FOR

ECONOMY INFRASTRUCTURE THE

From

NEW RANGE OF ROCK DRILLS TO CONQUER ALL TERRAIN

When drilling in rock, you need a rig that can take on the tough ground conditions. Vermeer’s latest additions to the HDD market are two new intuitive compact rock drills; the D23x30DR S3 and the D40x55DR S3.

The new DR HDD range has the bene t of superior steering in extreme conditions. They are easy to use, versatile for both rock and clay drilling, and have a quieter noise level at the operator's ear, making them the perfect machines when minimal disruption in urban areas is required. Call Vermeer Australia today for further information.

EDITOR’S WELCOME

Each edition of the magazine so far in 2020 has been put together in widely different circumstances than the last, and this issue is no exception. While our previous edition saw us move quickly to adapt to changes due to this new thing called COVID-19, the country is now arguably more settled into this new way of living during a crisis.

While the infrastructure industry has been great at keeping essential services going, the sector is also critically looking ahead at what these changes mean long term.

for you to hear, and be a part of, the conversations that come from this. You can find out more about the event on page 22.

Innovations come with challenges though as NSW’s Chief Data Scientist, Dr Ian Oppermann, notes in his article, with issues around data privacy and security also needing to be addressed, especially given Australia’s recent cyber security breach.

ABN: 36 426 734 954

204/23–25 Gipps St Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Assistant Editor

Kim Ho

Journalists

Lauren Butler

Imogen Hartmann

Eliza Booth

National Media and Events Executives

Rima Munafo

Brett Thompson

Design Manager

Alejandro Molano

Designer Jacqueline Buckmaster

Publisher Chris Bland

Managing Editor

Laura Harvey

The potential for innovation following economic turmoil has been well documented, and the post-COVID economy could provide these conditions once more. Throughout this issue, our expert contributors explore what the new infrastructure for a new economy could look like, from renewable energy to electro-mobility, smart cities, digital twins, and the circular economy. These could very well be part of the next wave of infrastructure innovation.

Looking at where new opportunities lie, and what can be done now in order to start planning and preparing our assets for the future, was a key focus of Infrastructure's recent Virtual Conference The Future of Infrastructure.

Similar to the magazine, we gathered some of the industry's brightest minds to explore what the industry will look like post-COVID, looking at everything from digital infrastructure to mobility, sustainability and asset resilience.

If you missed the event, we’ll be running it again in September as one part of the Critical Infrastructure Summit 2020. The summit involves five freeto-attend Virtual Conferences, running 2pm every Wednesday in September, covering the whole infrastructure lifecycle – construction, asset management and disaster resilience.

This mega conference has been in the works for a while now and I can’t wait

The last few months have seen a slowdown in many industries, with restrictions causing decreases in passenger numbers at airports, on trains and on our roads.

However, Australia’s freight and port sector saw the opposite, with a significant increase in demand. There’s a lot of exciting developments in the works for this sector, with the National Freight and Supply Chain Strategy and projects such as the $125 million Port Rail Transformation Project at the Port of Melbourne and Port Botany’s on-dock rail, among others. To quote Ports Australia CEO, Mike Gallacher, “Resilience is the first thing that comes to mind when reflecting on the ports’ role through COVID-19.”

Over the last few months, it has also been great to see the amount of funding that has gone towards fast-tracking shovel-ready infrastructure projects, to not only help the economy, but keep our workers employed. With recent spikes in COVID-19 cases again (especially here in Victoria which saw a large portion of Melbourne go back into lockdown), the pandemic is not an issue that is going away anytime soon, but it’s hopeful to see the continued resilience and adaptiveness of the industry, as well as the confidence that funding and accelerated projects are providing.

Let’s hope this continues as infrastructure has a big role to play in the country’s recovery.

Jessica Dickers Editor

HEADING

A WORD FROM INFRASTRUCTURE AUSTRALIA

REMAKING A RESILIENT ECONOMY

The year 2020 has produced a roll call of calamities that have tested the resilience of all Australians: bushfires, drought, floods and an ongoing pandemic. Now, after 28 years, Australia is in a recession, with the unemployment rate up to 7.4 per cent and expected to climb.

INDUSTRY INSIGHTS

THE NEW INFRASTRUCTURE FOR A NEW ECONOMY

The next economy is emerging rapidly based on new infrastructure that has been ready, but not yet mainstreamed.

CIVIL INFRASTRUCTURE SECTOR READY TO BOOST THE ECONOMY

SEVEN TRENDS SHAPING THE FUTURE AUSTRALIAN CONSTRUCTION MARKET

JOIN THE CRITICAL INFRASTRUCTURE COMMUNITY

MACHINERY THAT MAKES A BOOM

DIGITAL INFRASTRUCTURE

HOW INFRASTRUCTURE PROJECTS CAN EFFICIENTLY USE VIRTUAL EXPERIENCE TWINS

DIGITAL

ROAD AND

TRAFFIC

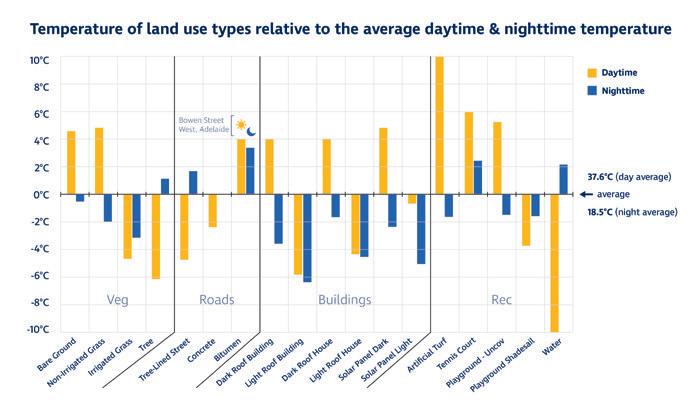

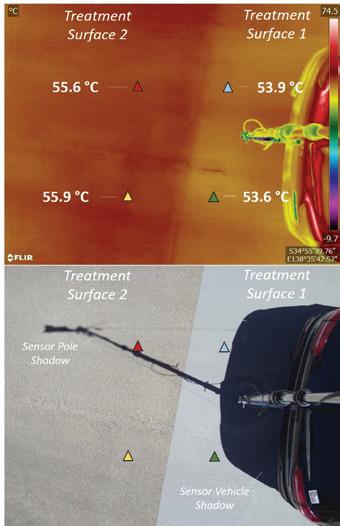

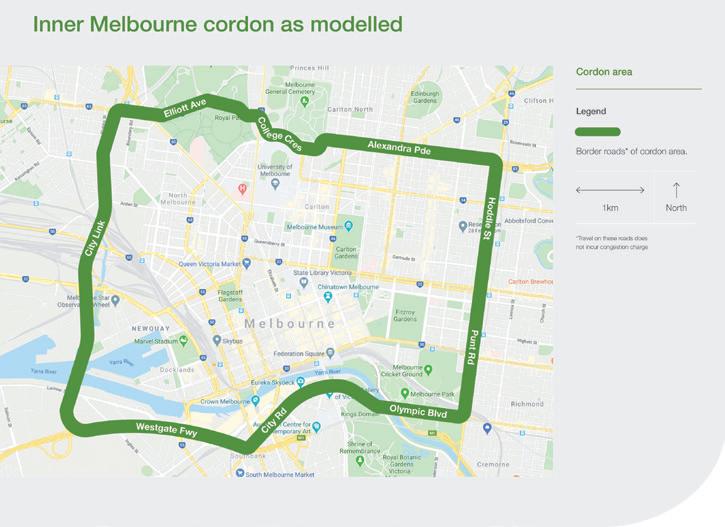

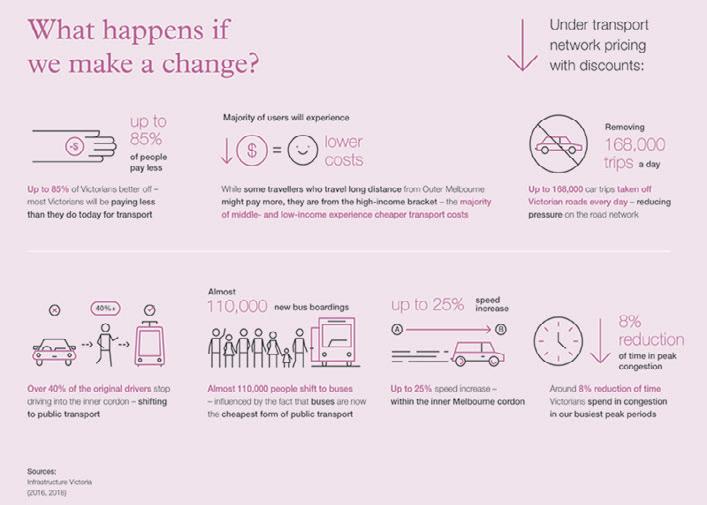

WHY CHANGING HOW WE PAY FOR TRANSPORT IS A GOOD MOVE

OPTIMISING TRAFFIC FLOW THROUGH DETECTION AND DATA

FREIGHT AND LOGISTICS

THE PLANS ARE IN PLACE, SO LET’S GET TO WORK

TIPS

USING RECYCLED MATERIALS IN MAJOR CONSTRUCTION PROJECTS

NEW VIRIBAR® 750 FITMENT IS SUSTAINABLE AND EASY TO SUBSTITUTE

REBUILDING SUSTAINABLY AFTER THE BUSHFIRES

ADAPTING ASSET MANAGEMENT TO NEW WAYS OF LIFE

SOUND PROTECTION MEASURES AGAINST RAILWAY NOISE

LEADING AN ASSET MANAGEMENT TEAM REMOTELY

With many companies and asset management teams now having to work from home, here are three areas of focus that can help teams transition to new ways of working and create more opportunities.

IMPLEMENT RADIO FREQUENCY IDENTIFICATION ON RAILROADS?

OPTIC SENSORS MONITORING BRIDGES AND CRITICAL STRUCTURES

PORTS

BUILDING RESILIENCE IN THE PORTS SECTOR

PORT BOTANY ON TRACK TO SUPPORT NSW

In the next 40 years, NSW’s population is forecast to grow to 12.5 million, which includes an extra 3.8 million people living in Greater Sydney alone. Ensuring our port supply chains are able to efficiently cater for the growing trade needs to support this population growth is crucial to the economic vitality of the state.

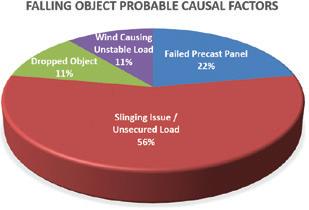

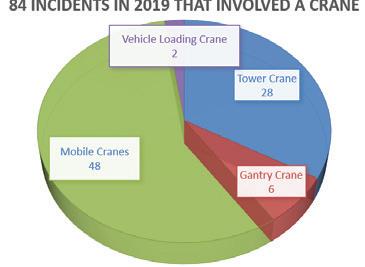

INCIDENT DATA PAVES WAY FOR CHANGE IN THE CRANE INDUSTRY

HOW TO CREATE SAFER, MORE EFFICIENT STORAGE FACILITIES

& HEAVY LIFTING SAFETY AND RISK MANAGEMENT

MANAGING WORKSITE COVID-19 SAFETY RISKS

Under Australia’s model Work Health and Safety (WHS) laws, employers are required to protect the health and safety of workers and others at the workplace by eliminating or minimising risks arising from work.

HEADING

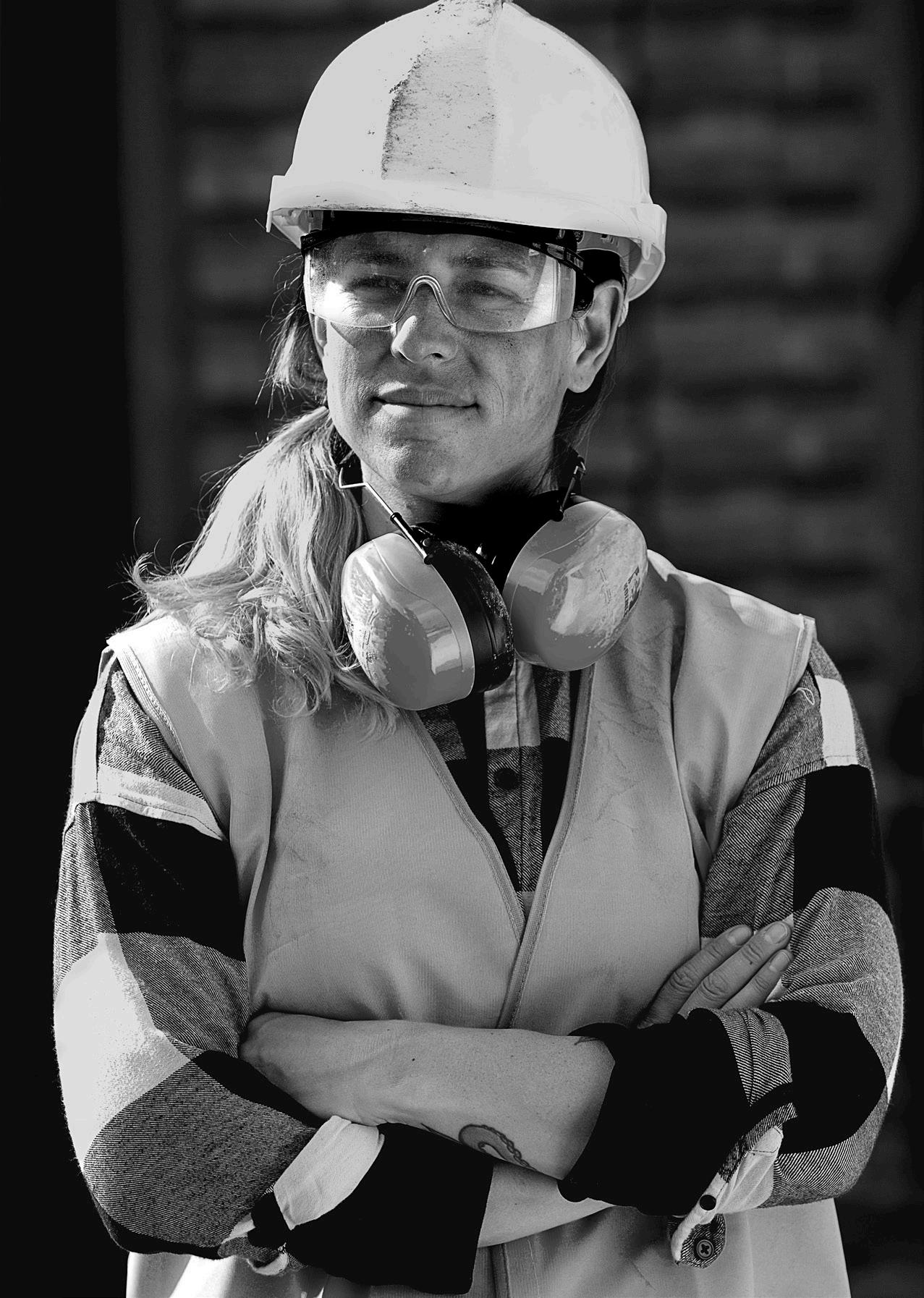

Tammy Falconer Director Engineering & Asset Management, KPMGPreamble

Tammy has carved out a successful career working for and driving change in state-owned corporations and public sector organisations. She is currently the Director of Engineering & Asset Management at KPMG and was previously the Head of Asset Knowledge at Sydney Water.

Tammy leverages her expertise in asset management, data and analytics to place trusted information into the hands of decision makers to deliver customer-centric asset management solutions. Her achievements span unique and diverse work experiences including increasing fare compliance and customer satisfaction across all modes of public transport in Sydney; leading the implementation of GIS and asset management information systems, and improving asset management practices to deliver power, water and wastewater services to 72 remote Indigenous communities across the Northern Territory.

FPeter

Newman Kirk Coningham OAM CEO, Australian Logistics Council (ALC)

Kirk Coningham OAM CEO, Australian Logistics Council (ALC)

Kirk has been the CEO of the Australian Logistics Council since January 2019. Prior to this, Kirk was the National Executive Director of the Urban Development Institute of Australia (until December 2018), and headed the Master Builders Association of the ACT as Chief Executive.

Kirk has also occupied senior positions with Leighton Holdings, the Australian Medical Association and the Murray Darling Basin Commission; served as a diplomat; been a Captain in the Australian Army; held senior media roles within government; and worked as a journalist. Kirk received his Medal of the Order of Australia for his work with the crisis taskforce following the bombings that occurred in Bali on 12 October 2002.

Professor of Sustainability, Curtin UniversityPeter is an academic who has written 20 books and over 350 papers on sustainable cities with a global reputation and has worked to deliver his ideas in all levels of government. Peter has worked in local government as an elected councillor in Fremantle; in Western Australia's State Government as an advisor to three premiers; and in the Federal Government on the Board of Infrastructure Australia and the Prime Minister’s Cities Reference Group. He is the Coordinating Lead Author for the UN’s IPCC on Transport In 2014, Peter was awarded an Order of Australia for his contributions to urban design and sustainable transport, particularly for his work in saving and rebuilding Perth’s rail system. In 2018/19 he was the WA Scientist of the Year.

Contributors

Dr Ian Oppermann

NSW Government’s Chief Data Scientist

Ian is the NSW Government’s Chief Data Scientist and an Industry Professor at the University of Technology Sydney (UTS). From 2015 to 2019, Ian was also the CEO of the NSW Data Analytics Centre (DAC). Ian has nearly 30 years’ experience in the ICT sector and has led organisations with more than 300 people, delivering products and outcomes that have impacted hundreds of millions of people globally.

Ian has held senior management roles in Europe and Australia as Director for Radio Access Performance at Nokia, Global Head of Sales Partnering (network software) at Nokia Siemens Networks, and then Divisional Chief and Flagship Director at CSIRO. He is considered a thought leader in the area of the digital economy and is a regular speaker on Big Data, broadband enabled services and the impact of technology on society.

Marika Calfas

Chief Executive Officer, NSW Ports

Marika has operated in the port sector for 18 years across a broad range of portfolio areas including strategy, planning, environment and infrastructure. Marika was appointed by the Federal Minister for Infrastructure and Transport to the Expert Panel advising the Government Inquiry into the National Freight and Supply Chain Strategy Priorities in 2017. Marika is a board member of Infrastructure NSW and Ports Australia, Deputy Chair of the Australian Logistics Council, member of Infrastructure Partnerships Australia’s National Advisory Board and Wollongong University’s SMART Advisory Council, as well as Australia’s representative to PIANC International Environmental Commission.

Michel Masson

Chief Executive Officer, Infrastructure Victoria

Michel started his career at Deloitte before joining the Bollore Group where he held various senior finance positions in the transport and logistics division in the UK, Australia and New Zealand. In 2005 he joined Keolis as head of Finance and Operations for the International Division where he was responsible for leading public transport operations in seven countries and held various non-executive director positions in UK and German rail franchises.

Michel was appointed CEO of Yarra Trams in 2009 and helped lead the development of Keolis Downer throughout Australia, before joining the Calibre group in 2014 to create and lead its Transport Infrastructure business.

Michel is a graduate from the EDHEC Business School in France, and the Australian Institute of Company Directors. He also completed the Advanced Management Program from the Harvard Business School.

PM COMMITS $1.5 BILLION TO INFRASTRUCTURE

The Federal Government will fast-track investment in critical infrastructure projects including Inland Rail; the Marinus Link; the Olympic Dam extension; NSW emergency town water projects; and road, rail and iron ore projects in Western Australia, as part of its new JobMaker plan.

In a speech at CEDA’s State of the Nation Conference, Prime Minister Scott Morrison, announced that infrastructure investment and deregulation would play a “critical” role in the five-year JobMaker plan, as well as skills, industrial relations, housing and construction, and major reform of funding approval processes.

The Prime Minister announced the Federal Government would commit a further $1.5 billion to immediately commence work on priority projects identified by states and territories as part of new bilateral partnerships designed to expedite approvals.

As part of this package, $1 billion will be allocated to priority projects that are shovel-ready, with $500 million reserved for road safety works targeting areas across the country, not only in rural and regional areas.

Investment will be directed to transport infrastructure, but also to water infrastructure to secure supply and underpin agricultural expansion; telecommunications services; the electrical infrastructure

required to remove bottlenecks in Australia’s electricity grid; and advance manufacturing, especially in regional areas.

Joint assessment teams will work on accelerating these projects, which are worth more than $72 billion in public and private investment and are expected to support over 66,000 direct and indirect jobs.

The Prime Minister’s priority list of fast-tracked projects includes:

♦ Inland Rail from Melbourne to Brisbane

♦ Marinus Link between Tasmania and Victoria

♦ Olympic Dam extension in South Australia

♦ Emergency town water projects in New South Wales

♦ Road, rail and iron ore projects in Western Australia

MAJOR DEREGULATION TO STREAMLINE APPROVALS

The Prime Minister said that the key to build the pipeline of future projects was for government to “get out of the way” and speed up progress by improving approvals processes.

“Ultimately, our objective is the streamlining of Commonwealth and state processes to a point of ‘single touch approvals’,” he said.

In an effort to drive a whole-ofgovernment approach to how regulatory policy is prosecuted, he announced he

would bring the Deregulation Taskforce into his own department, the Department of Prime Minister and Cabinet.

The Prime Minister established the Federal Deregulation Taskforce in 2019 with his Assistant Minister, Ben Morton. This included simplifying business registers, streamlining export documentation and making it easier for a sole trader and micro-businesses to employ people.

The next phase of the taskforce work will focus on areas to assist COVID-19 economic recovery.

The Prime Minister cited occupational licensing and registration requirements as a key example, often varying across states and territories, which increases costs on businesses and workers who operate or move across Australia.

A NEW BILATERAL MODEL BETWEEN FEDERAL AND STATE LEVELS

In addition to streamlining Commonwealth approvals, the Prime Minister said a new bilateral model would be implemented to speed up communication and decision-making between the federal, state and territory governments.

Under this new model, jobs will be brought to market earlier by targeting a 50 per cent reduction in federal assessment and approval times for major projects, from an average of 3.5 years to 21 months.

CONSTRUCTION ON WESTERN SYDNEY AIRPORT RAIL LINE TO BEGIN IN 2020

Construction is set to commence in 2020 on the $11 billion Sydney Metro – Western Sydney Airport rail line, providing an economic boost as NSW plans its recovery from COVID-19.

The rail line will service the greater Western Sydney region as well as the Western Sydney International (Nancy-Bird Walton) Airport, which is currently under construction.

The project includes six proposed metro railway stations:

♦ Two stations within the airport site, at the airport terminal and at the airport business park

♦ A station serving the commercial heart of the Western Sydney Aerotropolis

♦ A station at St Marys, interchanging with the existing suburban railway station and connecting customers with the rest of Sydney’s rail system

♦ A station at Orchard Hills to service a future commercial and mixed-use precinct

♦ A station at Luddenham to service a future education, innovation and commercial precinct

Construction on the project is expected to support about 14,000 jobs, including 250 new apprentices.

Sydney Metro – Western Sydney Airport is a key part of the Western Sydney City Deal, a 20-year agreement signed in March 2018 by the Federal Government, NSW Government and eight Western Sydney councils.

The new metro railway line will become the transport spine for the region, connecting travellers from the new airport to the rest of Sydney’s public transport system.

Under a new agreement between the Federal and NSW Governments, a further $3.5 billion will be injected into the project in time for the opening of the airport in 2026.

NSW GOV AWARDS TWO RAIL CONSTRUCTION CONTRACTS WORTH $600 MILLION

The NSW Government has awarded two contracts for modernisation and upgrade works on the state’s rail network, worth a combined $600 million.

The infrastructure upgrades, which form part of the NSW Government’s $4.3 billion More Trains, More Services program, will be delivered as two separate packages of work, each worth around $300 million.

The Next Rail partnership, comprising John Holland and Jacobs, will deliver all projects from Central to Hurstville, while the Transport for Tomorrow partnership, comprising Laing O’Rourke and KBR, will deliver all projects between Mortdale and Kiama.

The essential upgrades to rail infrastructure include the stabling yards, signalling, track, station platforms and power supply at key locations between

Central, the T8 Airport Line tunnel and the South Coast.

These lines are being prioritised because they are among the busiest on the network, catering for 440,000 trips in a typical day – approximately one third of daily rail customers.

Construction for the rail upgrades will begin in the middle of 2020 and be completed in advance of the service improvements, which are planned for late 2022.

Further improvements will be delivered under the More Trains, More Services program in 2024, including on the T4, T8 and South Coast Lines, to effectively integrate Sydney Metro City and Southwest.

NSW Transport Minister, Andrew Constance, said the two most recent contracts will support around 550 jobs.

The jobs will cover a range of disciplines including engineers, rail construction workers, security guards, truck drivers, electricians, plumbers, labourers, concrete workers and apprentices.

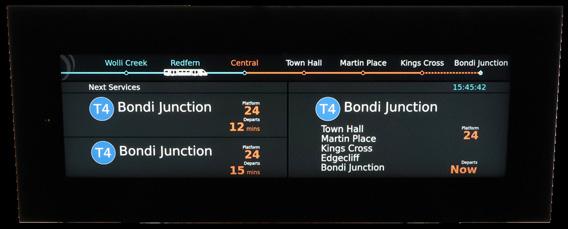

CUSTOMISING AND INTEGRATING PUBLIC INFORMATION DISPLAY SYSTEMS

The Smart pi EYE range now includes:

♦ PID – Passenger Information Displays module

♦ EYE-HD – 1080P Embedded HDMI Output for screens

At AusRail 2019 tm stagetec systems launched the new Smart pi EYE Public Information Display System. The Smart pi product range has evolved into high-quality hardware and software technology solutions for public information audio, display and distribution.

The flexible topology allows the system to be installed in smaller environments and expanded as needed to support more displays or integrate into other services. From a single web interface, content management administrators are able to select the display type/template, which automatically renders the information for the PID Client in the correct format and style.

The system is based on templates, allowing for easy customisation of all screen types, sizes and orientations. tm stagetec systems has partnered with Manuco Electronics

to provide Hyundai IT industrial outdoor screens, built to withstand harsh environments with IP65 and higher ratings.

Energy saving has also been a major consideration for the whole system. The embedded EYE-HD runs off a 5V USB input and has very low power consumption. Additionally the Hunyadi IT Screens automatically adjust brightness and fans depending on environmental requirements, saving significant power.

Smart pi EYE can be integrated with the entire Smart pi range including the Smart pi DSP and Smart pi DVA Audio Systems (and other AES70 devices). All server infrastructure can be virtualised to help reduce the hardware count across the entire network.

For more information, contact tm stagetec systems at www.tm-systems.com.au, or look for their stand at AusRail 2020

THE CHANGING FACE OF

INFRASTRUCTURE

The pandemic has seen a significant number of our subscriber base shift to working from home, while many others are involved on the frontline of essential projects. The demand for timely information has increased, and with the mainstream press providing constant updates on the broader situation, we have dedicated our resources to more analysis and reflection on the impacts on the infrastructure sector.

This has included an increased focus on digital newsletters, social content, videos, webinars and Virtual Conferences, all of which have received unprecedented levels of engagement since March.

According to Infrastructure Editor, Jessica Dickers, the sector has been particularly interested in stories about new infrastructure funding, and the fast-tracking of projects.

“The infrastructure industry has huge potential to help with Australia’s economic recovery, so people are craving updates on projects and funding, to see where these opportunities lie,” Jessica said.

“Content around digital technologies and innovations such as digital twins, for example, is also proving popular with our readers, as is any news on significant megaprojects such as the construction of Inland Rail and the Western Sydney Airport.

“This shows that the sector wants to know more about where the future of the industry is headed and what can be done now to prepare for challenges surrounding population growth, climate change, and the changes to how people live and move around the country after the current pandemic threat is reduced.”

And while change is a constant when it comes to the infrastructure industry and publishing alike, according to Infrastructure Publisher and Monkey Media Managing Director, Chris Bland, some things do stay the same.

Monkey Media, the publisher behind Infrastructure, has been adapting to the changed world brought about by COVID-19.

Top L-R: National Media and Events Executives, Brett Thompson and Rima Munafo.

Bottom L-R: Infrastructure Publisher, Chris Bland, and Infrastructure Editor, Jessica Dickers.

"While we will keep updating the platforms and methods of delivery, we have always focused on understanding the industry, and delivering the best content we can to the key players in that industry,” said Chris.

“That part of our approach hasn’t changed, we’re just reaching our audience in more ways now than ever before.”

This adaptation has led to a broader range of marketing services and options for companies looking to get their message to the industry, with custom EDMs, content marketing, lead generation, and Virtual Conferences and webinars among the most popular options.

The changing situation has also seen some changes to the team, with Brett Thompson recently joining as National Media and Events Executive. Brett brings years of experience in similar roles, and joins long-standing National Media and Events Executive, Rima Munafo. The two of them will work closely with Infrastructure's commercial partners to help them develop new content and strategies to communicate with our audience.

Chris said, "I've worked with Brett for many years previously, and it's great to be back on the same team with him again. There are so many exciting new ways that we're able to help companies to get their message out there and play a leading role in this sector.

“Brett and Rima both have a great passion for getting results for our partners, and I’m excited about what they’ll be able to achieve in the future.”

REMAKING A RESILIENT ECONOMY

by Romilly Madew AO, CEO, Infrastructure AustraliaThe year 2020 has produced a roll call of calamities that have tested the resilience of all Australians: bushfires, drought, floods and an ongoing pandemic. Now, after 28 years, Australia is in a recession, with the unemployment rate up to 7.4 per cent and expected to climb. In these challenging times, infrastructure is uniquely placed to support jobs and drive productivity.

One of our nation’s greatest infrastructure feats, the Sydney Harbour Bridge, was a product of the Great Depression, nicknamed the ‘Iron Lung’ as it sustained the lives of thousands of workers and their families.

While history might be on our side, we must still recognise that the acceleration of infrastructure investment and reform is not without risk. In order to ensure sustained growth and true economic resilience for future generations, spending should be productivity-enhancing to enable a stronger growth trajectory than prior to the crisis.

SMALL-SCALE PROJECTS ARE OF HIGH VALUE

Since the competing health and economic issues have impacted the economy, Infrastructure Australia’s advice has been to focus on a staged infrastructure recovery response; first by protecting and maintaining the existing pipeline of projects, then moving to the mobilisation of new projects, small and large. As important as large major projects are on the road to recovery, we must not forget the value of smaller projects.

While it may not draw the same fanfare and attention as new train lines and motorways, road maintenance is a great example of the need to prioritise a smaller program of work. A road maintenance program can generate high involvement of labour, trade and skills; deliver significant benefits to safety; and reduce transport costs for the growing freight industry and individual road users.

The Federal Government’s decision to bring forward $1.5 billion for local infrastructure projects, with $500 million of that targeted for road safety, is well placed. This decision aligns with existing priorities on the Infrastructure Australia Priority List, such as a National Road Maintenance strategy and a priority initiative for regional and rural WA road network safety improvements.

We expect our Infrastructure Priority List to continue to play an important role in supporting the national conversation around Australia’s spending priorities. Four of the fast-tracked projects already announced by the Prime Minister have come from the Infrastructure Australia Priority List, including Inland Rail, Marinus Link, and regional town and water security investment.

As we move past mobilisation and beyond shovel-ready projects, we will need to continue to develop a high-quality pipeline of infrastructure, ensuring it is constantly refreshed with high-quality projects. Investment in planning and design is critical to ensure the pipeline of projects continues. This pipeline gives confidence to industry, certainty to government, helps employ Australians, and supports the national economy. Maintaining this pipeline is especially true if we are going to attract private capital investment in infrastructure.

However, investment in building infrastructure will not be sufficient alone. We must also turn to the tougher path of reform.

REFORMS OF CURRENT SYSTEMS

We need to reform our planning systems and policy interventions to accelerate and boost productivity. We also cannot ignore that the acceleration of major infrastructure could reduce the opportunity to provide scrutiny of proposals prior to investment. Less scrutiny leaves the door open for the possibility of over-scoping and cost escalation.

While it could result in potential job creation, it could also leave communities with white elephant projects and our economy in a worse debt position than we started.

So, how do we avoid this? By ensuring business cases for large infrastructure projects continue to include rigorous planning, evidenced-based problem definition, options analysis and independent assessment.

The recovery from COVID-19 will likely be the most significant challenge for our generation. If we expect to build our way out of this crisis and breath life back into our economy, it will come down to industry, government and the community working in concert to take the right measured steps, in turn making our economy more resilient, not less.

Romilly Madew.

by Peter Newman AO, Professor of Sustainability, Curtin University, Perth

by Peter Newman AO, Professor of Sustainability, Curtin University, Perth

THE NEW INFRASTRUCTURE

The next economy is emerging rapidly based on new infrastructure that has been ready, but not yet mainstreamed.

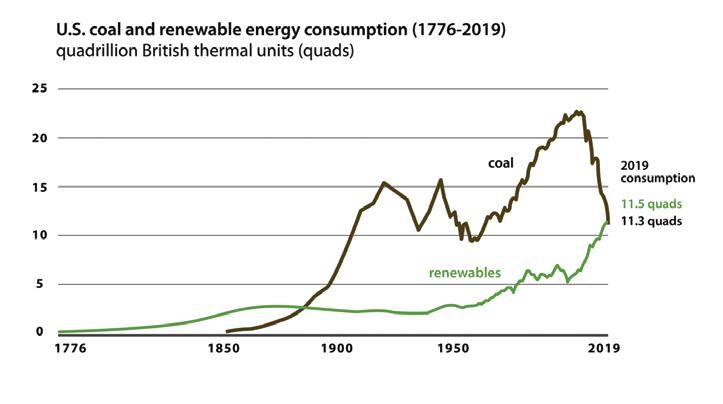

Since the 1920s long wave theory economists have analysed the waves of innovation following economic collapse in the past 250 years. Figure 1 shows the past five waves and the potential for innovation in the postCOVID economy.

The innovations in infrastructure outlined in Table 1, along with the suggested emerging innovations that replace the stranded old assets, attract new investment as they cost-effectively solve multiple problems. These include:

♦ Renewable energy, especially solar PV with batteries

♦ Electro-mobility, especially with non-automobile systems

♦ Smart cities, especially sensors, Apps and ICT focused on efficient demand management

♦ Hydrogen, especially replacing fossil fuels in heavy industry

♦ Circular economy waste and recycling technologies

♦ Biophilic urbanism bringing nature into buildings and infrastructure

1. Waves of innovation over the past 250 years that emerge after economic collapse and create the next economy.

The new wave of infrastructure is an integrated ‘cluster of innovations’ –especially the first three (solar, batteries and electro-mobility) which are rapidly being adopted. These three will be the focus of change over the next decade.

POWER: RENEWABLE ENERGY, PV AND BATTERIES

Solar and wind are now the cheapest form of power and are easy to mass produce and implement in most cities and economic systems. Cities will become much more distributed into

INFRASTRUCTURE

FOR A NEW ECONOMY

local areas of infrastructure management, but they will still fit into a grid for equity and balance.

Shared solar, using batteries and blockchain or other community-based methods, has now been demonstrated for medium and high-density areas, industrial estates, and rural and remote villages.

Electro-mobility will also be a part of grid stabilisation. Gas turbines (and diesel backup in small grids) have been seen as necessary for grid stabilisation but Li-ion batteries are now cost-effective at over 150MW, making them cheaper than gas turbines and more effective at providing a rapid peaking function.

100 per cent renewable power systems will rapidly take over with Australia being a leader. The 2020 AEMO report on the Australian grid shows that it can be 75 per cent renewable by 2025, which will be pushed mostly by rooftop solar.

The COVID downturn is accelerating this transition as shown in Figure 2, as new solar and wind systems have marginal costs near to zero, thus the reductions in demand must be made by fossil fuel-based power.

Accelerated adoption of renewables has been seen across all 41 nations in the OECD where IEA data showed that in March 2020, compared to the previous year, electricity fell by 3.6 per cent but coal fell by 21.6 per cent, as solar grew 15.6 per cent, wind by four per cent and gas by a mere 2.7 per cent (and that was almost all in North America).

This is a classic example of how exponential growth in renewables and batteries can be expected to take over power grids in the near post-COVID infrastructure future.

TRANSPORT: ELECTRO-MOBILITY, MICRO-MOBILITY, TRANSIT, WALKABILITY AND ACTIVE TRANSPORT

Electro-mobility has had a growth rate of over 40 per cent per year in the past decade, with predictions for how quickly the internal combustion engine will be phased out of new vehicles now coming down into the 2020s.

Electric vehicles are rapidly reducing in cost, with battery packs reduced from $1000/kWh in 2010 to less than $200/ kWh in 2020. EVs are also preferred for other social and environmental reasons such as cleaning up local air pollution, particularly since it was discovered that COVID is carried on diesel particulates.

Micro-mobility – electric tuk tuks, electric bikes, electric scooters and electric skateboards – is becoming a major part of the EV revolution. Electric micro-mobility will be a growing focus for the new economy, so cities will need to make space for them on shared paths.

The co-benefits of active transport are very high and include local economic development. Enabling local centres to work without cars and to enable transit systems to work without the need for car-dependent corridors has been

emerging over the past decades. Transit was seriously damaged during COVID, but so was car traffic, thus the growth of local walkability and active transport has been a global phenomenon, with many cities building this into permanent change.

A significant innovation in electromobility in terms of common-good outcomes is the electrification of public transport. The electrification of heavy train and tram systems is a mature technology but new Li-ion batteries have revolutionised the electrification

of buses into electric BRTs or Trackless Trams. These are now able to fit into cities by enabling whole main road corridors to be developed with dense precincts around stations due to their quiet, pollution-free accessibility. Such systems can replace the equivalent of six lanes of traffic.

All forms of electro-mobility need recharging, and in cities these can become part of Recharge Hubs to support grid balance. Power utilities will pay for these grid services as cities move to electrify their bus fleets (e.g. Shenzen and Canberra). Depots and stations covered in PV and with batteries inside can become important mini power/substations.

SMART CITIES-BASED DEMAND MANAGEMENT

Smart cities infrastructure works best in facilitating re-localised centres with reduced resource consumption. Localised infrastructure using machine learning can use sensors to manage local energy, water, waste and transport infrastructure, like a set of neural networks that are

constantly improving the ecosystem in which they operate. The local precincts set up with such simple technology will be highly efficient and can be optimised to share equitably and enable job creation through enterprise facilitation in local communities.

The hydrogen story is best left in Ross Garnaut’s hands. He suggests that Australia can become a superpower by applying solar-based hydrogen in northern regions to refine minerals. Hydrogen, the new circular economy and biophilic innovations are not going to go mainstream as quickly as solar, batteries and smart city infrastructure. These three are likely to at least continue to grow in niche demonstrations as part of the cluster of innovations for infrastructure in the next economy.

But solar, batteries and EVs will dominate the infrastructure of the next economy.

Segnut

CIVIL INFRASTRUCTURE SECTOR READY TO BOOST THE ECONOMY

by Chris Melham, CEO, Civil Contractors Federation (National)The civil construction industry has demonstrated its strength and resilience in its response to the challenges thrown at it from COVID-19. Companies continue to deliver much needed civil construction projects right across the country, helping to reinforce to governments the importance of the industry to the national economy.

The industry has been adaptable and flexible, with companies implementing new measures at worksites to manage the health and safety of their workers.

And in every state and territory, the Civil Contractors Federation is working tirelessly with governments to support and facilitate greater investment in civil construction projects.

COVID-19 is presenting a two-speed economy regarding its business impact on different industry sectors and its health impact and recurrence across the country. It continues to pose challenges for the industry in the weeks and months ahead.

COVID-19 does, however, present the industry with opportunities that it can take advantage of to ensure it emerges from this crisis stronger and more resilient.

To take advantage of these opportunities, Civil Contractors Federation National (CCF National) has been playing an active role on behalf of the civil construction industry by providing the Federal Government with a clear, consistent and unified voice.

CCF National is bringing to the government’s attention the steps that need to be taken to minimise the impact of the crisis on the civil construction industry and the Australian economy which is now in recession, and what needs to be done to come out stronger on the other side.

INDUSTRY PROVIDES FEEDBACK

CCF National is advocating directly to the Prime Minister, Deputy Prime Minister and Department of Infrastructure on some specific measures that need to be implemented as a matter of urgency to deal with short and long-term challenges.

It has put forward five separate submissions on the measures needed to bolster Australia’s response to COVID-19.

Central to these submissions has been its recommendation to bring forward capital investment from the already committed ten-year $100 billion infrastructure program, to disaggregate large projects, and to spread the allocation across as many Tier 2, Tier 3 and below companies as possible.

To strengthen its advocacy campaign, CCF National recently carried out a survey of its members to gauge the impact of COVID-19 on their businesses and in turn the civil construction sector to ensure it has strong evidence to support its submissions and recommendations.

The survey sought to obtain feedback and data on three key areas:

♦ The business impact of COVID-19 on civil construction companies

♦ The capacity for companies to tender for more civil construction projects in the short term

♦ The likelihood of companies employing more workers should they be successful in a tender

The survey was completed by companies who operate across the broad spectrum of civil construction, including: roads, bridges, drainage, ports, water, power, utilities, telecommunications, etc. and responses were received from Tier 1, Tier 2, Tier 3 and smaller companies.

The overriding conclusion of the survey strongly reaffirms the need for swift and targeted action by governments of all levels to manage the impacts of COVID-19, and importantly, it confirms that the civil construction sector has the capacity to boost the economy during these difficult economic times.

CCF members confirmed they can take on more civil infrastructure projects and employ thousands more workers to stimulate the Australian economy if additional project monies were invested into the sector.

♦ 92 per cent of respondents indicated they would be in a position to tender for projects in the value of $0-$50 million if the government increased funding for civil construction projects

♦ 64 per cent of respondents indicated they would need to employ additional people if they were successful in tendering for a new infrastructure project/s

These results send a strong message to governments that the civil construction sector is ready, willing and able to boost the economy during and after COVID-19.

CCF’S RECOMMENDATIONS

The survey report provides five key recommendations to government based on the results. These recommendations are designed to assist the government and CCF National’s policy making process, both during and post COVID-19, to ensure both government and industry challenges are addressed.

CCF National has provided the survey results to the Prime Minister and relevant ministers with a request that the government tables the report to members of the National Cabinet.

These investments and reforms include:

♦ Immediately increasing Federal Government spending for civil infrastructure projects by bringing forward monies from the ten-year $100 billion rolling infrastructure investment program

♦ Allocating more projects to civil construction companies operating at Tier 2, Tier 3 and below

♦ Disaggregating larger projects

♦ Ensuring there is a fairer spread of projects across all Australian jurisdictions

♦ Developing and releasing a public agency supplier payment policy as a matter of urgency as a form of injecting cash into the civil construction supply chain by ensuring the immediate payment of all outstanding claims and prompt payment of all future claims

♦ Urgently reforming contracts and the procurement policy/process aimed at achieving a more balanced approach to risk allocation and the development of collaborative contracts

♦ Increasing the level of training, education and up-skilling funding

CCF National will continue to advocate to the Federal Government on the industry’s behalf, both during and beyond COVID-19, including the need to increase the longer-term civil construction investment pipeline by using debt funding in this era of historically low interest rates.

In particular, it will build upon the results of its member survey to strengthen its ongoing advocacy agenda on behalf of the civil construction industry, which contributes $134.2 billion to the national economy and employs 1.1 million people.

Full results of the survey can be found at www. civilcontractors.com/communication/national-policies. For further information, visit www.civilcontractors.com or contact the CCF National Office on (02) 6273 8312.

About Civil Contractors Federation (CCF)

Civil Contractors Federation (CCF) is the peak industry body representing Australia’s civil construction industry, with more than 2,000 contractor and associate members nationally.

CCF Members are responsible for the construction and maintenance of Australia’s infrastructure, including roads, bridges, pipelines, drainage, ports and utilities. Our members also play a vital role in the residential and commercial building industry by providing earthmoving and land development services including the provision of power, water, communications and gas.

SEVEN TRENDS SHAPING THE FUTURE

AUSTRALIAN CONSTRUCTION

MARKET

Total construction activity in Australia has struggled since 2017. Forecasters predict that most of the market will remain flat or post small gains in the years ahead. Still, there are bright spots on the horizon as highlighted in an August 2019 report from Master Builders Australia.

CIVIL PROJECTS WILL LEAD THE WAY

The civil construction sector is expected to be ‘the biggest winner’ over the next several years, thanks largely to the ramping up of government-led transport infrastructure projects. Forecasters predict the best bets coming in civil are in oil and gas, rail construction and roads, while electric, recreation and telecommunications appear “to have peaked and are beginning to contract”, the report said.

RESIDENTIAL GROWTH IS STILL STRUGGLING

Due to a raft of circumstances such as lower birth rates, declining migration and an overbuilding of housing before 2017, residential growth has flattened in Australia and is expected to decline in the coming years, the report said. Expert estimates put residential projects at about 168,000 for 2020, which is 28 per cent lower than the peak in 2017.

COMMERCIAL GROWTH WILL STRUGGLE, BUT NOT IN EVERY SECTOR

Commercial growth has been a ‘star performer’ over the last couple of years, however, such above-average growth is expected to fall back to normal levels in the years ahead. Office buildings, education and accommodation will contract significantly, and although transportation, health and retail have more favourable projections, they aren’t enough to overcome the general slowdown. Expect that the drop in commercial growth will also lead to more spaces originally designed for offices to transition to other uses as people continue to switch to off-site or shared workspaces.

FEWER NEW HOMES, BUT MORE RENOVATIONS

If you’re in the Australian home renovation business, there’s good news – the ultra-low interest rates for loans are expected to help many Australians open up their floorplans or redo their kitchens. This is particularly true for houses built in the late 1980s.

MAJOR CONSTRUCTION FIRMS ARE INCREASINGLY ‘GREEN’

The largest construction firms in Australia – those handling the country’s big projects – are ‘greening’ their practices. For example, CPB Contractors has made environmental and sustainable solutions part of its approach to every project. Lendlease, the multinational Australian builder and property manager, has been recognised five years in a row by the Global Real Estate Sustainability Benchmark (GRESB) as the world’s most sustainable property fund.

MODULAR AND PREFAB WILL INCREASE MARKET SHARE

Most Western countries like Australia consider modular or prefabricated construction cheap or tasteless. Asian and Nordic countries, however, have long made prefabricated elements and even entire homes a significant part of their market. In recent years, prefabricated and modular homes have grown more popular for their cost savings and diminished environmental impact. And while the market for prefabs is only about 3.5 per cent in Australia, that is expected to double in the coming years as quality and design improves.

TECHNOLOGY IS SPEEDING UP THE BUSINESS

It might feel like construction sites are increasingly out of science fiction, with GPS-enabled equipment, wearable technologies, drones and digital documents such as blueprints and checklists. The result of this is that work happens faster, with better organisation, and with much tighter supply lines and schedules. Contractors will be well served to implement new technologies to keep their competitive edge – or at least understand and have a flexible attitude towards technology as the larger firms lead the way.

Read the full article at https://go.bluebeam.com/construction-trends.

The Critical Infrastructure Summit 2020 will be the premier event for the whole infrastructure lifecycle – construction, asset management and disaster resilience – and create an online community that can meet again in person once COVID restrictions ease. The Summit’s five Virtual Conferences will explore how we build, manage and protect our infrastructure, as well as the biggest issues the sector faces and future predictions. These issues will be the keystone of infrastructure in the post-COVID world.

FIVE INDUSTRY-LEADING VIRTUAL EVENTS

Each Virtual Conference will explore a certain part of the infrastructure industry, and combined, the Summit will be the place to go for industry updates, predictions and networking. The conferences include:

Critical Infrastructure: State of play – 2 September

This is the opening session of the Summit and will set the scene, exploring the state of infrastructure in Australia including current challenges and opportunities. This conference will feature presentations from keynote speakers, an industry panel, and a virtual networking session to allow you to make new connections, despite not being able to meet in person.

Construct 2020 – 9 September

Construct explores some of the biggest infrastructure projects underway in Australia across road, rail, airport, port, urban construction and utilities. The Virtual Conference will look at current projects, providing delegates with milestone updates, insights into new technologies and smart processes being employed, and a look at potential opportunities. Delegates will hear first-hand from the people leading some of Australia’s biggest infrastructure projects.

Asset Management for Critical Infrastructure – 16 September

Running for the sixth time, Asset Management for Critical Infrastructure is the place to be for updates on technologies, projects and processes that help to better manage critical assets in Australia, from water pipes and energy networks, to transport infrastructure.

JOIN THE CRITICAL INFRASTRUCTURE COMMUNITY

Infrastructure is hosting the Critical Infrastructure Summit – a landmark virtual event for the Australian infrastructure industry involving five free-to-attend Virtual Conferences, running every Wednesday in September.

It will explore topics such as developing strategic asset management plans in an uncertain future, resilient asset management, and the role of machine learning, artificial intelligence and digital twins. The event provides practical solutions to improve the way critical assets are managed, with a speaker lineup featuring senior leaders from utilities, infrastructure asset owners, industry associations, consultancies and government.

There will also be a separate Asset Management training workshop held the same week as this conference – limited spots available.

Disaster Management – 23 September

Disaster Management looks at the impacts a range of disaster events can have on the owners of critical assets; and provides tools to help essential service providers minimise the impact of a disaster, and emerge stronger than ever before. There’s never been a more pressing time for this kind of expertise with Australia dealing with bushfires, drought, cyber attacks and the COVID-19 pandemic. The Virtual Conference expert speaker lineup will help critical infrastructure organisations prepare for, survive and then thrive in the face of disaster.

The Future of Infrastructure – 30 September

The way people live, work and move around Australia’s cities has changed dramatically due to COVID-19, and while some things will soon go back to normal, there is likely to be a significant transformation of transport, utilities and social infrastructure in the future. Now is the time to take stock and look at what the future of the sector could look like, so critical infrastructure owners can start planning and preparing their assets. The Future of Infrastructure gathers the industry’s leading experts to explore their predictions for future trends and what these can mean for the sector and individual organisations.

To register for free to any or all of the conferences, or to find out more, visit critical-infrastructure.com.au.

Critical Infrastructure: State of play

BOOM MACHINERY THAT MAKES A

With Australia’s population expected to increase by 24 per cent by 2034, the infrastructure sector is seeing huge, ongoing growth – a boom that is expected to last for at least the next 15 years. With so many infrastructure projects currently underway, a competitive edge is more important than ever, making it critical for developers to invest in high-quality machinery and equipment that is fit for the job.

Large-scale civil construction contracts across Australia are being planned more quickly than they can be completed, making the completion of projects on time and on budget a high priority. According to Vermeer, investment in reliable, purposebuilt machinery is a key first step to reaching this goal.

With decades of experience in providing equipment solutions to the construction industry, the team at Vermeer are experts when it comes to getting maximum production out of each hour, and know all too well the impact that investment in machinery has on quality and efficiency.

THE COST OF DOWNTIME

While using the most inexpensive machinery and equipment may make finances look favourable in the short term, Vermeer’s General Manager of Sales, Jeff Lawson, warns that this often comes at the expense of cost and time.

“When heavy construction equipment breaks down, it’s not only a waste of time, but also of human resources,” Mr Lawson said.

Large-scale construction projects rely heavily on their equipment, meaning that a worksite effectively comes to a standstill when that equipment is not operational. With many sites functioning as a result of several pieces of machinery working seamlessly together, a single faulty piece of machinery can have a huge impact.

Not only does downtime on-site mean that a project may take longer to deliver, it also has a flow-on effect to the overall cost of construction.

“While one piece of machinery may be down, other costs will continue to build, regardless of whether the project is any closer to completion,” Mr Lawson said.

MACHINERY THAT MAKES SENSE

According to Mr Lawson, the large-scale infrastructure projects currently underway in Australia call for some serious machinery.

“If infrastructure developers want a competitive edge, they will need to increase the quality of machinery and equipment to ensure it’s up to the job. That’s where we come in,” Mr Lawson said.

When it comes to earthmoving, civil projects require machinery that offers fast, precise and on-grade surface excavation.

Vermeer’s range of Terrain Leveler surface miners precisely excavate rock while also managing noise levels, vibration and air quality, and are backed up by Vermeer’s trusted after-sales support and service.

Where hard rock is involved, an effective solution for dealing with residual dust and debris will increase productivity and reduce overhead costs. Systems such as Vermeer’s onboard dust suppression system, which is compatible with its range of T1255 Terrain Levelers, will also eliminate the need for a separate trail-behind dust system unit.

“There are many benefits to this type of technology. The suppression system is hydraulically driven and reduces the need for an external power source or an operator. This also helps to reduce diesel consumption, as well as emissions and labour costs,” Mr Lawson said.

Sites will also get more productivity from a piece of machinery if there are options for optimisation. Vermeer’s T1255 Terrain Leveler SEM for example, is available with either a chain drive or direct drive drum attachment depending on the requirements of a job.

“The chain drive drum is ideal for the removal of ground surface or creating a smooth, level area for preparing a site, whereas with the drive motor mounted directly to the cutter drum, the direct drive drum maximises efficiency and reduces wear costs that can be associated with other types of transmissions,” Mr Lawson said.

With no end in sight for the infrastructure boom, machinery that eliminates exhaustive processes and can take on a diverse range of tasks is an investment that requires careful consideration.

To talk about maximising machinery efficiency to deliver projects on time and on budget, get in touch with the Vermeer Australia team at vermeer.com.au/contact-us.

HOW INFRASTRUCTURE PROJECTS CAN EFFICIENTLY USE

VIRTUAL TWIN EXPERIENCES

All construction projects are expected to be delivered on time and on budget, but real value comes when asset owners can save money and create efficiencies across the whole asset lifecycle. With the industry now managing construction in a digital world, Virtual Twin Experience technology is allowing companies to spot mistakes virtually before construction starts, and collaborate remotely with all stakeholders using one source of data that can be used throughout construction, operation and maintenance.

While ‘digital transformation’ might be a buzzword for many industries, the fact is that technologies such as BIM and 3D modelling have enormous potential to reduce costs and increase efficiency on large infrastructure projects.

Prashanth Mysore, Global Strategic Business Development and Industry Marketing Director at Dassault Systèmes – a global leader in 3D design and engineering software – said the infrastructure sector is conservative compared to other industries when it comes to digital technologies because of long project lifecycles, but there is huge potential for cost savings using processes like Virtual Twin Experiences.

“In infrastructure, we work with large projects and budgets which can be very complex, so if people make errors in the field, the cost of fixing them is huge,” Mr Mysore said.

“The benefit of Virtual Twin Experiences is that we can simulate everything first in a virtual environment. We virtually build the whole project with 3D software so we can forecast all the issues and risks you might face in the field. If an error is made in the digital environment, it's easier to fix and the cost will be very low. In this way, we can make sure that the real construction can be successful in one shot.”

It’s also common in infrastructure for design changes to occur even once construction has begun. If 2D drawings are used there is potential for mistakes

to occur and it takes time to update designs manually, as well as analyse what these changes could mean for the project. However, 3D models can be updated faster and simulations can be run to view all possible scenarios.

Mr Mysore said that when talking about Virtual Twin Experiences, it’s important to recognise that at Dassault Systèmes it doesn’t just mean a 3D simulation of the final asset, but also simulations of all the processes used to build it.

“Our 3DEXPERIENCE platform is a lifecycle management system. We not only include the 3D model, but also the project information, simulations, and all of the data in one single source, which can be put on the cloud,” Mr Mysore said.

COLLABORATION REGARDLESS OF LOCATION

While spotting errors and making changes early can avoid major delays and additional costs, having a Virtual Twin Experience as the management system also creates a collaboration platform for all stakeholders working on a project.

In Australia, there are a large number of joint ventures and consortiums where different companies are working on the same infrastructure project.

The advantage of having a Virtual Twin Experience is that these companies can collaborate and access the same single source of master data remotely.

With more companies working remotely and hosting virtual meetings as a result of the COVID-19 pandemic, communication has to be extremely clear for everyone involved. Mr Mysore said the 3DEXPERIENCE platform is a very supportive mechanism for current conditions as it connects everyone in different locations and different time zones so they can work together.

“Everyone with authorisation will be able to access the information no matter where they are. It allows everyone on the project to be on the same page and always have access to the latest information because they are all working on the same platform with a single data source,” Mr Mysore said.

Dassault Systèmes’ 3DEXPERIENCE platform is currently being used in a number of major projects including the Danjiang bridge in Taiwan, Beijing Daxing Airport, and the 370km Mu-Jia line railway project by the China Railway Design Corporation (CRDC), to name a

few. The technology is also now available in the Australian market.

The Mu-Jia line rail project involved a designer in one city and multiple construction companies responsible for different parts of the railway distributed in different locations along the 370km track.

Using the 3DEXPERIENCE platform meant that if the designer made any changes, it automatically synchronised with all the contractors in different locations, keeping everyone informed and up to date.

USING DIGITAL TWINS ACROSS THE ENTIRE LIFECYCLE

One of the benefits of a Virtual Twin Experience is that it is not only used in the design and construction phases, but also for the asset’s operation and maintenance. While the construction company’s job is to deliver the infrastructure, asset owners will also be thinking about future operations.

“One way to think about a Virtual Twin Experience is that it’s alive, and the information will grow with a project into the operation phase. If we imagine we operated projects for 50 or 100 years, there will be a lot of information and you’ll want to keep all this historical data with the 3D model so that you can optimise efficiency and save costs, so all of this information is part of our Virtual Twin Experience,” Mr Mysore said.

Now asset owners are often asking for two project outcomes – the real built asset and the virtual asset. Being able to deliver both will help construction companies build good relationships and get future work as they are delivering continuous value. By

optimising operational costs throughout the lifecycle, the benefits significantly outweigh the costs of adopting the new technology at the start.

Dassault Systèmes’ 3DEXPERIENCE platform also proved invaluable when COVID-19 hit as it produced a 3D simulation solution for Leishenshan Hospital in Wuhan that looked at HVAC systems and air flow to determine how infectious molecules might spread throughout the hospital in order to protect healthcare workers and patients. The project was highly praised by the hospital owner as well as the local government, and now Dassault has more hospitals asking to use the same technology in their projects.

While other systems may also use the cloud, Akio Moriwaki, Construction, Cities & Territories Industry Marketing Director at Dassault, said its 3DEXPERIENCE platform is different because it provides a single source of data that is always up to date.

“Some solutions just connect to the server, then you have to upload and download again, so the model is not really managing one single source of truth, but ours is integrated and the single master model is always up to date for everyone, which is a pretty important aspect for a Virtual Twin Experience solution,” Mr Moriwaki said.

For more information on how Virtual Twin Experiences can benefit your infrastructure project or Dassault’s 3DEXPERIENCE platform, please visit https://ifwe.3ds.com/ construction-cities-territories.

DIGITAL INFRASTRUCTURE: THE INFRASTRUCTURE OF THE FUTURE

by Dr Ian Oppermann, NSW Government Chief Data Scientist and Industry Professor at University of Technology SydneyWith recent changes to how people live and work due to the COVID-19 pandemic, the move away from physical assets and towards cloud-based infrastructure is more significant than ever. Here Dr Oppermann explores a future world that is more digital and connected, and the impact of smart infrastructure, digital twins, and data privacy and security.

Many governments around the world have set smart city goals and funded pilot projects, but the reality is that little progress has been made in many countries. Challenges to these goals include the diversity of stakeholder interests, the complexity of coordinating planning/ construction/operation across stakeholders, and importantly, the lack of comprehensive digital twins of physical environments, and the lack of clear, data-driven outcomes frameworks.

Digital twins offer the potential to plan, model and optimise during all phases of smart infrastructure lifecycle and use. Outcomes frameworks allow the goals of smart cities to be described and measured. Smart cities are ultimately dependent on data-driven frameworks, indicators and models gathered from those who use the places and infrastructure of cities. Use of peoplecentric data needed to measure, model and analyse smart cities creates the final major hurdle in the form of privacy. All of these challenges must be addressed to make real progress in smart cities.

COVID ACCELERATING DIGITAL

Over dinner at an appropriately socially distanced hotel restaurant recently, I watched background footage of the foundations of Canberra being laid out and the growth of the city over the course of the 20th Century. It was stunningly old fashioned. Everything about the pomp and ceremony, the construction process, people learning to use these roundabout things was worthy of documentary. We are now much more digital, more connected and more online. We are living in the future.

The COVID-19 pandemic has taught us just how much of that last sentence is true. We rapidly jumped online rather than drive to work or drop the kids at school. We grappled with congested telecoms networks rather than congested roads. We switched between Teams, Zoom, Skype and Webex in seconds rather than fly between Sydney, Melbourne, Brisbane or Canberra for the day. We discovered some bottlenecks, but we largely went online and digital.

Productivity has arguably increased for “remoteable” professions. The network externalities of school start times, work start times, and the need to be seen to be “at work” changed. We survived, and we even started to understand some of the reasons why it has been so hard to be smart with our use of cities as we switched from moving atoms (us, our cars, our public transport) to moving bits (our voice, files, video feeds).

COVID was a major interruption to the steady progress of change towards the connected, online, digital future. The major drivers of this change are still coming from the intersection of a growing/ aging/urbanising population, a changing climate, the need to respond to an increasing number of global challenges (including pandemics), and our expectation of an ever-improving quality of life. These are challenging factors to reconcile and must be met with ever greater productivity and technological enhancements.

Our present, and future, are digital, hyper-connected and critically dependent on technology. For decades, most economies have been transforming towards a service dominated economy and our services economies are increasingly digital, online and driven by data. In all sectors, services are increasingly created, delivered and consumed via digital means, driven by the increasing adoption of online, mobile and digital technologies.

Recent years have witnessed dramatic changes in every aspect of our lives, from the way we consume music, watch movies, book holidays or choose hotels. Sometimes less obvious, there are dramatic changes underway in every industry, and in government, driven by changing consumer expectation, reduced barriers to new entrants and an increasingly borderless world of information flow.

The compounding factors of connected, digital and AI-driven “smart” means the rate of the change is actually accelerating. Hold on tight, these are now the “good old days”. We will never see the pace of change this slow again.

A DIGITAL TWIN

Digital twins of physical environments help us plan, model and optimise real world services. A smart light in your home, driven by a bit of AI, turns on and off as you move around the house, creates a simple digital model of your home and lighting use, and supports more efficient use of energy.

It will however also collect de-identified data about when you are home, which rooms you use and when, if there are other people in your home, and where in your home you spend your time. Within this de-identified data, there are insights about you and your relationships, habits and preferences.

In aggregate form, this data can be used by a service provider to optimise energy use and deliver more efficient lighting services to a suburb, by a smart grid to match energy demand to energy supply, or by a smart micro energy service provider to make best use of spot energy prices.

The benefit is the ability to locally optimise or individually personalise services based on personal preference, as well as to optimise the wider network for users and providers.

This idea of digital twin models of the home or office incorporate an ever-increasing range of “smart” devices (phone, TV, scales, toilet, refrigerator, watch) and “smart” environments (home, workplace, city). Increased efficiency, improved effectiveness and greater personalisation can present enormous benefits.

If these datasets are linked in a digital twin of the physical world, the resulting merged dataset may contain a great deal of personal information (PI), possibly enough to re-identify the individuals represented therein – making that data personally identifiable information (PII). How this data is used, by whom, and for what purposes determines risks and concerns. In many economies, it may force service providers and operators to rethink governance models to support regulatory requirements such as GDPR.

The challenge is quantifying the amount of PI in a dataset at any point in time and in any given context, and developing threshold tests for when an individual is reasonably identifiable, while considering personal attributes, temporal and spatial aspects of data, and rich contextual environments.

PI VERSUS PII

The terms personal information (PI) and personally identifiable information (PII) are often used interchangeably in legislative frameworks and in technical literature. The question becomes, how many features must be linked before

Dr Ian Oppermann.

Dr Ian Oppermann.

PI becomes PII for an individual known to be in a dataset? Context and rarity play important roles in the answer to this question.

Future smart or “mobile enabled” services will compound the complexity of these simple frameworks as greater fidelity and range of captured personal attributes, greater resolution in time and space, and richer contextual considerations are harnessed to deliver services or optimise network performance.

As feature-rich 4G mobile becomes 5G (and by 2030 becomes 6G), an understanding of the degree of PI in potentially highly time varying, context rich datasets, will challenge what we mean by de-identified data and the risk of re-identification. Understanding these challenges will provide a basis to anchor principles-based data sharing and governance frameworks to help ensure new smart or mobile enabled services operate within the regulatory frameworks designed to protect us all.

AUSTRALIA HELPING LEAD THE WAY

Through work with the NSW Government, the Australian Computer Society, Standards Australia and many other groups, ways to measure PI in data are being developed. The work is still at an early stage, but international standards are being explored to develop data sharing and use frameworks based on an understanding of context of data use, its inherent sensitivity, and the level of personal information in the data. It is early days, but the “Model T” tools developed so far show great promise for use in future smart services and smart cities. Stay tuned!

ACCESSING YOUR ON-SITE DEVICES FROM ANYWHERE

The workplace is changing, and this change requires us to be connected wherever we are. It requires us to be able to work from home, or on the road.

Imagine a device that helps you to work from home or wherever you are, that allows you to take control of worklife balance. A device that allows you to stay at home and be with your family and still be connected to the tools you need to run your business. For many workers, especially those in the utilities and infrastructure sectors, the ability to work seamlessly from home has been well and truly out of reach, until now.

In recent challenging times when normal working routines have been disrupted, InHand Networks offers a simple ‘plug and play’ service which enables you to access your devices anytime, from anywhere, and stay connected with your business.

The InConnect service builds secure remote networks from your machines, utilising a Software as a Service (SaaS) based solution. It features a user-friendly interface and offers users simple operation to keep you connected.

Key features of the InConnect service include: Convenient end-to-end remote access

With InConnect, you can access remote devices such as PLCs, HMIs and IPCs at multiple sites via PC/tablet/mobile phone. The InConnect supports various connections including user-to-device, site-to-site, device-to-device, one-to-one and multiple-to-multiple.

Network building with one click

With InConnect’s cloud connection service, networks can be built with just one click – no need for a data centre. You can access field devices anytime from anywhere.

Advanced security for data transmission

From firewall protections to encrypted data transmission, user authentication and access control, the InConnect service is fully secure for your applications. The client and the InRouter access the InConnect via CA authentication. Data is encrypted during transmission.

The InConnect service from InHand is a one-stop service integrating hardware and the cloud. It provides experience advanced security, management in the cloud, hassle-free plug and play, plus is highly scalable for IoT, and is free from operation and maintenance.

InHand has a wide range of products that support the InConnect service, including industrial cellular routers, edge gateways and vehicle terminals.

Madison Technologies is the exclusive agent for InHand in Australia and a B2B distributor of technology for commercial and industrial applications.

Simple and easy management for large scale M2M rapid deployment.

Control, monitor and automate with advanced security network services.

InHand offers industrial M2M cellular routers, gateways, Ethernet switches and IoT Management platforms to help critical infrastructure connect with remote assets.

9 Integrated 4G/LTE frequency bands to provide uninterrupted internet access

9 Enables access to remote assets for control, condition monitoring and automation

9 Suitable for fast large scale deployments

9 Python based OpenDevice programming platform

9 Plug & Play secure VPN connection available

Connect with confidence.

Madison Technologies is an exclusive distributor of InHand Networks in Australia. Our team is dedicated to ensuring our InHand Networks product portfolio is fully supported with an extensive range of hardware held locally across our national supply chain, and a team of InHand sales and technical support staff.

TIPS FOR RUNNING A SUCCESSFUL WEBINAR

The uptake of webinars and Virtual Conferences has exploded since COVID-19 hit and all trade shows and face-to-face meetings were banned, and they aren’t going away anytime soon.

The pandemic has highlighted that webinars aren’t just a substitute for live events – they have their own benefits when it comes to branding, customer engagement and quality lead generation.

If you’re thinking about reaching potential customers with a webinar, here are five tips to help you better connect with your audience and for your event to run as smoothly as possible behind the scenes.

1. AUDIENCE: ARE YOU REACHING YOUR TARGET MARKET?

The main purpose of any webinar or Virtual Conference is to provide information to your target market – the people you want to engage with your product or service. So the first thing you need to decide is whether you will be talking to your existing audience or if you want to reach new people.

If you’re targeting your existing audience, you can directly promote your webinar to them and offer educational and/or interesting content.

If you want to reach a new market, the best way to find the most relevant people is through external marketing. This could include social media promotion or other channels like advertising in industry newsletters, allowing you to precisely track how many registrations it drives. Using social platforms like LinkedIn also allows you to identify a new audience based on factors such as job title and location, so you can find exactly who you want to attend your webinar.

Monkey Media Managing Editor, Laura Harvey, said virtual events also tend to attract a lot more people than a live event. Monkey Media has run several Virtual Conferences in 2020, including Digital Utilities, Disaster Management, Asset Management for Critical Infrastructure, Flow Technology, and Smart Cities.

“For example, at our Smart Cities Conference, we’d normally get around 300 people for a live event, but by making it a Virtual Conference, we had more than 1,000 people registering,” Laura said.

Once you’ve decided who your target audience is, it’s important to engage with them before and after the event to foster the relationships. Before the webinar, think about setting up an automated newsletter that sends them useful information on the topic. During the webinar, ensure they can participate in the conversation using Q&A chat functions to send questions to speakers, or through poll questions.

2. CONTENT: WHAT VALUE IS IT OFFERING?

The content of the webinar or Virtual Conference is what will get people to register, so you need to be offering high-quality information and engaging speakers. Think about what your identified target audience and potential customers would want to learn about and create a program around their interests and pain points.

Laura creates the programs for Monkey Media’s Virtual Conferences and said the choice of speakers can play a big part in the success.

“You need to decide if you will use an internal speaker from your own company, external experts, or both. A mix is often good as it provides broader program appeal and can look less promotional,” she said.

“The key with speaker selection is to first define the topics you want to address in your webinar, and then choose the speakers who are well regarded and best placed to address these topics, internally or externally.

“Speakers who have a high public profile, and who have their own broad networks that they can leverage to attract more delegates to your event are also beneficial.”