By Ken Liebeskind CEG CORRESPONDENT

By Ken Liebeskind CEG CORRESPONDENT

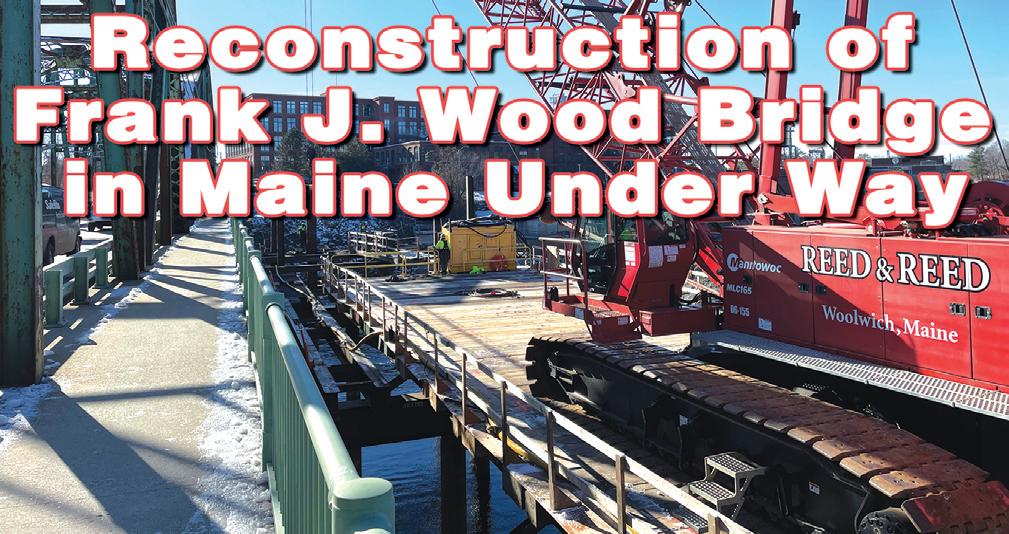

The Maine Department of Transportation has begun onsite construction to replace the Frank J. Wood Bridge. The bridge carries Route 201 over the Androscoggin River between Brunswick and Topsham.

The lead contractor on this project is Reed & Reed of Woolwich, Maine, and H.B. Fleming of South Portland,

Maine, is a subcontractor. The construction contract amount is $49,869,767.

Reed & Reed began work on the project in July 2023 with a completion date in late 2026, “but the new bridge is expected to be open to traffic earlier than that,” according to MaineDOT.

In August 2023, Reed & Reed continued hauling in material for the approach of the temporary work trestle.

Dealer Improves Hydraulic Hose Making Capability in N.H.

Chadwick-BaRoss recently announced that it made a significant investment in its hydraulic hose manufacturing capabilities at its Concord, N.H., facility.

“We just completed about a month ago the installation of a hydraulic hose assembly and manufacturing system that significantly improves our previous capabilities,” said Levi Wardner, general manager of the Concord, N.H., and Lancaster,

N.H., branches.

“This custom hydraulic hose assembly system, which is Volvo specific, but not Volvo exclusive, gives us the ability to build Volvo hoses without actually having to have the damaged hose and hydraulic fittings in our possession.

“Prior to this new system we could rebuild most Volvo hydraulic hose, but

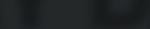

Reed & Reed’s Manitowoc MLC-165 supports H.B. Fleming’s drilling operations and is used for building the temporary work trestle.

Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” May 8 2024 Vol. LXII • No. 10 Levi Wardner, general manager of Chadwick-BaRoss’ Concord, N.H., and Lancaster, N.H., facilities assembles replacement hydraulic hose and fittings. see INVESTMENT page 4 see BRIDGE page 4 CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business Phil (413) 427-7171 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches

THE NEW ENGLAND EDITION A Supplement to:

Page 2 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com stk# 28000, 1901 hours, 8-15' propane screed, dual spraydowns..................................$89,500 2019 LEEBOY 8500D 78" drums, 2175 hours........................$39,500 2014 HAMM HD+120VVHF 1992 JOHN DEERE 624E Call Mark Doty @ 203-823-2316 stk# 28172, 4000 hrs, 8-15' HD electric screed, no seats, augur sensors or cables...... $49,500 2014 LEEBOY 8515C stk# 28445, 14,942 hrs, aux hyds, JRB hyd coupler..................................................$39,500 stk# 28624, 2428 hours, 8-15' screed..$59,500 2014 LEEBOY 8515C 3 available, 47" drums, PSI water system, low hours.............................................From $27,500 HAMM HD12VV stk# 24340, 78" drums, 1745 hours, dealer maintained............................................$39,500 2014 HAMM HD+120IVVHF 2019 JOHN DEERE 204L stk# 27203, 1492 hours, C/air, SSL coupler, 1 yd bucket with ride control................$69,500 2015 JOHN DEERE 544K stk# 28611, 9271 hours........................$89,500

OPRROOVVEN U WITH UPTI

PTIME IME KITS

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock

They are:

• Easy to order and ea t d t stock asy to s l

components and too

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

Hydraulic service k :kits shops ols ervice owing kits system kits nance service kits its kits

C BEYOND E H HE HIN D T MA virtual I ntime losellyt

NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 3

dow

y-t t act OGEN f tor ained technicians tr ned tec cians

rain e • T ervic ts • S Par

for (TCO)

par ing • Application Special customer very to machine” the “beyond ng NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle a uptime dependable deliver througho t ttachments • A Cost Total lower and its of life the out

e

Ownership of thinki We’re equipment.

a more Learn 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our w bout (800 Berli 1980 28 A 010 , M ow d om omers requipment.c cust 52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

Reed & Reed Leads Maine’s Frank J. Wood Bridge Project

BRIDGE from page 1

The contractor installed grout pads and anchor rods for pipe piles at bent #1 and bent #2 of the temporary trestle and installed the header beam of bent #1. Reed & Reed also began forming up the lower lift of the leveling slab for retaining wall #1 on the Topsham side of the project. Grout pads for the pipe pile at bent #4 were placed and the contractor began drilling the anchor rods for the pipe pile at bent #5.

In September 2023, work on the temporary trestle continued. Reed & Reed installed bent #5 pipe pile and bent #4 and bent #5 pile caps and installed cross bracing for bent #5, anchor rods and formed grout pads for bent #6. The contractor also installed span 3 steel and started span 4 steel erection and installed crane mat decking for span 3.

In October 2023, Reed & Reed completed excavation work on the Brunswick Temporary Pedestrian Sidewalk, adjusted existing curbs and commenced forming for concrete. Additionally, it wrapped up the fabrication of the driving frame for the pier 3 cofferdam and successfully formed and placed concrete for the temporary pedestrian sidewalk on the Brunswick approach, all while mobilizing a 518 crane.

In November 2023, Reed & Reed finished anchoring the span 8 steel and installed the crane mat decking, installed walers for the temporary structural support at the existing abutment #2, started excavating to ledge, completed installing the sheet piling for the pier 3 cofferdam and started excavating for the seal placement. Meanwhile, HB Fleming installed the driving frame and drilled pile for the temporary trestle bent #10.

In December 2023, Reed & Reed cleaned and excavated to sound ledge and completed cofferdam installation at pier 3. Seal concrete was placed for pier 3. Ledge removal operations continued at pier 2. HB Fleming installed the driving

frame and drilled pile for the temporary trestle bent #11. Dustin Littlefield, Reed & Reed project manager, said construction equipment on the Frank J. Wood bridge project includes a Manitowoc 12000 crane for installing Abutment 1 Cofferdam, a Manitowoc MLC-165 crawler crane for drilling operations and building temporary work trestle and a Caterpillar 314 excavator for removing ledge at Abutment 2.

“The existing bridge is more than 90 years old,” said MaineDOT. “A regularly scheduled bridge inspection was conducted and the findings prompted a more detailed inspection. The bridge engineers found rapid deterioration of structural steel, which triggered a drop in the ranking of the bridge deck and superstructure from fair condition to poor condi-

tion. Since November 2021, MaineDOT has prohibited all commercial traffic from using the bridge.

“The replacement bridge will improve safety and reliability for the surrounding communities,” MaineDOT added. “The new bridge will be located on a curved upstream alignment and will feature enhancements requested by a local design advisory committee. Designed to last for at least 100 years, the new bridge will have sidewalks on both sides (including pedestrian viewing bump-outs), wider shoulders on both sides, parks on both ends, special railings, lighting and other design details and unobstructed views of the natural and architectural features of the surrounding Pejepscot Falls site.” CEG

(All photos courtesy of MaineDOT.)

Chadwick-BaRoss Makes Significant Investment in N.H.

INVESTMENT from page 1

up,” he added. “Now all you need to do is give us a call with the parts number and pick up your new hose later that same day, or we can ship it to you at any other ChadwickBaRoss location. It’s important to note that we still have the ability to make hoses and fittings for all other equipment manufacturers, however, we will still need to have physical possession of the part.”

The purchase and installation of this new system at Chadwick-BaRoss’s Concord, N.H., facility created a second opportunity for the company to improve its customer service elsewhere in New Hampshire. The ChadwickBaRoss Lancaster, N.H., facility previously did not have hydraulic hose manufacturing capabilities and, in fact, within the Lancaster, N.H., area, hydraulic hose repair and replacement was hard to come by. So, the decision was

made to move the previous hydraulic hose manufacturing system from the Concord, N.H., facility to the Lancaster, N.H., facility to better serve customers in that area.

“Once we have the Volvo part number this new system tells us exactly what hose is needed, exactly what fitting is needed, and what angle the fitting needs to be placed at,” Wardner said. “The entire process takes less than an hour. With this system, we are also able to serve any Volvo customer anywhere in the Chadwick-BaRoss distribution area. We can also supply other Volvo dealers who have contacted Volvo to get a hose assembly and have found it to be on back order. Surprisingly, in most cases, purchasing the hoses from Chadwick-BaRoss will work out to be less expensive than purchasing from the manufacturer.”

(All photos courtesy of Chadwick-BaRoss.)

Page 4 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CEG

Reed & Reed’s Caterpillar 314 excavator removes the ledge at Abutment 2.

Chadwick-BaRoss recently announced that it made an investment in its hydraulic hose manufacturing capabilities at its Concord, N.H., facility.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 5

Page 6 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, W. Springfield, MA 01089 413-363-0780 Proud to be your Full Service Dealer NEW Inventory In Stock! WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net CR 3 Reversible Plate Rammer SRV 590 CF 2A Forward Plate Reversible Plate Compactors & Rammers CR 8 MFM Reversible Plate

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 7

‘Dirt Ninja’ Saves Time, Money With Diesel Fuel Trailer

By Drew Farrell THUNDER CREEK EQUIPMENT

By Drew Farrell THUNDER CREEK EQUIPMENT

For Tom Gardocki, known as Dirt Ninja on his popular social media channels, excavation and running heavy equipment is his passion.

Growing up in a family-owned landscaping business was the start of it all. Now, as co-owner of New Era Excavation in Londonderry, N.H., he and his business partner, Craig Hammel, have carved a niche in

completing site work for high-end residential new home construction. They also take on select commercial work.

“I want to be on the job site every day. I don’t want to be stuck in an office,” Gardocki said. “I like the challenging jobs. We don’t do big subdivisions, cookie cutter houses, one after another. They’re all unique projects. I like to use my brain every day, so I want to do something interesting.”

Gardocki and Hammel started New Era Excavation in 2015 and have grown the

business to specialize in waterfront excavation, whether it be on the ocean, ponds or lakes. They have invested in equipment and technology that allows the company to function at a high level on small, difficult lots of land. Their fleet includes equipment ranging from a five metric ton mini-excavator to 80,000-lb. excavators, a wheel loader, a bulldozer, a skid steer and two trucks, along with support equipment such as rollers and water truck trailers.

Gardocki is famous for his skill with

New Era Excavation invested in a No HAZMAT Fuel and Service Trailer (MTT) from Thunder Creek to facilitate the fueling and care of its equipment. see FUEL page 14

equipment and understanding how different machines can improve each job site — but with multiple jobs on the schedule at any given time, having a decentralized fleet scattered across New England can be a challenge.

Not only do Gardocki and Hammel need to oversee the logistics of getting the right equipment to the right job on time, but they also must service and fuel them onsite. Several years ago, they invested in a No

Page 8 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Because

The MTT690 model New Era chose has capacity for 690 gal. of diesel with the option for 100 gal. of DEF.

the New Era Excavation team can be working on multiple job sites at any given time, it’s an added advantage that any available employee can haul the MTT to where it’s needed.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 9

Page 10 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide • S SMART TS A ANSPOR T PULS LINK--BEL • T MAXIMIZE LIF 6 BOOM EXTEN • 262' | 79.7 m M • TWO 16' | 4.9 m • SMA TIPLEMULT • SIX SECTION P 38.3' - 164.1' | • ST AT SE 2.0 T m LA TM YARTFL VER A DE OR O F UCK T SELLING TR BES A-ST ECADE! K CRANES Lexing www.linkbelt.com | , USA entucky ton, K www.w or o New Y Pennsylva Massachus mon Ver w.com woodscr rk 315-676-2008 nia 717-795-0700 setts 508-499-1950 nt 802-658-1700 UTIONS ARTNERS • SOL P • SUCCESS

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 11 onthem cash in y OR Get a model*Eithe our pocket ear 3,0 5-y OUW O rway $5,50 up to 00-hour w Y WIN! depending 00 plu anty aarr us on the m model. Eithe OU W r way,

ARPA Funding Leads to Downtown Revitalizations in Conn.

On a recent weekday at La Stella Pizzeria, tucked into a flatiron building at Main Street and Market Street in Norwich, Conn., lunch hour was buzzing. Many of the city’s other historical storefronts along its downtown thoroughfares were empty and quiet — in some cases for over two decades — but nearly all hinted that some kind of transformation was under way.

But adjacent to La Stella, Water Street Lofts, a residential conversion of a 19th-century building, is nearly complete, and interior construction is visible through several storefront windows along Main Street and Franklin Street. People stop to lounge in pocket parks, and brightly painted murals call out from all corners of the city’s commercial district.

“It’s coming alive again,” said Kevin Brown, executive director of the Norwich Community Development Corp., as he stood at the Marina at American Wharf, where three rivers — the Yantic, Shetucket and Thames — converge.

Like many Connecticut cities and towns, Norwich has directed a small portion of federal COVID-19 relief funds, via the American Rescue Plan Act (ARPA), to breathe new life into its hobbled Main Street businesses, CT Mirror, a nonprofit online news service, reported April 24.

The pandemic accelerated a shift to remote work, dealing a blow to downtowns across the state that were already struggling to manage earlier losses of commerce to bigbox stores and online retailers.

“We’re in some ways living with a legacy of neglect,” said Michelle McCabe, executive director of the Connecticut Main Street Center, adding that now, “with workplace habits changing, we need to adjust. Businesses need help.”

She noted, though, that two pandemic-era trends, the rise in entrepreneurship, and new public and private housing investments in downtown districts, are beginning to drive change on Main Streets. Putting a small amount of ARPA funding toward things like helping commercial landlords bring their street-level properties up to code, so as to be ready for new storefront tenants, can be transformational.

With just over $4 million in ARPA funds, the Norwich Revitalization Program is working to aid 17 small businesses and contributing to four larger special projects in its downtown. Those efforts have attracted over $25 million in private investment and will result in nearly 200,000 sq. ft. of refreshed space.

“We’re turning the lights back on,” Brown told CT Mirror.

Of the more than $615 million in ARPA funds spent so far on addressing the pandemic’s “Negative Economic Impacts” in

Connecticut, roughly $45 million was distributed directly to businesses and nonprofits, including rehabilitating commercial properties.

The $1.9 trillion ARPA funding included $350 billion in State and Local Fiscal Recovery Funds (SLFRF) which must be obligated by the end of this year and spent by the end of 2026.

Connecticut state and municipal officials have budgeted over $3 billion in SLFRF projects, obligated $2.3 billion, and spent nearly $1.8 billion, according to the U.S. Treasury. Within the “Negative Economic Impacts” category, the state’s project budget is nearly $1 billion with $850 million obligated as of the beginning of 2024, CT Mirror noted.

“All these Main Streets are coming back to life with the funds to do wish-list items that aren’t just idealistic, but have a huge impact,” McCabe told the online news source.

Places like Norwich already have the “incredibly gorgeous bone structure” of historical buildings, she said, with “the bandwidth and resources to pull in entrepreneurs — that’s where you start seeing that new vibe going on.”

Establishing the ‘Ecosystem’

Elsewhere in the state, the town of Windsor used $100,000 in ARPA funds to help launch two new co-working spaces: one in a retrofitted industrial building near the train station downtown and another in a former bank in Windsor’s commercial district.

“By establishing these facilities in the community, we’re hoping that folks with the entrepreneurial spirit will get some technical assistance and bump into other like-minded people who are entrepreneurs, want to get

businesses launched that will someday move from their space to spaces in our downtown brick-and-mortar locations,” said Patrick McMahon, Windsor’s economic development director.

“Anything that we can do to build that sort of entrepreneurial ecosystem in the town is beneficial, helps create jobs, and creates vibrant neighborhoods,” he added. “We thought that was a really good use of ARPA funding.”

Several other towns and cities in Connecticut used ARPA funding to modernize aging infrastructure in their downtowns and commercial business districts to improve safety and usability for visitors and businesses.

For example, the town of Fairfield is spending hundreds of thousands of dollars to mitigate flooding around its central business district, while Bristol is slated to spend up to $1 million to install a retaining wall and refurbish a railroad overpass to accommodate more pedestrian activity in its Centre Square district. And Norwalk has put nearly $200,000 it received from ARPA funding toward a program called “Complete Streets,” aimed at improving pedestrian safety and accessibility.

Additionally, city leaders in Waterbury identified a pressing need to update the century-old sewer and water infrastructure below Main Street and Bank Street downtown in preparation for a streetscape improvement project. Over $10 million in ARPA was budgeted for those upgrades.

Given that the city’s historical downtown structures already require a heavier lift, along with more money, to outfit for modern tenants, that kind of below-the-surface improvement is key to attracting businesses, Dan Pesce, the director of Main Street Waterbury, said in speaking with CT Mirror.

“It’s a real benefit to us because we don’t have to worry about any infrastructure under the ground that’s aging,” he explained. “We won’t need to address the underground infrastructure in downtown Waterbury for a very long time. That’s going to be huge for us moving forward.”

Promoting ‘Strolling in Downtown’ Connecticut Cities

Since indoor spaces presented risks for many residents and visitors in Connecticut during the pandemic, development went outside toward recreation spaces, small urban parks, al fresco dining and a statewide expansion of public art installations.

In New London, for instance, city leaders are leaning into an aspect of the city’s identity that has the potential to draw a crowd with the construction of a new, $150 million National Coast Guard Museum, slated to open on the waterfront late this year or early in 2025. The museum is expected to attract 300,000 visitors a year to the area.

ARPA funds also have gone toward improving infrastructure to enable the city to accommodate more people, such as street lighting and wayfinding signage.

“We’re looking for foot traffic, that walkability, that sense of a place to be talked about,” said Elizabeth Nocera, economic development coordinator for New London.

The city also assisted in repairing the roofs and facades of downtown buildings as well as helped with code correction. The goal is to get historic storefronts to a state known as “vanilla box,” where a new tenant can come in and establish a personal footprint without having to worry about mechanical or structural issues.

Officials in both New London and

GRANTS page 18

Page 12 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The Connecticut Main Street Center has been awarded $150,000 for its new Diversity on Main Collaborative in partnership with the Black Business Alliance.

see

Connecticut Main Street Center photo

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 13 O Y NTHE R OUR O ELINE PUT E R VE EE NATIO Y Y IS YDA olu s S Sale engineered p y ee t k tha . T t t i e e g W d t ee u n o Yo eep s k Job Y unni d r n p a u u p yo ee t k ha s t tion P y entalit ” m one t d t i ge h a “ wit t n u g o ollin . R ward or g f ovin u m o h g t akin n m ee e b ’v y we h s w hat’ fi f e e or d m n r a aste e f on t d t i e o g eep s k imeline . T ougher g t tin get . ng. ter f Af rovidin achines w m e oves g m i e b ciently ter hor g s tin get g A tach u onstr C i h tac i H e y Becaus hi cm.us c n as c r me A y r ne h ac M on t c t e i v eser s d ustomer r c u d yo n . A t d i ne ar e e ou’v i Milford, NH 603.673.2640 Brentwood, NH 603.642.5666 Concord, NH 603.225.3361 chappelltractor.com Now Your Hitachi Dealer for Vermont, New Hampshire and Massachusetts

HAZMAT Fuel and Service Trailer (MTT) from Thunder Creek to facilitate the fueling and care of their equipment.

“That’s one of the main reasons we have the Thunder Creek. We can be at one to five jobs in a single day. If we’re all spread out, one of my guys or I can take the truck and the trailer around, and fuel and grease everything up,” explained Gardocki. “And if we’re all at one job, the MTT stays on that job.”

The MTT690 model New Era chose has capacity for 690 gal. of diesel with the option for 100 gal. of DEF — a feature that Gardocki especially appreciates. The trailer features Thunder Creek’s proprietary 2-in-1, closed loop DEF system, which helps ensure the cleanliness and quality of DEF while providing an efficient and self-contained way to deliver it to the field.

“Having DEF on that trailer has made my life easier, since all the new equipment takes it. Before we were using one-use jugs of DEF. There’s a lot of waste with that,” he explained. “So now we buy it in bulk. The DEF goes into the trailer and right out into the equipment. There’s no second handling of the DEF fluid, which is key for us. It stays clean, doesn’t get contaminated and it saves time.”

New Era Excavation Centralizes Fleet Management

Saving Hours in Fueling Time

Adding to that time savings is the ability to fill New Era Excavation’s equipment more quickly than the previous method Gardocki and team used, which was a transfer tank in the back of a pickup truck.

According to Gardocki, it would take around 20 minutes to empty 100 gal. of fuel, whereas with the MTT, it takes about two minutes.

“You’d be amazed at how much more flow these tanks provide to speed filling up the equipment,” Gardocki said. “If we’re on a job site and we’ve got five pieces of equipment, we’re taking fuel time from maybe an hour down to around 10 minutes, which is big. Obviously, the more uptime, the more money we can make.”

Advantage of No HAZMAT

Because the New Era Excavation team can be working on multiple job sites at any given time, it’s an added advantage that any available employee can haul the MTT to where it’s needed. The trailer features six separate 115-gal. tanks connected with a common manifold that leads to a commercial grade pumping system. This multi-tank

solution eliminates the need for drivers to hold a HAZMAT endorsement (a cost savings in time and labor), while still legally transporting the fuel. It also mitigates the need for a CDL (depending on the truck and trailer combination).

Gardocki and his team also like that the trailer tows so smoothly.

“Any of our guys can hop right into the truck and tow the trailer to any job site in all the states that we work in. The versatility of not needing a dedicated person with a HAZMAT license makes it easy for moving from one job to another and it reduces labor costs associated with that endorsement.”

This fueling and service platform also helps Gardocki keep his diesel acquisition costs down. The ability to fill the trailer tanks with bulk diesel from a supplier vs. relying on gas station prices adds to the cost savings for New Era Excavation. According to Gardocki, his supplier provides a lower per gallon price because of the storage capacity — an additional means for the company to gain a solid return on investment in its MTT.

The trailer also has proven easy to use — and it serves as a great centralized system for most daily preventive maintenance and daily fluids activities with the inclusion of the optional utility box with a generator, air

compressor and greasing system.

“Another thing I love about this trailer is that the diesel pump and air compressor have a gas-powered electric start. I can run an air gun or grease gun off the compressor for our routine maintenance or if we need onsite repairs,” he explained. “Being able to take care of that is the field is just huge.”

Aligning With Company Values

Two of the key values at New Era are efficiency and quality. The team takes pride in doing the best work possible in the most streamlined fashion — and Gardocki sees the MTT as a complement to that.

“I think what this trailer has provided us over the years is efficiency and that goes along with everything that we do in our company. From the people to the tools, to the equipment, to how we fuel equipment,” he explained. “Keeping everything moving as efficiently as possible is a huge key to our success as a company.

“Every day, we’re on-road and off-road, and we haven’t had any issues with this trailer. All the tanks are still secure and there are no cracked welds or other issues. I’ve been extremely happy with the quality of it.”

(All photos courtesy of Thunder Creek Equipment.)

Page 14 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

FUEL from page 8

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 15 SERVICE S TROMMEL WWWW..POWERSC COMCREEN-NE. SC. .O

Page 16 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

THE DOER’S DREAM

• www.constructionequipmentguide.com • May 8, 2024 • Page 17

See the Hyundai difference yourself at your local dealer or hceamericas.com Loved for the features. Trusted for the performance. Hyundai wheel loaders have the power and performance — not to mention top-notch interiors, accurate onboard weighing system, unique bucket design for better load retention, clear sight lines, and handy tech — that make life on the jobsite easier. So you can do more without feeling like Butler Equipment www.butlerequip.com 631 New Park Ave West Hartford, CT 06110 860-233-5439 Chappell Tractor www.chappelltractor.com 251 NH-125 Brentwood, NH 03833 603/642-5666 454 RTE 13 Milford, NH 03055 603/673-2640 391 Loudon Rd. Concord, NH 03301 603/225-3361 Kahn Tractor & Equipment, Inc. www.kahntractor.com 520 Pond Road North Franklin, CT 06254 860/642-7596 Lorusso Heavy Equipment, LLC www.lhequip.com 160 Elm Street Walpole, MA 02801 508/660-7600 Whited Equipment Co. www.whitedhyundai.com 2160 Hotel Road Auburn, ME 04210 207/346-0279 17 Houlton Road Presque Isle, ME 04769 207/346-0279 837 Portland Road Saco, ME 04072 844/430-6810

NEW ENGLAND SUPPLEMENT ADVERTISER INDEX

R.I. Posts RFP for Washington Bridge Demolition Project

The Rhode Island Department of Transportation posted a request for proposal (RFP) for the demolition project for the Washington Bridge. It is live for review by interested bidders here.

The RFP invites design-build teams to submit proposals to remove the bridge superstructure. The demolition process is divided into four groups. Each group includes different sections of the bridge — the Gano Street spans, the west end of the bridge, the east cantilever spans and the east end of the bridge — and has a required milestone date for completion. The final milestone date for completion of the entire project is scheduled for March 2025.

This manner of demolition allows for the safe removal of the bridge and will not have any impacts on the adjacent eastbound bridge. There are provisions for per-day rates for incentives for finishing before the milestone dates and disincentives for finishing after the dates. A maximum of $3 million is available to the selected design-build team for early completion. Likewise the designbuild team would face up to $3 million in disincentives if it exceeds the end dates.

To further incentivize companies to submit proposals, the state will provide a stipend of $100,000 to the second and third runnerup bidding teams.

The RFP submissions will be evaluated and awarded based on best value to the state, a combination of the bidders’ cost and technical proposals. Scoring of the submissions will be prioritized based on schedule, meaning teams with proposals to complete the work in the earliest timeframe will score higher when the state evaluates the proposals.

Final proposals to the RFP are due June 21, with interim submission requirements prior to this. The project is scheduled to be awarded and a notice to proceed issued by mid-July.

Further details on all submission deadlines, as well as the incentive program, are contained in the RFP.

In addition to the demolition RFP, RIDOT is developing a separate RFP to procure a design-build team to build the new bridge. Both the demolition and new bridge construction projects are expected to begin in July.

Many Conn. Towns Benefit From ARPA Funding Grants

Norwich have sought to multiply the impacts of ARPA funding by seeking out collaborators and additional sources of investment, both public and private, thus increasing the scale of the projects and their reach.

Rise of Mixed-Use Community

The recent wave of thousands of new hires each year at submarine manufacturer General Dynamics Electric Boat in Groton means nearby cities like Norwich and New London are managing an influx of not just tourists but hundreds more permanent residents in its downtown districts.

“That’s where the downtown and the Main Streets start taking advantage,” said Felix Reyes, director of New London’s Office of Development and Planning. “Once people live by where they work, then you get all that indirect and induced [economic activity]. You get small businesses, and you start getting markets [because] you need eggs and milk and gas and entertainment and

restaurants for those people.”

Bridgeport was already seeing that transition before the pandemic, and it has only accelerated in the last four years, Lauren Coakley Vincent, president of the city’s Downtown Special Services District, told CT Mirror.

She added that, in the downtown neighborhood, several former commercial buildings have been converted for residential use.

“There’s a big shift toward what would be called a mixed-use community,” she said. “That does influence the type of uses you see at the ground floor level.”

At the same time, Bridgeport was making ARPA-funded grants available to hundreds of small businesses throughout the city for storefront improvements or expansion.

Roughly 30 downtown Bridgeport businesses received grants, resulting in the district successfully retaining so many of its ground floor storefront businesses that the city’s turnover rate actually declined, Coakley Vincent noted.

Now, she added, the downtown “is much more geared toward sort of a 24-hour use

Page 18 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

GRANTS from page 12

The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT............................................6 ALTA EQUIPMENT COMPANY/NITCO LLC..............1,11 BARRY EQUIPMENT CO. INC.......................................20 CHADWICK-BAROSS INC................................................9 CHAPPELL TRACTOR..................................................13 EQUIPMENT EAST........................................................1,5 FOLEY INC - WORCESTER............................................1 GORILLA HAMMERS........................................................1 HYUNDAI CONSTRUCTION EQUIPMENT....................17 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 MILTON CAT....................................................................6 MTE EQUIPMENT SOLUTIONS INC..............................7 POWERSCREEN NEW ENGLAND................................15 ROGERS BROTHERS CORPORATION........................19 SHAWMUT EQUIPMENT CO INC....................................6 T-QUIP SALES & RENTAL INC......................................14 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3 WOODS CRW CORP......................................................10

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • May 8, 2024 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. On the job every day! ROGERS trailers are designed for your most demanding work! Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 20 • May 8, 2024 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

By Ken Liebeskind CEG CORRESPONDENT

By Ken Liebeskind CEG CORRESPONDENT

By Drew Farrell THUNDER CREEK EQUIPMENT

By Drew Farrell THUNDER CREEK EQUIPMENT