PPMA SHOW SET TO SHOWCASE THE THE UK'S PROCESSING & PACKAGING INDUSTRY

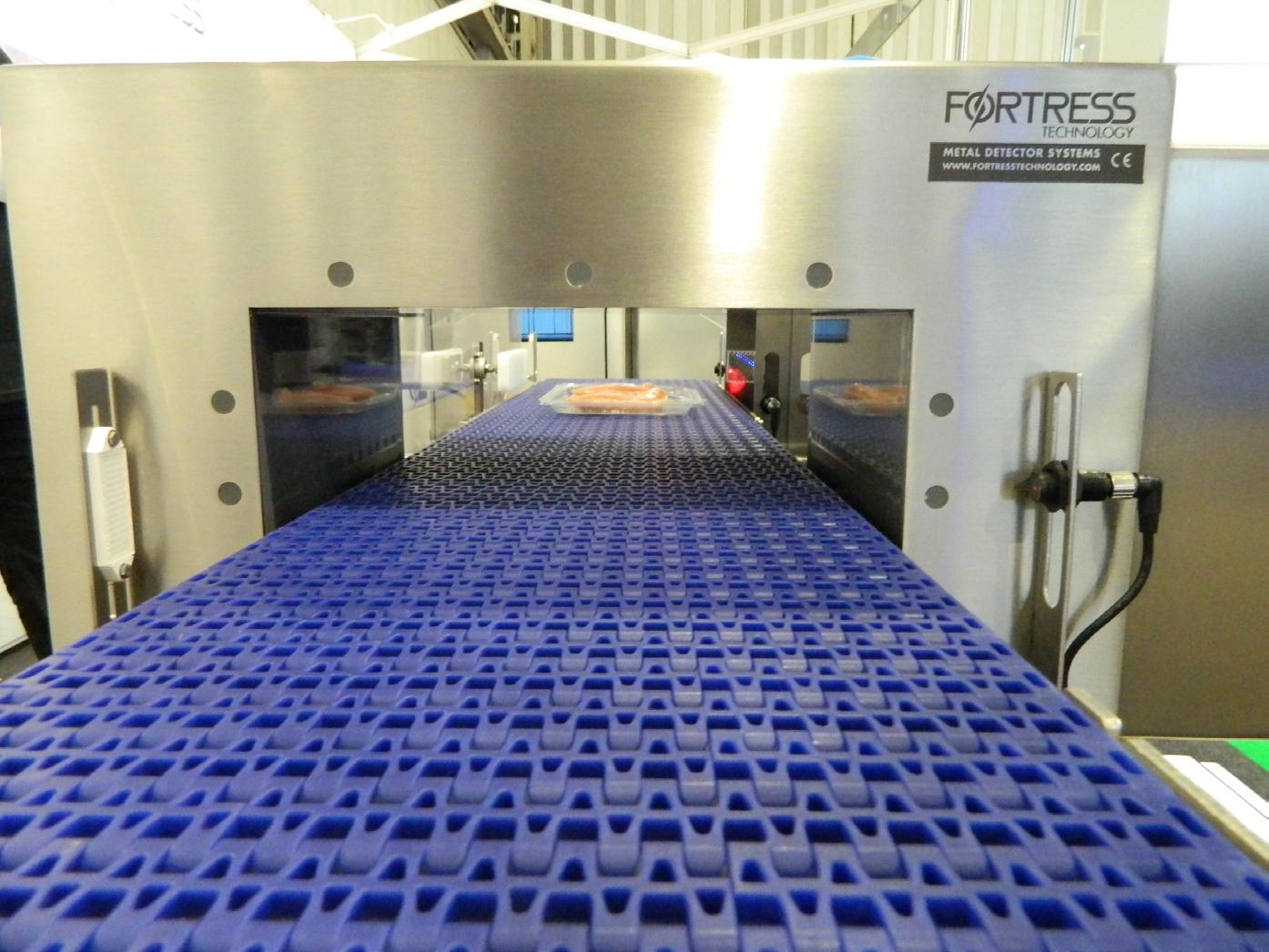

PROCESSING FORTRESS

TECHNOLOGY REVIEWS FDA’S NEW ERA GLOBAL REACH

September 2023 fdm-uk.co.uk

Production/Design

Editors Note

Welcome to the latest issue of Food & Drink Manufacturing UK Magazine.

Sales

Sales Executive Alex Costa alex@fdm-uk.co.uk

Publishing

In this edition we bring news of a couple of upcoming exhibitions, London Packaging Week, an exciting event being held at Excel, London on 21 & 22 September 2023.

Paul Attwood

Paul Attwood

The PPMA Show, the free to attend show at the NEC in Birmingham, runs from 26-28th September. This is a showpiece event in the processing and packaging machinery calendar and will feature keynote speakers and all the innovations and developments in the industry.

We also hear from Stanley Mitchell, Head of Business Development at Cambridge based company Xampla. He talks about the use of drop-in natural alternatives to polluting plastics, an important topic which affects all stages of manufacturing and production in the food and drink industry.

We hope you enjoy this issue and as always, if you have any news that you would like to feature, please email details to editorial@fdm-uk.co.uk

CONTENTS Editor Paul Attwood

Assistant Francesca Amato

editor@fdm-uk.co.uk Editorial

editorial@fdm-uk.co.uk

Features Editor Henry Peters editorial@fdm-uk.co.uk

Laura Whitehead laura@lapthornmedia.co.uk

Manager Holly Jones sales@fdm-uk.co.uk

Lapthorn Media Ltd 5-7

Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB 10 18 26 36 38

10

Director Maria Lapthorn maria@lapthornmedia.co.uk

Ozengell

Swift changes to raw material sourcing could cause latest food safety crisis London Packaging Week to light up the packaging industry PPMA Show to showcase developments in the UK’s processing & packaging industry Fortress Technology reviews FDA’s new era global reach Food Manufacturers Missing Out On R&D Tax Relief

Every effort is made to ensure the accuracy and reliability of material published in Food & Drink Manufacturing UK however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors. No part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher. 03 26 38 18 36 01843 808 117 www.fdm-uk.co.uk @fdmanufacturing

Editor

Food inflation slows to its lowest level in 2023

Food inflation continues to slow to its lowest level since December 2022 as acceleration rates fall month on month.

Food inflation decelerated to 13.4% in July, down from 14.6% in June, while fresh food inflation slowed to 14.3% down from 15.7% in June. This is the lowest level seen since November 2022. In July, ambient food inflation decelerated to 12.3%, down from 13% in June.

Annual Shop Price inflation has decelerated to 7.6% in July, down from 8.4% in June. This is below the three month average rate of 8.4%, and it is at its lowest level this year.

Helen Dickinson, OBE, chief executive of the British Retail Consortium, said: “Shop price inflation fell to its lowest level of 2023 and, for the first time in two years, prices fell compared to the previous month.

-

“Food price inflation also slowed to its lowest level this year, with falling prices across key staples such as oils, fats, fish, and breakfast cereals. These figures give cause for optimism, but further supply chain issues may add to input costs for retailers in the months ahead. Russia’s withdrawal from the Black Sea Grain Initiative and subsequent targeting

of Ukrainian grain facilities, as well as rice export restrictions from India are dark clouds on the horizon.

“We expect some global commodity prices to rise again as a result, and food prices will be slower to fall. Retailers continue working hard to keep falling prices on track.

“Government must also play its part and freeze business rates from next April, or else risk adding a £400m additional pressure on prices.”

Mike Watkins, head of retailer and business insight, NielsenIQ, said: “The summer holiday period should help discretionary spend a little and whilst inflation remains high, the outlook is improving. Shoppers continue to change how they shop as part of their coping strategies. This includes shopping at different retailers, buying lower priced items, delaying spend or only buying when there are promotions. This behaviour looks set to continue.”

Import checks on plant and animal produce from EU to be delayed indefinitely

First reported by the Financial Times (FT), UK Ministers are to delay the post-Brexit food import checks on fresh farm produce from the EU indefinitely.

This is the fifth time delays have been announced to the post-Brexit border controls.

The intention is said to be to give the Government more time to prepare for checks ahead of the controls being enforced.

Reports say that there are concerns of increased costs of food imports to

consumers as a result of the delays, risking further food inflation.

The Cold Chain Federation (CCF) has welcomed the delay, stating that some EU producers were not aware of the new requirements.

CCF chief executive Shane Brennan said: “Government has made the right decision to postpone. UK food retailers, hospitality businesses and consumers were in line for major disruption because many EU food producing businesses supplying into the UK are not ready for the new requirements. We recently asked Ministers to push back the export health

certificate requirement to give Government time to ramp up communications to EU businesses. The decision to postpone also means that there should be a fully staffed border inspection team on the ground by the time the new requirements come into force, able to provide support and advice for these EU importers.

“Meeting the new sanitary requirement will still increase costs for the EU food producers supplying into the UK, and we should expect these costs to be passed onto UK retailers and consumers but this change in the implementation timetable could make an important difference towards reducing that impact.”

04 Industry News

These figures give cause for optimism, but further supply chain issues may add to input costs for retailers in the months ahead.

Helen Dickinson

Many EU food

businesses

unaware

of new UK border laws

The Cold Chain Federation (CCF) is warning that many food businesses are unaware of changes to EU-UK exporting legislation, and that UK food retailers, hospitality businesses and consumers should expect “significant disruption” in the Christmas trading window as a result.

A new survey by the CCF has demonstrated what the trade body has called a “disturbing lack of preparedness” of food production businesses in Europe that supply to the UK, with 39% of the surveyed businesses not aware of the new rules and timeframes announced by UK Government.

One of the prominent post-Brexit changes to import rules declares that export health certificates signed by a qualified certifying officer will become mandatory for every consignment of ‘medium risk’ meat, dairy and fish products exported from the EU to the UK as of the 31st October 2023.

When surveyed, 41% of respondents said they do not have plans in place to ensure compliance with this crucial requirement.

Industry-wide communication campaign needed, says CCF Shane Brennan, chief executive of the CCF, said: “It is deeply worrying that well over a third of these food producing businesses supplying into the UK are not aware that these significant changes are looming. Communications from the UK Government to these businesses has not been good enough and it is the food retailers, hospitality businesses and consumers here in the UK who will pay the price with disruption, delays and losses.

“We have written to ministers setting out our survey findings and asking for the 31st October implementation of the export health certificates to be moved back to 31st January 2024. Government must use the extra time to deliver a much wider and better resourced communications campaign, starting now, to increase awareness among EU businesses in enough time for a full implementation on 31st January next year. By then the UK should also have a fully staffed border inspection team, enforcing the new rules but also providing support and advice for these EU importers. With so much stress, cost inflation and other pressures in the food supply chain this year, this marginal change in the implementation plans could make a big difference.”

Increasing costs for businesses, retailers and consumers

The survey also showed that 78% of the EU based food producing businesses surveyed believe costs will increase to their UK customers as a result of the new rules.

Brennan said: “Meeting the new export health certificate requirement will increase costs for the EU food producers supplying into the UK, even more so for businesses scrambling at the last minute. These costs will be passed onto UK retailers, ultimately leading to higher prices for UK consumers and pushing food inflation even higher.”

When asked about their intentions regarding the sale of their products to UK customers after the 31st October 2023, only 60% of respondents said they plan to seek to continue their service to the same customers at the same frequency. Another 10% plan to reduce the frequency and range of UK based customers they serve, 7% plan to stop altogether and 22% said they don’t know at this stage.

Pladis warehouse opens in Carlisle as part of £12m investment

Snack company Pladis has opened a new warehouse in Carlisle as part of a £12 million investment, creating 50 new jobs.

Over 150 people were recruited in the last 18 months and placed into permanent jobs within the company, which produces products for brands such as McVitie’s, Jacob’s and Carr’s.

The £2 million warehouse was opened by Carlisle MP John Stevenson. Commenting on the opening, Stevenson said: “I was delighted to be invited to open the warehouse extension at Pladis’ factory in Carlisle. This is a very welcome multi-million pound investment by Pladis into the site, bringing with it 50 new jobs to the local area. Another real boost to the Carlisle economy with more jobs for local people.”

The expansion has created the need to construct a new narrow aisle warehouse with 1600 pallet spaces. Also installed were four new production lines, including new process capability and packaging formats.

David Murray, UK managing director of Pladis, said: “Today’s announcement and expansion of our Carlisle facility marks a proud moment in the company’s 192-year history in the area.”

05 Industry News

Food label compliance: Double confidence with Belts & Braces verification process

With skeleton food safety crews, a leaner post-Brexit quality control workforce and Food Factory Managers wearing multiple technical hats, JentonDimaco Director Dr Russ Sion explores how a ‘belts & braces’ approach to label verification can save overtasked technical professionals sinking under the compliance and cost controls pressures.

Food factory managers today are carrying the weight of responsibility on their shoulders. Staffing; hygiene; allergens; contaminant detection; inflationary costs; energy price uncertainties; higher salaries; productivity; waste management; process controls; farm to fork traceability; and of course label compliance. The food production frontier is certainly a very daunting, more stressful and pressurised operational environment for senior technical personnel and factory managers today.

BELOW: Russ Sion explores why a ‘belts & braces’ approach to label verification can save overtasked technical professionals sinking under the compliance and cost controls pressures

Wearing multiple hats and juggling countless responsibilities, it’s enough to make the most organised and cautious senior food factory managers feel overloaded.

While adopting a belt and braces approach may appear unfashionably excessive to some, with demands continuing to climb, introducing a robust risk-based automated label verification strategy can collectively tick multiple conformity and compliance boxes in one go.

Eager not to get caught baring their compliance undergarments and the brunt of any ensuing finger-pointing Emergency Product Withdrawals (EPWs), food factory production managers are recognising the swift rewards of automating label verification processes.

Fact over fable

Parading a seemingly robust manual quality control process or smart camera label checking solution can be much like the ‘Emperor’s New Clothes’ folktale. A factory may catch the occasional mis-labelled product. Yet, this reliance on human sensory testing – how ever good it might appear - still leaves food processing sites unwittingly exposed and can promote a false façade and sense of compliance complacency.

For an industry that’s awash with productivity buzzwords and procedural hype, there remain multiple interpretations of good manufacturing practice. While having a manual label inspection process is clearly better than none, it’s open to falsifications

06

Food Safety

Wearing multiple hats and juggling countless responsibilities, it’s enough to make the most organised and cautious senior food factory managers feel overloaded.

- Dr Russ Sion

and human error. Not to mention the challenge of resourcing and allocating several responsible and fully trained technical team members dedicated to this repeatable task for an estimated of 30 percent of every shift.

Additionally, what may suffice when inspecting small batches, certainly doesn’t stand up to retailer scrutiny in mass-production food environments where each line can be inspecting in excess of 150 packs per minute. “The notion that manual label checks is a sustainable process in this day and age is no more than a foolhardy proclamation. The label inspection results are also subjective. Even the most carefully documented inspections, are limited to random checks, and certainly cannot spot any embedded label errors.

“From a strategy perspective, it may appear like the thrifty option. Yet, just one EPW is all it takes to completely eradicate brand value,” exclaims Russ.

Frequently positioned as the alternative to manual inspections are vision systems. As advanced as these cameras are at capturing label information, taking a picture is only half of the quality control narrative. As a minimum a system should have a good OCR to read text and printed characters, as well as 1D, 2D and data embedded codes. Many do not, instead relying on an off the shelf vision toolbox with inherent compromises!

Without connecting industrial vision systems to a reliable and validated data source, these label inspection systems can generally lack material substance.

“Checking the image quality and presence of a printed label is essentially only half the story and could be futile and non-compliant. Particularly if the production and retailer source data that food labels are being checked against isn’t correct or the most up-to-date version,” explains Russ.

The most common label integrity assumption, recounts Russ, is when processors invest in a high-end vision system, but still rely entirely on production operatives to manually input data from a spreadsheet into a lineside terminal. Compared to a fully-compliant offline or online JentonDimaco label verification

system, inputting data manually will not deliver anything close to the same data integrity benefits.

Russ cites the example of an operative diligently setting a printer up to print a use-by date of ‘Feb 30’. With the camera set up to verify ‘Feb 30’, all appears good. This so-called verification system is doing its job. Merrily passing all the packs, sending them out the warehouse door to retailers unaware of any issue!

Transparency sewn up

A true automated label verification system will not compromise on any aspect of performance. That’s why JentonDimaco adopts a ‘belts & braces’ approach, to prevent a food processor being caught out.

Aside from the contractual fines which can easily run into tens of thousands of pounds, the brand damage and reputational risks caused by an EPW can rapidly multiple. In the worst case

reaching into the millions, cautions Russ. He suggests that just one prevention of a label EPW can pay for a decade of robust Dimaco label verification protection.

“A ‘belts & braces’ automated approach to label verification can accelerate the verification process, catch mis-labelled products before they leave the high care environment, enabling product to be reworked and re-labelled. This in turn reduces food waste, which as well as protecting profits, also plays a significant role in safeguarding the environment.”

Describing it as better than an insurance policy, Russ likens a Dimaco offline and online automated label verification system to a fire alarm or sprinkler system. Alerting factory managers to a potential issue long before any irreversible damage takes hold in the public domain. Catching mislabelled products at this phase can be the difference between the cost of reworking several dozen products to a retailer fine, recall, brand damage, and potentially tonnes of good fresh produce being thrown away at a considerable cost to the environment.

Russ clarifies: “Label mistakes may still happen. However, what both and offline and online JentonDimaco label verification systems will do is find and take corrective action before a product range leaves the factory. Preventing a humiliating public disgrace and integrity challenge by those that wield the greatest power – the retailers.”

07 Food Safety

Continued >>>

RIGHT: A camera verification system set up to verify ‘Feb 30’, won’t identify any issue with pack dates until it’s too late.

Credit: iStock Madmaxer

A true automated label verification system will not compromise on any aspect of performance.

- Dr Russ Sion

Data detox

Shaping up and cleansing the data is the most critical and time-consuming aspect of the entire label verification process. It comprises all of the primary data, the processing data and, to close the loop, all of the MRP label verification data.

Every one of the ‘rules’ has to be configured on a product by product basis. It’s a massive undertaking. But one that JentonDimaco experts manage entirely for customers. Once this total data overhaul is complete, food factories have a fully automated, cleansed and integrated variable and non-variable data blueprint that can grow and adapt as their business evolves.

Russ expands: “JentonDimaco label verification systems are the most efficient way to authenticate all aspects of data and artwork on food retail labels including price, barcodes, use-by dates, promotional labels and artwork revisions.

Label Verification Technologies –It’s all about the data

JentonDimaco explores the multiple label verification options on the market, walking technical decision makers through the features, limitations and strengths of each.

“All of this data is verified against a master specification held on the JentonDimaco Veri-CENTRAL server, which sources data from each food manufacturer’s MRP server or production spreadsheets.”

When live, every single label passing along the production line is automatically checked against the Veri-CENTRAL blueprint. There are no printed spreadsheets, realms of Production Product Check Sheets, or human intervention required. Products with good labels continue down the line, badly printed products and those with missing labels are rejected for investigation, whilst incorrect data will stop the line.

Every time a supermarket makes a label adjustment during the production run, for example to a price, the JentonDimaco Veri-CENTRAL server will pick this up instantly. This information is then automatically relayed to every Veri-PACK labelling system within seconds and the action taken documented on Veri-VIEW.

Cleansing and rolling out this seamless data flow along with automated label reading tech is less convoluted than most anticipate. Rather than adding another layer of complexity to already overloaded factory managers, the JentonDimaco team creates a ‘belts & braces’ rollout roadmap factoring in all the macro-risks to eliminate disruption and production downtime.

Typically, this involves getting all the IT systems running in parallel, installing the equipment at night or over the weekend, running paper based systems for several weeks simultaneously while the workforce undergoes training, before switching over. “True label verification competence which verifies 100 percent of the data against every single product pack is the secret to food label compliance success. It requires an upfront investment, yet the ROI is undoubtedly swift,” states Russ.

Richard Canvin, CEO of Dovecote Park, agrees with the need for automated label verification, offering the following comment: “With the increasing pressure on all resources, the JentonDimaco label verification system removes one critical area of concern for us, ensuring that 100% of the products we produce are correctly labelled.”

LEFT: This simple matrix presents the strengths, features and limitations of the four main label verification options available

08 Food Safety

Jenton Dimaco is part of the Jenton Group, experts in the Design and Manufacture of UV Curing and UV Air Disinfection, Packaging and Converting www.dimaco.co.uk sales@dimaco.co.uk +44 (0) 1234 851515 Yes Yes (operator dependant) Yes (depending on disk space) Possible but unlikely No LABEL CHECKS MANUAL PAPER BASED SYSTEM SMART CAMERA BASED SYSTEM DIMACO OFFLINE DIMACO ONLINE First Product Last Product Every X Minutes After Line Stop Top / Side / Base 1D Barcode 2D Barcode Data Embedded Barcode Encrypted / Hidden Barcode RFID / NFC Tag 100% of Packs Checked User Definable Degree of Skew / Rotation /Misplacement Tolerance DATA SOURCE MANUAL PAPER BASED SYSTEM SMART CAMERA BASED SYSTEM DIMACO OFFLINE DIMACO ONLINE Manual Operator Check Spreadsheets Manual Data Entry MRP / ERP System Own Database Complete Data Traceability RESULTS / REPORTING MANUAL PAPER BASED SYSTEM SMART CAMERA BASED SYSTEM DIMACO OFFLINE DIMACO ONLINE Saved Images of Every Good Pack Saved Images of Every Bad Pack Auto Save Imaging Label Check Sheets User Configurable Reports Easy Retrieval for Audit Secure Reject Bin with Reject Confirmation Supermarket COP Approved

Preventing a humiliating public disgrace and integrity challenge by those that wield the greatest power – the retailers.

- Dr Russ Sion

The Significance of Labelling: Ensuring Safety, Efficiency, and Compliance

In the dynamic, ever-evolving world of food processing and distribution, the role of labelling cannot be overstated. Bluepoint, a renowned UK manufacturer of premium tags and labels, recognizes the critical importance of labelling within this industry.

Food safety stands at the forefront of their mission, understanding the dire repercussions that can arise from inadequate labelling. By providing a diverse range of top-quality labels and tag solutions, Bluepoint caters to every stage of the production and distribution process. From heat-resistant metal detectable tags to self-adhesive labels, barcode/batch labels to storage and distribution labels for chilled or frozen goods, Bluepoint satisfies the industry’s stringent requirements. Their commitment to customization ensures that their labels seamlessly integrate into clients’ existing printing systems.

Efficiency and hygiene are also paramount concerns within the food processing sector. With their extensive experience and excellent service, Bluepoint has established itself as a reliable partner to their customers. By manufacturing labels using approved materials and in various sizes, Bluepoint ensures products meet the exact specifications of their clients,

to aid streamlining operations and optimizing productivity, ultimately boosting overall efficiency.

Remaining compliant is nonnegotiable, Bluepoint’s comprehensive label range facilitates smoother compliance processes for their customers. By consistently delivering labels that adhere to regulatory guidelines, Bluepoint empowers their clients to maintain high standards and avoid potential penalties or setbacks.

Looking toward the future, Bluepoint envisions further growth and expansion, with exciting product developments in the pipeline. Their focus on innovative solutions includes the introduction of environmentally friendly alternatives, such as recyclable, compostable ECOpack wrap®. With the unwavering support of their loyal customer base, Bluepoint is poised to achieve new goals while continuing to provide exceptional service.

Directors Iain Pringle & Rob Burton expressed confidence in the company’s trajectory, reflecting on two years of unprecedented growth. Collaborating closely with both new and existing customers, Bluepoint prioritizes proactive planning to sustain the highest standards and ensure consistent product availability, always at the most competitive prices.

Bluepoint’s strengthened manufacturing capabilities and customer service foundation position them as a reliable partner for all labelling needs. Whether clients require in-house bespoke designs, standard stock labels for self-printing, or specific tailored projects, Bluepoint guarantees competitive prices, short lead times, and outstanding products. Supported by their friendly and knowledgeable team, Bluepoint is committed to assisting businesses in securing the best product and price for their unique requirements.

Where safety, efficiency, and compliance are paramount, Bluepoint stands as a trusted leader, delivering superior labelling solutions to propel the success of their valued customers.

09 Food Safety

For more information: E: sales@bluepointtags.co.uk T: +44 01392 927 030 W: www.bluepointtags.co.uk

Swift changes to raw material sourcing could cause latest food safety crisis

Leading global assurance partner, LRQA, is urging manufacturers to ensure heightened focus on change management to ensure supplier approval processes remain effective, following reports that one in three vegan products in the UK contain egg or milk.

The story, which led to the Chartered Trading Standards Institute warning of the potentially tragic consequences caused by an allergic reaction, is the latest indicator of heightened risks arising from a long line of challenges facing the food manufacturing sector. Climate change, severe weather events, ongoing geopolitical issues and the cost-of-living crisis are all having an impact on the availability of raw ingredients, forcing many manufacturers to seek new suppliers.

According to LRQA, the likelihood that manufacturers will be experiencing change is not going to decrease anytime soon, meaning more due diligence is required when seeking new suppliers. However, with multiple stakeholders involved in the supplier process, including quality, food safety, procurement and research and development teams, this could further complicate the process of appropriately

vetting new suppliers to meet short production timelines.

Kimberly Coffin, Global Technical Director for Supply Chain Assurance at LRQA, said: “Food manufacturers understand their roles and responsibilities when it comes to food safety, particularly when considering allergens. If they do not, then they simply should not be in the business of making food. However, over the last 18 months, achieving a steady supply chain has become very complicated for manufacturers, meaning we are seeing the potential for more instances of food safety issues.

As well as facing the need to replace ingredients due to the supply shortages, more manufacturers are beginning to adopt near sourcing –moving away from a single global supply to multiple suppliers at a regional level. This move further complicates supply chain assurance, Kimberly Coffin explains: “When changing ingredients, it’s highly unlikely that the material will be a like-for-like substitution, meaning some level of recipe redevelopment, process revalidation and verification of existing labelling compliance will be required. Any change to supply source opens a whole host of food safety threats, and to proceed without effective change management controls can have unintended adverse impact on consumers.”

“Unfortunately, there are so many drivers for change and there is added pressure to ensure margins are optimised. Making sure every box is ticked is therefore hugely challenging, especially if resources are stretched. As such, the role of food safety specialists has never been more important.”

LRQA supports global food manufacturers by providing a variety of supply chain verification services. From supplier approval program management to supplier qualification and maintenance via independent audits using a brand’s own standard or third party certification schemes, its services cover the entire food and beverage supply chain.

Kimberly adds: “As food safety specialists, we cannot stress how important it is to manage change properly. Are the controls and checks you have in place still relevant in today’s operating environment? Times have changed, so manufacturers now more than ever need to ensure their supplier management programmes leave no room for error.

“The consequences of not having a good change management system in place cannot be understated. If suppliers are not appropriately vetted, then we will likely see more product recalls and industry warnings, which ultimately damage reputations.”

For more information, visit www.lrqa.com

10

Food Safety

When changing ingredients, it’s highly unlikely that the material will be a like-for-like substitution, meaning some level of recipe redevelopment, process revalidation and verification of existing labelling compliance will be required. Any change to supply source opens a whole host of food safety threats, and to proceed without effective change management controls can have unintended adverse impact on consumers.

- Kimberly Coffin

LEFT: Kimberly Coffin, Global Technical Director for Supply Chain Assurance at LRQA

www.eit-international.com EIT INTERNATIONAL SPECIALISTS IN

BACTERIA & BIOFILM DETECTION SYSTEMS FOR THE REGULATED INDUSTRIES

UK grocery wholesaler A.F. Blakemore & Son choose RELEX Solutions to automate forecasting and replenishment

A.F Blakemore & Son Ltd, one of the UK’s largest privately owned family businesses operating across retail, foodservice and the largest SPAR wholesaler in the UK, has chosen RELEX Solutions, the provider of unified supply chain and retail planning solutions, to automate and optimise their supply chain processes.

AF Blakemore has 9000 SKUs in their product range and an annual turnover of £1.2 billion in 2022. The RELEX software will be implemented at their distribution centres, using the solution for forecasting and replenishment of fresh, ambient and frozen categories.

The new integrated system uses AI and machine learningbased analytics and replaces AF Blakemore’s previous arrangement of multiple overlapping ERP systems and manual spreadsheets.

Marco Ghirardello New President and CEO of FANUC Europe

FANUC Europe Corporation is pleased to announce the appointment of Marco Ghirardello as the new President and CEO. Ghirardello succeeds Shinichi Tanzawa, who has been leading the company since 2016 and will return to FANUC Headquarter for a new assignment. His contribution to FANUC Europe over the past years is highly appreciated.

“It is a great honour and responsibility for me to take over the lead of FANUC Europe, and I look forward to working closely with our customers and partners to build their competitiveness in the market and shape the future of the automation industry,” Ghirardello said upon his appointment.

Ghirardello, who has been with FANUC since 1994, brings a broad experience to his new role. Most recently, he served as the Senior Vice President of FANUC Europe, leading the Factory Automation business unit, which includes FANUC’s important CNC control business. His previous roles included Managing Director for FANUC Turkey and then FANUC Italy, where he played a crucial role in the company’s expansion in this key European market.

“With our high-quality products, global service network and strong organisational capabilities, we will continue to drive technological excellence in the automation industry across Europe,” Ghirardello said.

Commenting on the deal, Marc Deakin, Supply Chain Director at A.F Blakemore, said, “With our new RELEXpowered automated planning system, we aim to improve availability of in-store stock for customers, while also reducing waste and freeing up staff to focus on other core tasks.”

Deakin continued, “RELEX has a well-earned reputation based on their in-depth understanding of the convenience and grocery sector, including long-term relationships working with other SPAR franchise operators in both the UK and mainland Europe and also the performance of their technology solutions in streamlining and improving multiple supply chain processes through automation. RELEX was the natural choice to meet A F Blakemore’s operational needs.”

“Wholesalers and retailers alike today face a range of competing and interconnected business challenges, including managing costs, reducing waste, and handling disruptions to supply chains so that customers can continue to buy the products they want,” said Jason Berry, VP of Sales for EMEA at RELEX Solutions.

“AI and Machine Learning have a significant role to play in addressing these challenges by processing all relevant data at scale for far greater accuracy in forecasting and replenishment.

“We’re very pleased to work with A F Blakemore to automate this critical part of its operations,” said Berry.

12 Industry News

IDEAL FOR HACCP COMPLIANCE Therma

Manufactured in the UK, we offer a wide range of specialist thermometers for the food & drink industry from daily hand-held monitoring to Bluetooth® wireless technology & remote Wi-Fi logging

13

20 thermometer

VARO introduce the Pallet Unwrapper

The Pallet Unwrapper – one of few missing links in today’s automated factories, the system accepts pallets at its base then measures them, cuts through the wrapping without harming the contents, and finally removes the wrapping for recycling.

VARO’s revolutionary unwrapping solution, the Pallet Unwrapper, can gently remove the stretch film wrapped around pallets. The stretch film is gently but accurately cut and removed fully automatically. This is done without the need for human operation or interaction. It’s therefore the right choice for production companies that deal with unstable products and receive a large number of pallets every day.

The Pallet Unwrapper is available in 3 configurations: The Unwrapper Cut: for simple cutting of the wrapping film.

The Unwrapper Core: for the cutting and removal of wrapping film, and the Unwrapper Control: for the cutting and removal of wrapping film for unstable products.

Fast: High capacity, fully automatic multi-shift operation without breaks

Careful: Unwrapping without damage to the pallet goods

Safe: No more risk of injury for employees

Flexible: Easy integration into existing lines or use as stand-alone unit –quickly contributes to an effective flow

10 reasons you should automate your pallet unwrapping process:

The FMCG (Fast-Moving Consumer Goods) industry is known for its fastpaced nature, high volume production, and quick turnover of products. In such an industry, not automating processes can pose several risks and challenges as well as loss of profit. Here are some of the key risks of not automating the pallet unwrapping process:

Film Breakage: The film used to wrap the pallet may break during unwrapping, leading to instability and potential damage to the products.

Inefficient or Slow Unwrapping: If the pallet unwrapping process is slow or inefficient, it results in decreased productivity and increased labor costs.

Product Damage: Improper unwrapping techniques or equipment can cause damage to the products on the pallet, such as scratches, dents, or breakage.

Worker Safety: Manual pallet unwrapping can pose safety risks to workers, especially if they are required to use sharp blades, excessive force or repetitive motions.

Film Residue: In some cases, the wrapping film may leave behind residue on the pallet or products, which can be unsightly or cause contamination concerns.

Inconsistent Tension: Uneven or inconsistent tension during unwrapping can lead to pallet instability, making it more susceptible to tipping or shifting.

Difficulty in Film Removal: Some pallet wrapping methods or equipment may make it challenging to remove the film after unwrapping, causing inconvenience and potential delays.

Environmental Impact: If the wrapping film used for pallets is not effectively recycled, it causes waste and environmental concerns

Lack of Automation: Manual unwrapping processes can be timeconsuming and labor-intensive, limiting productivity and efficiency in warehouse operations.

Cost of Consumables: Excessive or inefficient use of wrapping film can lead to increased material costs over time, impacting the overall profitability of the pallet unwrapping process.

For further information visit: www.friedheim.co.uk

14

Packaging G

The Corrugated Packaging Manufacturer By buying our packaging you help take care of the world’s forests FSC® C147497 • www.fsc.org For Food & Drink

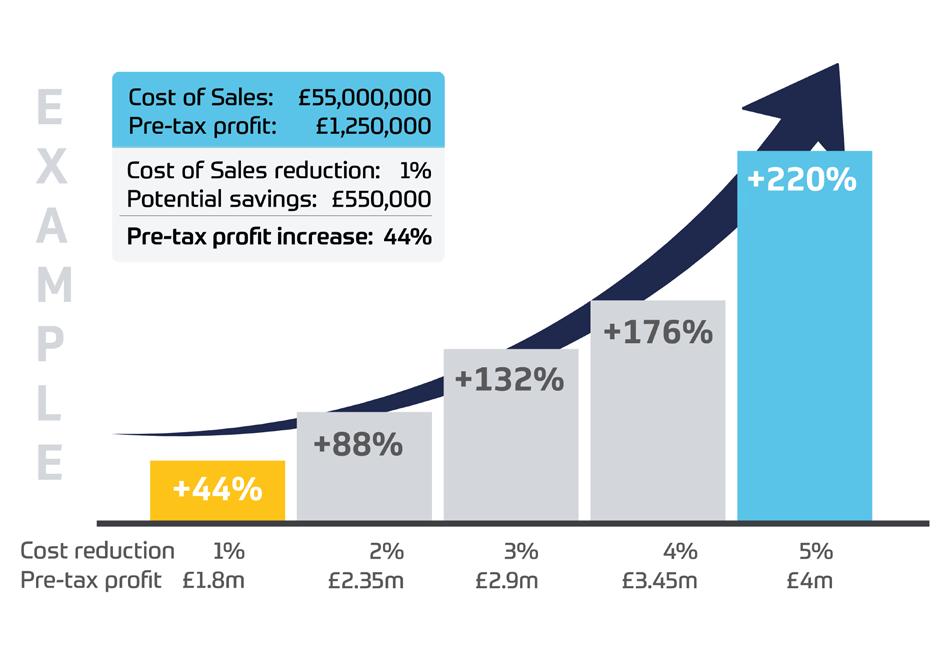

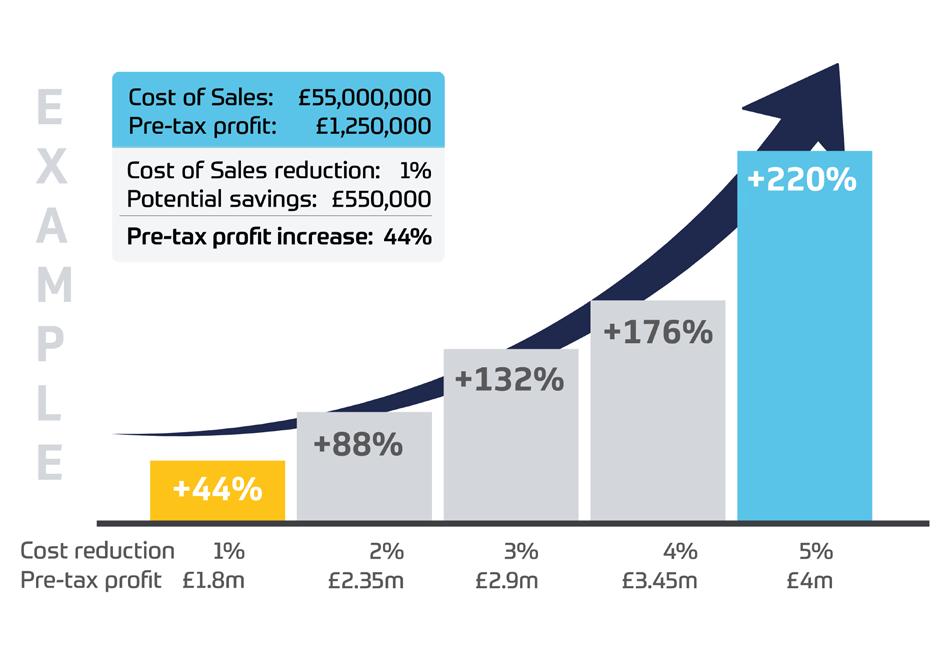

Performance Improvement… the Cost of Doing Nothing!

Beneficial Change requires investment, but doing nothing costs far more.

It isn’t the extent or the pace of change, which is surprising, but the extent to which so many companies seem reluctant to embrace beneficial change and instead, do nothing. For many, the rate of change has been stuck in neutral for far too long and it is beginning to show in their annual audited accounts.

Doing the Same Things, but Expecting Different Outcomes?

Whilst we design, manufacture, supply and support leading edge true state-of-theart performance improvement systems, we do not always see the rate of ‘take up’ and performance improvements amongst our clients that they expect to see. As the system is unequalled, let alone surpassed, the lack of engagement on the part of our clients is almost always the cause. Whilst it might be easy for us and our clients to see the weaknesses in the status quo, the fear of moving away from what they have always done, and embracing something new, is ever present.

Machiavelli recognised this more than 500 years ago in his novel, The Prince, which led to one of his most famous quotes: “There is nothing more difficult and dangerous, nor more doubtful of success than an attempt to introduce a new order of things.”

Spending Nothing is not the same as Costing Nothing!

Companies paralysed by inertia, will often justify ‘doing nothing’ with ‘we’ve always done it this way’.

Private companies must remain competitive in order to avoid losing market share, but many are having a tough time. The Government is threatening to legislate in order to force supermarkets to reduce prices. If this happens, it’s likely that the supermarkets will put even more pressure upon their suppliers, squeezing them still further.

In June 2023, compared with the same period last year, bankruptcies were up by nearly a third.

Performance Improvement: You Can’t Improve What You Don’t Measure

With ever increasing raw material prices, legislated annual minimum wage increases, a shortage of factory floor labour and the supermarkets pushing for further reductions in price, the food and drink manufacturers must look inwardly to reduce their transformation costs. To make these improvements, measurement becomes increasingly important. It is virtually impossible to chart improvements

if you have little understanding or metrics regarding the starting points. Measurement cannot be done effectively or continuously with pencil and paper, so an accurate analysis of the starting points is essential.

Choosing the Right CI System and Partner

Choosing the right system and performance improvement partner is essential. The right partner will understand your business, appreciate the risks and challenges that you face, will have an in-depth understanding of the difficulties encountered in the successful implementation of change and be enthusiastic to work with you to ensure the fullest understanding and engagement. Reduction of wastage and improvement of efficiency at every opportunity is now more essential than ever in order to survive, even thrive, in this increasingly competitive marketplace.

We’re here to help. See us at the PPMA Show, Birmingham NEC, on Stand B46 or give us a call +44 (0)1225 764461.

16

Packaging

WineGuard™ is the new and secure way to send your bottled beverages through the post/courier system. Protect your glass bottles in transit with Wineguard Allpack’s range of bottled beverages transit packaging solutions.

Manufactured using fully recycled materials and being fully recyclable, our pulp fitment ranges fit into specially designed cartons that can securely hold multiple bottled beverages, providing functional, affordable transit packaging protection.

Pulp Fitments and corresponding carton sizes available for the following amounts of bottles -

• x3

• x6

• x12 Scan to visit the full WineGuard™ range

www.allpack.uk.com sales@allpack.uk.com 01543 396 700 Introducing WineGuard™

100% recyclable WineGuard™ is manufactured from recycled materials and can be fully recycled or composed. Designed for maximum safety Designed for operational effectiveness with interlocking fitments, to save spills in-transit. Drop Tested for Peace of Mind WineGuard™ exceeds ISTA drop test protocols and removes in-transit damages/ breakages or spillages.

London Packaging Week to light up the packaging industry

Packaging

London Packaging Week organisers are warning potential visitors to this September’s must-attend exhibition to move now and secure their tickets, with demand continuing to skyrocket.

Registrations to attend the two-day event, which will take place at the world-famous ExCeL Centre in London on 21 & 22 September, have already doubled. And with over 6 weeks remaining, London Packaging Week is again proving to be the hottest ticket in town.

The showcase is a trusted platform for sourcing packaging solutions and connecting with new suppliers - and is the place to be if you want to stay ahead of the game and establish meaningful connections within the industry.

Last month, the leading multi-format event organiser confirmed its most exciting and diverse speaker line-up to date, with names like Mulberry founder Roger Saul, Fable & Mane co-founder and CEO Akash Mehta, Entrepreneurs Marisa Poster and

Teddie Levenfiche, who created Europe’s first matcha green teapowered energy drink – PerfectTed - and Candy Kittens’ co-founders Jamie Laing and Ed Williams already proving a huge draw.

Visitors to londonpackagingweek.com have soared an astonishing 1,539% in recent weeks, and with the number of expected attendees set to soar beyond 5,000, the message is to secure your place today!

“All things point to this being one of our busiest, but also enlightening packaging exhibitions to date,” said Community & Content manager Parisa Maleki.

“Whether you’re a seasoned packaging professional, an aspiring designer, or simply someone passionate about sustainable solutions, we want to ensure that anyone can come along and contribute towards the drive to meet consumer needs and solve longstanding challenges in the industry.

“As a co-located event featuring exhibitors from four show areas, namely Packaging Première, PCD, PLD, and Food & Consumer

London Packaging Week

- Parisa Maleki

Pack, London Packaging Week remains the ultimate platform for packaging businesses to showcase their products.”

London Packaging Week aims to create value and drive business growth for exhibitors and attendees. In 2022, more than 2,600 key decision-makers and representatives from over 2,000 brands attended the event.

“London Packaging Week offers a unique platform to connect, learn, and thrive, whether you’re a packaging supplier, specifier, buyer, or designer,” added Maleki. “The event facilitates knowledge exchange, keeping you up-to-date with the latest packaging trends and technologies.

“This year, a turnout that looks set to surpass the 5,000-mark demonstrates the trust and importance placed on London Packaging Week within the industry.

“London Packaging Week is where innovation meets collaboration, and the packaging industry comes alive.”

Visitor registration is now open. To register to attend, please visit londonpackagingweek.com

18

London Packaging Week

Thousands are already snapping up tickets for London

Week, which lands in the capital this September.

is where innovation meets collaboration, and the packaging industry comes alive.

80% PCR content and optimised design for recycling - adapa Group’s EcoString bag is the more sustainable alternative to the drawstring bag

adapa Group, one of Europe’s leading flexible packaging solutions companies, is taking the classic drawstring bag for hygiene and cosmetic products to a new level: the enhanced EcoString bag contains 80% post-consumer recycled (PCR) content, making it more sustainable than regular drawstring bags. This innovative single-material solution, in which both the bag and the drawstring are made of easily printable polyethylene, enables full recyclability and the use of recycled material.

True mono-material solution for hygiene and cosmetic products

Closing product loops is the supreme discipline of the circular economy for

packaging. To achieve this, packaging must be both recyclable and made from recycled materials. This is exactly the case with adapa’s innovative EcoString bags: the packaging is made from 80% mechanically recycled post consumer recyclate (PCR) and is recyclable because both the bag and drawstring are made entirely of polyethylene (PE). The familiar drawstring made of viscose is replaced by a plastic strap, while retaining its functionality. The resulting mono-material packaging eliminates the need to separate the components for recycling. EcoString bags are thus fully recyclable and with 80% PCR adapa closes the loop.

The innovative packaging from adapa is available as prefabricated bags with holes for simplified order picking.

They are characterised by their economical use of materials: With film thicknesses from 30 µm, they are among the thinnest products available on the market in this segment.

In addition, adapa also focuses on resource conservation in the production of the drawstring, as it is made from edge trimmings from the production of the bags. EcoString bags can be printed in up to 10 colours. Both the bag and the drawstring can be used for print communication. With their individual matte or glossy finish, they ensure a visually attractive product appearance at the POS. The use of recycled material and the recyclability of EcoString bags are a real selling point for conscious consumers.

Highest standards of quality and safety

As part of its commitment to greater sustainability and resource conservation, the packaging industry is looking for new solutions to expand the use of PCR. With the EcoString bag, adapa has succeeded in doing so in the drawstring bag segment. The use of PCR materials presents numerous challenges: high-quality PCR material is required, which adapa can quickly identify thanks to the expertise of its in-house PS Polymer Sourcing. In addition, specifications in the area of quality and consumer protection must be met:

“We have contributed our many years of experience in the production of EcoString bags as well as our expertise around sustainability and the requirements of the hygiene industry.

“With regular quality controls and checks in external laboratories, we at adapa ensure the highest product safety for our new generation of bags with 80% PCR content,” explains Joanna Herbst, Product Manager Converting at adapa.

20

Packaging

Springpack introduce Armour Wrap

Springpack, a leading provider of high-quality packaging products that optimise business processes, introduces their latest innovationthe Armour Wrap nano machine film. This cutting-edge film is engineered with precision and attention to detail, offering numerous advantages over traditional films. To demonstrate its potential benefits, Springpack presents the Machine Film Savings Calculator, an intuitive online tool designed to help businesses assess the cost-saving potential of Armour Wrap.

The Armour Wrap film stands out for its exceptional load stability, thanks to its multi-layer design that ensures maximum strength and security for your pallets. Compared to other highperformance or conventional films, Armour Wrap’s unique multi-layered composition acts like bulletproof glass, resulting in reduced pallet damages, breakages, and in-transit movement.

One of the most significant advantages of Armour Wrap is its cost-saving potential. Due to its superior strength, it requires less film to secure a pallet, leading to less plastic waste and substantial monetary savings. Additionally, each roll of Armour Wrap can wrap around 100 pallets, compared to the 70 pallets wrapped with conventional films, making it a more economical choice. Moreover, the use of 1kg cardboard cores instead of 1.8kg cores contributes to reducing cardboard waste.

The film’s multi-layer nanotechnology enhances its puncture and tear resistance, providing a higher containment force and making it suitable for unconventional pallets with sharp edges. Furthermore, Armour Wrap’s exceptional stretch capacity of up to 335% outperforms conventional films that typically stretch only 100200%. This feature minimizes wastage and ensures optimal performance.

Consistency and reliability are crucial factors for any packaging material. Armour Wrap excels in this aspect, as it is manufactured using only the highest quality materials and state-of-the-art machinery. This ensures that each roll of film maintains the same level of quality and performance, eliminating the risk of inconsistent results.

Take the first step towards optimizing your packaging process and start saving costs with Armour Wrap. Visit Springpack.co.uk or scan the QR code to access the Machine Film Savings Calculator and unlock the full potential of Armour Wrap for your business. 21 Packaging springpack.co.uk | 01905 457 000 CALCULATE YOUR MACHINE FILM SAVINGS ONLINE Compare and analyse your current machine film with Armour Wrap to discover your potential savings. SCAN TO ACCESS THE CALCULATOR

Rethinking Packaging: Embracing drop-in natural alternatives to tackle plastic pollution, writes Stanley Mitchell

Modern society is characterised by our reliance on convenience. We are all guilty of choosing convenience over the most sustainable option – from single-use disposable coffee cups to the polystyrene packaging and plastic bags used to keep takeaway food warm.

Over the past decade, however, the food and drink industry has been making some steps to implement greener packaging initiatives. This is sorely needed - in the UK alone, packaging makes up nearly 70 percent of our total plastic waste. With supermarkets offering in-store opportunities for consumers to recycle soft plastic and films, and re-use and refill schemes popping up across the country, it is clear that the industry is trying to tackle the sheer volume of plastic we consume and dispose of every day.

Yet no matter how much effort is made to make the product ‘recyclable’ - so long as it is plastic, it can never be truly ‘sustainable’. The world’s plastic production, use and disposal contributes to around 1.8 billion tonnes of carbon emissions annually – that’s equivalent to 150 million double-decker buses.

It is intrinsic to the molecular make up of plastic that it can only be mechanically recycled two or three times before its quality is too poor to be used again. In addition, each time plastic is recycled, virgin material is added to help “upgrade” its quality, so that the recycled product has a fighting chance in the market against new, durable, and fresh plastics goods.

In food and beverage applications, the situation is even more perilous as the contents tend to soil the packaging and further complicate the recycling process. Soft plastics, used for products such as bread bags and toilet roll wrap, account for the majority that is thrown away. This type of plastic is notoriously difficult to recycle, and Greenpeace research revealed that supermarket collections of these plastics often end up incinerated, exported to poorer

22

Packaging

Stanley Mitchell is Head of Business Development of Cambridgebased Xampla, experts of drop-in high-performance natural materials that replace the most polluting plastics.

countries, or in landfill, where they disintegrate, but remain chemically inert, for hundreds of years.

For these thin plastic films, recycling or reuse is simply not a practical option. New, natural materials that can seamlessly replace many of the barrier properties are our best option to cut plastic production at source.

UK innovators are creating drop-in solutions which can be made and formed on the same production lines presently used for plastic, enabling brands to make the simple swap with no disruption. Unlike its principal competitors, the material Xampla is producing is plant-based and requires no chemical modification or ‘crosslinking’. This ensures it decomposes naturally, mirroring the behaviour of the plants from which it is made.

These natural materials can protect food, with the added advantage of being fully biodegradable, the material

does not last forever – since nothing needs to be preserved in perpetuity. At the end of its life cycle, these materials act not as a plastic but more like a food. This means it can be collected and recycled with food waste and won’t

leave behind any harmful microplastics if it does enter the Earth’s soil or seas.

The development of next-generation materials, like Xampla’s, is all part of the system change the food and drink industry will be a part of in the coming years. As EU regulation tightens the thumb screws on plastic, and consumers increasingly grapple with a newfound eco-consciousness, we should expect to see a downward trend in plastic production and a greater uptake in alternative materials to replace plastic - as well as new systems that allow consumers to reuse packaging rather than throw it away.

The early adopters of these technologies have the potential to transform the packaging industry, reshaping it towards sustainability whilst gaining support from consumers. There is no better time to switch than now and become a trailblazer toward a more sustainable, plastic-free future.

23

New, natural materials that can seamlessly replace many of the barrier properties are our best option to cut plastic production at source.

Packaging

Stanley Mitchell

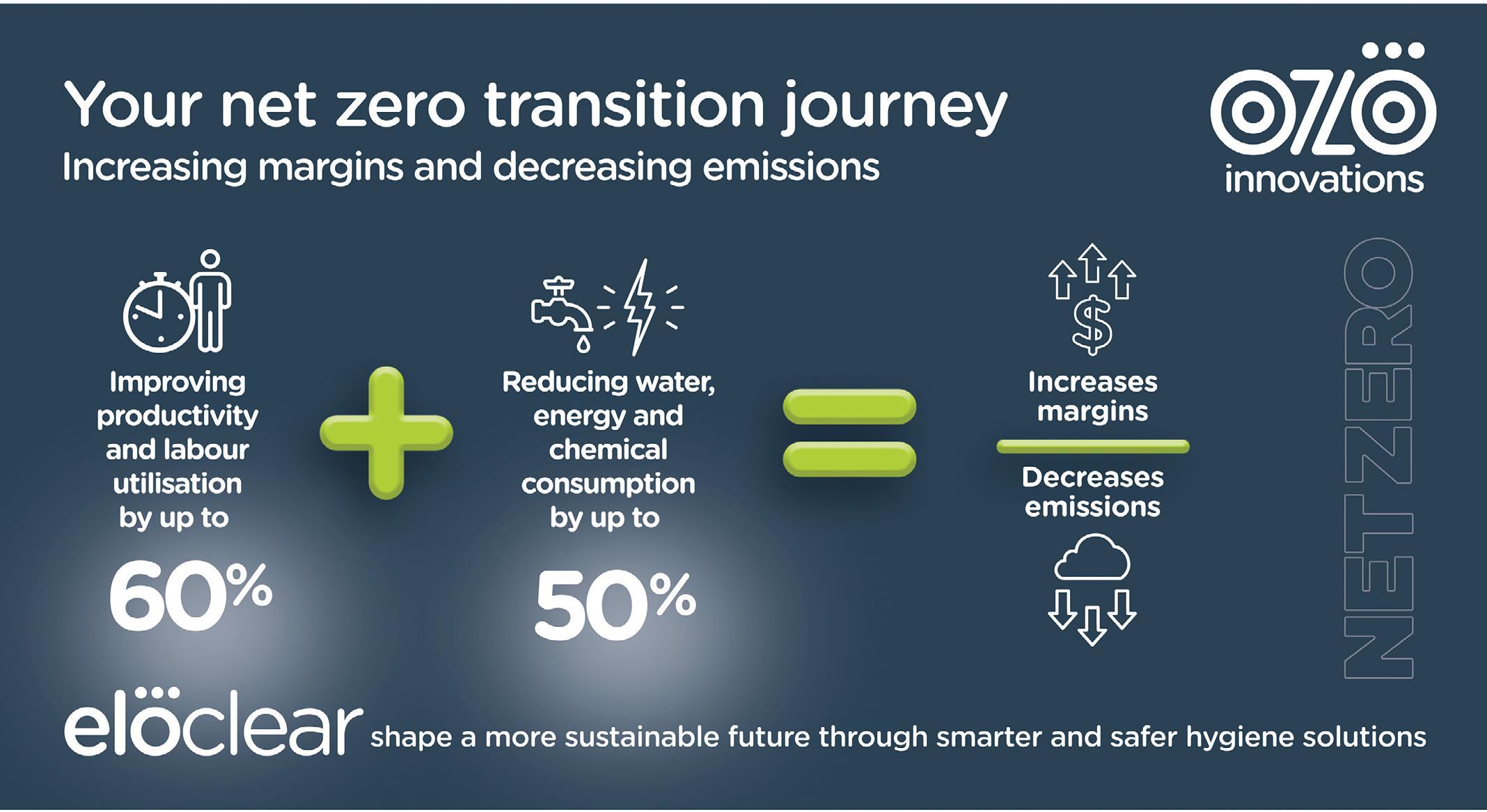

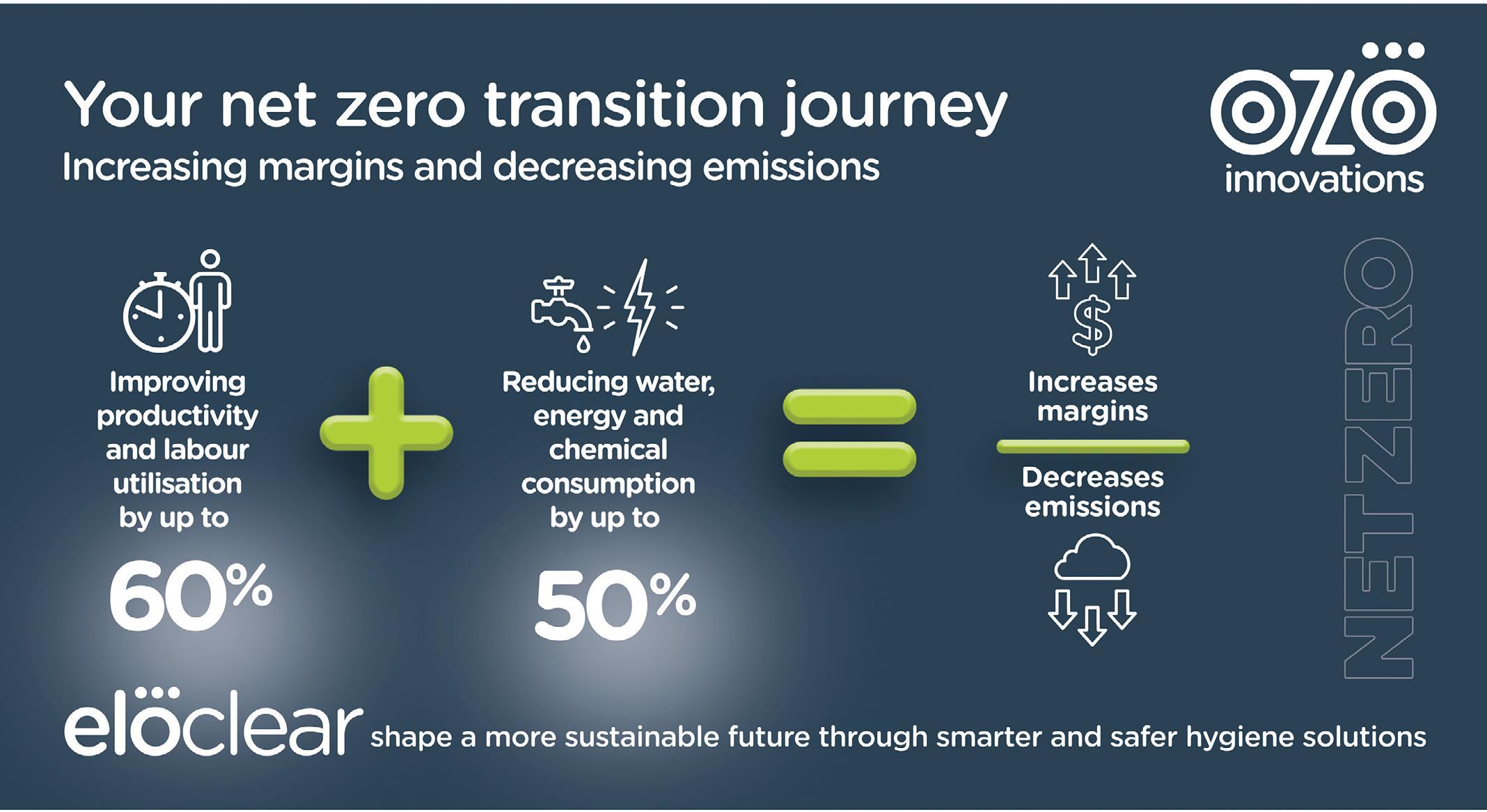

Ozo Innovations demonstrates its commitment to be net zero by

2035 with carbon partner Auditel

Ozo Innovations has further demonstrated its commitment to be net zero by 2035, by joining forces with its new carbon partner, Auditel.

Ozo Innovations is a cleantech start-up which helps customers to achieve their sustainability goals, by delivering environmental and productivity benefits that enable carbon net zero through innovative electrochemical solutions. Meanwhile, Auditel is a carbon footprint consultancy which helps clients on their journey towards net zero by simplifying the process – and reducing carbon emissions and costs at the same time.

Helping customers achieve their sustainability goals

Ozo Innovations’ purpose is to enable its customers to achieve their sustainability goals by reducing water, chemical and energy consumption while increasing their productivity and labour utilisation. The company’s novel electrochemical solutions transform salt and cold water into a powerful cleaning and disinfection solution that drive productivity in food production and processing, without compromising on food hygiene.

Deploying Ozo Innovations’ product, eloclear™, improves customer margins by: increasing productivity and labour utilisation by up to 60%; while reducing water, energy and chemical consumption by up to 50%.

24

Sustainability

LEFT: Ozo Innovations CEO Dr Mark Poole

ABOVE: Deploying Ozo Innovations’ product, eloclear™, improves customer margins by:

• Improving productivity and labour utilisation by up to 60%

• Reducing water, energy and chemical consumption by up to 50%

“The food industry is a major consumer of water and energy as well as a major source of greenhouse gas emissions,” says Ozo Innovations Dr Mark Poole. “We truly believe we have a solution that can help the food industry – and other industries – become more sustainable and achieve net zero.

“We can make a positive impact on scope 1 and 2 emissions reduction and we strongly believe we can impact scope 3 emissions via our disruption of the existing chemical supply chain.

“The team at Ozo is deeply passionate about this cause and as a business our goal is to demonstrate our own commitment by achieving net zero by 2035.

“It is important that we demonstrate our own credibility to our customers and suppliers, and that is why we are embarking on our own carbon journey, supported by Auditel.”

Mark Appleton Carbon Auditor at Auditel added, “It is really exciting to be working with the team at Ozo Innovations,” says Auditel Carbon Auditor Mark Appleton.

“Ozo Innovations has a terrific product range which helps their customers reduce their carbon emissions, and they fully understand

the credibility that measuring and reducing their own carbon adds to their customer offer.

“We look forward to continuing working with the team and their supply chain to help them achieve an industry recognised standard of carbon neutrality, as their first step on the road to achieve net zero by 2035.”

Innovation is the best weapon in the fight against climate change

During the Innovation Showcase session at the recent Innovation Zero event in London, Dr Poole gave a presentation called: “Driving productivity and carbon net zero with safe, smart and sustainable cleaning and hygiene processes”.

Innovation is the best weapon in the fight against climate change and the Innovation Zero event was held to shine a light on new solutions from the energy, transport, industrials, finance and the built environment sectors, with its mission to connect leaders from many sectors, to accelerate the low carbon transformation.

At the event, Dr Poole said: “Swift action is required to cut emissions and reduce the disastrous effects of climate change.

“Ozo Innovations has a solution that can help businesses – especially those in the food sector – to improve sustainability and reduce their emissions, by disrupting the existing cleaning and hygiene processes.

“We are helping to shape a more sustainable future through smarter, safer hygiene solutions for food manufacturing and other sectors.”

For further information: www.ozoinnovations.com

25 Sustainability

The food industry is a major consumer of water and energy as well as a major source of greenhouse gas emissions. We truly believe we have a solution that can help the food industry –and other industries – become more sustainable and achieve net zero.

- Dr Mark Poole (pictured left)

PPMA Show set to showcase the latest developments in the UK’s processing and packaging industry

The PPMA Show is traditionally the largest processing and packaging machinery exhibition in the UK showcasing the very latest in processing and packaging machinery, robotics and industrial vision systems.

The free-to-attend showpiece event on 26-28 September spans the full spectrum of the processing and packaging industry, with exhibitors displaying the latest innovations for sectors including food, beverages, pharmaceuticals, household products and toiletries, building materials and supplies, pet care, micro-brewery and distilleries, FMCG, as well as contract packers and more.

When the show opens its doors at the NEC in Birmingham, visitors will have the opportunity of networking face-toface with over 300 exhibitors, together representing more than 2,600 brands. There will be a host of new product launches and a content-rich seminar programme that will appraise people of the latest technological innovations and products helping to shape the various markets.

Virtually every aspect of the production line will be represented, from labelling, filling and packaging to processing, robotics, automation and industrial vision systems. As such, visitors will have the opportunity to source new ideas and solutions for innovating their processing and packaging solutions, added to the opportunity of meeting

with new suppliers and influencers, and tapping into the knowledge of leading experts in their field, all under one roof.

As guide to the 2023 show, here is a flavour of what visitors can expect:

• Live demonstrations of new machinery in action

• Video presentations by influential industry experts broadcast on screens across the exhibition and later on PPMA TV

• Major networking opportunities

• The ability to monitor the competition and benchmark best practice by gauging yourself against industry-leading performers

• Building new relationships, developing a deeper understanding of the industry, sharing information, and gaining valuable insights

The show’s unique seminar programme will help visitors stay ahead of trend so far as the latest processing and packaging solutions are concerned. Visitors can hear from a range of industry experts about the latest trends and innovations in their sector and how these can be applied to their own business.

Keynote speakers lined up so far include Ross Verrall, of Artificial Intelligence specialist, Nvidia. Ross will be completing on-trend, speaking about the disruptive nature of AI, the Industrial Metaverse, Robotics & the function of Digital Twins. Joining him

will be Dimitrios Spiliopoulos, of Amazon Web Services. Dimitrios will be addressing the importance of smart factories and the innovation offered by Machine Learning and AI.

Topics covered in other presentations will include food packaging innovation, the importance of sustainability, successful selling and how manufacturing is evolving to meet the needs of the processing and packaging sector.

Here are a few companies of the hundreds of exhibitors taking part in this year’s show: Reiser, ULMA, Omori UK, Ishida Europe, PFM, Somic, SMC, and Beckhoff.

With such an impressive array of exhibitors to choose from, visitors can take their time browsing through all the exhibitors on the PPMA Show website: https:// www.ppmashow.co.uk/ exhibitors-2023#/exhibitors/

To register for a free ticket to this year’s show, visit: https://ppma-show-2023visitor.reg.buzz/website

26

PPMA 2023: Show Preview

VISIT PPMA SHOW 2023 – THE UK’S NO.1 EVENT FOR THE VERY LATEST PROCESSING AND PACKAGING MACHINERY, ROBOTICS AND INDUSTRIAL VISION

SCAN THE QR CODE TO J0IN US

TECHNOLOGY

Showcasing the very latest and best technology in the processing and packaging industry – all under one roof.

KNOWLEDGE

Draw on the unique knowledge of hundreds of exhibitors to tailor the solutions right for your business.

EXPERIENCE

Invest with confidence; experience the latest machines on the market before you buy – only at the PPMA Show.

Embracing Eco-Friendly Innovations for a Sustainable Future - Reducing Energy Consumption and Waste in Production Processes

In today’s world, where environmental concerns dominate, businesses across industries are recognising the importance of reducing energy consumption and minimising waste in their production processes. Embracing sustainable practices benefits the planet and offers economic advantages. This article highlights two cutting-edge technologies –Ultrasonic Defoaming Technology and High Velocity, Low Pressure Air Knife Drying Systems – as examples of energy-saving innovation.

Ultrasonic Defoaming Technology: A new level of efficiency.

Imagine a manufacturing line operating smoothly with no issues caused by foaming. The Ultrasonic Defoaming System makes this a reality. By harnessing the power of ultrasonic technology, this system efficiently removes unwanted foam and bubbles from liquids, resulting in significant energy savings and uninterrupted line processing.

Benefits at a glance:

• Production efficiency with increased line speeds of up to 60%.

• Minimises product losses, by reducing foam overspill.

Imagine a manufacturing line operating smoothly with no issues caused by foaming.

• Low energy consumption technology using less than 80 watts.

• Reduces CO2 consumption on bubble breakers without compromising TPO/Oxygen levels.

• Reduce bottle & can rejects with optimised filling accuracy.

• Reduces product chilling requirements, therefore reduced energy costs.

• Eliminates contamination on caps and seals and improves hygiene of filler.

Benefits at a glance:

• Energy Efficient, on average, the Sonic drying systems are 75% more energy efficient when compared to other drying methods.

• Versatility and adaptable suitable for various product shapes, sizes, and materials.

• Oil Free drying ensures contamination free drying.

• Durability, manufactured with a robust construction and using highquality materials to ensure reliable performance and an extended service life.

The Ultrasonic Defoaming and highvelocity Air knife drying systems represent innovative technologies that cut energy consumption and improve operational efficiency, leading to production uniformity, product integrity, product quality, and waste reduction. By adopting these ecofriendly practices, businesses can shape a sustainable future that is both environmentally conscious and economically rewarding.

Low Pressure High Velocity Drying Systems: The Smart Solution to Energy Efficiency

Engineered Sonic Air Knife drying systems ensure consistent and reliable performance in effectively and efficiently drying products. These advanced systems employ a meticulously calibrated combination of air volume and velocity, resulting in optimal surface blow-off. The velocity effectively disrupts surface tension, while sufficient air volume guarantees precise force delivery to the product removing up to 98% of liquid. With precision engineering, the Sonic Air Knife drying systems offer unparalleled performance, ensuring thorough and rapid drying for enhanced productivity and quality.

Part of the CPA Group, CPA Engineered Solutions, combines engineering excellence and exceptional service. Since our founding in 1992, we’ve established ourselves as a leading provider of expertly engineered solutions across various industries.

We take pride in offering comprehensive aftermarket service packages that ensure long-lasting product sustainability and maximise the benefits of our energyefficient solutions.

For detailed information and to discuss your requirements, our product specialists will be available on stand K30 at the PPMA show.

Alternatively, visit our website www.cpa-group.com/ exhibitions/ppma to learn more.

28

PPMA 2023: Show Preview

The Cost of Doing Nothing for Manufacturers in

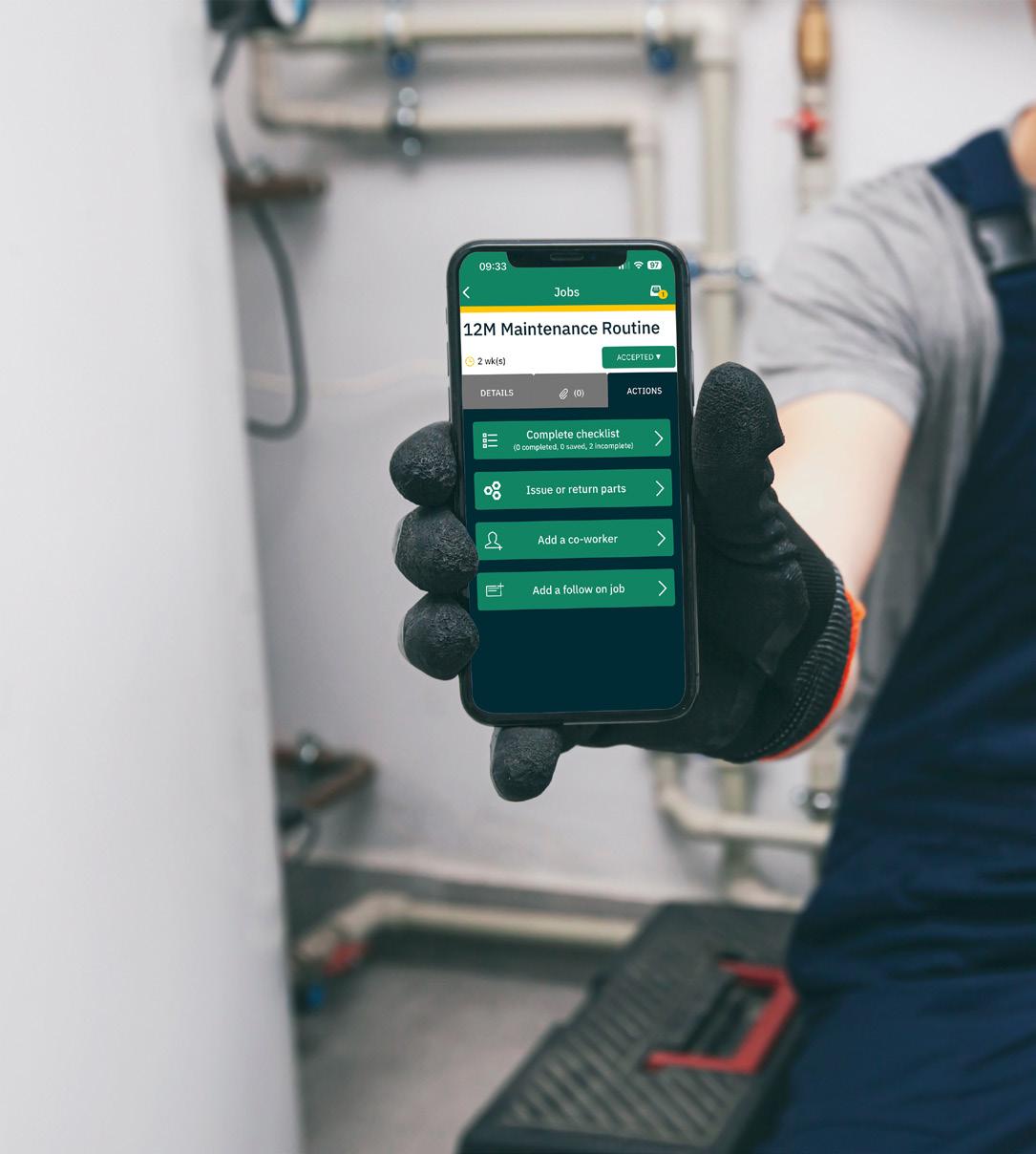

With over 45 years of experience and expertise in helping factories reduce costs and improve performance, Harford MES provides actionable insights in real time to help you spot every opportunity to save unnecessary costs in your factory.

Together we can act to weather the storm of this economic downturn and come out stronger at the other end.

2023

Let’s talk. www.harfordcontrol.com +44 (0)1225 764461 Waste of Energy and Labour Higher Transformation Costs Lower Bottom Line Profits See us on Stand B46 26 - 28 SEPTEMBER 2023 NEC, BIRMINGHAM

Rotech unveil entry-level coding system for bags & pouches at PPMA 2023

Coding and marking specialists, Rotech Machines expands their range of RF Lite feeders – costeffective systems for feeding and printing flat-form packaging –with a cleverly designed system specifically for small pouches and bags.

The new pouch edition of the RF Lite will be officially launched at PPMA 2023, where it will be at the forefront of stand A31. Like the original and shuttle variants, the RF Lite pouch is an entrylevel solution for companies looking to automate their coding process for the first time. It is also well-suited to larger manufacturers looking to install multiple systems for multiple products and short/trial production runs.

The system utilises vacuum technology to ‘pluck’ bags from a stack, before running them past a maintenance-free thermal inkjet printer, and returning them to a stack, ready for operator removal. This automatic process eliminates the need for coding and labelling by hand – which is often labour heavy, time consuming and inaccurate. Instead, users of the RF Lite can be reassured that their packaging will be coded quickly and accurately.

The system completes the RF Lite feeder range, proving that when it comes to cost-effective coding systems, three really is the magic number.

Printer for seamless large area printing on non-porous surfaces

Also new to the stand will be the Integra PP Razr 34 – an impressive piezo printer that bridges the gap between the capabilities of a thermal inkjet printer and a large area printer.

The Razr, which runs with the same inks used in a thermal inkjet printer, can guarantee excellent resolution printing (up to 600dpi) on both porous and non-porous substrates. It can seamlessly print on areas up to 34mm, making it ideal for applications where thermal transfer (TTO) would have traditionally been used.

The cartridge-based technology also brings other benefits over other coding methods. It’s fast – it can run at high speeds up to 150m/min at 300dpi and it starts up and shuts down instantaneously. The printer also has two separate nozzle channels that can be controlled individually, guaranteeing optimal printhead life and quality of print.

The Razr is truly revolutionary in the world of coding and marking and is sure to be popular among manufacturers looking to improve their efficiency and reduce their waste. All without compromising on quality.

Speak to the experts on stand A31

Rotech’s biggest asset is not its impressive portfolio of solutions, but it’s team of industry experts, who will be available to talk with you on stand A31 about any coding and marking queries or applications you may have.

Website: rotechmachines.com

30

PPMA 2023: Show Preview

The new pouch edition of the RF Lite will be officially launched at PPMA 2023, where it will be at the forefront of stand A31.

Appetite for plant-based milks prompts HRS to launch Direct Steam Injection

Directly injecting steam as a means of sterilising and diluting liquid drink products is a well-established technique for beverages such as plant-based milk products, which are experiencing a boost in popularity. According to a report by Mintel1, sales of vegan-friendly, plant-based milks have surged 10% over the past two years, and it is now the choice for almost 25% of Britons. In response to this increased customer demand, HRS Heat Exchangers has added a new Direct Steam Injection System to its established range of pasteurisation and sterilisation systems.

The benefit of sterilising using direct steam injection is the speed of the process, with sterilisation temperatures of 100°C to 145°C. being reached in around a second, much quicker than the fastest heat exchanger systems. For products such as plant milks, this rapid heating prevents cooking of the product and formation of carameltype compounds which can darken the product or produce unwanted flavours.

Some products, such as oat milk, also benefit from the additional dilution with water which the steam injection provides. In most cases, however the water which is added during the steam injection process needs to be removed from the end product. This is normally achieved using flash evaporation to remove excess steam and help cool the product, but there is a danger that volatile aromatic compounds can be lost, which could have a negative impact on certain products, such as fruit juices. For this reason, not all products are suitable for steam injection.

For products where direct steam injection is desirable, HRS Heat Exchangers has introduced the HRS DSI Series, which injects food grade steam into liquid products, providing an instant increase in the thermal process.

Global food supplier selects WCSEE treatment system

Global food supplier Griffith Foods has selected WCS Environmental Engineering technology to enhance the wastewater treatment process at its UK site in Wincanton, Somerset.

Griffith Foods provides seasonings, coatings, sauce, dressings and butter portions to the food industry, with the corporate purpose to “blend care and creativity to nourish the world”.

Its previous onsite water treatment system required updating to ensure compliance with tightening trade effluent requirements and maintain protection of the local

water environment. After laboratory testing of site effluent samples, WCSEE recommended a new system comprising a dissolved air flotation (DAF) system, balance and sludge tanks and a chemical mixing and dosing system.

The system was designed with particular focus on removal of fat, oil and grease (FOG), which can cause blockages in public sewer systems if not removed during industrial effluent treatment. DAF is a treatment process that removes a wide range of total suspended solids in wastewater and reduces FOG and chemical oxygen demand.

Each WCSEE DAF treatment system is customised for individual sites. Its modular design means the whole plant - including pumps, tanks, screens, chemical dosing and controls - can be manufactured offsite and easily transported for quick installation.

WCSEE also support industrial clients with sludge disposal though anaerobic digestion, a process which produces biogas and biofertiliser –and can generate a revenue.

31 Industry News

Continuous processing more efficient than dealing with batches

By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Products such as mechanically separated meat (MSM) and meat emulsions are commonly used in a wide range of products including sausages, chicken nuggets, patties and some minced meats. While different meat sources and products will have different processing and cooking requirements, it is important that the methods chosen to minimise the energy use involved, saving money and reducing greenhouse gas emissions.

Meat emulsions, slurries and reformed meat products have been used around the world since the early 1970s. Around the world there are strict rules, both about the raw materials used for the production of MSM, but also how it is processed and labelled. Similar cooking, handling and cooling methods are also used for other food products, such as ground (minced) meat and soups, and these products can also benefit from the same approach to choosing cooking systems.

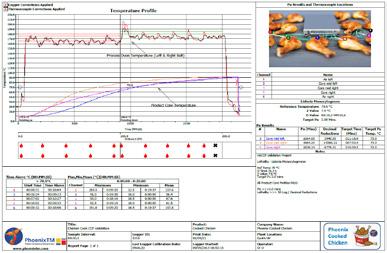

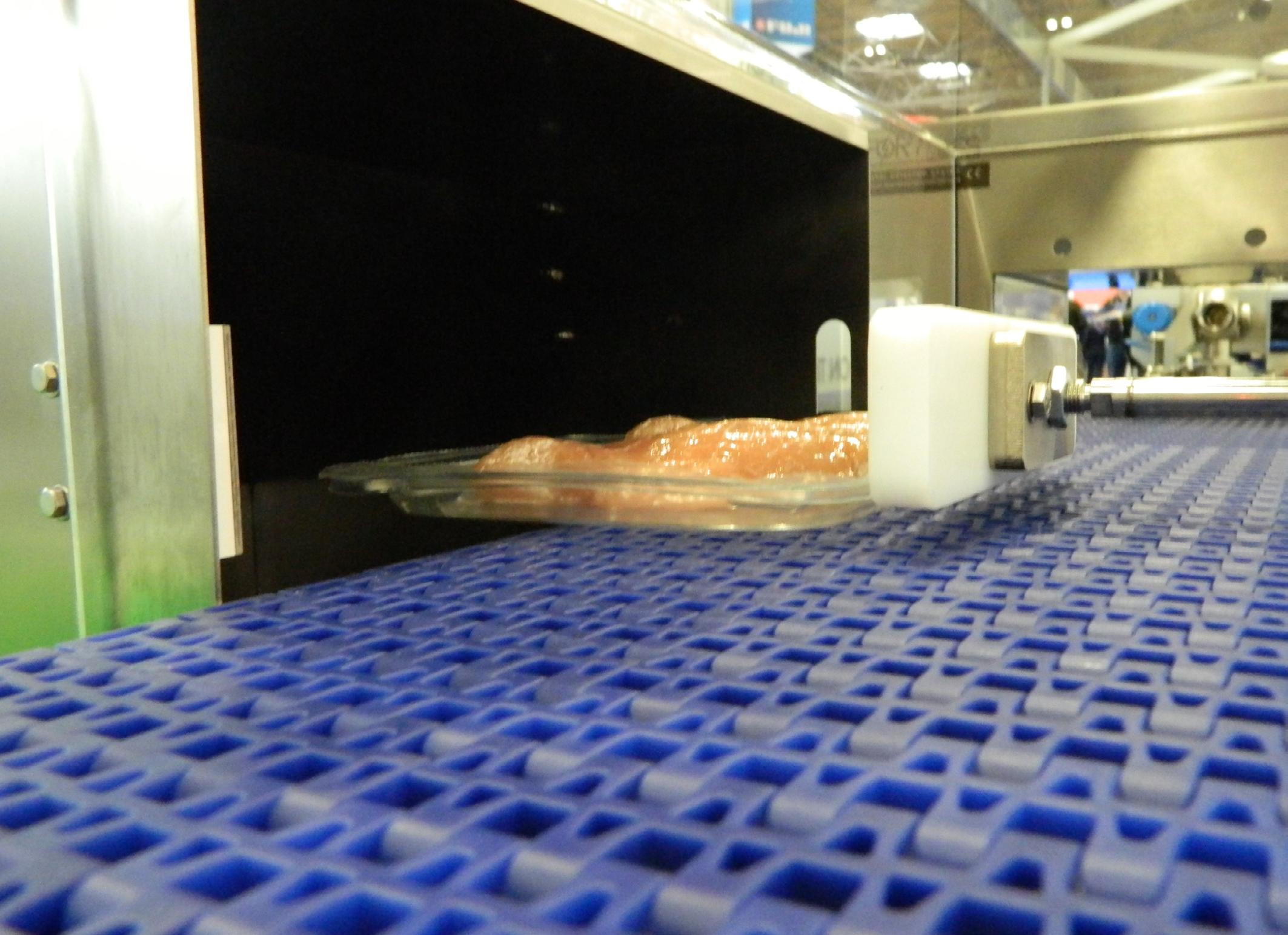

ABOVE: Continuous cooking of products such as mechanically separated meat, ground (minced) meat and soups can provide big energy savings

BELOW: Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

The European Food Safety Authority (EFSA) advises that, ‘Microbiological and chemical hazards associated with mechanically separated meat derived from poultry and swine are similar to those related to non-mechanically separated meat (fresh meat, minced meat or meat preparations). However, the risk of microbial growth increases with the use of high-pressure production processes.’

In addition, ‘High pressure mechanically separated meat must be immediately frozen and can only be used in cooked products.’

The European Food Safety Authority (EFSA) advises that, ‘Microbiological and chemical hazards associated with mechanically separated meat derived from poultry and swine are similar to those related to non-mechanically separated meat (fresh meat, minced meat or meat preparations).

- Matt Hale

These products are often cooked in batches prior to final product formation, often using large steampowered kettles or pressure vessels. Some companies processing large volumes of product may have ten or more vessels in various states of operation at one time. This is because, while these vessels are an effective method of cooking and pasteurising a range of products including MSM, they are limited in their capacity because it is important that the product is cooked through thoroughly. Because each vessel must be heated from scratch for every new batch of product, and the heat used is then lost when the vessel is emptied, this is an incredibly inefficient method of cooking such products.

A much more energy efficient method is to cook a continuous stream of product using a scraped surface heat exchanger such as the HRS R Series or Unicus Series. The HRS R Series uses

32

Processing

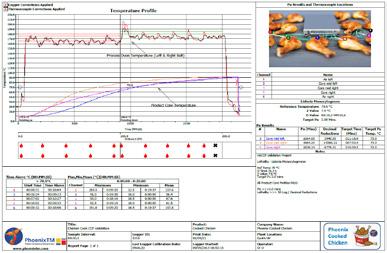

a rotating action to scrape the tube surface and a helix to ‘push’ material through the heat exchanger, ensuring thorough mixing and heat distribution. It provides an economic solution for situations where product mixing is a benefit in processing, or where physical integrity is less important than heat transfer. For example, it is ideal for MSM, meat emulsions and co-products (such as materials which are destined for the pet food market).