SUPPLY CHAIN GOES TO THE BOARDROOM

Prological MD Peter Jones on why supply chain is now mission critical

Körber’s Darren O’Connor explains Hangcha teams up with Coates for materials handling hire success DYNAMIC DUO WHY ADAPTABLE SOFTWARE IS CRUCIAL

MAY 2024

COVER STORY

Elevate APAC

Hosted at the Hilton Sydney on May 7-8 2024, Elevate APAC will feature supply chain transformation insights from leading businesses, a showcase of our leading supply chain solutions, and keynotes from HSBC Chief Economist Paul Bloxham and Australian icon Jessica Watson. Plus an exclusive networking event on a private vessel that will chart its course around the stunning Sydney Harbour.

Use code ELEVATE50 for 50% off your ticket

It’s time to secure your spot at

koerber-supplychain.com

Supply Chain Solutions

CONTACT

MHD Supply Chain Solutions is published by Prime Creative Media

379 Docklands Drive, Docklands VIC 3008

Telephone: (+61) 03 9690 8766

Website: www.primecreative.com.au

THE TEAM

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Edward Cranswick

Journalist: Joseph Misuraca

Business Development Manager: William Jenkin

Design Production Manager: Michelle Weston

Art Director: Blake Storey

Graphic Designers: Bea Barthelson, Kerry Pert

Client Success Manager: Janine Clements

FOR ADVERTISING OPTIONS

Contact: William Jenkin william.jenkin@primecreative.com.au

SUBSCRIBE

Australian Subscription Rates (inc GST) 1yr (6 issues) for $78.00 2yrs (12 issues) for $120.00 – Saving 20% 3yrs (18 issues) for $157.50 – Saving 30%

To subscribe and to view other overseas rates visit: www.mhdsupplychain.com.au or Email: subscriptions@primecreative.com.au

ACKNOWLEDGEMENT

MHD Supply Chain Solutions magazine is recognised by the Australian Supply Chain Institute, the Chartered Institute of Logistics and Transport Australia, the Supply Chain and Logistics Association of Australia and the Singapore Logistics and Supply Chain Management Society.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

MHD magazine is owned by Prime Creative Media. All material in MHD is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in MHD are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

STEPPING UP SUPPLY CHAIN

Welcome to the May issue of MHD Supply Chain Solutions we are proud to present an array of insightful articles that tap into the pulse of industry trends and strategic advancements.

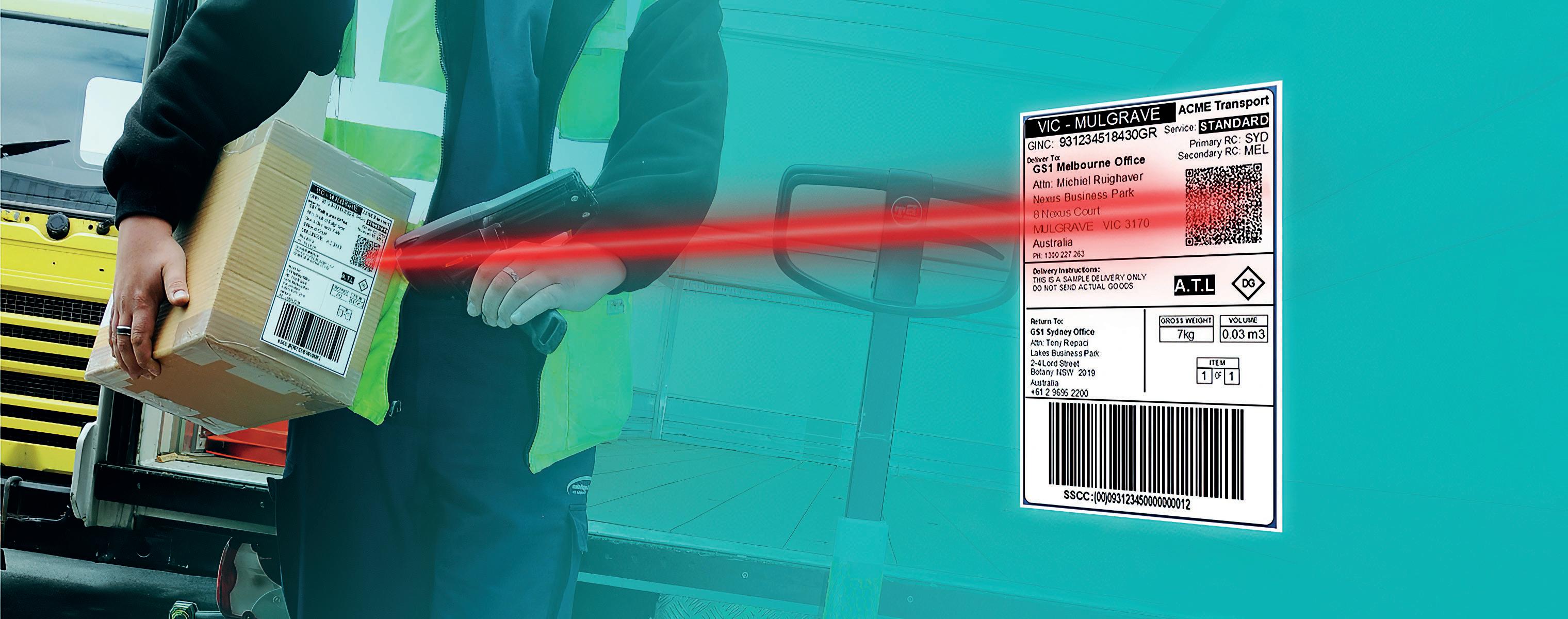

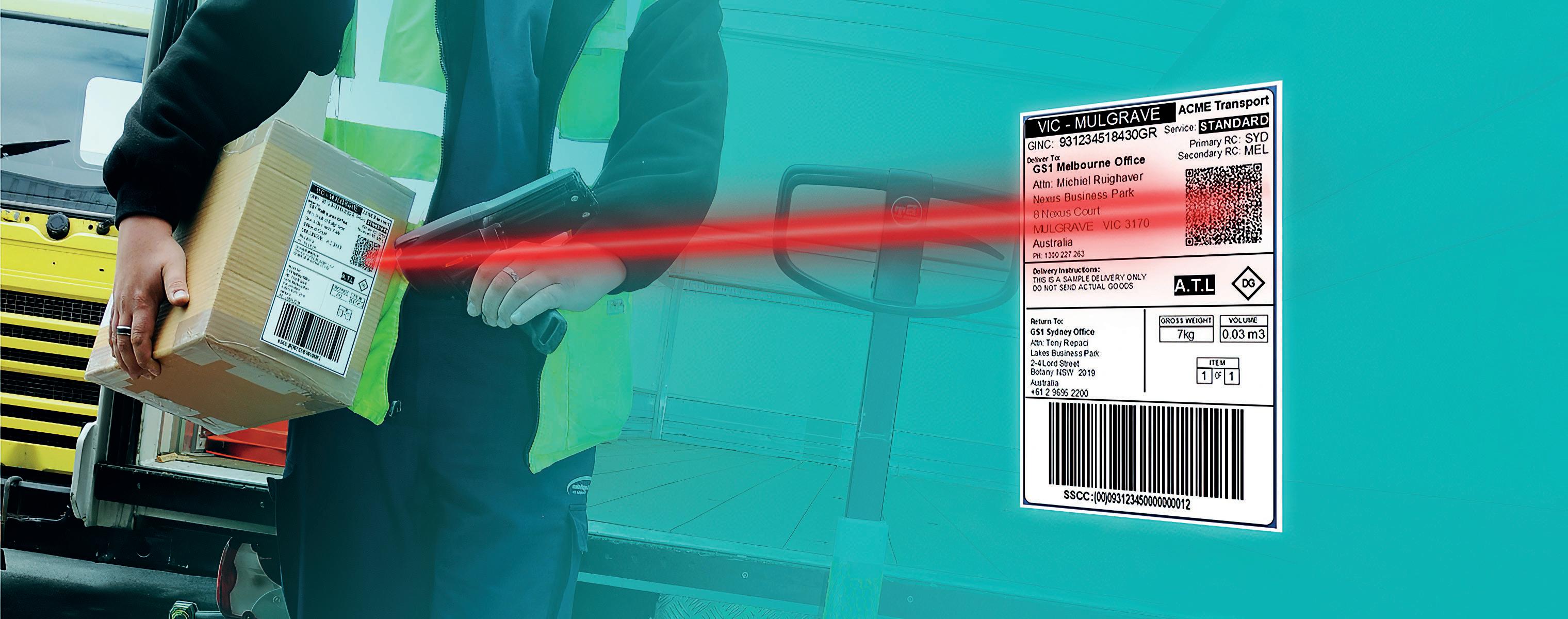

Our cover story features an in-depth exploration with Peter Jones, Managing Director at Prological, who discusses how supply chain dynamics are increasingly recognised as a vital component of strategic growth in boardrooms across Australia. This piece sheds light on the necessity of embracing modern technologies such as integrated systems and AI to enhance customer fulfilment and visibility.

We also delve into the adaptive software solutions from Körber, where Darren O’Connor highlights the importance of flexibility in today’s fast-evolving supply chain environments. His insights remind us that staying competitive means embracing systems that can pivot as quickly as market demands change.

Furthermore, our feature on the partnership between Coates and Hangcha illustrates the strategic alignment and sustainability efforts driving their collaboration, setting a benchmark for industry partnerships.

Beyond these highlights, the issue contains a range of other great stories that address the diverse challenges and opportunities facing our industry today. From innovative approaches to managing complex logistics to the latest advancements in equipment and technology, each article is designed to inform and inspire.

We hope you find these stories both enlightening and actionable, as you navigate the complex landscape of supply chain management. Thank you for joining us on this journey of continuous improvement and strategic foresight.

Happy reading. See you next month.

Edward Cranswick Editor edward.cranswick@primecreative.com.au

MHD

MHD MAY 2024 | 3

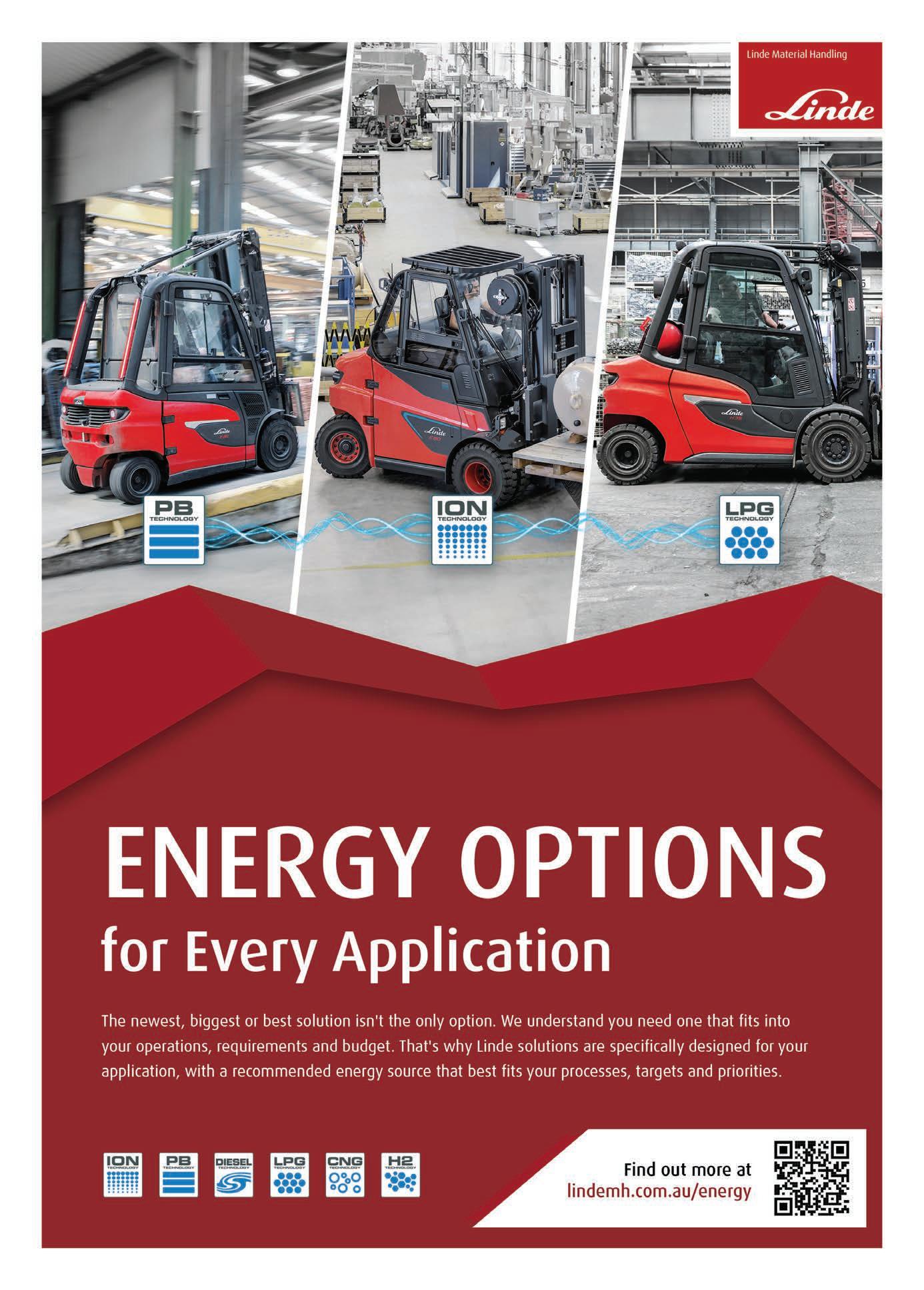

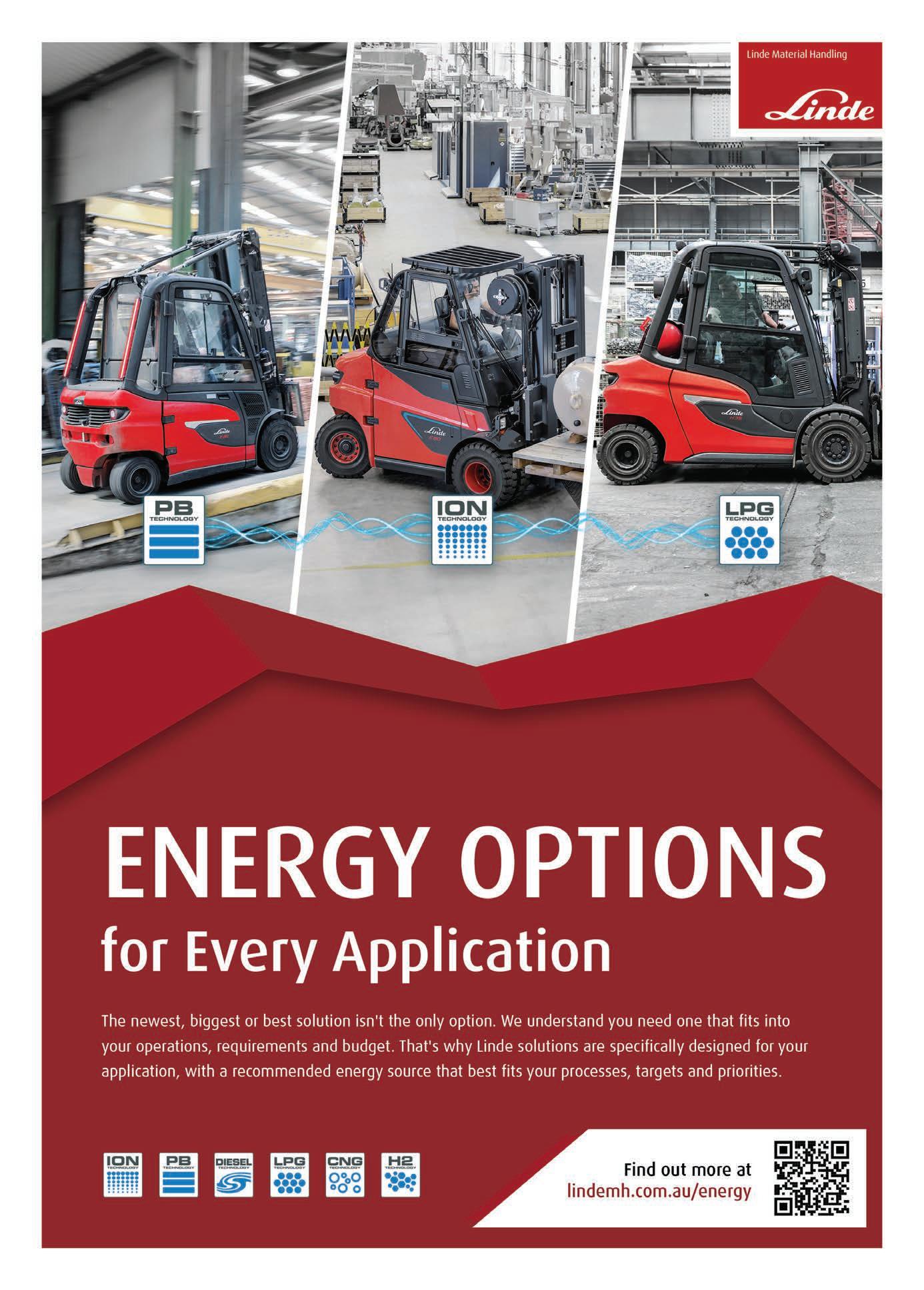

THIS ISSUE

COVER STORY

28 Prological on shaking up the C-Suite

SUPPLY CHAIN

36 Körber on adaptable software

40 GS1’s Scan4Transport

46 Enersys on expanding capacity

56 Nilfisk launches sweeper/scrubber combo

58 Sigma Healthcare on tailoring pharma solutions

60 Santova navigating innovations in logistics

62 Adaptalift equips facilities with Hyster forklifts

MATERIALS HANDLING

32 The Hangcha-Coates partnership

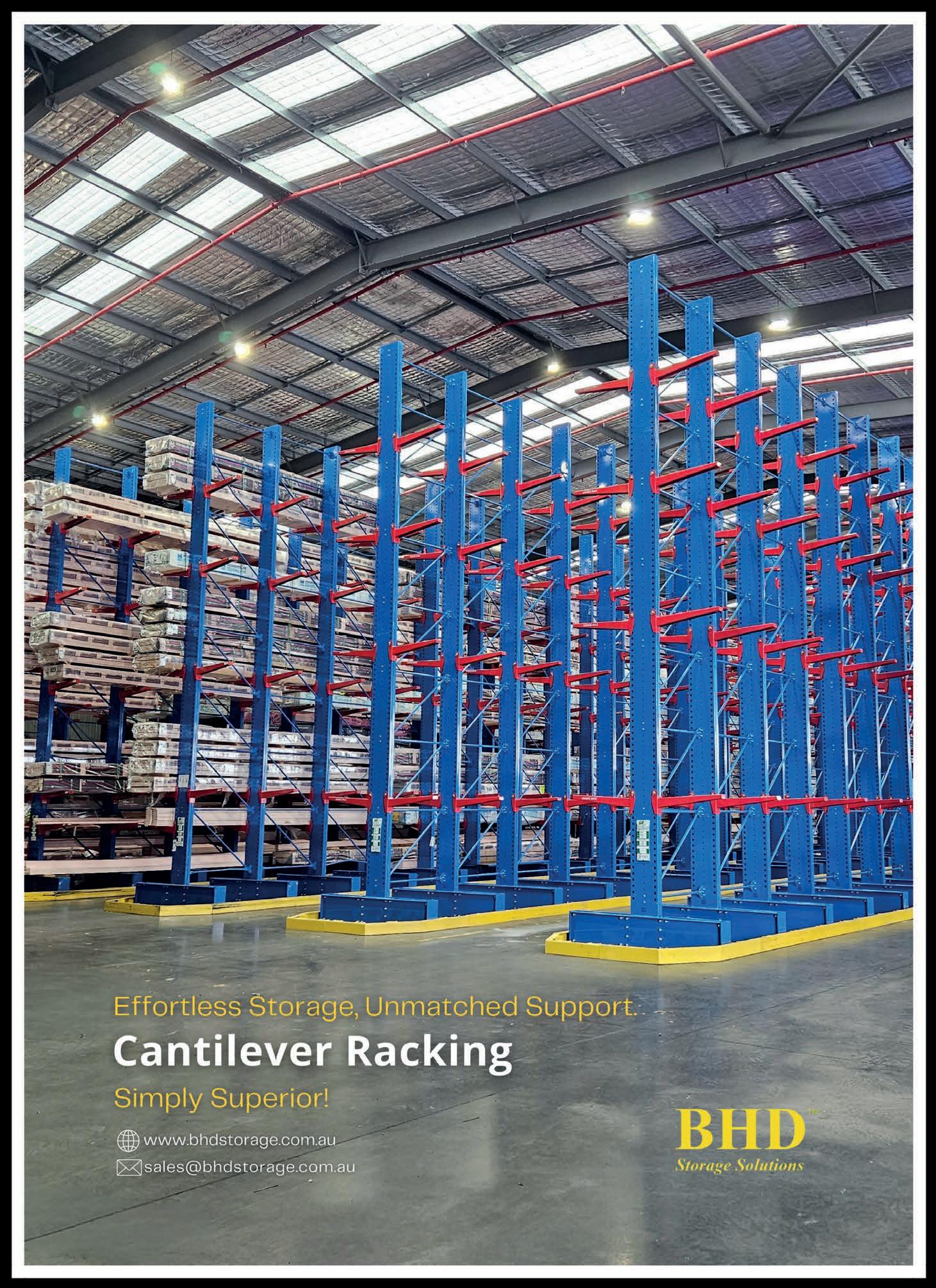

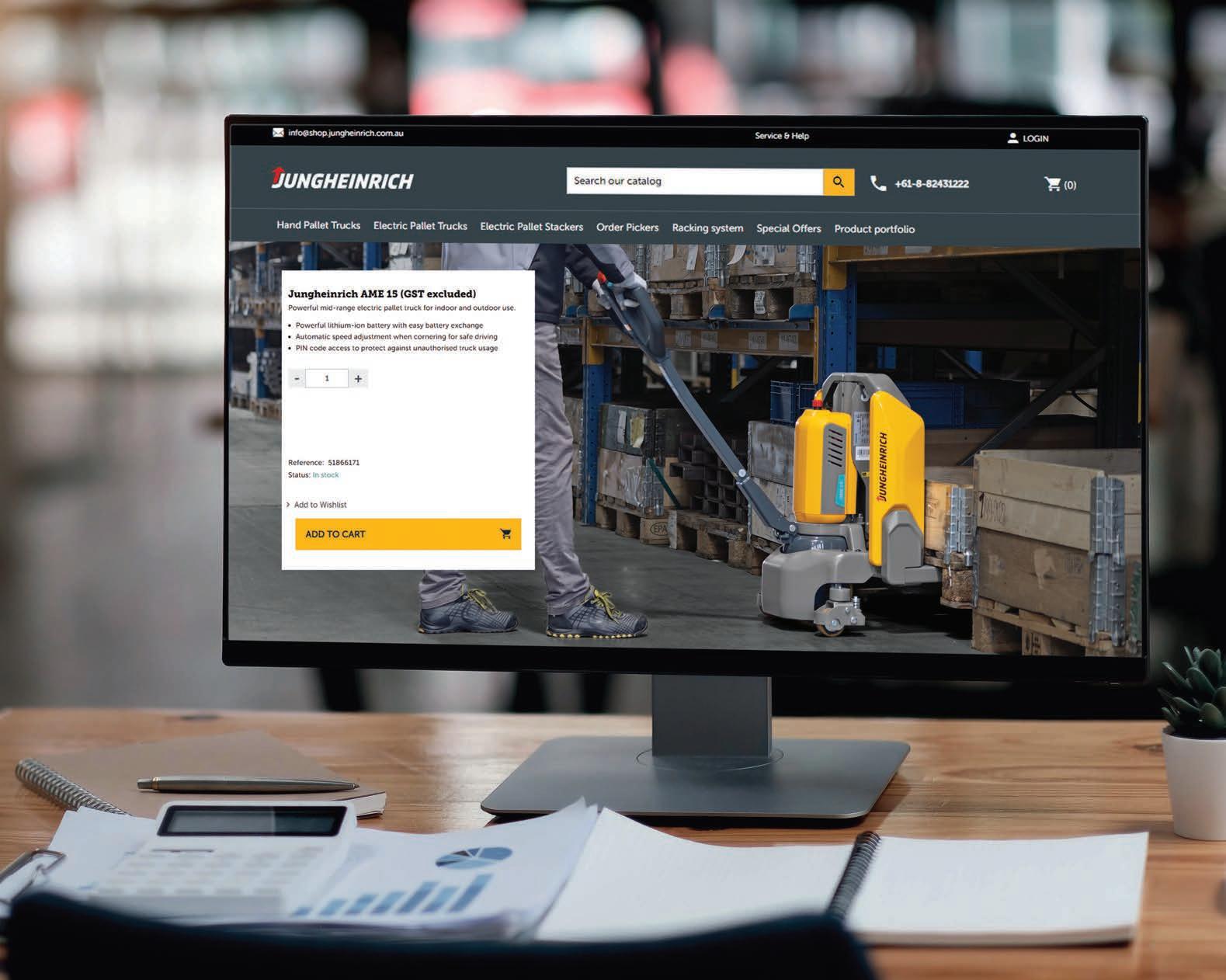

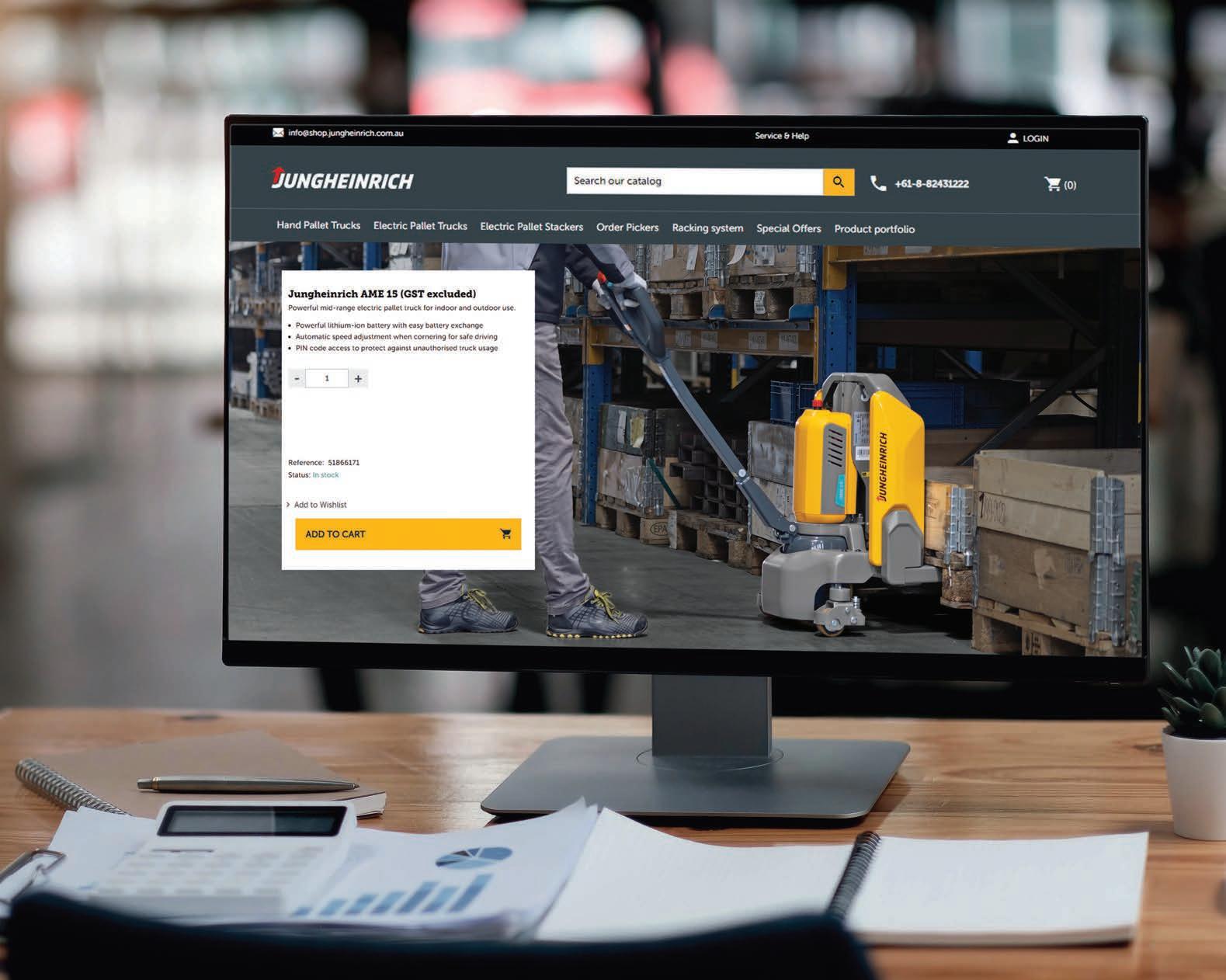

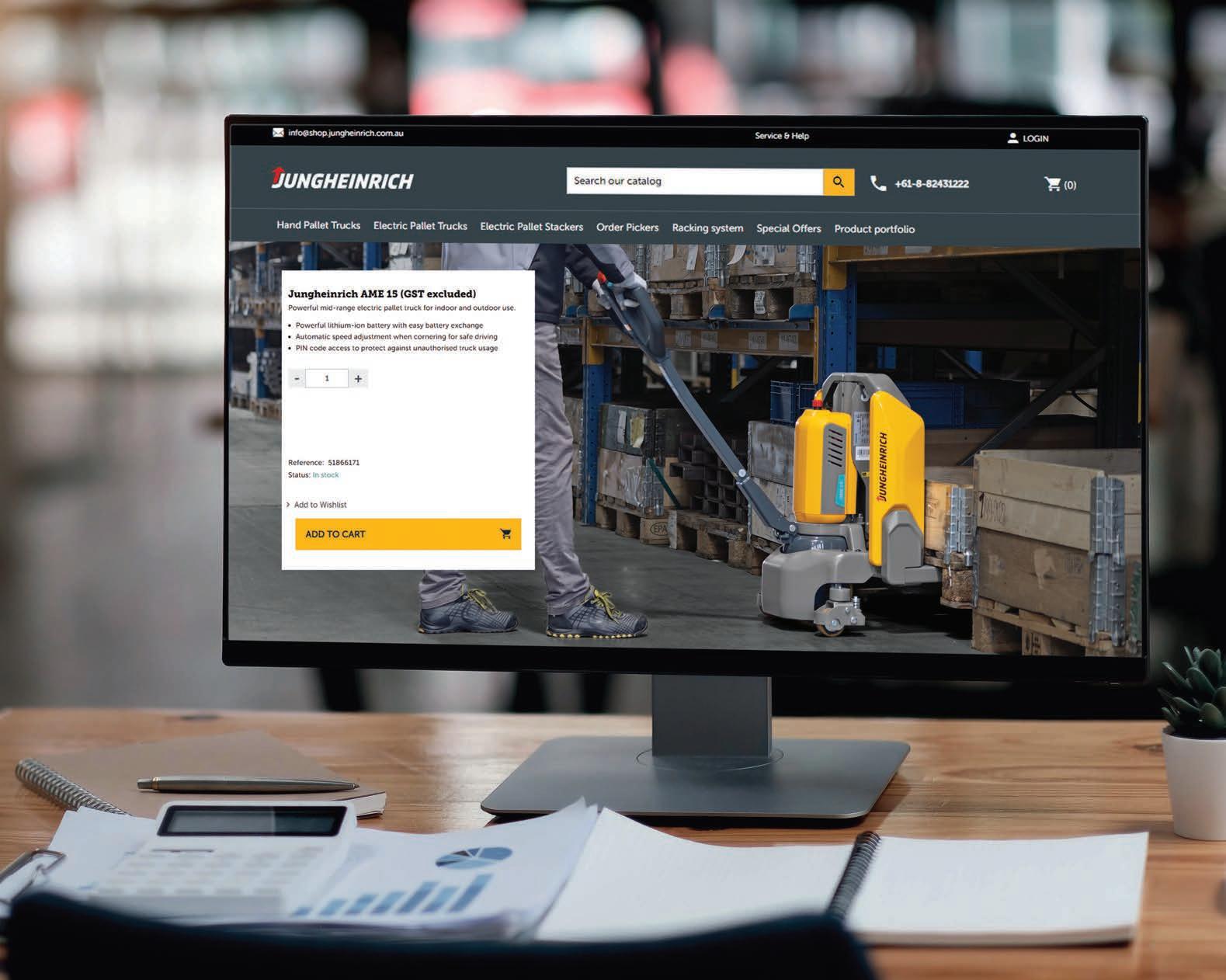

34 Jungheinrich on low level-order picking

38 TMHA helps expand ClarkSolutions

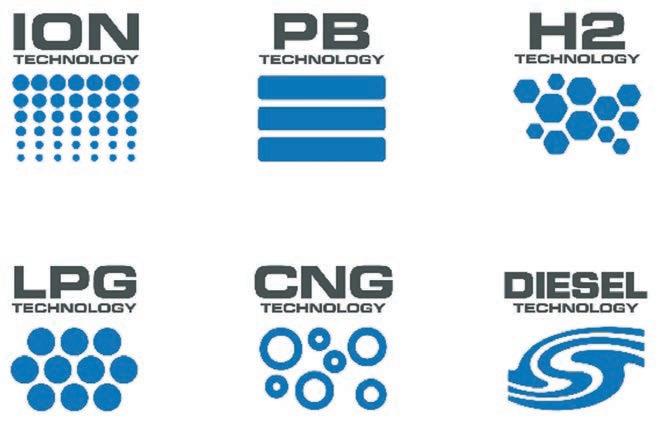

49 Linde on selecting the right energy sources

WAREHOUSING

52 Skywire and Zebra benchmarking excellence

54 Ferag on choosing the right WMS

ASSOCIATIONS, EVENTS, AND REGULARS

26 SEW Eurodrive speaks about Mercury Awards

43 MEGATRANS and Bearhug on pallet wraps

64 SCLAA advertising ASCL sponsorships

65 RWTA holding conference in Victoria

66 ASCI on series and partnerships

68 Product Showcase

70 People on the Move

Körber’s Darren O’Connor explains Hangcha teams up with Coates for materials handling hire success DYNAMIC DUO WHY ADAPTABLE SOFTWARE IS CRUCIAL MAY 2024 Prological MD Peter Jones on why supply chain is now mission critical SUPPLY CHAIN GOES TO THE BOARDROOM COVER STORY ON THE COVER Prological MD Peter Jones on why supply chain is now front-of-mind in the boardroom. MAY 2024

38 COVER STORY 24 ISSUE 03 VOLUME 55 58 MHD MAY 2024 | 5

SHOULD WE CHANGE HOW WE MANAGE RISK?

Supply chains need to contend with shifting demand and contradictory consumer behaviour. Image: Shutterstock/Gumbariya.

TMX Transform’s strategic advisor, Linda Venables, writes in this MHD op-ed about the occurrence of the polycrisis in the supply chain industry, questioning if we should change to manage risk.

EXPECT THE UNIMAGINABLE

Despite diligent risk management and contingency planning, I had not even considered the causes of some of the most catastrophic operational disruptions in my supply chain career. Until they happened.

Case in point: on a 13-degree day in April in western Sydney, a hailstorm belted our threeyear old distribution centre. The structural impact of the hail itself was not the culprit. The issue stemmed from a subsequent rainstorm, with the hail blocking drainage from the roof, trapping over 200 tonnes of water.

The weight of the water breached the DC roof in two areas, compromising the structural integrity of the building, rendering our key NSW site

inoperable, and disrupting the weekly supply of over a million cartons to customers.

A business continuity plan and crisis management process helped the leadership team make quick decisions. Relocating NSW team members and increasing local resources, supplemented our Victorian and Queensland throughput capacity. This increase in capacity, coupled with inventory repositioning and transport reconfiguration, meant customer service resumed within 48 hours.

MHD INDUSTRY NEWS & OPINION

6 | MHD MAY 2024

Trewin and Georgia Denton WesTrac Tomago, NSW

Trewin and Georgia Denton WesTrac Tomago, NSW

As one of the world’s largest authorised Cat® equipment dealers, WesTrac knows that the smallest of parts can make or break a machine, and have a big impact on site operations.

At its headquaters in Tomago, NSW, WesTrac implemented an AutoStoreTM automated spare parts storage and fulfilment system from Dematic, which allows WesTrac to keep stock organised, use warehouse space efficiently, and prioritise urgent orders to be ready in just 5-10 minutes.

With the AutoStore solution, WesTrac can get vital parts to customers quickly, keeping Australia’s heavy industry moving.

Learn more at dematic.com/westrac

Rapid spare parts fulfilment you don’t need to move the Earth for. Vital parts ready to go in 5 Dematic.com 02 9486 5555 info.anz@dematic.com Scan to watch the video!

Natalia

We then secured three local warehousing and distribution facilities to take us through the 16 months until we could return to the original premises.

This ‘black swan’ and other unimaginable events reveal the limitations of relying solely on the assessment of risk. Our risk register did not include the neat line item: “unseasonably severe hailstorm results in trapped water breaching the weight limit of the roof”.

BUT CUSTOMERS HAVE A RIGHT TO EXPECT A BUSINESS TO CONTINUE TO OPERATE

In an increasingly volatile, uncertain, complex, ambiguous (“VUCA”) world, as we seek resilience in our supply chains, we must also plan from a continuity perspective. Failure to manage business continuity can also impact your team members and retention, your brand value, and your shareholders.

A continuity plan includes alternative methods of operating, should one or more aspects of an operating model fail; a good plan reassesses the feasibility of such scenarios on an ongoing basis. For example, several factors render long-term interstate supply infeasible, so our plan required local alternate warehousing and distribution. Given the hailstorm impacted eleven other companies in our trading estate, the clarity of our plan saw us move quickly and secure alternative facilities.

THE NEW MEANING OF DISRUPTION

Even semantics has been disrupted. ‘Disrupt’ used to mean a gamechanging way of shaking up a sector. In supply chain we now see so many con-current disruptions, the industry has adopted the term ‘polycrisis’ (first coined in 1999 by French theorist Edgar Morin).

Supply chains must achieve performance targets despite the impacts of multiple disruptions. Disruptions impact physical operations, such as extreme weather events and labour

shortages, and the supply of goods, such as geopolitical conflicts. Supply chains need to contend with shifting demand and contradictory consumer behaviour (in apparel, for example, consumers want fast, free returns but for their vendor to operate sustainably) all whilst contemplating the rising tide of ESG compliance requirements and regulations.

DON’T YOU FORGET ABOUT ME

So why isn’t risk management front of mind for many of us?

Spending time in your business on risk management can be challenging. It is seldom seen as urgent. Risk ownership is often murky. It is clear who has oversight? Who is accountable for the level of risk in a business?

The CRO, the Board’s ARC, the CSCO? Has the Board set the company’s risk appetite? And who is responsible for ensuring risk remains in line with the company’s tolerance? Are known risks adequately mitigated and unknown risks contemplated? How are colleagues engaged when mitigations and contingencies require cross-functional collaboration?

ATTUNING TO EMERGING RISK

We tend to think of ‘risk’ in terms of dramatic physical events: a team member injury, warehouse fire, racking collapse, or systems outages. These are potentially catastrophic, but their scale tends to overshadow the far more likely, smaller risk events.

Consumers now interact directly with supply chains, and therefore represent an increasingly significant risk to businesses. Today’s consumer is more aware of where products come from (think provenance and modern slavery, traceability, and fraud), how product is made, packaged, and shipped (think resource and energy use and associated environmental impacts), and relies on being able to order at the last minute. The link between the sourcing and manufacturing of products, the operational

performance of the supply chain, and the company’s brand has never been more apparent.

As business leaders reflect whether their continuity plans are adequate, I’ll leave you with some more examples of the unthinkable occurring during the span of my career:

• At 6am one Sunday, a nearby fuel depot (Google ‘Buncefield depot’) had an explosion that was so large, it devastated nearby buildings and closed the industrial estate. The impact distorted the roller-shutter dock doors and triggered the sprinkler systems, damaging expensive inventory in an FMCG warehouse a mile away.

• A sprinkler pipe burst in the ceiling of a cold storage facility in WA, bringing down the ceiling, ruining the pre-assembled customer orders and turning the freezer into an ice rink. On the second of January, in the middle of a very hot Australian summer, I did not expect to be searching for ice removal equipment!

• A communications cable was accidentally severed in a nearby field, which took the warehouse network offline. Feeling confident of our BCP, to fail-over to the communications provider’s mobile network, we were dismayed to find all telco customers in the area had the same contingency and the mobile service had insufficient bandwidth.

You won’t feel the impacts of the warehouse roof that never collapses, the devastation of a safety incident that never occurs, or the pressure of staff shortages that don’t transpire. But things do and will break, so whilst it is at times comforting that they may not have broken in your business in recent years, the past is not a good predictor of the future.

Businesses need to be confident in their level of resilience.

Continuity planning plays a critical role in providing that confidence.

Linda Venables, Strategic Advisor, TMX Transform

MHD INDUSTRY NEWS & OPINION

8 | MHD MAY 2024

DEMATIC AUTOMATES PEPSICO’S THAI FACILITY

Following a partnership with PepsiCo, global leader in convenient foods and beverages, Dematic has integrated automation as a central feature of Pepsico’s expanded production and logistics facility.

The Rojana facility is a critical regional hub that produces a variety of products. With a growing demand for its products in Thailand, PepsiCo recognised the necessity to build capacity in both production and logistics.

“Rojana is one of our biggest plants, and it also has several different product platforms,” says Colin Matthews, Supply Chain Senior Director – IndoChina Foods, PepsiCo.

“We have potato chips, we have Stax-brand chips, and we have Fry Pack in extruded products as well. Those products are made at Rojana and are not only distributed nationally across Thailand, but also internationally to Vietnam and other

neighbouring countries.”

To support PepsiCo’s growth and address space constraints and labour challenges, Dematic worked closely with PepsiCo to develop an automation solution to address its storage, throughput capacity, and productivity needs in its logistics operations. The solution centres around an Automated Storage and Retrieval System with a direct link to both the production and order fulfilment areas.

“We foresee a manpower shortage being a major challenge for our local operations in Thailand,” explains Charan Techapattaraporn, Logistics Manager, PepsiCo. “Automation, therefore, is the perfect solution to take on this challenge, whilst also improving our facility operations across the board.”

The AS/RS stores pallets within five aisles of double-deep, high-bay racking with a total of 16,520 pallet locations.

A network of pallet conveyors and Rail-Guided Vehicles (RGVs) receives pallets automatically at the end of the production lines and transports them for storage, then directs them from storage to despatch docks or to automatically replenished pick locations for full-case order picking.

The solution includes Dematic Warehouse Control System software to manage all the automation, the material flow, and the inventory as well as to provide real-time tracking and visibility of all transactions.

“The AS/RS is at the heart of PepsiCo’s strategy to enhance its production and logistics efficiency at the Rojana facility,” says Phamondate Rukdee, Sales Manager, Dematic Thailand.

“It provides an extremely space efficient way to store products between when they are manufactured and when they need to be assembled and despatched for delivery to customers.”

MHD INDUSTRY NEWS & OPINION

10 | MHD MAY 2024

Dematic worked closely with PepsiCo to develop an automation solution to address its storage, throughput capacity, and productivity needs. Image: Dematic.

THREE STEPS TO TAKING CONTROL OF INDUSTRIAL FLOOR CLEANING

Facility cleaning may not be high on your priority list. Especially when you have allimportant productivity and safety KPIs occupying headspace. But whether the goal is site presentation, dust control, ensuring visibility of safety lines, or preparing for an upcoming audit – floor cleaning at your site does need to happen.

Conquest Equipment, renowned for their robust range of industrial sweepers and scrubbers, offer their 3 expert tips to taking control of floor cleaning at your facility. So, you can focus your attention on heading up a productive and safe operation.

Step 1. Choose the right floor cleaning equipment

With so many variables to be considered, it can be difficult to match your cleaning equipment needs to your unique business requirements. But choosing the right equipment is essential to ensuring reliability, longevity and cleaning performance.

Conquest recommends creating and enforcing a clear maintenance plan encompassing daily pre-operation inspections. Image: Conquest Equipment.

That’s why Conquest created their Intelligent Solutions Program, or ISP, to leverage their expertise and give you peace of mind that you’re getting the equipment you actually need to clean your facility and meet your safety obligations. It’s all starts with a complimentary site assessment.

A product solution specialist will come to your facility and make a recommendation based on their expert assessment of your facility size, surface type, safety considerations, operating environment, and cleaning requirements. No guess works. No fuss.

Step 2. Create a maintenance and servicing plan

Much like a passenger car, regular maintenance and servicing ensures

your floor cleaning equipment continues to operate to peak performance and minimises the risk of unplanned breakdowns or emergency repairs.

Conquest recommends creating and enforcing a clear maintenance plan encompassing daily pre-operation inspections, appropriate waste disposal and machine cleaning postoperation, and regular scheduled servicing. They can even help tailor a service and support package to your requirements. So, for you and the team onsite, it’s set and forget.

Step 3. Manage your fleet with Conquest FM

For those with multiple cleaning assets across various facilities and locations, Conquest’s latest offer – Conquest FM – simplifies fleet management and drives operational

efficiencies. The intuitive bolt-on system can be integrated with new and existing fleet assets and offers real-time usage data and reporting. Conquest FM also features built-in safety checks and performance monitoring to minimise downtime and promote operator safety. Accessible from a single portal and available on both desktop and mobile devices, Conquest FM puts you in full control of your floor cleaning fleet. No matter where you are.

TAKE CONTROL FLOOR CLEANING

As a busy Operations or Fleet Manager, you’ve got enough to do. But with Conquest behind you all the way, taking control of floor cleaning processes and assets at your operation is as simple as one…two… three.

MHD INDUSTRY NEWS & OPINION

12 | MHD MAY 2024

Bespoke 3PL Healthcare Solutions

HEALTHCARE LOGISTICS SOLUTIONS

• Flexible, bespoke 3PL/4PL contract logistics solutions

• IT integration capability

• Dedicated Account Management

WAREHOUSING AND DISTRIBUTION

• Over 60,000sqm dedicated 3PL space nationally

• New state of the art, modern, high security facilities

• Transport and Distribution

• Dedicated healthcare storage – ambient and cold chain temperature controlled, vault

• ISO 9001 and ISO 13485 accredited

• eQMS – Quality Management System

Contact Maria or Nick today to discuss a customised 3PL solution.

• Packaging/Repacking

• Continuous improvement

• Order to cash

Maria Machado

+61 438 620 294

• Customer Service

• Debtor management

Maria.Machado@sigmahealthcare.com.au

Nick Rimac

+61 429 169 832

Nick.Rimac@sigmahealthcare.com.au

QUALITY AND COMPLIANCE VALUE ADDED SERVICES

142599

TRENDS SHAPING AUSTRALIA’S TRANSPORTATION AND LOGISTICS INDUSTRY

Peter Langley, Vice President, FedEx Express Australasia explains in this op-ed for MHD the four main trends shaping Australia’s transportation and logistics industry as it significantly expands in 2024.

The transportation and logistics industry serves as the backbone of global e-commerce and business operations, seamlessly connecting the online and offline worlds. In Australia, the industry is poised for significant growth, with projections estimating a rise to USD 94.10 billion in 2024 and further expansion to USD 113.94 billion by 2029[1]. Here, we delve into the prevailing trends shaping the landscape of Australia’s

transportation and logistics industry in the year 2024.

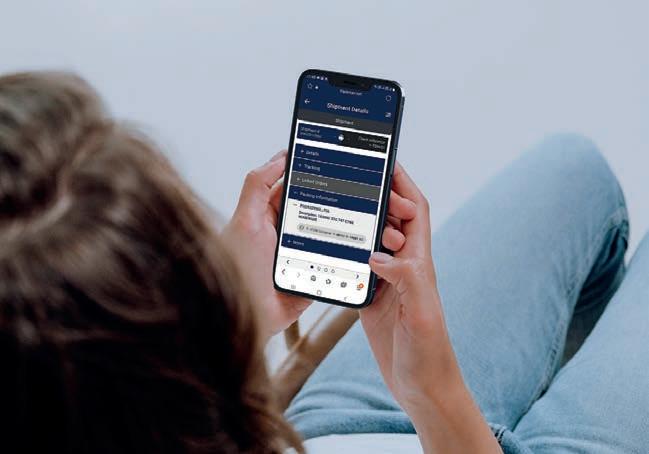

1. Data-led decision-making drives the industry forward

In the dynamic landscape of Australian business, digital innovation drives steady change. We are seeing an increasing number of companies recognising the importance of investing in data and digital technologies to drive their operations forward. A significant milestone was reached at the beginning of 2023, with 53 per cent of organisations in Australia planning to increase technology spending from 10 to 20 per cent.[2] This surge in investment underscores a strategic shift towards

The partnership between e-commerce and transportation and logistics is driving businesses and e-tailers to reach beyond traditional borders.

embracing technology as a catalyst for growth and competitiveness.

At FedEx, we have always known the power of the data we have in our hands. In fact, 45 years ago our founder, Fred Smith, said that the information we hold about the package is just as important as the package itself. But it is only with today’s computing power, data analytics, predictive modelling, AI and machine learning, that we are able to fully harness the power of this data, for the good of our company and our customers.

We see more businesses taking advantage of advanced analytics and technologies to support innovation, improve supply chain visibility and predictions and even minimis

MHD INDUSTRY NEWS & OPINION

Image: Shutterstock/Kritsana

Maimeetook 81.

14 | MHD MAY 2024

emissions. The application of advanced technologies to unlock the power of data will become ever more firmly embedded in how transportation and logistics providers empower SMEs to drive their business growth.

2. L everaging Data for Environmental Goals

Operating in a more sustainable manner is both a business imperative and an opportunity to cultivate trust with customers. More than ever before, customers today demand more sustainable products and services [3].

Thanks to advancements in digital solutions, businesses are able to harness data and analytics to monitor and achieve their sustainability objectives. These digital tools can provide businesses with estimates of emissions throughout their supply chains, enabling informed reporting and future planning. By leveraging such solutions, businesses can align with customer expectations for more sustainable products and services and advance their own environmental initiatives.

At FedEx, we have introduced FedEx® Sustainability Insights to

provide customers more visibility over the carbon footprint of their eligible shipments with estimates of their CO2 emissions, leveraging FedEx’s network data[4].

3. Easier Expansion to New Markets

With the right transportation and logistics provider, expanding into global markets is becoming more accessible for e-commerce businesses looking to grow beyond their local market.

A great starting point for those Australian businesses is taking on the New Zealand market. New Zealand is not only Australia’s closest natural ally but also a strong Trans-Tasman trade partner for small and medium businesses.

The Australia New Zealand Closer Economic Relations Trade Agreement and Single economic market has boosted and improved connectivity on the Trans-Tasman trade route may offer fertile ground for businesses to capitalise on the robust cross-border trade partnership between Australia and New Zealand.

Today, businesses can take advantage of improved connectivity on the Trans-Tasman trade lane, facilitated by the FedEx Trans-

Tasman service. Currently, this service offers regular flights connecting key cities such as Christchurch, Auckland, Melbourne, and Sydney, providing seamless access to markets and fostering business expansion opportunities.

4.Integration between E-commerce and Transport and Logistics

In today’s digital world, the partnership between e-commerce and transportation and logistics is driving businesses and e-tailers to reach beyond traditional borders. Success now hinges on delivering products quickly and reliably to customers worldwide. Adopting this integration may enable businesses to seize opportunities and navigate challenges in the dynamic marketplace of 2024.

Supply chains are rapidly evolving into smarter, techdriven ecosystems, revolutionising operations and paving the way for unprecedented transformation in the transportation and logistics sphere. As digital innovation accelerates, businesses should prioritise efficiency, transparency, and global reach to maintain a competitive edge and achieve sustained growth and success in the evolving landscape.

2024 presents a landscape of both challenges and opportunities for the industry. Supply chains are evolving into smarter, techdriven ecosystems, marking a profound shift in operations. The pace of digital innovation is poised to accelerate, heralding an era of unprecedented transformation in the supply chain and transportation and logistics spheres.

Disclaimer: The information in this article is of general nature only. It is not intended to address circumstances of any specific entity or individual.

[1] Freight & Logistics Market in Australia

[2] 2023 Tech Trends Report

[3] McKinsey Consumer Research

[4] https://www.fedex.com/en-au/ about/sustainability/carbonfootprint-insights.htm

Peter Langley, Vice President, FedEx Express Australasia

MHD INDUSTRY NEWS & OPINION

16 | MHD MAY 2024

In the dynamic landscape of Australian business, digital innovation drives steady change. Image: Shutterstock/Nightman1965.

SKYWARD BOUND: HANGCHA’S AERIAL WORK PLATFORMS

In the rapidly evolving landscape of industrial equipment, the need for innovative, reliable, and efficient solutions has never been more critical.

In response to the growing demand for versatile and safe aerial working solutions, Hangcha has expanded its product range to include a series of aerial work platforms.

Manufacturing forklifts since 1956 Hangcha Forklifts Australia has been set up to support our national dealer network. Call 1300 399 687 to be put through to your nearest local dealer. www.hangchaaustralia.com.au 20-24 Bessemer Drive, Dandenong South, VIC, 3175 sales@hcforkliftau.com Come visit us at CeMat for more information about our aerial platforms. Stand 420 from July 23-25

TOLL ANNOUNCES FACILITY CONSTRUCTION

Toll Group has announced the construction of a new, 10,000 sqm state-of-the-art healthcare facility at Tullamarine, near Melbourne, next to what will be one of its partners’ future manufacturing sites.

As a leading supply chain partner to CSL Seqirus, the facility is being custom built to support CSL Seqirus’ operations.

Toll notes by having its warehouse and DC next to what will be CSL Seqirus’s manufacturing site, it will bolster Toll’s tailored support for CSL Seqirus by handling both finished goods distribution and supplying raw materials and packaging to the CSL Seqirus manufacturing facility.

“We are proud to strengthen our partnership with CSL Seqirus and expand our footprint in the healthcare logistics sector,” says Perry Singh, President, Government & Defence at Toll.

“This new facility exemplifies our commitment to delivering high-quality, tailored supply chain solutions to meet the evolving needs of our customers.”

The new warehouse marks Toll’s commitment to providing comprehensive logistics solutions for the healthcare sector.

With operations commencing in Tullamarine, Toll aims to enhance efficiency and timeliness through just-in-time services.

The collaboration between Toll and CSL Seqirus underscores a shared dedication to innovation and excellence in healthcare logistics.

In addition to the Tullamarine facility, in April 2023 Toll opened new warehouse in Richlands, Queensland, further demonstrating its dedication to enhancing healthcare logistics infrastructure across Australia.

“The facilities are part of Toll’s

broader multi-million-dollar investment creating advanced warehouse management solutions to meet the changing dynamics in the healthcare sector, and providing customers with the logistical support they need,” adds Perry.

Toll’s facility will be situated adjacent to the soon-to-becompleted CSL Seqirus plant, a new world-class biotech manufacturing facility in Australia which will supply influenza vaccines to Australia and the rest of the world.

The state-of-the-art facility will use innovative cell-based technology to produce influenza vaccines for use in both influenza pandemics and seasonal vaccination programs – and will be the only cell-based influenza vaccine manufacturing facility in the Southern Hemisphere.

Toll’s warehouse and DC is due to commence operations in August 2024.

MHD INDUSTRY NEWS & OPINION

MHD MAY 2024 | 19

The new warehouse marks Toll’s commitment to providing comprehensive logistics solutions for the healthcare sector. Image: Toll Group.

VICTORIAN GOVERNMENT INVESTING IN DRIVER TRAINING

Through a partnership with the Victorian Transport Association (VTA), the Victorian government is investing an extra one million dollars in training more heavy vehicle drivers to keep Victoria’s supply chains moving.

Premier Jacinta Allan’s department notes this partnership offers accredited training for aspiring heavy vehicle drivers and assists them in securing employment as part of the VTA’s successful heavy vehicle driver delivery program.

“This partnership will see more Victorians get skilled up and behind the wheel to keep our state’s multibillion-dollar freight industry moving,” says Minister for Ports and Freight, Melissa Horne.

Since its launch in 2016, the program

has received continuous investment from the Labor government, resulting in the training and placement of nearly 400 skilled drivers on our roads.

In addition to improving safety on our roads, the program aims to tackle heavy vehicle driver shortages, tailored to attract and retain younger drivers for Victoria’s critical supply transport and logistics supply chains.

“The transport industry requires qualified and job-ready drivers to ensure Victorians can maintain the high living standards they are accustomed to and help address supply chain challenges.”

Victoria’s freight industry, contributing $21 billion annually to the state’s economy, employs more than 260,000 Victorians who play a

The Victorian government and Victorian Transport Association’s partnership offers accredited training for aspiring heavy vehicle drivers and assists them in securing employment.

crucial role in maintaining the state’s supply chains.

The VTA coordinates training with qualified providers and helps graduates secure stable positions with reputable transport companies.

“Skilled driver shortages in the transport industry is affecting our members who are under constant pressure to deliver around the clock and on time – we support this initiative,” says Transport Workers Union Branch Assistant Secretary, Mem Suleyman.

This partnership between government and industry to tackle skill shortages, follows the success of the 2023 Freight Industry Training for Jobseekers project, which facilitated employment for more than 125 individuals in freight and warehousing.

MHD INDUSTRY NEWS & OPINION

20 | MHD MAY 2024

Image: Shutterstock/ Aleksandar Malivuk.

Reliability for over 65 years

Experts for innovative Intralogistics

swiss engineering

Reliability for over 65 years

Experts for innovative Intralogistics swiss engineering

See the exclusive interview with Ferag in this issue’s article: Warehouse Management Systems - How not to get burnt

APEX BUSINESS PARK NOMINATED FOR MHD SUSTAINABLE WAREHOUSE COMPETITION

In a significant nod to its sustainable initiatives, Apex Business Park, developed by The GPT Group, has been nominated for the MHD Sustainable Warehouse Competition. This recognition underscores the park’s commitment to pioneering sustainable practices within the logistics and warehousing sector, a crucial step towards a greener future.

Located in the burgeoning corridor between Brisbane and Ipswich, Apex Business Park stands out not only for its strategic location but also for its exemplary sustainability credentials. With facilities designed to achieve a minimum Five-Star Green Star Design and As-Built rating, the park embodies the cutting-edge of ecofriendly industrial development.

Initiatives such as rooftop solar arrays, on-site batteries, and the use of low-carbon concrete highlight a comprehensive approach to reducing emissions and harnessing renewable energy sources.

Sustainability at Apex Business Park extends beyond energy efficiency. The park’s rainwater harvesting system, which supports both toilet facilities and landscaping, exemplifies a holistic environmental ethos. Moreover, the deployment of LED lighting and the choice of low volatile organic compound (VOC) materials, paints, and adhesives ensure a healthier environment for both the planet and the park’s workforce.

The MHD Sustainable Warehouse Competition, aligning with the MEGATRANS2024 exhibition,

seeks to celebrate such innovative efforts in warehouse sustainability.

Apex Business Park’s nomination reflects its role as a frontrunner in integrating sustainable practices with logistical efficiency and operational excellence.

As businesses increasingly prioritise green certifications and employee wellbeing, Apex Business Park’s development by GPT, a company with a rich heritage in high-quality property development, sets a benchmark for the industry. With its comprehensive suite of sustainability-focused features and amenities designed to enhance staff wellbeing, Apex Business Park is not just a logistics hub but a blueprint for the future of sustainable industrial development.

MHD INDUSTRY NEWS & OPINION

22 | MHD MAY 2024

Apex Business Park. Image: GPT Group.

Need to get your RF Scanning operations up and running tomorrow? Have issues with local wireless connectivity?

Meet the Zebra MC9400 Series now with 5G Connectivity. More Powerful Extended Range Enhanced 5G Connectivity

Discover how Zebra can revolutionise your workflow, enhance productivity, and streamline your operations.

Skywire Australia is excited to offer you a no-obligation, exclusive opportunity to put Zebra devices to the test in your warehouse and retail operations.

THE EVOLUTION OF WAREHOUSE OPERATIONS HAS ARRIVED.

SCAN TO GET STARTED FREE 6 WEEK TRIAL

A RENOVOTEC GROUP COMPANY AUSTRALIA | NEW ZEALAND info@skywire.com.au www.skywire.com.au Skywire is part of the Renovotec Group of Companies

EXPLORING THE RAIL FREIGHT OPPORTUNITY IN AUSTRALIA

Prological’s Peter Jones explains in this MHD op-ed the benefits of rail freight and how adopting aspects of the European model can help us decrease our reliance on road freight.

The benefits of rail freight compared to road transport are transparent. Trains use significantly less fuel to transport freight long distances, carry far more weight and volume, reduce highway congestion, improve safety by reducing the strain on commercial trucking and provide reliable and on-time delivery and scheduling.

Despite this, just two per cent of freight between Melbourne and Sydney goes by rail, down from near 40 per cent in the 1970s.

According to research by The Bureau of Infrastructure and Transport Research Economics, for everyone per cent of freight shifted from truck to rail nationally, an average of $71.9 million would be saved annually in terms of environmental damage, road conditions and pollution-related health outcomes.

In 2024, Australia is seeking global partners to transition our rail network and decarbonise our transport sector, which accounts for 19 per cent of our country’s total carbon emissions.

The Inland Rail Network has been set up to reduce our reliance on roads for moving freight, while high speed rail has become a priority on the Australian government’s agenda, even setting up a High Speed Rail Authority in June last year 2023.

The goal of our Inland Rail Network will be to connect Melbourne and Brisbane with a 1700km end-to-end rail freight corridor spanning rural Victoria, New South Wales and South East Queensland.

This will not only connect our rural industries with ports and logistics centres in the major cities, but also link Australia’s 2nd and

3rd largest cities with a faster rail service unencumbered of the constraints the existing ‘coastal via Sydney’ option is constrained by.

This investment in rail freight begs the question, why hasn’t Australia been able to reduce its domestic road freight? The primary answer is cost.

The fixed costs of the rail infrastructure and operations are spread across lower volumes, raising the cost per unit being transported.

Combined with the transloading and terminal infrastructure at both ends of the journey means the transition to rail hasn’t been financially viable in recent decades.

In addition, all rail options being offered to date involve the freight being containerised (excepting SCT’s wagons), which then requires significant changes in infrastructure for both senders and receivers. It also requires the impost of the land bridge costs at the origin and destination for pick-up and delivery of the containers.

To solve this problem, I had what I thought was an original idea. To show engineering firms and our rail industry how this might work, I had briefed an animator to create a video of the concept, only to have a colleague then find my ‘original idea’ was already operational in Europe with some maturity and very efficient, removing many of the barriers of road to rail transition.

At the end of 2023, I travelled to the intermodal terminal Bettembourg-Dudelange in Luxembourg to explore their systems for rail freight and determine whether such processes could be used in Australia to assist in road to rail conversion.

A new solution

In April 26 1956, a converted World War II tanker became the first ever container ship, sailing from the Port of Newark to Houston with 58 aluminium boxes.

Since then, shipping containers have become standardised, and so

have all containers for road and rail freight.

The inefficiencies of using containers for rail freight has held back its adoption, but European engineers have been implementing different systems to change this.

For instance, to better integrate freight generators and customers, engineers made modifications to semi-trailers so that they could be lifted directly onto the train, which results in a lot less movement and less time taken through the terminal.

To understand how Europe compares to Australia’s infrastructure and processes, it’s helpful to consider the ‘generations’ of converting road to rail.

With better infrastructure in place, Europe is on its fourth generation of rail freight – in moving rail containers off trains, Europe has seen four generations of process evolution. Australia is behind this development, having only experienced the first two generations of rail freight.

• 1st generation – Forklift, which evolved into a reach stacker

• 2nd generation – Rail mounted gantry cranes

• 3rd generation – Specially designed semi-trailers able to be gantry crane lifted (Europe only)

• 4th generation – Driving semitrailer directly onto the train (Europe only)

Data was gathered while in Europe of the efficiency gains as each generation was developed. From a terminal handling perspective alone, Gen 1 to Gen 2 offers just over a 100 per cent increase in throughput capability.

Gen 2 to Gen 3, offers another 25 per cent, but more than 50 per cent cost benefit in land bridge costs while Gen 4 in nine times more efficient inside the terminal and offers the same 50 per cent benefit on the land bridge costs.

As we expect, when systems and

MHD INDUSTRY NEWS & OPINION

24 | MHD MAY 2024

process develop across generations, we do expect better outcomes. In relation to Intermodal processes, this is what has happened in Europe.

Australia has its own unique environment and infrastructure, so it’s unfair to suggest implementing these new strategies within our unique environment would or should be easy.

Having said that, the gains being achieved in Europe and uptake of Gen 4 by industry is achieving the objectives Australia seeks to achieve. Therefore, exploring these and other new strategies in our supply chain should always be encouraged.

CargoBeamer, another intermodal transport system for shifting semitrailers onto rail, may work very well within Australian Port operations because it requires a much smaller footprint and can load and unload whole trains very fast (in minutes).

In this system, the semi-trailer is uncoupled from the tractor unit inside the terminal, where the driver and tractor unit can leave the terminal immediately or take another semi-trailer with them.

A terminal vehicle places the semitrailer onto an awaiting loading pallet next to the railway tracks which is used to lift it on to the wagon.

When the train arrives at the terminal, the semi-trailers are loaded off the train simultaneously and automatically, immediate followed by the loading of the prestaged outbound trailers.

The drawback of this system is it has the highest CapEx of the third and fourth generation options employed across Europe, but when one piece of infrastructure, 600m long up can handle one million TEUs per annum, on a footprint of

30,000 sqm, the cost per container is very small when compared to the alternate infrastructure investments required to do the same task.

The challenge for Australia is that the new rail terminals being developed are being conceived around what we’ve always had – what I would term as secondgeneration technology and engineering.

To develop innovative new strategies to decrease our reliance on road freight, we might need to look to Europe to understand the opportunities.

In order to maximise Australia’s exciting investments such as the Inland Rail Project, we could use some of Europe’s advanced thinking and engineering.

Peter Jones, Managing Director, Prological

MHD INDUSTRY NEWS & OPINION MHD MAY 2024 | 25

Peter Jones with Anna Samsonova (International Commercial Manager at Lohr Industrie) and Nicolas Bertrand (COO) at Lohr’s Head Office in Strasbourg. Image: Prological.

SEW EURODRIVE SUPPORTING MERCURY AWARDS

MHD sat down with SEW Eurodrive to talk about why it’s sponsoring the MHD Mercury Awards – a dinner gala celebrated biannually as part of MEGATRANS.

In 2024, the Mercury Awards will be held alongside the Australian Bulk Handling Awards, which recognise excellence in the bulk solids handling sector. With two awards programs running, a joint gala evening will be held featuring both sets of awards, providing an increased brand visibility and larger attendance for the evening.

NOMINATING CRITERIA AND INSTRUCTIONS:

Nominating criteria and instructions:

• Nominating is free and must be completed using the online form by 11:59pm Friday 5 July 2024.

• Nominations are unable to be

withdrawn once nominations are closed.

• Your nomination must be completed in one sitting; a partially completed form cannot be saved and reopened at a later date.

• A ll products and/or technologies must be manufactured and/ or commercially available in Australia.

• Please have any supporting documentation (i.e., brochures, photographs, testimonials) ready to upload. No single file should exceed 3MB in size. Any file above that size won’t be provided with judging files.

• A ll nominations must be accompanied by a high-resolution image (at least 1MB in size) suitable for print publication.

• A ll finalists are required to have a representative at the Gala Awards evening should they be successful. By submitting a nomination, you give Prime Creative Media permission to publish all or part of your nomination in MHD Supply Chain Solutions or another suitable publication.

The MHD Mercury Awards gala dinner is an opportunity to acknowledge and celebrate the outstanding achievements and successes of companies and

SEW Eurodrive is a sponsor of the 2024 Mercury Awards: Image: SEW Eurodrive.

MHD MERCURY AWARDS 26 | MHD MAY 2024

individuals in Australia’s logistics industry.

In 2024, the awards will be held on Wednesday September 18 in Melbourne from 7pm till late with the dress code being cocktail.

These awards highlight the innovation and excellence that abound within the logistics industry, which unfortunately often don’t get recognised.

Encompassing the entire nation’s logistics sector –from warehousing through to sea freight and everything in between, the awards acknowledge not only the major players in these industries but also the rising stars of tomorrow.

Sponsoring these awards is a great opportunity for your organisation to join this well-deserved recognition of our logistics industry. As a sponsor, you will have your name associated with the prestigious award of your choice, and the privilege of presenting that award to the well-deserved winner. You will also receive tickets to attend the event.

And, of course, you will be acknowledged as a sponsor in all of our pre and post event coverage.

Don’t miss out on this opportunity to be a part of the MHD Supply Chain Solutions Mercury Awards, and to be a partner in recognising and rewarding excellence and innovation in the logistics industry.

SEW EURODRIVE SPONSORING THE AWARDS

SEW Euro Drive says it’s sponsoring MHD’s Mercury Awards because it values supporting the supply chain and logistics industry.

“It’s a privilege to present an award that goes to a well-deserved winner, innovator or company that’s dedicated to their craft,” explains Katrina Dalgleish, Marketing Manager, SEW Eurodrive.

As a long-time sponsor of the award, SEW recognises the importance of innovative manufacturing and assembly and product solutions.

The Mercury Awards provides an opportunity to highlight the achievements of the often-overlooked logistics industry, which is integral to supply chain, and usually taken for granted.

There’ll be a diverse range of nominations across the logistics sector, including major logistics companies, small entrepreneurs, business leaders – many trailblazers within the field.

“There will be an acknowledgment of emerging talents as well as steadfast industry leaders who have provided a solid foundation,” says Katrina.

“It’s great to see a larger spotlight shone on those advancements and contributions across all sub-sectors within the industry. It’s also a great networking opportunity, helping foster growth, determination, and relationships.

“This is all because the person who’s sitting in that room could be the next industry expert who could be inspired to develop the next big thing.

“SEW Eurodrive has had a long-time connection with the logistics industry. Our own logistics sector relies on all those in the industry working together, and that’s why we really value it.” ■

MHD MERCURY AWARDS

WHY SUPPLY CHAIN IS NOW MISSION CRITICAL FOR THE C-SUITE

Global disruptions have exposed vulnerabilities in fragile supply chains, prompting more C-Suite leaders to prioritise the strength of their networks. Peter Jones, Managing Director at Prological, explains the developing role of logistics and supply chain as a strategic growth strategy in boardrooms across Australia.

No longer the sole responsibility of operations departments, supply chain has quickly become as complex as businesses taxation and foreign exchange, matters that have long been in the boardroom. The advent of integrated systems, automation, AI, next generation warehouses and B2C’s new capability in fulfillment and customer visibility demands a clear and aligned business strategy. Once tactical tasks, these modern technologies are now necessities for the battle to win and retain customers, says Peter Jones, Managing Director at Prological.

According to Peter, its not just the complexity that has escalated in the last few years, but the scale of supply chain investment now required to be an industry sector leader.

“For many businesses, supply chain is the highest level of investment, which will only escalate as capital investment opportunities continue to drive down operational costs, open up customer facing visibility and expedite order fulfillment,” Peter says.

“A simple example is nextgeneration, highly-automated warehouses enabling rapid fulfillment turnarounds, with very high CapEX’s but very low OpEx’s. These facilities can run into hundreds of millions in capital, requiring careful operational expense forecasting and solid medium to long term business strategies. This

is a new reality and beyond the remit of every functional logistician in the nation, requiring understanding and approvals from the C-suite and often, boards.”

UNLEASHING AGILITY, GROWTH & COMPETITIVE ADVANTAGE

By tightly integrating logistics mastery with boardroom vision, companies can transform supply chain functions from nodes of risk and costs into critically leverageable assets for competitive advantage. When optimised, agile supply chains unlock new revenue streams, fuel expansion into new markets, and catalyse gamechanging innovations.

“Over the next 5-10 years, we’ll see a clear delineation between the ‘haves’ and ‘have-nots’ in supply chain capability and market share,” predicts Peter. “The ‘haves’ invest in sophistication, robustness, and flexibility while the ‘have-nots’ revert to pre-pandemic practices.”

Peter advocates viewing supply chain as a core business competency requiring long-term planning and investment - a shift from traditional cost-cutting mindsets but one that fortifies resilience.

“Those businesses continuously refining logistics for resilience and responsiveness will find opportunities for growth, even among daunting headwinds, and in the good times,

will thrive, win market share and will be respected by their customers,” he says. “Businesses relying on outmoded, brittle supply chain infrastructure and models will be constantly reacting - bleeding revenue, profits and market share with each new disruption. This pivotal strategic divide will reshape industries in the next few years.”

Until recently, supply chain management was an undervalued corporate function – traditionally viewed as an operational necessity but rarely seen as a strategic asset. Those days are rapidly fading into the rear-view mirror, however, with a series of catastrophic global disruptions mercilessly exposing the vulnerabilities of fragile, inflexible supply chains, delivering a reality check to businesses worldwide.

The COVID-19 pandemic was the precipitating event, creating a “perfect storm” of logistics nightmares as lockdowns, labour shortages, and historic consumer demand swamped the intricate network of suppliers, manufacturers, transportation providers and distribution centres required to move goods to market. This initial chaos was then compounded by the geopolitical shockwaves of the Russia Ukraine war, snarling global trade routes and energy supplies.

Peter recounts how companies were left dangerously exposed, with

28 | MHD MAY 2024 MHD COVER STORY

“Recent Accenture research found 43 per cent of supply chain executives cite lack of strategic alignment as the reason they can’t unlock more enterprise value.

product lead times skyrocketing from weeks to over nine months as pipelines stalled. “Businesses found themselves very thin on inventory as their supply chains had been built on a ‘just-in-time’ strategy with minimal buffers. It put businesses under great financial stress very quickly,” he says. “That’s what took supply chain disruption right into the C-suite and boardroom conversations.”

The rapid awakening of severe disruptions has jolted senior executives around the world out of their lack of detailed awareness of supply chain, in turn making it a top priority.

The 2024 Prological Supply Chain Pulse Check Survey found 57 per cent of over 200 logistics professionals believed the C-suite is now more focused on supply chain resilience than before the pandemic.

“With supply chain now a critical focus for the C-suite, visibility is more important than ever,” Peter states. “The survey shows driving new investments and improving endto-end supply chain visibility are key focus areas for business leaders this year. It is clear businesses have seen the importance of a strong supply chain. In response, evidenced by the survey results, we are seeing rapid upgrades in supply chain capability and investment in preparing for an organisation’s next period of growth.”

TRANSCENDING SILOS

As supply chain strategies become more vital to the health of the entire enterprise, C-suite leaders can no longer afford to view logistics operations as separate, functionallysiloed workstreams. Creating truly resilient, adaptable supply chain capabilities requires a baked-in, continuous synchronisation between logistics and the overarching corporate strategy.

“Supply chain is an area of businesses that touches the customer,” Peter noted.

need to emulate the seamless fulfillment experience of online retailers and provide full transparency from order to delivery. B2C focussed companies are pushing into new supply chain capabilities, further broadening the capability gap between companies treating supply chain as strategic versus those who see it as tactical.”

Executive leadership is critical for embedding supply chain agility into the organisational DNA.

“The big shift is a mindset change where supply chain professionals

MHD MAY 2024 | 29 MHD COVER STORY

”

Peter Jones, Managing Director, Prological. Image: Prological.

Peter advocates viewing supply chain as a core business competency requiring long-term planning and investment. Image: Prological.

MHD COVER STORY 30 | MHD MAY 2024

own their ability to drive value,”

Peter says. “The pandemic showcased numerous examples of supply chain experts shaping internal narratives and earning C-suite roles themselves, which is a trend likely to continue.”

This convergence of supply chain resilience with corporate strategy futureproofs the business from the increase in disruptions. According to McKinsey research, supply chain shocks equate to 45 per cent of one year’s profits lost every decade without mitigation, highlighting how C-suite leadership helps prioritise and align logistics with operational and financial objectives.

Recent Accenture research found 43 per cent of supply chain executives cite lack of strategic alignment as the reason they can’t unlock more enterprise value. The C-suite partnership overcomes this barrier while tackling other roadblocks like inadequate skills (48 per cent), legacy IT systems (44 per cent), and securing resources to build resilient operations.

SHORING UP SUPPLIER PIPELINES

“Businesses will be well served by holding discussions with primary suppliers to understand the robustness of their supply chain end-to-end,”

For C-suites, it’s either put supply chain front-of-mind, or be left behind. Image: Prological.

Peter advises. “They should conduct audits, secure backup suppliers and invest in technology for full transparency.”

As supply chains grow increasingly complex with geographically dispersed, multi-tiered supplier networks, Peter stresses the need for C-suite oversight and comprehensive risk mitigation.

Too often, businesses solely hold Tier 1 vendors accountable without grasping potential chokepoints from secondary and tertiary providers.

“If a primary supplier relies on a single source that fails, they won’t be able to meet demands,” Peter explains. “Companies must deeply evaluate their supply chain’s end-to-end resilience, auditing and securing backup suppliers across all tiers, even if costlier initially.”

From global crisis to existential threat, a perfect storm of compounding pressures has ushered supply chain strategy into a new era of criticality for the C-suite. Enterprises prioritising logistics resilience, agility and digital visibility will be equipped to surmount even the most turbulent conditions. Those failing to adapt will be left treading water, always reacting, never fully recovering, says Peter.

“The awakening has sounded - boardrooms can no longer ignore supply chain mastery as a non-negotiable imperative for lasting success.” ■

MHD COVER STORY MHD MAY 2024 | 31

The convergence of supply chain resilience with corporate strategy futureproofs businesses from increasing disruptions. Image: Prological.

Coates acquired its first Hangcha unit in 2022. Image: Coates

STRATEGIC SYNERGY

In a world where efficiency, sustainability, and strategic foresight are paramount, the partnership between Coates, Australia’s leading equipment hire and solutions provider, and Hangcha, a forklift manufacturing powerhouse, demonstrates how like-minded collaborators benefit industry. MHD explores the strategic, customercentric, and sustainability-driven facets that drive innovation and mutual growth.

The inception of the CoatesHangcha partnership was not a decision taken lightly. It was the culmination of an extensive period of due diligence, involving technical reviews, demonstrations, and customer trials, leading to the acquisition of the first Hangcha unit in 2022. “Coates and Hangcha are steadily building a strong strategic relationship in the Materials Handling sector,” says Dan Goodfellow, Group Manager - Products & Fleet Trading at Coates.

Faced with the global supply chain challenges of 2020, Coates began exploring options among various Chinese OEMs, with Hangcha standing out for its shorter lead times and competitive pricing. This exploration was not merely about overcoming immediate challenges but was geared towards fostering a long-term strategic relationship. Dan highlights, “After undertaking extensive research and

conducting a number of demos, we bought our first units in 2021/22.” The adoption of Hangcha’s rough terrain forklifts and the consideration for expanding the product range within Coates’s fleet underscore a commitment to excellence and innovation.

SUSTAINABLE SYNERGY

The strategic alliance between Coates and Hangcha is underpinned by a shared commitment to sustainability and operational efficiency. The Hangcha products deployed by Coates, including the new “High Voltage” Lithium Rough Terrain forklifts, align with Coates’s “Greener Choices” range. This range encompasses battery electric, hybrid, and solar equipment, along with low pollutant Stage V engines, offering customers sustainable solutions for their projects. “The majority of our investment in Hangcha has been in our ‘Greener Choices’ range,”

Dan emphasises, showcasing the partnership’s role in supporting industry towards a greener future.

AMPLIFYING CUSTOMER VALUE

The business models of Coates and Hangcha, though distinct, complement each other in a manner that amplifies value for customers. Coates’s position as Australia’s largest equipment hire and solutions provider, combined with Hangcha’s stature as a globally recognised materials handling manufacturer, creates a formidable force in the industry.

This collaboration is not just about providing equipment; it’s about delivering comprehensive solutions that support customers’ net-zero commitments and operational needs. Dan reflects on the mutual understanding and shared goals that have been instrumental in providing

32 | MHD MAY 2024 MHD MATERIALS HANDLING

effective product solutions: “Hangcha’s focus on more sustainable electric equipment supports this. Hangcha also have efficient delivery times with equipment which assists with our fleet replacement strategy and enables us to match our fleet investment requirements with customer demand.”

EXCEEDING CUSTOMER DEMANDS

The partnership supports Coates in meeting the diverse demands of its customers, from large corporations to local tradespeople, across Australia’s vast landscapes. With $1.95 billion in available assets across numerous product categories, Coates provides its customers with end-to-end solutions across equipment hire, power and HVAC, temporary works engineering, and industrial shutdowns and maintenance. The national footprint of more than 145 branches enables the delivery of materials handling solutions that are efficient and safe for operators, irrespective of the project’s scale or location.

“Our customers require materials handling to safely move, place, replenish or just reduce manual handling on the site, from our top-tier customers like BHP or Downer, all the way through to the tradie improving a school for our kids,” says Dan.

“Australia is also a vast country, with remote sites and massive distances to travel which means warehouses and distribution centres are common across the country. With more than 145 branches across the country, we have the national footprint to offer materials handling like forklifts, telehandlers, pallet jacks or walkie stackers to make these sites efficient and safe for the operators.

“With so many sites to service, it’s important to have reliable partners like Hangcha on board.”

ELEVATING BRAND REPUTATION

At the heart of this partnership lies a shared emphasis on elevating brand reputation through diligence, quality, and innovation.

Coates’s rigorous supplier due diligence process and Hangcha’s commitment to product quality and improvement reflect a mutual dedication to excellence. “Whether we’re purchasing equipment from the US, Europe, or China, all suppliers must pass our compliance and fitfor-purpose test,” Dan remarks, underscoring the importance of reliability and maintenance in enhancing brand reputation.

CHARTING A PATH FORWARD

The strategic partnership between Coates and Hangcha is more than a response to immediate market needs; it’s a forward-looking collaboration that helps set a higher benchmark for industry. Through a shared vision for sustainability, a commitment to meeting diverse customer needs, and a dedication to elevating brand reputation, Coates and Hangcha are not merely navigating the present— they are shaping the future of the materials handling sector.

The Coates-Hangcha partnership illustrates the power of strategic collaboration in meeting and exceeding industry standards. By combining Coates’s extensive network and customer-centric solutions with Hangcha’s manufacturing excellence and innovation, this alliance not only addresses current challenges but also paves the way for a more sustainable and efficient future. In fact, this forward-thinking approach is baked in from the outset, as Dan explains:

“Before forming a strategic partnership with a supplier we will often spend time at their factory or with their R&D team to ensure they have the capability and resources to continue to improve the product. We are in the process of doing this with Hangcha and it’s been very productive. Rental equipment needs to be robust, so how a supplier responds to issues, breakdowns and feedback is important to us so we can continue to deliver high-quality equipment and excellent customer service for our customers.” ■

The Coates-Hangcha partnership is in part based on a shared commitment to increased sustainability of forklifts.

MHD MAY 2024 | 33 MHD MATERIALS HANDLING

Image: Hangcha.

Order picking is the grouping of specific partial quantities (articles) from available warehouse stock (inventory) on the basis of orders. Image: Jungheinrich.

IMPROVING OPERATIONS WITH ORDER PICKING

MHD sat down with Jungheinrich’s Product Manager, Robert Skalba, to discuss how lowlevel order picking processes and assistance systems improve warehousing operations.

At first glance, the low-level order picking process seems easy to manage. It’s simply collecting items from the warehouse and stacking them onto pallets.

Jungheinrich says efficiencies can be increased through many ways. Picking errors can be minimised, driving path lengths reduced, and the warehouse layout and goods and equipment setups can be optimised.

All these areas need to be deeply investigated to get the best results. Even if cutting-edge technology is implemented, when the warehouse layout doesn’t fit to the current process needs, it isn’t effective.

IMPROVING PROCESSES WITH ASSISTANCE SYSTEMS

Low-level order picking (LLOP) works like a mechanical device. It may function if some parts are low quality or sometimes even missing. But if a warehouse manager wants it to work like a Swiss watch, they’ll have to pay

attention to the details.

“I’ve met many customers and I’ve found that they think everything’s perfect, but after investigating, we notice we can improve their applications,” says Robert Skalba, Product Manager, Jungheinrich. “But each customer wants to increase the picks per hour, and it can be done in many different ways. We can also use some additional systems.”

Based on VDI (Association of German Engineers) guidelines, “order picking is the grouping of specific partial quantities (articles) from available warehouse stock (inventory) on the basis of orders.”

The operator drives around the warehouse and collects goods according to the customer’s orders. For instance, short distances between picking spots allow the operator to use semiautomatic solutions and reduce total picking time.

On the other hand, if too many fastrotating goods are stored in the same

area, there’s risk of a traffic jam. There’s no simple answer or universal solution for all applications.

Assistance systems are all technical solutions, which help prevent operators making mistakes, increase productivity or help them work comfortably. One of the leading solutions is pick-by-voice. The operator receives commands via headphones as to what to collect and confirms it by speaking into their earphone set.

Pick-by-weight is a similar system to the one which is used in supermarket self-checkouts. The system checks the weight of each collected item and compares it with the weight in the Warehouse Management System (WMS).

Another one is pick-to-light, which highlights the pallet where the current picking item should be placed. It all depends on the customer specific requirements as to which one is the best for the application.

34 | MHD MAY 2024 MHD WAREHOUSING

RAISING PLATFORMS AND AUTOMATING OPERATIONS WITH WMS

Jungheinrich knows the right truck and configurations are crucial to ensure effective processes. It starts with finding the correct model – depending on what the level order picking process is. If it’s just Level 0, standard LLOP usually will suffice.

If the picking process is going further up, it’s necessary to change the model to the one with a lifting platform or step in the operator’s area.

“Width across the forks have to be picked depending on the operated loads,” explains Robert.

“Sometimes additional forks accessories may be useful, e.g., stops on fork tips, or dedicated locking brackets.

“A fork’s length may vary depending on the loads, but also the warehouse layout. Backrests, seats, accessories, special equipment – all these components should be taken into consideration when choosing the right truck for the application.

can push the button to make it extend about one metre vertically. It all depends on the location of the loads in the warehouse layout.

“If we are talking about different solutions, you usually think about automation. It’s present in the order picking, but it’s like semi-automation,” notes Robert.

“We are talking about three solutions. The first one is the basic one. The operator can drive the truck a certain distance. It can be adjusted according to the customer’s requirements.

“The more advanced one, and I think the most popular one is the one where the truck follows the operator.”

Jungheinrich acknowldeges of the primary challenges in LLOP revolves around picking errors, which stand as a significant hurdle for companies striving to meet customer demands efficiently.

Selecting the right equipment for the job is crucial in optimising LLOP operations. Factors such as fork length, the suitability of standard versus elevating platforms, and the integration

essential tools and technologies all play a role in determining efficiency.

In pursuit of increased automation and efficiency, Jungheinrich understands businesses are exploring semi-automatic solutions, including remote steering, follow-me systems, and truck-WMS integration. These innovations promise to revolutionise LLOP.

“Operators can focus on their main job and in the case when the next load is too far away to go by foot, the WMS can send the information to the truck, so it knows where to drive,” says Robert.

“They can confirm they’ve picked up the goods by lodging the information into the terminal.

“Depending on the solutions and customer applications, they can expect productivity increases of up to 30 per cent. Here at Jungheinrich, we can help you optimise your warehousing operations by providing our LLOP services and advise you as to what solutions will suit your facilities. Feel free to find out more by contacting

Find out more: www.enersys.com/en-gb/throughput © 2024 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E. *As reported on www.talkinglogistics.com

of customers penalise suppliers for missed deliveries. If your equipment power fails, you jeopardise today’s deliveries and tomorrow’s business. Are you at risk? When it comes to power, EnerSys® can help you choose wisely. * Today it’s a missed delivery. Tomorrow it’ll be my job. MHD MAY 2024 | 35 MHD WAREHOUSING

50%

WHY ADAPTABLE SOFTWARE IS CRUCIAL

Körber’s Darren O’Connor explains why adaptable software is a must in the modern supply chain.

ISlotting.IQ helps organisations better utilise their space and reduce replenishment efforts.

Image: Körber

n today’s fast-paced world of supply chain management, following the crowd can be a recipe for mediocrity. A fit-forpurpose solution today may need to change in six months, while a legacy management system a business has relied on for years may not be delivering the same results. The current logistics and supply chain landscape calls for solutions which can cope with chaos, which is why flexibility and adaptability are core tenets of modern software for growing businesses.

At the enterprise WMS level, Körber’s software can be adapted to

fully support what an organisation really wants. Working with all sizes of business, this unique position in the market means that Körber attracts a certain profile of customer – organisations that want adaptable software, rather than an out-of-thebox solution. To continue to improve its software’s flexibility, Körber has introduced a new solution to run alongside its WMS: Slotting.IQ.

KEEPING UP WITH MODERN INVENTORIES

Supply chains are becoming more and more complex, exemplified by warehouse inventories that continually

vary depending on seasons, consumer preferences and product availability. More diverse customer preferences drive continuing stock keeping unit (SKU) proliferation, heaping the pressure on organisations to improve warehouse efficiency. High prices and low vacancy rates for industrial property have placed an onus on maximising warehouse floor space, making the targeted assignment of storage slots – placing inventory in its optimal position inside a warehouse –fundamental to a well-run distribution centre. Large, fast turning and seasonally changing inventories have exposed the limitations of manually

36 | MHD MAY 2024 MHD SUPPLY CHAIN

handling items, while traditional rule-based slotting tools are also insufficient for today’s demands.

Körber’s Slotting.IQ was developed to bridge this gap, giving warehouse managers a slotting solution that can handle large, complex, frequently changing product assortments.

Built to integrate seamlessly with Korber’s industry-leading Warehouse Management System (WMS) – which was recently named a Customers’ Choice in the 2023 Gartner Peer Insights ‘Voice of the Customer’: WMS report – Slotting.IQ optimises inventory placements to increase order picking efficiency. The technology harnesses an array of customer data, including item master transformation, warehouse layouts and historical pick paths. By employing advanced data science methodologies and projected future demand, it determines the optimal storage locations for every SKU. This strategic slotting maximises pick density, reduces travel time and accounts for product velocity, slot characteristics and customer-defined rules.

GAINING A COMPETITIVE ADVANTAGE

The benefits of a modern slotting solution are substantial. Initial customer results have shown efficiency gains of 5 per cent to 30 per cent for picking and replenishment processes, translating into significant labour cost savings. Slotting.IQ helps organisations better utilise their space and reduce replenishment efforts. It also helps improve order accuracy, workplace safety and reduce instances of item damage.

Flexibility and configurability are the key pillars of Slotting.IQ. Unlike traditional slotting tools with rigid, predefined rules, this new solution enables customers to provide extensive data inputs and define their own parameters. The tailored approach ensures that slotting recommendations align with each organisation’s unique processes, priorities and goals.

Slotting strategies vary depending on the business, so a solution which can adapt to minimising picking distance or reducing replenishments can be a major advantage. By simulating and comparing the impact of different approaches, organisations can make

“High prices and low vacancy rates for industrial property have placed an onus on maximising warehouse floor space, making the targeted assignment of storage slots –placing inventory in its optimal position inside a warehouse –fundamental to a well-run distribution centre.

”Flexibility and configurability are the key pillars of Slotting.IQ. Image: Körber

informed, data-driven decisions while being able to adapt and add slotting of new products or product lines.

Embracing a new, higher level of adaptability in our supply chains enables businesses to respond to a wide breadth of customer demands, increasing customer satisfaction.

Körber’s recent Supply Chain Benchmarking survey demonstrated that 90 per cent of consumers are less likely to buy from a brand again after a poor online shopping experience, showing second chances are hard to come by.

To thrive in today’s business landscape, solutions like Slotting.IQ are helping forward-thinking companies rise to the challenge. While techenabled supply chains are becoming the norm, we still need to think creatively to solve unique problems. No business is the same, nor is any one supply chain, so the technology behind them needs to reflect this individuality. ■

Darren O’Connor, Director of Solution Delivery at Körber Supply Chain

MHD MAY 2024 | 37

CLARKSOLUTIONS USES TMH A TO EXPAND BUSINESS

Melbourne-based commercial and industrial cleaning business ClarkSolutions has enlisted the strong and reliable performance of Toyota Material Handling Australia (TMHA) as it expands its business to include a small warehouse.

ClarkSolutions offers a wide range of services for businesses including after-hours office, warehouse, building, window and event cleaning as well as the recent production and sale of chemicals which has necessitated the acquisition of a warehouse to store the chemicals.

With the recent production and sale of chemicals, ClarkSolutions Director Peter Clark required a forklift for the first time, resulting in the purchase of a Toyota 32-8FG25 forklift.

“ClarkSolutions has recently

upscaled our business and have gone into manufacturing cleaning chemicals, and we required a forklift for receiving pallets of cleaning chemicals off trucks,” Peter says.

“They’re 200-litre drums of cleaning chemicals and there’s four drums on each pallet, so that’s 800 litres so we definitely needed a forklift.”

When beginning the process of choosing a new forklift for his warehouse, Peter consulted friends with experience in selling forklifts,