SANY introduces 40 TONNE BATTERY

TELE

FEATURES FUTURE PROOFING MCPHAN CRANE AND TRANSPORT FRANNA MAC25 ENHANCED SAFETY FEATURES SMITHBRIDGE GROUP AND VISUAL DISPATCH SCHEDULING SOFTWARE ia e ia artner THE DEDICATED RESOURCE FOR THE CRANE INDUSTRY / MAY 2024 INSIDE

ELECTRIC

CRAWLER

Withover30years’experience, UAAisthelargestandmost reputablespecialistmobile plantandmachineryinsurerin Australia,NewZealandand globally.

Ourinsuranceproducts aretailoredtoproducea handcraftedsolutionto meetyourbusinessneeds

TheUAAGrouphasthe knowledge,abilityandcapacity toinsureawidevarietyofplant andmachineryspanning numerousindustries.

Ourexperiencedclaimsteam hasaccesstoanetworkofthe verybestexpertindustry repairers,assessorsand suppliers.

EXPERTSINMOBILE

FormoreinformationonUAA’sIndustrialSpecialPlantandProcon products,pleasecontactyourInsuranceBrokerorvisitwww.uaa.com IndustrialSpecialPlantandProConunderwrittenbyQBEInsurance(Australia)Limited. ABN78003191035,AFSL239545. UnderwritingAgenciesofAustraliaPtyLtd.ABN86003565302AFSLicence238517. UnderwritingAgenciesofNewZealandLimited(UAA).4758199,NZBN:9429040999678. J6663

PLANTINSURANCE

IN THIS ISSUE

6 Sany & Tutt Bryant

Tutt Bryant Equipment introduces new Sany 40-tonne capacity battery electric telecrawler.

10 CICA Queensland Chair report Report on the recent Branch meeting in Gladstone.

12 CICA ISO Changes

David Solomon highlights how SO45004 OH&S Performance Evaluation recently received overwhelming approval.

14 CICA P

McPhan Crane and Transport is planning for the future.

18 Holding Redlich

Holding Redlich examines the importance of companies complying with their duty of care.

23 Baden Davis Crane Connection

Andrew Whyte joins The Baden Davis Crane Connection.

26 Franna

North East Link crane operator, Shauna Burgess, discusses the enhanced safety features on her Franna MAC25.

29 UAA

UAA explores the sharp increase in the theft of construction equipment.

Between Hook & Load features

33 LEEA

LEEA’s Justin Boehm goes in depth on workplace safety while also providing a preview of LiftEx 2024.

36 Ropes Technology

Rope Technology Corporation’s capabilities for the crane sector.

39 Modulift

The global spreader beam manufacturer has launched a new, shackle-free design.

40 Visual Dispatch

Smithbridge Group CEO, Oliver artin e a orates on the e ien ies induced by the Visual Dispatch scheduling software.

43 Potain new tower rane s e ifi a targeting Southern Hemisphere markets has been launched.

45 Mammoet

See how the global heavy lifting powerhouse completed a complicated ball mill exchange at an Australian refiner

47 Tadano

Adelaide’s Urban Cranes increases its capabilities with a new Tadano.

TIDD pick and carry proves a gem for Emerald Carrying Company.

Pace Cranes

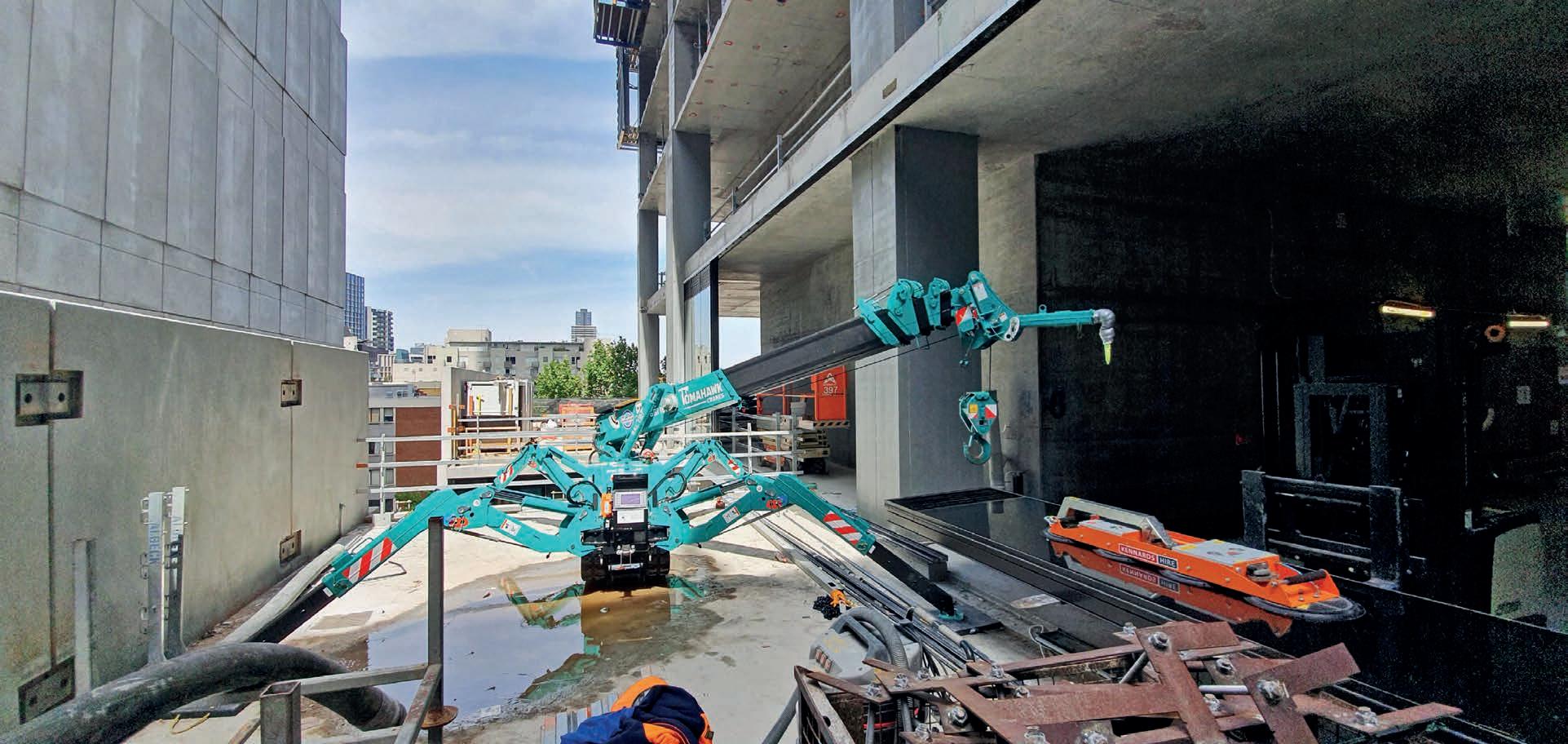

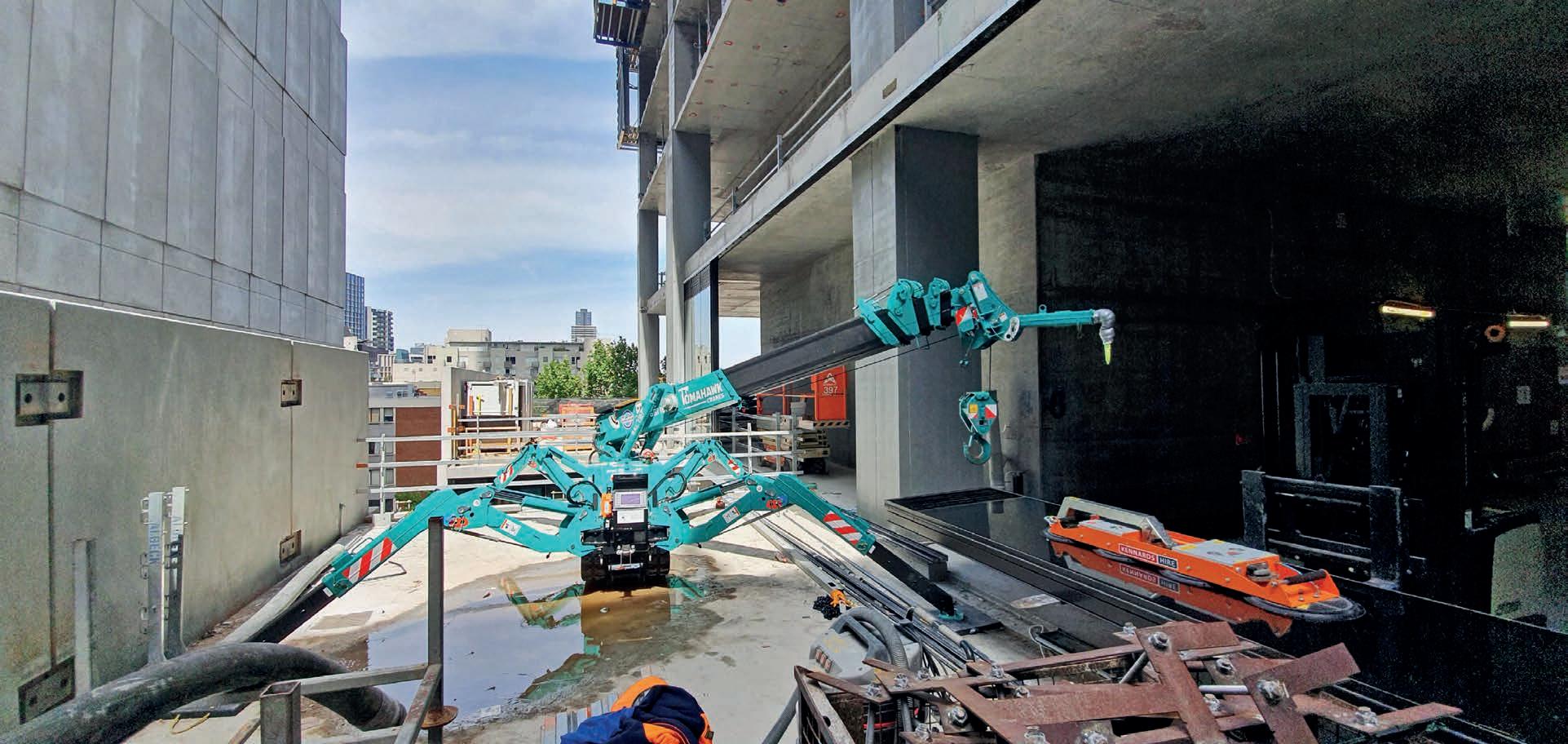

Tomahawk Cranes sharpen services with battery electric Maeda.

XCMG

The global crane manufacturer has broken its own world record for a seventh time.

Grove

Fleurieu Cranes hails Grove as great taxi crane.

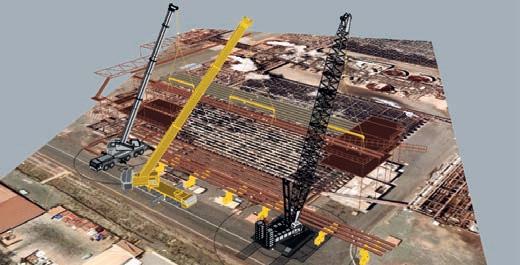

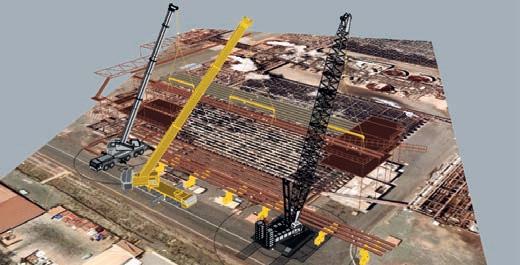

Tandem lifts on the Level Crossing Removal Project.

Cranepower

Cranepower’s game changing tower crane power.

Tutt Bryant

QWEST delighted with the performance from Tutt Bryant Equipment and Sany.

Gleason Cranes

The Australian crane dealer has made a signifi ant mo e to e an its resen e in Australia’s west.

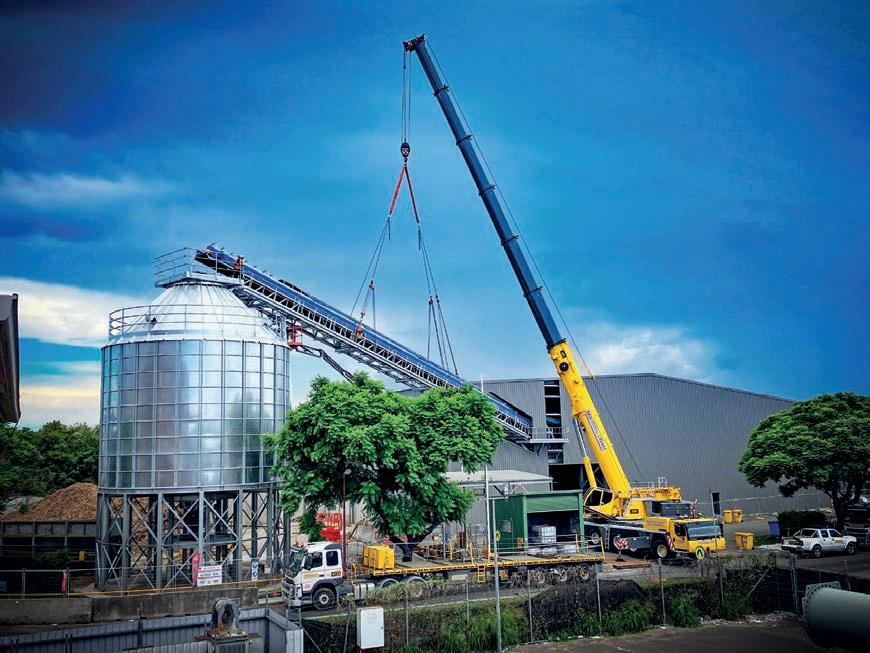

70 Lift of the Month

What our industry does best.

Cranes and Lifting Magazine cranes_and_lifting Cranes and Lifting SCAN THE QR CODE TO SUBSCRIBE TO OUR NEWSLETTER 62

May 2024 CAL / 3 www.cranesandlifting.com.au 40

SCX2800A-3

STAGE IV / Tier 4f

The SCX2800A-3 is engineered for versatility across various job sites. It features a robust winch that ensures stable operations, and its ‘Eco winch mode’ enhances efficiency in operations while optimising energy use. Crafted with innovative design principles for simplified use, it also offers options like wide shoes and specifications for reduced counterweight, making its highperformance lifting capacity of 275 tons perfectly suited for constructing the future.

tuttbryant.com.au 1300 658 888 Follow us on: BRISBANE | SYDNEY | MELBOURNE | ADELAIDE | PERTH Peter Lawgall (NSW, ACT, QLD, NT) Daniel Avard (WA) 0411 256 388 0419 099 835 Peter.Lawgall@tuttbryant.com.au Daniel.Avard@tuttbryant.com.au Philip Chadwick (SA, VIC, TAS) 0457 510 097Philip.Chadwick@tuttbryant.com.au

Engine - CUMMINS QSL9 TIER 4f Capacity at Full Reach - 1.5t x 78.3m Max Lift Capacity - 275t x 4.3m Max Boom Length - 91.45m Precise Swing Operation

FROM THE EDITORIAL TEAM

Published by:

WELCOME TO THE MAY ISSUE OF CRANESANDLIFTING

POSITIVE ROLES EXIST FOR ARTIFICIAL intelligence (AI) in cons uc on.

Ar cial intelligence (AI) has already made its way into many indus ies, including cons uc on, and the crane indus y will be no excep on. AI will play a signi cant role in the advancement of technology and in growing demand for safe and e ciency in crane opera ons.

Predic ve maintenance is one of the most promising areas for AI in the crane indus y. By analysing data om sensors and other sources, AI algorithms can predict when components are likely to fail, allowing for proac ve maintenance and reducing down me. is can result in signi cant cost savings and improved safe , as well as improved equipment reliabili and lifespan.

AI will also have a focal role to play in autonomous crane opera ons. Although not quite here yet, autonomous cranes will be equipped with sensors and cameras that will allow them to navigate and operate independently, without the need for human interven on. is can improve safe by reducing the risk of accidents and injuries, as well as increasing e ciency by reducing the me needed for crane opera ons.

AI can also be used to op mise crane opera ons by analysing data on factors such as wind speed, load weight and environmental condi ons. By taking these factors into

account, AI algorithms can recommend op mal crane con gura ons and opera onal procedures, improving e ciency and safe .

One of the biggest concerns is the poten al for AI to replace human workers, which could lead to job losses and other nega ve impacts. Addi onally, there is the risk of AI malfunc on or failure, which could result in accidents or other safe issues.

Overall, while there are certainly some risks and challenges associated with AI in the crane indus y, the poten al bene ts are signi cant. With the right precau ons and safeguards in place, AI has the poten al to revolu onise crane opera ons, improving safe , e ciency, and produc vi in the indus y. It will be interes ng to see what new AI technologies will enter the crane indus y in the coming years and how they will impact crane opera ons.

As always, the team at Cranes and Li ng is delighted to bring you the latest developments om our indus y and we hope you enjoy the read.

Simon Gould Editor, Cranes and Li ng

Simon Gould Editor, Cranes and Li ng

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO John Murphy E: john.murphy@primecreative.com.au

C Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor Andrew Hobbs E: andrew.hobbs@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Assistant Editor

Jack Alfonso E: jack.alfonso@primecreative.com.au

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

C M

Glenn Delaney E: glenn.delaney@primecreative.com.au

A D Bea Barthelson

Imaging Assistant Paul Breen

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

Images: Ryan Said/Shutterstock.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

May 2024 CAL / 5 www.cranesandlifting.com.au

SANY’S 40 TONNE BATTERY ELECTRIC TELE CRAWLER ARRIVES DOWN UNDER

THE CC 00T -E I A ATTERY E ECTRIC powered telescopic crawler with a li ing capaci of 40t.

e new ba ery elec ic crane is based on the highly popular telescopic crawler range om Sany but the diesel engine is replaced by an elec ic opera ng system capable of retaining the high level performance of the diesel powered version.

e SCC400TB-EV has a maximum boom length of 44m with an op onal jib length of 16m. e boom is made of a highs ength steel s ucture with a U-shape sec on area. It features ve sec ons, of which the basic boom is 11.3m. It also features a dual cylinder, full power rope row for telescoping.

e SCC400TB-EV includes a number of features designed to provide safe and reliable opera on whilst reducing maintenance costs. e ba ery elec ic telescopic crawler is equipped with the Danfoss EM-PM1375-T1100-1500 motor, with peak power up to 336kW and a dual motor con oller, which can provide torque of up to 2,500Nm.

e SCC400TB-EV is also equipped with a 210kWh lithium iron phosphate ba ery (LFP ba ery), which is capable of managing eight hours of opera on, depending on the work required on site. TBHL&S avelled to Sany China and physically tested the rst SCC400TB-EV to ensure that adver sed ba ery life was possible. e crane actually ran for 10 hours during tes ng on one charge. e BMS intelligent piping system monitors the ba ery voltage and temperature in real me, and the ba ery interior is made om VO-grade re-proof material.

For the launch of the SCC400TBEV, Sany has developed the SYIC-III

UP FRONT / SANY BATTERY ELECTRIC CRAWLERS 6 / CAL May 2024 www.cranesandlifting.com.au

T HL

T HL S .

S T H L S

S SCC T EV . S

Images Prime Creative Media

The SCC400TBEV features an intelligent work environment for the operator.

Integrated Con ol System that is designed to deliver high levels of integra on, precise opera on and reliable levels of crane operabili .

e ba ery power system includes a main con ol and a slave con ol in each ba ery pack and these adopt a ‘daisy-chain communica on’ to achieve the required levels of power in real me and e cient ba ery system data acquisi on and con ol.

e vector con ol drive motor system achieves high precision con ol of motor output and prevents overload, overhea ng, short circui ng and over-voltage protec on as well as other safe func ons.

e SCC400TB-EV Con ol System manages the ba ery system, the drive motor and power supply systems, main con ol, torque limiter, auxiliary and safe monitoring systems.

ese include a high voltage safe design system that protect against elec ical leakage. e high voltage systems on the crane have real- me insula on monitoring func ons that are able to cut o circuits should a sudden elec ic leakage occur.

e boom hoist mechanism on SCC400TB-EV features a dual-ac ng single piston hydraulic cylinder, with a safe balance valve and a lu ng angle of between 1.5 and80 degrees. e cylinder allows lu ng down through self-weight to reduce energy consump on and increase the stabili of lu ng down opera on.

e swing mechanism adopts a wet swing brake that is a spring loaded. It is normally a closed brake with braking provided through a spring force. e swing system is equipped with an integrated swing bu er valve that has a ee slipping func on. is assists with a steady start and con ol of an excellent inching func on.

e unique swing bu er design and steady brake provide an external gear swing drive with a 360 degree swing range, a maximum swing speed of two revolu ons per minute and maximum drive pressure reaching 20MPa. e swing lock cylinder device ensures the upperworks are locked in four direc ons a er the work is done or during ansport.

e counterweights are designed

The SCC400TB-EV has a maximum boom length of 44m with an optional jib length of 16m.

“The SCC400TB-EV is also equipped with a 210kWh lithium iron phosphate battery (LFP battery), which is capable of managing eight hours of operation, depending on the work required on site.”

May 2024 CAL / 7 www.cranesandlifting.com.au

The SCC400TB-EV Control System manages the battery system, the drive motor and power supply systems, main control, torque limiter, auxiliary and safety monitoring systems.

into blocks for self-assembly and easier ansport. e rear counterweight totals 13t and is capable of self-assembly.

e upper works of the crane features a high-s ength steel weld amework, with no torsion or deforma on. e parts are set out in a manner that makes maintenance and service easier. TBHL&S ansports the SCE400TB-EV as a complete unit without the need of support ucks.

e SCC400TB-EV features an intelligent work environment for the operator.

e integrated Load Moment Indica on (LMI) Con ol System is standard, and it is calibra on- ee. It ensures the safe opera on of the crane and improves the crane’s produc vi and e ciency.

e LMI system can automa cally detect the weight of the load, the working radius and boom angle and compares this with rated load weight and actual load, work radius and boom angle. In normal opera on, the LMI con ol system will make judgments and cut o opera ons if the crane is headed beyond its designed

capaci es. It also acts as black box to record overload informa on.

Over-release protec on device of the main/auxiliary winch features a threewrap protector installed on the main and auxiliary load hoist winches to prevent an over-release of wire rope. When the rope is paid out close to the last three wraps, the limit switch is ac oned, and the system sends an audible alarm as well as a displayed alarm on the ins ument panel, automa cally cu ng o the winch ac on.

If the func on lock level is not in the work posi on, all other handles won’t work, which prevents any misopera on caused by accidental collision. e elec ical swing lock will only allow swing ac on when the lock is released, so as to prevent any opera onal error and ensure the safe of the operator and those working close to the crane.

e remote monitoring system is standardised, providing func ons like GPS loca ng, GPRS data ansfer, machine status inquiry and sta s cs, monitoring of opera onal data and remote analysis and

remote diagnosis of failures.

e load indica on panel features three colours – green, yellow, and red – and these indicate the posi on of the load in real- me. When the actual load is less than 90 per cent of the rated load, the green light remains on.

When the actual load is between 90 and 100 per cent of the rated load, the yellow light switches on, the alarm light ashes and sends out intermi ent sirens. If the actual load reaches 100 per cent of rated load, the red light switches on, the alarm light ashes and the emits con nuous sirens. Should the actual load reach 102 per cent of rated load, the system will automa cally cut o the crane’s opera on. e display screen in the cab can then display the ba ery’s state of charge (SOC), power ba ery voltage, power ba ery charge and discharge. It can also display the instantaneous power of the driving motor, charging mark, li ing weight and boom angle, as well as other working parameters and numbers rela ng to the working status of the crane.

UP FRONT / SANY BATTERY ELECTRIC CRAWLERS 8 / CAL May 2024 www.cranesandlifting.com.au

ENGINES/ GEARBOXES DIFFERENTIALS/ TRANSFER CASES BARE/GLAZED CABS UPPER AND LOWER SERVICE EXCHANGE HYDRAULIC CYLINDERS BOOM SECTIONS/ FLYJIBS BEN BADEN SERVICES PTY LTD | PH (02) 9679 8333 | 43 HOLBECHE ROAD ARNDELL PARK 2148 MECHANICAL STRUCTURAL PAINTING MACHINING AND LINE BORING ENGINE AND TRANSMISSION OVERHAULS CASAR WIRE ROPE DISTRIBUTOR

SERVICES NO DOWNTIME! MOBILE CRANE REPAIRS COMPONENTS EXCHANGE PROGRAM DRY HIRE AVAILABLE WHILE YOUR CRANE IS BEING REPAIRED!

BEN BADEN

QLD BRANCH CHAIR UPDATE

Our recent Queensland Branch meeting in Gladstone provided a crucial platform for industry stakeholders to discuss the developments shaping the industry in our region.

WE HAD GUEST PRESENTATIONS FROM the Department of State Development & In as ucture, the Department of Transport and Main Roads, updates on road access ac vi es and new announcements for members locally and across the coun y.

DEPARTMENT

OF STATE DEVELOPMENT & INFRASTRUCTURE GUEST

PRESENTATION

Geo Kerr om the Department of State Development & In as ucture came in as a guest speaker to present on the Gladstone Engineering Alliance (GEA). e GEA was established in 2003 with the goal of enhancing collabora on within the Gladstone Region’s indus y supply chain among major indus y, GEA members and investors. Kerr highlighted the development of the CQ Renewable Energy integrated indus ial precinct and the resul ng posi ve e ects on Gladstone. He s essed the importance of sharing informa on throughout Aus alia and spoke on the increasing size of wind turbines. Kerr also in oduced ‘Gladstone Connects,’ a pla orm aimed at facilita ng connec ons between buyers and suppliers based on their capabili es and needs, with an emphasis on showcasing available resources and iden fying areas for partnerships with local businesses. He also emphasised the necessi of business regis a on in Gladstone and announced an upcoming Supply Day event.

PRESENTATION FROM THE DEPARTMENT OF TRANSPORT AND MAIN ROADS

Mandy Haldane, Russell Hoelzl, and George Haddad om the Department of Transport and Main Roads spoke on the Na onal Automated Access System (NAAS) during the branch mee ng. eir discussion cen ed on its applicabili to heavy vehicles throughout Aus alia and New Zealand, aiming to reduce permits by 90 per cent over ve years. e NAAS is designed to expedite decision-making processes

for Road Managers while enhancing ansparency, drawing upon the successful implementa on of the HVAMs system in Tasmania. As part of its adapta on for Queensland, the system can accommodate alternate vehicle con gura ons to devise tailored access solu ons, par cularly crucial given the challenges posed by the aging bridge network which is primarily designed for 3-axle ucks. e presenta on showcased the s eamlined process for obtaining special access permits through the TMR portal, involving assessments by engineers to determine speci c routes. e mee ng also highlighted the engagement of Aus alian crane manufacturer representa ves in a European road managers tour. A followup mee ng was scheduled to sustain collabora ve e orts, with the notable endorsement om the Brisbane Ci Council for the HVAMs ini a ve.

ROADS UPDATE

Damien Hense and Alice Edwards om CICA provided a comprehensive Roads Update during the branch mee ng. ey highlighted manufacturers’ prepara ons for impending changes to import requirements e ec ve July 1st, 2024, with a focus on the applicabili of all ADRs and exhaust emission standards.

A en on was drawn to the signi cance of comple ng paperwork for second-hand cranes before the deadline, especially given the an cipated ease of procuring European cranes post-July 1. e update also included insights into Queensland Transport and Main Roads (TMR) ac vi es, par cularly the ansi on of NHVR compliance and enforcement scheduled for April 20, 2024. is has been ten years in the making. To cope with the increase in heavy vehicle regulatory services delivered, the NHVR will create a new department within its Opera ons Division, the Northern Region. e new region will join the Cen al and

Southern teams and will see the crea on of 165 new roles that will mostly be lled by sta om the TMR.

Queensland is the sixth Aus alian jurisdic on – a er South Aus alia, Tasmania, the ACT, Victoria, and New South Wales – where the NHVR will be directly delivering heavy vehicle regulatory services.

e comple on of over 3070 bridge assessments under IAP 1 & 2 was highlighted, alongside prepara ons for the implementa on of the HVAMS system. e presenta on emphasised the role of CICA in local government spaces, par cularly concerning the analysis of NHVR portals and engagement with TMR dis icts. e discussion then shi ed to the Na onal Automated Access System (NAAS) and its role in enhancing safe and produc vi under the Heavy Vehicle Na onal Law (HVNL).

MEMBERSHIP & NATIONAL UPDATE

Paul Arztenhofer om CICA presented the Membership & Na onal Update during the branch mee ng. Various ini a ves were detailed, including the CICA On-Road Ar culated Crane Course, which is o ered ee for members. He also addressed proposed changes to highrisk work licenses, no ng the inten on to grandfather exis ng licenses and the provision of logbooks for rigging and dogging modules, with updates to the Dogging & Rigging Guide forthcoming for members. Another key focus was on the “Start Safe” program aimed at operator safe , emphasising the availabili of resources such as paper versions and uploads, provided ee of charge through the member portal. Arztenhofer encouraged members to reach out for demons a ons of the portal, underscoring CICA’s dedica on to suppor ng its members through accessible aining and resources.

10 / CAL May 2024 www.cranesandlifting.com.au

CICA QLD UPDATE

ANNOUNCEMENTS

e cross-hire agreement was launched on Tuesday March 19, with relevant documents accessible via the member portal.

e Li Supervisor Course was scheduled for July 10 and 11 in Brisbane, with regis a on details available on the CICA website.

Plans were also unveiled for the Women’s Leadership and Development Program, and the Emerging Leaders Development Program which is slated to commence in July 2024.

NATIONA REFERENCE RO P NR

e branch mee ng concluded with insights om the Na onal Reference Group (NRG), presented by Steve Gonano om the CICA QLD Steering Commi ee. Gonano highlighted a presenta on by organisa onal psychologist Fiana Wei, focusing on psychological hazards and risks within the workplace, underscoring the importance of addressing common issues such as s ess and management problems to ensure employee well-being. Discussions cen ed on road access challenges and poten al elec ical interference a ec ng cranes, with prepara ons underway for developing s ategies to mi gate risks associated with lightning s ikes. Finally, in the General Business segment, it was announced that the Mobile Crane Code of Prac ce will be ge ng the Ministerial sign o and is set to be released between August and September, signalling ongoing e orts to uphold indus y standards and safe protocols. is has been a very long process that started before COVID-19. We thank the subcommi ee for all their hard work, but a special thanks to Launa Williams for her dedica on and persistence that meant we could achieve the outcome that we have.

Mick Messer

Ac ng Chair, Queensland Branch

NE MEE IN E EN

• 8th May – Branch Meeting at Colmslie Hotel at 5pm

• 7th June – Industry Day at Pullman Brisbane King George Square at 10.30am – 4.30pm

• 23rd August – nn a ran h eeting a e ranes Unit 1 / 1326 Boundary Road Wacol at 5pm

• 17 – 19th October – ationa on eren e Adelaide

• 7th November – Branch Meeting at 5pm

• 29th November – Christmas Party at 6.30PM

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch hie e ti e er

03 8320 0444 0428 228 048

ceo@cica.com.au

Paul Arztenhofer

Membership Engagement/ Business Development Specialist 04 9093 9274 paul@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran CraneSafe and CrewSafe Technical Advisor 0488 004 274 pat@cranesafe.com.au

Damien Hense

CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant/ Board Secretariat 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship Coordinator 0491 047 118 Kate@cica.com.au

Shane Coupe CraneSafe & CrewSafe ministrati e ssistant er shane@cica.com.au 0491 047 134

Madeleine Flynn Senior Marketing omm ni ations er madeleine@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626 justina@cica.com.au

Ashleigh Gould e erations oor inator ashleigh@cica.com.au 03 8320 0466

nit e ia a e Mulgrave Vic 3170

Phone: 03 9501 0078 Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our CICA

May 2024 CAL / 11 www.cranesandlifting.com.au

Article by:

ISO OH&S EVALUATION RECEIVES RESOUNDING APPROVAL

ISO 45004-Ocupational Health and Safety Performance Evaluation received 98 per cent international approval rating.

David W Solomon FISQEM, CMSS, M A NS E O S H T R

Convenor ISO TC283 WG4 OH&S Performance Evaluation

ON FEBRUARY 13, 2024, THE interna onal Technical Commi ee (ISO TC 283) responsible for the design and development of ISO 45004:2024 OH&S Performance Evalua on, reported that the FDIS ballot yielded 54/55 suppor ng votes, equa ng to a very s ong 98 per cent interna onal ballot approval. ISO advised this new Standard would be published March 14, 2024.

ISO 45004:2024 is intended to help organisa ons to e ec vely monitor, measure, analyse and evaluate occupa onal health and safe (OH&S) performance. OH&S performance evalua on includes the processes that the organisa on uses to assess the adequacy of ac vi es that are expected to achieve intended results. OH&S performance is normally evaluated by using a combina on of processes and sources of informa on such as incident inves ga ons, inspec ons, audits, qualita ve and quan ta ve indicators, culture surveys and interviews.

BACKGROUND

ISO TC 283 is also the interna onal commi ee responsible for Occupa onal Health and Safe Management. ISO TC 283 held a mee ng in Trinidad & Tobago in 2015 for the ongoing development of ISO 45001:20181 OH&S Management Systems. During that mee ng the Head of the Swedish delega on started a conversa on about

Posi ve Performance Indicators. is was put on hold un l ISO 45001 was published March 12, 2018.

MBA LEADS DEVELOPMENT OF NEW INTERNATIONAL STANDARD

MBA NSW Execu ve O cer Safe Housing Technical & Risk, David Solomon (Aus alia’s Interna onal Head of Delega on) was nominated as the Co-Convenor of ISO TC283 Working Group 4 responsible for the development of ISO 45004:2024 by Standards Aus alia Na onal OH&S Commi ee (SF-001). Being a Co-Convenor as opposed to a sole Convenor provides the opportuni to undertake two roles, a) to convene mee ngs and b) posi vely con ibute towards the development of ISO 45004:2024 content, represen ng

not want Aus alia to have an unfair in uence over the dra ing of ISO 45004, hence only some elements om the Na onal dra were included.

GOVERNANCE AND PROGRAM

Working Group 4 is responsible for the development and dra ing of ISO 45004:2024. is ISO project was scheduled to run 36 months, commencing October 2020. ISO TC 283 WG4 currently has 96 par cipants om all over the world. Once the Standard is published the Working Group 4 will disband.

FOCUS AND DETAIL

e aim of ISO 45004:2024 is to shi the focus om Lost Time Injuries (LTIs) to help businesses consider

the views of Standards Aus alia SF001. Canada was the other nominated Co-Convenor.

THE NATIONAL COMMITTEE

Standards Aus alia OH&S Management Commi ee SF-001 (Chaired by David Solomon) dra ed its own Na onal Standard that was considered for the working dra of ISO 45004:2024. SF-001 used the Hudson Maturi Model2 with the X and Y axis targe ng requirements om ISO 45001:2018 when they dra ed a Na onal Standard. ISO TC 283 did

what daily tasks they are undertaking, how they are going to be measured and what units of measurement will be used to categorise them, so that the data obtained is more balanced and that it supports and re ects the OH&S performance of a building business. While LTIs are s ll relevant, they are a re ospec ve form of measurement and are s ll retained in the Standard. e Na onal Standards Aus alia OH&S Commi ee SF-001 saw the need to broaden the scope of the exis ng LTI Standard 1885.1:1990 Workplace Injury and Disease Recording Standard

12 / CAL May 2024 www.cranesandlifting.com.au

ISO

CICA ISO OH&S UPDATE

.

to include all the posi ve things that a business does, that should be considered and if e ec ve, relied on as a posi ve performance indicator.

A er all it is SF-001’s raison d’e e, to ensure the Standards that Aus alia is guided by are contemporary and t for purpose. Notwithstanding, AS 1885.1 was subsequently withdrawn as it was dated and possibly had too narrow a focus. Given that a new interna onal standard of OH&S measurement was in ain that not only captured LTIs and a orded much more, the decision was also unanimous to support the development of ISO 45004 OH&S Performance Evalua on as a more suitable replacement.

45004 can be used by organisa ons of all pes, regardless of whether they have implemented a formal OH&S management system (see ISO 45001:2018 and ISO 45002:2022). What ISO 45004:2024 provides is examples that demons ate how to evaluate performance to drive con nuous improvement and support the organisa on in achieving its intended results. ISO 45004:2024 recommends a balanced approach, based on selec on of performance evalua on processes and indicators, with emphasis on proac ve (leading) OH&S performance indicators. It recognises that over-emphasis on past performance (lagging) indicators, such as incidence and equency rates, can undermine e orts to improve OH&S performance.

As every organisa on is unique, and intended results vary, there is not a standardised set of performance evalua on processes or set of indicators that ful l the needs of all organisa ons. erefore, every organisa on has to iden fy performance evalua on processes and indicators to suit its own speci c needs.

E ec ve performance evalua on can help the organisa on to demons ate con nual improvement, and therefore may need to be adjusted when the organisa on’s performance changes. E ec veness is the result of selec ng the appropriate performance evalua on

processes and properly implemen ng them. When performance evalua on processes are used inappropriately (e.g. in a way that is perceived to blame individuals for system de ciencies), they can produce unintended consequences. e most common of these consequences are addressed in ISO 45004:2024.

SUMMARY

If we use car insurance as an analogy, when applying for an insurance policy, one is asked ques ons such as: is your car: parked o s eet? Garaged? Securi system in place? Securi system connected back to base? ose considera ons, if implemented all posi vely con ibute to discounts when insurance premiums are calculated, whereas the Building and Cons uc on Indus y (BCI) must comply with the WHS Act 2011 and WHS Regula on 2017 (speci cally Chapter 6). Yet with all the governance that is complied with, none is considered when measuring a building company’s OH&S performance. Let alone are any posi ve

OH&S performance ac ons into account to balance any non-conformances that a company may have incurred, categorised, measured or determined when assessing whether its OH&S performance is e ec ve or not.

ISO 45004:2024 is designed to complement ISO 45001:2018 by providing performance evalua on approaches that align with requirements of that standard. ISO 45004:2024 OH&S Performance

Evalua on can be used independently, by any organisa on, to improve OH&S performance.

N.B. ISO 45001:20181 OH&S Management

Sys ms is the same document as AS/NZS ISO 45001:2018 OH&S Management

Sys ms with the addi on of an Aus alian Preface and Foreword to provide con xt for the Aus alian workplace environment.

N.B. e Hudson Maturi Model2 plots the development of an organisa on’s safe culture. Each level has dis nct charac ris cs and is a progression om the previous level.

May 2024 CAL / 13 www.cranesandlifting.com.au

Image credit David Solomon.

David Solomon during an ISO meeting in Texas.

MCPHAN’S PLANS FOR THE FUTURE

With new cranes arriving, a planned expansion control business as well as having a training school in the wings, Central Coast business McPhan Cranes and Transport is certainly on the move. Founder Tony McPhan, his son Dré, daughter Lila and new recruit Mick (Phan) Sinderberry explain more.

MICK JOINED THE MCPHANS AT THE END of last year and with 39 years of crane indus y experience under his belt, he has worked for most of the major crane hire businesses in Sydney and Newcastle.

“I was with Wheeler Cranes and had many dealings with the McPhan family previous to and during my tenure. My wife and I moved to the Cen al Coast with an opportuni to have “buy in” into the McPhan’s vision for the future.

“It’s a great opportuni , it’s a good family business with massive poten al and I’m very happy with the move. I’m looking forward to consolida ng and growing the family group as well as con nuing to foster exis ng rela onships with our allies,” said Mick.

“Like most people in the indus y, I started out as a Dogman/Rigger

originally and stuck with that for 12 years. en I moved into the o ce as an allocator and then out on the road as a supervisor, looking at and quo ng jobs. I’m back to doing that again with Tony and the team managing pre-inspec ons, site inspec ons, preparing jobs… that sort of work. Being back out on the road and seeing customers is what I love about the role,” said Mick.

Mick has experienced pre much everything during his long and illus ious career, and he can see the value his experience will bring to the McPhan business.

“ ere are three more cranes coming in the next few months, including a 150t Liebherr all terrain, a Franna MAC25 and an AT40, which is exci ng. With Tony and Dré working on new direc ons,

14 / CAL May 2024 www.cranesandlifting.com.au

Mick (Phan) Sinderberry, Dré, Lila and Tony McPhan.

Prime Creative Media CICA MEMBER PROFILE

Images:

the company will con nue to grow. Tony has in oduced his family into the business, which is great and makes it even more exci ng for me. Young Dré and Lila are excelling in their pivotal roles. I’ll be here for a few years and will help the company grow,” he said.

Dré joined the business a er leaving high school and he is currently studying a double degree in Law and Commerce as well as working in the business full me. He is keen to take the business to the next level and sees Mick’s appointment as an important building block in this process.

“Coming out of high school you never really know what you want to do or where the world’s going to take you, but I am very thankful that I decided to join the family business, it feels like it was fated and meant to be,” said Dré.

“We have a young crew here, especially in the o ce, and we probably lacked a bit of experience and knowledge to fully navigate the crane indus y. We are full of passion and ambi on, but you do need someone who knows the ropes and has helped build businesses om the ground up. Mick is that guy and we have been interested in securing his services for a long me.

“Mick has worked with companies like Wheelers, Borger’s and Adairs so he knows his way around the crane indus y. For young people like Lila and myself he has been absolutely awesome. In today’s world, compliance is the name of the game and having someone that really understands the back end of the cranes, the charts and li plans, his experience has been next level, for the larger projects we are star ng to work on,” he said.

“Originally, Mick’s role was to help with the alloca on side of the business, but he’s come on board and taken on his own role, which is exactly what we wanted. He’s out there every day talking to customers, scoping the work, inspec ng jobs, and he’s doing a really great job. With Mick we know things are ge ng done properly.

“His arrival coincided with my sister Lila star ng in the business and with her burst of energy paired with Mick’s experience, the dynamics at McPhan

Cranes and Transport have increased emendously,” said Dré.

Being a family business is an important mo vator for Dré.

“We pride ourselves on being a family owned and run business. With my Dad, my Grandfather, Lil and myself have a business culture based on family values which to me is more important than money, growth or expansion. To come to work with a smile, face your challenges, enjoy the banter and leave at the end of the day feeling recharged rather than drained; to me that means you’ve already won in life,” said Dré.

Lila goes on to explain why she decided to join the family business.

“I nished my HSC on a Monday in November last year and om the Tuesday I started working in the business full me. Obviously, I’ve been brought up around cranes and I’ve always looked up to my Dad and Brother. Just seeing how hard and relessly they work for

our customers and understanding how rewarding it is seeing the shed emp and knowing the cranes are out working is reward enough. It’s libera ng and I’ve always wanted to have a role and con ibute to the family legacy,” said Lila.

“I’m studying Project Management at Universi and as I study and complete the course I will ansfer the learnings om the degree into the business and help manage projects with our cranes. at’s the end goal,” said Lila.

Dré provides some context around the move into a c con ol and the move north.

“Dad and I were brainstorming for a while about the opportuni es with a c con ol. With the changing business environment, compliance is the word of the day. 10 years ago, you could get away with having a lollipop s ck and crane set up in the middle of the road, but you can’t do anymore,” he said. “Dad and I sat down on a Monday and decided we

May 2024 CAL / 15 www.cranesandlifting.com.au

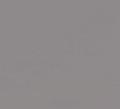

The McPhans are planning to add new cranes to the eet with in str training high on the agenda.

needed to o er our customers a c as part of our service con ol. Literally within a week we had the company registered and signs ordered and now it’s going really well. It’s a service customers appreciate because they can make one phone call and we take care of the rest, including the craneage and a c con ol. Dad and his partner Jelly, myself and Lila all have our ckets con nuing the family’s commitment to the business,” he said.

Dré is excited regarding the arrival of the cranes.

“One of Dad’s superpowers is his abili to take risks and invest in the business. He’s seen Lila and myself join the business and he’s decided to lock himself in and order a 150t capaci crane, which will hopefully arrive during the rst quarter of this year. at crane will open a whole new avenue of opportuni es for us. We’ve also got a couple big Frannas coming to expand the eets’ capabili es, enabling us to keep up with customer demand,” he said.

“Our plans for expansion are largely facilitated by the good rela onships we have built with other crane companies in the indus y. We’ve avoided stepping anyone’s toes, and we’ve focused on building rela onships and helping out other companies,” he said. “We know there are companies in the Hunter Region

looking for Frannas and bigger capaci cranes and we are happy to work in with them as a subcon actor. Our goal is to keep building the rela onships, extend up there, enter a new market which will help with further growth in the business.

Tony explains that aining has played a signi cant role for the business in the past.

“18 years ago, Dad started with an idea for a business primarily designed to upskill our exis ng sta , which is something we really priori se here. We’ve put a lot of our dogmen through their Riggers course, and we’ve o ered that as a way for them to progress in the business.

“We’ve never really been xed on locking people into one posi on and that’s where they are going to stay. Anyone who comes to this sort of family environment is eated like family and any opportuni they wish to pursue, whether it’s ge ng their open crane cket or becoming a Rigger we o er and encourage that growth.

“ e aining school was another way to upskill sta , keep on top of compliance, induc ons, all the necessary ckets but it morphed into its own business where other people were coming here to learn.

“By o ering those kinds of ckets, it brought a new talent pool to the yard,

and we were exposed to more people wan ng to get in the indus y or exis ng people wan ng to upskill. is enabled us to expand our sta , our dogmen, our operators by picking om a good talent pool. We see the new aining school as having a similar impact on the business today,” said Tony.

“Dré and Lila have di erent s les, but they complement each other really well. Sure, they share my ideas, but they’ve adapted the methods and processes that I in oduced and combined them with their own ideas and built on them. at was a major reason for ge ng Mick on board, too. My input is great, but they’re at the point, Dré especially, where he needs other experience to add to his ‘toolbox’.

“Mick brings plen of experience and he is prepared to share this with the team. He built his reputa on with the Adair business which was well-known and highly regarded for the way they did things.

“I’d hope Mick is here into his re rement and then well beyond, because it gives him a chance to put that nal stamp on this crew. He can pass on his knowledge, informa on and experience and I’m sure it will make him proud to see Dré and Lila con nue on with the things he’s been able to share. at will be Mick’s legacy for this family business,” said Tony.

16 / CAL May 2024 www.cranesandlifting.com.au

CICA MEMBER PROFILE

ra ontro is an a itiona ser i e ro i e han rane an rans ort

The New GMK5150XL is the latest sibling of the GMK5150L-1, with longest boom (69m) and most versatile road weights in class

• Reach further with 69m boom and 30m hydraulic luffing fly

• 50t GVM with outriggers in situ for reduced cost legal travel in all Australian states and territories

• 10.2t counterweight in situ at 12t per axle

• Increased safety and flexibility with MAXbase variable outrigger positioning

• Faster, intuitive set-up with CCS (Crane Control System)

• Grove Connect Telematics

• Capacity: 150t

• Main boom: 68.7m pinned*

• Maximum Jib: 30.2m (40O hyd luff)

• Maximum tip height: 99m

New GMK5150XL

MANAGING SAFETY RISKS IN THE WORK PLACE

The steps that a director can take to meet their statutory WHS duty of care has been clearly explained in the recent decision of SafeWork NSW v Miller Logistics Pty Ltd; SafeWork NSW v Mitchell Doble (Miller) . In this article, we examine the decision in Miller in which the director successfully defended charges laid against him with the Court outlining the practical steps that he took to avoid a conviction.

THE DUTY OF CARE

All jurisdic ons in Aus alia, other than Victoria, have adopted the model WHS Act which imposes a primary du of care on a person conduc ng a business or undertaking (PCBU) to take “reasonably prac cable” steps to ensure the safe of its workers and others. To discharge its du , a PCBU must consider and implement reasonably prac cable con ols. In Victoria, the same du is imposed on an employer. Company directors, in their capaci as “o cers” of the PCBU, also have a separate personal du to exercise due diligence to ensure that the PCBU complies with its primary health and safe du . is requires directors to adopt a proac ve approach to health and safe and to take reasonable steps to ensure that there are e ec ve systems in place to iden fy and manage safe risks as they arise in the workplace. In Victoria, a similar obliga on on o cers exists by imposing liabili on o cers for breaches by the company if it is a ibutable to the o cer failing to take reasonable care.

THE FACTS

Miller Logis cs P Ltd (Miller) is a eight dis ibu on company with eight ansport depots located throughout NSW and the ACT. Zen y P Ltd (Zen y) was con acted to provide eight

services at Miller’s ansport depot in Tamworth, NSW. Zen y employed uck drivers who would use Miller’s depot to load and unload their ucks.

PRIOR SAFETY NOTICES FROM SAFEWORK

In the lead up to the incident, SafeWork issued three improvement no ces to Miller over three years in rela on to the lack of a c management con ols at its Yennora, Beres eld, and Tamworth depots.

• On 23 October 2017, SafeWork issued a no ce to Miller’s Yennora depot, ordering Miller to develop and implement a documented a c management plan to con ol the interac on between forkli s and uck drivers (Yennora No ce).

• On 30 September 2020, SafeWork issued a no ce to Zen y in rela on to its opera ons at Miller’s Beres eld depot. is no ce was also provided to Miller and cited similar safe concerns, highligh ng the insu cient a c management con ols in place to separate pedes ian and forkli a c (Beres eld No ce).

• On 30 October 2020, just ve days before the incident, SafeWork issued an improvement no ce to Miller’s Tamworth depot. is no ce ordered Miller to rec fy the very same a c con ol risk that

materialised on the day of the incident (Tamworth No ce).

MILLER’S RESPONSE TO THE NOTICES

Miller employed a compliance manager, Mr Hayter. In response to the Yennora No ce, Mr Hayter:

• sent an email to all depot managers, including Tamworth, announcing the in oduc on of fortnightly toolbox talks to ensure workers maintained a three-me e distance between forkli s and pedes ians (3-me e rule).

• circulated the toolbox documents and required depot managers to provide a copy of the forms, signed by each driver who a ended the toolbox talk.

• asked the Opera ons Manager to follow-up with any depot managers who failed to return the signed toolbox forms.

• created a template a c management plan for the Yennora depot and

18 / CAL May 2024 www.cranesandlifting.com.au

CICA HOLDING REDLICH

forwarded a template a c management plan to the other depots, including the Tamworth depot.

In response to the Beres eld No ce, Mr Hayter personally a ended the Beres eld depot to update the exis ng a c management plan. He also arranged to have the lines repainted to be er delineate pedes ian and forkli a c.

In con ast, a er SafeWork issued the Tamworth No ce, Mr Hayter did not visit the Tamworth depot and assumed that there was a a c management plan in place. ere was no evidence that the Tamworth manager did anything with the template that was sent to them by Mr Hayter.

THE INCIDENT

On 4 November 2020, Mr Herden, a uck driver employed by Zen y, was assis ng another uckdriver, Mr Hill,

to load and secure his B-Double ailer at Miller’s Tamworth depot. Mr Herden was ins ucted by Mr Hill to search for a smaller eight pallet that would t beneath the mezzanine level of the B-Double ailer. While searching for a suitable pallet, Mr Herden crossed the loading zone and was s uck om behind by a forkli being operated by another worker employed by Miller.

e forkli was being driven with a full pallet, raised so high above the ground that it obs ucted the driver’s line of sight. Mr Herden su ered signi cant injuries as a result.

At the me of the incident, despite the previous improvement no ces, there were no oor markings or physical barriers in place to separate pedes ian and forkli a c at the Tamworth depot. While workers were encouraged to adhere to the 3-me e rule, this was not enforced by the Tamworth depot

manager. ere was also no updated a c management plan in place at the Tamworth depot.

THE JUDGMENT AGAINST THE COMPANY Miller unsuccessfully defended the charge brought against it under sec on 32 of the Work Health and Safe Act 2011 (NSW) (WHS Act) for having failed to comply with its health and safe du , which ul mately exposed Mr Herden to a risk of death or serious injury.

e Court held that Miller was not only on no ce of the risk due to the Tamworth No ce but should have reasonably known that “nothing short of total separa on of forkli s and pedes ians was adequate to ensure safe ”. Despite this obvious risk, the only precau on adopted by Miller at this depot was the 3-me e rule which was loosely enforced. A designated loading and unloading zone, line marking,

May 2024 CAL / 19 www.cranesandlifting.com.au

Image: Stock Studio 4477/Shutterstock.com

pedes ian exclusion zones and physical barriers could all have been implemented as higher level con ols compared to the adminis a ve con ol regarding keeping 3-me es away om mobile plant.

THE JUDGMENT AGAINST THE DIRECTOR

Miller’s sole director, Mr Doble was charged as an “o cer” of Miller under sec on 27 of the WHS Act for failing to exercise due diligence to ensure that Miller complied with its health and safe du . SafeWork alleged that Mr Doble breached his du to exercise due diligence by failing to:

• ensure that Miller had appropriate resources and processes to eliminate or minimise health and safe risks arising out of its opera ons; and

• verify that the resources and processes were being implemented at Miller’s Tamworth depot.

In nding Mr Doble not guil of any o ence, the Court found that Mr Doble “took an ac ve interest” in work health and safe as Mr Doble:

• employed Mr Hayter as a compliance manager to deal with work health and safe at each of Miller’s depots and as the “primary process or resource” for managing safe . As Mr Hayter had been responsible for health and safe within the business during this period, Mr Doble was en tled to reasonably rely on the informa on provided by Mr Hayter.

• a ended weekly management mee ngs where he was briefed on health and safe ma ers by Mr Hayter.

• followed-up safe issues at the next management mee ng to ensure the proposed safe measures had been implemented at each depot.

• remained informed about updates to the a c management plans.

• personally a ended each depot and ins ucted Mr Hayter to immediately x any health and safe issues which he observed.

• a ended mee ngs with the depot managers to discuss Mr Hayter’s compliance measures.

• signed-o on updated work health and

safe policies prepared by Mr Hayter.

• directed supervisors to chase-up any workers who disregarded safe ins uc ons provided by their respec ve depot manager.

• promptly responded to health and safe issues irrespec ve of the expense.

LESSONS LEARNED FROM THE DECISION

e steps taken by the director in Miller demons ates that an o cer will comply with their du of care if they take a proac ve approach to ensure properly quali ed and experienced managers are employed to implement an WHS management system, even if the system may fail on a par cular occasion. e fact that Mr Doble was ac vely receiving informa on about the e ec veness of the opera ons and how Mr Hayter was managing the processes in place, was

T

On the day of the incident, a worker was killed a er an explosion resulted om using a highly vola le cleaning spray and a high pressure water spray gun to remove the remaining resin solu on om the tank.

e evidence was that an audit of the site would have revealed that the depot had con nued to use a spray that they had been informed was too dangerous and should be discon nued.

Although Mr Ritchie was based in New Zealand and, like Mr Doble in Miller, had relied heavily on the General Manager, as well as the depot managers at each facili , to keep him informed about the day-to-day opera ons of the business, he had failed to exercise “all due diligence” to prevent Owens om breaching its health and safe du under OH&S laws. In par cular, Mr Ritchie had failed to:

M will comply with their duty of care if they take a proactive approach to HS fail on a particular occasion.”

su cient for him to discharge his du of care.

is approach can be con asted to the earlier NSW decision of Inspector Ken Kumar v David Aylmer Ritchie (Ritchie which involved a similar s uctured business to Miller. In Ritchie, a company director was successfully prosecuted under the former occupa onal health and safe (OH&S) amework following an explosion at one of the company’s wash bay facili es which resulted in the death of an employee.

At the me of the incident, Mr Ritchie was a director of Owens Container Services Aus alia P Ltd (Owens) which repaired, cleaned and stored shipping containers and tanks.

As part of its business, Owens operated mul ple tank wash bay facili es along the East coast of Aus alia.

• obtain informa on about the nature of the business and the speci c risks involved with opera ng a wash facili and to ensure that a risk assessment had been undertaken for that process.

• verify the quali ca ons of the General Manager and Human Resources Manager appointed to oversee safe at the facili when they did not hold such quali ca ons.

• seek expert advice to mi gate the risks and ensure the safe of workers on site.

• ensure health and safe o cers with appropriate aining were employed.

• ensure safe audits were conducted by a person with proper aining.

• ensure safe concerns were brought to his a en on following three serious injuries in the wash bay facili during the previous year.

20 / CAL May 2024 www.cranesandlifting.com.au

CICA HOLDING REDLICH

PROJECT OF THE YEAR

WINNER 2023 - John Holland for the Batemans Bay Bridge replacement project.

PLAN YOUR ENTRY

The Crane Industry Council of Australia (CICA) recognises excellence and innovation in the Australian crane industry with the CICA Lift Of The Year Awards.

PROJECT OF THE YEAR

INNOVATION OF THE YEAR

LIFT OF THE YEAR –UNDER 20T

LIFT OF THE YEAR –OVER 20T

THE INNOVATION AWARD went to Bullivants for the ADAPTA Adjustable

LIFT OF THE YEAR

LESS THAN 20 TONNE WINNER –

McMahon Services won for removal of the Heritage Listed Copper Kettle during demolition of the West End Brewery.

LIFT OF THE YEAR MORE THAN 20 TONNE WINNER -

Walz Group won for several Triple Crane Lifts completed to extract the 60m-long DN500 Jacketed Pipe Units at an alumina refinery.

April 2024 CAL / 21 www.cranesandlifting.com.au

CICA PHOTO OF THE YEARUniversal Cranes won for a complex lift of a Geodesic Dome Roof.

To enter the 2024 awards visit cica.com.au/awards-lift-of-the-year

5-Axle Range

Elevate your Experience

5-AXLES, 1 VISION - Optimise Efficiency, Productivity & Versatility.

Tadano’s robust all terrain cranes deliver safe & reliable performance virtually anywhere with a variety of boom lengths. Drivers enjoy all-wheel steering, maneuverability, highway speed capabilities, and exceptional comfort.

With our compact and lightweight design, our 5-axle range delivers large lifting capacities, especially with its main boom fully extended. Innovatively equipped and ideal for routes where axle load limits are crucial.

Take a closer look at Tadano. Offering lifting solutions with best-in-class service & support.

©Tadano Ltd. 2024. Tadano is a registered trademark of Tadano Ltd. or its subsidiaries WWW.TADANO.COM.AU I 1300 823 266

NEW FACE, MORE EXPERIENCE AT THE CRANE CONNECTION

At the end of last year, Andrew Whyte joined The Baden Davis Crane Connection. Andrew’s role

FOR THE LAST 10 YEARS ANDREW HAD HIS own crane hire business Andrews Crane Hire, so he knows well the challenges crane hire businesses face.

“I ran my own crane hire business, Andrews Crane Hire, for a decade. We operated a few Frannas, slew cranes and Maedas and we mainly focused on pe ochemical work in Sydney. Late last year we decided to close the company down. It seemed like a good me to move the machines on and y something new and I jumped at the opportuni to join Anthony and Ben at e Crane Connec on,” said Andrew.

“I have a couple of roles within the business, I am managing the dry hire machines and I’m also working on new and used crane sales for the TIDD, Kobelco and Link-Belt brands. e eet management is fairly s aigh orward, I’m overseeing the dry hire machines that come in and out of the yard,” he said.

Andrew goes on to discuss the hands-on experience he brings to the business and what customers can expect to see om him.

“I bring a lot of general crane hire knowledge which I think will help customers with the familiarisa on of a crane. ere was a bit of a gap here in terms of crane experience. Ben and his team are very mechanically focused with servicing and crane repairs and Anthony does a great job with new and used crane sales. My role and experience lls the gap between the two,” said Andrew.

“Customers will quickly understand that I have been in their shoes in terms of running a crane hire business and opera ng cranes on a regular basis. My approach to selling will be di erent, everything can sound perfect on paper, but we all know that isn’t always the reali . My conversa ons are around the features and

IN FOCUS / THE BADEN DAVIS CRANE CONNECTION May 2024 CAL / 23 www.cranesandlifting.com.au

C C .

Image Prime Creative Media

The Crane Connection’s Anthony Davis and Andrew Whyte.

bene ts of the crane and how these can prac cally bene t the customer,” he said.

Working with Anthony on crane sales is going to signi cantly bene t the customer, says Andrew.

I’ve worked for and with a number of crane people in the past and if they were to ring and say, “What are your thoughts on this model?” My answers will probably be slightly di erent to Anthony’s. He will price the crane easier than I can and he’ll have his nger on approximate ETAs. My approach is more likely to cover what does and doesn’t need to be done to the crane so we’ll work together to provide the customer with the best solu on we can,” he said.

Although he only been with the Crane Connec on for a short me Andrew is pleased with the way things are going.

“Sales on the new machines have been good and we are sending out lots of quotes. I am also busy interac ng with customers on the eet side of the business we’ve had a lot of cranes in and out of the yard which is also been good. Most of the eet work is with customers that have their cranes in for repairs, servicing or refurbishing and they dry hire a machine whilst that is happening.

“I pre much work across most elements of the business. I’m a cketed crane operator and another part of my role I really enjoy is tes ng the cranes. Once Ben and his team have put a crane through a ten-year inspec on or major refurbishment for example, I’ll work with the third par engineer spending the day tes ng the crane. I also help the team put the cranes together when they arrive in the yard. We did this recently with the Kobelco crawler which went to Borger Crane Hire. It’s always good to get your hands on the tools,” he said.

Andrew is happy to be working with quali brands and quali product.

“It’s a pleasure to be working with brands like Tidd, Kobelco and Link Belt. TRT, the manufacturer of the Tidd pick and carry takes a very innova ve approach to the design, engineering and manufacturing of its products and this is re ected in the launch of the new Tidd PC28-3G,” he said.

TRT has cons ucted the TIDD PC283G using the highest quali components, priori sing safe and performance throughout its design and incorpora ng

class-leading features including the Euro 6 Cummins Engine, the highest emission con ol diesel engine available with signi cantly more horsepower. is development has been driven by the new Aus alian Design Rules (ADR), which take e ect on July 1, 2024. e acceptable emissions levels for mobile pick and carry cranes are going to be updated again and will need to be at least Euro 5 compliant. TRT has gone a step further by releasing the PC28-3G crane with a Cummins engine, which is Euro 6 compliant.

e PC28-3G is powered by a 6.7-li e 320 horsepower (238kw) inline six Cummins ISB6.7 engine, cer ed to the world’s toughest on-highway diesel emission standard, Euro 6, which achieves near-zero emissions. Cummins designs, develops, and supports every component om the air intake to the exhaust a er eatment to work as an integrated system –working to op mise every func on.

“Sales on the new machines have been good and we are sending out lots of quotes. I am also busy interacting with customers on

of the yard which is also been good.”

e Cummins ISB6.7 comes equipped with leading-edge technology to provide key opera onal bene ts. is engine delivers excep onal performance, with the reliabili and durabili expected om Cummins. Whatever your applica on, the ISB6.7 will provide a low-cost opera on and maximum up me.

With the 18.65m full power boom, a 75 per cent sta onary chart for heavy li s and a 66 per cent pick and carry chart, the TIDD PC28-3G packs a massive punch. Made om high-tensile steel, telescope sec ons one and two are fully synchronised and provide hook compensa on. Telescope sec ons three and four are independently operated with their own hydraulic cylinder. With a 28t maximum li on the lug and 27.6t on the hook block, the TIDD PC283G delivers outstanding li ing capaci es for improved e ciency and greater li op ons, se ng a new benchmark in the

indus y. Moving om the sta onary chart to the pick and carry chart is as simple as turning o the hold brake. Operators can now li more and move more safely without compromise.

Andrew is also happy to be working with the Kobelco product.

“ e Kobelco range of crawlers is also proving to be very popular with customers. Most of the customers are pricing a new crane for a project they are working on, and they will base the cost of the crane over the dura on of that project. In many instances, customers have been surprised at just how cost e ec ve Kobelcos can be and how quickly we can deliver them.

“When you factor in the performance of the Kobelcos, operator acceptance, ansportabili , and li ing charts you can see why they are so popular in the indus y and why customers con nue to invest in the brand,” said Andrew.

24 / CAL May 2024 www.cranesandlifting.com.au IN FOCUS / THE BADEN DAVIS CRANE CONNECTION

Andrew is happy to be working with leading brands like Tidd, Kobelco and Link-Belt.

POINT CLICK SCHEDULE

•Cloud Solution

•Quoting

•eTickets / eDockets

•Payroll / Timesheets

•Reporting / Dashboard

•Purchase Orders

•Invoicing

•Fleet Maintenance

•Storage

•Visual, Drag and Drop Scheduling

•Form Designer

•ERP Integration

p 02 7908 3880 e sales@visualdispatch.com

Image The Crane Connection.

Crane Hire Industry Software

EFFICIENCY IS SAFETY WITH ENHANCED MAC25

North East Link Crane Operator Shauna Burgess discusses the enhanced safety features on the Franna MAC25 cranes customordered by the Spark Consortium to help deliver Victoria’s largest road infrastructure project.

COMING OUT OF SCHOOL, SHAUNA BURGESS knew she was a hands-on person and, whatever she decided to do, she knew that it was going to be prac cal.

Originally pursuing a career as a panel beater, things didn’t pan out as she’d hoped. So, at the age of 30, she drew inspira on om her uncle who worked with cranes, packed her bags, and headed to the South Aus alian cons uc on indus y. Her experience in the crane indus y since has le one resounding

message: it was the best decision she’d made. Star ng out as a Franna crane operator, she indicates the prac cal and dynamic nature of opera ng pick and carry cranes was something that, simply, kept her days interes ng.

“Opera ng Franna cranes is a lot of fun,” she says. “As an operator, you bounce around the site mee ng everyone because you’re very in demand.

“You don’t just sit in one place and li things repe ously; the work is

he first o the o r enhan e s has een s assem ing a t nne oring ma hine

consistently varying and keeps the job highly engaging.”

Now pushing 10 years in the crane indus y, Shauna has operated cranes up to 60-tonne all across Aus alia, such as being a FIFO operator for gas projects in Queensland and Northern Territory, working in a desalina on plant in South Aus alia and, recently, helping to do preliminary works on Victoria’s Me o Tunnel. Today, she’s opera ng on the North East Link Project being delivered by the Spark Consor um, working in Melbourne’s North East to help assemble tunnel boring machine components at the Project’s Watsonia launch box. Having worked for over a month on a project that is crea ng 10,000 new jobs, taking 15,000 ucks o the road each day and cu ng avel mes by up to 35 minutes, she laughs that it’s nice to be outside and in the light of day again. What’s even nicer for Shauna and her riggers are the improved safe features the Spark Consor um chose to invest in towards the back end of

IN FOCUS / FRANNA www.cranesandlifting.com.au 26 / CAL May 2024

2023, including a 360-degree camera, an enhanced safe radar and the inclusion of Robway telema cs on four of its Franna MAC25s.

“ ese new features eliminate any poten al prospect of people accidentally pushing the limit of what the cranes are designed to do,” she says. “ ey make the crane safer for anyone opera ng it, whether they’re seasoned campaigners or younger people who have just entered the indus y.”

In the process of delivering the twin 6.5km, three-lane tunnels, a split interchange at Lower Plen Road and Manningham Road and new ancillary in as ucture to support the upgraded eeway and tunnel network, the Spark Consor um is commi ed to delivering on its Health and Safe vision of leaving the indus y be er than it was when the joint venture found it. A cen al part of this is keeping the interac ons between people and plant to an absolute minimum; for Shauna, this is exempli ed by the 360-degree camera system installed in her MAC25.

“ e birds-eye view helps take the s ess out of being aware of my surroundings,” she says. “Of course, I’ve got my two riggers keeping lookout for me, but some mes people accidentally end up in the wrong spot at the wrong me: with this 360-degree camera, I can always see what’s going on around me, and I’m always aware of how much room I have for ar cula on and movement.”

e 360-degree camera isn’t the only safe feature making life easier for Shauna and her riggers. Also enhancing the opera onal safe of her Franna MAC25 is the enhanced safe radar that was installed at the start of this year on the back of a bespoke request om the Spark Consor um. Conduc ng high-risk work in con ned environments in undula ng, hilly, earthy terrains presents a lot of room for danger to work its way in; however, the safe radar counters a lot of that risk, according to Shauna.

“It’s a really prac cal system to use,” she says. “It derates the further you push it and alerts you if it gets a hint the machine is approaching its rela ve capaci according to boom extension, ar cula on, and slope.”

“ e crane alerts you instantly if something feels like it’s about to go wrong,” she con nues. “Opera ng a Franna, there’s so many moving parts to the job, and the alerts and alarms systems go a long way to ensuring that every one of those moving parts are paid due a en on.”

As discussed in the February issue of Cranes and Li ing, all four of the MAC25s were also ed with the Robway telema cs system. O ering the resource alloca on bene ts of seeing a machine’s idle me and usage levels to see if it is performing as required in its established scenario, the telema cs system installed

on the MAC25 also comes with an added safe element: if the Franna is in the red zone, supervisors are instantly informed via email. As an operator, Shauna hasn’t faced this scenario – but, for her, it’s an ex a safe net that can only help, especially with younger people coming onto the job.

Because, ul mately, for Shauna and the Spark Consor um, there’s only one way to get their scope of work done as e ciently as possible: and that’s as safely as possible.

“ ere’s a heightened level of safe in these cranes,” she says, “and that can never be a bad thing, because everyone deserves to go home safely at the end of their working day.”

Images: Prime Creative Media.

The 360-degree camera allows the operator to be constantly aware of their surroundings.

www.cranesandlifting.com.au May 2024 CAL / 27

Shauna’s story represents the growing level of inclusivity encouraging women to take up roles on the ground in modern day construction sites.

MOBILE PLANT THEFT ON THE RISE

UAA . G G UAA C C S O .

“WE CERTAINLY HAVE SEEN A SIGNIFICANT increase in the of mobile plant and equipment over the last 12 to 18 months. We’ve been examining the ends that might be causing the increase but there doesn’t seem to be much real rhyme or reason to the increase.

“ e increase is involving all pes of machinery, predominantly small to medium, but there have been some large pieces of kit stolen. ere seems to be more ac vi in and around organised crime and gangrelated the . e machinery is being stolen opportunis cally om environments where there is a lack of securi , no CCTV cameras and a lack of vigilance om sta and owners who are not protec ng the equipment appropriately,” said George. ere are issues with the machinery as well, with George saying many pes having common keys.

“Having common keys is a problem. You can buy a set of 41 keys of di erent pes of makes and models for less than $50 on eBay, it’s an indus y-wide issue. e in oduc on of keypad igni ons instead of keys would be useful.

“ ere is also a lack of GPS acking devices being ed and a lack of vigilance in terms of owners and sta securing machines overnight. ey should be tucked into corners with larger equipment ‘boxing’

them in, or posi oned in a way that makes it impossible for thieves to steal them.

“Obviously, this disturbing end is pu ng a lot of pressure on customers and there is a signi cant loss of business as a result of the . It is also applying a lot of pressure on insurance companies like UAA as costs con nue to increase,” he said.

Alarmingly, George es mates the increase in the s to be around 30 per cent across Aus alia.

“We es mate the increase to be around 30 per cent and it’s across the coun y. Victoria would be the worst, then Queensland, followed by New South Wales. Some of the the s may be related to the mo ves of business owners who are feeling nancial pressure with interest rates, in a on and xed interest rates star ng to come o and will con nue to come o as the year progresses,” he said.

George explains how the increase is going to be re ected in insurance premiums.

“ e ongoing increase in claims costs is certainly having an impact on premiums one way or another, either as an individual policy and or pool of insurance premiums, and par cularly if we don’t have the abili to recover these machines. Some mes you can recover them and o set the recovery costs against the claim, but if the machine is not found and there’s no recovery,

that’s a 100 per cent loss on insurance and insurance por olios. In turn, there is no op on but to increase rates or look at other ways to mi gate losses by reducing certain covers. Encouraging customers to mi gate their losses or mi gate as best as they can is important, but the increase in the is certainly going to have an impact on premiums,” said George.

George explains how customers can mi gate against the risk and what sort of measures they should be taking.

“To prevent a thief, you have to think like a thief, so look at how a piece of mobile

IN FOCUS / UAA www.cranesandlifting.com.au

me/Shutterstock.com

Image: Good Job with

George Grasso, UAA’s Chief Services er

plant could be stolen and mi gate against that as much as possible. In other words, consider what would you do to steal it, and then look to alterna ve mi ga on and deterrent s ategies to prevent that the . All the machines in the eyes of the common person, in essence, look similar - with many being the same/similar pe of s ucture and colour. Owners who invest to colour code equipment in their company colours present a greater deterrent.

“ at way if the machines are stolen, they are more iden able. Otherwise, it’s just another yellow machine that’s disappeared and there are tonnes of them driving or being ailered up and down roads and eeways every day and people are none of the wiser. If you paint or wrap machines, which is a more cost-e ec ve approach these days, it makes for more of a deterrent for thieves because it’s far more iden able.

AU & NZ Crane Manager

registered, then certainly register it through the Personal Proper Securi es Register. ere is evidence that less the occurs to registered vehicles/machines. A number of companies in the indus y are implemen ng dual GPS units where one is visible, with one being a decoy and the second unit hidden further in the machine. ieves will make every e ort to locate a GPS and will nd a way to remove it. ey o en take the path of less resistance and remove the decoy and then feel sa s ed they have mi gated their own risk. However, by hiding a second unit, there is a chance the thieves won’t look further for another and you/we then have a chance to ack the machine,” said George.

“But the main point is to plan against the in the rst place. ere are other simple technologies such as vandalism and the proof covers, where you x lockable wire mesh or wire metal plates across doors

lock the con ol systems. ese are small investments and with planning and ex a me they will save a lot of money in the long run.

“I know people are busy and there is an ‘It won’t happen to me, or ‘she’ll be right’ a tude, as all my machines are always going to be there when I come back, or there’s a lack of concern om the sta member leaving the machine as it’s not their asset.’ It’s those mes where the next morning you turn up and your machine’s been stolen.

“When you get that li le intui ve voice in you to perhaps double check something, you’re be er o spending the ex a me at the end of the workday to posi on the machine where it’s di cult for it to be removed. Park another large machine in ont of it or use building materials to make it di cult for a thief. ose ex a few minutes could save you om the loss of the

VIC David Kapahnke david@dnddiesel.com.au 0418 373 128 dnddiesel.com.au

NSW Kerry Fullbrook kerry@xcmgcranes.com.au 0488 373 370 dnddiesel.com.au

Stephen Broomfield stephenb@xcmg.net.au 0401 540 136 xcmg.net.au XCMG (NW

Robert Smith robert@ronco.com.au 0403 059 712 ronco.com.au

$585,000* +GST

IN FOCUS / UAA MB OM936LA ZF TRANSMISSION HIRSCHMANN COMPUTERS GOLF BALL JOYSTICKS WHEEL CHOCKS SPARE WHEEL FLY JIB FRIDGE TILTING CABIN RIGGING BOX RIGGING KIT WA

WA)

Parts Only

Mark Turner xcmg@ronco.com.au 1800 CRANES Service &

*Applies only to 2023 models SN: LXGCPA247PA007002 VIC SN: LXGCPA246PA006522 VIC SN: LXGCPA249PA007003 WA

FOCUSING ON THE IMPORTANCE OF RIGGING AND LIFTING EQUIPMENT

THE ONLY DEDICATED REGIONAL EXHIBITION FOR LIFTING INDUSTRY PROFESSIONALS

• Show floor of lifting and height safety equipment

• End user presentations discussing the latest technologies, advancements in safety, and industry best practices in Oli & Gas, Mining, Ports, Infrastructure and Construction industries

12-13 September 2024 The Star Gold Coast Australia

Book your exhibition stand now liftex.org/liftex-gold-coast #liftexgoldcoast

Hosted by:

Silver Sponsor

CRITICAL NATURE OF A SAFE WORKPLACE

Workplace safety is a critical

workers but also their .

THE RECENT MINE COLLAPSE IN BALLARAT, Victoria, that resulted in the agic death of a 37-year-old, and le a 21-year-old with life threatening injuries, serves as a horrible reminder of the importance of safe in this cri cal indus y. Although deaths in mining have fallen over recent decades, in the years 2018-2023 an average of eight miners lost their lives every year. is is stark reading. However, in researching this ar cle I found that on average 180 workers lose their lives each year in Aus alia – with the highest

number being in Cons uc on (31 lives lost in 2023) and Agriculture, Fishing and Fores y (21). It’s hard to comprehend. It is essen al that we take all necessary measures to prevent such incidents om happening, but it is a igger to remember that safe is not just about having a paper ail – or being able to point to a cer cate on a wall in the recep on area. It’s uly about fostering safe culture, whereby sta and stakeholder concerns can be easily and comfortably raised and where the well-being of workers is the top priori .

e Li ing Equipment Engineers Associa on (LEEA) plays a crucial role in promo ng safe to the indus y ver cals we support, including to our partners in the mining indus y. LEEA’s vision is to create a li ing and height safe indus y which has eliminated accidents, injuries and fatali es. Sure, Li ing Equipment is only one aspect of safe working, but it stands as a beacon in which safe culture can shine. We uly believe zero injuries is a lo but achievable goal that can be realised through aining, collabora on, networking and guidance.

LEEA, as the global ade associa on represen ng companies involved in the design, manufacture, hire, repair, refurbishment, maintenance and use of li ing equipment, provides documenta on and aining to its members to ensure they adhere to the highest standards of safe and their membership of LEEA provides them a network of likeminded, safe focused peers to share and collaborate with on new thinking.

At LEEA’s Li Ex Gold Coast 2024, we will be highligh ng advancements in technology and safe om some of the leading brands and professionals at the fore ont of this incredible indus y.

Li Ex will include speakers highligh ng safe prac ce and new products, and give me to a endees to network and collaborate on new ideas.