was not possible for the membrane to be heated or fixed in the wrong location.

Achieving circularity

T he drive for sustainability has evolved from a focus on environmentallyresponsible materials and improved building performance to a genuine commitment to preserving resources, using them well and considering their legacy. The Ecodorp project exemplifies these principles. As we look to a future where we have to tackle the issue of finite resources, the ability to reclaim materials with a cradle-to-cradle approach to circularity will be vital, so learning from projects and Government initiatives from other markets is a useful way of considering how the green agenda can be accelerated in the UK.

FC&A – SEPTEMBER – 202225 RCI

www.ccm-europe.com/gb/

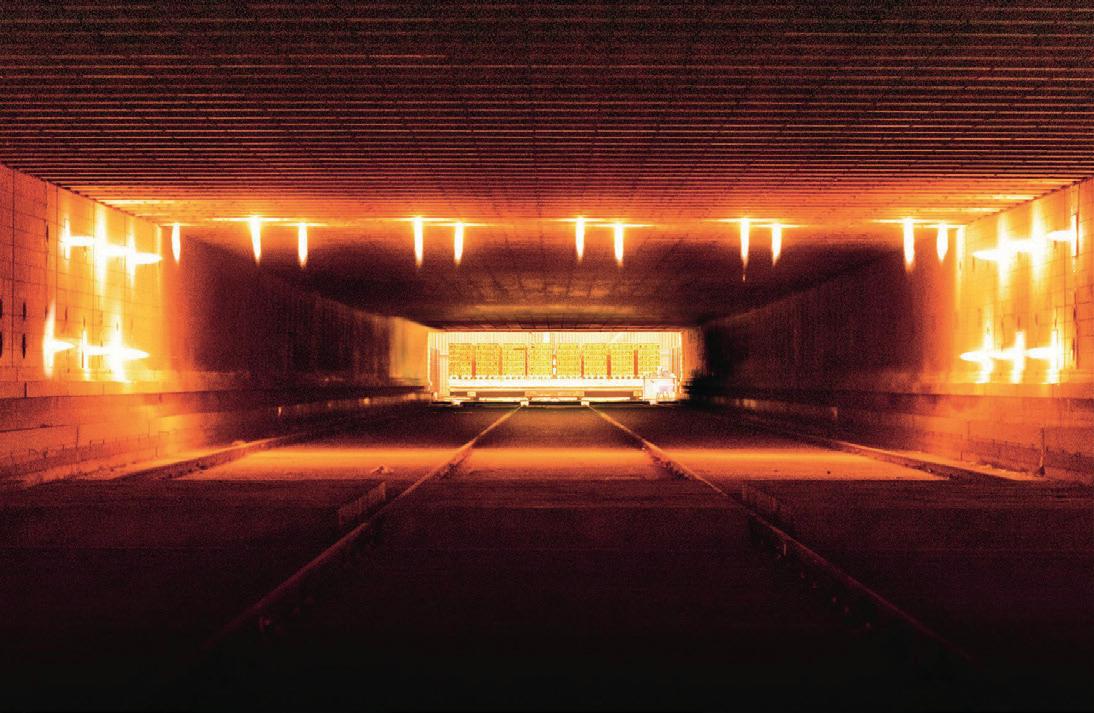

A DIFFERENT WAY OF THINKING

Depending on your outlook, HVAC within building design is either a nightmare of constraints and compromises or a stimulating balancing act of client needs, sustainability and cost. Occupancy levels, hybrid working, occupant health and wellbeing, indoor air quality (IAQ), energy consumption and sustainability are receiving new, higher levels of consideration alongside the conventions of aesthetic versus build cost, writes Jack Smith, Product Manager at AET Flexible Space.

Is it time to change your way of thinking?

One thing the COVID pandemic has taught us all is that there are alternative – and many would argue better – ways of doing things. It has forced us all to venture beyond the accepted; to think outside the box.

Historically, we design office spaces using the ceiling to provide the route for ventilation and air conditioning, whether those building services are exposed or concealed behind a suspended ceiling.

Why not turn the process upside down? I’m talking about underfloor air conditioning (UfAC). It’s not a new concept. In fact, we’ve been designing and supplying the Flexible Space System (FSS)

globally for nearly 30 years. But it is relatively undiscovered, especially in the UK.

What’s it all about?

UfAC makes use of the already existing void and mechanical framework that comes as part of a raised access floor system to deliver conditioned air to a space. Why take on the cost and go through the effort of ductwork design and ceiling suspended systems when a ready-made duct is right there below our feet?

Conditioned air is delivered to the void through a Conditioned Air Module (CAM), which is dispersed throughout the office space. Here, air is filtered, mixed with fresh air and then heated or cooled depending on space conditions.

From the void, the conditioned air is introduced to the space via a Fantile. The Fantile is installed into the existing framework of the raised access floor. This isn’t your standard displacement system where air leaks passively into a space regardless of conditions. Each Fantile is equipped with an EC fan, damper, trim heater, temperature sensors and controller to ensure that air is only delivered to the space if required.

Strategic positioning of the Fantiles across the floor plan ensures optimal occupant comfort without thermal imbalance from draughts or hot spots. Return air makes its way back to the CAM through either a separated return plenum within the floor void or through

high-level louvres where it is reconditioned and recirculated. The air delivery component of a UfAC system works at relatively low pressure, achieving up to 30% savings on energy costs and almost the same level of saving on CO 2 emissions compared to conventional ceiling-based systems. Consequently, UfAC can be a powerful tool when considering BREEAM, LEED and other green building accreditations.

Design freedom

From an interior design perspective, UfAC expands and liberates the use of the interior space. With air conditioning at a high level, allowances must be made for ducting, pipework and a false ceiling may be installed to

FC&A – SEPTEMBER – 2022 26 HVAC

AET FLEXIBLE SPACE

accommodate these services. UfAC releases this allowance into the internal space enjoyed by the occupants of a building. At low level, certainly in commercial spaces, allowance for cabling is prerequisite; an addition of 150mm is all that’s required to accommodate Fantiles.

As UfAC combines ventilation with temperature modulation, design freedom is further extended: there is no need to include radiators or trench heating. Use of interior space is not only optimised but extended; Fantiles are ‘plug and play’ so can be easily repositioned across the floor plan, delivering flexibility to the modern workplace, where hybrid working has become the norm, and a mix of open-plan and cellular offices dominate

agile work environments. This ease of reconfiguration is proven to reduce both building and tenant churn rates and expedite lettings, even to the extent of adjustments to accommodate sudden increases in occupancy, such as a corporate reception event.

In refurbishment and conversion projects, decorative ceilings and covings, architectural iron or concrete beams can be left exposed, giving the character of a building the chance to express itself. In new and old buildings alike, the gain in ceiling height provides a bright and open workspace.

The Flexible Space System (FSS) integrates seamlessly into the building fabric of a historical renovation or is used to complement the modern

aesthetic of a new build. Decorative louvre facades can be fitted to CAM containment cupboards; Fantiles can feature bespoke grilles with custom shapes, finishes and materials.

Cost savings

Implementing UfAC can increase room height by 10%; it eliminates the need for a ceiling ventilation zone – typically 600mm – and requires a minimal increase to the cabling void under the floor, 150mm. The resultant floor-to-ceiling height increases from 2250mm with a typical suspended ceiling to 2700mm with the use of the UfAC, whilst the slab-to-slab height remains at 3400mm.

Achieving a ceiling height of 2700mm in a new build would require a slab-to-slab height of 3850mm if you chose a ceiling-based system. The UfAC offers a 10% reduction in floor height for the same headroom. On a four-storey building, that equates to an overall height reduction of almost 2m, with the subsequent savings in construction costs and ease in planning considerations that come with it.

Being underfloor, UfAC facilitates the speed and cost of installation, eliminates working at height and keeps

ductwork to a bare minimum. The modularity of the system delivers benefits to churn rates. CAT B design layouts can be realised efficiently with minimal additional equipment requirements. It simultaneously delivers reduced embodied carbon and waste to landfill as an original system can adapt to changing needs. Whereas a traditional system would be ripped out and completely replaced.

Buildings with UfAC are proven to deliver savings of up to 7% on total construction costs and to cut construction time by up to three months.

A load of hot air?

The theory is not a load of hot air. It is proven in practice in some 300 projects across the world and used by (among others), Jaguar Land Rover, Sky, Microsoft, Kuwait State Audit Bureau, Shanghai International Port Cruise Terminal and the Institute of Physics.

To coin a cliche, try it; you might like it! Certainly, our experience is that, once consultants have ventured from the norm and specified UfAC, it becomes their ‘go-to’ option for commercial environments.

FC&A – SEPTEMBER – 202227 HVAC

www.flexiblespace.com

F. Ball’s Stopgap 1500 AquaPro water-mix

smoothing compound can be applied directly over old adhesive residues, removing the need for mechanical preparation

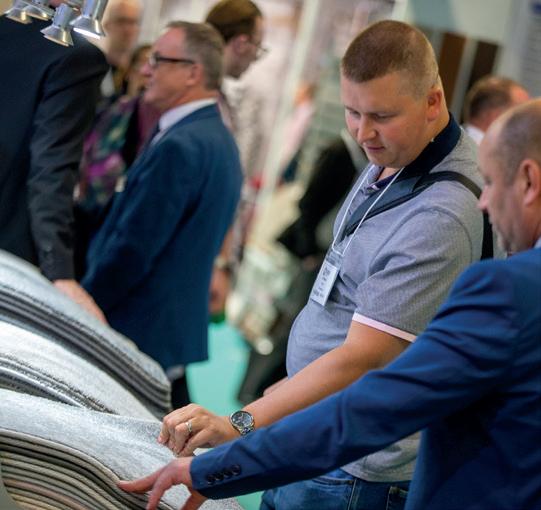

FAST-TRACK FLOORING INSTALLATIONS

Flooring installations increasingly face pressure to be completed to stringent time constraints, often requiring flooring contractors to work around other trades within narrow time frames to allow projects to be completed and areas brought into use as quickly as possible. Neil Sanders, Technical Director at leading UK manufacturer of subfloor preparation products and adhesives for flooring, F. Ball and Co., advises on cutting the time it takes to install floorcoverings without compromising on finished results.

F. BALL AND CO.

Nowadays, flooring installation products, including waterproof surface membranes, levelling compounds and adhesives, are available that, when used correctly and in combination, allow floorcoverings to be installed in less than a day. In contrast, it might have once taken several days, leaving areas inaccessible in the meantime.

Achieving a long-lasting, professional flooring finish also requires flooring contractors to follow best practice in subfloor preparation. Before undertaking any flooring installation, a thorough assessment of the subfloor should be completed to ensure it is sound, smooth and free of contaminants.

Moisture management

U nmanaged moisture, whether residual construction moisture or rising damp, is one of the leading causes of floor failure. For this reason, F. Ball recommends that a moisture measurement test should be carried out using a pre-calibrated hygrometer (in accordance with British Standards) to determine the relative humidity (RH) levels of the subfloor as part of any flooring installation.

Where the relative humidity (RH) levels in the subfloor are above 75% (or 65% if wood floorcoverings are to be installed), some form of moisture management solution will be required to prevent excess subfloor moisture from damaging floorcoverings and attacking adhesives, potentially causing complete floor failure. Several timesaving options exist where a solution for excess moisture is required.

Liquid waterproof surface membranes are the usual option, and advanced products are now available that will isolate excess subfloor moisture where relative humidity values are up to 98% with a singlecoat application and will fully cure in as little as four hours.

Even quicker, two-coat systems are also available. The first coat cures in 15 to 20 minutes, and a further 30 minutes of curing time is required for the second coat, creating a barrier against residual construction moisture where the relative humidity value is up to 95% in less than two hours and a structural membrane is present.

A smooth finish

F. Ball recommends the application of a levelling compound or smoothing underlayment to create a perfectly-smooth base for floorcoverings and optimise the finished appearance of an installation.

T he fastest-setting products on the market are ‘walk-on’ hard in 30 minutes and ready to receive new floorcoverings from 45 minutes. The same products

are low odour, easy to use, self smoothing and can be applied at thicknesses of up to 10mm.

W here flooring installations are part of a refurbishment and old adhesive residues (including bitumen and carpet tile tackifiers) are present after the removal of old floorcoverings, contractors can save time by using a smoothing underlayment that has been specially formulated for use over old adhesive residues, which would otherwise require mechanical removal. Such products are formulated to minimise the stresses inflicted on adhesive residues as the smoothing underlayment sets, meaning it is able to maintain its integrity when applied to subfloors where these are still present.

I n most cases, there is no need to apply a primer beforehand when using this type of smoothing underlayment, saving further time and expense. They also have the benefit of allowing contractors to use the same product in situations where newly-installed subfloors and areas with old adhesive residues present are next to each other.

FC&A – SEPTEMBER – 2022 28 FLOORS, WALLS & CEILINGS

New formulations

The latest advancements in technology have enabled F. Ball to create a fast-track, water-mix smoothing underlayment that can be applied over old adhesive residues, Stopgap 1500 AquaPro. Such products have previously only been available in bag and bottle formulations.

The new smoothing underlayment is suitable for preparing a wide range of sound internal subfloors prior to the installation of a new floorcovering and can be applied over bitumen, carpet tile tackifiers and ceramic tile adhesives, eliminating the need for mechanical preparation.

J ust as with market-leading bag and bottle versions, the product is walk-on hard in as little as 60 minutes after application and ready to receive floorcoverings from just four hours. As a water-mix smoothing underlayment, no bottle is required, meaning less plastic waste is produced by the flooring industry.

C hoosing the right adhesive

O nce the levelling compound has cured, the contractor can select a suitably fast-working adhesive to install appropriate floorcoverings. The choice of adhesive will often be determined foremost by what type of floorcoverings are to be installed and where, but there are options for when timesaving is a priority.

R ecently-launched adhesives for vinyl sheet and tile and rubber floorcoverings allow floorcoverings to be installed from just five minutes after application. The adhesive transitions from being wet lay when first applied to the subfloor to fully pressure sensitive, and fibres in the formulation limit the lateral movement of floorcoverings, making the installation of vinyl planks and tiles easier.

C arpet tile tackifiers are available that only take 30 minutes to form a permanently tacky film, which will prevent tiles from moving laterally under everyday traffic while allowing individual sections to be easily lifted and replaced if damaged or worn.

Compatibility check

To prevent a substandard finish or even complete floor failure, contractors should always ensure that adhesives are compatible with the chosen floorcoverings. To do this, contractors should consult the adhesive manufacturers’ recommended adhesives guides or see the floorcovering manufacturers’ instructions.

FC&A – SEPTEMBER – 202229 FLOORS, WALLS & CEILINGS

www.f-ball.com/en A moisture management solution, such as the application of a liquid waterproof surface membrane, is required where excess subfloor moisture is detected

The

fastest-setting levelling compounds on the market are ‘walk-on’ hard in 30 minutes and ready to receive new floorcoverings from 45 minutes The fast-drying formulation of Styccobond F58 PLUS pressure-sensitive vinyl adhesive enables LVT tiles and planks to be secured from just five minutes

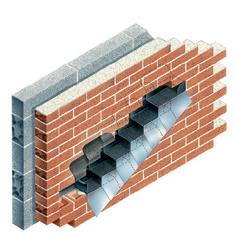

CLAY BRICK AND SUSTAINABILITY

Many criteria, from aesthetics and cost to performance, maintenance and durability, govern the choice of building materials when it comes to construction. However, with the Future Homes Standard scheduled to come into effect in England in 2025 and the UK aiming to reach a target of net zero emissions by 2050, an increasingly important consideration for building materials is the matter of sustainability.

FORTERRA

Wh ilst comparisons of the initial carbon impact of producing certain materials might be useful, determining which material is most sustainable is harder than it looks, not least because several other variables, such as comfort, longevity, durability and maintenance, themselves impact the sustainability of a product.

I t would be natural to assume that clay, a building material that has been around for thousands of years, might not be up to the task of net zero emissions; however, there are many reasons why clay brick remains the building material of choice for architects, developers, builders and planners across the UK, and why it will continue to be so as we move to ever more sustainable methods of construction.

F irstly, clay is a natural, raw material formed by mineral deposits that over a period of around 15,000 years accumulate in the ground. Once a clay pit has come to the end of its life, it can be given back to nature and often restored into abundant natural habitat capable of supporting a variety of species. In fact, Forterra’s own award-winning King’s Dyke Nature Reserve was itself once a clay pit.

One of the most scrutinised aspects of clay brick production when it comes to questions of sustainability is the firing process itself. The firing of clay bricks is an energy-intense process, since they must be fired at temperatures of over 1000°C. However, the industry has made great strides in reducing the energy consumption involved. For example, the heat generated from the kilns during production is now often used twice, being redirected to dry bricks prior to firing. At Forterra’s own Desford factory, it has invested in two new cutting-edge technology kilns designed to reduce energy consumption and emissions. With the aim to reduce carbon emissions further still, the industry has set out a decarbonisation and energy-efficiency roadmap 1 and is exploring other low-carbon fuels such as hydrogen and electric firing.

Another important factor to consider when choosing building materials is the cost of transportation from factory to construction site in terms of both economic and environmental costs. The industry is committed to reducing the emissions from clay brick transportation. Between 2012 and 2018, Greenhouse gas emissions (GHG) from HGV traffic increased by 14%. As a

FC&A – SEPTEMBER – 2022 30 TECHNICAL FOCUS

consequence, in 2018, the Government agreed to a voluntary, industry-supported commitment to reduce GHG emissions from HGVs by 15% from 2015 levels, aiming to reach this goal by 20252. To support this aim, some clay brick manufacturers, such as Forterra, are investing in upgrading their fleet to Euro 6 vehicles. In addition, efforts to update vehicle body design, thereby increasing payload, are currently in development, the success of which will see vehicle movements and, therefore, emissions reduced still further.

But it is, perhaps, the longevity of clay brick that most prominently contributes to its sustainability as a building material. Buildings constructed using clay brick have very long lifespans, which means that in order to maintain their original appearance, they may require only minimal upkeep. In fact, clay bricks often look better with age and weathering. You don’t need to look very far in the UK to see aestheticallyappealing clay brick buildings that are several centuries old. Magisterial clay brick buildings dating back to the Tudor period abound, from Hampton Court Palace in London to Leez Priory in Essex. Yet these buildings often date even further back. At Coggeshall Abbey, in Essex, some of the buildings are composed of bricks dating back to 1190AD, while in the town of Beverley, there is the Beverley North Bar, a town gate dating back to 1409AD. What’s crucial about these structures is that the brick has retained astonishing quality given the timeframe, requiring relatively little upkeep when compared to other materials. At the very minimum, a 150-year-old brick building will look at least as good as when the bricks were first laid. This is compared to the generally-accepted expectation that a new building will last for at least 60 years.