TILE LEVELLING SYSTEMS ULOCK: A SAFE WAY TO MIX

CLEARTILE CUSTOMISED FOR THE TILE INDUSTRY

TILE LEVELLING SYSTEMS ULOCK: A SAFE WAY TO MIX

CLEARTILE CUSTOMISED FOR THE TILE INDUSTRY

6 All-Over tile production technology allows the texture of the ceramic slab to be reproduced on the edge. Exclusive to Italian manufacturer Fondovalle.

8 The company’s “Respirable Silica Free” technologies are available at a time when there is an increased awareness of silicosis in the tile industry.

10 The uLock mixing system is a pail, platform and lid that supports the safe mixing of all powder products. Designed and engineered in Australia.

12 In this feature, we explore the history and developments of tile levellers, and provide a product overview for installers.

24 Ceramiche Refin’s Tamashi range is inspired by timber and designed for contemporary architectural settings.

26 Clear Software has been providing software solutions for the tile industry for a long time. We find out how it began and speak to a few key customers, Designer Stone Solutions and Wyllie Tiles.

30 Colors from Ceramica Rondine is a range of indoor porcelain stoneware wall tiles that won a 2023 Archiproducts Design Award.

32 Epegrout by Dribond Construction Chemicals is a threecomponent, water-washable, chemical resistant, epoxy tile grout for joints up to 3mm.

34 If you missed any major stories in Tile Today’s e-newsletters, we provide direct links to them on the website.

RLA’s new range of Respirable Crystalline Silica free* products provide a safer alternative in your work environment.

RLA Polymers' range of powder solutions are classified as free from respirable crystalline silica (RCS) hazards*, ensuring that mixing & application poses no threat of exposure to dangerous levels of RCS.

At RLA, we are dedicated to surpassing the hazardous requirements for RCS levels, guaranteeing the safety of our products.

In addition, we recommend the use of a PPE & dust masks due to the cementitious nature of the product. Always adhere to safety directives, in the products Safety Data Sheet (SDS) and consult the product's Technical Data Sheet (TDS) prior to application.

It might surprise some in the industry to realise that tile levelling systems have been around — commercially — for 17 years or so. Equally surprising is how much innovation there is in the field — and much of that comes from smaller, independent manufacturers, rather than major tiling supplies companies.

Drawing on information provided by tilers themselves, we've outlined what you should look for in a good system, and have provided an overview of the major players.

Talking about tools of the trade, for tile retailers, wholesalers and distributors, one of the vital parts of their businesses is the software they choose to drive it. Clear Software, which makes ClearTile, has been in business since the 1980s, and continues to develop innovative solutions.

They've added a cloud side to their desktop software, and provide access through a range of mobile devices as well. It's very rich software with lots of options, Australia-based support, and the ability to customise solutions for unique applications in the tile industry.

(l&r) Clear Software owner Gordon MacMaster with sales & operations manager Nigel Turner

Other notable stories in this edition include the development of the uLock safe mixing system that is a brand new idea — originating in Australia — that will help many people the industry.

A few noteworthy tile collections featured in this issue are Tamashi from Ceramiche Refin and Colors from Ceramica Rondine.

Look out for Tile Today’s coverage on Cevisama 2024 in the next e-newsletter.

To keep up to date on the latest news and developments in the tile industry, just click here or below to subscribe:

https://bit.ly/3dJ5EBc

See you next time,

Betty TanddoFrom the collaboration between Atlas Concorde and the Pritzker Prize-winning Zaha Hadid Architects comes a “disruptive” decorative proposal in the form of the Diamond décor. “Like an inclusion in a diamond, the insertion of a foreign body into a crystalline structure lends an unsuspected dynamism to the rigorous repetition of the rigid geometric mesh," said Paolo Zilli, associate director, Zaha Hadid Architects.

Proudly produced and distributed in Australia

ELITE PUBLISHING CO PTY LTD

ABN: 27 006 876 419

PO BOX 800, Templestowe, Victoria, Australia 3106

Ph: + 61 3 9890 0815

Fax: + 61 3 9890 0087

Email: info@elitepublishing.com.au

Website: www.tiletodaydigital.com.au www.elitepublishing.com.au

PUBLISHERS

Georgia Glimour

Michelle Cammiade

EDITOR

Betty Tanddo betty.tanddo@elitepublishing.com.au

INTERNATIONAL CORRESPONDENT

Joe Simpson joe.simpson@elitepublishing.com.au

TECHNICAL SPECIALIST

Tim Christopher info@consultile.com.au

GENERAL MANAGER

Georgia Gilmour

Georgia.Gilmour@elitepublishing.com.au

CIRCULATION

For circulation enquiries please email: info@elitepublishing.com.au

GRAPHIC DESIGN

Plum Publishing Pty Ltd dave@plumpublishing.com.au

PRODUCTION

For artwork and production enquiries please email: dave@plumpublishing.com.au

ELITE PUBLISHING CO PTY LTD

PUBLISHERS OF: Flooring Magazine, Tile Today Magazine, and Supplier Magazine.

Leading the Industry

Endorsed by Australian Tile Council www.australiantilecouncil.com.au

ELITE PUBLISHING CO PTY LTD. All rights reserved. No part of this publication maybe reproduced, transmitted or copied in any form or by any means, electronic or mechanical including photocopying, recording, or any information storage or retrieval system, without the express prior written consent of Elite Publishing Co Pty Ltd. Viewpoints, opinions, claims, etc expressed in articles appearing in this publication are those of the authors. The Publishers accept no responsibility for the information supplied or for claims made by companies or their representatives regarding product performance, etc or for any errors, omissions, misplacement, alterations, or any subsequent changes, or for any consequences of reliance on this information or this publication.

Please note: Shade variation is an inherent feature of tile production. The Publisher is not liable for any discrepancy between images published in Tile Today and actual products.

All-Over technology is a production process that allows the texture of the ceramic slab to be reproduced on the edge, digitally reprinted on the selected portion of the surface in a way that is very faithful to the original source material

This production technology is exclusively granted to Italian manufacturer Fondovalle and the subject of a patent application. It creates a more realistic textural effect on porcelain stoneware surfaces, maintaining a continuous texture from the top and throughout its thickness.

The All-Over look has been created to accurately reproduce the effects that occur in the environment with natural stones and their rich variations. Specifically, this replication is for the space between the horizontal surfaces of slabs and the edges, which cut through the veining, as that patterning is sometimes different.

With All-Over, the veining is perfectly continuous, running from the flat surface right through the depth of the perimeter edge. This is achieved through an exclusive, production process and sophisticated crafting techniques.

All-Over is Fondovalle technology, and unique on the market. The differences in patterning between the tile’s face and sides are a key characteristic.

It has been especially designed to finish tables and furniture from Fondovalle’s Shape collection. However, the surface technology can potentially be used to enhance custom-made furniture accessory or applied to finish architectural details, objects and design projects that are very detailed.

To conserve the beauty and distinctive colouring of All-Over surfaces, Fondavalle recommends the use of mild detergents which do not contain strong acids, aggressive solvents or abrasive pastes.

Cleaning All-Over surfaces with no undesirable side effects means

using detergents that won’t damage them. For example, commercial products for cleaning shiny surfaces or glass are ideal. A microfibre cloth is best to dry the surface after cleaning to maintain its shine. It will help to absorb any residual dirt smears.

Keeping sharp objects away will also help to prevent damage.

At the moment, the All-Over technology is only intended for indoor use but Fondovalle is working to extend it to outdoor areas. n

RLA Polymers’ (RLA) “Respirable Silica Free” technologies are available as a result of a complete range review of its cementitious products that commenced in October 2021. With an increased awareness of silicosis in the tile industry, RLA was driven to formulate and provide a premium grade range of ceramic tile adhesives that are safer to use.

As a direct result of working closely with its raw material suppliers, technical department and production team, RLA is proud to release the first of its new “Respirable Silica Free” technology products. Introducing RLA Mastik and RLA Addflextra, the first of its premium grade products engineered with new “Respirable Silica Free” technology and Green Tag Certification.

After significant investment in its production processes, and collaboration with raw material suppliers, RLA’s newest adhesives have strived to attain the goal of WorkSafe’s new regulations, ensuring added protection for all end users. RCS (Respirable Crystaline Silica) *Silica (Respirable Crystaline Fraction) levels in these new products are below the concentration limit for carcinogens (0.1%) as per schedule 6 of the Model Work Health Safety Regulations 2023.

RCS in the tile industry

It's worth taking a moment to consider why reducing RCS in tile adhesive products is so important to the industry. Over the years, we've all become familiar with scientists and health professionals improving our understanding of new risks, which sometimes emerge from what have been long-term accepted practices.

Back in the 1950s some scientists actually suggested smoking tobacco was good for your health, however, today we all recognise the risks. Similarly, as recently as the 1970s, asbestos was thought of as a "wonder product" when it came to insulation. Today, we are still struggling to effectively contain what we now recognise as a severe health risk.

RCS does not rank with those above mentioned health dangers, in that with safety and education users can effectively control and minimalize the health risks. While there has been significant publicity given to prime sources of RCS, such as engineered quartz stone, there are some places of exposure that have been little discussed.

One of those potential sources is from the process of mixing tile adhesive with water to produce tile-setting mortar (what in the US is known as "thinset"). In a Masters thesis study from 2020, Mark Williams of the South East Technological University based in Carlow, southwest of Dublin, studied the exposure to silica in the tile industry. The study was conducted by strapping a TSI SidePak AM520 Personal Dust and Aerosol Monitor rigged with a plastic tube, which took reading above the user's shoulder in the breathing zone.

There is a very high peak exposure at the start of the process. It only lasts about two seconds, as the powder is dumped into the water in the bucket, but it is a significant exposure.

While there are devices being designed and marketed that can cut down on exposure, the fact is they are seldom employed on most tiling

The graph below shows the monitor results for mixing tile adhesive with no dust extraction.

The graph below shows the monitor results for mixing tile adhesive with no dust extraction.

sites. In the hierarchy of fixes to RCS exposure, the most preferred option is simply to reduce or eliminate the risk at its source. Reduction and elimination is always going to be more effective than an afterthought device or technique. With RLA Mastik and Addflextra products, that's exactly what RLA has set out to do.

For additional information on silicosis safety, watch here:

https://www.youtube.com/ watch?v=GPV60j5vYAY

As an industry leading Australian manufacturer, RLA holds the distinct advantage of local manufacturing capabilities, enabling it to swiftly adapt to shifts within the tiling and construction industries.

RLA is able to respond promptly to emerging trends and changing regulations. This includes reformulating and refining its production processes to provide market firsts, particularly in regard to RCS levels. This agility not only

ensures a safer product for its users but also underscores the company’s commitment to providing advanced safety and innovative solutions to its customers, setting it apart from local and overseas counterparts.

At RLA, the safety of its end users remains paramount. The company will continue to focus on innovative technology and safety to ensure its cementitious products are not only of the highest quality but also providing customers peace of mind. n

The uLock mixing system is a genuinely innovative 23-litre pail, platform and lid that supports the safe mixing of all powder products. Its patented locking system, locks into the uLock platform and secures the pail in place while mixing.

Throughout his career, Jason Milani has worked in marketing roles for a number of different companies that supply the tile industry. In that time, his exposure to product development processes has given him a sense of how products are created from start to finish. Now he is using his experience and expertise to bring uLock to market.

As he told Tile Today: “While speaking to my mate in the trades, we spoke of a common issue we had when it came to mixing products.

“The issue we both had was the bucket constantly moving due to the pressure of the mixing tool. There were a number of close calls with the bucket slipping from the grip between our knees. I wanted to think of a safer way to mix products and that’s how I developed the idea of uLock.

“In my mind, uLock is going to provide users with a safer option to mix products and reduce the risk of absorbing airborne crystalised silica [RCS]. It’s going to save professional tradespeople time and physical effort when it comes to mixing and reduced the chance of injuries.”

“With my contacts and my design mindset, I was able to leverage some suppliers and get things moving with uLock.”

The product

Ulock is designed to tackle a number of worksite issues, related to safety, ergonomics and efficiency. It's not uncommon to see workers from various trades struggling with the (apparently) "simple" task of mixing a powder product with water in a bucket. It's a little funny when a bloke finds instead of mixing, he has the bucket spinning at a high rate of rotation between his work boots — but it's not really funny, because

it could result in poorly mixed product, an expensive spill, or worst case, a leg injury.

In short, power mixers have solved a lot of problems, and added in extra efficiency, but they've also created a few problems of their own. Ulock is the accessory that can help tradies really unlock the full potential of those powerful mixers, making the job both safer, faster and with a great result.

A really important addition to that is protection from accidentally inhaling respirable crystalline silica (RCS) particles. While there have

been real advances in reducing the amount of RCS in adhesives and other tiling products, it still remains a major concern. Much of that exposure comes in the early stages of mixing, when the dry powder is added to the small amount of water in the bucker, creating a "bloom" of fine powder dust — most often inhaled by the tradie. Ulock is a really well thought-out solution to radically reducing that risk.

The basics of the product are this: There is a platform made from moulded plastic, 520mm

Supporting progressive outcomes is a significant part of the company’s ethos and approach

Building certifiers and authorities have stepped up their watch on compliance of waterproofing products and tiling systems, to keep product suppliers and manufacturers accountable. The key path to compliance is testing to ensure products in the market meet the requirements of AS/NZS 4858 and AS 4654.1, and Australia’s internal and external waterproofing standards, AS ISO 13007.5 and AS ISO 13007.6, the standard which tests the system of waterproofing membranes and tile adhesives bonded to ceramic tiles. XTec Gen also tests to AS ISO 13007.2, the test standard for the compliance of tile adhesives and grouts.

XTecGen Materials Testing Services, Australia’s only NATA registered laboratory to evaluate waterproof membranes to AS 4858 and AS 4654.1, has full capacity to carry out testing to all the requirements of these respective standards.

Manufacturers, suppliers, distributors, wholesalers and importers of waterproof membranes, tiling systems and building products engage the testing services of XTecGen. They do this to not only ensure their products

comply to relevant standards, but also to better understand the performance limitations of their products.

Heightened building activity across Australia is heavily focused on waterproofing to ensure many of the sins of the past few decades are not repeated. Building certifiers and authorities have stepped up their watch on compliance of waterproofing products and tiling systems, to keep product suppliers and manufacturers accountable. The key path to compliance is testing, to ensure products in the market meet the requirements of AS/ NZS 4858, AS 4654.1, AS ISO 13007.2, AS ISO 13007.5 and AS ISO 13007.6. XtecGen can also test the compatibility of membranes to different substrates, primers, adhesives, etc. This provides a greater understanding of the performance of the product, outside the scopes of the standards. Waterproofing and tiling systems used in domestic and commercial construction are being assessed more frequently than ever before. That is because the industry is pushing to eliminate the costly problems attributed to inadequate product quality that have contributed to building failures.

XTecGen was created for the building industry and is here to support

progressive outcomes. XTecGen helps aid in development of products and RnD for clients, supporting continuous improvement and helps provide better outcomes for the building industry as a whole. This helps drive the industry to better overall quality, which will support the modern movement in building and construction.

Along with providing a full suite of tests and reporting to AS4858, AS4654.1, AS ISO 13007.2, AS ISO 13007.5 and AS ISO 13007.6, XTecGen provides testing to specific requirements. This enables manufacturers and suppliers to test custom requirements that may not need the full scope of testing. XTecGen has a wide range of equipment, versatile to many different standards such as Australian, British, American, European, etc. This means that XTecGen is not limited to the test standards listed previously but has the ability adapt and test to unique client enquiries.

Some of the unique capabilities XTecGen offers through their laboratory testing includes:

• Elongation and Tensile Strength

• Chemical Immersion Testing

• Temperature Resistance Using Heat Chamber and Lab Freezer

• Water Vapour Transmission

• Water Absorption

• Abrasion Resistance

• Cyclic Movement Tests

• UV Exposure and Accelerated Weathering Tests

• Seam Testing and Dimensional Stability Tests for Sheet Membranes

• Puncture and Tear resistance of Sheet Membranes

• Bond strength

• Pull Off Adhesion Test

• Root Resistance Test

• Hydrostatic Pressure Test

Some of the largest global brands operating in the Australasian construction market are now utilising the testing services of XTecGen to have their waterproofing and tiling systems tested to ensure they have products that meet all the demands and requirements of Australian Building Standards.

For more tests, visit the XtecGen website: https://xtecgen.com/. Enquire at info@xtecgen.com or call on 1300 152 298.

External Waterproofing Compatibility Testing Tiledeep by 660mm wide. The 23-litre uLock bucket locks directly into that platform; it simply cannot rotate at all. The user stands on the platform, so he/she is perfectly positioned over the bucket.

The lid of the bucket folds back so that water and mixture can be added in a controlled way. The mixer can be inserted and the lid locked down, so that the mixing takes place under the lid of the bucket. A vacuum hose can also be attached to further reduce the risk of dust escaping.

It's a sensible, safe solution.

When Jason originally came up with the design of uLock, it

didn’t make it past the initial phase because of engineering complications. He learnt from that experience to work more closely with the engineers to understand why his design was not suitable. After a few more drafts, he was able to translate the requirements of uLock into a manufactured design.

There has also been some real-world testing of the product.

So far, Jason has organised a demonstration day at Kerakoll in Melbourne and apprentices from Holmesglen TAFE have also used it under teacher Frank Vanzella’s supervision.

A number of comments from end-users came out of the demonstration days. One

comment related to the size of the bucket and whether it could be made bigger so that two bags of adhesives (or another product) can be boxed in together. Jason said, “The answer is 'no' purely because then it becomes a 55kg bucket. It's not about the volume, it's about the weight of lifting up 55kg.

“The market states that bags should be between 16 to 20kg. If you remember that years ago cement bags were 25kg. So they've gotten lighter. Anything more than 20kg, they would prefer a two-man lift. Two men can't be lifting a bag of cement! At least, I hope not.

Another comment related to the lid being clear. As Jason explains, “Unfortunately it can't be done

because having a clear lid means it has to be an acrylic and then you can't fold it. It will snap.

“And the only one that picked it up on the spot was actually Vvo, (Ian Middleton from Australian Tile Geeks). He said once you've put your vacuum in your powder, after 30 seconds of mixing, then you take your lid off and finish your mix.

“So the initial thoughts were that you had to fully mix with the lid on. But no, it's only to stop the dust for that whole 25 seconds. Then you take your lid off and you mix as you would normally require.”

One positive outcome from the demonstration at Holmesglen TAFE with 18 apprentices is that the uLock will be the only bucket it uses, and Melbourne Polytechnic had similar feedback. An upcoming generation of tilers and tradies will be mixing products differently and more safely.

According to Jason, there is currently nothing like the uLock available in the market. He said: “The only similar product is in America where someone has made a ring with two little steps on it. And you would try and put your bucket in and that way, you'd put it like a flap, but it doesn't work because every single bucket around the world is different size.

“It's not good in practice. So technically no, there is no such thing as a platform. And that's why I was able to have a patent on it. I have patented in 177 countries.

“And it's been a year and a half with no contestants, and no one said this product is similar to mine.”

In creating the uLock, Jason has also invested a lot of time putting together displays and signage for stores that will eventually stock it. As he puts it, “Visual merchandising is what I specialise in.

“The way I've designed it, a store would potentially have a row of buckets. Then there would be a packet for the platform. And then on the top of those platforms, there would be a little shelf for the lids.

“To display it, I've designed exactly the actual platform as a sticker that retailers can stick on their concrete floors in front of their trade counter.

“So they [tradies] physically step on a piece of sticker – remember the ones during COVID? ‘Please stay at a safe distance’. Mine are exactly the same. So they will be right in front of the trade counter and as soon as they step on it, it turns around and says, 'Have you got your safe mixing system?'

“So it takes up no space. To a degree, it's like a little map. Not even, it's just a sticker on their floor.”

In addition to the retail channel, Jason hopes to be able to partner with a number of well-known suppliers in the market. n

The first question that most of us want to ask about almost any technological invention is: why now? For example, electric vehicles would likely not have come along without the evolution in battery technology caused by the burgeoning mobile phone market. In fact, one of the fastest growing EV companies in the world, Build Your Dreams (BYD), started as a manufacturer of mobile phone batteries.

But what about tile levelling systems? The first mainstream patents for these began cropping up around 2005, and the first production systems hit the market around 2007. If they are such a good idea, why weren't they developed ten or 20 years before?

The answer to this comes down to one change in the industry: the advent and increasing popularity of

large format tiles. These tiles began to become more available starting in 2002/03, with the creation of systems such as the original Continua through a collaboration between Italian tile manufacturer Italgraniti and Italian process machine manufacturer SACMI. In an interview from 2022 with then-CEO and current president of Italgraniti, Francesco Maturo, he described Continua:

"In 2002 Italgraniti came up with the initial Continua technology concept that we then developed alongside SACMI’s technicians and engineers. It was a revolutionary ceramic principle: continuous compaction of a spray dried powder bed. The huge innovation of this machine lies in its slab and tile manufacturing flexibility, allowing producers to respond deftly to market needs."

However, in the beginning uptake was slow. Only a limited number of companies used the new processes, and there were relatively high fees to gain access to it. Another complicating factor is that the large format tiles were produced at 3mm thick — which understandably gave many tilers nightmares! (Thin, large and very expensive.) These were strengthened later with a 0.5mm fibrous layer on the back, but it took some time for the current 6mm+ large format tiles to become common.

Another problem is that these earlier large-format tiles tended to be mono-colour. While inkjet technology was first developed in 1999, and commercialised in 2000 (by Kerajet), it wasn't until 2005 that the technology began to spread more

widely, and not until 2008/09 that it started to really take off. According to "Technical Evolution of Ceramic Tile Digital Decoration":

"In 2005, in collaboration with Durst Phototechnik AG, a company devoted to image processing, Torrecid, a multinational frit, glaze and ceramic colour producer, launched a range of pigmented inks. These inks were designed for singlepass digital inkjet printing machines with Fujifilm Dimatix (Spectra) printheads, also of the binary type. After the appearance of this new option in the market, inkjet printing began to spread more quickly in the ceramic sector."

Additional printing techniques were developed, with more equipment becoming available on the market. All this meant that by around 2012 large format tiles had become a very attractive option for architects and interior designers. This was also the stage when, not surprisingly, there was a second burst of activity when it came to developing new tile levelling systems.

Searching through the US patents, it's evident that while there were some earlier tile levelling patents, it took until around 2005 before truly viable systems were available, and these began to launch on the market a few years later.

The two companies that seem to be the "pioneers" in this area are QEP with its Lash system

and Tuscan. It's interesting to see that right from the beginning, tile levelling was split between the two basic alternate way of doing this: the "wedge" systems and the "cap" systems.

The Lash system is still sold in a form that seems close to the original, using a disposable spacer fitted between adjacent tiles, with a plastic "wedge" then slid through the spacer on top of the tiles. These wedges can be tightened by hand or with a specialised pair of pliers, to bring the two tile surfaces into flat alignment. Lash continues to be popular.

Tuscan at its origins was a "cap and strap" system. As with the wedge system, a disposable spacer would be placed between adjacent tiles, the cap fitted over this. A notched plastic strap (like an extra-thick cable tie) was threaded through the cap from the spacer, and a tool was used to tighten the cap down on the tiles, bringing them into flat alignment. The caps were re-usable.

Around 10 years ago, Tuscan evolved a second system, to provide a more unique solution. The Tuscan Seamclip system uses just one part. This slips beneath adjacent tiles, then two plastic "wings" are folded down, immediately levelling the tiles. It's a faster system to use, and requires not tools, but the entire leveller needs to be discarded. As these can cost around $0.50 each, that can mean something of a cost disadvantage.

With an idea of how the levelling systems work, in the context of increased use of larger tiles, how do those two things fit together?

The main difficulty with larger tiles is that they are far more likely to be bowed to some extent. Combined with their length, this creates a major problem in avoiding lippage. That's added to by a trend towards narrower grout lines on larger tiles, which will tend to accentuate any lippage that does occur. This is true of the more rare, large slab tiles, but it is also true of the long, plankshaped tiles that are designed to emulate wood. With tiles placed in a staggered pattern, the dip at the ends of one tile typically lines up with the rise in the middle of the adjacent tile.

There may (almost) be little chance of avoiding lippage without tile levelling systems on long, bendy, plank-like tiles. At the very least, they will contribute to less time spent on the job.

That said, it's important to state that tile levelling systems are far from being a panacea for all substrate and tile problems. It's important to think about the systems as not being in any way "automatic", but requiring both craft and care in their effective use. It's important to get the right thickness of adhesive, varying that based on the size of the tile, how flat the tile is overall, and how flat the substrate the tile is being laid on is at that point.

The story of the EZE-Clip began when ACT Australia – best known as an adhesives manufacturer –looked at the clips systems that were available in the market and saw an opportunity to significantly improve the products.

According to ACT Australia: “One of the biggest issues with cheap clips comes into play when tilers use them with large format tiles. They put the wedge in and before they get the tiles perfectly flush, the clip breaks. What happens is they have to try and lift the tile up, which is hard because the suction holds them down, especially with large format tiles. Then they clean up and re-apply the glue ... and start again hoping that the next clip doesn't snap.”

“It becomes a real nightmare for them to have to basically re-lay a tile and put another clip in. As a result, a couple of dollars saved on cheap imported clips can turn into a lot more money wasted in time and materials.

“All we've done is improved existing systems through the innovative product design, and the manufacturing process. The key to this improvement is at the break-off point between the stem of the leg and the base. We call it a T-post design,” it said.

“We have used a different type of raw material and adjusted production process. That makes it very strong and flexible.”

EZE-Clip’s design received an Australian patent immediately after production began. After several years and major investment into the approval process, the US design patent was granted in 2023. Now ACT Australia is planning to expand the brand into the North American market too. It said:

“The beauty of our clip is it's very durable. You can really put a lot of pressure on the wedge to install the clip and get the tiles to the right position without the clip breaking. At the same time, when you come in next day to knock off all the clips,

they break easily and they break at that design point between the stem and the base.

“In addition, a lot of existing clips on the market look identical to each other regardless of the size. With the naked eye, it's very difficult to work out a 1.5mm clip from a 2mm clip. It can cause mix-ups when tilers hold various sizes at the back of their ute. In contrast, EZE-Clips are colour coded, which makes a lot easier to identify the right one on the job.

“We didn't stop there. Not only are our wedges made from a highquality material so our blue wedge will last a long time, we have also improved its ergonomics. The large thumbprint on the back of the wedge

reduces the strain on the hand while working on big tiling projects. At the same time, it allows for faster application.

“We are probably the only adhesive company globally who has designed and manufactured their own tile and clip system. But being passionate about Australian owned and manufactured products, it makes it increasingly harder to compete with cheaper and lower quality alternatives. However, in the years of EZE-Clip system being on the market, it has proven to provide so many benefits for end users in saved time and material costs that significantly outweigh the marginal price difference.”

Josh and Jess Gartshore own and operate Trend Tiles in Inverell (NSW). Josh started out as a tiler and was managing a crew for nearly 12 years prior to setting up the shop just before COVID. In November this year, the store will celebrate its fifth anniversary.

The local economy in and around Inverell has kept the store busy, according to Josh. “It's been good. No doubt it has slowed down a little bit, but a lot of our builders have got good jobs booked up. We're still getting quite a lot of work coming through from that,” he explains.

Josh was already familiar with the EZE-Clip when he was a tiler, often using them, and stocked the product when he opened the shop. “I've actually been using Colin's stuff from pretty much the day he started. I knew him quite well from the day he started ACT.

He believes the product does well in the store partly because of its packaging. “Just the presentation of the box and colouring as opposed to a lot of other products that come in plain bags. The quality is great … and they're unique with the breaking point down the bottom. They break off quite well. Also the wedges are a good size wedge with the thumbprint on the back of it, so you don't have to use a tool.

There are currently four staff at Trend Tiles selling tapware vanities with a significant flooring section in addition to tiles. “I've got two guys full-time laying flooring for us as well,” said Josh.

Neville Thomson from Floor Me in Bundaberg (QLD) has owned the store for almost eight years. As a retailer, it has been busy with a lot of residential and commercial construction in the region. He said: “We do new builds, we do renos, we do schools, we do

hospitals, we do everything, and I don't think it'll stop for the next five, eight years.”

Floor Me has been an exclusive stockist of the EZE-Clip (and the ACT brand of adhesives) since he became store owner. Neville said of the EZEClip: “The tilers love it. They break off easily, and they're easy to use. He's got 1.5mm or 3mm for pavers and that sort of stuff. I stock a lot of it.

“I’ve known Colin probably 19 years, but his products are really good. I'm the only one in Bundaberg that stocks his products.”

There is also a special display for the EZE-Clip in-store. “I've got a board up, but I've also got it all on a stand on big racks. When you walk in the store, you can see all the EZEClips in their boxes,” he said. n

The EZE-Clip showcased at Floor Me in Bundaberg (QLD Part of the exterior of the Floor Me store in Bundaberg (QLD)ACT Australia EZE-ClipWedge1.5mm,

Ding Yue

No1800Australian designed and manufactured tile levelling system in this list. See page 16 for more info.

No2000Amark makes a standard clip-and-wedge levelling system.

No350Ding Yue makes a standard clip-andwedge levelling system. Frequently re-branded.

No3000LevTec makes a standard wedge sysem. Mapei MapeLevel EasyWDG System

to 12mmNo250MapeLevel EasyWDG System wedges are 114mm long by 16mm wide.

Mapei MapeLevel ProWDG System Wedge0.5mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm, 4.0mm, 5.0mm

Mapei MapeLevel Easy System Cap 1.0mm, 1.5mm, 2.0mm, 3.0mm, 5.0mm

Mapei MapeLevel EasyClick System Cap 1.0mm, 1.5mm, 2.0mm, 3.0mm, 5.0mm

Perfect Level Master T-Lock TIle Levelling System Wedge1.0mm, 2.0mm, 3.0mm

Klassen Bronze PeygranWedge0.5mm, 1.0mm, 2.0mm, 3.0mm

3mm to 12mm

12mm to 20mm

3mm to 21mm

No250MapeLevelProWDG System offers wider wedges and more durability.

Yes, T and X 100MapeLevel Easy System is a standard cap system, except that the caps have an oblong “handle” on them, which may improve ergonomics.

3mm to 21mm

N/A

3mm to 12mm

12mm to 30mm

Yes, T and X 100An adaptation of the Easy System with a button release on the caps.

No300A wedge system that includes a shield that goes under the wedge to protect the tile surface.

No4000The Peygran system comes in two sizes, Classic and Compact, and features a shield to protect the tile surface.

Xtreme system is slightly wider and more robust than LASH.

system in regular and HD (heavy duty). Includes under-wedge shield. RUBI

This leads us to a really crucial point, which is you really cannot expect a tile levelling system to compensate for a poor substrate. They can help to moderate some of the effects, but, as always, what you see on top is going to reflect what is underneath. There are cases where a tile levelling system has enabled an installation with almost no lippage — but, because the substrate is not flat, the resulting tiled floor is not flat either.

Not all tile levelling systems are created equal. If you look through the patent applications over the past decade, you would be amazed at how many variations are available. While some of these are simple "patent dodging" — finding a "new" way to essentially copy an existing design — there are also some real innovations and novel solutions.

Speaking with a range of tilers who use these systems, the main requirements boil down to this list:

1/ The material and construction need to be just right. You should be able to apply enough pressure to level-out the tiles, but it also needs to be easy to break off the top portion of the clip after the adhesive has set. Getting that right is as much about the quality of production as it is design.

2/ Speed of use. Most of the time gets spent in tensioning with the wedge, spinner cap or strap. It's a repetitive motion, and on larger jobs it can result in significant wear-andtear on both hands and wrists.

3/ Visibility. There is the concern that as the leveller is tightened, grout lines can shift slightly. Being able to clearly see through the leveller to the grout lines helps the tiler catch when this happens, and can save some fiddly adjustments.

4/ Corner spacers. There is some mild controversy about whether

tile levelling systems that can be applied at corners are reliable. On the negative side, the concern is that the corner is the most vulnerable part of the tile structurally, and that accidental over-tightening might chip the tile. On the plus side, tilers who uses systems with three- and four-way junctions say it helps to make better grout lines and it cuts down on the number of levellers needed per tile.

5/ Spacing choice. The majority of tilers use the tile levelling clips as spacers, though it's very common to supplement these with additional spaces as well. So it's important that a system you adopt offers a wide range, at the very least 1mm to 6mm, if not all the way out to 12mm. There are also some tilers who will always use the most narrow tile levelling spacer, then use wider spacers to set the grout lines. There are some very involved discussions online regarding this, and how there may be some technical advantages. However, some of this is just about tilers having poor experiences with badly made system that did not break off cleanly.

6/ There are some additional concerns about matters such as tile levelling systems that can scratch of the surface of some wall tiles. That usually happens when the cap or wedge gets some dried adhesive stuck on it. Many cap-based and wedge-based systems offer shields to make sure they don't scratch.

Also, how easy is it to extract the reusable part of the tile clips

from the bit you need to throw away? Cost is another factor, and that relates both to how much the disposable part of the clip costs to buy, as well as how long the reusable part lasts (some wedges deteriorate rapidly). The general consensus — not unexpectedly — is that the cheapest systems are costly in hidden ways, and then you are best buying a better-known, reliable brand. (TEMU might not be your best source!)

This is one of those debates where there really is no final winner. Those on team cap say that they are more ergonomic to use, in that the twisting action is less stressful. They also cite being able to adjust the tension by hand, rather than through a tool, as important, as this helps to avoid over-pressure and potential cracks or chips.

Those on team wedge regards this as simpler solution that is quick to use and less expensive overall. With caps, after use you have to unscrew them from the stem of the clip, while with wedges the process is much simpler.

Probably the biggest "danger" signal in any wedge system is if the clips and the wedges are being made from the same material — something you only find on the cheapest systems (Alibaba is not always your friend!). The wedges need to be made out of decent material if they are to last a long time. The part that wears out quickest are the knurled ridges on top of the wedge, which "click" into place to hold the tension with the clip.

The second thing to consider is simply size. The wider the wedge is, in general, the more force it can exert on the tile (through the clip), and the easier it will be to get the overall tile level. Another feature to look our for is a 3mm or so lip on the back end of the wedge. This helps to extend the overall surface area in contact with the tile, but it also acts as a shield between the tightening pliers and the tile surface, limiting the chance of damage there.

The other thing to check for is what deals are available on bulk purchases of clips. Some wedge

systems let you buy these by the thousands, which costs a bit upfront, but reduces overall costs.

What makes a good cap system?

There seem to be fewer poor quality cap systems on the market than there are poor wedge systems. One feature to consider is whether the clip part of the system comes just in a single flat shape, or if it includes T-shaped and cross-shaped guides as well. While this is some controversy around using levelling clips on corners, the general consensus is it is OK if used carefully, and this can really cut down on the number of clips you need to use.

The other main concern is how well the cap works in terms of spinning it on and off. This can vary a lot depending on how large your hands are, whether you always wear gloves and so forth. Each manufacturer has its own ideas about what is ergonomic.

Again, too, you want to check out what the cheapest deals on clips are for each brand.

The market for tile levelling systems is a very interesting one. Most of the potential major players — such as the makers of adhesives and tile tools — were a little late getting into the market. One consequence of this is that there is a very active market for smaller, more independent suppliers. Only a little surprisingly, most of the innovation and new product development is originating with those smaller suppliers.

Outside of those two groups, there are also a number of Chinese manufacturers, who make OK products which end up being rebadged with local branding. There are also quite a few mass Chinese manufacturers who make very inferior product (and we have not listed any of those).

To start with the independents, one of the outstanding companies is adhesive manufacturer ACT Australia. As with its adhesives, its EZE-Clip wedge-based tile levelling system is made in Australia. We detail EZE-Clip later (see box on page 16). It's worth going into the details ACT gets right, because these are the basics of good product design.

The EZE-Clip wedge-based design concentrates on getting two elements correct. The first is the issue of the clip itself. There is little so frustrating as to have a clip break

off while it's being tensioned. So ACT concentrates on getting both the shape of the clip and the material it's made from exactly right, so that it won't break off during tensioning, but it will snap off at the base when being removed.

The second element is that ACT recognises that the useful life of the wedge is important in keeping costs down. So instead of just making the wedge out of the same material as the clips (as some manufacturers do), they instead use an ultradurable nylon. That means the ridges on the wedges don't get rounded off, so that when they are tensioned they click properly into place. Worn down ridges in the knurling can result in too little or too much tension.

Another independent innovator with a very different alternative to the wedge system is US-based Tuscan. As we mentioned above, Tuscan was one of the pioneers in this area, along with QEP's LASH. The Tuscan Seamclip system is really worth a look, though it likely works best in very specific cases. As there is no fiddling around with tensioning clips to a cap or wedge, they can be installed very quickly. As we stated previously, the problem is they cost a bit more at $0.50 per unit, and there are no reusable components.

An independent brand that's very popular in the US is Russo's Spin Doctor cap-based system. While there are no single features that stand out, it's known as a reliable brand which produces a reliable and durable product in the cap area.

In terms of major brands getting involved in tile levelling systems, there are Mapei, RUBI and Raimondo. All three of these have launched multiple versions of tile levelling systems, though there is not all that much innovation involved.

Mapei's MapeLevel system has two wedge-based systems, EasyWDG and ProWDG, with the latter featuring wider wedges among other more "pro" features. Then there is MapeLevel Easy, which is a cap-based system, and MapeLevel EasyClick. This latter system features a cap with buttons that release the grip on the thread, making it easy to push on and pull off the cap from the threaded clip.

Raimondi offers fairly standard wedge and cap-based systems. RUBI actually offers three systems: cap based, wedge, and cap-and-strap system. The latter has a rigid plastic ratchet strap sticking out of the top of a cap, and a special tool is used to tension this.

To just restate the obvious: tile levelling systems are not a panacea. They cannot compensate for a completely wonky substrate, for example. For DIY tile installers they are an absolute benefit, and can at least smooth out the worst of their inevitable mistakes.

For professionals, they offer both speed and surety — you will be just that little bit less likely to find yourself facing a tricky problem. That's especially the case with longer, more warped tiles, as you can apply force directly to the tile for a sustained period until the adhesive is at least partially cured. n

Tamashi – soul in Japanese – by Ceramiche Refin is a new collection of wood-inspired porcelain tiles that are inspired by contemporary natural woods currently widely used in furnishings

The result of intense research to find the ideal graphic and colour balance, the collection offers uniform, balanced surfaces characterised by fine, dense, parallel veins and subtle colour nuances, according to the manufacturer.

The selection features seven shades and available in 25 x 150cm planks.

To create Tamashi, Ceramiche Refin said it worked on reduction, with the aim of gaining the essence of wood. An image of cleanliness comes from the absence of knots and the choice of dense, fine and regular veins, resulting in a seamless, linear and fluid surface. The result is a modern and natural simplicity that stems from a skilful graphic and colour balance.

The palette expands from the traditional woods to include seven colours that it studied — ranging from light to dark — to give the collection a new modernity. The evocative names chosen for the shades – Sugar, Vanilla, Cream, Tea, Walnut, Caviar, Pepper — convey pleasant sensations. Tamashi is offered in the classic board size that is updated to provide rooms with a level of elegance while retaining all the charm of the wood material.

The Leaf decoration is available in the 60×60 cm size and in three colour combinations: Leaf Tea (Cream+Tea), Leaf Walnut (Vanilla+Walnut), Leaf Pepper (Sugar+Pepper). Depending on its rotation direction, the arch pattern can create multiple geometries to give rhythm to both floor and wall surfaces.

The slight chromatic variation and the veining of the product is an intrinsic feature to re-create the randomness and richness of the colour shading of natural stones to which the collection is inspired. For these reasons,

Ceramiche Refin recommends installing the product by choosing tiles from different boxes in order to guarantee a variable and random effect of the finished surface. Due to these

intrinsic features of the product, the colours represented in the images from the catalogue must only be considered an example of the many possible colour shades.

As part of Gruppo Concorde, Ceramiche Refin has been a presence on the international market since 1962 with a broad range of porcelain stoneware solutions for residential and project-planning destinations. Refin is part of the Gruppo Concorde, a leading ceramic group at global level.

It has a constant commitment towards aesthetic research and technological innovation when it develops its collections. This has helped the company achieve product and production excellence.

Refin designs and produces porcelain stoneware in-house and only in Italy, running a company that is based on the pursuit of quality and on respecting the environment.

Ceramiche Refin produces more than 7 million m² of tiles per year, supported by the latest machinery for the creation of surface graphics and post-manufacturing processes. All the phases of its production undergo strict quality control procedures and the standards of its products are certified by the key international certifications. n

In the tile industry, retail is not like any other retail and the same can be said of wholesalers. Each has its own unique features as a business. Those requirements are so custom that trying to squeeze operational processes into one of the "one size fits all" just doesn't work out.

Enter Clear Software with its ClearTile software package. Owned by Gordon MacMaster, the origins go back to the 1980s and 1990s when his father, Ian McMaster, started a company named The Software Magician — known as TSM — to produce custom accounting software for companies before stock accounting packages were easily available. As Gordon tells Tile Today:

"I've owned the business since 2007. And in 2007 we renamed the business to Clear Software to be similar to what our product was called, and at that stage we'd just finished developing our first version of the tile software, the ClearTile software."

ClearTile was developed in the

best way possible, by working with a customer in the tile industry. Gordon explains: "I think it was back in the 1990s, we had a tile business from the Sunshine Coast approach us. They basically said, ‘Look, there's nothing out there. Can you modify your software for our tile business? We'll tell you all the requirements that it needs’.

"We developed that for them, and that was very successful. And then they said, look, we know a lot of people in the tile industry, we can help you sell this product because there'll be a strong market out there for other businesses that need tile specific software.

"So whether or not we were the

first, we were certainly one of the first ones to develop specifically for the tile industry. And it's really just grown from there. I would say probably 50% of our business is from the tile industry.

"We've got a lot of new customers coming on board all the time. And we continually develop the software based on the requirements around the tile industry."

Gordon says that ClearTile is suitable for multiple business types in the industry, including retailers, wholesalers and distributors. "We do 27

have a lot of retail tile businesses. We have a lot of wholesale tile businesses, and then we have some clients that are effectively both retail and wholesale, and run them together.

"So does it work differently? Yeah, a

little bit. I mean, retailers focus more on selling to the public. Wholesalers focus more on selling to retailers. So there is a lot of functionality behind just the sales and inventory control as well.

Paolo Cannizzaro, owner of Melbourne-based wholesaler and tile importer Designer Stone Solutions, said he has worked with ClearTile to develop it from a basic point of sale system that did the business activity statements for the tax office and wages, to something that also manages its online portal, website and in the last two years, a delivery and dispatch module. He said:

“We can track when goods are picked, when they're packed, and when they're actually dispatched. So it's easier to invoice, and in this way, you'd never forget to invoice something.”

General manager, Laura Giordano, said ClearTile has helped the business to become a paperless warehouse. She explains:

“ClearTile has been integrated with our tablets so when an order is placed online or in our office, it's automatically sent through to our warehouse staff to know exactly what to pick, what's the next in order, what date the delivery is, and they know exactly the bin locations, all the information is there.

“It can also be updated in real time. If one of the people in our warehouse says the stock they’re looking for is not in that bin, we can change it instantly in our office and it updates on the tablets. It just means it's a quicker and more efficient system.”

Laura said ClearTile has been very important in streamlining the business. She explains: “ClearTile enables us to have everything in one system and it links to our portal which is customer facing, and our website. It means that we only need to update one system and it links to everything.

"We are a point of sale, I guess is a good description, inventory control, and a full accounting suite as well. And it's all integrated into one system."

“For us, it means that we are working smarter and not harder with the ClearTile system. It allows us to be as transparent as possible for our customers because anything we update in the ClearTile system, whether it's an ETA of when new products are arriving, or orders in the system, it gives them live feedback as to what's available and when things are coming. I think in this day and age, when everyone wants the information right now, ClearTile enables us to give that to our clients.”

Laura goes on to say that the back end of the business is managed like the front end. “It also allows our customers to select and place orders online and immediately secure that stock. As soon as they place an order on the online portal, it immediately secures that stock for them. If someone else looks at the portal afterwards, within the next couple of minutes, it's gone.

“…As a wholesale business, we're not open on a Saturday or a Sunday, but our clients are. So it means they've still got access to all of our stock and information on all our products online without us actually needing to be open.”

Paolo believes a key benefit of using ClearTile is that any business working with Designer Stone Solutions that is also running ClearTile software can link directly into its inventory to check stock rather than going through the portal. “Just one button and within seconds they’ve got access to our stock levels in our warehouse,” he said.

Although Designer Stone Solutions has no vested interest in ClearTile, Laura mentions that it has been promoting it to its clients so that processes can be more seamless when both companies are using the same system.

Part of the showroom at Designer Stone Solutions in Melbourne (VIC)Designer Stone Solutions warehouse

Part of the showroom at Designer Stone Solutions in Melbourne (VIC)Designer Stone Solutions warehouse

But Clear Software also goes far beyond that common basic functionality. Gordon explains: “The functionality I'm referring to, we call foreign shipping and overseas creditors and things like that. It's been in development for a long time and we've built the software up based on requirements of all sorts of different clients. Some of them are wholesalers and some of them import, and some of them do other things as well. So there's addon functionality that we haven't even mentioned yet that other businesses use as well.”

For Gordon, that extra functionality, and all the options ClearTile provides, is a core part of what the product offers.

"A big part of our offering is we're more than happy to modify the system to work specifically for a particular business. And these days, a lot of businesses, they all do things a little bit differently and some of them are happy to change their processes and others are like, no, this is the way we work. We expect the software to work with us.

"So I think that is a big part of our company, that we do. We are more than happy to modify the software to get it exactly the way that the customer wants."

As a custom product, sales and operations manager Nigel Turner — who has been with the company since 2005 — takes a good deal of time to demonstrate and sell to each prospective customer. After an initial contact, that usually begins with an online presentation and demonstration, then provides a quote based on customer preferences. Those preferences typically develop over time.

Once the customer has decided to go with ClearTile, the company allocates a team of technicians to install and configure the software for the customer.

ClearTile develops both a "live" system and a training system for each customer. Training is very important to Clear Software. Nigel explains: "The training system is used initially to train people on. So we would deliver that, and part of the overall quote would

be a number of training courses, structured training courses mostly, that we would then deliver to the customer, teach them how to use the software, introduce them to various functionality, and more.

"Once they've had some training, they'll probably jump into their training system and have a bit of a play. At least that's what we recommend. And then we'll set a go live date. So a date that they choose, that will be when they literally switch over from perhaps an old system to our ClearTile system. During the go live stage, we can provide onsite go live support. Sometimes we do, sometimes it's not necessary. It depends on the client."

As part of the move to the live system, there is usually a good deal of data transfer, which is another aspect that Clear Software can assist with. It begins by formatting data to work with the system, and will typically do a second batch of processing right before the system goes live, so the customer is working with up-to-date, current information.

Clear Software can offer more extensive support services, if a customer opts for that, which can include assistance in the form of sourcing hardware such as desktop computers, servers and printers.

Established in 1969, Wyllie Tiles has six outlets in Tasmania.

Operations manager Terry Atkinson said it has been using Clear Software since 2007. Prior to this, the retailer was using a program called NatSoft which was an old DOS program.

At the time, he described changing over the new system as “fairly challenging” because just getting used to the new system and it probably took a couple of months to really get your head around what was going on. “I think it was just getting everyone used to a new system was the main thing. But ClearTile was good. They were here with us for I think the first week or so anyway, one or two people flew down to Tassie,” said Terry.

Most importantly for Wyllie Tiles, the software provides a way to gain more insight into what categories are profitable for them. As a group of stores, it sells vanities, carpet and vinyl as well tiles to homeowners, mainly DIYers. The tile category represents between 50 to 60% of its sales, mainly sourced from China, Spain and Indonesia.

Laura Giordano from Designer Stone Solutions said there was a lot of training involved. “ClearTile

Gordon MacMaster and Nigel Turner in their Robina (QLD) officeflew down from Queensland to be able to give us one-on-one support. They have a fantastic help desk system where you can either email or call, and they've always got staff there.

“Obviously it's great with them being local in Australia to be able to help with that. And they've also got a really great online help system where you can just search what you need to do and it tells you — we call them macros — the different items and information that the system can provide you.”

(For more about Designer Stone Solutions, see page 27)

While ClearTile is essentially a desktop product running under Microsoft Windows, the software can also be run in a cloud environment (hosted in Microsoft's Azure), according to Nigel. That helps in cases where broader access to data is needed, such as with multi-locations. "We have

anyone from say, a single user business, right up to 30 or 50 users potentially utilising the system", Nigel tells us.

One recent addition the company is proud of is ClearLink, which is a range of add-ons that help to provide limited access to data to non-company partners — so that, for instance, retailers can easily check for stock with wholesalers.

The company has also extended functionality into a range of mobile experiences. For example, it is common practice in tile for builders (or home buyers) to select the tiles they will use in a house on a roomby-room basis. Clear Software has developed technology to help with this, according to Nigel:

"We have functionality in both ClearTile and now in the ClearLink interface that they can use on a tablet PC as they're working around the showroom to do these quotes."

Clear Software also helps its ClearTile clients with developing

e-commerce platforms. It utilises a secure API into the ClearTile data. That enables customers to develop their own websites, and then to rely on Clear Software to effectively link in their business data. That gives the customer the freedom to develop the website they want, with a substantial part of the backend supplied by Clear Software. Nigel explains:

“Product information can be passed up, and order information can be passed back down to ClearTile from that e-commerce solution. We build the infrastructure and put all that in place and to some extent manage that for them and then hand the keys over to them to build their look and feel to whatever they like. The tile industry has very creative people, they make the website into what they want it to be, and we just handle the logic and functionality behind it.” n

Ceramica Rondine was inspired by the beauty of colours and their chromatic power when it created the Colors series. Available from Designer Stone Solutions.

As a complement to its Brick Generation collection, Colors is a range of indoor porcelain stoneware wall tiles. There are ten colour shades available, designed to suit any style and architectural context.

The Colors series is not just a set of porcelain stoneware bricks, according to Ceramica Rondine. The company believes the value of actual colours are a “tribute to cultural diversity that speak a universal language and are capable of uniting different cultures and ethnicities. Colors celebrate

the beauty and uniqueness of each culture, allowing harmonious, multiethnic environments to be made”.

With the new 4.8 x 45cm size, Colors offers more possibilities for customising spaces, providing aesthetic solutions with great visual impact. Ceramica Rondine has been able to grasp the symbolic significance of chromatic strength and use it to create a series of bricks that can enrich and breathe new life into spaces.

The writer Italo Calvino once wrote, “Every colour has an aura, a voice of

its own, a thickness of its own” and the Colors series is no exception. As a result of their glazed finishes, they reproduce the handmade effect of majolica, giving surfaces a touch of elegance and originality.

Majolica glazed earthenware has been around since the 15th century, but it has become increasingly popular in modern homes thanks to its bold patterns and rich colours.

Innovation and technological advancements now make it possible to reproduce brick with porcelain stoneware, retaining its timeless charm but offering a product that does not alter over time, retaining its aesthetic qualities and strength, and remaining easy to clean.

As its name suggests, Brick Generation represents a new generation of stoneware tiles that combine technical knowledge and history, classicism and modernity.

Colors makes its material authenticity a distinguishing feature, evoking building traditions that have spanned the centuries, and stand out at the same time, for their timeless relevance. These high quality products can retain their beauty over time. They are the ideal choice for those seeking a perfect balance between elegance and functionality, for an environment in which beauty is not sacrificed to achieve efficiency.

Colors by Ceramica Rondine is a winner in the 2023 Archiproducts Design Awards. With over 305,000 products, 3,500 brands and 3.7 million registered users, Archiproducts is considered the largest online network for architects, designers and retailers. They visit the website in search of the finest solutions to design, inspire, build and furnish. It is a continuously updated product catalogue with detailed product data sheets, including technical specs, information request forms, pdf catalogues and ready-fordownload BIM and 3D files.

Ceramica Rondine is part of Italcer Group which majority owned by Investitile S.p.A, and is led by Italian investment fund Mandarin Capital Partners II and Graziano Verdi. n

Ideal for areas that require moderate chemical resistance such as commercial kitchens, hospitals, wineries, breweries, food processing and soft drink factories

Epegrout by Dribond Construction Chemicals is a three-component, water-washable, chemical resistant, epoxy tile grout for joints up to 3mm. Manufactured to have excellent adhesion to damp and dry surfaces, the product is waterproof, hygienic, hardwearing and impact resistant.

It has good resistance to a chemical attack, for example, dilute acid and alkaline detergents, oils, fats, salts and solvent.

In terms of performance data, compression strength is >20MPa. Also resistance to mild alkali, acids and petroleum solvents is good while concentrated acids (and prolonged chemical attack) is fair, according to Epegrout’s datasheet. A simple 1:1 resin hardener ratio can also be applied.

Epegrout should only be used by experienced tradespeople. It is advisable to use a two or three-person team, with one applying the grout and the others cleaning off. This will ensure a total clean up before the Epegrout sets.

Based on the manufacturer’s recommendations, apply the Epegrout with a grouting tool. Spread only 1-2 square metre sections at a time and clean up after each section. Point the joint with the edge of a grouting tool or piece of rubber to pack the grout firmly into place.

When mixing or applying Epegrout, gloves and protective glasses must be worn to avoid possible irritation to sensitive skin. It should only be used in accordance with all relevant Construction Chemicals technical information. See here:

https://constructionchemicals. com.au/tech-info/

Do not allow the grout to cure on the face of the tile. Remove surplus grout when the grout has initially set (10 minutes, the grout will pull out of the joint and smear the tile if removed too early) then do a final clean 30 minutes

later with a damp epoxy cleaning sponge and a bucket of warm water. Do not flood the surface or use excess water.

1. Use a rubber grout float in a diagonal motion to remove any excess grout from the tile surface.

2. Grout haze is removed with a damp epoxy cleaning sponge used in a circular motion. Frequently clean the sponge and if required the addition of a cup full of vinegar in the wash water will make cleaning easier.

3. Use a chamois or similar to remove any remaining grout haze. It is essential that the grout haze/smear is completely removed within 24 hours of the grout application. Stubborn smears can be removed with a white, clean scourer. Again, the addition of a cup

full of vinegar in the wash water will make cleaning easier.

Other products in the Epegrout range include Epegrout Trade, a waterbased, commercial, sanded epoxy tile grout for joints 2mm to 10mm and Epegrout Ultra, an easy clean off, solvent-free, pool grade epoxy grout with chemical and physical resistance combined with easy application properties.

View the YouTube video here:

https://www.youtube.com/ watch?v=o9f1hLJb-AQ

Epegrout is also part of Tile Today’s Grout and Sealant Guide. To see more, click here:

https://tiletodaydigital.com.au/ groutsealant

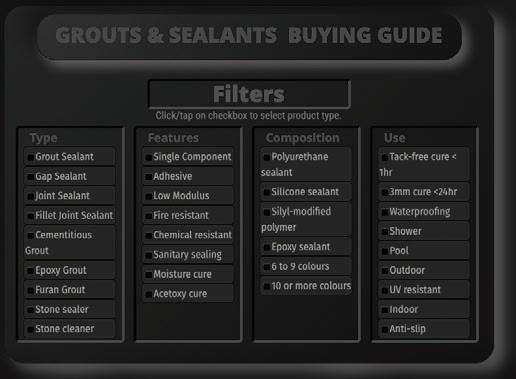

For tile businesses, preparation is every bit as important as execution.

Performance in execution comes from craft, skill and experience. You’ve got that covered.

Performance in preparation relies a lot on planning. At Tile Today, we’ve been developing ways to help boost your planning performance.

We’ve worked with major manufacturers to put together our Buying Guides. These offer an extensive range of adhesives, waterproofing materials, grouts and sealants.

You can filter these products by your needs, quickly narrowing down to an exact match. Links to product data sheets make it easy to confirm your selection.

All on your mobile phone, iPad or desktop.

If you missed a number of stories that were featured in Tile Today’s recent e-newsletters, here is an overview on a few of them and some useful links that will take you directly to the story page.

Given high interest rates and a slowing economy, it remains likely that the residential construction market will slow during 2024. However, there are strong signs also of market resilience in the building approval numbers the final quarter of 2023.

https://tiletoday.au/articleGeneral/2024-09-1708973825265-005/general

A debate has begun over which products should be included in the engineered stone ban in Australia. While some want only engineered stone banned, others believe the ban should extend to some porcelain products as well.

https://tiletoday.au/articleGeneral/2024-06-1707192000414-007/general

The PPI for ceramic tiles hit 119.2 in December quarter 2023, falling by 2.9 points over the preceding quarter. While the overall price index remains high, declining demand should see further falls in calendar 2024.

https://tiletoday.au/articleGeneral/2024-06-1707192000413-006/general

Kaolin Tiles and Taubmans have launched a collection, featuring eight largeformat porcelain tiles in four different colour schemes. The Equilibrium collection references Taubmans paint with a paint-like finish that mimic textured brushstrokes.

https://tiletoday.au/articleGeneral/2024-09-1708973825265-004/general

Johnson Tiles in the UK and tableware maker Churchill China are partnering on projects focused on efficiency and sustainability with the AMRICC (Applied Materials Research, Innovation, & Commercialisation Company) Centre. The centre enables organisations from around the world to trial new products at a commercial pilot scale.

https://tiletoday.au/articleGeneral/2024-09-1708973825264-003/general

ARDEX Australia said it is near completion of its manufacturing regional headquarters in NSW. It is the single largest infrastructure investment - $140 million - that the privately-owned, global company has funded in its 70 years of operation. Oceania regional managing director, Fabian Morgan, said the move underscores the company's sustainable vision.

https://tiletoday.au/articleGeneral/2024-06-1707192000412-005/general

The Porcelanosa Group has a new plant dedicated to the production of porcelain tiles using the sintered stone technique in large format. The corporate group is betting big on these types of tiles under the Xtone brand, and said it has an "ambitious plan for growth through its extensive distribution network".

https://tiletoday.au/articleGeneral/2023-51-1703005527409-001/general