HIGHWAY ENGINEERING AUSTRALIA

TRANSPORT INFRASTRUCTURE ITS TECHNOLOGY

SINCE 1968

AT THE CUTTING EDGE OF CONNECTED MOBILITY

JUNE 2023 PROUDLY SUPPORTED BY

PRINT POST APPROVED - 100001888

V54.4

Are you getting the steel you specified?

Does ALL of the steel you’re receiving comply with the right Standards?

With ACRS Certified steels, you can be confident that you are getting the AS/NZS compliant steel you ordered.

By providing an effective, independent, continuous review of both the manufacturer and the fabricator/processor, the ACRS 2-stage product certification scheme, together with the ACRS traceability certification scheme, significantly reduce the risk of non-conforming steels being delivered to your project.

Talk to us TODAY about how ACRS Certification gives you confidence in your steel supply.

ACRS - Independent, Expert Third Party Certification and Verification of Reinforcing, Prestressing and Structural Steels for Compliance with Australian and New Zealand Standards

How

www.steelcertification.com Ph: (02) 9965 7216 E: info@steelcertification.com ABN: 40 096 692 545

well do you know your steel?

Published by: Editorial and Publishing Consultants Pty Ltd PO Box 510, Broadford Victoria 3658 Australia 1300 EPCGROUP (1300 372 476) +61 3 5784 2210 Publisher and Managing Editor 1300 EPCGROUP (1300 372 476) 0414 788 900 ats@epcgroup.com National Advertising Sales 1300 EPCGROUP (1300 372 476) +61 3 5784 2210 ats@epcgroup.com Business Development Manager 0418 543 821 lawrencewhiter@bigpond.com Advertising Sales - SA Jodie Gaffney - AmAgo 0439 749 993 jodie@amago.com.au Advertising Sales - WA Licia Salomone - OKeeffe Media 0412 080 600 licia@okm.com.au 0416 087 412 Registered by Australia Post Publication No. 100001888 ISSN 0046-7391 This publication is published by Editorial and Publishing Consultants Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright ©2023- EPC Media Group

Nestled amongst the massive freight forwarding, logistics and warehousing facilities that dominate the local landscape, Directed Technologies’ new $15 million Connected Mobility Innovation Centre is helping to cement Australia’s reputation as a global leader in connected mobility. Turn to Page 8 for the full story. 2 Editor’s Column 4 Industry News 8 Cover Feature: Directed Technologies at the Cutting Edge of Connected Mobility 16 Special Report: Gender Equity in Engineering 18 Innovative Solutions 22 Equipment Focus 24 TCA News 28 Electric Vehicles 30 Road Safety 32 National Precast News 36 Tunnelling 4 16 28 36 contents JUNE 2023 Volume 54 Number 4

About the Cover

REDUCING MUCH MORE THAN COMMUTER TRAVEL TIMES THE 15-MINUTE CITY…

Dear Readers,

While the post-pandemic move back to CBD offices is taking much longer than expected, the majority of people in Australia’s capital cities (and an alarming number of major regional centres) are already once again facing ever-increasing daily commute times to and from their place of employment.

Indeed, for commuters in our five major capitals, a daily commute time of 30 minutes would be considered ‘a dream run’, with average commute times now running at 60 minutes or more. Even at 30 minutes each way, it equates to a minimum of 5 hours per week (or 200+ hours per year for an average work year) just to get to and from work.

Unfortunately, for many, it’s considerably more than that, with daily commutes of 4560+ minutes each way not uncommon. And it’s not just about the time – it’s also about the cost! With fuel, vehicle running costs, and for many, the added burden of tolls, commuting has also become a significant household budget item for most families.

While mandatory ‘work from home’ rules did overcome traffic congestion issues almost overnight, it is also important to remember that for many having to work from home was both onerous and challenging on many levels.

With that in mind, I want to make it clear that I’m not suggesting a return to ‘work from

home’ or for that matter, the elimination of CBD office spaces or centralised commercial/ industrial areas. After all, it is neither practical nor for that matter, desirable to suggest ‘abandoning the cities’ or eliminating planning or land use guidelines. As well as being completely wasteful and pointless, it would also result in an economic crisis for the building, construction, and real estate sectors.

What I am suggesting, however, is that the experience of the COVID-19 restrictions (both across Australia and globally), especially in terms of reducing traffic congestion, pollution and wasted commute time, should provide us with a major catalyst for rethinking the way many of us live and work – especially in terms of how far we travel to and from our primary place of employment.

While the concept of ‘The 15-minute City’ (where cities are designed so the majority of residents can live within 15 minutes of their workplace, essential shopping and recreation facilities) is not new, the glimpse of a less polluted and less congested world offered by the COVID-19 shutdowns has once again brought the concept back to the fore, with many arguing that it delivers a significant amount of benefits for residents and the planet alike. Benefits that extend well beyond a reduction in commute times and costs.

Reduced pollution, reduced carbon emissions, an increased opportunity to

move to Electric Vehicles and improved opportunities for localised transport options such as shared MaaS (Mobility as a Service) models, reduced ‘commuter stress’, improved work-life balance, expanded economic opportunities… the list goes on.

For Australia, I believe ‘the 15-minute City’ concept also presents us with a valuable opportunity to start decentralising our population growth away from the major east coast capitals.

While it’s clear that there are many more things to be considered when it comes to rethinking the design of our cities and regions than a simple one-page editorial will allow, I believe that as long as it’s not developed as a ‘prescriptive control’ – rather encouraged through favourable land-use, planning and zoning cooperation, with tax incentives for home and/or hub offices, shared facilities, Electric Vehicle purchases and choosing MaaS services over private vehicle use – the ‘15-minute City’ model can play a significant role in improving many peoples’ quality of life, while at the same time significantly reducing our impact on the planet.

Anthony T Schmidt Managing Editor

2 Highway Engineering Australia | June 2023 EDITOR’S COLUMN

Introducing Ezy-Guard High Containment, a member of the next-generation Ezy-Guard barrier family, providing superior motorist safety. Ezy-Guard HC is proven and crash tested to the latest MASH Test Level 4 standard, distinguishing it from all existing public domain guardrail barrier systems in Australia.

• Crash tested to MASH Test Level 4

10,000kg Truck

• Narrow footprint saving road width

• Easy to transport and simple to install

• Consideration for motorcyclists with rounded post corners

• Can be installed as a post-on-baseplate for areas where underground services restrict posts from being driven into the ground

Ref: PP0615 www.ingalcivil.com.au sales@ingalcivil.com.au

• Sydney (02) 9827 3333 • Brisbane (07) 3489 9125 • Melbourne (03) 9358 4100 • Adelaide/NT 0438 153 482 • Perth (08) 9452 9111 • Newcastle 0400 235 883 • Wagga 0427 779 588 • Local call 1300 446 425 INGAL CIVIL

High-Containment Roadside Safety Barrier

PRODUCTS

Consideration for motorcyclists Narrow footprint saving road width Baseplated installation Australian Made MASH TL4 MASH TL3 MASH TL4: 10,000kg Truck + 2,270kg Utility

–

TL4 1.20m TL3 1.16m Ezy-Guard HC Deflections at 2m Post Spacing

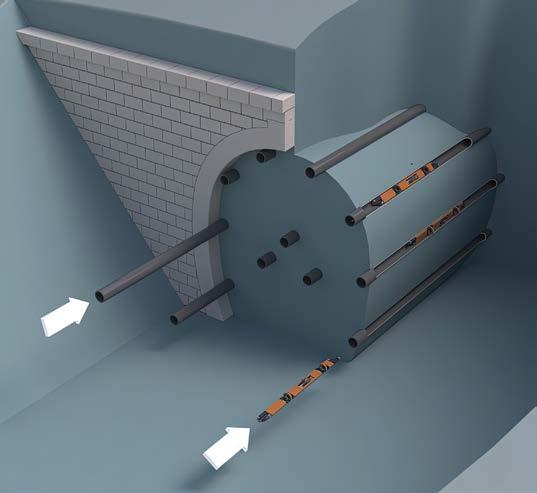

Works continuing to upgrade Adelaide’s Heysen Tunnels

Work on the refit of Adelaide’s Heysen Tunnels is continuing to ensure they continue to service South Australia for decades to come. Following successful investigation works over the past 2 months, the main construction phase got underway during May.

The Australian and South Australian governments have jointly committed funding towards work as part of the South Eastern Freeway Upgrade Project. The tunnel refit work will address current elements that are at the end of their service life to improve safety, traffic management and incident response capabilities.

The scope of works includes:

• upgrades to the tunnel lighting to a new LED system;

• installation of a new automated fire suppression system;

• upgrades to the tunnel ventilation system;

• repairs to the tunnel lining and installation of monitoring equipment;

• upgrades to the Intelligent Transport System (ITS) equipment including thermal incident detection systems, new and replacement CCTV, electronic speed and messaging signage and over height vehicle detection;

• upgrades to the traffic management system to restrict access to the tunnels in the event of an emergency incident; and

• upgrades to emergency communication systems, including public address, radio rebroadcast, in-tunnel signage and help phones to improve safety and network reliability.

AfPA Calls for Greater Collaboration to Address Workforce Participation and Labour Shortage Crisis

McConnell Dowell Constructors (Aust.) Pty Ltd has been appointed as the Managing Contractor for the works and where possible, local sub-contractors and suppliers will be engaged to deliver packages of works.

Over fifty-thousand vehicles travel through the tunnels each day, with approximately 10% of these being heavy vehicles. To minimise the impacts on road users during the project, the majority of works are being undertaken Sunday to Thursday between 7pm and 6am. It is not anticipated that works will be undertaken on Friday and Saturday nights or public holidays, however, advance notice will be provided by on-site messaging boards if this changes.

During the works, the Adelaide-bound (down-track) tunnel will close between 8pm and 6am (with traffic restrictions from 7pm). During these closure times, the Crafers bound (up-track) tunnel will accommodate traffic in both directions via contraflow.

As work progresses, closures will alternate between the up-track and downtrack tunnels until completion in late 2024.

During the works, speed will be restricted to 40km/h in both directions on the approach to the tunnels and through the open tunnel. From 6am each morning, traffic arrangements will return to normal, with posted speed limits to be reinstated for both carriageways.

For more information visit: https://dit. sa.gov.au/infrastructure/road_projects/ heysen_tunnels_refit_and_safety_upgrade

The Australian Flexible Pavement Association (AfPA) has called for greater collaboration between Government and industry in light of the recent launch of its Diversity and Inclusion (D&I) Roadmap. The Roadmap sets a new strategic direction for the flexible pavement industry as a whole, aiming to attract a diverse range of new entrants to diversify the sector and address the prevalent skills shortages stifling the industry.

The Roadmap tackles crucial industry challenges that have come to light, including the importance of gender equity and workforce diversity to create sustainable and long-lasting change, not only for the flexible pavement industry but also for the building and construction sector more broadly. AfPA has called on the Federal Government to apply the Roadmap on a national scale to establish consistent standards, procedures, and guidelines that promote best practices and ensure uniformity in delivery.

The Federal Budget’s upcoming changes to the Australian Skills Guarantee, taking effect from 1 July 2024, will ensure

4 Highway Engineering Australia | June 2023 INDUSTRY NEWS

Image courtesy: SA Department for Infrastructure and Transport

the increased representation of female apprentices on tenders, a focus that will ensure the industry can not only address the current skills shortage but also create a diverse pipeline of skilled professionals for the future.

While the need for gender diversity in the roadwork and construction industry is clear, the reality is that the sector remains heavily male-dominated in Australia. Despite women comprising 47.9% of the Australian workforce, only 13% of the construction workforce are women, a figure that shrinks to single digits when focused on trades.

AfPA identifies within the Roadmap that fostering a dynamic and inclusive work environment that welcomes young people and underrepresented groups is equally important to industry improvement and growth.

To address critical skill shortages across the industry, AfPA believes that promoting and attracting new entrants while retaining current workers is essential. However, diversity and inclusion require proactive leadership, accountable commitments, cultural change, and measurable outcomesbased initiatives.

AfPA proposes a set of initiatives and strategies that aim to increase awareness and break down barriers to participation among underrepresented groups, such as:

• AfPA Diversity and Inclusion Charter, a senior leadership national commitment to recognise and support a diverse and inclusive workforce and lead best practice strategies essential to industry.

• AfPA National Knowledge Exchange Program, designed to engage all educational establishments in raising awareness and highlighting the benefits of young people entering the flexible pavement industry.

• AfPA Diversity and Inclusion Mental Health and Wellness Program, designed to assist in mentoring and establishing mental health and wellness standards across the industry. To reinforce the industry's commitment to training, AfPA has also launched its Industry Skills Card, an 11-part qualification initiative. Already supported by the NSW State Government, the Industry Skills Card was created to train and support better career development for industry workers in a sector facing a skills shortage at a time of

People & Projects Awards

unprecedented demand for infrastructure projects and repairs. AfPA has called on more Governments across Australia to adopt the Skills Card on a national scale to ensure unified industry standards for skills recognition within the flexible pavement industry.

“We invite the Federal Government and industry bodies in the flexible pavement and roadwork sector to nationally endorse training initiatives like the Diversity and Inclusion Roadmap and the Industry Skills Card.

We see the Diversity and Inclusion Roadmap as a way forward, but not the last step in addressing gender inclusion and diversity in the flexible pavement industry. Diversifying our workforce is not just a matter of social justice; it is also essential for driving national innovation and capability in our sector.

The roadwork and construction sector are in a transitional phase, and we welcome organisations to join in acknowledging the barriers to inclusivity in an industry that needs women, young people, and minority groups as well as the retention of the workforce to increase productivity.”

For more information, visit: https://www.afpa.asn.au

Nominations close 4 July engaus.org/awards →

Acknowledging and rewarding engineering excellence. Nominate a person or project for their conspicuous service to the engineering profession. June 2023 | Highway Engineering Australia 5 INDUSTRY NEWS

The Rozelle Interchange Project honoured for suicide prevention work

The Rozelle Interchange Project has received the Workplace Award at the R U OK? 2023 Barbara Hocking Memorial Awards. The awards recognise those who help create a world where we are all connected and protected from suicide and are presented in five categories: Workplace, Education, Community, Conversation Leader, and Young Conversation Leader.

The judging panel recognised the outstanding contribution The Rozelle Interchange Project is making to suicide prevention work through building an R U OK? Culture within its workforce.

The Rozelle Interchange Project is an infrastructure joint venture between John Holland and CPB Contractors. Both organisations have committed to address challenges of mental health and suicide prevention for staff, sub-contractors and their families. The Project recognises that ‘prevention is better than cure’ and focuses on three pillars; trained mental health first aiders, trained management, and all of project personnel engagement.

Across The Rozelle Interchange Project, there are now 230 trained Mental First Aiders who wear uniquely colourful high-vis shirts and provide on-the-ground peer support.

In parallel, training has been held with the Project’s management team to ensure they are able to identify and respond appropriately to staff needing further support.

Announcing the award as a virtual ceremony, R U OK? Community Ambassador, Mostapha Kourouche, congratulated The Rozelle Interchange Project team for their workplace efforts.

“The Workplace Award recognises organisations that are building a culture where everyone feels safe, supported, and encouraged,” said Mr Kourouche. “The Rozelle Interchange Project has helped those at John Holland, CPB Contractors, and their families feel more supported and connected when they are going through a tough time, and we commend them for their work to build an R U OK? Culture on the site.”

In 2019 R U OK?Day was among the first initiatives to engage all of the project personnel on site, and since then, the project has marked R U OK?Day, Movember, Mental Health Awareness Week and Mates in Construction as part of ongoing efforts to promote an on-site culture of making every day the day to ask, ‘are you OK?’.

The Barbara Hocking Memorial Awards were first presented in 2019 in memory of the late Barbara Hocking OAM.

“Barbara was a fearless mental health advocate and campaigner,” said Katherine Newton, R U OK? CEO. “Her leadership and achievements had a positive impact on how people living with mental illness and their families are treated and regarded in Australia.

“These awards honour her lifelong commitment to peer support by highlighting the opportunity we all have to make a difference to those in our world.

“Barbara was one of the first leaders in the mental health and suicide prevention sector to recognise the merit of the R U OK? mission in breaking down stigma. Our nominees demonstrate the values she lived by every day.”

Details of all categories, finalists and winners for The Barbara Hocking Memorial Awards can be found online at: www.ruok. org.au/barbara-hocking-memorial-award

About the Barbara Hocking Memorial Awards

The Barbara Hocking Memorial Awards are organised by suicide prevention organisation R U OK?, and recognise those who help create a world where we are all connected and protected from suicide.

Barbara Hocking OAM (d. 2016) was one of Australia's leading advocates for people affected by mental illness. Her leadership and achievements positively changed how people living with mental illness and their families are treated and regarded. Barbara was the first full-time Executive-Director of SANE Australia - a national charity working for a better life for all people affected by mental illness

through education and support, applied research and campaigning for improved services and attitudes. As well as being a Director of SANE Australia, she also served on the boards of Mental Health Australia and R U OK?

The Barbara Hocking Memorial Awards aim to recognise and celebrate the people and organisations who have made an outstanding contribution to share the R U OK? message in their community and inspire others to become involved with R U OK? They also aim to encourage others to have regular meaningful conversations and invest more time in the people around them.

About R U OK?

• R U OK? is a public health promotion charity that aims to inspire and empower everyone to meaningfully connect with friends, family and colleagues who might be struggling with life.

• A renowned suicide prevention theory is that of Dr Thomas Joiner[1]. Joiner’s theory describes three forces at play in someone at risk of suicide, one of which is a decreased sense of belonging. This lack of belonging and sense of connection is what R U OK? are working to prevent.

• R U OK?Day is an annual National Day of Action; held on the second Thursday of September (14 September 2023) and a reminder that every day is a day to start a conversation that could change a life.

• R U OK? delivers free resources yearround that increase the willingness and confidence of all Australians to recognise the signs someone is struggling, start a genuine conversation and lend appropriate support. R U OK? also tailors these resources to meet the needs of targeted population groups and settings.

• R U OK? draws on the valuable insights of those with lived experience in the development of all campaigns.

• R U OK?Day was founded in 2009 by adman Gavin Larkin who tragically lost his father to suicide in 1995. Larkin (who died of non-Hodgkin’s lymphoma in 2011) wanted to spare other families the grief his family endured.

• A spark of an idea has since become a nationwide community movement that encourages everyone to genuinely ask, ‘are you OK?’ and have a meaningful conversation with anyone in their world who might be struggling.

Conversation tips and crisis support contacts can be found at https://ruok.org.au

[1] Joiner, T.E. (2007) Why People Die by Suicide. Harvard University Press

PICTURED LEFT: The Rozelle Interchange Project's award-winning team of trained Mental First Aiders. Easy to identify on site thanks to their uniquely colourful high-vis shirts, the First Aiders provide on-the-ground mental health peer support.

6 Highway Engineering Australia | June 2023 INDUSTRY NEWS

AMMANN GENUINE PARTS

COVERING ALL NEEDS

Genuine parts from Ammann, the ultimate peace of mind, ensuring trouble free maintenance and sustainable plant operation.

Ammann Parts are manufactured to the same exacting standards as our equipment. They pass the very same rigorous endurance tests.

Ammann Plants are custom made, and that means they also require customized parts. That’s why all of our parts and pieces work together seamlessly to provide customers with superior and sustainable performance from an Ammann equipment.

YOUR BENEFITS

• Ensure availability throughout equipment’s lifetime

• Reduce operating cost

• Minimize equipment downtime

• Extend service life

• Single window for all Ammann equipment parts

Jason Tate

Territory Manager Spare Parts

Mobile: +61 488 552 003

Ammann Australia Pty Ltd. 8/85 Pasturage Road, Caboolture, QLD 4510 For additional product information and services please visit : www.ammann.com Materials and specification data are subject to change without notice. PDM-3111-00-EN | © Ammann Group

CALL US TODAY TO DISCUSS YOUR NEEDS AMMATEX FILTER BAGS AMDURIT ® AMMLUB LUBRICATION SYSTEM

AT THE CUTTING EDGE OF CONNECTED MOBILITY

While to most passers-by, the Directed Technologies facility in the Melbourne Airport precinct may look much the same as many of the other facilities in this new major transport and logistics hub, nothing could be further from the truth. In fact, it’s fair to say that most of the heavy vehicle drivers passing the site on a daily basis (even those who may happen to notice it) would be completely oblivious to the important connection that this facility has to their industry – not to mention the many benefits it delivers to many major multinational vehicle manufacturers and society.

Nestled amongst the massive freight forwarding, logistics and warehousing facilities that dominate the local landscape, this new $15 million facility is, without a doubt, a major ‘feather in the cap’ for Australian manufacturing, technology and ingenuity. What’s more, it is helping to cement Australia’s reputation as a global leader in connected mobility. And while that in itself may seem

somewhat of a bold statement, most who are fortunate enough to get a look inside this new high security global connected vehicle and IoT technology hub agree that it is the type of facility that would usually be more at home in Silicon Valley than metropolitan Melbourne.

Representing the next milestone in what is an incredible Australian business success story, the Directed Technologies Connected Mobility Innovation Centre is the

new frontline of Australia’s ‘next-generation’ automotive manufacturing industry –automotive tech manufacturing – where it’s not about manufacturing the chassis, body or wheels; it’s about designing and manufacturing the high-tech solutions and componentry that connects these vehicles and their operators (if they have operators), to each other, the road network, and the world... regardless of the brand.

8 Highway Engineering Australia | June 2023 COVER STORY

This truly is a world-class facility, the importance of which cannot be overstated in terms of jobs, export opportunities and Australia’s standing in the global IoT, ITS and high-tech manufacturing sectors. Working at the cutting edge of digital mobility technology, the Connected Mobility Innovation Centre is set to fuel the rapid growth of connected vehicle technology and IoT solutions that save lives, reduce emissions, and enhance productivity across Australia and around the globe.

“You don’t need to look to Silicon Valley or Europe for cutting-edge automotive technology,” said Steve Siolis, CEO of the Directed Group. “The idea that we don’t make great technology products in Australia is simply not true.”

“We’ve built a world-class facility and developed innovative solutions for the world’s biggest transport companies that have allowed us to compete against global competitors – and win.”

“Because of this team’s work, we deliver significant productivity and safety benefits to our partners and the environment,” he said.

“This facility is the only one of its kind nationally and one of the few full-stack solution centres of its kind globally. With all telematics solutions designed and built

right here on site, there will be significant local employment opportunities as we scale up around the globe,” Steve Siolis added. Major global telematics and connected vehicle technology suppliers will no doubt be taking note, if not be worried about Directed’s rapidly expanding footprint from its humble beginnings in Melbourne to now where it is selling its advanced technology into 22 countries, and with this announcement a next wave set to hit EU and North American shores.

NEXT-GENERATION FLEET DIGITISATION

A Victorian-owned and operated company, Directed Technologies is known for its cutting-edge, factory-fitted connected solutions for a variety of fleet and passenger vehicles, including trucks, trailers, cars, motorbikes, and electric delivery vehicles. The multi-award-winning company’s brandagnostic, cooperative approach to the development of software, hardware and ‘fullstack’ solutions has resulted in exponential growth across Australia, New Zealand and the Asia-Pacific.

The company’s locally-manufactured telematics devices are already used in over 2,500 vehicle fleets globally, including those of Australia Post and Ambulance Victoria,

as well as in leading truck brands like HINO, Mercedes-Benz, Kenworth, DAF, and IVECO. Directed Technologies has also been selected by renowned brands like Ford to export locally designed hardware solutions to the global passenger vehicle market.

Not surprisingly, Directed Technologies is also a ‘great Aussie export success story’, with the company’s homegrown technology now exported throughout 15 APAC countries, including Japan, South Korea, Malaysia, Thailand, Singapore, Guam, Indonesia, and Vietnam.

The new Connected Mobility Innovation Centre will advance Australia’s capabilities in next-generation fleet vehicle digitisation and electrification, while also providing a foundation for Directed Technologies to scale its APAC class-leading solutions to global markets. It will double the company’s local manufacturing capabilities in both telematics and IoT, allowing it to meet an ever-increasing demand for its high-tech products.

In welcoming the attendees at the official opening ceremony in May, Brent Stafford, Executive Director of Directed Technologies, highlighted the role that the new world-class operations centre is already playing in driving fleet safety, security and efficiency.

“I’m very proud to work in an Australian business that is transforming other

“We’ve built a world-class facility and developed innovative solutions for the world’s biggest transport companies that have allowed us to compete against global competitors – and win.”

June 2023 | Highway Engineering Australia 9

(L-R): Victorian Minister for Small Business, Natalie Suleyman MP; Steve Siolis, CEO of the Directed Group; and Brent Stafford, Executive Director of Directed Technologies, inspecting the PCB production line at the new Connected Mobility Innovation Centre in Melbourne.

businesses, including car and truck manufacturers, emergency services, freight companies, last-mile delivery companies and many of the world’s leading fleet operators through digital innovation.”

“The reinvigoration of the automotive industry in Victoria is accelerating, with datadriven solutions, as well as innovations in electric and hydrogen vehicle development and advanced materials manufacturing.”

“The opportunities in connectivity, data analytics and machine learning are right here on our doorstep. These opportunities will not only help to diversify the economy, they will also help solidify Victoria’s position as the centre of automotive manufacturing in Australia,” Brent Stafford added.

AUSTRALIAN INNOVATION AND LOCAL JOBS

Backed in part by the State Government’s Victorian Jobs and Investment Fund, the $15m state-of-the-art centre will place Victoria at the centre of global connected vehicle opportunities, driving the growth of digital skills and manufacturing capability by providing hundreds of jobs for highskilled workers across design, production, engineering and manufacturing.

Speaking at the official opening, Victorian Minister for Small Business, Natalie Suleyman MP said, “Partnering with Directed Technologies creates better innovation and stronger ties globally. But most importantly, it’s about creating jobs."

“We support businesses like Directed Technologies because they bring skilled jobs and investment to Victoria, which further cements our status as the nation’s advanced manufacturing hub.”

“Our advanced manufacturing industry supports many small businesses along their supply chain – boosting the economy and creating local jobs. They’re the backbone of manufacturing in Victoria – leading the way nationally and globally. The technology that is created here, it truly a success story and one that we are absolutely proud of,” Minister Suleyman said.

These sentiments were echoed by the Member for Sunbury and Parliamentary Secretary for Transport, Josh Bull, who added: “Investing in innovation now will increase Victoria’s competitiveness and help create the industries and jobs of the future.”

Importantly, the new Connected Mobility Innovation Centre is already delivering a significant tangible economic boost, particularly in terms of generating new jobs. Indeed, since its establishment, employment growth within the centre has more than doubled the company’s high expectations.

“This centre represents the launchpad to our next growth phase,” Steve Siolis said. “At the time of planning this facility, we predicted aggressive growth in employment here from 100 people to grow to 200 people by the start of 2025.”

“I’m pleased to announce that we reached that milestone three weeks ago - a full two years ahead of schedule - and we now have a talented team of over 220 people employed here at the centre,” he added.

FULL-STACK SOLUTION CENTRE

Together with its focus on quality and innovation, one of the keys to Directed Technologies’ outstanding success and growth, has been its emphasis

on delivering ‘full-stack’ solutions that incorporate everything from software and hardware development, component and equipment manufacture, system integration, live monitoring, support and highly secure data management.

The Connected Mobility Innovation Centre currently manages over 200 terabytes of data, processing some 20 billion probe data points a day, including live video feeds, vehicle and driver behaviour alerts and efficiency measures, and vehicle fault codes. It provides customers with a live view and advanced analytical insights of their people, vehicles, and assets across the global road

Working at the cutting edge of digital mobility technology, the Connected Mobility Innovation Centre is set to fuel the rapid growth of connected vehicle technology and IoT solutions that save lives, reduce emissions, and enhance productivity across Australia and around the globe.

Working at the cutting edge of digital mobility technology, the Connected Mobility Innovation Centre is set to fuel the rapid growth of connected vehicle technology and IoT solutions that save lives, reduce emissions, and enhance productivity across Australia and around the globe.

10 Highway Engineering Australia | June 2023 COVER STORY

The company’s locally-manufactured telematics devices are already used in over 2,500 vehicle fleets globally, as well as in leading truck brands, including MercedesBenz, HINO, Kenworth, DAF, and IVECO.

network to support fleet optimisation and driver assistance programs that reduce congestion, cut carbon emissions through fuel savings and, most importantly, save lives.

Rather than relying on aftermarket solutions which plug into the ODBII service port of vehicles, these Directed OEM approved solutions do not place the vehicle into diagnostic mode and risk interfering with the vehicle warranty, something of particular importance given the high cost of repairing or servicing advanced vehicle safety systems such as lane departure warning or automatic emergency braking technology.

Mr Ross Cureton Director of Product Planning at Paccar Australia the name behind the great Kenworth Trucks and DAF Trucks brands commented at the launch, “Australian transport is quite different to what it is overseas, and Directed understand that, and they know the needs of our customers, they have local manufacturing, so all those things combined make them an attractive supplier to us.”

The benefits of this full-stack solution approach is clearly evidenced in Directed Technologies’ awarding-winning solutions for Australia Post and Ambulance Victoria.

AUSTRALIA POST ‘SAFE RIDER’ VIDEO TELEMETRY SYSTEM

For the Australia Post ‘Safe Rider’ Video Telemetry ITS System, Directed Technologies developed and manufactured a customised multi-camera and onboard telemetry system for Australia Post’s fleet of 20,000+ delivery riders.

Designed in collaboration with Australia Post, the world-first system is the largest single deployment of a vehicle telemetry system in Australia’s urban landscape.

Fitted to Australia Post’s fleet of eBikes, motorbikes and electric 3-wheelers, the system comprises a series of customdesigned, heavy-duty, lightweight, weatherproof and secure camera and telemetry components that monitor the

Directed Technologies developed and manufactured a customised multicamera and onboard telemetry system for Australia Post’s fleet of eBikes, motorbikes and electric 3-wheelers.

Data from the onboard telematics is transmitted in real-time to Directed Technologies’ central dedicated control room, which is monitored 24/7 by a trained incident response team.

vehicles’ location, operating conditions and status. By combining vehicle safety metrics with event-based video information, incidents are recorded and available for rider coaching and protection purposes, providing verifiable evidence of events if required. In addition, the system features a panic/duress button and tilt sensors that activate a rapid assistance protocol in the event of accidents or other safety-related incidents, including dog attacks or physical assaults.

Data from the on-board telematics is transmitted in real-time to Directed Technologies’ central dedicated control room, which is monitored 24/7 by a trained incident response team who are able to provide assistance to delivery riders in the event of an accident or incident.

June 2023 | Highway Engineering Australia 11 COVER STORY

Directed Technologies is also working with renowned brands, including Ford, Nissan and Mercedes-Benz, to export locally designed hardware solutions to the global passenger and commercial vehicle market.

AMBULANCE VICTORIA CONNECTED VEHICLE SOLUTION

Working with the team from Ambulance Victoria, Directed Technologies has also developed an Australian-designed and built connected vehicle solution for Ambulance Victoria’s fleet of over 1,200 Emergency Service Vehicles.

Embedded within the vehicle’s electronics, the system monitors an array of data, including engine temperature, fuel status, battery health, service data, crash alerts and seatbelt warnings.

Uniquely, the system is also integrated into the on-board auxiliary systems in the back of the ambulance, as well as lights and sirens, and the secondary battery system, which is used to charge the defibrillator, ECG machines and other mission-specific components. This allows the system to generate unprecedented mission-critical telematics insights into ambulance operations, including data on safety system activation, light and

The Directed Technologies system is also integrated into the onboard auxiliary systems in the back of the ambulance, as well as lights and sirens, and the secondary battery system, which is used to charge the defibrillator, ECG machines and other missionspecific components.

siren status, occupant detection and emergency equipment charging status.

Much more than just a simple vehicle tracking system, data from the Directed Technologies’ Connected Vehicle Solution is already fuelling a new suite of intelligent services, built through cloud-based data analytics and machine learning.

Importantly, the technology has been developed to allow rapid adaptation to other onboard digital CANbus signals as required, or for other emergency vehicle types. Indeed, while the system was initially developed using Ambulance Victoria’s Mercedes-Benz fleet, Directed Technologies have already adapted and integrated the system for Toyota, Ford, Volkswagen and Nissan vehicles.

Needless to say, being able to rapidly adapt and integrate this technology across a wide range of vehicle brands and types from across all global regions, provides Directed Technologies with unprecedented export opportunities.

Directed Technologies has also developed an Australian-designed and built connected vehicle solution for Ambulance Victoria’s fleet of over 1,200 Emergency Service Vehicles.

LOOKING TO THE FUTURE

Not surprisingly, despite the company’s numerous successes, world-leading high-tech solutions and staggering global growth, this is definitely not a company that ‘rests on its laurels’. In fact, the team from Directed Technologies is currently working on a number of new connected mobility solutions that look set to revolutionise everything from remote vehicle diagnostics and rapid response maintenance services, through to transport efficiency, traffic flow control and reducing heavy vehicle emissions through the provision of ‘green light corridors’.

ABOUT DIRECTED TECHNOLOGIES

Directed Technologies is a digital innovation partner of choice, curating connected technology solutions at scale that save lives, reduce emissions, and enhance productivity.

Its global team design, manufacture and manage tailored end-to-end solutions for automotive, transport and logistics and other organisations on a digital transformation journey. Founded on deep industry expertise and an engrained culture of customer collaboration, its services span hardware, software, cloud services and business intelligence.

Headquartered in Melbourne Airport, Australia, with a growing global footprint, across, New Zealand, Thailand, South Africa, and Hungary, Directed Technologies' innovative automotive solutions are found in more than 2,500 vehicle fleets globally, including 25% of trucks on Australian roads being supplied with ‘factory fitted’ telematics systems designed and built by Directed. The business continues to experience rapid growth, increasing its revenue by 45% year-on-year in FY22.

Directed Technologies is part of the Directed Group, which includes Directed Australia, a leading developer, supplier, and distributor of Mobile and Consumer Electronics across Australia and New Zealand. Visit https://directedtechnologies.com.au for further information.

12 Highway Engineering Australia | June 2023 COVER STORY

Climate Smart Engineering Conference

29-30 November 2023 | Melbourne

ACCELERATING AUSTRALIA’S TRANSITION TO NET ZERO EMISSIONS

Connecting engineering minds, ideas and opportunities, Climate Smart Engineering Conference (CSE23) will showcase the latest solutions to pave the way for net zero emissions in Australia. Book early and save up to $210.

Register now

Conference partners

www.engineersaustralia.org.au/cse

inspection data - from historical reports, photos and videos, through to current drone imaging and LiDAR data - to provide asset owners and managers with a comprehensive condition report for their assets. Our AI-based predictive analytics utilise your current and historical data to prioritise maintenance requirements and optimise your infrastructure asset management activities. T: 1300 552 878 www.dynamicinfrastructure.com.au WHERE AI MEETS All of your asset data…

ASSET MANAGEMENT

Right at your fingertips

Tested by certified engineers, Dynamic Infrastructure utilises proven, cutting-edge AI technology to provide asset owners and maintenance managers with actionable insights to save money and increase maintenance e ciency.

• Identify defects before they evolve into large-scale failures

• Prevent unplanned expenses & manage risk

• Maximise warranty through automated tracking of repairs

• Gain full field-to-o ce visibility

DISCOVER MORE

Delta +25% since 2018 Corrosion Spall Delta +25% since 2015 Crack Delta +12% since 2017

FALLING BEHIND OTHER STEM INDUSTRIES IN GENDER EQUALITY… BUT THERE ARE SOLUTIONS

Over the past 25 years, the lack of gender equity within science, technology, engineering, and mathematics (STEM) in Australia and worldwide, has become more apparent. There have been numerous programs, plans and strategies drawn up to tackle the gross underrepresentation, but despite progress in other STEM industries, engineering is still falling behind. Without equal representation, engineering cannot achieve inclusive design or well-rounded problemsolving, which can lead to costly or time-consuming retrofits and revisions[1].

Hatch, an award-winning global multidisciplinary leader in delivering engineering, operational and development projects in the metals, energy and infrastructure industries, is seeking to address and rectify female under-representation in its industry ahead of International Women In Engineering Day on 23 June.

In 2019, Science in Australia Gender Equity revealed the percentage of women studying or working academically within the STEM industry. Natural and physical sciences had the highest proportion at 51 per cent, followed by information technology at 26 per cent. By comparison, engineering and related technologies had just 19 per cent of women proportionally.[2]

This is not where the issue solely lies, as even when women are brought into the engineering workforce, the gender distribution of senior positions remains significantly imbalanced. Only seven per cent of CEOs and 21 per cent of senior managers in architectural, engineering and technical services are women.[3]

Therein lies a catch-22: if entry-level female engineers do not see themselves represented in senior positions, they are more likely to feel disengaged and uninspired by their engineering career progression, and so the underrepresentation cycle continues.

However, this underrepresentation in engineering goes back even further, as girls at school have been discouraged from the subject as they enter their teenage years. The Workforce Gender Equality Agency asked girls and boys aged 12-17 whether they were interested in STEM subjects, only 36 per cent of girls said they were interested in engineering, compared to 61 per cent of boys. Comparatively, 64 per cent of girls and 70 per cent of boys said they were interested in science.[4]

Duncan Mallord, Head of Diversity and Inclusion at Hatch, says firms should be inspired, and not dismayed, by engineering’s currently disproportionate workforce.

“We know that equity and equal representation can be achieved in engineering.”

“EngineeringUK announced in 2021 that 370,000 more UK women were working in engineering jobs than in 2010[5]. But it takes hard work and buy-in from across the board; it’s not just a tick-box exercise.”

“It is the responsibility of male engineers and male hiring managers to create a working environment that appropriately supports and recognises the integral contributions that female engineers can offer. We need to start creating tomorrow’s role models today,” Mallord added.

TACKLING THE GENDER PAY-GAP IS FIRST STEP TO EQUITY

In 2021, architectural, engineering, and technical services were one of the STEM industries with the largest gender pay gap, at 24 per cent, following oil and gas extraction (26 per cent) and metal container manufacturing (25 per cent)[6]. Since the gender pay gap refers to the average male salary across a business compared to the average female salary, the above data indicates that the roles with higher salaries, e.g., CEOs and senior leaders, are predominantly male. Duncan says addressing the disparity requires actively bringing more females into senior roles.

16 Highway Engineering Australia | June 2023 SPECIAL REPORT

ENGINEERING

Companies could also recognise the additional value in the ‘perspective’ that female engineers bring.

“If a male and female engineer are applying for the same role with the same level of experience and similar skill sets, the female candidate could bring additional value to the engineering team: that of a female’s perspective to the design process and increasing the diversity of thought. For this reason, engineering companies should offer the female applicant an equitable premium.”

According to the Australian Bureau of Statistics, female engineering graduates earned slightly more than their male counterparts for the first time in 2017. The median starting salary for female engineering graduates was $65,000, whereas for male engineering graduates, the median starting salary was $63,500.[7]

CREATING A WORKING ENVIRONMENT THAT SUPPORTS FEMALE DEVELOPMENT AT ALL STAGES OF THEIR CAREER

Even with a higher entry-level salary, the pay gap remains, which can be put down to the lack of women in senior engineering positions. With only 73 per cent of architectural, engineering, and technical services organisations having a gender retention policy or strategy in place, more women are likely to leave during their tenure.[8]

Duncan says: “While bringing in female engineers at entry-level roles is necessary, it’s a fruitless process if they leave after a few years due to lack of career opportunities or unsupported lifestyle choices. Engineering companies need to provide female engineers with role models that can show a clear path for younger women to follow.”

“For example, women should know that they will be supported by the business if they choose to have children, and the best way to do that is to have a solid regime in place, which has been used by other engineers before them. To enable this, we need to encourage and support females to take on leadership roles and become influencers in the company.”

MALE ALLIES NEED TO STAND UP AND SPEAK OUT

“Engineering has historically and notoriously been a boy’s club, and with that comes an increased likelihood of misogynistic remarks or actions,” Duncan said.

“While most male engineers recognise and value differences and welcome perspective of thought from everyone, some lack the wherewithal to incorporate actively inclusive actions or call out toxic behaviour,” he added. “Addressing unconscious bias should be part of every company’s mandatory training program.”

Duncan says: “It’s everyone’s issue. If we want the best team, project, result, and business, then it shouldn’t be left to a diversity and inclusion committee to work on it in their free time.”

“You don’t have to be female to acknowledge a female engineer’s contributions or back a female’s promotion application. In fact, I think one most important thing for D&I committees is to show that allies must educate themselves, speak up, and make a difference,” he concluded.

References

[1] The Benefit of Designing for Everyone (centreforinclusivedesign.org.au)

[2] Gender equity in higher education | SAGE (sciencegenderequity.org.au)

[3] Workforce and gender equity policies in STEM and other industries | STEM Equity Monitor | Department of Industry, Science and Resources

[4] Youth perceptions and attitudes to STEM | STEM Equity Monitor | Department of Industry, Science and Resources

[5] Engineering Council (engc.org.uk)

[6] Gender pay gaps in STEM and other industries | STEM Equity Monitor | Department of Industry, Science and Resources

[7] 4125.0 - Gender Indicators, Australia, Sep 2018 (abs.gov.au)

[8] Workforce and gender equity policies in STEM and other industries | STEM Equity Monitor | Department of Industry, Science and Resources

4" TRASH PUMP ... DIRTY WATER SPECIALIST

ü Self priming to 7.6m ü Fast, easy set up ü Flows to 1,600 lpm ü 10HP Yanmar diesel

ü 5 year pump warranty

Mobile Media Blasting - Soda & Garnet

• Specialising in Concrete preparation for Carbon Fibre application

• Abrasive & Non-Abrasive Blasting

• Paint, rust & contaminant removal from many substrates

• Line marking removal

• Graffiti removal & protection

• Removal of sealers & coatings

• Creation of non-slip surfaces

• Compact machinery for easy access

• Low media usage which means less environmental issues with reduced containments and dust

• Suitable for confined space blasting

1300 240 337

www.enviroblast.com.au

EnviroBlast

Australia

aussiepumps.com.au

we’reforAustralia June 2023 | Highway Engineering Australia 17

4" DIESEL TRASH PUMPS Australian Pump Industries Aussie Pumps 02 8865 3500

AUSSIE PRODUCTION SOARS

ZERO EMISSION OPTION NOW AVAILABLE FOR ANY SPMT TRANSPORT

AUTOLIV TO LAUNCH ITS FIRST MOTORCYCLE AIRBAG IN 2025

Autoliv, Inc., is pioneering improved safety for 200 million road users through its holistic approach to motorcycle and scooter safety. The first new motorcycle safety product to reach the market will be the bag-on-bike airbag, with production beginning in Q1 2025. The bag-on-bike airbag can significantly reduce the risk of serious injury for powered two-wheeler riders in frontal crashes.

The number of powered two-wheelers continues to rise, due to widespread urbanization and the practicality of powered two-wheelers.

Today, many scooters and motorcycles are equipped with advanced safety systems, such as ABS (Antilock Braking System) and ASR (AntiSlip Regulation), and the addition of airbags will be a further step in this direction. Powered two-wheeler riders have not benefited to the same extent as car occupants from the many developments in vehicle safety.

“Autoliv is committed to our vision of Saving More Lives and to providing world-class lifesaving solutions for mobility and society,” said Mikael Bratt, CEO and President, Autoliv.

“Therefore, we are developing products that specifically protect vulnerable road users, such as riders of powered two-wheelers. The development of these products is an integral part of our sustainability agenda,” Mr Bratt said.

THE BAG-ON-BIKE AIRBAG: A COMPLETE AIRBAG SYSTEM

Autoliv's extensive research into powered two-wheeler riding behavior and crashes has resulted in two sets of solutions - on-vehicle safety solutions and on-rider safety solutions. The first product to reach the market will be the bag-on-bike airbag, which is planned to go into production with the first customer in 2025.

“Our goal is to offer a complete and costefficient bag-on-bike system to facilitate the introduction of this technology for a wide variety of motorcycles,” said Jordi Lombarte, Chief Technical Officer, Autoliv.

“The Autoliv bag-on-bike airbag system will include an airbag and an optional in-housedeveloped electronic crash sensor to complete the system,” Mr Lombarte added.

EVOLVING SAFETY REGULATIONS FOR POWERED TWO-WHEELERS

Cecilia Sunnevång, Vice President Research, Autoliv, said “To reach the global target of halving road traffic fatalities we need to increase the safety for powered two-wheeler riders.”

“Through working with real-life data, we understand the most frequent crashes and injury types and how to assess them in a laboratory environment.”

“Through virtual and physical testing, we have demonstrated the benefit of the airbag in frontal crashes, and we acknowledge that there is a need for additional solutions to cover more crash situations and rider behaviours," Ms Sunnevång added.

The safety of motorcycle riders is the focus of many regulators and consumer crash test organizations. Euro NCAP is targeting enhanced motorcycle rider safety by expanding vehicle crash avoidance testing to include powered twowheeler crash scenarios.

In Asia, the Malaysian Institute of Road Safety Research (MIROS) indicates that the rating of onvehicle safety solutions will be adopted in 2024 in their Malaysian Motorcycle Assessment Program (MyMAP).

AUTOLIV

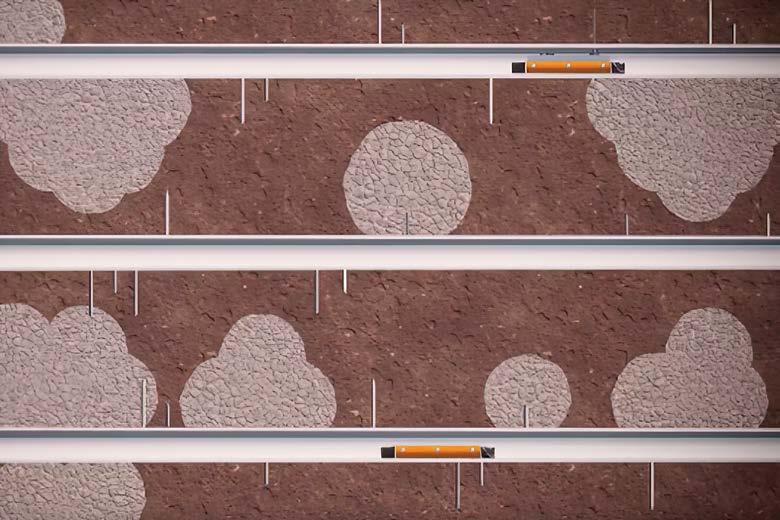

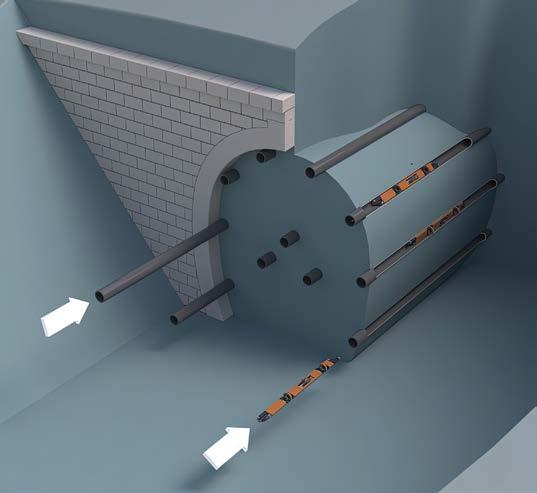

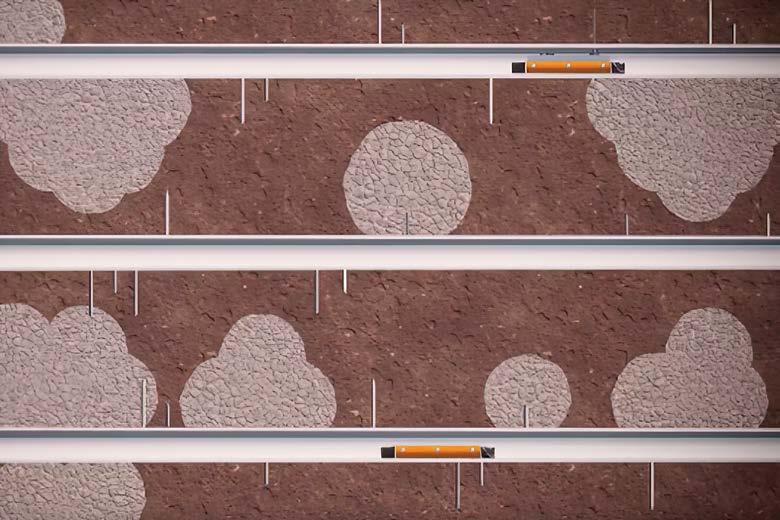

World leader in transporter technology Mammoet, is now offering a zero-emission option for any Self-propelled Modular Transporter (SPMT) compatible with any trailer in its fleet.

This development has been made possible through a conversion process for SPMT power pack units (PPUs), which replaces the diesel powertrain inside existing trailers with an electric alternative. Once retrofitted, each trailer combination has comparable power to existing industry standard units.

The PPU vastly reduces noise levels at project sites, resulting in a safer and more productive work environment for our customers and colleagues. With reduced noise, communication between staff is clearer, while at locations where sound restrictions are in place, longer operational windows are now possible.

The system represents another step towards zero-emission on-site, eliminating the carbon footprint of SPMT transport entirely. This allows SPMT to meet increasingly strict environmental legislation more easily, reducing the impact of transport phases on surrounding communities and infrastructure.

It also demonstrates Mammoet’s strong commitment to the energy transition and to its own sustainability. Retro-fitting existing SPMT fleets cuts down on both waste and additional fabrication when compared to sourcing new zero-emission equipment.

This solution was part-financed by the DKTI, a Dutch government program to develop climate technologies and innovations in logistics. Mammoet worked with a leading provider of zero-emissions powertrains for heavy industry to bring the electric power pack solution to market.

Developed by Mammoet in 1984 and with over 40,000 axle lines in use globally, the SPMT, or Self-propelled Modular Transporter, revolutionized heavy industry by allowing practically any load to be transported and manoeuvred safely, efficiently and with precision.

The company believes that this next step in its story will be just as significant - reducing its CO2 and NOx emissions to nil and pointing the way towards a sustainable future for heavy transport. To find out more, visit: www.mammoet.com

ABOUT

Autoliv, Inc. is the worldwide leader in automotive safety systems. Through its group companies, it develops, manufactures and markets protective systems, such as airbags, seatbelts, and steering wheels for all major automotive manufacturers in the world as well as mobility safety solutions, such as pedestrian protection, connected safety services and safety solutions for riders of powered two-wheelers. For more information, visit: www.autoliv.com

18 Highway Engineering Australia | June 2023 INNOVATIVE SOLUTIONS

THE EQUIPMENT YOU NEED – THE SERVICE YOU EXPECT A1 Roadlines Pty Ltd | 89 Rushdale Street, Knoxfield, Victoria 3180 | www.a1roadlines.com.au P: 1300 217 623 (A1ROAD) | E: sales@a1roadlines.com.au

INFINITY TESTING

'Infinity

NO RELIANCE ON ROLL-AHEAD DURING AN IMPACT

Rather than relying on some of the impact energy being absorbed by the forward movement of host vehicle on which the TMA is fitted, with ‘Infinity Testing’ the host vehicle is anchored to the ground to prevent any forward movement during an impact.

‘WORST CASE’ SCENARIO TESTING

Compared to standard testing with an unrestrained host vehicle, Infinity Testing is a much tougher testing regimen. It is considered ‘worst-case scenario’ testing which makes it much more difficult to meet the pass criteria for IS values, as all of the Ridedown Acceleration must be provided by the TMA absorbing the energy from the impact.

TMA ABSORBS & DISSIPATES 100% OF THE IMPACT ENERGY

Testing the TMA on a host vehicle which is anchored in place, tests – and for both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMAs – confirms the capacity of the TMA to absorb/dissipate 100% of the impact energywithout the benefit of the host vehicle roll-ahead.

NO UPPER LIMIT FOR HOST VEHICLES

From a practical standpoint, the fact that both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMAs were successfully tested to MASH Standards using the ‘Infinity Testing’ method, means both units are MASH certified with no upper weight limit for the host vehicle.

www.a1roadlines.com.au

Testing’ is without a doubt the harshest method of testing the performance of a Truck Mounted Attenuator (TMA) during an impact.

THE ULTIMATE TEST OF ATTENUATOR PERFORMANCE

HOW IT’S DONE

With ‘Infinity Testing’ the host vehicle is anchored in place during the impacts to assess the TMA's capacity to absorb/ dissipate 100% of the impact energy without the benefit of roll-ahead.

WHAT ABOUT ROLL-AHEAD DISTANCES?

Importantly, to emulate ‘real world’ operating conditions, both the Scorpion II® TL-3 and Scorpion® II METRO® TL-2 TMA have also been successfully tested and MASH certified using standard ‘non-anchored’ host vehicles, with both units posting impressively low roll-ahead distances.

THE EQUIPMENT YOU NEED – THE SERVICE YOU EXPECT A1 Roadlines Pty Ltd | 89 Rushdale Street, Knoxfield, Victoria 3180 P: 1300 217 623 (A1ROAD) | E: sales@a1roadlines.com.au

Scorpion® II TL-3 TMA Crash Test: MASH Test 2-53 Impacting Vehicle Weight: 2266kg Impact Angle: 10.3 Degrees Impact Speed: 103.8km/h Roll-Ahead Distance: 5.1m Scorpion® II METRO® TL-2 TMA Crash Test: MASH Test 2-53 Impacting Vehicle Weight: 2295kg Impact Angle: 9.9 Degrees Impact Speed: 81.6km/h Roll-Ahead Distance: 12.4m

BITUMEN CLEAN UP

Our hardworking specialist road resurfacing contractors are faced with real challenges. The recent floods have not only created potholes in country roads but even the M2 approaches to the Harbour Tunnel in Sydney is desperately in need of resurfacing.

Now there’s a challenge! How to stop the traffic long enough to get that job done… and done properly so it doesn’t wash out next time we get heavy rain.

Unfortunately, it appears that a number of big projects like the Coffs Harbour Bypass, together with other major works in western Queensland, NSW and Victoria, may now be in danger of losing funding. At the same time, there are any number of projects (large and small) across the country that require roads to be built or rebuilt so that they will hopefully be impervious to what appears to be more frequent and more extreme climate changedriven floods.

DO IT ONCE - DO IT RIGHT!

When you consider the devastating impact that torrential rains have had on the nation’s road network over the past year aloneparticularly in regional and remote areas - one has to ask why sufficient funding hasn’t been allocated to build a more ‘climate resilient’ road network – one with the supporting infrastructure that will enable it to better withstand the extreme weather events.

The first step, of course, is drainage. Without the proper drainage engineering being done in advance, even a good road, properly graded,

compacted and surfaced, will cause issues. With the drainage and other supporting infrastructure in place, it comes down to good design and good engineering, followed by quality construction by skilled teams using quality materials and high-quality, wellmaintained equipment.

A BIG COUNTRY NEEDS GREAT ROADS

A big country needs great roads… and building great roads takes skilled people, quality materials and specialist equipment that is capable of delivering results in what can be some of the toughest road-building conditions on the planet.

Fortunately, across Australia, we have many highly skilled infrastructure engineering and design specialists, as well as an abundance of road construction companies and contractors ready to answer Australia’s major road construction challenge.

Not surprisingly, as part of their efforts to deliver quality results while also boosting both productivity and worksite safety, many of these contractors have invested heavily in the world’s best equipment.

From earthmoving, profiling, compaction and grading equipment, through to hot mix tankers, paving machines, rollers, mobile asphalt production plants and, of course, a fleet of tippers and truck-dog combos of truly staggering proportions, there can be no doubt that high-quality, well maintained equipment plays a critical role in quality road building.

KEEPING HOT MIX EQUIPMENT CLEAN

Needless to say, keeping this equipment clean not only plays a key role in keeping it working to its full potential, in many instances, removing the dirt and detritus from equipment is a necessity before the equipment is able to be maintained. This is a particular challenge when it comes to cleaning hot mix equipment, where cleaning generally can’t be achieved efficiently with cold water pressure cleaners.

With that in mind, one Australian company, Australian Pump Industries, has made a speciality of working with hot mix operators to deliver effective equipment cleaning solutions – producing a range of hot wash and steam cleaning high-pressure machines that will get the job done efficiently and at the lowest possible cost.

“Coming out of the earthmoving industry, we know about hot mix plants,” said Aussie Pumps Chief Engineer John Hales. John was a cadet engineer at Tutt Bryant’s Barber Greene Division back in the 1960s and 70s and knows what he is talking about.

“We always dreaded having to clean the equipment after a job especially when we had been out demonstrating the latest Barber Greene paver,” he said.

Aussie’s simple solution is to use highpressure hot water or steam to get the job done fast.

22 Highway Engineering Australia | June 2023 EQUIPMENT FOCUS

Working with big and small paving specialists, the team at Aussie Pumps have found that going from cold water to hot or steam machines can reduce cleaning time by an average of two-thirds.

“The heat simply melts the material, and when used in conjunction with a good degreaser, gets the job done fast,” said Hales.

IN DEPOT OR FIELD

Although the majority of plant is taken back to the depot before being cleaned, Aussie Pumps has engineered a range of new machines that can carry out this cleaning task on the worksite - a key benefit when it comes to preparing a machine for on-site maintenance or repair.

One steamer, called the Aussie Heatwave, delivers 4000 psi pressure and up to 130° C steam. It’s mobile and, can be mounted either on the back of a ute or truck or, even pushed around the site.

The Aussie Heatwave machine comes in a heavy-duty stainless steel frame with wheels for mobility if required.

Most of these machines, many of which are operated by local government bodies, can perform a multitude of tasks for councils or earthmoving contractors. The Aussie Heatwave has a diesel-fired burner and uses a Honda 13hp electric start engine to drive both the pump and steam system. The ignition for the boiler comes from Honda’s 12v electrical circuit, making it a neat and cost-effective solution.

The machines can be fitted with a stainless

Big diesel drive machines with more flow and pressure, are also available, however, some may require operators to be certified under the current Pressure Cleaner Safety Standards prior to use.

CLEANING AT THE DEPOT

Cleaning at the depot can provide a degree of convenience as the high-pressure steamer can be permanently mounted in a wash bay and powered electrically. To that end, the Aussie Pumps team has also produced a hot steam cleaner capable of delivering 15 lpm @ 4000 psi, with temperatures up to 130° C steam.

“We tested the first prototype at Coates Hire Depot at Moorebank. They gave it a hammering and we checked on it every couple of weeks to see how it went,” said Hales.

The unit was then moved around to a number of other Coates Hire branches, and the positive feedback was unanimous… the operators liked the extra punch of 4000 psi which enabled to clean big plant faster thanks to the extra steam pressure.

“Everybody likes to work with clean equipment,” said Hales. “That said, nobody particularly likes spending hours cleaning equipment, and that’s why the Aussie Heatwave machines are so popular. They dramatically cut cleaning times, which helps to reduce overall servicing time and equipment downtimes. And they produce a great finish to boot,” John Hales added.

Established in Sydney in 1993, Aussie Pumps

Their high-pressure cleaning equipment is used by local governments, public and private sector organisations, and contractors large and small across the infrastructure, construction, mining, defence, fleet, and equipment hire industries.

For further information on Aussie Pumps’ “Hot Shot” range of high-pressure steam cleaning equipment, contact Australian Pump Industries High Pressure Cleaning Division, or check out their website at: https://aussiepumps.com.au

FREE ONLINE OPERATOR TRAINING COURSE

Aussie Pumps also offers a free training program for high-pressure cleaning operators. The course is extremely thorough and is based Aussie Pump’s extensive experience in the design, manufacture and supply of high-pressure water and steam cleaning equipment to a wide range of industries.

The ‘Aussie Blaster Safe Operator’ course aims to inform users on the safe operation of Class A and Class B high-pressure water blasters to 500 Bar maximum pressure. The course covers a range of key topics, including Australia Safety Standards for Operators, and high-pressure technology, as well as maintenance and operation of the machines.

Scan code to access Aussie’s Safe

When it’s photography you need… There’s only one name you need to remember T: 03 9347 9156 E: info@casamento.com.au www.casamento.com.au Specialising in: › Architecture › Infrastructure › Industrial › Events › Portraits › Headshots June 2023 | Highway Engineering Australia 23 EQUIPMENT FOCUS

COLLABORATIVE STUDY TO HELP UNDERSTAND MOVEMENT OF DANGEROUS GOODS VEHICLES

A new industry-led data sharing initiative between Transport Certification Australia (TCA) and the National Bulk Tanker Association (NBTA) aims to provide better understanding of the movement of vehicles transporting dangerous goods and bulk liquids on the road network.

Speaking at the Bulk Tanker Day 2023 in Brisbane, TCA’s General Manager of Strategy and Delivery Gavin Hill said the new initiative builds upon the success of an earlier data sharing arrangement between TCA and the NBTA, which involved transport operators in the dangerous goods sector.

“What we found from the previous study was that many dangerous goods transport operators had not necessarily seen a macro view of their vehicles’ footprint across the network. So, instead of leaving that as a one-off study, we’ve decided to launch an

evergreen study, where we’ll work with the industry to make sure they get true benefits out of it,” Hill said.

A key aspect of this new initiative is that the types of dangerous goods being carried by vehicles will be collected. When combined with vehicle movement data, the collection of dangerous goods types will provide valuable insights into the movement of dangerous goods on the road network, Hill explained.

“We recognise that different operators may collect this information in different ways, and we’ll work with individual operators to ensure there’s a streamlined process to share dangerous goods load information with us.”

He also highlighted how the construction transport sector has established a data sharing initiative with TCA.

“We currently have 2,000 construction transport vehicles sharing data with us. The

TCA AT THE BRISBANE TRUCK SHOW

Transport Certification Australia

(TCA)

attended the Brisbane Truck Show 2023 on 18-21 May, which this year received a record turnout from the heavy vehicle and road freight industries. It was particularly pleasing to see so many technology providers and suppliers recognised through the National Telematics Framework (NTF) at the Brisbane Truck Show and supporting the needs of the Australian transport industry.

A key area of interest for many was Smart On-Board Mass (OBM), and what’s required by transport operators to satisfy requirements in Tasmania, Victoria, New South Wales and Queensland. Show-goers were able to speak directly with five Smart OBM suppliers at the show, who offered different technologies to satisfy the needs of different users.

With an increased number of technology providers now participating in the NTF, coupled with the roll-out of new telematics schemes being activated across the country, TCA plays a key role in providing transport operators with easy-to-understand information and advice.

Each Certified Application Service Provider has pairing approvals with one or more Smart OnBoard Mass (OBM) supplier.

More information on the existing pairings between type-approved telematics devices and Smart OBM systems is available at: https://tca. gov.au/smart-obm-systems/

WHAT’S NEW IN TELEMATICS?

TCA also joined with Heavy Vehicle Industry Australia (HVIA) to host a series of information sessions called “What’s New in Telematics?” at the Brisbane Truck Show. The sessions were targeted to provide relevant information to heavy vehicle operators, drivers and fleet managers about recent and emerging developments in telematics.

The speakers at the forums included Gavin Hill and John Gordon from TCA, Greg Forbes and Adam Ritzinger from HVIA, Wayne Dale from the National Heavy Vehicle Regulator and David McIntosh from Telstra.

The speakers used the opportunity to shed light on some of the pressing questions in the

reports and analysis derived from the data being shared is helping the construction transport sector better understand the footprint of construction vehicles across the road network, to manage community and environmental concerns.”

A key foundation of all industry-led data sharing initiatives managed by TCA is the transparent consent arrangements, which fully disclose the purpose for which data is collected, how it will be used and importantly, how it will not be used. These arrangements, coupled with TCA’s independent role, are essential to establishing the trust necessary for transport operators to enter into voluntary data sharing initiatives.

FBT Transwest is one of the companies that have already signed up for participation in the study.

Cameron Dunn, FBT Transwest’s Managing Director and Deputy Chairman of the NBTA, said: “The important thing for bulk tanker operators is getting that granularity [of data]. We’re looking at inputting data on all dangerous goods classes that we carry, as well as milk and other non-DG liquids. This is required so we can have an informed discussion about network access with the Department of Transport and Planning Victoria.”

Find out more about the Dangerous Goods Voluntary Data Study and how to get involved at: https://tca.gov.au/dangerous-goodsvoluntary-data-study/

industry, such as: “Are all telematics devices the same? Why does my Smart OBM need to be paired with a certified ASP? What is the telematics data collected from my vehicle used for? What will happen when the 3G network closes down in June 2024?”

The great turnout and the active engagement from participants indicate an appetite within the industry to learn more about telematics and data, and how digital technologies are now a critical dimension of modern heavy vehicle operations.

24 Highway Engineering Australia | June 2023 TCA NEWS

Wayne Dale, Product Manager Predictive Analytics at the National Heavy Vehicle Regulator was among the speakers at the forum.

AIRTEC’S

NEW

SMART OBM

SYSTEM

TYPE-APPROVED BY TCA

Transport Certification Australia has announced that Airtec Corporation has obtained typeapproval for its new AXS Series (AXS101D and AXS102D) Smart On-Board Mass (OBM) system. Smart OBM systems capture vehicle axle mass measurements as digital records, and can be used to improve productivity, compliance management and safety outcomes.

The new Airtec AXS Smart OBM system introduces new features when compared with earlier Smart OBM systems offered by Airtec. A key feature of the ASX series is the use of a variable colour ring, which indicates whether an axle group is underloaded, loaded to legal limits of overloaded.

The Airtec TruckOBM app allows drivers to check their weights remotely from their smartphone.

Details of the new Airtec Smart OBM system type-approved by TCA are listed below:

David Hewett, Managing Director of Airtec Corporation, said: “The development of the AXS series Smart OBM system responds to the feedback we’ve received from customers. We knew that the market needs an easyto-understand Smart OBM system, and have delivered a durable product that can endure the Australian road conditions and an integrated technology that just works.”

TCA’s General Manager of Strategy and Delivery Gavin Hill said: “TCA plays an important role in assessing the performance requirements of Smart OBM systems.”

“TCA’s type-approval involves the assessment of OBM system ‘types’ against the performance-based requirements contained in the OBM System Functional and Technical Specification. Airtec’s AXS Series has met all the requirements put in place for a TCA type approval Category B.”

“With the adoption of road access policies which rely on the use Smart OBM systems, in conjunction with schemes offered through the National Telematics Framework, the transport industry continues to benefit from new technologies and the latest product offerings to improve productivity and safety,” he added.

Find out about the three categories of type-approved OBM Systems (Categories A, B and C) which meet the needs of different stakeholders at: https://tca.gov.au/obm

FIRST IN-FIELD ASSESSMENTS BEGIN FOR INNOVATIVE TEMPORARY TRAFFIC MANAGEMENT DEVICES

A solar-powered mobile traffic gate is amongst the first temporary traffic management innovations to be put through its paces as part of the Austroads Innovative Temporary Traffic Management Device and Solution Assessment (AITDSA) scheme.