SPRING 2023

www.timbermedia.co.uk

ISSN 2517–26X (PRINT)

VANDECASTEELE 18

Leading the sustainable way and the route to trading only in certified timber by 2025

TERRY EDGELL 16

We hear from Premier Forest’s CEO on new business expansion and market strengths

TRADER UK

TIMBER SKILLS 26

Why training and developing staff talent is so important to long-term plans

20

02 News

A range of news and views from across the industry.

12 Timber & Skills Action Plan

New guidelines are aimed at equipping the UK construction industry with the skills to increase the use of timber and achieve net zero targets.

14 A Future UK Resource

Confor’s Stuart Goodall, examines the threats to homegrown timber supply and why the UK must urgently move productive tree planting up the agenda.

16 Powered by Premier

We spoke to Premier Forest’s CEO Terry Edgell, about recent business developments and its expanding role in the timber marketplace.

18 Certified Timber is the Way Forward

Vandecasteele Houtimport are one of the leading European timber merchants and have ambitious aims to trade only in certified timber by 2025.

20 Markets Still Need Refocusing

A recent survey by the National Buying Group identified a ‘service level disconnect’ between builders’ merchants and suppliers.

26 Preparing the Future

Two timber firms recently outlined how they are going about expansion programmes with an eye on developing and holding onto future talent.

32 Making the World Go Round

Sutherland-based timber specialists GMG Energy has put circular economy theory to practical use in a tie-up with a Dumfriesshire transport specialist.

34 Business in Everyone’s Hands

Two timber companies recently entered employee ownership trust status – what is this and what are the benefits for all involved

The Perfect Partner for the Timber Industry

Managing Editor: Terry Hanlon

terry.hanlon@timbermedia.co.uk

01925 872371

Artwork: Pete Awad

artwork@timbermedia.co.uk

Follow Timber Media:

@Timber_Media

Registered address: 9 Viaduct Street, Newton-le-Willows, Merseyside WA12 9PL

Company registered in England and Wales. Company Number 10839173.

Timber Trader UK Magazine Autumn 2022 01 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring 16 14 18 32 34 12 02 26 20

TIMBER TRADER UK ISSUE 20 CONTENTS

Timber Trader UK magazine 185 x 62 Liz 2023.indd 1 12/04/2023 10:46:42

combilift.com

Travis Perkins praised for tackling climate change

The UK’s largest distributor of building materials and a leading partner to the construction industry, has been recognised by CDP for their work to engage with suppliers to jointly tackle climate change. This means the Group is amongst the 8% of companies globally which have been recognised for supplier engagement within its 2022 disclosure of climate change information to CDP – a not-for-profit charity that runs the most established and well recognised global disclosure system that help businesses and organisations manage their environmental impacts.

The Group has developed a multifaceted strategy for working with suppliers to understand and address their unique challenges and opportunities to reduce their carbon emissions. Travis Perkins’ executives, commercial teams and sustainability experts have carried out supplier assessments, supplier training workshops and a Scope 3 CEO engagement event. As a result of this work over 50% of the Group’s spend is now confirmed as being with product suppliers who have at least calculated their own Scope 1 and 2 carbon and who have set a reduction target. Product-level carbon data, and supporting Environmental Product Declarations (EPDs), are being collected to share with customers.

Travis Perkins plc first announced its Science Based Targets initiative (SBTi) decarbonisation targets in November 2021. These are in line with a 1.5°C trajectory and are an integrated part of the Group’s broader sustainability plans. In 2022 the Group set interim targets for 2027 with plans in place to reduce carbon by 40% across the Group’s property portfolio and by 27% across the Group’s fleet; both against the 2020 baseline. The Group has a Scope 3 carbon reduction roadmap which includes a target to have 70% of product spend with suppliers who are engaged on carbon by 2024.

Group sustainability director for Travis Perkins plc, Megan Adlen, said: “The construction industry has a significant role to play in driving decarbonisation of our country and addressing climate change. Travis Perkins believes greater transparency is key to driving climate action,

and so we have continued to disclose the progress we are making towards our ambitious decarbonisation targets by publishing regular updates to our decarbonisation roadmaps on our website. As part of our broader Scope 3 emissions commitment, we are also working with suppliers and customers to reduce supply chain emissions, in particular in-use emissions from products sold and the embodied carbon in products, and we are proud that this work has now earned us a place as a leading company on CDP’s 2022 Supplier Engagement Leaderboard.”

Global head of value chains for CDP, Sonya Bhonsle, added: “This year’s report shows that environmental action is not happening at the speed, scale and scope required to limit global temperature rises to 1.5 degrees, with many companies still not acknowledging that their impact on the environment extends far beyond their operations and that of climate change.

“COP 15 couldn’t have been clearer in the call to action on corporate reporting on nature. If a company is not preparing for future regulations on nature in the supply chain, they are open to a wide range of risks and could also be missing out on the opportunities that safeguarding nature will bring. Quite simply, if a company wants to be in business in the future, they need to start embedding nature into the way that they buy and collaborating with suppliers to drive action in the supply chain. Therefore, we need to see environmental leadership from companies right now by tackling their impacts on climate change and nature together, working with their suppliers in an integrated way that includes nature as standard, and incentivizing this engagement within their organisation.”

CDP’s environmental disclosure and scoring process is widely recognised as the gold standard of corporate environmental transparency, and the full list of companies that achieved a place on the CDP leaderboard this year is available on the CDP website.

More at www.cdp.net www.travisperkins.co.uk

Timber Trader UK Magazine Autumn 2022 02 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring TIMBER TRADER UK NEWS

Fire safety website set to provide timber industry guidance and regulations

The timber industry has launched a comprehensive new fire safety website. It has been developed and launched as a collaborative project between Swedish Wood, Timber Development UK (TDUK) and the Structural Timber Association (STA), with a commitment to a periodic review and update curation process to reflect any changes in regulation, outcomes of latest research and industry guidance.

The information in this first iteration has been provided by technical and industry experts from the UK and Sweden, reviewed by a separate expert group drawn from the UK timber industry and independent consultants, and curated by Professor Julie Bregulla FREng, consultant to Swedish Wood.

Fire safety design can take many different pathways, influenced by such factors as architectural vision, client demands and product choices. The site gives the user underpinning principles and approaches, as well as background references and cross-links to further advice and guidance, so as to provide them with context and UK industry resources in support of their wood projects. David Hopkins, CEO of Timber Development UK said: “We cannot stress this enough. The most important thing is to provide designers with the principles of timber design for fire safety, not try to do the design for them.”

Professor Bregulla says: “Understanding fire safety principles underpins good design. We hope this website will bring an accessible and flexible resource to the wider community to inform their design processes with timber solutions and facilitate their wider supply chain collaborations.”

Referencing European standards where appropriate, but with a focus on UK regulations and standards, the site is designed so that a range of different users can explore subjects at different levels of

detail – from architects and structural engineers to building owners and the many stakeholders making successful timber projects possible. Although the site allows navigation to specific areas, users are encouraged to follow the suggested topic flow site map to get a good understanding of the inter-connectedness and multi-disciplinary nature of fire safety.

David Hopkins and Andrew Carpenter, CEO of the STA added: “This site brings together a wealth of knowledge and expertise from across the construction spectrum. It is one of many projects we are working on to try and reduce barriers to the use of timber in construction. It’s also been good to have a true collaboration with our colleagues at Swedish Wood. We will continue to work together to promote best practice in all areas of timber safety and design.”

Anna Ryberg Ågren, director of Swedish Wood, said: “We are delighted to be partnering with TDUK and the STA to produce this important, independently verified, website. It forms part of our aim to help UK building professionals in the construction sector access factual information concerning timber and fire safety. as well as to be able to link to like-minded information on a European level”.

More at: www.timberfiresafety.org

Timber Trader UK Magazine Autumn 2022 03 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

TIMBER TRADER UK NEWS

inkjet

for

needs Tel: 0870 803 1877 www.timbermark.co.uk

printers

all your timber marking

New design awards will raise the roof

A new awards scheme has been launched to celebrate the ingenuity and technical skills of designers in the trussed roofs sector. The Roofscape Design Awards are being run by the Trussed Rafter Association (TRA). The awards will recognise projects that showcase the highest standard in design, innovation, and sustainability in the use of timber trussed rafter roofs.

The awards will be given in three categories: Residential Project of the Year (for newbuild dwellings), Conversion and Refurbishment Project of the Year (for existing housing projects) and Commercial Project of the Year (for all non-domestic projects).

Nick Boulton, chief executive of the TRA said: “Timber trusses are a proven, widely used modern method of roof construction making use of nature’s most sustainable building material. Yet the highly technical skills required in the design of those trussed rafter roofs are not yet fully recognised or rewarded in the housebuilding and construction industry.

“This is what we want to shine a spotlight on: to demonstrate the designers’ problem-solving and spatial ingenuity at work, to give credit where it is due, and to showcase timber engineering design as a very attractive career for talented people. The Roofscape Awards recognise and promote the exceptional design work that has been completed by our members. Some of the projects worked on by TRA members are

extraordinarily complex and clever, so it is time to raise the roof and celebrate the beautifully completed projects of 2022.”

A panel of experts in timber engineering, architecture and sustainable design will judge the entries and select the winners. The award winners will be announced at the TRA’s annual conference and dinner at Kettering Park Hotel on 21 April 2023.

More at www.tra.org.uk

International Timber joins STARK Group

International Timber has joined STARK Group. The acquisition first announced on the 12 December 2022 confirmed that International Timbers’ parent company had reached an agreement to sell International Timber to STARK Group. This sale has completed, and International Timber are now wholly owned by STARK Group.

International Timber has now joined one of the fastest growing merchants and distribution groups in Europe and a business completely focused on its expertise in distributing building materials for tradespeople. The International Timber brand name, much recognised and respected by those in the industry will continue and International Timber will become part of the UK subsidiary of STARK Group, STARK Building Materials UK.

Paul Martin, managing director of International Timber, said: “STARK Group is a leading distributor of building materials across Europe and their business will bring their experience of successful growth. They have a culture of sharing best practice and will be supporting our plans to deliver the solutions, services and great experience that will help customers grow and make their life easier. So it’s great for our customers and for our suppliers who are also a critical part of our success.

“Customers won’t notice any immediate change, as it’s very much business as usual and we will continue to trade as normal for customers. Over time we will be working closely with STARK, sharing and building on our great plans for our customers. We have a lot of opportunities now to share best practice with STARK and learn from their business and operations elsewhere in Europe. They have a tremendous track record of growth and delivering a great experience to their customers. We’ll be spending time seeing in what ways we can learn from this experience to support our local customers.”

STARK Group CEO Søren P. Olesen said: “We are very pleased to have completed this acquisition in great time and look forward to welcoming the International Timber colleagues and branches to STARK. We have a strategy that successfully focuses on professional tradespeople and the renovation and maintenance market together with specialist distribution for a range of customer segments.

“Entering the UK market is a great opportunity for our combined business to share best practice across the Nordics, Germany, Austria and the UK making life even easier for tradespeople. We’re delighted to

now be a major employer in the UK, with 9,000 colleagues, where we will continue to operate as a good corporate citizen, placing a strong emphasis on sustainability, valuing and caring about our new UK employees and supporting UK growth and building decarbonisation.”

More at www.internationaltimber.com

Timber Trader UK Magazine Autumn 2022 04 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring TIMBER TRADER UK NEWS

Paul Martin

More ‘regular’ timber import patterns seen in Q4 2022

The gap between record 2021 volumes and low 2022 volumes began to close in November, with imports resembling more regular winter totals reported Timber Development UK (TDUK) in January.

The disparity in total volumes between 2021 and 2022 was just 14% in November 2022, compared to 22% in October and 21% in September. The reduced disparity between 2021 and 2022 was seen most clearly in the softwood category, where a 182,000m3 gap in October was reduced to 72,000m3 in November.

Overall, imports in 2022 have been significantly lower than the records set last year, with totals from January to November 2.4 million m3 lower than the same period in 2021. Only hardwood has seen growth in 2022, up 13% compared to last year.

TDUK head of technical and trade, Nick Boulton, said: “Totals in Q4 are beginning to resemble the levels of previous years, with the large disparity seen between 2022 and 2021 starting to close. These more ‘regular’ volumes, however, are largely due to reduced winter demand in previous years rather than increased volumes this year, with the timber market often winding down for the festive season.

“Overall, volumes have been low in 2022, with healthy stock levels and market uncertainty being reflected in this year’s import patterns. Looking forward, 2023 is set to be another tricky year for the timber

trade, with the CPA predicting reduced activity in crucial private housing and RM&I sectors. The CPA has predicted a shallow recession in 2023, with demand likely to pick up again in 2024. Demand for timber is also likely to increase significantly in the long-term, as the UK looks to reduce emissions in the built environment and achieve net zero by 2050.” More

Timber Trader UK Magazine Autumn 2022 05 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring TIMBER TRADER UK NEWS

at www.timberdevelopment.uk

National Timber Systems appoints design director

National Timber Systems, the engineered wood products division of National Timber Group, has appointed Julian Elsbury to the newly created role of NTS design director. Julian has almost 40 years’ experience in engineered wood products design, sales and management and is well-respected in the industry. He has been NTS design manager since 2020 when he joined the division from Pasquill. Based in Bristol, he has led the design teams across NTS’s four manufacturing sites at Bristol, Sheffield, Newcastle and Northallerton.

Julian will continue to bring consistency of approach to designs as well as ensuring that the National Timber Systems’ team have the necessary technical and commercial knowledge to provide a best in class experience for its wide range of customers.

Julian Elsbury said: “I am very proud and honoured to be promoted to and entrusted with this key role within the NTS team. I’m looking forward to helping my colleagues steer NTS from strength to strength. I am fortunate to have a good team of designers around me and through continual advancement in training and skillset I believe we can grow the business to rank alongside those sitting at the ‘top table’ of our sector.”

Nick Kershaw, NTS managing director commented: “Julian quickly established himself as head of the NTS Design Department when he

joined us and I am delighted he is our first design director. I am confident that he will continue to improve the way we operate. The new role is part of our ambition to be a leader in the specialist engineered wood products market, recognised for innovation and consistent high quality.”

National Timber Systems provides products for housebuilders and developers nationally, including the offsite manufactured panelised roof system NTSROOF, gable and party spandrels, trussed rafters, engineered joists, and floor and roof cassettes. The company has a turnover of almost £50 million. There are 240 employees across the division’s four sites in Yorkshire, the North East and South West England and work is underway to open a new site in the MKM Midlands.

More at www.nationaltimbersystems.co.uk

Predictions for the merchant sector complicated says ECI survey

Financial instability, rising materials costs and the cost of borrowing are some of the top concerns within the building materials distributors sector, according to a new poll of builders’ merchants. People in the sector will need to turn to merchant-specific software to grapple with the lasting impact of the COVID-19 pandemic on the supply chain, as well as the on-going war in Ukraine if they are to get ahead of the curve, the report highlighted.

The findings have been published in a new report, ‘Predictions for Builders’ Merchants in 2023’ by ECI Software Solutions, a software specialist for building trade suppliers. ECI polled those in the industry on their top challenges and opportunities for the year ahead. This comes as new data revealed that the construction sector represented 18% of all company insolvencies in 2022 – the largest percentage out of all sectors tracked.

Craig Sanders, joint managing director at Protrade, explained how rising business costs could pose a threat to the industry which, “could lead to businesses going into administration if they are unable to pass on costs” which could cause “a reluctance to invest or proceed with construction projects.” Despite an easing in the supply constraints of

many construction-related projects, a handful of key items are still in short supply and high demand. This often means that projects can get off the ground, but come to a grinding halt, part way through the build.”

Andy Scothern, director of business development – eCommerce at ECI Software Solutions commented on the findings from the report saying: “With fears of an economic downturn, it’s no surprise that there’s feelings of unease across the industry. Rising inflation and fears of recession means builders’ merchants are faced with trying to tighten their belts to reduce business costs while retaining the workforce and holding onto ‘just enough’ stock. Rather than grasping at straws to find ways to trim costs, it’s important to consider how builders’ merchants can take advantage of software solutions to better manage their product inventory and work seamlessly with suppliers – not at a disconnect.”

Timber Trader UK Magazine Autumn 2022 06 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring TIMBER TRADER UK NEWS

The full report is available at www.ecisolutions.com/en-gb/blog/survey-builders-merchantsshare-challenges-for-year-ahead/

Julian Elsbury

Andy Scothern

Donaldson Timber Systems appoints new manufacturing director

Leading UK offsite timber frame manufacturer, Donaldson Timber Systems (DTS), has appointed Frank O’Reilly as manufacturing director of its UK-wide operations.

Frank began his career 23 years ago working in both Ireland and Australia on major civil infrastructure works, before focusing on timber frame, truss and pre-hung door set manufacturing. He moved to Scotland in 2011 to join what was then Stewart Milne Timber Systems in Westhill, and transferred to the Witney, Oxfordshire factory four years later.

In his new role, Frank will join DTS’ management board and will take a greater lead on continuing to develop the business’ customer offering, including the creation of future strategies for DTS’ manufacturing facilities. He will also provide support in developing processes across the wider business and assist other departments in building strong working relationships with customers.

Rod Allan, managing director of DTS, said: “Frank joined our business 12 years ago and across his various roles, has always approached them with

The Pallet LOOP scoops Sustainability Award from Willmott Dixon

The Pallet LOOP is celebrating after picking up a Sustainability Award from Willmott Dixon at the construction company’s 2023 North West Supply Chain Awards. The award – which was given out under the heading, ‘Sustainability - Now or Never’ – recognises the calibre of the pallet collection service that The Pallet LOOP delivered to Willmott Dixon during 2022, and the financial and environmental benefits the scheme is delivering.

Over the last twelve months, The Pallet LOOP has collected almost 4,000 single use ‘white’ pallets from Willmott Dixon sites in the North West of England – diverting them from wood skips. As a result of this collaboration, The Pallet LOOP estimates that Willmott Dixon has reduced site waste volumes by more than 750m3, saved an estimated £10,000 in waste disposal costs, and prevented nearly half a tonne of CO2 emissions in this region alone. Nationwide the numbers are even more striking. To date, The Pallet LOOP has collected more than 27,000 pallets from over 70 Willmott Dixon sites across the UK. That’s an estimated 5,500m3 reduction in waste; a staggering £78,000 saving in waste disposal costs plus a drop in CO2 emissions of over three tonnes.

The Pallet LOOP has started picking up single use white pallets ahead of the roll out of its distinctive green circular economy pallets – which are due to enter the building materials supply chain later this year. The back end of the service is already proving incredibly popular with principal contractors and housebuilders, who are left to dispose of pallets once they have been used to transport building materials to sites.

Charlie Law, head of construction and ESG at The Pallet LOOP, picked up the award at a ceremony hosted in Manchester on Thursday 2nd March. Commenting he said: “Switching on our collection service before releasing our

dedication and a commitment to help support our growth plans. As we progress with our investment programme, manufacturing is an area that deserves the best of attention. Frank has been instrumental in the design and the ongoing refit of the Witney factory over the last two years. We look forward to Frank having greater influence and input into the ongoing development of our systems and services in what is a highly competitive marketplace.” Currently led by the sixth generation of Donaldson, the 162-year-old Donaldson Group comprises a total of 17 specialist timber and building product businesses and brands, operating throughout the UK from 46 locations employing over 1,700 people. The businesses that make up the Group trade and operate independently, sharing best practice, innovation, purchasing synergies, and market analysis.

green pallets into the sector, is the first step in the operational roadmap of The Pallet LOOP. It might seem strange that we’re collecting white pallets, which our multi-use green pallets are ultimately designed to replace. However, it does make sense. Conscious that switching to a circular economy distribution model will require a shift in mindset, we wanted to get the back end of our service up and running so the sector starts to see pallets differently.”

“For too many years, the disposal of pallets has proved problematic. They are notorious for cluttering up building sites and normally end up in skips, which is costly on many levels. Our green pallets will change all that. Reverse engineering our model and getting collections going now will help the sector get in the habit of stacking pallets for collection and booking a pick-up. It’s a simple change, that will make a huge difference to the success of our green pallet scheme; the delivery of net-zero emissions and waste; and the bottom line of construction businesses nationwide. We’re delighted that the likes of Willmott Dixon are already gaining so much from this service.”

Anthony Dillon, Willmott Dixon managing director in the North West, said: “Congratulations to Pallet LOOP, worthy winners of our sustainability award. The work of Pallet LOOP has contributed to Willmott Dixon reducing absolute construction waste by 58% since 2012, which is a significant output of our Now or Never strategy that guides our sustainable development approach.”

More at www.thepalletloop.com

Timber Trader UK Magazine Autumn 2022 08 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring TIMBER TRADER UK NEWS

at www.donaldsontimbersystems.com

More

Frank O’Reilly

NEW PRODUCT

Just landed! Our NEW pre-primed OSB is a blank canvas, perfect for applying for marketing messages and graphics. With all the inherent properties of our popular OSB3, SterlingOSB Zero PrimedPlus has a primed textured finish, and is designed for promotional messages, screening, exhibition stands, walkways and hoardings, inside or out.

Timber Trader UK Magazine Autumn 2022 09 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

Combilift donates its 75,000th truck to international charity

As part of Combilift’s celebrations for its 25th anniversary, the Irish materials handling specialist has announced that it is donating its 75,000th truck – an Aisle Master articulated forklift – to Convoy of Hope, a non-profit humanitarian and disaster relief organisation.

Convoy of Hope works alongside communities and its wide network of volunteers aim to alleviate poverty and hunger and to bring help and hope wherever they are most needed in the world. As this type of aid is sadly always in demand, operational expansion has also seen a corresponding increase in the requirement for warehousing capacity to accommodate the vast volume of supplies that are stored and ready for delivery to areas in need.

The World Distribution Center is based in Springfield, Missouri, and from this location at the ‘crossroads of America’ truckloads of relief supplies and food are sent on their way across the USA and further afield around the globe. Combilift supplied its first Aisle Master for this site four years ago, and a further three units were delivered last year.

Convoy of Hope’s senior director – distribution, Jeff Smethers said: “A lot of our exponential growth has been down to the Aisle Masters as they enable us to get more loads in and out faster. And thanks to Combilift’s free warehouse layout service and the Aisle Master’s narrow aisle capability we have achieved the best possible storage density and very efficient operation.”

The announcement was made at a gala dinner in Chicago during the ProMat trade fair, and Combilift’s CEO and co-founder Martin McVicar

said: “The work that Convoy of Hope does is invaluable to relieve suffering around the world and we wanted to make our own contribution by donating our 75,000th truck to this very worthwhile charity.”

Erick Meier, senior vice president – supply chain at Convoy of Hope added: “We are so grateful that Combilift and Martin and the whole team have actually given us one of these trucks for our operations. This is going to help people for years – and ensure that every day someone in the world will receive aid - and that brings hope.”

More at www.combilift.com convoyofhope.org

MKM invests in mental health training program

MKM, the UK’s leading independent builders’ merchant, has launched a training program for staff seeking to become mental health workplace responders for their colleagues.

Part of the merchant’s wider work in tackling poor mental health in the construction sector, MKM is aiming to put more than 70 staff through the FAQ Level 2 Award in Mental Health Workplace Response qualification by April. Over 50 staff have already completed the course since November, which is run by St John’s Ambulance and St Andrew’s Ambulance.

Last year research conducted by the Office of National Statistics found that the number of suicides in the construction industry had risen from the previous year and was the highest it had been since 2015. The course seeks to empower participants by giving them a comprehensive understanding of mental health conditions and episodes, tips on how to recognise poor mental health and how to offer appropriate support The course also dispels some of the myths surrounding mental health and highlights some of the support services available.

Because of the ongoing mental health issues affecting the construction industry in the UK, qualified Mental Health Workplace

Responders are a much-needed resource – able to provide initial support to colleagues in need.

Kerry Hunt, learning and development business partner at MKM, said: “It is important for the business that we have Mental Health Workplace Responders available to our teams at every level of the business, right across the country. We have branches from the north of Scotland right down to Kent and Cornwall, so it is key for us that every member of the team feels valued and knows how to access help and support, should they need it.

“The course does not aim to make people mental health practitioners or make them responsible for solving problems. This scheme allows MKM to take care of its staff and customers, as is in keeping with the ethos at MKM. Giving more people the training they need to become Mental Health Workplace Responders can help us tackle the sector’s mental health crisis in a positive and proactive way. I am enormously proud of everybody who has shown support and signed up to the scheme.”

Timber Trader UK Magazine Autumn 2022 10 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

at

TIMBER TRADER UK NEWS

More

www.mkm.com

Proven performance

in wood protection

Tanalith® E high pressure water-based wood preservative has over three decades of real-word performance. With BARamine® application technology for:

- improved penetration;

- enhanced preservative distribution.

Built-in colour

Add colour to Tanalith® E treated timbers with Tanalith® Lifestyle colours.

w: trusttreatedtimber.com

e: timberprotectionadvice.ukca@arxada.com

Timber Trader UK Magazine Autumn 2022 11 www.timbermedia.co.uk @Timber_Media Use wood preservatives safely. Always read the label and product information before use.

The Pine cladding image shown above illlustrates the type of colour that can be achieved when using Tanalith® Lifestyle Grey with Tanalith® E.

Tanalith® E 8000 and 9000 are BPR authorised products. Cladding photos courtesy of Foreco. Timber Trader UK Magazine Spring

Timber & Skills Action Plan

TDUK chief executive, David Hopkins, tells us more about its new Skills Action Plan, aimed at equipping the UK construction industry with the skills to increase the use of timber and achieve net zero targets.

Ihe construction industry is responsible for almost 40% of global emissions and consumes half of all materials extracted from the environment. As a result, it faces a steep climb to achieve its net zero targets as one of the worst-performing industries.

To reduce these figures and significantly reduce its carbon emissions, experts have identified the use of timber as a key solution. Engineered products such as cross laminated timber (CLT) can capture and store carbon within the built environment, resulting in a potential net benefit of 754CO2/m2 reduction compared to other forms of construction.

TDUK has produced a ‘Skills Action Plan’, in partnership with the HCI Skills Gateway, Edinburgh Napier University and NMITE, which provides an industry-agreed breakdown of the skills and knowledge required for building with timber. The plan will aid the development of training programmes across the timber supply chain and also support CPD progression, giving built environment professionals a better understanding of how to incorporate timber into their building designs.

Tackling the skills shortage

Such skills are badly needed. The UK construction industry employs 3.1 million people, yet the skills crisis means we need at least 350,000 more full-time workers over the next decade to deliver the built environment’s ambitions. At present, too few professionals have the skills, knowledge and confidence to work confidently with timber.

Timber is lightweight, easily workable, and can be processed efficiently using modern methods of construction, reducing waste and improving productivity. This provides solutions for affordable, energy-efficient housing, national retrofit targets, and net zero public sector buildings. With the launch of the Skills Action Plan, the UK construction industry can take a significant step towards achieving its net zero targets and reducing its impact on the environment. To achieve this,

we worked with a coalition of partners across industry, academia and funders to create the competency framework that sits at the heart of the plan. A number of core technical competencies are identified which apply across the timber supply chain:

• Design and specification

• Sustainability and the circular economy

• Core behaviours and meta skills

• Manufacture

• Health, safety, regulation and legislation

• Construction

• Building science and materials.

Within each of these competencies, the plan sets out the knowledge and skills that are considered important for those working within these areas. This is intended to enable companies across the timber supply chain to consider whether or not their current workforce has all the competencies they need and develop training programs to address any gaps.

The framework already underpins a set of short, practical courses developed by NMITE‘s Centre for Advanced Timber Technology (CATT), in partnership with TDUK. These Timber TED (Technical Engineering & Design)

courses provide comprehensive and flexible training for modern timber construction methods, enabling professionals to upskill and reskill in this critical area.

Our ambition is that the Skills Action Plan will support every built environment professional to identify and address timber skills and knowledge gaps so the industry can make the best possible use of timber in construction. Timber provides a ready-made solution that doesn’t rely on greenwashing, speculative innovations, or progress in other industries to deliver genuine carbon savings in the short and medium term. We now need the construction sector and government to hear this call to action.

The Skills Action Plan has been published online as an open access resource available to anyone interested in improving their timber skills. The plan is an industry-agreed definition of what a skilled construction practitioner should know and be able to do when building with timber.

The Timber in Construction – Skills Action Plan is available to download at www.timberdevelopment.uk/skillsaction-plan-launched-at-futurebuild

Timber Trader UK Magazine Autumn 2022 12 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

FEATURE TDUK

DESIGN|MANUFACTURE|INSTALLATION|SUPPORT PERFECT FORTIMBERSTORAGE, WICKENSRACKINGCANHELPYOUWITH… •Increasingstoragecapacityonsite. •Allowingaccesstoselec�vestockandenablingstockrota�on. •Reducingproductdamagefromstorageonthefloor. •Decreasingmaterialhandling�meandimprovingsite efficiency. TIMBERSTORAGE Getintouchtoday forasitevisitand abespokerackingquotation: WWW.WICKENS.CO.UK sales@wickens.co.uk 01905456780

A Future UK Resource

IIt should be concerning to everyone when a mature economy with the perfect conditions for growing a wide range of tree species should be in a potentially precarious position in relation to wood supply. But that’s exactly where we find ourselves. For decades we have not taken responsibility for investing in our domestic wood supply, leaving us exposed to fluctuating prices and fighting for future supplies of wood as global demand rises and our own supplies fall.

UK: the big net importer

The UK is the world’s second largest importer of wood after China, importing around £7.5 billion annually, because it currently grows only around 20% of its wood requirement, leaving it exposed to a very significant balance (80%) needing to be imported from other countries. In 2020 the UK imported 48 million cubic metres of wood products, of which 22% was sawnwood and wood-based panels destined for use by the building and construction industry. By 2021 this had increased by 15%, with the UK importing an average of one million m3 of timber and panel products every month – a rare occurrence according to Timber Development UK. Specifically, softwood import volumes increased by over 21%, hardwoods by 26% and plywoods by over 13%, demonstrating increased demand even during ongoing Covid restrictions.

Beyond the UK, it is estimated by the World Bank that global demand for wood products will treble by 2050, driven by an increased population of 7.8 billion today, to 10 billion in less than 30 years. This huge increase is being driven primarily by higher living standards, greater urbanisation - including China’s almost inexhaustible need for timber for both construction and manufacturing - and greater use of what is increasingly seen as a more sustainable building material.

These trends are being compounded at a time when a number of other global developments are coalescing. In particular, security of supply of natural resources is under ever greater threat from geo-

political upheavals, as witnessed by the Russian-Ukrainian crisis and soaring energy prices. While the UK may not be directly affected by Vladimir Putin’s incursion into Ukraine – overall Russian timber imports into the UK are relatively small at only 1.25% – Russia remains the world’s largest supplier of timber globally. With potentially longerterm economic sanctions placed against Russian exports, there will inevitably be significant disruption to supply chains, price hikes and pressure on countries typically supplied by Russia, Ukraine and Belarus, to seek building material imports from other sources – including those Scandinavian countries that the UK relies upon so heavily.

In addition to being the largest overall exporter of wood products, Russia is also the largest exporter of sawn timber. Although the UK only imports 6% of its sawn softwood imports and 7% of its plywood from Russia, the impact on the UK’s building and construction sector will be much wider, as the overall global availability of wood products will be reduced and competition likely to intensify considerably.

Price rises and supply chain woes

Even before the Russian invasion, 2021 was a year when demand for wood outstripped supply and timber prices rose significantly – with imported sawn or planed wood jumping by more than a fifth during the summer - leading to an increase in construction costs and delays in completing projects. The National Federation of Builders called for ministers to step in and urge councils to show greater flexibility on materials changes, while the Building Back Britain Commission warned in November that the government’s housebuilding targets might be at risk.

To add to potential supply chain woes, there also remains some uncertainty of supply due to Brexit. New regulations and disrupted shipments can mean materials from overseas are often delayed or challenging to source. Labour shortages have also played a part, including the lack of HGV drivers. While the upward trend in UK and global demand for wood is clear, the UK Government’s own forecasts

Timber Trader UK Magazine Autumn 2022 14 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring FEATURE HOMEGROWN TIMBER

Confor’s Stuart Goodall, examines the threats to homegrown timber supply and why the UK must urgently move productive tree planting up the agenda.

show that supplies of homegrown wood will fall from the 2030s, meaning there will be less wood available in future than there is now.

The UK has ideal conditions for growing wood to build low-carbon homes and is a global leader in certifying that its forests are sustainably managed, yet while the UK government has stated its ambition for more tree planting, there has been little action on the ground outside of Scotland. Confor is now calling for much greater impetus behind those aspirations to ensure we have enough wood to help meet increasing construction demand.

The causes of the UK’s current position whereby wood supply is falling just at the time we need it to increase, is complex and ranges from outdated perceptions of productive forestry to a disconnect in thinking between consumers demand for wood products and understanding the need to plant the forests that they come from. It also encompasses significant hesitation on behalf of farmers and other landowners to invest in longer term planting projects.

While productive tree planting can deliver real financial benefits to rural economies and contribute to the UK’s net zero strategy, the focus of government support continues to narrowly be on flood prevention and the planting of native woodland solely for biodiversity, alongside an assumption that this means more native woodland and fewer trees grown to produce wood. While these are critically important activities, the importance of future supplies of wood and the opportunity to deliver a wide range of benefits in modern, well-designed, mixed woodland has largely been overlooked.

Confor believes there is a step-change needed in attitudes towards productive tree planting, which, if achieved, will enable government to meet its own ambitious tree planting targets, and meet its ambitions to use more homegrown timber in construction - without one you can’t achieve the other. Achieving this will require the government to communicate the benefits of productive woodland for the building of more energy efficient low carbon homes, carbon sequestration, as well as biodiversity and flood control, to combat the misconceptions that hamper productive tree planting applications.

Optimise our forests

“Being a highly populated, mature economy with a limited land mass, the UK is likely to always be a large importer of wood products. However, we are in the enviable position of having excellent growing conditions for productive planting, a robust regulatory system in place to ensure good forestry management and a deep commitment to biodiversity and achieving net zero status by mid-century.”

We also need to ensure that our existing productive forests are optimised. We need to better avail of planting stocks that deliver higher productivity and improved quality of fibre for downstream processing and manufacture, with further research to guarantee we are using the most productive species. Some adoption of tree planting on shorter rotations (typically 15-19 years) could also supply manufacturers with wood for products like panel boards to fill the gap before new forests mature in 30-45 years’ time.

At the end of 2021, Confor undertook a survey to establish the level of public support for producing more home-grown wood. In summary, over 90% of respondents were unaware that the UK imported 80% of its wood resources. 50% of respondents saw domestic wood

production as being important – and just behind the importance of food production – with a similar number agreeing that growing more domestic timber is beneficial for the environment. A further two-thirds said that there should be forest expansion.

Being a highly populated, mature economy with a limited land mass, the UK is likely to always be a large importer of wood products. However, we are in the enviable position of having excellent growing conditions for productive planting, a robust regulatory system in place to ensure good forestry management and a deep commitment to biodiversity and achieving net zero status by mid-century. The building blocks of a stronger domestic security of wood supply are in place. What is needed now is greater stimulus by the UK government to leverage these advantages into reality.

More at www.confor.org.uk

Timber Trader UK Magazine Autumn 2022 15 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

FEATURE HOMEGROWN TIMBER

Operating from 13 sites across the UK with the three founders remaining as shareholders, Premier Forest is a large scale vertically integrated timber group, bringing together its core activity of bulk importation and distribution of softwood, hardwood and sheet materials with divisions associated with sawmilling, reprocessing, joinery production and timber engineering.

Premier has an extensive product range encompassing panel products, softwoods, hardwoods and fencing materials – imported or produced in bulk. “We effectively offer a one-stop-shop for all things timber related with a focus on choice, quality and added value,” says Terry. This makes us highly competitive and unlike other specialists in our market space. Our distribution infrastructure across the UK, including a large fleet of owned vehicles, gives us the capability to deliver nationally with ease and speed.”

Supply chain security

Premier has grown by acquisition in recent years and recently brought Decorpanel into the Group which seems an excellent fit for Premier Forest and adding geographic expansion into the north of England. “This simultaneously enhances our processing and machining capability and capacity to meet growing customer demand,” says Terry. “Decorpanel brings additional sheet material processing capability to our cutting and CNC facility, along with additional wholesale customers and for both organisations the benefit of increased purchasing power Additional synergies include Decorpanel utilising Premier’s sales force of an extra 46 individuals along with access to enhanced IT and operational infrastructure.”

The timber material supply chain is constantly changing and there have been many pressure points with the combination of the energy/ inflation/cost-of-living crisis affecting trading conditions. “Supply chains have posed no issues to us over the past six months due to a softening of demand and an over-stocked UK position,” says Terry “Access to certain products, such a birch plywood imported from the Baltics, have caused some issues, but it has made us creative with finding alternative options for customers, which in some cases have actually brought cost savings for the consumer.

“Energy cost increases have caused a rise in overhead costs where long-term contracts had not been in place, however our investment into renewable energy production has, in the most part, offset any major impact. With our new custom-built biomass gasification system, wood waste is compressed into briquettes which are fed into the

Timber Trader UK Magazine Autumn 2022 16 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

FEATURE MERCHANT FOCUS

Founded in 1993 by Terry Edgell, Dilwyn Howells and Nigel Williams, Premier Forest has grown to become one of the UK’s leading independent timber companies, we spoke to CEO Terry Edgell.

Powered by Premier

Terry Edgell, CEO of Premier Forest

system, producing syngas and biochar. The syngas is immediately filtered and cooled before combustion in an electricity generator. The power is used on-site at our Newport head office, generating 80% of Premier Forest’s electricity with any excess exported to the grid.”

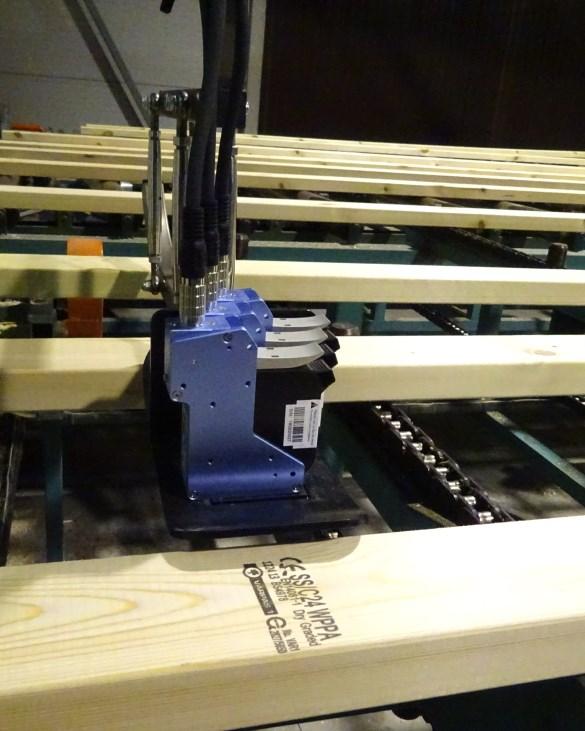

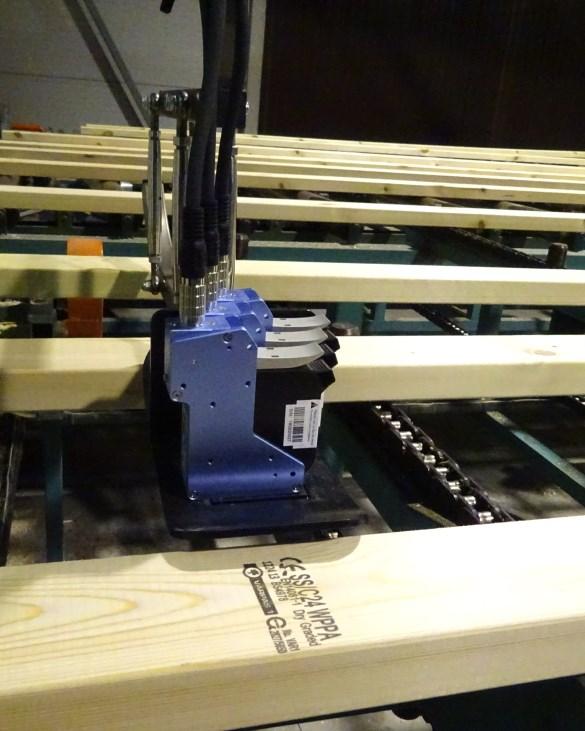

Processing power

Premier’s processing divisions include the processing of timber into mouldings and claddings from three sites – Merlwood (Haverfordwest), Duchy Timber (Cornwall) and Mon Timber (Newport) – while its sheet material processing operation is from two sites – Premier Processing (Newport) and Decorpanel (Tyne & Wear). Terry adds: “Value is added with the wholesale capability of taking standard materials and producing components from them, whether that’s laminating, CNC machining, profiling or edgebanding. Our timber engineering division is growing, with timber roof trusses and I-beam manufacture having doubled and our production capacity trebled in the space of just 18 months, thanks to a heavy investment in new machinery and warehousing. These value-added processes allow us to provide our customers with a fully rounded offering.”

Fencing and cladding products have become real growth areas within the marketplace generally and this year will see a major shift in focus for Premier as it invests heavily in its cladding range. “When the company acquired its first sawmill in 2014, it catapulted the business into the world of fencing material and fence panel production,” says Terry. “Which at the time opened new product and market opportunities and ensured a period of great organic growth for the Group.

“In the last two years we’ve seen a big shift and timber cladding becoming extremely fashionable in the construction of both domestic and industrial buildings. We felt it was a fantastic opportunity to expand our offering into a bigger, increasingly receptive marketplace.

Our new in-house manufacturing facilities mean that we aren’t reliant on other suppliers to fulfil orders and have been able to streamline our process to the benefit of our customers, with investment in kilning, treatment and our moulding capacity. The choice of timber species used for cladding has also expanded – we recently added Douglas Fir to the Premier Claddings range, which is proving very popular. This is in addition to homegrown larch, homegrown cedar, Thermowood® and Shou-Sugi Ban.”

The future is looking busy for Premier Forest as it reaches its 30th year in business this year, but what does the development of the wider timber and merchant sector look like over the next 18 months? “We see the outlook for the wider timber market as very positive,” says Terry. “Timber’s Environmental, Social and Governance (ESG) and carbon locking credentials gaining traction, environmental sustainability, incredible thermal properties and pure beauty ensuring demand for the long term.

“The sector has begun to consolidate in recent years, especially within the builder’s merchants’ arena, and that’s a theme that needs to continue across all sectors of the timber trade. It will deliver efficiencies and cost savings for the consumer whilst ensuring that timber remains a cost-efficient building material for the long term. This in turn enables each business to produce profit with which to invest in its people and infrastructure.

More at www.premierforest.co.uk

Timber Trader UK Magazine Autumn 2022 17 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

FEATURE MERCHANT FOCUS

“Value is added with the wholesale capability of taking standard materials and producing components from them, whether that’s laminating, CNC machining, profiling or edgebanding. “

Certified Timber is the Way Forward

The Belgian fifth-generation family company, founded in 1883, Vandecasteele Houtimport specialises in the import, trading and export of tropical hardwood from Africa, Southeast Asia and South America, Scandinavian and NorthAmerican softwood, North American and European hardwood.

Sustainability and reliability are an essential part of Vandecasteele Houtimport’s DNA. With over 140 years of experience, the company is determined to achieve the goal of trading only certified timber by 2025. The challenge lies with the hardwood and especially the tropical hardwoods.

Today they are at 80% certified and have a clear vision: only certified timber has a future.

A long-term goal that can only be achieved by including all partners Substantial investments have been made over the years to be able to realise this future goal. You cannot achieve this goal overnight. This is a long-term job in which all partners must be included. If we want to assure our customers that we keep our promise to only trade timber that comes from well-managed, certified forests, we need to be sure that all our trading partners share the same strictest certification and sustainability processes as we do.

Vandecasteele Houtimport has a unique business model. Importing timber from all over the world, keeping in stock for several years, in some cases, even decades. Stock is our strength and our specialty. In times where

supply is difficult or tight, we can count on our invested stocks to guarantee continued supply.

In order to achieve our goal we have taken several actions within the company. First, we were assisted by external experts to get the procedures and protocols in place. Secondly, the team at Vandecasteele was reinforced with two forest engineers in Brazil. That way we can keep a finger on the pulse of every shipment and we are able to accurately apply the ever-changing legislation in Brazil with great precision. This sends an important signal to our suppliers. They know that doing business with Vandecasteele Houtimport means complying with a procedure that is continuously refined and adapted. All timber transport requires our approval. When in doubt the timber is not accepted.

Timber Trader UK Magazine Autumn 2022 18 www.timbermedia.co.uk @Timber_Media

Vandecasteele Houtimport are one of the leading European timber importers and have ambitious aims to trade only in certified timber by 2025.

COVER STORY VANDECASTEELE HOUTIMPORT

Masters in diversification

Vandecasteele has a long-term commitment to preserving the forests. The family business imports more than 130 different species of timber coming from 40 countries and has over 120,000 cubic meters in stock, mainly certified hard and softwoods. We support the LKTS program of FSC® Denmark with which we want to help promote the use of lesser known species. We keep these lesser-known species in stock and offer them as alternatives.

Timber is too often prescribed from a specific well-known species. From the point of view of responsible forest management, we must dare to choose the right durability class for an application instead of a specific timber species.

Rethink everything: a positive evolution in consumer purchasing behaviour

Customers are increasingly asking questions about certification and the origin of the timber. Buyers are becoming more and more aware of the need to use certified timber. Importing tropical wood goes further than just asking for timber. There is a continuous evolution, because of new insights and new legislation. We work together with external experts, we are broadening our internal knowledge and we continually make progress. Making progress is an ongoing process. Considerable steps have already been taken with the EU Timber Regulation but we can and should do better. We want to see and monitor a stronger application and support for certified timber.

Vandecasteele communicates continuously with the users via its website and campaigns in order to spread that message.

This is necessary because the purchase of FSC® certified wood contributes to 14 of the 17 United Nations Sustainable Development Goals (SDGs). The purchase of FSC® certified timber contributes to biodiversity.

Since the year 2000, Vandecasteele Houtimport has committed itself through the Corporate Durability Charter by signing up to environmental objectives exceeding

the applicable legislation. In 2018, the charter started a partnership with CIFAL Flanders, the local HUB of UNITAR, the Training and Education Centre of the UN. In 2020, Vandecasteele Houtimport was the first timber company in the world to obtain the international recognised ‘SDG Pioneer certificate’ from UNITAR CIFAL. In 2022, we were the first timber company in the world to have achieved the “SDG Champion award”

More at www.vandecasteele.be

Timber Trader UK Magazine Autumn 2022 19 www.timbermedia.co.uk @Timber_Media

COVER STORY VANDECASTEELE HOUTIMPORT

Preservation of the forest in a well-managed forest. Only mature trees are harvested which amounts to one to three trees per hectare. After that, felling will not take place for at least 25 years. In this way the forest is preserved for the future.

Markets Still Need Refocusing

Merchants and suppliers from across the building products sector are being urged to engage in meaningful conversations more frequently after a recent survey revealed potential disagreements over perceptions of service level quality.

The survey, by National Buying Group (NBG) put questions to 165 of its affiliated suppliers and 76 of the group’s partners to identify key priorities and concerns among its members in the run-up to its annual Conference. With the theme of the event being ‘A Changing Landscape,’ the organisation wished to see how the industry had been impacted in the three-year COVID-induced delay since its 2019 Conference.

As part of the survey, NBG asked partners and suppliers to rate the service they provided to merchants out of 10, with the former’s 5.0 result greatly contrasting with the latter’s 8.3. According to NBG managing director Nick Oates, this marked difference demonstrates a disconnect in perception between what constitutes good service, which must be addressed to ensure relationships and sales do not suffer.

“We’re always keen to keep our finger on the industry’s pulse at NBG,” said Nick Oates. “Our hope was that this survey would generate healthy discussion and debate at our Conference and beyond about business changes and challenges. In that regard, we definitely haven’t been disappointed, as a clear dip in service levels has been identified by our partners in comparison to pre-COVID times.

“Yet what’s interesting here is that it hasn’t been mirrored in supplier perceptions. We understand why this might have happened

Timber Trader UK Magazine Autumn 2022 20 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring

FEATURE SUPPLY CHAIN PRESSURES

A recent survey by the National Buying Group identified a ‘service level disconnect’ between builders’ merchants and suppliers.

BMBI Reports Sales Increase

The latest Builders Merchant Building Index (BMBI) report reveals that builders’ merchants’ value sales were up +0.2% in January 2023 compared to the same month in 2022. This nominal growth came largely from inflation as volume sales were down -16.5% while prices rose +19.9%. With an extra trading day this January, like-for-like sales were -4.6% lower.

Nine of the twelve categories sold more in January compared to the previous year. Renewables & Water Saving (+46.0%) continued to perform strongly, while Decorating (+20.5%), Plumbing, Heating & Electrical (+17.5%), Workwear & Safetywear (+14.4%) and Kitchens & Bathrooms (+12.4%) also did better than overall sales. Timber & Joinery Products (-14.6%), Landscaping (-11.8%) and Services (-0.5%) sold less.

Month-on-month, total merchant sales were +31.1% higher in January 2023 than seasonal low month, December 2022. Volume sales also grew sharply (+28.6%) with price slightly up too (+1.9%). With five more trading days in January, like-for-like sales were flat (-0.1%). Renewables & Water Saving (+49.6%) grew the most, followed by Ironmongery (+38.0%). Services (+10.2%) was the weakest category.

– as our survey later underlines, the increasing cost of raw materials and energy means these organisations are likely to have focused internally to mitigate these potential impacts. However, with a recession on the horizon, many material costs falling and demand slowing, more joined-up thinking and communication is required. This is especially the case for independent merchants, where sales are reliant on support in the form of training, product information and competitive pricing from suppliers.”

NBG’s survey also identified an opportunity between suppliers and partners on the development of sustainable products. Specifically, 66% of suppliers said sustainable products initiatives had improved, compared to 30% of the group’s partners. According to Nick, while this figure is undoubtedly encouraging, it underlines the need for suppliers to provide better sales focus and product communications to merchants on the steps they are taking to improve the sustainability of their products.

“The shift towards more sustainable practices has clearly been a success story for the sector post-COVID, and is definitely welcome news,” says Nick. “Though short-term concerns around the energy crisis and supply chain have undoubtedly dominated the news agenda, we cannot as an industry lose sight of long-term environmental goals. As such, being able to pass good news down the supply chain, from Supplier to Partner, and from merchant to customer, will be key to continuing a virtuous circle of increasingly greener practices.” More

By Order of the Owners, due to retirement, Marriott & Co. offer for sale by

MAJOR ONLINE AUCTION

The complete well-maintained & presented contents of Timber

Merchants, Importers & Sawmillers

Including:

Two Weinig Raimann ProfiRip KM 310 M multi-rip saws (2007 & 2004) 2016 Weinig Powermat 1500 seven-head automatic planer/moulder 2001 Weinig Unimat 30 EL & 1999 Weinig Unimat 23 EL seven-head planer/moulders 2004 Weinig Profimat P26 Fortec four-sided planer with fifth spindle

Four Stenner resaws & eighteen Wadkin planers /thicknessers, crosscut saws etc A Forestor 150 electric horizontal band saw 2017 Striebig Compact 11 type 6164 vertical panel saw

2007 Viet S1 211TM 220 twin-head calibrating sanding machine

2014 RanHeat 600kW bio-mass boiler system (RHI qualifying)

Over 60 lots of profile cutters, cutter blocks & tooling, including HSK85 PowerLock cutter blocks Five forklifts (Heli/Halla/Lansing Bagnall), two Bradshaw tow tractors & five side-loaders (Linde/Lancer Boss/COMBiLiFT) Two Volvo BM LM 841 wheeled loaders, with various attachments Sixteen lots of Stakapal & Atol heavy-duty cantilever racking Dust extraction equipment (Dustraction) and air compressors (Hydrovane) DAF/LDV/Nissan dropside & curtainsiders

Over 140 towable trollies (in over twenty-five lots)

Over 50 lots of engineering equipment & hand tools

Over 250 lots of rough-sawn, planed, moulded & sheet softwood & hardwood timber in pack sizes ranging from 0.5m³ to 4m³

Viewing Days:

Monday 24 and Tuesday 25 April 2023

At: Morgan Timber, Knight Road, Rochester, Kent, ME2 2BA

Bidding Closes on Wednesday 26 April 2023 from 12 noon

Further

19

T:

E: sales@marriottco.co.uk

Timber Trader UK Magazine Autumn 2022 21 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring FEATURE SUPPLY CHAIN PRESSURES

available at

information, registrations, and online bidding

https://auction.marriottco.co.uk/

East Street Farnham GU9 7SD

01252 712083

at www.nationalbuyinggroup.com

Find the Leak, Fix the Leak, Seal the Leak

Timber construction is about many things including providing a natural and healthy interior: but what about air quality? Bernard Hornung, head of built environment, Coltraco Ultrasonics Limited explains more.

Checking ‘building health’ and airtightness with a micro air leak detector will save you time and money by ensuring that you will pass the mandatory pressure test, first time and every time. We must not lose sight of the unique nature of buildings, for example increasing natural ventilation might be a sound strategy for some buildings at certain times of the year, but could create poor temperature and humidity in another, leading to a reduction in immune system health and an overall increase in viral transmission risk.

At present air quality has a direct and wide impact upon society. Understanding how biological contaminants and viruses can rapidly build up indoors, in the context of human health and user comfort has become more relevant since the Covid-19 outbreak, to protect the health and well-being of a world population of which 70% spend 90% of their lives in a building.

One planet

The construction industry contributes up to 40% of global carbon emissions and the total area of additional floor space in the world will double in the next 30 years. It is daunting to see how we can affect the industry anytime soon. But we can make a difference with one building, one strategy (Passive House) and one choice at a time. The cheapest energy is the energy which we do not use and by improving the insulation, airtightness and heating and cooling sources of our buildings, we will have warmer or cooler and cleaner places in which to live and work.

We are also being kinder to the one planet we all share, and Passive House’s exponential growth comes as no surprise. Great design and specifications give us a better-quality building with a smaller carbon footprint. However, whilst designing new build is exciting, we must accept that over 80% of the buildings which exist today will still exist in 2050

Timber Trader UK Magazine Autumn 2022 22 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring FEATURE DIGITAL TOOLS

At the event, spanning the 2nd and 3rd of March in Stratford-upon-Avon, Kerridge

James Mitchell, Managing Director of KCS in the UK and Ireland, opened the conference and set the scene for the two days, focusing on the company’s new and exciting digital solutions. ‘We believe that digitisation, sustainability and profitability do go hand in hand, and over the course of the next two days, we would like to share initiatives with you that can significantly help your business reduce its carbon footprint, while delivering greater efficiencies and cost savings and helping you grow your profits – a win/win/win scenario!’

KCS staff conducted in-depth demonstrations and workshops on the company’s latest mobile and web solutions, including a range of intuitive apps that deliver their customers’ efficiencies in all aspects of warehousing and operation management. In addition, KCS showcased many partner solutions, such as their relationship with Phocas, an integrated BI platform that delivers real intelligence from the rich data held within KCS ERP solutions. They also took the opportunity to announce their partnership with the EFT solutions from Dojo and WorldPay for electronic payments, as well as the robotic process automation tools from Apollo that enable everyday tasks to be automated.

‘A superb event, I’m hugely impressed with the investment that KCS has made in digital solutions that really make a difference for our business’ commented James Platt, Operations Director at Caswells Group.

KCS also created an intuitive mobile app for conference delegates to use that enabled them to view agendas and brochures, watch videos and arrange meetings from their smart devices in line with its approach to digitisation.Focusing on its key market sectors of distribution, automotive and rental, The company also unveiled many initiatives to deliver key benefits to all industries where its customers operate. For example, its new Konnect Online platform will enable KCS to quickly develop and deliver partner solutions that can be made available across all of its markets and core products. This approach underlies the company’s strategy of offering its customers best-of-breed digital products that complement its core business solutions. As market leaders in their specialism, KCS concentrates on developing core ERP solutions that deliver on their commitment to

helping their customers embrace their carbon reduction targets and provide improved performance without compromising profits.

‘We recognise that our customers need our support as they work to deliver their carbon reduction strategies, and we are proud to develop and to showcase solutions that can help’, added James Mitchell. ‘Our EasyAP solution, for example, enables customers to automate their Accounts Payable processes and to remove paper, filing and storage.

They can extract invoices from email, import and match, and electronically file an image of the supplier invoice. This innovation removes paper and printing, which means there’s no storage and results in a more efficient administration process.’

KCS also delivered updates to customers on the latest web strategies available. Customers can choose integrated B2B or B2C web trading products to quickly implement into their business to support their ecommerce strategies, together with a range of sophisticated tools that enable a customer to forge strong integrations with their customers and suppliers. ‘Digitisation is not a scary word or strategy for our customers,’ says James, ‘it’s a journey that they have been on for some time. Our customers were early adopters of our cloud technology as a means to outsource their IT infrastructure and reduce their energy consumption. They have been using hand-held technologies to improve efficiencies but, up to now, the high hardware costs have always been a barrier to adoption. However, the emergence of new digital technologies has enabled us to harness the power of cloud computing to deliver cost-effective solutions into areas of the business that staff members manually controlled in the past. This change enables them to greatly enhance efficiencies and grow profits whilst removing much paper, ink and energy waste that results in a significant carbon footprint. However, it doesn’t stop there,’ James added, ‘we are committed to delivering even more over the coming months, and it’s been fantastic to see how our customers are embracing this next generation of technology and putting it to use for all of our benefits. Digitisation, sustainability and profitability truly do go hand in hand.’

More at www.kerridgecs.com

Timber Trader UK Magazine Autumn 2022 23 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring ADVERTORIAL KERRIDGE CS

Commercial Systems (KCS) welcomed over four hundred delegates to its first live UK event post-pandemic.

Kerridge Commercial Systems unveils exciting and sustainable initiatives at its Konnect conference

and well beyond. Much of our work is now going to include retrofit and assessing which buildings might have to be demolished and rebuilt, and where retrofits are the better choice. Operational data from occupants will not always be available as some of these buildings might not be occupied, and the data you need, you are going to have to generate yourself.

Surveys are going to have to be thorough and the more accurate the data you have access to, the sharper your decisions. Retrofits are challenging. But in a resource depleted world and where both operational carbon emissions as well as embodied carbon emissions must be reduced, we need to save as many buildings as possible, and to explore cost effective, regenerative retrofits. Thermal comfort cannot simply be procured in the form of mechanical equipment alone. This is why the notion of electrify everything is misleading. If your walls and windows are cold, you are going to lose radiant heat and occupants are going to feel cold.

Scan for loss

To achieve a low carbon, high comfort building for the same price as a conventional retrofit does mean that we must change the way we work. The Portascanner® and the Portascanner® AIRTIGHT can be used as diagnostic instruments to collect critical data in deep retrofits. By conducting regular airtightness checks throughout the build programme, you will know what air permeability values you are achieving, and you can approach the pressure test with the confidence

of a first-time pass. Many deep retrofits sometimes include as many as 8 to 10 air pressure tests, and the leaks are found by a slow and expensive method of elimination. There is now no need for this.

The definition of a healthy building by The World Health Organisation is: “A space that supports the physical, psychological, and social health and well-being of people.” Whilst this is true, there is no mention of the health of the actual building itself. Today the value of buildings is intrinsically linked to their energy efficiency and actual building health levels. We all understand the former, but only a few understand the latter. The few that do are those who aspire to close the performance gap, and who accept that a high level of airtightness, complemented by either controlled passive or mechanical ventilation, or more likely a hybrid solution, is necessary.

Some other benefits of well-ventilated airtight buildings include thermal comfort, acoustic insulation, energy efficiency, pest and infestation control, prevention of water ingress, rot, mould, condensation, and dampness, and importantly achieving fire suppression. Fire prevention in non-occupied buildings, where hypoxic environments can be created and maintained, is becoming relevant too.

The quantification of air flow rates through individual leak sites as small as those with a diameter of 0.5 mm and being able to detect, and to locate with microscopic accuracy, individual leak sites as small as those with a diameter of 0.06 mm (invisible), are the innovative aspects of the Portascanner® AIRTIGHT.

There is no other commercially available device capable of quantifying the air flow rate from an individual leak site using ultrasound, not requiring any form of pressurisation. Checking airtight seals in industry, and in our everyday lives, provides more applications. This unique technology empowers trained operators to work smartly, and to be better, faster, and cheaper than all their competitors, in finding the leak, sealing the leak, and fixing the leak. It is the ideal instrument to ensure that you achieve your desired level of airtightness.

More at www.coltraco.co.uk

Timber Trader UK Magazine Autumn 2022 24 www.timbermedia.co.uk @Timber_Media Timber Trader UK Magazine Spring FEATURE DIGITAL TOOLS

PSC AT520 main unit with wand

Timber Trader UK Magazine Autumn 2022 25 www.timbermedia.co.uk @Timber_Media K8: Business management solution of choice for the timber industry • Cloud-based software that’s affordable, flexible and scalable • Optimise your warehouse management and meet your customers’ delivery expectations • Get trading online and open up new channels to market quickly and easily • Powerful financial control – manage your rebates, automate invoice processing • Improve your team’s performance, manage your margins and boost profits www.kerridgecs.com Your business. Your way. Timber Trader UK Magazine Spring

Preparing the Future

W.Howard Group has implemented a significant business reorganisation as part of its ongoing growth and expansion plans with strong leadership helping the business provide the very best customer service.

Established in 1958 and now celebrating its 65th year, the W.Howard Group is always looking to evolve and provide the best possible service experience to its customers, suppliers, employees and shareholders. Following years of steady growth, the MDF profile supplier has reached the point at which it is ready to undergo a significant expansion and reorganisation plan, under the experienced leadership of its current board.

Among the many talented and committed people who work at W.Howard, the Group has a particularly strong and dynamic board of directors. Recent changes have been made among the board to better reflect their particular skills and to make the best use of their talents as the company prepares to expand even further over the coming years.

Group chief operating officer (COO) Graham Williams explains: “A large part of our continued success over the past 65 years has been our ability to recognise the importance of change and renewal. The future of the business lies in the hands of our directors, and we are delighted to announce a significant business reorganisation designed to deliver continued growth and secure the future of the business.”

Supporting staff development

As part of his new role Graham has taken specific responsibility for HR and wellbeing, part of which means ensuring that the company continues to support the personal and professional development of its staff. To this

end, W.Howard recently arranged for 13 of its team to take part in, and complete, a comprehensive Leadership Impact Programme course.