Willmott Dixon school wins

Passivhaus award

MIDKENT COLLEGE

Is your construction business ready for the sustainable skills revolution?

Eight Raimondi flat-top tower cranes deployed in Sharjah, UAE

JRA COMPLETES WORK ON SKANSKA UK’S HEAD OFFICE

UKCW BIRMINGHAM

RETURNS WITH SPOTLIGHT ON INNOVATION

LIGHTBULB CREDIT

CREDIT RATINGS EXPLAINED

September CONSTRUCTIONMAGUK.CO.UK 2023

BUSINESS

www.doorcontrolsdirect.co.uk 01305 263300 sales@doorcontrolsdirect.co.uk Dependable Door Control Solutions At Door Controls Direct, we understand the unique requirements of the fire safety and building industries, and we provide a wide range of fire-rated and compliant products to keep people safe and secure. www.doorcontrolsdirect.co.uk

door solutions

will keep people

and

Door Controls Direct, your dependable source for

that

safe

secure.

Sales Executive Hannah Marshall hannah@constructionmaguk.co.uk

Sales Manager Adam Jeakins adam@constructionmaguk.co.uk

Circulation Manager Leo Phillips subs@constructionmaguk.co.uk

Tel: 01843 808 106

Website: www.constructionmaguk.co.uk

Twitter: @constructionukm

LinkedIn: @constructionmaguk

73

effort is made to ensure the accuracy and reliability of material published in Construction UK Magazine however, the publishers accept no responsibility for the claims or opinions made by advertisers, manufactures or contributors.

part of this publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including photocopying) or stored in any information retrieval system without the prior consent of the publisher. 26 32 35 36 04 38 70 10 September 2023 Contents 04 Henry Brothers starts work on British Army project 10 Rishi Sunak sees work start on new £7m school in Northallerton 26 The RA40 pair helping carry the load for Atlas Quarries 32 JRA completes work on Skanska UK’s head office 35 Eight Raimondi flat-top tower cranes deployed in Sharjah, UAE 36 UKCW Birmingham returns with spotlight on innovation 38 Conquip: Accelerating Excavation Progress with BulkX at Crossrail 46 Company News: 70 Years of innovation from Doorfit 70 Cambridge Cancer Research Hospital appoints construction firm 73 Steelwork being installed at Preston’s £45m+ Animate leisure complex 78 Do you understand the importance of Fire Stopping testing & certification? 65 65 ‘Topping Out’ marked at the new Belfast Grand Central Station Lapthorn Media Ltd 5-7 Ozengell Place, Eurokent Business Park, Ramsgate, Kent, CT12 6PB Editor Maria Lapthorn editor@constructionmaguk.co.uk Editorial Assistant Francesca Amato editorial@constructionmaguk.co.uk Production/Design Laura Whitehead laura@constructionmaguk.co.uk Accounts Richard Lapthorn accounts@constructionmaguk.co.uk

Every

No

Construction UK Magazine - September 2023 03

WARMFLAME DEVELOPMENTS ANNOUNCES ANOTHER INDUSTRIAL SCHEME IN NORTHAMPTON

A specialist in the construction of industrial and distribution units, Warmflame Developments, is to develop a further 47,275 sq ft scheme on Moulton Park in Northampton. Demand for industrial space remains strong in the area; with one unit already pre-sold off plan.

This new scheme on Anglia Way marks the second site to be developed on the industrial estate by the Solihull based company and underlines its commitment to delivering quality mid-box developments throughout the Midlands.

The company will break ground on its latest project - WD.Park Anglia Way – in July, which will see the construction of two new industrial/warehouse units of 21,528 sq ft and 25,747 sq ft.

Each high-quality warehouse unit will offer a comprehensive mezzanine floor that can be fitted out to provide offices or additional storage space. Other features include an 8m clear internal height, electrically operated loading doors, electric vehicle charging points and generous yard areas.

Unit 1 of 21,528 sq ft has already been pre-sold to a leading global provider of products and services that support patient care.

HENRY BROTHERS STARTS WORK ON BRITISH ARMY PROJECT

Contractor Henry Brothers Construction has broken ground on a £22.5m scheme at Beacon Barracks in Staffordshire.

The company is delivering new facilities at the Ministry of Defence site for 280 (NATO) Signal Squadron – the only British Army unit permanently assigned to NATO.

The infrastructure is being delivered to enable the squadron, which contributes to the NATO Response Force, to move from Dorset to its new home at Beacon Barracks.

As a Deployable Communication Module, its role is to install and control strategic communication and information systems supporting a deployed NATO headquarters.

Henry Brothers is building a new two-storey facility for the Squadron within a secure compound at Beacon Barracks which includes offices, conference rooms, a reception area, workshops, garaging, storage

rooms, welfare facilities and M&E plant rooms. It will feature solar panels on the roof.

The company is also delivering a single-storey satellite communications building as part of the development.

Personnel at the groundbreaking event included representatives from NATO, 280 Signal Squadron, the Defence Infrastructure Organisation (DIO), and contractor Henry Brothers Construction.

Construction Director at Henry Brothers Construction Justin Hicklin said: “We are excited to be starting work on this new facility at Beacon Barracks for 280 (NATO) Signal Squadron, who play an important role in NATO. Henry Brothers has worked in partnership with the Ministry of Defence and the Defence Infrastructure Organisation (DIO) on numerous projects over many years, helping to deliver a wide range of infrastructure improvements. This is our first contract at Beacon Barracks, but the latest in a long line of developments that we have successfully completed for our armed forces.”

The project, which is scheduled to be DREAM Excellent, is being delivered by Henry Brothers for the Defence Infrastructure Organisation (DIO) via the Crown Commercial Service Framework. Work is due to be completed in early 2025.

04 Project News Construction UK Magazine - September 2023

BEARD COMPLETES

SECOND PHASE AT BRUNEL’S HISTORIC CARRIAGE WORKS

Swindon-based construction firm Beard has completed the second phase of redevelopment at the town’s historic Carriage Works.

The £2.5 million project saw Beard complete the structural refurbishment and re-roofing of two units, as well as the construction of a mezzanine at the Grade II listed building. Unit 7 will be an Innovation Centre for Applied Sustainable Technologies for the University of Bath, while unit 9 will serve as a state-of-the-art media facility for local production company Create Studios.

The two newly refurbished units have been delivered by Beard ready for use this summer.

It forms just one part of a wider regeneration project by Swindon

Borough Council, utilising major government investment to breathe new life into the historic site and upgrade other parts of the town.

Built in 1876 as part of Brunel’s Great Western Works, the Carriage Works and other heritage buildings in the area have also received funding from Historic England as part of its Heritage Action Zone programme.

The project follows Beard’s involvement in transforming an adjacent unit into the new Cultural Heritage Institute for the Royal Agricultural University.

The facility provides a postgraduate and professional hub to train the next generation of heritage managers and professionals.

CADDICK COMPLETES NORTH WEST’S NEW £6M SUSTAINABLE MEDICAL CENTRE

Caddick Construction has completed construction of Milnrow & Newhey Medical Centre in Rochdale, becoming United Healthcare Development’s most sustainable healthcare facility that will bring improved services to patients in Greater Manchester.

The development marks the second healthcare facility built by Caddick on behalf of United Healthcare Developments, which also includes the recently completed Carlisle Healthcare South Hub. Both Milnrow & Newhey Medical Centre and Carlisle Healthcare South Hub have achieved a BREEAM Outstanding rating, achieved through a meticulous design and build process focussed on integrated ventilation systems and a ‘fabric first’ energy efficient design.

The Milnrow & Newhey Medical centre comprises one single building spanning over 4,470m2 with ground, first and second floor levels that will be used to provide suites for consultation, examination, treatment and meetings. With an EPC rating of A+ (-8), this building now sits proudly in the Net Zero Operational Energy Category.

Phase

three of the Carriage Works will include further development of the street facing units and the exterior elevations of the building.

Established in 1892, Beard is a family-owned company with headquarters in Swindon and offices in Bristol, Oxford and Guildford. The firm will soon expand its reach with the addition of an office on the south coast in 2024.

Located on Newhey Road, this vital development will provide easy access to patients travelling from the wider area. Work included a secure car park for employees, patients and visitors, a paved area, lighting and landscaping to create a high quality outside space.

In the extra care sector, Caddick’s team previously completed Broomfields, a contemporary apartment living scheme in Appleton for those aged 55, for the North West’s largest affordable housing provider, Torus.

Elsewhere in the North West, Caddick Construction’s projects include new and improved science facilities at world-leading life science and innovation campus, Alderley Park, and the construction of Base at Manchester Science Park, a vibrant science and tech community in the heart of the Oxford Road Corridor Innovation district.

05 Project News Construction UK Magazine - September 2023

WILLMOTT DIXON CHOSEN TO REVAMP SOUTHEND LANDMARK

Willmott Dixon’s extensive track-record for breathing new life into popular cultural attractions has seen it chosen by Southend Council as its construction partner for a proposed major upgrade of the Cliffs Pavilion.

As part of a pre-construction agreement with the council, Willmott Dixon will carry out design development and a pre-

FINAL STAGES OF CONSTRUCTION AT BOVIS HOMES LOCATION IN STAPLEHURST

Construction work is entering the final stages at a Bovis Homes location in Staplehurst, where the last remaining homes are for sale.

The housebuilder is building 167 new homes at The Meadows, on a 16.5acre site which was formerly part of Fishers Farm. The development will feature 101 private homes and 66 affordable properties available for local people through low-cost rent or shared ownership.

The company has so far built 73 per cent of the private homes and hopes to complete construction at the site in Autumn 2023.

Just 15 of the private homes remain for sale, while 59 of the affordable homes have been completed and handed over.

Alongside the new homes, The Meadows will feature areas of landscaped public open space with ponds and footpaths. Many homes will include an electric vehicle charging point.

construction health and safety plan as well as a construction methodology and programme planning including phasing. The company will then agree a full contract subject to planning approval, an agreed cost plan and works programme that enables the Cliffs Pavilion to stay open for performances throughout the work.

This work at Cliffs Pavilion Theatre will help secure its long-term future as one of the top ten regional theatres in the country. It is owned by the council and operated by Trafalgar Theatres (for Trafalgar Entertainment).

Over £8m is set to be invested into the theatre to fund a major expansion of the restaurant, a new entrance and lobby to improve the customer experience, upgraded ventilation, a new outdoor piazza and several other improvements to the bars, toilets, lifts and other areas.

The theatre will remain open throughout the project, which is expected to start in January 2024, with £5.5m of the project funded through Round 1 of the Levelling Up Fund announced by Government on 27 October 2021, with additional investment from the City Council and Trafalgar Entertainment.

A revised planning application will be submitted in July, when a resident event will take place and artists impressions will be available.

Cllr Derek Jarvis, cabinet member for arts, culture, heritage and leisure, said: “The Cliffs Pavilion Theatre is one of Southend’s key venues for culture, arts and events and adds so much to our reputation as a cultural destination and brings millions of pounds into the local economy. This work will ensure that we reinforce its position as one of the top ten regional theatres in the country.

The proposed expansion and upgrade of the theatre will also help us to secure the future success of the Cliffs Pavilion, in the hopes of benefiting from larger touring shows and bringing larger audiences to Southend whilst also benefitting our local economy.

This is the latest in a series of major projects for Willmott Dixon to improve the cultural and heritage offering of major towns and cities. Others include The Globe in Stockton, the east wing of Alexandra Palace, The Box in Plymouth, Darlington Railway museum and Bristol Beacon. It is currently on site at Walthamstow transforming the EMD Cinema into an entertainment venue run by Soho Theatre.

06 Project News Construction UK Magazine - September 2023

EstimateOne is the online commercial construction marketplace connecting subcontractors to main contractors at tender time.

Helping Main Contractors:

Helping Subbies:

• Speed up tender time by removing manual processes in one centralised, digital system

• Remove risk with automated document transmittals

• Achieve greater quote coverage with access to a wider subbie network

• Unlock insights and information for superior supply chain management

• Access a network of top-rated main contractors in the UK

• Grow their business by finding new jobs in their area

• Win more work relevant to their skillsets

• Keep track of tenders by receiving project updates directly to their inbox

Join for free today estimateone.co.uk

the UK building landscape.

Join

“THE STRINGENT IMMIGRATION RULES HAVE CREATED A BUREAUCRATIC NIGHTMARE”: URGENT REFORMS NEEDED TO AVERT CRISIS

By Mandie Sewa,

The construction industry heavily relies on skilled workers from abroad.

With strict immigration policies and issues arising from Brexit, it has become increasingly difficult to find and hire skilled workers in the construction industry. This has resulted in a severe shortage of labour, causing significant setbacks and delays in construction projects across the country.

This not only hampers the progress of construction projects, but also puts a strain on the existing workforce, leading to increased workloads and burnout.

The stringent immigration rules have created a bureaucratic nightmare, making it almost impossible for construction companies to hire talent they desperately need. The shortage of skilled workers has led to increased competition among companies, driving up costs and ultimately burdening the end consumer.

The lack of skilled labour has also compromised the quality of some

Head of Immigration at Brevis Law

construction projects. With fewer experienced workers available, companies are forced to hire less qualified individuals, leading to subpar workmanship and potential safety hazards. This puts the workers at risk and endangers the lives of those who will eventually use these structures.

jobs after a short period of time, this constant turnover disrupts the workflow and increase the costs of recruitment and training for employers.

Some question how effective the sponsorship model will be in an industry with a high level of self-employment, as well as significant numbers of SMEs who may not have the money and know-how to sponsor foreign workers.

The shortage occupation list was updated on 17 July to include bricklayers, masons, roofers, roof tilers, slaters, carpenters, joiners, construction and building trades n.e.c and plasterers. The Construction Leadership Council wanted steel erectors, scaffolders, stagers and riggers, road-construction operatives, thermal insulation installers, plant operatives, general labourers, and ground workers to be added to the list but these were rejected by MAC.

With vacancies in the industry at 65% compared 42% in the overall economy, I fear that whilst the additions to the shortage occupation list are welcome, they may not pose a real solution. Companies will still need to go through the arduous process of applying for a sponsor licence and ensuring foreign workers adhere to the complicated immigration requirements. In most cases, foreign workers will have to pay significant visa costs and prove that they can speak English to a required level. The job must also pay at least £25,600 a year and involve skills equivalent to an A-level or higher. In an industry where many workers tend to leave their

It’s disheartening to witness the consequences of these immigration policies on an industry that plays a vital role in our society. The construction industry is the backbone of infrastructure development, and without a steady influx of skilled workers, we risk falling behind in progress and innovation. The bureaucratic red tape and complex regulations in the construction industry add to the burden faced by employers. Navigating through the maze of permits, licenses, and compliance requirements can be time-consuming and costly, further delaying projects and increasing administrative burdens.

For the industry, the government still needs to do more to fix the labour crisis. Brian Berry, chief executive of the Federation of Master Builders, says: “Going forward, there is an urgent need to develop more home-grown talent, with an emphasis on encouraging more employers to take on more apprentices and greater investment in our further education colleges”.

We need to address these problems and find solutions that promote a skilled and diverse workforce, streamline regulations, and provide support to construction employers. It’s time for policymakers to reconsider their approach and find a balance between immigration control and the needs of our industries. We need a system that allows skilled workers to contribute to our economy without unnecessary barriers and red tape. Only then can we hope for a brighter future where the construction industry can thrive and contribute to the overall development of our nation.

The construction industry is the backbone of infrastructure development, and without a steady influx of skilled workers, we risk falling behind in progress and innovation.

Mandie Sewa

08 Opinion Piece Construction UK Magazine - September 2023

KEEPMOAT STARTS CONSTRUCTION ON NEW DEVELOPMENT

Top 10 housebuilder Keepmoat, has started construction on its new housing development, Park View, at Hawkfield Way on the outskirts of Bristol.

The development will consist of 91 homes, all of which will be sold to housing association Bromford, to provide affordable housing in the area. Residents will have the use of public open space, access routes, and close connectivity with surrounding developments, including Keepmoat’s neighbouring development, Jessop Park.

Sixty-nine of the new homes will be available for social rent, with Bromford making the remaining 22 homes available to partbuy, part-rent through its shared ownership scheme. There will be 74 two, three and four-bedroom houses in addition to 17 one and two-bedroom apartments.

Planning permission for Park View was granted on 24th March 2023. Construction will take around two years, with the first of the new homes expected to be complete by the end of 2023. Overall completion is expected towards the end of 2024.

RISHI SUNAK SEES WORK START ON NEW £7M SCHOOL IN NORTHALLERTON

MP Rishi Sunak took part in a special ground-breaking ceremony at the site of a new multi-million pound primary school in Northallerton.

Mr Sunak, who is the MP for Richmond in North Yorkshire, joined the milestone occasion which signalled the start of construction at the Alvertune Road site.

Also in attendance were representatives from North Yorkshire Council, the Dales Academies Trust and the contractors, Hobson & Porter.

The school, which academy leaders have promised will be a “flagship of excellence”, will be run by the Dales Academies Trust and will be based in the northern part of Northallerton, where a major new housing development is being built.

The Dales Academies Trust was selected as the sponsor for the school following a competitive process, which attracted interest from several trusts. The trust has announced the new educational establishment will be called Oakbridge Church of England Primary School and will begin welcoming its first pupils in September next year.

The 2024 opening date gives certainty to the availability of school places in a part of North Yorkshire where housing growth is expected to increase the population. A phased opening will start with reception children in 2024, expanding to the full cohort over seven years.

Speaking about his visit, Mr Sunak said: “It was great to see work under way on a very important multi-million-pound investment in education in

10 Project News Construction UK Magazine - September 2023

Northallerton. This is a vital element of the North Northallerton development project, part of making sure the new housing has the appropriate infrastructure in place to support the families that will be moving here.”

The school’s location is close to the new link road which spans the site earmarked for housing, ensuring access for pupils, staff and other members of the public is convenient.

The site was acquired through a planning condition agreed with a housebuilder developing land nearby and Oakbridge Primary itself will account for investment of more than £7 million when complete.

During his visit, the Prime Minister also took time out to see North Yorkshire Council’s Multiply team in action. A series of ‘fun on a budget’ workshops were held for families at the campus in Northallerton.

The Multiply scheme is an adult numeracy programme which has been allocated £2.6 million to be spent in North Yorkshire through the UK Shared Prosperity Fund up to March 2025.

The overall objective of the Multiply programme is to increase the levels of numeracy for adults across the country.

Meanwhile, the Multiply team works with community groups and individuals aged 19 and over who would like to feel more confident with maths in everyday life.

£286M PRISON OPENS TO BECOME ONE OF THE LARGEST OPERATING IN THE UK

A brand-new category C resettlement prison has completed in Leicester, delivering more than 600 permanent jobs in the local area, with a core focus on prisoner rehabilitation through skills-based training and employment opportunities.

HMP Fosse Way, which was named following extensive consultation with the local community, forms part of a UK government plan to deliver 3,360 additional prison places by 2023 at Fosse Way and the recently opened HMP Five Wells in Wellingborough.

The £286 million project will initially house 1,715 prisoners across a 16-acre site, with an additional cell block and ancillary building extension approved by Blaby District Council and Oadby and Wigston Borough Council last December, extending capacity further.

Leading independent property, construction, and infrastructure consultancy Pick Everard was appointed as lead designer for the project, providing architecture, interior design, civil engineering, building engineering, sustainability and energy, structural engineering, landscape architecture and interior design services. Its team has closely collaborated with the Ministry of Justice (MoJ) and prison operator Serco.

In total, seven houseblocks and six ancillary buildings come together under a vision from the MoJ to transform prisoner rehabilitation in the UK.

Prisoners have access to a central services hub, which includes a gym, library, educational classrooms, faith halls, as well as workshops and external horticultural areas, with the potential for Serco to work closely with local employers to deliver on-the-job training opportunities.

HMP Fosse Way has been built on the old HMP Glen Parva site, a former young offenders’ institution that closed in 2017.

Its design has included several sustainable considerations, with offsite construction maintaining product quality, whilst helping reduce capital and operational costs. In addition, air sourced heating powers elements within the northern compound, while solar panels have been installed on ancillary buildings.

Work on the planned extension is expected to commence in August, with the project currently at RIBA Stage 4.

11 Project News Construction UK Magazine - September 2023

Justice Secretary Alex Chalk visiting HMP Fosse Way

NOT LIKE THAT! TOP MISTAKES WE SEE WHEN USING SCRAPERS

The more often you drive, the more comfortable it becomes. After ten or more years, driving becomes second nature. It’s no different in the construction industry when working with the same equipment every day. But when we get too comfortable, it’s easy for little slip ups to sneak their way in, in the same way drivers can pick up bad habits over time. To help crews overcome productivity barriers on the jobsite, Dave Bigham, global director of training at surface preparation equipment manufacturer National Flooring Equipment, highlights some bad habits he often encounters with people using scrapers.

When it comes to scraper faux pas, it’s not always due to lack of care.

Often, there’s a multitude of reasons why crews are using equipment wrong from lack of equipment training to wrong tooling choice, but the end result is the same ― delays that could have been easily avoided. Depending on the issue, production can grind to a halt entirely, taking a few days to rectify the issue. So, how does this happen?

Unprepared

Insufficient preparation can result in poor surface preparation. This could mean having the wrong tooling or scraper, or not having enough equipment to complete the job on time. A bad habit that some crews fall into is the idea that once at a job site, you have to work with what you got. Insisting on continuing job without the proper tools can take even longer than if teams went back to base to get what they need. If problems do occur from incorrect tooling, the job would need to be put on hold until the correct tooling was on the machine and any damage to the floor surface must be corrected, increasing project time.

Dave Bigham

12 Tools, Plant & Equipment Hire Construction UK Magazine - September 2023

Often, there’s a multitude of reasons why crews are using equipment wrong from lack of equipment training to wrong tooling choice, but the end result is the same delays that could have been easily avoided.

CHARGE AHEAD WITH LITHIUM-ION LIFT TRUCKS

Lift trucks depend on strong, reliable power to move diverse construction materials. These are typically demanding, high-intensity applications, which have historically depended on lift trucks with internal combustion engines (ICEs). However, with the expansion and advancement of new electrification options, the motive power landscape is shifting.

Lithium-ion batteries started small, powering pallet trucks moving loads of consumer goods. But now, lift trucks

carrying heavy loads in harsh conditions can be powered by lithium-ion batteries.

Electric forklifts no longer have a reputation for being ‘indoors only’ and are often tough enough for applications in demanding industries. And with the right battery management, the trucks offer even longer operating times.

Hyster® J10-18XD counterbalance lift trucks with integrated lithium-ion power are available for lifts up to 18-tonnes, with the performance that operations previously

expected only from an ICE-powered truck. They are well suited to moving building materials such as bricks, blocks, concrete precast, cement, wood and composite, metals, plastics, and insulation materials.

These trucks offer opportunity charging, maximise uptime, and have the potential to reduce emissions. But to make the best choice when evaluating lift truck power, operations need access to specialised expertise across the whole range of industrial trucks and available power options. The right fit can make fleets more efficient, help retain forklift operators, and help reach productivity targets all shift long, day after day.

Hyster can help. With tough lift trucks, including lithium-ion power options, applications in the construction industry have a complete range of solutions at their disposal. Service, support, maintenance, parts, and aftermarket solutions are also available locally through the global network of Hyster® dealers.

Machine size

Another issue is using the wrong size or type of equipment for the job. Before going to any jobsite, it’s important to know what the situation is to better plan what kind of scrapers are required. Factors that impact the type of equipment used include, how big the space is, whether the scraper will need to move up and down stairs, how small individual rooms are if there is more than one space. It will also indicate how many scrapers are needed and tools needed to accompany them, like grinders, dust collectors and shanks.

Machine use

What’s important is understanding how to use your equipment. With various solutions entering the market, it can be difficult to keep up with the latest training manuals. Most floor scrapers require very minimal maintenance, as long as contractors use the machine as intended. To ensure success, first make sure the scraper is set up correctly: has the speed control been set to the right level? Are the wheel pins in? Most machine suppliers will have a variety of

training and operating resources to use if crew members are unsure.

Avoiding stick ups

Heavy-duty adhesive residue can be left on the subfloor after removal and must be fully removed before any new floor can be laid on top. If left behind, new flooring may be uneven and its longevity will be reduced. Assessing the floor type will help determine what method is needed for example, vinyl flooring may require heat application to soften the adhesive, while tile or hardwood requires scoring ahead of scraping.

Cleaning as you go

When removing flooring, it’s usually the job of the contractor to safely dispose of any waste. During floor removal and clean-up, contractors must prioritise their safety and wear protective gear such as face masks and dust collectors to minimise the inhalation of dust. A common mistake we see is contractors sweeping up the dust left behind, but this can cause serious health problems if breathed in, even if others in the area are using dust collectors.

Floor sweepers can also be used to help collect debris so that polishers can then buff the floor surface.

While being a seasoned contractor means you work like a well-oiled machine, it’s important to look for ways to improve and knock any vices that affect the quality and effectiveness of the job, no matter how comfortable they may seem. While tried and true methods used at the start of your career may get the job done, there is so much best practice advice out there to help make surface preparation easier and more productive.

Visit www.hyster.com to learn more about solutions for the construction and building materials industry.

What’s important is understanding how to use your equipment. With various solutions entering the market, it can be difficult to keep up with the latest training manuals.

13

Construction UK Magazine - September 2023

Tools, Plant & Equipment Hire

COMPACT LOADERS UK

Compact Loaders UK is the trading name of Ranger Equipment Ltd, with a history in the supply of niche Compact Machinery that create solutions to mechanise where larger machinery just can’t work. The aim is to enable safe working, with enhanced productivity and increased profitability to those who previously had to make do with old methods and sheer hard work.

The company’s mission is a simple but effective one, and it’s products, supply and support ethos certainly mirror it: ‘It is our mission to help you transform your work by adding Productivity and reducing Labour & Costs, whilst enhancing Safety and adding genuine value to your Profit Margins.’

MultiOne

Celebrating their 25th anniversary this year, MultiOne Srl are dedicated to the design and manufacture of MultiFunction Mini Loaders.

With a range of features reflected in very few other brands, MultiOne offer the broadest range of Loaders, from the diminutive 1 Series, to the Class Leading 11.9K. A total of 19 models are available, including the EZ range with Zero Emissions 100% Electric drivetrain.

With ‘cab forward’ design to place the operator in a commanding position, looking directly down the boom and onto any

attachment that may be fitted. This direct line of site is uninterrupted during steering, as the cab and seating position is mounted to the front chassis of the articulated steering design.

High flow auxiliary hydraulics (up-to 95 l/min), with quick connect attachments interface make the MultiOne amongst the most powerful attachments ‘tool carriers’ of their size.

The Telescopic Boom helps keep everything compact, with class leading closed dimensions. Great reach is also achieved with maximum boom heights upto 3.6m, another class leading statistic.

The Articulated steering, coupled with 4WD Hydrostatic Transmission make the MultiOne a go anywhere machine.

MultiOne MultiOne

MultiOne

Sherpa Sherpa

14 Construction UK Magazine - September 2023 Tools, Plant & Equipment Hire

A range of Labour Saving Mini Loaders and Dumpers to enhance Productivity and Safety on any job site.

DBS (Dynamic Block System) and Torque Divider are switchable, allowing for high traction when needed, but also can be set for minimal to no ground damage for delicate ground. With this a MultiOne can be engaged with challenging Forestry or Agricultural Terrain in the morning, and switch to Lawn Mowing in the afternoon.

Low gross weight is another key feature, with many MultiOne owners choosing to transport their Loader by 3.5T plant trailer. This is even achievable with the flagship 11 Series models, with a gross weight of only 2320kgs and a max tipping load of 3180kgs, it offers the highest lifting capacity of any Telescopic Loader that can legally be transported this way.

Sherpa

I refer to the SHERPA Mini Loader as our ‘greatest labour saver’ and it’s often overlooked due to it’s diminutive size. However, these little machines can work almost anywhere, they fit through single doors and gateways, the electric models work indoors and with a range of innovative attachments they reduce manual labour by a massive margin in spaces where machinery can’t normally be used.

- Steve Hadfield, MD at Compact Loaders

- Steve Hadfield, MD at Compact Loaders

Tools, Plant & Equipment Hire

SHERPA Mini loaders B.V. was founded in The Netherlands in the late 1980s and like MultiOne, is another brand with a long history of innovation and development. Initially the Importer for BENELUX of the Opico Skidster, this transitioned into the SHERPA Mini loader in the mid 1990s and ‘evolution, not revolution’ has continued ever since.

The SHERPA is of ‘stand on design’, with compact dimensions. From just 76cm wide, only 150cm in length and around 135cm tall, many customers transport these diminutive Loaders in the back of their van!

SHERPA were the first to launch an Electric Skidsteer model as early as 2014 and this has become a favourite amongst internal Construction, Demolition and Soft-Strip professionals across the world. In countries like the USA where construction site labour cost is exceptionally high, it’s a real winner. The extended battery run time of 6 hours (continuous use in loading application) from one charge can be further enhanced with a battery ‘change-over’ system to allow multi-shift use of one machine.

The new Z Series is currently in launch, with some models already out with customers. This is a new range of ‘premium’ performance SHERPA Mini Loaders, with enhanced ergonomics, increased lifting capacity, higher torque transmission and much more. In 2020 the Z Series designer’s were rewarded with a European Product Design Award in the transportation category, based on a prototype - https://www. productdesignaward.eu/

Twinca

TWINCA was the latest addition to the range, added in 2022 and is the ideal companion to the SHERPA Mini Loader, especially in Electric guise. These are innovative machines, built to a very high quality level in Denmark from Manufacturer TWINCA A/S.

“For our SHERPA customers looking for the ultimate in labour saving, adding a TWINCA Dumper makes great sense especially for internal applications. For example, an Internal Demolition or Soft-Strip team can be clearing the job site with SHERPA Electric Mini Loaders and use them to load the TWINCA. The Dumper can then transport loads of upto 800kgs swiftly from indoors to outside where their high tipping capability can discharge into skips. Even high capacity Ro-Ro skips can be reached.” Says Steve.

Just like the SHERPA, the TWINCA has an extended battery run time of upto 6 hours, which is ample for the typical 8hr shift patterns on UK sites nowadays. After shift, re-charging is achieved via an on board dual voltage charger, this is ‘self seeking’ from 110v to 240v.

More info…

Tel: 0800 233 5490

Email: info@compactloaders.co.uk

Web: www.compactloaders.co.uk

MultiOne – www.multione.co.uk

Sherpa – www.sherpaminiloaders.com

Twinca – www.electricdumpers.co.uk/ twinca

Social Media…

www.facebook.com/ CompactLoaders

www.linkedin.com/company/ compactloaders

www.twitter.com/ MultioneUk www.instagram.com/ compactloaders_uk/

UK.

15 Construction UK Magazine - September 2023

Twinca Twinca

AIR & HYDRAULIC TOOL HIRE

The APP Group consists of Air Power Products (Compressed Air Specialist) and Procut Engineering (CNC Precision Engineering) and APP Site Services (Site Supplies and Tool Hire). The group benefits from a full-service department with a wealth of air and hydraulic tool knowledge. We provide an excellent service, not only with the range of products but with the level of care each order is given and the speed with which we can deliver.

The main focus of the business is the hire department for construction tools. The hire fleet has been built up over a long period of time and the tools are always fully serviced and inspected before every hire.

We have a range of tools and associated products available to hire which include Rebar Cutters, Rebar Benders, Hydraulic Splitters, and Pneumatic Picks.

Rebar Cutters

We have a range of hydraulic rebar cutters to suit both factory and on-site applications that can cut up to 40mm Rebar. Designed for professionals that need to cut high tensile rebar in all environments.

Rebar Benders

We have a range of hydraulic rebar benders to suit both factory and on-site applications that can bend up to 40mm Rebar. Designed for professionals that need to bend high tensile rebar in all environments.

Concrete Splitters

Splitters are handheld demolition devices which controllably split material with the use of hydraulic pressure. They are used when larger conventional demolition devices are ruled out due to their excessive dust, vibration, and flying debris.

Concrete Combi Shears

The combi shears are the ultimate in handheld demolition. The interchangeable jaw sets mean that this machine is incredibly versatile and can cut and crush a wide range of materials.

Pneumatic Picks

We don’t just sell & hire the H11, We have a full range of medium duty demolition picks.

Whatever your scenario we have an option for you…

Above are just a few machines we have to offer. For our full range give the office a call on 01909 519 519. Most tools are available for Same Day or next day delivery.

Site Spillage

As well as the hire fleet APP Site Services offer a range of site spillage solutions including the mobile spill kit. If you need further information on the range of spillage solutions we have to offer, please visit the website www.appsiteservices.co.uk

PPE Solutions

As part of the full package, we also stock a range of PPE equipment and workwear for our customers. If you are looking for gloves or a mask to go with your hire or purchase we have got you covered.

www.appsiteservices.co.uk

Tel: 01909 519 519

16 Tools, Plant & Equipment Hire Construction UK Magazine - September 2023

APP SITE SERVICES Unit 1,2,and 8 Abbey Way │ North Anston Trading Estate Dinnington │ Sheffield │ S25 4JL UK 01909 519 519 │ appsiteservices.co.uk Air & Hydraulic Tool Hire We have a wide range of construction tools for hire 01909 519 519 appsiteservices.co.uk PART OF THE

XCMG RELEASES NEW ELECTRIC TRUCKS AND CONSTRUCTION MACHINERIES IN BRAZIL

XCMG Machinery recently released a lineup of new electric products in the Brazilian market, including five trucks, two loaders and one excavator, as XCMG Brazil inaugurates operations of its electric equipment division to push forward sustainable industry development.

The E7-49T electric truck adopts an electric motor with output of 482hp and torque of 2,000Nm, as well as 4-speed automated transmission that saves energy on starts. While the E7-29Ris a semiheavy 8x4 model with a rigid chassis to support transportation of various cargo

types, the electric truck can also adapt to urban environments as it has the advantage of lower noise design. The battery has a maximum charging capacity of 282 kWh and range of 150 kilometers.

XCMG introduced three off-road trucks that are more suitable for mining operations. The XGE5900E has an electric motor yielding 680hp and 1,000Nm of torque, the intermediate model XEGE95 (816hp and 1,400Nm of torque) that can carry net load of 60 tons and reaching maximum speed of 43km/hour, and the XDR80TE, the largest electric off-road model from XCMG that has an engine with

749hp and 4,9000Nm of torque, as well as 525 kWh battery charging capacity, 4-speed gearbox and track on the two rear axels.

XCMG Exports Large Meter Concrete Pump Trucks to Morocco, A New Generation of Equipment Developed by XCMG and XCMG Schwing

In the meantime, the pure electric loaders XC918-EV and XC968-EV are designed to adapt to operations in smaller spaces and tackling “heavy lifting” respectively, boasting stability and reliability. The XE270E electric excavator which truly achieves zero emissions with an ultralarge battery pack with total capacity of 525.1kw/h, is the industry’s largest tonnage pure electric excavator.

“XCMG is committed to promoting dynamic and sustainable development of construction machinery industry, we continually develop and customize products that best suit the customers’ needs, and elevates our overseas service network, thriving to support global infrastructure projects and build a better future for all,” said Yang Dongsheng, CEO and Chairman of XCMG.

Over 10 Units of XCMG Large-tonnage

LW700KN and LW800KN Loaders Working at the Diamond Mine in Angola

Earlier, XCMG has exported two units of large meter concrete pump trucks to Morocco, the HB69V and HB62V, a new generation of equipment product developed by XCMG and XCMG Schwing. The HB69V is by far the largest concrete pump truck China has exported to Africa, which has a vertical distribution height of up to 68.1 meters.

With a fully optimized design, the HB69V truck can easily achieve high distribution rate, easily meeting the requirements of local customers for high pumping volume, high construction height, and broad operation range. The HB69V can be widely used in the construction projects including housing improvement, hospital, municipal engineering, ports and more.

While in a diamond mine site in Angola, more than 10 units of XCMG largetonnage LW700KN and LW800KN loaders

Large Meter Concrete Pump Trucks, codesigned by XCMG and XCMG Schwing, Delivered in Morocco

XCMG Large-tonnage LW800KN Loaders Works at the Diamond Mine in Angola

18 Construction UK Magazine - September 2023 Tools, Plant & Equipment Hire

have been working an average of 21 hours a day since 2021 to transport raw materials in the harsh environment with high temperature, humidity, and dust. The excellent performance as well as XCMG’s reliable services have won recognition from the customer and an additional batch order of loaders and wheel dozers, which are expected to deliver soon. The highperformance 9-ton loaders will equip with the newly upgraded load-sensitive, fully variable hydraulic system, re-optimized powertrain, and multi-functional dualbrake combination brake pedal.

A fleet of XE500DK excavators from XCMG have been working in mines in the Democratic Republic of the Congo, with an average operation time of 18 hours per day, the XE500DK has been appraised as a pioneering mining equipment and “steel beast” for its robust power and high performance. It’s equipped with the Cummins engine which has low fuel consumption and powerful output, which is coupled with high-duty main pump and new main valve that has low pressure loss, stable performance, and precise control. The main structure components adopt

anti-fatigue design to enable the excavator to operate nonstop with extended service life. XCMG has also deployed technical service teams to complete routine inspections across the mines.

XCMG is also expanding operations in countries of Asia, further supporting its international allies in speeding up their infrastructure constructions.

In central Vietnam, eight XR280E rotary drilling rigs from XCMG are now working in a new plant construction project of a steelmaking factory. The project site is located in a mountainous region with complex stratigraphic environment, the XR280E has significantly improved construction efficiency as it achieves drilling depth of 10 meters per hour, while guaranteeing stability and drilling success. XCMG’s on-site supporting staff are also providing all-day services as well as operation trainings.

“From customization of products and solutions to setting up professional service teams to guarantee smooth and reliable operation, XCMG hopes to bring ‘Advanced and Endurable’ products and services to our global customers and contributing to the global infrastructure constructions and economic development,” said Yang.

19 www.tnsgroup.co.uk Construction and Industrial Dealers for East Anglia Get in touch with our Construction & Industrial team to discuss your machinery requirements David Banks T: 07798 585608 E: davidbanks@tnsgroup.co.uk Callum Gaskell T: 07826 552676 E: callumgaskell@tnsgroup.co.uk Construction UK Magazine - September 2023 Tools, Plant

Equipment Hire

XCMG’s XE500DK Excavators are put into use in the Democratic Republic of the Congo

&

INTRODUCING CAVITY TRAY CLEANER: A REVOLUTIONARY TOOL FOR THE BUILDING INDUSTRY

The Cavity Tray Cleaner is an innovative and time-saving tool designed specifically for bricklayers and builders in the United Kingdom. Developed by a professional bricklayer, this tool collects excess mortar that falls onto the cavity tray, saving both time and money.

With its simple three-part assembly, the Cavity Tray Cleaner can be easily clipped together and disassembled within minutes. Its efficiency is unparalleled, capable of effortlessly cleaning a 10m long run. For larger projects, sets of up to 40 meters are available, making it ideal for full house constructions.

“The traditional method of cleaning cavity trays is outdated,” says Ashley Williams, founder of the Cavity Tray Cleaner. “It’s a laborious and time-consuming task that costs bricklayers valuable hours and money. After witnessing this problem firsthand, I’m proud to introduce a product that will revolutionize the industry. The Cavity Tray Cleaner is not a luxury but a necessity for professionals who value efficiency, time, and cost savings.”

The Cavity Tray Cleaner features a trainlike design, connecting in a series. Made in the UK using recycled plastic, these ecofriendly trays are reusable. The scorpionlike tail design ensures that mortar does not track back into the tray, keeping it clean throughout the cleaning process.

“This tool is perfect for both experienced and trainee bricklayers,” adds Ashley Williams. “It accelerates training and saves valuable time spent on scraping with wooden battens or struggling with muck-filled trays. No matter how skilled you are, dropping some mortar in the cavity is inevitable. The Cavity Tray Cleaner eliminates the wasted time and money associated with traditional methods.”

In addition to reducing cleaning time, the Cavity Tray Cleaner prevents damage

to the cavity trays and ensures that ‘weep holes’ remain unobstructed. It is a sustainable investment for builders and bricklayers, meeting the standards set by the NHBC (National House Building Council).

The Cavity Tray Cleaner is set to become an invaluable tool for thousands of professionals and companies across the country, revolutionizing the way cavity trays are cleaned and maintained.

For more information visit: www.cavitytraycleaner.co.uk

Tools, Plant & Equipment Hire 20 Construction UK Magazine - September 2023

Creating Future-Proof Battery Systems Cost effective, modular and scalable battery solutions for e-mobility applications. In-House Prototyping & Testing Thermal Management for Optimal Performance Highest Quality & Safety Standards email: Tom.miller@webasto.com tel: 07875 021770 www.webasto.co.uk Integrated Plug-n-Play Battery Solution

NO POSSIBILITIES FENCED OFF WITH YANMAR’S SV26 MINI EXCAVATOR

Dorset-based agricultural contracting company, Hurn Bridge Fencing, relies on the versatility and sure-footedness of a single Yanmar CE EMEA SV26 compact excavator to keep its operations running smoothly.

All good things come to an end, and so it was earlier this year when fencing and agricultural contractor, Hurn Bridge Fencing (HBF), decided to swap out its old trusty tractor in favour of a more modern, slimmer and altogether more versatile machine. Its model of choice, explains Director Lawrence Wickham, was Yanmar Compact Equipment EMEA (Yanmar)’s SV26 Conventional Tail excavator – and the company hasn’t looked back since.

HBF calls home the picturesque town of Christchurch, on the Dorset coast, where agriculture is the historic mainstay of the region’s rural communities. Born of farming stock himself, Wickham joined his father seven years ago and together founded HBF, specialising in building, installing and maintaining different types of fences; predominantly for farms, but also for residential and commercial properties.

“When researching excavators, we found that the SV26 is a lot more versatile than others on the market, which is exactly what we need. We’re only a team of four, and therefore depend on a machine that can wear many hats and keep up the pace with our diverse day-to-day activities,” explains Wickham.

Wearing many hats

As is often the case for countryside contractors, HBF is required to get involved in a mixed bag of groundworks, trenching and various agricultural projects, alongside its fencing activities. The company fits its SV26 unit with various attachments in order to do so, making this single multifaceted tool carrier the backbone of many of the team’s tasks:

The great thing about the SV26 is that it can be fitted with a ton of different attachments – not only your typical buckets for groundworks and digging trenches, which most are familiar with, but also wire rollers and post drivers for erecting fences. We even fit our Yanmar unit with a rock spike, which is great when we need to firmly position our fencing posts in hard or rocky ground.

Heavy-duty environments

With an operating weight of 2,740 kg, class-leading stability and low ground pressure, the SV26 has also

proven highly beneficial for HBF’s projects on rough, uneven or unstable terrain. The machine benefits from a conventional structure with reduced tail overhang, which gives it increased lifting performance and stability in even challenging work environments. In addition, a long track base adds to digging stability and lifting capacity, while the 300 mm wide tracks offer excellent traction.

“Due to the compactness and weight of the SV26, we can also easily work on steep inclines or boggy areas without scuffing up the areas too much with the tracks. Whereas with larger excavators or tractors, we have found that they can weigh a lot and sink into the ground, especially when it’s wet. The arm is also a good length (1150 / 1400 mm), helping us to carry out our projects safely and with ease”.

Wickham purchased his Yanmar unit from Hunt Forest Group, a long-standing approved Yanmar dealer also situated in Devon, not 30 minutes away from HBF’s facilities.

“The work we do is tough and I like the physicality of it,” Wickham shares. “But having a machine that can alleviate the manual strain of digging holes and breaking up rocks has made a big difference to efficiency of our work. We’re really happy with our decision to purchase the SV26, and the support provided to us by Hunt Forest Group”.

22 Tools, Plant & Equipment Hire Construction UK Magazine - September 2023

Let’s do something about it! Does this look familiar? We’re on a mission to improve site safety and welfare standards Contact us today to enhance your site safety Find us on our website or on the socials 0161 549 0002 www.site-pod.co.uk

THE ONLINE COMMUNITY THAT UNLOCKS RENTAL COMPANIES POTENTIAL

UK e-commerce brand Rent Pay Go has emerged with its exciting new rental community.

With collaboration at the heart of its business Rent Pay Go is designed to help rental companies build partnerships, improve efficiencies and drive sustainability online.

When it comes to digitalisation in rental in many cases the rental industry has been left behind, with customers forced to rent products in a more traditional way using phone, email, or SMS. Traditional ways have served its purpose over the years, but not all contractors want to work this way.

Rent Pay Go has recognised that digitalisation will play a key part in how the rental industry needs to operate to be successful.

By connecting its users to their customers online, rental companies will be able to provide digital ordering with ease.

The benefits to both the customers and rental company can be great. By offering a consistent customer experience online can unlock rental companies’ potential.

By choosing Rent Pay Go as your e-commerce provider, you join a community where you can work in isolation with your customers or expand your network and collaborate with other rental companies.

With Teamwork it gets better, construction sites are busy places where teamwork is vital, often when it comes to renting equipment for a job site it may mean contractors dealing with multiple rental companies to find the right available equipment. This can lead to multiple calls and waiting around, time taken away from site duties can lead to frustrations and delay important decisions.

Forward thinking rental companies can team up with other trusted rental companies to provide a single source solution for their customers. This allows rental companies to strategically extend their offerings without holding additional inventory.

With many contractors working around the UK, rental companies can offer local hire with national power. Be part of a bigger community all over the UK, with like-minded people, joined together in an industry that wants to be successful.

If we can get the industry working together, it’s better for everyone, and the planet too - a rising tide lifts all boats.

Rent Pay Go has the technology to make this happen, connecting supply chains to enable a great customer experience.

“A win win for the contractor who needs local equipment and rental companies building partnerships”.

24 Tools, Plant & Equipment Hire Construction UK Magazine - September 2023

Join our Rental community – A community that creates opportunities for all sized rental companies online. Are you looking to offer your Rental equipment Online but don’t know where to start? Are you struggling with time and need help setting up? We are here to help, we can even set you up, ready to go if you like. Book your free demonstration online: www.rentpaygo.com Contact@rentpaygo.com Tel: 0116 2187166 Whatsapp: 07507 785085 Instagram: rentpaygoltd Maximise your rental opportunities Connect with your customers Reduce admin Your rental equipment online Protect your customer base Collaborate and build partnerships

THE RA40 PAIR HELPING CARRY THE LOAD FOR ATLAS QUARRIES

In New Zealand, Rokbak RA40 articulated haulers supplied by long-time machine partner Porter Group are in Atlas Quarries’ fleet at its tough, steep site.

One of New Zealand’s leading quarrying and aggregate production companies Atlas Quarries has added two Rokbak RA40 articulated haulers to its Brynderwyn site. These robust haulers are now assisting quarry operations, accompanied by a brand promise to deliver exceptional performance, efficiency and productivity.

Approximately 100km north of Auckland, the Brynderwyn site, known for its rugged terrain and challenging working conditions, required a robust and reliable hauling solution capable of meeting the demands of heavy-duty quarrying operations. After careful evaluation and consultation with dealer Porter Group, Atlas Quarries selected the Rokbak RA40.

New trucks in New Zealand

A variety of industries in New Zealand contribute to growing articulated hauler

demand in this developing environment. Orders are often required for civil work along freeways and for general construction, alongside Atlas’ speciality of quarrying and aggregates.

The RA40 has the capacity to carry 38 tonnes (41.9 US tons). A modulating transmission retarder coupled with an efficient exhaust brake and fully enclosed oil-cooled multidisc brakes offer superior braking performance – something which is greatly appreciated by operators at the Brynderwyn site.

“Where we haul and fill out to is pretty steep, so with a full load onboard you need to know the truck is going to stop where you want it to,” says Brynderwyn quarry manager, Tony Turnbull. “It’s one thing to scramble up a hill without any worries, but when you’re at the wheel, you also want to know the machine will remain predictable and maintain traction on the way down too.

“In investing in the Rokbak haulers we were also looking for a big improvement in reliability and safety. The trucks are well designed for servicing and all the main checkpoints are at ground level.”

Still run by the Collie family today, Atlas Quarries has been a reliable supplier of quarry aggregates for almost 75 years. A prominent production company with a strong presence in Auckland, it specialises in providing high-quality construction materials for various infrastructure projects across the region.

The company produces around 300,000 tonnes of material annually. And with over 100 years more raw material resource to mine, Atlas Quarries should be helping lay the foundations of Auckland’s growth well into the future – and the RA40s are now right there with them, 11,000 miles away from the Rokbak factory in Motherwell, Scotland.

Big asks and tough tasks

The RA40 offers a range of features designed to maximise performance and operator comfort. The hauler’s robust construction and superior capabilities allow it to navigate the challenging terrain of the Brynderwyn site. When working conditions are more arduous and punctuated by steeper inclines and tricky ground structure, tractive effort can be increased by approximately 50% to provide the necessary performance.

The automated limited slip cross-axle and manually applied inter-axle differential locks distribute torque between axles and / or across the axles to limit wheel spin and maintain machine momentum. This adaptable traction control provides excellent machine stability in poor conditions, while the operator-friendly cabin design provides exceptional visibility and ergonomic controls to maintain operator comfort throughout.

The successful implementation of the haulers not only enhances operational efficiency at the site but also contributes to a significant reduction in maintenance costs. The haulers’ durable design and advanced diagnostic systems minimise downtime, resulting in increased productivity and substantial cost savings.

“We are pleased to have partnered with Atlas Quarries in optimising its operations at the Brynderwyn site alongside our Global Parts Dealer of the Year, Porter Group,” says Lee Irving, Rokbak Regional Manager. “The success achieved with them in New Zealand and an increased Rokbak profile in the country demonstrates our commitment to delivering innovative, high-performance solutions tailored to the unique needs of our customers wherever they operate in the world.”

26 Construction UK Magazine - September 2023 Tools, Plant & Equipment Hire

TRAVIS PERKINS PLC ANNOUNCES UK’S LARGEST ELECTRIFICATION FORKLIFT PROGRAMME TO ACCELERATE DECARBONISATION

which encompasses Safety, People, Quality, Environment and Community to ensure all projects are delivered to the highest possible standards, while positively impacting its clients and society as a whole.

As part of this Standard, the Group pledged in August 2021 to reduce carbon emissions from all site equipment by over 90% within the following two years.

Travis Perkins Group, the UK’s largest distributor of building materials, is accelerating its decarbonisation plan by switching out its diesel forklift trucks - up to 1,100 - with electrics by mid 2024.

This multi-million pound investment, which the Group refers to as ‘Project Switch’, is one of the largest forklift truck change programmes of its kind, and involves the diesel powered forklift trucks being replaced with electric alternatives up to eight years ahead of schedule.

Rye Group, a leading provider of demolition, remediation and ground and enabling works has achieved carbon neutral status, after switching from standard red diesel to HVO [Hydro-treated Vegetable Oil] Green D+ fuel.

Rye Group adheres to its own Sustainable Standard philosophy,

In working closely with national fuel and lubricant provider, New Era Fuels, Rye has successfully replaced the use of diesel fuel with HVO within all site plant and machinery, and across its entire fleet of company vehicles.

As result, it has reduced its annual carbon emissions figure from 3,065 tonnes to 135 tonnes within just 12 months. This represents a reduction of over 92% in just one year, demonstrating what is possible with decisive action.

To then obtain carbon neutral status, Rye Group offset the residual emissions via two VCS (Verified Carbon Standard) schemes that focus on forest protection in Brazil and Colombia, whilst addressing ten of the UN’s 17 Sustainable Development Goals.

Once the new forklift trucks have been rolled out across the Group’s branch network, it is estimated Project Switch will reduce the Travis Perkins plc scope 1 carbon emissions by up to 6,600 tonnes per annum - equivalent to the carbon emissions of nearly 4,000 cars¹.

Project Switch is just one of the actions implemented by the Group to achieve 27% reduction in vehicle and plant fleet emissions by 2027. Other steps include trialling alternative fuels and providing training for drivers to ensure they operate the machinery and trucks in the most energy efficient way. Decarbonising its fleet is an integrated part of the Group’s decarbonisation roadmaps, which set out in detail how the Group plans to meet its ambitious 1.5°-aligned carbon reduction targets, which were announced by the Group in 2021 and accredited by the Science Based Targets initiative (‘SBTi’)².

Briggs Equipment will be the provider of the new forklifts, which will also feature the latest technology including; upgraded safety systems, an improved turning circle to improve site safety whilst also lessening stock and racking damage. These improvements will help reduce running costs of the machines, reduce downtime and ensure easier management of compliance.

The 18-month forklift truck electrification switchover will commence this Summer and is estimated to be completed by mid2024.

CARBON NEUTRAL

SWITCH

HVO GREEN D+ FUEL 28 Tools,

News Construction UK Magazine - September 2023

RYE GROUP ACHIEVES

STATUS AFTER

TO

Plant & Equipment Hire

0345 745 0000 nationwideplatforms.co.uk All you need in Powered Access Nationwide availability UK’s largest powered access fleet Contribution to Safe Working at Height Innovative Technology Prize (Harness ON) Contribution to Safe Working at Height Safety Innovations Digital account management services Powered Access hire Working at Height training

People On The Move

PLACEFIRST APPOINTS INVESTMENT DIRECTOR AS EXPANSION PLANS CONTINUE

Leading UK build-to-rent provider Placefirst has appointed Henry Marshall as its new investment director, to drive forward the business’s ambitious growth plans.

Henry joins the senior leadership team in this newly created role at a key moment for the business which looks to build on recent success. Henry will be based in the London office and will be responsible for leading Placefirst’s expansion geographically, which will include working with third party delivery partners.

Henry has more than 15 years’ experience in real estate investment, specialising in the living sectors. He was most recently at property investment firm Realstar responsible for the acquisition and asset management of residential investments, helping grow the business to over 4,000 units. Prior to this, Henry held transaction roles at Quintain and Deloitte.

This is a pivotal time for Placefirst which has established itself as a leader in the singlefamily BTR market and has ambitious aims to reach 6,500 homes in the coming years.

SISK UK NORTH APPOINTMENT ANNOUNCEMENT

John Sisk & Son is pleased to announce the appointment of Chris Cant as Regional Director in its UK North Division. Chris brings a wide range of experience and will support the business as it looks to grow in the Fit-Out Sector in particular.

Commenting on the appointment

Alan Rodger, Managing Director, John Sisk & Son UK North said: “There is a growing market that we feel we are well placed to service, as clients & landlords look to decarbonise their assets and achieve their net zero ambitions and we are delighted that Chris has joined us to help deliver a Sisk offering in this sector. Sisk’s commitment to our purpose of creating places for future generations and our recent success on the Pagabo Fit-Out Framework, combined with our relevant experience across the business in the UK, Ireland and Europe puts us in a strong position to move forward.”

Speaking on joining Sisk, Chris said: “I am really excited about the opportunity to work with the Sisk

team and help grow the business. Sisk has a wide range of experienced people.

I am passionate about construction and most enjoy delivering exceptional projects of high quality in a collaborative manner and I look forward to working with the Sisk team to do just that.

Chris graduated from the University of Northumbria with a degree in construction management in 1993 and started his career with Taylor Woodrow working on various projects in the north west joining as trainee QS before being responsible for his own projects.

He then spent eight years with Styles&Wood, initially as a quantity surveyor progressing to senior quantity surveyor where he worked on prestigious fit out projects including Debenhams and John Lewis on Oxford Street, London.

30

Construction UK Magazine - September 2023

MOORES APPOINT NEW KEY ACCOUNT MANAGER IN THE SOUTHEAST

Leading British kitchen manufacturer, Moores, have recently welcomed Holly Adeniji to the company as Private Development Key Account Manager for the Southeast.

In her new role, Holly will be responsible for maintaining relationships with existing customers in the area, as well as driving forward new business opportunities

KEESTRACK

ASSIGNS

NEW MANAGING DIRECTOR FOR THEIR CHINESE FACILITIES

Richard Li, has been assigned as new managing director of Keestrack Construction Equipment Co., Ltd. based in Chuzhou, China since June first.

“With over 33 years of experience within the construction equipment industry and having loads of management experience, Richard Li is an asset for Keestrack”, says Frederik Hoogendoorn, Vice president Sales & Marketing.

Richard Li is a member of the management committee of

the Chinese Association of Equipment Manufacturers since 2006 and has been selected into the Top 100 influencers in the Chinese Construction Equipment Industry from 2006 onwards. After Richard graduated from university in 1989 he has been involved in the Construction Machinery Industry, first as customer at the Municipal Construction department of the city of Xiamen, later in his career as construction equipment dealer and manufacturer in several enterprises.

Richard has an impressive track record with companies such as WesTrac, Doosan Infracore, NFLG, Bauer and IngersollRand, and has proven to be a highly efficient managing director in a variety of roles.

within the private development housebuilding sector.

Having worked in the KBB sector for a number of years, Holly has developed a vast knowledge of the kitchen industry, working in both design and sales roles for Benchmarx and B&Q Contracts.

Holly comments: “I am thrilled to have joined the Moores team and am looking forward to getting to know our customers across the region.

“It’s great to work for an industry leader in the KBB market with a commitment to innovative product design and sustainable practice, so this is a very exciting time to join and I’m looking forward to being a part of Moores growth.”

31 People On The Move Construction UK Magazine - September 2023

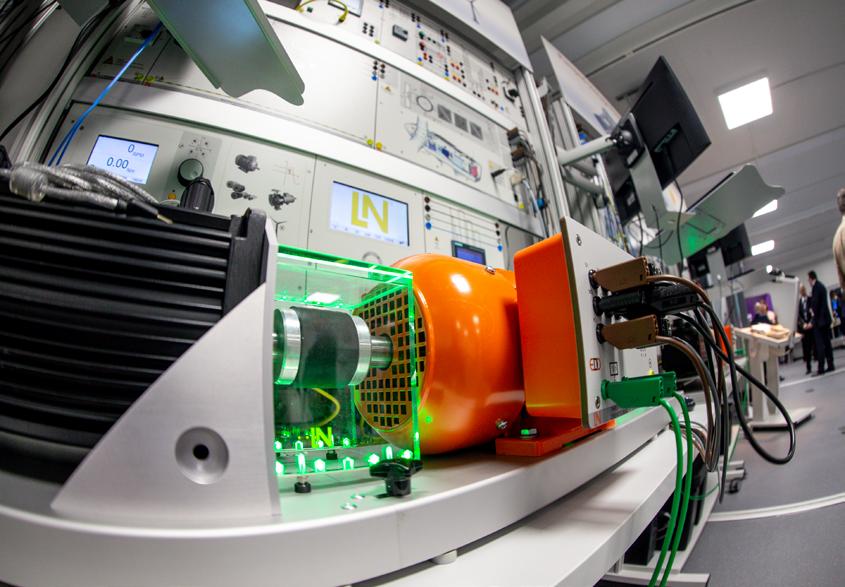

JRA COMPLETES WORK ON SKANSKA UK’S HEAD OFFICE

JRA has completed the new Skanska UK head office, 1 Hercules Way, in Leavesden Park, Hertfordshire.

Skanska UK appointed JRA as a long-term design and architecture partner to develop the workplace strategy and interior design of the four-storey, 6,000m2 head office in 2021.

Acknowledging how working patterns and office cultures have been impacted

by the pandemic, JRA’s design focused on producing both a sustainable and futureproofed central office with hybrid working / hotdesking models integrated throughout, including multiple collaboration and agile working spaces.

This approach:

• Enables employees to communicate within project and client teams as effectively as possible

• Supports Skanska in becoming a customer-centric business

• Uses embedded technology that allow for more‐efficient hybrid working models

• Puts digital productivity at the heart of its design

• Incorporates extensive biophilic elements which align with Skanska’s strong sustainability focus

• Aligns, overall, with Skanska’s position as a low carbon leader

Working in collaboration with representatives from across Skanska, JRA’s design has resulted in the creation of a range of different ‘homezones’ or ‘neighbourhoods’ across the building which are engineered to meet the needs of each team. These zones are supplemented by a rich mix of agile and collaborative spaces

As a leader in sustainable construction, Skanska required an office space that offered significant carbon reductions by optimising the reuse and recycling of materials as well as use of low carbon products.

including around 50 meeting rooms, collaboration centres, and training areas.

The integration of these spaces supports Skanska’s open and transparent working culture, encouraging employees to come together to share ideas and learning. The incorporation of a mixture of formal and informal spaces have helped to give the building a sense of community and a clear identity.

To support employee wellbeing – and to mirror some of the attractions of remoteworking – JRA has integrated breakout areas, wellbeing rooms, and quiet spaces across the building.

Images: © Peter Cook

32 Construction UK Magazine - September 2023 Project

As a leader in sustainable construction, Skanska required an office space that offered significant carbon reductions by optimising the reuse and recycling of materials as well as use of low carbon products. 80% of the floor finishes are reused, as well as 30% of the furniture, while the new furniture uses recycled materials wherever possible. The materials palette evokes Skanska’s brand focus on the use of natural and sustainable materials. Natural oak has been used throughout the building’s four floors of workspace. This is incorporated in a range of approaches including wall decorations, space partitions, and various wooden design elements including oak storage cabinets, welcoming tea-points, and meeting islands.

A key focal point for capturing Skanska’s philosophy of responsible construction is the new reception desk, which pairs oak with ultra-high performing 100% cementfree concrete. Evoking both sustainability and engineering, the desk pattern is a reference to the design developed for concrete structures by Pier Luigi Nervi in 1958, where structural optimisation was inspired by the leaves of the waterlily, Victoria Cruziana.

The reception is linked to the ground floor plate through a sequence of arches, conceived as reference to one of the biggest revolutions in the history of engineering, the introduction of arches, which enabled the building of bridges and aqueducts, covering spans never achieved before and still standing today. 3D backlit branding shapes complete the space, while curated furniture pieces showcase the best of Scandinavian design.

In the interiors, the wooden panels are complemented by green and earthy tones. Running planters, freestanding pots, and isolated tree benches are among the biophilic features which aim to bring elements of nature into the office, accentuated by the significant amount of natural light across the building.

The result is an environment that is the embodiment of Skanska’s brand values and its Swedish heritage, working with, rather than against, the existing building.

Festus Moffat, Director of John Robertson Architects, says: “As a long-term design partner for Skanska, we previously completed 51 Moorgate, its London offices, which embodies the company’s desire for agile workspaces with a clear focus on flexible working and employee wellbeing.

“Our work on 1 Hercules Way builds upon these aspirations and our understanding of Skanska’s strategic vision.

As a practice with a strong focus on retrofitting legacy commercial assets, we’re pleased to be able to bring forward this progressive workspace.

“The resulted is a future-proof design which still maintains much of the existing building fabric, this must be the future of sustainable workplace design.”

Harvey Francis, Skanska UK Executive Vice President and project sponsor says: “Working together with JRA, Leavesden Park has given Skanska UK a smart, sustainable, and inspiring workplace which supports a modern, collaborative, and hybrid way of working. It truly embodies the Skanska brand and our values.

“The huge range of spaces, meeting rooms, studios and large collaboration hubs also support our focus on inclusion, creativity, learning, and sharing.”

33 Construction UK Magazine - September 2023 Project

35 YEARS AND COUNTING

2023 sees GEZE UK celebrate another milestone in the company’s history –35 years in business, and in that time the company has grown and developed hugely.

Formed in 1988, GEZE UK was the second subsidiary to be established by German parent company, GEZE GmbH, following GEZE France. Based in Chelmsford, Essex,

the company started trading mainly in the distribution of door closer products.

Recognising a gap in the UK market, a new division was set up in 1997, in Tamworth, Staffordshire to concentrate on the provision of complete automatic door solutions from design to installation and including technical advice and guidance on building regulations.

By 2003, GEZE UK had outgrown the Chelmsford office and the decision was taken to merge it and the Tamworth operation into new purpose-built premises at Fradley Park in Lichfield, Staffordshire.

In 2008 the first service office was set up followed by a further 6 offices throughout the UK. The Scottish office, near Glasgow, is a full service provider for the Scottish

market, dedicated to the specification, installation and service of automatic doors.

Kaz Spiewakowski, MD of GEZE UK, said “During my 10 years at GEZE UK I have seen many changes and challenges including Brexit, the Covid pandemic and a recent cyber-attack. As a company we have shown fantastic resilience and the ability to all pull together in difficult circumstances.

From a handful of staff in the early days to over 250 today, the company would not have developed as it has without their expertise, determination and dedication.

“As we look to the future we continue to focus on offering the very best customer service, as well as managing issues such as product certification, sustainability and fire safety. We also look to ‘give back’ through our corporate social responsibility programme”.

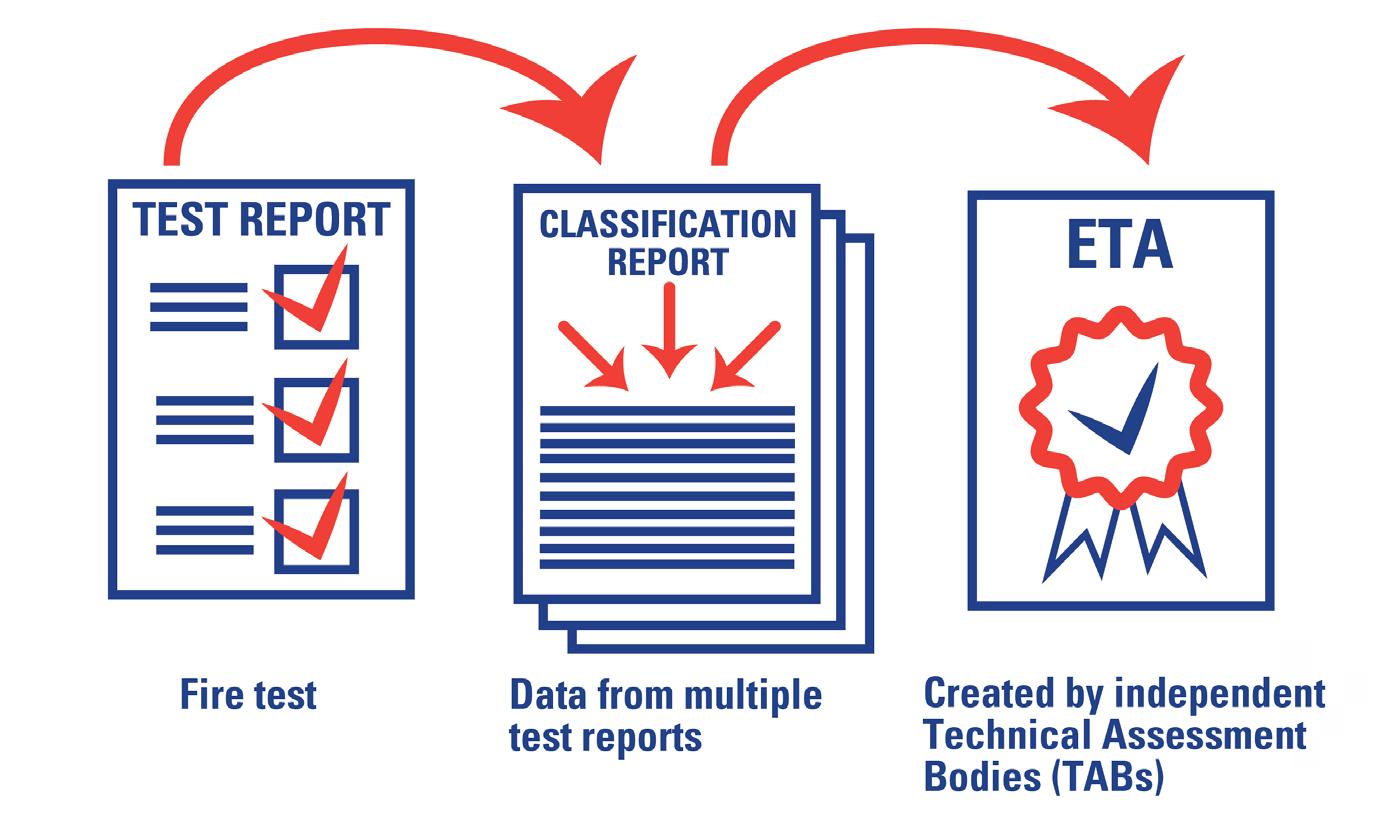

To find out more about GEZE UK and the comprehensive range of automatic and manual door closers, and window technology products, email info.uk@geze.com or visit www.geze.co.uk.