A SHINING LIGHT

Fulton Hogan is championing the next generation of female leaders in the infrastructure sector

DOING THE HEAVY LIFTING

Roads & Infrastructure Magazine takes you inside the West Gate Tunnel, one of the largest projects in Australia’s history

BETTER FOR ALL The latest safety and technological developments that are enhancing infrastructure delivery

MAY 2024

OFFICIAL MEDIA PARTNERS OF AUSTRALIA’S ONLY SPECIALIST ROAD MANAGEMENT, CONSTRUCTION AND CIVIL WORKS MAGAZINE

FEEDING IN ALL SITUATIONS. The MT 3000-2 Offset is suitable for classic feeding, but can also feed mix to the side. This is because its conveyor can be pivoted to the left and right by 55°, enabling it to cover a vast range of applications, from “hot to hot” paving and hard-shoulder rehabilitation to backfilling trenches and filling the spaces between safety barriers. It can be cost-efficiently transported to the job site on a low-bed trailer. MT 3000-2 Offset – an uninterrupted, non-contacting supply of mix for more quality in road construction.

WIRTGEN AUSTRALIA Pty Ltd · Lot 2, Great Eastern Highway (Off Ivy St) · South Guildford WA 6055 T: +61 8 6279 2200 / www.wirtgen-group.com/australia www.wirtgen-group.com

A WIRTGEN GROUP COMPANY

The Ultimate All-Rounder! POWERFEEDER MT 3000-2 OFFSET

COVER STORY

7 A shining light

Fulton Hogan is supporting the upskilling and elevation of female team members, exemplified by its almost entirely female civil sub-contractor team.

PROJECT REPORT

11 Doing the heavy lifting Premier Cranes & Rigging are helping to deliver the mega West Gate Tunnel Project.

SOFTWARE

16 The whole package

Reveal has provided a suite of subsurface detection technologies, supporting the delivery of the Eastern Busway project in Auckland, New Zealand.

19 Evolution, Not Revolution

Bentley Systems’ Paul King, Director of Product Solution Engineering, sheds light on what is in store for the technological development of infrastructure applications.

23 Digital Adoption

AUSREO has developed and introduced to market a cutting edge and pioneering software, aiding the delivery of large Infrastructure projects.

TECHNOLOGY

38 Swipe and start

It might look like an ordinary excavator bucket, but the RodRadar red bucket is ground-breaking in the field of underground utilities location.

28 More, with less

The recording and assessing of road data is essential in maintaining a high performing road network. Until now.

31 Setting the standard

The importance of regulatory transport programs, which are playing a key role in the continued success of Australia’s transport network.

34 Seeing more Mooven is guiding both infrastructure projects and general road agencies towards success.

SUSTAINABILITY

36 From trash to treasure

Tyrecycle’s line of crumb rubber products are helping to provide high-quality, sustainable options to the infrastructure sector.

39 Future-proofing communities

An insight into the SAMI Bitumen Technologies’ ethos for community support and sustainability.

INSURANCE

42 Thwarting theft

Underwriting Agencies of Australia is educating the sector on risk mitigation strategies to help staunch machinery theft claims.

MACHINERY & EQUIPMENT

45 On the front foot

Wirtgen has partnered with Strata Worldwide to install compatible collision avoidance technology, helping to improve the safety of HAMM AG rollers.

48 The next phase

John Deere is introducing its 950 P-Tier and 1050 P-Tier large dozer models, which boast advanced visibility and safety features as part of the transition to P-Tier.

51 End of the pothole pit?

The bane of many councils is the existence of potholes in its roads. Repairing them takes time but one machine makes that job much easier.

54 Trailers abound

Avijohn Contracting has been laying asphalt on roads across the Sydney metropolitan area for over 30 years, with help from a major machinery manufacturer.

56 Evolving diversity programs

The construction and mining industry has always been male-dominated, but global equipment manufacturer Komatsu is working to change that.

59 Asphalt royalty

Tutt Bryant has supplied world-class compaction technology to the Australian market since 1986. New equipment is now on the way.

ASSOCIATION PARTNERS

60 Australian Flexible Pavement Association

61 National Precast Concrete Association Australia

REGULARS

4 Editor’s letter

62 Contracts & Tenders

roadsonline.com.au 3

MAY 2024 CONTENTS

Premier Cranes & Rigging has contributed multiple crane models and crews as part of its works on the West Gate Tunnel Project.

Image: Premier Cranes & Rigging.

THE DIFFERENCE MAKERS

ACCORDING TO THE AUSTRALIAN Constructors Association, women make up 12 per cent of Australia’s entire construction workforce.

More companies in the roads and infrastructure sectors are embracing new methods to attract talented individuals from an increasingly diversified and wide employment pool.

But there’s clearly more work to be done, in order bridge the gap in representation. For the May edition, Roads & Infrastructure Magazine celebrates the work being done by inspirational figures across the sector to encourage and support greater diversity, in what remains to be a male dominated industry.

In the cover story this edition, we learn more about Fulton Hogan’s unique approach to diversity and inclusion. Aspiring towards a family-like culture, Fulton Hogan is a pioneer in the infrastructure sector as a Tier One provider. Roads & Infrastructure Magazine sits down with four of its female employees from the Utilities Team, to hear about their journeys, as well as how Fulton Hogan is helping to lay a path for their futures within the sector.

We also celebrate the Australian Flexible Pavement Association’s recent tour of International Women’s Day breakfast events. These breakfasts, across multiple states, united the industry with its calls for greater opportunities and empowerment of women in the construction sector. Fantastic keynote speakers and panel sessions were just some of the highlights of what may now become an annual occurrence for the sector.

We also hear from ResourceCo and Tyrecycle on the recent opening of a new $15 million tyre recycling plant at East Rockingham, in Perth.

This plant will provide a boost for crumb rubber manufacturing throughout the region, on top of Tyrecycle’s existing network of facilities across Australia. Each of these plants is helping to transform used tyres into high quality and sustainable materials for road construction. Hear more about what’s in store for the future of this exciting space.

This and much more in the latest edition of Roads & Infrastructure Magazine.

Happy reading!

Tom O’Keane Roads & Infrastructure Magazine

COO

Christine Clancy

christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING

EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Tom O’Keane tom.okeane@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey

DESIGN

Bea Barthelson

BUSINESS DEVELOPMENT MANAGER

Brad Marshall brad.marshall@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive, Docklands VIC 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.roadsonline.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Roads & Infrastructure Australia is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Roads & Infrastructure Australia is owned and published by Prime Creative Media. All material in Roads & Infrastructure Australia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without the written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Roads & Infrastructure Australia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 ROADS MAY 2024

Contact your local dealer today 1300 522 232 www.jcbcea.com.au PRODUCTIVE, COMPACT & AGILE JCB 18Z MINI EXCAVATORS ROBUST 100% steel bodywork for maximum impact protection and ease of repair EFFICIENT Premium, Class-Leading precision hydraulic flow share for ease of use and maximum output SAFE 10 integral easily accessible tie-down points make the transportation process safer and quicker COST EFFECTIVE 500-hour Dig-End greasing intervals to reduce regular downtime EASY TO SERVICE Swing-out counterweight provides unrivalled and easy service access 0% * Only available to ABN holders through CEA Financial Services, provided by De Lage Landen Pty Ltd ABN 20101692040. 0% p.a. based on $10,000 deposit, no repayments for first 6 months, followed by 24 equal monthlies in arrears. Subject to credit approval, terms, conditions and fees apply. Offer ends 28/06/2024 or until stocks last, machine must be purchased and settled by 28th June 2024.The purchase of additional attachments or a trailer may result in a blended rate. OFFER ENDS 28TH JUNE 2024 or while stocks last SECURE YOUR NEW MACHINE AND A GREAT FINANCE RATE TODAY! per annum FINANCE *

A SHINING LIGHT

FULTON HOGAN IS SUPPORTING THE UPSKILLING AND ELEVATION OF FEMALE TEAM MEMBERS, EXEMPLIFIED BY ITS ALMOST ENTIRELY FEMALE CIVIL SUB-CONTRACTOR TEAM BASED IN WESTERN AUSTRALIA.

At almost a century old, Fulton Hogan has always remained at the forefront of modernity, utilising the latest technologies and methods to produce high-quality infrastructure for its clientele.

Fulton Hogan also prioritises the condition and support for its staff just as much as its equipment, an ethos that can be tracked back to the culture and attitudes developed by founders Jules Fulton and Bob Hogan in 1933.

Now spanning 10,000+ staff across both Australia and New Zealand, Fulton Hogan’s emphasis on creating a family-like culture across the business has helped to create equal opportunities for its team members.

The company’s REAL values are just one example. These values of Respect, Energy and Effort, Attitude, as well as Leadership aim to ensure that each individual within the company can feel empowered and supported.

This culture is also helping to internally support and promote Fulton Hogan’s female team members.

SMASHING DOWN BARRIERS

Breaking down the barriers and driving gender equality are goals that many businesses across the construction industry are striving to achieve. What sets Fulton Hogan’s approach apart from the rest?

The company has also worked hard to partner with organisations that are leading

the charge. One example is its ongoing partnership with the Richmond Football Club’s women’s program.

This program assists female players to establish a career in both the AFLW/VFLW and the construction industry, providing opportunities for greater representation across both sport and construction.

Another example is the company’s ‘a day In Her Boots’ program. Aimed at year 9-10 female and non-binary students, the program is set to create awareness around current and future opportunities within the infrastructure industry, showcasing the variety of career pathways available across the sector at all levels.

The program launched in Melbourne last year, following the success of a similar program that’s been running for several years in New Zealand, and will be rolled out nation wide this year.

ON SITE

While aiming to attract the next generation of female and non-binary team members, Fulton Hogan also has an ever-growing representation of female leaders that are helping to shape Australia’s infrastructure pipeline.

A new contract that was taken up last year led to the formation of a new utilities team for works in the Southwest region of Western Australia.

Rebecca Harding is the supervisor of

this team of six, with four of these team members being female. Harding says the work is dynamic and at times challenging, but made easier thanks to the team’s close camaraderie.

“At the moment we’re working on one project, that’s the fibre optic networking. That incorporates the installation and upgrading of pits, as well as hauling and overall upgrades to the network,” she says.

Three crew members within the team are comparatively young and new to the sector.

For Paige Ward – Leading Hand, Mikayla Bulman – Labourer, and Jordie Harcombe – Labourer, this post with Fulton Hogan represents some of their first working experiences out of high school.

For Ward, it was the opportunity to get straight into the workforce during high school, as well as an enticing traineeship program that led her to Fulton Hogan. She says the change has been a positive one when it comes to the team itself, as well as the working environment.

“As part of my apprenticeship, I was doing heavy maintenance. I came back over to the utilities team to complete these works,” she says.

“It’s a bit different, going from working with some of the older guys to a smaller team like this. They can sometimes be a bit grumpy!” She jokes. “It’s good being here”.

Bulman says construction and infrastructure have always been a part of her life. As such,

roadsonline.com.au 7 COVER STORY

Fulton Hogan aims to support and empower greater diversity throughout its entire business.

Image: Fulton Hogan.

working at Fulton Hogan felt more like a natural progression.

“I graduated from high school in 2022,” she says. “I studied a certificate three in health services, so my main goal was to go down that path. But growing up, through Dad, I’ve been around machinery and the sector for a while.”

“I was already friends with Paige (Ward) from high school – we’ve known each other for years. She told me about the opportunity to work at Fulton Hogan, so I just wanted to get my foot in the door to see if I liked it.”

Harcombe originally resided in New Zealand, in a country town outside of Auckland. At the time of joining the business, her mother had already been a Safety Advisor for Fulton Hogan for close to three years.

“I finished high school in 2022 and I was just doing the normal part-time work during that time. I was starting to look into full time jobs and mum was asking around to see what was available. This role came up, so I moved to Perth, originally doing utilities works, then I was transferred down to Busselton,” she says.

“For my first job out of high school, it’s been really nice. I’m used to being around machinery and working long hours from my time on the farm.”

Moving into such a vast and intensive industry may be daunting to some, but all three haven’t looked back, quickly acquiring new skills, while also facing the challenges that come with being new to the industry. Under the trusted stewardship of Harding, all three have so far impressed, both in terms of their attitude, as well as their work proficiency.

Bulman says the size of the team, as well as the similar ages between her co-workers, helped to make the transition to working life much easier.

“I think it’s more comforting coming to work,” she says. “You get to know everyone on a personal level because it is such a small team. It makes it easier being around [Paige and Jordie] because we’re all around the same age. It’s helped to form some friendships.”

Harcombe says she knew of the Fulton Hogan culture through her mother. That being said, she’s still impressed with the support that new employees receive.

“Everyone has been really supportive. There isn’t a lot of pressure because I know that I can always ask anyone in the team if I’ve got any questions. It’s been really great, going from being one of the few females

on other sites, to come here and see other females in good roles – it’s great to see,” she says.

Despite all taking different paths, all six team members are united in their enthusiasm, as well as their already extensive knowledge around infrastructure application.

Harding herself originally worked in horticulture, before having her own landscaping business, and then training people living with disabilities on how to use machinery. Initially employed as a vegetation officer, Harding moved on to supervise heavy maintenance, leading her to the current works.

She says leading the works has been a challenge that she and the rest of the team have been ready to embrace.

“I think the most challenging and fun aspect for this contract is that we’ve all come in on the same level. We’re all learning together and starting to build the team up. It’s something that none of us have ever done before, so there has been some challenges, but it’s been a great experience all being on the same page and learning together,” she says.

along with the installation of thermostat pits comprise of the majority of the teams works, which will soon also include the hauling of optic fibre cables and clearing of blockages to ducts underground. Harding says there’s still two years left on the contract.

“I’m definitely proud of the girls and how far they’ve come. They’ve stuck at it, and they should be proud too of what they’ve achieved so far,” Harding says. “Fulton Hogan has also been really supportive throughout my employment, particularly when it comes to recognising women in construction. I can’t fault them.”

Harcombe says Fulton Hogan’s values are there for all to see, from both micro and macro factors such as the representation of female staff, to the enjoyment and fulfillment on site.

“There’s a standard that everyone gets treated the same, you’re expected to help each other out. It’s just a great working environment. ‘Bec’ has been great as well as a supervisor, she’s always looking out for us,” she says.

“As much as she’s there to make sure we’re doing our jobs, she wants to make sure

“FULTON HOGAN’S VALUES ARE THERE FOR ALL TO SEE, FROM BOTH MICRO AND MACRO FACTORS SUCH AS THE REPRESENTATION OF FEMALE STAFF, TO THE ENJOYMENT AND FULFILLMENT ON SITE.”

To support and assist the team, Fulton Hogan conducted a training program, showing what needed to be completed and how.

Harcombe says the program enabled the team to visually build upon its existing knowledge basis, with a step-by-step walkthrough on project components.

“Being on-site and being given information to read was a big help. I was fortunate enough to have a rough idea around the works thanks to my time in Perth, but I was still quite new,” she says. “It’s been really great to attain that knowledge and have the chance to ask a tonne of questions.”

Bulman says the training played an important part in increasing the overall confidence of the crew.

“It was a big eye opener, actually going up there and seeing how the job gets done. To see how it gets done, it was a little daunting to begin with. But once you get in there and because we have such a good group, that definitely helps,” she says.

Pit removals, upgrades and replacements,

that we’re safe and that we’re having fun and having a laugh along the way. That’s something that we all really appreciate.”

Bulman believes the skills and experiences from this project will play a big part in each of the team member’s futures. Futures that by all accounts, look very bright.

“The skills that we learn every day on the job are benefitting and going towards our future. Getting that experience in the construction industry and getting to know people in the industry could potentially help us out big time in the long term,” she says.

Harding adds that the progress made by Ward has been particularly impressive when it comes to the development of the project team.

“They just get down and get on with the job. The job entails some pretty heavy duty and hard work, but they never complain. I’m proud of all of them and Paige is really coming into her own as the Leading Hand. It’s great to see her confidence grow and develop within herself in that role,” she says.

“I tip my hat off to them.”

8 ROADS MAY 2024 COVER STORY

FEATURES ARE OPTIONAL.

Sometimes you want the latest tech. Sometimes you just want the essentials done exceptionally well. That’s why we offer distinct levels of innovation, comfort, and performance so you can get done faster, more efficiently, and on budget.

JOHNDEERE.COM.AU/WHEELLOADERS SCAN TO LEARN MORE NEVER IDLE 644 UTILITY WHEEL LOADERS

RELIABILITY ISN’T

Komatsu intelligent Machine Control (iMC)

The

future today

Komatsu’s proven intelligent Machine Control (iMC) concept has now penetrated markets worldwide. Thousands of operators and owners enjoy the safety and precision of Komatsu’s exclusive technology, factory fitted on both dozers and excavators, and the outstanding improvement in productivity it brings to the jobsite. Customer productivity is the driving principle behind Komatsu intelligent Machine Control.

Call us today on Sales: 1300 074 249 | Support: 1300 445 978 komatsu.com.au

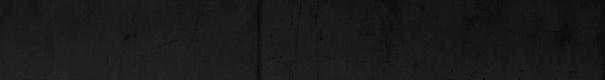

DOING THE HEAVY LIFTING

PREMIER CRANES & RIGGING’S 350-TONNE LIEBHERR CRAWLER CRANE IS BEING USED AS PART OF WORKS ON THE WEST GATE TUNNEL PROJECT. ROADS & INFRASTRUCTURE LEARNS WHAT IT TAKES TO DELIVER ON SUCH A LARGE PROJECT.

How do you set yourself apart, in such a heavily congested sector?

This question, while asked by many, is often only answered by the few that truly understand what it means to provide a unique perspective and solution within the infrastructure sector.

For Premier Cranes & Rigging, providing the latest technology and experienced crane crews as part of its crane hire service offering wasn’t enough.

Since its foundation 16 years ago, the team at Premier Cranes & Rigging have always stressed the importance of developing a supportive and inclusive company culture.

Referred to as #TeamLifting, this philosophy aims to empower the company’s staff, while also highlighting the importance of each team members contributions in delivering recognised success to its clients.

Kye Giacomin , Head of Business Development – Premier Cranes & Rigging, says this ethos can be felt right through the business, leading directly to higher quality project delivery outcomes, as well as greater client satisfaction.

“Internally we use a system called ‘Bonusly’ where you can recognise your peers. Whether it’s someone at a leadership level, or someone on site, they can equally be recognised for their achievements and their great work,” he says.

“It’s great for morale day to day, and it’s great to see people wanting to achieve even more, regardless of their role in the company. I’ve never seen a system like it. It’s awesome. It all forms part of the larger #TeamLifting attitude.”

This same attitude transcends to the company’s culture around safety and expertise, with internal processes ensuring that all crew members and operators are not only suitably experienced and certified but also acquire the necessary soft skills to diligently handle jobs no matter how

big or small.

Each team member is regularly handpicked for specific projects, based on their previous experience and skillset.

Giacomin says the company’s approach to project delivery is focused on delivering the right result for the end client.

“We go above and beyond, and our approach is consistent, even if it’s a small sized project or something quite large. We can help them internally throughout every department. In some ways we’re a tool. When we’re helping with the management

Images: Premier Cranes & Rigging. roadsonline.com.au 11 PROJECT REPORT

Premier Cranes & Rigging has contributed multiple crane models and crews as part of its works on the West Gate Tunnel Project.

of a project, the client can feel at ease,” he says.

This approach helps to make sure projects can be delivered on time and on budget.

But, Premier Cranes & Rigging rarely rests on its laurels, a key factor in the company’s keenness to get one of its largest crane’s onto its next project.

THE LR1350/1

The company’s vast crane hire options is ever growing, obtaining a crane model that is rarely being used across Victoria.

The LR1350/1 crawler crane comes with a 350-tonne maximum load lifting capacity, making it suitable for major infrastructure

works with diverse lifting requirements. It features a lightweight design, built to increase the ease of transportation and set-up. The crane also features a derrick boom and suspended ballast, for greater load capacity.

Andrew Esquilant, General Manager, Mobile Crane and Crawler Cranes –Liebherr Australia, says the LR1350/1 crawler crane is emblematic of the evergrowing professional relationship between the manufacturer and Premier Cranes & Rigging.

“It’s a very versatile crane. If you had all of the associated parts you could potentially end up with thousands of different configurations that you can put

together. They’ve bought a crane that can tap into a unique niche market in some ways. I think that’s where Premier Cranes & Rigging have done quite well,” he says.

The LR1350/1 also comes with a superlift, helping to increase the stability of the crane during heavy lifts, on top of what is already a stable design, aimed at evenly distributing the operating weight throughout the base of the machine.

The superlift also adds further flexibility to what is already a highly customisable crane configuration.

With client satisfaction at the forefront of their decision-making, Premier has gone a step further to acquire all necessary components to ensure its clients can use any LR1350/1 configuration for whatever their site-specific challenges necessitate.

Esquilant adds that the crawler crane is perfect for tackling the Big Build projects in Victoria.

“The 1350 was designed from our factory to go into a crane fleet similar to the size of Premier Cranes & Rigging,” he says. “There’s a particular focus on assembly and it’s easy to erect from an operational point of view, while at the same time being able to carry out good solid lifts.”

The LR1350/1 is just another in Premier Crane & Rigging’s existing range of Liebherr cranes. Esquilant says the relationship has been developed and grown on trust, as well as a commitment to achieving the best possible outcome for both companies.

“If there are any concerns, we can sit together as colleagues, have a professional discussion, find a solution, and move forward. We both like to keep it real. No matter what it is, we can pick up the phone and talk through it. That’s something that I really enjoy about dealing with a company like Premier Cranes.”

THE WEST GATE TUNNEL

The growth in Premier Cranes & Rigging’s profile as well as its capabilities has resulted in the company becoming a key player in infrastructure works across Victoria.

A core reason for the company’s selection for works on the West Gate Tunnel Project in Victoria, one of the largest infrastructure projects in the country.

The $6.7 billion project, being delivered by the Victorian Government in partnership with Transurban (with

12 ROADS MAY 2024

Premier Cranes & Rigging acquired the LR1350/1 crane over three years ago to support its position as a heavy-lift crane contractor.

Premier Cranes & Rigging working on a key data centre project in Truganina, installing 95 tonne precast concrete beams using the LR1350/1’s superlift for enhanced lifting capacity.

Premier Cranes & Rigging’s works on bridge 73, as well as the West Gate Tunnel Project portals exemplify the company’s capabilities for major infrastructure works.

construction contractors CPB Contractors and John Holland), will establish an alternative route to the heavily congested West Gate Freeway.

This will include widening the West Gate Freeway from 8 to 12 lanes, the construction of new twin tunnels under Yarraville, and deliver a new bridge over the Maribyrnong River, which will join a new elevated road along Footscray Road, providing a new connection to the city’s north and significantly improving efficiencies in Melbournians’ daily commute across town.

It’s during these works on the elevated road along Footscray Road that Premier Cranes & Rigging was able to showcase the LR1350/1.

Antony Feek, Senior Project Engineer –CPB Contractors, first joined the project in September 2021 and has played a key role in the delivery of the West Gate Tunnel Projects steel portals in 2022, as well as current works on Bridge 73.

“I worked with Premier Cranes & Rigging when they provided the steel rigging crew for the steel portals. For the works on Bridge 73, this is where they deployed the LR1350,” he says.

The company’s works, including bridge girders, precast beams and temporary

structure installations have impressed. So much so that the company nominated its 95-tonne bridge girder lift and installation for CICA (Crane Industry Council of Australia) lift of the year 2023 in the over 20 tonnes category.

The lift included the use of the LR1350/1, lifting a 40-metre-long steel girder over the CityLink off ramp, less than a metre from live traffic. This was achieved using a variable derrick, allowing the LR1350/1 derrick to move during the lift and avoid the existing bridge structure during the slew movement.

This represents just one of Premier Cranes & Rigging’s many intricate lifts completed on the project.

Feek says the company has made a positive impact on the project, contributing not only equipment and machinery, but also essential expertise.

“They’ve provided some important resources to the project, from the people on site, as well as their engineers that are doing some of the studies and helping with bookings. They’ve provided a great level of knowledge.”

“Logistically they’ve been a big help, providing a lot of support. That extends to our operation staff, through to our engineers, making sure that any required

changes are able to be implemented on site quickly,” he says.

Giacomin says Premier Cranes & Rigging’s project management-led approach to project delivery is what makes the difference.

“We’ve got a lot of backend support. Through our compliance team, operations team, planning team, as well as our in-house engineers, we can assist our customers as they progress through each stage of a project,” he says.

“With our people being on site, between the field crew and the office crew, there’s a lot of communication between the site group and the audit group. The overall support starts right from the planning phase, right up to execution and delivery. It helps us to fully understand what the customer requires.”

Feek says he’s proud of the teams’ contributions to the West Gate Tunnel Project, saying he looks forward to seeing the end product.

“It’s a proud feeling to be able to see the impact that you’ve had on the site. I’m very much looking forward to being able to drive on it when the projects complete.”

Premier Cranes & Rigging’s Liebherr 350 tonne crawler crane and expert crew is now available for project-based hire.

PROJECT REPORT roadsonline.com.au 13

PEOPLE ON THE MOVE

ROADS & INFRASTRUCTURE HELPS YOU KEEP UP WITH THE LATEST MOVEMENTS ACROSS THE ROADS AND INFRASTRUCTURE

SECTORS.

BECA APPOINTS NEW MANAGING DIRECTOR FOR AUSTRALIA

Beca has appointed a new Managing Director – Australia to drive business growth, commencing 18 March. Based in Sydney, Andrew Mailer joins Beca with more than 15 years’ strategic leadership experience gained through roles in Australia, New Zealand and Canada. Most recently he served as a General Manager at Tetra Tech Coffey, and as Asia Pacific Head of Strategy and Growth at Tetra Tech. Beca Group Chief Executive, Amelia Linzey, said Mailer brings strong leadership expertise to the role and will support Beca’s desire to grow in Australia. “Mailer’s Australian market knowledge and commercial experience, combined with a unique global perspective, aligns with Beca’s strategic priority of growth in Australia,” she said. Mailer said he was eager to begin his tenure and was impressed by Beca’s strong, values driven culture.

Image courtesy of Beca.

NEW LEADER BOOSTS GHD’S TRANSMISSION AND DISTRIBUTION TEAM

GHD has appointed Carl Parlongo as Australia and New Zealand Power Transmission & Distribution Leader to help its clients deliver a step change in demand for reliable and sustainable power networks. The new appointment comes as the Australian Energy Market Operator’s Draft 2024 Integrated System Plan (ISP) predicts 10,000 kilometres of new and upgraded transmission lines will be needed to connect new generation projects to the National Electricity Market by 2050. The Western Australian Government’s South West Interconnected System (SWIS) Demand Assessment also found that Western Power’s network may need an additional 4000 kilometres of new transmission lines over the next 20 years. Parlongo has over 25 years of experience in both business development and project delivery for electricity transmission and distribution services, across power networks in Australia, New Zealand, Asia, the Middle East, and the UK.

Image courtesy of GHD.

ROSS HARPER APPOINTED TO SMARTCRETE CRC BOARD

The SmartCrete Cooperative Research Centre (CRC) has appointed Dr Ross Harper as NonExecutive Director to the SmartCrete Board. Harper is a well-respected senior executive, and recognised leader within Australia’s concrete ecosystem. As a former Group President Operations of Boral Ltd, he brings a wealth of industry and applied research experience to the SmartCrete Board. Over the past decades, Dr Harper has been involved in many concrete-related initiatives and has served in several board and committee positions including Concrete Cement and Aggregates (CCAA), Cement Industry Federation (CIF), and Cement and Concrete NZ (CCANZ). Consistent with his view that meaningful advances in Materials Science are vital to reduce emissions, he was recently MCi Carbon’s (MCi) Strategic Advisor accelerating the implementation of MCi’s siliceous and carbonate products. Harper was nominated for appointment by BG&E as part of the merit-based appointment process for the SmartCrete Board.

Image courtesy of SmartCrete CRC.

14 ROADS MAY 2024

AUSTRALIA’S SAFEST PICK AND CARRY CRANE JUST

Australia’s safest pick and carry crane is now powered by the Cummins Euro 6 Engine, the highest emission control diesel engine available with significantly more horsepower.

Including more powerful front suspension cylinders, lifting capacity has increased by an average of 17% when articulated or working on a side slope and in some cases by over 40% in lifting performance.

The latest Allison Transmission with retarder provides

superior downhill braking, delivering increased safety and control, lowered operational expenses, and reduced noise in urban areas.

The new TIDD PC28-3G is driven by our continuous focus on innovation and actively exceeding expectations for our customers.

Talk to us today to learn more about the TIDD PC28-3G Pick and Carry Crane.

NOW CLEANER, SAFER, STRONGER. TRT Australia TRT New Zealand AUS, NZ, PNG, & Asia Pacific 07 3890 8800 cranesales@trtaust.com.au trtaustralia.com.au tiddcrane.com.au

05.2024 INFORMATION BETTER...

GOT

THE WHOLE PACKAGE

REVEAL HAS PROVIDED A SUITE OF SUBSURFACE DETECTION TECHNOLOGIES, SUPPORTING THE DELIVERY OF THE EASTERN BUSWAY PROJECT IN AUCKLAND, NEW ZEALAND. REVEAL’S TEAM DISCUSS HOW THESE TECHNOLOGIES AND THE PROJECT WILL BENEFIT THE COMMUNITY IN THE COMING YEARS.

The Eastern Busway is one of New Zealand’s largest transport projects, aiming to transform the way locals and visitors travel in and around the region for generations.

The project, which has an estimated total cost of $1.5 billion (per Australia New Zealand Infrastructure Pipeline) consists of four stages, all aiming to improve transport choices and connections in the region.

By 2028, the busway is expected to carry 18,000 passengers daily, more than four times the 3700 bus passengers per day before COVID-19. Despite delays and further cost and scheduling impacts from the COVID-19 pandemic, works on the project are powering ahead.

Major utility relocations are playing a fundamental role in the delivery of these works, an aspect that previously was often a difficult task due to incomplete, outdated and inaccurate utility records.

Reveal were approached by the Eastern Busway Alliance in late 2022 to develop a proposal for the works.

Luke Herlihy, Chief Product Officer –Reveal, says the project presented an ideal opportunity to implement a unified utility model – a new concept being developed by Reveal that combines existing network utility models held by asset owners with the results of geophysical investigations to produce a 3D model of the underground that has been verified to best-practice subsurface utility engineering standards.

“The main Busway is being put in the existing road, and the road is being widened to accommodate this. Utilities need to be relocated from the carriageway into a Combined Services Trench outside of the carriageway,” he says.

“These kinds of large construction projects are really utilities projects with a road on top of them.”

Reveal’s combined hardware and software approach to subsurface detections aims to provide a

comprehensive picture of underground utilities, helping to increase the efficiency, safety and sustainability of works concerning the subsurface.

Utilities such as cables, ducts and piping can all be viewed and clearly identified from a centralised source in Reveal’s platform. Each object in the model has a chain of evidence and “trust score” attached to it, highlighting the sources of evidence and degree of confidence to the detection, so design engineers can make informed decisions about the risks of a particular excavation.

For the Eastern Busway, Reveal used a vehicle with a multichannel groundpenetrating radar (GPR) array to drive over and around the project area to supplement the traditional utility locating workflow.

Jordan Moratti, Project Delivery Manager for Reveal, says the company’s services helped to overcome the biggest challenge for the project delivery authority: the lack of records or knowledge around the location and variation of underground utilities.

“Putting myself in the client’s shoes, not having that firm understanding about what’s underground due to poor quality existing records or ‘unknowns’ from a design perspective, would be quite problematic,” he says.

“As they’re effectively extending the road out and then building dedicated bus lanes, it involves a huge amount of utility relocation. They don’t want utilities underneath the dedicated bus lanes, because obviously if there’s a fault with the utilities or they need maintenance they don’t want to have to shut down these bus lines.

“They’re building combined service trenches, so relocating most of these services to combined service structures. Utilities are a huge element for this project. That’s why they’ve had a real focus on trying to de-risk as much of the underground space, as early in the project as possible.”

Herlihy says these records also play a greater role in ensuring that a project can satisfy other requirements such as safe,

16 ROADS MAY 2024

Reveal’s Underdots technology uncovered the existence of many unknown utilities in the road corridor not present on any existing utility plans.

Images: Reveal.

timely and sustainable project delivery.

“Having that digital 3D model underground will help to improve health and safety outcomes, and importantly, improve the productivity and efficiency of delivering within the tight timeframes that the alliance had to adhere to as well,” he says.

With the assistance of Reveal’s newly launched Underdots data processing service, the Reveal team transformed this raw data set into an easily accessible 3D model for the construction alliance.

Underdots is a software capable of translating raw ground-penetrating radar data into a 3D model, depicting the size and frequency of radar detections through grouped or clustered dots. Solid objects such as pipes, ducts and other utilities can be distinguished from surrounding soil, making Underdots an invaluable visualisation tool for getting quick insights into the underground environment.

Moratti says Underdots fuelled the efficiency and accuracy of the united utility model that was provided to the project delivery team.

“Underdots was a key change, because at the time of the project proposal, we hadn’t developed Underdots as a deliverable, so it was a change from what we initially proposed,” he says.

“The main benefit of that was the ability

to give the delivery authority multichannel array GPR data faster. We did the capture in July and by August we had made Underdots available for the project. The final deliverable wasn’t until December, so traditionally they would have had to wait until we were fully finished to even get a glimpse of what was going on underground with the GPR data.”

This comprises 22.4 hectares worth of mapping within the unified utility model, a significant area covered for works such as this. This model could also be exported into BIM, 12d, AutoCAD and GIS compatible file formats.

All up, 20 per cent of the utilities in the Unified Utility Model were previously unknown assets.

“That [percentage] is standard for works such as this, but it’s fascinating how much in the underground that we just don’t know about or isn’t contained on any records,” Moratti says.

Since delivering this final data set, Reveal has provided ongoing service and support for the project delivery authority, who are actively seeking expertise around the data sets provided.

“We’re still providing answers to their questions around the data in the unified utility model. [The Eastern Busway project delivery authority] is actively doing a lot of potholing or daylighting of the utilities

Reveal’s end-to-end technology and services offering was crucial to the delivery of the final unified utility model in only three months.

associated with the project. There is a bit of back and forth between us just clarifying specific utility information that they’ve found during their potholing,” he says.

“That’s the best quality utility information that you can get – what you can actually see in the ground. The intention is to assist them and help them to understand that information.”

Feedback from the client, as well as other construction partners, further points to the technology’s success.

“That feedback has been really positive. We managed to deliver in the timeframe that we agreed on at the beginning. Even with all the complexities of working around on site with other work parties, we still managed to complete the field works within the original program,” Moratti says.

“The client is really thrilled with the outcome and the data that we presented to them. All of the feedback has been really positive.”

Moratti adds that the potential for wider use of unified utility models, including Underdots, is an “extremely exciting” prospect.

“To be able to do these large-scale utility mapping works and then provide that to a client with a unified utility model provides great value for any project. I’m really excited to be able to undertake projects similar to this,” he says.

roadsonline.com.au 17 SOFTWARE

COMPACT SIZE CAN MEAN

A HUGE ADVANTAGE

CAT® AP400 ASPHALT PAVER

The Cat® AP400 is the perfect machine for those asphalt paving jobs where space is at a premium.

It’s got the compact size, flexibility and versatility you need, especially in built-up urban areas.

Plus, when you purchase a new Cat AP400, you’ll also have the option of:

• access to locally supported parts via the national dealer network

• a comprehensive warranty package

• a Cat Customer Value Agreement (CVA).

To find out more contact your local Cat dealer or visit cat.com/AP400-au

GREAT FLEXIBILITY WITH CONFIGURABLE SCREED DESIGN OPTIONS SIMPLE OPERATION WITH ALL-ROUND VISIBILITY LIGHTWEIGHT AND COMPACT FOR EASY TRANSPORT Service and support options are available from Caterpillar’s independent dealers, at prices and on terms and conditions determined individually by each dealer, and may vary. Contact your preferred dealer for details. © 2024 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

NSW/ACT WesTrac 1300 881 064 SA Cavpower 08 8343 1600 QLD/NT Hastings Deering 1300 868 538 WA WesTrac 1300 881 064 VIC/TAS William Adams 1300 923 267 NZ Terra 0800 93 39 39 SCAN HERE

EVOLUTION, NOT REVOLUTION

BENTLEY SYSTEMS’ PAUL KING, DIRECTOR

OF

PRODUCT SOLUTION ENGINEERING,

SHEDS LIGHT ON WHAT IS IN STORE FOR THE TECHNOLOGICAL DEVELOPMENT OF INFRASTRUCTURE APPLICATIONS.

For Bentley Systems, the future looks exciting. With innovative applications already available, such as its iTwin Platform or open design and modelling applications, the organisation is looking to push the limits of infrastructure engineering software.

Paul King, Bentley’s Director of Product Solution Engineering, explains that the development of technologies in this space is an evolution, rather than a revolution, growing on the progress made throughout Australia’s infrastructure sector.

He has seen the application of such technologies on projects first-hand. “I joined Bentley in 2006 during our works with building information modelling (BIM) on the Olympics in London,” says King. “I then spent some time in the Middle East on some big construction projects. Then, we had the Global Financial Crisis (GFC) that marked the start of my journey to Australia. It was interesting to take some of those best practices from big projects outside of Australia, to Australia. A lot of Australian projects and teams are now leading globally.”

King is a part of the Bentley Infrastructure Cloud team, managing the company’s solution engineers in the Asia Pacific region and advising on all aspects of project delivery technology.

This journey to the top has been a gradual progression of improvement and embracing new technologies. As King explains, Australia has come a long way—quickly—when it comes to these aspects.

“In the United Kingdom, we have the ISO 19650 international standard for project collaboration,” King says. “It helps you to standardise how you create and name files. It’s important to manage risk and ensure better outcomes.

“When I arrived at Australia, I came armed

with one of the first copies of that standard. I sat down with four big contractors who were discussing technology. They essentially said, ‘We saw that you did at the Olympics and we want to learn from you.’ I brought this document out and two of the four said that they wanted an Australian standard, not a British one.

“It opened my eyes to the cultural differences between the two countries when it came to technology. Over time, unsurprisingly, more people have been willing to use overseas standards and best practice. That cultural shift has been impactful.”

Bentley has played a key role in opening the door for Australian contractors and infrastructure providers to use the latest in infrastructure engineering software. This focus has long been on getting the technology in the right hands, instead of delivering a blanket solution for everyone.

King said that he has seen this ethos track back to his first contributions on the 2012 London Olympics.

“Since the early part of the century, Bentley has invested in and recognised that it is not just about the software, it is also about how you use it and how you can get people to adopt it,” he says. “From a technology perspective, something that has always been a part of our solutions is the connected data environment.”

The connected data environment is an essential aspect for collaboration on infrastructure projects, connecting project stakeholders from different supply chains into a singular data environment. It represents a space where data and design are shared and accessible by all. It helps streamline changes and alterations to designs, as well as queries around specific design decisions.

“By standardising modelling protocols and methodologies, stakeholders can have information shared easier and across different disciplines and teams,” says King.

King adds that embracing cloud technology is another aspect that has changed in terms of culture. He says Australia is one of the premier users and developers of cloud technology globally.

“Over ten years ago, when I arrived, very few firms were prepared to use cloud services. There was a perception that it was less safe than having a traditional server. In the last three to four years, that’s completely shifted the other way,” he says.

“I think the GFC had a huge impact on this

Paul King, Director of Product Solution Engineering – Bentley Systems.

roadsonline.com.au 19 SOFTWARE

cultural shift. We essentially had to do more with less. Now, there’s a significant shortfall of engineers that we require to tackle the coming pipeline of infrastructure. Everyone needs to recognise how important it will be to do more with less.”

There are already examples of major works in Australia, where this focus of doing more with less has proven to be effective. One example is WSP. Recognising the pivotal role of effective information management and the limitations of previous technology approaches, the organisation sought a comprehensive digital solution that could streamline data management and facilitate efficient collaboration while building trust in new digital workflows.

It needed user-friendly, integrated technology applications that foster a holistic approach to data management, ensure compliance with ISO-19650 standards, and support a widespread digital shift.

Embracing the capabilities of Bentley Infrastructure Cloud, WSP selected ProjectWise and iTwin to address data management, collaboration, and project lifecycle engineering challenges, enhancing decision-making and delivering superior project outcomes. Leveraging Bentley’s applications, design teams can collaborate, visualise, and review the design model in real time.

Using their Port Rail Transformation Project (PRTP) as an example, WSP saved approximately 300 resource hours, reducing rework and the project timeline. By communicating and exemplifying the advantages of digital workflows, the company has instilled confidence in the national business shift to digitisation, driving innovation in enterprise engineering.

“I think project teams and organisations are starting to realise that this is what success looks like–delivering your project on time and under budget. They’re asking themselves, ‘what’s the differentiator?’ Having these examples has been critical,” says King.

“The industry has gone full circle from when I first started in the U.K. The difference now is that these technologies are now off the shelf. People are no longer spending millions of dollars on complex technology. It’s about using that data better.”

Bentley Systems can provide the full spectrum.

“We’ve been creating software to support digital workflows on projects

through the full lifecycle,” King says. “We work from planning and design through to construction, handover, and asset management. We have insight working with our customers in the space around what they need to do, what does success look like to them, and we then design the software to support that.

“It’s not revolutionary, it’s evolutionary. It’s principally adopting best practice wherever you can find it.”

De-risking is another feature of Bentley Systems’ technological offerings. King says it is about getting the best possible information, whether it’s models, drawings, and/or specifications to get the complete set of design information.

“Increasingly, construction teams are saying that they need to work with their supply chain to ensure that the information that they get is complete, correct, and consistent. You can have all that information, but it’s just as important to connect it. That’s where a connected data environment is so important,” he says.

The iTwin Platform is just one specific example of Bentley System’s connective technology. This platform optimises infrastructure delivery and performance

because I can see it and interact with it.”

Bentley applications are compatible with other systems and programs, enabling multivendor-based teams to share their information and pool it without worrying about the file formats.

The organisation will soon showcase these technologies and more as part of its upcoming Bentley Illuminate infrastructure engineering conference. The event will pool together like-minded individuals around the future of infrastructure engineering software and hardware, as well as more efficient methods and processes for infrastructure development.

Bentley Illuminate will also host key speakers who will address themes that include sustainability and infrastructure resilience. The event will also include big players from across the sector, including owner-operators, engineering firms, and contractors.

At the event, Bentley’s Mike Campbell, Chief Product Officer, and Oliver Conze, Senior Vice President for Bentley Infrastructure Cloud, will present a technology vision and roadmap offering a glimpse into Bentley’s exciting innovations and advancements for infrastructure digital

“INCREASINGLY, CONSTRUCTION TEAMS ARE SAYING THAT THEY NEED TO WORK WITH THEIR SUPPLY CHAIN TO ENSURE THAT THE INFORMATION THAT THEY GET IS COMPLETE, CORRECT, AND CONSISTENT. YOU CAN HAVE ALL THAT INFORMATION, BUT IT’S JUST AS IMPORTANT TO CONNECT IT. THAT’S WHERE A CONNECTED DATA ENVIRONMENT IS SO IMPORTANT,”

throughout an asset’s lifecycle. The digital twins can be constantly updated and synchronised to ensure all project stakeholders are on the same page. Streamlining design changes and client communication boosts not only project timelines, but also a company’s bottom line.

Engineering, geospatial, and operational data can all be centralised, while also incorporating real-world conditions to predict future conditions for inspections, reporting, and insights using artificial intelligence and machine learning.

“As a project manager, I can open a web browser to view a full three-dimensional model of that piece of infrastructure,” says King.

“If I’m a project manager, I don’t care if it’s from one authoring application, or six,

twins and artificial intelligence.

Attendees will also hear from Aurecon’s CIO Carl Duckinson, SparkNEL’s Digital Delivery Director Jayson Winchester, and TfNSW’s Executive Director of Digital Engineering Services Devon Middleditch. These executives will provide insight on the challenges they are facing today on their major projects, as well as their perspective on the changing industry landscape.

King will be one of the key speakers at the event and said that it will showcase the progress made so far, as well as a path forward for continual improvement from across the infrastructure sector.

“We’ll be asking how and what can we do better as an industry, as companies, and as individuals. Whether you’re designing, building, or operating, there’s something for you at Illuminate,” he says.

20 ROADS MAY 2024 SOFTWARE

YOUR CHOICE REGULATORY PARTNER

Need assistance with a regulatory program?

Let us open up a world of opportunities as your choice TCA-approved provider for the IAP, OBM, TMA, and RIM programs.

IAP

Increase your payload to instantly boost productivity, turn around times, and profits.

Smart OBM

Increased payload, unprecedented access, and ability to run PBS enabled vehicle configurations.

TMA &

Scan to learn more

RIM Applications that provide a level of balance between compliance & productivity. NHVAS

Digital solutions to help you and your drivers comply with Heavy Vehicle requirements.

1300 111 477 TeletracNavman.com.au

IN CONSTRUCTION AUSREO’S DIGITAL ADOPTION

OVER THE PAST 10 YEARS, AUSREO HAS DEVELOPED AND INTRODUCED TO MARKET A CUTTING EDGE AND PIONEERING SOFTWARE, AIDING THE DELIVERY OF LARGE

INFRASTRUCTURE PROJECTS.

Building large complex infrastructure projects is made simpler with digital technology and early engagement to provide better project outcomes.

AUSREO represents a blend between industry know-how and IT integration and the company has forged strong partnerships to deliver what is a suite of services dedicated to steel reinforcing. This is more than just utilising off the shelf construction software.

One such relationship is that with ADDA, the developer and distributor of software made specifically for steel reinforcement analytics.

As Paul Barbuto, General ManagerBusiness Development – AUSREO explains, the software has been built by reinforcers, for reinforcers. This is a big plus for AUSREO, who has an exclusive deal in Australia for the use of this software.

“The biggest difference is that this software has been built for reinforcing specifically. Competitor software is basically off the shelf, but this has been tailored,” he says. “We’re not trying to adapt off the shelf software to reinforcing, because we don’t have to.

“This software has also been integrated into our production, operations team and all departmental experts internally, whereas a lot of our competitors will outsource the software and the technical staff. We’ve kept the entire package within our business. We’re the pioneers in this space.”

This technology is useful in ensuring project timelines, budgets and safety is met. It is also designed to make stakeholder engagement and plan changes simple in a controlled environment away from the dayto-day challenges on site.

Working collaboratively is another benefit. Ultimately ensuring engineering and construction companies are optimising expert involvement while embracing software to achieve greater project outcomes. As Paul Lowden, General

AUSREO’s platform is centred around collaboration and innovation, helping its customers to achieve greater project outcomes.

Manager, Construction Solutions –AUSREO details.

“Using our experts in the business, once design commences, we model it in the BIM environment. That’s where we’re talking to the contractors before the job starts, to identify solutions that could provide savings around the project. That might be time savings, material savings, so where they could potentially use less steel for example,” he says.

“Once the job starts, then we look at the project detail area by area, element by element. While our teams are modelling we are simultaneously reviewing those models with the project engineers.

The introduction of discussions around build-ability with site engineers within the modelled environment provides an alternative with a time and cost comparison that delivers value throughout the total value stream.”

This helps project managers and contractors by improving build-ability and increasing the value throughout the project value chain, with savings up to 20 per cent on project time, materials, and waste.

The program, and AUSREO’s approach to project delivery, also create greater connectivity and communication with the material supply chain. Early engagement and collaboration throughout an integrated supply chain helps to identify opportunity, minimises waste and optimises product procurement. This enables a project to be delivered safely, accurately, on time and within budget.

This is achieved by using a virtual twin BIM model. It’s here that users can achieve a greater understanding. Reinforcement lifecycle, combined with a data-rich BIM model of Bar Bending Schedule (bar list), and production understanding of piece count vs tonnes, are the main criteria that establishes the analytics that enable informed decisions to be made.

This includes factors such as forecasting, scrap analysis and waste identification.

AUSREO’s focus on workflow optimisation ensures reinforcement is recognised as a sustainable product on any critical path.

ALL TOGETHER

AUSREO’s places its responsibility to

Images: AUSREO. roadsonline.com.au 23 SOFTWARE

all stakeholders and communities as paramount. The 3D reinforcement model focuses on the design and build-ability requirements that ensure a safe workplace throughout the total supply chain.

Through clash detection, collaborative reviews, simulating reinforcement placement allows collective creation of method statements from the virtual model to ensure safe loading, handling and installation practices are implemented and achieved.

Lowden says the clarity provided by the ADDA software and AUSREO’s services can help to increase the safety and prevent issues arising on site.

“Having the clarity in the data in a 3D sense, within an environment that’s technologically advanced allows communication to be clearer and more accurate,” he says. “Just imagine, sitting at a table with drawings all over the desk, trying to sort out a complex situation.

“We take that issue away. With our model you can talk about it, look at it, zoom in and identify where bars may clash or impossible to place. We can identify those building issues, in some cases before they

Forecasting, scrap analysis and waste identification are just some of the aspects that can be achieved through the use of AUSREO’s platform.

arise. The engineers can come to us and say, ‘we’ve got an issue on site, how can we resolve it together?’ That all starts with this model.”

AUSREO’s software suite and experienced local and international detailers enables comparison of traditional loose bar reinforcement placement against a prefabricated, modular or sub assembly reinforcement solution.

PROJECT PROVEN

Through persistence, professional development, and product invention AUSREO with ADDA has created an integrated software system for infrastructure works.

Its project delivery focused team of 65 professionals can deliver complex projects of all sizes. Using its knowledge and expertise, AUSREO has delivered many iconic infrastructure projects, providing savings of up to 20 per cent.

This includes works on some of Australia’s largest infrastructure projects, such as Sydney’s M4/M5 Widening and Rozelle Interchange project and the Sydney Metro Project.

In Victoria, works on the Melbourne Metro Tunnel including CBD North, South, Eastern Portals and Anzac Station have been completed, on top of additional works on the North East Link.

In total more than 100,000 tonnes of reinforcing steel have been accurately supplied to these projects, plus others where the benefits of AUSREO’s digital and engineering expertise have helped to deliver project success.

Gino Federico, National Sales Manager – Major Projects – AUSREO, says the company was able to impress by providing a

complete, end-to-end solution, rather than an external service.

“As part of our works that recently finished on the WestConnex Rozelle Interchange, we provided reinforcing plus modelling services. There were a number of complex structures, all underground so we did a lot of clash detection and a buildability analysis on different elements,” he says.

“The collaboration that results from this is far superior to what you get from traditional methods.”

AUSREO has pioneered change where the industry can effectively and efficiently look closer at reinforcing steel procurement and delivery. And this has been done alongside several like-minded people from the construction industry to ensure the entire supply chain can build with confidence and maintain sustainable outcomes for the project lifecycle.

Barbuto says it’s time for the sector to embrace the digital world and welcome AI by adopting the digital transformation the industry “so deserves”.

“The more work we do, the larger our library of data gets,” he says.

“Our goal is to create a data-rich encyclopedia or library that can be used to create efficiencies and benefits for future projects. Systems like Artificial Intelligence will start to be introduced eventually to this software. No one in the reinforcing industry is really talking about it, but we are.

“We’re trying to innovate in a noninnovative industry. Construction hasn’t really changed significantly in the last 50 years, compared to other sectors. We’re not going to change that, but at least for the reinforcing supply chain, that’s what we’re trying to change.”

Federico says continued development of both the software and hardware will benefit the sector as a whole.

“We’re continuously investing in the software to push it further. From that point of view, there’s always something in the works,” he says.

“This is the way forward – it’s the future. There’s still some resistance in the sector, particularly for people who haven’t worked in the digital reinforcing space before.

“Generally speaking, the industry is moving towards digital. They want to collaborate digitally with multiple parties and away from traditional methods. Our services, along with the ADDA platform, are that next step that people can take when they come onboard.”

24 ROADS MAY 2024 SOFTWARE

AUSREO has now worked on some of the largest infrastructure projects in the country.

WE’RE HERE FOR THE LONG HAUL.

At Tyrecycle, we are committed to recycling end-of-life tyres otherwise destined for landfill. We are paving the way to produce more Crumbed Rubber Asphalt to cater to growing domestic demand with over $40 million invested in setting up new and upgrading plants, creating long term value for all stakeholders.

MRPV TRIALS LIVE DIG RADAR

This might look like an ordinary excavator bucket, but the RodRadar Live Dig Radar ground scanning technology (pictured above) is groundbreaking in the field of underground utilities location... without needing to break any ground.

As part of Major Road Projects Victoria’s commitment to safety and innovation, its Safety team recently tested the new RodRadar technology, which is capable of locating utilities and prevents service strikes and operator injuries.

In one of the first uses of the system in Victoria, RodRadar was put through its paces in a demonstration on Pakenham Roads Upgrade project site, run by MRPV and Bildgroup.

The device incorporates a groundpenetrating radar (GPR) system within the bucket assembly and can be easily attached to a standard excavator.

One swipe of the RodRadar bucket over the dig area allows operators to assess what is underground beneath the machinery – preventing potentially life-threatening service strikes.

It is radar imaging technology that enables automatic, real-time, on-site alerts, to

prevent damage to underground utility infrastructure during excavation.

Major Road Projects Victoria Senior Safety Manager, Jamie Dineen, says the technology could help to improve the overall safety of infrastructure development.

“It was great to put RodRadar’s Live Dig Radar through its paces with a demonstration on our Pakenham Roads Upgrade jobsite recently,” Dineen says.

“Eliminating underground service strikes on our job sites would decrease delays and additional costs to projects, and this product will play a big part in eliminating most of these accidents.”

The ability of this technology to reduce the likelihood of costly service strikes would see construction progress more smoothly. This can be achieved through limiting delays by accurately and non-destructively locating buried utilities underneath the machinery.

RodRadar Australia National Sales and Marketing Manager Mark McLachlan, says the company’s innovation and development provides a big boost for both underground utility and ground level construction works.

“RodRadar’s Live Dig Radar technology

offers the triple benefits of safety, efficiency and cost-saving,” McLachlan says.

“We are thrilled that MRPV has been testing the Live Dig Radar and will look into opportunities to use the system on their projects.”

“Damaging underground utilities represents significant safety and efficiency risks, and pre-existing utility data can be unreliable. We are excited to deliver a system that enables any operator to avoid utility strikes during excavation, without the need for expert analysis.”

McLachlan adds that the ability to immediately and accurately survey the area underneath the machinery has great potential within the industry.

Operators can dig with confidence, avoiding utility strikes that would otherwise impact project schedules and profitability.

The system is easy to operate and fit to new or existing excavators.

MRPV will continue to trial RodRadar and other technologies across its project sites.

“We’re always on the lookout for cuttingedge technology to bring into our projects to ensure we’re getting them completed as quickly, cost-effectively and safely as possible,” Dineen says.

26 ROADS MAY 2024 TECHNOLOGY

The RodRadar technology was recently trialled at Major Road Projects Victoria’s Pakenham Roads Upgrade project site.

Image: MRPV.

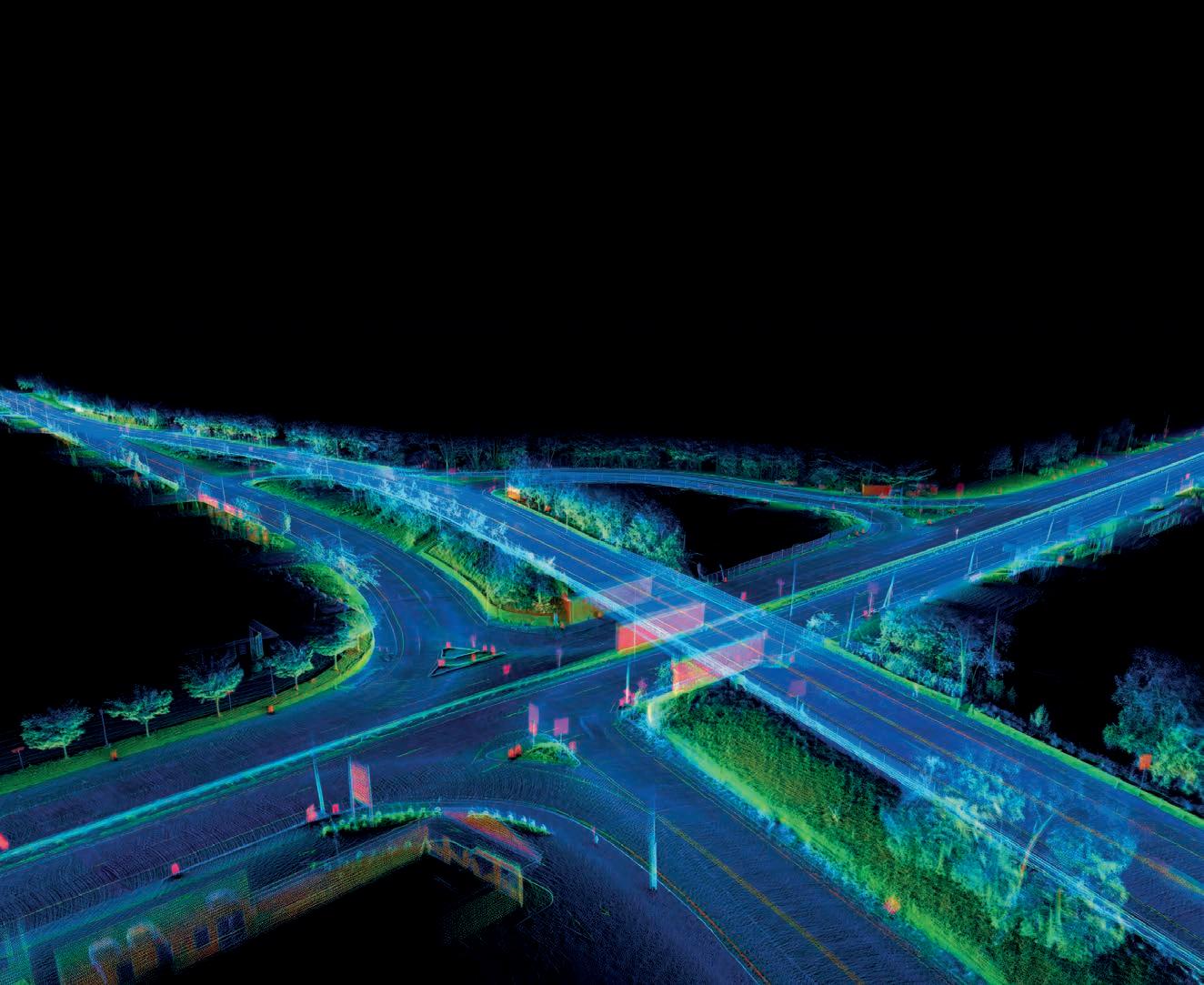

MORE, WITH LESS

THE RECORDING AND ASSESSING OF ROAD DATA IS ESSENTIAL IN MAINTAINING A HIGH PERFORMING ROAD NETWORK. MANY FACTORS MAKE THIS DIFFICULT, SO ROADS & INFRASTRUCTURE MAGAZINE LOOKED AT WHAT TECHNOLOGIES CAN ASSIST.

Australia’s network of roads and highways have a length of 873,573 kilometres, making it one of the world’s most vast road networks (Worlddata.info).

Tracking, managing and evaluating the vastness of this road network can be trying, especially in rural areas, where the road network can often be difficult, or too large to track.

Essential resources rely on these roads to be maintained and of a high quality, with agriculture, freight, shops and emergency services all relying on the highways and main roads across the country.

In a landmark report from the Grattan Institute (Potholes and pitfalls: How to fix local roads) released in November of last year, concerns and potential issues around road infrastructure maintenance were placed in the limelight.

With financial pressures and less resources, councils are often unable to fulfill their usual services. And this is happening to

more councils than you might expect, as Civiltech Solutions Founder and CEO Leigh Carnall explains.

“It’s a critical issue. There is a shortfall in funding and other factors that are leading to a lack of data and information that councils require for their road network, as well as grave limitations that councils have in understanding their own network,” he says.

This is an issue that has also been exacerbated by a growing resilience and pressure on councils to deliver a multitude of services.

“Compared to when I started out in local government 23 years ago, there’s been a huge increase in the responsibilities that councils have for the community. There’re more and more things that councils are now expected to deliver,” Carnall says.

“Whether it be implementing legislation from other levels of government, through to local expectations around infrastructure and assets, they are all essential functions of a community. Roads often get neglected,

or councils just go out and fill up a pothole. That attitude is having a big impact on our road network.”

According to the aforementioned report, 75 per cent of Australia’s roads are managed by councils, which includes both sealed and unsealed roads. The Institute estimates that an extra $1 billion is required in the next 12 months just to keep the same roads in the same condition that they’re in today.

But it’s not all doom and gloom. Far from it. Luckily, recent developments in technology are opening the door for councils across the country to achieve far more, with less.

THE

CIVILTECH

DIFFERENCE

Data collection is vital to accurately assessing when and where upgrades are needed. The latest National State of the Assets report showed that less than 20 per cent of responding councils said they base their infrastructure performance data on high-quality evidence. Poor data in many cases leads to poor road quality, longevity,

28 ROADS MAY 2024

Civiltech Solutions’ technology helps councils and road authorities to achieve more, with less.

Image:

Civiltech Solutions.

sustainability and performance.

Civiltech Solutions is hoping to turn the tide by providing affordable, easy-to-use and accurate road and infrastructure mapping. Founded in 2011, the company is responsible for the development of sustainable infrastructure solutions. Its current endeavour, working with Cyvl.ai, is helping to optimise AI technologies to improve project outcomes.

In laymen’s terms, this technology uses sensors to record data and imagery of road asset conditions. It therefore turns imagery into actionable data that can help to influence decisions around upgrade works, repairs and more.

“The Grattan Institute said that funding for many councils has plateaued off. So effectively they’re trying to do more with less. This isn’t working due to the lack of funding backing that up,” Carnall says.

Cyvl.ai’s sensor can be mounted to any vehicle, ensuring that the technology is easy to install and non-invasive. Once installed on the roof of a car for example, the sensor –along with Cyvl.ai’s AI algorithms – evaluate factors such as pavement conditions, pavement markings and signage.

“With the Cyvl sensor we use computer vision to detect the cracks and potholes down the road. Uniquely we’ve also integrated LIDAR radar into the sensor. The AI will look at the data sets to differentiate between a shadow and a pothole for example,” Carnall says.

“By using the AI, the system is much more accurate. Plus when you’re looking at road cracking, what typically happens is water gets into the pavement and starts to weaken the base course layer. Every time a car goes over this, water squishes into the pavement.

Now with LIDAR radar, it’s easy to detect this cracking using computer vision.”

This information can be viewed in actionable reports within days, with the process of completing field surveys being up to 10 times faster than traditional methods.

Currently, this technology is being adapted to the Australian market, a task that is gathering momentum as both companies eye a widespread release across the nation in the coming months.

“Whether you’re in a regional council or a metropolitan council, there’s benefits across all levels when you utilise technology like this. Even if you don’t have a current roadmap, this is a great way to start your blank canvas and build up that pool of data,” Carnall says.

A new report from the Grattan Institute indicates that some councils are under resourced and unprepared to adequately care for their respective road networks.

“Even for those who might have a deep understanding of their road network, it’s fantastic to gain additional information, especially for assets that may have been too expensive to record previously. We can collect all of that and more, all in one pass thanks to this technology.”

Carnall says that for some the technology needs to be seen to be believed. It’s making an impact already in the US and soon Australia.

“I love going out to councils and talking about asset management, talking about roadways, showing them what this magic black box can do. It does seem like magic,” Carnall says.

“I’m passionate about what this technology means for the nation. Once we start collecting this information on a regular basis, the thought of what we’ll be able to achieve with this information is really exciting.”

roadsonline.com.au 29 TECHNOLOGY

The Cyvl.ai’s sensor uses Artificial Intelligence to increase the quality and accuracy of road network management.

Image: Civiltech Solutions.

Image: stock.adobe.com/ bilanol.

BF200C-2 and BF300P-2: Innovative Solutions To Transform Road Construction

Discover the future of paving with Tutt Bryant Equipment’s BF200C-2 and BF300P-2 pavers, leading an extensive lineup. The BF200C-2 excels in tight spaces, offering unmatched versatility, efficiency, and ease of operation with a minimum paving width of 1.10m.

For larger projects, the BF300P-2 extends capabilities up to 5m widths, featuring MAGNALIFE heating for rapid, even heat distribution. Both models underscore a commitment to performance, maneuverability, and maintenance ease. Choose Tutt Bryant Equipment for comprehensive paving solutions that blend innovation with reliability.

Brisbane | Sydney | Melbourne Adelaide | Perth tuttbryant.com.au 1300 658 888 Follow us on:

STANDARD SETTING THE

TELETRAC NAVMAN’S JAMES FRENCH TALKS ON THE IMPORTANCE OF REGULATORY TRANSPORT PROGRAMS, WHICH ARE PLAYING A KEY ROLE IN THE CONTINUED SUCCESS OF AUSTRALIA’S TRANSPORT NETWORK.

Regulatory Telematics has become an essential aspect of managing Australia’s national road network, providing road managers and regulators with essential and accurate data.