www.supplychain-outlook.com

DHL EXPRESS

The undisputed global leader in international express shipping

www.supplychain-outlook.com

DHL EXPRESS

The undisputed global leader in international express shipping

With a proud heritage, Philippine Airlines continues to forge a path of innovation and customer-centric service with Captain Stanley Ng at the helm; the President and COO discusses plans, pilots, and progress

DELTA CARGO

A vast and reliable global cargo network

WEERTS GROUP

Optimising efficiency with logistical flow

Trendsetters in end-to-end package delivery solutions, we unwrap what makes UPS Canada stand out with President, Stephanie Dexter

Africa Outlook, APAC Outlook, EME Outlook, North America Outlook, Mining Outlook, Healthcare Outlook, Manufacturing Outlook, and Supply Chain Outlook are digital publications aimed at boardroom and hands-on decisionmakers, reaching an audience of more than 800,000 people around the world. With original and exclusive content compiled by our experienced editorial team, we look to promote the latest in engaging news, industry trends and success stories from across the globe.

Your company can join the leading industry heavyweights enjoying the free exposure we provide across our platforms with a free marketing brochure, extensive social media saturation, enhanced B2B networking opportunities, and a readymade forum to attract new investment and to help you grow your business. Visit www.outlookpublishing.com/work-with-us for details on how your company can feature for free in one of our upcoming editions.

Regional Director: Joshua Mann joshua.mann@outlookpublishing.com

HEADS OF PROJECTS

Callam Waller callam.waller@outlookpublishing.com

Deane Anderton deane.anderton@outlookpublishing.com

Eddie Clinton eddie.clinton@outlookpublishing.com

Josh Rayfield josh.hyland@outlookpublishing.com

Ryan Gray ryan.gray@outlookpublishing.com

BUSINESS DEVELOPMENT DIRECTOR

Thomas Arnold thomas.arnold@outlookpublishing.com

SALES AND PARTNERSHIPS MANAGER

Donovan Smith donovan.smith@outlookpublishing.com

PROJECT MANAGERS

Cameron Lawrence cameron.lawrence@outlookpublishing.com

Jordan Levey jordan.levey@outlookpublishing.com

Kierron Rose kierron.rose@outlookpublishing.com

Kyle Livingstone kyle.livingstone@outlookpublishing.com

Liam Pye liam.pye@outlookpublishing.com

Nicholas Kernan nicholas.kernan@outlookpublishing.com

Poppi Burke

poppi.burke@outlookpublishing.com

Taylor Green taylor.green@outlookpublishing.com

ADMINISTRATION

Finance Director: Suzanne Welsh

suzanne.welsh@outlookpublishing.com

Finance Assistant: Suzie Kittle

suzie.kittle@outlookpublishing.com

Finance Assistant: Victoria McAllister victoria.mcallister@outlookpublishing.com

It is my pleasure to introduce you to our inaugural issue of Supply Chain Outlook – the new multi-channel brand launched by Outlook Publishing, bringing you the very latest developments from the supply chain industry. A variety of players make up the supply chain, ranging from local raw materials suppliers to large, transnational corporations. Each plays a crucial role in the creation and distribution of products and services that fuel everyday life, from the food we eat to the clothes we wear and much more.

Flying high on the front cover of our very first edition is Philippine Airlines, who takes pride in supporting the global economy by providing air cargo and charter services, along with scheduled non-stop flights to numerous destinations, both within the archipelago and around the world.

“We are known for our warm and gracious service anchored in ‘Buong Pusong Alaga’, meaning wholehearted care, which embodies Filipino hospitality at its best,” says Captain Stanley Ng, President and COO.

Just as Philippine Airlines is easily identifiable by its two red and blue sail triangles with an eight-rayed yellow sunburst, UPS has become a familiar sight on streets across the world with its iconic brown trucks.

The planet’s largest package delivery company made its first international expansion into Canada in 1975, where it is now an integrated provider of air and ground pick-up and delivery services throughout the country.

Led by Stephanie Dexter, its first female President, UPS Canada offers a wide range of domestic and global shipping and logistics services.

“Whether it is a local delivery or an international shipment, we have services that cater to businesses of all sizes across every industry,” Dexter informs us.

Delta Cargo likewise reaches hundreds of destinations and carries thousands of shipments a day, having worked hard to build a reputation for world-class handling, efficient operations, and speedy processing, regardless of the type of cargo.

“Cargo is an important piece of Delta’s long-term revenue diversification strategy, and the company is focused on investing and growing in this space,” comments Rob Walpole, Vice President of Delta Cargo.

We hope that you enjoy the first of many issues to come, which also includes corporate stories from DHL Express, Darwin Port, Digistics, and more.

Jack Salter Head of Editorial, Outlook Publishing

70 SHOWCASING LEADING COMPANIES

Tell us your story and we’ll tell the world

72 Philippine Airlines Pioneers of the Skies

Exploring an aviation trailblazer

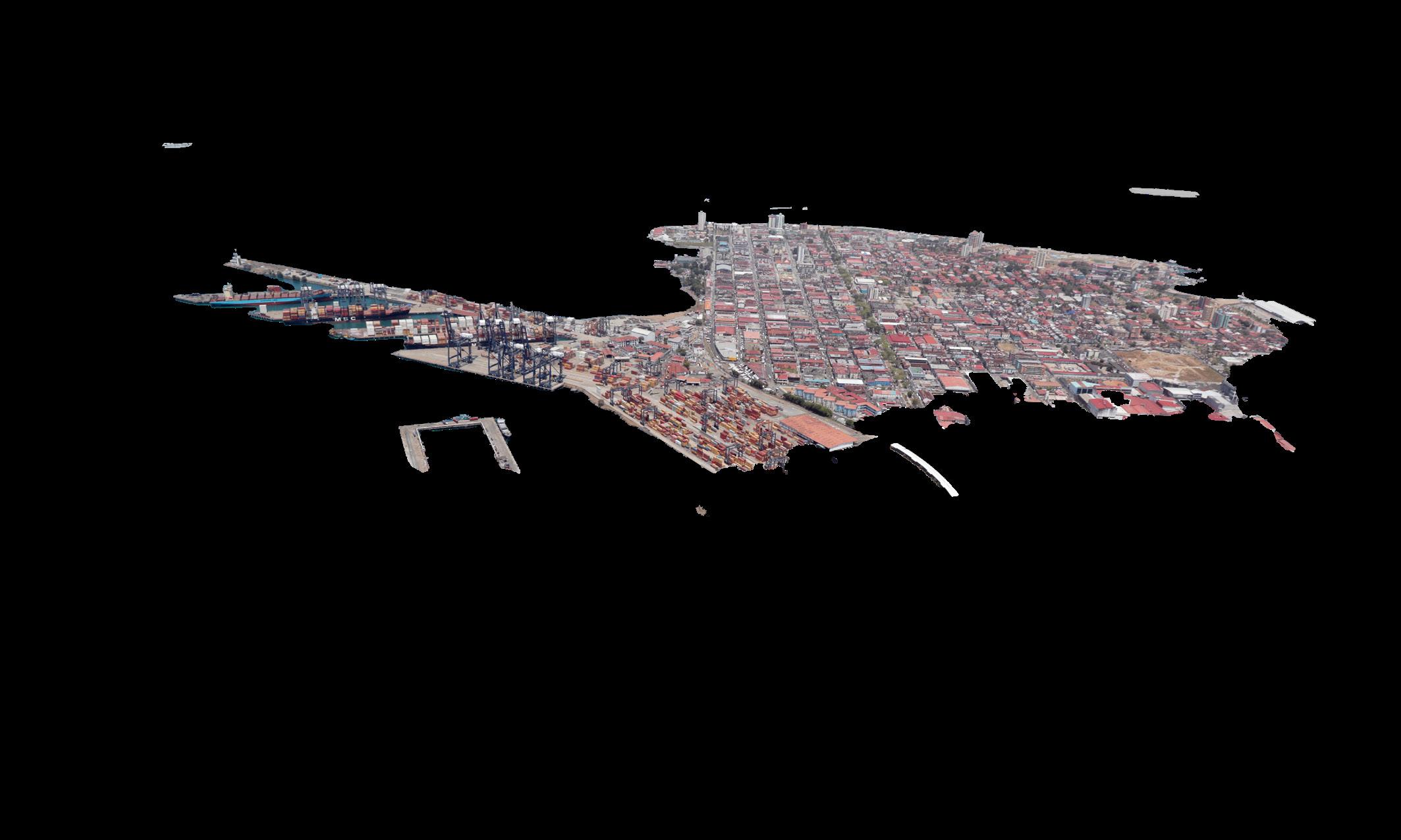

86 Darwin Port Sailing to Success Coastal cargo advancing Australian trade

102 Alexander Group

262 MHI RJ Aviation Group

Innovation in Aviation Moving the world forward

270 Helijet International

Enabling Evolution

Facilitating the future of aviation

278 J.D. Irving, Limited

Spearheading Logistical Synergy Service, quality, and innovation since 1882

284 Halifax Transit

Transforming Transit

Meeting the demands of a net zero future and increasing ridership

290 Digistics

Delivering Supply Chain Success

Resilient logistics and distribution operations

EUROPE & MIDDLE EAST

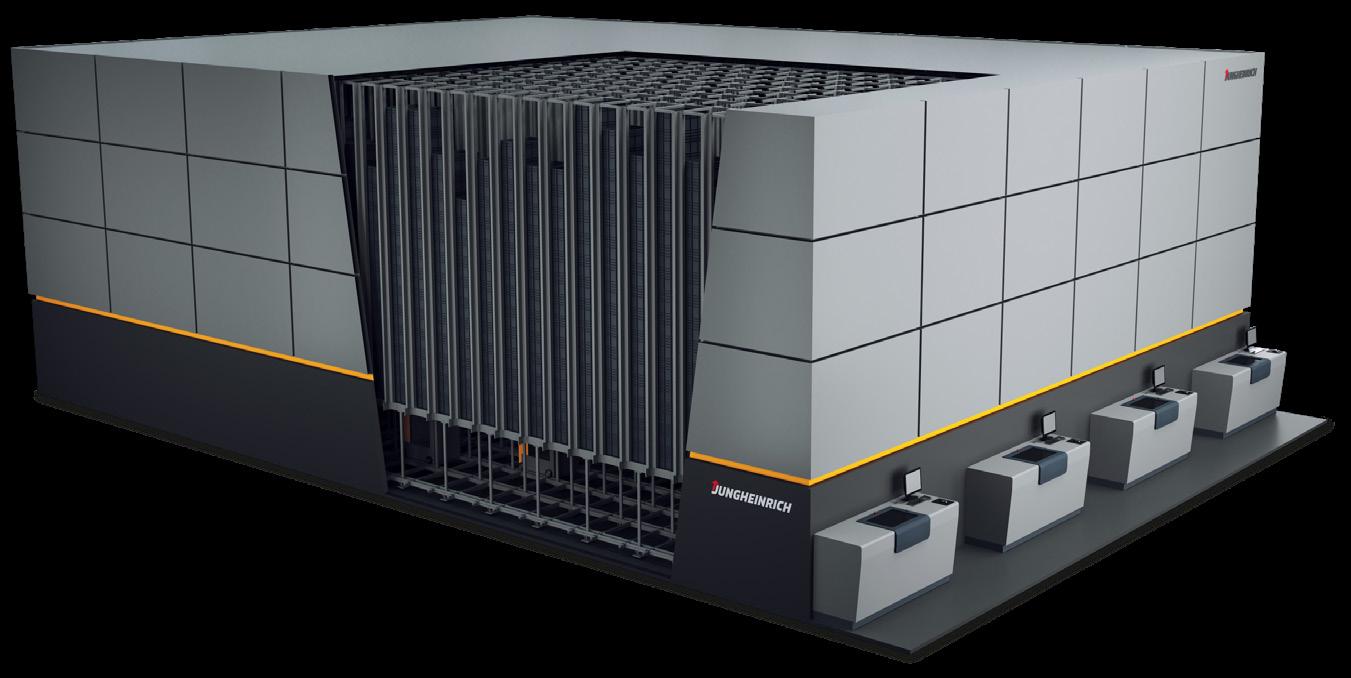

306 Weerts Group

Seamless, Streamlined, and Sustainable Success

Optimising efficiency with logistical flow

Around the supply chain sector in seven stories…

LAST MONTH, a shipping vessel on its way to Colombo, Sri Lanka crashed into the Francis Scott Key Bridge in Baltimore, causing it to collapse catastrophically.

The movement of ships within the Port of Baltimore has since been suspended to allow authorities to search the river for casualties.

Whilst the bridge collapse has directly impacted the lives and livelihoods of local people, it has also caused a strain on the flow of goods for wider industry supply chains, including freight and rail, construction, manufacturing, logistics, and automotive, to name a few, which have witnessed extended disruption.

In many cases, industry experts have advised shippers to review their contracts and obligations, and consider alternative port assessments.

SECTOR

AS TAIWAN continues to deal with the aftermath of the 7.4-magnitude earthquake that hit the country’s east coast on Wednesday 3rd April, the chip industry is assessing how the disaster might impact the global semiconductor supply chain.

Taiwan Semiconductor Manufacturing Company (TSMC)

is the main chip contractor for companies such as Apple and Nvidia. As a result of the earthquake, TSMC

SECTOR

GLOBAL SPORTSWEAR retailer, Nike, is planning to use eco-friendly biofuel in 36 percent of its Frenchbased operations.

In an arrangement with French shipping and logistics company CMA CGM, Nike will ship maritime cargo using biofuel, which is hoped will reduce its overall carbon dioxide (CO2) emissions by 25,000 tonnes.

As Nike’s supply chain is currently responsible for 90 percent of its carbon footprint, the company has historically implemented a range of initiatives to shrink this figure. For example, it has collaborated with materials suppliers to utilise renewable energy in manufacturing.

CMA CGM has also offered Nike other low-carbon logistics solutions, such as liquefied natural gas (LNG) and biomethane, to further lower the company’s emissions.

was forced to pause production at some of its plants, placing potential pressure on chip and semiconductor supply chains.

However, TSMC noted that its overall tool recovery efforts had reached 70 percent just hours after the earthquake, and that no critical equipment, including its extreme ultraviolet (EUV) lithography tools, was damaged, appeasing supply chain leaders.

SECTOR HAVING RECENTLY introduced increases to its Fulfilment by Amazon (FBA) fee, which generally contributes to covering the company’s picking, packing, and shipping costs, Amazon will credit sellers using its updated FBA service this April.

The new FBA fee applies to standard-sized products with less than 28 days of inventory relative to historical demand. By applying fees to products that meet this threshold, Amazon hopes to reduce overall

IN A move to create a more robust platform for overseas procurement whilst enabling significant operational cost savings, US retailer Big Lots has opened two new buying offices in Asia.

The new locations have been strategically chosen due to their proximity to significant manufacturing facilities and vendor partners.

costs to the end user and improve fulfilment speeds.

As the new charge has come rapidly into effect this April, Amazon plans to alleviate the fee for sellers whose products meet the criteria between 1st and 30th April, as a gesture of goodwill.

SECTOR

Situated in Ho Chi Minh City, Vietnam, and Shanghai, China, the company hopes the new offices will enhance its ability to competitively source products, including close-out deals and extreme bargains.

Big Lots’ international expansion intends to bring the company’s third-party sourcing team in-house by allowing it to directly obtain new contracts without intermediaries. This, in turn, will help the retailer regain its characteristic ‘bargain heritage’.

SECTOR UPS, THE global shipping and supply chain management giant, has announced plans to consolidate many of its US locations as part of its Network of the Future initiative, which aims save the company USD$3 billion by 2028, largely by reducing its labour needs.

As such, UPS will close around 200 US facilities, whilst increasing volume within its growing fleet of automated packaging hubs.

Additionally, the company is closing 40 of its sorting facilities this year and seeking to automate other aspects of its operations, such as dispatch services for package cars.

It is thought that facility consolidation will lower UPS’ customer service costs, whilst significantly improving its volumeper-resource ratio.

ANGLO-SWISS FOOD and beverage manufacturer, Nestlé, recently revealed two projects aimed at reducing carbon emissions within its cocoa supply chains. The announcement contributes to the company’s overall pledge to reach carbon net zero by 2050.

Nestlé reported it would develop the projects alongside suppliers Cargill and Export Trading Group (ETG) over the course of the following five years.

Through the projects, Nestlé is seeking to address the impacts of climate change on the cocoa industry by promoting agroforestry and regenerative agriculture, and subsidising the reforestation of land around cocoa farming communities.

Integrating social value throughout the supply chain should be standard practice for any responsible organisation. Guy Battle, CEO of Social Value Portal and co-Chair of the Sustainable Procurement Pledge, describes the evolution of social value and what a successful environmental social governance strategy looks like

Writer: Guy Battle, CEO of Social Value Portal and co-Chair of the Sustainable Procurement PledgeCorporate social responsibility (CSR) is under closer scrutiny than ever before, so it makes sense to ensure that organisations, and the businesses they procure from, are managing risks as well as thinking about moving beyond environmental, social, and governance (ESG) to social value creation.

Social value is the term used to describe the value an organisation creates for individuals, communities, and society as a whole and has become standard practice for the majority of businesses in the UK.

Examples of social value initiatives include designating staff time for volunteering, committing to sustainable procurement practices, offering apprenticeships and training programmes, buying and employing locally, and reducing carbon emissions.

On a global level, the UN’s Sustainable Development Goals (SDGs) provide a good proxy for social value.

In practice, the meaning of social value is likely to change from one job or project to the next, as different

communities will have different needs. For example, seeking suppliers that can provide training for local people makes sense in areas where unemployment is high.

From the Public Services (Social Value) Act in 2012 to the new Procurement Act 2023, organisations across the public and private sectors have been gaining a wider understanding of the many and far-reaching benefits to be had from generating social value throughout the supply chain.

This is having a ripple effect on both a global and local level. Internationally, we are already starting to see countries such as the Republic of Ireland, Canada, and Australia moving towards embedding social value into procurement legislation.

The key to success lies in understanding the needs of a given community and developing a framework that caters for those needs. This will ensure that, together with suppliers, organisations can

make a targeted and meaningful contribution.

Therefore, companies with extensive supply chains should be thinking about how they can unlock social value through their supplier relationships by channelling the spirit of the Social Value Act.

Of course, private sector organisations are not bound by the act (unless they are working directly with the public sector), but even so, they should consider how to embed value creation in their own procurement and supply chain management solutions.

There is a good business rationale for doing this, such as bettering customer relations, attracting and retaining high-quality people, increasing brand awareness, and reinforcing brand reputation.

The bottom line is that everyone stands to benefit from a company’s contribution to building a flourishing community. For example, the local workforce becomes more resilient, which in turn leads to a booming local economy that feeds back into the supply chain, thus forming a virtuous circle.

Broadly speaking, the bigger the company, the more scrutiny it comes under. Yet RepRisk, a due diligence database on ESG and business conduct risks, recently found that nearly one in three public companies linked to greenwashing are also associated with social washing.

Buyers have an integral role to play in guaranteeing that their organisation will be beyond reproach, simply by ensuring that suppliers are contractually bound to deliver on their social value commitments when bidding for the work.

By putting in place a system that ensures social value delivery, it will naturally become business as usual - and this stands to benefit every stakeholder on many levels.

The most effective way to capture and report social value performance is by using a robust measurement framework such as the Themes, Outcomes, and Measures (TOM) System™.

In the UK, it is endorsed by the Local Government Association that ensures procurement spend goes as far as possible, enabling buyers to track and measure social value from commitment to delivery. It is fully compatible with the UN SDGs and is already the UK’s most established and widely adopted method for recording and reporting social value in the supply chain.

Where profit is measured in standard accounting terms, social value is measured by actions, with a financial merit attributed to it. For instance, providing a job for someone who has been in long-term unemployment saves money for the UK government in benefit payments and provides income to the newly employed individual that will be spent in the local economy.

Furthermore, as a result of having an income, they are likely to be healthier for longer and therefore not become a burden for the NHS. Thus, all of these benefits can be valued.

The TOM System™ is fully transparent and the data is validated by a third party, which adds another layer of protection against accusations of greenwashing and social washing.

Demand for third party data validation and reporting is naturally expected to increase, with both suppliers and buyers relying more heavily on measurement frameworks to report on social value performance. After all, reporting inflated results has the potential to do significant harm to an organisation’s reputation.

Social Value Portal has created a resource for buyers that sets out what best practice looks like when embedding social value into procurement.

With a career spanning more than 30 years, Guy Battle has been leading and prioritising sustainable change, aiming to tackle large-scale issues such as sustainable design, climate change, and social impact.

Battle set up an online measurement, evaluation, and reporting platform, known as Social Value Portal, in 2014 and currently works cross-industry on developing social value solutions that deliver real and tangible impacts.

He is passionate about the contribution businesses can make to improving society and is often asked to speak at industry events and conferences about the power and potential of social value.

DHL Group (DHL), a multinational company headquartered in Germany, generated revenues of more than €94 billion in 2022.

Over time, DHL has evolved from a document courier into an international express shipping company, boasting one of the world’s largest fleets of over 300 aircraft, carrying just about anything permitted for air carriage. Today, DHL is the logistics company for the world, with the purpose of ‘Connecting People and Improving Lives’.

DHL offers customers a convenient door-to-door package delivery service, providing access to 220 countries and territories worldwide.

Known for its speed and commitment to its customer promise of ‘Excellence, Simply Delivered’, DHL’s focus strategy resonates with every employee: “motivated people drive great service quality, which creates loyal customers and in turn a profitable and sustainable network.”

As someone who has been with

Transporting urgent documents and goods reliably and on time from door to door, DHL Express is the undisputed global leader in international express shipping. Chitra Shinde, Vice President of Operations at DHL Express New Zealand, details the division’s operations in the country

Writer: Chitra Shinde, Vice President of Operations, DHL Express New ZealandDHL for 25 years, I consider myself fortunate to have witnessed the company’s growth through investments in infrastructure, fleet expansion, introduction of automation, scalable software, and innovative processes.

DHL Express, one of the five main divisions of DHL, commenced operations in 1969.

The division started by flying shipping documents to pre-clear cargo on ships, followed by banking and other time-sensitive files.

I started my career as a trainee at DHL Express in Mumbai, India. I have worked in five different countries, including Papua New Guinea (PNG), Fiji, Australia, and presently New Zealand, where I hold the position of Vice President of Operations.

DHL Express began its operations in New Zealand in 1973, recently celebrating its 50th anniversary in October 2023.

Renowned for our strong

trans-Tasman connection, 76 percent of our exports head across the ditch to Australia.

DHL Express first introduced an overnight aircraft service to connect New Zealand and Australia in 1991 via Auckland and Sydney. The aircraft operated five nights a week, and in 2018 was upgraded to a larger aircraft to cater to the growing demand for trans-Tasman trade.

To further enhance our transTasman service, we introduced an additional aircraft in 2020 that connected Auckland to Melbourne five times a week. This route was quickly upgraded in 2023 to accommodate higher demand.

Moreover, this aircraft also flew to Christchurch, marking the first time DHL Express connected the North and South Islands of New Zealand. Our overnight service covers major cities like Whangarei, Auckland, Wellington, Christchurch, Hamilton, Tauranga, Rotorua, Taupo, Napier, Hastings, Palmerston North, Queenstown, New Plymouth,

Dunedin, Nelson, and Blenheim, with further connections to smaller towns.

While everyone is asleep, our dedicated team starts operations as early as 2am (even before our farmers) to ensure the successful delivery of overnight services, so that customers can open their business with confidence around New Zealand.

We understand that our people are the core of everything that we do. For four consecutive years, we have been named one of the world’s best workplaces, ranking second globally and first in Asia, Latin America, and Europe.

This is no easy feat for a logistics company that is so diverse with a presence across the globe. It is the result of relentless focus and a passion for people, led by a very competent senior leadership team.

DHL Express believes in delivering great results without compromising on respect. We also ensure that our front-line supervisors and managers emphasise a passion for customers, speed, a can-do attitude, and getting

things right the first time.

By attracting and retaining the right talent, fostering collaboration, and promoting teamwork, we have built a culture that drives excellence.

My role requires me to execute our global strategy locally. This involves motivating and developing our team’s skillsets to provide the best service to our customers.

We prioritise inclusivity, collaboration, and creating a great place to work for all. To achieve continuous improvement, we actively seek input from our employees, leaders, business partners, and customers.

Passion for continuous improvement is part of our DNA and the reason why we launched ‘First Choice’ - a worldwide programme to drive continuous improvement of processes and services.

Through the Insanely CustomerCentric Culture (ICCC+) programme, we collect direct feedback from customers to identify areas for improvement based on their experiences. This approach has fostered an irreplaceable culture of excellence.

The recent COVID-19 pandemic was an unprecedented crisis that exposed the frailty of supply chains. Businesses faced challenges in sourcing products, experienced long delays, and dealt with cost increases.

At DHL Express, we also faced significant disruptions as we lost access to passenger flights overnight, which is a significant part of our network, especially in this part of the world. To adapt, we chartered passenger flights and repositioned our network to maintain connectivity.

We were able to change flight routes due to our expanded intercontinental network. We kept the world connected as we moved urgent medical supplies and lifesaving equipment and vaccines. This lack of air network capacity resulted in unprecedented demand for cargo space.

In New Zealand, we also lost access to our domestic commercial passenger air network, prompting the need for us to introduce the new aircraft to connect the South Island to Auckland.

From Auckland and Christchurch, we established road connections to reach all domestic locations. It was an intense time of unprecedented change, creativity, and innovation to ensure that our customers were not

“AT DHL EXPRESS, WE CONSIDER OURSELVES FACILITATORS OF GLOBAL TRADE, WORKING CLOSELY WITH REGULATORS AND CUSTOMERS TO ENSURE EASY AND ACCESSIBLE TRADING FOR ALL”

– CHITRA SHINDE, VICE PRESIDENT OF OPERATIONS, DHL EXPRESS NEW ZEALAND

impacted and could rely on us for their own business continuity.

As the logistics company of the world, we embrace our responsibility to set industry standards in environmental, social, and governance (ESG) matters. Due to the nature of our industry, we have a huge responsibility; we therefore set an ambitious goal in 2017 to achieve net zero carbon emissions by 2050.

To work towards this goal, we aim to electrify 60 percent of last-mile vehicles by 2030. We focus

on implementing carbon-neutral designs for new buildings,

educating employees as Certified GoGreen Specialists and engaging in environmental activities such as tree planting.

We recently launched the GoGreen Plus service, which is about reducing carbon emissions using sustainable aviation fuel (SAF). An aircraft flying on SAF emits up to 80 percent less CO2 over time than an aircraft flying on traditional jet fuel.

At DHL Express, we consider ourselves facilitators of global trade, working closely with regulators and customers to ensure easy and accessible trading for all.

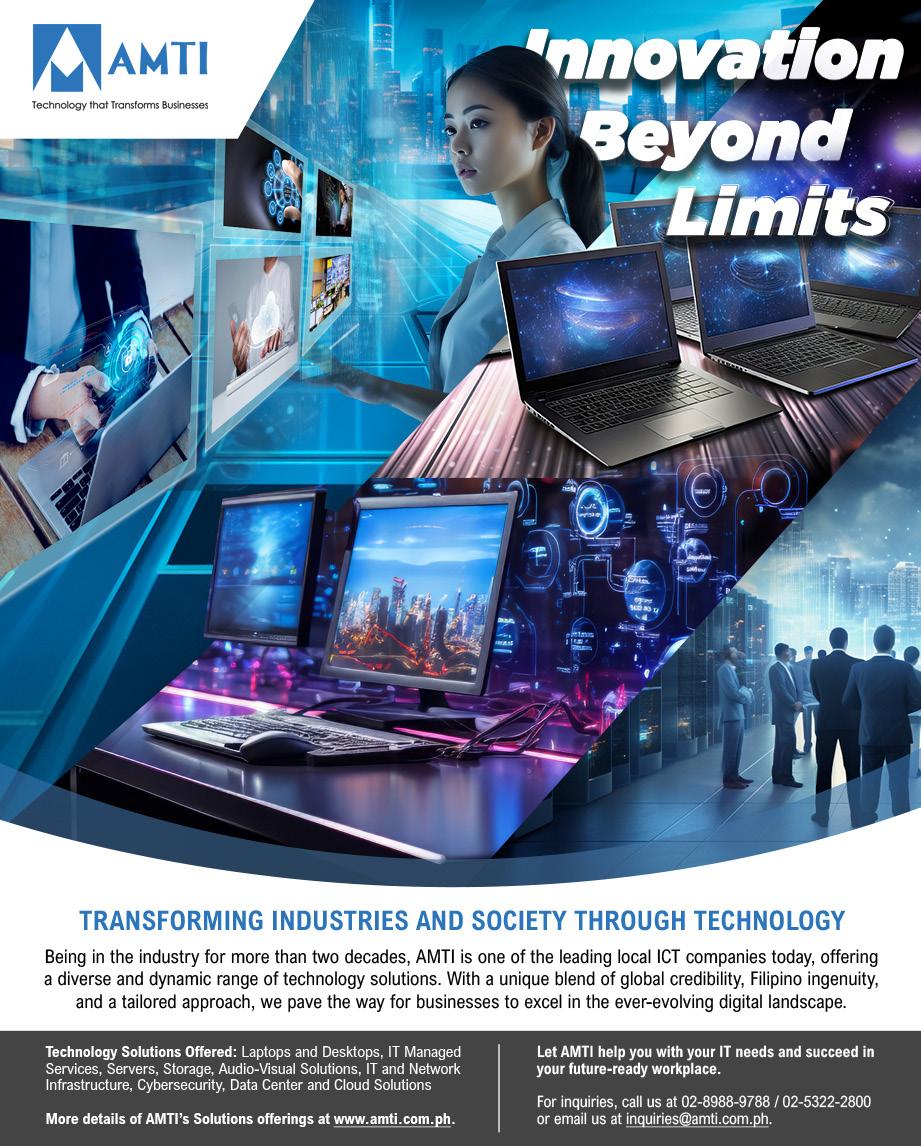

Building on the global success of our regional titles – APAC Outlook, Africa Outlook, EME Outlook, and North America Outlook – Outlook Publishing is proud to introduce a digital magazine and web platform, dedicated to the supply chain sector.

As supply chain organisations worldwide confront unprecedented change, embracing technological innovations and incorporating critical environmental sustainability agendas, now more than ever is the time to showcase the strides being taken in this dynamic sector.

A multi-channel brand, Supply Chain Outlook brings you the positive developments driven by organisations across the global supply chain industry through its various platforms. Discover exclusive content distributed through its website, online magazine, social media channels, and dispatches delivered straight to your inbox with a bi-weekly newsletter.

Through this compelling new venture, we foreground the movers and shakers of the industry. To participate as a featured company and join us in this exciting endeavour, contact one of our Project Managers today.

www.supplychain-outlook.com

Venipak Commerce proposes a new all-in-one service to bridge the gap between sales channels, warehousing, and distribution in the Benelux region’s fast-expanding e-commerce sector. Michael van der Wal, Regional Managing Director, and Justas Šablinskas, CEO, tell us more

Writer: Lily Sawyer

Apioneering e-commerce and logistics solutions company, Venipak Commerce (Venipak) caters to European distributors, suppliers, and manufacturers who wish to bolster their online presence.

“With a focus on supplier acquisition, marketplace expansion, and advanced technological integration, Venipak offers a comprehensive range of sales and fulfilment services, designed to adapt to shifts in the market,” opens Justas Šablinskas, CEO.

By integrating advanced technology solutions

and e-fulfilment services, Venipak hopes to facilitate seamless international sales and accelerate delivery times across key regions in the Benelux, Germany, Poland, and the UK.

The Benelux region, comprising Belgium, the Netherlands, and Luxembourg, has witnessed a marked rise in e-commerce of late. 74 percent of all internet users in the region reportedly purchase their goods online, whilst the Dutch e-commerce market alone is expected to generate over USD$52 billion by 2029.

As a result, Venipack has launched a new multi-channel solution that is able to transform e-commerce fulfilment, drive sales, enhance operational efficiency, and improve the overall customer experience, placing the company in an ideal position to benefit from a burgeoning sector.

“Our all-in-one service encompasses all operational processes, from e-commerce sales channel brokerage to warehousing and distribution,” reveals Micheal van der Wal, Regional Managing Director.

The company’s expansion in the region follows Venipak’s strategic acquisition of Dutch wholesaler Strengholt Entertainment BV (Strengholt) in 2023, which also contributed to the company’s emerging status as a global market player.

“At Venipak, we have studied the upsurge in the Benelux’s e-commerce activity and located various limiting issues. We aim to remove the burden from our customers’ shoulders, allow them to save money and concentrate on purposeful development without geographical or business process barriers,” he adds.

“Our mission is to help clients expedite their growth. In turn, we start off new partnerships with a strategy best suited to their plans to accelerate their sales and logistics journey”

– JUSTAS ŠABLINSKAS, CEO, VENIPAK COMMERCEJustas Šablinskas

Venipak’s recent acquisition of Strengholt has allowed the company to onboard localised expertise with insight into the Benelux’s unique market needs, providing a robust foundation upon which to build a new niche in logistics services.

Due to staff shortages, labour costs, and inflation impacting 82 percent of businesses in the region, a strong leaning towards automation is evident.

As such, around two-thirds of businesses seek investment in software-led solutions, outlining the

region’s willingness to embrace current and modern opportunities.

“As the e-commerce market shows exponential growth, the demand for automated and increasingly efficient logistics solutions becomes more pronounced,” Šablinskas posits.

Therefore, Venipak has established a strategic stance to meet this demand.

“We are in a good position to enter deeply into this niche while expanding the scope of what’s previously been possible,” he adds.

“Our all-in-one service encompasses all operational processes, from e-commerce sales channel brokerage to warehousing and distribution”

– MICHAEL VAN DER WAL, REGIONAL MANAGING DIRECTOR, VENIPAK COMMERCE

As the e-commerce sector continues to evolve, Venipak has identified a new focal point – e-fulfilment. As a highly efficient method of managing e-commerce inventory, e-fulfilment caters to the unique needs of online sales, optimising space as well as resources.

“It is aligned with the specific needs of e-commerce, such as variable demand and the handling of single-purchase items,” van der Wal notes.

In addition, e-warehousing allows businesses to access accurate inventory management and optimised return processes through advanced software integration and specialised systems, all of which are integral for maintaining a competitive edge within a saturated market.

Michael van der Wal

According to Šablinskas, the e-wholesale niche’s true potential is still emerging.

“Whilst looking for ways to expand globally, we tried to deconstruct the whole trading chain and found this niche, which is practically non-existent – not only in Europe but also throughout the world,” he reveals.

On a mission to provide the best local options with faster deliveries in any major market, Venipak hopes to benefit from developments in e-fulfilment.

In addition to its more recent developments, Venipak offers e-commerce brokerage services between clients and brands such as Amazon, Allegro, Zalando, and Bol, amongst others, as well as physical outlets such as Aldi, Lidl, and Action.

“Our e-commerce brokerage services enable Venipak to act as an intermediary for the introduction of customers’ products into foreign markets like the US, Europe, and Asia, through integrations with Amazon and other trading platforms and supply chains,” says Šablinskas.

In addition, new and emerging partnerships with e-commerce businesses reduce risk when entering new markets.

“Our mission is to help clients expedite their growth. In turn, we start off new partnerships with a strategy best suited to their plans to accelerate their sales and logistics journey. We don’t want our clients to have blind spots on what is possible when it comes to cost saving and optimisation,” he concludes.

Thus, Venipak’s expansion marks a transformative approach to e-commerce logistics in the sense that it offers integrated solutions that are able to meet rising demands in the sector, while a focus on automation and e-warehousing exemplify the company’s commitment to increasing scalability and efficiency.

venipak.com

The distant sight of summer on the horizon signals festival season across the UK as the nation grabs its wellies and gets ready to party at one of the many music events taking place across the country.

Whatever your musical taste, be it rock, pop, hip-hop, house, or anything in between, there’s a perfect event for everyone. Indeed, whether your heart desires to get stuck into the middle of the action, deep in the mosh pits, or you prefer a serene, seated view of things, British festivals continue to offer the entire spectrum of musical diversity.

We compile a comprehensive plan and prepare the logistical festival. From talent acquisition scouting, we detail all the Writer:

Every summer season, come rain or shine, the nation witnesses hundreds of thousands of music lovers united in a field, park, or innovative city location, celebrating the incredible sound of their favourite artists.

From world-renowned mega-events like Glastonbury, Reading and Leeds, and the Isle of Wight Festival to the newer surfing festival, Boardmasters, or family-friendly Camp Bestival and Latitude, there’s an event to suit every age range and demographic, as the biggest acts across the globe descend on the UK to take part in these iconic

Ed

Ed

We examine some of the key logistical areas that must be studiously prepared for when organising a successful UK music festival. comprehensive guide on how to effectively logistical elements of a music acquisition to security and location the essential information

gatherings. In terms of the meticulous preparation for these gigantic spectacles, nothing can be left to chance. A complex network of components must be perfect in order to offer the best shows, guarantee the safety of everyone who has paid to live the experience, and make sure everything runs smoothly. This is sometimes not the easiest challenge, and the planning and preparation of a successful music festival is a great logistical mission for its organisers.

Requiring a monumental amount of intense work

before, during, and after the event, which often remains invisible to the general public, festival organisers must be able to comprehensively manage large numbers of staff and equipment and facilitate effective mobility, as well as plan the setup of complex infrastructure, often in remote places and adverse weather conditions.

Choosing a venue should be at the top of any festival logistics checklist.

Location — A festival must be situated somewhere that suits your goals, and if a large number of attendees are expected to travel to get there, you need a location with a variety of convenient transport links nearby.

Mock-up — When dealing with an expansive area and numerous different activities and performances, it becomes important to visualise your space with a site map. The most important thing is to make sure that it’s accurately scaled and easy to read.

Equipment — An element that is often overlooked in the logistics planning department is festival equipment. Artists and vendors will undoubtedly be carting large electrical apparatus, sound gear, stage setup, and booth materials into the venue. For this, there’s no better way to organise the surplus hardware than with reusable, plastic, collapsible bulk boxes.

‘A range of diverse activities and spectacles, such as art installations, water features, outdoor film screenings, or pop-up shops will keep guests engaged between big performances’

SECURING TALENT

You can’t have a festival without headliners, and while designing an event’s lineup is definitely one of the most exciting parts of the planning stage, it also requires juggling lots of scheduling responsibilities.

Pitch — The most affordable way to book talent is to reach out to acts directly by creating a succinct, wellorganised pitch that outlines your event and can be sent to desired artists. For events on a bigger budget, partnering with a booking agency can be a good way to secure performers.

Schedule — A smooth, well-organised festival depends on smart scheduling. Not only is it key to ensure that attendees get to see all the artists that they want to see, it also guarantees that festival staff are scheduled and deployed at the appropriate times.

Enhance — The best festivals feature more than just glamorous headliners; they also showcase compelling extras that might convert a previously on-the-fence fan to a committed devotee. A range of diverse activities and spectacles, such as art installations, water features, outdoor film screenings, or pop-up shops keep guests engaged between big performances.

Once a date is set, it’s then time to consider ticketing. To generate buzz for your event, it’s often a good idea to offer presale tickets to a select group of fans or attendees. It is also vital to ensure the use of a reliable, easy-to-use online ticketing platform to minimise customer service issues.

Attendee flow — Anyone who has ever been to a large event of any kind will know that getting in and out of the arena or location is one of the most challenging and often stressful parts of the experience. Before the festival starts, it is important to create a detailed plan of how to funnel guests to where they need to go without causing heavy traffic and to identify and clearly signpost all exits.

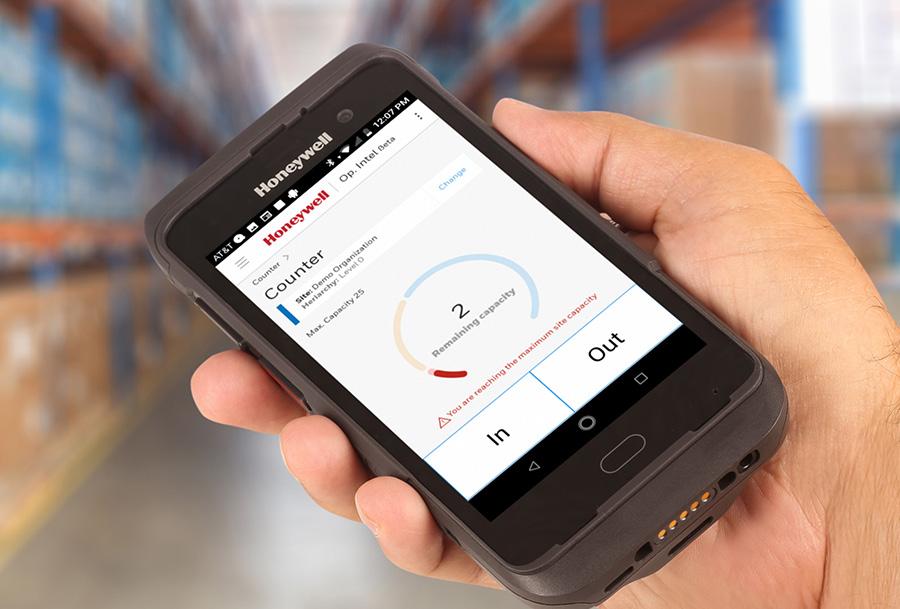

Scanners — If you’ve sold over a few hundred tickets, you will undoubtedly require an investment in ticket scanners to ensure that event-goers get through the gates quickly, safely, and efficiently.

Security — Security teams play a crucial role in managing the crowd by controlling the flow of people in and out of the festival grounds. They also ensure that visitors are not overcrowded and maintain order in the event of an emergency.

Payments — Accepting all forms of payment, both on-site and online, will help boost overall event sales. Not only will this make it easier for customers to secure tickets, but it will also make an event look more reputable and legitimate. Many festivals also now offer staggered payment plans, which can help increase sales.

spend a huge amount of money on their tickets and often consider these events as an escape or retreat from everyday life. Therefore, organisers cannot afford to make crucial services, artist performances, key information, and food a hassle to find.

Information — Any festival setup must include numerous accessible information hubs so that festival-goers can seek guidance when they need it. Additionally, information booth workers should provide maps and flyers, and be able to quickly direct attendees to medical services, lost and found, security, and other on-site facilities. Furthermore, all this information must also be easily available on the event website or app.

Customer service — It is absolutely essential to designate a few trusted members of event staff as customer service professionals so that volunteers and other attendees can direct any conflicts or issues to a specific person.

The festival must simultaneously have a clear strategy in place for how to handle issues with ticketing, entry, vendors, and more.

Personalisation — Every festival should aim to create a truly unique and memorable experience by adding a personal touch.

Once everything else is prepared and ready, it’s essential to effectively market the event and start to build excitement as far in advance as possible. This shouldn’t pause once the gates open, either. Throughout the preparation process, it is vital to consistently engage audiences on social media platforms, which can lead to locking in the crucial influence of promoters and press coverage. Every festival should be considered as a brand in itself, featuring its own personality, narrative, and goals.

Authenticity — The first rule of event marketing is to remain authentic. A valuable lesson learned from the now infamous Fyre Festival disaster, which spent millions on glitzy marketing materials featuring Kendall Jenner and a fleet of private jets, is that it’s crucial to be upfront and honest with ticketholders every step of the way.

Social — If the target audience of the festival is largely from a digital generation, you cannot afford to underplay social media engagement. Creating a hashtag and incorporating it throughout the event is a key example of something that visitors are more likely to share.

Livestream — Social media potential can be maximised and interest can be enhanced for the following year by livestreaming some of the biggest and most well-attended, iconic festival moments.

The envy of industry around the world, Australia’s high-productivity heavy vehicles are ready to undertake any and every task imaginable thanks to their ingenuity in design, engineering, and manufacturing Writer: Jack Salter | Project Manager: Deane Anderton

Australia is a world leader in many aspects of heavy vehicle transport.

The country has a thriving and robust local industry that comprises hundreds of forward-thinking manufacturers and suppliers of innovative trailers, trucks, and other specialised vehicles, components, equipment, and technology.

This is in addition to the product assembly of global heavy vehicle brands such as Mack, Kenworth, DAF Trucks, SEA Electric, Hyzon, and Volvo. The latter is Australia’s largest heavy vehicle powerhouse and the sole truck manufacturer to have been awarded the

Heavy vehicles in the country are manufactured to withstand Australia’s climate and operating challenges. Indeed, customers Down Under must contend with heavier loads, greater distances, and changeable weather, from the hot, dusty Outback to the Snowy Mountains.

These tricky conditions mean that heavy vehicles have to work harder in Australia than just about anywhere else in the world and are therefore tailored accordingly.

Australia also boasts many unique truck and trailer combinations that simply do not exist in any other country.

It is well known that Australia has pushed the boundaries

in truck and trailer size, gross mass, and configuration. Decades ago, it even broke new ground in terms of the roads that vehicles drive on as, unlike many other developed countries, much of Australia is thinly populated and features incredible distances between its centres of population, both large and small.

This creates a complex infrastructure when it comes to providing an expansive yet reliable network of sealed roads, suitable for both light and heavy vehicles.

Australia’s heavy vehicle industry directly employs over

70,000 people, who are responsible for designing, manufacturing, servicing, and repairing some of the world’s most efficient, safe, innovative, and technologically advanced vehicles.

The sector’s vast workforce is also involved in the importation, distribution, modification, and sale of these impressive vehicles, as well as their components, equipment, and technology.

A career in the heavy vehicle sector requires far more than just a singular skillset. As vital cogs in the machinery that allows the industry to keep Australia moving, it’s about how individual contributions fit into the bigger picture.

However, the heavy vehicle industry in Australia continues to suffer critical shortages of skilled labour. This is not an anomaly, either, as labour market skill shortages are as deep as they are wide across the country.

The current pipeline of workers is struggling to keep pace with growing demand in the sector, with an order book extending well into 2024 that needs filling. The

work does not end there, as once those vehicles are on the road, they also need to be maintained.

Recent vacancy figures indicate that several thousands of motor mechanics, electricians, metal fitters, and machinists are required to address the shortage.

In Victoria, the state government is also injecting an extra AUD$1 million into training more heavy vehicle drivers to keep supply chains moving through a partnership with the Victorian Transport Association (VTA).

The partnership offers accredited training for aspiring heavy vehicle drivers and assists them in securing employment as part of VTA’s Driver Delivery programme, which has received continuous investment from the government since it was launched in 2016, resulting in the training and placement of nearly 400 skilled drivers on the roads.

In addition to improving road safety, the programme aims to tackle heavy vehicle driver shortages, tailored to attract and retain younger drivers for critical transport and logistics supply chains.

Along with the Technical and Further Education (TAFE) network and other Registered Training Organisations (RTOs), a stream of skilled workers from the Australian school system is required to rectify the labour shortage.

There is an overwhelming need to disseminate career information to students, and the wider public for that matter, to provide a more comprehensive understanding of the sector, the roles on offer, its operational diversity, and the job needs of the future.

A variety of initiatives promote careers across the country’s heavy vehicle industry, including the Brisbane Truck Show, the southern hemisphere’s largest road transport event displaying the most comprehensive range of trucks, trailers, components, equipment, accessories, and technology in Australia.

With an incredibly rich, continuous history that dates back half a century, the Brisbane Truck Show has always been about coming together, sharing ideas, discussing challenges, and showcasing the innovative ways to address them.

A record number of pupils were hosted at last year’s running of the Brisbane Truck Show, with well over 1,600 students from over 50 schools in attendance.

Australia’s largest-ever showcase of commercial zeroemission heavy vehicles (ZEHVs) was also on display at the 2023 event, from both major original equipment manufacturers (OEMs) as well as a raft of new players.

The ZEHVs exhibited ranged from battery electric vehicles (BEVs) and hydrogen fuel cell electric vehicles (HFCEVs) to more conventional trucks powered by renewable diesel, an advanced biofuel made from animal fats, vegetable oils, and agricultural waste.

Significant investment has been made towards increasing vehicle efficiency and reducing the emissions of diesel-powered vehicles to accompany the shift towards ZEHVs.

There are also calls for the Australian government to support the enablement of onshore renewable diesel refining, as the fuel is not currently commercially available in the country.

This is despite renewable diesel playing a critical role in decarbonisation, given its chemically identical properties to conventional diesel, which means that machinery using the fuel does not require modification and is widely supported by OEMs.

Access to domestically produced renewable diesel represents a significant and immediate opportunity to decarbonise a range of hard-to-abate sectors where alternative technologies are not readily available.

Diesel engines, traditionally the driving force behind the industry, have become a highly efficient and productive way of powering heavy vehicles since they were first

developed over a century ago.

However, as Australia reduces its environmental impact in line with international commitments to reduce carbon emissions, the push towards ZEHVs has gained huge momentum.

All levels of government are currently considering the development of a coordinated approach to decarbonising the heavy vehicle task, covering a range of issues both transport and non-transport related.

As progress is made towards decarbonisation, the industry may change, reprioritise, or develop new technologies.

There’s an old saying in the road freight transport industry: ‘If the wheels aren’t turning you aren’t earning’. Vehicle downtime can cause delays, decrease productivity, and ruin reputations. If this is caused by something like a discharged battery, there’s a cost-effective solution on hand to give operators – whether owner drivers or fleet managers – some insurance.

Power-packed, the IS3000 and IS5000 Jump Starters are ideal for use on large industrial and commercial equipment including heavy-duty trucks, tractors, and agricultural equipment. Until now, there hasn’t been an easy or efficient means of jump-starting heavy equipment, with users often resulting to moving large batteries around on unwieldy trolleys to jump start the machines. With their easy portability, light weight (10.6kg and 13.5kg respectively) and patented Rapid Recharge Technology (RRT), the IS3000 and IS5000

industrial jump starters alleviate these pain points, adding convenience and efficiency for users. The IS Jump Starter range also reduces the risk of being caught out without charge when going to jump start a vehicle, as recharging the trolley rigs can often be forgotten.

By leaving the INTELLI-START Jump Starters connected to a vehicle’s battery once started, RRT can fully replenish the energy that was discharged during the starting process in just 40 seconds. This feature means that the INTELLI-START Jump Starters will then be ready to use in the next emergency without needing regular recharging –its clever technology that is unique to the Projecta INTELLI-START Jump Starter range.

The IS3000 is suitable for both 12V and 24V electrical systems and provides 1000A clamp

power for 12V systems and 850A for 24V electrical set-ups, along with 3000 peak amps – it’s enough to start petrol and diesel engines up to 12L displacement in 12V machines and all 24V engines. The larger IS5000 has even greater clamp power, an impressive 1500A in 12V electrical systems and 1000A for 24V systems – in both cases peak amps are 5000. This output is sufficient to breathe life into petrol and diesel engines up to 16L capacity in equipment with 12V systems, and unlimited capacity in the case of vehicles with 24V electrics. The two jump starters also offer ‘no battery’ operation and can jump start vehicles without a starter battery.

Both the IS3000 and IS5000 Jump Starters feature a strong exterior casing that uses a steel chassis and rubber over-moulded construction with integrated handle and concealed cable storage. Also, these products ensure reliability and safety, utilising ‘no solder’, high current connections and solid 3mm clamp teeth, while an advanced allin-one protection system prevents surges, short circuits and overheating in these units.

For greater convenience, both models also boast auto sensing clamp connection, while operating this equipment is also simple via the intuitive LCD display with real time updates.

When it is finally time to recharge the IS3000 and IS5000, this is done using the included docking station, which provides hassle-free benchtop charging. Owners can also rest easy knowing that the INTELLI-START range is equipped with premium LiFePO4 batteries, the safest lithium technology available.

Additionally, the units feature an advanced, ‘all-inone’ protection system that prevents surges, short circuits, and overheating.

The IS3000 and IS5000 also deliver excellent longevity for users because they’re designed to deliver up to 2000 battery cycles, around four times more than competitor Lithium Cobalt based jump starters.

Other Projecta INTELLI-START models in the lineup include the IS920, IS1220, IS1400, IS1500, and IS2000. All INTELLI-START variants are Restriction of Hazardous Substances (RoHS)-compliant, and Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) certified, and feature the globally patented RRT.

The latest additions to the INTELLI-START Jump Starter range are available from leading automotive and transportation outlets nationwide and are covered by a generous two-year product replacement or refund warranty.

NARVA Ultima Connect+ Controller offers complete lighting control

The new Ultima Connect+ Controller has arrived, offering owners of the recently launched Ultima LED Light Bar range, the ability to further maximise the performance of their light bars, by adjusting the beam shape and intensity to suit the environment and driving conditions.

An optional extra across the new Ultima LED Light Bar line-up, the controller offers further lighting adjustment with three preset, customisable driving modes.

For highway driving, the beam can be set for maximum distance with less spread to avoid road sign flare. In regional and rural areas, the distance can be reduced with a focus on maximum spread allowing possible hazards such as wandering livestock or wildlife, providing additional safety.

Ultima Connect+ Controller also allows drivers to alter brightness (main and aux controls), provides a boost mode that delivers 15 percent more power

for 30 seconds, and with its LIN Bus technology, acts as a single point of control for all Ultima Connect+ enabled products.

The controller’s generously sized buttons make it easy to use on bumpy roads and corrugations, while multiple mounting options and single wire installation provide easy fitment across a wide range of vehicles.

The Ultima Connect+ Controller is the perfect companion to the Ultima LED Light Bar range, which include eight- and 24-inch models that can be combined to also provide 40- and 48-inch bar configurations. With Ultima, owners can also select from both hybrid and flood beam light bar options depending on their preference. Together, Narva offers buyers customisation options like never before.

Narva’s new Ultima Connect+ Controller, Ultima LED Light Bars and associated accessories are available nationwide from leading automotive, four-wheel drive and transportation outlets.

For decades, improvements have been made to the environmental footprint of the country’s heavy vehicle industry.

The Australian government estimates that since 1990, heavy vehicle noxious emissions standards have reduced carbon monoxide (CO) and hydrocarbon (HC) emissions by over 80 percent.

This is despite the fact there are now approximately 60 percent more heavy vehicles on the road, and the total distance travelled has almost doubled.

However, even though the industry provides some of the world’s most efficient, safe, innovative, and technologically advanced vehicles, there remain significant barriers to the adoption of ZEHVs.

Some of these barriers include vehicle design rules, a lack of electric truck recharging and hydrogen refuelling infrastructure, and a temporary but significantly higher upfront cost.

The industry has made a compelling case for the removal of such obstacles for heavy vehicles operating across Australia. Therefore, its position on the regulatory changes needed to support next-generation ZEHVs is clear, but urgent action is required by the government and its policy and regulatory agencies.

This includes a need to review heavy vehicle axle weight limits, a position that is unilaterally supported by industry

associations, manufacturers, and suppliers to the road freight transport sector.

The sheer volume of industry and stakeholder discussions on ZEHVs is overwhelming, yet current axle load limitations are one key theme that has emerged.

If low truck axle load limits are not addressed, it will strangle efforts to further decarbonise freight transport, preventing the industry from contributing to mandated domestic emissions reductions targets. Although Australia has a legislated commitment to net zero emissions, there is no plan for reducing emissions from road freight transport.

Electric trucks typically weigh more than their diesel counterparts, limited by high front axle loads, which means the existing weight limit in Australia has presented an industry-wide roadblock for the adoption of zeroemission technology.

One of the main reasons why Australia has lower load axle limits than other developed countries is due to its sprayed seal road structures.

An interesting departure from other road structure designs, sprayed seals are effectively a thin layer of bitumen that is sprayed as a hot liquid onto a compacted base layer, which is then covered with a layer of aggregate to form the road surface.

Often, the base layer beneath the bitumen is unbound, which means that it may be treated with a stabilising agent such as cement, but sometimes it is not treated at all.

The result is a relatively cheap, flexible road type that is easy to construct and suitable for roads carrying several thousand vehicles a day. Usage of sprayed seals therefore grew rapidly after their introduction in the early 20th century, and they now account for around 70 percent of the total length of all sealed roads in Australia.

On the other hand, sprayed seals are very thin and susceptible to increases in applied load, unlike other rigid road structure types such as asphalt and concrete.

This is disadvantageous for ZEHVs in Australia, which have higher tare weights than conventional internal combustion engine (ICE) trucks due to the equipment comprising the electric drivetrain, such as the battery in the electric motor.

For HFCEVs, the problem is exacerbated even further when you add in the weight of the fuel cell and the hydrogen storage and delivery system.

A number of actions are required to address this issue, including research into next-generation sprayed seals to support higher axle loads.

Allowing heavier electric and hydrogen trucks across the whole of Australia will be vital in opening access to new low-emission heavy vehicles and ZEHVs, which alongside

Heavy vehicles could soon be able to charge wirelessly as they drive on the highway thanks to a new AUD$3 million grant from the Australian government.

The world-first project, led by the Swinburne University of Technology, Melbourne, aims to implement an embedded dynamic wireless charging technology into roads, unlocking the uptake of electric heavy vehicles.

It is claimed that electrifying heavy vehicles could save Australia AUD$324 billion by 2050, while contributing to a greener, safer, and more efficient transport sector.

The AUD$8.2 million prototype for embedding advanced wireless charging infrastructure on regional roads is funded by the Australian government’s Cooperative Research Centres Projects (CRC-P) Grants scheme, which supports short-term collaborative research projects.

How Geotab’s Electronic Work Diaries are driving success for Australian fleet managers

David Brown, Associate Vice President Sales, ANZ, Global Channel, Geotab

David Brown, Associate Vice President Sales, ANZ, Global Channel, Geotab

Whether you’re managing a fleet of cars or heavy trucks, Geotab’s Electronic Work Diary (EWD) helps keep a finger on the pulse of every vehicle movement and activity. This innovative system monitors and records the work and rest times of heavy vehicle operators, ensuring they are aligned to legal requirements. Here’s why you should get your fleet onboard:

Heavy trucks that cover long distances are legally obligated to adhere to regulations regarding driver fatigue. EWDs assist fleet managers in maintaining compliance with national heavy vehicle regulations by accurately recording driver work and rest time. By automating data entry and streamlining the record-keeping process, EWDs not only reduce errors but also alleviate the administrative burden on both drivers and fleet managers.

EWDs offer real-time visibility into driver activities, a critical aspect of workplace safety. Through real-time monitoring, fleet managers can ensure the safety and accountability of all staff.

Monitoring driving hours, rest breaks and compliance status in real-time allows for the proactive management and timely interventions to address potential issues.

EWDs also facilitate efficient reporting by quickly generating data for audits, compliance checks and internal reviews, thereby relieving pressure on fleet managers.

EWDs offer a great deal of valuable insights into driver behavior, vehicle performance, idling times, fuel consumption and overall fleet efficiency. The information collected is presented in an easyto-understand format, which empowers fleet managers to maximise the utility of the data. For mixed fleets that contain both EVs and internal combustion engines (ICE), fleet managers can extract specific details about each vehicle. Additionally, they can also advance their business by optimising routes, vehicle maintenance.

Additionally, EWDs provide a comprehensive fleet management solution through seamless integration with telematics. Fleet managers have the flexibility to tailor their user interface platform to align with their business needs. This customisation involves building upon the base plan, which provides essential details such as location, speed and driver identification. The effortless and non-intrusive integration between the EWD and telematics solutions makes it easy to adopt and scale as needed to fit any fleet.

In summary, integrating Electronic Work Diaries into fleet management reflects a company’s commitment to safety, technological advancements and operational efficiency. They empower fleets to align seamlessly with evolving regulations and industry standards. For fleet managers, EWDs play a pivotal role in ensuring compliance, alleviating administrative burdens, improving safety and providing valuable data to optimise overall fleet management practices.

Harness fleet asset data for efficiency, cost control, and safety with Geotab’s unrivalled fleet management solution

From in-vehicles coaching to advanced collision prevention, we have a comprehensive ecosystem of driver safety solutions to manage any heavy truck fleet in the country.

One platform for optimal fleet performance powered by AI and data intelligence. Unlock actionable insights and recommendations to boost fleet efficiency, compliance, safety, and sustainability.

4 million+

75 Billion+

Our pillars of innovation: data points processed daily v globally connected ehicles

Productivity

Track, route and dispatch drivers to ensure a productive fleet

Optimisation

47,000+

customers in 150 countries

Drive efficiency & cost savings in fuel efficiency and planned fleet maintenance

Safety

Analyse and encourage safe driver behaviour with reports and in-vehicle coaching

Sustainability

Reduce fuel consumption and carbon emissions, or integrate EVs and electrify your fleet

Compliance

Comply with regulations likes Australia Standard HoS rules and be audit-ready for safety reviews

Expandability

Our open platform lets you integrate hardware or software options to drive performance

Go further with Geotab: geotab.com/au

reducing environmental impact are also expected to provide other benefits such as reduced maintenance and greater permitted operating hours – currently restricted in some areas due to noise.

In March 2024, the Queensland government formalised a long-awaited change to maximum axle weight limits, allowing heavy vehicles to operate with a steer axle weight of up to eight tonnes (t) on selected roads in the southeast of the state.

The announcement puts Queensland on the map as a leader in future electric truck manufacturing, and ZEHVs will make a significant contribution to the state’s own emissions reduction targets.

The change means Queensland has become the fourth state to allow heavy-duty electric trucks on its roads. It follows trials of higher mass limits for ZEHVs in New South Wales and South Australia, as well as the granting of a three-year permit to Volvo for the operation of a battery electric prime mover and semi-trailer combination on a network of state-owned roads.

Despite these promising reforms in individual states, the ongoing contribution of the heavy vehicle industry to Australia’s economy and emissions reduction targets remains at stake, and there is a need for the federal government to accelerate truck axle mass regulatory reforms at all levels.

The nation has everything it needs to meet emissions reduction targets, creating more local jobs and additional investment opportunities in the process.

The only missing piece of the puzzle is the regulatory framework to support the heavy vehicle industry, which seeks to transition to ZEHVs using technology that is currently available.

The process of changing some areas of heavy vehicle regulation, including mass and dimension requirements, demands careful analysis and requires time and attention.

To address this, a ‘maturity model’ is applied by regulators which uses the full range of tools available to support the industry, while the process of making regulatory change is followed.

As well as regulatory reform, there is a significant focus on innovations, several of which have more than proven to save time, money, and most importantly, lives.

Sophisticated fleet management systems (FMS), for example, allow information associated with heavy vehicles and other related assets to be visualised, monitored, and managed.

More businesses have turned to FMS as technology has advanced, as they provide numerous benefits such as complete visibility across operations, streamlined day-to-day tasks, improved maintenance planning, and the identification of deeper issues that impact fleet and business performance, to name a few.

Fleet management has transformed as the evidently positive impacts an efficient fleet can have on key variables such as people, vehicles, and operations are realised by adopters of the technology.

Cost savings are widely agreed to be the key driver behind developing a fully functioning FMS, which can also include the management of drivers, the environment, and compliance.

The latter is just as important and a fundamental necessity for safe and successful fleets, most of which have the same issues to address in terms of compliance.

For example, vehicles must be safe, maintained, and properly equipped for the nature of their use to ensure roadworthiness, as well as being suitably taxed and insured. This requires a robust service and maintenance system, regular internal inspection policies, and the strict management of warranties and policies.

Risk assessments, meanwhile, involve considering the risks of routes that drivers are asked to travel, operations they need to undertake, and compliance with safe and legal driving times.

Drivers also require licences that are up to date and comply with the vehicle they are at the wheel of. From a health and safety point of view, they additionally need to drive and conduct themselves appropriately on the road.

Ultimately, however, employers are responsible for the health and safety of their drivers. Whilst this involves many of the aforementioned issues, it is a fundamental starting point when maintaining compliance as part of FMS.

In most cases, this involves investing in software and establishing a database that collates all-important compliance factors, such as key dates, requirements, and criteria, and can trigger action through notifications and alerts.

Fleet compliance is ultimately a continuous process that demands visibility, organisation, and consistent policies to avoid fines, penalties, safety violations, excessive admin costs, and significant delays or disruption.

In-vehicle monitoring systems (IVMS) are another innovation that is considered integral to achieving effective and successful fleet management.

IVMS consists of electronic devices installed in a vehicle to monitor driver activities and identify potentially dangerous behaviours, such as excessive speed, harsh braking, and rapid acceleration.

In response, these sophisticated systems can provide warnings and evidence of a wide range of undesirable driving practices. Other behaviours that are monitored include tailgating, rough cornering, and driver drowsiness.

The technology is therefore crucial to the monitoring, maintenance, and improvement of road and driver safety standards in heavy vehicles, which pose significant risks to public safety due to their sheer size and weight as minor errors can have more serious consequences compared to light vehicles.

With a legacy rooted in a commitment to excellence, innovation, and customer satisfaction, Krueger Transport Equipment has spent the last 45 years making Industry Awarded Semi-Trailers that are built for the Australian Industry and Environment.

Australia’s transportation industry asserts its dominance by moving more tonnes per kilometre (t/km) than its global competitors annually. In recent years, the sector has witnessed a surge in performance-based standards (PBS) adoption and the integration of electric vehicles (EVs) and hydrogen technologies as part of its ongoing expansion.

Kevin Dennis, CEO of Krueger Transport Equipment (Krueger), acknowledges, “Australia’s transport industry has a legacy of pushing boundaries, making it the most respected, productive, and efficient transportation landscape worldwide.”

As Krueger, a pioneer in innovative semi-trailer design, gears up for its 46th year in business, it remains committed to the foundational principles that have defined its brand. “2024 promises to be another dynamic year for Krueger as we continue to enhance our products,” Dennis affirms. “This commitment stems from decades of engineering expertise and a relentless pursuit of excellence that defines the Krueger trailer.

“In the product realm, we are poised to ramp up production of our newly introduced K-Van range (Dry van) by year-end, following successful pilot runs with key clients. This expansion into a new market

segment solidifies our position as a major player through broadening our product portfolio.”

Furthermore, strategic investments in cutting-edge technologies, such as a laser cutting facility, has revolutionised Krueger’s manufacturing processes. “By the conclusion of 2023 and into early 2024, we are already reaping significant benefits and efficiencies from these investments,” notes Dennis. “Our newly implemented laser cutting machine and facility has notably enhanced quality and time efficiency, translating into improved manufacturing standards and reduced production times. This ultimately results in delivering more high-quality Krueger trailers to the market.”

Hearing from John Krueger, Founder of Krueger Transport, and Adis Selmic, Manager - Projects & Production Engineering, they shed light into the past, present and future of the core of Krueger’s business, engineering and design.

When you first started Krueger, what was your intention in building semi-trailers?

John Krueger, Founder (JK): It all started 48 years ago at the kitchen table when I conceptualised my first design. I’d been a truck driver for many years and driven Skeletal Trailers. During this time, I’d encountered numerous safety challenges and operational difficulties with various trailer brands, notably the dangers and weekly accidents and incidents you would hear about posed by poorly designed 20-foot container skeletal trailers.

The first trailer I built was for my own use as an owner-driver, which took me six to nine months to construct in my own driveway and my intention was to increase my rig’s capacity from carrying one 20-foot (ft) container to two, doubling my trip’s efficiency.

A crucial aspect of the trailer design was to stop the issues around manoeuvrability under load, which caused dangerous and sometimes fatal incidents on

the roads, as well as a safe and efficient decoupling of the trailer from the truck at the dock point, which in those days had huge issues with trailers sinking on poor footed ground or diving headfirst as the weight was not evenly spread lifting the rear of the trailer and trapping workers or forklifts and destroying cargo. It was a huge amount of work, but ultimately it was a huge success, literally. This catalysed a change in the industry, and we began Krueger Transport Equipment. My journey as an owner-driver gave me such an understanding of the complexities in trailer design, safety aspects and maximising productivity. When we first started producing trailers as Krueger Transport Equipment, for the first 10 years, I spent more time in the field analysing our product to keep innovating. Our designs where not without their critics, as industry and competitors spent years disparaging the designs. Then years later they eventually copied my designs, as customers became more and more frustrated with outdated ideas and continual issues and incidents from their products.

Today, Krueger stands as a pioneer in establishing fresh industry benchmarks within Australia. This distinction is attributed to our pioneering role in

solving the problems of the industry and innovating and executing various aspects and elements of trailer design. This also meant consistent recognition through multiple industry accolades.

Our commitment to innovation is underscored by the number of successful patents we have all designed to address safety in load cartage and restraint issues as well as occupational health and safety.

How has the company’s engineering and design process evolved over the last 45 years?

JK: I don’t think much has changed outside of the use of technology and changes to transport regulations. The innovation hasn’t stopped. Since its inception, Krueger has prioritised R&D, laying the groundwork for our stringent policies and procedures. By adhering to rigorous standards, we ensure that only the highest quality materials are used in the manufacturing of our trailers and that we stay up to date with the latest trends, techniques, and processes to ensure the safety and well-being of our customers.

I still am heavily involved in the engineering process and the conceptualisation of answers to customers problems and feedback. Over the

years, our engineering team’s dedication to quality remains unwavering. It’s what has and continues to distinguish us in the industry and has made Krueger synonymous with excellence. Whether it’s engineering, manufacturing, design, or delivery – innovation and quality are at the forefront of everything we manufacture.

From an engineering and manufacturing perspective, what differentiates Krueger from the competition?

Adis Selmic, Manager of Products and Production Engineering: Before my time at Krueger, John Krueger was extremely hands on in creating the strategy and

procedures within the engineering department, and these are the core values that my team and I work by today.

What sets Krueger apart from the competition is our unwavering commitment to excellence and innovation, regardless of the design’s complexity. Our engineering team works tirelessly on new ideas and continuous improvements, ensuring that each trailer we produce is of the highest quality and safety.

Vehicle operators and other road users have an increased chance of detecting, avoiding, and surviving crashes thanks to advanced safety technologies, which will continue to be developed in the short-to-medium term and must be monitored by transport regulators.

As well as fleet management, compliance, monitoring, and safety systems, electronic work diaries (EWDs) are another innovation that is used to record the work and rest times of heavy vehicle drivers.

EWDs are approved by Australia’s National Heavy Vehicle Regulator (NHVR), whose vision is to cultivate a safe, efficient, and productive heavy vehicle industry that serves the needs of the country.

The devices can be used as an alternative to keeping records in a written work diary. Drivers, transport operators, record keepers, and authorised officers still have the same obligations as they do for a written work diary when they are using EWDs, however they can automate many of these functions, making day-to-day operations faster and easier.

Transport operators have the option to either develop their own device, buy one off-the-shelf, or adopt an EWD that can be integrated with other regulatory systems.

In any case, the technology must meet specified performance requirements to be approved for operation, whilst appropriate training is needed for transport operators as well as drivers to inform them of the correct use of their EWD.

At all times, EWD approval holders, record keepers, and drivers must ensure that the devices function in accordance with the standards and conditions set by NHVR.

Information collected by an EWD can be provided to numerous recipients, such as the driver to check that the record information is correct, the driver’s record keeper to fulfil record-keeping obligations, and an authorised officer to confirm the driver is complying with work and rest regulations.

In addition to the general duty to not drive a heavy vehicle whilst fatigued, drivers must comply with certain maximum work and minimum rest limits.

Parties in the supply chain have to undertake reasonably practicable measures to prevent drivers from exceeding these limits, similar to occupational health and safety laws.

This means that heavy vehicle drivers must be allowed to stop if they are at risk of exceeding the specified limits and make alternative arrangements.

The development of automation is also well underway, as evidenced by the work of the likes of Tesla, General Motors (GM), Google, and more in the light vehicle industry.

Despite the notable progress made in the light vehicles space, the application of automation in heavy vehicles is still in its infancy.

However, many of the systems required to automate heavy vehicles will derive from the developments in light vehicles, as well as the maturation of advanced driver assistance systems (ADAS).

ADAS for heavy vehicles primarily aims to help drivers avoid accidents or mitigate unavoidable collisions.

Such features include lane-keeping assist, which sends a signal to the driver when they have started to veer into

another lane. Blind spot monitoring likewise sounds an alert when the driver signals to change lanes with another vehicle in a blind spot alongside.