MAY 2023 www.ethanolproducer.com PLUS Unpacking Last Year’s Profitability PAGE 18 More Ethanol Producers Getting Into RNG PAGE 32 PAGE 24 Inside Green Plains’ Separation Strategy Just Over the Horizon

INNO VA TION is more than products, it ’s people . Introducing our new Operations Services & Support team There are times when you need more than service, you need support. CTE Global’s Operations Services & Support team will work with you to improve your plant’s profitability, guiding you at every turn. 847-564-5770 | cte-global.com

7.5 billion gallons per year of SAF by 2040

The

Edge

SAFFiRE

• Ultralow CI Score • Additional Revenue Source • Reduce Operating Costs • Produce High-Demand Aviation Fuel

4 | ETHANOL PRODUCER MAGAZINE | MAY 2023 DEPARTMENTS 5 AD INDEX/EVENTS CALENDAR 6 EDITOR'S NOTE Reinvesting In Growth, Efficiency and Whole New Markets By Tom Bryan 8 GRASSROOTS VOICE The ‘E’ Is Silent By Ron Lamberty 10 DRIVE It’s Time to Reevaluate U.S.-Brazil Trade Relations By Emily Skor 12 GLOBAL SCENE Beyond the ‘Food vs. Fuel’ Dichotomy: The Facts On Biofuels and Food Security in Europe By David Carpintero 14 BUSINESS BRIEFS 43 MARKETPLACE Ethanol Producer Magazine: (USPS No. 023-974) May 2023, Vol. 29, Issue 5. Ethanol Producer Magazine is published monthly by BBI International. Principal Office: 308 Second Ave. N., Suite 304, Grand Forks, ND 58203. Periodicals Postage Paid at Grand Forks, North Dakota and additional mailing offices. POSTMASTER: Send address changes to Ethanol Producer Magazine/Subscriptions, 308 Second Ave. N., Suite 304, Grand Forks, North Dakota 58203. FEATURES 18 MARGINS After A Good Year Defining what made 2022 quite profitable By Katie

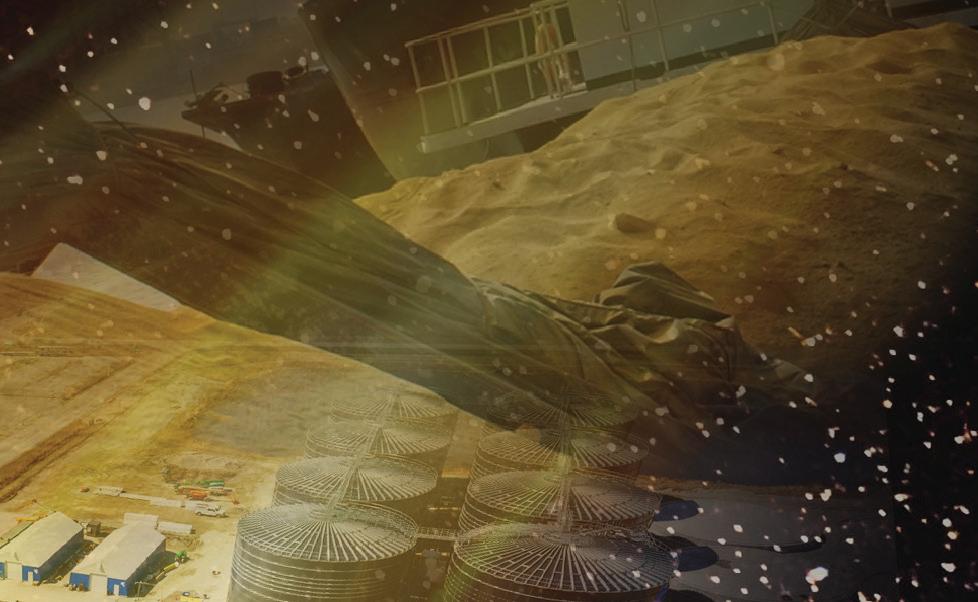

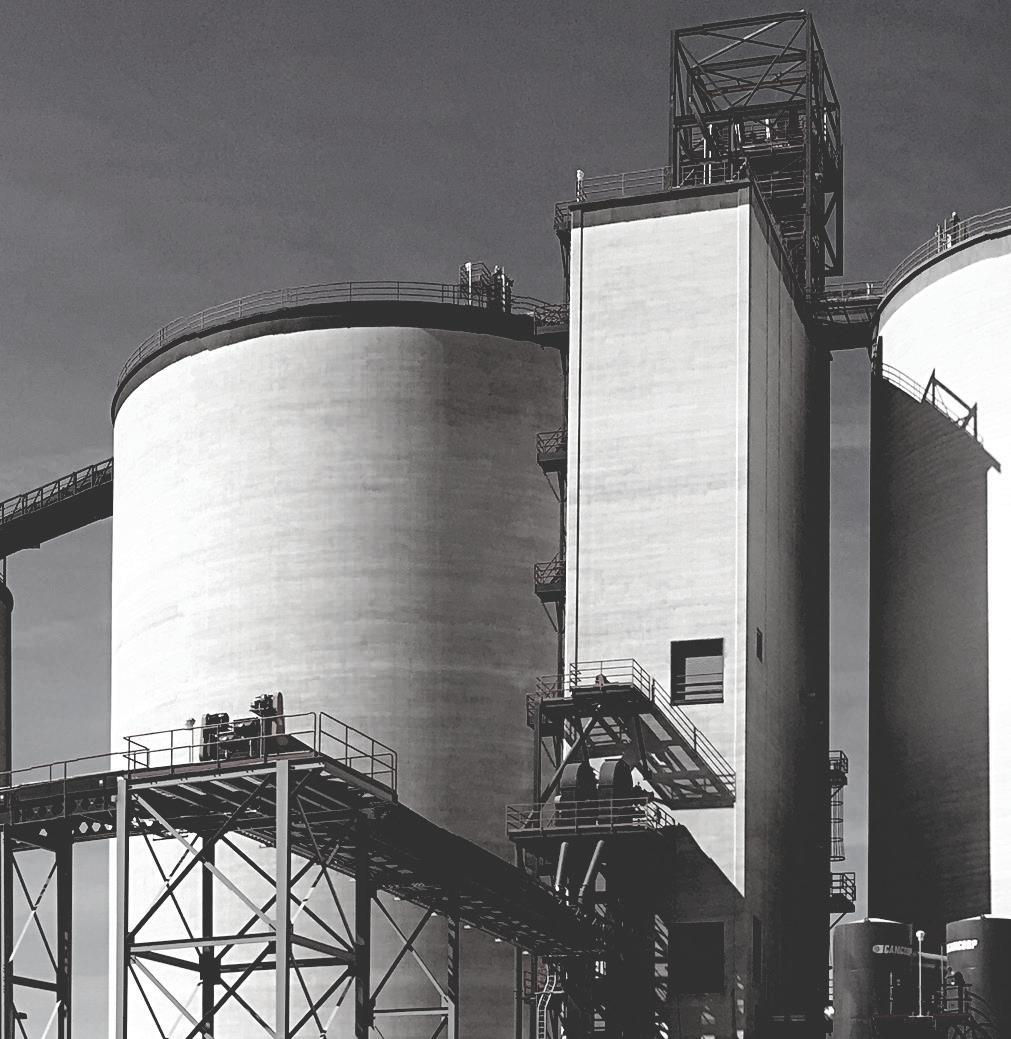

24 INSIGHT Finding New Markets Revisiting Green Plains' strategy of separation By Katie Schroeder 32 BUSINESS Two Fuels, One Place How RNG and ethanol production pair up By Luke Geiver 38 PROJECTS Busy with Upgrades Plant enhancements and capacity-boosting installs By Luke Geiver Contents ON THE COVER This biorefinery in Central City, Nebraska, is among the ethanol plants in Green Plains' fleet that are pursuing decarbonization, new products and new markets that could distance the company from its conventional ethanol production competitors.

Schroeder

MAY 2023 VOLUME 29 ISSUE 5 18 24 32 38

PHOTO: GREEN PLAINS

EDITORIAL

President & Editor

Tom Bryan tbryan@bbiinternational.com

Online News Editor

Erin Voegele evoegele@bbiinternational.com

Staff Writer

Katie Schroeder katie.schroeder@bbiinternational.com

DESIGN

Vice President of Production & Design

Jaci Satterlund jsatterlund@bbiinternational.com

Graphic Designer

Raquel Boushee rboushee@bbiinternational.com

PUBLISHING & SALES

CEO

Joe Bryan jbryan@bbiinternational.com

Vice President of Operations/Marketing & Sales

John Nelson jnelson@bbiinternational.com

Senior Account Manager/Bioenergy Team Leader

Chip Shereck cshereck@bbiinternational.com

Account Manager

Bob Brown bbrown@bbiinternational.com

Circulation Manager

Jessica Tiller jtiller@bbiinternational.com

Marketing & Advertising Manager

Marla DeFoe mdefoe@bbiinternational.com

EDITORIAL BOARD

Ringneck Energy Walter Wendland

Little Sioux Corn Processors Steve Roe

Commonwealth Agri-Energy Mick Henderson

Aemetis Advanced Fuels Eric McAfee

Western Plains Energy Derek Peine

Front Range Energy Dan Sanders Jr.

Advertiser Index

Upcoming Events

2023 Int'l Fuel Ethanol Workshop & Expo June 12-14, 2023

CHI Health Center, Omaha, NE (866) 746-8385 | FuelEthanolWorkshop.com

From its inception, the mission of this event has remained constant: The FEW delivers timely presentations with a strong focus on commercial-scale ethanol production—from quality control and yield maximization to regulatory compliance and fiscal management. The FEW is the ethanol industry’s premier forum for unveiling new technologies and research findings. The program is primarily focused on optimizing grain ethanol operations while also covering cellulosic and advanced ethanol technologies.

2023 Biodiesel Summit: Sustainable Aviation Fuel & Renewable Diesel June 12-14, 2023

CHI Health Center, Omaha, NE (866) 746-8385 | BiodieselSummit.com

The Biodiesel Summit: Sustainable Aviation Fuel & Renewable Diesel is a forum designed for biodiesel and renewable diesel producers to learn about cutting-edge process technologies, new techniques and equipment to optimize existing production, and efficiencies to save money while increasing throughput and fuel quality. Produced by Biodiesel Magazine, this world-class event features premium content from technology providers, equipment vendors, consultants, engineers and producers to advance discussion and foster an environment of collaboration and networking through engaging presentations, fruitful discussion and compelling exhibitions with one purpose, to further the biomass-based diesel sector beyond its current limitations.

2023 National SAF Conference & Expo

August

29-30, 2023

Minneapolis Convention Center, Minneapolis, MN (866) 746-8385 | www.nationalsafconference.com

The National SAF Conference & Expo is designed to promote the development and adoption of practical solutions to produce SAF and decarbonize the aviation sector. Exhibitors will connect with attendees and showcase the latest technologies and services currently offered within the industry. During two days of live sessions, attendees will learn from industry experts and gain knowledge to become better informed to guide business decisions as the SAF industry continues to expand.

2023 National Carbon Capture Conference & Expo

November 7-8,

2023

Iowa Events Center | Des Moines, IA (866) 746-8385 | www.nationalcarboncaptureconference.com

Please recycle this magazine and remove inserts or samples before recycling

COPYRIGHT © 2023 by BBI International

Customer Service Please call 1-866-746-8385 or email us at service@bbiinternational.com. Subscriptions Subscriptions to Ethanol Producer Magazine are free of charge to everyone with the exception of a shipping and handling charge for anyone outside the United States. To subscribe, visit www.EthanolProducer.com or you can send your mailing address and payment (checks made out to BBI International) to: Ethanol Producer Magazine Subscriptions, 308 Second Ave. N., Suite 304, Grand Forks, ND 58203. You can also fax a subscription form to 701-746-5367. Back Issues, Reprints and Permissions Select back issues are available for $3.95 each, plus shipping. Article reprints are also available for a fee. For more information, contact us at 866-746-8385 or service@bbiinternational.com. Advertising Ethanol Producer Magazine provides a specific topic delivered to a highly targeted audience. We are committed to editorial excellence and high-quality print production. To find out more about Ethanol Producer Magazine advertising opportunities, please contact us at 866-746-8385 or service@bbiinternational.com. Letters to the Editor We welcome letters to the editor. Send to Ethanol Producer Magazine Letters to the Editor, 308 2nd Ave. N., Suite 304, Grand Forks, ND 58203 or email to editor@bbiinternational.com. Please include your name, address and phone number. Letters may be edited for clarity and/or space. TM

The National Carbon Capture Conference & Expo is a two-day event designed specifically for companies and organizations advancing technologies and policy that support the removal of carbon dioxide (CO2) from all sources, including fossil fuel-based power plants, ethanol production plants and industrial processes, as well as directly from the atmosphere. The program will focus on research, data, trends and information on all aspects of CCUS with the goal to help companies build knowledge, connect with others, and better understand the market and carbon utilization.

ETHANOLPRODUCER.COM | 5 2023 Int'l Fuel Ethanol Workshop & Expo 11 CTE Global, Inc. 2 D3MAX LLC 30-31 Fagen, Inc. 20 Fluid Quip Mechanical 34 Fluid Quip Technologies, LLC 9 Growth Energy 36 Hydro-Thermal Corporation 21 ICM, Inc. 7 IFF, Inc. 37 Jacobs Corporation 27 Lallemand Biofuels & Distilled Spirits 16 McCormick Construction, Inc. 26 Novozymes 13 Phibro Ethanol 23 POET LLC 42 SAFFiRE Renewables 3 Summit Carbon Solutions 17 Trinity Rail Group 29 Trucent 44 Victory Energy Operations, LLC 28

Reinvesting In Growth, Efficiency and Whole New Markets

Last year taught us that inflation environments, despite causing higher input costs, can produce good returns. For much of 2022—the exception being Q4—strong values for everything coming out of our plants (ethanol, distillers grains, corn oil) made up for the inflated expense of everything coming in (corn, natural gas, chemicals). This resulted in a months-long stretch of good profitability, for many, that has been hard to replicate in 2023. Still, the industry remains steady, even busy, this spring, and as we learn in “After A Good Year,” on page 18, some production costs are dropping.

Corn prices were high last year and that hasn’t changed in 2023. But natural gas prices have fallen considerably. Experts tell us that, last year, plants that were able to lock in their gas prices or reduce their usage tended to do better than average. Now, with natural gas prices and other input costs moderating with easing inflation, it’s just a matter of how well ethanol and coproduct prices hold up over the remainder of the year. That, of course, depends more than we’d like on the price of gasoline—and, to some extent, the availability of E15 this summer.

As we report in “Finding New Markets,” on page 24, one U.S. ethanol producer is tired of being hamstrung by the volatility of commodity and fossil fuel markets. Green Plains, the fourth largest ethanol producer in North America, is moving assertively toward a biorefining model that “does not center ethanol production.” The company, which owns and operates 11 U.S. biorefineries, is in the early stages of a transition away from being a producer of fuel ethanol, toward making the highest value products it can— like protein, corn oil and clean sugar—while decarbonizing its operations and going all-in on sustainable aviation fuel. “It’s going to take a while, but I am one hundred percent certain we will look very different two years from now than we look today,” Green Plains CEO Todd Becker tells us, emphasizing SAF and clean sugar as being key to the company’s move away from conventional participation in the ethanol market.

We look at another diversification strategy in “Two Fuels, One Place,” on page 32, a story about the hard-to-define benefits of pairing ethanol and renewable natural gas (RNG) production. While biogas/ RNG production has the financial benefit of D3/D5 RIN generation, and sometimes onsite power, there’s not a long list of obvious reasons to make both fuels at or near the same complex. But a growing number of producers are. To explain the financial and operational synergies of producing the two biofuels together, or in parallel, we revisit three plants currently making RNG—Calgren, Aemetis and Verbio—and a fourth, Lincolnway Energy, beginning to explore it.

Finally, be sure to read “Busy with Upgrades,” on page 38, a look at expansions and facility enhancements at four U.S. ethanol plants that serve as good examples of the sort of bold reinvestments producers are making in efficiency, speed, output and storage.

6 | ETHANOL PRODUCER MAGAZINE | MAY 2023 FOR INDUSTRY NEWS: WWW.ETHANOLPRODUCER.COM OR FOLLOW US: TWITTER.COM/ETHANOLMAGAZINE Editor's Note

The ‘E’ Is Silent

When I came to ACE from the world of petroleum marketing in 2000, I was surprised to learn the ethanol industry didn’t necessarily see the U.S. Environmental Protection Agency as its friend. I mean, ethanol use got its original boost from the Clean Air Act, and EPA oversees that, right? And ethanol is good for the environment, right? Maybe ethanol folks were just ... needy?

Over the years, however, I began to understand, and learned a catchphrase the old-timers used when they talked about disappointing decisions and actions made by EPA: “the ‘E’ is silent.”

Nothing hammered home the disconnect between EPA and the first word in its name more than the past decade of trying to make E15 a mainstream fuel. And maybe it’s because I’m one of the old-timers now and have forgotten more egregious actions in the past, but I can’t recall a time when EPA’s cozy partnership with the oil industry—the world’s worst polluters—was more on display than its recent proposed rule responding to eight Midwest Governors’ requests to remove the 1-pound Reid vapor pressure (RVP) waiver from all fuels during the high-ozone season to facilitate year-round blending of E15.

In the rule, EPA acknowledges that upon notification by the governor of a state, and with required documentation, the EPA administrator “shall, by regulation, apply the volatility limit.” Simple and straightforward. And yet, EPA waited almost a year to say they’ll obey the law ... later.

EPA also acknowledges the “shall” gives them “limited if any discretion [to] consider other issues such as economic impacts of removing the 1-psi waiver.” Yet, immediately after pointing out those facts, EPA limits itself to about 20 pages of consideration of the economic impacts of removing the 1-psi waiver. They use the codename “adequate supply” instead of economic impact, but the “impacts” examined are unsurprisingly similar to the usual boatload of red herring refiners dump on every rule ever proposed to expand E15 availability. EPA’s conclusions also echo the oil industry’s tired warnings of “it’s too difficult” and “prices will rise astronomically.” Unfortunately, the oil guys can make that second part true any time they want.

Any shred of doubt that the “E” is silent and EPA looks out for its oil BFFs first, was removed for me when, in the rule, EPA lamented refiners’ “lost opportunity cost for having to sell the removed butane at market prices for butane instead of blending it into high value summer gasoline.” EPA defending more butane in gas? What?

While EPA examined the real and imaginary objections typically offered by refiners, it conspicuously gave zero consideration to the economic impact its “gap year” would have on E15 retailers and consumers. Retailers who have offered E15 and consumers who purchased E15 yearround in 2020, 2021, 2022, and who will buy it again in 2024 would be forced to switch for three and a half months because EPA dragged its feet on the governors’ requests. Retailers would have increased costs from switching fuels in their tanks twice, service calls to adjust blender pumps twice, and changing out pump decals twice. Consumers who use E15 because it saves 5 to 15 cents versus E10, and is 45 to 95 cents cheaper than “clear” gas, will have to spend more for fuel they don’t want during the busiest time of the year.

EPA should show retailers, consumers, and the environment a fraction of the concern they’ve shown for refiners, by urging the Administration to grant an emergency 1-psi RVP waiver for blends above 10 percent ethanol in 2023. It's the least EPA could do (which is traditionally what they’ve done for ethanol).

8 | ETHANOL PRODUCER MAGAZINE | MAY 2023

Ron Lamberty Chief Marketing Officer, American Coalition for Ethanol rlamberty@ethanol.org

Grassroots Voice

PUT DECADES OF EXPERIENCE TO WORK IN YOUR FACILITY. Scan here to schedule a meeting today! ©202 3. All rights reserved Fluid Quip Technologies , LLC. All trademarks are proper ties of their respec tive companies. Engineering solutions, providing insight and guidance on process improvements, optimization, and st rategies.

in transformative technology.

The experts

It’s Time to Reevaluate U.S.-Brazil Trade Relations

Years of innovation and hard work have established the United States as the world’s largest producer and exporter of ethanol. It’s an achievement worthy of pride, and American biofuel producers are eager to build on that record by supplying a growing share of the world’s low-carbon transportation needs. In the past, that quest was shared by Brazil. The two nations enjoyed strong, free trade relations, while working collaboratively to support the efficient distribution of climate-smart fuels around the world. No longer.

Years of increasingly protectionist trade policies, along with blind spots in U.S. fuel policy, have allowed Brazil to unfairly eat into U.S. markets, without contributing greater value to customers or the climate. The shift gained speed after 2017, when Brazil first instituted a 20 percent tariff on U.S. ethanol imports. Then, in 2019, Brazil’s new program RenovaBio, went into effect. Similar in ways to the U.S. Renewable Fuel Standard, RenovaBio aims to promote renewable energy in the transportation sector. But unlike the RFS, the program prioritizes Brazil’s domestic industry over carbon reduction. In fact, despite years of effort, Brazilian officials have refused to approve or certify imports from a single U.S. ethanol producer.

In contrast, the U.S. has rolled out the welcome mat for Brazilian ethanol. Aside from free access to our markets, Brazilian sugar cane ethanol enjoys preferential status under California’s Low-Carbon Fuel Standard (LCFS), and it qualifies as an advanced biofuel under the RFS. As a result, Brazilian producers can pocket lucrative premiums in U.S. markets, even when competing against American-made ethanol that delivers similar lifecycle emissions reductions.

The impact on trade has been profound. By 2022, U.S. exports to Brazil fell to 56 million gallons, down from 660 million gallons in 2017. At the same time, Brazilian producers export a growing share of sugar cane ethanol— to capture extra value under our own domestic climate policies—while burning their own corn-based ethanol at home, where it gets special treatment. That shuffling of resources hurts American producers and creates inefficient trade flows and needless shipping, actively undermining global climate goals.

So how do we restore balance?

First, U.S. diplomats must take an unapologetic approach to challenging Brazil’s patently unfair trade practices. Fortunately, the U.S. Senate recently confirmed strong leaders to spearhead that effort: U.S. Department of Agriculture Under Secretary for Trade and Foreign Agricultural Affairs Alexis Taylor and United States Trade Representative-Chief Agricultural Negotiator Doug McKalip. Growth Energy met with both on the topic of Brazil this February, and I’ll be participating in a delegation trip to Brazil this spring.

Lawmakers are pushing too. A February letter to President Biden from a bipartisan coalition of U.S. Senators emphasized that, “American industry should not be subject to prohibitive tariff and non-tariff barriers while Brazilian ethanol producers enjoy duty-free access to our market and biofuel programs.”

The second step towards balance requires regulators to take a closer look at outdated models of lifecycle emissions. Unfortunately, the EPA is not only relying on lifecycle modeling from more than a decade ago, but by law, corn-based ethanol—regardless of the carbon intensity measurement—cannot be classified as an advanced biofuel, putting the U.S. ethanol industry at a disadvantage.

Meanwhile, programs like California’s LCFS impose an unjustified higher land use penalty on U.S. ethanol— again, ignoring decades of hard data from DOE’s Argonne National Laboratory and USDA—while continuing to favor the carbon intensity of Brazilian agriculture. Given the impact on the Amazon and the industry’s burning of eucalyptus trees to fuel their production facilities—an emerging trend with troubling implications—that imbalance in treatment undermines the very purpose of the RFS and LCFS.

We cannot allow Brazilian ethanol producers to game the system merely to steal markets away from U.S. competitors, both here and abroad. Growth Energy will continue to make this fight a priority for U.S. diplomats. We’re grateful to our supporters in Congress, the Biden administration and our industry partners. Together, we are committed to ensuring that U.S. investments in innovation, from carbon capture to climate-smart feedstocks, will be recognized and valued in Brazil and around the world.

10 | ETHANOL PRODUCER MAGAZINE | MAY 2023

Drive

Emily Skor CEO, Growth Energy 202.545.4000 eskor@growthenergy.org

JUNE 12-14, 2023 Omaha, Nebraska F uelEthanolWorkshop .c om

ENERGY INDUSTRY

TO CHANGE 866-746-8385 | service@bbiinternational.com | #FEW23 @ethanolmagazine Produced By C o-locatied Ev ents Register by May 3rd Save $200 on Full Registration All Events For One Registration Price Production Facilities Receive Complimentar y Passes

THE

IS ABOUT

Beyond the ‘Food vs. Fuel’

Dichotomy: The Facts On Biofuels and Food Security in Europe

Europe’s biofuels sector produces one of the most cost-effective and sustainable alternatives to fossil oil while also contributing to both EU energy independence and food security. But unfortunately, constant changes in EU policy direction—sometimes based on wrong assumptions and misleading dogma such as the “food vs. fuel” myth, have slowed progress and hampered investments.

Despite their proven track record of contributing significantly to the fight against climate change, reducing imported fossil fuel, generating high-protein animal feed and strengthening rural economies, innovation and productivity, the EU’s biofuels and agriculture sectors are consistently criticized and given short shrift in policy discussions relating to food security and energy independence.

In other biofuels-producing countries around the world, these synergies and contributions are better understood and valorized. But in the EU, some policymakers keep chanting the “food vs. fuel” argument like a mantra in papers and reports—even though a majority of members of the European Parliament, motivated by facts and conscious that biofuels are indispensable to achieve our collective goals, voted last September to keep sustainable biofuels in the EU transport energy mix.

Nevertheless, the “food vs. fuel” drumbeat continues. One recent example is a European Commission´s staff working document on “Drivers of Food Security,” published in early January, in which the institution’s secretariat highlights concerns that a “food versus fuel trade-off” is created by biofuel production from food crops, and that continued expansion of biofuel production increases pressure on global food security.

This document from the Commission offers no real-world evidence for these assumptions and contradicts its own recent statements that biofuels production has had negligible or no impact on food prices and requires only a minuscule percentage of EU arable land. These assumptions also run counter to the Commission’s own Renewable Energy Progress Reports, which regularly confirm the sustainability of EU biofuels production and find no significant environmental impact from feedstock cultivation.

What’s needed for the EU to achieve its many goals is a consistent, fact-based policy that acknowledges 1) that biofuels production isn’t about “food vs. fuel,” but food and fuel; 2) that biofuels are already subject to strict environmental criteria over their full life-cycle; and 3) that biofuels are needed to decarbonize the existing fleet for at least the next 15 years. (Note: a full breakdown of each of these three points is provided in the online version of this column.)

Even now, many EU Member States are falling short of their transport emissions reduction goals, especially when the impact of multipliers is removed. Multipliers give a counterproductive and unrealistic view of progress towards climate goals.

Meanwhile, crop-based biofuels remain, by far, the main renewable energy source in EU transport. Further marginalizing their use based on misleading claims about their impact on food security will only make it harder for EU Member States to achieve their climate goals. And it will also leave Europe more reliant on fossil fuels and imported protein.

The EU does not have to choose between its climate, energy and food security goals when it has a pragmatic, proven, homegrown solution that is already delivering results and could do much more with the right approach. Europe needs policymakers to see how biofuels contribute significantly to climate, energy and food security goals, rather than be blinded by the simplistic, detrimental “food vs. fuel” dogma.

12 | ETHANOL PRODUCER MAGAZINE | MAY 2023

Global Scene

David Carpintero Director General, ePURE, the European Renewable Ethanol Association carpintero@epure.org

BUSINESS BRIEFS

Gevo finalizes agreement with Zero6 Energy for hydrogen project

Gevo Inc. has finalized a hydrogen development services agreement with Zero6 Energy (formerly Juhl Energy) for the development of a 20-megawatt hydrogen production facility in Lake Preston, South Dakota, using Cummins Inc. electrolyzer technology. The facility, known as the Dakota Renewable Hydrogen Project, will be an integral part of Gevo’s Net-Zero 1 renewable hydrocarbon plant that is under development.

“We are excited to again be working with the Zero6 team on the development of a project that is crucial to the decarbonization

Detailed engineering begins on Marquis Energy CCS project

Gas Liquids Engineering Ltd. has started detailed engineering on a carbon capture and sequestration (CCS) project for Marquis Carbon Capture LLC at the Marquis Industrial Complex that houses the 365 MMgy Marquis Energy-Illinois LLC ethanol plant. Carbon dioxide will be captured from the facility, compressed, dehydrated and injected into an onsite well for permanent underground storage, all located within the Marquis Industrial Complex. Once constructed, the project will be the largest operational BECCS (bioenergy carbon capture and storage) project in the

Navigator CO2 expands scope of Heartland Greenway pipeline

Navigator CO2 Ventures LLC has filed an updated permit application with the Illinois Commerce Commission to expand the scope of its proposed carbon capture, utilization and storage (CCUS) pipeline—the Heartland Greenway. The updated application includes the addition of 42 miles of proposed pipeline that will connect to additional permanent storage locations in central Illinois.

The company says the revised application is a significant step toward the acceleration of carbon sequestration in the region.

of Gevo’s liquid transportation fuels and our long-term goal of developing net-zero emissions fuel and chemical products,” said Gevo President and COO Chris Ryan. “After our mutual success on the development of wind power for the defossilized electrification of our development facility in Luverne, Minnesota, we are confident that Zero6 will be an excellent partner for our Net-Zero 1 hydrocarbon production facility.”

state of Illinois, permanently sequestering 1.2 million tons of CO2 per year.

"This project is an exceptional application for CCS technology and will make Marquis a leading producer of low-carbon bioproducts,” said Ryan Arnold, director of business development at Gas Liquids Engineering. Jason Marquis, COO of Marquis Inc., said the company is on path to building a more sustainable world by decarbonizing its bioproducts.

“Central Illinois is home to some of the world’s most well-studied and proven geology for carbon storage, and Navigator is working diligently to help advance this opportunity,” a company press release stated. “By leveraging the region’s top-tier geology, Navigator will be able to expand the economic benefits of CCUS to more stakeholders in Illinois, increase storage capacity, and provide a range of carbon management solutions to its growing customer base.”

14 | ETHANOL PRODUCER MAGAZINE | MAY 2023

PEOPLE, PARTNERSHIPS & PROJECTS

‘A Vision and Beyond:’ POET Celebrates 35 Years

Sioux Falls, South Dakota-based POET, the world’s largest producer of biofuels, is celebrating its 35th anniversary this year. The company, which built its success from humble beginnings, has experienced unparalleled growth since its inception in 1987—becoming the largest and fastest-growing biofuels company on the planet.

What began as a small-scale bioethanol plant on the Broin family farm led to the purchase of a 1-million-gallon-per-year facility in Scotland, South Dakota, and has fueled what the com-

PROtect acquires Houston Integrity Consultants

PROtect LLC has acquired Houston Integrity Consultants based in Houston, Texas. The acquired company is a specialized provider of risk-based inspection services including inspection data management system software. The company is well known for its proficiency in addressing complex inspection and reliability challenges faced by the oil and gas, petrochemicals, pharmaceuticals, renewables and refining industries. PROtect LLC, a longtime service provider to the ethanol industry, is a leading safety, reliability and compliance services company based in Wichita, Kansas.

Rondo Energy adds thermal energy storage at Calgren

Rondo Energy, a provider of zero-carbon industrial heat, and Calgren Renewable Fuels, a producer of low-carbon intensity (CI) ethanol, biodiesel and renewable natural gas, have commissioned a 2 MWh Rondo Heat Battery (RHB) at Calgren’s facility in Pixley, California.

The heat battery captures intermittent renewable electricity, stores it at very high temperatures in brick materials and delivers continuous industrial heat on demand. About half of the total

pany calls “a legacy of innovation and economic growth across America’s Heartland.” Today, POET boasts an annual production rate of 3 billion gallons of bioethanol, 14 billion pounds of animal feed and 1 billion pounds of corn oil at its 33 bioprocessing plants.

POET is marking the milestone by releasing a short film titled “A Vision and Beyond: The Story of POET.”

Visit https://poet.com/history/ to watch the film.

"The acquisition of Houston Integrity Consultants represents a significant milestone for our company and complements our current mechanical integrity (MI), process safety management, and engineering capabilities,” said Nathan VanderGriend, CEO of PROtect. “With HIC's capabilities and experience, we can now offer our clients additional MI inspection program strategies and highly desirable software applications to support their overall programs.”

carbon emissions of liquid biofuel comes from fossil fuel used in the refining processes. Rondo Heat Batteries eliminate these emissions by replacing fuel combustion with renewable electricity, dropping into existing facilities without process changes. According to Rondo, biofuels produced using this type of heat and power can cut their CI in half. The RHB is delivering heat to Calgren on a heat-as-a-service basis, supplying energy at a cost per MMBtu lower than gas-fired heat.

ETHANOLPRODUCER.COM | 15

MEET TODAY’S GOALS. ANSWER TOMORROW’S QUESTIONS.

SOLUTIONS, DESIGNED BY LBDS.

We put Fermentation First™. You get yeast, yeast nutrition, enzymes and antimicrobial products, alongside the industry leading expertise of our Technical Service Team and education resources. Find the right solution for your ethanol business at LBDS.com.

© 2023 Lallemand

& Distilled Spirits

Biofuels

Ethanol producers are coming off an undeniably strong year. 2022 was not devoid of challenges, but it was replete with landmark policy and marketplace dynamics that, on balance, allowed the vast majority of U.S. ethanol producers to do quite well financially. Mirroring that financial success this year would be like a pro baseball pitcher throwing back-toback perfect games—it doesn’t happen—

and, sure enough, the last quarter of 2022 and the first quarter of 2023 already reflect that. But this year’s margins may not disappoint, with at least some of last year’s margin-making factors still in play.

Dave Zimmerman, CEO of Big River Resources LLC, tells Ethanol Producer Magazine those 2022 factors included the RVP waiver for E15 last summer; high prices— not only for gas, but for ethanol, distillers grains and distillers corn oil (DCO); ethanol

producers receiving Covid relief funding; and the passage of the Inflation Reduction Act, with its funding for biofuels infrastructure and more. There were also impediments to profit in 2022, including high natural gas prices, rail delays coupled with the months-long threat of a rail strike, and regional corn supply shortages. But none of it was enough to drag healthy ethanol plants out of far-positive territory. “I mean, 2022 was a phenomenal year for most ethanol

18 | ETHANOL PRODUCER MAGAZINE | MAY 2023

A Good Year

Industry experts and ethanol producers explain what caused markedly high production margins in 2022—strong markets, exciting policy and good prices—while analyzing the first couple months of 2023 and predicting what’s to come.

By Katie Schroeder

By Katie Schroeder

producers,” says Zimmerman, who oversees Big River Resources’ four ethanol plants, including two plants in Iowa, one in Wisconsin and another in Illinois, which collectively produce more than 430 MMgy.

Despite ethanol prices decreasing 7.5 percent in the last three months of 2022, as compared to the same time period in 2021, according to an investor update released by Southwest Iowa Renewable Energy, many ethanol producers reported higher net gains

compared to 2021. The report also highlights that distillers grains prices were up 30 percent because of a supply shortage in the Midwest due to operational challenges caused by unusually cold temperatures.

Connie Lindstrom, senior biofuels analyst with Christianson Benchmarking LLC, explains that in 2022 the margins were overall fairly good, despite high natural gas and corn prices, since the high energy prices also boosted the price of ethanol, DCO and dis-

tillers grains. Christianson has been collecting data on the ethanol industry since 2003, gathering information on producers’ operational and financial statistics. Lindstrom explains that the average grind margin in 2022 was about 42 cents per gallon of ethanol.

“The price of ethanol has risen, and that’s helpful to the bottom line. And then the price of distillers grains products has gone up corresponding to the price of corn,” she says. “Fortunately, the price of

ETHANOLPRODUCER.COM | 19

Margins

Margins

ethanol has been high enough to compensate for those high corn costs and natural gas costs. So, still quite profitable for the plants overall.”

Looking Back

The fourth quarter report from CoBank’s Knowledge Exchange explains that average ethanol production margins (grind margins minus operating expenses) reached pre-Covid levels, with margins averaging around 27 cents in the fourth quarter, compared to 25 cents for the first nine months of the year. Kenneth Scott Zuckerberg, industry analyst for grain, farm supply and biofuels, explains that these numbers are in line with the 15-to-20-year average for ethanol profits, which is between 25 and 30 cents per gallon.

Zimmerman, Zuckerberg and Lindstrom outline some of the key market drivers in 2022, as well as the input costs that influenced producer margins. “[CoBank]

pay[s] a lot of attention to natural gas and corn prices,” Zuckerberg says. “Corn being a feedstock for ethanol, and of course natural gas used as an energy source in the production of fermented alcohol at the ethanol plants.” Natural gas prices in 2022 reached 20 cents (per gallon of ethanol) on average, the highest on record since 2008, when the price of natural gas per gallon of ethanol was 28 cents on average, and a price increase of roughly eight cents compared to 2021 prices, Lindstrom explains. However, the range between the bottom quartile and the top quartile was 10 cents, meaning producers in the bottom quartile were paying 14 cents, while those in the top quartile were paying as much as 25 cents. Lindstrom says that the producers who were able to keep their costs lower utilized a variety of methods, including selling wet distillers grains to local feed markets instead of using extra natural gas to dry the coproduct, locking in the price with their natural gas provider last

year or using CHP or other alternative energy sources such as wind energy.

According to Zimmerman, natural gas wasn’t the only extra expense producers faced last year. “Our input costs, our fixed and our variable costs went up pretty dramatically, mostly in 2021 and 2022 when we were at more or less peak inflation,” he says. “Whether it be labor costs or natural gas costs or enzyme costs, they all took a pretty steep increase over the last 18 months. My expectation and hope is that those moderate through 2023.”

Good news for the ethanol market in 2022 included the increased usage of high ethanol blends like E15 and E85 across the nation, particularly during the summer months, when gas prices skyrocketed. The Renewable Fuels Association, in an analysis of data from the Minnesota Department of Commerce, determined that E15 sales—in that state alone—reached 171 million gallons, a 31 percent increase over 2021 vol-

20 | ETHANOL PRODUCER MAGAZINE | MAY 2023

umes. E85 use in California remained near record levels, too.

Corn prices in 2022 were high due to weather events throughout the Midwest. Prices have reached up to $6.75 per bushel, which has cooled the export markets somewhat and triggered demand rationing. Zimmerman explains that corn and ethanol prices tend to correlate, giving producers great margins in spite of a higher price for feed-

stocks. An inflation environment tends to produce the best returns for most businesses, and ethanol is no exception, he explains. “That’s a common misconception. A lot of folks will think that if corn is $6.50, then we probably aren’t making much money, but that’s not really true,” he says. “Overall, I would say I’m not viewing 2023 as favorably as what we saw in 2022 ... simply due to the deflation of the bubble that’s going on

right now, driven mainly by the higher interest rates.”

Moving Forward

So far, 2023 has not been as profitable as 2022, according to Zimmerman. “Coming into 2023, the first quarter of every year is notoriously heavy, meaning that we tend to overproduce in the first quarter each year; [gasoline] demand is generally pretty

ETHANOLPRODUCER.COM | 21

low in the first quarter [when] you’re talking weather,” he says. “As we sit here today, versus 2022, our margins are greatly reduced from where we were in 2022.”

Although corn prices are difficult to predict, Zimmerman is hoping for a good crop based off of weather modeling that predicts an El Niño coming in June and July, since crops in El Niño years usually produce above trendline.

The outlook for the ethanol market looks to be in a stable position, on average, through the rest of 2023, according to Zuckerberg. “That being said, there is certainly the risk of upside and downside volatility on both sides, but we’re pretty much ... in a neutral position, but with a possibility of an upward bias,” Zuckerberg says.

For Zimmerman, the presence of an RVP waiver this summer is a key factor to determining this year’s market outlook. Although several governors throughout the Midwest submitted appeals to opt out of the RVP requirement, which would allow E15 to be sold year-round in those states. “I think an important thing that we can continue to do is continue to lobby and strive

for increased ethanol usage within the gasoline pool, and we’re doing that,” Zimmerman says. “There are a lot of political things at play here that tend to effect the overall demand for ethanol as we go throughout the year.”

He explains that it is key that the waiver is in place before May 1, when the RVP limits are put in place. Zimmerman emphasized the importance of implementing an RVP waiver for the summer driving season. “If you look at these eight states, 15 percent of the entire gasoline sales occur in these states, in that Midwestern region,” he says. “You look at it in terms of E15 sales; if you throw those states and a few other fringe areas that are also selling E15, it accounts for about 60 percent of the E15 sales. But having that waiver this summer is very, very important.”

In March, the EPA gave a belated response to the governor’s request, granting an RVP waiver for the states beginning in June of 2024. Prior to this announcement, the Energy Information Association estimated that the U.S. ethanol industry would produce 990,000 barrels of ethanol per day in 2023. In March, that estimate shifted up-

wards to 1 million barrels per day following the EPA’s response to the eight Midwest governors. As of early March, the states of Iowa and Nebraska announced that they plan to pursue legal action against the EPA if the implementation date is not moved to summer 2023.

From the feedstock perspective, the USDA increased its corn price estimates to $6.70 per bushel in February, and decreased its projection for how much corn would be used in ethanol production in 2023 by 25 million bushels, from 5.275 billion bushels to 5.25 billion bushels.

Zuckerberg explains that he has some policy concerns moving forward related to the implementation of the Inflation Reduction Act and the impact of e-RINs generated by electric vehicles charged using biogasbased electricity, and how obligated parties could buy those credits without supporting the ethanol industry. “It’s not clear what the final rule is going to look like and then, you know, you’re clearly bringing the e-RIN into this while you’re trying to satisfy the ethanol industry,” he explains. “And this administration has a tendency to try to create a series of rules that make everyone happy, and if rules make everyone happy, then there’s something more to it, it’s not what it seems. That’s part of our concern.”

Zimmerman believes 2023 is a transitional year. “Many of us are looking to lower our carbon scores right now, and the new paradigm that we expect to see in the coming years is really going to be focused on reducing carbon,” he says. “And you’ve seen a lot of uses that are out there that have strong potential for the ethanol industry, and I think as we transition toward some of those new uses, whether that be SAF or renewable diesel, I think we’re going to see a slow change in the drivers of our overall revenue.”

Author: Katie Schroeder

Contact: katie.schroeder@bbiinternational.com

22 | ETHANOL PRODUCER MAGAZINE | MAY 2023

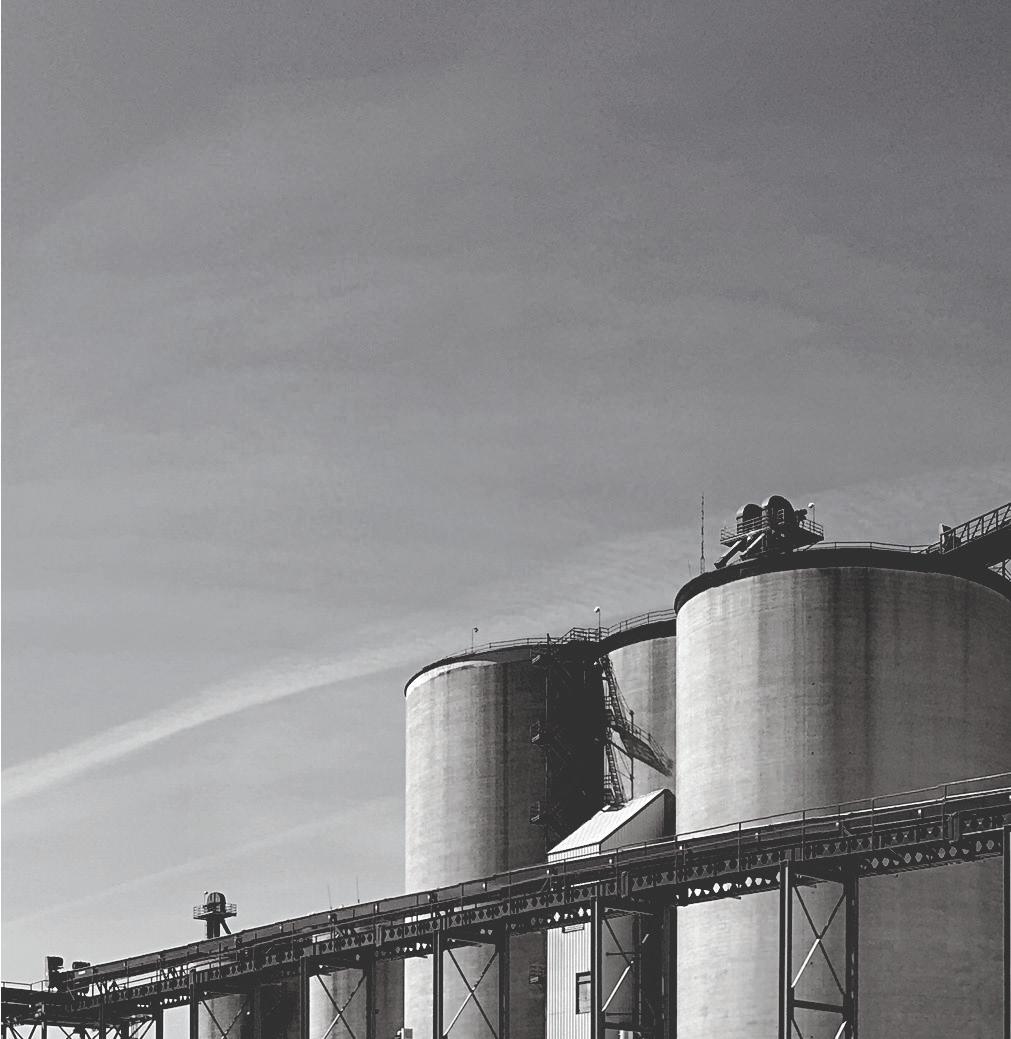

SKIPPING THE DRYER: U.S. ethanol plants able to reduce their natural gas usage in 2022 by producing all or some of their distillers grains in wet form were able to take fuller advantage of the year's high margin environment.

PHOTO: STOCK

WAITING AGAIN: Eight Midwest governors submitted appeals to opt out of the RVP requirement, which would allow E15 to be sold year-round in their states, Unfortunately, the EPA's response (which allows E15 sales in the summer of 2024 but not this summer) falls short of industry and retailer expectations.

PHOTO: EPM

Margins

Finding New Markets

Insight Green Plains is moving away from dependence on the ethanol market by developing new technologies and coproducts. CEO Todd Becker talks about the company’s various projects related to protein, corn oil, clean sugar and carbon, as well as a newly announced joint venture in SAF.

By Katie Schroeder

By Katie Schroeder

Green Plains is moving assertively toward a biorefinery model that does not center ethanol production. The company owns and operates 11 biorefineries in Illinois, Minnesota, Iowa, Nebraska, Indiana and Tennessee. Early in 2023, Green Plains, Tallgrass Energy and United Airlines announced a joint venture in Blue Blade Energy, which is currently in the process of developing the Pacific Northwest National Laboratory’s catalyst technology. The potential for SAF production provides Green Plains with another customer for its ethanol besides oil companies. Todd Becker, CEO of Green Plains, explains the company’s strategy and focus moving forward. “We’re slowly moving away from being wholly dependent on [fluctuating gasoline sales] every day at the pump,” Becker says. “It’s going to take a

while, but I am one hundred percent certain we will look very different two years from now than we look today.”

SAF is not the only endeavor Green Plains is pursuing to diversify its products; the key pillars of Green Plains’ business focus moving forward include protein, sugar, corn oil and carbon. Becker discussed Green Plains’ status on each of its various pillars, along with the future of the U.S. ethanol industry and how the company is pursuing new markets.

Blue Blade

The announcement of Blue Blade as a joint venture between Green Plains, United Airlines and Tallgrass Energy to optimize PNNL’s catalyst for commercial-scale SAF production lays out the roles each partner will play. Currently, Green Plains is assisting in optimizing the catalyst. Should it scale

up successfully, Green Plains will play the role of operator for the pilot and eventually commercial-scale refining facilities. Green Plains’ focus right now, within its role as the future feedstock provider for Blue Blade, is to work on lowering the carbon intensity of its alcohol.

Becker sees opportunity in SAF at a time when gasoline usage in the U.S. is shrinking. Since widespread adoption of higher blends seems uncertain to Becker, SAF is a good way to use that volume in an industry that needs it. “They want our

24 | ETHANOL PRODUCER MAGAZINE | MAY 2023

fuel, and that’s the difference this time. The airlines want sustainable aviation fuel. The automakers were influenced by Big Oil, and they didn’t care if Big Oil controlled the gas tank and controlled the gas station,” he says. “It’s really going to be fascinating to watch this whole thing play out, but we’ve got to decarbonize; we need a strong U.S. ethanol industry.”

Becker explains that the company’s alcohol, which is currently going into gas tanks, needs to shift to other outlets, even though ethanol is a low-cost, high-quality

octane additive. Expansive blends would be a great solution for the ethanol industry, but blends like E20 or E30 still have an uncertain future. “Alcohol-to-jet is really the path that has to work, and I think it will work actually. But it’s really, really important that we’re successful in converting our ethanol into jet fuel,” Becker says.

Decarbonization

The decarbonization efforts Green Plains is involved with are key to making sure the alcohol it produces stays competi-

tive, whether it is used in an alcohol-to-jet process to make SAF, or in ground transportation. One of the major efforts Green Plains is pursuing in the decarbonization sphere is signing eight plants onto Summit Carbon Solutions’ CCS pipeline, which will capture each facility’s fermentation CO2, transport it to a sequestration site and deposit it underground. Along with this strategy, Green Plains also has partnerships with Tallgrass and Osaka Gas to explore the feasibility of producing synthetic methane and synthetic natural gas. Becker explains that

ETHANOLPRODUCER.COM | 25

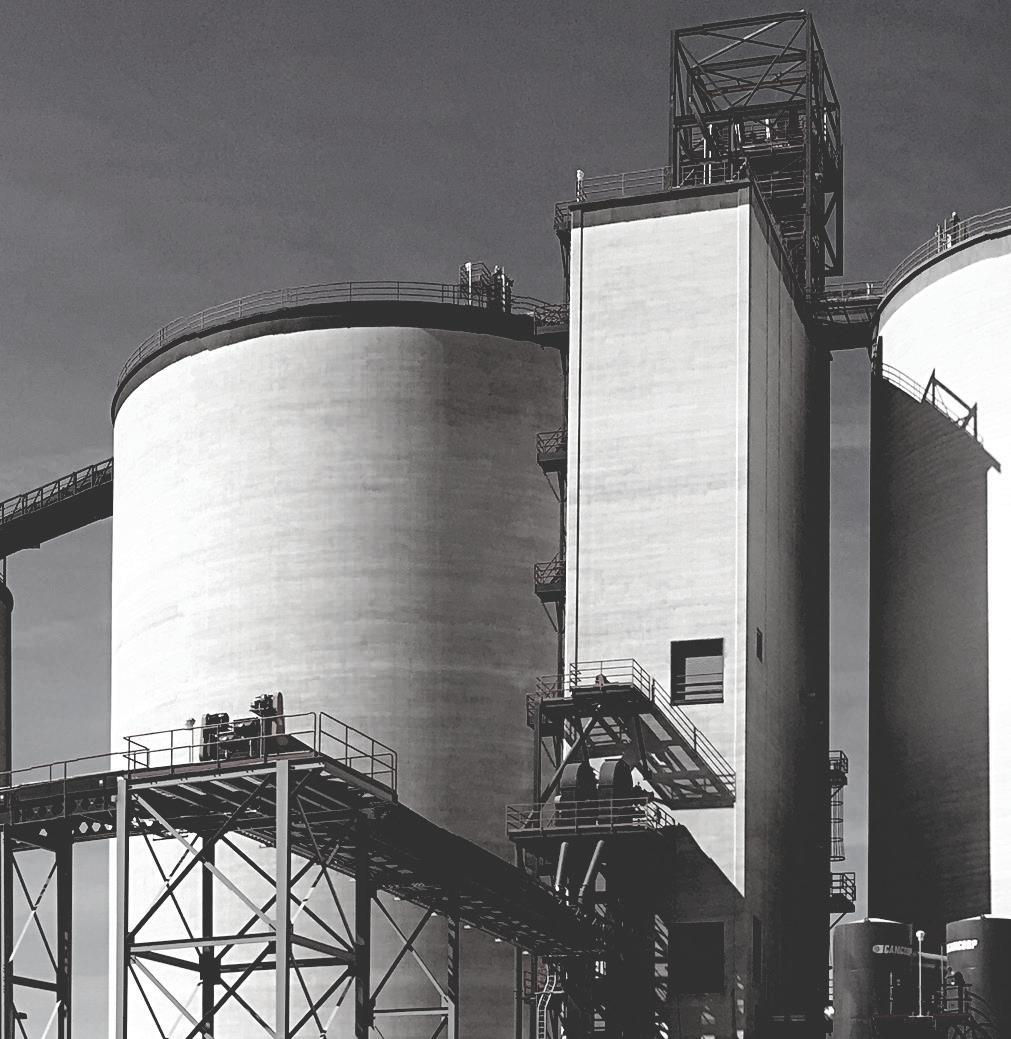

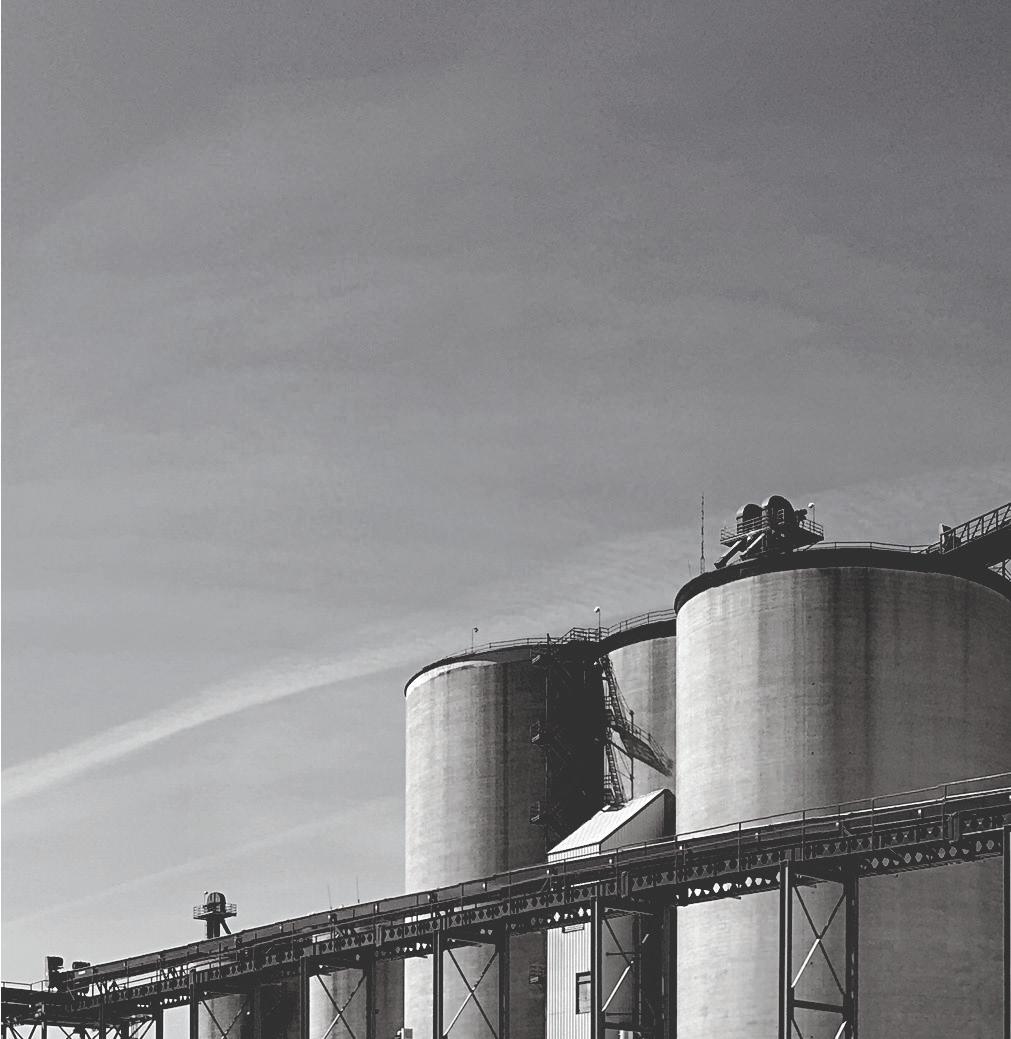

PIPELINE TO WHAT'S NEXT: This biorefinery in Central City, Nebraska, is among eight ethanol plants in Green Plains' fleet that have signed onto Summit Carbon Solutions’ proposed CCS pipeline, a critical decarbonization step on the path toward SAF production.

PHOTO: GREEN PLAINS

the company is also considering strategies to lower CI scores associated with electricity and heat, such as implementing combined heat and power technologies or using renewable natural gas.

“We’re being open to the fact that there will be many winners [in] lots of different areas, whether it’s going to be around jet,

or it’s going to be around carbon,” Becker says. “If we just choose one and we choose wrong, we’re not going to be in a great place. But if we are kind of involved in a lot of different opportunities ... we’ll see a lot and determine what’s the best opportunity for us to be involved in.”

Clean Sugar

One of Green Plains’ pillars is clean sugar production. At the 2022 International Fuel Ethanol Workshop & Expo, Becker talked about developing clean sugar technology with Fluid Quip Technology, which Green Plains and partners BlackRock and

26 | ETHANOL PRODUCER MAGAZINE | MAY 2023 Insight

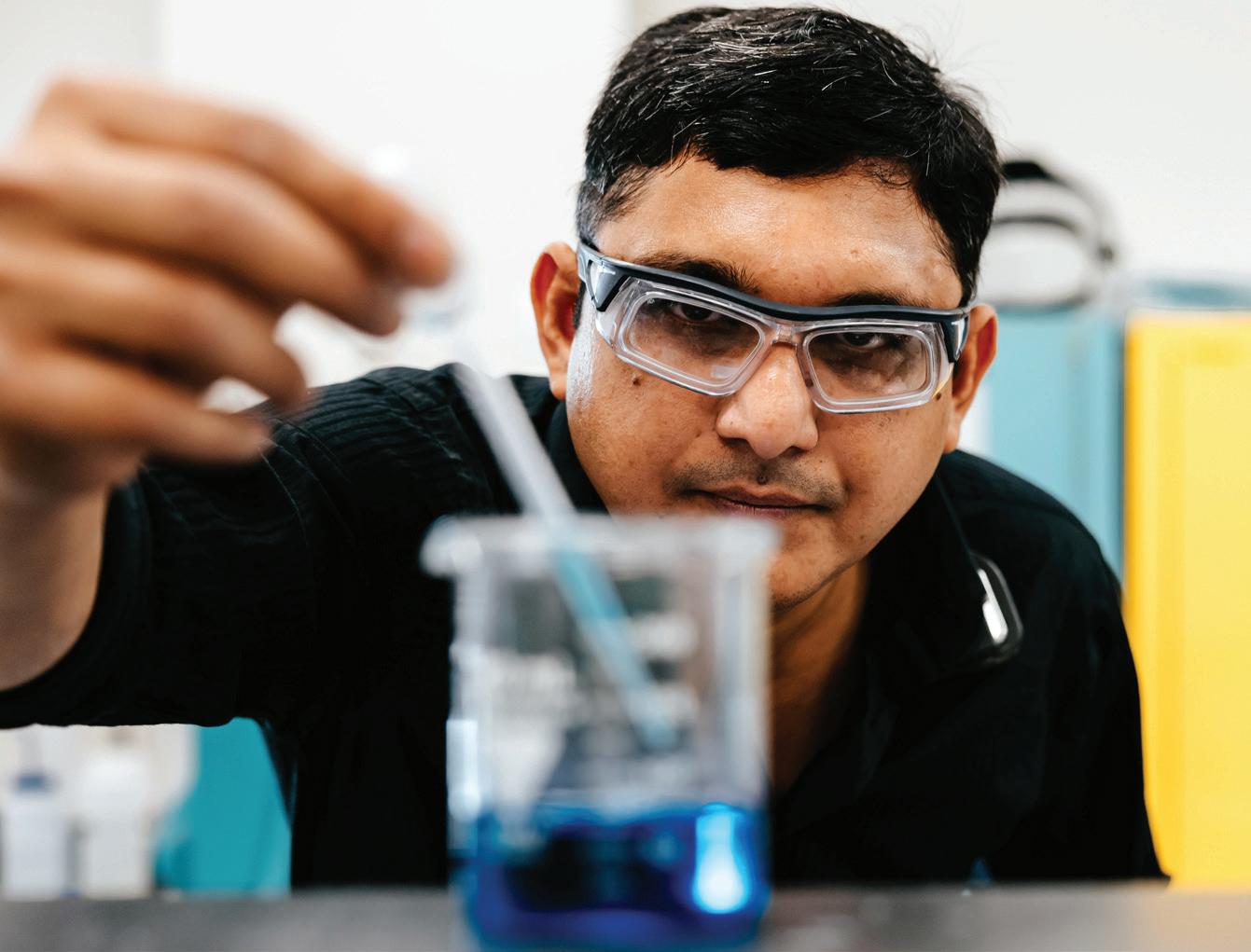

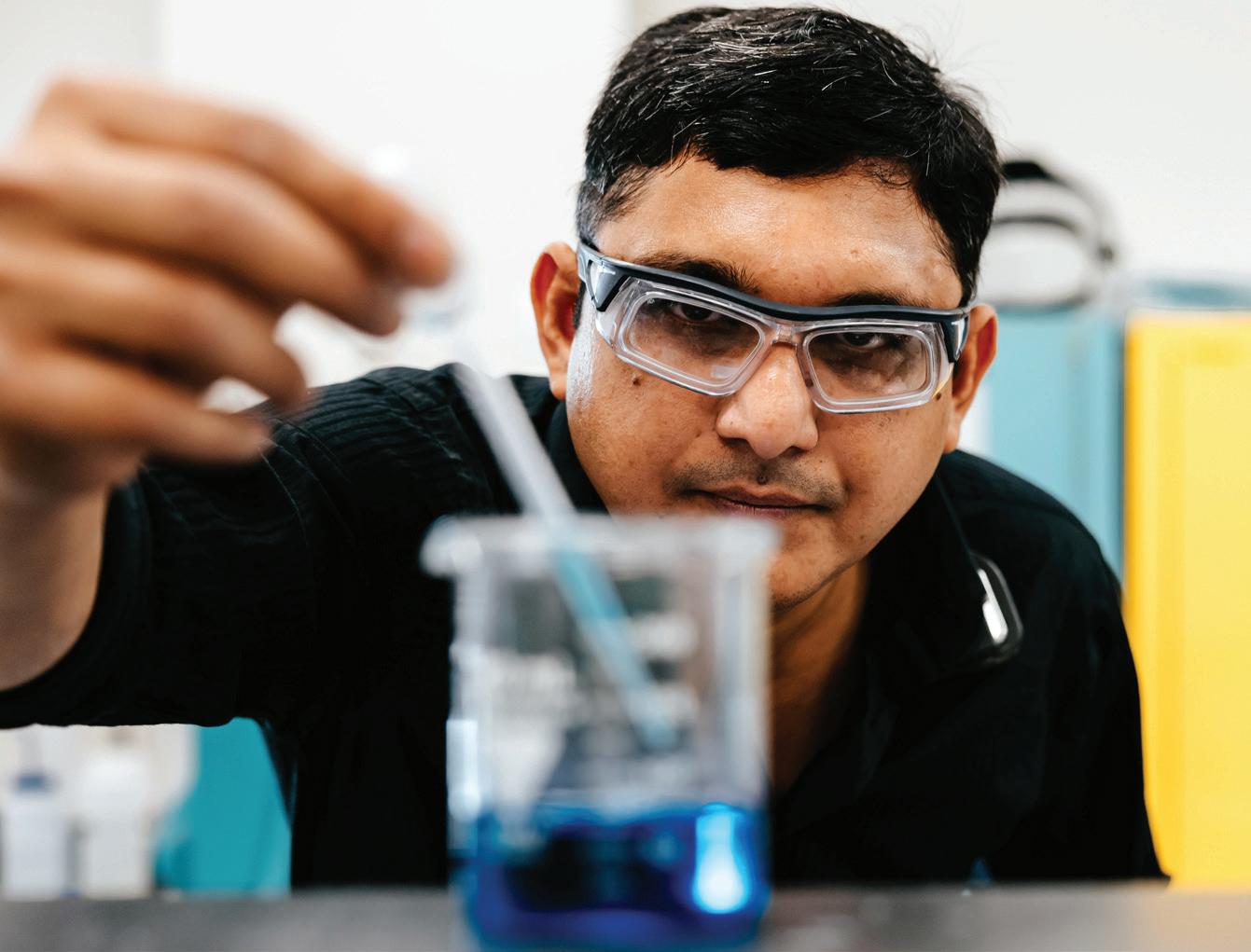

IN SEARCH OF SEPARATION: Green Plains is pursuing R&D in several new product areas, including the production of clean sugar (dextrose that is equivalent to sugar produced at a wet mill), which could help the company move away from conventional participation in the ethanol market.

PHOTO: GREEN PLAINS

Ospraie acquired majority interest in back in 2021.

Becker says clean sugar is still a major emphasis for the company, and progress is being made on construction of the first commercial-scale system at the company’s biorefinery in Shenandoah, Iowa.

The technology will make dextrose that is equivalent to sugar produced at a wet mill, while having a 50 percent lower CI score, according to Becker. “It’s extremely difficult,” he says. “You’ve got to put [up] significant dollars and invest behind it. You just can’t build it and think you’re going to make dextrose equivalent to what comes out of a wet mill. It’s not as easy as that.”

The goal is to reach 43 percent to 95 percent dextrose equivalent. While the first commercial-scale facility is under construction, Becker is confident that it will be successful and provide Green Plains with an important new market, giving them freedom to move away from being a conventional

participant in the ethanol market. “Some of our plants will still make alcohol, just not all of them can be converted into sugar based on location, so we’ll make the low carbon alcohol, but the sugar is really where we’re going,” he explains.

Protein Markets

Clean sugar technology will not be the first time Green Plains has utilized a technology developed by FQT. Over the last few years, Green Plains has implemented FQT’s Maximum Stillage Coproduct system and, subsequently, its sales of high protein to customers around the globe has proven even more successful than anticipated, according to Becker. “We’re sold out every day. It’s not easy to bring a new product to market, and it’s a very different product than distillers grains—it has unique characteristics—[and] you can do many different things to alter its performance. [It’s] a very different way to run your plant,” he says. “But we’re really excited about our protein technology.”

The company has seen success in a variety of markets, including aquaculture, pet and poultry feeds. Becker explains that the Green Plains’ plants are not settling for 50 percent protein; instead they continue to upgrade the product, both in protein levels

and in palatability and amino acids levels. FQT’s system has reached 60 percent protein, and 70 percent protein is in sight. “If we have customers that we are committed to, we will absolutely sell our 50 pro, but our goal is to move up to protein purities, move up very fast, and sell very high value products to the world,” Becker says.

FQT has been a key partner in pursuing clean sugar, oil and high protein, due to its deep bench of intellectual properties and expertise on a variety of “precision separation” technologies, Becker explains. “What we know how to do is take that little kernel of corn and go find the very highest value product in it, and we know how to get it out, we know how to separate them [from each other],” he says. “And nobody else in the world—in my view, in my opinion—nobody else in the world can do it as well as Fluid Quip can.”

Industry Outlook

Diversification is Becker’s strategy for the future of Green Plains; pursuing markets in SAF, protein, oil and more are key to adapting and ensuring the longevity of the ethanol industry. “This has to work for this industry because gas demand is not going higher; it’s only going to go

Todd Becker CEO, Green Plains

lower in our lifetime,” Becker says. “But it’s not going to go higher. And that’s something we’re going to have to come to grips with as an industry.”

The U.S. ethanol industry has an oversupply problem, according to Becker. “This industry has some soul searching to do to determine how ... we earn more as an industry instead of making as much as we can without a market that will take all of it,” he says. Looking ahead to 2023, Becker sees this year as a challenge and an opportunity. “We just make a product that needs to compete every day, and we are just a little oversupplied,” Becker explains. “I think we need a little rationalization in our thought processes around what this industry really wants to be.”

Although some Green Plains plants may keep producing ethanol and supplying it for ground transportation, the company plans to think creatively and seek out the highest value markets for the products produced.

Author: Katie Schroeder

Author: Katie Schroeder

Contact: katie.schroeder@bbiinternational.com

ETHANOL PRODUCER MAGAZINE | MAY 2023 ETHANOL PRODUCER_HALF PG AD_VISION BURNERS_12-09-2022_PRINT.pdf 1 12/9/2022 4:41:49 PM

Insight

REDEFINING BOUNDARIES: In 2022, Fluid Quip Technologies announced the potentially game-changing effectiveness of its DCO Technology, getting up to 1.4 pounds of DCO, or “renewable corn oil,” per bushel of corn at Green Plains’ Wood River, Nebraska, biorefinery (shown here), which has fully integrated the technology into its Maximum Stillage Coproduct system.

PHOTO: GREEN PLAINS

THE PREMIER PROVIDER. YOUR TRUSTED PA RTNER.

Thanks to our integr ated platf orm of r ailcar pr oducts and servic es, TrinityRail is the industry’ s unmatched r ail r esour c e, pr o viding the co n fidenc e y our business deserves. Trust N orth America’ s pr emier pr o vider of r ail tr ansportation solutions to deliver the quality, innovation and e xpertise y ou need to meet every business challenge. Ev ery time. Learn more at TrinityRail.c om.

TWO FUELS, ONE PLACE

By Luke Geiver

The relationship between ethanol production and biogas can be hard to define. While both fall under the umbrella of renewable energy production, a connection between the two biobased outputs has never been a nobrainer for U.S. ethanol producers. Other than RINgeneration and the possibility of onsite power, there are few other obvious reasons why the two should coexist (if at all), but several plants have found financial success or operational synergy by making both ethanol and biogas. The existing plants that are running anaerobic digesters in parallel to ethanol and coproduct production have invested in the necessary storage, processing and upgrading biogas-to-RNG infrastructure for reasons particular to their respective facility. The range of reasons is wide, including: access to waste feedstock needed for anaerobic digestion (from dairy manure to corn stover); regional demand for biogas or its upgraded version, renewable natural gas (RNG); local or national policy and tax incentives; and, as most ethanol producers are coming to understand, a desire to achieve a lower overall carbon intensity (CI) score.

A one-size-fits-all approach to biogas and ethanol doesn’t exist, but as several successful facilities running ethanol and biogas/RNG operations in conjunction have shown, there seems to be benefits to producing the two biofuels together.

Big Returns from Big Biogas Policy

In 2014, California-based Calgren Renewable Fuels powered up a biogas production operation to provide power to its 55 MMgy ethanol plant. Lyle Schlyer, president of Calgren, tells Ethanol Producer Magazine, that today biogas from its onsite digester is exclusively used in the plant’s renewable fuel production processes. The plant initially started producing biogas from an 1,800-cow dairy operation that was only a mile away. Today, more than 20 local dairies are involved in Calgren’s expansive biogas operation.

In addition to ethanol, Calgren produces biodiesel, corn oil and provides a site for carbon dioxide liquefaction. The entity is no stranger to integrating tech into an overall operation based in ethanol production. According to Schlyer, the biogas produced onsite is also made from biodiesel wastewater and other substrates.

Calgren starts with raw biogas before upgrading the product to serve the RNG market in California. According to the U.S. Environmental Protection Agency, to upgrade biogas to RNG, the methane content must be increased by removing water vapor, hydrogen sulfide, other impurities and most importantly, carbon dioxide. After that happens, it can be injected and transported via natural gas pipeline, serving as a direct substitute for natural gas.

32 | ETHANOL PRODUCER MAGAZINE | MAY 2023

A growing number of U.S. ethanol producers have found a way—and a reason—to produce biogas, often upgraded to renewable natural gas, at the same complex or in close proximity.

Business

ETHANOLPRODUCER.COM | 33

SIXTEEN STRONG: In Nevada, Iowa, Verbio North America has assembled 16 anaerobic digesters to produce biogas from corn stover sourced in the region.

PHOTO: VERBIO NORTH AMERICA

PLANT UPTIME IS IMPORTANT TO EVERYONE

Our full service team of experts have 20 years of ethanol plant maintenance reliability and uptime history 24/7 support and ready access to a full inventory and all Fluid Quip equipment parts, ensures that you maintain your plant’s uptime status.

PARTS

• OEM Parts Warehouse

• $1 million+ on-hand inventory

• Fully stocked trucks

• Overnight/hot shot shipping

EQUIPMENT SERVICE

• Factory Trained & Certified

• MSC™ Systems

• SGT™ Grind Systems

• FBP™ Fiber By-Pass Systems

• MZSA™ Screens

• Paddle Screens

• Grind Mills

• Centrifuges

Biogas produced at Calgren is cleaned up to pipeline standards, injected into a common carrier pipeline system and transported to CNG refueling stations in California. A portion of that RNG is used for process energy on the ethanol and biodiesel side.

Schlyer and his team recognized early on that the lifecycle carbon intensity value of renewable fuels was important. “Our presence in California, and our desire to maximize benefits under its LCFS, probably helped in that regard,” he says. “Perhaps that has made us more willing than most to consider technologies such as biogas and CCUS that can dramatically reduce CI values.”

When Schlyer looks at the current market for biogas and upgraded RNG, he calls it “developing.”

“We think the CI value of biogas and regional considerations will be big factors in driving future demand,” he says. “For example, the market for extremely low CI value biogas from swine and dairy manure digesters for use in refueling California CNG vehicles is strong. But that may change in the future.”

Right now, one of the driving incentives for Calgren to produce biogas correlates to methane reduction. The majority of the Pixley-based biogas is produced by capturing methane that would have otherwise been released into the atmosphere at surrounding dairy farms. That biogas, cleaned up to natural gas standards and injected into a natural gas pipeline system for transportation and use at CNG refueling stations, is given a CI value well below zero. Calgren gets credit for the methane emissions that are avoided. “That may change in the future since California is considering eliminating the ability to credit CI values with avoided methane,” Schlyer says. “That may necessitate a change in how we use our biogas.”

Since firing up the first digester in 2014, Schlyer and his team have learned a lot about biogas production and everything that comes with it. The issues and required actions linked to the federal Renewable Fuel Standard and California’s Low Carbon Fuel

Standard far overshadow the physical issues of operating a biogas site, he says.

To other producers considering the addition of biogas production in parallel to ethanol, Schlyer says there are many cross-linked opportunities from the operations side and for CI reduction scores. All producers, he says, should remember this: “Biogas and other decarbonization technologies are driven solely by policy incentives,” he says. “Since policies change over time, it is important for producers to think ahead and maintain flexibility. That is exceedingly important.”

Another California RNG producer, also making ethanol, exemplifies a renewables producer that is benefiting, operating and planning based on favorable policies. Aemetis Inc., which describes itself as a leading producer of below-zero-carbon intensity dairy RNG and developer of carbon-zero renewable jet/diesel biorefineries that use carbon sequestration, has a multiyear plan for RNG and biofuels.

In February, the NASDAQ listed (AMTX) company, announced a five-year plan (filed with the SEC). The plan includes the expansion of RNG production, sustainable aviation fuel, renewable diesel, carbon sequestration and other low- or below-zero carbon products. The reason for the ambitious plan? Eric McAfee, chairman and CEO of Aemetis, offered an answer.

Business

RENEWABLE CNG: Most of the biogas produced at Calgren Renewable Fuels is cleaned up to pipeline standards and transported to CNG refueling stations in California. A portion is used for process energy at the ethanol and biodiesel production plant.

PHOTO: CALGREN

“With the passage of the Inflation Reduction Act, Congress provided a clear incentive to support meaningful reduction of air and carbon pollution, which we expect to achieve in this Five-Year Plan,” he said. The plan, according to McAfee, would grow the company’s revenue to $2 billion in 2027.

Recent milestones helped Aemetis see a reality in the future plan. In just the past year, the company completed 40 miles of biogas pipeline, finished construction of a biogas-to-RNG upgrading facility, completed construction of a gas pipeline interconnect unit, brought four additional dairy digesters closer to service and made progress in the permitting process required to start-up a renewable jet/diesel facility.

According to Aemetis, the Inflation Reduction Act provides for the transfer of tax credits from incentives connected to the production of product, as well as investment tax credits and other credits. In total, those tax credits will improve the company’s net income by a projected $341 million in 2027.

The Beginning of More Biogas and RNG?

Not all biogas or RNG projects are scaled to connect ethanol sites to natural gas pipelines, multiple dairy manure production operations or other large-scale projects.

Lincolnway Energy LLC, a 90 MMgy dry mill corn ethanol plant in Nevada, Iowa, has been producing ethanol and distillers grains since May 2006. The company’s goal is to reach 100 MMgy, and based on its recent award from the U.S. Department of Energy, to expand into biogas production and usage.

Through the DOE’s Bioenergy Technologies Office, Lincolnway was recently awarded more than $450,000 to explore a biogas process that would utilize stillage and other feedstocks to reduce the carbon intensity of its ethanol. The project was selected as part of a funding opportunity created to meet the DOE’s goal of achieving a 70 percent reduction in greenhouse gas emissions by 2030. In total, 17 different projects were awarded for a total of $118 million in funding.

The projects were selected based on four areas: pre-pilot scale-up of integrated biorefineries; pilot scale-up of integrated biorefineries; demonstration scale-up of integrated biorefineries; and, Gen-1 corn ethanol emission reduction.

The Lincolnway project will evaluate the feasibility of deploying biogas tech using various forms of stillage and/or corn stover in a site-specific design that would link the biogas produced at the site to the ethanol production process. The DOE hopes what’s learned can be applied across the entire industry. “With two corn ethanol plants involved, the

analysis will leverage actual plant data, designs, samples and operating procedures to create an industry-ready, biogas platform,” DOE said of the Lincolnway project.

Already running in Nevada, Iowa, the Verbio biorefinery is making major strides with its RNG operation. Verbio could be well on its way to offering a blueprint to other producers looking to connect biogas and ethanol production. This year, Verbio noted a successful year-plus of operating an RNG production facility that upgrades cornstover-based biogas into RNG. That RNG is sold to a commercial customer.

Two corn stover storage facilities were built at the plant in Nevada to hold a combined 100,000-plus stover bales for use in its anaerobic digestion process. The cellulosic feedstock is purchased from local corn farmers. Although the success of Verbio in prooving out its corn stover-to-RNG process in Iowa to date is a notable accomplishment, what’s coming this summer will be even more closely watched by the ethanol sector. Verbio’s full vision is to begin operating as a corn-based ethanol plant that produces RNG from corn stover/stillage, and it plans to begin working towards that this summer.

“Marking the one-year anniversary of our RNG production in Iowa is an important milestone for our company,” says Greg Faith, Verbio Nevada plant president and

ETHANOLPRODUCER.COM | 35

ARRIVING FEEDSTOCK: The Nevada, Iowa, Verbio site has two corn stover storage facilities for the bales it acquires from local farmers.

PHOTO: VERBIO NORTH AMERICA

CLEANER ROAD TR IPS AWAIT

general manager. “We are taking big steps towards reaching full production capacity at our Nevada plant.”

It's not just ethanol producers working to expand the link between ethanol and biogas. More solutions providers are now committing to the industry. In early 2023, BIOFerm, a Madison, Wisconsin-based gas upgrading and anaerobic digestion system provider, announced it was entering the ethanol industry. BIOFerm is now an official member of the Renewable Fuels Association.

Scott Orsini, vice president of sales at the company, said BIOFerm is excited to join the RFA and to “partner on opportunities to turn existing ethanol plant waste streams into additional green energy.”

RFA President and CEO Geoff Cooper said the addition of BIOFerm will provide technology solutions and expertise that can help ethanol producers achieve greater efficiency, enhance competitiveness and achieve a smaller carbon footprint.

BIOFerm has been in the anaerobic digester and RNG space for more than 15 years and provides services to other industries that include distilleries, landfills, wastewater recovery plants, food processors and agricultural operations.

Some new RNG players trying to exist in the ethanol production space are thinking a bit bigger than the rest. In Calgary, Alberta, Green Impact Partners is on its way to creating North America’s largest carbon negative RNG and ethanol project. Using low-grade wheat to produce renewable natural gas and ethanol, the Future Energy Park site is being built—from the start— with the idea of combining RNG production with that of ethanol.

Once complete, the plant is expected to produce more than 3.5 million MMBtu per year of RNG; almost 80 MMgy of ethanol; nearly 260,000 tons of distillers grains; and once fully operational, the plant could capture roughly 440,000 tons of CO2 for the creation of carbon credits.

“A first-of-its-kind, Future Energy Park is an exciting opportunity for us to link the circular economy and decarbonize agriculture and our energy future,” says Jessie Douglas, CEO of Green Impact Partners. “The facility will be fully integrated, co-producing two forms of renewable fuels using advanced technology, including capture from the production process to go beyond the goal of net-zero CO2 emissions.”

The company is advancing multiple projects across North America. In February, Green Impact Partners signed a strategic partnership deal with Amber Infrastructure out of London in a deal representing $545 million in total investment for a 50 percent project-level equity interest stake in each of Green Impact Partners projects.

In Iowa, the company will be operating a multi-dairy RNG production facility that generates 350,000 MMBtu in annual RNG production. In Colorado, the Calgary-based team expects gas production to begin at its GreenGas Colorado RNG project this year. Although the facility will start producing roughly 180,000 MMBtu of RNG for the first year, it will eventually grow to more than 360,000 MMBtu in run-rate production.

There might not be a one-size fits all approach to implementing biogas or upgraded RNG into the operational footprint or fiscal plans of every ethanol plant across North America. But, as the connected ethanol and RNG projects spanning a geographical range from California to Iowa to Canada show, for those that do want to produce ethanol and a biogas-based product in parallel, the benefits and options to do so exist.

Author: Luke Geiver Contact: editor@bbiinternational.com

Business

We’ve put together some eco-friendly, perfect-for-spring itineraries with Get Biofuel stops and mustsee sights built in.

Browse the itineraries & learn

more at

SY NE RX IA ®

GEMS TO NE CO LLE CT IO N

Whether your goal is increased yield, robustness or plant throughput, we have the right yeast or yeast blend tailored to your specific process and market conditions.

SYNERXIA® SAPPHIRE – Our most robust yeast delivering a power ful combination of yield and glucoamylase expression

SYNERXIA® RUBY – Our highest yielding yeast driving plants to the peak of performance

SYNERXIA® EMER ALD – Our fastest yeast geared for maximum plant throughput

ww w.xcelis.com ©2022 International Flavors & Fragrances Inc. (IFF). IFF, the IFF Logo, and all trademarks denoted with ™, or ® are owned by IFF or its affiliates unless otherwise noted.

XCELIS® Yeasts

Busy with Upgrades

While nuts-and-bolts ethanol plant improvements typically don’t make national headlines, facility enhancements and capacity-boosting installations are always happening. Here’s a look at some of the work recently completed or still underway.

By Luke Geiver

By Luke Geiver

38 | ETHANOL PRODUCER MAGAZINE | MAY 2023

EXPANDED VISION: By adding more corn storage to its footprint, Elite Octane was able to boost its total feedstock capacity to 8 million bushels. The Iowa plant has made it a priority to upgrade the site not only for the direct benefit of the plant, but to support area farmers.

ETHANOLPRODUCER.COM | 39 Projects

PHOTO: ELITE OCTANE

Activity across the North American ethanol sector is never lacking. With more than 190 ethanol plants operating at some capacity in the U.S. alone, there’s always more going on at the facility level than casual observers realize. From capacity augmentations and tech upgrades to large-scale maintenance and replacement work, leading producers are continually executing on capacity and efficiency enhancements. Much of the work is low-profile, technical and of little interest to those outside the plant gates. But for those linked to the industry—producers, vendors, shareholders and growers—there’s a notable story behind every project. Here are four project updates that offer snapshots of trending plant improvements.

Enhancing the Farmer Experience at Elite Octane

Based in Atlantic, Iowa, Elite Octane LLC is a dry mill ethanol facility that began operations in 2018. Able to produce 150 MMgy, the plant features nine fermentation tanks (each rated for over 800,000 gallons of capacity) and three finished ethanol storage tanks rated to hold 2 million gallons each, giving the plant ample liquid capacity. On the DDGS side of the operation, the plant has a flat storage building able to hold 8,000 tons of dry coproduct. The facility also has a DDGS bulk-weigher and loadout system rated for 350 tons per hour and able to load a semi-truck in less than five minutes.

The plant has a long list of impressive features, but for Nick Bowdish, president and CEO of Elite, it is the facility’s enhanced ability to quickly handle incoming feedstock—and a lot of it—that’s most meaningful to area growers. Last year, the company added 4 million bushels of corn storage and a 30,000 bushels-per-hour receiving system. The expansion came online just prior to harvest and took the facility to a total of 8 million bushels of storage and 90,000 bushelsper-hour of receiving capacity.

“Elite Octane prides itself on offering

great customer service and this investment acknowledges that a farmer’s time is one of the most valuable resources in agriculture today,” Bowdish says, adding that the project represents Elite’s renewed commitment to “continue to grow alongside farmers” in southwest Iowa.

Part of Elite’s story is its effort to continue to build off the previous site owner’s vision. Previous entrepreneurs interested in the benefit of an ethanol plant—specifically one in Cass County, Iowa, where the plant resides—built infrastructure over a two-year timeframe from 2006 to 2008. That work included constructing fermenter foundations, process tank foundations, energy center foundations, DDGS storage buildings, administration buildings and grading and drainage work, along with the installation of eight water wells.

The recent expansion effort was mainly linked to storage and site usability for farmers, Bowdish says. Buresh Building Systems completed the installation at Elite, which featured commercial grain bins manufactured by Sukup Manufacturing. The expansion also included a second inbound scale, a new probe shack with multiple probes, and an enhanced RFID card reading system provided by Compuweigh to upgrade the automation of the facility.

Storage and CI Reduction Focus at Dakota Ethanol

Dakota Ethanol near Wentworth, South Dakota, has also been expanding and up-

grading its site. In 2022 the facility executed on several projects. Last August, Dakota Ethanol put in an eighth fermentor, which increased capacity above 100 MMgy (previous nameplate capacity was 90 MMgy), while also increasing production efficiency. To match current plant production capabilities, an additional grain bin install was also on the list. Nearly 1 million bushels of storage was added “to improve customer service and meet storage needed to match current plant production.”

On the outbound ethanol side, the plant added a new storage tank. At 2 million gallons, the tank will reportedly boost Dakota Ethanol’s ethanol storage capacity to 5 million gallons and, according to management, “help the plant buffer against logistical issues and railroad performance.”

Starting production over two decades ago, the plant was championed and developed by the members of Lake Area Corn Processors (comprised of growers, investors and community members), a group that transformed an idea into one of the area’s flagship workplaces. Today, their vision continues to evolve.

In addition to physical upgrades at the plant, Dakota Ethanol is an active promoter of low-carbon farming practices and, with the right policy supports, the carbon intensity (CI) score reduction associated with it. A visit to the plant’s online homepage shows that it is participating in the USDA’s Regional Conservation Partnership Program, part of a strategy to secure compensation for farmers who produce low-carbon intensity commodi-

40 | ETHANOL PRODUCER MAGAZINE | MAY 2023

Projects

WAVE OF PROJECTS: Dakota Ethanol, a now 100 MMgy ethanol plant in Wentworth, South Dakota, recently added a fermentation tank, an additional grain bin, and 2 million gallons of extra ethanol storage capacity.

PHOTO: DAKOTA ETHANOL

ties through existing and future low-carbon fuel standard markets.

In 2021, the plant celebrated the production of 1 billion barrels of ethanol. The facility utilizes roughly 30 million bushels of corn and also produces corn oil, along with several distillers grains products sold as dry distillers grains with solubles, modified distillers with solubles, wet distillers with solubles and Dakota Cake, a proprietary product with higher moisture content than MDGS but lower moisture content than wet cake.

One Earth Energy Looks to Expand

Some of the construction work in the ethanol industry hasn’t even been officially announced (as of press time in late March). In Illinois, One Earth Energy LLC is in the early stages of making a major addition to its 150 MMgy ethanol facility. Steve Kelley, president and CEO, met with the Gibson City Council’s Planning and Zoning Commission in February to get a 103-acre tract adjacent to the existing plant rezoned from agriculture to manufacturing. The land is already owned by One Earth. In a vote of 5-0, the commission decided in favor of One Earth’s request and rezoned the land to be more suitable to the company’s expansion vision. The current footprint of the facility is 85 acres. Details of the future plans for the rezoned land have not yet been disclosed by One Earth Energy or Kelly. Even the Gibson City council members noted in their documentation of the recent meeting the

lack of specifics for the rezoned property. The details should emerge later this year.

One Earth Energy, which is majority owned by Rex American Resources Inc., has also been exploring the possibility of carbon capture and sequestration. The ethanol producer has been working with the Illinois State Geological Survey over the past couple of years to determine if the 500,000 tons of CO2 the plant produces each year could be collected, liquefied and injected near the site. Early testing shows the geologic formation below the area would be favorable to a CO2 injection well.

Efficiency Upgrades at Glacial Lakes Energy

Glacial Lakes Energy, which owns and operates multiple ethanol facilities in northeastern South Dakota, has not only been active in promoting the use of E30, but also doing boots-on-the-ground work across its facilities in the areas of Aberdeen, Huron, Mina and Watertown.