BY ISABEL DANDO

BY ISABEL DANDO

While the global dairy environment reflects an increasingly volatile trade environment, Japan remains a steadfast market for Australian dairy products.

And as one of the world’s largest dairy importers, exports to Japan have remained rel atively steady during the past five years.

Despite a shrinking population, demand for dairy in Japan has been steadily rising.

A lot of the demand for dairy in Japan stems from the tourism industry and associated food service, and Japanese consumers continue to grow more health conscious and recognise the nutritional benefits of dairy in their diets.

The outbreak of COVID-19 in Japan caused significant disruptions to the tourism indus try and the hotel, restaurant and institutional (HRI) sector.

This led to a focus on further processing of surplus milk into products such as butter and skim milk powder (SMP), increasing domestic stockpiles and reducing the need for import ed product. As such, exports of SMP from Australia declined by 74 per cent during the past two years.

With the return of foreign visitors, demand for dairy is expected to rise again alongside a rebounding tourism industry, however stock piles of SMP reportedly remain.

While this will likely induce some import ing growth, inflationary pressures and high freight costs are likely to continue weighing on importing/exporting activity.

Despite the volume of cheese imported from Australia declining 31 per cent during the past five years, this Australian product still accounts for 25 per cent of Japan's total cheese imports.

About 90 per cent of Australian dairy imported into Japan is cheese, worth US$295 million in 2021-22. Increased demand for dairy has seen cheese consumption surge over the past 10 years, with natural cheese now gaining popularity among consumers.

With Australian cheese typically sitting at a premium to other key exporting regions, firm demand from Japan has continued to show support for Australian product through recog nition of its high quality.

During the past five years, Australian dairy exports to Japan have decreased 37 per cent

while imports from the United States and European Union have increased.

In 2015, the Japan-Australia Economic Partnership Agreement (JAEPA) entered into force, allowing Australia a reduction in tar iffs and additional country-specific quotas for selected dairy products.

Since then, the US and EU have both estab lished bilateral free-trade agreements with Japan.

In February 2019, the Japan EU Economic Partnership Agreement (Japan EU EPA) came into force and included a ‘protection’ clause for a range of Geographical Indicators.

The ratification of this agreement prevents Australian exporters from selling dairy prod ucts into the Japanese market under these pro tected names.

With the JAEPA scheduled to be reviewed soon (after an initial deadline of 2021), Dairy Australia and the Federal Government are working to seek market access improvement

for Australian dairy in the Japanese market through this process.

Despite the competitiveness of other key exporters increasing through free-trade agree ments, Australia remains an important export er of dairy product to Japan.

While disruptions caused by the COVID-19 pandemic have weighed on Japan’s import ing of some products, demand for Australian cheese remains robust through the current vol atile trade environment.

Favourable outcomes from the upcoming JAEPA review will ensure that Australia can continue to rely on Japan as a mature, vital and high-value market.

ɋ

For more information on the Japan market and other key export markets, access and subscribe to Dairy Australia’s market briefs here: https://www.dairyaustralia.com.au/ industry-statistics/industry-reports/international-market-briefs

JASON AND Kelly McRae run three farms in South Gippsland, producing 9.5 million litres of milk annually on a pasture-based system, with cows receiving 6-10kg/day of grain.

Jason and Kelly are looking to increase production after a new 80-bail rotary dairy currently under construction on their Kongwak farm is commissioned.

“We’re growing cow numbers and growing production, and with the next generation inter ested in coming into the dairy industry, it was time to invest in this farm,” Jason said.

“It’s also our first dip in the water for a rotary dairy.”

Of course, increasing cow numbers isn’t an overnight decision, so Jason and Kelly have been upgrading the capacity of their Kongwak farm to service the increased herd size.

They have also invested in infrastructure upgrades across their farm holdings.

The McRaes aren’t strangers to hard work or succession planning.

Jason and Kelly are in a partnership with his parents, Len and Heather.

Len and Heather bought the Tarwin dairy farm in 1983 and initially milked 100 cows. Jason and Kelly took over in 2004 and have since expanded the family partnership’s hold ings with an additional two dairy farms. They employ sharefarmers at their Kongwak and Wattle Bank dairy farms.

The three farms’ Holstein herds are split-calving and cows are carried over. The majority of each herd is spring-calving. Joining is by using bulls bred locally.

All three farms supply milk to Burra Foods.

About 300 heifers are retained each year and

are grown out on the Wattle Bank farm as herd replacements for all three farms.

The Tarwin dairy farm run by Jason and Kelly has recently benefited from an infra structure upgrade, with two centre pivots installed. The decision was made after a parcel of irrigation water on the Tarwin River system became available.

The 162-hectare farm was hosting 315 Holstein cows but the irrigation upgrade has meant the herd can grow.

“We’re now milking 400 cows, and moving numbers up to 430,” Jason said.

A dry summer and the opportunity to buy irrigation water were the impetus for the irrigation upgrade, in a district renowned for good pasture growth.

“We bought a bit of water on the Tarwin River and the opportunity for installing pivots came up,” Jason said.

“We installed the pivots at the end of last summer — we put the superstructure in at the beginning of November (2021) and finished in February (2022). We should see the benefits come this summer.”

Irrigation is available from October to May in the district.

Effluent water can also be distributed through the pivots.

The irrigation is a key factor in growth on the Tarwin farm. Production has grown to four million litres a year.

All the February/March-drop calves — heifers and bulls — are reared. Steers are grown out to 2.5 years old and sold over the hooks or through the local saleyards. Heifer calves are reared and grown out at the Wattle Bank farm.

The Wattle Bank farm, bought in 2004, is 202ha of heavy country. Sharefarmers Daniel

and Chelsea Grant milk 300 cows, producing 2.5 million litres annually.

This dryland farm produces all the silage for the herd, but pasture hay is bought in.

Significant investment has been made into the Kongwak farm, particularly with Jason and Kelly looking for opportunities for the next generation. Their son is interested in the dairy industry, and having realised significant bene fits themselves, they are very supportive of him finding a role.

The Kongwak farm, with Tim Harris and Katheryn Hazel as sharefarmers, was bought about seven years ago.

It is 283ha of mostly flat country, with heavy black soils. The dryland farm is a combination of 182ha of milking platform and 101ha to grow out heifers.

The old 20-swingover herringbone dairy cur rently milks 400 Holstein cows, producing an average of three million litres annually.

“We’re looking to raise numbers from 400 to 650 milking cows,” Jason said.

“By next season we’ll be milking 500 cows. The herringbone isn’t comfortable for milking in and can’t cope with that level of herd increase. It was tired and needed a big investment.”

Jason and Kelly had already invested in a new 15,000-litre milk vat, in a new vat room, with an eye to increasing milking numbers. Laneways have been upgraded and paddocks improved. The farm is in a reliable rainfall district.

“The farm is pretty well self-sufficient, producing all the pasture silage and hay we need there, in round wrapped bales,” Jason said.

“At Christmas we begin feeding out fodder through to February, then we increase feeding to the end of April, when we come into grass again.

“There’s plenty of land and we had to make a decision for the longer term. It was either make a big investment and retain it as a dairy farm, or move into beef cattle.

“So we chose to replace the old herringbone with a new rotary dairy.”

It wasn’t a decision taken lightly, consider ing the other farms have herringbone dairies. Because of a broken hand, Jason had to take some time off from milking, and he spent that time visiting other dairy farms and looking at their set-ups.

He looked at herringbone, rotary and robotic dairies.

“We decided to stick with the rotary,” Jason said.

“The farm gets big floods on it, and I didn’t like the idea of running the robots with the herd accessing the dairy on only one laneway.”

Jason’s brother Shaun, of McRae Engineering at Meeniyan, has undertaken the build, which is managed by Peter Farrell of PFC Group Australia.

Rockwork was installed to weatherproof the site, and the shed roof was built on-site and lifted in June. Large-diameter gutters and pipes were installed to capture rain water.

Under the shed roof, as well as the 80-bail rotary, is a large undercover veterinary area to treat cows. There is enough floor space for an office area, a tea room, a change area, storage room and the vat room.

Uniquely, Jason designed a walkway that enables people to walk under the rotary milk ing platform and into the milking area. This access will enable maintenance and repairs to be efficiently undertaken, as well as milking and cleaning.

The rotary dairy will include automatic draft ing, wash and teat spray, and cups on and off.

“We expect to be using the same number of labour units, but the milking time will be less. We estimate it’ll take two hours to milk the increased number of cows in the new dairy,” Jason said.

Sharefarmer Tim Harris is looking forward to his new work environment, citing lifestyle benefits.

“Using the rotary dairy will enable us to take time off,” he said.

“That means a better lifestyle for all of us.”

Before erecting the new dairy shed, significant earthworks were undertaken to secure the site against floods. A lot of concrete has been used in the new shed, including to build an underground access way for people to effectively use and clean the dairy, and undertake maintenance and repairs.ɋ

The Australian Dairy Sustainability Framework has reached its 10-year milestone.

The framework is underpinned by four commitments — to enhance economic viability and livelihoods, improve the wellbeing of people, provide the best care for animals, and reduce environmental impact.

This is the first agricultural framework of its kind and sets the standard for sustainable dairy production in Australia to 2030, and beyond.

During the past 10 years the industry has made significant progress, including:

ɋ Ninety-four per cent of dairy farmers are implementing measures to reduce emissions on-farm.

ɋ

Dairy manufacturers’ emissions intensity has reduced 25.5 per cent since 2010-11.

Dairy companies generate more than $15.7 billion in contributions to the Australian economy, supporting more than 70,000 full-time equivalent jobs in communities across Australia.

ɋ All dairy farmers support compliance with animal welfare standards, and most go well beyond this to provide best

care for their animals.

ɋ Milestone research has been undertaken in dairy’s role in healthy sustainable diets, with key research findings revealing increased dairy consumption reduces fractures in aged care residents by 33 per cent, and 88 per cent of general practitioners feel confident to recommend dairy as a part of a balanced diet.

The internationally recognised framework was created in consultation with dairy farmers, manufacturers and a broad group of stakeholders including government, retailers, customers, NGOs and interest groups.

It is owned by the Australian Dairy Industry Council, including Australian Dairy Farmers and Australian Dairy Products Federation. Dairy Australia is responsible for developing and implementing the framework in line with ADIC’s direction

Dairy Australia’s Helen Dornom said the industry’s sustainability journey was one of constant reviewing, adapting and evolving.

“Since 2012, we’ve made big strides in our commitments, with farmers providing good stewardship of our natural resources and meeting the challenges of climate

change. However, we know there is more to be done,” Ms Dornom said.

“It’s undeniable that the world needs nutritious food options such as dairy.

“As food producers, we have a responsibility to produce food in a sustainable way, and we won’t stop striving to adapt our production systems to be more sustainable now and into the future.”

Dairy farmer Tom Middlebrook, from Bowman in NSW, said sustainability took a collective effort from everyone in the supply chain.

“As farmers, we are committed to implementing processes and innovations on-farm to address sustainability challenges in areas such as improving water efficiencies through recycling, as well as land management to improve biodiversity, soil and carbon capture, food waste management and antimicrobial stewardship,” Mr Middlebrook said.

“I recognise that people want to know how the food they eat is produced, with sustainability playing an increasingly important role in their food choices.

“As a key part of the dairy food production cycle, it’s my goal to always be proud of how we farm, continuously looking to evolve our practices to ensure sustainability is at the fore.”

DAIRY AUSTRALIA conducted a brief annual general meeting on November 23 in an online format with pre-recorded videos.

The 45-minute meeting, broadcast from Melbourne, heard from manag ing director David Nation and chair man James Mann.

Dr Nation outlined the long and short-term strategies of Dairy Australia, the focus on research, promotion of the industry, the part nerships with other related organ isations, the support for dairy-re lated education and referenced the ‘Raising the Roof’ field day based at

Echuca in May as an example of ser vices to industry.

There were no questions submit ted online prior to the meeting but several were sent during the meet ing, including one about the format of the annual general meetings and a previous suggestion that meetings would be held in the regions.

Mr Mann said both he and Dr Nation had moved around the eight regions this year and he expected some future meetings would be held in the regions.

Dr Nation noted the success of the meeting that had been held at Lardner Park in Gippsland.

Professor Allan Bell and Andrew

Maughan were elected to fill two vacant board positions.

Mr Maughan grew up on a family farm in the Goulburn Valley which he says influenced much of his pro fessional life.

He is managing director of corpo rate advisory and investment firm Somerset Capital, chair of AgLink Australia, AGnVET Services and Langdon Group. He has also been Gardiner Dairy Foundation director.

He holds a Bachelor of Law, Bachelor of Science and has com pleted MBAs in Strategy and Finance from the University of Chicago and the University of Melbourne.

Prof Bell grew up on a dairy farm

A record number of cows has been genomically tested by the Australian dairy industry this past year, delivering farmers better quality genetic information for breeding and management decisions.

This increase in genomic testing comes as the average rate of genetic gain for Balanced Performance Index (BPI) in sires of Holstein cows has increased to $35.69 a cow a year — a rise of almost 23 per cent in the past five years.

An increase of more than 24 per cent to $22.30/cow/year was recorded for the Jersey breed.

DataGene chief executive officer Matt Shaffer revealed at the organisation’s annual general meeting on November 17 in Melbourne that 61,531 females — including 50,000 heifers — were genomically tested during 2021-22.

“This drive to increase the number of heifers genomically tested is a commitment by both Dairy Australia and DataGene to collaboratively drive

genetic gain, which is responsible for about 30 per cent of the productivity gains,” Dr Shaffer said.

“This has allowed us to leverage Dairy Australia’s ongoing investment in genetics to help farm productivity.”

Australia’s dairy rate of genetic gain has recorded a “sharp increase” since the introduction of genomics and DataGene and its collaborators continue to deliver innovative herd improvement products to the local dairy industry.

One of these is mid-infrared spectroscopy (MIR) Conception, one of the newest tools to sit on the HerdPlatform dashboard on the DataVat website.

MIR Conception uses information about the cow and its herd test sample to predict the odds of getting pregnant to its first insemination. It builds on the work of the MIR 4 Profit project and ongoing research by DairyBio.

Dr Shaffer told the DataGene AGM that in a “world first development” this

in South Gippsland.

He was educated at the University of New England and the University of Glasgow and has held research and teaching positions in Australia, Scotland and the United States.

He was chairman and extension leader of the Department of Animal Science at Cornell University from 1997 to 2007, with responsibilities for teaching, research and extension in livestock biology and management.

From 2007 until his retirement in 2012 he was CSIRO Livestock Industries Australia chief, with responsibility for research opera tions in Queensland, NSW, Victoria, and Western Australia.

technology was rolling out to farmers in Victoria, NSW and Queensland as the newer herd test centre machines allow.

Outgoing DataGene chairman Ross Joblin highlighted the organisation’s growth and how this had led to income diversification and an increase in the ability to deliver innovation for dairy farmers.

“Our sources of revenue have expanded into work with international dairy counterparts, other Australian dairy industry partners and also into new industries such as cotton and red meat,” Mr Joblin said.

“All these projects leverage the core skills of DataGene — technology, genetic evaluation, people development and project management.

“As a result, we have been able to not only maintain our service offering to the Australian dairy industry, but we’ve also expanded it using revenue from these projects.”

Mr Joblin stepped down from the board and as DataGene chair after six years and the end of his term.

“I am proud to leave an organisation that has successfully navigated its start-up years, is financially stable, has a strong governance and people culture and has a pipeline of innovation for dairy farmers,” he said.

Former Dairy Australia chair Jeff Odgers is replacing Mr Joblin as the Dairy Australia-nominated director on the board.

Gippsland dairy and beef farmer Tim Jelbart and host of the DataGene’s ImProving Herds National Muster in 2018 was also re-elected to the board.

Graeme Gillan was elected chair. Mr Gillan has been on the board since its inception and has more than 45 years’ experience in herd improvement, including as former chairman of the National Herd Improvement Association of Australia, former CEO of Holstein Australia and numerous roles with genetics companies.

Andrew Maughan, who grew up in the Goulburn Valley, was elected to the Dairy Australia board on November 23.

Andrew Maughan, who grew up in the Goulburn Valley, was elected to the Dairy Australia board on November 23.

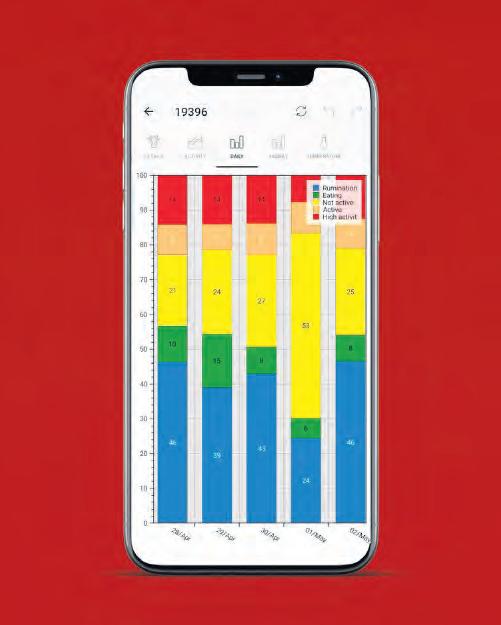

Your cow’s ears are full of data. CowManager ear sensors measure ear temperature combined with behaviour, giving you actionable insights about the health, fertility and nutrition of your herd. Catch sick cows days before they show clinical signs and never miss a heat. Know exactly which cows to focus on – and why.

www.cowmanager.com

BUNGAREE NEAR Ballarat is well known for its spuds, but the Trigg family has found a way to successfully blend in a dairy business.

A.J. Trigg and Sons is a rare example of com mercial dairy and seed potato operations work ing together on the same property.

It has been that way for generations and partner Mark Trigg sees no reason for it to change.

Innovations over the past decade — includ ing a huge cow shelter and introduction of a robotic dairy — have made sure the future looks bright.

As the only potato-dairy farm in the region, it’s also one of only about six surviving dairy farms in the Ballarat area, west of Melbourne.

The farm is a fifth-generation partnership between Mark, his father Ron Trigg, cousin Tony Trigg and partner David Lee.

Pete McAdam takes care of the cropping side of things and has been with the farm for 14 years after arriving as a tractor-driving backpacker.

The farm still includes the original eight hectares selected by the Trigg family more than a century ago, but has now grown to nearly 500 hectares.

Although it takes up less space than the 350 cows, the potatoes are more intensive and it’s about a 50:50 split between the two business streams.

“It’s always been a mix and it works in well with rotations,” Mark said.

Running two businesses on the one farm serves up some challenges, but there are also benefits.

Irrigation is shared through both businesses as needed and the rotation and re-sowing sys tems are not down pat.

“We grow all our own fodder for the dairy — maize, grass silage and half our wheat,” Mark said.

“We plough up poorly performing pastures and put potatoes, maize, wheat and biannual rye-grass on them.”

Pete uses two-year rotations for the dairy pastures and it’s usually five to six years between potato crops.

“We’re chasing protein out of the grasses so we find Italian rye-grasses are best for us,” he said.

“We get up to three per cent more protein by planting every two years and it’s more for giving on your harvest date. With annuals you have five to 10 days and you’re in trouble if you

miss it.”

In the rocky paddocks that will go back to spuds every five to six years, they use peren nials, most recently rye-grass, but that could change to a mixed species to help diversity.

“They’ll sit there for five to six years till you’re ready to go back to spuds and you get a bit more winter growth off them,” Pete said.

“But for the bulk feed to put into your silage, you can’t beat Italian rye-grass. In years like this, we try to plant a little bit later and prefer a tetraploid over a diploid and use AR37 to make sure the root aphids aren’t a problem.

“Everything we plant is between a plus-12 and plus-18 flower date.”

Mark said the aim was to be as self-sufficient as possible.

“We only buy in a few concentrates, canola meal and Malte combings, and maybe a couple of loads of cereal hay. We supply all our hay and grass and maize silage.

“About 350 cows is ideal for growing our own fodder and having potatoes at the same time.

“To go for more cows, we’d have to sacrifice potatoes or we’d have to buy more land and that’s so expensive at the moment.”

The farm has access to water, but it’s metered and that governs what can be grown.

They are considering stopping maize and putting in more wheat for silage, buying crushed corn and substituting that with fibre content from the wheat to free up more water.

“If we had a bit more land, we’d be able to do that instead of growing maize which we find very taxing on the soils,” Pete said.

“It would be half the work for the same result but be less taxing on the land. Maize can need as much water as the potatoes.”

The wet winters and the need to make the most of the land prompted construction of a 160-metre long by 40-metre wide shed about 10 years ago.

“We had to get the cows off the pasture,” Mark said.

“Our winters here are shocking and we had trouble moving cows around and with lameness.”

The shed was also the starting point for robots.

“We needed a new dairy so decided to get the cows out of the paddock and then look at robotic dairy,” Mark said.

The plan was to reduce staff and achieve lifestyle improvements. They have had four DeLaval robots in use for the past six years, with two more to be installed.

“We built the barn with robots in mind,” Mark said.

“We put straw into it for the first winter to get the cows out of the mud and house them at night, but we were going through 12 to 14 big square bales of straw a week to keep them clean and dry.

“That wasn’t sustainable so we cleaned that out and started concreting the following year.”

They milk 200 cows on the four robots and the overflow goes onto the rotary.

The system selects cows that need to be milked with a feed-first guided traffic with the use of a one-way gate and smart gates.

The mostly Friesian herd is producing well, averaging about 38 litres a day through the robots — an increase on their previous output.

The cows average 2.4 milkings a day and get milked when they like. The top cows can peak over 60 litres and get milked up to four times a day.

In another nod to future farming, the prop erty is home to three shipping containers where a methane digester is being investigated by a Ballarat engineering company.

The Triggs already have success with their manure.

“It goes back on our pastures and we’re getting great results,” Mark said.

“It’s such a great resource and cost saver.”

While the seed potatoes are sold to McCains contract growers and other processors, the milk is collected every second day and goes all the way to Saputo near Warrnambool.

The huge shelter shed and robotic dairy have allowed the Trigg family to continue dairy farming. A Ballarat company is conducting a methane trial on the farm. Pete McAdam and Mark Trigg run a successful rotation system that allows both dairy and potato businesses to flourish. The wet winters and the need to make the most of the land prompted construction of a 160-metre long by 40-metre wide shed about 10 years ago.program that really stacks up.

At CopRice, we’re committed to delivering nutritional solutions that drive the profitability and long-term success of pasture-based dairy production systems. Our tailored programs are designed meet the exact nutritional requirements of your cows throughout the lactation based on your available feed resources and feeding objectives. The bottom line is improved production at less cost. Book an obligation-free on-farm consultation and find out how CopRice can deliver a

Animal health company Zoetis has raised $100,000 for the Beyond Blue Support Service in an effort to support good mental health and reduce suicide rates across rural Australia.

Every year since 2016, Zoetis has donated $5 from each sale of vaccines and drenches up to $100,000 for the Beyond Blue Support Service.

This year Zoetis once again reached its yearly goal of raising $100,000, bringing the total donated to the support service to $700,000.

Remoteness is a major risk factor contributing to mental health issues and suicide, and suicide rates in regional areas are 60 per cent higher than rates in major cities.

Beyond Blue’s Patrice O’Brien said demand for its support services increased 20 per cent during the pandemic and remained higher than pre-pandemic times.

“We know that people are doing it tough right now and ongoing impacts of the pandemic, cost of living pressure and extreme weather events will continue to affect people’s mental health,” she said.

”There are some indicators to look for if you think a family member, friend or colleague might need help.“

Ms O’Brien said sadness and worry were normal human emotions.

“However, if the behaviour has been going on for two to three weeks, then a quiet conversation might help,” she said.

“Such behaviours might include a drop in their performance at work, they may be getting into conflicts, they might be withdrawn, not sleeping or there might be drug or alcohol use.”

Ms O’Brien thanked Zoetis for its efforts.

"To date, over 14,500 people have been able to get the support they need through these funds,“ she said.

“As well as the importance of the funds raised, Zoetis’ support of Beyond Blue in rural and regional communities, ensures that more people in those communities are aware of our services being available to them, which is so important.”

For resources and information, visit www.beyondblue.org.au or talk to a mental health professional for free, 24/7 on 1300 224 636.

A NEW online bushfire resource — Recovering After a Farm Fire — is hoping to provide Aussie farmers with the support and information they need to help them process and recover after a bushfire.

Launched in October by the University of South Australia, the free interactive self-help resource has been designed by Australian farm ers affected by fires, for Australian farmers.

It hopes to share information and practical tools to help farmers and their supporters to adapt effectively if they have experienced a fire, and to prepare psychologically in case of future fires.

Led by UniSA’s Dr Kate Gunn, the new bush fire resource is part of the successful ifarm well website, to help farmers cope effectively with life’s challenges and get the most out of each day.

“Growing up on a farm myself, gave me an insight into the ups and downs that farmers face,” Dr Gunn said.

“When farmers in my community were struggling and wondering where to seek confi dential, free help, we came up with the ifarm well website.

“The new bushfire module focuses on equip ping farmers with practical strategies that are helpful for coping with a range of challenges, including stress and trauma, which are often experienced by farmers who are significantly affected by fires.

“It’s based upon things that other farmers affected by bushfires have told us they found helpful — as well as evidence-based psycholog ical techniques.

“It covers topics such as how to deal with post-bushfire workloads, how to manage stress, anger, and worry, and importantly, how to maintain good relationships with your com munity and those around you.

“Ultimately, it gives farmers practical tools, based upon psychological science and what other farmers have found useful, to help man age their individual situation.”

The free 30- to 60-minute module can be accessed on a computer, smartphone or tablet

— anywhere with internet access — so farmers have the choice to connect from their tractor, shed or home.

It includes contributions from 16 farmers who collaborated on the project, to help other farmers who may have faced similar challenges to them.

South Australian dairy farmer Mick Kowald has been running the family farm for 20 years.

In the aftermath of the 2020 bushfires, he worked around the clock as he cleaned up after the fire and kept the farm running.

After three to four days of constant work, little sleep and extreme stress, Mick ended up in hospital with a panic attack.

“I realised I couldn’t deal with the bushfire impacts on my own; I had to take a step back and slow down,” he said.

“The fire was bigger than anything I could fix in a couple of days, and it was going to take a long time to repair the damage on our farm.

“So, I took a few days off and stepped back from it all. I spent a lot of time in my vegie patch, I made sure I cut back on the alcohol, I got involved with community recovery efforts and I spent a lot more time with my family.

“After a bushfire event like I’ve been through, I think it’s so important that you really take time to look after yourself, pace yourself, be aware that you may suffer similar things that I’ve been through.”

As an advocate and contributor to the ifarm well site, Mick willingly gave advice on what the new bushfire module should contain and shared his experiences in a video.

He said the value lay in the content being specifically tailored to farmers.

“The ifarmwell website has been a great resource for me over the years,” Mick said.

“Certainly, it takes some time and commit ment to work through, but the advice and strat egies on the site are all practical and focused for farmers, so it’s all very real and relatable.

“My advice is simple. Keep talking to your mates and neighbours, share your stories, don’t be afraid to open up, and seek advice from resources like ifarmwell if you need it.”

9:30am

Making Calf Rearing Easier

10:30am

Silage Preservation Process and Technology Advances in Inoculants

11:30am

Feed them and Breed them Solutions for increasing your heifer’s fertility and performance and your profits

9:00am

The Latest Findings from Terragen’s Research

10:00am Pending 11:00am Milking frequency in grazing-based Lely single box robotic milking system

Presented by: Tom Newton, Business Manager

Presented by: Jason Scott, National Silage Specialist & Microbial Lead

Presented by: Andrea Henry, Area Sales Manager

Hosted by: Maxcare

Hosted by: Pioneer Seeds

Hosted by: Jefo

Presented by: Joss West , (MBA, BVetBiol/BVSc) Vet Scientist, and Orlando Ramirez (DVM, MSc, PhD), Project Manager of The Big Cow Project

Presented by: Pending

Presented by: Dr (Paul) Long Chen, Senior Lecturer in Livestock Nutrition and Grazing Management, U. of Melbourne and Innocent Rugoho, FMS Advisor.

Hosted by: Terragen Biotech

Hosted by: Holstein Australia

Hosted by: Lely

If you are unable to attend IDW 2023 you can tune in on the livestream at www.idwaus.com

12:00 pm

EcoFeed® identifies dairy genotypes for Feed Conversion Efficiency

1:00 pm

Breeding Profitable Commercial Cattle With Style

2:00 pm

Improve Performance and Fertility in your herd - NOW to increase profitability!

3:00 pm

Factors affecting the quality and quantity of bovine semen

10:00am

A particularly profitable pathway to sustainability dairy

11:00am Central Steel Build Dairy Buildings

Presented by: Kevin Ziemba, STGenetics USA

Presented by: Brian Behnke, Business Manager, St Jacobs

Presented by: Dr Razaq Balogun, Technical Sales Manager – Ruminants

Presented by: Hadi Safar, Master’s degree in Agriculture Animals Science (Animal Breeding)

Presented by: Dr Les Sandles , Head of Science & Innovation

Presented by: Richard Grace, Project Consultant

Hosted by: STG Australia

Hosted by: ABS Australia

Hosted by: Jefo Hosted by: Total Livestock Genetics

Hosted by: 4 Sight

Hosted by: Central Steel Build

MILK PROCESSING giant Fonterra is expected to pay out $25 million in a class action launched by dairy farmers over its price drop in 2016.

The settlement, on November 3, came only a few weeks before the class action was expected to hit the courts.

Suppliers launched the action for financial compensation over retro spective price drops for the farmers who supplied Fonterra in May and June 2016.

The plaintiffs claimed misleading and deceptive conduct, but in the settlement, Fonterra has not admit ted any liability and the company said it wanted to see the matter set tled so all parties could move on.

Lead lawyer in the case, David Burstyner, said he had been receiv ing positive emails and text messag es from farmers one after the other since the news of the settlement came through.

“They get a nice bit of news before Christmas and, with court approval targeted for (the first quarter) next year, a nice payout in 2023,” Mr Burstyner said.

“It was an intense court process to get here — Fonterra fought hard and we fought hard for farmers.

“We looked at 55,000 documents (using a team of around 30 legal staff at one point) and prepared many detailed witness and expert statements.

“We were fired up for a trial next month, and thought our case had some really good points.

“But anything can happen at tri al, and then there can be appeals that can take months, if not years to resolve, and this settlement avoids all that.”

Fonterra Australia managing director Rene Dedoncker said the company had, during the past six

years, invested a significant amount of time and effort to overhaul their relationship with farmers to rebuild trust and strengthen the dairy industry.

“We are proud of the good rela tionships we have today with our farmers and the wider industry and are committed to investing in the future of Australian dairy for years to come,” Mr Dedoncker said.

“ The settlement sum of $25 million, inclusive of interest and all costs, has already been provid ed for in the prior year’s finan cial statements and will not have a material impact on Fonterra Co-operative Group Limited’s financial position.”

Mr Burstyner said the legal team was honoured and proud to have been able to achieve the outcome, and grateful for the exceptional support from the financier LLS, who provided a war chest of millions of dollars.

“We congratulate the plaintiffs from Strathmerton who put in a superhuman effort, as well as the other farmers who joined in the class action and assisted us in preparing a strong case,” he said.

The settlement is subject to court approval.

For the second year in a row, Norco Co-operative received the Excellence in Large Business Award at the 2022 Northern Rivers Business Awards.

One of the northern NSW region’s largest private employers, independent judges praised Norco for continuing to safeguard its community of 292 Australian dairy farming producers while also cementing a strong, vertically integrated business with exceptional expertise in food and rural retailing.

Receiving the prestigious award was Norco’s Adrian Kings, who said it recognised the hard work and commitment of every single individual within the co-operative.

“This award is for our people,” Mr Kings said.

“The catastrophic floods in February really tested our strength and resilience but it also gave us the spirit to bide together.

“Having staff working and assisting the general community was a show of nothing else but love for the local area and without it I’m not sure where we would be right now.

“We have also rolled up our sleeves in other areas that we feel are fundamental for farmer and community wellbeing including our proactivity towards farmer mental health via our Employee Assistance Program and the Norco Member Cow Purchase Program, which assists farmers in rebuilding their herds following the unprecedented February flooding.”

Norco was also in the running for the Outstanding Employee, Outstanding Young Business Leader and Outstanding Employee categories.

“I was absolutely delighted to share the award celebration with three of my esteemed colleagues who were ‘Team Norco’ finalists and are the champions of our values,” Mr Kings said.

“Two of our finalists have been with us for over a decade and have quietly worked their way up to lucrative careers, a journey that truly deserves to be recognised and celebrated.”

The 2022 Northern Rivers Business Awards recognises and celebrates business excellence across its diverse regional economy with strong industries such as manufacturing, tourism, health and education.

A new app launched by MaxCare are aims to make calf rearing easier.

The app, MaxCare Animal, features calculators, feeding guidelines and other easy-tofollow instructions.

The animal nutrition group said the app was designed to give farmers a tool on their phone that gave them access to information at their fingertips.

“We are very excited to launch the app,” MaxCare business manager Tom Newton said.

“The app helps maximise productivity by guiding farmers through a consistent and targeted approach with their infant animals, accessed easily through the handy location of their mobile phone.”

“This is an industry first, we want to help our customers achieve the best possible results with the resources they have. This app was created to simplify some of the potentially confusing messaging around calf rearing.

“My favourite feature is the calculators. They help enable

A new app aims to help farmers with calf rearing.

farmers to be more accurate and consistent, while removing a lot of the thinking work required, out of an already very busy daily schedule.”

The MaxCare Animal app is available to download on IOS via Apple App Store and Android via Google Pay.

ɋ

For more information, visit maxumanimal.com

us about five-and-a-half hours the first milking but everything went really well.”

SOUTH-WEST

Paul Smith has never seen his cows so keen to get into the dairy.

It’s still early days, but it’s a case of “so far, so good” for a new robotic dairy on Paul and Marsha’s farm at Mepunga, and Paul can see long-term time, financial and health benefits.

The new GEA DairyProQ robotic rotary dairy, which went into action mid-October, is the first of its type built in Australia and the first in the world to operate on a pasture-based farming system.

“They’re going on better than the last dairy,” Paul said.

“We only have to use the back gate for the last 50, previously it was the last 200. They’re just filing in.”

Paul said the cows liked the automation.

“Generally, when you’re cupping up on a rotary, you’re standing right where they’re walking in,” he said.

“Because there’s no-one there, they’re just piling on better than I’ve ever seen them walk on a rotary.”

The conversion was an easy process with no major changes to the milking system.

“We just run them on here like we normally would,” Paul said.

“I had a crew of local helpers for the first couple of milkings, which was really great.

“A new dairy is always a challenge and it took

Over the first two weeks, milking time has been cut to about 3.5 hours in the morning and three at night. That’s about half-an-hour slow er than the old dairy but it’s 10 units shorter — 40 instead of 50.

“It’s probably on-par,” Paul said.

“If we have a good run, we’re milking 240 an hour which is pretty much where we were before. I was hoping for 250 an hour and we’re not far off that already.”

It’s too early to gauge any production chang es because most cows are drying off.

“The good news is we haven’t gone down from where we were,” Paul said.

There have been no staff changes as yet but Paul expects two backpacker positions won’t be refilled, leading to long-term savings.

They are milking about 700 Holsteins and the vast majority are settling in well with the robotic system.

“The robots try about five times to attach the cups,” Paul said.

“If they don’t connect, the system sends an alert. We’re milking about 700 and only have to help about 50 with getting a cup on.”

The dairy includes a nearby colour-coded screen showing what’s happening on the plat form, including all production, cell count and health information.

“We haven’t had any major teething issues,” Paul said.

“We’re only two weeks in but so far, I’m hap py we made the investment.”

The previous rotary dairy was built in 1998 and remained in use during the changeover. The DairyProQ robotic rotary is about 300 metres from the existing dairy.

With the DairyProQ rotary parlour, every milk ing procedure step is performed inside the teat cup in a fully automated process, including key sensors to constantly analyse and monitor the flow of milk and industrial touchscreens provid ing thorough insights into the milking process.

DPQ dairies can go up to 80 stalls to milk 600 cows an hour.

VICTORIAN farmer

Paul and Marsha invested in the new tech nology following years of research, starting with YouTube videos and followed by lengthy discussions with GEA and farmers who use the system.

The robots will try five times to attach to a cow and in the rare times they miss, an alert is sent.

Backing out is easy after the cows have been milked.

Mepunga farmer Paul Smith is pleased with the smooth transition to a robotic dairy. A screen near the robotic rotary provides all the data and raises any alerts.

VICTORIAN farmer

Paul and Marsha invested in the new tech nology following years of research, starting with YouTube videos and followed by lengthy discussions with GEA and farmers who use the system.

The robots will try five times to attach to a cow and in the rare times they miss, an alert is sent.

Backing out is easy after the cows have been milked.

Mepunga farmer Paul Smith is pleased with the smooth transition to a robotic dairy. A screen near the robotic rotary provides all the data and raises any alerts.

EXCITED STUDENTS from across Victoria were recognised at three online Cows Create Careers presentation days in October and November.

The presentation days celebrated the achievements of students who have completed the innovative Cows Create Careers project, which aims to increase the awareness of dairy industry careers.

To lead by example, the Cows Create Careers project was delivered online for the second half of this year, due to the possible implications of foot and mouth disease.

Students and teachers from schools across Victoria have participated in these high-energy online events, to celebrate their achievements as part of the project.

The fun-filled days saw students participate in industry-based games and the project’s winning teams awarded prizes.

The program manager is Jaydee Events.

Jayedee Events director John Hutchison said it was encouraging to see students so passionate to learn, and connect with, Australia’s vibrant dairy industry.

“The presentation days are a great way to recognise and celebrate both the students’ and teachers’ dedication to the Cows Create Careers project,” he said.

“Each year we continue to be inspired by their enthusiasm for the project.”

During 2022, more than 60 Victorian schools were provided with dairy industry curriculum, at no cost. Students took an

online journey through Willbrae Farm where they were introduced to two dairy calves, ‘Bright’ and ‘Future’.

Over five weeks, students found out how to care for the calves and watch them grow through engaging videos. Students also learnt about the environment, technology and machinery used on-farm through quirky activities and competitions.

“Cows Create Careers allows students learn about the wide range of skills, educational pathways and careers in Australia’s dairy industry,” John said.

“It’s extremely encouraging to see the ongoing benefits of the project; not only are the students learning about the diversity of skills required in the industry, but it also directly connects them to their local community.”

Cows Create Careers was established in 2004 with dairy farmers in the Strzelecki Lions Club in Victoria and nine Gippsland schools. It has now grown to more than 230 schools across Australia with more than 1500 students completing the project in 2021.

John said the project’s passionate volunteers were vital to the continued success of the Cows Create Careers project.

“Since its inception, Cows Create Careers has gained support from industry, regional development programs, dairy farmers and sponsors across Australia.

“Last year alone 425 passionate volunteers gave 2125 hours of their time across 23 Australian dairying regions.”

For the second consecutive year, Lactalis Australia employees have rolled up their sleeves to participate in World Clean Up Day.

Lactalis Australia partnered with local not-for-profit organisation Clean Up Australia to activate clean-ups across its Lidcombe (NSW), Scoresby (Victoria) and Brisbane (Queensland) sites on September 19.

The clean-ups saw 104 Lactalis Australia employees head out into their local communities, gloves on and garbage bags in hand, removing a combined 2208 pieces of waste from the environment.

Forty-two per cent of rubbish collected was soft plastics, with 66 per cent collected from waterways.

During two weeks, from September 12 to 25, Lactalis sites in 42 countries took

action to organise or relay local litter collection operations and raise employees’ awareness about the importance of sorting and recycling waste.

More than 3300 employees and their families volunteered, and more than 30 tons of waste were collected.

“The state of the environment means people are expecting their employers — and brands — to show leadership and be true stewards for the future,” Clean Up Australia chair Pip Kiernan said.

“It takes a collaborative effort to solve our waste challenges and we’re thrilled to partner with organisations like Lactalis Australia.

“When we take time to connect with the environment and clean it up, we become more conscious of our environmental footprint.”

VIRTUAL REALITY is being used to bring the paddock to schoolchildren, many of whom have never been on a farm, met a farmer or know where milk, butter, cheese and yoghurt come from.

Dairy Australia hopes to bridge the gap between dairy farming and urban primary school students by bringing on-farm experiences into the classroom to help them understand how dairy farmers work to supply nutritious, sustainable food to fuel a healthier Australia.

Dairy Australia’s Virtual Reality initiative was launched on November 15 at St John’s Grammar Primary School in Belair, in Adelaide, with children in the classroom being taken through the entire process of making dairy foods, from the paddock and milking shed, to packing and even cheesemaking.

Schools throughout Australia will be able to download the content.

Dairy Australia spokesperson Jess Phillips said educating the next generation about the dairy industry and the importance of dairy foods for overall health and wellbeing was critical.

“We know young Australians are more conscious of what they are consuming than ever before,” she said.

“However, an alarming 60 per cent of school-aged children are not getting enough dairy during a critical time for bone growth.

“Through the use of virtual reality, this new experience allows students to learn in an engaging way, that is easily accessible to

educators — and helps students connect with the food they consume each day.”

The virtual reality program supports Dairy Australia’s commitment to working with schools and its popular curriculum program Picasso Cows and Discover Dairy resources.

South Australian dairy farmer Bec Walmsley, whose farm features in the virtual reality program, said as consumer interest and food

production transparency continued to grow, there was increasing need to connect the farming community with wider Australia.

“Through educating students on the manufacturing process, from milking to final consumer product, we hope to inspire young Australians in making healthy food choices, to better their health and support the industry,” she said.

“Through the use of virtual reality, this new experience allows students to learn in an engaging way, that is easily accessible to educators...”

In the wake of recent natural disasters, animal health business Elanco has entered an initial three-year financial partnership with national charity Rural Aid.

Elanco will support Rural Aid financially through annual donations and donation matching, team volunteering hours and Elanco animal health product donations, as well as helping raise awareness of the services provided by Rural Aid.

“Disaster relief is so much more than waiting for the waters to subside,” Rural Aid CEO John Warlters said.

“While response and recovery are key, preparedness and prevention strategies are where real change occurs.

“It’s the ongoing support of businesses like Elanco that allows us to plan and invest in new

thinking to create meaningful change.

“The short term is survival, the long term is where we set Australia up as a resilient nation; it’s where we thrive.”

Elanco general manager Hendrik Van Der Walt said they were proud to help the organisation provide response, recovery, prevention and preparedness support for rural communities battling the effects of natural disasters.

“In our business, we focus on holistic, longterm animal health solutions,” he said.

“So, it was important for us to partner with

in real, long-term change.

“Rural Aid knows the importance of being on the ground when natural disaster strikes, and they’re often the only lifeline for many of our brothers and sisters in rural and regional communities.

“And we’re proud to be right there with them.”

Farmers are encouraged to register with the following: faa.ruralaid.org.au to streamline assistance in times of disaster; and

BROWNES’ YOGHURT tubs will now be made from ocean-bound plastic.

Ocean-bound plastic is described as plastic that’s found within 50 kilometres of Australia’s coastline.

In addition to using ocean-bound plastic, the Western Australian business’ new yoghurt tubs will also be fully recyclable by kerbside waste management operators.

The initiative will be an important step in preventing ocean waste, with projections that by 2050 the world’s oceans will carry more plastic than fish (by weight).

“Brownes Dairy is showing our commitment to sustainability through action,” Brownes Dairy CEO Natalie SarichDayton said.

“We were first to introduce Australia’s most sustainable milk cartons and we wanted to push the envelope again by using recyclable ocean-bound plastic in our yoghurt tubs.”

Brownes has partnered with companies including Heng Hiap Industries and PakPot, which are certified by Zero Plastic Oceans, which is an NGO dedicated to addressing plastic pollution.

“Working with certified partners not only prevents plastic waste from ending up in the ocean, it also creates employment opportunities for underprivileged coastal communities,” Ms SarichDayton said.

By switching to ocean-bound plastic yoghurt tubs, about 2.7 million virgin plastic tubs a year will no longer be created.

In addition to the sustainable yoghurt tubs, Brownes is also transitioning the CHILL 750ml Flavoured Milk bottle range to 100 per cent recycled plastic.

Studies suggest 90 per cent of Australian consumers are concerned about sustainability, with all age segments having the view that businesses and brands should be most responsible for the impact on the environment.

As part of its sustainability focus, Brownes has also partnered with Trillion Trees, an environmental replenishment not-for-profit organisation, to contribute to the Trillion Trees Challenge.

The organisation has been active since 1979 in Western Australia and has planted close to 15 million native trees.

Since 2016, Brownes has also been an active signatory of the Australian Packaging Covenant Organisation (APCO), which is a packaging value chain that collaborates to keep packaging materials out of landfill and retains the maximum value of the materials, energy and labour within the local economy.

BY JEANETTE SEVERS

BY JEANETTE SEVERS

THE VICTORIAN Government has pledged to support workers, but Gippsland leaders are condemning the decision by Saputo to close the Maffra dairy processing factory and powdered milk lines at the Leongatha facility as part of the international corporate’s ratio nalisation plans.

The rationalisation decisions will be effec tive in early 2023.

The decision by Saputo to reduce its activ ity in Gippsland comes on the sunset of an agreement it made to continue to buy milk from Murray Goulburn’s existing suppli ers, when it bought the failed cooperative in 2017.

That agreement, under the terms of the sale and purchase agreement, is void at the end of this year.

The dairy industry in both affected regions are key contributors to the local and state economy.

Milk supply out of the Macalister Irrigation District in Wellington Shire, which the Maffra facility traditionally processed, makes it the third largest dairy region in Victoria.

Wellington Shire Mayor Ian Bye condemned Saputo Australia for its unwillingness to dis cuss its plans with the council, but pledged to work with Saputo management.

“(The November 9) announcement is disap pointing in that there has been no discussion with the community or council to leverage

other opportunities, or consider responsible transition of local employees,” Cr Bye said.

“If you ask anyone in Maffra, they’ll tell you how important Saputo was for the region. It has been an integral part of the community, and it’s now time for us to look at transition options for the future.

“As a council, we are confident that with a number of different sectors looking for work ers, we can start a conversation with Saputo and work towards a solution to benefit every one involved.

“While Maffra is a resilient and growing community, this decision by Saputo to close the factory brings to an end an important eco nomic and community piece of Maffra’s history that stretches back decades.”

Collectively, the dairy industry in South Gippsland Shire is directly worth about $1 bil lion annually, and is the single biggest employ er within the region.

More than 900 people, or 6.7 per cent of all people employed in the shire, are within the dairy industry, with another 500 employed in dairy processing.

The value of the dairy industry in South Gippsland Shire has a significant flow-on eco nomic benefit through other industry sectors to the rest of the economy.

South Gippsland Shire Council CEO Kerryn Ellis was disappointed to hear that processing operations would be scaled back, and job losses would occur, at the Leongatha dairy factory.

Both South Gippsland and Wellington shire councils have pledged to work with Saputo

management to help workers affected by Saputo’s rationalisation plans.

Federal Member for Gippsland Darren Chester said he was disappointed that Saputo Australia made the news of the closures public in the lead-up to Christmas.

“The Maffra community is extremely resilient and I know it will overcome these challenges, but that doesn’t soften the news for staff and families directly impacted by this decision,” Mr Chester said.

“I will be working with the community, Wellington Shire Council and other levels of government to secure more investment in infrastructure and services to boost the local economy.”

He also commended the long history — more than 100 years — that Maffra had hosted a dairy processing factory, creating local jobs and supporting milk suppliers in the region.

State Member for Gippsland East Tim Bull said it was a disappointing announcement for Maffra and the local community, with no fore warning from Saputo Australia.

He is hopeful the infrastructure will attract new investors, if Saputo intends to sell or lease it.

“This [decision] has occurred in a period where we have workforce shortages across other sectors and industries that I am hope ful those people impacted can transition to,” Mr Bull said.

“I am also planning to discuss the future of the site and prospective new industries and uses with Saputo and agencies like Wellington Shire Council.

“It is a resilient and growing community that will continue to prosper.”

The Victorian Government has committed to supporting the local communities.

“We are ready to help affected employees and will continue to support new investment and job creation in Gippsland,” a government spokesperson said.

Saputo has said it would work closely with affected employees to consider redeployment and retraining opportunities, or if suitable roles were not available, employees would receive severance and outplacement support.

The company said many of the impacted production and packaging functions at the facilities would be absorbed or integrated into its other facilities.

“While a very difficult decision to make, (this) announcement continues our journey towards

long-term success for our business in Australia by increasing our efficiency and productivity, and making our business more competitive,” Saputo (International and Europe) president and chief operation officer Leanne Cutts said.

“These strategic steps taken to further streamline our network aim to leverage SDA’s broader manufacturing network capabili

while creating synergies to maximise the return on every litre of milk.”

Saputo said it did not expect the changes would affect suppliers.

Earlier this year Saputo closed its cheese slice line at the Cobram factory in northern Victoria and in September said it was looking at rationalising its Australian dairy factories in its implementation of a new, four-year global strategic plan.

SAPUTO AUSTRALIA’S rationalisation of its Australian assets is part of a global streamlining response.

This response includes the closure of the Maffra processing facility and stoppage of the powdered milk processing line at its Leongatha factory in southern Victoria, and closure of a plant at Tulare in California.

The packaging and packing lines at Mil-El in South Australia are also stopping, with that work undertaken at other processing facilities. In line with decisions made by the company in other countries, it would not be unexpected if Saputo Australia contracts this role to a third party.

The news comes on the back of a decision earlier this year when Saputo Australia closed the sliced cheese production area at its Cobram factory in northern Victoria.

The moves are part of a four-year global rationalisation program the company is implementing.

In an interview earlier this year reporting on fourth quarter 2022 fiscal results, Saputo CEO Lino Saputo said implementing the rationalisation program would see closure of processing plants and production lines in the company’s US network and Australian network by the end of financial year 2025.

The company is also focusing on upgrading its processing plants in Canada, the United Kingdom and Argentina.

The decision in Australia is not unexpected given the ageing processing plant at Maffra, and other supply chain considerations.

Mr Saputo also said milk supply in Australia was declining year-on-year, which was affecting local production efficiencies and financial forecasts.

The production lines affected in Australia are the dried/powdered milk markets.

In the US and Europe, Saputo’s competitors have been investing in improved autonomous production lines, to offset risk against manufacturing and supply chain disruption similar to what’s been experienced in the past couple of years during the pandemic.

Already Saputo has outsourced its warehouse and distribution activities and centralised packaging as part of rationalisation decisions overseas in the last financial year.

At the same time, the Saputo network has experienced acute challenges around supply chain logistics and labour shortages in the US.

Saputo is continuing to invest in its cheese manufacturing lines, particularly premium and

direct-order categories. The traditional markets for Saputo products have been and remain in these cheese categories.

The largest retail market for cheese globally is the US, with consumption more than double any other country. Saputo is continuing to manufacture cheese at its processing plants in Wisconsin and California.

Cheese is the highest value dairy commodity market globally, with the largest market growth in Europe.

Analysts forecast a compounded annual growth rate of three to four per cent in global demand for cheese.

This is in line with rapid product innovation demonstrated by many dairy processors, providing a smorgasbord of premium foods — house and provenance branded — on the supermarket shelf.

Mr Saputo has said the company will focus on increasing its branded retail offering and diversifying its product mix in response to new market dynamics and growth opportunities.

Saputo already owns plant-based cheese and spread brand Vitalite and acquired Bute Island Foods in the last financial year.

Bute Island Foods manufactures plant-based cheese brands and has expanded beyond its initial UK and European retail and customer base to Canada, Australia, South Africa and a number of Asian countries.

This investment diversification is in line with a number of other global cheese manufacturers.

Vegan cheese sales have grown to a value of US$2.7 billion, and are expected to double in the next couple of years.

The company is also responding to consumer and shareholder expectations around environmental and governance sustainability, as well as company commitments to net-zero emissions by 2050 that requires significant change along the supply chain.

Saputo’s dairy net-zero commitment requires action to reduce greenhouse gas emissions across the dairy sector.

Mr Saputo said the company’s net-zero commitment included sourcing 100 per cent of its principal processing ingredients with guarantees along the supply chain that robust measures were being implemented to reduce emissions.

The trend outside Australia is for consumers to demand proof, and the global corporation is responding to that demand.

The justification for guarantees around animal welfare is also a permanent trend, particularly with customers in countries outside Australia, particularly the US and Europe.

LABOUR ISSUES, the housing crisis, cattle prices and land values — all these factors are combining to rip the band-aid off issues that matter in the dairy industry specifically, and agriculture more widely.

A string of dairy herd dispersals in October has shone the spotlight on a changing industry.

There are more complete herd dispersals planned for Victoria and NSW farms between now and July 2023.

At risk is Australia’s milk production, espe cially export markets.

While farm gate prices have risen due to increased competition between processors, that masks the reality that domestic milk pro duction is stable at the expense of export vol umes, due to decreased cow numbers.

In the same report on estimates, Dairy Australia expects domestic volume to remain stable because of increased pasture produc tion. This estimate was made prior to contin ued widespread flooding and ongoing wet con ditions across dairy regions in NSW, Tasmania and Victoria.

These results are being seen in the market place, with farmers exiting from dairy.

Terry Ginnivan, livestock agent with Nutrien Ag South Gippsland Livestock, said more than 550 dairy cows were sold through his agency in the past month.

“Herds are being reduced or sold because of

the workforce shortage,” he said.

Terry’s view is endorsed by other agents.

Andrew Mackie, of Dairy Livestock Services, said many farmers selling dairy cows were selling their farms, downsizing their herds or switching to beef cattle.

This was having a flow-on effect to the local economy, not only to his industry.

“I’m losing clients who are getting out of agriculture, but it’s affecting milking machine technicians and service providers to the dairy industry,” Andrew said.

“It’s diminishing the milk pool for the whole of Australia.

“It’s mostly domestic consumption that will be retained. Australia’s production to the export market is diminishing.”

He saw two clients sell their herds in October, after selling their dairy holdings and downsizing.

But there have been some fantastic prices paid for commercial milking cows and heifers.

At the Avonlea sale, held on the property of John Gardiner and family at Nar Nar Goon, a heifer backed by four generations of EX dams and many show winners sold for $32,000.

Avonlea Denver daughters sold at $28,000, $26,000, $21,000 and $16,000, to registered buyers from all over Australia.

The SpringValley commercial Jersey sale, held at Mortlake Selling Centre in October, saw a record price paid for an unregistered five-year-old cow at $11,000. Other cows sold for $8000, $8500, $6500, $5500 and $5000.

The 43, two-year-old milking heifers aver aged $4262. The herd of 138 Jersey cows and heifers grossed $511,500 and averaged $3706.

At Koonwarra VLE, the Gwenalan Holsteins herd was dispersed on behalf of Grant and Sheryl Hosking, of Milford. The couple decid ed to retire from the dairy industry, and have retained a herd of F1 cows to breed vealers and trade steers.

“My father purchased this property in 1955 and always had a registered dairy herd, that he brought across from Dromana,” Grant Hosking said.

“Sheryl and I have been dairy farming for the past 42 years.”

He was pleased to see the younger cows, up to fifth lactation, sell well to $3800.

Most of the herd stayed local, scattered among a number of buyers, with a few older cows heading into South Australia.

“We sold all our heifers to the export mar ket,” Grant said.

Andrew Mackie said buyers from northern Victoria and across Gippsland bid on the cows that were part of the Wildwood dispersal sale, held at Lardner Park Selling Centre in October. A heifer topped the sale at $7000, and one of her sisters sold to the same buyer for $6500. Other young cows went for $5500, $5100 and $5000 for an average of $3815 for 102 cows and $4000 average for 56 milking two-year-olds.

The dispersal sale of the Blossomvale Holsteins herd, at Jancourt East, attracted bid ders from western and northern Victoria and

saw prices attain a high of $7500, for an eightyear-old cow.

Other registered cows sold for $6500, $6000 and $5000, for a gross of $466,400 and average $3405 for the herd of 137 Holsteins.

Ross Suares, of Dairy Livestock Services, said many farmers in the Western District had decided it was a good time to get out of the dairy industry, although not everyone was sell ing their farms.

“We’ve had a lot of sales statewide, there’s a generational change occurring,” Ross said.

“A lot of farmers are 60 and above, and are transitioning out of the dairy industry.

“Some of them are selling their farms. They can realise quite a bit of money now with a decent sized farm, and can set up a pretty decent super fund from the sale proceeds.

“Others are transitioning to beef, mostly to have a break from the workload and transition slowly to retirement.”

On the other hand, Ross also said the milk price was encouraging other people to stay in dairy, or move into dairy.

“I’d say two years ago, 90 per cent of dairy farms were sold and were used for beef and sheep. This year, 50 per cent are retained as dairy farms,” he said.

“We’ve sold a few herds of cows to people coming back into dairy in western Victoria and Gippsland.

“Some are investors and some are farm ers from the north looking for more reliable rainfall.”

A major factor in the exit from dairy was labour and housing, and those issues were con nected, Ross said.

“Every time we have a round table discus sion, between ourselves and other industries, it’s the same. There’s major shortages of peo ple available to work, there’s even a shortage of overseas workers,” he said.

“It’s the same for everyone, definitely labour is the big issue for 90 per cent of farms. Particularly once you get over 200 cows, and you have to have a labour unit.

“Lack of labour is not sustainable long term. Many of the farmers leaving the dairy industry have been doing it without labour for a couple of years, and they can’t keep doing it.

“You won’t get a farm worker without a house, unless it’s someone who already lives locally.

“Rental housing is a major factor in the avail ability of labour.”

At the recent Jobs and Skills Summit, hosted by the Federal Government, agriculture was rec ognised as an industry producing $100 billion a year in food and fibre products. Dependent on that goal is a reliable skilled workforce.

In the summit outcomes statement, the last paragraph on the last page is the only ref erence to agriculture — committing govern ment, industry and unions to pursue solutions to attract and retain workers in the agriculture sector.

Without referring specifically to the food and fibre sector, the summit outcomes state ment does refer to the Pacific Labour Mobility scheme as part of a raft of recommendations to increase numbers of migrants to meet skilled labour shortages, including in regional areas. But without housing in regional areas, par ticularly in dairy areas that are still recovering from bushfires and floods, how can workers be attracted and retained?

Faced with a shortage of workers due to border lockdowns during the COVID-19 pandemic, Kelvin Jackson, of Hazel Park in South Gippsland, had a worker shortage.

Kelvin recently sold surplus cows at the same sale as Grant and Sheryl Hosking, at Koonwarra VLE on October 17. His cows sold to $3300.

Kelvin said he had too many cows for the ongoing wet conditions.

He has also seen the trend for farmers to sell and leave the dairy industry.

“I hope for the industry’s sake it picks up,” he said.

Kelvin’s herd is split-calving and he uses sexed semen to join the cows, which gives him a lot of heifers twice a year.

In recent years his focus has been on raising the heifers to 12 months old and selling the entire drop to the export market.

In the last couple of years, Kelvin realised he was reliant on backpacker labour, which wasn’t a sustainable business model for his farm. Along with a longterm farm worker, Jessie, and his son, Alan, more labour units were needed.

Kelvin explored the opportunity offered by overseas workers and now has a man and woman from the Phillipines, Darlene and Jun, working on the farm.

Key to the success of employing people is housing. Kelvin provides houses on the farm for all his workers. His next move is

to build himself a new home and provide his existing abode for Darlene and Jun, who are sharing accommodation with Jessie.

“Darlene arrived last year, and Jun came across this year,” Kelvin said.

“It cost a lot of money in airfares and fees and hotel quarantine, but at the end of the day they each have four-year visas. It’s been a very good decisions and I hope they stay permanently.”

Kelvin said farmers tended to believe workers could contribute as much time to the farm as themselves, because they worked long hours themselves. But he said this expectation was wrong.

“It’s a challenge to find people who want to dairy farm. There’s a lot of work involved but everyone in dairy gets paid well,” he said.

“You the farmer have to communicate well and apply good work practices.

“When I interview people, I talk to them about the potential to have a farming career, it’s not just a job that’s a stepping stone to the future.

“I think you have to sell a career in the industry. It won’t be for everyone.

“Some people want to work the hours and get paid. Others want to learn and progress. Either way is fine.

“It’s my farm and I’m employing people. If I get the people issues right, invest in and encourage people, I think you’ll be successful as an employer.”

IT’S COMING up to Christmas, the barbecues are firing up and everyone is applying the insect repellent.

As the flies have started to descend, it’s time to think about pink eye again.

Pink eye, or infectious bovine keratoconjunctivitis (IBK), is a common eye problem in Australia’s cattle herd.

You’ll recognise cattle with IBK because they will have a watery or sometimes pus-filled discharge running down their face from the affected eye.

They’ll also probably be squinting because light coming into that eye causes pain and the eyeball itself will either have a blue appearance, due to the swelling of the cornea, and/or an ulcer (seen as a ‘divot’ out of the middle).

In severe cases the eyeball changes to a red or pink colour and starts to form a cone shape. These cases can result in rupture of the eyeball.

Just remember that IBK only affects the eyes, so if the cow has other problems — like a discharge from the nose or is off her feed — then there could be something else going on.

IBK is also a disease of herds, so we expect more than one animal to be showing signs.

Having IBK can affect the eyesight of cattle but also significantly affects their welfare. Cattle will seek shade to alleviate the pain of light entering the affected eye, and ruptured eyeballs require a vet visit to surgically remove them.

The total annual cost of IBK for southern Australia has been estimated to be $8.9 million, in terms of treatment, prevention, and production outlays (Cost of Endemic Disease Report 2022, MLA).

Traditionally, the main cause of IBK was considered to be the bacteria Moraxella bovis

spread by dust, flies, woody herbage and close contact.

However, in recent years the way IBK occurs is now thought to be more complex.

Not only does Moraxella bovis have multiple strains, but other bacteria have also been identified as being involved in IBK outbreaks.

These include Moraxella bovoculi, Mycoplasma bovis, Mycoplasma bovoculi and bovine herpes virus 1.

There is also increasing evidence around various risk factors playing a significant role, rather than just spreading of the causative agent.

Bos taurus breeds are more susceptible than Bos indicus breeds, while cattle under the age of two years are at greatest risk as well as those with properties with high dust and fly levels.

It’s a complex problem and there are many different treatment options, control options and prevention options available.

These range from eye patches, eye ointments and sprays as well as methods to control environmental dust and flies. Vaccines can also be part of the solution.