Issue 11 June 2019 ROAD - RAIL - AIRPORT - PORT - URBAN - UTILITY MEET AUSTRALIA’S NEW INFRASTRUCTURE CHIEF The future OF FLEXIBLE PAVEMENT Asset management: REMOVING THE ROADBLOCKS TO SUCCESS MINIMISING NOISE AND VIBRATION AT MELBOURNE METRO

WE’RE PROUD TO BE THE SPECIALIST EQUIPMENT PARTNER OF THE CONTRACTORS THAT ARE LEADING THE WAY FORWARD. NORTH QUEENSLAND 671 Ingham Road Mount St John QLD 4818 QUEENSLAND 147 Archerfield Road Richlands QLD 4077 NSW & ACT 45 Eastern Creek Drive Eastern Creek NSW 2766 VICTORIA & TAS 415 Fitzgerald Road Derrimut VIC 3026 SOUTH AUSTRALIA 9-11 Hakkinen Road Wingfield SA 5013

Vermeer surface miners and track trenchers have been part of methodologies proven on numerous Australian infrastructure projects. Whether it’s lowering the bench in a road tunnel, a box cut for a train station, or trenching a comms channel, we have the equipment and team to support your project. Contact your local Vermeer team to learn more.

Australia

VERMEER.COM.AU | 1300 VERMEER Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2019 Vermeer Equipment Holdings Pty Ltd. All Rights Reserved. . / VermeerAustralia

Monkey Media Enterprises

ABN: 36 426 734 954

204/23–25 Gipps St

Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

EDITOR’S WELCOME

We’ve reached the end of another election campaign with the Liberal-National Coalition now holding majority government for the next three years. While this result may have been a surprise for some commentators, what is clear is that infrastructure was one of the issues at the forefront of debate. In particular, infrastructure played a strong role in the Liberal-National Coalition’s campaign, especially since its promise of $100 billion in infrastructure investment in the 2019–20 Budget released in April.

As with all election campaigns, there was a flurry of promises, funding announcements and major project promises in the lead up to the polls, including projects such as $2 billion for the Fast Rail Link between Melbourne and Geelong; $1.6 billion for road and rail infrastructure across Western Australia, and the establishment of a freight data hub; national water grid and Road Safety Innovation Fund, among others. The big question now is whether these can all be delivered, and we’ll be watching closely for any new developments.

given you a peak into some of these topics in this issue, with articles on the use of drones in railways and bridge management, as well as mitigation works to prevent noise and vibration issues during construction.

The management of our roads and pavements is also a significant issue, and one that is allowing the sector to come up with some pretty innovative solutions. In particular, one council we’ve profiled is recycling plastic and glass into its road materials — a move that is becoming increasingly common to try to help with current problems around waste and recycling. Infrastructure Victoria is also currently providing advice on recycling and resource recovery to the Victorian Government.

Business

Alastair Bryers

Rima Munafo Senior

Alejandro Molano

Publisher

Sam

Here at Infrastructure, we cover all the major new project announcements across Australia and while those stories are always interesting and popular with industry, the topic of how best to manage these assets once completed also remains a key issue. So much so that several years ago we created the event Asset Management for Critical Infrastructure to provide the sector with practical applications and a look at what others in the field are doing when it comes to asset management.

The event is back again for 2019, running from 20–21 August in Sydney, and this year features the addition of two new targeted streams, plus a new expert line-up of speakers. We’ve

This issue will be distributed at the 18th AAPA International Flexible Pavements Conference and Exhibition, an event that will delve even further into new materials and innovations like this in the road sector. You’ll also see this issue at the AFR National Infrastructure Summit; Ports Australia's Business and Operational Conference, and Asset Management for Critical Infrastructure. I hope to see you all at these events, as well over the coming months and get your thoughts on where the sector is heading for the rest of 2019.

Jessica Dickers Editor

Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to call me on 03 9988 4950 to let me know what you think. DAY. BIGGER. DEERE. Issue 11 June 2019 ROAD RAIL - AIRPORT PORT URBAN UTILITY INFRASTRUCTURE JUNE 2019 MEET AUSTRALIA’S NEW INFRASTRUCTURE CHIEF The future OF FLEXIBLE PAVEMENT Asset management: REMOVING THE ROADBLOCKS TO SUCCESS MINIMISING NOISE AND VIBRATION AT MELBOURNE METRO 8,648 This publication has been independently audited under the AMAA’s CAB Total Distribution Audit. Audit Period: 1 October 2018 – 31 March 2019

Published by

Kim

India

Editor Jessica Dickers Assistant Editor

Ho Journalists

Murphy Siobhan Day

Development Manager

Designer

Designers Jacqueline Buckmaster Danielle Harris

Managing

Operations Manager

Chris Bland

Editor Laura Harvey

Digital Marketing Manager

Kirsty Hutton

Penny ISSN: 2206-7906

NO LIMITS FOR THE RAILWAY INDUSTRY

WAGO can make vibration proof fast maintenance free connections in local and long-distance transport possible with spring pressure connection technology. We offer comprehensive range of Railway approved solutions.

TOPJOB®S Rail Mount Terminal Blocks

• New Tooless Lever and Push-button TOPJOB®S versions

• Push-in CAGE CLAMP® Spring Pressure Technology

• For all conductor types

Low Profile Power Supplies

• Protective conformal coating for PCB

• 110 VDC and 72 VDC versions

PFC200 XTR Controllers

• Controls for eXTReme environmental conditions

• Linux® real-time operating system

• Integrated IT security standards EN 50121.3.2 Isolation and Immunity to Interference

• Ideal for distribution boards or distribution boxes Worldwide Railway Standard EN 50155

EN 45545

EN 61010

High Current Rail-Mount Terminal Blocks

• Conductor cross-section upto 185 mm2

• Rated current up to 353A

• Time-saving no ring terminals of ferrule required Fire Protection Conformity

Pluggable Modules for TOPJOB®S Terminals

• Available as Relay, SSR and switching modules

• Easy retrofitting applications

• Extended temperature range from -40°C ... +70°C Safety Requirements

WAGO is a registered trademark of WAGO Verwaltungsgesellschaft mbH. sales.anz@wago.com | (03) 8791 6300 | www.wago.com.au

A WORD FROM INFRASTRUCTURE AUSTRALIA

MEET AUSTRALIA’S NEW INFRASTRUCTURE CHIEF

As she takes the reins as Chief Executive of the nation’s independent infrastructure advisor, Romilly Madew AO outlines her vision for Infrastructure Australia and the challenges ahead for the sector.

INDUSTRY INSIGHTS

BREAKING BARRIERS FOR WOMEN IN CONSTRUCTION

Construction has long been a male dominated industry, with the archetypal construction worker synonymous with masculinity. But when most industries are striving to dismantle these gender norms and are moving towards equality, why is the construction industry gender gap getting worse?

ELECTION 2019: WHAT ROLE DID INFRASTRUCTURE PLAY AND WHAT DOES THE RESULT MEAN FOR THE SECTOR?

The Liberal-National Coalition, led by Scott Morrison, has won the 2019 Federal Election. Having campaigned on strategic infrastructure investments, the question arises: what role did infrastructure play in the outcome of the election, and what does a Coalition victory mean for the sector going forward?

ASSET MANAGEMENT

GETTING ASSET MANAGEMENT RIGHT: A NEW FRAMEWORK

ASSET INSPECTION & DRONES/UAVS

REMOTE TRACK INSPECTIONS USING DRONES

EARTHMOVING OUTLOOK

IMPROVING PRODUCTION ON TUNNELLING PROJECTS WITH SURFACE MINERS

EARTHMOVING INDUSTRY OUTLOOK 2019/2020

THE NEXT LEVEL OF DOZER GPS MACHINE CONTROL PERFORMANCE

PREPARING THE SITE FOR AUSTRALIA’S LARGEST INTERMODAL TERMINAL

NOISE AND VIBRATION

MELBOURNE'S METRO TUNNEL WORKING TO MINIMISE DISRUPTION

QUIET CONFIDENCE: CUSTOM-ATTUNING ACOUSTICS ON THE SYDNEY METRO

THE FUTURE OF FLEXIBLE PAVEMENTS

RECYCLING PLASTIC AND GLASS INTO ROAD MATERIALS

4 June 2019 // Issue 11 www.infrastructuremagazine.com.au CONTENTS

BIGGEST NAMES IN ASSET MANAGEMENT RETURN TO SYDNEY

18 22 28 36 26 32 40 50 42 46 48 54 56 60 FLEXIBLE PAVEMENTS

5 www.infrastructuremagazine.com.au June 2019 // Issue 11

AIRPORTS GREENER BUILDING A

FUTURE: A NEW ERA OF GREEN INFRASTRUCTURE ARE OUR PORTS CONNECTED AND EFFICIENT ENOUGH? 06 CONTRIBUTORS 80 ADVERTISERS’ INDEX 80 FEATURES SCHEDULE NEWS 74 08 THREE CROSS RIVER RAIL CONTRACTS AWARDED 10 NORTH EAST LINK SHORTLISTS TWO CONTRACTORS 10 MELBOURNE AIRPORT EMBRACES SMART SECURITY TECHNOLOGY 11 SEVERAL FIVE-YEAR ROAD MAINTENANCE CONTRACTS AWARDED 12 2019 SMART CITIES AWARD WINNERS ANNOUNCED 14 VERSATILE, RELIABLE ANCHORS 15 DOUBLE-DECKER SUBSTATION IN MELBOURNE CBD 16 CHANGING THE IMAGE OF SEWAGE TREATMENT BRIDGES

NEW FRAMEWORK FOR THE INTERNET OF THINGS SMART CITIES: THE NEW PARADIGM FOR THE PLACES WE LIVE, WORK AND PLAY REVOLUTIONISING BRIDGE HEALTH MONITORING 70 72 62 66 76 SUSTAINABILITY PORTS

MAKING AUSTRALIA’S

SUSTAINABLE

SMART INFRASTRUCTURE

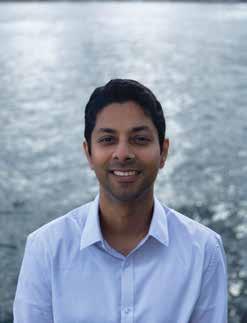

Romilly Madew AO

CEO, Infrastructure Australia

Recently awarded an Order of Australia in acknowledgment of her contribution to Australia’s sustainable building movement, Romilly is recognised around the world as a leader and advocate for change in the property and construction sector. She led the Green Building Council of Australia for 13 years, representing over 650 companies with a collective annual turnover of $40 billion, and presiding over the Green Star rating system which has seen more than 2250 projects certified across the country. Romilly holds Board positions with Sydney Olympic Park Authority and Chief Executive Women, and has sat on numerous ministerial panels including the Cities Reference Group, National Urban Policy Forum and the China/Australia Services Sector Forum.

Rami Affan

Executive Director, Asset Management at Infrastructure NSW

Rami has over 14 years of experience in asset management in the infrastructure sector. During the last five years, Rami has specialised in capital investment and asset management strategies for the NSW State Government and across various public sector organisations in the United States. Rami is now the Asset Management lead at INSW and will be delivering, in collaboration with NSW agencies, a new statewide Asset Management framework as a critical part of the State Infrastructure Strategy 2018–2038 recommendations.

Ravi Ravitharan

Director, Institute of Railway Technology, Monash University, Australia

Ravi Ravitharan has 30 years of experience in railway research. He is the Director of the Institute of Railway Technology (IRT) at Monash University in Australia. From 2006 to 2008, Ravi was the National Executive Chairman of Engineers Australia’s Railway Technical Society of Australasia (RTSA). For his outstanding contribution to the Australian and international rail industry, the RTSA Life Membership (2011) and the coveted RTSA Individual Award (2014) were awarded to him. Ravi has also been awarded the prestigious Australian Academy of Technological Sciences and Engineering (ATSE) Clunies Ross Award in 2014 for the application of science and technology for the benefit of Australia.

Ravi is a Fellow of Engineers Australia, Chartered Professional Engineer and Engineering Executive. Ravi is a Technical Advisory Panel member of Singapore SMRT and an advisory board member of Industrial Transformation Training Centre for Advanced Technologies in Rail Track Infrastructure in Australia.

6 Contri

June 2019 // Issue 11 www.infrastructuremagazine.com.au

butors

Carlos Rial Chief Executive Officer, AAPA

Carlos Rial Chief Executive Officer, AAPA

Carlos brings over 20 years of road industry experience paired with over ten years as a senior organisational leader, working in partnership with both the public and private sectors. He is a broadly experienced senior organisational engineering manager who has demonstrated the ability to lead diverse teams of professionals to new levels of success across public and private sectors. He is a recognised road industry leader with strong technical and business qualifications, and an impressive track record of hands-on experience in strategic planning, business unit development, project and product management while maintaining strong technical engineering skill and aptitude.

Dr Phillippa Carnemolla

Senior Research Fellow at UTS

Dr Phillippa Carnemolla is an industrial designer specialising in the design and evaluation of inclusive environments, products and information. Her research investigates the breadth of health, care and social impacts resulting from inclusive design approaches, including smart cities, aging in place and disability housing models.

In her role as Senior Research the Fellow in Faculty of Design Architecture and Building at UTS, Dr Carnemolla is working on a diverse range of projects which investigate the impact of the inclusive and participatory design practice on service provision, caregiving and quality of life for older people and people living with disability. Dr Carnemolla was the recipient of the 2018 NAWIC International Women’s Day (IWD) Research Scholarship. Awarded annually since 2009, and generously sponsored by CULT, the $20,000 scholarship prize enables research that improves, benefits and empowers women in the construction industry.

Leigh Gapp

Sustainability Manager, Adelaide Airport

Leigh has 15 years’ experience across the waste, infrastructure construction, mining and aviation sectors, and is passionate about delivering value and efficiency through a data driven approach. Leigh serves as a member of the Airports Council International – Asia Pacific Regional Environment Committee and the GRESB Infrastructure Benchmark Committee.

7

www.infrastructuremagazine.com.au June 2019 // Issue 11

The Queensland Government has chosen its preferred consortia for two major packages for its $5.4 billion Cross River Rail Project, as well as its European Train Control System.

The successful consortia were: Tunnel, Stations and Development (TSD) public-private partnership

Preferred – Pulse

A CIMIC Group-led consortium, including Pacific Partnerships, CPB Contractors, UGL, BAM, Ghella and DIF Rail, Integration and Systems (RIS) alliance

Preferred – Unity Alliance Including CPB Contractors, UGL, Jacobs, AECOM European Train Control System

Preferred – Hitachi Rail STS

CIMIC GROUP EMERGES AS A BIG WINNER

The CIMIC Group said the Pulse consortium will deliver tunnelling works, new underground stations and ongoing maintenance services for the project.

CIMIC Group has led the development of Pulse’s proposal. Pacific Partnerships is the lead sponsor and will provide 49 per cent of the equity finance, with 51 per cent to be provided by DIF, BAM PPP PGGM and Ghella Investments & Partnerships.

CPB Contractors will deliver the design and construction in a joint venture with Ghella and BAM International with UGL delivering the mechanical and electrical (M&E) works. UGL will also provide maintenance services for the project over 24 years.

Revenue to the CIMIC Group companies will be approximately half of the project value and will be finalised at contract execution which will occur mid-2019.

RIS CRUCIAL FOR INTEGRATING THE CROSS RIVER RAIL

The RIS package will provide critical operational, signalling and other support systems for the new 10.2km Cross River Rail link.

Crucial to the overall delivery of the Cross River Rail Project, it will deliver the design, supply and installation of the supporting rail systems and brownfield works to integrate Cross River Rail into the wider Queensland Rail train network.

THREE CROSS RIVER RAIL CONTRACTS AWARDED

The package includes:

♦ An upgrade of the existing Exhibition Station

♦ Augmentation of Mayne Yard

♦ Rail operational systems, signalling and telecommunication works across the Cross River Rail Project

♦ Revenue to the Alliance will be confirmed at contract execution

A MAJOR ECONOMIC IMPACT

Collectively, these investment decisions mark a major milestone for the project and the Delivery Authority and its specialist advisors should be congratulated on advancing procurement to this stage.

IAQ’s Chief Executive Officer, Steve Abson, noted that a project of this scale will have a significant impact on the economy, with spending in the construction and operating phases generating income and employment for hundreds of Queenslanders.

“Organisations in the preferred consortia have a track record of delivering complex rail and transport projects and have the know-how to leverage local content. We expect the benefits of the project will flow to many local suppliers and businesses throughout Queensland.”

While the project is scheduled for opening in 2024, Mr Abson noted the ramp up in effort needed to bring the project ‘on-line’ into the Queensland Rail network has already begun.

Lessons learnt from similar complex projects around the world show that operational readiness has to start early.

“Operational readiness doesn’t grab the headlines like a huge tunnel boring machine does, but it’s perhaps the most crucial aspect of any mega project being spliced into an existing busy inner-city network,” Mr Abson said.

“This activity will necessitate high levels of collaboration across government organisations such as the Delivery Authority, Queensland Rail, Transport and Main Roads, and TransLink, and it’s worth acknowledging the enormous effort already going on behind the scenes to get this right.”

NEWS June 2019 // Issue 11 www.infrastructuremagazine.com.au 8

WATER SCIENCE TECHNOLOGY

NORTH EAST LINK SHORTLISTS TWO CONTRACTORS

The Victorian Government has shortlisted two major construction firms to deliver the first package of works on the North East Link.

The works package will start in 2020, once planning approvals are in place and deliver a range of power, water and other utility works to pave the way for major construction on the $15.8 billion project.

The biggest road infrastructure project in Victoria’s history, the North East Link will include:

♦ A 6km tunnel under Banyule Flats and the Yarra River

♦ An upgrade to the Eastern Freeway to streamline traffic flow and reduce congestion

♦ A busway down the middle of the Eastern Freeway

The North East Link will create the missing link between the Eastern Freeway and the M80 Ring Road, slash travel times, take more than 15,000 trucks a day off local streets and

The Victorian Government has not announced the names of the shortlisted contractors. However, it confirmed both builders have now received tenders, with their proposals for the work expected back by mid-2019.

The State Government will finalise get the chance for the $7–9 billion primary detailed design and Victoria’s longest twin road

The global search continues and bidders will be shortlisted later in 2019. Construction will start in 2020 and the North East Link will open in 2027.

MELBOURNE AIRPORT

EMBRACES SMART SECURITY TECHNOLOGY

In an Australian first, Melbourne Airport has unveiled a fully integrated security screening point aimed at making the process easier and more efficient for travellers.

The redeveloped T2 security screening zone includes eGates plus Smart Security lanes that feature new body scanners and automated tray return systems.

Three additional screening lanes, dedicated fast track lanes, and a staff and goods lane have also been installed, generating 35 per cent more capacity.

Melbourne Airport’s T2 security screening point also includes a new façade with a prominent ‘Melbourne’ sign, plus brighter signage to guide travellers towards departures.

The interior has also improved with additional lighting and artwork by local artist Britt Salt, lifting the space through optical effects.

Melbourne Airport Acting Chief of Aviation, David Hall, said he was proud that Melbourne is leading the way in its approach to security.

“We are thrilled to be the first airport in Australia to introduce a

security screening zone that is fit out with world leading Smart Security technology, creating enhanced security outcomes while improving the traveller experience,” Mr Hall said.

“Victorian travellers and visitors alike will reap the benefits through spending less time in queues, creating a more streamlined experience at what can often be one of the most stressful parts of the traveller journey.

“By using eGates we can review multiple boarding passes at any one time, reducing queues at the entrance to

the hall. The eGates also have the ability to integrate with facial recognition technology in future.”

Mr Hall said that automated tray return systems would permit travellers to essentially overtake slower passengers, by encouraging multiple people to place their luggage into trays on any one lane.

“The area overall is a lot more welcoming through its design and aesthetics and we look forward to our travellers using the space.”

Each security screening lane contains around $1 million in equipment, ensuring security outcomes and customer service is aligned with world standards.

The T2 screening hall meets the government mandated increases to aviation security.

Mr Hall said the future of travel is trending towards automation.

“At Melbourne, we’re embracing change and preparing for the future by not only making improvements to security technology, but also through introducing self-service check-in zones and automated bag drop facilities, giving travellers more control of their journey.”

NEWS June 2019 // Issue 11 www.infrastructuremagazine.com.au 10

SEVERAL FIVE-YEAR ROAD MAINTENANCE CONTRACTS AWARDED

The Queensland Government has awarded minimumfive-year contracts to maintain the 2,500km road network of the South East Queensland (SEQ) region.

Contracts were awarded for the Brisbane Metropolitan region (Fulton Hogan Industries), Gold Coast region (Ventia) and Sunshine Coast region (Downer Works EDI) to maintain statecontrolled roads for the Department of Transport and Main Roads (TMR).

Queensland Minister for Transport and Main Roads, Mark Bailey, said SEQ is home to about 2,595km of statecontrolled roads and that the management and maintenance of these roads would be a huge and demanding job.

and build in innovations to the new contracts to improve services across SEQ.

The new contracts will run over an initial five years and sustain more than 380 jobs across the region over that initial contract period.

Mr Bailey said previous contracts were awarded in 2013, giving TMR an opportunity to learn from those agreements

The Queensland Government has a $46 billion infrastructure program that is supporting 38,000 jobs in 2019.

Mr Bailey said the renewed contracts would also create a single point of contact for responsive maintenance works to ensure TMR reacts quickly to incidents to minimise road closures across the region.

‘‘The responsive maintenance contract has been awarded to RoadTek, which will specialise in technically difficult, hard-to-scope, high risk and short-leadtime maintenance activities,” Mr Bailey said.

As a leading engineering and consulting company in the rail sector, we offer sustainable, made-to-measure mobility and transport solutions. From light rail to high-speed traffic, from industrial railway to complex logistics concepts –as a full-service provider we take care of consulting, design and realization, from the idea to operations. No matter what challenges you face – we will find the best solution. We always keep the goal in mind: to make your project a success.

www.db-engineering-consulting.com

www.infrastructuremagazine.com.au June 2019 // Issue 11 11 NEWS

SHORTLISTED

The winners of the 2019 Smart Cities Awards have been revealed at a Gala Cocktail Party and Awards Ceremony as part of the Smart Cities 2019 Conference in Melbourne.

Six awards were handed out celebrating the greatest achievements in the development, technological advancement and interconnection of cities around Australia.

The aim of these awards is to gather some of the best ideas and talent when it comes to the development and enhancement of our cities, so that we can all learn and benefit from the exciting work already being undertaken across the sector.

THE WINNERS ARE:

Smart City of the Year - Metropolitan

City of Newcastle

City of Prospect

Smart City of the Year - Regional

Latrobe City Council

City of Darwin

The finalists were:

Cities 2019 2019 SMART CITIES AWARD WINNERS ANNOUNCED

The winning entries were deemed the best in smart cities for 2019, and were among high-quality finalists in each category.

Smart City of the Year – Metropolitan

City of Newcastle

Moreland City Council

Lake Macquarie City Council

Randwick City Council

City of Prospect

Townsville City Council

Smart City of the Year – Regional

Southern Grampians Shire Council

Broken Hill City Council

Latrobe City Council

City of Darwin

Best Integration of an Individual Technology

Woollahra Municipal Council – 3D modelling platform

Melbourne

Best Integration of an Individual Technology

City of Wanneroo - RailSmart Planning Support System

Best Residential Innovation

Solar Analytics

Smart Innovator of the Year

David Klingberg

Young Smart Innovator of the Year

Oliver Lock

The awards were judged by Leigh Osterhus from the Cities Leadership Institute; Sean Holden from the Local Government Association of South Australia; Dr Jonathan Spear, Executive Director and General Counsel at Infrastructure Victoria; Professor Mark Burry AO, Founding Director of the Smart Cities Research Institute at Swinburne University of Technology; and Lorraine Tighe, Smart Cities and Innovation Consultant.

The awards proved to be a great opportunity for delegates to learn about some of the incredible things that are happening in the industry; and also allowed the shortlisted companies and winners to showcase the work they are doing in the smart cities space.

City of Wanneroo – RailSmart Planning Support System

RACV – Smartphone application integrating Melbourne’s public and private transportation options

Brimbank – Suite of smart bin sensors, barbeque failure sensors, park utilisation mobotix cameras, air quality and weather stations, and facility use counters at Buckingham Reserve

Sydney Metro – Driverless (advanced signalling) train technology

SAGE Group – Matilda the smart transit hub

Best Residential Innovation

Solar Analytics – Solar monitoring software

City of Canterbury Bankstown – Closing the Loop on Waste Project

SMEC – Atherstone Estate

City of Gosnells – Cool Roofs Project

Smart Innovator of the Year

Peter Auhl, Chief Information Officer, Central Coast Council

David Klingberg, Director and Principal, Smart City Strategies and Solutions

Jagpreet Walia, Sustainability Lead, City Of Melville

Young Smart Innovator of the Year

Oliver Lock, PhD Candidate, UNSW

Rebecca Jacobs, Smart City Lead, Randwick City Council

NEWS June 2019 // Issue 11 www.infrastructuremagazine.com.au 12

2019,

International keynote speaker, Mark Dowd, with Infrastructure Editor, Jessica Dickers

The EcoSys enterprise projects performance platform consists of three products with integrated business processes to support portfolio, project, and contract management.

EcoSys from Hexagon PPM is designed to improve performance throughout the full project lifecycle. With built-in industry best practices and flexibility to support organization and project-specific requirements, EcoSys is the ideal platform for:

• Capital Efficiency

• Project Portfolio Management

• Resource Planning & Management

• Project & Program Management

• Project Controls

• Cost Management

• Earned Value Management

• Construction Management

• Turnaround Management

Ineffective project practices could be costing you millions.

Complete a 10-minute project performance maturity assessment, based on PMI’s OPM3 framework, to understand how effective your organisation is at managing project performance. Once completed you’ll receive an in-depth report tailored to your organisation’s maturity levels in three key areas: process, human capital, and technology. Discover how to better deliver projects - on time and budget. Take the assessment today at https://connect.hexagonppm.com/maturity-assessment/infra2019

STRATEGY EXECUTION Portfolios Projects Contracts ECOSYS

For more information visit ecosys.net

© 2019 Hexagon AB and/or its subsidiaries and affiliates. All rights reserved. 08/18 PPM-US-0448A-ENG

VERSATILE, RELIABLE ANCHORS

Anchorage is crucial to ensuring the stability of key infrastructure as well as safety on construction sites. Given the enormous range of assets requiring anchoring — trees, walls, moorings, towers, sheet piles and cranes, both on land and underwater — it is not enough for anchor systems to be trustworthy and reliable. They must also be versatile.

The AncorLoc system offers a range of tried-and-tested anchors to suit all sizes and applications across civil and structural infrastructure, including bridges and roads. Honed through years of technical and practical experience across a range of industries, the anchors deploy a simple, innovative solution to deliver maximum stability with minimum soil disturbance.

Most anchoring products use concrete, grouts and screw type fixtures which require additional costs and time to install. The AncorLoc system is different as it works alone. Anchors are driven into the ground using a drive rod and once it reaches the required depth, the rod or cable then rotates the anchor into undisturbed soil like a toggle bolt, ensuring optimal grip.

The combination of the anchor’s size and the depth that it can go allows it to have a strong holding capacity

in every soil type. Even if the soil has been affected by things like flooding, AncorLoc’s products can be driven to depths below the affected topsoils or poor soil groups.

SPECIFIC ANCHORING SOLUTIONS FOR DIFFERENT PROJECTS

The Duckbill – the smallest in the range – is a cabled anchor designed for smaller loads, from trees through to civil and structural applications. Duckbill anchors can be cabled with a variety of tendons, from galvanized aircraft cable for normal usage to stainless steel for superior corrosion resistance, making them highly adaptable.

The Manta Ray and Sting Ray anchors are perfect for larger tonnages such as towers, retaining walls (including sea walls), moorings and assisted footings. They can be used both on land and underwater.

Once they are driven into the ground, AncorLoc anchors are tipped and loadlocked with Foresight’s Anchor Locking Kit. This provides an immediate proof test of each anchor.

The simplicity of AncorLoc’s applications allow for quick installation, saving labor costs and reducing the amount of concrete and steel needed on a project. In addition to infrastructure projects, these anchors have provided solutions for utilities, port authorities, portable buildings, shade structures and landscape design.

For more information on which anchoring solution is right for your project, visit ancorloc.com.au.

14 June 2019 // Issue 11 www.infrastructuremagazine.com.au NEWS // PARTNER SOLUTIONS

DOUBLE-DECKER SUBSTATION IN MELBOURNE CBD

In order to maximise space and prepare for High Capacity Metro Trains, a custom-designed, multistorey substation has been installed in Melbourne’s CBD.

In the heart of Melbourne’s Central Business District, a team of engineers and construction workers installed Victoria’s first ever modular traction substation to boast a ‘double-decker’ design.

The substation was custom designed to squeeze onto a narrow strip of land near the major transport hub of Southern Cross Station.

Along with several others along the Cranbourne/Pakenham line, the Southern Cross ‘subbie’ forms part of a major upgrade being carried out in preparation for bigger High Capacity Metro Trains.

Multi-storey substations are rare in Australia. This structure was built off-site using prefab technology.

Two separate modules, each more than 25m long, were delivered to site all the way from South Australia, with one lifted on top of the other in a complex twelve hour operation.

The double-decker design aims to maximise space and help transport infrastructure keep up with Melbourne’s burgeoning population.

Rail substations take electricity from the existing power network and convert it into a form that can be fed through to trains.

Due to its location, the Southern Cross facility is electrically larger than most,

containing around twelve kilometers’ worth of cabling compared to the average of eight or nine.

Humble from the outside, modern substations are built to high-spec standards, incorporating fail-safe mechanisms and vital communications connections to allow them to ‘talk to’ network control centres. Substations are also weather and fire proof.

PREFABRICATION TO SAVE TIME

Contractors were able to design and build the structure within a relatively short timeframe.

Power Manager, Evan Broughton, said the use of prefab technology meant the substation could be built off-site at the same time as the foundations, saving time and eliminating the potential for weather delays.

“We were originally looking at constructing a traditional building in this locale, but the tight timeframe meant that the modular building method was the way to go,” Mr Broughton said.

“This substation was custom designed for the footprint, to make optimal use of the space while allowing room for an access road.”

Mr Broughton said while he had seen a lot of prefabrication in construction throughout his career, a multi-storey substation in the inner city takes it to a new level.

“Rail environments pose unique challenges and we need to monitor the

movement of people, machinery and construction with absolute precision,” he said.

Dean Chaplin, a project manager for LAI Switchboards, one of Australia’s leading switchroom and substation providers, said the superstructure was essentially 100 per cent completed on arrival to site in Victoria and had to be centimetre-perfect.

LAI has delivered a series of new substations along the Cranbourne/ Pakenham line and rates the Southern Cross job as the company's most complex, but also among the most efficient construction projects.

“The team effort was phenomenal. Every piece of communication had to be on point, and every action had to be quick,” Mr Chaplin said.

CONSTRUCTION SNAPSHOT

♦ Prefab substation module makes a 2.5-day journey from South Australia to Melbourne on the back of a 16 axel expandable platform trailer, measuring 31m long

♦ Trailer enters site and positions itself over crushed-rock foundation

♦ Foundation legs drilled and chem set in place

♦ Trailer removed in sections from underneath the buildings (as there wasn’t room to remove it all in one piece)

♦ Second module is delivered to site and subsequently lifted in place

15 www.infrastructuremagazine.com.au June 2019 // Issue 11 NEWS

CHANGING THE IMAGE OF SEWAGE TREATMENT

Integrated Fixed Film Activated Sludge Plants (IFAS) rely on the use of a media on which a bio-film is grown, which results in a compact footprint as a majority of the biomass is fixed to a high surface area as opposed to being suspended.

Arecent development of this process by Organica Water has been to combine naturally occurring plants with engineered media. To put simply, a botanical garden is placed on top of the IFAS reactors, with the plant roots penetrating into the reactors.

The interaction of enzymes and various organic acids from the plant roots to the bio-media creates a diverse biology, leading to increased process stability, less sludge production and lower energy demand when compared to conventional activated sludge plants. And the sewage treatment plant looks like a botanical garden.

Large-scale installations in Europe have been in operation for over ten years.

Bio-film technology in wastewater treatment has been around since the 1970s, available as moving bed bio-film reactor (MBBR) systems or integrated fixed film activated sludge processes (IFAS). In general, the bulk of the developments in this field relates to increased surface area, scouring and bio-film growth.

Generally the media used in either MBBR or IFAS is a non-metallic surface. Both systems provide benefits such as reduced reactor size, high total available biomass inventory, high tolerance

against biomass washout during storm events and simultaneous nitrificationdenitrification within the bio-film layer.

Organica’s Food Chain Reactor (FCR) combines the use of naturally occurring plants, such as bulrushes or marsh reeds, together with an IFAS-based process. A greenhouse is typically used to house the process, resulting in an aesthetically pleasing treatment system. For warmer climates, a shaded structure is used.

EIGHT YEARS OF REFINEMENT

Pilot work for the FCR process was conducted in 2001, and was mostly based on the use of plants, to provide a high surface area for biomass growth. Full-scale wastewater treatment plants were then constructed for 2000 and 5000EP systems, based on sequencing batch process.

Over the next eight years, the process was refined to enable the use of the technology in larger scale wastewater treatment plants, and to improve energy efficiency and with lower biomass yield.

The combined use of the natural plants and engineered media meant that there was no limit on size for the FCR process.

REACTOR CONFIGURATION

The sequential batch process was then configured to a continuous multistage cascade process. Similar to MLE, an anoxic zone with internal recycle from the last stage was incorporated as part of the nitrogen removal loop.

OBSERVED OPERATIONAL BENEFITS

The multi-stage cascade FCR was observed to provide a number of operational benefits. What was found in the pilot scale has been verified in full-scale installations that have been in operation for several years.

Key observations include:

♦ Independent development of biomass and ecology within each stage

♦ A significant increase in the diversity of biomass speciation due to the interaction of the natural plants and biomass

June 2019 // Issue 11 www.infrastructuremagazine.com.au 16

NEWS // PARTNER SOLUTIONS

Figure 1: Food Chain Reactor (FCR) –Cross section of the reactor process

♦ Very high total biomass inventory, due to the bio-film growth

♦ Very high observed sludge retention time (SRT)

♦ Reduced biomass yield, due to a predatory effect and higher SRT

♦ A low MLSS in the water phase of 300 mg/L

♦ Increased alpha factor within the aeration system, due to the lower free MLSS

♦ Relatively odour free

♦ No need to return activated sludge (RAS) in process design

The lower free MLSS means that the phase separation step post FCR can be designed with a lower loading. Rather than using secondary clarifiers, phase separation can occur in a horizontal disc filter which has a tenth of the footprint as compared to a conventional clarifier.

In addition, the lower MLSS results in a higher diffuser alpha factor, meaning that less air is required to deliver and process the oxygen needed. This results in a lower energy demand.

Diversity of biomass speciation results in adaptive ecologies forming in each FCR stage. As opposed to 300 to 400 species commonly present in activated sludge plants, the FCR exhibits up to 3000. This diversity creates a very stable process, which is tolerant to shock loads and in the last stage, the presence of eukaryotes results in the consumption of decayed bacteria.

Operating data from several facilities has demonstrated the robustness of the FCR system, as well as consistent effluent quality. The discharge quality that can be achieved can be designed to match any conventional activated or MBR process.

The total observed biomass within the FCR system is typically 16,000 mg/L, which is three to four times that of conventional systems. Although MBR systems exhibit similar high MLSS, the energy demand associated with FCR is significantly less due to a simplified secondary clarification phase.

AESTHETICS

The FCR can be housed within a greenhouse structure, or provided with a shading structure. The selection is generally based on minimum temperatures in the winter period.

The end result is a wastewater treatment plant that resembles a garden or greenhouse facility, with low odour emissions and a very aesthetically pleasing look.

In some European installations, buffer zones around the treatment plant have been reduced from 350m to 50m, freeing up additional land for development and providing a net positive attitude from local communities.

more dense bio-film is created, when compared to other IFAS systems or MBBR processes.

With an observed total biomass concentration that is three times conventional systems, a reduced footprint of up to 65 per cent can be achieved. Savings in energy demand and sludge disposal are two other key benefits of the process, particular over MBR-based systems that exhibit similar space saving features.

Full-scale installations as large as 80MLD have demonstrated the technology’s application within the municipal and industrial wastewater field.

UPSCALING YIELDS ECONOMIC BENEFITS

The use of bio-film technology provides a number of advantages with regard to footprint and biomass inventory. The combination of natural plants and IFAS results in a process that has been scaled up to full size treatment facilities, that provides a number of capital and operational cost savings.

The natural plants do not actually treat the wastewater, but provide nutrients, organic acids and enzymes that create a highly diverse biology within the plant roots and IFAS modules. A much

The aesthetically pleasing look of the Organica FCR has changed local community attitude towards wastewater treatment, and has provided a place for communities to interact with process in a very positive way.

As rapid urban growth continues in many cities around the world, this technology has demonstrated its use as a decentralised facility that can be constructed in the middle of a dense urban landscape, to relieve load on existing sewer systems and enable water reclamation in these environments.

Hydroflux Epco is the exclusive Australian and New Zealand representative for Organica Water’s Food Chain Reactor process. Contact Hydroflux Epco on 1300 417 697 or visit www.hydrofluxepco.com.au.

www.infrastructuremagazine.com.au June 2019 // Issue 11 17 NEWS // PARTNER SOLUTIONS

Figure 2: The multi-stage Food Chain Reactor (FCR) process

Figure 3: Le Lude STP – France. A view of the integrated process

MEET AUSTRALIA’S NEW INFRASTRUCTURE CHIEF

A WORD FROM INFRASTRUCTURE AUSTRALIA June 2019 // Issue 11 18

As she takes the reins as Chief Executive of the nation’s independent infrastructure advisor, Romilly Madew AO outlines her vision for Infrastructure Australia and the challenges ahead for the sector.

WHAT ATTRACTED YOU TO THIS ROLE AT INFRASTRUCTURE AUSTRALIA?

After 13 years leading the Green Building Council of Australia, I wanted to take on a role that drew on my long-held passion for creating more sustainable, productive and liveable communities.

I am looking forward to turning my focus to ensuring Infrastructure Australia continues to provide the advice, research, advocacy and collaboration needed to deliver better infrastructure for all Australians.

This is an organisation that I am incredibly passionate about and proud to be leading, because infrastructure is fundamental to our quality of life.

It connects us to economic, education and social opportunities. It supports our health, safety and security.

It provides us with the essential services we rely on — from energy, water and telecommunications, to social infrastructure such as hospitals, schools and parks, and access to fresh produce and other goods that most Australians could not imagine living without.

However, too often, our infrastructure doesn’t meet community expectations.

Congestion, overcrowding, rising bills, outages and declining service standards are undermining public confidence in our infrastructure.

These are also signals that our infrastructure needs to work harder to support Australia into the future.

When Australia’s governments invest well, there is a clear opportunity to unlock the nation’s potential, reduce congestion on our infrastructure networks, and raise the standard of living in our cities and regions.

Infrastructure Australia’s independent, evidence-based advice is crucial to achieving this future. We have a responsibility to take a longer-term view of our collective needs as a nation — one that enables our leaders to look beyond elections and budgetary cycles to pursue the infrastructure investments that will improve our quality of life.

WHAT ARE YOU HOPING TO ACHIEVE IN YOUR TENURE AS CHIEF EXECUTIVE?

Since its establishment, Infrastructure Australia (IA) has played an important role in championing best practice in the infrastructure sector, advocating improvements in infrastructure and promoting public awareness.

I plan on continuing this focus, working with the team and stakeholders to deliver advice and support to drive transformation in the sector.

Infrastructure Australia works closely across government jurisdictions on the feasibility and quality of major infrastructure proposals. This is on the basis of rigorous analysis of costs and benefits from an economic, environmental and land use perspective, and includes business case development and project selection.

Infrastructure Australia has developed an assessment process for major infrastructure, with one clear aim — to ensure that public funds are directed towards projects that will deliver the best outcomes for Australians.

Quality business case development is critical to ensure public funds are spent where they are needed most, and this remains an important focus for the organisation.

As part of working with jurisdictions to support the improvement of business case quality, Infrastructure Australia hosts Business Case Improvement workshops across the country. Over the past year this has been attended by more than 300 project proponents, government officials and their advisors.

Through this process, we have seen a real improvement in the number and quality of proposals submitted for inclusion on the Infrastructure Priority List.

However, it is critical that we remain focused on selecting the right projects, and ensuring public infrastructure funds are spent where they are needed most.

Well-developed business cases, supported by early project development studies, such as strategic options analysis, feasibility studies and cost-benefit analysis, help ensure that the right infrastructure solution is selected.

Another area of focus will be to continue the already groundbreaking work Infrastructure Australia has done through providing advice on Australia’s current and future infrastructure needs and priorities through the Reform Series and Infrastructure Priority List.

I am also focused on driving greater collaboration with our stakeholders across government, industry and the community. This collaboration could include considering the sectors capacity and capability to identify opportunities to increase this to deliver the number of projects currently underway and planned.

Likewise, the Infrastructure Australia I lead will seek to be a valued collaborator to ensure that infrastructure decisionmakers are always planning for the future, and our investment and reform agenda is evolving to meet the challenges ahead.

A WORD FROM INFRASTRUCTURE AUSTRALIA www.infrastructuremagazine.com.au June 2019 // Issue 11 19

WHAT ARE CURRENTLY THE KEY CHALLENGES YOU SEE FOR THE INFRASTRUCTURE SECTOR?

Infrastructure has been fundamental to Australia’s economic success to date, supporting a world-class standard of living that is rightly a source of national pride. However, when it comes to delivering the infrastructure we need, the sector is facing a period of unique uncertainty.

What makes Australia unique is:

♦ Our population is growing and changing

♦ The structure of the economy is shifting away from manufacturing and resources towards knowledge-based industries

♦ Our communities and natural environment are experiencing weather extremes

♦ Rapid technological change is fundamentally reshaping our day-to-day lives

Looking to the future, it is clear that as the needs of our communities evolve, our infrastructure will likely look very different to what we have experienced in the past.

Access to appropriate skills at all levels is also a key challenge for the sector. For major projects in our faster growing cities, the largest skill constraints are among professional project managers, bid teams and skilled labour. Our research has also found that professional skills in the rail sector, electricity network maintenance and emerging technology sectors face long-term constraints. In regional centres and remote areas, attracting and retaining a semiskilled construction work force is a key challenge for industry.

WHAT ARE SOME OF THE CURRENT TECHNOLOGIES OR INNOVATIONS THAT YOU THINK WILL HAVE THE BIGGEST IMPACT ON THE SECTOR?

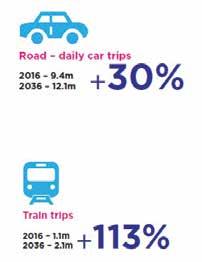

Rapid technological change is fundamentally changing how people interact with infrastructure, and how services are delivered. In particular, smarter mobility through electrification, automation and rapid improvements in communications technology is having a transformative effect on our cities.

New service models such as on-demand, rideshare and carshare are disrupting the transport market in particular, and these trends are being complemented by improvements in digital communications, which allow access to real-time information and new user experiences.

The pace and scale of technological change today provide profound opportunities for the Australian infrastructure sector — to improve quality of life, provide better access to services, enhance productivity and grow new industries.

However, technological advancements and data generation also create new challenges around control and privacy of data, and raise questions around how to ensure the benefits of technological advancement are available to all Australians.

Infrastructure Australia’s forthcoming release, the 2019 Australian Infrastructure Audit, will take stock of the most important issues facing the sector as we prepare for a changing future, and work towards better leveraging Australia’s technological expertise.

June 2019 // Issue 11 www.infrastructuremagazine.com.au 20 A WORD FROM INFRASTRUCTURE AUSTRALIA

WHAT SHOULD INDUSTRY EXPECT FROM THE 2019 AUSTRALIAN INFRASTRUCTURE AUDIT?

The 2019 Australian Infrastructure Audit covers transport, energy, telecommunications, water and — for the first time — social infrastructure.

It highlights the key issues and trends impacting each sector, as well as the challenges requiring action in the near future. It’s the second Audit Infrastructure Australia has undertaken, after the first was published in 2015, and focuses on outcomes for users in terms of access, quality and cost.

The Audit is crucial to ensure Australia’s infrastructure not only keeps pace with demand, but also helps to unlock future growth. Rather than adopt conventional state and territory boundaries, it will frame infrastructure needs by the type of community or area they serve.

We have identified the different needs and challenges of fast-growing cities, smaller cities and regional centres, small towns, remote communities, and developing regions.

The 2019 Audit also takes a user-based approach, with an emphasis on increasing access and understanding of Australia’s infrastructure at all levels. It will focus on understanding the role infrastructure plays in supporting Australians’ diverse lives, now and into the future.

What’s next for Infrastructure Australia following the release of the 2019 Audit?

The 2019 Audit provides governments, industry and the community with an evidence-based view of the challenges and opportunities facing our infrastructure.

It will also become the foundation of Infrastructure Australia’s future research program, and help us to identify the most pressing opportunities for investment for the 2020 Infrastructure Priority List.

Following the release of the Audit, we will invite all stakeholders and the public to provide feedback and submissions. The results of this three-month consultation will inform the development of the next Australian Infrastructure Plan.

Romilly Madew AO is a keynote speaker at the 2019 Asset Management for Critical Infrastructure Conference where she will further explore the industry insights from the 2019 Infrastructure Audit and look into comprehensive resilience strategies to ensure optimal lifecycle of Australia’s assets.

For more information, visit assetmanagementevent.com.au.

www.infrastructuremagazine.com.au June 2019 // Issue 11 21 A WORD FROM INFRASTRUCTURE AUSTRALIA

BREAKING BARRIERS FOR WOMEN IN CONSTRUCTION

by Siobhan Day, Journalist, Infrastructure magazine

by Siobhan Day, Journalist, Infrastructure magazine

June 2019 // Issue 11 www.infrastructuremagazine.com.au INDUSTRY INSIGHTS 22

Construction has long been a male dominated industry, with the archetypal construction worker synonymous with masculinity. But when most industries are striving to dismantle these gender norms and are moving towards equality, why is the construction industry gender gap getting worse?

Infrastructure spoke with Dr Phillippa Carnemolla, a Senior Research Fellow at the University of Technology

Sydney, and Dr Natalie Galea, a Postdoctoral Fellow at the University of New South Wales, to find out about current industry perceptions and barriers to women entering and progressing in the construction industry.

Dr Phillippa Carnemolla was the 2018 recipient of the National Association of Women in Construction (NAWIC) International Women’s Day scholarship. This scholarship required her to spend 12 months undertaking a research study, with the scholarship funding the research.

Dr Carnemolla’s research involved investigating the perceptions of the construction industry by female high school students. Keeping in mind that women entering and remaining in the construction industry sits well below parity, Dr Carnemolla’s research examines how construction is portrayed and perceived by the very women it hopes to attract, as well as where they come from.

She’s now working closely with Dr Galea, also a past recipient of the NAWIC scholarship, whose research focuses on the barriers to women’s recruitment, retention and progression in construction.

The Australian Bureau of Statistics’ research on gender participation in the construction industry — the most male dominated industry in Australia — shows the significant disparity between men and women in the sector, particularly when looking at middle and upper management. The stats show a staggering 97 per cent of CEOs and 88 per cent of senior managers in the industry are men.

“This is proportionately greater than the male dominance found in Australian business generally,” Dr Carnemolla said. Perhaps more telling however is that women’s participation in construction is actually falling, decreasing from 17 per cent in 2006 to 12 per cent in 2018.

Dr Phillippa Carnemolla

Dr Phillippa Carnemolla

www.infrastructuremagazine.com.au June 2019 // Issue 11 INDUSTRY INSIGHTS 23

SOCIAL, ECONOMIC, EDUCATIONAL AND EXCLUSIONARY BARRIERS

A diverse workforce is known to increase well-being and talent retention, but it can also lead to tangible economic benefits. A study by McKinsey & Company found that companies in the top quartile for gender diversity on executive teams were 21 per cent more likely to outperform on profitability and 27 per cent more likely to have superior value creation. Additionally, companies in the bottom quartile for diversity were significantly less likely to achieve above-average profitability.

Without gender diversity, construction and infrastructure — the second largest industry in Australia and the third largest employer — is missing out on the talent pool of half the population and potentially reducing profitability.

So, why aren’t women entering, staying and progressing in the construction industry? Dr Carnemolla and Dr Galea believe the answer is multidimensional.

“The barriers to entering the sector range from social, economic, educational and exclusionary industry practices. The reasons women leave the sector are equally diverse and range from a lack of flexibility and progression, poor parental leave practices and a tolerance of sexism,” Dr Carnemolla said.

STRUCTURAL PROBLEMS

Recruitment

In Dr Carnemolla’s study and accompanying report, Girls’ Perceptions of the Construction Industry: Building a Picture of who isn’t Interested in a Career in Construction and Why, the all girls high school students interviewed consistently reported the belief that the construction industry is not appealing because of its perceived exclusivity and gender imbalance.

The study found that schools, teachers and parents were not recommending a career in construction to girls, and parents’ perceptions of the industry are influential in steering students away from it.

Dr Carnemolla noted the lack of female role models in the construction industry, and the lack of understanding about the diverse scope of jobs and careers that comprise the sector. The participants also felt that the only women they see in the industry are generally young women holding the lollipop signs and directing traffic.

While these barriers to recruitment tend to be around

perception, further barriers are encountered by women who have the interest and knowledge to enter into the industry. The research report by Dr Galea and colleagues at UNSW, Demolishing Gender Structures, found that the recruitment practices of the construction industry perpetuate a gender bias, with ‘informal’ recruitment, a lack of transparency in recruitment, and adherence to problematic work cultures.

According to the study, men are much more likely to access and benefit from ‘male’ networks, like sporting teams and industry connections, to secure employment opportunities and progress their careers. Alternatively, women are more likely to be recruited through formal channels, like online applications, which feature far less construction opportunities.

The report also found that companies in the sector tend to place a particular emphasis on ‘cultural fit’ when interviewing potential employees, which can severely limit women’s access and opportunities because of intrinsically masculine cultures.

Progression

For those women who do enter and remain in the industry, career progression is another hurdle and one that Dr Galea has experienced first hand.

“I studied construction management and spent 15 years delivering building, civil, defence and mining projects in Australia and the Middle East and North Africa for large contractors. I found it very difficult to progress within construction companies, despite being one of the few women in an operational role and working very hard,” she said.

DECONSTRUCTING THE ISSUES

Dr Carnemolla and Dr Galea are now working together to try and break down these barriers and increase gender equality in the industry. The next part of their research that they are collaboratively undertaking is about understanding how other industries have tackled this issue.

“We need to speak with all stakeholders including employees, employers and prospective recruitments in order to understand how to best design any rebrand. It is an important next step for us,” Dr Carnemolla said.

Dr Galea said employers are concerned about the sector’s looming skills shortage and are funding academic research to understand the problems.

“UNSW research showed employers were focused on setting targets on female graduates and had reviewed their graduate recruitment processes. The research also showed that young women joined companies where they could see women leading and developing a strong career. Retaining and progressing women in construction however, remains an area that employers need to focus on,” Dr Galea said.

Dr Carnemolla said a commitment to diversity in any workplace will result in positive outcomes across many professional and personal domains of productivity and wellbeing.

“In our workplace, having better diversity in teams leads to improved problem solving and innovation, and workplaces where everyone feels they belong and can contribute equally. It also addresses the skills shortage our sector faces and improves the sector’s gender pay gap. It’s good for men too. The business case for diversity has been documented in reports internationally.”

June 2019 // Issue 11 www.infrastructuremagazine.com.au INDUSTRY INSIGHTS 24

Dr Natalie Galea

REBUILDING THE SECTOR

As a result of her research findings, Dr Carnemolla made a series of recommendations that will enable NAWIC, employer groups, leading companies and broader construction networks to better engage with high school girls and to communicate the potential for a construction career.

These recommendations include:

♦ Construction needs to reposition itself as a career for both women and men. The construction sector’s employer groups and leading companies should undertake a campaign that rebrands construction as an aspirational career. Students, parents and schools need to be convinced

♦ The industry needs diverse role models and champions to communicate the potential and diversity of roles within a construction career

♦ Further research into the role that schools play in supporting careers in construction for girls is recommended. This will enable a better understanding of how schools can be better informed about opportunities within the construction industry for all female students, across all levels of academic achievement

♦ The construction industry should be encouraged to review its recruitment practices to include non-school leavers — warranting further research into exactly where interest in construction training comes from and how it can be encouraged from an early age. Further research is needed into how construction training and tertiary education is marketed/targeted to understand why particular schools are drawing more interest

Dr. Carnemolla is optimistic about the future of the construction industry pointing to the opportunities created by the fourth wave of industrial revolution and Australia’s increasing commitment to inclusive workplaces.

“The introduction of new technologies, coupled with the important work already underway in understanding women’s experiences throughout the entire work cycle, offers new ways to renegotiate assumptions around gender preferences — not just in the construction industry, but a variety of industries,” Dr. Carnemolla said.

Dr Galea was more cautious in her response regarding the journey ahead, “I am less optimistic. I think the sector — clients, contractors and unions — have a lot of work to do. They first must acknowledge the problem and their responsibility to address it.

“We hope that this most recent NAWIC Report will encourage construction and infrastructure companies to stop, reflect and act on how the industry is perceived by people outside it — including the women it hopes to recruit, their families and their educators.”

To learn more about NAWIC, the IWD Scholarship or to download a copy of Dr Phillippa Carnemolla’s report

Girls’ Perceptions of the Construction Industry: Building a Picture of who isn’t Interested in a Career in Construction and Why, visit nawic.com.au.

INDUSTRY INSIGHTS www.infrastructuremagazine.com.au June 2019 // Issue 11 25

ELECTION 2019: WHAT ROLE DID INFRASTRUCTURE PLAY AND WHAT DOES THE RESULT MEAN FOR THE SECTOR?

By Kim Ho, Journalist, Infrastructure Magazine

The Liberal-National Coalition, led by Scott Morrison, has won the 2019 Federal Election. Having campaigned on strategic infrastructure investments, the question arises: what role did infrastructure play in the outcome of the election, and what does a Coalition victory mean for the sector going forward?

In a fiercely fought election campaign, the Federal Government and Opposition both ran on platforms of job creation and economic security. Infrastructure was often at the forefront of debate, with discussions around planning for growing urban populations and the underutilised potential of Australia’s regions.

The Liberal-National Coalition’s victory can perhaps be attributed to its 2019–20 Budget, founded on the exciting promise of $100 billion in infrastructure investment. Whether it can deliver on that promise over its next term will be the next test for the Morrison Government.

A BUDGET FULL OF POLICY… BUT NOT JUST YET

So what role did infrastructure play in determining this outcome? For a start, the Budget gave the Coalition a chance to launch its re-election campaign with a detailed vision of Australia’s future.

Crucially, however, the Federal Government did not commit to implementing this suite of investments immediately. Only a small percentage of funds will be made available for projects like the Melbourne-Geelong Rail Link in early forward estimates.

The Coalition leveraged the Budget to articulate a clear narrative around how its transport infrastructure investments would kill two birds with one stone, easing urban congestion and overpopulation, and helping struggling regional economies.

This dual commitment was reflected in its cabinet, having portfolios for both Infrastructure and Regional Development, held by Nationals Leader, Michael McCormack, and for Cities,

Urban Infrastructure and Population, held by Alan Tudge. By placing their investments as part of a broader picture, the Federal Government was able to make a case for why their investments might be necessary.

QUEENSLAND: THE DECIDING STATE

It is clear that Queensland’s rejection of Labor was instrumental in returning the Morrison Government to power. And with Queensland receiving $4 billion in infrastructure funding in the Coalition’s Budget, the second-best funded state, it is tempting to put this down to strategically-placed election promises.

And with funding announcements in Queensland well before the Budget was released or the election was announced, it appears the Federal Government began its election campaign early.

June 2019 // Issue 11 www.infrastructuremagazine.com.au

INDUSTRY INSIGHTS 26

In the months leading up to the April Budget announcement, the Federal Government announced a swathe of transport infrastructure projects across the state. These included:

♦ Millions of upgrades for the Warrego Highway, Lindsey Highway, Carnavon Highway and Bruce Highway

♦ Over a billion dollars for transport projects through the Northern Australian Infrastructure Fund, which Labor promised to replace

♦ Upgrades to ease congestion in Brisbane, attended by the Prime Minister himself

♦ Major milestones and positive data on Inland Rail, for which Labor announced it would launch an Inquiry

♦ Millions on road safety as part of the Black Spot Program

♦ A City Deal for South East Queensland

♦ $200 million for Townsville’s water infrastructure before its devastating floods

Cumulatively, these projects may have laid the groundwork for Queensland’s swing towards the LNP.

In addition, the Coalition also went hard on water infrastructure, announcing plans to expand the National Water Infrastructure Development Fund, establish a new Future Drought Fund, the North Queensland Water Infrastructure Authority and a National Water Grid.

With Adani’s controversial Carmichael mine’s groundwater management plan getting the green light just in time for the election, Queenslanders may have seen both job security and water security despite major criticism over the project’s environmental impact.

In an election where sustainable planning, renewable energy and zero-emissions vehicles were major topics of debate, swinging a state towards roads and the Adani mine was a remarkable feat.

WHAT DOES A COALITION VICTORY MEAN FOR THE SECTOR?

While the re-elected Federal Government has flexibility to dictate policy in a range of areas, the Budget’s $100 billion infrastructure pledge means that it will be judged on its ability to meet key funding commitments.

Some of the high-profile projects the government has pledged include:

♦ $2 billion Fast Rail Link between Melbourne and Geelong, designed to cut travel times in half to thirty minutes and open up the regional city

♦ $1.6 billion for road and rail infrastructure across Perth and regional Western Australia

♦ $1 billion for upgrades to the Princes Highway over Victoria, NSW and SA

♦ $1.14 billion to the Suburban Roads Upgrades in Melbourne, designed to reduce congestion on suburban arterial roads in south-eastern and northern areas of the city

♦ An additional $1 billion for the Roads to Recovery program

♦ $3.5 billion for Stage 1 of the Western Sydney North South Rail Link

♦ $3 billion for the second round of Urban Congestion Fund (including a Commuter Car Parking Fund)

♦ $1.5 billion for the North-South Corridor in South Australia

♦ $550 million for the Black Spot Program, which delivers vehicle safety infrastructure at high-risk areas and crash spots

♦ An additional $275 million each for the Heavy Vehicle Safety and Productivity Program, and the Bridges Renewal Program

♦ Funding for the National Heavy Vehicle Regulator

The Federal Government has also pledged to establish the following authorities and bodies:

♦ A national Office of Road Safety

♦ A Road Safety Innovation Fund

♦ A freight data hub

♦ A National Faster Rail Agency to identify and support the development of fast rail connections between capital cities and key regional centres

♦ A National Water Grid to deliver strategic planning and water management for water policy and water infrastructure across Australia

INFRASTRUCTURE TO REMAIN A KEY POLICY ISSUE

Questions still swirl around the future of Australian infrastructure. Without federal support, the Victorian Government is facing a $10 billion hole in its budget for the Suburban Rail Loop in Melbourne. At the same time, Federal Treasurer, Josh Frydenberg, has already suggested that his government will be prepared to wholly fund the controversial East-West Link road to encourage concurrent construction with the North-East Link road.

Labor’s major policy proposal to provide $1 billion to begin securing the corridor for a High Speed Rail Link between Brisbane and Sydney also appears to be shelved indefinitely. It is also unclear whether there will be a Federal Inquiry into Inland Rail.

Nevertheless, with Shadow Minister for Infrastructure, Transport, Cities and Regional Development, Anthony Albanese, being a strong contender for Labor leadership, it is highly likely that infrastructure will continue to be a battleground of federal policy in the years ahead.

www.infrastructuremagazine.com.au June 2019 // Issue 11 INDUSTRY INSIGHTS 27

GETTING ASSET MANAGEMENT RIGHT: A NEW FRAMEWORK

by Rami Affan, Executive Director, Asset Management, Infrastructure NSW

The management and use of NSW’s assets must become smarter, more productive and efficient to manage the upward pressure on maintenance requirements and expenditure, and the 2018 NSW State Infrastructure Strategy has recommendations for how best to do this.

The 2018 NSW State Infrastructure Strategy recommendations demonstrate the critical asset management response by the NSW Government, which currently manages assets worth more than $340 billion, to the challenges of population growth, climate change, expectations of level of service offered by infrastructure and the age profile of assets.

A strong asset management framework is critical to extract maximum benefit from the asset portfolio of NSW and to ensure that the state’s infrastructure spending remains sustainable to meet future service demand.

This article outlines the whole of NSW Government approach, as led by Infrastructure NSW, to develop a new modern NSW Asset Management Framework that is focused on improving the asset management capability and accountability of the NSW public sector. This approach was in response to the anticipated challenges of population growth, climate change, expectations of level of service offered by infrastructure and the age profile of assets as outlined in the NSW State Infrastructure Strategy 2018–2038

THE NEED FOR CHANGE

In February 2018, the State Infrastructure Strategy 2018–2038 (Infrastructure NSW, 2018) was released. This strategy set out a 20–year vision for the state to have the right infrastructure in the right places, that is well managed and put to good use, boosting productivity, global competitiveness and improving the quality of people’s lives.

NSW currently has the largest state infrastructure investment program in the nation (over $87 billion from 2018/19 to 2021/22), supported by the strongest state economy in Australia (NSW Treasury, 2018). Unlike prior state infrastructure strategies, this strategy looked beyond existing infrastructure needs.

The recommendations in the State Infrastructure Strategy 2018–2038 identify investment and policy priorities that are

achievable, affordable, and that deliver the highest economic, employment and liveability benefits to the people of NSW.

This strategy is less about a recommended list of projects — NSW already has a healthy pipeline of capital works — and more a set of policies and strategies required to make more efficient use of existing and new infrastructure with a focus on optimising efficiency, better asset management and managing peak demands while delivering essential infrastructure in the most cost-efficient way.

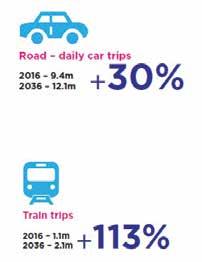

As outlined in the State Infrastructure Strategy 2018–2038, the demand for infrastructure to meet growth is increasing, but governments alone cannot afford to build its way out of demand. Population growth, climate change and increasing service expectations (as shown in Figure 1) offered by infrastructure are placing risks on asset performance and the NSW economy, which is forecast to grow from $539 billion today to $1.4 trillion by 2056.

years (Infrastructure NSW, 2018).

In response to these challenges, the State Infrastructure Strategy 2018–2038 makes recommendations for the NSW Government to introduce an asset management policy that includes a new assurance model managed by Infrastructure NSW by the end of 2018 to transition NSW state agencies into a new asset management framework in line with modern accepted asset management standards and practices.

At the 2018–19 NSW State Budget (NSW Treasury, 2018), an anticipated growth of 22 per cent in assets from the significant

June 2019 // Issue 11 www.infrastructuremagazine.com.au

28 ASSET MANAGEMENT

Figure 1 – Forecast of demand on services in the next 20

level of investment noted previously by 2022, is placing significant pressure on maintenance funding. In addition, the current age profile of assets and service expectations is placing significant upward pressure on maintenance requirements and expenditure in the near term.

Further compounding these challenges is the current asset management capability in the NSW public sector and industry. In April 2018, the Asset Management Council of Australia (Asset Management Council, 2018) surveyed a cross section of organisations from a variety of industries throughout Australia and determined that the state of asset management capability within the industry remains a current challenge across Australia, as summarised in Figure 2.

agencies was a significant lack of investment in their asset management capabilities.

In response to these challenges, and the asset management recommendations contained in the State Infrastructure Strategy 2018–2038, a new Asset Management Policy for the NSW public sector is being developed by Infrastructure NSW in collaboration with NSW Treasury and in consultation with NSW state agencies. The NSW Asset Management Policy is designed to achieve a consistent approach to parts of the asset management cycle across the NSW public sector in line with industry accepted asset management standards, enabling agencies to:

Without the right kind of investment in asset management capability and improved efficiencies in the NSW public sector we may end up in a very similar situation to the US. During my time consulting in the US across various states and cities, I encountered many public sector agencies without visibility of their asset portfolio and limited understanding of asset risks and challenges in service delivery, as summarised in Figure 3. The one common thread within these US public sector