ROAD - RAIL - AIRPORT - PORT - URBAN -

BUILDING BRIDGES

TO LAST 100 YEARS

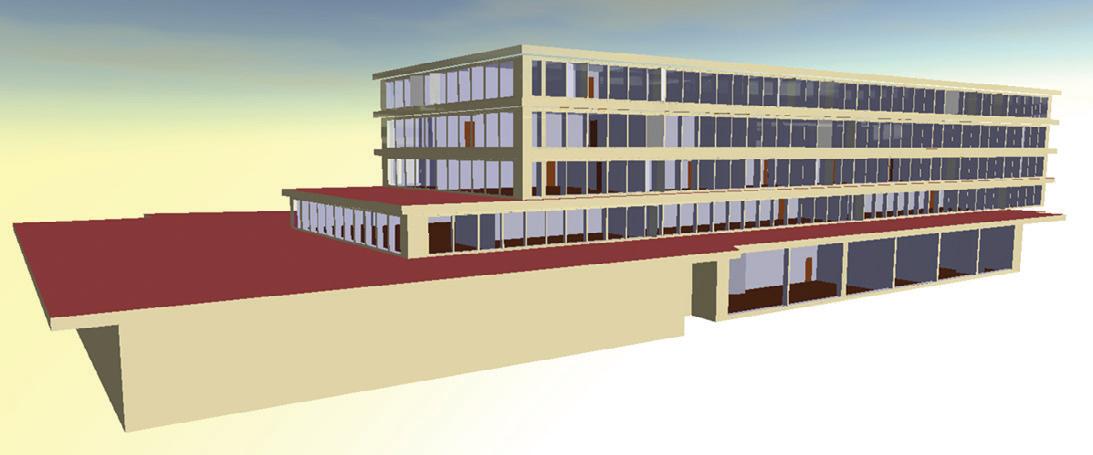

3D MODELLING SYDNEY’S CBD

A gripping case for crumb rubber

AS AUSTRALIAN INFRASTRUCTURE PROGRESSES, WE’RE PROUD TO PARTNER WITH THE CONTRACTORS THAT ARE LEADING THE WAY FORWARD.

Preamble

7,217

Published by

Monkey Media Enterprises

ABN: 36 426 734 954 PO Box 1763

FPreston South VIC 3072

irst para Officimporum, est prae doloreh eniaeruptat ut vitiumquam volupta qui cum reptatibus nes ationse aut et aut mo quos aruptatus int, nonsequid magnis nonsedipsunt explitas andi que sandae veles cuptatiis et as ut omnimetur acerum ese eos sit, cus non restrum que nat maximod mi, quia dolupta tustis dent pra prat as sus.

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Associate Editors

Lauren Cella

Charlotte Pordage

Journalists

Elisa Iannunzio

Nicole Valicek

Kirsty Hutton

Marketing Director

Amanda Kennedy

Marketing Associate

Sam Penny

Marketing Assistants

Rima Munafo

Katie Chancellor

Helena Brace

Production and Customer Service

Titian Bartlau

Senior Designer

Alejandro Molano

Designer

Jacqui Abela

Publisher

Chris Bland

Managing Editor

Laura Harvey

EDITOR’S WELCOME

We might only be in March, but it’s clear that 2018 is truly gearing up to be the year of the infrastructure boom. The rail sector has seen an increased focus on the freight network, with contracts awarded and first steel delivered for the Inland Rail, the largest freight rail infrastructure project in Australia, as well as preparation for the development and release of the National Freight and Supply Chain Strategy.

Since the last issue of Infrastructure in November, we’ve had two changes to the position of Federal Infrastructure and Transport Minister, with Michael McCormack recently taking over the Deputy Prime Minister position and Infrastructure and Transport portfolios from Barnaby Joyce. Regardless of who is the minister, there are still issues in the sector that require attention, from a predicted skills shortage to problems with aging assets. These are some of the issues that need to be put front and centre, along with a focus on the big ticket infrastructure projects.

With such a large number of projects underway, national forecasts suggest an additional 300,000 construction workers will be required by 2024 to staff major infrastructure projects in Australia. This could prove difficult for the infrastructure HR sector given the current skills shortage, changes to 457 visas and factors such as workforce diversity.

Infrastructure magazine aims to provide some practical solutions to these issues through the one-day conference InfraPeople, that will be held on 8 August in Melbourne, and will bring together leading experts in the infrastructure and human resource space. For more information on the event, visit www.infrapeopleconference. com.au.

Looking to our roads, projects from the Bruce Highway upgrade, to NorthConnex and the West Gate Tunnel Project, are moving forward and have helped to start the conversation around the best methods for designing and building Australia’s roads. Some of the discussion and current research is delving into the materials used such as crumb rubber, EME2 and foamed bitumen stabilisation to find out if these will make roads safer and more durable,

with the research and trials so far looking positive.

This edition features some of these outcomes, with the Australian Asphalt Pavement Association (AAPA), and Queensland Transport and Main Roads discussing what they are doing with these new materials in the road surfacing and design space. The state of Australia’s aging bridge stock is also an area that has been getting a lot of attention with questions surrounding if our bridges are strong enough to handle increased loading while remaining durable and sustainable. The concept of the 100-year design life has become a main aim, and is something that is being thoroughly researched by associations such as Austroads.

A common theme throughout these major projects, and many others currently underway, is the implementation of technologies, increased connectivity and the use of ‘smart’ infrastructure, whether this be high-capacity signalling, spatial technologies, or road automation. Using spatial technologies in infrastructure is one of the ways the sector is really starting to utilise its data to make better planning decisions, with evidence of this ranging from mapping city buildings to the use of satellite positioning to further the uptake of automated vehicles.

I’m also pleased to announce that I will be stepping into the editor’s chair for Infrastructure magazine and I can’t wait to meet some of you at upcoming events. We’re looking forward to attending and distributing the magazine at several events over the next few months including Core2018, ARRB National Conference, Locate 18, and the Australian Smart Cities and Infrastructure Summit, so we’ll see you there.

Jessica Dickers Editor

BRIDGES

A PROBLEM IGNORED: HIGHWAY BRIDGES AND AUTOMATED TRUCK PLATOONS

With automated truck platoons - trucks controlled by automatic systems that drive very close together - expected to come to Australia, one question that industry hasn’t thought about is the impact of these platoons on Australia’s aging bridge infrastructure. Here, Colin Caprani, asks if our bridges can handle it?

ACHIEVING SUSTAINABLE AND DURABLE BRIDGES

Sustainability, limited resources and environmental concerns are increasingly front of mind for bridge design and optimised maintenance of bridges. It’s important to look at whole of life costs as well as alternative materials to improve in service life and to minimise greenhouse gas emissions. We spoke to Dr Richard Yeo, Program Manager, Assets, at Austroads, to find out about some of the innovative research that Austroads has been undertaking on bridges and how the results could change the way bridges are designed and constructed.

HIGH-CAPACITY SIGNALLING MOVES MELBOURNE TRAINS IN A RAPID NEW DIRECTION

CONDITION MONITORING AND MAINTENANCE

DO OLD TRACK STANDARDS STILL MEASURE UP IN TODAY’S RAILWAYS?

CORROSION REMAINS A COMPLEX CONCERN

ROAD SURFACING AND DESIGN

A GRIPPING CASE FOR CRUMB RUBBER

THE IMPACT OF NEXT GENERATION CONNECTIVITY

COLLABORATION LEADS TO LOWER-COST, QUALITY INFRASTRUCTURE

SATELLITE POSITIONING TRIAL HINTS AT THE FUTURE OF OUR ROADS

NEW GEOSPATIAL CENTRE MAPPING SYDNEY’S INFRASTRUCTURE

POSITION PARTNERS ACQUIRES

ANNOUNCED FOR

CROSS RIVER RAIL

SYDNEY AIRPORT

BEGINS ON AUSTRALIA’S LARGEST WIND FARM

AUSTRALIA’S INFRASTRUCTURE PROJECTS

Contributors

Philip Davies

CEO, Infrastructure Australia

Philip Davies is the Chief Executive Officer of Infrastructure Australia. He is an experienced infrastructure executive who has over 25 years experience shaping policy, delivering nationally significant infrastructure projects and leading reform within the infrastructure sector. Before joining Infrastructure Australia, Mr Davies led AECOM’s Infrastructure Advisory business in Asia Pacific, providing government and private sector clients with infrastructure policy, strategy, business, program, planning and operations advice.

Deanna Hutchinson

Chief Executive Officer, Spatial Industries Business Association (SIBA) and Geospatial Information and Technologies Association (GITA ANZ)

Deanna has a passion for simulation and virtual reality. She has experience within the mining, healthcare, defence, transport and manufacturing sectors in designing and implementing complex simulation projects. She was elected Chair of Australia’s international simulation conference, SimTecT, from 2008 to 2013 where she joined the international simulation community, forging strong relationships with organisations and thought leaders in Europe and the Americas.

As CEO of SIBA|GITA, Deanna is focused on developing sector-wide governance infrastructure (such as professional accreditation and standards) and knowledge about emerging applications such as virtual reality, simulation and BIM. She contributes as either a committee member or speaker at several emerging technology events and has an influential voice in the spatial business industry.

Simon Thomas

Programme Delivery Director for Inland Rail, Australian Rail Track Corporation

Simon is responsible for leading and overseeing the delivery of the construction elements of the Inland Rail Programme. Inland Rail is a $9.3 billion, once-in-ageneration project that will complete the spine of the national freight network between Melbourne and Brisbane via regional Victoria, New South Wales and Queensland. Simon has been with Inland Rail since late 2015 and brings with him over 30 years’ experience delivering major rail, road, water, mining and building infrastructure projects in Australia, UK, Asia and the Middle East. In 2014 he was awarded Project Director of the year High Commendation by the Australian Institute of Project Management for his work as Project Director of Aurizon’s $904 million Wiggins Island Rail Project.

Contributors

Andrew Meier

Executive Director/Chief Executive Officer, Australasian Centre for Rail Innovation

Andrew was appointed Executive Director and Chief Executive Officer of the Australasian Centre for Rail Innovation (ACRI) in July 2017, having led for the previous decade a collaborative national land transport information program whilst at the Australian Road Research Board (ARRB).

Andrew has been a leader of international transport information sharing initiatives, including the first Australian chair of the International Transport Research Documentation (ITRD) Operational Committee which operates under the secretariat of the International Transport Forum/OECD. He was a key participant in facilitating the merger of two international resources to form the TRID database of transport resources, maintained by the US Transportation Research Board and now attracting almost two million visits annually. Andrew has authored conference and journal papers at national and international level including collaborative work on international taxonomies and guidance for information professionals on levels of evidence and research standards.

John Kilgour

CEO,

CEO,

Civil Contractors Federation’s (CCF) Victoria Branch

John Kilgour is the Chief Executive Officer for the Civil Contractors Federation Victoria, a peak industry body supporting over 500 members responsible for the construction and maintenance of over $9 billion per annum of Victoria’s major infrastructure, including roads, bridges, pipelines, drainage, ports and utilities.

CCF members also play a vital role in the residential and commercial building industry by providing earthmoving and land development services including the provision of power, water, communications and gas. Known for his strong advocacy work and networks at local and state government levels, John joined CCF in February 2016 from the Committee for Ballarat where he was CEO.

Prior to this, John has a long and distinguished career in the downstream oil industry with BP. During his 34 years with the BP Group of companies, John delivered major investment projects in the oil and gas, retail, petrol and convenience sectors throughout Australia, New Zealand and South East Asia. In February 2017, John was appointed President of the Victorian Civil Construction Industry Alliance, which CCF is a member.

Erik Denneman

Director Technology and Leadership at the Australian Asphalt Pavement Association (AAPA)

As Director, Technology & Leadership, of the Australian Asphalt Pavement Association, Erik Denneman (PhD, CPEng, RPEQ) supports the flexible pavement industry in the implementation of innovative pavement solutions. Before joining AAPA in July 2016, Erik led the ARRB Pavement Technology and Asset Management team in Brisbane. He specialises in performance based design and specification of bituminous materials, and the development of pavement design models. Erik has worked in the Netherlands, South Africa, the US, and since 2012, Australia.

NEW FEDERAL MINISTER FOR INFRASTRUCTURE AND TRANSPORT

Former Minister for Small Business, Michael McCormack, has been sworn in as the leader of the Nationals and Deputy Prime Minister, taking over the Infrastructure and Transport portfolio.

The appointment of Mr McCormack comes after the resignation of former Deputy Prime Minister Barnaby Joyce.

Mr McCormack said the party had placed “huge trust, faith and responsibility in me.

“I will honour that by doing my best always. I’m a team player, doing it with the very best team in rural and regional Australia.

“I want to make sure that people know that in me they will have a fighter. I have a huge challenge ahead of me.”

Prime Minister, Malcolm Turnbull, said he is delighted at the appointment of

Mr McCormack as the new leader of the National Party and Deputy Prime Minister.

“Michael McCormack is a strong advocate for rural Australia. He will continue his party’s long tradition of standing up for farmers and all those living in regional Australia.

“I congratulate Michael McCormack on his appointment and I look forward to working closely with him and the entire Coalition team in the interests of all Australians.”

The Australian Logistics Council (ALC) also welcomed Mr McCormack’s appointment as Minister for Transport and Infrastructure.

ALC Managing Director, Michael Kilgariff, said, “It is pleasing that the second most senior figure in the government will retain portfolio

responsibility for this crucial area, given the importance of developing transport infrastructure to support national supply chain efficiency and build Australia’s export capacity.

“As an industry leader on freight and supply chain policy, ALC always seeks to have a cooperative and productive relationship with the key ministers in portfolio areas that impact our industry.”

SHORTLIST ANNOUNCED FOR QUEENSLAND CROSS RIVER RAIL

The Queensland Government has announced the companies shortlisted for the contract to build the Cross River Rail.

Queensland Deputy Premier, Jackie Trad, said the announcement followed a comprehensive evaluation by the Cross River Rail Delivery Authority of the Expressions of Interest received for the project’s two major works packages: The Tunnel, Stations and Development (TSD) public-private partnership, and the Rail, Integration and Systems (RIS) alliance.

The Tunnel, Stations and Development public-private partnership consortia shortlist includes:

♦ Pulse: CIMIC Group-led consortium, including Pacific Partnerships, CPB Contractors, UGL, BAM, Ghella and DIF

♦ Qonnect: QIC, Capella Capital, Lendlease, John Holland and Bouygues

♦ CentriQ Partnerships: Plenary Group, ACCIONA, GS Engineering & Construction, Salini Impregilo and Spotless Group

The Rail, Integration and Systems alliance shortlist includes:

♦ River City Alliance: Laing O’Rourke Australia Construction, GHD, Aurecon Australasia, SYSTRA Scott Lister Australia

♦ Unity Alliance: CPB Contractors, UGL Engineering, Jacobs Group (Australia), AECOM Australia

“Cross River Rail is a transformational project that will unlock the bottleneck at the core of our transport network and increase its capacity to deliver ‘turn-up-and-go’ public transport,” Ms Trad said.

“Shortlisted companies will now be required to prepare detailed bids that demonstrate innovation and offer Queenslanders the highest possible value for money.

“Once the assessment process is complete, the consortia selected from these shortlists will be building this project.”

WESTERN SYDNEY AIRPORT CONNECTION DESIGN UNVEILED

The early design of the M12 Motorway which will connect to the Western Sydney Airport has been unveiled.

Federal Minister for Urban Infrastructure and Cities, Paul Fletcher, said the new 16km road would mean that when the new airport opens in late 2026, it will have a direct connection to Sydney’s motorway network, unlocking the economic benefits Western Sydney Airport will deliver to the region and beyond.

The $5.3 billion airport, funded by the Federal Government, will support more than 11,000 jobs in the construction phase and 28,000 jobs by 2031.

“With an extra one million people expected to live in Western Sydney by 2031, the Turnbull and Berejiklian Governments are delivering the infrastructure needed to make a growing Western Sydney work for residents, and an ever better place to live and do business,” Mr Fletcher said.

NSW Minister for Roads, Maritime and Freight, Melinda Pavey, said the preliminary design had been developed and community feedback was now being sought to inform the next stage of design.

“Since the previous announcement, changes include moving the eastern section of the route northward to maintain the integrity of the Western

Sydney Parklands, and maintain the integrity and development potential of the area for future generations,” Mrs Pavey said.

NSW Member for Mulgoa, Tanya Davies, said the M12 would be delivered in time for the opening of the Western Sydney Airport in 2026.

“The M12 Motorway is the next major project in the $3.6 billion Western Sydney Infrastructure Plan, which has created hundreds of jobs,” Mrs Davies said.

Detailed investigations will take place in the next 12 months as the design is developed and the environmental assessment drafted.

IMPROVING INFRASTRUCTURE KEY TO ROAD SAFETY

The NSW Government has released a new road safety plan which includes a range of measures aimed at improving infrastructure to enhance safety outcomes for drivers across the state.

The comprehensive package addresses speeding, drink driving, drug driving, driver distraction, driver fatigue, truck safety and funding to improve safety on country roads.

The Road Safety Plan will bring the government’s total commitment to targeted road safety programs from the Community Road Safety Fund to $1.4 billion over five years.

Minister for Roads, Maritime and Freight, Melinda Pavey, said one of the biggest challenges remains on country roads, which accounted for almost 70 per cent of the state’s road toll last year.

“If you live in the country you are four times more likely to die in a road crash than if you live in metro NSW,” Mrs Pavey said.

“This is why we will roll out 1600km of rumble strips and 300km in targeted safety works, such as flexible, wire-rope barriers to help prevent run-off-road and head-on crashes on our road network, including the Princes Highway.”

Roads Australia welcomed the focus on road infrastructure

improvements in the new road safety plan.

Roads Australia President, David Stuart-Watt, said, “Making road infrastructure safer is obviously a cornerstone of a successful Safe Systems approach to road safety, so it’s very pleasing to see the NSW Government targeting high risk regional roads in particular.

“Relatively small, low-cost improvements – be they realigning of dangerous curves, installation of barriers or improvements to line-marking – can make a significant difference.

“Combined with strategies to address driver behaviour through education and enforcement, targeted funding for infrastructure improvements is a welcome response by the NSW Government to the state’s rising road toll.”

Mr Stuart-Watt said safety was ‘top of mind’ for road designers and builders.

“Our industry is always looking at how we can improve road safety through better design, materials and technologies.

“We continue to work closely with our clients, including governments, to mitigate the risks associated with new and existing road infrastructure.”

TOWNSVILLE PORT EXPANSION RECEIVES GOVERNMENT APPROVAL

The Federal Government has approved the Environmental Impact Statement (EIS) for the Townsville Port Expansion Project.

The approval of the EIS for the project means that preliminary works on stage one, the $193 million Channel Widening Project, can begin before April 2018, pending a resolution on final funding between the State and Federal Governments.

Port of Townsville Chief Executive Officer, Ranee Crosby, said the $1.64 billion, 30-year development plan would ensure the Port of Townsville could expand to allow it to become a globally competitive port.

“After nearly ten years in the planning phase, our team is looking forward to getting works underway to widen the shipping channels into the Townsville Port,” Ms Crosby said.

“The EIS was a very rigorous environmental review and project assessment, so we are delighted to

have now received the go-ahead for the project from both the Queensland Coordinator General and the Federal Government.

“Ships are getting bigger and the widening of the channel is absolutely critical to the future viability of the Port of Townsville.

“Bigger ships coming to Townsville will mean lower shipping costs for freight, better connectivity to global trade markets, as well as allowing larger cruise ships to visit the city, which will further

boost cruise tourism in the region.

“At the moment Townsville cannot accept ships longer than 238m in length, which by today’s global standards is completely inadequate.”

Port of Townsville will fund $43 million for the Channel Capacity Upgrade, the Queensland Government has confirmed a $75 million funding commitment and has sought a matched $75 million contribution from the Federal Government for the project to proceed.

CONSTRUCTION BEGINS ON AUSTRALIA’S LARGEST WIND FARM

The first sod has been turned at the almost $850 million Coopers Gap Wind Farm in Queensland’s Darling Downs.

The 453 megawatt (MW) Coopers Gap Wind Farm is about 250km west of Brisbane, and will produce approximately 1,510,000 megawatt hours (MWh) of renewable energy annually. This is sufficient to power more than 260,000 average Australian homes when fully operational in mid-2019.

The renewable energy produced from the wind farm’s 123 turbines will also reduce CO2 emissions by 1,180,000 tonnes annually, the equivalent of taking 340,000 cars off the road.

Work has already started to connect the wind farm to the grid. Queensland’s high voltage transmission provider Powerlink is building a new 275kV substation at Cooranga North, with commissioning expected by the end of 2018.

Minister for Energy, Dr Anthony Lynham, said this is the second large-scale renewable project in the Western Downs to get underway.

“Coopers Gap will bring $850 million of investment, 200 construction jobs, and up to 20 ongoing operational jobs to the Western Downs.

“The Western Downs is fast becoming Australia’s renewable energy capital, with Coopers Gap and 10 approved solar projects.

“Together, they represent more than 2000MW of renewable energy that will help power Queensland’s electricity grid and

its regional economies, and help us meet our international emissions reduction commitments.

Dr Lynham said ongoing private sector investment, like AGL’s, was concrete endorsement of Queensland’s renewable energy policy.

“Our 50 per cent renewable energy generation target by 2030 has encouraged an unprecedented level of renewable energy investment in 23 large-scale projects that are currently financially committed to or under construction right across the state.

“When complete, these projects will more than double Queensland’s renewable energy output and produce enough electricity to power around 987,000 homes.”

Correction: In the article Moving forward for safer bitumen spraying published in the November 2017 edition of Infrastructure magazine, the article incorrectly used an image of a bitumen operation, not a sprayed seal operation.

SKILLING AUSTRALIA’S INFRASTRUCTURE PROJECTS

National forecasts suggest an additional 300,000 construction workers will be required by 2024 to staff the increasing number of major infrastructure projects in Australia. In 2015, jobs advertised in the construction industry obtained an average of 3.5 applications compared to 9.9 applications in 2008, with only 0.5 of those applicants being appropriately skilled for the job. If the industry continues like this it could result in a nation-wide critical skill shortage.

Australia’s infrastructure sector is set to boom in the coming years with Victoria alone undertaking projects such as the Metro Tunnel, North East Link, Level Crossing Removals and the West Gate Tunnel. The looming challenge for the industry will be implementing workable strategies to recruit, retain and train skilled people to deliver these projects and Australia’s next generation infrastructure.

Working in Human Resources (HR) in infrastructure means more than just recruitment. Managers have to ensure they’re acquiring appropriately skilled workers while juggling economic volatility, industrial disputes, an aging workforce and the ever changing rules of engagement to ensure successful delivery of their projects.

This means HR must continuously evolve, adapt and proactively seek out new ways to add strategic value to their organisations.

InfraPeople 2018 is a one-day conference that will bring together some of the leading experts in the infrastructure and human resource space to share practical solutions on how best to approach the big issues facing people in infrastructure.

The conference will be held in Melbourne on 8 August, and delegates will hear expert presentations regarding issues such as important 457 Visa changes that will impact the recruitment process; approaches to mental health challenges; workforce diversity; navigating the skill shortage; and learning how major

projects are innovating in the HR sector.

Aimed at roles such as Chief Human Resources Officers, People and Culture Managers and Operations Officers, the conference will attract the most senior decision makers from infrastructure asset owners, government agencies and major contractors.

InfraPeople 2018 offers the chance to get up-to-date on the biggest infrastructure projects in Victoria while networking with peers and industry leaders in formal and casual networking sessions.

Infrastructure magazine is excited to bring you this new event to help ensure your organisation remains equipped to face the challenges of the next ten years and beyond.

InfraPeople 2018 will feature topics including:

» Managing the skills shortage for both high-level and entry-level positions

» Recruitment strategies

» International recruitment and visa changes

» Changing technology

» Risk management

» Diversity and inclusion

» Safety

» Mental health

» Managing the generation gap and much more.

For more information or to register for event updates, please visit www.infrapeopleconference.com.au.

A PROBLEM IGNORED: HIGHWAY BRIDGES TRUCK PLATOONS

With automated truck platoons - trucks controlled by automatic systems that drive very close together - expected to come to Australia, one question that industry hasn’t thought about is the impact of these platoons on Australia’s aging bridge infrastructure. Here, Colin Caprani asks if our bridges can handle it?

IGNORED: AND AUTOMATED

by Colin Caprani, Senior Lecturer, Chartered Structural Engineer, Monash University.

BRIDGES

Automated truck platoons are coming to Australia it seems. To power the Australian economy, around 3.5 million tonnes of freight is moved by trucks every day. This “freight task” is expected to double between 2008 and 2030. Reducing the cost of this task will make Australia more competitive, and our goods cheaper. Automated truck platoons are seen as a paradigm shift in this regard. We can expect hugely reduced labour costs, improved safety, and fuel consumption savings of about 18 per cent for bumper-to-bumper gaps of four metres. It’s enough to make truckies nervous and tech company CEOs jittery with excitement.

Automated truck platoons consist of a number of closely-spaced trucks controlled by automatic systems that control driving tasks such as steering and braking. The main benefit is the reduced fuel consumption of the follower trucks, due to the reduced aerodynamic forces.

While not necessarily driverless, these technologies, when coupled with autonomous driving systems, could

mean that a platoon of six semi-trailers has just one driver. So, the savings are at least twofold: reduced fuel consumption, and reduced labour costs. The first of these relies heavily on the gap maintained between the trucks, meaning the closer the better.

In terms of the regulatory environment, the National Transport Commission (NTC) has been working on autonomous vehicles since 2015, and late last year the national enforcement guidelines were published. Laws will soon be changed around Australia to accommodate these smart vehicles on our roads. State road authorities are responding to the new environment. Vicroads, as just one state road authority, even offers grants to encourage trials of autonomous vehicles.

So, it seems that everybody is in favour of this future with just a few issues remaining to be finalised; truck driver concerns, and the legal and insurance framework (the technology itself seems already proven).

Except, nobody seems to have thought of the bridges.

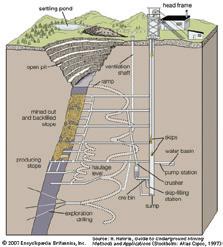

CAN OUR BRIDGES SUPPORT HEAVIER LOADS?

Approximately 70 per cent of Australia’s road bridges are more than 40 years old. About two-thirds of the country’s dual carriageway network was built before 1974. With good maintenance, it’s expected a bridge can last 100 years, but we cannot be sure. The technologies and materials used in many of the bridges on our road network have not even been around for 100 years. Indeed, the bad news is that about half our bridge stock is rated as being in poor condition, and the majority of bridges are not being inspected as frequently as they should.

Of course, the strength of even a degraded bridge is only one half of the problem, the real question is whether or not the bridge is strong enough to carry the loads on it. Of the several load types a bridge must support, the traffic loading is the most significant. For bridge lengths up to around eight metres, the maximum weight of axle groups (tandem, tridem, etc.) is critical; up to about 20m, the maximum weight of a single-truck per lane governs; up

to about 40m, multiple trucks per lane govern; and beyond that, congested traffic is critical, in which queues of closely-spaced trucks govern. Clearly then the two key components of bridge loading are the weight of trucks, and the spacing of trucks.

But how heavy is a truck? Roughly, the legal limits for vehicles in Australia have been increasing about 10 per cent per decade. However, it is not the legal limits that tends to drive bridge design or assessment, but the number and magnitude of illegal overloading. As a result, a statistical analysis is required to find the weight of the one in 100-year truck, or similar such measure.

TRUCK SPACING ALSO AN ISSUE

And what is the spacing between trucks? In dense but fast-flowing traffic, the gaps between trucks are not usually smaller than one second, and more typically over two seconds, leading to physical gaps which are certainly more than 20m. For slow-moving congested traffic these gaps can be substantially smaller at around 7.5 to 10m.

The safety assessment of new and existing bridges relies on accurate models of bridge traffic loading, which are calibrated against these weights and spacings of trucks. So far, this approach has served us well, and bridges are amongst the safest of all civil engineering structures.

So here is the problem: automated truck platooning voids the assumptions underpinning current bridge assessment practices. By significantly reducing the gaps between trucks, and by dramatically increasing the frequency of these small gaps, the current calibrated traffic load models are rendered invalid.

Surely such a significant existential threat to the roll-out of automated truck platooning has received the attention it deserves? Not so.

For example, state road authority Vicroads’ procedures for approving trials do not make any reference to infrastructure. Even worse, the NTC’s Guidelines for Autonomous Trials simply says that, “trialling organisations must inform road transport agencies of any infrastructure or network requirements for the trial”, the clear implication being that the public must fund whatever infrastructure demands trialling companies make.

So, to summarise the current state: bridges are getting older and their strength is degrading, trucks are getting

heavier and more frequent, and the way we check bridge safety does not allow for automated truck platoons. There is clearly a problem.

THE IMPLICATIONS NEED TO BE ADDRESSED

Such existential problems to the advancement of a new technology are usually identified and addressed. But this has not happened here; no research has been done to assess the impact of automated truck platoons on bridge loading.

In part, this is because the asset owner (the public) and the beneficiary (private industry) are different entities. One presumes the thought processes are, why should the public directly fund capital for private profit, and why should private industry fund a public asset? Until a clear financial link between investment and beneficiary is made, it is hard to see who should shoulder the cost of the research and development that is required.

Nevertheless, there is a silver lining. The technology that is used in automated truck platoons can be adapted to manage the loads imparted to the bridge. A recent study has shown that actively managing the gaps between trucks can lead to significant beneficial outcomes for bridge safety (Figure 1).

If just 10 per cent of trucks maintain a 20m control gap going over a bridge, the lifetime extreme loading is reduced by 10 per cent. If 90 per cent of trucks maintain a 50m control gap, it reduces by nearly 50 per cent. And these reductions are compared to the base condition of current traffic, not the condition of extreme loading implied by the presence of automated truck platoons.

In spite of these promising results, a single study is insufficient grounds to build a new industry and assume that the roll-out of automated truck platoons will be unhindered. Indeed, without more preparatory work, the nascent industry will be in for a shock when applications to run truck platoons are eventually assessed against the limitations posed by degraded bridge capacities and consequently rejected.

ACHIEVING AND DURABLE

Sustainability, limited resources and environmental concerns are increasingly front of mind for bridge design and optimised maintenance of bridges. It’s important to look at whole of life costs as well as alternative materials to improve in service life and to minimise greenhouse gas emissions. We spoke to Dr Richard Yeo, Program Manager, Assets, at Austroads, to find out about some of the innovative research that Austroads has been undertaking on bridges and how the results could change the way bridges are designed and constructed.

Austroads is the peak organisation for Australasian road transport and traffic agencies, with its members collectively responsible for the management of over 900,000km of roads valued at more than $200 billion.

In order to support member agencies to deliver an improved road transport network, Austroads undertakes leading road and transport research to support policy developments, and provide guidance in the design, construction and management of roads and associated infrastructure.

In the area of bridge technology, Austroads has brought together representatives from state and territory road agencies, the National Transport Commission and the Australian Road Research Board, to form the Bridge Task Force. The Task Force is responsible for maintaining the Austroads Guide to Bridge Technology, preparing specialist reports, and arranging for research and testing. It considers all aspects of bridge planning, design, construction, operation and maintenance.

Bridge Task Force on site at the Darlington Upgrade Project south of Adelaide Feb 2018.

The Bridge Task Force coordinates research that is working towards:

♦ Developing enhanced bridge design guidelines

♦ Improving evaluation methods for bridge load capacity and associated traffic demand

♦ Ensuring the Austroads Guides are up-to-date and better integrated with jurisdictional supplements

♦ The revision of Bridge Design Standard AS5100

Two research reports have been released by the Task Force to help pave the way forward for achieving longer service life and increasing the sustainability of bridges.

ACHIEVING A 100 YEAR DESIGN LIFE

Improving service life by examining different methods for concrete deterioration protection was the focus of the reports delivered through the project, Realising 100-year

SUSTAINABLE BRIDGES

Design Life of Bridge Structures in an Aggressive Environment.

Dr Richard Yeo, Program Manager, Assets, at Austroads said the research looked at structures like the Gateway Bridge in Brisbane and the mechanisms available that will ensure a 100 year design life is achieved.

“The project involved a very thorough literature review and critical assessment of available means to ensure that the durability of those particular concrete structures would achieve that outcome,” Dr Yeo said.

reinforcement is connected to allow for future cathodic protection if needed.”

Dr Yeo said the recent research found that it can’t be guaranteed that construction on-site will be as planned.

“You can’t always guarantee that the cover requirements will be met for the reinforcement and that impacts on the durability,” Dr Yeo said.

“Usually bridge designers prepare a durability plan for concrete structures based on a common approach with specific reinforcement cover requirements and making sure all steel

“At the end of the day, you might get critical zones of the structure, such as the piles, pile caps or interfaces, which are typically either underwater or buried and very difficult to access for later repair or replacement should early deterioration issues occur down the track. Typically that’s where we have problems, particularly in aggressive environments.”

The research looked at a wide range of options to prevent concrete deterioration, and the whole of life implications and costs, and came up with a different solution.

The study found that the most costeffective long-term solution was the replacement of around 20 per cent of steel reinforcement with stainless steel reinforcement in those critical zones. It found that even if the construction is not quite right or the environment adversely impacts the structure, the stainless steel will not be affected, mitigating the issues that are often seen in aggressive environments.

Dr Yeo gave an example of a bridge in Cairns in Far North Queensland that was built 30 years ago which had significant issues with corrosion of the reinforcement in the piers just below the waterline.

“If 30 years ago they had used this type of approach, they would not have an issue, it would not be deteriorating in that way. Of course, to inspect and repair that structure in that environment, you have problems with crocodiles. Now just to go and look at the problem is a challenge, because it’s not safe.”

AN IN-DEPTH LOOK AT DURABILITY

The findings are split into two related reports - experimental work and literature review.

The experimental work was informed by the extensive literature review and focused on concrete durability. The work comprised investigations into concrete deterioration mechanisms and their mitigation, including corrosion of steel reinforcement as influenced by chloride diffusion into concrete, carbonation of concrete, corrosion resistance of stainless steel, alkali-aggregate reaction and sulfate resistance of concrete.

“The research team did a whole range of laboratory tests to validate that you could buy the stainless steel reinforcement, and what type of stainless steel you should use. That in an aggressive environment it would not deteriorate, compared with say a conventional reinforcement,” Dr Yeo said.

The literature review took a more in-depth look at the durability issues that affect the service life of reinforced concrete structures, and considered information from sources within Australia and overseas.

It looks at the range of options available for improving durability, including the use of epoxy to coat the reinforcement. The research considered the pros and cons of the different alternatives but found that there were issues that could compromise their suitability. For example, if an epoxy coating is scratched or there is a breakdown in the barrier, corrosion will be able to take hold where these defects occur.

“Everybody I talk to says yes, we’ve done a durability plan, and yes we’ve defaulted to what we always do. Yet, this report is more or less challenging that, and saying have you really thought about all of the options, and the whole of life cost implications of those? Because things like cathodic protection can be expensive and difficult to maintain over long periods,” Dr Yeo said.

“We’re talking 100 plus years. So if you have problems at year 30 and you put that in place, you’ve got 70 years of maintaining a system. Or you could have stainless steel built from the outset, and you won’t have a problem.”

BREAKING DOWN THE SCIENCE OF GEOPOLYMER

Another key problem that the Task Force is working to find a solution to is greenhouse gas emissions. One of the concerns with using concrete for components is the large amount of greenhouse gases that are produced, and the energy required for cement manufacture.

Because of this, Dr Yeo said that people have been working to create alternative cement mixes and types of cement for decades, with one of these being geopolymer cement.

“Geopolymer concrete does not use ordinary Portland cement. It uses alternative materials, often by-products of other processes, which have a cementitious effect. The interesting part is it’s been around for some decades. But what was tending to happen in the market was that it wasn’t readily available, and what was available was proprietary product with limited information on the active ingredients in the mix,” Dr Yeo said.

The led to the Task Force releasing a report, Specification and Use of Geopolymer Concrete in the Manufacture of Structural and NonStructural Components, that looked into the properties of geopolymer and how it works in concrete. As geopolymer is not typically used as a structural concrete, the research focused on the parameters around using it for structures.

“Importantly we wanted to look at what the active constituents and reactions are, to provide an explanation of how it actually works. The research sought to open up the chemical nature of geopolymer cements so that asset owners considering this alternative material can better understand what ingredients it should have, what properties they should be looking for, and indeed being able to make their own mixes without having to require or rely on a particular supplier saying, ‘Trust us, it’s good’, Dr Yeo said.

The Austroads funded research took place over five years and involved the Australian Road Research Board working in collaboration with Swinburne University. Dr Yeo said the challenge of the project was breaking down the chemistry of the product and trying to understand it, as geopolymer manufacturers were not willing to divulge this information.

The research team then undertook a thorough literature review to see what information had been published, and then started to formulate their own mixes using ingredients that they knew worked. The team was able to focus in on the types of mixes and materials used to manufacture geopolymer and were able to create and assess small scale samples up to full structural beams to prove that it could be used as a structural concrete.

Dr Yeo said while research and experiments can predict the performance and long-term durability of geopolymer concrete, the problem with new technology such as this is that

you can’t wait 100 years to see how well it lasts compared to conventional concretes.

“We were able to do the accelerated deterioration tests, which take 12 months to two years, and look at how this concrete performs, relative to the standard Portland cement concrete.

“In fact, you can look at all the test data, and the trends show that this was a better product in durability than conventional concrete. So in addressing the problem of predicting the long-term durability, the observed positive trends give you some confidence,” Dr Yeo said.

“We followed up the research with a survey and asked who is using this as early adopters across our member road agencies? Are there some good examples of its use? The survey looked at road agency adoption of geopolymer concrete, specifications that might allow its use and barriers to adoption as well as experiences to date.

“The champions I think were VicRoads, they were absolute leaders. They had modified their standard specifications in five different areas to allow for geopolymer concrete used for, in this case, non-structural applications. We found that they had a wide range of concrete applications where they allow

for geopolymer concrete mixes. The door is open for other road agencies to adopt or adapt the VicRoads specifications.”

Dr Yeo said estimates of the amount of greenhouse gas emissions savings that could be achieved by using geopolymer instead of Portland cement had been developed.

“If you were to build a dual carriageway, four-lane highway with geopolymer concrete as the pavement, as opposed to Portland cement concrete, around 2,000 tons of greenhouse gas emissions would be saved per kilometre.”

“So every time someone proposes a concrete road, I say, ‘Are you going to use geopolymer concrete?’ Because we’ve shown how it can be used,” Dr Yeo said.

THE NEXT CHALLENGE

Dr Yeo said that while research and specifications for new bridges is going well, the biggest challenge is managing Australia’s bridge stock to facilitate greater freight productivity.

“There’s a lot of work on assessment of bridges, and a lot of angst, I suppose, around the ability of older bridges to sustainably carry heavier trucks,

particularly emerging high productivity freight vehicles, over mass super loads and large mobile cranes which develop concentrated loads, and allowing them access.

“We have certainly changed our views from ‘we can’t let them go because the bridge will be damaged’, to ‘what can we let go? How far can we push things? What is the real capacity and associated risk’,” Dr Yeo said.

“When you look at the bridge stock, a state road agency may manage 5,000 bridges and major culverts. You refine it down and you might have around 200 bridges that assessment indicates structural inadequacy for a certain vehicle mass and axle spacing. Means to work beyond the current AS5100 assessment provisions while managing the risks become a key consideration.”

An ongoing challenge connected to this is getting the funding needed to maintain or strengthen these bridges.

“There’s a lot of discussion at the Task Force around bridge assessment and what live load factors are required. What access we can provide, and when we can’t, we’ve really got to draw the line. Optimised asset management for bridges is a current focus of the Task Force.”

Reducing humidity below critical levels prevents corrosion.

EMBRACING NEW RAIL TECHNOLOGIES

by Andrew Meier, Executive Director/Chief Executive Officer, Australasian Centre for Rail Innovation

The Transport and Infrastructure Council (TIC), which functions under the Council of Australian Governments (COAG) to progress nationally significant reforms, aims to capitalise on the opportunities afforded by new and emerging technologies, and support adaptable and resilient infrastructure and transport systems.

Access to knowledge is a key component of this. Initially the Federal Government aided industry by setting up the Rail Cooperative Research Centre (Rail CRC), which ran for two iterations before winding up in 2014. Private and state government entities supported a continuation of cooperative rail research and the not-for-profit Australasian Centre for Rail Innovation (ACRI) was established.

Its aim is to facilitate independent research and analysis, to provide innovative solutions tailored to rail industry needs. It is overseen by a board representative of both industry and government, and operates on a shared intellectual property model with research findings disseminated across all participants.

ACRI’s program of research is agreed cooperatively by funding participants within heavy haul, passenger and freight

In launching the National Innovation and Science Agenda in 2015, Prime Minister, Malcolm Turnbull, said, “We cannot future-proof ourselves from change, nor should we seek to do so”. What was sought was the “agility to identify opportunities and embrace risk”. Fully embracing risk may feel like a bold step for most, but understanding that advances in technology bring great opportunity, as well as disruption, need not be.

rail, and level crossing focus areas. Now in its fourth year of operation and second research funding tranche, there are presently 25 research initiatives in delivery or development, having completed more than 20 projects since its inception.

THE IMPACT OF TECHNOLOGICAL CHANGE

Activities to advance the health monitoring of infrastructure include readying industry for the implementation of new technologies in broken rail detection, through the independent evaluation of a commercially developed locomotivemounted broken rail detection device, in a variety of Australian weather and rail stress conditions.

Technology also aids the understanding of the human interaction with rail infrastructure. Current initiatives utilising eye tracking include evaluating level crossing visual warning devices for pedestrians, and furthering knowledge on slips, trips and falls within rail station environments in order to aid design improvements.

Such research initiatives address currently tangible challenges for rail, but the industry must also be ready and open to those that are emerging. Presently two frameworks are being developed to address the impact

of technological change within rail organisations, one aimed at all aspects of rail operations and the other with a specific focus on track worker safety and competencies. These holistic tools aim to mitigate the challenges of introducing new technology, and improve industry competitiveness by identifying, in advance, the training and management adjustments that may be required.

The speed with which rail can identify and adapt innovation from outside the industry will also have a significant impact on industry competitiveness. This may require some facilitation as those researching emerging technologies do not necessarily have applications in transport and infrastructure foremost in mind. ACRI is presently evaluating the suitability

of a technology originally from the naval operations sector for locomotivemounted rail condition monitoring which has been developed and tested to its current state within New Zealand.

COLLABORATION TO INCREASE COMPETITIVENESS

Also important for rail industry advancement and competitiveness are activities in cooperation, linking operations with academia and linking Australasia with international developments.

Initiatives like the Australian Research Council Industrial Transformation Training Centre for Advanced Technologies in Rail Track Infrastructure (ITTC-Rail), which will combine higher degree civil rail engineering research

with significant periods of industry placement, aim to not only deliver industry-relevant research but also importantly industry-ready post graduates.

Internationally ACRI has fostered formal relationships with entities in the United States, Canada, United Kingdom, Italy, and with the International Union of Railways (UIC), providing channels for currently international knowledge to inform Australasian rail infrastructure practices.

For example, the largest ever Australian freight rail infrastructure project, the 1,700km Inland Rail line connecting Melbourne and Brisbane is now underway, with ACRI participant the Australian Rail Track Corporation (ARTC) managing delivery over the next decade.

By lowering freight supply chain costs, providing regional connectivity to ports, reducing road congestion and allowing the opportunity for increased passenger rail services on the Sydney network, Inland Rail will strongly impact on industry efficiency, sustainability and competitiveness. Importantly it presents a major opportunity for rail innovation as it is easier to apply new technology to new projects than retrofit it to existing infrastructure.

Innovation can bring challenge or significant opportunity, with the outcome influenced by informed decision making and planning. Through knowledge advancing entities like ACRI, the Australasian rail industry is well positioned to take advantage of the opportunities ahead.

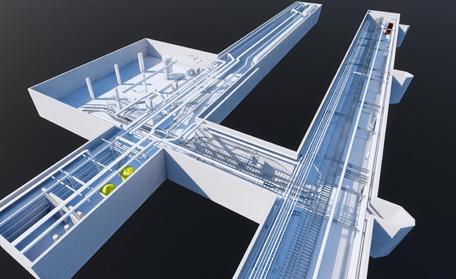

MOVING INLAND RAIL FORWARD

by Simon Thomas, Programme Delivery Director – Inland Rail, Australian Rail Track Corporation (ARTC)

Proposals for railways across inland Australia have been around for more than a century. With 2017 delivering a firm commitment to Inland Rail from the Federal Government, the project is steaming ahead. Significant milestones have been passed in early 2018, including the first delivery of new steel rail and awarding contracts in Queensland for engineering and environmental investigations.

With major construction work getting underway in 2018, we are expecting the first trains to operate between Brisbane and Melbourne in 2024-25. Inland Rail will connect Australia’s second and third largest cities via regional Victoria, central New South Wales and southern Queensland, to complete the ‘spine’ of the 1,435mm standard gauge national freight rail network.

Inland Rail is Australia’s largest freight rail infrastructure project since completion of the Alice Springs – Darwin line more than a decade ago. To give an indication of the scale, the route is as long as New Zealand and it will require enough steel to build five Sydney Harbour Bridges.

CONNECTING AUSTRALIA

Inland Rail is a transformational project bringing lower costs and greater efficiencies to rail freight customers. Ultimately it will allow rail to deliver more produce and goods to consumers, creating long-term jobs, boosting regional economies and helping businesses grow.

The transport and logistics sectors currently contribute 14.5 per cent of Australia’s Gross Domestic Product, with the supply chain worth around $150 billion a year. In order to compete in international markets, Australia needs to have competitive domestic freight transport and efficient supply chains.

Around 70 per cent of Australia’s population lives along the east coast, accounting for 78 per cent of all employment and generating 75 per cent of the nation’s GDP. Our population is expected to increase by 60 per cent over the next 40 years, and the volume of freight moving in Australia is predicted to double or even treble in the next 50 years.

Continued reliance on road transport, which today handles around 74 per cent of the inter-capital freight moving between Brisbane and Melbourne, would pose significant impacts in terms of safety, energy efficiency and environmental impact, particularly as the number of trucks increases to accommodate growing freight volumes.

Inland Rail has thus been designed to pass through Australia’s four most productive farming regions, offering

supply chain benefits and cost savings for agricultural producers, as well as flow-on effects to regional communities. It will also open up new demand, and create opportunities thanks to improved accessibility and greater efficiency.

DELIVERING MARKET-DRIVEN REQUIREMENTS

ARTC has been leading the development of the Inland Rail project since 2006. The project has been shaped by market needs and community feedback as much as engineering constraints.

Following extensive consultation with train operators and the freight logistics industry, ARTC developed a detailed service offering and established four key parameters: transit time, price, reliability and availability.

Transit time is key for the operators. Rail freight moving between Melbourne and Brisbane currently runs via Sydney and the NSW coastal route. The long transit time has been a deterrent for potential customers, with freight rail’s share of this market standing at only 26 per cent.

The shorter inland route will be up to 10 hours faster, allowing freight to move directly between Melbourne and Brisbane without having to thread its way through the congested Sydney area.

As well as a transit time of less than 24 hours, our customers told us that reliability and availability are also paramount. They also wanted provision for longer trains to improve productivity, so Inland Rail is being designed for longer trains for greater capacity.

Using 60kg per metre rails on new concrete sleepers, Inland Rail will accommodate 1,800m long doublestack trains with a 21 tonne axle load, running at a maximum speed of 115km/h and it will be future proofed for 3,600m long trains with a 30 tonne axle load, running at a maximum speed of 80km/h. One 1,800m double stacked train will carry the same freight as 110 B-double trucks, reducing the number of trucks on our major highways and creating safer roads.

Inland Rail will also have 7.1m clearances which are needed for double stack operation. At present the only route in Australia that can accommodate double-stack trains is the east-west corridor linking Parkes in central NSW to Perth.

Interoperability is a key technical characteristic that underpins the Inland Rail service offering. To be competitive, and to meet the needs of our operators, we will provide full interoperability with the interstate mainline standard gauge network.

The dual-gauging in Queensland will provide connectivity to the Queensland

narrow gauge for the regional network. And connections to the NSW country regional network will provide for standard gauge connections to the ports of Melbourne, Port Kembla, Sydney, Newcastle, Brisbane, Adelaide and Perth.

From the outset, the north-south corridor has been designed to make use of as much as possible of our existing interstate network. Around 65 per cent of the 1,700km route will use existing alignments, which will be upgraded where necessary.

Inland Rail will follow the existing interstate line for 490km from Melbourne through northern Victoria to Illabo, NSW, north of Junee. It will then run via Parkes, Moree and Toowoomba using a mix of new and upgraded tracks, to join the existing Sydney – Brisbane interstate line at Kagaru, giving access to the terminals at Acacia Ridge and Bromelton in southeast Queensland.

CONSTRUCTION CHALLENGES

Building Inland Rail consists of a complex mix of upgrading existing tracks, and building new tracks in a variety of environments – from passing through suburbs, traversing mountainous terrain, boring tunnels under ranges, to crossing floodplains.

The Victorian section of Inland Rail is planned along 305km of existing rail corridor from metropolitan Melbourne to the Victoria-NSW border at Albury-Wodonga. This project will see enhancements of existing structures and increased clearances along the rail corridor. The enhancement works

are required to accommodate doublestacked trains of 1,800m in length to be run on the track.

The NSW section of the Inland Rail is divided into seven projects which will require enhancement of 649km of existing rail corridor and building 381km of new tracks.

In Queensland, there are five projects which will require enhancement of a total of 127km of existing track and building 272km of new tracks to complete the Melbourne to Brisbane Inland Rail.

One of the most exciting projects will be the construction of a 6.4km long tunnel near Toowoomba to carry the line under the Great Dividing Range west of Brisbane. The tunnel will have an 11m diameter to provide clearance for double stacked containers and it will be one in 65 grade, meaning trains will be able to ascend and descend the length of the tunnel without requiring assistance.

The most difficult technical challenge is the ventilation of the tunnel. Keeping diesel trains travelling uphill cool enough to operate without de-rating or even stalling will require significant mechanical ventilation, especially considering the heat of the Queensland summer. ARTC has approached many world leading ventilation specialists to assist in overcoming this challenge, with the optimal solution to be developed in collaboration with the private sector.

This section of the project not only comprises tunnels, but numerous viaducts are also required throughout southern Queensland. Some of these viaducts will be up to 40m high and others over 1km long in order to traverse mountain ranges or to span floodplains.

ARTC will be one of the first railways to construct with flood modelling taking into account the updated Australian Rainfall & Runoff (ARR 4th edition) –which now considers projected rainfall patterns associated with modelled climate change impacts, in addition to historical and anecdotal evidence.

ARTC’s guiding principle is that in sections where Inland Rail will be upgrading existing lines, it will not materially change current flooding patterns, and in sections new tracks are being built, design will be based on modelling for one in 100-year events. The challenge here is steep – every section has a one in a 100-year event at a different time, and every event differs from the rest in terms of the volume of water, the velocity of the flood waters

and how quickly or slowly the flood levels recede.

To build the best possible rail line, ARTC will follow a robust plan, consulting as widely as possible and constructing to the best engineering plans.

Throughout the alignment, Inland Rail will come across a multitude of crossings – from highways of differing sizes and traffic volumes, to local roads, private roads and traditional stock movement routes. These each will pose their individual challenges, which will in turn require tailored solutions to ensure the communities and businesses served by these roads continue to have access.

WHERE NEXT?

ARTC has already undertaken extensive community consultation, hosting more than 1,200 stakeholder engagement events, meetings and technical workshops since 2016.

The Inland Rail project team has been growing steadily, and we now have around 120 staff spread across offices in Brisbane, Toowoomba, Sydney and Melbourne, supported by a range of consultants. More will be added in the first half of 2018, particularly in the area of stakeholder engagement and communication.

ARTC has stepped up the pace of the project. The first 600 tonnes of the 14,000 tonnes of steel rail required for the Parkes to Narromine section was delivered in January 2018, with further deliveries scheduled to start off the upgrade of the existing line and 6km of new construction to improve connections at Parkes.

ADELAIDE

The work involves replacing the steel rail, concrete sleepers and ballast; realigning some of the tighter curves; raising the level of the formation where required; and strengthening or replacing culverts and bridges as necessary.

We expect construction to begin in 2018 once all the necessary state and federal approvals have been received.

With 2024-25 fast approaching, there is still a lot of work to do, but the end of the long road is now on the horizon. The completion of Inland Rail as the north – south spine of Australia’s rail network will finally bring to fruition the vision of advocates over many years, allowing the nation to reap the benefits of this essential project.

HEAR FROM INDUSTRY LEADERS AT CORE2018

by Katharina Gerstmann, Conference Organising Chair, CORE2018Join us at the 11th RTSA Conference on Railway Excellence (CORE) and Exhibition. CORE is the premier technical event in the Australian rail conference market, delivering high-quality papers covering a wide range of rail engineering, operations, planning and management topics.

CORE2018 will be celebrating 20 years of RTSA and will be the first CORE conference to be held in Sydney at the International Convention Centre from 30 April to 2 May.

The conference will give participants a platform to exchange ideas, discover novel opportunities, reacquaint with colleagues, meet new friends, and broaden their knowledge. Our keynote speakers come from around the world, representing the very best in their field including Jean-Pierre Loubinoux, Director-General of the UIC, and Leslie Woo, Chief Planning Officer at Metrolinx, Ontario Canada with our Master of Ceremonies, US-based Sally Dominguez. Joining our international keynote speakers will be the Hon. Andrew Constance MP, Minister for Transport and Infrastructure, NSW who will

officially open CORE2018, and Ms Lucy Turnbull AO Chief Commissioner, Greater Sydney Commission who will deliver the closing keynote address about planning for the growth of cities and how it defines the need for growth of passenger mass transit.

WHAT TO EXPECT FOR 2018

The conference program will deliver over 80 technical papers regarding the solutions and challenges for the way we plan and deliver rail services and infrastructure in Australia and overseas. There will be presentations on project management, infrastructure advances, infrastructure track design and electrical automation, as well as many more technical and informative presentations. There is also an exciting site tour program to be held pre and post CORE2018 including site visits to metro and light rail operations, including the new Sydney Trains Operation Centre at Green Square, as well as some heavy haul operations at Newcastle and Hunter Valley.

The success of a conference is due to many people and organisations, so we’d like to thank our Host Partner, Transport for NSW, our platinum sponsors, ARTC, Aurizon and Sydney Trains, as well as WSP, SNC Lavalin, Speno, Comsteel, Institute of Railway Technology, Pandrol and Geofabrics, as well as our Media Partner Infrastructure Magazine and Supporting Partner, Railway Gazette.

The Australasian Centre for Rail Innovation will again be providing the “Knowledge Zone” for delegates to update their skills and knowledge. We are also having a shared plenary session and technical stream with our colleagues from the System Engineering Society (SESA) and their conference SETE2018.

I encourage you to register now to be in the best location to hear from industry experts and leaders in the rail industry, network with industry representatives and be part of the next generation rail industry leaders.

There is something of interest to everybody in the industry and I look forward to seeing you at CORE2018.

CONFERENCE ON RAILWAY EXCELLENCE

Rail: smart, automated, sustainable

30 APRIL – 2 MAY 2018

CORE2018 opens its doors at the International Convention Centre in Sydney on April 30.

Join us to hear from our International and national keynote speakers.

Register now to be in the best location to hear from industry experts and leaders in the rail industry, network with industry representative and be part of the next generation of rail industry leaders.

Leslie Woo

Chief Planning Officer Metrolinx

Hon. Andrew Constance MP Minister for Transport and Infrastructure, NSW

Jean-Pierre Loubinoux Director General International Union of Railways

Jean-Pierre Loubinoux Director General International Union of Railways

Ms Lucy Turnbull AO, Chief Commissioner Greater Sydney Commission

GALA DINNER SPONSOR HOST SPONSOR SUPPORTING PARTNERS PLATINUM SPONSORS

YOUNG PROFESSIONAL SCHOLARSHIP SPONSOR

Sally Dominguez Master of Ceremonies CORE 2018

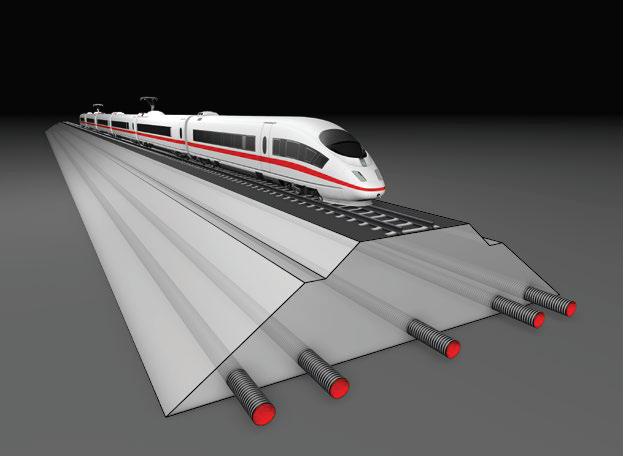

A NEW APPROACH TO RAILWAY TRACK DRAINAGE

Variances in moisture levels around railway tracks can compromise bearing capacity and the stability of surrounding soil, ultimately resulting in track geometry degradation. The only materials currently used to install a sufficient draining system are reinforced concrete, fibre reinforced concrete or steel, which are highly susceptible to rust and corrosion. One German manufacturer – FRÄNKISCHE – is changing the way the industry thinks about track drainage with an innovative new pipe design.

Arailway track’s geometry is highly influenced by the initial state of the soil, hydraulic conditions and atmospheric conditions such as temperature and moisture. Changes in these conditions, usually due to excess moisture, plays a significant role in the weakening of track geometry and can induce softening and weakening of the load bearing capacity.

Appropriate drainage methods are required to intercept water flow and direct it away from the track ballast.

FRÄNKISCHE has designed a high-quality polypropylene pipe with optimised profile geometry to offer an extremely hardwearing pipe for track drainage.

FRÄNKISCHE’s RailPipe complies with the extremely demanding requirements of Deutsche Bahn AG in terms of impact strength and flexural fatigue strength which has made it the first twin-wall pipe to meet all the standards and requirements of Deutsche Bahn AG and the German Federal Railway Authority (Eisenbahn-Bundesamt, EBA). RailPipe can therefore be used as a single pipe solution for all pressure ranges of the roadbed and track.

CHANGING THE GAME

Concrete and steel drainage systems can corrode and rust over time through excessive exposure to water and runoff. This means continuous maintenance and inspection is required to prolong the pipe’s life and durability.

The game changing RailPipe design offers a number of benefits over its concrete and steel counterparts, including being drastically lighter weight for easy installation, eliminating rust and corrosion which cuts ongoing maintenance costs and having a longer lifespan than traditional materials.

The controlled drainage of railway tracks is also required for safety reasons. Accumulating infiltration water must be removed from waterbodies and soils in compliance with protection requirements. RailPipe has a high infiltration rate thanks to perfectly arranged perforations and high permeability.

RailPipes round shape and smooth inside create a cross-section that is beneficial in terms of hydraulics and maintenance. It is delivered in straight lengths of six meters including coupling and sealing rings which can then be cut to length as desired and remaining pieces can be reused using couplings.

Stephen Herd, Australasian Regional Business Manager Drainage Systems, said the development of the RailPipe system was a five-year long process.

“We’ve designed RailPipe as a single pipe solution for all applications. Not only can it be used outside of and in the external pressure range of the roadbed and track but also in the inside pressure range.

“RailPipe has passed rigorous quality control by the external

centre of MFPA Leipzig in terms of safety and stability. The thorough testing included Dynamic fatigue tests determining the fatigue strength in 108 load cycles. The results proved the durability of the design as it was still able to hold its integrity.”

RailPipe can also be coupled with an additional RailControl; a flushing and inspection shaft of modular design comprising shaft bottom, extension pipe and adapter. The addition was specifically developed to allow for easy inspection and flushing of the connected pipe systems.

RailControl satisfies the highest requirements in terms of safety and stability while being resistant to acids, bases, oils and greases, and is UV-resistant and temperature resistant from - 40 to + 80°C.

INDUSTRY LEADERS IN DESIGN

FRÄNKISCHE is an innovative, growth-oriented industry leader in the design, manufacturing and marketing of technically superior corrugated pipe systems for drainage, electrical, building technology and industrial applications.

With the combination of RailPipe and RailControl, FRÄNKISCHE has developed the perfect system for the requirements of track drainage. Both components have been ideally matched to form a homogeneous system that provides the highest functional reliability for planning engineers, users and builders.

For all fields of track drainage RailPipe® with EBA certification

The RailPipe drainage pipe is the first twin-wall pipe to meet all the standards and requirements of Deutsche Bahn AG and the German Federal Railway Authority (Eisenbahn-Bundesamt, EBA) and can therefore be used for all pressure ranges of the roadbed and track.

www.railpipe.com

RIGHT RAIL FOR NEWCASTLE

Expected to be fully operational in 2019, the Newcastle Light Rail will form the centrepiece of a fully integrated, vastly improved public transport network for Newcastle, which will stimulate urban revitalisation and provide a solution to transport demand for years to come.

The Newcastle Light Rail is a key part of Revitalising Newcastle, a NSW Government program focused on enhancing the city, attracting more people, jobs and tourism to Newcastle

Revitalising Newcastle Program Director, Michael Cassel, said that the government is investing more than $650 million to transform the city centre by strengthening connections between the city and waterfront, creating job opportunities, providing new housing and delivering attractive public spaces connected to better transport.

“Newcastle Light Rail will provide a frequent and reliable travel option throughout the city centre, connecting key activity precincts, reinvigorating Hunter and Scott streets, and opening up great urban renewal opportunities,” Mr Cassel said.

“Light rail construction follows the truncation of Newcastle’s heavy rail line between Wickham and Newcastle stations. The truncation allowed the foreshore and the city centre to reconnect to the city centre, removing the divide.”

The Newcastle Light Rail project received planning approval

in August 2016 and major construction started in September 2017. Downer EDI is the principal contractor and the project is on track to see customers start using light rail services in 2019.

More than $300 million worth of funds from the Revitalising Newcastle program has been put aside for the construction of the Newcastle Light Rail and associated works.

In August 2017, the NSW Government announced an additional $150 million in funding for the Revitalising Newcastle program, taking the total investment to more than $650 million.

The additional $150 million includes:

♦ $75 million plus any future land sales for new public spaces on the former heavy rail corridor

♦ $35 million to deliver wire-free light rail, much-needed footpath upgrades at key locations on Hunter and Scott streets and street trees

♦ $40 million to deliver road and intersection upgrades to support traffic flow and road safety as light rail is introduced

PRESERVING NEWCASTLE’S HERITAGE

One of the main challenges around the construction of the Newcastle Light Rail has been the historical significance of the land that the light rail alignment runs through.

“Located near and under Newcastle’s light rail alignment are archaeological artefacts including part of Australia’s first rail line, which delivered coal to the harbour. A key consideration for construction is therefore preserving, where possible and being respectful of Newcastle’s rich history,” Mr Cassel said.

“Prior to European settlement, the part of Newcastle where light rail construction is underway was Aboriginal land. The Awabakal people were the original inhabitants.”

Mr Cassel said another consideration has been the relocation and upgrading of a large number of existing underground utilities and services, including telecommunications, gas, electricity, water and sewer assets – some almost as old as Newcastle itself.

“Part of the light rail construction involves replacing sections of Newcastle’s century-old sewer network, which is up to six metres deep. This work involves using microtunnelling to replace the mains away from the light rail alignment,” Mr Cassel said.

TECHNICAL SPECIFICATIONS

Another project in the Revitalising Newcastle program, the Newcastle Interchange, is a new multi-modal transport hub at Wickham in the city’s west, linking trains, buses, taxis, kiss

and ride facilities, and from early next year, the Newcastle Light Rail.

Newcastle’s Light Rail will start at the Newcastle Interchange, travelling along the old heavy rail route for approximately one third of the 2.7km journey before moving onto Hunter and Scott streets.

Stops will be located at Newcastle Interchange, Honeysuckle (near Hunter Street TAFE), Civic, Crown Street, Market Street and Pacific Park.

The Newcastle Light Rail is capable of transporting 1,200 people per hour. Each Light Rail Vehicle (LRV) has a maximum capacity of 270 passengers, with services running every 7.5 minutes during peak hour.

The light rail network has been designed so it can easily be extended in the future.

“Any extension would need to integrate with the six existing URBOS LRV’s. As these LRV’s are modular in design, any changes can be incorporated to ensure an integrated network for future stages,” Mr Cassel said.

“Depending on an extended route, the LRV’s could run up to 70km/hr, carrying the same capacity of passengers and provide the same level of comfort and service.”

The LRV’s, which are being built by CAF Rail, are the same as the Inner West Extension.

While only one aspect of the Revitalising Newcastle program, Newcastle’s Light Rail looks set to play a pivotal role in the city’s successful urban transformation.