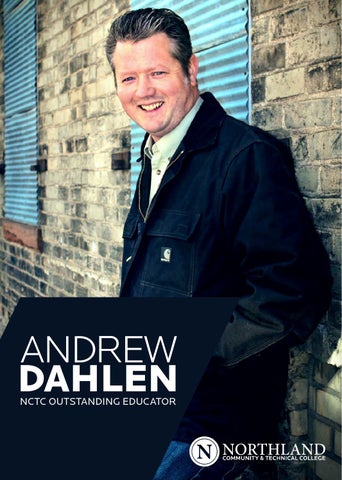

ANDREW DAHLEN NCTC OUTSTANDING EDUCATOR

Table of Contents Teaching Philosophy ........................................................................................................................................ Content Expertise and Professional Growth .............................................................................................. Appendix A: Strategic Plan Assignment ............................................................................................... Appendix B: Original VEX Robotics Proposal ...................................................................................... Appendix C: Graduate Oral Defense Power Point Slides ................................................................... Appendix D: Letter from Dr. James McCracken .................................................................................. Teaching Strategies and Materials .............................................................................................................. Appendix E: PLC Syllabus ...................................................................................................................... Appendix F: Stepper Motor Lesson Plan ............................................................................................ Appendix G: Stepper Motor Pre-Lab Worksheet ................................................................................ Appendix H: Stepper Motor Project ..................................................................................................... Appendix I: PLC Programming Rubric ................................................................................................. Appendix J: Karen White’s Letter ......................................................................................................... Appendix K: Kyle Meier- ETAS Student Letter ..................................................................................... Appendix L: Reid Landsrud - ETAS Alumni .......................................................................................... Appendix M: New and Emerging Technology Final Project Report .................................................. Standards for Assessment of Student Learning ........................................................................................ Appendix N: Series Parallel Quiz .......................................................................................................... Appendix O: Lab Report Format ......................................................................................................... Appendix P: Tom Pittman’s Letter ........................................................................................................ Appendix Q: Rick Trontvet’s Letter ...................................................................................................... Service to Students, Profession, Institution, System .............................................................................. Appendix R: Troy Haugen’s Letter ........................................................................................................ Appendix S: Marc Couture’s Letter ..................................................................................................... Appendix T: Aaron Barker’s Letter ....................................................................................................... Appendix U: Laura Reese’s Letter ........................................................................................................ Appendix V: Fisher Fire Department ................................................................................................... Curriculum Vitae .............................................................................................................................................. End Page .............................................................................................................................................................

3 6 12 15 17 22 23 27 32 33 38 39 40 41 42 43 44 47 48 49 50 52 59 60 61 62 63 64 71

TEACHING PHILOSPHY

Teaching Philosophy I am curious and fascinated by all aspects of technology, so I set out each day to learn and to share knowledge with others. I want to inspire students to explore new technologies in the classroom and on the job. It is gratifying and exciting to witness automated machinery “come to life� under the control of programs and wiring connections. My curiosity and passion help me to energize learners for a career in electronics and automated systems. Technical programs are by their very nature designed to meet the workforce needs of business and industry. Although this is an important guiding principal, technical programs are not simply churning out students to serve as robots destined to mesh with the cogs of industry. At the center of my teaching philosophy is the student. I am driven to prepare students for a rewarding career in a field that is continuously introducing new technologies. Working with electronics and automation technologies is engaging, interesting, challenging and dynamic. I want each graduate of the Electronics Technology Automated Systems (ETAS) Program to be fulfilled and passionate about their career. My teaching philosophy is designed to provide the learner with skills needed to enter a challenging and rewarding career.

Prior to teaching I worked in the manufacturing industry starting as a technician and later as an engineer. These roots in manufacturing are evident in the classroom. It is important to model the environment which the ETAS graduates will be working. The technologies, equipment, processes, materials, working conditions, and culture found on the job should be replicated in technical programs at a college. The electronics program doesn’t exist in a vacuum. Advisors from business and industry are an integral part of monitoring the details of technical programs. Part of my teaching philosophy is being responsive to the voice of industry expectations. Both students and industry benefit when technical programs teach the right skills on relevant

4

Andrew Dahlen I Portfolio

equipment. When a class doesn’t have access to a particular piece of equipment I schedule field trips to local facilities or have the students complete internet searches for video and animations related to the topic. Close collaboration with industry advisors and other colleges can create new opportunities. In addition each company has its own culture. Employers are looking for soft skills as well as technical skills. These skills including reliability, punctuality, accountability, and collaboration are stressed throughout in the ETAS Program. I expect students to treat classroom time with the same respect as they would time on the job. In fact some of the ETAS students are being paid for their seat time in class by their employer’s scholarship programs. I emphasize active hands–on learning in all of my classes. Students in the electronics classroom are more likely to be constructing circuits and experimenting than listening to a lecture. Active learning immerses the student into the content. The student’s mind is better focused on a topic when they are using measurement equipment, calculating values, and searching user manuals and data sheets. To facilitate this teaching philosophy I combine the lecture lab environment. A new unit often starts with a lab in which students build and test a circuit. It is easier to understand an electrical circuit by experimentation. Certain skills like programming automated equipment must be acquired through practice and experience. Simply observing or following step by step instructions will not prepare individuals to tackle new applications. To truly understand a concept it is healthy for the learner to “get stuck” and begin a mental wrestling match. If a teacher, classmate, or internet source comes to the rescue too quickly the leaner may not have invested significant resources to truly understand the solution, and the learner may move on only to be stumped in the near future when a similar obstacle arises. In contrast the student who has experimented, investigated, double-checked, and scrutinized a problem to arrive at a solution is acquiring valuable skills. Not only has the student negotiated a solution for today’s problem, but more importantly the student is practicing and learning a problem solving method which will assist them in overcoming future obstacles. Electronics and automated equipment frequently encompass fickle and tedious parameters. A misstep in configuration or overlooking a minute detail will prevent devices from working. Learners need to develop a keen attention to detail in order to be successful in the electronics and automation field. Frequently one has to acquire knowledge and skills by persistently digging through manuals, data sheets, experimentation, searching help menus, and internet resources. Students need to be able to master the skill of finding and applying information to fulfill a job requirement. Students need to rely on their own abilities to solve problems and complete the job autonomously. Students complete multiple projects throughout the ETAS program in order to practice the skills needed for a successful career. My teaching philosophy is simple: prepare the leaner for a fulfilling career in electronics and automation by replicating the environment, equipment, working conditions, and expectations of industry.

Andrew Dahlen I Portfolio

5

CONTENT EXPERTISE & PROFESSIONAL GROWTH

Content Expertise & Professional Growth The license plate of my car reads LEGOS. I am what some call an AFOL: Adult Fan of Lego. As a child I spent countless hours constructing marvels out of these plastic bricks. When I got a new Lego set, I built it once or twice per the directions, and shorty after that the pieces were added to the brightly colored collection on the floor. I loved to free build without following directions. I learned that inside a pile of Legos there was a castle, a robotic arm, a crane, a spaceship, a monster truck, a drag racer, or whatever I imagined. I failed countless times when attempting to construct a creation, but it didn’t matter. I could simply disassemble the failed design and try again. With enough trial, error, and persistence I could create what I had imagined. I just needed to select the right parts and assemble them in a sturdy or aesthetic configuration. It was never that simple. Through the building process I discovered dozens of ways to fail, and I experienced a personal satisfaction that comes with completing a project. I was proud to show off my creations to my siblings and parents, but most importantly I felt confident and accomplished. As I contemplate my professional development and growth as a technician, engineer, and teacher, my process of growth is similar to building with Legos, but the pieces look different. I view the world in terms of Lego bricks. As long as I can remember I have been fascinated by how things work. When I go on vacation, I marvel at strange things. At amusement parks I am focused on the sensors, motors, actuators, and the mechanical designs of the roller coasters and other rides. While visiting the Statue of Liberty, I am intrigued by the support structure and metal fabrication rather than the patriotic or historical significance. The first thing I look for when traveling to a new destination is factory tours. I want to see how objects are built and what makes them work. I look for small details like parting lines and tooling marks which provide clues in how objects are created. It’s no wonder that I pursued a career in manufacturing. I tell my students they should never stop learning. As I began my career, my fascination and passion for technology served me well in college and in industry. In my first job out of college I was a Process Engineering Technician for Hutchinson Technology Inc., a manufacturer of computer hard drive components. I worked directly with engineers to reduce defects and improve the machinery and processes used to manufacture their products. I was encouraged and mentored by my engineering colleagues. I learned the statistics, experiment methods, and software which engineers use to evaluate test conditions. I was required for legal and intellectual property reasons to maintain a detailed engineering notebook. I also learned the culture and expectations of the manufacturing industry. Prior to teaching I worked as a manufacturing engineer designing and building automated equipment. Anyone who has watched the TV show How it’s Made has observed manufacturing equipment in action. My equipment designs ended up on the factory floor and were used to fabricate, assemble, and produce the finished products. I was responsible for new equipment from the initial design conception to implementing the finished machinery into production. While some equipment cost over $250,000, a typical project budget was $75,000 with a three month deadline. To develop automated manufacturing machinery one needs to have a breadth of skills including mechanical design, electronic control, programming, project management, and troubleshooting skills. I often told my coworkers that if I did my job well, my machine designs or projects should come together like a Lego set.

Andrew Dahlen I Portfolio

7

If one bolt, pneumatic fitting, or component was overlooked the whole project was on hold. If there was interference between parts because of tolerance or oversight the parts had to be disassembled, redesigned, modified, and reassembled. Redesign and rework are time consuming processes. If I did my job right there should be no problems in assembling and building the equipment. Each electrical and mechanical part bolts into place, the correct quantities of purchased parts are available, and the program works as intended. Five extra minutes in planning some meticulous detail can save hours of rework and scrambling. My experiences as a technician and engineer working in industry are of vital importance in the classroom. I frequently relay stories about equipment that I worked on to demonstrate concepts in the curriculum. In addition to technical topics I also share experiences related to safety, project management, work habits, and employer expectations. My job is to prepare people to enter the world of work and I want the graduates to be ready. When building with Legos I am always seeking to find the Lego parts which fit well and enhance my design. Teaching has many Lego pieces. Each teacher is able to pick and choose which pieces work based on preference, discipline, and creativity. When I made the transition from engineering to education, I discovered a pile of new Lego pieces. I didn’t have the experience to know exactly how to build with the unfamiliar parts, but I’m not afraid to jump in and experiment with common course outcomes and teaching strategies.

MNSCU requires new teachers to take the Teacher Education Series (TES) classes. I opted to take the TES classes for graduate credit at Bemidji State University. I appreciated the timeliness of the classes. While I was immersed in the details of being a new teacher, the TES classes exposed me to teaching topics including assessment, curriculum development, philosophy, and advisory committees. Many of the class projects in the TES classes were directly tied to work that needed to be completed for the ETAS program; thus adding more Lego pieces to my teaching set. I recall a project in the Methods of Teaching Career and Technical Education Class where we needed to author a personal, 5 year, strategic plan. I speculate Dr. Kingsbury wanted all the new instructors to thoughtfully consider the possible impact they could have on their programs and colleges. Today this assignment is an entertaining reflection (see Appendix A). When I wrote this assignment back in 2007, I may have been inflating the content and strategies to impress Dr. Kingsbury. However, it is gratifying to realize that many of the goals have been accomplished. It took me longer than anticipated to complete a Master’s Degree in Career and Technical Education (CTE). Other items listed in the strategic planning assignment addressed strong relationships with industry partners and this activity continues to be of critical importance. If I repeated this assignment today, many of the strategies defined would persist. After completing the TES courses I continued my professional growth by taking more classes at Bemidji State University.

8

Andrew Dahlen I Portfolio

Each course in the CTE Program helped me in my professional growth as a teacher. I am fortunate to work for an employer who values education and offers professional development benefits. I studied Leadership and Supervision in CTE which enlightened me with methods in which administration can influence instruction and student learning by fostering a culture of learning. Investigating topics in Leadership and Supervision of Career and Technical Education provided a better perspective of the education system. A few of the CTE classes allowed me to choose technical topics related to the Electronics Program. In the IT 6240 Advanced Skills in Industrial Technology course I set out to gain the knowledge, skills, resources, and materials needed to effectively teach a class in PIC microcontrollers and the C programming language. At the time the Microcontrollers II class was newly minted by the ETAS advisory committee and approved by NCTC’s Academic Affairs Committee. I wasn’t satisfied with my knowledge and skills to effectively teach the class so I challenged myself to develop these skills. During the IT6240 course I chose a project to evaluate microcontroller equipment for use in the ETAS Microcontrollers II course. I spent considerable amounts of time getting familiar with the Hi-Tech PICC complier and the syntax of the C programming language. I completed a project as part of the IT 6240 class that featured a digital temperature display on a LCD screen. The research and project completed in the graduate class served as integral preparation as I worked to develop the ETAS Microcontrollers II class. In the IT 6200 Application or Emerging Technologies Course I selected Bluetooth Communication Technology for a major project. Once again I was able to select a project for a CTE graduate course which complimented the ETAS curriculum. I am constantly looking for ways to incorporate new and advancing technologies into the ETAS curriculum. Bluetooth is a ubiquitous technology and as such I want students to learn and use it. After the IT 6200 course I found a great Bluetooth breakout circuit board which my students are currently using to bring wireless connectivity to class projects. In the summer of 2010 I enrolled in the Grants and Contract writing course taught by Dr. Elaine Hoffman. This class played a large roll in my pursuit of K-12 outreach programs as a recruitment tool for the ETAS and other programs. The course required each student to write a grant proposal and I authored a grant aimed at creating a high school FIRST Robotics Team in East Grand Forks. Although this grant was not funded, the assignment got me thinking critically about Robotics Competitions and outreach methods. Many of the other classes in the CTE Master’s Program at BSU lead me to research the decline of technical education in high schools and the skills gap facing our nation’s workforce. With each CTE class I accumulated fresh perspective on the problems facing technology education. The Grants and Contract Writing Course in particular got me thinking - is there something I can do to help with the problems facing technology education? I authored a grant proposal for the class assignment which may have impacted a dozen students. It seemed inadequate. A few months later I found a promising option to increase high school students interest in technical careers after researching the VEX Robotics Competition. In October 2010 I presented a proposal to the 360° Manufacturing and Applied Engineering Center of Excellence Strategy Council to seed seven VEX Robotics Teams in Minnesota (see Appendix B). The 360° group approved the funding and I began the work of

Andrew Dahlen I Portfolio

9

establishing VEX Robotics Teams in Minnesota. Since its modest beginnings, the VEX Robotics Competition has grown to over 100 Teams in Minnesota. The VEX outreach program in Minnesota broadcasts a clear message to the students, teachers, and parents in promoting manufacturing jobs. The VEX Robotics Competition would have eventually taken roots in Minnesota. It is a great program. Because of my original proposal and the subsequent work of an incredible team, 360째 and MNSCU have a monopoly on marketing and promoting technical programs through the VEX Robotics Program. We expect the VEX Robotics program to reach 500 teams by the year 2020. At roughly 6 students per team, 3000 students every year will be influenced by the VEX Robotics Program, and MNSCU stands to directly benefit. The opportunity I had to study Career and Technical Education at BSU is what lead me to purse the VEX Robotics Competition.

My graduate research paper evaluated the longitudinal impact of the RoboStorm summer camp. From the summer of 2007 to the present Northland Community and Technical College has hosted the RoboStorm Summer Camp for 6-8th grade students. This camp provides students with an opportunity to build and design Lego Robots to complete in various challenges. In addition, students experience a tour of a local manufacturing company. My research paper surveyed the alumni campers to determine if the camp had a lasting impression (see appendix C for more information about this research). The literature review section of my paper was yet another opportunity for me to explore and assess the issues related to career and technical education. I enjoyed exploring the different ways others implement technology camps and robotic competitions to attract youth into STEM careers. In addition I gained valuable insight into the process of academic research and writing. Dr. Jim McCracken was the chair of my graduate committee (see appendix D for a letter from Dr. McCracken).

10

Andrew Dahlen I Portfolio

During the Fall Semester of 2014 I took a single semester sabbatical to learn about Computer Networking Technologies. The primary purpose of my sabbatical was to improve my knowledge and skills in the field of computer network technology as this field has a strong overlap with the electronics technology program. My prior work and education background was void of computer networking experiences. My sabbatical gave me the opportunity to learn about the personal computer and the technologies used to establish communication in a variety of networks. In addition my sabbatical plan allowed me to explore computer maintenance and visual basic programming. An unexpected benefit of this sabbatical was the opportunity to witness other teachers in action and to associate with students. I experienced first-hand what it is like to be a student through a different lens; on the other side of the lectern. I hung out with my classmates over lunch and we helped each other understand the coursework. For my own reference I created study guides and decided to email them to my classmates. This fall I bumped into one of my Networking classmates and he informed me that my study guides are being used by the next cohort of networking students. NCTC and 360° have given me further opportunity for professional growth by attending conferences and formal training workshops. I received 40 hours of SolidWorks (CAD) training at Symmetry Solutions as part of a Carl Perkins Program Development Grant. I learned about the machine tool and robotics industry by attending the International Manufacturing Trade Show (IMTS) in 2008. I studied new products, industry trends, and security concerns while attending the Embedded Systems Conference in 2010. I was part of a panel which discussed the accomplishments of the 360° Center of Excellence in Applied Engineering and Manufacturing in 2011 at the High Impact Technology Exchange Conference. This summer I will deliver a half day workshop on VEX Robotics Programming at the High Impact Technology Exchange Conference in Portland Oregon. Other conferences I have attended include topics on 3D printing, the Internet of things, PLC Programming, Robotics and VEX Robotics. Each of these opportunities has helped me bring more pieces and parts back to the students. I will never stop learning. When I started teaching there were some subjects I didn’t know well. I had a background in programming industrial machinery, but I was not trained or experienced in programming microcontrollers. What better way to learn a topic than to teach it! I spent copious numbers of hours learning how to program the Basic Stamp Microcontroller. Someone who knows how to program in one platform is able to pick up other languages rapidly. I acquired the knowledge of programming microcontrollers by reading books, online resources, and lots of trial and error. In the electronics industry one must have the ability to learn on the fly. Teaching for me is akin to my childhood experience of building with Legos. There are a ton of different parts and pieces to teaching. I find most of the pieces are within arm’s reach while others need to be sought after. Teachers need to be creative in assembling their craft. I want to take things apart and see how they work. My work experience as a technician and engineer equipped me with technical knowledge and skills. My progression through the Master’s Program in Career and Technical Education was a great way for me to dissect and learn about the teaching profession. A good builder is constantly assessing how well the pieces fit together. I am always keeping my eyes open for the next perfect fitting brick.

Andrew Dahlen I Portfolio

11

Appendix A: Strategic Plan Assignment

12

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

13

14

Andrew Dahlen I Portfolio

Appendix B: Original VEX Robotics Proposal

Andrew Dahlen I Portfolio

15

16

Andrew Dahlen I Portfolio

Appendix C: Graduate Oral Defense PowerPoint Slides

Andrew Dahlen I Portfolio

17

18

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

19

20

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

21

Appendix D: Letter from Dr. James McCracken

22

Andrew Dahlen I Portfolio

TEACHING STRATEGIES & MATERIALS

Teaching Strategies & Materials The variety of equipment and applications in the automation industry makes it difficult to prepare learners for what they may encounter in future employment. My teaching strategy for each course and every student is to teach them a process of problem solving and hands on learning which will serve them throughout their career. I want students to learn a process for working with new or unfamiliar technologies. The process starts with knowing where to look for, find, and apply information. Students need to discern technical information like data sheets, manuals, and software guides. The smallest detail can make a big difference in working with technical equipment. An example would be when programmers need to spot errors in their code. A program will not compile if the programmer accidently types a curly bracket in place of a square brace, or a parenthesis. Students learn that with enough persistence a problem can be solved all the while developing a professional attitude toward problem solving. Learning this process takes practice. Teaching Strategy: Examples from the ETAS 2224 PLC Course. A PLC (Programmable Logic Controller) is a flexible, programmable computer used to control industrial automated machines. Stepper motors are used to achieve accurate position in copy machines, vending machines, robots, and CNC machines. In the ETAS PLC class I teach a unit on stepper motors (see Appendix E for the PLC syllabus and Appendix F for a lesson plan on stepper motors). A technician needs to be able to find and decipher information. To prepare for a larger lab section I have the students complete a preparation assignment. The preparation assignment provides the learner with an opportunity to get familiar with the equipment and circuits prior to coming to class. This activity is designed to replicate what a technician or engineer would have to do prior to starting a project. One can’t simply pull unfamiliar equipment out of the box and set it to use. The preparation portion of a lab requires students to research the equipment. They learn about the variables, settings, wiring, and multiple parameters which need to be configured based on the particular equipment being used. The preparation assignment gives the learner practice in reading and deciphering user manuals and data sheets (see Appendix G). Finding and using information is critical for a technician. It is equally necessary to apply information to complete a task. At the beginning of the class period I perform a spot check to assess student completion of the preparation assignment. Then we dive straight into the lab. Based on their research students are directed to setup the hardware and make the necessary electrical connections. In the class we demonstrate key concepts while troubleshooting any problems that arise. Because the learner has completed background research the class can accomplish more work in a given lab period. The class is lead through an informal and open discussion and demonstration of how the software and hardware work together. At this point the learner has a basic understanding of key programming tools and techniques needed to control the new hardware. It is great to understand something, but it is most valuable to apply that understanding into a useful application. Programmers seldom develop code to suit their own liking. People who program industrial automated machines need to satisfy the demands of production management and the end user. As an engineer I recall multiple times when I thought a program was finished only to be confronted with a list of changes mainly related to the operator controls. A typical programming assignment for the PLC class has a detailed list of

24

Andrew Dahlen I Portfolio

criteria on how the finished program needs to operate. Once again I am trying to replicate the expectations that future employers will have for these students. The stepper motor programming assignment outlines specific criteria for a PLC program to control the stepper motor (see Appendix H). The PLC program rubric is used to assess the stepper motor program assignment and all other PLC programs created by the students during the PLC class (see Appendix I). Teaching Materials: Instructional Materials Teaching materials for technical programs includes instructional equipment as well as assignments and lesson plans. College budgets are finite and securing funds for instructional equipment is challenging. The 360° Applied Engineering and Manufacturing Center of Excellence is an integral partnership for NCTC and the Electronics Program. I authored many 360° program improvement request forms. Over the years 360° has provided over $250,000 in instructional equipment to the ETAS program. Without 360°’s financial and strategic support the ETAS program would not have state-of-the-art instructional equipment. Nearly every class in the ETAS curriculum is utilizing instructional equipment purchased with 360° funds. From the time I started teaching 360° funds have paid for robots, hydraulics and pneumatics trainers, PLC training equipment, microcontrollers, machining equipment, and 3D printers. In order to stretch equipment dollars further I often purchase individual components and put my engineering background to good use designing instructional training equipment. I designed an automated pop can crushing machine for the PLC class as well as motor control trainers. In some instances a $10,000 piece of instructional equipment can be built in house for $4000 in components. Students assemble much of this equipment during class. This experience is valuable as these students may be assembling and wiring automated machinery on the job in the near future. Partnerships with industry have also been useful in stretching equipment dollars. Last year DigiKey and LeCroy Corporation assembled a deal to supply new digital oscilloscopes for the ETAS program for a deeply reduced rate. This year as MNSCU experimented with a leveraged equipment funding program, DigiKey made another large contribution to the ETAS program for benchtop power supplies and function generators. Partnerships are important for technical programs. Curriculum: As part of the 360° Center of Excellence I have worked on curriculum development projects. When the faculty of 360° gets together I enjoy sharing ideas about teaching equipment and strategies. It is fascinating to walk through the electronics and robotics labs at other colleges. Instructors in the 360° partnership view each other as colleagues instead of competition. I assisted 360° in developing the online eTech curriculum (see Appendix J for a letter from the director of 360°). In this process faculty from all over the state worked together comparing common course outlines and program outcomes to find commonality. As we compared notes on our classes we defined what fit well into each eTech course. An unplanned result of this work was an informal assessment of the ETAS classes. It became evident that while each college seasons its technical programs to suit the likings of local industry, 90% of the classes are the same. I elected to teach one of the courses online, Analog Circuits. As a group the

Andrew Dahlen I Portfolio

25

360° faculty decided that electronics classes shouldn’t be 100% online; students need a hands-on learning experience. The original online classes required 4 on-site lab dates. Students needed to travel to the host campus and endure full lab-packed days. This model worked, but the on-site labs were challenging in terms of travel time and financial commitment for the student. In 2014 I authored a proposal to 360° to redesign four of the eTech Automation technologies classes to replace the on-site labs with a myDAQ device. This handy little device allows students to complete labs at home on real hardware. I have spent many hours re-designing the labs to compliment the myDAQ device. I have recorded videos for each lab along with lab assignments. Students inform me the Analog Circuits Class is the most hands-on, online class they have ever taken. Project Learning: I use a variety of learning strategies in the classroom. I like to structure the classroom such that we are a community of learners. In many of the electronics classes we perform circuit analysis. Numerous formulas are used to determine the theoretical voltage, current, and resistance of a circuit. My preference is to hook up the circuit first and then walk through the analysis and formulas on the board. When the students can probe the circuit with a meter to find the matching results of a formula, ideas and concepts are solidified. I will produce a similar circuit and ask the students to perform the circuit analysis individually on a piece of scratch paper. Once they have an answer I ask them to share with their neighbors. This gets the learners to practice using the vocabulary and terms as well as troubleshooting one another’s computational errors. The classroom is a community of learners which should interact with one another (see Appendix K and Appendix L for student’s perspective). A microcontroller is a programmable, single chip computer used to control devices like coffee pots, anti-lock brakes, and furnaces. The Microcontrollers I class has weekly programming projects. Rather than using a textbook the students purchase a microcontroller kit which they can take home and work on projects outside of class time. The projects are assigned on the last day of class for the week and are due at the beginning of the next class period – a four day time frame. The learner must work on the project outside of class time and submit the final project into the D2L drop box prior to the start of the next class. At the beginning of the next class period students divide into groups to look at one another’s programs. They have to explain to another student how their code works. Those who didn’t complete the assignment can learn from other students and hand it in for less credit. In the peer review all learners are actively discussing, defending, and critiquing each other’s programs. Throughout the ETAS program I incorporate a few larger student projects. Students in the Electronic Fabrication class learn how to design circuit boards using software. The last three weeks of this class I ask the students to complete a project which matches generic specifications. The point of the project is to have the students demonstrate the tools and techniques learned in class and to address new problems as they arise. New and Emerging Technology is a capstone course which students select a project of their choice to work on for an entire semester. This class requires students prepare a project proposal document. A project can be overwhelming when staring at the big picture. In the project proposal students break the project into smaller sections and set milestones for completion. At the end of the semester students are required to submit a final project report (see Appendix M). I insist students write the final report according to the writing guidelines set by an electronics magazine.

26

Andrew Dahlen I Portfolio

Appendix E: PLC Syllabus

Andrew Dahlen I Portfolio

27

28

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

29

30

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

31

Appendix F: Stepper Motor Lesson Plan

32

Andrew Dahlen I Portfolio

Appendix G: Stepper Motor Preparation

Andrew Dahlen I Portfolio

33

34

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

35

36

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

37

Appendix H: Stepper Motor Project

38

Andrew Dahlen I Portfolio

Appendix I: PLC Programming Rubric

Andrew Dahlen I Portfolio

39

Appendix J: Karen White's Letter

40

Andrew Dahlen I Portfolio

Appendix K: Kyle Meier - ETAS Student Letter

Andrew Dahlen I Portfolio

41

Appendix L: Reid Lansdrud - ETAS Alumni

42

Andrew Dahlen I Portfolio

Appendix M: New & Emerging Technology Final Project Rubric

Andrew Dahlen I Portfolio

43

STANDARDS FOR ASSESSMENT OF STUDENT LEARNING

Standards for Assessment of Student Learning My background is in manufacturing. It is ineffective to assess the quality of finished goods just before items are boxed and shipped. Inspection is not a value added step in the manufacturing process. Rather inspection or assessment of manufactured goods is something that needs to happen at each process step. The processes, procedures, and equipment need to be designed with a quality in mind. Multiple quality checks throughout each process are more likely to catch and correct quality issues. If a final inspection process uncovers defective products, there is a good chance everything in the queue is also defective. Education is very different than manufacturing but I embrace the notion of building assessment into smaller more-frequent steps. The ETAS program is a brand and the students are the product. I have the responsibility of producing graduates which will satisfy the workforce needs of local business and industry. Graduates of the ETAS program will be working directly with engineers and production supervisors on a wide variety of equipment, processes, and projects. It stands that the ETAS program should employ a variety of assessment tools to compliment the industry I serve. Some concepts in electronics are foundational and I insist on student memorization. For example electronic measurements use scientific notation: milli, micro, nano, pico, killo, mega, giga, and terra. Learners in this discipline have to be able intuitively convert between these units. Likewise certain formulas like ohms law and the formulas used to analyze series and parallel circuits must be committed to memory. After working through multiple in-class exercises students take quizzes in circuit analysis (see Appendix N). No resources other than a calculator are allowed for the quizzes. The students have to memorize the formulas, understand scientific notation, and be able to understand the series and parallel relationships in a circuit. By insisting on memorization of foundational concepts the learner develops an intuition about circuits and the learner can rapidly estimate voltage and current levels. This helps in evaluation and troubleshooting of future circuits.

Andrew Dahlen I Portfolio

45

I utilize a number of performance based assessment tools in the ETAS Program. In the DC Power class I insist students demonstrate use of electrical test equipment on actual circuits. This is another fundamental task. I directly observe and assess students measuring resistance, voltage, current, frequency, and amplitudes. Assessment is also a great opportunity to learn. Through direct observation instructors can assess and provide immediate feedback to the learner. In other classes I assess troubleshooting skills by inserting faults into instructional equipment. Students need to isolate and identify the fault in the circuit. In the PLC class I use programming skills tests to assess a student’s proficiency in programming. Students have two hours to create a program based on defined criteria. I allow students to use reference materials like programming manuals and user guides during the programming proficiency tests. Even the most experienced programmer needs to look up a few details. Lab reports are another assessment technique I use in the ETAS program. A lab report will have many sections which document the materials, process, circuits, theories, and results of a lab experiment (see Appendix O). Engineers and technicians need to document their work. In the classroom we are often experimenting with new sensors or control equipment. As a specific example, in the Robotics Programming class I have a section on motor torque. Students set up a torque test stand and measure motor torque, RPM, amperage, and speed of the motor. All of these variables are graphed using excel and included with explanations and conclusions in the lab report. The ultimate assessment for a technical program is the performance of the students on the job after graduation. I work closely with the advisory committee to keep the ETAS program current. Tom Pittman is an electrical engineer at Central Boiler and he is active in the ETAS advisory committee (see Appendix P for a letter from Mr. Pittman). Tom has been an adjunct instructor for the ETAS program and hired three of the ETAS graduates. Feedback from advisors like Tom is very valuable in assessing the ETAS program. DigiKey Corporation has been a tremendous supporter of the ETAS program. The majority of the graduates from the ETAS program are employed by DigiKey Corporation (see Appendix Q for a letter from DigiKey). DigiKey’s active participation in advisory committees makes the ETAS program stronger.

46

Andrew Dahlen I Portfolio

Appendix N: Series Parallel Quiz

Andrew Dahlen I Portfolio

47

Appendix O: Lab Report Format

48

Andrew Dahlen I Portfolio

Appendix P: Tom Pittman's Letter

Andrew Dahlen I Portfolio

49

Appendix Q: Rick Trontvet's Letter

50

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

51

SERVICE TO STUDENTS, PROFESSION, INSTITUTION, SYSTEM

Service to Students, Profession, Institution, System

At some point it became tradition for Volunteers to receive a shirt for helping with a given event or being part of an organization. I currently have over 20 shirts in my closet from robotics camps, robotic tournaments, first responder, fire department, and city events. I am modeling a few of my volunteer shirts in the photo above. As an instructor at NCTC I am granted a great deal of autonomy in the activities and opportunities I pursue. I grew up in Goodridge, Minnesota, just a few miles east of Thief River Falls. I graduated from Northland Community College in 1994. Being an electronics instructor at NCTC is more than just teaching classes. I am working to build relationships between industry partners, other MNSCU institutions, high schools, other agencies, and students. The projects I work on outside the classroom aim to serve the needs of Northwest Minnesota and provide opportunities for students to pursue technical careers. I spend a good portion of my summers teaching robotics camps. When I started working at Northland Community and Technical College in 2007, the 360째 Center for Applied Engineering and Manufacturing had funds available for K-12 outreach. I immediately suggested the Lego Mindstorm equipment when Kirsten Michalke, Director of Workforce Development, and Joel Zeigler, welding instructor, and I gathered to brainstorm K-12 outreach ideas. For the past seven years Northland Community and Technical College has hosted the RoboStorm summer camp. Hundreds of students have participated in the RoboStorm Camp. The purpose of the RoboStorm summer camp is to highlight manufacturing and engineering careers for sixth, seventh, and eighth grade students. During the camp students learn to apply design and problem solving skills to complete defined challenges. As the self-proclaimed Lego guy I have developed the activities and challenges for these camps. Over the years I have had students programming robots to solve mazes, climb hills, perform sumo wrestling, launch ping pong balls, and create Rube Goldberg Machines. Campers build

Andrew Dahlen I Portfolio

53

and program robots which complete various tasks or missions. The Lego Mindstorms building system is an effective tool for learning about mechanical design as well as an introduction to programming. Each camp also includes a tour of a local manufacturing plant such as Arctic Cat, Polaris, or Cirrus Design. We want students to see an explicit relationship between the manufacturing equipment and the robots used in camp. First Lego League (FLL) is a competitive robotics program for 9 to 14 year old students. The FLL Competition is a worldwide competition with over 20,000 teams in multiple countries. FLL features the Lego Mindstorm programmable robot. To program a Lego Robot Students use a graphical based software. I have volunteered as a First Lego League Coach for the past seven years at the Fisher Public School. I love being a Lego League Coach. Each year a new themed challenge is released with different mission models. Each mission model is constructed out of Legos and precisely positioned on a 4’ x 8’ mat. FLL students are challenged to design a robot which can gather, manipulate, or climb over mission models to earn points. There are no building instructions for the robot. The students are tasked with figuring out how to design a robot to meet the demands set by the mission models and the rules. Students also need to create computer programs capable of controlling the robots actions to accomplish the missions. FLL stresses the ideal that the kids do the work, and it is great fun to witness the students’ creative problem solving process unfold throughout the season. Coaching FLL is a fun and rewarding experience.

54

Andrew Dahlen I Portfolio

It is easy to get young students interested in FLL – just ask. The harder part is to find a coach who is willing to volunteer their time and talents. This realization led me to rethink some of my outreach efforts. I was accustomed to hosting camps and coaching teams to get youth interested in STEM concepts, but I contemplated the impact of hosting adult workshops. Coaching a team and putting on camps are wonderful activities which impact a limited number of students. If I could train one adult mentor, that mentor could train dozens of students each year. A small adult workshop with five participants could give 40 to 60 young students each year exposure to STEM topics. I set out to share my experiences teaching summer camps and coaching robotics teams with other adults. In 2013 the first workshop was sponsored by 360° and hosted at Northland. The last two workshops I completed were sponsored by Tri-State Manufacture’s Association (TSMA). Troy Haugen, Career & Technical Education Coordinator for the Lakes Country Service Cooperative organized the last two adult workshops. There were 15 teachers in the last workshop. Outreach efforts like these have the potential to influence many students to pursue a career in Science, Technology, Engineering, and Math (STEM) (see Appendix R for a letter from Troy Haugen). I am happy to share the Lego Mindstorm equipment and camp resources with others working on STEM outreach. I enjoy helping other FLL coaches. I work with the Boy Scouts in Grand Forks to help the scouts earn robotics merit badges. I have also brought one day robotic classes to the East Grand Forks School for a Career Day. This work evidently got some attention as last year I was honored to receive the volunteer of the year award at the University of North Dakota’s First Lego League Championship Tournament.

Part of teaching at a technical college is working to recruit students. I had gone to high schools and career fairs to speak with students about careers in electronics and automation, but I found this approach ineffective. To the average high school student the manufacturing world is invisible. I was looking for a better method to recruit and interest students in technical careers. At the time I was taking graduate classes in Career and Technical Education. An overarching theme in these classes was an impending workforce skills gap crisis, and the desiccation of technical programs in secondary schools. How can students develop an interest in something they have never experienced? Earlier this year during a presentation I asked a group of 20 technical faculty to share with their neighbor what first piqued their interest to pursue a technical career. The informal survey revealed most of the faculty referenced an early childhood experience as the impetus for their career choice. It is clear that recruitment efforts need to start at an early age. Robotics outreach programs can provide the initial spark of interest for a student which will ignite a technical career. Andrew Dahlen I Portfolio

55

Five years ago I presented a proposal to 360° Applied Engineering and Manufacturing Center of Excellence to seed seven VEX Robotics teams in Northwest Minnesota. The proposal was accepted by the strategy council and I began the work of establishing teams. The proposal allocated each school a $1500 robotics kit which they could keep as long as they participated in our VEX Robotics Tournaments. I invited schools in Northwest Minnesota to attend an informational event where I delivered a sales pitch. In no time I had commitment from eight teams. We met as a group at Northland three times prior to a May tournament. My goal was to establish a community of robotics teams which can learn from one other. These eight teams were Minnesota’s first VEX Robotics Teams. The first year tournament was a small success. Marc Couture, the regional representative for the Robotics Education and Competition Foundation, was impressed by the construction of the robots built by a pack of rookie teams. Marc also had a few kind words to say about my work in the VEX Robotics Program (see Appendix S). VEX Robotics grew rapidly in Minnesota. After the first pilot year, other 360° partner colleges joined the outreach effort. St. Cloud Technical and Community College seeded a number of teams in their region. Later Pine Technical College, Central Lakes College, and Bemidji State University got involved. The growth of VEX Robotics in Minnesota is outstanding and the credit for this growth is equally shared between the talented faculty and staff of the 360° partner colleges. Today there are nearly 100 VEX Robotics Teams in Minnesota.

This school year I have volunteered to emcee each of the 5 VEX Robotics Tournaments in Minnesota: Bemidji, Albany, Albert Lea, Osseo, and St. Cloud. The tournaments are on Saturdays, but I usually help with setup on Friday. In addition, I have hosted three VEX robotics Scrimmages at Northland, and assisted with two weekend scrimmages at local high schools. I have become accustomed to filling the back of school vans with the 12’ x 12’ field and schlepping across the great state of Minnesota to the next VEX Robotics event. Today I cherish the relationships that I have built with all of the volunteers, coaches and students in the VEX Robotics Competition. In many ways we have evolved into a family of nerds (see Appendix T and U).

56

Andrew Dahlen I Portfolio

Vex Robotics has a university division and three years ago I started a VEX Robotics Team at Northland Community and Technical College. I serve as the faculty advisor to the robotics student club. One of the reasons behind the VEXU team was the need for a workforce to assist with the VEX Robotics high school outreach efforts. Northland’s Robotics team actively assists me in hosting monthly VEX Robotics Scrimmages. NCTC’s team members volunteer at high school VEX Tournaments. These guys also need to build and design two robots to compete in the VEXU division. This is a lot to ask of students with full credit loads, jobs, and families at home. I truly respect the students who make time in their lives to participate in the robotics club. I make every attempt to get the team the resources they need to purchase equipment and attend events. At about $10,000 a year supporting a VEXU team is expensive. When the team was selling HexBug Robots as a fundraiser I sat in the commons area and walked into college offices selling the miniature robots to students and coworkers. I have filled out grant applications, and sponsorship forms to get money for the team. I have had some success in convincing local business to donate items to the team. This year I donated my $2500 VEX Robotics stipend to support Northland’s Robotics Team. Nearly half of the team’s budget is used to purchase robotic equipment and the other half goes to travel expenses. Northland’s VEXU team has been to the VEXU World Championship Tournament for the past two years. Hosted at the Anaheim Convention Center, the championship tournament is an awesome event bringing over 700 teams and over 10,000 participants from around the globe. The VEXU division is a mix of technical colleges and four year colleges like Purdue University. I am very proud of the performance demonstrated by Northland’s Robotics Team at both World Championship appearances. Each time the team ended up in the middle of the pack, but I was enthusiastic to report that Northland’s team outranked Purdue University at the VEXU Robotics World Championship Tournament. I volunteered as a Judge at the VEX World championship Tournament and was inspired by the talent demonstrated by the high school and university students. I met an all-female team from Northeastern State University in Tahlequah, Oklahoma. The team members were majoring in various education disciplines. They talked to me about being in their words “girly girls”. They stepped outside their comfort zone and got involved in robotics competitions because they felt technology was important to the future of education. The Northeastern State University team broadcast a simple message: women excel in technical and engineering work. I also spoke with teams from Mexico, Columbia, China, and New Zealand. Many times I needed a translator to complete the judging interview. I set out with a scoring rubric which listed 10 points for the highest score. The talent at the tournament was outstanding. By the end of the day the top score on my rubric score sheet had crept up to 20 points. Volunteering at the VEX Robotics World Championship Tournament was a terrific opportunity to see how robotic competitions can impact students regardless of gender or ethnicity. This summer I am excited for a new sort of robotics camp. This camp will be a collaborative effort between Central Boiler, DigiKey and Northland. Students will actively participate in the design and manufacturing of a custom robot. The three wheeled robots will be cut, bent, and powder coated on Central Boiler’s production equipment. Students will visit DigiKey, an electronics distribution company, to order the electronic parts needed for their robot. The students will be able to see the massive inventory at DigiKey and see fist-hand how orders are filled. Finally the students will assemble and program the robots at Northland and take them home. The heart of these robots is an Arduino Microcontroller. The finished robot will be an expandable platform which students can use to explore programming and navigation at home. What a great opportunity to learn about manufacturing.

Andrew Dahlen I Portfolio

57

I have served on a number of committees and groups at Northland Community and Technical College. I am currently the Division Chair of the Trades Programs. In this roll I am working on a project between Northland College and Lincoln High School in Thief River Falls to create a high school survey course. In this unique opportunity high school students will rotate through the Auto Body, Automotive Services, Welding, and Electronics Technology programs in three week intervals. NCTC faculty appreciates the recruitment potential afforded by this project. I was the MSCF Treasurer for a number of years, and as such I was a member of the Shared Governance Council. I have also served on the facilities and safety committees.

Community is important to me. Fisher, Minnesota is my home. When my family and I moved to Fisher in 2006 I signed up to become a volunteer fireman. In 2008 I joined the first responders. The volunteer fire service is a great way to get to know people and help the community. The annual fireman’s pig roast, Halloween chili feed, and Fisher Landings Day (city festival) mark significant dates for the small town of Fisher. These opportunities allow people to visit and celebrate life together. During Fisher Landing’s Day I am in charge of setting up bounce houses for the children and serving snow cones. If the weather is hot I fire up the deluge gun on the pumper truck so the kids can play in the water. A 100 foot tall, 1000 gallon per minute sprinkler is a fairly memorable event. In 2013 I became the Fire Chief. The fire chief position is like another teaching job. The Fire Chief needs to run meetings, schedule training, plan, budget, organize, attend conferences, complete reports, and even write grants. The list could have been taken directly from a teacher’s job description. One of the best parts of being a fireman is visiting the Fisher School. In fire situations little kids may scare and hide from firemen dressed in full turnout gear. I was the subject of many snickers as I donned my gear and mask in the classroom. We talked about fire safety and the kids tried on my oversize jacket and helmet. Now when I enter the Fisher School, the kids are wave and shout “Hi Mr. Fireman”, “Hi Andrew”. (see Appendix V for a letter from the kindergarten class). Throughout my life I have been blessed by having plenty of opportunity and the support and encouragement of other people. Through collaborative efforts I have the capacity to develop opportunities for others. I volunteer. I serve. I teach.

58

Andrew Dahlen I Portfolio

Appendix R: Troy Haugen's Letter

Andrew Dahlen I Portfolio

59

Appendix S: Marc Couture's Letter

60

Andrew Dahlen I Portfolio

Appendix T: Aaron Barker's Letter

Andrew Dahlen I Portfolio

61

Appendix U: Laura Reese's Letter

62

Andrew Dahlen I Portfolio

Appendix V: Fisher Fire Department

Andrew Dahlen I Portfolio

63

CURRICULUM VITAE

Andrew Dahlen I Portfolio

65

66

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

67

68

Andrew Dahlen I Portfolio

Andrew Dahlen I Portfolio

69

70

Andrew Dahlen I Portfolio

End Page

1/23/2014 VEX Robotics State Tournament Volunteer Photo

Andrew Dahlen I Portfolio

71