Transforming wastewater INTO A SUSTAINABLE RESOURCE

Overcoming challenges TO FAST-TRACK REZ DELIVERY

JEMENA’S NEW MANAGING DIRECTOR

JEMENA’S NEW MANAGING DIRECTOR

www.utilitymagazine.com.au Issue #42, May 2024

MEET DAVID GILLESPIE,

WATER SEWER ELECTRICITY GAS

CALL 1800 800 878 OR VISIT CAPS.COM.AU CAPS INDUSTRIAL AIR AND TURBO BLOWERS Visit CAPS at Melbourne Ozwater’24 Showcasing BOLLFILTER and CAPS Blower Product range. Stand B15 Melbourne Convention and Exhibition Centre 30 April – 2 May 2024 • WATER TREATMENT • WASTERWATER MANAGEMENT • S EWERAGE TREATMENT • MINERAL PROCESSING

Published by

Prime Creative Media

ABN: 51 127 239 212

379 Docklands Drive

Melbourne VIC 3008 Australia

P: (03) 9690 8766

www.primecreativemedia.com.au enquiries@primecreative.com.au

ISSN: 2203-2797

Editor

Katie Livingston

Assistant Editor

Steph Barker

Journalists

Stephanie Nestor, Tess Macallan, Kody Cook, Sarah MacNamara

Design Manager

Alejandro Molano

Designers

Danielle Harris, Jacqueline Buckmaster

National Media Executives

Rima Munafo, Brett Thompson, Ryan Sheehan

Marketing Manager

Radhika Sud

Marketing Associates

Rhys Dawes, Bella Predika, Georgia Rogers

Digital Marketing Assistant

Emily Gray

Publisher

Sarah Baker

Managing Editor

Laura Harvey

FROM THE EDITOR

The first quarter of 2024 has been a hectic time for Australian utilities – from extreme weather events causing catastrophic damage and grid outages, to gas uncertainty and water security challenges.

The race to net zero remains the key focus for the industry, and while the conversation often revolves around the critical role the energy sector is playing in meeting these targets, improving sustainability is a ubiquitous responsibility for all industries.

In this issue, we turn our attention to the vital role that water will play in averting a climate crisis and share some initiatives that water utilities are undertaking to create a sustainable water future for all Australians.

For South East Water, this involves establishing a circular economy and transforming waste into valuable resources. We spoke with the utility and its research partners about its innovative new pyrolysis technology that is revolutionising biochar production. We also delved into how Water Corporation’s recently unveiled Woodman Point water resource recovery facility is helping the utility transform wastewater into a sustainable resource.

Over in the energy sector, utilities are tackling the mammoth task of transitioning the NEM to renewables, while managing predicted gas shortfall and ensuring that the grid remains secure.

This edition covers the latest updates on some of the major generation, transmission and storage projects that are driving this transition, including the recently completed SA component of

EnergyConnect and Territory Generation’s Darwin-Katherine BESS project.

We also heard from some key figures in the energy sector, including Jemena’s new Managing Director, David Gillespie, who discussed some of the major work that the utility has in the pipeline for 2024.

While these issues will continue to pose major challenges for the industry, it’s inspiring to see the fantastic work already being achieved by Australian utilities and the drive and innovation that is continuously pushing the industry forward.

Katie Livingston Editor

welcome May 2024 ISSUE 42 1 Drop Katie a line at katherine.livingston@primecreative.com.au or feel free to call us on 03 9690 8766 to let us know what you think. Don't forget to follow Utility Magazine on social media – find us on LinkedIn, Twitter and YouTube.

Utility Magazine acknowledges Aboriginal Traditional Owners of Country throughout Australia and pays respect to their cultures and Elders past, present and emerging. Scan to subscribe to Utility magazine’s weekly newsletter – delivered to your inbox every Thursday morning. This document has been produced to international environmental management standard ISO14001 by a certified green printing company.

INDUSTRY INSIGHTS

Accelerating the delivery path for renewable energy zones 20

The development of renewable energy infrastructure alone is an enormous task, made all the more challenging by labour and supply chain shortages, planning delays and community pushback. Here, APA General Manager, Terry Chapman, shares some insight into how governments can tackle these challenges and fast-track the delivery of renewable energy zones.

The next generation of long-term, tank base corrosion protection. 22

Securing a sustainable water future 24

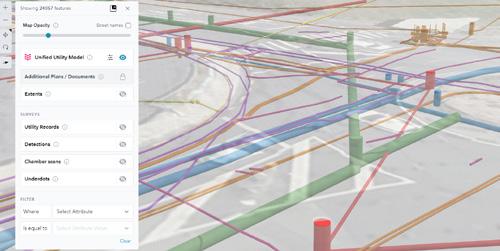

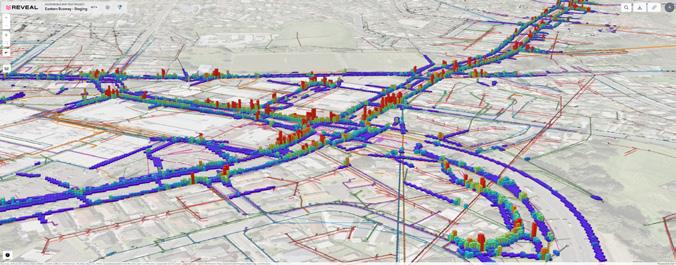

Preparing our network for the future: Jemena's new Managing Director 26

ENERGY STORAGE

Power move: Territory Generation’s second DarwinKatherine BESS project ............... 80

Powering the future: NaNiCl batteries revolutionising utility management 84

ACCELERATING ACTION

Revolutionising biochar production with new pyrolysis technology

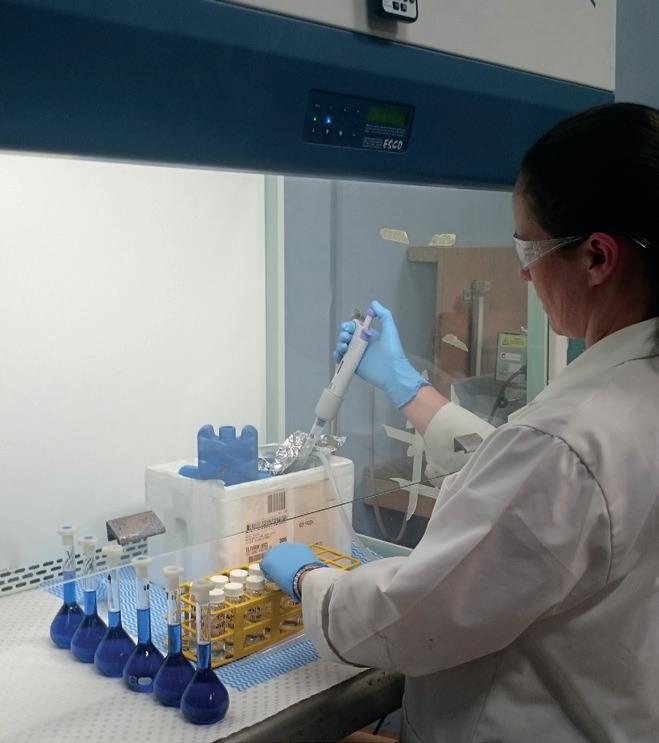

South East Water’s Research and Development team works to identify emerging trends and technologies to help solve problems presented by wastewater management and treatment, particularly in relation to sustainability and the circular economy.

Working together for better drinking water in the bush .......... 30 Facility upgrade turning wastewater into a sustainable resource 34

Circularity in water – people are your greatest asset 36

SMART METERS

Stanthorpe's Smart Water Network: a blueprint for water security ............................... 86

Gas will continue to play an important role in Australia’s journey to net zero –but how will gas supply and consumption change in the transition to clean energy? Project EnergyConnect: successfully delivering

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 2 CONTENTS

Smarter

Leeton 92 EQUIPMENT Creating the ultimate AVK valve solution ............................... 94 Optimising small-volume chemical handling 96 Tackling challenges during wastewater pressure main realignment 98 HDD tooling changing the game 100 Innovative centralisers elevate industry standards ...................... 102 Durable drainage systems for utility demands 104 80 86 94

MANAGEMENT Making sure every heat pump hot water system is safe ............. 38 Participants, not recipients: consumers hold the key to Australia’s renewable power 40 AEMO GSOO:

.............. 44

leak detection: saving Apollo Bay’s water 88 Saving the day (and the beer) in

DEMAND

preventing gas shortfall

transmission project

ElectraNet’s largest

.................... 48

28

38 28 20

SUSTAINABILITY

The foundation days of NULCA

As the major representative body for locators in Australia, NULCA today provides essential leadership and support to its members and works to eliminate network damages, personal injury and costs to the community during excavation and construction activities.

Delivering a historic desalination upgrade for outback SA community 60

For the first time, residents and businesses in Marla can access safe and clean drinking water directly from their taps, with SA Water’s new desalination plant now operating in the Far North South Australian town.

Innovative solutions for hydrogen electrolysis 62 Interflow’s sustainability strategy: for climate, communities and our kids 64

Pioneering the global energy transition for a connected and sustainable future ........................ 66

Having the right equipment can make all the difference in the success of pipe maintenance. This article looks at how water jetting technology can both optimise operations and reduce the costs of maintaining these assets.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 3 May 2024 ISSUE 42 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index �������������������������������������������������������������������������������������������������������������������� 108 Editorial schedule �������������������������������������������������������������������������������������������������������������������� 108 54 72 60

UTILITY LOCATION

Australia .......................... 52

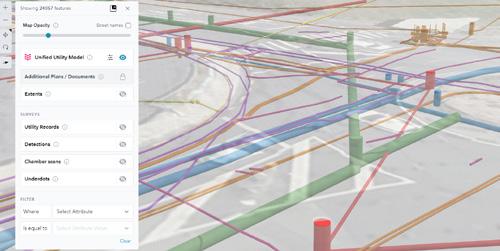

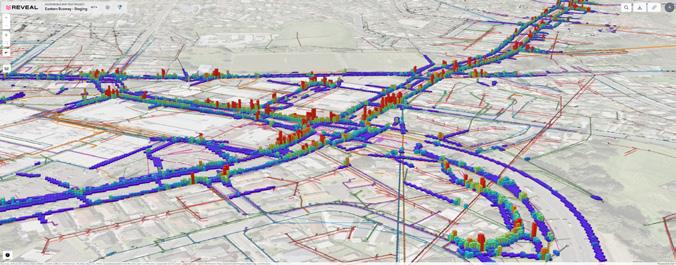

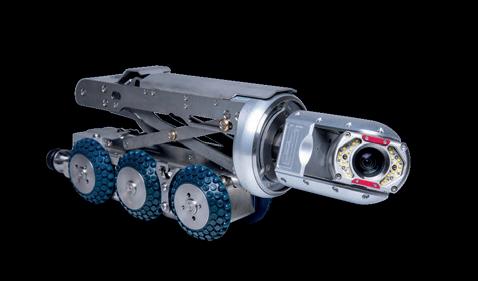

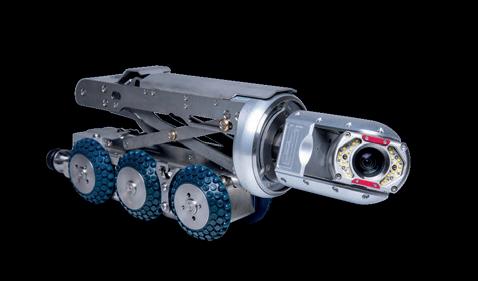

Delivering smarter professional locating services with new technology ................... 55 Unified Utility Models helping engineers to trust underground data 56 CYBER SECURITY Cybersecurity challenges in the water and wastewater industries 58 INSPECTION, CCTV & CONDITION ASSESSMENT Enhancing visibility over operations at Endeavour Energy 68 Handling the pressures of water treatment with process automation ..................... 70 What is non-destructive testing and what are its advantages? 72 Revolutionising remote monitoring 74 The future of pipeline condition assessment................... 76 The

power of water jetting .......... 78

106

CHARTING THE COURSE – A SNAPSHOT OF THE ENERGY NETWORKS 2024 CONFERENCE

In the glass-panelled halls of the Adelaide Convention Centre, the future of energy took centre stage at the Energy Networks 2024 Conference, a convergence of industry experts and innovative thinkers. The jam-packed event left attendees with insights into the world's ever-evolving energy landscape.

The conference centred on the urgent need for energy transition, and amid the backdrop of global momentum towards net zero emission, the discussions ranged from the practical to the visionary.

A SEISMIC SHIFT

Throughout the conference several key themes emerged, shedding light on the change underway within the industry. Participants emphasised the need for a transformational, rather than merely transitional, leap in energy generation, networks and investments to meet Australia’s net zero commitments.

The conference location also showcased exemplary progress in renewable energy adoption, with South Australia poised to reach 100 per cent renewable electricity by 2027.

Insights from diverse perspectives outside the Australian energy sector offered fresh insights. Keynote speaker Laura Sandys CBE advocated for a deeper understanding of consumer needs, while Tim Jarvis AM highlighted the role of adventure in fostering commitment to the cause. Moreover, contributions from First Nations’ voices served as reminders of the just and holistic approach needed to navigate Australia’s energy transition.

The takeaway for energy professionals was clear – stay agile and informed to navigate the technological, regulatory and community acceptance path ahead.

INNOVATION SPARKS CONVERSATIONS

Technological strides shared the spotlight, particularly the development of smart grids and AI. A hands-on exhibit allowed attendees to interact with the next generation of energy tech, from drone-assisted maintenance to cutting edge engineering and consulting.

Machine learning algorithms, which predict potential system failures and weather-related disruptions, were a key talking point, emphasising the importance of preventative measures in minimizing outages and maintaining system integrity.

A shared resolution throughout the event was that our grids must continue to evolve – at pace – to support our transition. As they evolve to accommodate bi-directional flows and renewable sources, digitisation emerges as a crucial tool.

A COLLECTIVE STRIDE TOWARDS CHANGE

One of the most potent messages from the conference was the sheer necessity of cross-sectoral collaboration. These partnerships are vital cogs in the wheel of progress, enabling shared expertise and resources in the pursuit of a common goal – a robust energy system.

From the bustling exhibition floor to the deep-dive concurrent sessions, it was evident that networking was not just a by-product, but a crucial objective of the conference.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 4 A WORD FROM ENERGY NETWORKS AUSTRALIA

The connections made here, the case studies shared, and the strategies debated will undoubtedly ripple out into the real world, influencing decisions and pushing the boundaries of what's possible.

In the plenary hall and concurrent sessions, speakers acknowledged the significance of consumer engagement and the need to bridge the gap between industry initiatives and consumer expectations. Furthermore, the notion of energy justice emerged as a central tenet of the discussions, emphasising the need for a just transition that ensures equitable distribution of benefits and burdens.

POWERING THROUGH CHALLENGES

Yet, the conference wasn't just a showcase of triumphs; it was a platform for acknowledging ongoing and upcoming challenges. Discussions on cybersecurity stressed the importance of fortifying the grid against increasing threats, a concern for all given the rise in cyber-attacks on critical infrastructure in recent years.

The issue of equitable access to clean energy also spurred earnest conversations. As an industry, we must address the persistent energy divide; thus conference attendees considered the socio-economic implications of their business models and innovations.

THE FUTURE IS NOW

While the challenges that lie ahead are undoubtedly complex, the mood at the Energy Networks 2024 (EN2024) Conference was optimistic. The diverse perspectives and experiences that converged cast a light on all facets of energy networks – from transmission and distribution to regulation and consumer engagement.

For energy professionals, the conference delivered a clear message: the road to our energy future is paved with innovation, collaboration, and an unwavering commitment to transition.

The outcomes of the EN2024 conference have set the stage for an incredibly dynamic period. In the energy sector, change is the only constant and events like EN2024 are significant beacons, charting the course for industry evolution and the quest for a more affordable, sustainable, and resilient energy framework. The future of our energy systems hangs in a delicate balance, and it lies within the hands of those who dare to innovate and imagine a brighter, cleaner tomorrow.

A future fuelled by clean, efficient, and reliable energy is not just a distant dream – it's a vision that's being meticulously charted by industry professionals today. And with initiatives like EN2024 charting the course, the outcomes of this collective quest are as promising as they are imperative.

5 UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU

ENA CEO DOM VAN DEN BERG MODERATING A PANEL SESSION.

ADVENTURER TIM JARVIS AM DELIVERS A KEYNOTE.

A WORD FROM WSAA

ELEVATED INVESTMENT ENVIRONMENT

REINFORCES NEED FOR A NATIONAL AGREEMENT

As the Productivity Commission completes its inquiry on the progress of all Australian governments in achieving the objectives, outcomes and timelines anticipated under the 2004 Intergovernmental Agreement on a National Water Initiative (NWI), it is time to reflect on the heightened need for a new national agreement.

The drivers of change are well known. They centre on maintaining ageing assets and service levels, servicing rapid population growth and responding to climate change. Each of these challenges are now forcefully driving necessary investment to record levels. The water industry is expanding. The scale of changes across the industry could place pressure on existing pricing and institutional governance arrangements.

However, these assets need higher levels of maintenance and upgrade if they are to continue to provide services for future generations.

In turn, rapid population growth means that we need to provide further capacity. This is required in both our underground pipes and in our sources of water. We need to provide higher levels of treatment to used water to protect our precious inland waterways and beaches.

With record levels of investment required (WSAA’s forward looking data on capital expenditure shows a doubling of investment by 2027 to more than $10 billion annually) the era of flat prices is over in many jurisdictions and the future will be one of managed price increases.

There are short term and long-term factors that impact upon water prices. In the short term, inflation and rising costs are affecting water as these pressures affect all industries. But the long-term factors will increasingly be the most important. These are:

• The need to maintain and upgrade an ageing asset base

• The need to provide services to a rapidly growing population, and critically,

• The need to be resilient in the face of climate change. The dams, pipes, and treatment plants used to provide water and treat and manage wastewater last a long time. Many of these assets were built, and paid for, by generations past. These assets have lasted well and have not required a significant contribution from the current generation.

These issues are compounded by the impact of climate change. We need to provide water supplies in an increasingly uncertain climatic outlook. There is a need to diversify our sources of water to incorporate non-rainfall dependent sources of supply including further desalination, recycling for industry and purified recycled water for drinking.

The elevated investment environment and associated price impacts in Australia reinforces the need for national reform. Rising prices will directly and indirectly affect many elements of a new agreement. Directly they will test the full cost recovery model across jurisdictions, and it is important that these existing elements of the NWI be reinforced. Utility balance sheets will also come under pressure and it will be important that all governments commit to maintaining an investment grade credit rating for water utilities. Under all circumstances, unless we have a strong water industry, water security, regional water services and closing the First Nations water gap will all be significantly harder.

SECTION

Read WSAA’s submission to the Productivity Commission’s Inquiry into National Water Reform at www.wsaa.asn.au/publication/submission-productivity-commission-inquiry-national-water-reform-2024

SINTALOCK® II - A REVOLUTIONARY JOINT DESIGN FOR AN EVER-EVOLVING WATER PIPELINE INDUSTRY

A step forward into the future of the water industry, Steel Mains’ Sintalock® Type II Rubber Ring Joint is an Australian-made fully restrained joint for high pressure water pipelines that goes further beyond today’s standards than any other joint in the market.

With no need to enter the pipe for welding or lining reinstatement, safety is optimised while corrosion protection is fully enhanced and laying rates are maximised.

www.steelmains.com

QLD GOV TO DOUBLE SIZE OF WAMBO WIND FARM

The Queensland Government has announced plans to almost double the capacity of Wambo Wind Farm in the state’s southwest, adding an extra 41 turbines to the project.

The Queensland Government had previously committed to a 42 turbine wind farm in Jandowae, with an extra 41 turbines to be added to the project.

The state government said the additional turbines are expected to add enough generation to the overall project to power the equivalent of 312,000 homes with renewable energy once complete.

It also said that the Queensland Energy and Jobs Plan and renewable energy projects, including Wambo stages one and two, are expected to save households about $150 each year by 2032, while small businesses will see a reduction of around $1,495 off their annual power bills.

The government said that wholesale prices are expected to decrease by approximately 15 per cent by 2040 due to Queensland’s plan to transition to renewable energy.

Doubling the size of Wambo means the facility is predicted to generate 506MW of energy by 2026, with the 83 turbines reaching 247m up in the air.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 8 NEWS Lanco Group personnel is comprised of professionally qualified engineers that receive ongoing training both externally and in-house to continually develop a strong understanding of design and construction principles. Providing strategic and significant civil engineering services since 1998. Level 2, Suite 26/20 Enterprise Drive, Bundoora, Victoria, 3083 1300 1 LANCO (52626) / tenders@lancogroup.com.au lancogroup.com.au

The wind farm, which will feature some of the largest onshore wind turbines in the nation, will contribute to Queensland’s target of 70 per cent renewables by 2032.

The government said the project will boost the local economy, with about 200 direct construction jobs and up to 500 more indirect jobs during the multi-year build.

Foundations for the first wind turbines on stage one are underway with construction of stage two expected to commence in mid-2024.

Commercial operation of stage one is projected for 2025, while stage two is projected for 2026.

The project is expected to create an additional eight ongoing jobs.

The project is being delivered in partnership between publicly owned energy company, Stanwell Corporation, and global sustainable developers, Cubico.

Under the venture, Stanwell will own 50 per cent of the energy produced, and will purchase the rest of the power from Cubico under a 15-year agreement.

Wambo Wind Farm stages one and two are backed by a $455 million investment from the Queensland Government’s Queensland Renewable Energy and Hydrogen Jobs Fund for Stanwell’s share in the project.

Queensland Minister for Energy and Clean Economy Jobs, Mick de Brenni, said, ”Queensland has the cheapest power of any state in Australia thanks to our nation-leading cost of living relief support and growing renewables base.

“Queensland has been the world leader in rooftop solar, and now we are building world-class wind power thanks to

partnerships between publicly owned energy companies like Stanwell, and world-renowned clean energy company Cubico Sustainable Investments.

“Queensland’s abundant wind resources are attracting growing global interest, creating jobs and economic opportunity for Queensland,” Mr de Brenni said.

Stanwell CEO, Michael O’Rourke, said, “Wambo Wind Farm is one piece of Stanwell Corporation’s rapidly advancing portfolio of renewable energy assets. It is the 14th renewable energy project in which we have an interest or offtake and moves us one step – or 41 turbines – closer to our target of nine to 10GW of clean energy by 2025.

“We are thrilled to partner with global clean energy leader, Cubico Sustainable Investments on the next stage of Wambo Wind Farm,” Mr O’Rourke said.

Cubico Head of Country, David Smith, said, “As a world leading renewable energy company, Cubico is proud of our role assisting Queensland to achieve its ambitious renewables goals, with more than 500MW achieving construction to date.

“Cubico’s pipeline of development projects is at 2GW and growing, signalling our commitment to being a key partner in the decarbonization of Queensland’s and Australia’s energy landscape and a long-term partner for local communities.

“Cubico is proud to be partnering with Stanwell with the expansion of Wambo Wind Farm to further deliver upon the Queensland Government’s Energy and Jobs Plan,” Mr Smith said.

No time to waste!

Explore Grundfos Wastewater Pumps for Municipal and Industrial Use

SCAN TO LEARN MORE

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 9 NEWS www.grundfos.com/au

SCAN HERE

YARRA VALLEY WATER CROWNED VIC’S BEST TASTING TAP WATER

The Water Industry Operators Association (WIOA) has announced the Victorian winner of the 2024 Ixom Best Tasting Tap Water in Australia competition.

Yarra Valley Water took out the top prize over finalists Barwon Water, North East Water and Central Highlands Water at WIOA’s 85th Victorian Water Industry Operations Conference and Exhibition.

Competition judges included De.mem-Stevco Director, Steve Russell, Albury City Council Team Leader Treatment Services (Water and Wastewater), Heidi Josipovic, and IXOM representative Zarif Yazid.

The judges were in agreement that all the samples were of a very high standard across the three categories, odour, taste and clarity.

Yarra Valley Water will now go on to battle it out against the best from other states for the Australian title in November 2024.

The 2024 national competition will be hosted in Tasmania, after TasWater’s Fern Tree water treatment plant took out the Australian title in 2023.

Water samples are subjected to a blind taste test and rated according to the Water Tasting Wheel, which

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU INSTRUMENTATION & CALIBRATION PTY LTD SPECIALISTS AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field. www.ams-ic.com.au Flow Measurement Specialists www.ams-ic.com.au sales@ams-ic.com.au NEWS 10

outlines some of the attributes that water professionals use when judging water such as colour, clarity, odour and taste – think wine tasting without needing to spit out the samples and you won’t be far wrong.

The winner of the IXOM 2024 Best Tasting Tap Water in Australia competition will have the opportunity to represent Australia at the annual Berkeley Springs International Water Tasting Competition in West Virginia, US.

Pipe Penetration Seal Solutions

Link-Seals offer hundreds of solutions to seal pipe penetrations ranging in size from 10mm to 3.6 metres diameter.

Link-Seals are suitable for most types of pipes including PVC, HDPE, Copper and Steel.

Resistant to water, oil, gas, aggressive chemicals and fire.

Projex Group helps calculate the right Link-Seal size and model for your application.

Link-Seal

mail@projex.com.au

Link-Seal

1800 001 114 11 NEWS

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU

FED GOV INVESTING IN FIBRE INTERNET UPGRADES FOR NSW AND VIC HOUSEHOLDS

Two million households and businesses in New South Wales and Victoria will now be able to upgrade to fibre-to-the-premises (FTTP) internet from slower, less reliable copper connections.

The Federal Government said FTTP is capable of delivering speeds 18 times faster than the average broadband connection over copper, and is less likely to drop out or degrade.

The milestone means more people than ever before across both states will be able to access faster speeds while streaming, gaming and working from home.

Following NBN Co’s initial construction work, fibre upgrades are available on-demand at no installation cost when an eligible household or small business takes out an eligible higher-speed plan.

Average data usage in Australia has increased ten times over the past ten years, with the average home now hosting 21 internet-connected or smart devices.

NBN Co is currently consulting with industry on a new plan to turbocharge speeds available over the network. The plan

would give customers who upgrade to full-fibre speeds of up to 500Mbps, at no extra wholesale cost.

Upgrades to full fibre access will continue across the country, with the Federal Government investing $2.4 billion to expand full-fibre access to an additional 1.5 million premises, including more than 660,000 in regional communities.

Upgrades to the network are designed to enable more than ten million homes and businesses to access NBN Co’s fastest residential speed plan by the end of 2025.

Federal Minister for Communications, Michelle Rowland, said, “Fast and reliable full-fibre broadband unlocks greater social inclusion and economic productivity. It’s essential infrastructure in 2024.

“This is a fantastic milestone for two million households in New South Wales and Victoria who have been saddled with slow and unreliable copper technology.

“Access to this technology is a gamechanger for families who have had to struggle with drop outs and slow speeds over copper,” Ms Rowland said.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au | W: pezztrenchless.com.au Still the

up to

Used for gravity sewers, water mains, storm water, gas

electrical conduits. Specialists

all sizes The

NEWS 12

market leaders in laser guided microtunnelling Bore diameters from 325mm

2800mm

and

in “free bore”, sleeve boring and pipe jacking in

Next Generation in Trenchless Technology

Protect your critical assets with the most reliable systems made in Australia.

Century Yuasa has been protecting critical power assets for 30 years with our local design, construct and onsite teams. Our DC systems are built with the best of global technologies and supported with the globally recognised Yuasa VRLA batteries which are the only batteries you can genuinely rely on to protect your critical assets and business services year after year.

To learn more about Australia’s own DC power systems, maintenance services, and the Yuasa range of VRLA batteries, visit our website.

For enquiries call 1300 364 877 https://cyb.com.au/industries-markets/industrial

PROJECT ENERGYCONNECT RECEIVES LEADING SUSTAINABILITY RATING

The Infrastructure Sustainability Council (ISC) has awarded Transgrid’s EnergyConnect project a design sustainability rating of ‘leading’, in recognition of industry-leading initiatives in the design and delivery of the critical interconnector.

It is the first project to receive an official sustainability rating in Australia.

Transgrid Chief Executive Officer, Brett Redman, said, “Transgrid and our construction partner Elecnor Australia are going above and beyond to set the benchmark in sustainability best practice for the future pipeline of energy transmission projects across the country.”

Key sustainability measures being implemented on EnergyConnect include:

• A 35 per cent reduction in clearing on the western alignment (South Australian border to Buronga) and eleven per cent reduction on the eastern section (Buronga to Wagga) to preserve valuable biodiversity including trees up to 1,000 years old. Hundreds of thousands of trees have been physically inspected by arborists to assess their archaeological, ecological and cultural significance. Many trees, including Aboriginal scar trees, have been retained within the transmission line easement while still complying with vegetation clearance requirements. Annual inspections will ensure the lines stay clear to prevent bushfires

• Using guyed towers that require 21 per cent less steel and 15 per cent less concrete to construct compared to conventional self-supporting structures

14 UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU

NEWS Visit us online for more info toolkwippumps.com.au P: +61 3 8805 0500 E: sales@toolkwippumps.com Available in: NSW • VIC • QLD • SA • TAS ECO FRIENDLY PUMPING Pumping Solutions for the Utility Sector DEWATERING • SEWER BYPASS • BULK WATER SUPPLY S RANGE FEATURES + Auto-prime to 8.8m + Vortex impeller for superior solids handling + Run dry + Eco-friendly HYDRAULIC SUBMERSIBLE PUMPS HOSES & ACCESSORIES

• Locating transmission line structures to avoid valuable biodiversity and culturally sensitive sites.

• The use of low carbon concrete in tower footings and substations. Contractors are required to use concrete with 35 per cent supplementary cementitious materials (SCMs) and 30 per cent replacement of virgin fine aggregate with manufactured sand (where available).

• Replacing tree hollows with nestboxes to provide fauna habitat for local species, with more than 1,500 installed on the western alignment, and thousands more to follow on the eastern section.

• A 31 per cent reduction in construction water use by using non-water based dust suppression alternatives and grey water from worker accommodation camps.

• A 78 per cent replacement of potable water with non-potable sources including treated grey water from worker accommodation camps.

• Enduring benefits for local communities along the project alignment including the multi-million-dollar Legacy 100 program to train Australia’s own transmission line construction workforce and a $2 million scholarship fund for engineering students at Charles Sturt University.

• Reducing waste to landfill including recycling 400 tonnes of wooden pallets and 50,000 cans and bottles from worker accommodation camps.

• Comprehensive physical climate change risk assessments to safeguard the new infrastructure against the changing climate through the introduction of treatment and mitigation strategies in the design, construction and operation of EnergyConnect.

Elecnor Australia Operations Director, Samuel Basanta Lopez, said, “This is a significant project milestone that occurred across nearly all project disciplines and in collaboration with Transgrid. We are immensely proud of the result.

“As a Project Team we strive to maximise positive environmental, social and economic outcomes throughout all stages of our design and construction activities. We value sustainable development and believe respect for the environment and the community in which we operate are fundamental to business success.”

Infrastructure Sustainability Council Acting Chief Executive Officer, Patrick Hastings, said, “Congratulations to the EnergyConnect team and Transgrid on achieving a Leading IS Design Rating. Through this project they have demonstrated their commitment to sustainability by being the first to achieve a Design Rating on a transmission project. EnergyConnect is well-positioned to deliver an asset that will provide a positive ecological benefit while also minimising its contribution to GHG emissions. This is a monumental step for transmission projects and an encouraging sign of progression in the sector.”

15 NEWS UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU

NT TO RECEIVE $53.1M OF WATER SUPPLY PROJECTS

In an effort to shore up water security for remote communities in the Northern Territory, the Federal and Territory Governments are investing $53.1 million in the development of a number of water supply projects.

In Maningrida, the two governments are investing $21 million for three infrastructure upgrades to increase the reliability of the local water supply network. This work will increase water storage capacity via the construction of a water tank, new pipes to move the water from the water storage to the community and upgrades to the water network.

On the Gove Peninsula $8.9 million is being invested which will upgrade a water pipeline in Yirrkala – to save water that is currently being lost –and includes a water infrastructure assessment for Gunyangara to identify water infrastructure needs.

In Numbulwar the governments are investing $3.2 million in planning and investigation work, such as investigative drilling, to identify new water supplies.

The Federal Government has said that these projects are an important step in its $150 million investment to make sure remote First Nations communities have access to clean drinking water.

It follows the $26.7 million funding previously announced for Yuendumu and Milingimbi, where work on these projects has also created numerous economic and community benefits including the ability to build much-needed new housing.

The governments have also said that reliable water is vital for tourism and economic development, which is why in Yulara they are together investing $18.2 million, along with $5 million from Voyages Indigenous Tourism Australia, to construct the Yulara Water Supply project.

The project will provide water security for what is the primary service centre for the Uluru-Kata Tjuta National Park and the wider Ngaanyatjarra Pitjantjatjara Yankunytjatjara regions.

The Federal Government is also investing $1.8 million towards science and research projects to help plan for future water management.

16 UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU NEWS

The PL1500 is a gamechanger for pipeline construction. The unique, quick-hitch, vacuum lifter attaches to your existing excavator, reducing your machine hire cost and getting things moving fast. Capable of safely lifting 15,000kg, the heavy-duty, self-contained unit can handle all types and lengths of pipe. It integrates seamlessly with the host excavator, using the main controls and hydraulics to operate the vacuum lifter. Plus, built-in smart tech ensures it’ll only pick up or put down a pipe on a solid surface. That’s safer than many other vacuum lifters on the market. To find out more, speak to the Pipeline Plant Hire team today.

ONE CALL - PROBLEM SOLVED 1300 367 046 PIPELINEPLANTHIRE.COM.AU

PIPELINE DRILLERS

With over two decades of expertise in trenchless technology, our proudly Australian-owned company has grown from strength to strength. Boasting 11 cutting-edge directional drilling rigs, 2 pneumatic pipe rammers and a skilled team of over 40, we’re your go-to for HDD projects of any scale.

795 HDD Pipelines Installed 2033m Longest HDD Installed 100-2050m Bore Lengths 25-1500mm Hole Diameters

450-1520mm Steel Casing Ramming 10 Ocean Outfalls Installed

UNEARTHING EXCELLENCE

sales@pdgroup.com.au www.pdgroup.com.au 07 3390 4740

YOUR TRUSTED VEGETATION EXPERTS! YOUR TRUSTED VEGETATION EXPERTS!

Vegetation Management (power line, gas pipeline, land and easement clearance)

Tree Lopping and Weed Control

Environmental Services

Mulching Machine and Equipment Hire

P | 07 3288 8800 W | www.savco.com.au E | info@savco.com.au

SAVCO SAVCO SERVICES SERVICES

ACCELERATING

THE DELIVERY PATH FOR RENEWABLE ENERGY ZONES

By Terry Chapman, APA General Manager, Project Delivery

By Terry Chapman, APA General Manager, Project Delivery

The development of renewable energy infrastructure alone is an enormous task, made all the more challenging by labour and supply chain shortages, planning delays and community pushback. Here, APA General Manager, Terry Chapman, shares some insight into how governments can tackle these challenges and fasttrack the delivery of renewable energy zones.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 20

INDUSTRY INSIGHTS

The withdrawal of coal from our energy system and the concurrent build-out of renewable energy zones (REZs) across the country is a monumental undertaking.

Australia currently generates approximately 35 per cent of its power from renewables and this journey has taken the best part of two decades.

If the Federal Government is to meet its target of 82 per cent renewables by 2030, we need to deliver in six years more than one and a half times what has been delivered in the last 20.

And we are facing this challenge against a backdrop of significant global competition for skilled labour and critical minerals, along with rising costs, environmental concerns, planning delays and increased community focus on the impacts of these major projects.

As a proudly Australian-owned and listed energy infrastructure business, APA sees several opportunities for governments to address these issues and accelerate the delivery of infrastructure for REZs.

STREAMLINING PROJECT APPROVAL

First, the process of selecting a preferred consortium to deliver these projects could be simplified. The rising cost of capital and a tight domestic employment market means governments can’t afford to have multiple organisations tied up in a tender process for up to 12 months before work commences.

At present, there is more work to do than resources to deliver it. While commercial processes need to remain transparent and competitive, contractual frameworks need to pivot to address current market constraints and to ensure projects can move to delivery sooner.

UPSKILLING THE WORKFORCE

Second, we must continue to build technical skills and capabilities in the domestic market.

Australia is currently in deficit when it comes to the skilled labour capacity required to deliver high voltage substation and transmission line projects at the scale required. And these challenges are more acute given skills and resources will be needed in regional areas. Upskilling the existing workforce from adjacent infrastructure projects is one opportunity. We must also accelerate investment in apprenticeship programs to develop a pipeline of the right trades.

Federal Skills Minister Brendan O’Connor recently noted the slow uptake of spaces in the New Energy Apprenticeships Program launched in 2023. The Federal Government needs to balance attracting more young Australians into the energy sector with the opportunity for skilled migration to help us fill the gaps.

Global partnerships also have a role to play. International know-how and best practice needs to be linked with Australian organisations to deliver this huge program of work.

For example, APA has partnered with leading global energy infrastructure organisation EDF Group to leverage their leading global experience in electricity transmission infrastructure delivery with APA’s strong local experience in the construction and operation of critical energy infrastructure. This will ensure we are well positioned to deliver emerging projects in what is a highly competitive environment.

BUILDING AN EXTENSIVE SUPPLY CHAIN NETWORK

Third, we must look to our past to help secure our future. New South Wales, Victoria and Queensland have all delivered major transport and infrastructure projects over the last decade that have created a valuable skills legacy and extensive supply chain network.

I was proud to be the Project Director of Australia’s largest ever road infrastructure project – the recently completed WestConnex in New South Wales.

The scale and complexity of WestConnex has accelerated the experience of a large cohort of contract administrators, commercial analysts, planners and community engagement specialists. The project has also built significant expertise in engineering and design, construction management, commissioning and operation along with skills in critical trades.

We must now move quickly to attract these people to the energy sector, with many of the skills needed for electricity transmission projects being transferrable.

We must also leverage the learnings around community engagement from these mega transport projects. While the infrastructure might be different, the reality is the issues faced are much the same.

The significant landholder and community opposition to REZs is not unlike that faced during the delivery of WestConnex. It wasn’t so long ago that this project was subject to community protests and local councils preventing road access and refusing to grant construction permits.

But with a clear process for engagement and ongoing efforts to listen and build community trust, the infrastructure was delivered responsibly.

At APA, as we consider future REZ projects, we are already thinking about how we can best engage with the community, how we can minimise impact, and importantly, what legacy we can leave.

Governments and successful consortia must clearly communicate these short and long-term benefits. Employment and skills development, investment in regional businesses, positive engagement with communities are just some examples.

That's not to say these challenges will be easy to overcome. However, thinking innovatively and leveraging the significant knowledge and expertise across the infrastructure sector will give us a great chance of meeting our renewable energy targets.

21 UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU

INDUSTRY INSIGHTS

OF LONG-TERM, TANK BASE CORROSION PROTECTION The Next Generation

If left untreated tank base corrosion is a serious risk that will compromise the integrity of water storage systems, resulting in leaks, contamination and structure failure. Here, Denso Australia discusses the importance of implementing long-term corrosion prevention solutions, and answers some questions about its innovative visco-elastic coating system.

Since the beginning of 2024, the team at Denso Australia have been hard at work training applicators nationwide on the ins and outs of its latest innovation – the Viscotaq™ Tank Chime Sealing System.

Here, the team have compiled the questions most commonly raised at these training sessions and shared some insights into what the system offers, how it can be applied and how long users can expect the corrosion protection to last.

WHY IS TANK BASE/CHIME CORROSION PROTECTION AN IMPORTANT CONSIDERATION?

Water industry decision-makers understand that the repercussions of neglecting tank base corrosion are farreaching. Compromised tank integrity can lead to issues including contamination, leaks, and eventual structural failures – all of these outcomes are usually both costly and hazardous.

As such, long-term corrosion prevention solutions are not merely beneficial, they’re essential for ensuring the safe and reliable operation of water storage systems as well as for safeguarding the environment from potential contamination.

Denso’s Viscotaq™ Tank Chime Sealing System has been designed to combat the issues listed above by preventing water infiltration at the concrete ring wall interface of a tank; the area of a tank where corrosion is most likely to occur.

WHAT IS VISCOTAQ™?

Viscotaq™ are Denso Australia’s next generation of truly surface tolerant, visco-elastic coating systems which can be applied to pipelines (straight run pipe, t-sections, field joints, soil to air transitions), structural steel and tank bases/chimes.

WHAT ARE THE COMPONENTS OF THIS NEXT GENERATION SYSTEM?

The Viscotaq Tank Chime Sealing System consists of a suitable concrete coating, the use of a sealant, a mastic, a visco-elastic coating system and a UV topcoat. We’ve summarised each component below:

1. Concrete Coating

A Denso-approved coating such as Protal™ ST Epoxy or SeaShield™ 550 Epoxy to ensure a sound substrate for the other system components to adhere to.

2. Sealant

In cases where an annulus or void between the annular ring and the tank base exceeds 0.5 inches, Viscotaq ViscoSealant is used to fill these gaps, ensuring a uniform and secure base for the sealing system.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 22

INDUSTRY INSIGHTS | Sponsored editorial

3. Mastic

Viscotaq ViscoMastic is used both in instances where the sealant is required and also when it is not required. ViscoMastic is used to seal all voids, gaps, and cracks between the base of the tank and the ring wall.

4. Visco-elastic coating system

Viscotaq EZ Wrap is applied over the mastic. This wrap is designed with a paintable backing to assist with the application of the topcoat.

5. UV Topcoat

A Denso approved topcoat is used to paint over the Viscotaq™ EZ Wrap (which has a paintable backing) to add strength to the system and prevent any breakdown due to possible UV rays.

A VISCOTAQ PEEL TEST REVEALING 100 PER CENT ADHESION OF THE MATERIAL TO THE SUBSTRATE AND CORRECT SURFACE PREPARATION.

WHAT ABOUT SURFACE PREPARATION?

The minimal surface preparation required for the system is St2/SP2. Applicators are required to remove all oil, grease and other contaminants from the surface of the substrate using an approved solvent. Following this, the use of a wire brush is required. It is essential for the surface of the substrate to be dry and free from rust, scale and other foreign matter. In order to evaluate the effectiveness of your surface preparation, you’ll need to conduct a ‘peel test’, a process that the Denso team covers in its training sessions.

WHAT IS THE EXPECTED SERVICE LIFE OF THIS SYSTEM?

As is the case with all applications, a system’s service life is reliant on the quality of the materials applied and the way in which they have been applied. For this reason, Denso ensures that its applicators are highly trained and have an intimate understanding of the system before going on site. If applied correctly, Viscotaq systems should have a service life exceeding 20 years. This figure is based on many Viscotaq applications from around the world that have been applied more than 20 years ago and are still in excellent condition.

HOW CAN I BOOK TRAINING AND LEARN MORE?

To request a training session, please contact National Viscotaq™ Manager, Adam Matthews at adam@densoaustralia.com.au or call +61 458 837 300.

To view and download all current literature on the Viscotaq Tank Chime Sealing System, please visit: densoaustralia.com.au/products/viscotaq-tank-chime-sealing-system/

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 23 Sponsored editorial | INDUSTRY INSIGHTS

SECURING A SUSTAINABLE WATER FUTURE

As climate change and population growth continue to put drinking water supplies under pressure, water utilities are exploring all options to ensure a secure and diverse water supply for generations to come.

In South East Queensland, the population is expected to grow by two million people over the next 25 years. Ensuring a plentiful, safe, reliable, affordable and sustainable water future for the communities in our service region is a big job – and one that will require multiple solutions.

Non-potable recycled water is one such solution. By increasing our use of recycled water for industry, agriculture and irrigation, we’re easing pressure on our drinking water supplies and reducing nutrients to waterways. Using recycled water can also help lower an organisation’s carbon footprint and achieve ESG objectives.

HOW RECYCLED WATER WORKS

Recycled water means turning wastewater into a non-potable but usable water product. This water can be used for irrigation, cooling or other uses that don’t involve consumption or contact.

Existing wastewater treatment plants can be upgraded to create recycled water. Plants that can create recycled water are known as Resource Recovery Centres (not to be confused with plants that can create Purified Recycled Water which is suitable for drinking – those are known as Advanced Water Treatment Plants).

The process follows on from traditional wastewater treatment, which takes influent flow (the undiluted wastewater that flows to the treatment plant for processing) and processes it into effluent, which is normally released safely back to the environment. Resource recovery centres turn this effluent into recycled water via treatment, and export it to customers via a dedicated network of pipes.

HOW RECYCLED WATER IS USED

Here’s a look at how much recycled water is produced at Resource Recovery Centres across Urban Utilities’ service regions of Brisbane, Ipswich, Lockyer Valley, Scenic Rim and Somerset.

FY22

• 8,877ML of recycled water (RW) was produced from 149,223ML of effluent, indicating that 5.94 per cent of the effluent was utilised as recycled water

FY23

• 10,443ML of RW was produced from 116,415ML of effluent, indicating that 8.97 per cent of the effluent was supplied as recycled water

• Out of 10,443ML, 35 per cent of RW was supplied for industrial purposes, 44.7 per cent was used for irrigating sporting fields and parks, and 19.6 per cent was used for agriculture and 0.7 per cent was used onsite for irrigation or other purposes

1ST JULY TO 31ST DECEMBER 2023

• 56,472ML of effluent was produced from 60,630ML of influent, out of which 3,856ML of RW was exported and supplied to various customers

• 31 per cent of RW was used for industrial purposes, 9 per cent was utilised for institutional purposes, and 41 per cent was used for irrigating parks and gardens. 0.8 per cent was used for site irrigation and other purposes

WHO IS USING RECYCLED WATER?

Recycled water can meet all kinds of industry, agriculture and irrigation needs.

For example, Urban Utilities supplies recycled water to the Kilcoy Race Club to keep the track lush and green all year-round, no matter the rainfall.

The utility is also using recycled water for its own environmental initiatives. Urban Utilities has planted 1,600 native trees at the Helidon Wastewater Treatment Plant to create a new local koala habitat. The blue gum plantation is irrigated with recycled water.

At the Toogoolawah and Boonah Wastewater Treatment Plants, the utility is growing five hectares of vetiver grass and irrigating it with recycled water. The grass is regularly harvested and donated to farmers for use as livestock fodder.

Urban Utilities has also supplied recycled water to Brisbane Airport Corporation to support the construction of Brisbane’s new runway, saving more than 500 Olympic-sized swimming pools of drinking water.

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 24

INDUSTRY INSIGHTS | Sponsored editorial

For more information on recycled water in South East Queensland, visit urbanutilities.com.au/business/business-services/recycled-water

ULTRA STRONG. FAST. VERSATILE.

A VERMEER EXCLUSIVE. CHANGING THE DRILLING GAME FOREVER.

The Ultra X3 drilling system is designed for utility-sized rigs (up to 40,000-lb) digging in most ground conditions. Equipped with a unique, non-torqued spline connection system, it offers compatibility with a wide range of pilot bit and pullback configurations. This enhances the operator’s ability to move from one drill to another and maintain familiarity with the HDD tooling, and eliminates the need for starter rods and adapters in select applications. Contact your local HDD specialists today.

VERMEERAUSTRALIA.COM.AU | 1300 VERMEER Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. Product specifications are subject to change by OEM. © 2024 RDO Equipment Pty Ltd (trading as Vermeer Australia). All Rights Reserved.

JEMENA’S NEW MANAGING DIRECTOR PREPARING OUR NETWORK FOR THE FUTURE:

Appointed Managing Director of Jemena in late 2023, after 17 years with the business, David Gillespie’s wealth of leadership experience and long history in the industry made him an obvious choice for the role. He sat down with Utility Magazine to discuss the challenges currently facing the sector and the work that Jemena is undertaking to tackle them.

Jemena owns and operates a large and diverse portfolio of energy assets including gas and electricity distribution networks, gas transmission pipelines and gas processing facilities across the eastern coast of Australia and is responsible for connecting millions of homes and businesses to electricity and gas every day.

For almost two decades David Gillespie has been with the business in various roles, starting in finance and moving up to the Chief Financial Officer position before December 2023. Prior to joining the team at Jemena, Mr Gillespie worked for Alinta Energy – which later became Jemena and Deloitte.

“I have been in the role a little over nine months now; it has been a busy start to the year and I don’t think it’s going to slow down,” Mr Gillespie said.

“The culture at Jemena is a great one, and I plan to continue and build on that culture to ensure our people are supported in the work they need to achieve.

“Leadership is just that: leading. And you need a team to do that. COVID definitely taught us that as executives and people in leadership roles, we need to step out from behind the desk and that people have families and homes and things important outside of

work and you can’t just put a wall up and say, this is work and this is home.

“We’ve fostered a great culture of supporting our people to lead meaningful lives professionally and personally, and this has not been by accident; I’m very proud of the work we’ve done to set up a framework that encourages all of our people to come to work as their authentic selves.”

DELIVERING A SAFE, AFFORDABLE AND RELIABLE TRANSITION

The transition to renewables is undoubtedly a hot topic in every corner of the industry, and while having the right conversations is a pivotal part of ensuring the success of this transition, the next and most important step is turning those plans into actions.

“The biggest challenge facing the industry is the transition. Anyone who is in the industry or adjacent to it knows that delivering on our net zero targets and decarbonising our energy system is the thing on everyone’s lips,” Mr Gillespie said.

“We’ve spent quite a few years, a decade really, talking about the problem. Now we are well and truly on the road to putting those discussions into actions. It's incredibly important work, but what we also need to ensure, particularly as a distributor,

is how do we deliver that transition safely, reliably, and at the least cost to the customer. And that’s where the challenge is.

“Jemena is certainly on that journey, along with the rest of the energy industry. In some ways, we are leading that journey. From the installation of community batteries across the network, to ensuring consumer energy resources (CER) such as electric vehicles (EVs) and solar panels are plugged into the grid in a safe and reliable way to finding new and innovative partnerships with other industries to ensure we are all on the same pathway and helping one another achieve net zero.”

To that aim, Mr Gillespie explains that the introduction of EVs is a major focus for Jemena.

“In the electricity system EVs and the introduction of them on our roads is a big focus at Jemena. As they become more commonplace and more families are drawing off the grid to power their cars, Jemena needs to ensure we have

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 26

INDUSTRY INSIGHTS

enough energy in the system for when it’s needed.

“We spent a lot of last year engaged in trials that helped us better understand how people use their EVs. This year we’ll be focused on working with governments to ensure that we have the right policy settings in place and the flexible services available to ensure people can charge their cars when they need to.

“EVs are just one piece of the puzzle and we are also exploring things like Community Batteries, and taking steps to ensure our network can handle increases in things like rooftop solar. At the same time, we need to ensure that our customers are at the heart of all of these changes, that their needs, preferences, and vision for the future inform the work we do. To this end, we will continue to spend a lot of time engaging with and listening to our customers – particularly as we start developing our future pricing and services plans,” Mr Gillespie said.

FORGING AHEAD WITH RENEWABLE GAS

Decarbonising the grid and reducing carbon emissions are also key focuses for Jemena when it comes to meeting net zero goals. Investment in renewable gas is pivotal to achieving these targets, and Mr Gillespie is proud to share that Jemena is leading the way in this area, particularly in biomethane production.

“The Malabar Biomethane Injection Plant is co-located next to Sydney Water's Malabar Water Resource Recovery Facility. Jemena has partnered with Sydney Water to create basically a circular economy where biogas is produced from organic waste at the Resource Recovery Facility and turned into biomethane.

“At the facility, about 95TJ of energy is produced annually which is the equivalent of 6,300 household’s yearly energy needs. By repurposing waste that otherwise would end up being emitted into the atmosphere, we can create a product which can be used in the same way natural gas currently is.

“In addition, participating in Channel 10’s MasterChef has been a real opportunity to demonstrate how renewable gas, in particular that

biomethane can be used in a very practical and tangible way.

“It’s been a great undertaking between the entire industry, including AGIG, TasGas, ATCO, the team at the Malabar site who had to get the biomethane to Melbourne. It was a real group effort. And as a result, biomethane that has come from the Malabar Biomethene Plant is being used in the MasterChef Kitchen. This means viewers at home can see that renewable gas is here, it’s ready and it looks and works just like natural gas,” Mr Gillespie said.

WHAT’S IN THE PIPELINE FOR JEMENA?

Gas shortfall is also a pressing issue for all utilities and their communities, and Victoria has been flagged as particularly high risk for shortages in the near future.

“Last month we announced the reversal of the Eastern Gas Pipeline, which could see up to 300TJ/d of gas being sent south from New South Wales into Victoria. Given forecast gas shortages in Victoria, this is an innovative solution designed to ensure customers in Victoria have access to natural gas during winter when they really need it,” Mr Gillespie said

“We will also be finalising our pricing and services plans for our electricity and gas distribution networks in Victoria and New South Wales respectively, before submitting the plans to the Australian Energy Regulator (AER) for review and endorsement.

“We’ve spent the best part of 18 months developing the plans in consultation with our customers across our electricity and gas networks. Their feedback has proven crucial in shaping things like how much we invest in new energy services, such as renewable

gas, as well as how we best navigate the transition while keeping energy affordable and reliable.”

On the electricity front, Mr Gillespie explains that Jemena is continuing to prepare its network for the future, noting that the way in which customers use the electricity grid is continuing to evolve.

“For our residential customers this means ensuring we’re prepared for things like an increase in rooftop solar installations and greater uptake of EVs. For our large customers this means working collaboratively to ensure we’re designing bespoke solutions that meet their needs,” Mr Gillespie said.

“As a case in point, we’re working with a number of data centres who can, in some instances, use as much electricity as a small town. Data centres are a crucial part of modern life and contain the physical infrastructure which make things like the internet, AI, cloud computing and a host of other applications possible.

“For these customers we are continuing to develop solutions that make available not only the large amount of energy they need, but do it in a way that ensures they can be confident it will be there when needed, and that the system is reliable.

“While it certainly is a challenging time for our sector, I’m really excited by the once in a lifetime opportunities the energy transition presents. The transition demands that we work collaboratively towards a shared goal for the benefit of current and future generations – something we can all be proud of,” Mr Gillespie said.

“I look forward to meeting new people over the year and reconnecting with long-standing colleagues and friends!”

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 27

INDUSTRY INSIGHTS

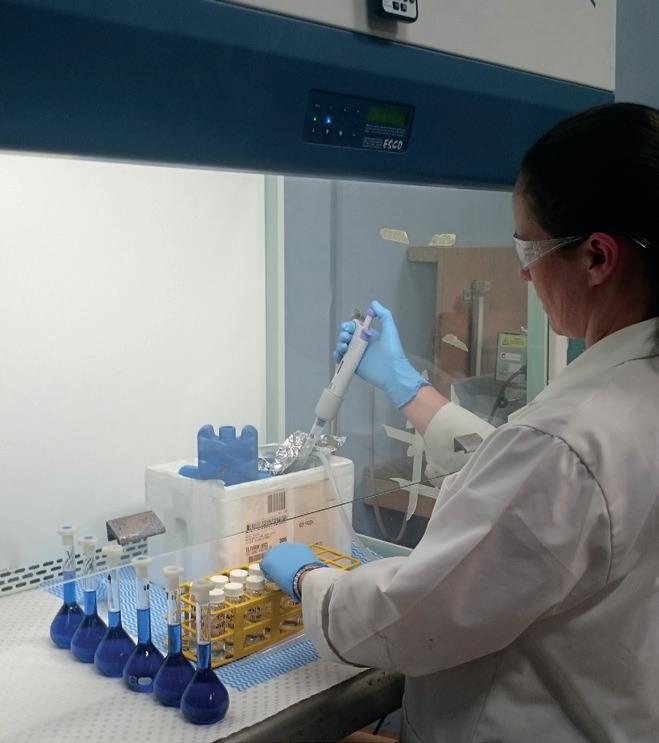

REVOLUTIONISING BIOCHAR PRODUCTION

WITH NEW PYROLYSIS TECHNOLOGY

South East Water’s Research and Development team works to identify emerging trends and technologies to help solve problems presented by wastewater management and treatment, particularly in relation to sustainability and the circular economy. In this interest, South East Water has partnered with engineers from RMIT University and Manipal University, India, to trial pyrolysis, a groundbreaking technology that revolutionises how the biosolids produced through wastewater treatment be reused and recycled.

Wastewater offers huge potential for renewable initiatives. With Australians producing over 300,000t of wastewater every year, there is no shortage of material to work with. Treated wastewater produces two materials: treated water and biosolids. Treated water is reused and recycled in a number of ways – but reusing biosolids is a more difficult task.

A pioneering technology, pyrolysis, opens up a whole new world of uses for biosolids by turning the material into biochar. Biochar is a solid carbonaceous material of organic feedstock, which contains stable and porous structures, and possesses desirable physicochemical and morphological attributes for many applications.

INTRODUCING PYROCO

RMIT University Professor and Group Leader for Innovative Resource and Waste Conversion Technologies, Kalpit Shah, has developed a specific pyrolysis technique, called PYROCO, which uses a process called fluidised bed pyrolysis. Fluidised bed pyrolysis heats biosolids to a high temperature (approximately 500–700°C), keeping the temperature stable to ensure high quality product. Fluidised bed pyrolysis can be used for sustainable and cost-effective upcycling of contaminated wastes, with a reactor used to convert biosolids to biochar.

Professor Shah explained that, “PYROCO is a first-of-itskind fluidised bed pyrolysis technology that can be used for

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 28 ACCELERATING ACTION

sustainable upcycling of waste into energy and high-value products. PYROCO is essentially a fluidised bed heat exchanger device that significantly improves heat and mass transfer in the process, resulting in huge savings in capital and operating costs as well as generating the highest quality biochar product.

“We believe that PYROCO can achieve the high throughput per unit cost compared to other technologies. Unlike other technologies such as auger or rotary kiln-based systems, PYROCO (a fluidised bed heat exchanger) is simply made up of tubes and pipes, which is far easier to fabricate and maintain. Also, unlike other technologies, PYROCO has minimal moving parts and, therefore should achieve the high plant availability. PYROCO’s innovative process design also offers flexibility to deal with feedstocks with varied quality, where other technologies will struggle,” Professor Shah said.

TRIALLING THE TECHNOLOGY

The fluidised bed pyrolysis technique is currently being trialled by South East Water, Intelligent Water Networks and Greater Western Water at the Melton Recycled Water Plant.

South East Water Research, Development and Innovation Manager, David Bergmann, said, “The key is in the absence of oxygen. You take whatever you started with, and you turn it largely into forms of carbon. And it turns out carbon actually has a lot of uses. If we can take that from a waste product that otherwise has no value, then that's a great outcome.”

The circularity concept is to keep valuable nutrients in biosolids – such as carbon, nitrogen and phosphorous for reuse in applications such as agriculture, construction, energy, batteries etc.

For South East Water, the potential benefits are significant. Mr Bergmann explained that, “The volume reduction for

us, distribution cost reduction, creating material of value, destruction of contaminants are the core benefits for us. We believe this technology is going to be able to make that conversion with lower carbon emissions, lower greenhouse gas emissions, than our traditional processes would. So it's going to help us achieve our greenhouse gas emissions targets as well.

“Further to that is carbon in its most basic form, so effectively, it's inert. It can no longer have any greenhouse gas emissions, so by then using it in agriculture or construction, we are locking it down. We're taking it out of that carbon emission cycle. And so that's a great thing for our climate targets that we're all trying to achieve,” Mr Bergmann said.

Mr Bergmann believes one of the key factors to increasing uptake of this technology in water utilities is changing the way we see wastewater treatment facilities.

“We really need to start seeing our water recycling plants, not as waste processing facilities but as manufacturing facilities. A facility that manufactures, yes, water, but also a quality sludge or biosolids product that we then convert into a quality carbon product. It's a manufacturing production plant that produces consistent materials for an end user that can put it into batteries, electronics and other high end applications.

“That's quite a shift in how we're running. When you're running a waste treatment plant, it's about focussing on volume throughput. When you run a factory for carbon, it needs to be an optimised operation focussed on tight end user specification and requirements, it's a mindset change, and you're thinking about producing good quality products at the end of the day. I think that's the shift that we need actually in the way we run our operations and our treatment plants.”

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 29 ACCELERATING ACTION

Working together FOR BETTER DRINKING WATER IN THE BUSH

The Goyder Institute for Water Research has released a comprehensive report outlining the outcomes of the national Working together for better drinking water in the bush forum, which brought together diverse participants from across Australia – from First Nations groups to utility companies – to discuss the issues restricting drinking water supply in remote regions. Here, we take a look at the 12 key action areas identified by the forum that are expected to support the development of better water quality for Australia’s remote communities.

The collaborative Working together for better drinking water in the bush forum, held in Mparntwe (Alice Springs) from 27–29 June 2023, highlighted the significance of working together to support safe and reliable access to drinking water for remote First Nations communities. A key aim of the forum was to prioritise First Nations voices to ensure that they are incorporated in decision making going forward.

The forum was delivered in partnership with the Federal Government through the Department of Climate Change, Energy, the Environment and Water (DCCEEW) and Desert Knowledge Australia (DKA), and brought together representatives from South Australia, the Northern Territory, Queensland and Western Australia – including First Nations community members, state and territory water utilities, state and territory policy makers, land councils, health regulators, and service providers, as well as national, state and territory, and local government agencies.

The forum gathered knowledge through workshops encouraging small group interactions of attendees merging different backgrounds, individual informal interviews, and one-on-one sharing. The goal was to capture the challenges currently halting progress and the enabling actions required to achieve resolutions and ultimately to determine key items which should be prioritised to address better drinking water in the bush.

Consensus was achieved on many challenges that need to be addressed, along with a list of 12 key focus items for action, which, if implemented in combination, could assist in delivering better water quality for the bush communities.

THE KEY FOCUS ITEMS

PRIORITISED:

• Resolution of social challenges such as trust and empowerment

• Engagement in truly integrated partnership

• Governance, including a focus on self-determination for sustainability and building respect

• Education to build skills and capacities of local communities

• Methods for information sharing to overcome perceived silos associated with multiple levels of government and challenges of remoteness from metropolitan centres

The outcomes of the forum were presented in a report for consideration as areas for immediate and future action. While leadership to address various responses for each key action item is suggested, all of the key focus items are cross-jurisdictional in nature, and a shared, multi-jurisdictional approach to these items will create opportunity for partnership, cost sharing, knowledge sharing and collaborative action.

THE

12 KEY ACTION AREAS

The report outlines 12 key items for action which were identified

by extracting and matching up themes that arose throughout the forum’s workshops.

Attendees were also asked to indicate whether they felt each of the 12 items were important and/or urgent. Attendees were almost unanimous in determining that each of the 12 key items were important and many of the items were seen as both important and urgent.

The areas for action are:

National principles on safe drinking water

Setting national principles on safe drinking water for remote communities including to prioritise drinking water and source protection, and incorporating cultural knowledge, Indigenous-led and localised community engagement.

Prioritising health

Addressing national health targets through better understanding of water quantity and quality issues.

Local First Nations water authority with First Nations voices

Creating a localised First Nations water authority which includes First Nations voices and provides expertise on water in remote communities.

Community education

Community education through a coordinated education program to empower the whole community to understand their own water supply

UTILITY • MAY 2024 WWW.UTILITYMAGAZINE.COM.AU 30

ACCELERATING ACTION

delivered through schools and community engagement processes.

Guidance on appropriate technology

An option list of water treatment systems that includes information about the systems’ suitability or reliability as an approach to de-risk the choice of technologies for communities.

Community water rangers

Indigenous-led program for local community water rangers that act as the connection between governing agencies, utilities and the community.

Joined up planning approach to water

Working together to integrate planning for water supply across all services such as health, housing and energy.

National standards for water security

National standards for water security infrastructure and levels of service including water quality, quantity and supply.

Data dashboard

A national data platform, with understandable, easily accessible, and up-to-date water quality information presented in culturally appropriate formats.

National commitment to action (national action plan)

A national commitment to ongoing action on water issues in remote communities and homelands incorporating all states and territories.

Community workforce

The building of a community workforce to support operation and maintenance of water infrastructure in the community.

Community of practice

A collective of water professionals, both industry and government, with input from water rangers, to share information and knowledge on a regular basis.

CHALLENGES PREVENTING IMPROVED WATER QUALITY

The forum also identified nine areas that presented major challenges to efforts to improve water quality, which were examined to determine solutions and to identify which of the key action areas might assist in resolving the challenges.

The challenge areas and their associated key actions are:

Truth-telling

The notion of ‘truth-telling’ as encompassing challenges around sharing of knowledge and information, specifically localised data, communication, transparency and developing trust and respect was strongly advocated by all attendees, in particular the First Nations community members.

Attendees of the forum said that currently there is no two-way sharing of information with the community.

“Communities can see the water is being sampled but they don’t get the results – but they could jointly solve the problems.”

One attendee said that all stakeholders need to be on the same

page regarding water knowledge and data.

“Communities would like to get information through meetings and a traffic light system online showing water quality and availability information.”

Governance

Areas of challenge for governance identified in the forum included responsibility, accountability, complexity, transparency and lack of consistency across jurisdictions.

Attendees agreed that there needs to be one body that takes responsibility for water quality and is the point of contact for communities.

“Long-term strategic planning is required – including support for programs rather than projects – and providing adequate time to complete, e.g. six to eight years rather than two to three years.”

Education, training and skills development for employment in communities

The challenges of employment, skills, education and training for water management were identified under headings concerning: the need for regular, ongoing employment of water resource management staff in remote areas, skills, and education and training.

Discussion was also had on the enabling opportunities for broader economic uplift of employing locals in the community.

The attendees identified four prioritised actions which would assist in resolving the challenges of education, training and employment by employing local community members.

31

ACCELERATING ACTION

Infrastructure

Challenges around the ongoing reliable provision of water infrastructure in remote communities, which require complex interactions between physical resources, institutions and endusers, often across governance and cultural boundaries.

The complexity of resolving infrastructure challenges was seen in attendees’ responses to key actions for prioritisation. Aspects of infrastructural challenge were identified as maintenance, ownership, replacement of assets, reliance on band-aid solutions, funding capital as well as operational expenditure and identifying appropriate technologies which were fit-for-purpose in the local environment.

Planning

Challenges in planning for safe drinking water covered lack of integration, lack of engagement, funding allocations and an emphasis on ‘short-term’ solutions.

Attendees found that, currently, there is a lack of integrated planning – especially long term planning – and